Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

404results about How to "High torque transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

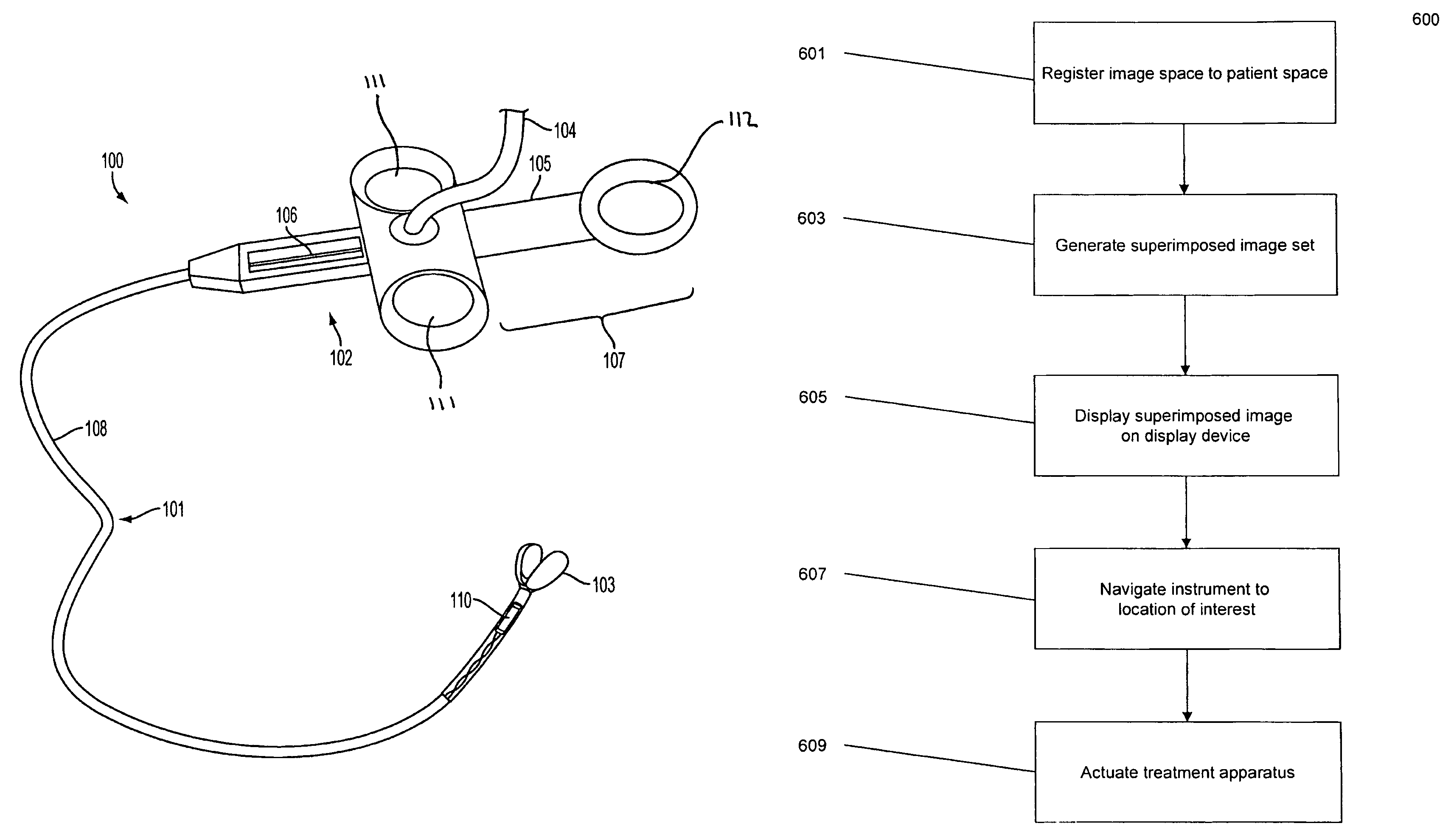

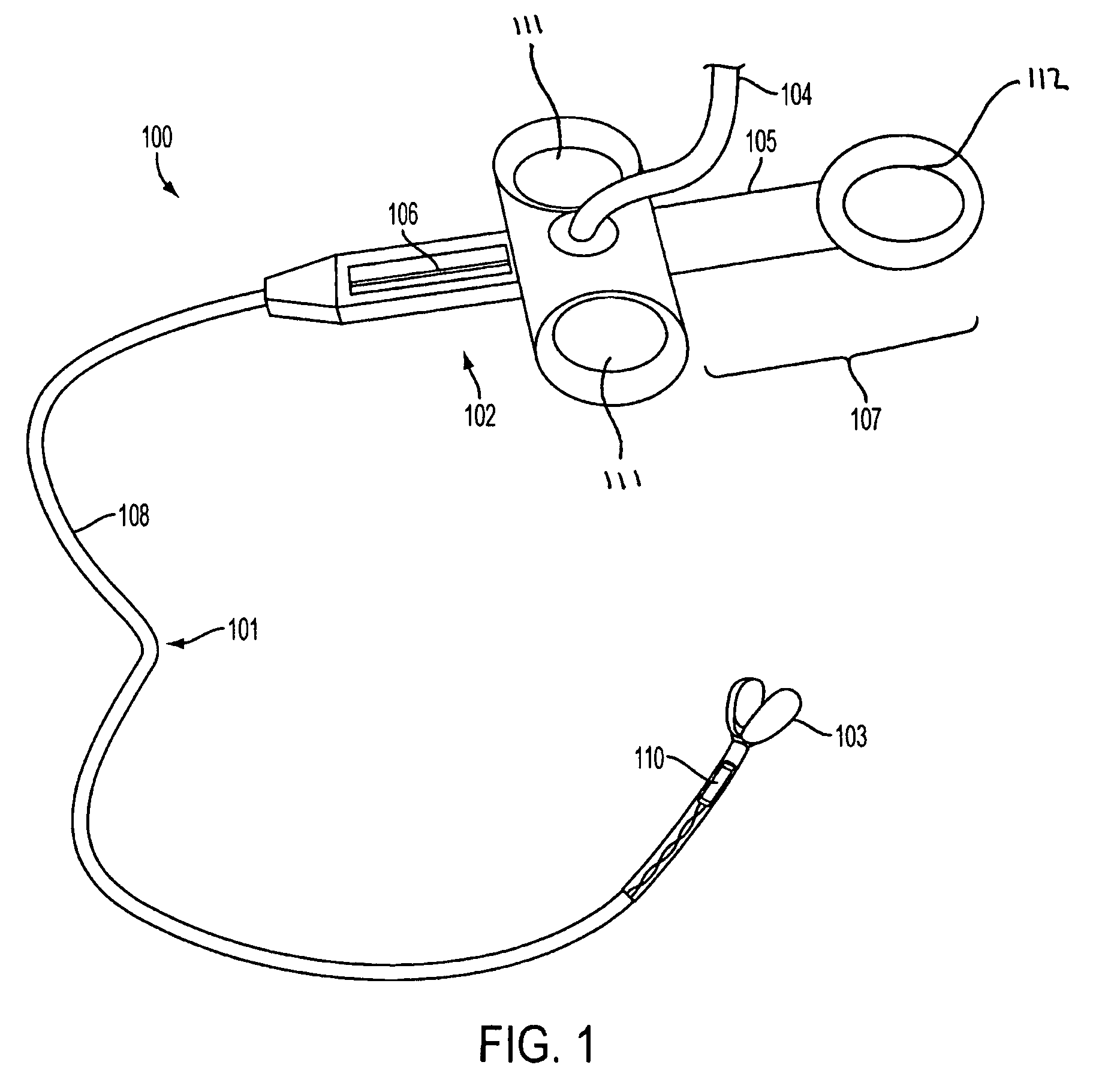

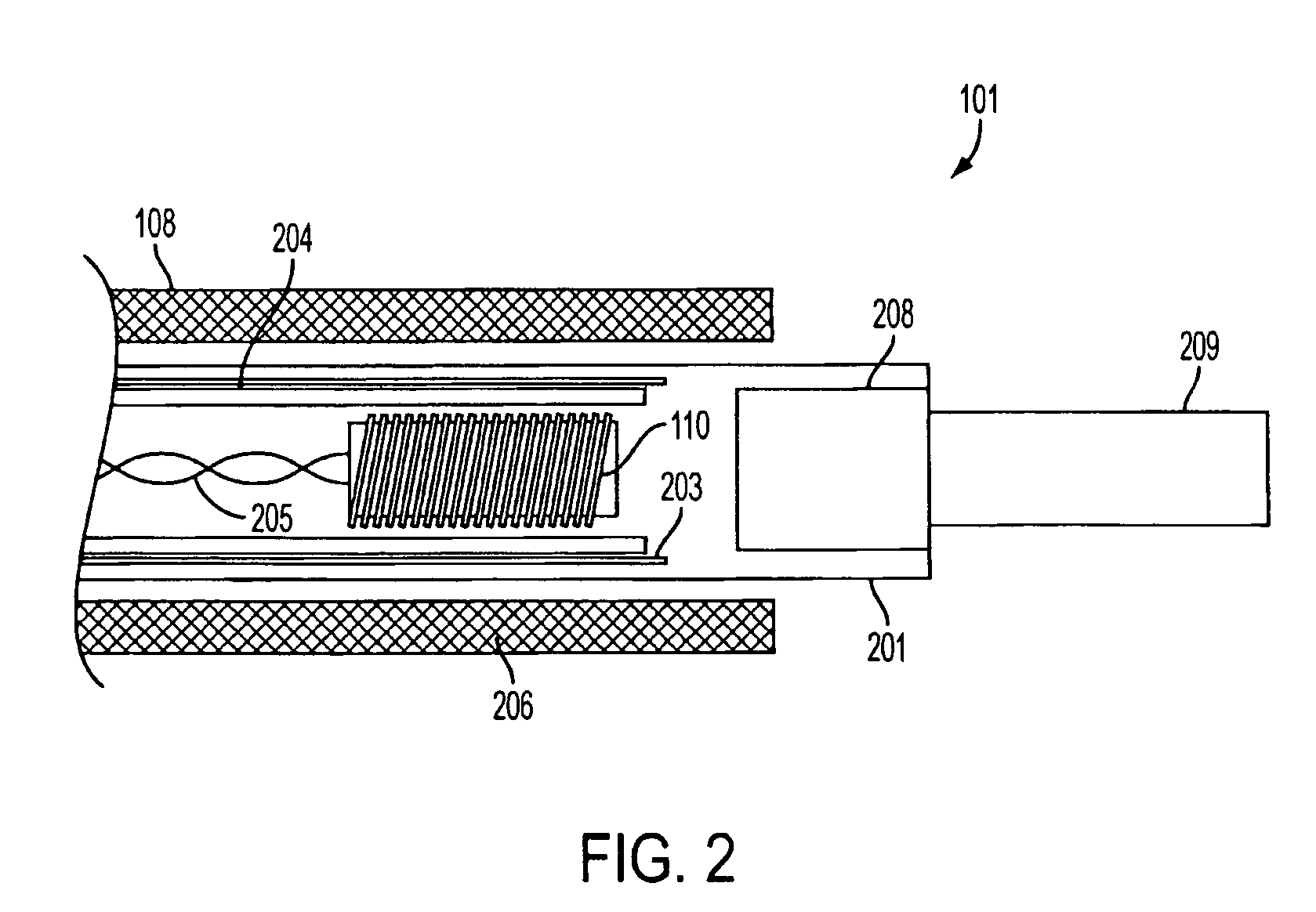

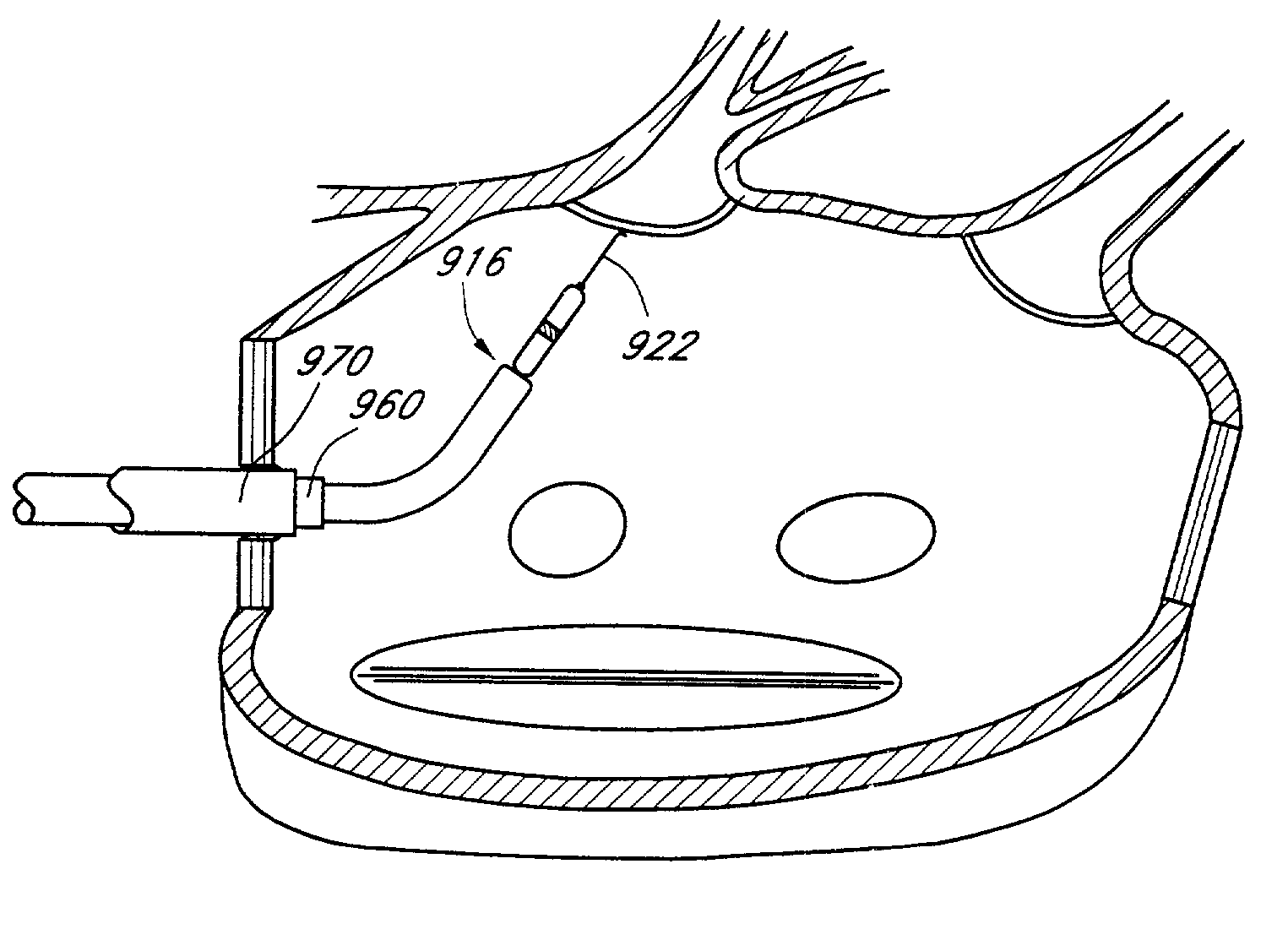

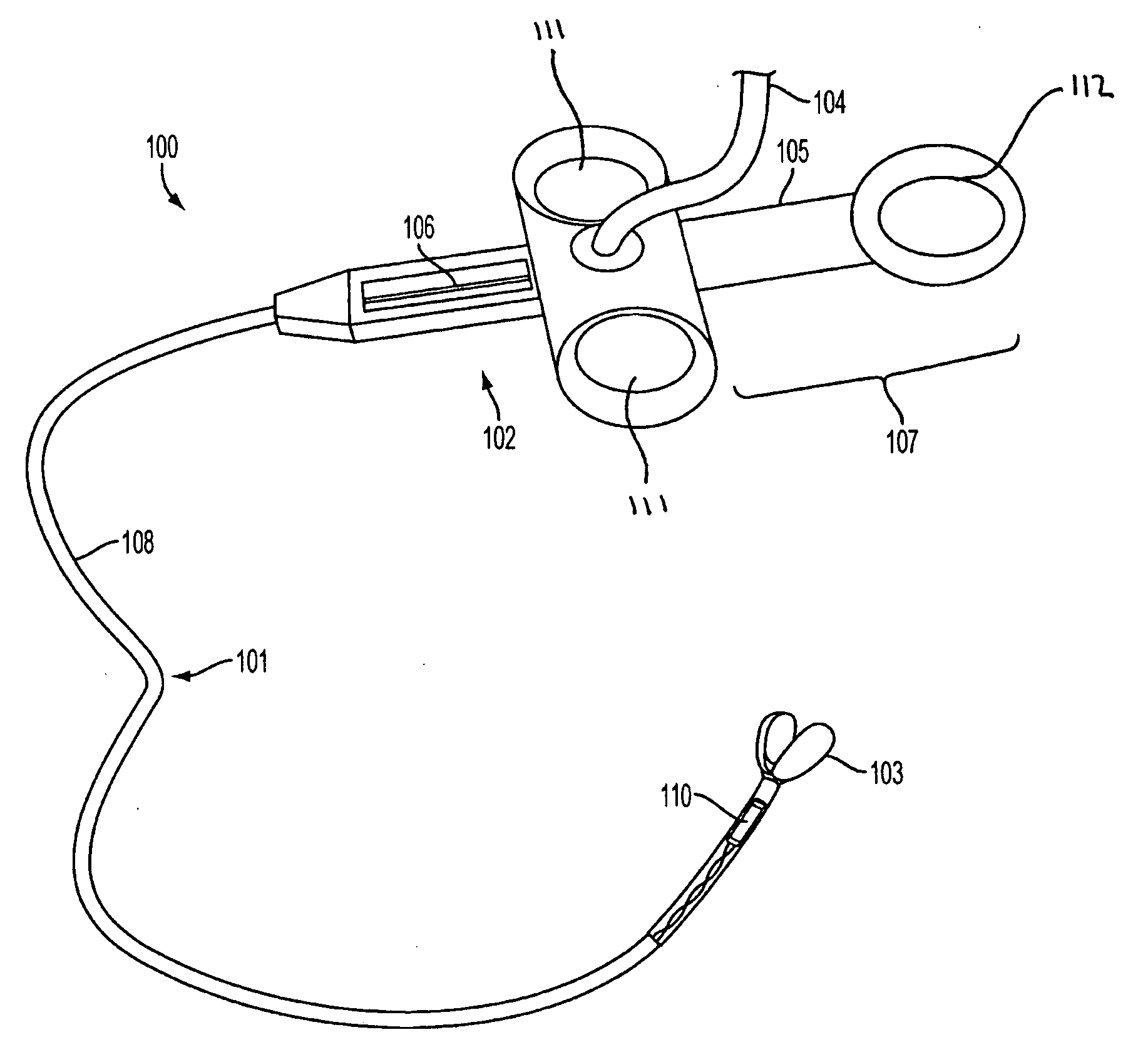

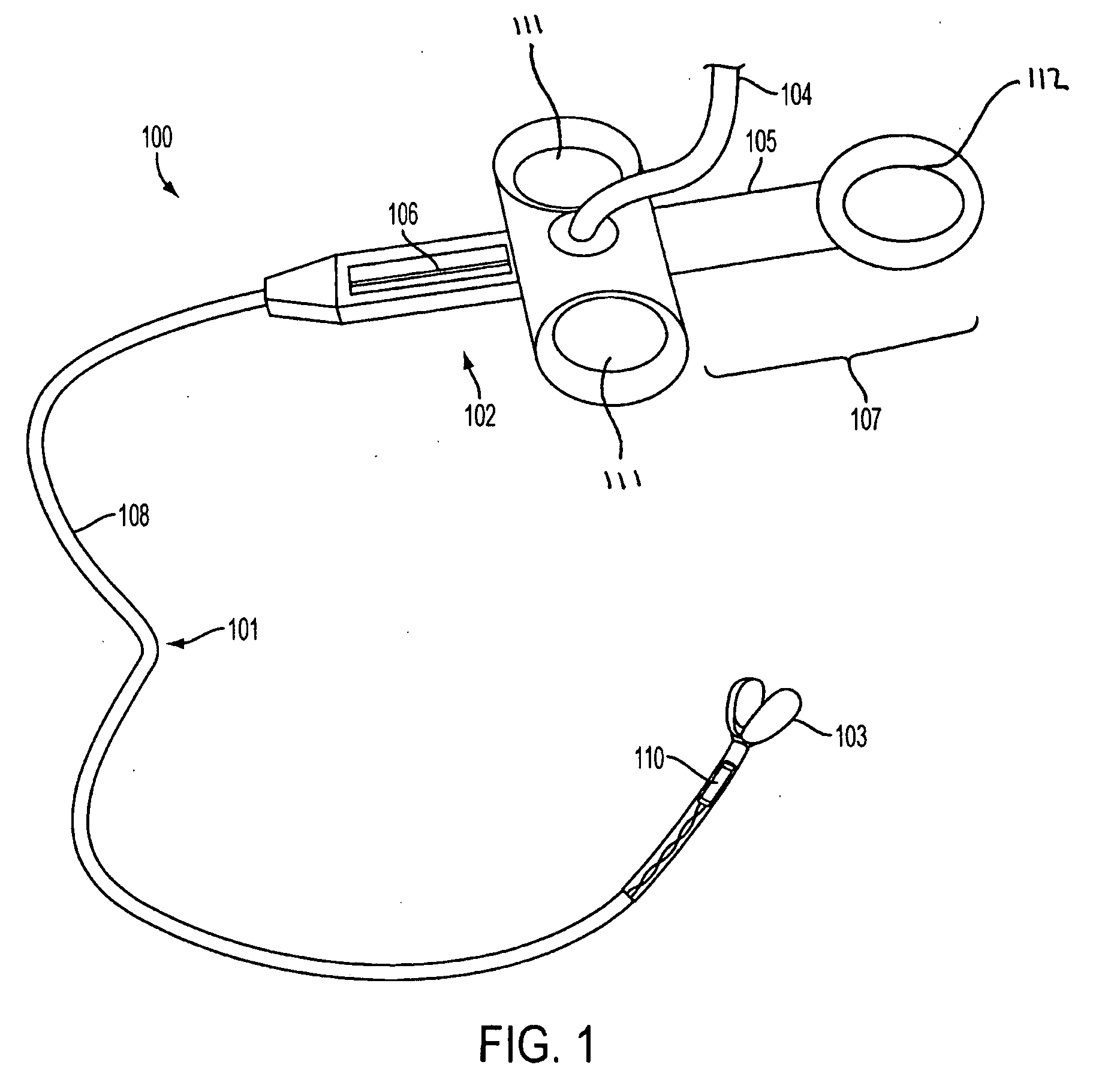

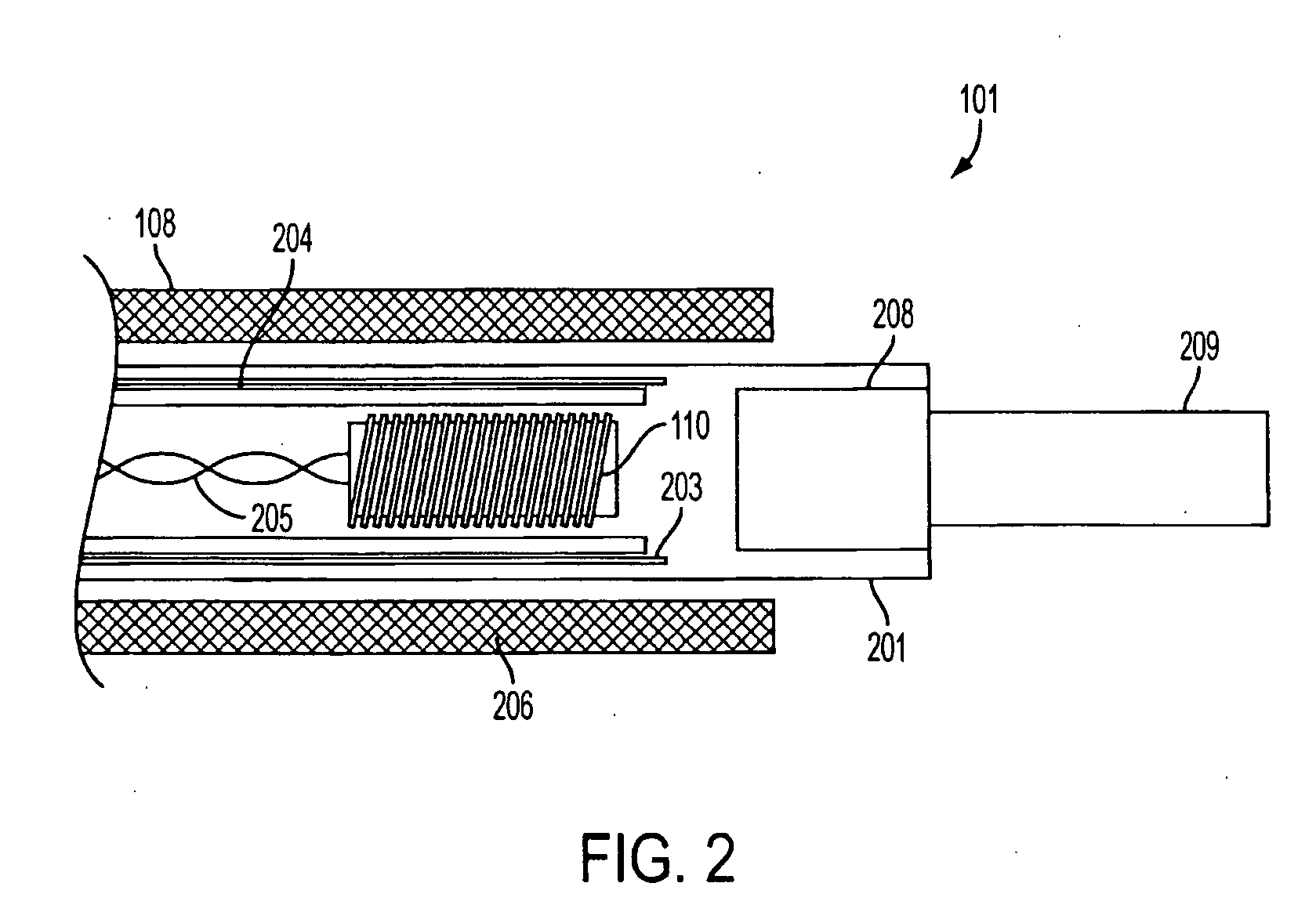

System, method and apparatus for navigated therapy and diagnosis

ActiveUS8632461B2Increase thrustHigh torque transmissionSurgical navigation systemsEndoscopesEngineeringMedical instruments

The invention provides an image-guided medical instrument that utilizes a tracking device to track the location of at least a portion of the instrument on at least one image of a patient's anatomy. The instrument may include a handle having an operating element, an elongated flexible body member connected to the handle, wherein the body member includes a lumen, a transmission element housed within the lumen of the body member, and a treatment apparatus connected to end of the transmission element, wherein actuation of the operating element actuates the treatment apparatus via the transmission element. The body member also includes at least one sensor element that is utilized by the tracking device to determine position information regarding the treatment apparatus that is used to display the location of the treatment apparatus on the at least one image of the patient's anatomy.

Owner:PHILIPS ELECTRONICS LTD

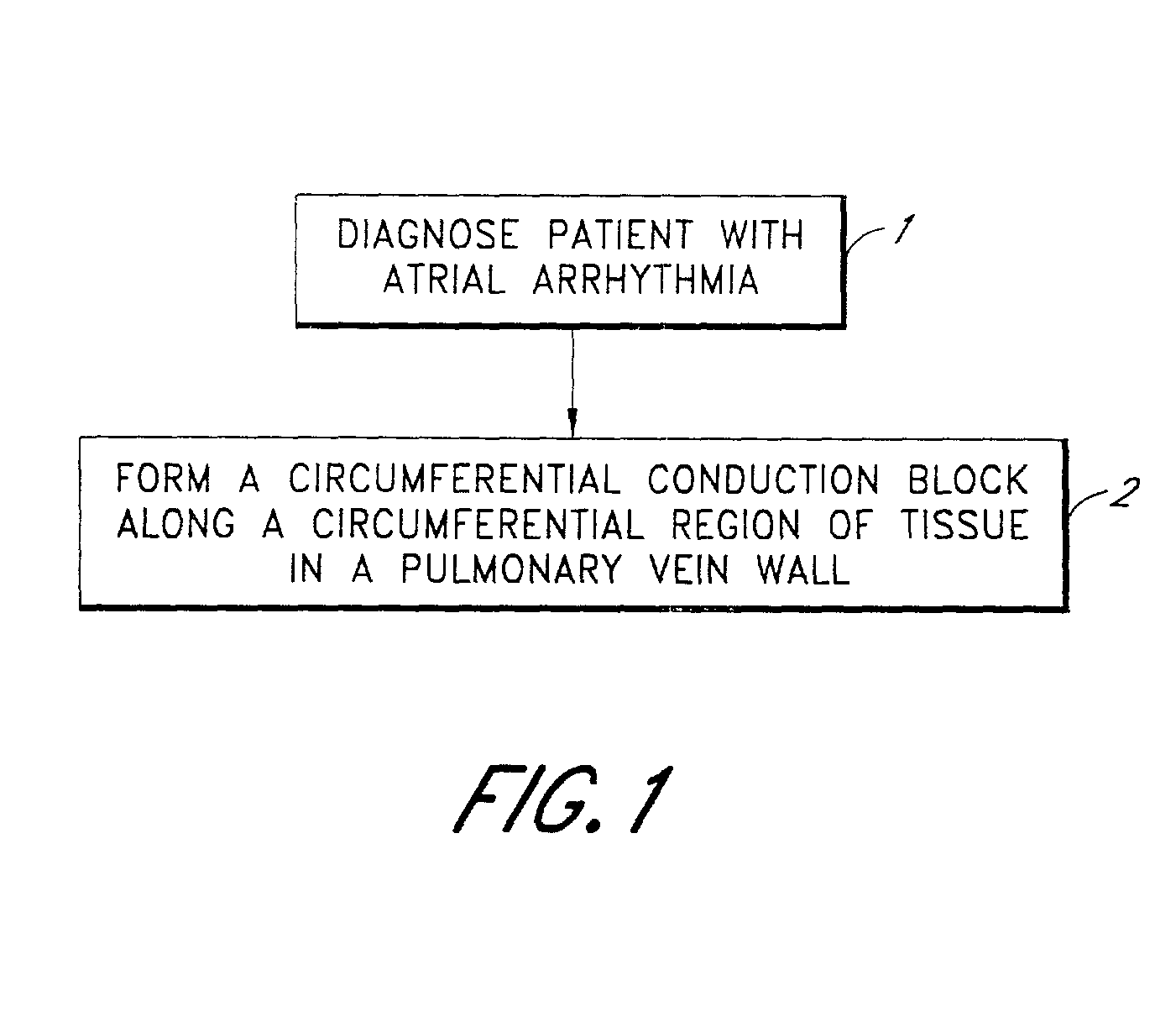

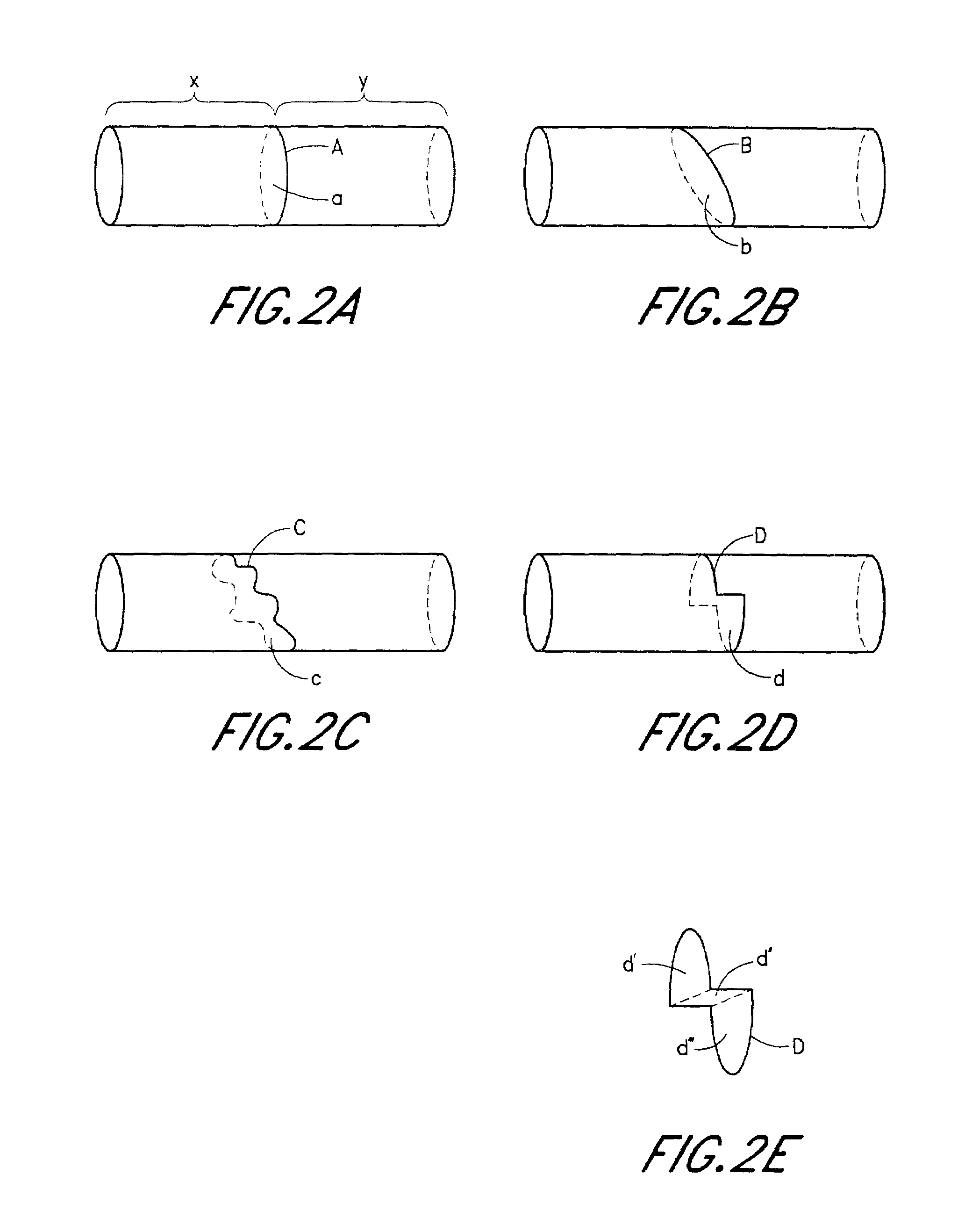

Deflectable tip catheter with guidewire tracking mechanism

InactiveUS7089063B2Eliminates atrial arrhythmiaImprove abilitiesUltrasound therapyStentsSharp angleUltrasound

A deflectable tip catheter that is used in combination with a guidewire for delivery of an ablation element to target areas of a patient's vasculature. The deflectable tip catheter has a handle portion, an elongated shaft and a deflectable tip portion. A guidewire lumen extends through the elongated shaft and deflectable tip portion. A guidewire passes through the guidewire lumen and exits from a port in the distal end of the deflectable tip portion. The deflectable tip of the catheter is deflected by manipulation of the handle portion to direct the advancement of the guidewire as the guidewire is advanced out of the distal port. By using the deflectable tip portion to direct the advancement of the guidewire, the physician's ability to navigate sharp angles is greatly improved. The deflectable tip catheter is particularly suitable for delivering an ablation element to a pulmonary vein or pulmonary vein branch for performing circumferential ultrasound vein ablation to treat atrial fibrillation.

