Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Assembly compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

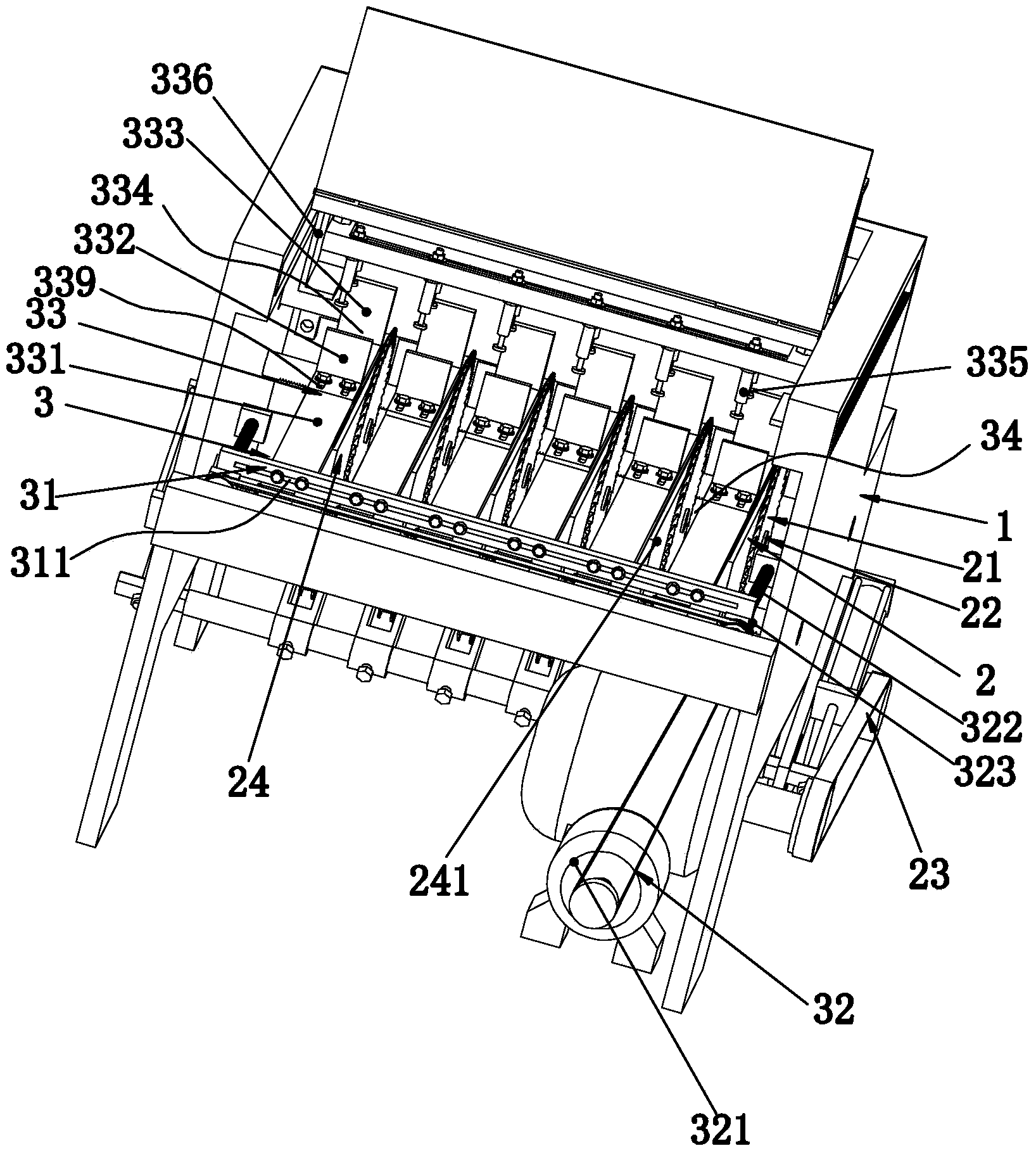

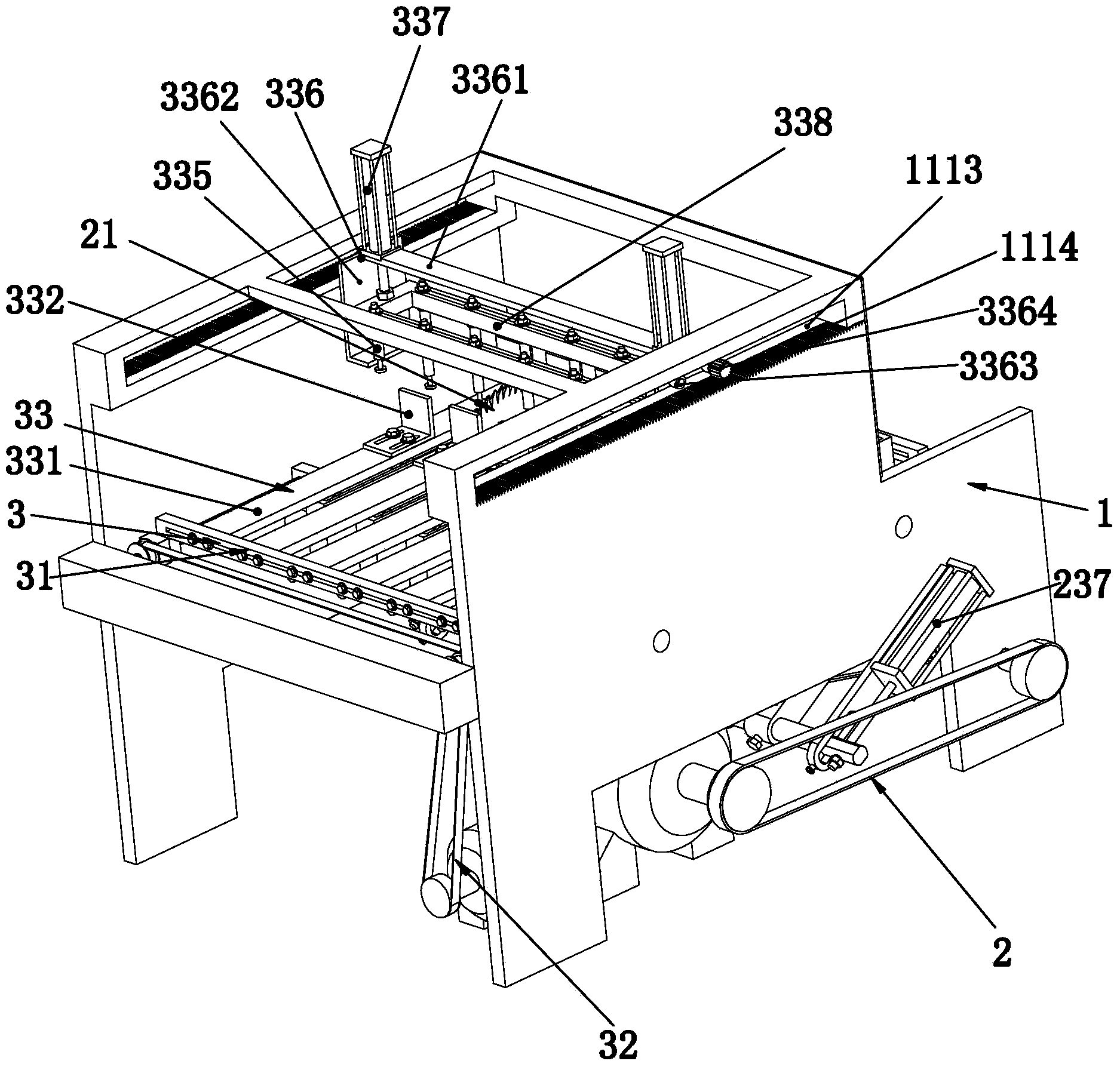

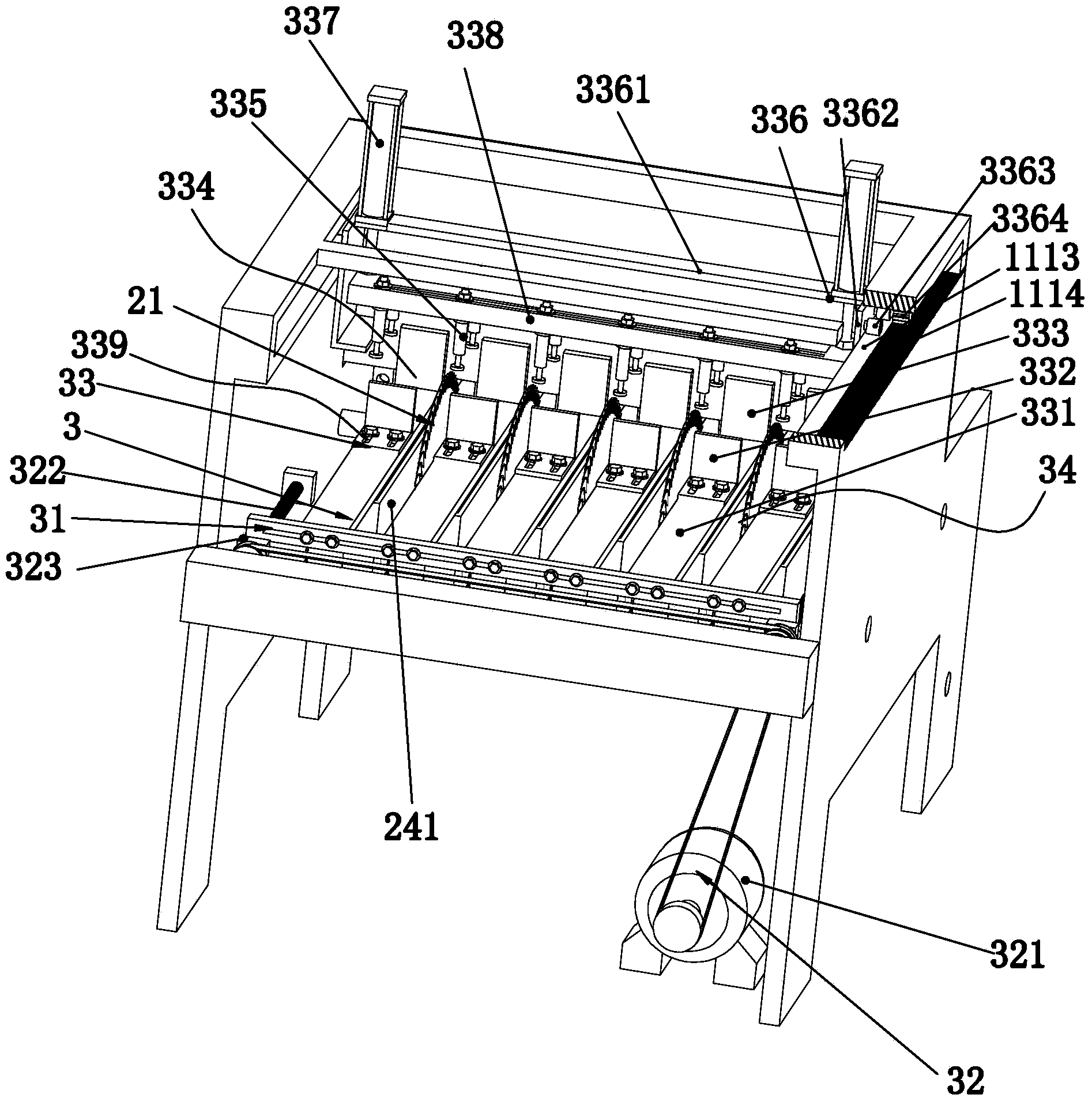

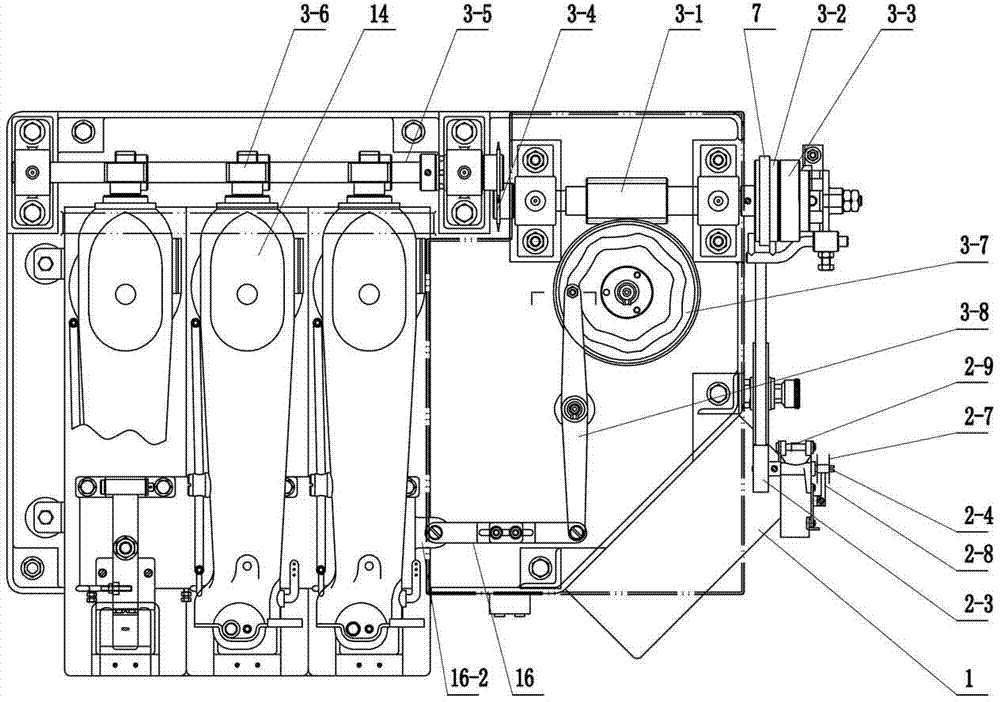

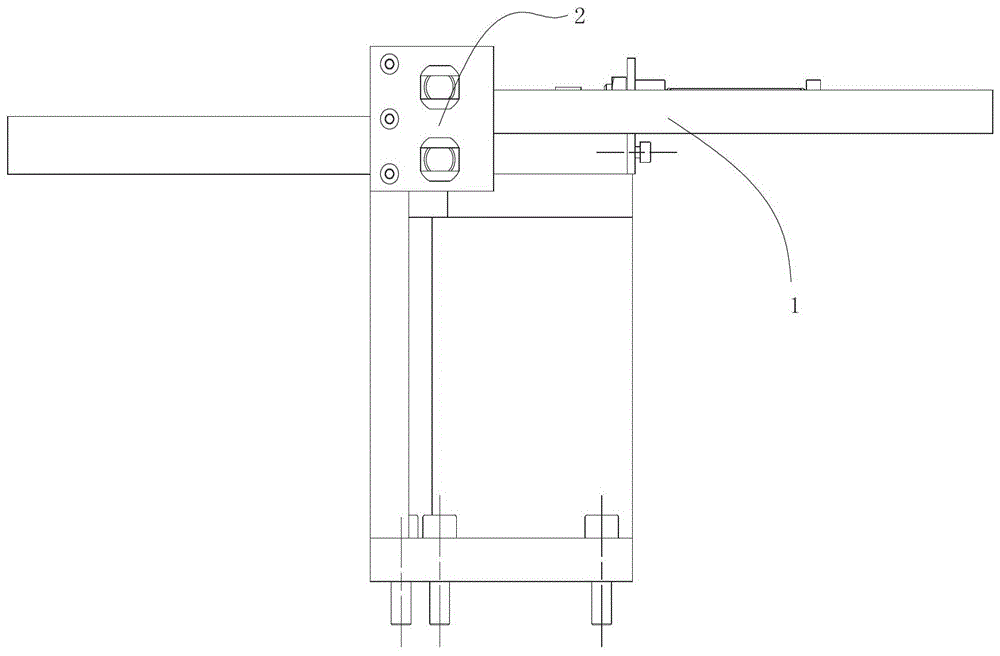

Safe type timber cutting machine with multiple cutting saw blades

The invention relates to a safe type timber cutting machine with multiple cutting saw blades. The safe type timber cutting machine comprises a machine base and a cutting device arranged on the machine base. The cutting device comprises a plurality of cutting saw blades, a saw blade mounting rotary shaft and saw blade driving mechanisms, wherein the cutting saw blades are coaxially assembled, and the spacing between the cutting saw blades can be adjusted, the saw blade mounting rotary shaft is used for allowing the cutting saw blades to be installed on, and the saw blade driving mechanisms drive the cutting saw blades to rotate and are in drive connection with the saw blade mounting rotary shaft. The machine base is further provided with an automatic feeding device. The automatic feeding device comprises a feeding rack and a feeding driving mechanism, wherein the feeding rack is arranged in a moving and sliding mode in the rotating and cutting direction of the cutting saw blades, and the feeding driving mechanism drives the feeding rack. A plurality of timber fixing platforms are arranged on the feeding rack, the number and the positions of the timber fixing platforms correspond to those of the cutting saw blades. The timber fixing platforms are coaxially arranged. Timber cutting passages for allowing the cutting saw blades to enter and cut timbers are formed between the adjacent timber fixing platforms in a spaced mode. The spacing between the adjacent timber fixing platforms can be adjusted. Compared with the prior art, the safe type timber cutting machine with the multiple cutting saw blades can automatically feed the timbers and is more convenient and safer to operate.

