Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Cutting safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

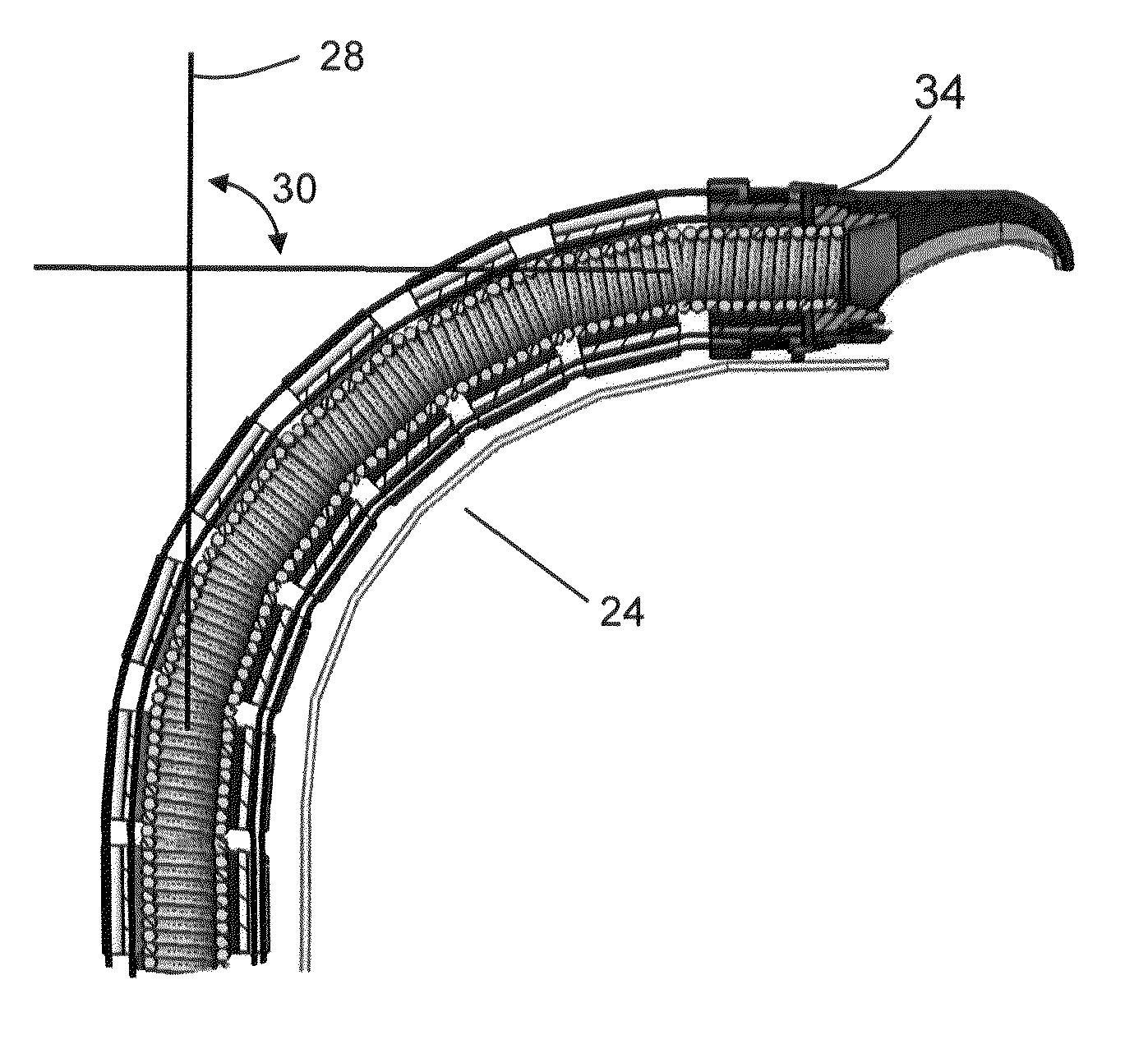

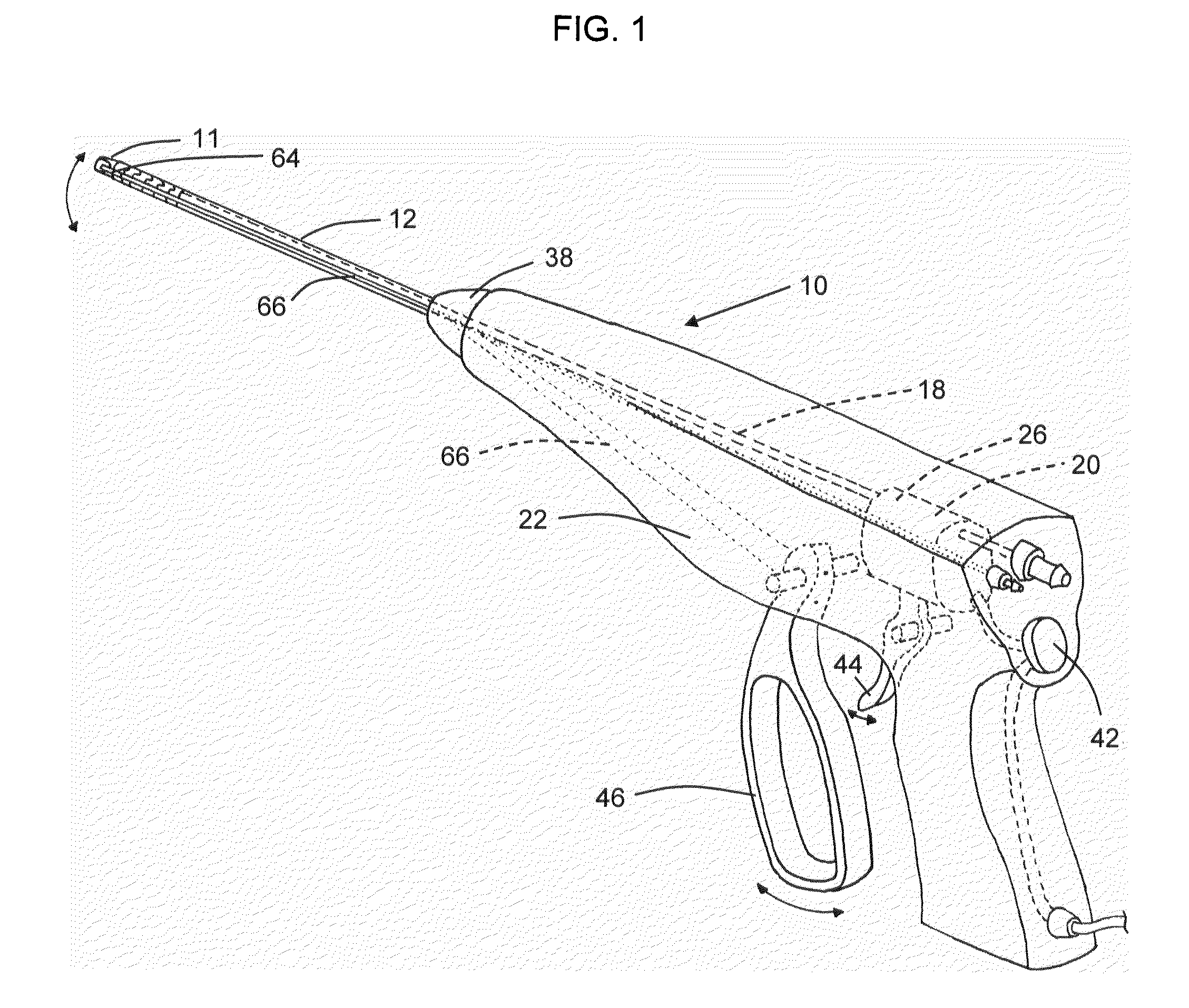

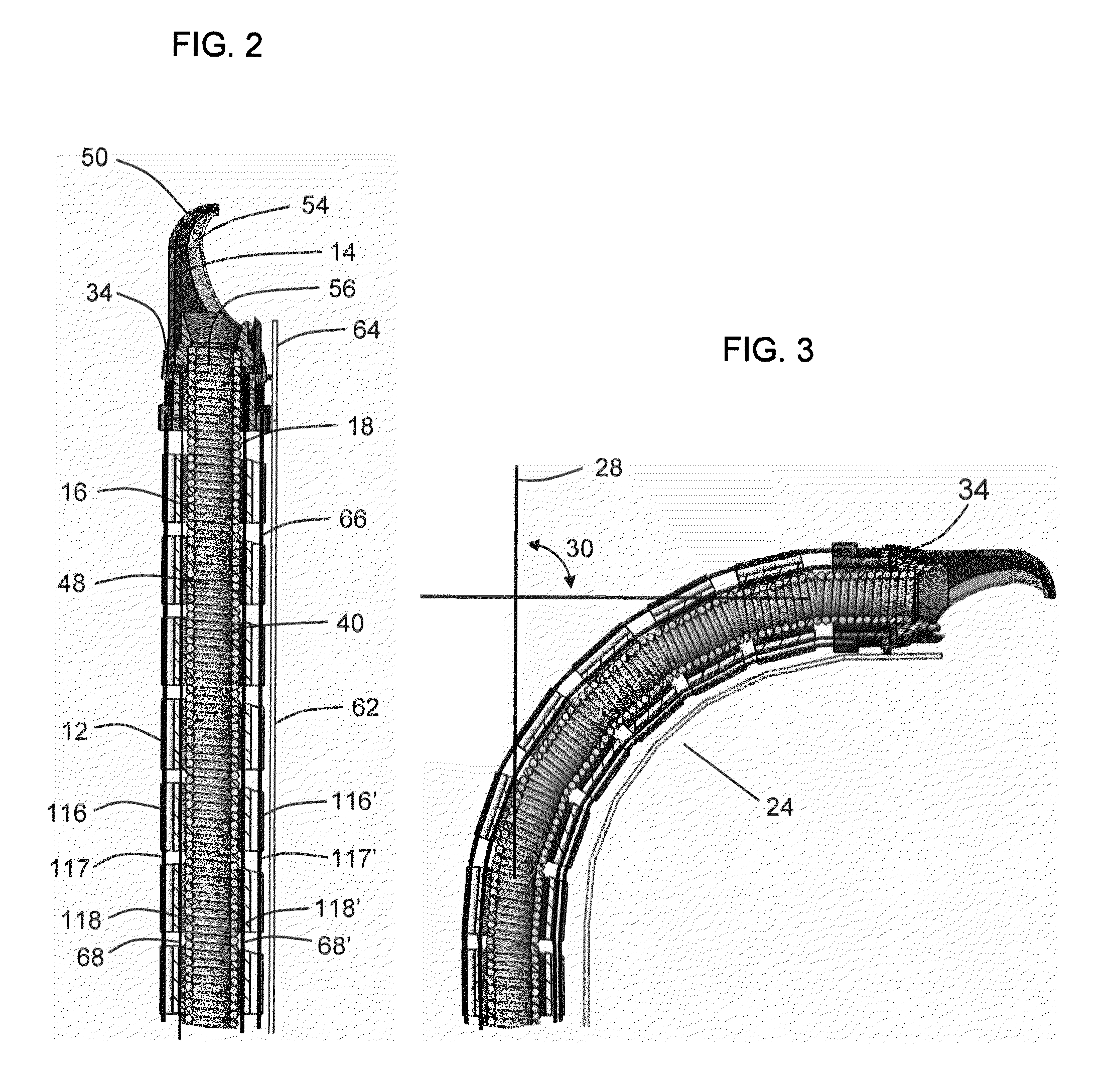

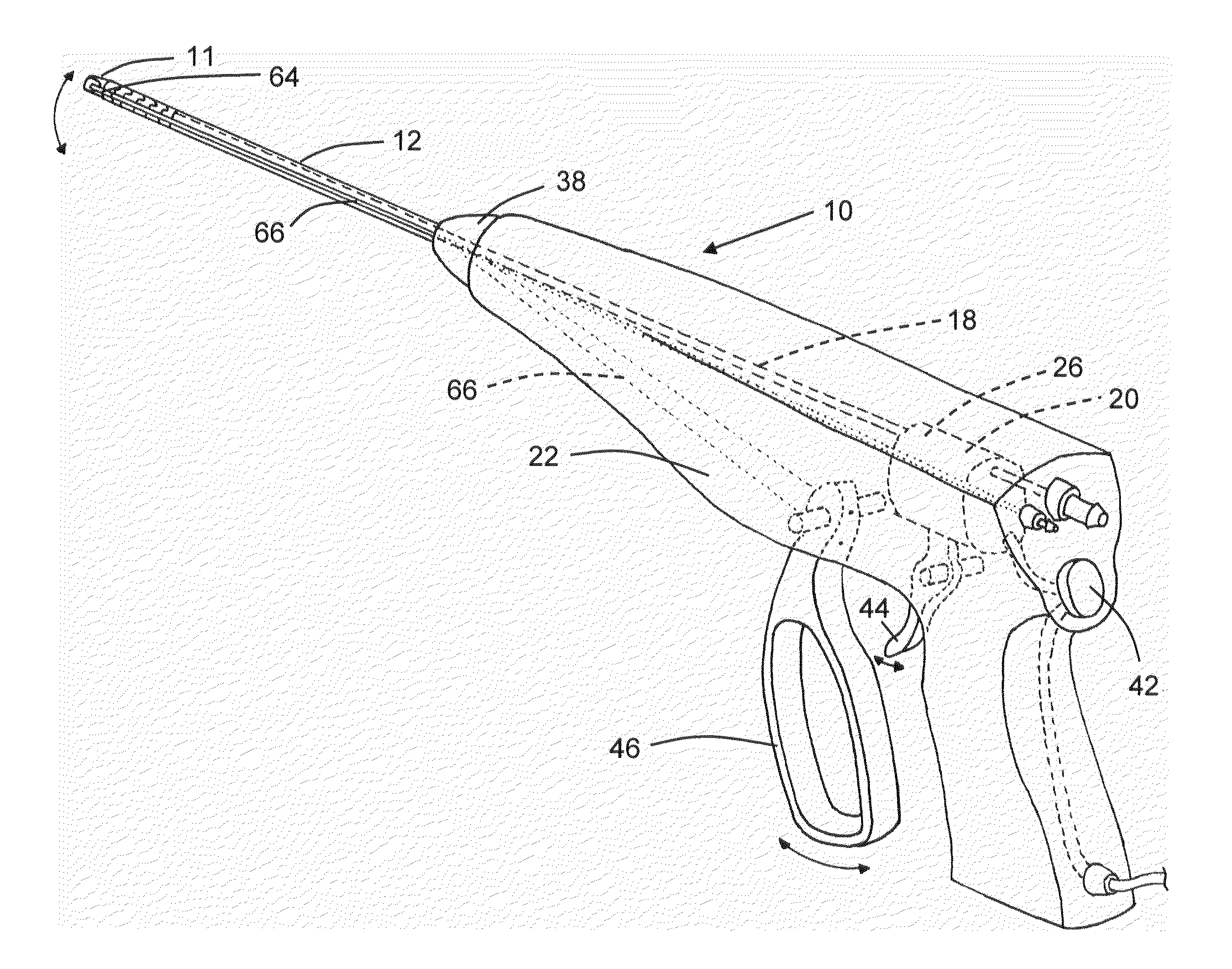

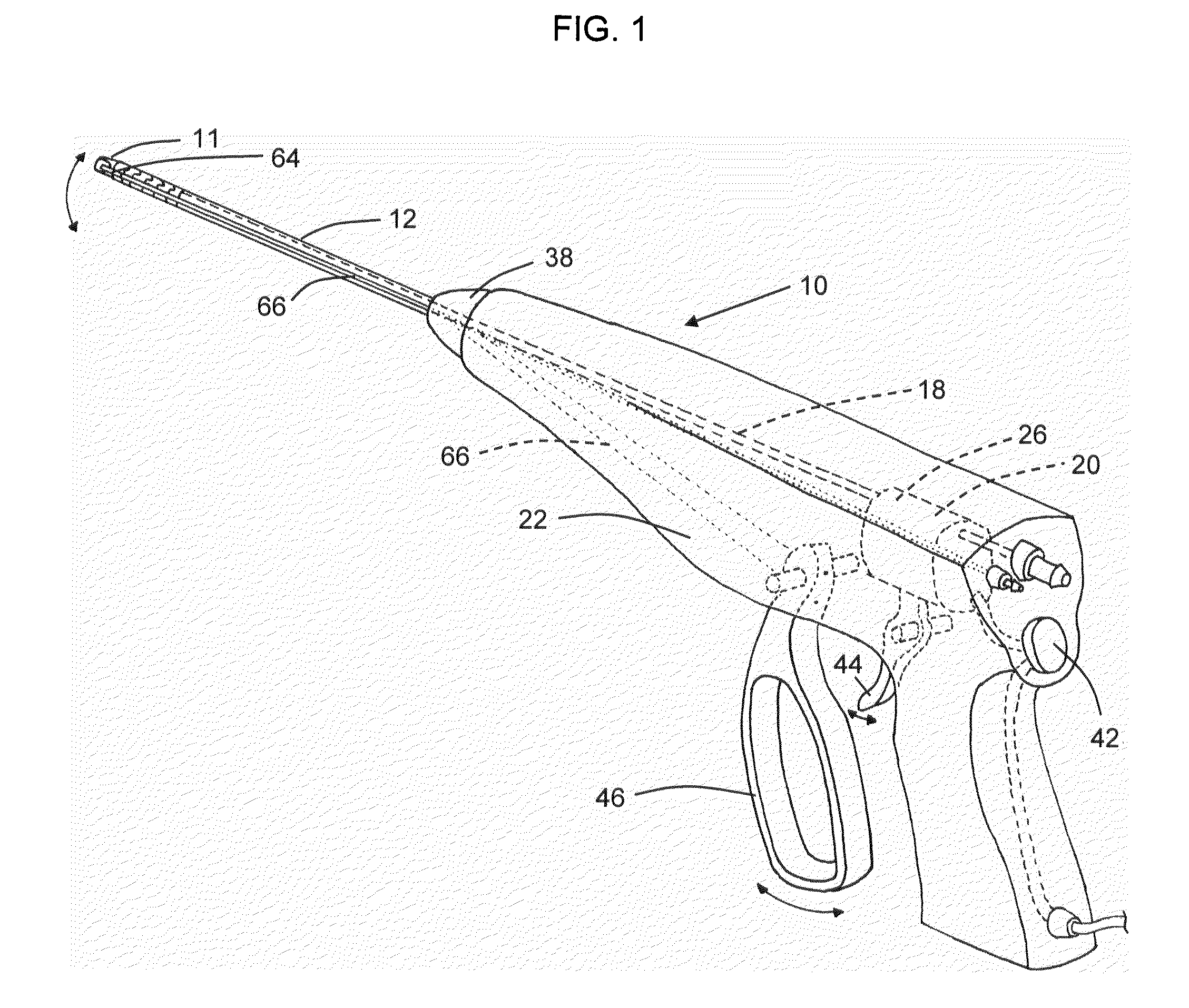

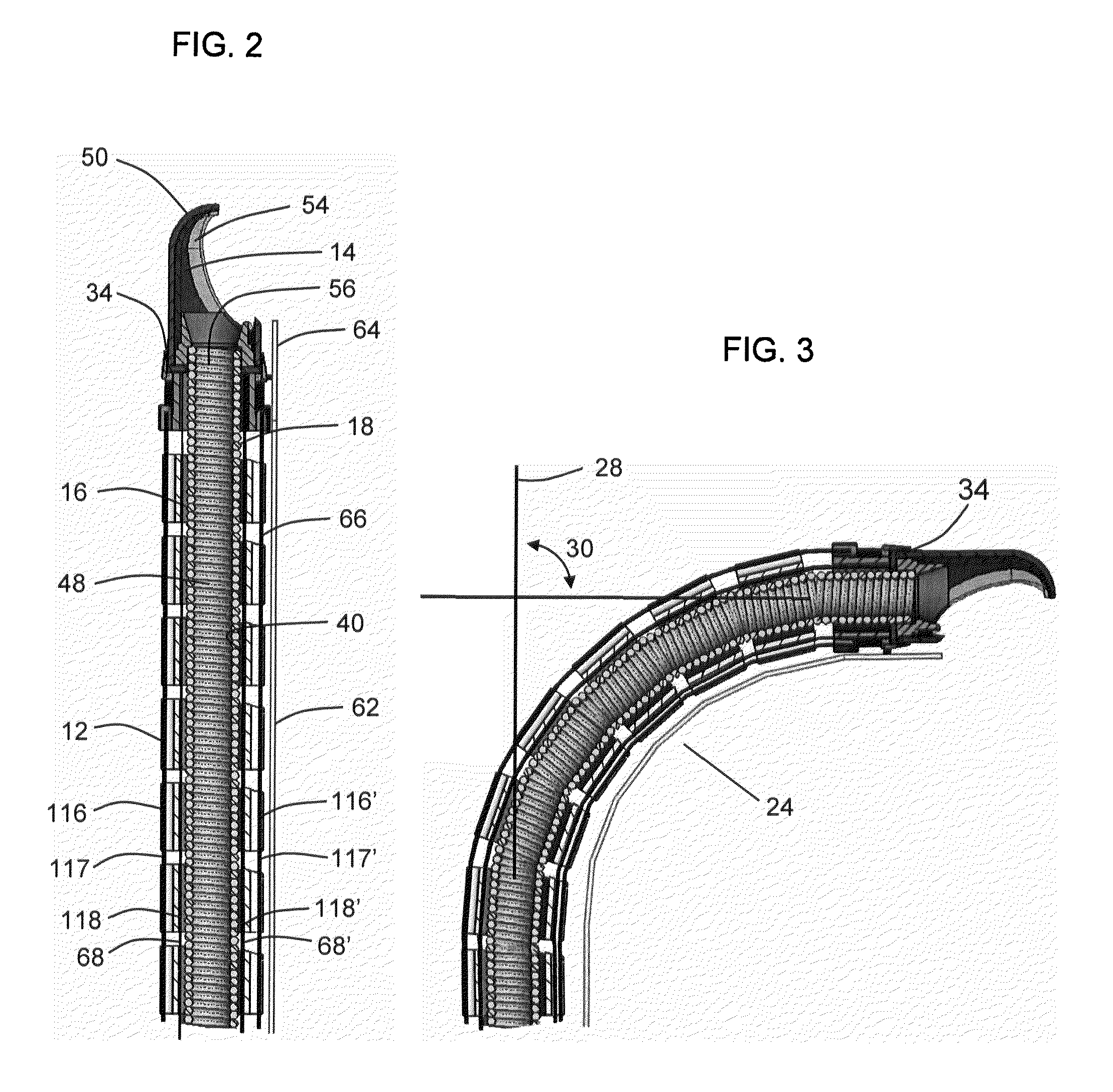

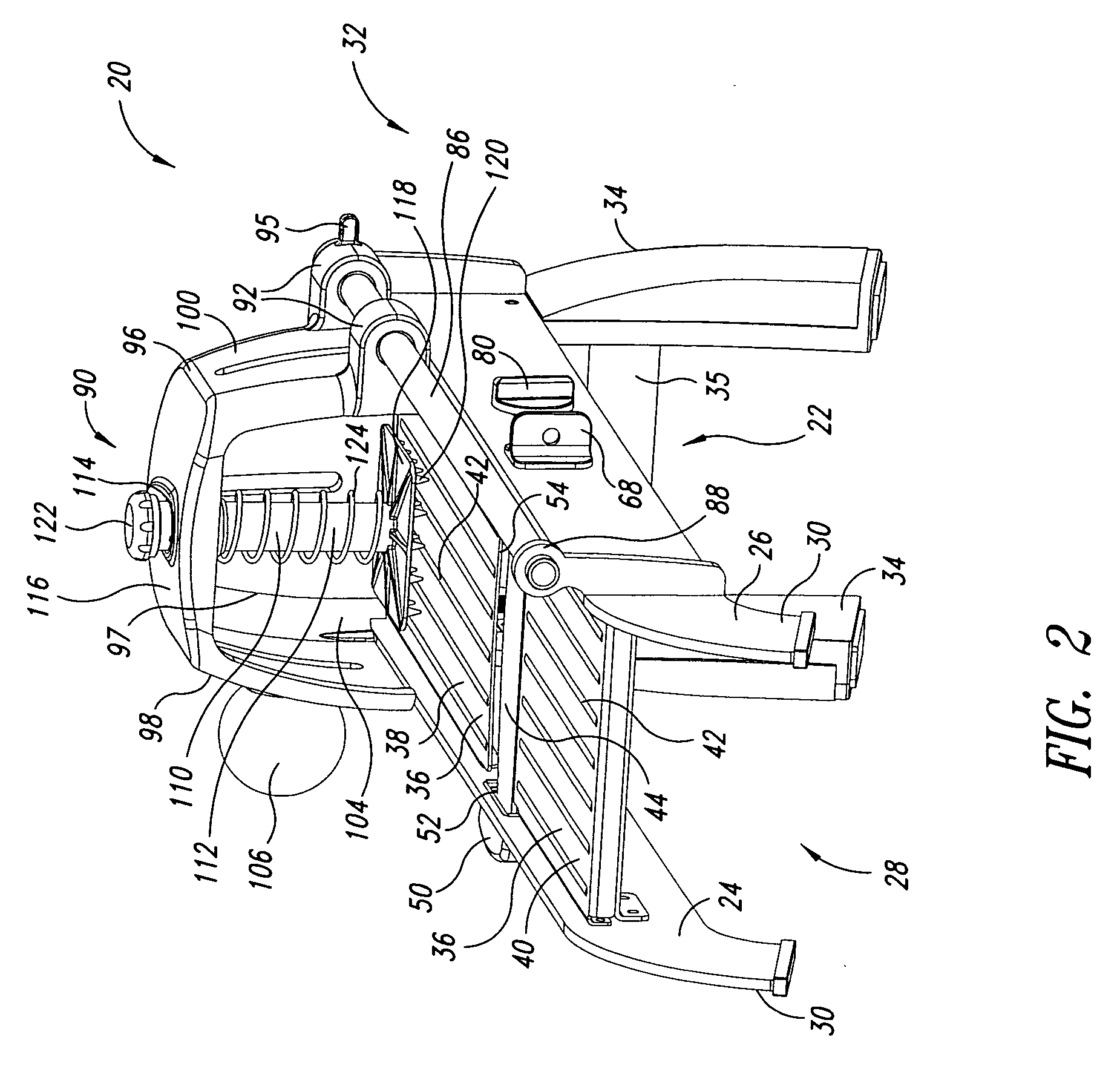

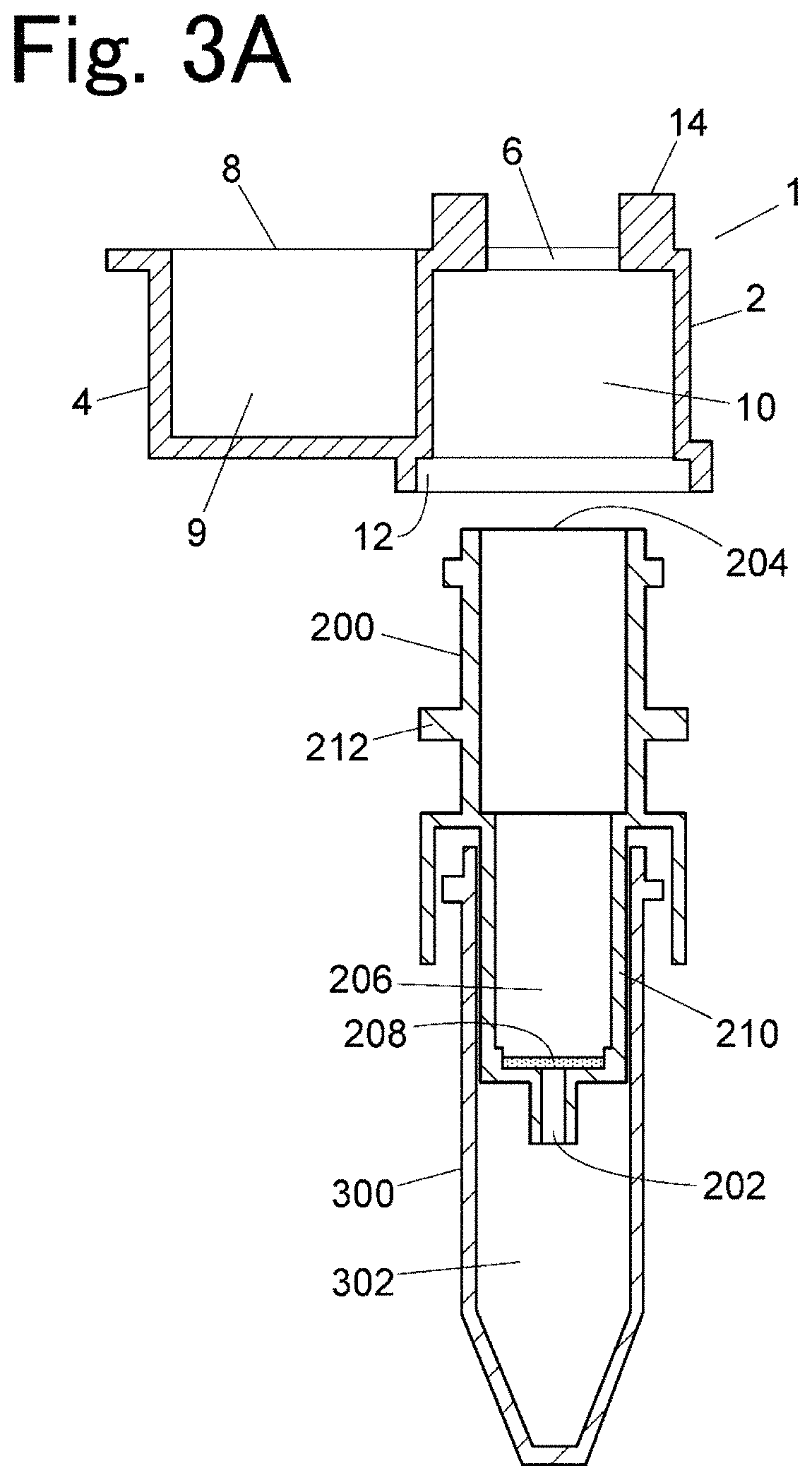

Apparatus and methods for removal of intervertebral disc tissues

ActiveUS8123750B2Cutting safetyAvoid damageExcision instrumentsEndoscopic cutting instrumentsIntervertebral discDrive shaft

Apparatus and methods for removing tissue from an intervertebral disc are disclosed. The apparatus can include an elongated guide tube, a rotary cutting member and a drive shaft. Other apparatus can include an elongated guide tube, an inner guide tube, a cutting head, a rotary cutting member and a drive shaft. The elongated guide tube has a bendable end. The apparatus are generally configured to extend and withdraw a rotary cutting member while controllably bending the bendable end of the guide tube.

