Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Inhibition of elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

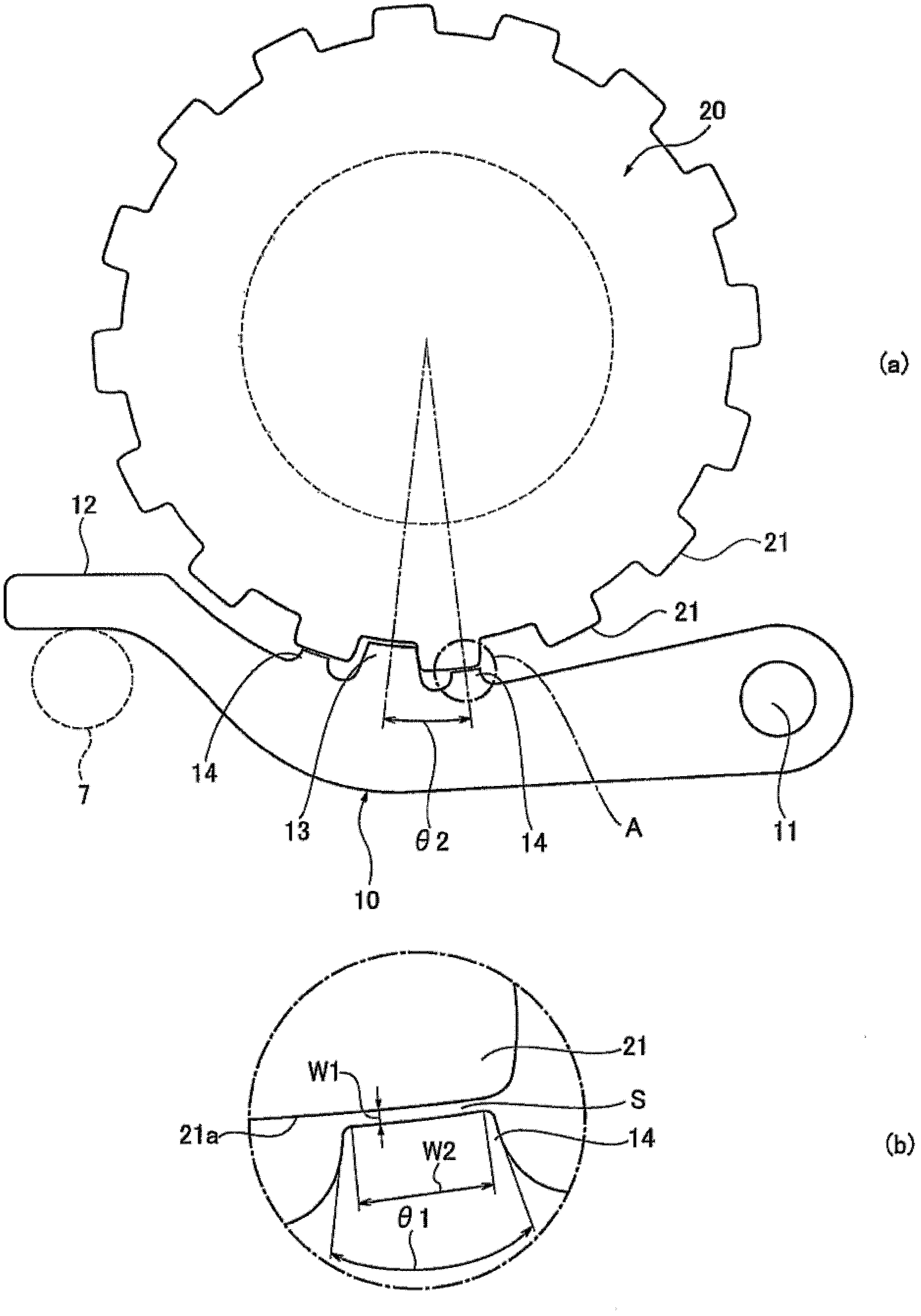

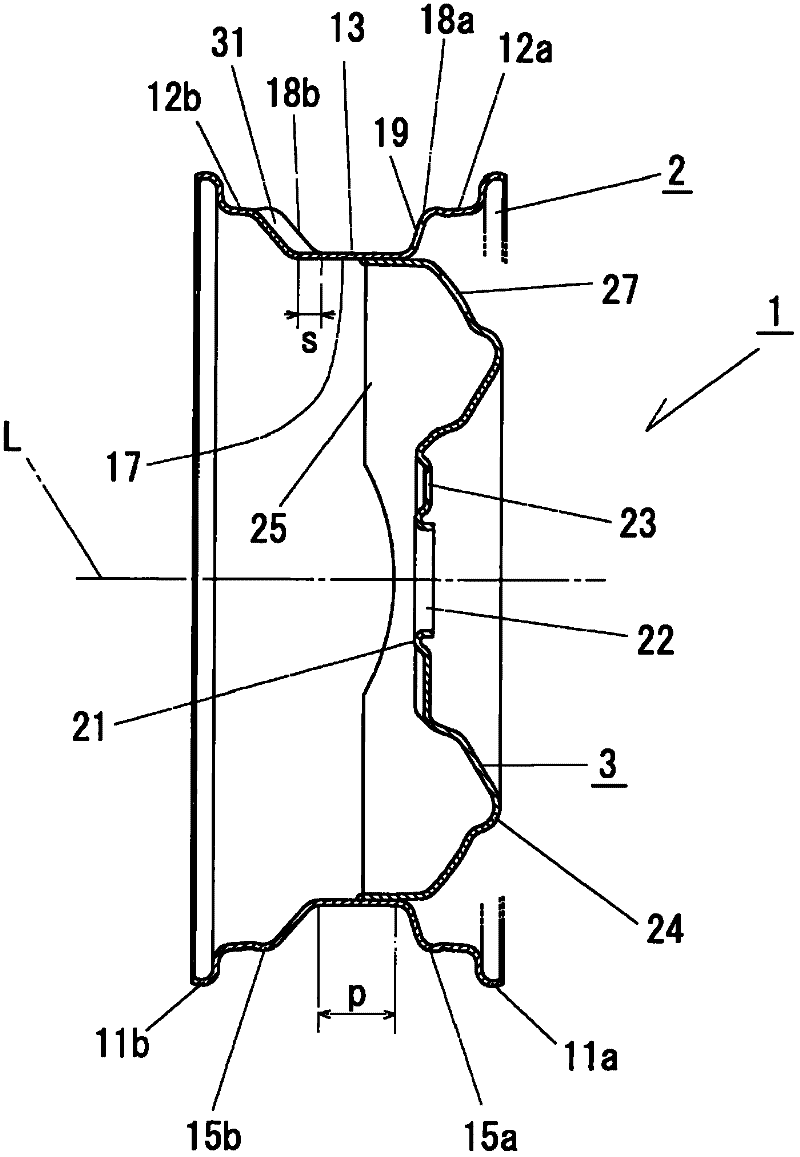

Eccentric swing type planetary gear device

ActiveCN1914438AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsGear wheelEngineering