Owner:邹建静

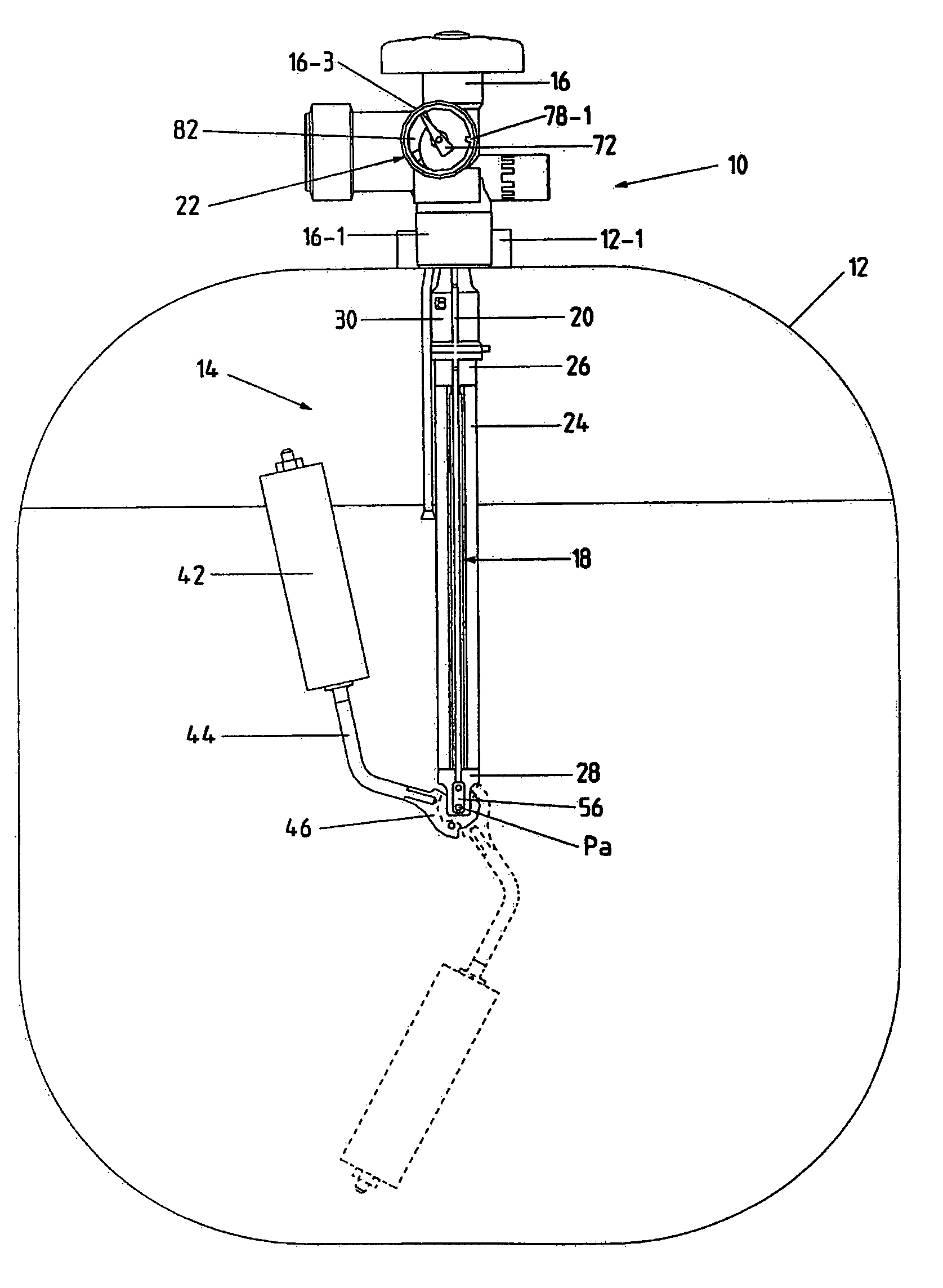

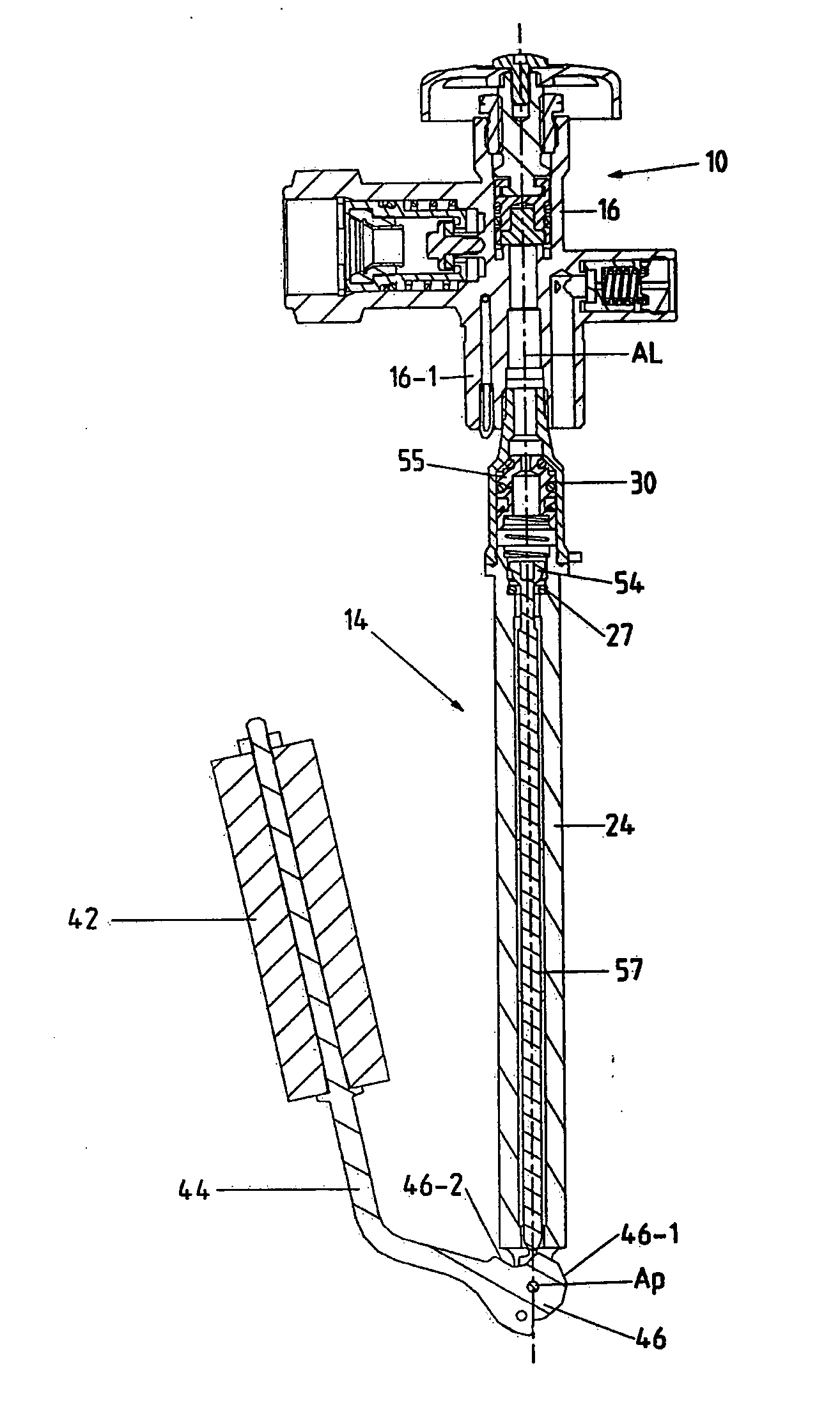

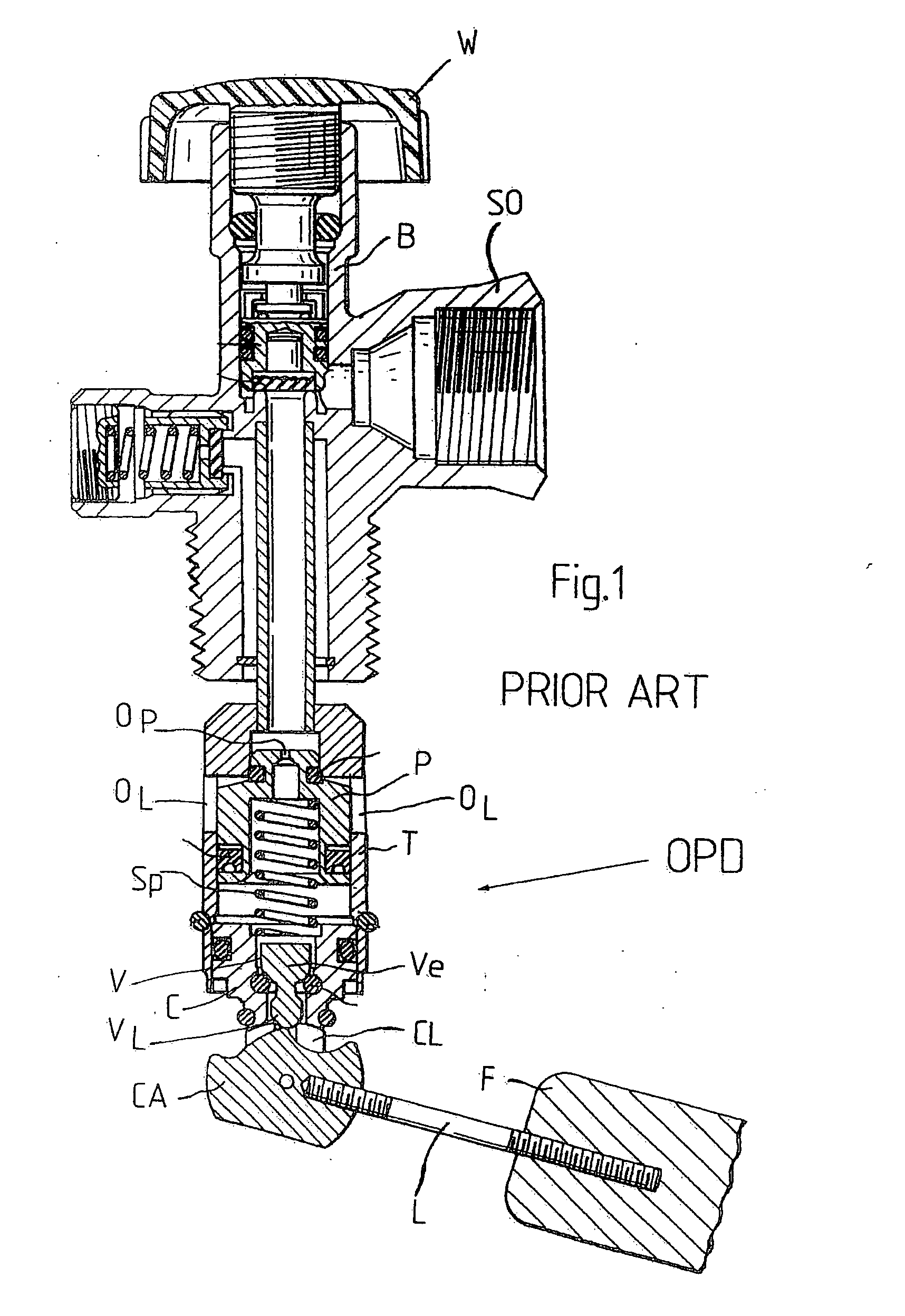

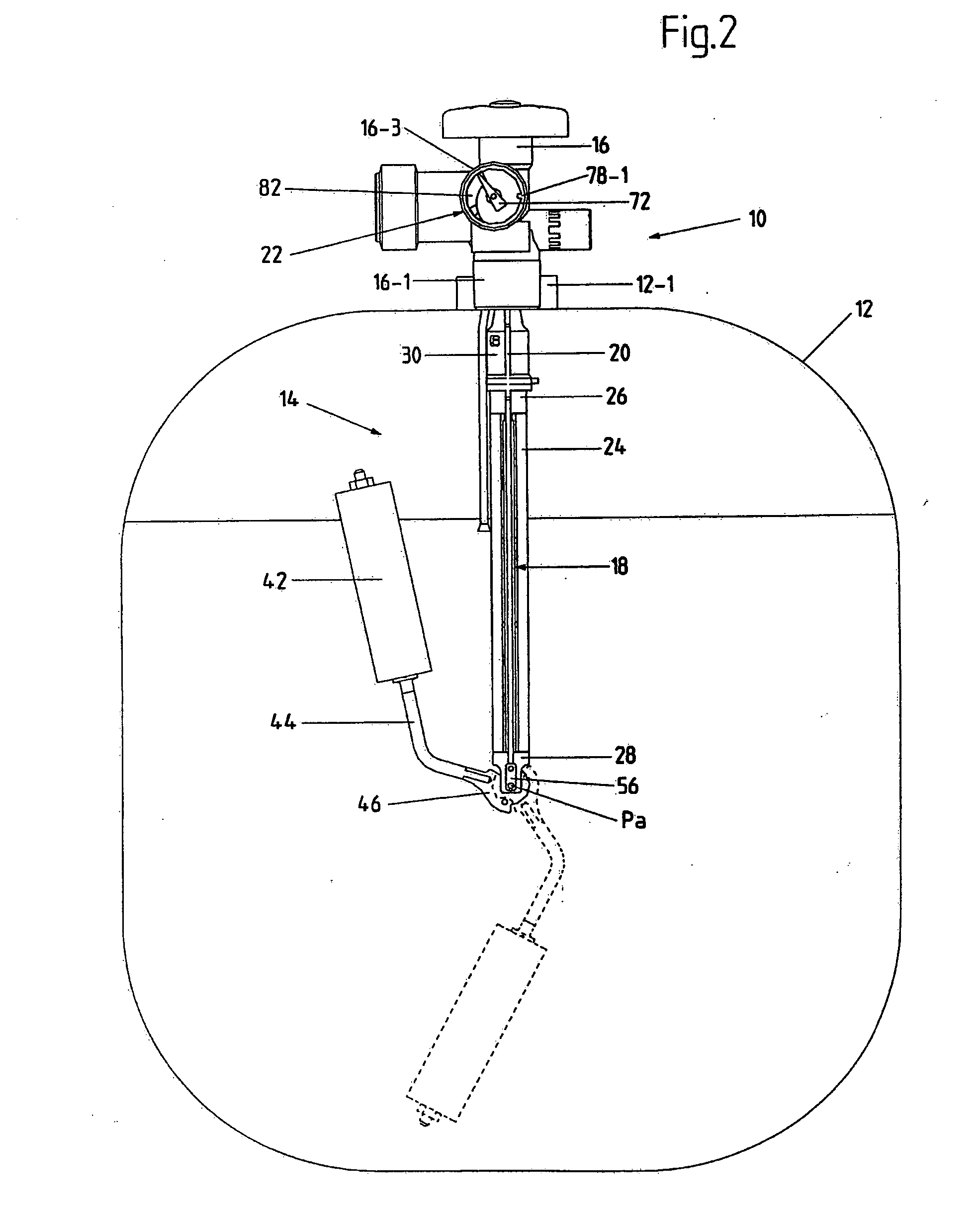

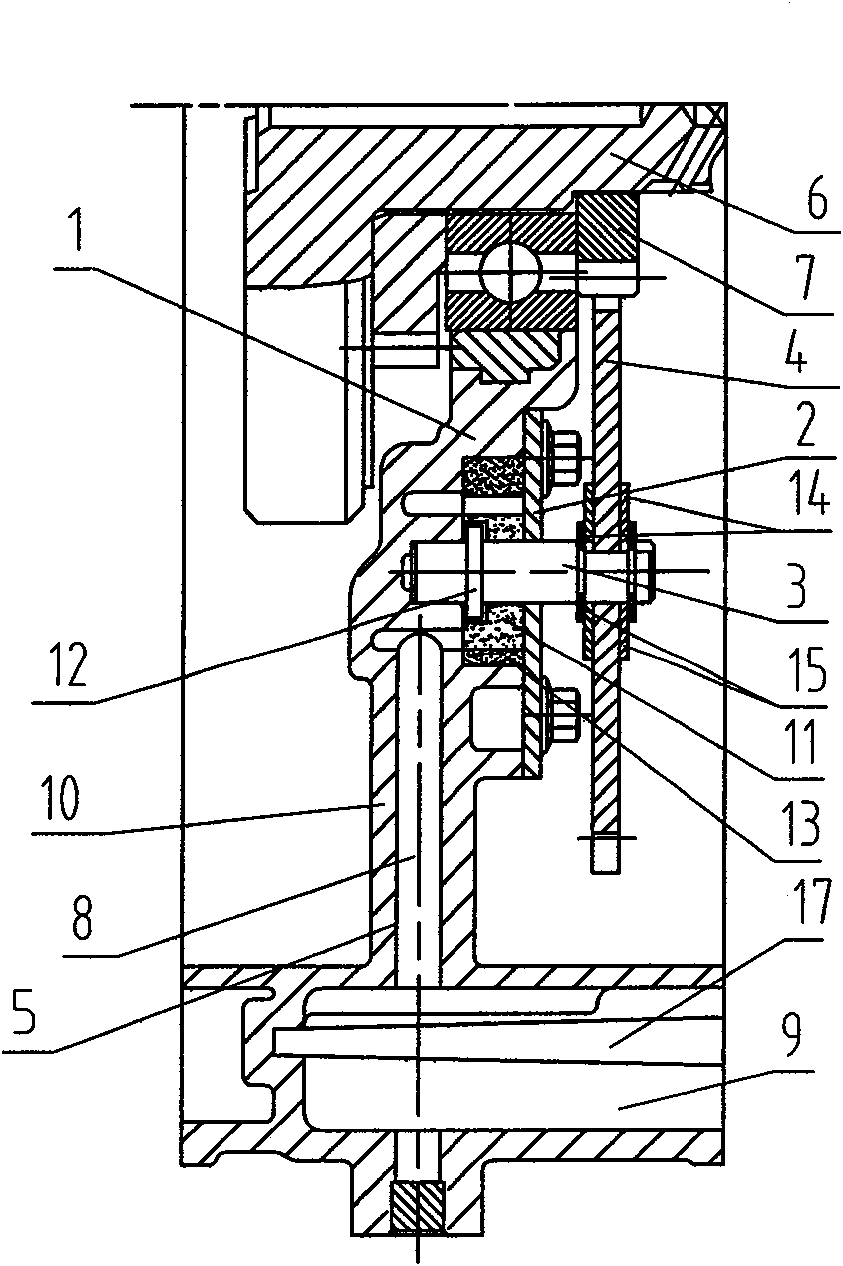

Tap assembly for a liquid vessel having an overfill protection device and a float controlled magnetic level gauge

InactiveUS7219686B2Assembly compactLess spaceOperating means/releasing devices for valvesPipeline systemsAxial displacementLevel sensor

This invention relates to a tap assembly for a liquid vessel, having an overfill protection device and a float controlled mechanical or magnetic level gauge. A single float actuates a stem of the overfill protection device as well as a rod of the level gauge. The rod of the level gauge has one end movable linearly in a valve body bore and carrying a permanent magnet for actuating a magnetic level indicator. In one embodiment a crank mechanism may be provided between a float lever and the rod of the level gauge to cause the rod to effectuate a swinging movement and simultaneously displace the rod longitudinally to cause linear displacement of the permanent magnet in the valve body bore. In another embodiment the rod may be actuated by a cam to cause axial displacement thereof without swinging motion.

Owner:TORRENT TRADING

Tap assembly for a liquid vessel having an overfill protection device and a float controlled magnetic level gauge

InactiveUS20060169325A1Assembly compactLess spaceOperating means/releasing devices for valvesLevel controlAxial displacementLevel sensor

This invention relates to a tap assembly for a liquid vessel, having an overfill protection device and a float controlled mechanical or magnetic level gauge. A single float actuates a stem of the overfill protection device as well as a rod of the level gauge. The rod of the level gauge has one end movable linearly in a valve body bore and carrying a permanent magnet for actuating a magnetic level indicator. In one embodiment a crank mechanism may be provided between a float lever and the rod of the level gauge to cause the rod to effectuate a swinging movement and simultaneously displace the rod longitudinally to cause linear displacement of the permanent magnet in the valve body bore. In another embodiment the rod may be actuated by a cam to cause axial displacement thereof without swinging motion.

Owner:TORRENT TRADING

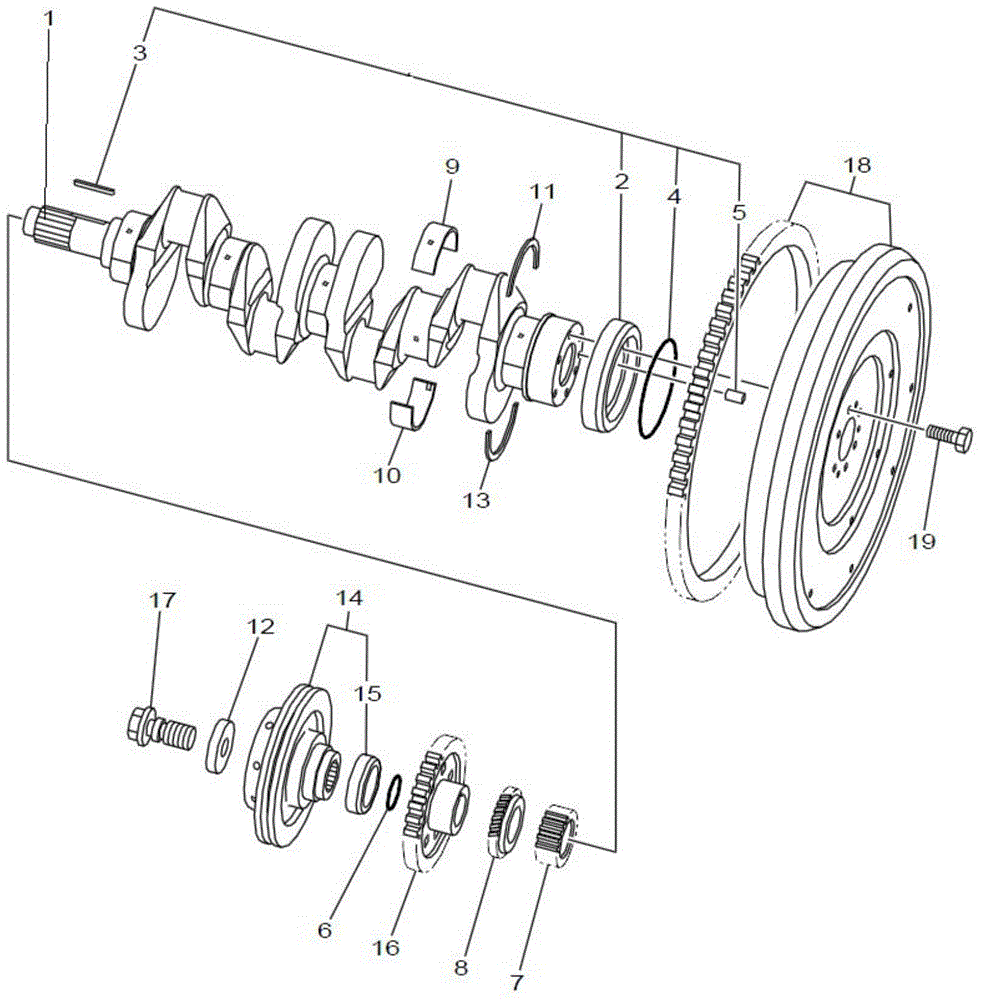

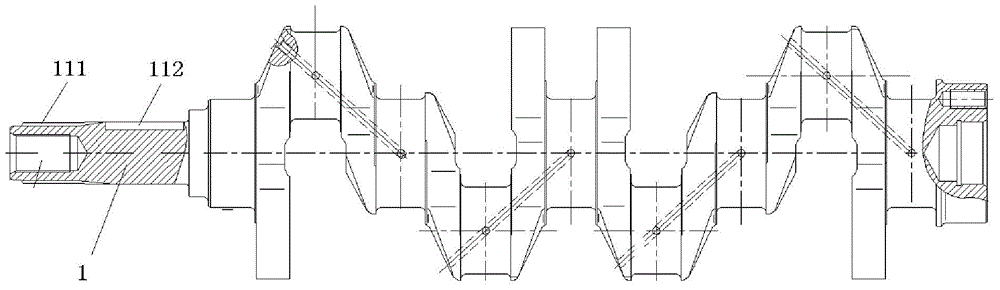

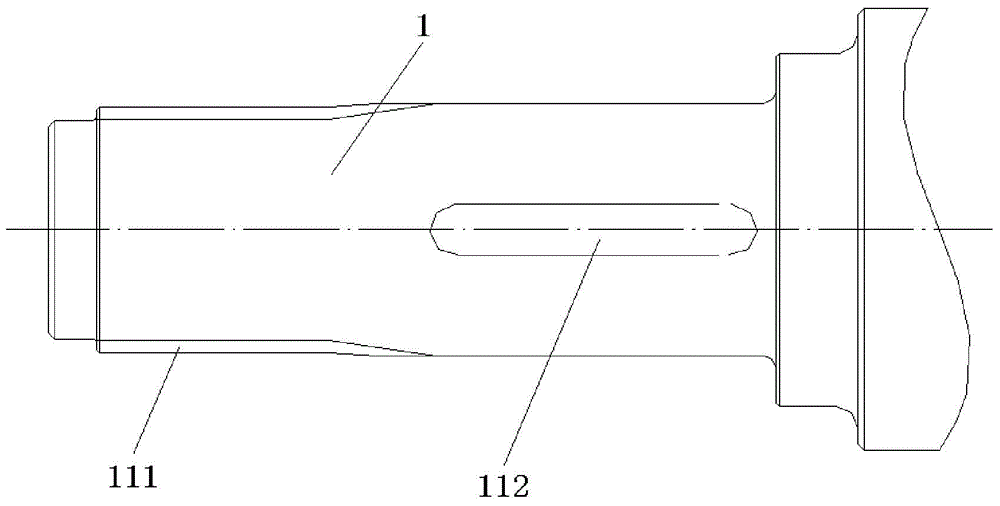

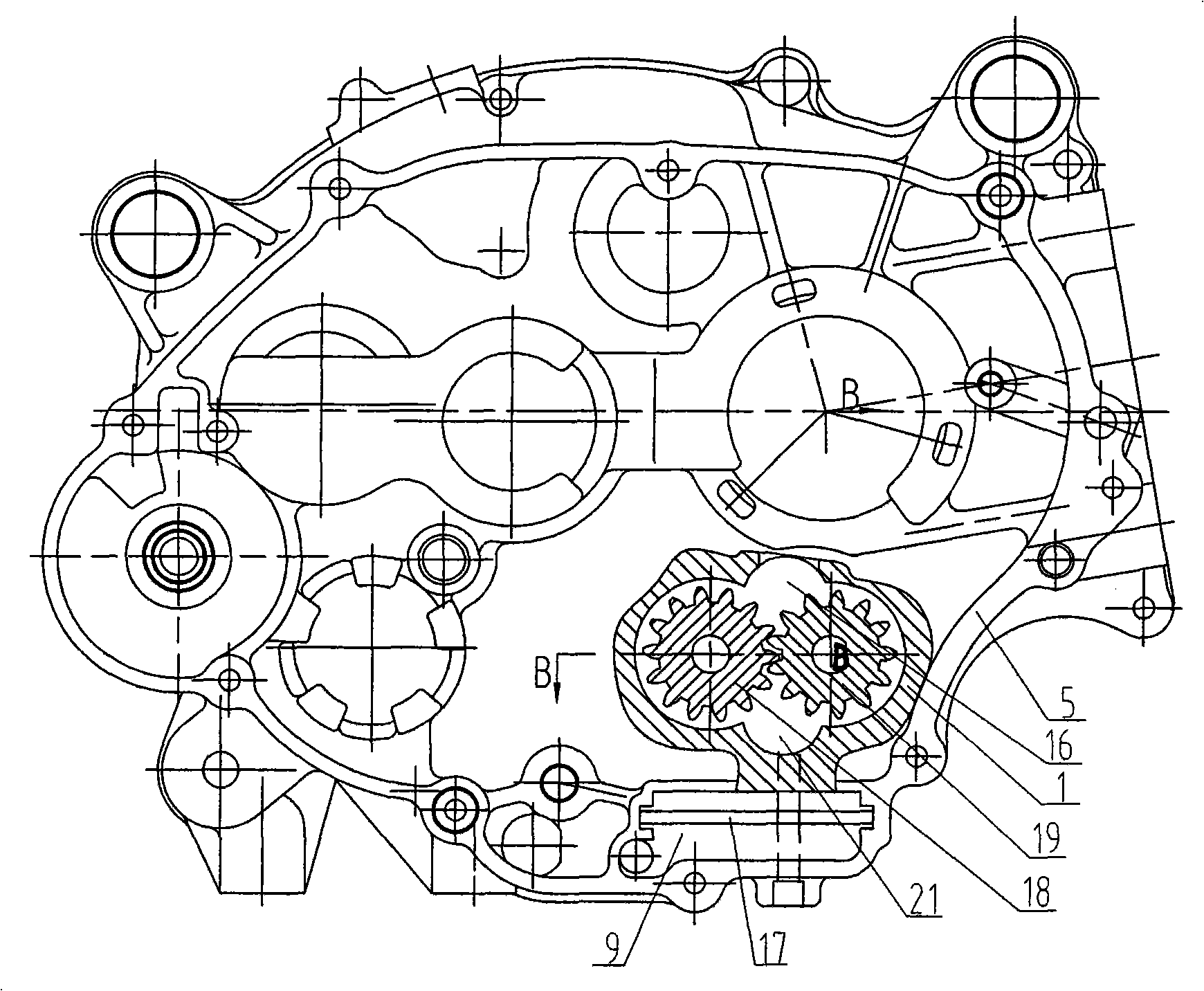

Crankshaft front-end structure of diesel engine

InactiveCN104405526AHigh torque transmissionIncrease powerSealing arrangements for enginesMachines/enginesGear wheelEngineering

The invention discloses a crankshaft front-end structure of a diesel engine. The crankshaft front-end structure of the diesel engine comprises a crankshaft front end, a crankshaft belt pulley, a balance shaft drive gear, a crankshaft timing gear and an oil pump drive gear, wherein the crankshaft front end is positioned at one end of a crankshaft; an external spline is formed in the outer side of the outer circumferential surface of the crankshaft front end; a first flat key groove which extends axially is formed in the inner side of the outer circumferential surface of the crankshaft front end and is used for arranging a flat key; an internal spline which is matched with the external spline of the crankshaft front end to form spline connection is formed in the inner circumferential surface of a central shaft hole of the crankshaft belt pulley; a second flat key groove which is in flat key connection with the flat key of the crankshaft front end is formed in the inner circumferential surface of the central shaft hole of each of the balance shaft drive gear, the crankshaft timing gear and the oil pump drive gear. According to the crankshaft front-end structure of the diesel engine, the crankshaft belt pulley is connected with the crankshaft front end through the spline, so that the assembling structure is compact; the transfer torque of the crankshaft front end is large; the power of a drive accessory is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

