Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3638results about "Jackets/cases materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

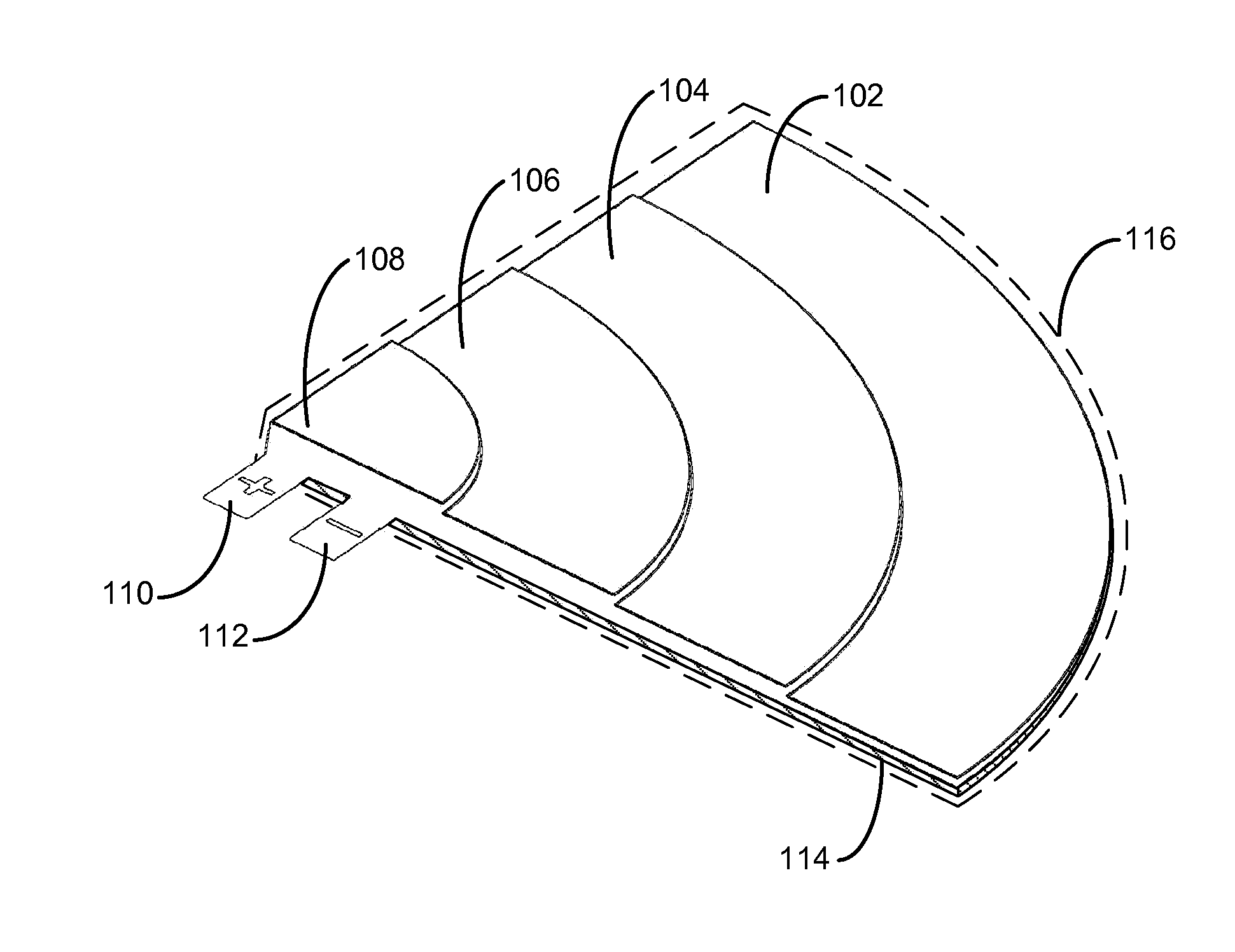

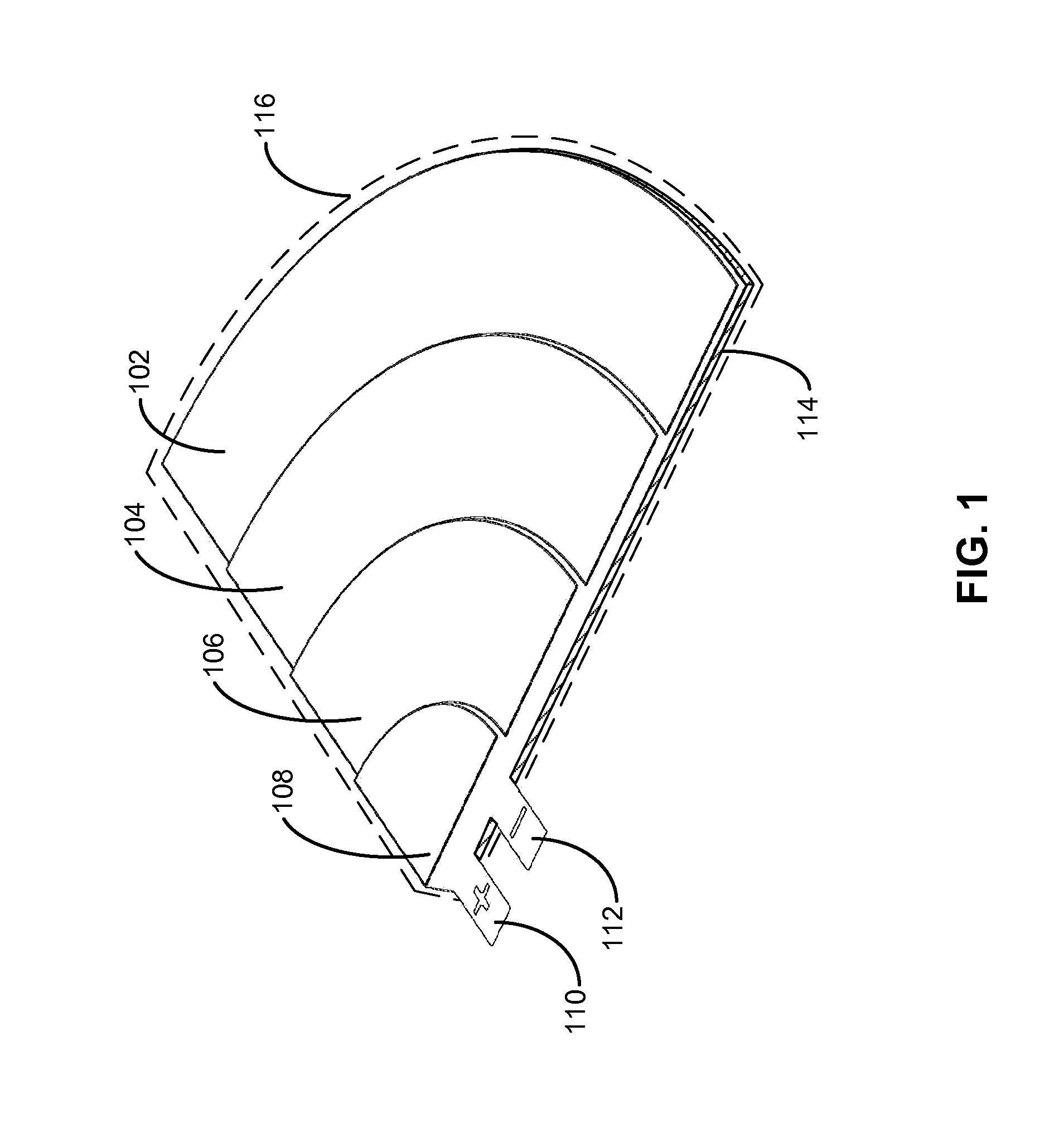

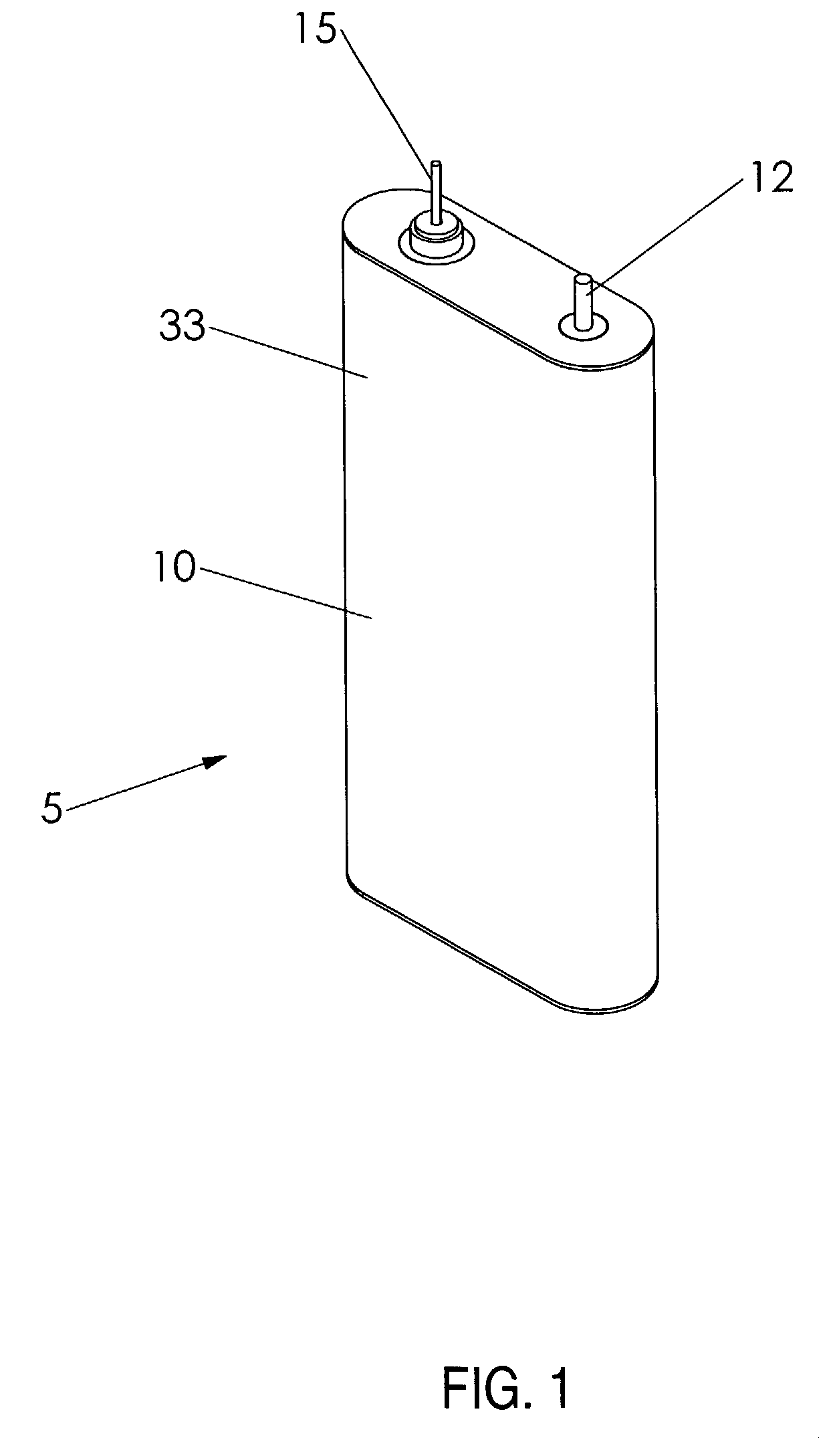

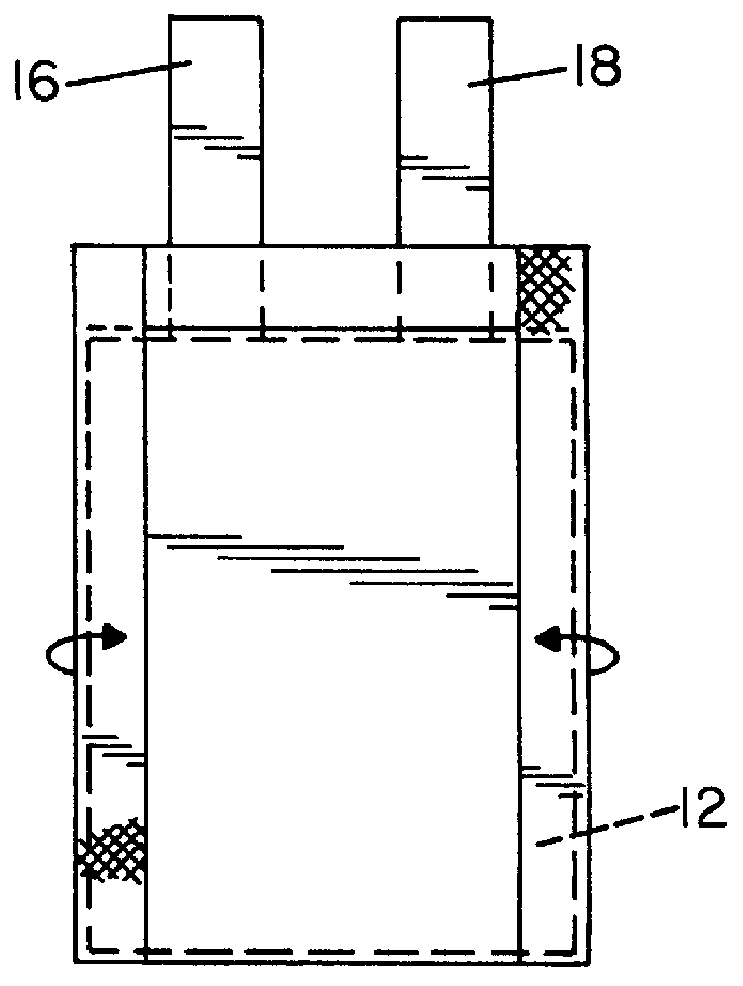

Design and construction of non-rectangular batteries

ActiveUS20120015236A1Facilitate efficient use of spaceEasy to carry and useFinal product manufactureSmall-sized cells cases/jacketsEngineeringBattery cell

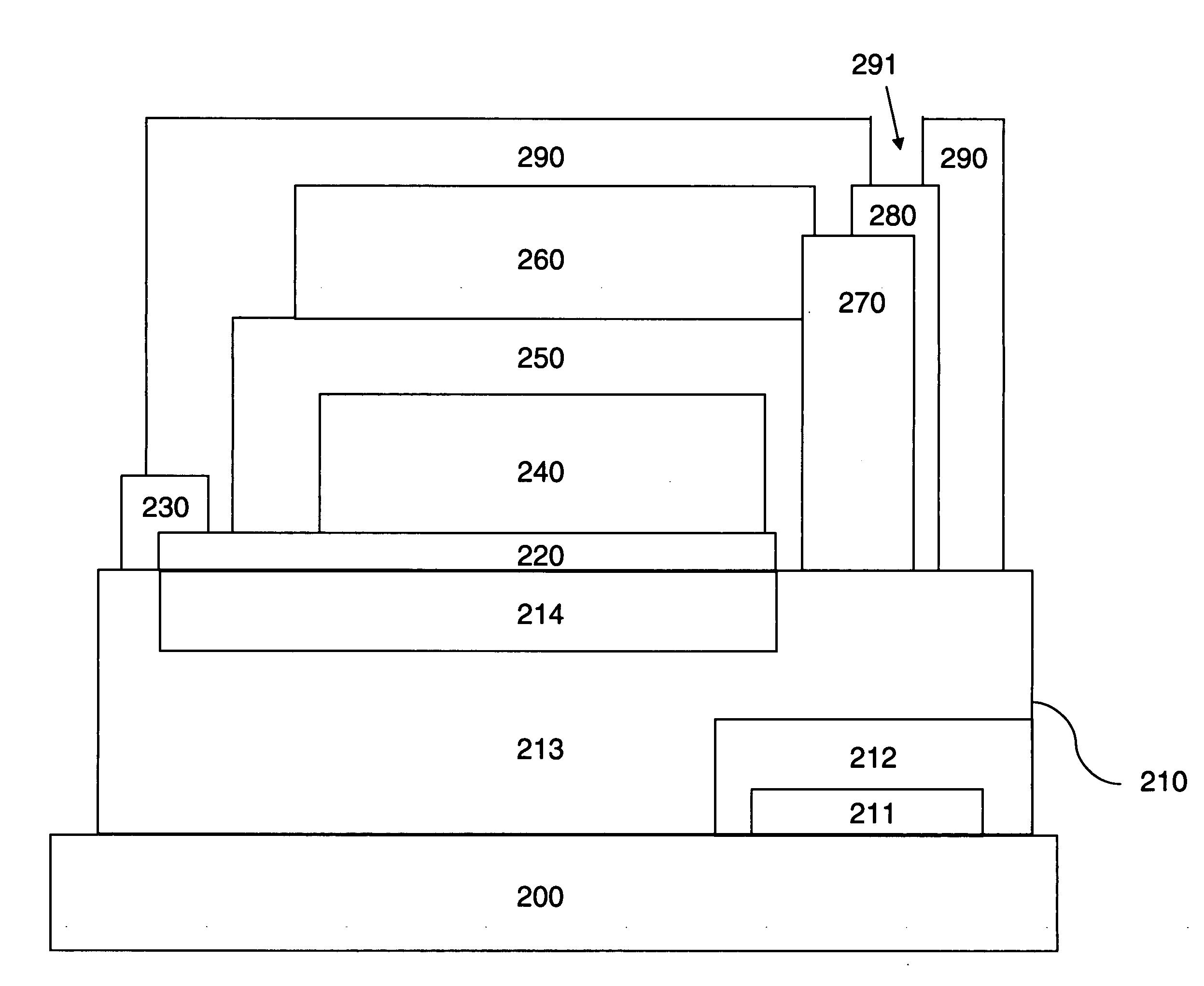

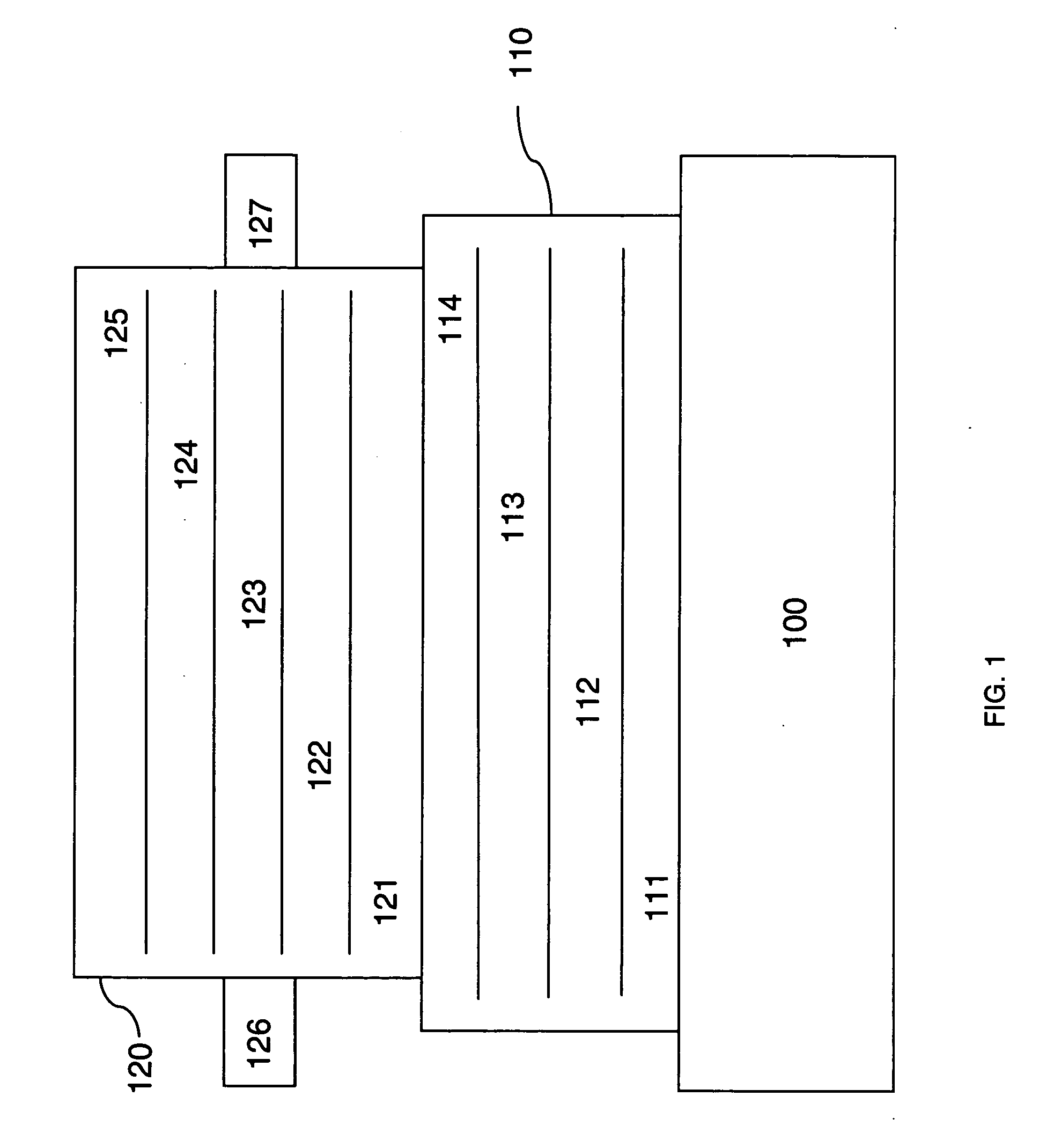

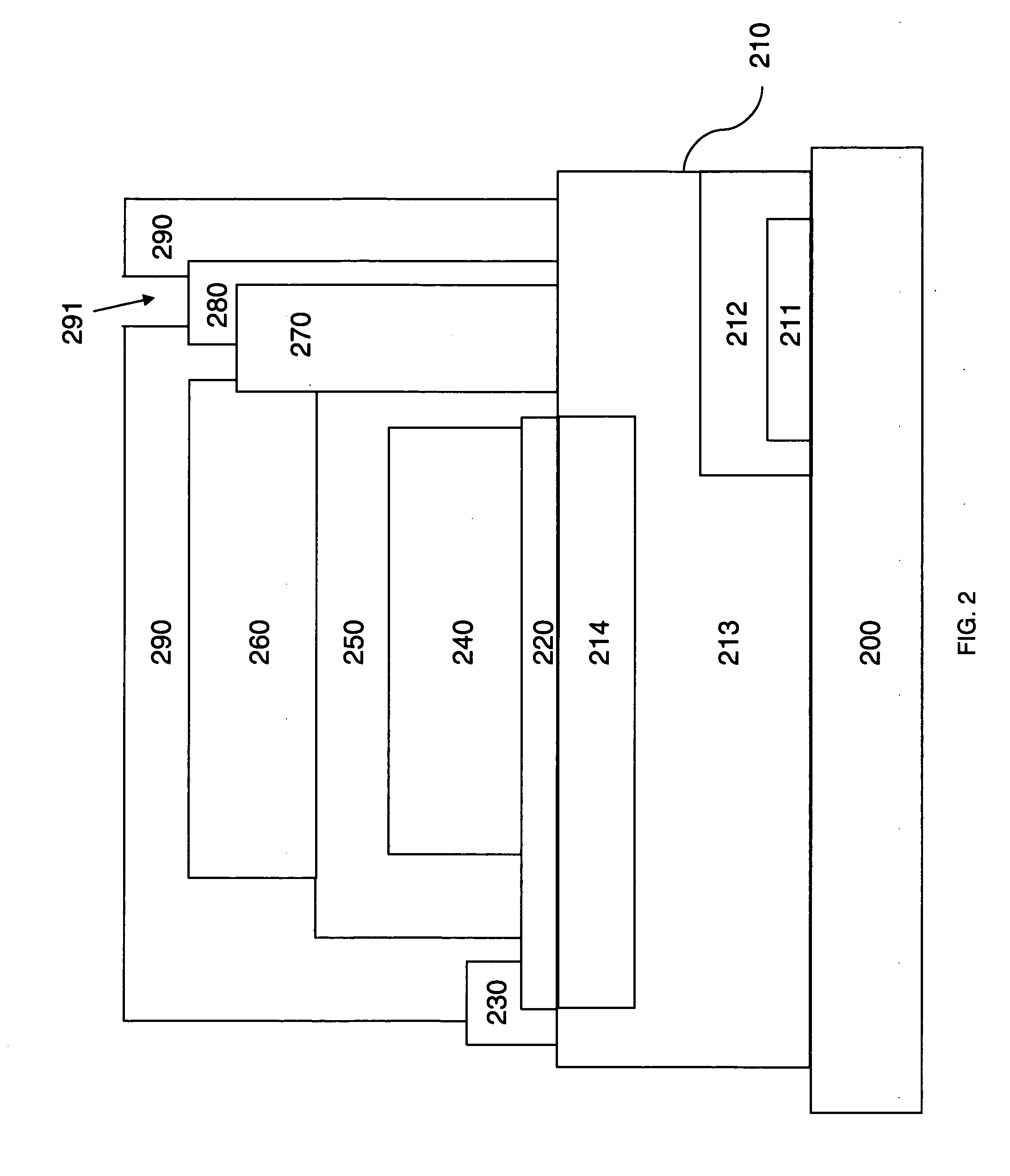

The disclosed embodiments relate to a battery cell which includes a set of electrode sheets of different dimensions arranged in a stacked configuration to facilitate efficient use of space inside a portable electronic device. For example, the electrode sheets may be arranged in the stacked configuration to accommodate a shape of the portable electronic device. The stacked configuration may be based on a non-rectangular battery design such as a toroidal design, an L-shaped design, a triangular design, a pie-shaped design, a cone-shaped design, and / or a pyramidal design.

Owner:APPLE INC

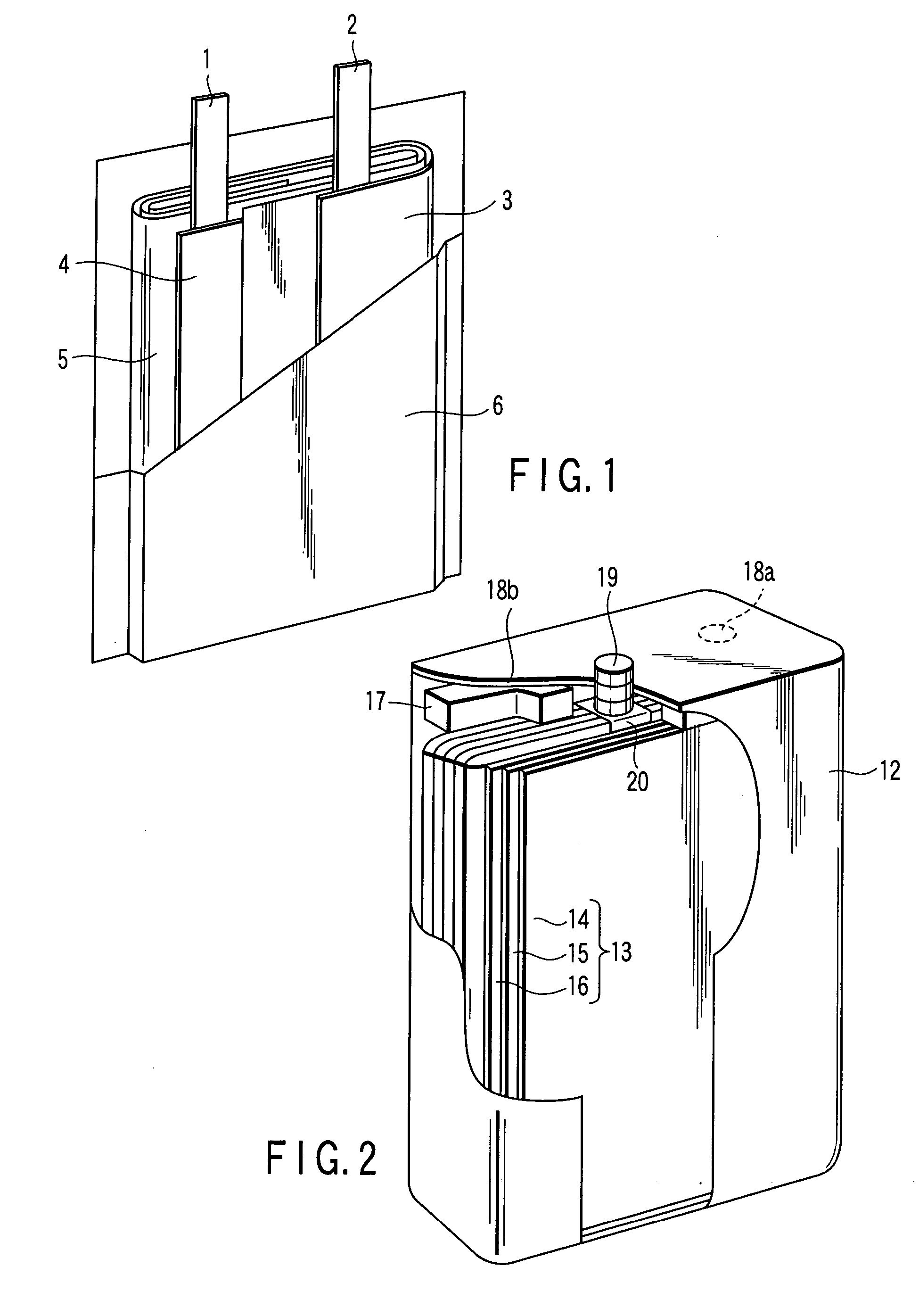

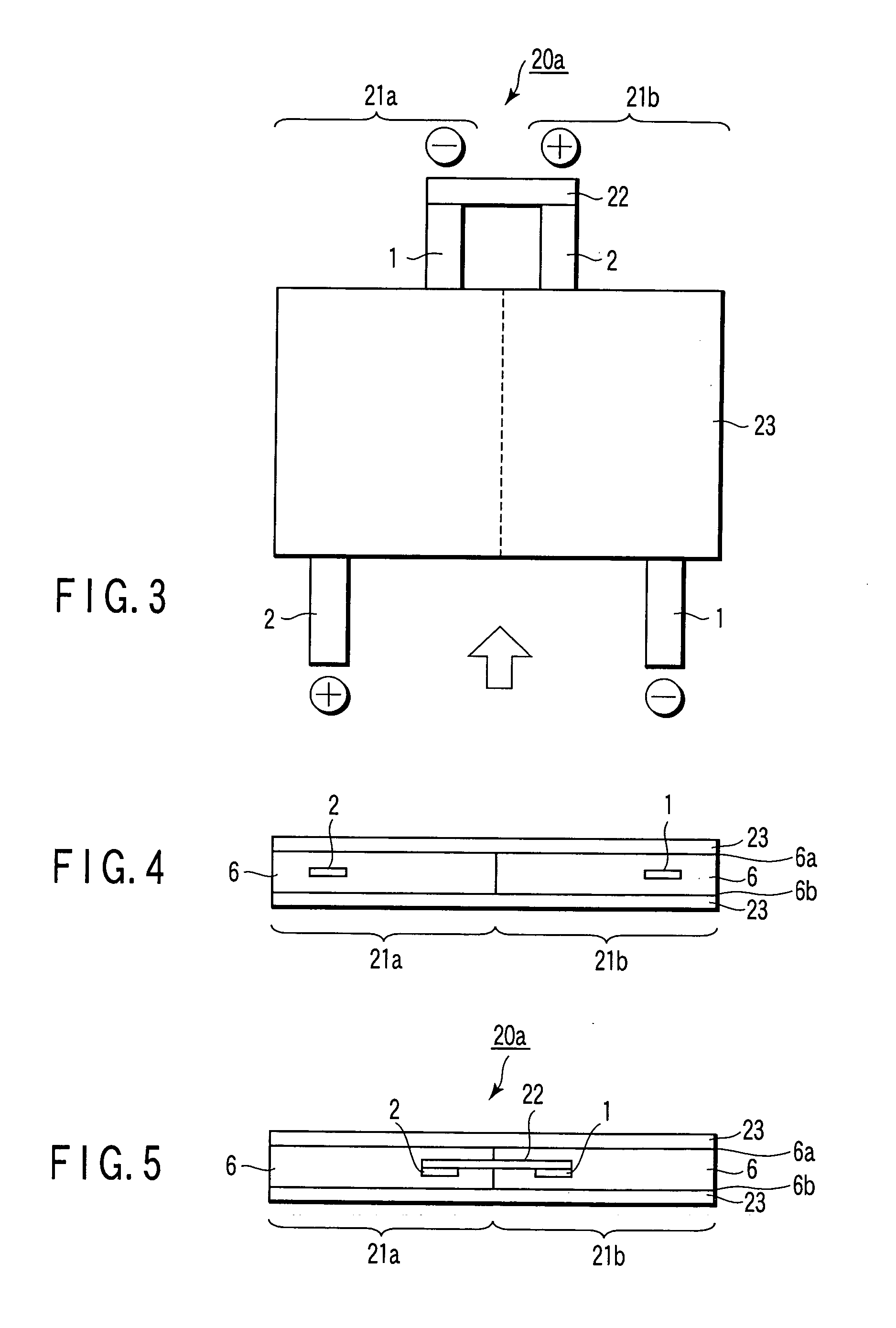

Nonaqueous electrolyte secondary battery and battery module

ActiveUS20050069777A1Excellent in battery capacity characteristic and cycle performanceEasy dischargeFinal product manufactureElectrode carriers/collectorsAlloyAluminum foil

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case, a positive electrode provided in the case, and a negative electrode provided in the case, the negative electrode comprising a negative electrode current collector and a negative electrode layer that is carried on the negative electrode current collector and contains negative electrode active material particles, and the negative electrode current collector comprising an aluminum foil having an average crystal grain size of 50 μm or less or an aluminum alloy foil having an average crystal grain size of 50 μm or less.

