Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Concentrated force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

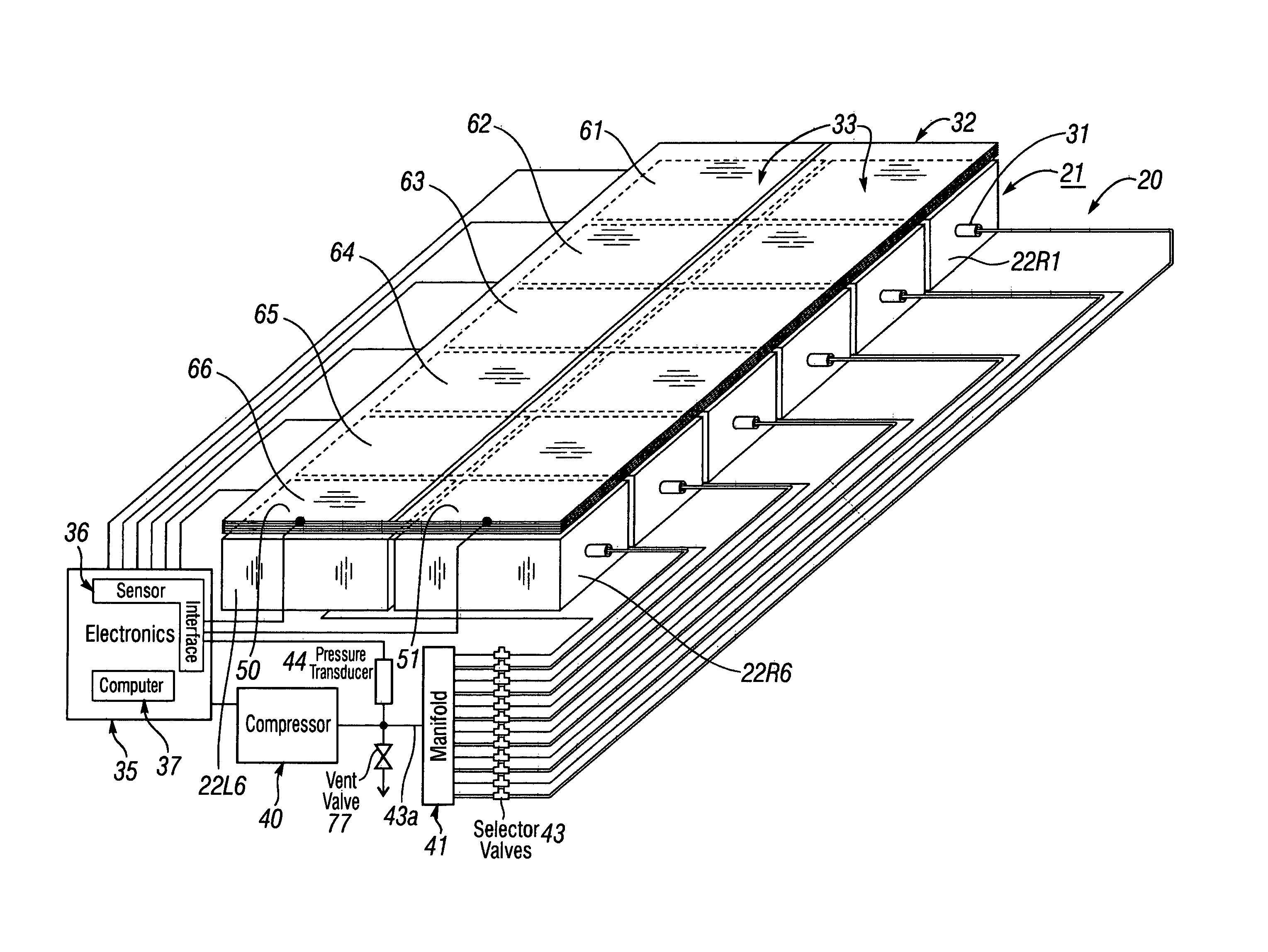

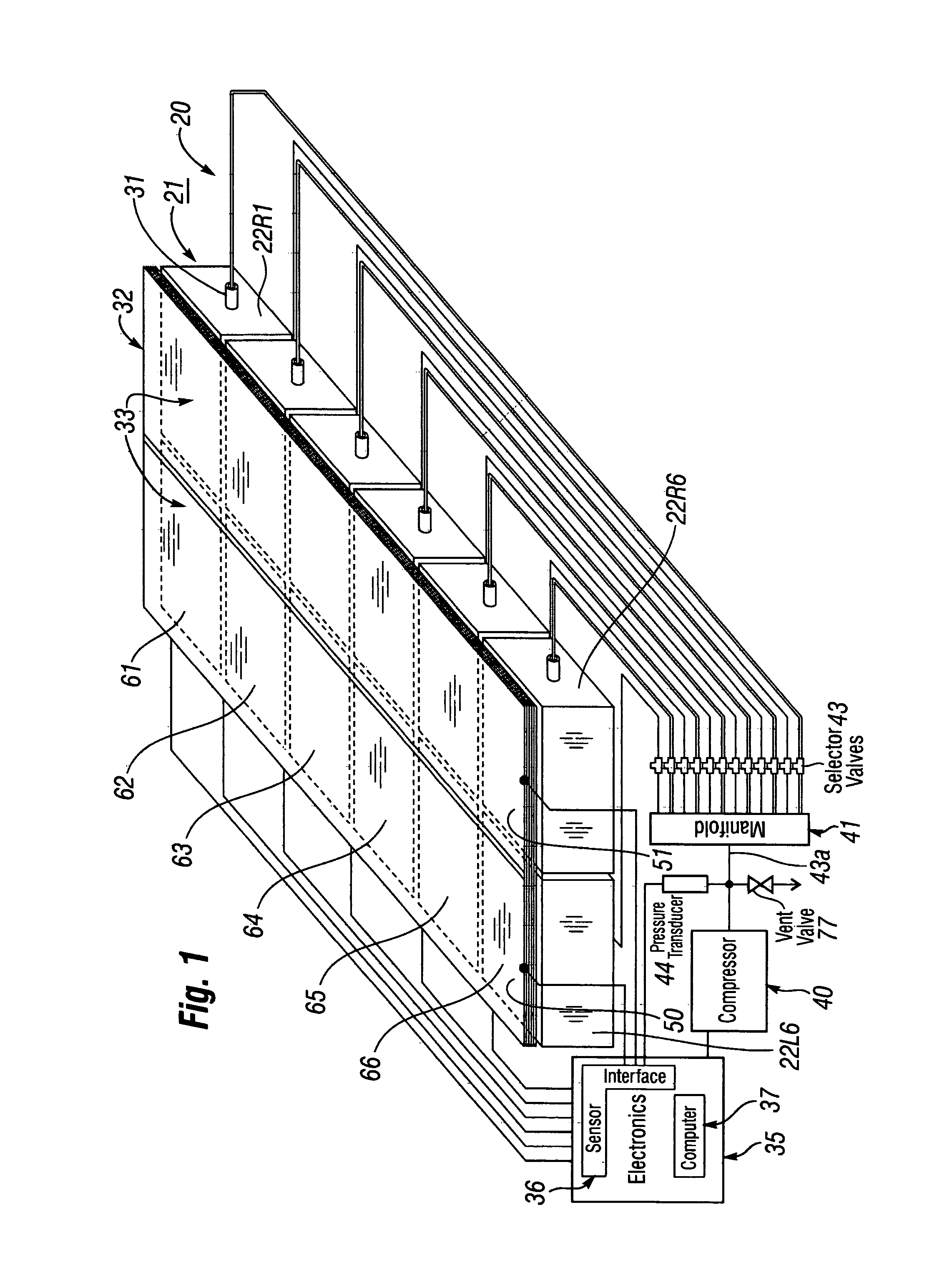

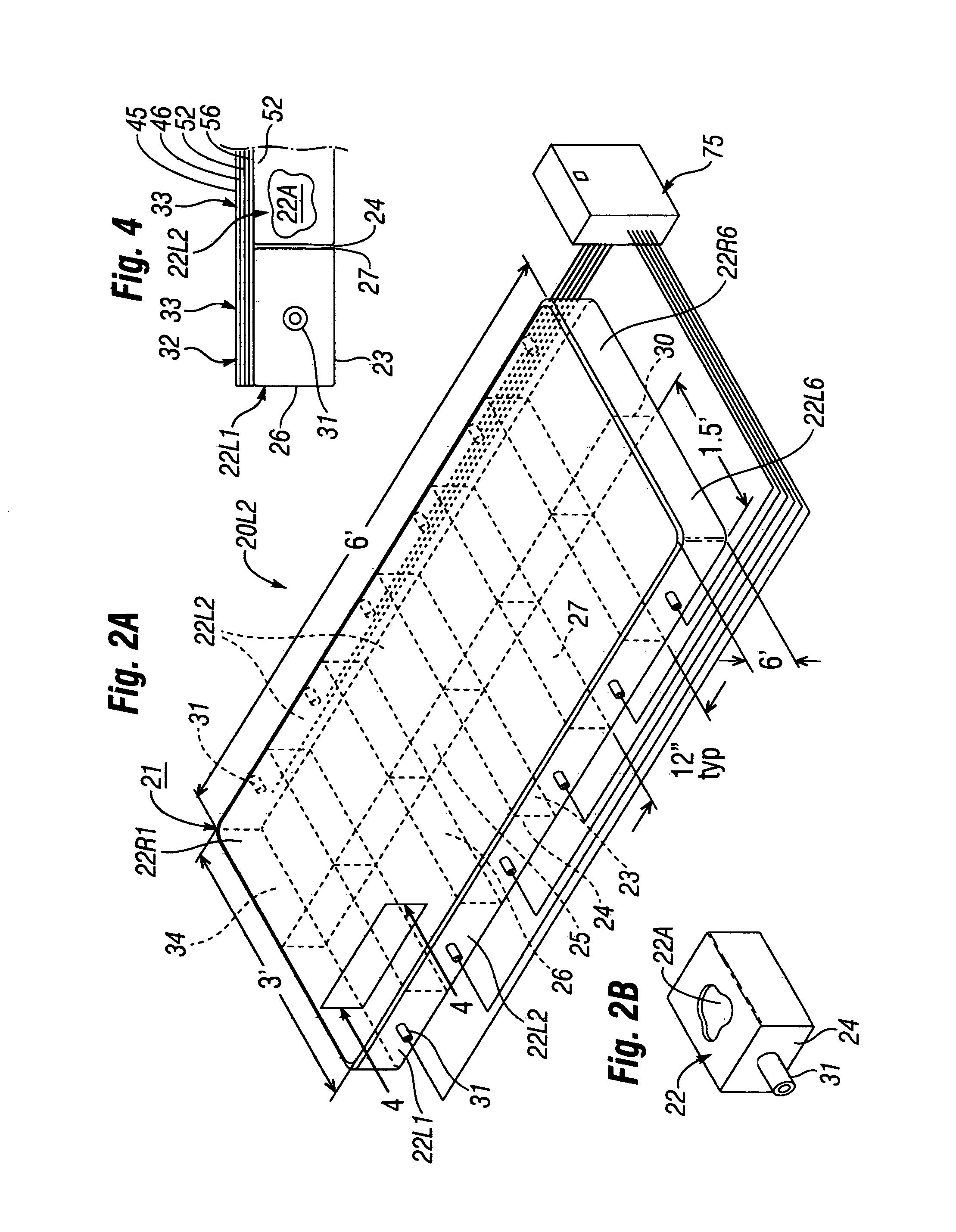

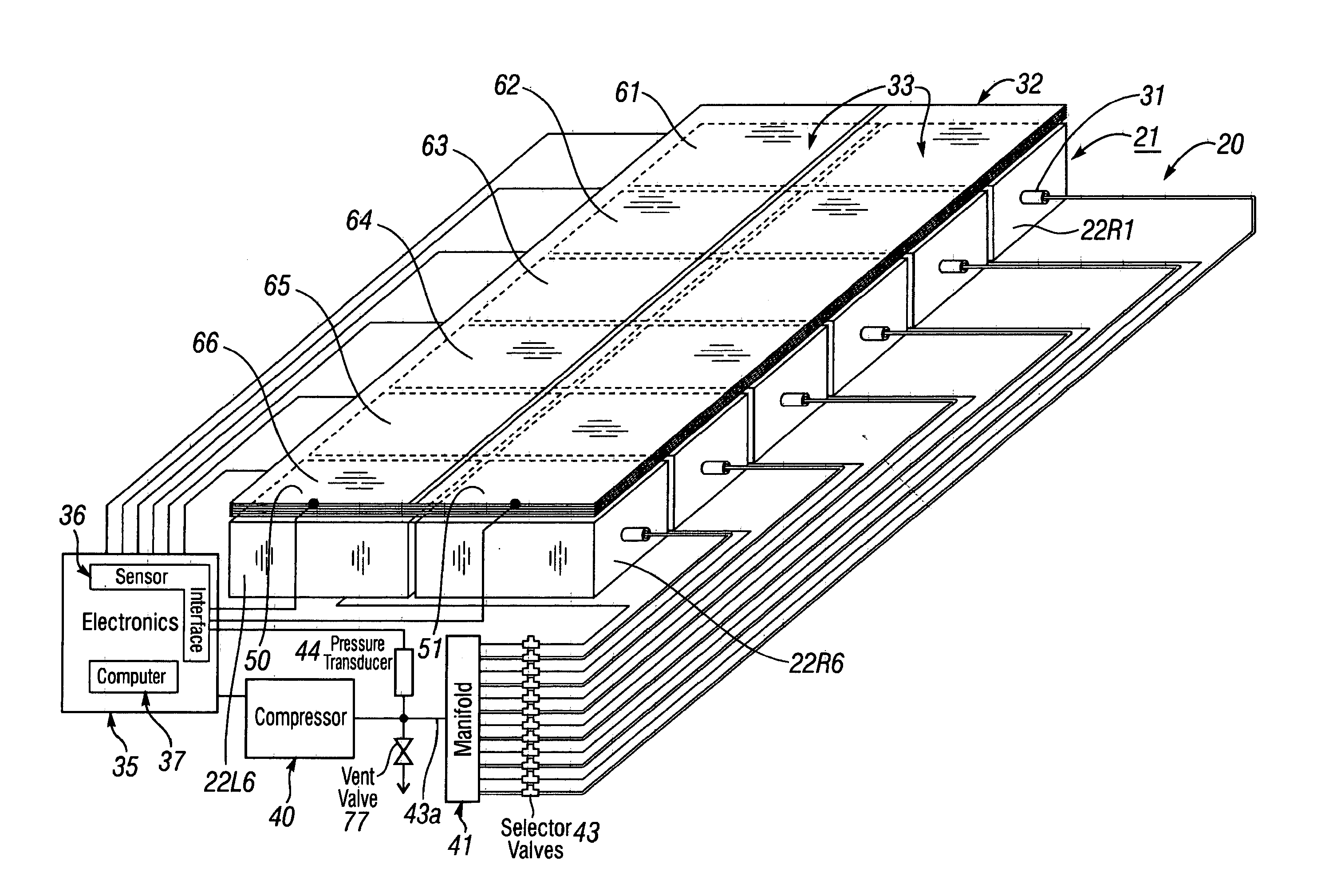

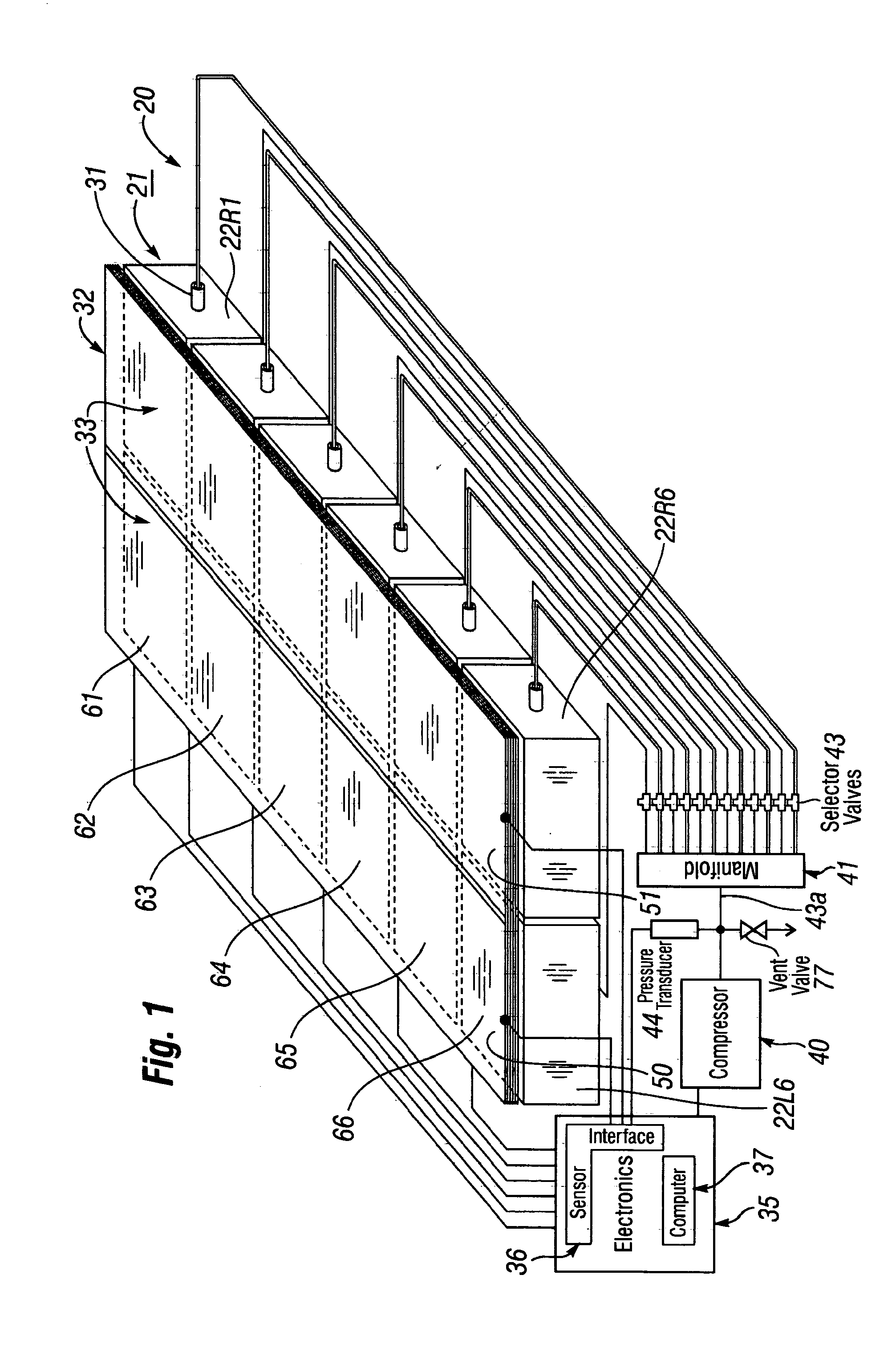

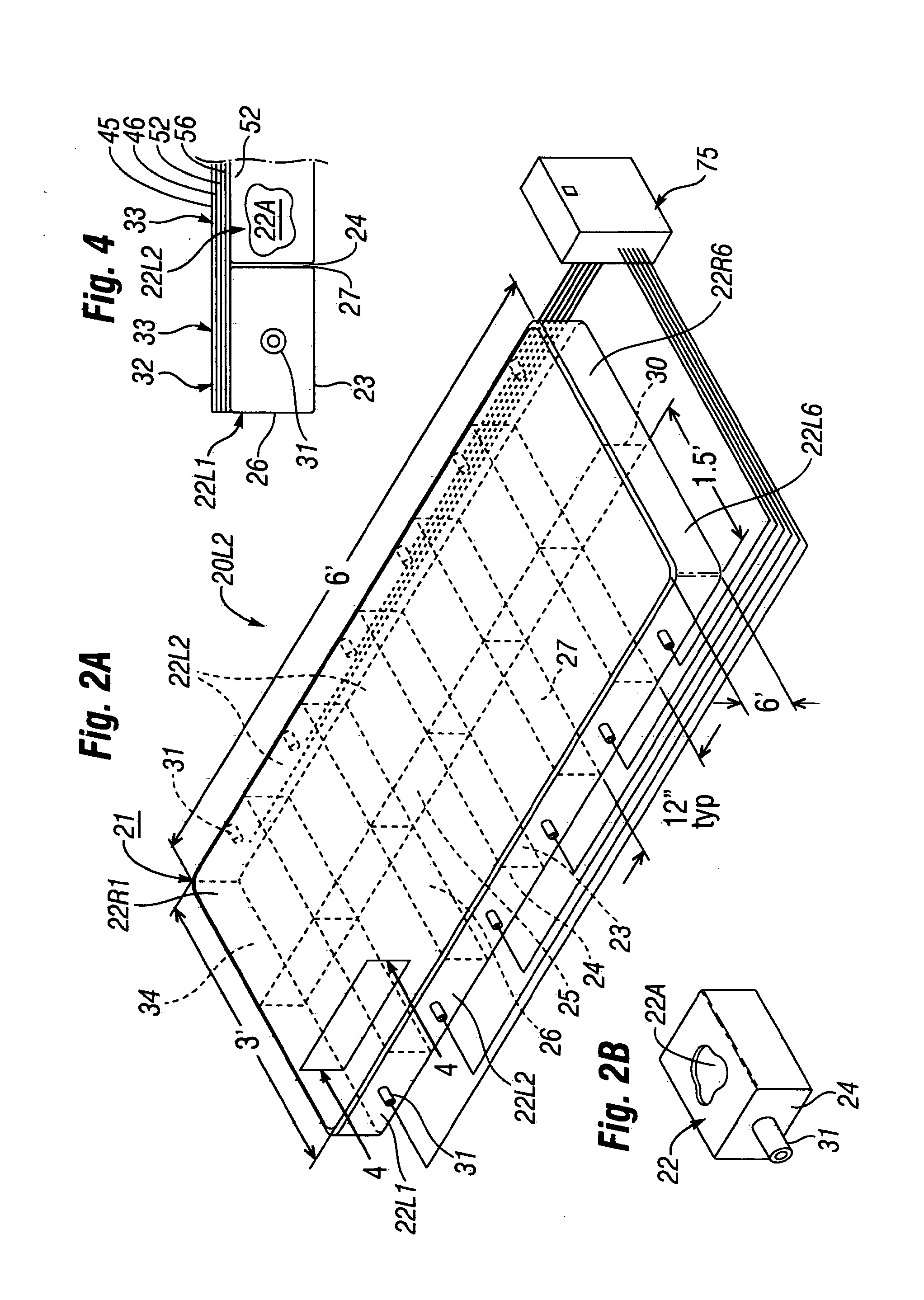

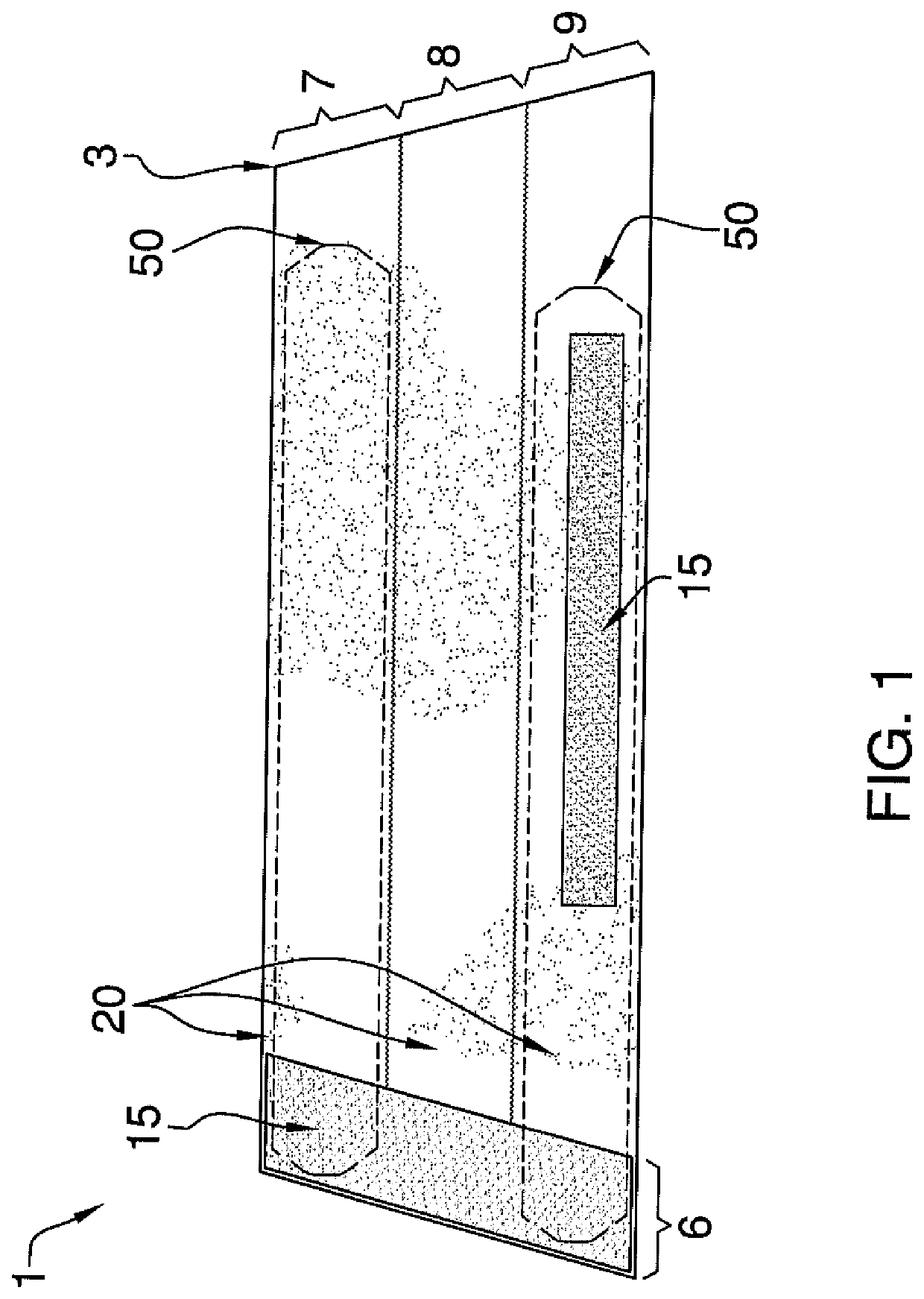

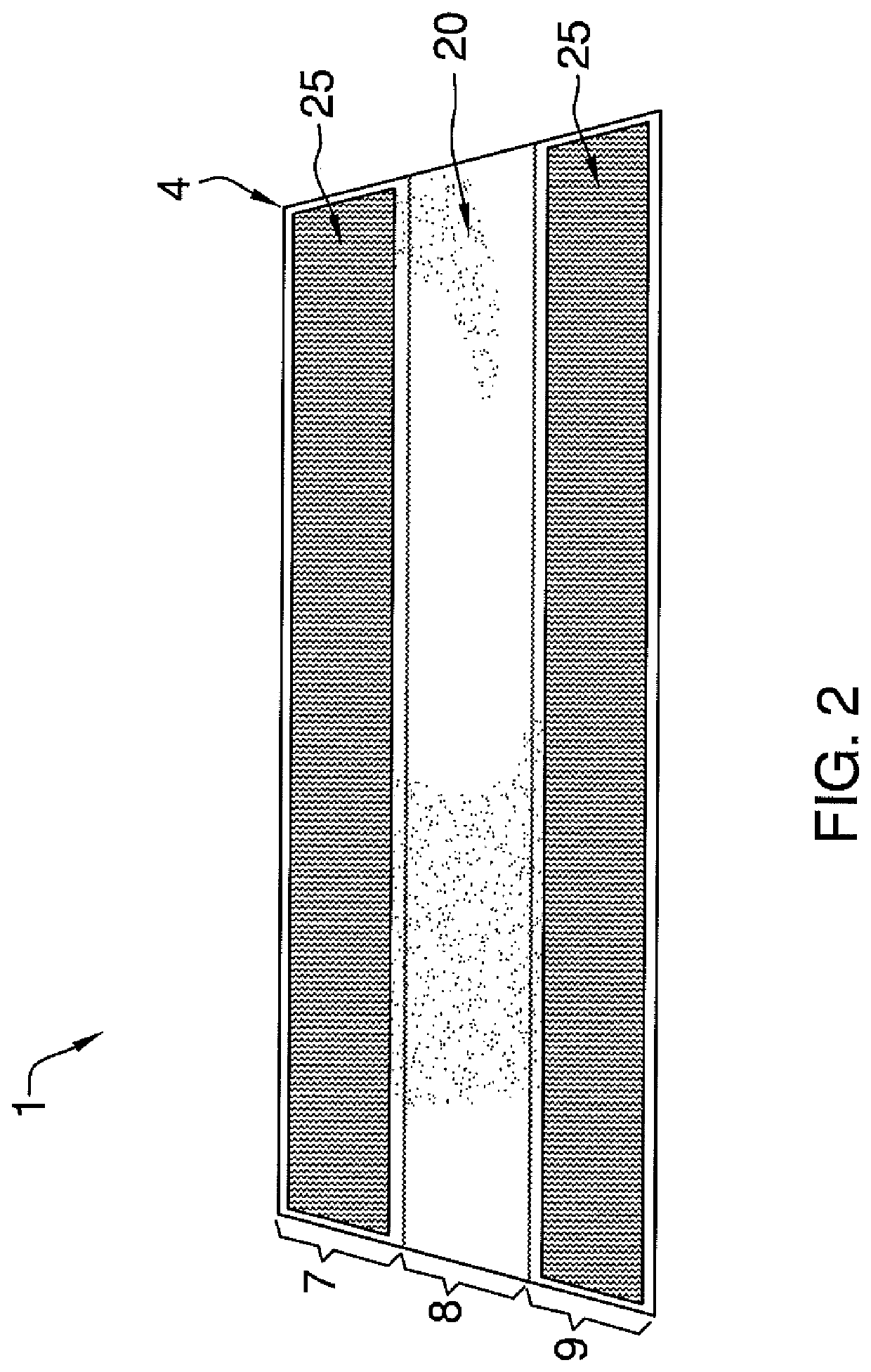

Adaptive cushion method and apparatus for minimizing force concentrations on a human body

ActiveUS8533879B1Minimizing reaction forceMinimize ambiguityStuffed mattressesSpring mattressesControl systemTransducer

An adaptive cushion apparatus for minimizing force concentrations on body parts of a person seated or lying on a chair or bed includes an overlay cushion having a plurality of individual air bladder cells, each having thereon a stretchable piezoresistive force sensor of novel design and construction. The apparatus includes an electro-pneumatic control system for inflating and deflating individual air bladder cells to pressures measured by a pressure transducer which tend to minimize force concentrations sensed by the force sensors. A force minimization method according to the invention includes varying the inflation pressure in a first air bladder cell while measuring the sum of the forces exerted on all air bladder cells, repressurizing the first cell to that pressure for which a minimum total force was obtained, repeating the cyclical variation in pressure and re-inflation to a minimum force-obtaining pressure for each of the remaining air bladder cells, and repeating the sequence for all air bladder cells until the force variations are minimized below a predetermined threshold value.