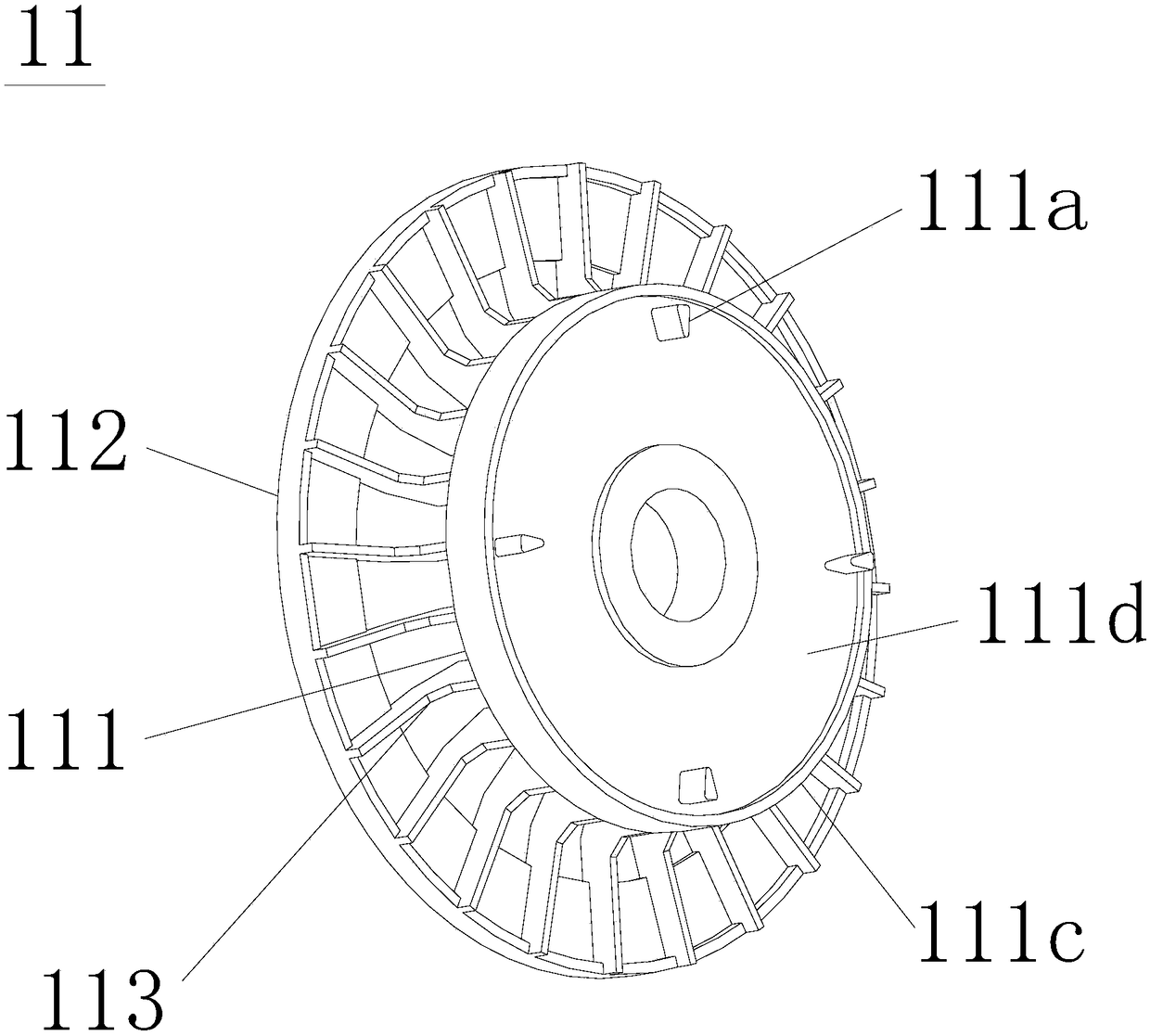

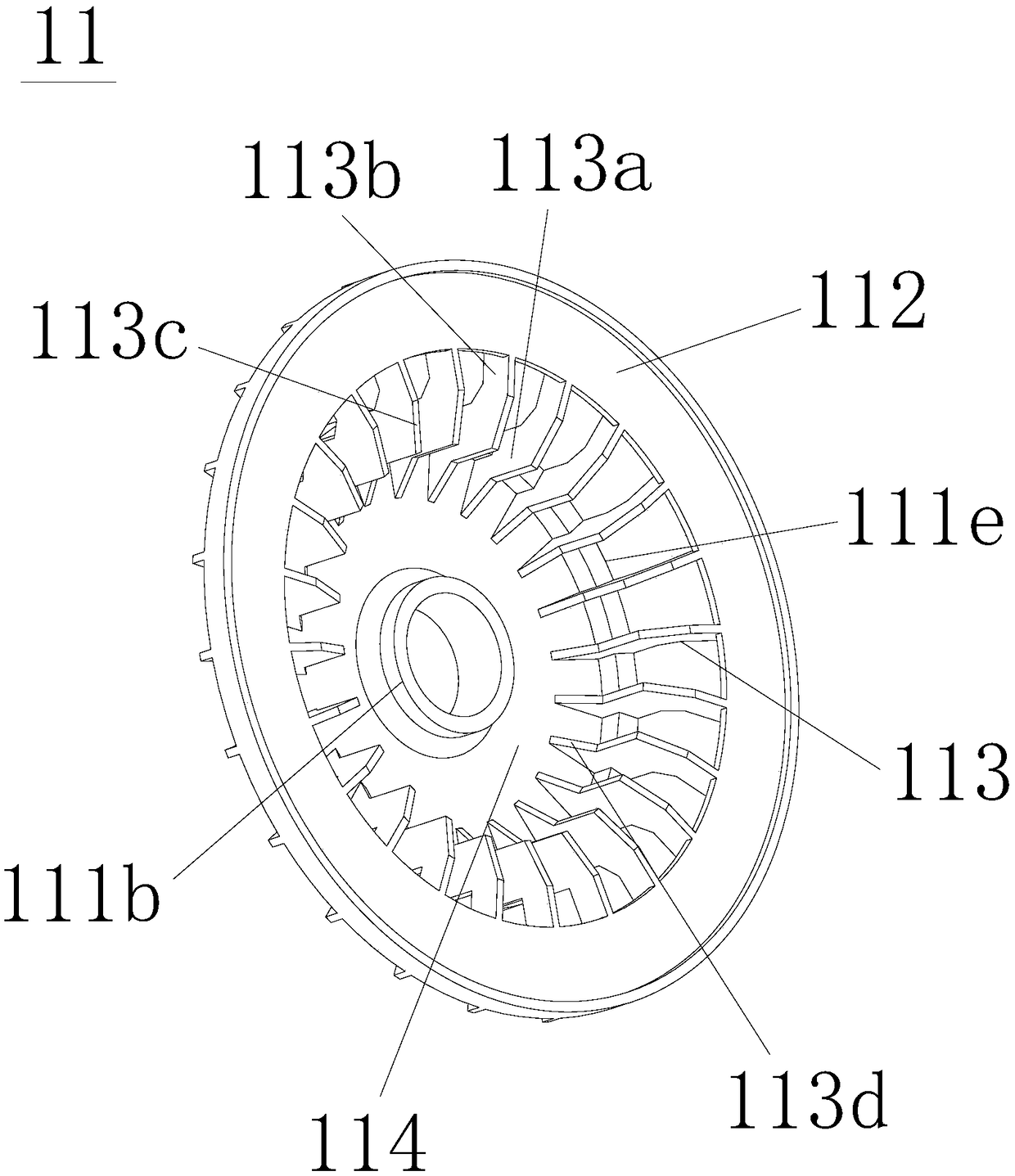

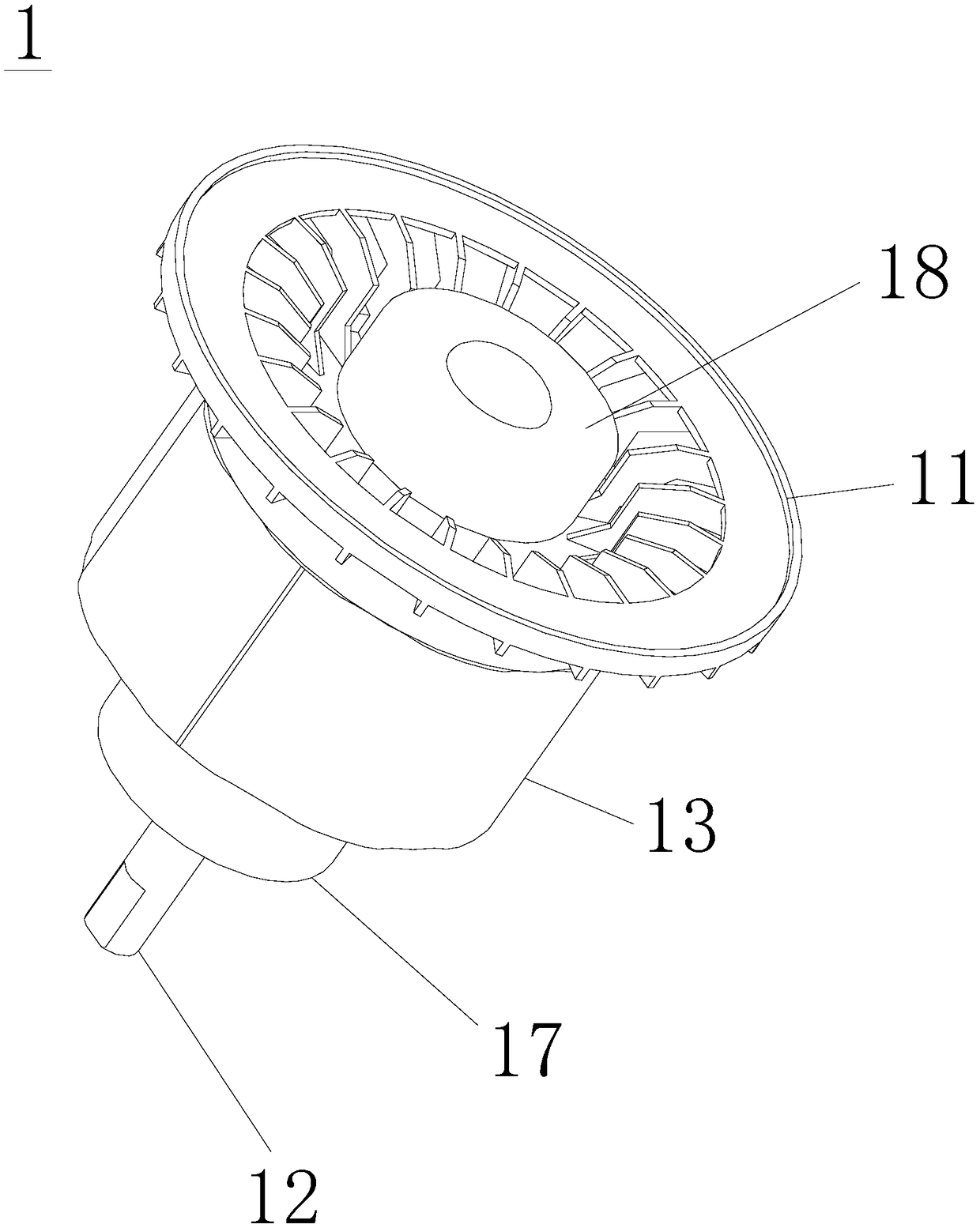

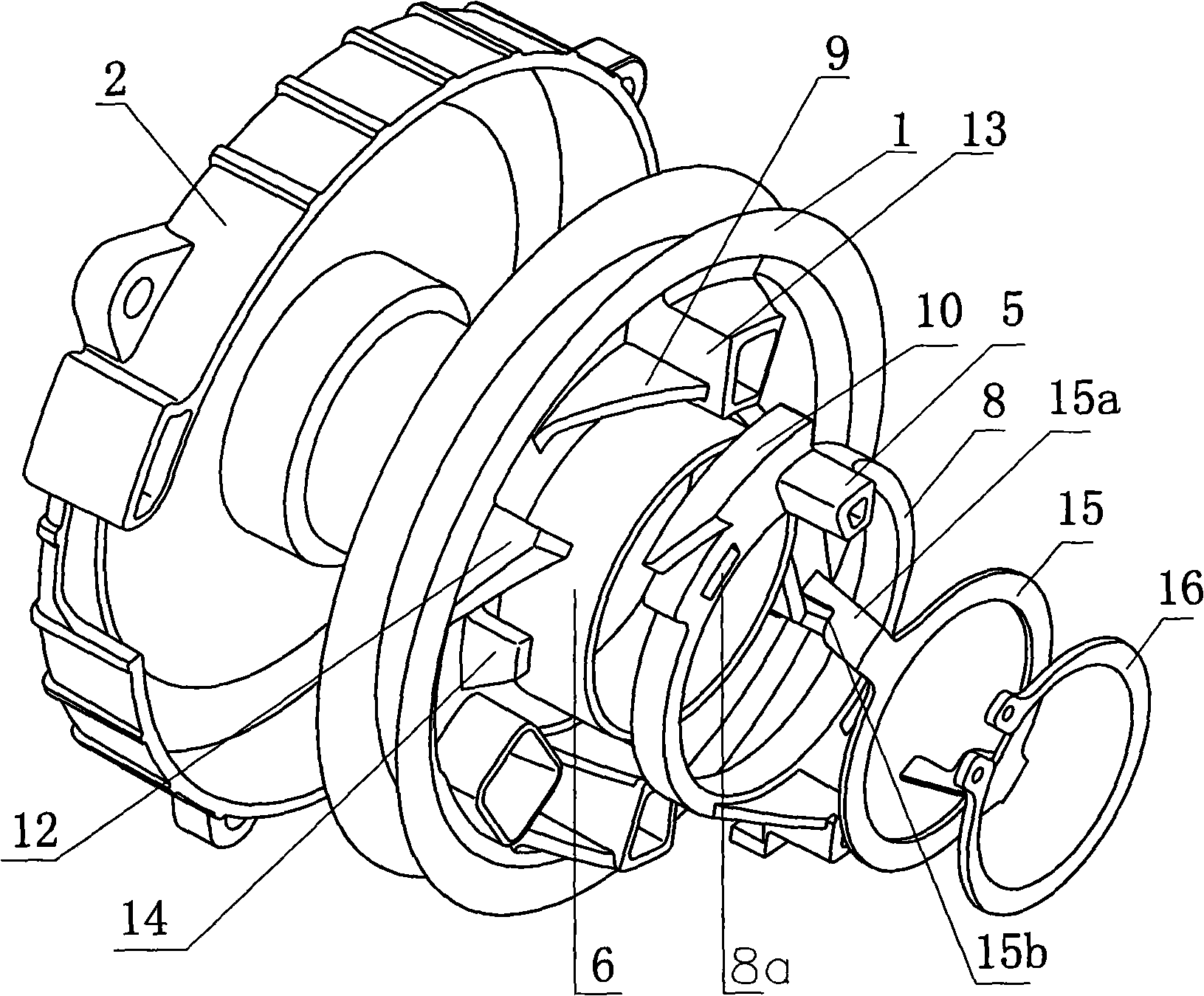

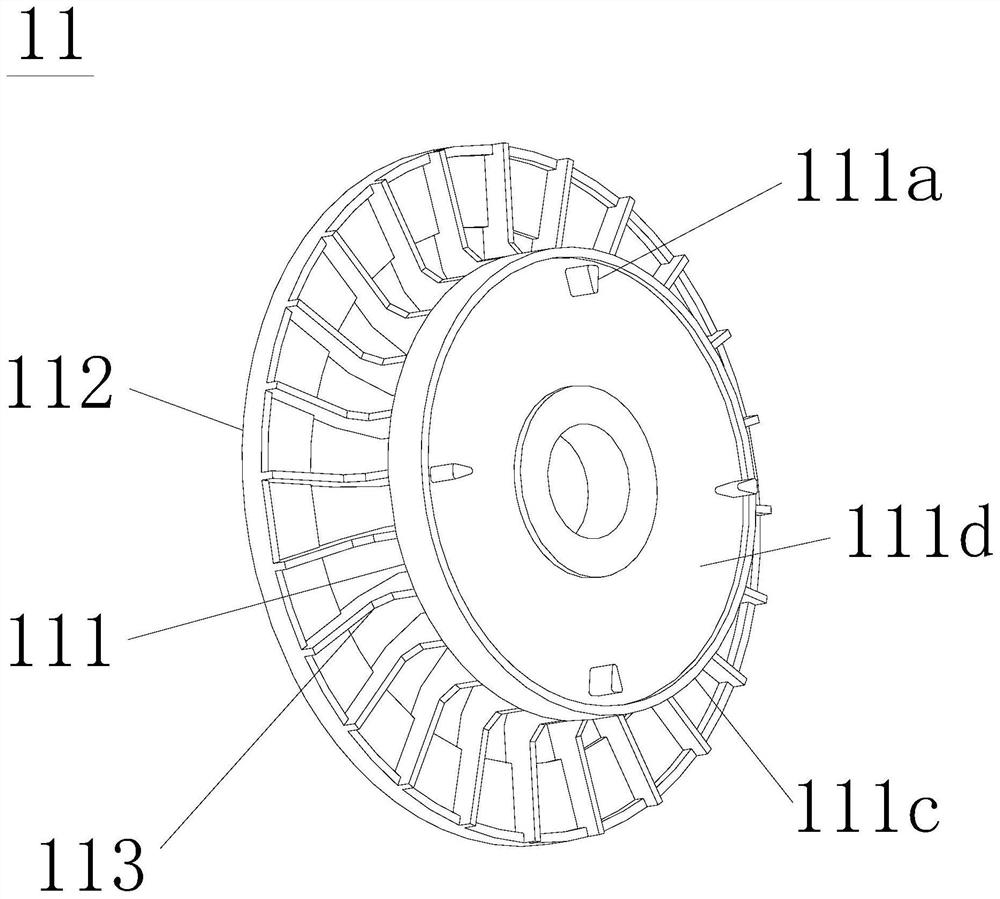

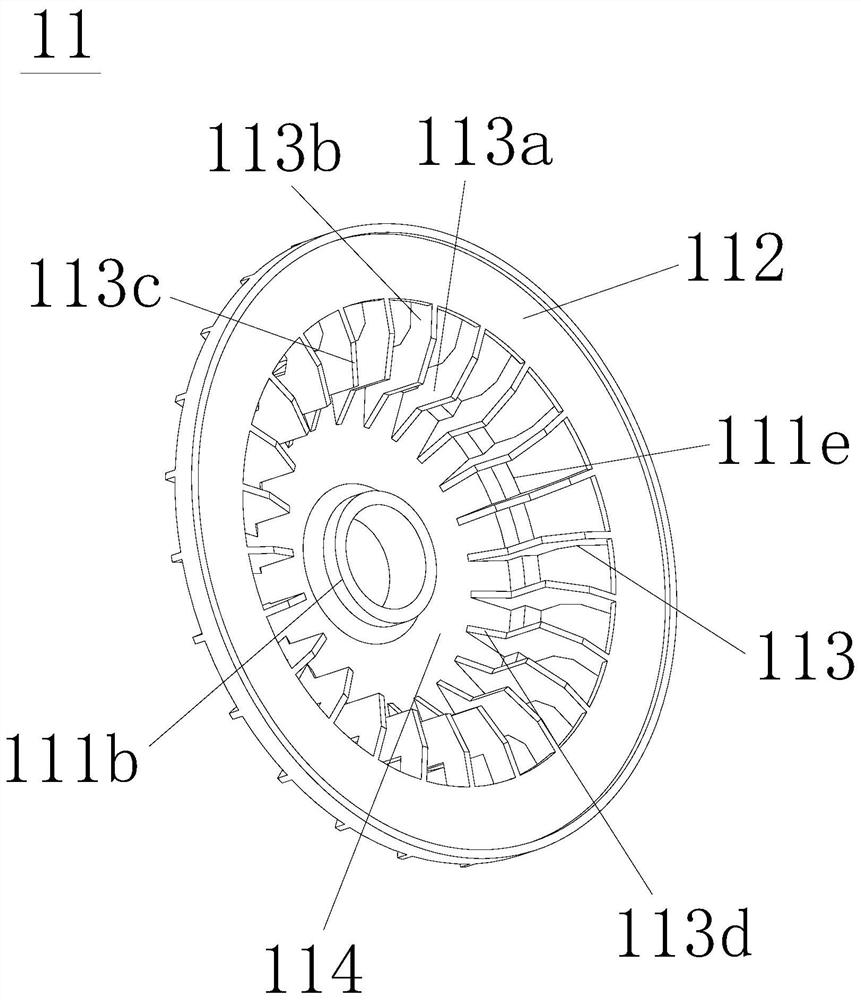

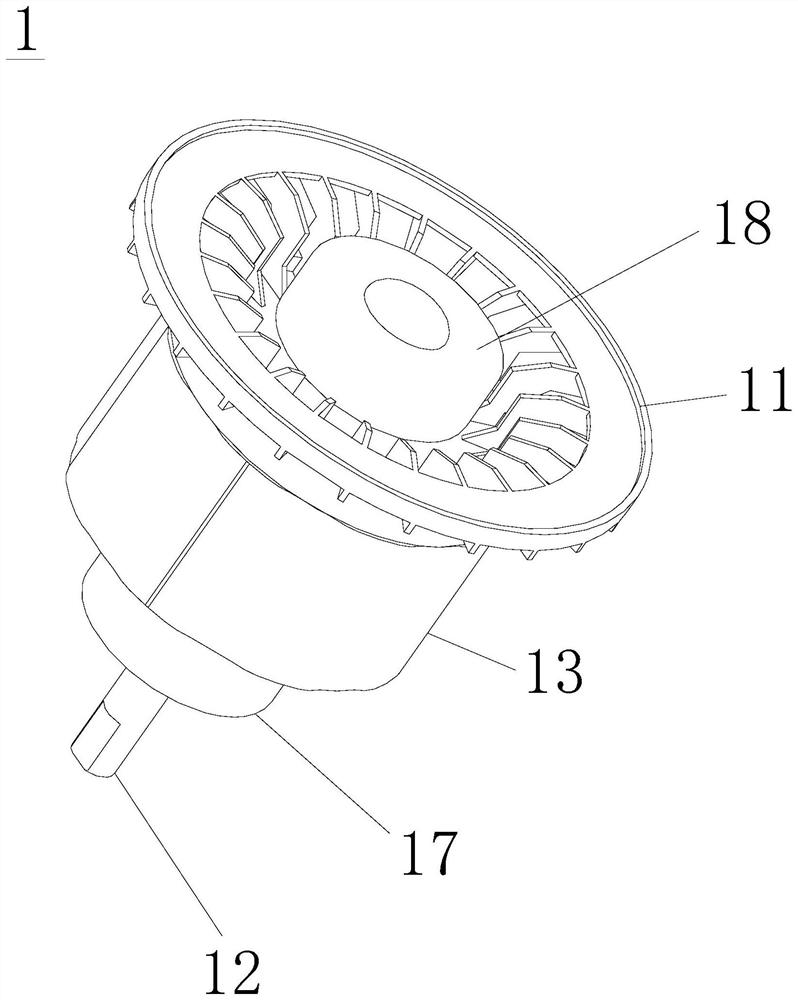

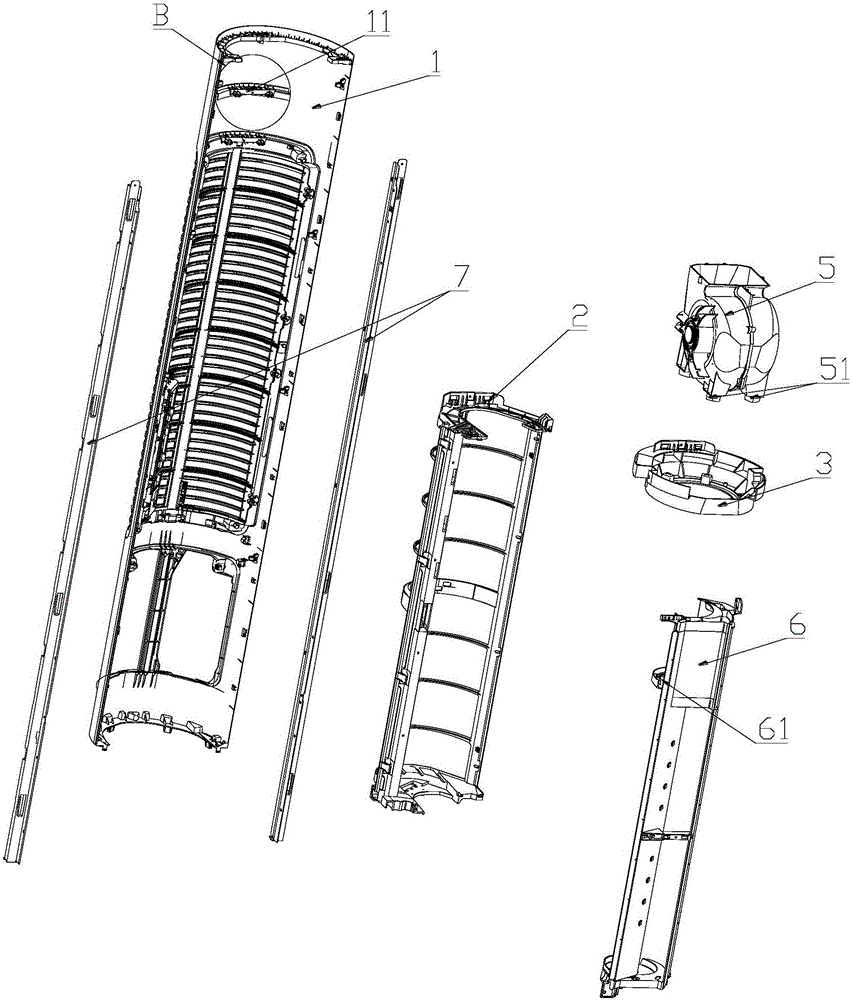

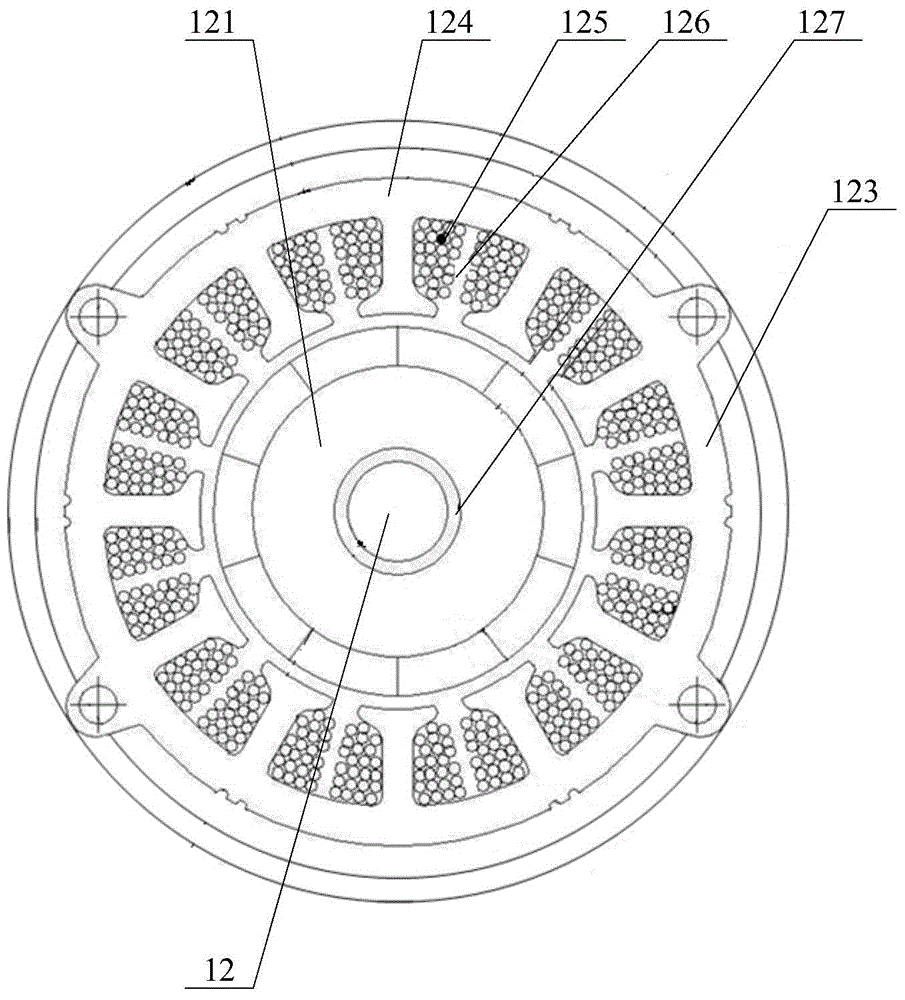

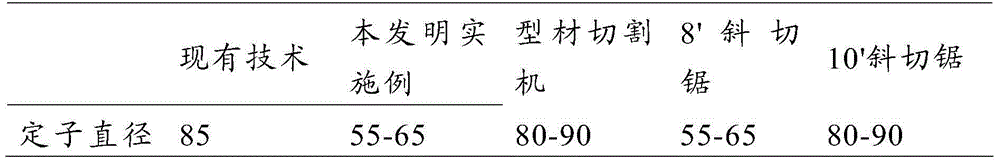

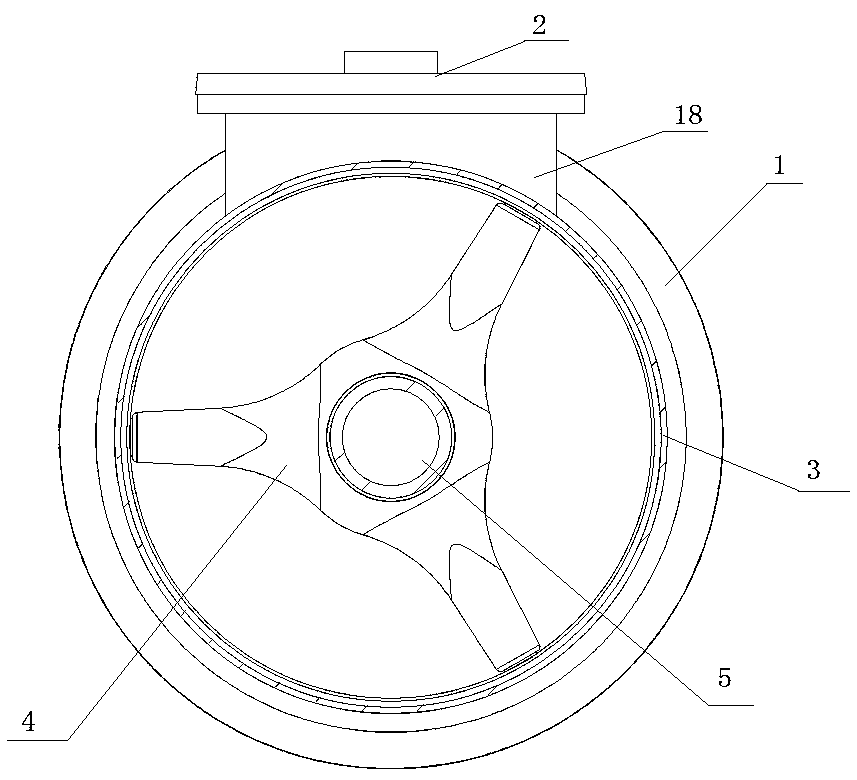

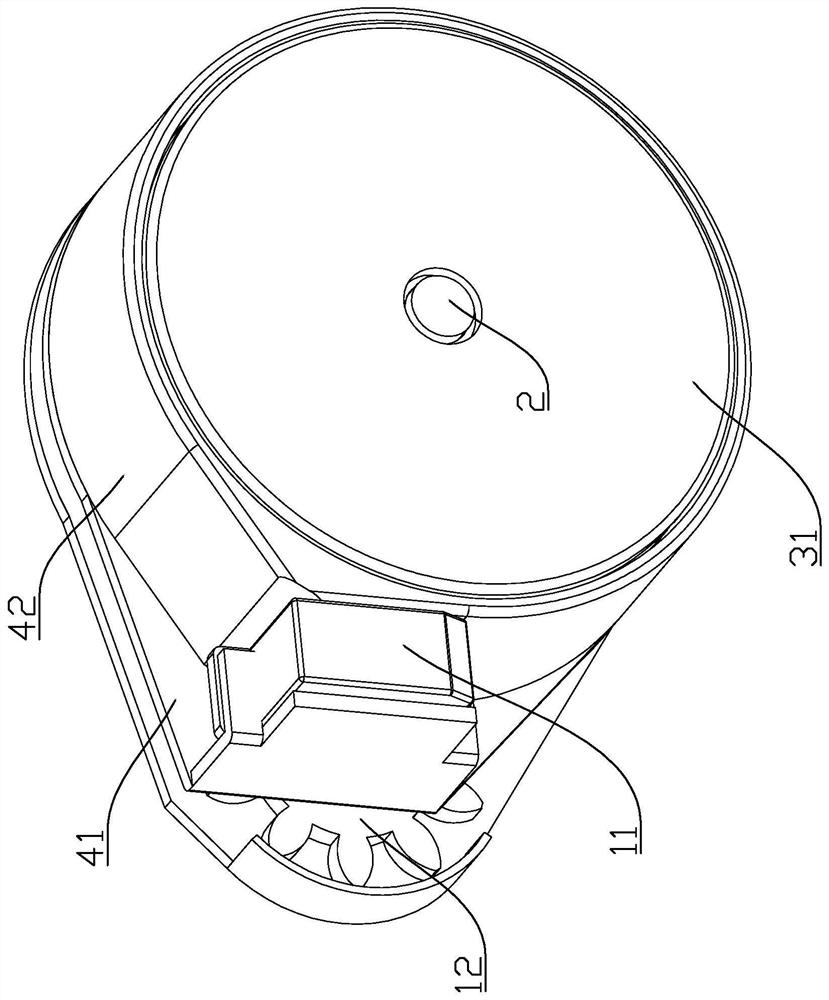

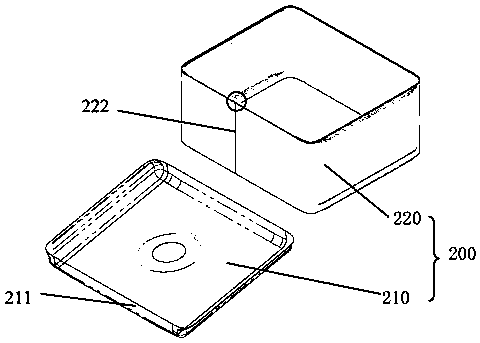

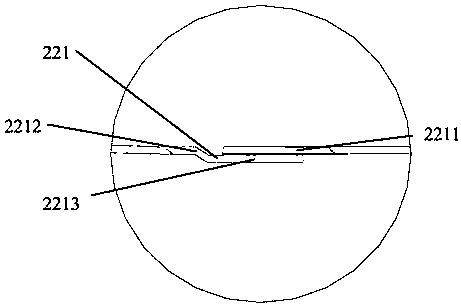

Motor blade, brushless motor, rotor assembly of brushless motor and food processor