Owner:CORESPINE TECH

Apparatus and methods for removal of intervertebral disc tissues

ActiveUS20100100098A1Safely cutPrevent be damageJoint implantsExcision instrumentsBiomedical engineeringIntervertebral disk

Apparatus and methods for removing tissue from an intervertebral disc are disclosed. The apparatus can include an elongated guide tube, a rotary cutting member and a drive shaft. Other apparatus can include an elongated guide tube, an inner guide tube, a cutting head, a rotary cutting member and a drive shaft. The elongated guide tube has a bendable end. The apparatus are generally configured to extend and withdraw a rotary cutting member while controllably bending the bendable end of the guide tube.

Owner:CORESPINE TECH

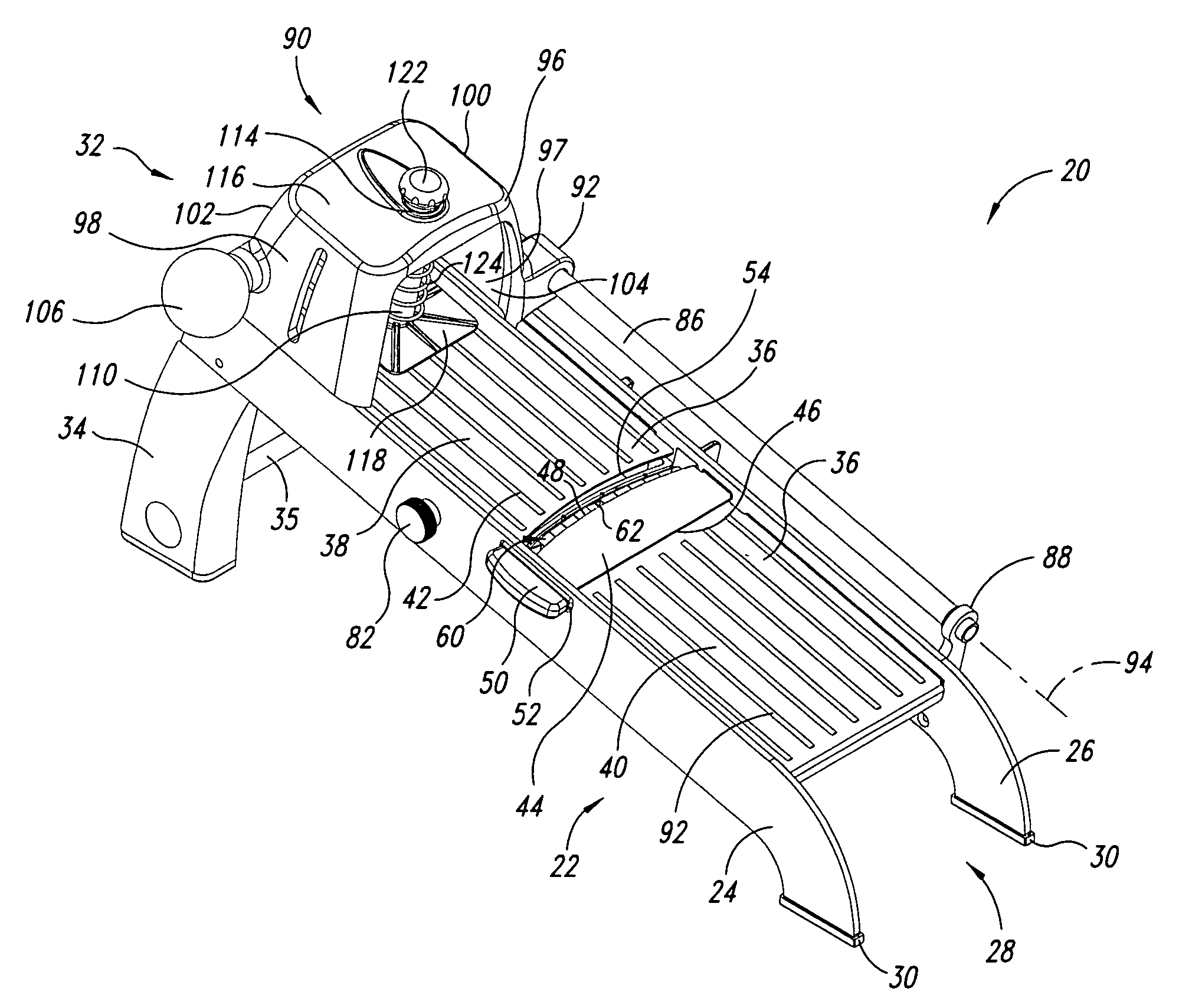

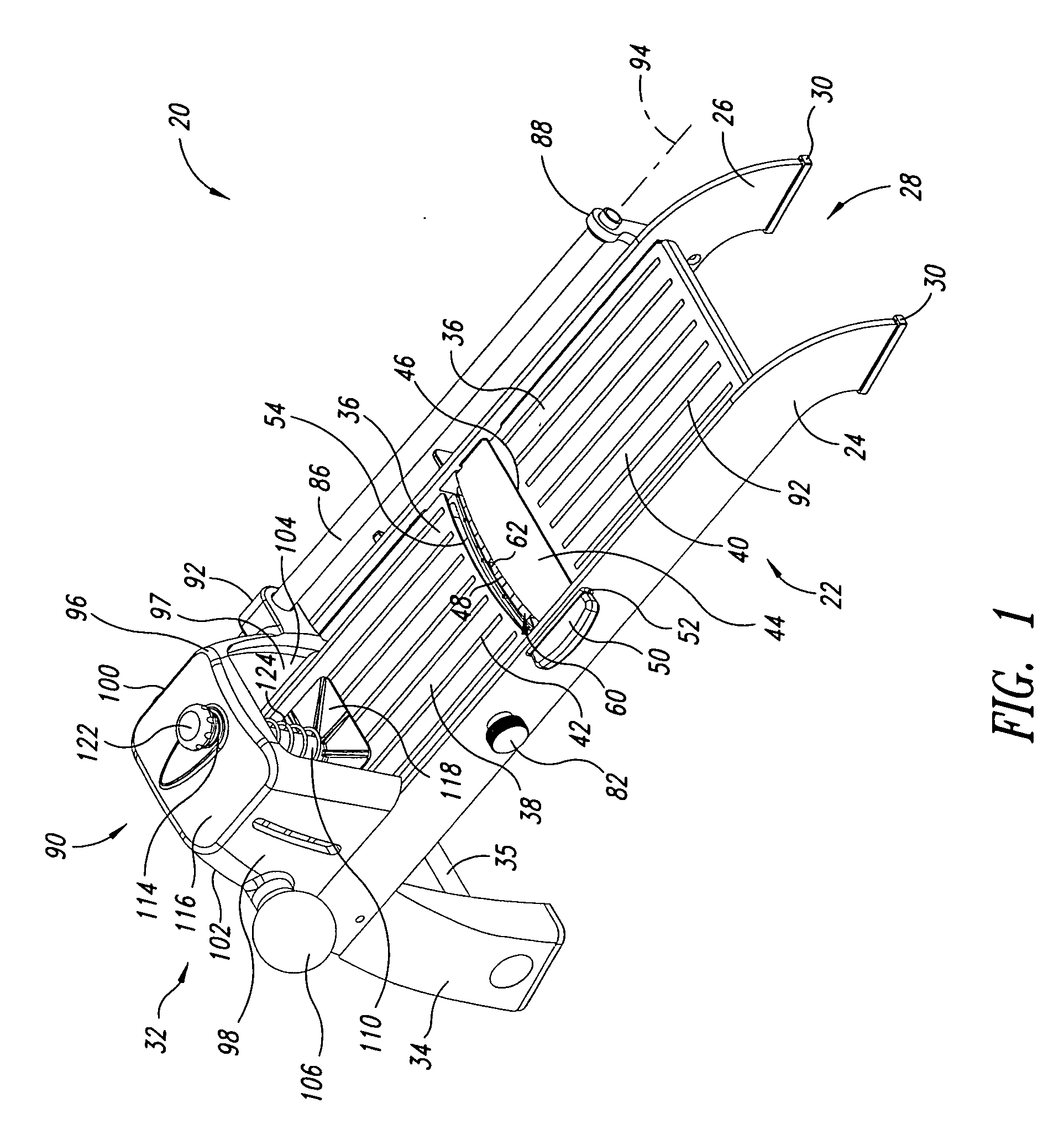

Mandolin slicer

ActiveUS20070125207A1Improve securityUniformity and stabilityMetal working apparatusEngineeringDelivery system

A mandolin slicer having one or more safety features, including a food carrier having one or more guards to protect a user's hand and a food carrier delivery system that helps ensure uniform and predictable movement. The mandolin slicer also provides an ability to safely and effectively cut oversized, long, and awkwardly shaped food articles.

