Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

583 results about "Elastic membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastic Membrane - Dedicated to creating high quality, unique samples and sound packs for electronic musicians, DJs, and producers. Original sounds recorded from modern and vintage analog music gear.

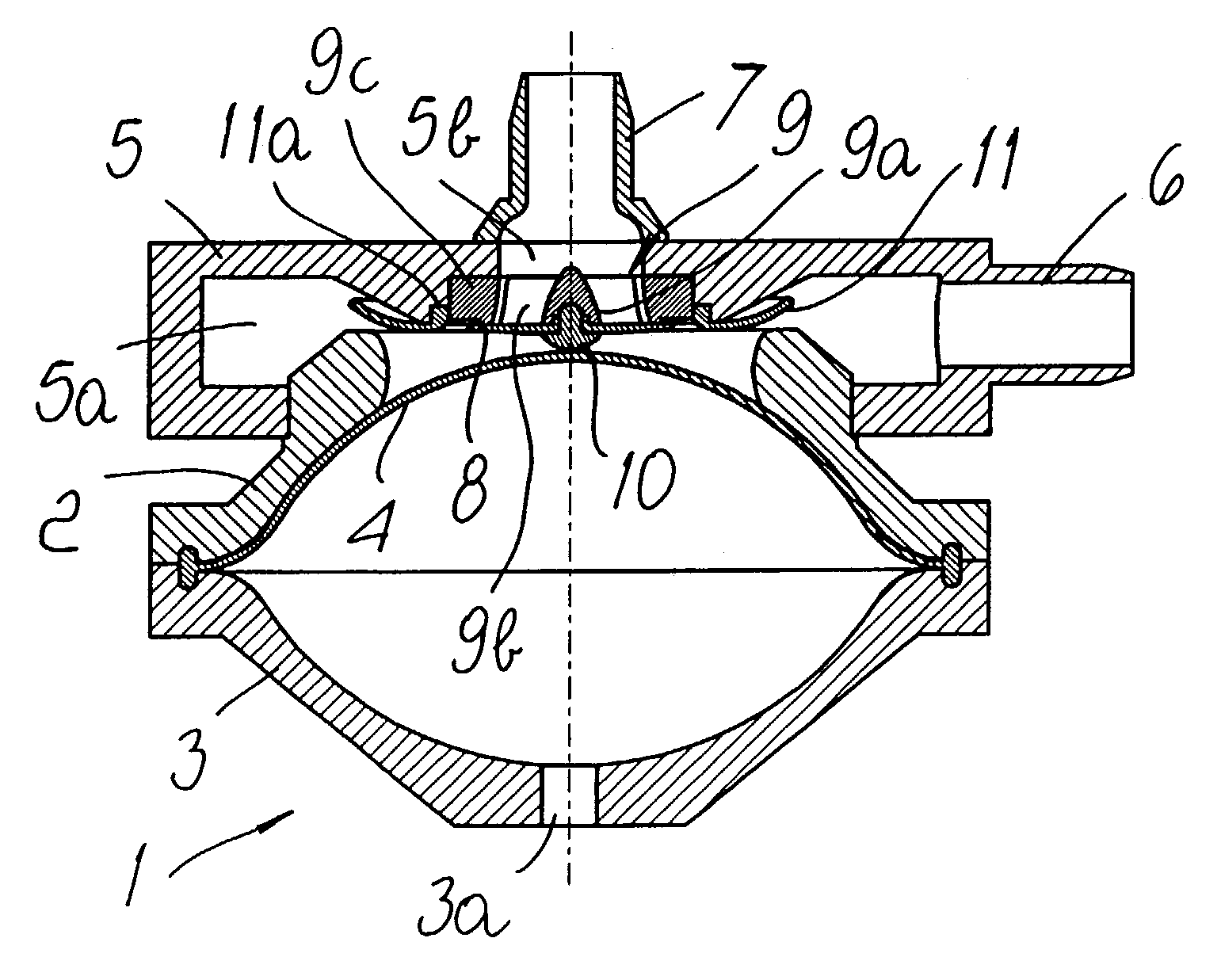

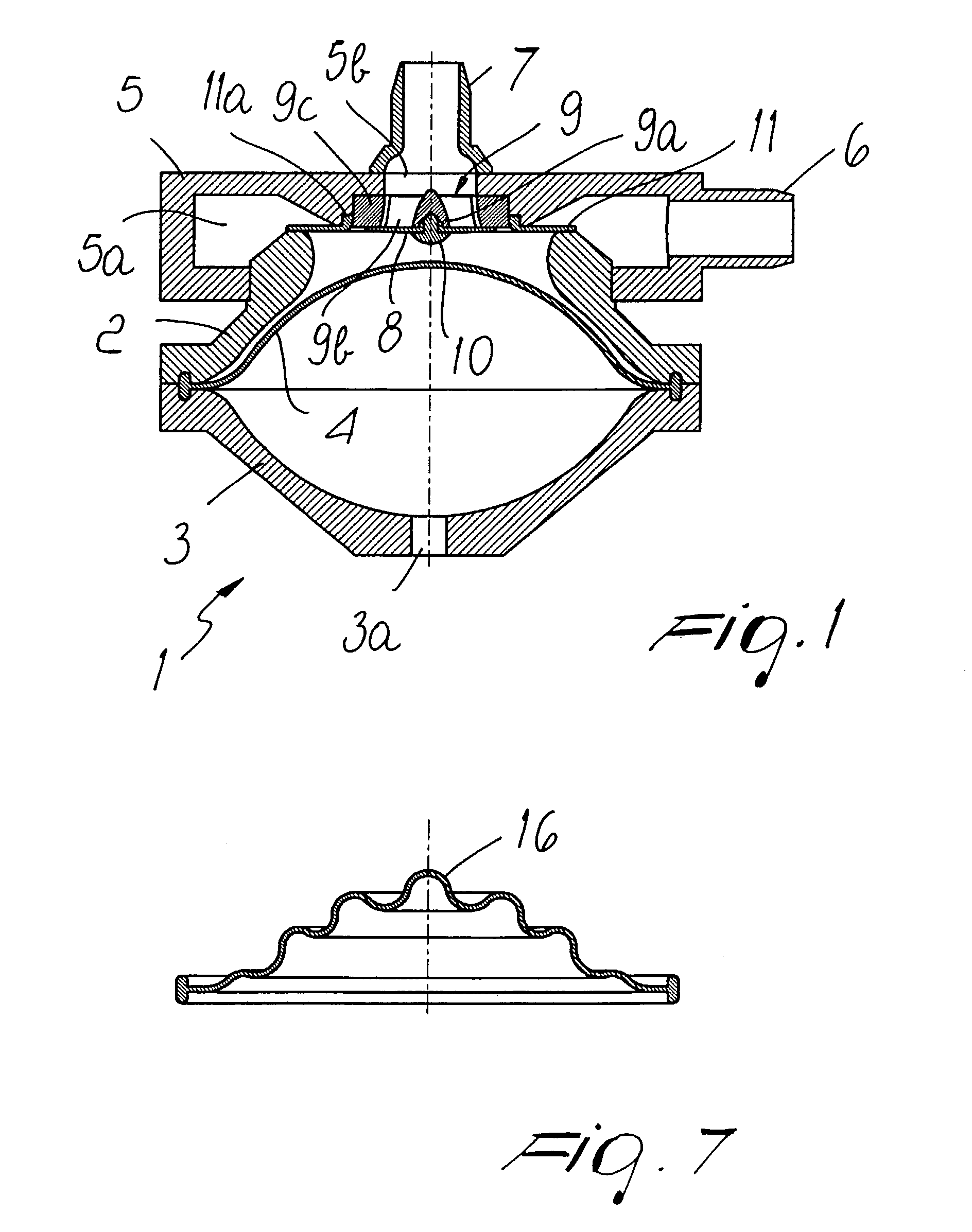

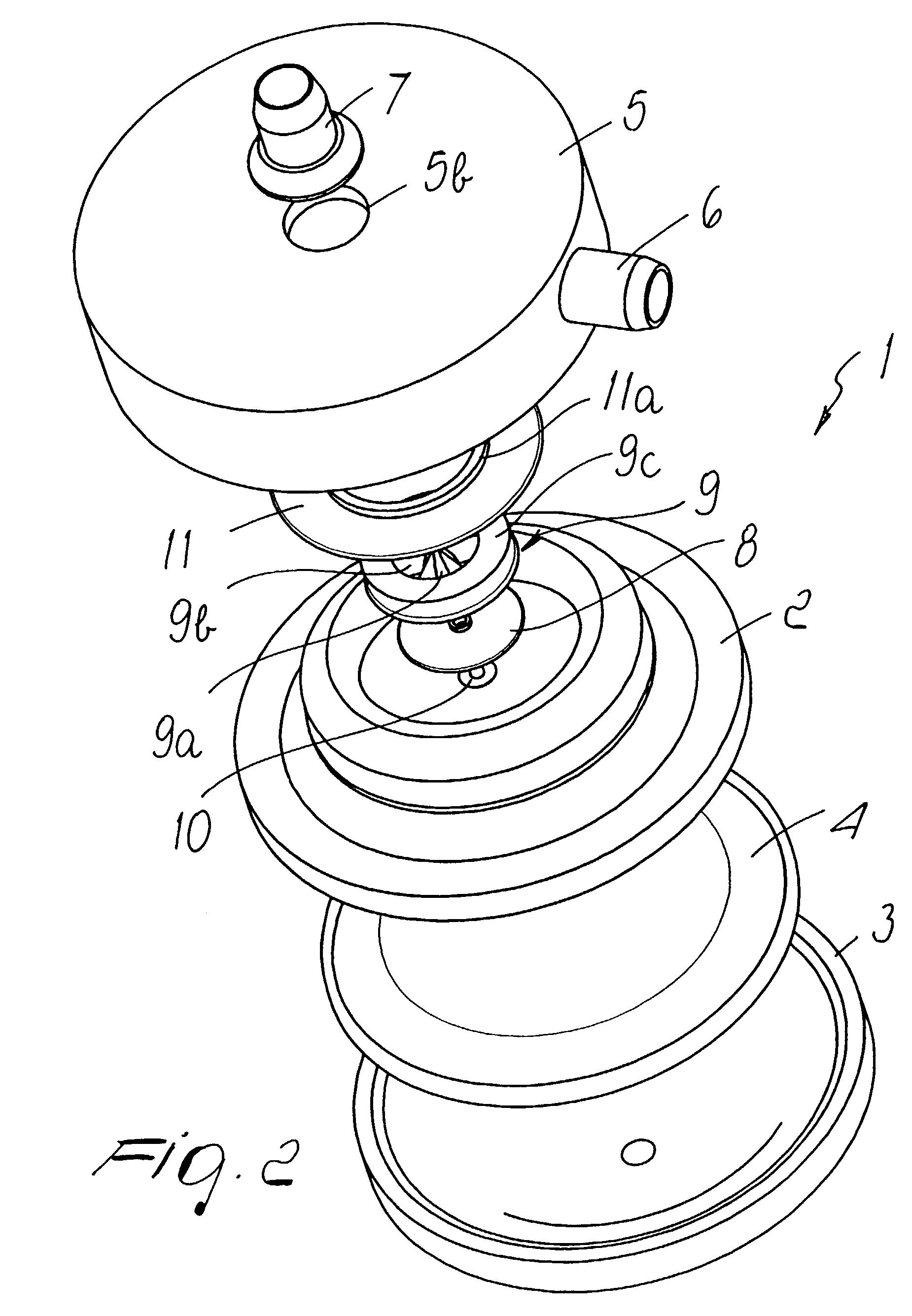

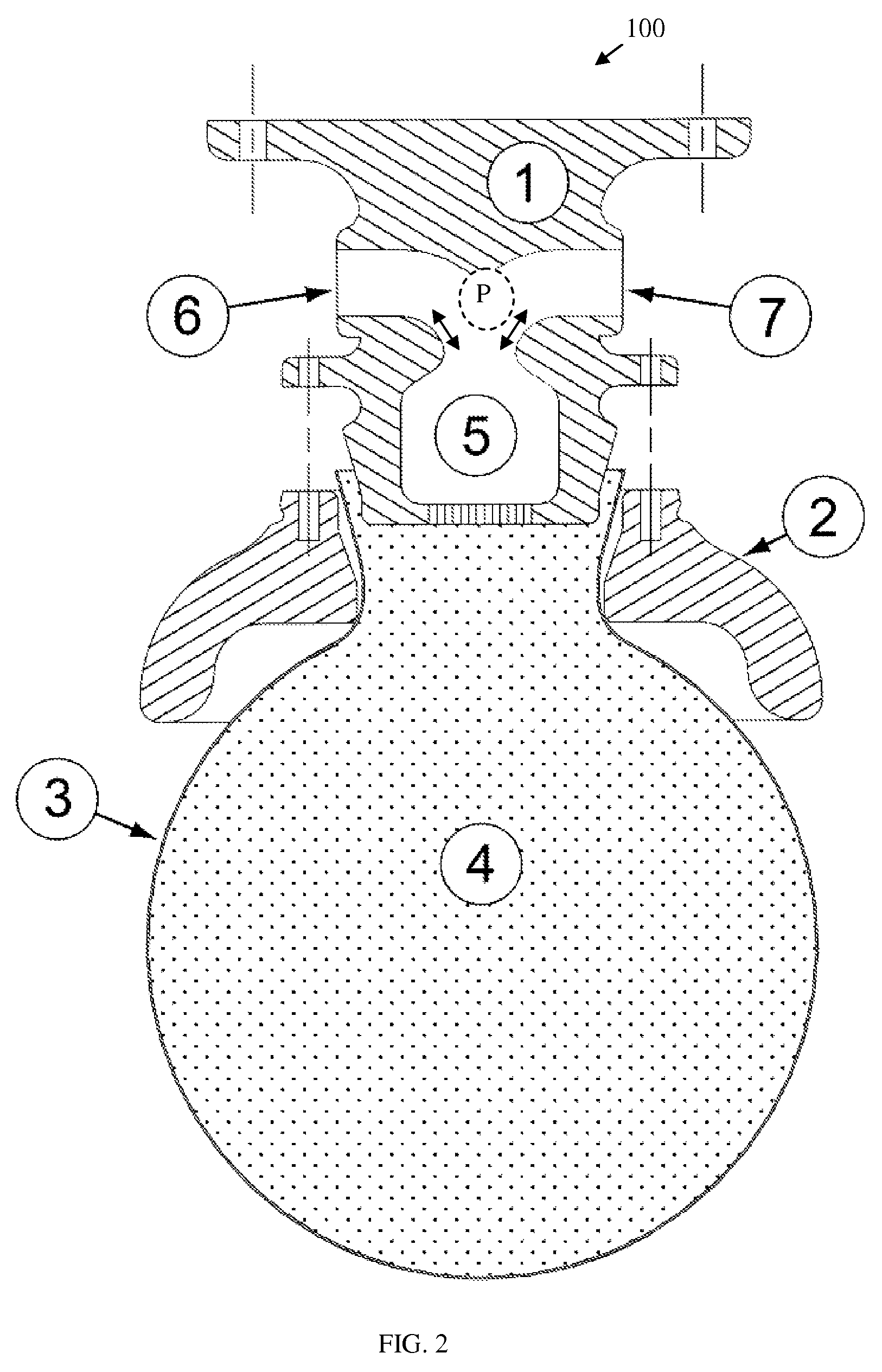

Blood pumping unit, with a coplanar disk inlet valve and an annular outlet valve

InactiveUS7029245B2Maximum of constructive simplicityLow costFlexible member pumpsDialysis systemsWorking fluidInlet valve

A unit for pumping fluid, particularly blood, is provided with an enclosure that has two half-shells and an elastic membrane fixed perimetrically to the enclosure in order to divide its space into two parts. One of the half-shells is provided with valves that are located at the opening of two connecting ducts for the intake and delivery of the fluid, and the other half-shell is connected to a line of working fluid that is alternately pressurized and depressurized. The first valve is a disk-shaped sheet made of elastic material. The first valve is in a central position with a support that is fixed to the opening of the first duct for connection to the outside and is suitable to rest at its peripheral region on the support. A second valve is a sheet of elastic material located at the peripheral region of the disk at the opening of the second duct for connection to the outside which lies at the peripheral region of the opening of the first duct.

Owner:SORIN GRP ITAL SRL

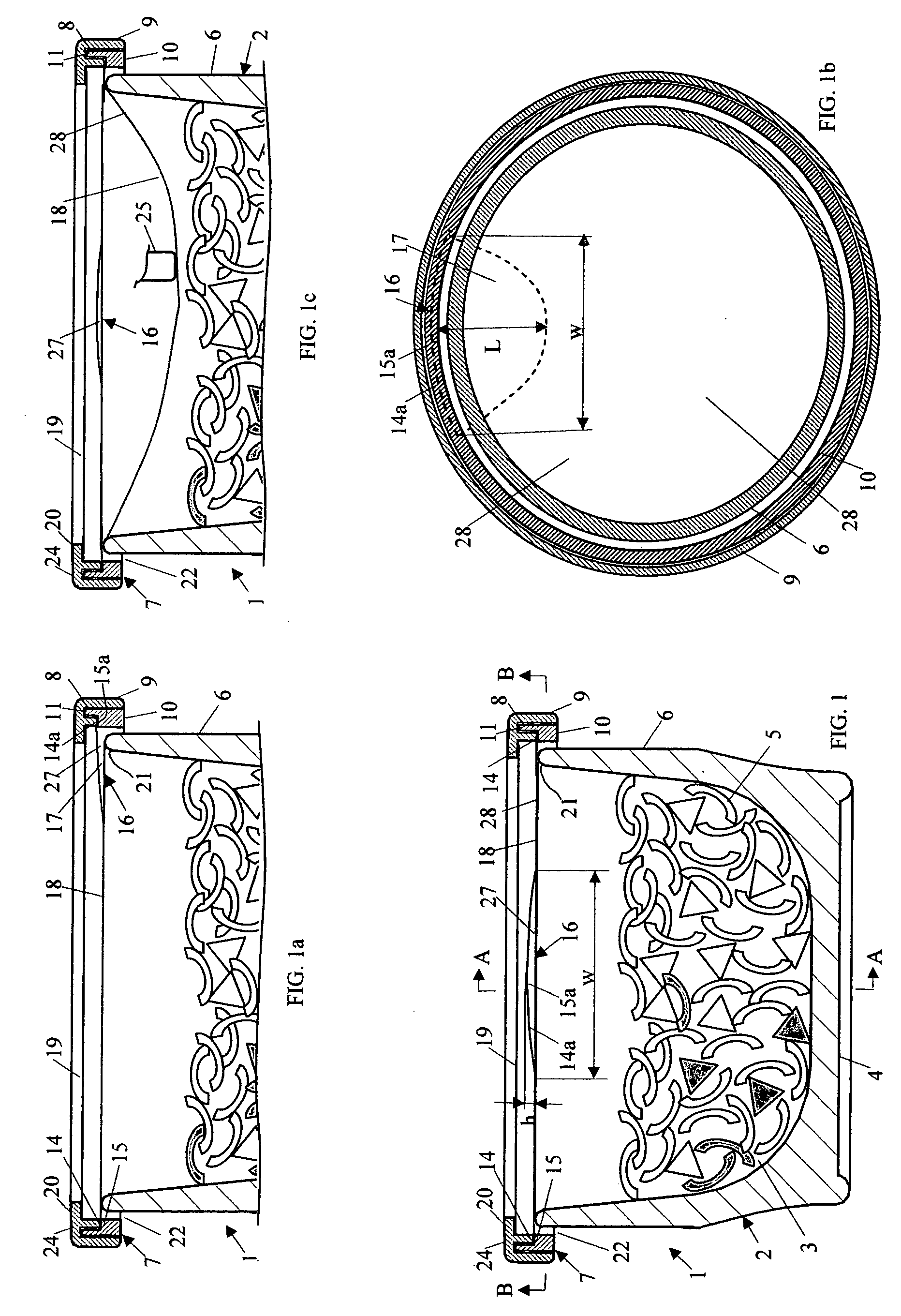

Fluidic intraocular lens systems and methods

The present invention relates to a fluidic intraocular lens inserted into a capsular bag of an eye to replace a crystalline lens. The fluidic intraocular lens may be shaped by elastic membranes bonded to a support ring. The space inside the device may be filled with optically transparent fluid or gel having an index of refraction greater than the index of vitreous humor. The device may be such designed so that the focusing power of the lens can be changed by the deformation of the capsular bag, which may be subsequently controlled by a ciliary muscle.