Owner:PATIENTECH LLC

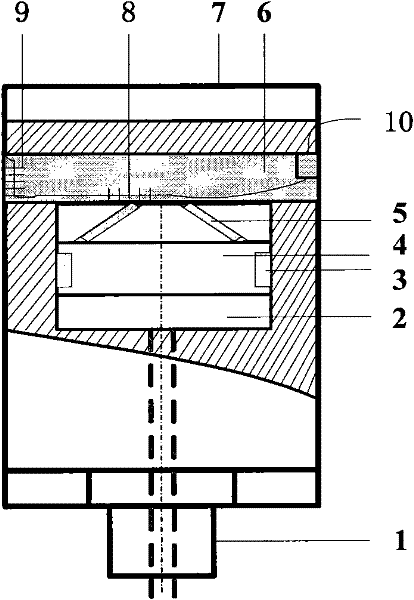

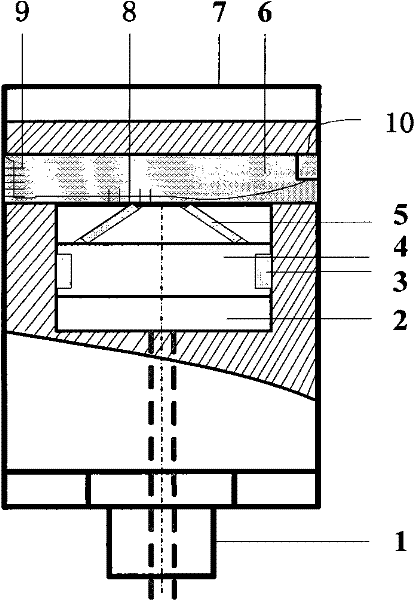

Fiber grating earth pressure sensor

ActiveCN102162757AAvoid chirpingConcentrated forceForce measurement by measuring optical property variationFiberPressure transmission

The invention discloses a fiber grating earth pressure sensor which comprises a sensor shell, a pressure transmission component and a fiber grating. The earth pressure sensor is characterized in that the pressure transmission component is of a rhombus structure, and the is positioned between a bearing-type top cover and a bottom plate, and is in contact with the bearing-type top cover and the bottom plate; clearances are arranged among the pressure transmission component and the left side and the right side of the sensor shell; a grating is pasted on a metal elastic membrane; the metal elastic membrane is arranged on a transverse diagonal line between a left angle and a right angle of the pressure transmission component; and two sides of the metal elastic membrane are fixed on the left angle and the right angle of the pressure transmission component. The earth pressure sensor provided by the invention has the characteristics of large measuring span, high accuracy and simple structure, is good for miniaturization of the integral structure.

Owner:青岛飞博科技有限公司

Adaptive cushion method and apparatus for minimizing force concentrations on a human body

ActiveUS20140026327A1Minimizing reaction forceMinimize ambiguityStuffed mattressesSpring mattressesHuman bodyEngineering

Owner:PATIENTECH LLC

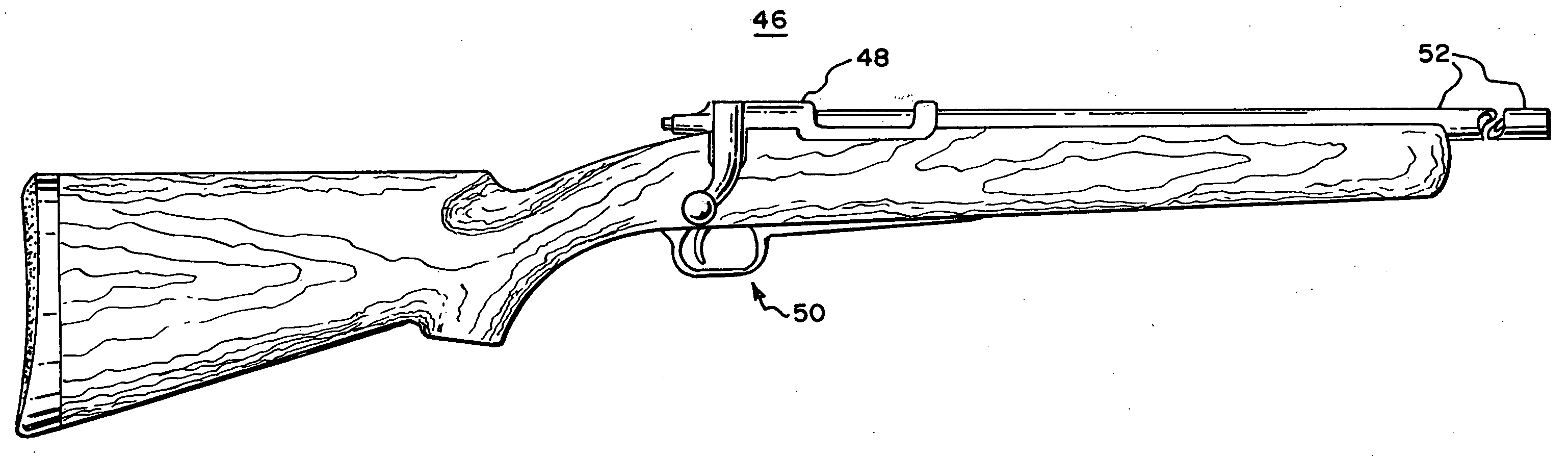

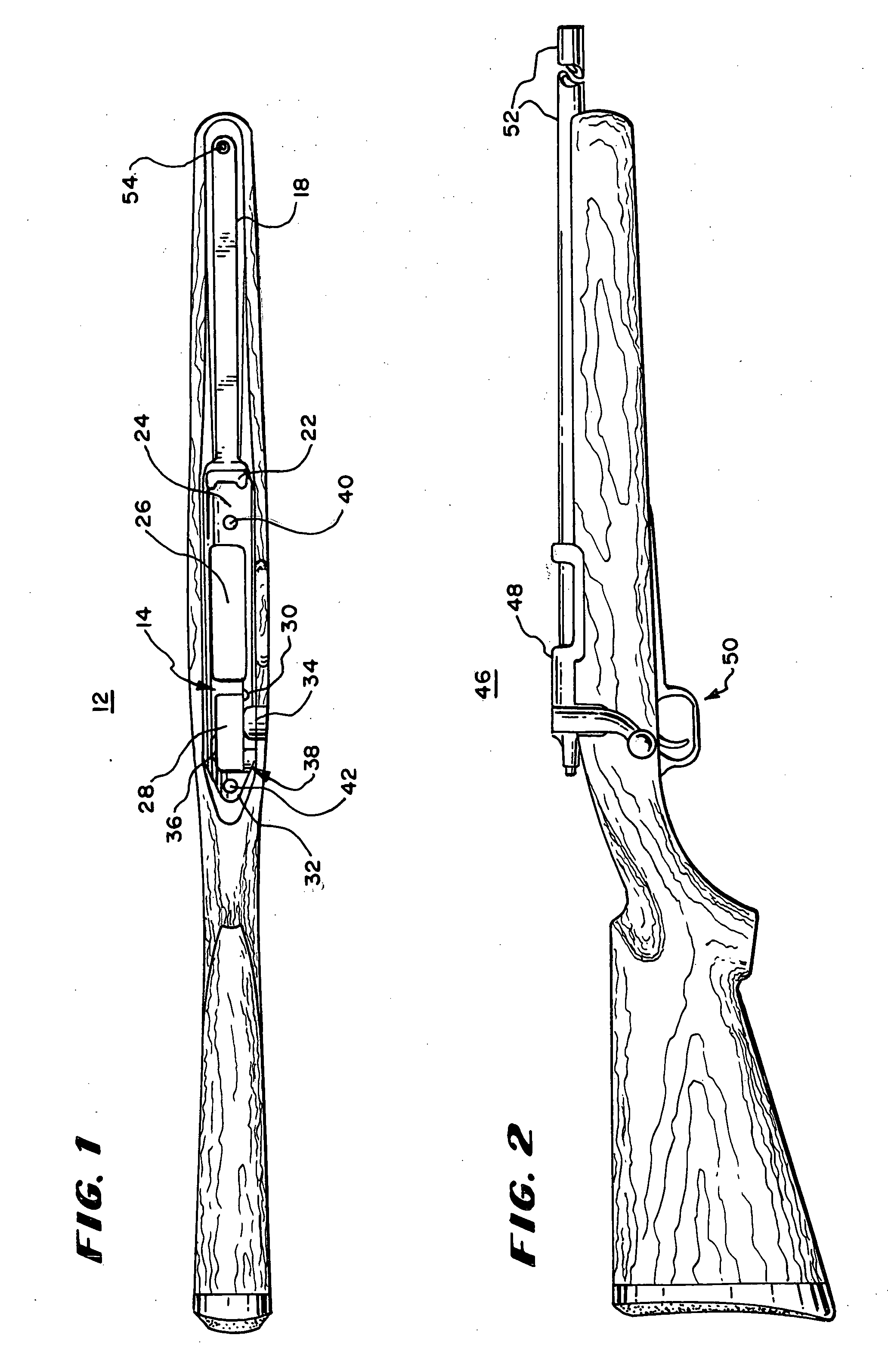

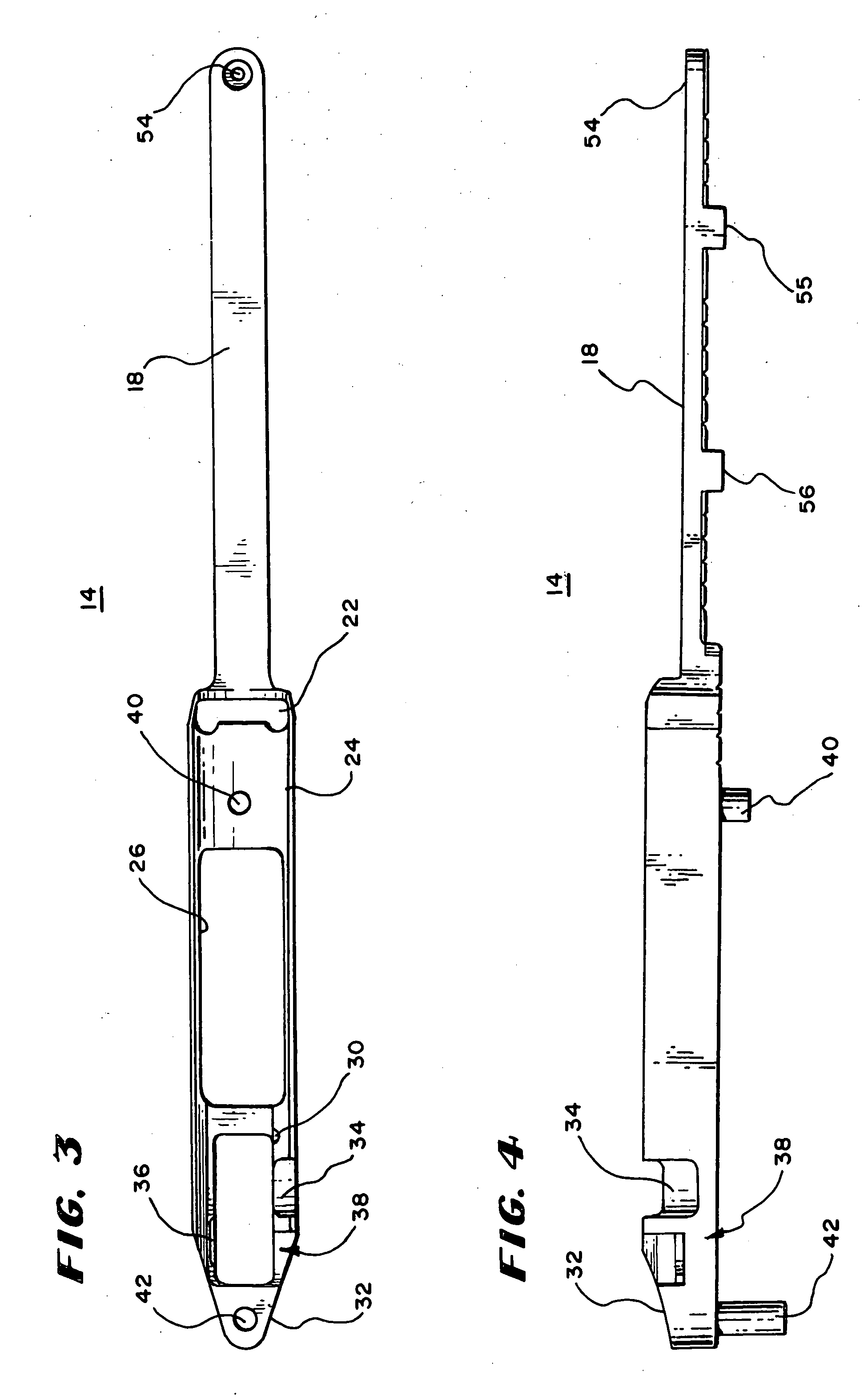

Gunstock

InactiveUS20050115135A1High modulusDissipates concentrated forceButtsBarrel mountingWide areaEngineering

The action and barrel of a firearm are in direct contact with a high modulus of elasticity holder that receives the vibrations of recoil directly and distributes the vibrations over a wide area. The high modulus of elasticity holder, which may be made of a metal such as aluminum, transfers the forces to the wooden portion of a wooden gunstock over a wide area greater than 12 square inches so that there are substantially no concentrated stresses placed upon the wood.

Owner:ACCURATE INNOVATIONS

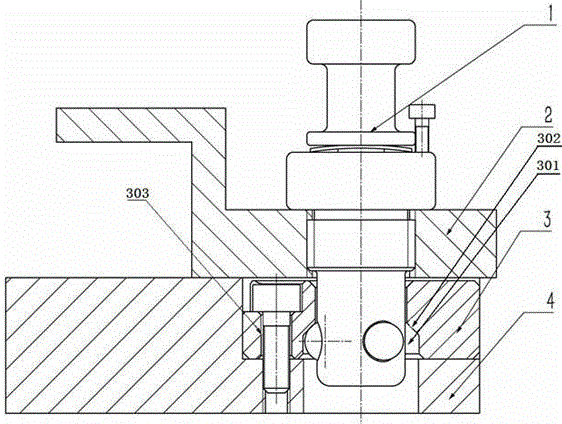

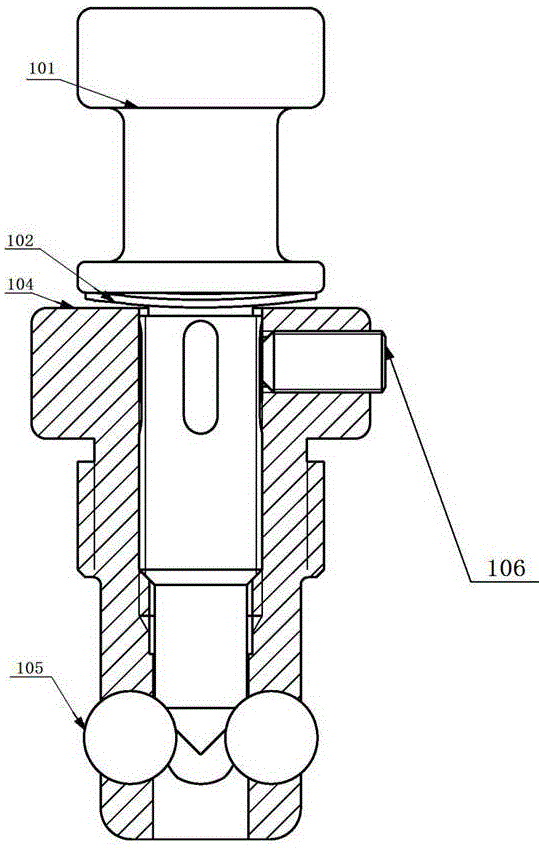

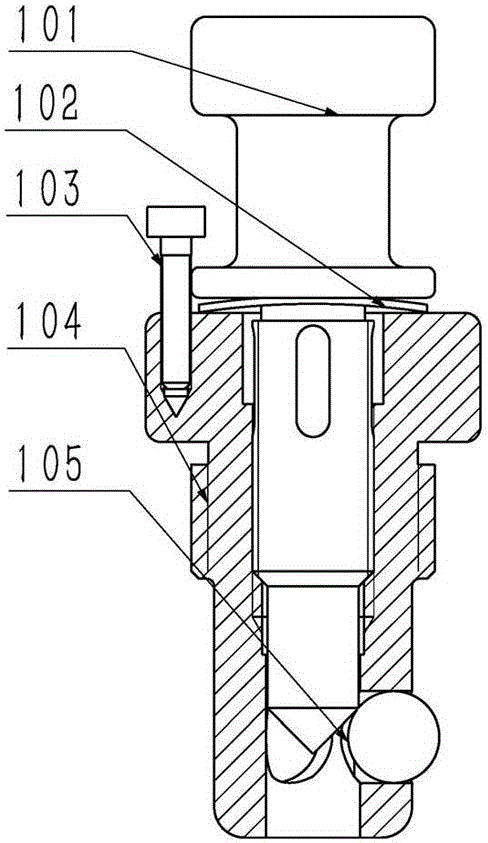

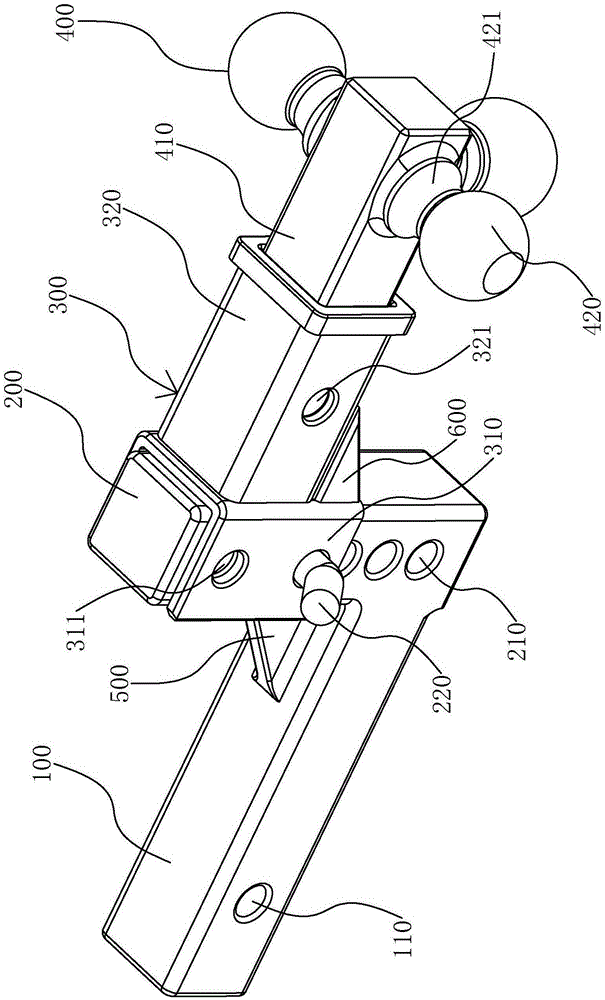

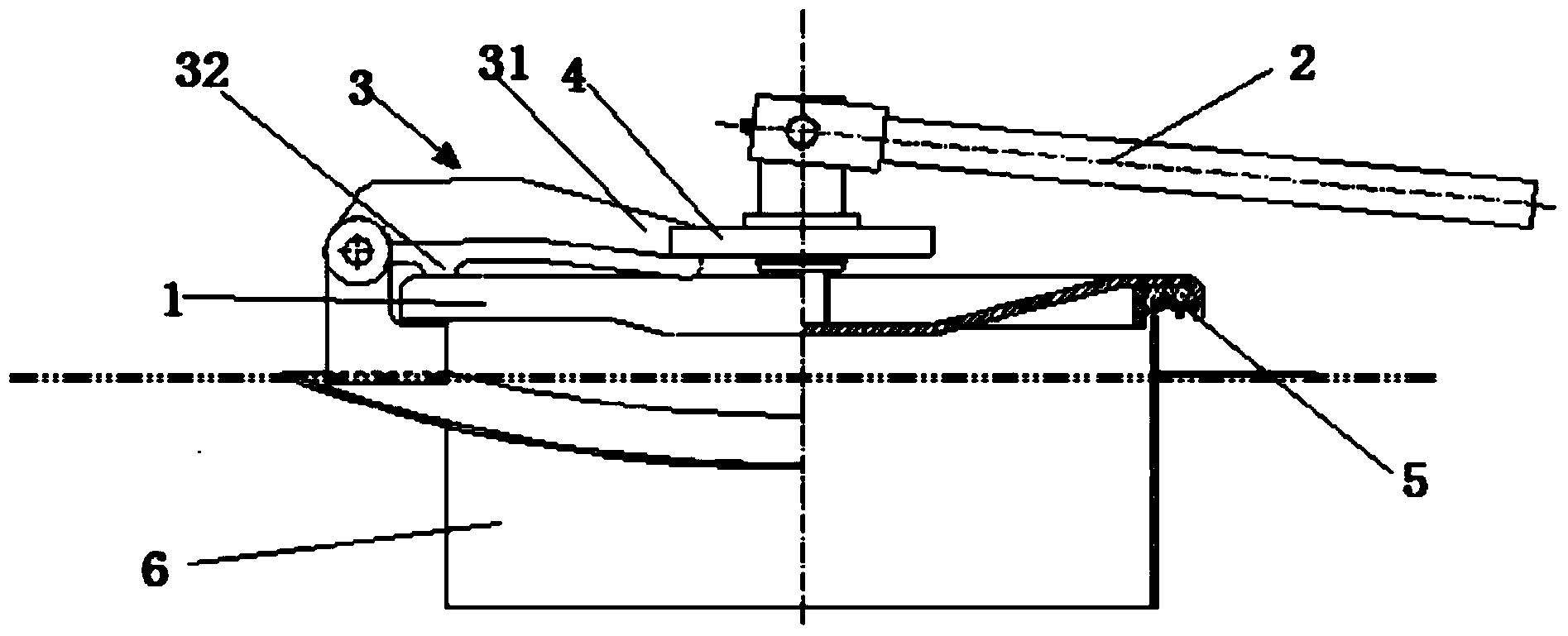

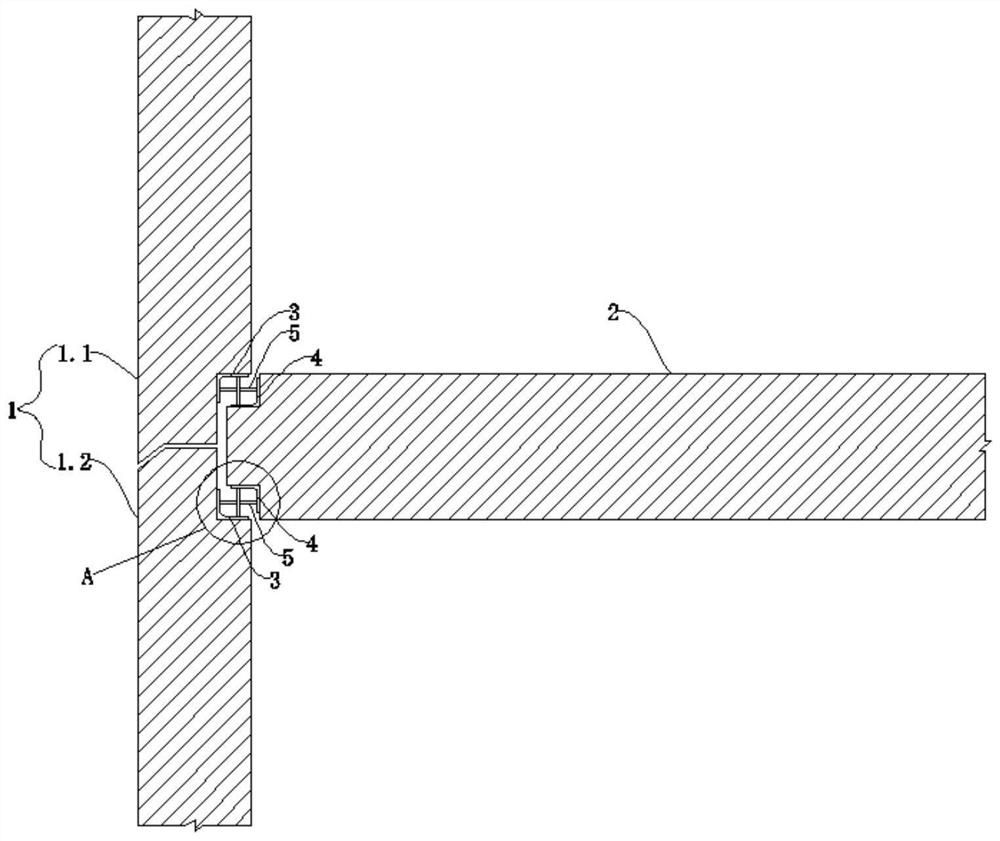

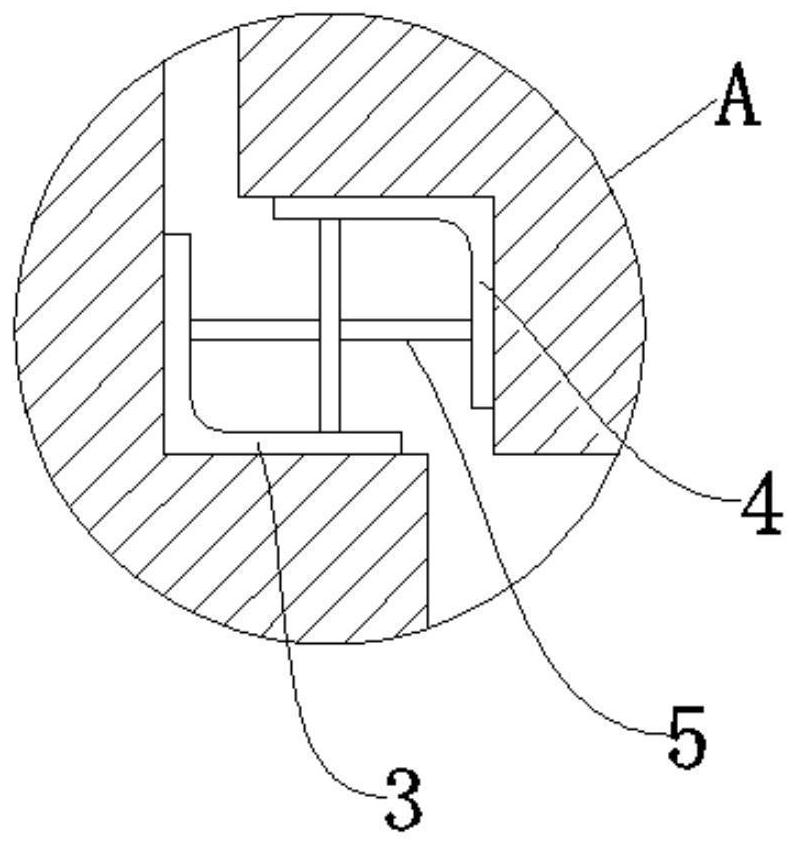

Connecting structure capable of being rapidly mounted and dismounted

The invention relates to a connecting structure capable of being rapidly mounted and dismounted. The connecting structure comprises a locking pin and a locking block. The locking pin comprises a pin shaft and a pin shaft sleeve arranged on the lower portion of the pin shaft in a sleeving mode through threads. The bottom surface of the pin shaft is a conical surface. The lower portion, under the pin shaft, of the pin shaft sleeve is provided with a plurality of through holes evenly distributed around the axis, and a steel ball which can freely move but can not fall out is arranged in each through hole. The locking block is provided with a connecting hole and a containing cavity, the connecting hole is formed in the top surface of the locking block, and the bottom of the connecting hole is communicated with the top of the containing cavity, and the top surface of the containing cavity is a conical surface. In the installation process, the pin shaft sleeve and the locking block are fixed to a connector and a connected part respectively, the pin shaft sleeve penetrates through the connector and enters the containing cavity of the locking block through the connecting hole, the pin shaft is rotated downwards so that the steel balls can be pushed to squeeze the conical top surface of the containing cavity through the conical bottom surface of the pin shaft, and the connector and the connected part squeeze and fix each other when subjected to force in opposite directions. In the dismounting process, the pin shaft is rotated upwards, the steel balls are not subjected to force, and then the connector and the connected part are separated.