Owner:KK TOSHIBA

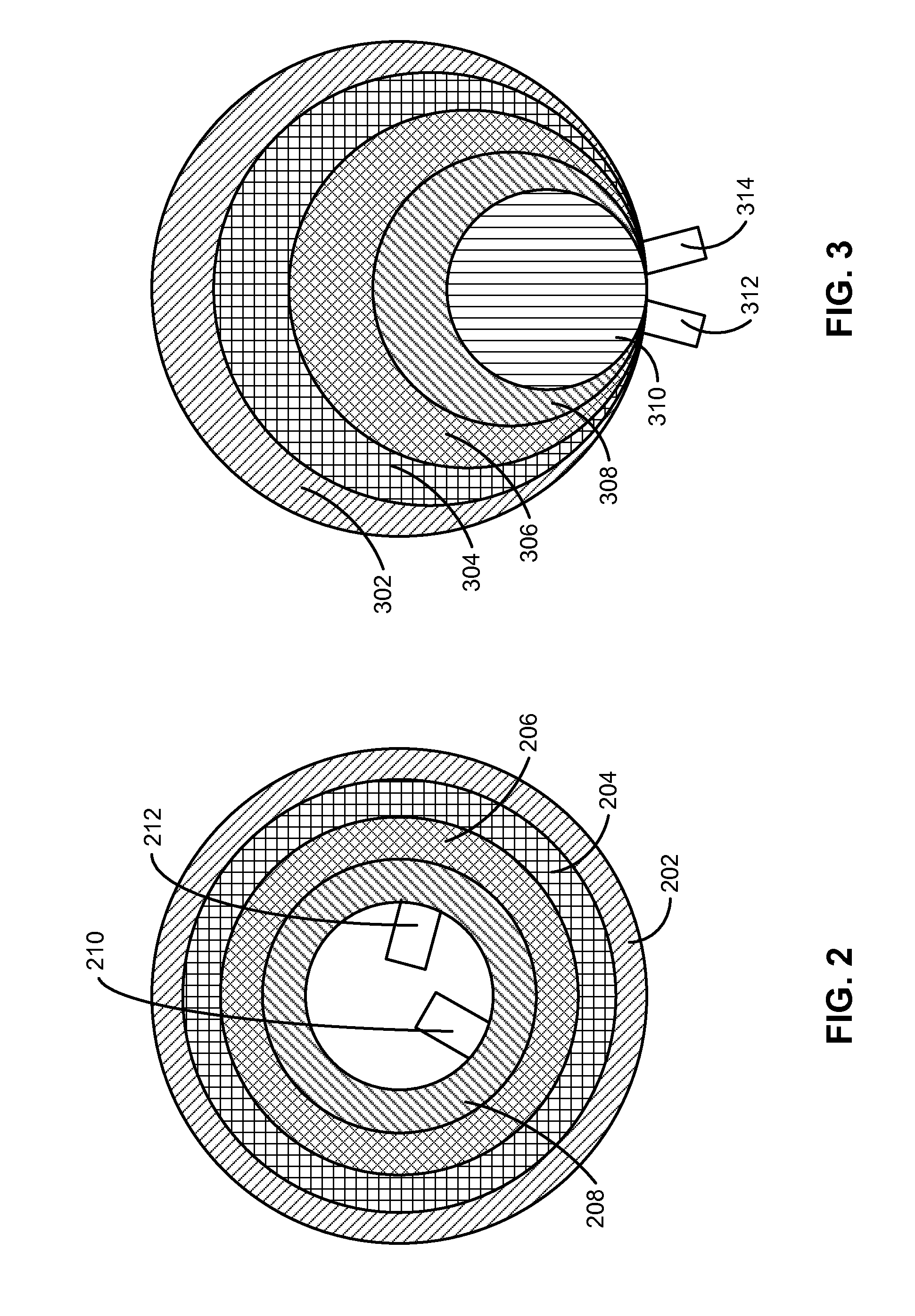

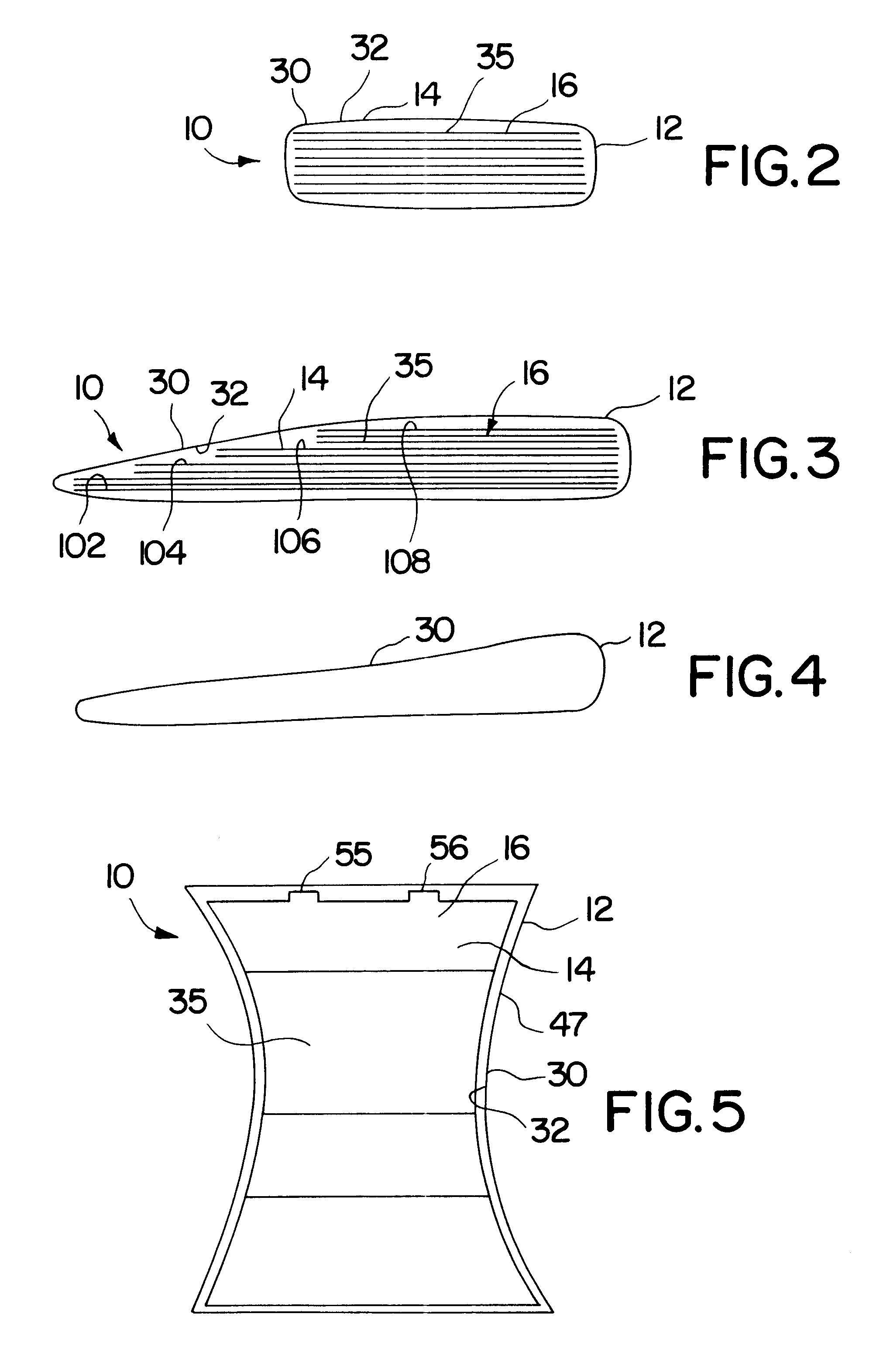

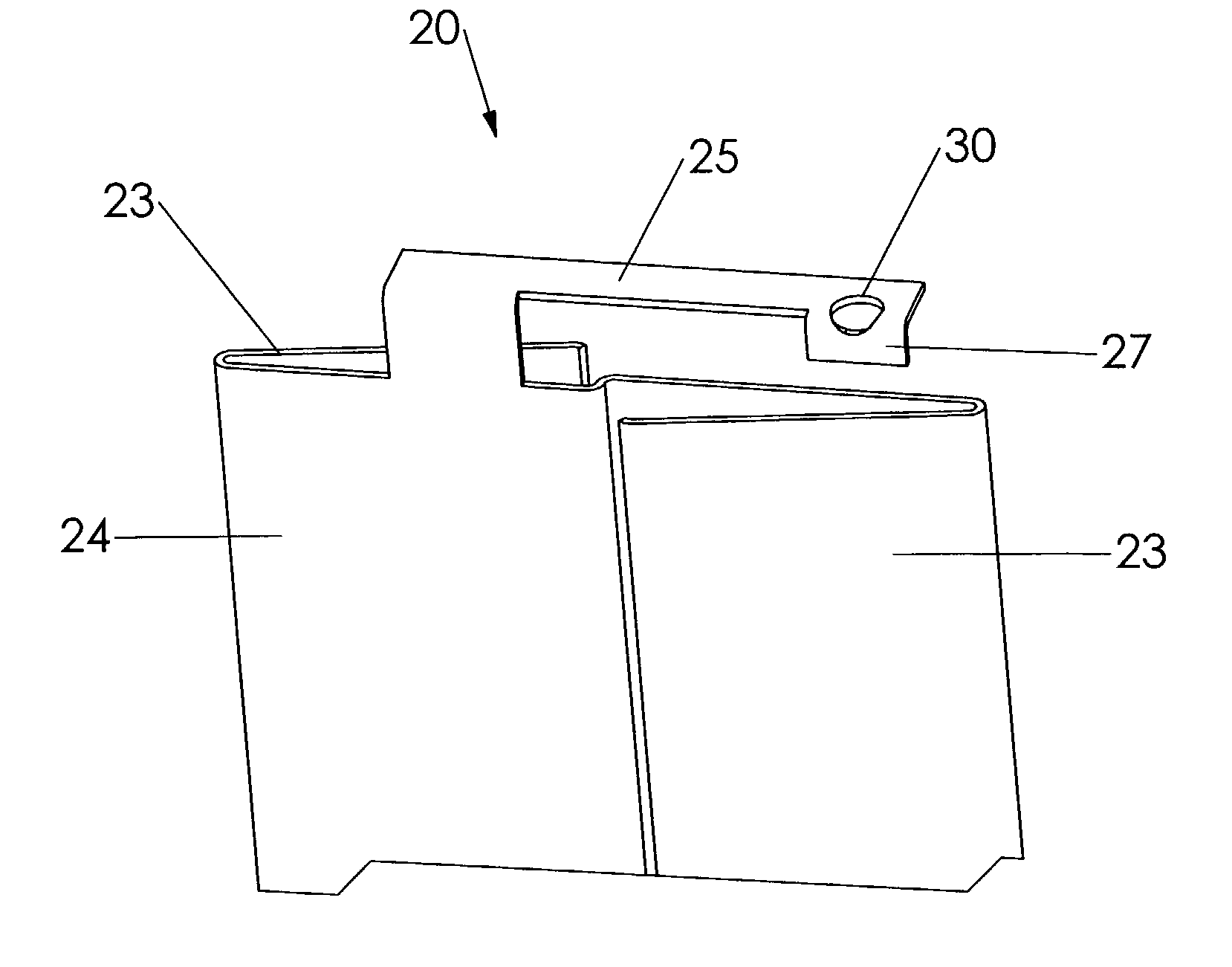

Three dimensional free form battery apparatus

A battery apparatus comprising a casing, at least two stacked lithium ion cells a member for maximizing the utilization of the casing and a member for precluding inadvertent deformation of the casing. The casing includes a non-uniform inner periphery. Each of at least two stacked lithium ion cells is positioned within the casing. The utilization maximizing member maximizes the utilization of the inner periphery of the casing by facilitating the independent shaping of each of the at least two stacked lithium ion cells to confirm to the inner periphery. As a result, the shape of one cell does not limit or dictate the shape of any other cell. The deformation precluding member is associated with each of the at least two lithium ion cells, and, substantially precludes inadvertent deformation of the casing by the at least two lithium ion cells, during cell cycling and storage. The invention further includes a process for fabricating a battery apparatus.

Owner:MITSUBISHI CHEM CORP

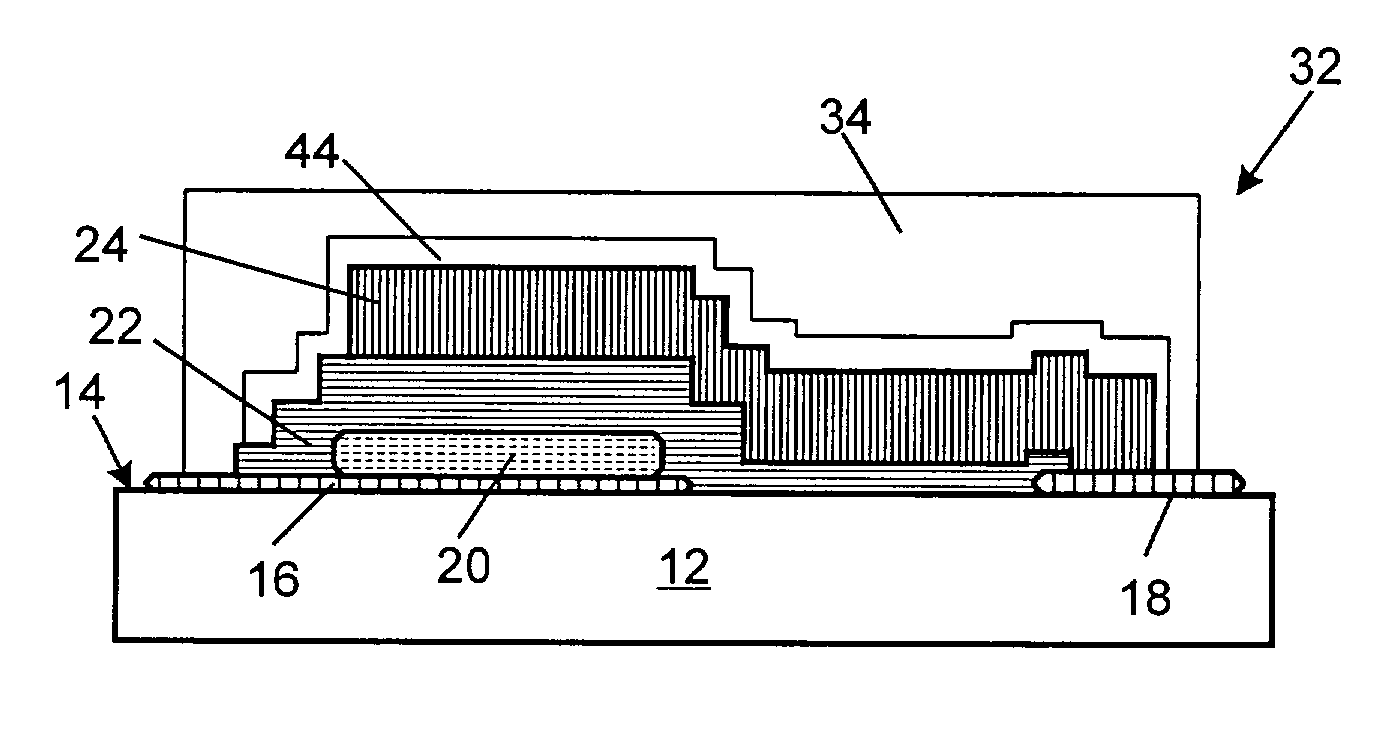

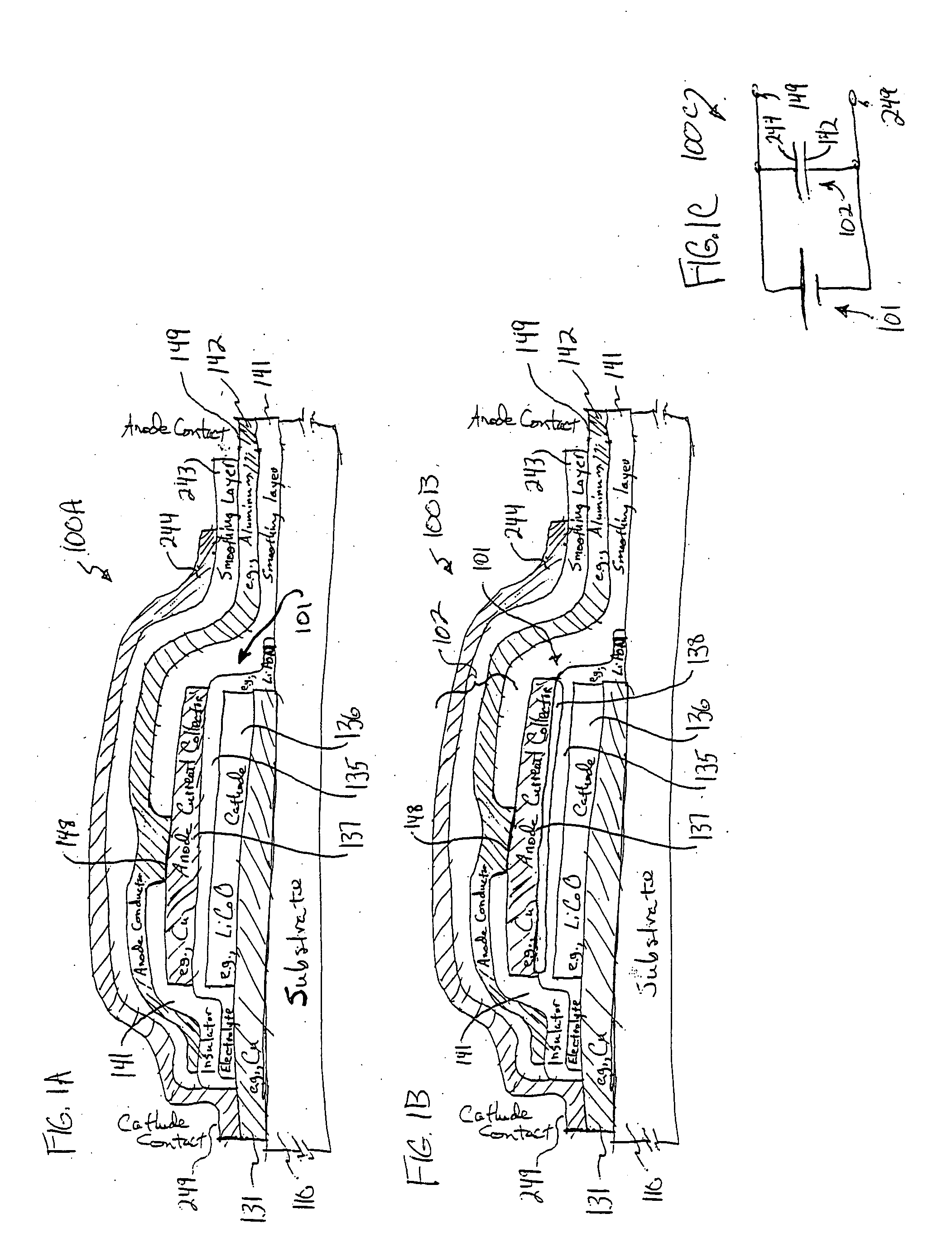

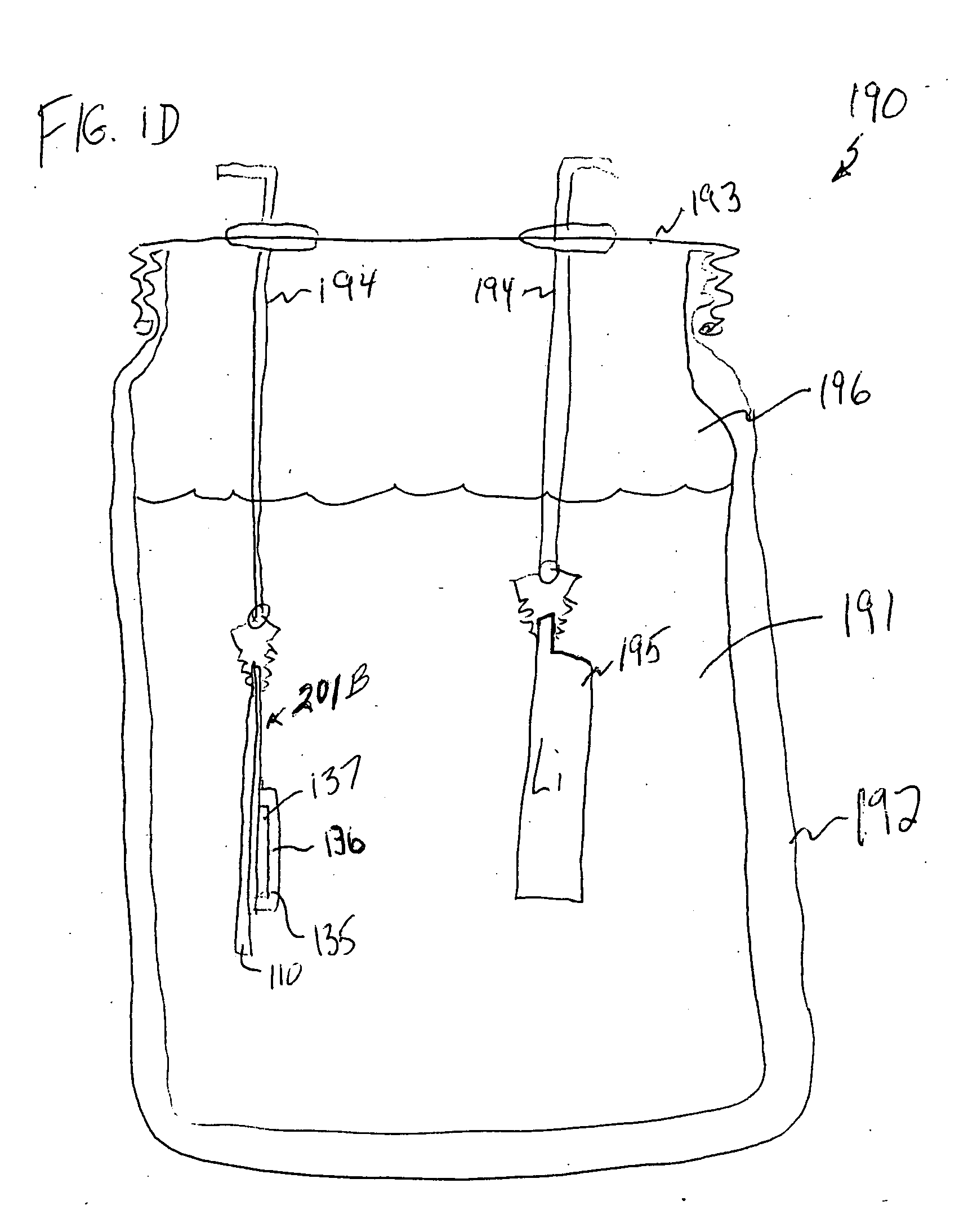

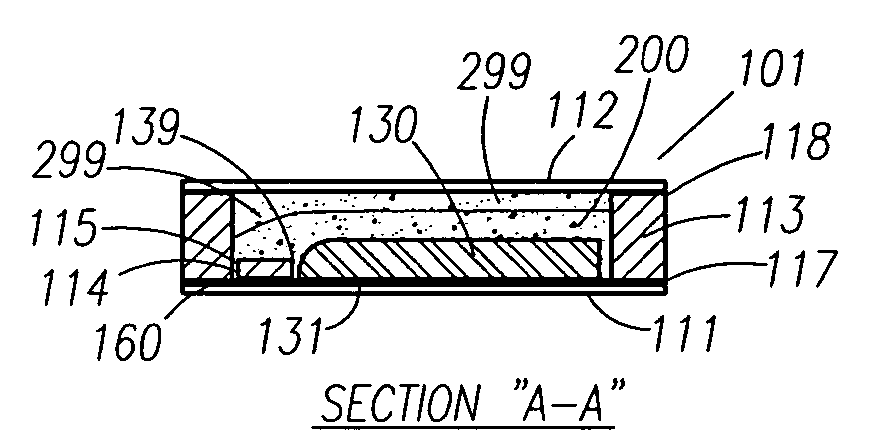

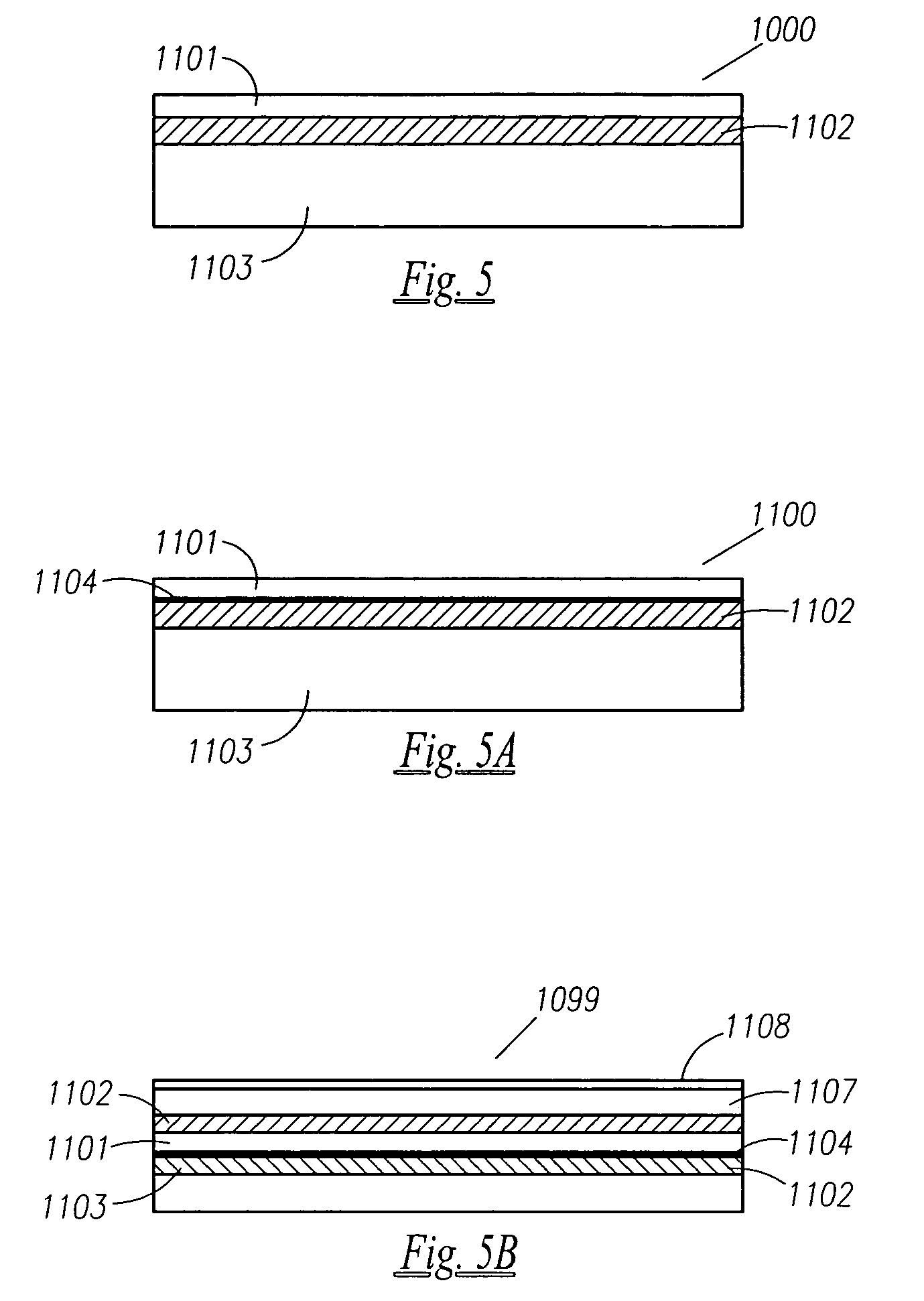

Long life thin film battery and method therefor

InactiveUS6994933B1Extend battery lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsOxygen fluxSurface roughness

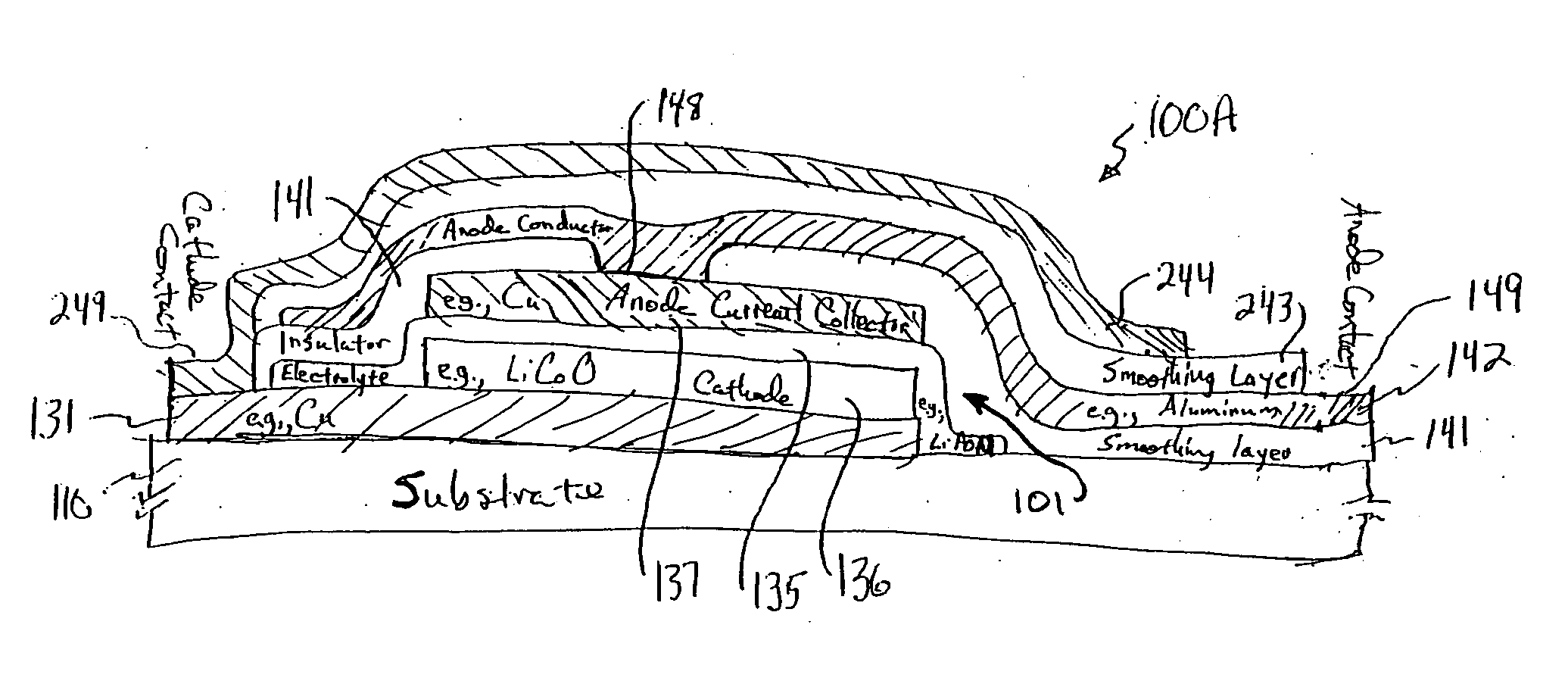

A thin film battery including an anode layer, a cathode layer and a solid electrolyte layer. The battery also includes, a planarization layer applied to the thin film battery. The planarization layer has a surface roughness of no more than about 1.0 nanometers root mean square and a flatness no larger than about 0.005 cm / inch. A barrier layer is applied to the planarization layer. The barrier layer is provided by one or more layers of material selected from the group consisting of polymeric materials, metals and ceramic materials. The planarization layer and barrier layer are sufficient to reduce oxygen flux through the barrier layer to the anode layer to no more than about 1.6 μmol / m2-day, and H2O flux through the barrier layer to the anode layer to less than about 3.3 μmol / m2-day thereby improving the life of the thin film battery.

Owner:OAK RIDGE MICRO ENERGY

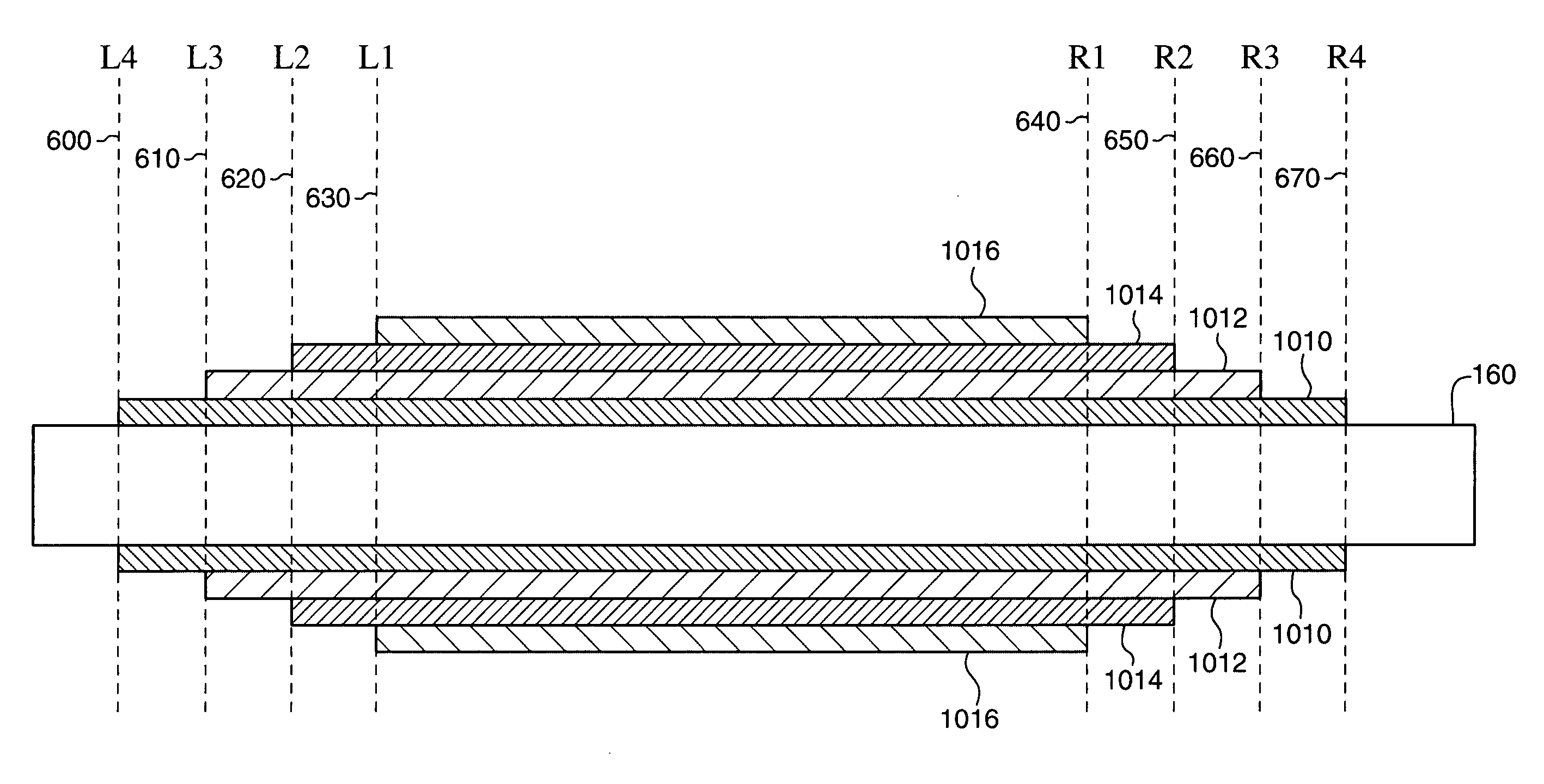

Electrochemical apparatus with barrier layer protected substrate

ActiveUS20060286448A1Inhibited DiffusionEfficient separationFinal product manufactureElectrode carriers/collectorsElectrochemistrySilicon

The present invention relates to apparatus, compositions and methods of fabricating high performance thin-film batteries on metallic substrates, polymeric substrates, or doped or undoped silicon substrates by fabricating an appropriate barrier layer composed, for example, of barrier sublayers between the substrate and the battery part of the present invention thereby separating these two parts chemically during the entire battery fabrication process as well as during any operation and storage of the electrochemical apparatus during its entire lifetime. In a preferred embodiment of the present invention thin-film batteries fabricated onto a thin, flexible stainless steel foil substrate using an appropriate barrier layer that is composed of barrier sublayers have uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for a LiCoO2 positive cathode.