Owner:KAI US

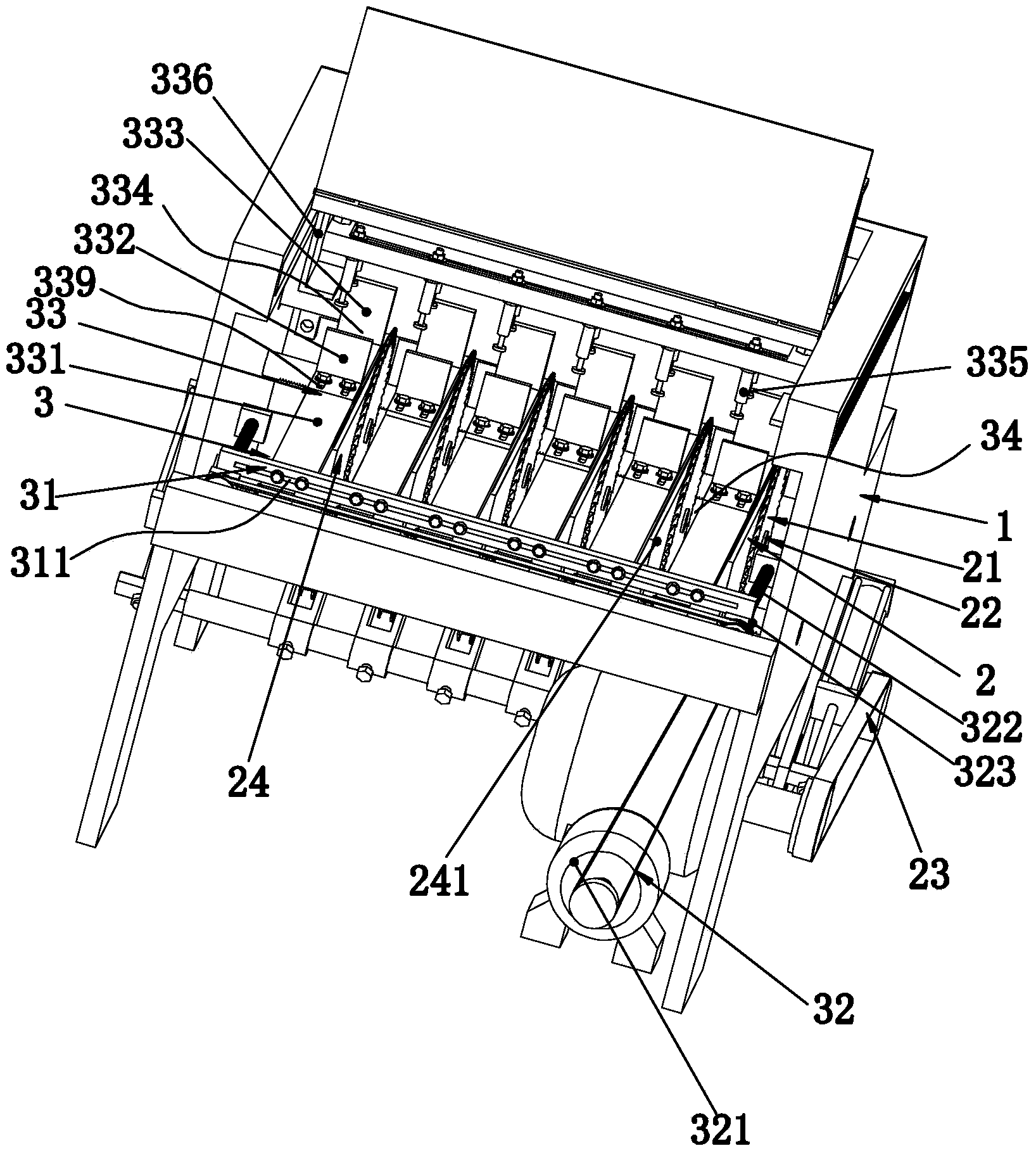

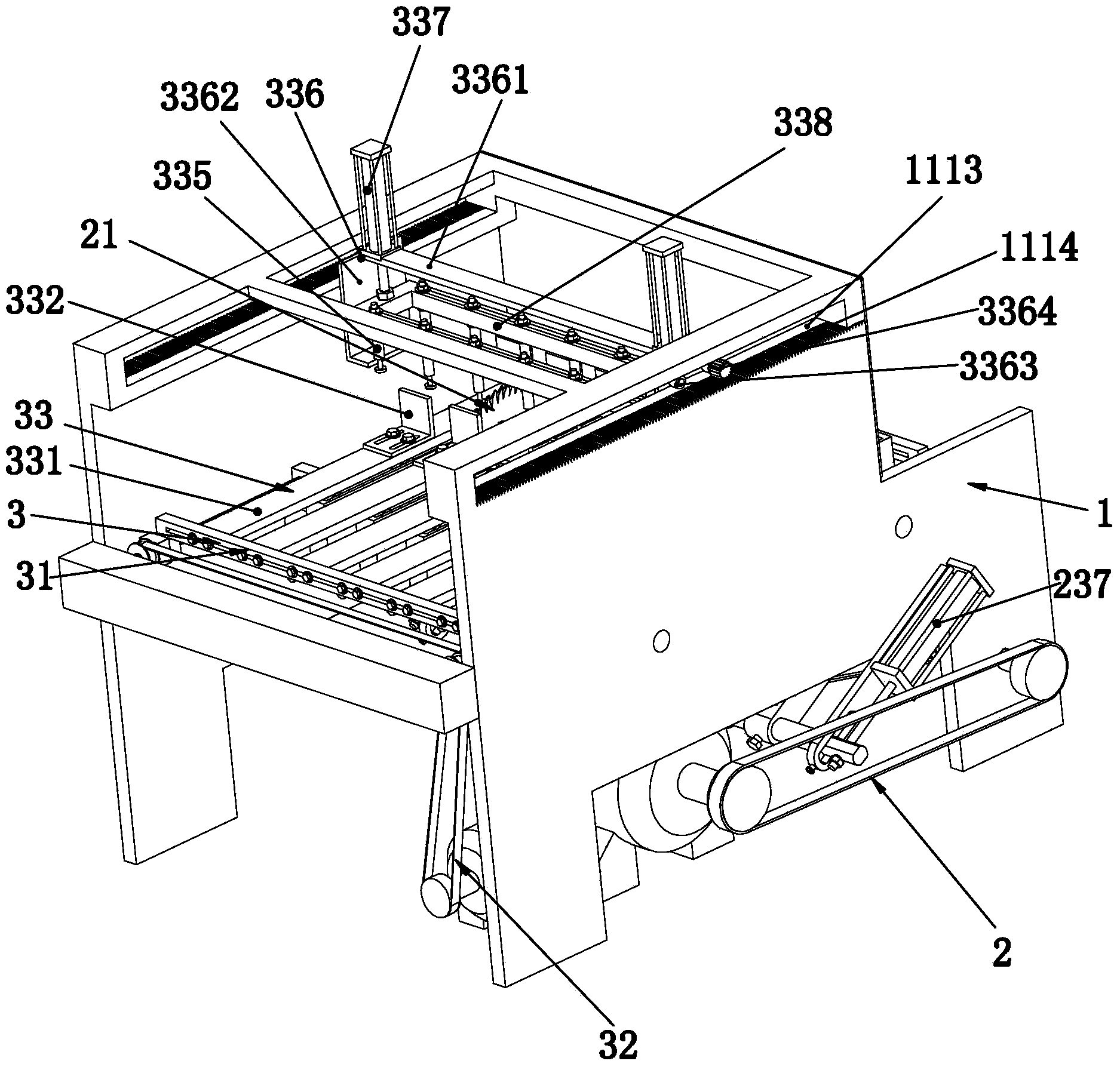

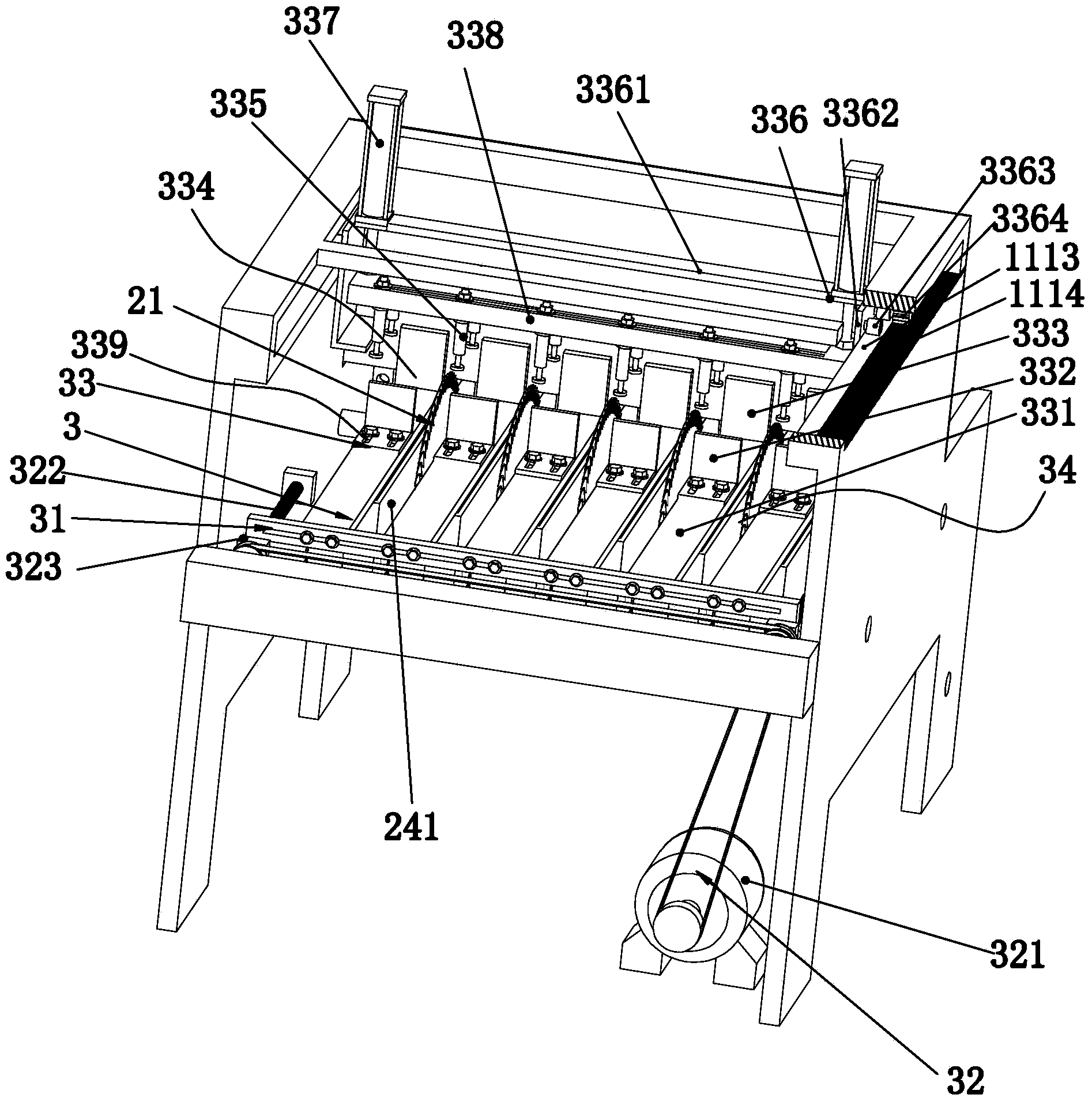

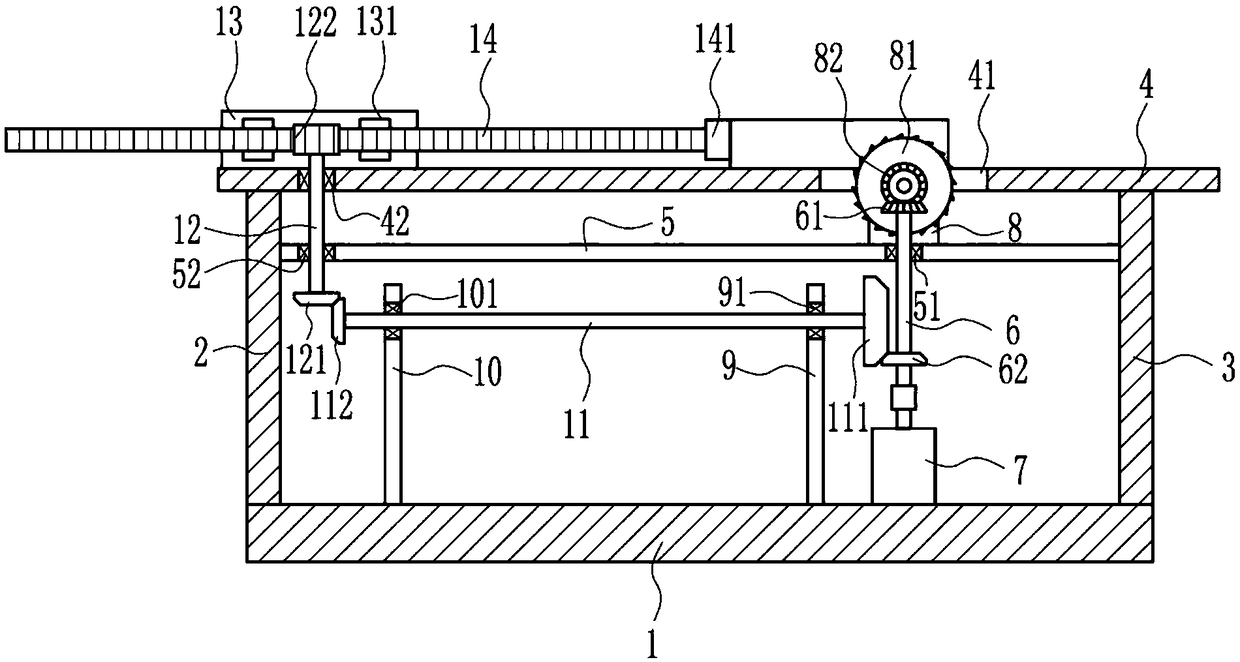

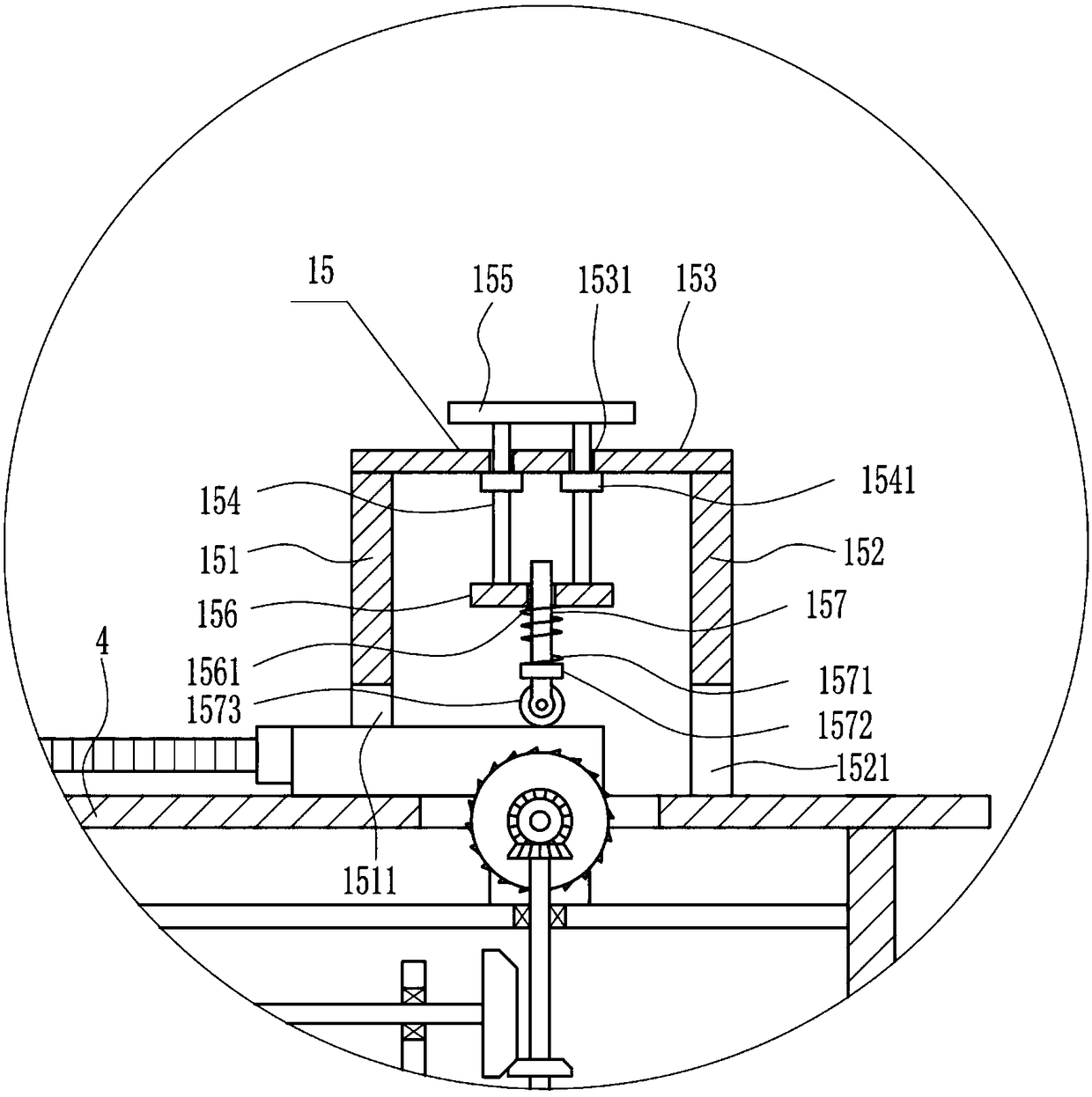

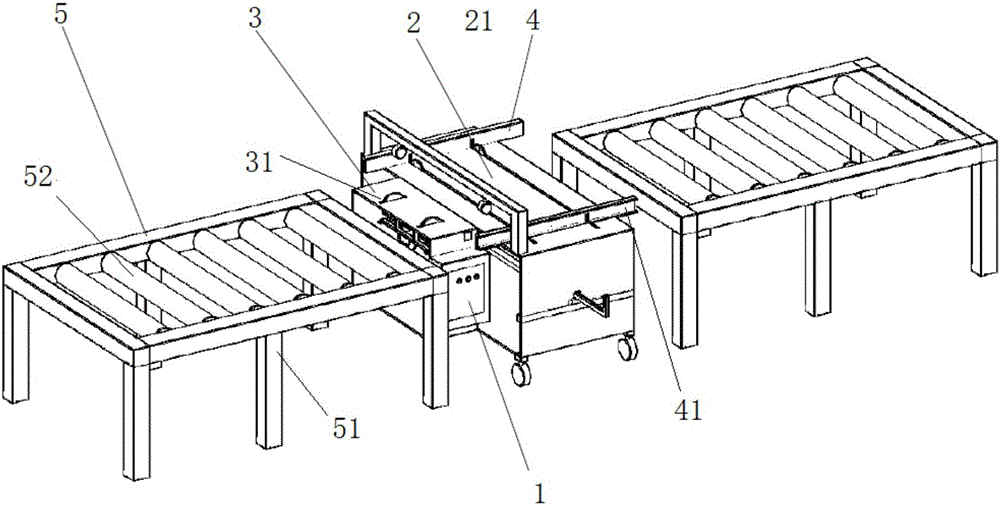

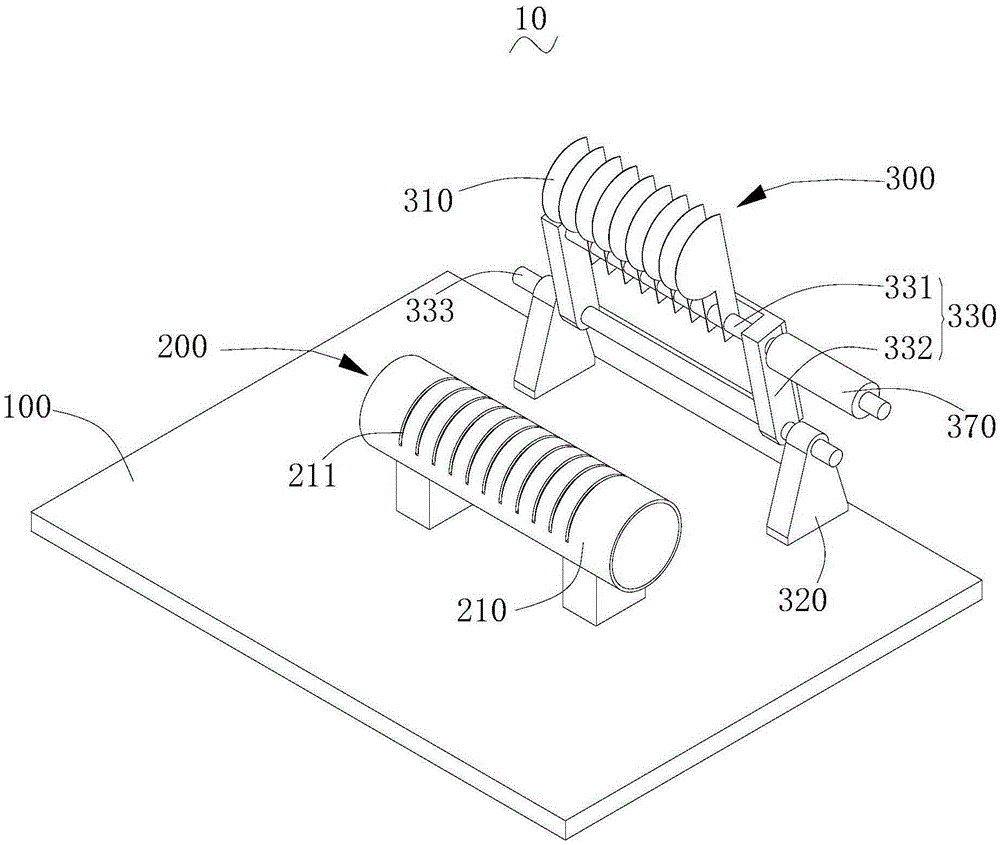

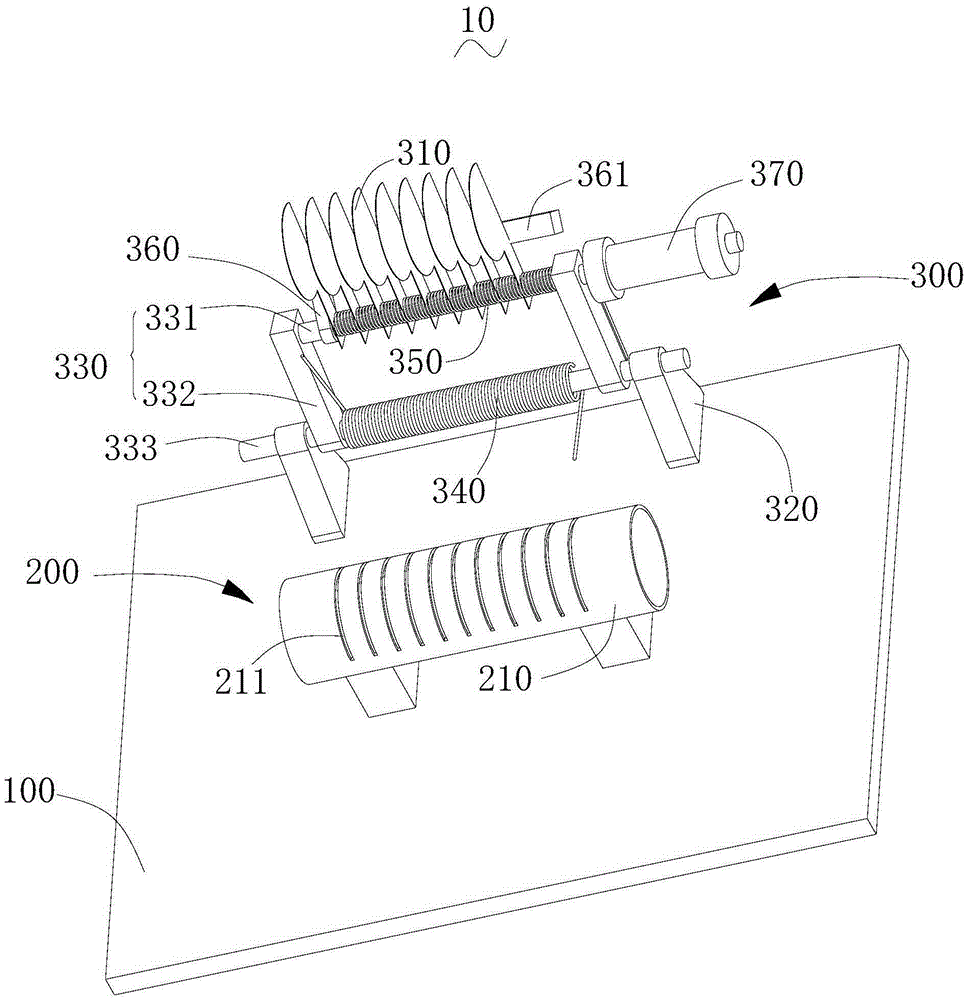

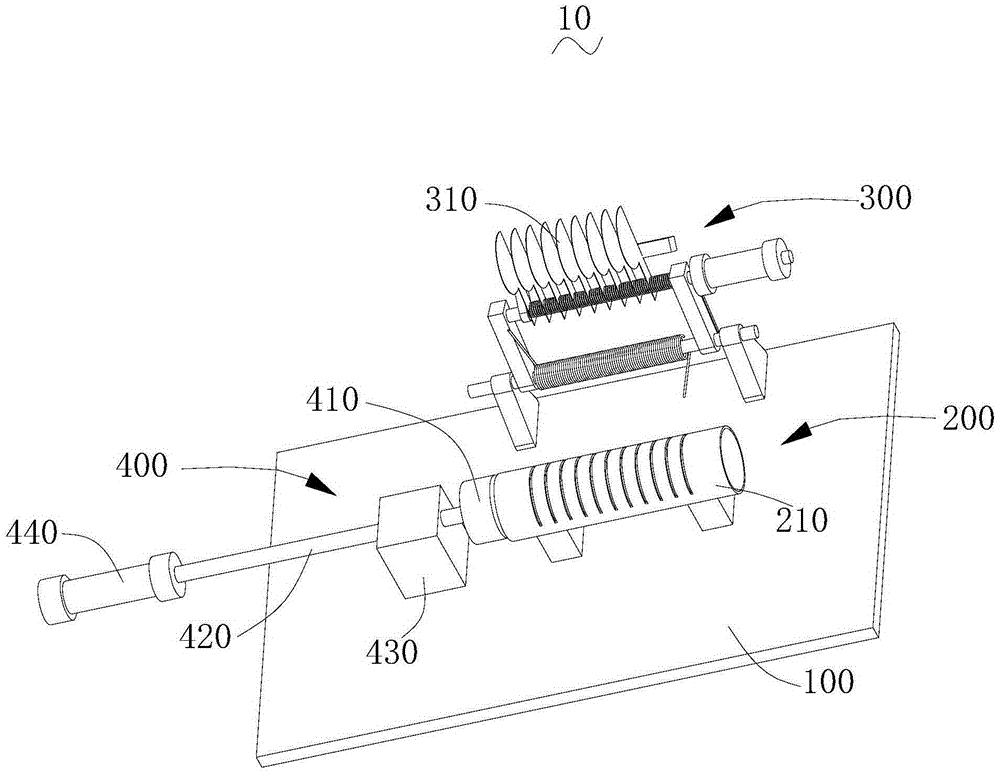

Safe type timber cutting machine with multiple cutting saw blades

The invention relates to a safe type timber cutting machine with multiple cutting saw blades. The safe type timber cutting machine comprises a machine base and a cutting device arranged on the machine base. The cutting device comprises a plurality of cutting saw blades, a saw blade mounting rotary shaft and saw blade driving mechanisms, wherein the cutting saw blades are coaxially assembled, and the spacing between the cutting saw blades can be adjusted, the saw blade mounting rotary shaft is used for allowing the cutting saw blades to be installed on, and the saw blade driving mechanisms drive the cutting saw blades to rotate and are in drive connection with the saw blade mounting rotary shaft. The machine base is further provided with an automatic feeding device. The automatic feeding device comprises a feeding rack and a feeding driving mechanism, wherein the feeding rack is arranged in a moving and sliding mode in the rotating and cutting direction of the cutting saw blades, and the feeding driving mechanism drives the feeding rack. A plurality of timber fixing platforms are arranged on the feeding rack, the number and the positions of the timber fixing platforms correspond to those of the cutting saw blades. The timber fixing platforms are coaxially arranged. Timber cutting passages for allowing the cutting saw blades to enter and cut timbers are formed between the adjacent timber fixing platforms in a spaced mode. The spacing between the adjacent timber fixing platforms can be adjusted. Compared with the prior art, the safe type timber cutting machine with the multiple cutting saw blades can automatically feed the timbers and is more convenient and safer to operate.