Owner:RHEVISION TECH

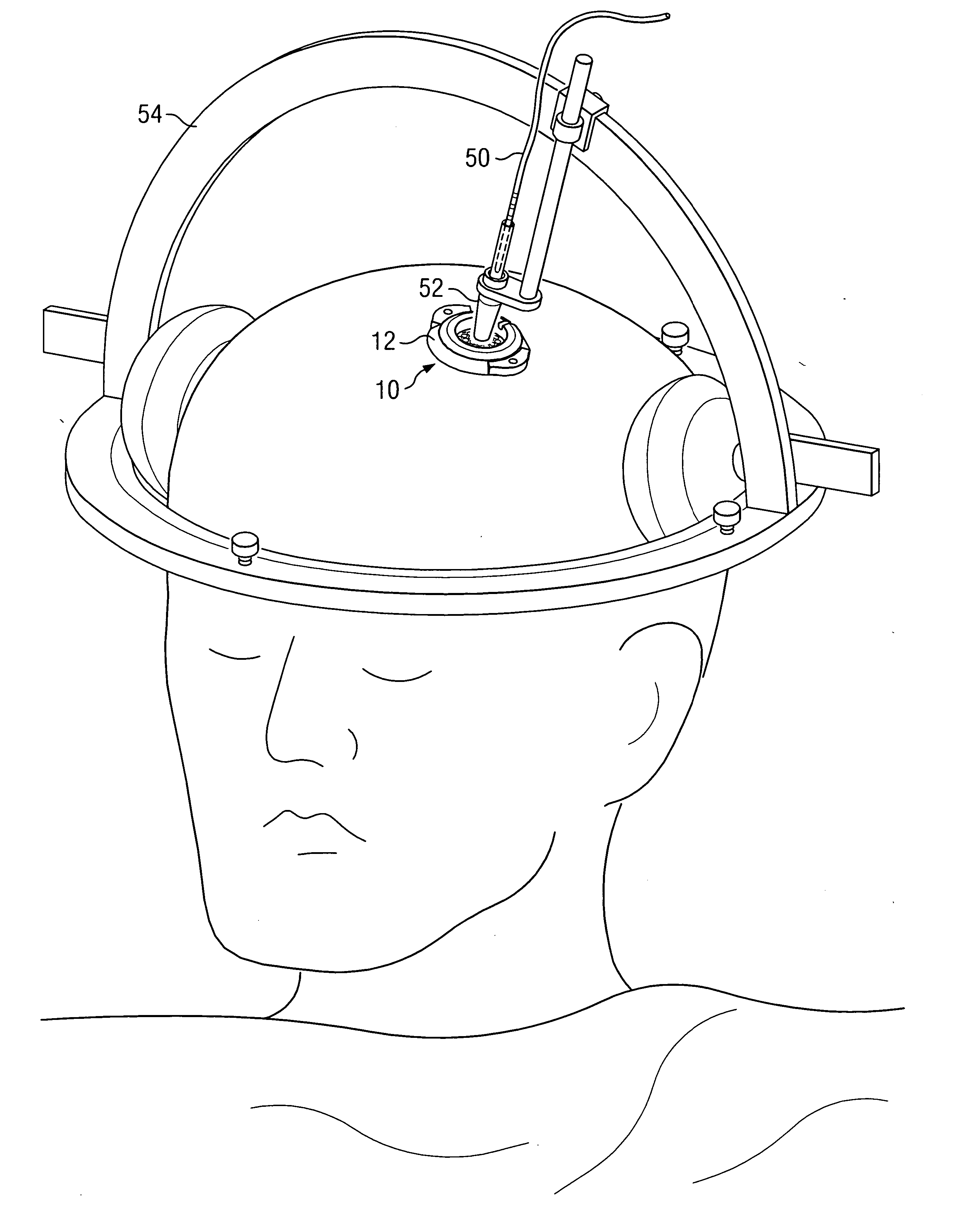

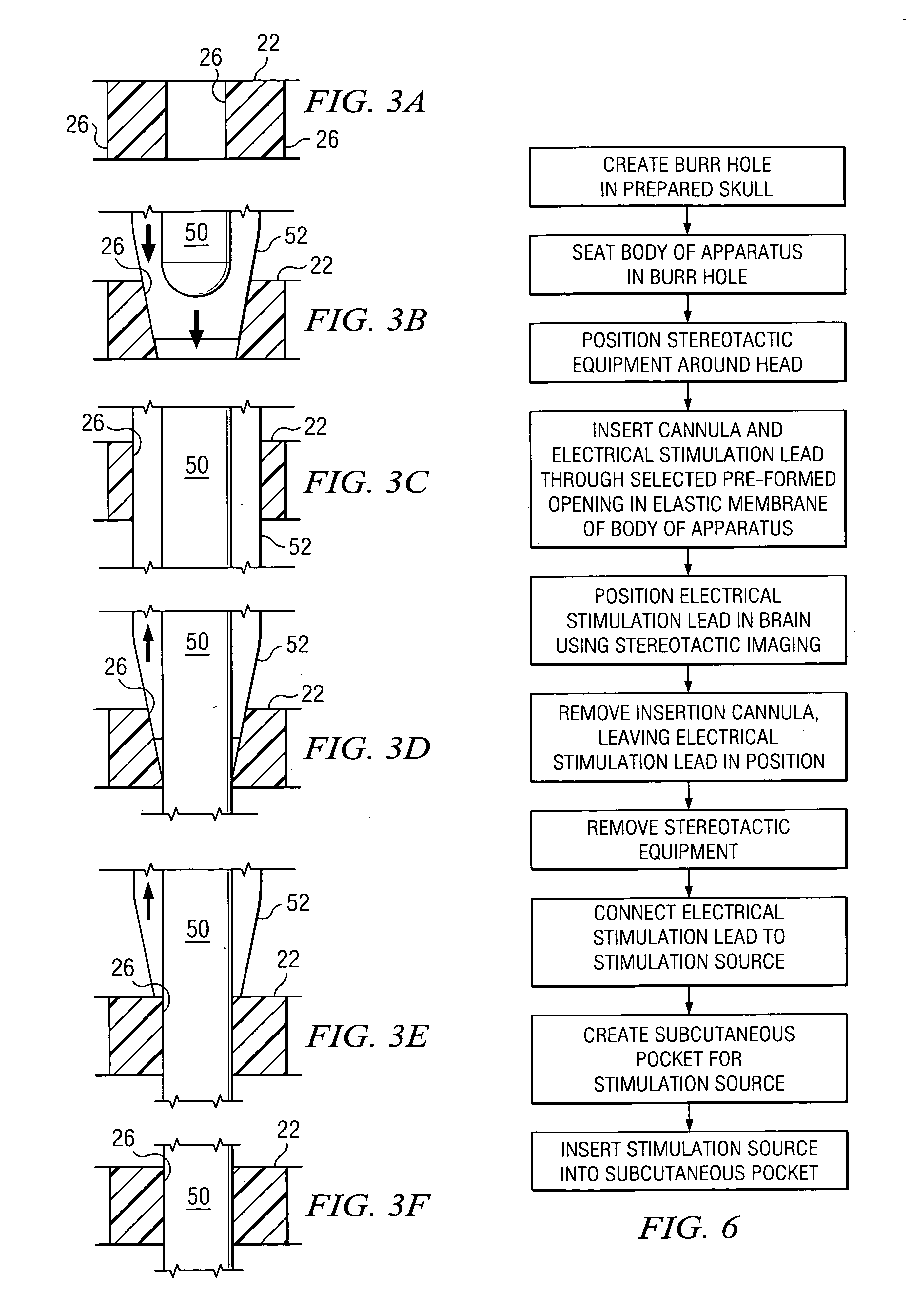

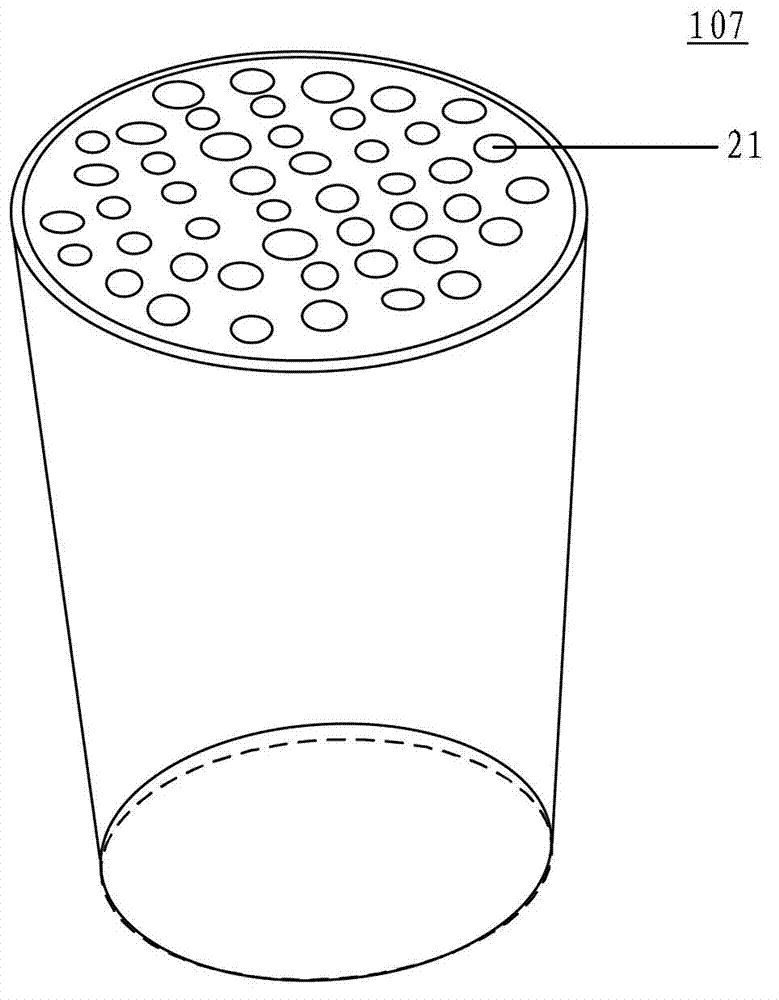

Electrical stimulation system and associated apparatus for securing an electrical stimulation lead in position in a person's brain

InactiveUS20050143799A1Simply and easily insertedReduce riskHead electrodesIntracranial pressure measurementElectricityBurr holes

In one aspect, an apparatus is provided for securing an electrical stimulation lead in position in a person's brain. The apparatus includes a body configured to seat within a burr hole formed in the person's skull. The apparatus also includes a central elastic membrane coupled to the body and extending across a central aperture of the body. The elastic membrane includes a number of pre-formed openings provided for purposes of securing the lead in position within the brain after implantation. Each pre-formed opening may penetrate through an entire thickness of the elastic membrane. Each pre-formed opening may be selected for insertion of the lead into the brain. Each pre-formed opening is adapted to elastically expand as the lead is inserted through the pre-formed opening and positioned in the brain and is adapted to elastically contract on the lead to secure the lead in position within the brain after implantation.