Owner:SAPURAST RES

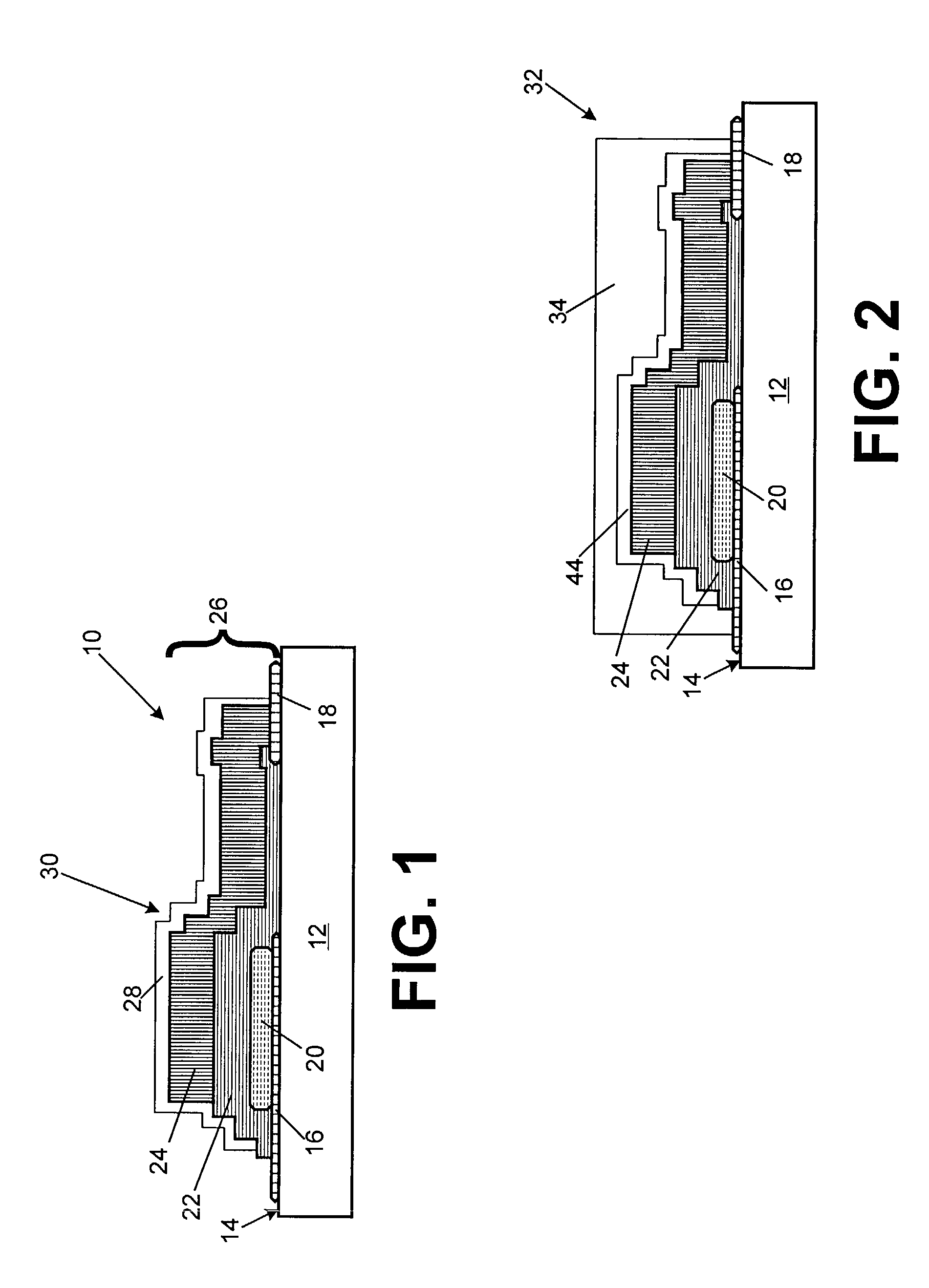

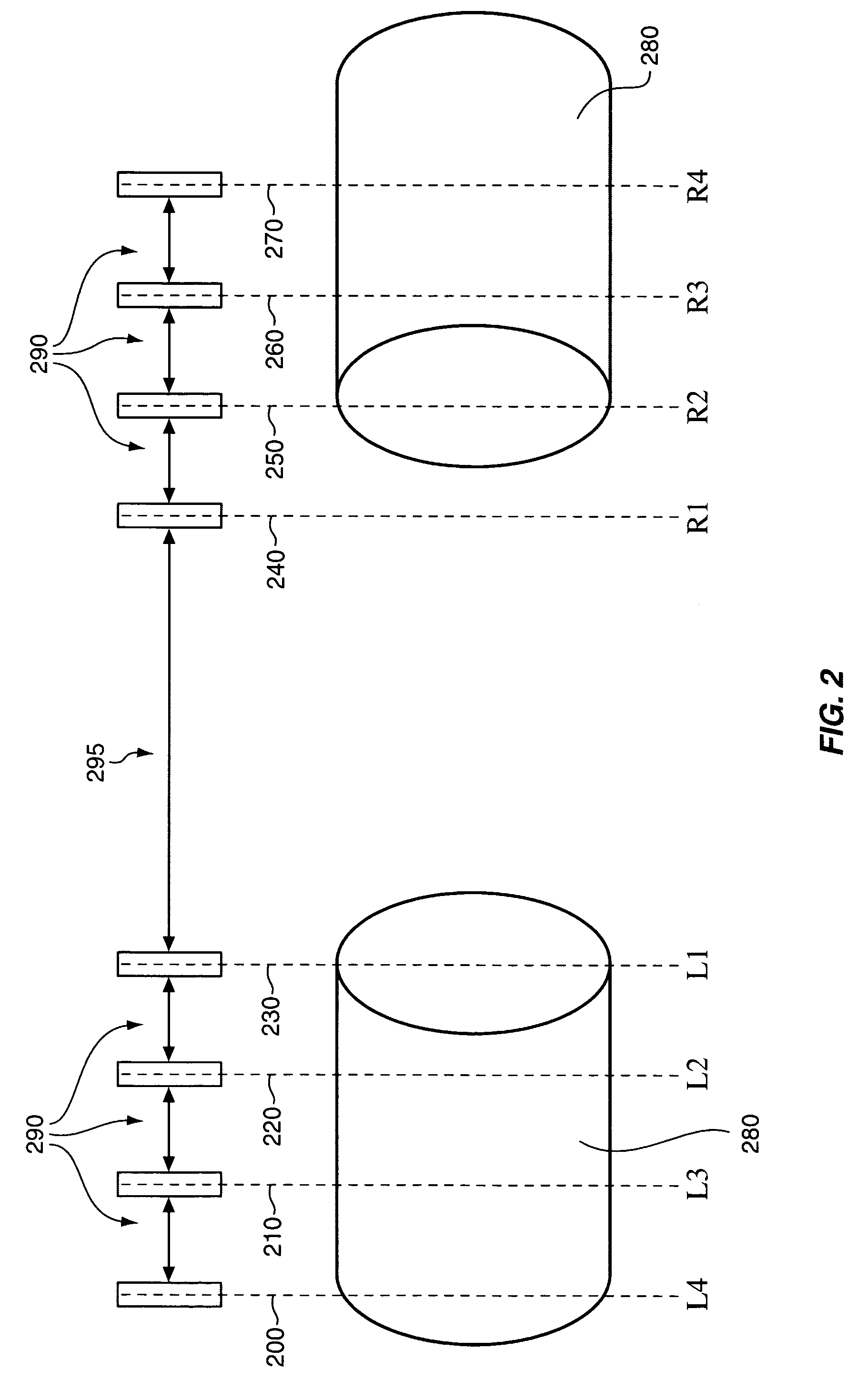

Layered barrier structure having one or more definable layers and method

InactiveUS20050147877A1Reduce transmissionLow rateFuel and primary cellsElectrode manufacturing processesDielectricLithium compound

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

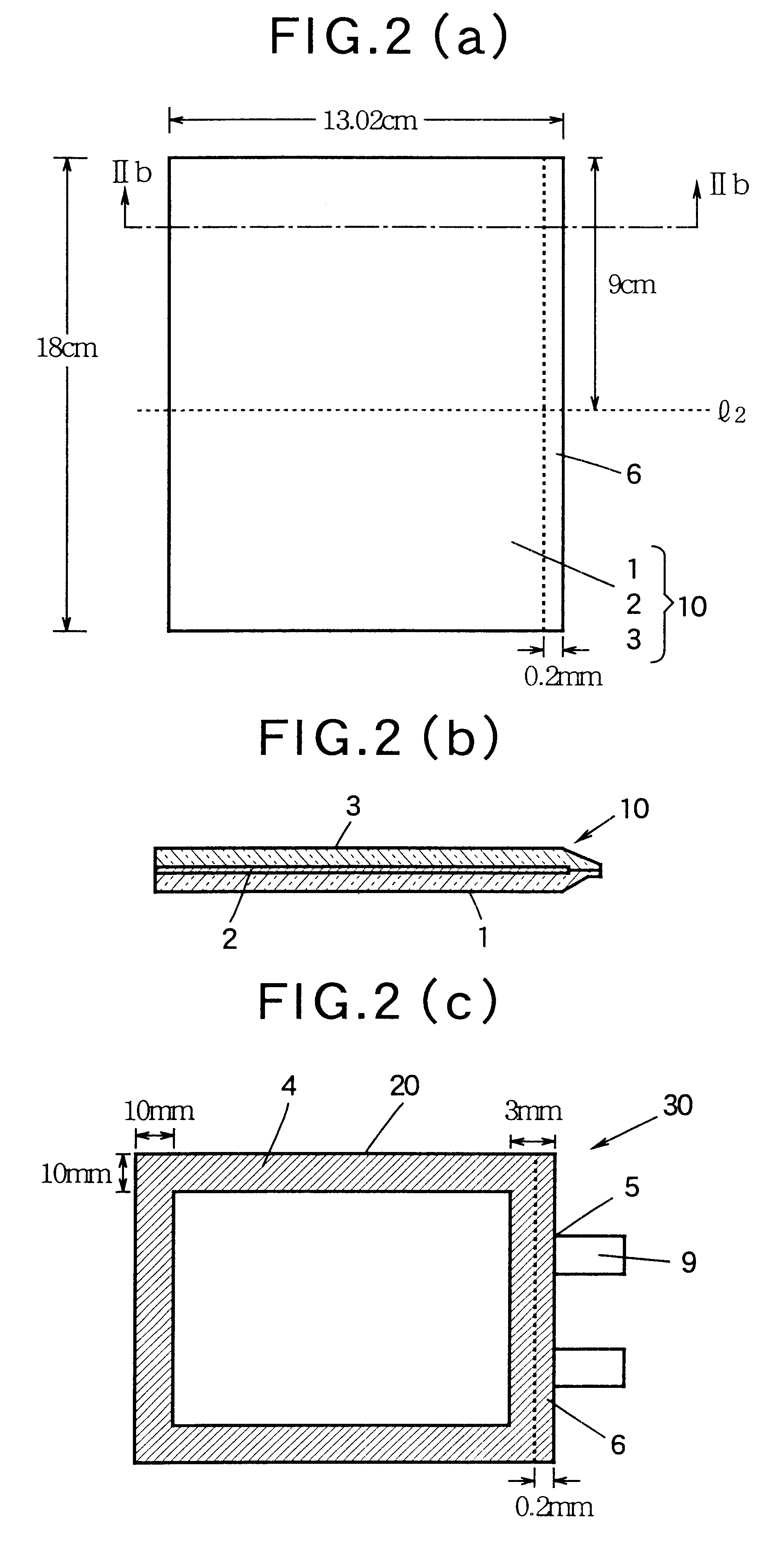

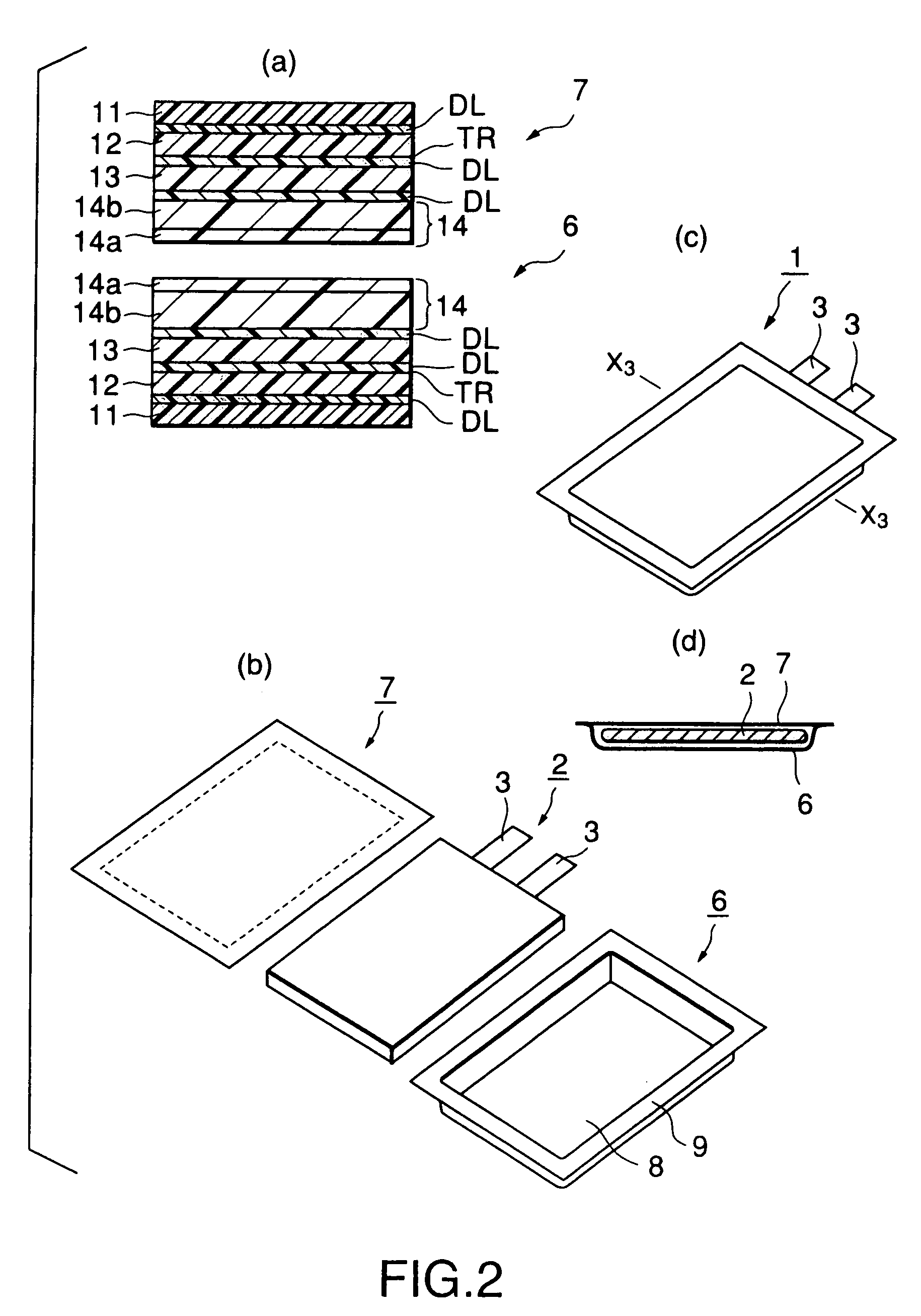

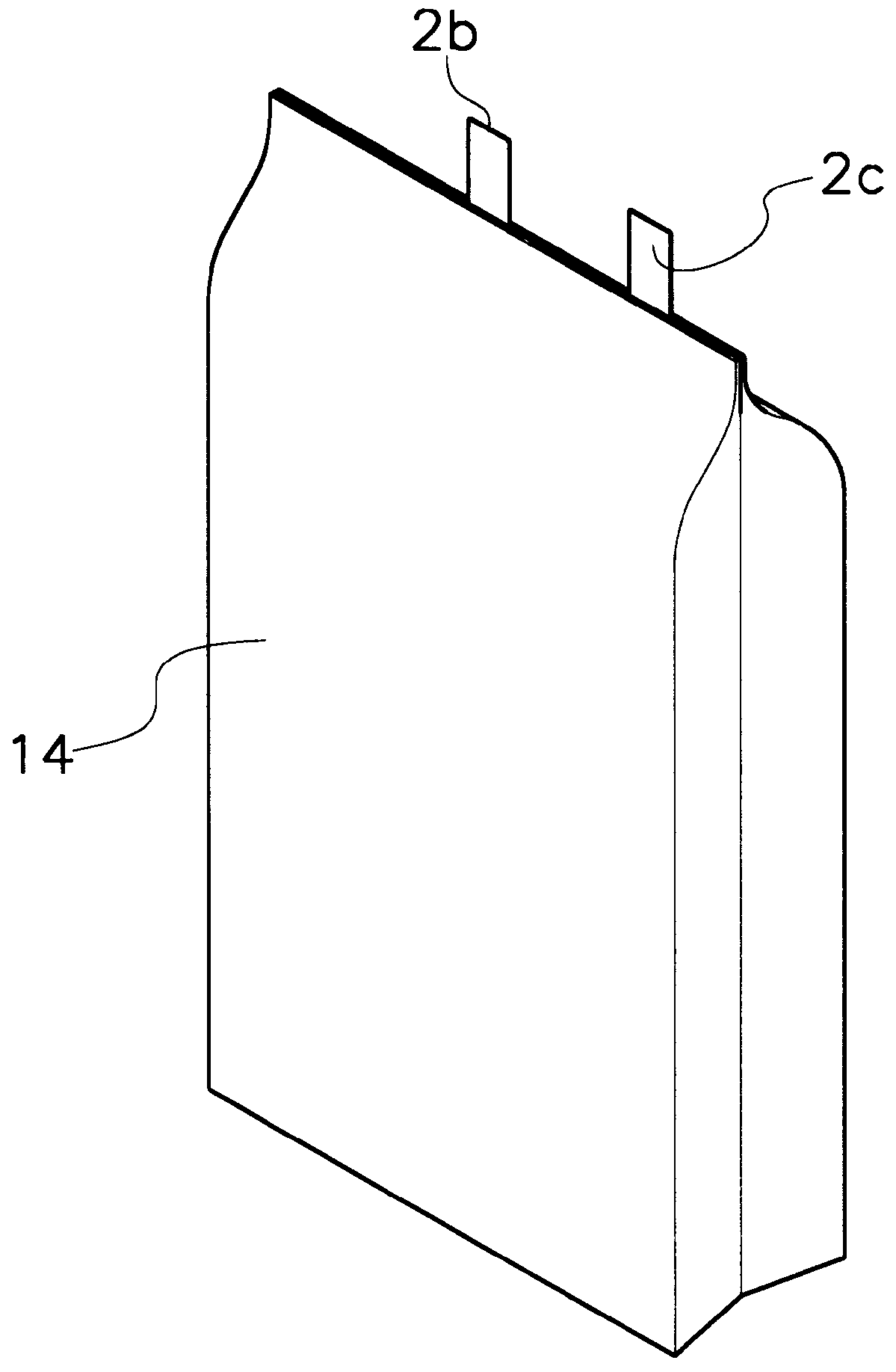

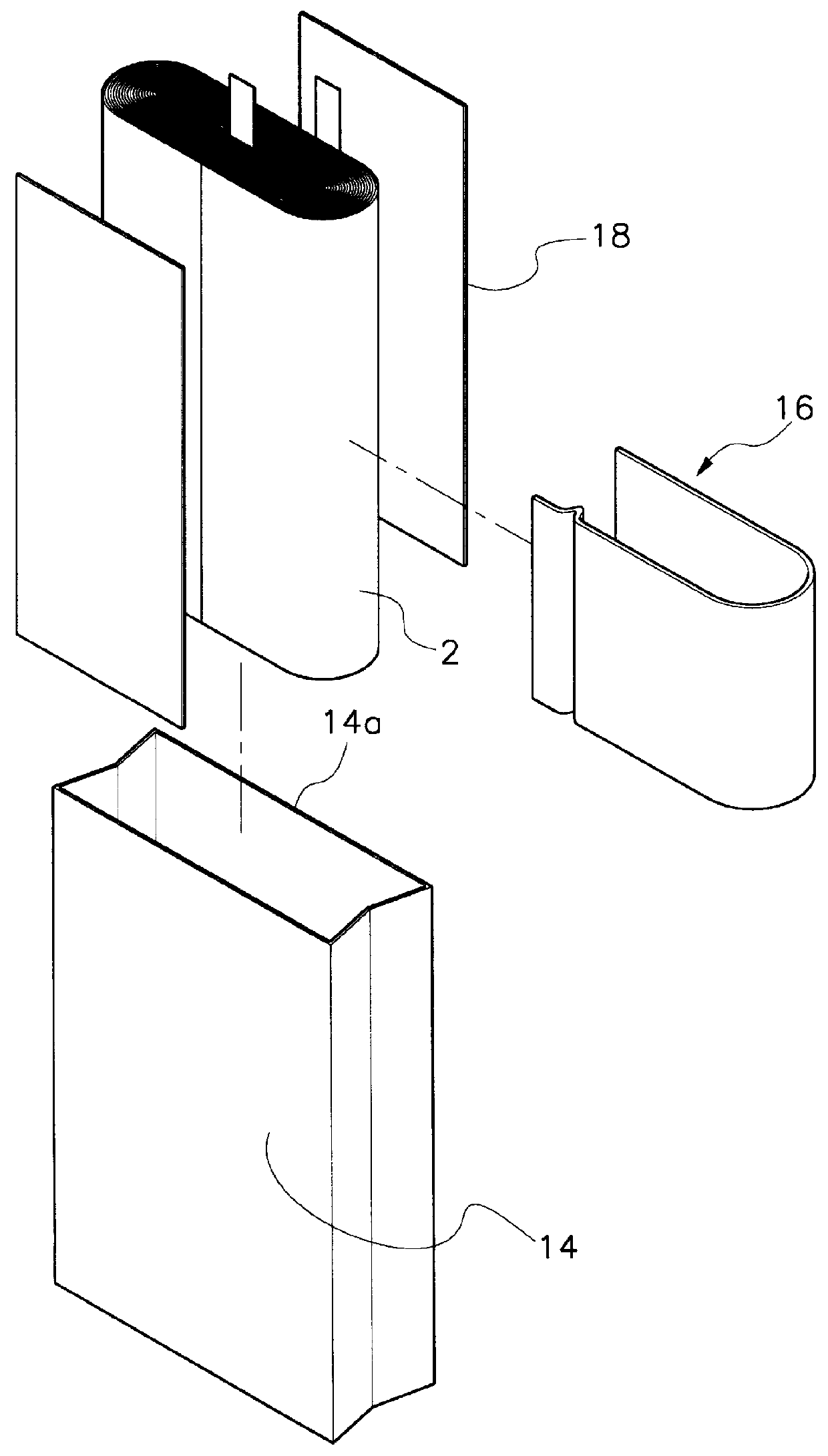

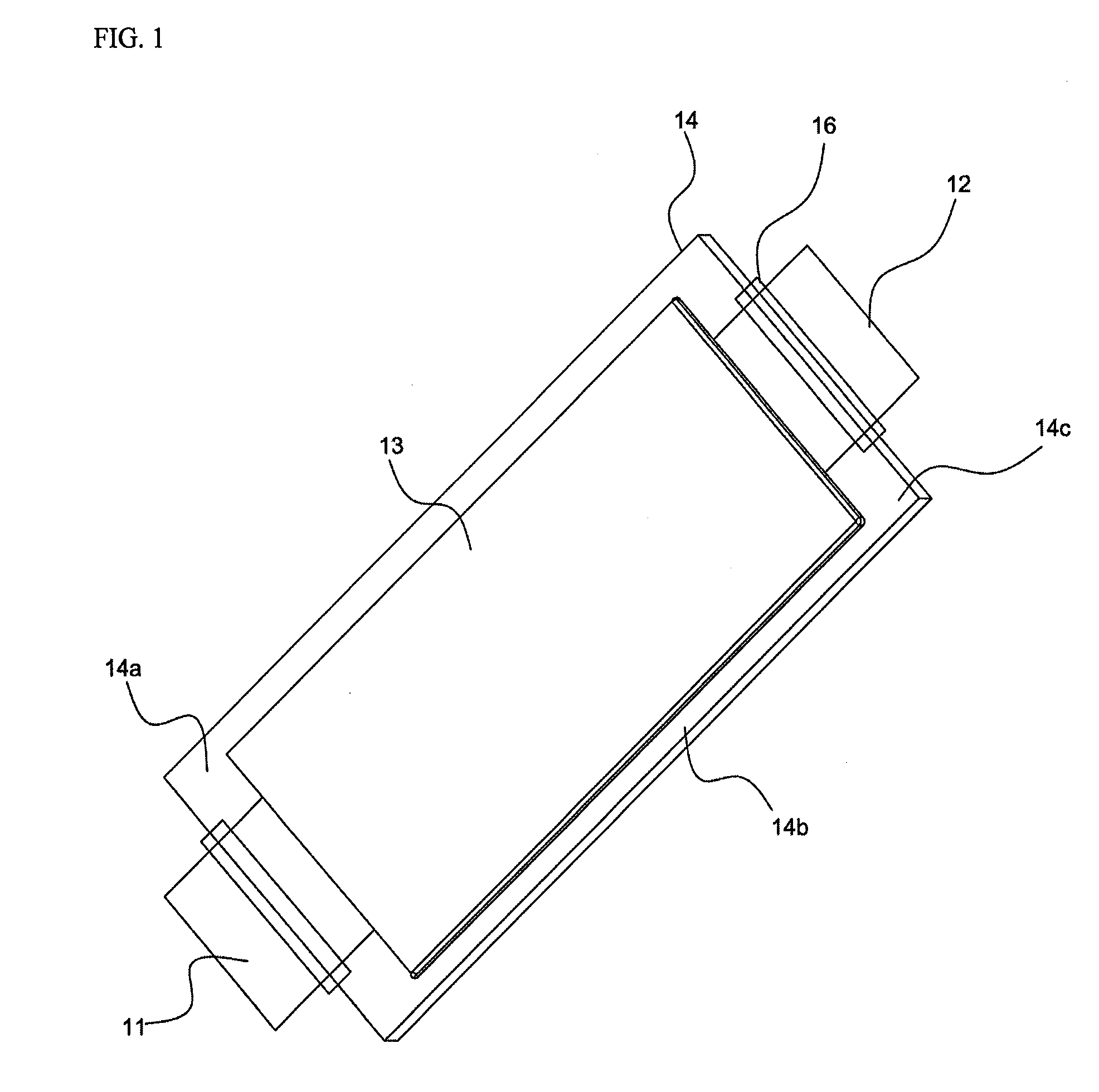

Non-aqueous battery of a thin configuration

InactiveUS6461757B1Small-sized cells cases/jacketsActive material electrodesMetallic foilElectrical battery

A non-aqueous battery is provided in a pouchy casing comprising opposing sheets of at least three-layer laminates, each laminate comprising (1) an inner thermoplastic resin layer, (2) a middle metal foil layer, and (3) an outer electrically insulating material layer, wherein the pouchy casing has an elongated, hermetic adhesion area along a periphery of the pouchy casing, and the middle metal foil layer has a peripheral elongated region in the elongated, hermetic adhesion area of the pouchy casing, and at least a pair of terminals electrically connected to the cathode and anode of the battery extends through and protrudes from the terminal-withdrawal sites in the elongated, hermetic adhesion area toward the outside of the pouchy casing, and the battery has at least one of the following features: (i) the peripheral elongated region of the middle metal foil layer has cut-out portions around the terminal-withdrawal sites and (ii) the surface of the peripheral edge of the pouchy casing is provided with electric insulation at least at portions around the terminal-withdrawal sites.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Methods of and device for encapsulation and termination of electronic devices

InactiveUS6916679B2Improve sealingPrevent buildupPV power plantsFinal product manufactureElectricityElectrical devices

A novel method for production of and an apparatus for an encapsulated solid-state electrochemical device is disclosed. The present invention provides for electrical devices, such as, for example, thin-film batteries with sensitive chemistries that can survive environmental exposure while providing external electrical contact to the internal cell chemistry. The method of packaging of the present invention may include bonding one or more protective multi-layer laminates to the environmentally sensitive surfaces of an electronic device. The present invention may provide the advantage of avoiding entrapped air beneath the laminates.