Owner:ATRIONIX

System, method and apparatus for navigated therapy and diagnosis

ActiveUS20070032723A1Increase thrustHigh torque transmissionSurgical navigation systemsEndoscopesTherapeutic DevicesEngineering

Owner:PHILIPS ELECTRONICS LTD

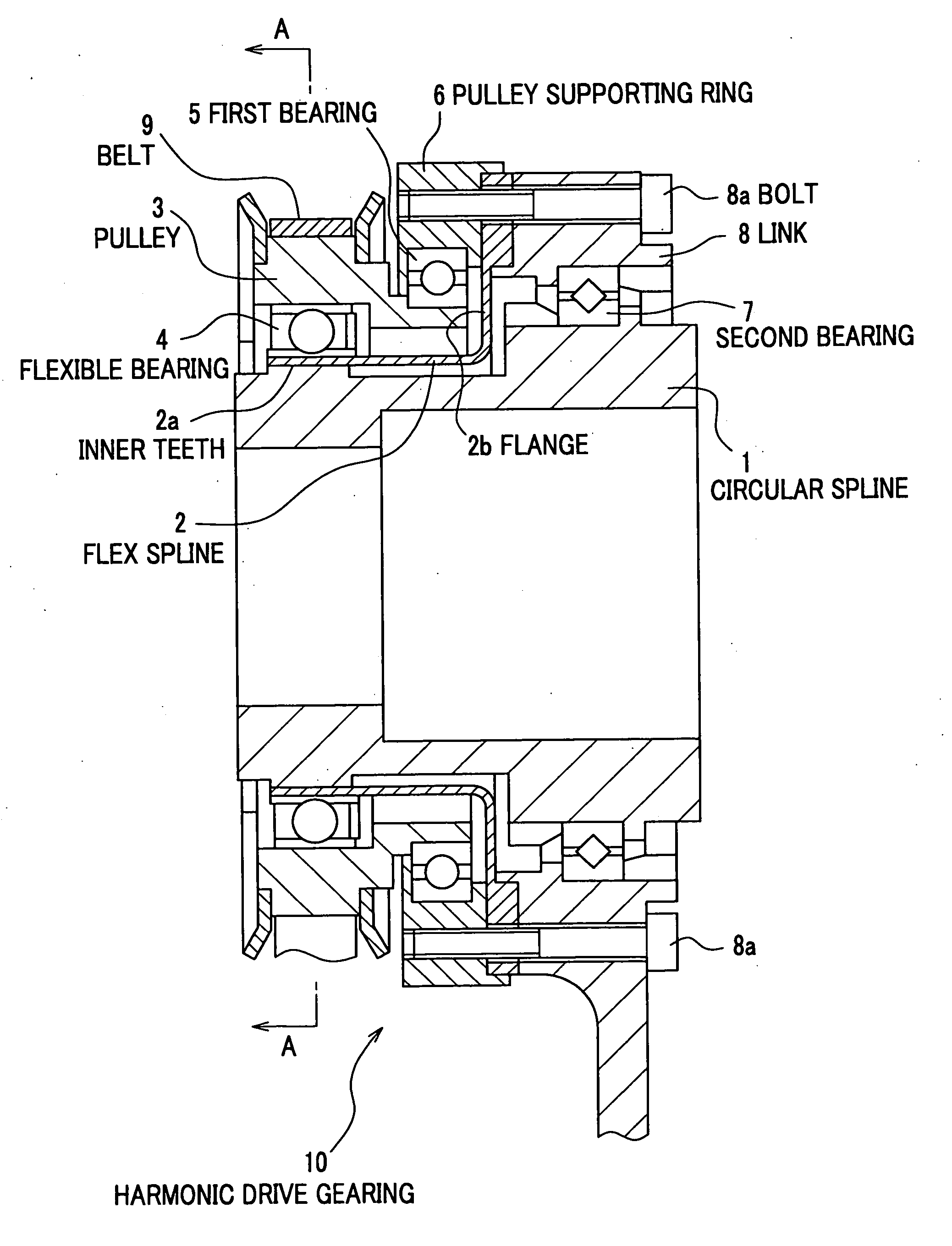

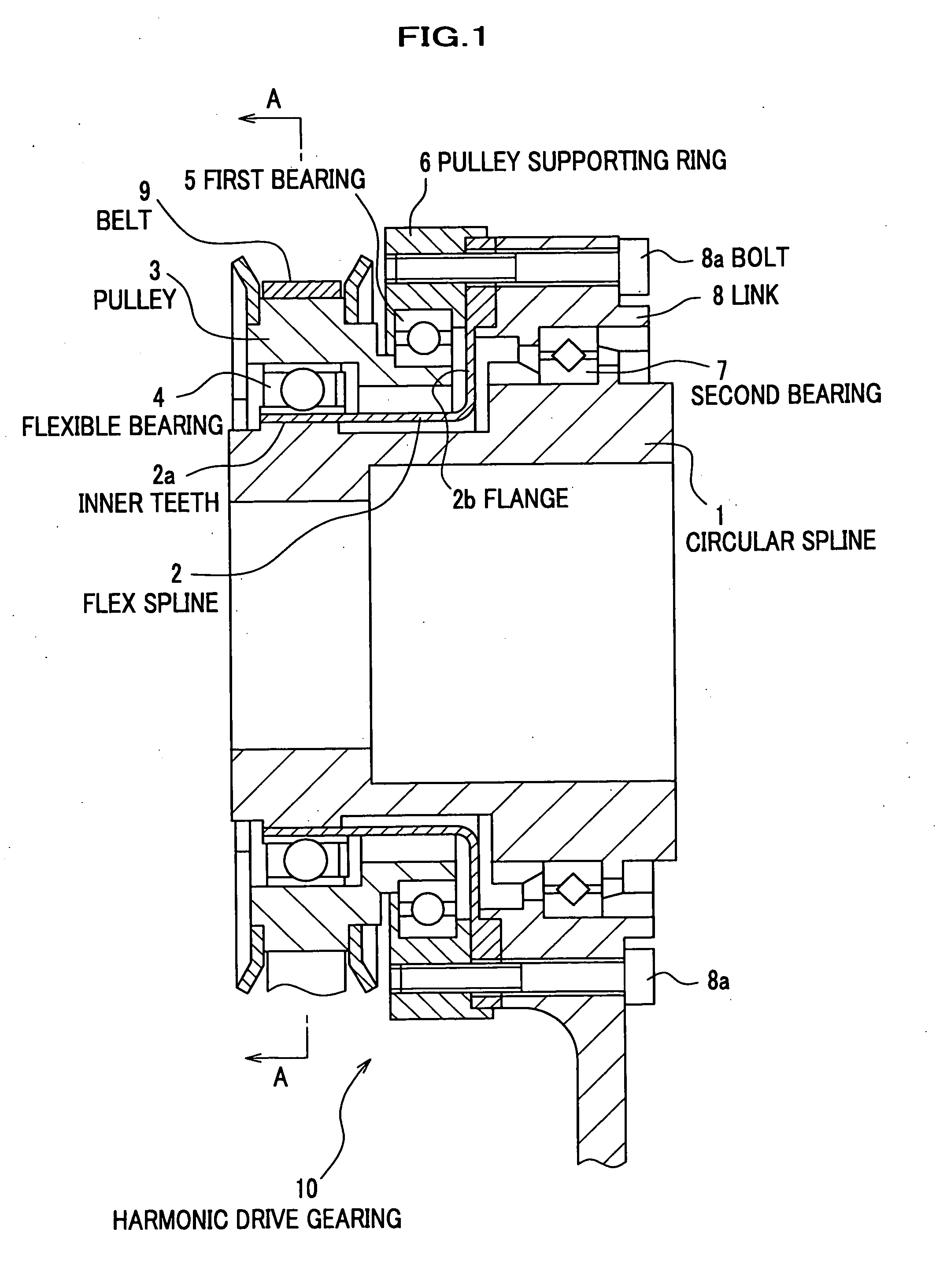

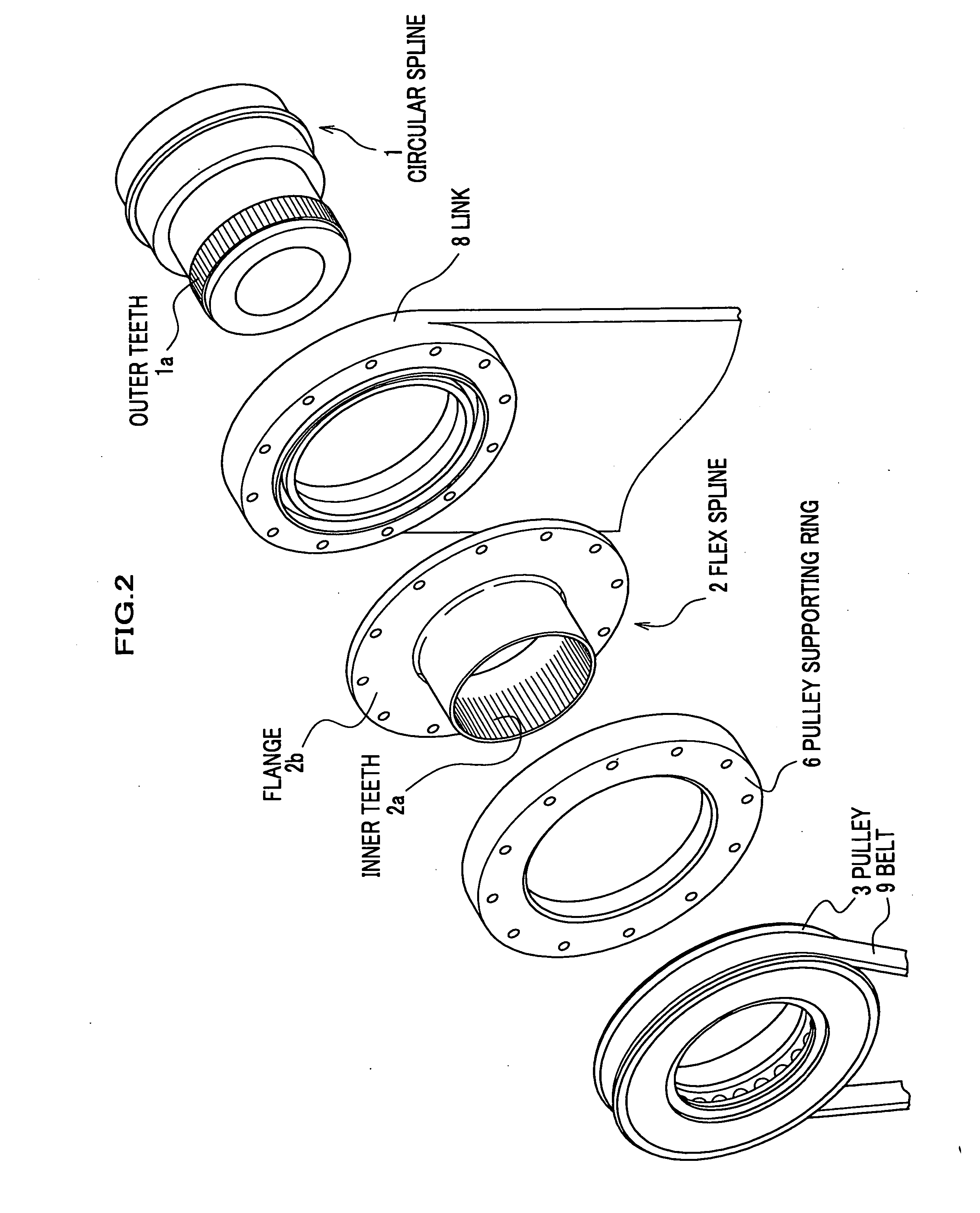

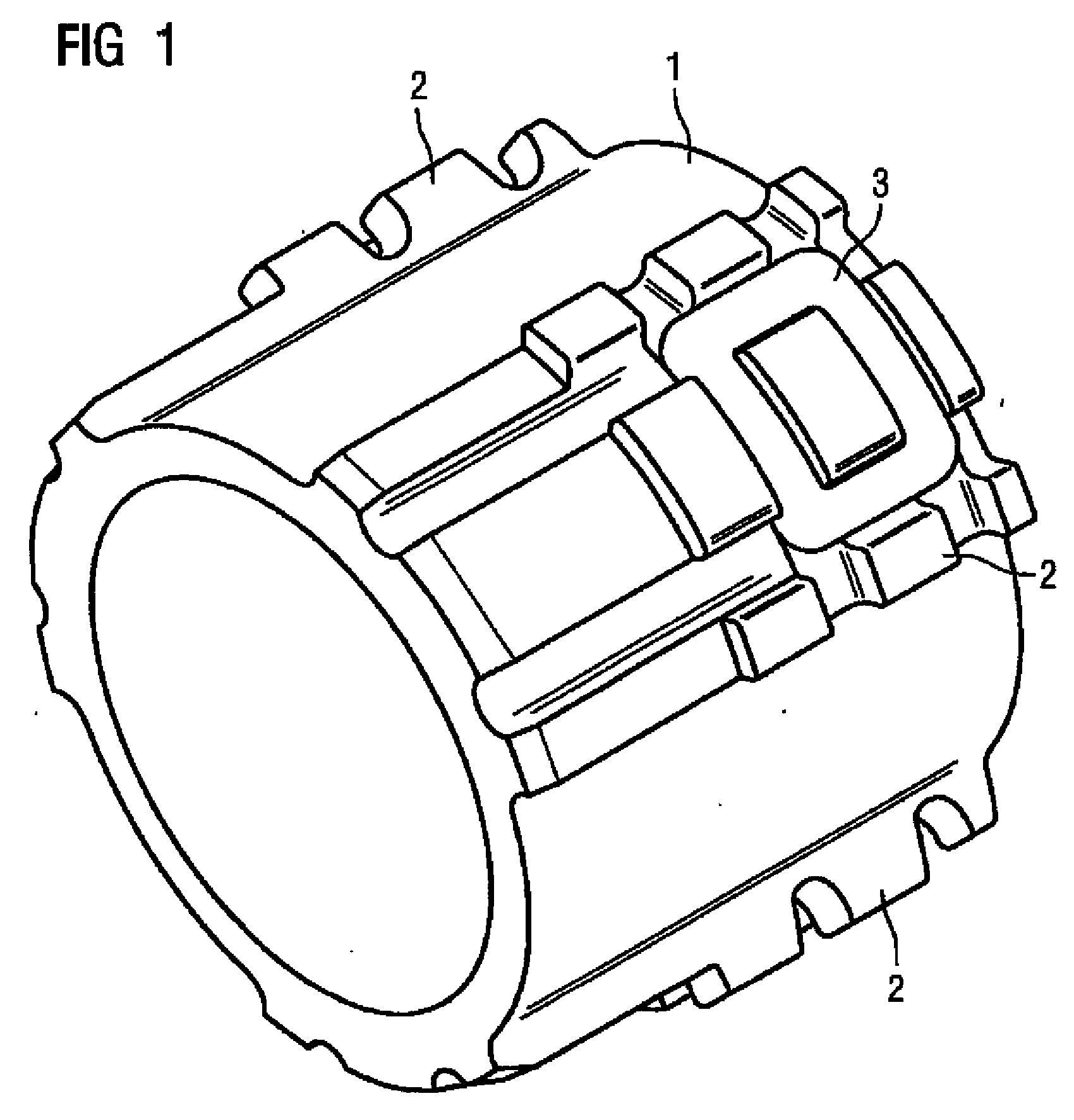

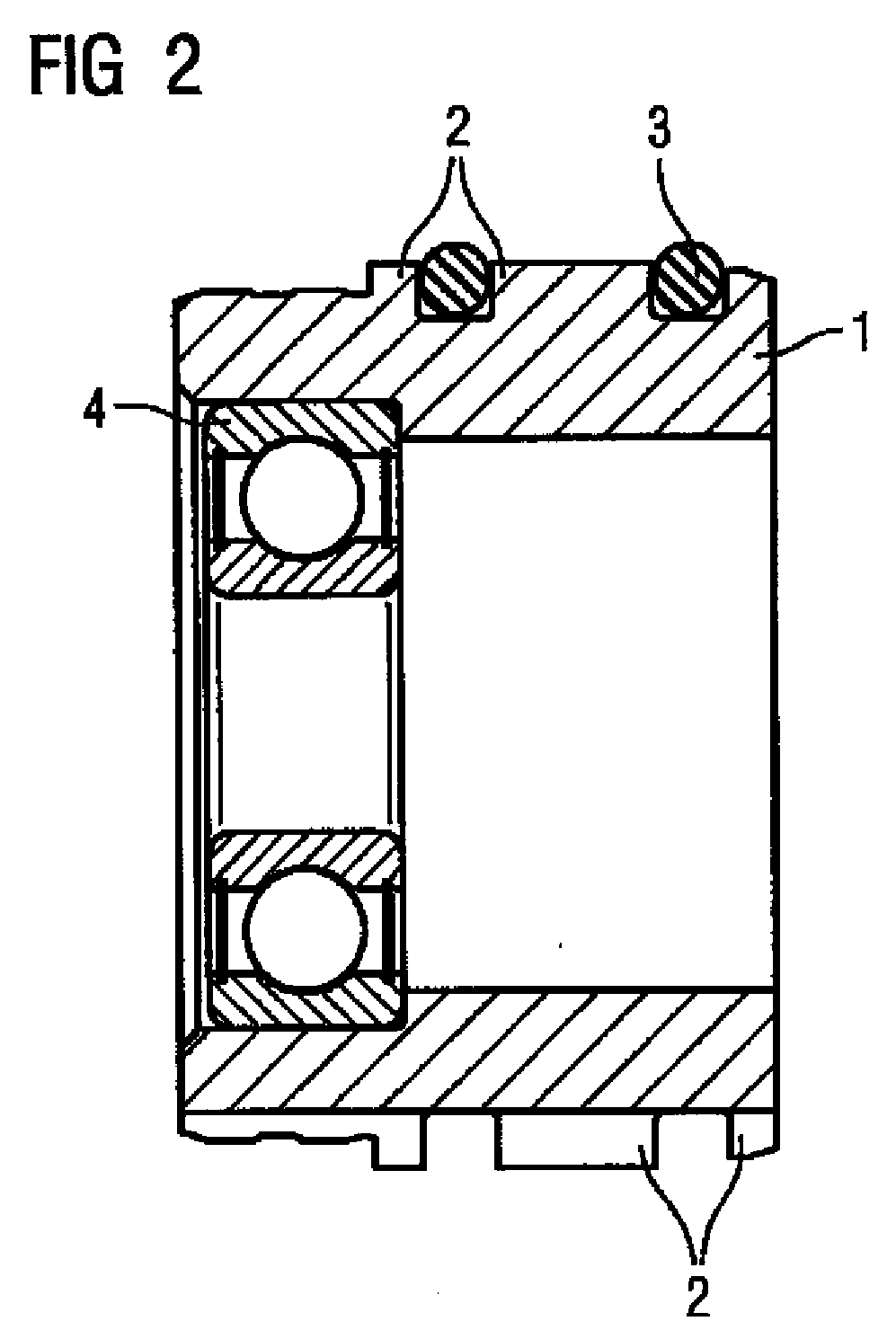

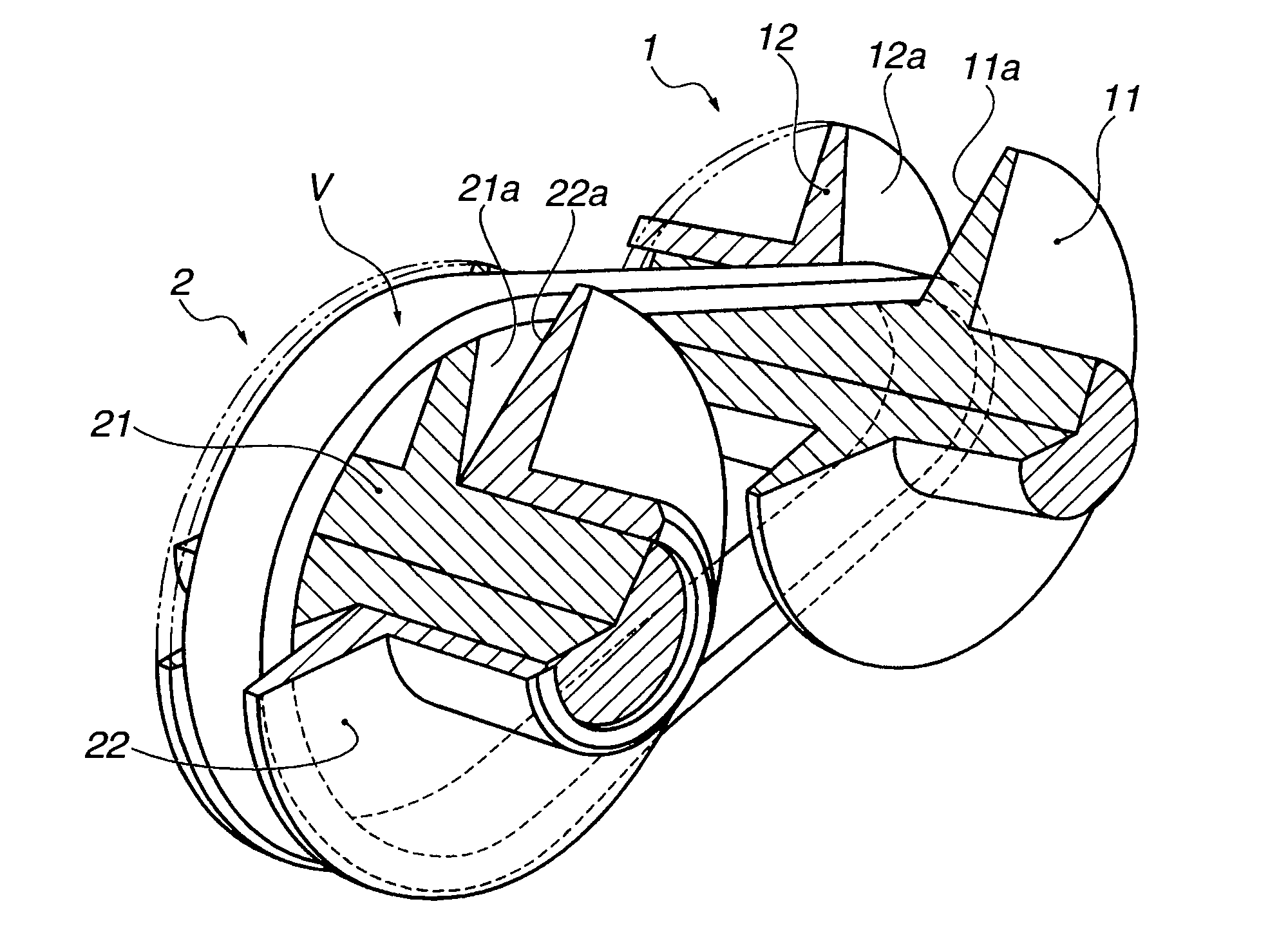

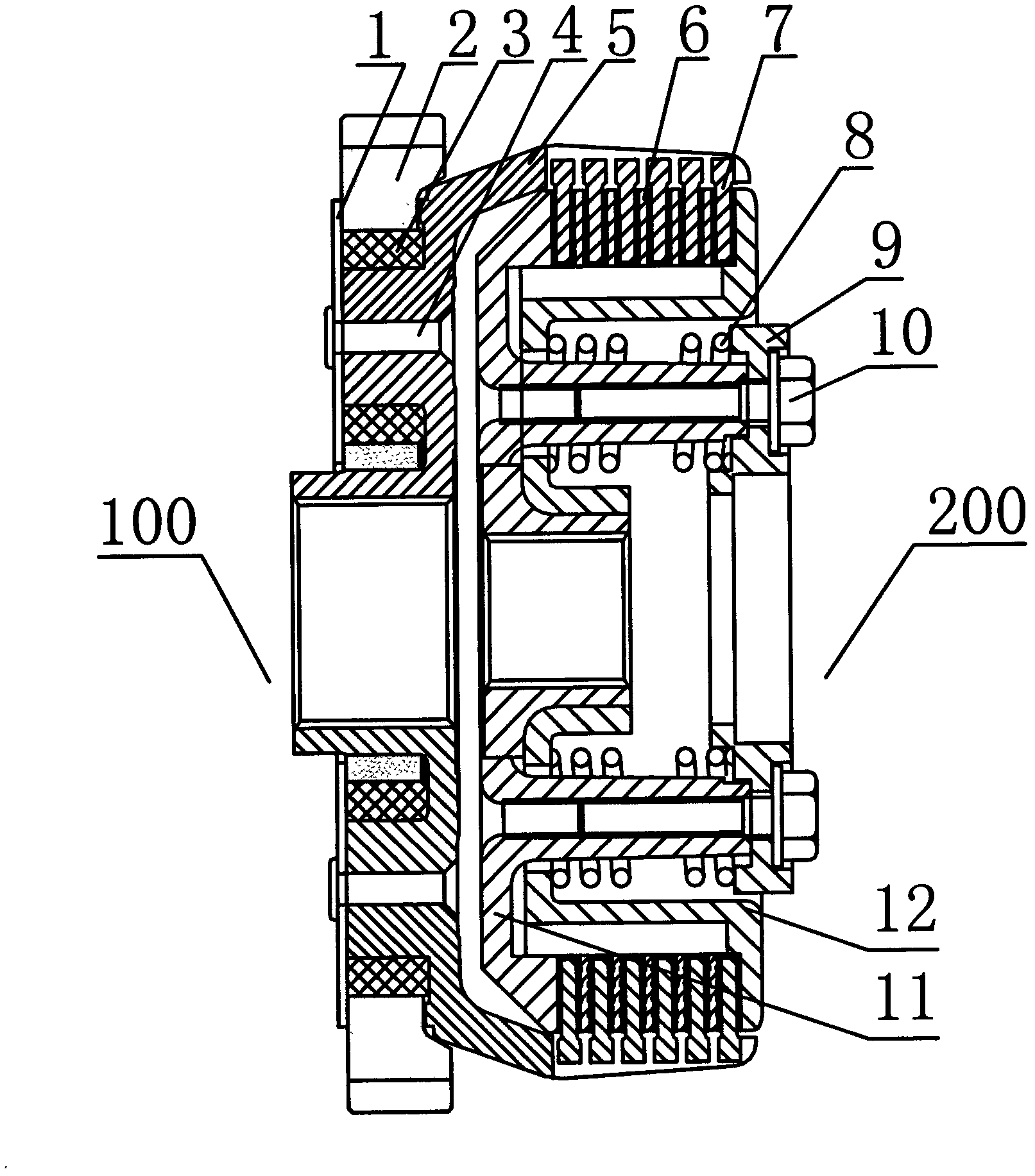

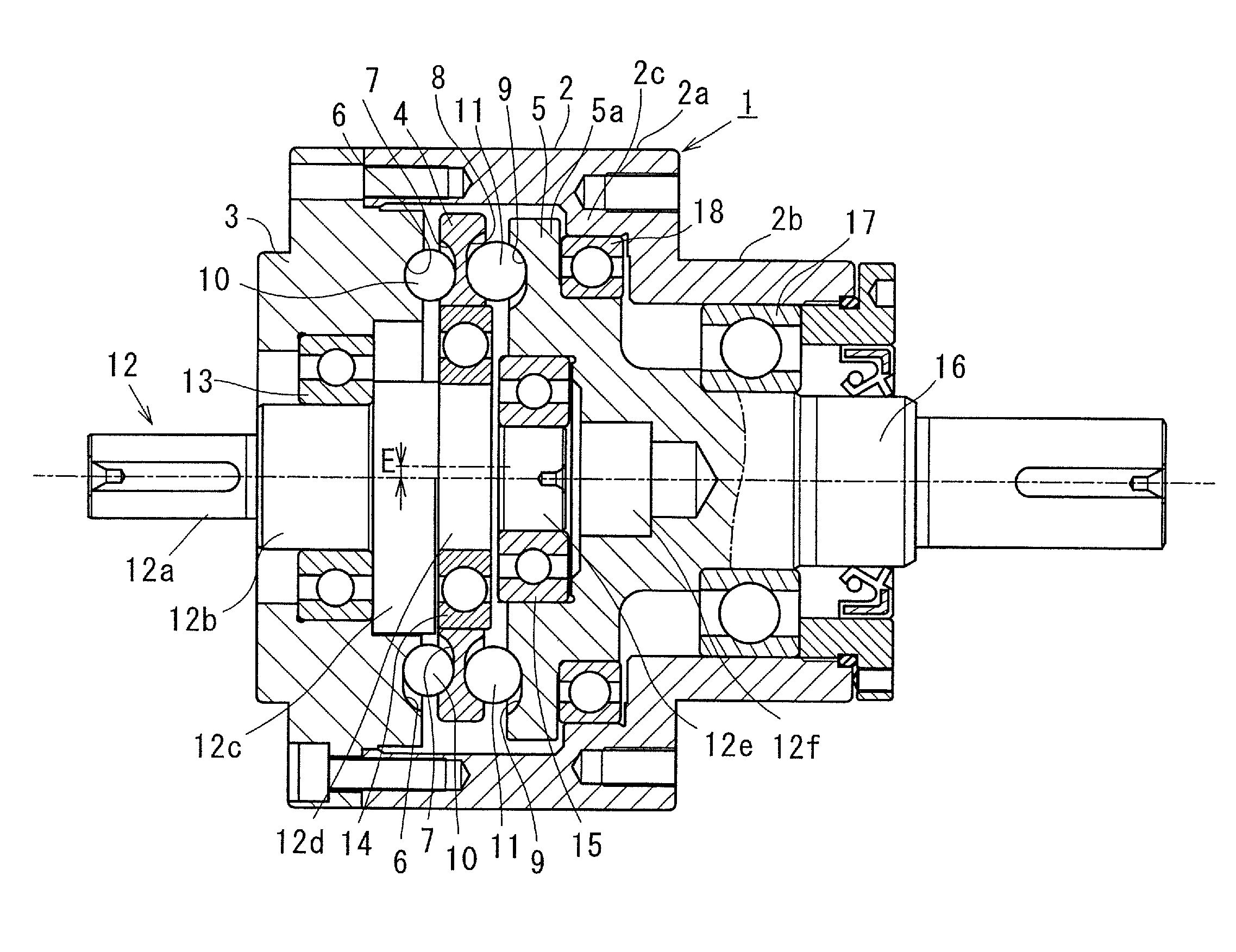

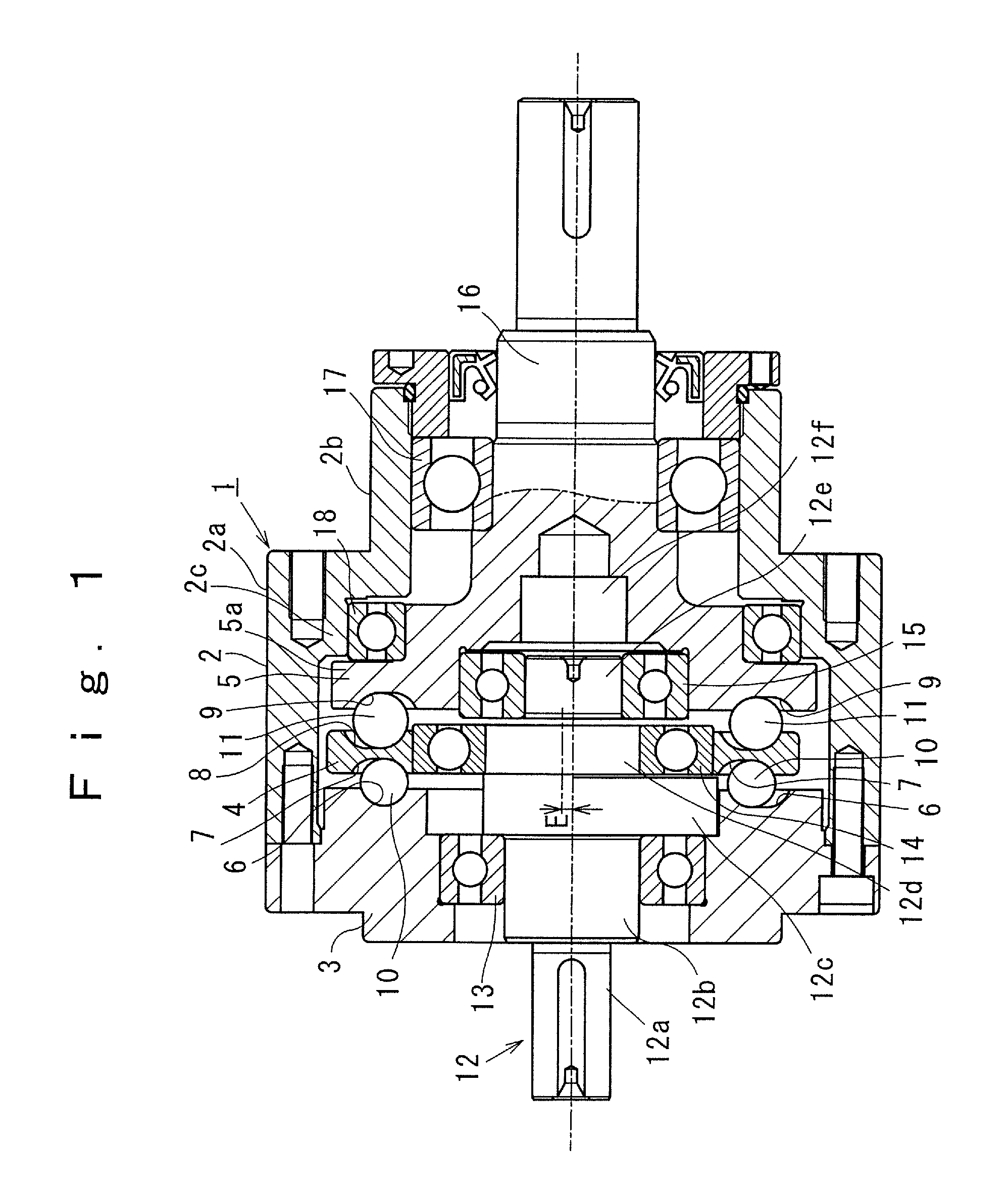

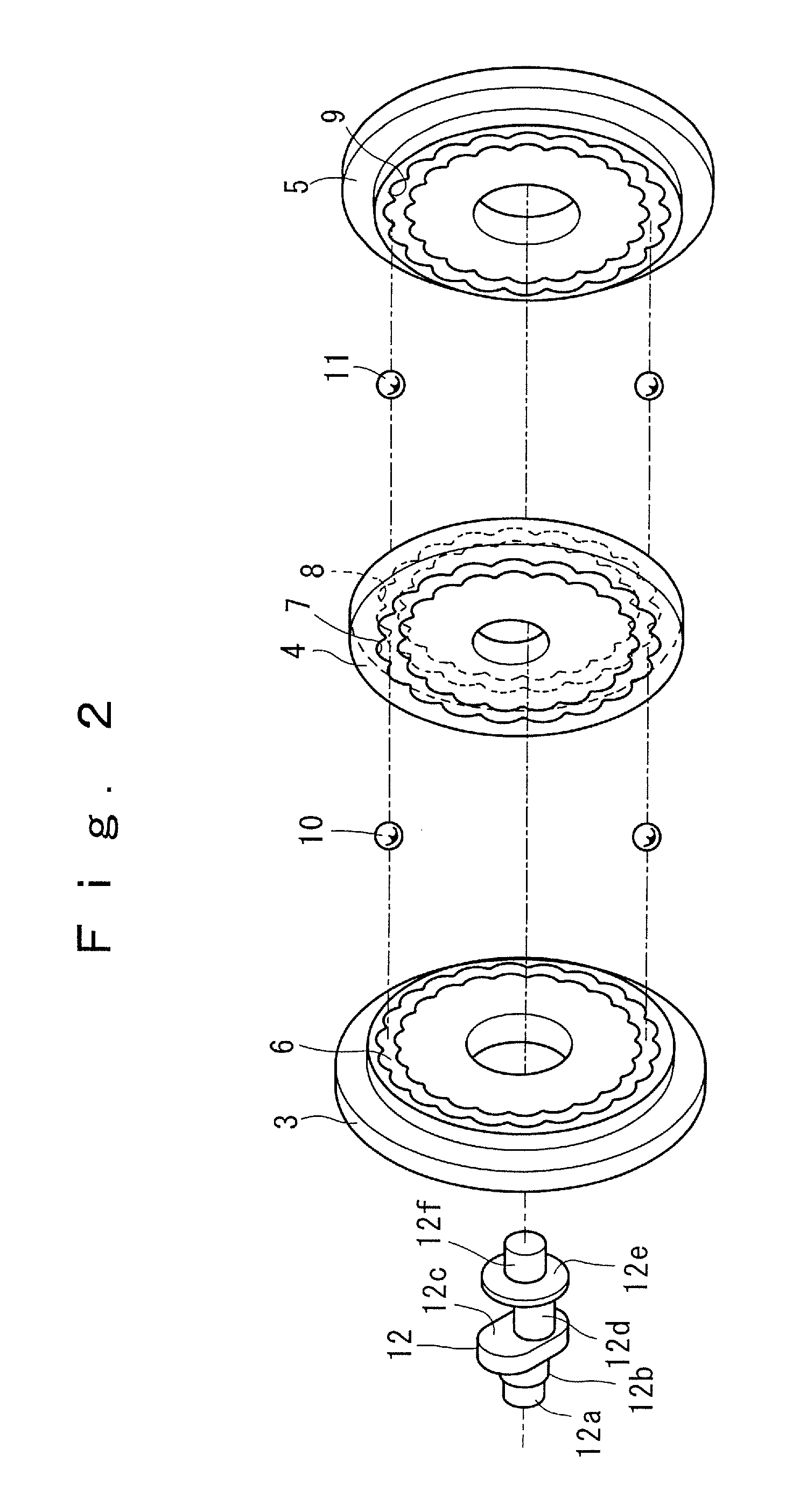

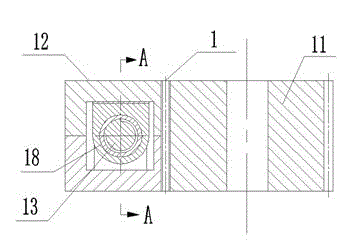

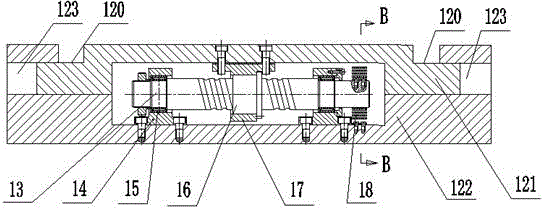

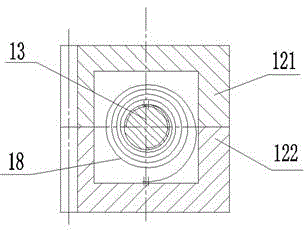

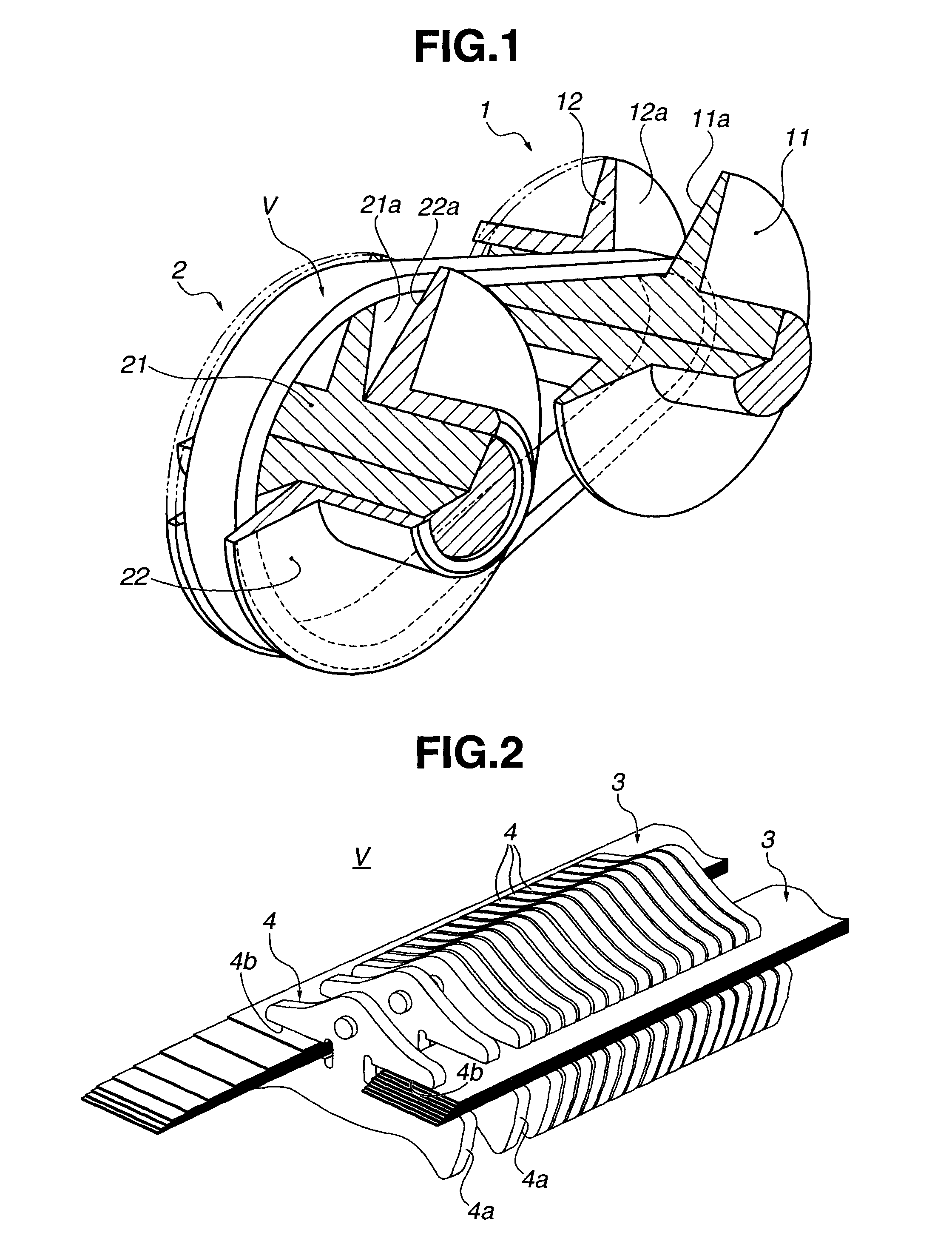

Drive unit with reducer

ActiveUS20070039414A1High torque transmissionMinimized in sizeGearingPropulsion systemsHarmonic driveMinor axis

To provide a harmonic drive gearing with high degree of freedom in terms of layout. A harmonic drive gearing 10 includes a circular spline 1′, having outer teeth formed on an outer peripheral surface; an flexible spline 2, positioned at the outside of the circular spline 1′, and having inner teeth, which are engageable with the outer teeth of the circular spline 1′, formed on an inner peripheral surface; and a rotor 16 which is disposed at outside of the flexible spline 2 and serves as a wave generator, wherein the rotor 16 deflects the flexible spline 2 by minor axis portions of the inner peripheral surface of the flexible spline 2 and engages the inner teeth of the flex spline with the outer teeth of the circular spline 1′ and thereby the engagement position between the inner teeth and the outer teeth is adapted to move in a circumferential direction.