Owner:AEROSPACE LIFE SUPPORT IND LTD

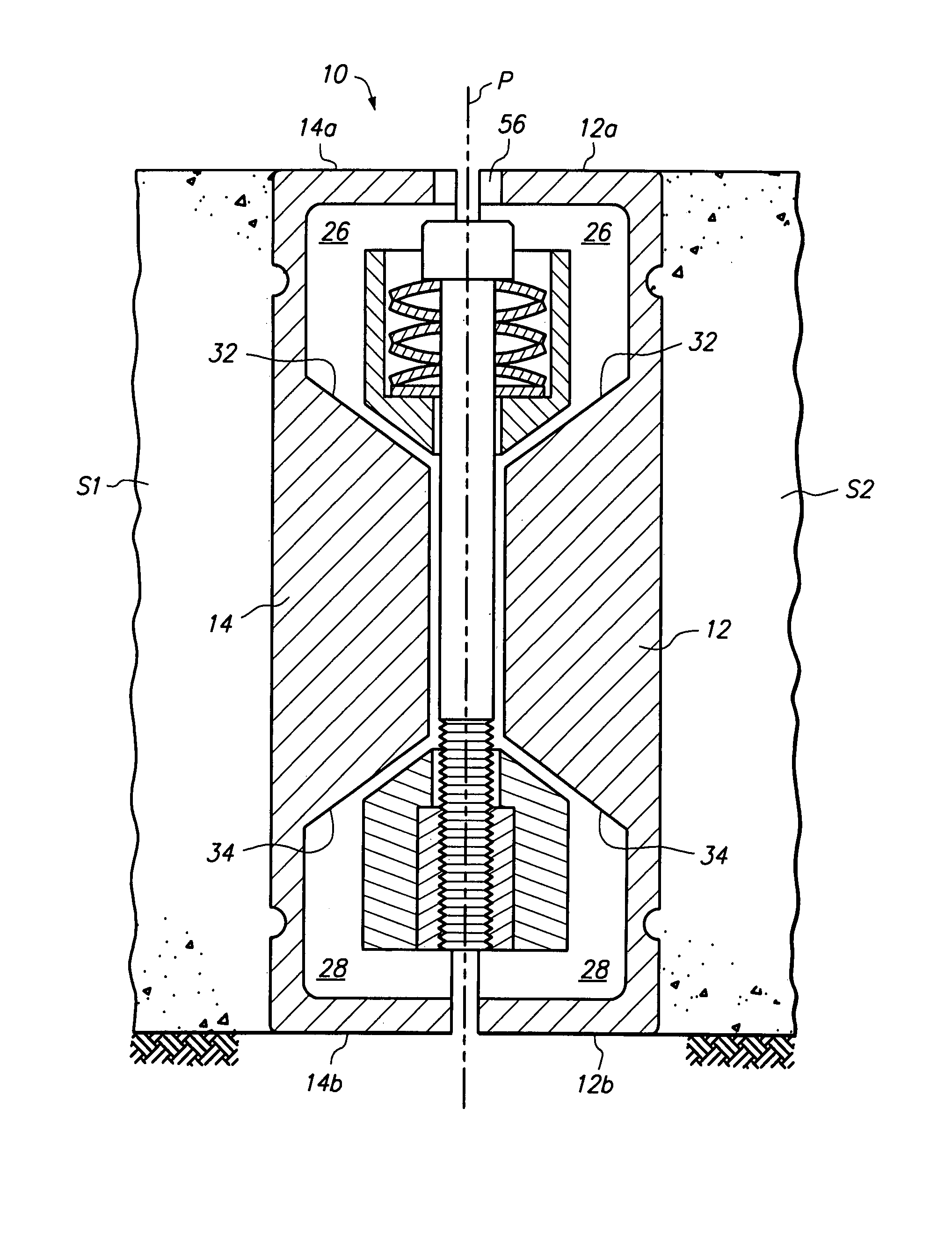

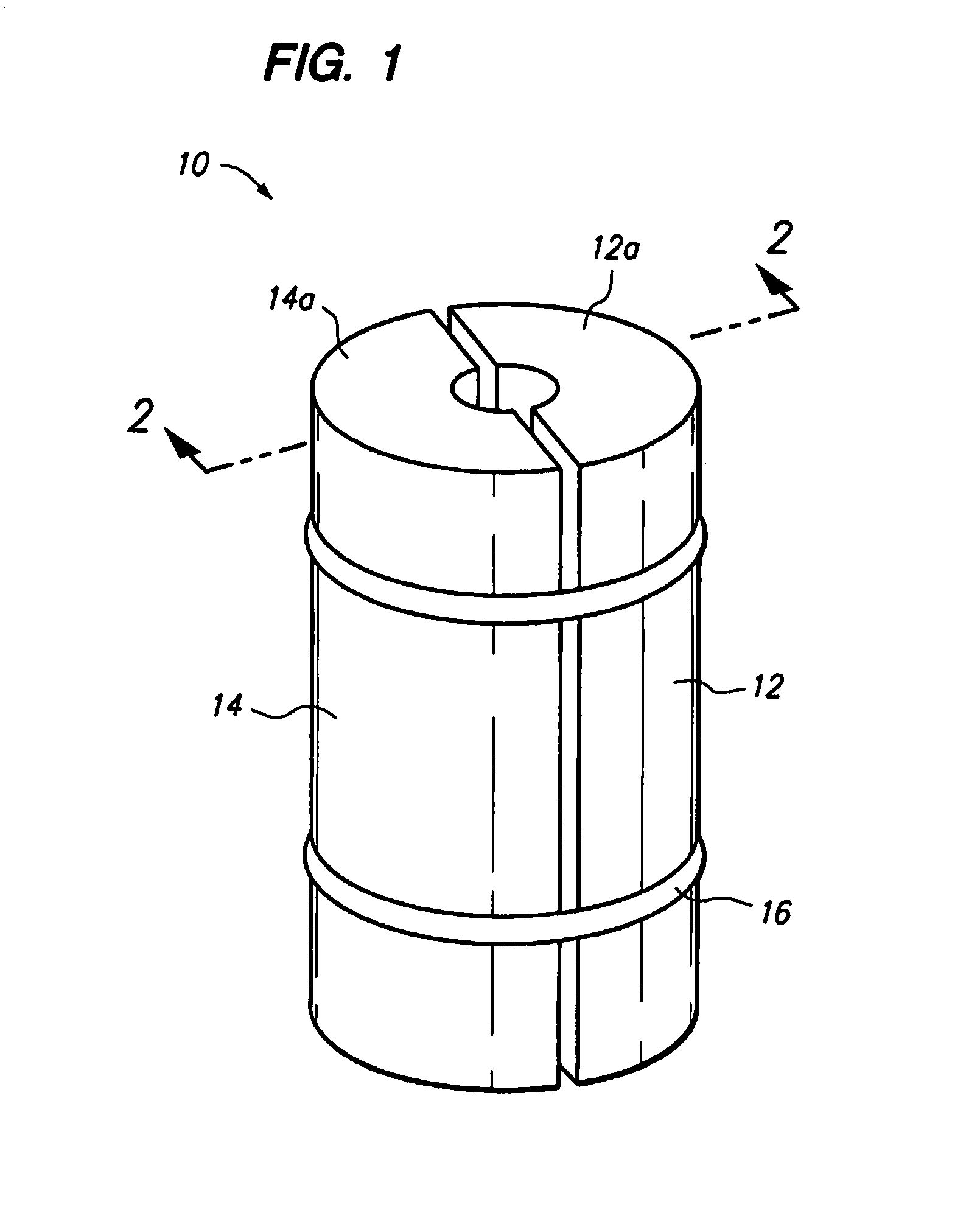

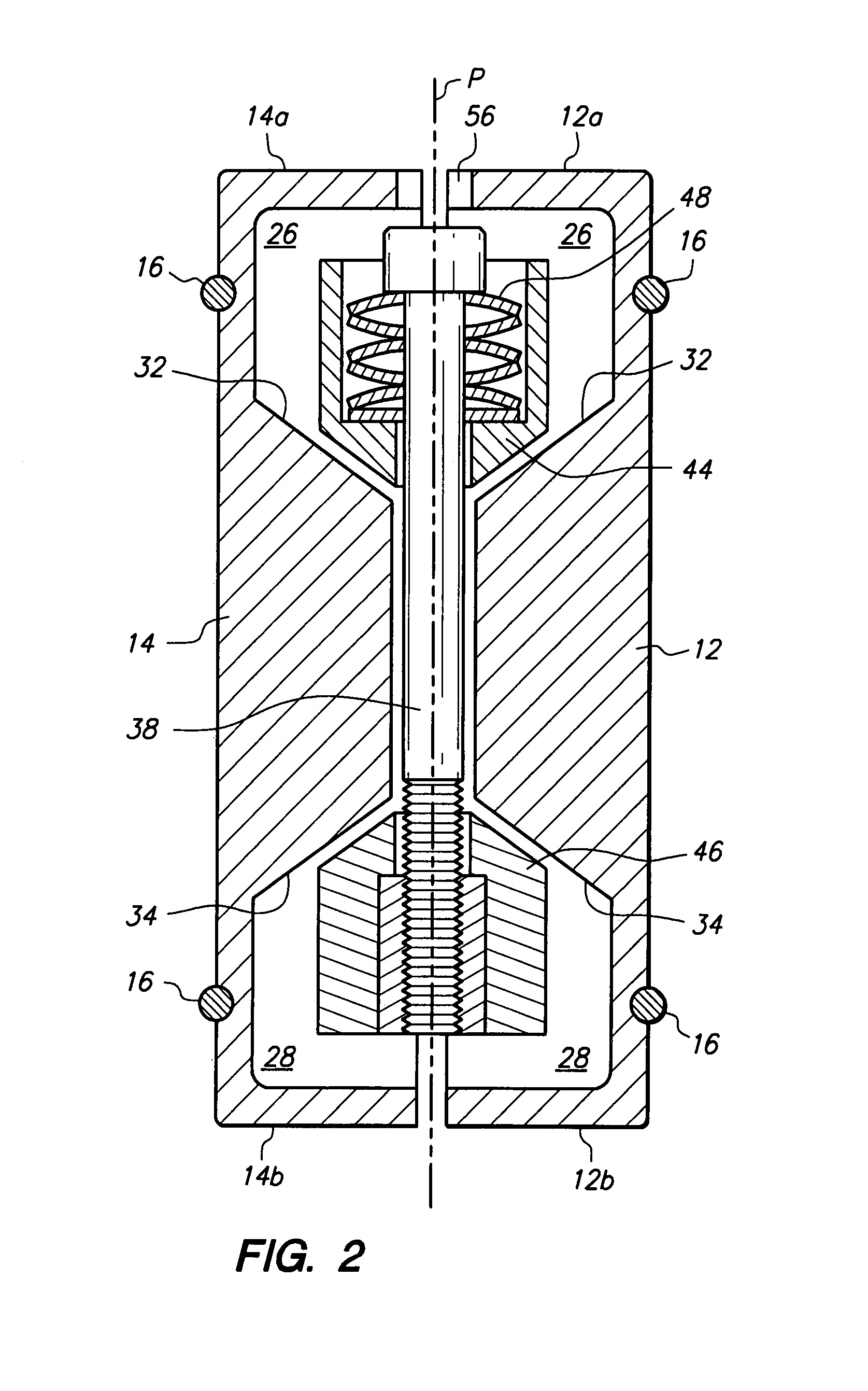

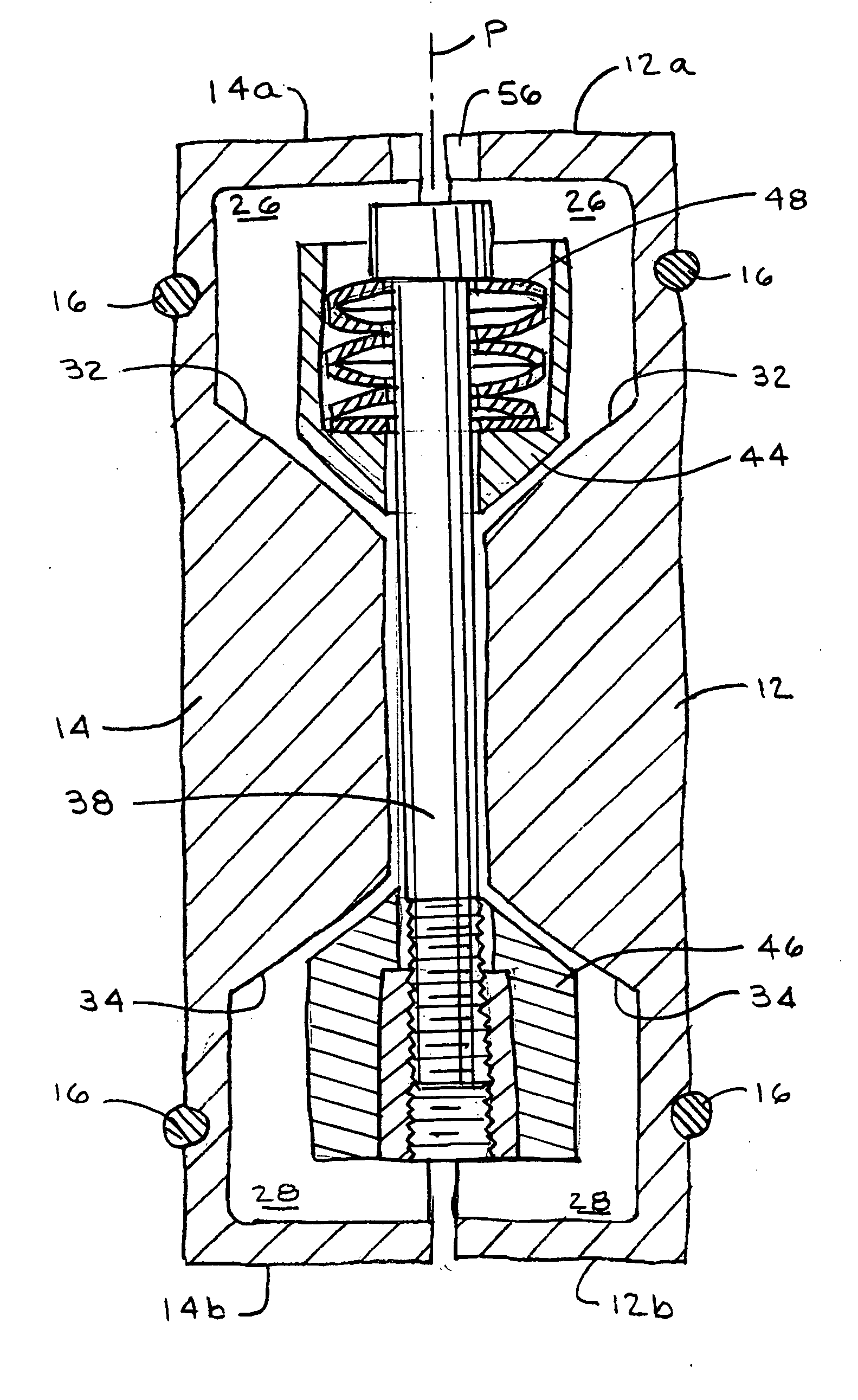

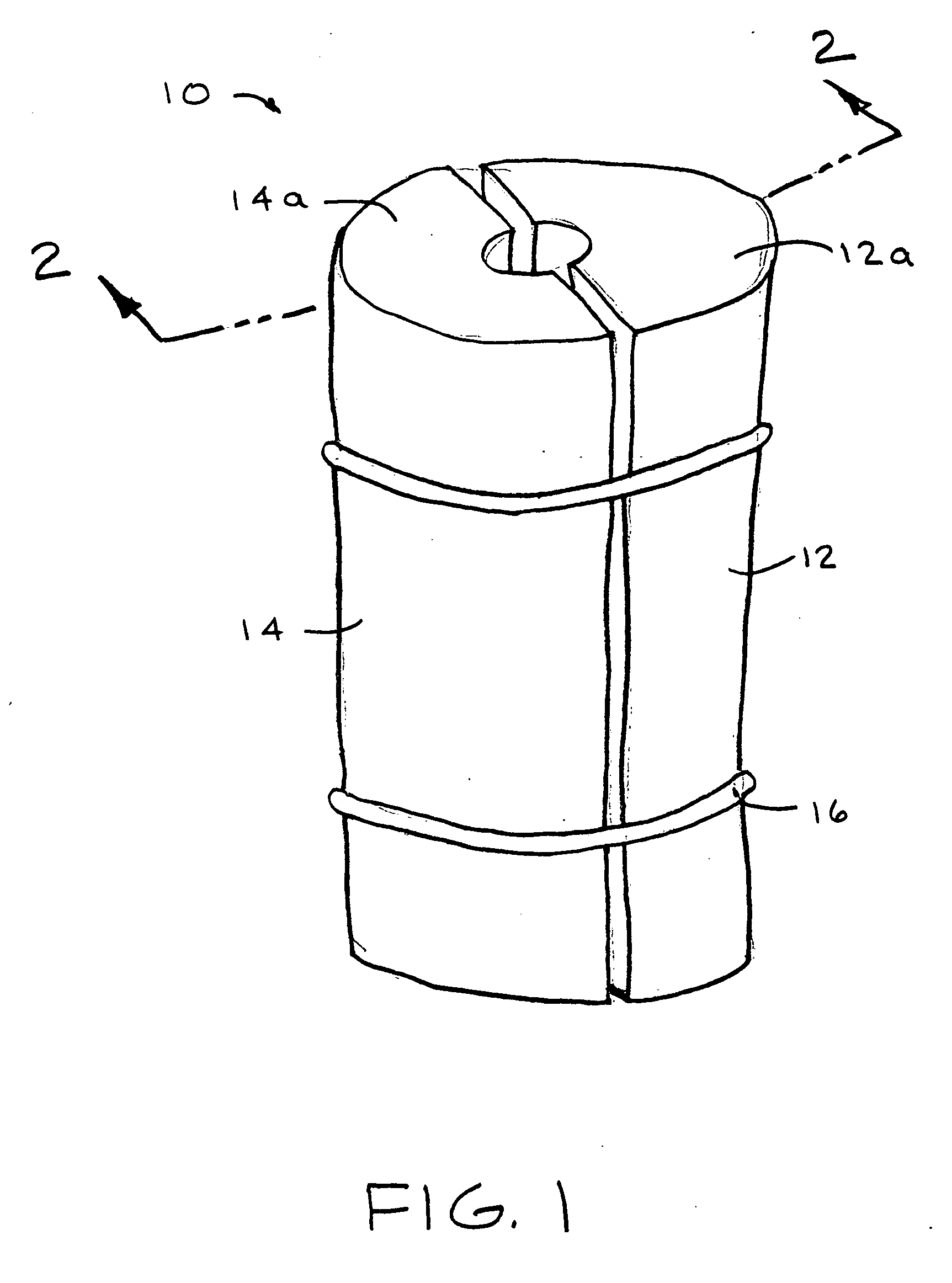

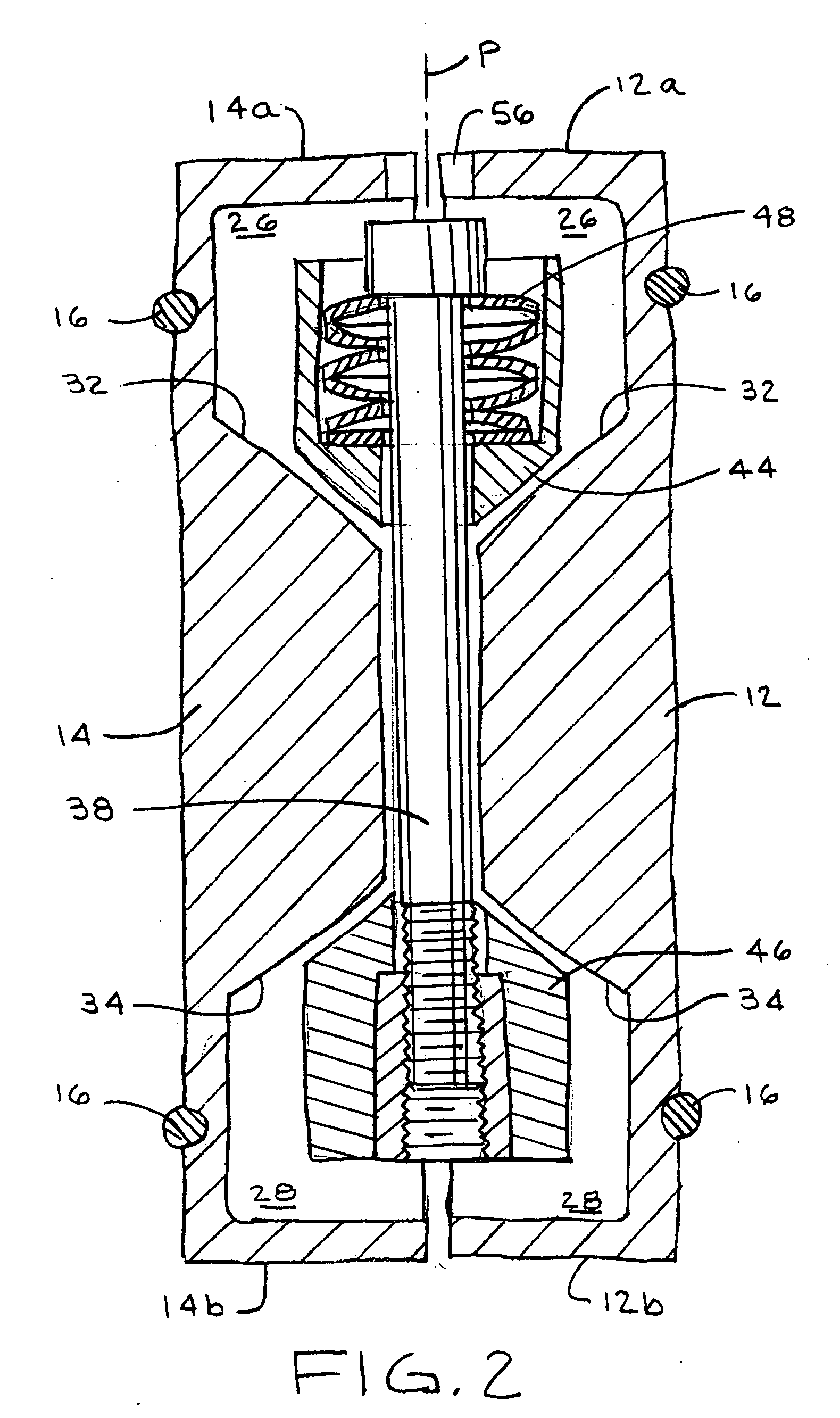

Concrete slab joint stabilizing system and apparatus

ActiveUS7334963B2Concentrated forceMinimizationPaving reinforcementsIn situ pavingsRelative motionVertical displacement

A joint stabilizing apparatus having an expandable cylindrical housing is inserted into a circular hole drilled at a “loose joint” of a concrete slab that is to be stabilized against relative vertical displacement between adjacent slab sections. The hole is drilled downward into the concrete, centered on the plane of a lateral opening / joint in the concrete slab. The expandable housing comprises two rigid semi-circular housing halves, and the assembly is oriented inside of the circular hole such that the two housing halves are on opposite sides of the centerline of the lateral opening / joint. The housing halves are pushed apart by turning of a threaded bolt inside of the housing. Turning of the bolt causes two bi-laterally symmetric wedge blocks to draw towards each other, and pressing the bearing surfaces of the wedge blocks against inclined surfaces inside of the respective housing halves. As the housing halves are pushed apart, the outside surfaces of the expandable housing engage the walls of the drilled hole and apply opposing horizontal compressive forces to the slab sections. Friction between the expandable housing and the concrete slab sections prevent the slab sections from vertically moving relative to each other.In other embodiments of the invention, the joint stabilizing apparatus is used to prevent relative motion between non-horizontal construction members, and between four adjacent slab sections separated by intersecting loose joints.

