Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

225results about How to "Increase the reduction ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

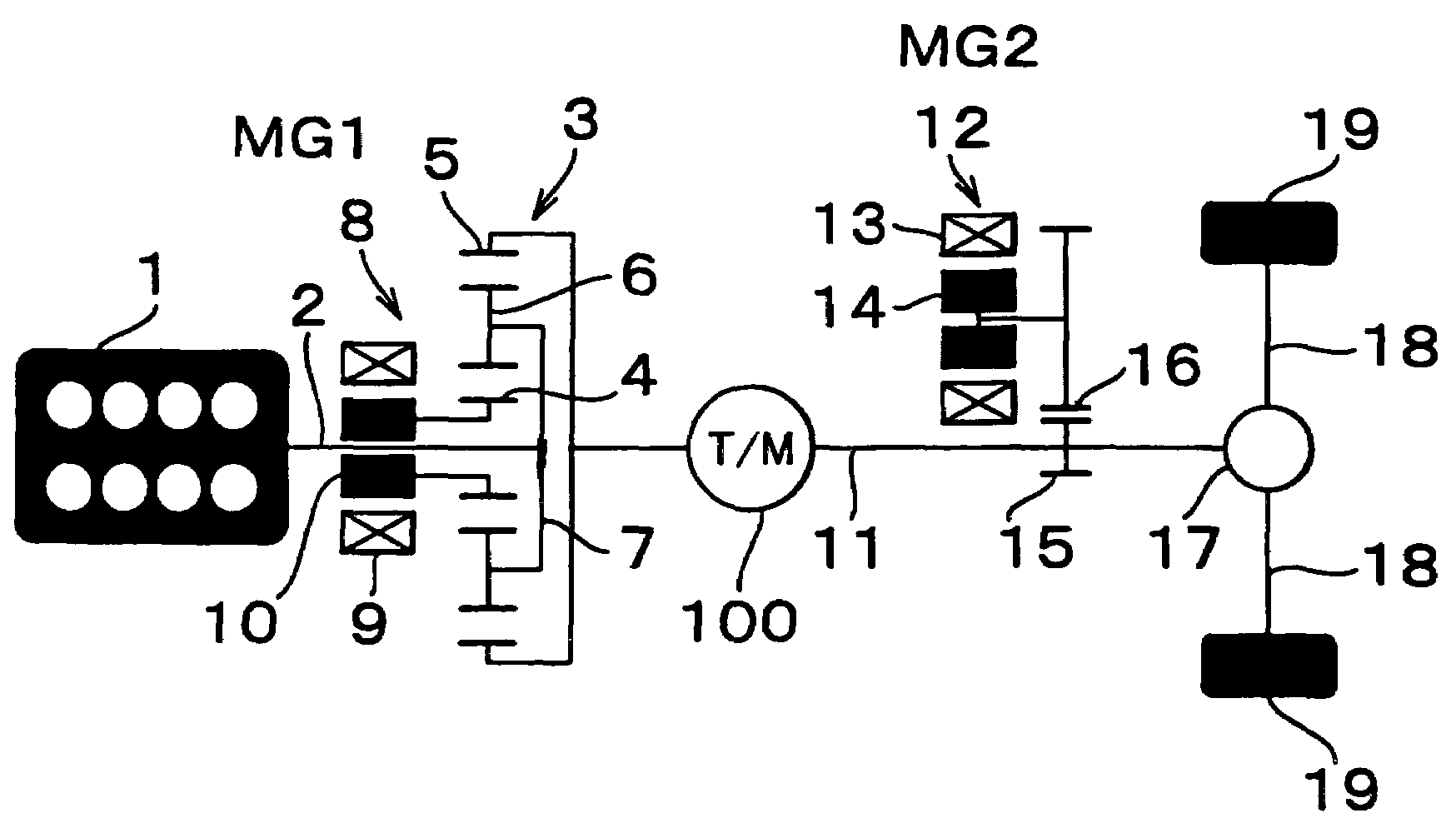

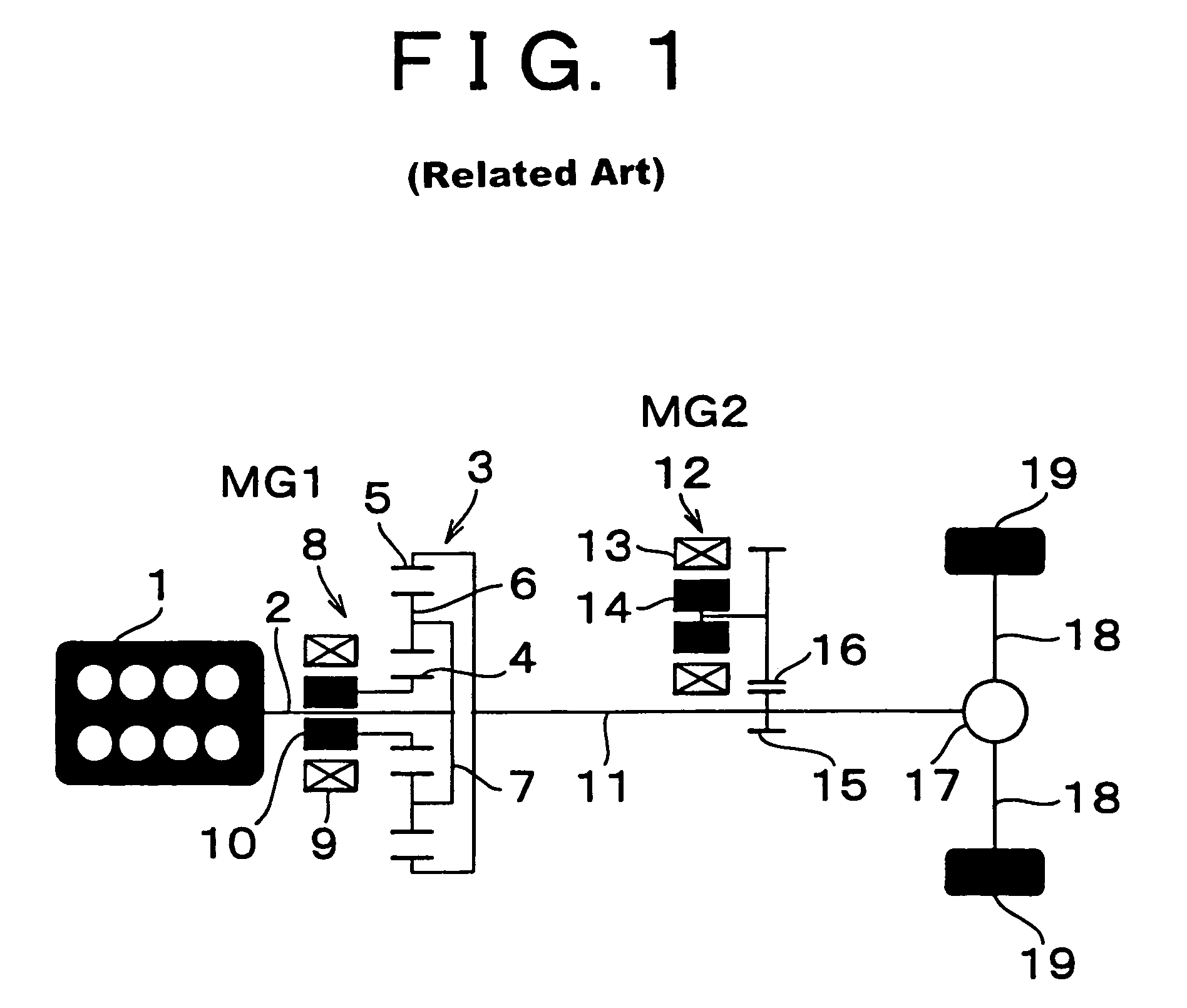

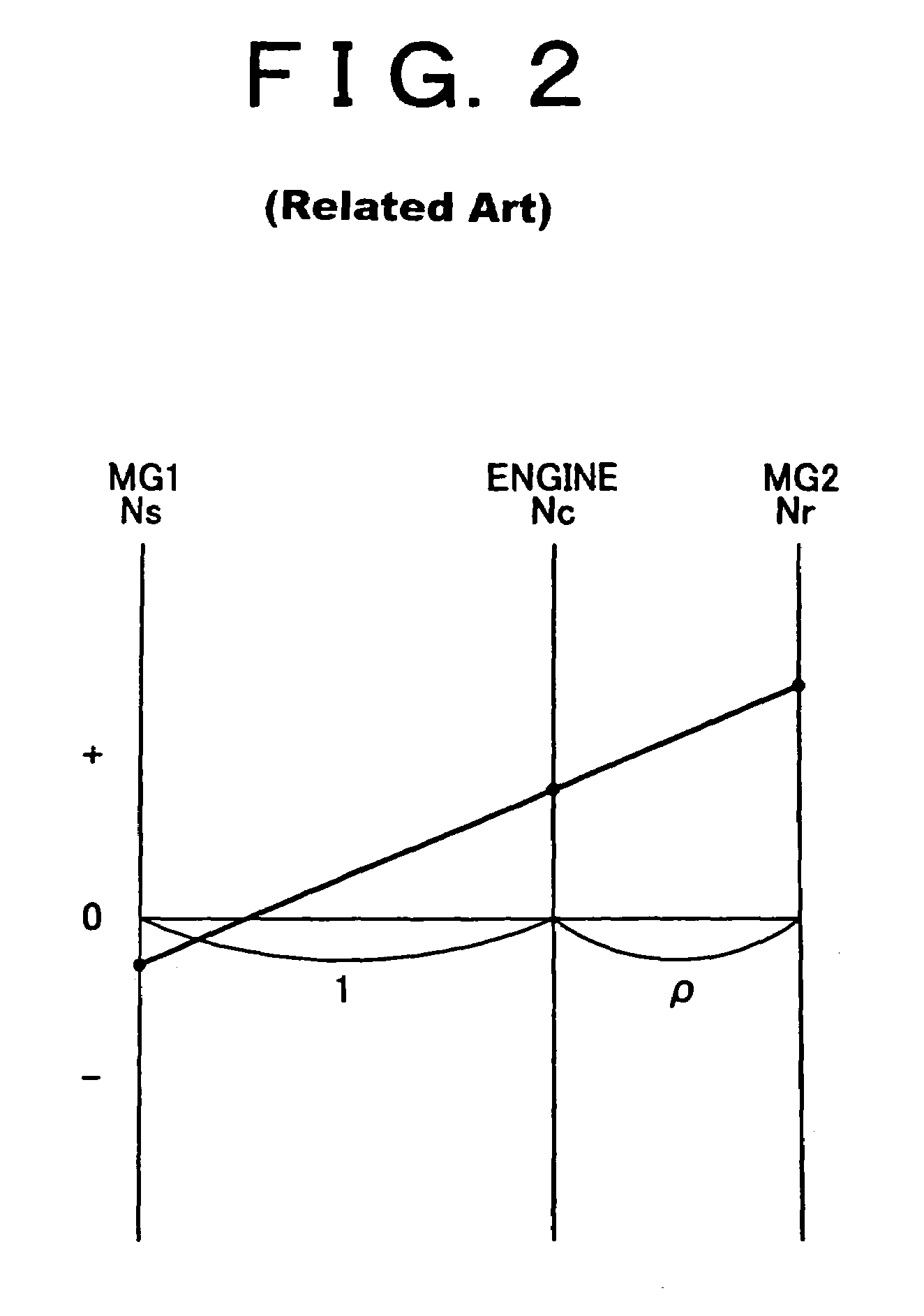

Hybrid-vehicle drive system and operation method with a transmission

InactiveUS7223200B2Increase speedHigh torqueElectric propulsion mountingRailway vehiclesVariatorWheel drive

A hybrid-vehicle drive method and system includes an internal combustion engine that includes an output shaft, a first electric motor / generator connected to the output shaft of the internal combustion engine via a power distribution mechanism, a wheel drive shaft connected to the output shaft of the internal combustion engine via the power distribution mechanism, a second electric motor / generator connected to the wheel drive shaft, and a transmission located on at least one of the wheel drive shaft and a connecting portion of the second electric motor / generator with the wheel drive shaft.