Owner:ADVANCED NEUROMODULATION SYST INC

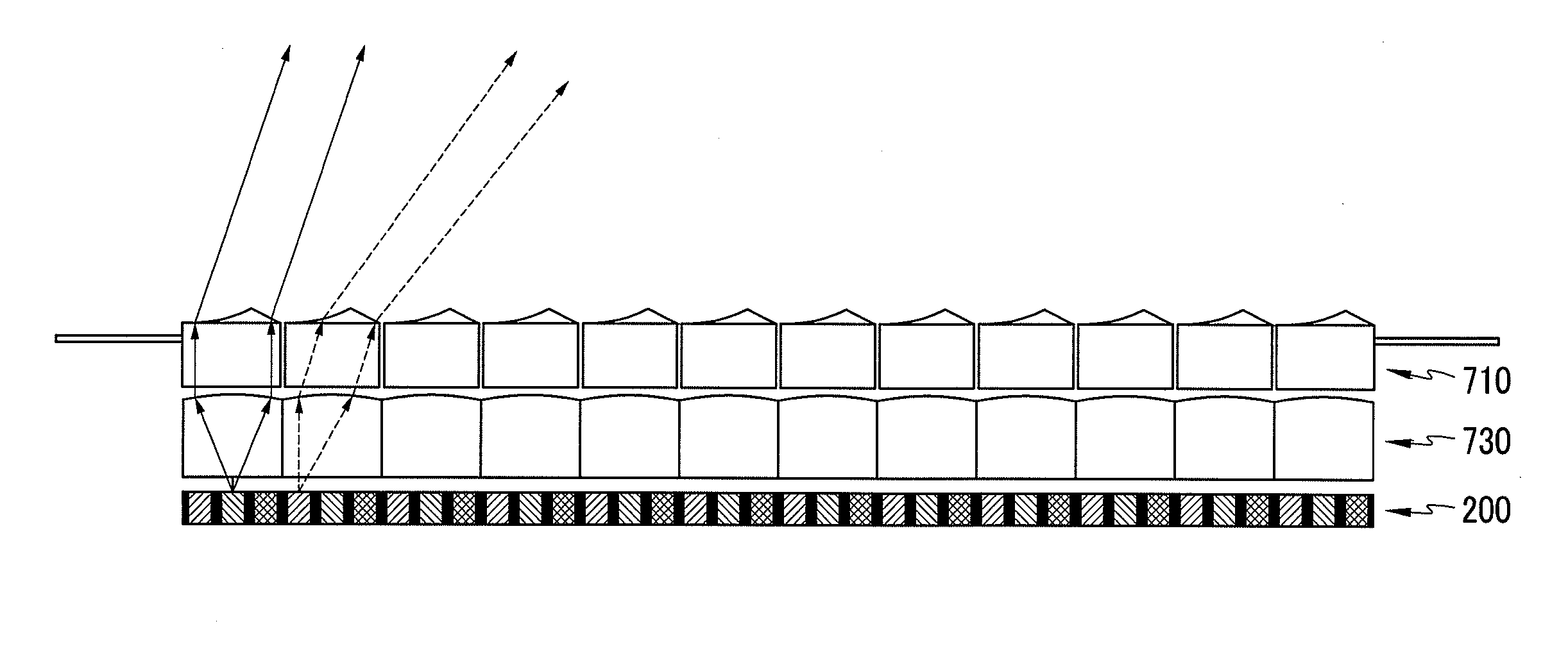

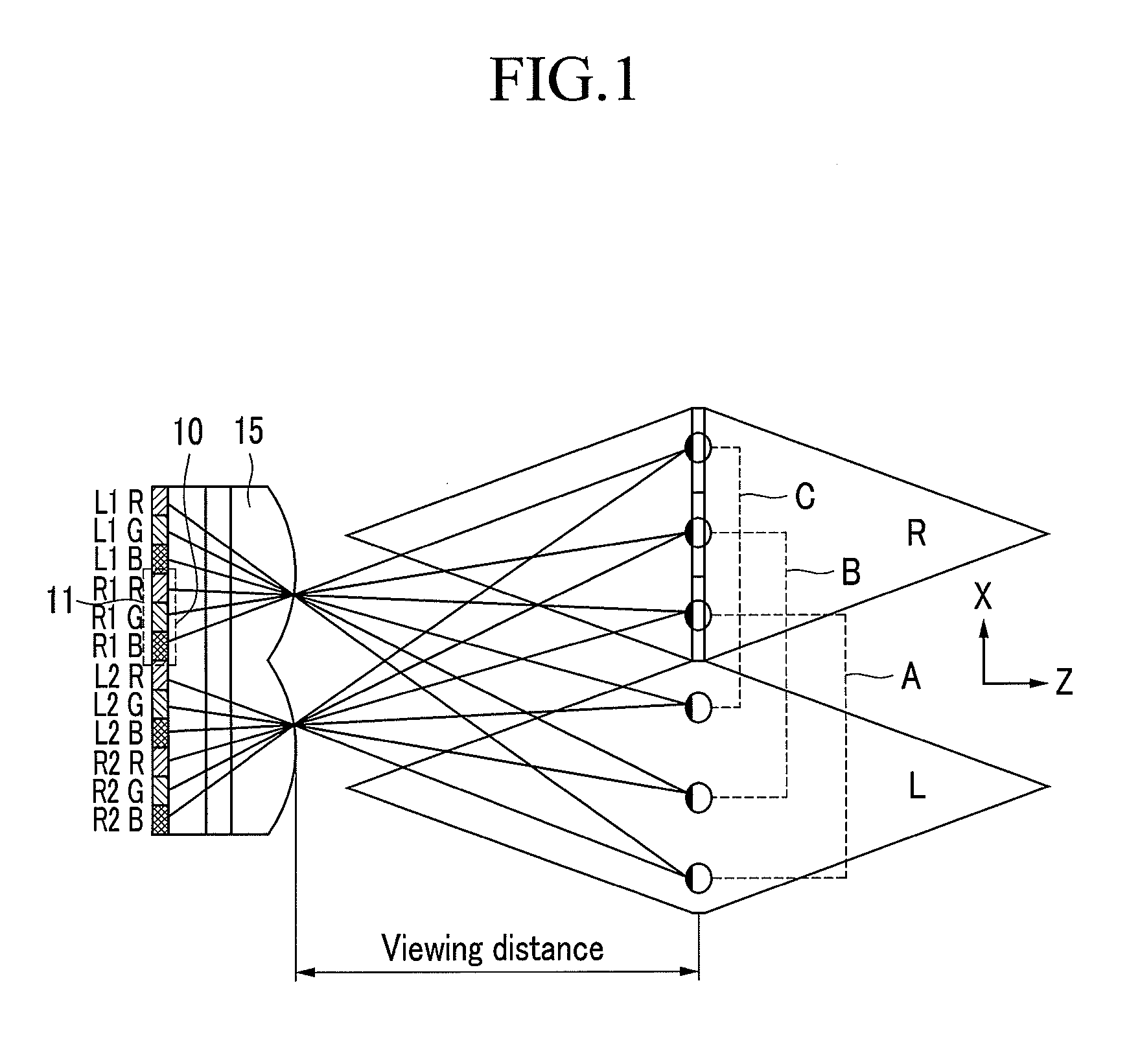

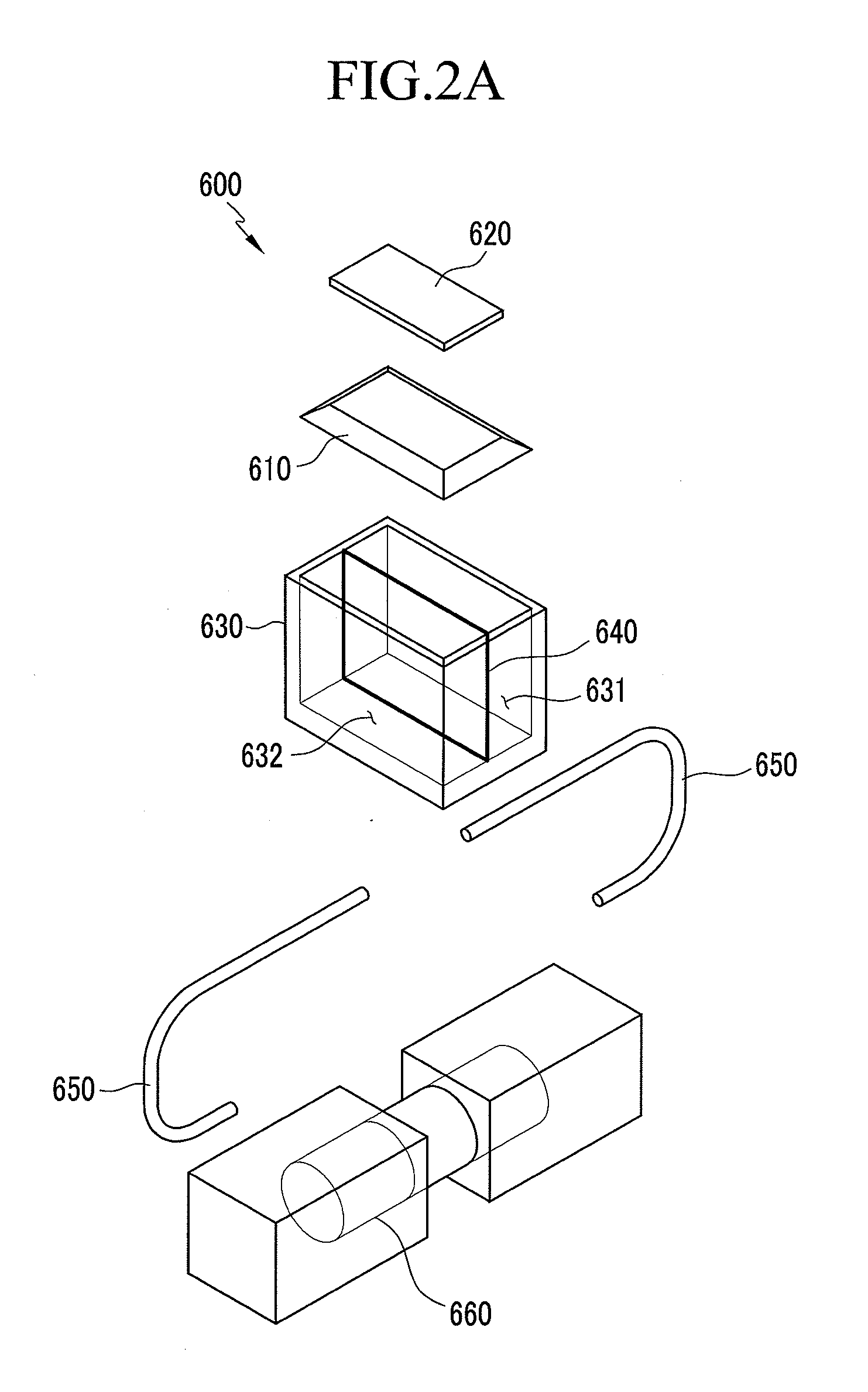

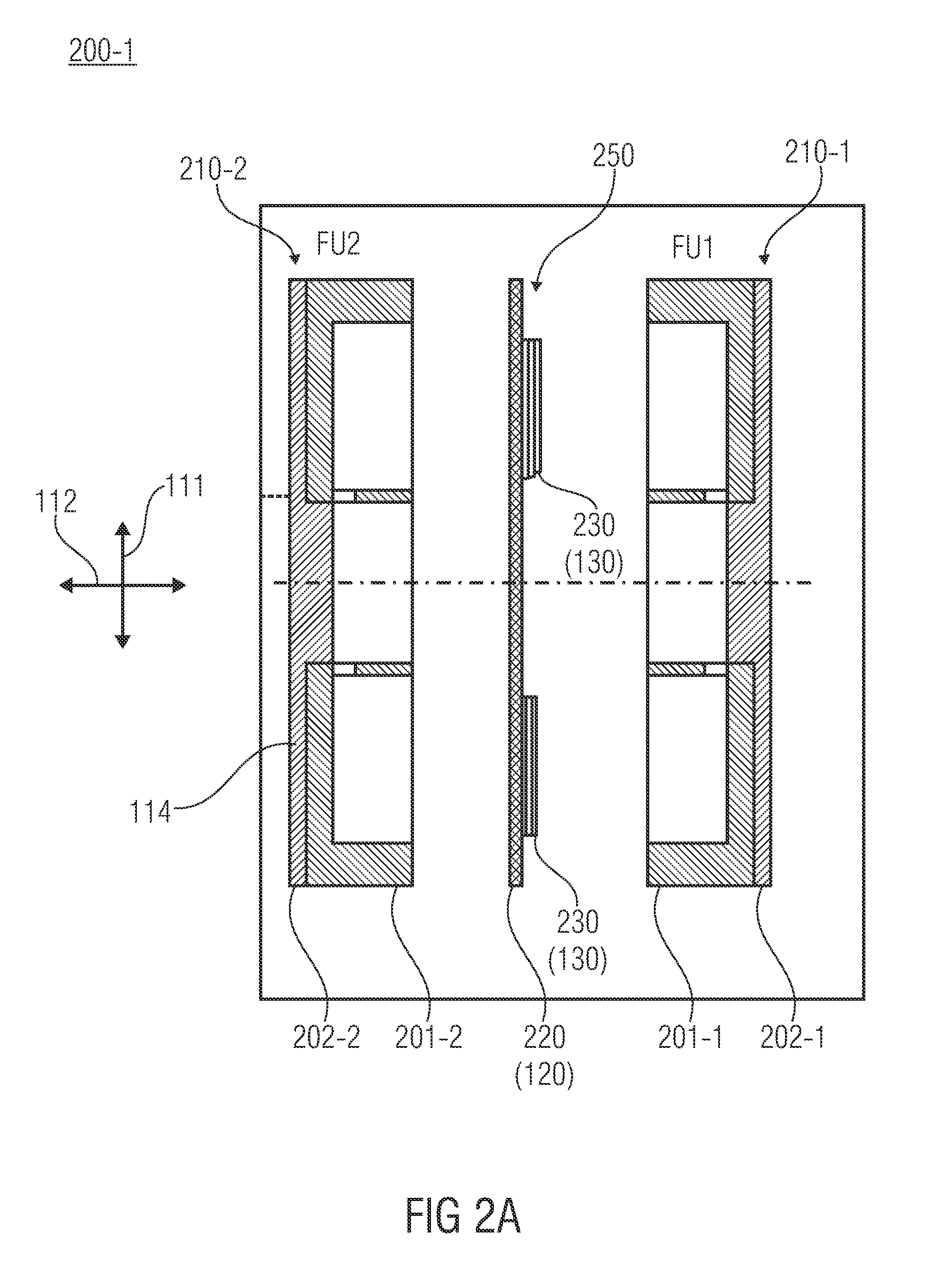

Liquid elastic membrane prism and 3 dimension display device having the same

A stereoscopic display is provided. The stereoscopic display is able to control a viewing position and make a viewing angel wide. On top of a display panel, an image is provided through a plurality of pixels and is separated to a left-eye image and a right-eye image by a lenticular lens. An elastic membrane prism array controls an angle of emitted light. An elastic membrane prism array is disposed on the lenticular lens or on and under the lenticular lens. The elastic membrane prism array includes a prism body having a first chamber and a second chamber, a wall disposed between the first and second chamber, a prism plate connected to the wall, a piston adapted for moving back-and-forth and a transporting tube disposed between the piston and the prism body.

Owner:SAMSUNG DISPLAY CO LTD

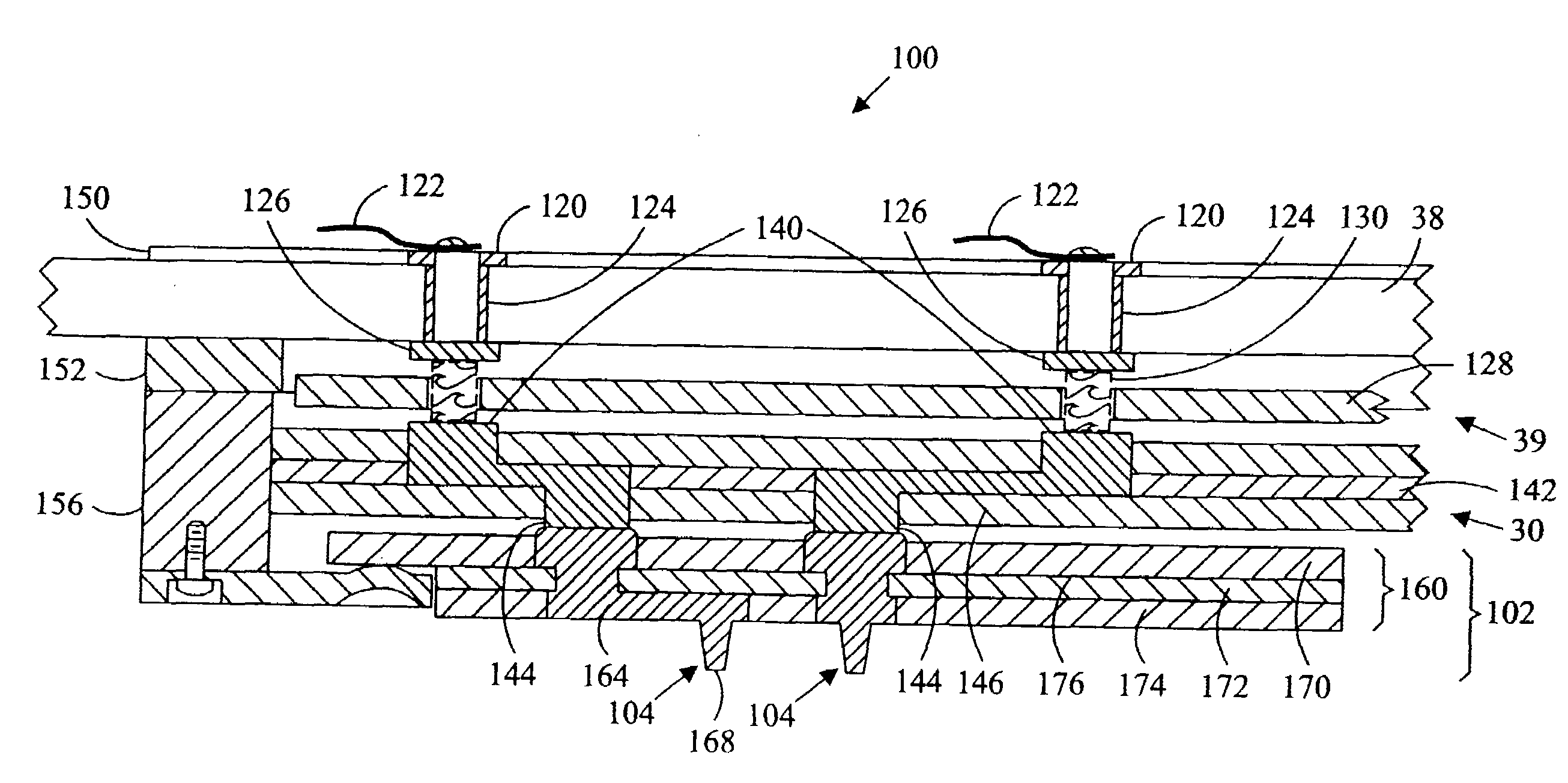

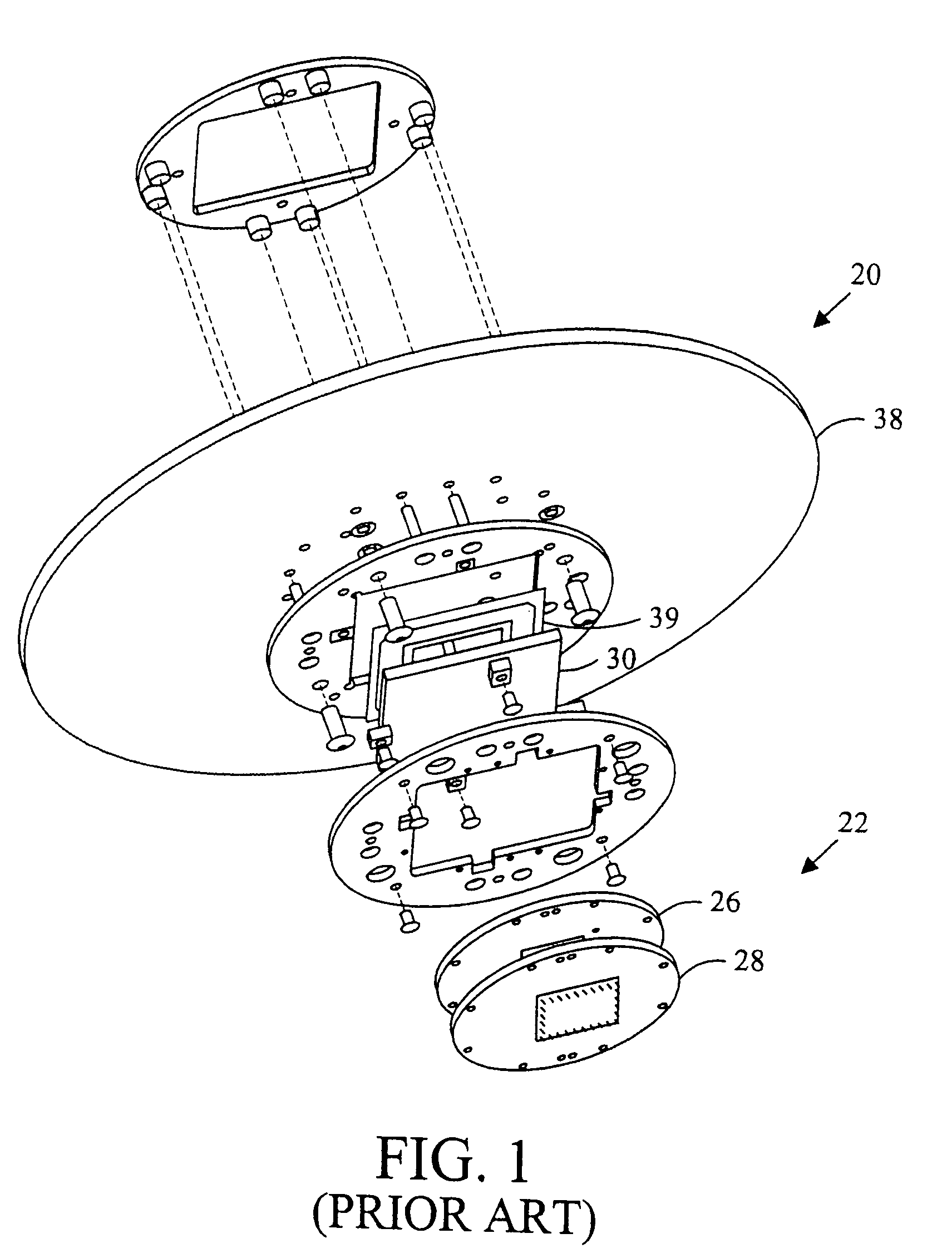

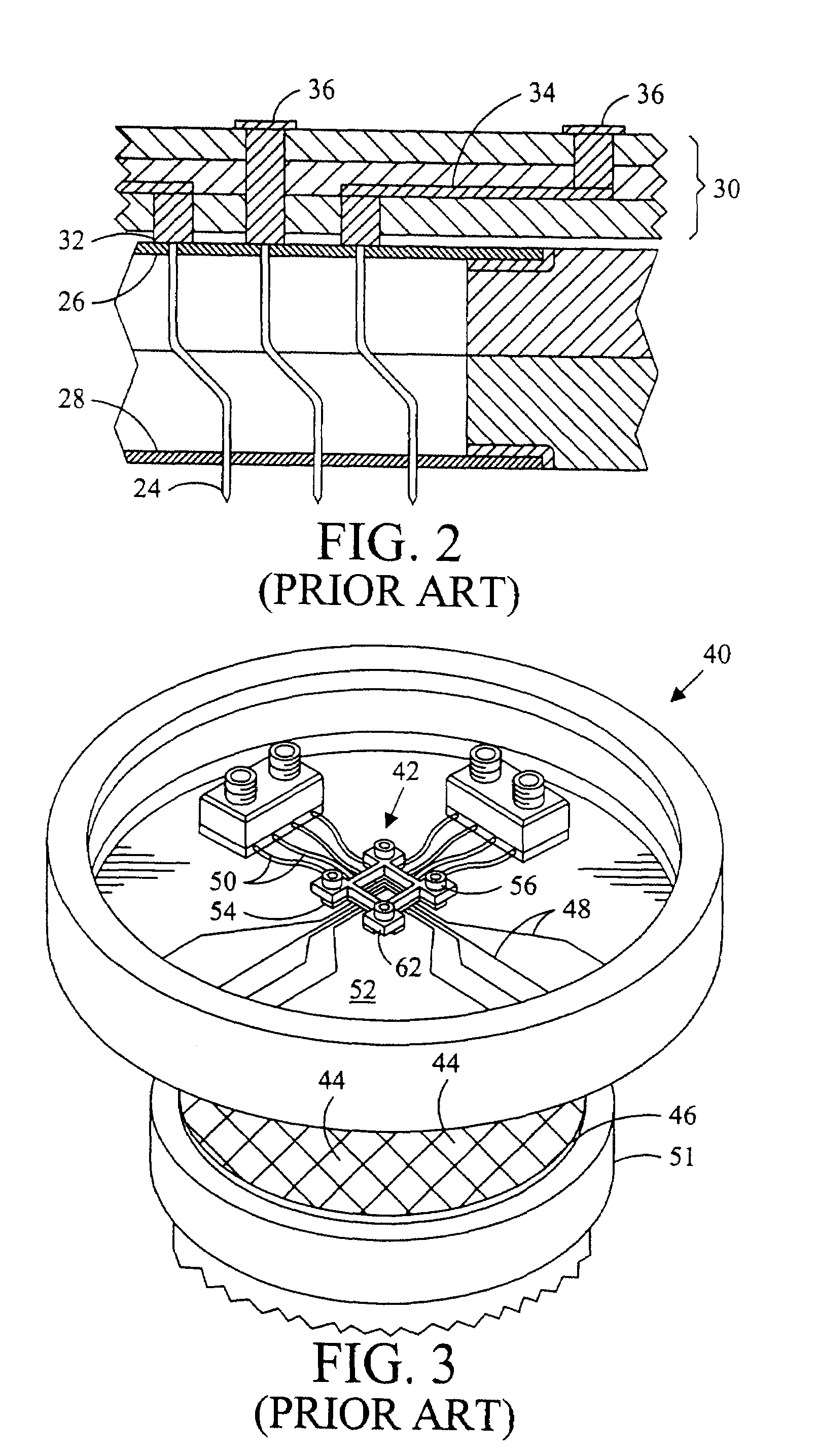

Probe head having a membrane suspended probe

ActiveUS7368927B2Semiconductor/solid-state device testing/measurementElectrical measurement instrument detailsEngineeringRestoring force

A probe head including an elastic membrane capable of exerting a restoring force when one of the surfaces of the elastic membrane is distorted. A conductive probe includes a beam having a first end and a second end, with a probe tip proximate the first end for contacting a device under test. A beam contact proximate the second end of the beam. The beam being movable to deform at least one surface of the elastic membrane.

Owner:FORMFACTOR INC

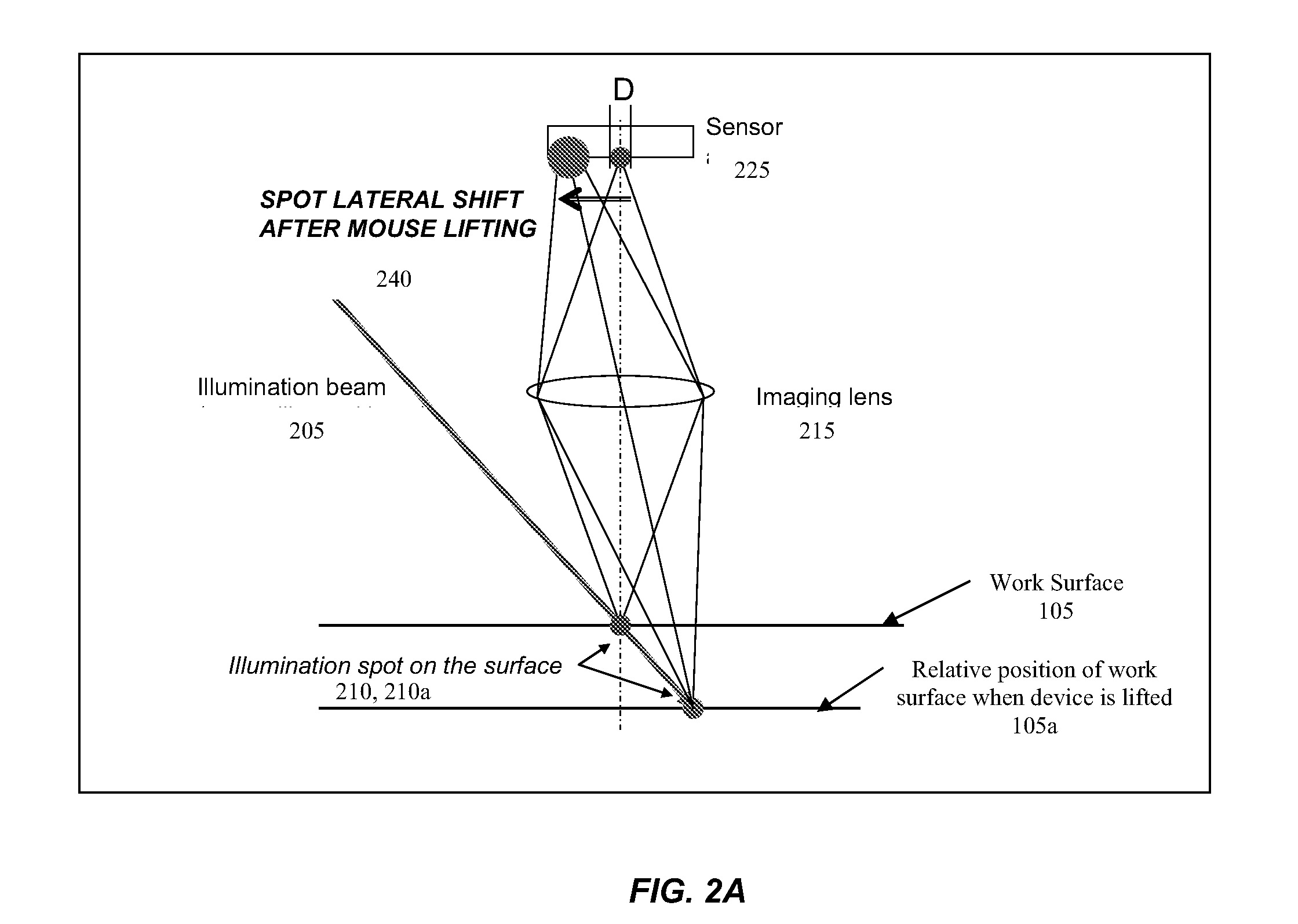

System and method for accurate lift-detection of an input device

InactiveUS20090135140A1Accurate detectionEasy to trackInput/output for user-computer interactionCathode-ray tube indicatorsCapacitanceDielectric

Various systems and methods are employed for lift-detection. Beam triangulation can be used, and in one embodiment, an optical lift detection module is separate from the optical tracking module. In one embodiment, a capacitive lift detection technique is used. A capacitor is built into the bottom case of the mouse. When the mouse is resting on a surface, the surface material serves as a dielectric for the capacitor, while air serves as the dielectric when the mouse is lifted. This dielectric change leads to a change in the capacitance value, leading to detection of lift. In one embodiment, a capacitor with an easily compressable material inserted between the two electrodes is used. In another embodiment, a mechanical plunger with an elastic membrane is used for lift detection. Lift detection can be tunable and / or customizable. The actual height of the life can be detected, rather than simple on-off notifications.