ActiveCN108768070AAssembly compactAchieving a flat setupKitchen equipmentMechanical energy handlingBrushless motorsElectric machine

The invention discloses a motor blade, a brushless motor, a rotor assembly of the brushless motor and a food processor. The motor blade (11) comprises a blade body, wherein a plurality of insertion parts (111a) are arranged on an end surface of the blade body at intervals along a circumferential direction. By arranging the plurality of insertion parts on the end surface of the blade body of the motor blade at intervals along the circumferential direction, the motor blade can be internally arranged on a rotor core, so that the motor is optimized to be a flat structure, the axial size of the food processor is greatly reduced, and the vibration and the noise generated by the working process of the food processor are reduced; and on the other hand, the motor blade is provided with a built-in installation structure, the assembly of the rotor assembly can be greatly simplified, the production efficiency is greatly improved, moreover, the production process is clean, no pollution is generated, and the health of a producer can be effectively guaranteed.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

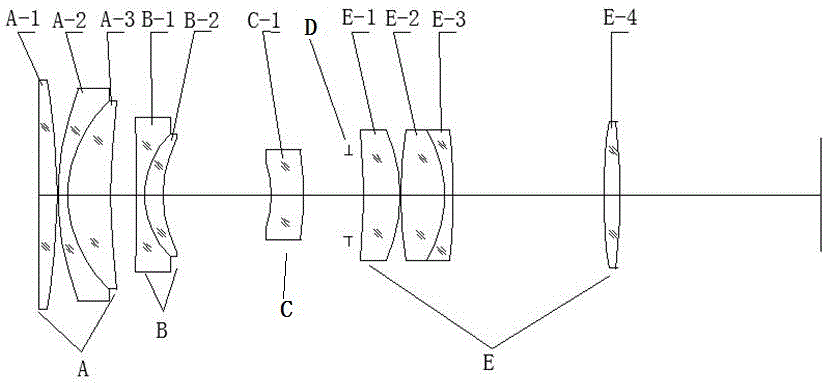

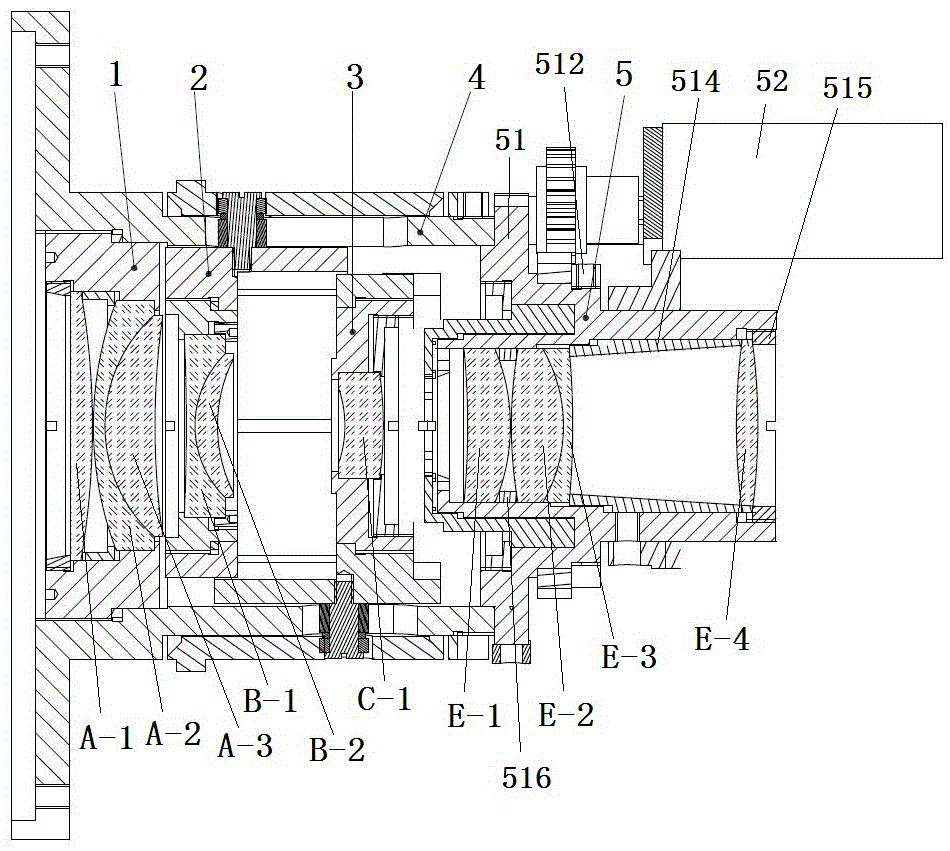

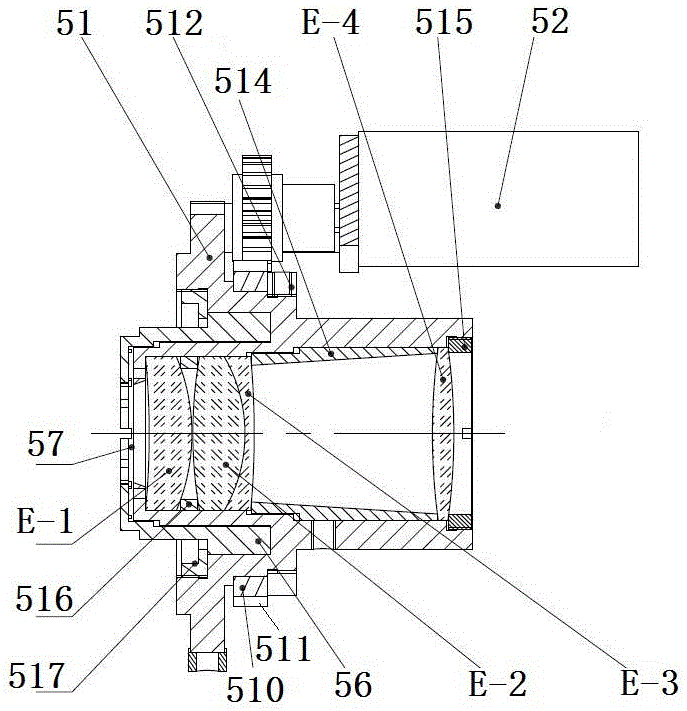

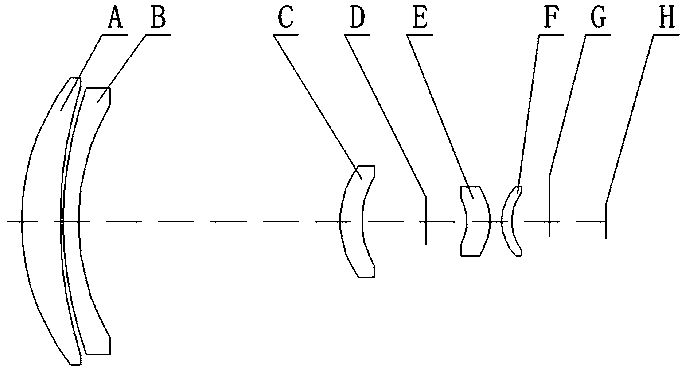

Zooming short-range projection lens and zooming method thereof

The invention relates to a zooming short-range projection lens. An optical system of the lens is sequentially provided with a positive focal power front fixing set A, a negative focal power zoom set B, a negative focal power compensation set C, a variable diaphragm D and a positive focal power back fixing set E along a left-to-right light incident direction, wherein the positive focal power front fixing set A comprises a flat convex lens A-1, a crescent negative lens A-2, a crescent positive lens A-3 which are sequentially arranged from left to right, the negative focal power zoom set B comprises a double concave negative lens B-1 and a crescent positive lens B-2 which are sequentially arranged from left to right, the negative focal power compensation set C comprises a crescent negative lens C-1, the position of the variable diaphragm D is not changed relative to the positive focal power back fixing set E, and the positive focal power back fixing set E comprises a crescent positive lens E-1, a double convex lens E-2, a crescent negative lens E-3 and a double convex positive lens E-4 which are sequentially arranged from left to right. According to the zooming short-range projection lens, the structure of the optical system is simple, intelligible projection of a 190mm object distance can be realized, and length of the lens structure is short.

Owner:FUJIAN FORECAM OPTICS CO LTD

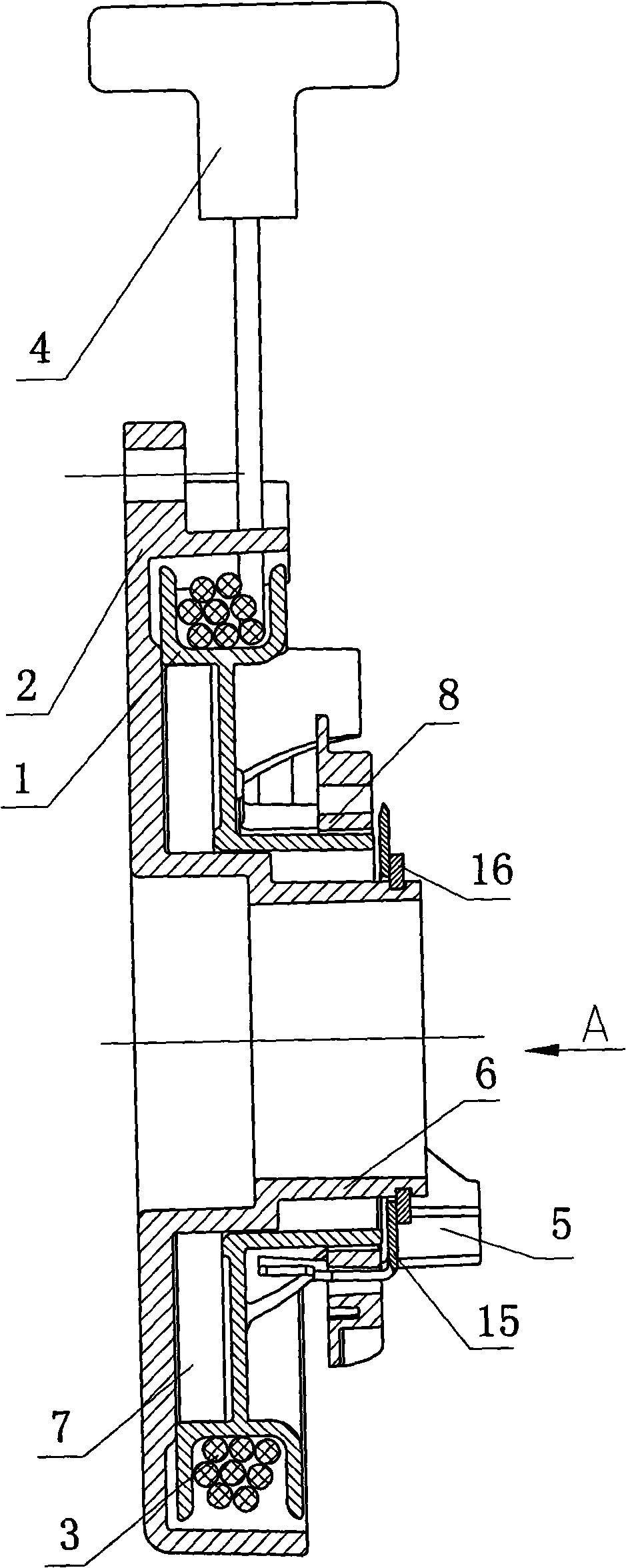

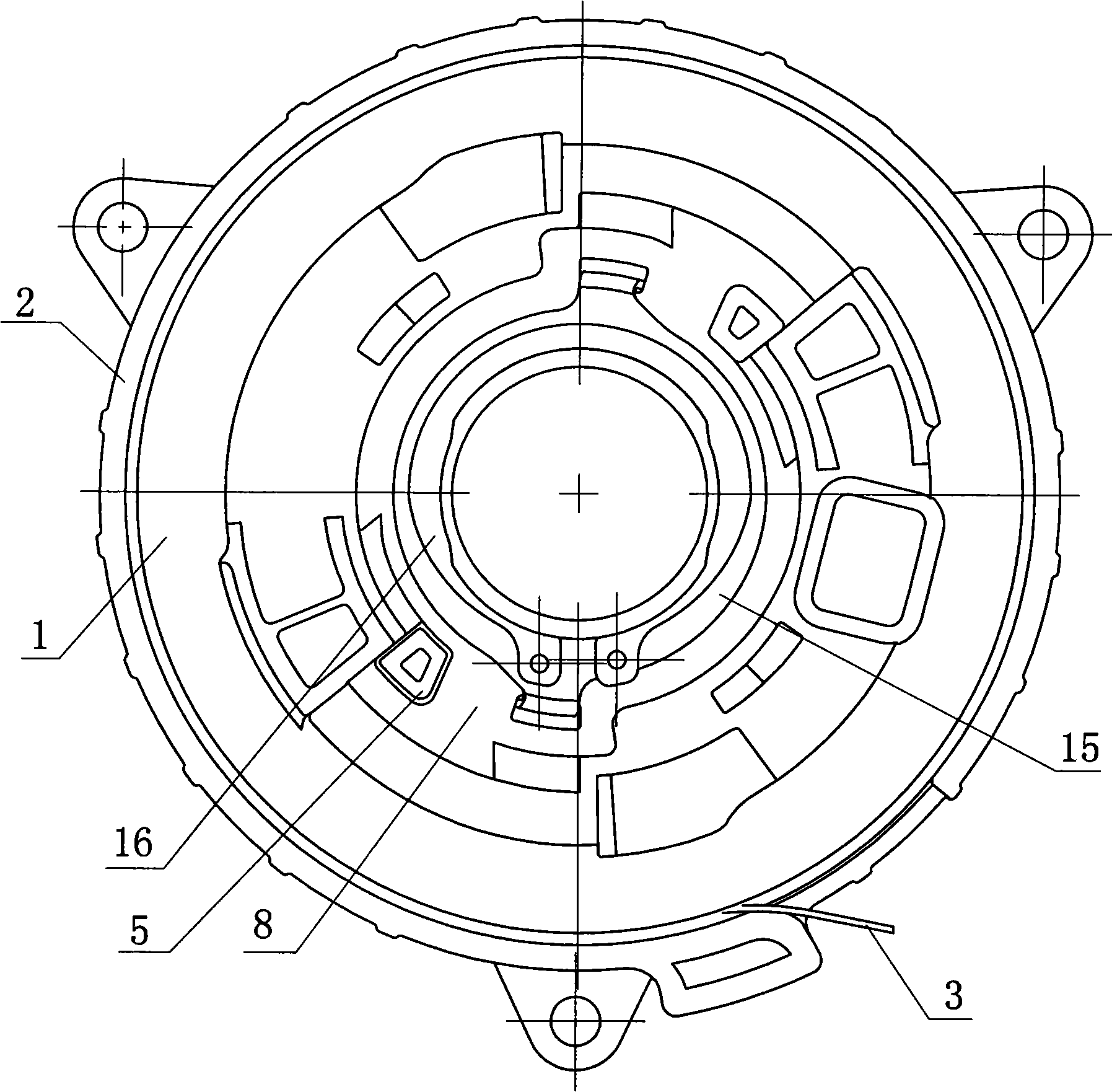

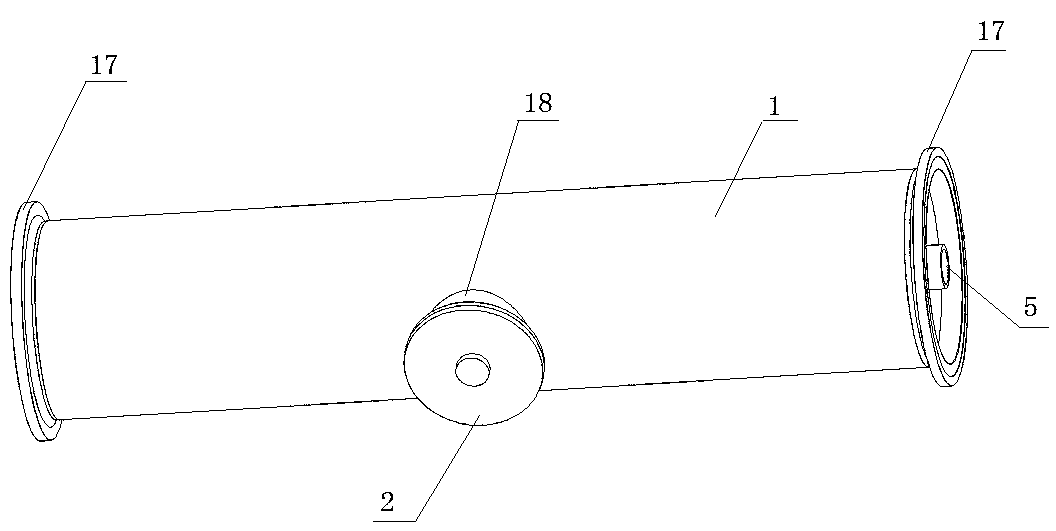

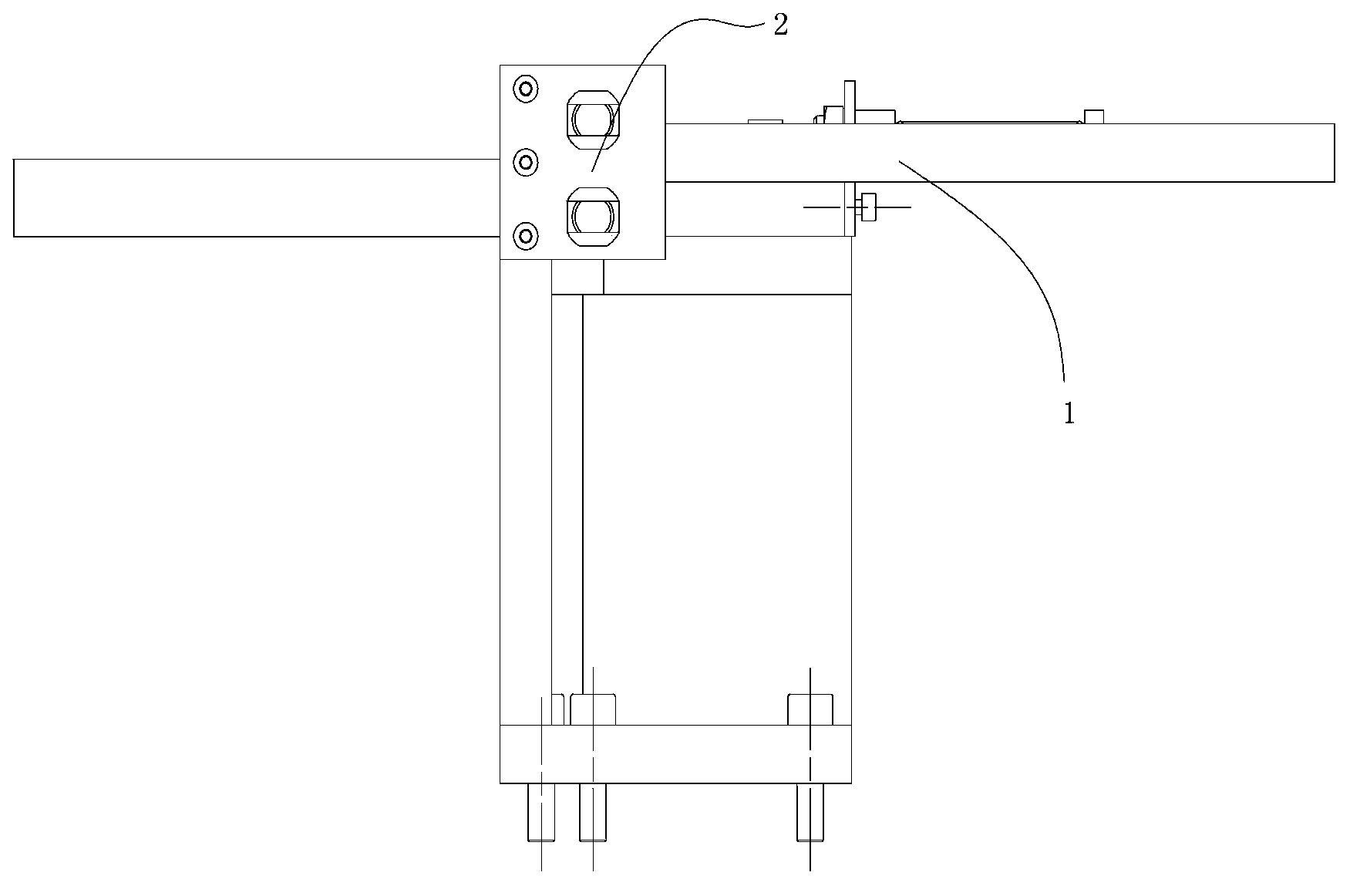

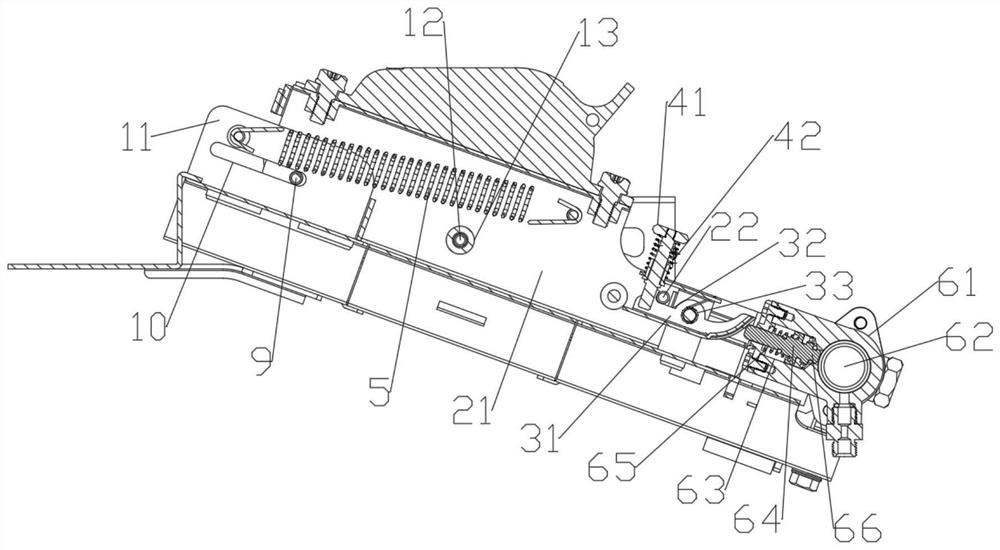

Engine hand pulling starter

InactiveCN101280757AHigh strengthEasy to assembleMuscle operated startersMachines/enginesEngineeringCrankshaft

A hand-pull motor starter is provided with a pulling rope plate (1), a plate seat (2), a pulling rope (3), a handle (4) and a pawl (5). The pulling rope plate (1) is flexibly sheathed on the central post (6) of the plate seat (2) and a returning spring (7) is arranged between the pulling rope plate (1) and the central post (6). One end of the pulling rope (3) is connected with the handle (4) while the other end is connected and winded on the pulling rope plate (1). The shaft neck of the pulling rope plate (1) is flexibly sheathed with a sliding disk (8) and an upright post axially extends on the head face of the sliding disk (8) to form the pawl (5). Inclined plane structures which are mutually coordinated are arranged between the pulling rope plate (1) and the sliding disk (8). When the pulling rope plate (1) rotates, the sliding disk (8) axially moves by the use of the incline plane structure. By adopting the hand-pull motor starter of the invention, the crank shaft of the motor has more compact assembled structure at the start-up end and the axial dimension of the crank shaft is shortened so as to enable more reliable start-up operation.

