Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451results about How to "Large reduction ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

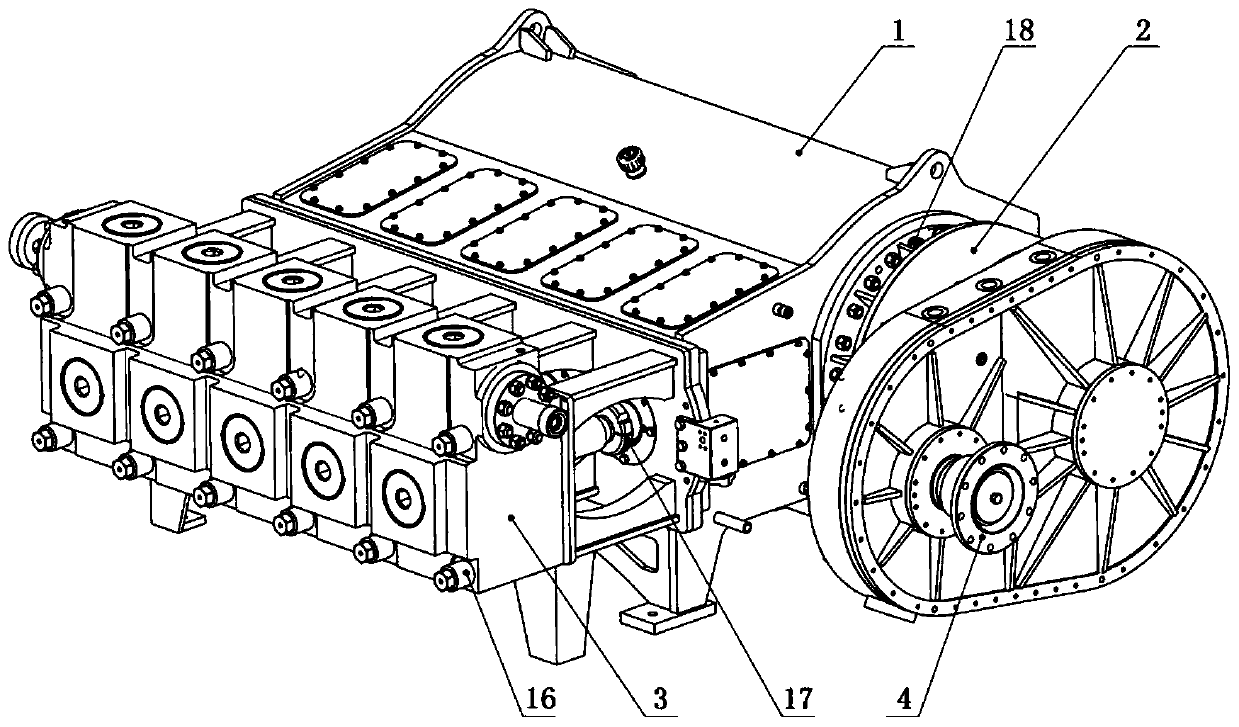

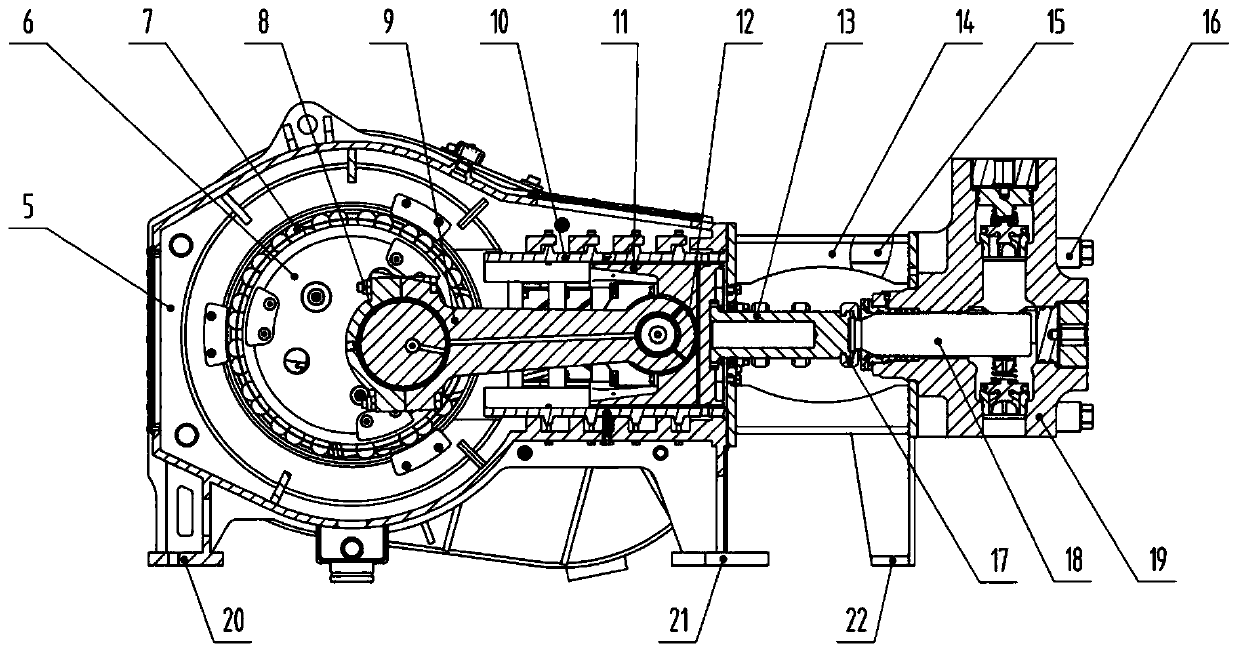

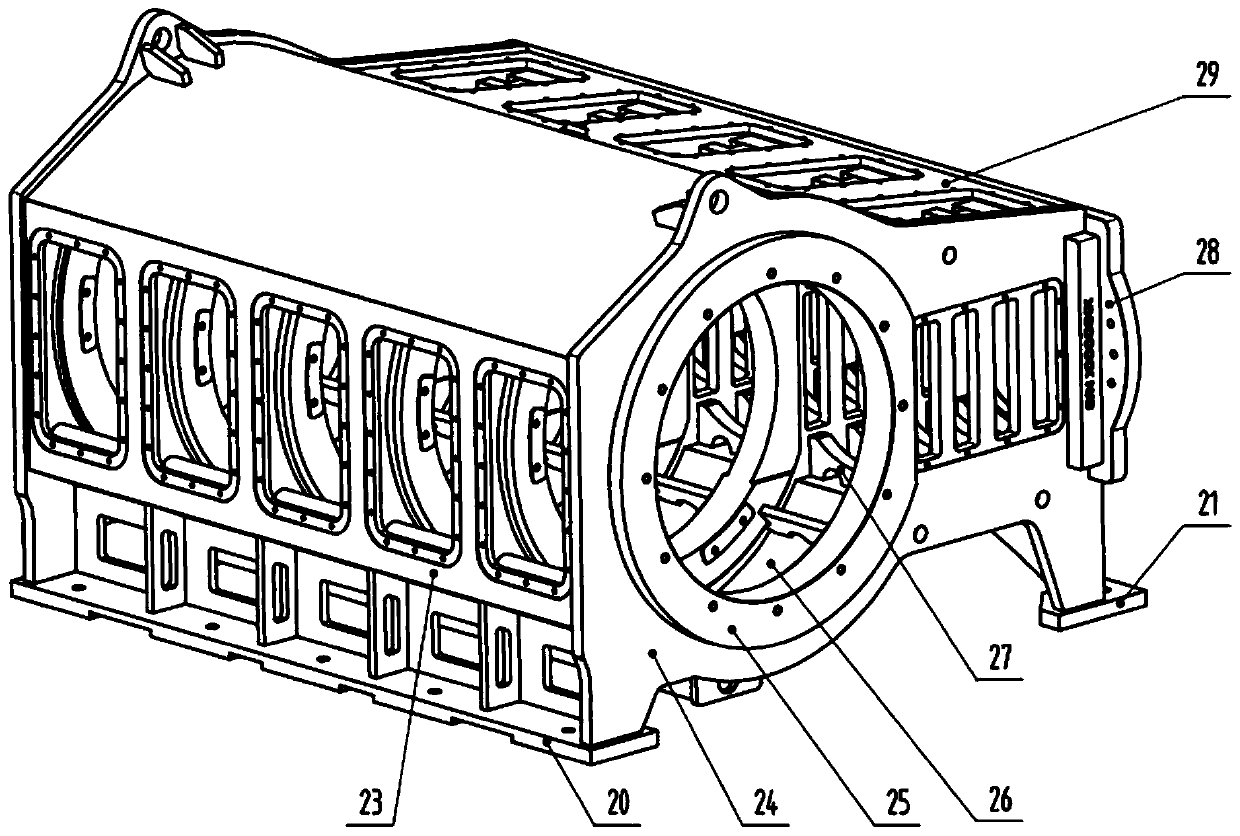

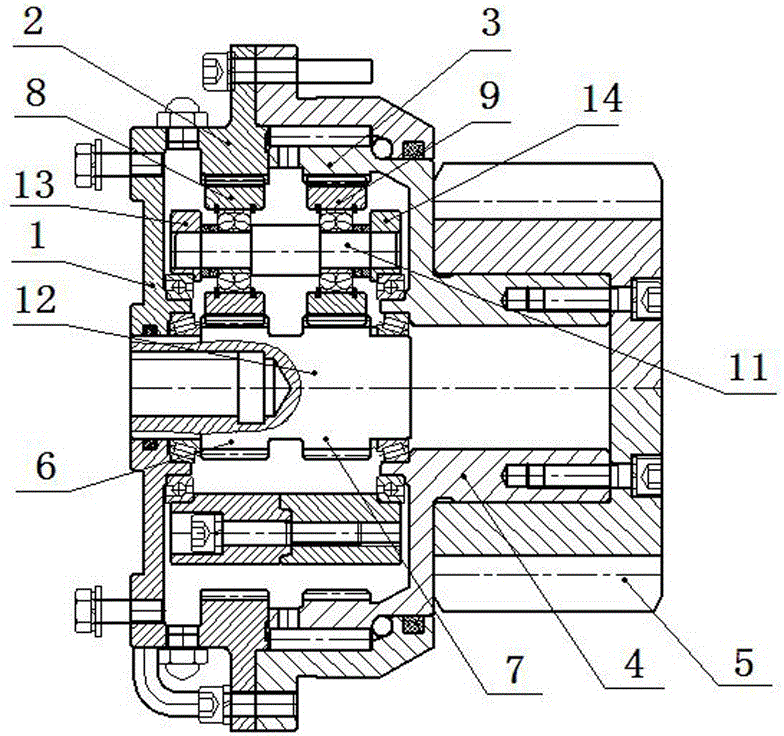

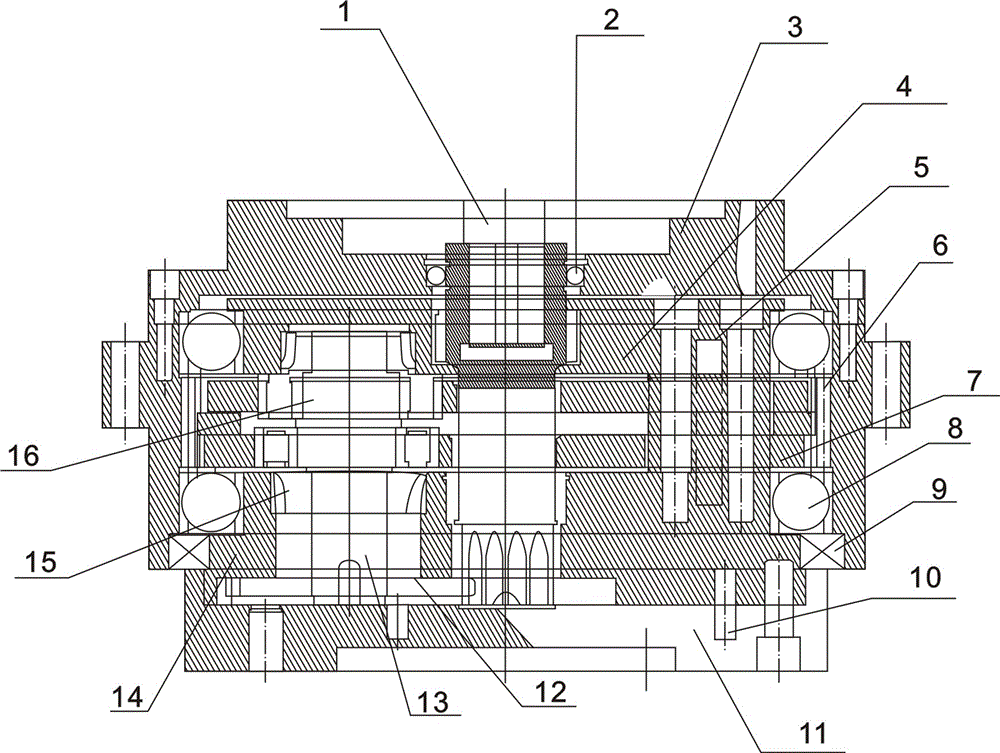

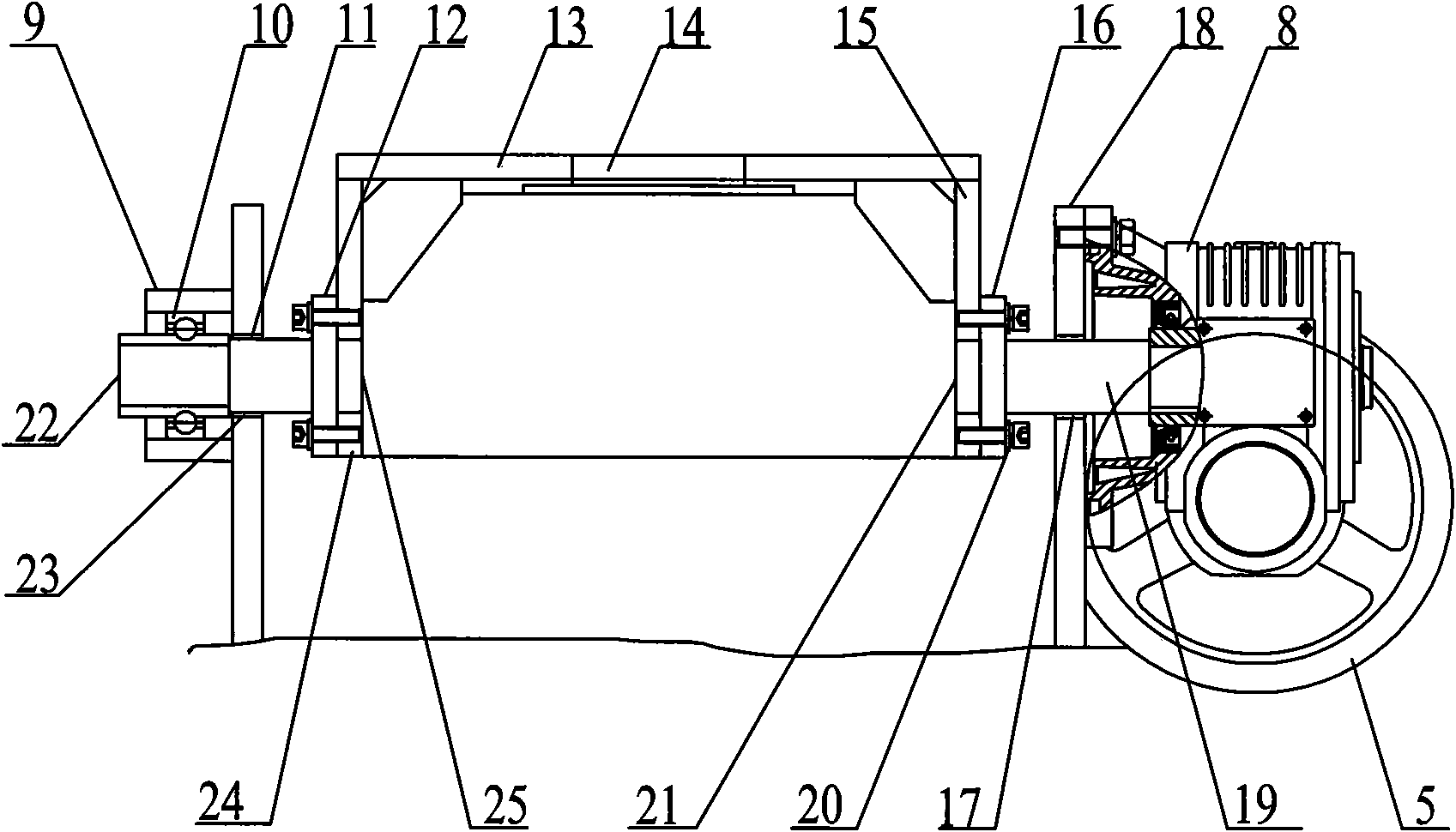

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

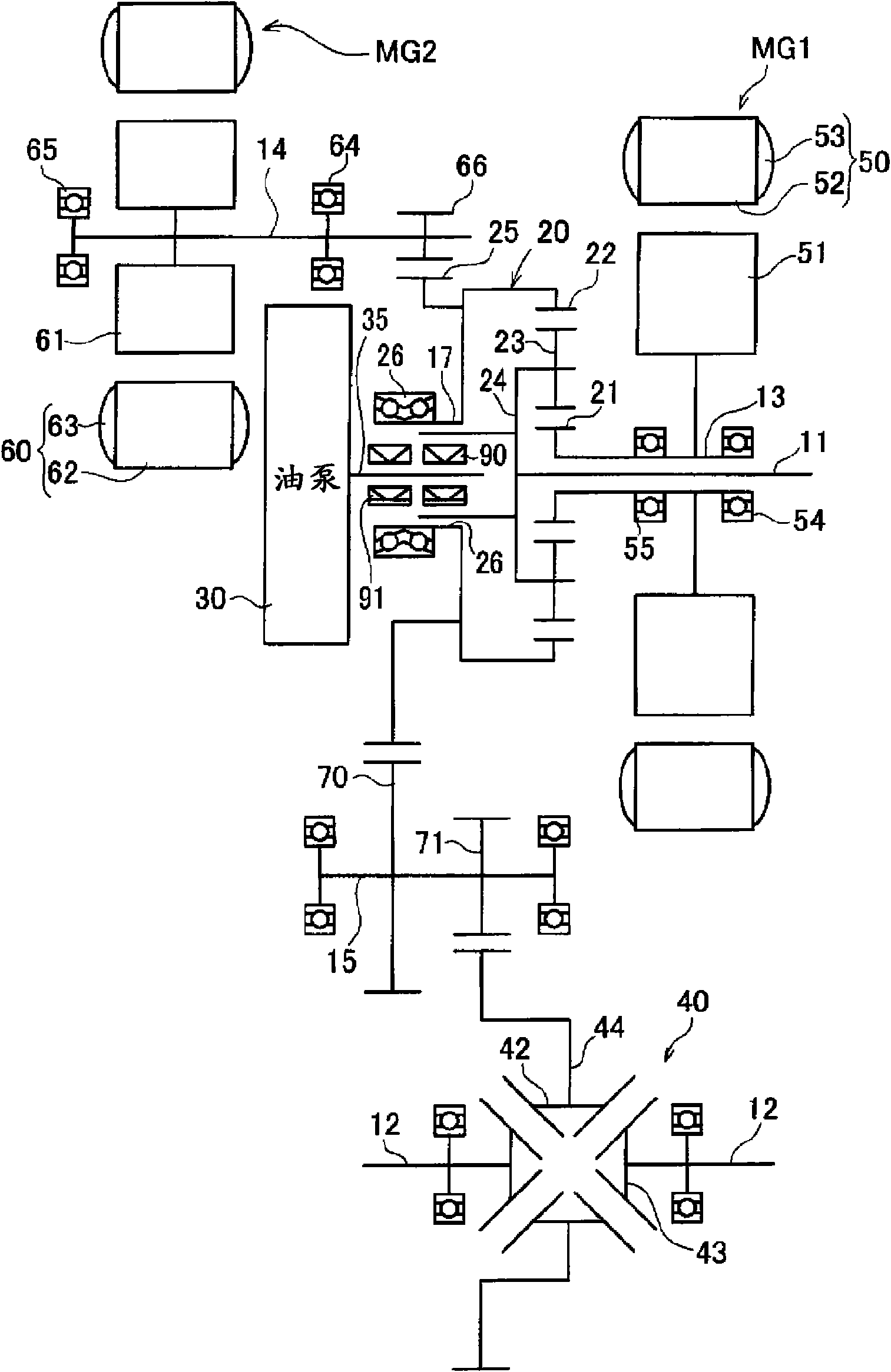

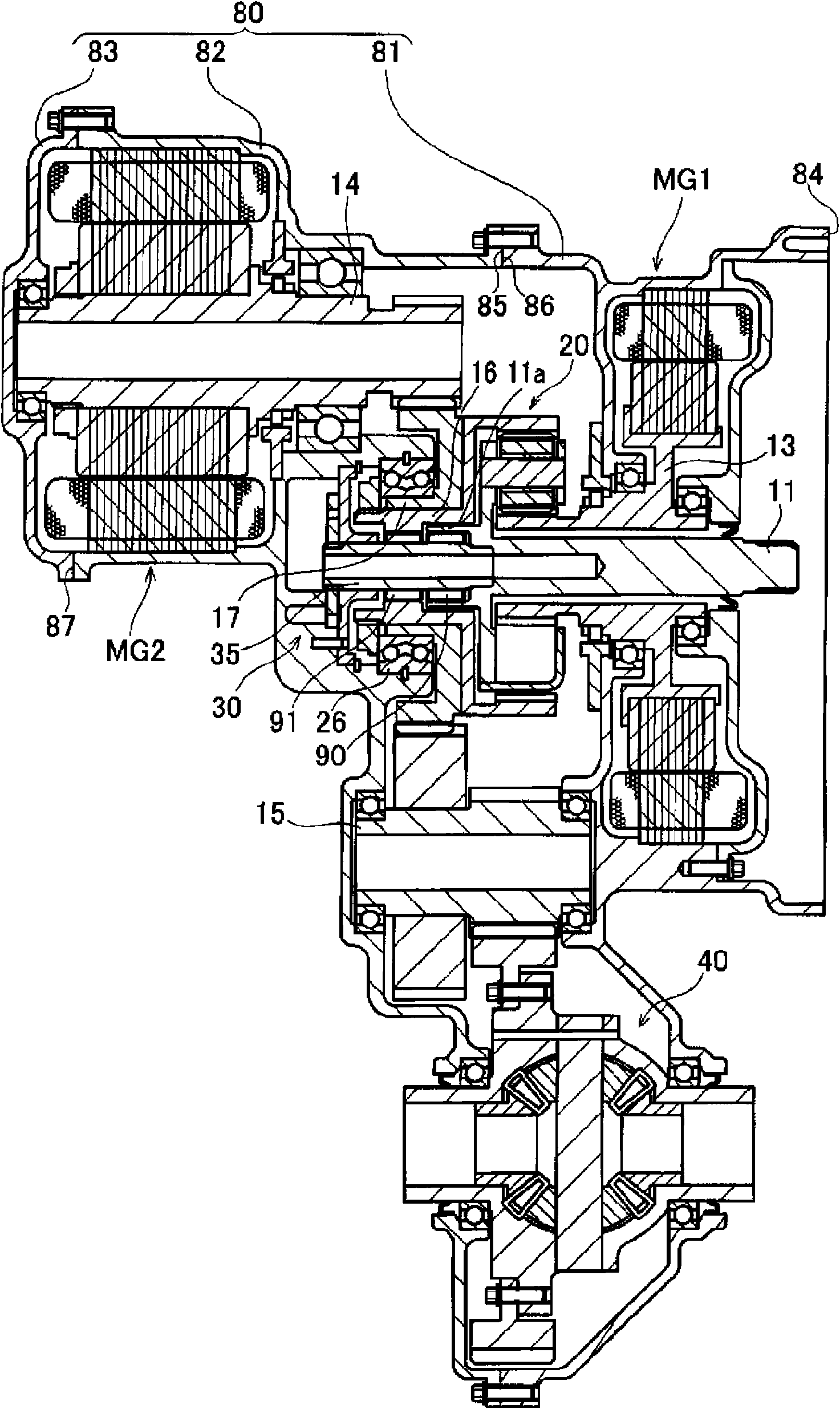

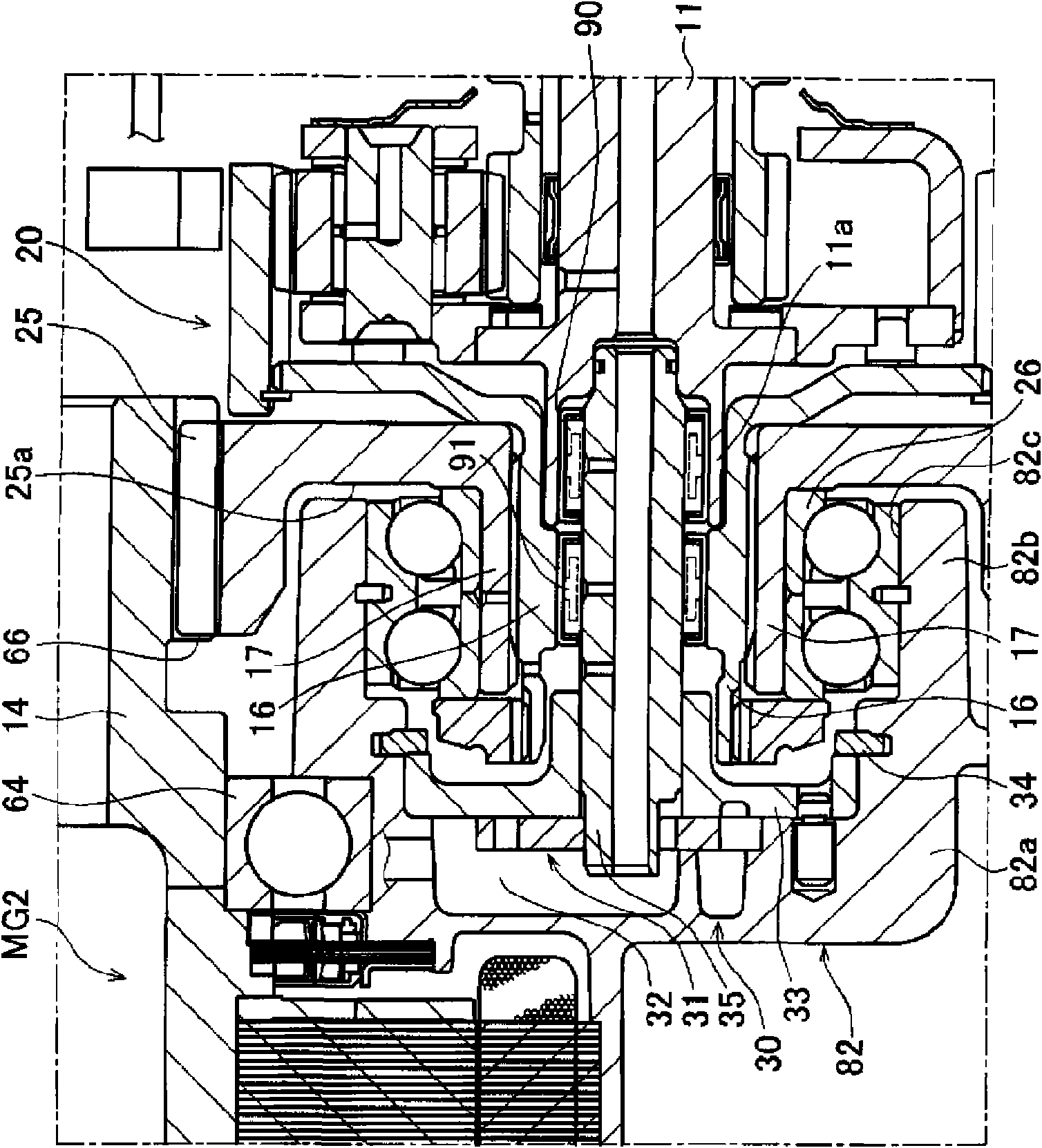

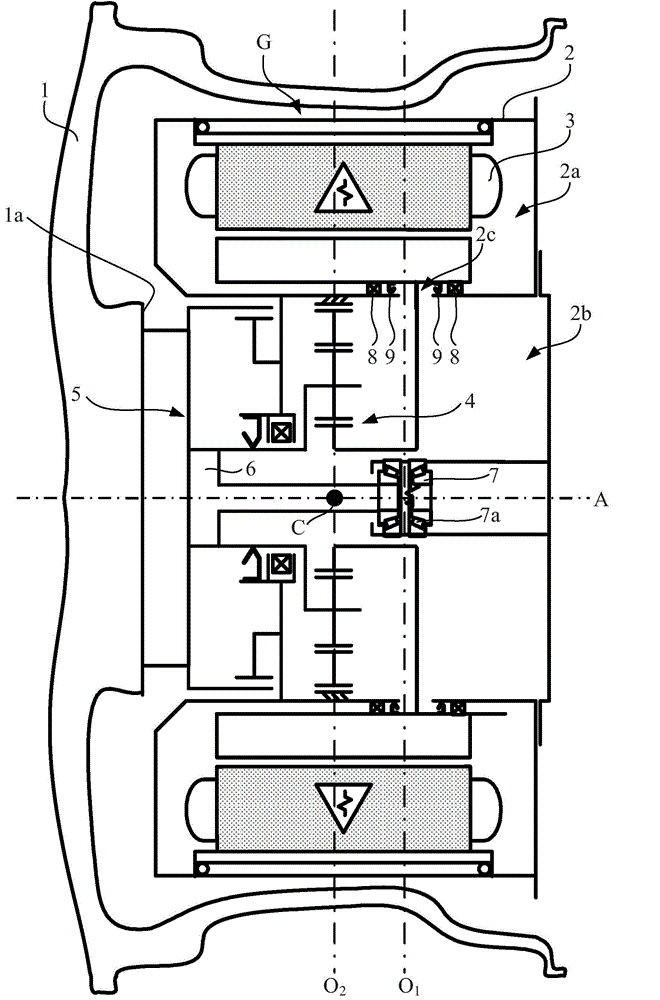

Drive device for hybrid vehicle

InactiveCN101626914AShorten the length of the axial directionEasy to assembleHybrid vehiclesAuxillary drivesHybrid vehicleClutch