Owner:邹建静

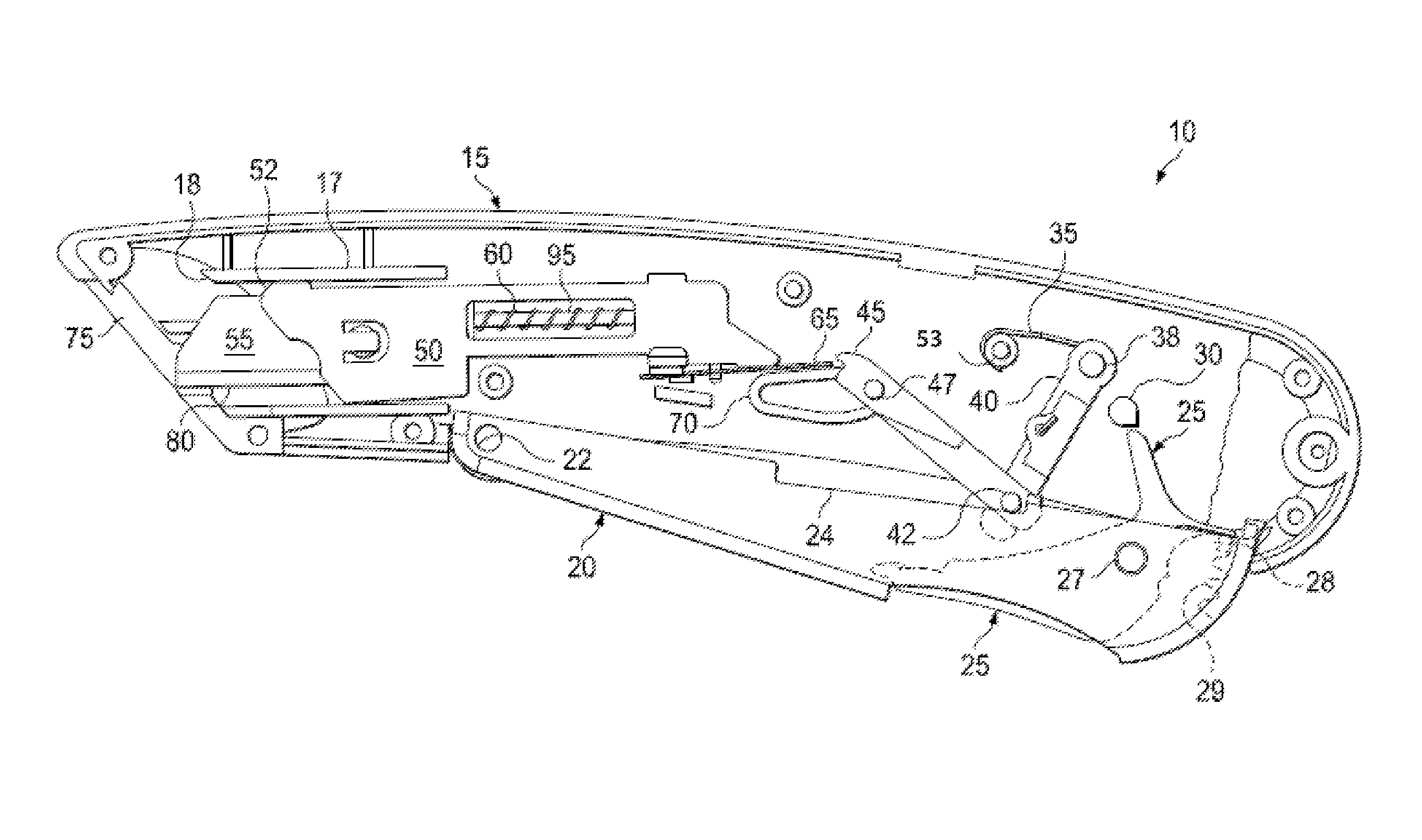

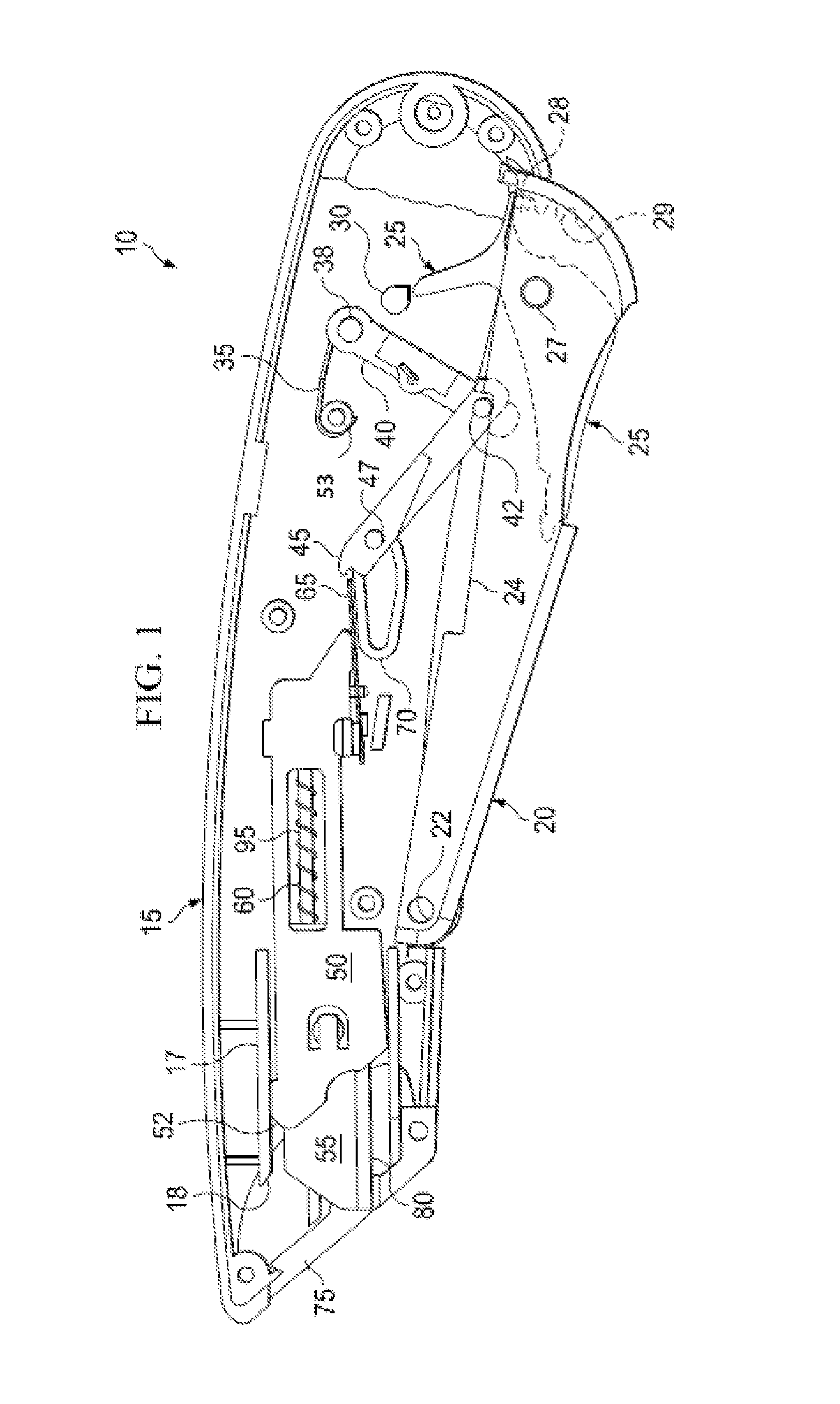

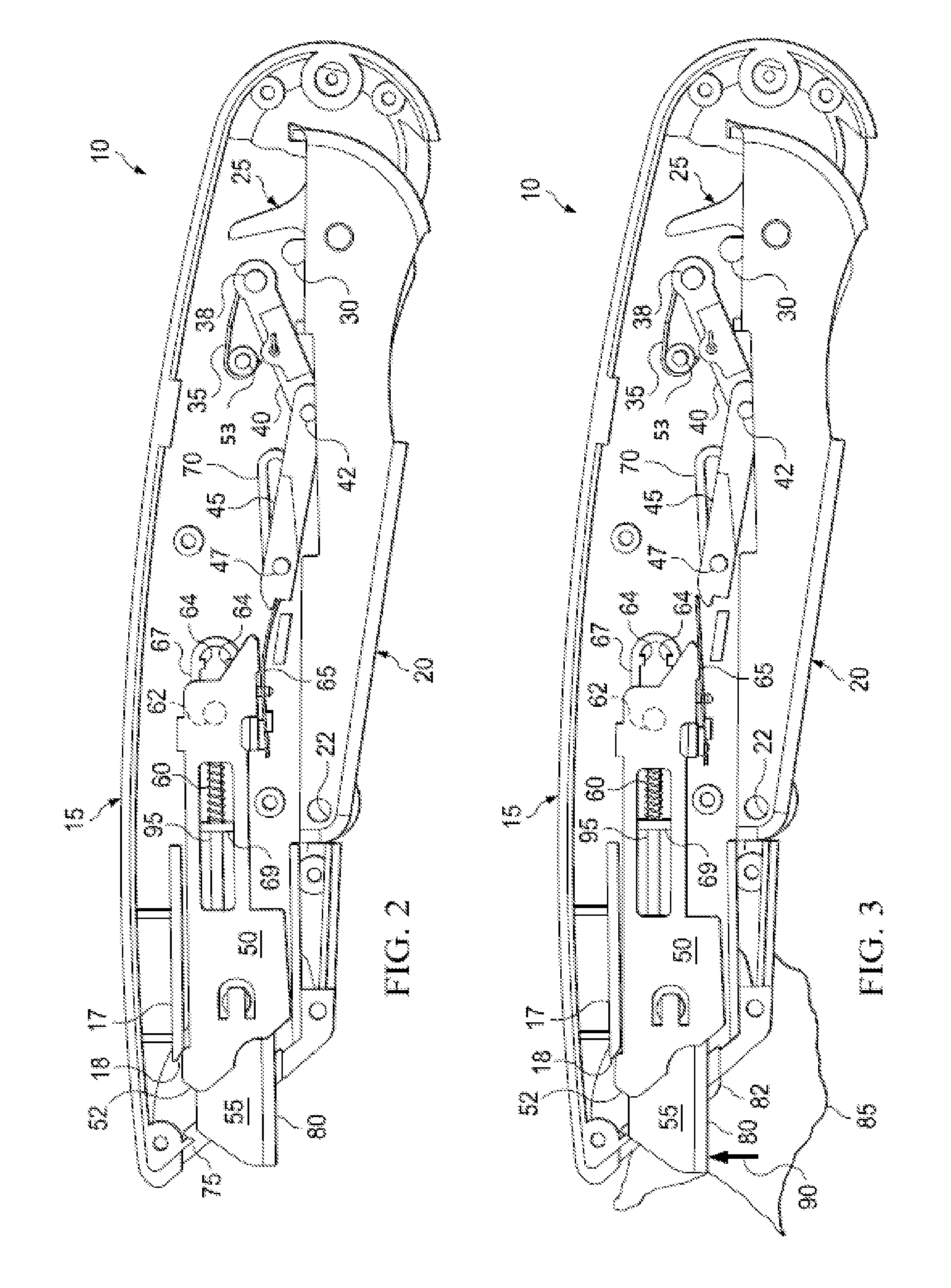

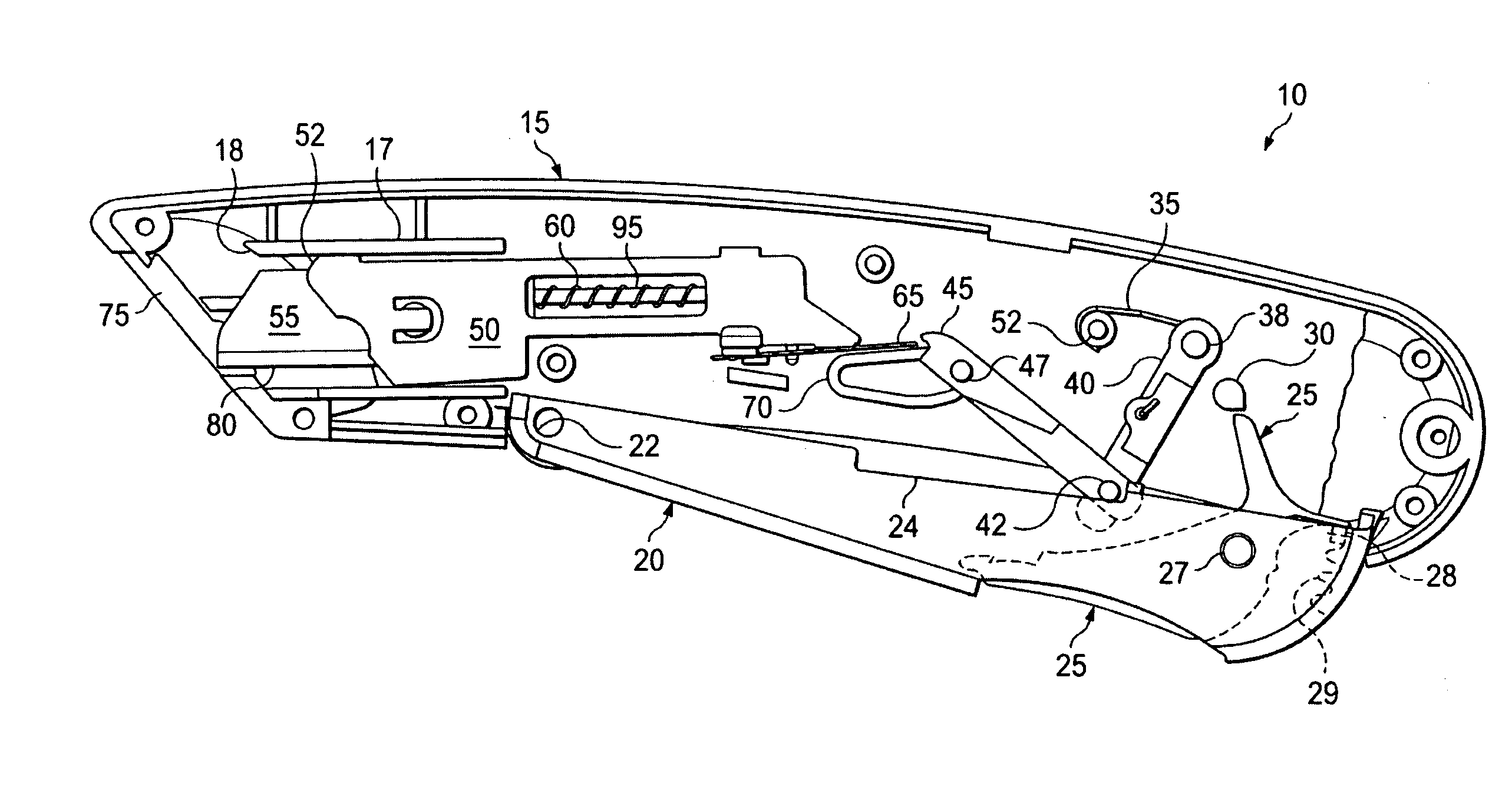

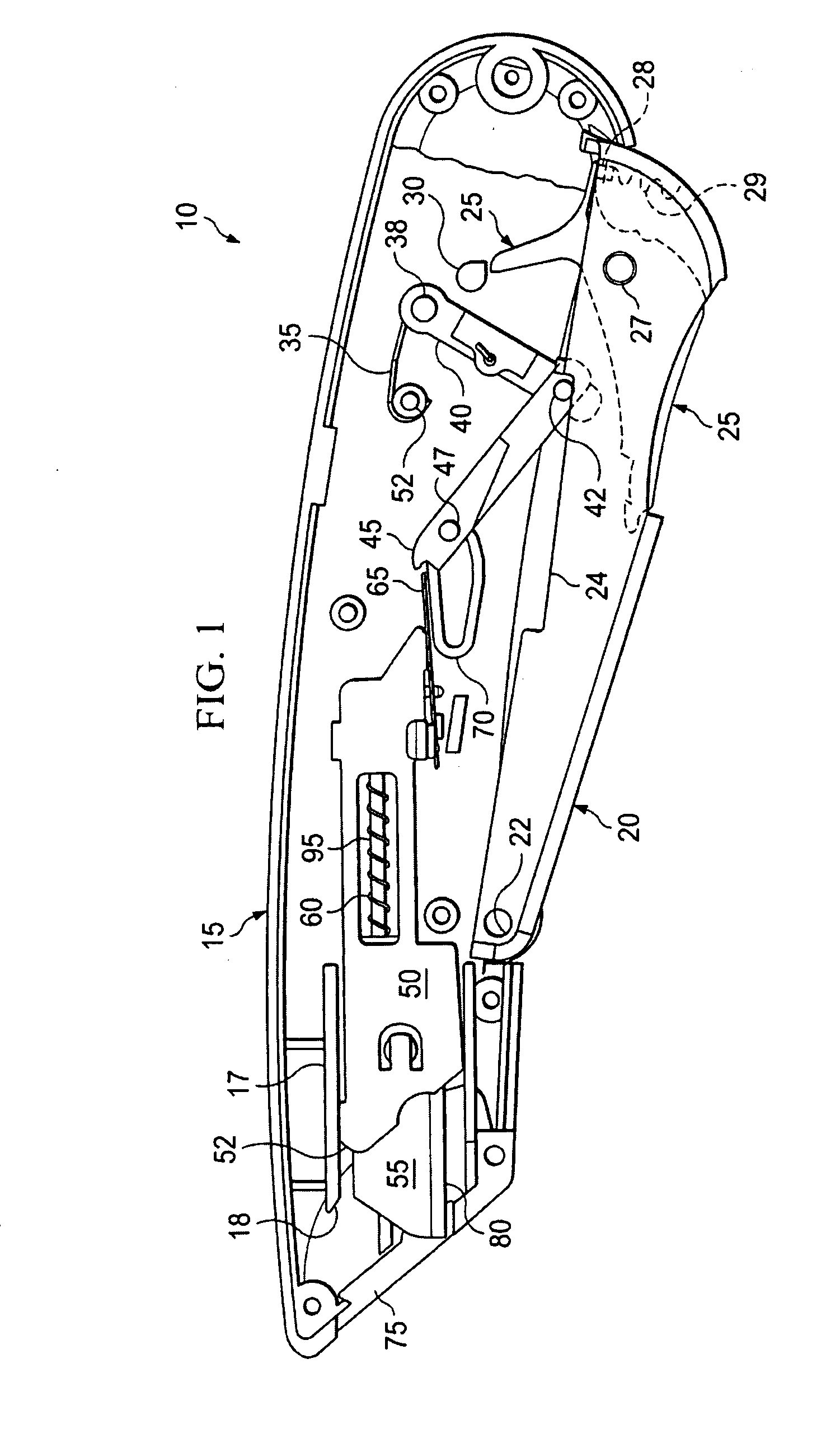

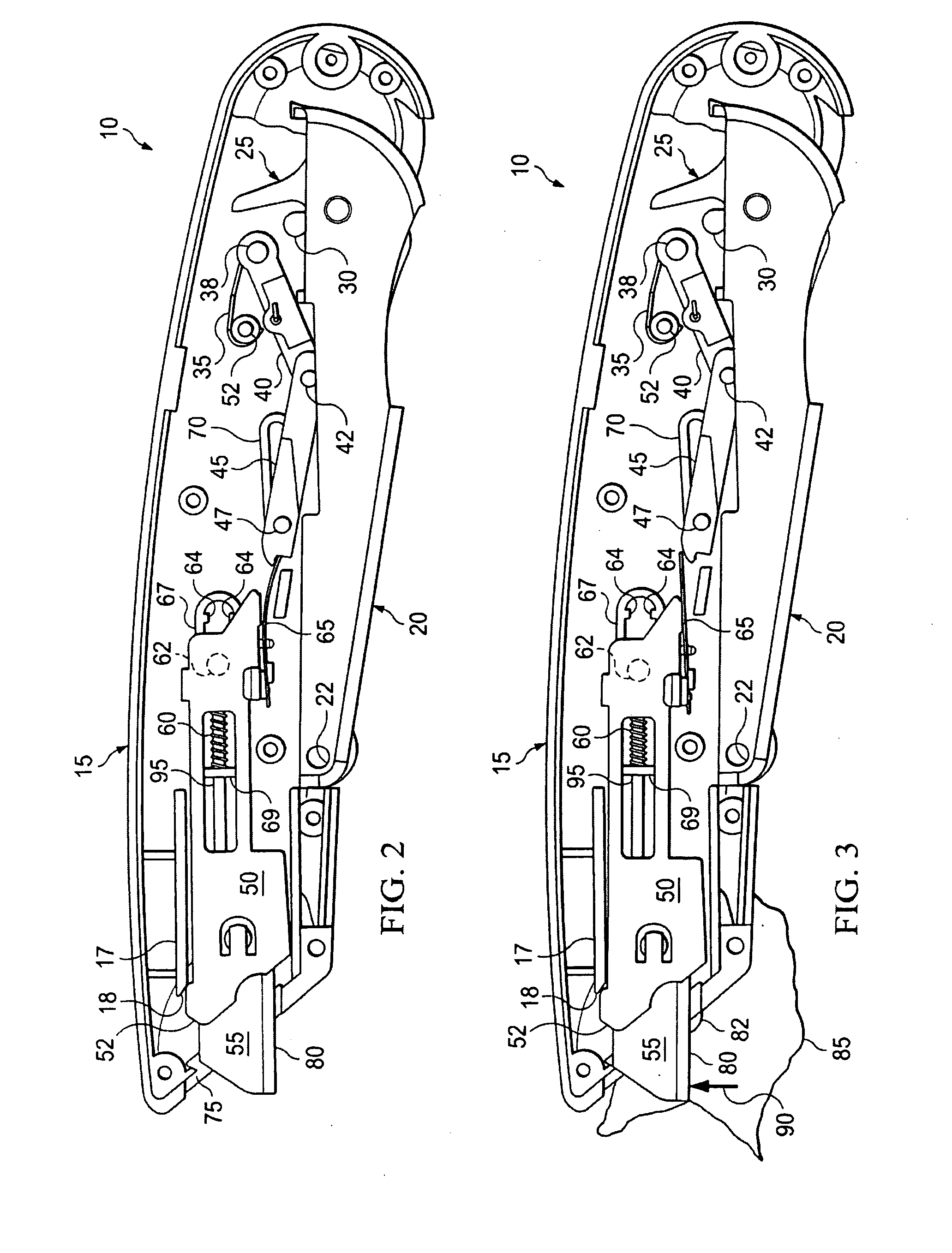

Utility cutter

ActiveUS8307556B2Prevent rotationPrevent decouplingThrusting weaponsWeapon componentsEngineeringEmbedded system

Owner:ADCO IND TECH

Utility Cutter

ActiveUS20100319200A1Prevent decouplingCutting safetyThrusting weaponsWeapon componentsKnife bladesEmbedded system

Owner:ADCO IND TECH

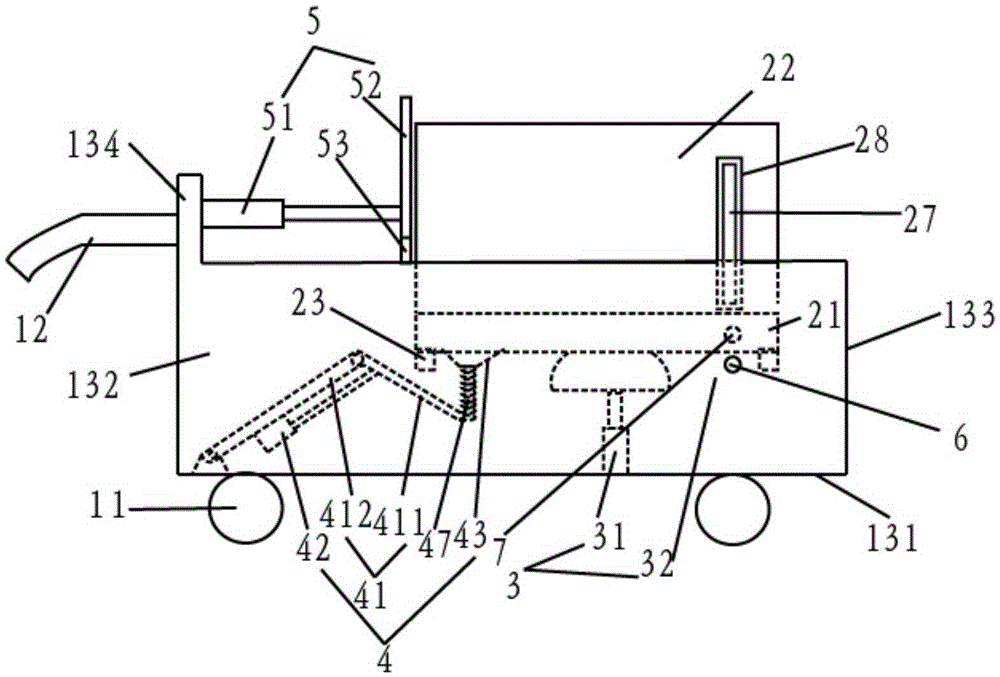

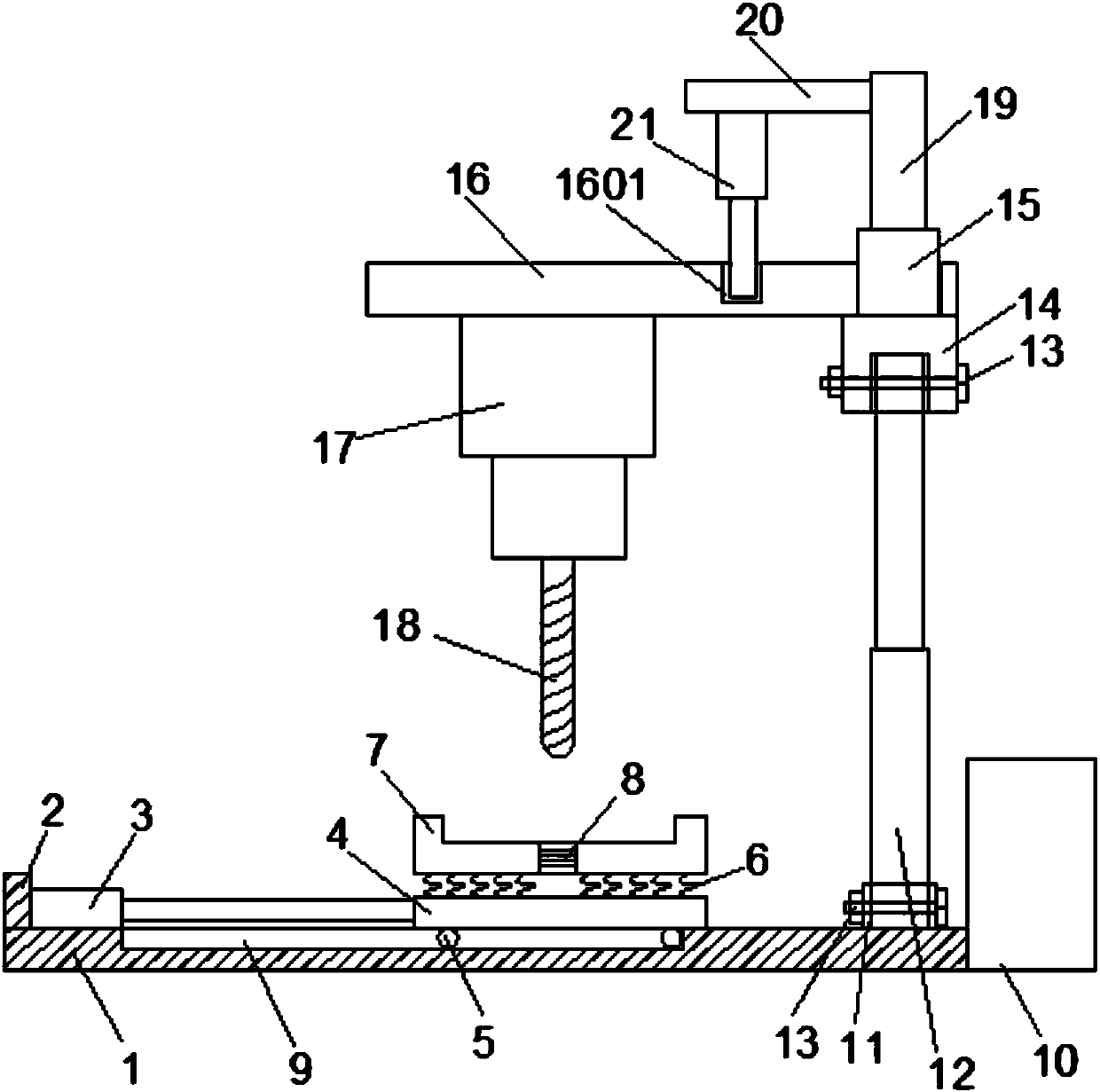

Pushing type wooden board cutting device for construction

InactiveCN108818756ACutting safetyPlay a guiding roleFeeding devicesCircular sawsMechanical engineeringBuilding construction

The invention relates to a cutting device, in particular to a pushing type wooden board cutting device for construction. The pushing type wooden board cutting device aims at achieving the effects of pushing a wooden board automatically and conducting cutting without hand pressing. The pushing type wooden board cutting device comprises a base, a first bracket, a second bracket, a worktable, a first bearing, a third bracket, a second bearing and a third bearing. The first bracket is fixedly connected to the left side above the base, and the second bracket is fixedly connected to the right sideabove the base. The top ends of the first bracket and the second bracket are fixedly connected with the worktable, and a first slot is formed in the left side of the worktable. The cutting device hasthe function of cutting the wooden board, solves the problem of danger caused by manual pushing of the wooden board for cutting, and further achieves the function of pressing the wooden board for fixing to ensure the safety of an operator. A fixed block and a handle are arranged. When a first fixed plate moves up, the first fixing plate can be prevented from dropping and clamping the hands of theoperator.

Owner:李子轩

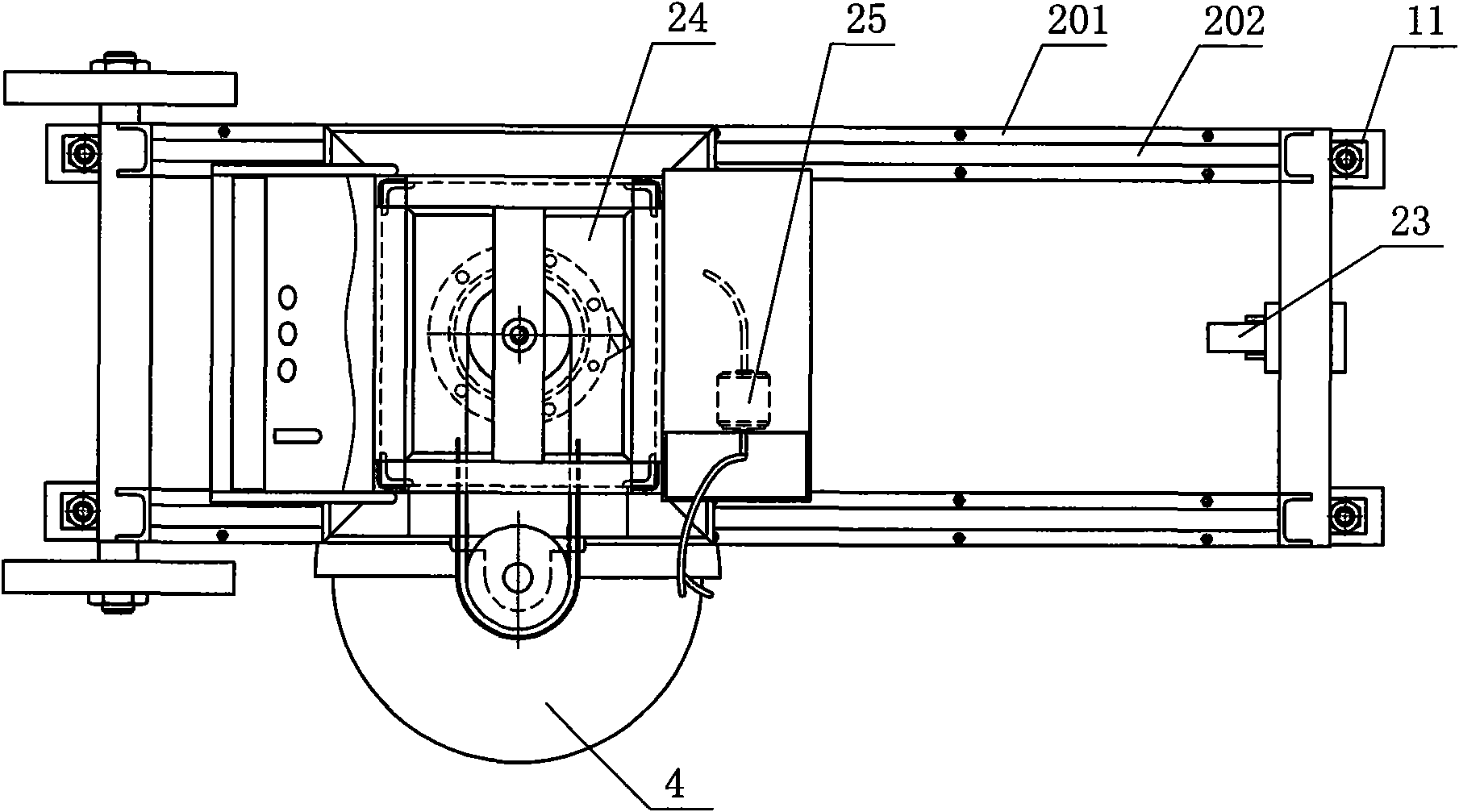

Pallet box transferring device

ActiveCN105417041AAddress flexibilitySolve the shortage restricted by the transshipment siteConveyor partsMechanical conveyorsEngineeringPallet

The invention discloses a pallet box transferring device. The pallet box transferring device comprises a transferring cart, a pallet box, a lifting mechanism, a turnover mechanism and a push-out mechanism. The pallet box is arranged in an inner cavity of the transferring cart; the fixed end of the lifting mechanism is disposed on the bottom wall of the inner cavity; the lifting end of the lifting mechanism upwards extends and is used for supporting the pallet box; the connecting end of the turnover mechanism is hinged to the bottom wall of the inner cavity; the free end of the turnover mechanism can be attached to the bottom of the pallet box; the fixed end of the push-out mechanism is disposed on the rear wall of the inner cavity; the retractable end of the push-out mechanism forwards extends and is close to the pallet box. The pallet box transferring device has the advantages of being good in flexibility and stability, large in bearing load, high in transferring efficiency and capable of safely blanking materials.

Owner:淮北市宇控信息技术有限公司

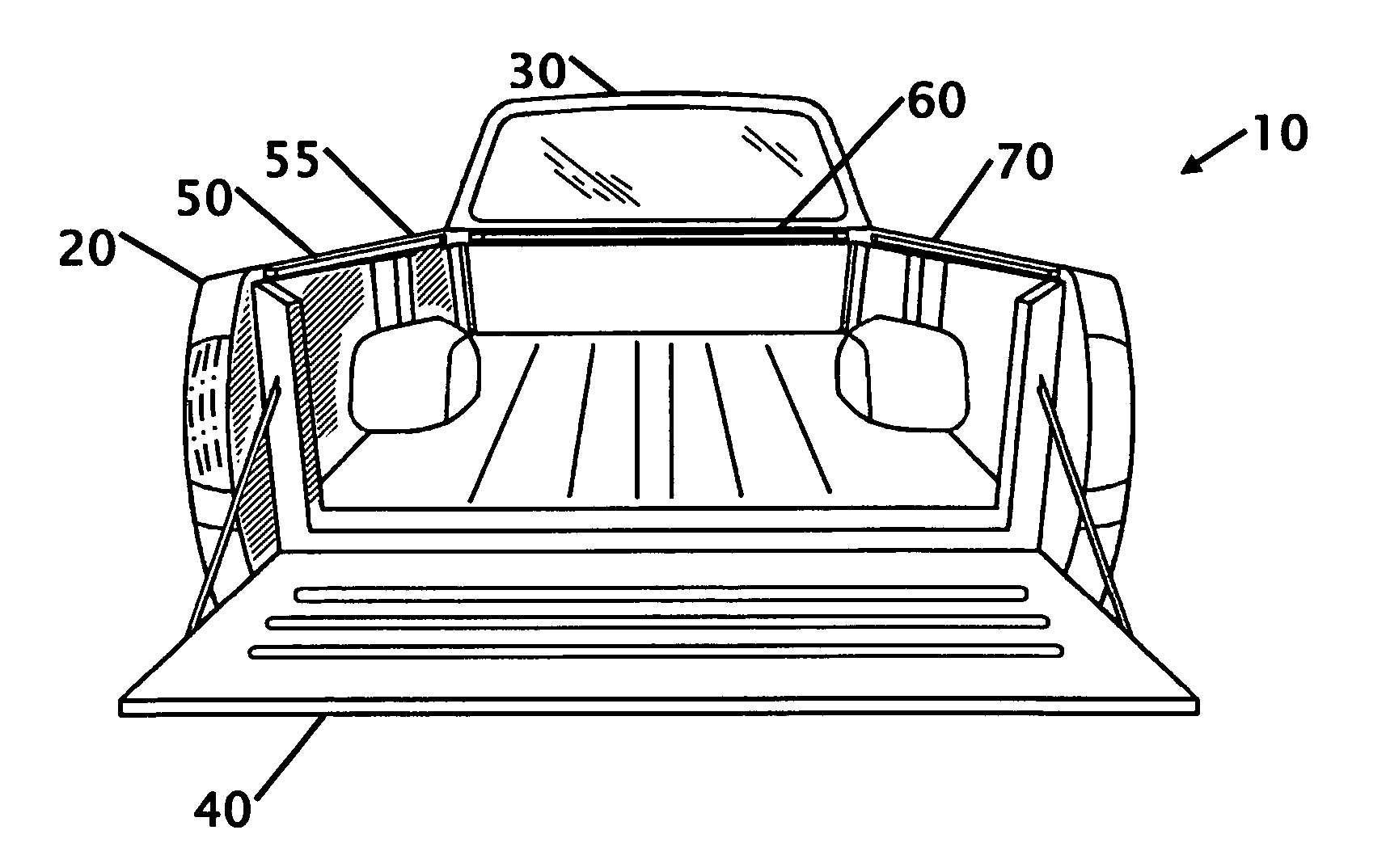

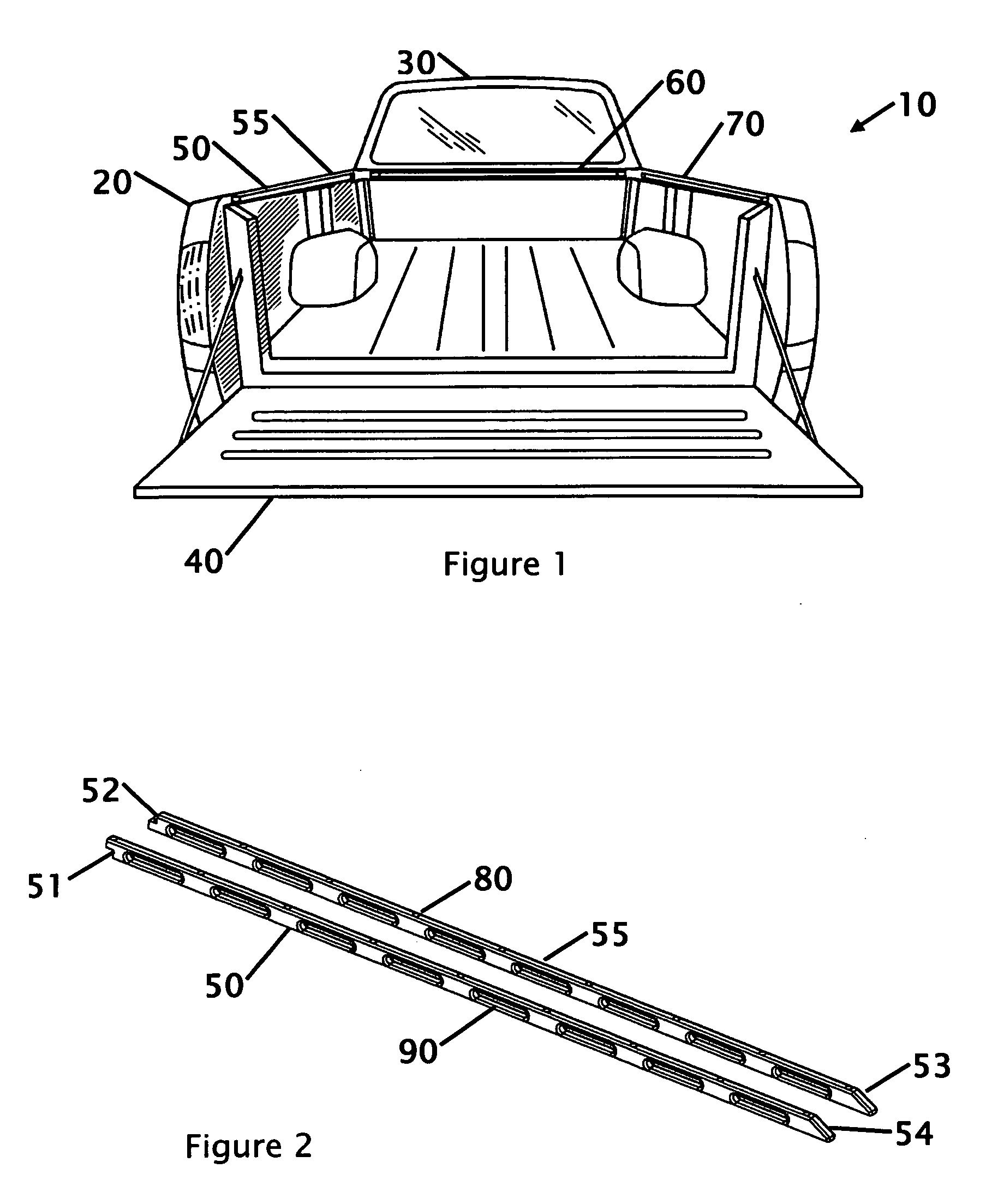

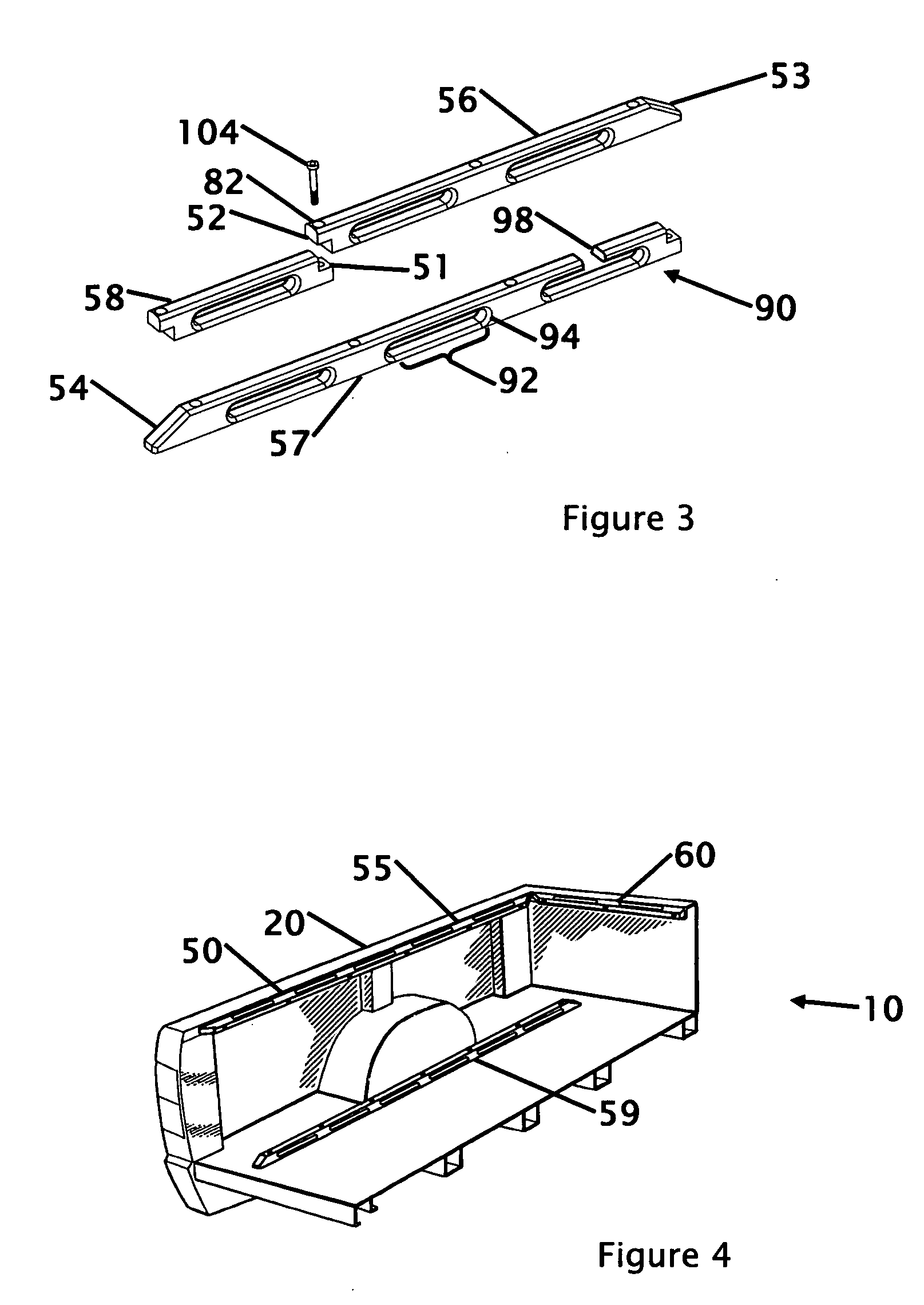

Side mounted truck tie-down rail

InactiveUS20080014041A1Cutting safetyReduce the possibilityFlexible elementsCargo supporting/securing componentsPickup truckEngineering

This invention relates to the art of securing cargo in the bed of a pickup truck. A slotted bar is secured to the upper inside wall in the bed of a truck where the structural flange is formed around the bed. When the rail is mounted on a vehicle it provides a plurality of tie down locations and increases the structural strength of the side walls. The tie down does not interfere with a bed cover. The tie down is fabricated from one or multiple pieces that are linkable to extend the length of the tie down and allow for configuration changes based upon the dimensions of the truck bed.

Owner:RANDAZZO MARK +1

Discharge mechanism of pallet box transfer device

The invention discloses a discharge mechanism of a pallet box transfer device. The discharge mechanism comprises a transfer body, an elevating mechanism arranged on the transfer body, an overturning mechanism and an ejecting mechanism. A fixed end of the elevating mechanism is arranged on the bottom wall of a cavity of the transfer body. An elevating end of the elevating mechanism extends upwardly and is connected with the bottom of a pallet box. A connecting end of the overturning mechanism is hinged onto the bottom wall of the cavity of the transfer body. A free end of the overturning mechanism can be adhered to the bottom of the pallet box. A fixed end of the ejecting mechanism is arranged on the back wall of the cavity of the transfer body. A telescopic end of the ejecting mechanism extends forward and is close to the pallet box. The discharge mechanism of the pallet box transfer device has following advantages: based on softness and brittleness of material, different discharge methods are selected.