Owner:SAPURAST RES

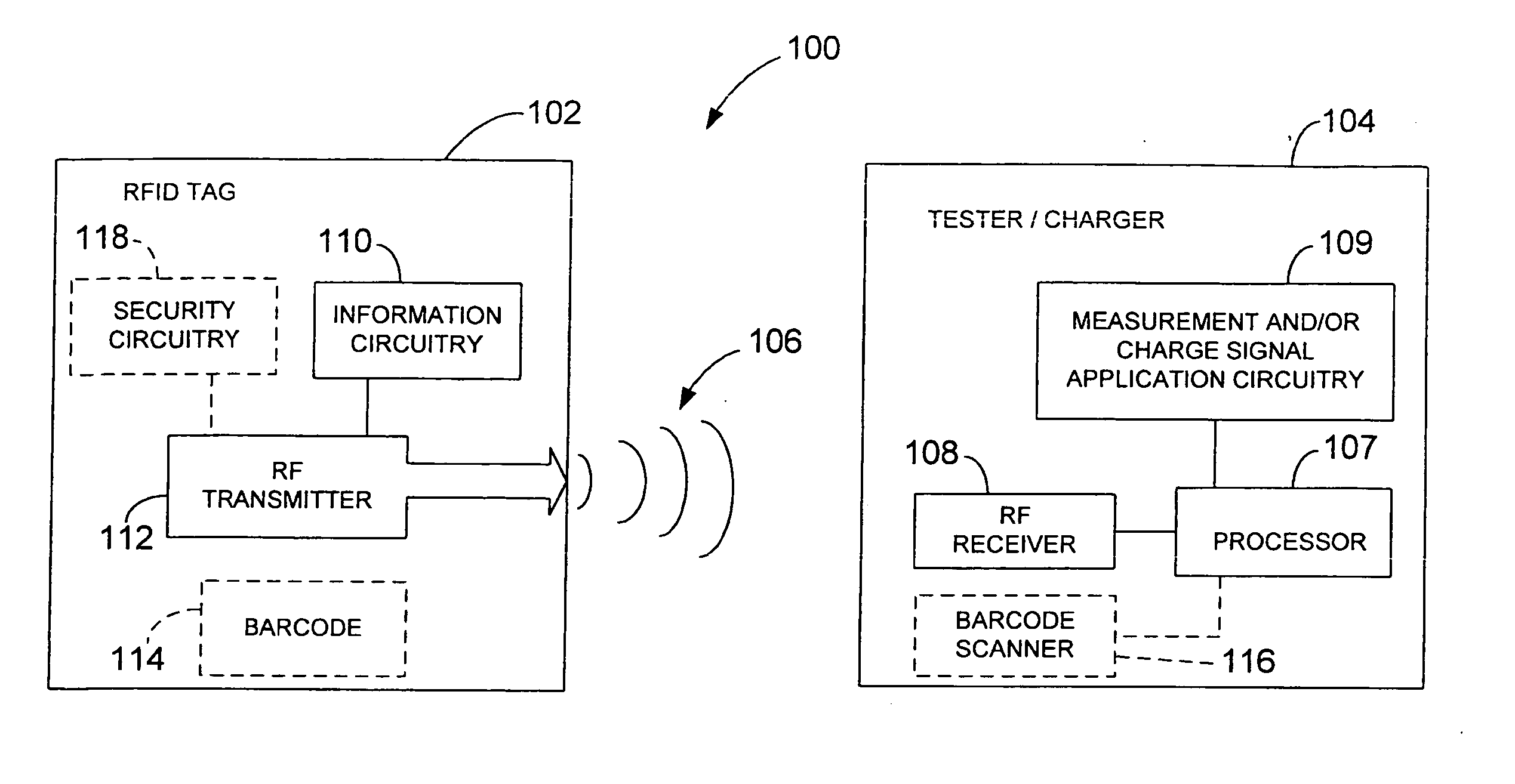

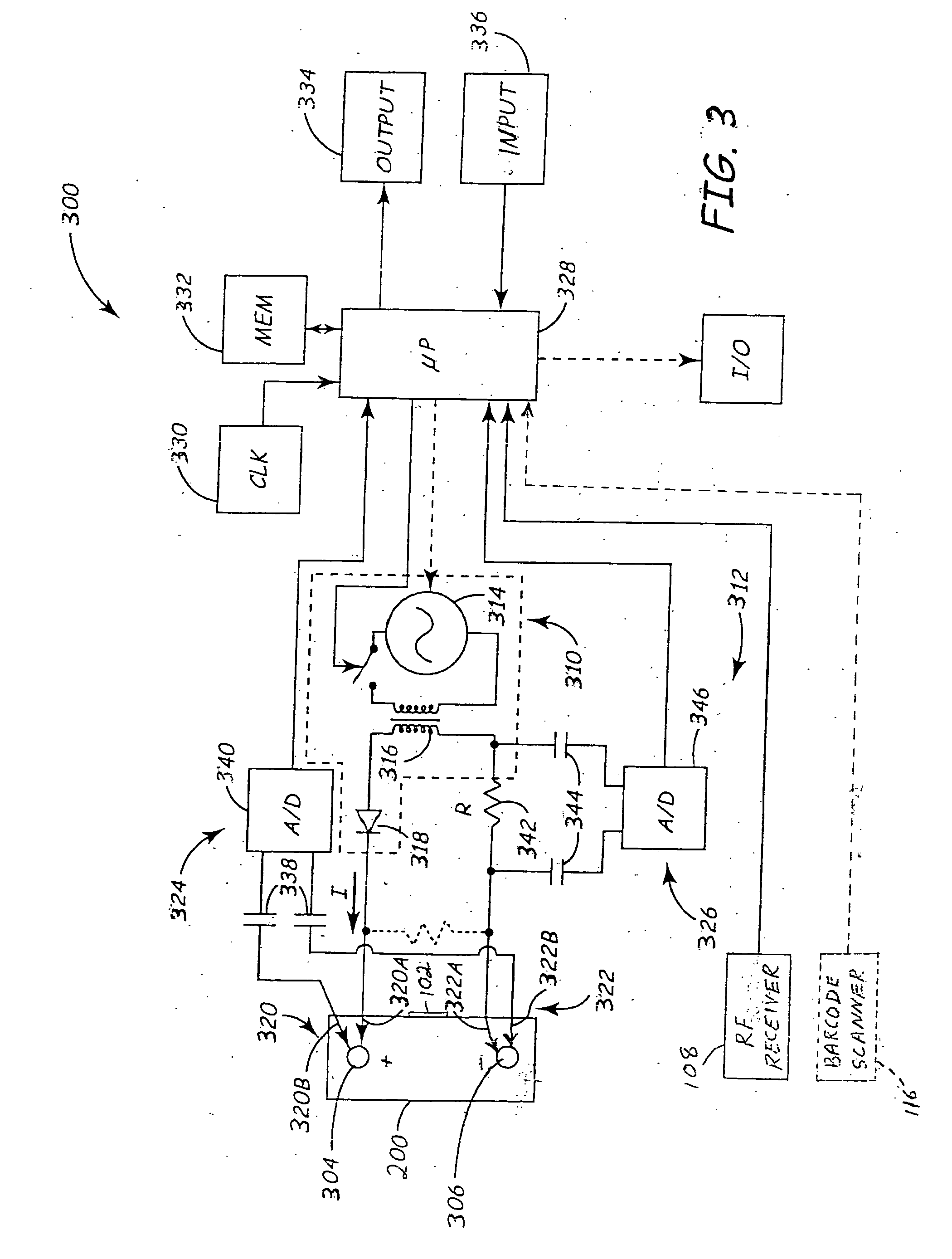

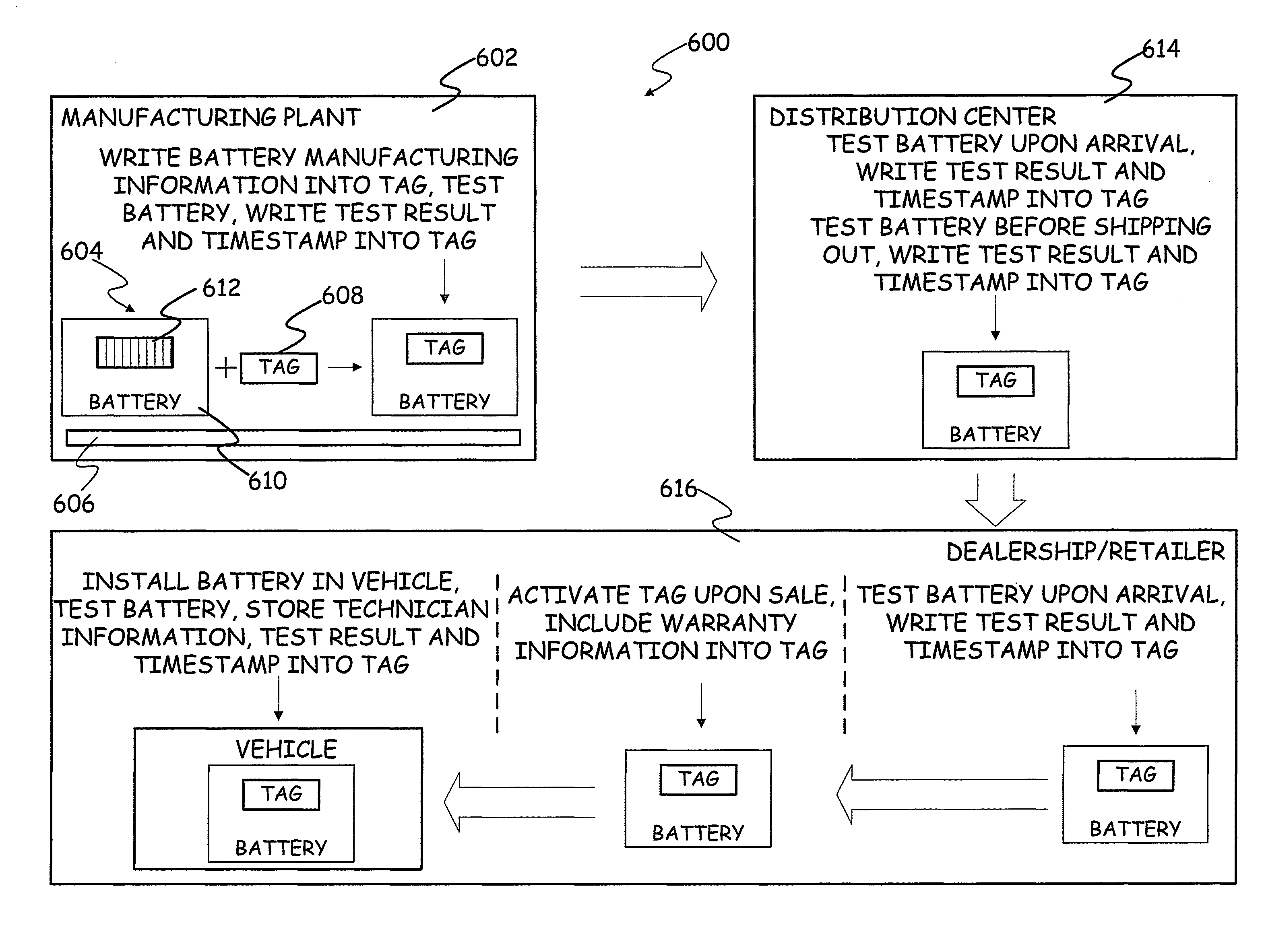

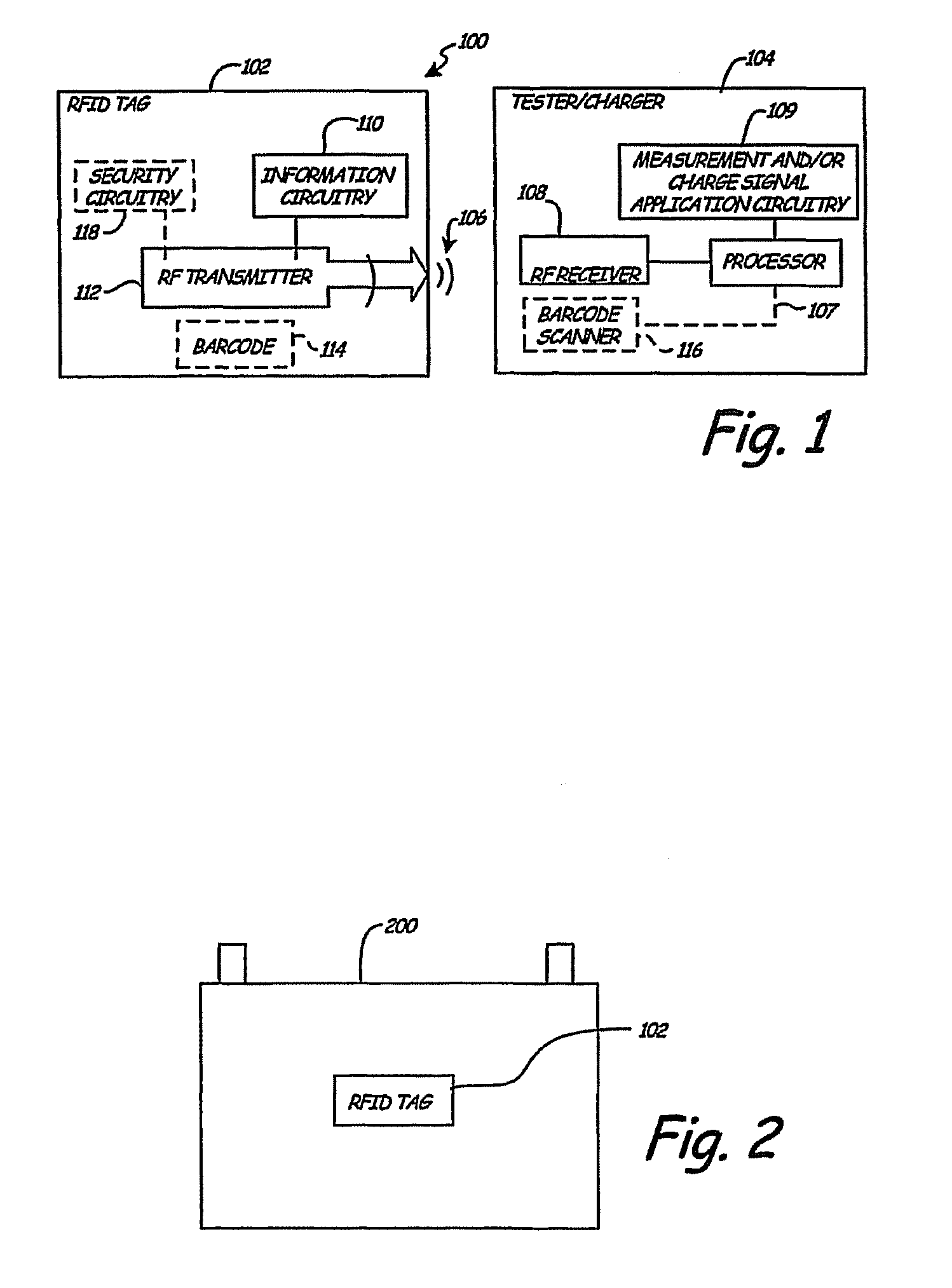

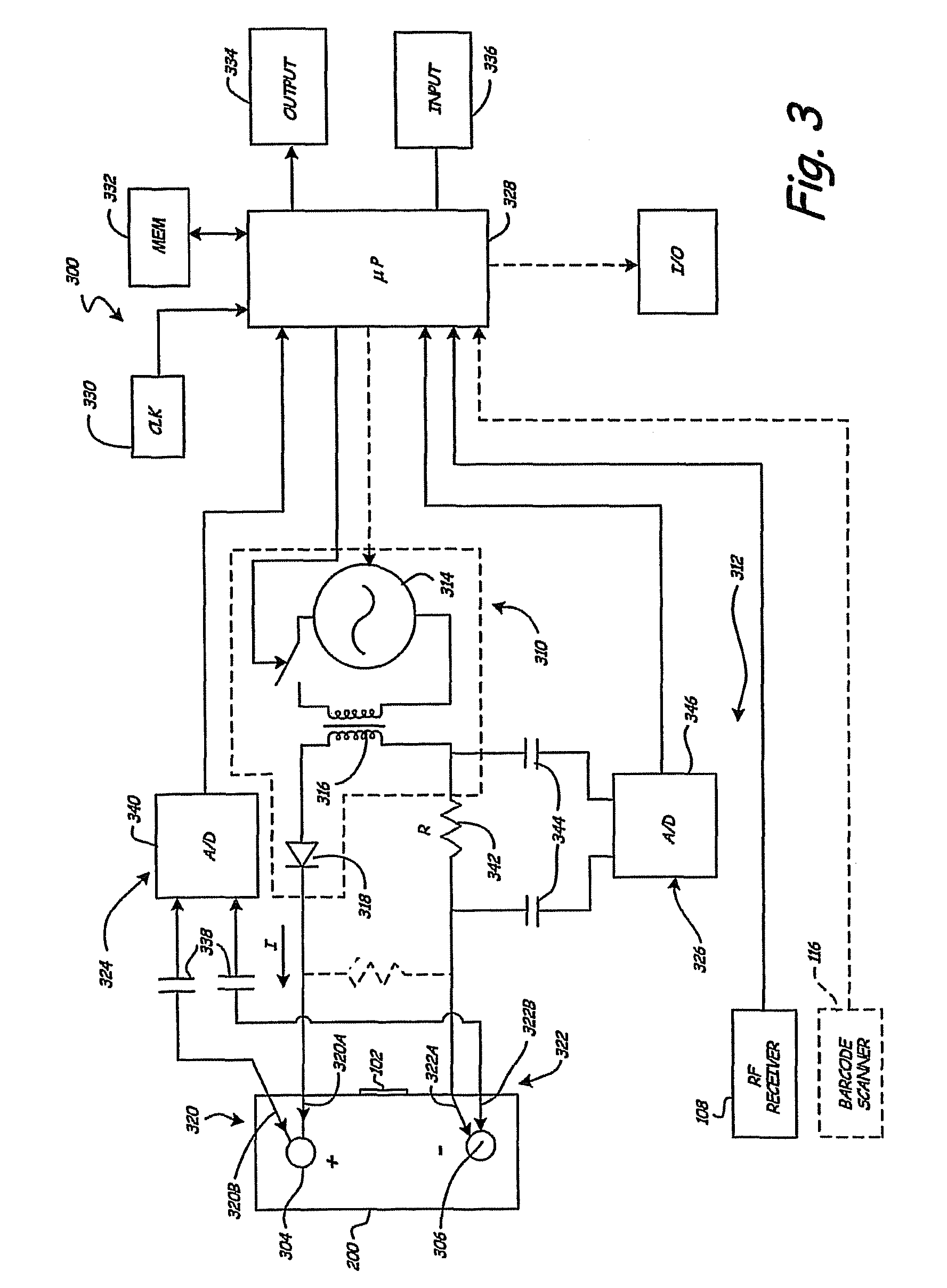

System for automatically gathering battery information for use during battery testing/charging

InactiveUS20060038572A1Material analysis by electric/magnetic meansSecondary cellsElectrical batteryTester device

An apparatus and method for testing / charging a storage battery includes a radio frequency identification (RFID) tag that can be affixed to the storage battery, the RFID tag is configured to store and transmit information related to the battery. The apparatus also includes a battery tester / charger. The tester / charger includes a radio frequency (RF) receiver configured to receive the transmitted information related to the battery, and testing / charging circuitry configured to utilize the received information related to the battery to test / charge the storage battery.

Owner:MIDTRONICS

Packaging for primary and secondary batteries

InactiveUS20050112461A1Extended calendar lifeDeferred-action cellsSynthetic resin layered productsMetal foilEngineering

Owner:UCHICAGO ARGONNE LLC

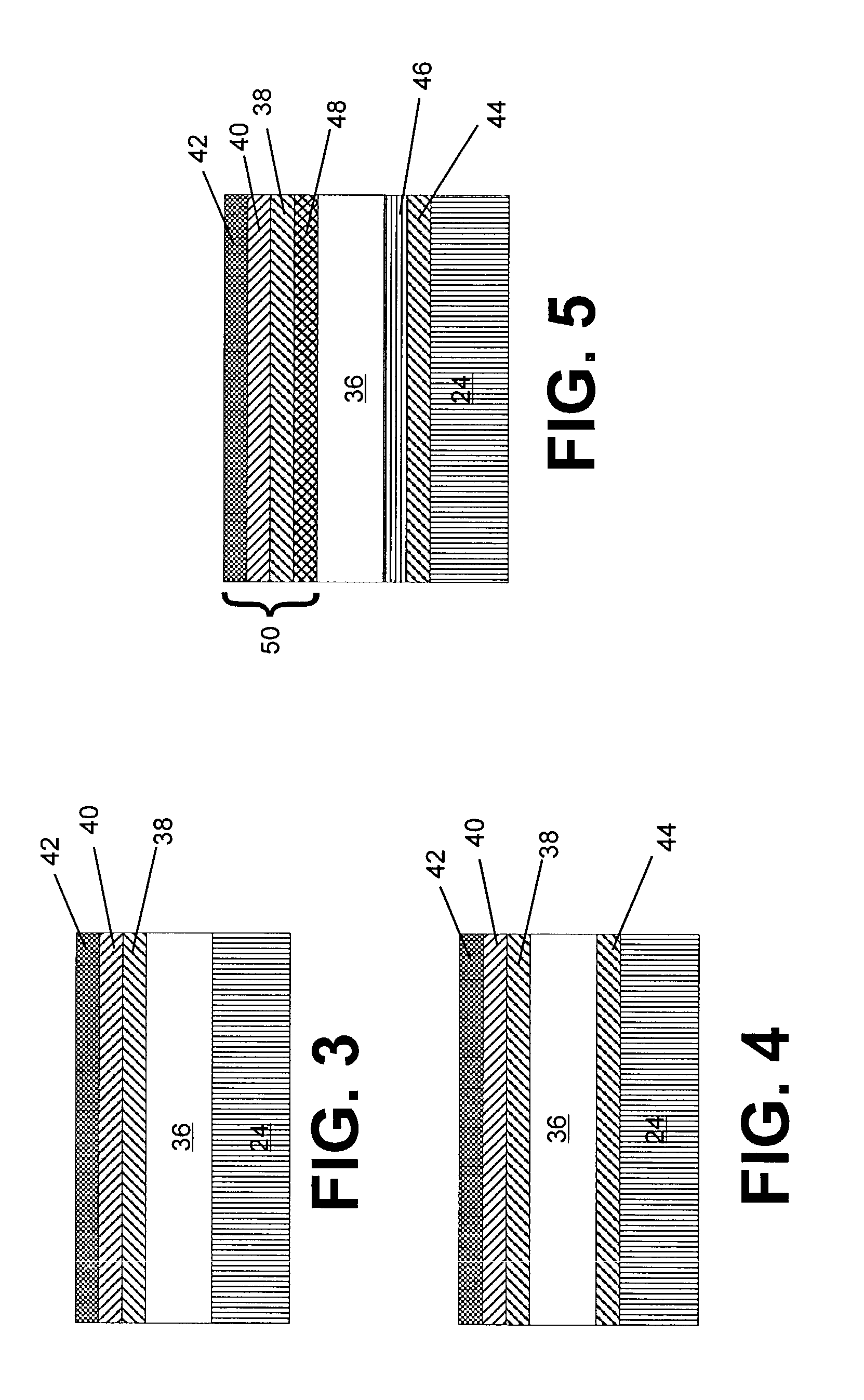

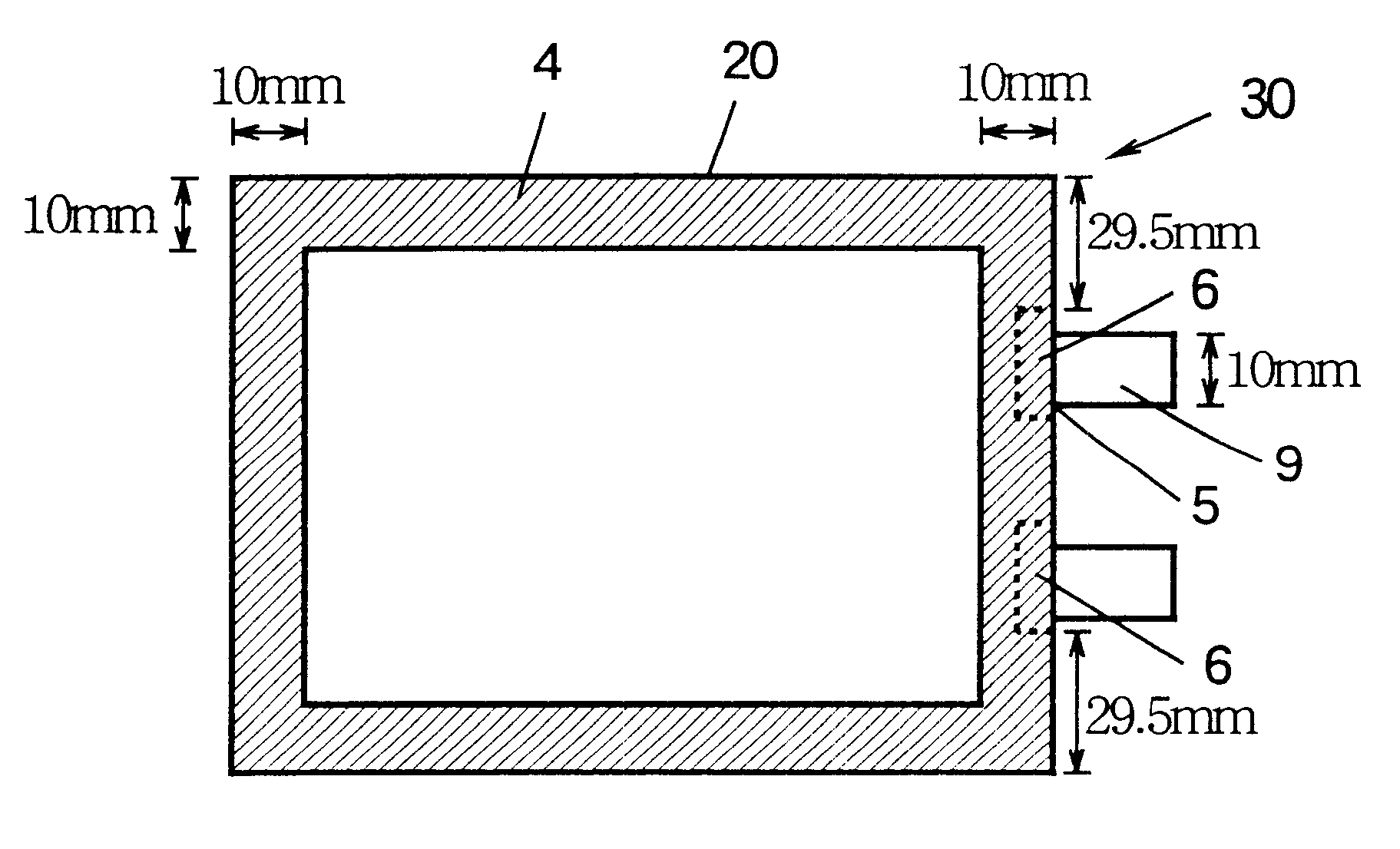

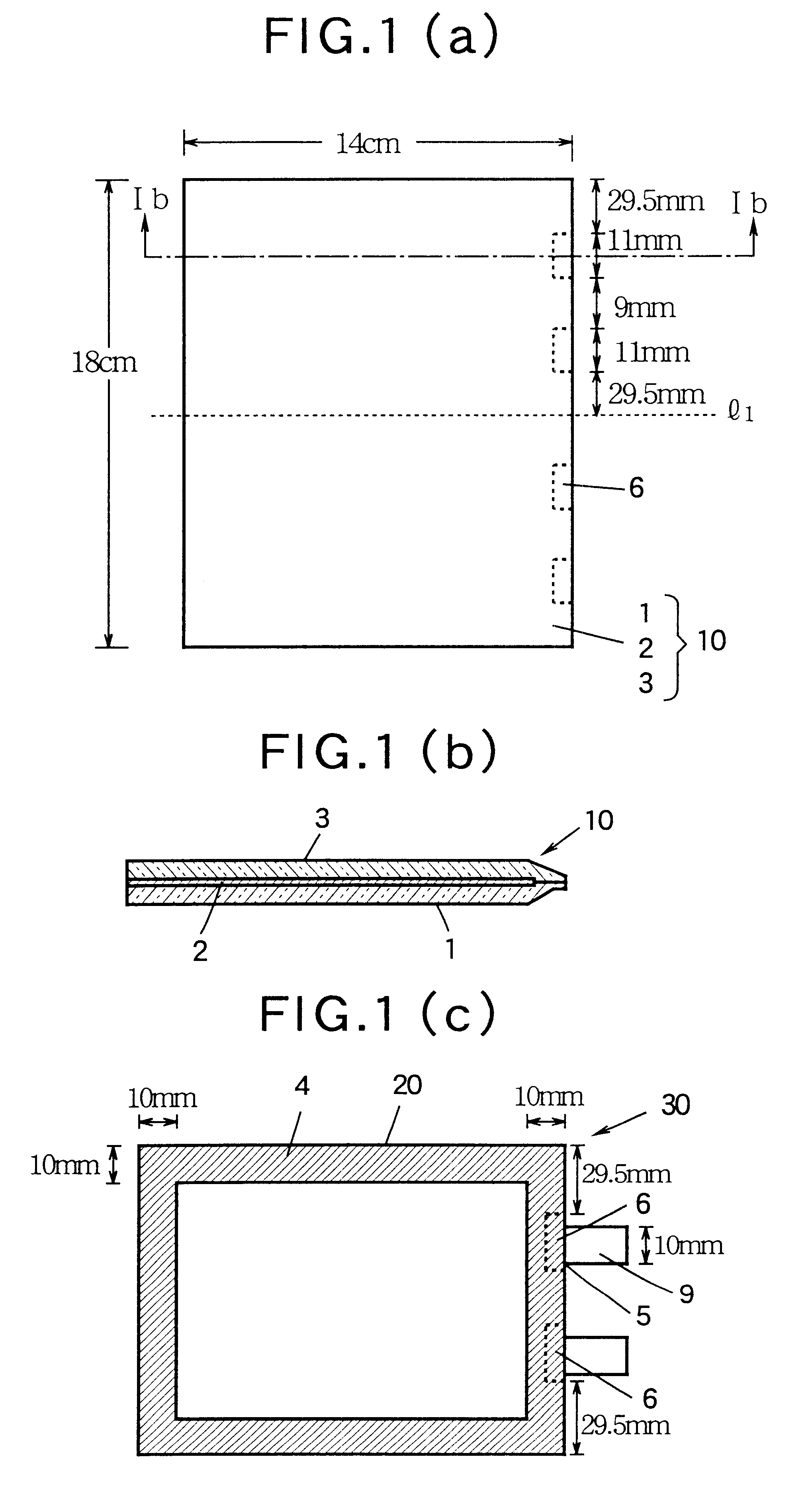

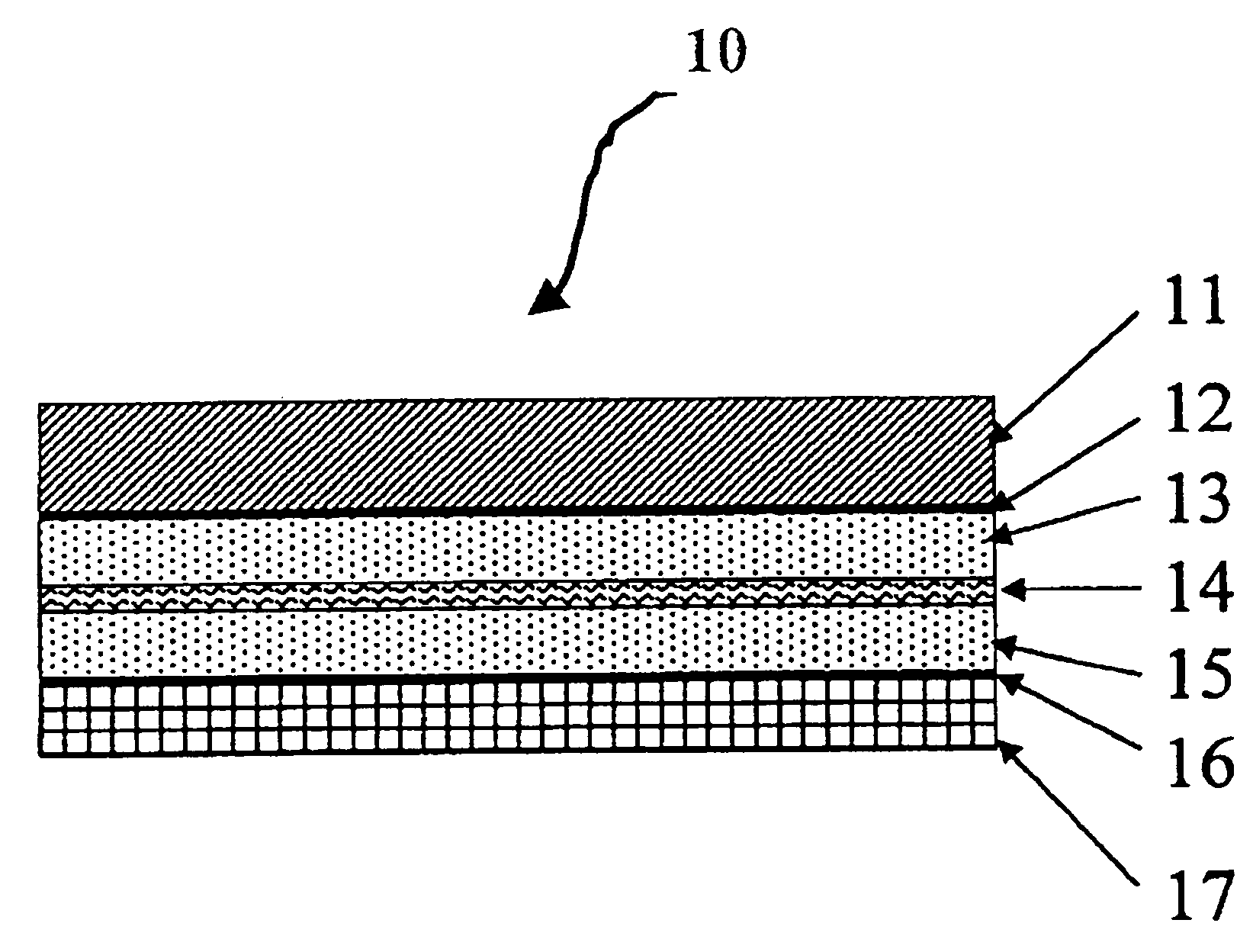

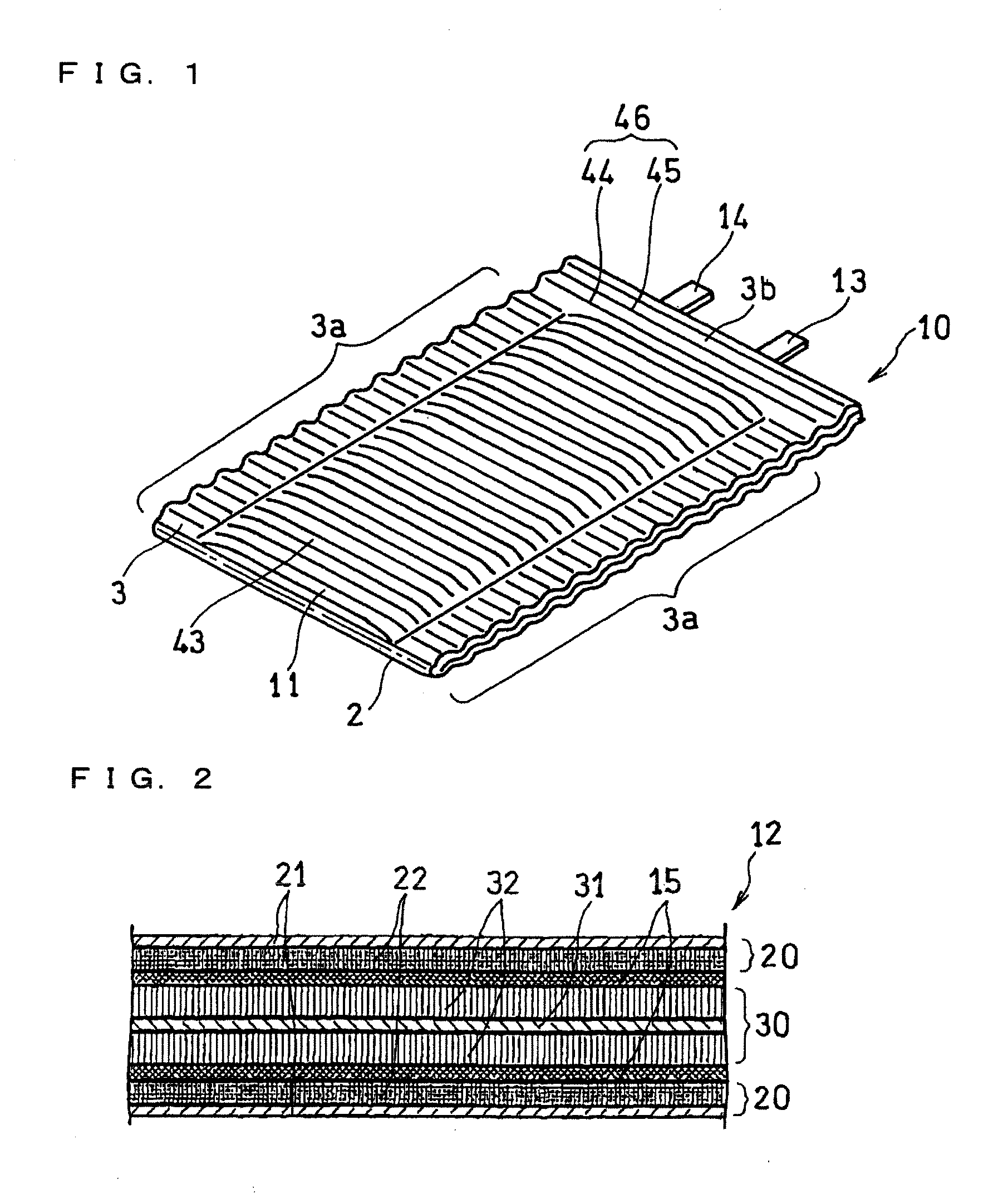

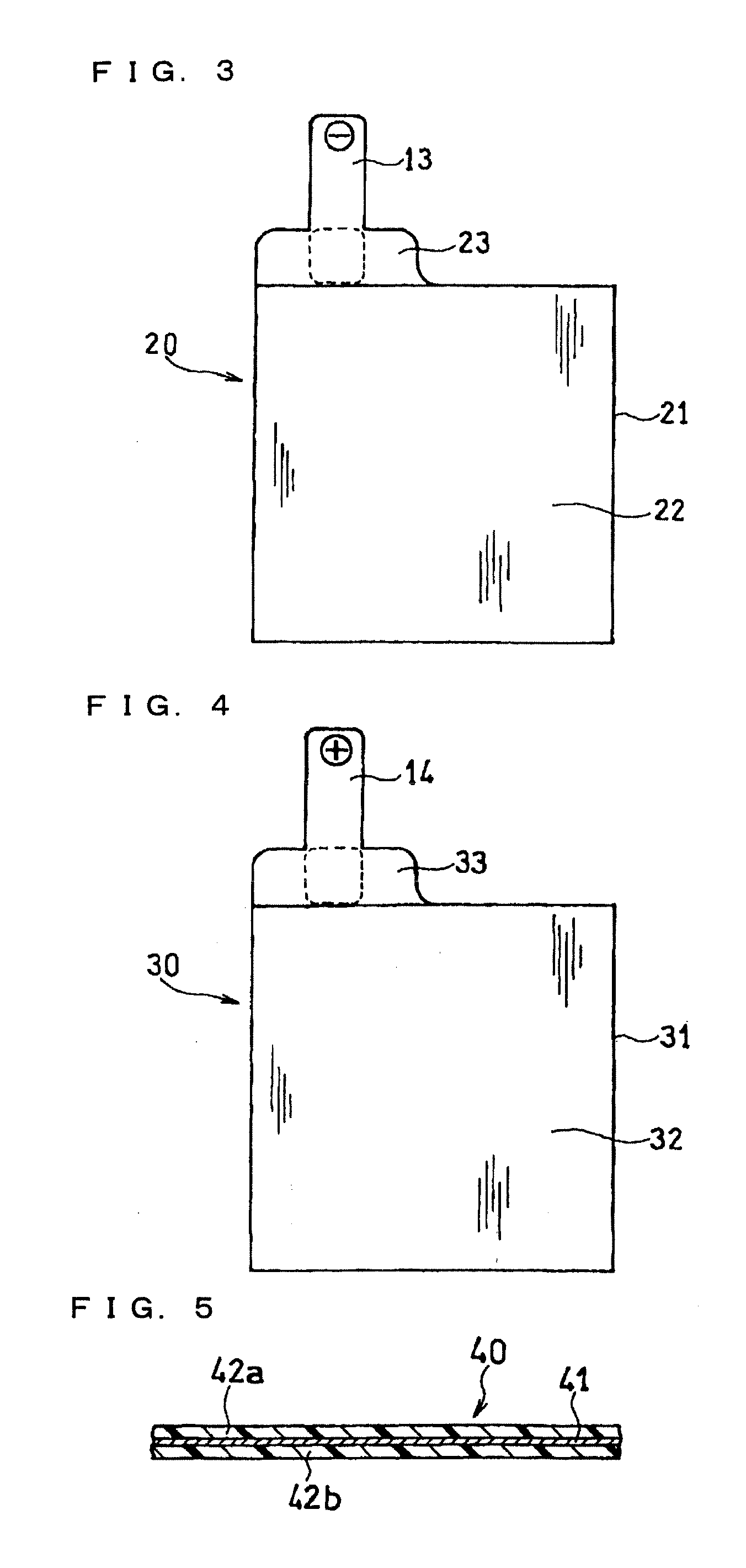

Material for packaging cell, bag for packaging cell, and its production method

InactiveUS7285334B1Excellent gas barrier performanceHigh mechanical strengthNon-aqueous electrolyte accumulatorsSynthetic resin layered productsEngineeringMethods of production