Owner:TOYOTA JIDOSHA KK

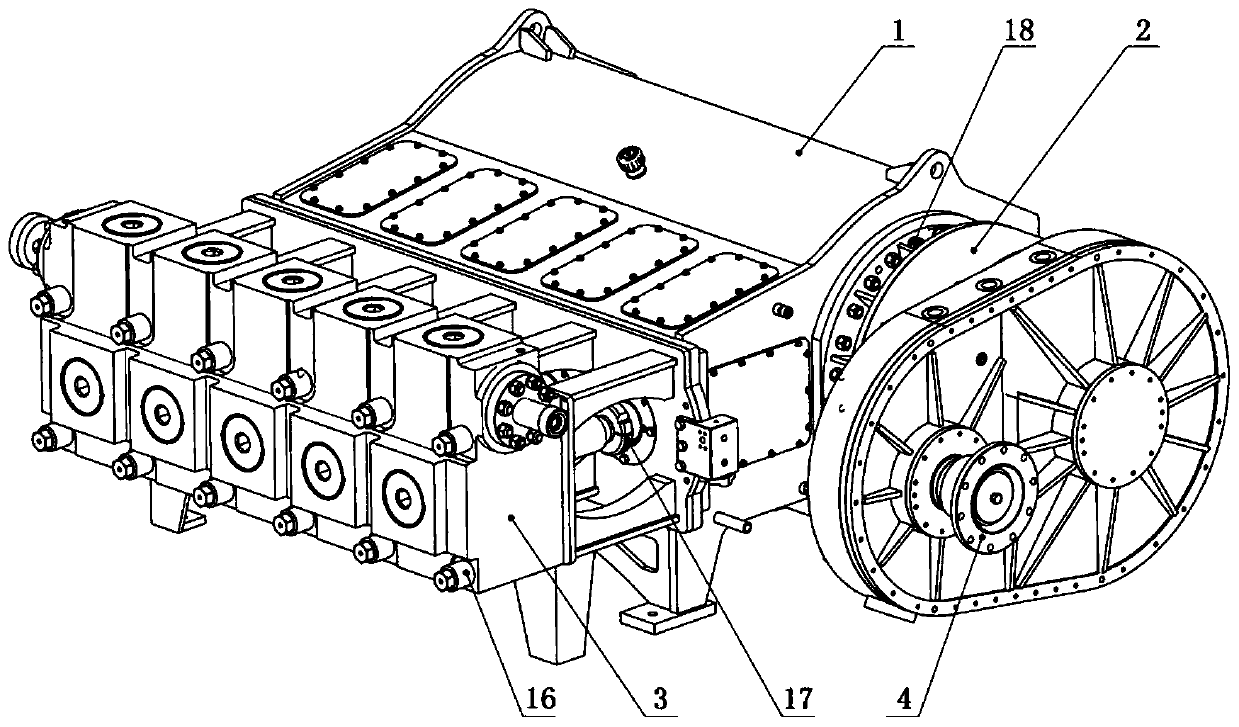

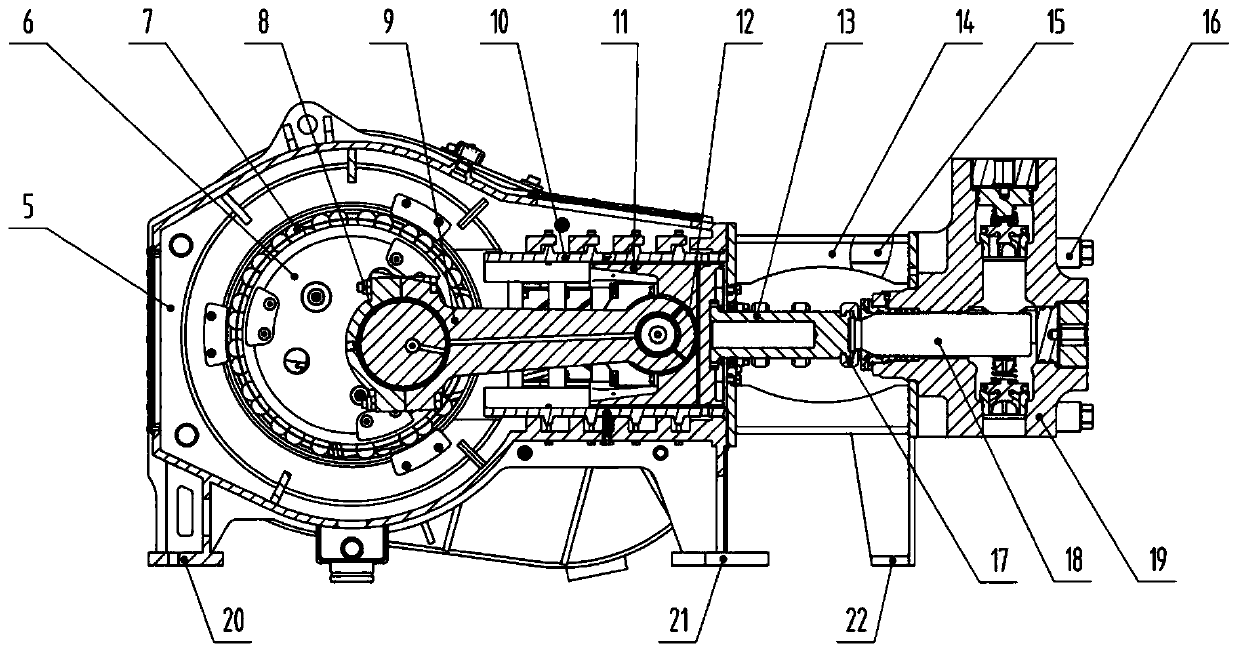

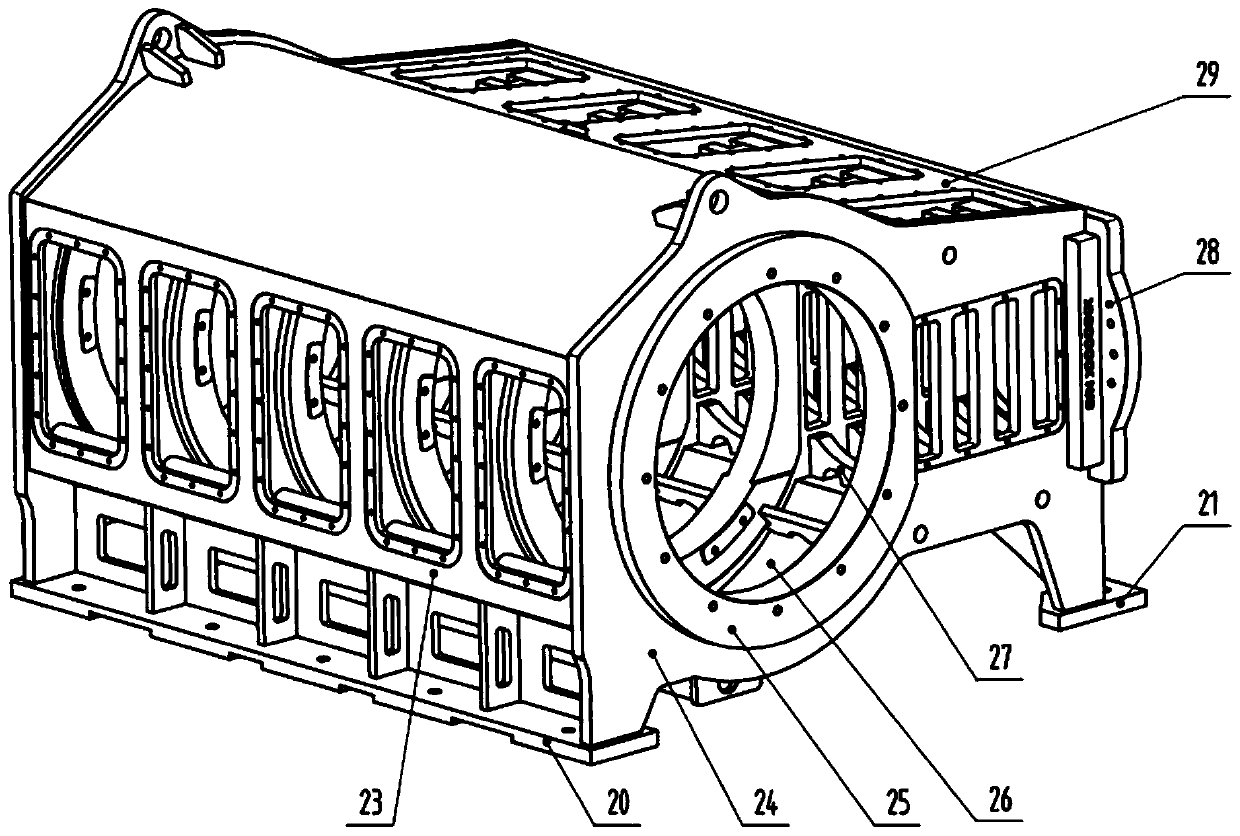

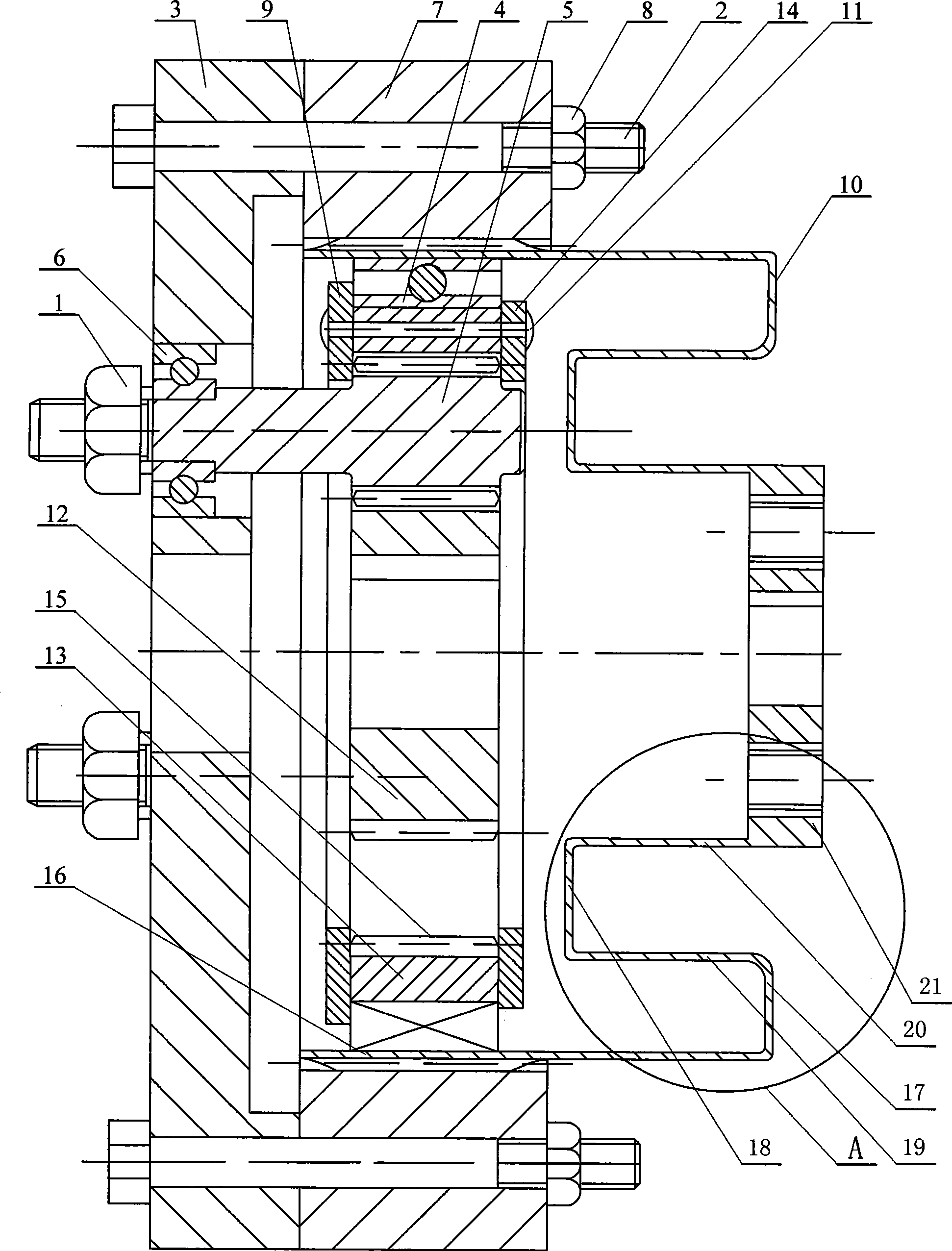

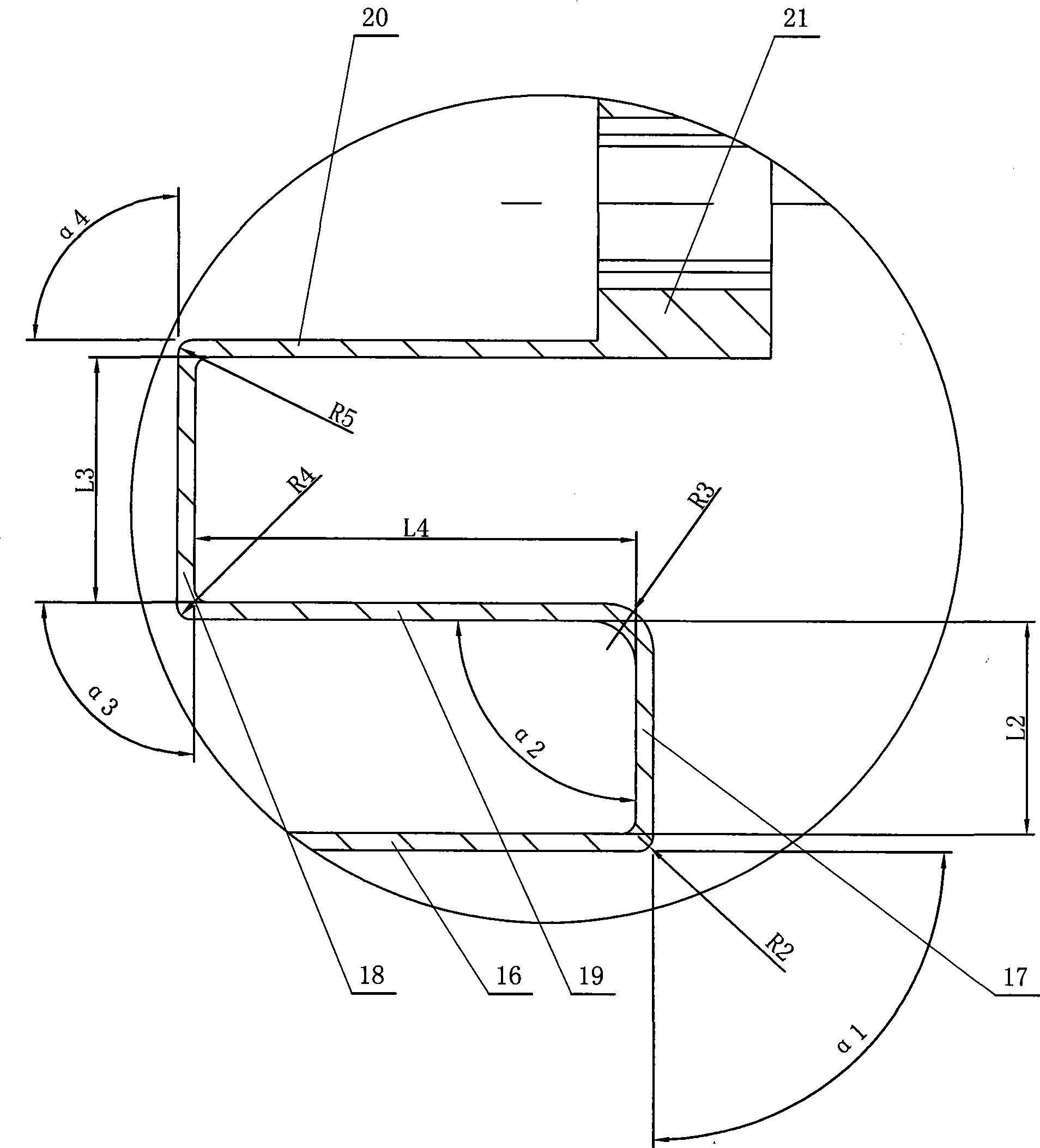

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

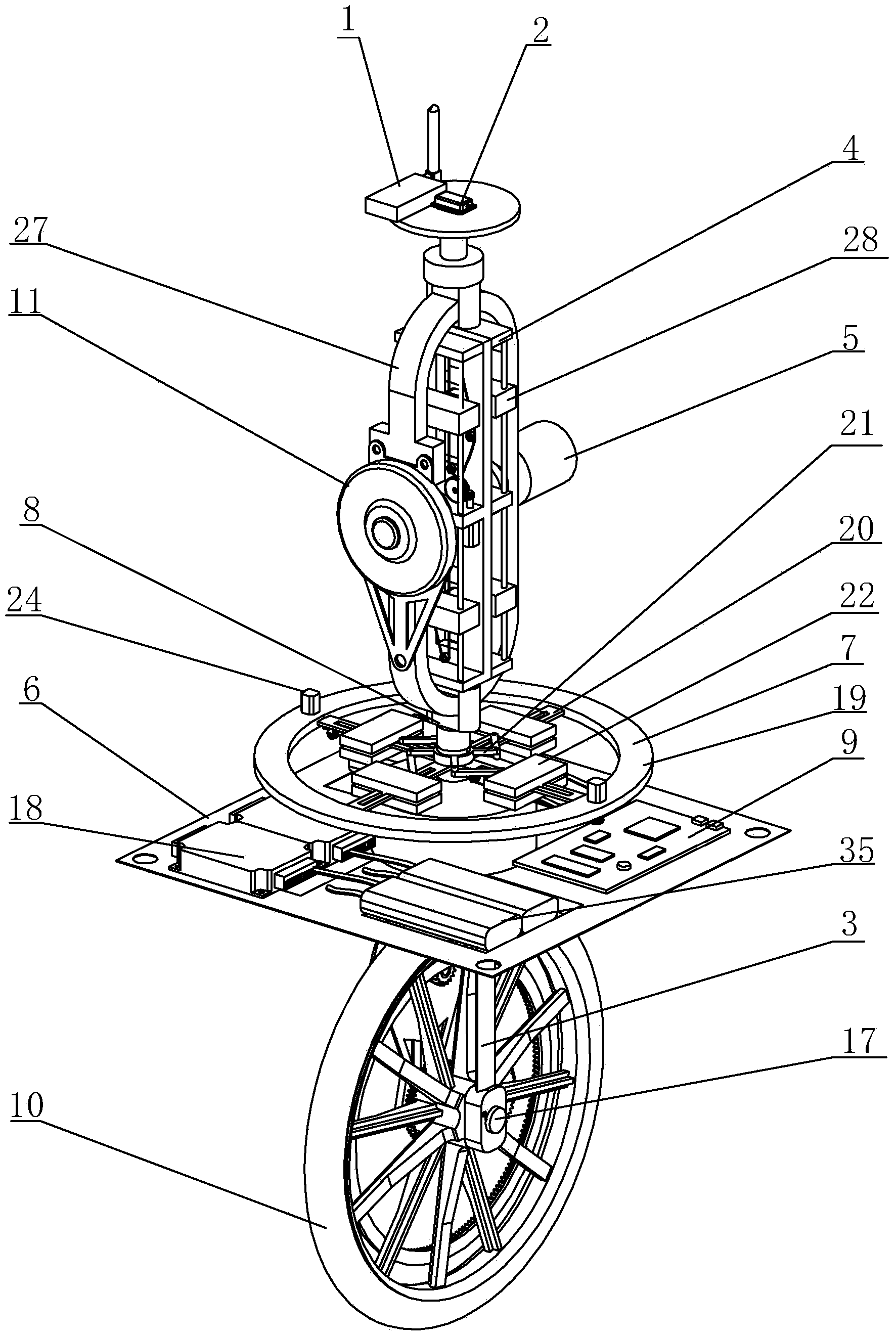

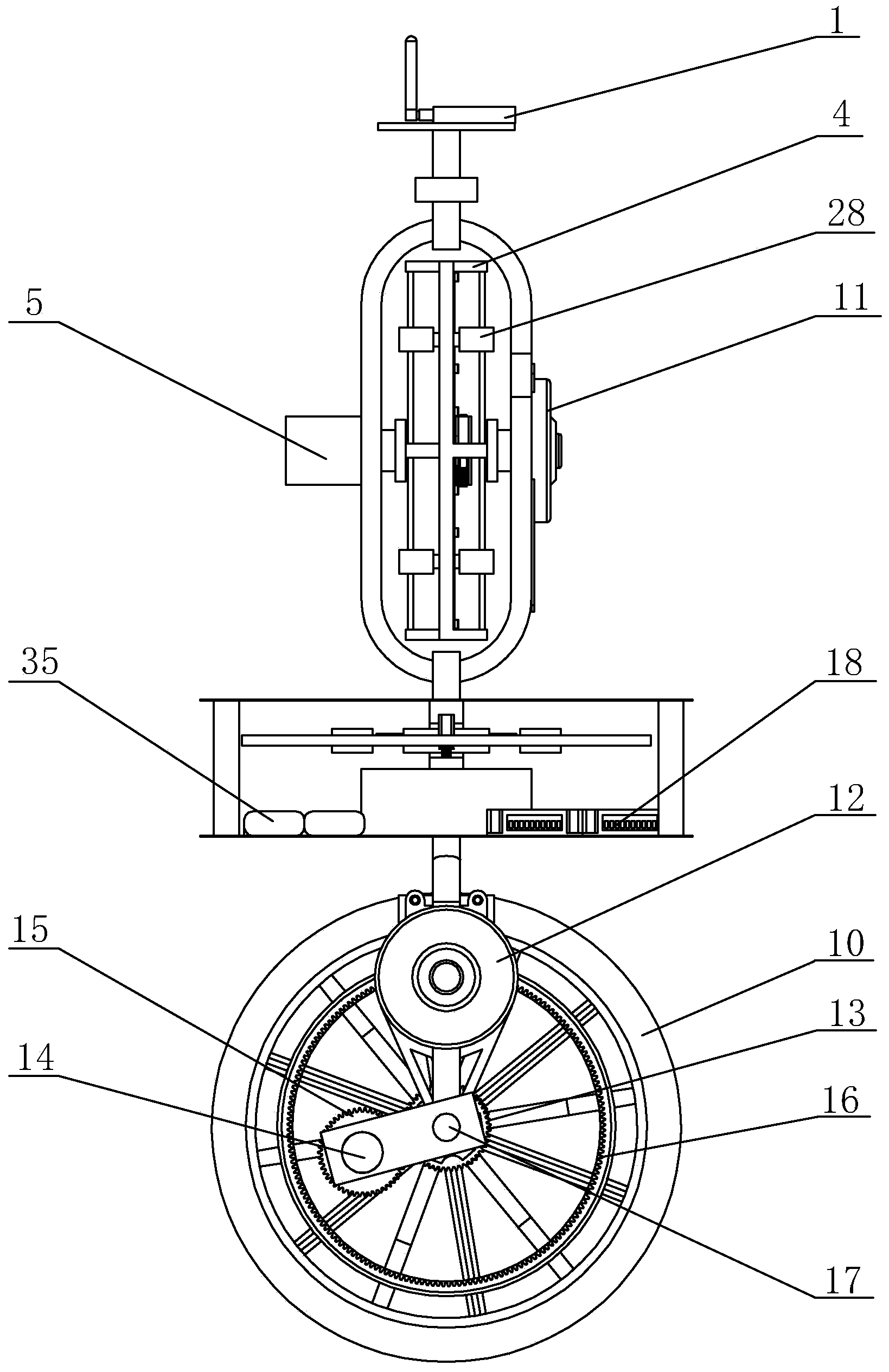

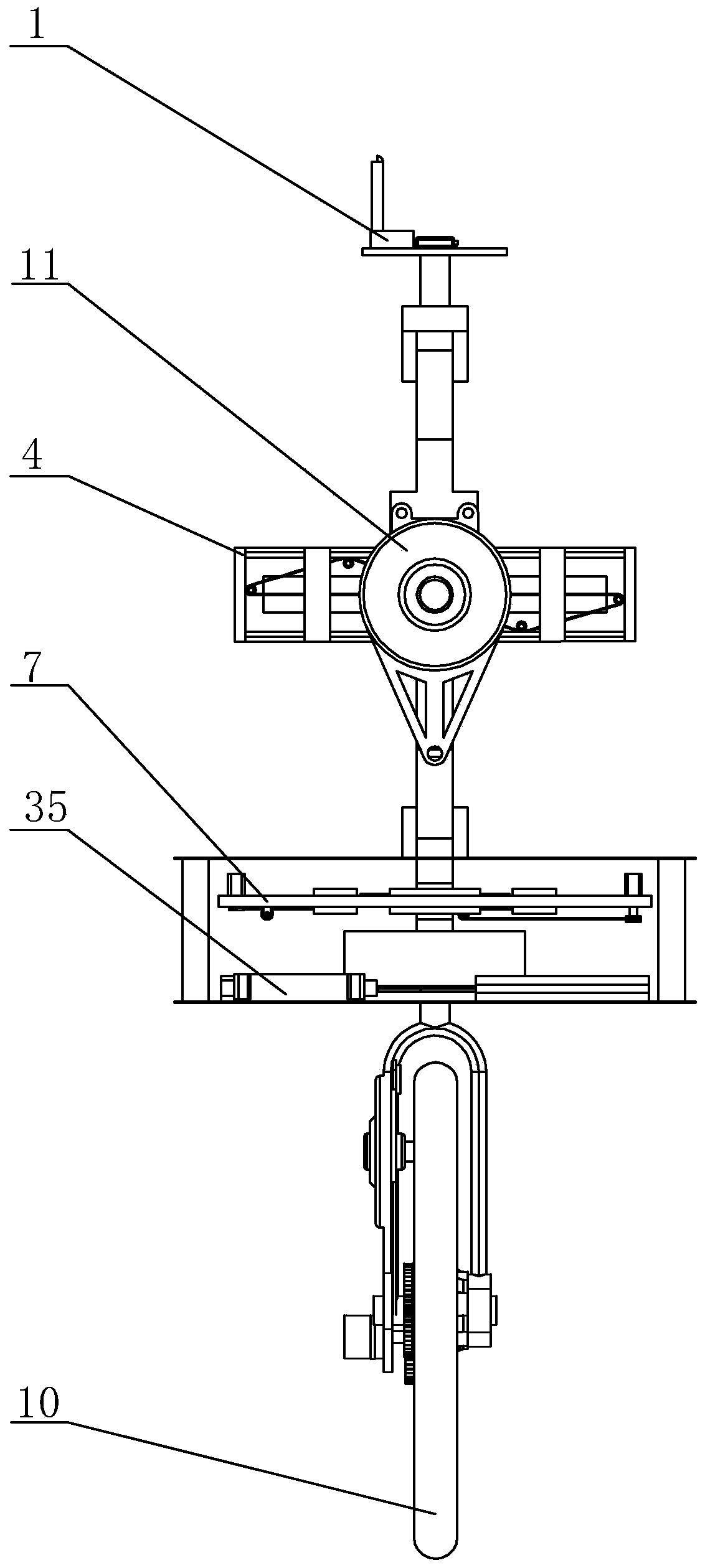

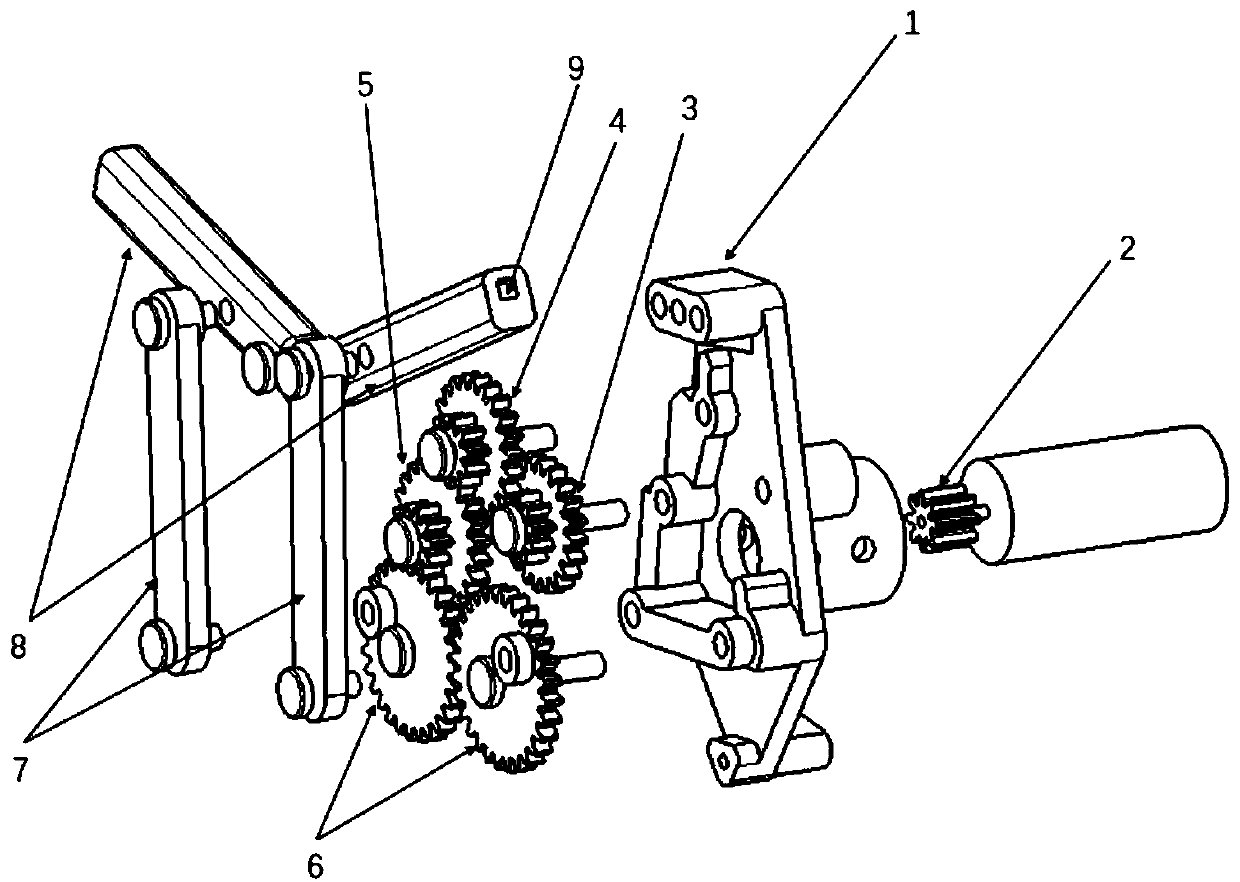

Unicycle robot with function of self-balancing realization

ActiveCN103645735AAdjustable center of gravityLarge adjustment inclinationPosition/course control in two dimensionsGyroscopeMotion controller

The invention discloses a unicycle robot with the function of self-balancing realization. The unicycle robot comprises a wireless module, a gyroscope, a motion controller, and a servo driver. The servo driver includes an oscillating bar servo driver, a waist plate servo driver, a wheel servo driver, an oscillating bar, a waist plate, and a wheel; and the oscillating bar servo driver, the waist plate servo driver, and the wheel servo driver are respectively connected with the motion controller by leads. The gyroscope and an oscillating bar encoder collect a unicycle body gesture; a signal is fed back to the motion controller; the signal is processed by the control program and thus a control instruction is sent to the oscillating bar servo driver, the waist plate servo driver, and the wheel servo driver, so that the oscillating bar, the waist plate, and the wheel are controlled to rotate to adjust and control the gesture of the robot. According to the invention, the rotation inertia of the oscillating bar and the waist plate can be adjusted by an on-line way; the adjusting capability of the balancing and turning of the unicycle robot can be enhanced; and the aadaptability to the dynamic complex environment, of the robot can be improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

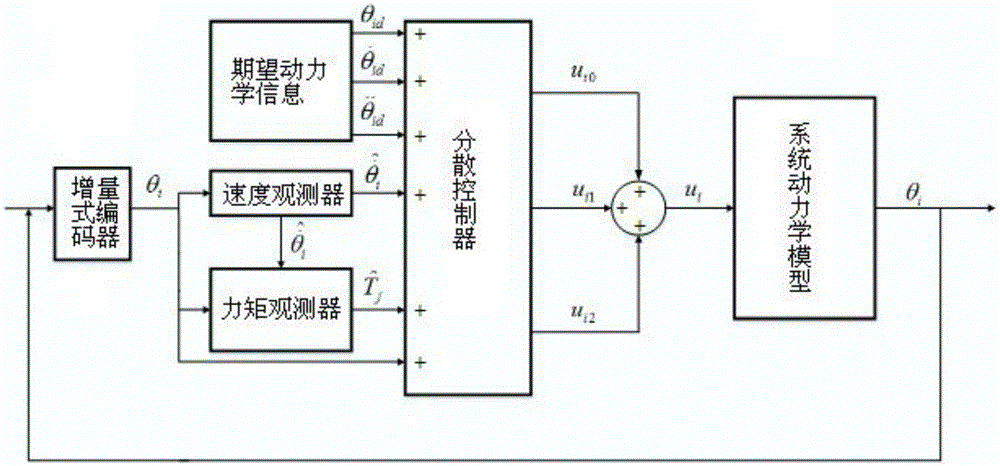

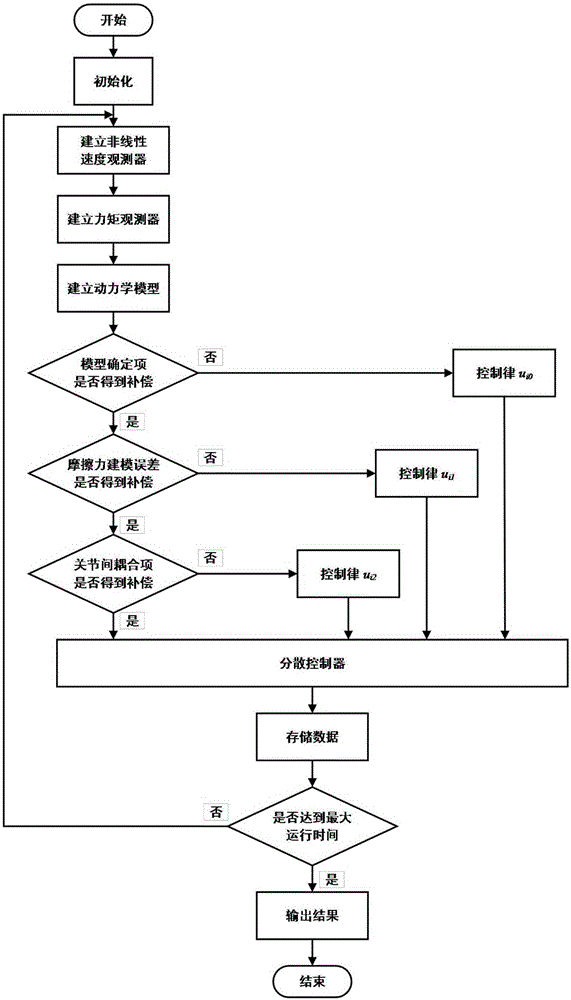

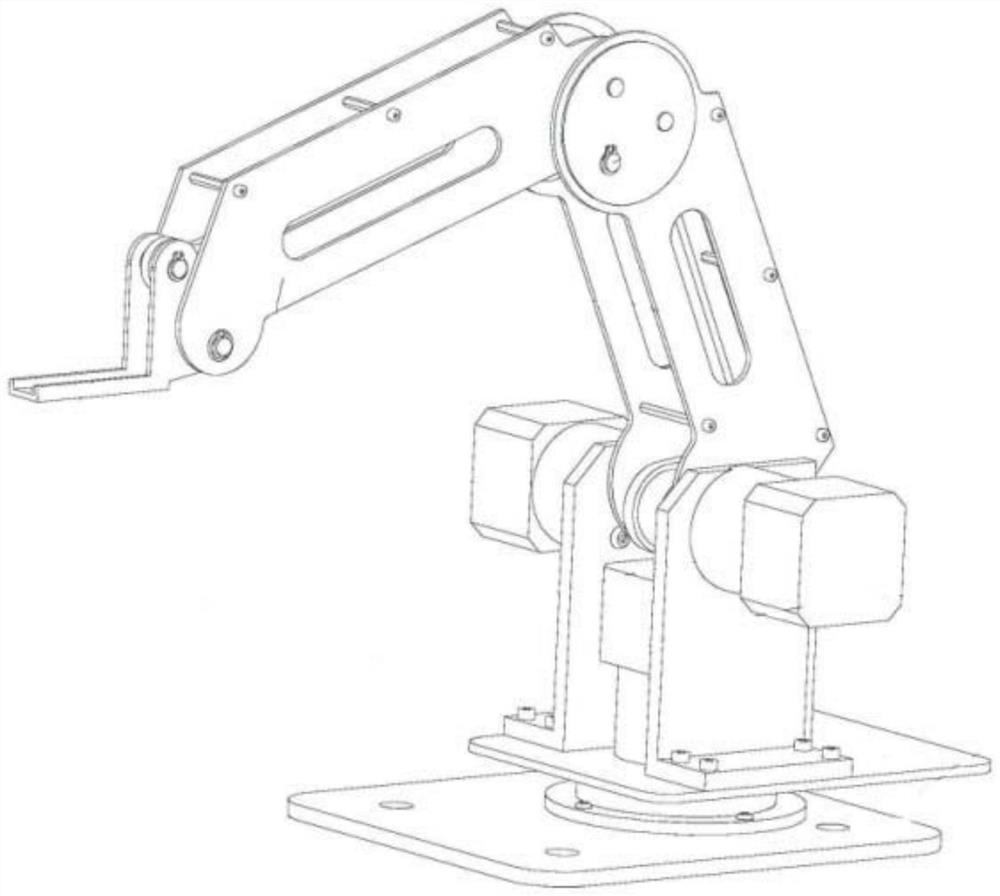

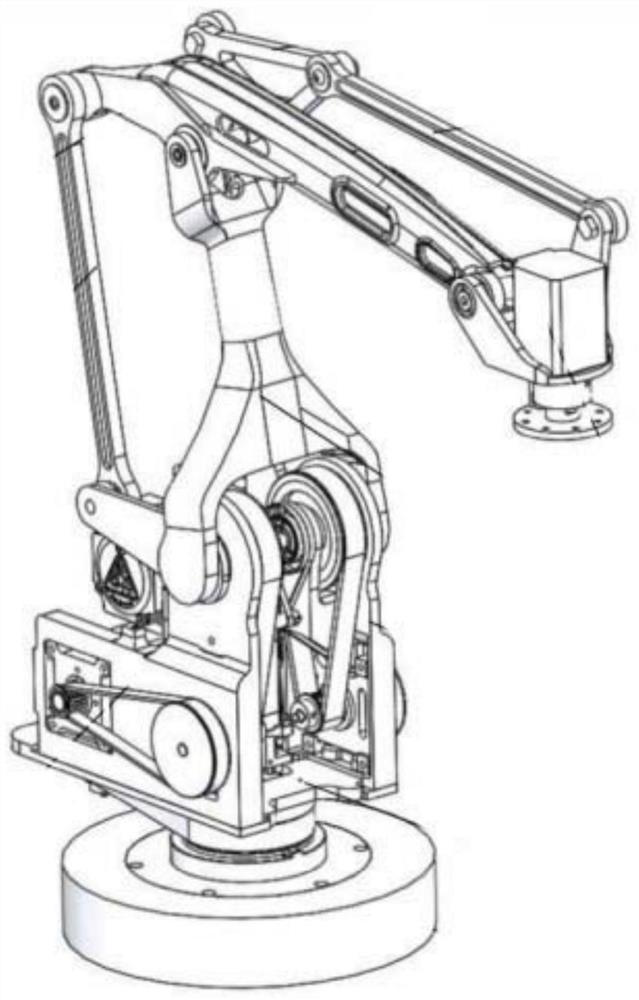

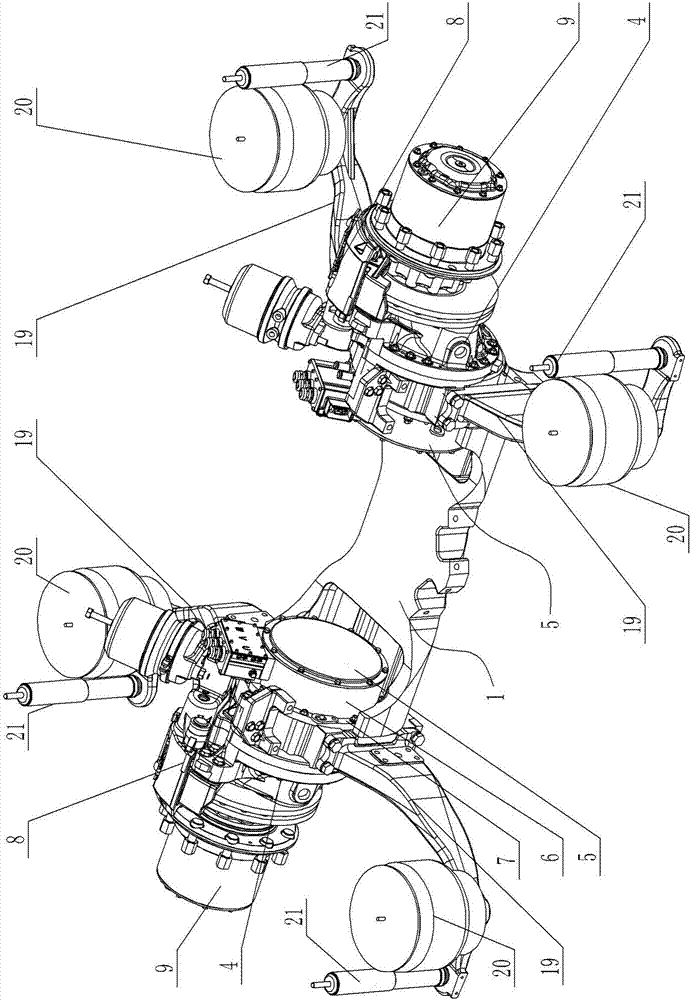

Reconfigurable mechanical arm decentralized control system and control method adopting position measuring

ActiveCN105196294AIncrease the reduction ratioReduce volumeProgramme-controlled manipulatorKinetic informationControl system

A reconfigurable mechanical arm decentralized control system and control method adopting position measuring belong to the field of robot control systems and control algorithms, and aim to solve the problems existing traditional reconfigurable mechanical arm control systems and methods thereof. The control method comprises the steps of initializing a system, detecting a reading of an incremental encoder to obtain position measuring information, and establishing a non-linear speed observer based on the information; according to the established non-linear speed observer, establishing a disturbance observation model; adopting an observation value obtaining a joint speed and a joint torque to establish a reconfigurable mechanical arm system dynamics model; by a given joint speed observer, a torque observer, expected dynamics information and the system dynamics model, adopting dynamics information of local joints to design a decentralized controller, compensating the modeling errors containing model determining items and friction and coupling items among joints, and inhibiting buffeting of the controller and enabling a mechanical arm joint to precisely trace an expected track.