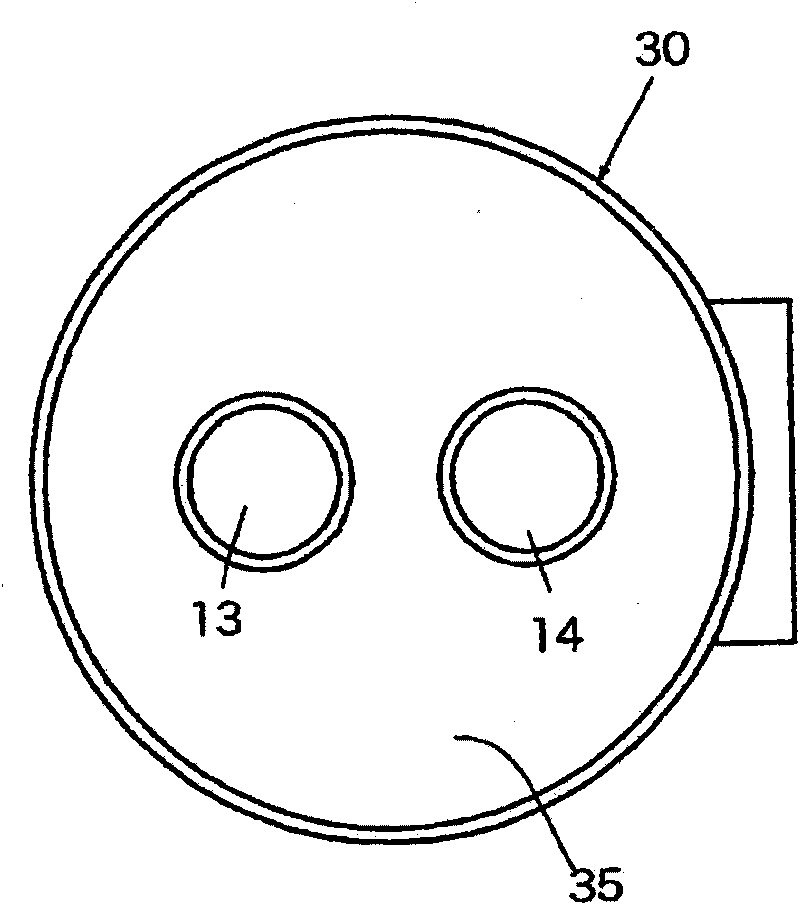

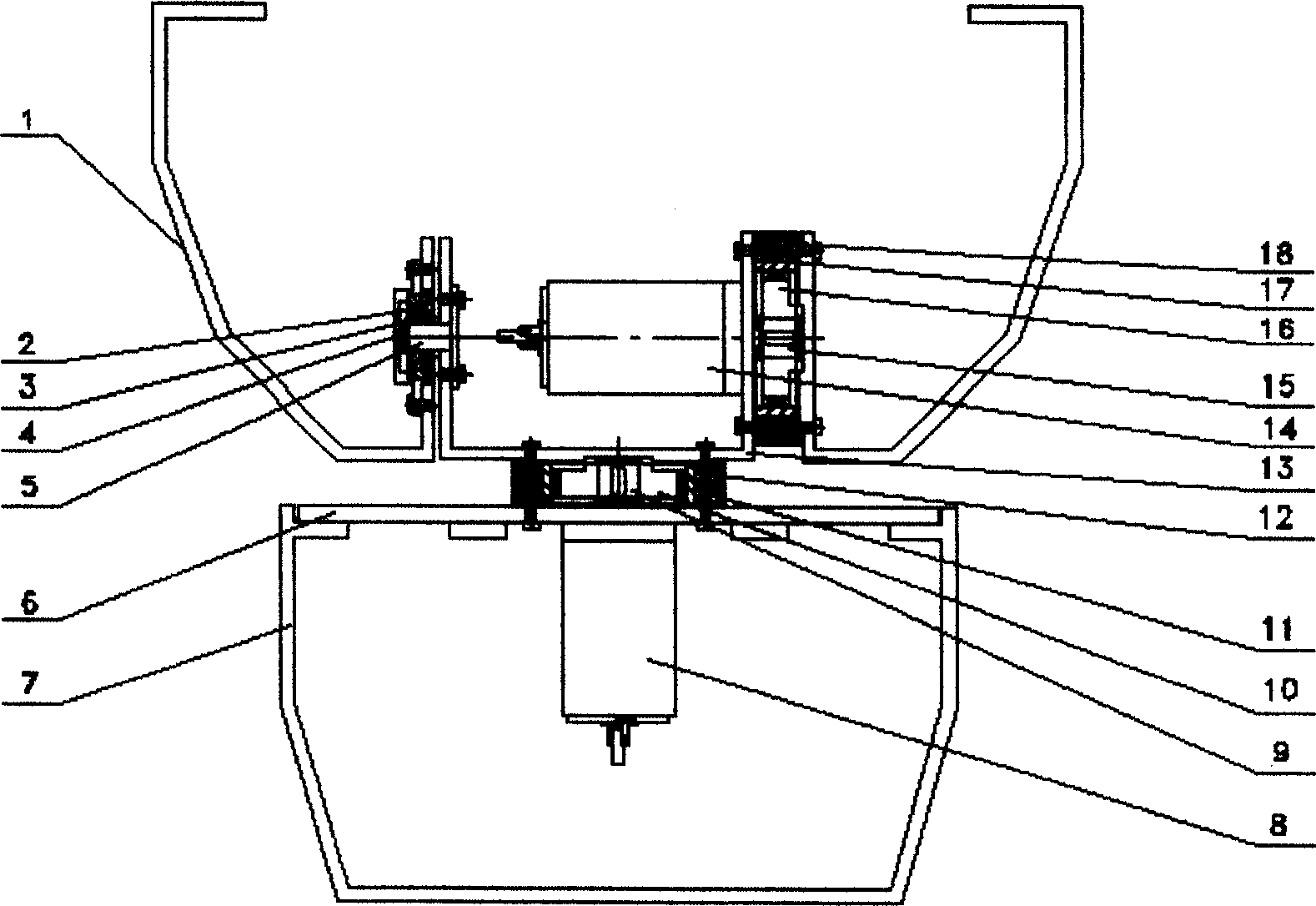

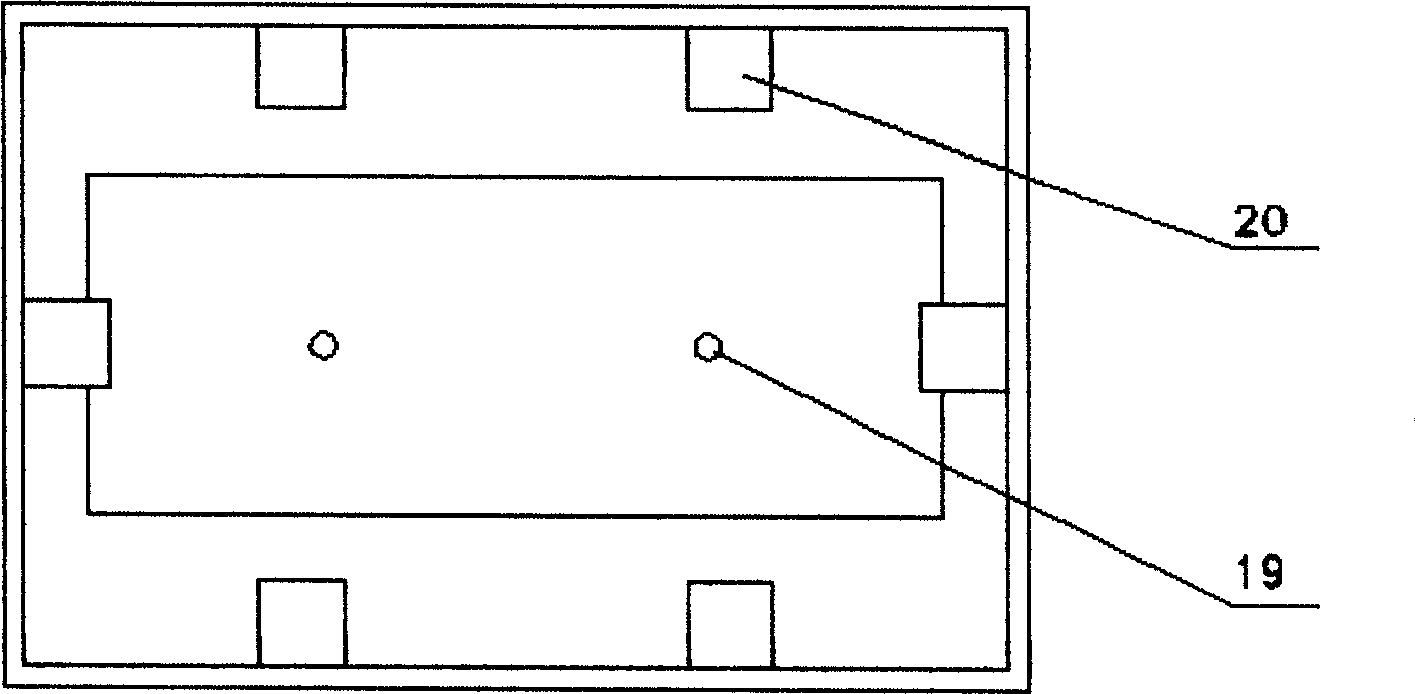

A drive device for a hybrid vehicle, in which a oil pump can be operated by power of either an input side rotating shaft or an output side rotating shaft without a reduction in performance of the oil pump and which is downsized by reducing the axial length of the drive device. An oil pump shaft (35) connected to an oil pump gear mechanism (31) of the oil pump (30) is drivably connected to an input shaft (11) through a one way clutch (90). The oil pump shaft (35) is also drivably connected to a ring gear shaft (16) connected to a counter gear (25) through a one way clutch (91). The one way clutches (90, 91) are caused to axially overlap a bearing (26) for supporting the counter gear (25), and this arranges the one way clutches (90, 91) at positions on the inner peripheral side of a boss (17) of the counter gear (25).

Owner:AISIN AW CO LTD +1

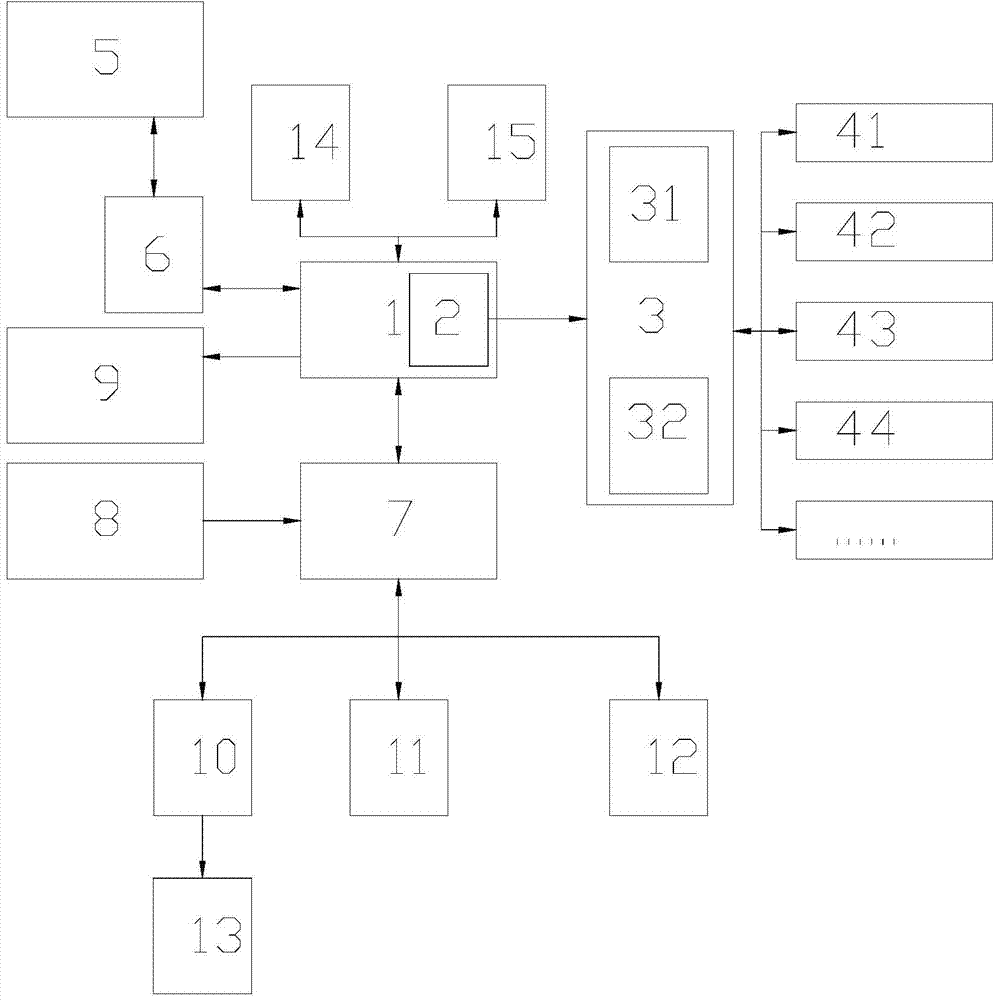

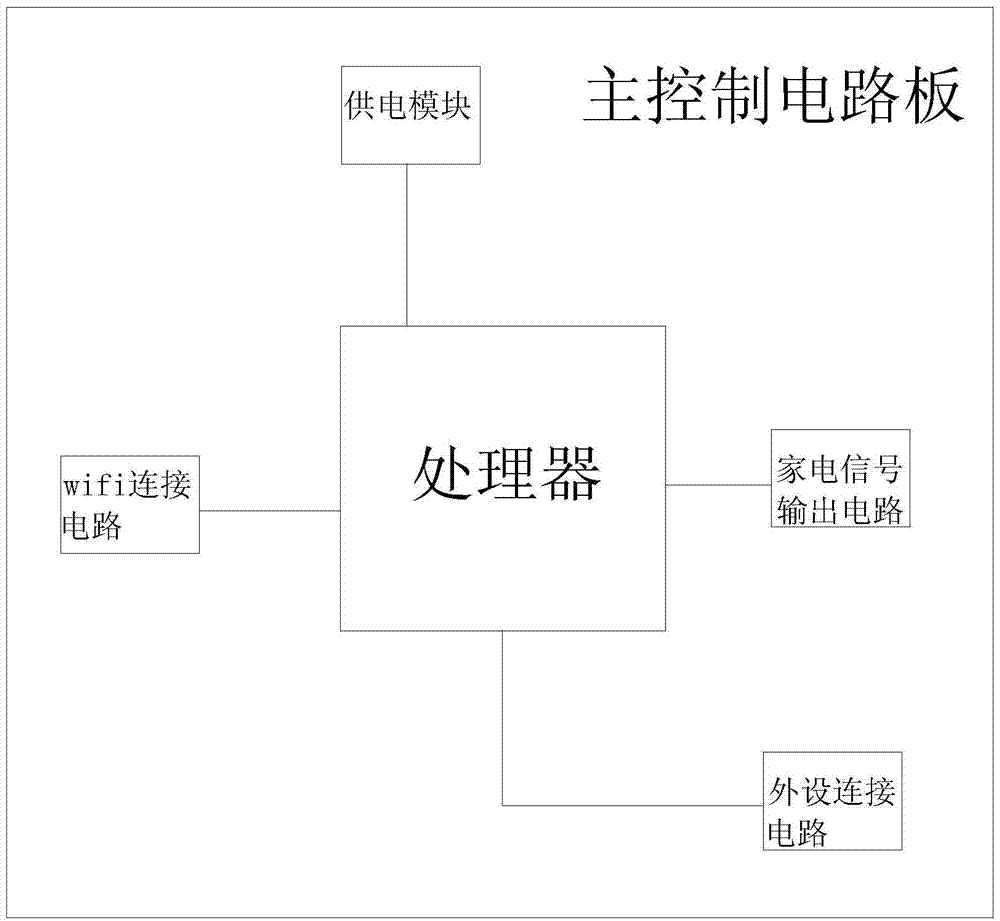

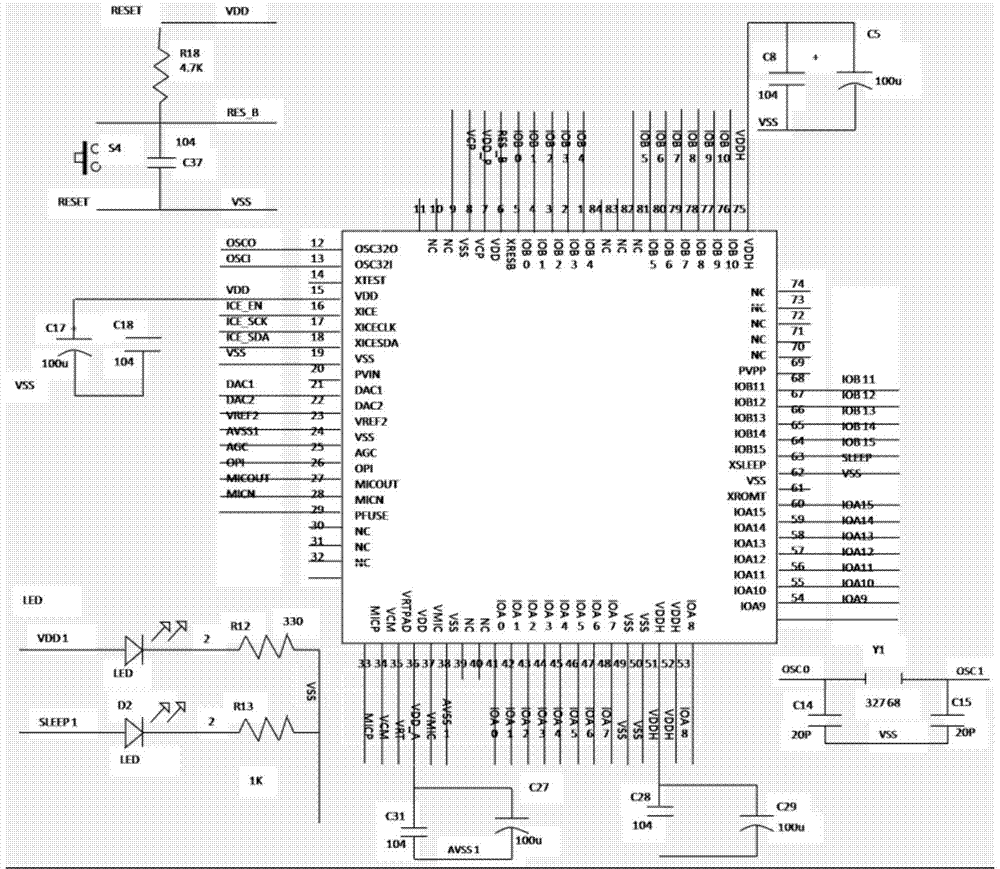

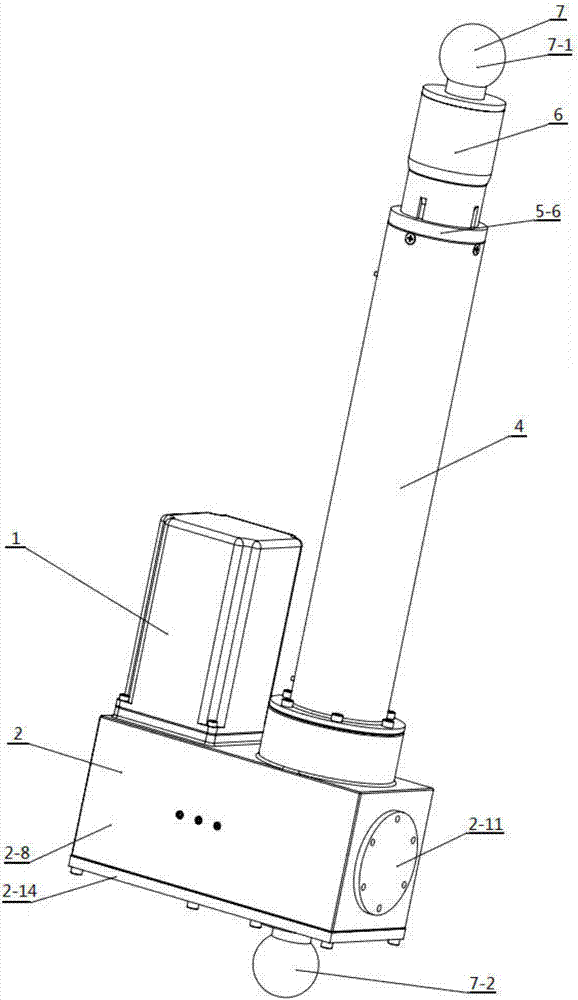

Intelligent household robot

PendingCN104714411AAccurate judgmentAvoid influenceComputer controlPosition/course control in two dimensionsControl signalControl system

The invention relates to an intelligent household robot. The intelligent household robot includes a robot body. The robot body is provided with a control circuit board and a household control system. The household control system comprises a household appliance control unit and a signal emitting and receiving unit, wherein the household appliance control unit is arranged on the control circuit board, and the signal emitting and receiving unit is connected with the household appliance control unit. A remote control command signal transmitted by a user is received by the signal emitting and receiving unit to the household appliance control unit. The household control unit stores, processes and analyzes received data to generate household appliance control signals of all household appliances, and the household appliance control signals are transmitted by the signal emitting and receiving unit to all the household appliances. The robot body is further provided with at least one of a remote monitoring system, an environment monitoring system and an entertainment system. The robot integrates four functions of the household control system, the remote monitoring system, the environment monitoring system and the entertainment system by integrating the different devices on the robot, so a full range of household requirements of the user are met, and household comfort and convenience are improved.