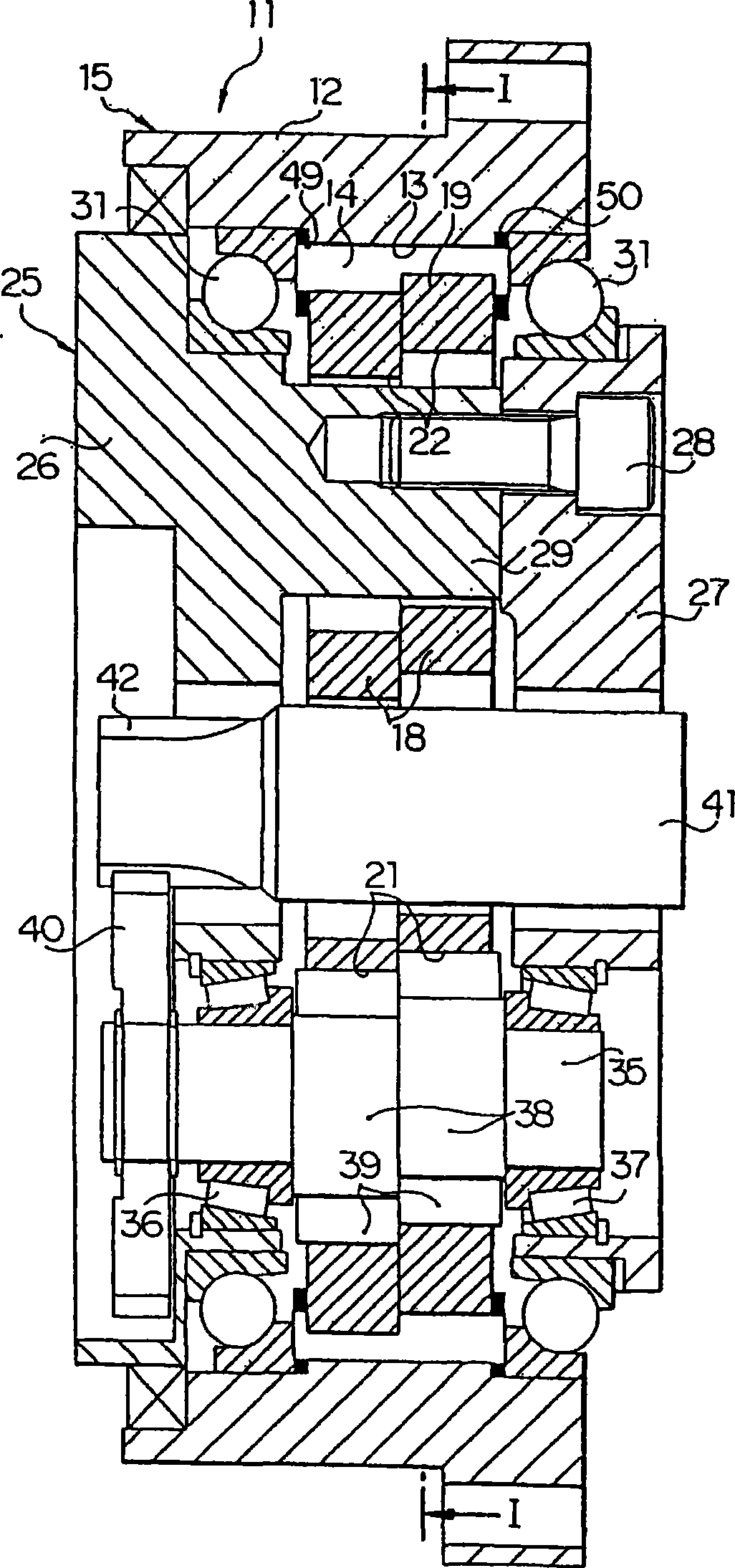

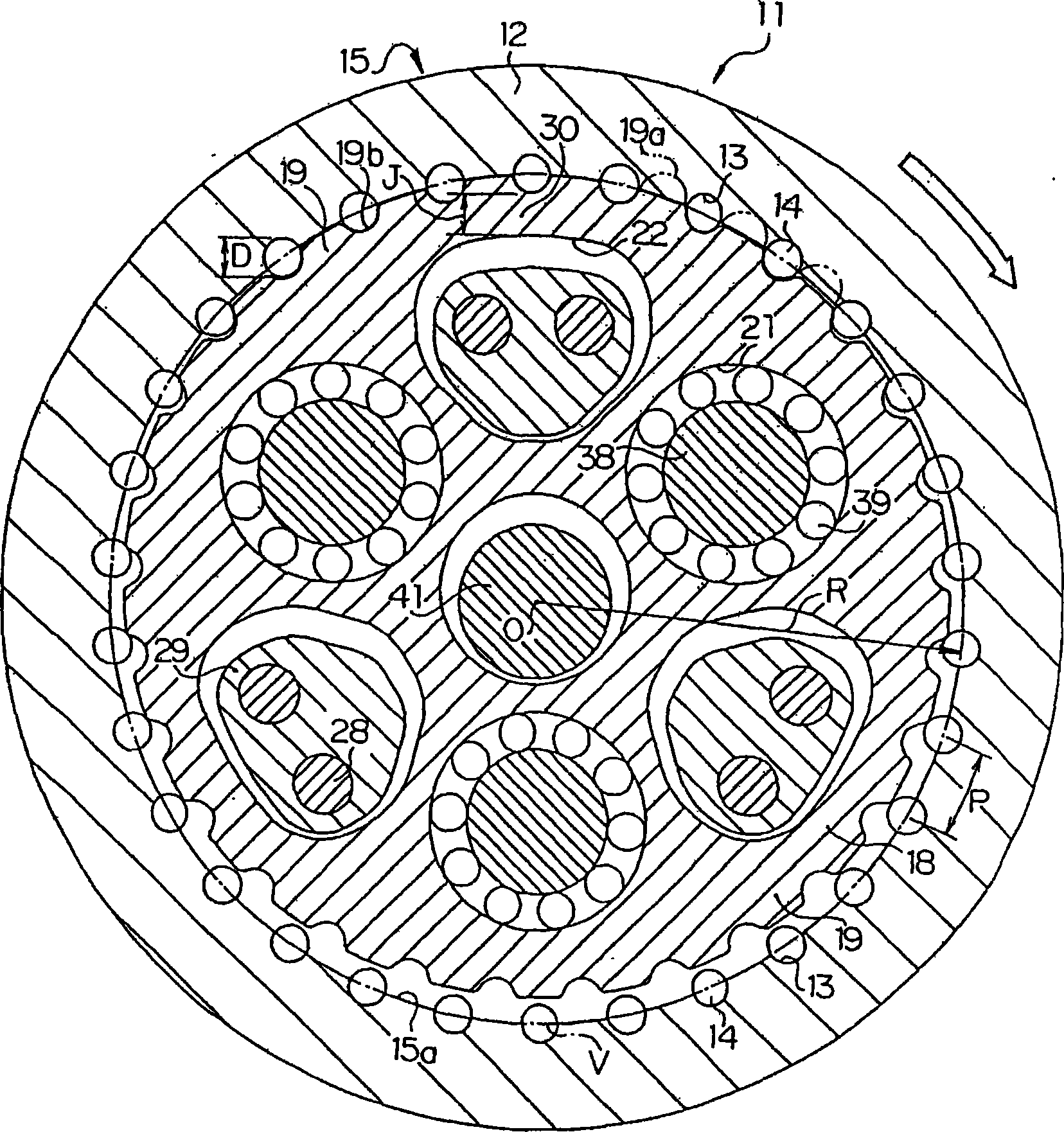

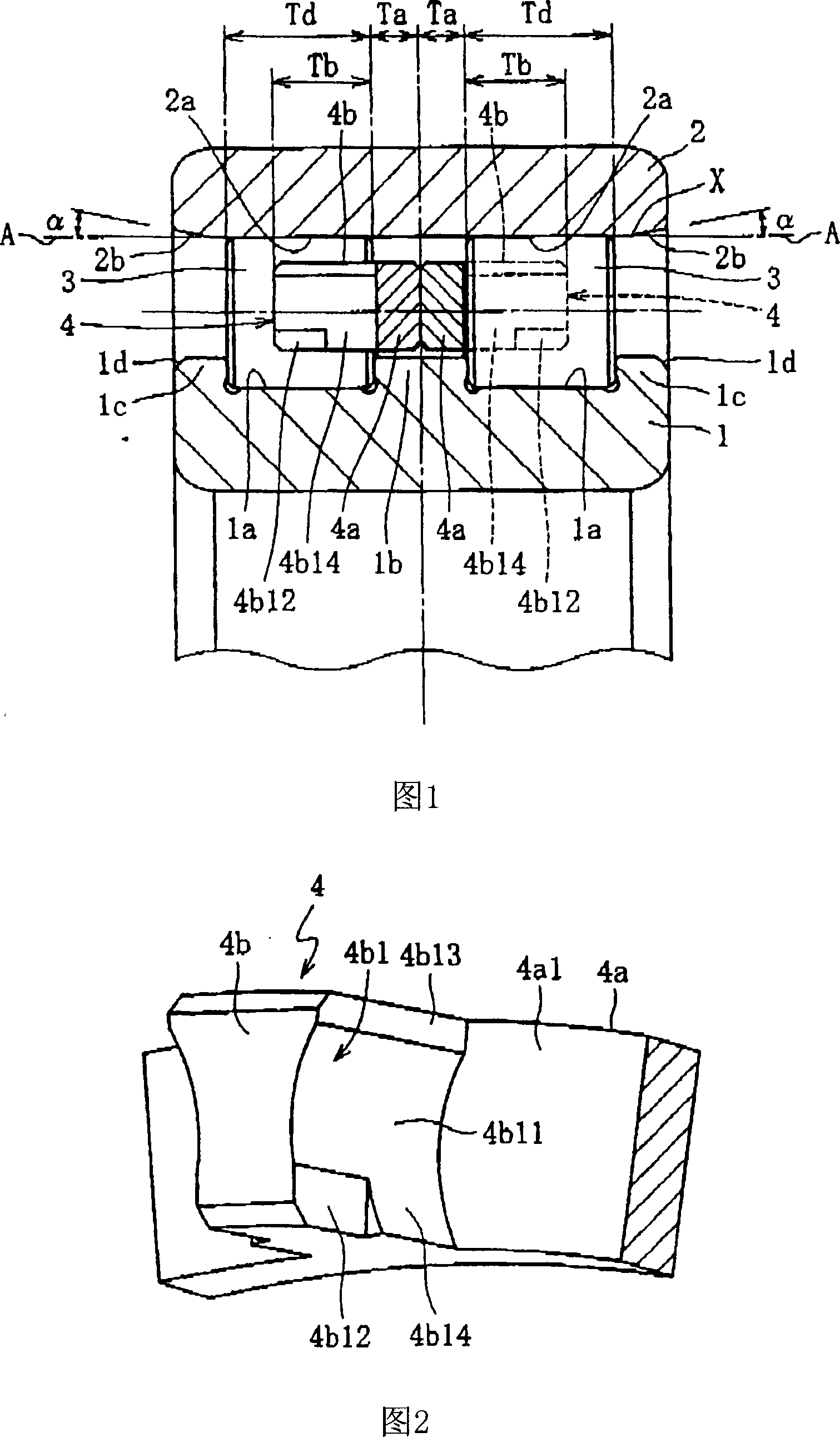

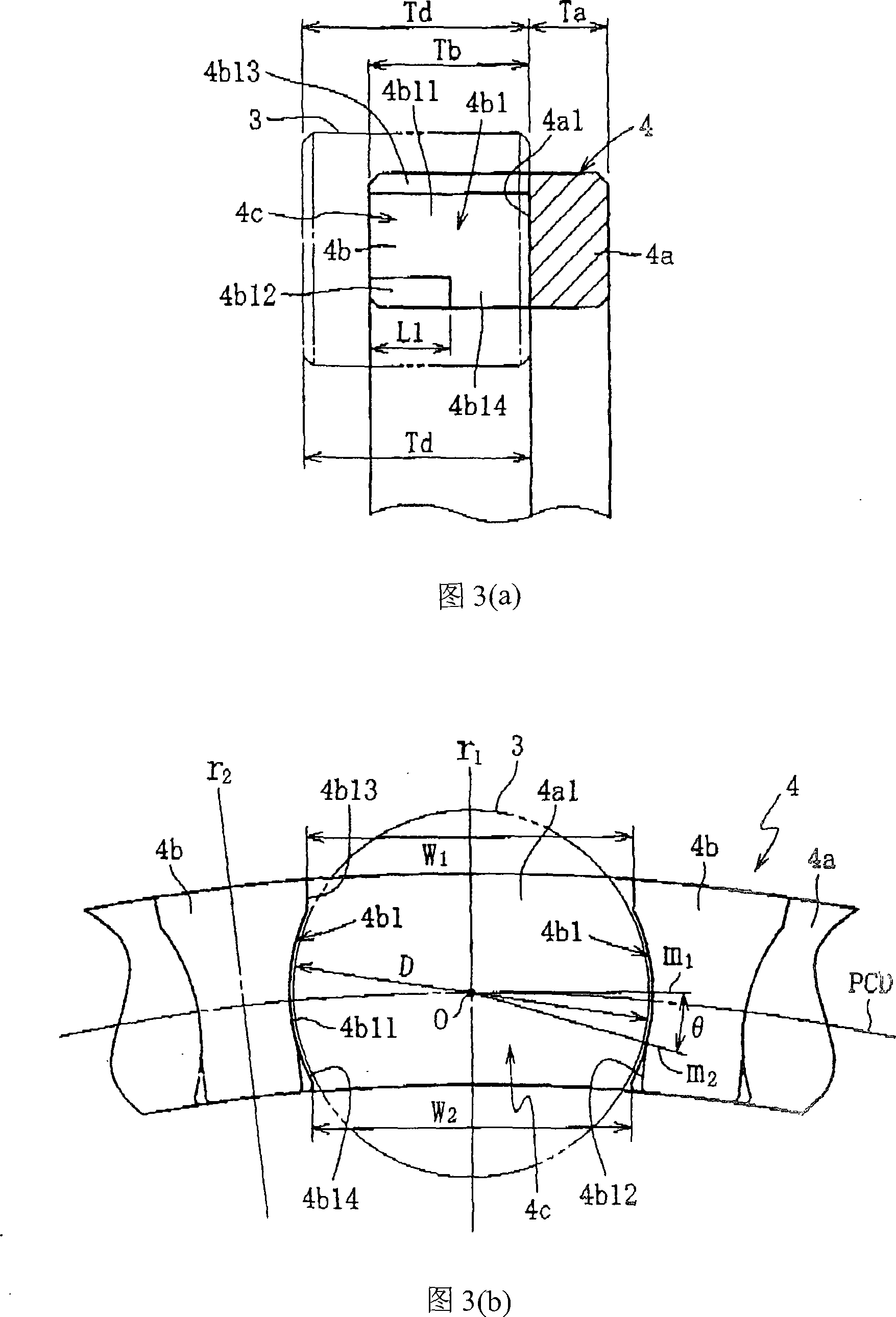

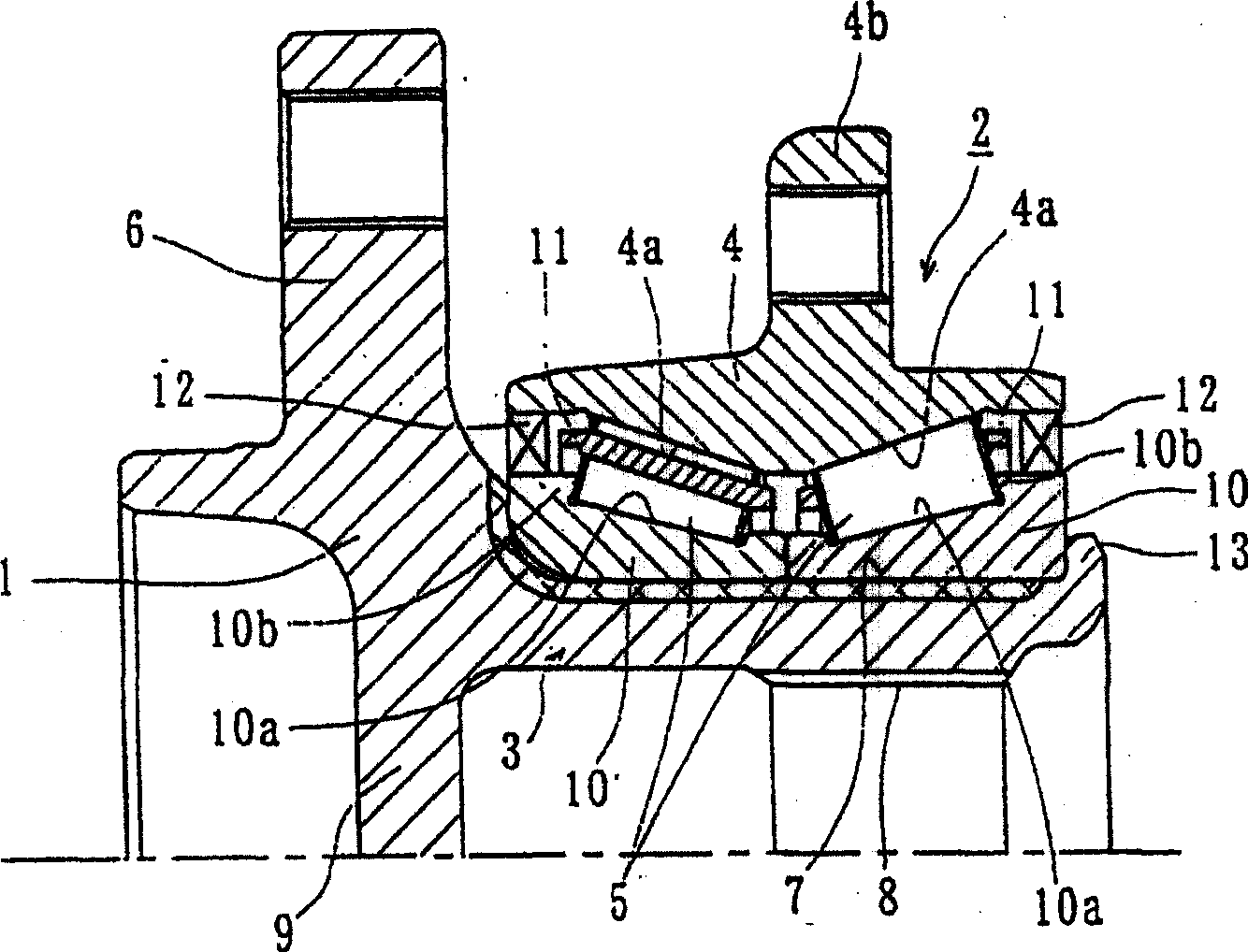

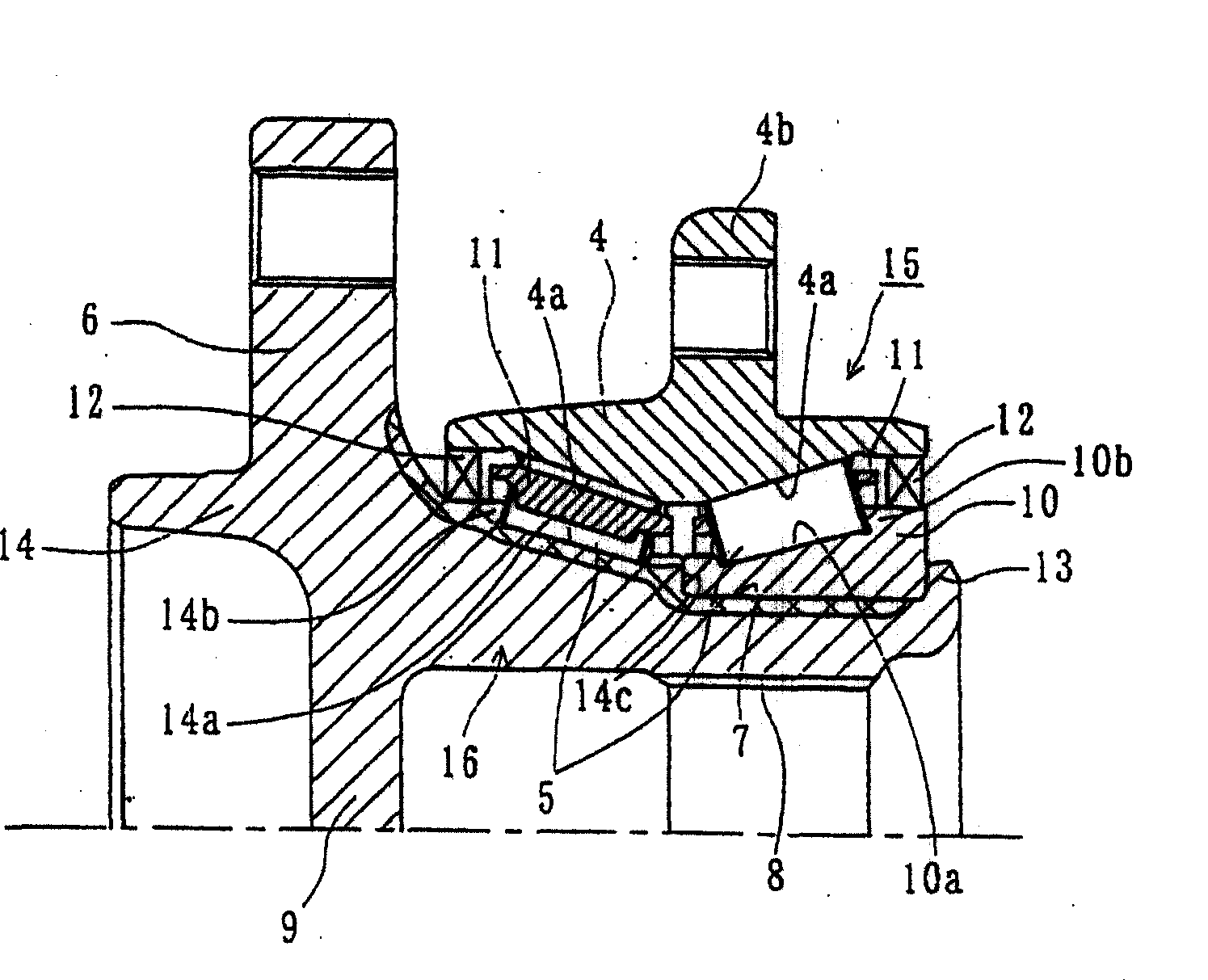

The invention provides eccentric swing type planetary gear device, deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