Owner:CHANGCHUN UNIV OF TECH

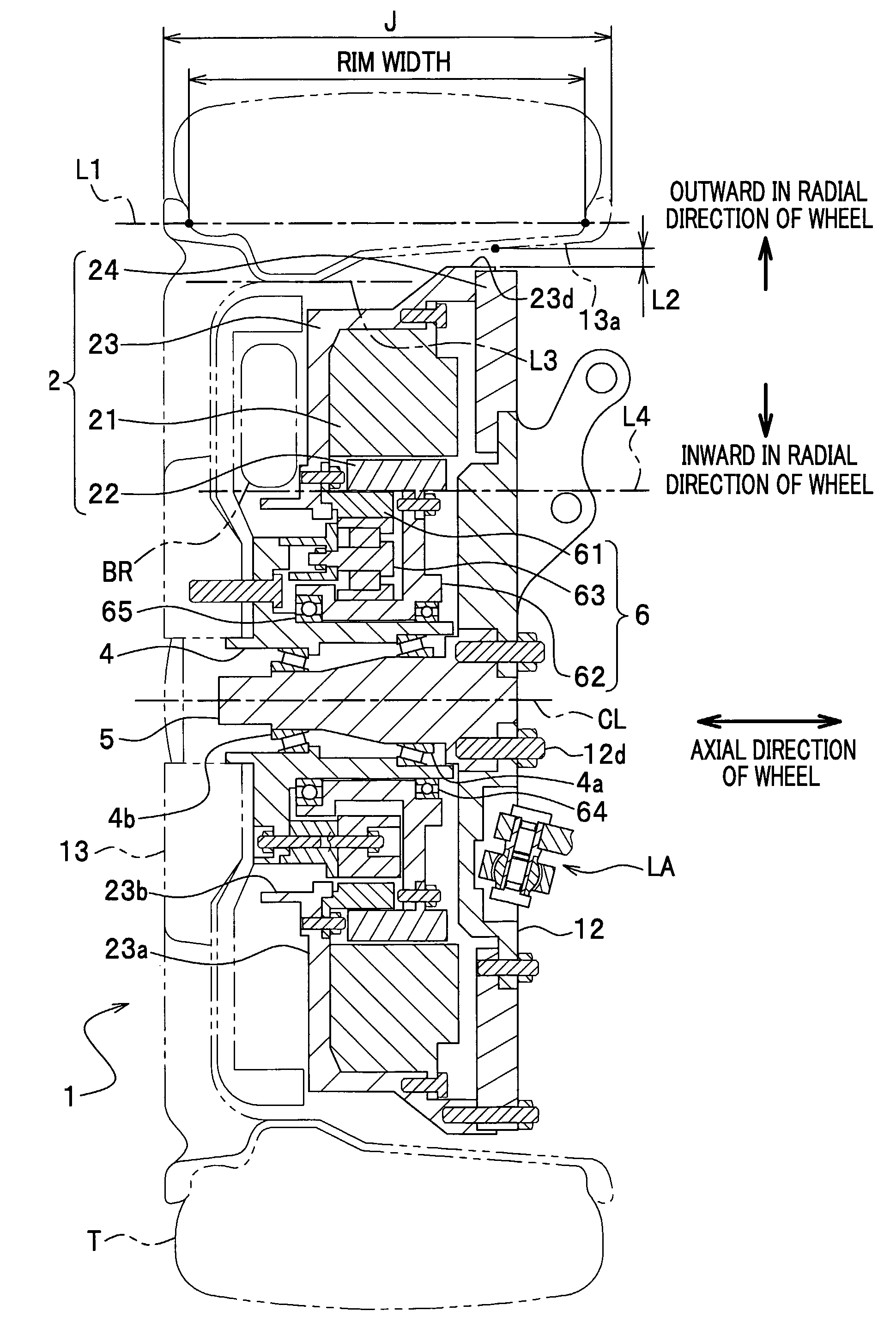

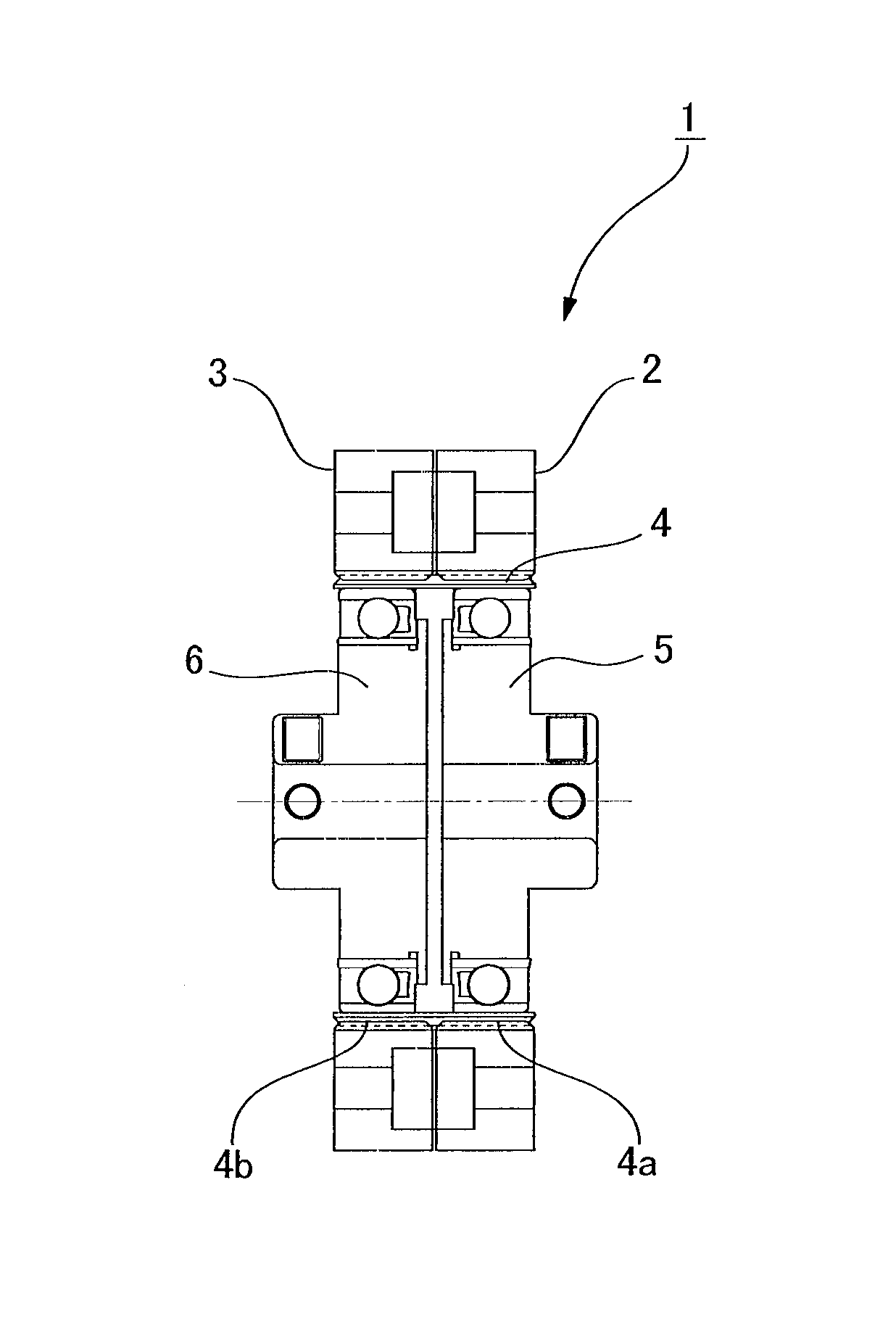

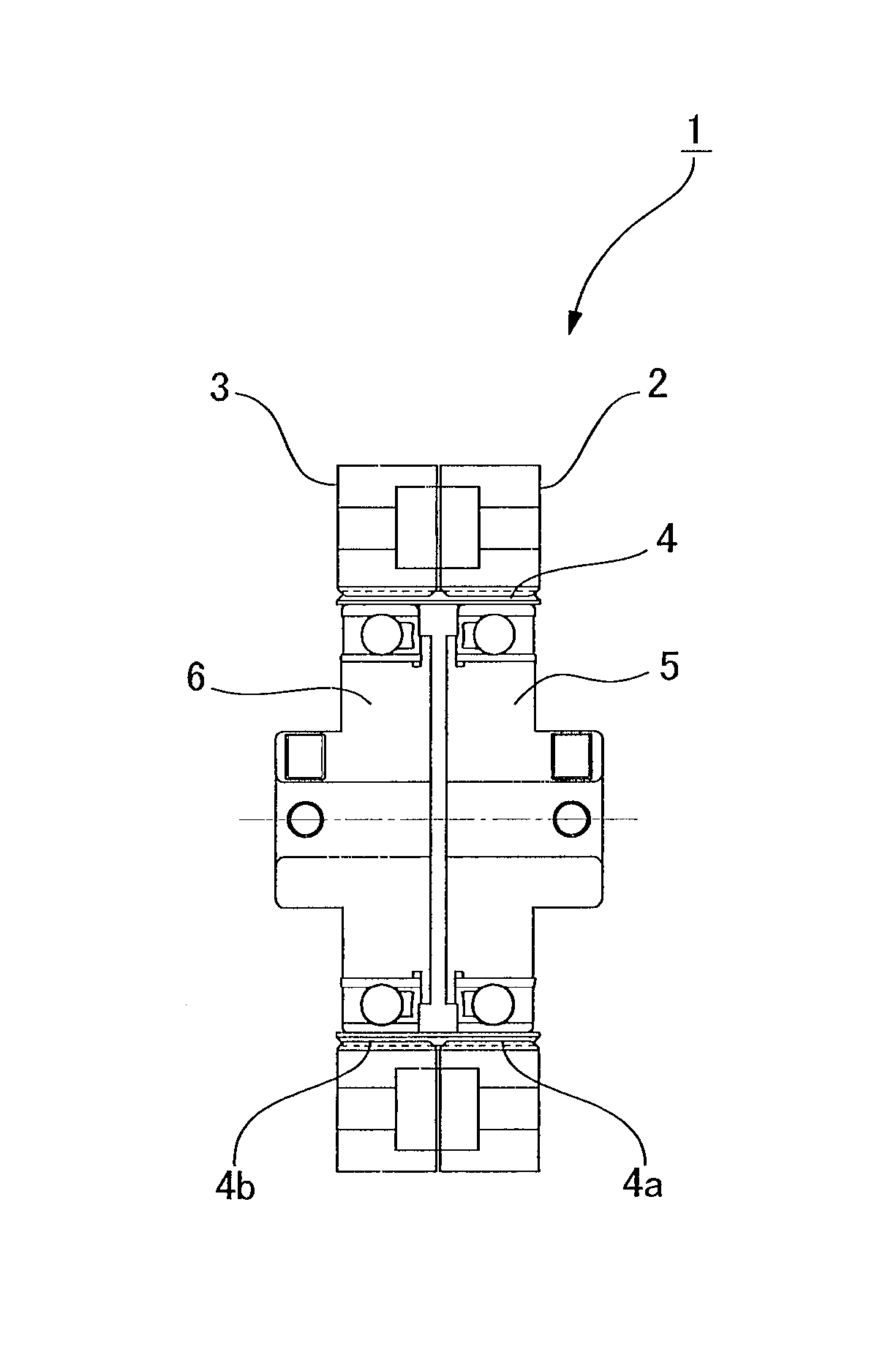

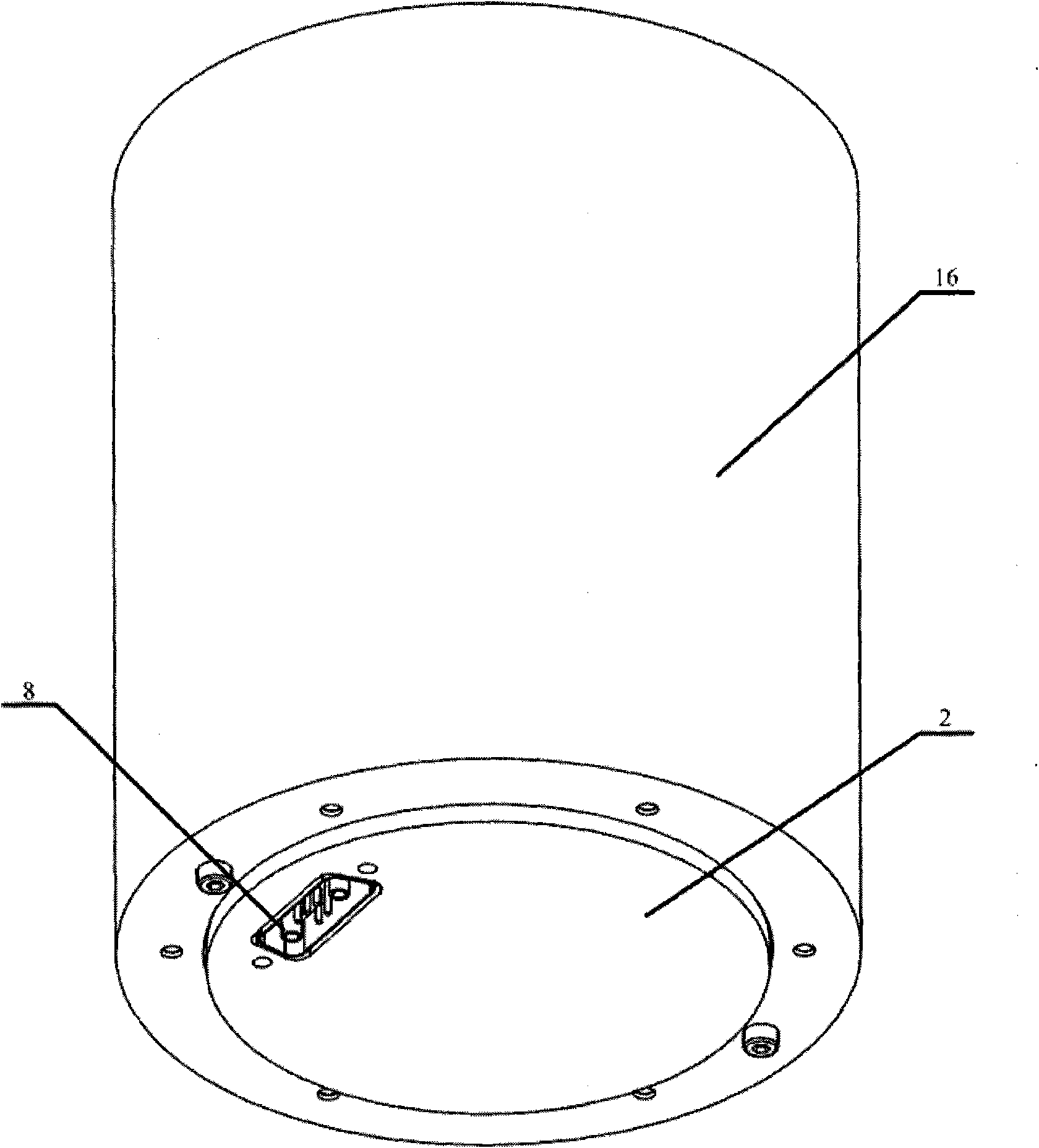

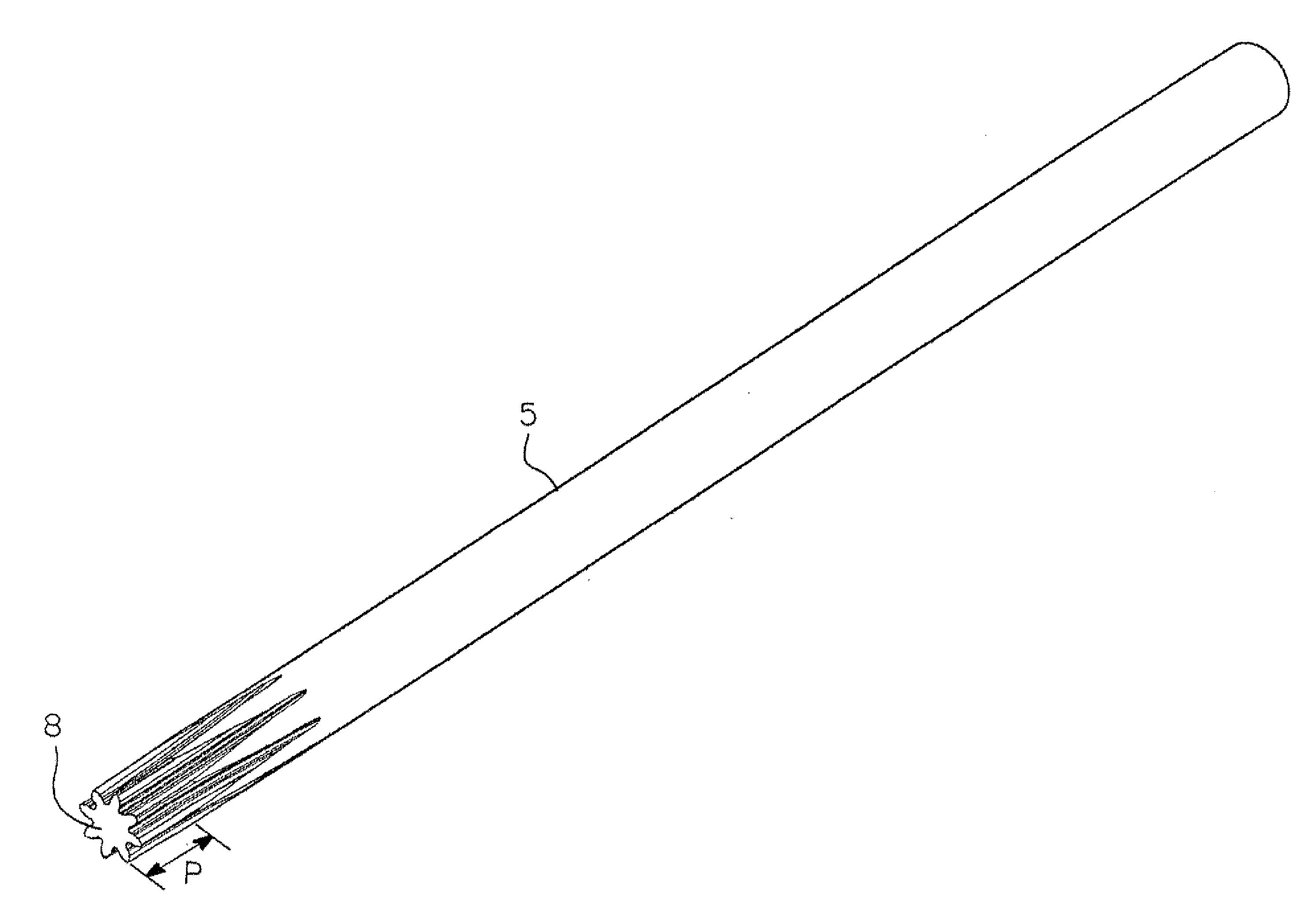

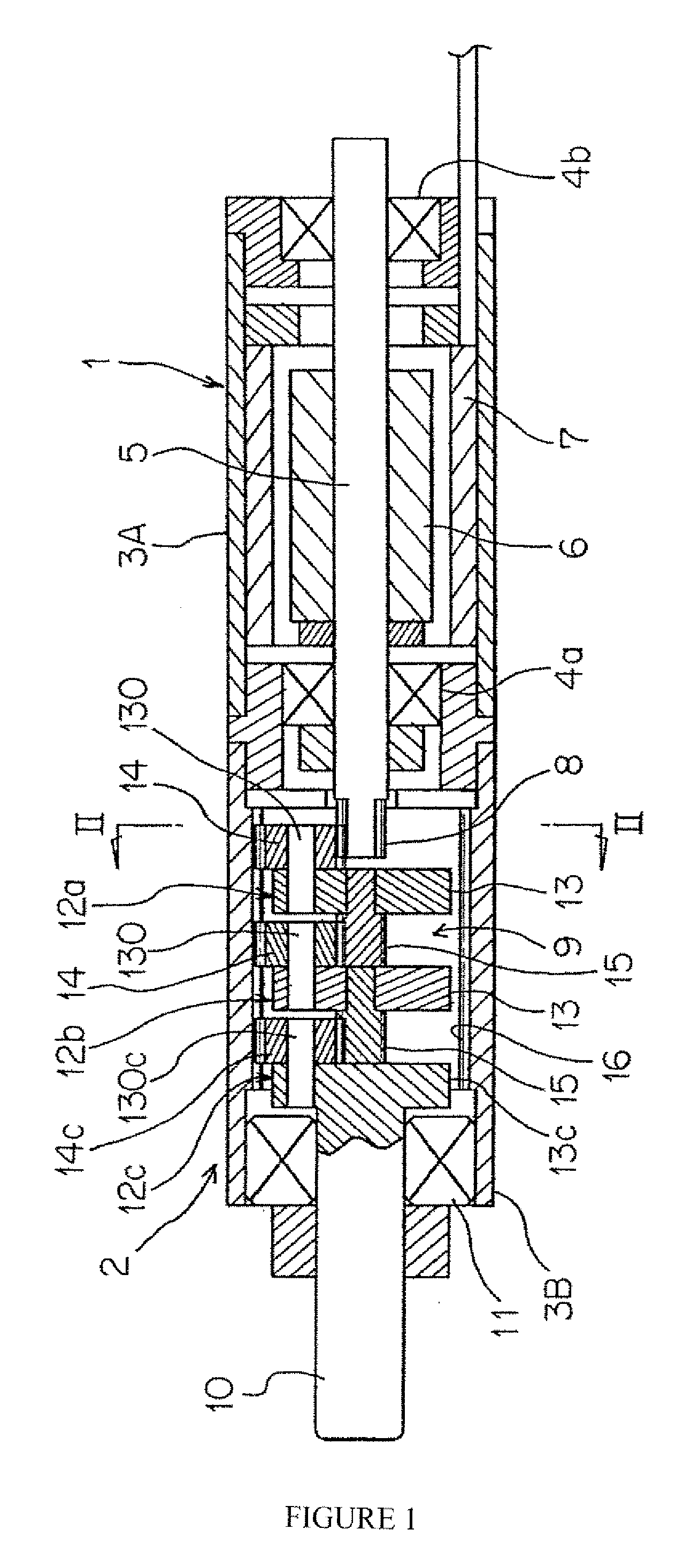

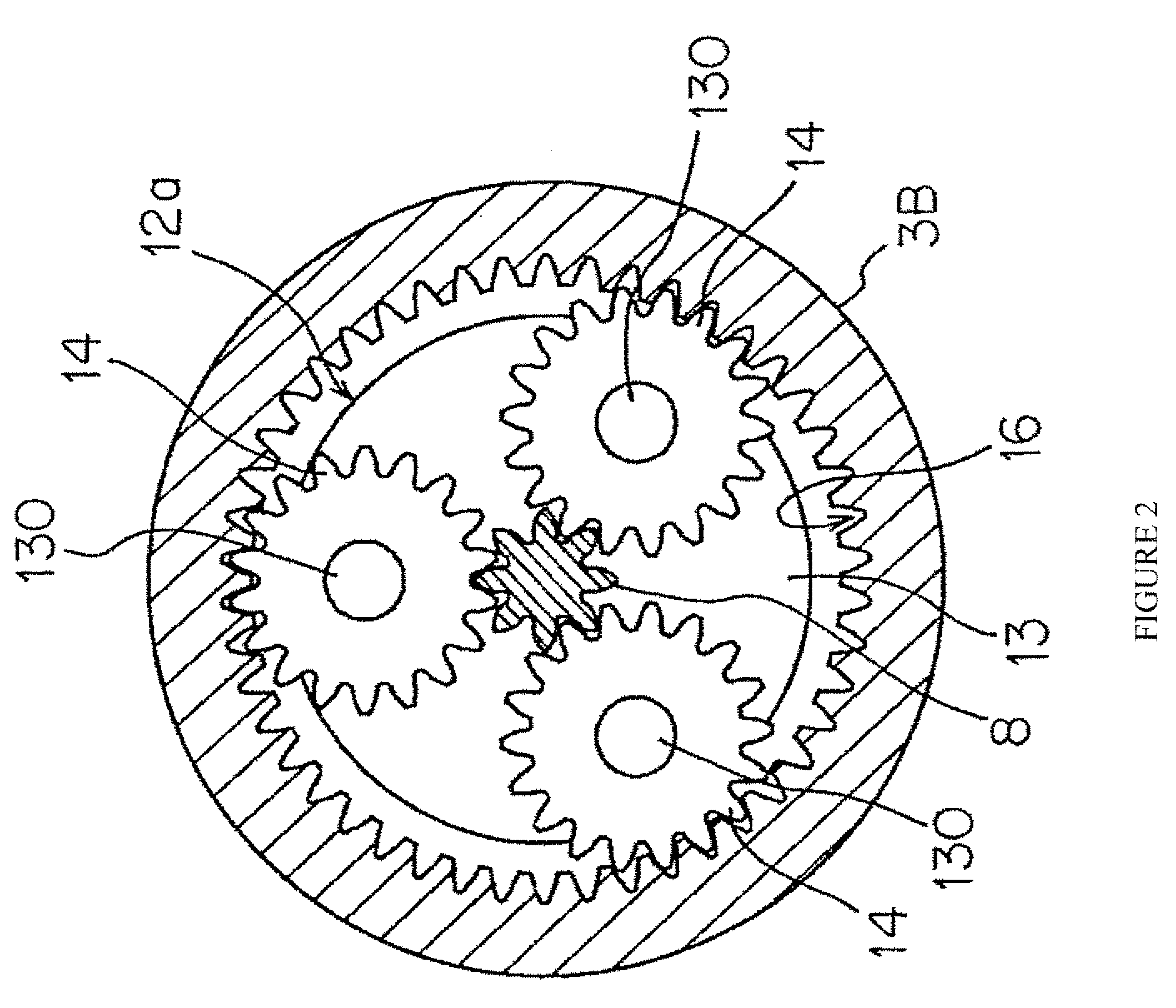

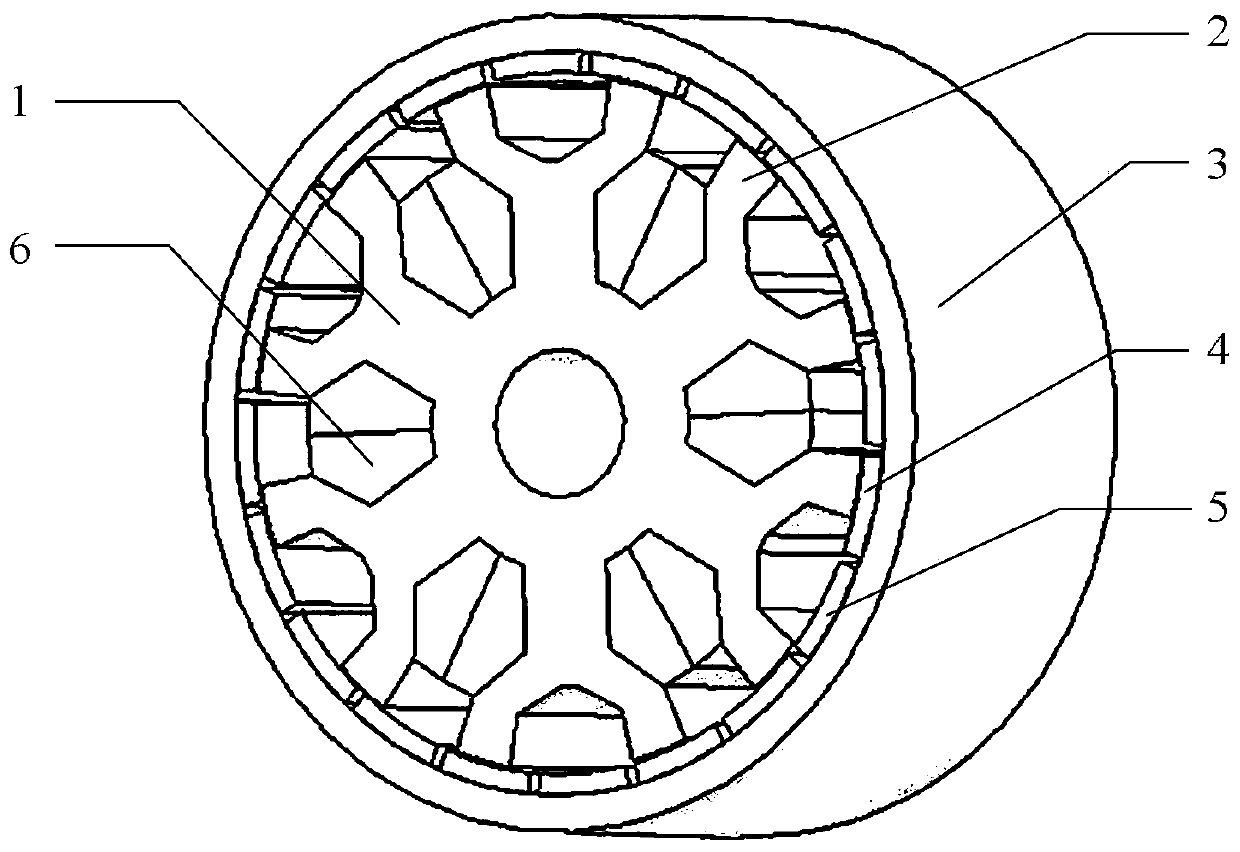

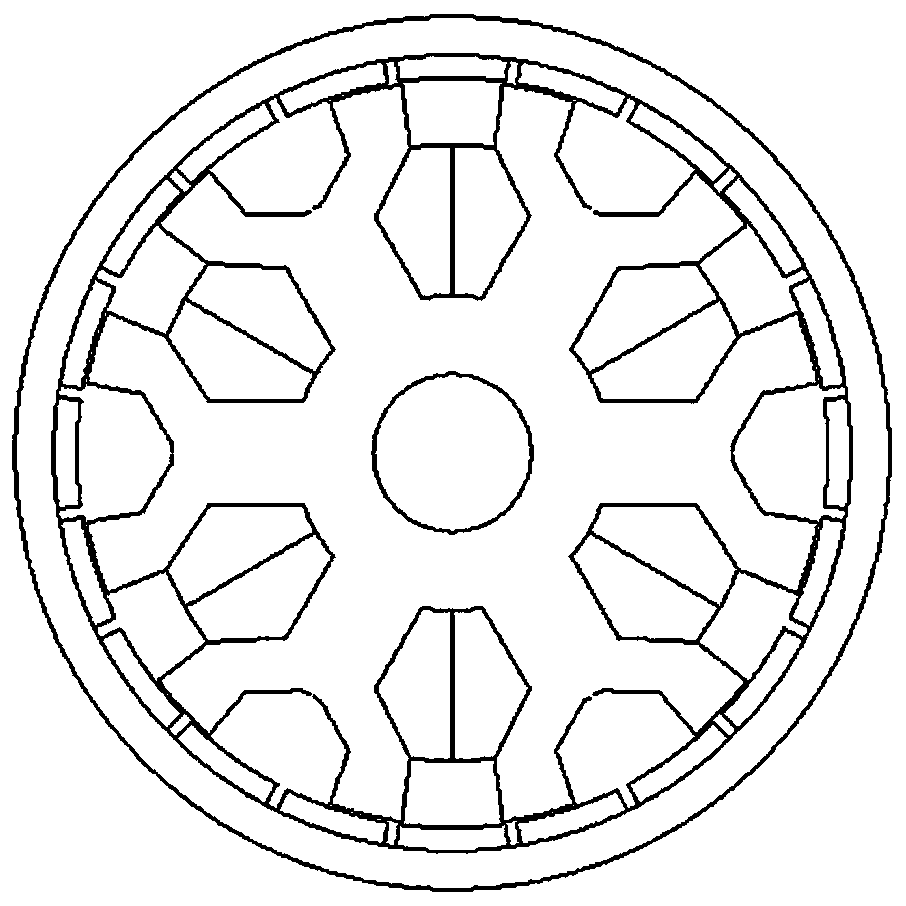

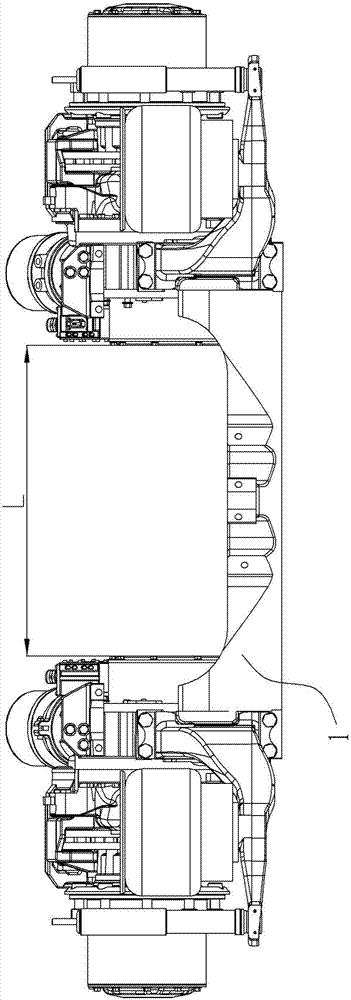

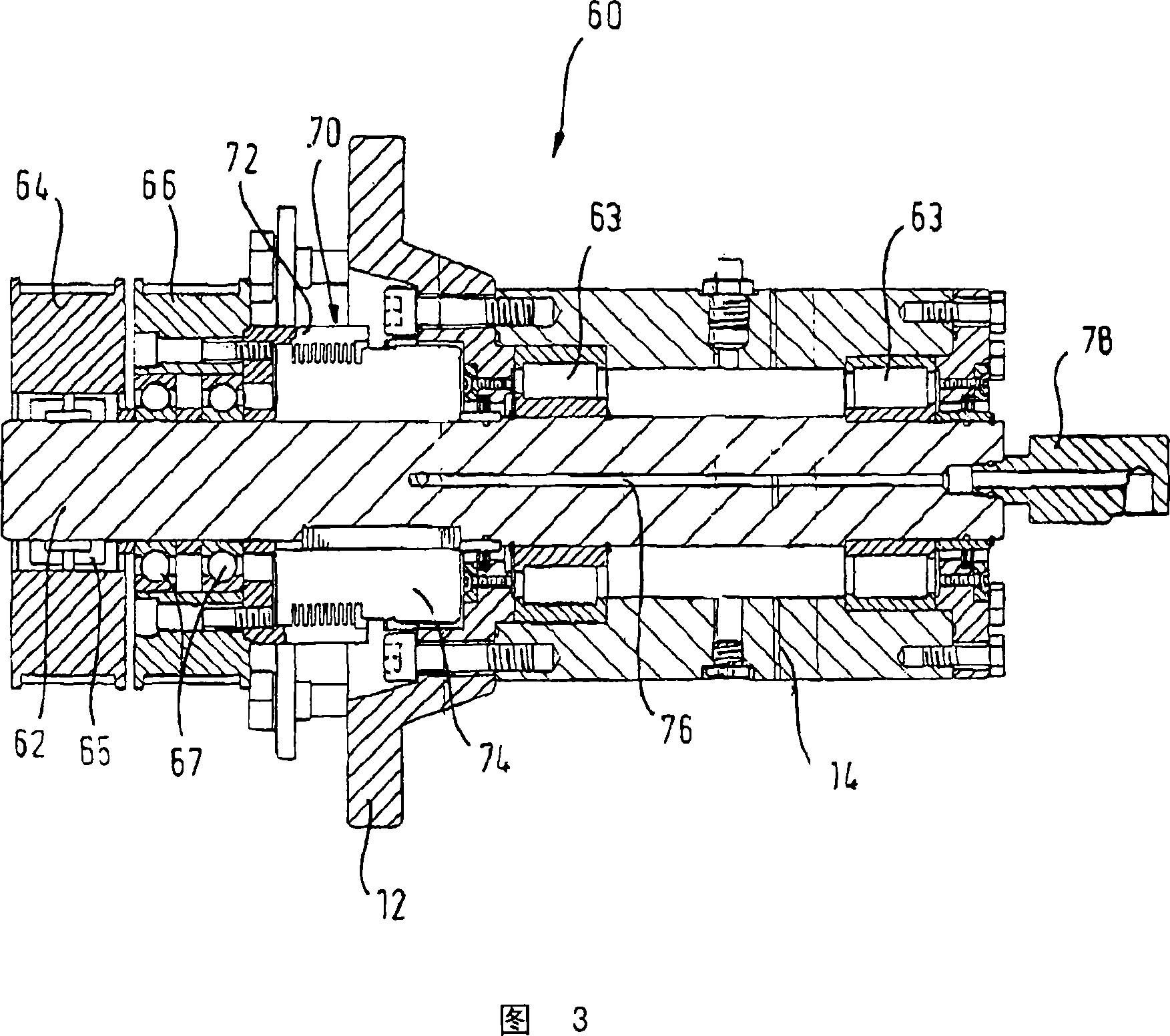

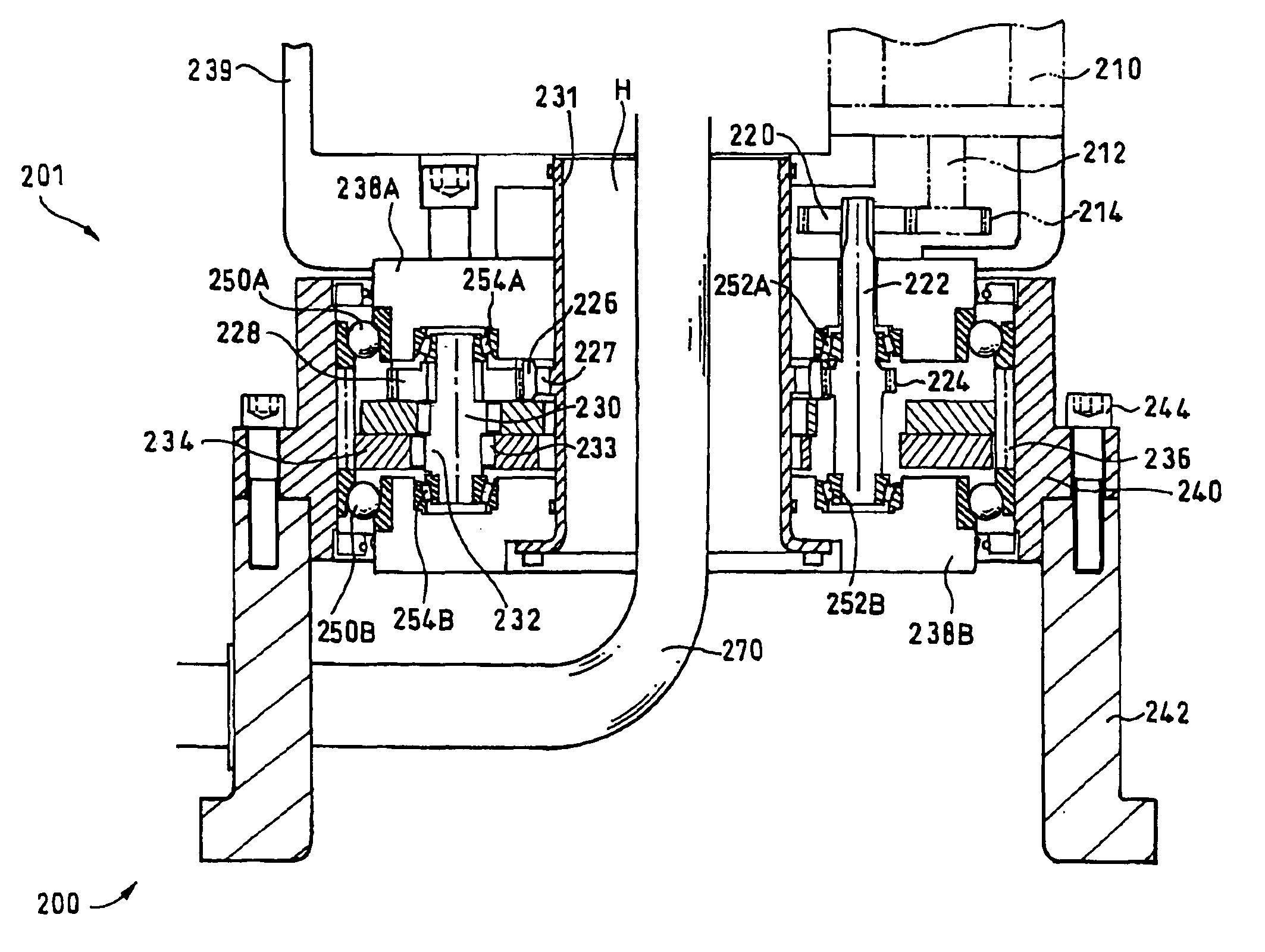

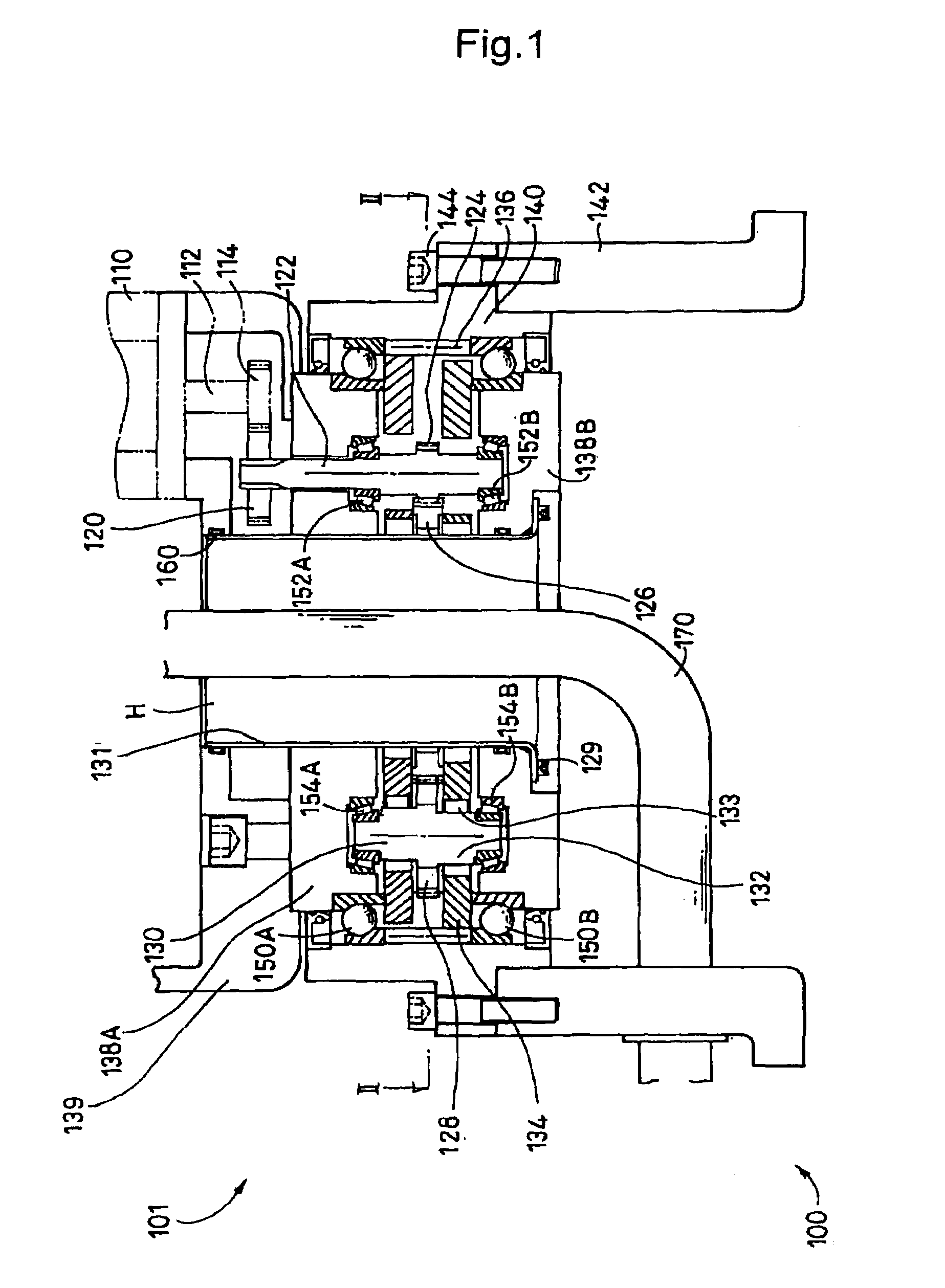

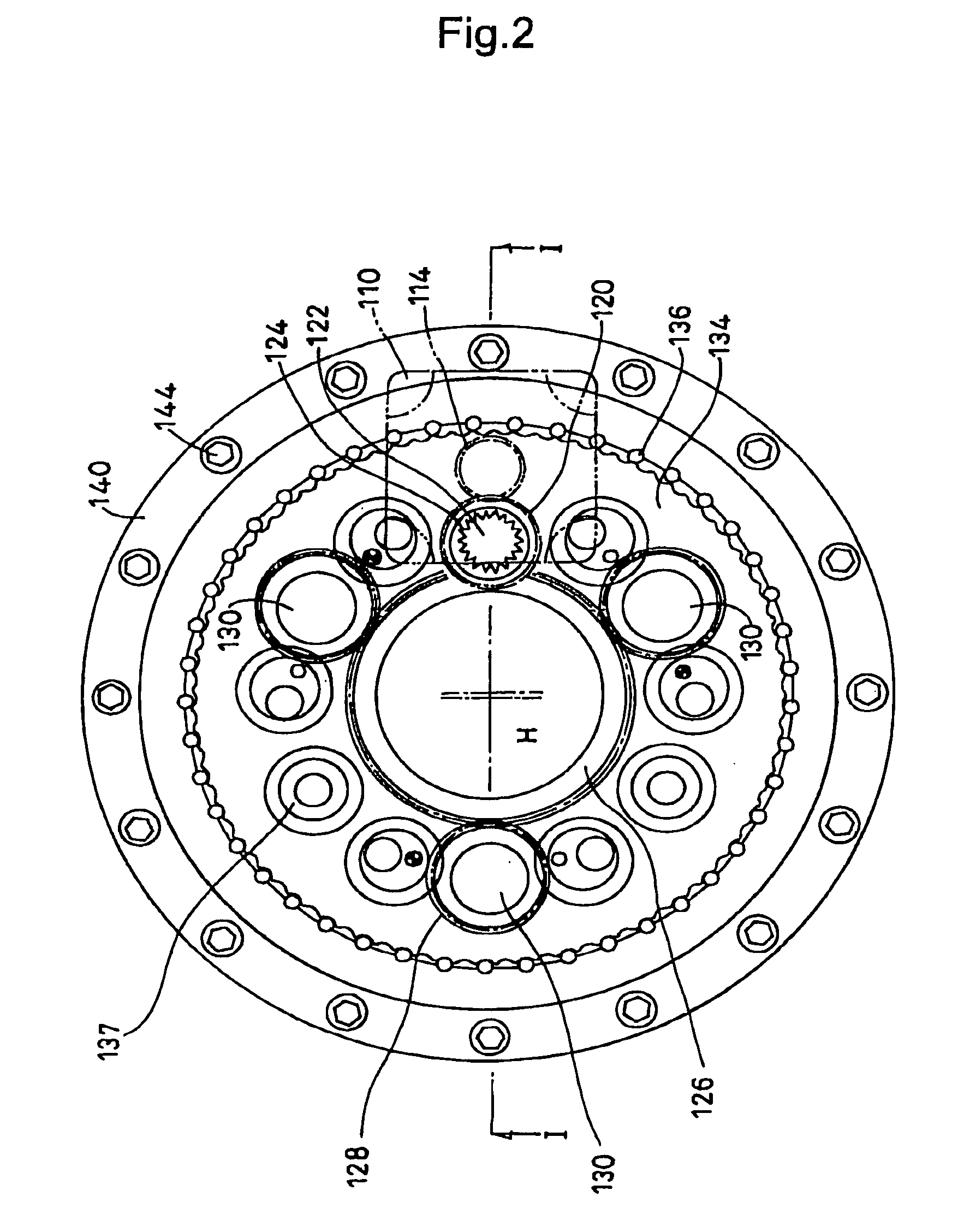

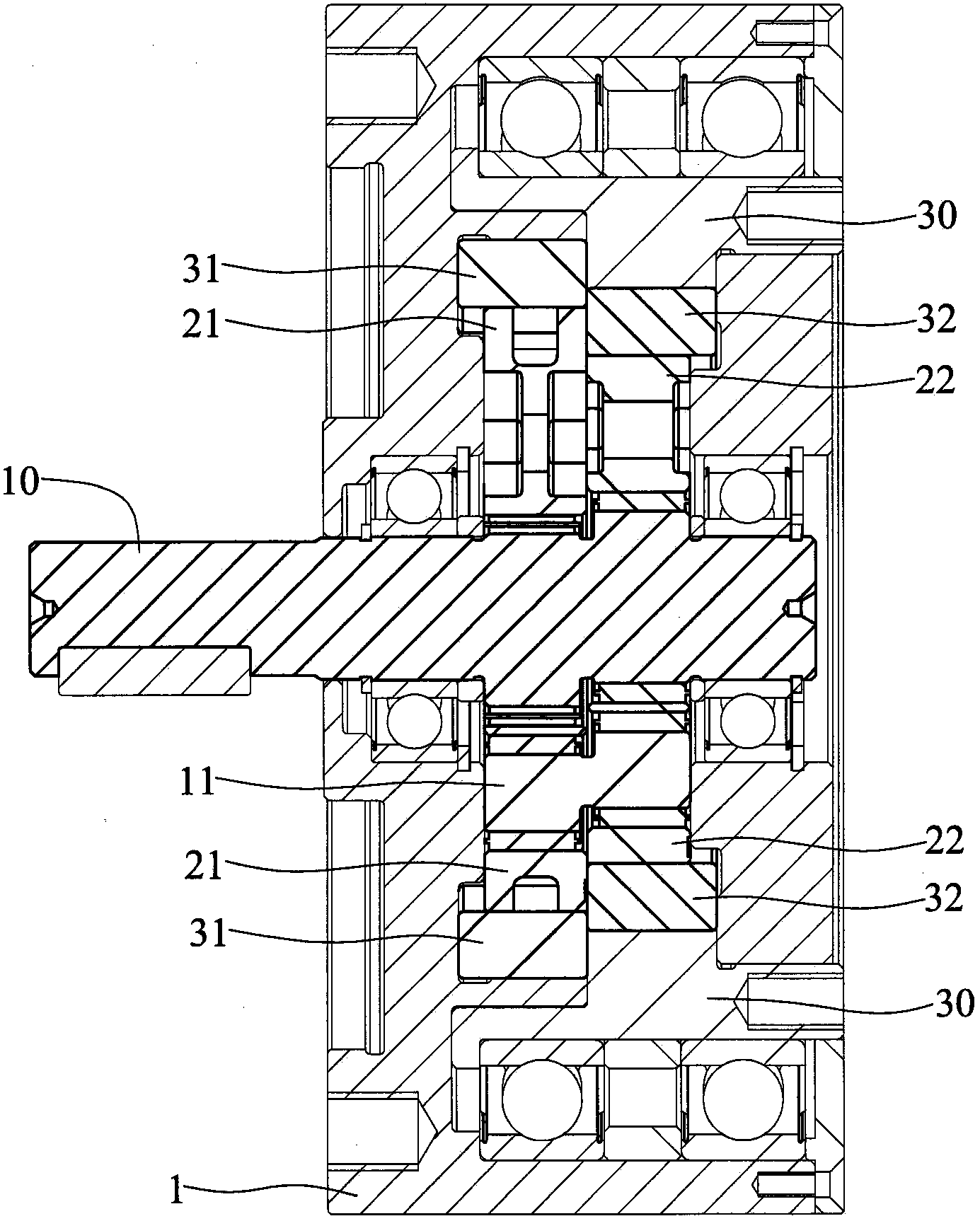

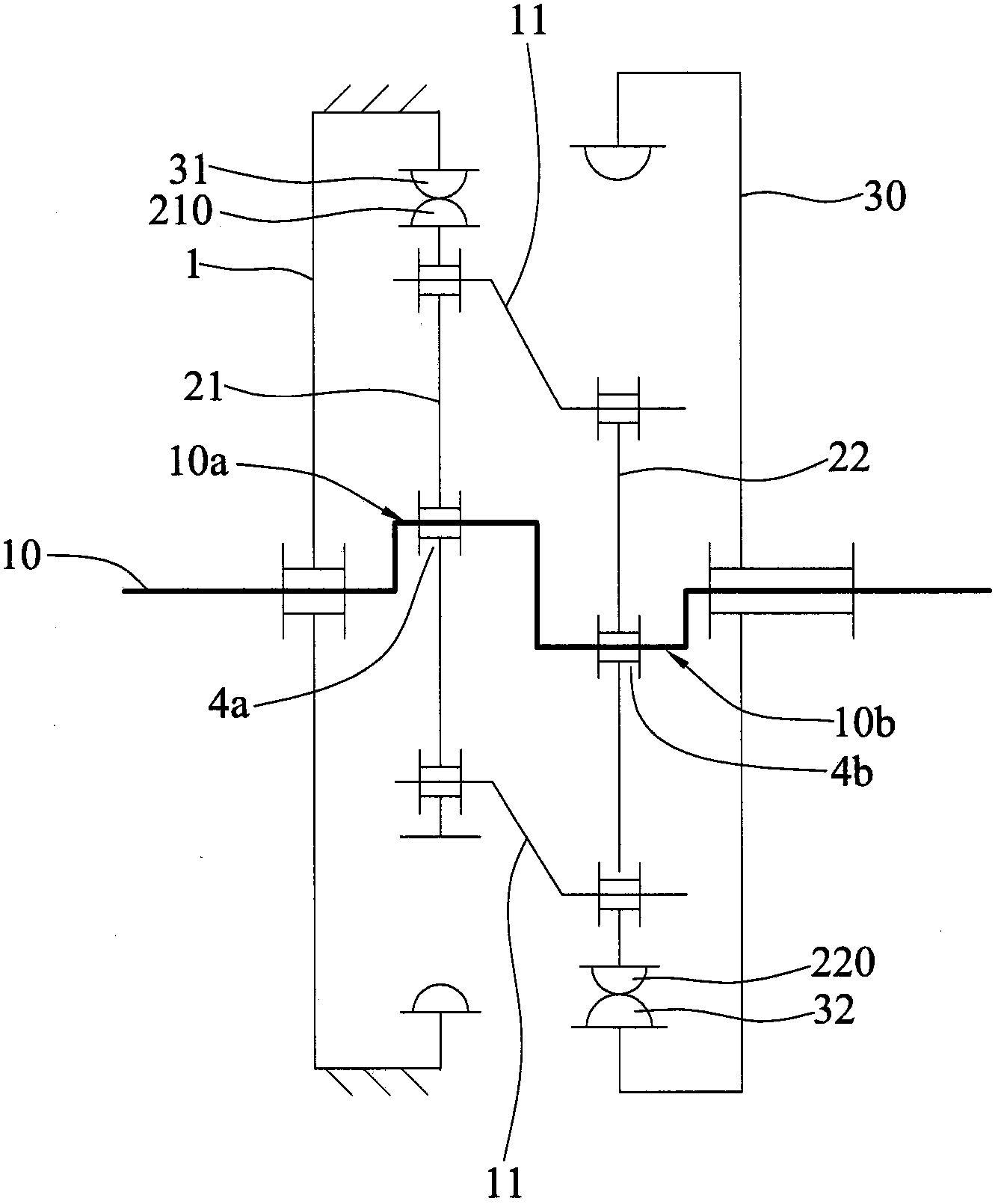

Wheel rotating device for in-wheel motor vehicle

InactiveUS8186467B2Increase the reduction ratioSufficient output performanceHybrid vehiclesElectric devicesReducerMotorized vehicle

A wheel rotating device (1) for an in-wheel motor vehicle includes a motor (2), a speed reducer (6) coupled to an output part of the motor (2), a hub (4) coupled to an output part of the speed reducer (6), and a spindle (5) fixed relative to a vehicle body and supporting the hub (4) in a manner that permits the hub (4) to rotate. The hub (4) is coupled to a wheel (13) to rotate the wheel (13). A stator (21) of the motor (2) is disposed inwardly in radial directions of the wheel (13) along an inner circumferential surface of the wheel (13). A rotor (22) of the motor (2) is disposed inwardly in radial directions of the stator (21). The speed reducer (6) is disposed between the rotor (22) and the hub (4) with bearings provided between the speed reducer (6) and the hub (4).