Owner:QINGDAO HAIER ROBOT CO LTD +2

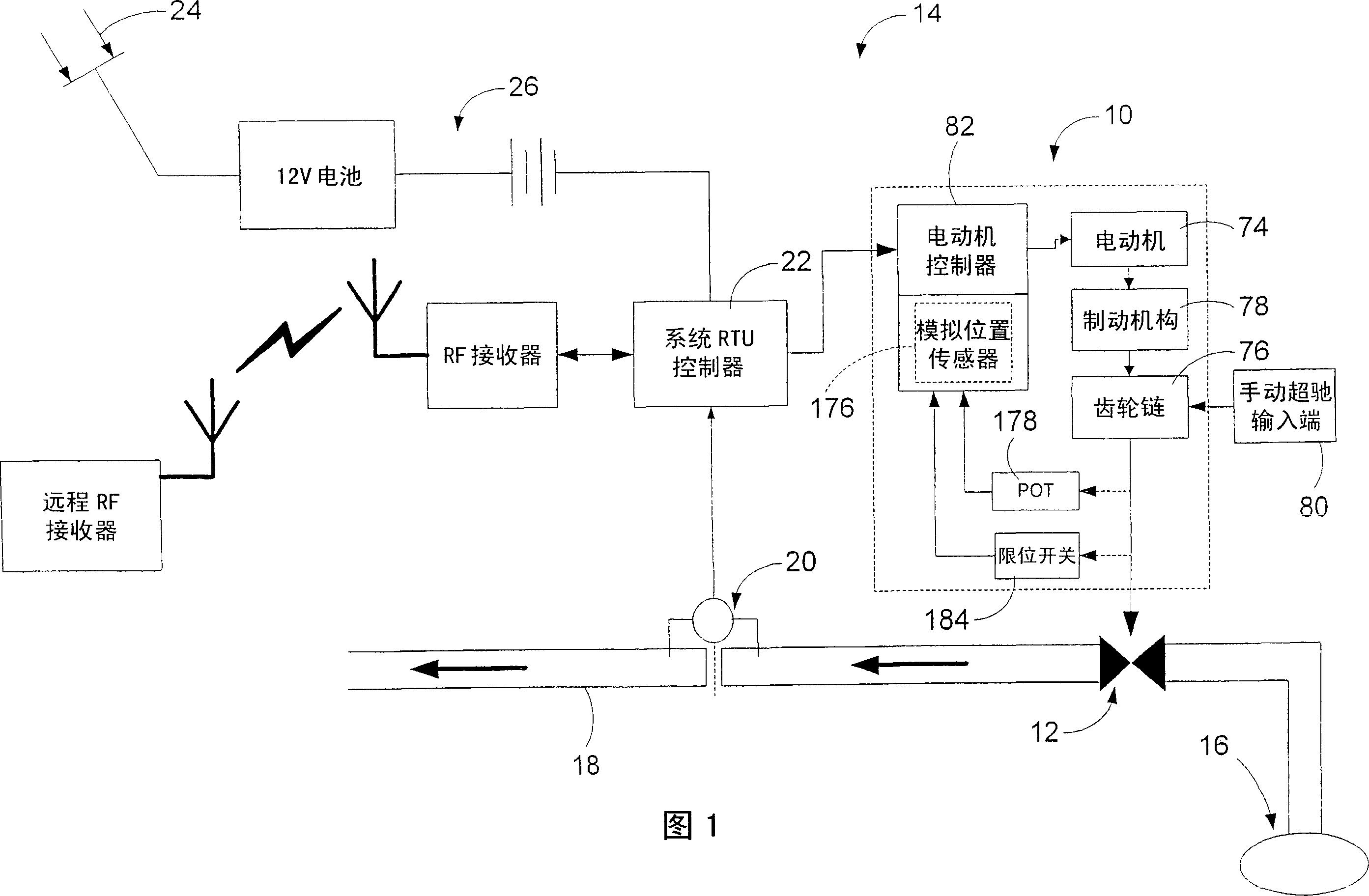

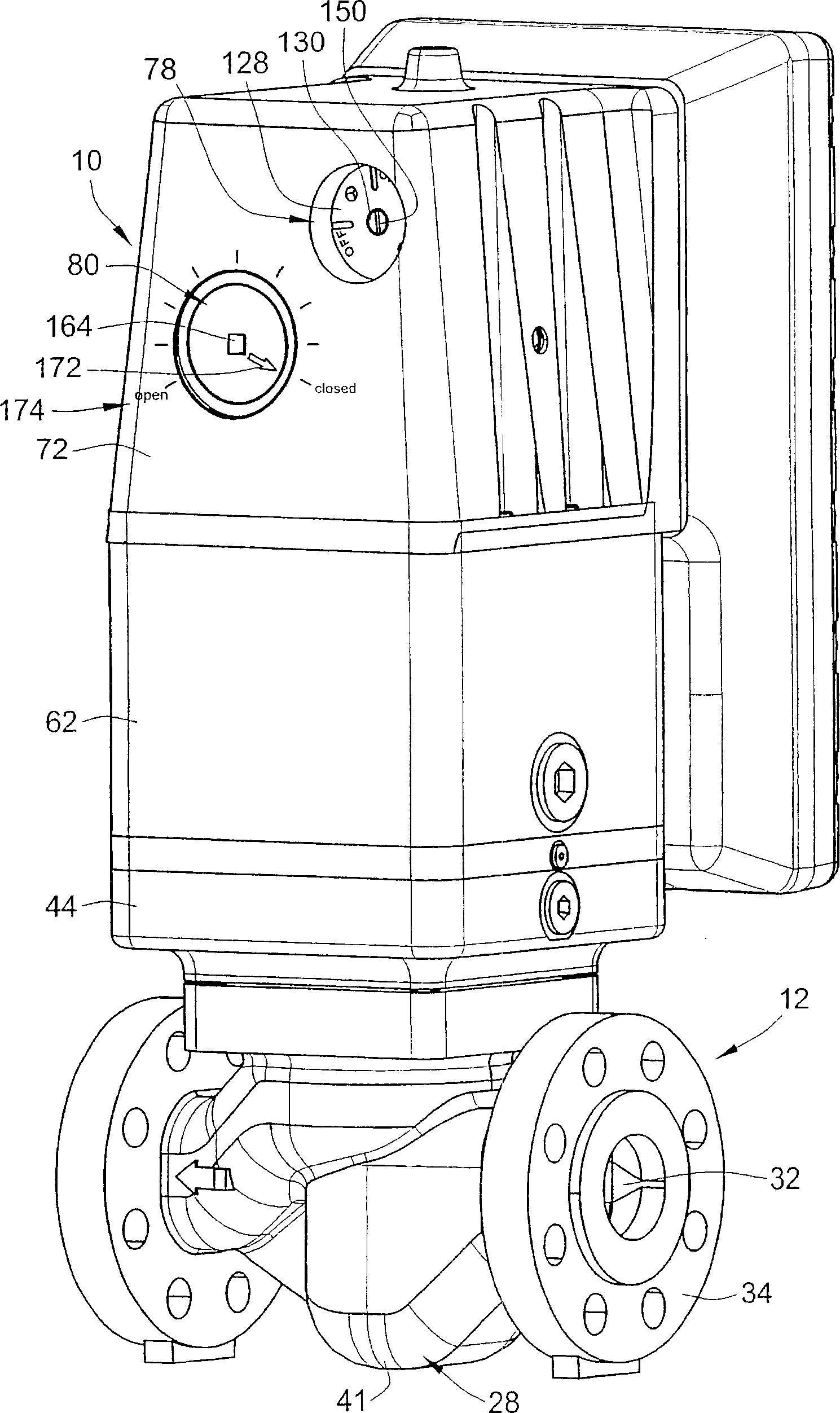

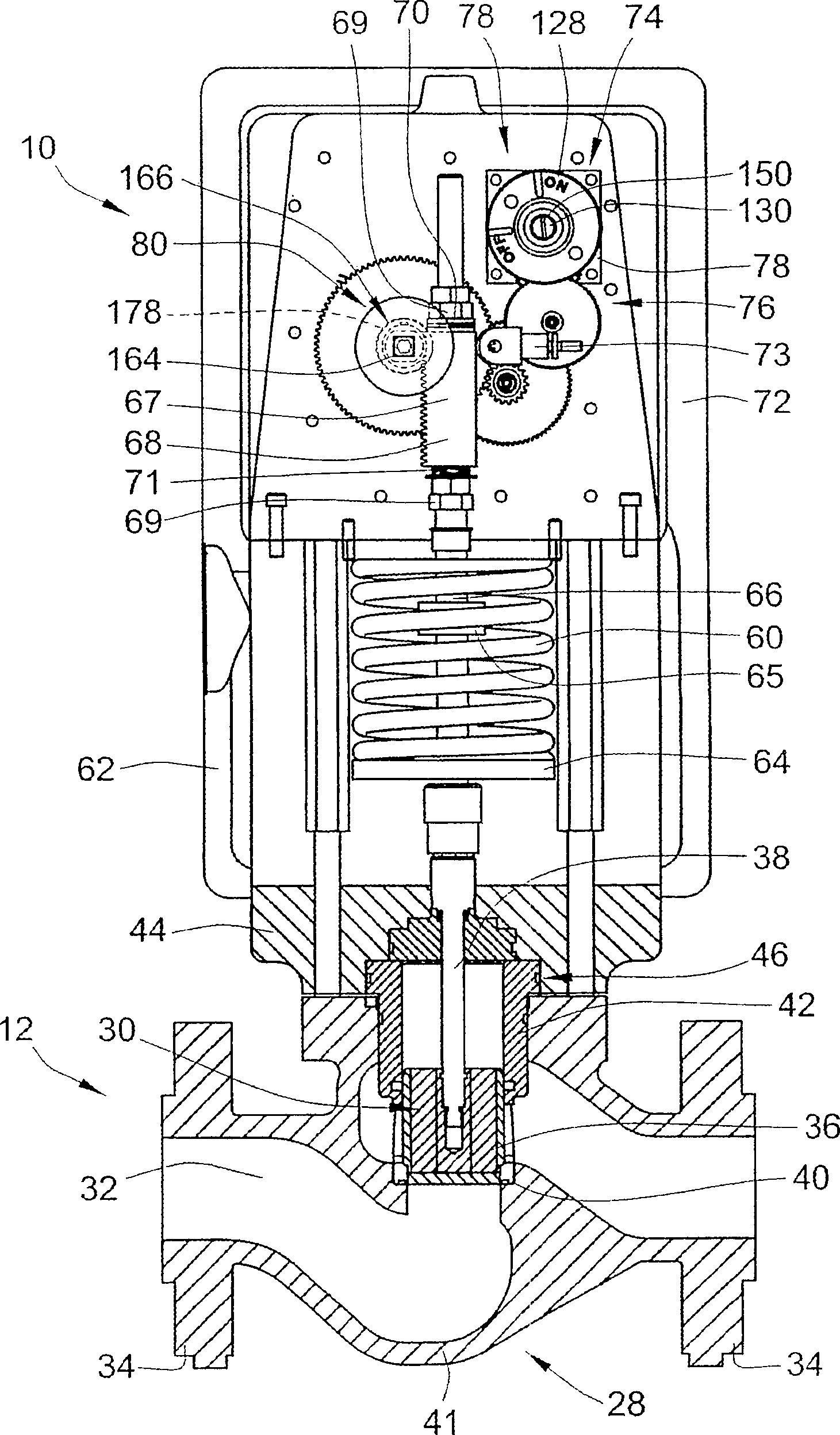

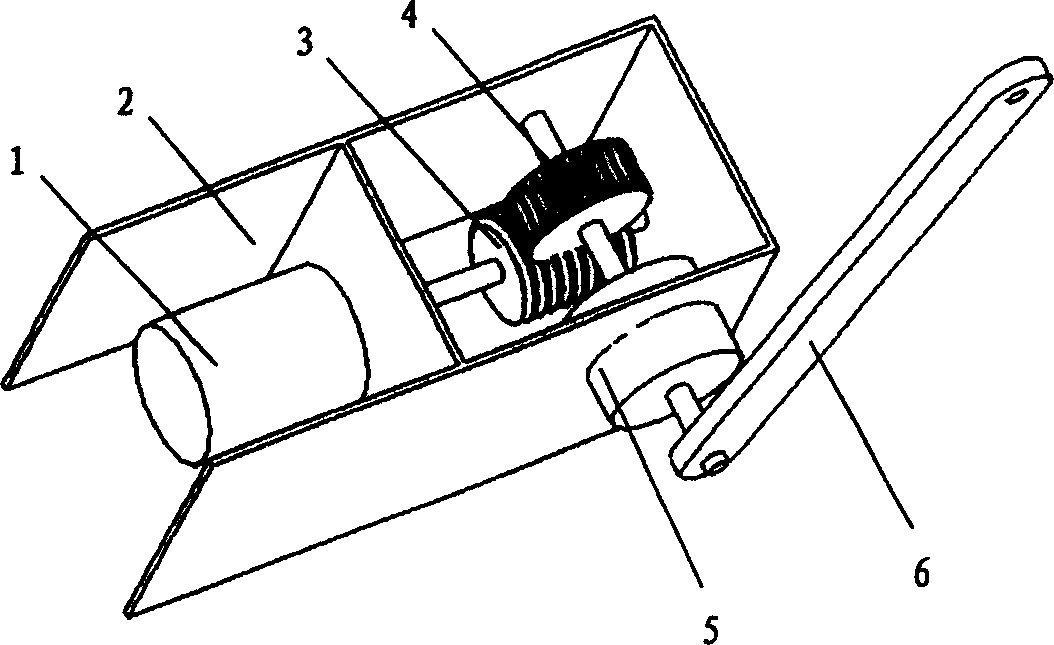

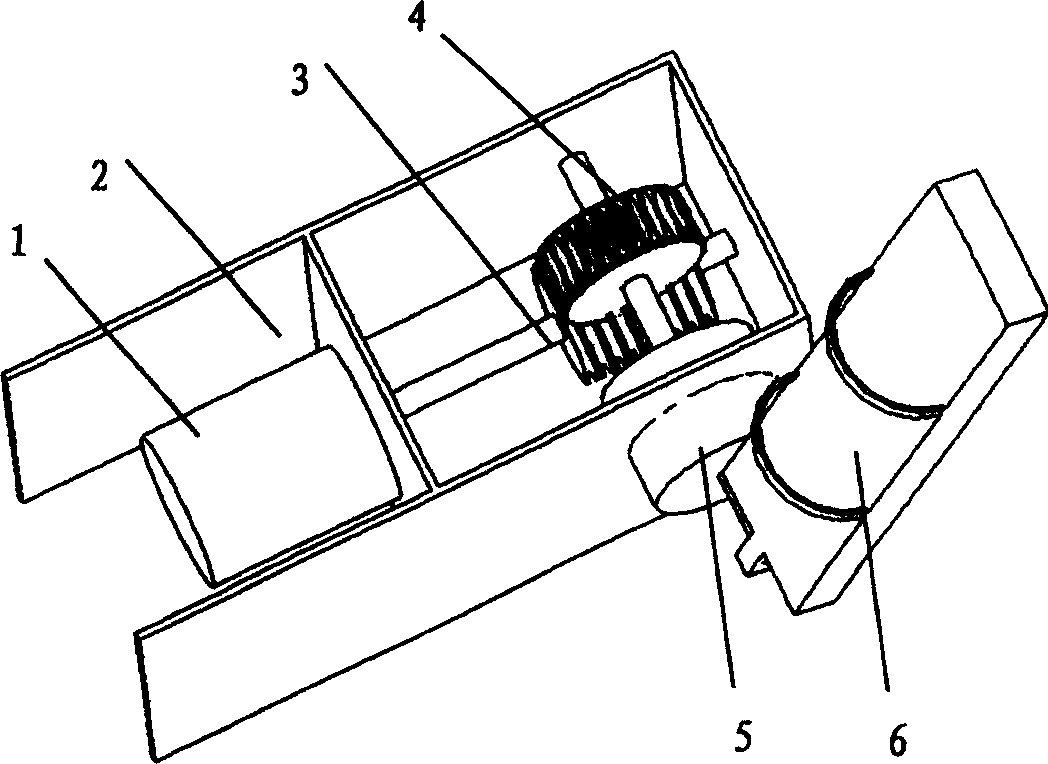

Actuator for well-head valve or other similar applications and system incorporating same

InactiveCN1748072AReduce the speed of the actuationEmission reductionOperating means/releasing devices for valvesFlushingElectricityElectrical battery

The invention discloses an electric actuator which is particularly suitable for driving wellhead valves to adjust the flow rate of natural gas in production wells. The electric actuator can be driven by the prior local power supply (typically for solar panels and batteries) in a wellhead valve system. The electric actuator can comprise a gear reducing chain, a brake and a manual override input unit with clutch protection. The electric actuator can be configured into three different operation modes, and provides preset positions during power off which comprise a fault bias fixation, a fault opening and a fault bias closing.

Owner:WOODWARD GOVERNOR CO

Drive device and vehicle with same

ActiveCN102362097ALarge reduction ratioImprove handling stability (turn)Hybrid vehiclesElectric propulsion mountingEngineeringElectric motor

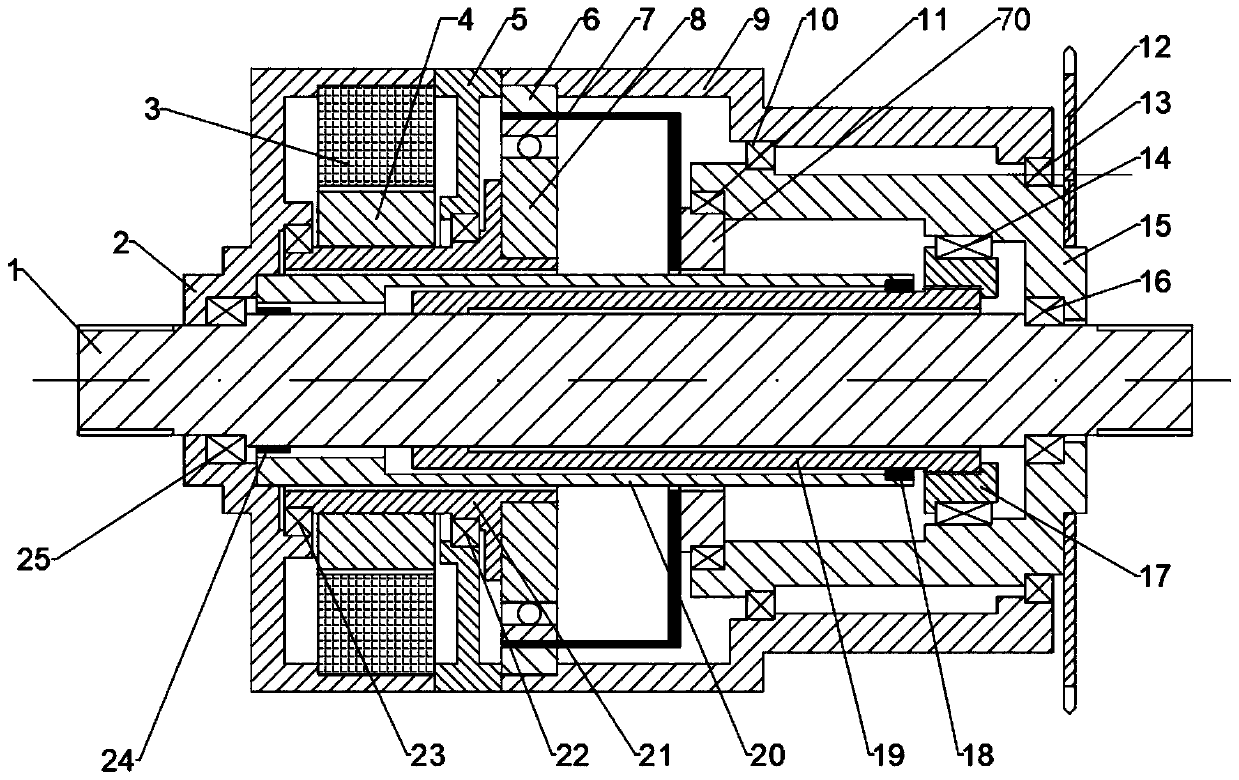

A drive device (1A) provided with electric motors (2A, 2B) for outputting driving power and also with planetary gear type reduction gears (12A, 12B) arranged between axles (10A, 10B) connected to circular tube shafts (16A, 16B) serving as the output shafts of the electric motors (2A, 2B) and to rear wheels (LWr, RWr). The drive device (1A) is also provided with a unidirectional power transmitting means provided in a transmission route from the electric motors (2A, 2B) to the axles (10A, 10B) and transmitting the unidirectional rotational power of the electric motors (2A, 2B) to the axles (10A, 10B) and with a bidirectional power transmitting means for transmitting the bidirectional rotational power of the electric motors (2A, 2B) to the axles (10A, 10B).

Owner:HONDA MOTOR CO LTD

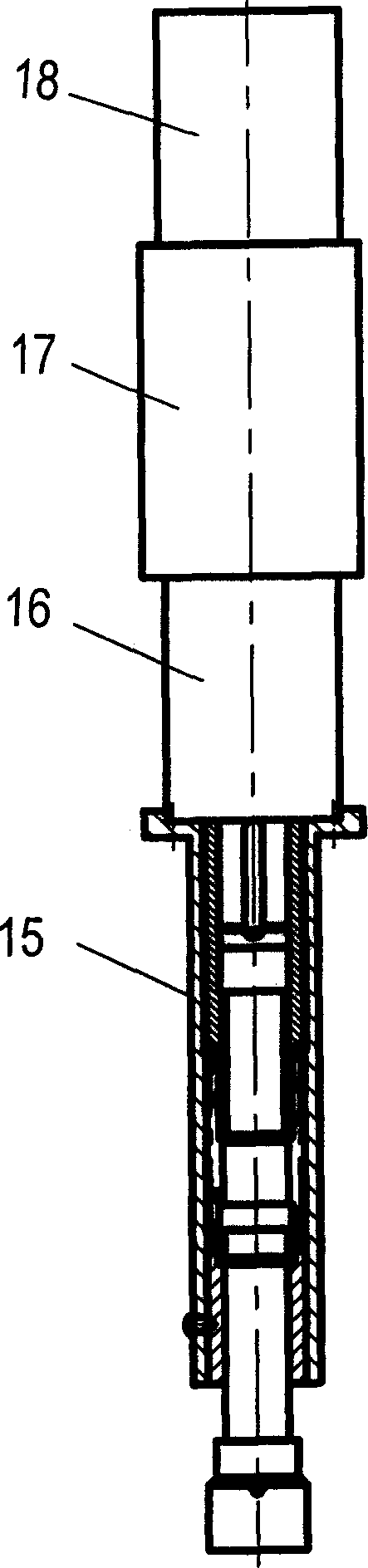

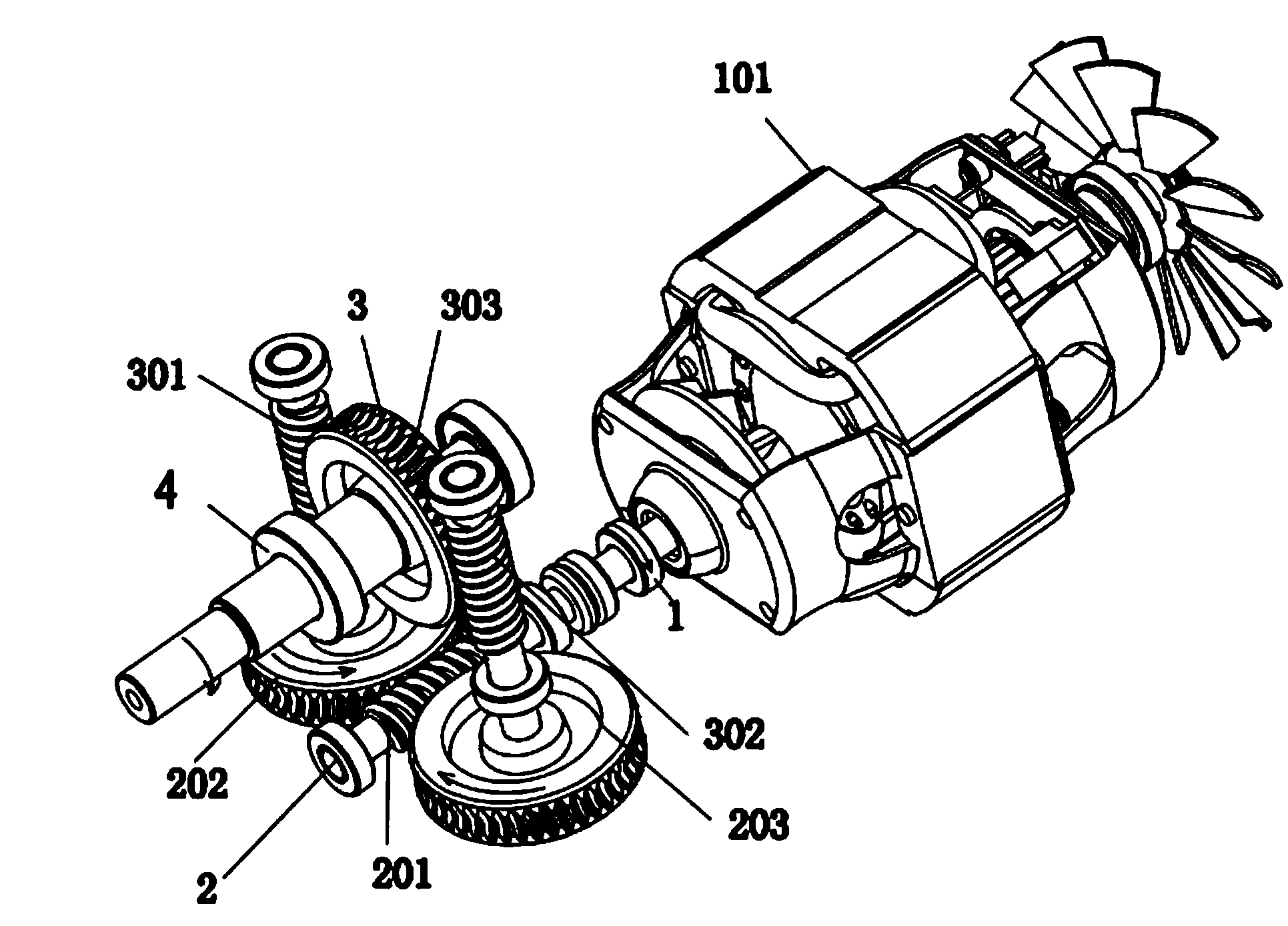

Screwing machine based on servo system

The invention relates to screw thread screw-up machine based on servo system. Its features are that the servo motor is used as the driving mechanism. Reducing mechanism and toque sensor are set between the driving and output mechanism. The reducing mechanism is adopted two grade reducing; the first grade is planet gear train; the second grade is low tooth difference driving. It is adopted dynamic toque sensor; one end of the strain axis of the sensor is directly connected to the output end of the reducing mechanism; the other end is directly connected to the spline housing used as the driving input in the output mechanism. The invention possesses high assembling efficiency and high assembling precision, especially suits to motor dom, can realize relatively precise control to the screwing up of the bolt.

Owner:HEFEI UNIV OF TECH

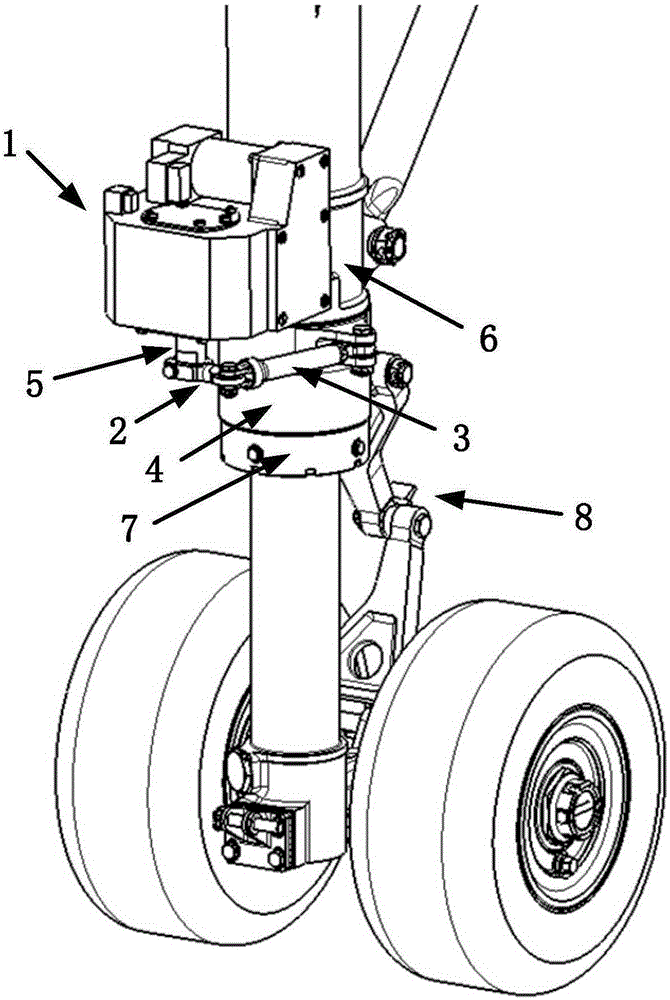

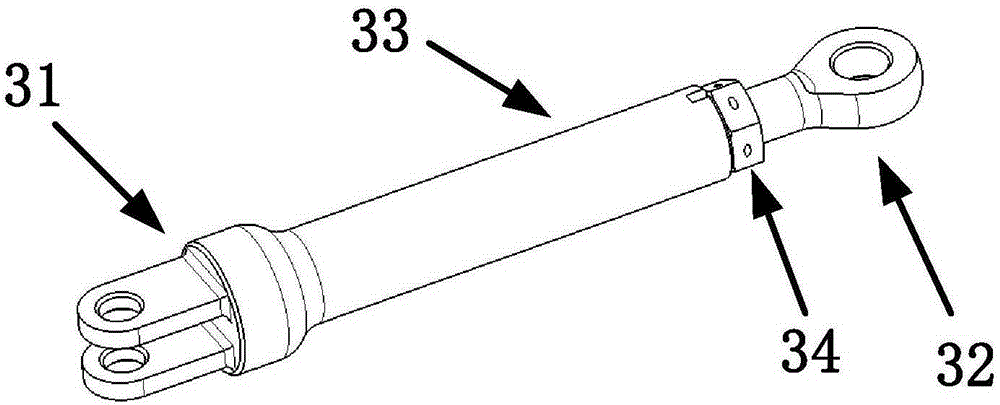

Electrically-driven nose wheel steering device for unmanned aerial vehicle

The invention relates to an electrically-driven nose wheel steering device for an unmanned aerial vehicle. The electrically-driven nose wheel steering device comprises a steering drive actuator, a steering torque arm, a link assembly and a drum assembly, wherein a motor in the steering drive actuator drives an output shaft to rotate through a transmission mechanism; the steering torque arm rotates along with the output shaft, the steering torque arm is connected to the link assembly through a knuckle bearing, and the link assembly drives the drum assembly to rotate; and the drum assembly is connected with an upper torque arm of an undercarriage torque arm, and drives nose wheels to steer through the undercarriage torque arm. The electrically-driven nose wheel steering device disclosed by the invention is driven by the motor, has the advantages of being light in weight, high in reliability and maintainability, and the like, as well as is more applicable to undercarriage systems of small and medium-sized unmanned aerial vehicles. The electrically-driven nose wheel steering device disclosed by the invention is obtained through an improvement on the basis of the existing undercarriage structure, and an undercarriage does not need to be re-designed, thus avoiding the high cost brought by the re-designing.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

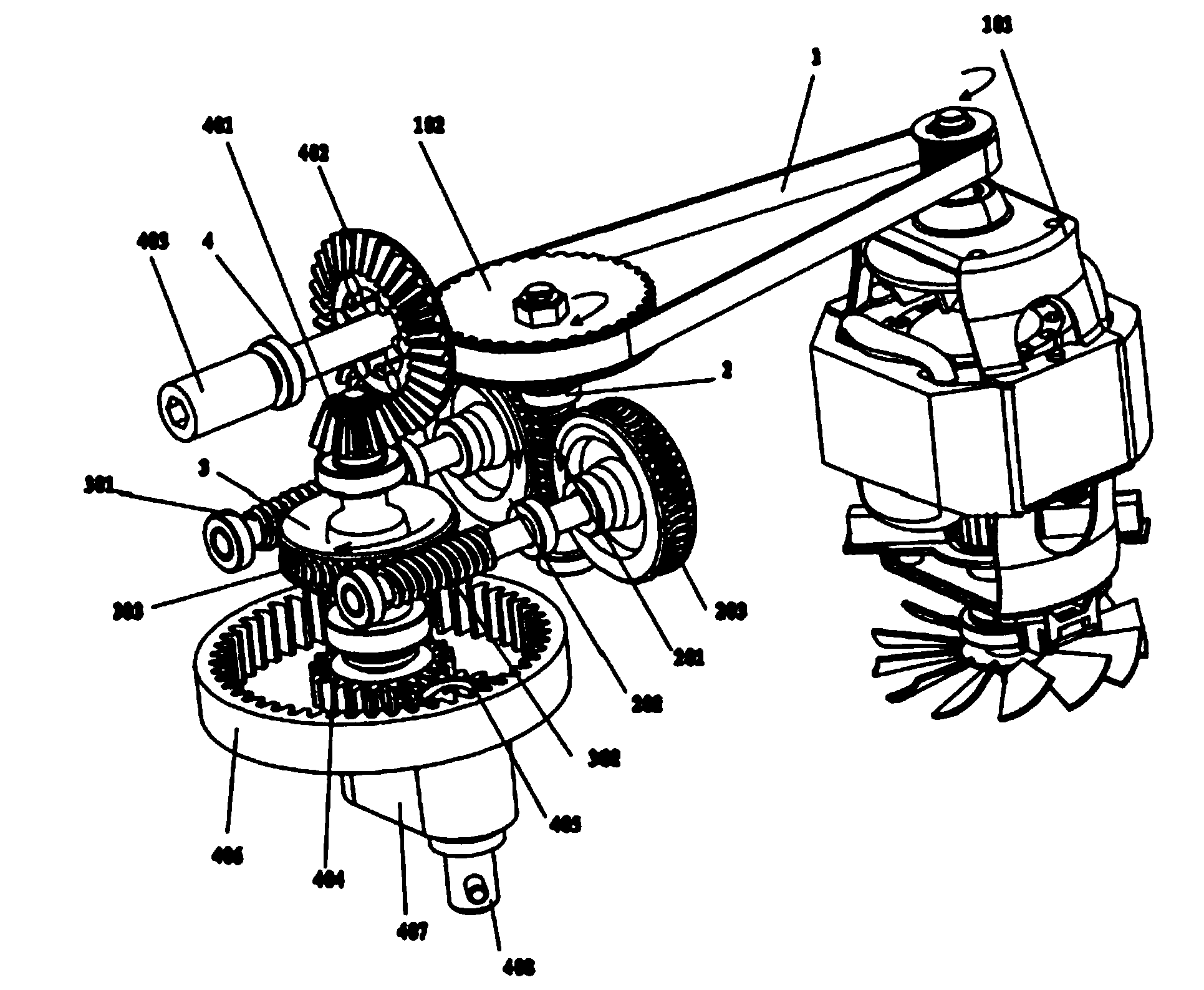

Robot arm part

InactiveCN102085667ALarge single-stage transmissionLarge reduction ratioProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

The invention provides a robot arm part which comprises a first hollow arm part, a second hollow arm part and a connecting joint used for connecting the first hollow arm part with the second hollow arm part, wherein the connecting joint comprises a driver with an output shaft, a harmonic wave retarding mechanism and a belt transmission mechanism, wherein the harmonic wave retarding mechanism comprises a wave generator, a flexible wheel arranged outside the wave generator, and a rigid wheel arranged outside the flexible wheel and meshed with the flexible wheel; the flexible wheel is relativelyfixed with the first hollow arm part, and the rigid wheel is relatively fixed with the second hollow arm part; and the belt transmission mechanism comprises a drive belt wheel, a driven belt wheel and a transmission belt, the drive belt wheel is fixedly connected with the output shaft of the driver, and the driven belt wheel is relatively fixed with the wave generator to drive the wave generator to rotate around a rotating axis. The robot arm part can obtain larger retarding ratio, has a compact structure, and is convenient for installation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Solar Corresponding Device

ActiveCN102298393AReasonable structureImprove mechanical propertiesPosition/direction controlEngineeringEnergy consumption

The invention relates to a sunlight corresponding apparatus, which comprises a solar energy assembly mount, a raised support bracket, a rotating support framework, a left-and-right angle corresponding driving member and a pitch angle corresponding driving member. The solar energy assembly mount is hinged on the rotating support framework that is hinged on the raised support bracket; and accurate tracking on sunlight is realized on the basis of coordinated movements of the left-and-right angle corresponding driving member and the pitch angle corresponding driving member. According to the invention, the apparatus has a simple and reasonable structure; energy consumption for running is low; and the running accuracy is high; besides, the apparatus is easy to control and is convenient for installation and daily maintenance.