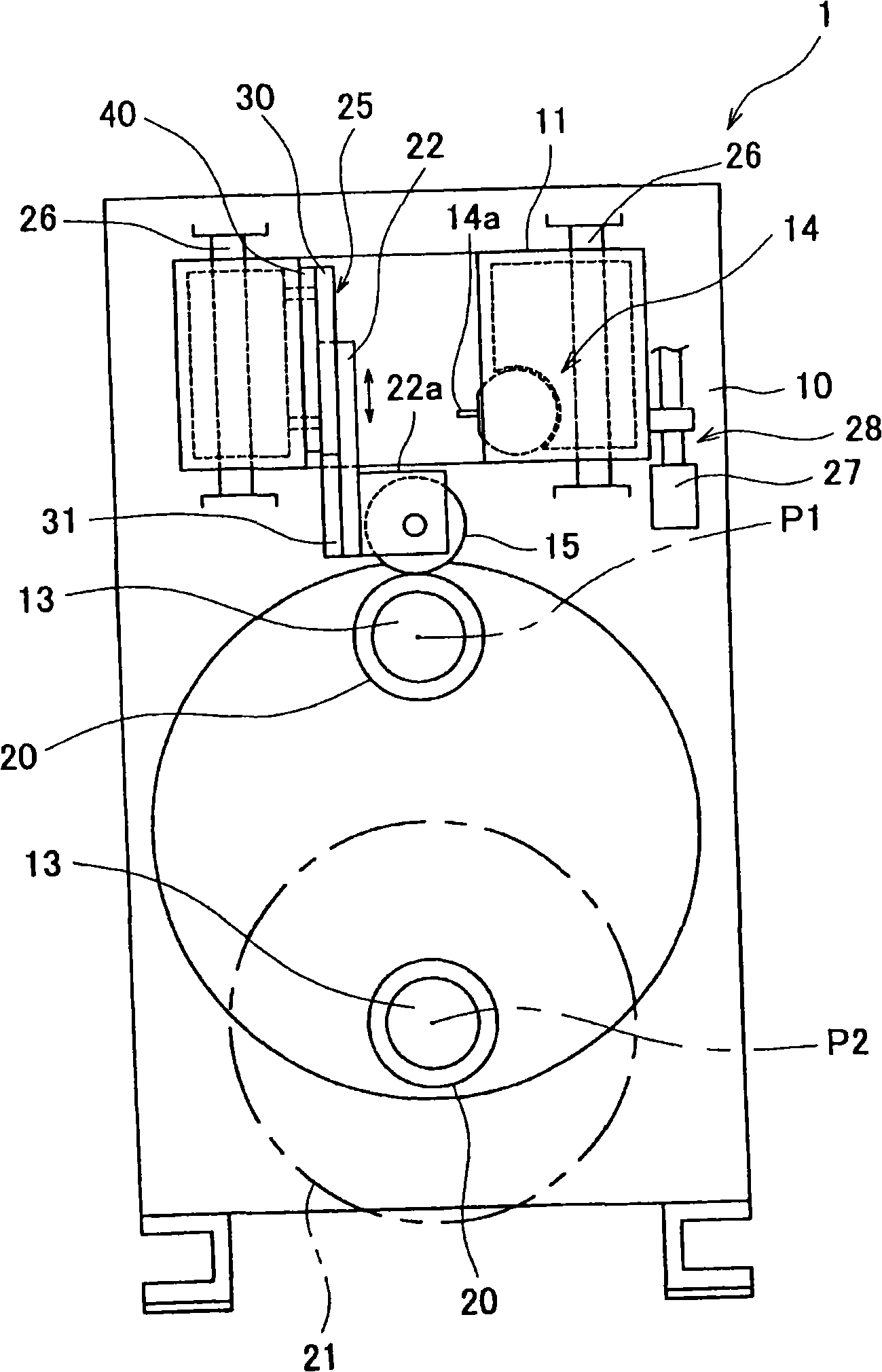

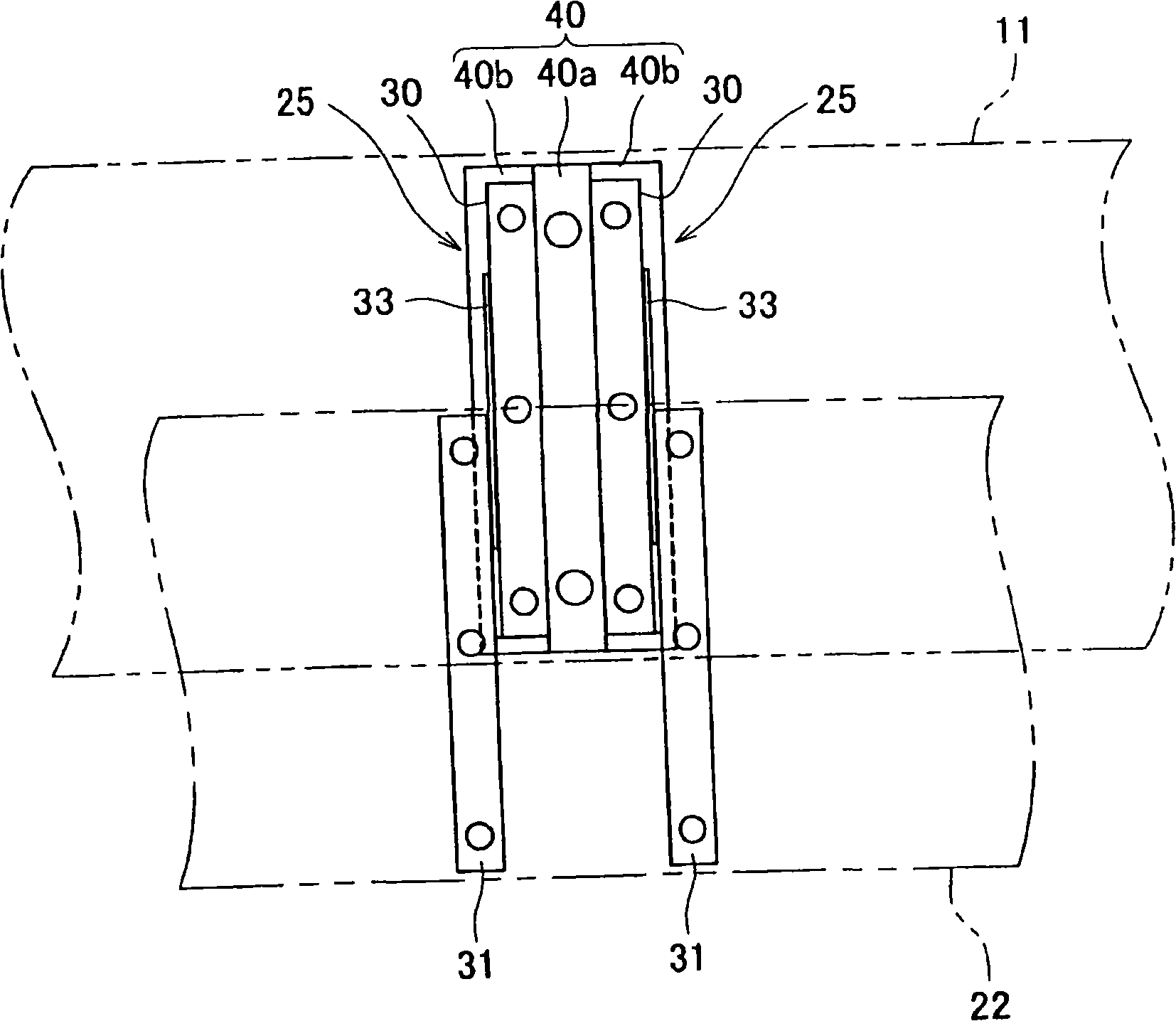

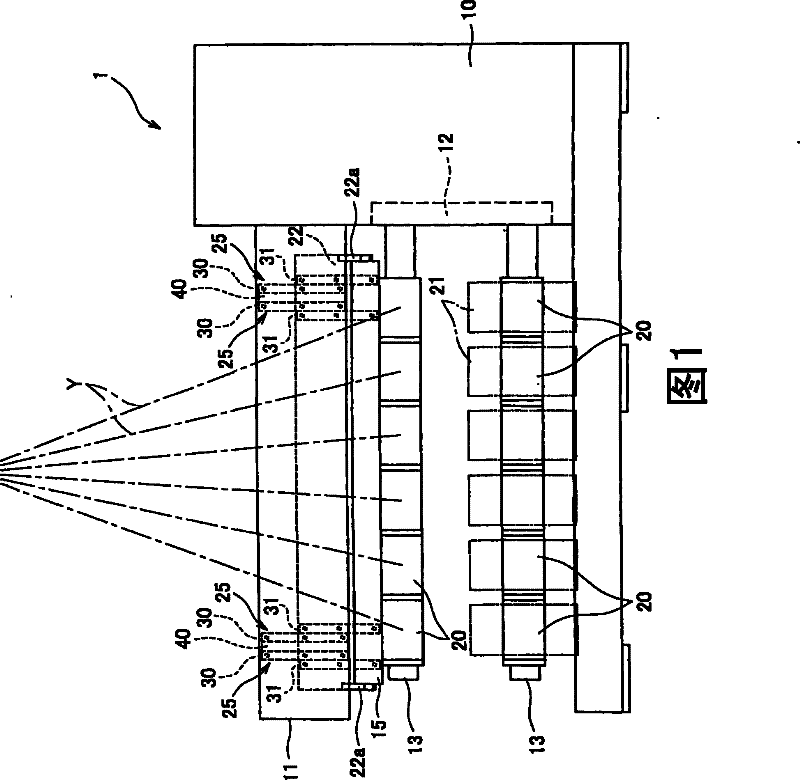

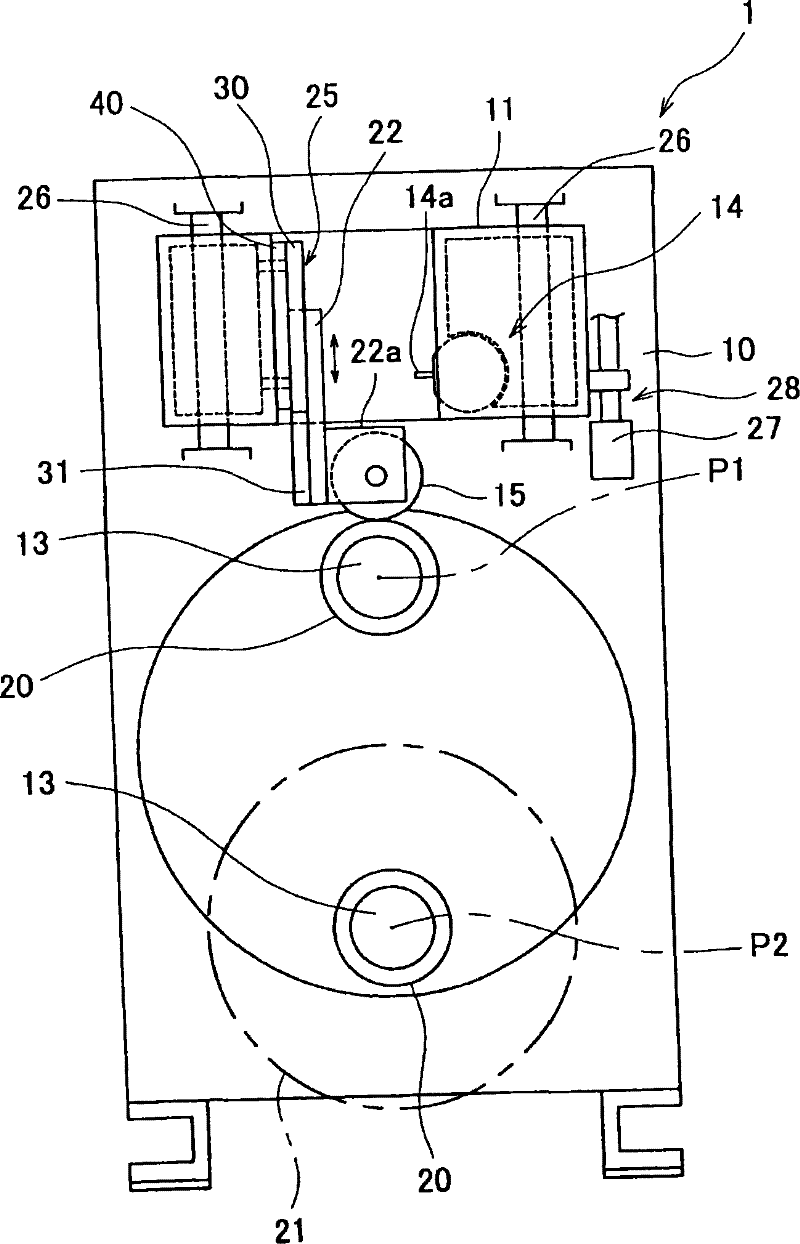

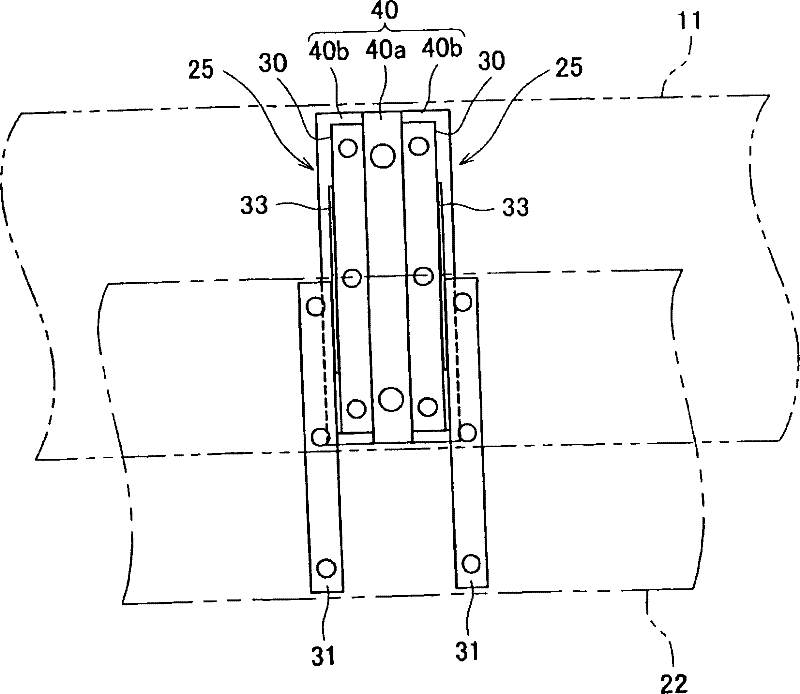

Yarn reeling machine

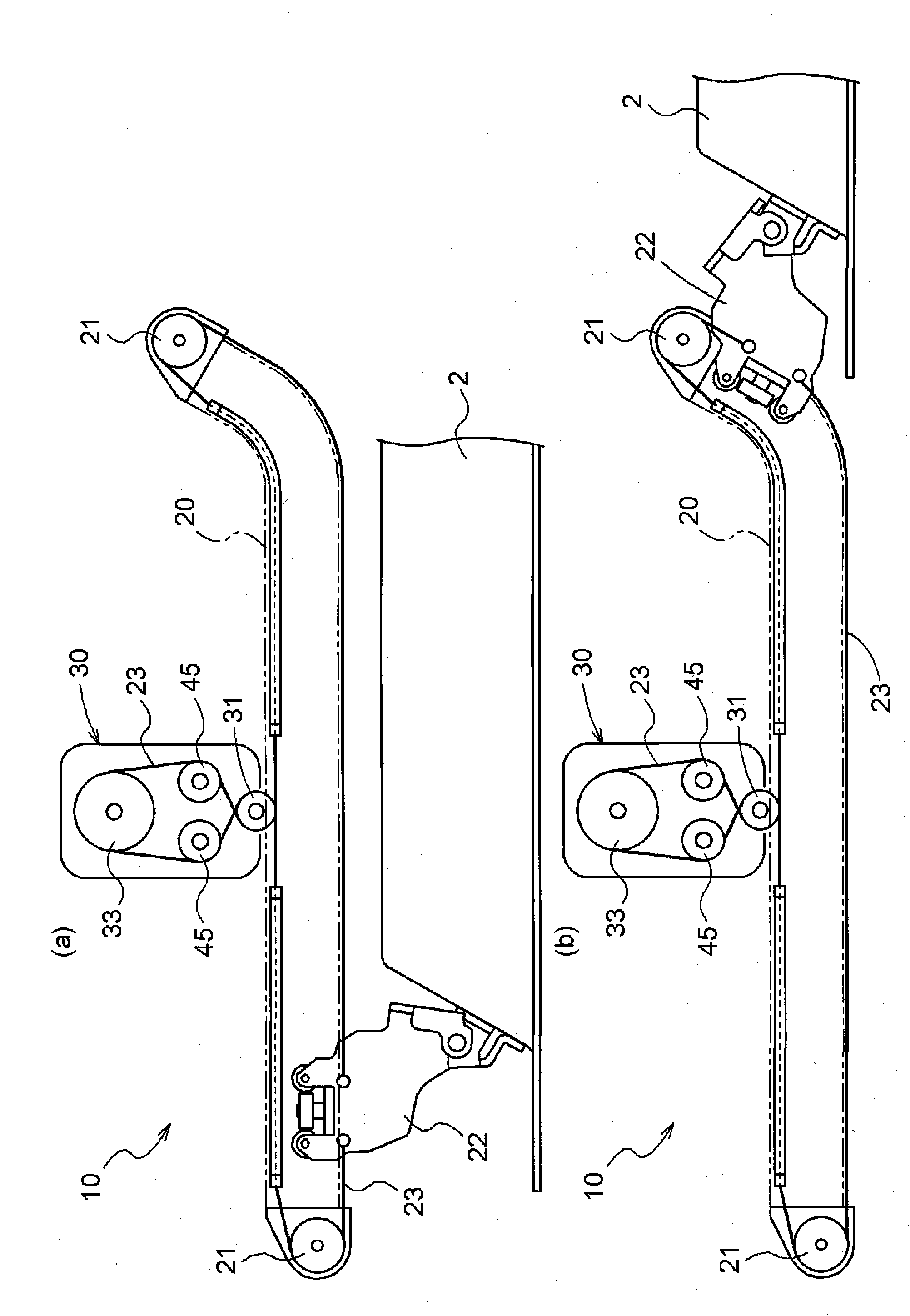

ActiveCN101311090AImprove rigidityInhibition of elastic deformationFilament handlingYarnContact pressure