Owner:LOGITECH EURO SA

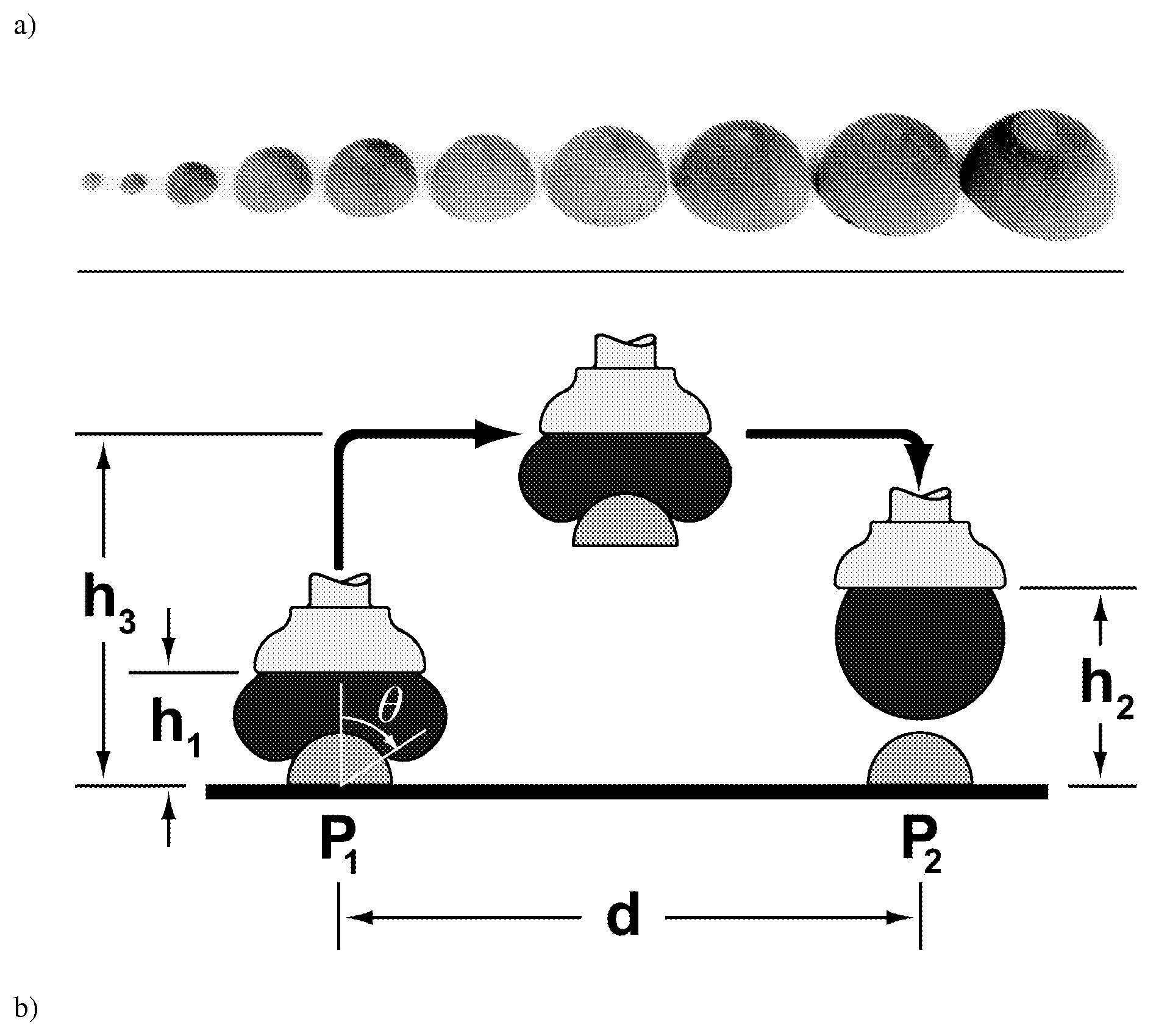

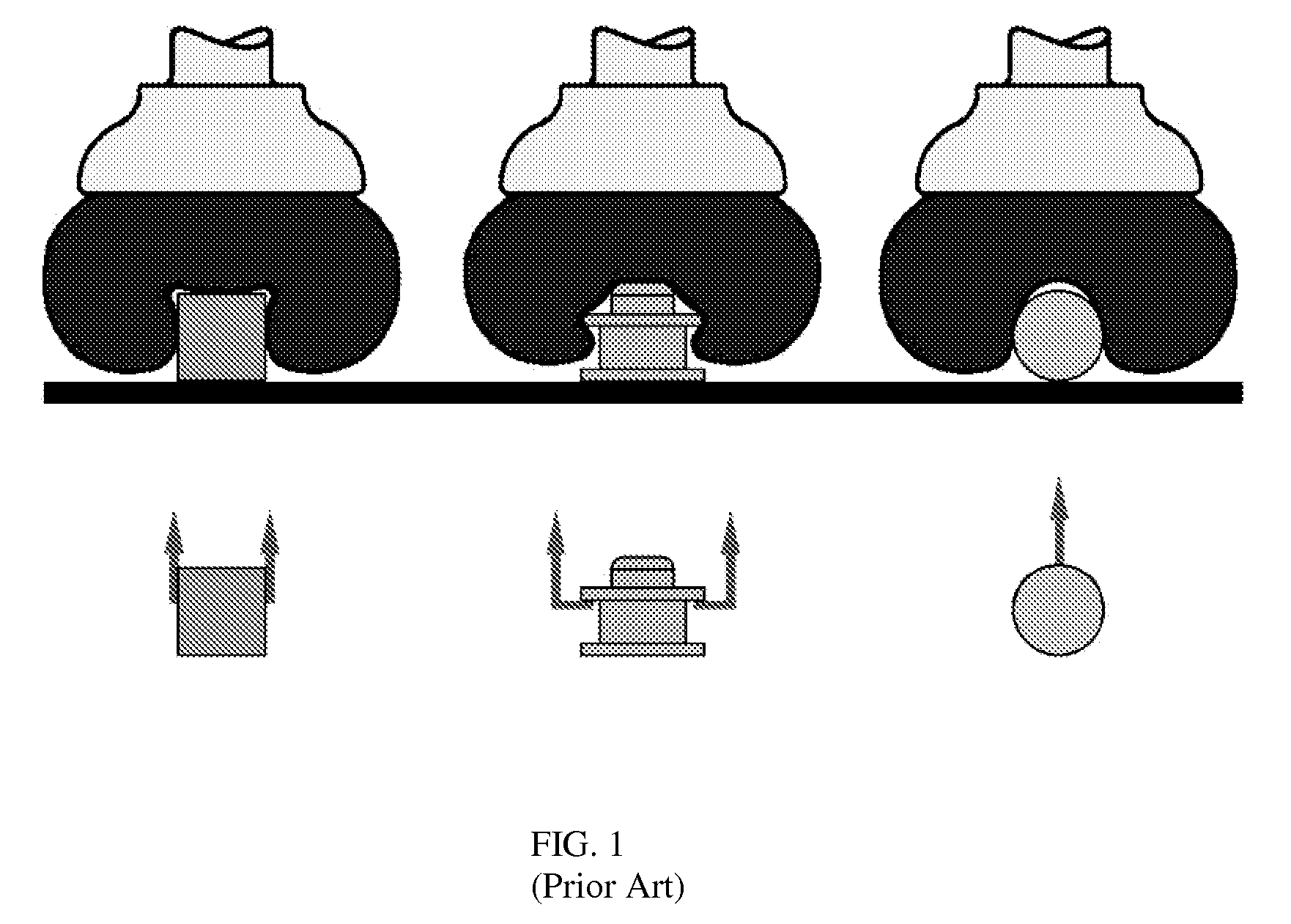

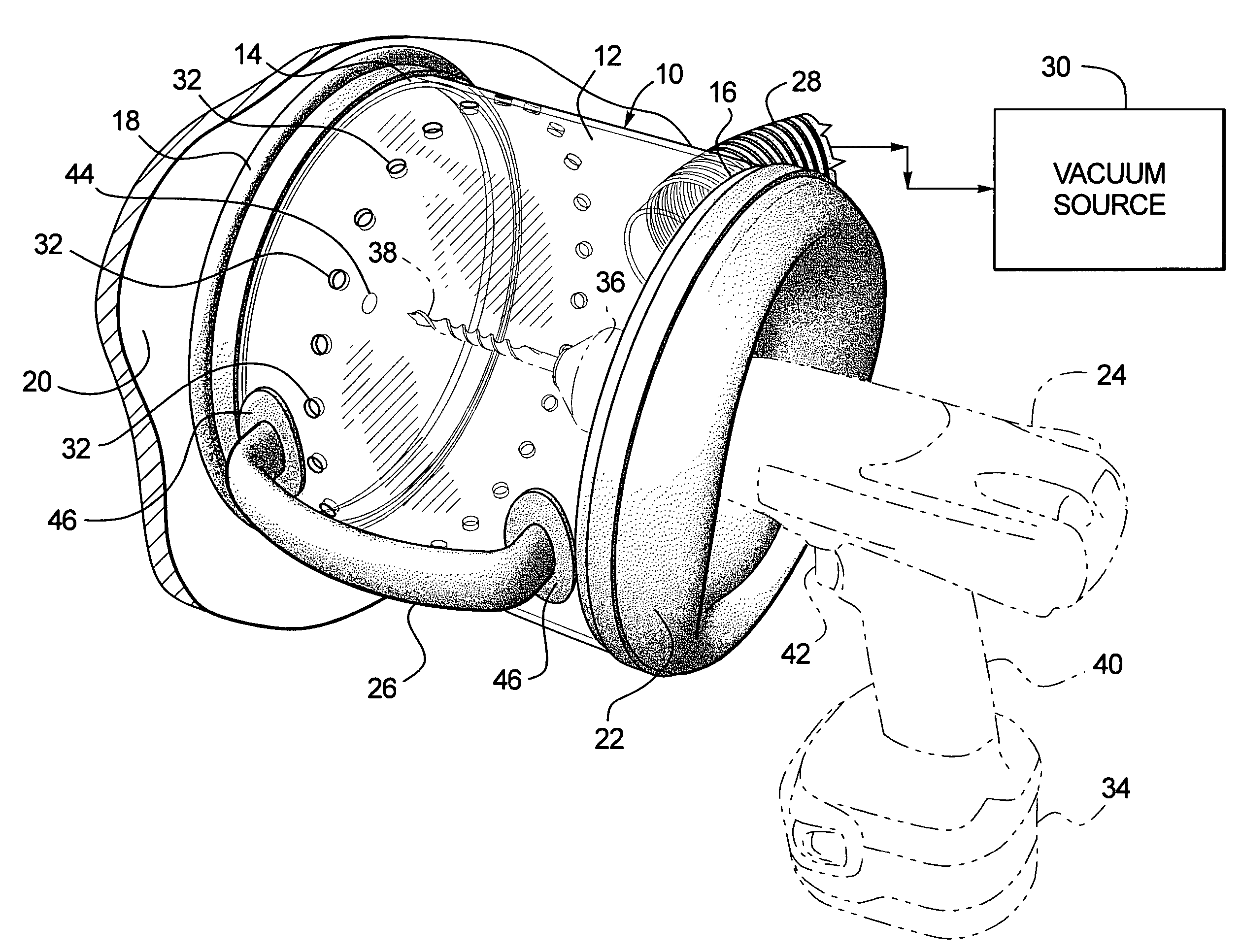

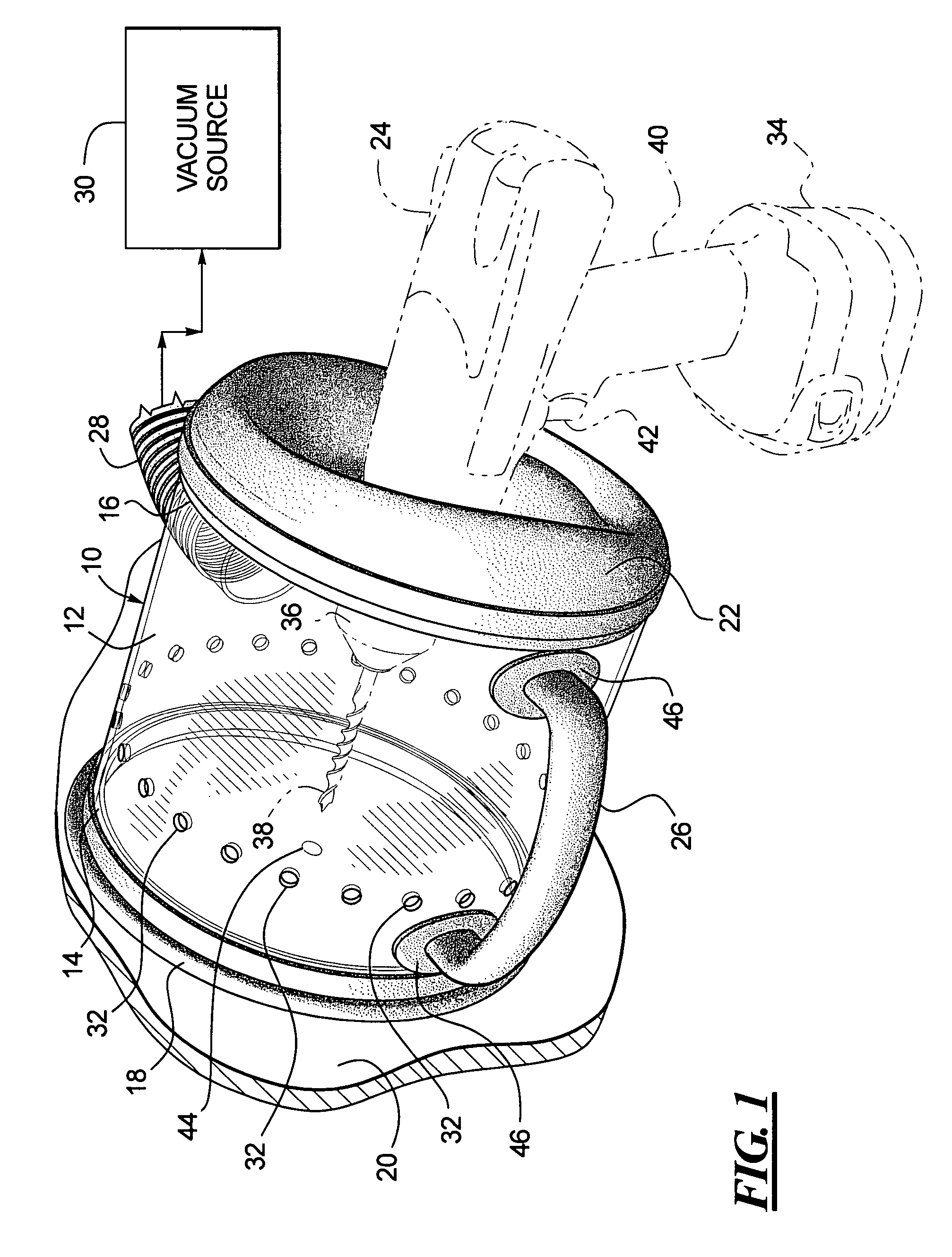

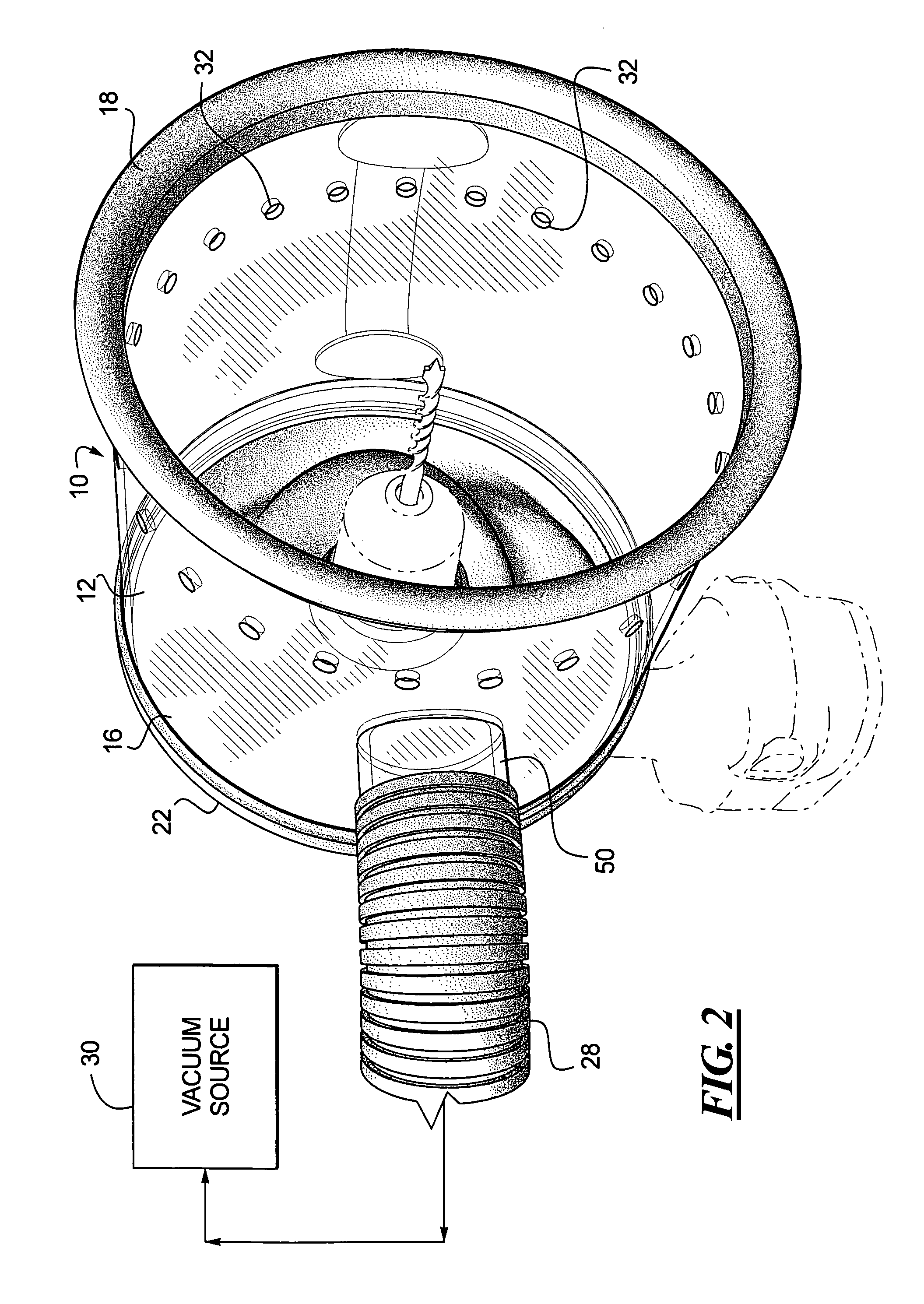

Gripping and releasing apparatus and method

ActiveUS8882165B2Improvement factorImprove performanceGripping headsRobotPositive pressureEngineering

A passive universal gripper includes a mass of granular material encased in an elastic membrane. Using a combination of positive and negative pressure, the gripper can rapidly grip and release a wide range of objects that are typically challenging for conventional universal grippers, such as flat objects, soft objects, or objects with complex geometries. The gripper passively conforms to the shape of a target object, then vacuum-hardens to grip it rigidly; later using positive pressure to reverse this transition—releasing the object and returning to a deformable state. The apparatus and method enable the fast ejection of objects from the gripper, as well as essentially instantaneous reset time between releasing and gripping.

