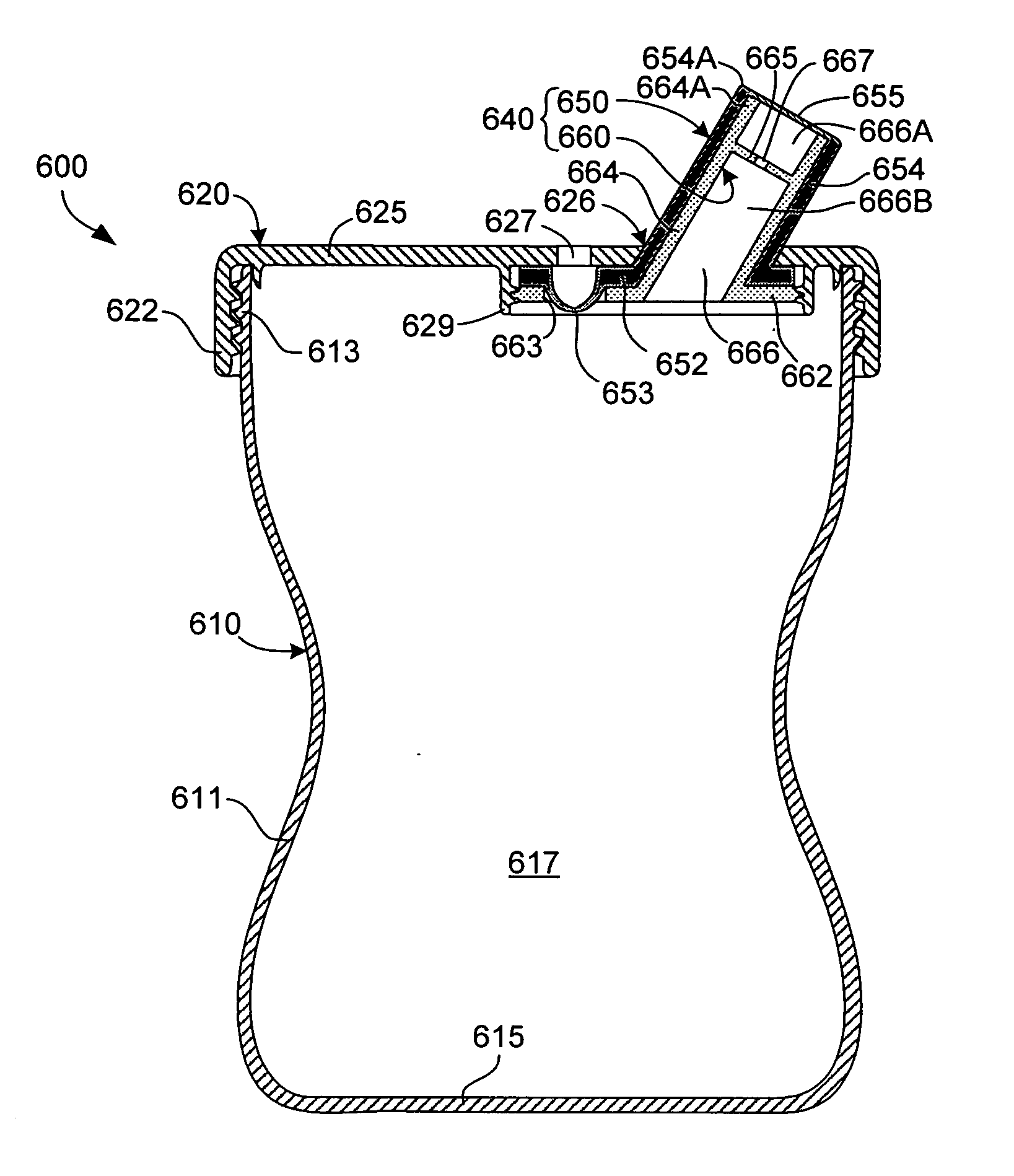

Non-spill container with flow control structure including baffle and elastic membrane having normally-closed pinholes

a flow control device and non-spill container technology, applied in the field of non-spill beverage containers, can solve the problems of reducing the resilient force needed to close the slit flap, slits and/or become obstructed, and the slit flaps cannot close, so as to achieve the effect of facilitating fluid flow rate, limiting fluid pressure, and enhancing the “no drip” characteristi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