Owner:LONCIN MOTOR

Motor blades, brushless motors and their rotor assemblies, food processors

ActiveCN108768070BAssembly compactAchieving a flat setupKitchen equipmentMechanical energy handlingBrushless motorsElectric machinery

The invention discloses a motor fan blade, a brushless motor and its rotor assembly, and a food cooking machine. The motor fan blade (11) includes a fan blade body, and the end surface of the fan blade body is arranged at intervals along the circumferential direction. Multiple insertion parts (111a). In the present invention, a plurality of insertion parts arranged at intervals along the circumferential direction are arranged on the end surface of the blade body of the motor blade, so that the motor blade can be built-in and installed on the rotor core, thereby optimizing the motor to have a flat structure , thereby greatly reducing the axial size of the food cooking machine and reducing the vibration and noise generated during its operation. On the other hand, because the motor fan blade of the present invention has a built-in installation structure, the assembly of the rotor assembly is greatly simplified, thereby greatly improving production efficiency, and the production process is clean and pollution-free, and the health of production personnel can be effectively guaranteed.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

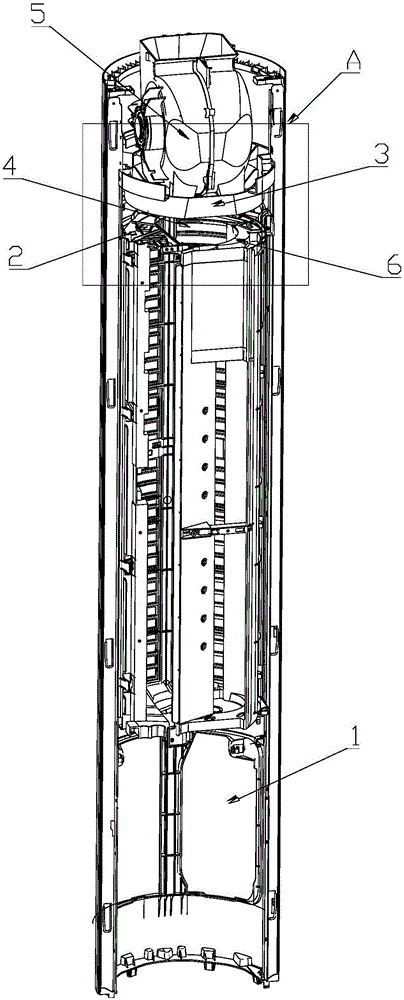

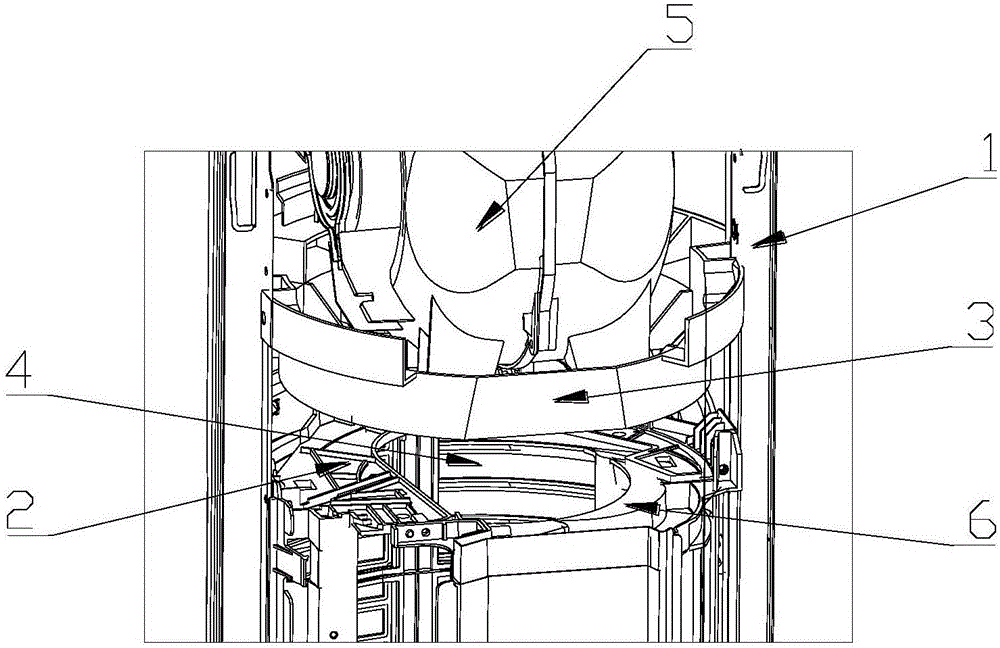

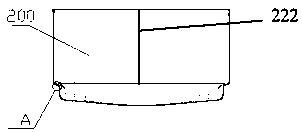

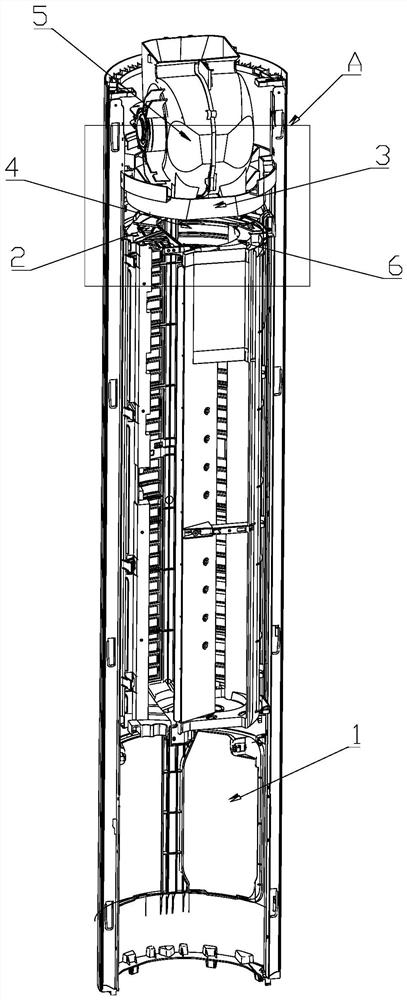

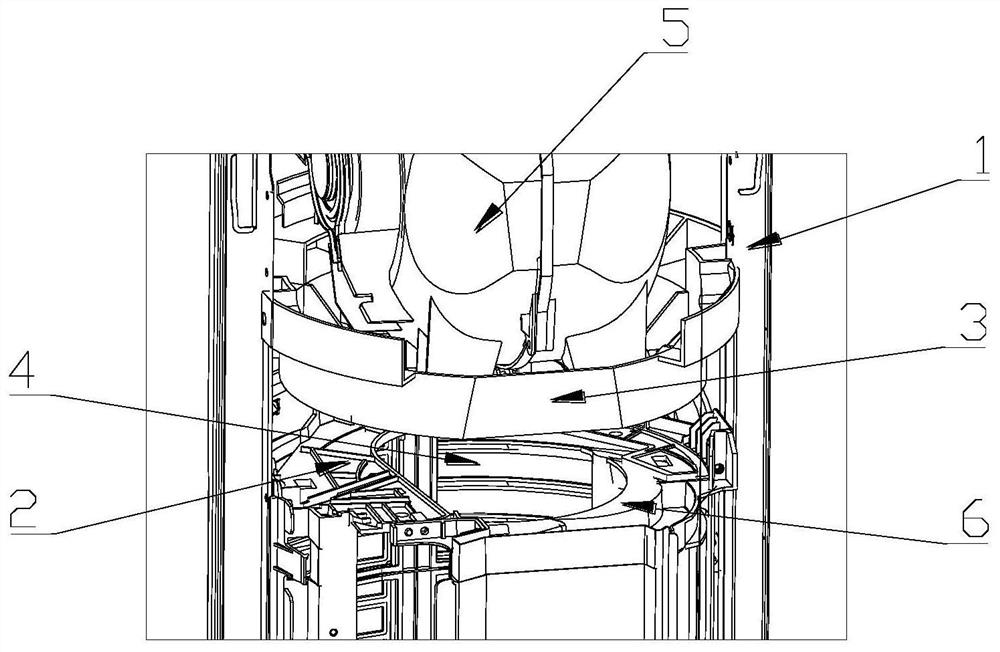

Vertical type cross-flow air conditioner with top air outlet function, and control method

ActiveCN106403043AAvoid affecting performanceMeet the needs of one-key operationMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeat exchanger

The invention relates to a vertical type cross-flow air conditioner with a top air outlet function, and a control method. The vertical type cross-flow air conditioner with the top air outlet function comprises a shell, a heat exchanger assembly, a volute assembly, a top air outlet assembly and a front air outlet assembly, wherein the shell is vertically arranged and is of a long cylinder structure, and the heat exchanger assembly, the volute assembly, the top air outlet assembly and the front air outlet assembly are mounted in the shell; the top air outlet assembly is mounted at the top of the interior of the shell, and part of air flow, subjected to heat exchange through the heat exchanger assembly, in the shell is exhausted from the top; the volute assembly is located below the top air outlet assembly, and the front air outlet assembly is mounted in the volute assembly; a mounting support is fixed to the inner side wall of the shell, and the top air outlet assembly is fixedly mounted at the upper end of the mounting support; and gaps are reserved between the lower end of the mounting support and the upper end of the volute assembly as well as between the lower end of the mounting support and the upper end of the heat exchanger assembly. According to the vertical type cross-flow air conditioner with the top air outlet function, and the control method, the mounting support is fixed to the inner side wall of the shell, and the gaps are reserved in the lower end of the mounting support, so that the whole top air outlet assembly is borne by the shell, and the situation that the performance of the whole air conditioner is affected due to the fact that the volute assembly or the heat exchanger assembly at the lower end of the mounting support is overloaded is avoided.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

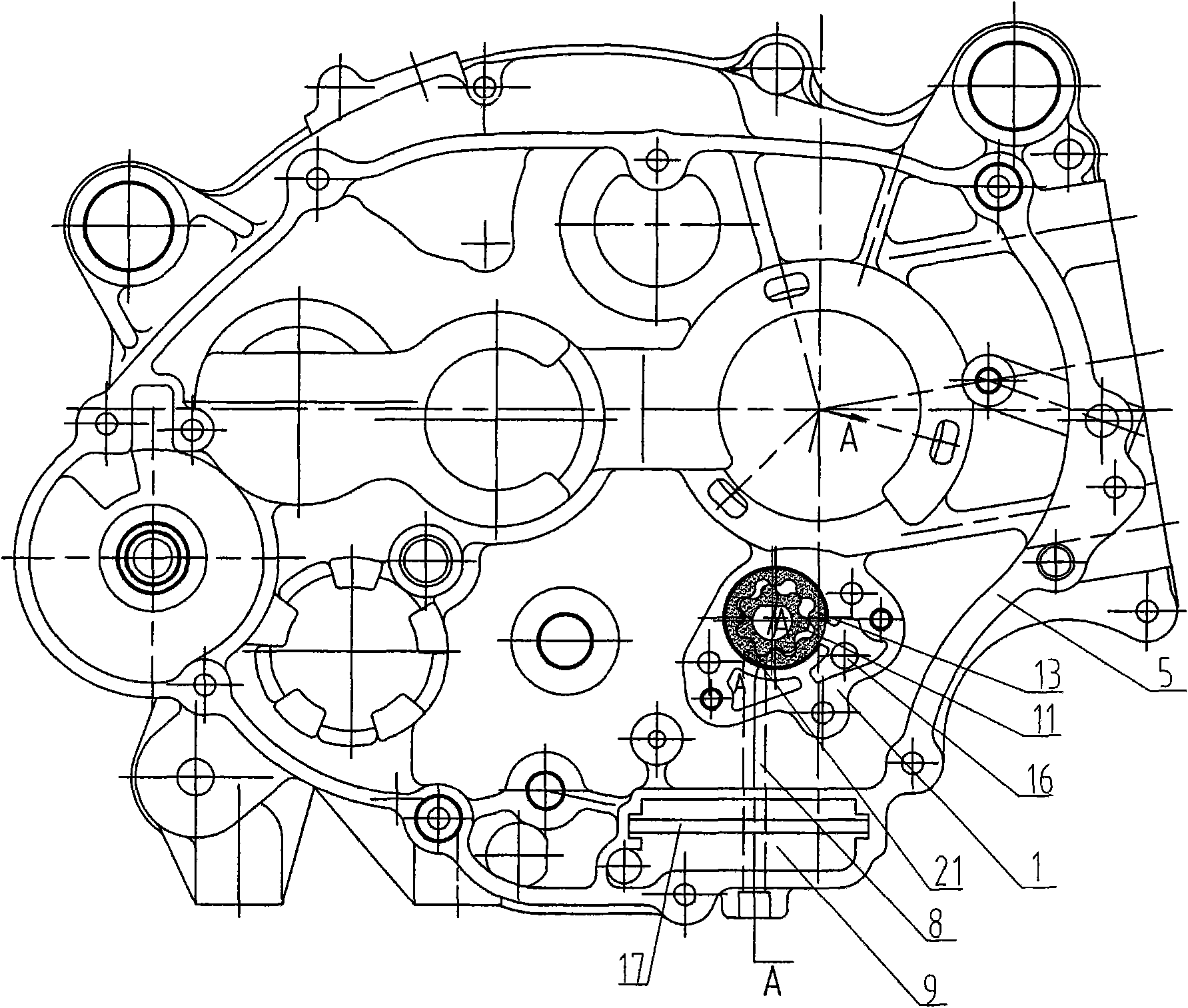

Engine oil pump construction

InactiveCN101634240AAssembly compactMake sure the center distance meets the requirementsPressure lubrication with lubrication pumpEngineeringCrankshaft

The invention provides an engine oil pump construction which comprises an oil pump seat (1), an oil pump cover (2), an oil pump shaft (3), an oil pump driven gear (4) and a gear component or a rotor component. The gear component or the rotor component is mounted on the oil pump shaft (3) and arranged in an inner cavity of the oil pump seat (1); the oil pump seat (1) and the inner wall of a crank box body (5) are integrally formed; and the oil pump driven gear (4) mounted at one end of the oil pump shaft (3) is engaged with an oil pump driving gear (7) on a crank (6). The engine oil pump construction has compact structure of an engine, decreases the manufacture cost and obviously lowers the engagement noise between the oil pump driving gear and the oil pump driven gear.

Owner:CHONGQING LONCIN MOTOR

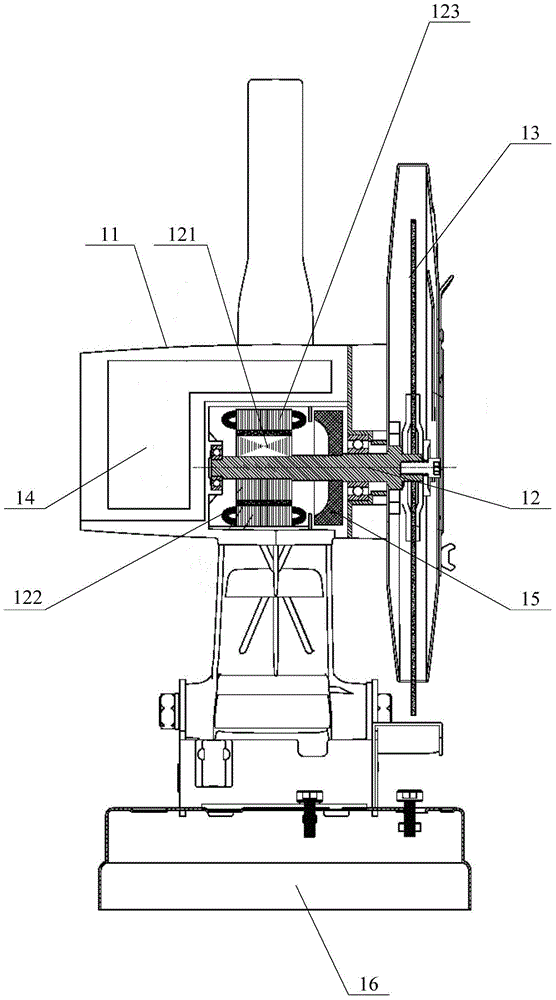

Desk-type cutting tool

InactiveCN105449927AImprove transmission efficiencyAssembly compactMetal sawing devicesMagnetic circuit rotating partsBrushless motorsEngineering

The invention discloses a desk-type cutting tool, and the tool comprises a case. The interior of the case is provided with a brushless motor and a controller, wherein the brushless motor comprises a motor rotating shaft. An external end part of the motor rotating shaft is provided with an output disc in a linkable sleeving manner, and the axis of the motor rotating shaft is perpendicular to the operation surface of the output disc, and passes through the center of the output disc. The periphery of the internal end of the motor rotating shaft is coaxially provided with a rotor core in a sleeving manner, and the peripheral surface of the rotor core is provided with a permanent magnet. The interior of the case is also provided with a stator cooperating with the permanent magnet. The tool is simple and compact in structure, is longer in service life, and is higher in transmission efficiency.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

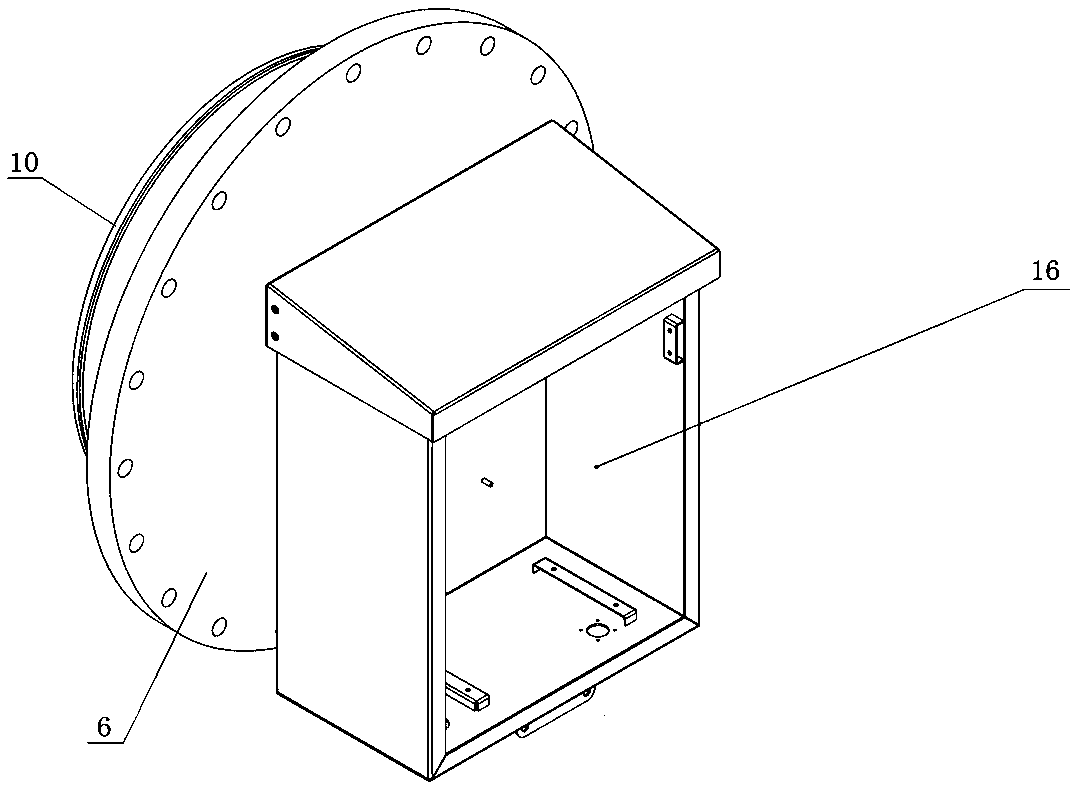

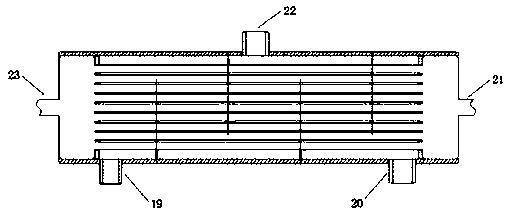

Integrated VFTO measuring bus and bus cylinder thereof

ActiveCN111049085AReduce on-site construction operationsEasy to measureTesting dielectric strengthTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

The invention relates to an integrated VFTO measuring bus and a bus cylinder thereof. The VFTO measuring bus comprises a bus cylinder, a conducting rod arranged in the bus cylinder and a supporting insulator used for supporting the conducting rod. A VFTO measuring device is integrated on the bus cylinder, the bus cylinder is used for being in butt joint with a GIS / GIL bus, a supporting insulator is arranged in the bus cylinder, and the supporting insulator is used for supporting the conducting rod; and the VFTO measuring device is used for measuring the VFTO between the bus cylinder and the conducting rod. The integrated VFTO bus adopts an integrated structure and can be directly butted with a corresponding GIS / GIL bus during installation and can be directly connected with corresponding measurement equipment for measurement during measurement and is easy to operate and convenient to measure.

Owner:PINGGAO GRP +2

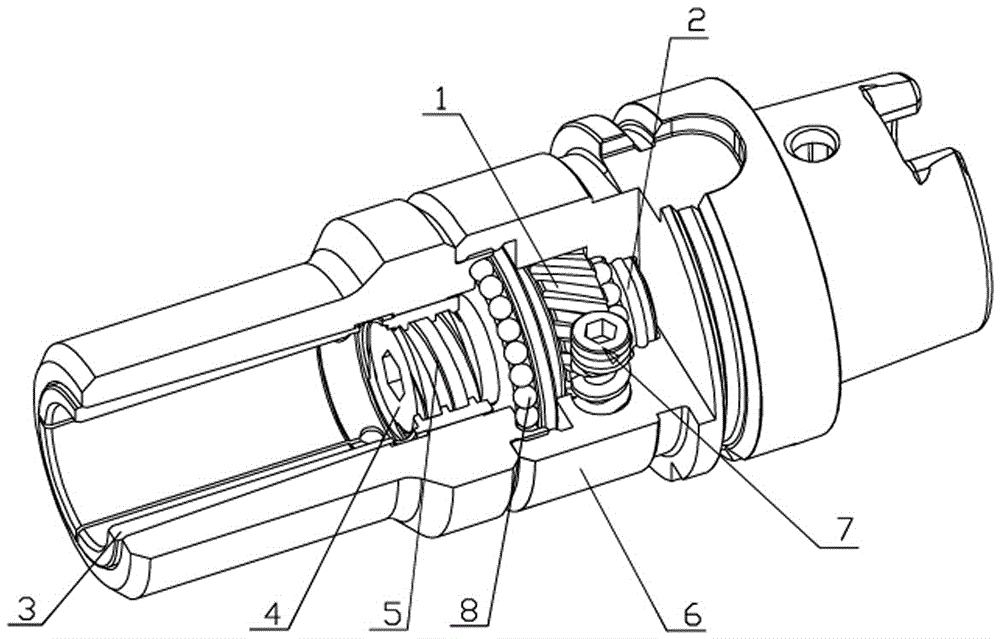

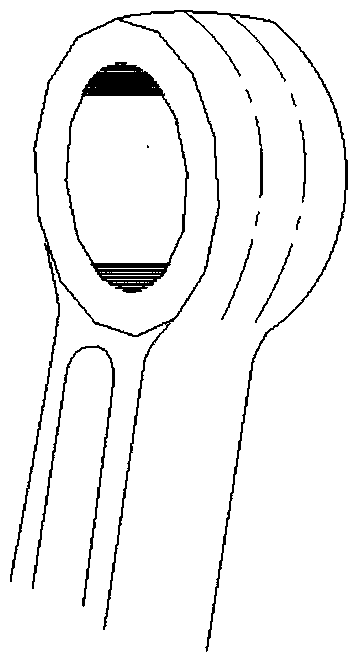

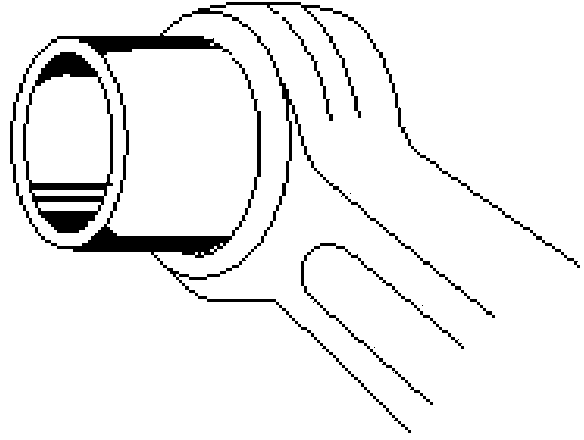

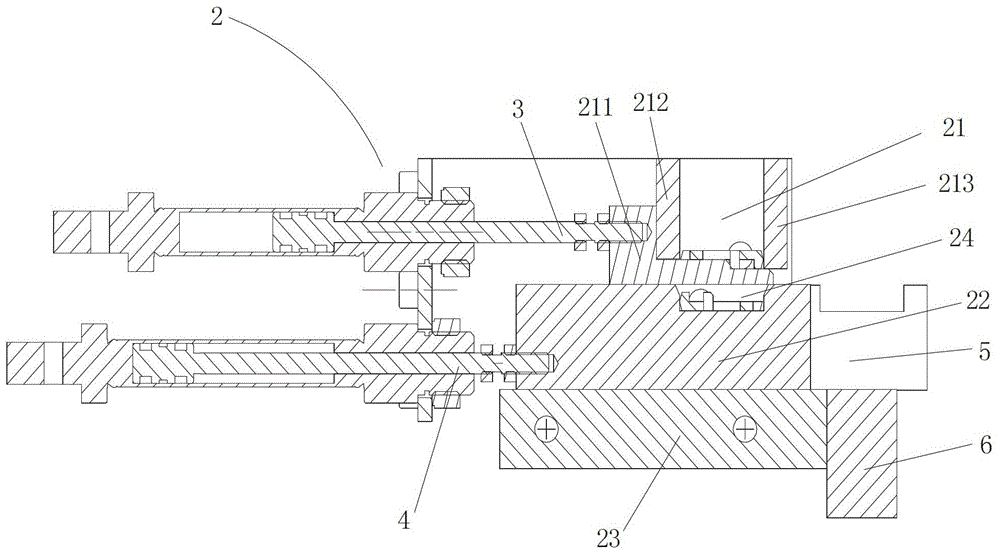

Locking device for torque tool handle collet

ActiveCN105665764AEasy to lockExtended service lifeTurning machine accessoriesEffective lengthEngineering

A locking device for a torque tool handle collet comprises a tool handle body, the collet and a worm wheel and worm mechanism. A central shaft hole is formed in the tool handle body. The collet is arranged in a conical cavity in the front end of the central shaft hole in a matched manner. A worm wheel in the worm wheel and worm mechanism is arranged in the middle of the central shaft hole. The worm wheel and the tool handle body are coaxially installed. A lengthening assembly is connected between the worm wheel and the collet in a threaded manner. A tool is locked or released through the worm wheel and worm mechanism, and therefore labor is saved, and replacement and adjustment are convenient. The lengthening assembly is arranged in the tool handle body; on one hand, the effective length of a tool handle can be increased, and replacement types of the worm wheel are reduced; and on the other hand, radial tightening force is converted into axial tensioning force exponentially, time and labor are saved during operation, and the locking device is simple and compact in structure and low in cost.