Owner:CORNELL UNIVERSITY +1

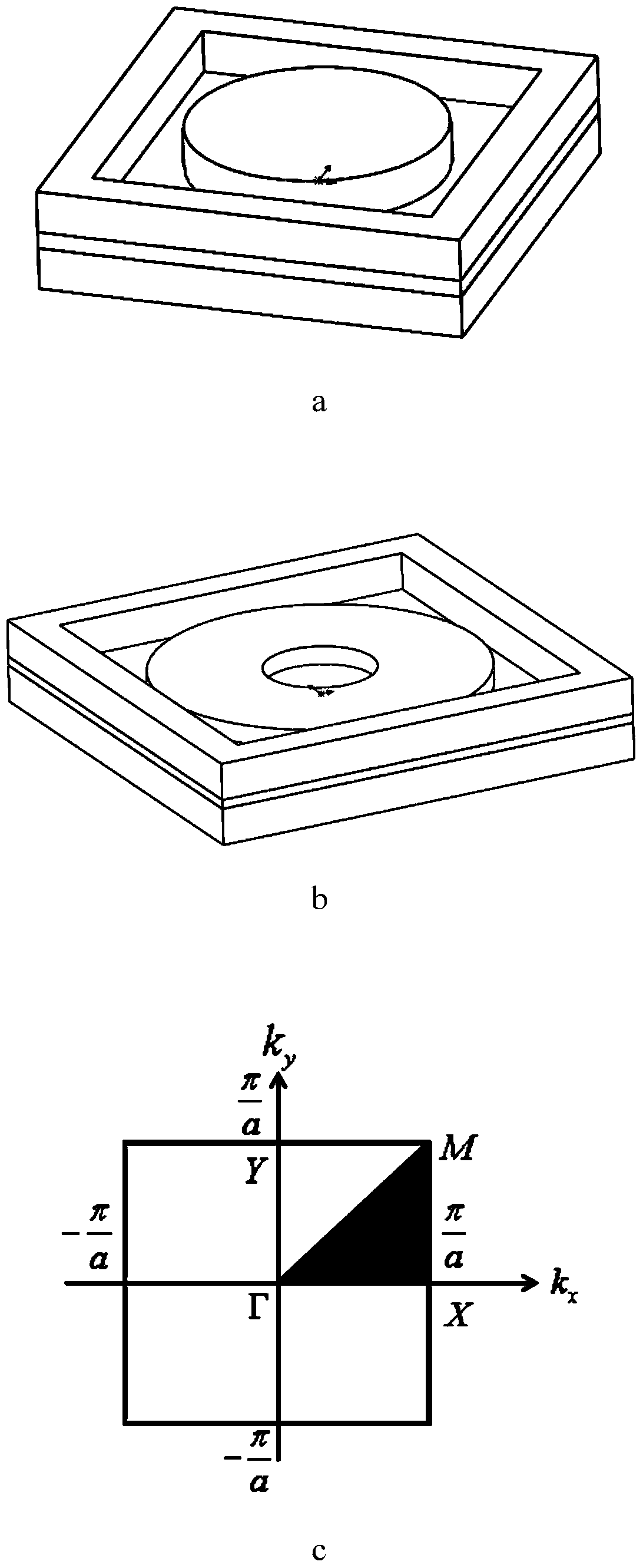

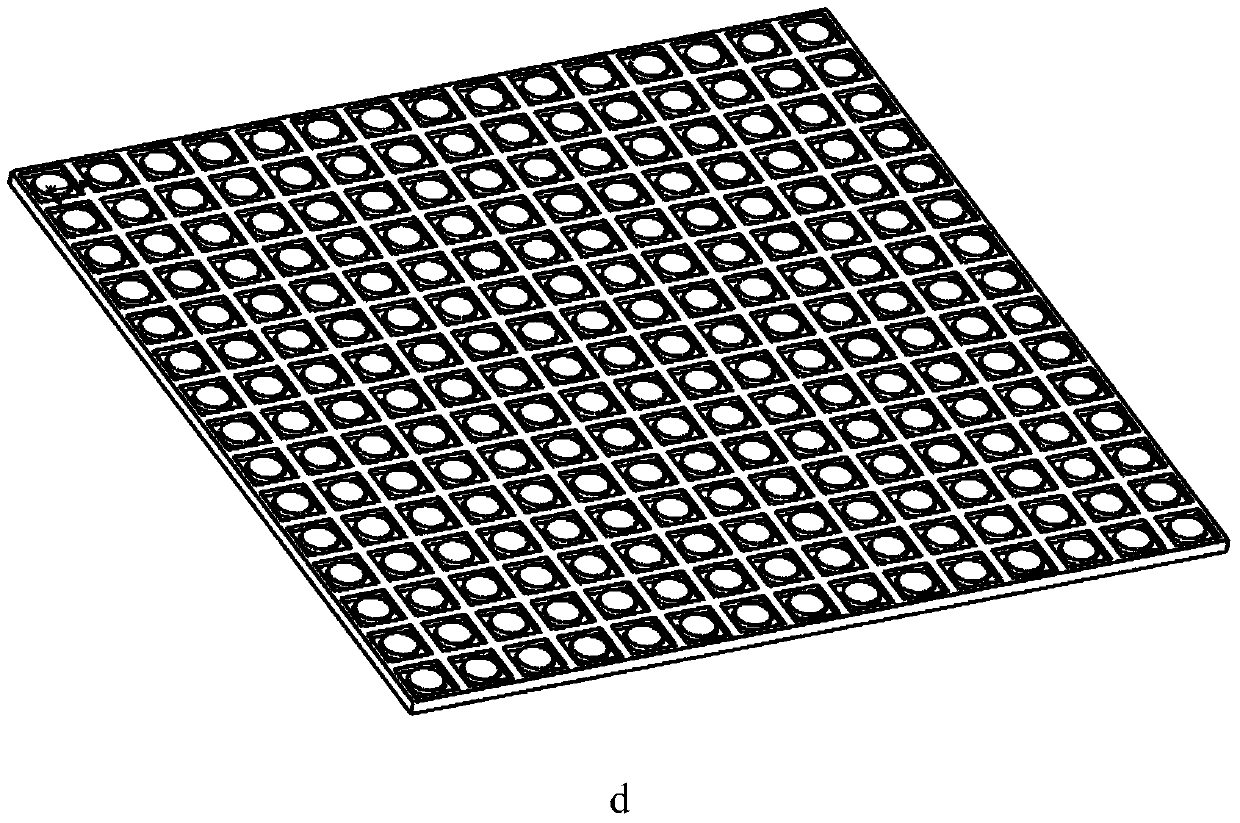

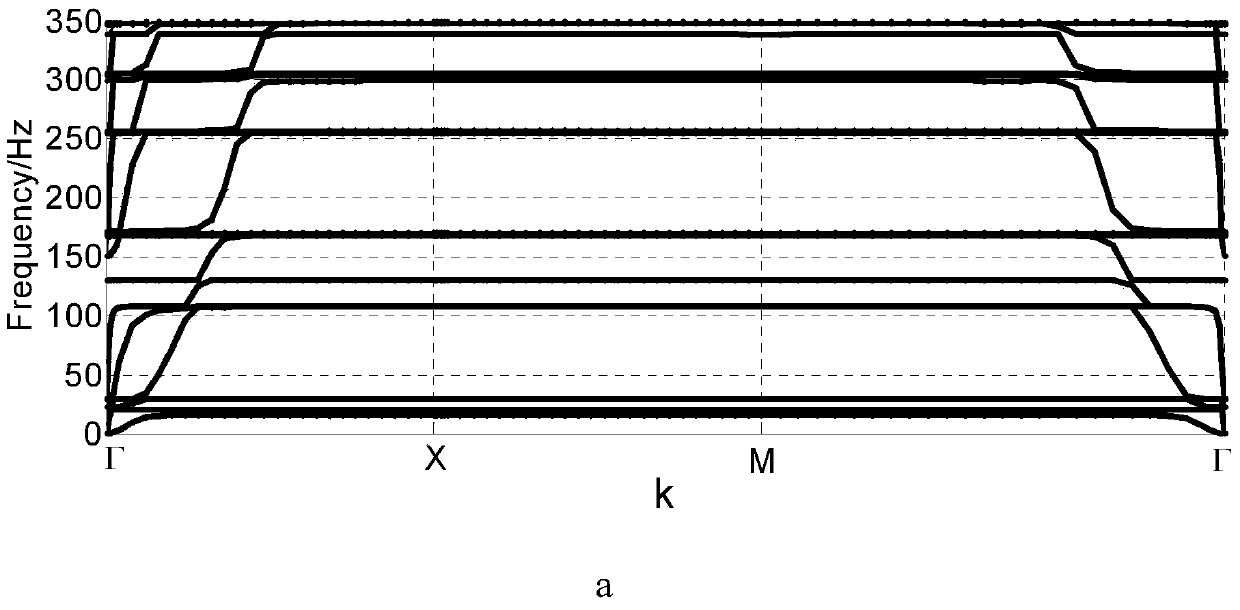

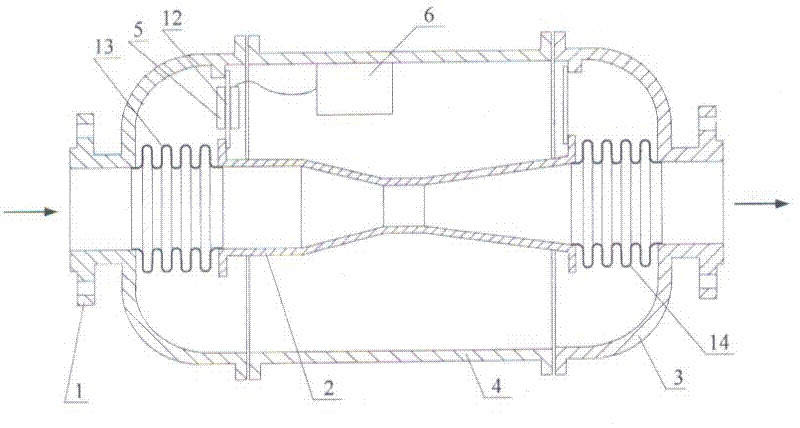

Elastic membrane-type low-frequency sound insulation metamaterial structure

InactiveCN103996395AMeet the requirements of low frequency sound insulationImprove sound insulationSound producing devicesLow noiseBroadband

The invention discloses an elastic membrane-type low-frequency sound insulation metamaterial structure which comprises two frames and a silicone rubber elastic membrane arranged between the two frames. A plurality of mass blocks are pasted on one side of the silicone rubber elastic membrane, and the mass blocks are separated with one another through the frames. The elastic membrane-type low-frequency sound insulation metamaterial structure solves the problems that a traditional sound insulation material is poor in low-frequency sound insulation performance, large in thickness, heavy in mass and the like and meets the five requirements of low-frequency sound insulation, wherein the five requirements include the low-frequency sound insulation requirement for noise below 500 Hz, the broadband requirement, the requirement for low structural thickness and low weight, and the requirement of easy design processing and low processing difficulty. The elastic membrane-type low-frequency sound insulation metamaterial structure has excellent low-frequency sound insulation performance, can effectively isolate low-frequency noise ranging from 200 Hz to 500 Hz, and can be applied to various carrying tools such as planes, automobiles, trains and ships and various types of building decoration. A brand new sound insulation solution is provided for creating low-noise working and living environments.