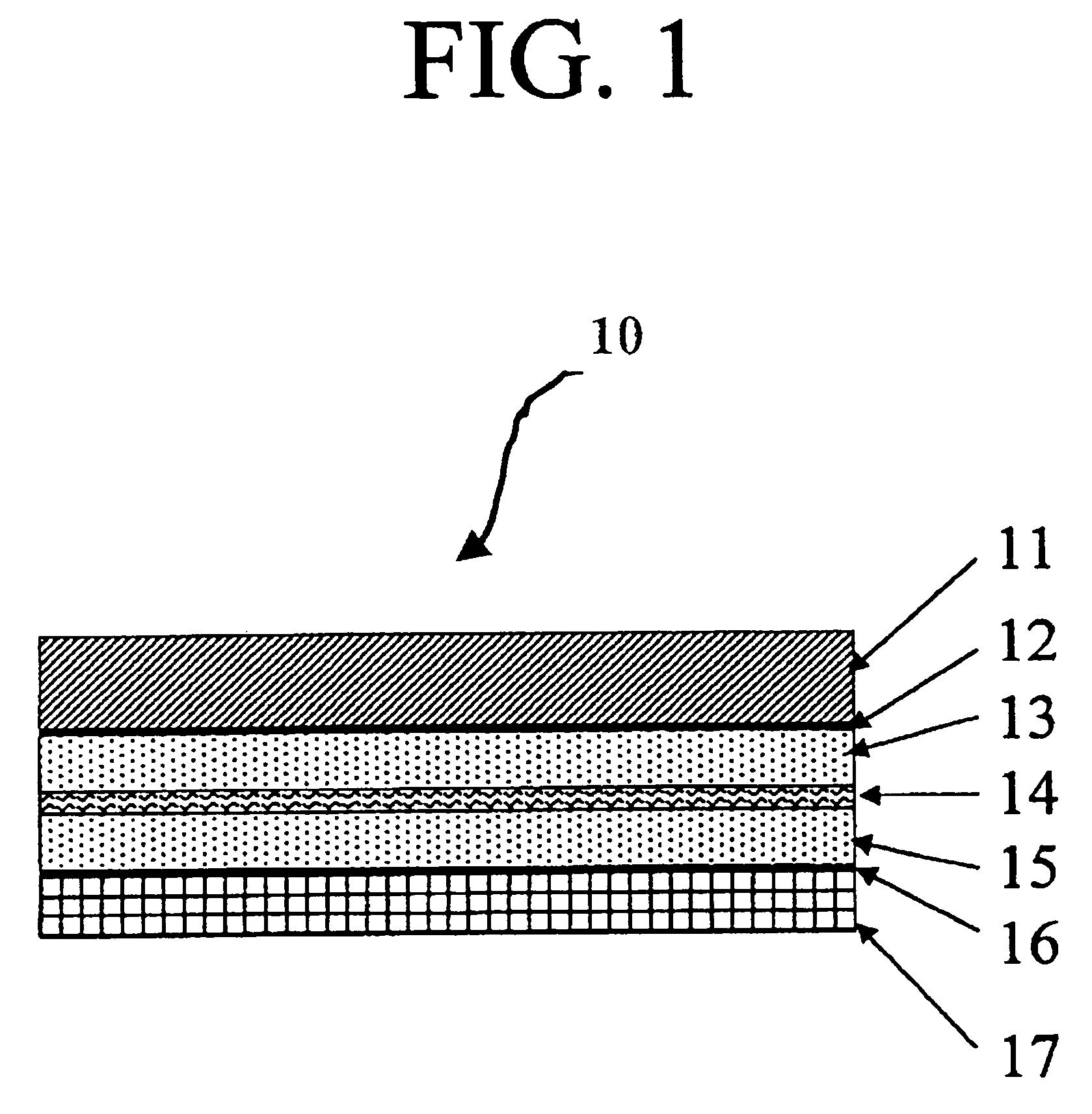

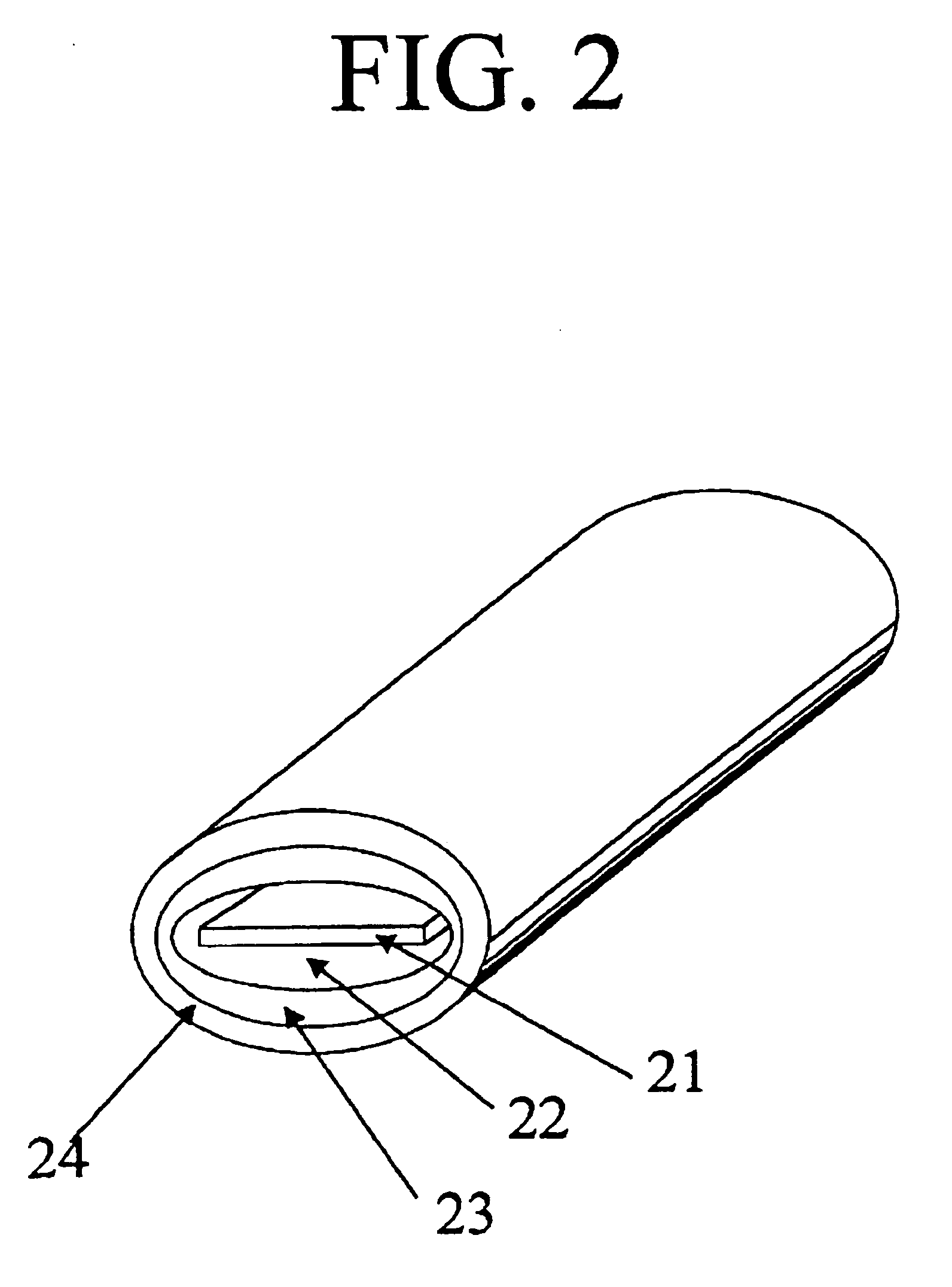

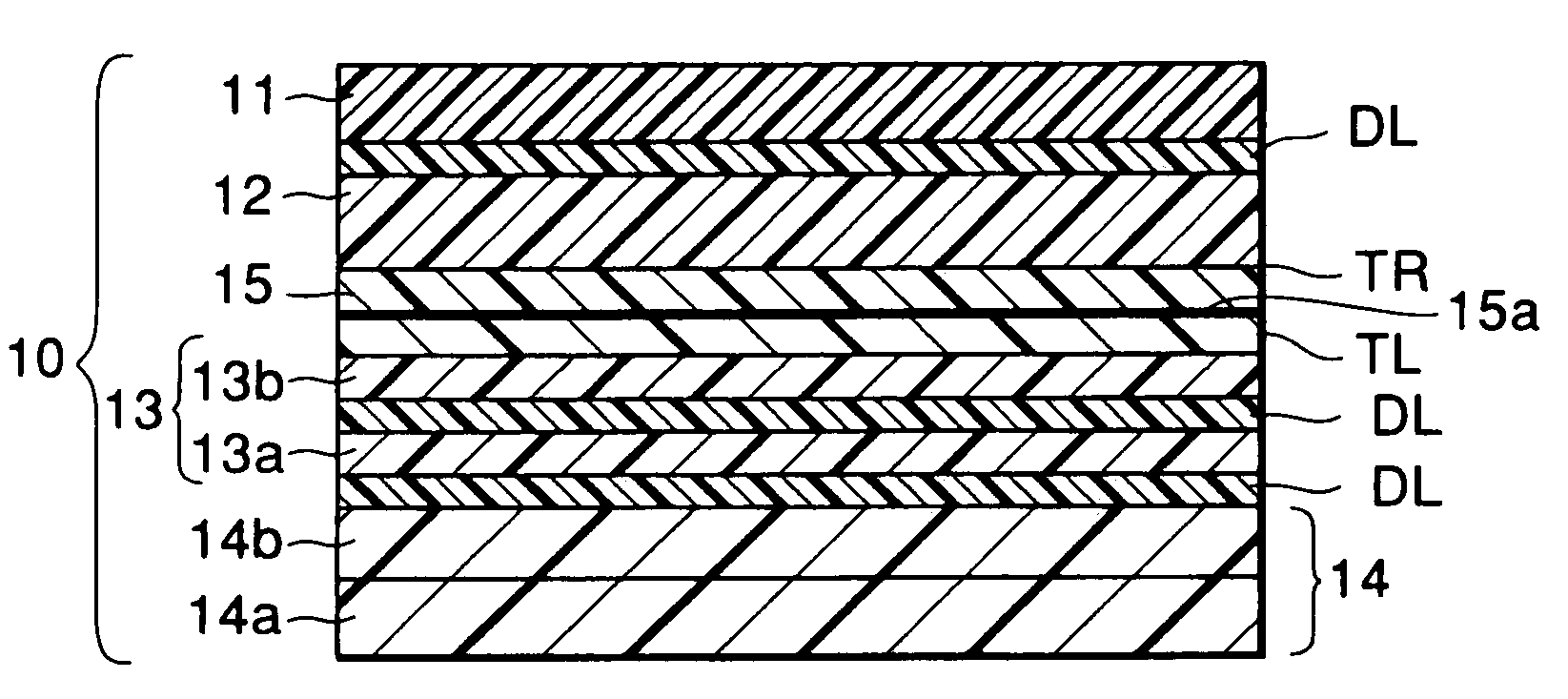

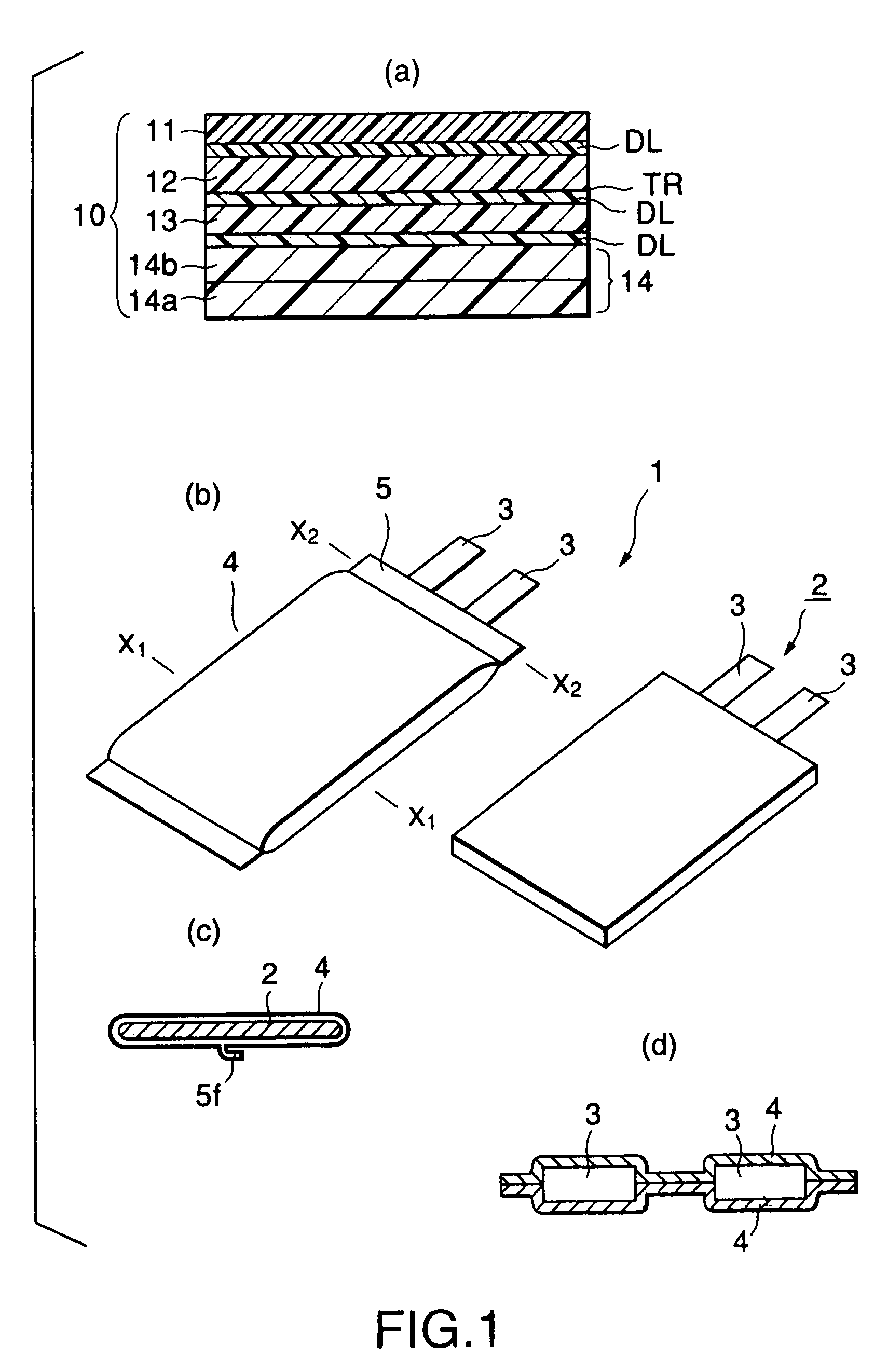

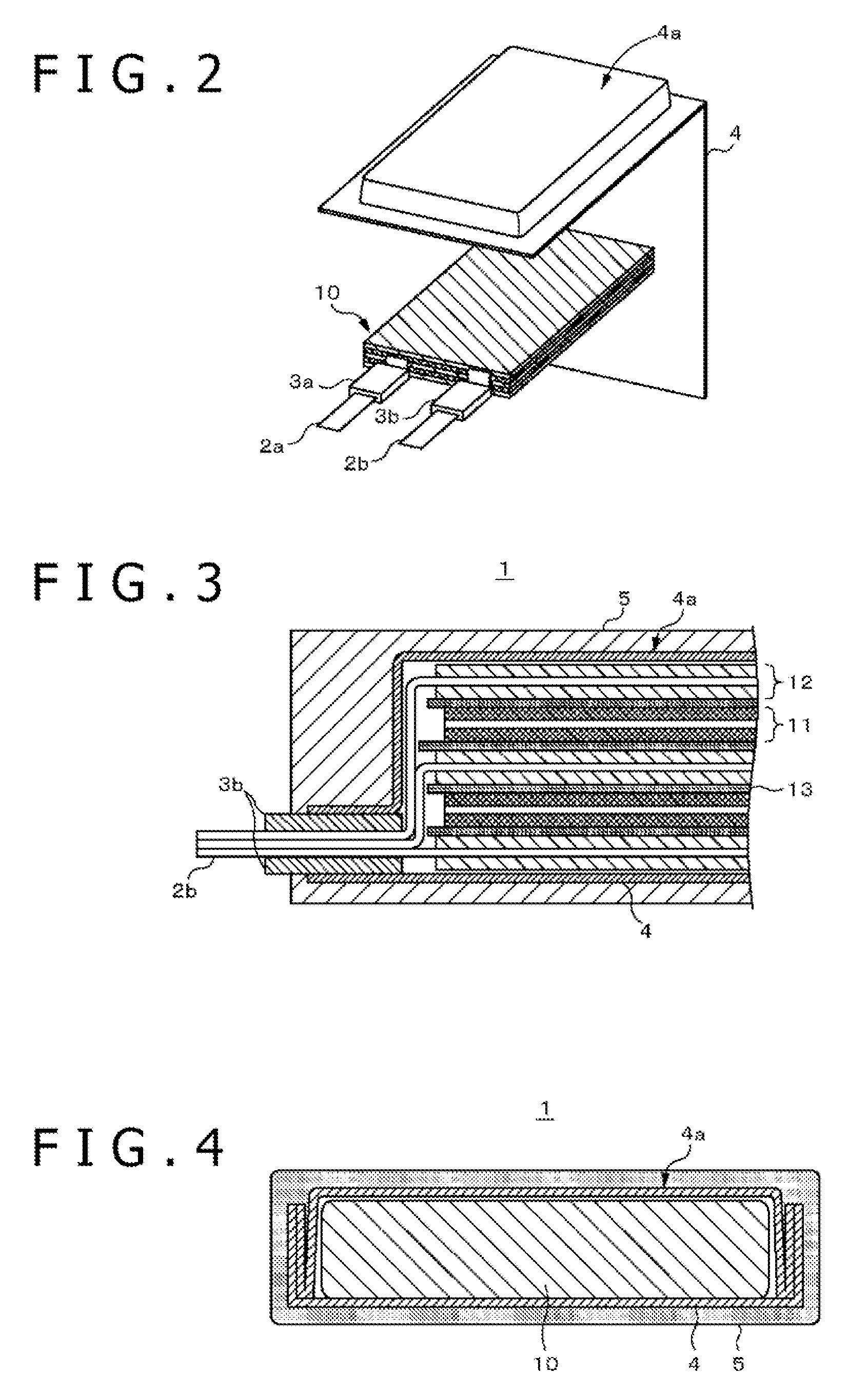

A lithium battery comprises a pouch (4) and a lithium battery module (2) packaged in the pouch (4). The pouch (4) is formed from a battery packaging laminated structure (10). The laminated structure (10) has an outermost layer (11), a barrier layer (12) and an innermost layer (14), or an outermost layer (11), a barrier layer (12), an intermediate layer (13) and an innermost layer (14) superposed in that order. The outermost layer (11) is formed of a formable base material, the barrier layer (12) is formed of a impermeable base material having a barrier property, the intermediate layer (13) is formed of a formable base material and the innermost layer (14) is formed of a heat-adhesive base material.

Owner:DAI NIPPON PRINTING CO LTD

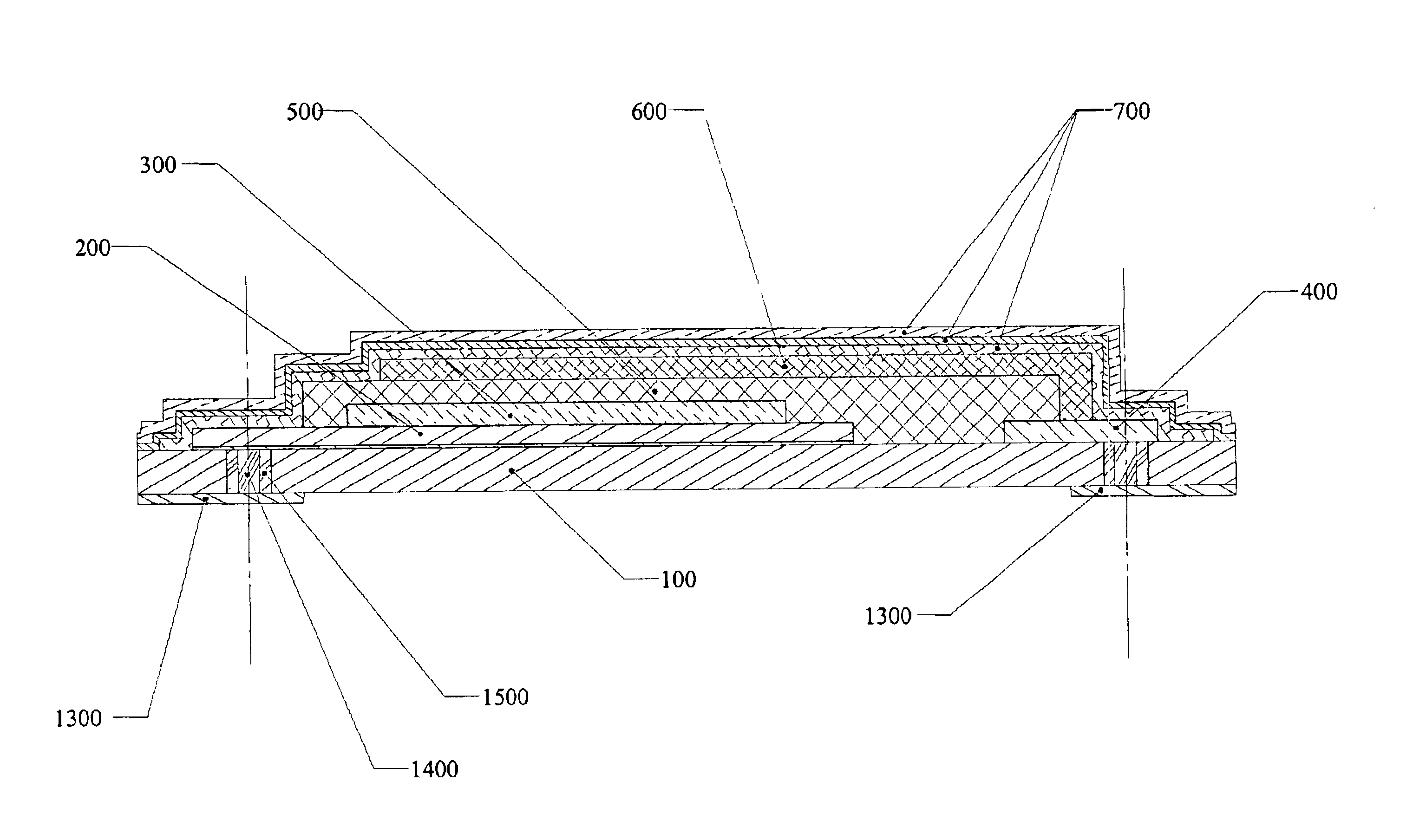

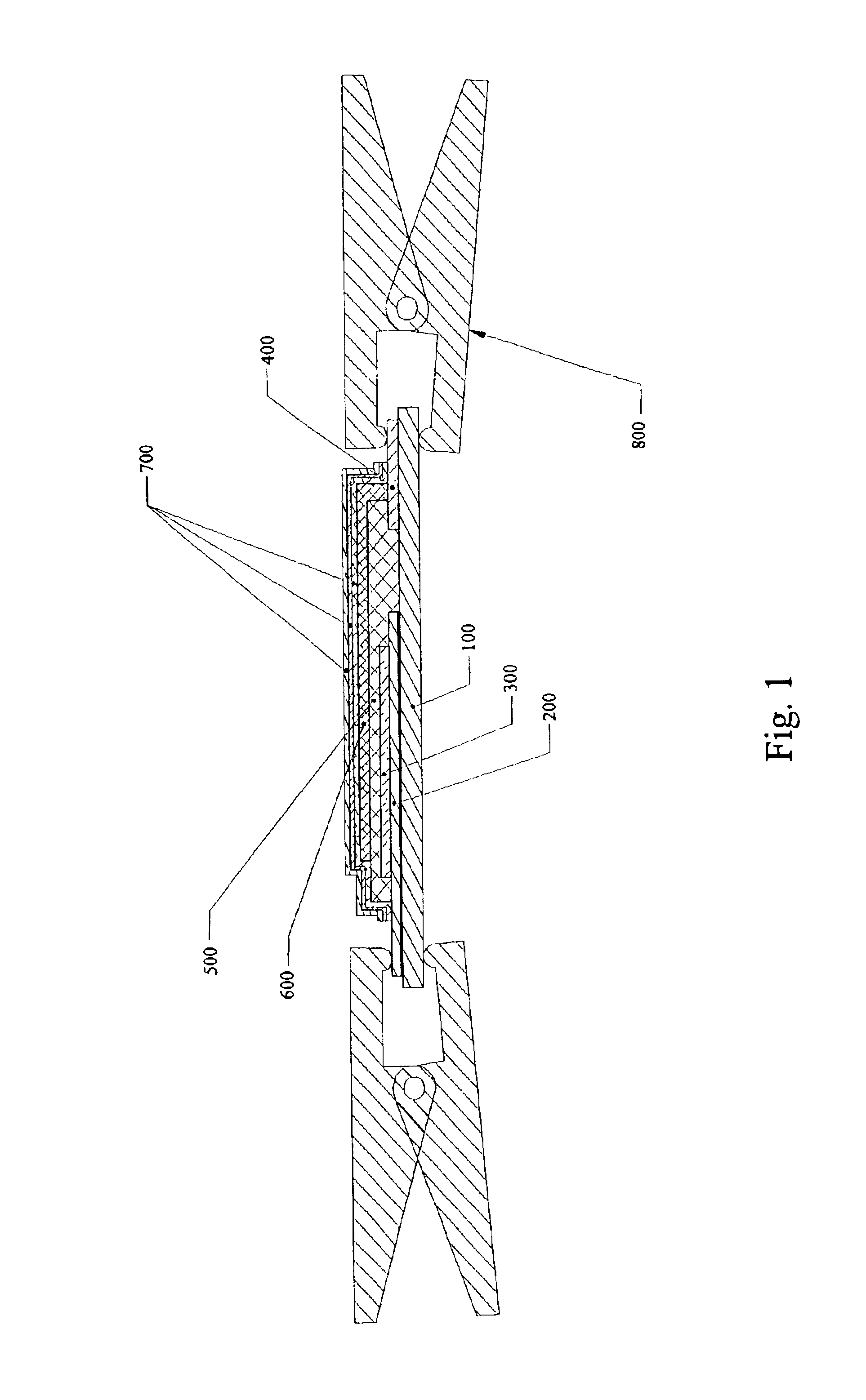

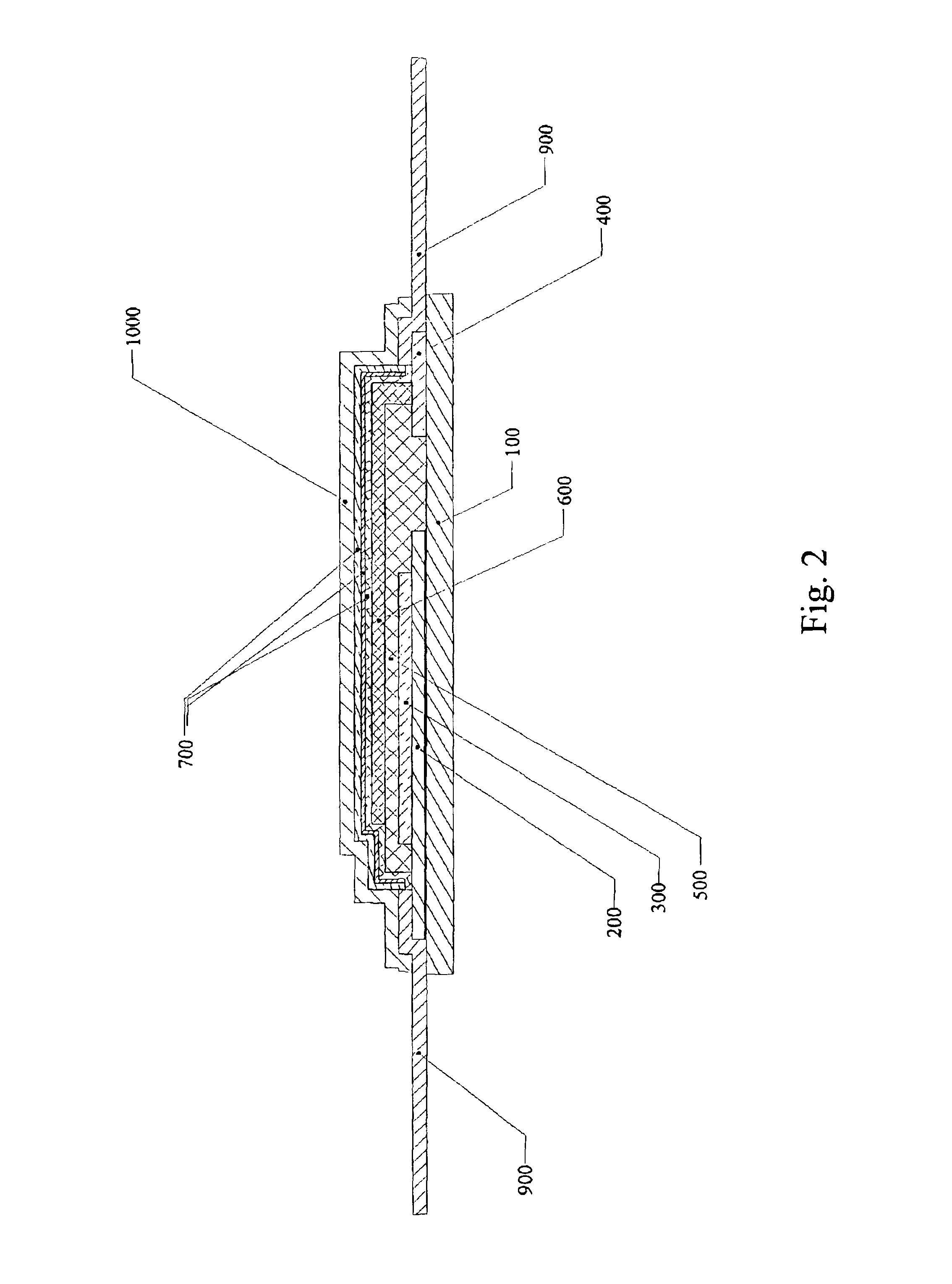

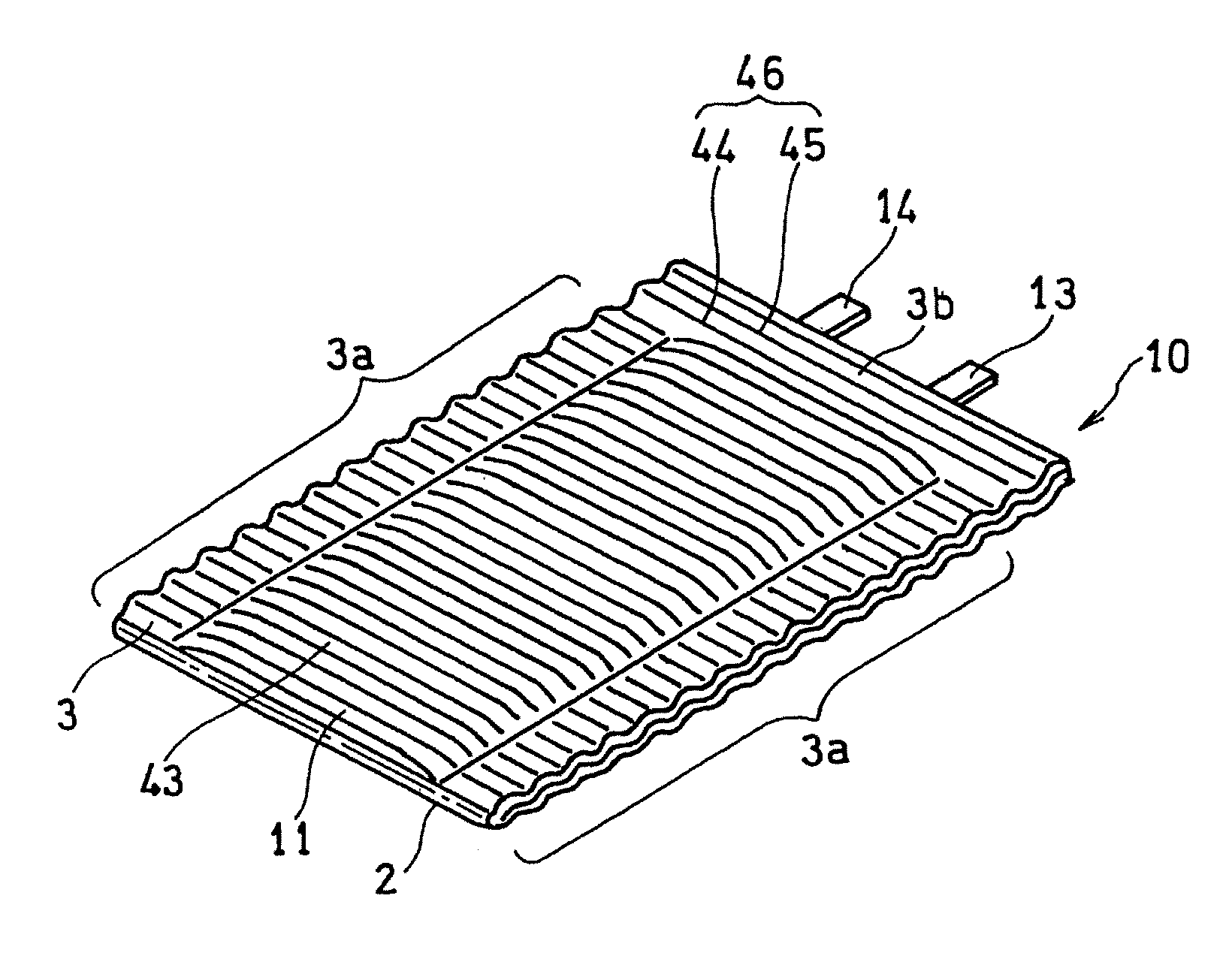

Flexible battery and method for producing the same

InactiveUS20130101884A1Impart high flexibilityImproves sealing reliabilityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFlexible battery

Disclosed is a flexible battery including a sheet-like electrode group, an electrolyte, and a housing with flexibility enclosing the electrode group and electrolyte. The housing includes a film material folded into two in which the electrode group is inserted. The film material has two facing portions respectively facing two principal surfaces of the electrode group, a fold line which is between the two facing portions and along which the film material is folded, and two bonding margins respectively set around the two facing portions. The two bonding margins are bonded to each other into a bonded portion. At least the two facing portions of the film material are formed in a corrugated shape having a plurality of ridge and valley lines arranged in parallel to each other. The ridge lines in one of the two facing portions are overlapped with the valley lines in the other. The fold line is parallel to the ridge and valley lines.