Owner:QUFU CHONGDE PRECISION MACHINERY CO LTD

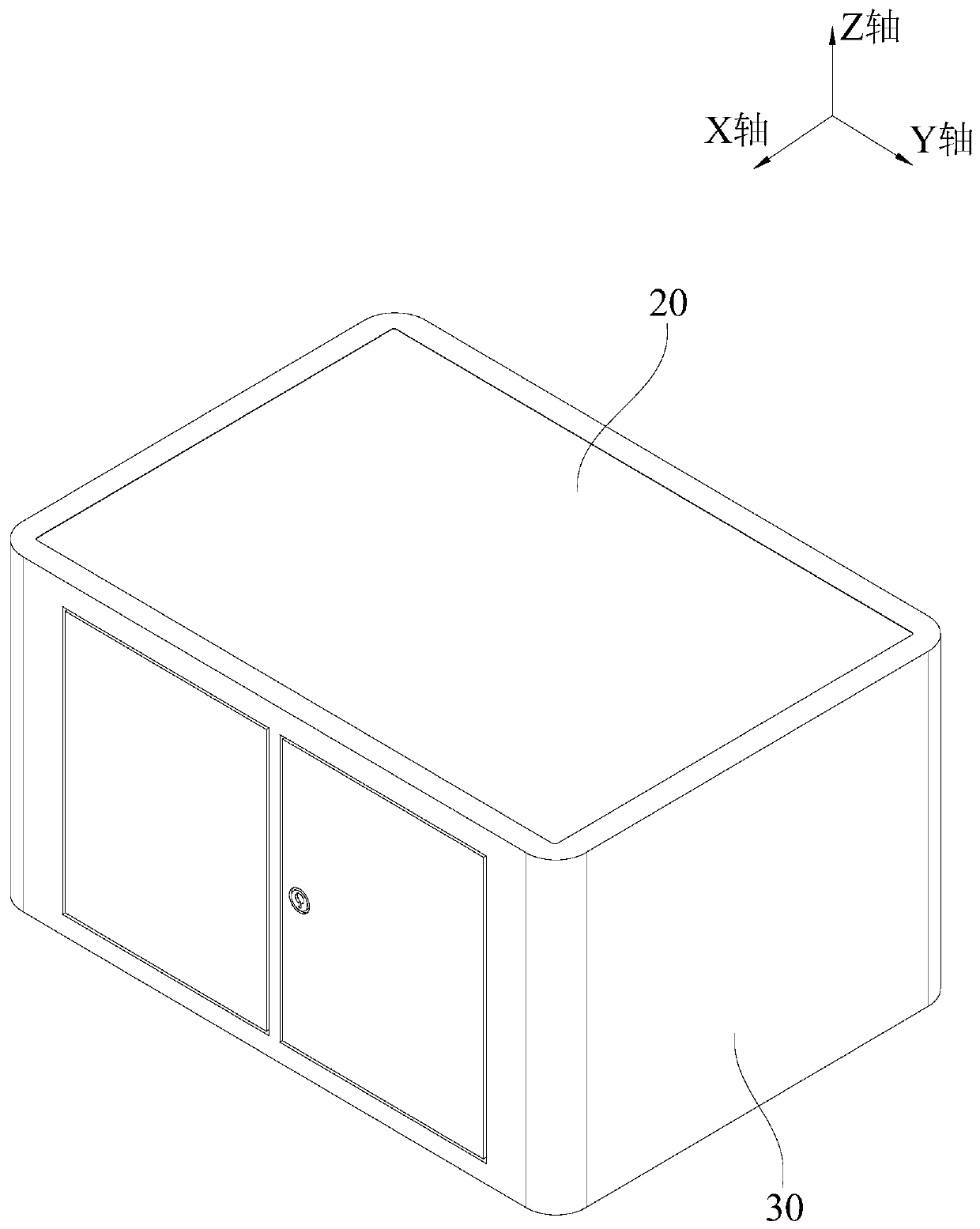

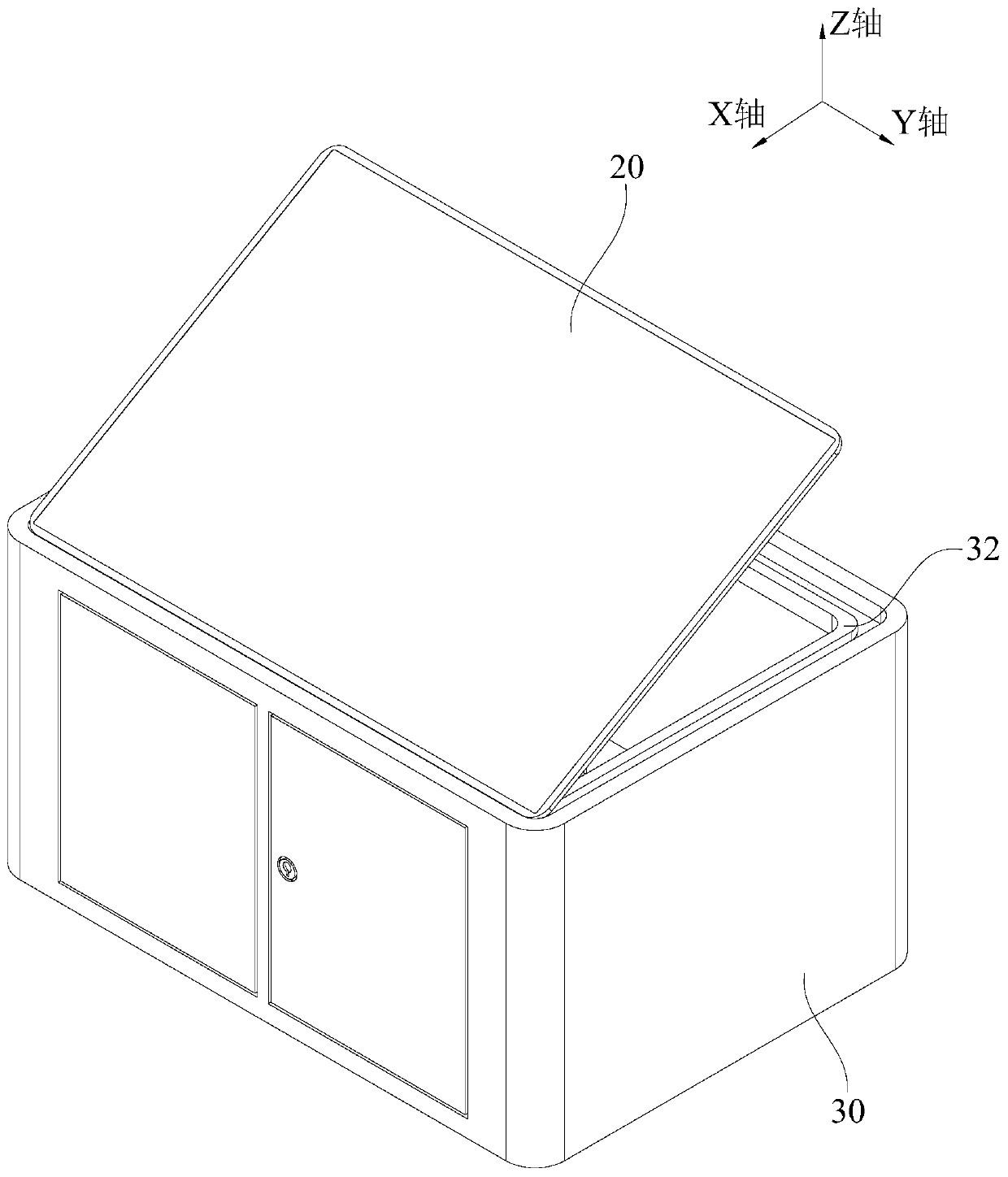

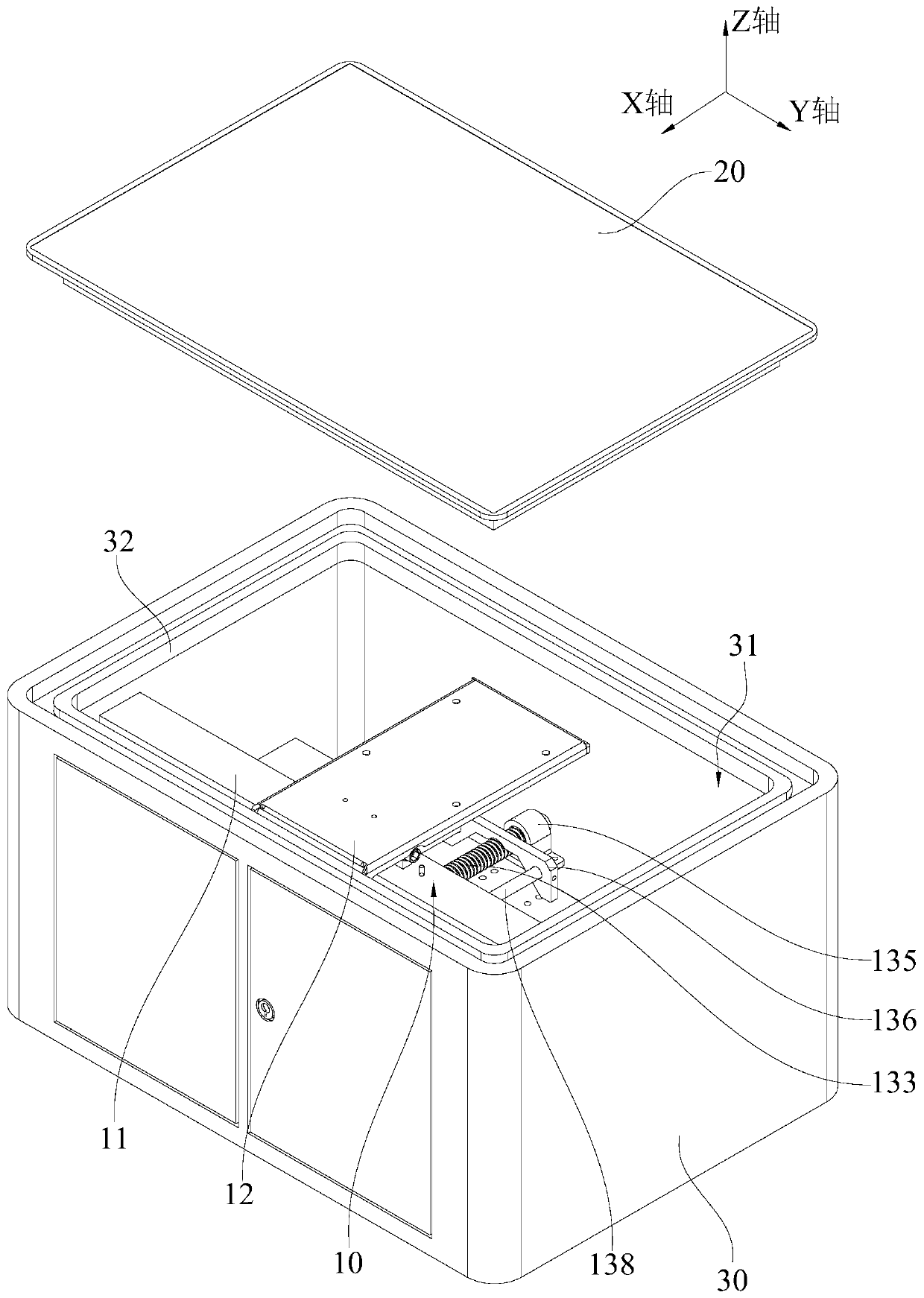

Turnover display device and tea table

InactiveCN110477609AReduce manufacturing costReduce maintenance difficultyOffice tablesFurniture partsDisplay deviceEngineering

The invention belongs to the technical field of display equipment, in particular to a turnover display device and a tea table; the turnover display device comprises a turnover mechanism and a displayscreen, wherein the turnover mechanism comprises a bearing part, a screen supporting plate, a driving module and at least one driving arm; the screen supporting plate is rotationally arranged on the bearing part, and can rotate around the direction of a Y axis; one end of the driving arm is rotationally connected with the driving end of the driving module and can move in the X-axis direction underthe driving of the driving module; the screen supporting plate has a connecting side, the other end of the driving arm is connected with the connecting side of the screen supporting plate and used for driving the screen supporting plate to rotate in the Y-axis direction relative to the bearing part under the driving of the driving module; and the display screen is fixed on the screen supporting plate. According to the screen supporting plate, the bearing part serves as a supporting point, the turning over of the display screen can be realized, the turnover action of the display screen can berealized only by the cooperation of the driving module and the driving arm, so that the structure is simple, the compact structure layout is easy to realize, and the assembling space occupation rate of the turnover display device is also reduced.

Owner:CHONGQING HUIKE JINYANG TECH

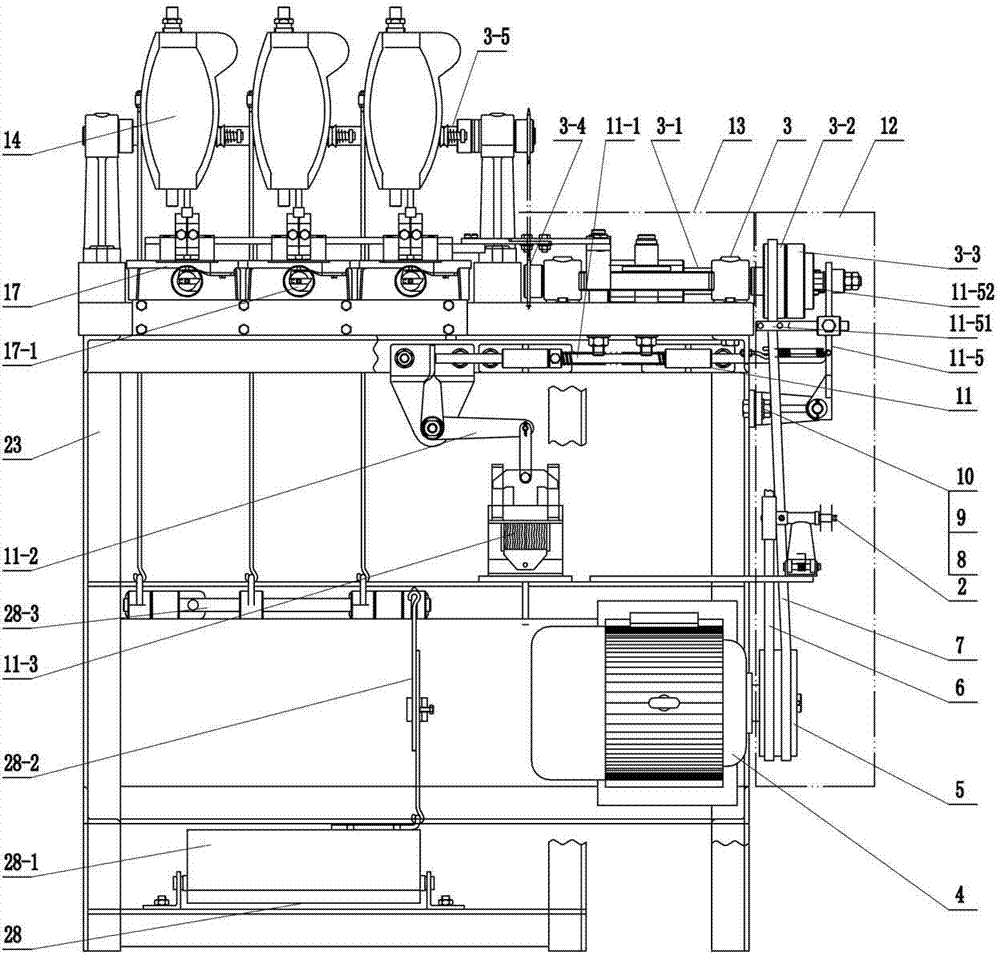

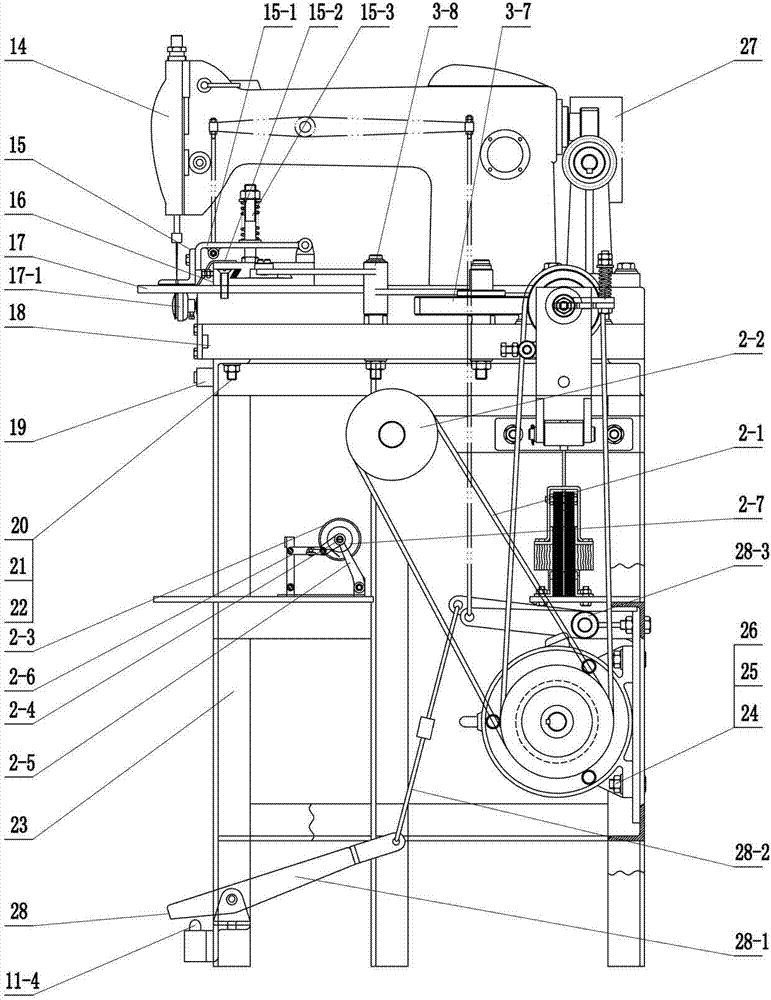

Closure sewing and knotting machine

InactiveCN104846562AClosely connectedImprove operational efficiencyCombination sewing machinesPressersElectric machineryEngineering

The invention relates to a closure sewing and knotting machine comprising a frame unit, at least three noses, a base unit, a transmission unit, a carriage unit, a presser foot unit, a footboard unit and a motor. The motor is disposed on the lower portion of the frame unit; the output end of the motor is in transmission connection with the transmission unit arranged above the motor. The carriage unit and the presser foot unit are disposed below sewing needles of the noses disposed at the top of the frame unit. The carriage unit is in transmission connection with the transmission unit; the carriage unit synchronously drives the presser foot unit, in fitly connection with the carriage unit, to move back and forth. The presser foot unit is connected with the footboard unit and is controlled by the footboard unit to raise or lower a presser foot. The noses are all in transmission connection with the transmission unit; under transmission of the transmission unit, the noses synchronously knot stitch sewing and knotting. The closure sewing and knotting machine is high in mechanization level and higher in productivity, product quality is ensured, and the closure sewing and knotting machine is compact in assembled structure, capable of running stably, and convenient to operate and maintain.

Owner:JIHUA 3517 RUBBER PROD

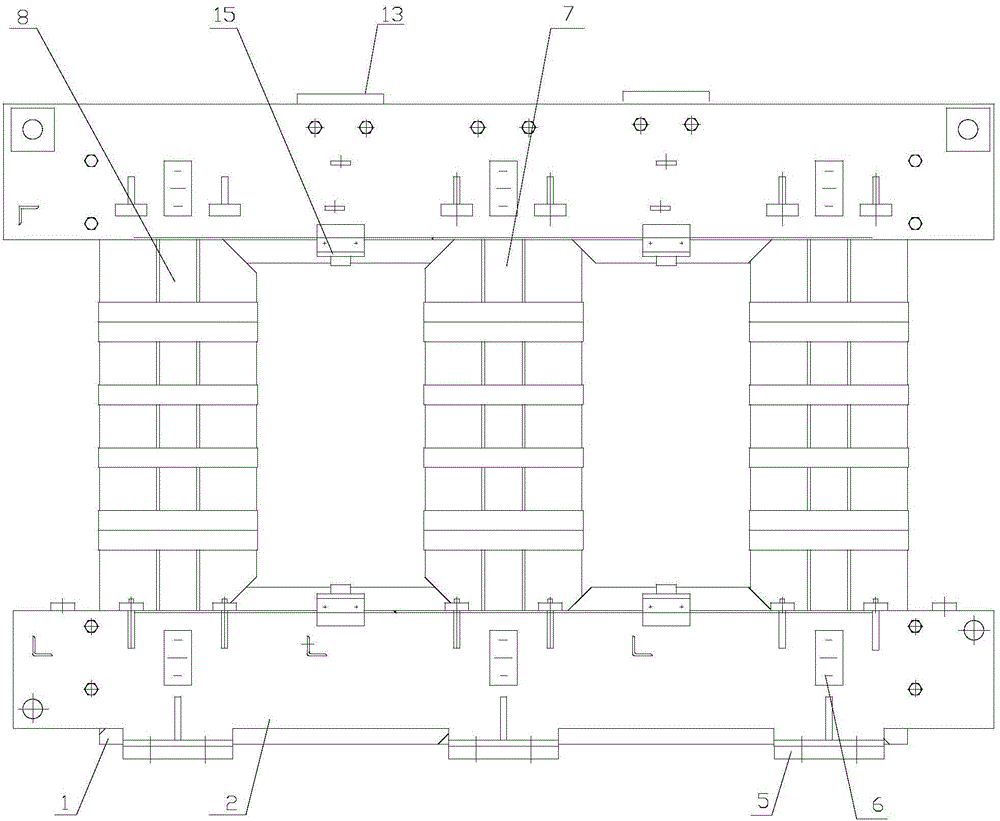

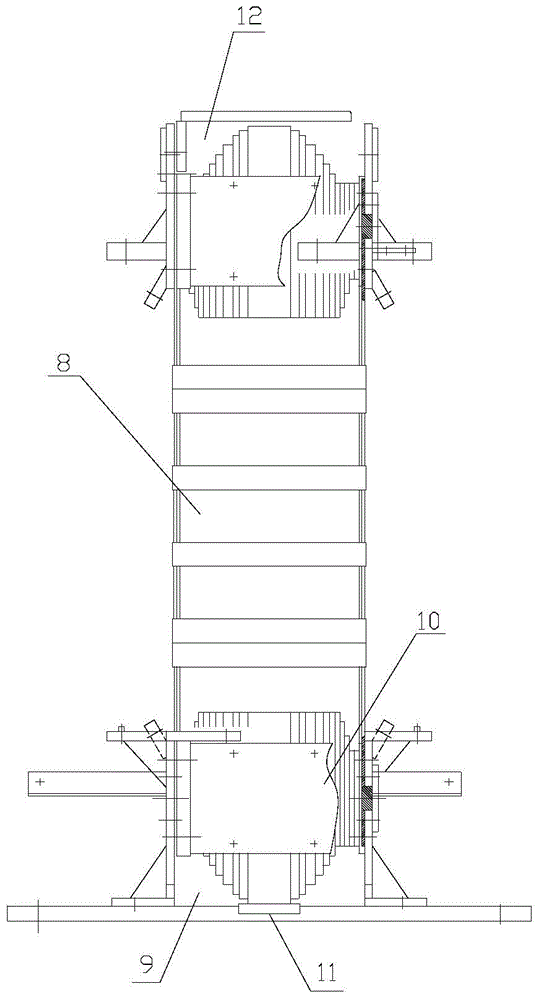

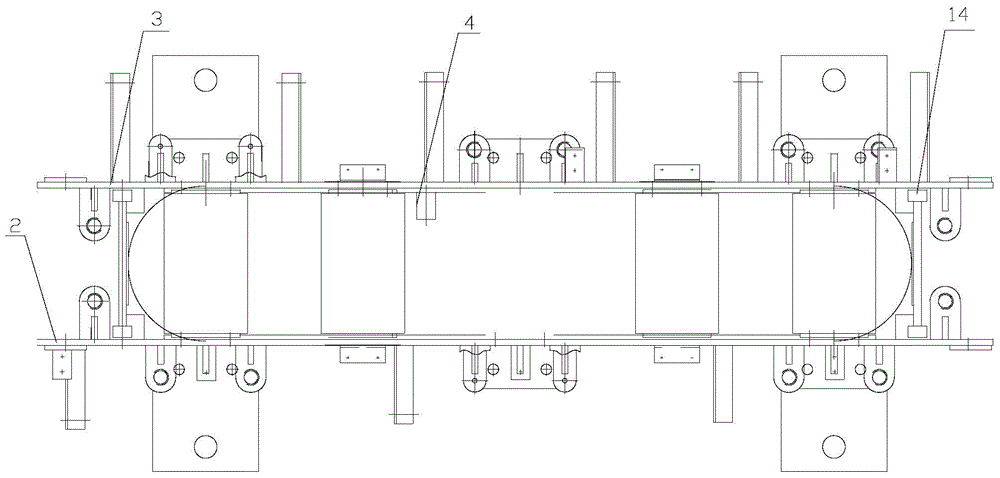

Assembling structure for power transformer iron core

InactiveCN106298182AAssembly compactReasonable designTransformers/inductances magnetic coresTransformerEngineering

The invention relates to an assembling structure for a power transformer iron core. The assembling structure comprises an iron core and a high and lower pressure clamping members arranged on two sides of the iron core, wherein a grounding sheet is arranged on one side, where the upper end of the iron core is close to the low pressure clamping member; the lower end of the iron core is provided with a food pad; a foot pad insulating block is arranged between the foot pad and the iron core; one side of the high pressure clamping member is provided with a cover plate assembly; the high pressure clamping member is connected and fixed with the upper end of the low pressure clamping member via an insulated retractable belt; the iron core is rectangular; two sides of the iron core are provided with side columns; a middle column is disposed in the middle of the iron core; the cover plate assembly is formed by a cover plate, a lock sheet and a shaft all connected with each other; a foot pad cushion block is further placed between the iron core and the foot pad; the upper end of the iron core and one side of the low pressure clamping member are provided with a wood cushion block; side beams are arranged on the external sides of the side columns on two sides of the iron core; the upper end of the iron core is provided with an upper beam; and two sides of the upper end of the iron core are respectively provided with a paper plate. Compared with the prior art, the assembling structure for the power transformer iron core has compact structure and rational design, requires low manufacturing cost, and has great product heat radiation speed, low temperature increase, great reliability and low energy loss.

Owner:TAIZHOU TIANLI IRONCORE MFG

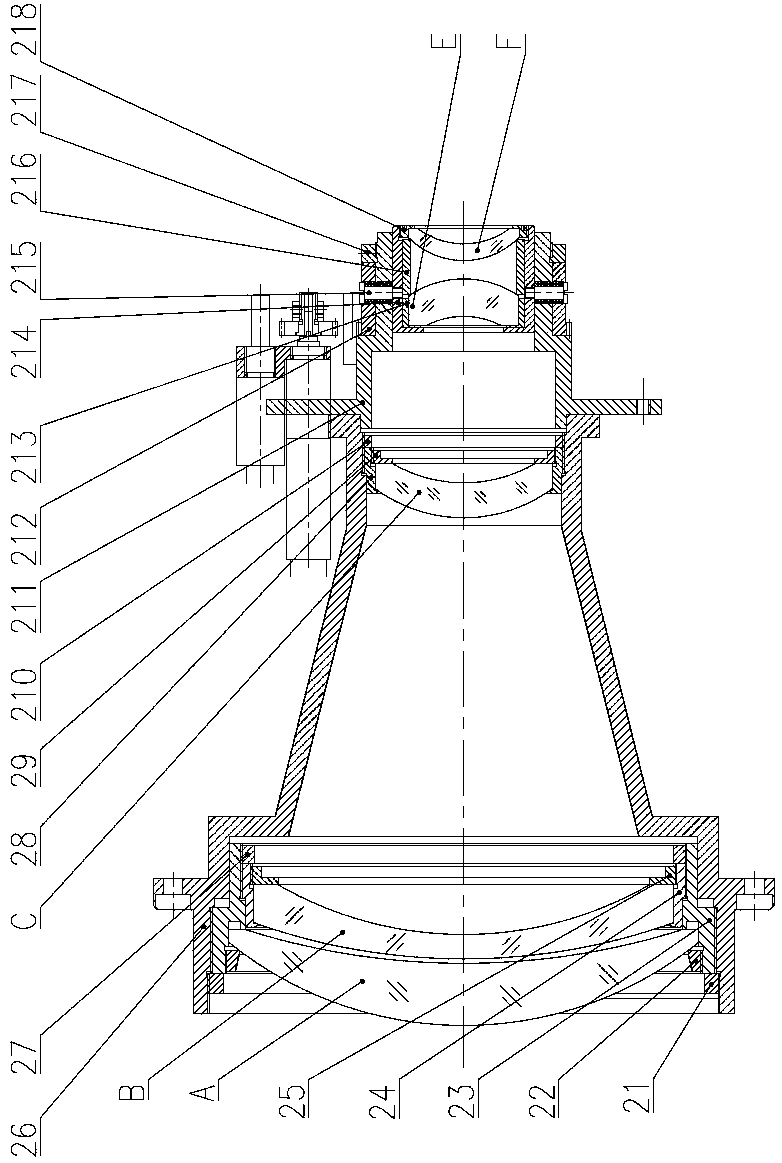

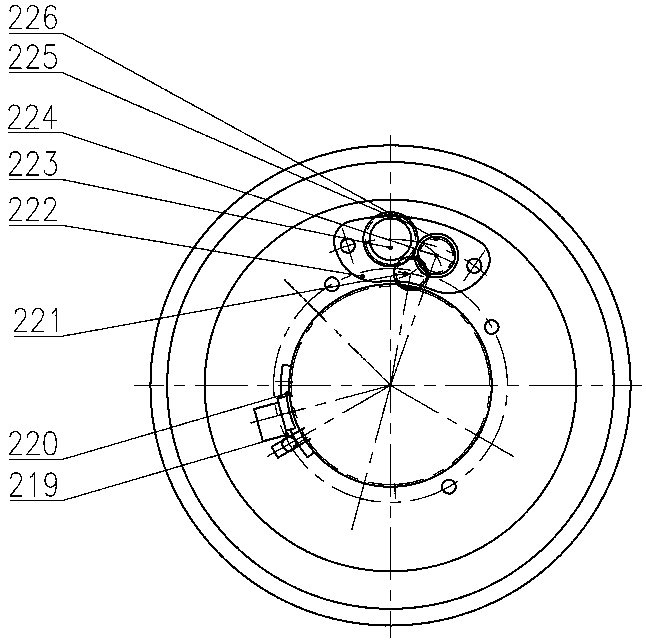

F200mm refrigeration-type infrared athermalization lens

ActiveCN107608061ASimple optical system structureAssembly compactProjector focusing arrangementCamera focusing arrangementAthermalizationCamera lens

The invention relates to an f200mm refrigeration-type infrared athermalization lens, and the optical system of the lens is sequentially provided with a meniscus lens A with the positive focal power, ameniscus lens B with the negative focal power, a meniscus lens C with the positive focal power, a secondary imaging plane D, a meniscus lens E with the negative focal power, a meniscus lens F with the positive focal power, a diaphragm G and an image plane H from the left to the right along the light. The lens is small and exquisite in structure, achieves the athermalization through electromechanical focusing, and is high in stability. The impact on the lens from the environment factors is small, and the lens just employs two types of optical materials, thereby greatly reducing the productionand processing cost.