Owner:全椒县富民优质粮种植专业合作社

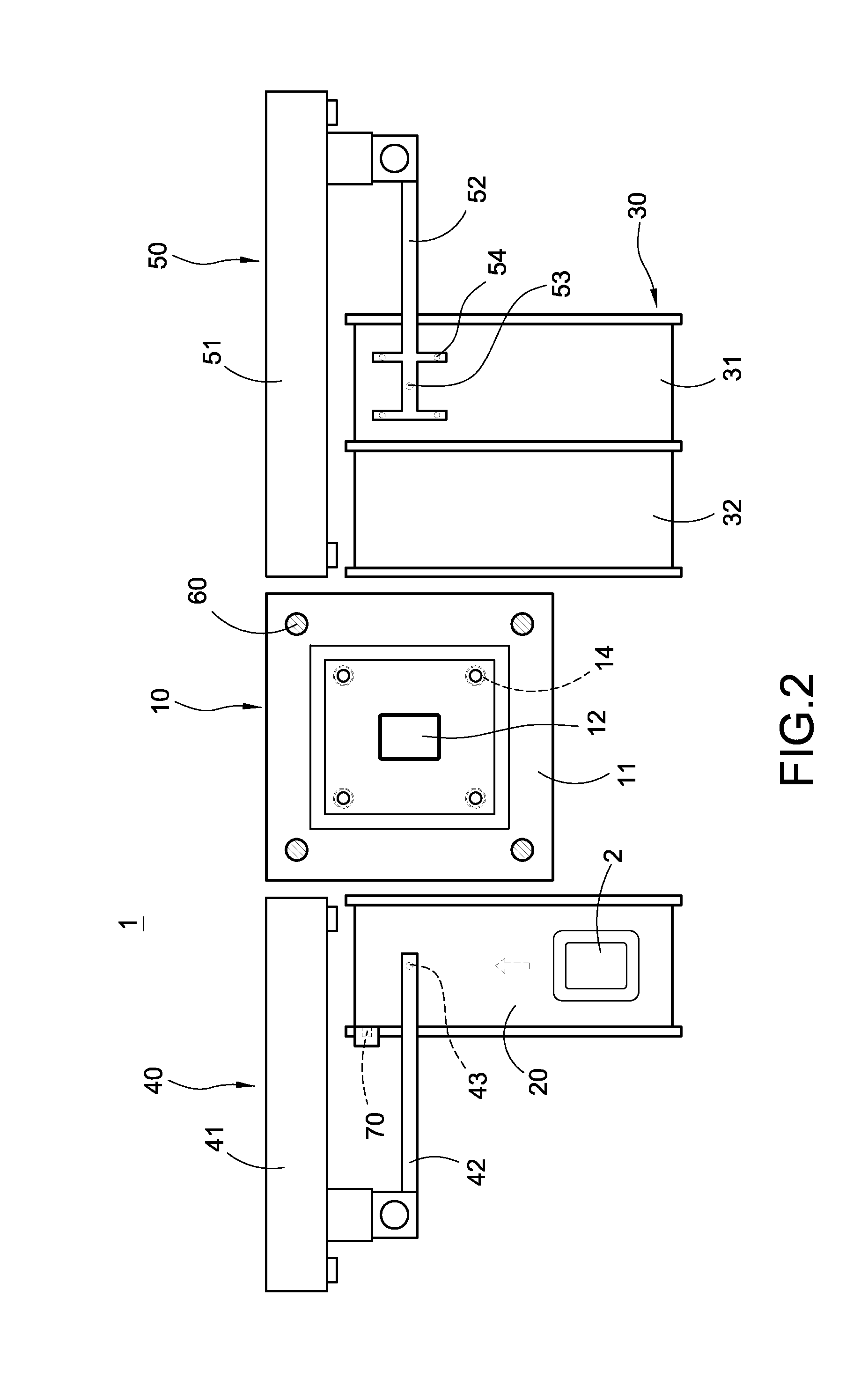

Machine for automatically cutting and sorting boxes and remants

ActiveUS20140041498A1Cutting safetyReduce processProgramme-controlled manipulatorGripping headsRobot handEngineering

The machine of the invention includes a cutting device, a first conveyor, a second conveyor, a first moving arm and a second moving arm. The cutting device includes a platform, a lower mold on the platform and an upper mold correspondingly over the lower mold. The first conveyor is disposed near one side of the platform for conveying boxes to be cut. The second conveyor is disposed near the other side of the platform for conveying cut boxes and remnants. The first moving arm includes a first transmission and a first robot hand driven thereby for moving the boxes to be cut to a position between the lower mold and the upper mold. The second moving arm includes a second transmission and a second robot hand driven thereby for moving the cut boxes and remnants to the second conveyor.

Owner:GOLDEN ARROW PRINTING

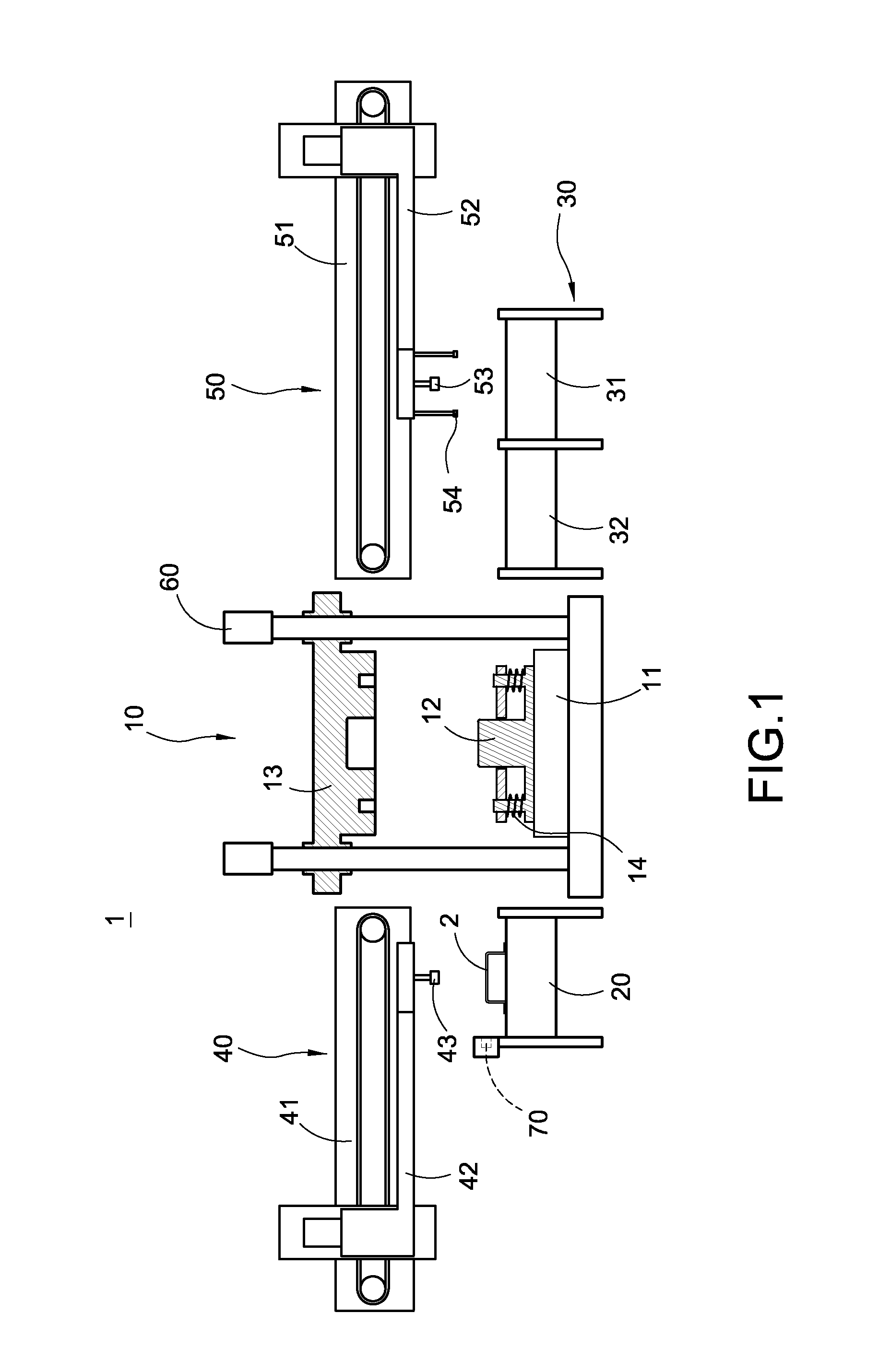

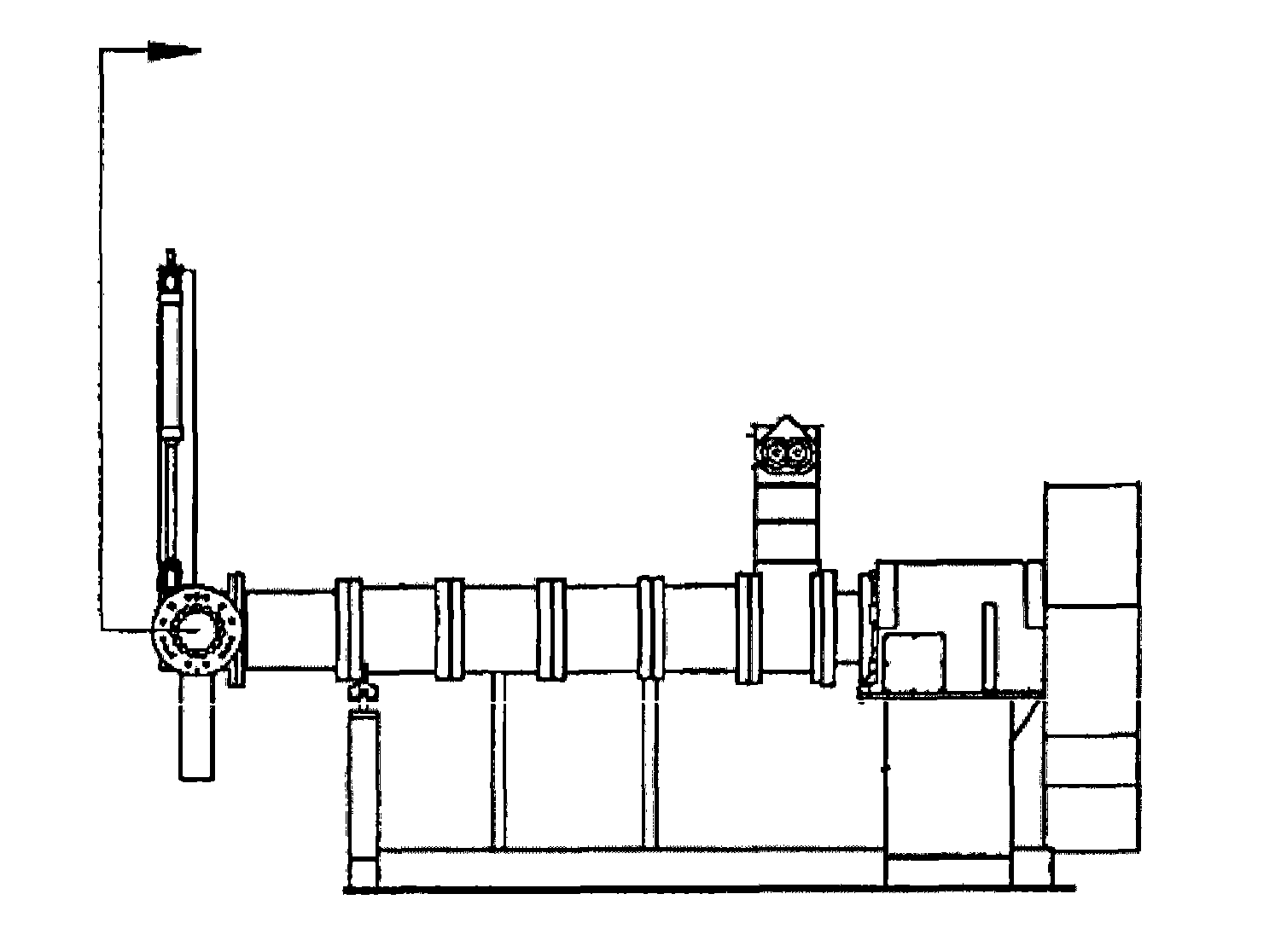

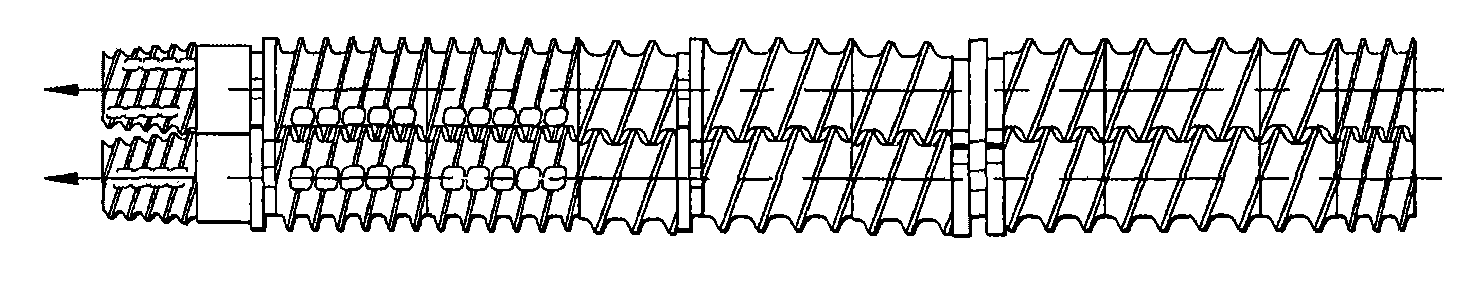

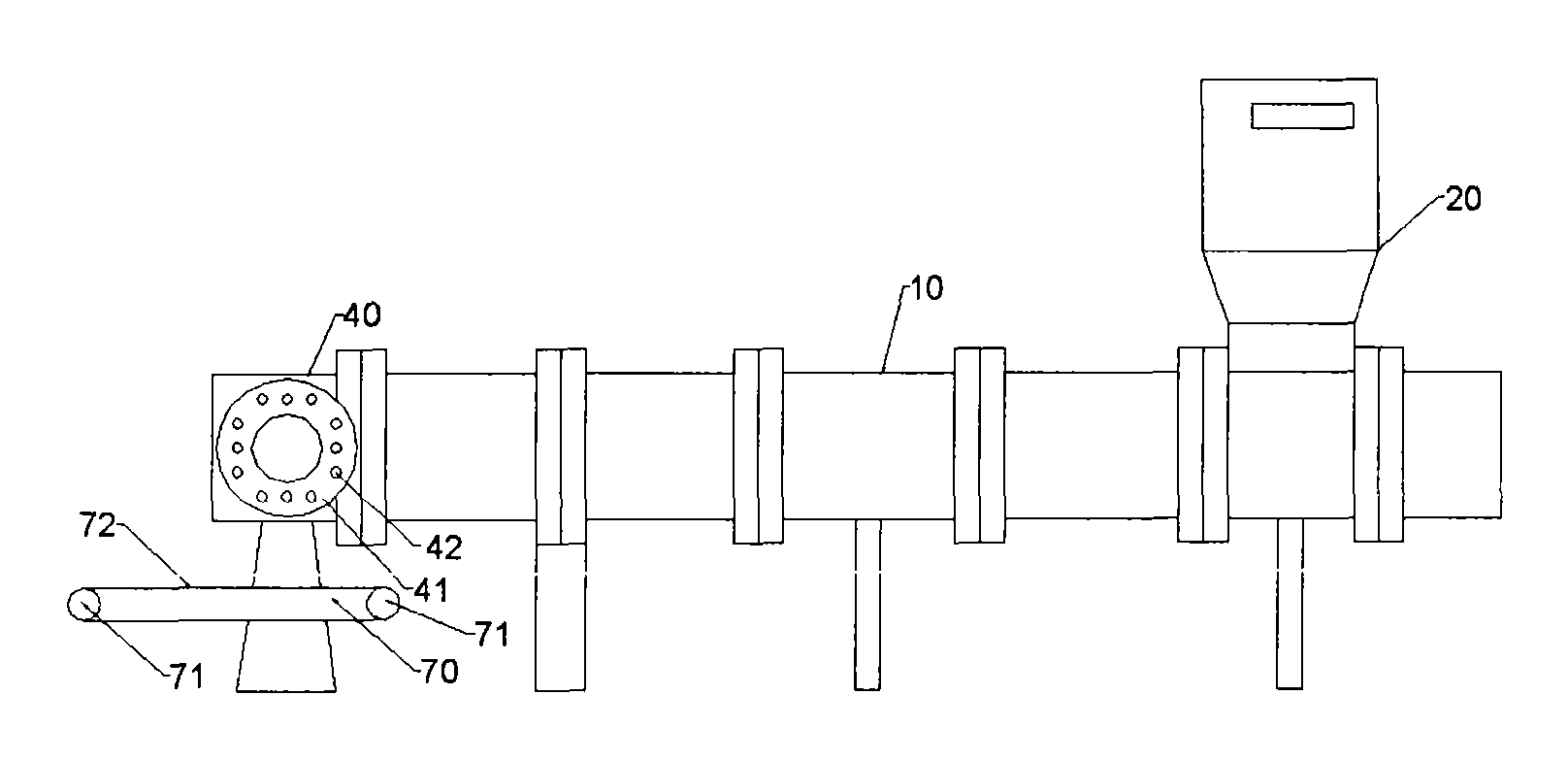

Integrated extrusion molding equipment

InactiveCN101878945AAccurately obtainedCleaning during cuttingFood shapingDomestic articlesEngineeringHigh pressure water

The invention provides integrated extrusion molding equipment, which comprises a feeding device (20), a screw extruder (10), an extrusion die (40), a rotary motor box (50), a coating device, a conveying device (70) and a cut-off device (90) in turn. The screw extruder (10) comprises a plurality of screws which are closed and occluded one another; the extrusion die (40) has two extrusion discs (41); the conveying device (70) comprises a driving roller and a conveyor belt (72) with adhesiveness; and the cut-off device (90) is arranged between the adjacent conveyor belts, and comprises a jet orifice (91) and high-pressure jet (92) emitted from the jet orifice to cut strip continuous materials (200) into sectional materials (210) with fixed lengths. The sectional treatment of the extrusion molding materials is realized through the conveying device with height fall and a high-pressure water jet system, products with specified lengths can be accurately obtained, and the cutting process is clean and safe.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

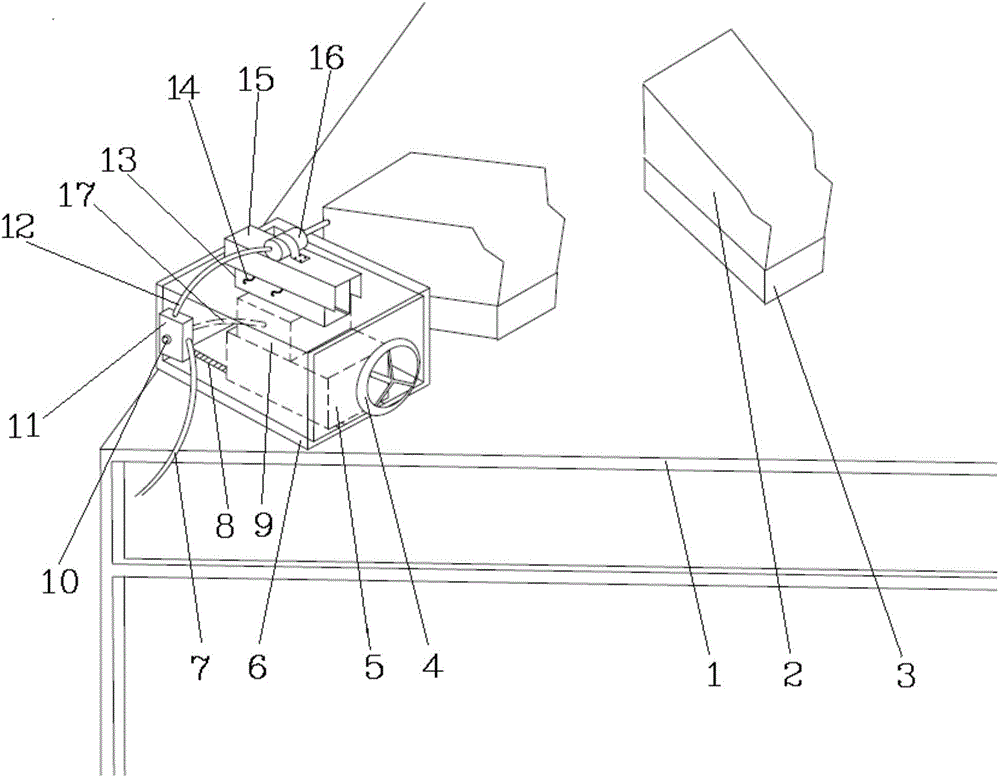

Drilling device

InactiveCN102773511AImprove processing efficiencySafe loading and unloading processPositioning apparatusMetal-working holdersDrill holeDrill bit

The invention discloses a drilling device which comprises a base, wherein a guide column and a first power device are fixed on the base, the guide column is flexibly connected with a first motor, and the first motor moves upwards / downwards along the guide column. The first motor is fixedly connected with a second motor, the second motor is connected with a drill bit in rotating mode, the first power device is flexibly connected with a sliding block, and a second power device and a limit block are fixed on the sliding block. A containing space for placing parts is arranged in the limit block, and the second power device drives a jacking head to enter the containing space and fix parts in the containing space. The drilling device can improve part processing efficiency and simultaneously improves safety performance in processing.