Owner:HONDA MOTOR CO LTD

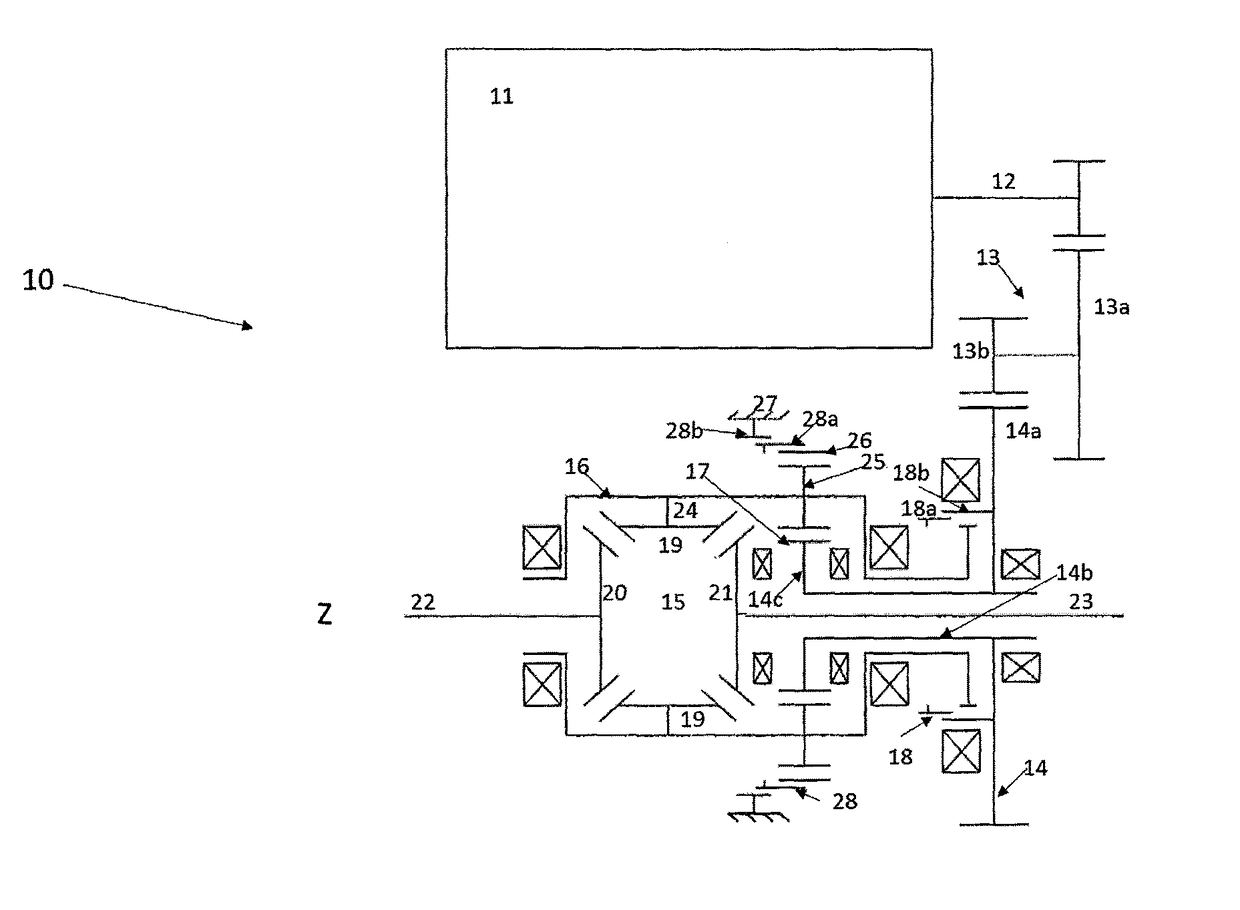

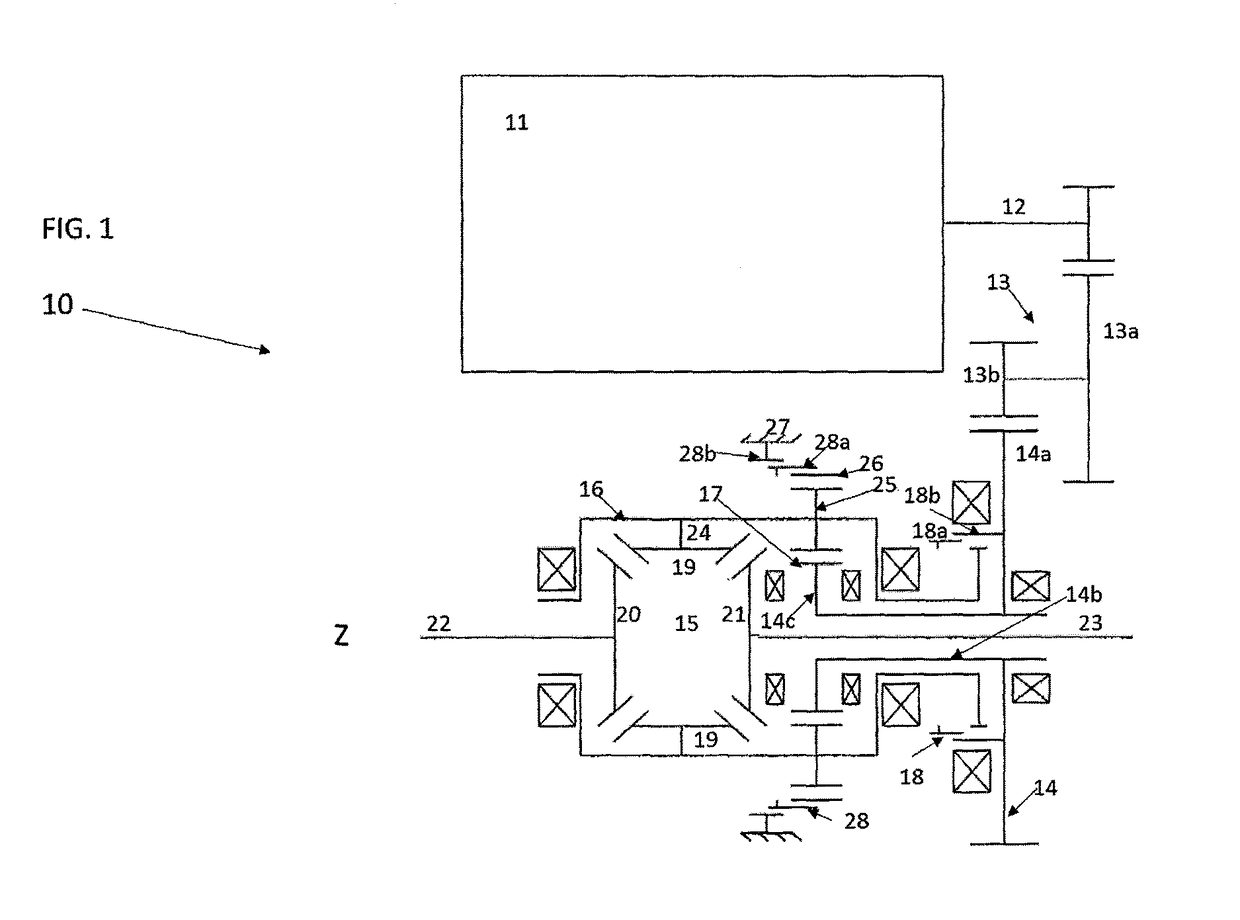

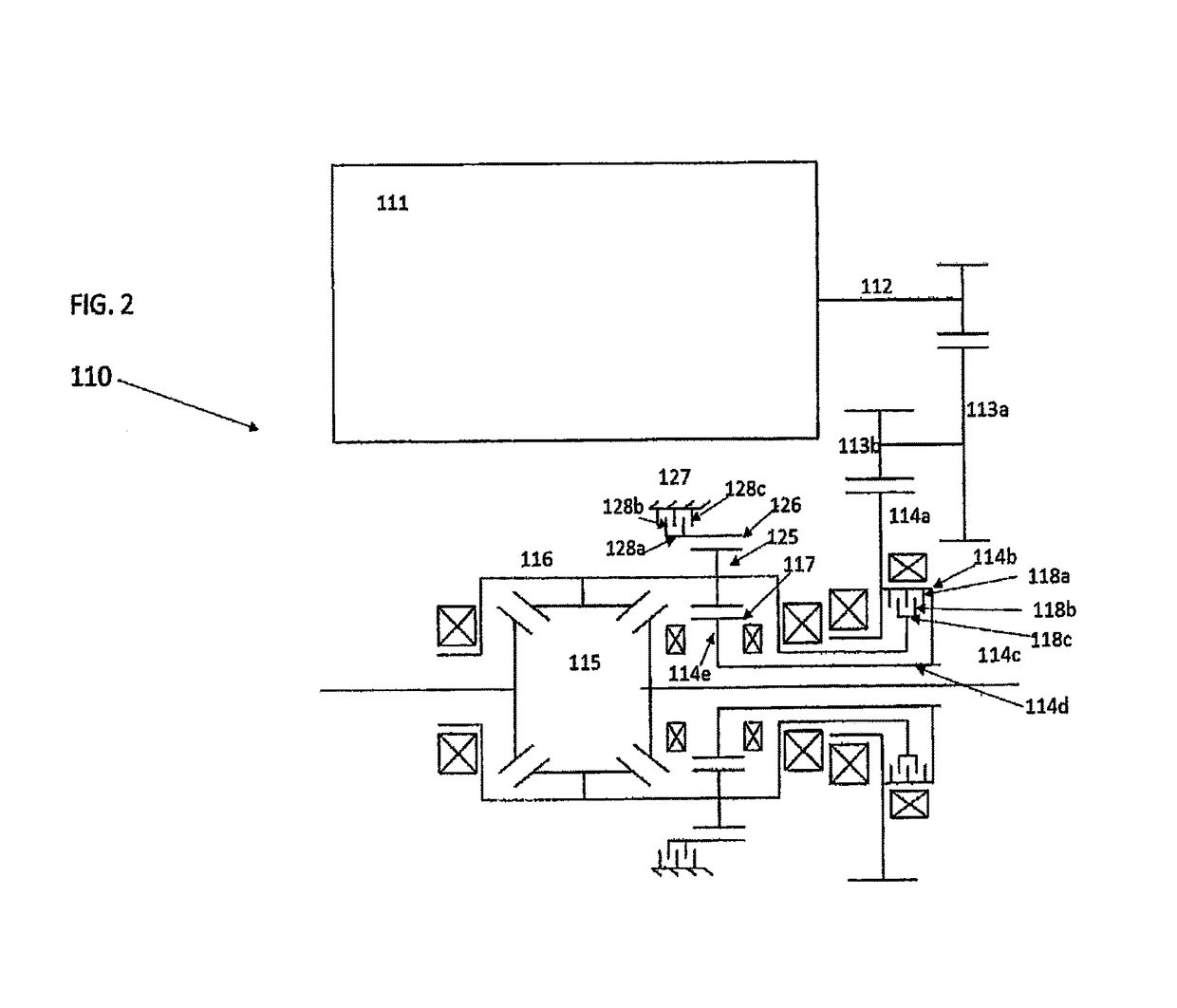

Two-speed electric drive unit

ActiveUS9637127B1Improve mobilityIncrease the reduction ratioElectric propulsion mountingDifferential gearingsElectricityEngineering

An electric drive unit for a vehicle including an electric motor, a differential housing, a reducing gear set, a drive input gear, a first clutch and a second clutch. The differential housing forms a carrier for a plurality of planetary gears which are in driving engagement with the drive input gear. The drive input gear is in driving engagement with the reducing gear which connected to the electric motor. A ring gear outside the differential housing is in driving engagement with the planetary gears. The first clutch can be engaged to couple the drive input gear to the differential housing resulting in the electric drive unit being placed in a first drive ratio and a second clutch can be engaged to ground the ring gear resulting in the electric drive unit being placed in a second drive ratio.

Owner:DANA AUTOMOTIVE SYST GRP LLC

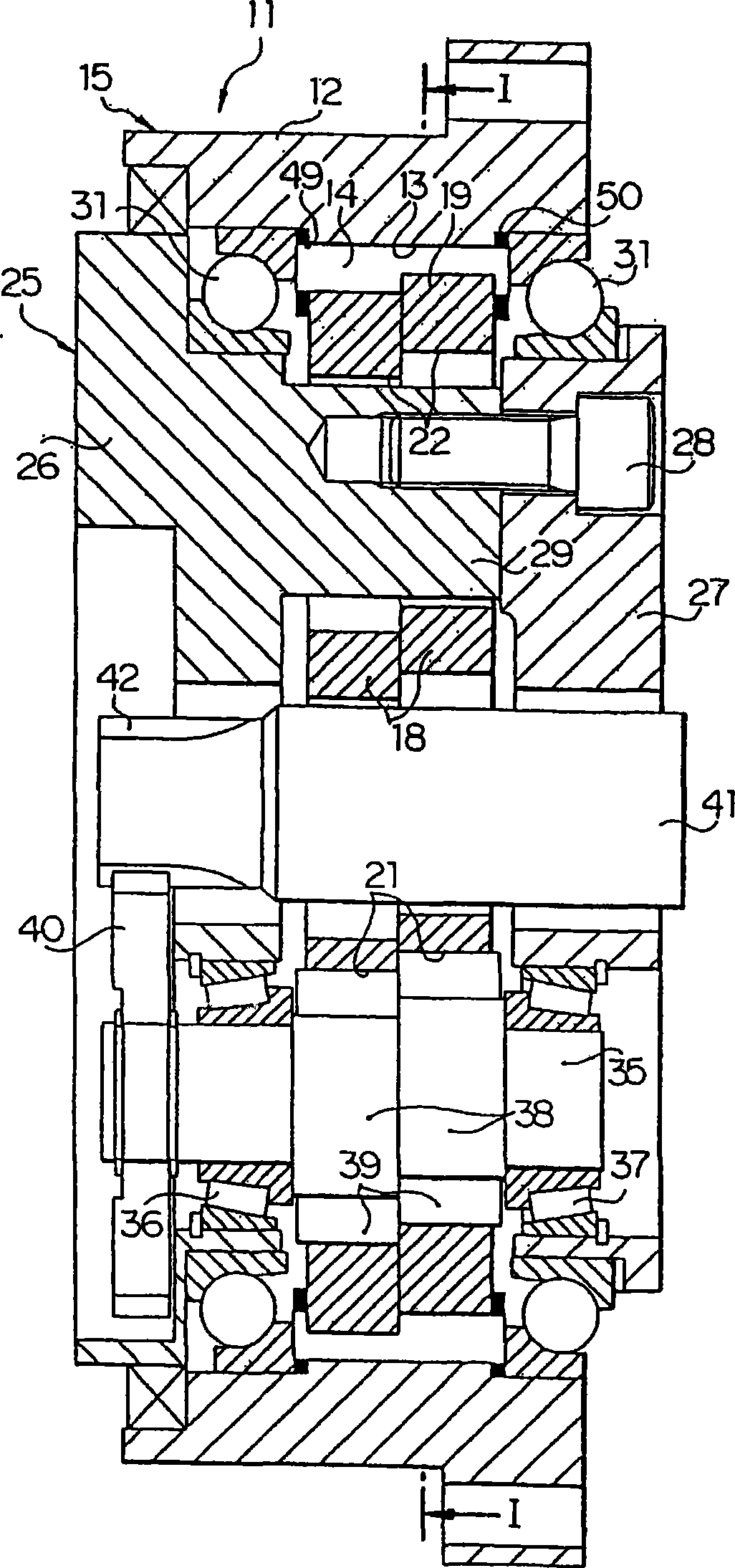

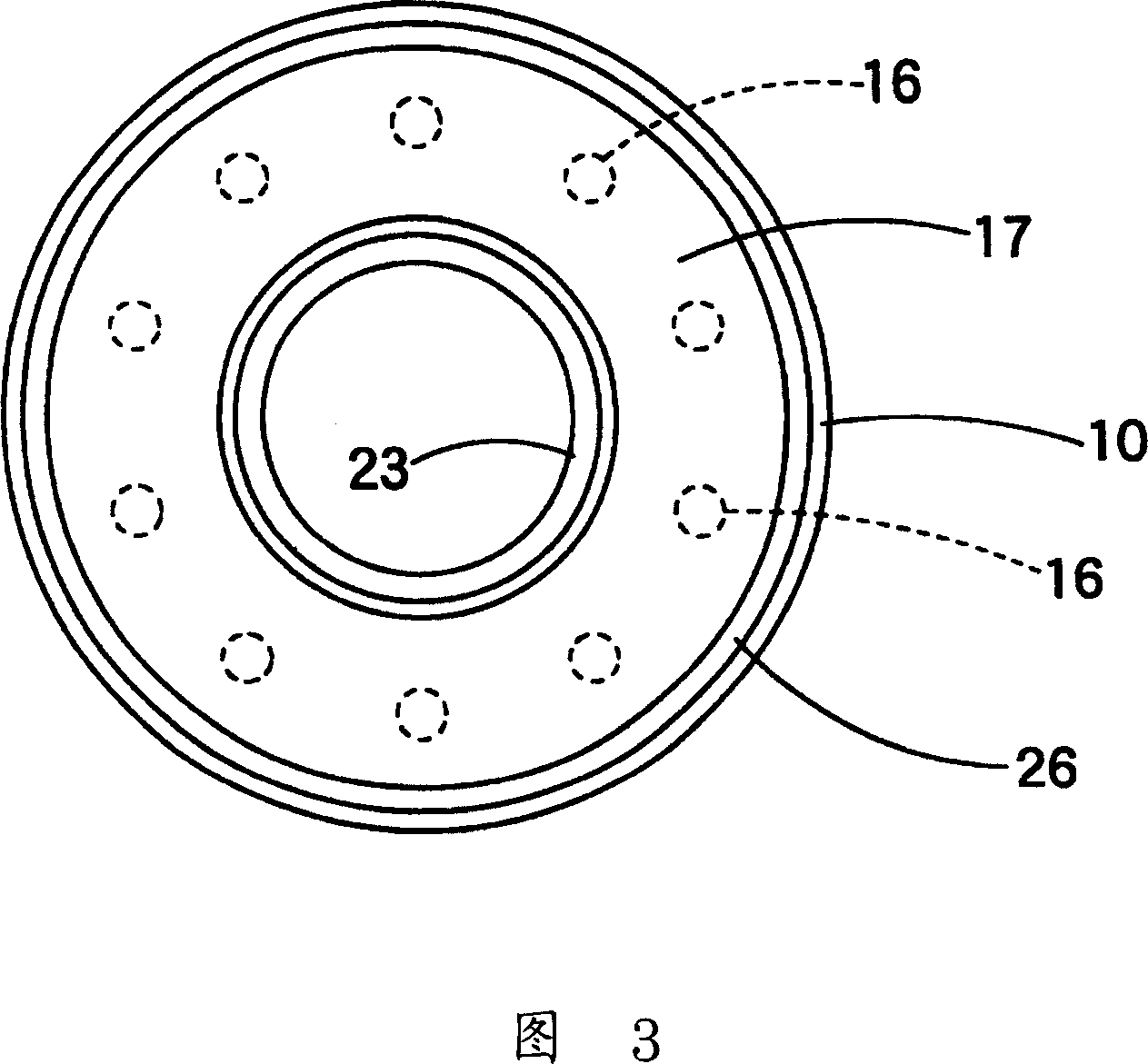

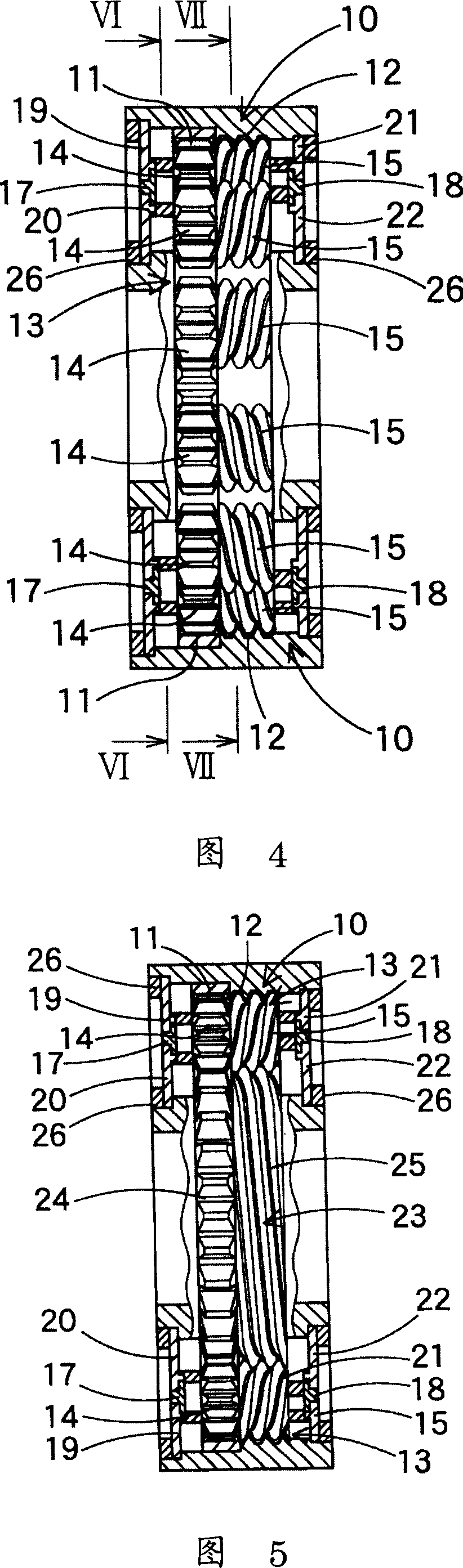

Eccentric swing type planetary gear device

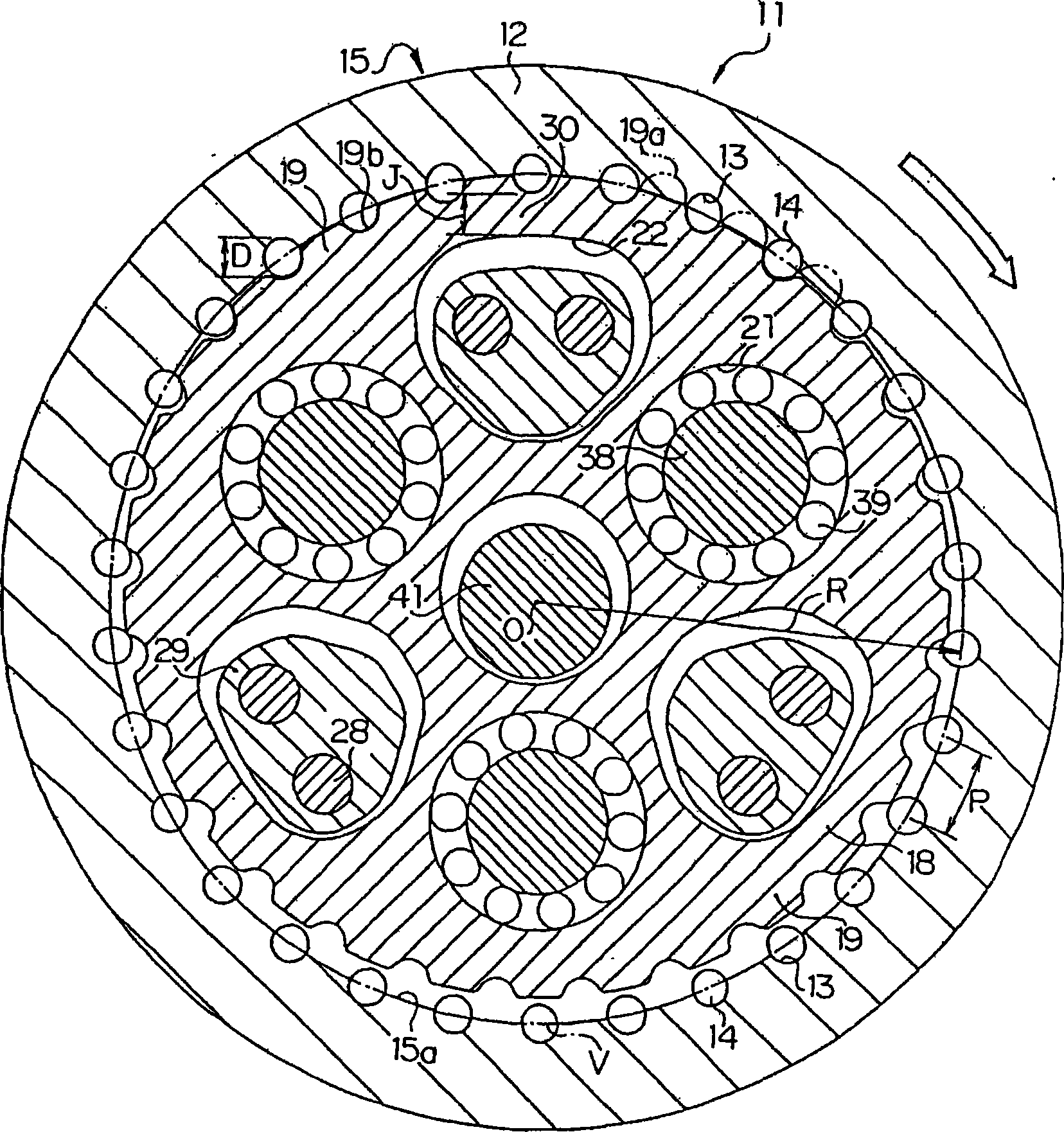

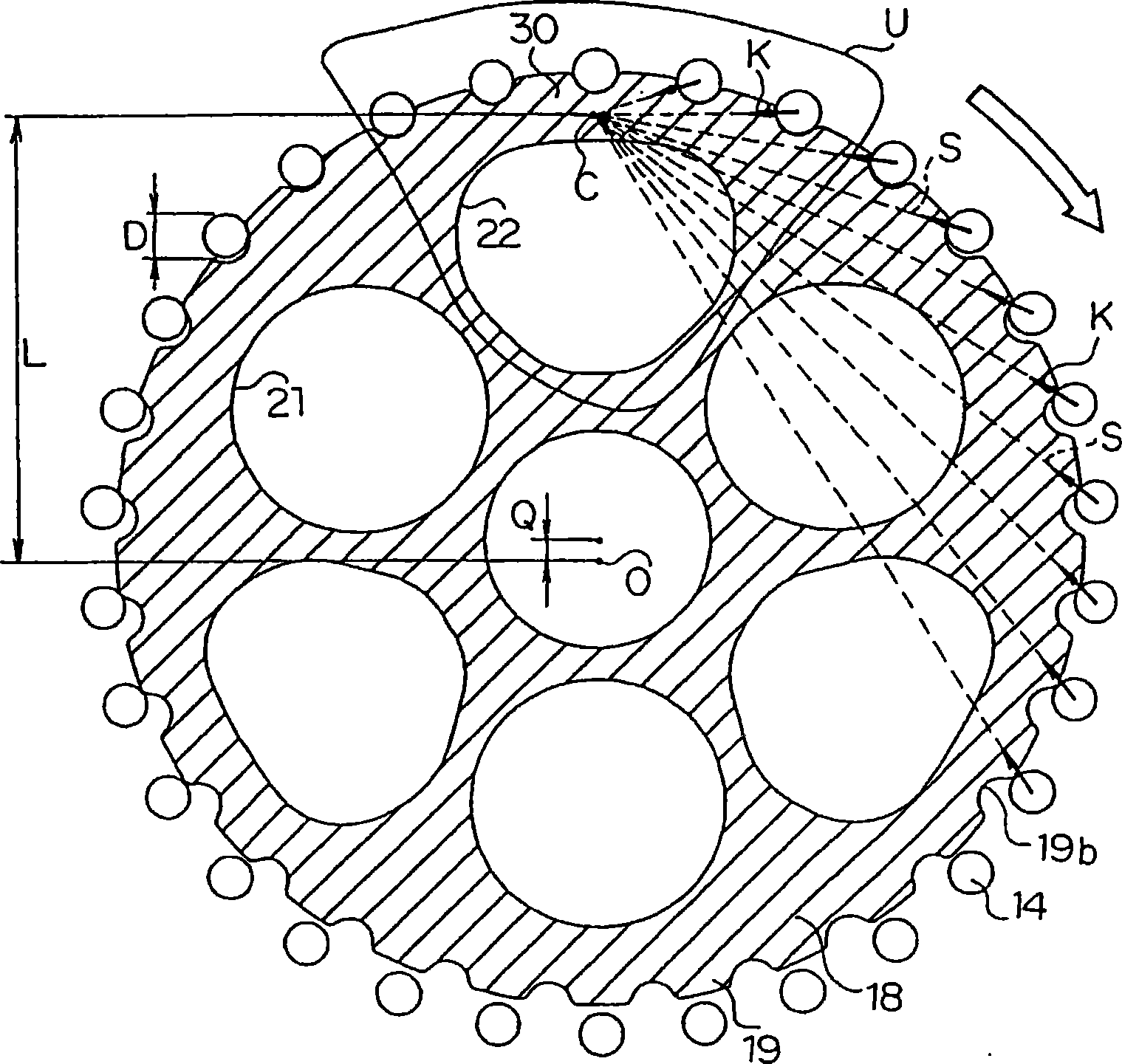

ActiveCN1914438AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsGear wheelEngineering

The invention provides eccentric swing type planetary gear device, deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

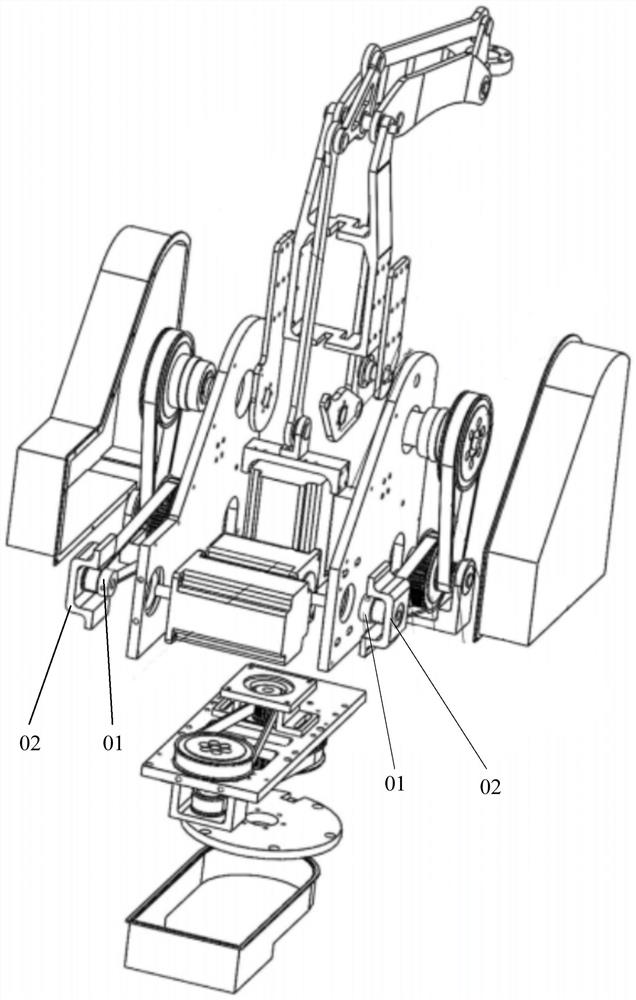

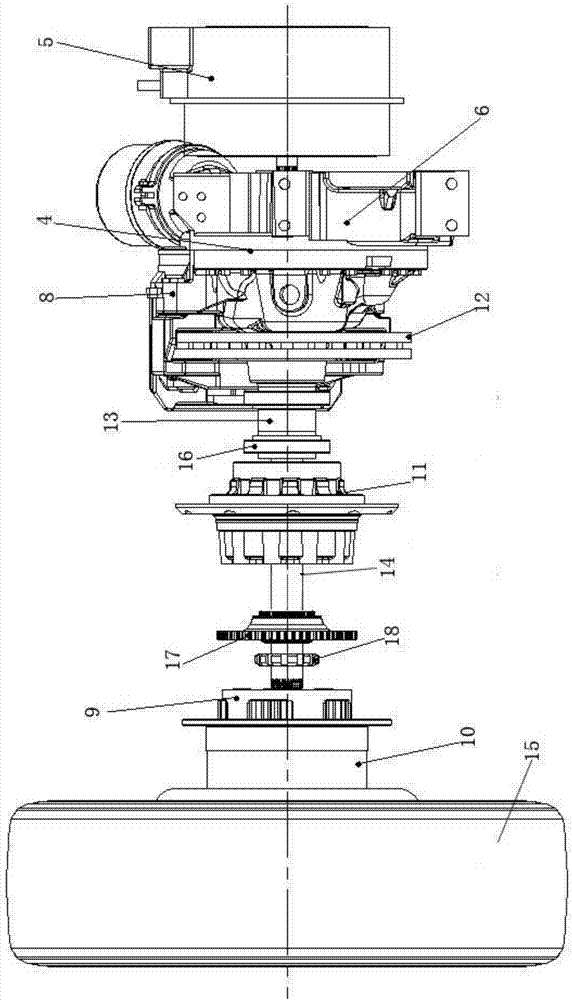

Rotary table of desktop mechanical arm, desktop mechanical arm and robot

PendingCN112454328ARealize away from the arrangementAvoid affecting the transmissionProgramme-controlled manipulatorArmsElectric machineryMechanical engineering

The invention discloses a rotary table of a desktop mechanical arm. The rotary table is provided with a base, a large arm driving motor, a small arm driving motor, a large arm speed reducing assemblyand a small arm speed reducing assembly, wherein the large arm driving motor and the small arm driving motor are located at the rear side of the base and arranged in an up-down stacking manner; the large arm speed reducing assembly and the small arm speed reducing assembly are located on the left outer side surface and the right outer side surface of the base separately; the large arm speed reducing assembly comprises a large arm first-level synchronous belt wheel and a large arm second-level synchronous belt wheel located between the large arm first-level synchronous belt wheel and the base;and the small arm speed reducing assembly comprises a small arm first-level synchronous belt wheel and a small arm second-level synchronous belt wheel located between the small arm first-level synchronous belt wheel and the base. According to the rotary table of the desktop mechanical arm, the safety is improved; for a speed reducing synchronous belt, arrangement for auxiliary assemblies is reduced, so that the manufacturing cost is reduced, and the speed reducing ratio can be increased and the speed reducing effect can be improved, so that the control precision is ensured; and moreover, the rotary table of the desktop mechanical arm is simple in structure, easy to detach and install, and convenient to maintain.