Owner:刘建中

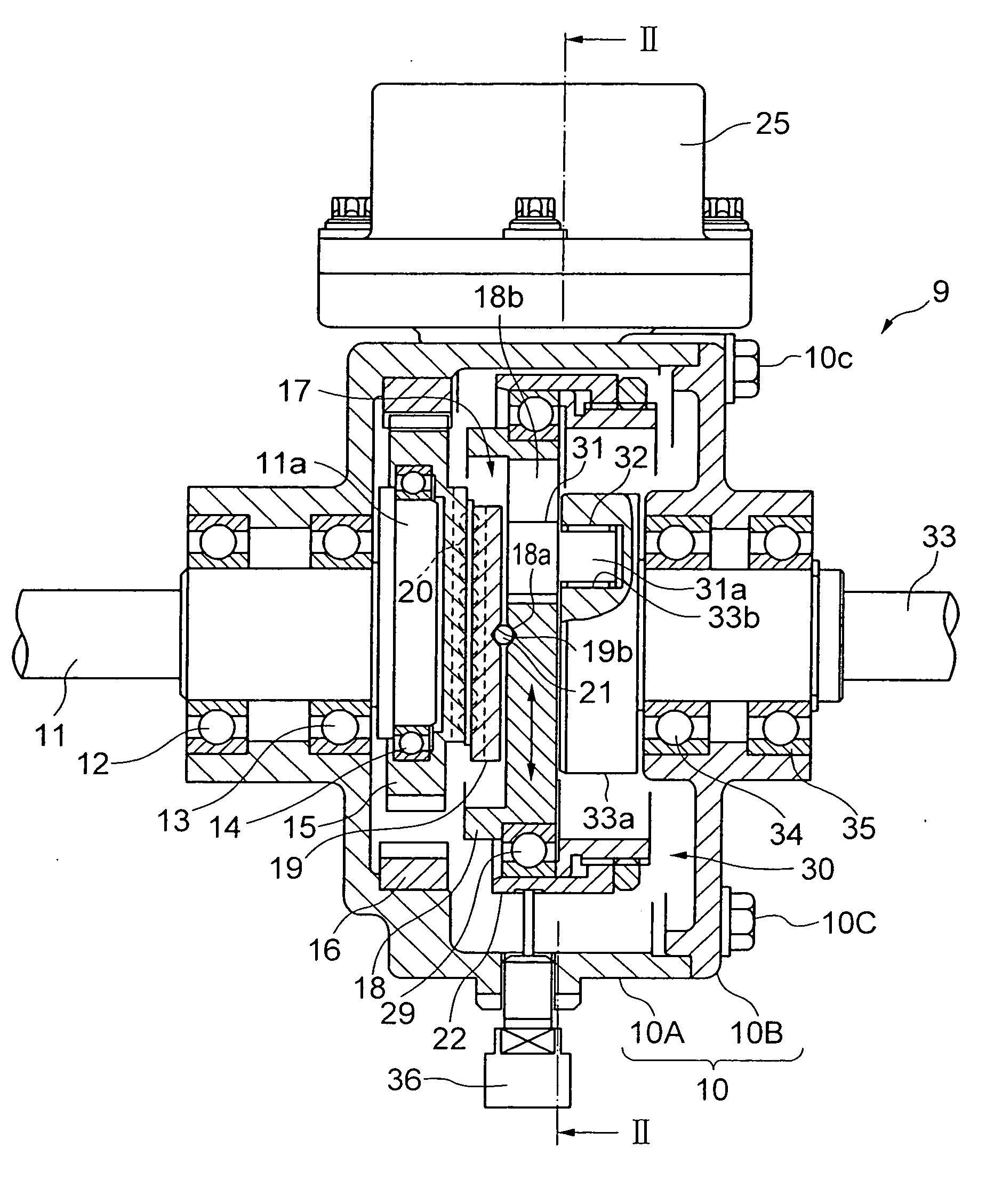

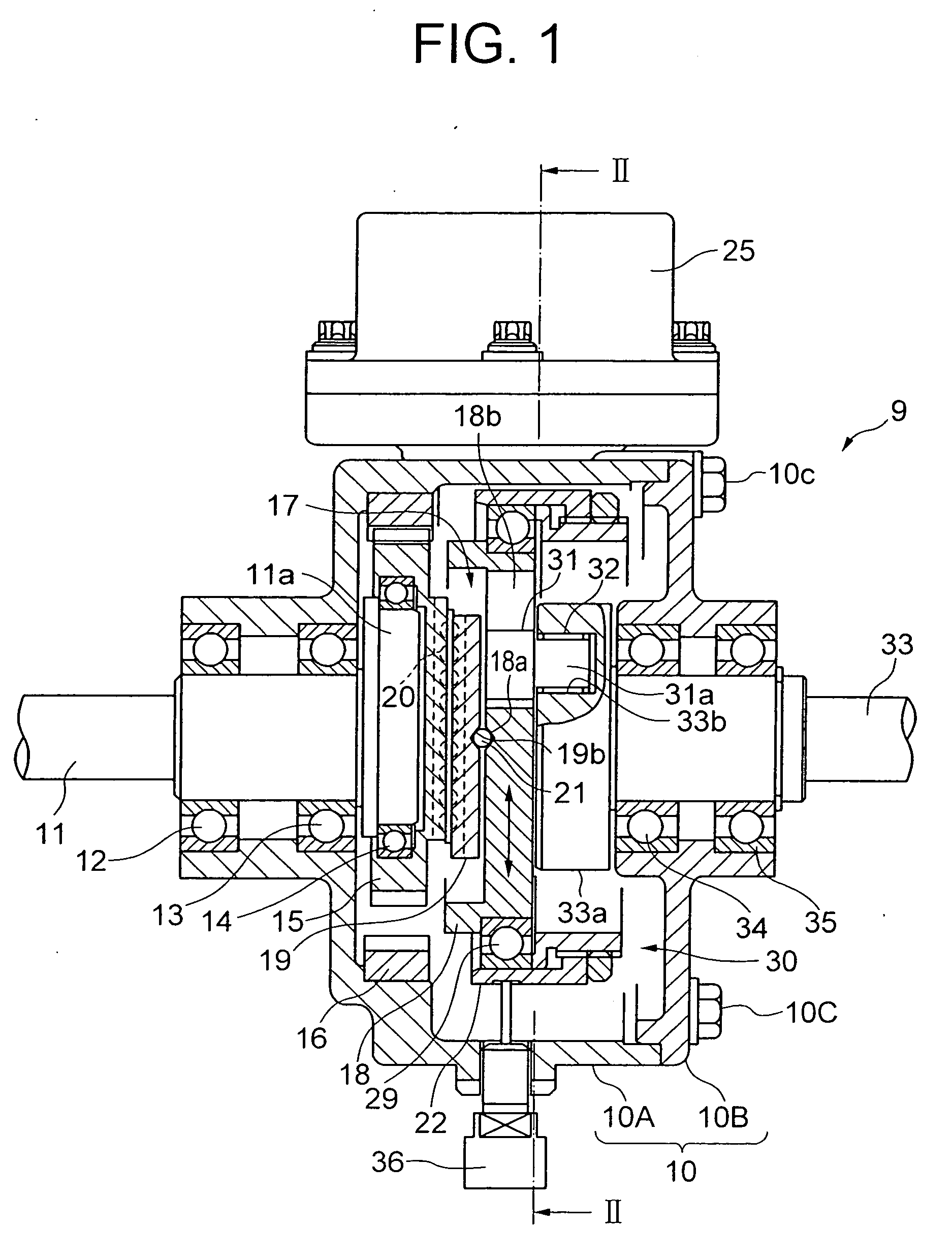

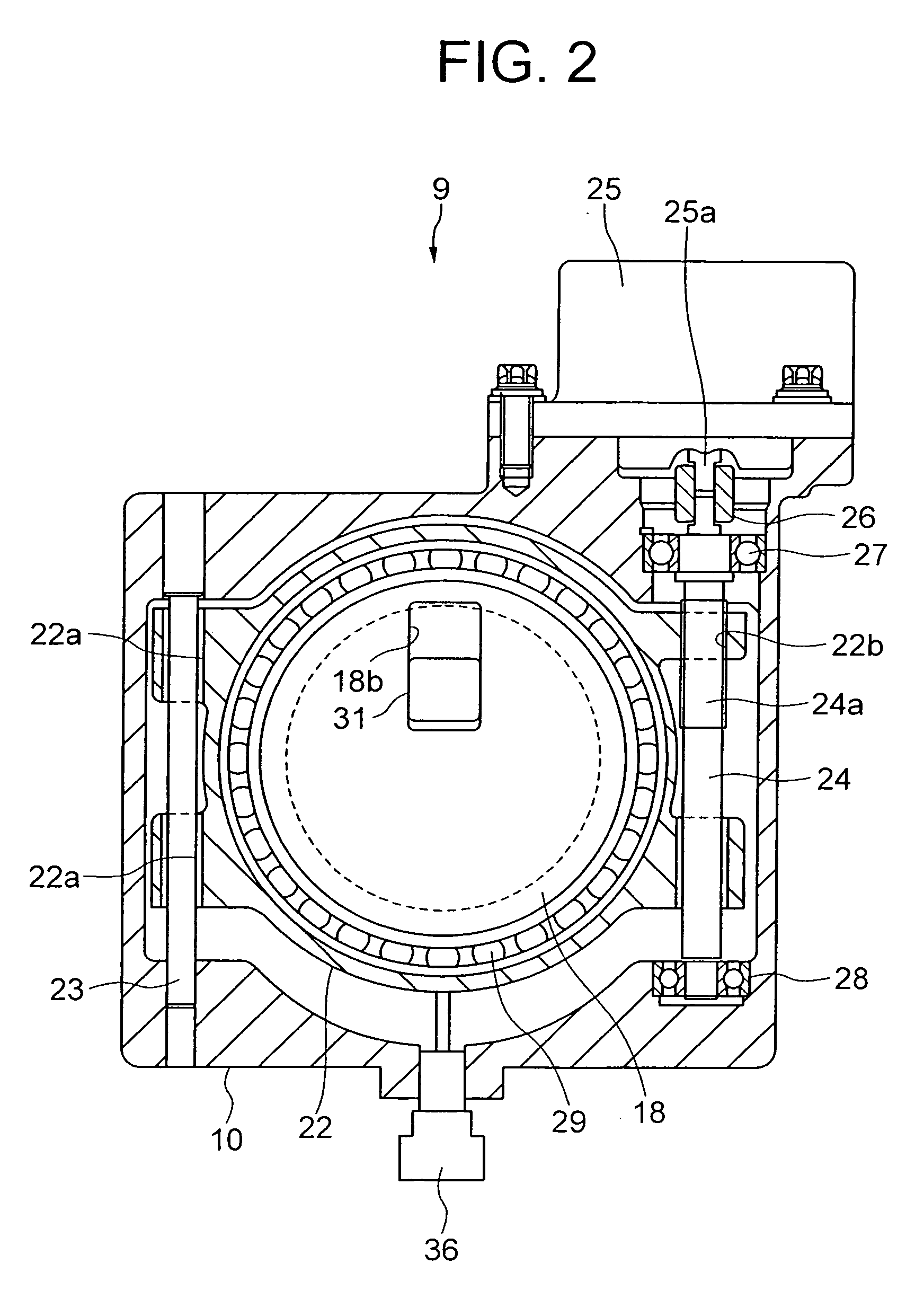

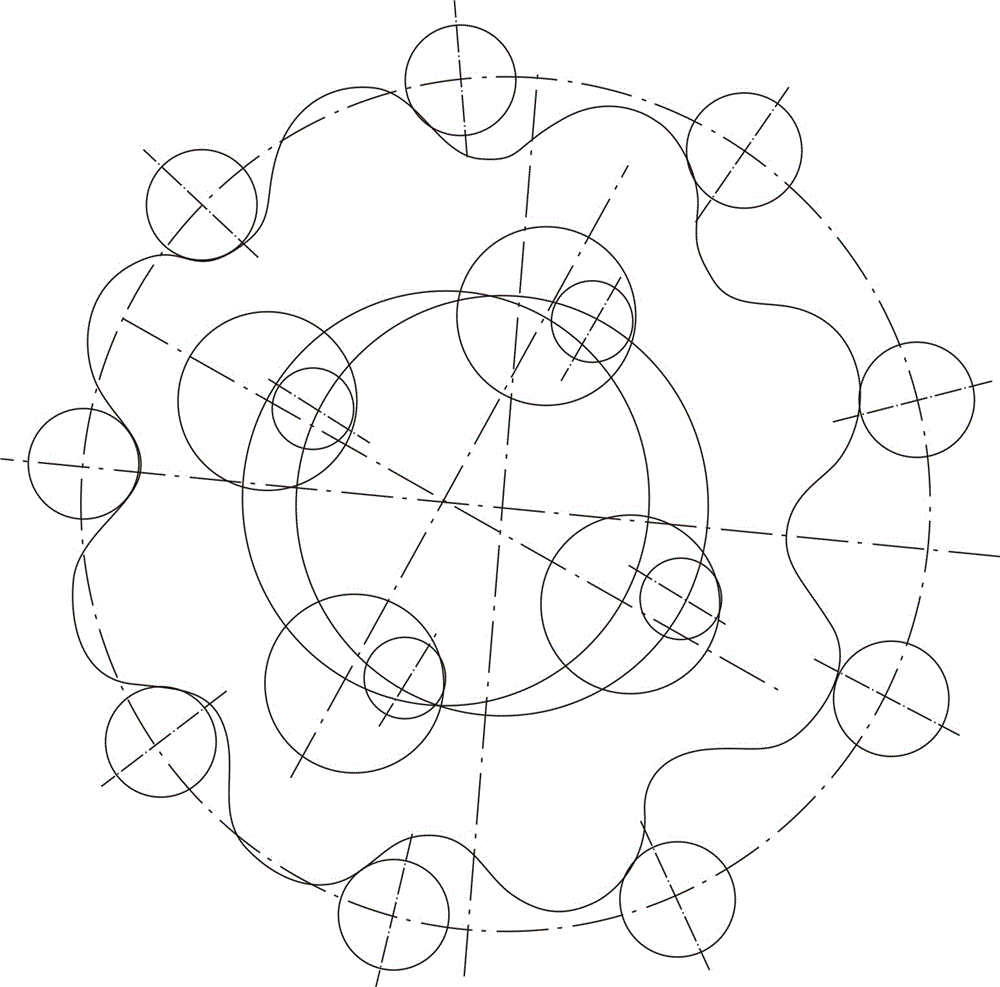

Steering device

InactiveUS20060151235A1Light weightCompact configurationControlling membersYielding couplingCouplingEngineering

A variable steering gear mechanism (9) is constructed of an external gear (15) connected to an input shaft (11), an internal gear (16) fixed to housing (10) and meshing with the external gear (15), an intermediate member (19) receiving a rotary force transmitted from the external gear (15), change means (18a, 31, 33a) capable of changing a rotation ratio of the output shaft (33) to a rotation of a guide member (18), and an Oldham coupling (17) connecting the intermediate member (19) to the guide member (18). When a speed reduction ratio thereof is set to, e.g., 6:1, it follows that the input member (18) of the change means makes a ¼ rotation (rotates through 90 degrees) during one-sided 1.5 rotations (540 degrees) of the input shaft (11), whereby a characteristic of the change means can be effectively utilized. A gear mechanism such as a hypocycloid mechanism has a characteristic capable of, though compact in configuration, obtaining a speed reduction ratio as large as 6:1, and also such a characteristic that the external gear (15), in addition to the self-rotation, revolves around the axis line of the internal gear (16), i.e., rotates while being eccentric. By contrast, according to the present invention, the use of the Oldham coupling (17) enables only the self-rotation to be extracted and transmitted by absorbing the eccentricity of the external gear (15). Additionally, a meshing length between the external gear (15) and the internal gear (16) becomes large, whereby smoother power transmission can be attained.

Owner:NSK LTD +1

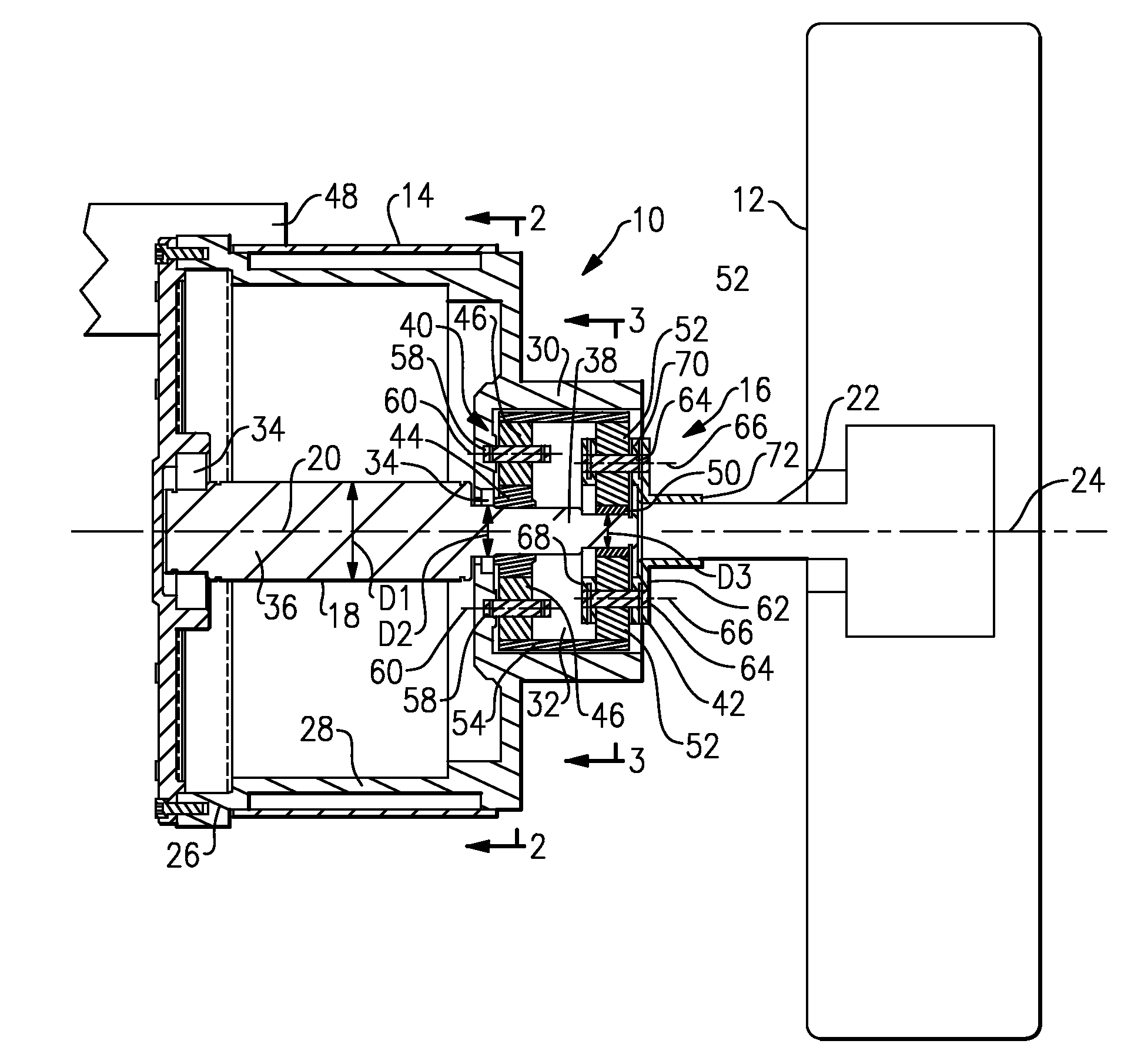

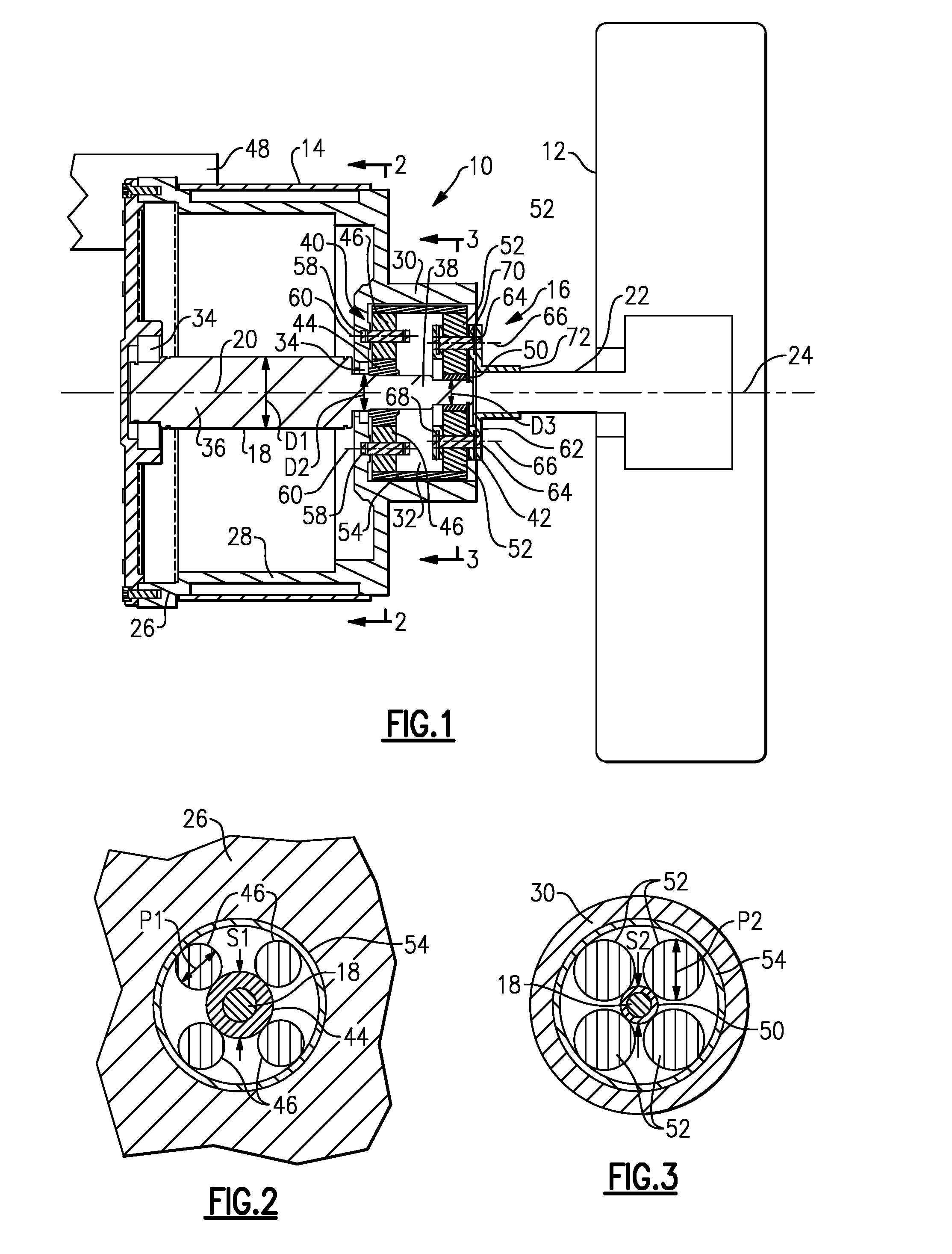

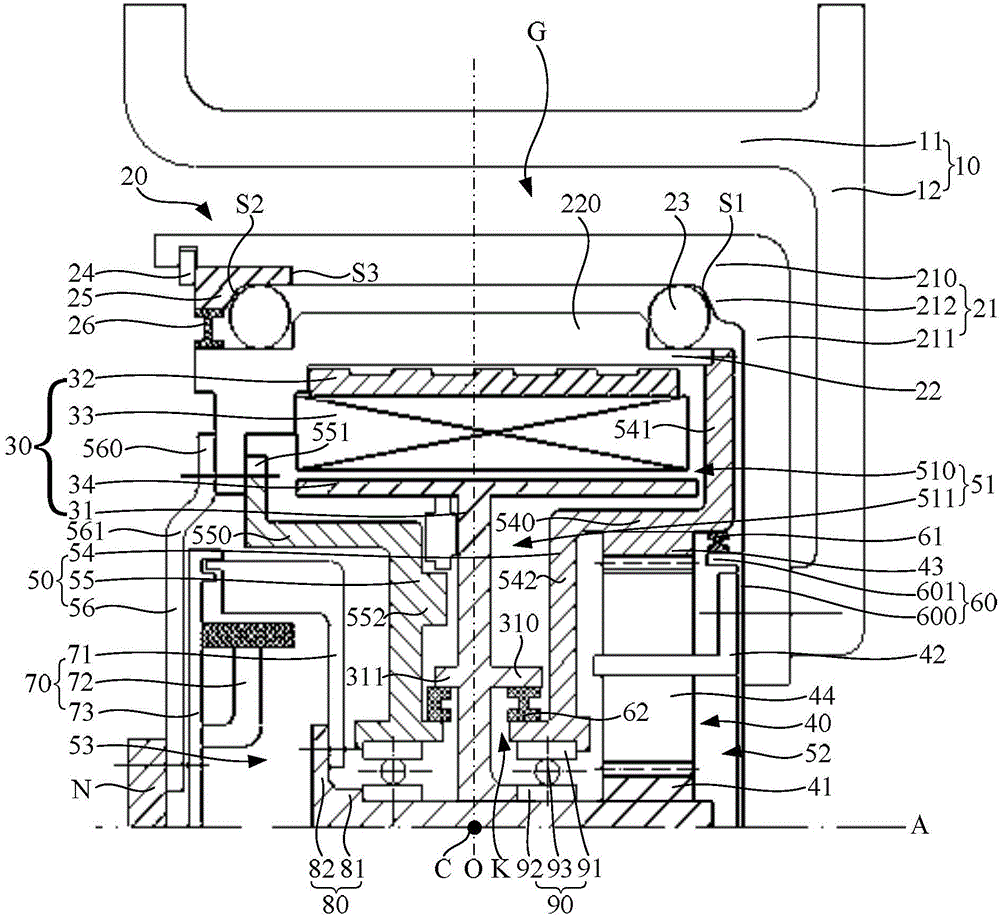

Electric powertrain system with planetary drive

ActiveUS20080236908A1Simplified packaging configurationLarge reduction ratioElectric propulsion mountingToothed gearingsElectricityElectric drive

An electric drive unit for a vehicle wheel includes an electric motor that powers a planetary drive having a first stage gear set and a second stage gear set. Each of the first and second stage gear sets includes a sun gear that is driven by a motor output shaft. Each of the first and second stage gear sets also includes a plurality of planet gears that are in meshing engagement with a respective one of the sun gears. The first and second stage gear sets share a common ring gear. A planet carrier of the second stage gear set provides driving output to a wheel shaft that drives the vehicle wheel.