Owner:ANHUI QIFENG MACHINERY & EQUIP

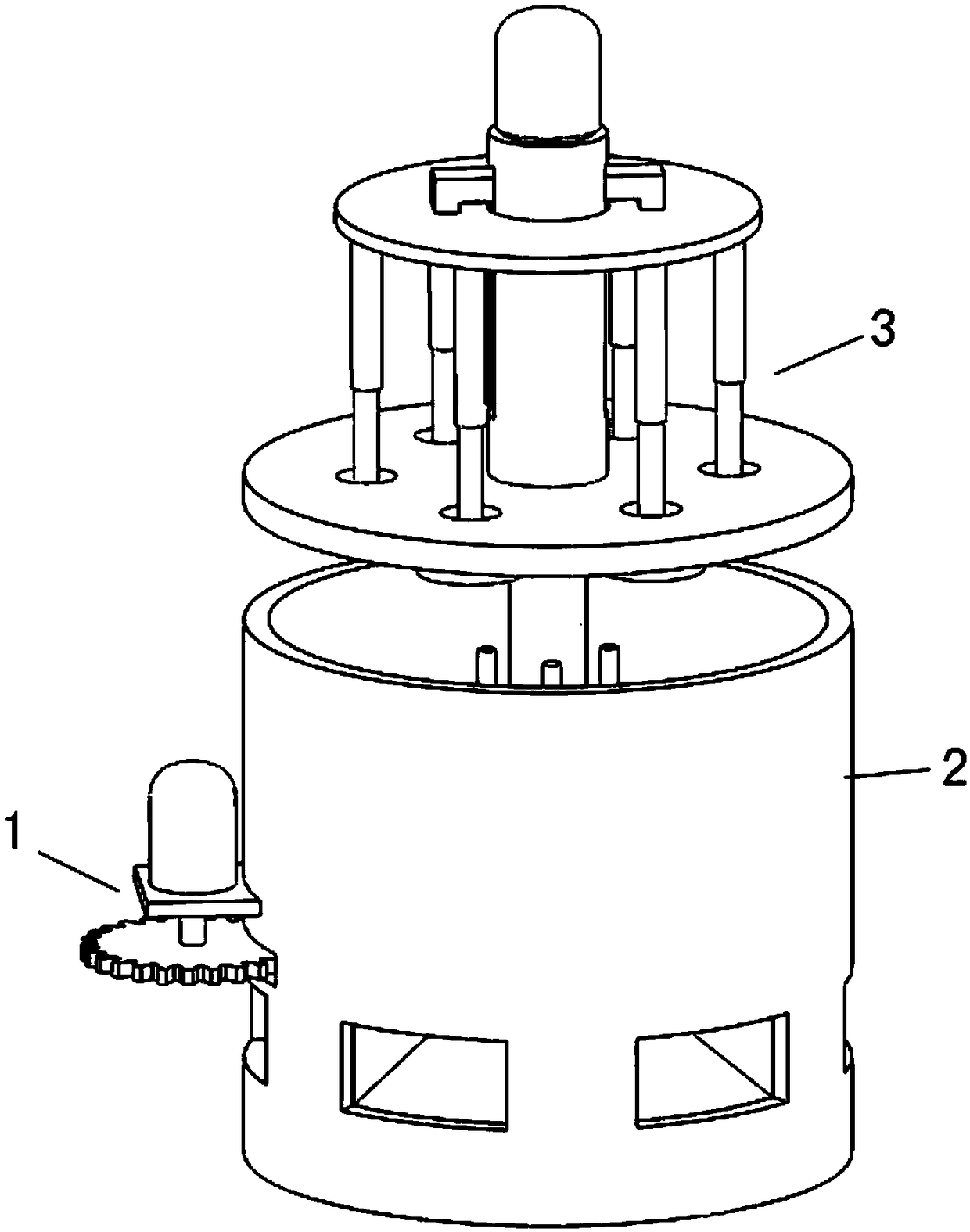

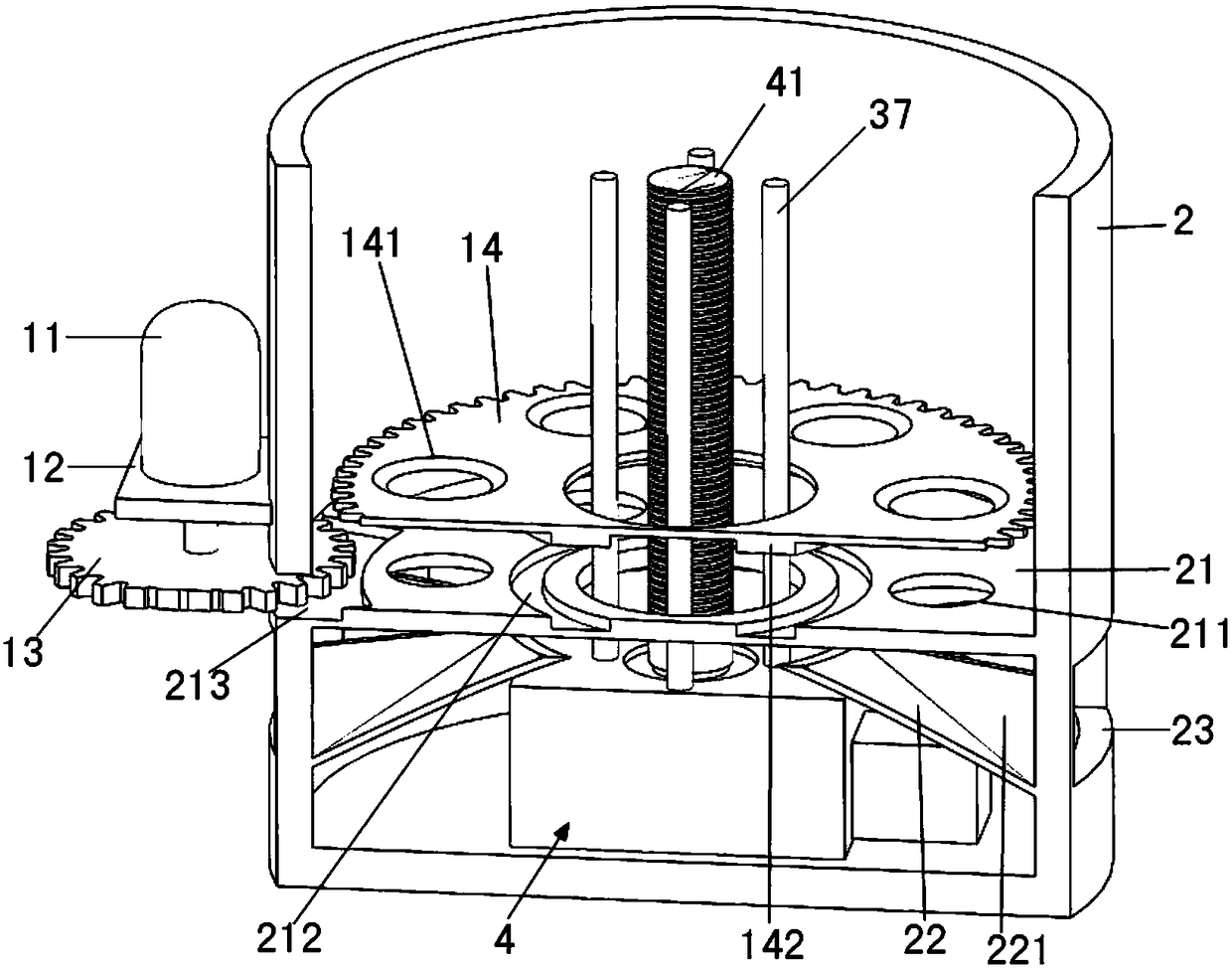

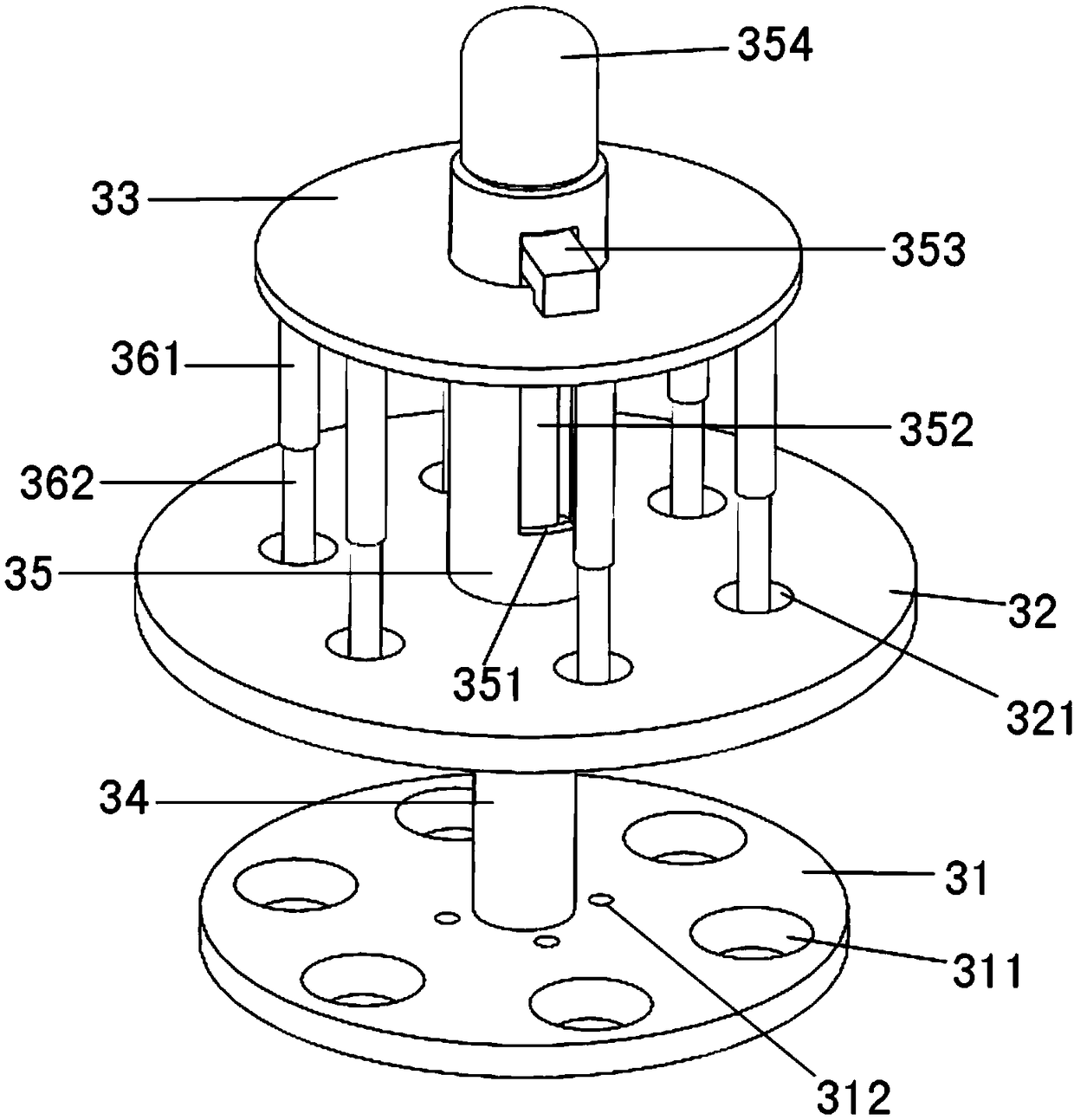

Household carrot cutting device

The invention discloses a household carrot cutting device which comprises a processing shell, wherein the processing shell is designed to be a hollow cylindrical barrel; a lifting driving device is arranged on the bottom surface of the processing shell; a rotating rod provided with a screw thread at the upper end is inserted into the lifting driving device and capable of rotating; a lifting fixingdevice is in threaded connection with the rotating rod and comprises a tray provided with a plurality of placement holes; a connecting column is formed at the center of the upper surface of the tray;a fixing device is arranged at the top end of the connecting column; a fixed cutting disc is arranged on the inner-ring wall body of the processing shell; a gear cutting disc is rotationally arrangedon the upper surface of the fixed cutting disc; and a gear driving device used for driving the gear cutting disc to rotate is arranged on the outer surface of the processing shell. The household carrot cutting device disclosed by the invention has the following advantages: a plurality of carrots can be fixed; through the adjustment of the distance at which the carrots are lowered every time, thecarrots can be automatically sliced or diced by utilizing the household carrot cutting device; the efficiency is high; and the cutting process is very safe.

Owner:湖州南浔郎小沐电子商务有限公司

Multi-head parting saw for boards

InactiveCN105690487AImprove efficiencyCutting stabilityGuide fencesFeeding devicesElectrical controlEngineering

The invention discloses a multi-head slitting saw for plate materials, which comprises a cutting part. The cutting part is provided with an electric control part. The cutting part includes a crosscutting part and a longitudinal cutting part. On the lower station of the cross-cutting part, and the stations on both sides of the cutting part are also equipped with transmission parts; wherein, the cross-cutting part includes a cross-cutting saw connected by a telescopic assembly, and the slitting part includes a cross-cutting saw connected by a telescopic assembly. of two slitting saws. Beneficial effects of the present invention: In the present invention, the cross-cutting part and the longitudinal cutting part respectively adopt a corresponding motor to drive two rotary cutting saw heads to cut, which has the advantages of high efficiency and stable cutting, and the longitudinal cutting and cross-cutting head parts It adopts an inverted type and the effective cutting height of the saw blade can be adjusted. It has the functions of less dust and safer cutting during cutting operations. Its equipment is equipped with 2 universal wheel sets and 2 directional wheel sets to facilitate on-site mobile and fixed equipment.

Owner:湖北卓宝建筑节能科技有限公司

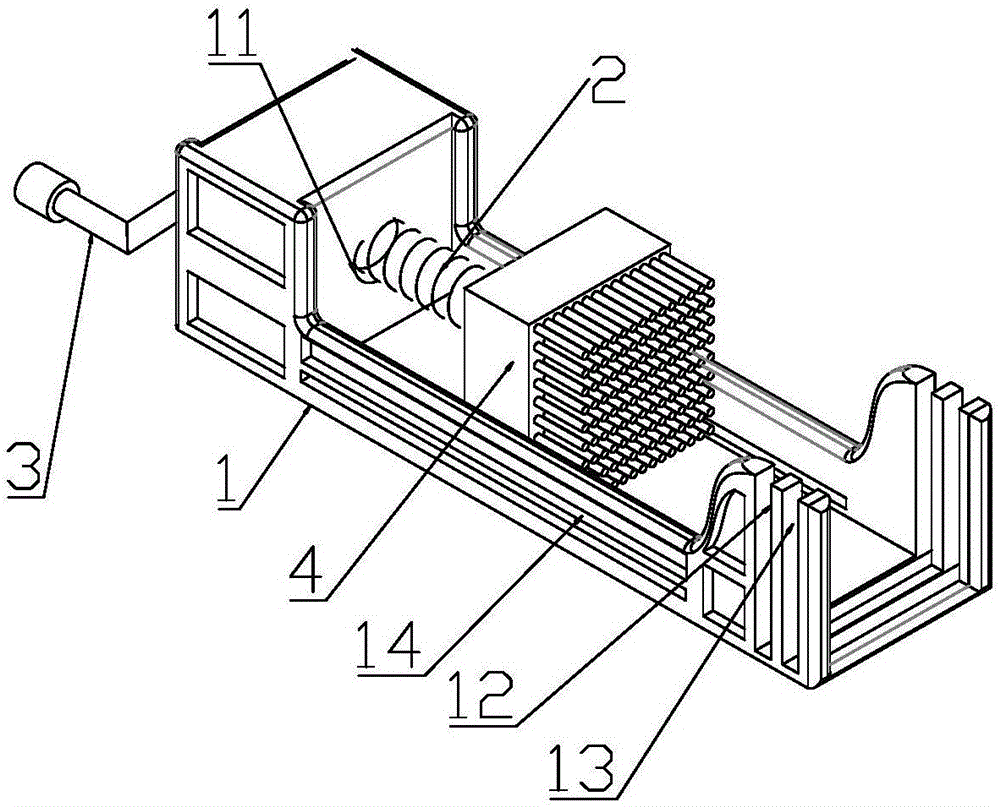

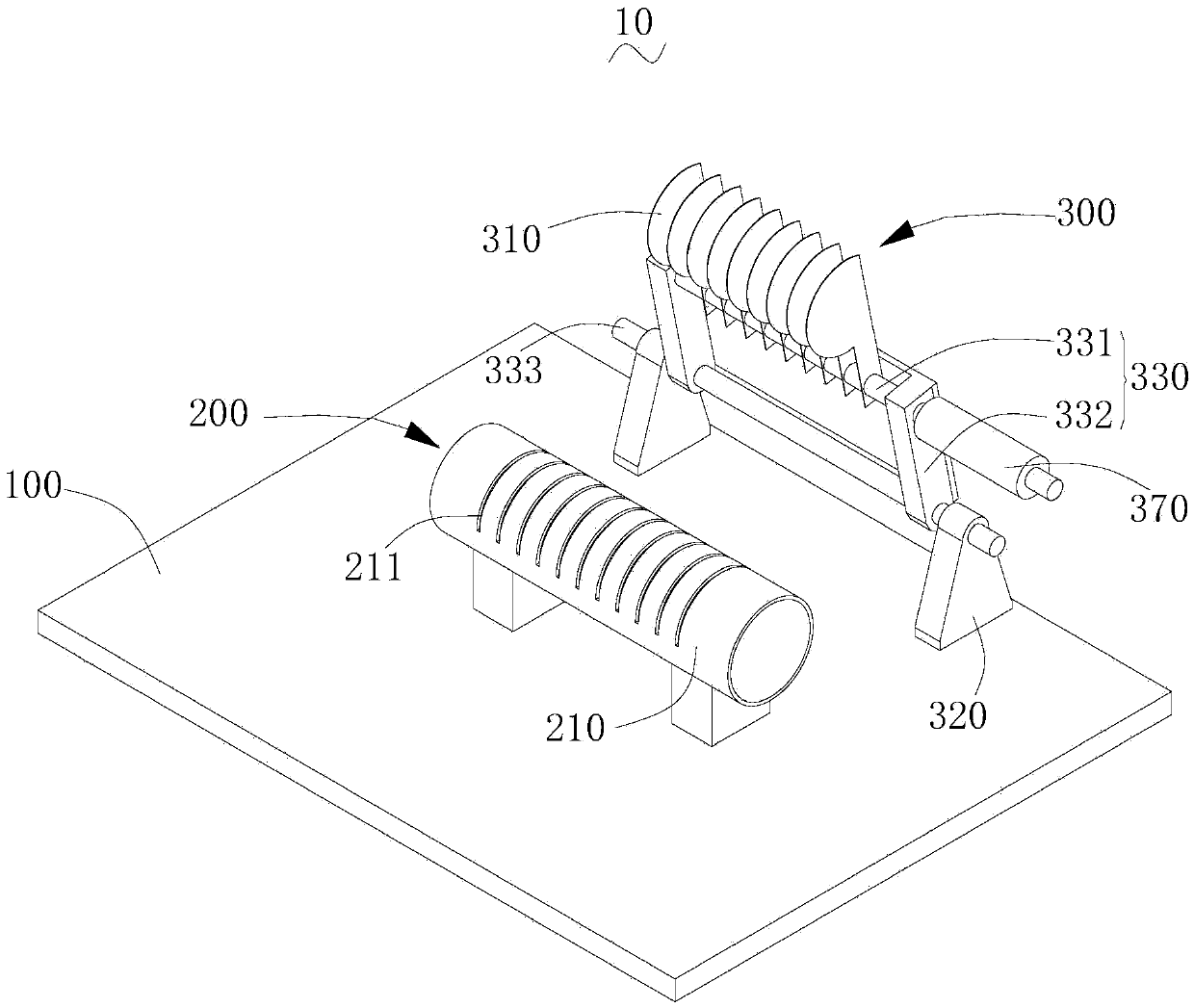

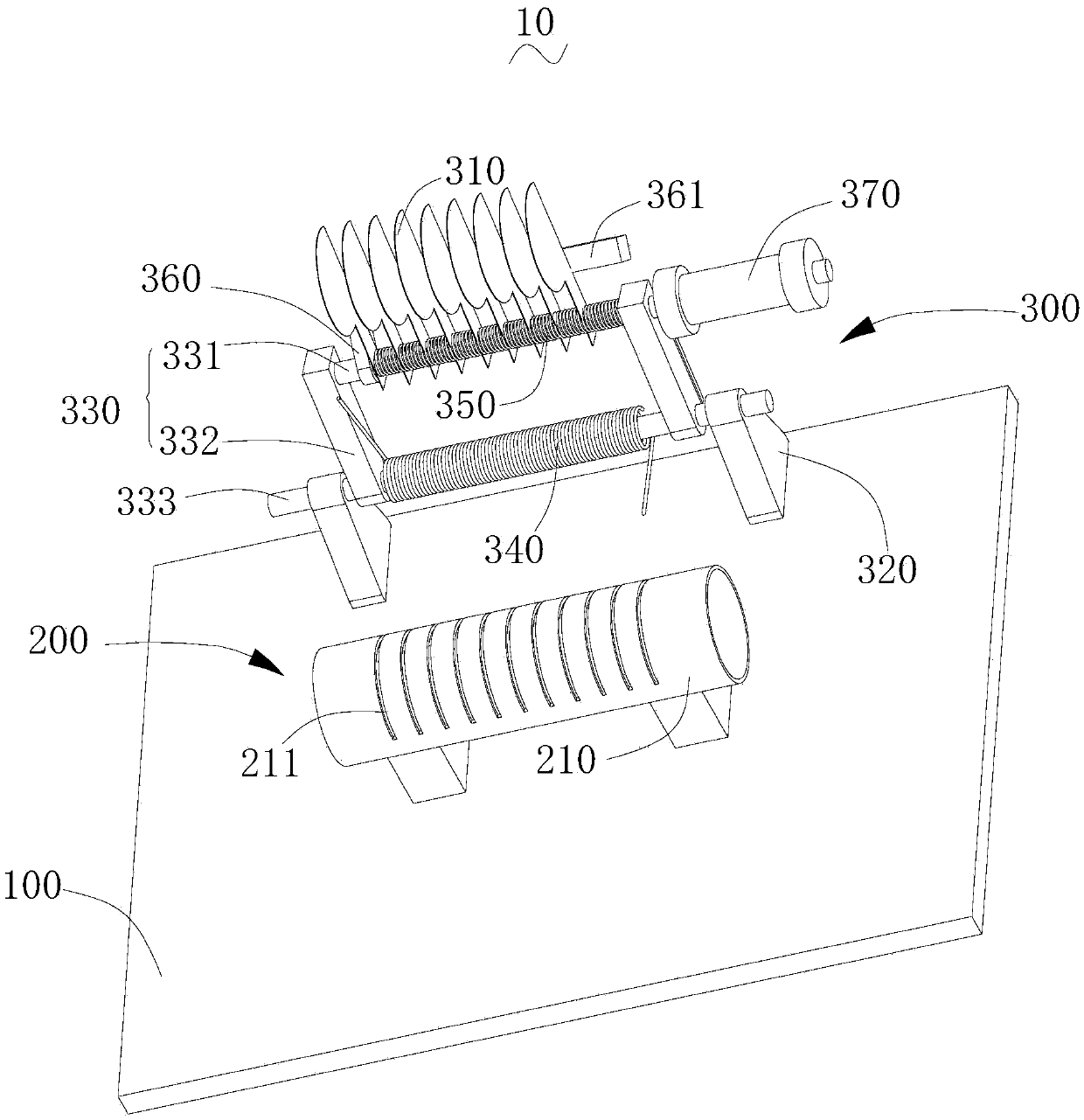

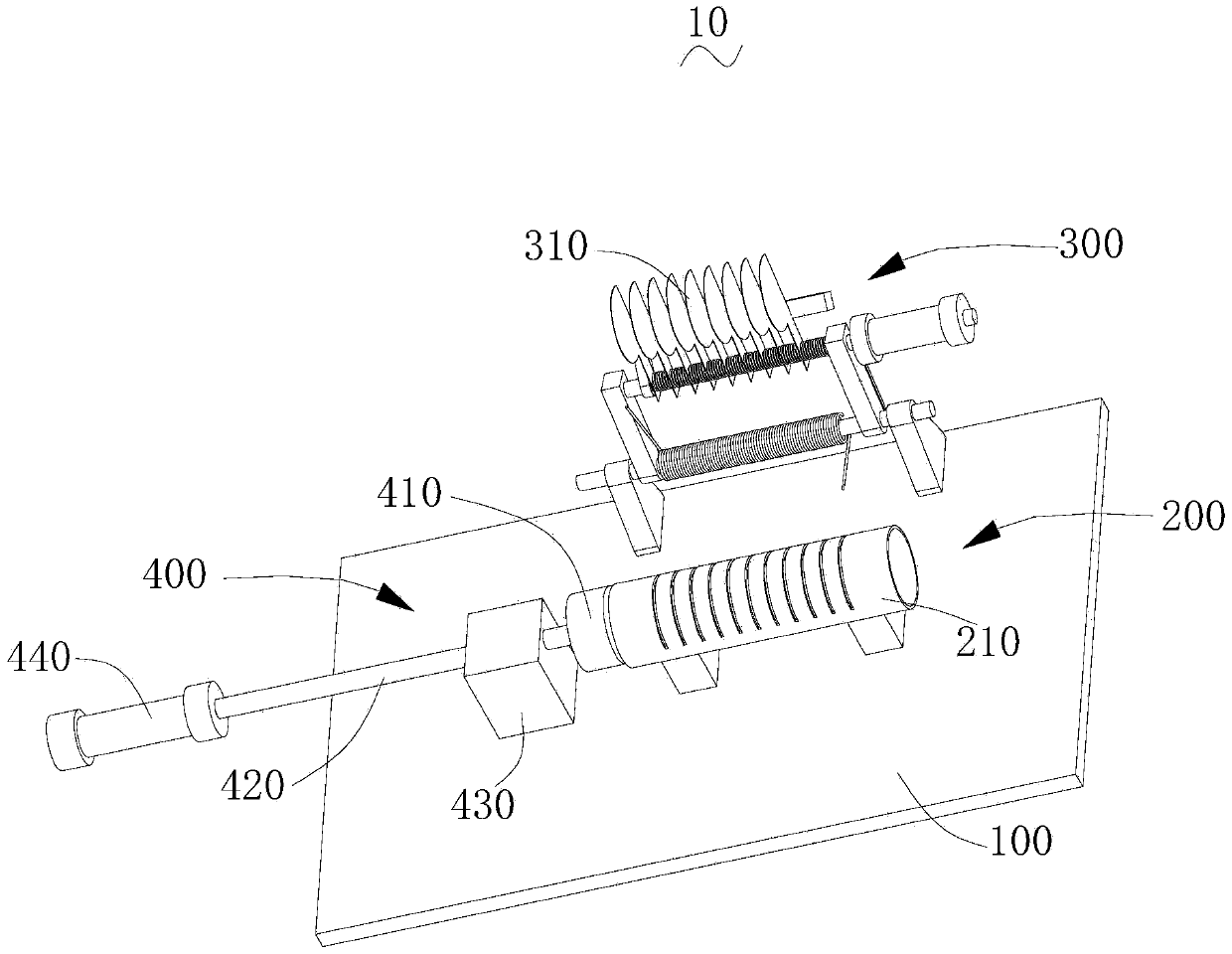

Fruit and vegetable cutting device

InactiveCN106695914ACut evenlyImprove cutting efficiencyMetal working apparatusEngineeringFruits and vegetables

The invention provides a fruit and vegetable cutting device comprising a base, a spiral rod, a rocking handle, a fruit and vegetable push piece and mesh-shaped blades. A threaded hole is formed in the rear end of the base. The spiral rod is movably connected in the threaded hole. One end of the spiral rod is connected with the rocking handle, and the other end of the spiral rod is connected with the fruit and vegetable push piece used for pushing fruits and vegetables to move. Mesh-shaped blade clamping grooves and manual tool notches are sequentially formed in the front end of the base from inside to outside. The mesh-shaped blades are detachably connected to the mesh-shaped blade clamping grooves in a clamping manner. The fruit and vegetable cutting device has the beneficial effects that the structure is simple, cost is low, popularization is convenient, fruit and vegetable cutting is uniform, the cutting efficiency is high, the cutting process is safe and reliable, and fruits and vegetables can be chosen to be cut into food of different shapes and lengths.