Owner:SHENZHEN YUEJIANG TECH CO LTD

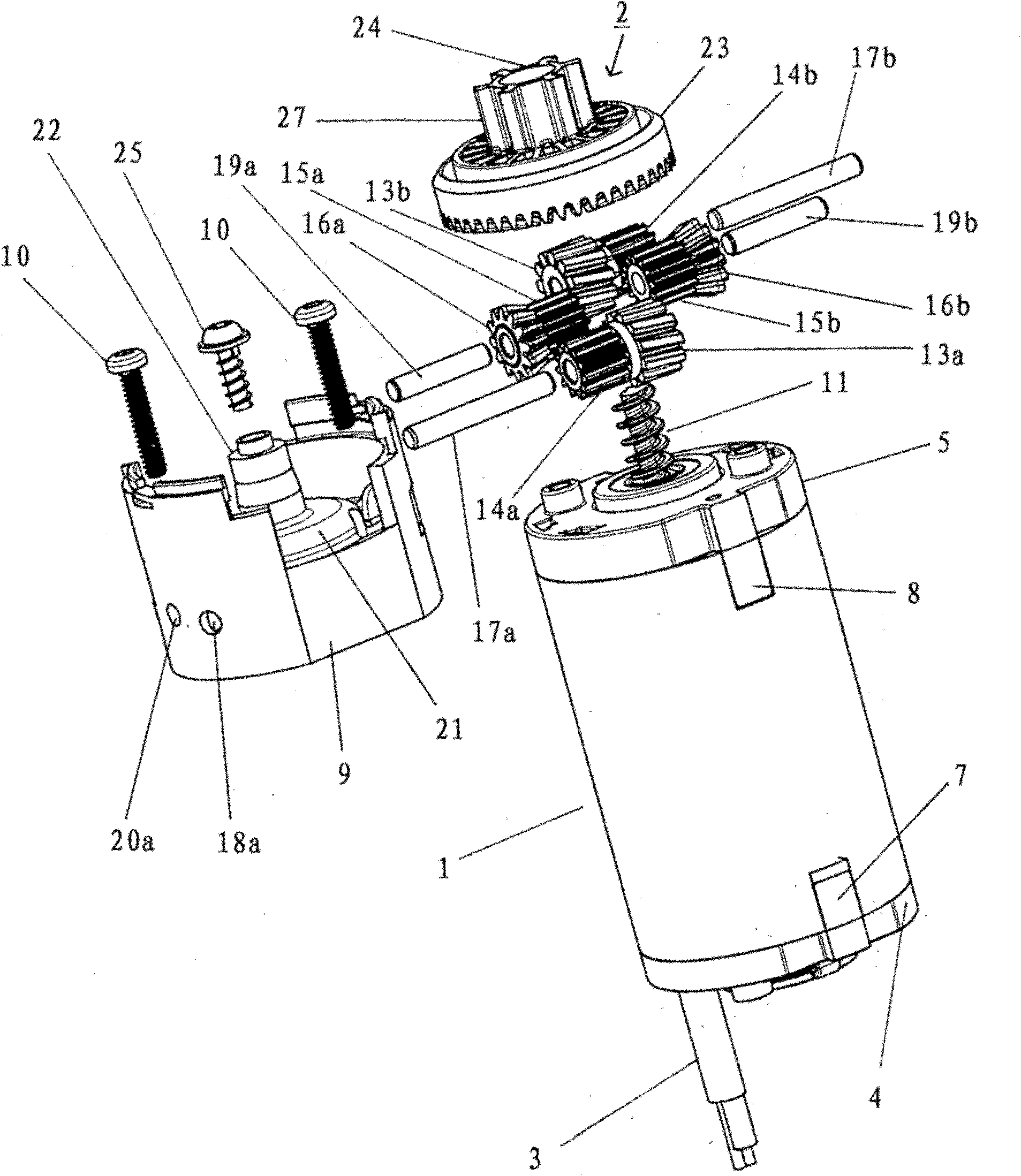

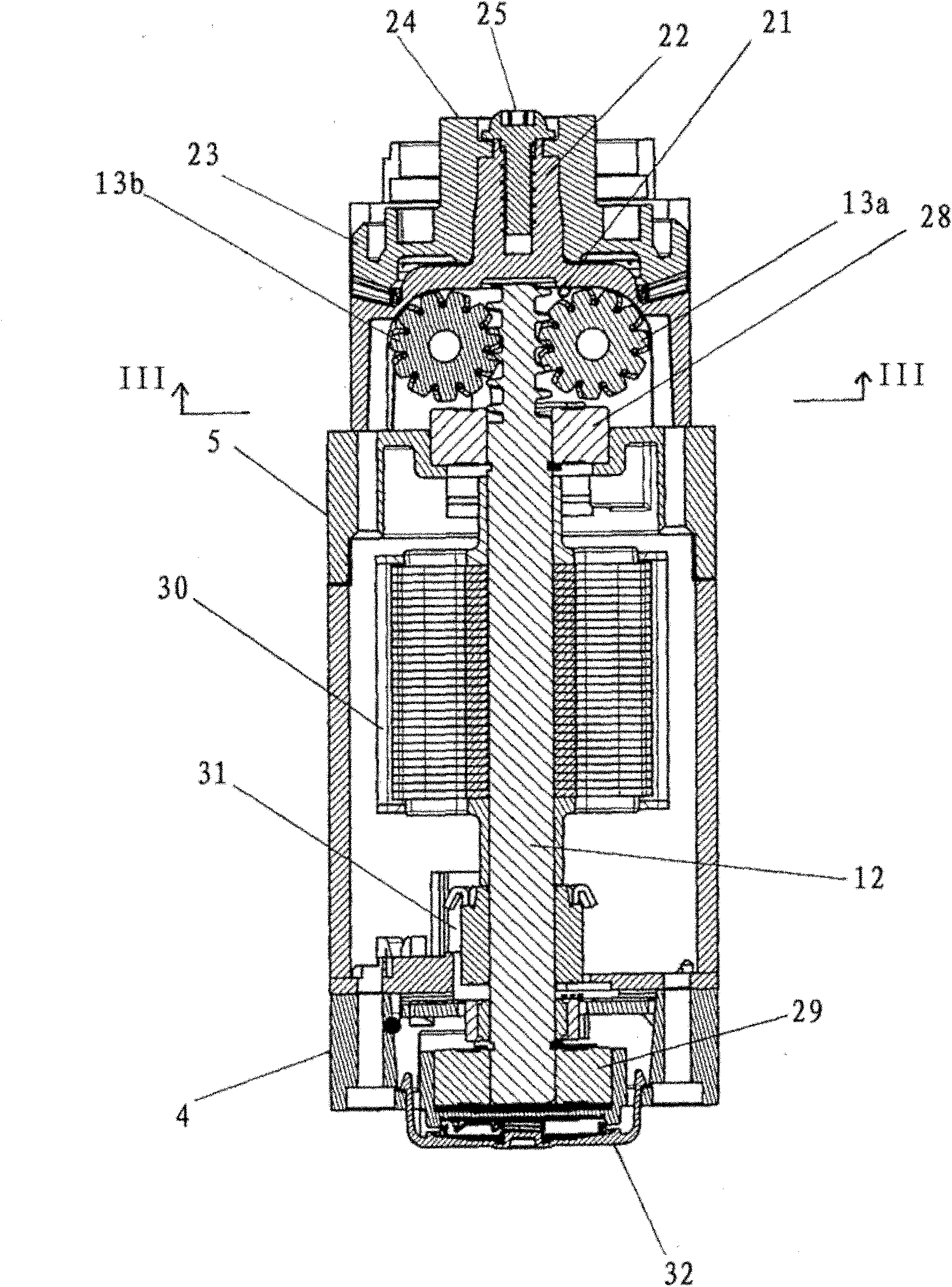

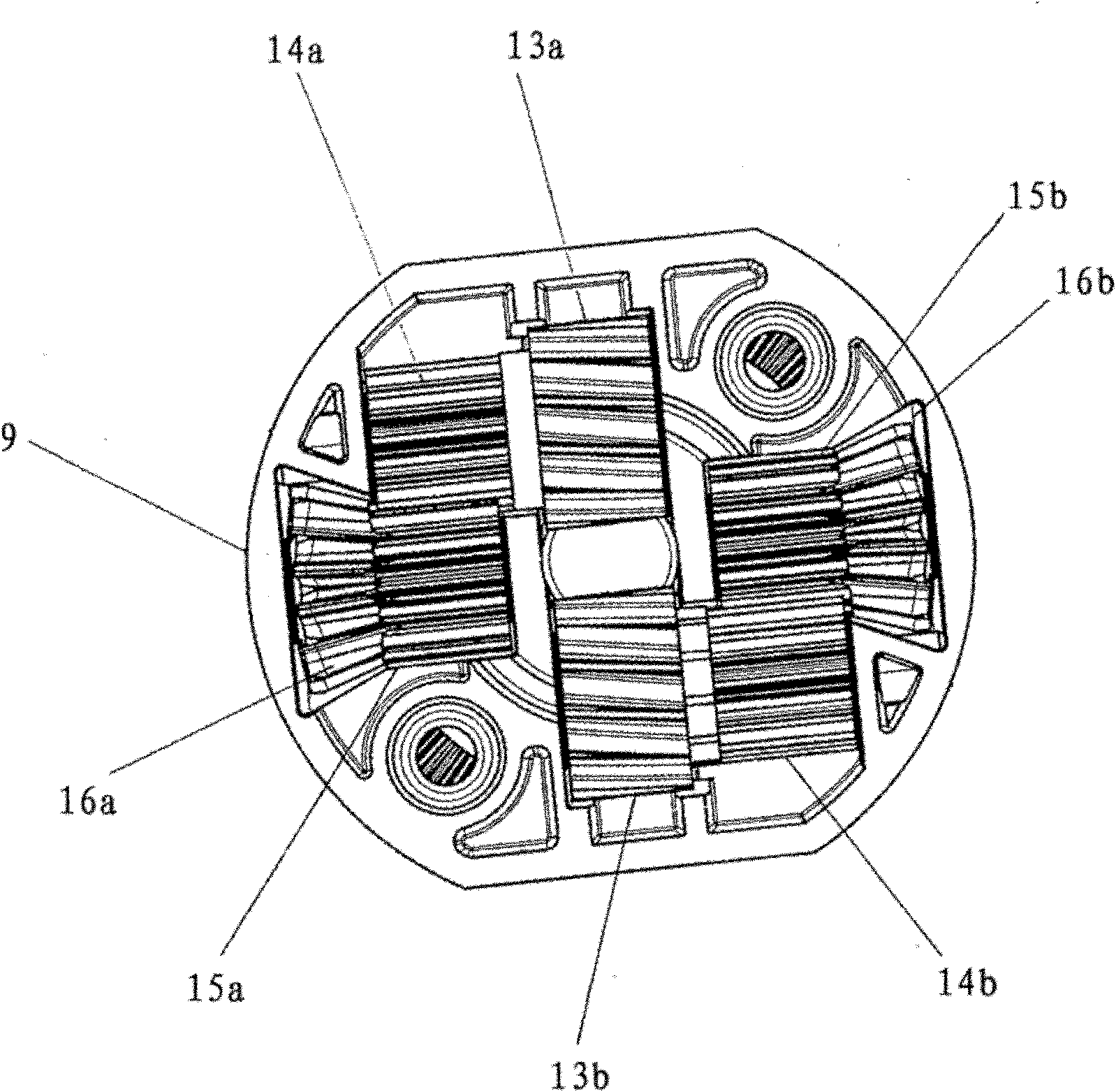

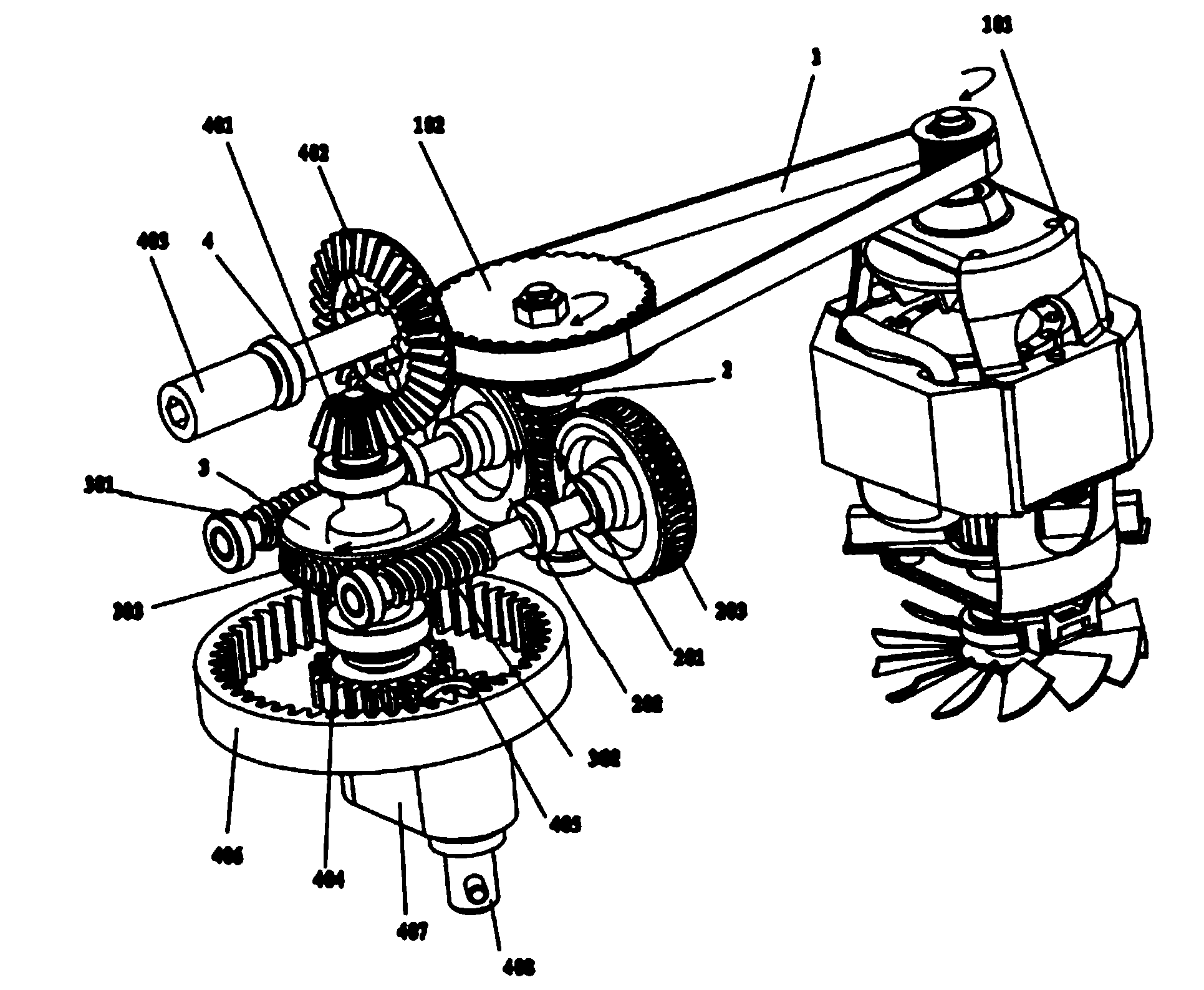

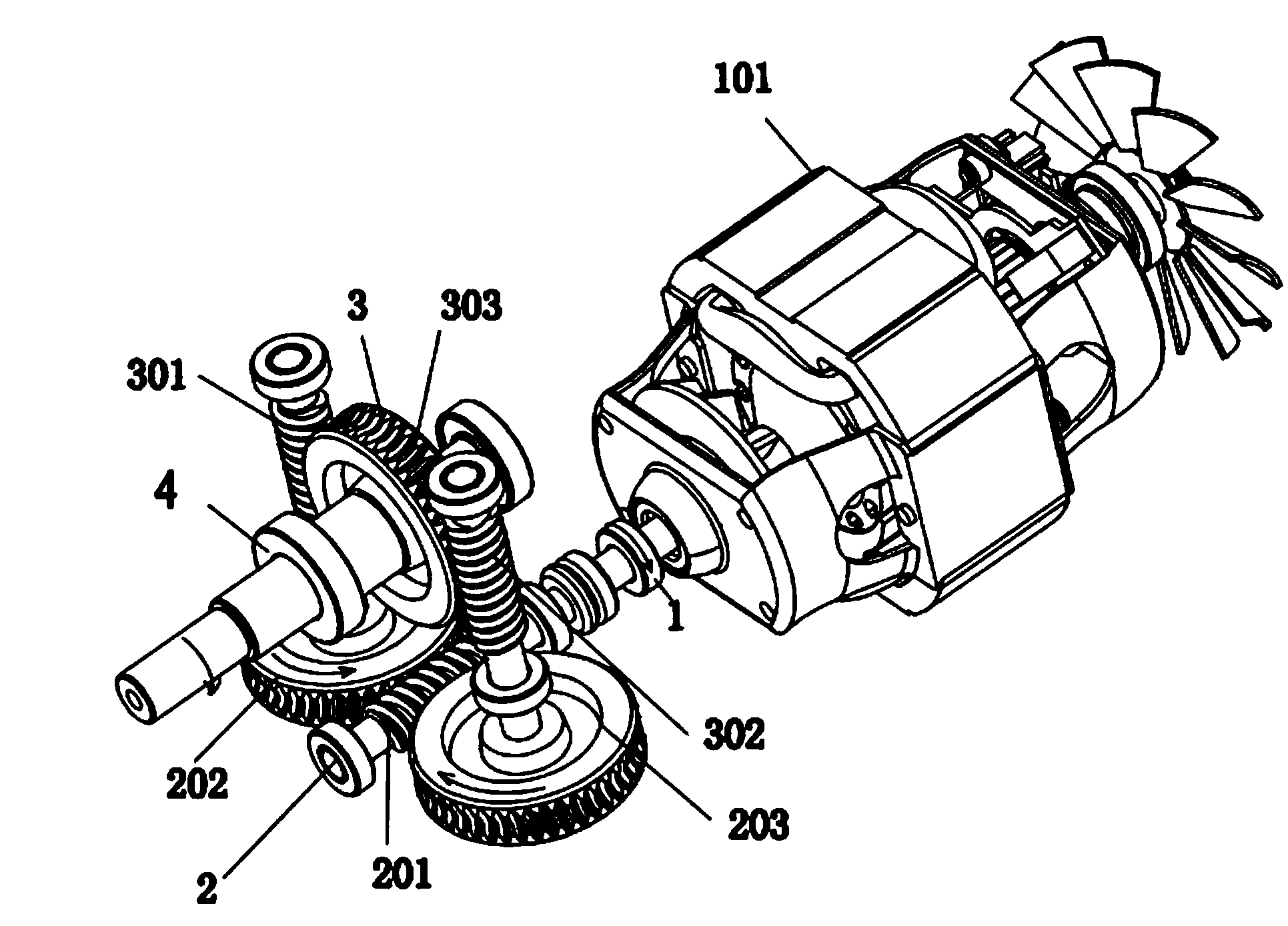

Gear with at least two gearing stages, a linear actuator comprising such a gear and a table leg comrising such a linear actuator

ActiveCN102057183ACompact structureIncrease the reduction ratioToothed gearingsVariable height tablesGear driveGear wheel

Gear, preferably for actuators of the type, where an electric motor (1) through the gear drives an activation element, such as a pivotal arm or a longitudinally movable element, and where the gear has at least two gearing stages. The first stage is constituted by a worm drive with a worm - (11; 13a, 13b) and the subsequent gearing stage is constituted by a crown and bevel wheel (23; 16a, 16b). The crown wheel faces towards the worm drive and has a power take-off (24,27) in extension of or in all essentials in extension of the worm (11) or parallel thereto. The bevel wheel (16a, 16b) is with its axis of rotation arranged perpendicular in relation to the axis of rotation of the worm (11), and the worm wheel (13a, 13b) is in drive connection with the bevel wheel (16a, 16b) through a gear train (14a, 15a;14b;15b). Thus a relatively compact transmission with a high gearing is achieved, and by having worm wheels, toothed gearing and bevel and crown wheels of plastic the transmission is in addition silent. A good tooth mesh between bevel wheel and crown wheel is particularly important. The gear may be used in a linear actuator which again may be used in a height adjustable table leg.

Owner:LINAK AS

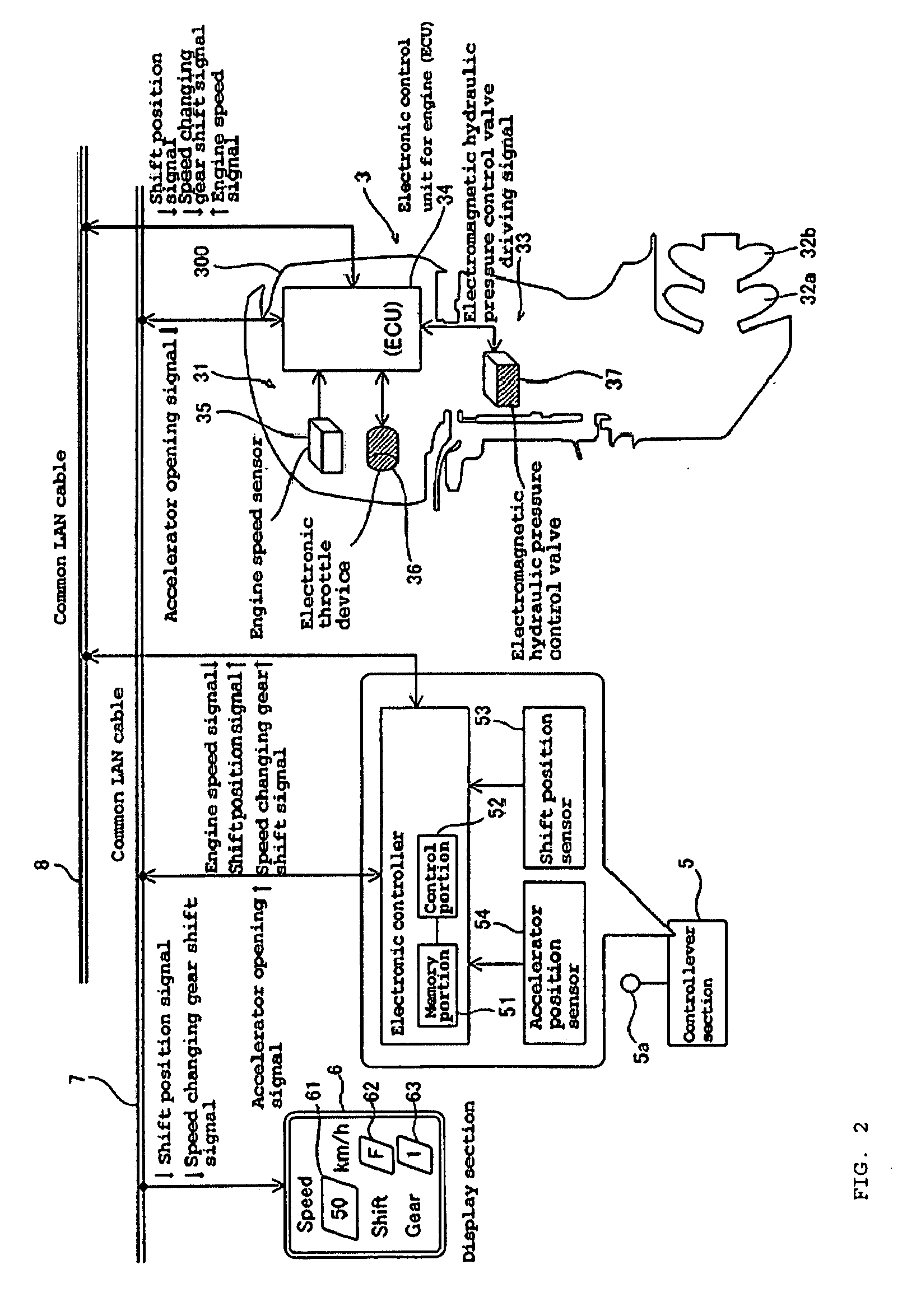

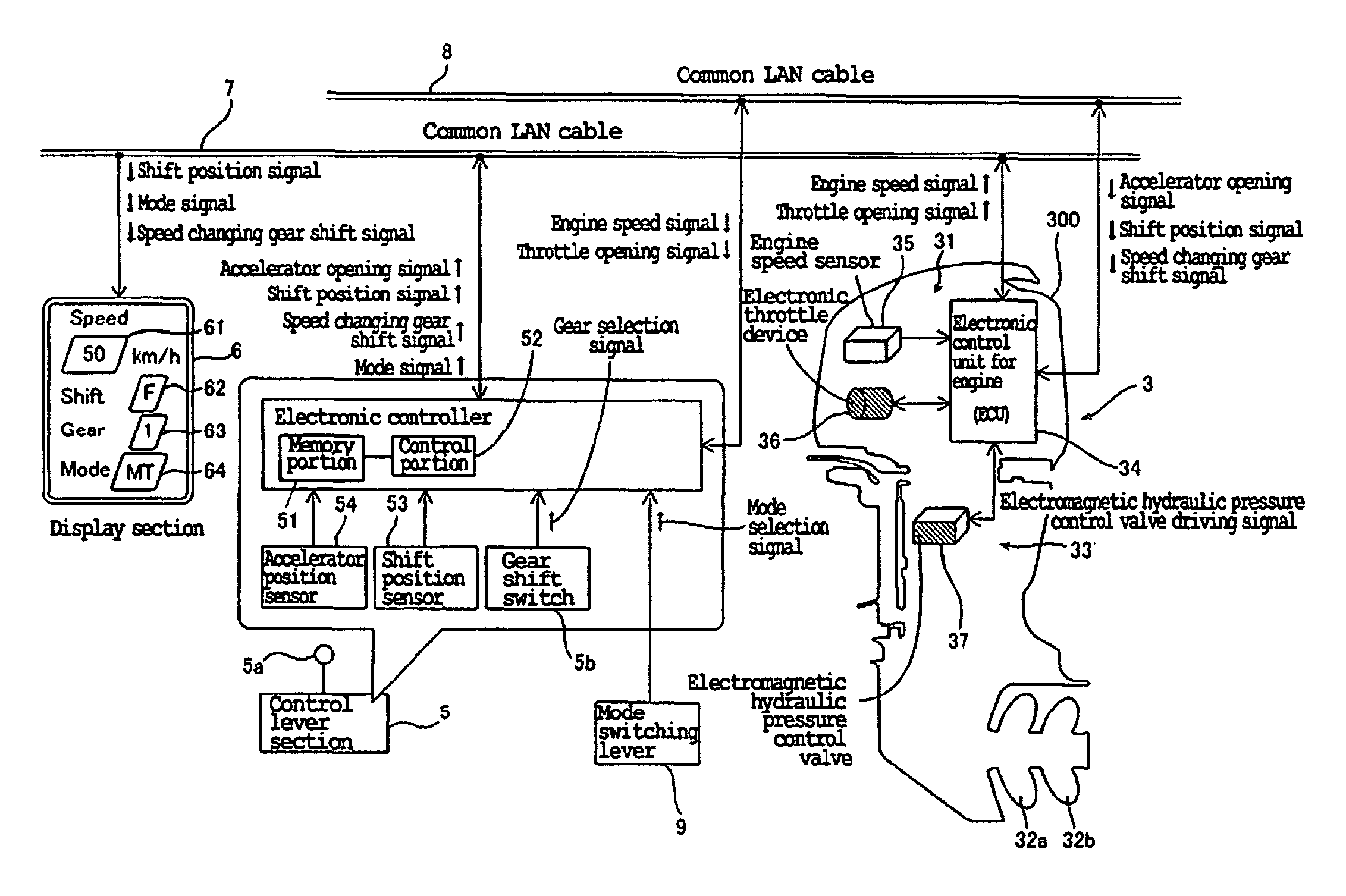

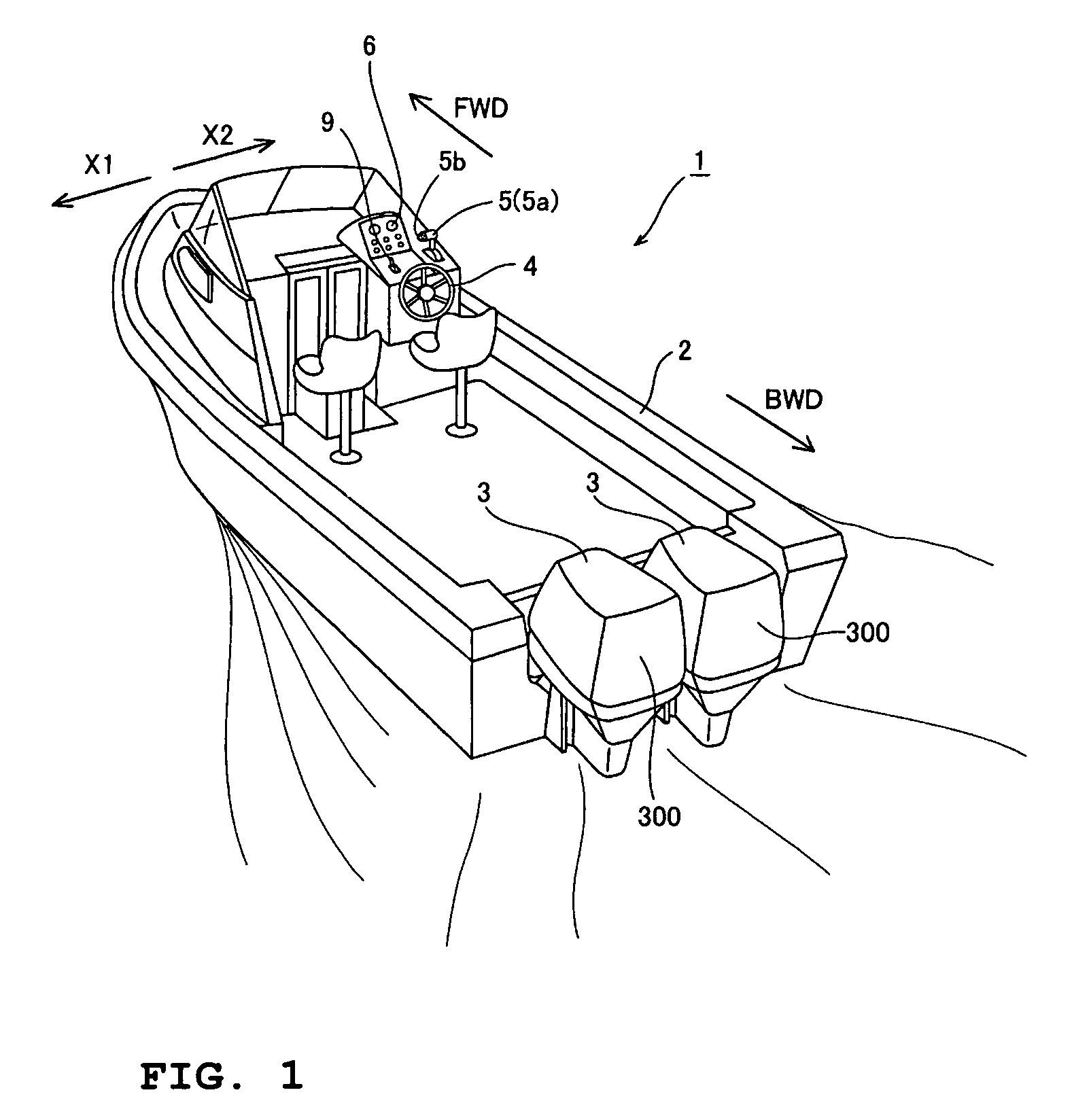

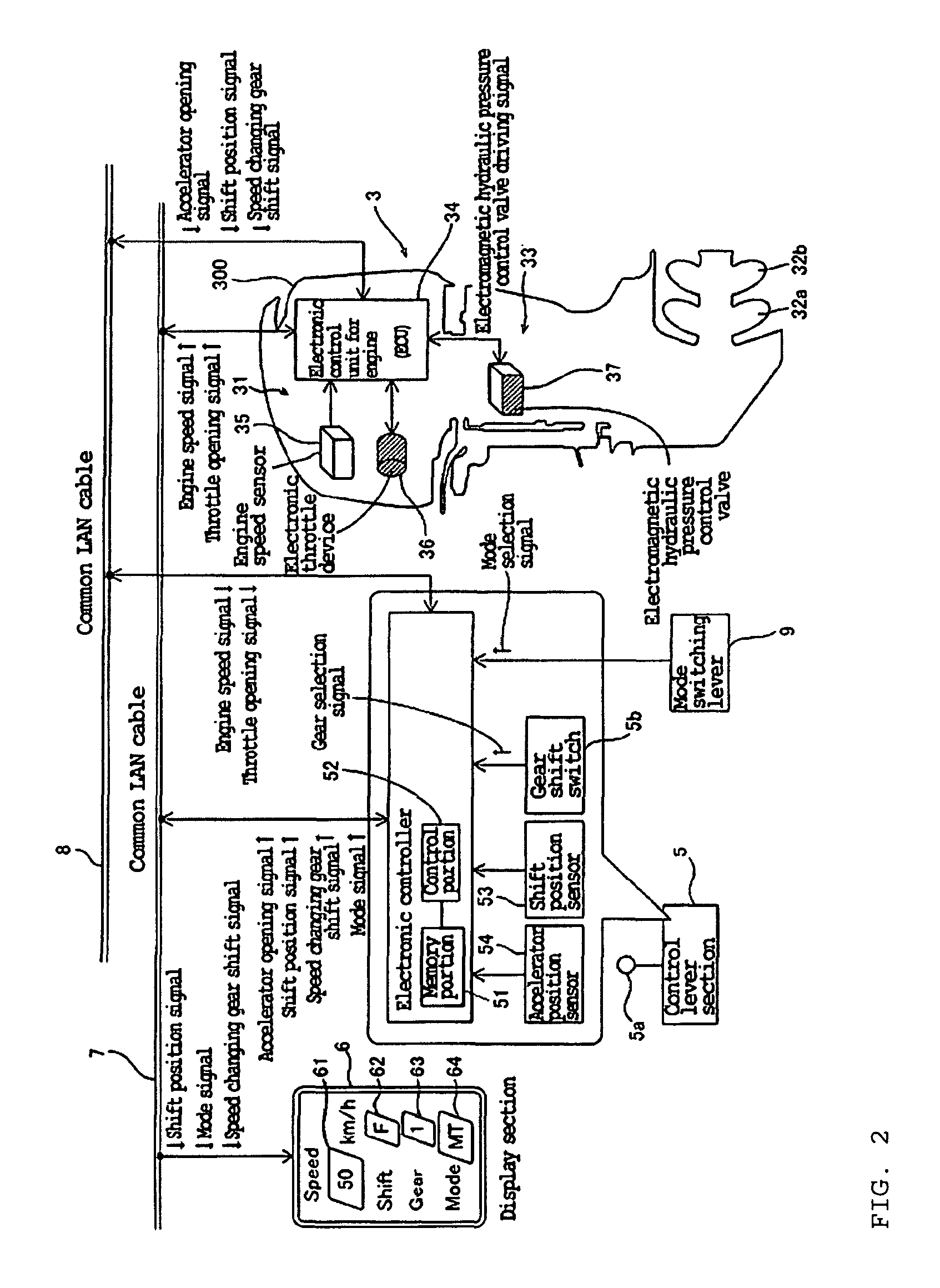

Marine propulsion system

ActiveUS20090209151A1Increase speedMinimize consumptionPropulsion power plantsPropulsive elementsLow speedMarine propulsion

A marine propulsion system includes a transmission mechanism arranged to transmit a driving force generated by an engine to propellers with a speed thereof changed to a low speed reduction ratio and a high speed reduction ratio; a control lever section operated by a user in controlling drive of the engine; and a control portion and an ECU controlling a shift between reduction ratios of the transmission mechanism based on operation of the control lever section by the user. The control portion and the ECU control a shift between reduction ratios of the transmission mechanism based on a transmission control map providing a reference for a shift between reduction ratios of the transmission mechanism taking into consideration an engine speed of the engine and a lever opening of the control lever section. This arrangement provides a marine propulsion system in which both acceleration performance and maximum speed can approach levels that a user desires.