Owner:FUJIAN FORECAM OPTICS CO LTD

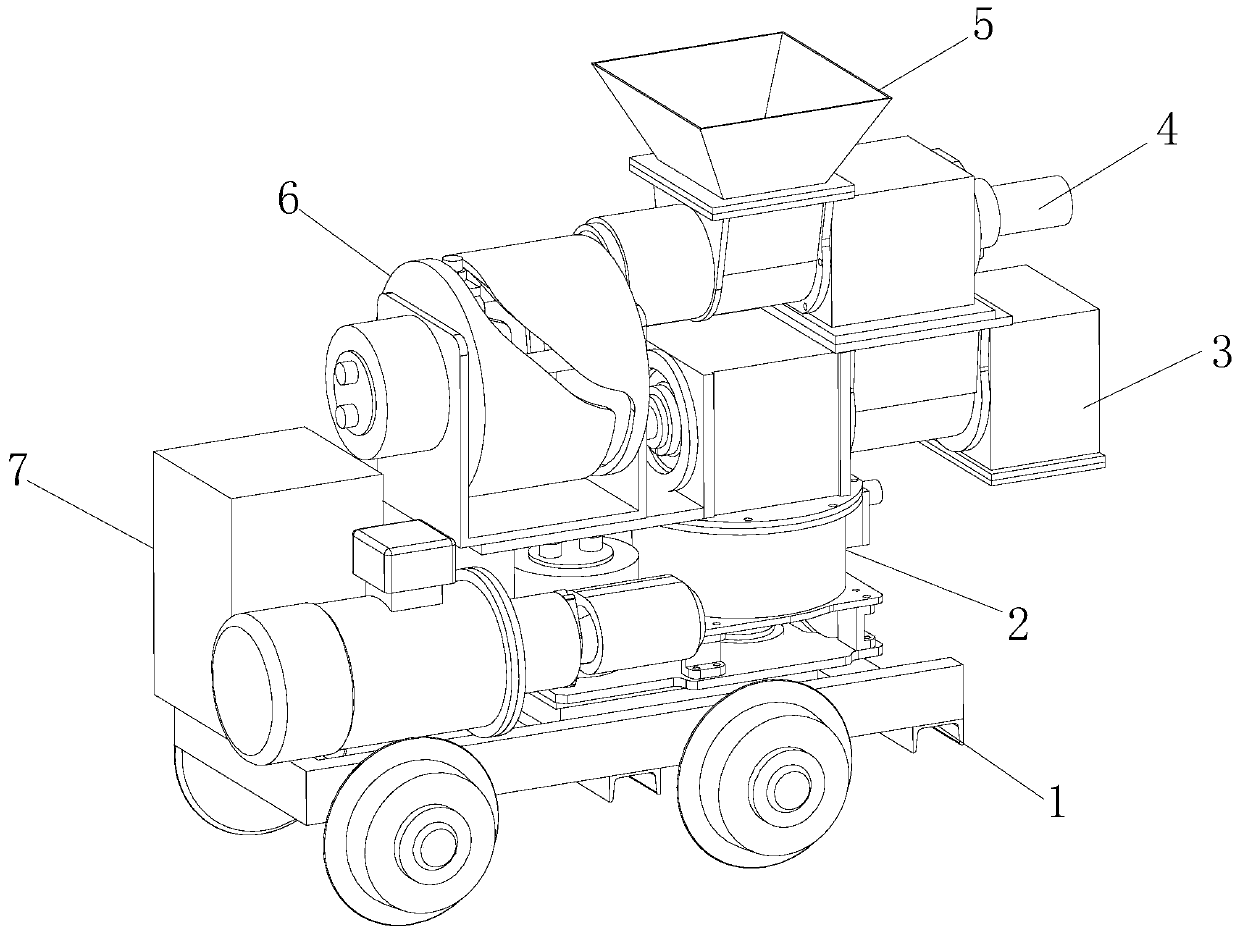

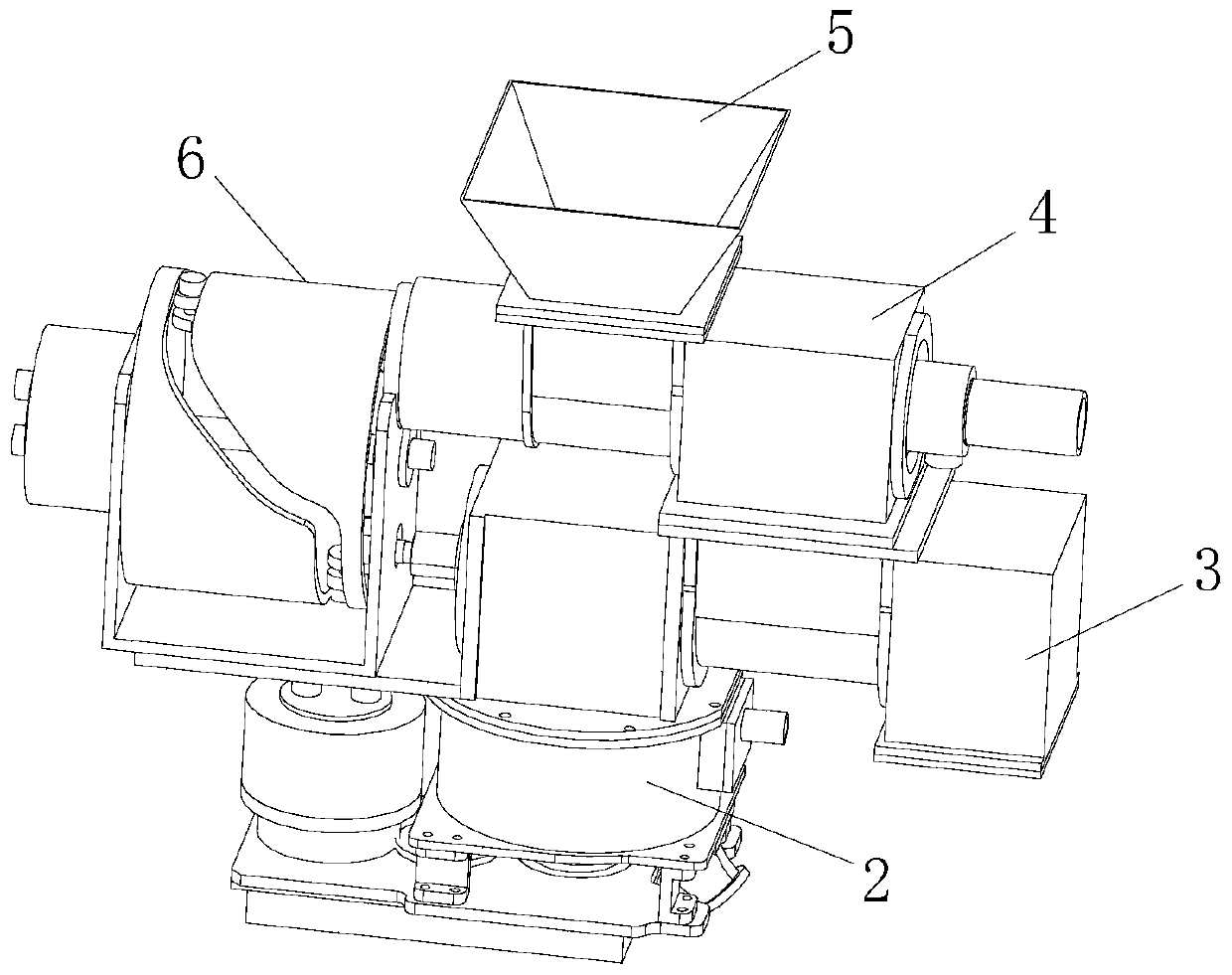

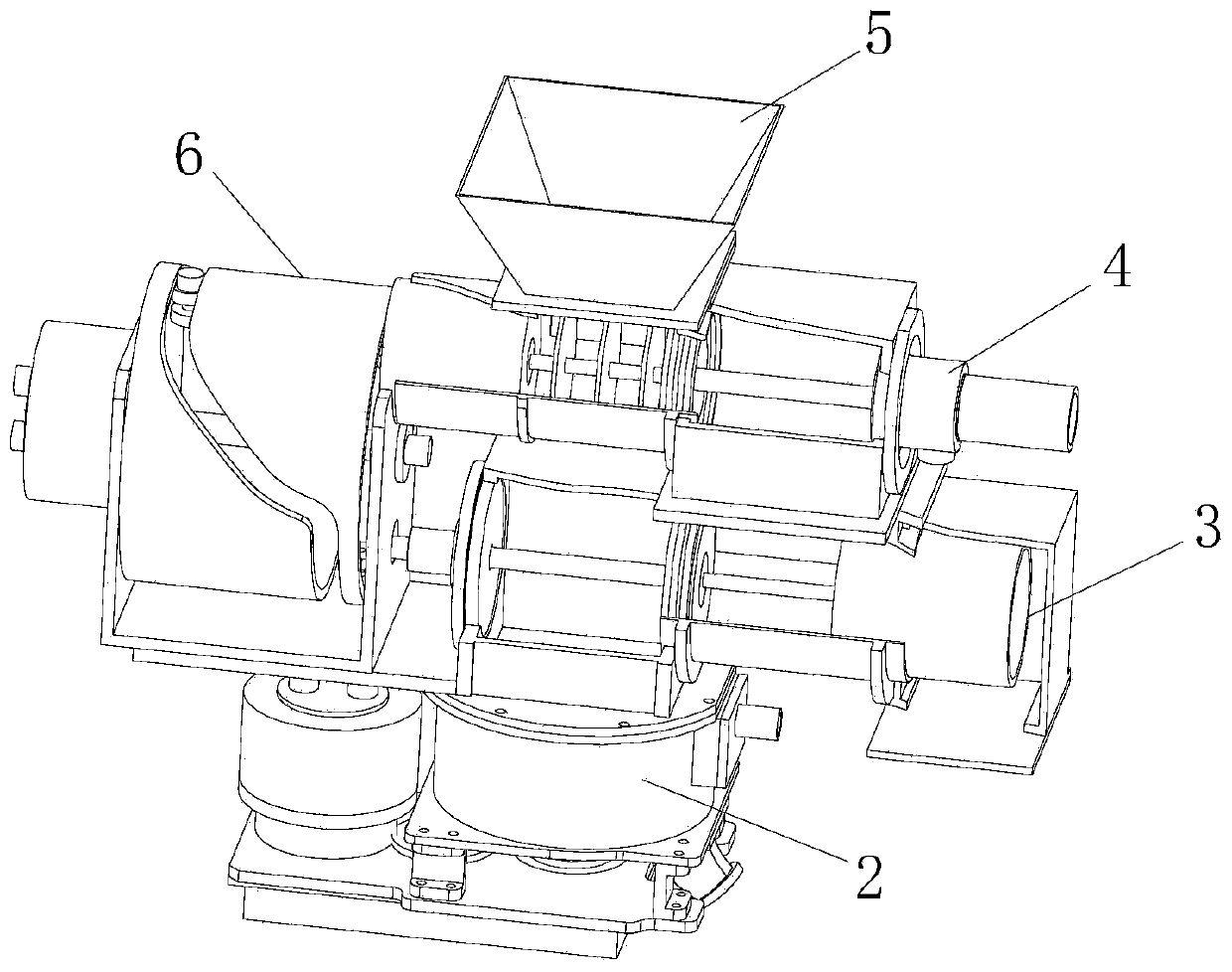

Double-piston type pneumatic conveyer

The invention provides a double-piston type pneumatic conveyer, and relates to the technical field of pneumatic jetting devices. The double-piston type pneumatic conveyer comprises a rack, a rotor mechanism, an upper cylinder barrel mechanism, a lower cylinder barrel mechanism, a piston drive mechanism and a hydraulic mechanism. The hydraulic mechanism is arranged on the rear side of a bottom frame, the rotor mechanism is fixed to the front side of the bottom frame, the lower cylinder barrel mechanism is configured above the rotor mechanism, the upper cylinder barrel mechanism is configured above the lower cylinder barrel mechanism, and a hopper is mounted above an upper cylinder barrel of the upper cylinder barrel mechanism. The upper cylinder barrel mechanism and the lower cylinder barrel mechanism are arranged in the same direction, the piston drive mechanism simultaneously drives the two cylinder barrel mechanisms, and an upper sealing piston and a lower sealing piston are alternately located at a sealing position. Materials in all material bins are continuously jet through the rotor mechanism in the rotating process of a rotor. According to the pneumatic conveyer, the contradiction that pushing and sealing need to be achieved by the rotor and the pistons is solved, friction between the materials and the sealing pistons is reduced, the sealing effect is improved, the jetting distance is increased, dust generated in the conveying process is reduced, and the service life is prolonged.

Owner:SHANDONG UNIV OF SCI & TECH

Non-contact pressure measuring device and method

InactiveCN111678636ANo need to change the structureMeet the needs of pressure measurementFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by thermal meansControl powerContact pressure

The invention relates to a pressure measuring device and method, in particular to a non-contact pressure measuring device and method, which are suitable for pressure measurement of a gas cylinder module in a rocket attitude and orbit control power system and are also generally suitable for other pressure containers with pressure measurement requirements. The technical problems that the sealing reliability and safety of an original structure are reduced and long-term pressure monitoring is not facilitated in the prior art are solved. The non-contact pressure measuring devicecomprises a cable, ademodulator, a strain sensor and a temperature sensor, wherein the strain sensor and the temperature sensor are respectively adhered to the outer surface of the pressure-bearing shell of the gas cylinder module to be measured; the strain sensor and the temperature sensor are connected with the demodulator through the cable; and the demodulator is provided with a calibration value input equipmentinterface. The method is carried out by using the device.

Owner:XIAN AEROSPACE PROPULSION INST

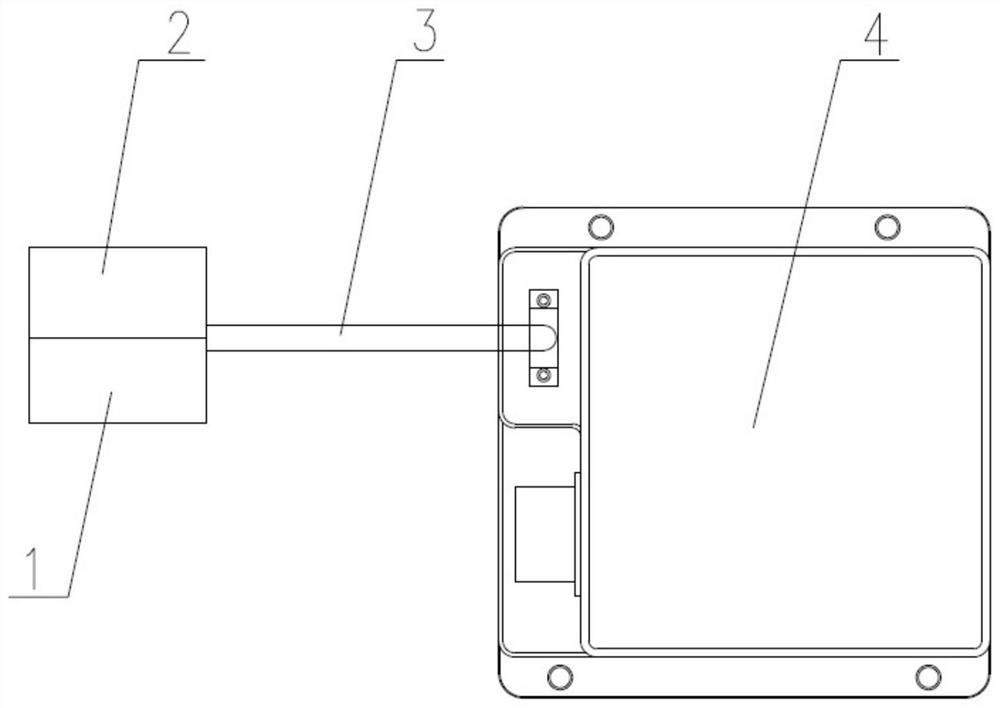

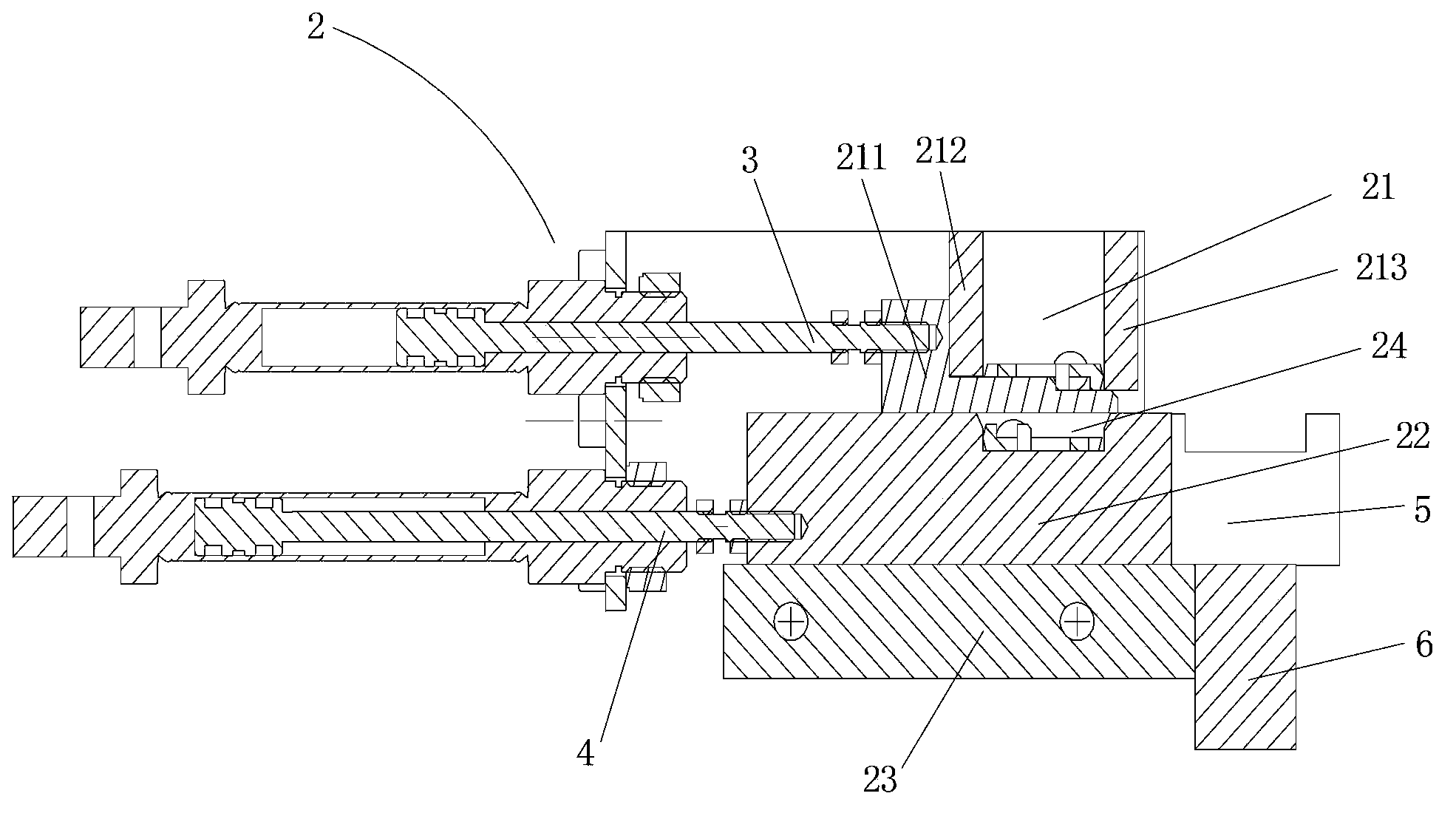

Symmetrical component automatic assembling mechanism

ActiveCN103659212ASimplify the assembly processAssembly compactMetal working apparatusSymmetrical componentsEngineering

The invention discloses a symmetrical component automatic assembling mechanism which comprises a vibration type feeder and an assembling component matched with the vibration type feeder. The assembling component is connected to the tail end of the vibration type feeder. The vibration type feeder is provided with an upper feeding channel and a lower feeding channel, and the upper feeding channel and the lower feeding channel are communicated with an upper storage position and a lower storage position of the assembling component respectively. The upper storage position is in transmission connection with an upper drawing-out type base plate of the upper storage position through an upper driving cylinder; a lower driving cylinder drives the lower storage position. The symmetrical component automatic assembling mechanism further comprises a removing channel used for removing a workpiece after assembling is completed. Because the workpiece directly enters two vertically aligned assembling preparation positions through the channel of the vibration type feeder in the assembling process, an extra mechanical device is not required for grabbing the workpiece. In this way, the symmetrical component automatic assembling mechanism is wide in application range and is barely affected by the material, structure and shape of the workpiece. Furthermore, the assembling process is simple, the assembling structure is compact, and therefore the symmetrical component automatic assembling mechanism is easy to install and use.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH +1

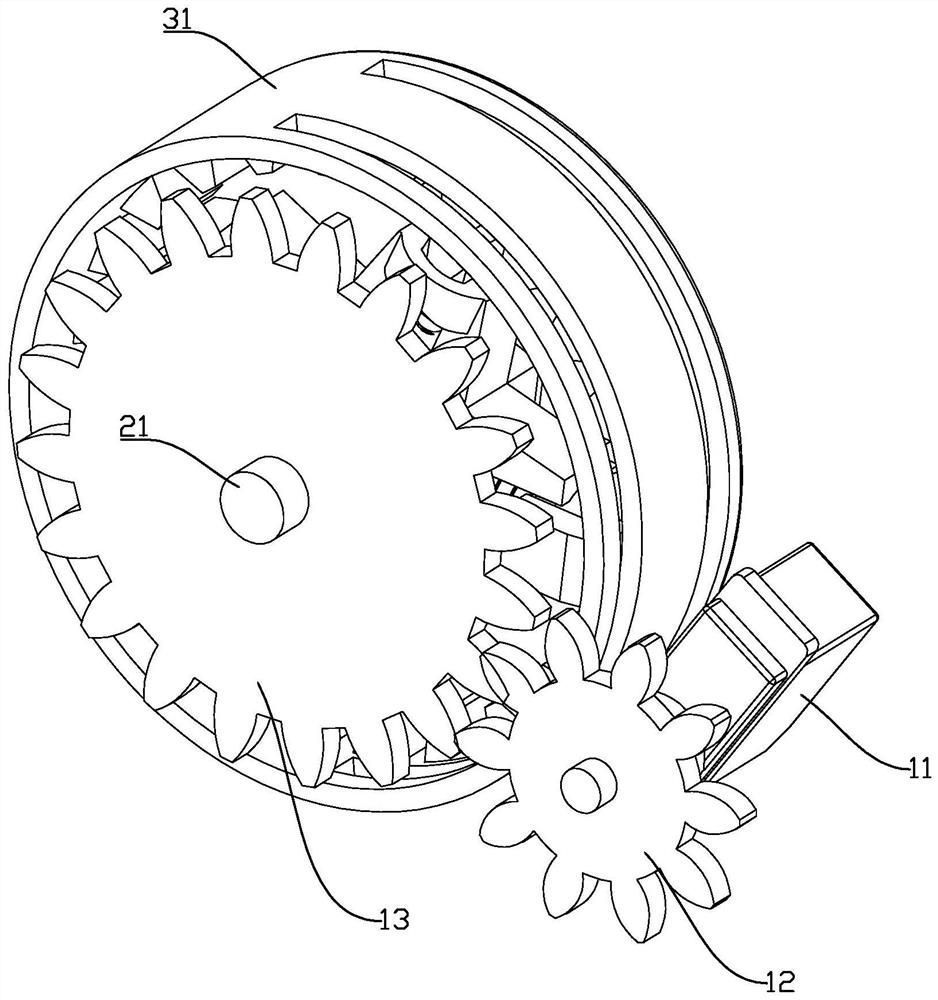

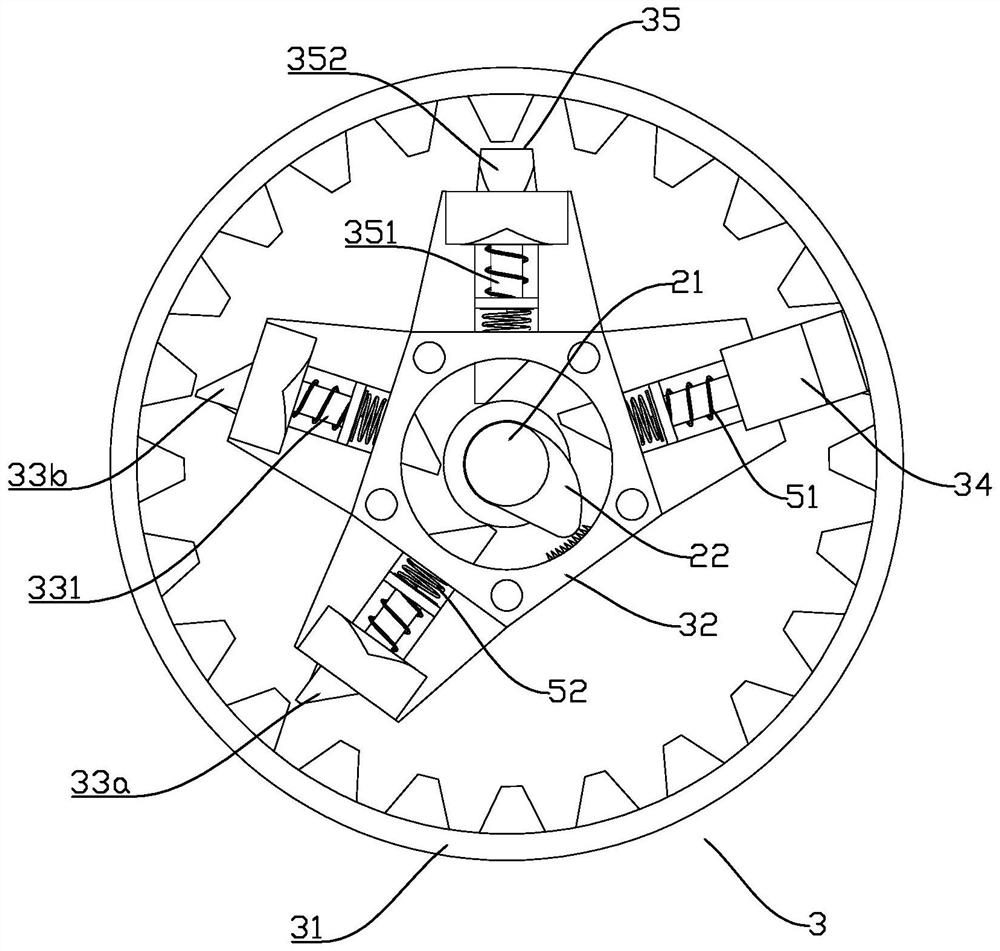

Integrated multifunctional power-assisted gearshift mechanism

PendingCN111795140AAchieve fixationImprove accuracyGearing controlMechanical energy handlingProcess engineeringCam

The invention discloses an integrated multifunctional power-assisted gearshift mechanism. A central rotary shaft of the integrated multifunctional power-assisted gearshift mechanism is provided with arotary shaft body and a cam installed on the rotary shaft body; a gearshift module comprises an inner gear, a central shell arranged at the middle part of the inner gear, and a plurality of gear assemblies which are slidably nested onto the central shell; the rotary shaft body stretches into an empty cavity of the central shell, the gear assemblies are distributed around the rotary shaft body, and the whole assembly structure is simple and compact, so that realization for miniaturization production is benefited; the cam is capable of being abutted against one end of any gear assembly while rotating, the gear assembly is ejected to the other end to be connected with the inner gear, fixing for a gear is realized, and in this way, switchover for the different gears can be realized by virtueof the rotation of the cam, and the gearshift process is flexible and convenient; and moreover, a return component is arranged, the gear assemblies can automatically return to the original positions after separating from the cam, and interference among the different gears can be avoided, so that the accuracy of gear switchover is increased; and the integrated multifunctional power-assisted gearshift mechanism is used in the field of gearshift control machinery.