Owner:PANASONIC CORP

Laminate Including Active Material Layer and Solid Electrolyte Layer, and All Solid Lithium Secondary Battery Using the Same

InactiveUS20070259271A1Improve life characteristicsSmall internal resistanceElectrode thermal treatmentFinal product manufactureLithiumX-ray

A laminate includes an active material layer and a solid electrolyte layer bonded to the active material layer by sintering. The active material layer includes a crystalline first substance capable of absorbing and desorbing lithium ions, and the solid electrolyte layer includes a crystalline second substance with lithium ion conductivity. An X-ray diffraction analysis of the laminate shows that there is no component other than constituent components of the active material layer and constituent components of the solid electrolyte layer. Also, an all solid lithium secondary battery includes such a laminate and a negative electrode active material layer.

Owner:PANASONIC CORP

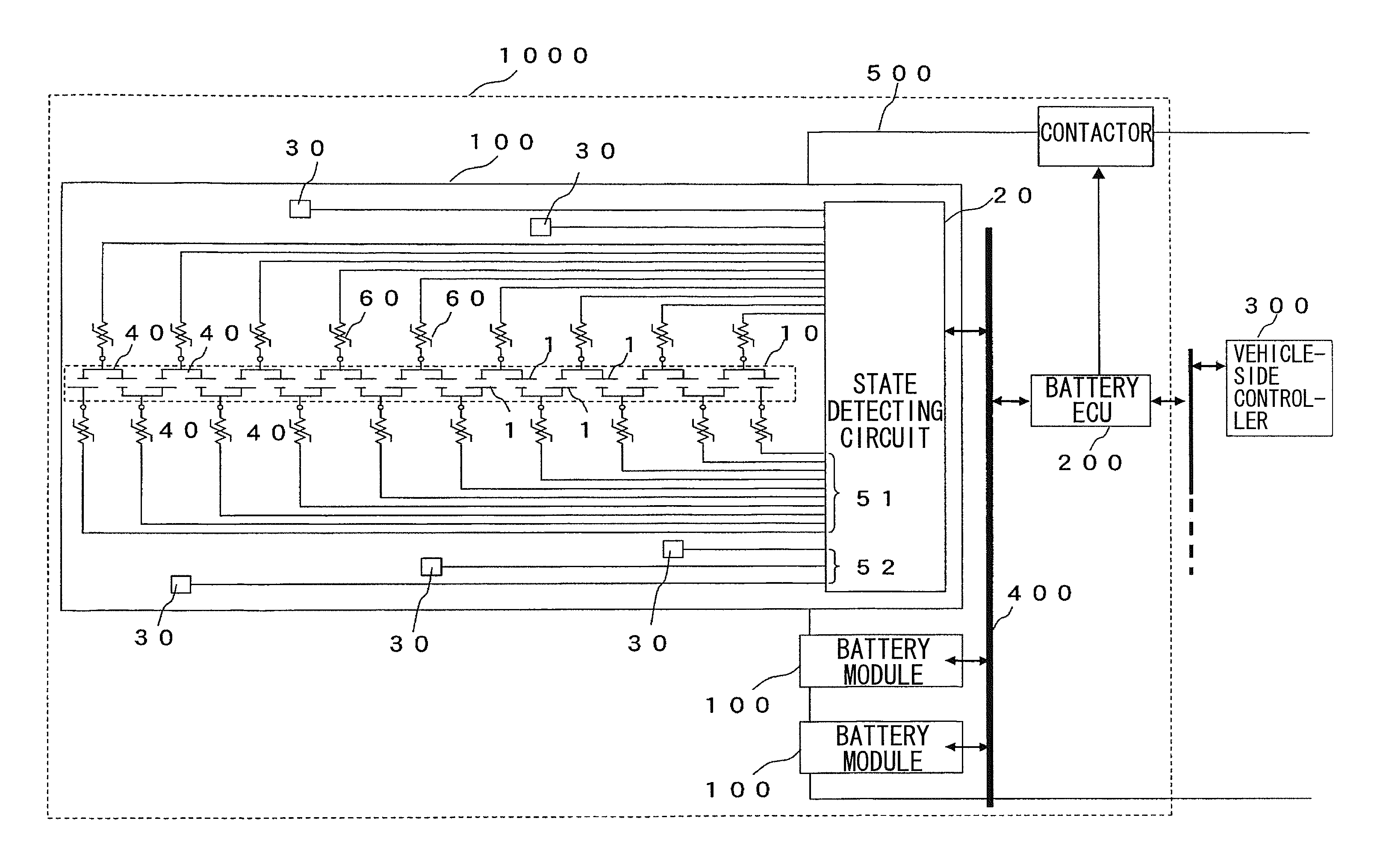

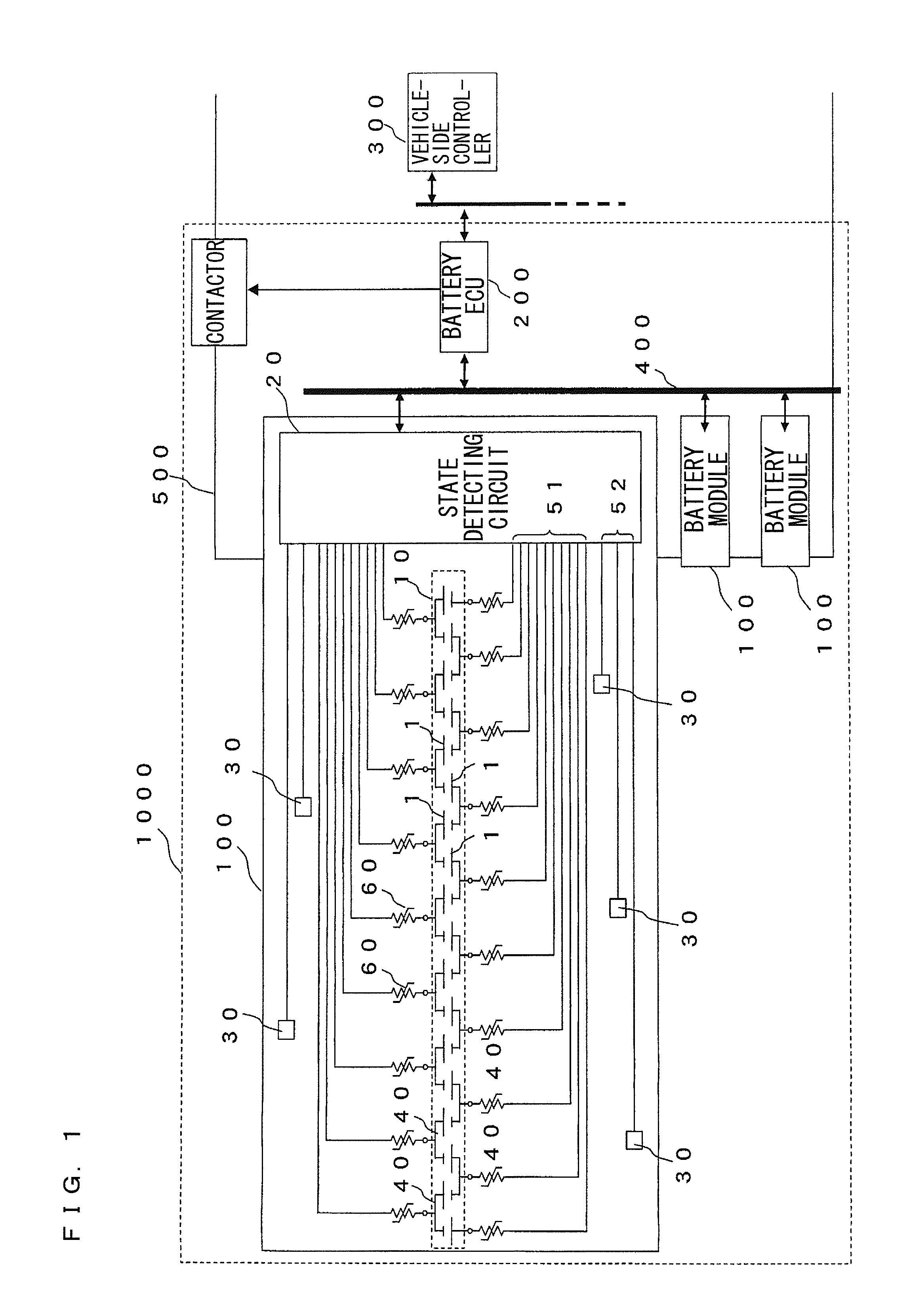

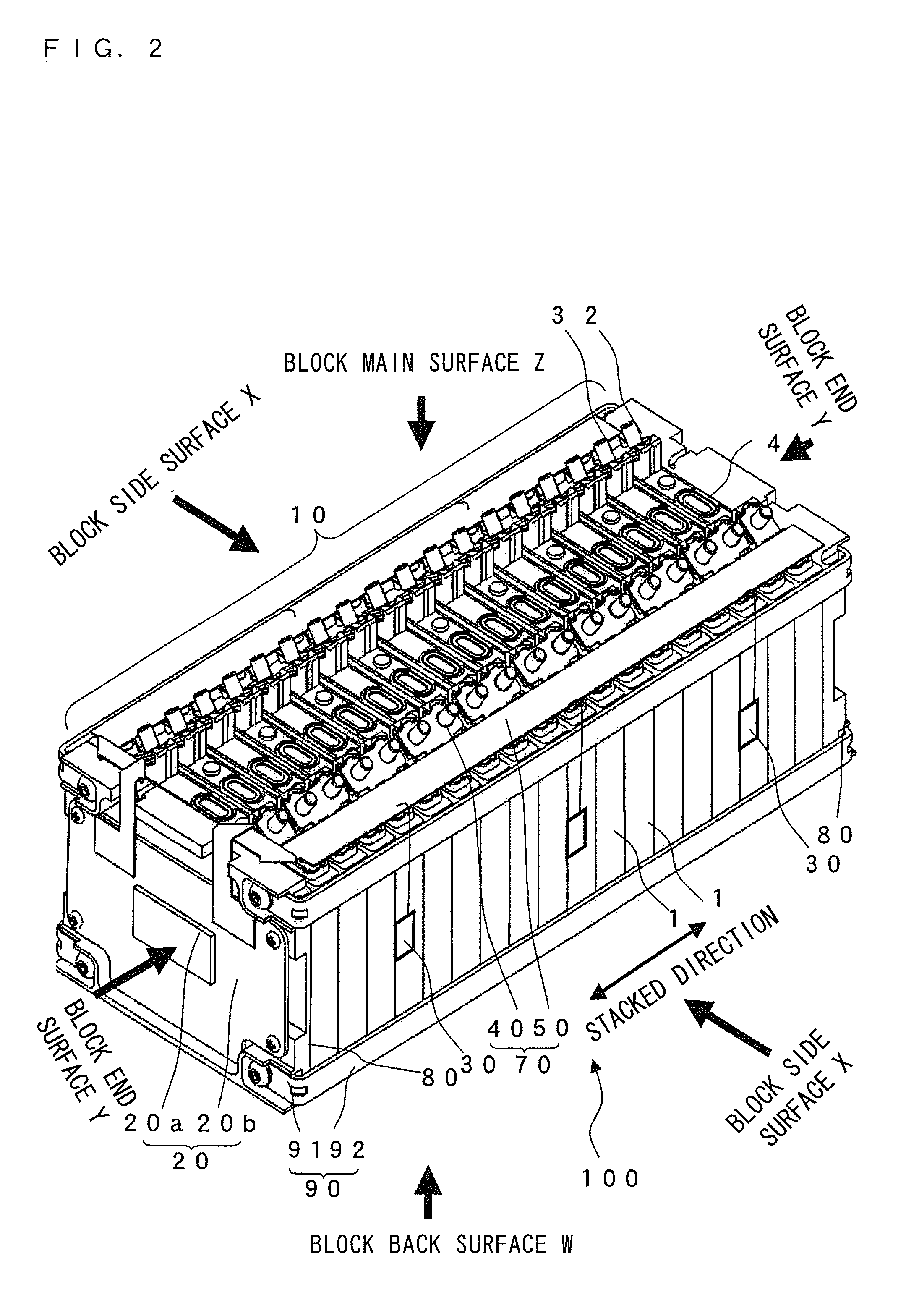

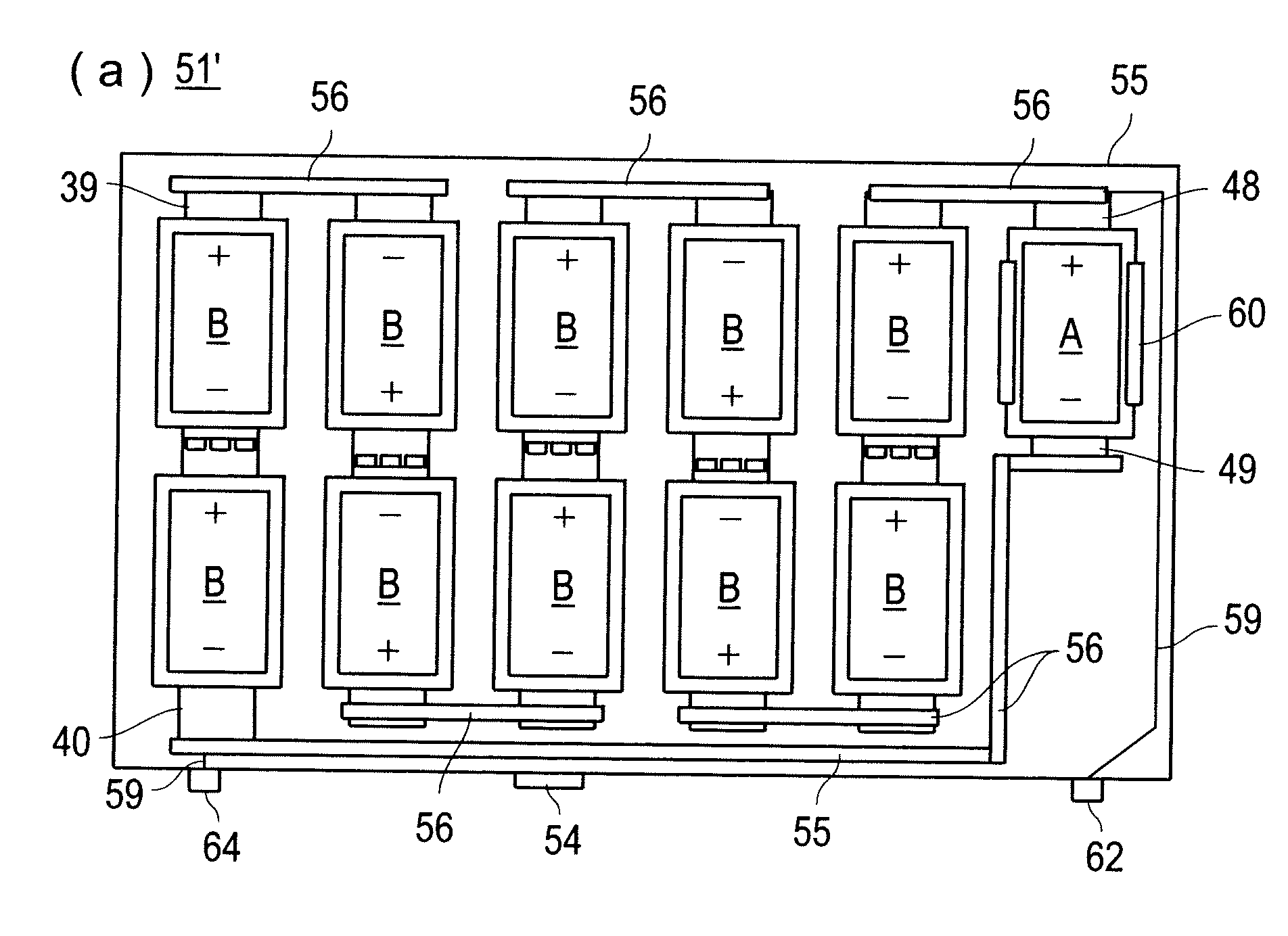

Battery module, battery system and electric vehicle

ActiveUS20120019061A1Improving complicated wiringBatteries circuit arrangementsElectric devicesElectricityElectric vehicle

A battery block composed of a plurality of battery cells and a voltage detecting circuit (state detecting circuit) for detecting a voltage between terminals of each battery cell are included, and a flexible printed circuit board, in which a voltage detecting line for electrically connecting a positive electrode terminal or a negative electrode terminal of the battery cell and the voltage detecting circuit (state detecting circuit) is integrated with a substrate made or a flexible material, is provided.

Owner:PANASONIC ENERGY CO LTD

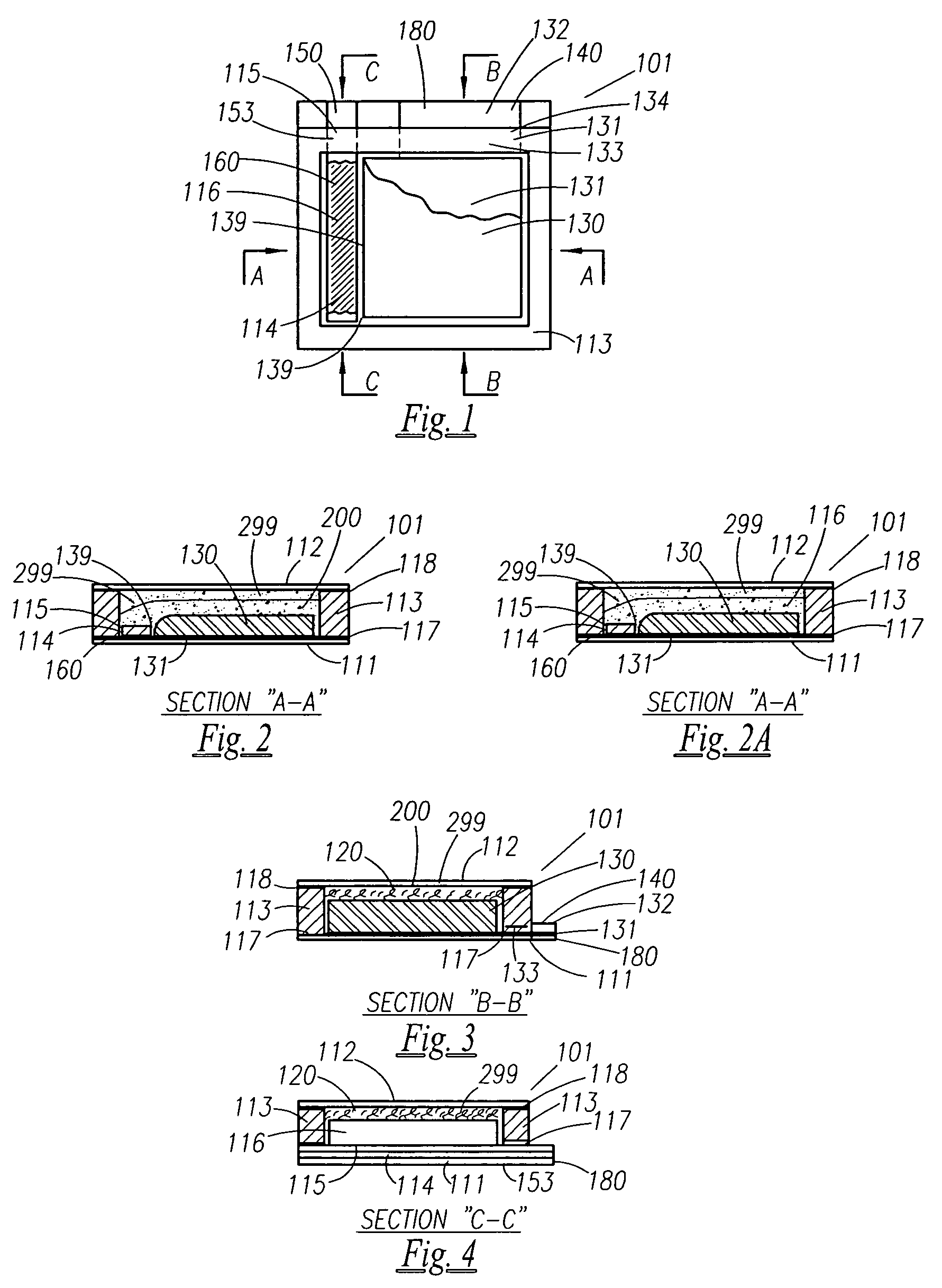

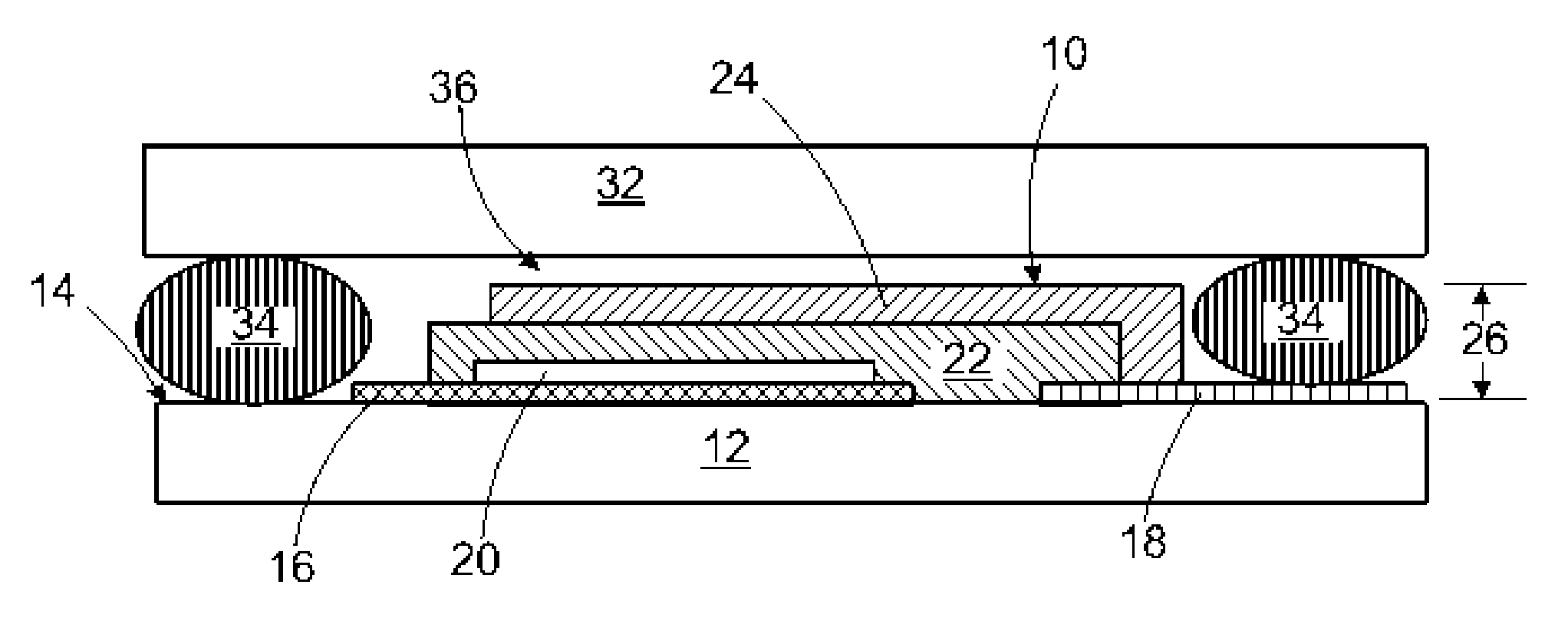

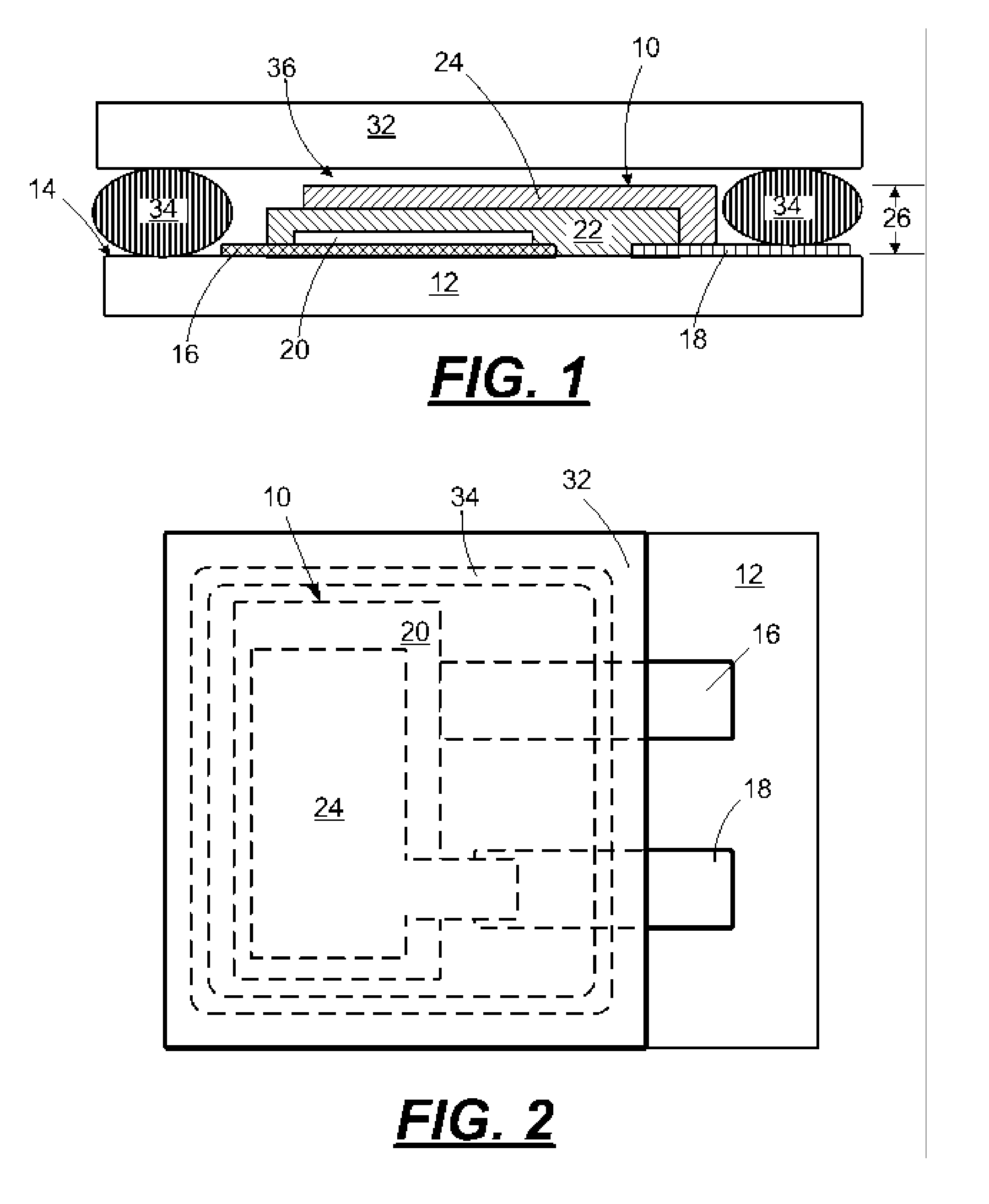

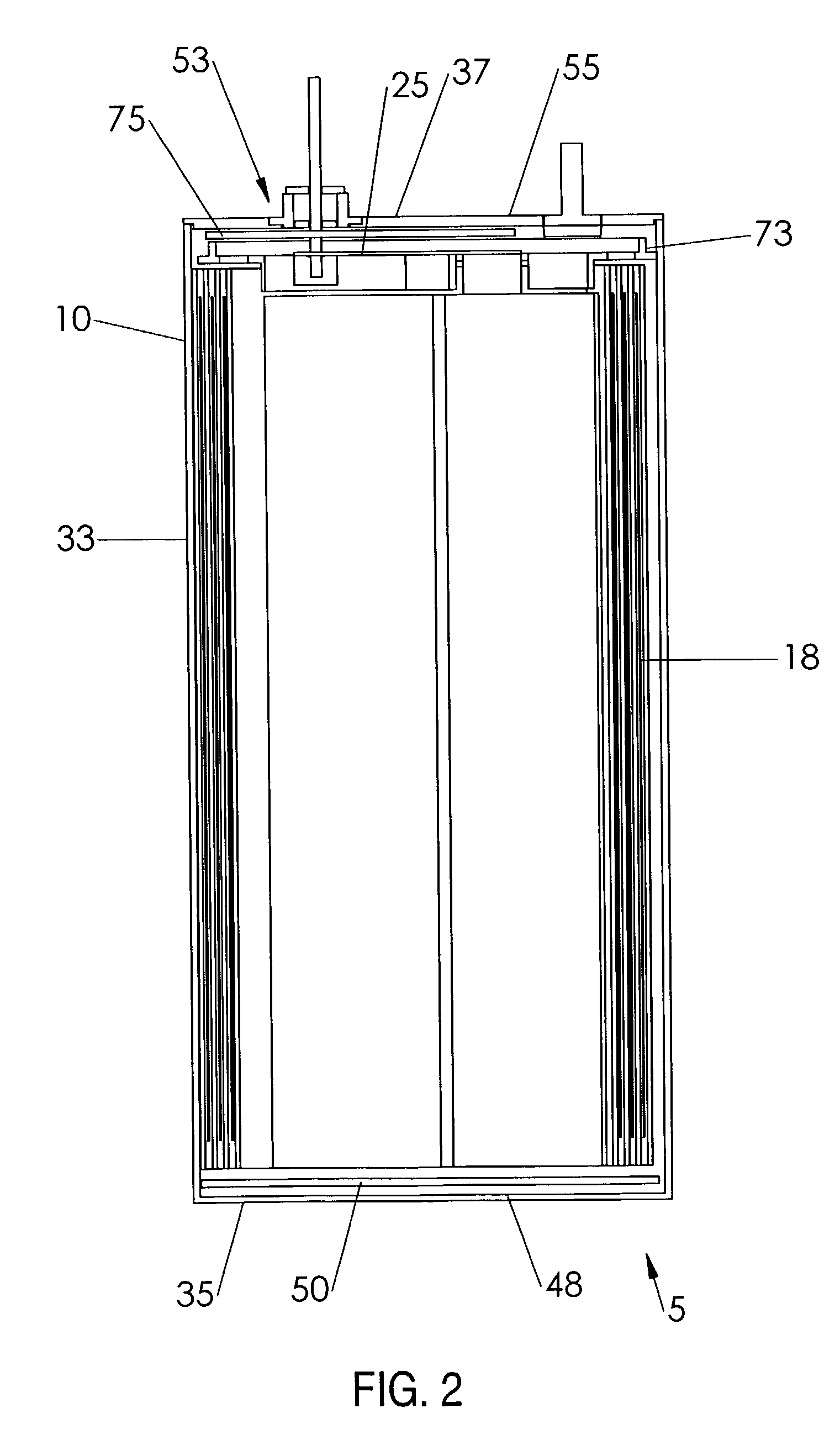

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

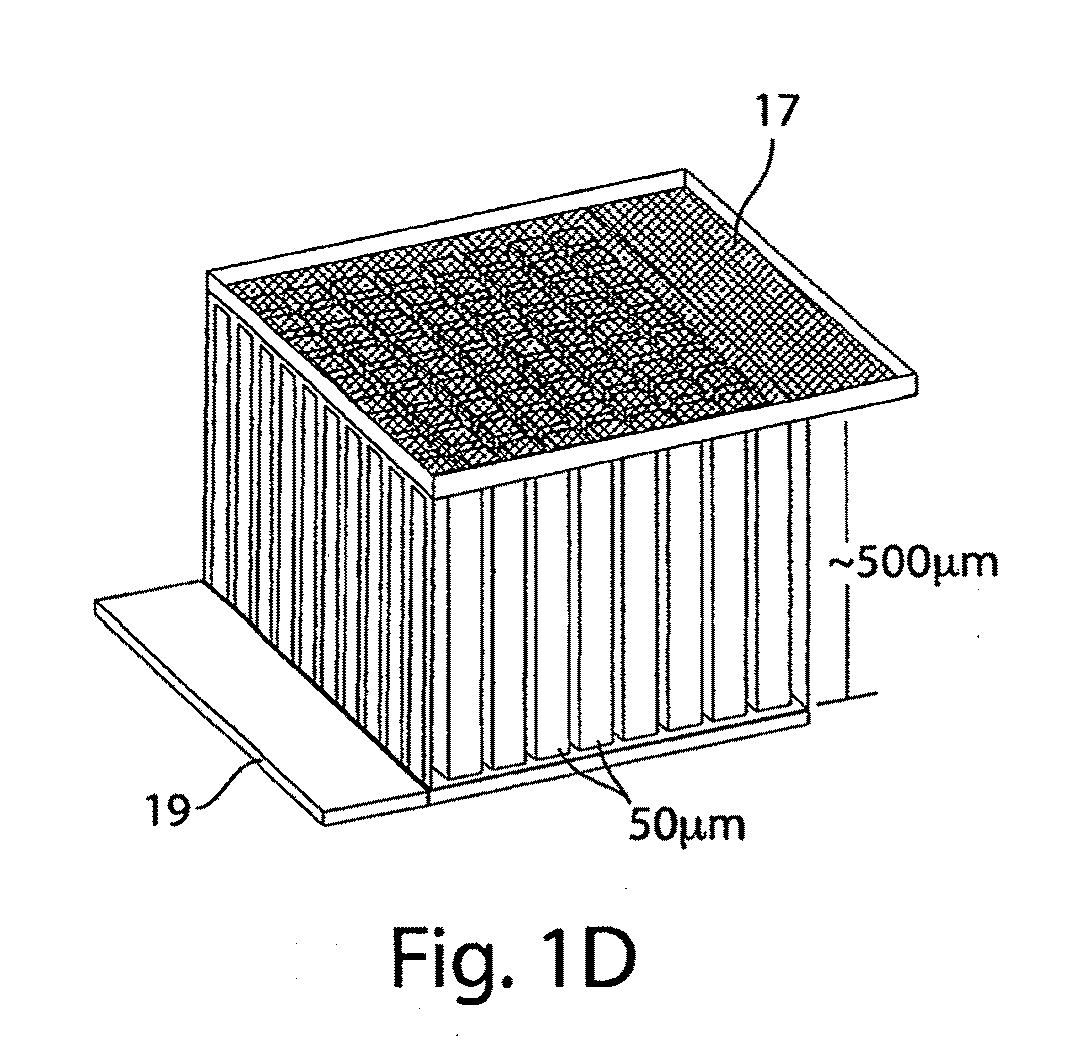

Small-scale batteries and electrodes for use thereof

The present invention generally relates to batteries or other electrochemical devices. In some embodiments, the present invention relates to small-scale batteries or microbatteries. For example, in one aspect of the invention, a battery may have a volume of no more than about 5 mm3, while having an energy density of at least about 400 Wh / l. Other aspect of the invention is directed to techniques of packaging such batteries.

