Plane-push lift type transverse cutting machine for concrete

A concrete and cutting machine technology, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems affecting the performance and function of the pile head, uneven cross section, low efficiency, etc., and achieve simple structure, wide application, cutting smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

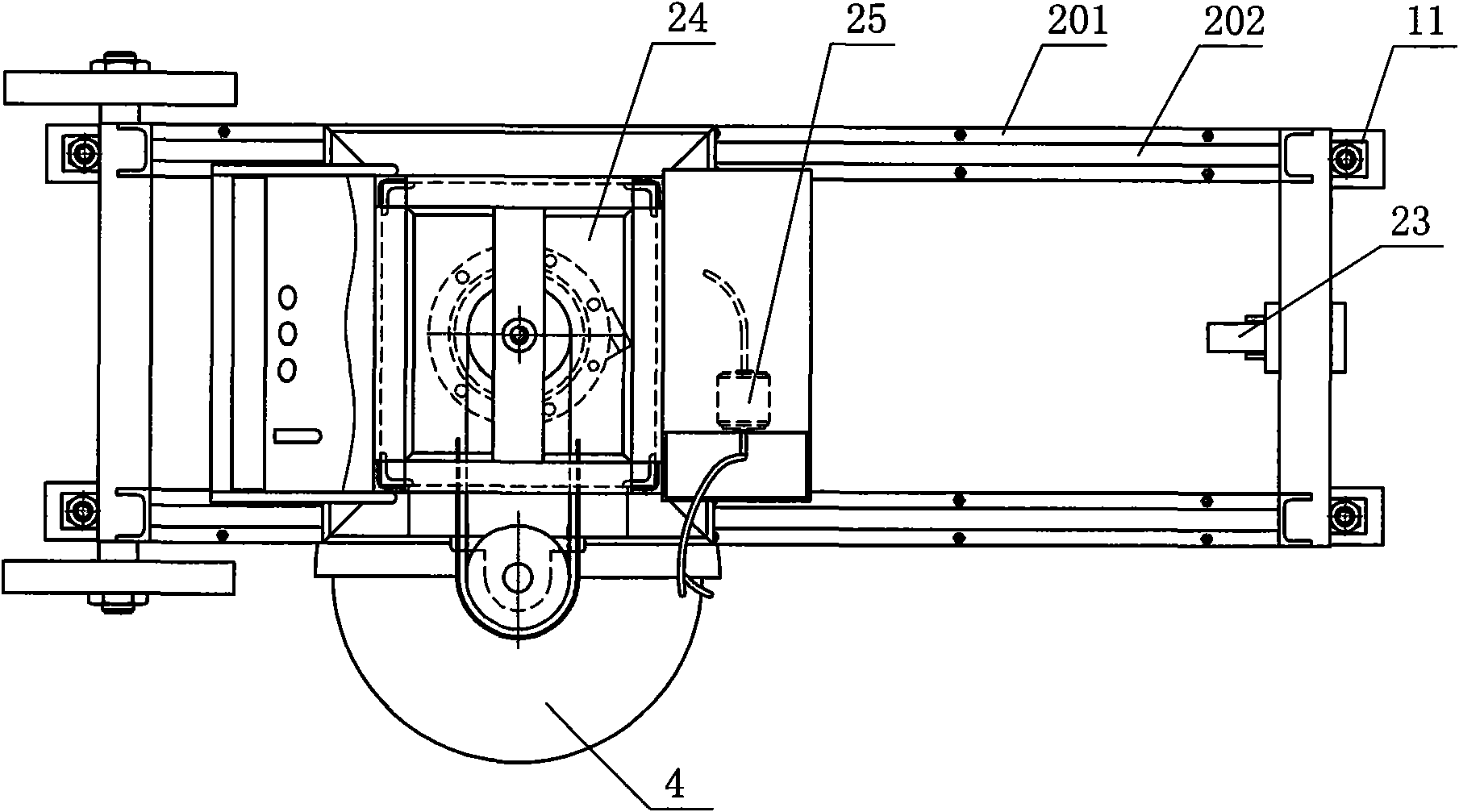

[0015] As shown in the figure, the present invention has a chassis frame 1. The chassis frame 1 is a rectangular frame welded by channel steel, and the chassis frame 1 is provided with traveling wheels. To wheel 23 and the positioning wheel 10 that is installed on chassis frame 1 rear end both sides constitutes. Four corners at both ends of the chassis frame 1 are respectively fixed with lifting support bases 11 . Both sides of the chassis frame 1 are longitudinally symmetrically provided with a slideway 2, and the slideway 2 is composed of a slideway seat 201 fixed on the chassis frame 1 by bolts and a stainless steel slideway shaft fixed on the slideway seat 201. 202, a frame 13 that can slide along its axial direction is supported on the slideway shaft 202, and slide seats 12 are respectively installed at the four corners of the bottom of the frame 13 corresponding to the slideways 2 through bolts, and the frame 13 slides The seat 12 and the linear bearing arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com