Owner:YAMAHA MOTOR CO LTD

Composite wave gear drive

ActiveUS8485064B2Low reduction ratioIncrease the reduction ratioToothed gearingsGear driveGear wheel

In a composite wave gear drive, a flexspline (having a number of teeth Nf) is disposed on the inner side of first and second circular splines (numbers of teeth Nc1 and Nc2, respectively). One side of the flexspline is bent into an elliptical shape by a first wave generator, the other side of the flexspline is bent into an elliptical shape by a second wave generator, and the flexspline meshes with the first and second circular splines. The first wave generator is a rotational input component, the second wave generator is a reduced-speed rotational output component, and the first and second circular splines are kept from rotating. The number of teeth is set such that Nc2=Nc1+2 and Nc1=Nf+2. A backlash-free gear drive having a low reduction ratio can be obtained.

Owner:HARMONIC DRIVE SYST IND CO LTD

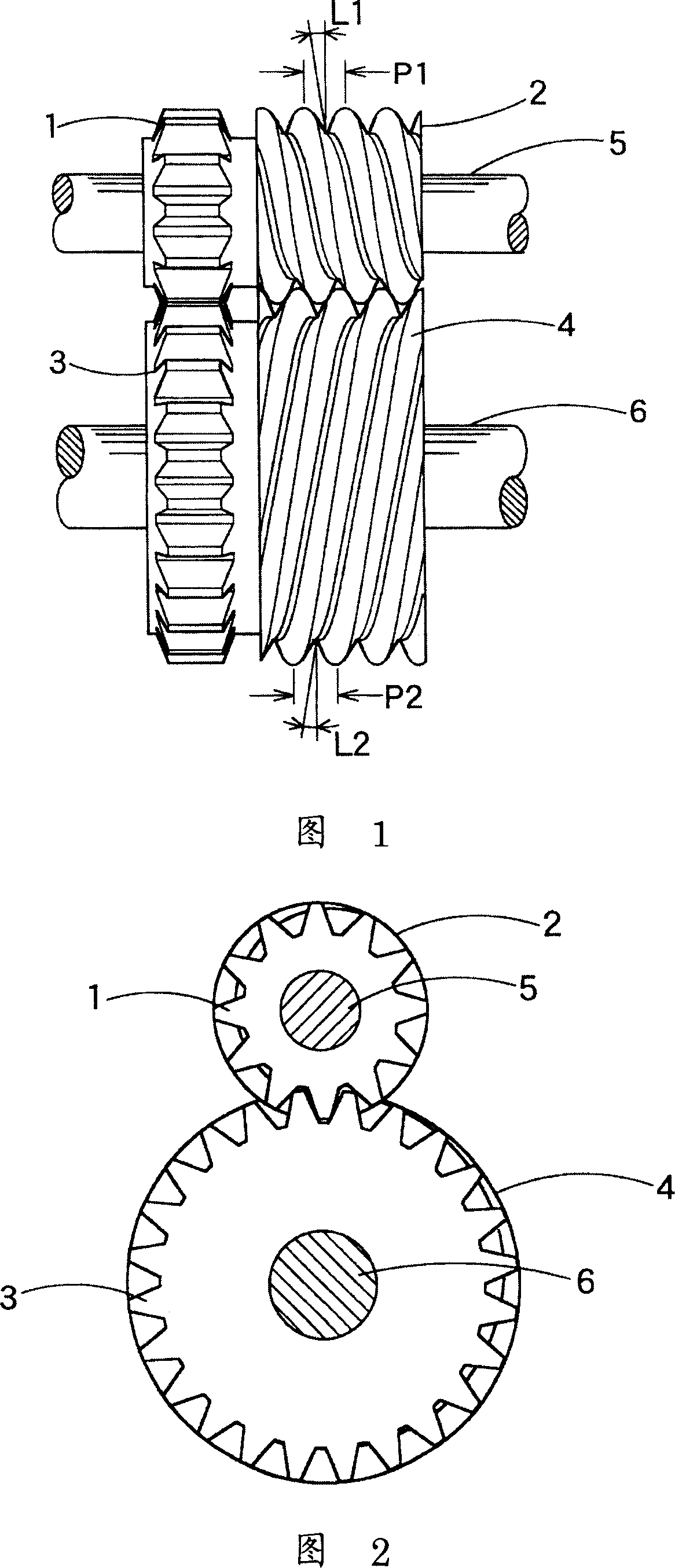

Gear mechanism, planetary gear device, rotating bearing device, and magical planetary gear speed reducer

InactiveCN1973149ASuppress crashSmall backlashRolling contact bearingsToothed gearingsGear wheelReducer

A gear mechanism having extremely less backlash, capable of suppressing the rattling noise of gears, having a large loading resistance in the thrust direction, and capable of transmitting high torque by using the gears transmitting a force by the meshing of the gears with each other in place of the transmission of the force by friction. The gear mechanism is formed by disposing the plurality of spur gears in the meshed state with each other. The screw-like gears (2) and (4) are disposed on the same axis as the spur gears (1) and (3) in the meshed state with each other. The screw-like gears (2) and (4) adjacent to each other are formed in screw shapes having lead angles extending in the reverse directions to each other and equal in angle to each other. The spur gear (1) and the screw-like gear (2) are rotated integrally with each other to transmit its rotation to the spur gear (3) and the screw-like gear (4) adjacent to each other.

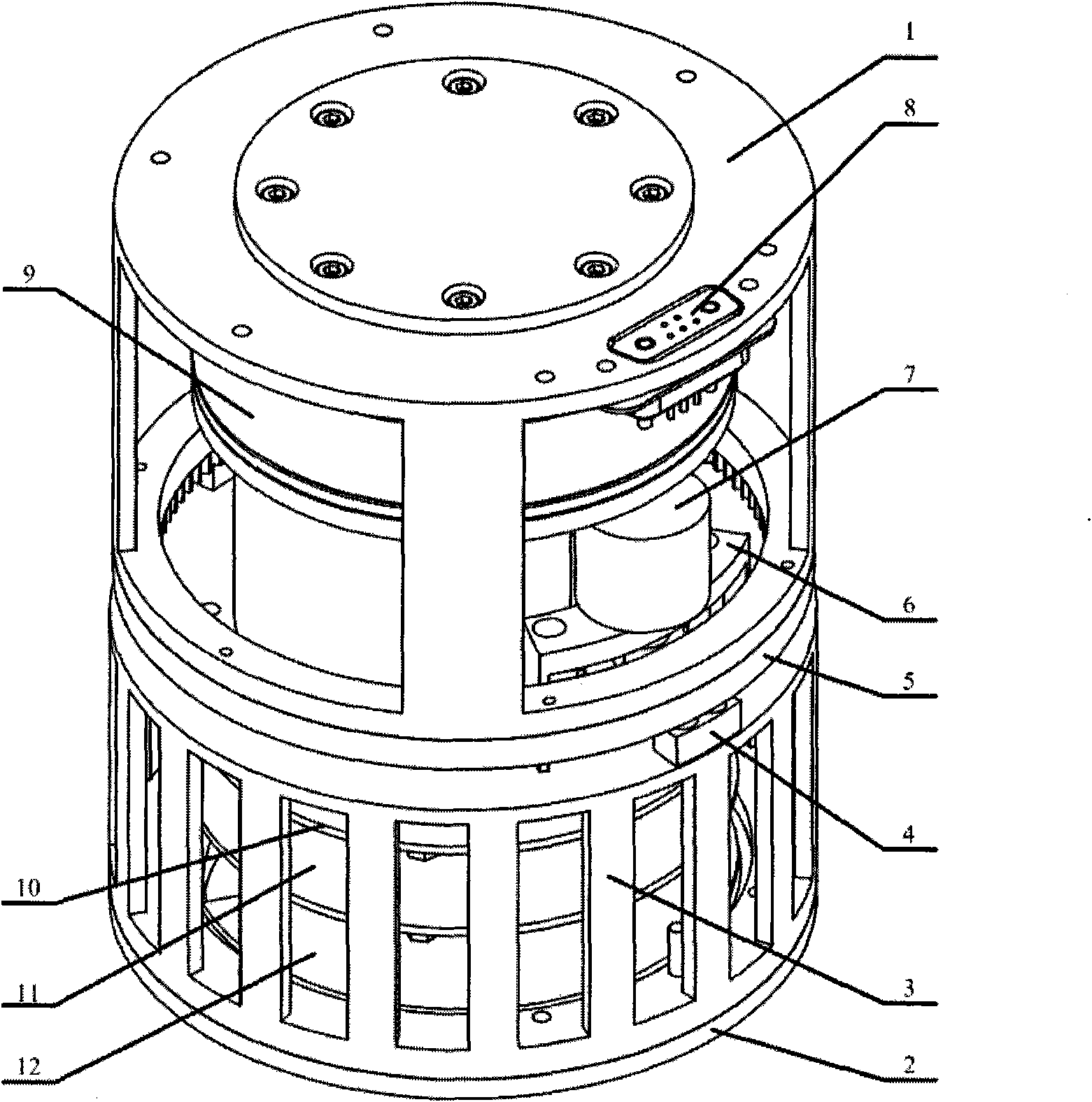

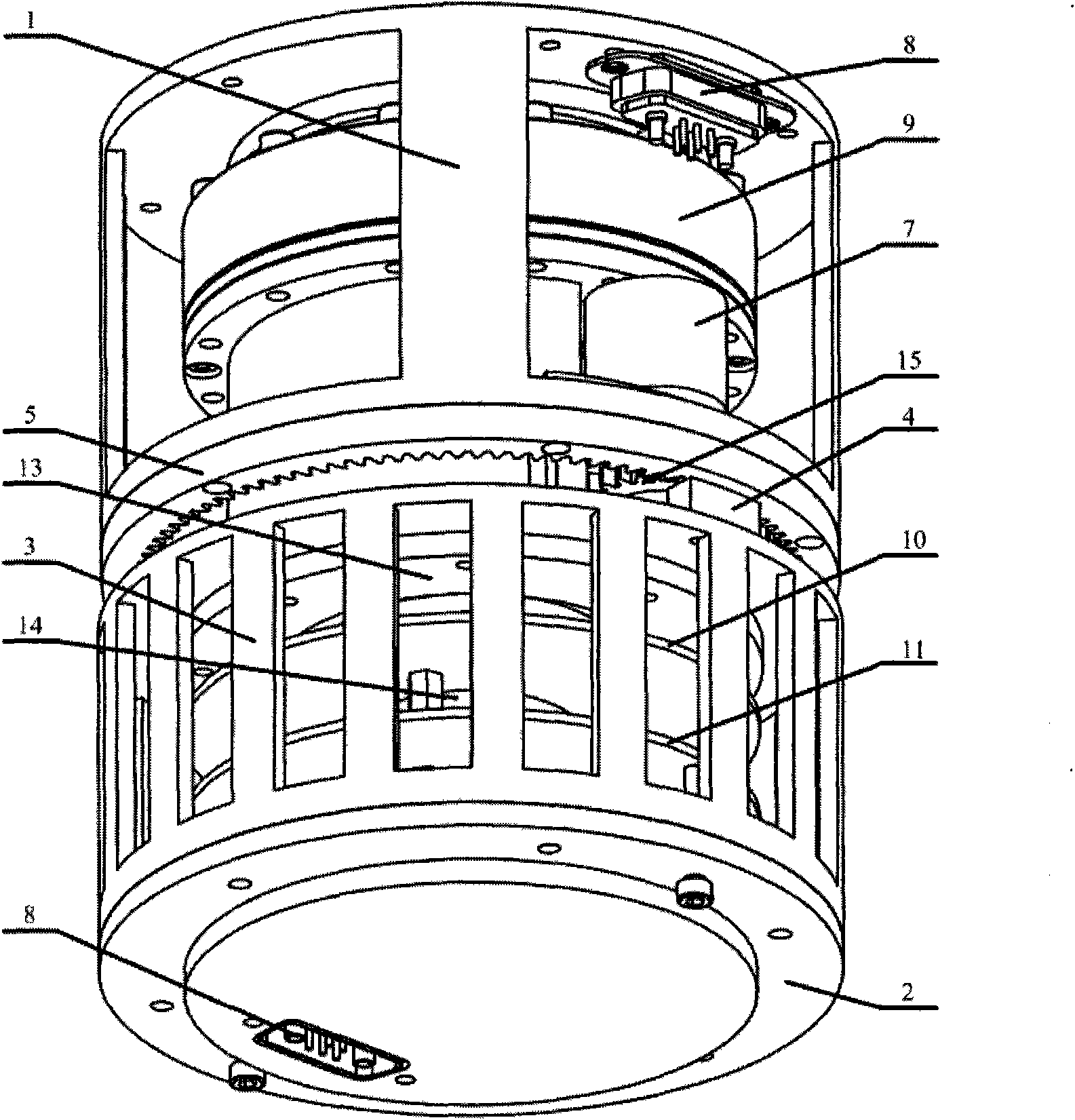

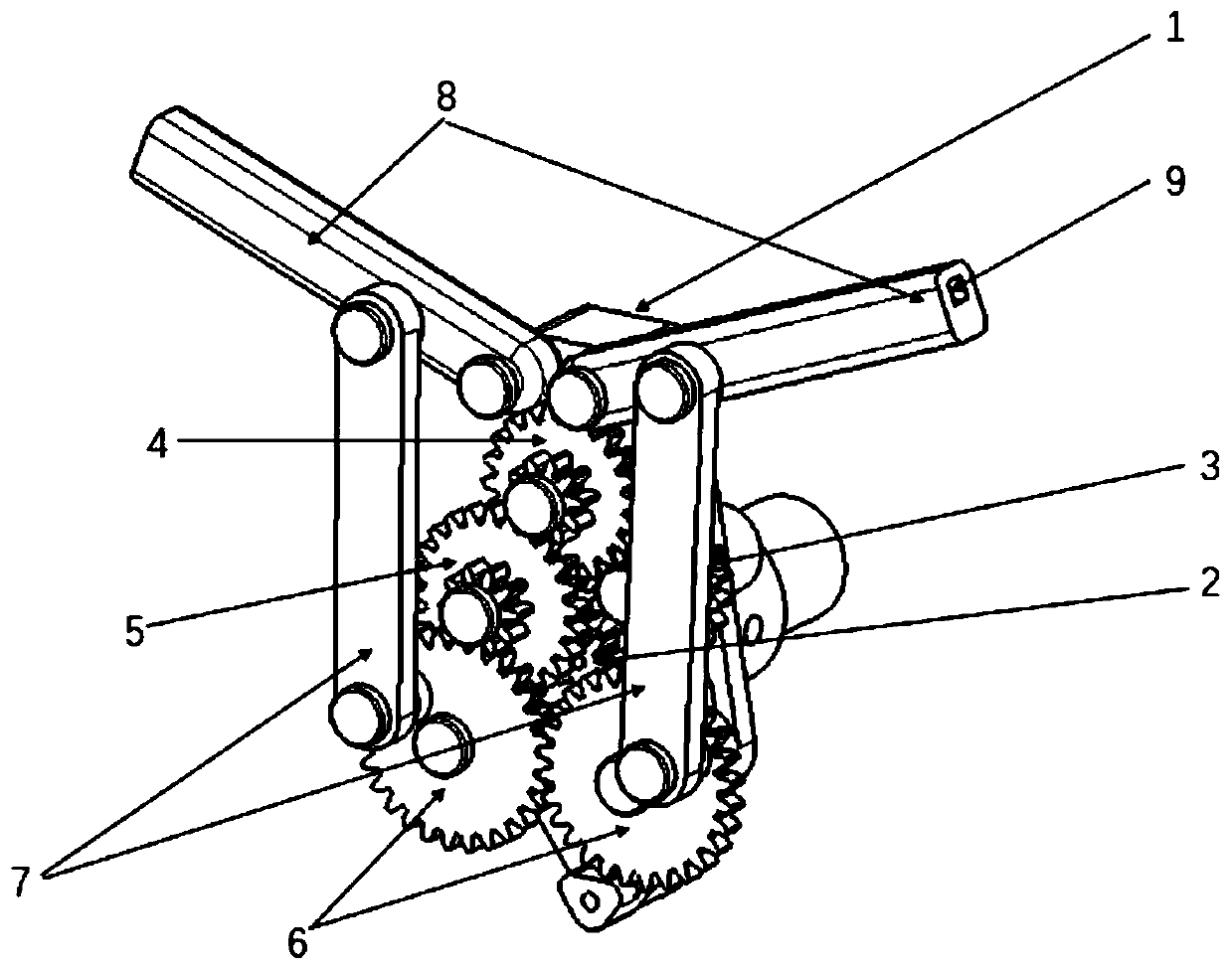

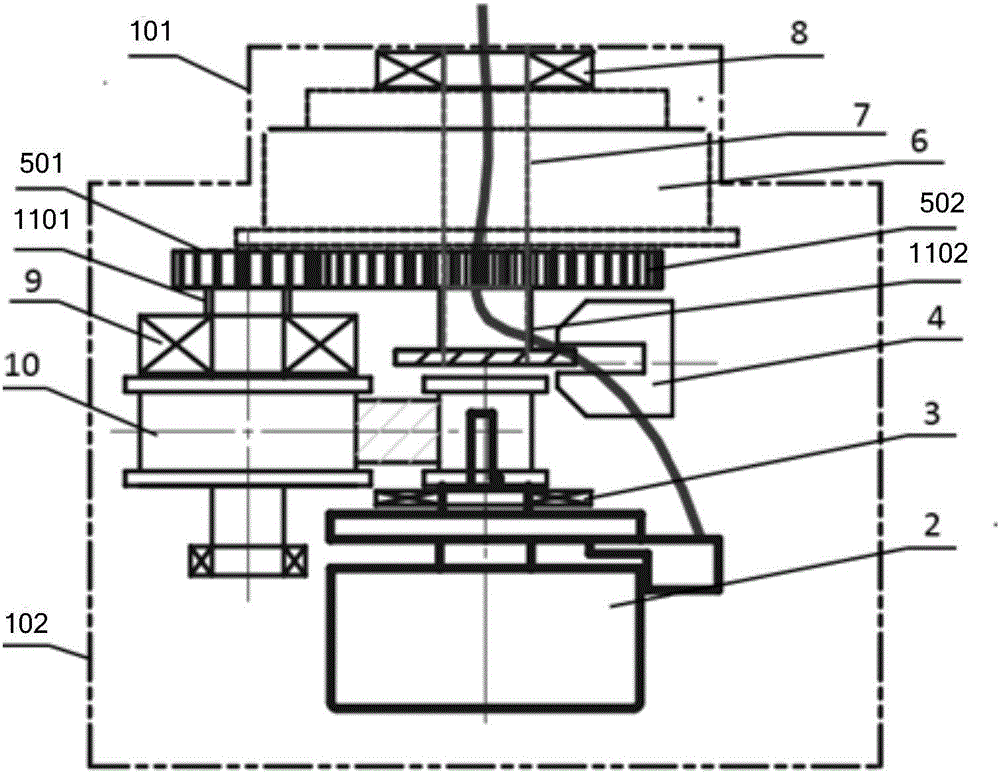

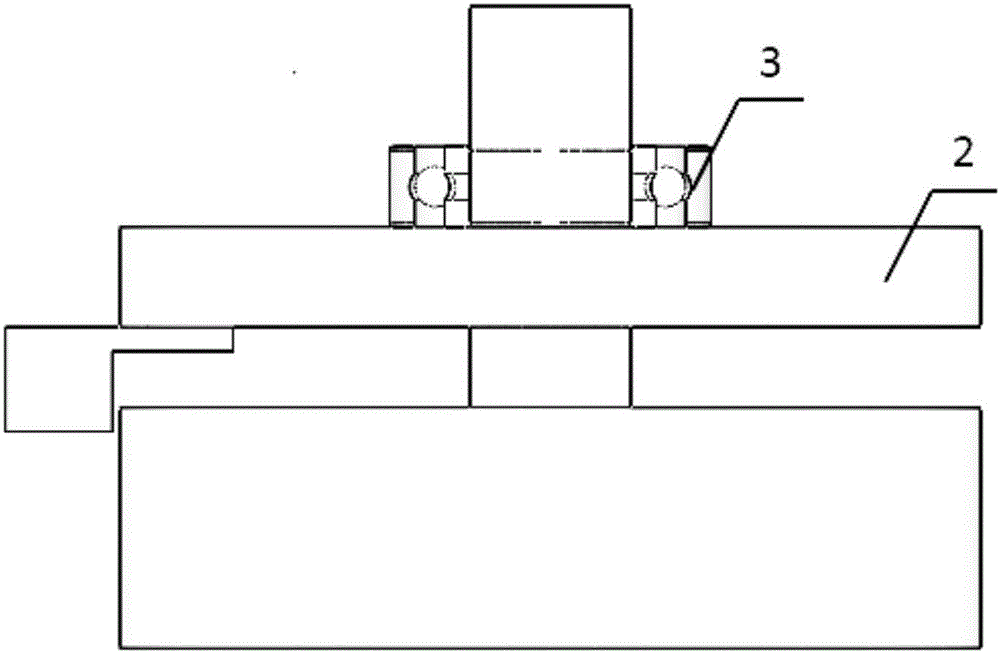

Rotational joint module of modularized reconfigurable robot

The invention discloses a rotational joint module of a modularized reconfigurable robot. On the basis of planetary reduction, one level of harmonic reduction is added on motor output, a reduction ratio is improved, an output torque is added, and the transmission precision of the module is improved. An upper end cover and a lower end cover serve as installation joints, the flange-type design with locating seam allowances and pin holes is adopted, and the module is accurately and conveniently connected and located. All electric wires are arranged in a cage-type support, the upper end cover and the lower end cover and are isolated and protected by an outer cover, thereby avoiding the problem that the electric wires are coiled when a robot moves. Mechanical limit and electric limit are arranged in the module. On the basis of adopting an incremental coded disc, a rotating potentiometer is added to measure the assistant position of module movement, absolute position information is recorded under the condition of accidental power failure, and the system can continuously work after being electrified. The rotational joint module has the advantages of reasonable and simple structure, high precision and inner routing, is convenient to install and position and is safe and reliable to use.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Motor shaft for micromotor, and micromotor

InactiveUS20090031839A1Increase the reduction ratioLow failure rateToothed gearingsMechanical energy handlingGear wheelReduction ratio

[Problems] A motor shaft for a micromotor where a high reduction ratio can be obtained by a speed-reduction gear mechanism and where high coaxiality between the motor shaft and a pinion can be achieved.[Means for Solving problems] The invention is based on the fact that, because a micromotor has a very small motor torque, even a pinion having a diameter smaller than that of a shaft has sufficient strength for the motor torque. Based on this, the motor shaft of the invention has a pinion integrally formed on the front end side of the shaft and the pinion has an outer diameter equal to or less than that of the shaft. Because the pinion can be sufficiently reduced in diameter, a high reduction ratio can be obtained by a speed-reduction gear mechanism. In addition, since the pinion can be integrally formed on the motor shaft, high coaxiality between the shaft and the pinion can be achieved.

Owner:NAMIKI PRECISION JEWEL CO LTD

Torque ripple weakening method for concentrated winding outer rotor magnetic field modulation motor

ActiveCN111525713AIncrease sineIncrease the reduction ratioElectronic commutation motor controlMagnetic circuit rotating partsElectric machineTorque density

The invention discloses a torque ripple weakening method for a concentrated winding outer rotor magnetic field modulation motor, and the method employs a method of building a target function to adjusta modulation polar coefficient combination and rotor axial segmentation for inhibition for main odd harmonics and even harmonics in the counter electromotive force of the motor. According to the method, the reduction of motor torque ripple is taken as an objective function, and an optimal modulation polar coefficient combination is obtained through a method of combining analytical calculation anda finite element method so as to suppress the influence of main odd harmonics. A rotor of the concentrated winding magnetic field modulation motor is divided into two sections in the axial direction,permanent magnets of the two sections are magnetized with N polarity and S polarity respectively, and the upper permanent magnet and the lower permanent magnet are arranged in a staggered mode by thedistance of one pole so as to restrain the influence of even harmonics. The torque ripple suppression method is easy to operate and obvious in effect, and the concentrated winding outer rotor magnetic field modulation motor has the advantages of being high in torque density and low in torque ripple.

Owner:SOUTHEAST UNIV

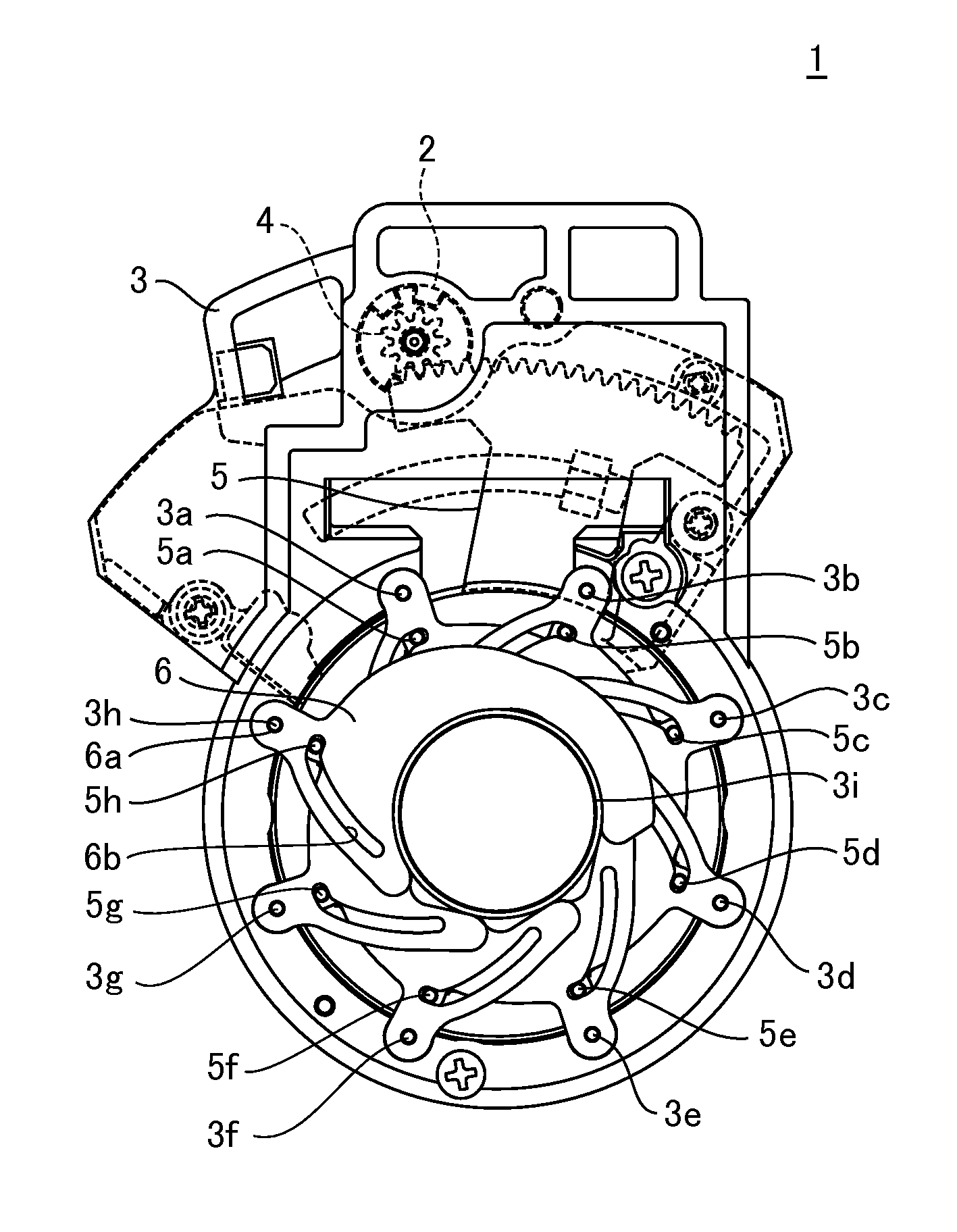

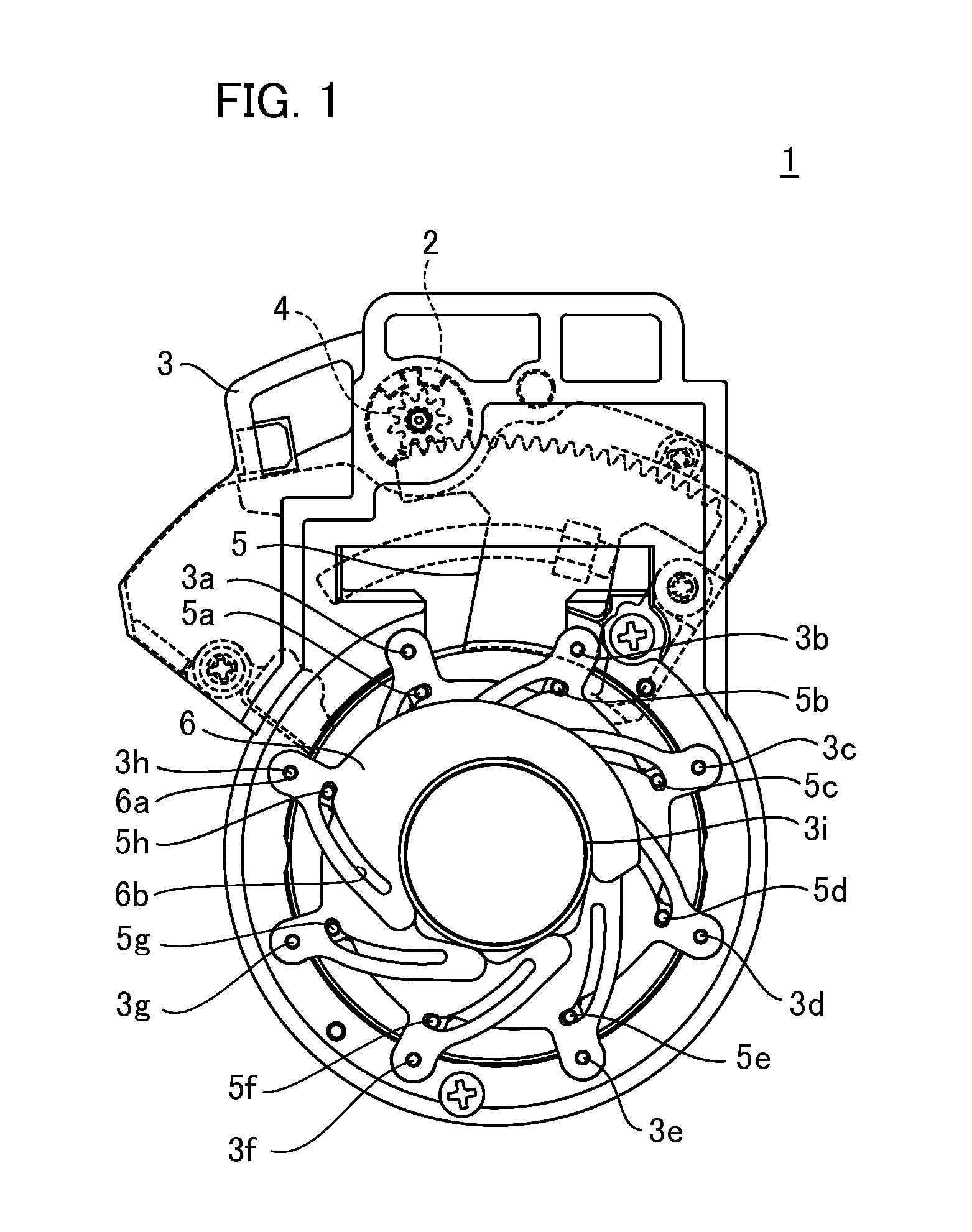

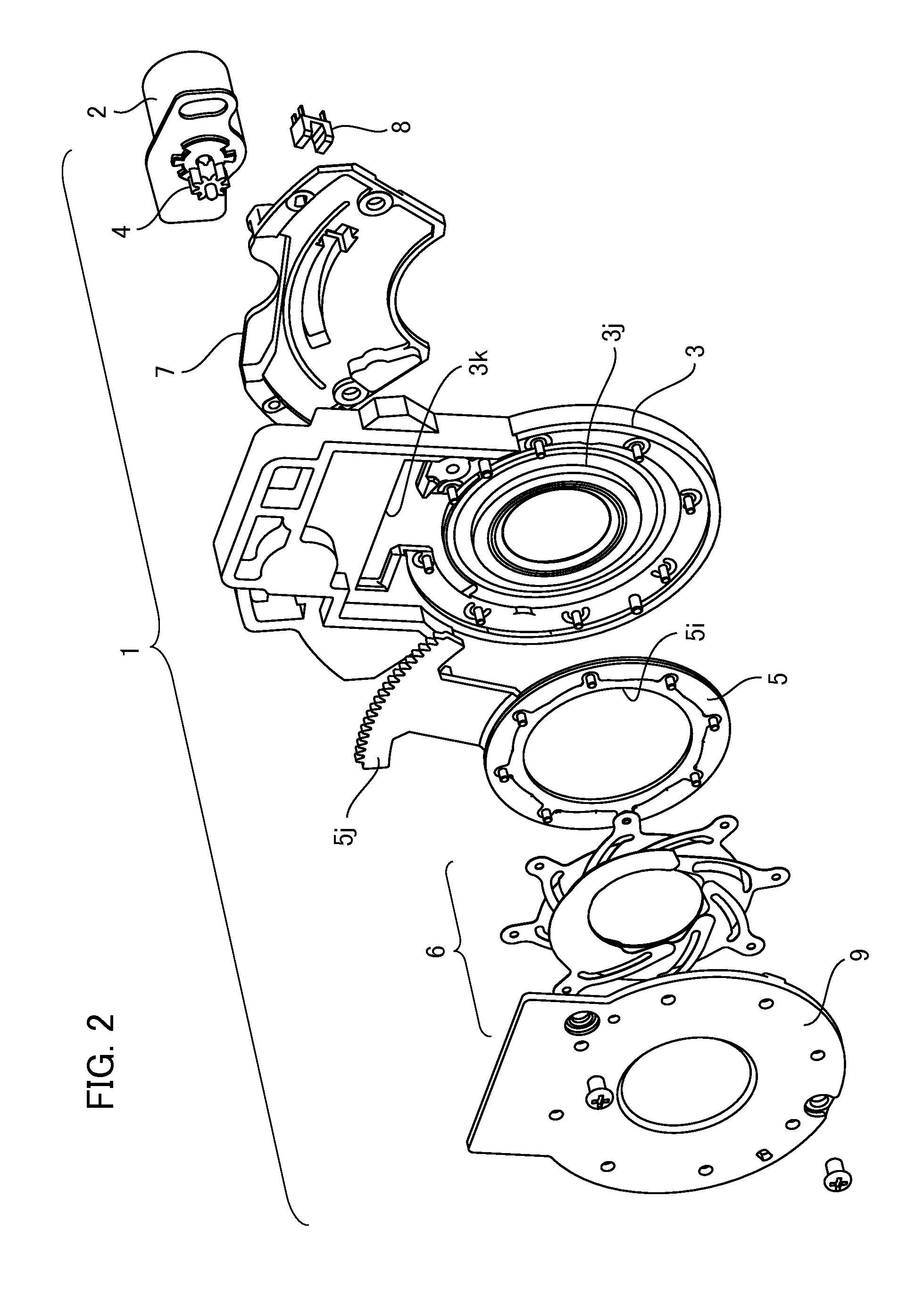

Light amount adjusting apparatus, lens barrel, and imaging apparatus

ActiveUS20140212123A1Improve accuracyIncrease the reduction ratioCamera diaphragmsEngineeringMechanical engineering

Owner:CANON KK

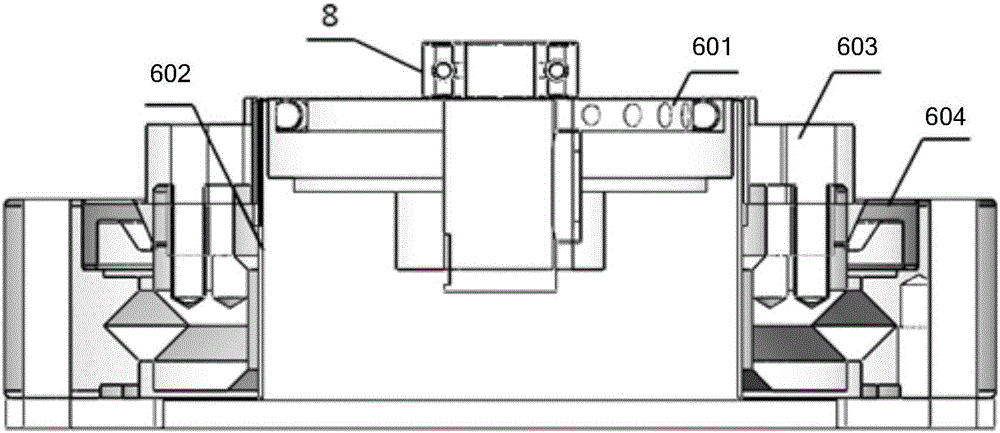

Pure electric wheelhub drive axle unit

PendingCN107284214AAdjustable lengthAchieve movementElectric propulsion mountingControl devicesBrakeReduction drive