Owner:HONDA MOTOR CO LTD

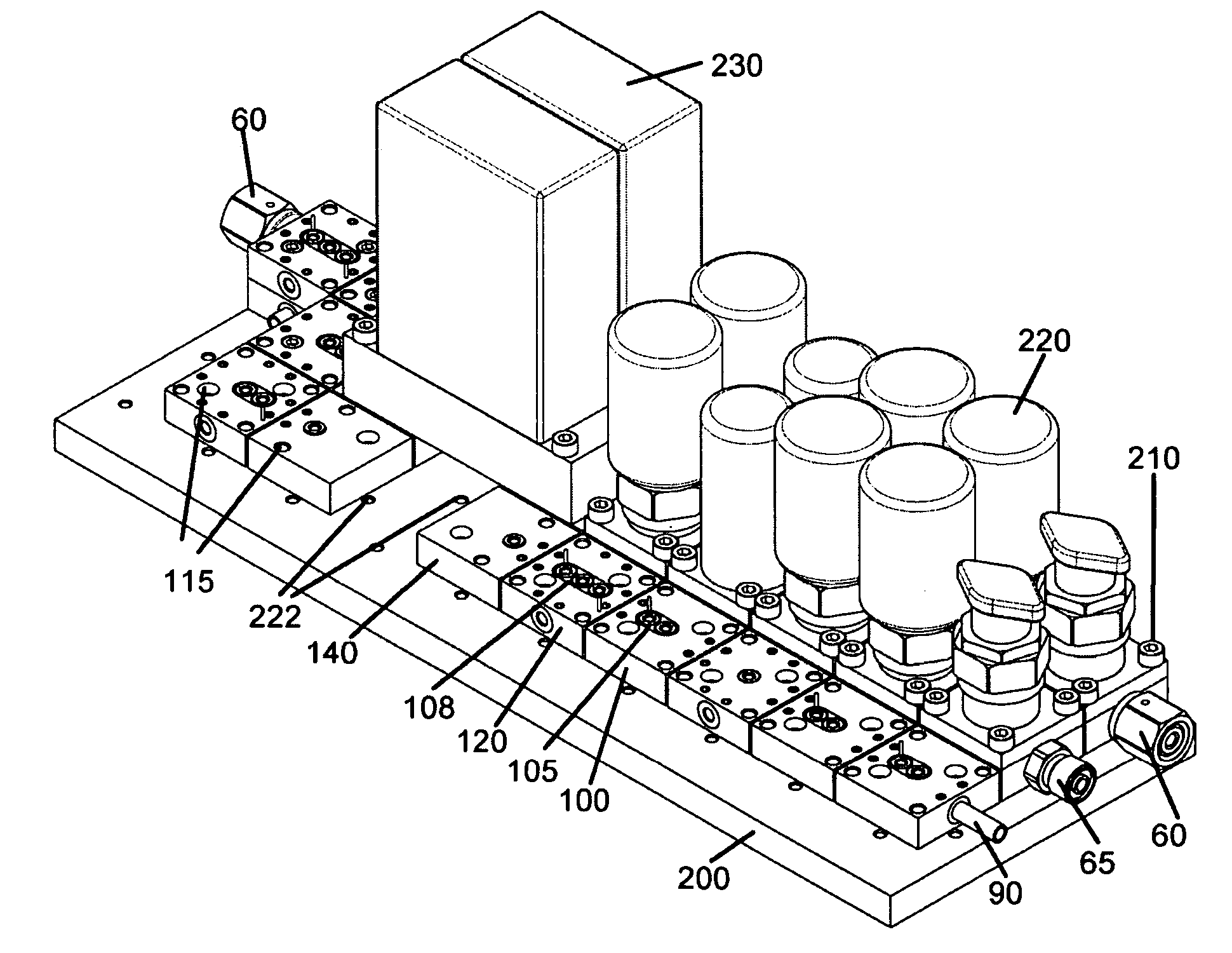

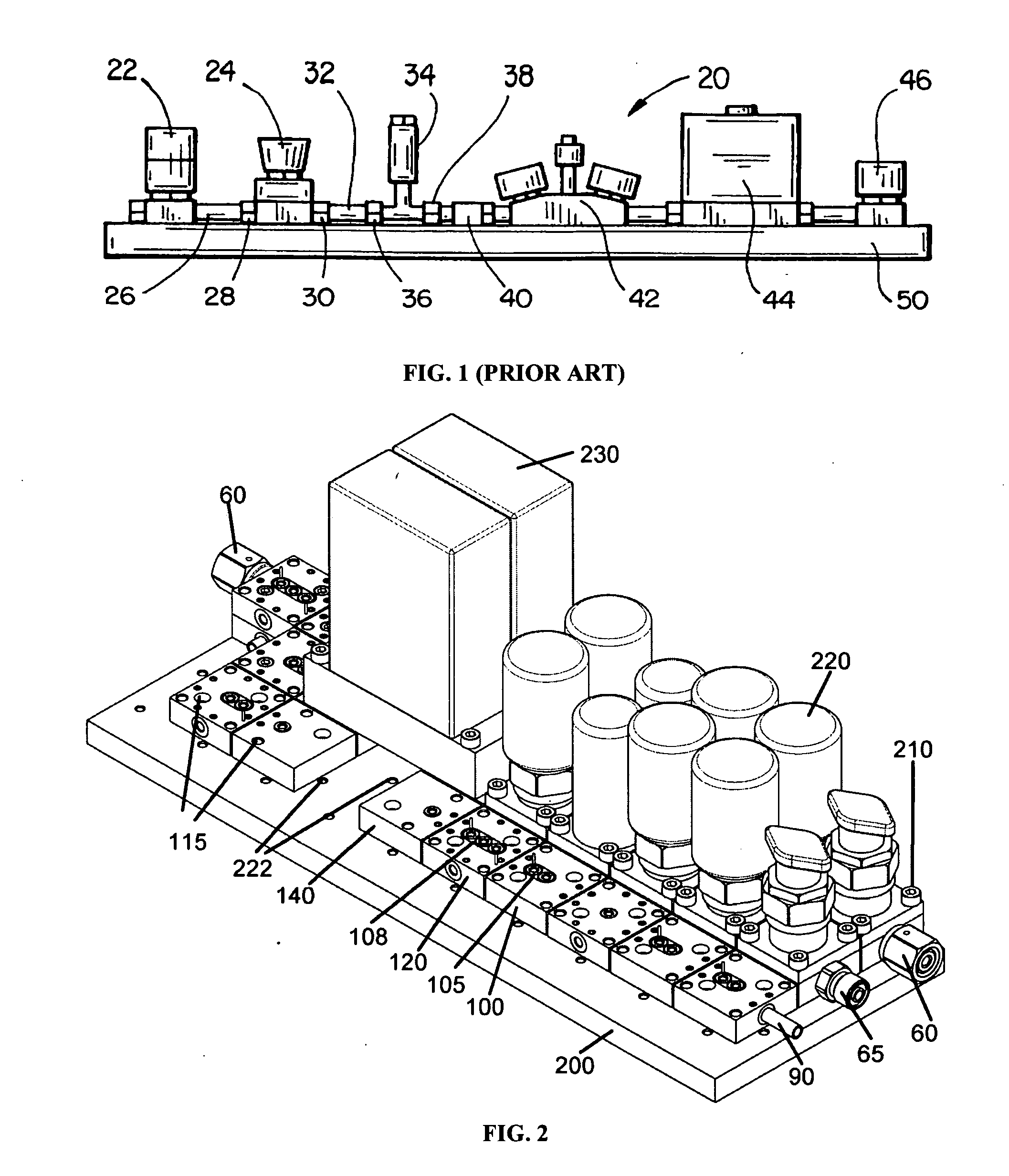

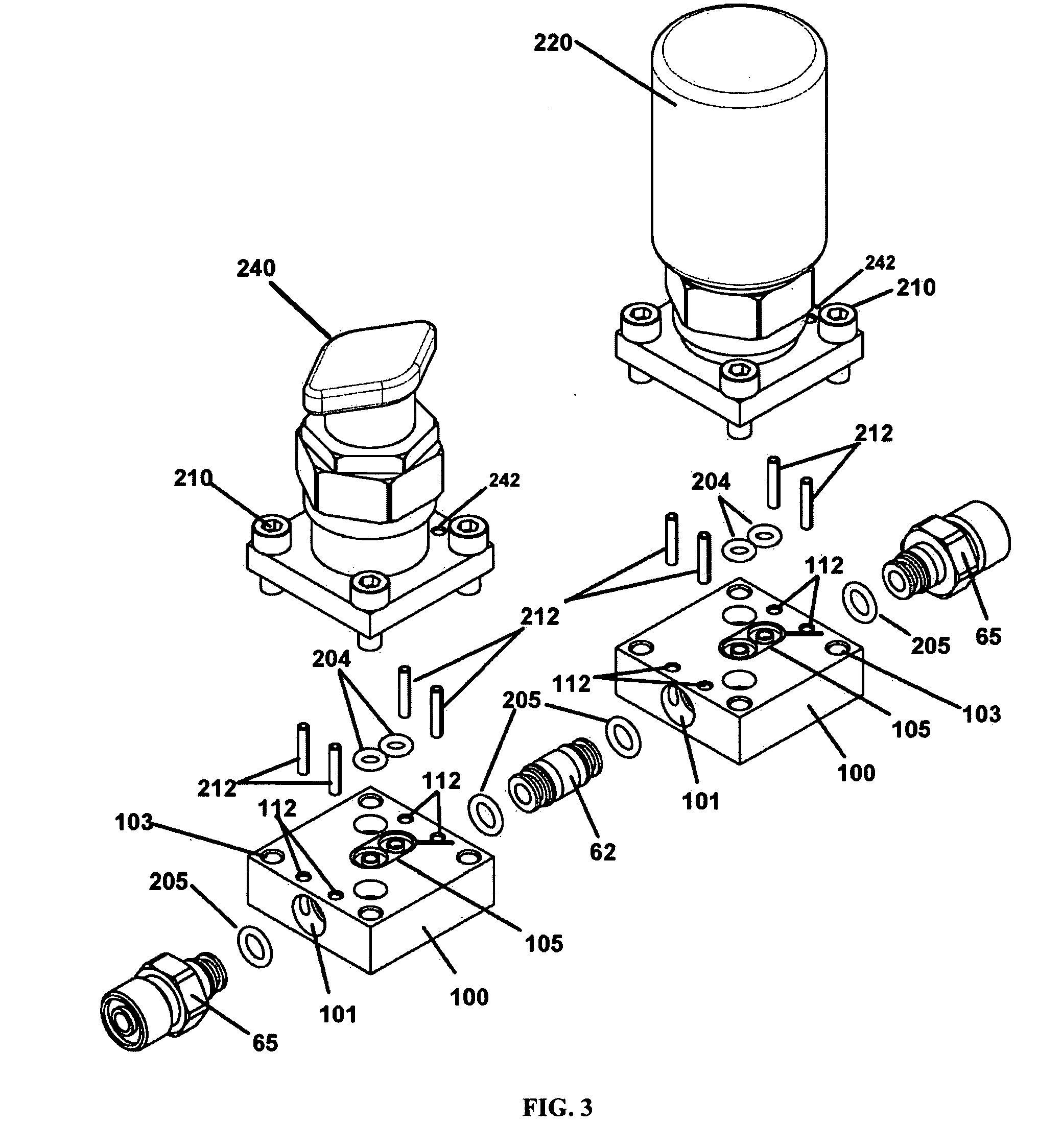

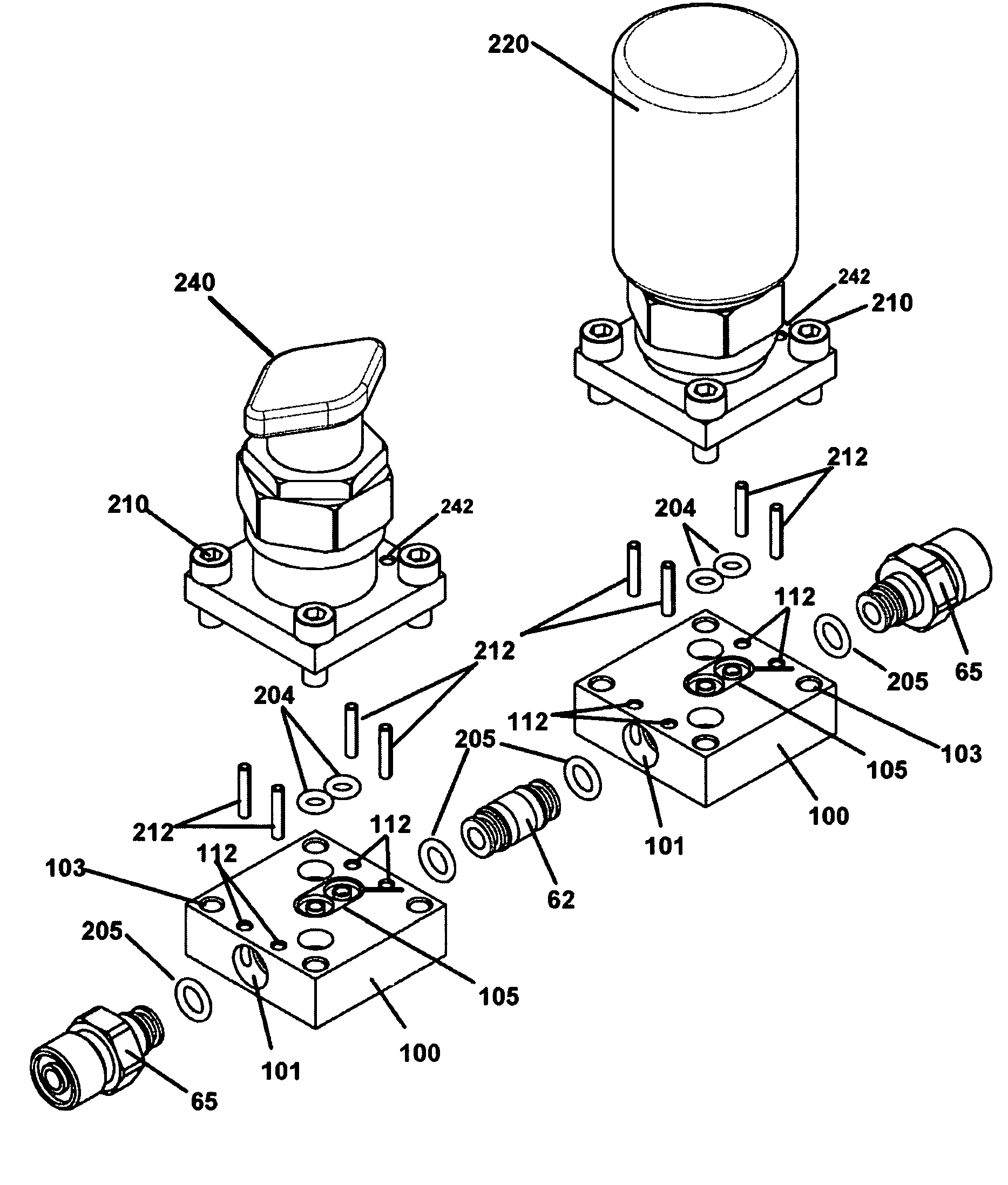

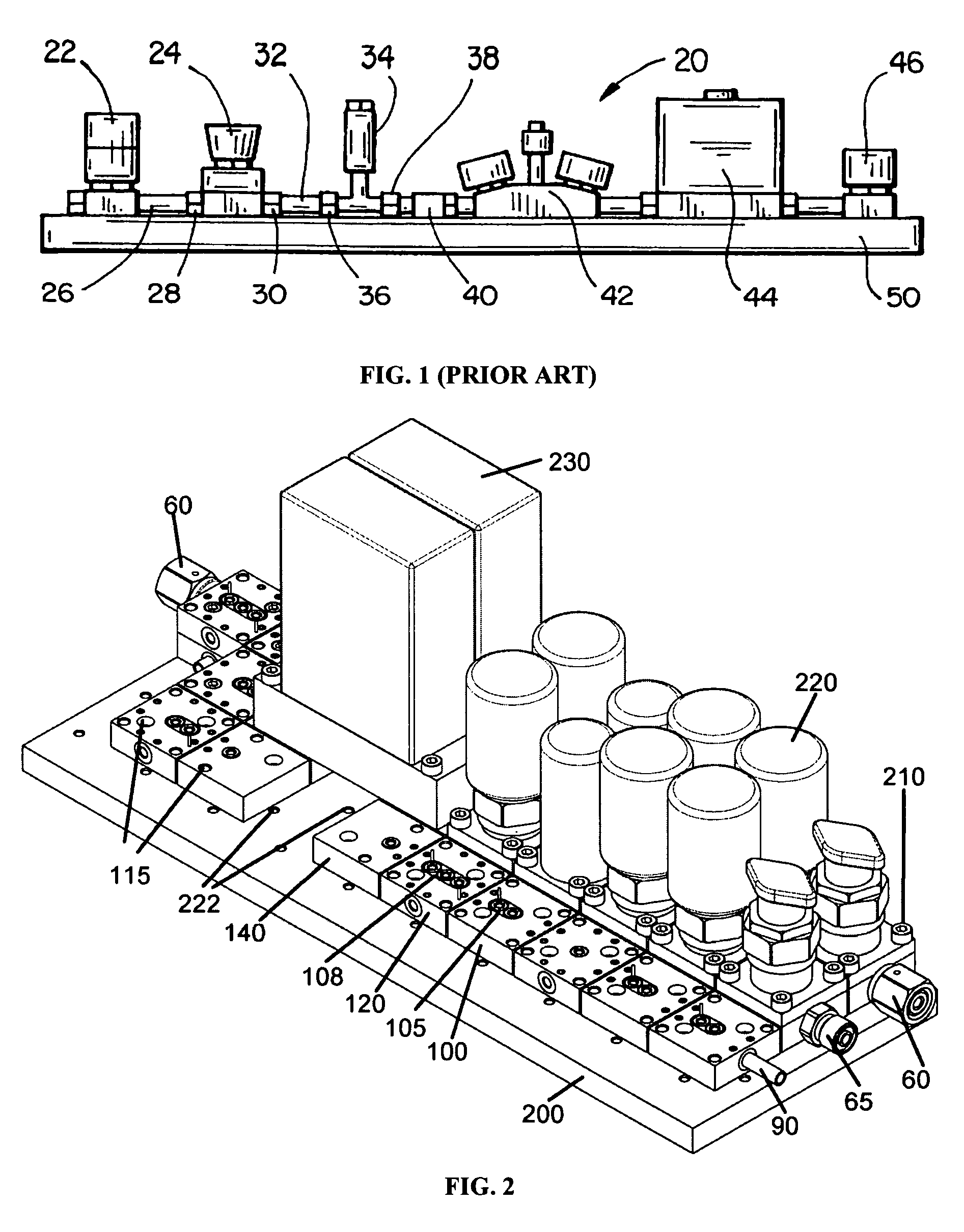

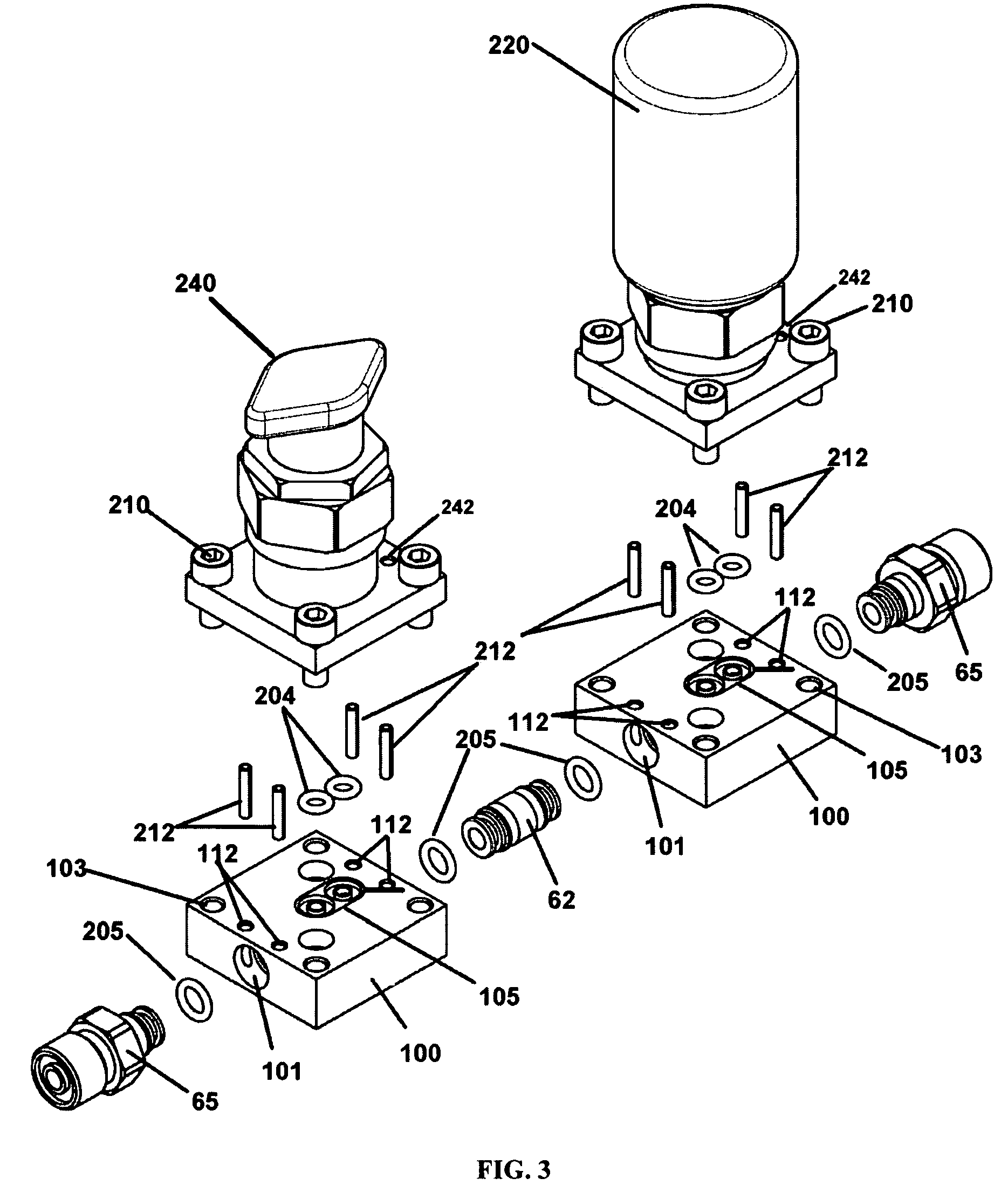

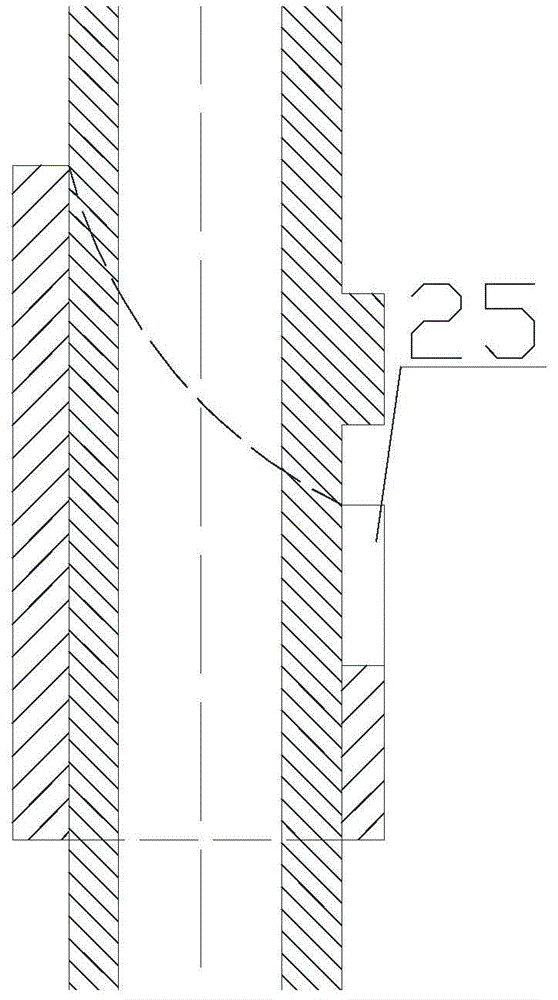

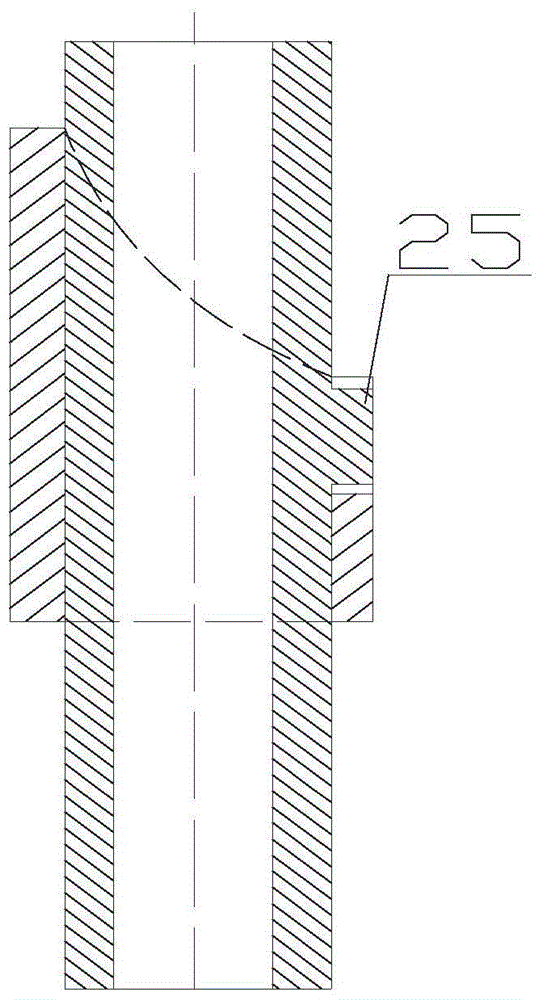

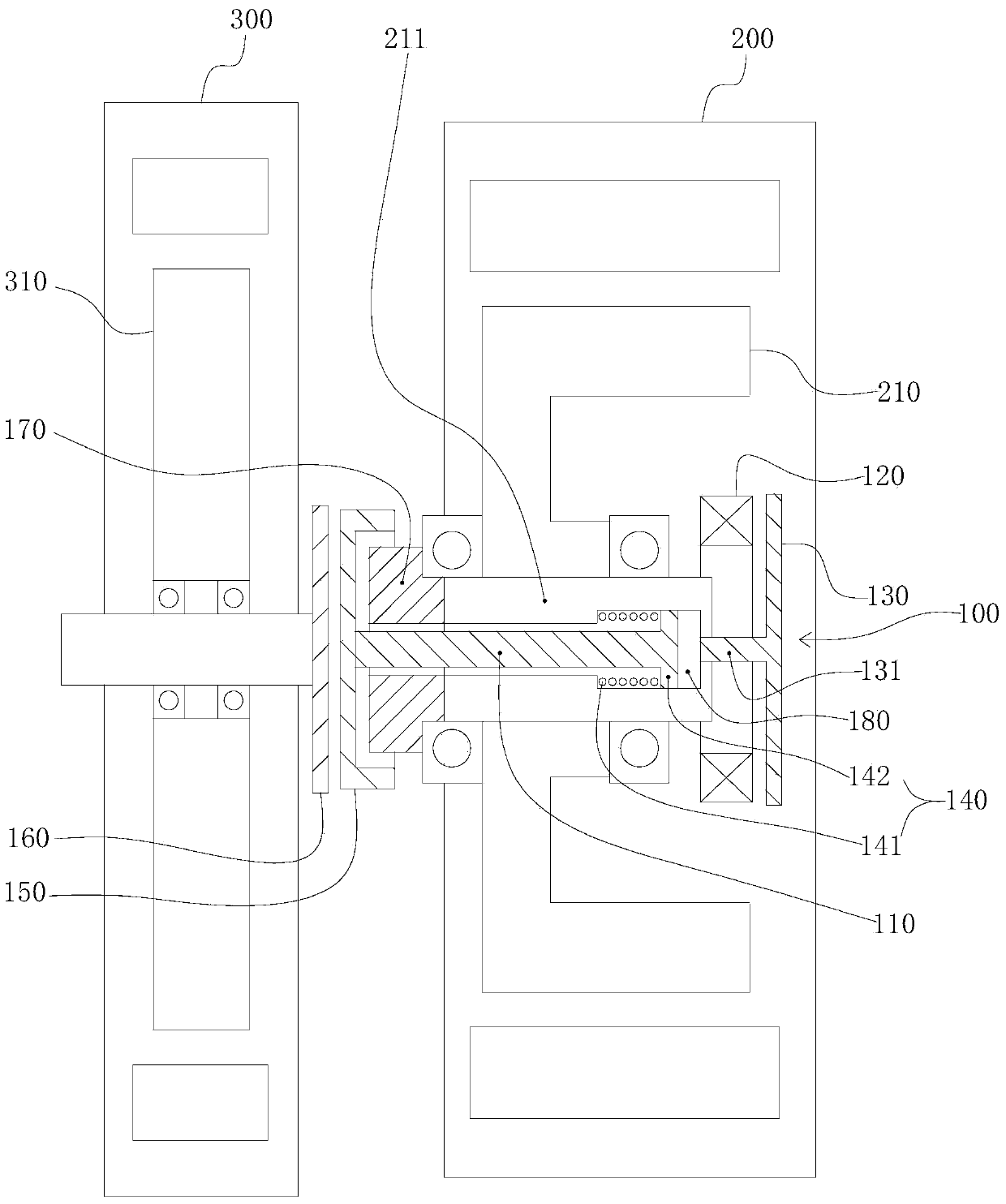

Modular fluid distribution system

InactiveUS20060185746A1Lower labor requirementsLarge flowServomotor componentsCouplingsHermetic sealEngineering

An interconnection assembly for the transport of a fluid between an external fluidic means and a mounting block of a modular fluid distribution system, comprising: a cylindrical cavity formed through a face of the mounting block; a cylindrical flow element, a fluid passage formed therethrough, at least one retaining groove being formed on the outer surface; a retaining means; wherein the cylindrical flow element is inserted into the cylindrical cavity, the annular sealing means being compressed, the annular sealing means forming a hermetic seal between the fluid passage and the fluid port, the retaining means engaging retaining groove, the retaining means being braced against the mounting block; and wherein said fluid is transported between said external fluidic component and said mounting block via said cylindrical flow element.

Owner:DOYLE MICHAEL

Modular fluid distribution system

InactiveUS7370674B2Large flowHigh torque transmissionServomotor componentsMultiple way valvesHermetic sealDistribution system

An interconnection assembly for the transport of a fluid between an external fluidic means and a mounting block of a modular fluid distribution system, comprising: a cylindrical cavity formed through a face of the mounting block; a cylindrical flow element, a fluid passage formed therethrough, at least one retaining groove being formed on the outer surface; a retaining means; wherein the cylindrical flow element is inserted into the cylindrical cavity, the annular sealing means being compressed, the annular sealing means forming a hermetic seal between the fluid passage and the fluid port, the retaining means engaging retaining groove, the retaining means being braced against the mounting block; and wherein said fluid is transported between said external fluidic component and said mounting block via said cylindrical flow element.

Owner:DOYLE MICHAEL

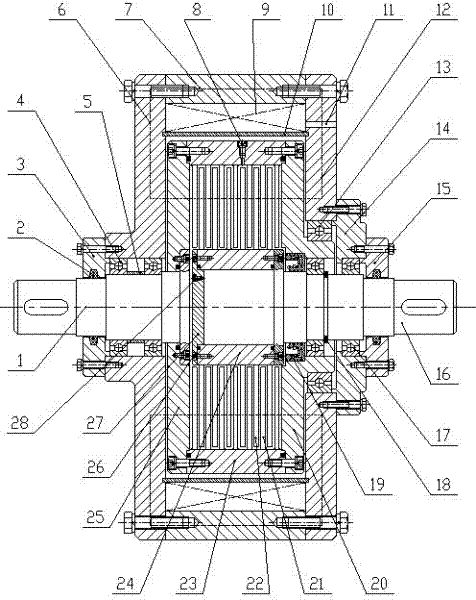

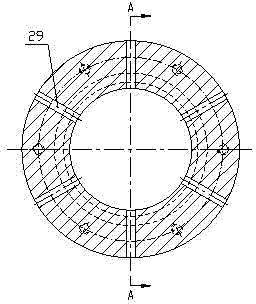

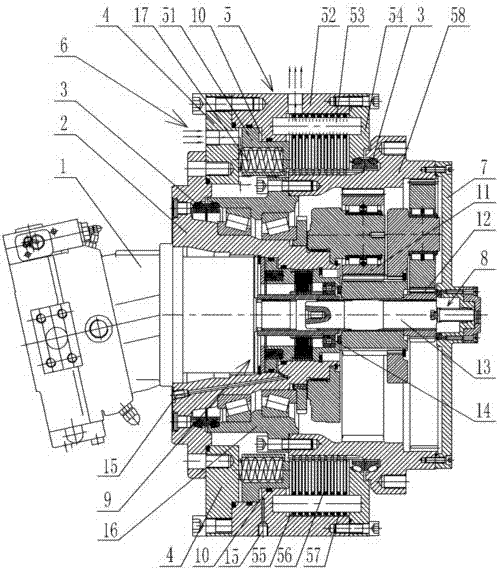

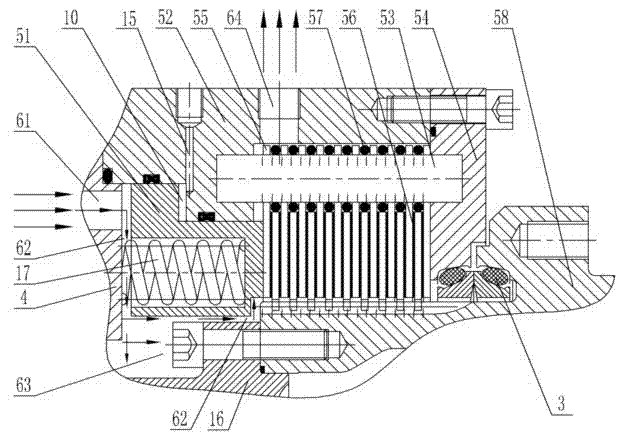

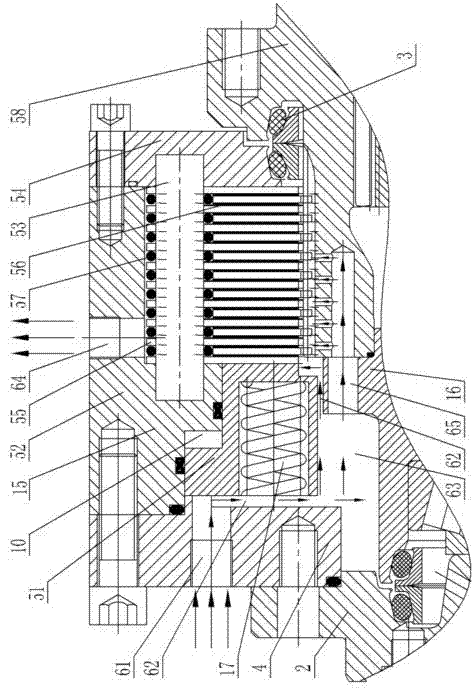

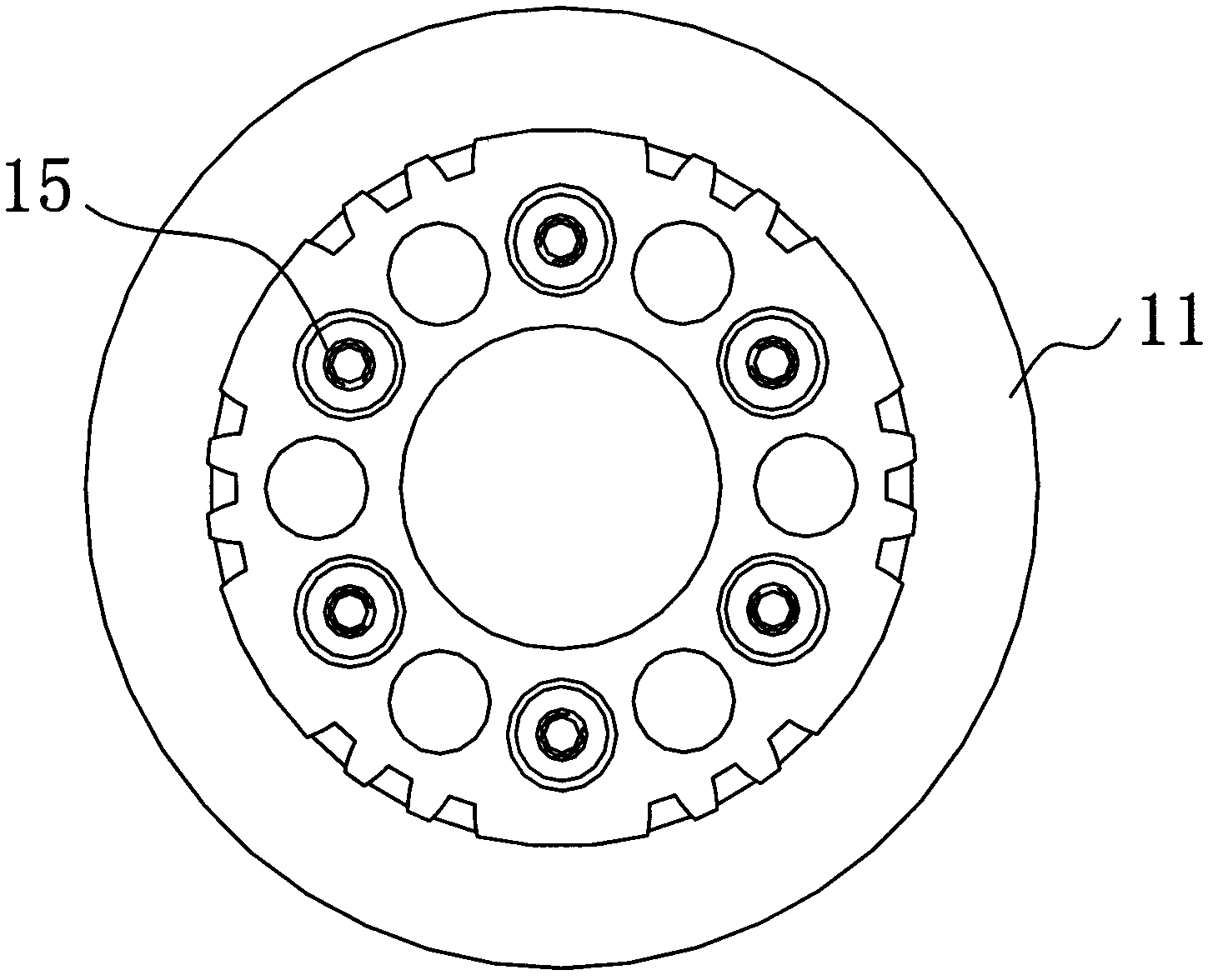