Owner:XI AN JIAOTONG UNIV

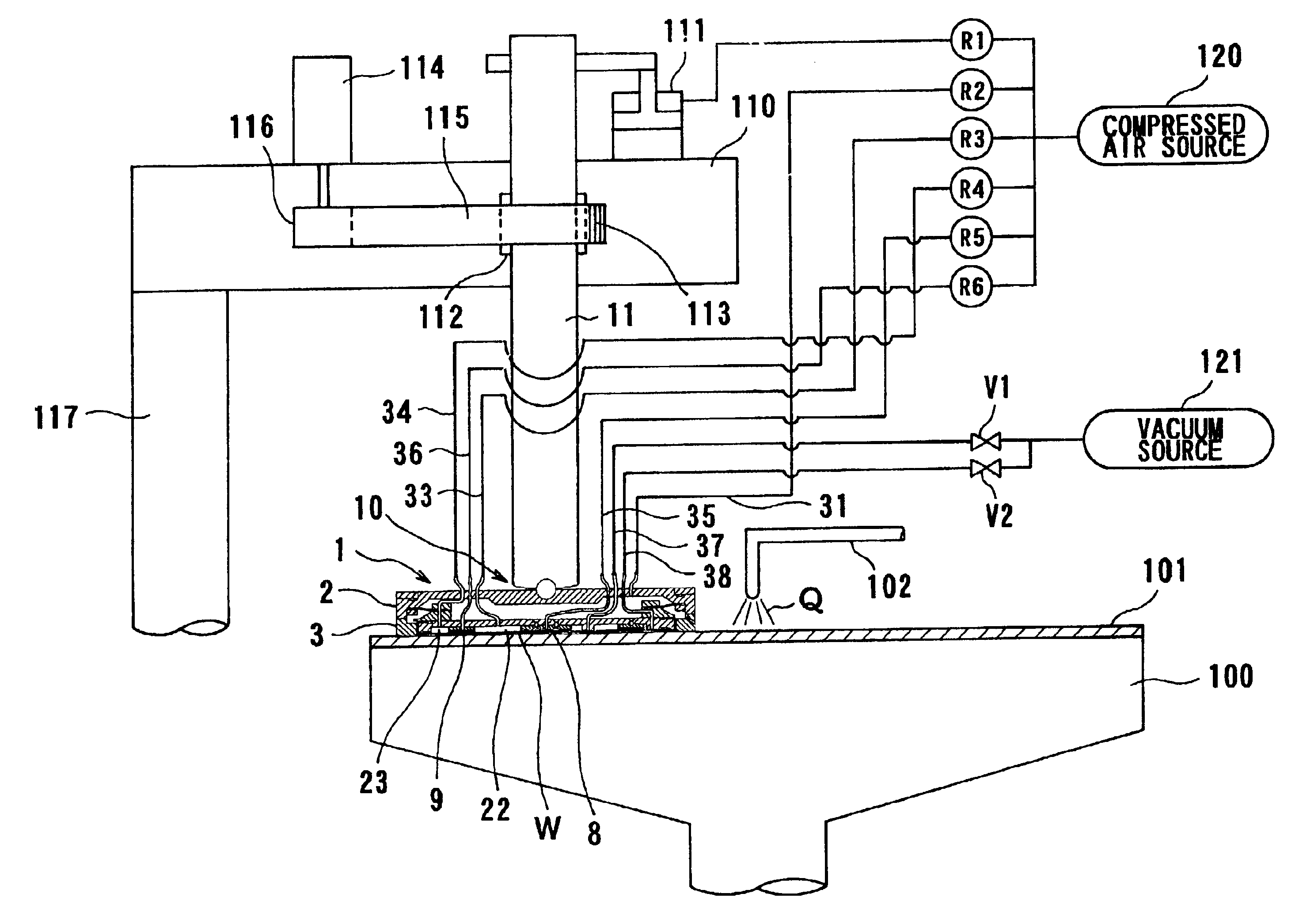

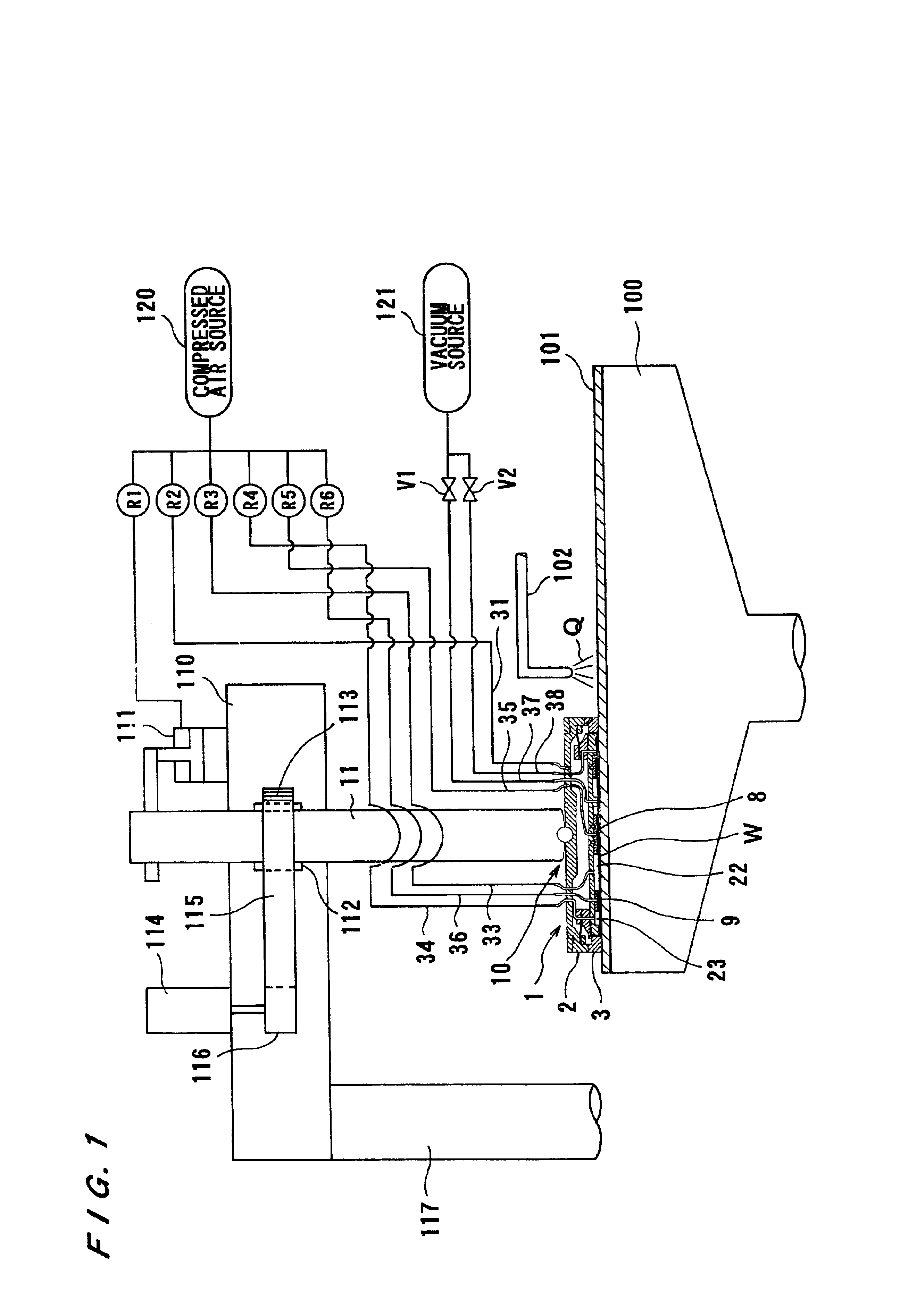

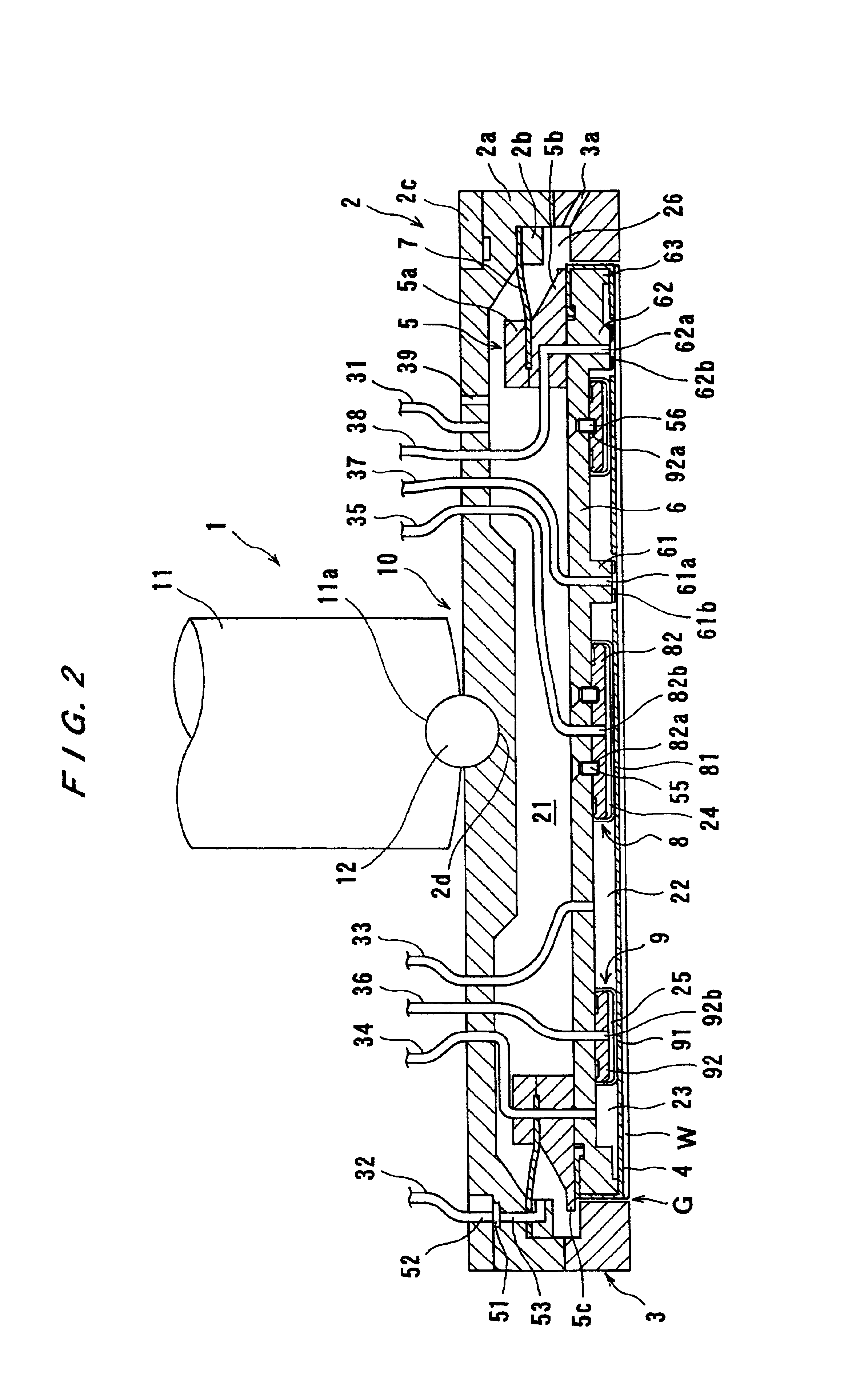

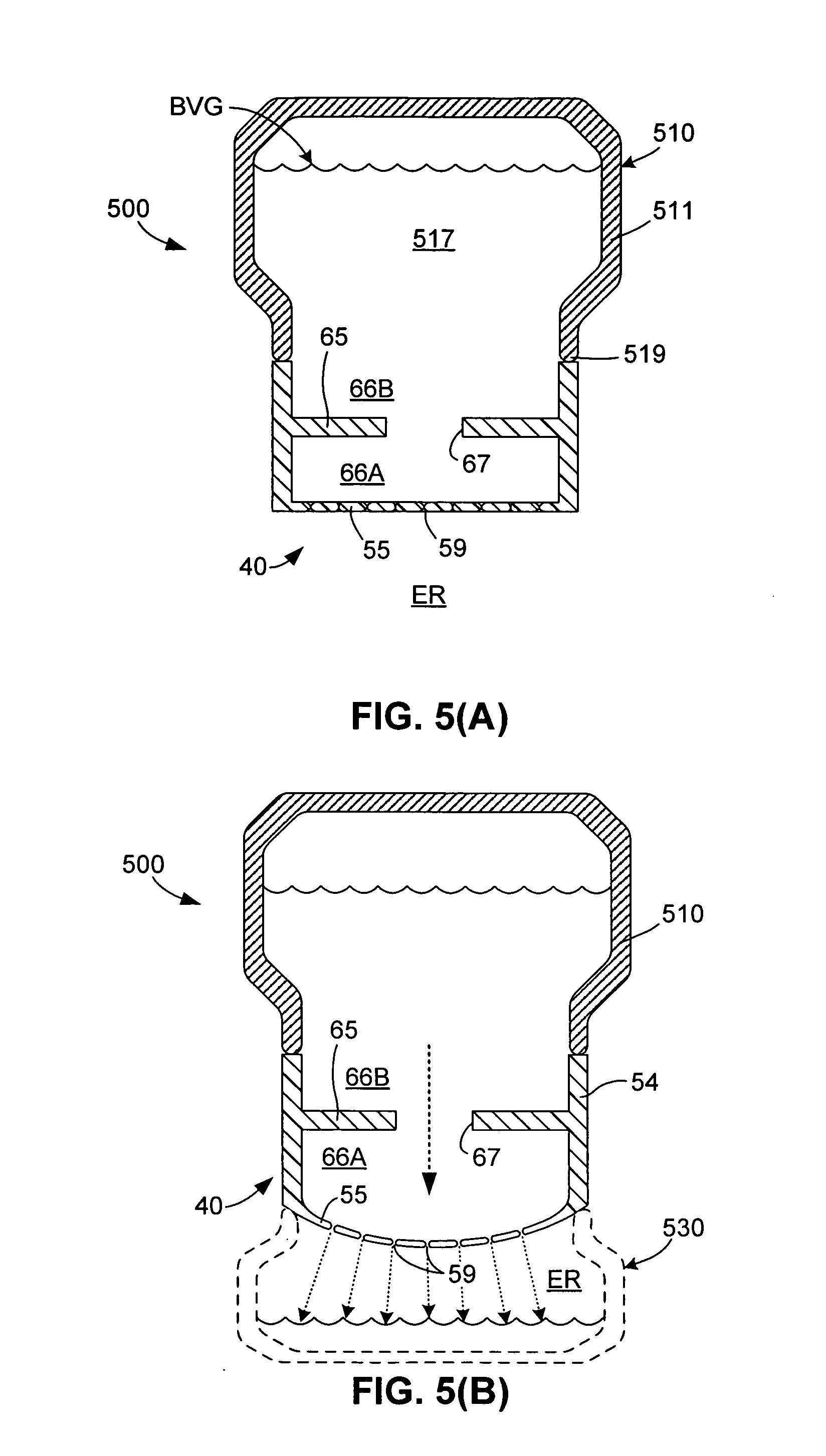

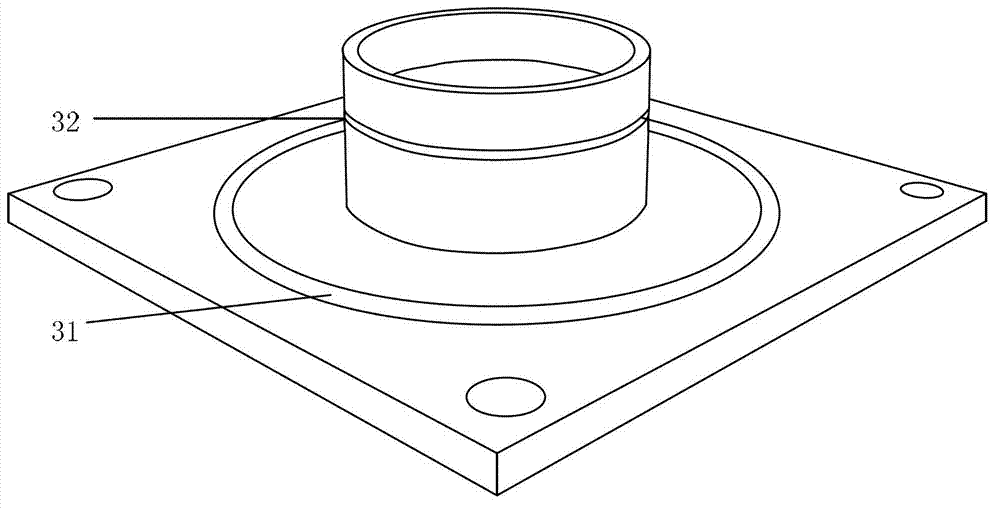

Substrate holding apparatus

InactiveUS6852019B2Uniform film thicknessSmooth movementPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention relates to a substrate holding apparatus for holding a substrate to be polished and pressing the substrate against a polishing surface. The substrate holding apparatus comprises a top ring body for holding a substrate, an elastic pad for being brought into contact with the substrate, and a support member for supporting the elastic pad. The substrate holding apparatus further comprises a contact member mounted on a lower surface of the support member and disposed in a space formed by the elastic pad and the support member. The contact member has an elastic membrane for being brought into contact with the elastic pad. A first pressure chamber is defined in the contact member, and a second pressure chamber is defined outside of the contact member. The substrate holding apparatus further comprises a fluid source for independently supplying a fluid into, or creating a vacuum in, the first pressure chamber and the second pressure chamber.

Owner:EBARA CORP

Intragastric stent for duodenum bypass

A porous weave of bioabsorbable filaments is encased in an elastic membrane to form a thin-walled stent. The stent is sized to be snugly fitted in the proximate portion of the duodenum of a patient, to induce weight loss by limiting uptake of food passing through the stent. After a predetermined period, the stent degrades and passes from the body without surgical intervention.

Owner:BOSTON SCI CORP

Single slice integration temperature, humidity, pressure sensor chip based on polymer material

InactiveCN1845327AReduce volumeReduce power consumptionThermometers using electric/magnetic elementsSolid-state devicesDielectricCapacitance

The single integrated sensor chip for temperature, humidity and pressure is manufactured by: on substrate, processing a parallel plate as the electrode of a capacitor for humidity and three resistances as the strain resistance and thermistor; preparing one layer of polymer on the plate and resistances as the capacitor dielectric medium and the elastic membrane respectively; arranging a grid plate on former dielectric medium as another capacitor electrode; forming a voltage-measuring bridge by resistances on pressure-sensitive membrane and substrate; vacuum sealing the cavity under the pressure-sensitive film to measure absolute pressure.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

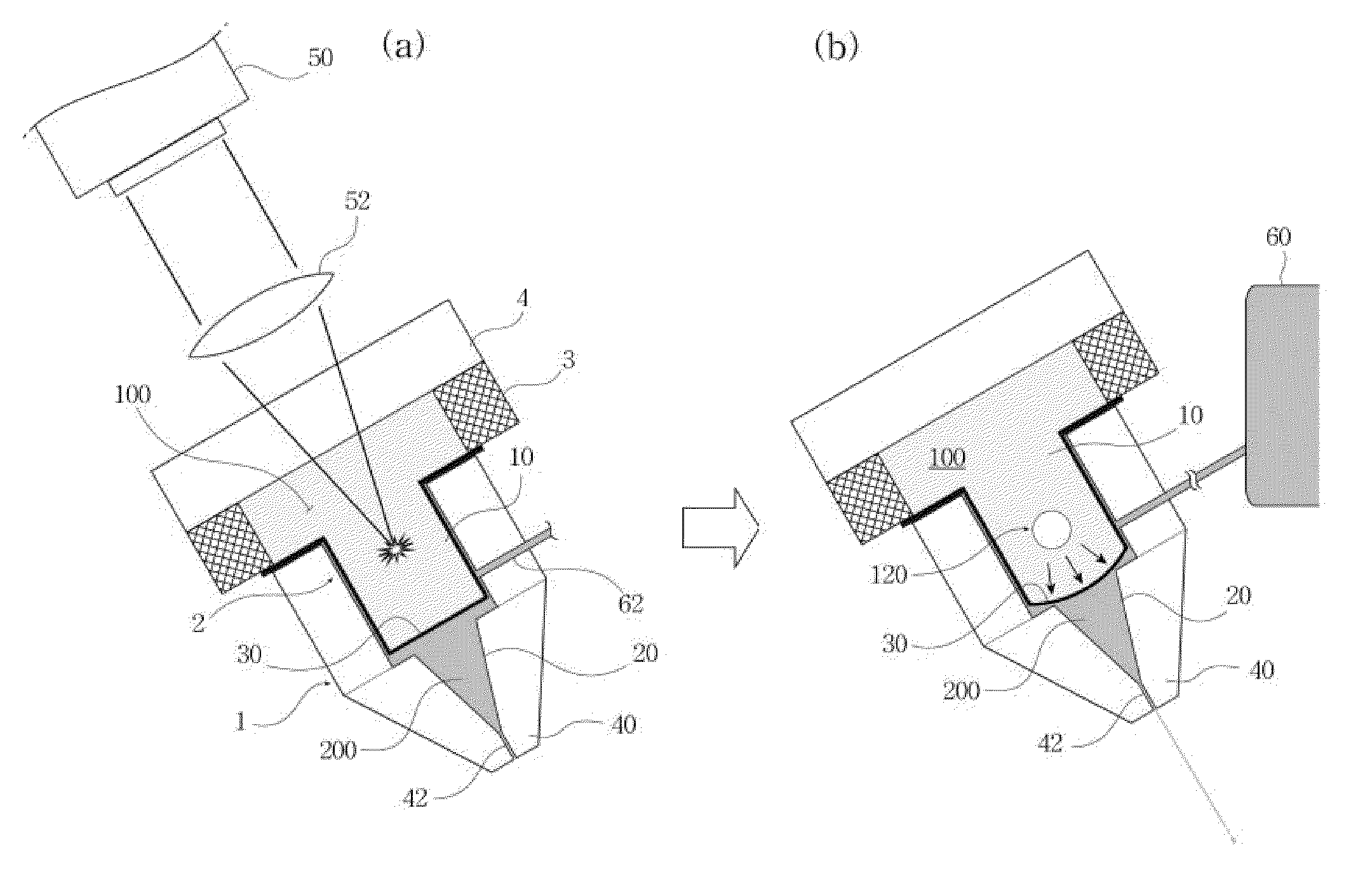

Microjet drug delivery system

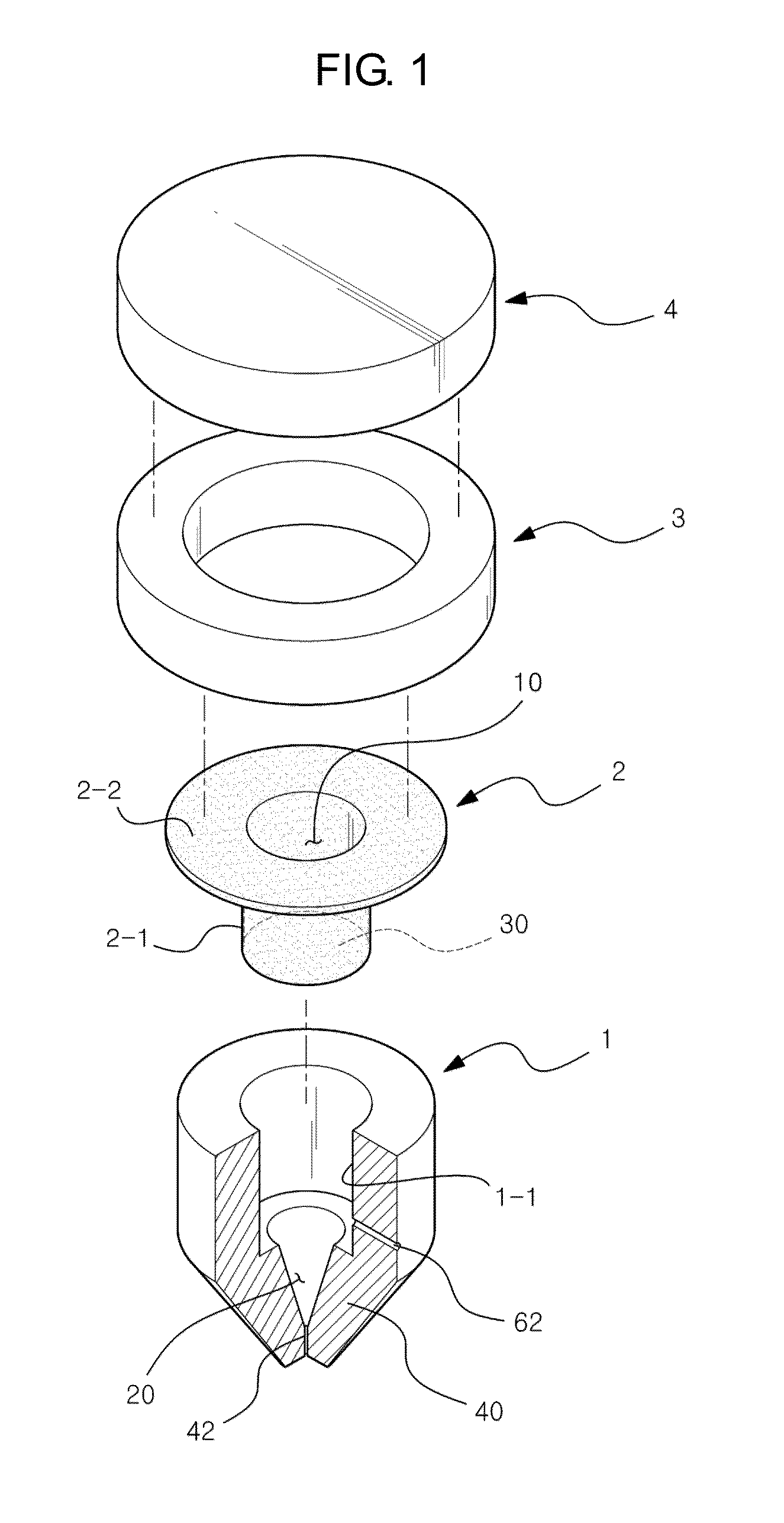

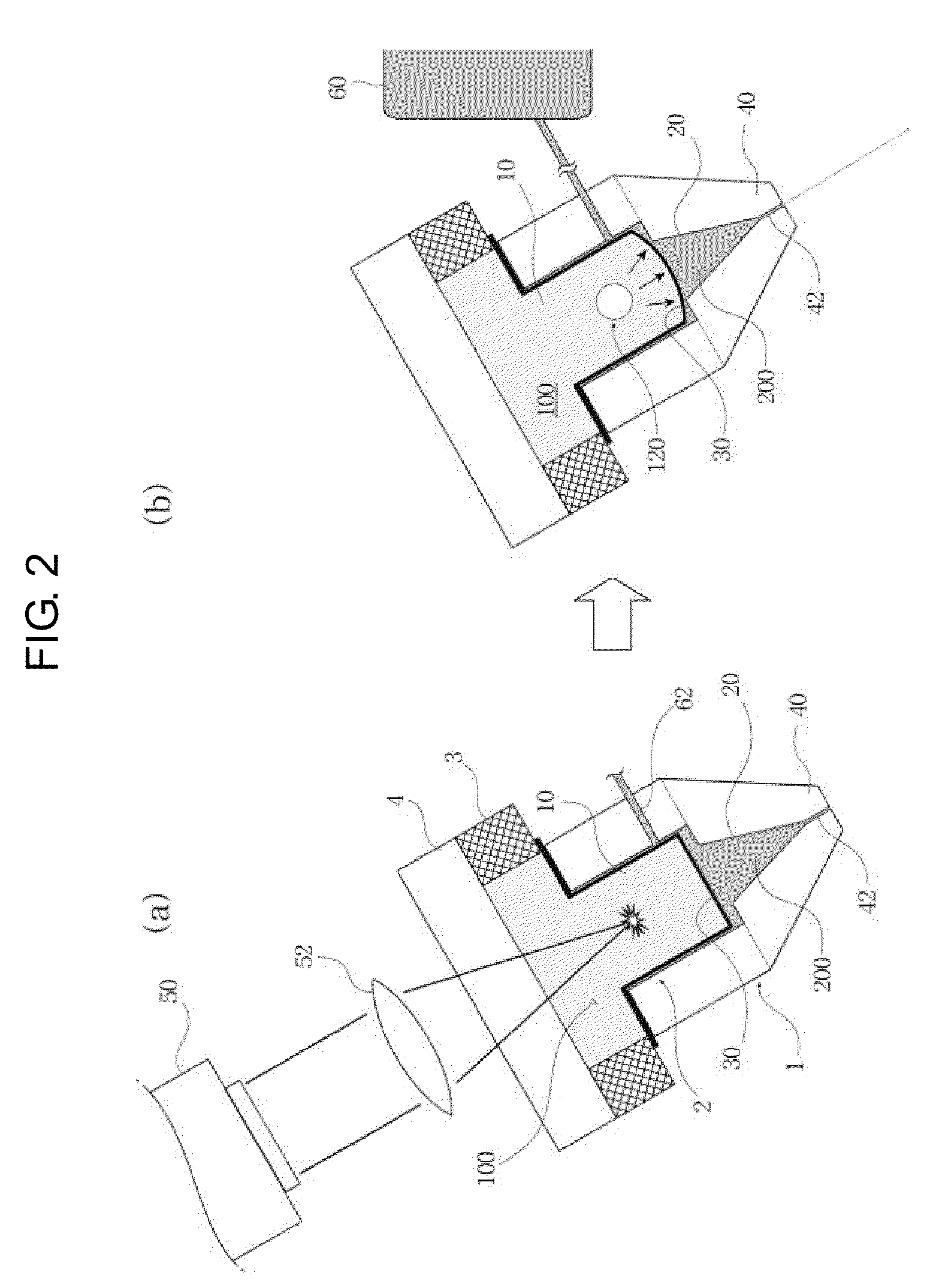

ActiveUS20110230826A1Relieve painReusable and very advantageous in a hygienic aspectJet injection syringesMedical devicesNeedle freeDrugs solution

The present invention relates to a novel type of a needle-free drug delivery system in which strong energy such as a laser beam is focused inside liquid contained in a sealed pressure chamber to cause bubble growth and the volume expansion in the sealed pressure chamber due to the bubble growth so as to elongate an elastic membrane, so that an instantaneous pressure is applied to a drug solution contained in a drug microchamber adjacent to the elastic membrane to allow the drug solution to be injected in the form of a liquid microjet, thereby enabling the drug solution to rapidly and accurately penetrate into the bodily tissues of the patient.

Owner:BAZ BIOMEDIC CO LTD

Non-spill container with flow control structure including baffle and elastic membrane having normally-closed pinholes

InactiveUS20060261064A1Reduced characteristicsControl pressureClosuresDrinking vesselsDifferential pressureEngineering