Owner:ILLINOIS TOOL WORKS INC

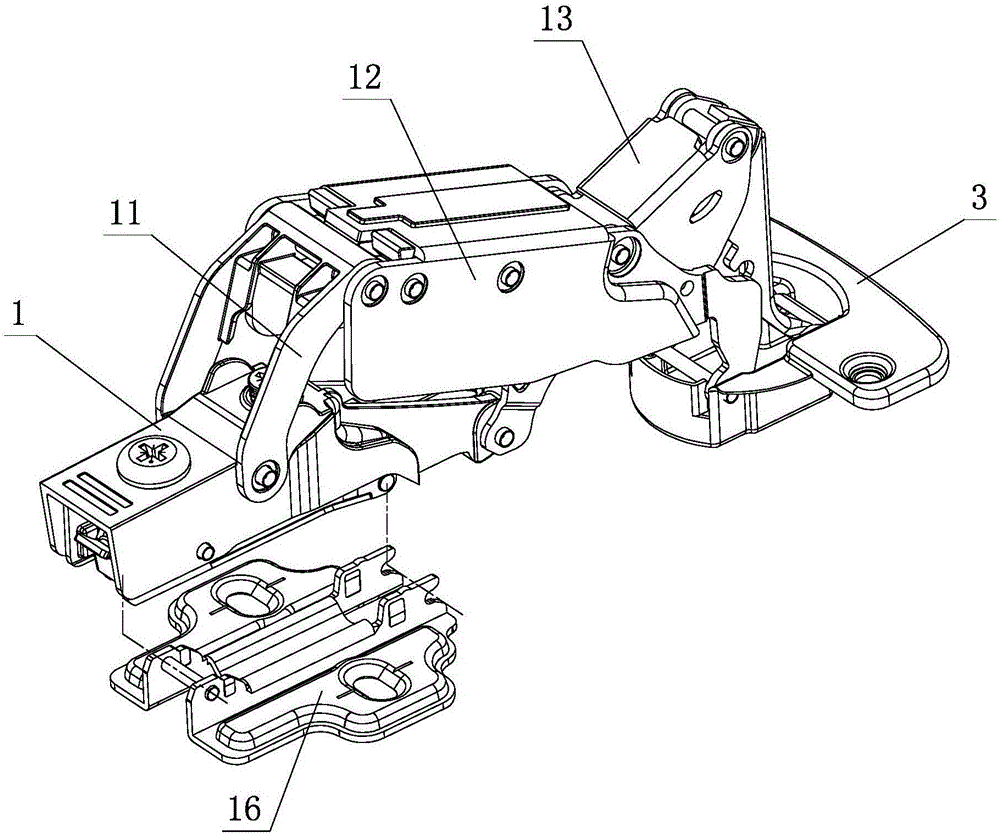

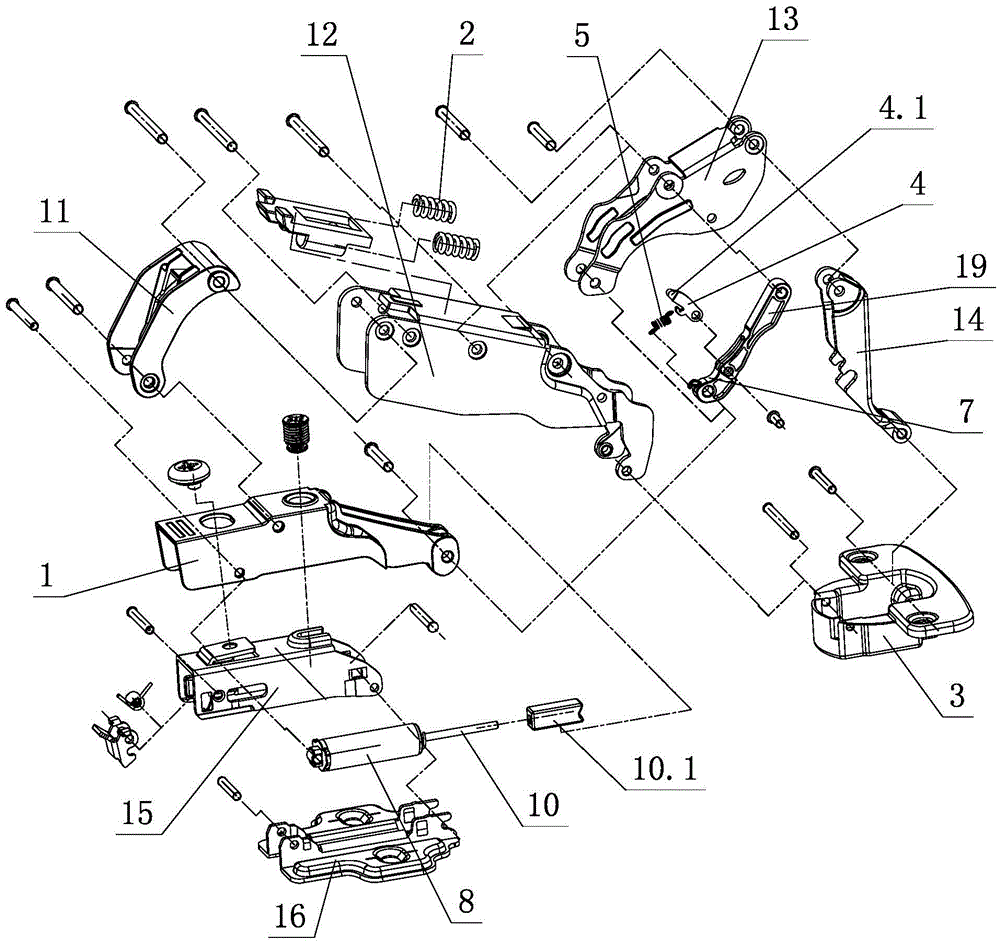

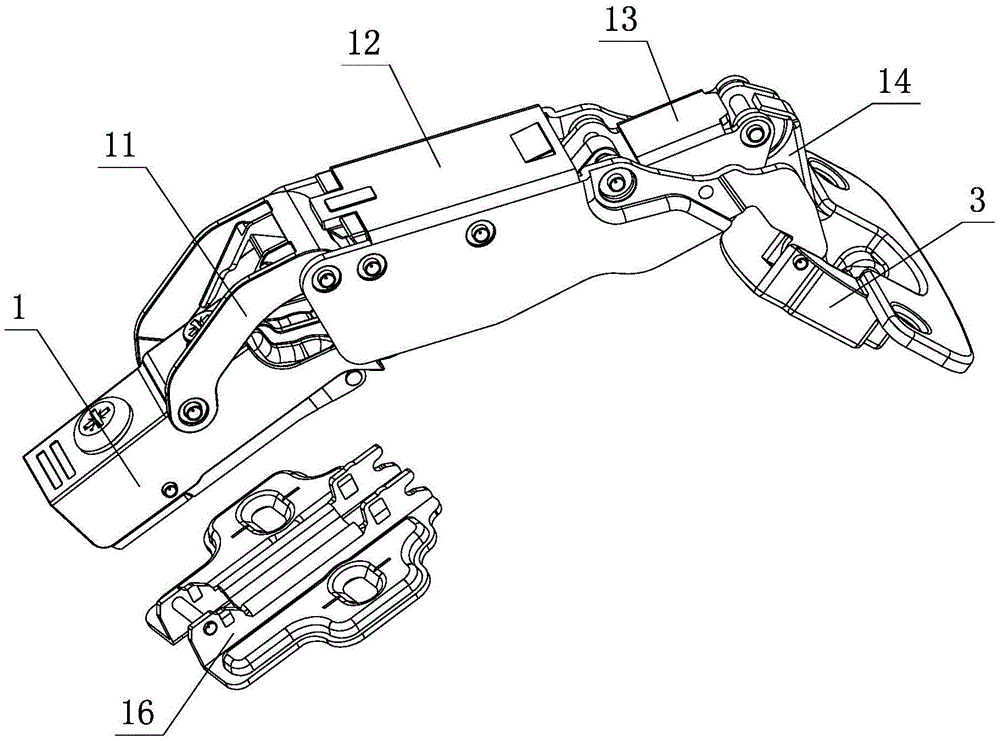

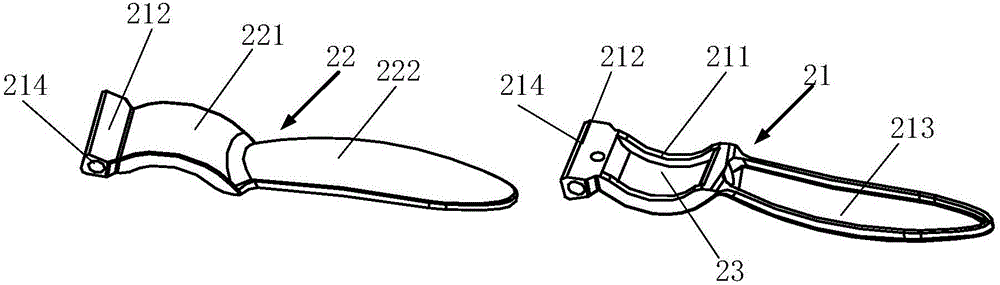

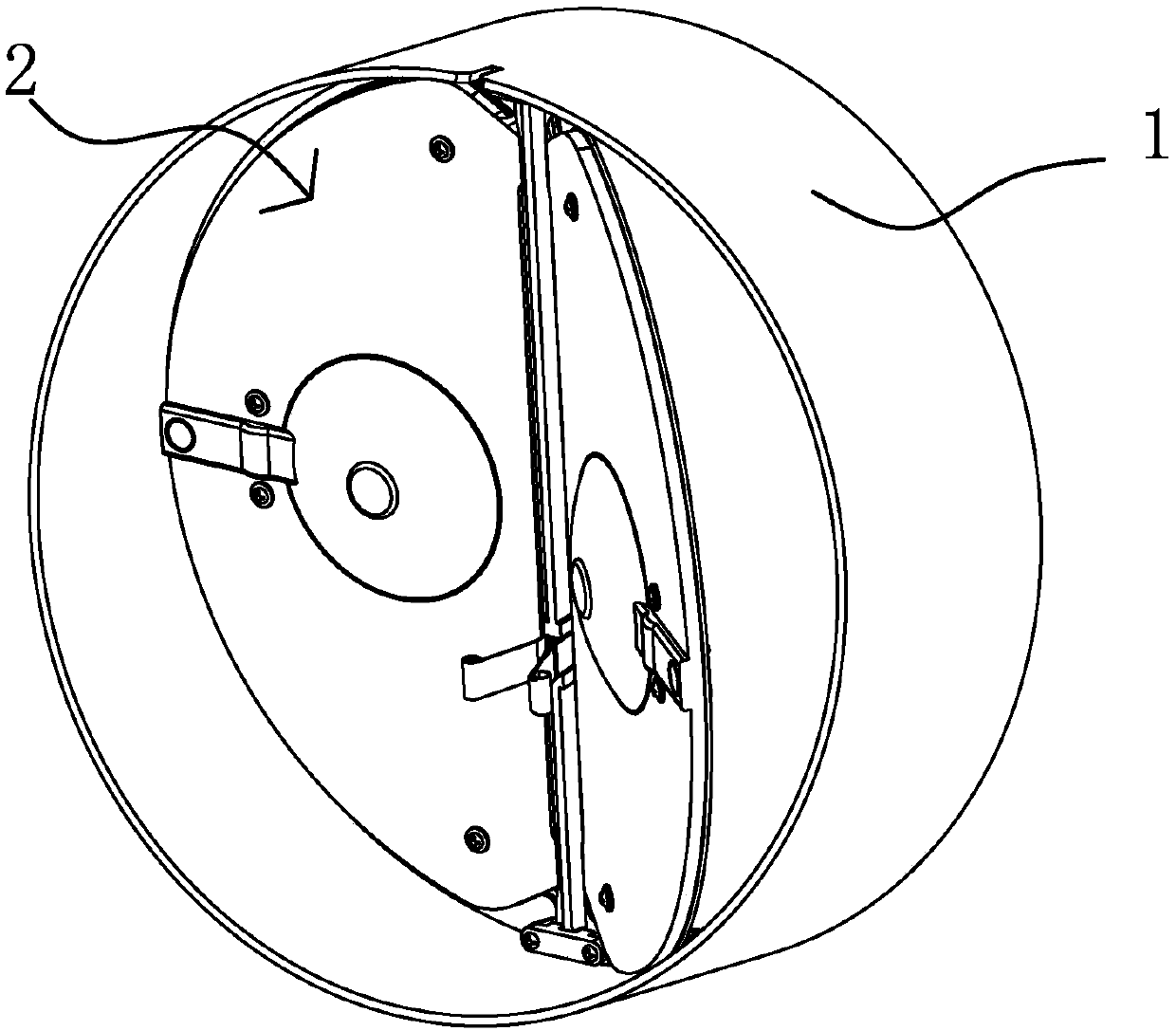

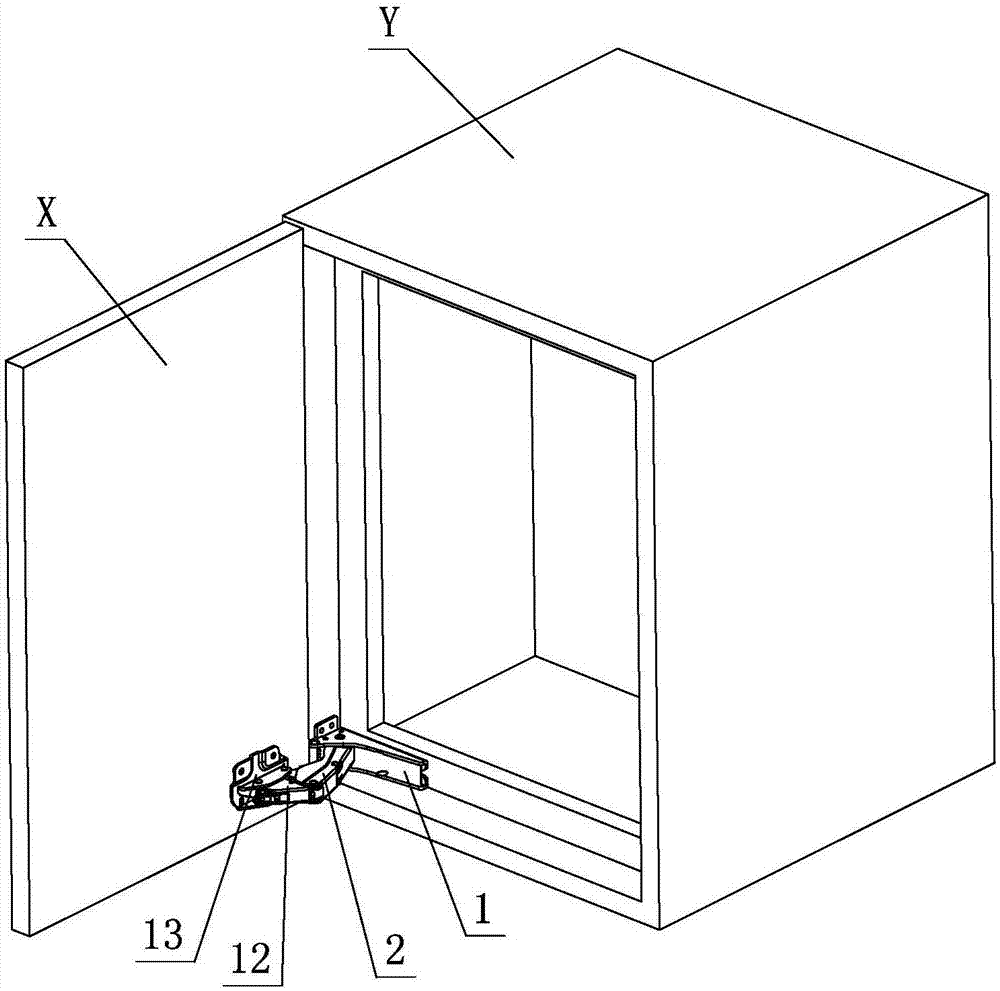

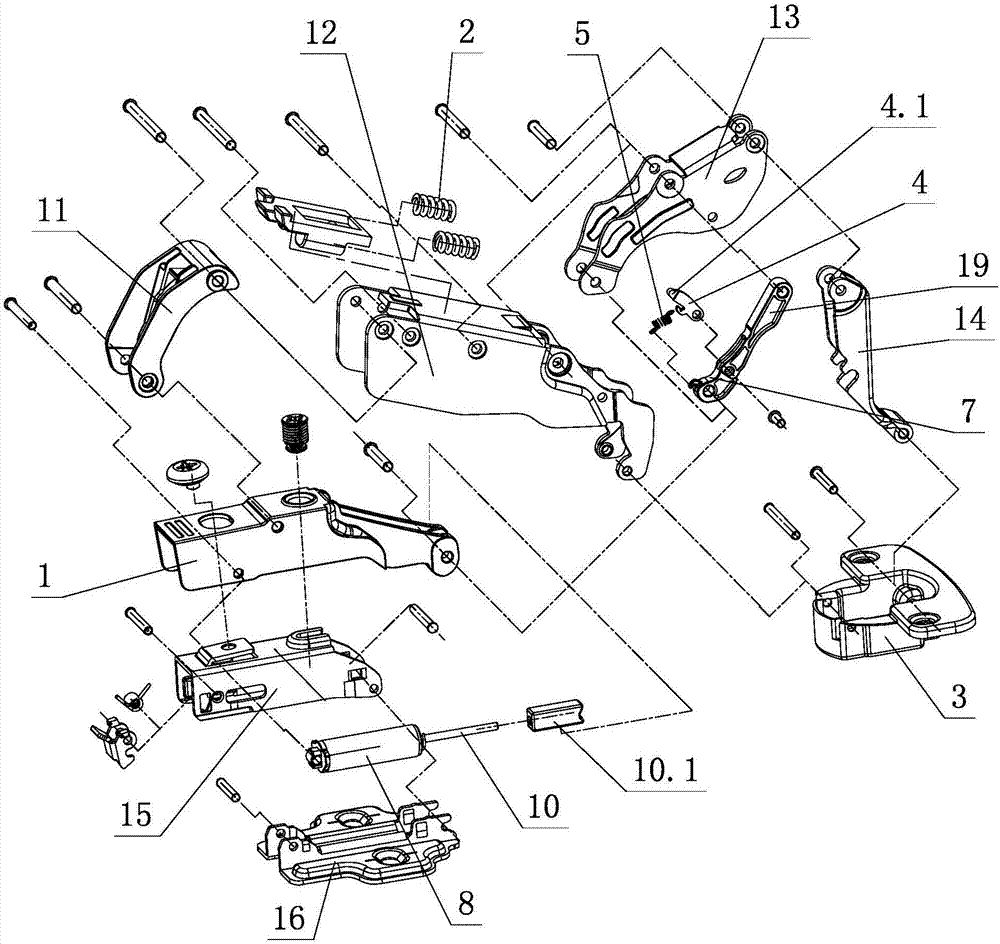

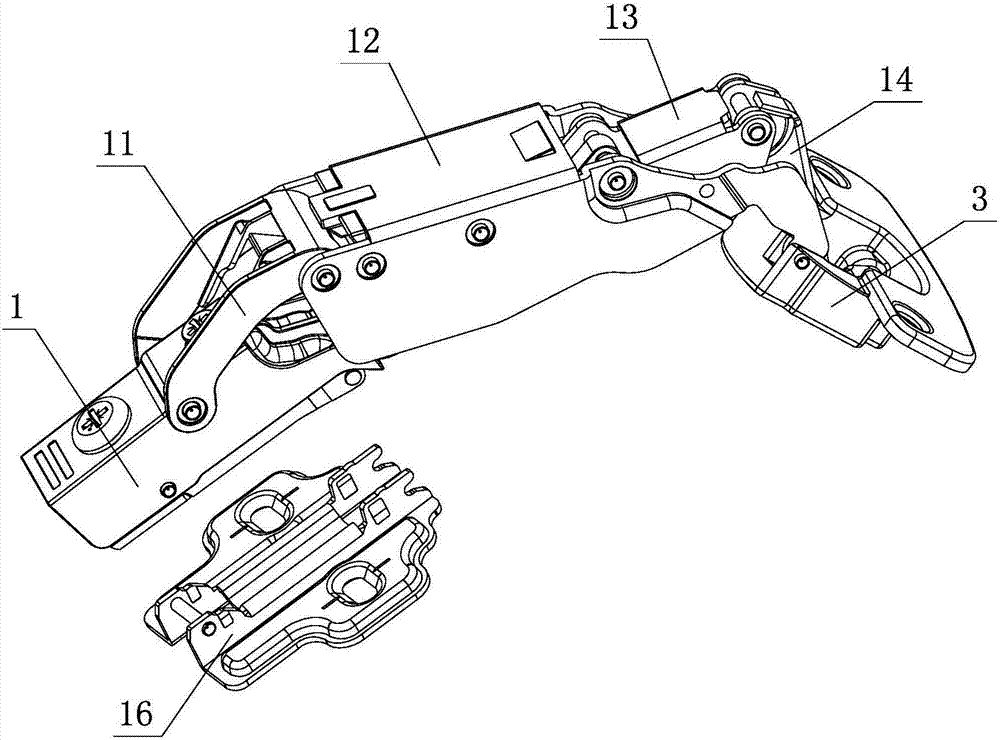

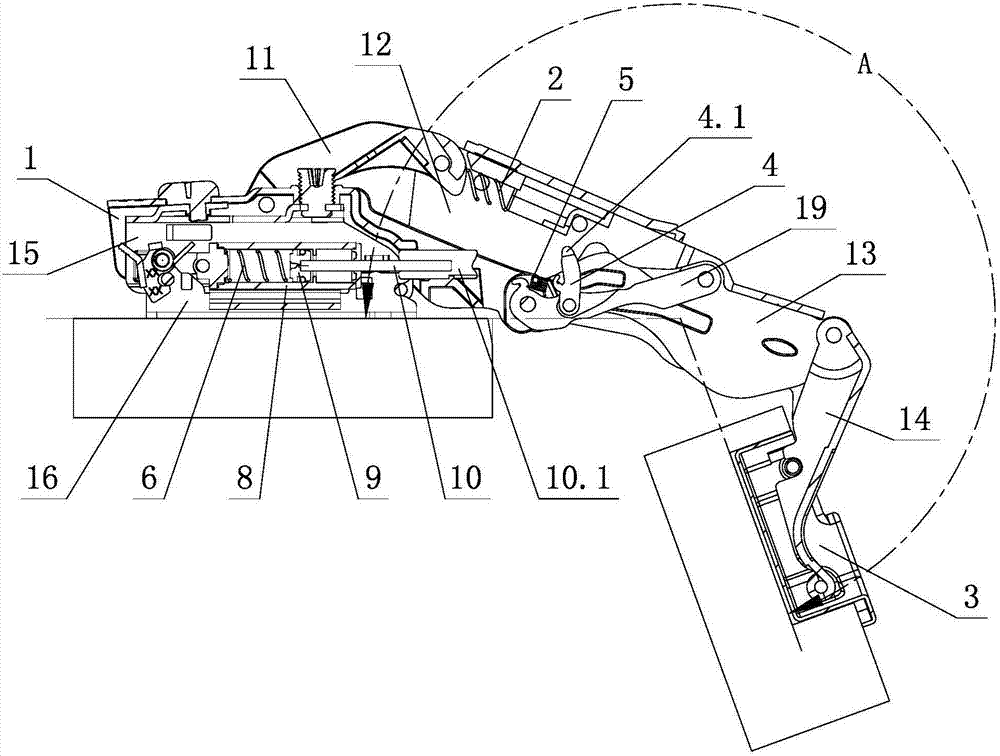

Hinge damping buffer structure

InactiveCN105822170AElastic telescopic sliding position is accurateAvoid job failureBuilding braking devicesPin hingesControl theoryShock absorber

The invention discloses a hinge damping buffer structure which comprises a connection arm, a hinge cup seat, a transmission arm assembly and an elastic assembly, wherein two ends of the transmission arm assembly are respectively connected with the connection arm and the hinge cup seat in a rotatable manner; the elastic assembly is arranged on the transmission arm assembly; the connection arm is hinged with the hinge cup seat through matching between the transmission arm assembly and the elastic assembly, to realize opening and closing of a hinge. The hinge damping buffer structure is characterized in that a damper is arranged on the connection arm in a sliding manner; the transmission arm assembly is hinged with a pushing element; a zigzag region is arranged on the pushing element and at least acts on one end of the damper when the hinge closes a travel; the damper slides on the connection arm and is compressed to generate damping buffer force; the zigzag region is at least separated from one end of the damper when the hinge opens a travel; the damper slides on the connection arm and is reset to the initial position. The hinge damping buffer structure has the characteristics of simple and reasonable structure, excellent performance, quickness in assembling, long service life, low manufacturing cost, easiness in production and implementation, safety and reliability, and is high in practicability.