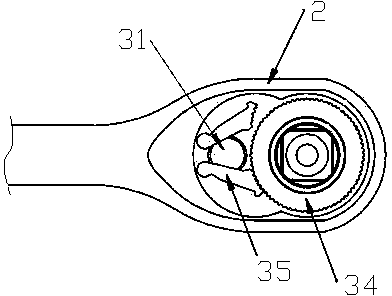

Multi-disc type fine-pitch magnetorheological clutch

A multi-disc type fine-pitch magnetorheological clutch mainly consists of a driving shaft, a driven shaft, a magnetic conduction shell, magnetic conduction baffle plates, a magnet exciting coil, driving discs, driven discs, a magnetic isolated sleeve, a magnetic isolated hub, a support and a sealing device. The driving discs and the driven discs are respectively mounted on the magnetic isolated sleeve and the magnetic isolated hub in a clearance manner, and are respectively connected with the driving shaft and the driven shaft via the magnetic conduction baffle plates, a clearance between each driving disc and the adjacent driven disc is micron-sized, magnetorheogical fluid is fully filled in the clearances, the magnet exciting coil is fixed in a cavity formed by the magnetic conduction shell and a magnetic isolated copper ring, cooling liquid is filled in a cavity of the magnetic isolated hub via a water injection screw plug, sealing of the cooling liquid is realized by a sealing ring, during working, the cooling liquid flows into the driven discs via radial round holes on the magnetic isolated hub, heat dissipation of working devices is accelerated, the temperature of the magnetorheogical fluid is reduced, and slip frequency power of the device is increased. The multi-disc type fine-pitch magnetorheological clutch is compact in structure, high in transmission torque, fine in heat dissipation performance and long in service life, and does not generate electric sparks.

Owner:CHINA UNIV OF MINING & TECH

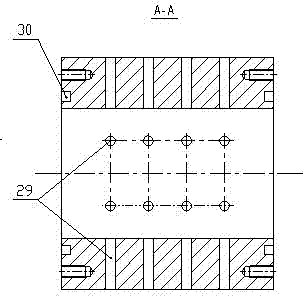

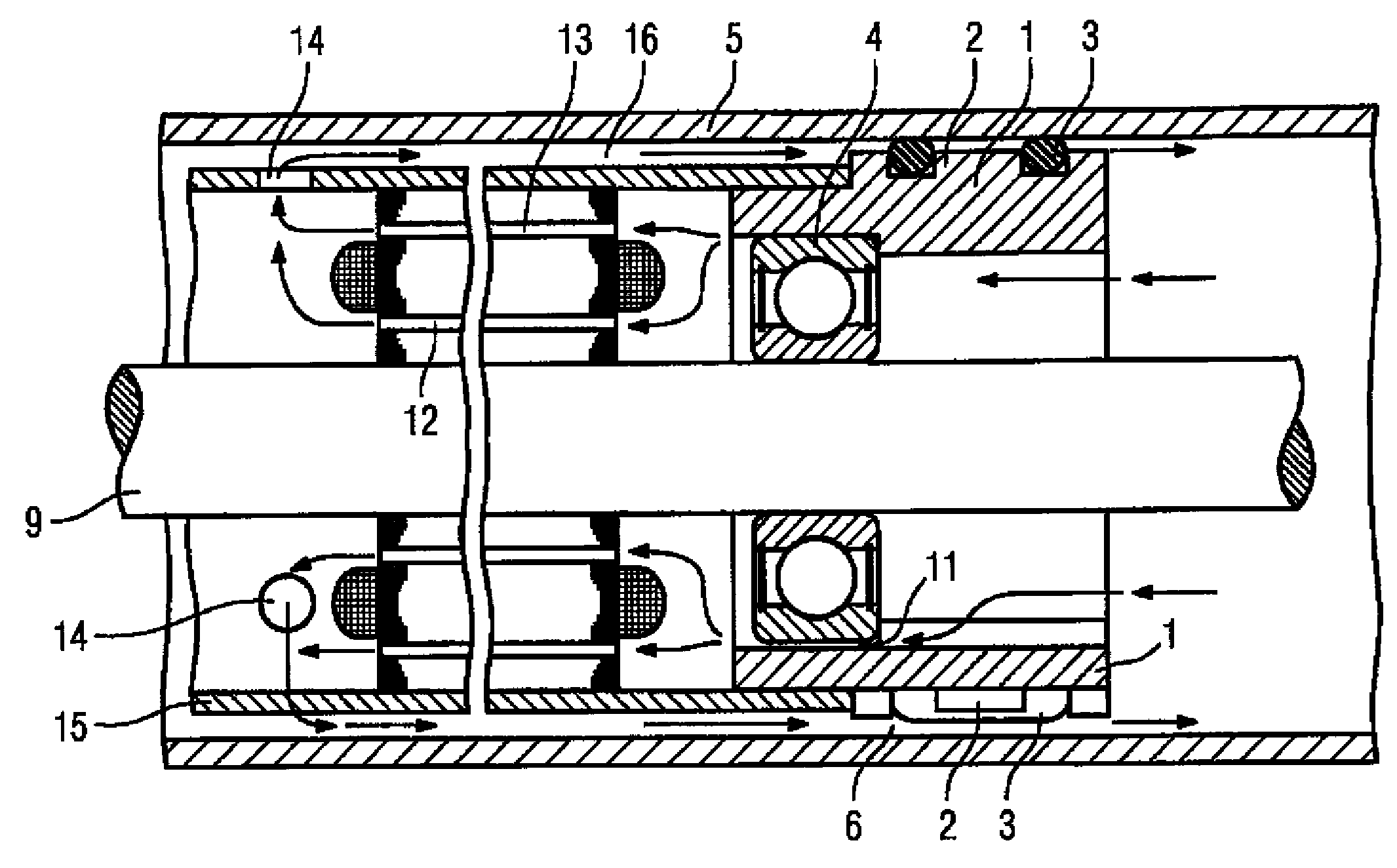

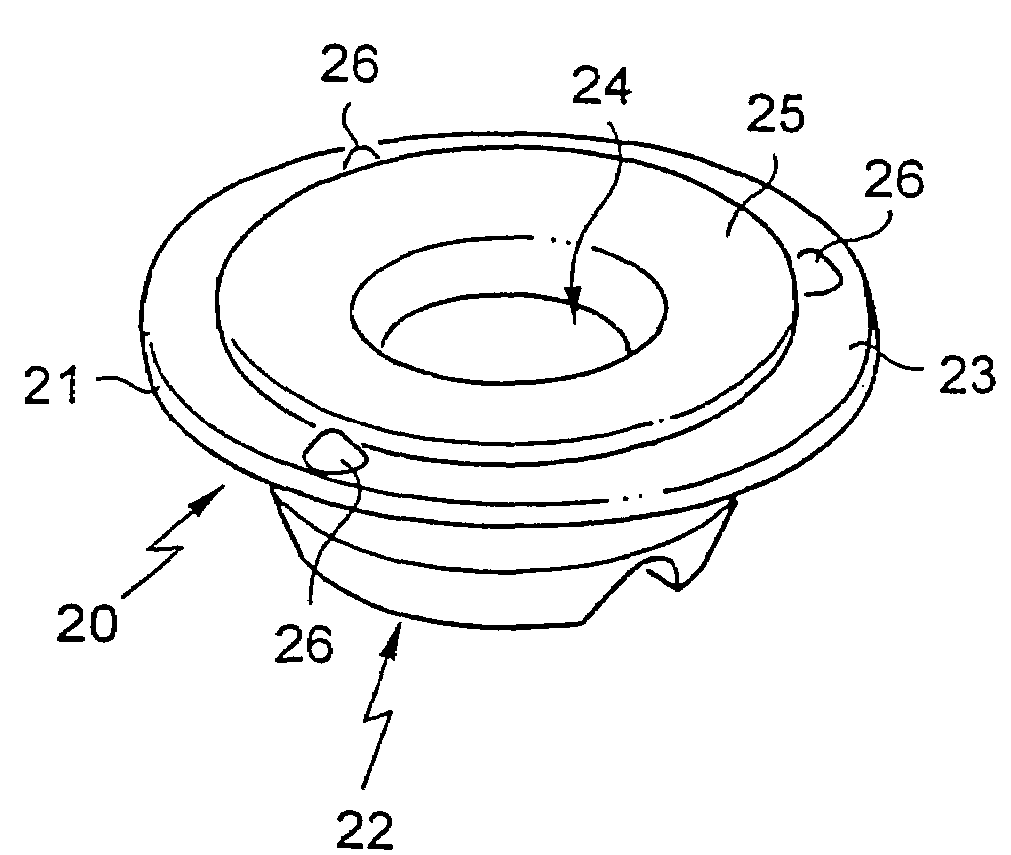

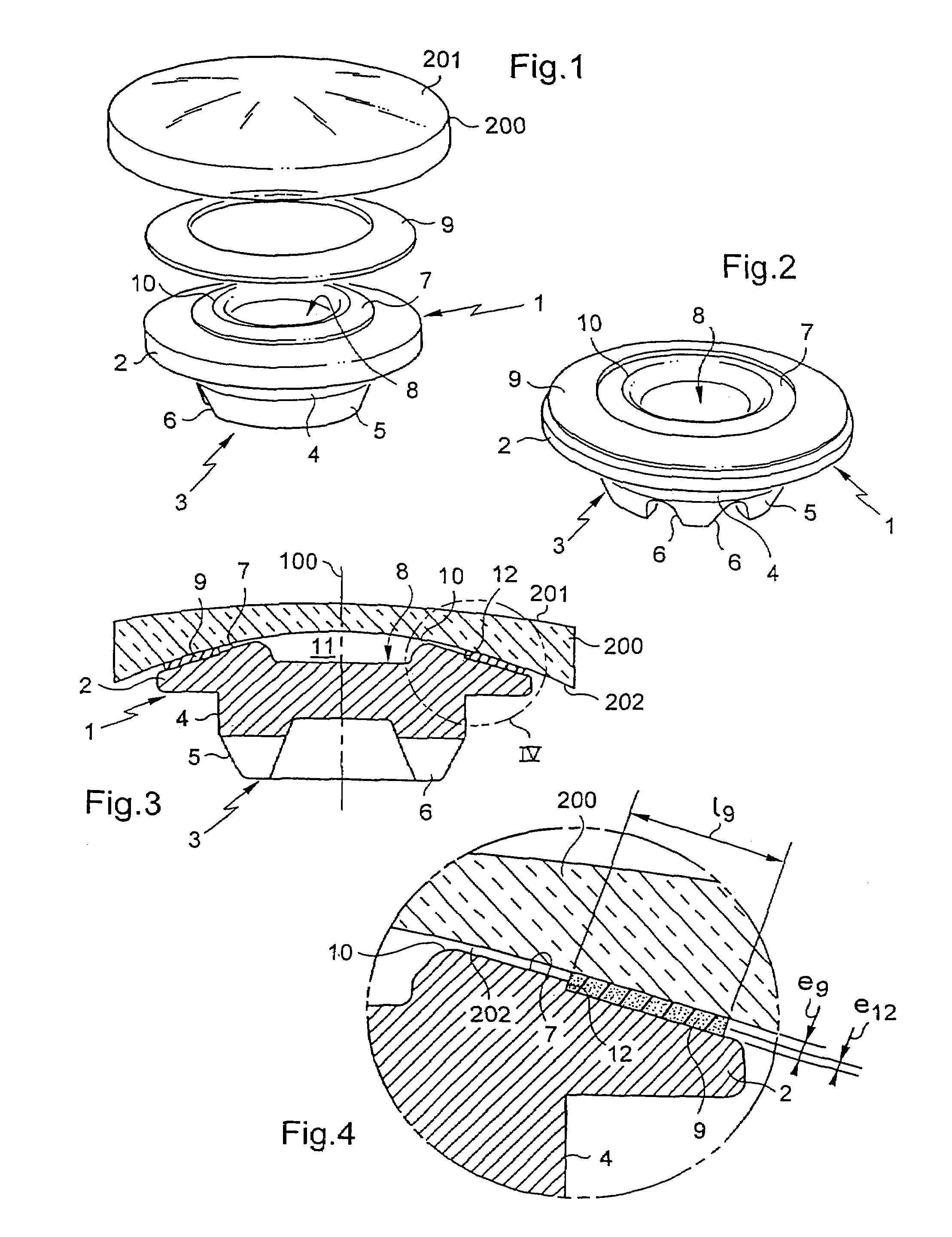

Rotary support with elastic connection device for installation of electric machines in tubes

InactiveUS20070096588A1Reduce manufacturing costEasy to installConveyorsMagnetic circuit rotating partsElectric machineCoolant flow

Torque transmission between a tube and a drive unit mounted in the tube is ensured with the aid of a component which is optimized for installation while providing a sufficient centering effect. A rotary support is hereby provided which is constructed as a hollow cylindrical body (1). An elastic connection device (3), e.g. an O ring which is disposed on the outer circumference of the hollow cylindrical member (1) in a defined arrangement, is used for elastically connecting the hollow cylindrical member (1) to the tube. The elastic connection device (3) has a centering and damping effect while ensuring the torque transmission, and channels (6) ensure a coolant flow passage / cooling circuit.