The invention provides a pure electric wheelhub drive axle unit. The pure electric wheelhub drive axle unit is of a left-right symmetric structure, more uniform in a loading and bearing capacity, low in processing and manufacturing difficulty, adjustable in a total length of the driving axle, adaptable to various models of vehicles, reduces a development cost, improves a reduction ratio and improves an energy utilization rate. The pure electric wheelhub drive axle unit comprises the main axle body; the main axle body is of a left-right symmetric structure; motor arrangement grooves are arranged on two sides of the main axle body; positioning thread holes are arranged on end surfaces on two sides of the main axle body; the housings of the wheelhub decelerators are fixedly connected to the positioning thread holes on end surfaces of corresponding sides through bolts; a driving motor on the corresponding side is arranged inside the motor arrangement groove; a motor seat of the driving motor on the corresponding side is connected to an inner end surface of the housing of the wheelhub decelerator through a connection flange; and a brake assembly is fixed on the outer end surface of the housing of the wheelhub decelerator.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

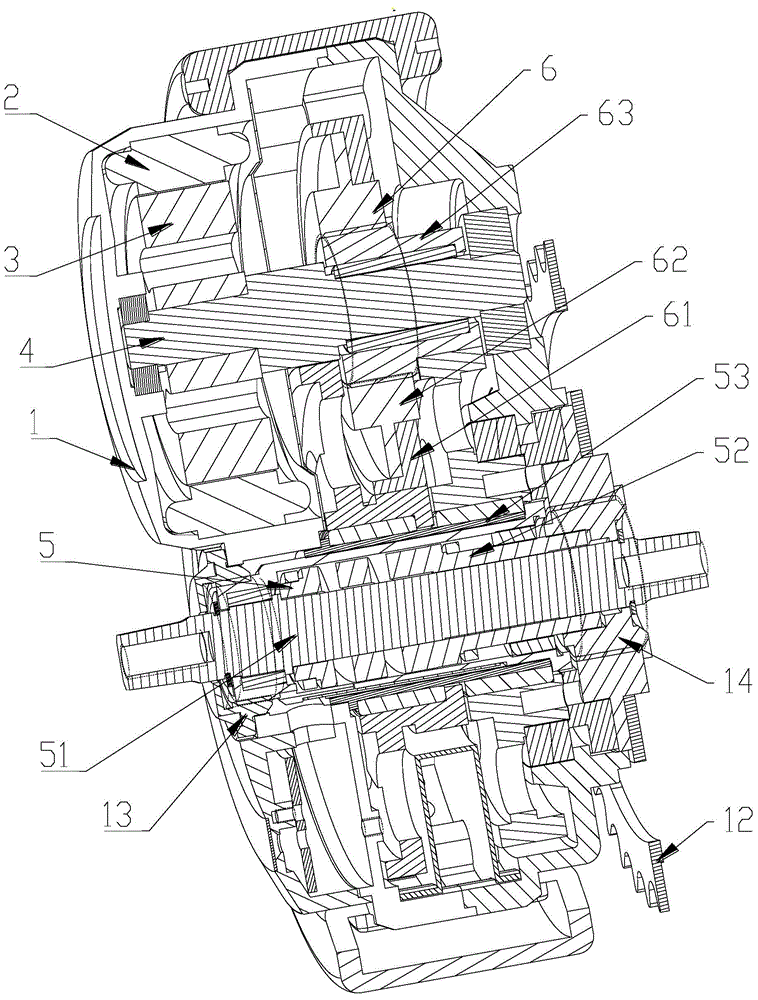

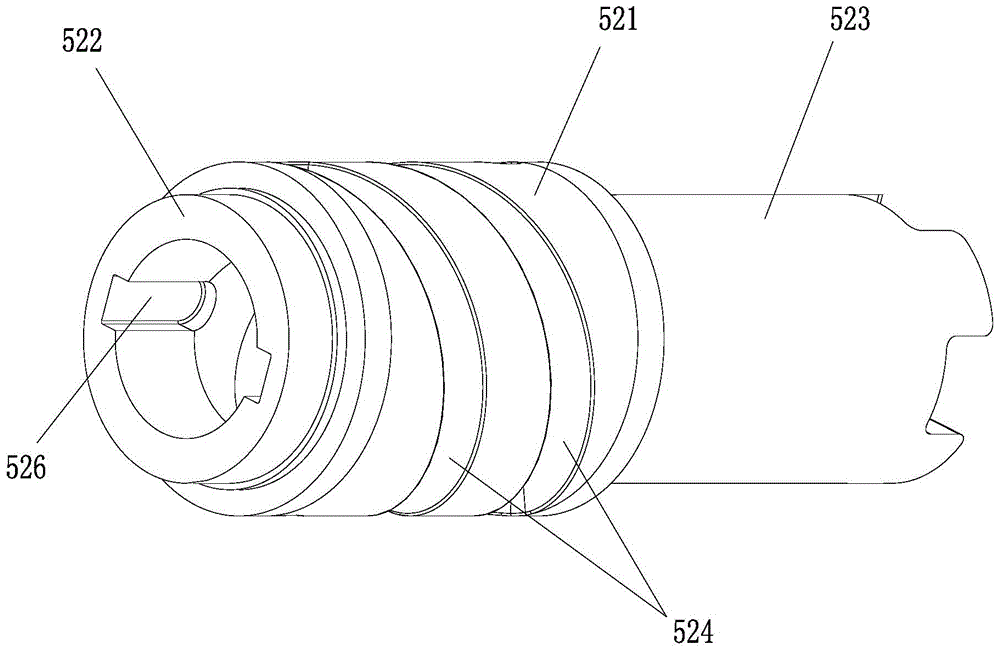

Planetary-harmonic composite gear reducer

ActiveCN101545524ASmall aspect ratioIncrease the reduction ratioToothed gearingsAviationBall bearing

The invention relates to a planetary-harmonic composite gear reducer, which relates to a reducer, and aims at the problems that the prior cup-shaped harmonic reducer has small reduction ratio, large axial size, large volume, large mass and the like. A sun gear is engaged with at least two planetary gear shafts and is arranged in an elliptical internal gear ring of an elliptical cam, the at least two planetary gear shafts are engaged with the elliptical internal gear ring of the elliptical cam to form a primary planetary reduction gear train, the elliptical cam is arranged in a flexible ball bearing, the primary planetary reduction gear train and the flexible ball bearing form a wave generator, the flexible ball bearing is arranged in a flexible gear, the flexible gear is arranged in a rigid internal gear ring and is engaged with the rigid internal gear ring under the action of the wave generator, and a planetary gear shaft arranged in a shaft hole of a tie bar is provided with a rolling bearing. The reducer has the advantages of large reduction ratio, small axial size, small volume, light mass and the like, and is particularly suitable to be applied in the fields such as aviation and space detectors, various instruments and meters, and driving units of precision robots and the like.

Owner:成都川哈工机器人及智能装备产业技术研究院有限公司

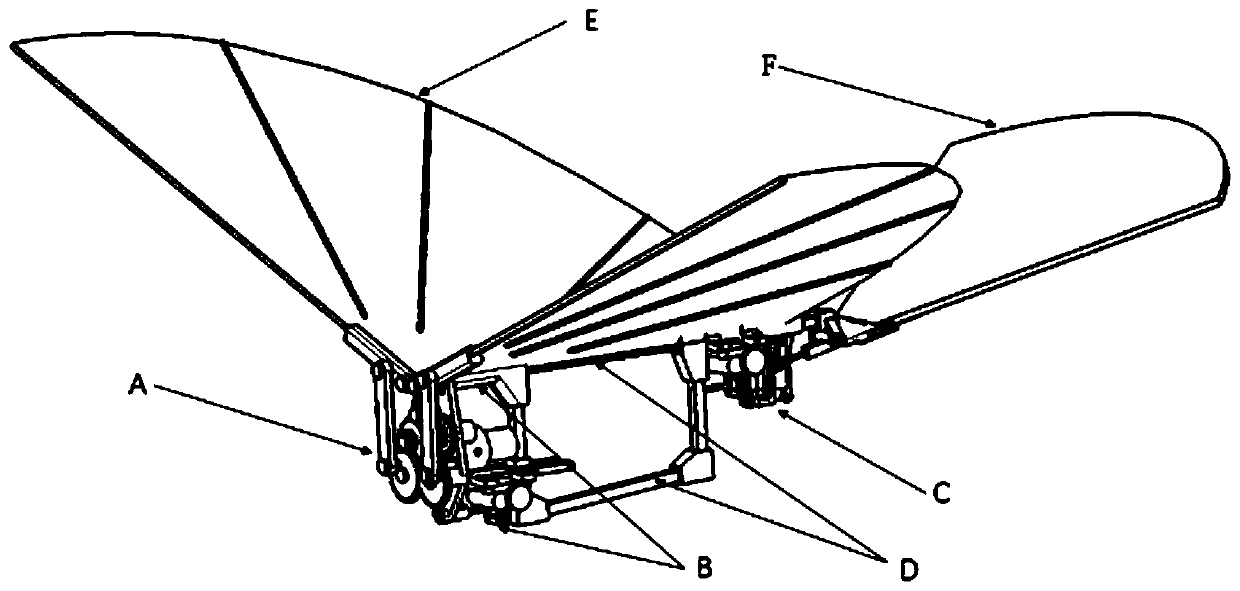

Bionic flapping wing flying robot with deflectable driving mechanism

ActiveCN110588970ASimple structureImprove stabilityAircraft stabilisationWith power amplificationFlapping wingAttitude control

The invention provides a bionic flapping wing flying robot with a deflectable driving mechanism. The bionic flapping wing flying robot with the deflectable driving mechanism comprises a driving mechanism, a deflection mechanism, a tail fin control mechanism, a robot body, a flight control board, wings and a tail fin; the driving mechanism is used for driving the wings to flap at a high frequency to generate main power; the tail fin control mechanism is used for controlling a left-and-right deflection angle and an up-and-down upturning angle of the tail fin; and the deflection mechanism is usedfor enabling the driving mechanism to swing from left to right around a central axis of the flapping wing flying robot so as to drive the wings to deflect so that the direction of aerodynamic force of a flapping wing is changed. According to the bionic flapping wing flying robot with the deflectable driving mechanism, controllable amounts comprise flapping wing frequency, the direction of the aerodynamic force of the flapping wing and the left-and-right deflection angle and the up-and-down upturning angle of the tail fin; the bionic flapping wing flying robot with the deflectable driving mechanism realizes flying attitudes of straight flying, hovering and steering when being combined with the flight control board and has an attitude self-stabilizing function; and as the controllable amount of a flapping wing flying robot driven by a motor is additionally arranged, more stable flight and flexible attitude control can be realized.

Owner:UNIV OF SCI & TECH BEIJING

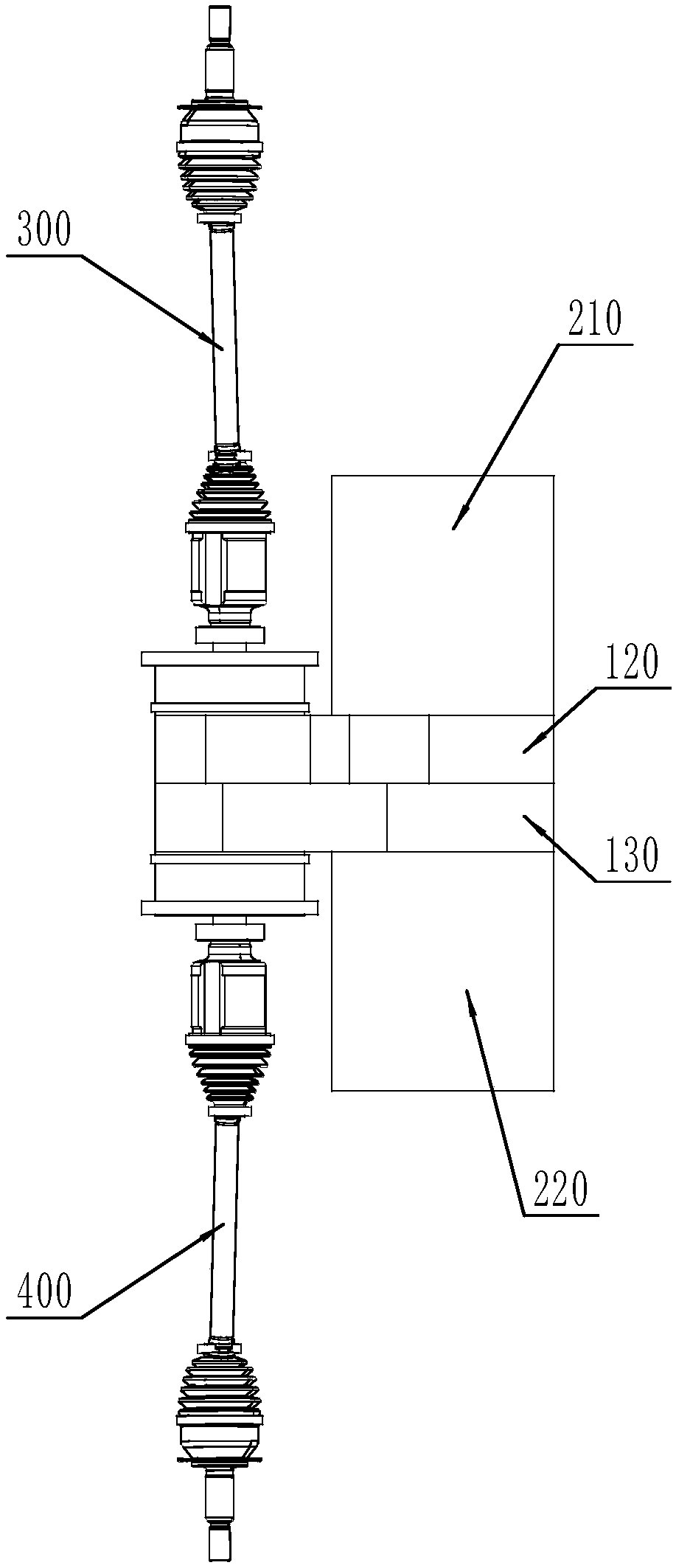

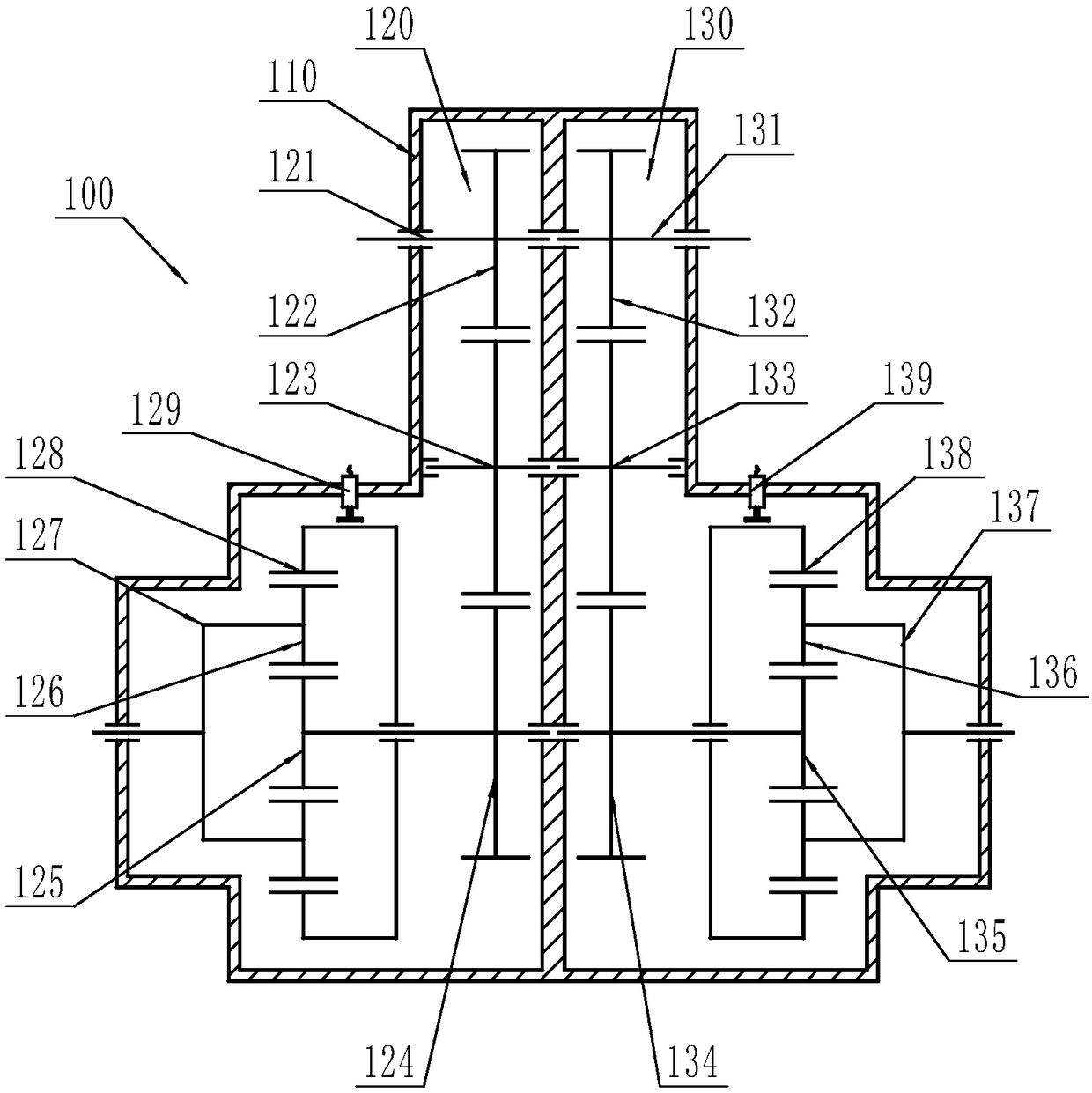

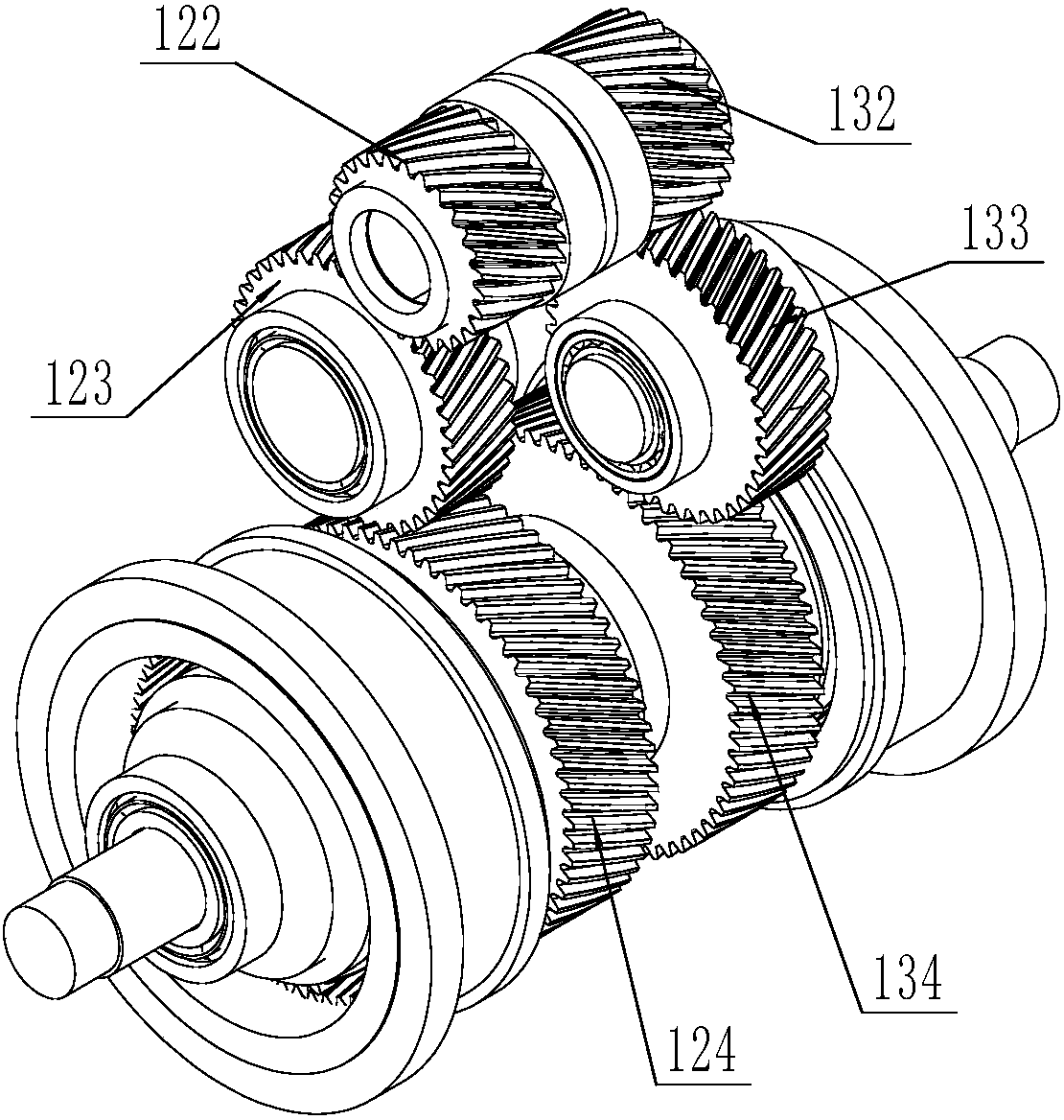

Electric vehicle and dual-motor planet gear power transmission system thereof

ActiveCN108528186AFree rotationAvoid out-of-control phenomenaElectric propulsion mountingToothed gearingsLow speedVehicle frame

The invention belongs to the field of automobiles, particularly provides an electric vehicle and a dual-motor planet gear power transmission system thereof and is intended to solve at least one of theproblems of the prior art that wheels of an electric vehicle driven by a single motor cannot output high torque through a reducer and wheels of the electric vehicle driven by the single motor are unsuitable for independent adjustment of driving torque. The dual-motor planet gear power transmission system mainly comprises two power transmission subsystems which are identical; each power transmission subsystem includes a motor and a reducer arranged on an auxiliary frame, and the motor is connected with an axle shaft of the electric vehicle through the reducer such that wheels can be driven torotate. Each reducer mainly includes a single-stage cylindrical gear reduction mechanism and a planet gear reduction mechanism which are in driving connection, the two mechanisms enable the reducer togain a high reduction ratio at the premise of compact layout space, and therefore, the electric vehicle can gain better low-speed performance.

Owner:NIO ANHUI HLDG CO LTD

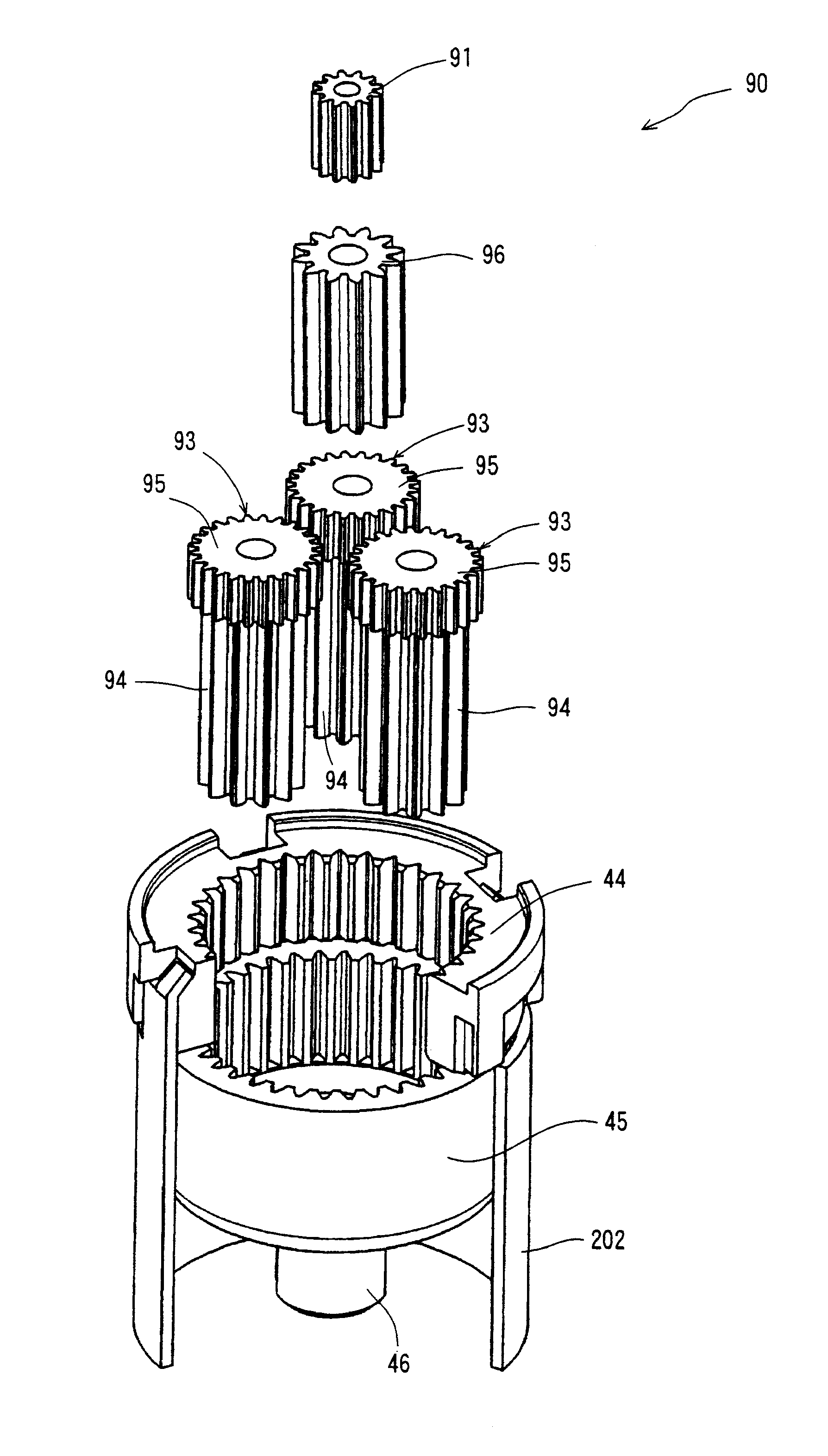

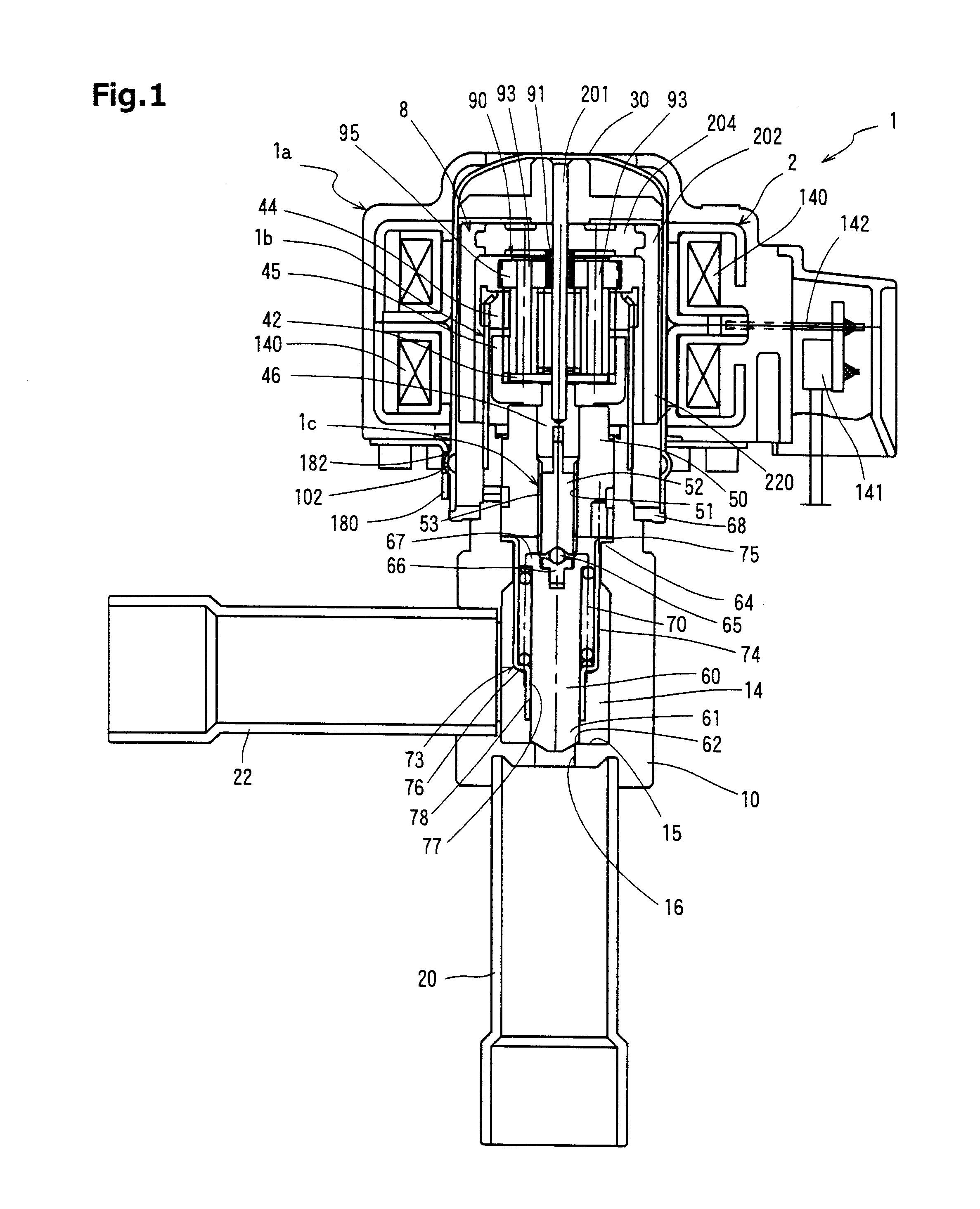

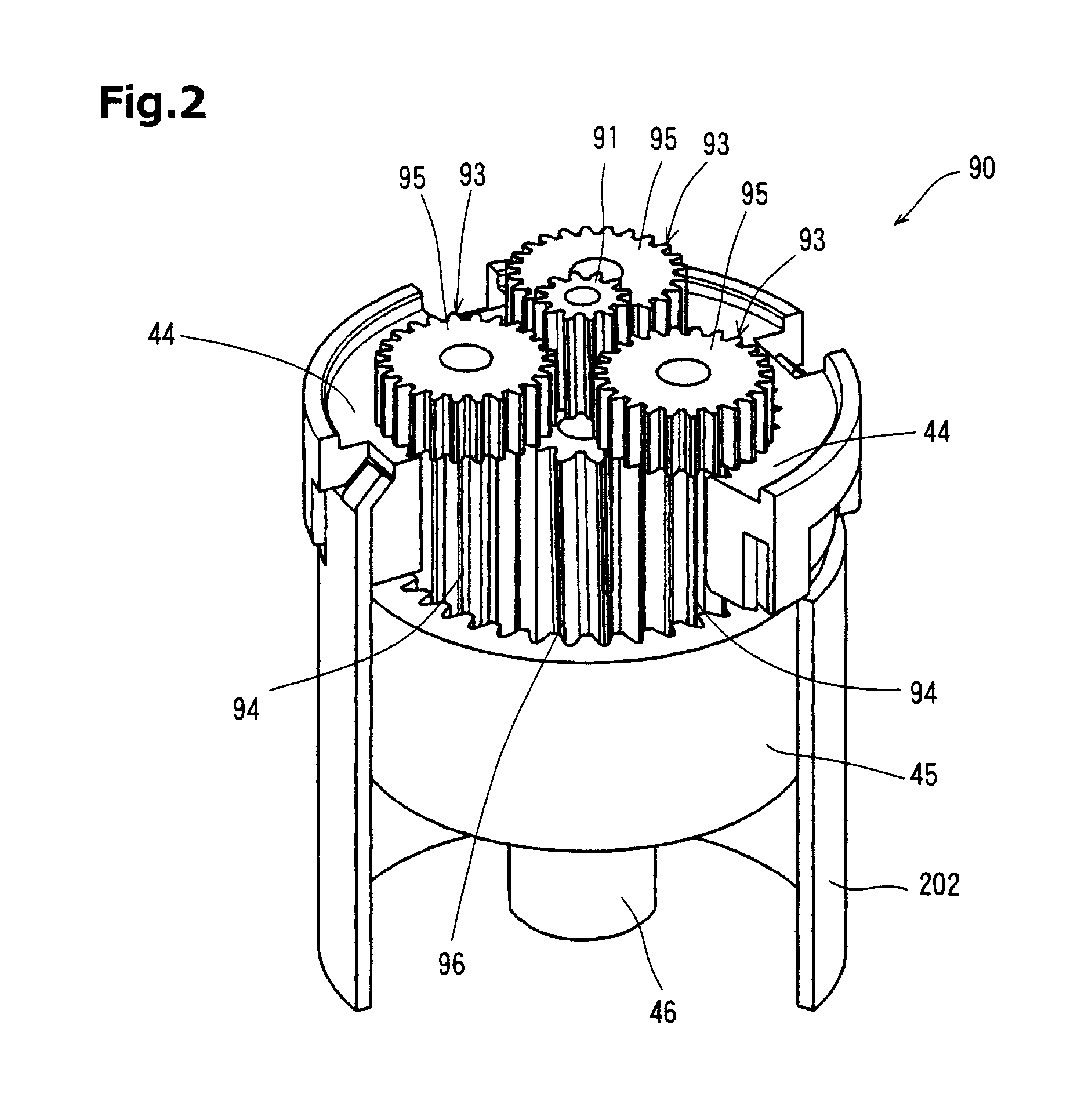

Planetary gear mechanism and motor-operated valve using the same

ActiveUS20120068098A1Increase the reduction ratioIncrease output torqueOperating means/releasing devices for valvesToothed gearingsEngineeringGear ratio

The invention provides a planetary gear mechanism achieving a greater reduction gear ratio without increasing the number of teeth of the gears, thereby enabling downsizing. In a planetary gear mechanism 1, a sun gear 91 functioning as an input gear receives smaller load than an internally toothed output gear 45, so gears (second planet gears 95) having a smaller module are connected to the planet gears 93, and the sun gear 91 is in engagement with the second planet gears 95. The sun gear 91 is formed of a same module as the second planet gears 95. The rotation of the sun gear 91 is reduced in speed and transmitted to the second planet gears 95, and rotation of the second planet gears 95 rotated at a reduced speed is further reduced by the slight difference in the numbers of teeth of the ring gear 44 and the internally toothed output gear 45 before being output.