Owner:INSTA MIX INC SUBSIDIARY A DBA UMIX +1

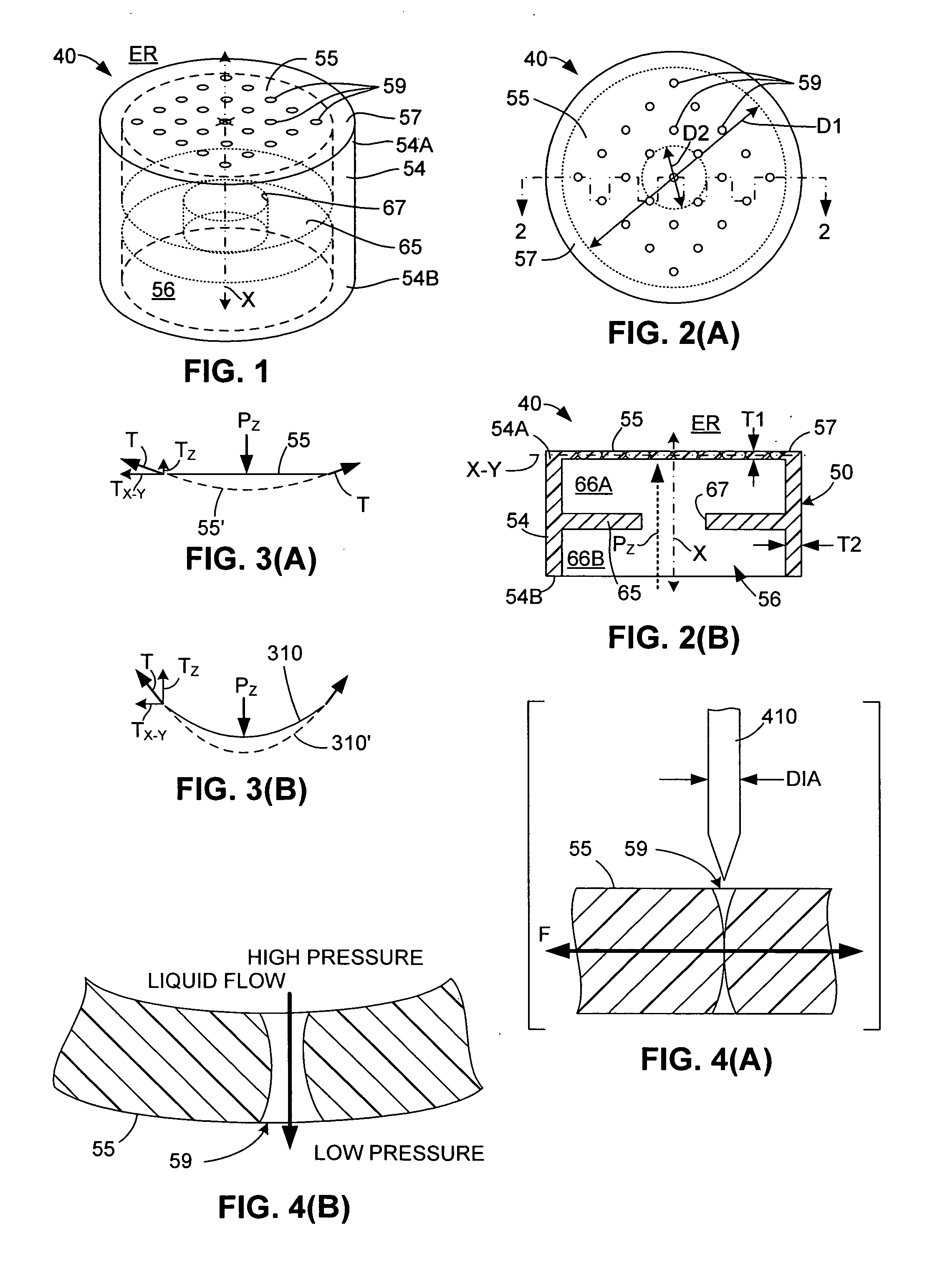

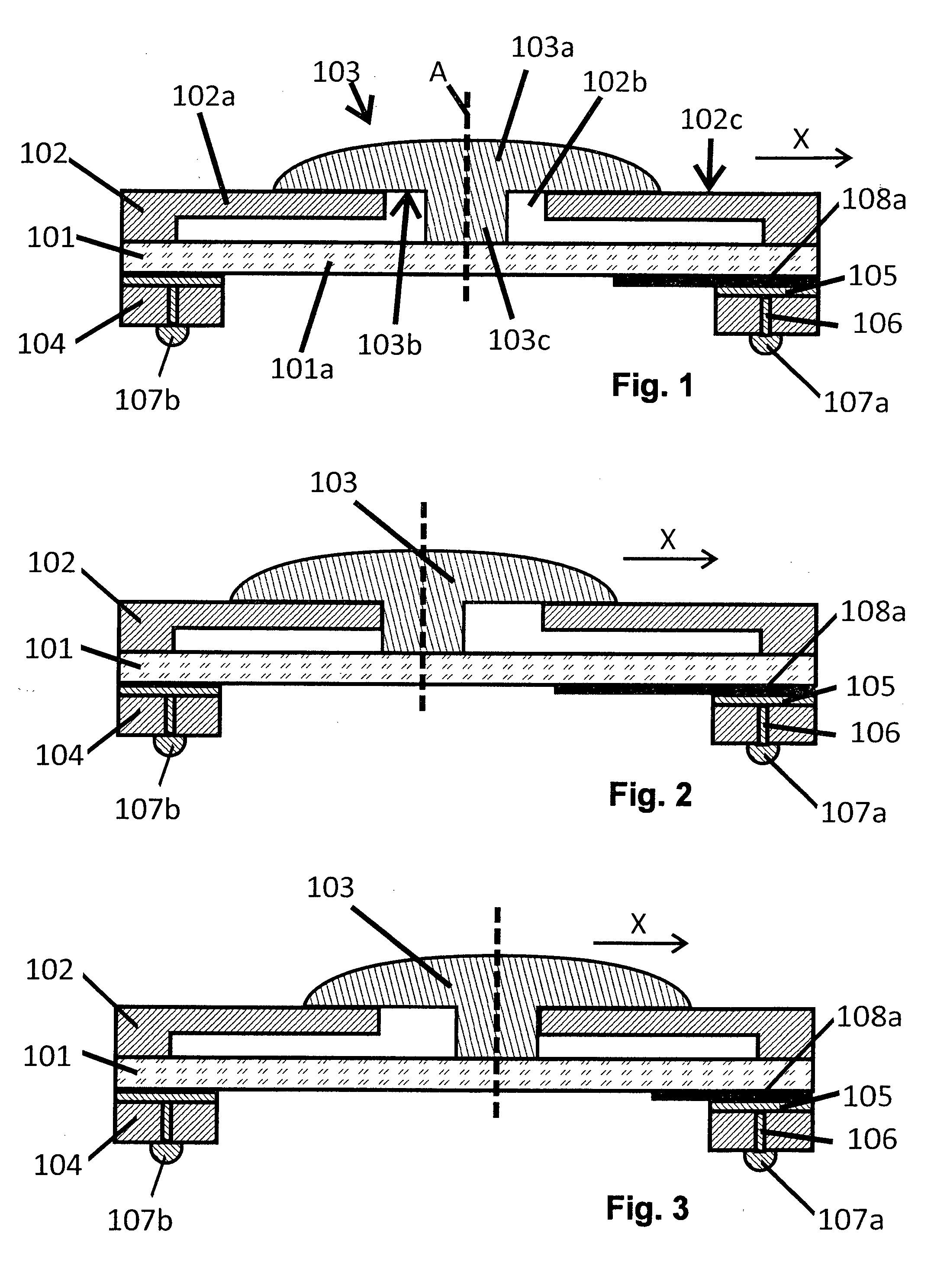

Fluidic variable focal length optical lens and method for manufacturing the same

A fluidic variable focal length optical lens has a sealed housing having a first fluidic chamber filled with a first fluidic medium and a second fluidic chamber filled with a second fluidic medium, the first and the second fluidic chamber being separated from each other by an elastic membrane, wherein the first and the second fluidic medium have different refractive indices, and a deformator configured to deform the membrane laterally within a pump zone, thereby laterally displacing the first fluidic medium from the pump zone to a lens zone and the second fluidic medium from the lens zone to the pump zone, so that the membrane also deforms in the lens zone and changes a focal length of the lens zone along a normal direction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

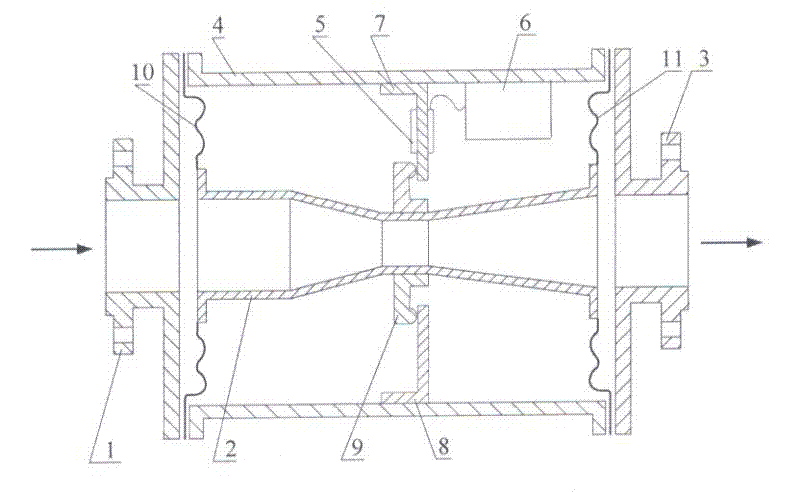

Fluid-sealed anti-vibration device

InactiveUS6910683B2Improve seismic performanceAvoid slappingMachine framesLiquid springsElastic membraneBiomedical engineering

In an anti-vibration device having a partition member dividing a fluid-sealed chamber into upside and downside, aimed at enhancing the anti-vibration performance by preventing unwanted leak of the fluid through through-holes of the partition member. To that end, the partition member is constructed of an elastic membrane partitioning the fluid-sealed chamber, and a pair of grids limiting displacements of the elastic membrane; and the elastic membrane is provided at its either surface with projecting streaks integral therewith, the projecting streaks surrounding through-holes, defined by the grids, over their whole peripheries and abutting on the grids, thereby regulating the flow of fluid among adjacent through-holes.

Owner:NISSAN MOTOR CO LTD +1

Fiber grating earth pressure sensor

ActiveCN102162757AAvoid chirpingConcentrated forceForce measurement by measuring optical property variationFiberPressure transmission

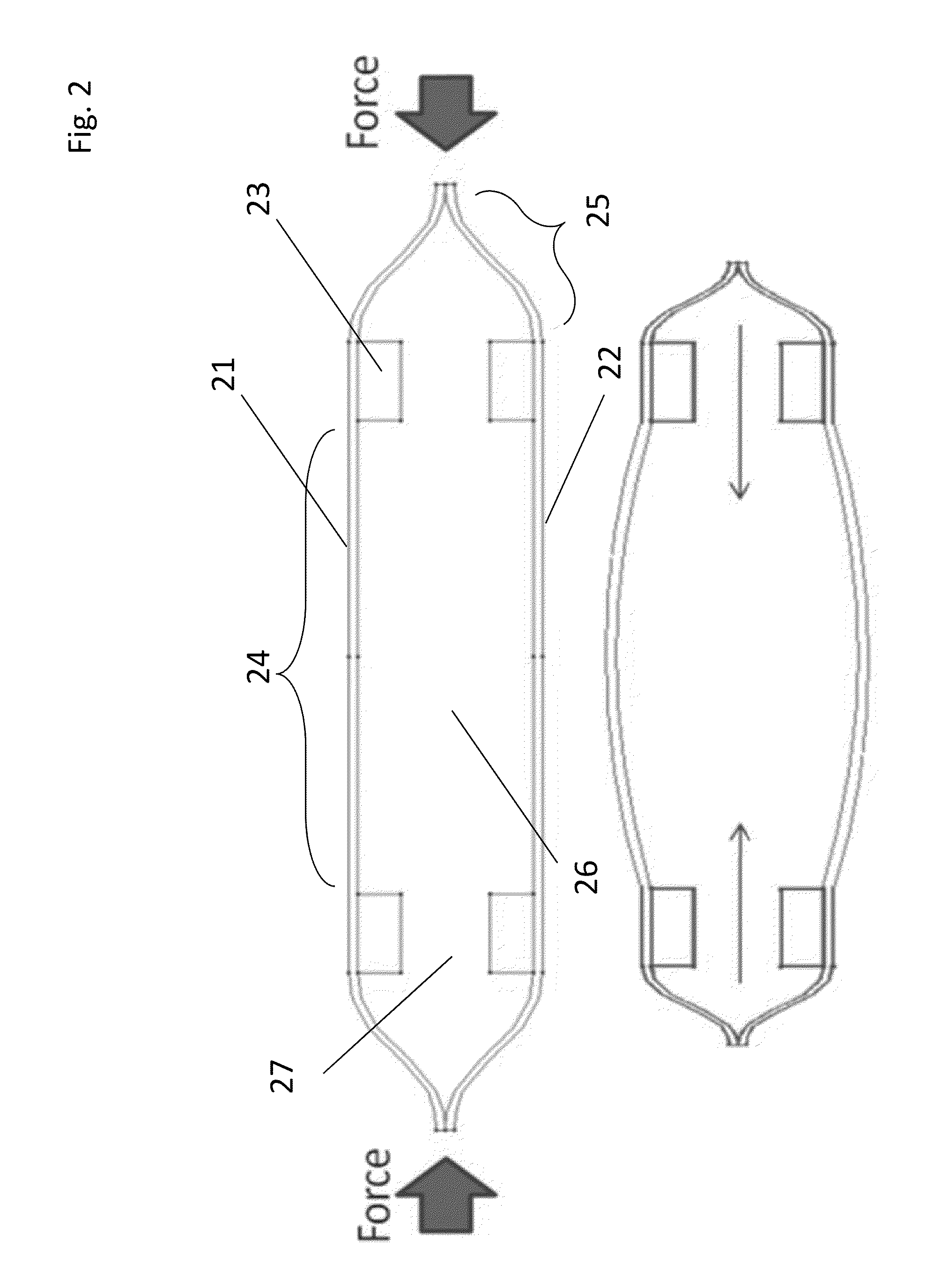

The invention discloses a fiber grating earth pressure sensor which comprises a sensor shell, a pressure transmission component and a fiber grating. The earth pressure sensor is characterized in that the pressure transmission component is of a rhombus structure, and the is positioned between a bearing-type top cover and a bottom plate, and is in contact with the bearing-type top cover and the bottom plate; clearances are arranged among the pressure transmission component and the left side and the right side of the sensor shell; a grating is pasted on a metal elastic membrane; the metal elastic membrane is arranged on a transverse diagonal line between a left angle and a right angle of the pressure transmission component; and two sides of the metal elastic membrane are fixed on the left angle and the right angle of the pressure transmission component. The earth pressure sensor provided by the invention has the characteristics of large measuring span, high accuracy and simple structure, is good for miniaturization of the integral structure.

Owner:青岛飞博科技有限公司

Dust collector for drill

ActiveUS7396193B2Avoid distributingThread cutting feeding devicesBoring/drilling componentsElastic membraneDrill

Owner:KESTEN DOUGLAS

Machine tool electrical spindle reliability testing stand centering adjusting device

ActiveCN104833506AAccurate and reliableThe reliability test is accurateMachine gearing/transmission testingElectricityCoupling

The invention aims to solve technical problems so as to eliminate harmful influences that misalignment generates additional force, torque, vibration and the like on a to-be-tested electrical spindle in the machine tool electrical spindle reliability testing, and provides a machine tool electrical spindle reliability testing stand centering adjusting device. The machine tool electrical spindle reliability testing stand centering adjusting device comprises horizon iron, a control cabinet and a dynamometer which is used for loading simulated cutting torque on a to-be-tested electrical spindle. An input shaft of the dynamometer is in coaxial key joint with the to-be-tested electrical spindle through an elastic membrane shaft coupling. The machine tool electrical spindle reliability testing stand centering adjusting device is characterized by also comprising a rotating table, an X-Z working table, a lifting platform and a pitching working table. The machine tool electrical spindle reliability testing stand centering adjusting device can timely adjust five degree of freedom of any type of misalignment, eliminates harmful influences caused by misalignment between the to-be-tested electrical spindle and the input shaft of the dynamometer, is suitable for different types of machine tool electrical spindles and mechanical spindles and other equipment with high misalignment error requirements, and has high versatility and flexibility.

Owner:JILIN UNIV

Sample preparation device for remoulded soil with different stress ratios

InactiveCN103033406ALimit contractionUniform moisture contentPreparing sample for investigationStress ratioEngineering

The invention provides a sample preparation device for remoulded soil with different stress ratios. The device comprises a clamping unit, an upper fixing plate, a lower fixing plate, a confining pressure cover, an elastic membrane, a force transmission element, a first water-permeable element and a second water-permeable element, wherein the clamping unit comprises an upper clamping plate and a lower clamping plate; the upper clamping plate is provided with a hole; the upper fixing plate is provided with an upper hole matched with the hole; the lower fixing plate is provided with a lower hole having the same diameter as the upper hole; the two ends of the confining pressure cover are fixed on the upper fixing plate and the lower fixing plate respectively; the two ends of the elastic membrane are fixed at the peripheries of the upper hole and the lower hole in a defining manner respectively; and an outer wall of the force transmission element is clung to the elastic membrane. According to the sample preparation device for the remoulded soil with the different stress ratios, thin mud is poured into the sample preparation device, the force transmission element applies vertical pressure on the thin mud in the elastic membrane, and water in the confining pressure cover applies lateral pressure on the thin mud in the elastic membrane, so that the different stress ratios are controlled, a soil sample is solidified, and a remolded soil test sample with the uniform water content is obtained.

Owner:SHANGHAI JIAO TONG UNIV

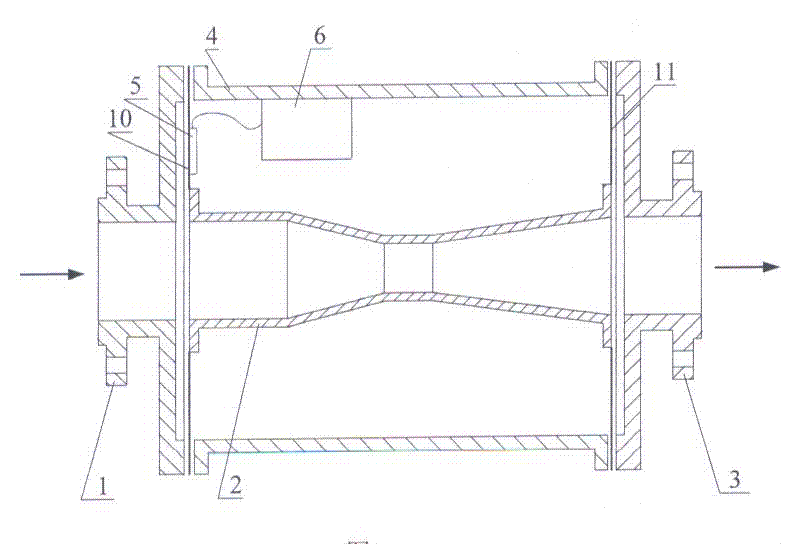

Flowmeter with middle through-hole movable throttling element connected with elastic membranes or bellows

InactiveCN102353406ALittle flow resistance lossEasy to useVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a flowmeter with a middle through-hole movable throttling element connected with elastic membranes or a bellows, which belongs to the throttling flowmeter in the automatic detection technical field; the patent 'a middle through-hole movable throttling element flowmeter' depends on the thrust of the movable throttling element, and does not like a fixed throttling element which measures the flow according to the flow differential pressure, so a pressure pipe can be dispensed, the flowmeter is applicable to measuring small calibers and dirty liquids, the isolation, the pressure-bearing, the support and other functions of the flowmeter are all respectively realized through different components, and the integral structure is more complicated. The flowmeter adopts the elastic membranes or the bellows to be connected with the middle through-hole movable throttling element, the isolation, the pressure-bearing, the support and other functions are realized independently by the elastic membranes or the bellows, the integral structure of the flowmeter is greatly simplified, not only are all the advantages of the through-hole movable throttling element obtained, but also a plurality of performances are improved, and the invention makes the through-hole movable throttling element flowmeter which is a novel meter be more easily popularized and used.

Owner:王可崇

Elastic membrane container closure

InactiveUS20050082248A1Smooth rotationEasy to closeClosuresLiquid flow controllersEngineeringMechanical engineering

The invention relates to a closure of the iris diaphragm type engaging a neck portion of a container. The closure includes a thin, flexible elastic tubular member having one end connected to a rigid mobile tubular member and the other end connected to the fixed neck portion of the container. Two male protrusions on the inner surface of the mobile rigid tubular member engage female notches on the fixed outer surface of the container neck such that when the mobile member is rotated, it causes the elastic tube to twist and fold upon itself in an iris-diaphragm fashion thereby rendering a fluid, solid and light impermeable seal at the iris. The mobile member can be rotated variably thereby reducing the matter flow through the center of the container.

Owner:AL JADDA OMAR +1

Vacuum generating device for sealing perishable products and method of use

InactiveUS20080041852A1Easy to disassembleAvoid deformationRemovable lids/coversPackaging under vacuum/special atmosphereEngineeringForced-air

A vacuum sealing device comprises a lid having a rigid rim with a lower opening for receiving a dish, an impermeable elastic membrane peripherally affixed to the rigid rim for sealing the dish, and a valve-less air evacuator formed between the elastic membrane and the dish rim. The valve-less evacuator allows air to flow out of the dish when the lid is being pressed and becomes closed when the lid is released to cause said lid to rebound to form a vacuum in the dish. The rigid rim prevents lid deformation when the lid is pressed, thus enabling the vacuum formation. To facilitate lid removal, the device has a valve-less vacuum releaser comprising a finger-receiving chamber and a section of the elastic membrane located above the chamber and connected to the rigid rim for releasing the vacuum in the dish. To prevent vacuum loss during storage in freezer or fridge, the elastic membrane is sufficiently thinned prior to being affixed to the rigid rim. In use, one places the lid on a dish, forces air out of the dish via the air evacuator between a section of the elastic membrane and the dish rim by pressing the lid, and releases the lid to cause the air evacuator to close and vacuum to form in the dish. To restore the device's capability to generate and maintain vacuum after numerous uses, the lid is exposed to a hot fluid having a temperature higher than 45° C. for a period of time.

Owner:CAI EDWARD Z

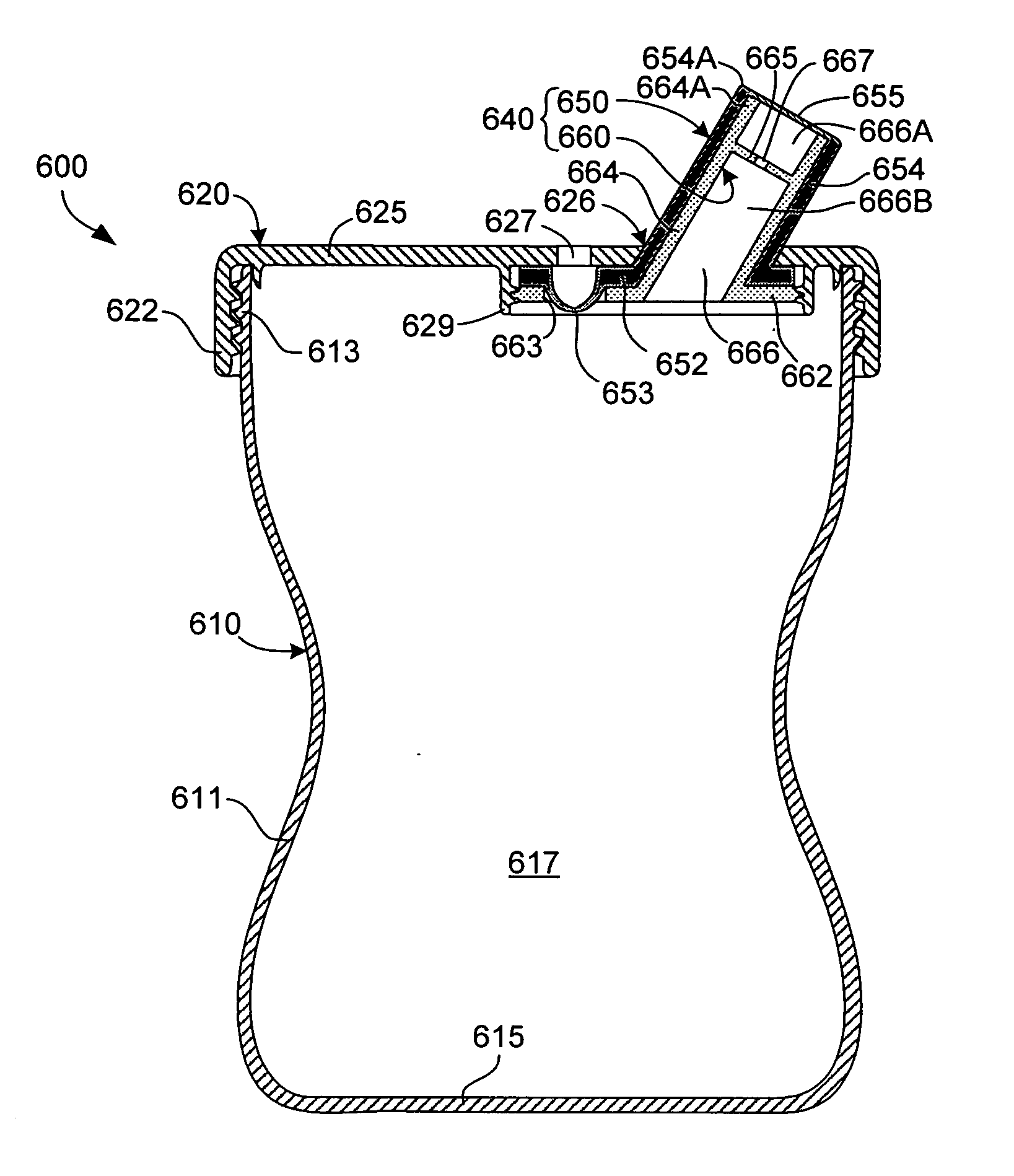

Beverage container vent mechanism including perforated elastic membrane and support plate

A venting mechanism includes a rigid support member and a thin, elastic membrane that is perforated with multiple pinholes. The support member includes a peripheral flange that is secured to the beverage container body, and a rigid support plate that defines one or more always-open vent holes. A flow control member includes the membrane and a peripheral collar surrounding the membrane that is secured to the container body by the peripheral flange. The membrane includes a thin sheet of a suitable elastomeric material that rests against an inside surface of the support plate when the pressure inside the container is equal to or greater than the surrounding environment. The pinholes are formed in the elastomeric material such that they are closed when the membrane is in the resting state, and open when the membrane is stretched in response to a pressure differential or an applied force.