Owner:SIEMENS AG

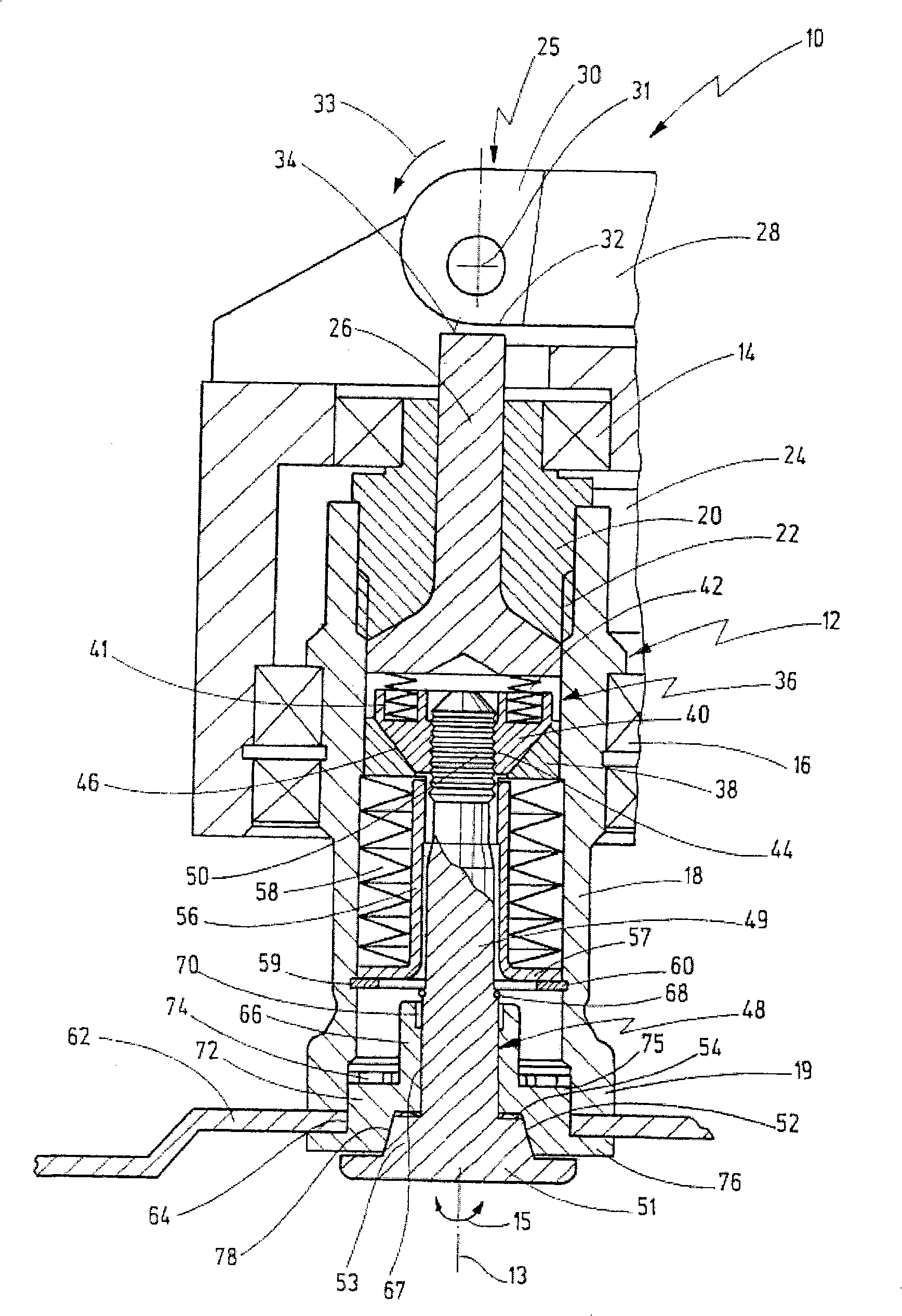

Power-driven hand tool

InactiveCN101347936ASafe deliveryIncrease clamping forceGrinding wheel securing apparatusPortable grinding machinesHand toolHand held devices

A power-driven hand tool comprises a drive spindle adapted to drive a tool, that can be driven to oscillate about its longitudinal axis, which tool can be fixed on a retaining section of the dive spindle by a securing element, and further comprises a displacing device that serves to displace the securing element between a releasing position in which the securing element can be released from the drive spindle and a clamping position in which the securing element is clamped on the retaining section by a spring element, the securing element comprising a clamping shaft adapted to be inserted into the securing element, which is axially fixed in the drive spindle for clamping the tool in the clamping position, and which can be detached in the releasing position. For clamping of the tool a split chuck is provided which is clamped on the retaining section by the securing element in the clamped position and is connected with the retaining section in form-locking engagement.

Owner:C & E PANYIN CO LTD

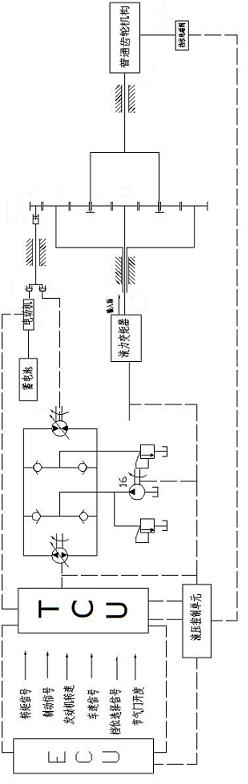

Novel double-braking rim driving device

ActiveCN103032560AAvoid damageImprove work efficiencyAxially engaging brakesBrake actuating mechanismsHydraulic motorRubber ring

The invention discloses a novel double-braking rim driving device, and relates to a double-braking device for tire parking braking and driving braking. The novel double-braking rim driving device comprises a supporting base, a hydraulic motor, a planetary gear speed reducer, a parking brake, a driving brake and the like, wherein a plurality of groups of movable friction sheets of the driving brake are respectively embedded into splines arranged outside an inner gear shell of the planetary gear speed reducer; a plurality of groups of steel sheets are simultaneously connected onto a connecting rod in series; and a rubber ring is arranged between each steel sheet and each movable friction sheet, which are adjacent. The braking on the inner gear shell is directly carried out so that the braking is more reliable and safer; elastic auxiliary steel sheets of the rubber rings and the movable friction sheets are completely separated, so that movement failure is prevented from happening; the driving brake is additionally provided with a cooling circulating system, so that heat generated by the driving braking can be eliminated, parts are prevented from being damaged at a high temperature, and the service life is prolonged; and the improved rim driving device also has the advantages of compact structure, high working efficiency, large transmission torque and the like.

Owner:INI HYDRAULIC

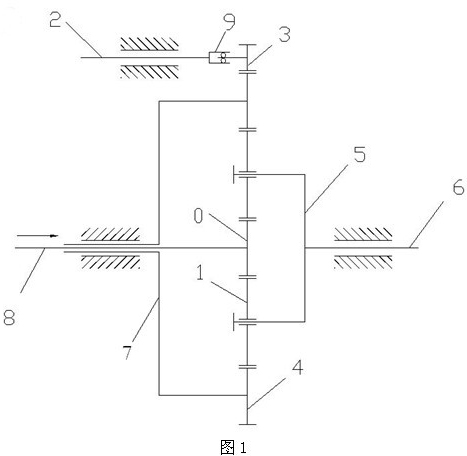

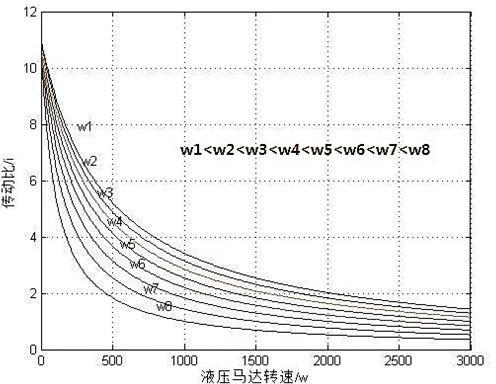

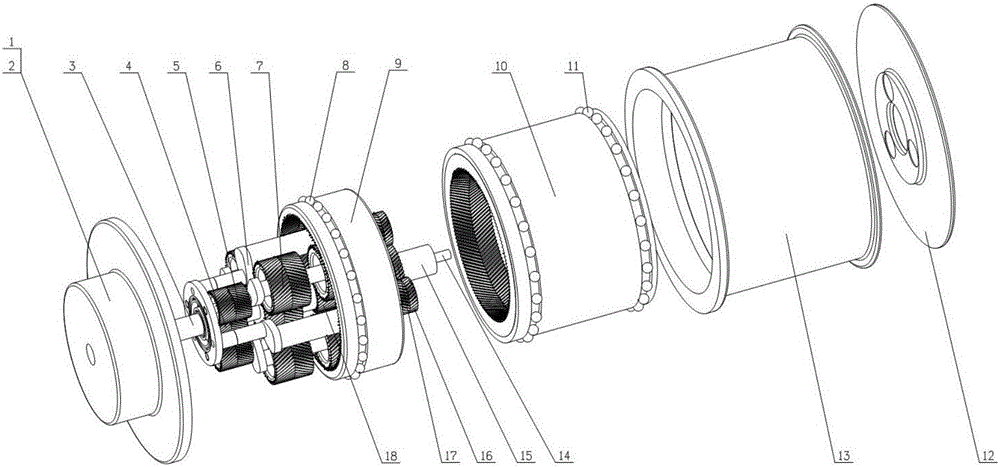

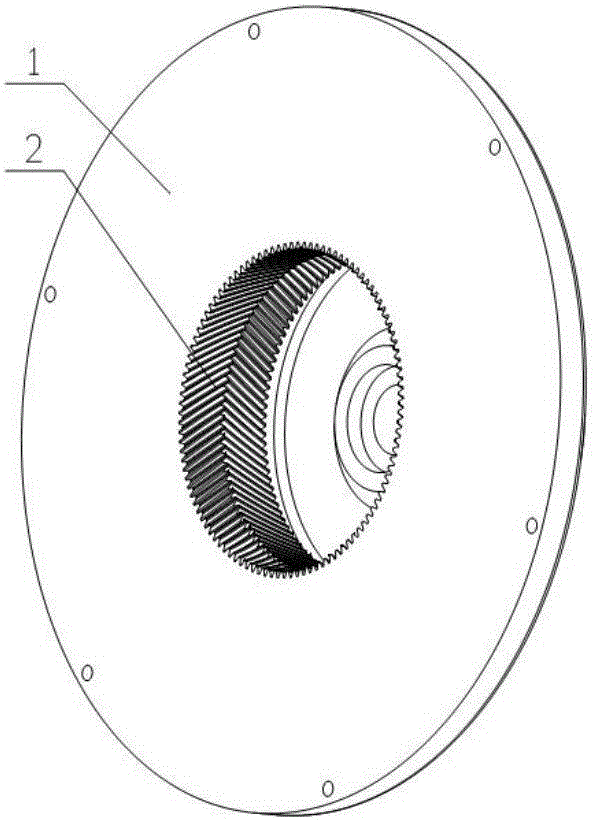

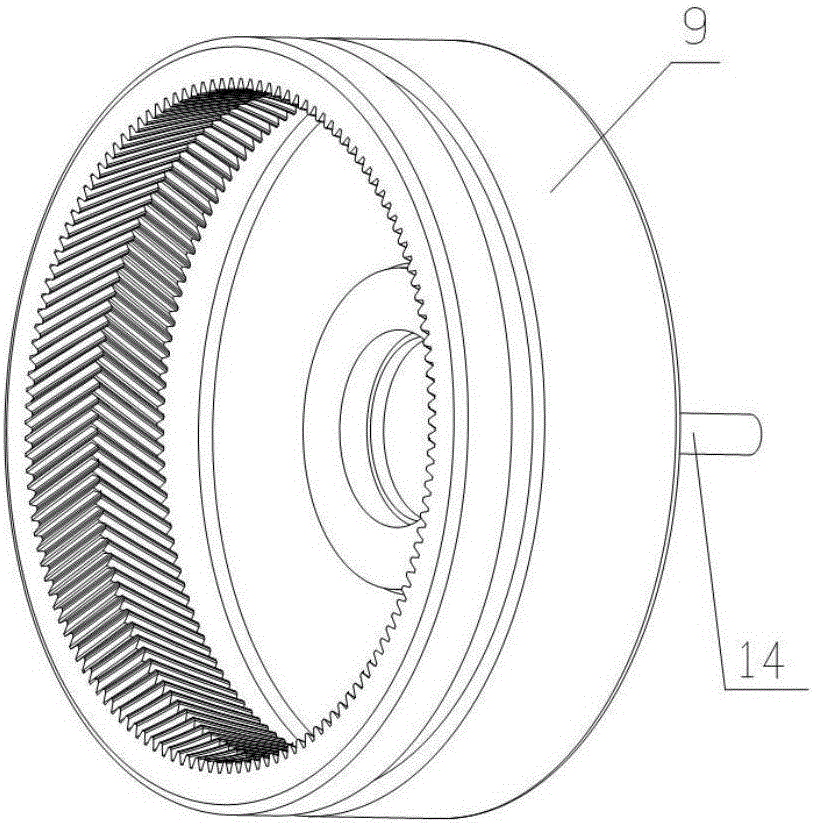

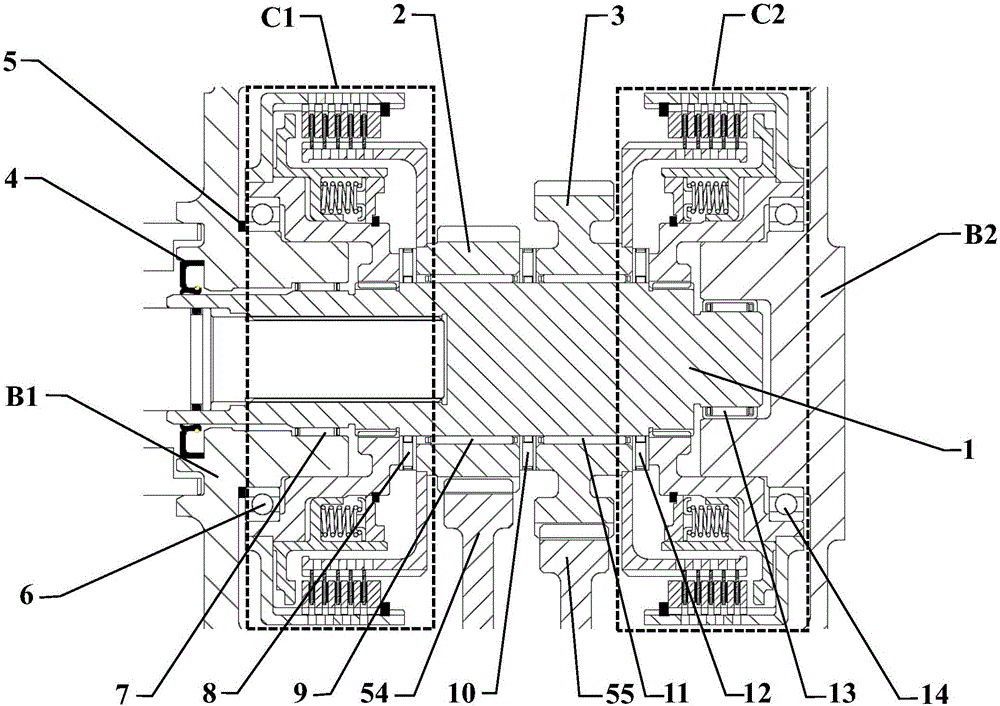

A planetary gear stepless transmission

InactiveCN102287498AChange gear ratioHigh torque transmissionToothed gearingsGear wheelControl theory

The invention discloses a novel gear continuously variable transmission, aiming to provide a continuously variable transmission with large transmission torque, high transmission efficiency, good reliability and good fuel economy. The present invention includes a first input shaft, a second input shaft, a one-way clutch, a gear, a planetary ring gear, a planetary gear, a first planetary carrier, a sun gear, a second planetary carrier and an output shaft, and the planetary gear continuously variable transmission passes through The power input of two degrees of freedom of the first input shaft and the second input shaft realizes the function of stepless speed change. The invention has the advantages of simple structure and convenient manufacture, and can effectively realize the stepless speed change function.

Owner:NANJING INST OF TECH

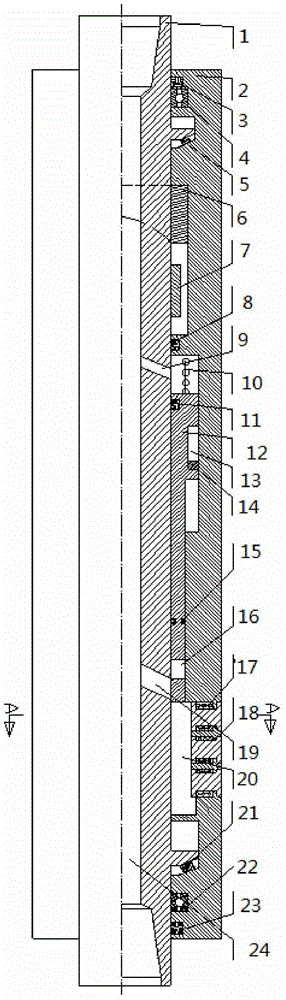

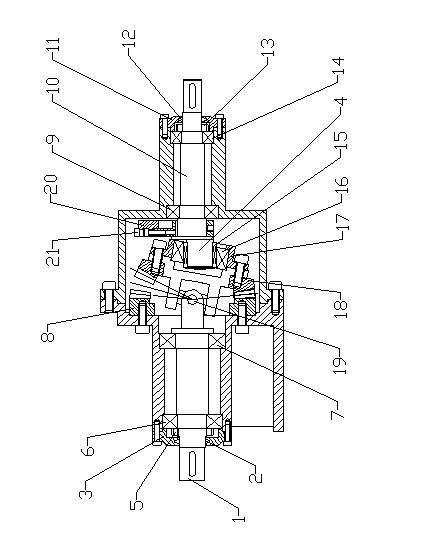

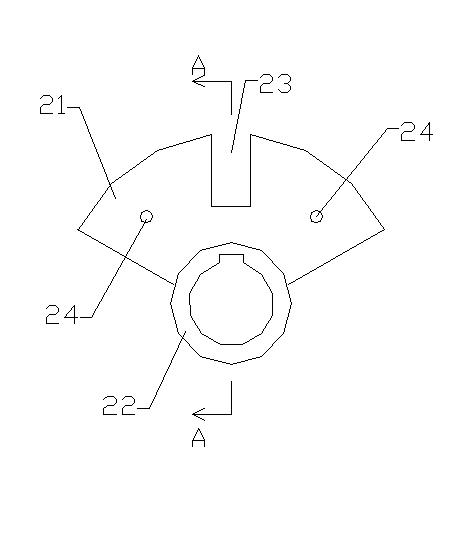

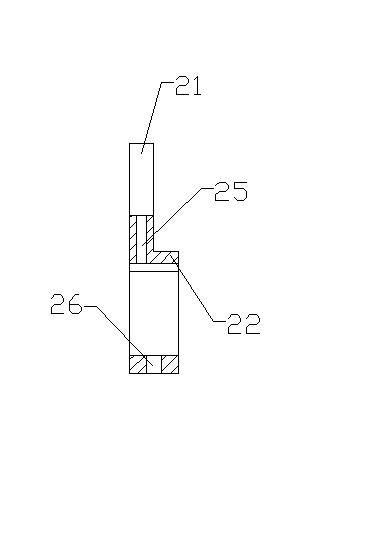

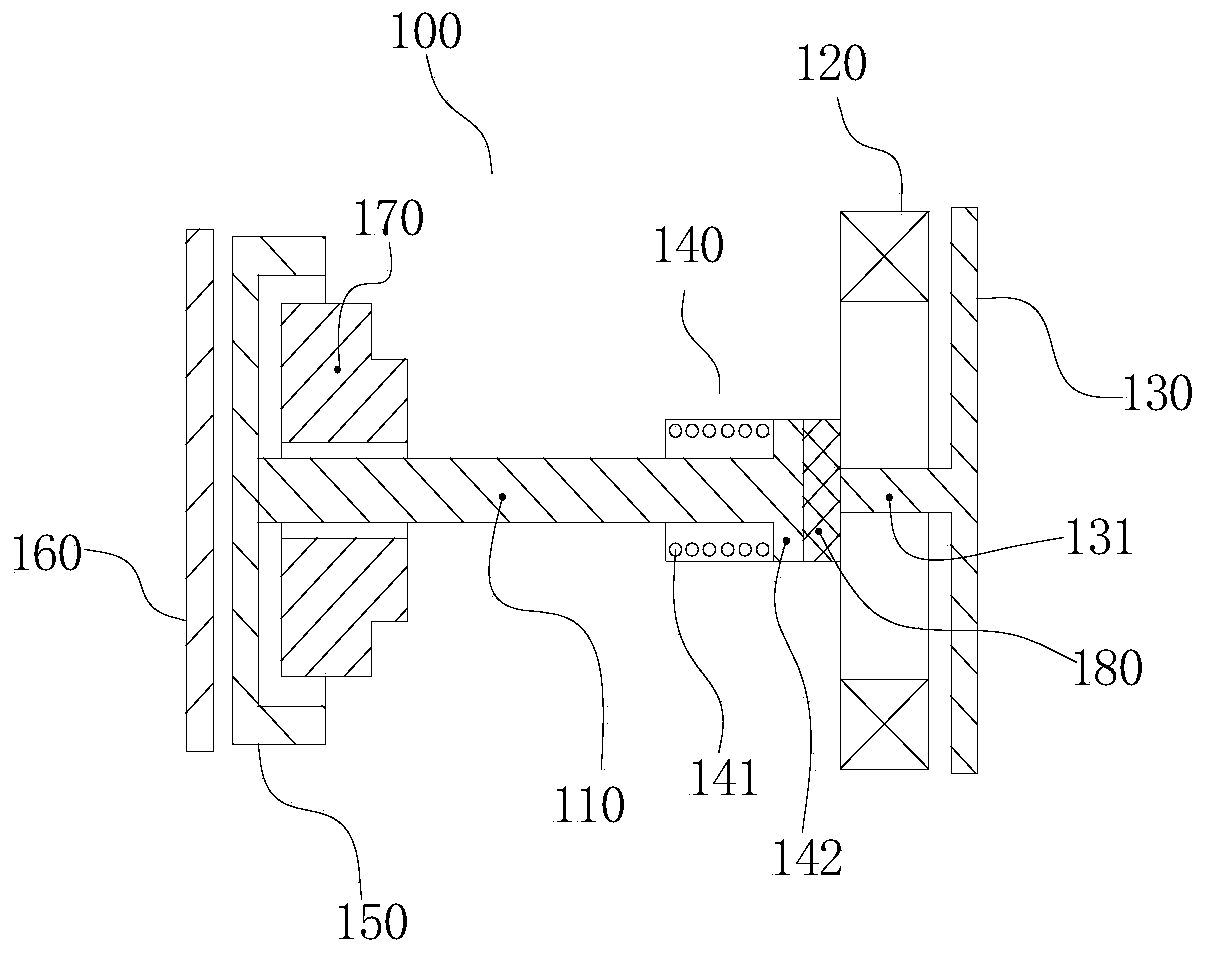

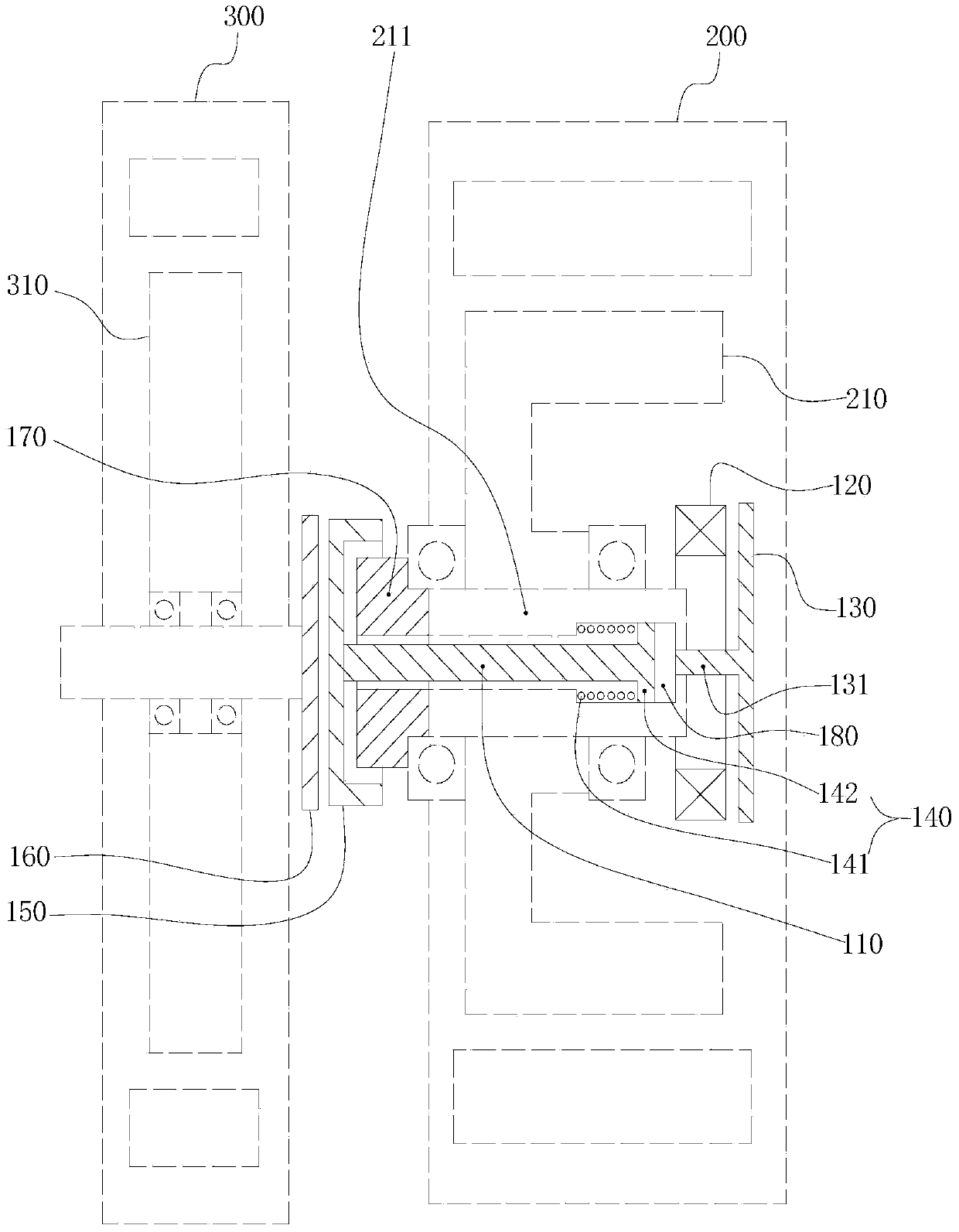

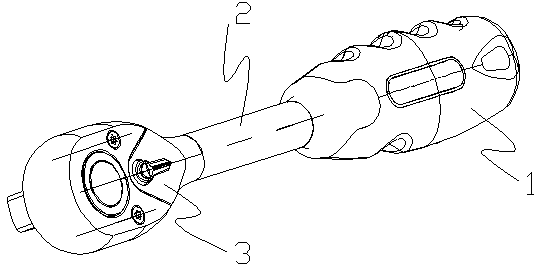

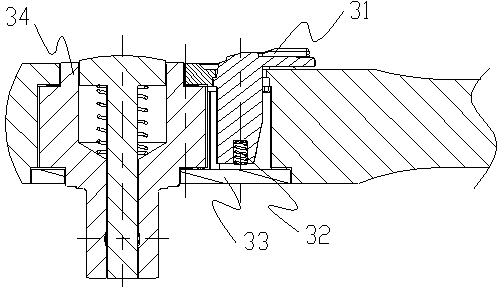

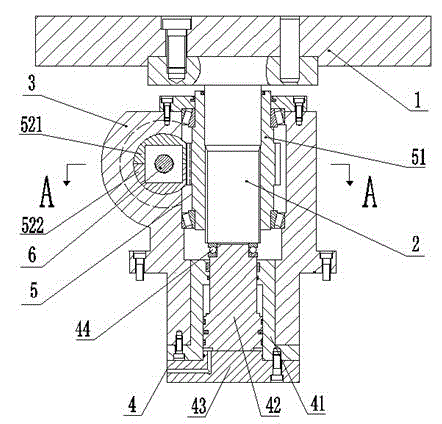

Rotary steering well drilling device

ActiveCN105525875AReal-time adjustmentImprove controlDirectional drillingAutomatic control for drillingWell drillingControl valves

The invention relates to a rotary steering well drilling device in the field of well drilling tools. The rotary steering well drilling device is mainly composed of a central spindle, a positioning cylinder, a positioner, a positioning key, a tension spring, a control valve, a control pin, a compression spring, an offset block, a bearing and a sealing device. The central spindle is connected with a drill column and a drill bit. During deflecting, an offset mechanism stretches out, the drill column and a well hole are eccentric, the positioning cylinder and the offset mechanism do not rotate, the drilling pressure and the torque are transmitted to the drill bit through the central spindle, and therefore a deflecting section can conduct rotary and directional drilling. During angle holding, the offset mechanism retracts back, the drill column and the well hole are concentric, the drilling pressure and the torque are transmitted to the drill bit through the central spindle, and therefore an angle holding section conducts rotary drilling. The rotary steering well drilling device is high in deflecting capability, wide in application range and capable of greatly reducing the well drilling cost of a well of a complex structure, and meanwhile the rotary steering well drilling device has the beneficial effects of being simple and reliable in structural design, convenient to machine, large in transmission torque, stable in operation and the like.