Owner:伍志勇

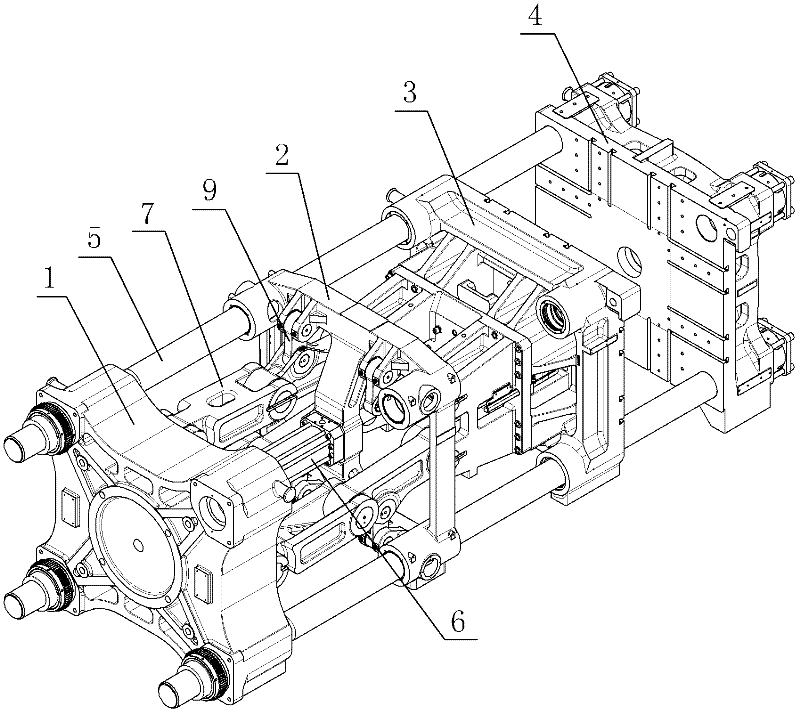

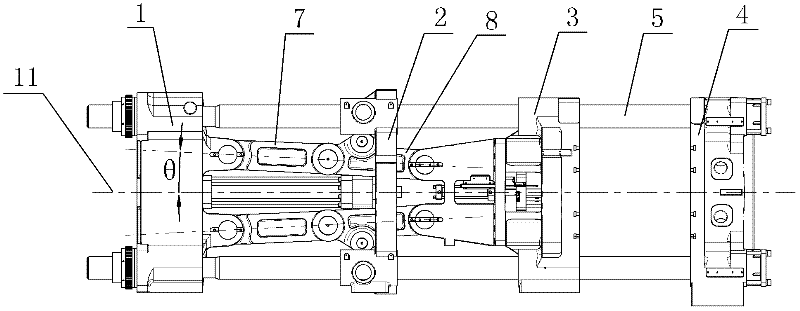

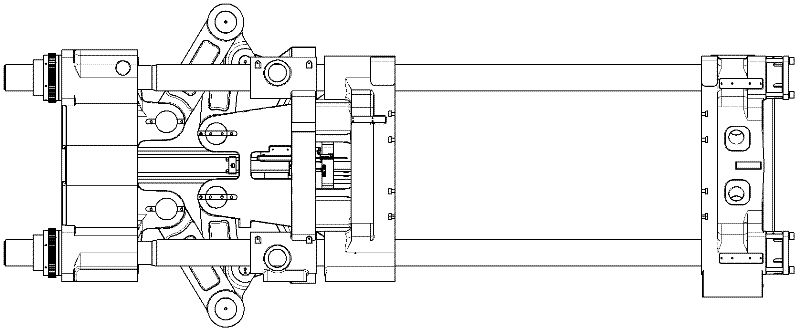

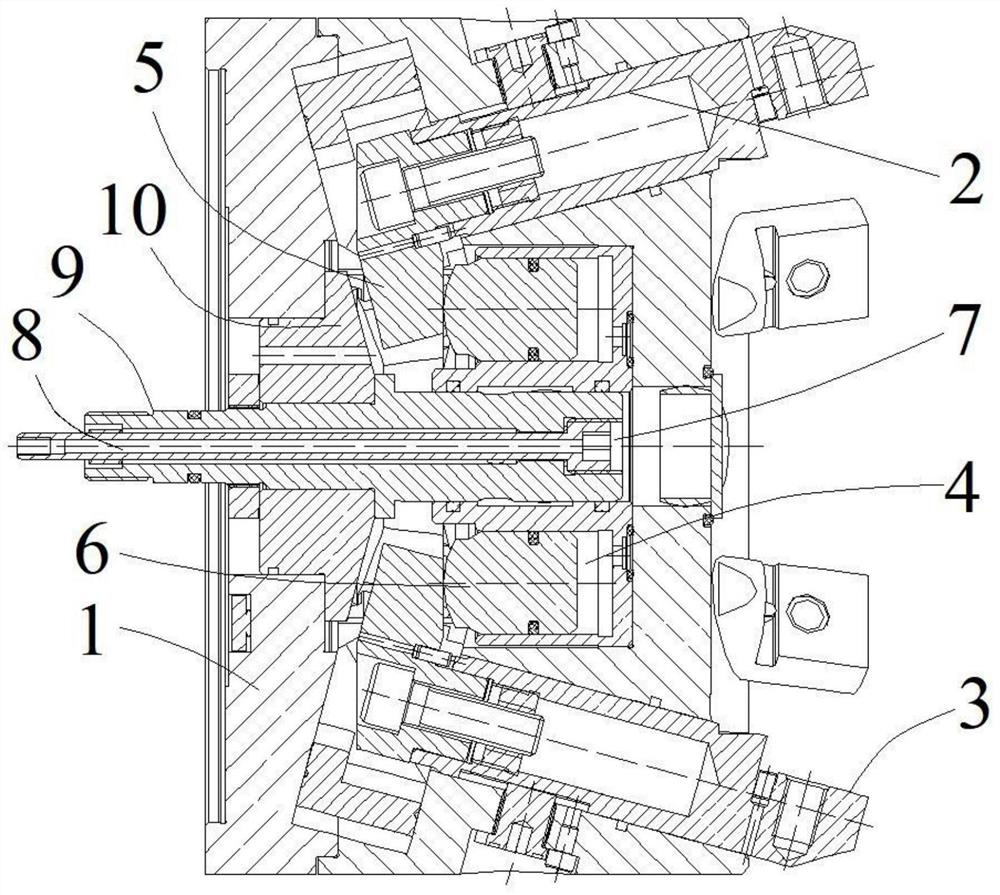

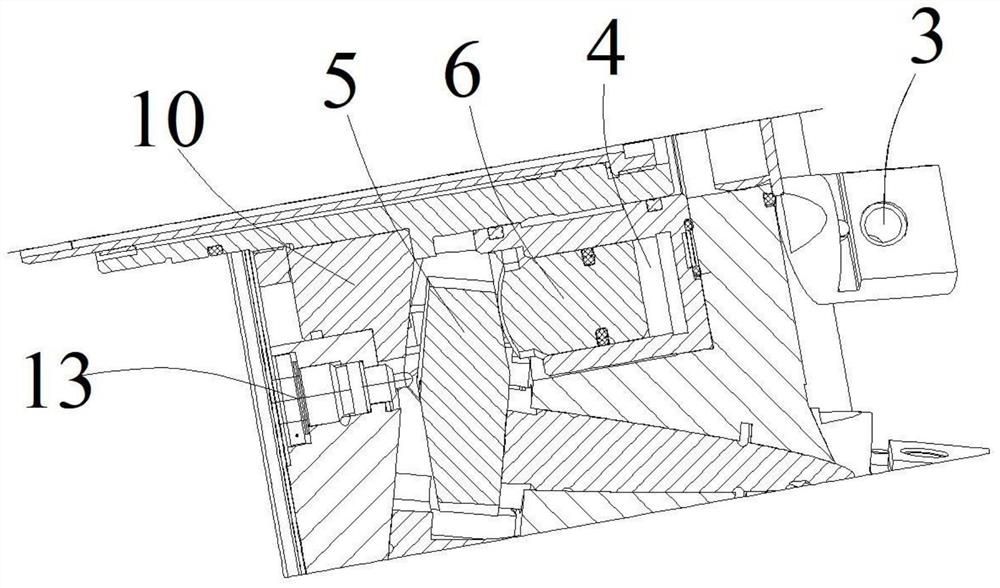

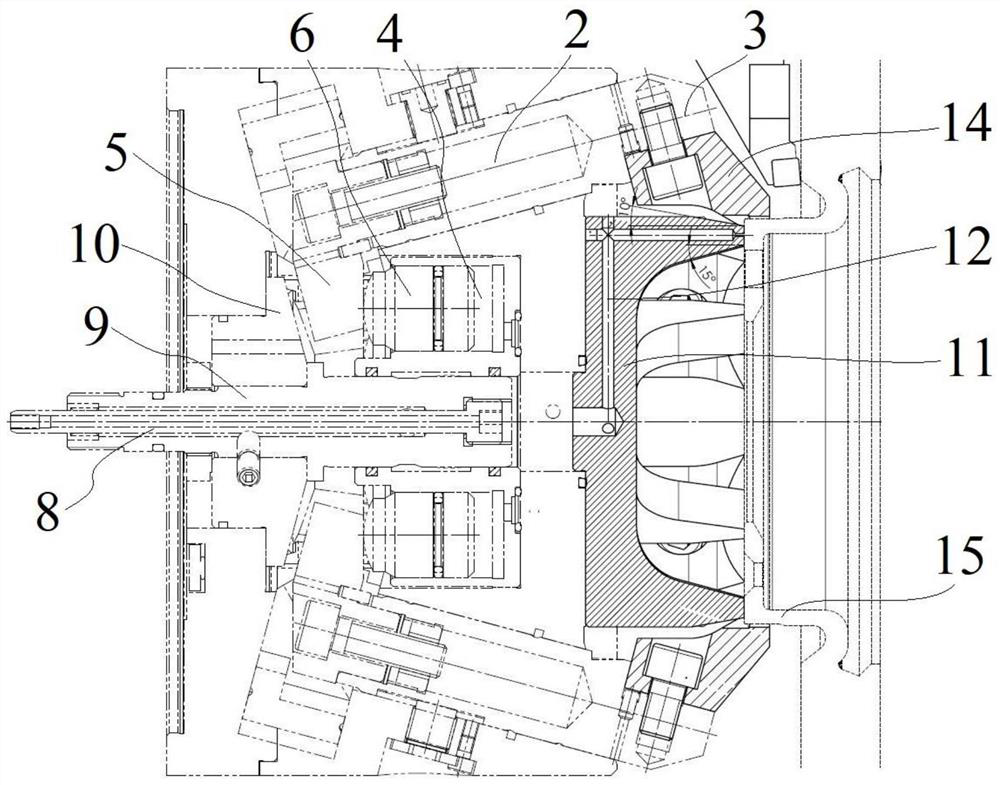

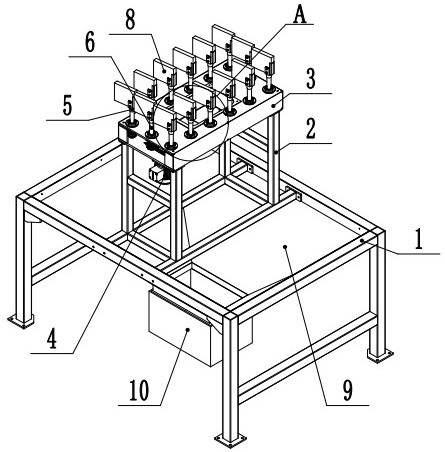

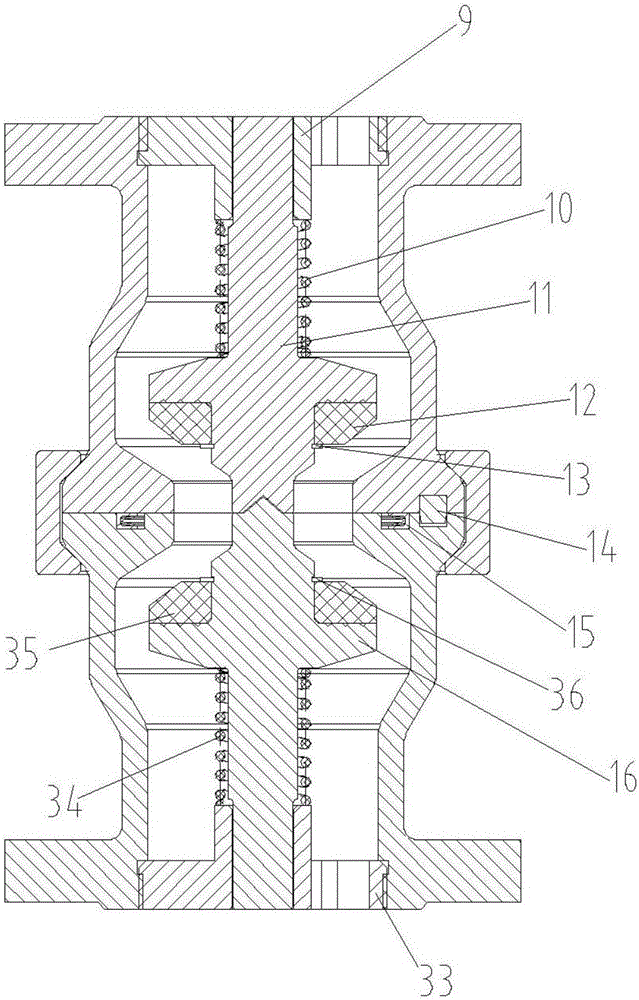

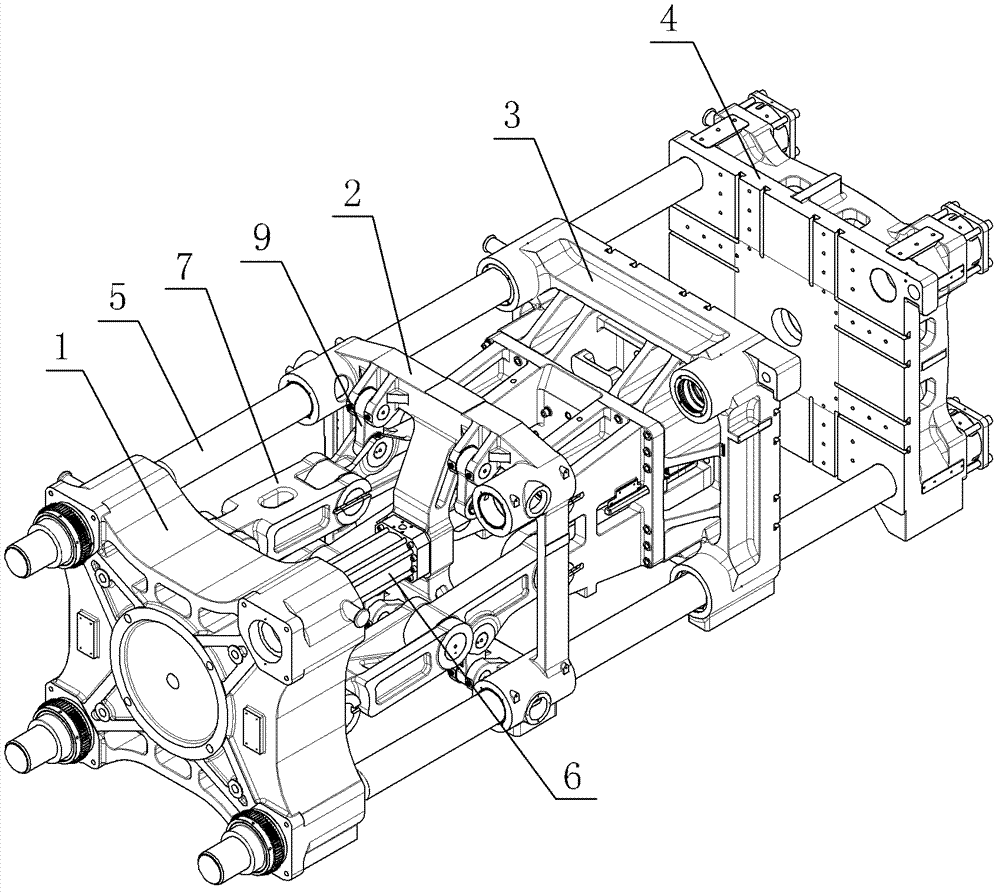

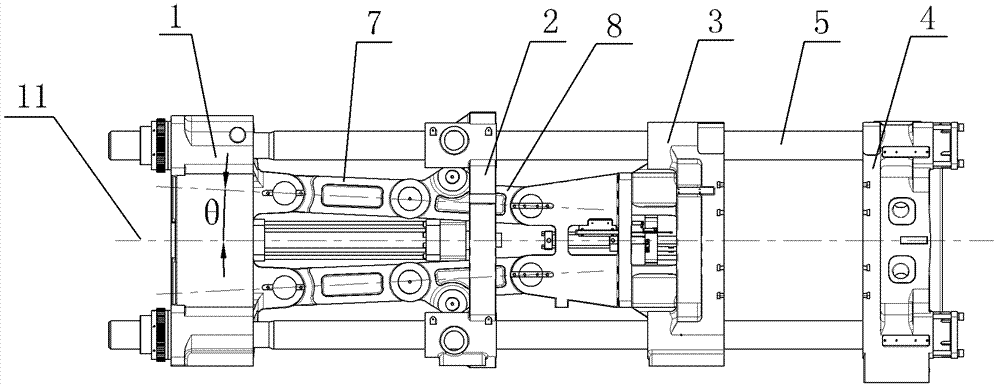

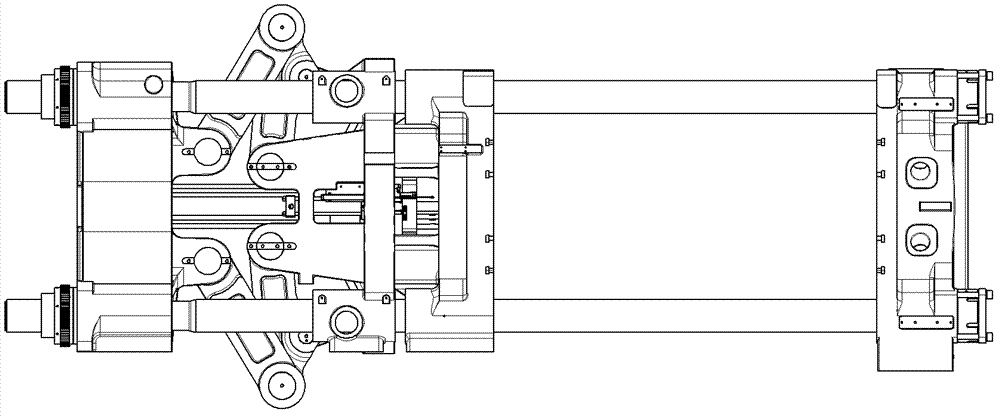

A clamping mechanism of a plastic injection molding machine

Owner:NINGBO SHUANGMA MASCH IND CO LTD

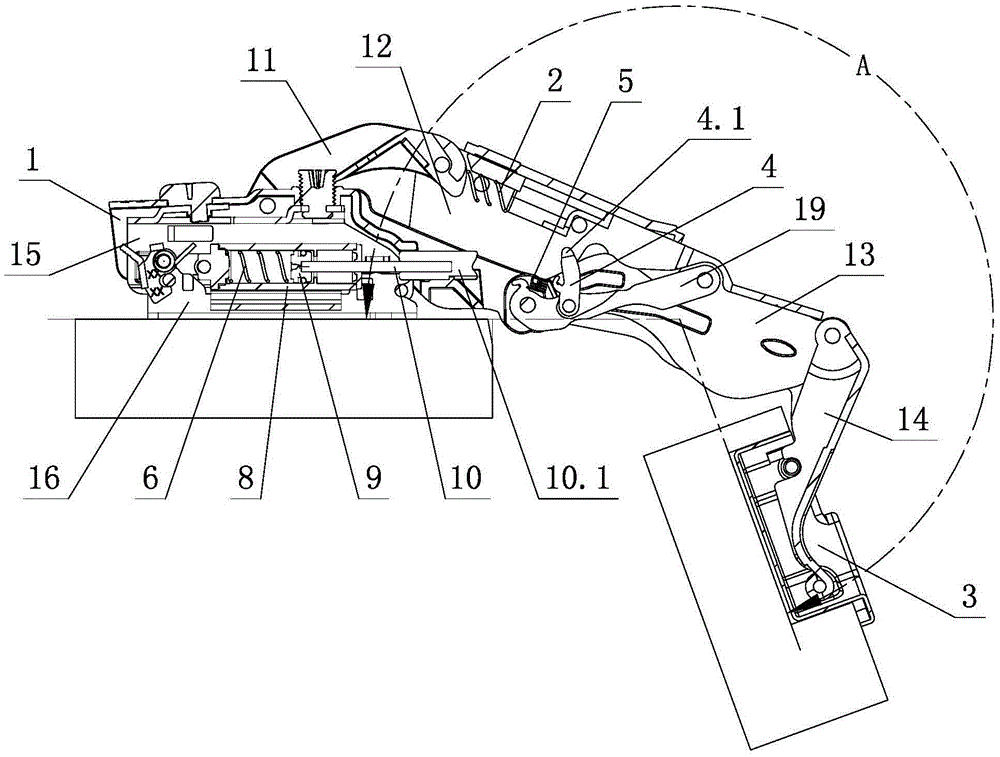

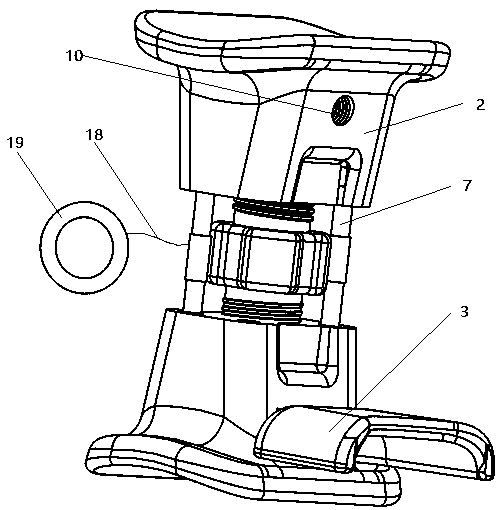

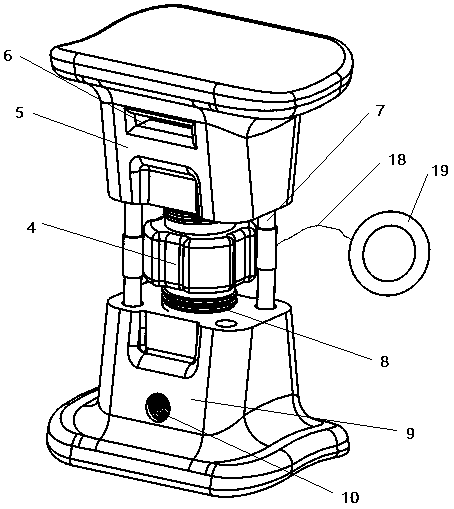

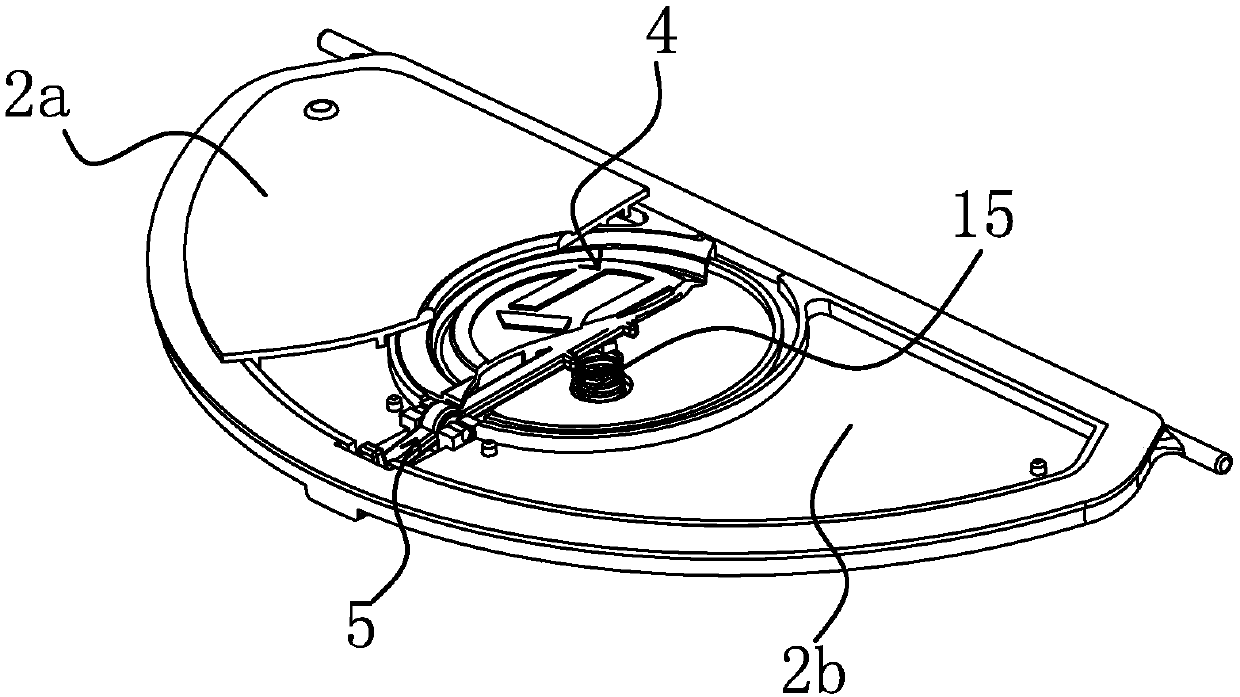

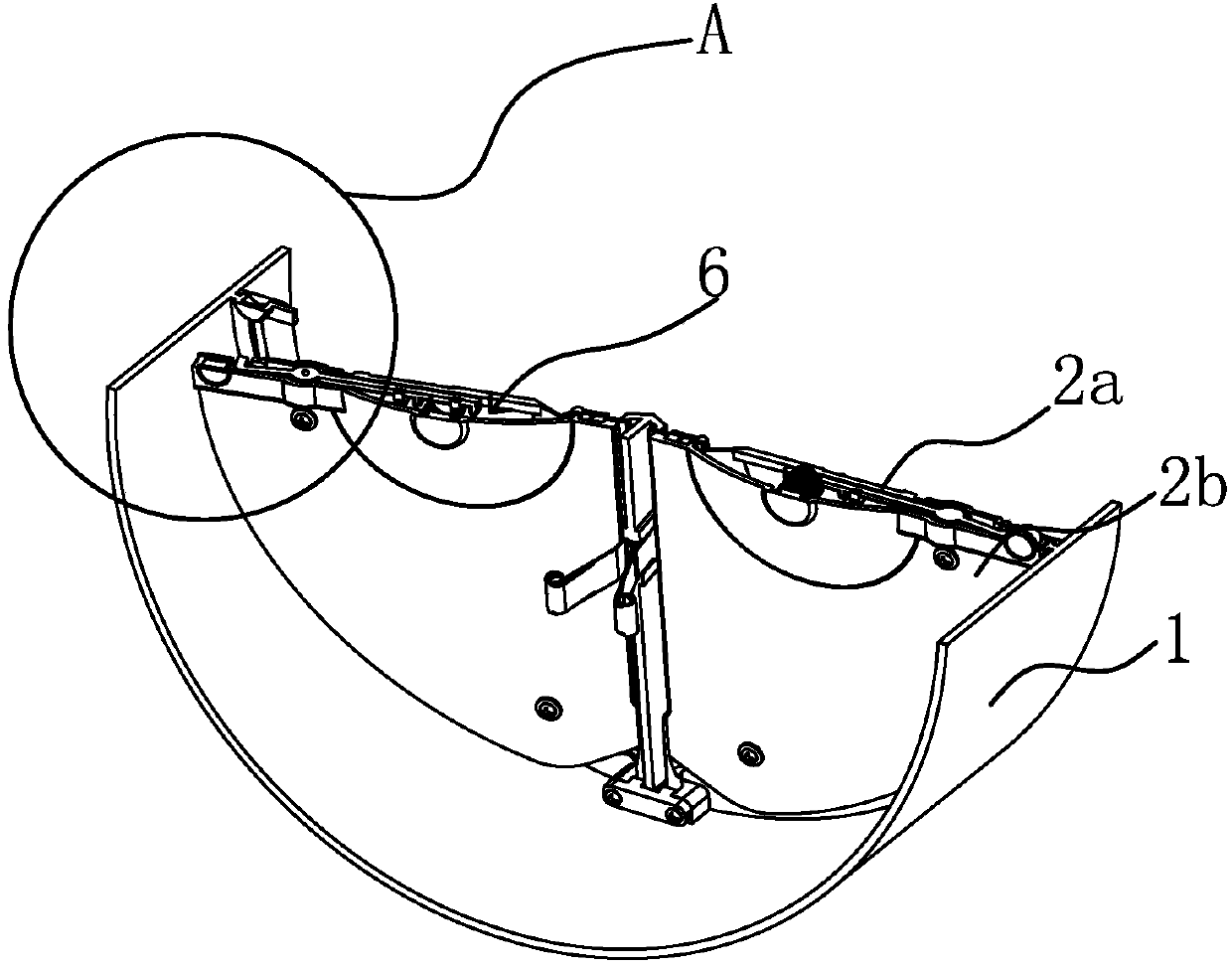

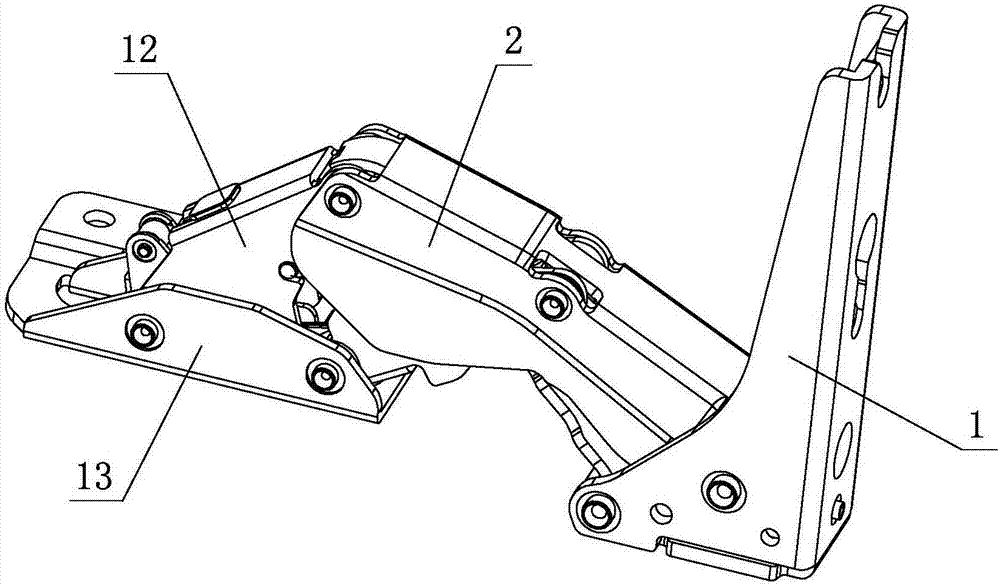

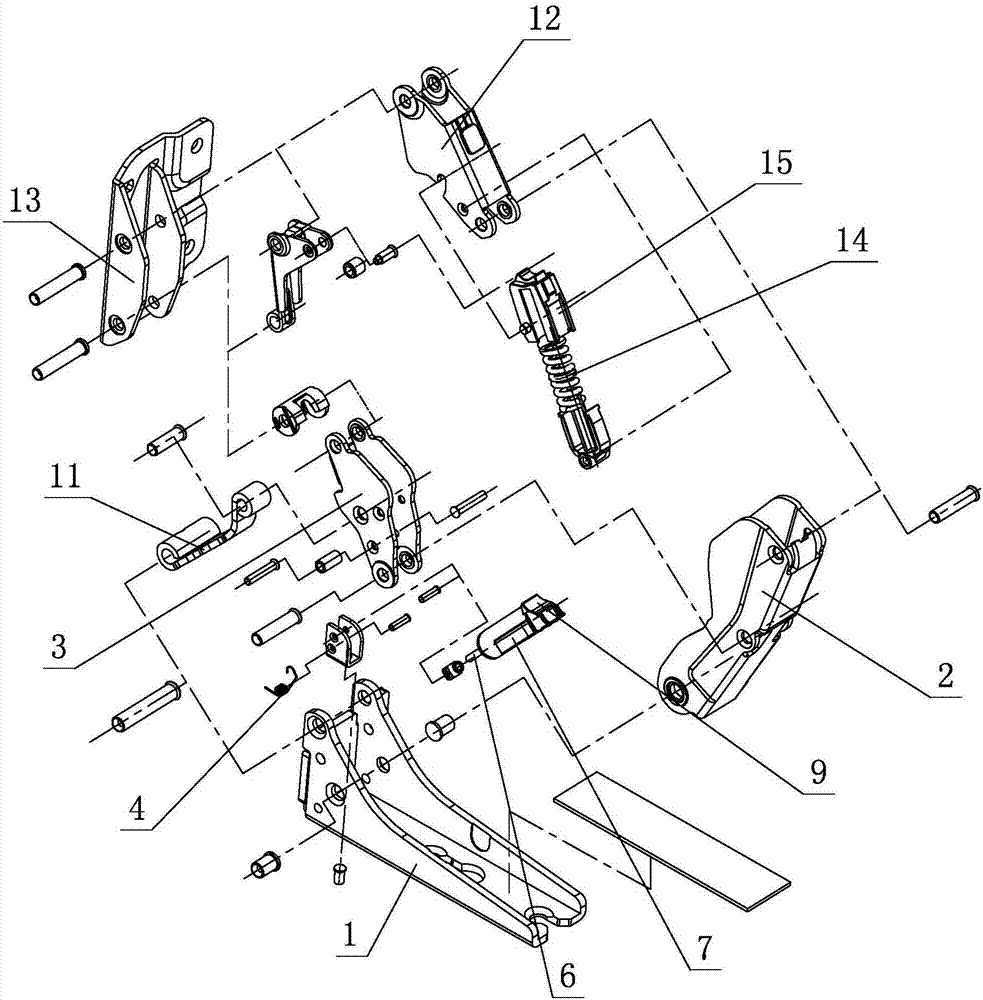

Damping buffer closing structure for furniture hinge

ActiveCN105672800AAvoid safety hazardsElastic telescopic sliding position is accurateBuilding braking devicesWing accessoriesMechanical engineeringEngineering

A damping buffer closing structure for a furniture hinge comprises a connecting arm, elastic pieces, a hinge cup seat, a damper, a transmission arm assembly and a poking assembly. The poking assembly is arranged on the transmission arm assembly. The damper is arranged on the connecting arm. The two ends of the transmission arm assembly are rotationally connected with the connecting arm and the hinge cup seat correspondingly. The connecting arm is hinged to the hinge cup seat to open and close the furniture hinge in a hinged manner through cooperation of the transmission arm assembly and the elastic pieces, and an included angle A is formed between the connecting arm and the hinge cup seat. The poking assembly comprises a poking element and an elastic poking element. The poking element is elastically and rotationally located to the transmission arm assembly through the elastic poking element. The damper is provided with an elastic damping element. The damper elastically stretches and contracts to slide on the connecting arm through the elastic damping element. By improving the structure, the damping buffer closing structure has the beneficial effects of being simple and reasonable in structure, excellent in performance, fast and convenient to assemble, long in service life, low in manufacturing cost, easy to produce, easy to implement, safe, reliable, high in practicability and the like.

Owner:伍志勇

Oral cavity supporting device of adjustable tongue retaining plate

InactiveCN109498199AMeet the needs of the actual situationRelieve fatigueDentistryBite registrationFixed length

The invention discloses an oral cavity supporting device of an adjustable tongue retaining plate and relate to a dental auxiliary medical apparatus. The oral cavity supporting device has the functionsof distracting the oral cavity and preventing disturbance of the tongue. The oral cavity supporting device comprises an oral cavity supporting device body, the adjustable tongue retaining plate, a fixed length tongue retaining plate and a bidirectional lead screw, wherein when the oral cavity supporting device body is placed on one side of the oral cavity, the adjustable tongue retaining plate isconnected to the oral cavity supporting device body and a height adjusting rotary knob is connected to the middle of the bidirectional lead screw to adjust the height of the oral cavity supporting device body; a positioning rod is used for fixing corresponding positions of upper and lower parts of the oral cavity supporting device when the longitudinal height is adjusted. The oral cavity supporting device is I-shaped, the engaging part is of a concave arc shape, and the stress of the I-shaped structure is more centralized during engagement; the adjustable tongue retaining plate is of an embedded telescopic structure and a tongue retaining plate body is inserted into a tongue retaining sleeve to form the tongue retaining plate. The depth, inserted into the tongue retaining plate sleeve, ofthe tongue retaining plate is adjusted through three length adjusting holes. Balls on a V-shaped positioning elastic sheet are sunken into the three length adjusting holes to adjust and fix the stretching length of the tongue retaining plate body.

Owner:滕琦

Concrete slab joint stabilizing system and apparatus

ActiveUS20060204329A1MinimizationConcentrated forceIn situ pavingsClimate change adaptationRelative motionVertical displacement

A joint stabilizing apparatus having an expandable cylindrical housing is inserted into a circular hole drilled at a “loose joint” of a concrete slab that is to be stabilized against relative vertical displacement between adjacent slab sections. The hole is drilled downward into the concrete, centered on the plane of a lateral opening / joint in the concrete slab. The expandable housing comprises two rigid semi-circular housing halves, and the assembly is oriented inside of the circular hole such that the two housing halves are on opposite sides of the centerline of the lateral opening / joint. The housing halves are pushed apart by turning of a threaded bolt inside of the housing. Turning of the bolt causes two bi-laterally symmetric wedge blocks to draw towards each other, and pressing the bearing surfaces of the wedge blocks against inclined surfaces inside of the respective housing halves. As the housing halves are pushed apart, the outside surfaces of the expandable housing engage the walls of the drilled hole and apply opposing horizontal compressive forces to the slab sections. Friction between the expandable housing and the concrete slab sections prevent the slab sections from vertically moving relative to each other. In other embodiments of the invention, the joint stabilizing apparatus is used to prevent relative motion between non-horizontal construction members, and between four adjacent slab sections separated by intersecting loose joints.

Owner:ILLINOIS TOOL WORKS INC

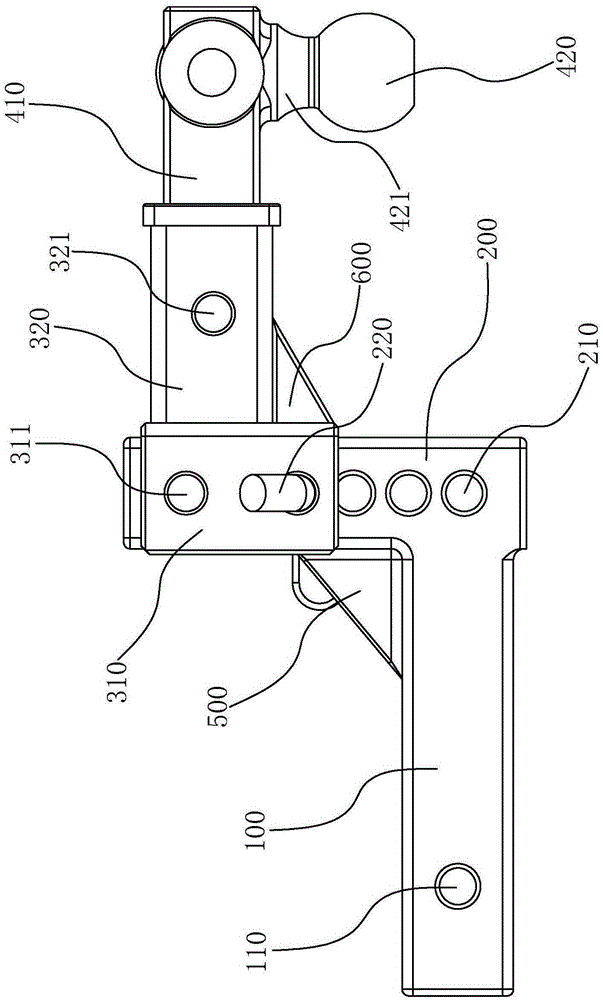

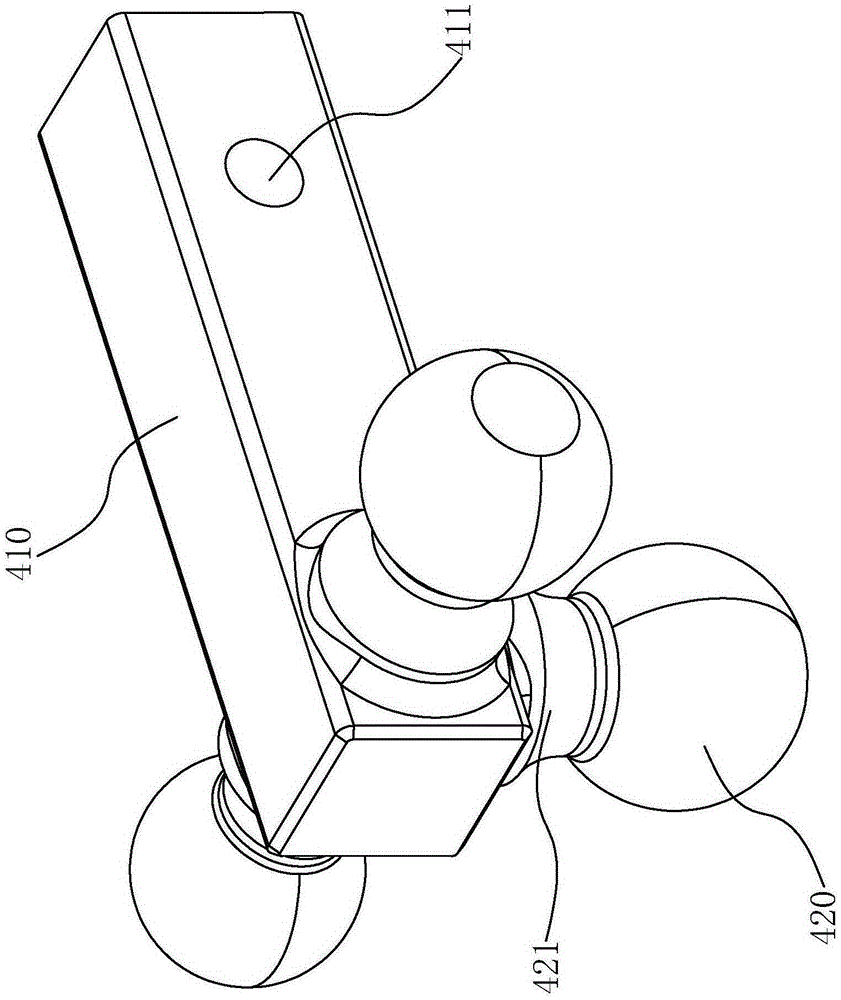

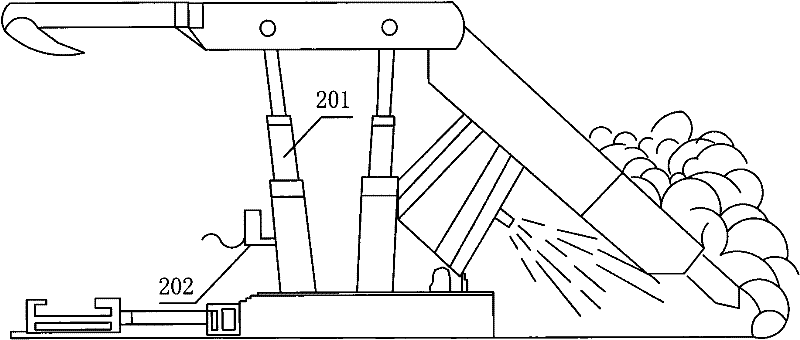

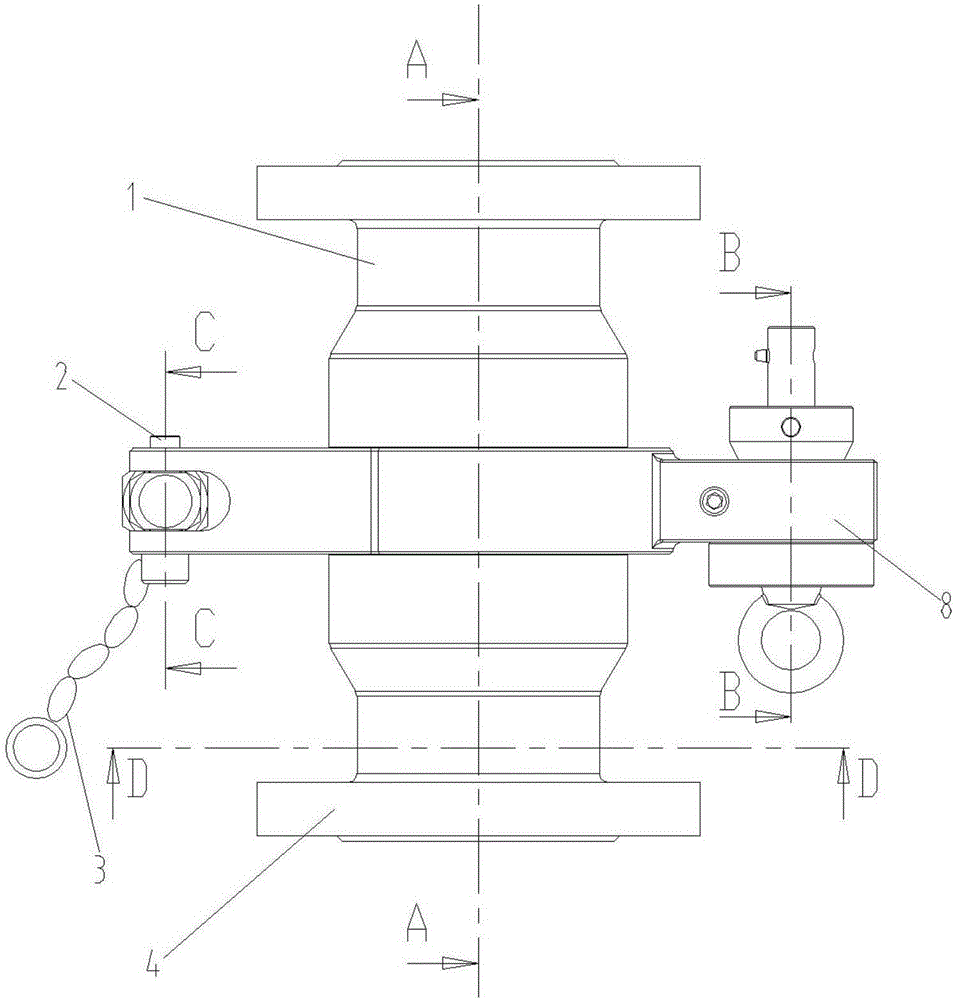

Adjustable trailer device

InactiveCN105398295AThere is no breakageExtended service lifeTowing devicesEngineeringMechanical engineering

The invention provides an adjustable trailer device and belongs to the technical field of motor vehicle accessories. The adjustable trailer device solves the technical problems that in an existing trailer arm, trailer balls are prone to being broken and the trailer arm is prone to being damaged. According to the technical scheme, the adjustable trailer device comprises a main arm, an adjusting ram and a trailer ball assembly, wherein the main arm is fixedly connected with a motor vehicle; the adjusting arm is vertically and fixedly connected with the end of the main arm; the trailer ball assembly is used for being connected with another motor vehicle; the trailer ball assembly makes contact with the adjusting arm and can vertically move on the adjusting arm, and when the trailer ball assembly moves to the designated position, the trailer ball assembly can be fixed to the adjusting arm. The adjustable trailer device has the beneficial effects that the trailer ball assembly is movably connected with the main arm, so that the situation that the trailer ball assembly is broken is avoided, the trailer ball assembly is longer in service life and can be fixed to positions, with different heights, of the adjusting arm, the stress of the trailer ball assembly is more concentrated, the loss of force is less, and the damage rate of the main arm is smaller.