Owner:ARVINMERITOR TECH

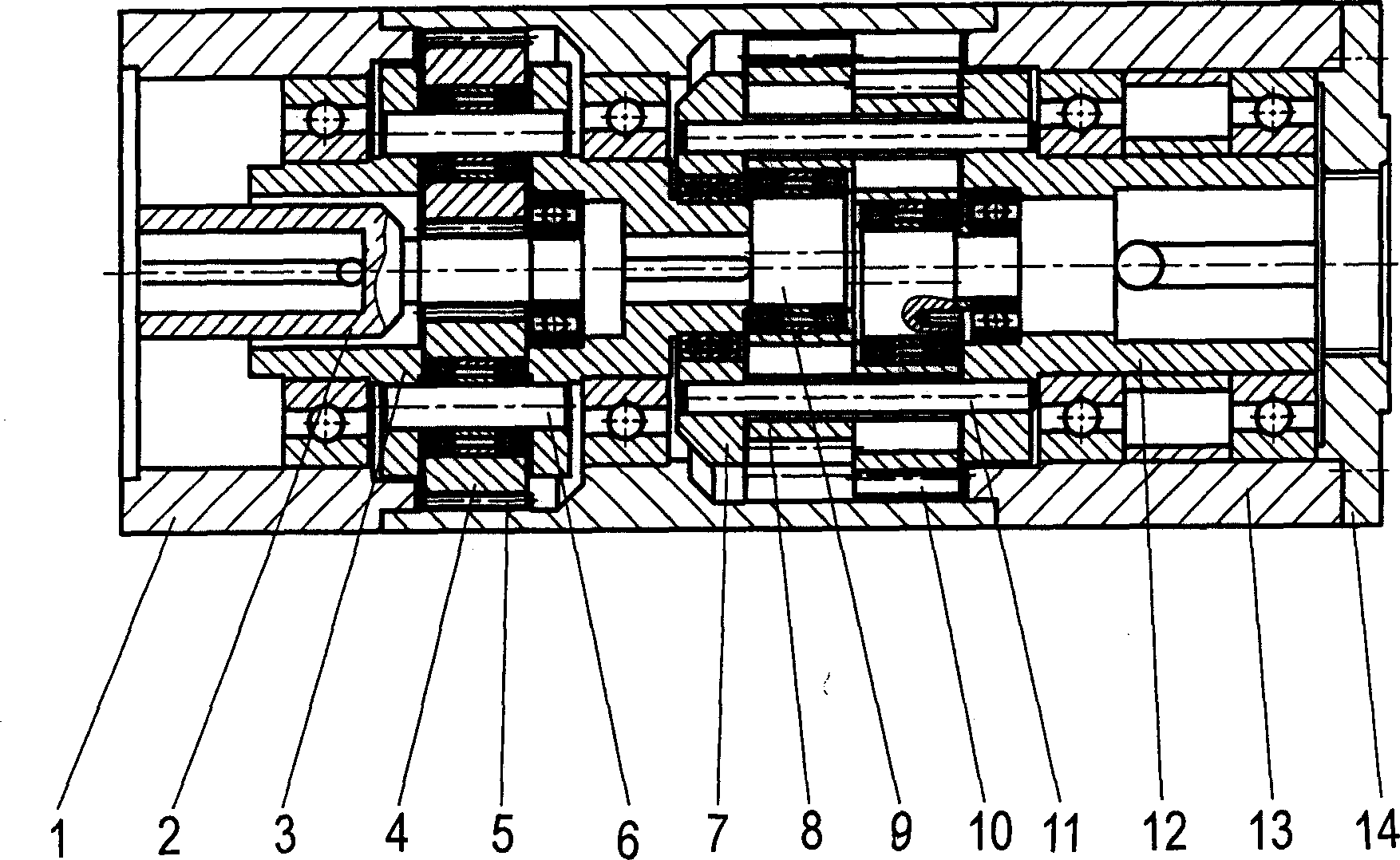

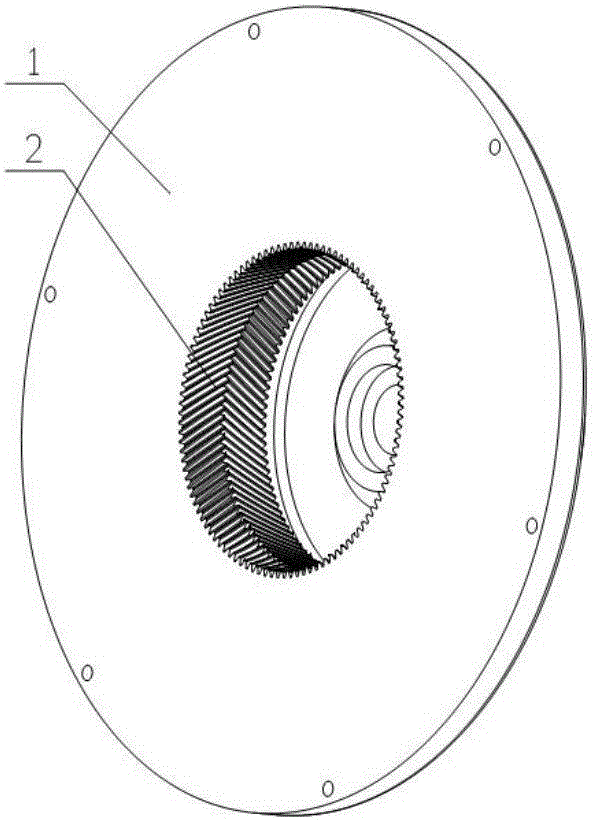

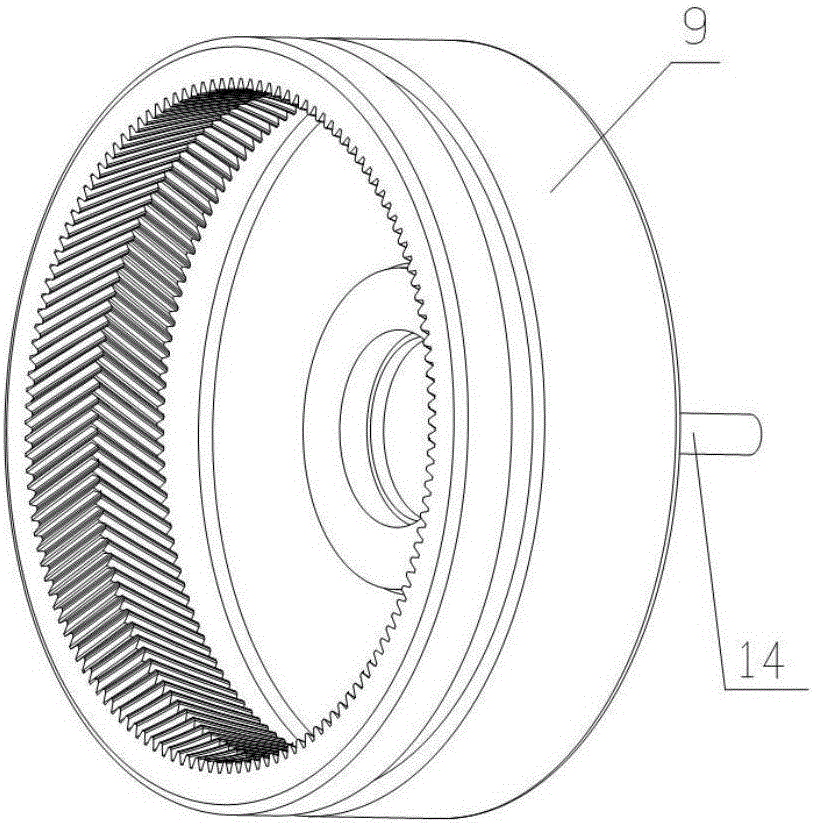

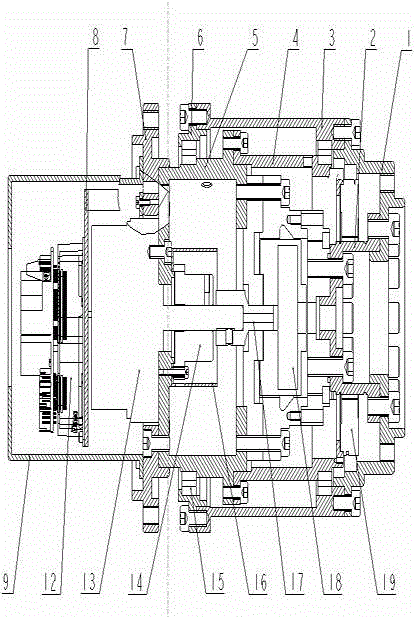

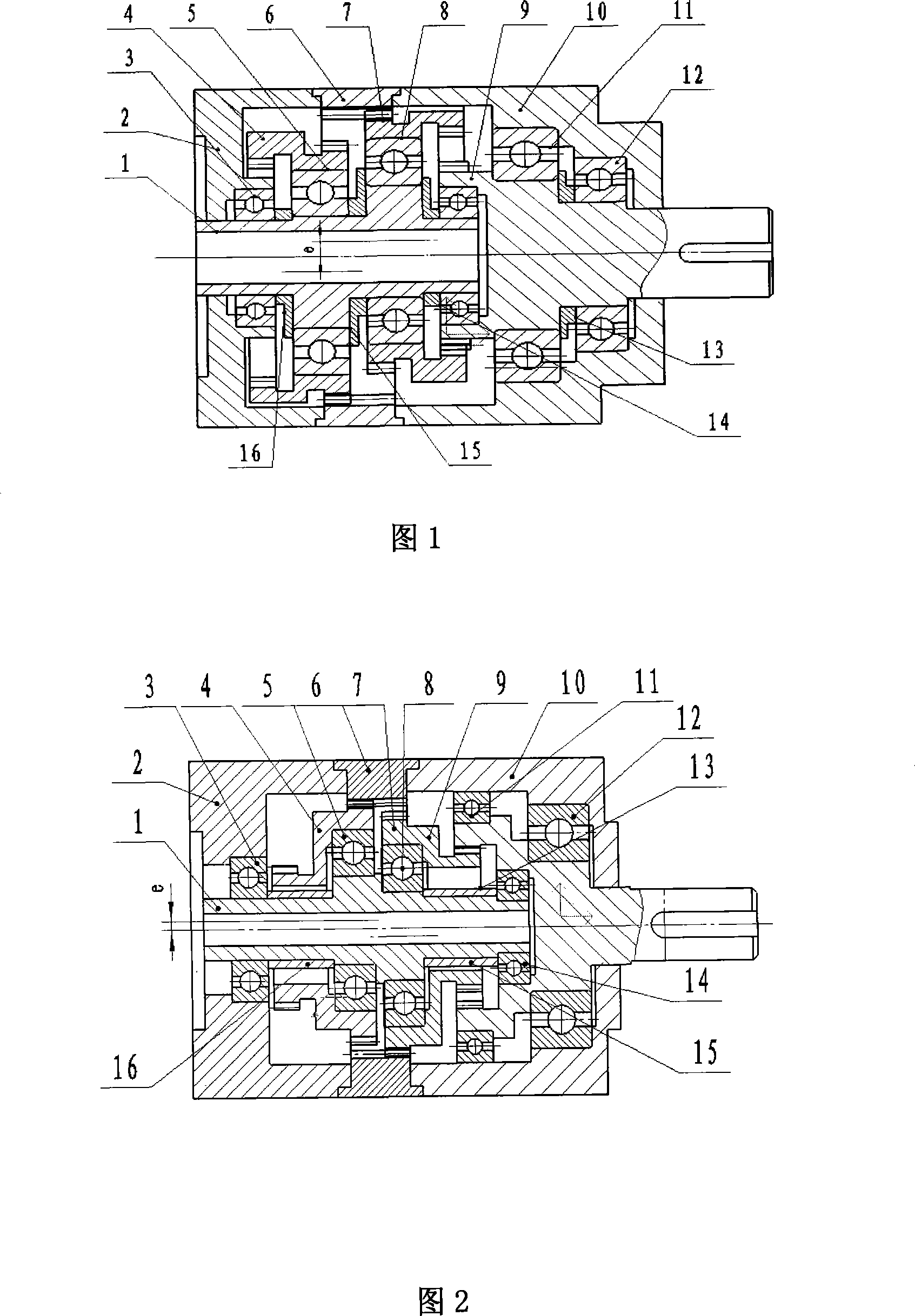

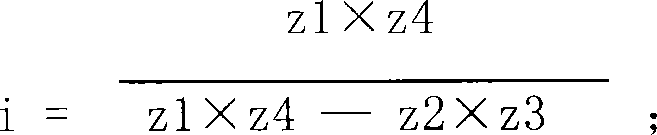

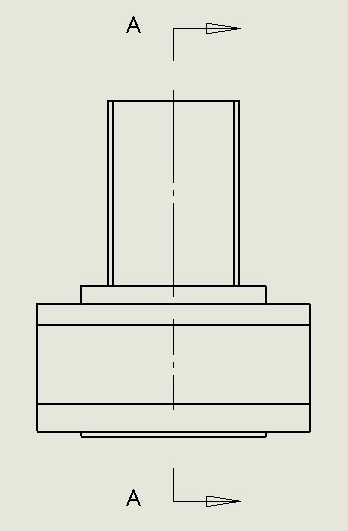

Differential planetary reducer

InactiveCN104989803AReduce power densityExtended service lifeDifferential gearingsGearing detailsReducerBearing capacity

The invention discloses a differential planetary reducer. The differential planetary reducer comprises a base, a primary annular gear, a secondary annular gear, an input shaft, an output shaft, central wheels, planetary wheels and a planetary frame. The differential planetary reducer is characterized in that the center wheels include a primary center wheel and a secondary center wheel which are respectively fixed on the input shaft and integrate the input shaft; the planetary wheels include a primary planetary wheel and a secondary planetary wheel; the primary planetary is engaged with the primary center wheel and the primary annular gear simultaneously, so that a primary reduction system can be formed; the secondary planetary wheel is engaged with the secondary center wheel and the secondary annular gear simultaneously, so that a secondary reduction system can be formed; the primary planetary wheel and the secondary planetary share the planetary frame; and the secondary annular gear is fixedly connected with the output shaft. Besides the advantages of an NGW type planetary reducer and an NGWN type planetary reducer, the differential planetary reducer further has the advantages of simple structure, small size, light weight, strong bearing capacity, long service life and convenient processing and manufacturing.

Owner:许奉成

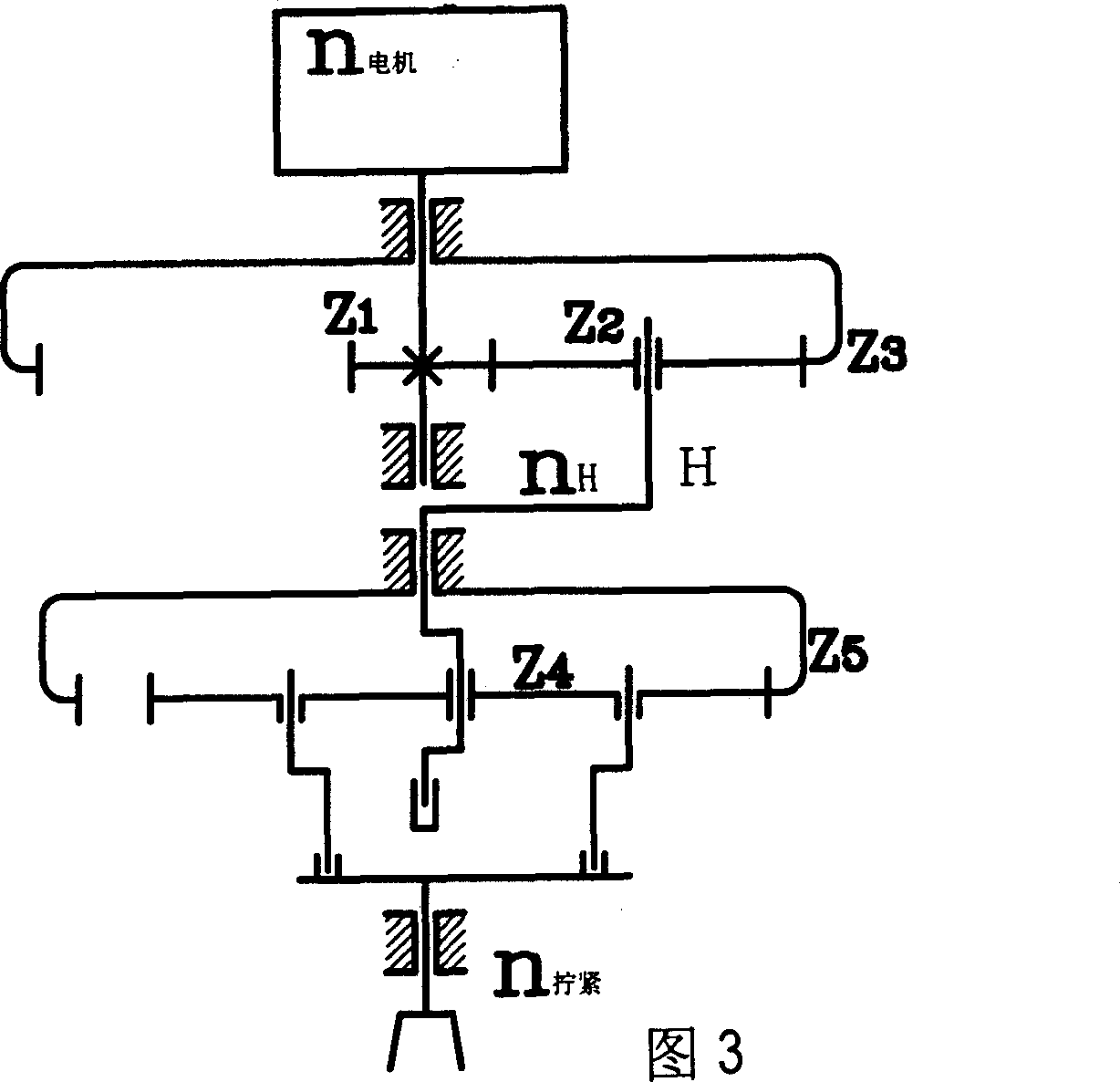

Coaxial contrarotating speed reducer

The invention discloses a coaxial contrarotating speed reducer. A first-level planetary gear train is used for speed reduction, and two inner gear rings of a second-level composite differential gear train are used for realizing speed reduction and a constant speed output function of coaxial contrarotating. A first-level planetary gear is simultaneously engaged with a first-level center gear and a first-level inner gear ring to form a first-level speed reduction system; a second double planetary gear, a second-level double center gear, a second-level inner gear ring, a second-level double inner gear ring, a second-level fixed shaft gear and a second-level sun gear form a second-level coaxial contrarotating speed reduction system. The first-level center gear and the second-level double center gear are separately fixed to an input shaft. An output shaft is divided into an output inner shaft and an output outer shaft, the output inner shaft penetrates through the output outer shaft, and the inner and outer shafts are connected with an output optical axis. The second-level inner gear ring is fixedly connected with the output inner shaft to complete the positive output of the system; and the second-level double inner gear ring, the second-level fixed shaft gear and the second-level sun gear are fixedly connected with the output outer shaft to complete the negative output of the system. The speed reducer has the advantages of simple structure, high speed reduction ratio, large transmission torque and smooth operation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Joint structure for rehabilitation training robot

InactiveCN1876335ASimple structureRealize the self-locking featureJointsDrive shaftElectrical polarity

The invention relates to a robot joint means for recover training, comprising generator, framework, mechanical arm and reduction apparatus. Said generator is fixed on framework, the input end of reduction apparatus is connected with turning cylinder of generator, place between reduction apparatus and mechanical arm is provided with a clutch-damper, the drive shaft of clutch-damper is connected to output end of reduction apparatus, drive shaft is in connection with mechanical arm; the shell of clutch-damper is equipped with driving and driven disc fixed connected with driving shaft and driven shaft, the relative surface of driving and driven shaft is equipped with electrode plate with converse polarity respectively, intramural electrode plate with polarity corresponding to that of electrode plate on internal wall of shell beside driving and driven disc, and the internal cavity of shell is filled with current ;liquid. The invention is characterized by simple structure, accurate control, convenient shift and safe and stable operation.

Owner:江苏亚星波纹管有限公司 +1

Reduction gear with combination of gear change structure and eccentric cycloidal roller pin gear change structure

InactiveCN104019190AImprove mechanical efficiencyReduce friction lossGear vibration/noise dampingToothed gearingsSpur gearEpicyclic gearing

The invention relates to a gear eccentric cycloidal roller pin reduction gear, in particular to a reduction gear with the combination of a gear change structure and an eccentric cycloidal roller pin gear change structure. A composite 2-level reduction gear with the combination of a planetary gear structure and an eccentric roller pin structure is designed. The reduction gear is composed of an input part, a speed reduction part and an output part. The reduction gear is characterized in that a spur gear planetary mechanism without an outer gear ring is used for first level speed reduction, a sun gear on the input shaft drives three planetary gears to be used for achieving first level speed reduction, a pair of double-eccentric structure which is misplaced by 180 degrees is arranged on the three planetary gears, and two bearings, namely rotating arms, are arranged on each segment of eccentric cylinders to be used for driving two cycloidal gears to rotate. The reduction gear has the advantages of being high in reduction ratio and high in efficiency, the single-level transmission can reach the reduction ratio of 1:3, the efficiency reaches 90%, and if multi-level transmission is adopted, the reduction ration will be greater.

Owner:四川奥斯廷科技有限公司

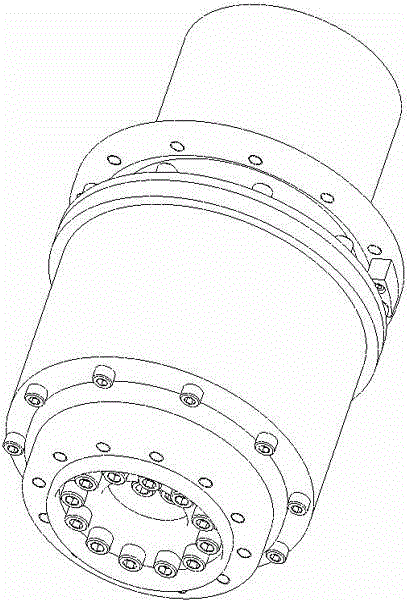

Space manipulator modular driving joint

A space manipulator modular driving joint comprises a motor driving assembly, a mechanical transmission assembly, a sensing control assembly and a structure supporting assembly. The motor driving assembly comprises a brushless DC motor, and the mechanical transmission assembly comprises a harmonic reducer and a planetary reduction gear. The sensing control assembly comprises an absolute position encoder and a driving controller. The structure supporting assembly comprises an input flange, a motor support, a bearing inner pedestal, a bearing outer pedestal, an output flange, a harmonic wave output shaft, a bearing end cover, a mechanical limiting block, a controller support and a controller shell. The space manipulator modular driving joint has the beneficial effects that the problems that in an existing space manipulator technology, a driving joint is low in precision, and the size and the weight of the joint are large are solved; modular design is adopted, the interchangeability between joints is good, and the refinement degree and the load capacity of space manipulators are improved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

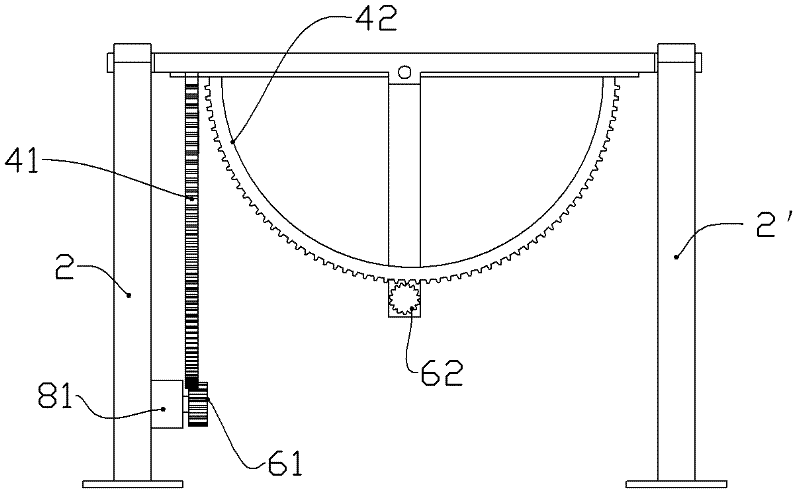

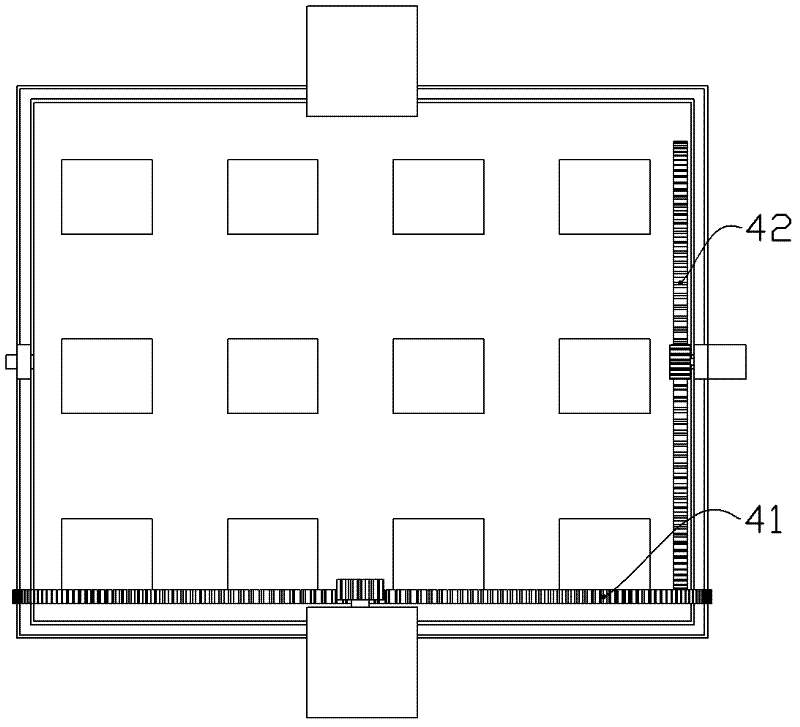

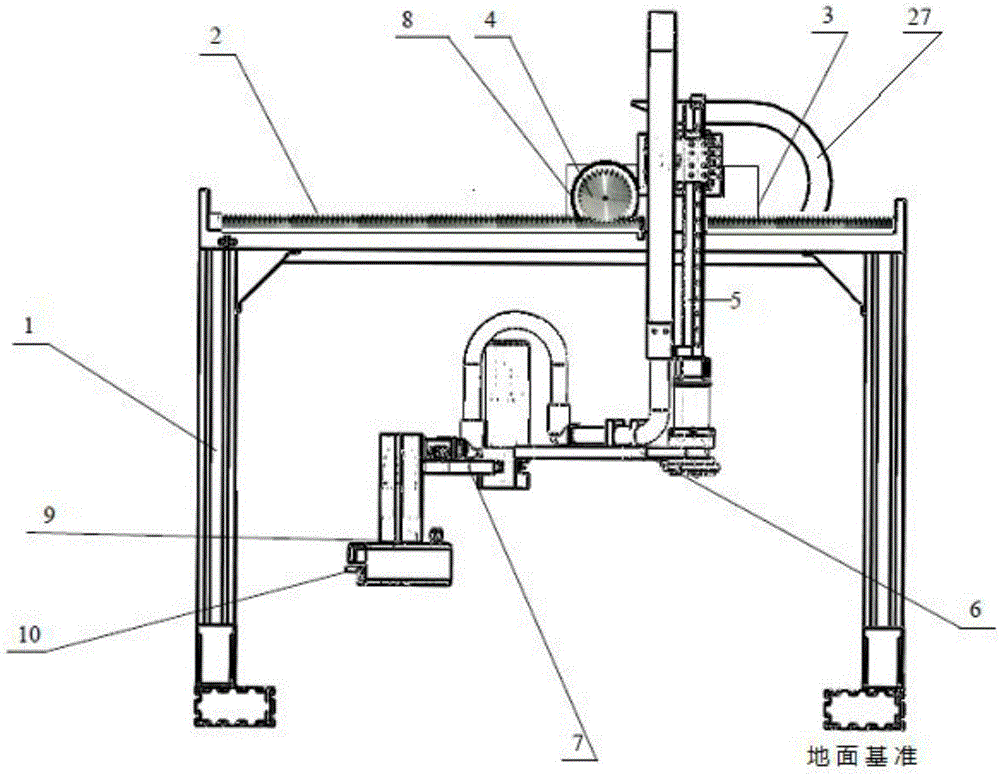

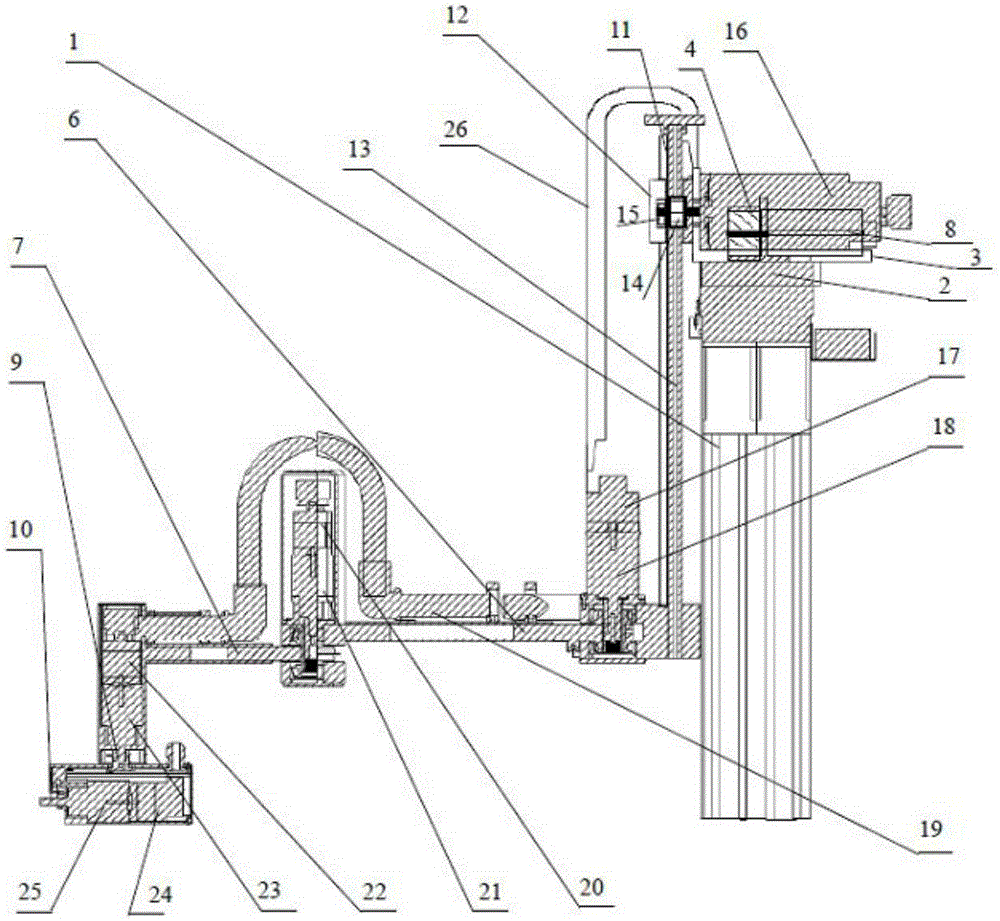

Six-DOF (degrees of freedom) three-dimensional-manipulation robot

InactiveCN105415352ASimple structureImprove reliabilityProgramme-controlled manipulatorGear wheelThree-dimensional space

