Coaxial contrarotating speed reducer

A rotating reducer and coaxial technology, applied in the field of coaxial counter-rotating high-speed composite gear train reducer, can solve the problems of small deceleration range, small single-stage deceleration, large volume, etc., and achieve the effect of stable operation and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This implementation example is a coaxial counter-rotating reducer.

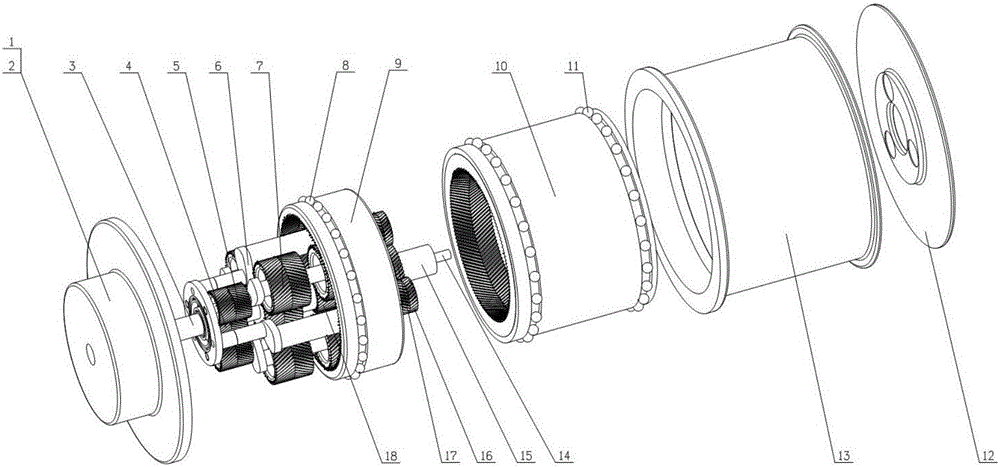

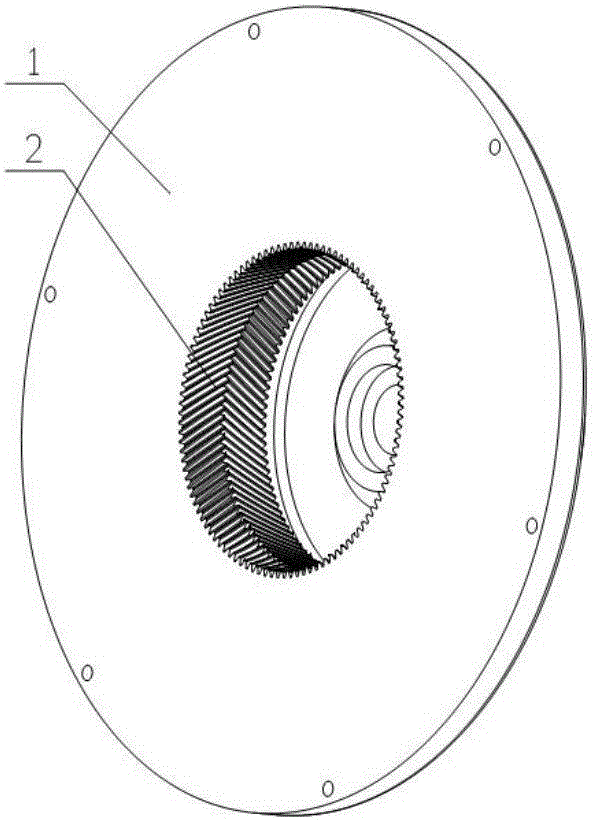

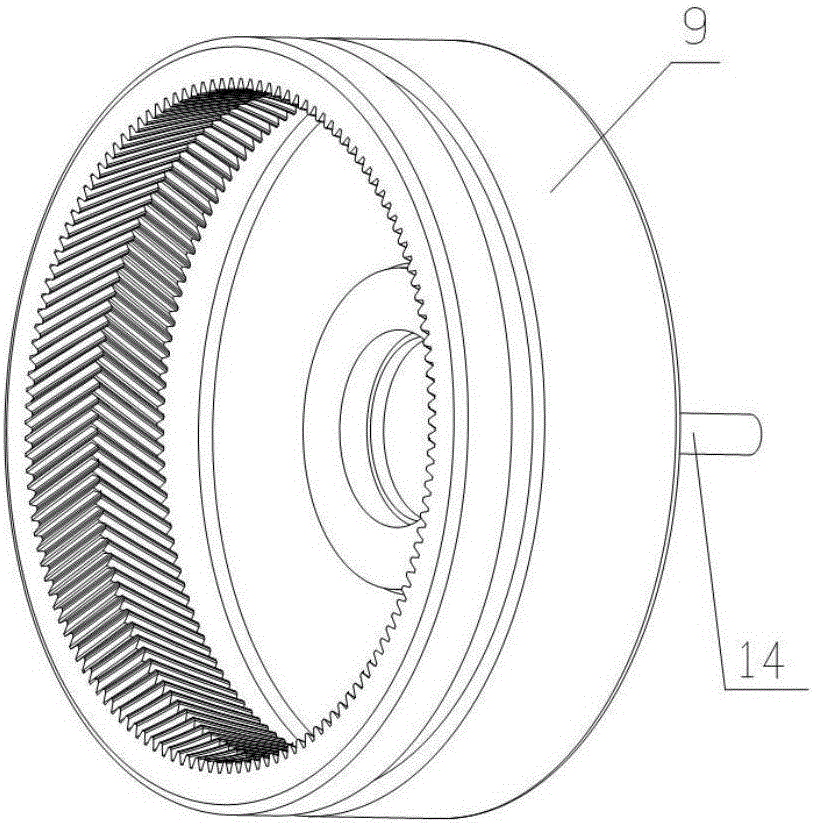

[0025] refer to Figure 1 to Figure 7 , The coaxial counter-rotating reducer of this implementation example consists of a box body 13, a front end cover 1, a rear end cover 12, an input shaft 3, a first-stage inner ring gear 2, a second-stage inner ring gear 9, and a second-stage double-connected inner ring gear 10 , first-level planetary gear 5, second-level double-connected planetary gear 7, planetary carrier 6, first-level center wheel 4, second-level double-connection center wheel 18, second-level fixed shaft gear 16, second-level sun gear 17, output inner shaft 14 , the output outer shaft 15, the first ball assembly 8, and the second ball assembly 11; the two ends of the box body 13 are respectively connected with the front end cover 1 and the rear end cover 12 by bolts. The input shaft 3 is installed on the front end cover 1 and the secondary inner ring gear 9 of the box body through bearings, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com