Owner:NINGBO YINZHOU LONGTENG TOOL FACTORY

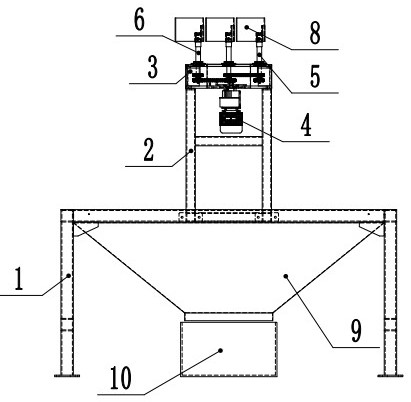

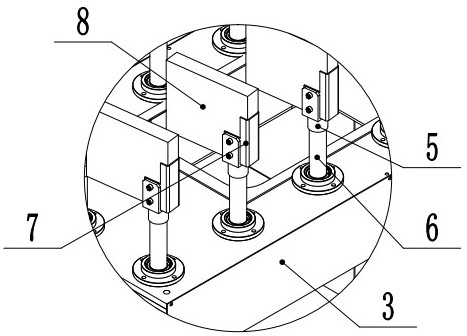

Man-hole cover mounting structure and storage tank

The invention discloses a man-hole cover mounting structure, comprising a man-hole (6), a cover body (1), a fastening handle (2) with internal threads at the head part, and a pressing lock plate (3) hinged around the man-hole; a double-screw bolt (11) is arranged on the cover body (1); the fastening handle (2) is connected with the double-screw bolt (11) by the internal threads; a protruding part (32) is arranged the lower side, close to the hinging end, of the pressing lock plate (3); when the cover body (1) is positioned in the state of closing the man-hole (6), the fastening handle (2) presses the pressing lock plate (3) to enable the protruding part (32) to press the edge of the top face of the cover body (1). In addition, the invention also discloses a storage tank comprising the man-hole mounting structure, and the man-hole (6) is formed in the body of the storage tank. According to the man-hole cover mounting structure, the airtightness of the storage tank can be improved, the connection is firmer and more stable and problems such as material leakage are effectively avoided.

Owner:BEIQI FOTON MOTOR CO LTD

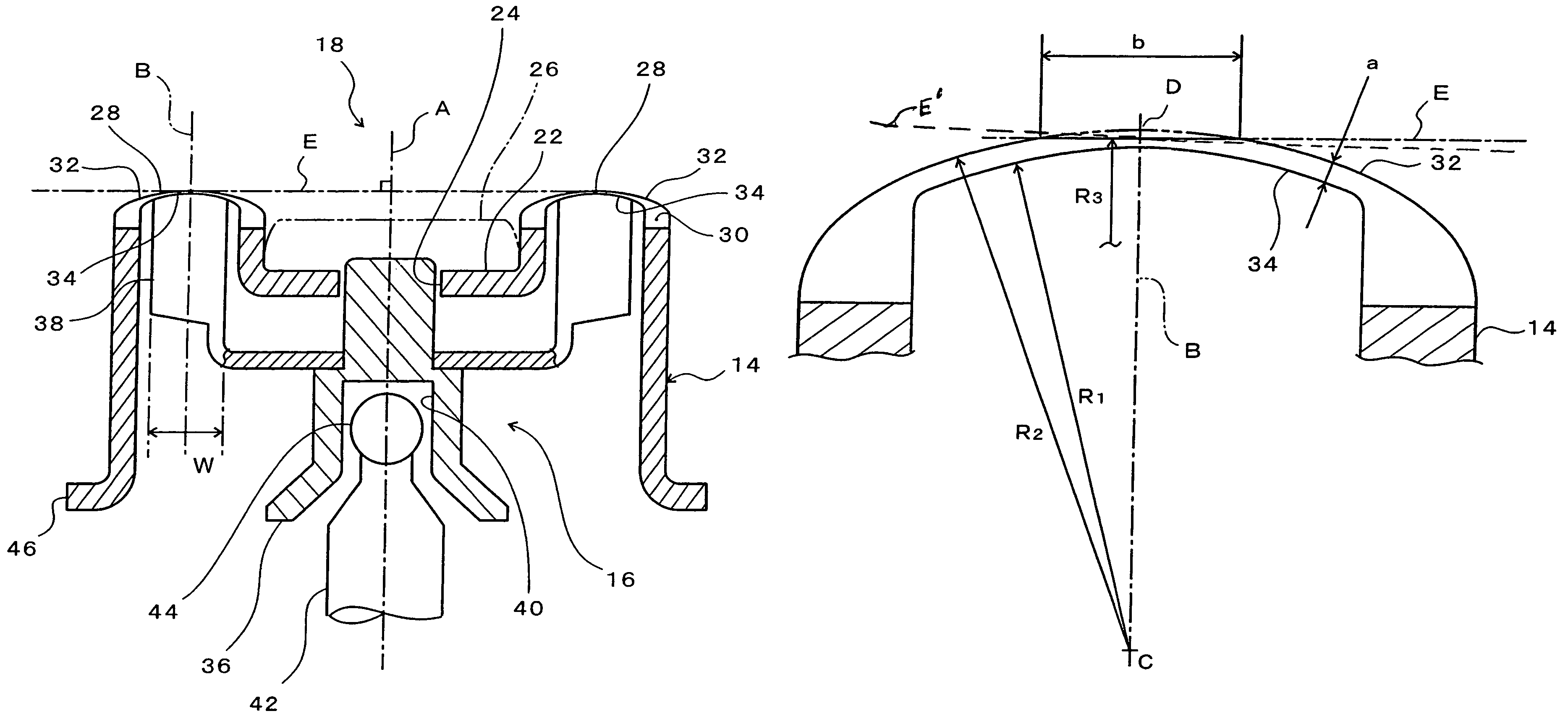

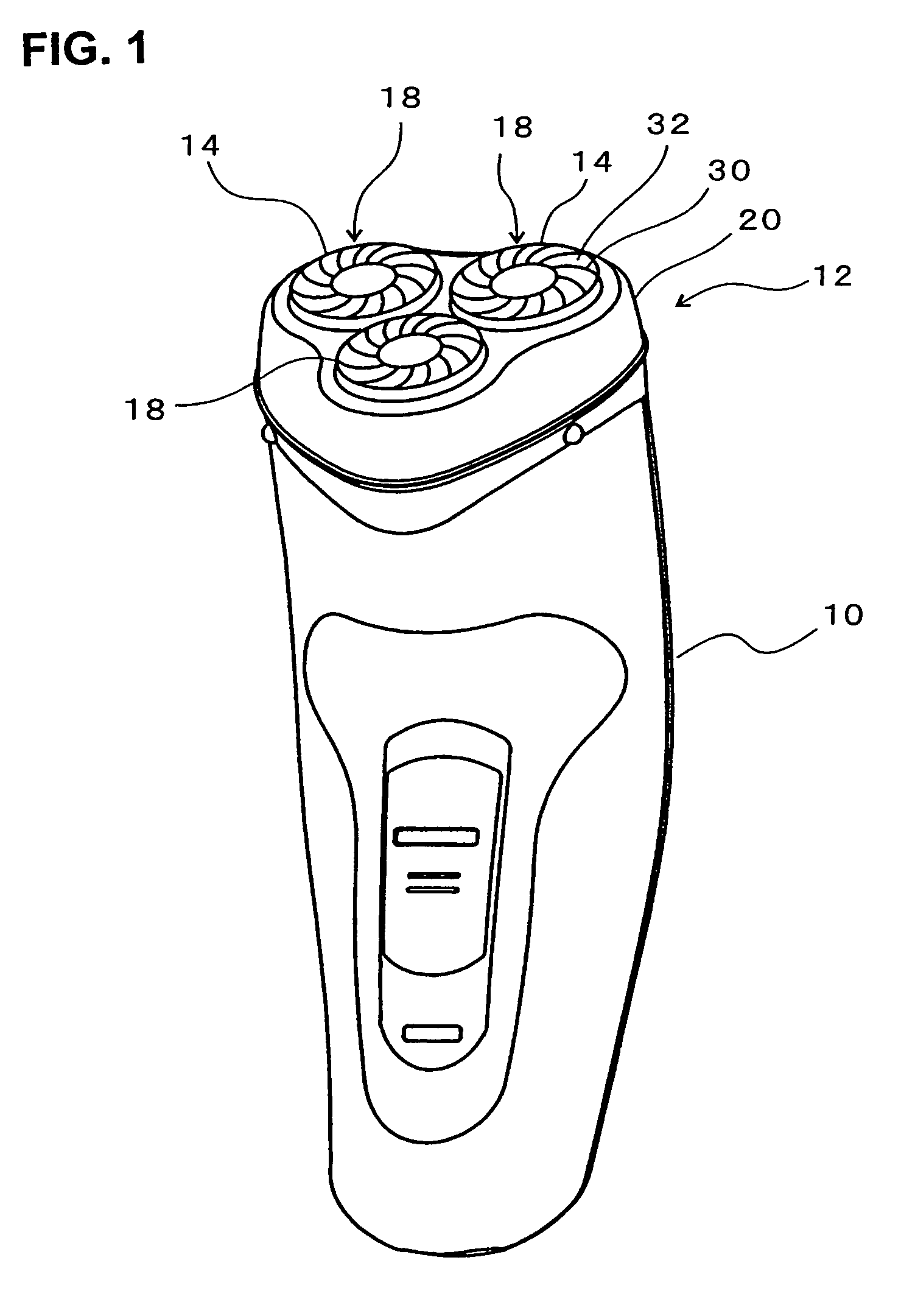

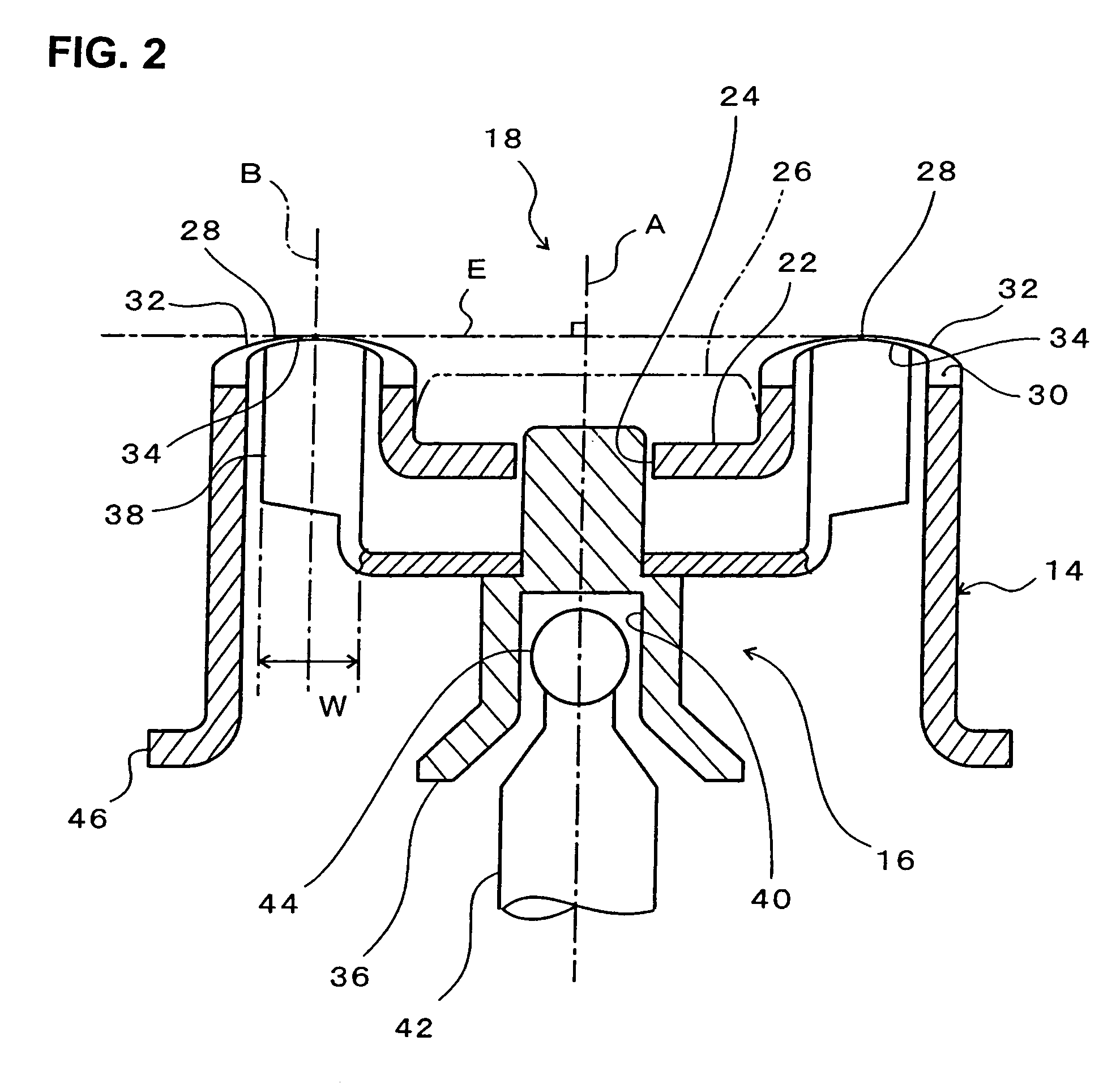

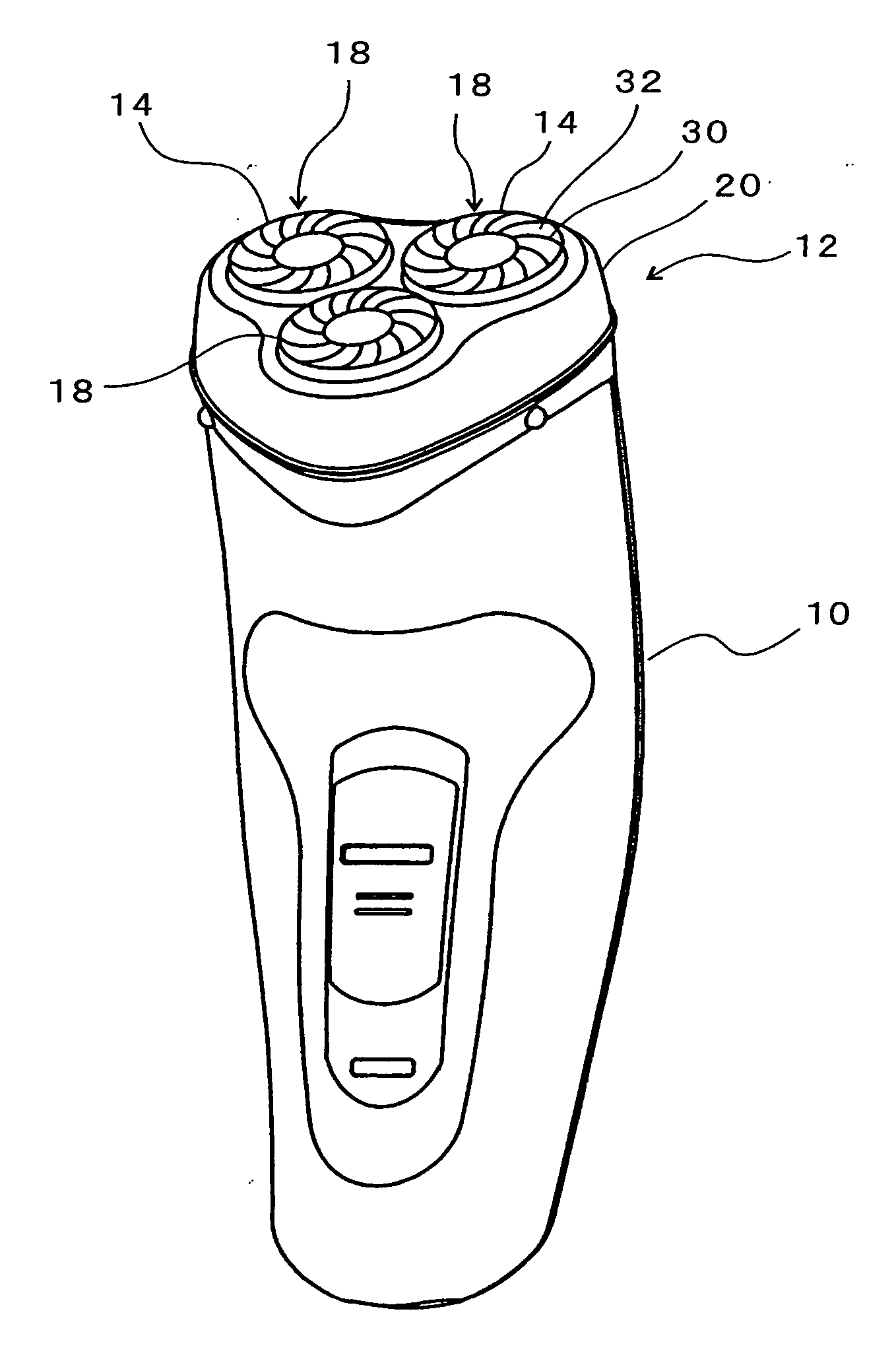

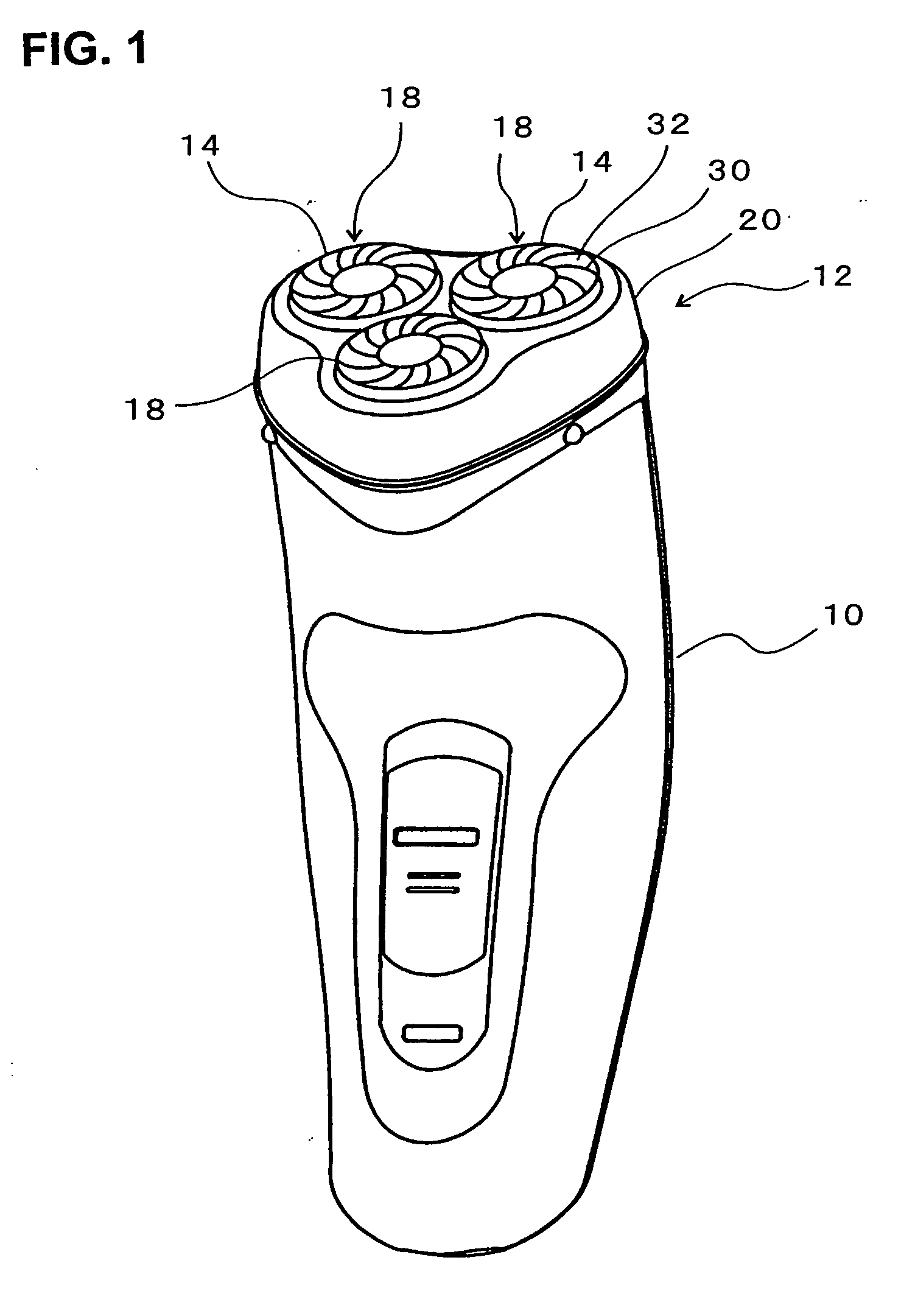

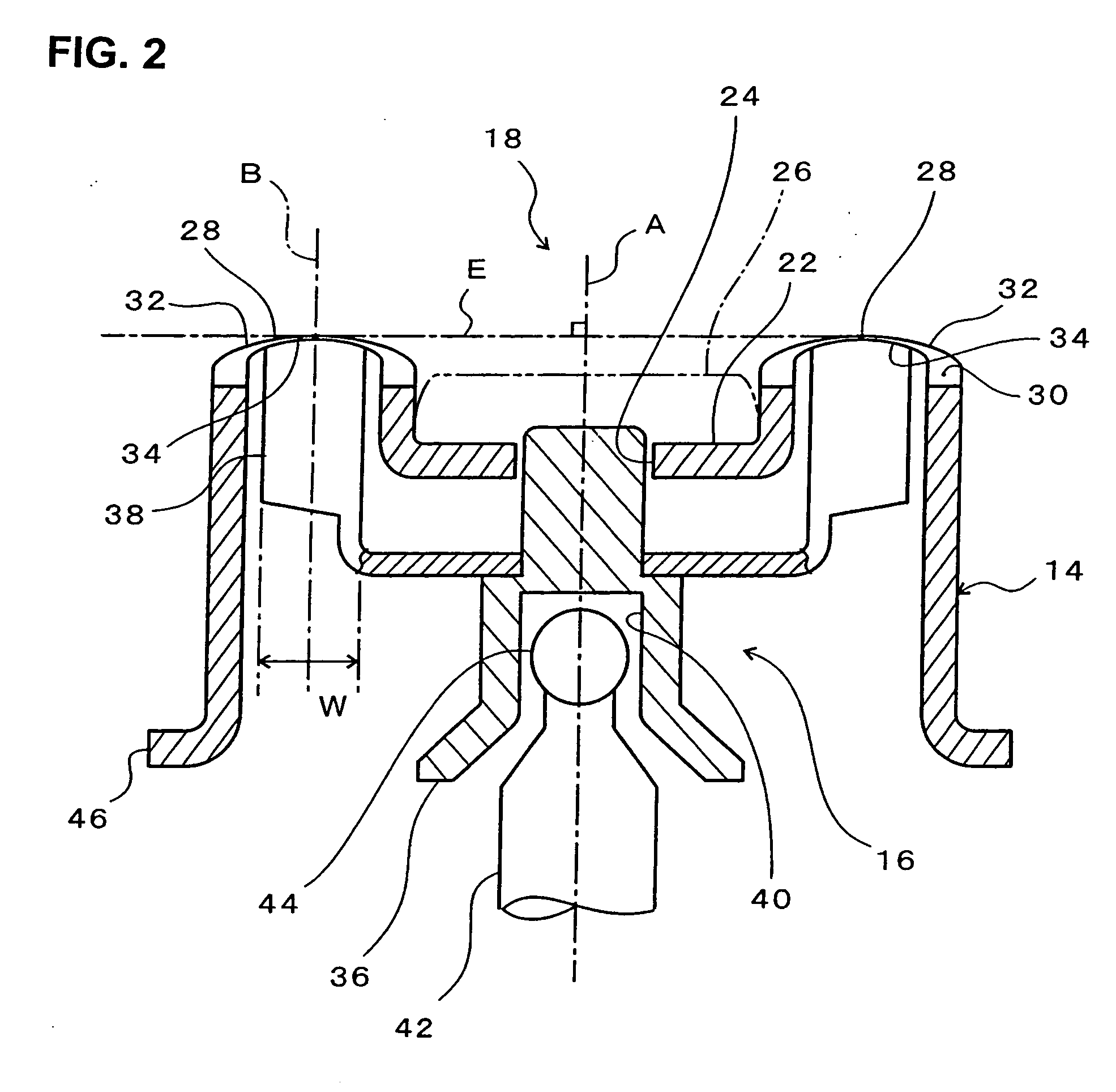

Rotary type electric shaver

InactiveUS7743507B2Consistent and excellent shavingReduce the amount requiredMetal working apparatusRazor stropCentre of rotation

A rotary type electric shaver with an outer cutter frame provided on a shaver main body. An outer cutter installed in this outer cutter frame and having its shaving surface on the upper surface of a ring-shaped thin layer portion. An inner cutter 16 having a cutter body that rotates and makes sliding contact from below with the lower surface of the outer cutter 14, wherein a thin layer portion 28 is formed in a substantially arc shape that is convex upward in a radial and vertical cross section that includes a center axis line which is the rotational center of the inner cutter. The thickness of the thin layer portion near the apex of the upward convex is smallest at the apex and gradually becomes thicker as distance increases away from the apex.

Owner:IZUMI PROD CO

Full-mechanized hydraulic support fiber bragg grating pressure sensor

InactiveCN101782443BHigh sensitivityLarge measuring rangeForce measurement by measuring optical property variationFiberGrating

Owner:SHANDONG UNIV OF SCI & TECH

Rotary type electric shaver

InactiveUS20060179658A1Consistent and excellent shavingReduce the amount requiredMetal working apparatusEngineeringSliding contact

A rotary type electric shaver with an outer cutter frame 20 provided on a shaver main body 10, an outer cutter 14 installed in this outer cutter frame 20 and having its shaving surface on the upper surface of a ring-shaped thin layer portion 28, and an inner cutter 16 having a cutter body 38 that rotates and makes sliding contact from below with the lower surface of the outer cutter 14, wherein a thin layer portion 28 is formed in a substantially arc shape that is convex upward in a radial and vertical cross section that includes a center axis line A which is the rotational center of the inner cutter 16, and the thickness of the thin layer portion near the apex of the upward convex is smallest at the apex and gradually becomes thicker as distance increases away from the apex.