Owner:CHARLES STARK DRAPER LABORATORY +1

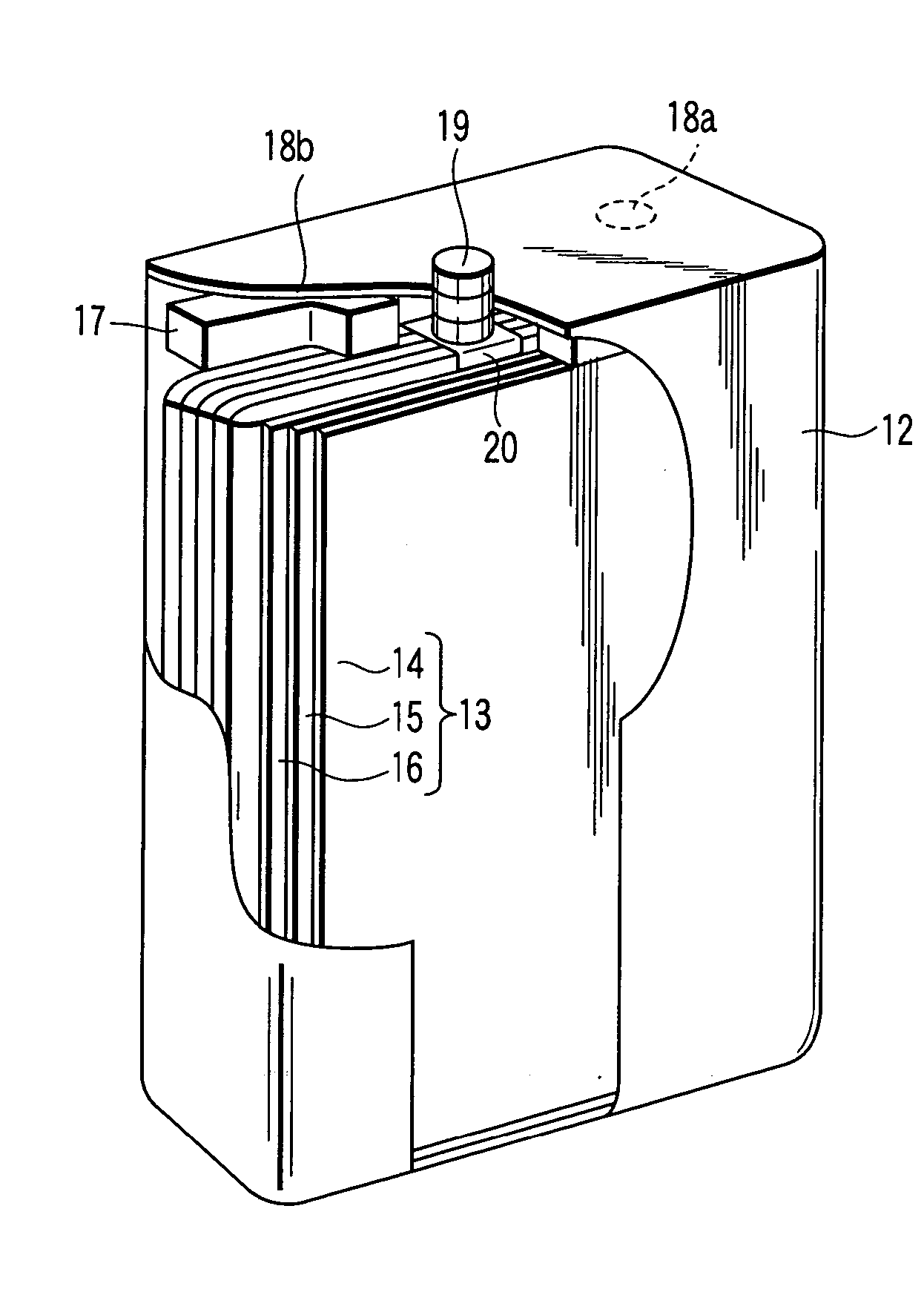

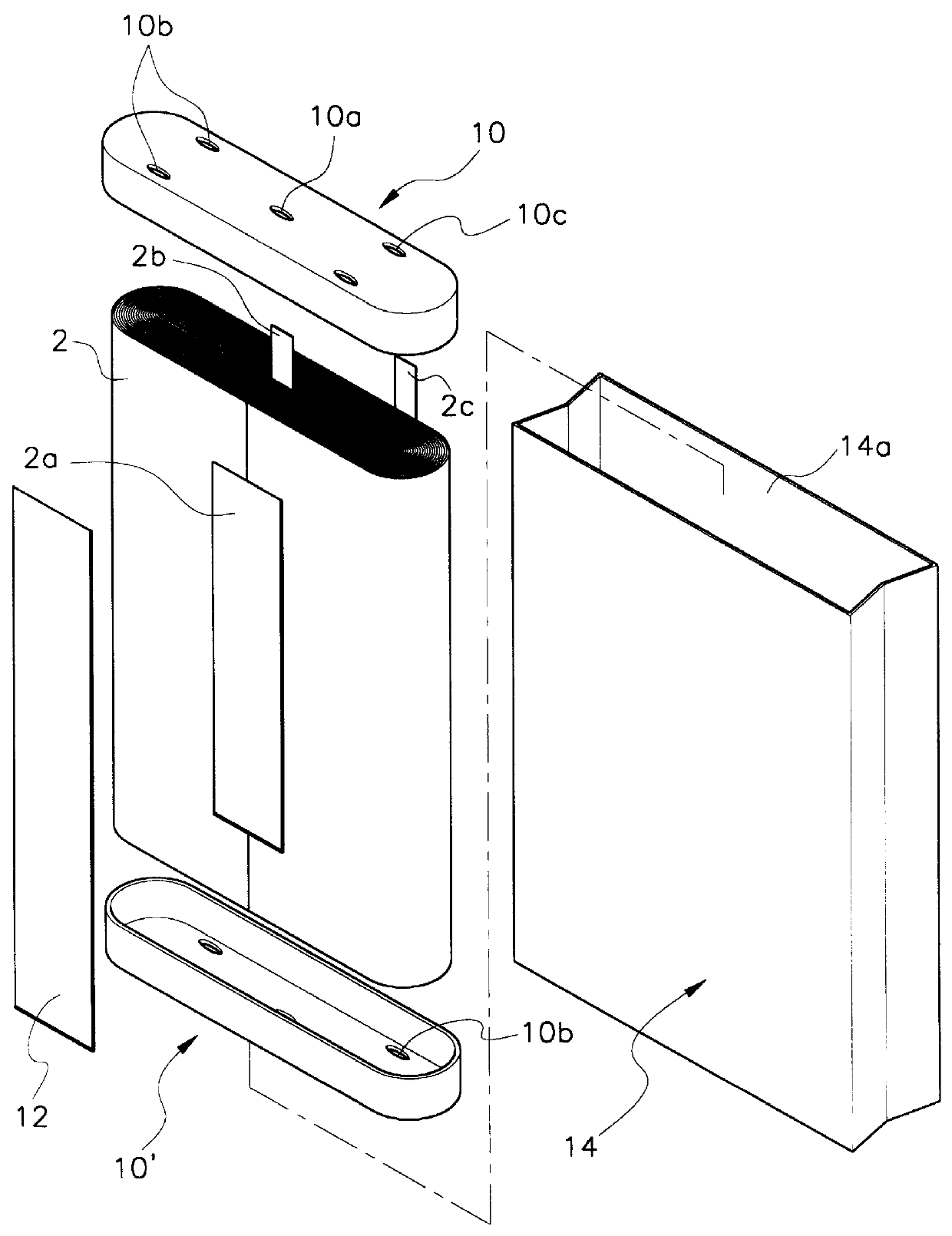

Secondary battery with electrode assembly fixing device

InactiveUS6083640AShorten the soaking timeNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesEngineeringCharge and discharge

A secondary battery includes a case, a rolled electrode assembly disposed within the case, and an electrode assembly fixing member receiving a portion of the rolled electrode assembly so that expansion and contraction of the rolled electrode assembly can be suppressed during charging and discharging operations of the battery, and deformation of the rolled electrode assembly caused by outer impact can be prevented. The electrode assembly fixing member comprises a cap fitted onto at least one of upper and lower ends of the rolled electrode assembly. The electrode assembly fixing member further comprises a gripper holding the rolled electrode assembly.

Owner:SAMSUNG ELECTRONICS DEVICES CO LTD

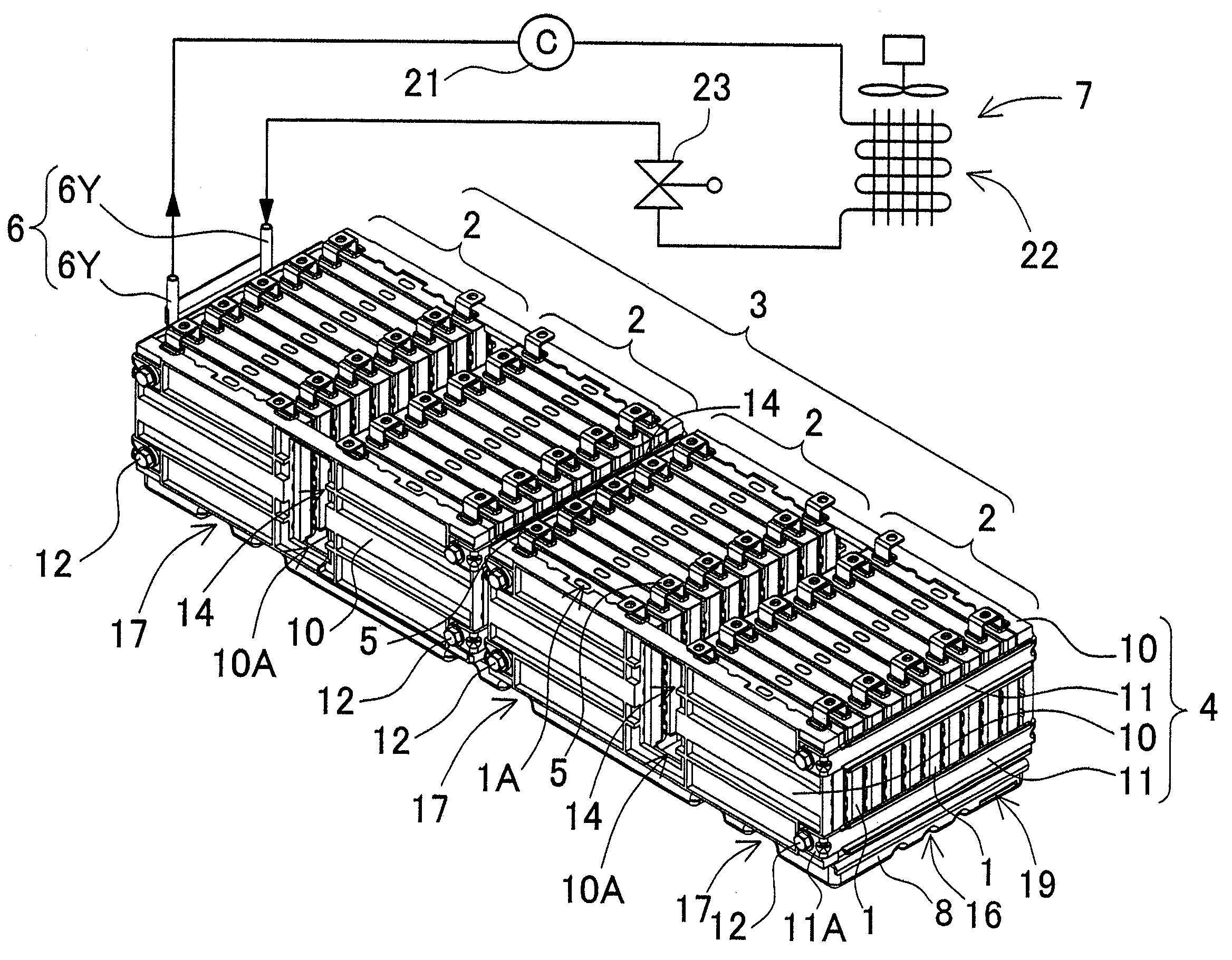

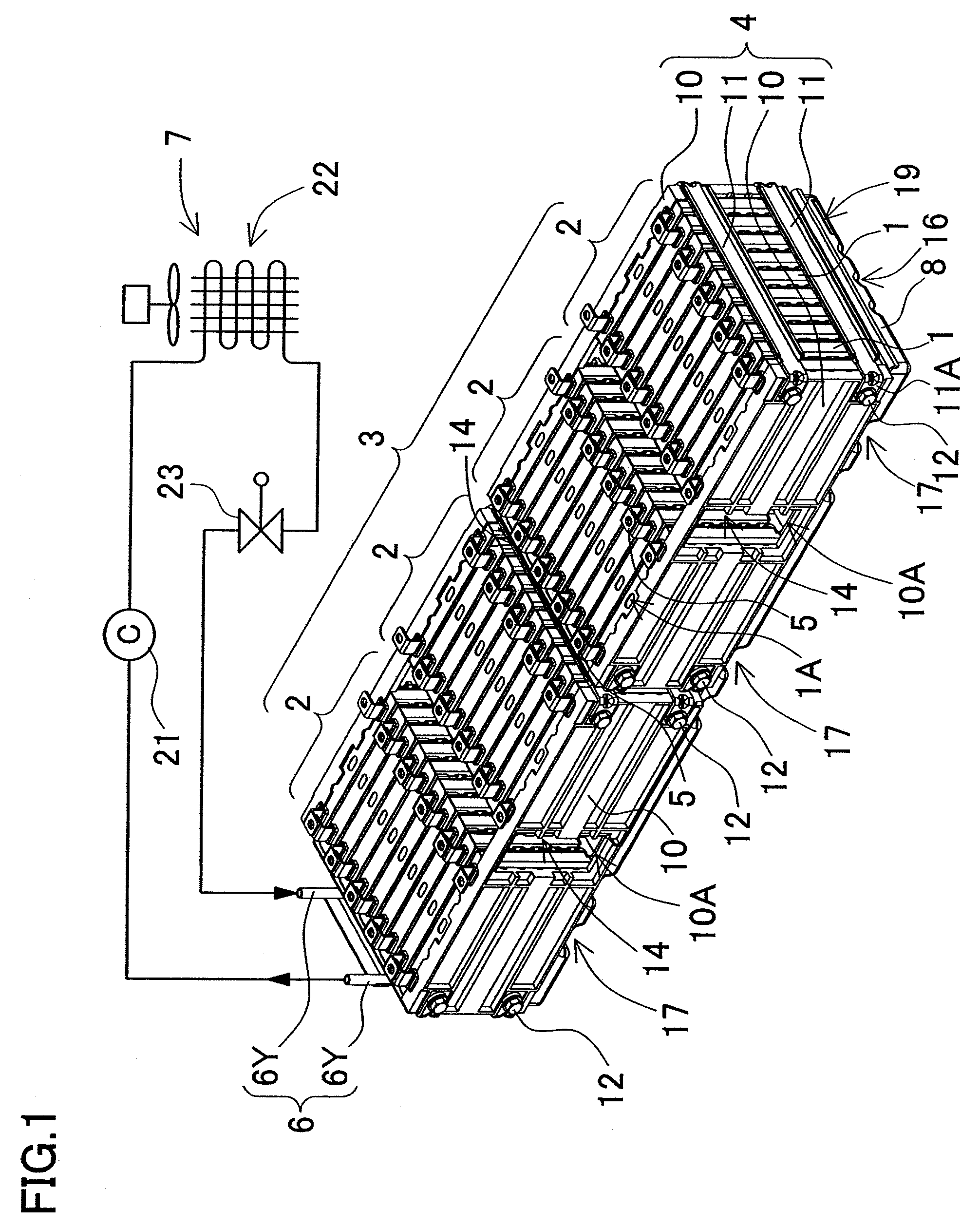

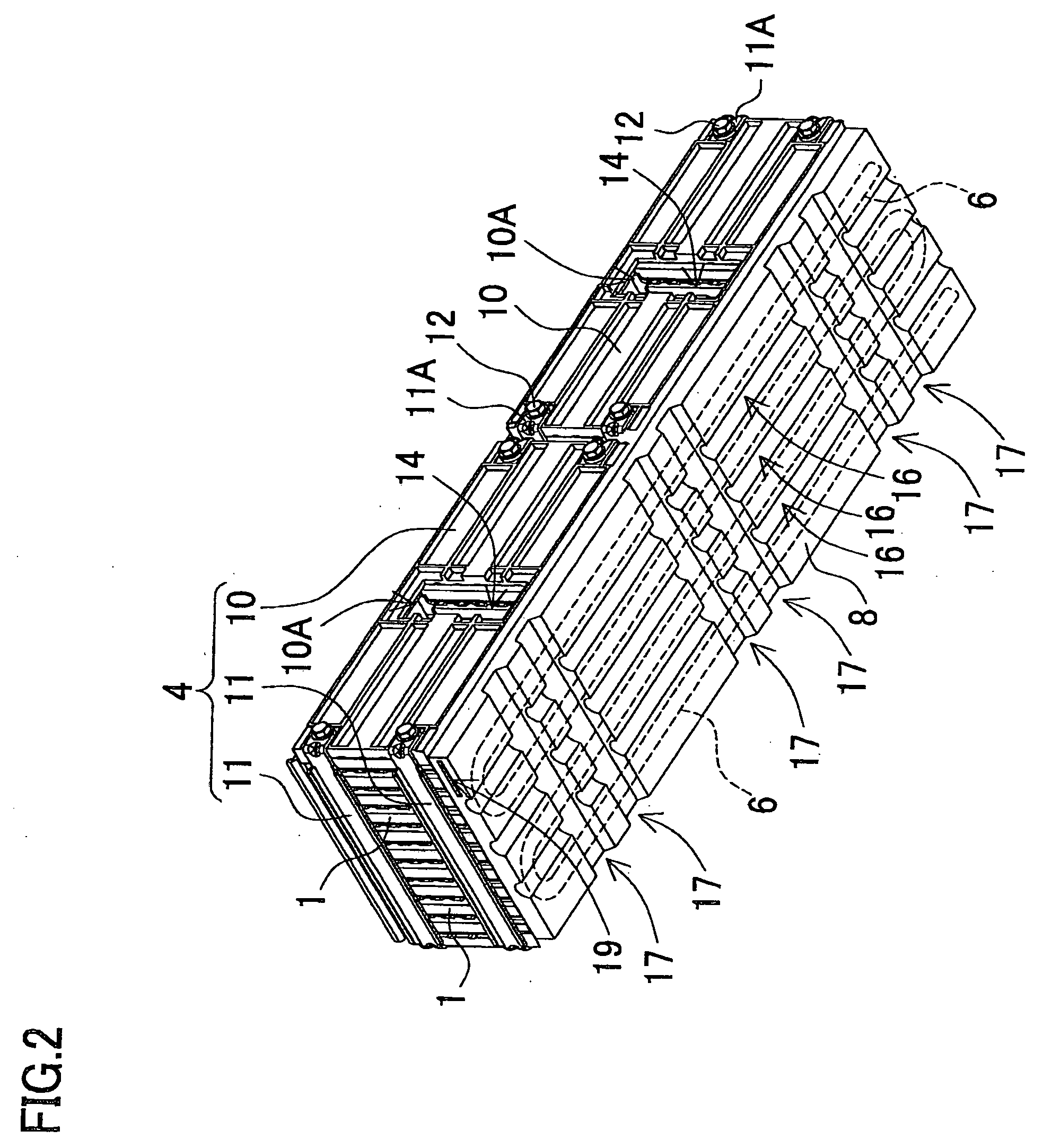

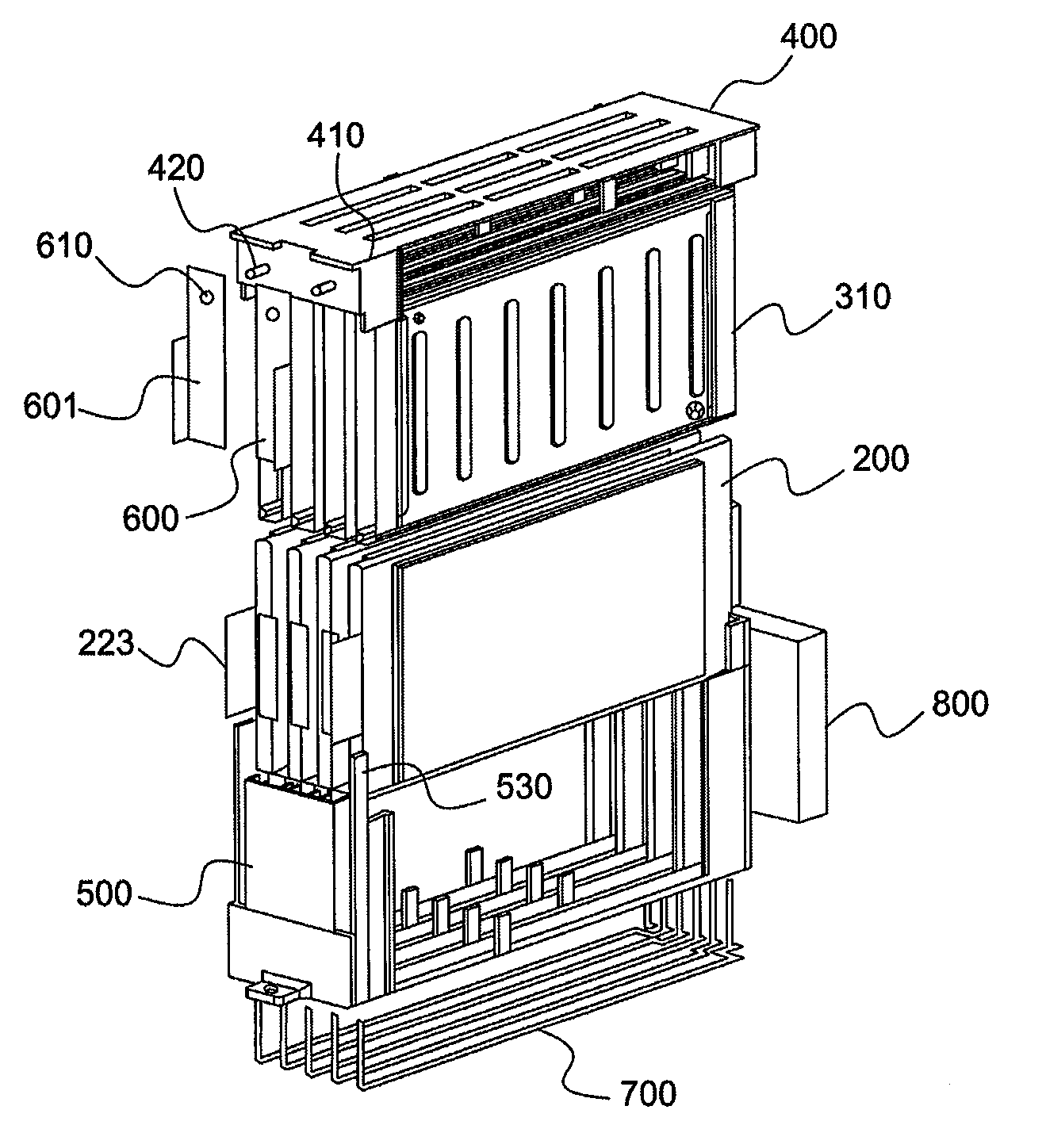

Battery system cooled via coolant

InactiveUS20090142628A1Increase contact areaImprove cooling effectSmall-sized cells cases/jacketsCell temperature controlThermal contactCooling pipe

The battery system cooled via coolant has a battery block 3 with a plurality of rectangular batteries 1 retained in a stacked configuration by a battery holder 4; a cooling plate 8 disposed in thermal contact with the bottom surface of the battery block 3 and having a hollow region 18 inside; cooling pipe 6 disposed inside the hollow region 18 of the cooling plate 8; and a coolant supply device 7 to supply coolant to the cooling pipe 6. The hollow cooling plate 8 has a surface plate 8A that makes thermal contact with the bottom surface of the battery block 3, and cooling pipe 6 is disposed within the hollow region 18 in contact with the inside of the surface plate 8A. Further, the cooling plate 8 hollow region 18 is filled with plastic foam 9.

Owner:SANYO ELECTRIC CO LTD

System for automatically gathering battery information

ActiveUS8344685B2Data processing applicationsMaterial analysis by electric/magnetic meansElectrical batteryEngineering