Owner:SHANDONG UNIV OF SCI & TECH

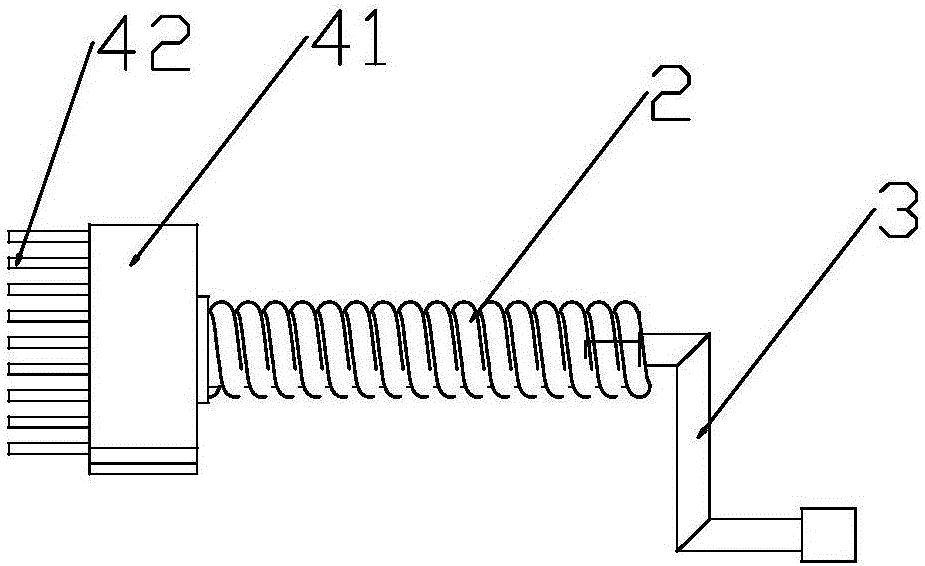

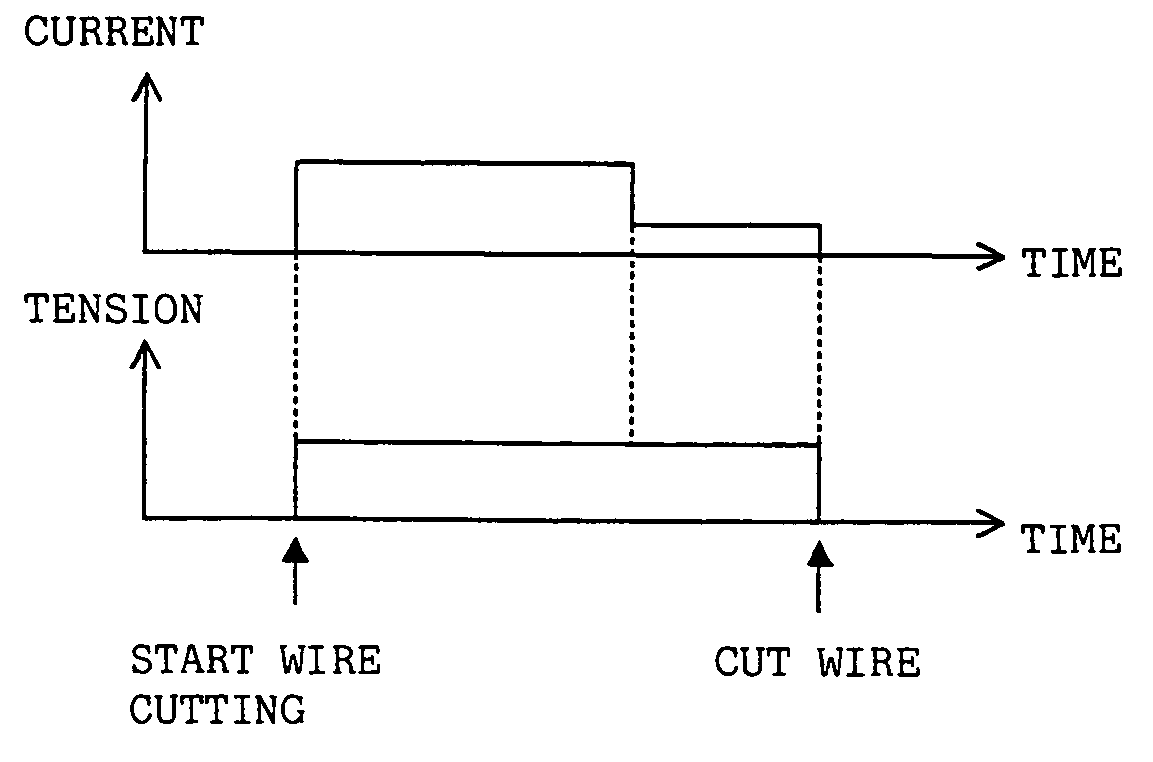

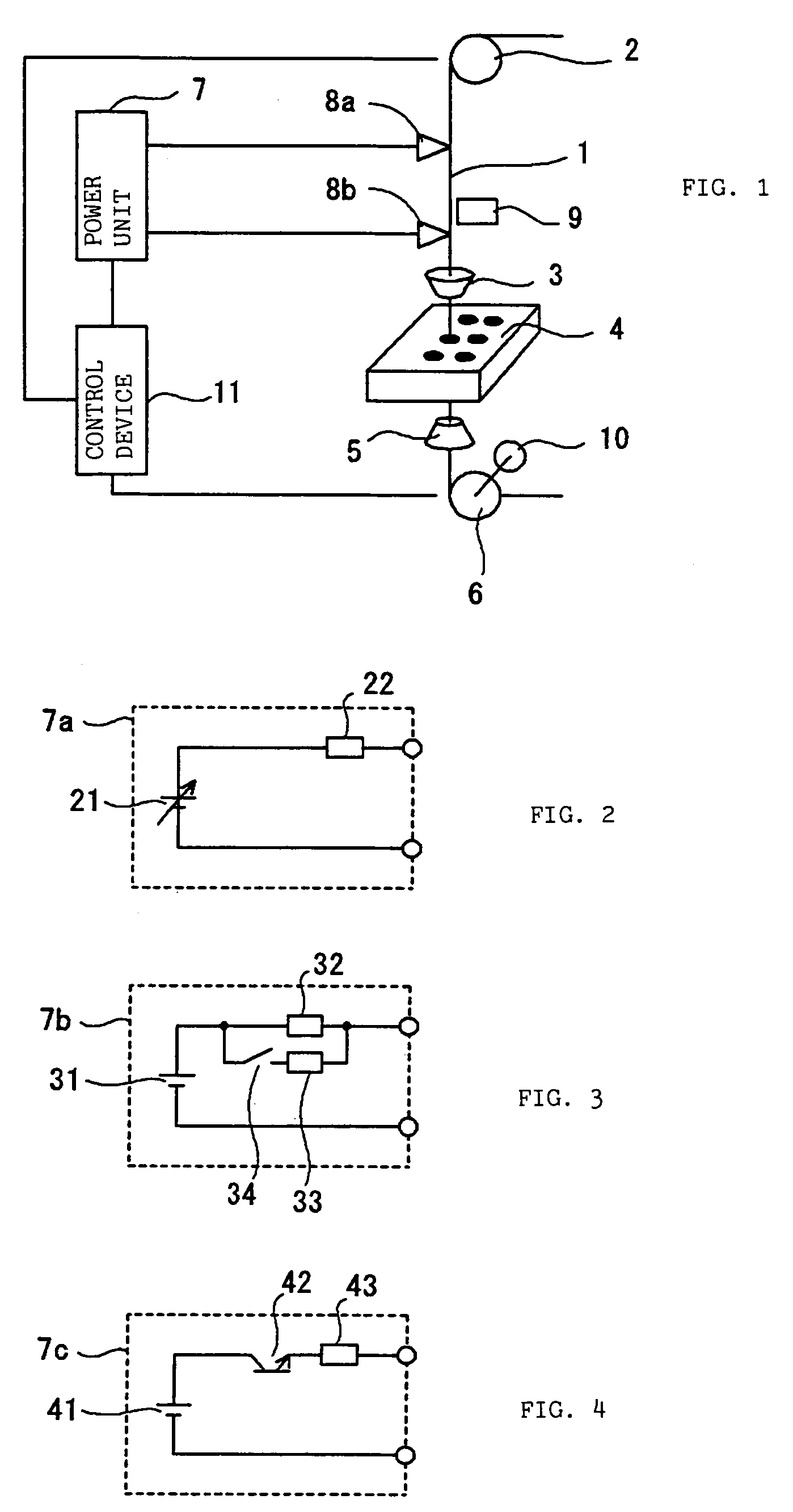

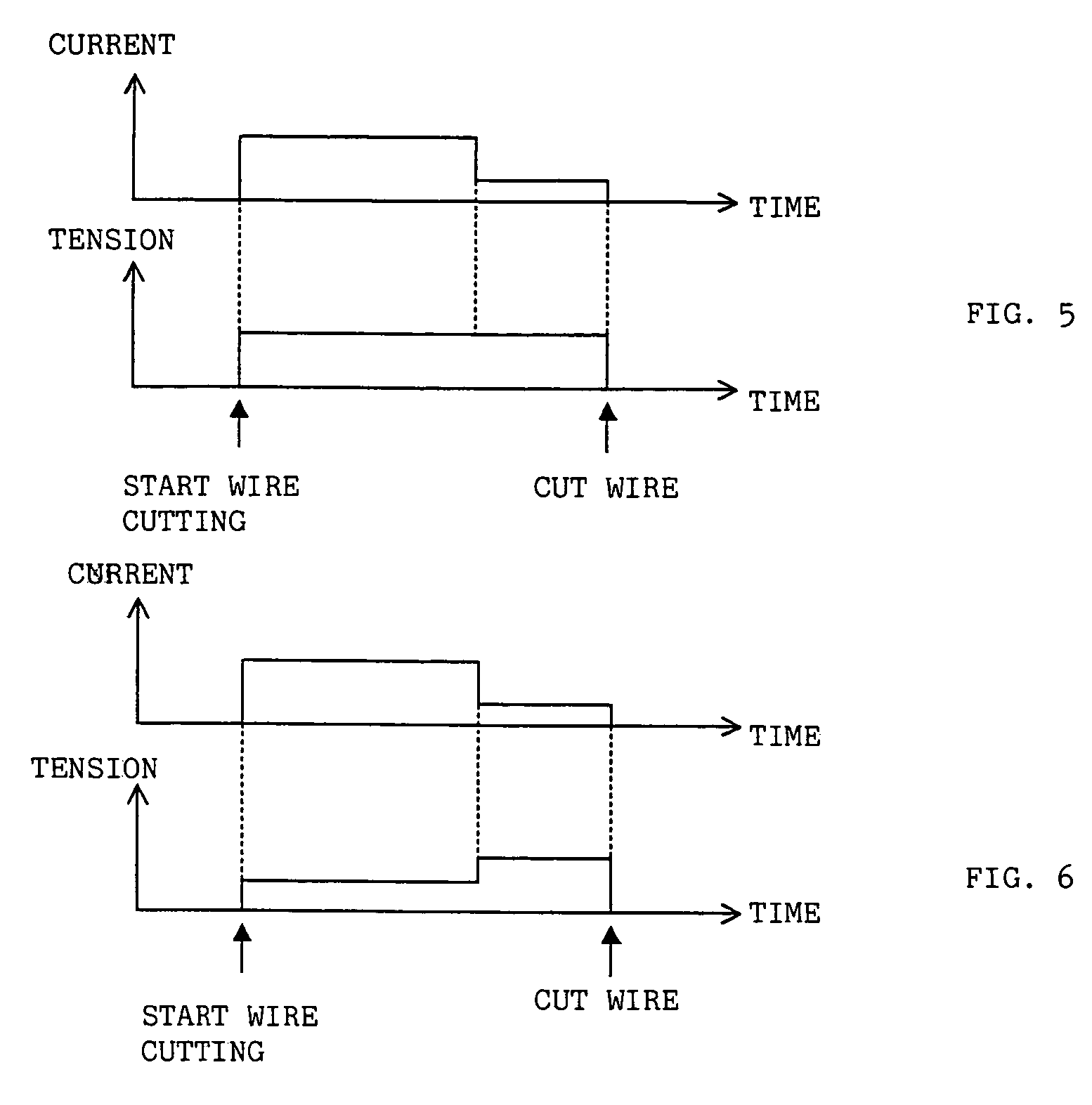

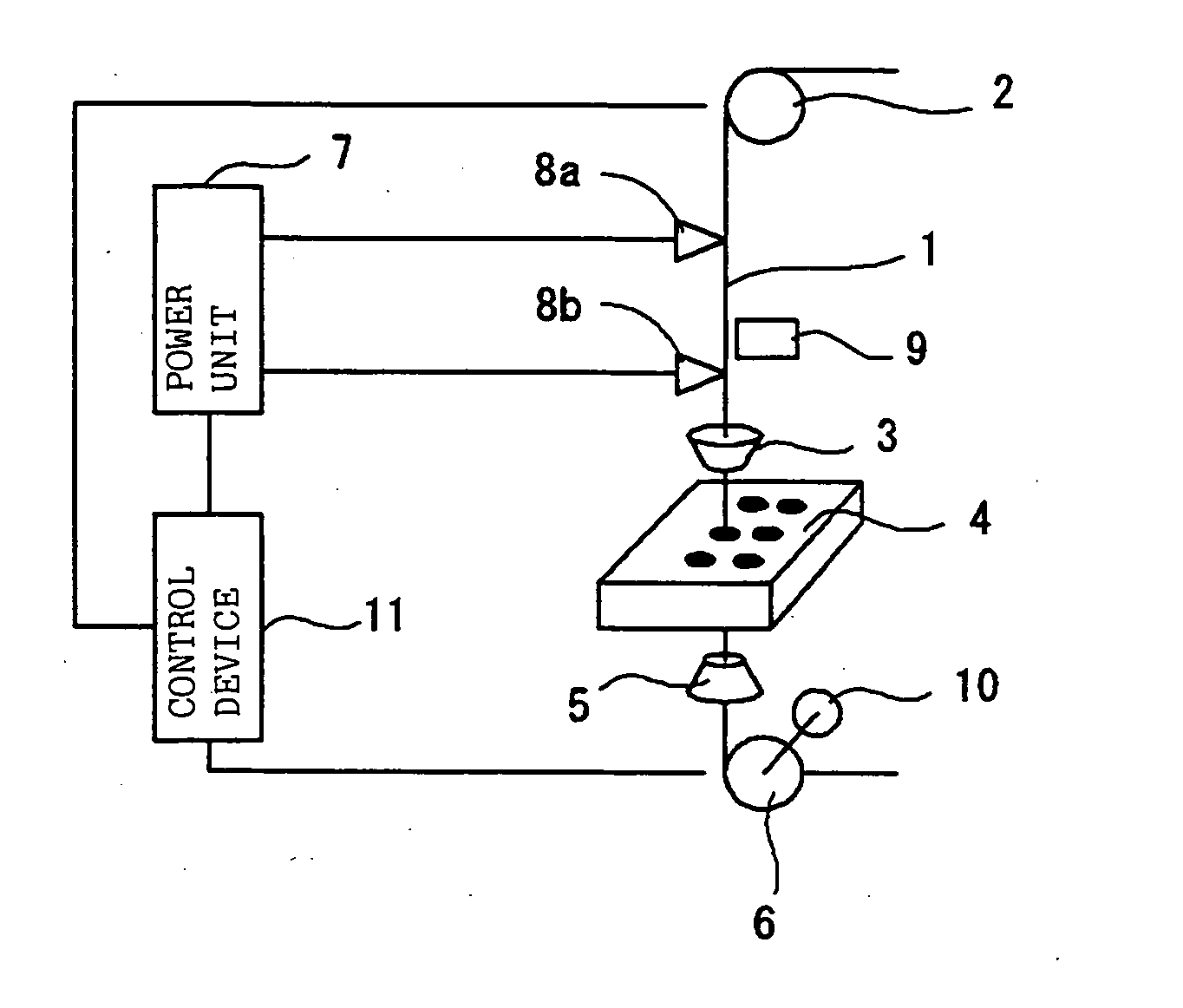

Wire cutting device of wire electric discharge machine

ActiveUS6979794B1Total current dropReduce tensionElectrical-based machining electrodesElectric dischargeWire cutting

When starting a wire cutting operation, a first predetermined current is supplied from a power unit to a wire, and at the same time predetermined tension is applied from a tension applying device to the wire. When a first predetermined time elapses since the start of the wire cutting operation, the current supplied from the power unit is switched to a second predetermined current which is smaller than the first predetermined current, and also the predetermined tension is continuously applied, such that the wire is cut.

Owner:FANUC LTD

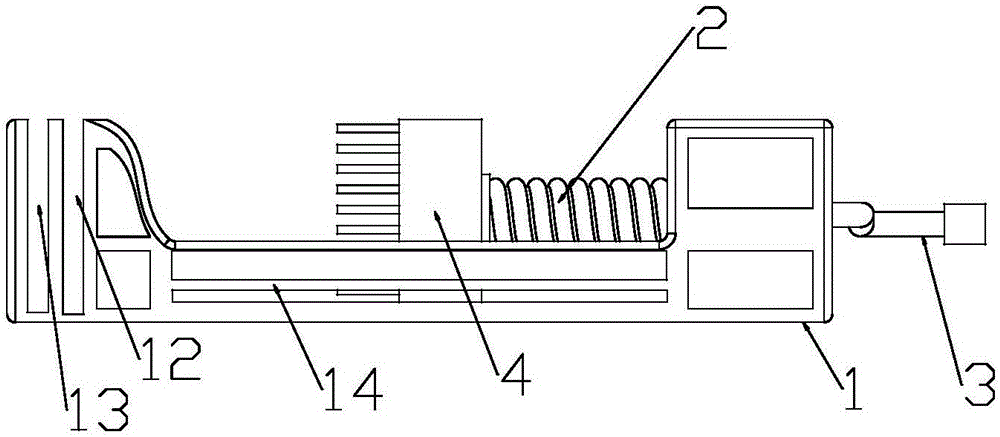

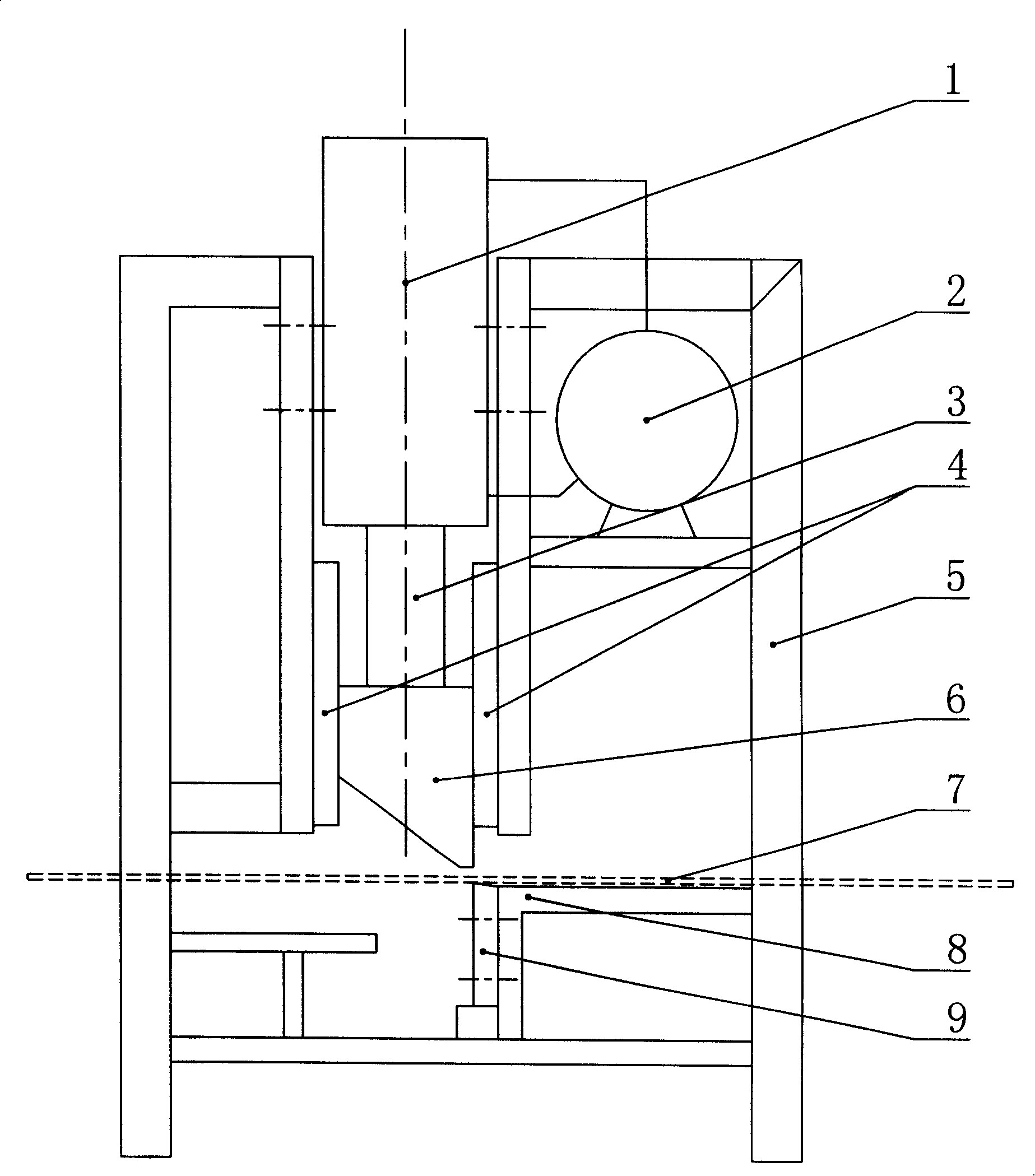

Workpiece combined clamp for abrasive wheel cutting machine

InactiveCN101797711AEasy dischargeEasy clampingGrinding machine componentsGrinding machinesReciprocating motionEngineering

The invention discloses a workpiece combined clamp for an abrasive wheel cutting machine, which comprises a clamping mechanism and an elastic movement mechanism, wherein the clamping mechanism comprises a press plate for holding a workpiece and a bottom plate, and a compacting screw and an adjusting bolt are arranged between the press plate and the bottom plate; the elastic movement mechanism is arranged below the clamping mechanism and comprises a screw rod, the middle part of the screw rod is provided with a cam, and a screw rod nut is fastened to a work table; a guide sleeve is arranged on the work table, a guide post is arranged in the guide sleeve, a spring is arranged on the guide post, and the top of the guide post is positioned in a groove in a panel on the lower side of the bottom plate and forms a clearance fit with the groove; and the lower side of the work table forms a slide fit with a guide rail through a fixed slide block. The combined clamp can conveniently and quickly clamp the workpiece. In the cutting process, the workpiece can make a back-and-forth up-and-down aggregate reciprocating motion, thereby being beneficial to reducing cutting resistance, facilitating the discharge of cuttings, avoiding binding, preventing an abrasive wheel from damage, enhancing the work efficiency of the abrasive wheel cutting machine and enabling the cutting process to be safer.

Owner:HEBEI AGRICULTURAL UNIV.

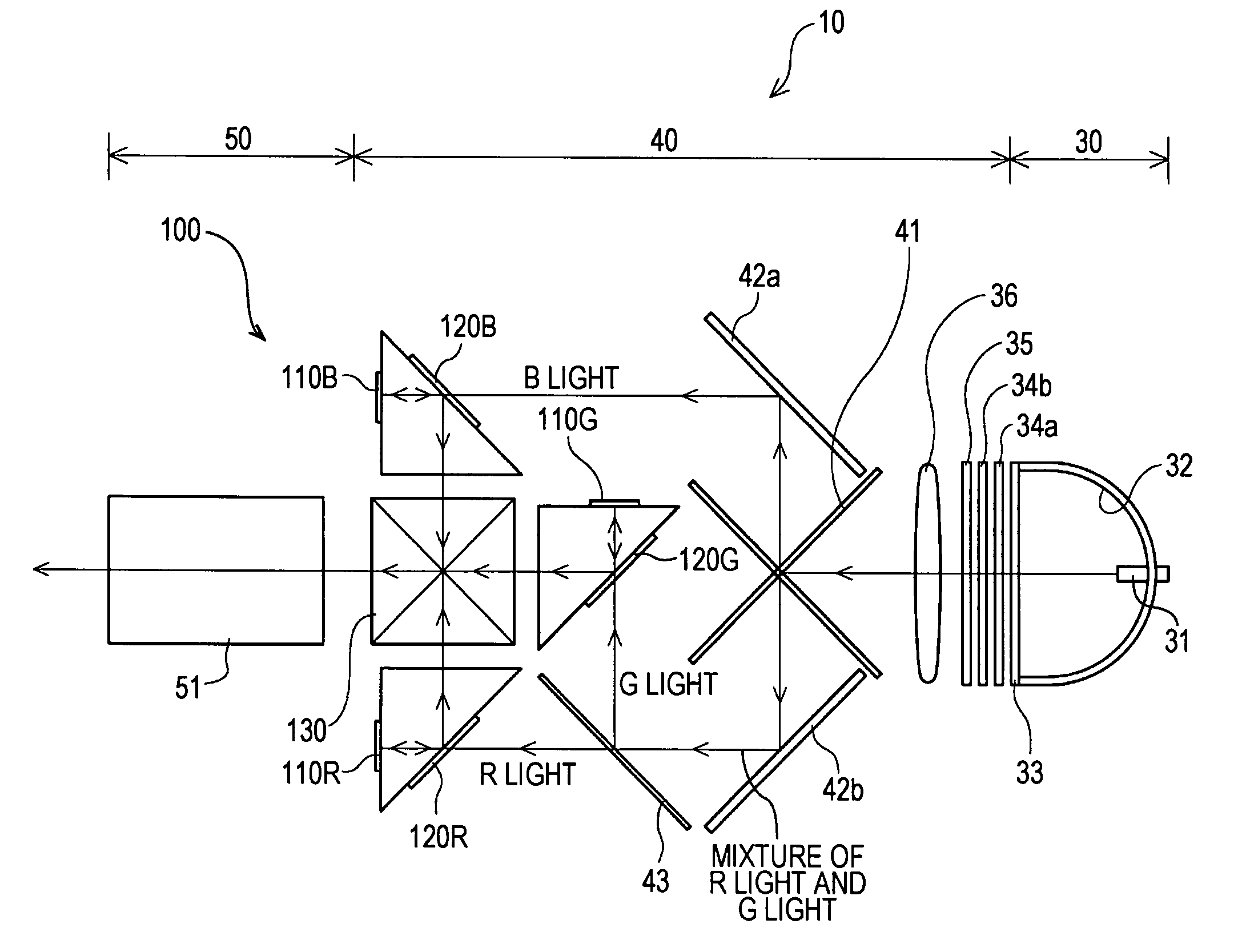

Optical device and projection device

InactiveUS8480239B2Cutting safetyAvoid misregistrationProjectorsColor photographyImage signalOptical polarization

Owner:SONY CORP

Slicing device

ActiveCN105397857ASimple structureReduce volumeMetal working apparatusEngineeringMechanical engineering

The invention relates to a slicing device. The slicing device comprises: a working table; a fixed cylinder fixed on the working table and having a cylinder wall, wherein the internal of the cylinder wall is a hollow structure, and two ends have openings, and multiple incisions are formed in the cylinder wall of the fixed cylinder; a cutting mechanism movably arranged on the working table and provided with multiple blades, wherein the blades are movably inserted in the incision; and a heating mechanism connected with the fixed cylinder and used for heating the fixed cylinder. As the blades of the cutting mechanism are pushed to insert in the incisions of the fixed cylinder, foods in the fixed cylinder are uniformly cut; on the one hand, the foods cutting is safer and more convenient; and on the other hand, the slicing device is simple in structure, small in volume and low in manufacturing cost, and reduces the use and maintenance costs.

Owner:南通江海港建设工程有限公司

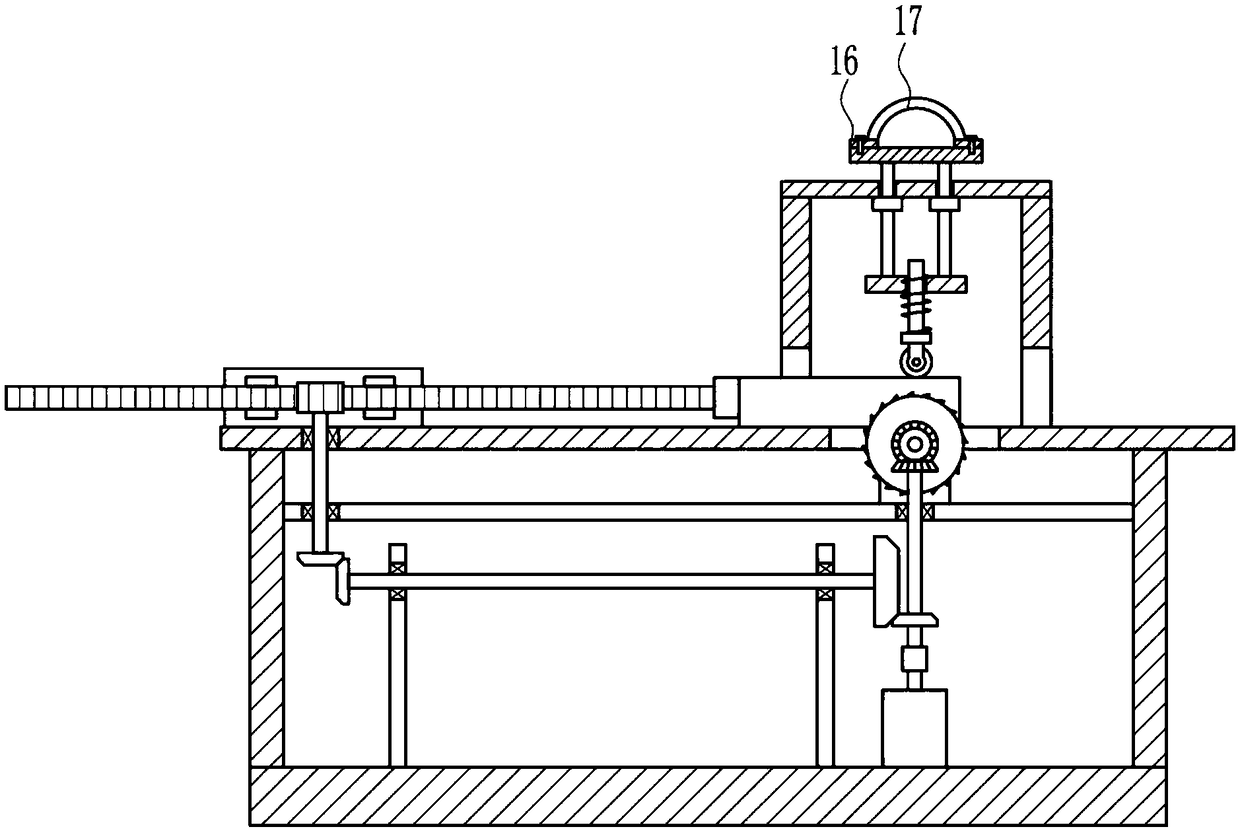

Steel bar hydraulic pressure cutting machine

InactiveCN101209482ACutting safetyNo dustInput/output processes for data processingHydraulic cylinderReciprocating motion

The invention discloses a hydraulic bar cutting machine, pertaining to the field of bar cutting equipment in construction, which comprises a body provided with a working table, a cylinder vertically positioned at the body over the working table, a piston rod of the cylinder extending from the lower end of the cylinder, an upper cutter connected with the extending end of the piston rod, a guiding plate vertically arranged at the two sides of the upper cutter, a lower cutter which is matched with the upper cutter, arranged below the upper cutter and fixed on the body below the working table. When in working, hydraulic cylinder is supplied with oil and the piston rod drives the upper cutter to perform vertical reciprocating motion; the bar is put on the working table, thus leading the position needing cutting to be aligned with the matching position of the upper cutter and the lower cutter and to be cut by the shearing motion of the upper cutter and the lower cutter; the guiding plate can offset lateral thrust generated during the shearing motion so as to prevent the piston and the piston rod from lateral thrust. No dust, noise and spark exist during the process of bar cutting and the cutting is safe and convenient; therefore, the invention can be applied to construction.

Owner:周才森

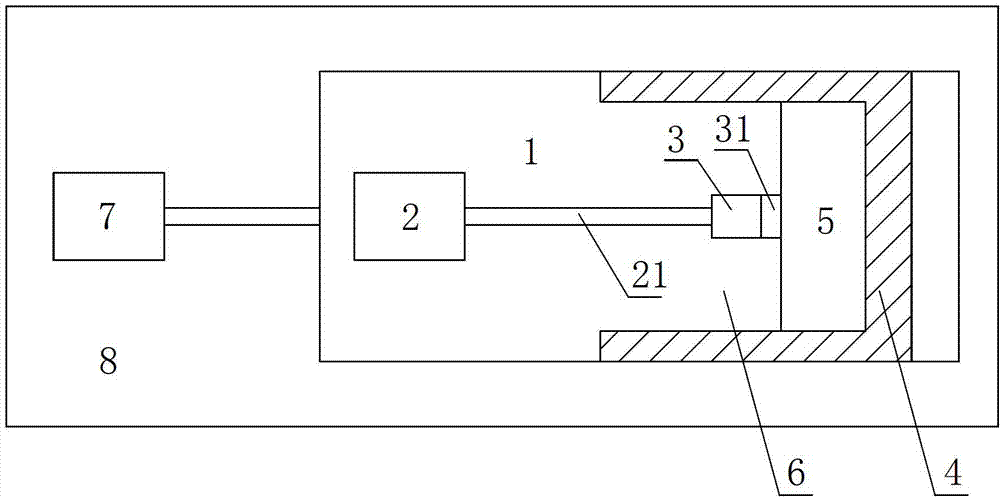

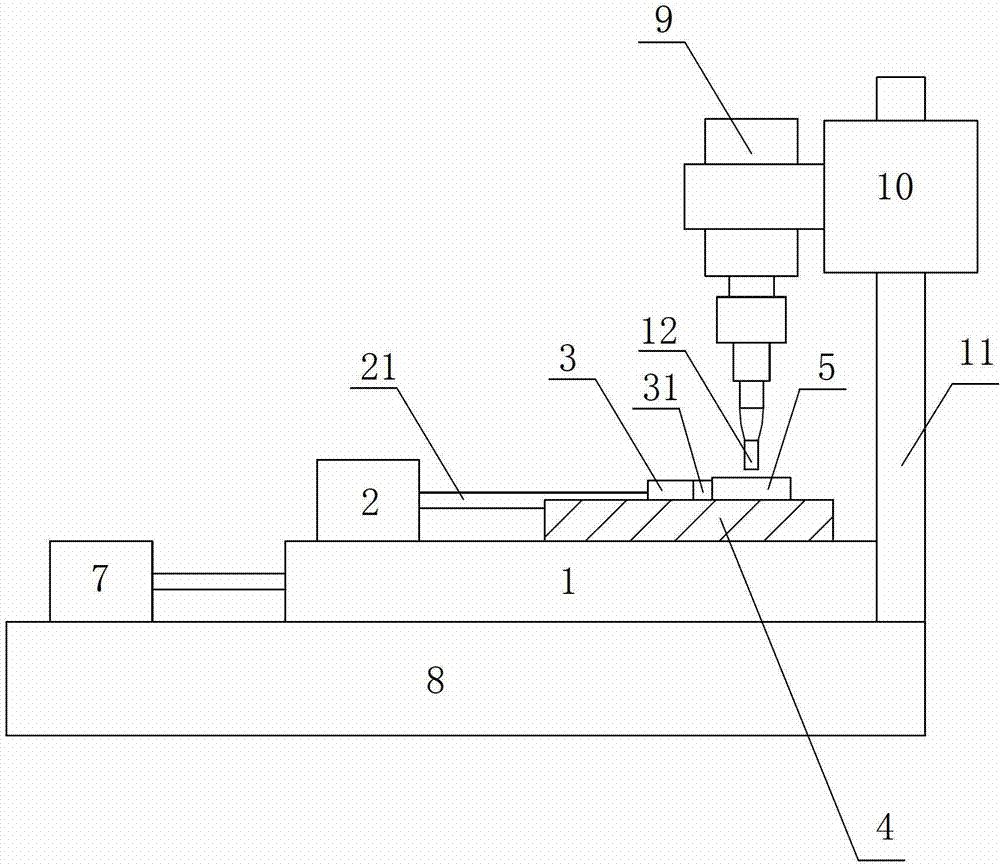

Plane-push lift type transverse cutting machine for concrete

InactiveCN101676081ASimple structureEasy to useStone-like material working toolsDrive shaftEngineering

The present invention provides a plane-push lift type transverse cutting machine for concrete which comprises a chassis rack, a ground wheel is arranged on the chassis rack. The plane-push lift type transverse cutting machine for concrete is characterized in that: a lift support seat is arranged on two ends of the chassis rack, a slideway is arranged on two sides of the chassis rack along the longitudinal direction, a machine frame is supported by the slideway, an inner rack is arranged in the machine frame, a lift mechanism is arranged on the machine frame, the lift mechanism connects with the inner rack, a motor is arranged on the inner rack, a vertically disposed transmission shaft is arranged on one side of the inner rack, the transmission shaft connects with an output shaft of the motor through a transmission mechanism, a saw blade is arranged on the down part of the transmission shaft. The plane-push lift type transverse cutting machine for cutter has advantages in that: 1. simple structure, easy use and maintenance, low manufacture cost; 2. convenient moving, stable cutting, safe use, high operating efficiency, flat and beautiful cutting surface; 3. wide purpose, the cuttingmachine can be used for transversely cutting various concrete pile heads in the base treatment, such as road, railway, bridge, etc.; dismounting small-sized storied house, bungalow and workshop; cutting and dismounting various concrete structure objects.