Owner:IZUMI PROD CO

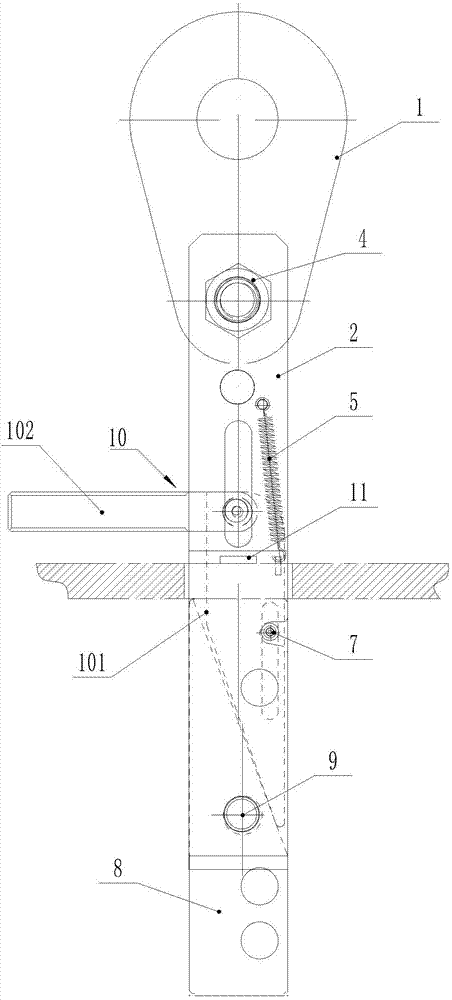

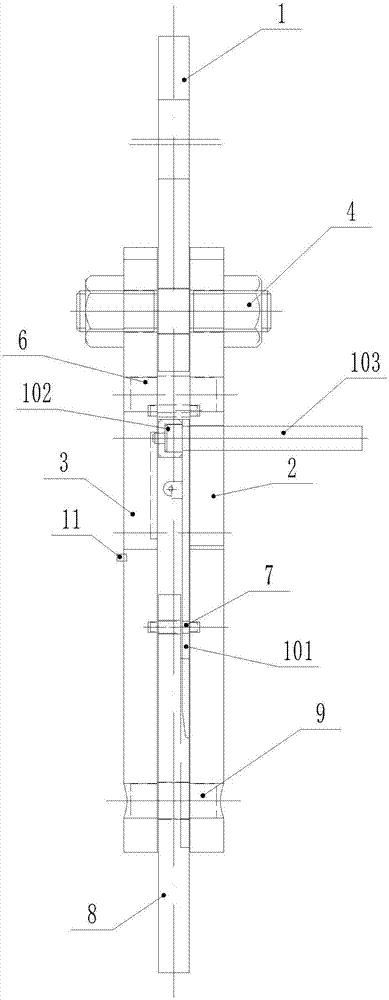

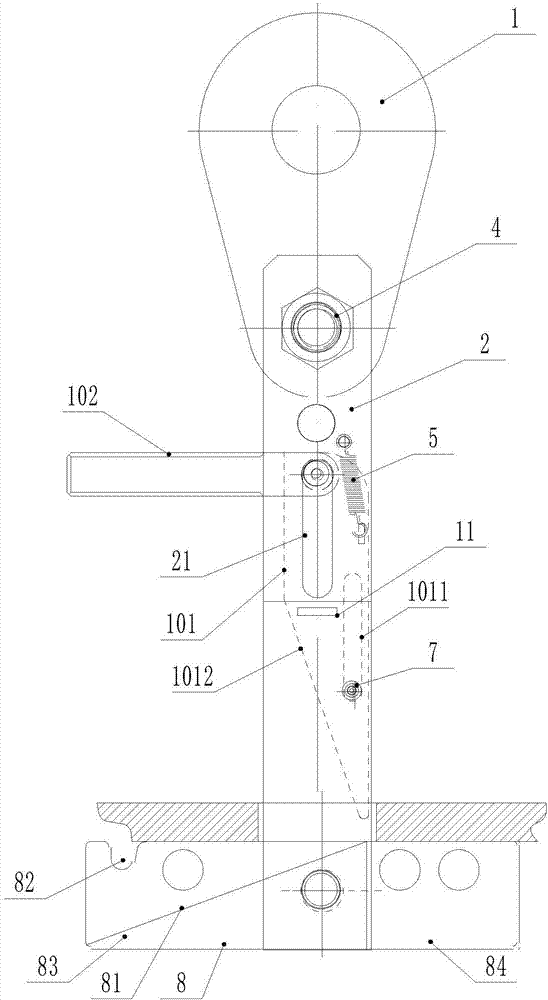

Lifting appliance for perforated steel structure component

PendingCN107539875AEasy to insertReasonable forceLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a lifting appliance for a perforated steel structure component. The lifting appliance comprises a lifting lug, a first lifting plate, a second lifting plate, a movable tongue plate and a pushing device, wherein the middle part of the movable tongue plate is rotatably mounted on the lower sections of the first lifting plate and the second lifting plate through an articulating shaft; the articulating shaft divides the movable tongue plate into a long plate section and a short plate section; the pushing device comprises a pushing plate and a handle; the lower end of the pushing plate is correspondingly matched with the short plate section of the movable tongue plate; a hanging slot is formed in the long plate section; hanging pins are arranged on the first lifting plate and the second lifting plate; the lower end of the pushing plate pushes the short plate section so that the movable tongue plate rotates to hook the hanging slots on the hanging pins; when the hanging slots are separated from the hanging pins, the upper side edge of the movable tongue plate is a hanging edge in contact with the steel structure component. The lifting appliance can be inserted into the hole to lift the perforated steel structure component, thus, the lifting point can be selected reasonably, stress on the component is more reasonable during the lifting, and the safety is higher.

Owner:张家港凯航通力船用设备有限公司

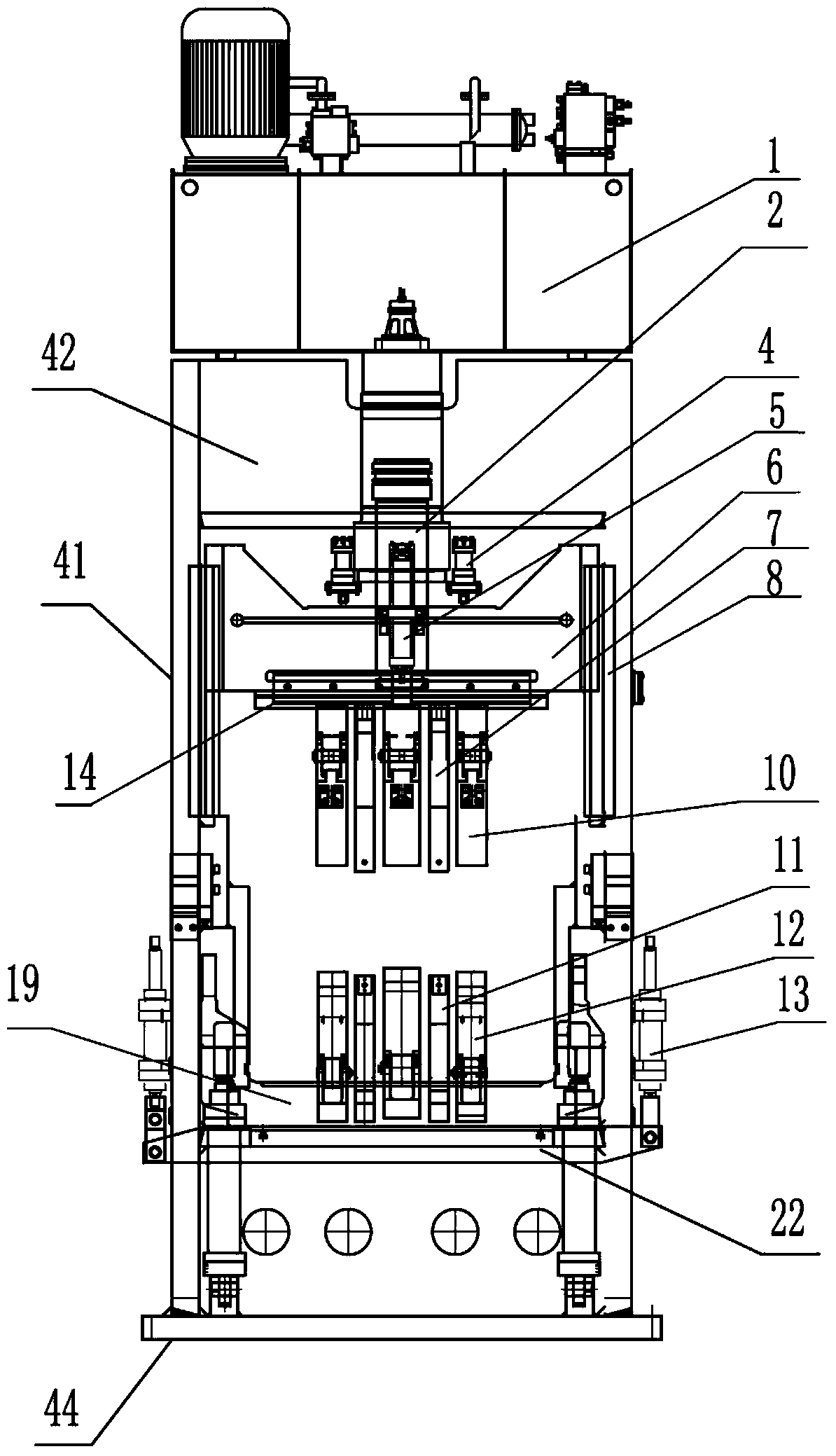

Special crankshaft multi-bend reversing machine

InactiveCN103934405AStrong torsional powerPowerfulForging/hammering/pressing machinesEngine componentsHydraulic cylinderCrankshaft

The invention provides a special crankshaft multi-bend reversing machine. A hydraulic machine is fixedly installed on a single rectangular machine body vertical support, a sliding block with an upper die part is driven through a main hydraulic cylinder in a driving mode, the sliding block is in sliding fit to stand column longitudinal sliding rails on the two sides of the machine body vertical support in a sliding mode, a lower die part is installed on a lower support, a fixed die frame and a rotary die disc which correspond to each other in an up-and-down mode are assembled in the upper die part and the lower die part, a twisting arm is pivoted between stand columns on the two sides, and a pivoting center is coaxial with the rotary die disc. According to the technical scheme, a conventional three-beam four-column main machine structure is removed, device occupied space and land occupied areas are greatly reduced, operation space is accordingly released to the maximum degree, it is important that the twisting structure has the advantages that the power is high, and the maximum twisting corner is large in scope, the twisting quality and the twisting effect are guaranteed, and the machining efficiency is improved.

Owner:DANDONG DONGDA CONTROL EQUIP

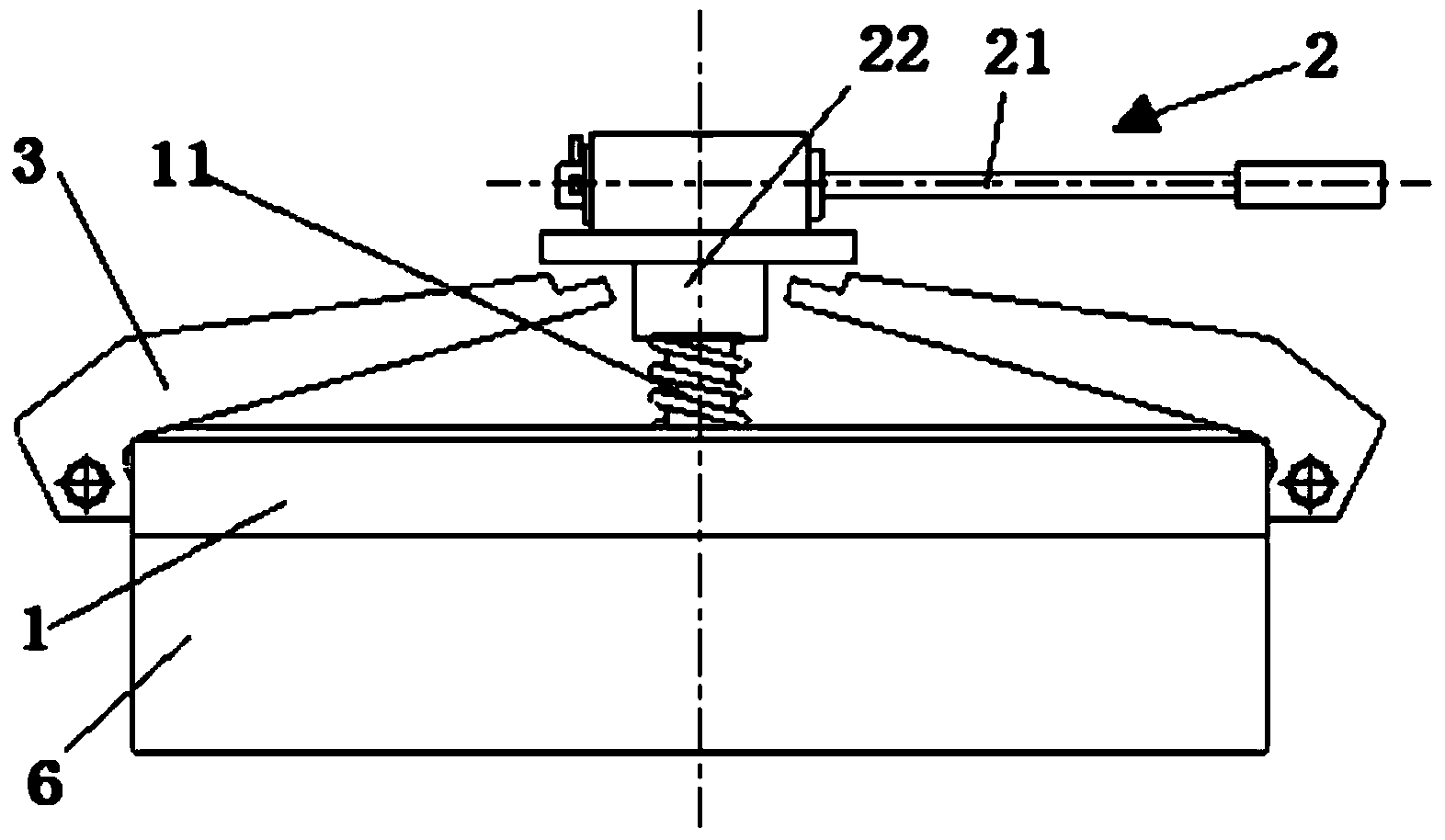

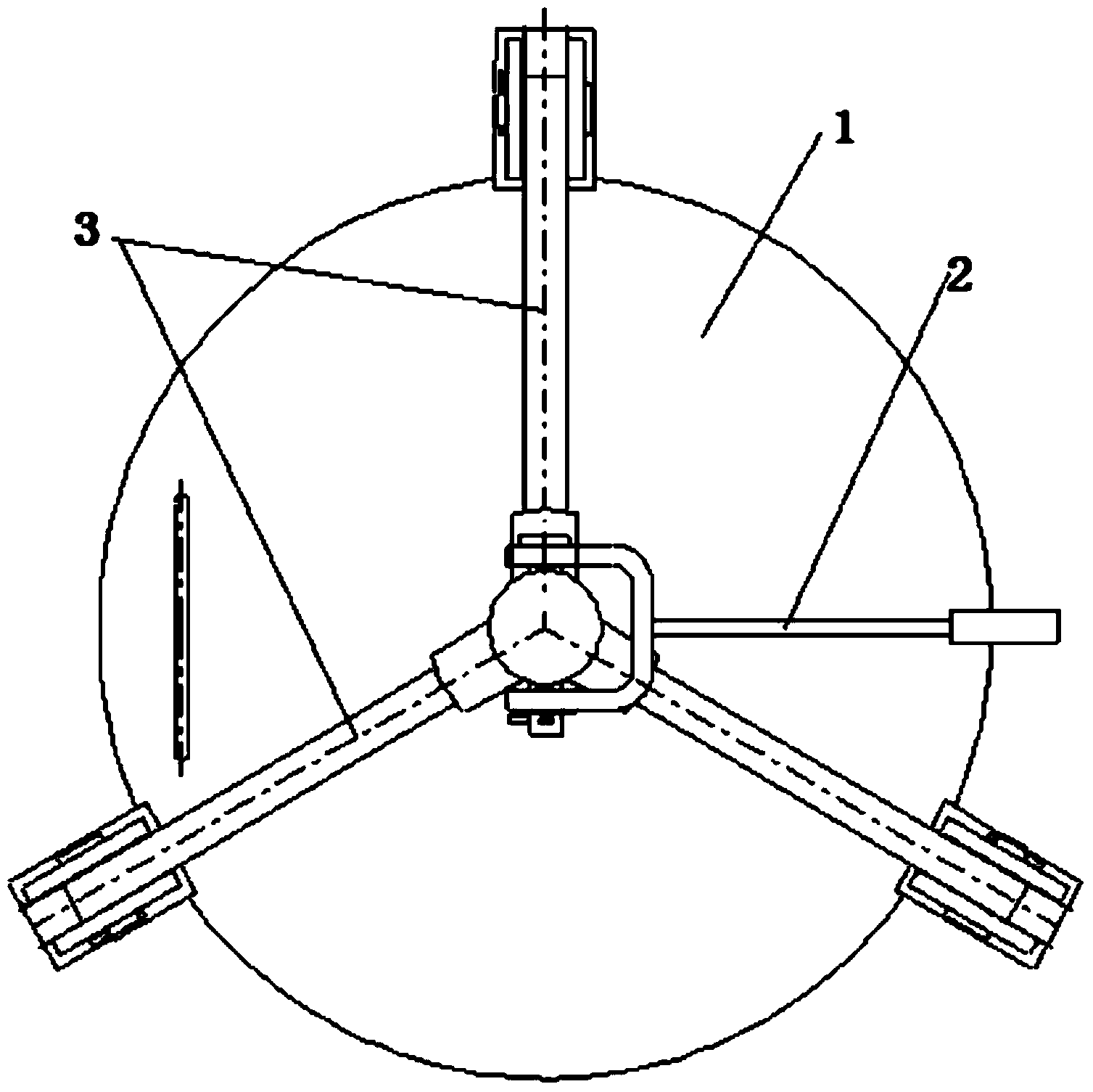

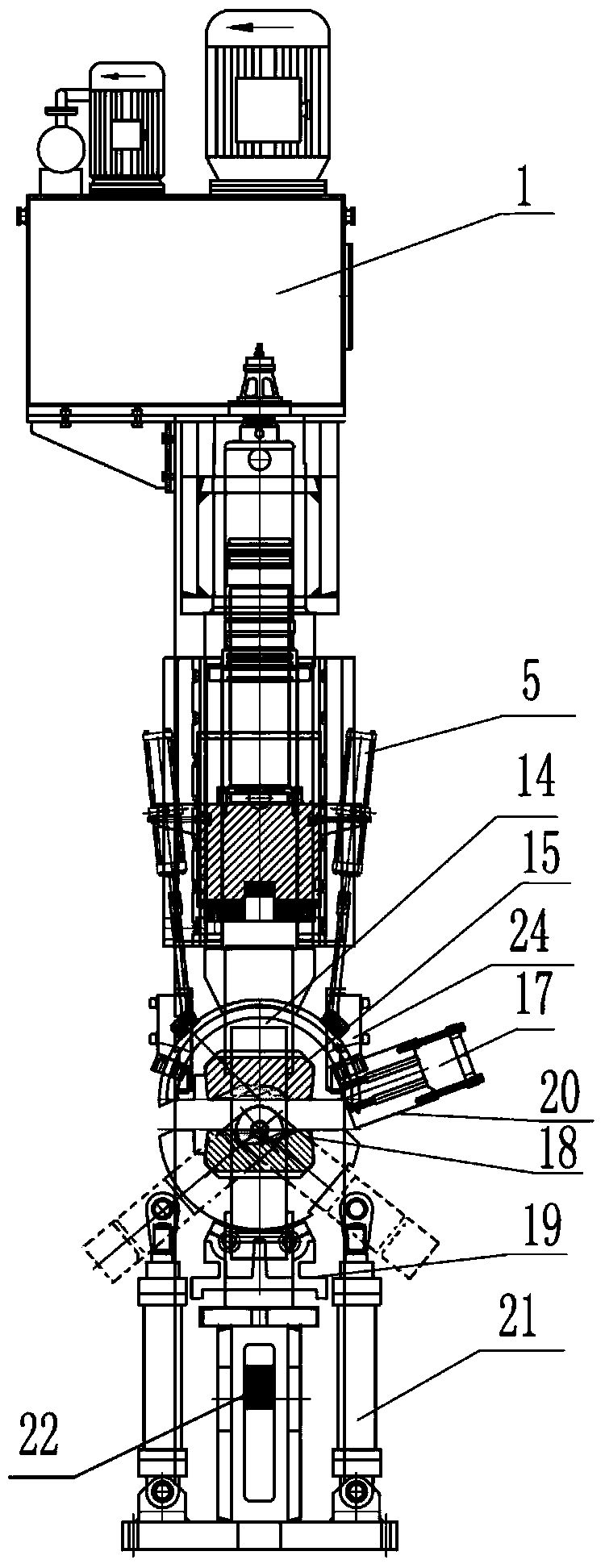

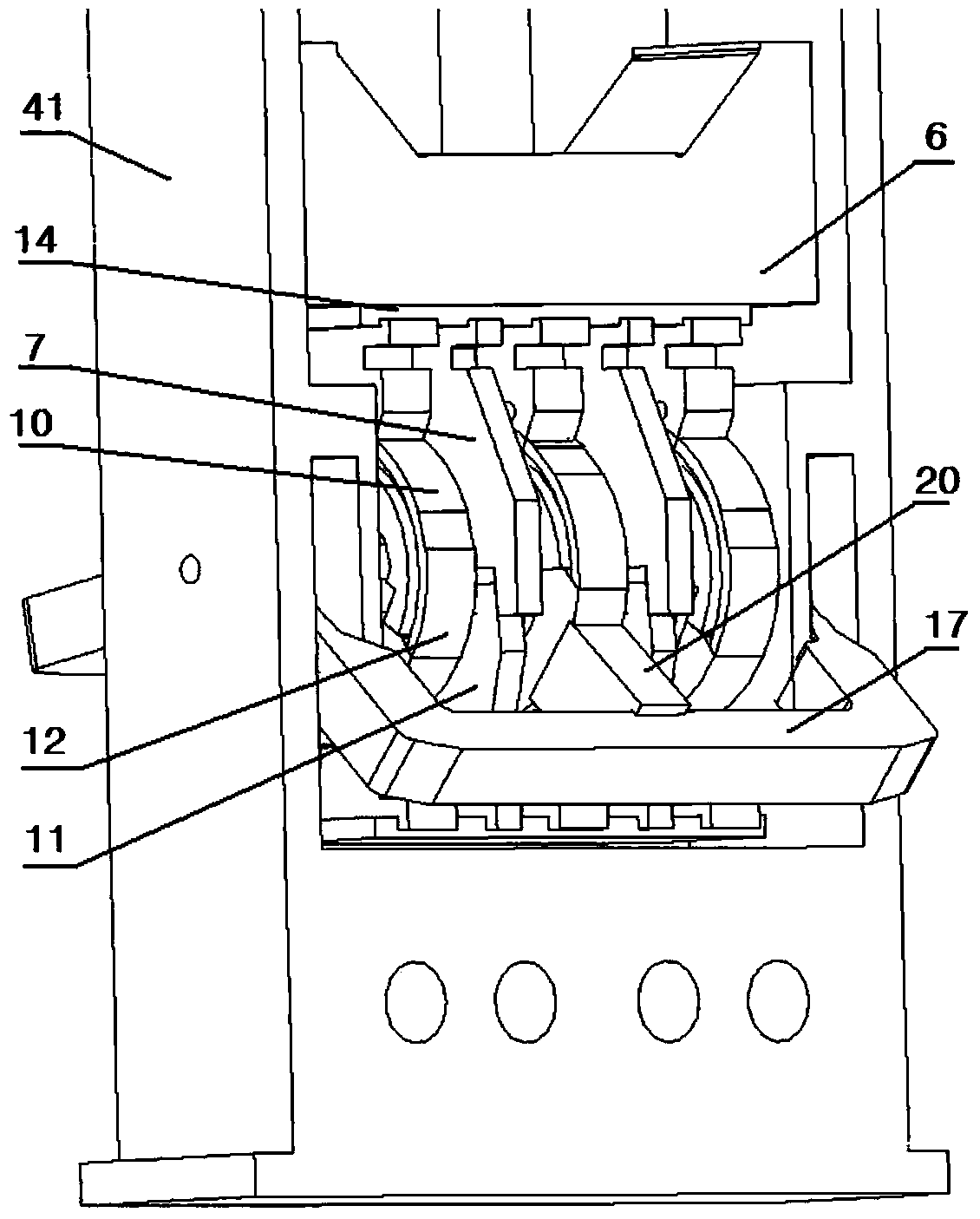

High-precision six-jaw duplex floating type self-centering clamping mechanism and clamping method

PendingCN113770750AStable clampingPrecise gripping methodPositioning apparatusMetal-working holdersThermal deformationEngineering

The invention relates to the technical field of clamp structures, in particular to a high-precision six-jaw duplex floating type self-centering clamping mechanism and a clamping method. The clamping mechanism comprises a clamp body and further comprises at least two sets of clamping jaws, and each set comprises at least three clamping jaws; an inclined mounting groove is formed in the clamp body; each clamping jaw comprises a diagonal draw bar, which is arranged in the mounting groove in a penetrating mode and can move in the length direction of the mounting groove, and a clamping jaw body, which is fixed to the end, extending out of the outer side of the clamp body, of the corresponding diagonal draw bar; plunger cylinders used for driving the diagonal draw bars to move along the mounting groove so as to tighten the clamping jaw bodies to clamp a workpiece are arranged in the clamp body; and the plunger cylinders are in one-to-one correspondence with the diagonal draw bars, the driving speeds of the corresponding plunger cylinders in the same set of clamping jaws are consistent, and the driving speeds of the plunger cylinders in different sets of clamping jaws are different. The clamp is simple in structure and convenient to operate, pre-clamping and pre-positioning of the workpiece are achieved by controlling the clamping speeds of different sets of clamping jaws, the clamping precision of the workpiece is improved, and the technical problem of turning thermal deformation is solved.

Owner:东风汽车动力零部件有限公司

Cut tobacco box cleaning device

The invention relates to the technical field of cigarette auxiliary machinery, in particular to a cut tobacco box cleaning device. The device comprises a driving box, a motor is arranged at the bottom of the driving box, and an output shaft of the motor penetrates through the bottom wall of the driving box to be connected with a driving chain wheel. A plurality of brush assemblies are arranged at the upper portion of the driving box and evenly distributed in the circumferential direction of the driving box. Each brush assembly comprises a rotating shaft, wherein the top of the rotating shaft is connected with a guide groove, a cleaning brush is arranged in the guide groove, and the cleaning brush is higher than the guide groove; and the bottoms of the rotating shafts penetrate through the top wall of the driving box to be connected with driven chain wheels, the driving chain wheel is connected with one driven chain wheel through a driving chain, and the driven chain wheels are sequentially connected through driven chains. According to the device, a cut tobacco box can be automatically cleaned, the cleaning efficiency is improved, and the manual cleaning cost is reduced.

Owner:山东朗科智能装备有限责任公司

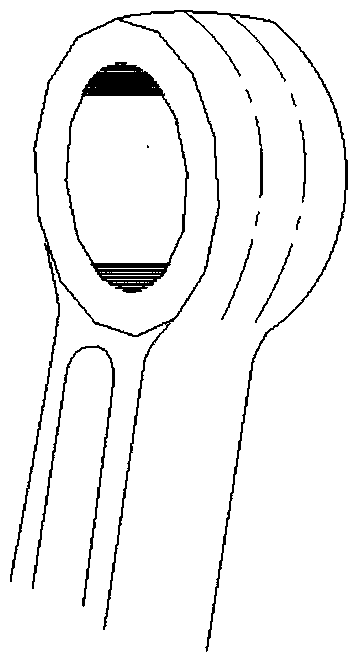

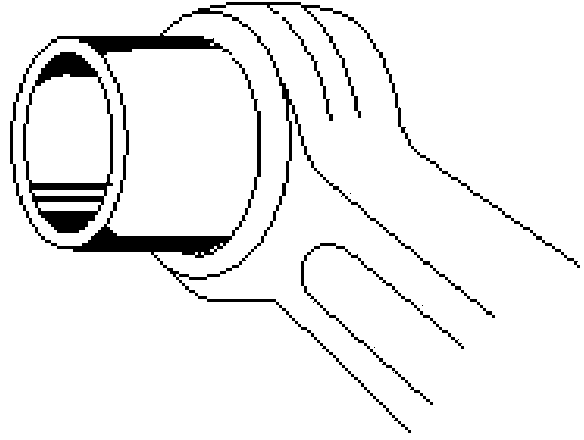

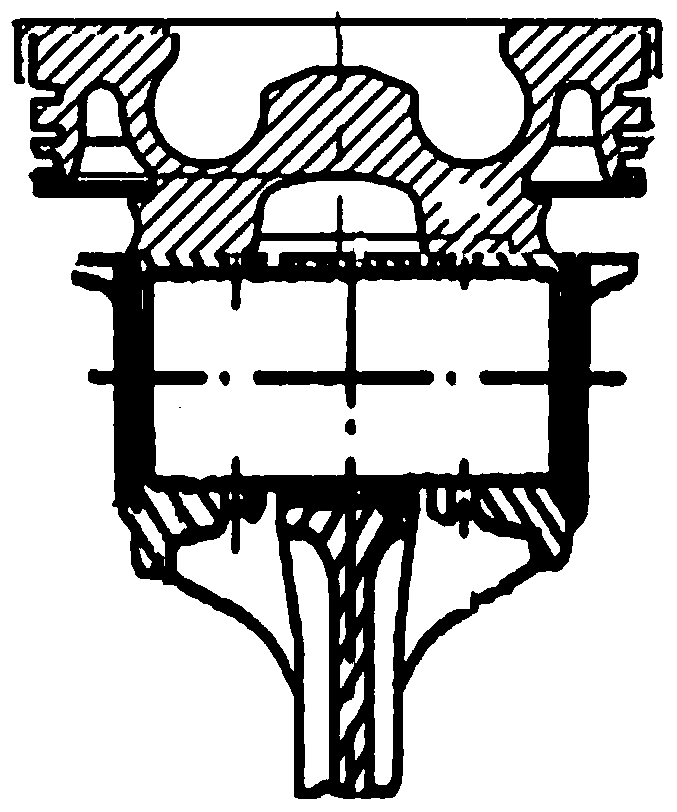

Piston connecting rod

ActiveCN104165179AAssembly compactConcentrated forceConnecting rodsEngine lubricationPistonLubrication

The invention relates to the technical field of the design of engine parts and specifically relates to a piston connecting rod. The piston connecting rod comprises a connecting rod small end (1), a connecting rod big end and a rod body; the connecting rod small end (1) is of a dual-pin boss structure; the dual-pin boss structure is provided with a pin hole (2) for realizing pin connection with a pin boss of a piston end of a single-pin boss structure. The dual-pin boss connecting rod small end adopted by the piston connecting rod provides structural support for a piston of the single-pin boss structure; the connection manner of the piston and the connecting rod small end is changed so that the assembled structure of the piston and the connecting rod can be more compact and the stress can be more concentrated. The dual-pin boss connecting rod small end adopted the piston connecting rod improves the motion load of the connecting rod structurally, and the oil collecting hole and the oil storage chamber of the connecting rod small end are formed to provide technical support for continuous cooling and lubrication of a piston pin. A bush is arranged at the pin hole of the connecting rod small end to provide further protection for the abrasive resistance of the pin hole at the connecting rod small end on the basis of ensuring cooling and lubrication.

