Connecting structure and method for externally-hung wallboard and precast beam

An external wall panel and connecting structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of concentrated force at the steps, hidden dangers of stability, etc., achieve uniform force, avoid excessive force concentration, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

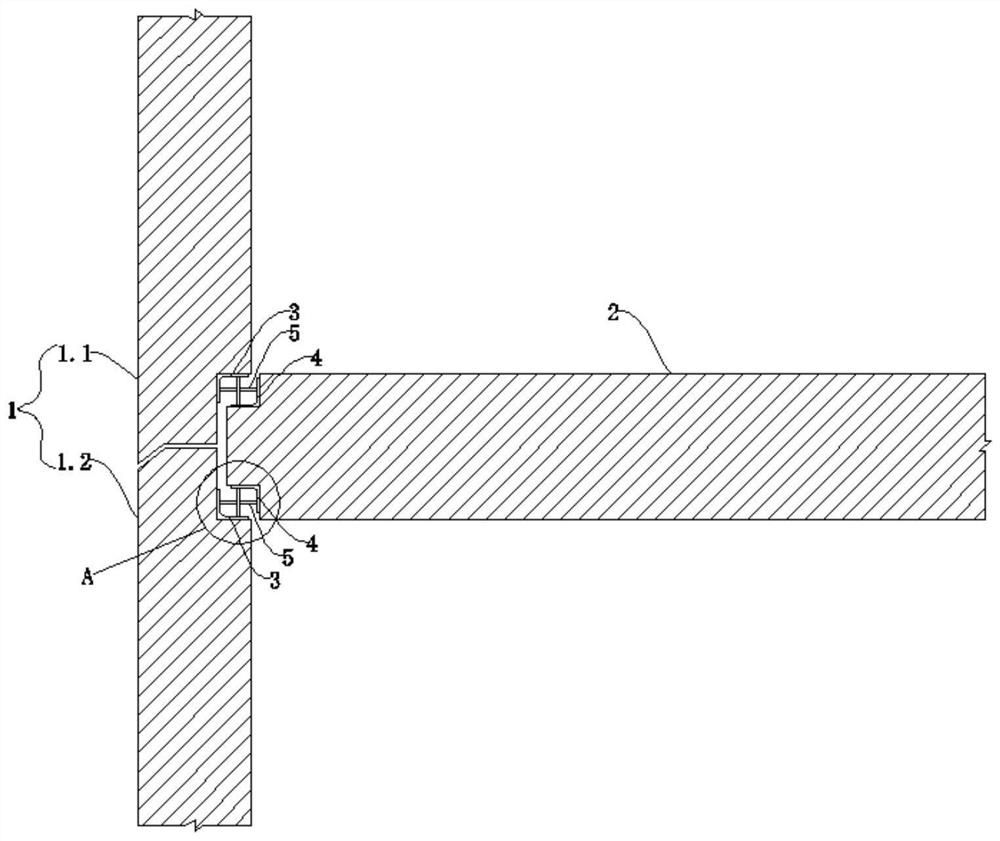

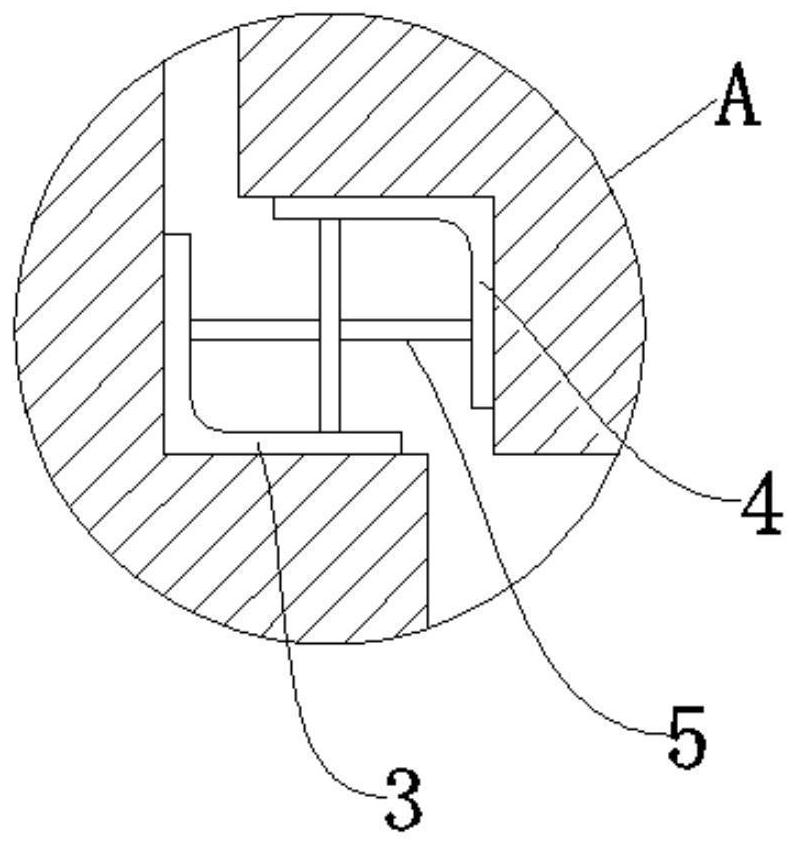

[0036] Such as Figure 1-3 As shown, this embodiment provides a connection structure between an external wall panel and a prefabricated beam, including an external wall panel 1, a prefabricated beam 2, an L-shaped anchor plate A3, an L-shaped anchor plate B4, and a connector 5. There are installation grooves, the prefabricated beam 2 is arranged horizontally, and one end of the prefabricated beam 2 is provided with a "convex"-shaped step. The L-shaped anchor plate A3 is provided with two groups and is respectively arranged at the upper and lower inner right angles of the installation groove. The L-shaped anchor plate B4 There are two groups and they are respectively arranged at the upper and lower steps at one end of the prefabricated beam 2. There are several sets of connectors 5, and several connectors are connected between the L-shaped anchor plate A3 at the upper and lower positions and the corresponding L-shaped anchor plate B4. 5.

[0037] In this embodiment, L-shaped a...

Embodiment 2

[0043] Such as Figure 1-3As shown, this embodiment provides a method for connecting an external wall panel to a prefabricated beam, comprising the following steps:

[0044] S1: Open an installation slot at the connection of the external wall panel 1;

[0045] S2: forming a "convex"-shaped step at one end of the prefabricated beam 2 using a mold;

[0046] S3: The L-shaped anchor plate A3 is pre-embedded in the upper and lower inner right angles of the installation groove of the external wall panel 1, and the outer right angle of the L-shaped anchor plate A3 fits the inner right angle of the installation groove;

[0047] S4: L-shaped anchor plates B4 are pre-embedded at the upper and lower steps at one end of the prefabricated beam 2, and the outer right angle of the L-shaped anchor plate B4 fits the inner right angle of the steps of the prefabricated beam 2;

[0048] S5: Align the end of the prefabricated beam 2 with a "convex"-shaped step with the installation groove of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com