The invention relates to a six-DOF (degrees of freedom) three-dimensional-manipulation robot. The six-DOF three-dimensional-manipulation robot comprises a pedestal bearing, a horizontal sliding table, a vertical moving arm, an upper arm lever, a forearm lever, a swing flange and an output shaft; the pedestal bearing consists of vertical upright columns and horizontal crossbeams supported on the upright columns; the horizontal sliding table is arranged on the crossbeams and does horizontal translation through pinion and rack transmission, so as to form a horizontal movement degree of freedom; the vertical moving arm is connected with the horizontal sliding table and does vertical movement through pinion and rack transmission, so as to form a vertical movement degree of freedom; the upper arm lever is connected to the lower end of the vertical moving arm and does rotational movement, so as to form a first rotational degree of freedom; the forearm lever is connected to the front end of the upper arm lever and does rotational movement, so as to form a second rotational degree of freedom; the swing flange is connected to the front end of the forearm lever and does rotational movement, so as to form a third rotational degree of freedom; the output shaft is connected to the side end of the swing flange and does rotational movement, so as to form a fourth rotational degree of freedom; the output shaft achieves operation of a predetermined trajectory in a three-dimensional space through the combined action of the six degrees of freedom. The six-DOF three-dimensional-manipulation robot has the advantages of simple structure, high reliability, large working space and the like.

Owner:付艺晗

Decelerator for control motor

The invention relates to a speed reducer used for controlling a motor, which comprises an input shaft, a step planetary gear, an internal gear, an output shaft, a right housing, a left housing and a plurality of support bearings. The invention has the advantages that: a high rotational speed meshing is arranged for the gear of the speed reducer, so the processing of the gear is simple with low noise and little heat generating, which is especially obvious with the reducing speed ratio increasing; rolling bearing matching is adopted for the gear and the bearing with high efficiency and convenient installation of the output and the input shafts; 4 to 7 gears participate in meshing work when the gear is meshed with good equal load property, little heat generating, low noise and long service life due to low speed meshing of the gear; four gears can form a speed reducer with less than 100 of drive ratio, thereby adapting to requirement of each sequence reduction ratio and facilitating serial production; reasonable addendum coefficient, modification coefficient and serrated angle of pressure are adopted, thereby achieving a higher transmission efficiency.

Owner:重庆创坤科技发展股份有限公司

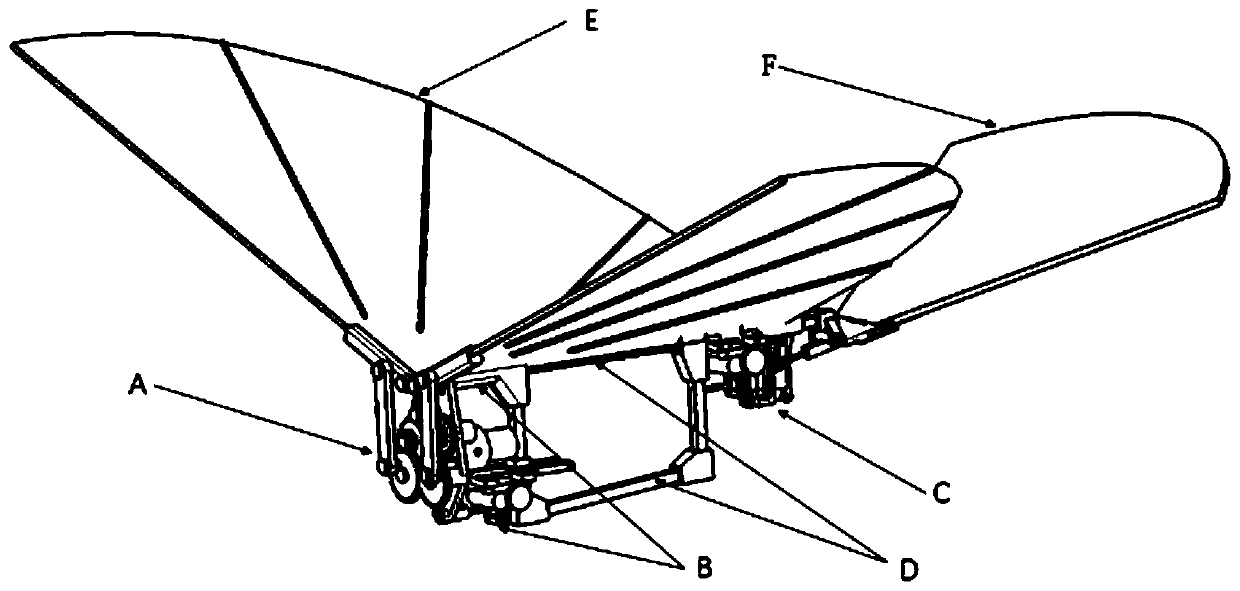

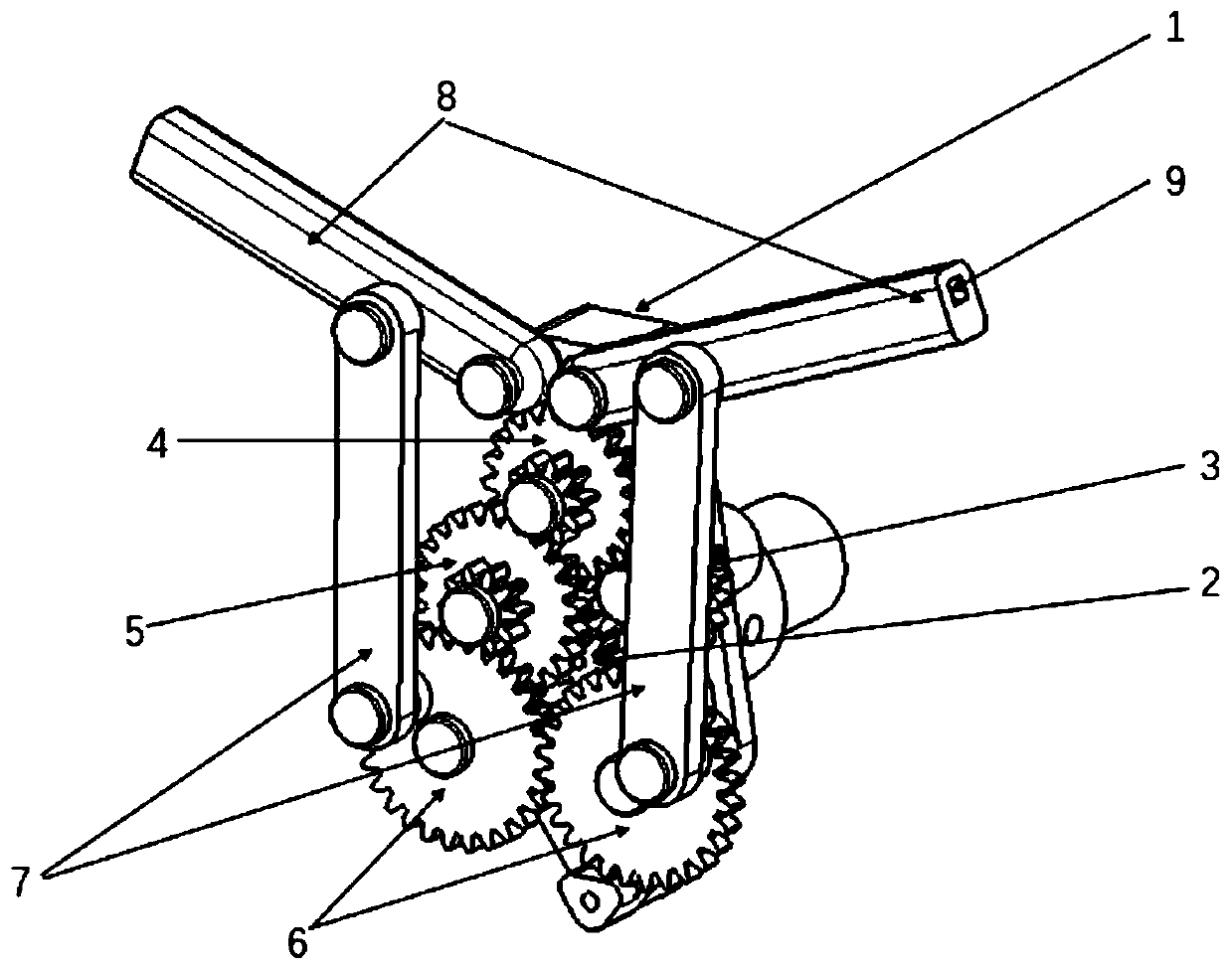

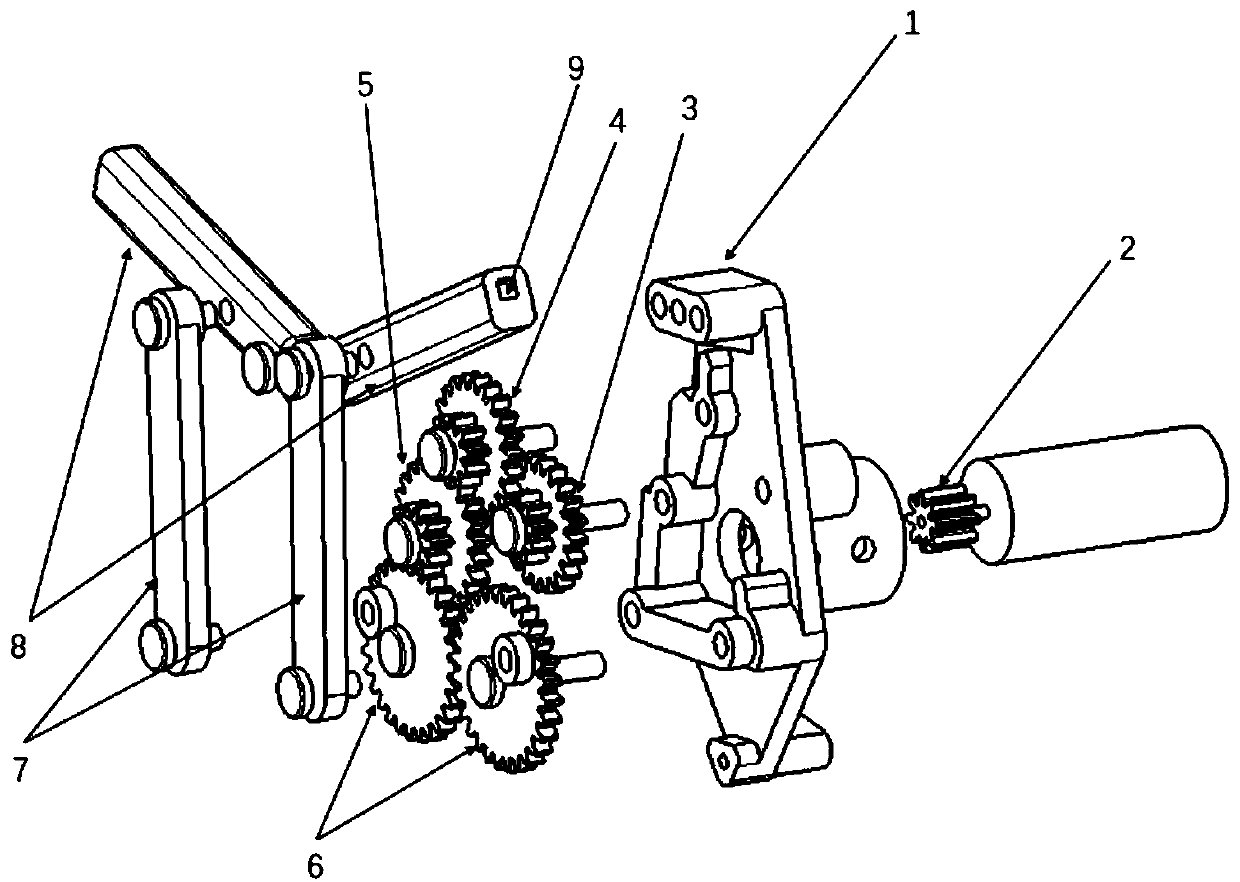

Bionic flapping wing flying robot with deflectable driving mechanism

ActiveCN110588970ASimple structureImprove stabilityAircraft stabilisationWith power amplificationFlapping wingAttitude control

The invention provides a bionic flapping wing flying robot with a deflectable driving mechanism. The bionic flapping wing flying robot with the deflectable driving mechanism comprises a driving mechanism, a deflection mechanism, a tail fin control mechanism, a robot body, a flight control board, wings and a tail fin; the driving mechanism is used for driving the wings to flap at a high frequency to generate main power; the tail fin control mechanism is used for controlling a left-and-right deflection angle and an up-and-down upturning angle of the tail fin; and the deflection mechanism is usedfor enabling the driving mechanism to swing from left to right around a central axis of the flapping wing flying robot so as to drive the wings to deflect so that the direction of aerodynamic force of a flapping wing is changed. According to the bionic flapping wing flying robot with the deflectable driving mechanism, controllable amounts comprise flapping wing frequency, the direction of the aerodynamic force of the flapping wing and the left-and-right deflection angle and the up-and-down upturning angle of the tail fin; the bionic flapping wing flying robot with the deflectable driving mechanism realizes flying attitudes of straight flying, hovering and steering when being combined with the flight control board and has an attitude self-stabilizing function; and as the controllable amount of a flapping wing flying robot driven by a motor is additionally arranged, more stable flight and flexible attitude control can be realized.

Owner:UNIV OF SCI & TECH BEIJING

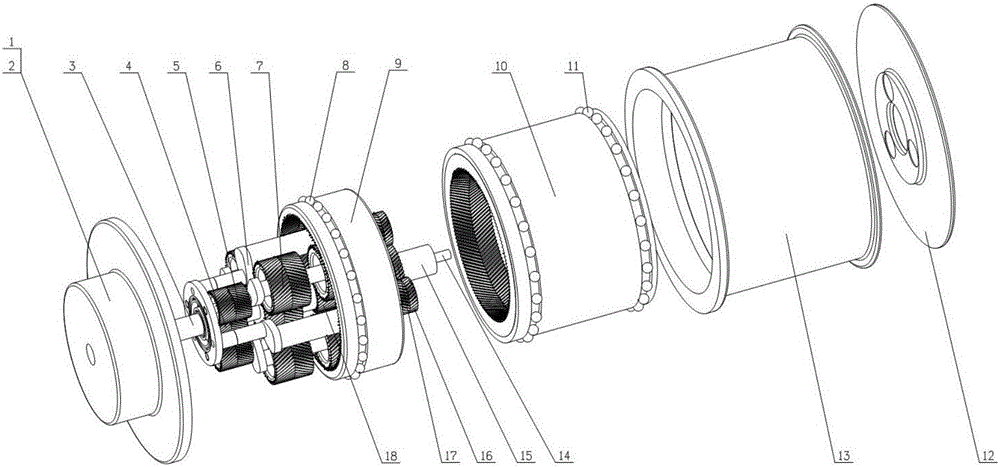

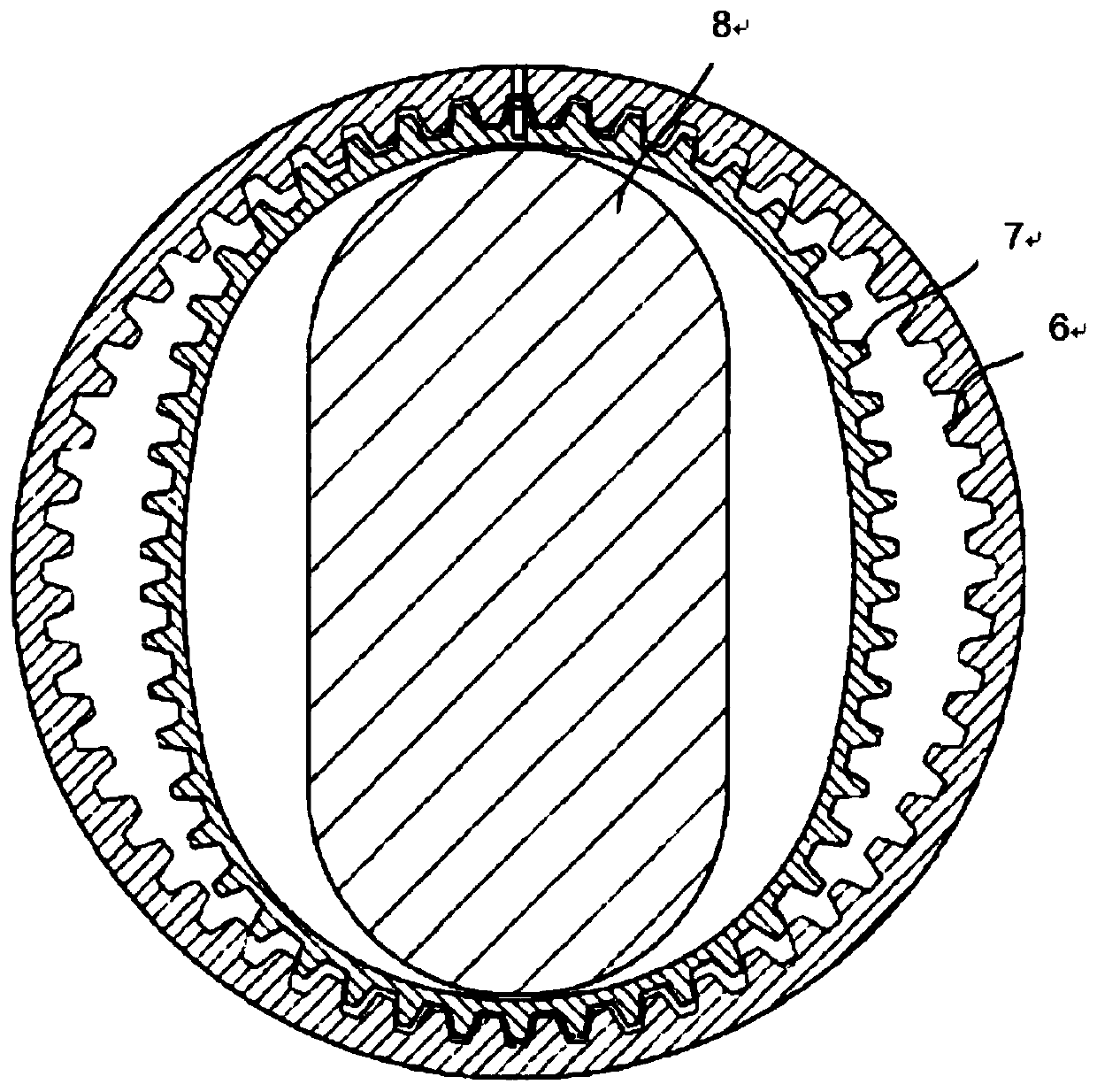

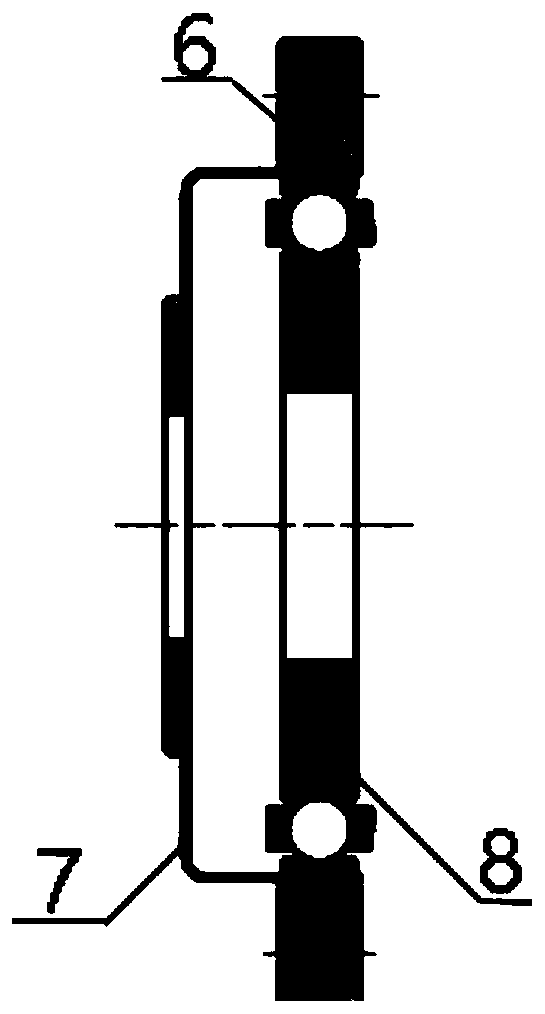

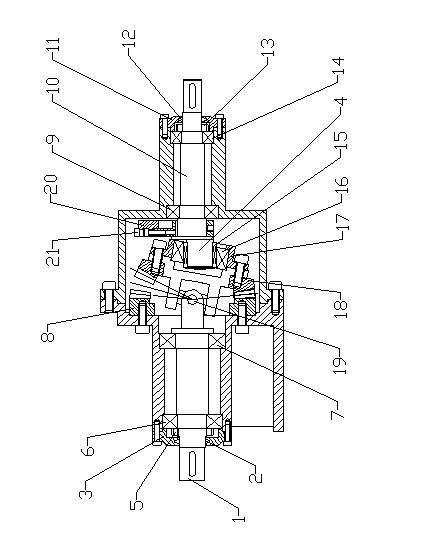

Single row crossed roller bearing harmonic speed reducer

InactiveCN102042365ACompact structureHigh precisionGearboxesToothed gearingsReduction driveElectric machine

The invention provides an original crossed roller bearing harmonic speed reducer. The speed reducer consists of a wave generator (7), wherein the wave generator (7) is arranged on a shaft of a motor (1), and is connected with the motor (1) by a flat key (2); the motor (1) is arranged on a flange plate (3) which is connected with a rigid gear (9) through a bolt (12); the rigid gear (9) is connected with a crossed roller bearing outer ring (4) through a bolt (10); a flexible gear (8) is connected with a crossed roller bearing inner ring (6) through a bolt (11); a bearing roller (5) is arranged between the crossed roller bearing outer ring (4) and the crossed roller bearing inner ring (6); and the flexible gear (8) is arranged between the wave generator (7) and the rigid gear (9); the shaft of the motor (1) drives the wave generator (7) to rotate, and the flexible gear (8) is engaged with the rigid gear (9); because the difference of teeth number of the flexible gear (8) and the rigid gear (9) is 2, a large reduction ratio is generated; and the flexible gear (8) is fixed on the crossed roller bearing inner ring (6), and the crossed roller bearing inner ring (6) rotates and outputs along with the flexible gear (8) to achieve the aim of reducing speed. The crossed roller bearing harmonic speed reducer has the advantages of compact structure, high accuracy, high bearing force, large reduction ratio, less return difference, small volume, light weight and the like.