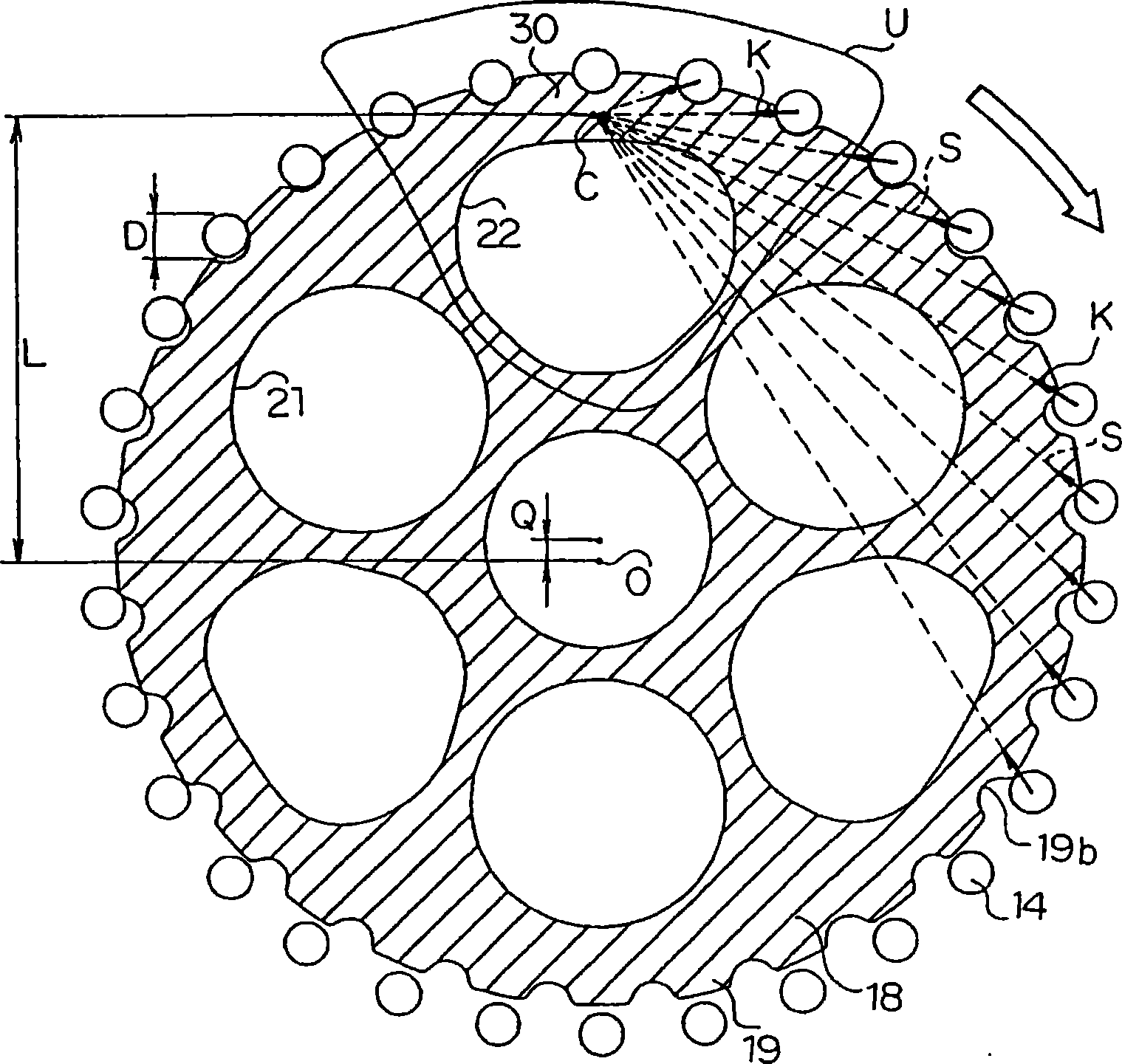

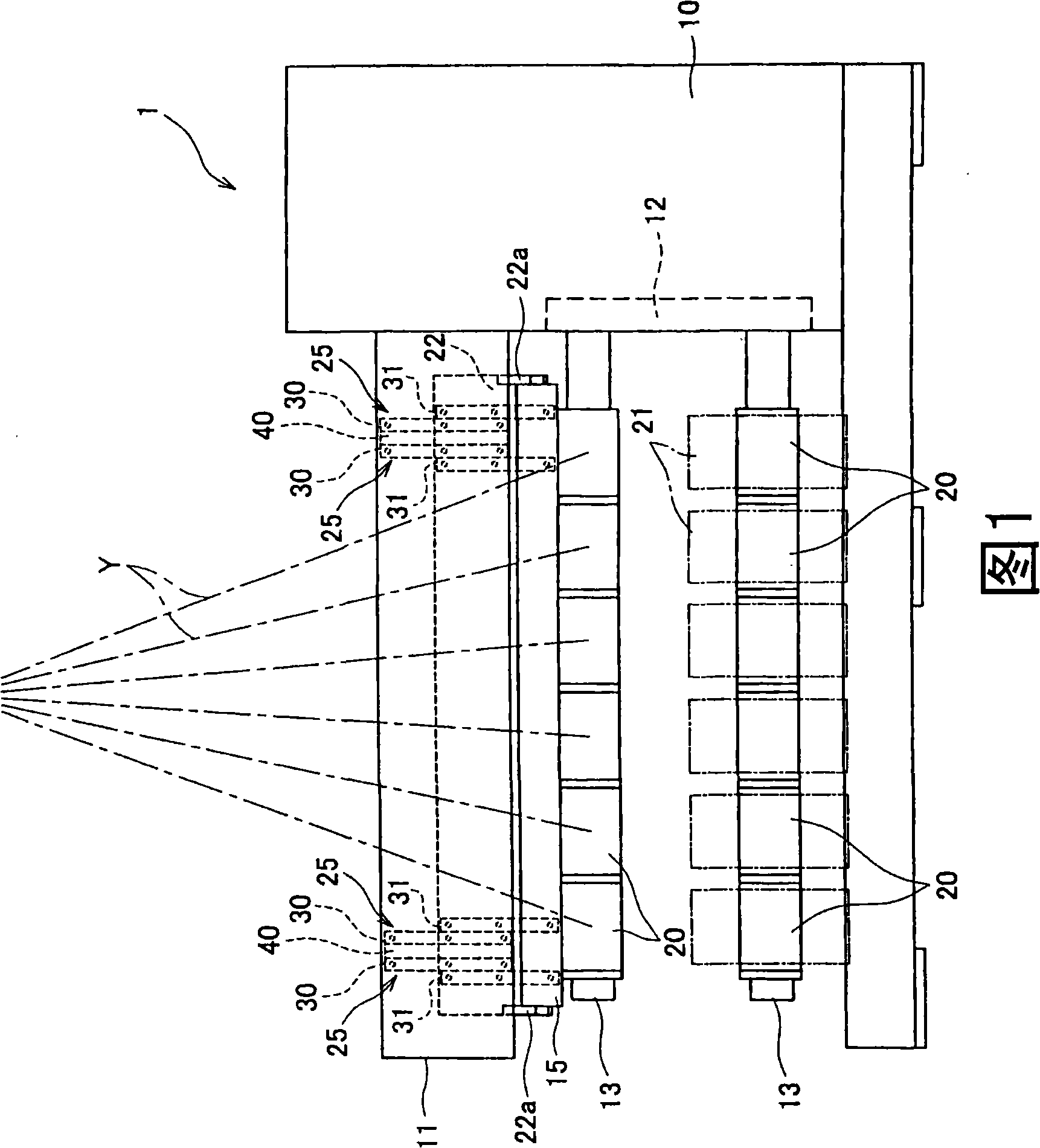

The invention provides a yarn reeler, causing a contact roller to move swimmingly corresponding to the thickness of a package, and restraining disproportionation of the contact pressure applied on the package. The yarn reeler (1) comprises a spool stand (13) supported on a frame (10) of a main body, and equipped with a barrel (20); a lifting frame (11) movably supported on the frame (10) of the main body along the vertical direction; a contact roller (15), arranged in parallel with the spool stand (13) and contacted with a cirumferential surface of the package (21) with the barrel (20) or formed on the barrel (20); a supporting plate (22), movably supported on the lifting frame (11) along the vertical direction for rotating freely to support the contact roller (15); a guide unit (25) for guiding the supporting plate (22), along the vertical direction relative to the lifting frame (11).