Owner:FUJIKOKI CORP

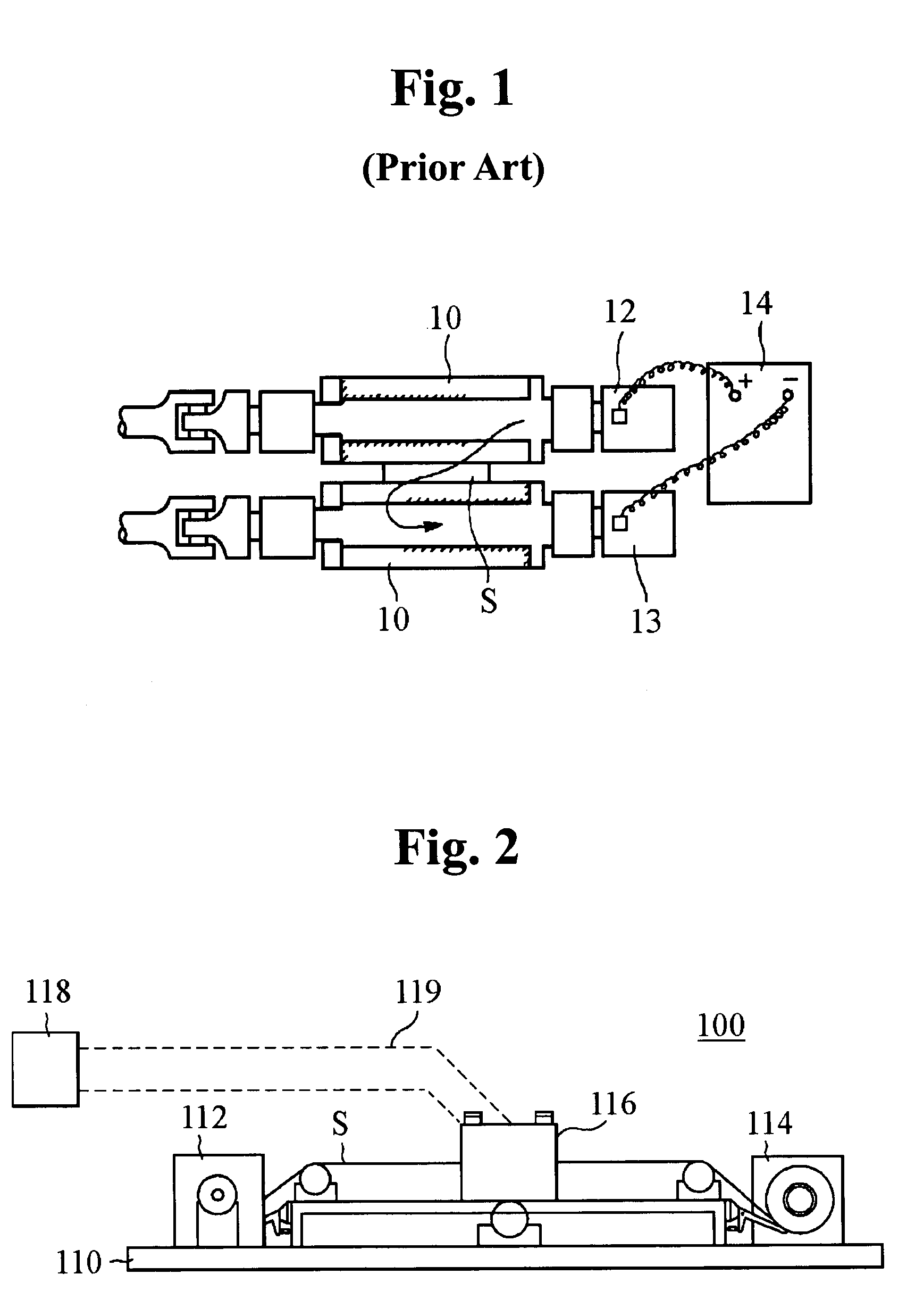

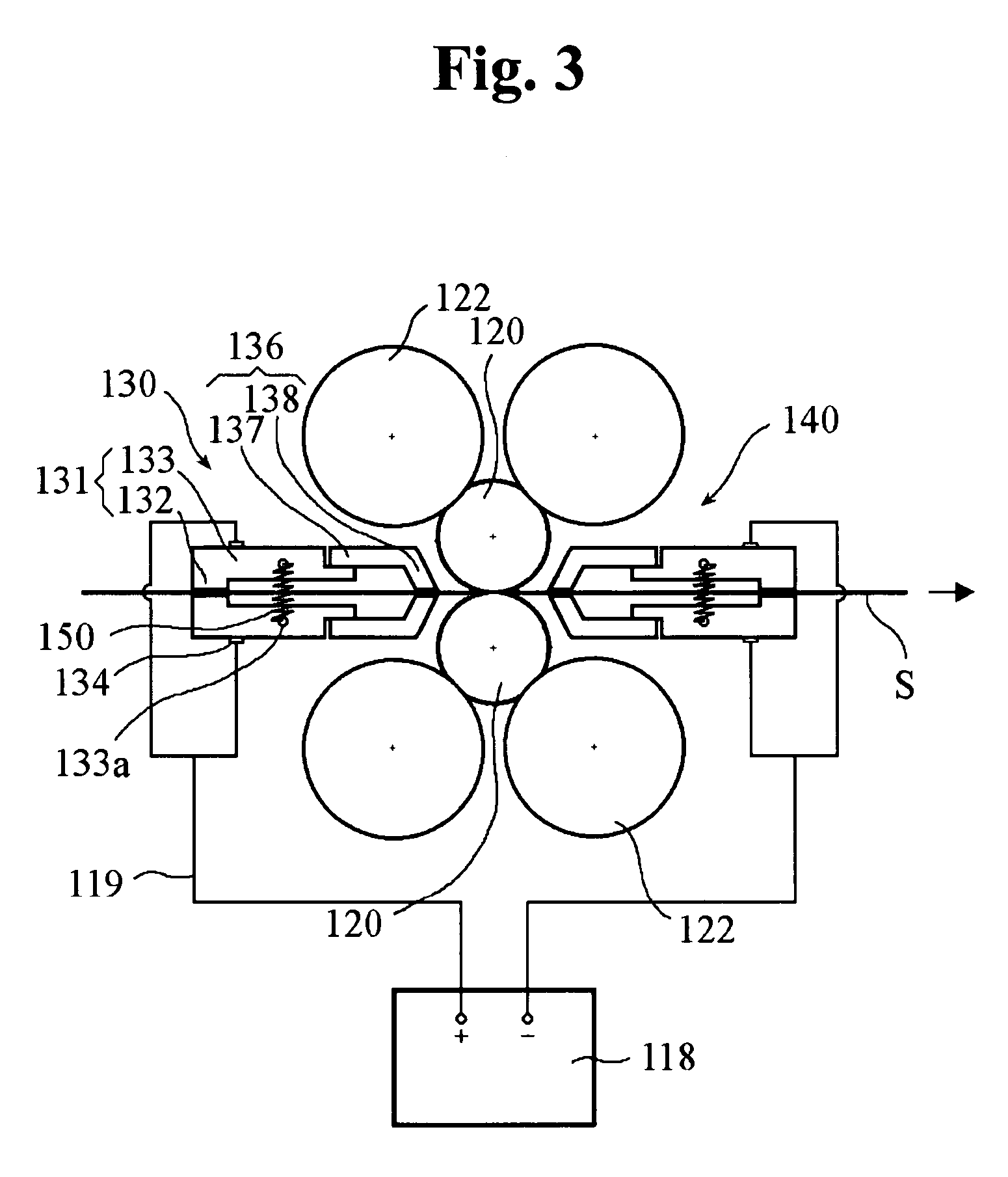

Electric heating type rolling device

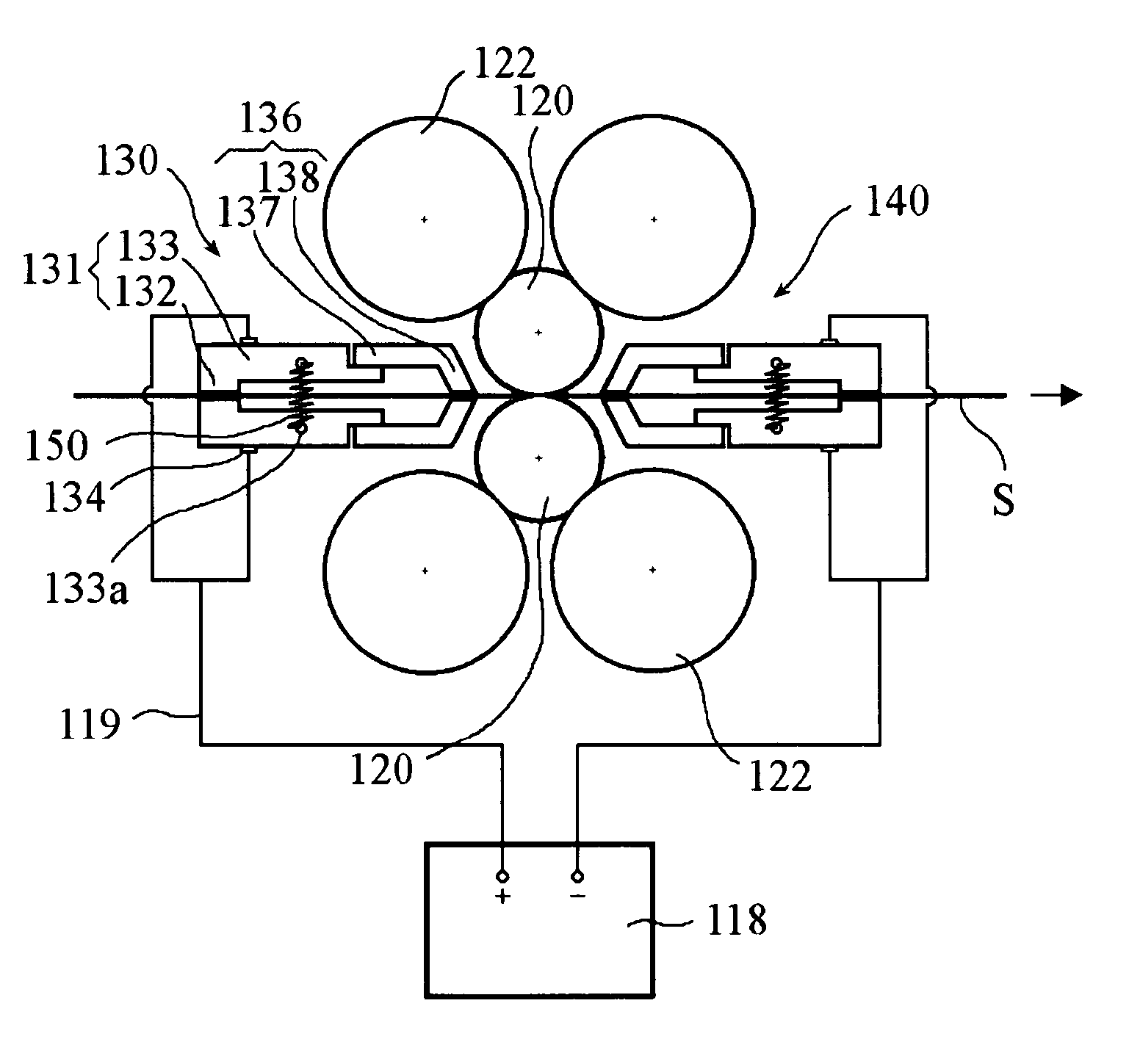

InactiveUS7028522B2Increase the reduction ratioAvoid overall overheatingShaping toolsMetal rolling stand detailsElectricityWork roll

An electric heating type rolling device comprises work rolls for rolling a metal strip, a power supply for generating a pulse current, a pair of upstream contact members which are disposed in a location before the metal strip passes through the work rolls, and a pair of downstream contact members which are disposed opposite to the upstream contact members in a location after the metal strip has been rolled by the work rolls and passed thereby. The contact members are electrically connected to the power supply. Each contact member includes a first contact portion contacting the metal strip, a flat portion which is extended from the first contact portion toward the work rolls while being spaced apart from the metal strip, and a second contact portion which is extended from the flat portion to contact the metal strip.

Owner:KYONG IN SPECIAL METAL

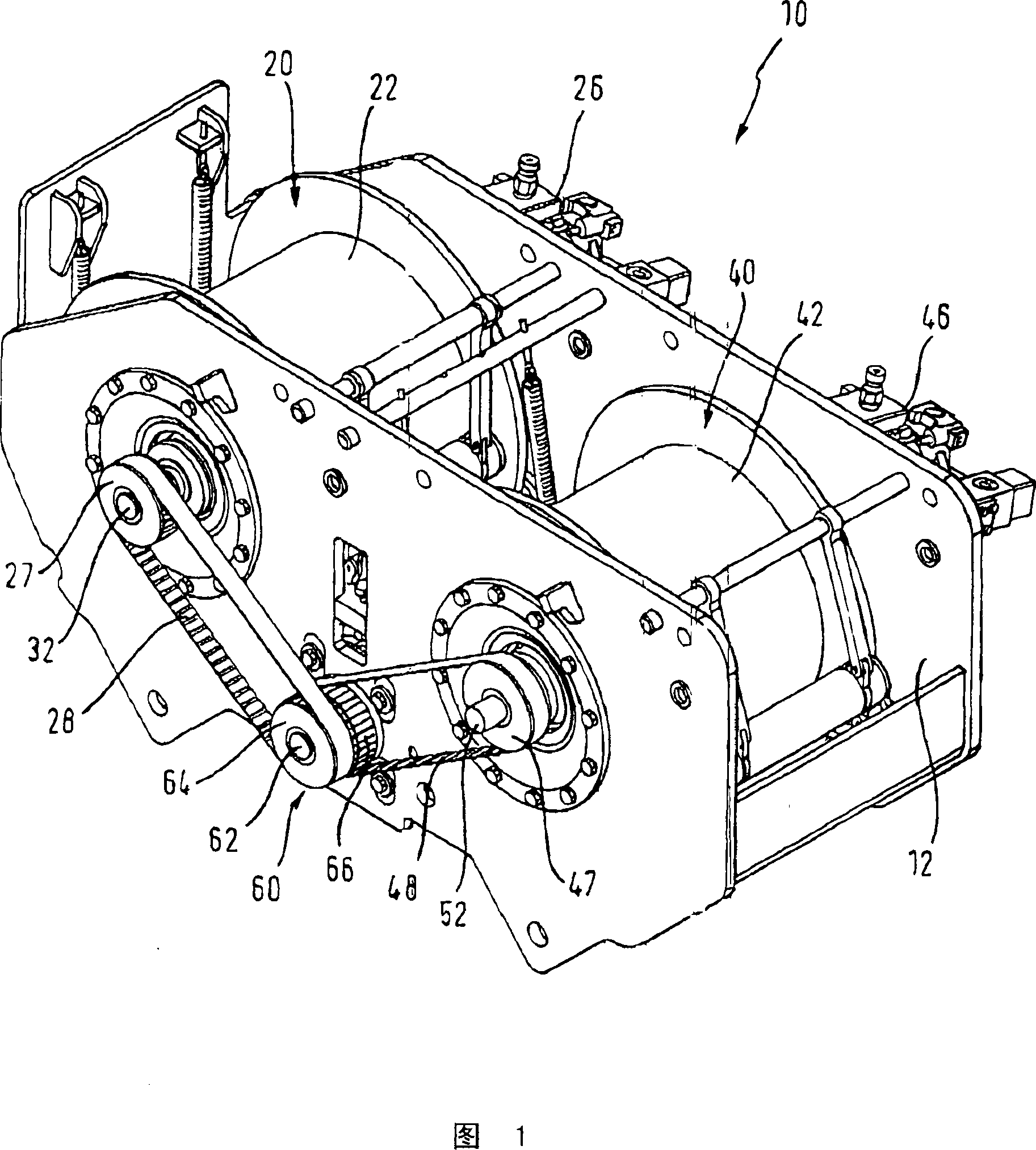

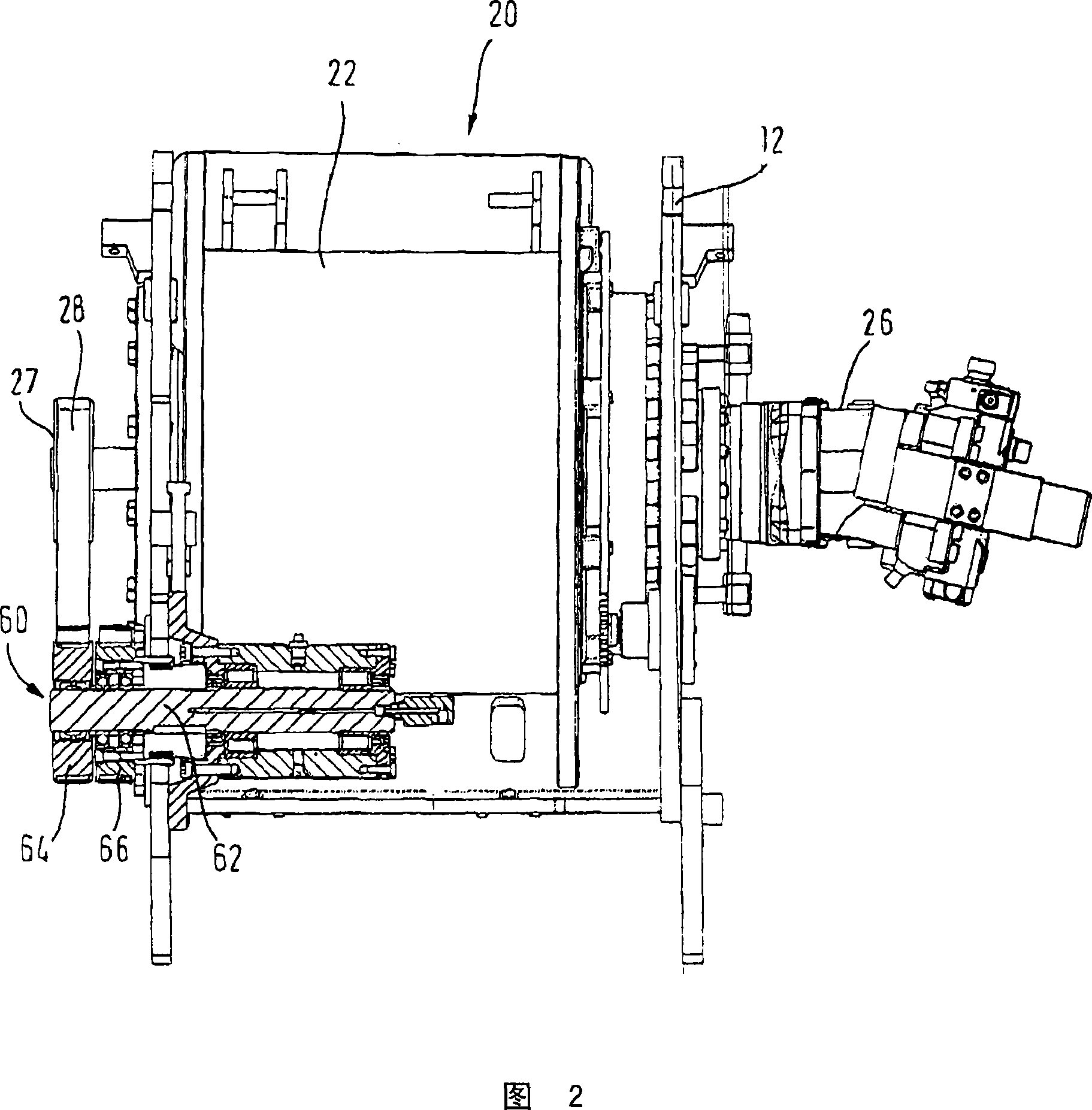

Winching device

InactiveCN101239694ASimple and reliable mechanical synchronizationNo torque surgeWinding mechanismsEngineeringWinch

The invention relates to a winch arrangement comprising a first winch with a first winch drum and a second winch with a second winch drum. There are also synchronizing devices by which the rotation of the first winch drum can be synchronized with the rotation of the second winch drum. Further, a differential shaft with a first synchronous wheel and a second synchronous wheel is provided, the first synchronous wheel is connected to the first drive by a first rotary connection device and the second synchronous wheel is connected to the second synchronous wheel by a second rotary connection device. driver.

Owner:BAUER MASCH GMBH

A worm and worm gear decelerating mechanism

InactiveCN104141738AReduce impactLarge reduction ratioGear vibration/noise dampingToothed gearingsLow noiseDrive motor

A worm and worm gear decelerating mechanism comprises a driving mechanism, a first worm and worm gear transmission mechanism connected with the driving mechanism, and a second worm and worm gear transmission mechanism. The decelerating mechanism is a double-stage progressive worm and worm gear decelerating mechanism. Large speed reduction ratio and low noise are realized by the first worm and worm gear transmission mechanism. High torque transmission and low noise are realized by the second worm and worm gear transmission mechanism. The power transmitted by a driving motor is decomposed by the first worm and worm gear transmission mechanism to a first worm gear and a second worm gear via a first driving worm, and then further delivered to a first transmission worm and a second transmission worm of the second worm and worm gear transmission mechanism. The driving force of the driving motor is delivered to a third worm gear by the first transmission worm and the second transmission worm and finally output by an output mechanism. The decelerating mechanism reduces the impact force of the driving motor and efficiently reduces noise. By double-stage transmission decomposition, the travel is prolonged, the rotating speed is reduced, and the torque and speed reduction ratio are efficiently improved.

Owner:SHENZHEN MUREN APPLIANCE

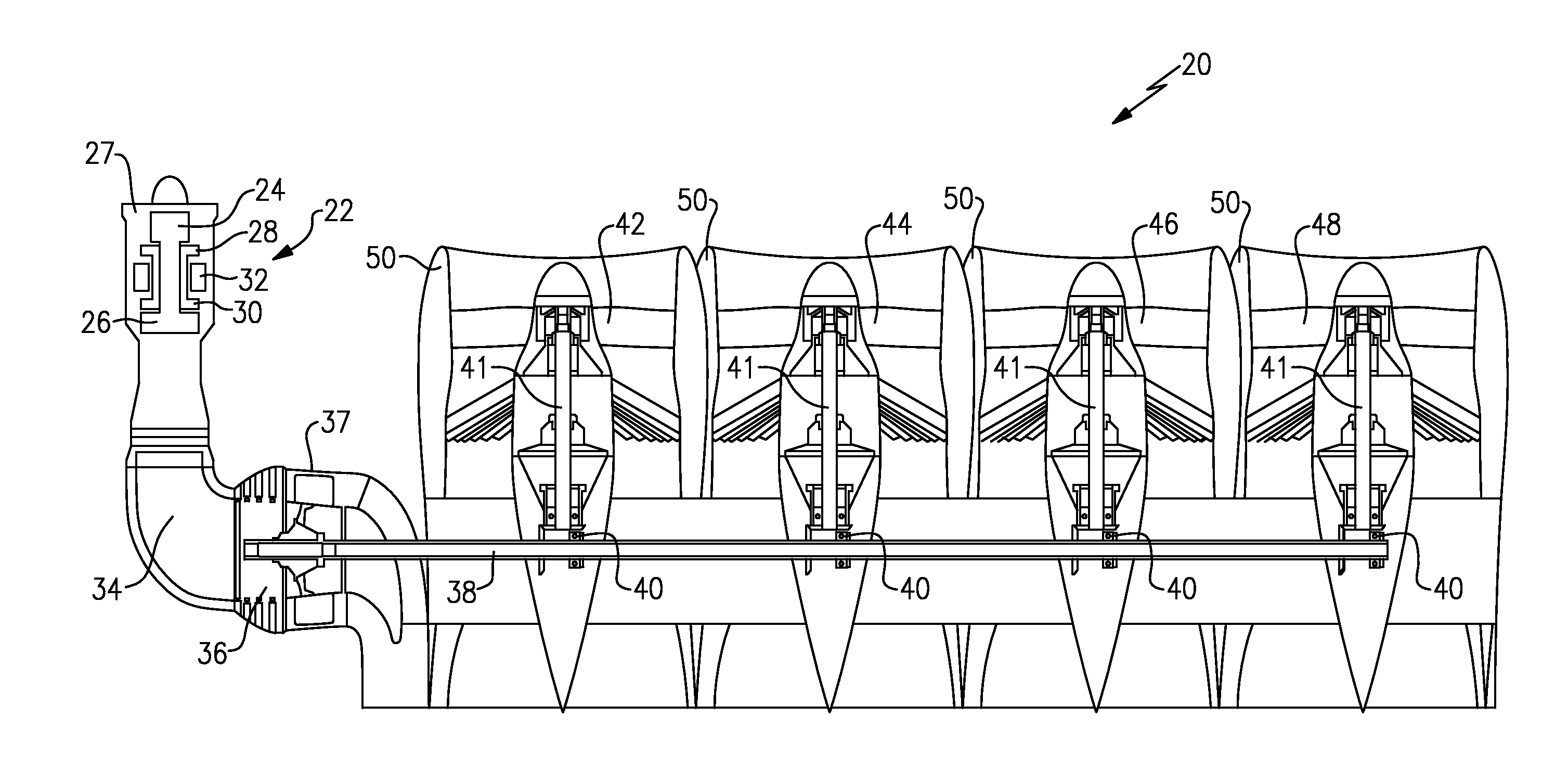

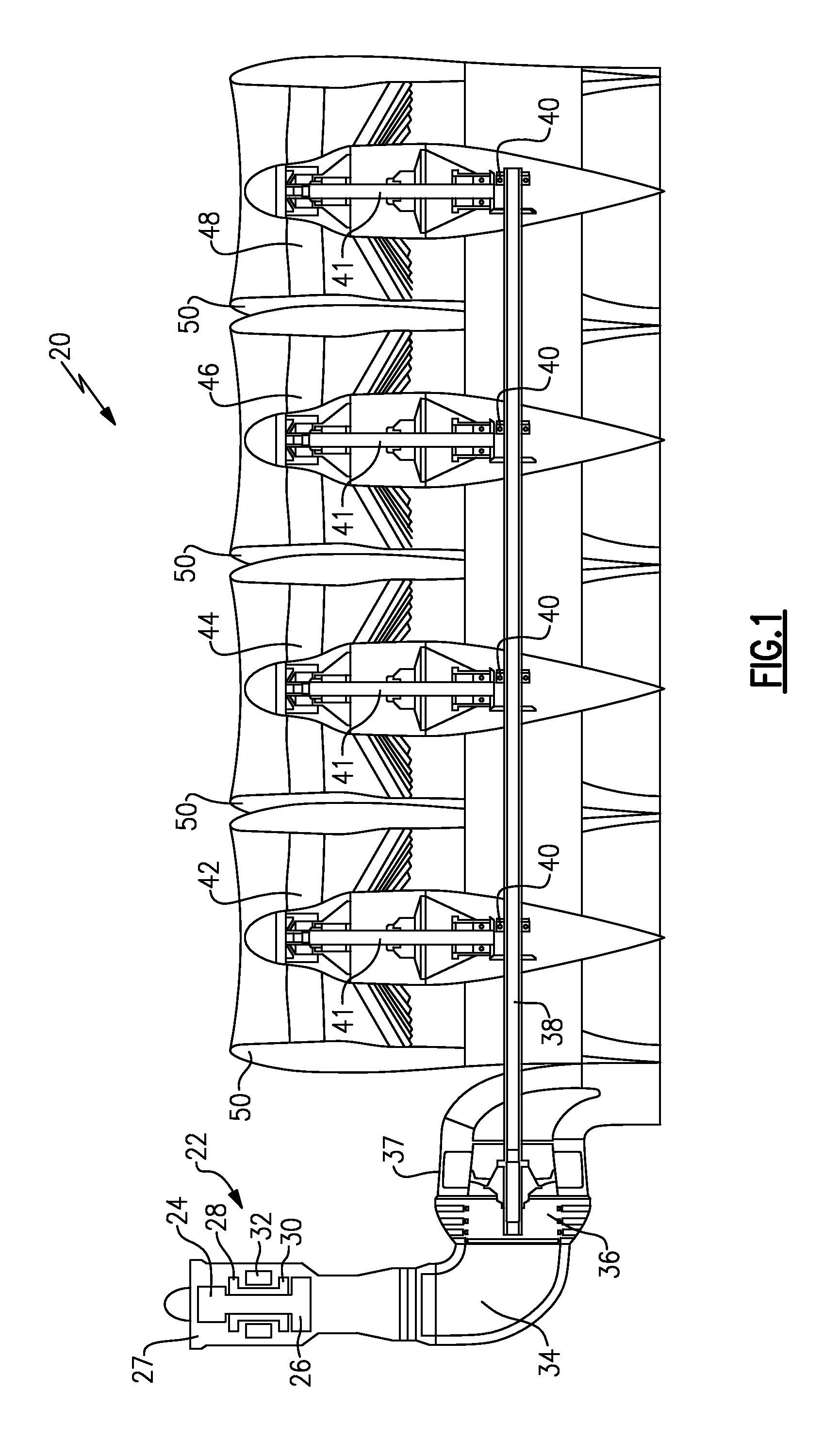

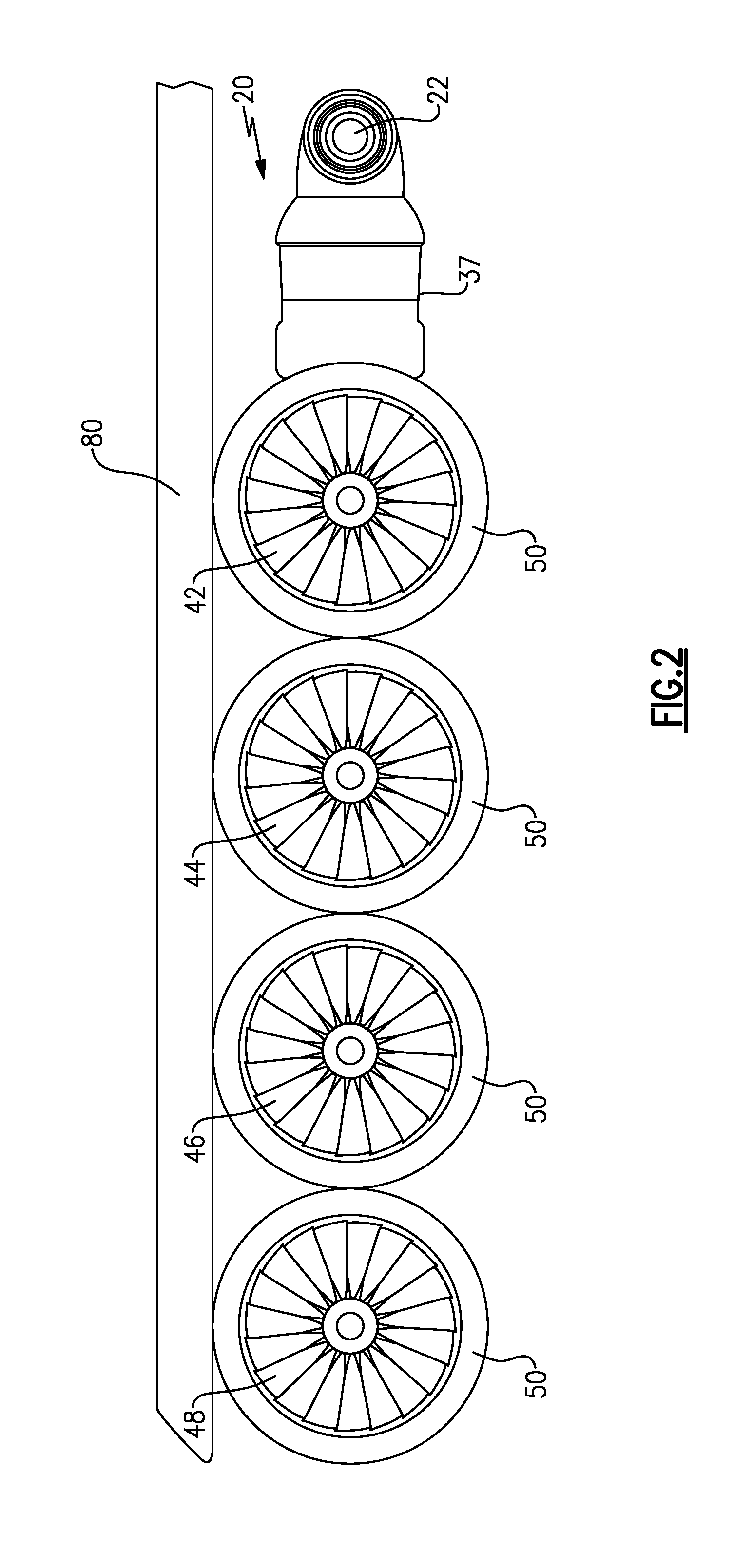

Gas turbine engine with distributed fans

ActiveUS20150226117A1Increase the reduction ratioEngine manufactureCombination enginesCombustionGas turbines

A gas generator has at least one compressor rotor, at least one gas generator turbine rotor and a combustion section. A fan drive turbine is positioned downstream of a path of the products of combustion having passed over the at least one gas generator turbine rotor. The fan drive turbine drives a shaft and the shaft engages gears to drive at least three fan rotors.

Owner:RTX CORP

Multifunctional large-torque integrated robot joint

The invention provides a multifunctional large-torque integrated robot joint which comprises a direct-current servo motor, a belt wheel set, a gear set, a hollow harmonic reducer, a hollow output shaft, a hollow encoder and a hollow output shaft end bearing. The belt wheel set comprises a large belt wheel and a small belt wheel. The gear set comprises a small gear and a large gear. The direct-current servo motor drives the small belt wheel. The small belt wheel drives the large belt wheel. The large belt wheel is connected with the small gear through a belt wheel shaft. The small gear is engaged with the large gear. One end of the hollow output shaft is connected with the large gear and the hollow encoder, and the other end of the hollow output shaft is connected with the hollow harmonic reducer and an inner ring of the hollow output shaft end bearing. In the multifunctional large-torque integrated robot joint, due to the optimization and combination of the speed reduction ratios of three levels of speed reduction, application requirements in different places and different fields can be met.

Owner:SHANGHAI JIAO TONG UNIV

Oscillating internally meshing planetary gear reducer

To provide an oscillating internally meshing planetary gear reducer capable of realizing a low cost and a high speed reduction ratio, the oscillating internally meshing type planetary gear reducer is constituted so as to include: an input shaft provided with an input gear which is circumscribed and meshed with a pinion provided on a motor; an input shaft gear formed on the input shaft; a plurality of eccentric body shafts each provided with an eccentric body for oscillating an oscillating external gear; an eccentric body shaft gear which is formed on each eccentric body shaft; and a distributing gear which is meshed with the input shaft gear and the eccentric body shaft gear.

Owner:SUMITOMO HEAVY IND LTD

Two-stage differential cycloidal speed reducer with a high reduction ratio

ActiveCN103542041AIncrease the reduction ratioReduce weightToothed gearingsGearing detailsReduction ratioEngineering

A two-stage differential cycloidal speed reducer with a high reduction ratio is provided, including: a plurality of supporting crank shafts; an input shaft including a first crank shaft portion and a second crank shaft portion; a first cycloidal gear provided on the first crank shaft portion; a second cycloidal gear provided on the second crank shaft portion and connected with the first cycloidal gear through the supporting crank shafts; a plurality of first ring pins provided around the outer circumference of the first cycloidal gear and in sliding contact with a plurality of teeth on the periphery of the first cycloidal gear; a first annular gear with the plurality of first ring pins; a plurality of second ring pins provided around the outer circumference of the second cycloidal gear and being in sliding contact with a plurality of teeth on the periphery of the second cycloidal gear; and a second annular gear with the plurality of second ring pins.

Owner:IND TECH RES INST

Two-shaft three-stage deceleration middle torque transmission system

InactiveCN104802912AEasy to assembleIncrease the reduction ratioWheel based transmissionRider propulsionThree stageGear wheel

The invention discloses a two-shaped three-stage deceleration middle torque transmission system. The two-shaped three-stage deceleration middle torque transmission system comprises a stator, a rotor, a motor shaft, a torque sensing device and a gear disc, wherein the torque sensing device comprises a middle shaft, an elastic connector, a shaft sleeve and a sensor; the motor shaft is provided with a first-stage transmission gear; the motor shaft is provided with a second-stage transmission gear, a first toothless flying wheel and a third-stage input gear which are concentrically fixed through bearings in a supporting way; the shaft sleeve is respectively provided with a duplicate gear and a third-stage output gear through bearings in the supporting way; the duplicate gear is respectively meshed with the first-stage transmission gear and the second-stage transmission gear; the third-stage output gear is meshed with the third-stage input gear; an output flange of the outer side end of the third-stage output gear is connected with the gear disc together through a second toothless flying wheel to form an output end; the output end of the elastic connector is rotationally connected with the second toothless flying wheel through a small flange so as to realize the synchronization of the elastic connector and the gear disc. According to the two-shaped three-stage deceleration middle torque transmission system disclosed by the invention, a two-shaft three-stage deceleration design is adopted, the deceleration ratio is high, the size is small, and the assembly is convenient.

Owner:苏州捷诚科技有限公司

Marine propulsion system

InactiveUS7909670B2Lower ratioIncrease the reduction ratioPropulsion power plantsOutboard propulsion unitsLow speedMarine propulsion

A marine propulsion system includes an engine, propellers rotated by the engine, a transmission mechanism arranged to transmit a driving force of the engine to the propellers with a speed thereof shifted to at least a low speed reduction ratio or a high speed reduction ratio in forward travel and reverse travel, and a gear shift switch operable by a user to shift speed reduction ratios of the transmission mechanism to the low speed reduction ratio in at least the reverse travel. This arrangement provides a marine propulsion system in which both of acceleration performance and a maximum speed can approach levels that a user desires.

Owner:YAMAHA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com