Owner:青岛创想机器人制造有限公司

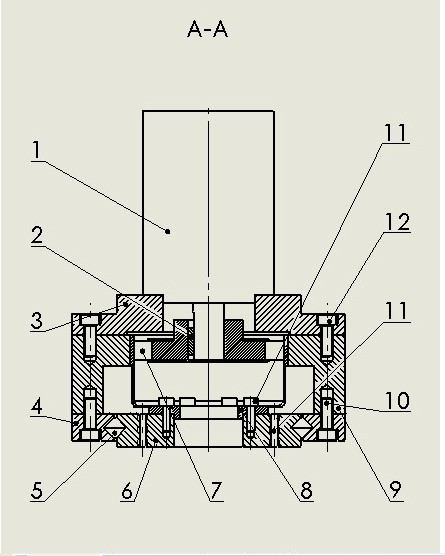

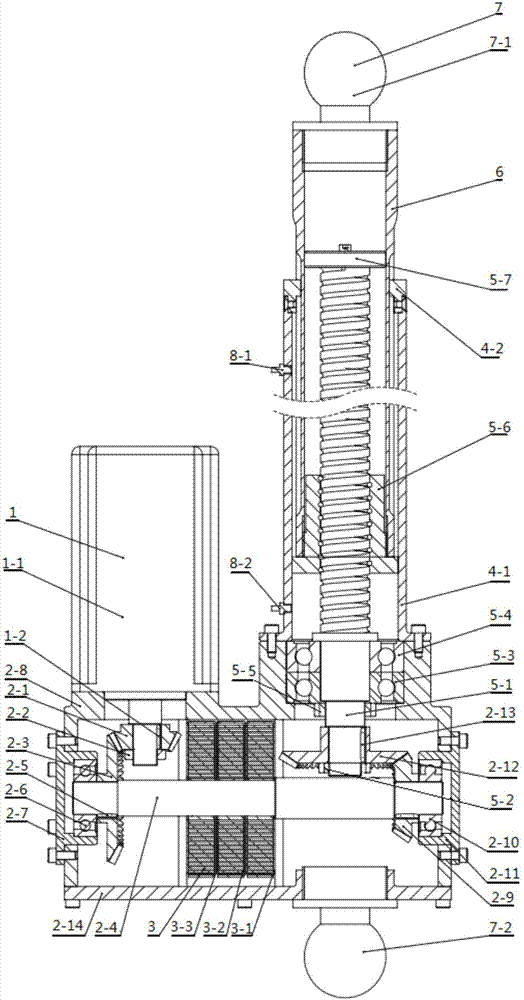

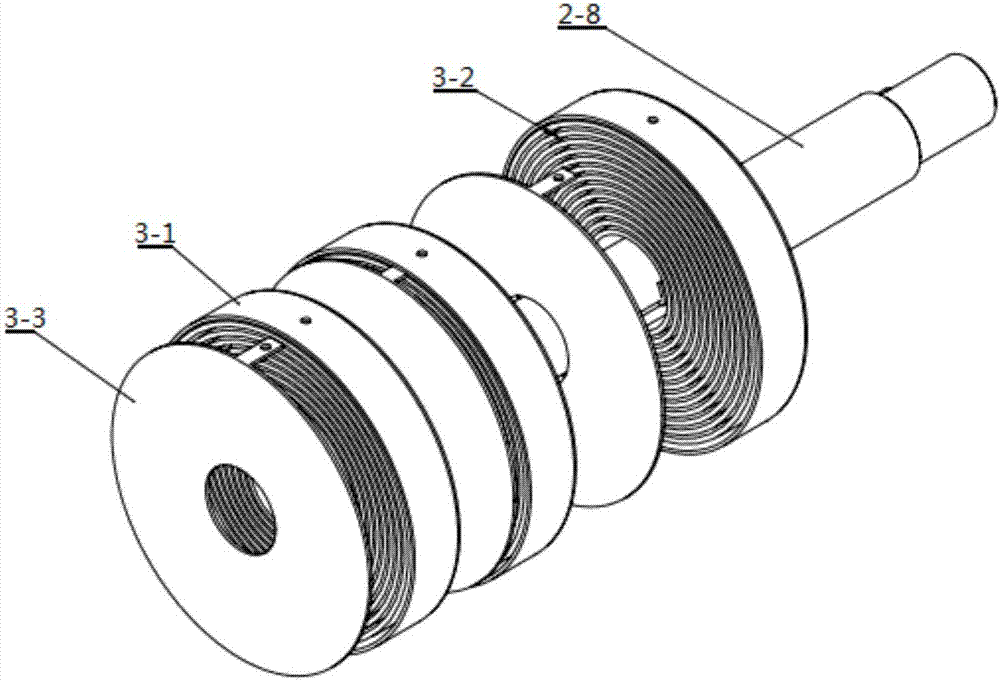

Energy storage electric cylinder

ActiveCN107288830ATo achieve the purpose of energy savingLow costSpring motorMachines/enginesStored energyCarrying capacity

The invention discloses an energy storage electric cylinder. The energy storage electric cylinder is composed of a motor assembly, a speed reducer, a coil spring assembly, a screw pair assembly, a cylinder body assembly, a push rod, an installation assembly and limit switches. The motor assembly is installed at the input end of the speed reducer, and the screw pair assembly is installed at the output end of the speed reducer. A feed screw nut and the push rod are fixed into a whole and further slide in the cylinder body assembly together. The cylinder body assembly is installed at the output end of the speed reducer. A ball 1 is installed at the top end of the push rod, and a ball 2 is installed on a speed reducer bottom cover. The limit switch 1 is installed above the cylinder body assembly, and the limit switch 2 is installed below the cylinder body assembly. The coil spring assembly is installed on a transmission shaft of the speed reducer and used for storing or releasing energy along with rotation of the transmission shaft. According to the energy storage electric cylinder, gravitational potential energy of a conveyed object or kinetic energy of a motor in the idle stroke is converted into elastic potential energy of a coil spring to be stored, the stored energy is released in the other stroke, electric energy consumed by the motor can be greatly lowered, and carrying capacity of the motor can be improved obviously.

Owner:NANJING TONYS AUTOMATION TECH CO LTD

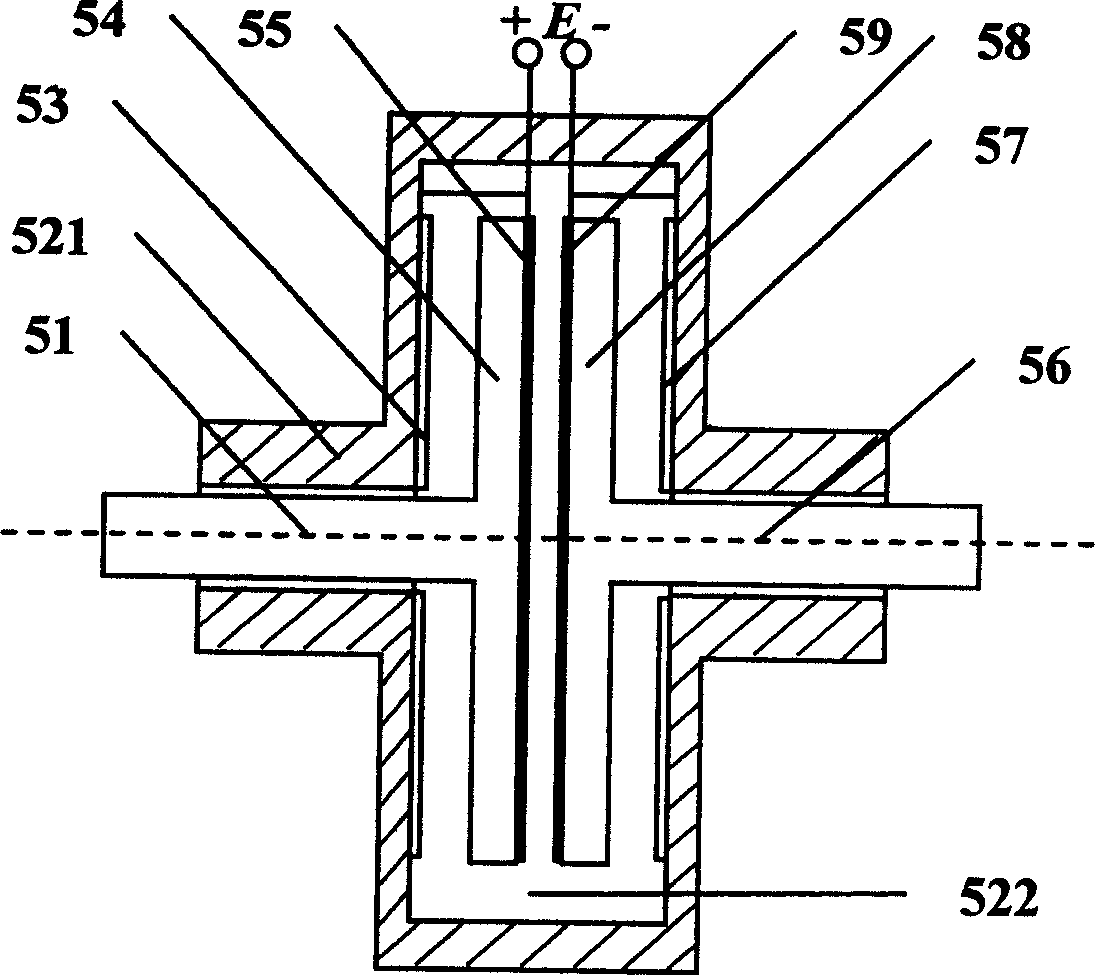

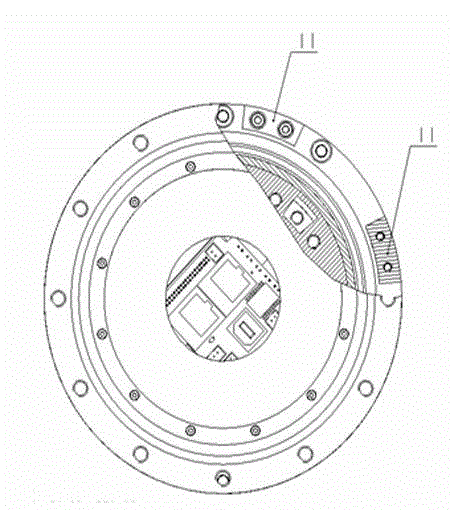

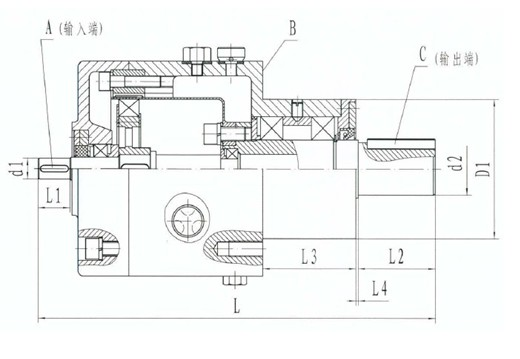

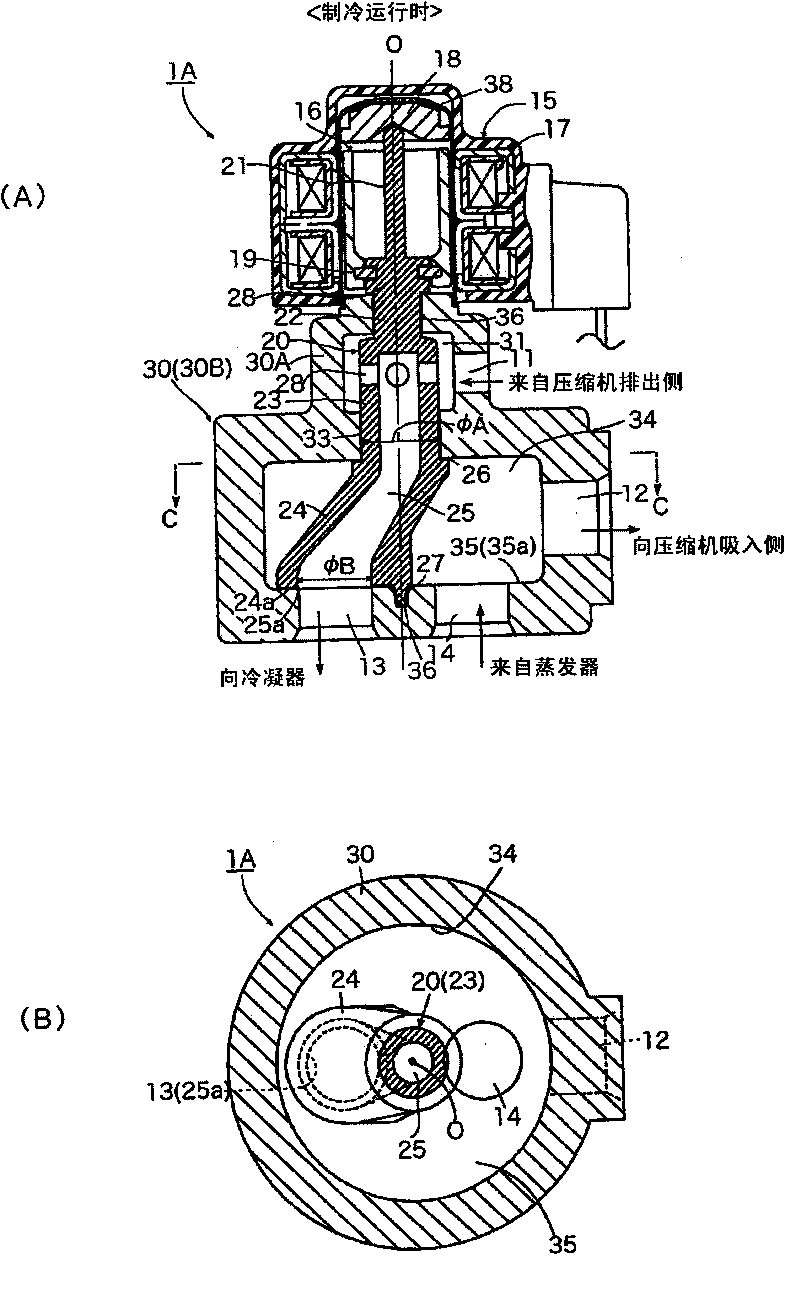

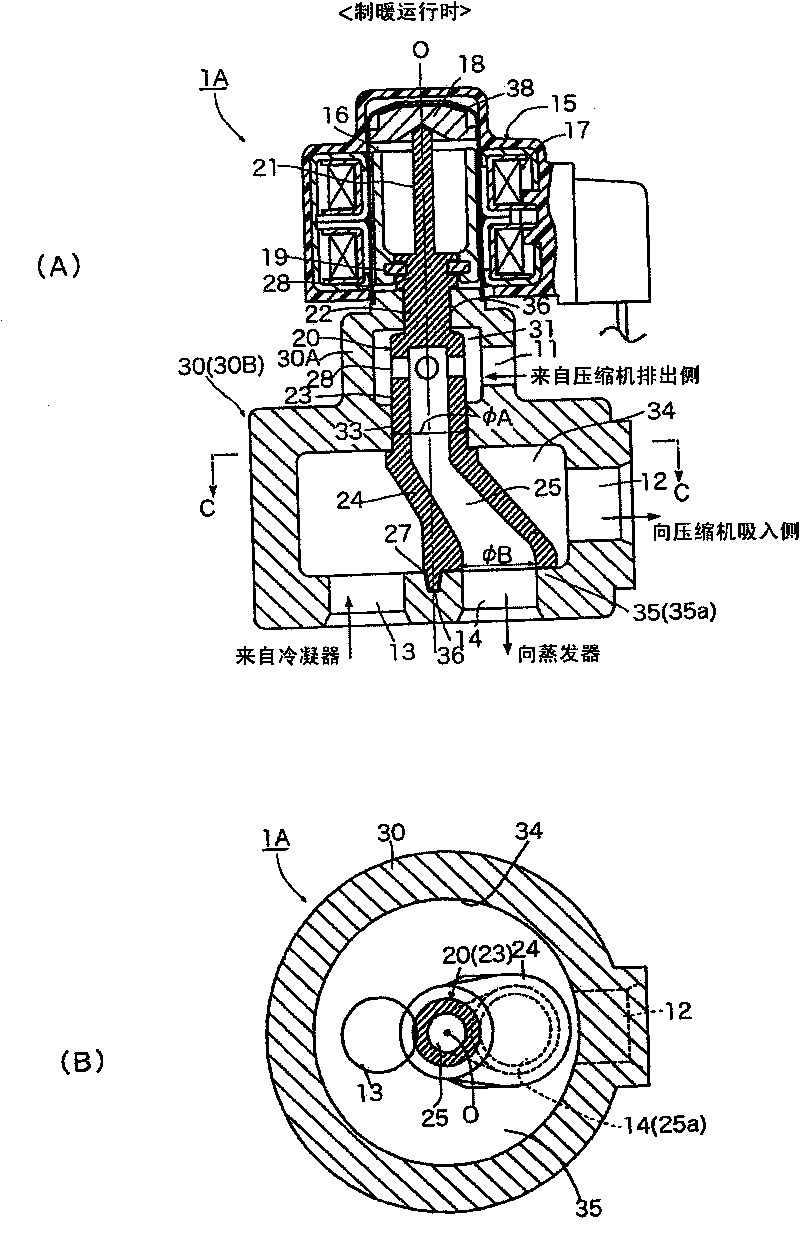

Multi direction changeover valve

ActiveCN101737528AReduced torque lossLittle flow changeOperating means/releasing devices for valvesValve members for absorbing fluid energyStatorEngineering

To provide a multi-way selector valve properly used for a vehicle, with a smooth flow path switching operation even in case of a large pressure difference between the inside and outside of a valve body, a reduced refrigerant passing noise at a time of switching a flow path, and an easy flow path switching operation, the multi-way selector valve includes a valve body 50 rotated by a flow path switching actuator 15, and a valve main body 60 rotatably holding the valve body 50, the flow path switching actuator is a stepping motor 15 including a rotor 16 placed on the inner peripheral side of a can 38 and a stator 17 placed on an outer periphery of the can 38, and a planetary gear type speed reduction mechanism 40 is inserted between the rotor 16 of the stepping motor 15 and the valve body 50.

Owner:FUJIKOKI MFG CO LTD

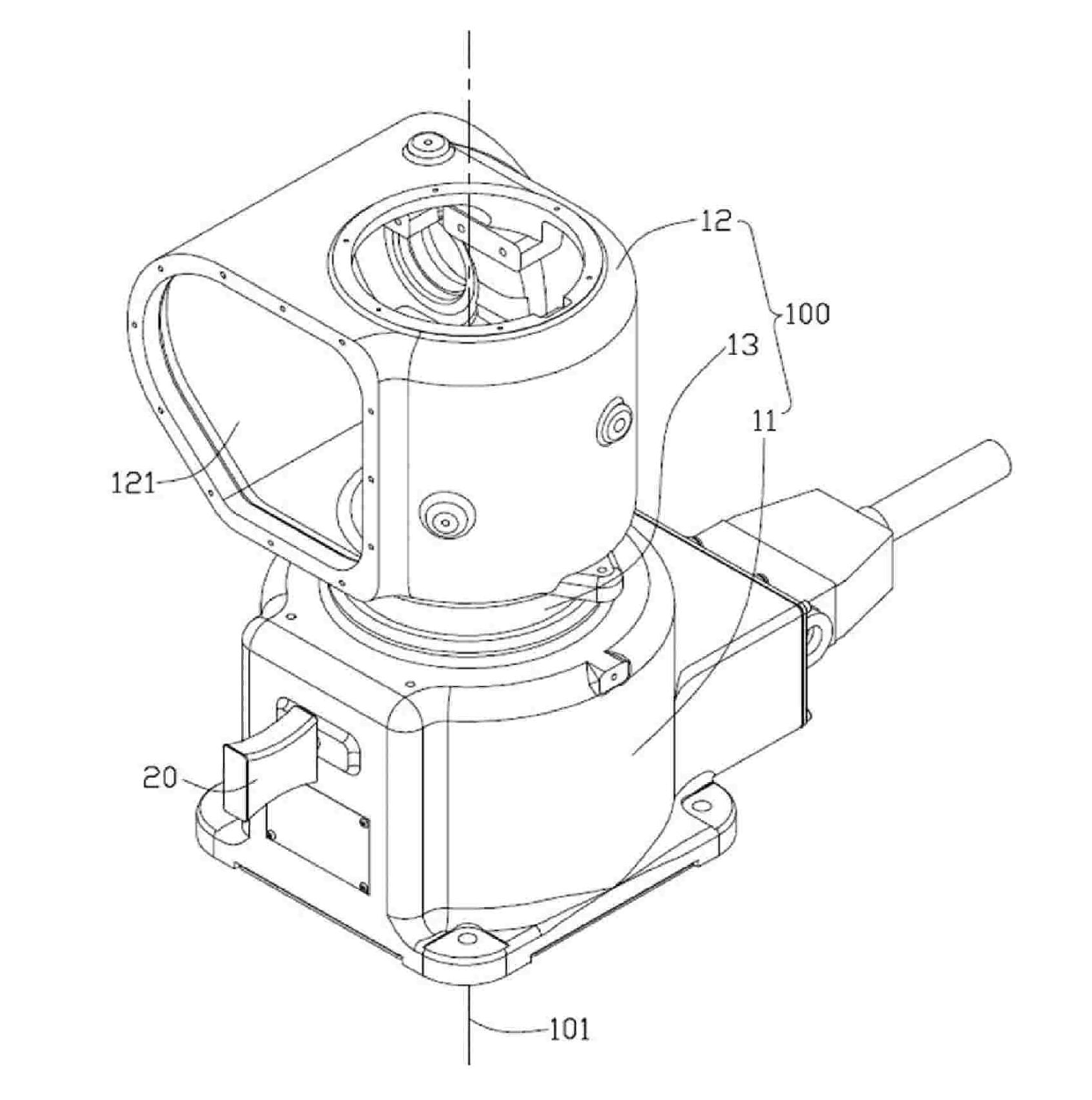

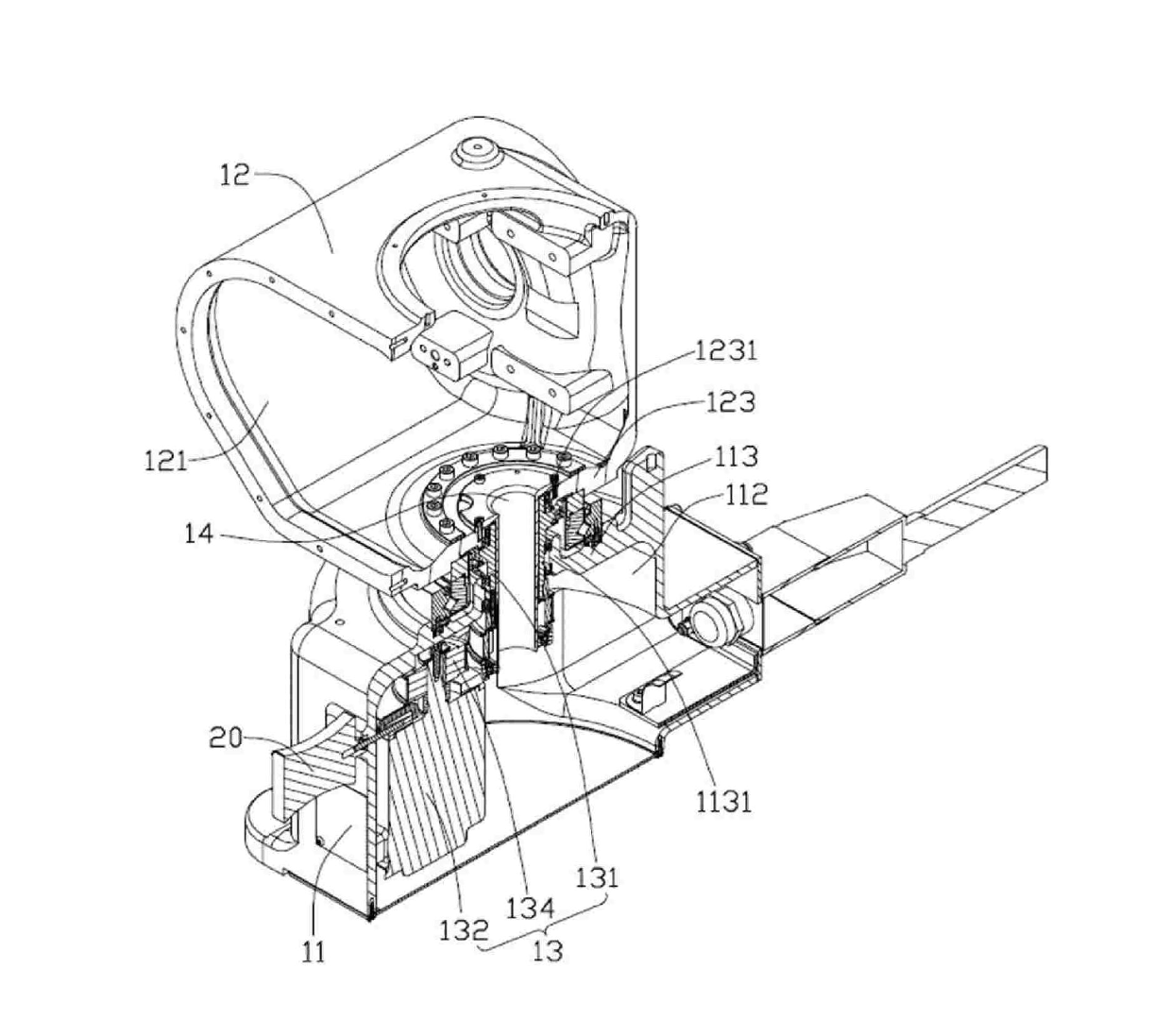

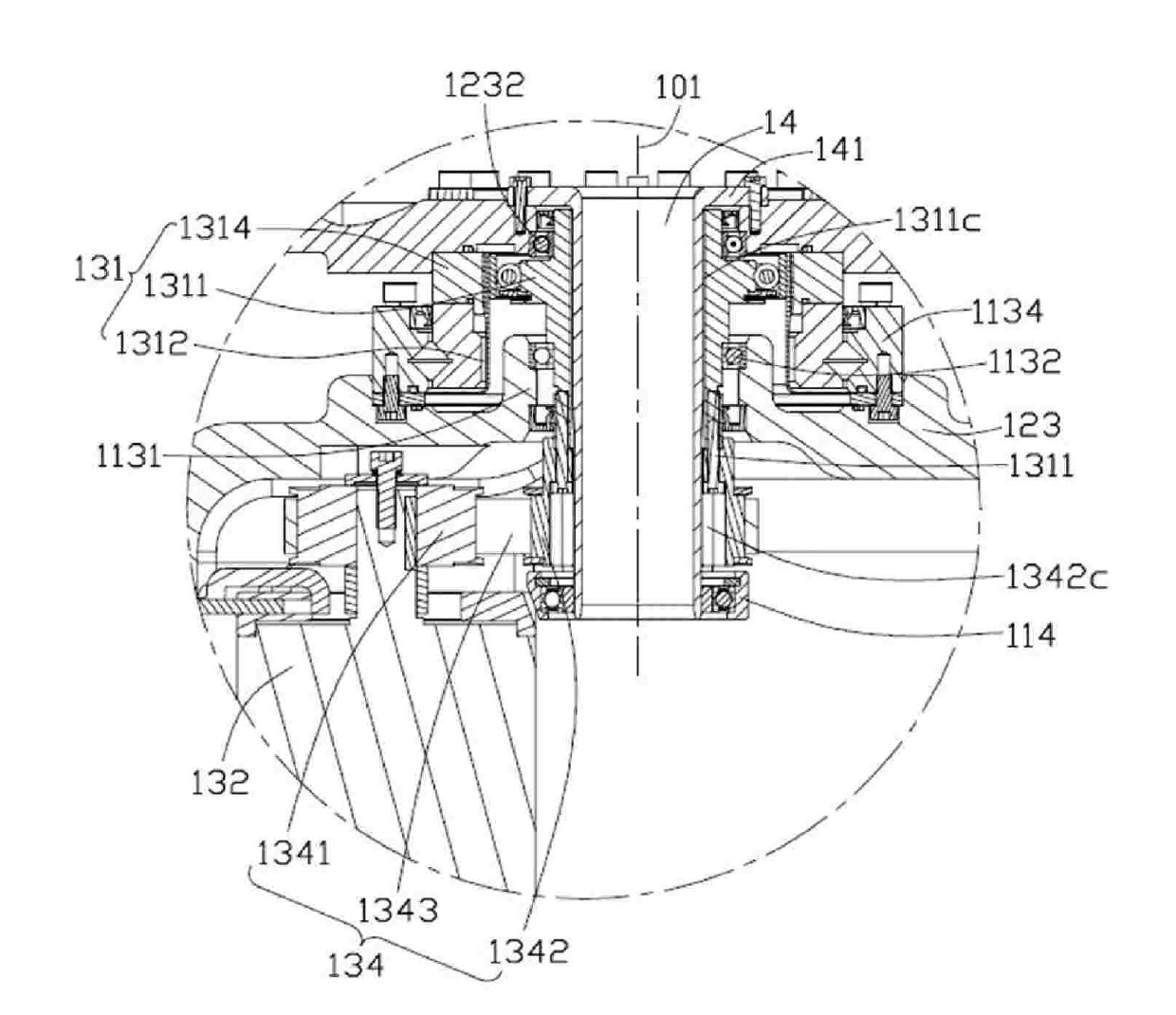

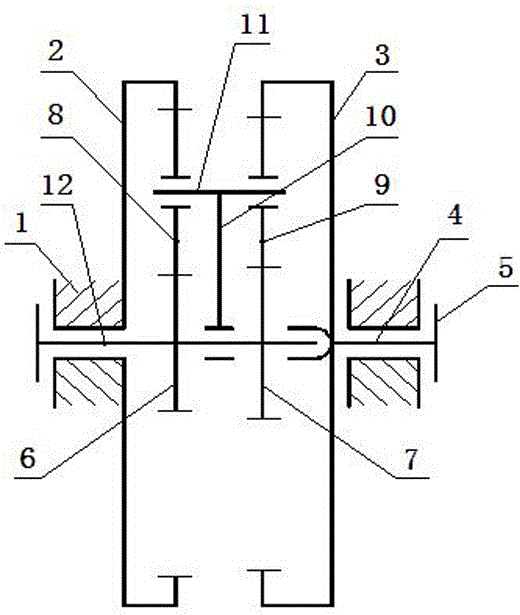

Pitching transferring integrated waist structure of human-like robot

The invention relates to a waist structure of robot whose pitching and turning motions are integrated, belonging to the robot technique. Wherein, the angle contact ball bearing is inside the end cover, to be fixed via binding ring and end cover axle; the left part of thorax plate and the left part of connecting plate are connected by the end cover axle; the stable wheel of second harmonic reducer is connected to the right part of connecting plate; the movable wheel of second harmonic reducer is connected to the right upright plate of thorax plate; the input axle sleeve of second harmonic reducer is sheathed on the output axle of pitching driving motor; the stable wheel of first harmonic reducer is fixed to the cover plate of abdominal cavity; the movable wheel of first harmonic reducer is connected to the connecting plate; the input axle of first harmonic reducer is sheathed on the output axle of transfer driving motor. The invention uses integrated structure, while the pitching driving motor and the transfer driving motor are serially connected to themselves harmonic reducers coaxially, with large motion range. Said waist structure can meet the pitching and transfer demands in wide range.