Owner:TMT MACHINERY INC

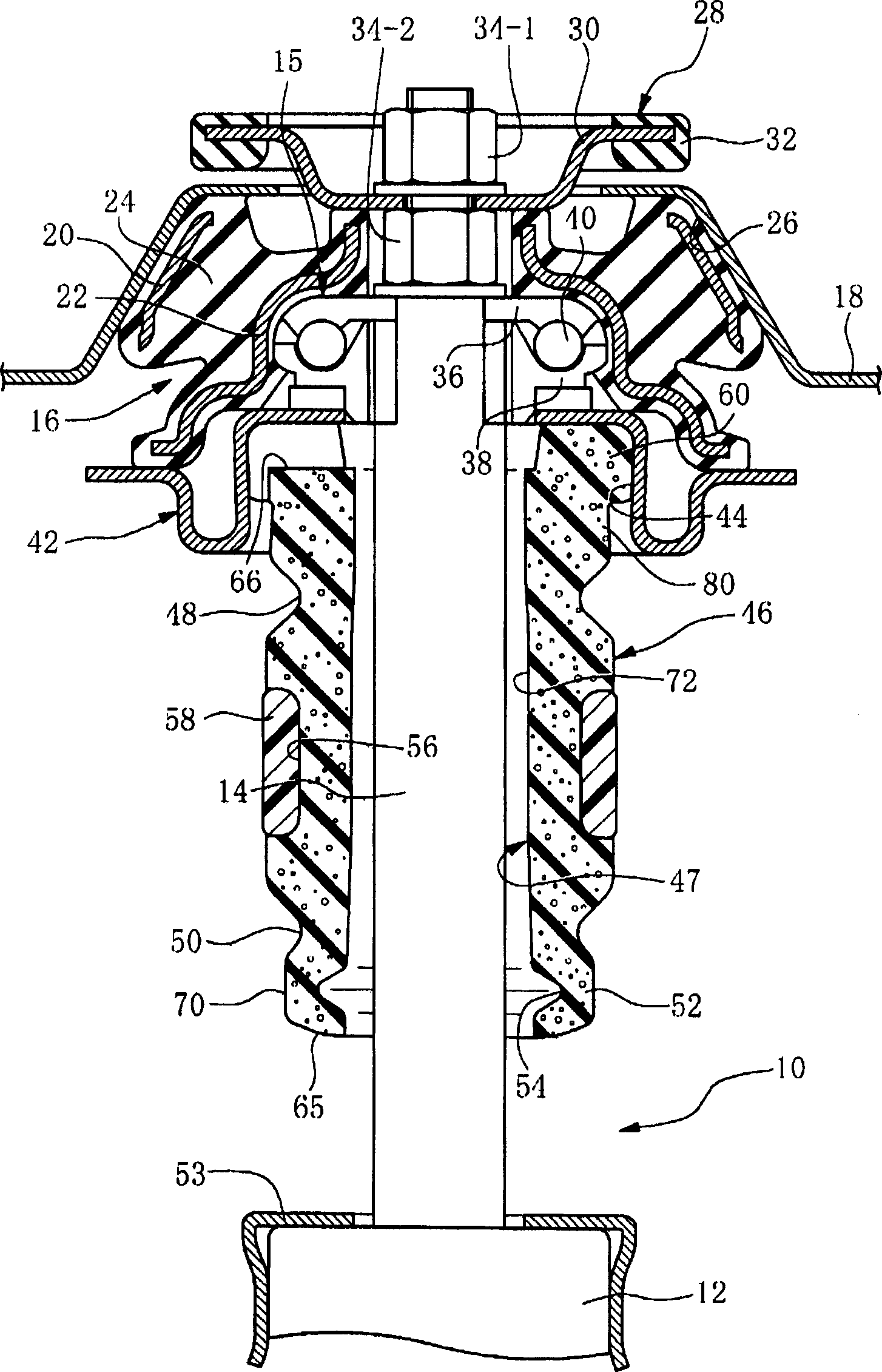

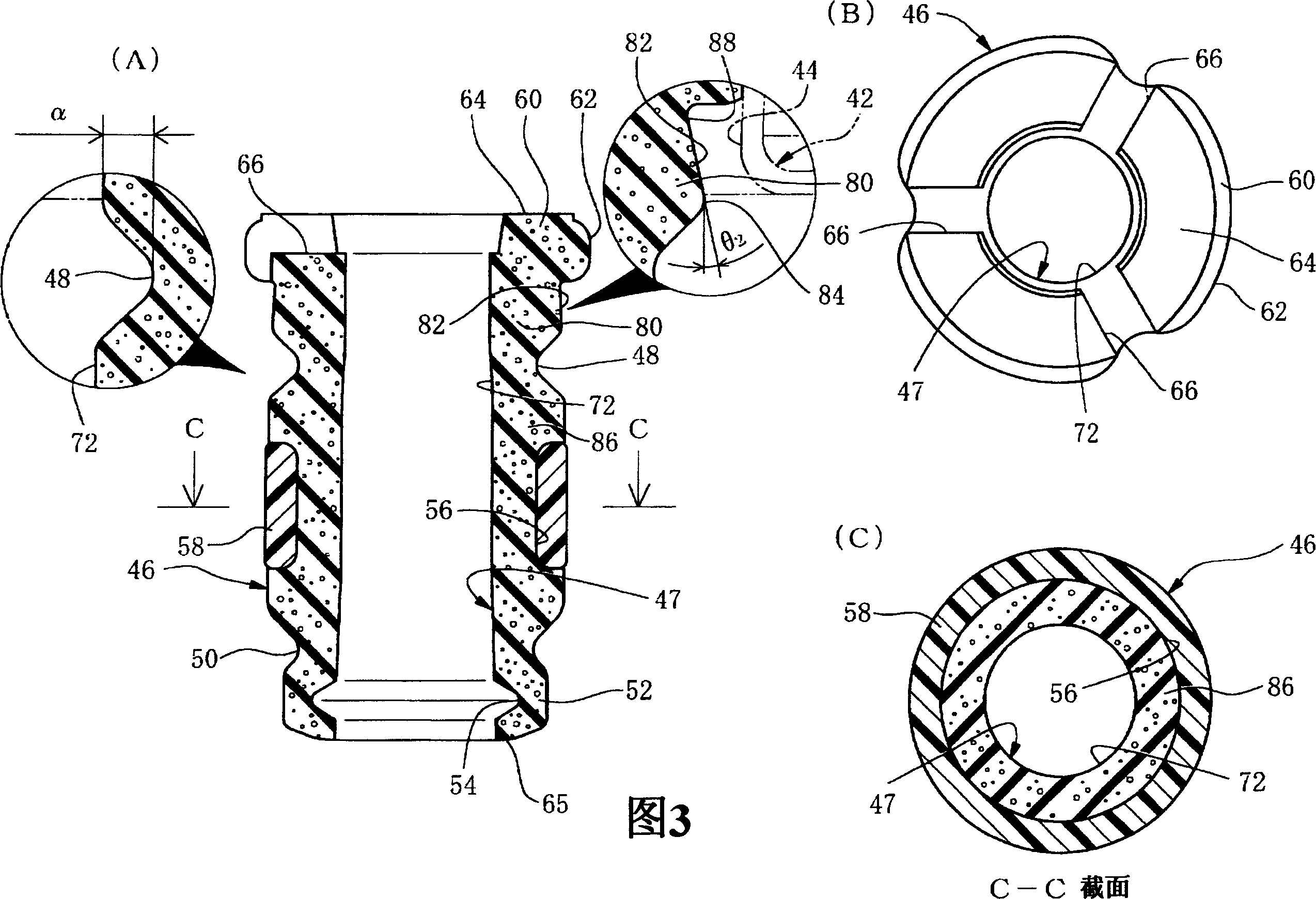

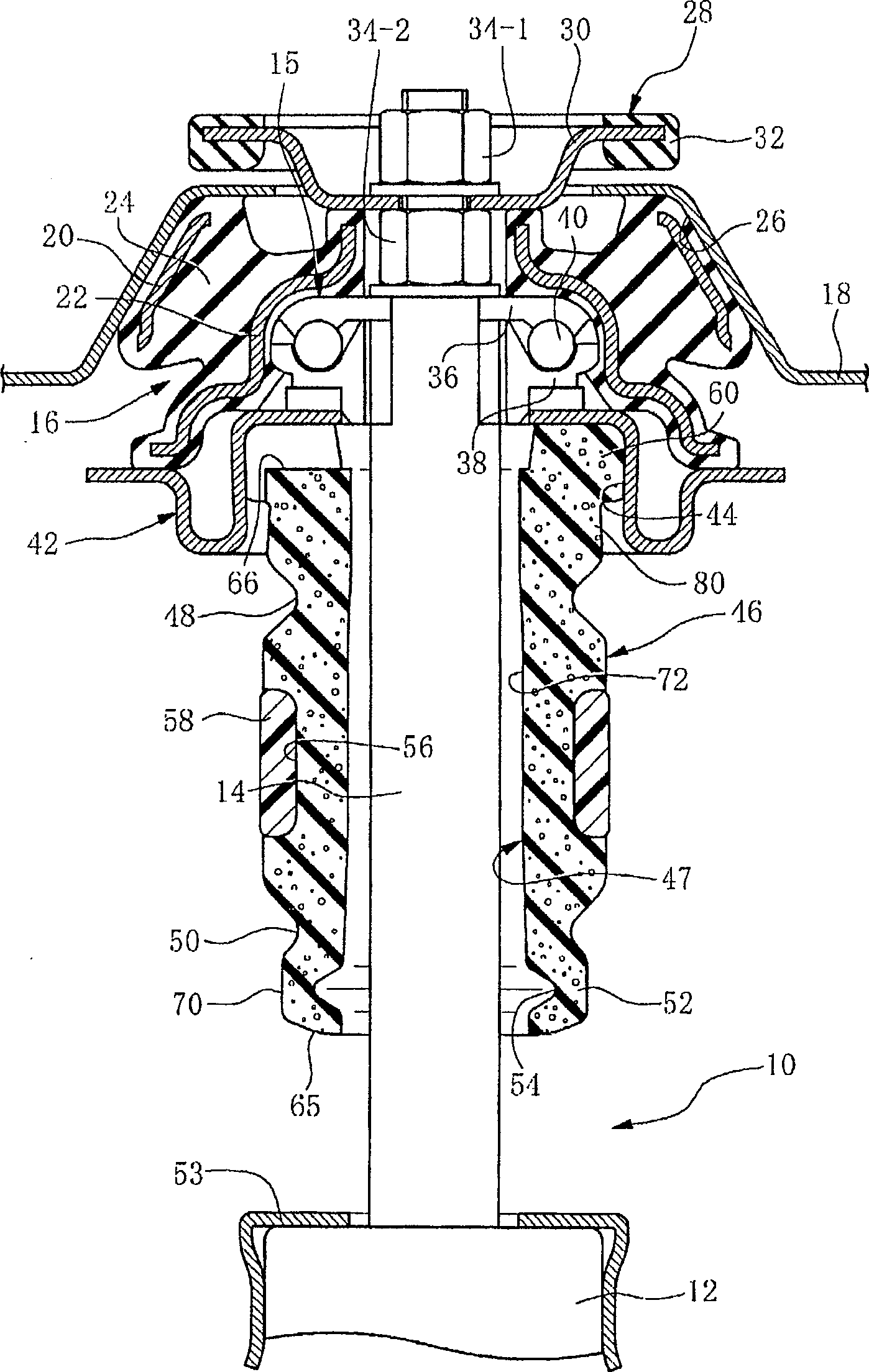

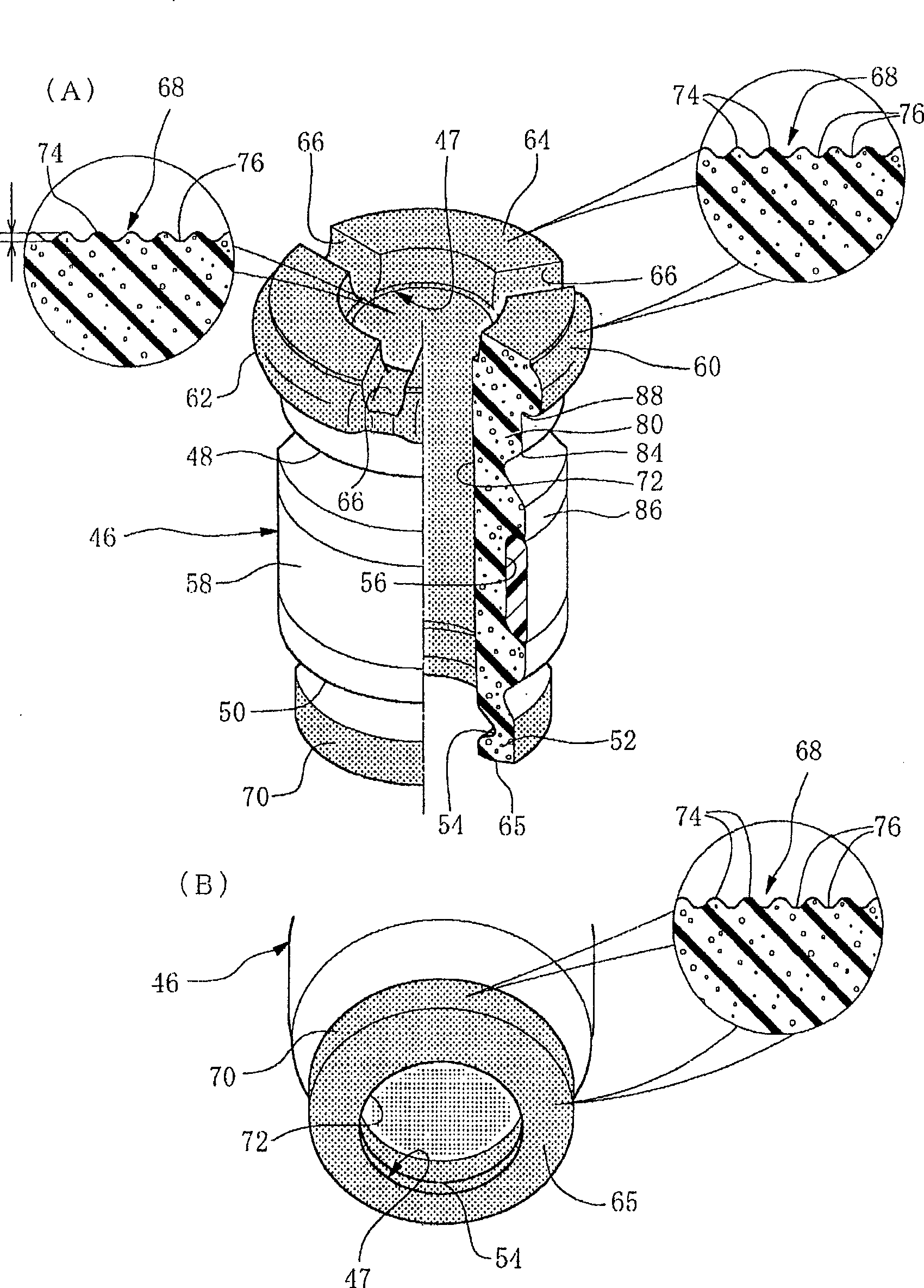

Collision stop for suspension apparatus

InactiveCN1789028APrevent unpleasant abnormal soundsPlay efficientlyPivoted suspension armsAxial compressionEngineering

Provided is a shock stopper made of polyurethane foam for a suspension device, which can prevent the generation of unpleasant abnormal sound caused by friction against a spring seat when the stopper acts. In the impact stopper (46) made of foamed polyurethane that elastically abuts against the cylinder to limit the excessive contraction displacement of the shock absorber when jumping, the large-diameter fitting portion (60) at the upper end and the axial compression The portion between the deformable ring-shaped narrowing portion (48), and the insertion portion (80) in the state of being inserted into the concave fitting portion (44) of the spring seat (42) in the state of compression deformation when the vehicle jumps On the outer peripheral surface, a diameter reduction inducing portion (82) is provided, which has a substantially inverted tapered shape whose outer diameter gradually decreases toward the upper side, and induces a diameter reduction deformation accompanied by compression deformation, and at least at the insertion portion An annular gap for diameter-reducing deformation is formed between the inner peripheral surface (72) of the center hole (47) of (80) and the piston rod.

Owner:SUMITOMO RIKO CO LTD +1

Battery-case aluminium alloy plate exhibiting excellent moulding properties, heat-dissipation properties, and welding properties

InactiveCN104838025AFast heat conductionGood formabilitySecondary cellsJackets/cases materialsLithium-ion batteryElectrical resistivity and conductivity

Provided is a 3000 series aluminium alloy plate which exhibits heat-dissipation characteristics applicable to large lithium ion battery containers, and which also exhibits excellent moulding properties, shape fixability, and laser welding properties. This aluminium alloy plate is a cold-rolled annealed material which has: a component composition including over 0.2 mass% but less than 1.4 mass% of Fe, 0.5-2.0 mass% of Mn, over 0.2 mass% but not more than 1.1 mass% of Si, 0.05-1.0 mass% of Cu, and less than 0.05 mass% of Mg, the remainder comprising Al and impurities; a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 30 MPa but less than 85 MPa; and an elongation value of at least 10%. Otherwise, this aluminium alloy plate is a cold-rolled material which has: a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 90 MPa but less than 180 MPa; and an elongation value of at least 3%.

Owner:NIPPON LIGHT METAL CO LTD

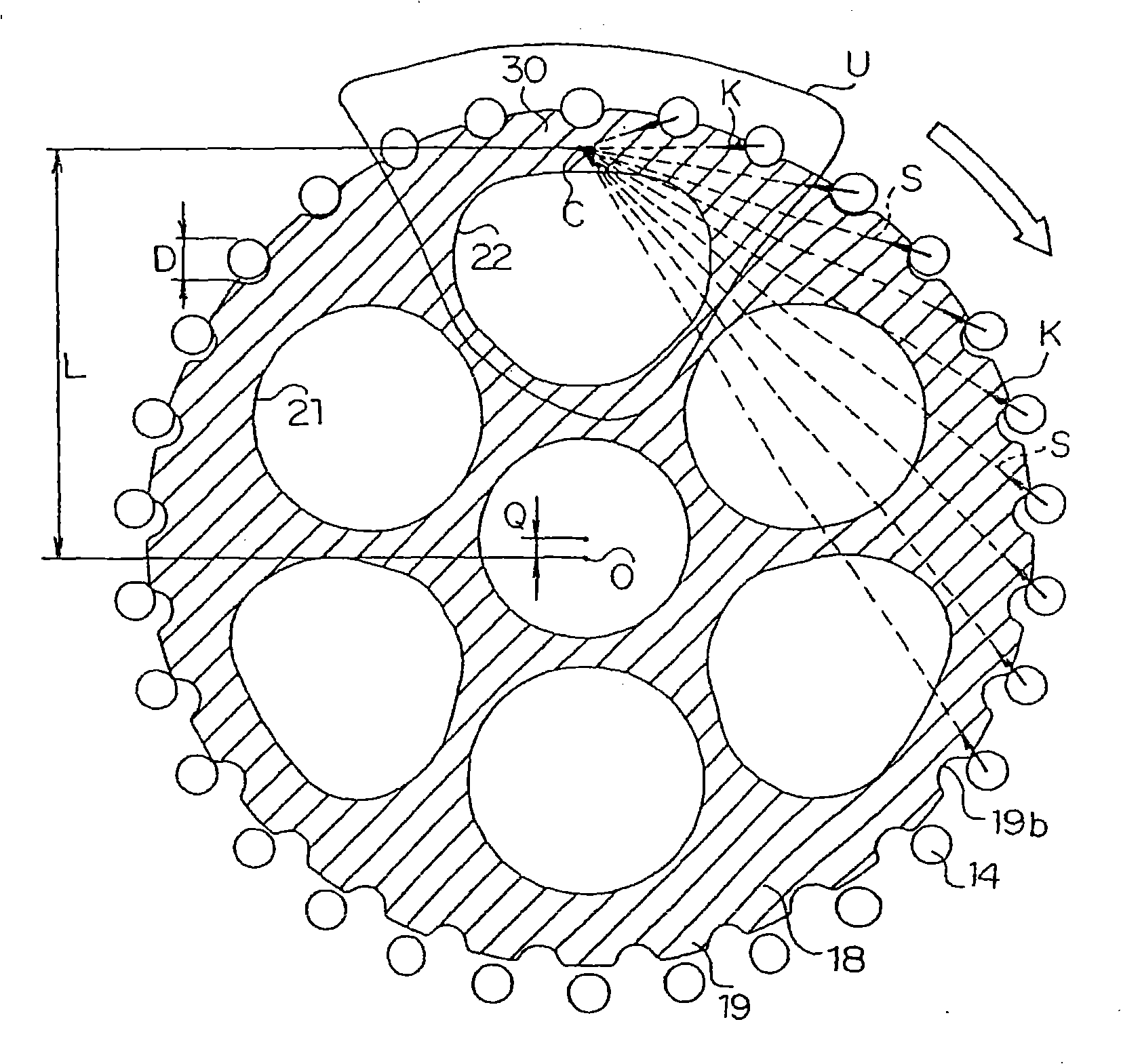

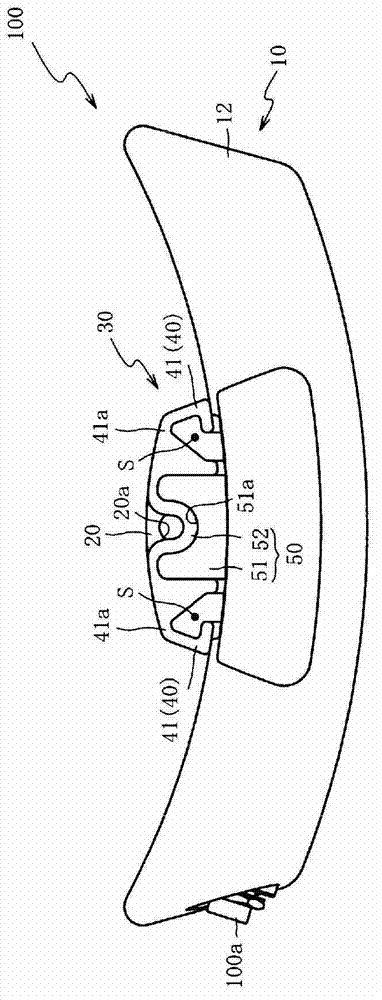

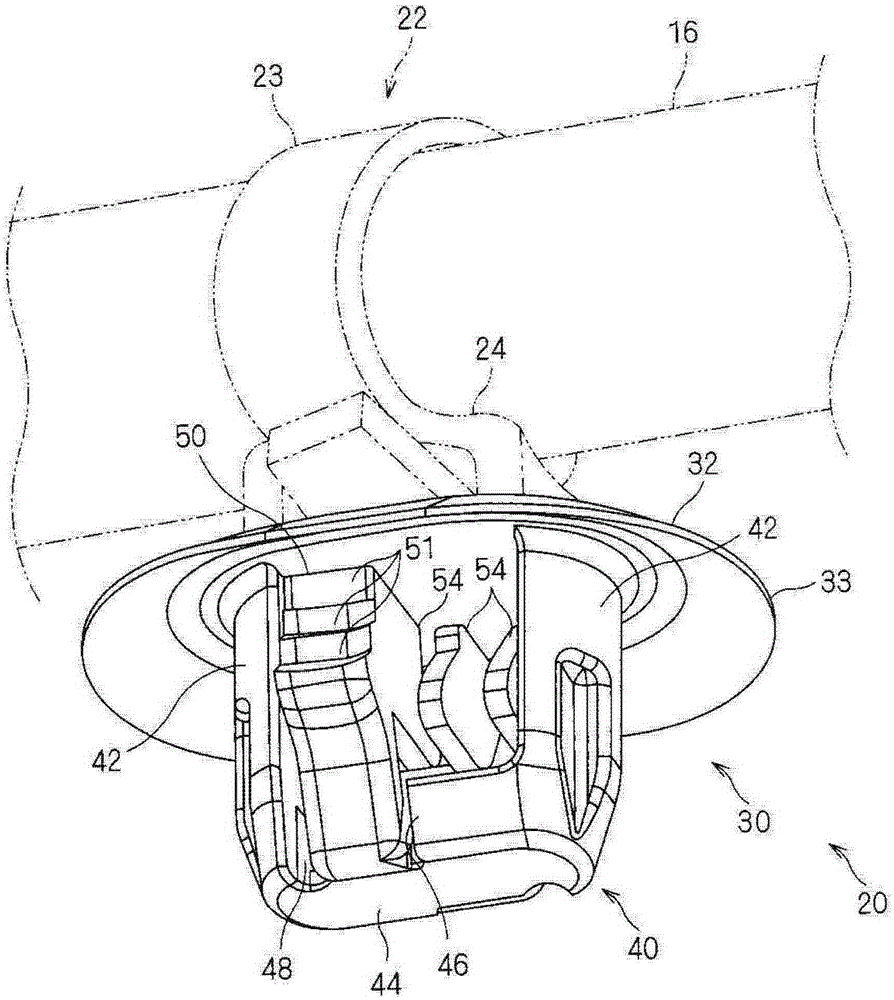

Wire harness fixing member

ActiveCN103423520AReduce protrusionReduced installation insertion forcePipe supportsEngineeringMechanical engineering

An object of the invention is to reduce installation insertion force of a wire harness fixing member and reduce protruding amount of a fixing portion as much as possible. The wire harness fixing member (20) is inserted into an installation hole fixedly formed on an installation plate. The wire harness fixing member (20) is provided with a wire harness mounting portion (22) and the fixing portion (30). The fixing portion (30) is provided with a fixed body portion (40) including a pair of sidewall portions (42) and a connecting portion (44) for connecting the front parts of the pair of sidewall portions (42); and locking sheets (50) which are protrudingly arranged in an outward inclined posture from a side part of the connecting portion (44) to the base part of the fixed body portion (40). Two side parts of the base of the locking sheets (50) are separated from the connecting portion (44) by a pair of concave portions (46, 48).