Owner:CHINA PETROCHEMICAL CORP +1

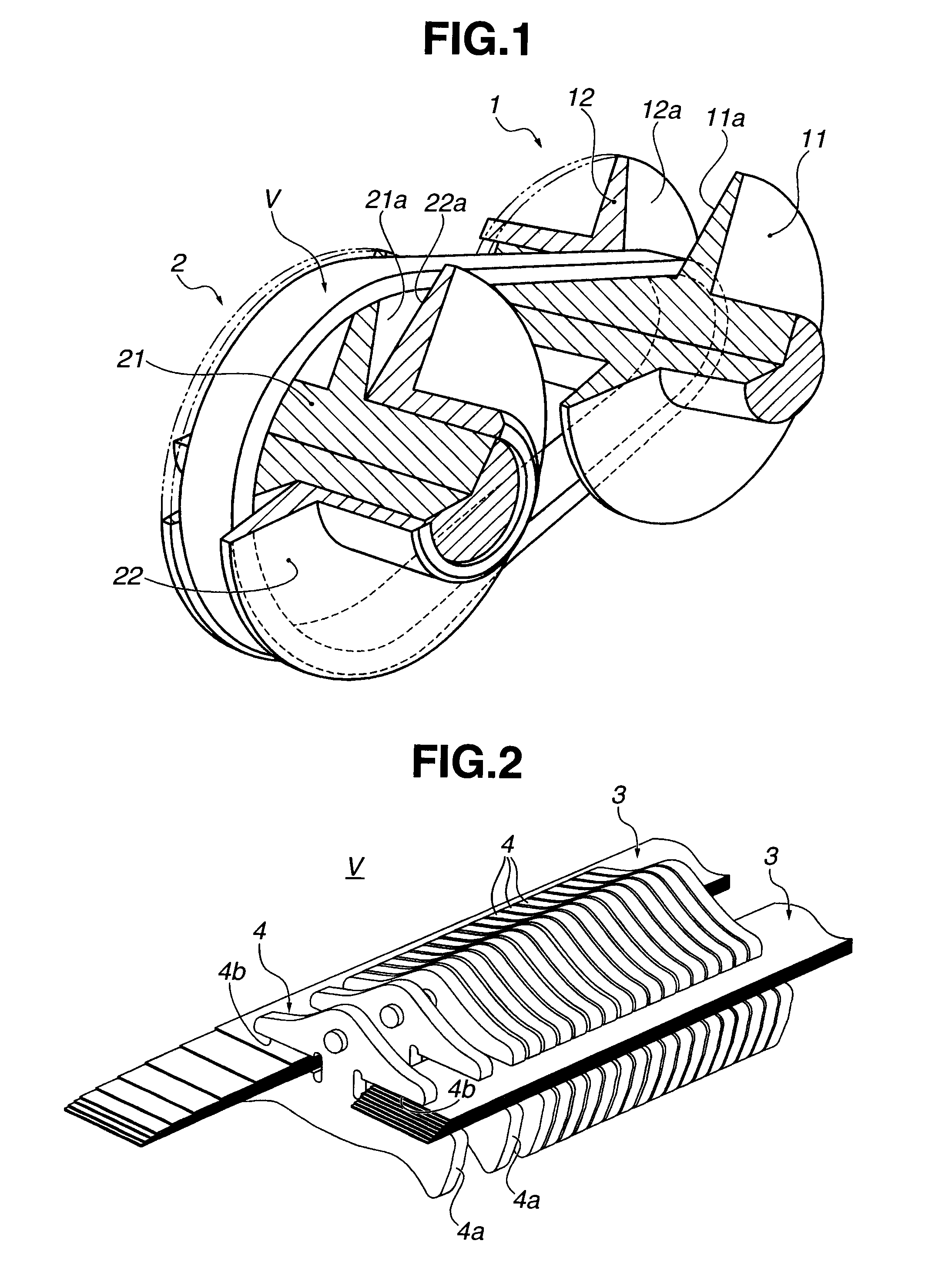

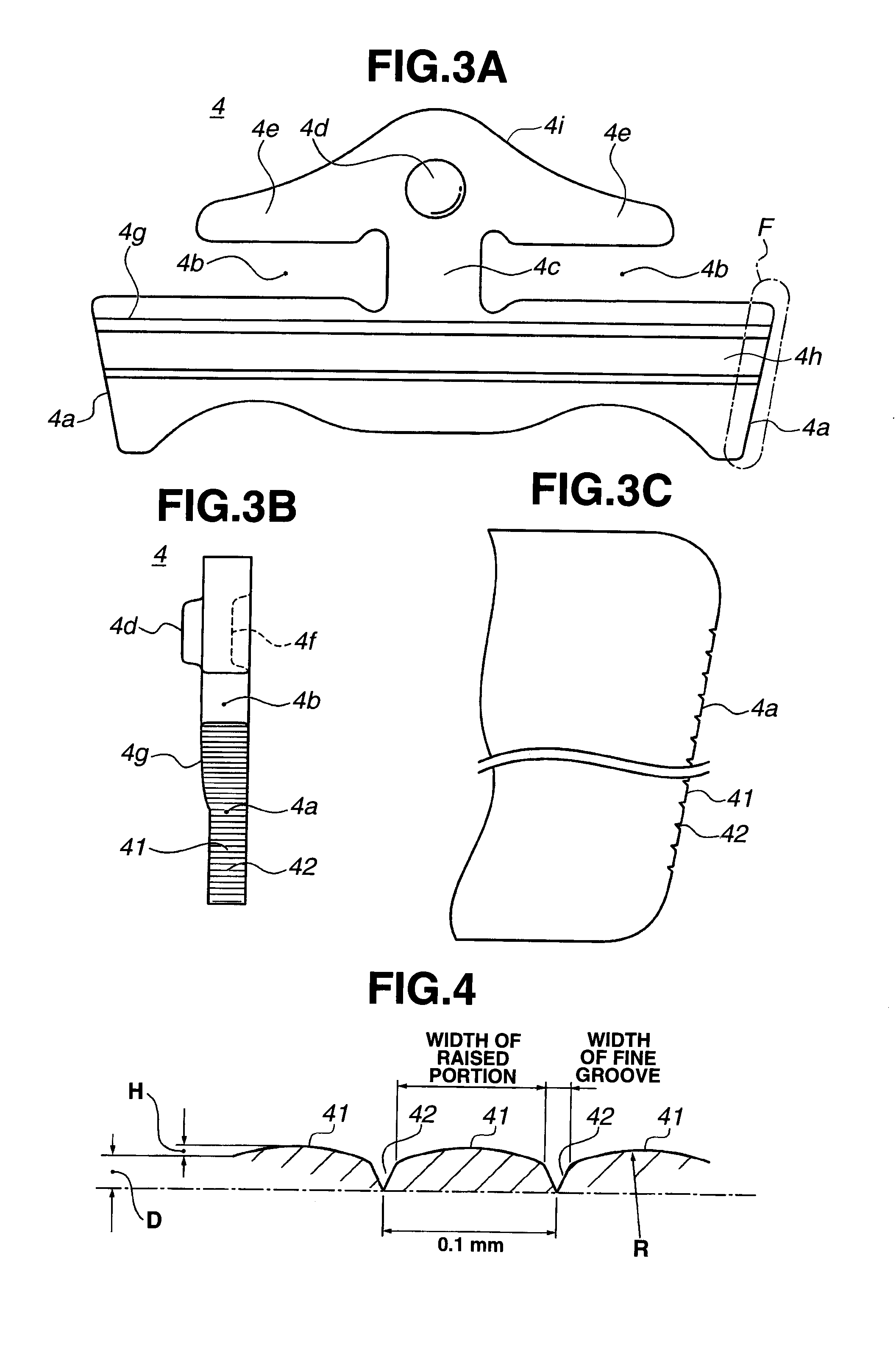

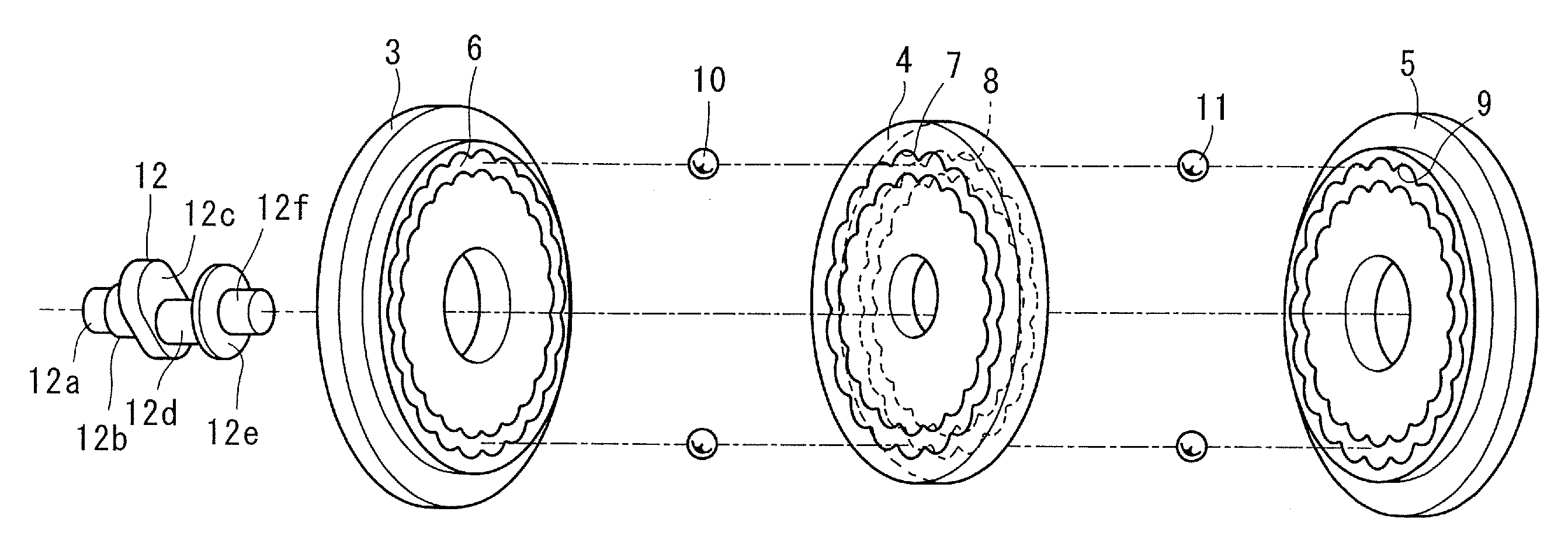

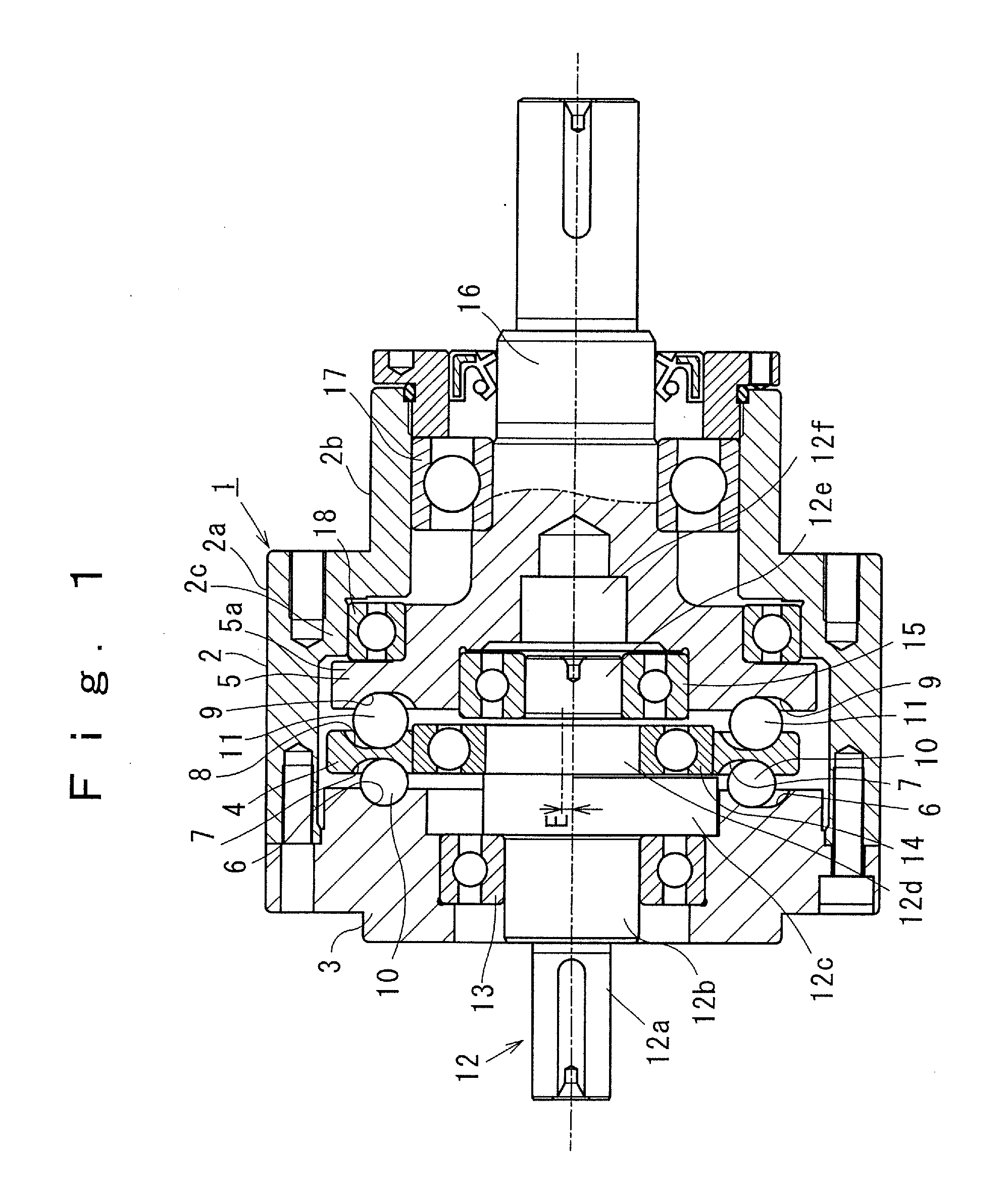

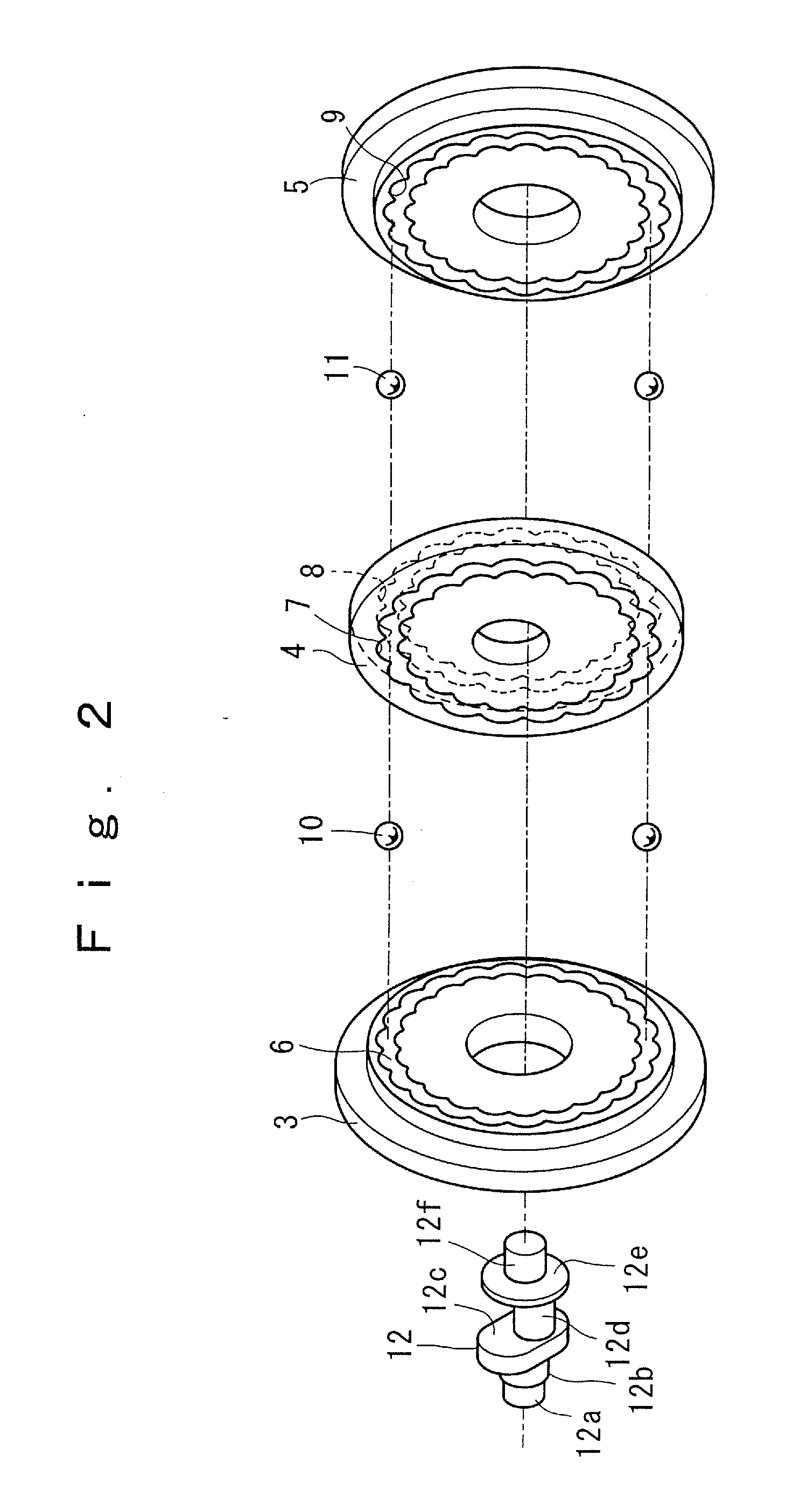

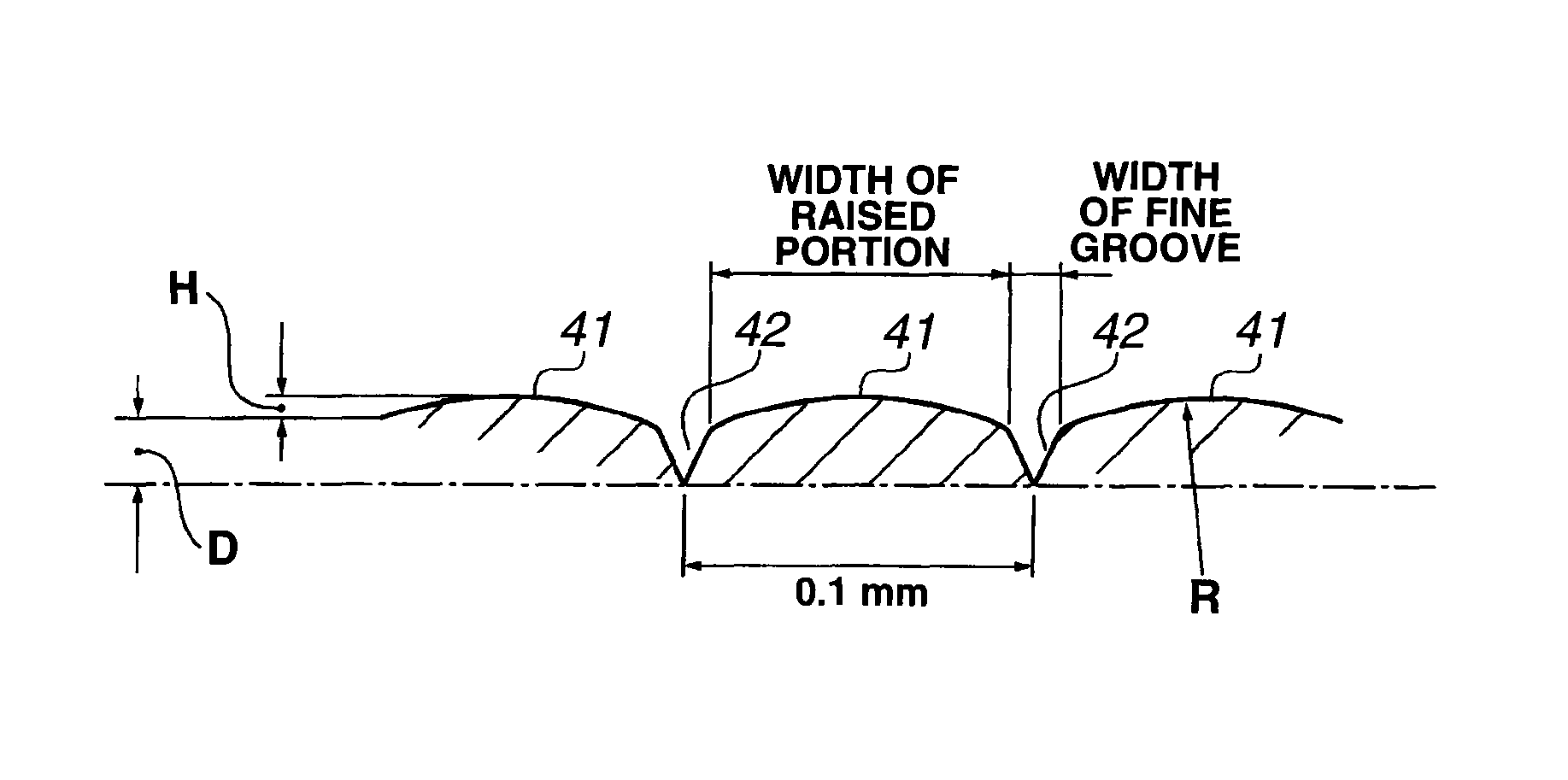

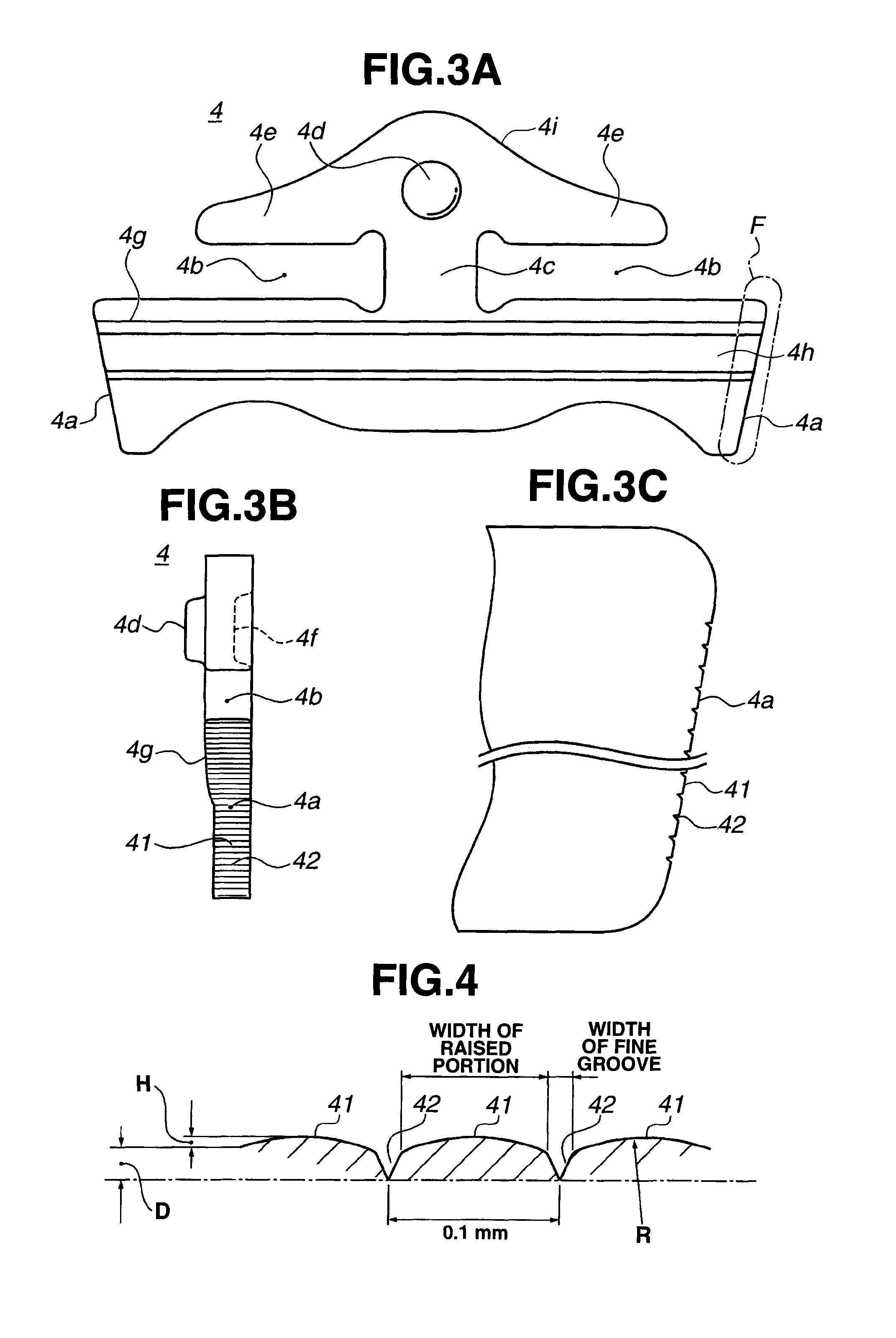

Metal v-belt of continuously variable transmission

ActiveUS20090280940A1Long-term useHigh torque transmissionV-beltsDriving beltsEngineeringLubrication

Each steel element for a V-belt of a continuously variable transmission has a flank (4a) that comprises a plurality of equally spaced raised portions (41) each being placed between two fine grooves (42). A flat flatness ratio (FR) given by the equation (1) is set to the highest one of values that are capable of practically machining the flank (4a) of the steel element (4) and capable of causing the flank (4a) to exhibit a given and satisfied lubrication oil discharging effect, and a groove pitch (GP) that is a distance between the two fine grooves (42) is set to a value that is capable of practically machining the flank of the steel element and capable of causing the flank to exhibit a given and satisfied lubrication oil discharging effect. The groove pitch thus set is a value that is permitted by the higher value of the flatness ratio thus set.FR (%)=WRP / (WRP+WG)×100 (1)wherein:FR: Flatness ratioWRP: Width of the raised portion (41)WG: Width of the groove (42)

Owner:JATCO LTD

Rolling Ball Type Two-Stage Low Speed Changer Device

InactiveUS20100216585A1Prevent vibrationReduced Thickness DimensionsToothed gearingsWobble plate gearingsHigh torqueBall type

In a rolling ball type two-stage low speed changer device 1, empirical formulas are obtained as a relationship between number of first, second, third and fourth lobes z1, z2, z3, z4 of a hypo based groove 6 (8) and an epi-based groove 7 (9). The relationship is represented by z1>z2, z3>z4, z1−z2=2, z3−z4=2 and z3=n×z2×½ (n: integer), and enables to a precise and smooth rotational transmission without inviting differential slippage and incurring an irregular rotation and uneven torque transmission on an output shaft 16 within the practical usage, and reducing a thickness dimension to render a whole structure compact, achieving a high transmission efficiency without inviting a backlash, and attaining a high torque transmission with low noise.

