Symmetrical component automatic assembling mechanism

An automatic assembly and assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as reducing structural reliability and practicability, complex grasping and positioning actions, and inability to complete parts grasping and positioning. , to achieve the effect of easy installation and use, wide application range and compact assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

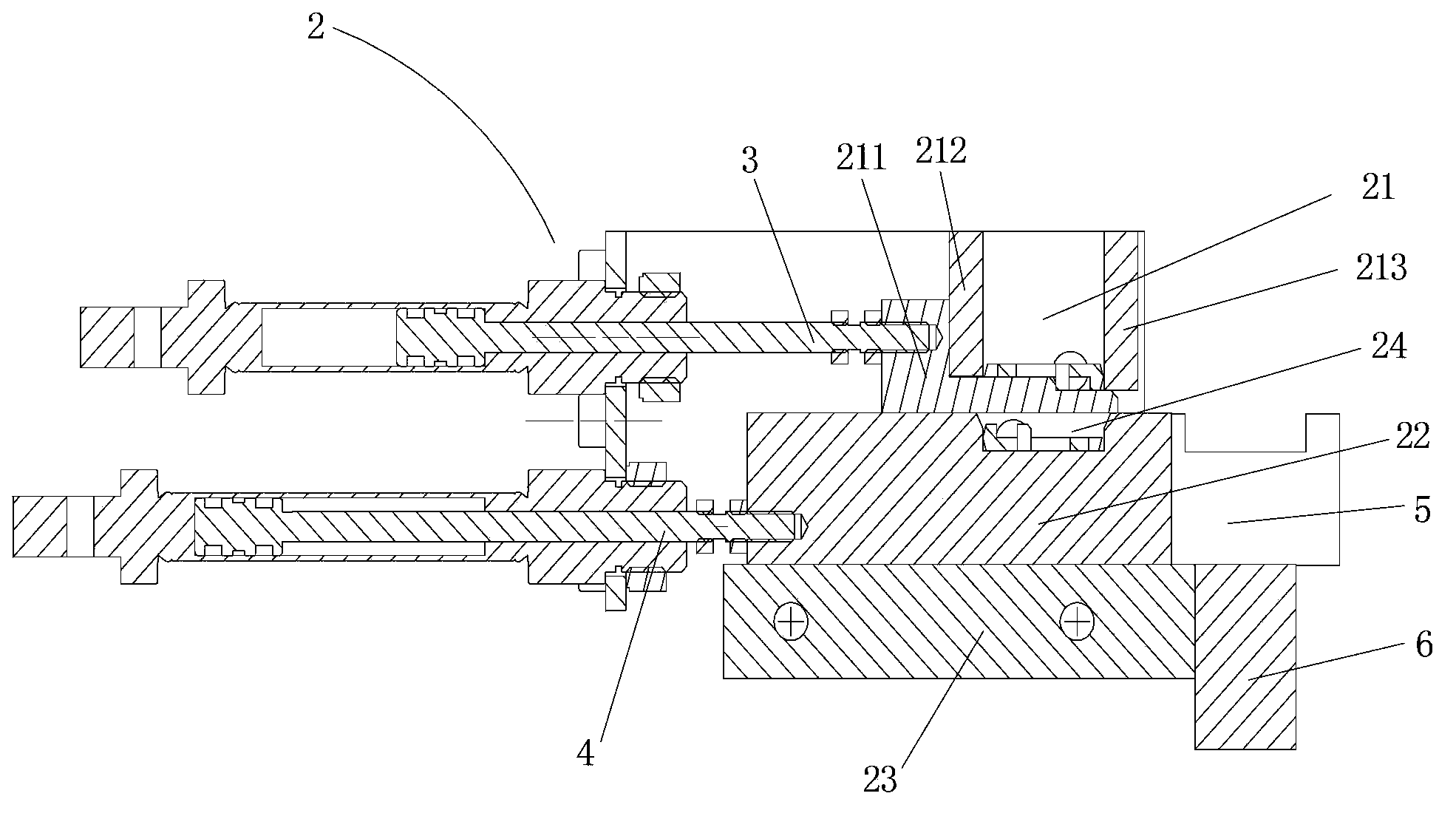

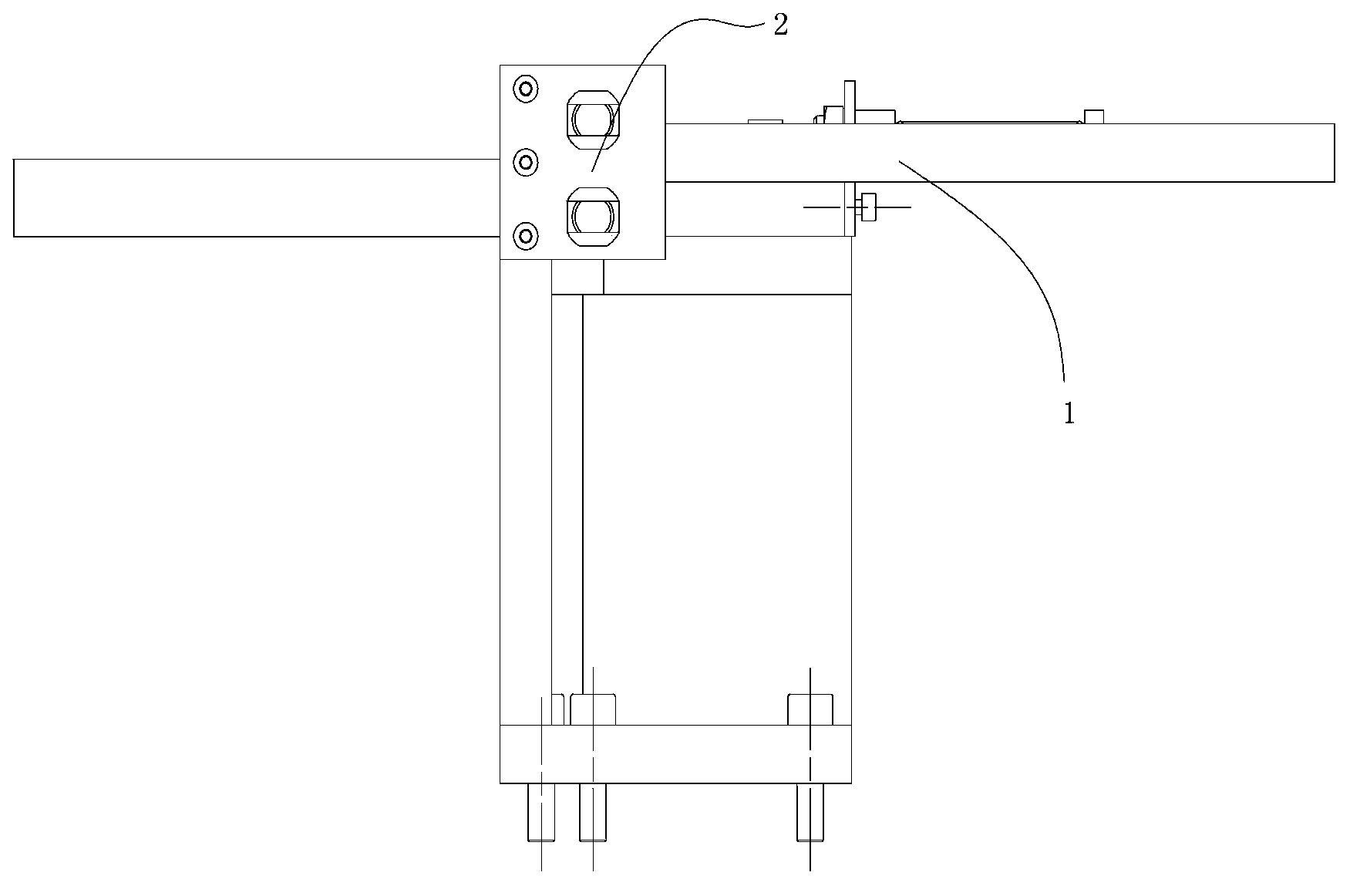

[0018] see figure 1 with figure 2 As shown, an automatic assembly mechanism for symmetrical components includes a vibrating feeder 1 and an assembly assembly 2 matching it. The assembly assembly 2 is connected to the end of the vibrating feeder 1, and the vibrating feeder 1 The upper and lower feeding channels are respectively connected with the upper and lower storage positions of the assembly assembly 2, and the upper storage position 21 is in transmission connection with the upper draw-out bottom plate 211 of the upper storage position 21 through the upper driving cylinder 3, The lower layer driving cylinder 4 drives the lower layer storage position 22, and also includes the removal material passage 5 of the removal mechanism after the assembly is completed. The removal material passage bottom is located at the bottom of the removal material passage 5 adjacent to the bottom support plate 23 of the assembly mechanism. Support plate 6.

[0019] see figure 1 As shown, the assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com