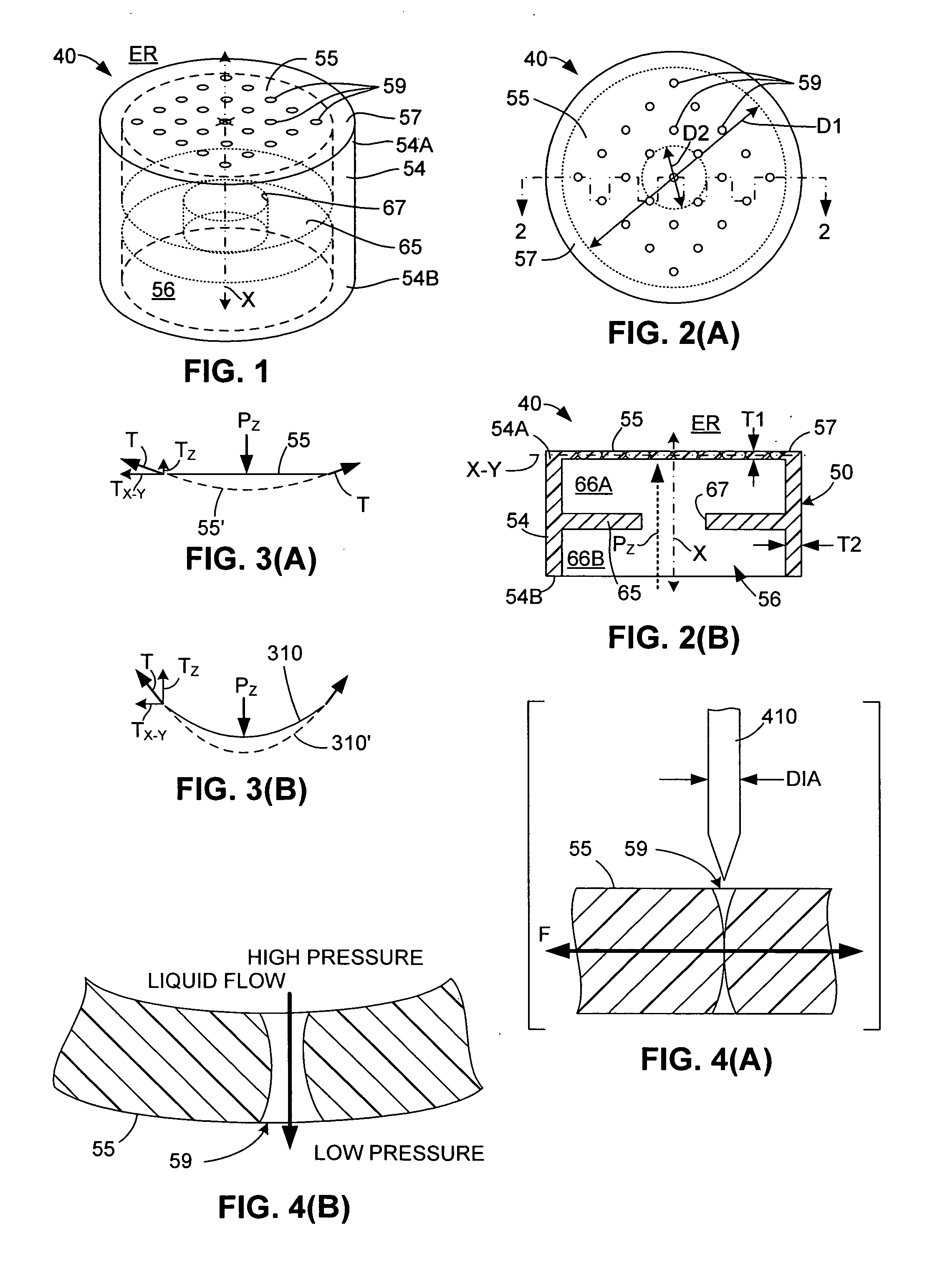

[0024]FIG. 1 is a perspective view showing a flow control structure 40 according to a generalized embodiment of the present invention, and FIGS. 2(A) and 2(B) show flow control structure 40 in top plan and cross-sectional side views, respectively, where FIG. 2(B) is taken along section line 2-2 of FIG. 2(A).

[0025] Flow control structure40 includes a molded (first) member 50 including a tube-like spout 54 defining a substantially cylindrical flow channel 56, a membrane 55 mounted on an upper (first) end 54A of spout 54, and a baffle 65 mounted inside flow channel 56 between upper end 54A and a lower end 54B of spout 54. Spout 54 is a relatively rigid (i.e., compared to membrane 55) tube-like structure extending generally along a central axis X between upper end 54A and lower end 54B of spout 54. As indicated in FIG. 2(A), in one embodiment spout 54 has a circular cross section having an inner diameter (width) D1. In other embodiments, spout 54 may have, for example, an oval, square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com