Owner:SUMITOMO WIRING SYST LTD

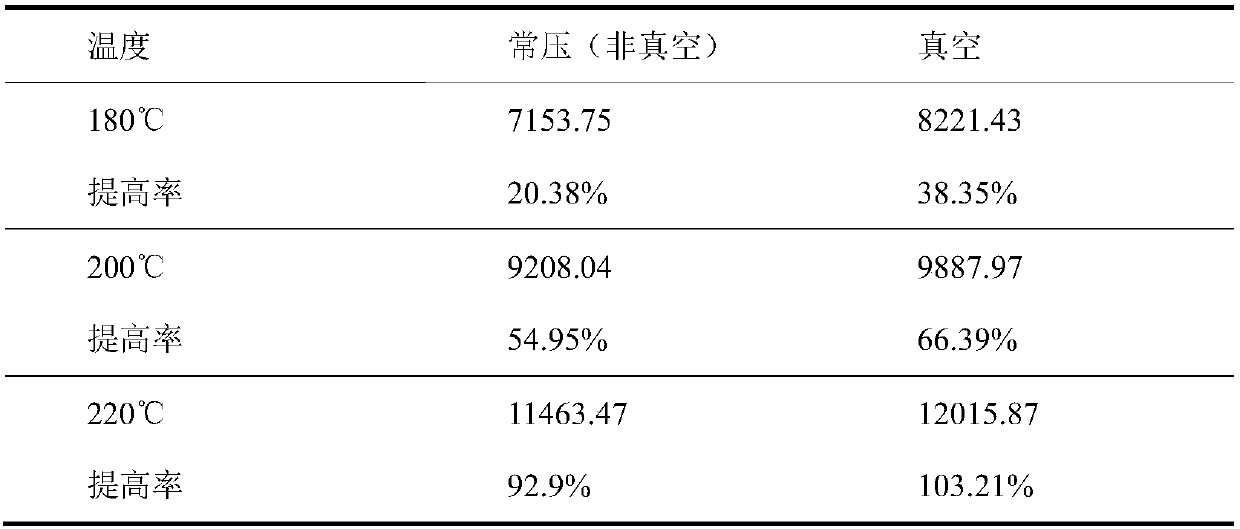

Method for compressing and compacting wood materials in vacuum

ActiveCN109591122ASolve easy discolorationFix stability issuesWood veneer joiningColor changesUltimate tensile strength

The invention discloses a method for compressing and compacting wood materials in vacuum, and belongs to the field of wood material production and preparation. According to the method, the wood materials undergo hot-pressing setting treatment under the vacuum condition, the treated wood materials are large in specific modulus, so that the technical problems that in the case of an existing wood material compression and compaction technology, the hot-pressing setting time is long, the manufacturing efficiency is low, the color change and the size are not stable are solved, the compression and compaction manufacturing of the wood materials is performed under the vacuum condition, so that the gluing strength of the wood gluing materials is also improved.

Owner:NANJING FORESTRY UNIV

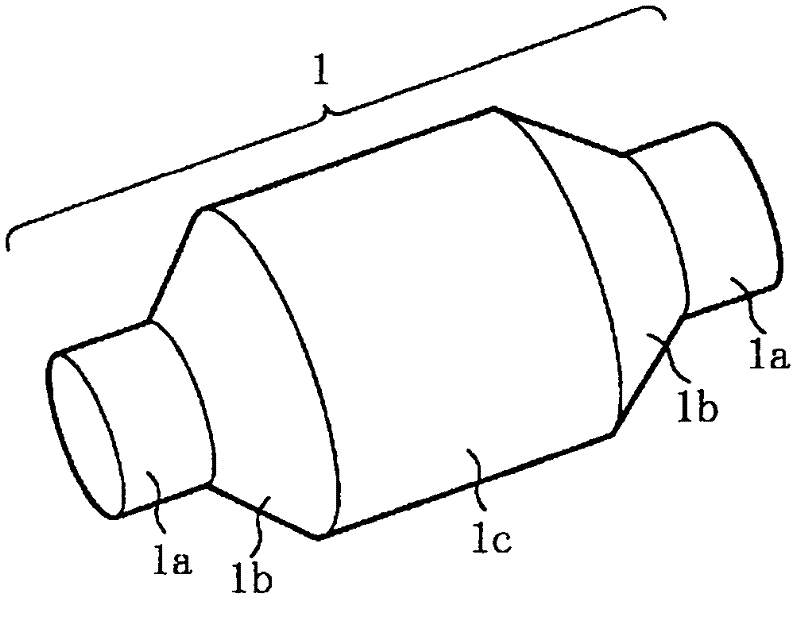

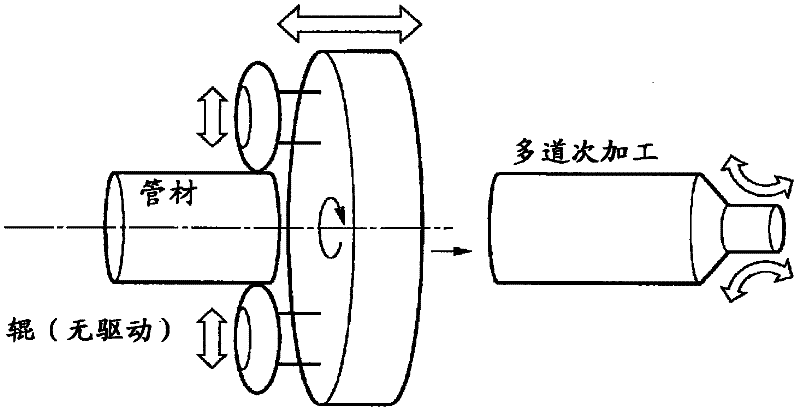

Spinning method

InactiveCN102292174AGood removal effectInhibition of elastic deformationEngine componentsEngineeringSpring steel

Owner:NISSHIN STEEL CO LTD

Method for compressing and compacting wood materials

ActiveCN108177209ASolve easy discolorationFix stability issuesWood veneer joiningColor changesSpecific modulus

The invention discloses a method for compressing and compacting wood materials, and belongs to the field of wood material production and preparation. According to the method for compressing and compacting the wood materials, the wood materials are subjected to hot-pressing and setting treatment under the vacuum condition, and the processed wood materials are large in specific modulus, and the technical problems that, in an existing wood material compressing and compacting technology, the hot-pressing and setting time of is long, manufacturing efficiency is low, the color changes, and the sizeis not stable are solved; and the wood materials are subjected to compressing and compacting manufacture under the vacuum condition, so that bonding strength of the wood materials laminated with glueis also improved.

Owner:NANJING FORESTRY UNIV

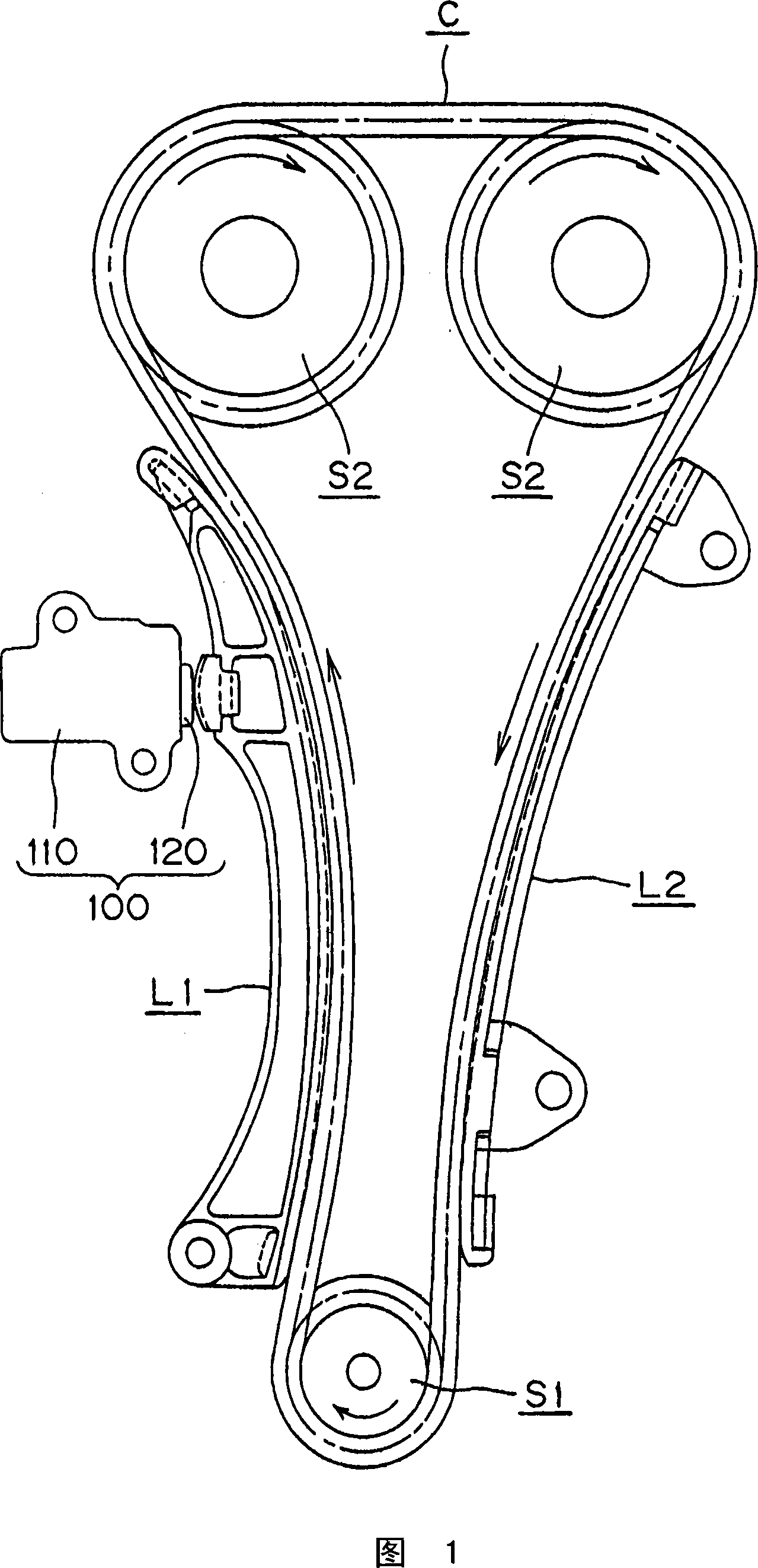

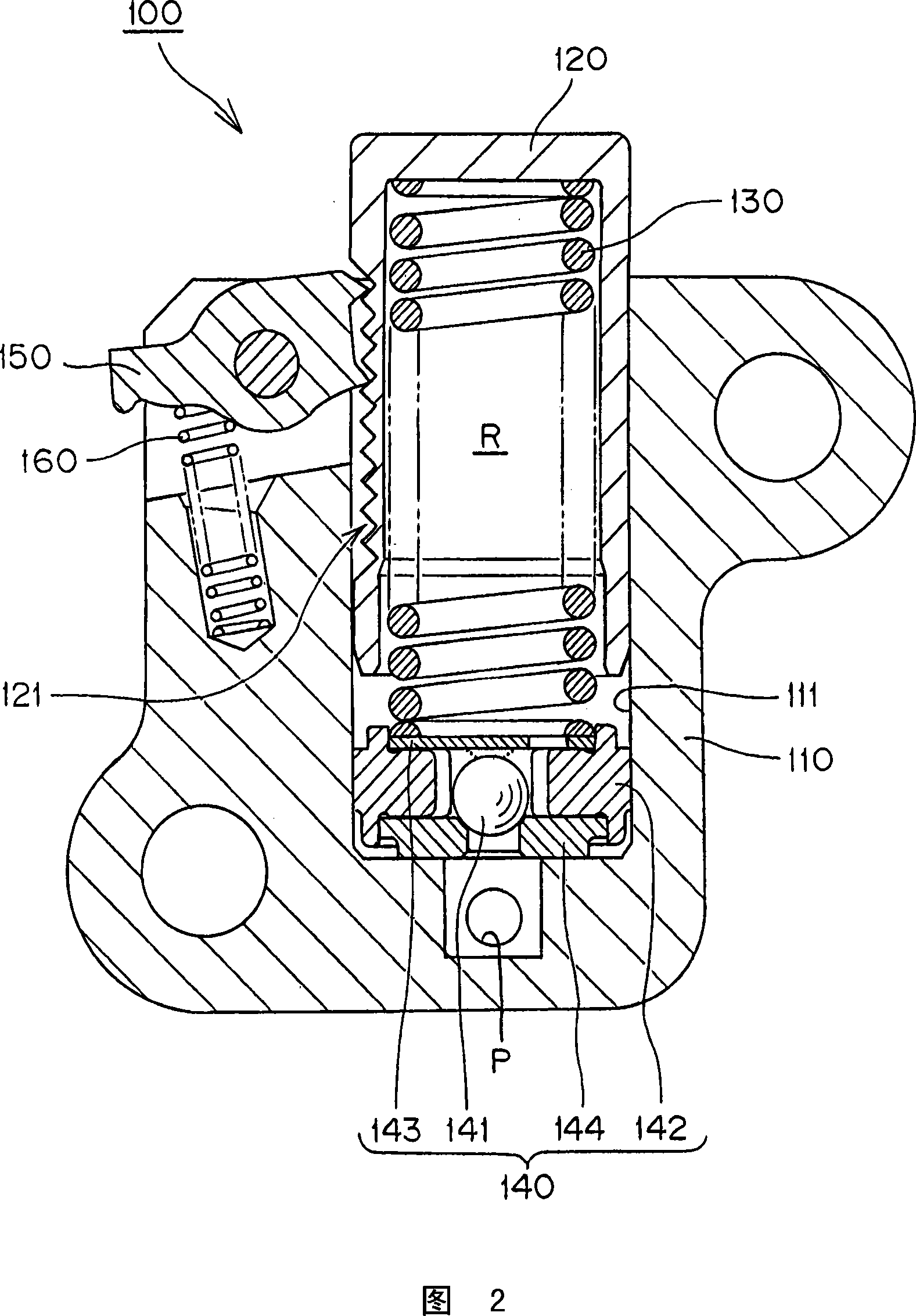

Hydraulic tensioner

The invention provides a hydraulic tensioner. A check valve unit has no elastic deformation or expansion caused by high-pressure in high-pressure oil chamber or high-temperature change in engine indoor, and can play a role of a check valve, furthermore, the check valve unit can be simply and firmly mounted on a case mainbody. The check valve unit (140) in a hydraulic tensioner (100) comprises: a check ball (141) allowing a limited range of pressure oil flow; a steel ball guide (142) having an inner wall allowing movement of a ball non-return valve; a steel retainer (143) attached to the high pressure oil chamber side of the ball guide (142); and a steel ball seat (144) attached to the oil supply side of the ball guide (142); bulged portions (142c) formed on an outer surface of the ball guide (142) are press-fit into the plunger-accommodating hole 111 of the tensioner.

Owner:TSUBAKIMOTO CHAIN CO

Cylindrical roller bearing

ActiveCN101187400ALess likely for insufficient lubrication conditionsSatisfactory lubricityBearing componentsFree rotationEngineering

A cage for a cylindrical roller bearing includes an annular portion, a plurality of posts extending in a unitary, continuous manner from the inner surface of the annular portion, and a plurality of pockets forming a gap between the inner circumferential sides of adjacent posts. Space, and the cylindrical roller is supported in a free-rotating manner. The axial side of the column includes arcuate surfaces formed in the ID and OD directions from the pocket PCD (pitch circle) that passes through the pocket center of the pocket, and a rolling pin at the inner peripheral portion of the tip. Go to the part (lubrication groove).

Owner:NTN CORP

Eccentric oscillating-type planetary gear device

ActiveCN101328953AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsFriction gearingsGear wheelControl theory

Deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

Support, electronic device, and method for manufacturing the same

InactiveCN107817872AInhibition of elastic deformationInhibit sheddingDetails for portable computersElectrical apparatus casings/cabinets/drawersElectronic equipmentChassis

The invention provides a support, an electronic device, and a method for manufacturing the same. The support can be easily installed in the frame of an electronic device and is difficult to fall. Thesupport can be easily attached to and is less likely to separate from an opening of a chassis of an electronic device. The support has a first elastic member having a recessed portion and configured to be fitted into the opening so that an opening surface of the recessed portion is directed to an inside of the chassis, and a second member having a protruding portion configured to be fitted into the recessed portion of the first member.

Owner:LENOVO (SINGAPORE) PTE LTD

A method for compressing and densifying wood materials

ActiveCN108177209BSolve easy discolorationFix stability issuesWood veneer joiningUltimate tensile strengthMaterials science

The invention discloses a method for compressing and densifying wood materials, which belongs to the field of wood material production and preparation. In the present invention, the wood is subjected to hot-pressing and setting treatment under vacuum conditions, and the treated wood has a large specific modulus, which solves the problems of long hot-pressing and setting time, low manufacturing efficiency, discoloration and dimensional instability in the existing wood compression and compaction technology. Technical problem; the compression and densification of wood materials under vacuum conditions also improves the bonding strength of wood glued materials.