Owner:SOUTH CHINA UNIV OF TECH

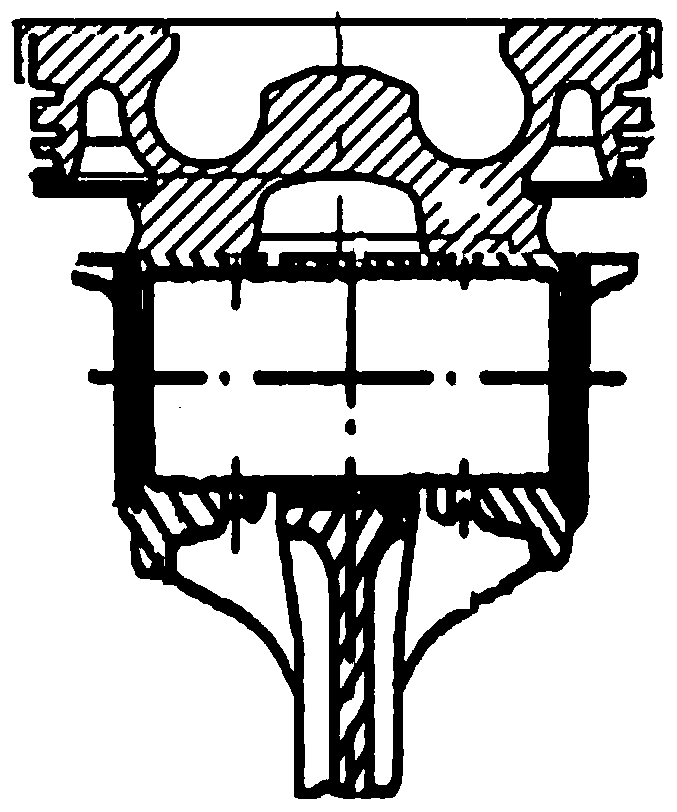

Piston connecting rod

ActiveCN104165179AAssembly compactConcentrated forceConnecting rodsEngine lubricationPistonLubrication

The invention relates to the technical field of the design of engine parts and specifically relates to a piston connecting rod. The piston connecting rod comprises a connecting rod small end (1), a connecting rod big end and a rod body; the connecting rod small end (1) is of a dual-pin boss structure; the dual-pin boss structure is provided with a pin hole (2) for realizing pin connection with a pin boss of a piston end of a single-pin boss structure. The dual-pin boss connecting rod small end adopted by the piston connecting rod provides structural support for a piston of the single-pin boss structure; the connection manner of the piston and the connecting rod small end is changed so that the assembled structure of the piston and the connecting rod can be more compact and the stress can be more concentrated. The dual-pin boss connecting rod small end adopted the piston connecting rod improves the motion load of the connecting rod structurally, and the oil collecting hole and the oil storage chamber of the connecting rod small end are formed to provide technical support for continuous cooling and lubrication of a piston pin. A bush is arranged at the pin hole of the connecting rod small end to provide further protection for the abrasive resistance of the pin hole at the connecting rod small end on the basis of ensuring cooling and lubrication.

Owner:强道前

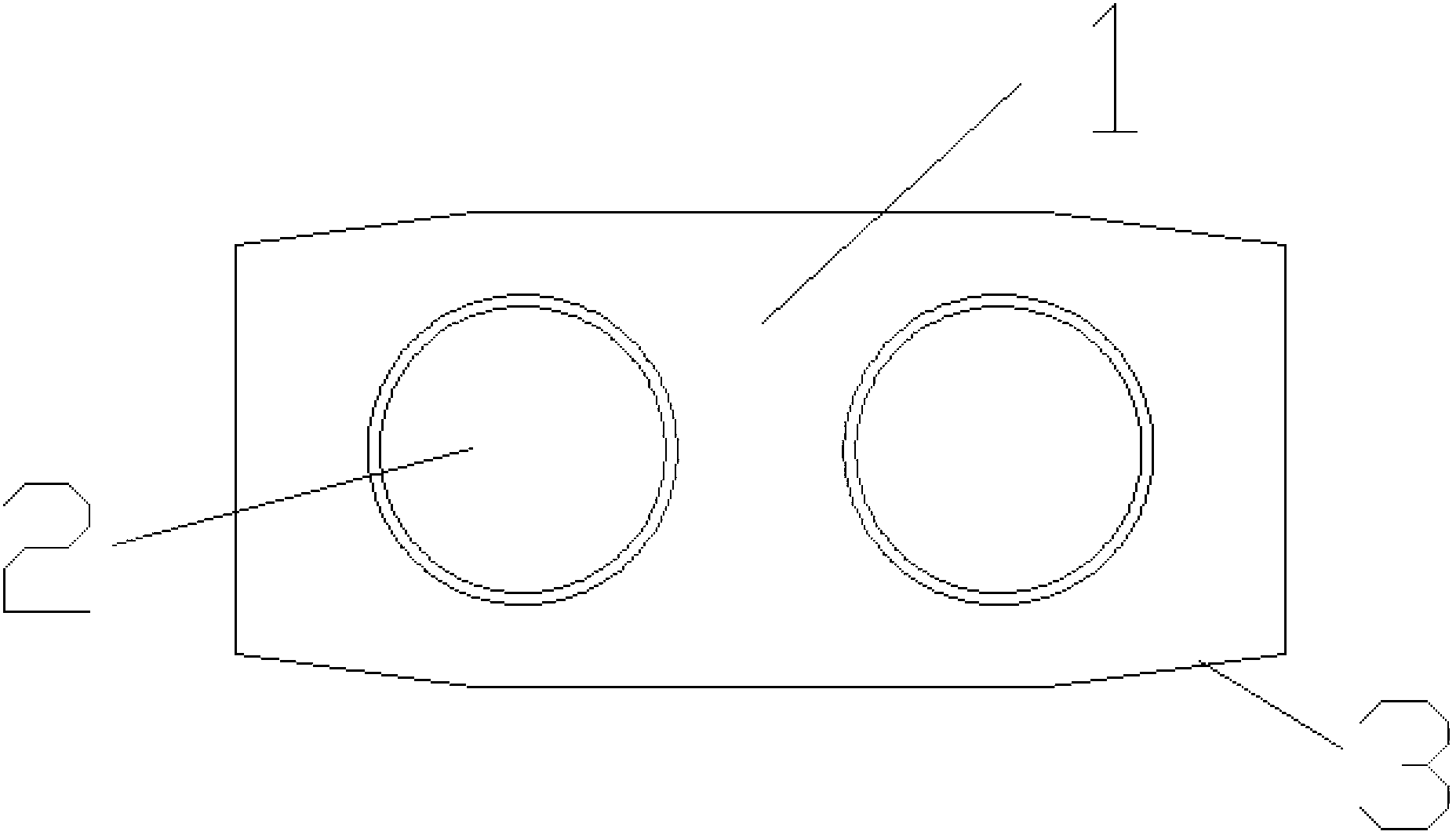

Assembly structure and terminal

InactiveCN106455397AReduce thicknessLarge capacityCircuit arrangements with support structuresTelephone set constructionsEngineeringBattery capacity

The invention provides an assembly structure and a terminal. The assembly structure comprises a display module, a printed circuit board PCB, a battery module and a casing body. The casing body is provided with a unidirectional opening to form an accommodation cavity. The PCB 2 and the battery module are fixed on the casing body and are accommodated in the accommodation cavity. The PCB and the battery module are located between the display module 1 and the casing body 4. The display module matches the casing body to seal the accommodation cavity. According to the assembly structure, the PCB, the battery module and the display module are fixedly arranged without a rigid structure; the PCB and the battery module are fixed on the bottom surface, which is opposite to the unidirectional opening, of the casing body; the display module is fixed on the side of the accommodation cavity of the casing body; the rigid structure is eliminated; the depth of the accommodation cavity of the casing body is reduced; the thickness of the assembly structure becomes smaller, or the thickness is the same; the battery capacity is increased; and the assembly structure in a compact structure is realized.

Owner:BLACKSHARK TECH NANCHANG CO LTD

Shuttle rebounding connection rod

InactiveCN102995231ALittle room for rotationPlay a role in avoidingLoomsEngineeringAssembly structure

The invention discloses a shuttle rebounding connection rod comprising a shuttle rebounding connection rod body, wherein the shuttle rebounding connection rod body is arranged as a rectangular block-shaped structure. The shuttle rebounding connection rod is symmetrically provided with two circular through-holes in the length direction. The four top angles of the shuttle rebounding connection rod body are respectively provided with first fillets; and the radians of the first fillets arranged on the four top angles of the shuttle rebounding connection rod are the same. The upper openings and lower openings of the circular through holes are respectively provided with second fillets of which the radians are the same. The shuttle rebounding connection rod disclosed by the invention has small rotary space while being used, so the avoiding action on the other parts is achieved, and the assembly structures of gripper shuttle looms are impact; at the same time, the upper openings and lower openings of the circular through-holes are respectively provided with the second fillets of which the radians are the same, so that the shuttle rebounding connection rod is conveniently assembled with the other parts.

Owner:SUZHOU DEMING TEXTILE MACHINERY PARTS

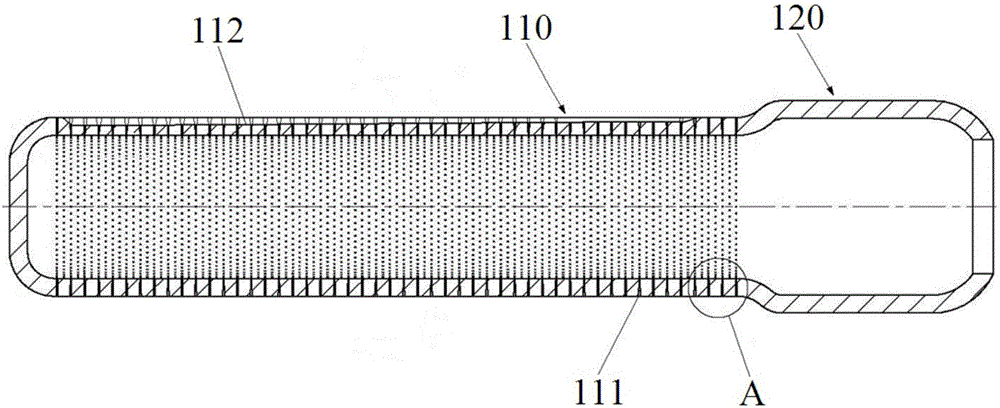

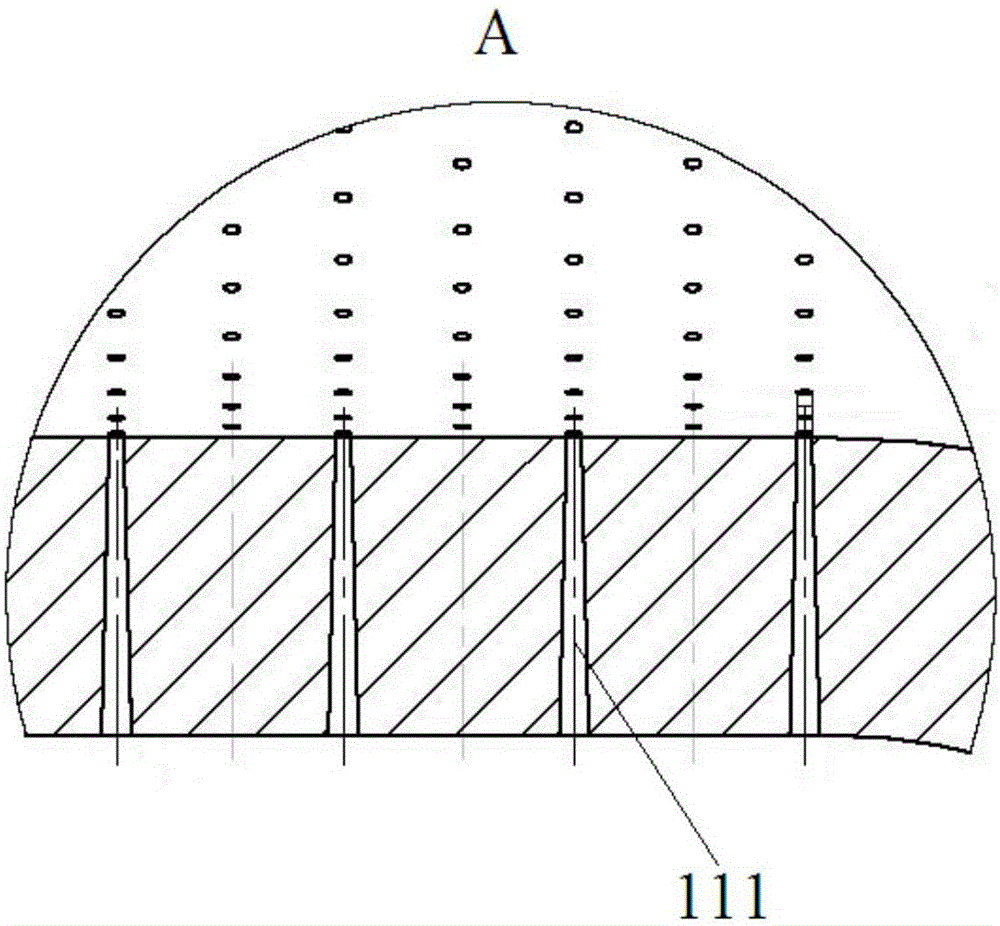

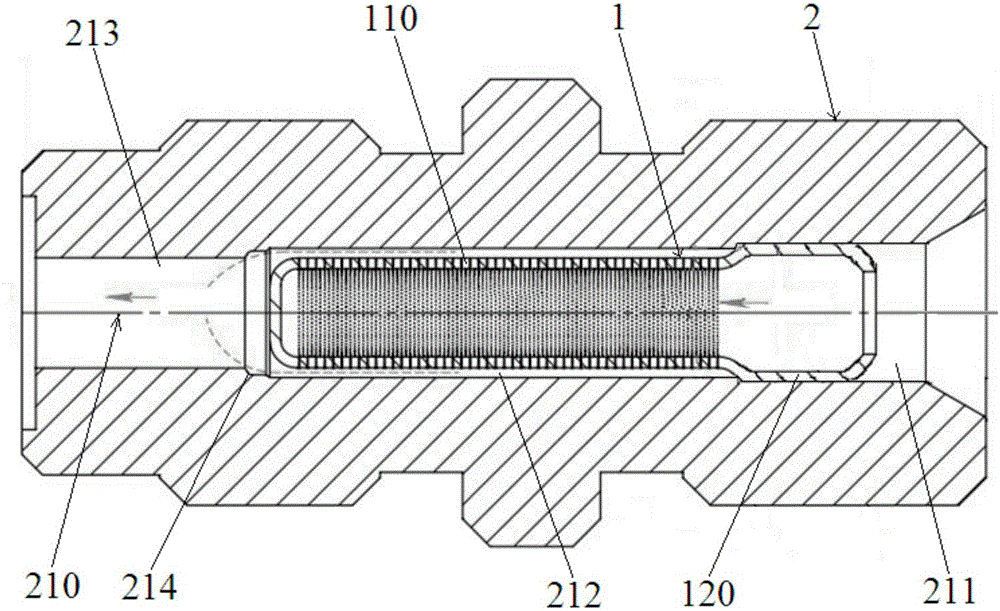

Fuel oil pre-atomization device, fuel oil atomization joint and manufacturing method of fuel oil pre-atomization device

ActiveCN106000677AImprove combustion efficiencyAvoid erosionInternal combustion piston enginesSpray nozzlesInjection pressureMicrometer

The invention discloses a fuel oil pre-atomization device, a fuel oil atomization joint and a manufacturing method of the fuel oil pre-atomization device. The fuel oil pre-atomization device comprises a cup-shaped body of which one end is a blind end and the other end is an open end. The side wall of the cup-shaped body is provided with an atomization portion adjacent to the blind end and a mounting portion located at the open end of the cup-shaped body. The side wall of the atomization portion is provided with multiple atomization holes with the pore diameter ranging from 10 micrometers to 60 micrometers. The fuel oil atomization joint comprises a straight-through connecting joint in which a step hole is formed. The fuel oil pre-atomization device is assembled in the step hole. The manufacturing method of the fuel oil pre-atomization device comprises the following steps that the cup-shaped body with the mounting portion and the atomization portion is stamped through a die; the atomization holes are machined in the atomization portion of the cup-shaped body through lasers; diversion trenches are cut in the atomization portion of the cup-shaped body; and polishing treatment is conducted on the cup-shaped body. By the adoption of the fuel oil pre-atomization device, pre-atomization can be conducted on fuel oil, the pre-atomized fuel oil can be prevented from forming an eddy in a spray head, and the injection pressure and the atomization effect of the fuel oil are guaranteed.

Owner:陕西华远动力科技有限公司

Inner container structure of dish-washing machine

PendingCN111513645AAvoid scourExtended service lifeTableware washing/rinsing machine detailsWater flowEngineering

The invention discloses an inner container structure of a dish-washing machine. The structure is characterized in that: the structure comprises an inner container body and a sealing frame body; the sealing frame body is installed on a top opening of the inner container body in a sealing mode, the side wall of an inner container is provided with a water blocking structure used for blocking water flow from entering a gap between the sealing frame body and the wall face of the inner container body, and the water blocking structure can be arranged in the gap to match the sealing frame in a clampedmode and can also be arranged at an opening of the gap. Due to the arrangement of the water blocking structure, washing water is prevented from flowing into a gap between the sealing frame and the wall face of the inner container, the sealing structure is prevented from being scoured by the washing water, and the service life of the sealing structure is prolonged; when the water blocking structure and the sealing frame are installed in a clamped and matched mode, an assembling structure between the sealing frame and the inner container is tighter, and safety is improved.

Owner:QINGDAO HAIER DISHWASHER +1

A vertical cross-flow air conditioner capable of ejecting wind and its control method

ActiveCN106403043BFirmly clamped and fixedPrecise positioningMechanical apparatusSpace heating and ventilation safety systemsMechanical engineeringPhysics

The invention relates to a vertical cross-flow air conditioner capable of ejecting wind and a control method thereof, the vertical cross-flow air conditioner comprises a vertically arranged elongated cylindrical shell and a heat exchanger installed in the shell assembly, volute assembly, top air outlet assembly and front air outlet assembly; the top air outlet assembly is installed on the top of the casing, and discharges part of the airflow in the casing after heat exchange by the heat exchanger assembly from the top; the volute assembly is located on the top Below the air outlet assembly, the front air outlet assembly is installed in the volute assembly; a mounting bracket is fixed on the inner wall of the housing, and the top air outlet assembly is fixed on the upper end of the installation bracket; the lower end of the installation bracket and the upper end of the volute assembly and the heat exchange There is a gap at the upper end of the device assembly. In the present invention, by fixing the installation bracket on the inner side wall of the housing and leaving a gap at the lower end of the installation bracket, the entire top air outlet assembly is loaded on the housing, avoiding the load of the volute assembly or the heat exchanger assembly at the lower end of the installation bracket Excessive weight will affect the performance of the whole machine.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

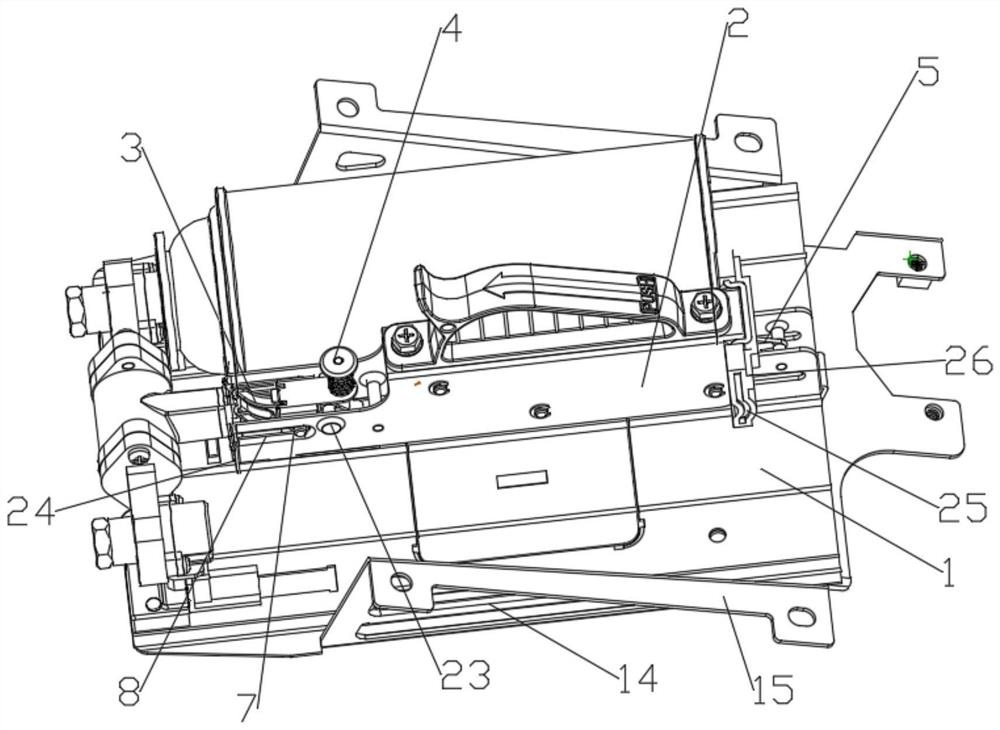

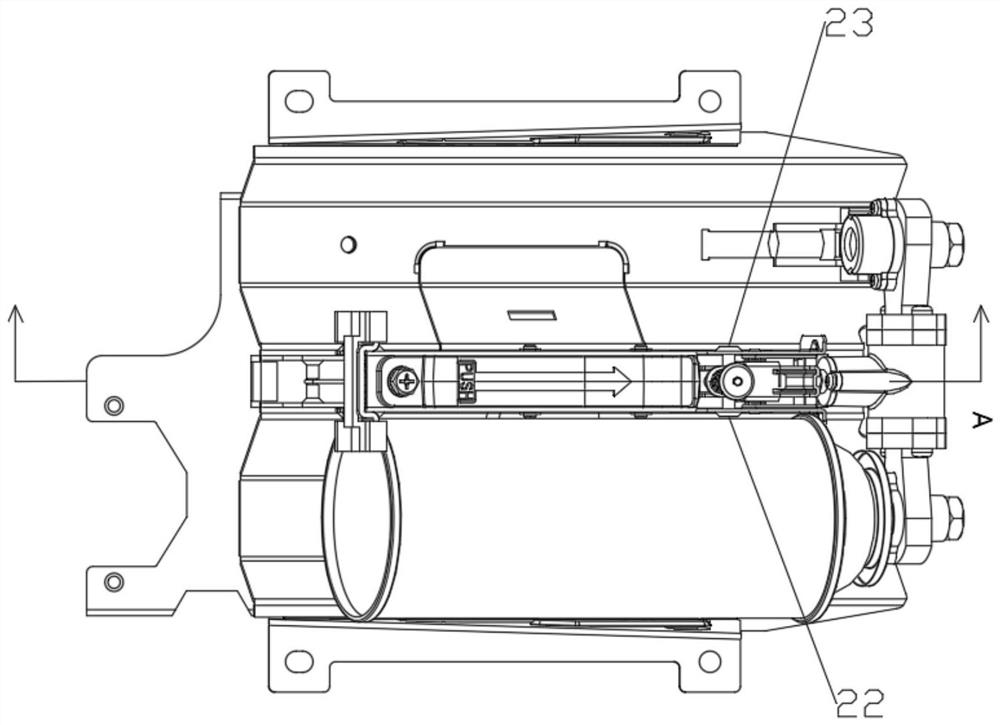

fuel tank loading device

ActiveCN112113133BPrevent leakageSafe storageVessel mounting detailsContainer filling methodsControl engineeringFuel tank

The invention discloses a fuel tank loading device, belonging to the technical field of gas tank loading mechanisms, comprising a main bracket, a limit assembly, a stop assembly, a release assembly and a return assembly, the main bracket is used for loading the fuel tank, the main bracket corresponds to the unlocking position and locking position of the fuel tank, the limiting component is used for limiting the position of the fuel tank and can drive the fuel tank to displace between the unlocking position and the locking position, the stop The assembly is used to lock the limit assembly when the fuel tank is in the locking position, the release assembly acts on the stop assembly to unlock the limit assembly, and the return assembly is used to release the limit assembly The assembly moves from the locked position to the unlocked position. The device of the invention can slide and lock the fuel tank, and manually disengage it without cumbersome manual operation and observation, which facilitates the use, storage and replacement of the fuel tank.

Owner:CHONGQING RUNTONG TECH CO LTD

A Symmetrical Component Automatic Assembly Mechanism

ActiveCN103659212BSimplify the assembly processAssembly compactMetal working apparatusSymmetrical componentsEngineering

The invention discloses a symmetrical component automatic assembling mechanism which comprises a vibration type feeder and an assembling component matched with the vibration type feeder. The assembling component is connected to the tail end of the vibration type feeder. The vibration type feeder is provided with an upper feeding channel and a lower feeding channel, and the upper feeding channel and the lower feeding channel are communicated with an upper storage position and a lower storage position of the assembling component respectively. The upper storage position is in transmission connection with an upper drawing-out type base plate of the upper storage position through an upper driving cylinder; a lower driving cylinder drives the lower storage position. The symmetrical component automatic assembling mechanism further comprises a removing channel used for removing a workpiece after assembling is completed. Because the workpiece directly enters two vertically aligned assembling preparation positions through the channel of the vibration type feeder in the assembling process, an extra mechanical device is not required for grabbing the workpiece. In this way, the symmetrical component automatic assembling mechanism is wide in application range and is barely affected by the material, structure and shape of the workpiece. Furthermore, the assembling process is simple, the assembling structure is compact, and therefore the symmetrical component automatic assembling mechanism is easy to install and use.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH +1

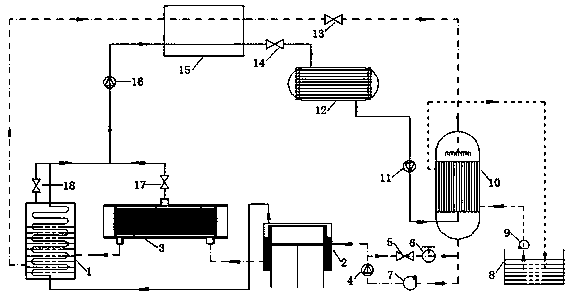

A heat exchange system and device for utilizing waste heat of engine exhaust gas

InactiveCN106705482BStrong absorption capacityNo crystallizationMechanical apparatusClimate change adaptationNew energyCooling effect

The invention relates to a heat exchange system and a device for utilizing waste heat of engine tail gas, belonging to the technical field of refrigeration. Aiming at the high temperature of engine exhaust waste heat, which has not been effectively utilized at present, and with the promotion of new energy vehicles such as electric vehicles and the reduction of power consumption and other application backgrounds, a new type of exhaust heat exchange system and device has been developed, specifically The difference between the two schemes, scheme 1 and scheme 2, is that the connection sequence of the three generators changes, and the structure and connection of the rest are consistent. , first pressure control valve, second pressure control valve, third one-way valve, condenser, second pressure reducing valve, throttle valve, evaporator, second one-way valve, absorber, water pump, water tank, solution pump , The first one-way valve, the first decompression valve, and the hand valve are driven by the exhaust heat of the engine exhaust, which can realize the cooling effect of the vehicle air conditioner while saving the energy consumption of the vehicle.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com