Owner:MEDELA HLDG AG

Dust collector for drill

ActiveUS20070264092A1Avoid distributingThread cutting feeding devicesBoring/drilling componentsEngineeringDrill

A dust collector for a power drill is provided that includes a cylinder of sufficient size to accept at least a foremost portion of a power drill. The cylinder includes a gasket or seal at the forward end for contact with the wall or working surface to be drilled. A rubber or other elastic membrane or web is provided over the opposite end of the cylinder and an opening is formed in the membrane or web to fit snugly around the forward end of a power drill. A narrowing or neck may be used in place of the web to provide an opening for the forward end of a power drill. An arrangement of holes is formed in the wall of the cylinder. A vacuum hose is connected to the cylinder by a direct connection to the cylinder or by connection of the vacuum hose to a pistol grip handle attached to the cylinder. By connecting the vacuum hose to a shop vacuum, household vacuum or other vacuum source, the power drill may be inserted into the opening in the web and holes drilled in walls or other surfaces without disbursing dust into the surrounding area.

Owner:KESTEN DOUGLAS

Variable focus liquid lens

ActiveUS20120275030A1Wide rangeLow production costTelevision system detailsProjector focusing arrangementCamera lensEngineering

A variable focus liquid lens includes: a lens barrel which is configured to include a first cavity to contain first and second liquids which are not mixed with each other in upper and lower portions of the first cavity, respectively; a fluid pressure driving unit which is configured to include a second cavity, a fluid pressure generating groove, and an actuator generating a fluid pressure on the second liquid so as to adjust the fluid pressure of the second liquid by using the actuator; a first transparent elastic membrane sealing an upper portion of the first cavity of the lens barrel; and a conductive transparent substrate sealing a lower portion of the second cavity of the fluid pressure driving unit. The focal length is adjusted by changing the curvatures of the surfaces of the first and second liquids and the curvature of the first transparent elastic membrane by a voltage.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

Lid for a pan, plate, bowl or the like

InactiveUS20120199582A1Improve reliabilityPrevent leakageSealingLidsMembrane configurationElastic membrane

A vacuum seal lid for turning existing containers including plate, bowl, pan and even cutting board into a vacuum storage container comprises a top plate having an opening, a sidewall, sealing means for preserving vacuum, and a knob adapted to be at a first position in which it is above the opening to facilitate evacuation and handling, a second position in which it is at least partly below the opening to facilitate stacking and storage and a third position between the first and second positions in which the vacuum is released. The top plate may further comprise a first plate in which the opening is located and a second plate having an elastic membrane and a smooth lower surface constituting part of the sealing means for sealing containers smaller than the lid. The sealing means also comprises a sealing membrane located below the bottom surface or on the outer surface of the sidewall for sealing containers larger than the lid. To improve the seal, the sealing membrane is separable or apart from the bottom or outer surface of the sidewall. To improve the seal further, at least part of the sealing membrane is sloped at an angle relative to a horizontal plane. The knob has a knob head, a valve opening, and a valve sealer adapted to clean the valve opening by moving the knob head to improve the reliability of the lid.

Owner:CAI EDWARD Z

Flow control element including elastic membrane with pinholes

InactiveUS6991122B2Increase fluid flowRealize automatic adjustmentClosuresBottlesEngineeringControl valves

A flow control element (e.g., a baby bottle nipple or a child sippy cup flow control valve) that includes a tube-like wall section defining a flow channel, and a substantially flat membrane supported by the wall section such that membrane impedes flow through the flow channel to an external region. The membrane punctured to form multiple, substantially round pinholes arranged in a two-dimensional pattern that remain closed to prevent fluid flow under normal atmospheric conditions, and open and to facilitate fluid flow rate through the membrane under an applied pressure differential (e.g., when sucked on by a child). The wall section has a greater rigidity than the membrane (which is formed from a relatively highly elastic material). Different sized pinholes are produced using different sized pins, thereby facilitating different flow rates in response to different applied pressure differentials. The pinholes are generated while stretching the membrane in a radial direction.

Owner:MEDELA HLDG AG

Input device with elastic membrane

InactiveUS20130021087A1Hampering unwanted rotational movementEnhance resilienceManual control with multiple controlled membersContact surface shape/structureCapacitanceEngineering

A device includes a flexible polymer membrane with compliant electrodes attached thereto. The membrane is suspended in a frame. A handle, which is displaceable in respect to the frame, is connected to the membrane. A displacement of the handle causes the electrodes on the membrane to be deformed, thereby changing their area and resistance. The change of area or resistance is measured by a capacitive or resistive sensing circuit and is used to measure the deformation and therefore the displacement of the handle.

Owner:OPTOTUNE AG

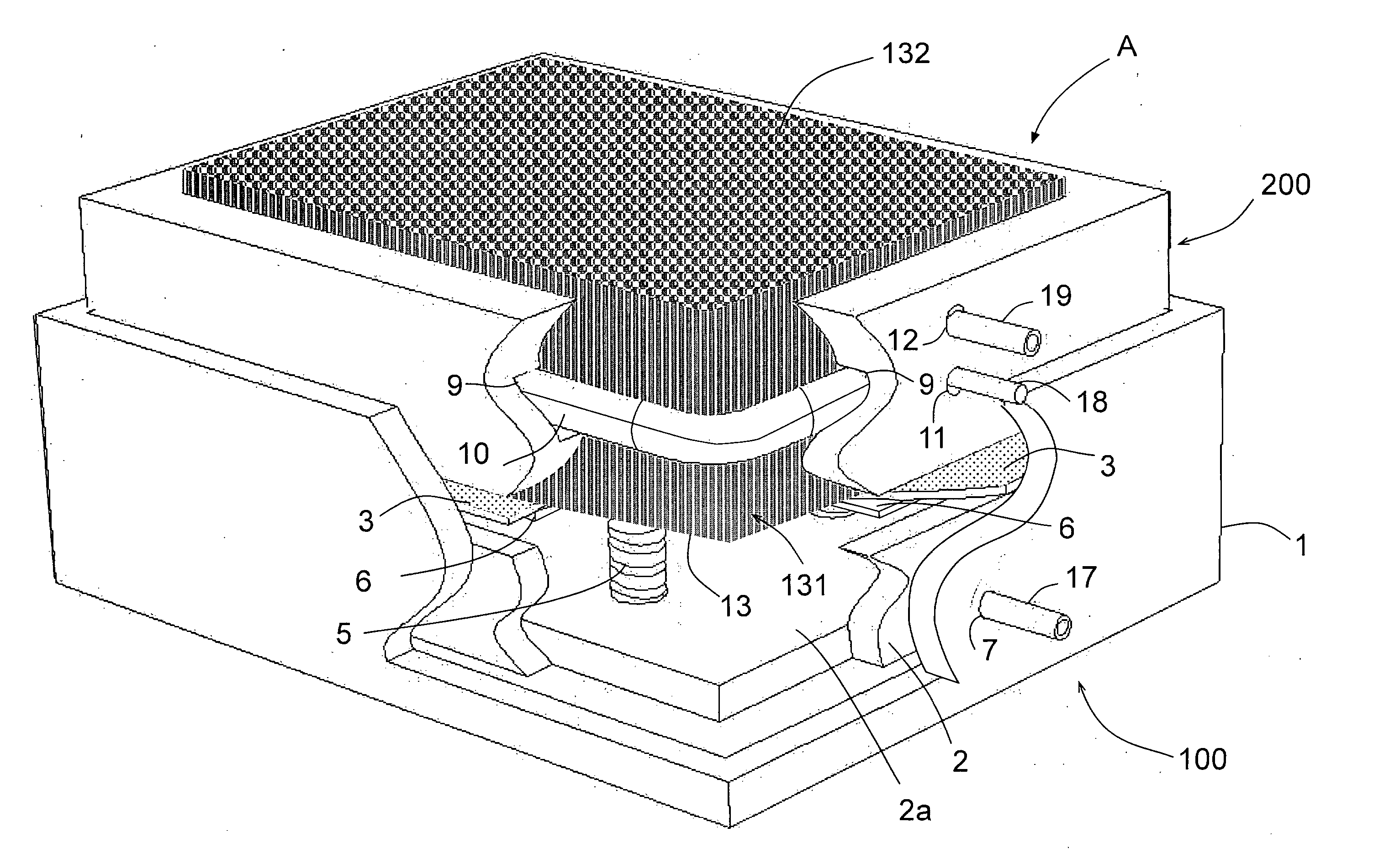

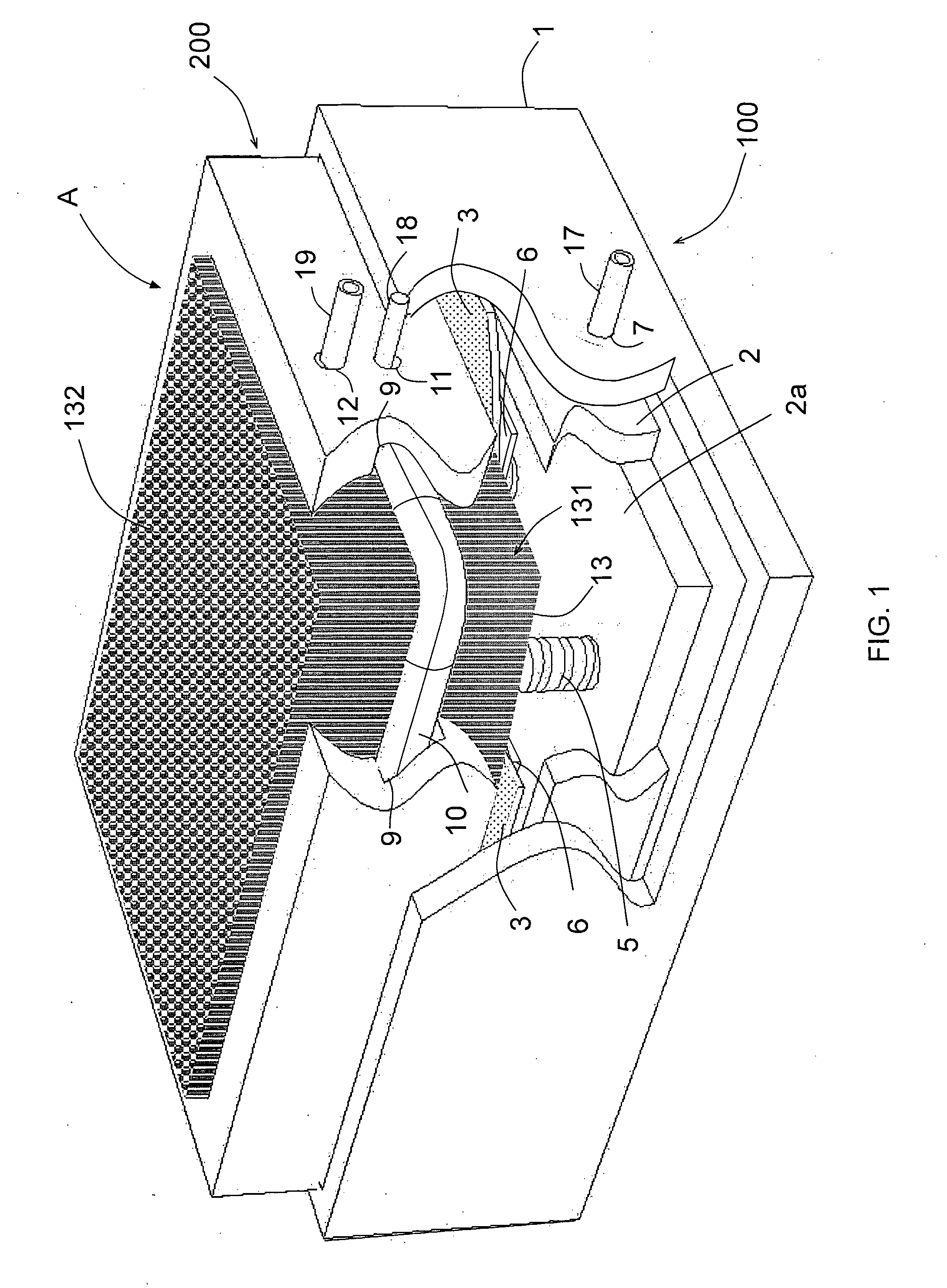

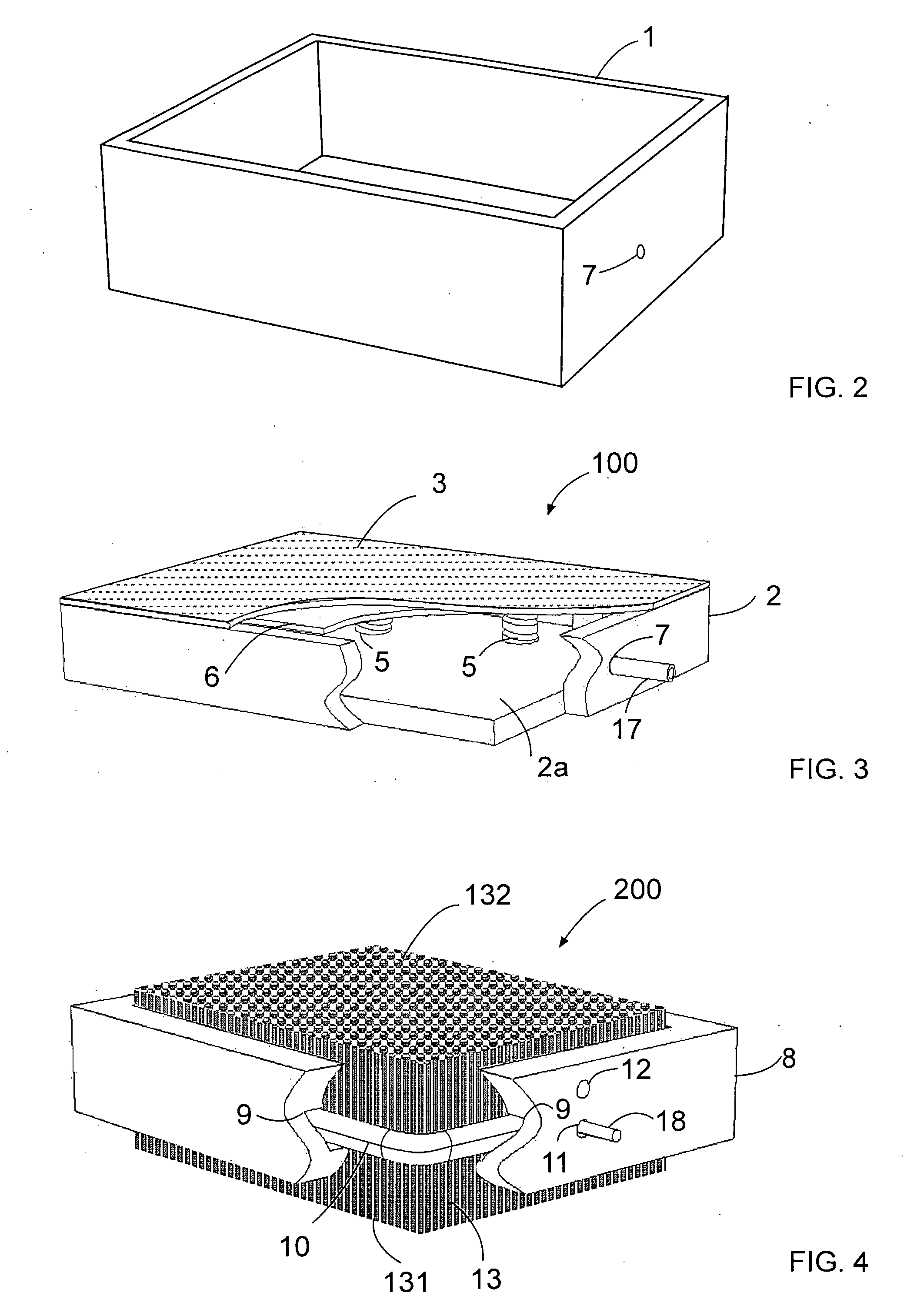

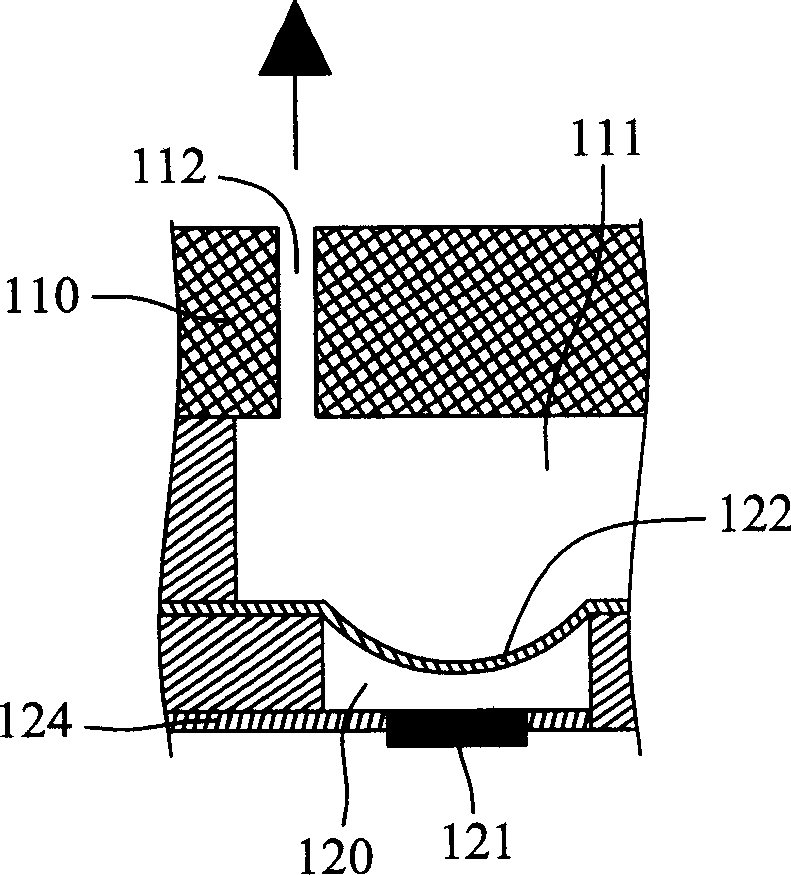

Apparatus and Method for Replicating a Plantar Surface of a Foot

InactiveUS20080028625A1Improve sensing reliabilityOptimize locationFoot measurement devicesSurgeryPlantar surfaceEngineering

An apparatus and method for replicating the profile of a plantar surface of a foot are provided. It has particular application in the production of footwear insoles, the apparatus comprises a pressure resistant container (2); an elastic membrane (3) sealed to an open face of the container, thereby defining a variable volume chamber within the container; means for reversibly introducing fluid (15) into the chamber; a bed of elongate rods (13) of substantially equal length, in which, in one configuration, the rods can slide freely, one relative to another, along their length; and clamping means (10) for reversibly clamping the bed of rods so that the relative sliding movement of the rods is resisted; the bed of rods being arranged, in use, outside the container so that ends of the rods abut the face of the membrane. In this way, a positive and negative mould of the surface can be formed.

Owner:NUDELMAN WILLYN +1

Low voltage and low power thermal bubble film type microfluid driving device

InactiveCN1521500AControl flow directionEasy to combine controlMicrobiological testing/measurementMaterial electrochemical variablesBoiling pointLow voltage

The invention relates to a low voltage low power heat bubble thin film type micro-fluid drive apparatus, wherein the fluid arrangement includes a fluid channel, in which fluid fills and flow from and out from the opening of the fluid channel, a heat bubble thin film type actuator comprising heating plates arranged on the bottom of the confined fluid chamber, which is insulated from the fluid channel through elastic membrane and is filled with low-boiling point liquid.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com