Owner:KAMOSEIKO

Coaxial contrarotating speed reducer

The invention discloses a coaxial contrarotating speed reducer. A first-level planetary gear train is used for speed reduction, and two inner gear rings of a second-level composite differential gear train are used for realizing speed reduction and a constant speed output function of coaxial contrarotating. A first-level planetary gear is simultaneously engaged with a first-level center gear and a first-level inner gear ring to form a first-level speed reduction system; a second double planetary gear, a second-level double center gear, a second-level inner gear ring, a second-level double inner gear ring, a second-level fixed shaft gear and a second-level sun gear form a second-level coaxial contrarotating speed reduction system. The first-level center gear and the second-level double center gear are separately fixed to an input shaft. An output shaft is divided into an output inner shaft and an output outer shaft, the output inner shaft penetrates through the output outer shaft, and the inner and outer shafts are connected with an output optical axis. The second-level inner gear ring is fixedly connected with the output inner shaft to complete the positive output of the system; and the second-level double inner gear ring, the second-level fixed shaft gear and the second-level sun gear are fixedly connected with the output outer shaft to complete the negative output of the system. The speed reducer has the advantages of simple structure, high speed reduction ratio, large transmission torque and smooth operation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

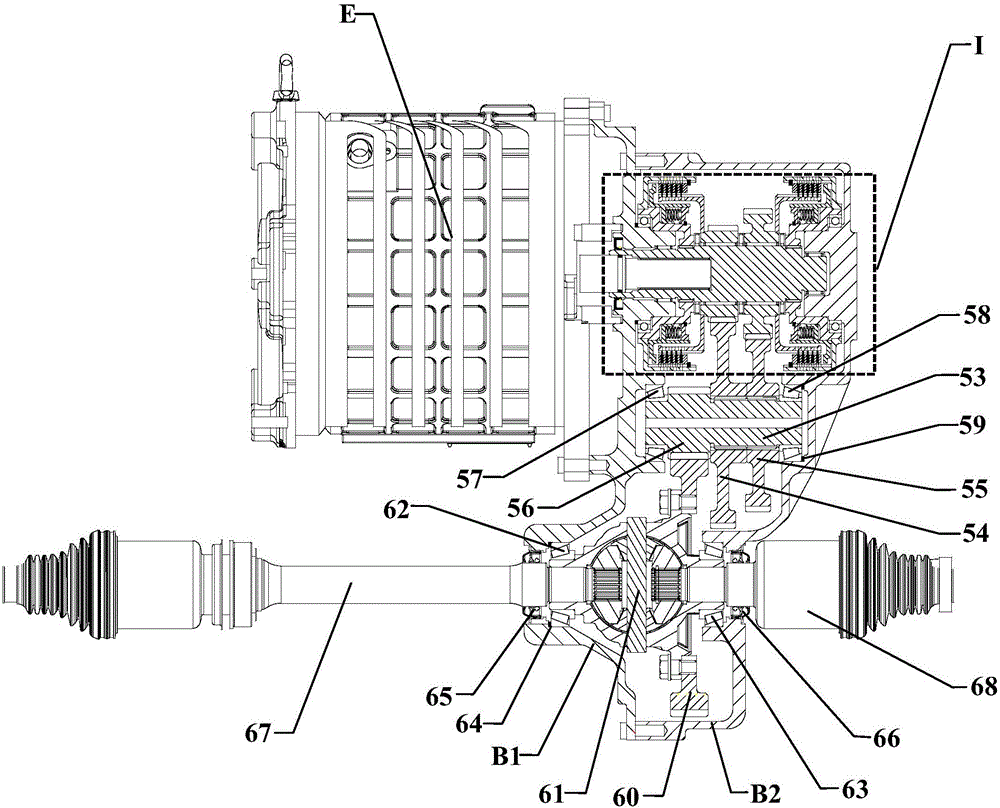

Two-gear transmission for electric vehicle

InactiveCN106763619AImprove transmission efficiencySimple structureGearboxesGearingElectricityElectric machine

The invention discloses a two-gear transmission for an electric vehicle. The two-gear transmission is applicable to front-engine front-drive or rear-engine rear-drive vehicles, is positioned at the output end of a driving motor, and is of a three-shaft structure. The two-gear transmission comprises an input shaft assembly, an intermediate shaft assembly, an output assembly and a case assembly, wherein rotation central lines of the input shaft assembly, the intermediate shaft assembly and the output assembly are parallel; the input shaft assembly, the intermediate shaft assembly and the output assembly are mounted and supported on the case assembly. According to the two-gear transmission, the transmission efficiency is high, the structure is simple, the transmission ratio is liable to match, and the production and manufacturing cost is relatively low; the transmission torque is large, gear shifting control is accurate, reliability is high, and performance requirements that power is not interrupted during the gear shifting process, the time of the gear shifting process is short, and the gear shifting process is smooth can be met; the lighter driving motor can be adopted, and the cost of the driving motor is reduced; and the driving motor and a transmission system are integratedly designed, so that the comprehensive cost of an electric driving system is greatly reduced, and the loading compatibility on different vehicles is higher.

Owner:BEIHANG UNIV

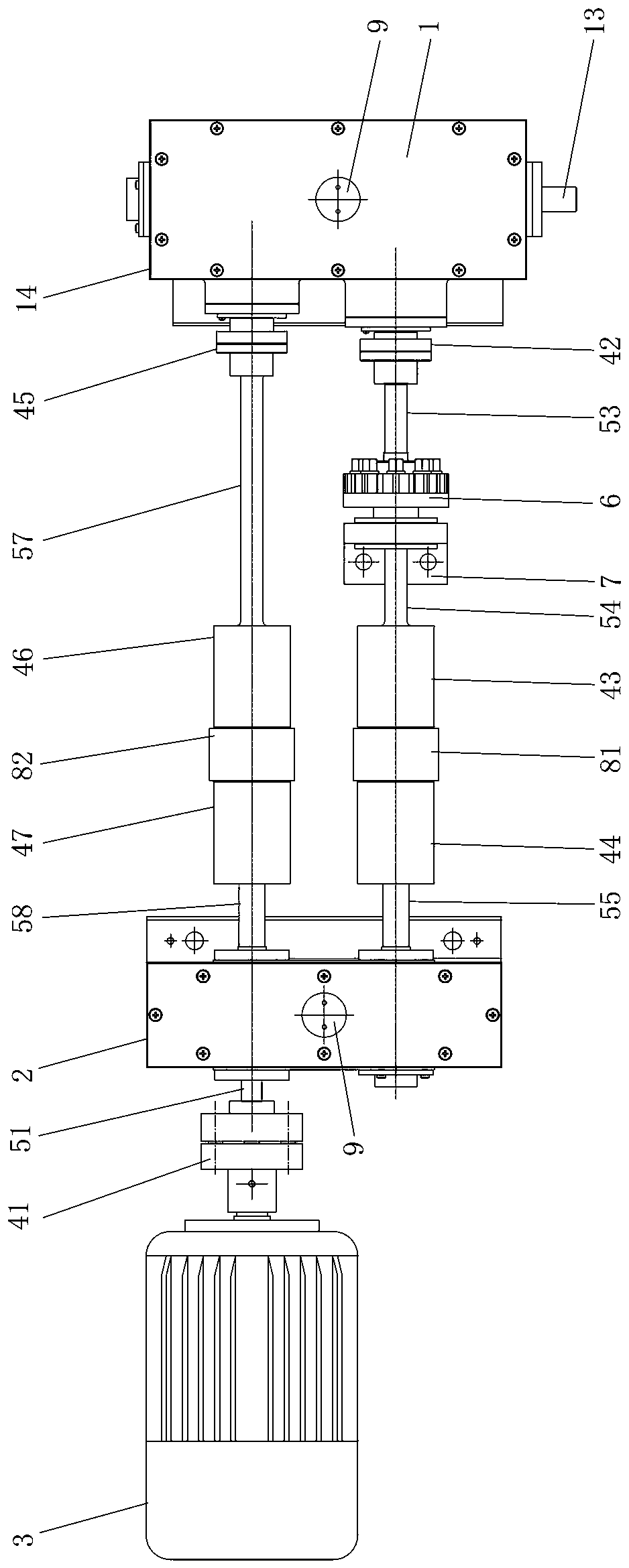

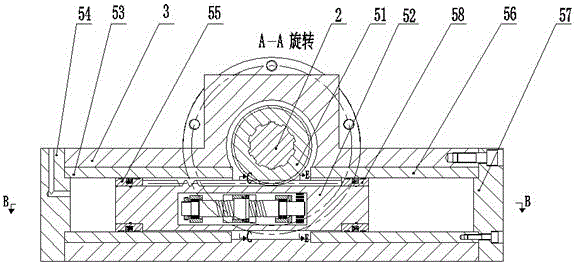

Mechanical enclosed test bench of bevel gear

ActiveCN107621366AGuaranteed meshing accuracyEasy to installMachine gearing/transmission testingBall bearingEngineering

The invention discloses a mechanical enclosed test bench of a bevel gear. The test bench comprises a bevel gear box including a tested bevel gear group, an accompanied tested bevel gear group, and a shaft. The tested bevel gear group consists of a first tested bevel gear and a second tested bevel gear that are engaged and are perpendicular to each other. The accompanied tested bevel gear group includes a first accompanied tested bevel gear and a second accompanied tested bevel gear that are engaged and are perpendicular to each other; the first tested bevel gear and the first accompanied tested bevel gear are installed on the shaft. An angular contact ball bearing is installed between the first tested bevel gear and the first accompanied tested bevel gear on the shaft; and cylindrical roller bearings are installed at the two ends of the shaft. A first adjusting assembly for adjusting the axial position of the first tested bevel gear is arranged at the shaft. The test bench having a simple structure is installed conveniently; the performances are stable; the bearing capability of the shaft is large; and the engaging precision of the bevel gear is high; and the test bench is capableof testing the transmission performance of the bevel gear at a high speed.

Owner:CENT SOUTH UNIV

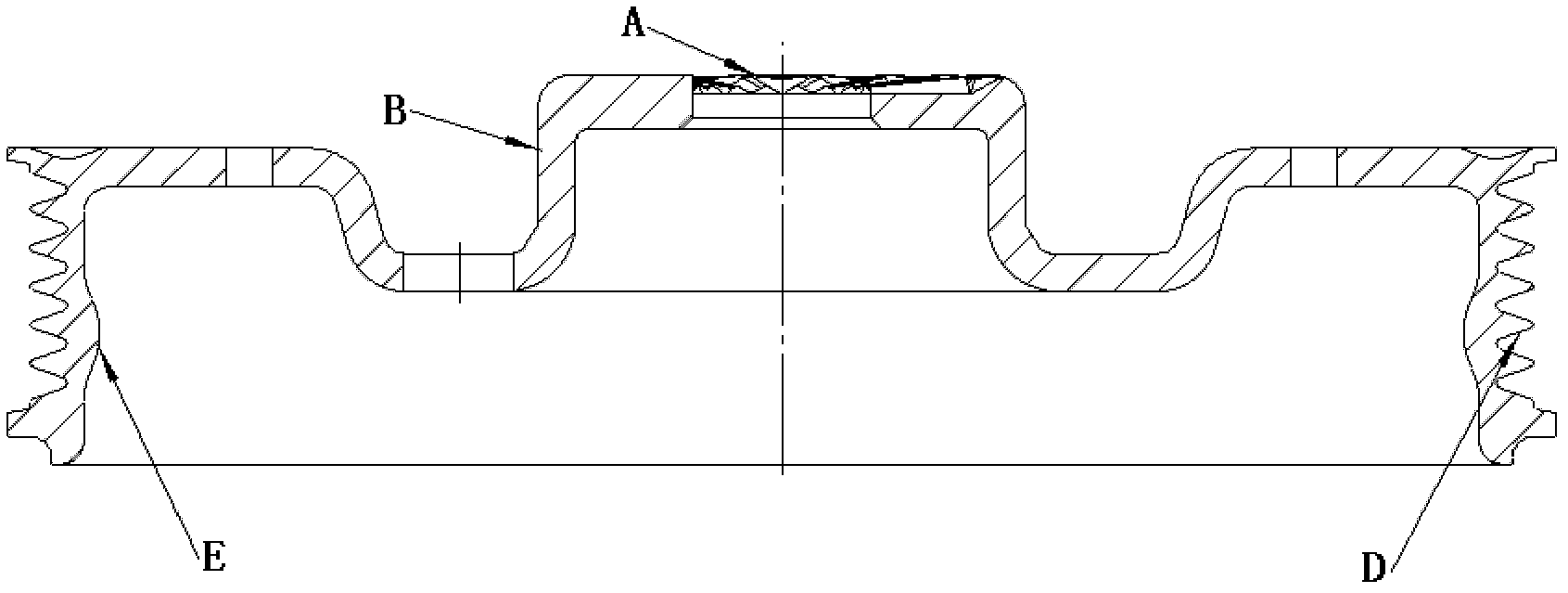

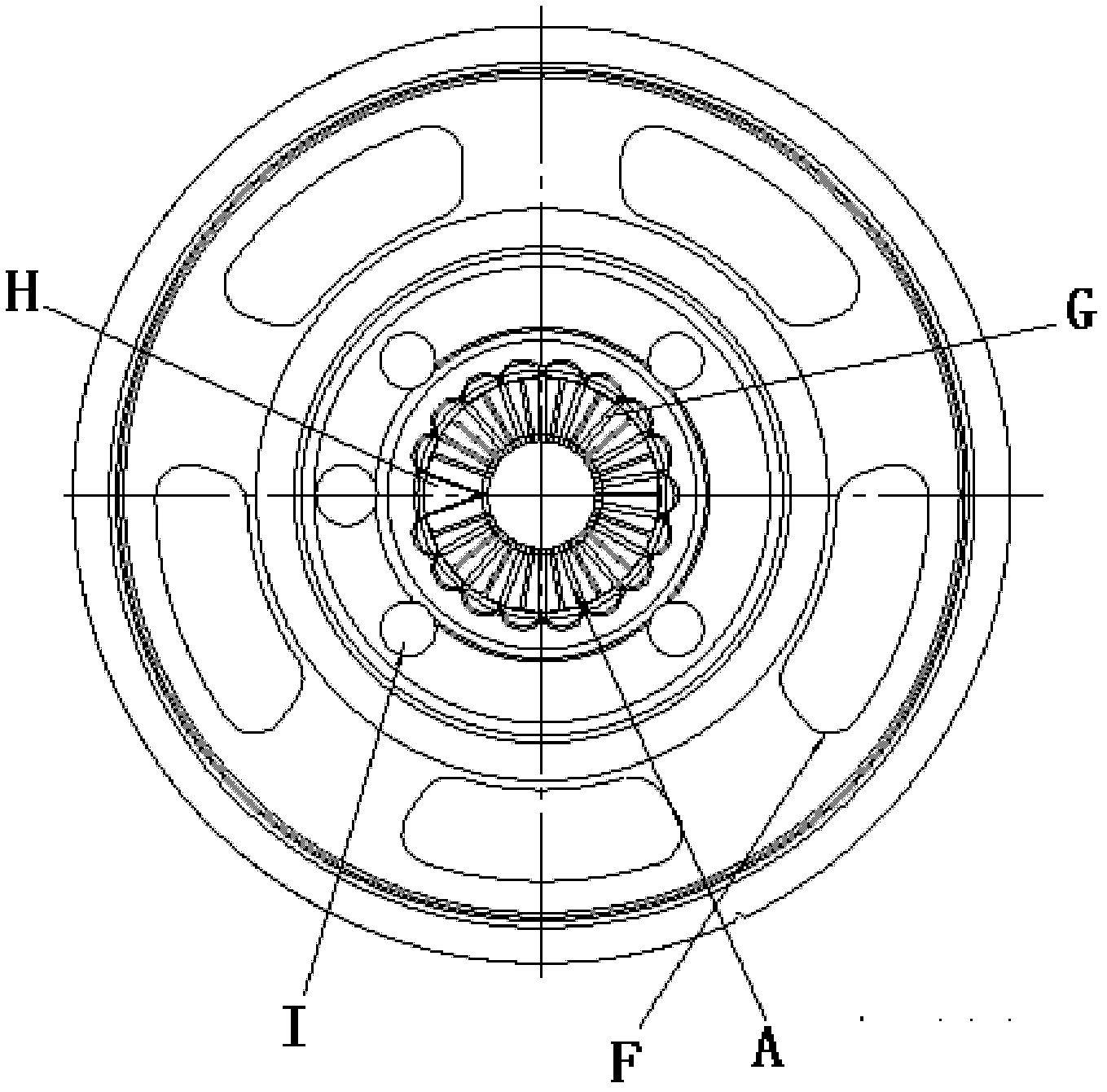

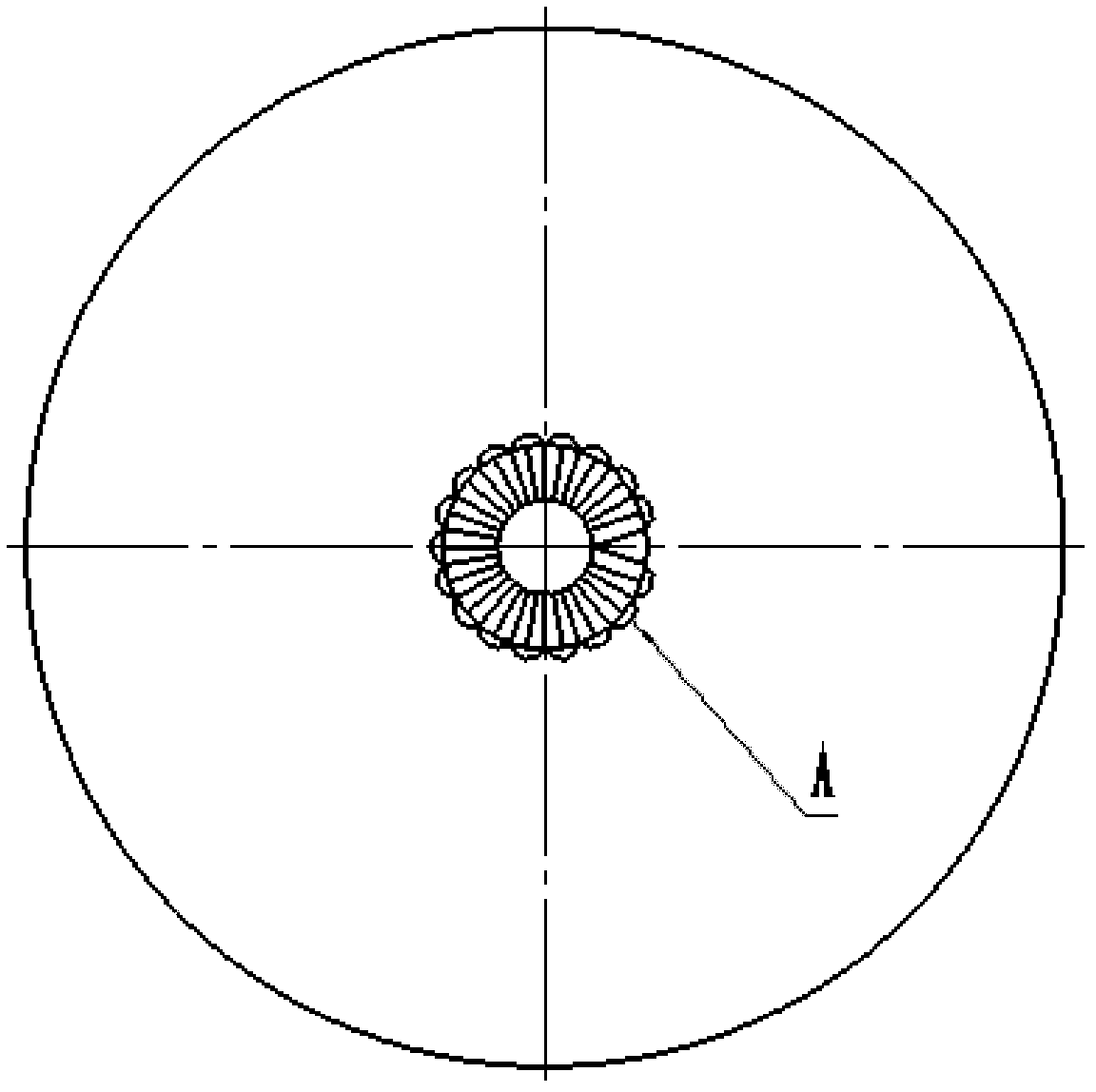

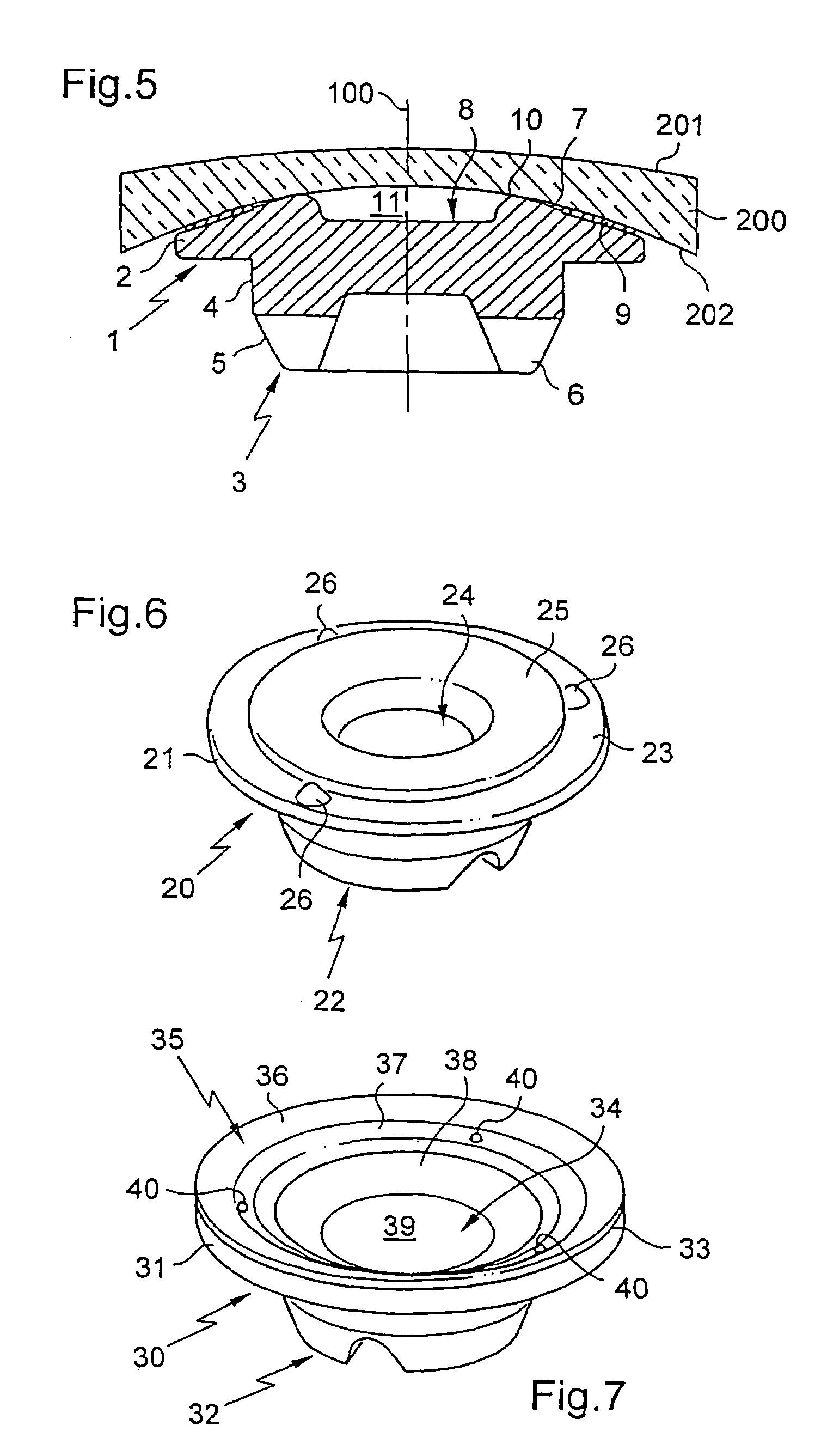

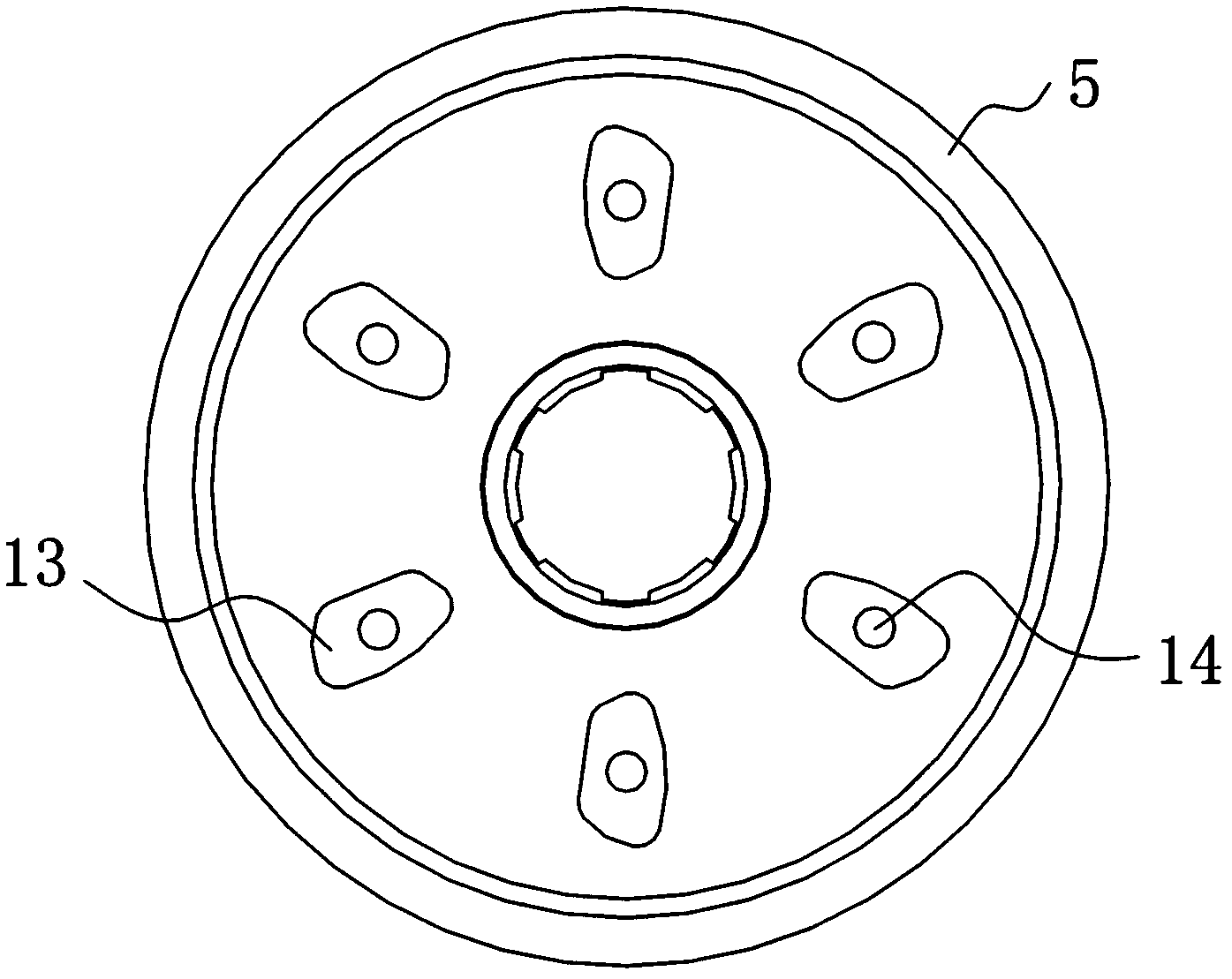

Processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc

The invention relates to a processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc. The specific steps are as follows: (1) processing an end surface rat fluted disc A on the metal circular sheet material by using end surface spinning technology; (2) processing a cylindrical assembling surface B at the outer side of the end surface rat fluted disc A by the spinning technology; (3) processing a curve C on the outer side radiation plate of the cylindrical assembling surface B by the spinning technology; (4) processing a multi-wedge tooth D on the blank excircle obtained in above procedures by the spinning technology; (5) processing an annular assembling surface E with an anti-slide bulge at the inner side of the multi-wedge tooth D by machining method; (6) punching a technological hole 1 and an installing hole F on the spoke. The processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc has the end surface rat tooth to be tightly engaged with the crankshaft tail, thus the transmission is precise and the transfer torque is larger; meanwhile, by fully using the spinning technology, the processing method is simple in manufacturing technique, convenient in installation and low in cost; at the same time, the processing method has small dynamic balance quantity, lowers noise of the engine and improves service life of the crankshaft.

Owner:WUHAN HONTRUST AUTO PULLEY IND

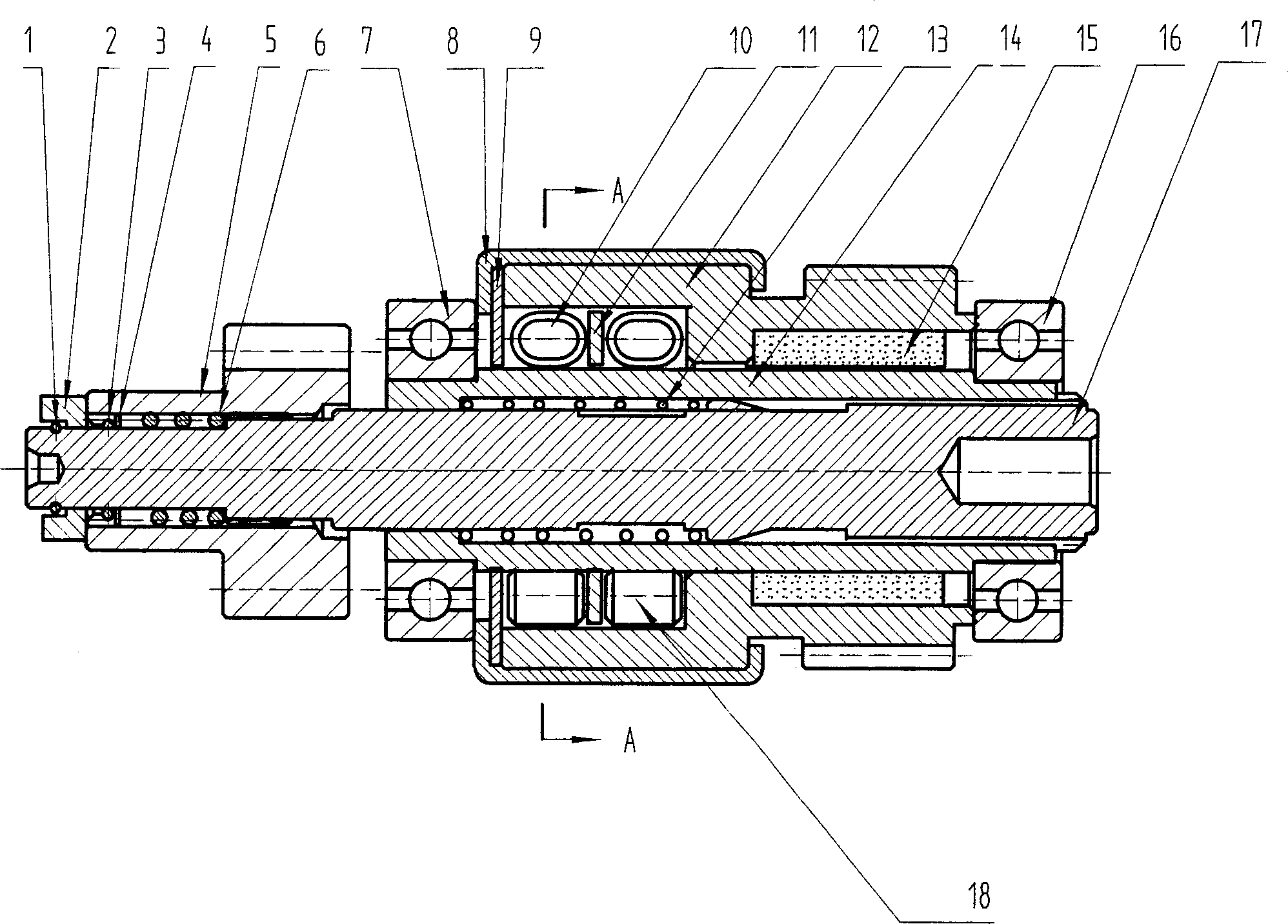

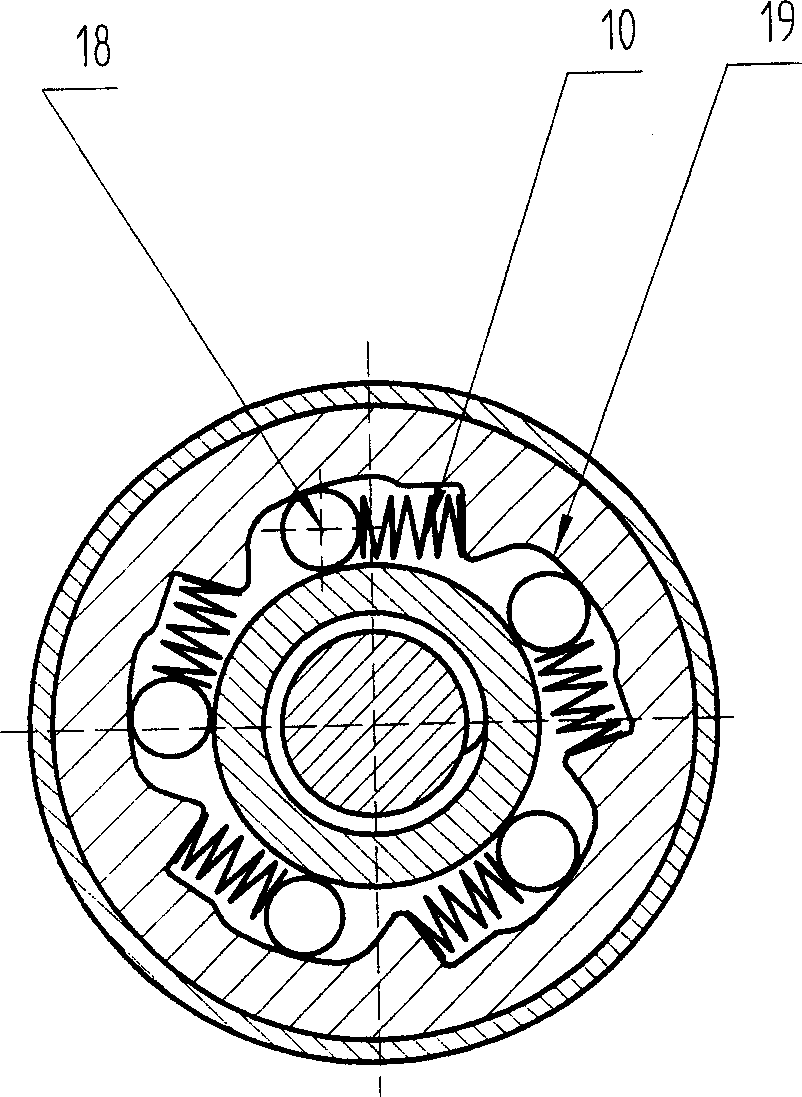

Single-way speed-reducing clutch

InactiveCN1908456AAchieve normal startupSimple structurePower operated startersMachines/enginesLow noiseEngineering

The invention relates to a speed-reduction one-way clutch, which comprises: a spindle axle (17), a hollow axle (14), and a large spring (13), wherein the hollow axle (14) and the large spring (13) sheathes the spindle axle (17); one end of spindle axle (17) extrudes outside the hollow axle (14), while another end is arranged with external screw spindle axle to match the internal screw spindle of hollow axle (14); said hollow axle (14) via axle linear (15) is arranged with gear spindle sheath (12) whose outer ring at one end is the external gear while the inner ring at another end has five rolling rooms (19), and each room (19) has at least one group of rollers (18) and flat springs (10); the outer end of rolling room (19) is arranged with clamp plate (9) and cover (8). The invention has simple structure, low cost, low noise, large transmission torque and stable operation.