Owner:SHANGHAI JIAO TONG UNIV

Electric moped and transmission device

The invention provides an electric moped and a transmission device. The transmission device comprises a motor, a harmonic reducer and an output shaft. The motor comprises a rotor; the harmonic reducercomprises a wave generator, a flexible gear and a rigid gear, and the wave generator is in anti-torque connection with the rotor; and the output shaft is configured to be in anti-torque connection with the rigid gear or the flexible gear of the wave generator. By the adoption of the provided transmission device, the harmonic reducer and the motor are integrated so as to achieve speed reduction torque increase transmission, the large reduction ratio can be obtained in a limited installation space, transmission mechanisms such as the multi-stage gear transmission mechanism, the planet gear transmission mechanism and the bevel gear transmission mechanism are not needed, and a whole integrated transmission mechanism is more compact in structure, lighter in mass, higher in transmission efficiency and high in obtained output torque.

Owner:SCHAEFFLER TECH AG & CO KG

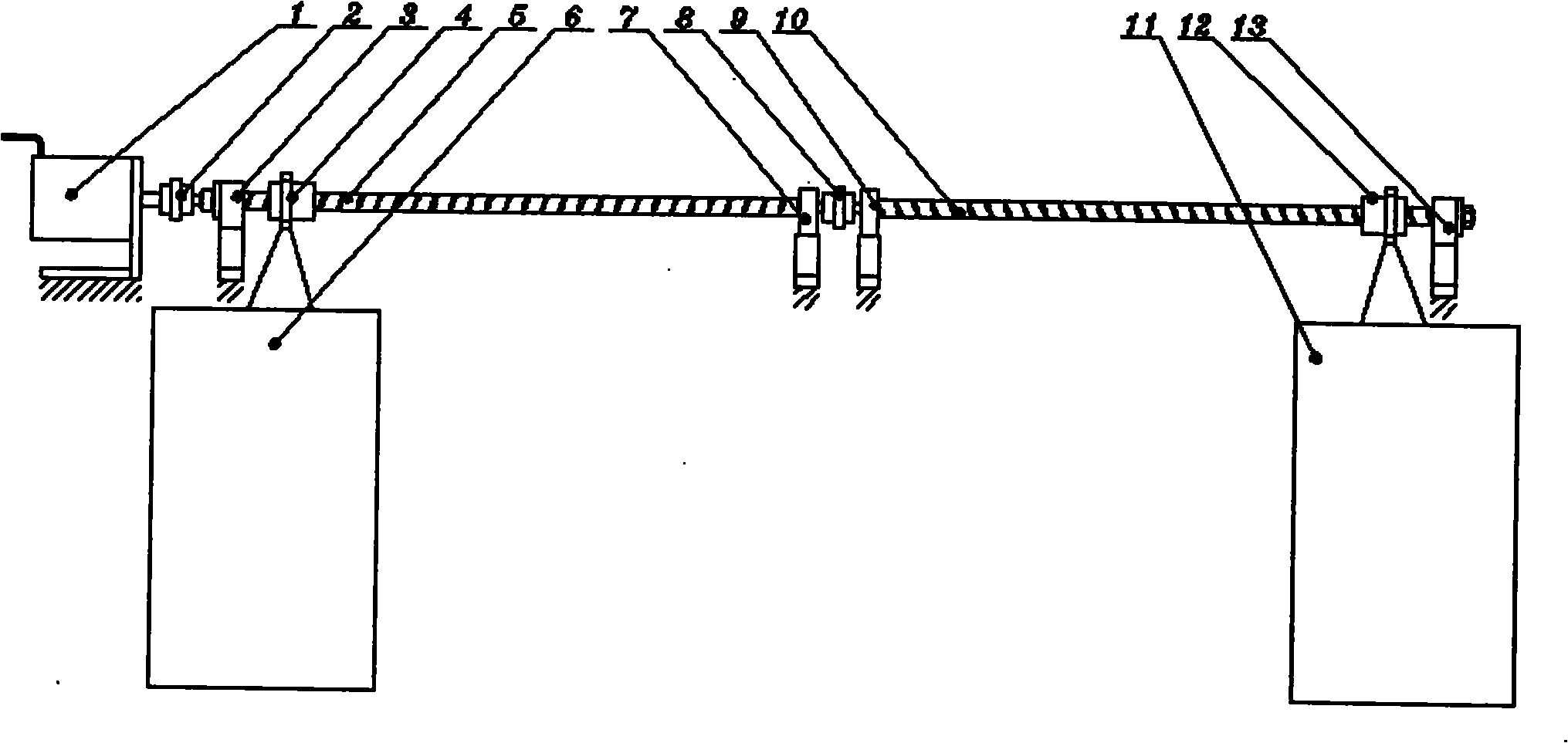

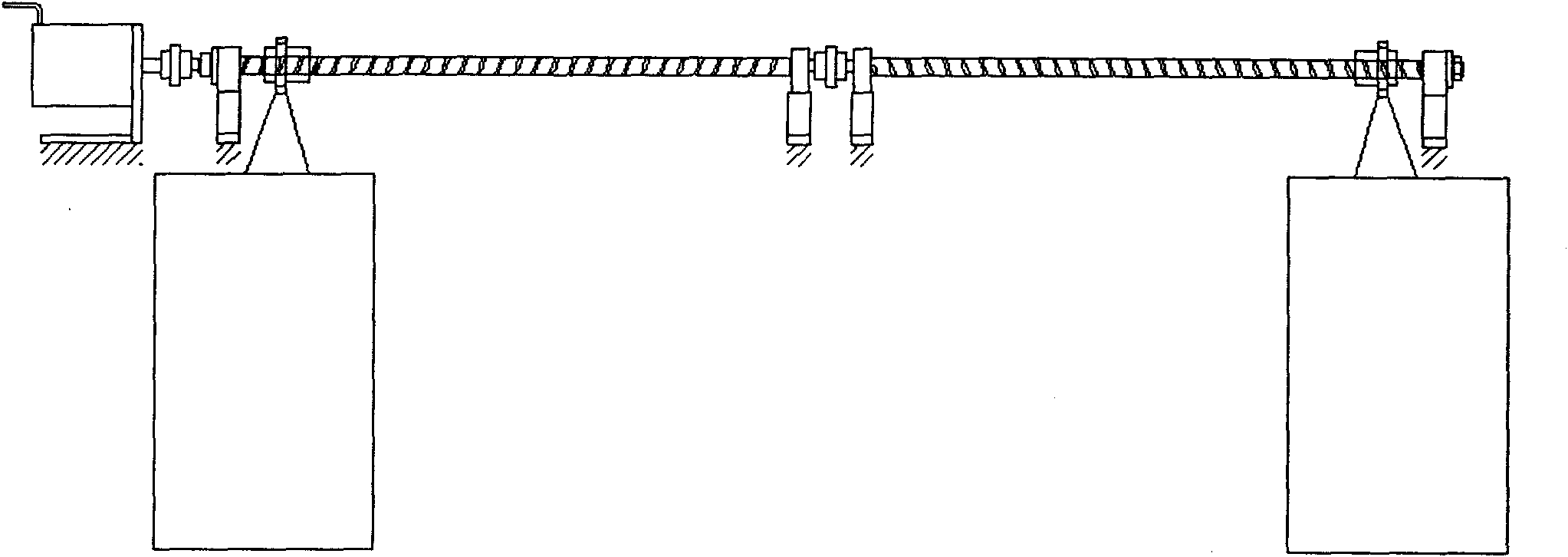

Feed screw nut-driven transmission device of screen door for subways

InactiveCN101812958ASimple structureReduce wearRailway componentsPower-operated mechanismMechanical engineering

The invention relates to a feed screw nut-driven transmission device of a screen door for subways. The invention is characterized by comprising a motor (1), a left feed screw nut (3), a levorotatory screw rod (5), a screw rod coupler (8), a dextrorotatory screw rod (10) and a right feed screw nut (12), wherein the output shaft of the motor (1) is connected with one end of the levorotatory screw rod (5) or the dextrorotatory screw rod (10), the levorotatory screw rod (5) and the dextrorotatory screw rod (10) are connected by the screw rod coupler (8) to synchronously rotate, the left feed screw nut (3) is screwed in the levorotatory screw rod (5), a left moving door (6) is connected with the left feed screw nut (3), the right feed screw nut (12) is screwed in the dextrorotatory screw rod (10), a right moving door (11) is connected with the right feed screw nut (12), the left feed screw nut (3) and the right feed screw nut (12) are both connected with one end of the respective locking crank (2-2), and the other end of each of the locking cranks (2-2) is movably inserted in a guide groove (2-1). The invention has the advantages of simple structure, long service life and low cost.

Owner:NANJING PANDA MECHATRONICS INSTR TECH +2

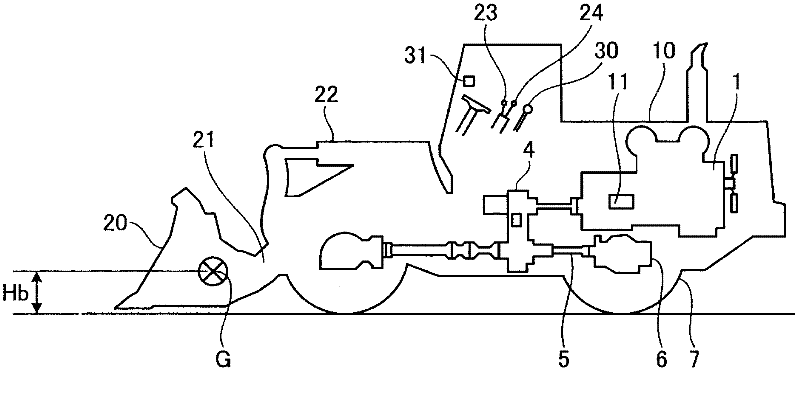

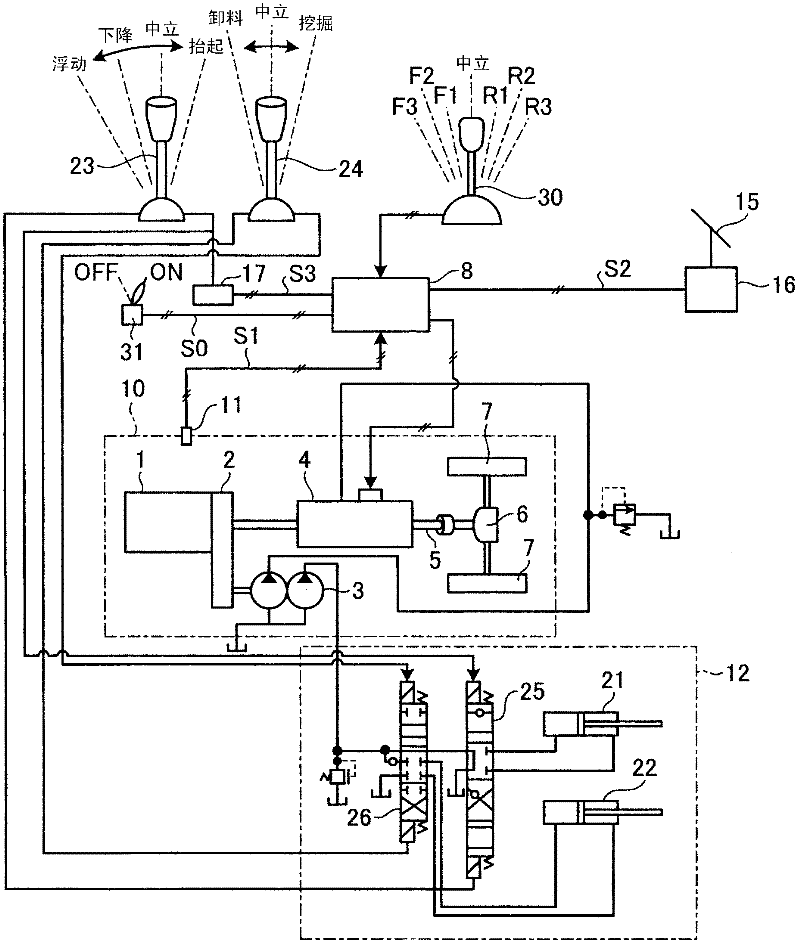

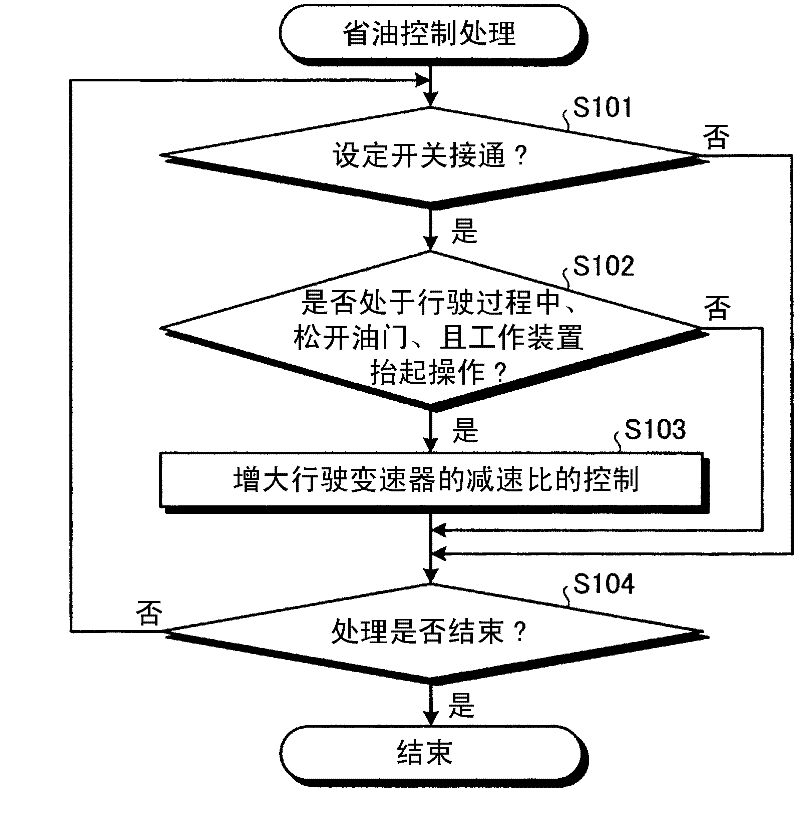

Fuel saving control device for working machine and fuel saving control method for working machine

InactiveCN102365227ALarge reduction ratioImprove recovery/recycling efficiencySoil-shifting machines/dredgersLifting devicesReduction ratioEnergy recovery

A fuel saving control device for a working machine and a fuel saving control method for a working machine improve energy recovery and regeneration efficiency to further promote a reduction in fuel consumption and are provided with: a vehicle speed detector (11) for detecting whether or not the vehicle is traveling; an accelerator operation detector (16) for detecting whether or not an accelerator operation member is not being operated; a boom operation lever (23) for detecting whether or not there has been an instruction for boom raising operation by which load handling and carrying work is performed; and a controller (8) for performing control for increasing the reduction ratio of a travel transmission (4) when the vehicle speed detector (11) detects that the vehicle is traveling, the accelerator operation detector (16) detects that the accelerator operation member is not being operated, and the boom operation lever (23) detects that there has been an instruction for the boom raising operation.

Owner:KOMATSU LTD

Reducer with less tooth difference

The invention relates to a reducer with less tooth difference, comprising a box body, an input shaft and an output shaft, wherein a universal coupler is arranged between the input shaft and the output shaft; an eccentric shaft head is arranged at the end part of the input shaft and is provided with an oscillating bearing; the oscillating bearing is provided with a bearing bush; the input end of the universal coupler is fixedly connected with the bearing bush and a swinging bevel gear; the box body is fixed with a fixed bevel gear meshed with the swinging bevel gear; and the input end of the universal coupler is connected with an output shaft; teeth of the fixed bevel gear are more than teeth of the swinging bevel gear, the structure is compact, and when fixed bevel gear is meshed with theswinging bevel gear, a crossed axis angle ranges from 150 degrees to 178 degrees. Due to the arrangement, the number of the meshed teeth of the fixed bevel gear and the swinging bevel gear are more than those of traditional hear transmission, so that transmitted torque is large, and speed change with the large reduction ratio and large load can be realized; and due to the arrangement of a balancedevice, the problem of laterality when the swinging bevel gear rotates can be solved, so that a reduction gear can move more stably and has low noise.

Owner:宿孝廷

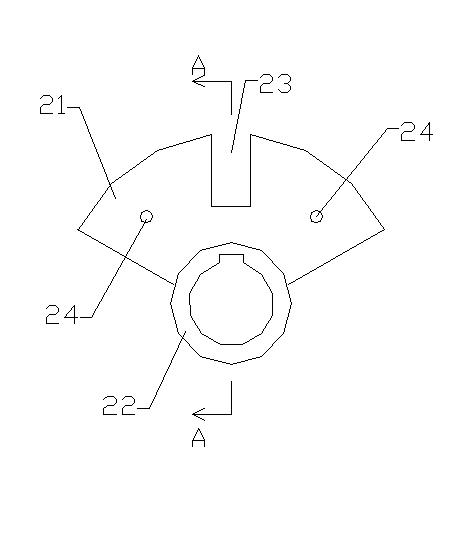

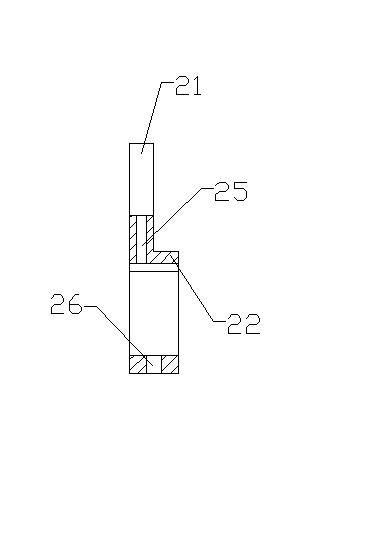

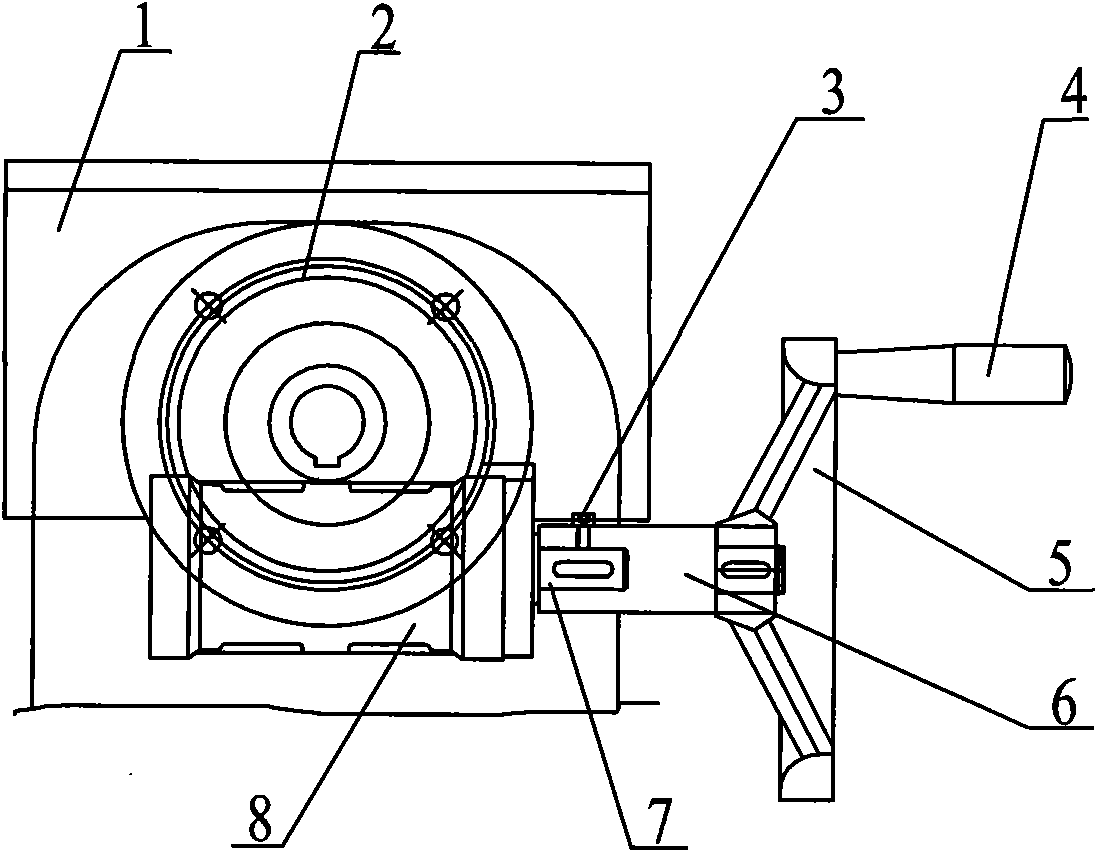

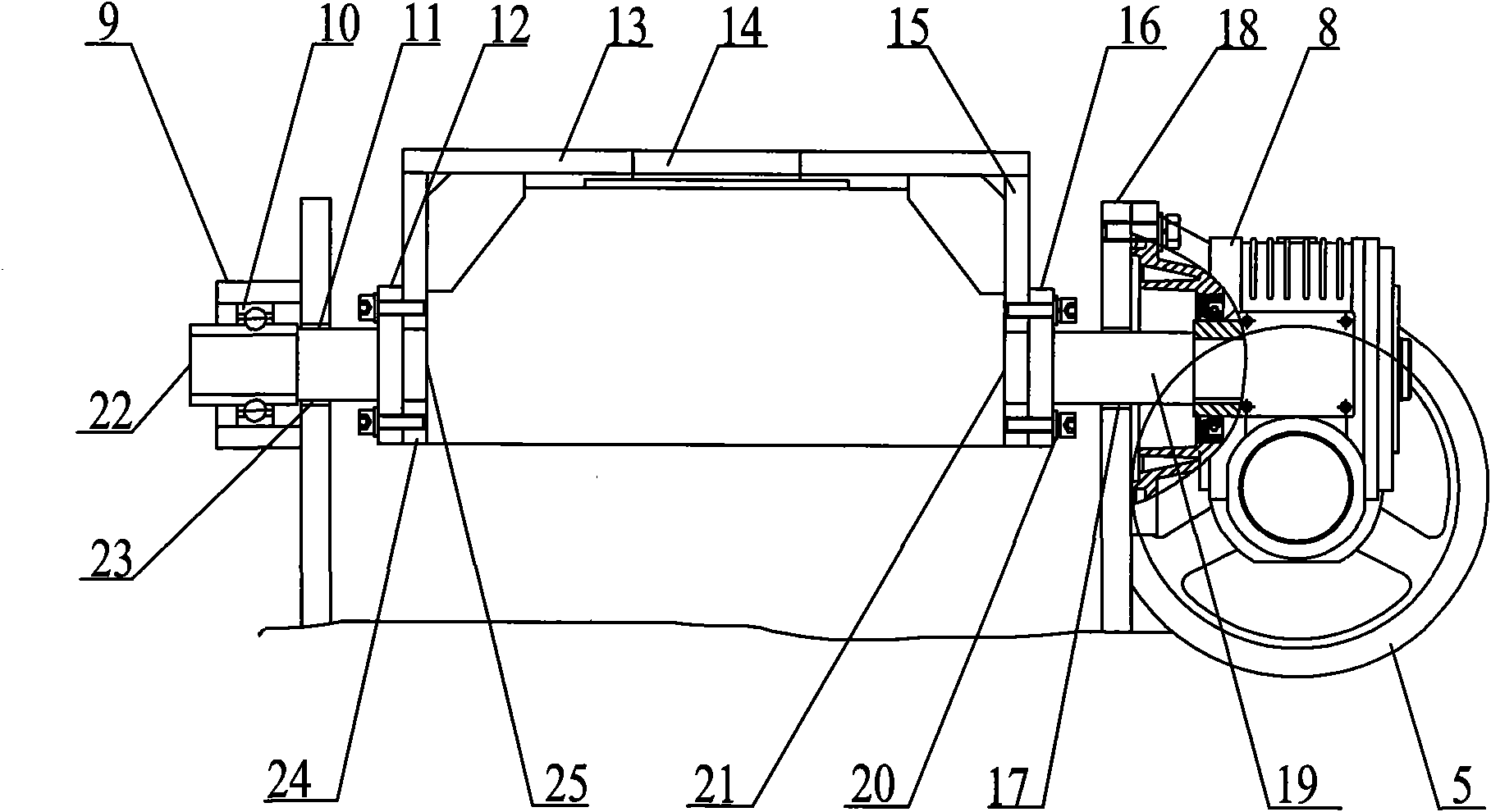

Dumping mechanism of welding positioner

InactiveCN102009312ALarge reduction ratioSmooth rotationWelding/cutting auxillary devicesAuxillary welding devicesReducerEngineering

The invention relates to a dumping mechanism of a welding positioner, comprising a stand and a dumping seat arranged in the stand. The dumping seat comprises two side boards, a first end side board and a second end side board, wherein the first end side board is provided with a first mounting hole, the second end side board is provided with a second mounting hole, the stand is provided with a first connecting hole and a second connecting hole, a second dumping shaft is arranged in the second mounting hole, a first dumping shaft is arranged in the first mounting hole and provided with a speed reducer corresponding to the end part penetrating into the first connecting hole, and an output shaft of the speed reducer is fixedly connected with the first dumping shaft. The speed reducer of the invention adopts a worm gear speed reducer, drives the dumping seat to rotate through an output shaft of the worm gear speed reducer, has simple structure and can transfer great torsion to stabilize the rotation of the dumping seat because of the greater reduction ratio of the worm gear speed reducer. The worm gear speed reducer rotates through a handwheel and can lock the position when a worktable rotates to an appointed angle so as to work safely and reliably.

Owner:WUXI HENGFU TECH

Hub driving assembly

InactiveCN105691103AIncrease radial sizeIncrease stiffnessHubsMotor depositionReduction driveRoad surface

A hub driving assembly comprises a hub, a hub bearing, a motor, a speed reducer and a housing, wherein the hub bearing is positioned in the hub. The hub bearing comprises an outer ring, an inner ring and a rolling body, wherein the rolling body is positioned in a radial gap between the outer ring and the inner ring; the housing defines a motor chamber, in which the motor is accommodated, and a speed reducer chamber, in which the speed reducer is accommodated; an output end of the motor extends out of an opening of the motor chamber and is connected with an input end of the speed reducer; an output end of the speed reducer is connected with the hub; the motor, the speed reducer and the housing are all positioned on the internal side of the hub bearing in a radial direction; the outer ring is fixedly connected with the hub, or the hub is also used as the outer ring; and the inner ring is fixedly connected with the housing. According to the technical scheme of the invention, problems that the rigidity of the hub bearing in the traditional hub driving assembly is not enough, hard matters may stop the rotation of the hub and wear and tear the hub when the hard matters on a pavement are clamped into the internal circumferential surface of the hub in the vehicle running process, and the speed reducer cannot obtain a large speed reduction ratio are solved.

Owner:SCHAEFFLER TECH AG & CO KG

A worm and worm gear decelerating mechanism

InactiveCN104141738AReduce impactLarge reduction ratioGear vibration/noise dampingToothed gearingsLow noiseDrive motor

A worm and worm gear decelerating mechanism comprises a driving mechanism, a first worm and worm gear transmission mechanism connected with the driving mechanism, and a second worm and worm gear transmission mechanism. The decelerating mechanism is a double-stage progressive worm and worm gear decelerating mechanism. Large speed reduction ratio and low noise are realized by the first worm and worm gear transmission mechanism. High torque transmission and low noise are realized by the second worm and worm gear transmission mechanism. The power transmitted by a driving motor is decomposed by the first worm and worm gear transmission mechanism to a first worm gear and a second worm gear via a first driving worm, and then further delivered to a first transmission worm and a second transmission worm of the second worm and worm gear transmission mechanism. The driving force of the driving motor is delivered to a third worm gear by the first transmission worm and the second transmission worm and finally output by an output mechanism. The decelerating mechanism reduces the impact force of the driving motor and efficiently reduces noise. By double-stage transmission decomposition, the travel is prolonged, the rotating speed is reduced, and the torque and speed reduction ratio are efficiently improved.

Owner:SHENZHEN MUREN APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com