Owner:NANJING FORESTRY UNIV

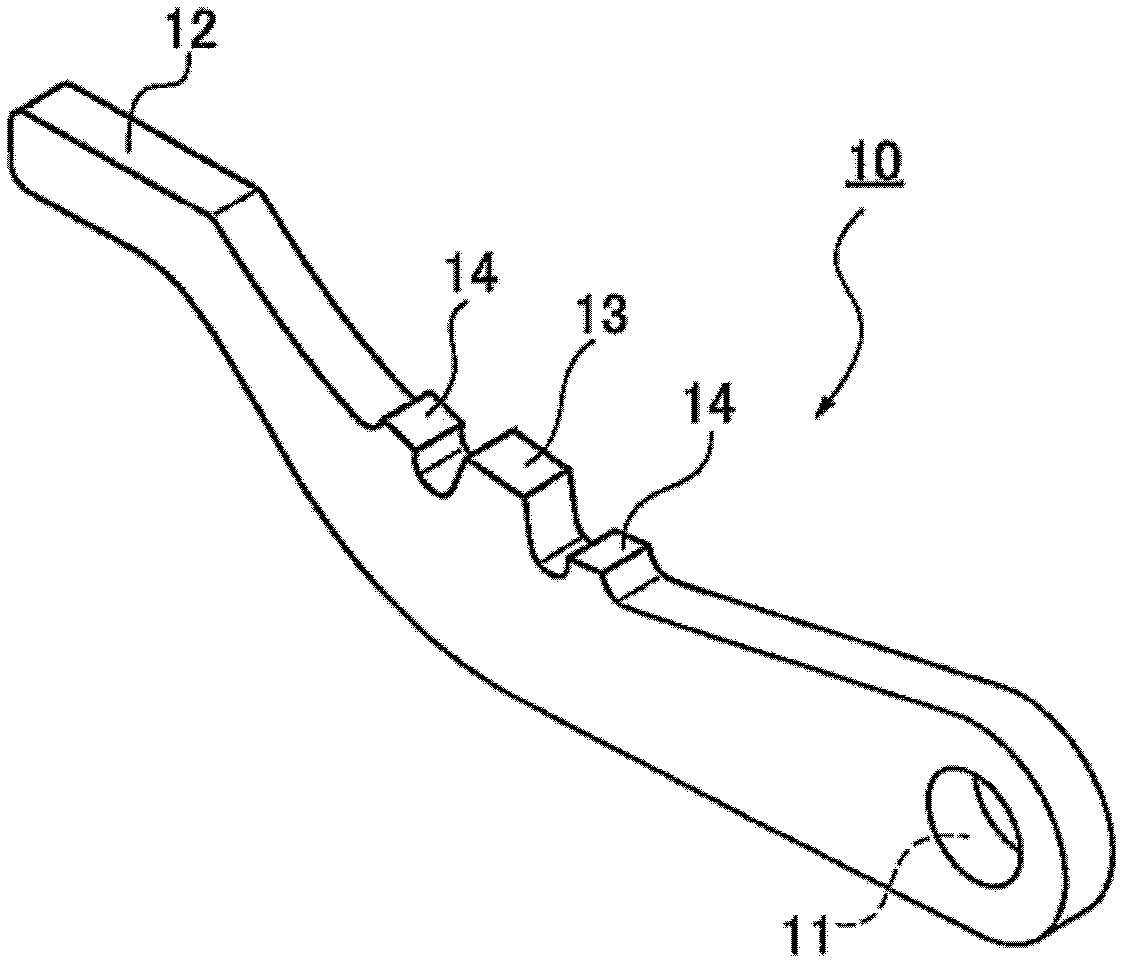

Parking mechnism for automatic transmission

InactiveCN102454779AInhibition of elastic deformationReduce bending momentGearing controlAutomatic transmissionUltimate tensile strength

The present invention provides a parking mechanism for an automatic transmission, which can restrain elastic deformation of a parking rod when a pulling-out force is applied and improves strength reliability. According to the parking mechanism for the automatic transmission, through engaging or releasing between a pawl (13) which is equipped on the parking rod (10) and tooth part (21) of a parking gear (20), the parking gear (20) is rotated and fixed, wherein, the parking rod (10) is adjacent with the pawl (13), and a projection part (14) which contacts with the tooth part (21) through elastic deformation of the parking rod (10) is provided.

Owner:JATCO LTD

Percussion attachment

ActiveCN103871394AReduce stressAvoid breakingElectrophonic musical instrumentsPercussion musical instrumentsBiomedical engineeringEngineering

A percussion attachment is provided to be detachably installed on a percussion instrument. The percussion instrument comprises a plurality of tension bolts applying a tension to a head part through a hoop . The percussion attachment includes a main body part having a struck part to be struck by a player, an extended part extending from a side surface of the main body part to be locked to one of the tension bolts, and a restricting part protruding from the side surface of the main body part near the extended part and supporting the percussion instrument to restrict a displacement of the main body part in a state that the extended part is tightened together with the hoop by one of the tension bolts.

Owner:ROLAND CORP

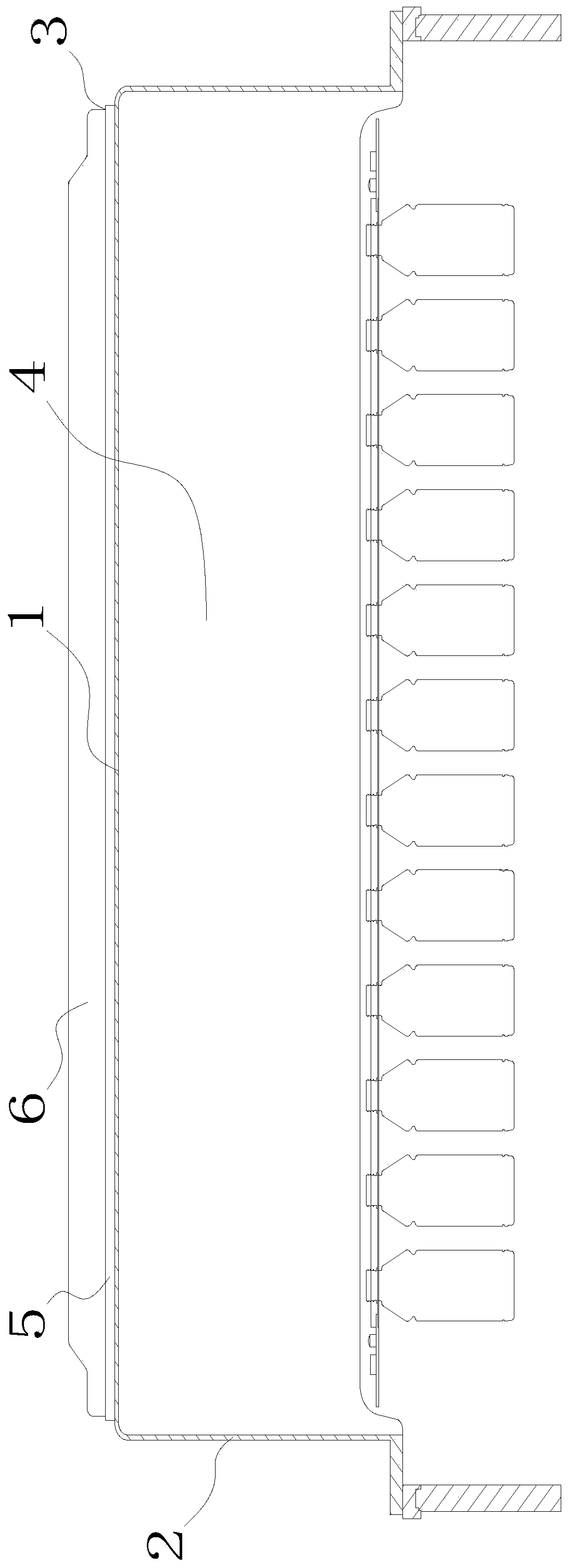

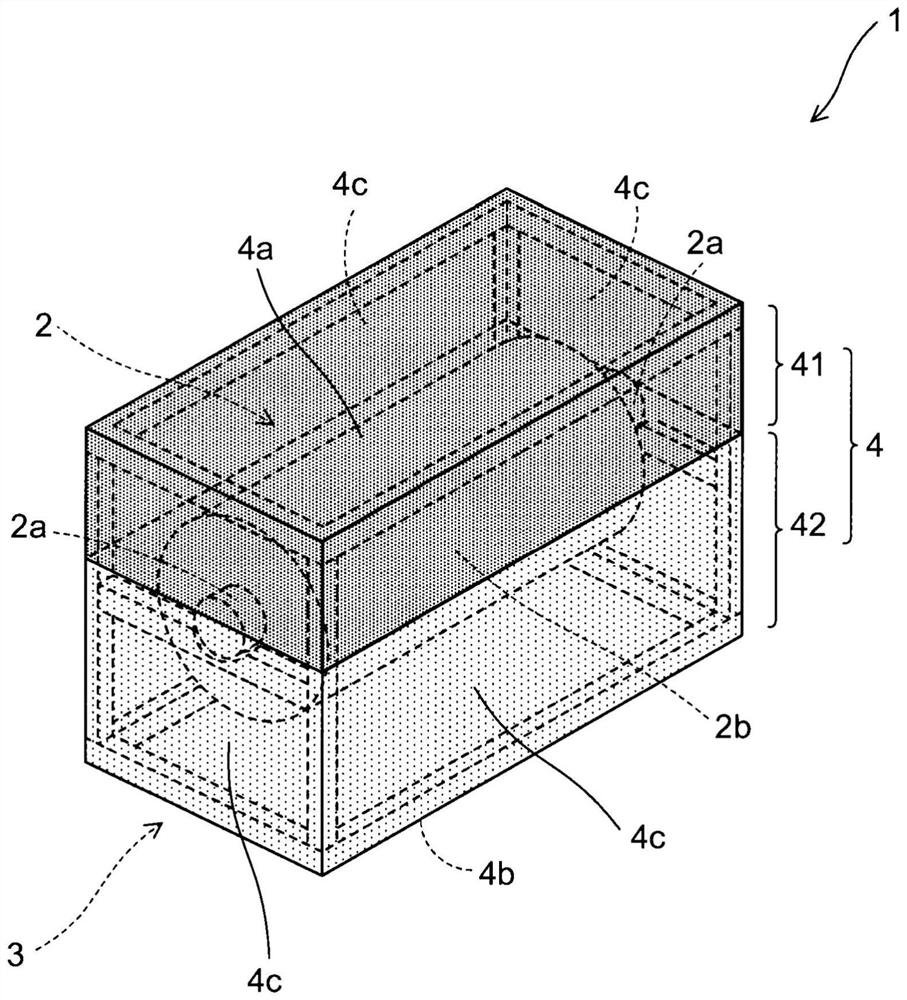

Aseptic bin

PendingCN111152996AInhibition of elastic deformationHigh mechanical strengthPackage sterilisationBottle-handling machinesSurgeryUltimate tensile strength

The invention discloses an aseptic bin. The aseptic bin comprises a top part and a supporting part, the supporting part is distributed on the top part, the supporting part is perpendicular to the toppart, a storage cavity is arranged between the top part and the supporting part, reinforcing pieces with integrated structures are arranged on the aseptic bin, each reinforcing piece comprises a connecting part and a reinforcing part, the reinforcing parts are positioned on the connecting parts, the reinforcing parts are perpendicular to the connecting parts, the reinforcing parts and the connecting parts are connected into a whole, the connection parts are fixed to the top part, and the reinforcing pieces are distributed in the width direction of the storage cavity. The aseptic bin inhibits the elastic deformation of the top part of the aseptic bin in the vertical direction through the externally arranged reinforcing pieces, so that the mechanical strength of the top part of the aseptic bin is improved to obtain the technical effect of improving the overall mechanical strength, the aseptic bin not only can be made of thinner materials, but also can allow functional components to be directly mounted on the aseptic bin, the weight of the aseptic bin is reduced while the bearing capacity is improved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Toroidal CVT

ActiveCN106104080BAvoid frettingSmall elastic deformationCouplings for rigid shaftsFriction gearingsInterference fitContinuously variable transmission

Fletching wear caused by elastic deformation in the axial direction of an input-side disk 2c due to thrust force of a pressure device is prevented. A female-spline section 13a formed around the middle section in the axial direction of the inner-circumferential surface of a center hole 19 in the input-side disk 2c and a male-spline section 12a formed around the outer-circumferential surface of one end section in the axial direction of an input rotating shaft 1b engage with a spline engagement. A disk-side fitting surface section 22 formed around a portion of the inner-circumferential surface of the center hole 19 in the input-side disk 2c that is adjacent to the other end side of the female-spline section 13a and a shaft-side fitting surface section 23 formed around a portion of the outer-circumferential surface of the input rotating shaft 1b that is adjacent to the other end side of the male spline section 12a are fitted together with an interference fit.

Owner:NSK LTD

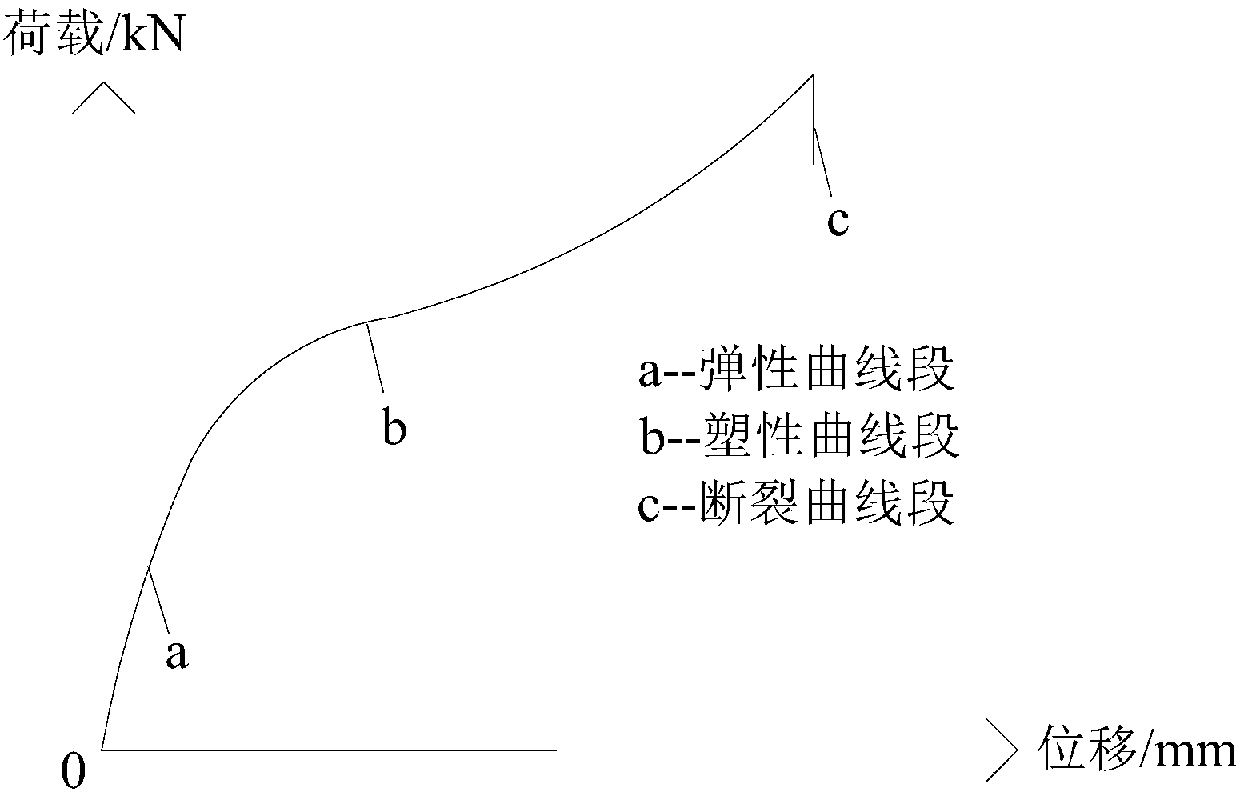

Bearing structural element, supporting base, connector assembly and pipe joint assembly

ActiveCN107559543AAvoid defectsInhibition of elastic deformationMachine framesLinear bearingsEngineeringRigid structure

The invention discloses a bearing structural element, a supporting base, a connector assembly and a pipe joint assembly. The maximum counter force provided by the bearing structural element is the designed threshold of the bearing structural element under the effects of the external load, that is to say, when the external load is larger than the designed threshold of the bearing structural element, the bearing structural element deforms and provides the counter force equal to the designed threshold; the supporting base of the bearing structural element comprises at least one bearing structuralelement, and the connector assembly and the pipe joint assembly are each provided with the supporting base. The bearing structural element can effectively inhibit deformation as a rigid structural element when the external load is not high and lower than the designed threshold, can deform when the external load exceeds the designed threshold, and meanwhile provides the stable supporting counter force lower than the external load, and the bearing structural element can be applied to the supporting base, the connector assembly and the pipe joint assembly, plays a role of protecting the structure or key structural elements, and can be widely applied to the field of bridge design, building structure design, tunnel design and the like.