Owner:张帅 +1

Simple cutting machine

ActiveCN105364970ASimple structureReduce volumeMetal working apparatusEngineeringMechanical engineering

The invention relates to a simple cutting machine. The simple cutting machine comprises a worktable, a fixed cylinder, a cutting mechanism and a rotating mechanism. The fixed cylinder is fixed to the worktable and is provided with a cylinder wall, the interior of the cylinder wall is of a hollow structure, openings are formed in the two ends of the fixed cylinder, and a plurality of notches are formed in the cylinder wall of the fixed cylinder. The cutting mechanism is movably arranged on the worktable and is provided with a plurality of blades, and the blades are movably inserted into the notches. The rotating mechanism is movably inserted into the fixed cylinder and rotates coaxially with the fixed cylinder. According to the simple cutting machine, by pushing the blades of the cutting mechanism to be inserted into the notches of the fixed cylinder, food in the fixed cylinder can be uniformly cut, and therefore food cutting is safer, more convenient and faster. In addition, the simple cutting machine is simple in structure, small in size and low in manufacturing cost, and the use cost and the maintenance cost are lowered.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

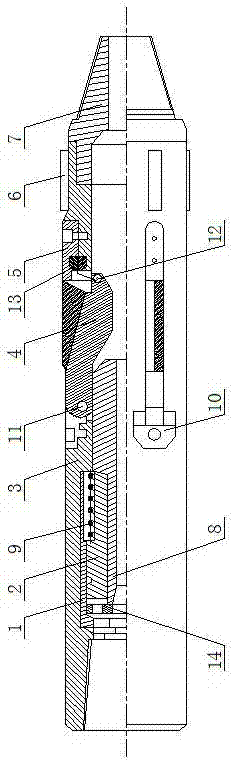

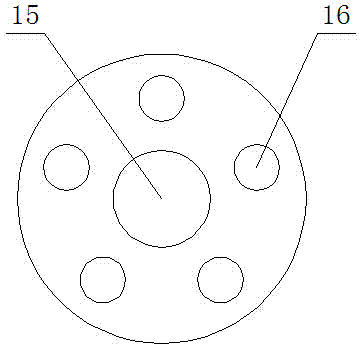

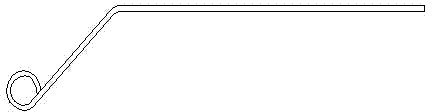

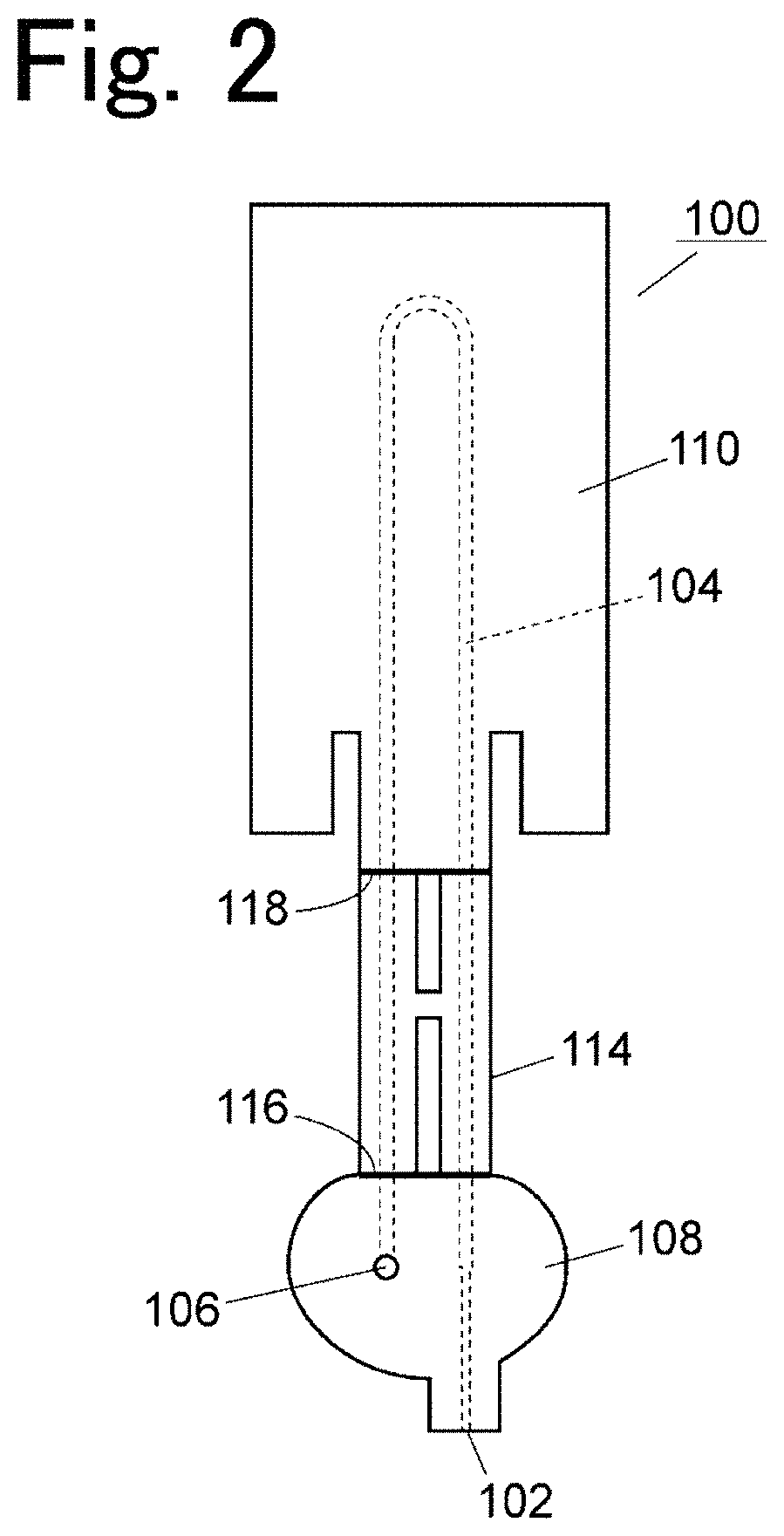

Hydraulic internal cutter for cutting sleeve in deep sea

The invention relates to a hydraulic internal cutter for cutting a sleeve in a deep sea and belongs to the technical field of petroleum and natural gas sleeve repairing tools. The cutter is composed of a shell, a cutter assembly, a piston assembly and the like and is characterized in that the piston assembly and a lower connector are installed at the two ends of the shell respectively, and the cutter assembly is installed in the middle of the shell; a centralizer is installed outside the shell; a flow channel is formed in the middle of the piston assembly and in the middle of the lower connector, hard alloy is embedded to a cutting edge of a cutter body, and the two sides of the tail end of the cutter body are provided with leaf springs through pin shafts; a center hole is formed in the center of a valve disk, and small holes are formed in the periphery of the small hole; a piston is in positioning connection with a cylinder sleeve through the valve disk, and a spring is installed between the piston and the shell. The cutter body is high in hardness and long in service life; the cutter body can retract freely, it is guaranteed that the cutter body performs operation in the center, the structure is simple, operation is convenient, and cutting efficiency is greatly improved; the problems that an existing cutter body cannot retract into the shell easily, the hardness of the cutter body is poor, service life is short, the structure and the operation are complicated, and cutting accidents can happen very easily are solved.

Owner:YANGTZE UNIVERSITY

Assembled milling cutter tool

ActiveCN104690349AReduce processing costsEasy to operateFeeding apparatusLarge fixed membersMilling cutterEngineering

The invention relates to an assembled milling cutter tool. The assembled milling cutter tool comprises a worktable, wherein the worktable is in a rectangular shape, the worktable is fixed on the ground by virtue of four legs, one corner of a table-board of the worktable is fixedly provided with a dustproof box, the side wall of a shell of the dustproof box is fixedly provided with an air valve, the bottom surface of an inner cavity of the dustproof box is provided with a horizontal moving platform by virtue of a slide rail, one end of a lead screw is installed in the horizontal moving platform, the other end of the lead screw stretches out of the side surface of the dustproof box to be fixedly connected with a rocking handle, an air cylinder is installed in a vertical moving platform above the horizontal moving platform, an output end of the air cylinder stretches out of the upper surface of the dustproof box to be fixedly connected with a supporting seat, a track platform is fixed on the dustproof box at the inner side of the supporting seat, the track platform is connected with a connecting rod on the inner side surface of the supporting seat in a positioning manner, and a milling cutter drive machine is fixed on the supporting seat. By adopting the assembled milling cutter tool, the mold does not need to be reopened for cutting a door panel, so that the machining cost is greatly reduced; meanwhile, the milling cutter can move along the track only by pressing an air valve switch while the handle is cranked by a hand, so that more safety in cutting is realized, and accidents are prevented.

Owner:延锋汽车饰件系统宁波有限公司

Tapping machine easy to adjust

The invention relates to the technical field of tapping equipment, in particular to an easy-to-adjust tapping machine, including a workbench, a fixed plate, a first electric telescopic rod, a base, a roller, a buffer spring, a fixing piece, a tooth groove, a chute, a control Box, first connecting piece, second electric telescopic rod, bolt assembly, second connecting piece, fixed shaft, rotary table, tapping device, tap, fixed column, cross bar and third electric telescopic rod, the upper surface of the table is the most The left side is provided with a fixed plate, and the right side of the fixed plate is provided with a first electric telescopic rod. The right end of the first electric telescopic rod is fixedly connected to the left side of the base, and the bottom of the base is provided with rollers. The invention is easy to install and disassemble, with simple structure and convenient operation , High degree of intelligence, with shock absorption and buffering effect, prolonging the use time of the fixing parts, easy maintenance or replacement, high safety, and strong practicability.

Owner:扬州汇翔精密冲件有限公司

Wire cutting device of wire electric discharge machine

ActiveUS20050284846A1Total current dropReduce tensionElectrical-based machining electrodesElectric dischargeWire cutting

When starting a wire cutting operation, a first predetermined current is supplied from a power unit to a wire, and at the same time predetermined tension is applied from a tension applying device to the wire. When a first predetermined time elapses since the start of the wire cutting operation, the current supplied from the power unit is switched to a second predetermined current which is smaller than the first predetermined current, and also the predetermined tension is continuously applied, whereby the wire is cut.

Owner:FANUC LTD

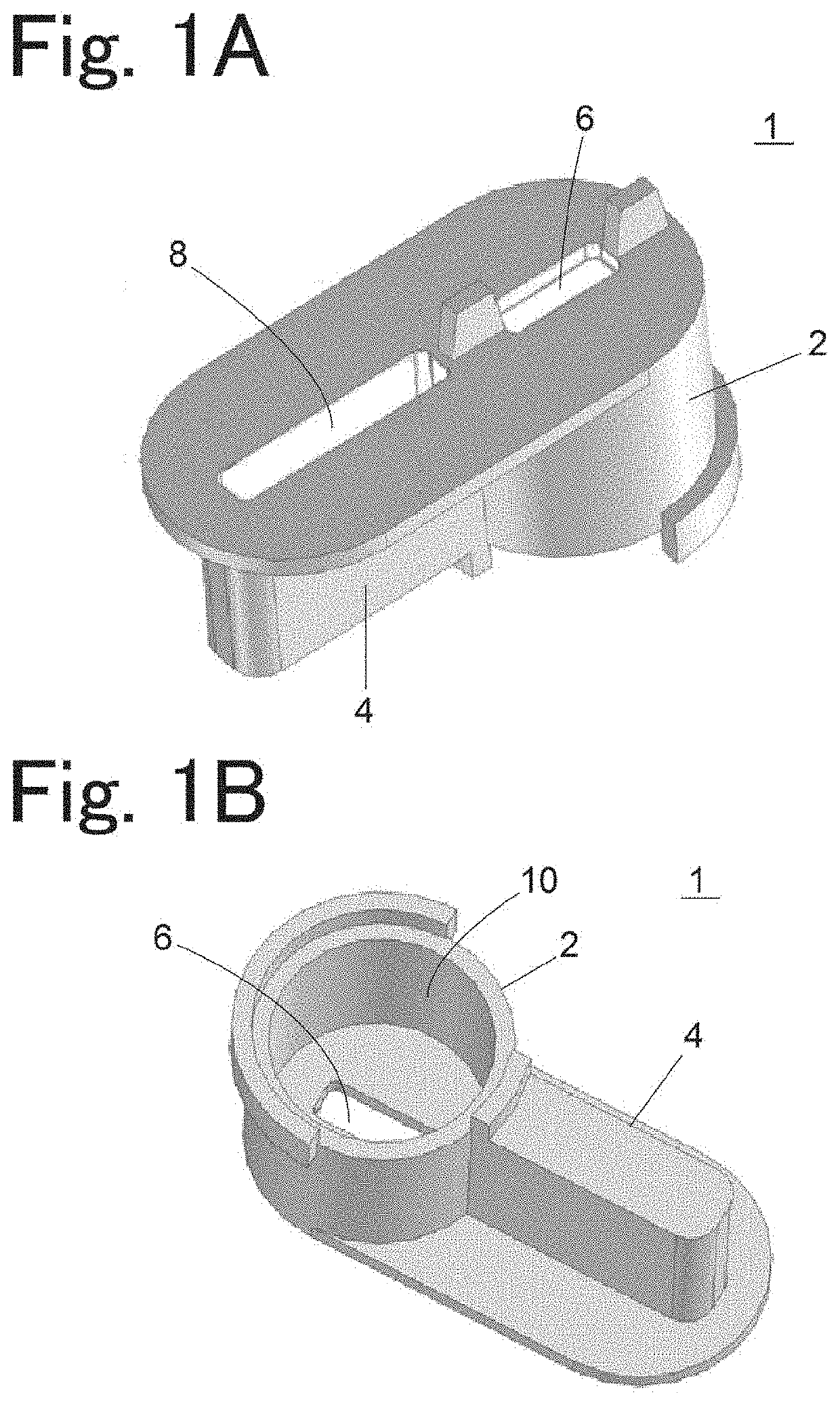

Sample extraction tool

ActiveUS20190368977A1Good reproducibilityCutting safetyWithdrawing sample devicesPreparing sample for investigationEngineeringSample extraction

An extraction portion which is a piece of a micro sampling chip is safely cut, and the cut extraction portion can be accommodated in a predetermined container without impairing quantitativeness of a sample.A sample extraction tool comprises a through hole for cutting the extraction portion from the micro sampling chip by bending the micro sampling chip while inserting the extraction portion to the through hole, the sample extraction tool is configured to be attached to an upper portion of a container for accommodating the extraction portion in such a state that the through hole is disposed on an open upper surface of the container.

Owner:SHIMADZU CORP

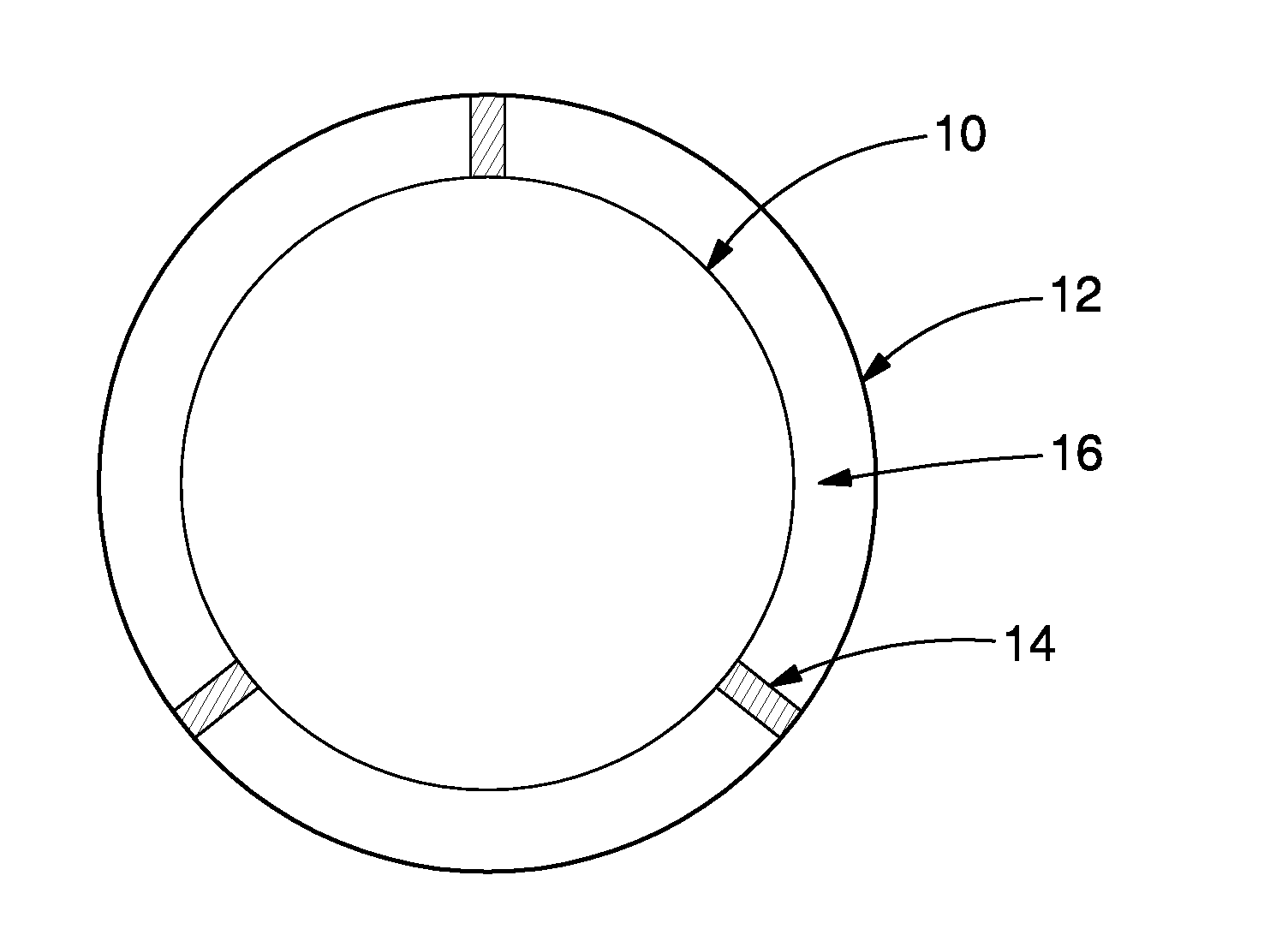

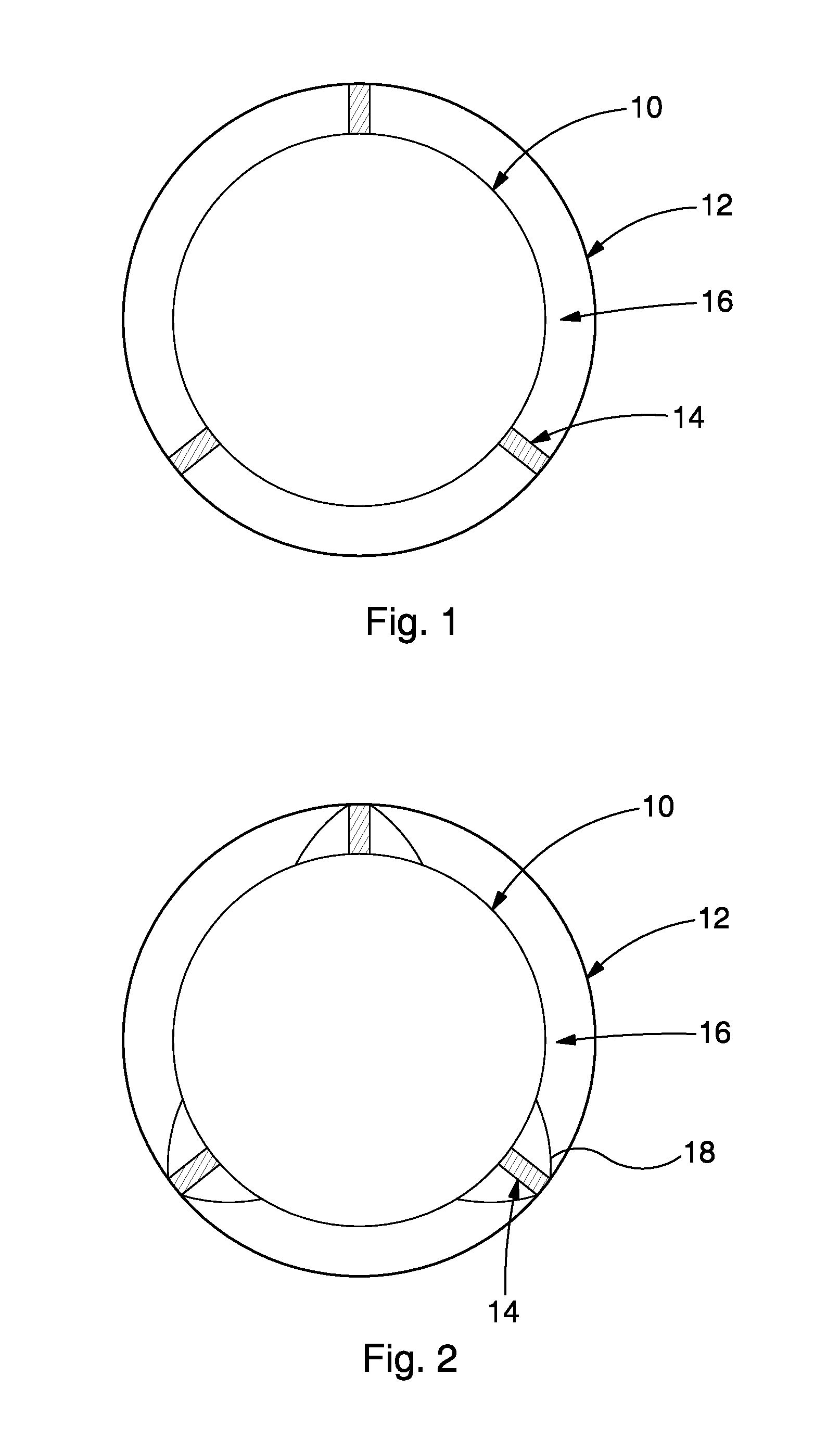

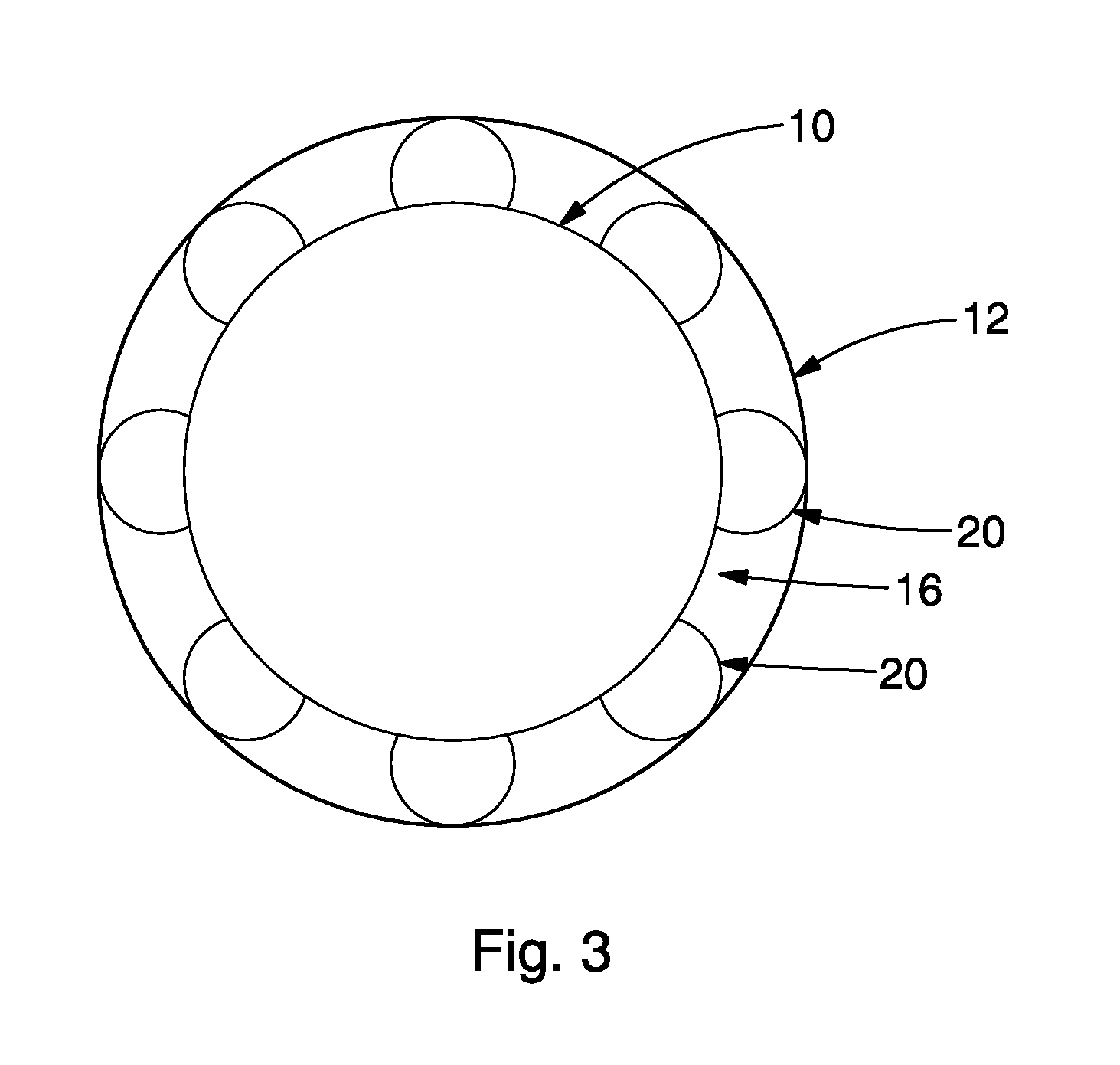

Method of centralising tubing in a wellbore

ActiveUS20160237763A1More time-efficientMore corrosive environmentDrilling rodsFluid removalBiomedical engineeringWellbore

A method of centralising tubing (10) in a wellbore comprises either providing one or more expandable elements (14) between a tubing and a surrounding casing (12) located in a wellbore and expanding the expandable elements against the casing so as to cause the tubing to centre within the casing; or expanding one or more portions (20) of a tubing against a surrounding casing located in a wellbore so as to cause the tubing to centre within the casing.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Method for cutting water quenching slag ladle

InactiveCN102849283AEliminate the risk of personal accidentsOperational securityArticle unpackingSlagClose range

The invention discloses a method for cutting a water quenching slag ladle; the method is to arrange cutting tools on the left and right sides of the water quenching slag ladle, and then cut the water quenching slag ladle by horizontally moving the cutting tools. A suspending method is used for the working parts of the cutting tools, the cutting tools at the left and right sides are distributed asymmetrically, and inserted in the water quenching slag ladle from the side bottom. The left and the right cutting tools can move synchronously, so as to cut eight openings in a crossed form at one time, and the length of each opening is greater than the semi-diameter of the water quenching slag ladle. The method is simple in operation and facilitates maintenance, and can implement a remote operation in cooperation with a small portable type remote controller, so that the accident potential caused by a close-range manual operation is eliminated, and meanwhile, the dust pollution is reduced, and the requirement of safety production can be met. The predetermined function is achieved efficiently, fast, safely and reliably with the effective combination and action of mechanisms in the entire working process.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com