Owner:强道前

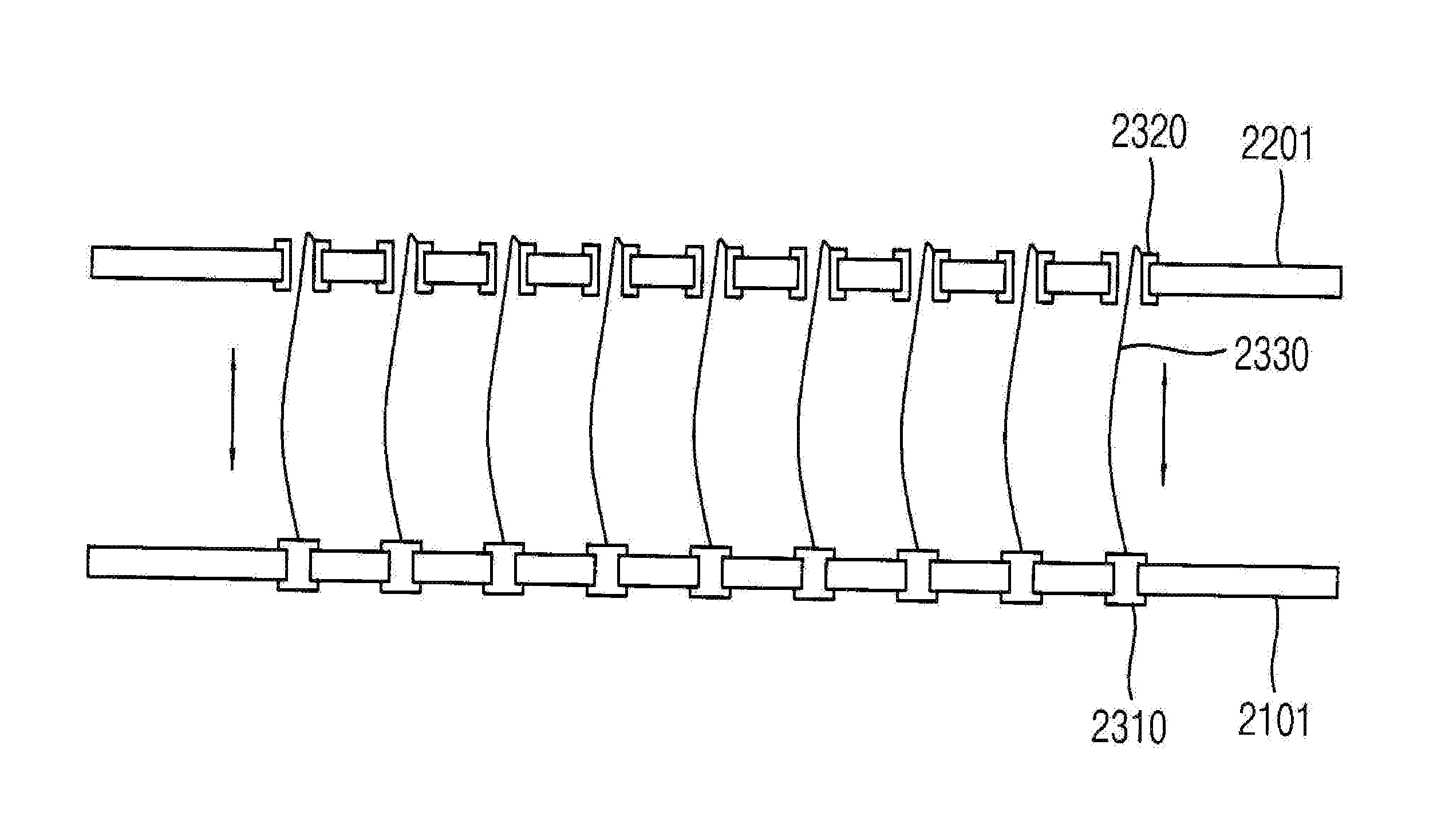

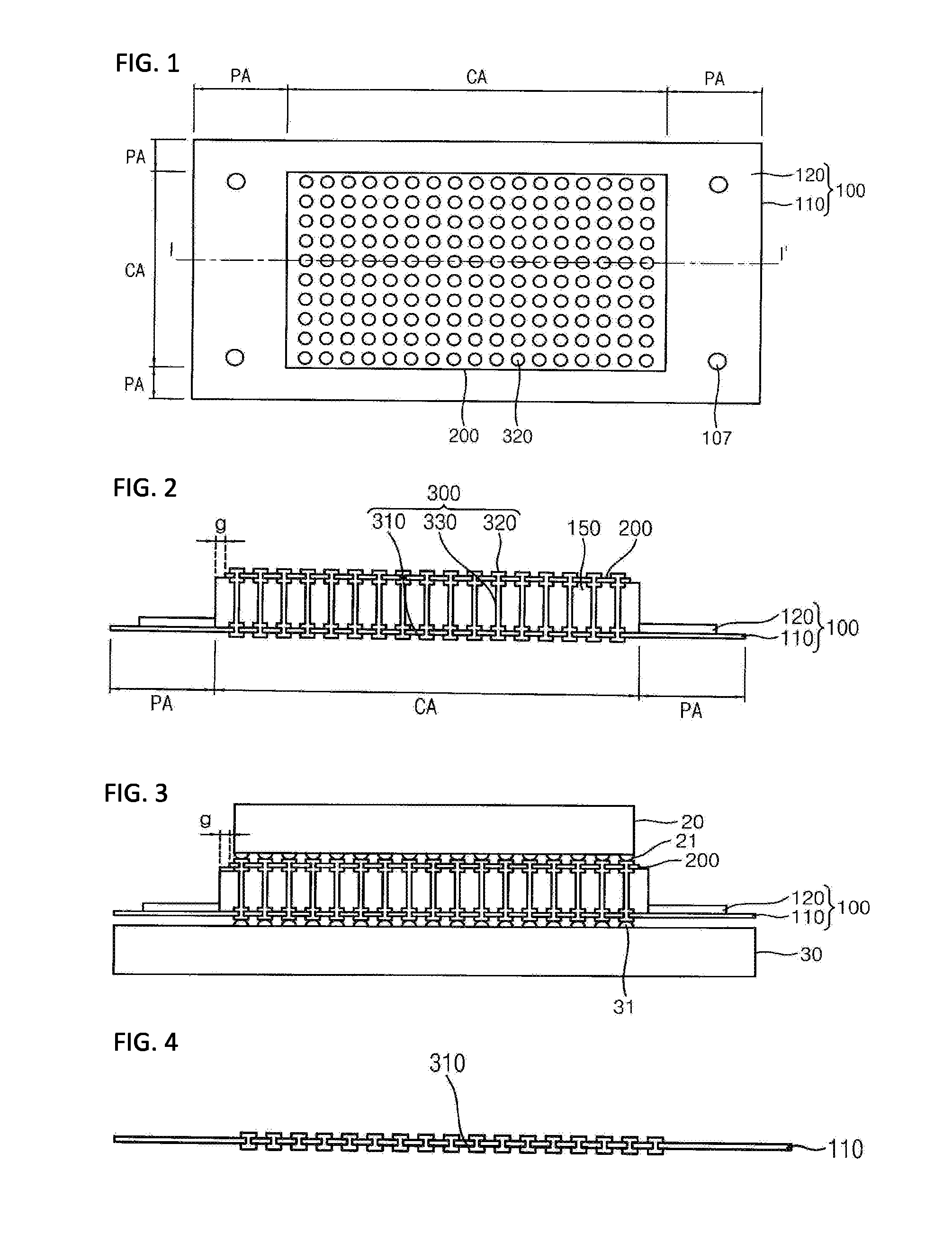

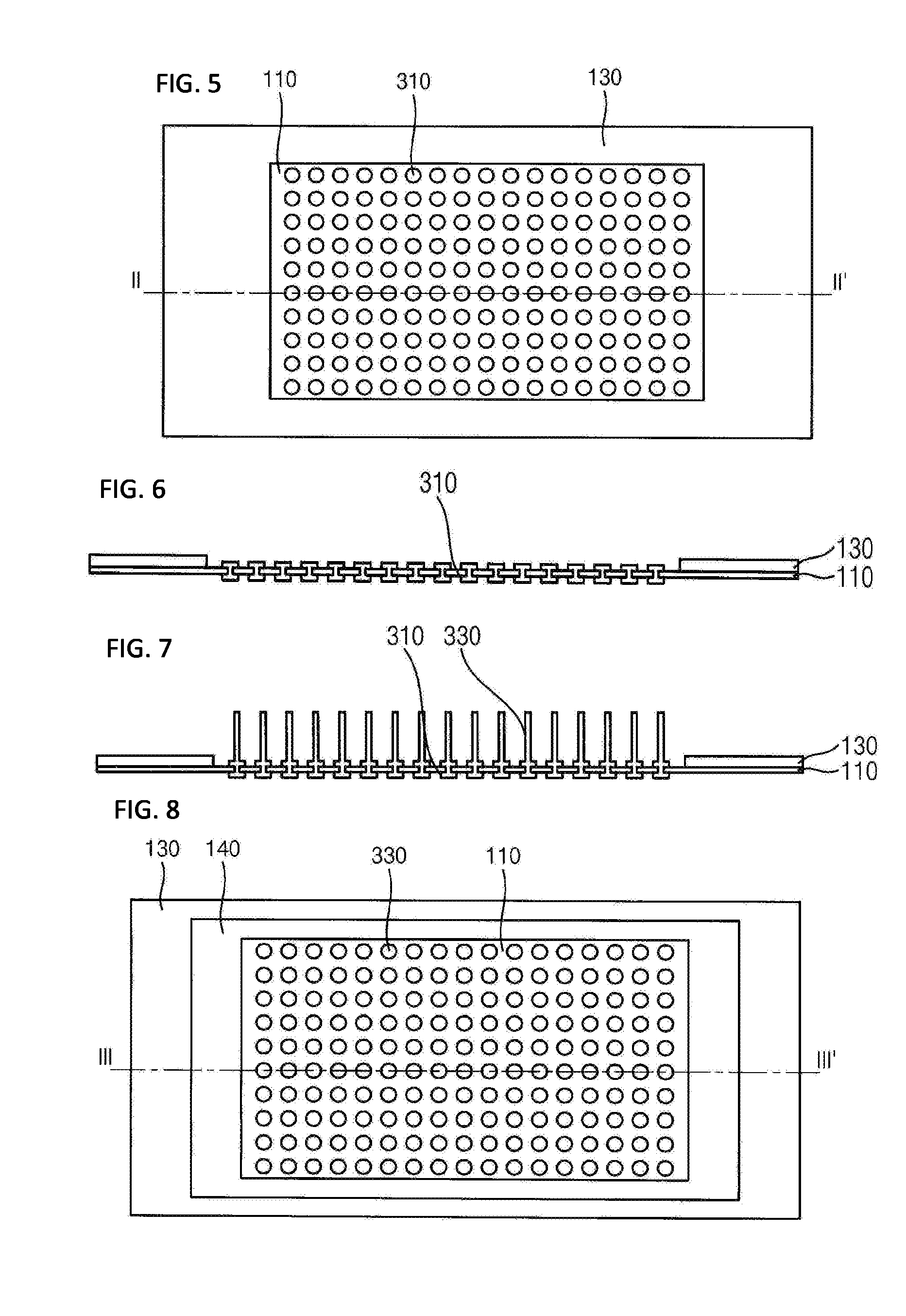

Wired rubber contact and method of manufacturing the same

InactiveUS20160356816A1Easy disposalEasy to fixContact member manufacturingElectrical measurement instrument detailsEngineeringElectrode

A wired rubber contact including a lower film, an upper film, a plurality of conductive wires, a rubber layer, and a film guide. The lower film includes a plurality of lower electrode parts formed in openings. A periphery of the upper film is disposed within an interface between the central area and the peripheral area. The conductive wires are disposed between the lower film and the upper film, and connect between the lower electrode parts and the upper electrode parts. The rubber layer includes elastic material. A periphery of the rubber layer is protruded toward an outer side from the periphery of the upper film. The rubber layer maintains a constant distance between the lower film and the upper film. The film guide is disposed in the peripheral area of the lower film along a side surface of the rubber layer and integrally formed with the lower film.

Owner:HYUNG IK KIM +1

Connecting structure and method for externally-hung wallboard and precast beam

Owner:CHENGDU CHENGTOU YUANDA CONSTR TECH CO LTD

Low-temperature emergency release coupler

ActiveCN106523754AConcentrated forcePull off sensitiveEqualizing valvesSafety valvesEmergency medicine

Owner:JIANGSU CHANGLONG PETROCHEM EQUIP

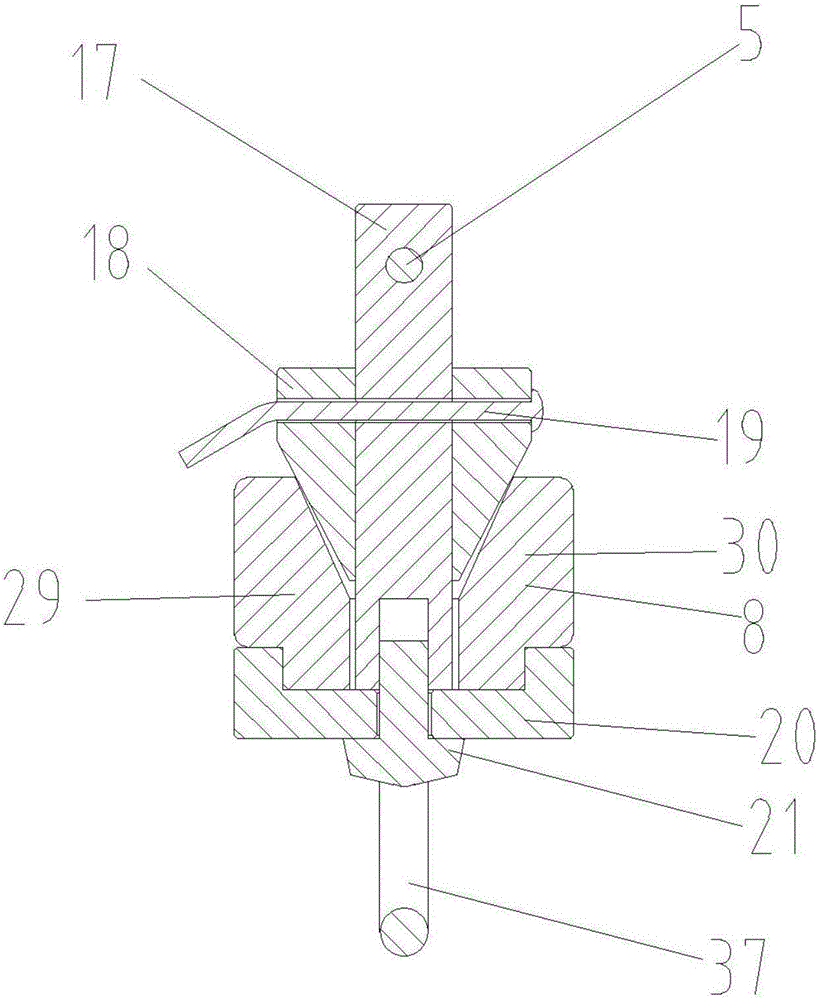

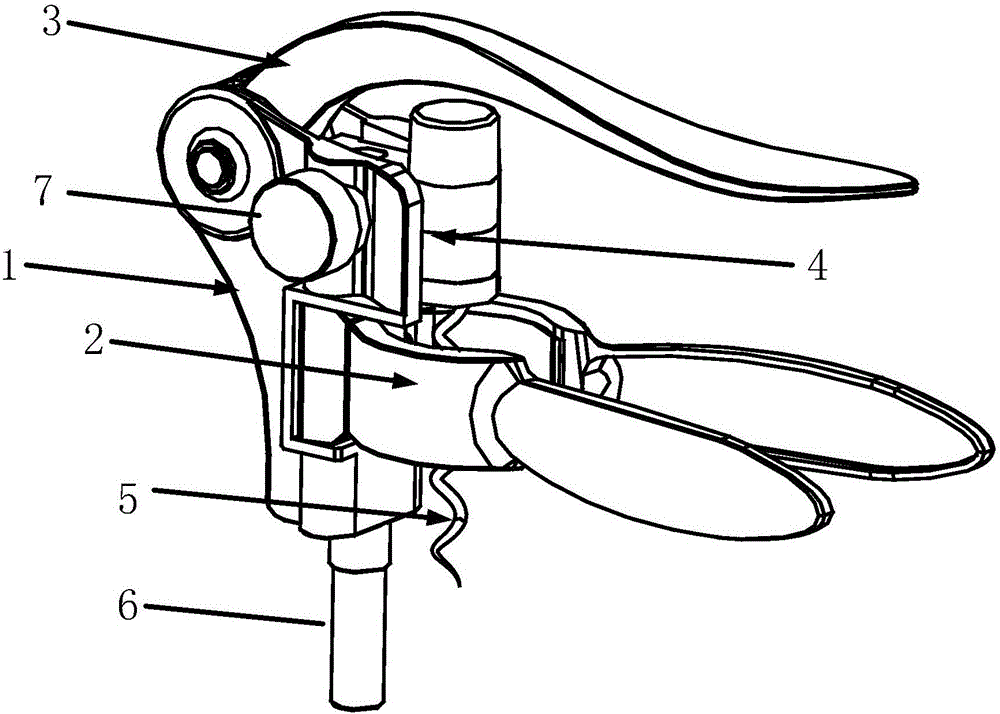

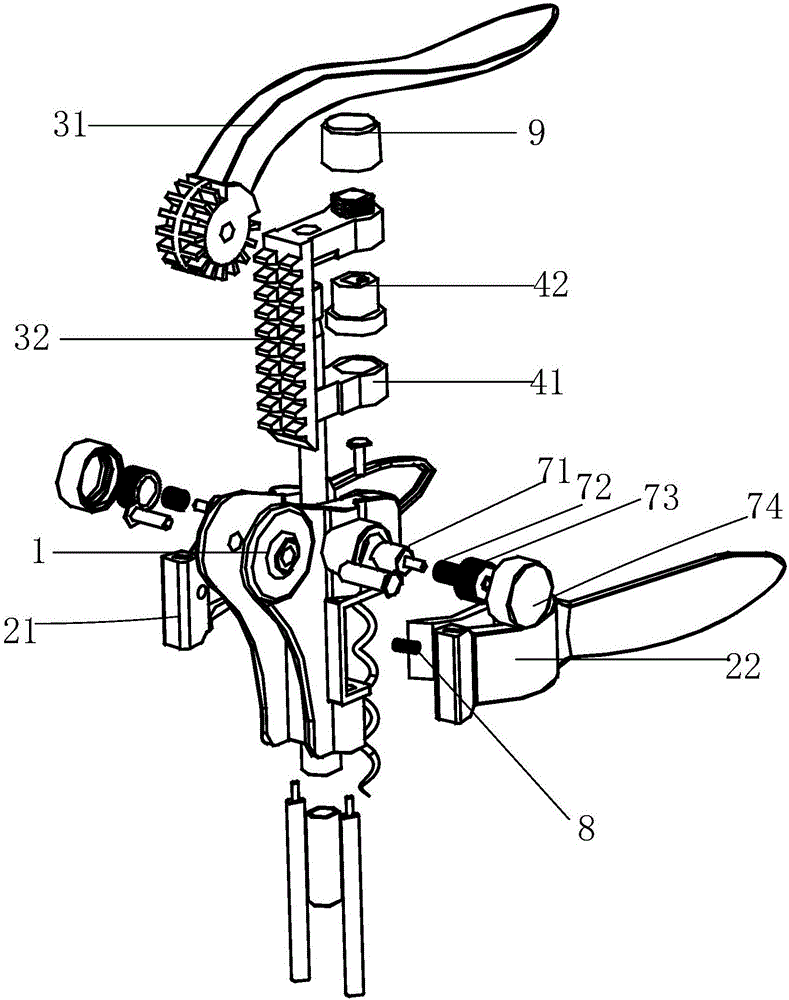

Bottle opener pressing structure and bottle opener

InactiveCN105800532ARealize the shaft connectionWon't breakBottle/container closurePower operated devicesEngineeringBottle

The invention discloses a bottle opener pressing structure. The bottle opener pressing structure is characterized by comprising a main body, a wrench and a pressing plate. The wrench can be rotatably arranged on the main body, one end portion of the wrench is connected with the pressing plate, the wrench rotates to drive the pressing plate to axially move, a threaded rod is arranged on the pressing plate, and the threaded rod axially moves along with the pressing plate. The bottle opener pressing structure and a bottle opener which are more labor-saving are provided.

Owner:邢皓宇

Auxiliary opening mechanism for flue check valve

The invention provides an auxiliary opening mechanism for a flue check valve, and belongs to the technical field of pipeline structures. The auxiliary opening mechanism solves the problem that valve plates cannot be opened after long-term use in the prior art. The auxiliary opening mechanism for the flue check valve comprises a shell and a plurality of valve plates; an annular sealing baffle edgeis arranged in the shell; the valve plates are hinged in the shell; the edges of the valve plates can be attached to or can be separated from the annular sealing baffle edge; and the shell is providedwith an air inlet end and an air outlet end. The auxiliary opening mechanism is characterized by comprising swing rods; an installation cavity is formed in each valve plate; the swing rods are arranged in the installation cavities in a swinging mode; openings I and openings II are formed in the sides, close to the air inlet end, of the valve plates; an elastic pad is arranged on each opening I; one ends of the swing rods make contact with the elastic pads; the openings II are formed in the edges of the valve plates; and when the elastic pads deform to drive one ends of the swing rods to swing, the other ends of the swing rods can penetrate out of the openings II to abut against the annular sealing baffle edge. The auxiliary opening mechanism has the advantage of enhancing the opening force of the valve plates.

Owner:MARSSENGER KITCHENWARE CO LTD

A damper opening and closing angle changing mechanism of a hinge

ActiveCN106761110BPrecise positioningImprove stabilityBuilding braking devicesWing accessoriesControl theoryShock absorber

Owner:伍志勇

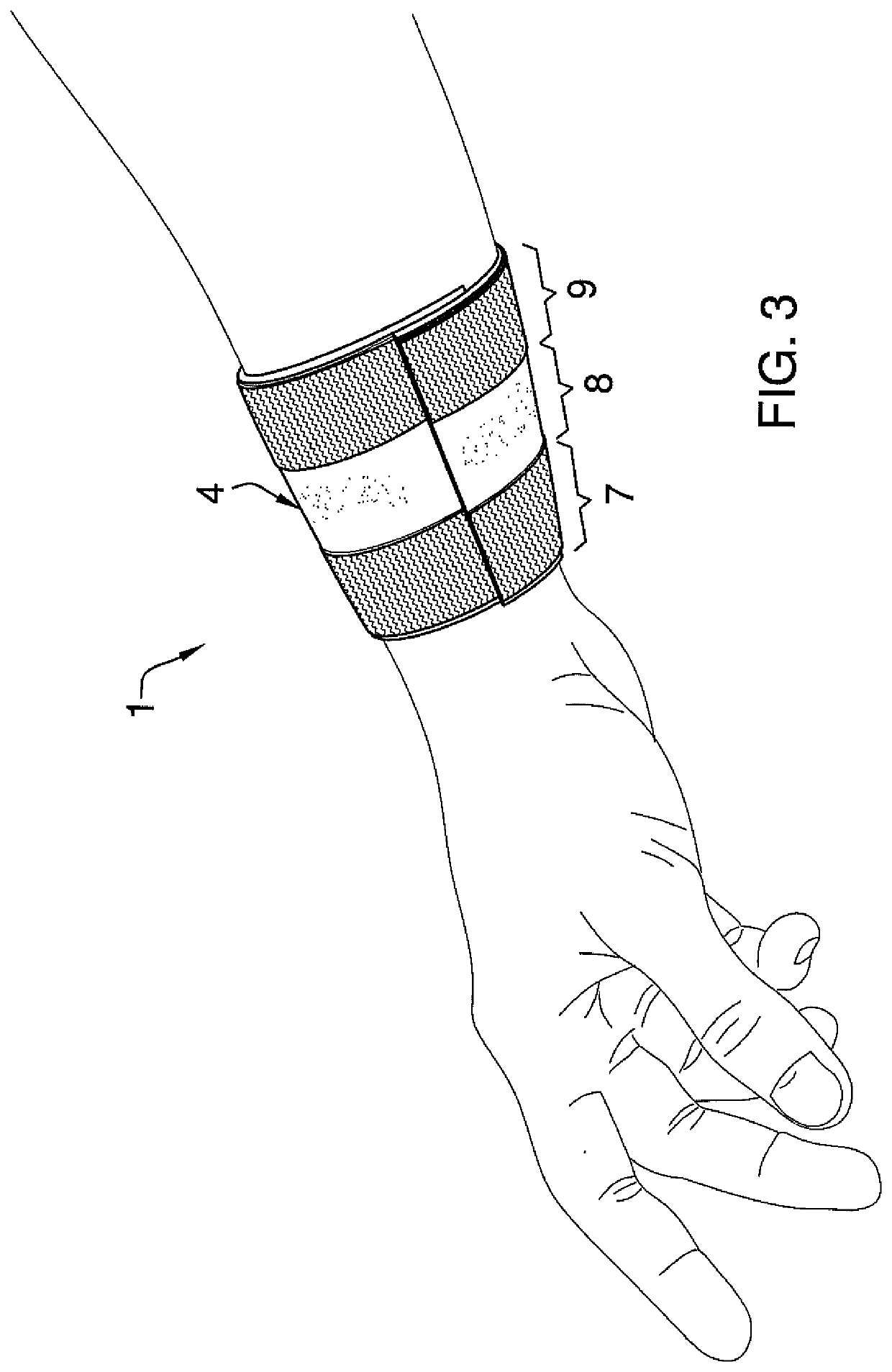

Multi-Use Utility Sleeve

ActiveUS20210361056A1Concentrated clasping forceImprove gripTravelling carriersHoldersPhysical medicine and rehabilitationEngineering

This invention relates to a wearable adaptative multi-use utility sleeve that enables quick, convenient, and tenacious securement of the multi-use utility sleeve to a person's appendage or torso while also allowing for the swift and convenient attachment and detachment of one or more handheld items to the utility sleeve. The present invention offers several embodiments, each of which utilize a plurality of bistable ribbons, that allow for a one-size-fits-all design that provides the ability to conform to the user's body.

Owner:KITZER PAUL STEVEN

Mold locking mechanism of plastic injection molding machine

The invention discloses a mold locking mechanism of a plastic injection molding machine, comprising a base, a thrust seat, a moving mold plate and a fixed mold plate which are arranged in sequence, wherein the centers of the base, the thrust seat, the moving mold plate and the fixed mold plate are positioned on the same central axis; a guide rod is fixedly arranged on the base; the thrust seat and the moving mold plate are sheathed on the guide rod; the fixed mold plate is fixedly connected with the end part of the guide rod; and a connecting rod group is arranged between the moving mold plate and the base. The mold locking mechanism is characterized in that the thrust seat is internally and fixedly provided with at least one oil cylinder; and a piston rod of the oil cylinder is fixedly connected with the moving mold plate. The mold locking mechanism has the advantages that the length of the whole mold locking mechanism is reduced, the structure of the whole mechanism becomes compact, and the whole volume is reduced; and when the moving mold plate and the fixed mold plate are positioned in a locking state, the included angle of the center connecting line of a first connecting rod and a second connecting rod and the horizontal surface of the central axis is more than 0 degree but less than or equal to 10 degrees. In the structure, the acting force of the mold locking mechanism on the mold tends to the center of the mold, the stressing of the mold is more concentrated, and the qualification rate of plastic products is effectively improved.

Owner:NINGBO SHUANGMA MASCH IND CO LTD

Damping buffer closure structure of furniture hinge

ActiveCN105672800BAvoid safety hazardsElastic telescopic sliding position is accurateBuilding braking devicesPin hingesMechanical engineeringEngineering

A damping buffer closing structure for a furniture hinge comprises a connecting arm, elastic pieces, a hinge cup seat, a damper, a transmission arm assembly and a poking assembly. The poking assembly is arranged on the transmission arm assembly. The damper is arranged on the connecting arm. The two ends of the transmission arm assembly are rotationally connected with the connecting arm and the hinge cup seat correspondingly. The connecting arm is hinged to the hinge cup seat to open and close the furniture hinge in a hinged manner through cooperation of the transmission arm assembly and the elastic pieces, and an included angle A is formed between the connecting arm and the hinge cup seat. The poking assembly comprises a poking element and an elastic poking element. The poking element is elastically and rotationally located to the transmission arm assembly through the elastic poking element. The damper is provided with an elastic damping element. The damper elastically stretches and contracts to slide on the connecting arm through the elastic damping element. By improving the structure, the damping buffer closing structure has the beneficial effects of being simple and reasonable in structure, excellent in performance, fast and convenient to assemble, long in service life, low in manufacturing cost, easy to produce, easy to implement, safe, reliable, high in practicability and the like.

Owner:伍志勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com