Owner:严绍康

Reducer with less tooth difference

The invention relates to a reducer with less tooth difference, comprising a box body, an input shaft and an output shaft, wherein a universal coupler is arranged between the input shaft and the output shaft; an eccentric shaft head is arranged at the end part of the input shaft and is provided with an oscillating bearing; the oscillating bearing is provided with a bearing bush; the input end of the universal coupler is fixedly connected with the bearing bush and a swinging bevel gear; the box body is fixed with a fixed bevel gear meshed with the swinging bevel gear; and the input end of the universal coupler is connected with an output shaft; teeth of the fixed bevel gear are more than teeth of the swinging bevel gear, the structure is compact, and when fixed bevel gear is meshed with theswinging bevel gear, a crossed axis angle ranges from 150 degrees to 178 degrees. Due to the arrangement, the number of the meshed teeth of the fixed bevel gear and the swinging bevel gear are more than those of traditional hear transmission, so that transmitted torque is large, and speed change with the large reduction ratio and large load can be realized; and due to the arrangement of a balancedevice, the problem of laterality when the swinging bevel gear rotates can be solved, so that a reduction gear can move more stably and has low noise.

Owner:宿孝廷

Pneumatic blocking support for an optical lens

ActiveUS7500908B2Ensures stability and precisionIncrease contact areaRevolution surface grinding machinesOptical surface grinding machinesCamera lensElastic compression

Owner:ESSILOR INT CIE GEN DOPTIQUE

Novel clutch for tricycle

InactiveCN102661330ALarge radius of actionIncrease friction areaFriction clutchesDrive wheelWear resistant

The invention relates to a clutch, in particular to a novel clutch for a tricycle. The novel clutch comprises a driving disc component and a driven disc component, wherein the driving disc component comprises an outer cover, and a driven wheel is arranged on the outer cover; the driven disc component comprises a central sleeve, a plurality of driving friction plates matched with the axial inner grooves of the outer cover in a sliding manner are sleeved on the central sleeve, a plurality of driven steel sheets are matched with the periphery of the central sleeve in a sliding manner, and the driven steel sheets and the driving friction plates are sequentially superposed to form a friction pair; the two ends of the friction pair are positioned by the central sleeve and a platen, and the relative position between the central sleeve and the platen is limited by an elastic part arranged between the central sleeve and the platen. The novel clutch for the tricycle is stable in use, not easy in sliding, high temperature resistant, wear resistant, convenient in operation, long in service life and is suitable for popularization.

Owner:张捍宏 +1

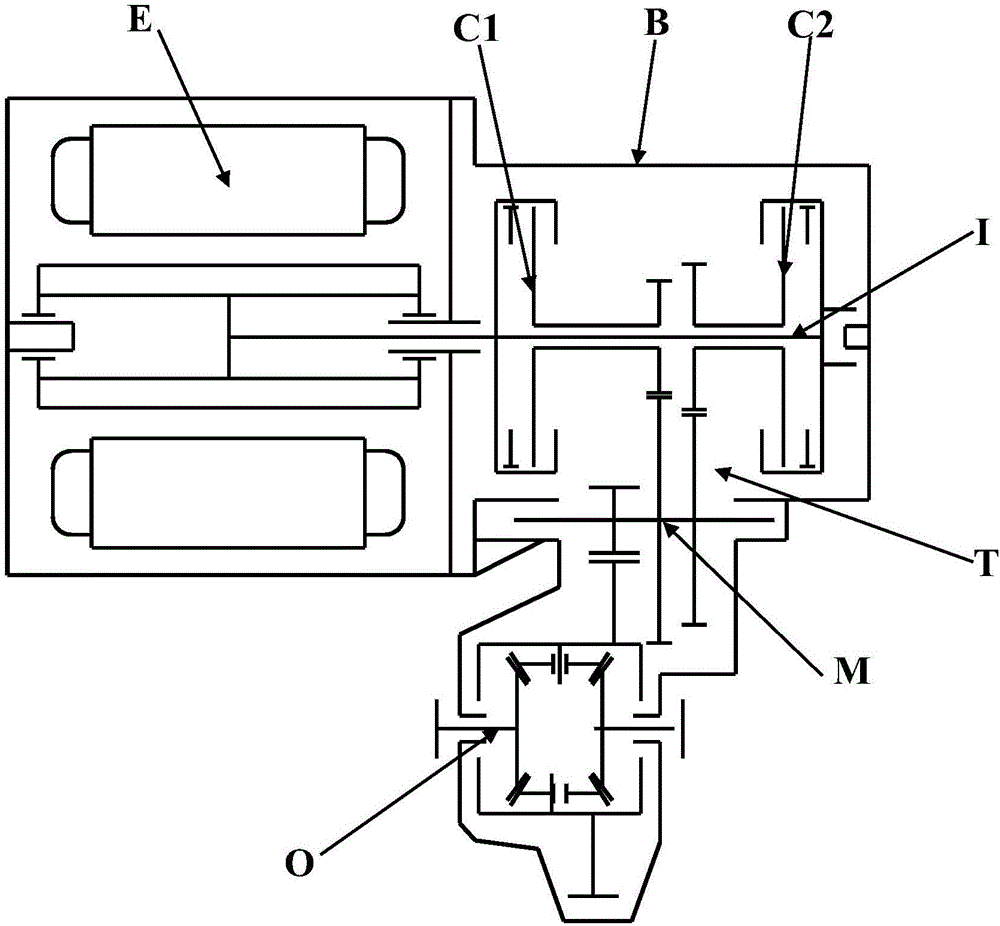

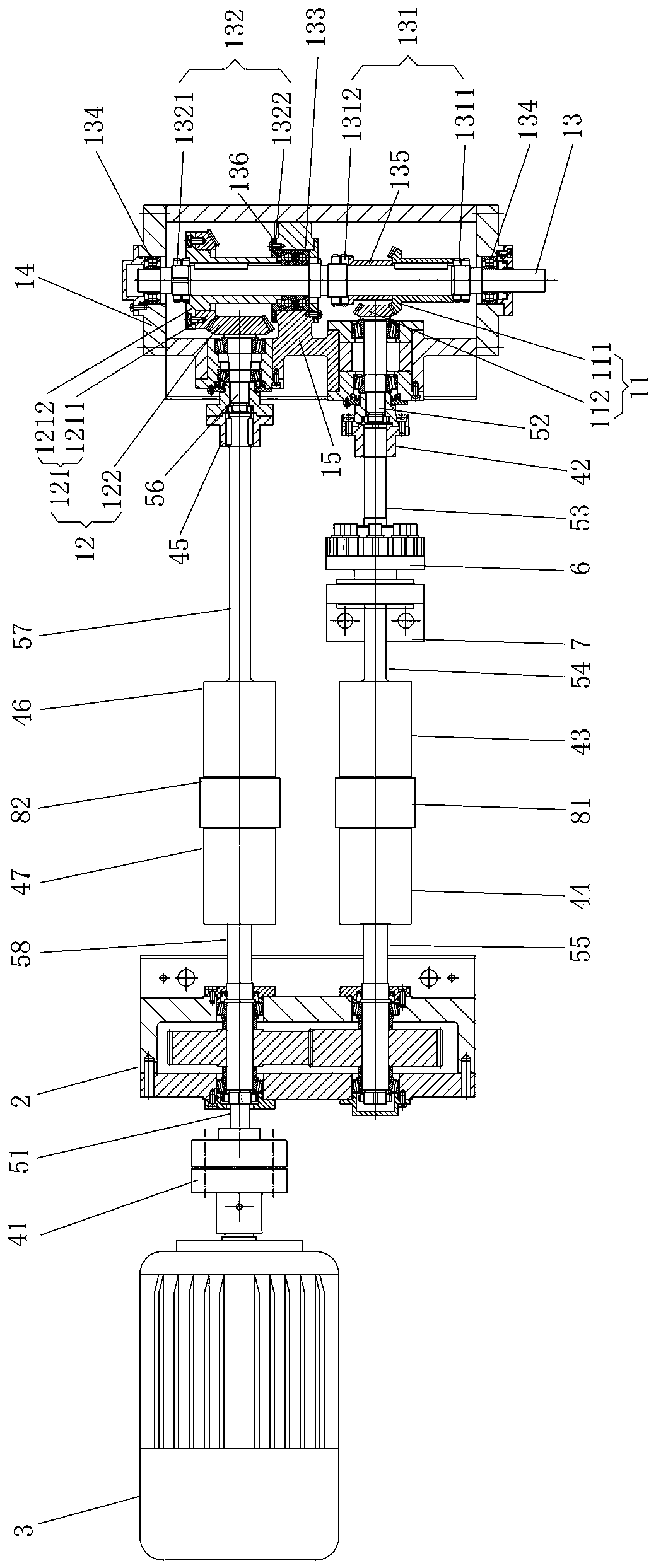

Electromagnetic tooth embedding type clutch and two-motor hybrid power system

ActiveCN104191953ASave spaceMove quicklyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingJoystickEngineering

The invention discloses an electromagnetic tooth embedding type clutch used for achieving driving separation and reunion of a first motor and a second motor. The clutch comprises a joystick, an annular electromagnet, an armature, an elastic reset mechanism, a movable end face gear and a fixed end face gear, wherein the joystick is inserted in an inner cavity of a rotor of the second motor, the two ends of the joystick are located on the two sides of the rotor of the second motor respectively, a magnetic attraction mechanism and a mesh transmission mechanism are located on the end sides of the rotor of the second motor respectively, compact axial arrangement is achieved, and therefore space of the clutch is substantially saved, and structural compactness degree of the clutch is improved. The invention further discloses a two-motor hybrid power system, under the action of the structural characteristics of the electromagnetic tooth embedding type clutch, an engine, the first motor and the second motor can be coaxially arranged, and according to the arrangement mode, not only is the advantage that the structure is compact achieved, but also transmission efficiency is improved.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

Rolling ball type two-stage low speed changer device

InactiveUS8162790B2Reduced Thickness DimensionsImprove transmission efficiencyToothed gearingsWobble plate gearingsLow noiseLow speed

In a rolling ball type two-stage low speed changer device 1, empirical formulas are obtained as a relationship between number of first, second, third and fourth lobes z1, z2, z3, z4 of a hypo-based groove 6 (8) and an epi-based groove 7 (9). The relationship is represented by z1>z2, z3>z4, z1−z2=2, z3−z4=2 and z3=n×z2×½ (n: integer), and enables to a precise and smooth rotational transmission without inviting differential slippage and incurring an irregular rotation and uneven torque transmission on an output shaft 16 within the practical usage, and reducing a thickness dimension to render a whole structure compact, achieving a high transmission efficiency without inviting a backlash, and attaining a high torque transmission with low noise.

Owner:KAMOSEIKO

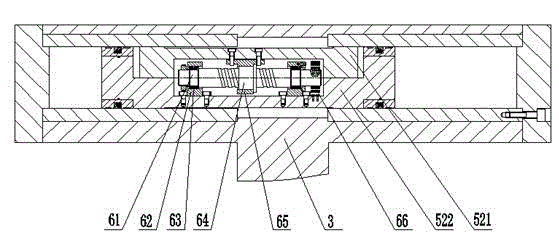

Gear and rack transmission anti-backlash mechanism

InactiveCN104964022AEliminate transmission backlashHigh torque transmissionPortable liftingGearing detailsNumerical controlMachine tool

The invention relates to a gear and rack transmission anti-backlash mechanism. The gear and rack transmission anti-backlash mechanism comprises a gear and a rack. The rack is formed by stacking a first rack body and a second rack body and is meshed with the gear. The anti-backlash mechanism further comprises a lead screw shaft, a bearing support, needle bearings, a nut, a nut support and a plane spiral spring which are placed in a cavity formed in the first rack body and the second rack body. The two ends of the lead screw shaft are installed on the bearing support through the needle bearings, and the bearing support is fixed to the second rack body. The lead screw shaft is matched with the nut, and the nut is installed on the first rack body through the nut support. The two ends of the plane spiral spring are fixed to the lead screw shaft and the second rack body respectively. According to the anti-backlash mechanism, when a transmission backlash occurs between the gear and the rack, teeth of the two rack bodies are staggered under the elasticity effect of the spiral spring, the equivalent tooth thickness is increased, the transmission backlash between the gear and the rack is eliminated, transmission torque is large, the structure is simple, work is reliable, and the gear and rack transmission anti-backlash mechanism is suitable for the field of numerical control without backlash transmission, and especially for high-accuracy numerical control machine tools and robots.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Metal V-belt of continuously variable transmission

ActiveUS8814735B2Long-term useHigh torque transmissionV-beltsRopes and cables for vehicles/pulleyEngineeringLubrication

Each steel element for a V-belt of a continuously variable transmission has a flank (4a) that comprises a plurality of equally spaced raised portions (41) each being placed between two fine grooves (42). A flat flatness ratio (FR) given by the equation (1) is set to the highest one of values that are capable of practically machining the flank (4a) of the steel element (4) and capable of causing the flank (4a) to exhibit a given and satisfied lubrication oil discharging effect, and a groove pitch (GP) that is a distance between the two fine grooves (42) is set to a value that is capable of practically machining the flank of the steel element and capable of causing the flank to exhibit a given and satisfied lubrication oil discharging effect. The groove pitch thus set is a value that is permitted by the higher value of the flatness ratio thus set.FR (%)=WRP / (WRP+WG)×100 (1)wherein:FR: Flatness ratioWRP: Width of the raised portion (41)WG: Width of the groove (42).

Owner:JATCO LTD

Double-snap reversing ratchet wrench

The invention relates to a double-snap reversing ratchet wrench to solve the problems of the conventional ratchet wrench that a clutch device is complicated in structure, a plurality of components are arranged to cause low loading torsion, parts are positioned in a single way to cause high processing cost and the service life is short. The double-snap reversing ratchet wrench comprises a handle and a wrench body connected to one end of a stress application rod, and is characterized in that a ratchet perpendicular to the stress application rod is arranged in the wrench body; one end, facing the stress application rod, of the ratchet is provided with a direction switch; the direction switch comprises a direction handle and a steering body which is positioned below one end of the direction handle and is perpendicularly connected with the direction handle; two sides of the steering body are respectively provided with a snap; the bottom end of the steering body is provided with a spring hole seat; the wrench body at one end of the spring hole seat is provided with a cover plate. The double-snap reversing ratchet wrench is provided with a few parts, and is simple in structure and compact in integral structure, the positioning way between the components is flexible, a single component has sufficient strength design space, and the double-snap reversing ratchet wrench transfers large torque and is reliable, wear-resistant, easy to assemble and maintain, and easy and convenient to operate.

Owner:ZHEJIANG LIYUAN TOOLS CO LTD

Gear rack drive revolving worktable

InactiveCN104942609AEliminate transmission backlashHigh torque transmissionLarge fixed membersHydraulic cylinderEngineering

The invention relates to a gear rack drive revolving worktable. The gear rack drive revolving worktable comprises a working table, a box, a lifting driving mechanism, a revolving driving mechanism and a gap eliminating mechanism, wherein the revolving driving mechanism is driven by a gear and a rack; the rack is formed by laminating two racks; and the gap eliminating mechanism comprises a lead screw shaft, a bearing bracket, a rolling needle bearing, a nut, a nut bracket and a plane scroll spring placed in a cavity formed in the two racks. The revolving worktable is driven by a hydraulic cylinder, can realize 180 degrees of fixed-angle transposition, can automatically eliminate the gap, and is large in transfer torque, simple in structure and reliable in operation.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

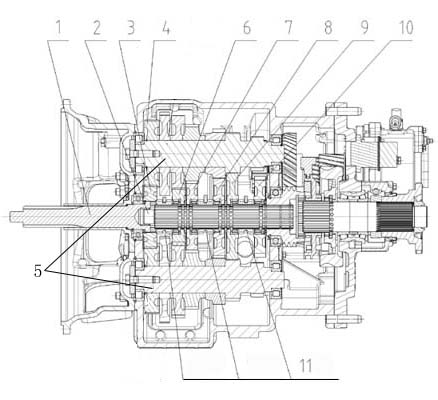

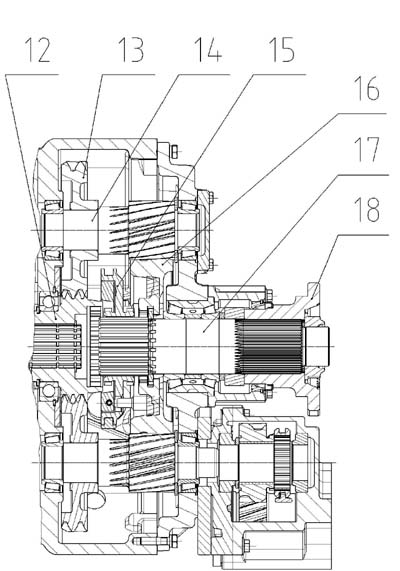

Heavy ten-gear speed changer assembly

The invention relates to a heavy ten-gear speed changer assembly, which consists of a main box and a secondary box. The heavy ten-gear speed changer assembly is characterized in that five gears manually controlled by the main box adopt a combined sleeve for gear shifting, two gears pneumatically controlled by the secondary box adopt a synchronizer for gear shifting, and ten advancing gears are totally formed. A secondary box fully bevel gear structure is arranged on a ten-gear double-intermediate-shaft speed changer, and a speed changer can take force from the side surfaces and the bottom part of the main box or the back ends of two intermediate shafts of the secondary box. The invention reduces the gear shifting force, prolongs the service life of a synchronizer, and reduces the fault rate of the whole vehicle. The gears are clear, the gear shifting is flexible, a single H, a single lever, double levers and a flexible shaft can be adopted for operation, and the transmitted torque is increased so that the whole system is more reliable and durable. The invention has the advantages of large transmission torque, reliability, durability, smaller axial dimension and wide application range, and can be conveniently processed and produced.

Owner:FAW GROUP

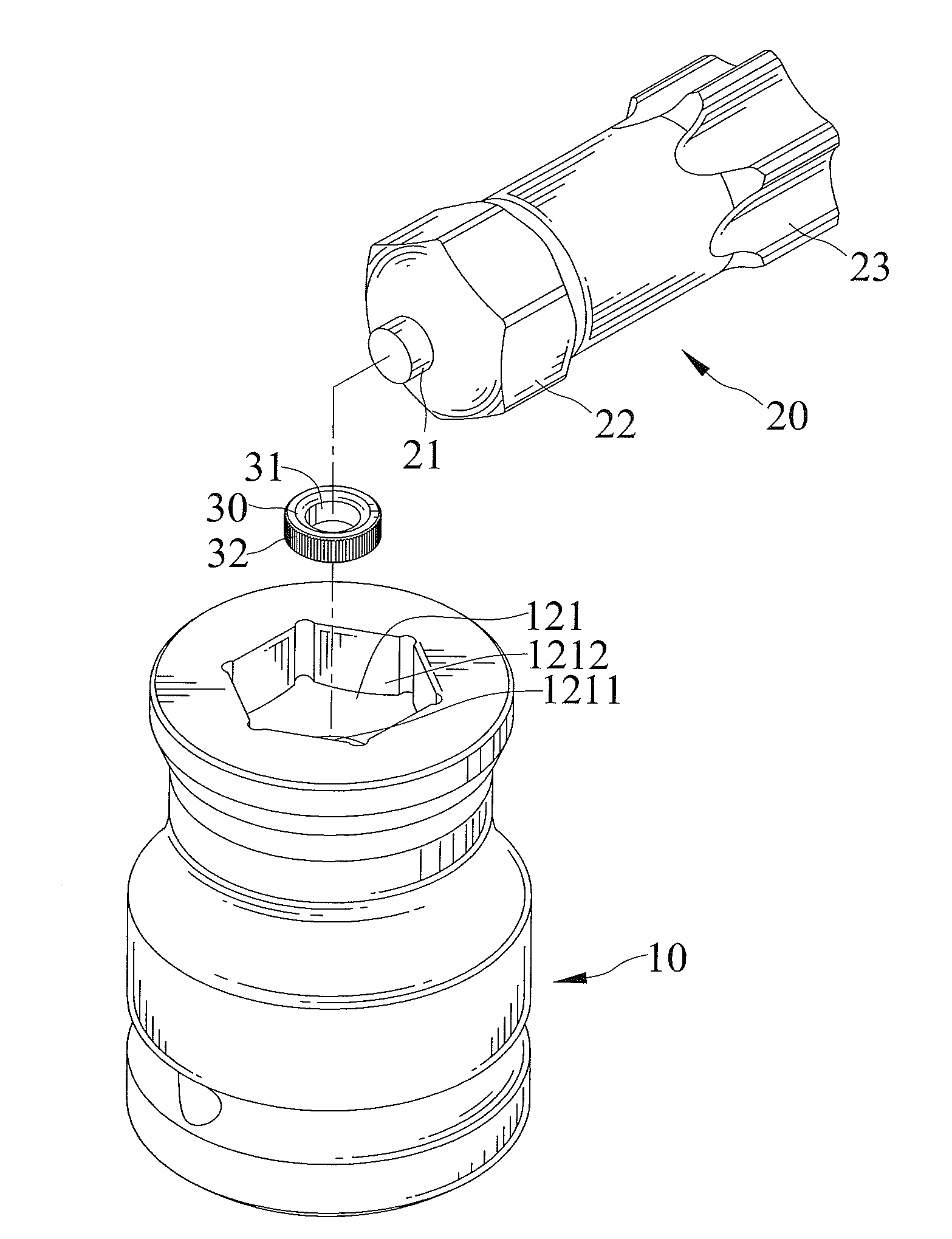

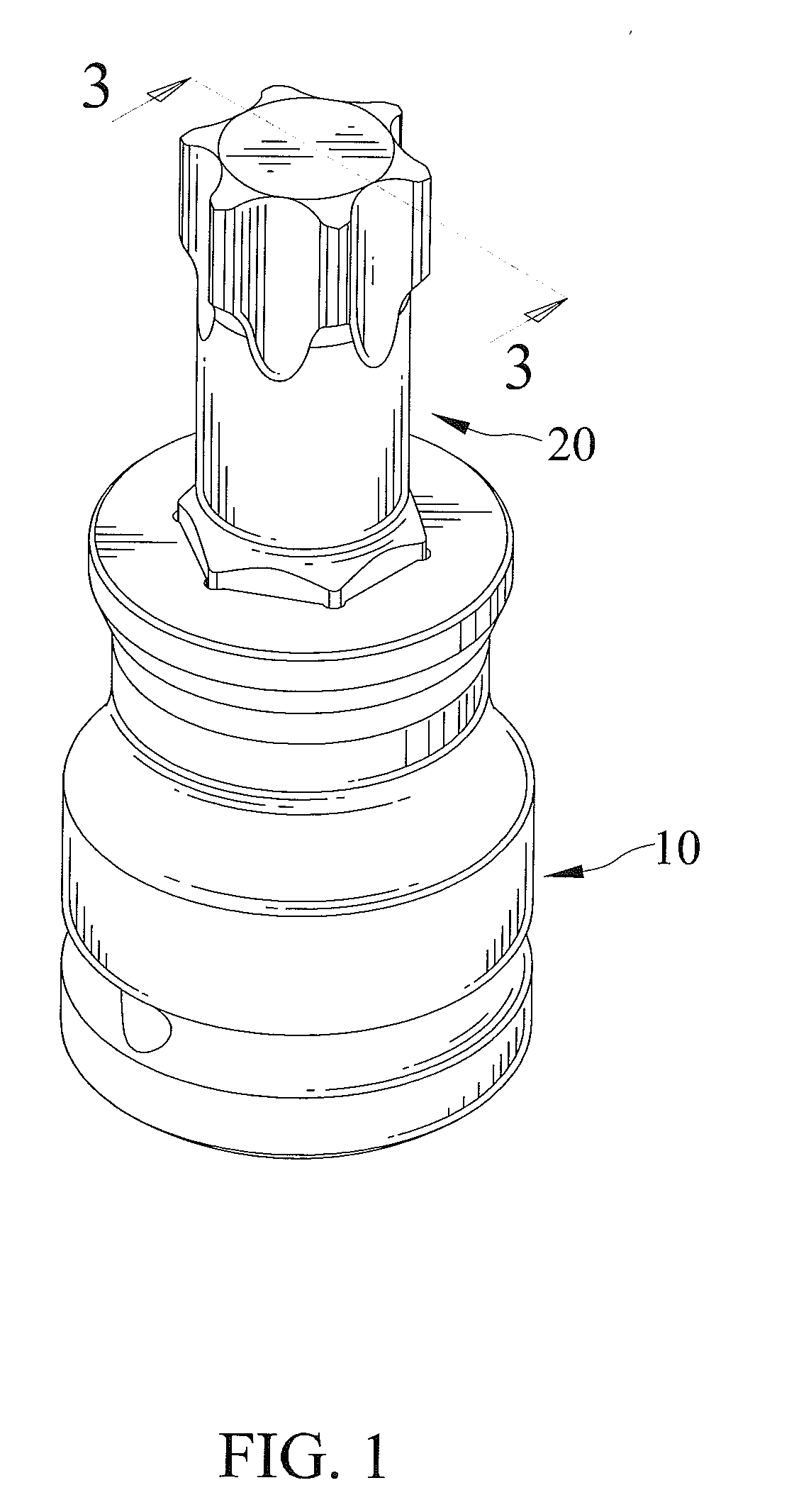

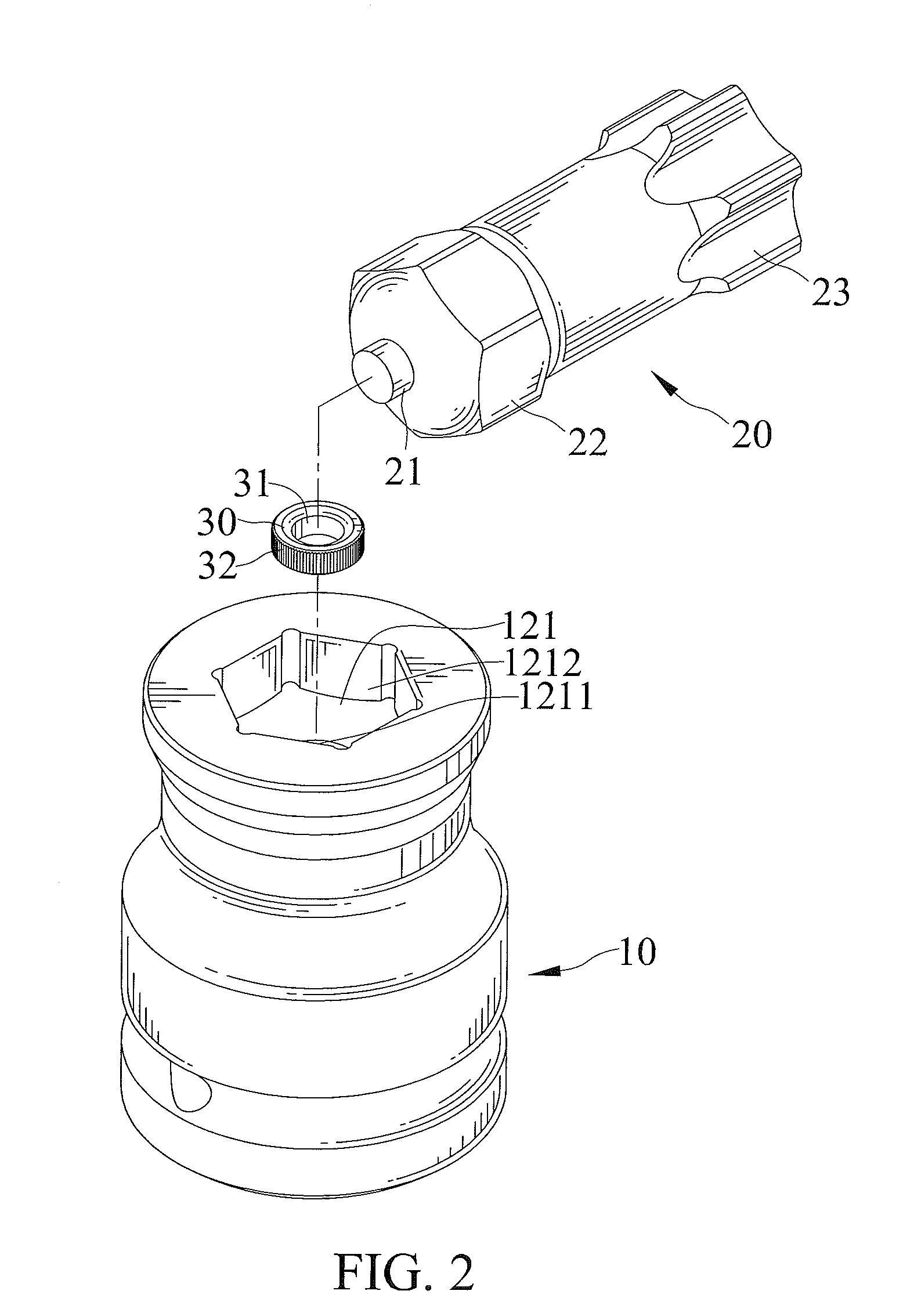

Tool Head

Owner:HONG ANN TOOL INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com