Owner:CHINA COMMUNICATIONS CONSTRUCTION +3

Collision stopper for suspension apparatus

InactiveCN100480074CSuppression of bulgingPrevent unpleasant abnormal soundsPivoted suspension armsAxial compressionCompressive deformation

Owner:SUMITOMO RIKO CO LTD +1

Toroidal continuously variable transmission

ActiveCN106104080AAvoid frettingSmall elastic deformationCouplings for rigid shaftsFriction gearingsInterference fitEngineering

In order to prevent fretting wear based on elastic deformation in the axial direction of an input-side disk (2c) due to the thrust force of a pressing device, female spline parts (13a), which are formed in the middle section in the axial direction in the inner circumferential surface of a center hole (19) of an input-side disk (2c), and male spline parts (12a), which are formed in the outer circumferential surface at one end in the axial direction of an input rotary shaft (1b), are spline coupled to each other, and a disk-side mating surface part (22), which is formed at the portion of the inner circumferential surface of the center hole (19) which is adjacent to the other end of the female spline parts (13a), and a shaft-side mating surface part (23), which is formed at the portion of the outer circumferential surface of the input rotary shaft (1b) which is adjacent to the other end of the male spline parts (12a), are mated to each other with an interference fit.

Owner:NSK LTD

Clamping device, motor, and disk drive device

InactiveCN102568504AReduce vibrationSuppress noiseRecord information storageMechanical energy handlingDisk loadingEngineering

The invention provides a clamping device, a motor, and a disk drive device. In the clamping device, a disk loading portion for loading a disk and a self-aligning portion for supporting the inner periphery of the disk are split parts. That is to say, the disk loading portion and the self-aligning portion are not continuous and respectively directly fixed on a shaft or indirectly fixed on the shaft via more than one part. Thus, relative to the surface used as a design reference, the disk loading portion and the self-aligning portion are respectively arranged at high position precision. Compared with the way of fixing a one-piece part comprising the parts like the disk loading portion on a position near to an upper end of the shaft, the load near to the upper end of the shaft is lightened. Thus, the elastic deformation near to the upper end of the shaft is suppressed. Therefore, the vibration and noise of the disk are suppressed during the rotating process.

Owner:NIPPON DENSAN CORP

Device for driving opening/closing body for vehicle

InactiveCN101795882AReduce tensionInhibition of elastic deformationWindowsWindscreensDrive wheelEngineering

Owner:AISIN SEIKI KK

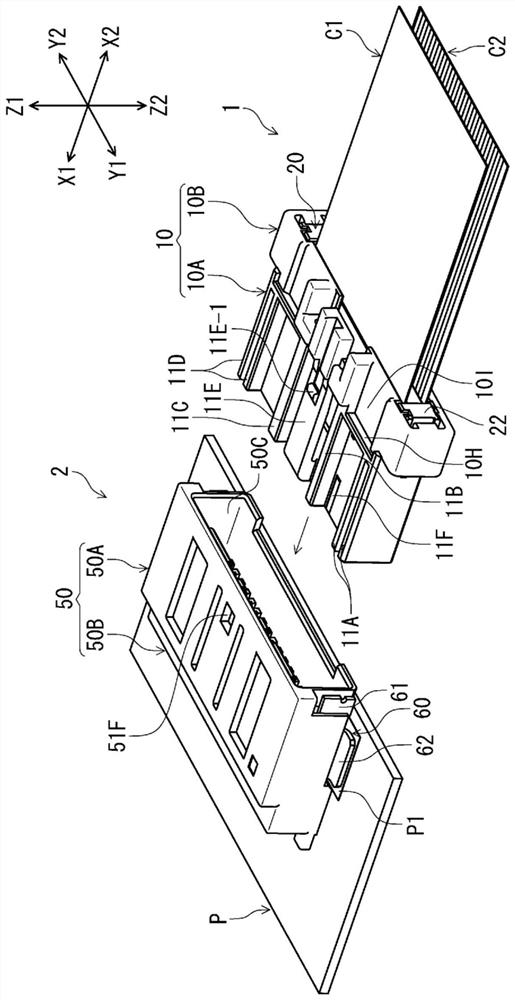

Electrical connector with flat conductor, counterpart electrical connector, and electrical connector assembly

PendingCN114267973AInhibition of elastic deformationFull contact pressureSecuring/insulating coupling contact membersCouplings bases/casesElectrical conductorElectrical connection

The invention provides an electric connector with a flat conductor, a counterpart electric connector and an electric connector assembly, wherein the connector is not large in size in the thickness direction of the flat conductors when the two flat conductors are oppositely arranged and used in parallel, and the counterpart electric connector and the electric connector assembly are provided. The flat conductors (C1, C2) face each other at positions separated from each other in the thickness direction of the flat conductors with one surface on which the contact portions (C1A-1, C2A-1) are arranged as inner side surfaces, and a receiving space (10D) for receiving the fitting portion (54) of the mating electrical connector (2) is formed between the inner side surfaces, and the housing (10) has a fitting portion (10A) in which the contact portions (C1A-1, C2A-1) are inserted into the receiving space (10D). The fitting part can accommodate and support the front end side part of the flat conductor and is fitted with an object shell (50), and the fitting part can support the outer side surface of the front end side part of the flat conductor through fitting walls (11, 12) which face the outer side surface of the front end side part of the flat conductor.

Owner:HIROSE ELECTRIC GROUP

Automobile wheel

InactiveCN102481805AImprove operational safetyImprove ride comfortRimsTyre measurementsEngineeringAtmospheric pressure

Disclosed is an automobile wheel configured so that a well recess is formed at the area at the back side well wall of the well of the wheel rim that faces a valve hole, said well recess receding toward the back along a well bottom of the well. Through this configuration, the vibration that is generated by the centrifugal force of an air valve equipped with an air pressure detection device when the vehicle is moving can be suppressed due to the shape of the well recess, and stable driving of the automobile and comfortable riding are thus improved. The same effect is also demonstrated when an automobile wheel is configured so that a well recess is formed at the area at the front side well wall of the well where the valve hole is to be formed, said well recess receding toward the front along the well bottom of the well of the wheel rim so that the front side portion of the air pressure detection device of the air valve can be fit therein.

Owner:CENTRAL MOTOR WHEEL CO LTD

Harness Fixtures

ActiveCN103423520BReduce protrusionReduced installation insertion forcePipe supportsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Parking mechanism for automatic transmission

InactiveCN102454779BInhibition of elastic deformationReduce the amount of bendingGearing controlAutomatic transmissionGear wheel

PROBLEM TO BE SOLVED: To provide an automatic transmission parking mechanism for suppressing an elastic deformation of a parking pawl when a removing torque is applied, and thereby improving strength reliability. SOLUTION: The automatic transmission parking mechanism 1 is configured to rotate and fix a parking gear 20 when a pawl 13 installed in the parking pawl 10 is engaged or disengaged with teeth 21 of the parking gear 20. In the parking mechanism, the parking pawl 10 is adjacent to the pawl 13, and is provided with a protrusion 14 which comes into contact with the teeth 21 by the elastic deformation of the parking pawl 10.

Owner:JATCO LTD

Yarn reeling machine

ActiveCN101311090BImprove rigidityInhibition of elastic deformationFilament handlingYarnContact pressure

The invention provides a yarn reeler, causing a contact roller to move swimmingly corresponding to the thickness of a package, and restraining disproportionation of the contact pressure applied on the package. The yarn reeler (1) comprises a spool stand (13) supported on a frame (10) of a main body, and equipped with a barrel (20); a lifting frame (11) movably supported on the frame (10) of the main body along the vertical direction; a contact roller (15), arranged in parallel with the spool stand (13) and contacted with a cirumferential surface of the package (21) with the barrel (20) or formed on the barrel (20); a supporting plate (22), movably supported on the lifting frame (11) along the vertical direction for rotating freely to support the contact roller (15); a guide unit (25) for guiding the supporting plate (22), along the vertical direction relative to the lifting frame (11).

Owner:TMT MACHINERY INC

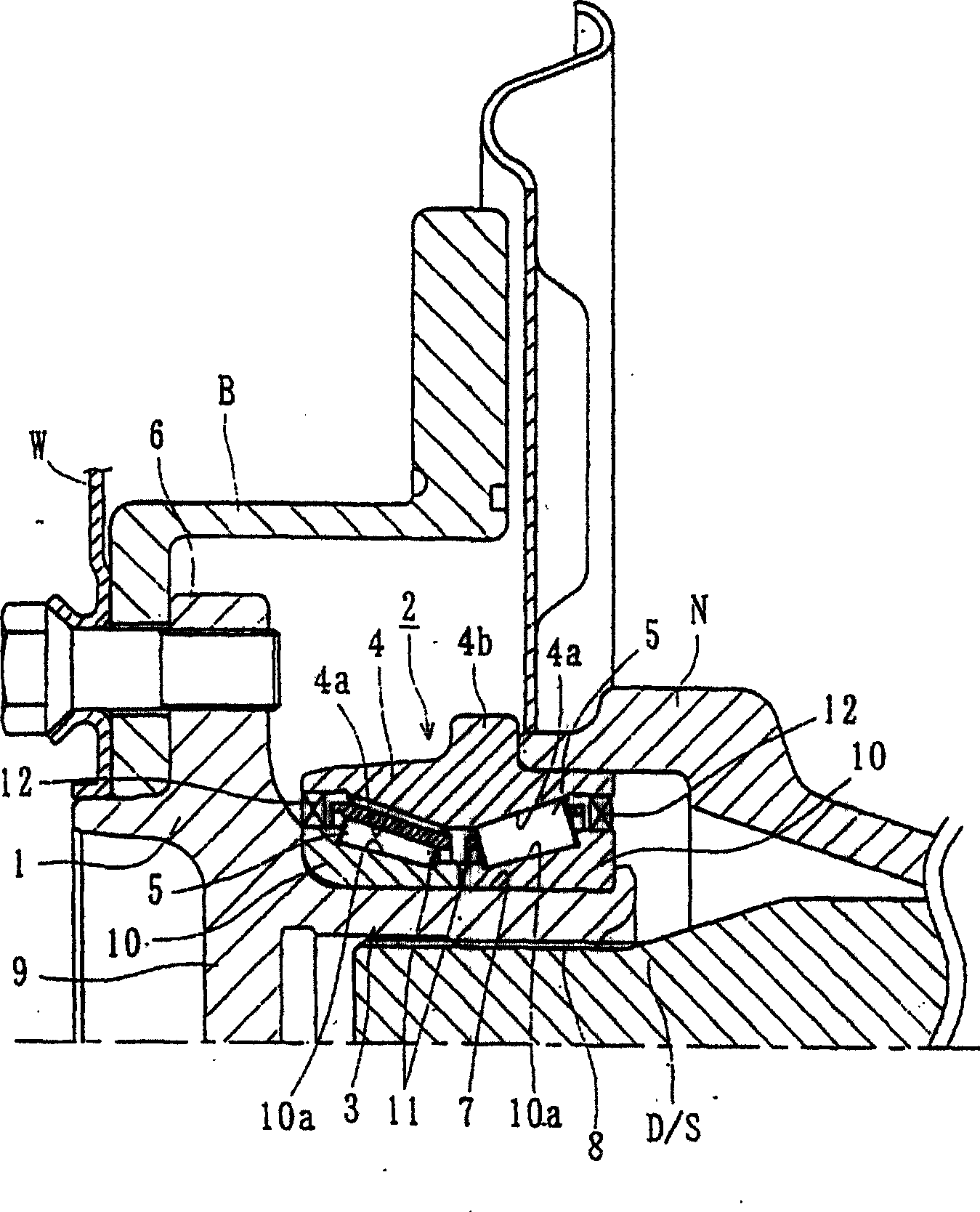

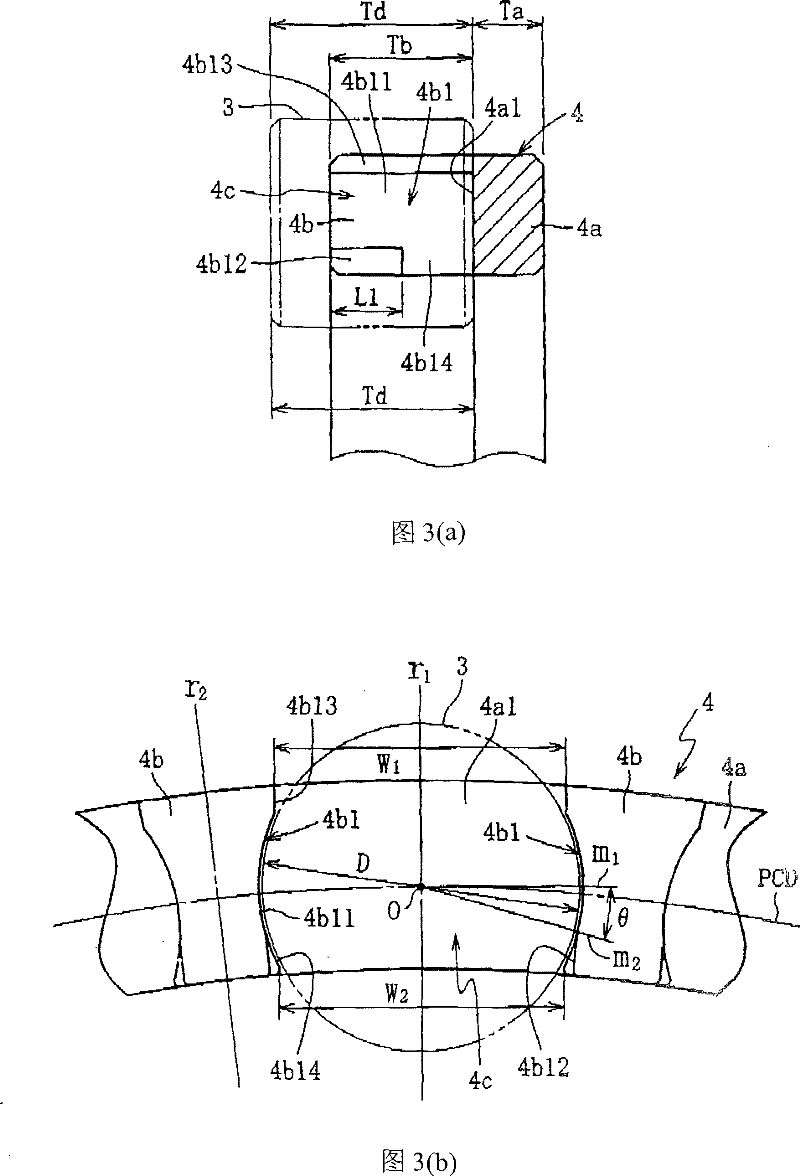

Wheel bearing and semi-floating type wheel bearing device having the same

Provided is a wheel bearing device reduced in weight and compacted in size and capable of preventing entry of rain, dust, or the like and leakage of differential oil. A wheel bearing device comprises an inner member (3) consisting of a cylindrical small-diameter step (7) integrally having a wheel attachment flange (6) at one end and disposed around the outer periphery to extend axially, a hub wheel (1) having serrations (8) formed around the inner periphery for engagement with a driving shaft (D / S), and a pair of inner rings (10) press-fitted on the small-diameter step (7) and having inner rolling surfaces (10a) formed around the outer periphery, an outer member (4) which has a car body attachment flange (4b) fixed to an axle tube (N) and which is formed with two rows of outer rolling surfaces (4a) around the inner periphery to be opposed to the inner rolling surfaces (10a), plural rolling elements (5) received between the two rolling surfaces for the outer and inner members (4, 3), a cage (11) rollably holding the rolling elements (5), and seals (12) for sealing the annular spaces of the inner and outer members (3, 4). The outboard end of the hub wheel (1) is integrally formed with a partition wall (9) blocking the inner diameter section.

Owner:NTN CORP

Cylindrical roller bearing

ActiveCN101187400BLess likely for insufficient lubrication conditionsSatisfactory lubricityBearing componentsCentrifugal forceSynthetic resin

The invention relates to a cylindrical roller bearing comprising a cage made of a synthetic resin. The cage of the cylindrical roller bearing includes an annular section, a plurality of pillars that extend axially in an integrated, continuous manner from the inside surface of the annular section, and a plurality of pockets, which are formed between the inner circumferential direction side faces of adjacent pillars, and hold the cylindrical rollers in a freely rotatable manner. The circumferential direction side faces of the pillars incorporate a circular arc surface formed in both the inside and outside diameter directions from the pocket PCD which passes through the pocket center of the pocket, and a roll-off section (lubricant reservoir) provided at the tip end inner circumferential section, wherein the peripheral edge of the lubricant reservoir is preferably formed so as to be inclined in an opposite direction to the direction of inclination of the pillars relative to the center axis that occurs when the pillars undergo outward elastic deformation due to centrifugal force.

Owner:NTN CORP

Packaging body for film roll

ActiveCN113772276AAvoid temperature riseBalanced cooling effectDomestic cooling apparatusLighting and heating apparatusPolymer sciencePolymer chemistry

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com