Owner:MIDTRONICS

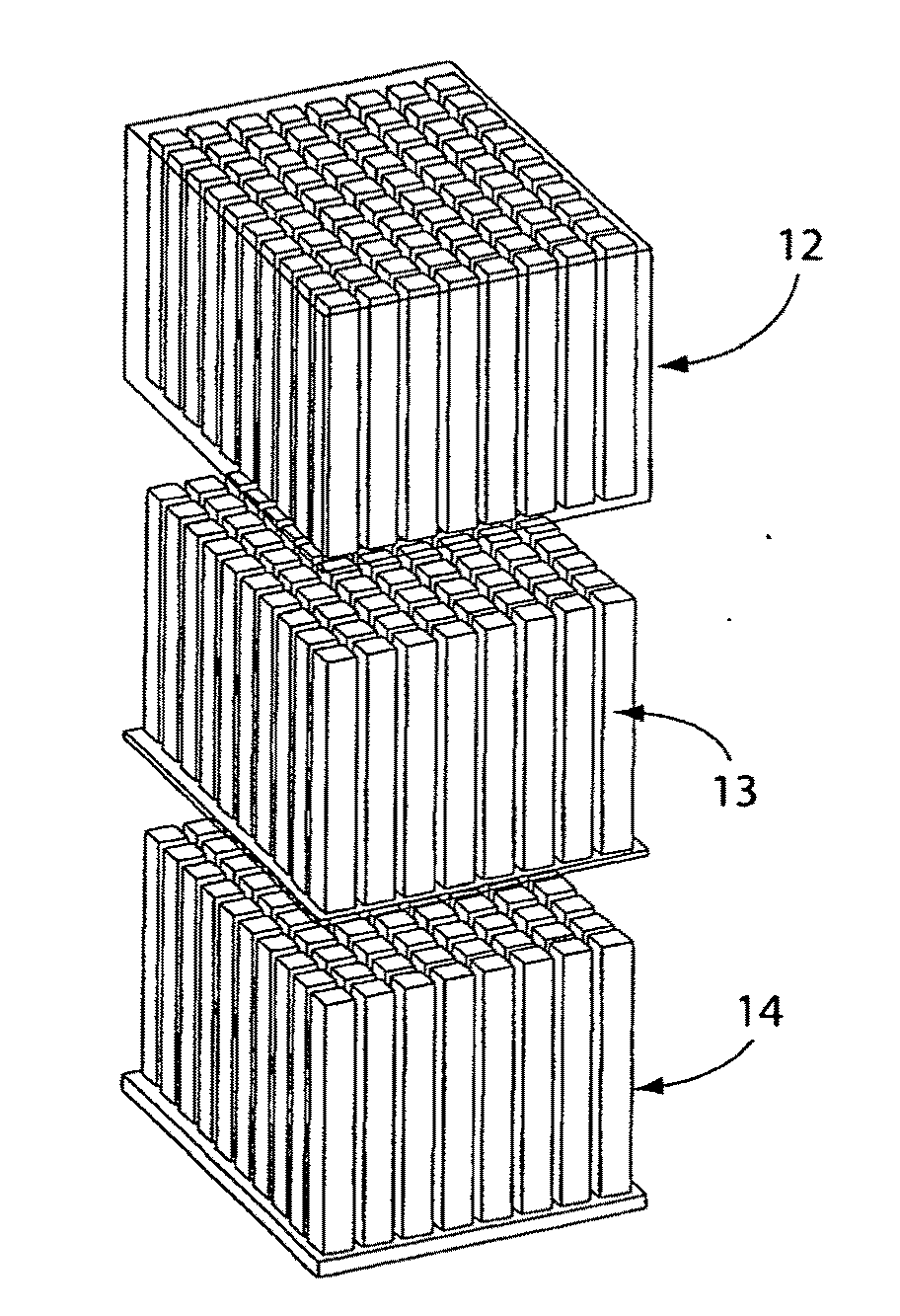

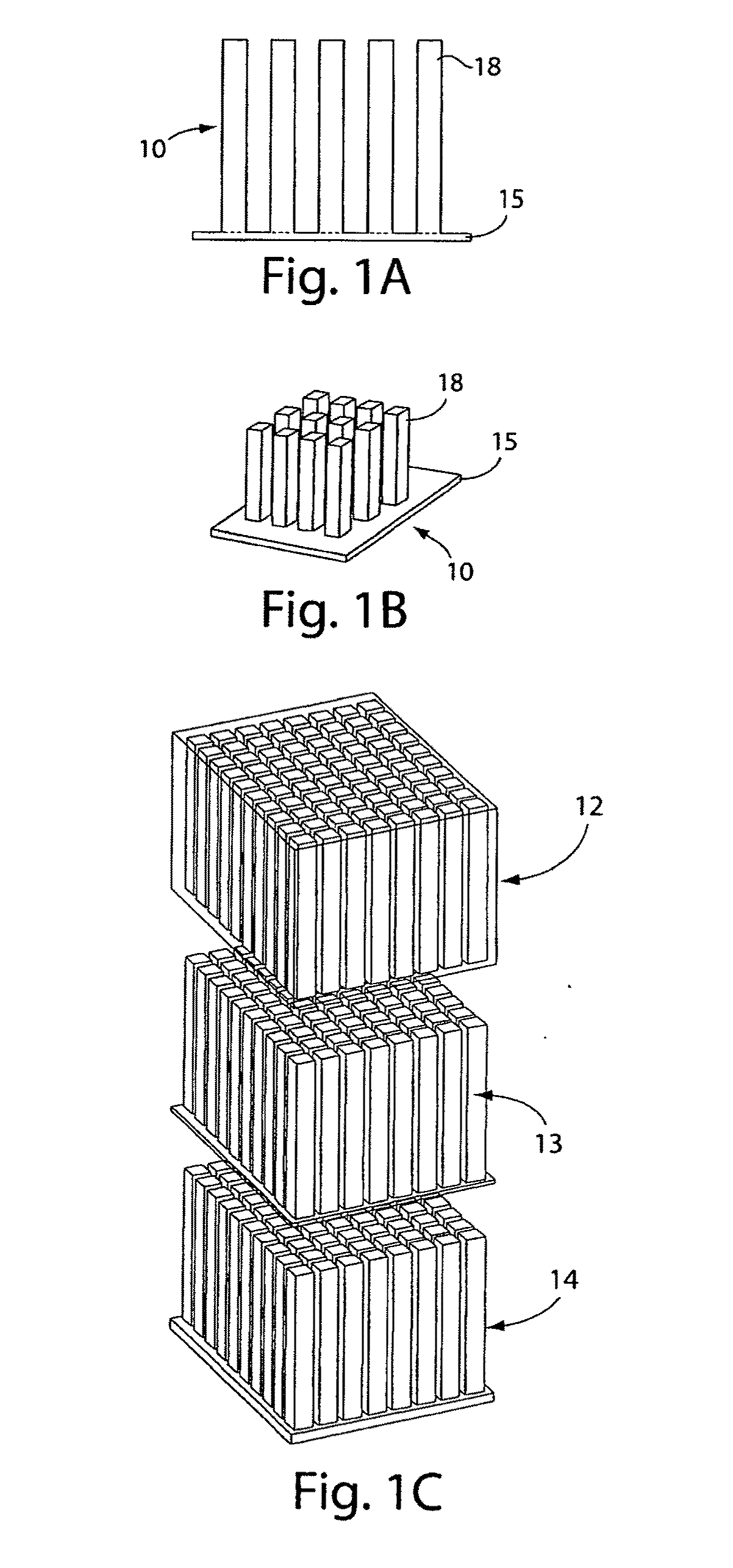

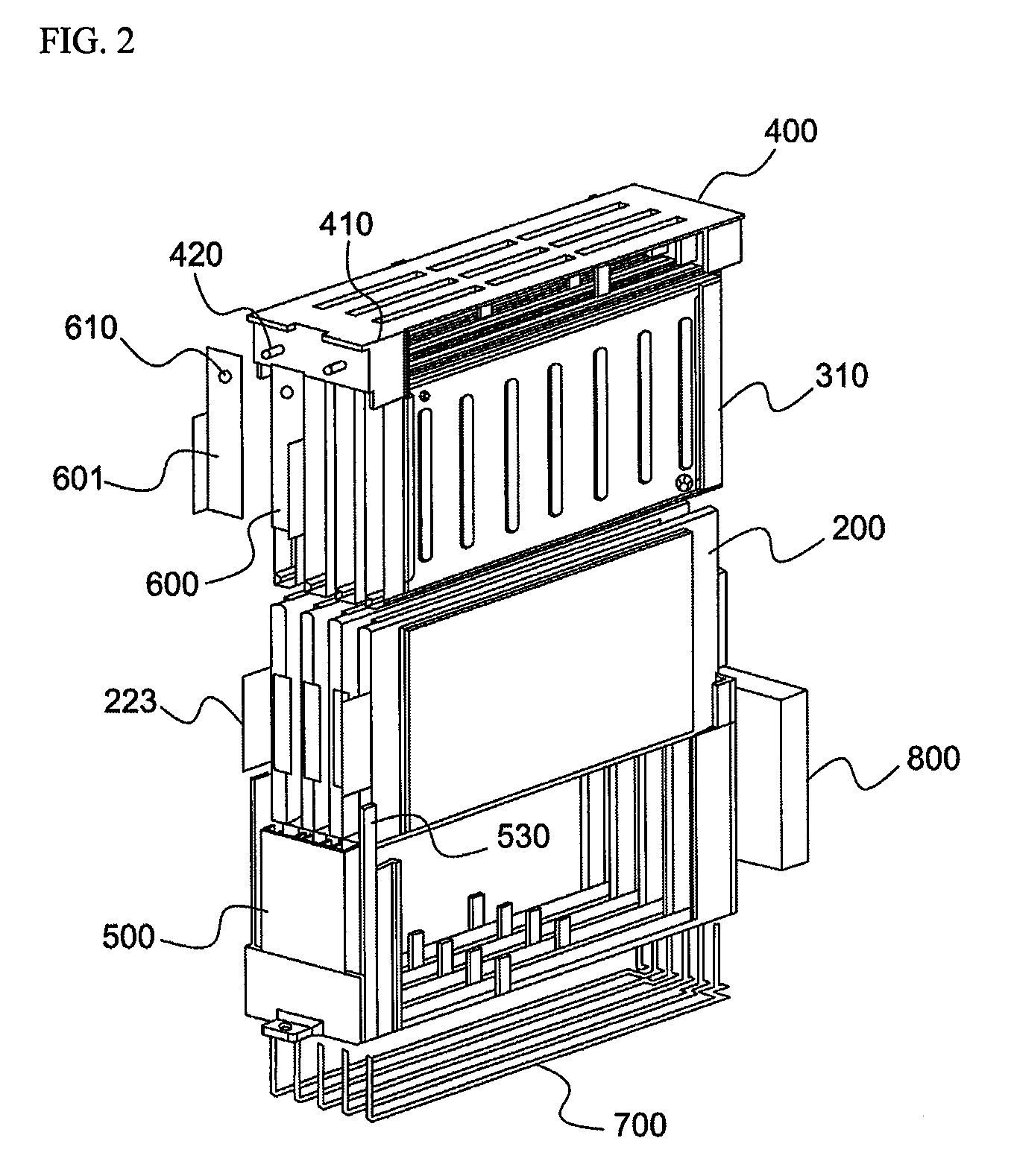

Middle or large-sized battery module

ActiveUS20100021802A1Stably accomplishedReduce in quantityPrimary cell to battery groupingSecondary cellsElectricityCoupling

Disclosed herein is a middle- or large-sized battery module including two or more unit modules each having one or more plate-shaped battery cells, as unit cells, surrounded by a high-strength sheathing member made of synthetic resin or metal, and separable upper and lower frame members coupled with each other in an assembly-type coupling structure such that the unit modules are vertically mounted in the upper and lower frame members. The present invention has the effect of easily mounting a sensing unit that is capable of minimizing the weight and size of battery cells while effectively reinforcing the low mechanical strength of the battery cells and sensing the operation state of the battery cells to a middle- or large-sized battery module. In addition, the present invention has the effect of manufacturing the battery module by a simple assembly process without using a plurality of members for mechanical coupling and electrical connection, thereby decreasing the manufacturing costs of the battery module, and effectively preventing the battery module from being short-circuited or damaged during the manufacture or the operation of the battery module. Furthermore, the present invention has the effect of manufacturing a middle- or large-sized battery system having desired output and capacity using the battery module as a unit body.

Owner:LG ENERGY SOLUTION LTD

Long life thin film battery and method therefor

InactiveUS20080003492A1Improve air tightnessIncrease costSolid electrolytesFinal product manufactureEngineeringThin film rechargeable lithium battery

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

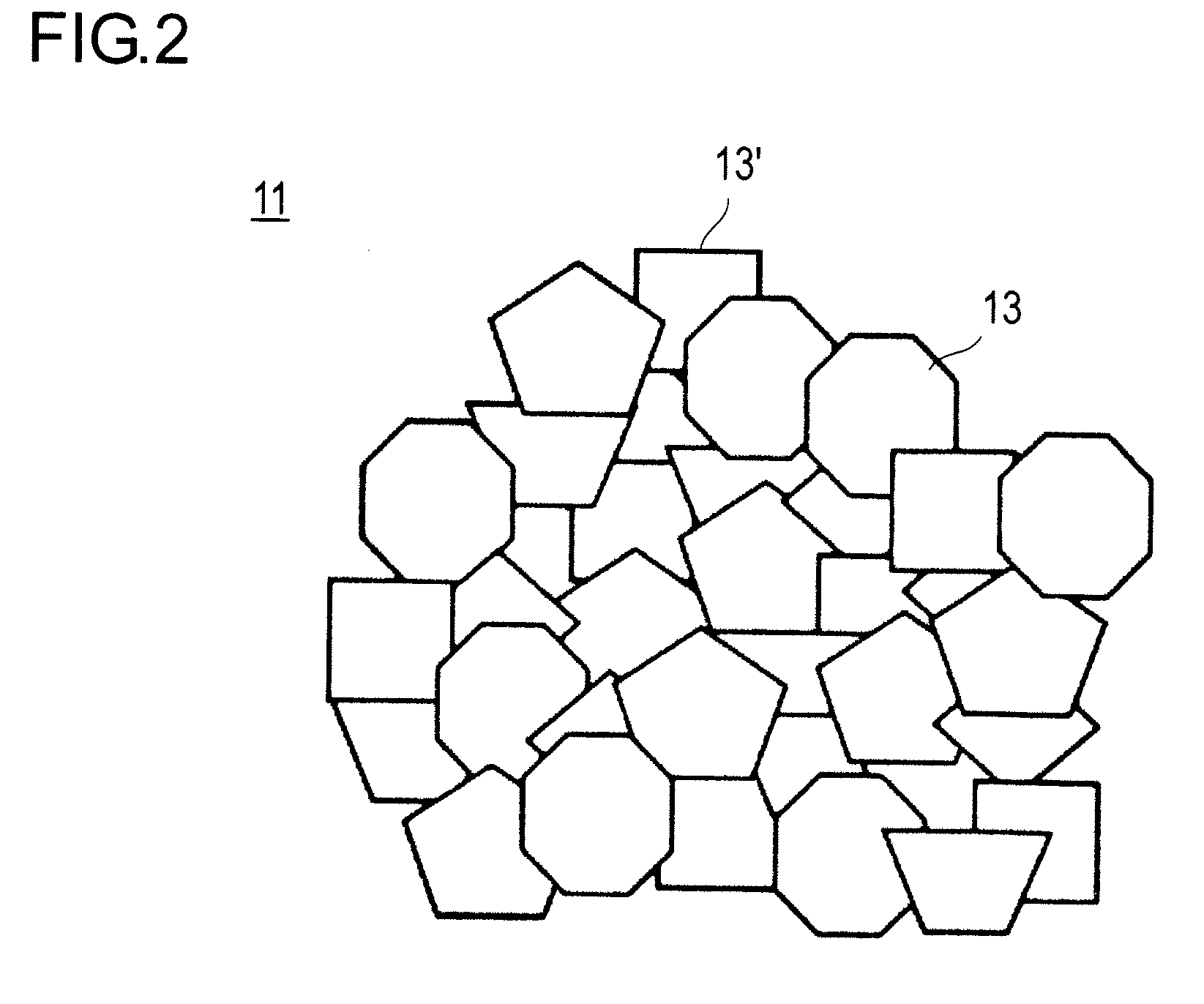

Positive electrode material for lithium ion battery with nonaqueous electrolyte, and battery using the same

ActiveUS20090029253A1Increase output powerAvoid crackingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithium-ion batteryComposite oxide

An object of the present invention is to provide a positive electrode material for non-aqueous electrolyte lithium-ion battery which capable of discharging high output power and inhibiting cracking of secondary particle in the cyclic endurance at a high temperature. The above object can be attained by a positive electrode material for non-aqueous electrolyte lithium-ion battery of the present invention, characterized in that said material comprises secondary particles composed of primary particles of lithium nickel composite oxide containing the primary particles having different aspect ratios, and that at least a part of said primary particles having different aspect ratios are arranged so as to make the longitudinal direction (the long side direction) thereof oriented toward the center of the secondary particle.

Owner:ENVISION AESC JAPAN LTD +1

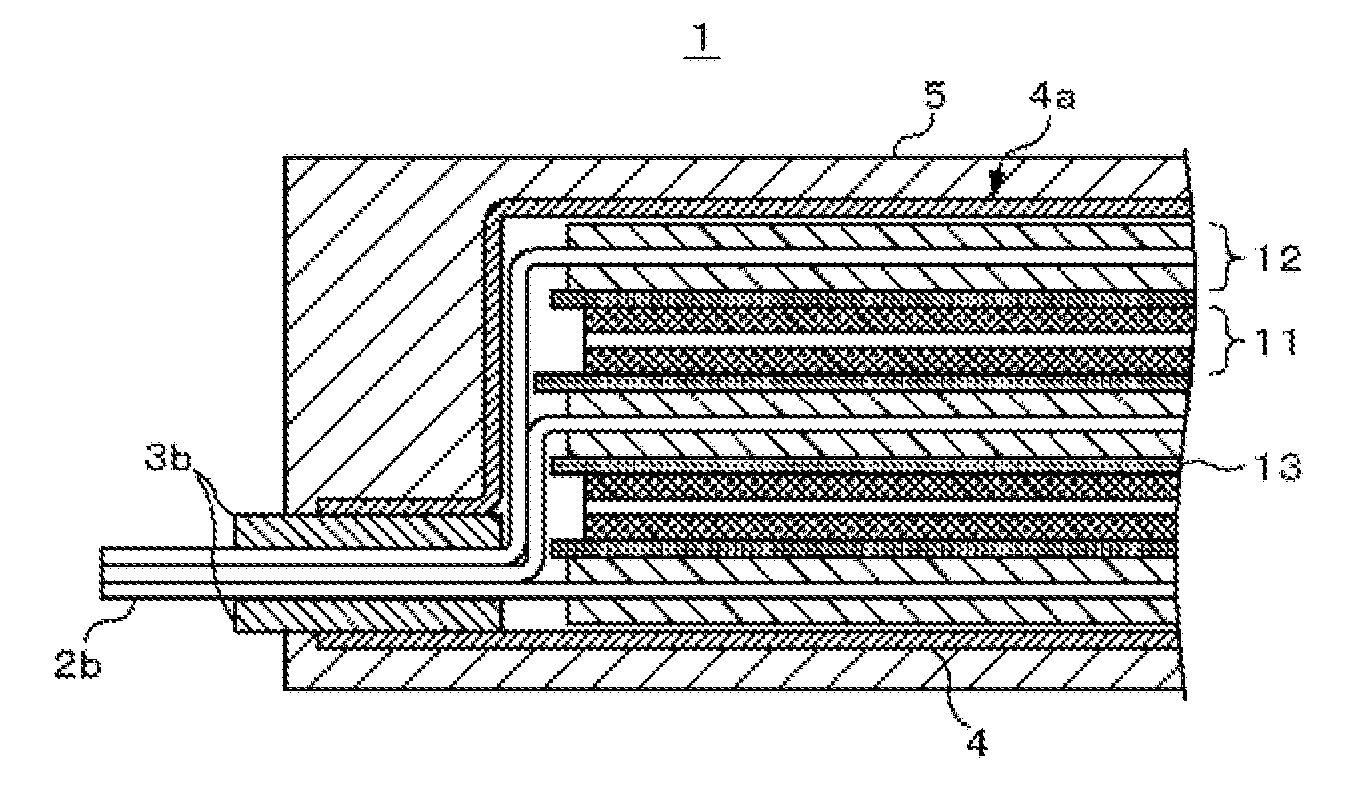

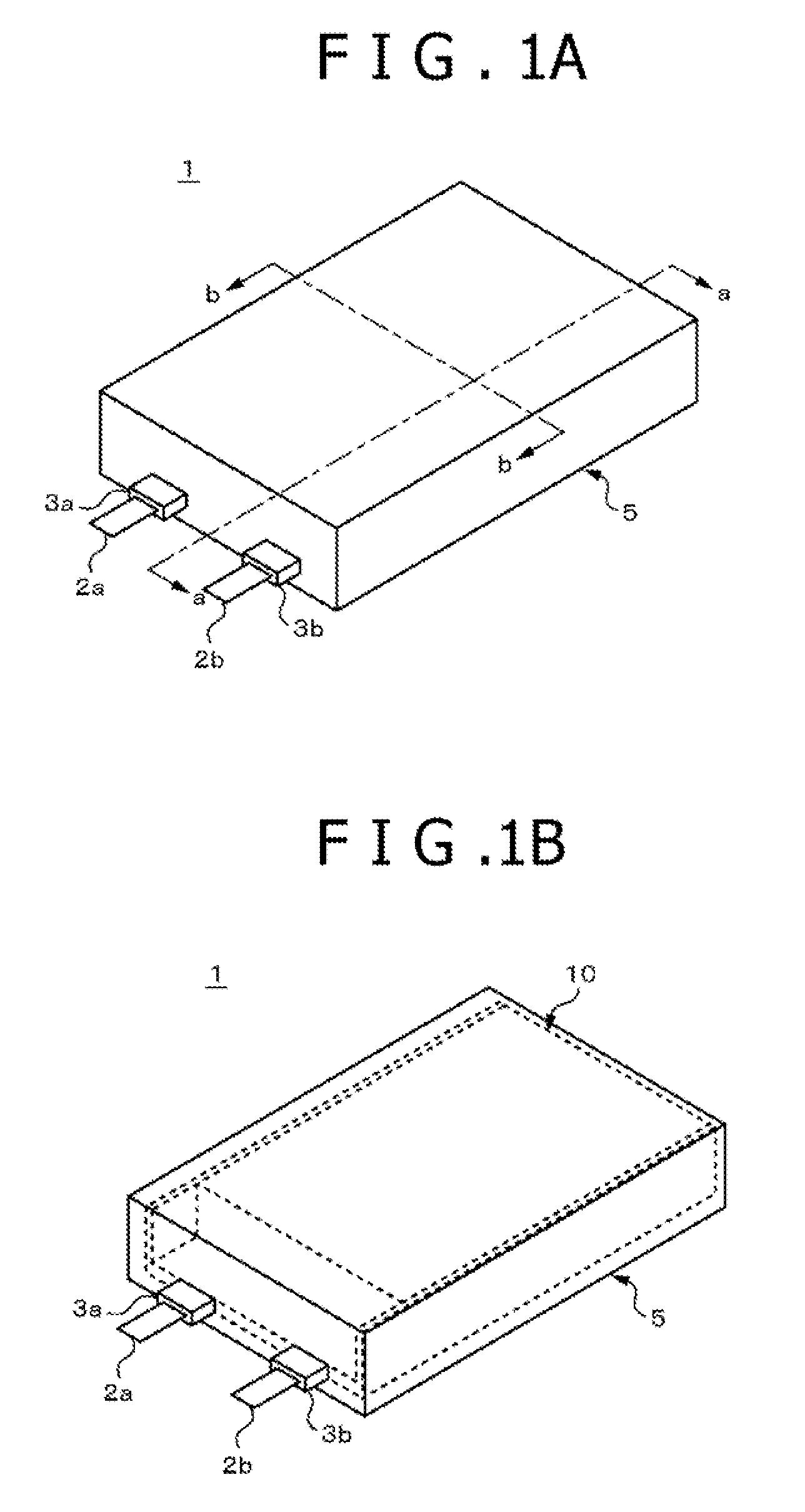

Non-aqueous electrolyte battery and method for producing the same

ActiveUS20090186270A1Improving battery strengthHigh strengthFinal product manufacturePrimary cellsEngineeringNon aqueous electrolytes

A non-aqueous electrolyte battery includes a battery element, a film-form casing member, and a resin protective layer. The battery element includes a positive electrode, a negative electrode, and a separator disposed between the positive electrode and the negative electrode. The film-form casing member contains the battery element and an electrolyte in an enclosed space thereof. The resin protective layer is formed along the surface of the film-form casing member and has a substantially uniform thickness.

Owner:MURATA MFG CO LTD

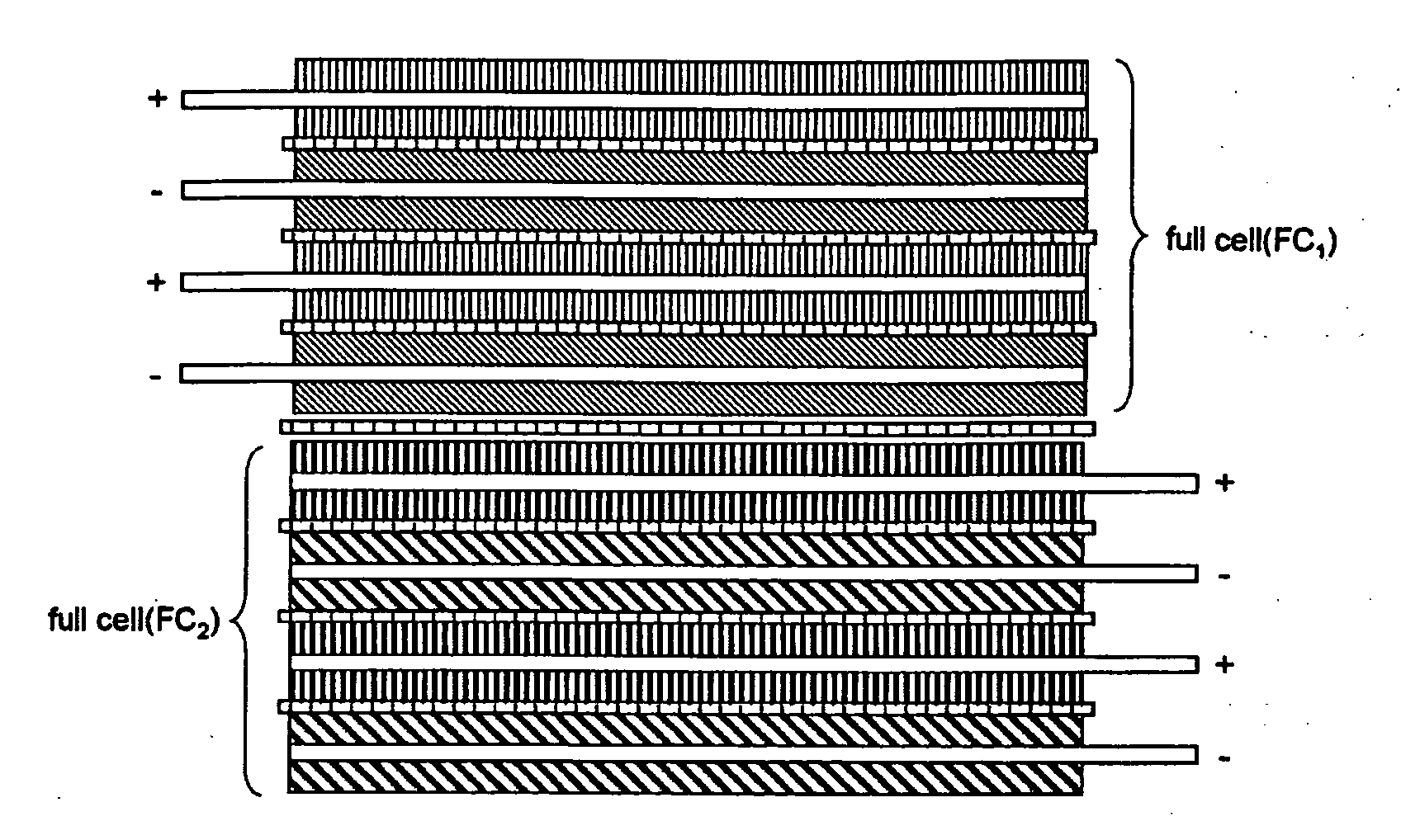

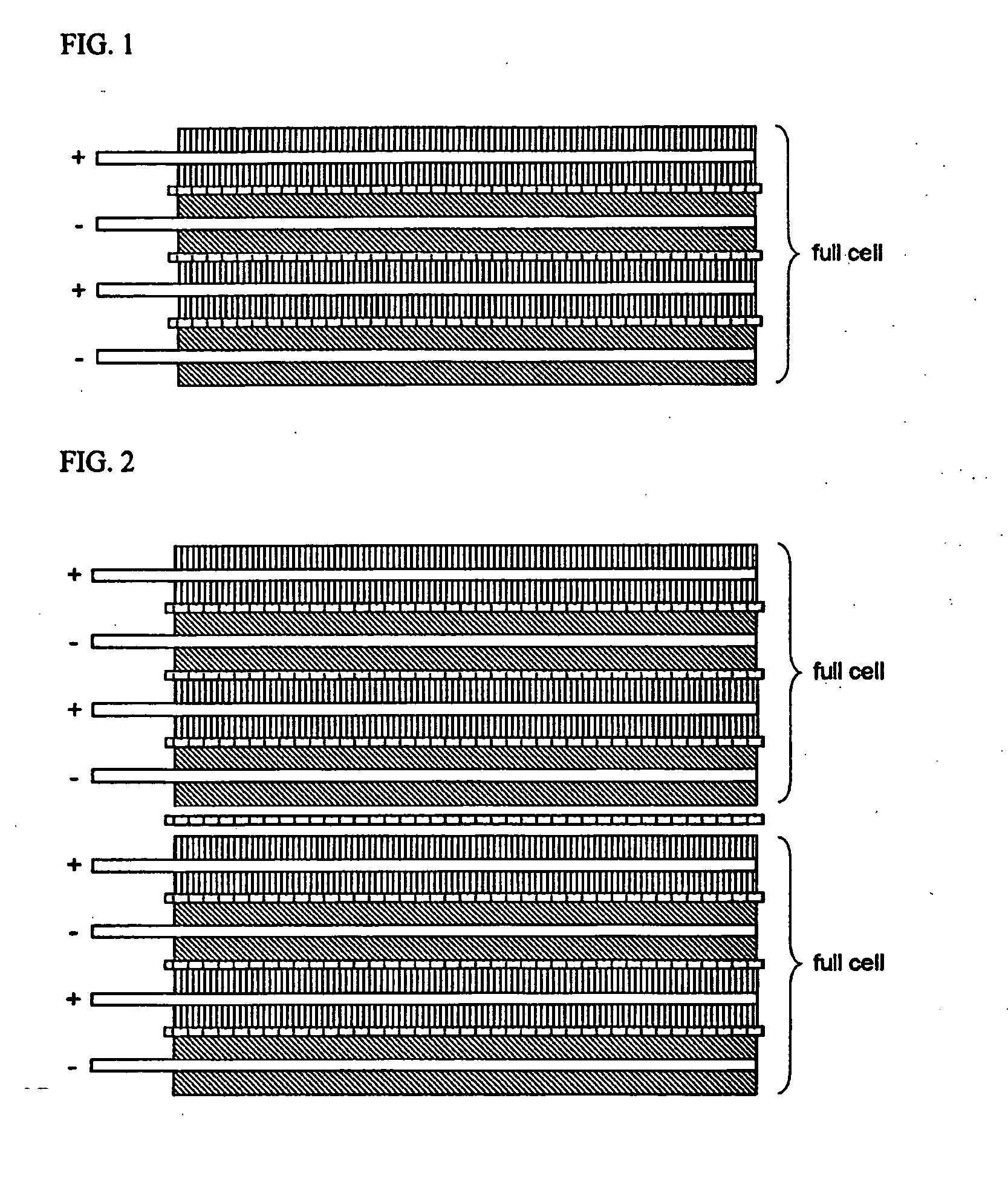

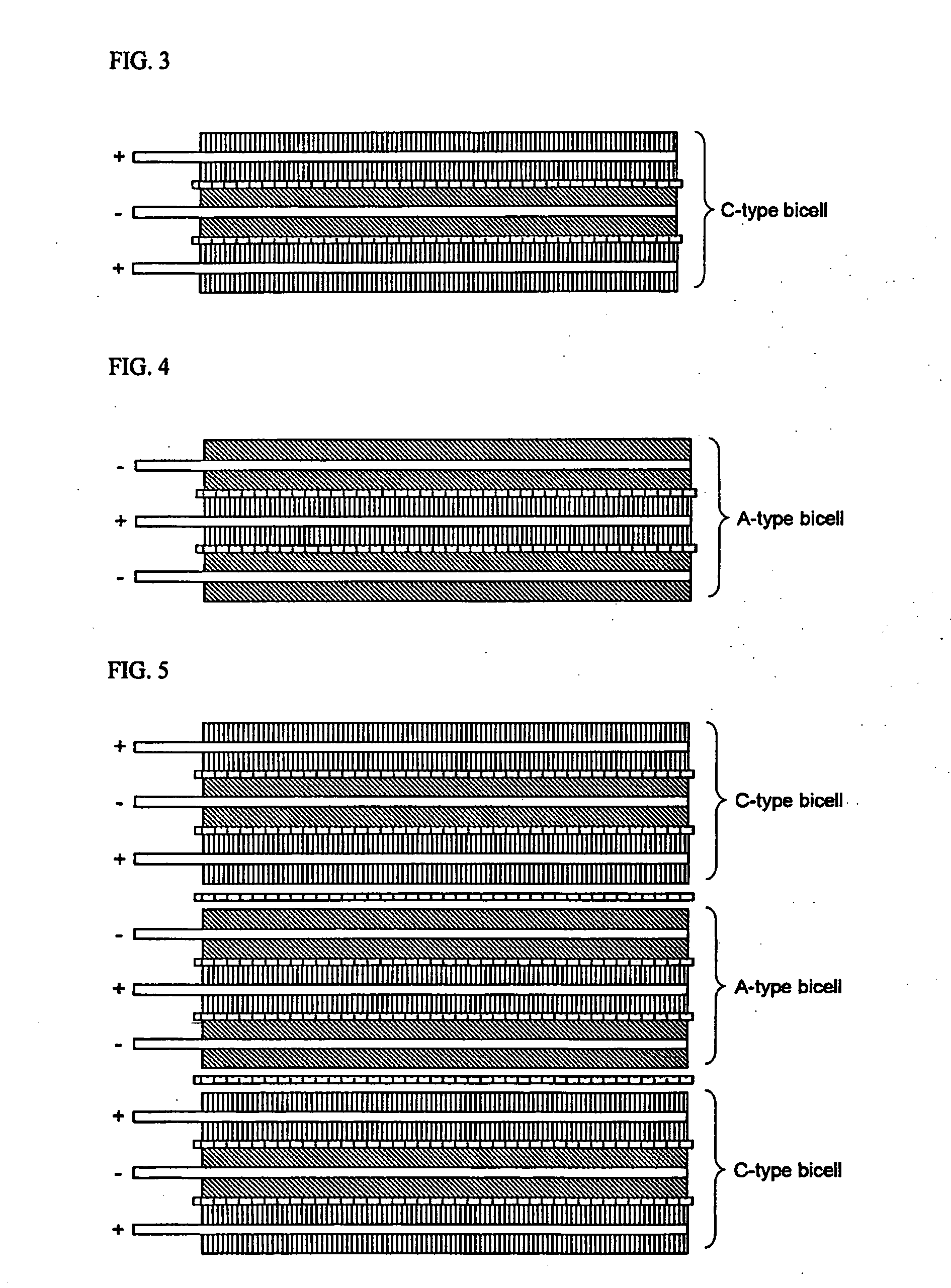

Stacking-typed secondary battery providing two or more operation voltages

Provided is a stacked-type secondary battery comprising a battery cell formed by stacking a plurality of full cells having a structure of cathode / separator / anode or bicells having a structure of cathode(anode) / separator / anode(cathode) / separator / cathode(anode), as a unit electrode assembly, wherein a cathode active material and / or an anode active material in two or more unit electrode assemblies are configured to have a different composition to induce a voltage difference and separate electrode terminals are installed in a battery case according to the voltage difference to thereby simultaneously provide two or more voltages by a single battery.

Owner:LG ENERGY SOLUTION LTD

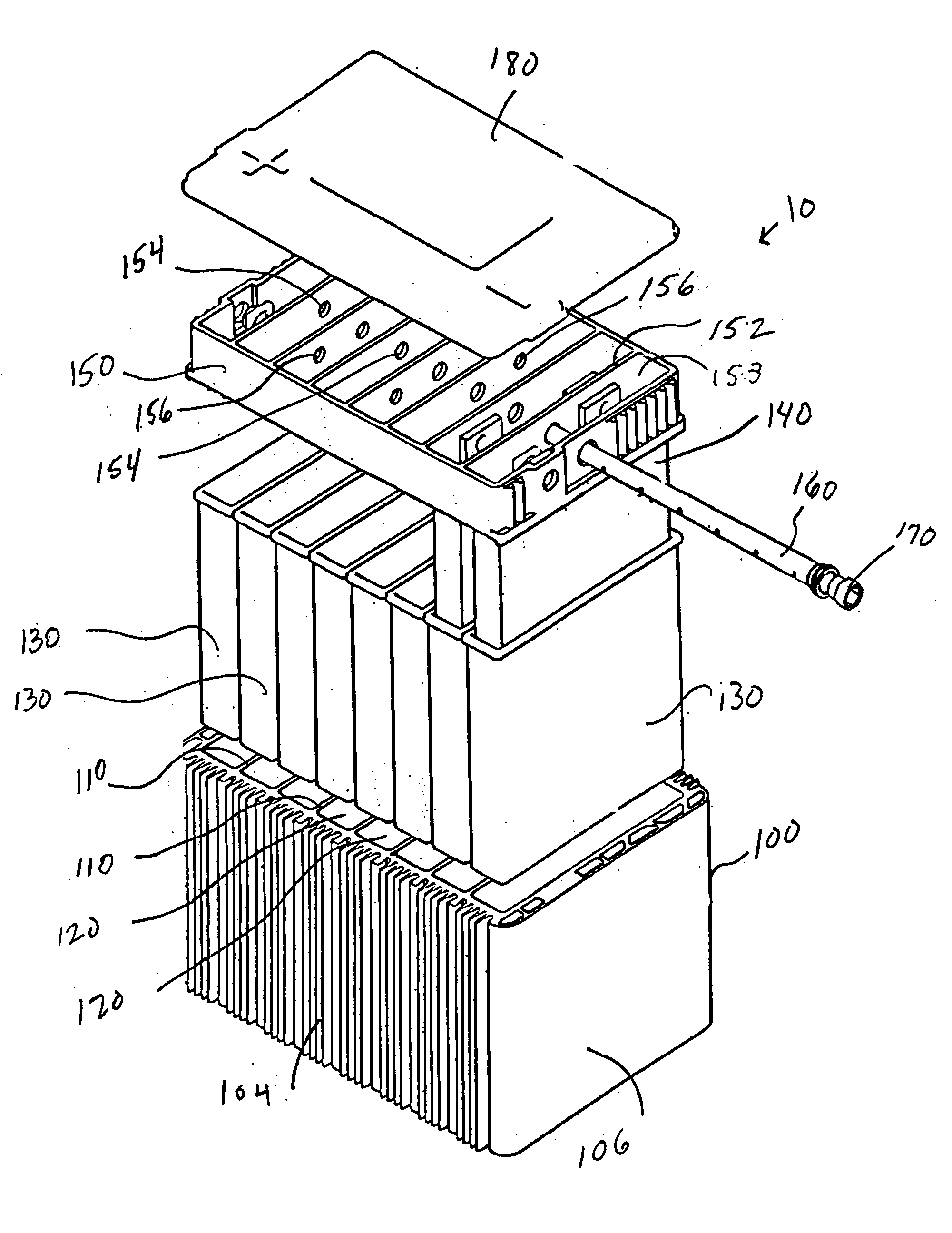

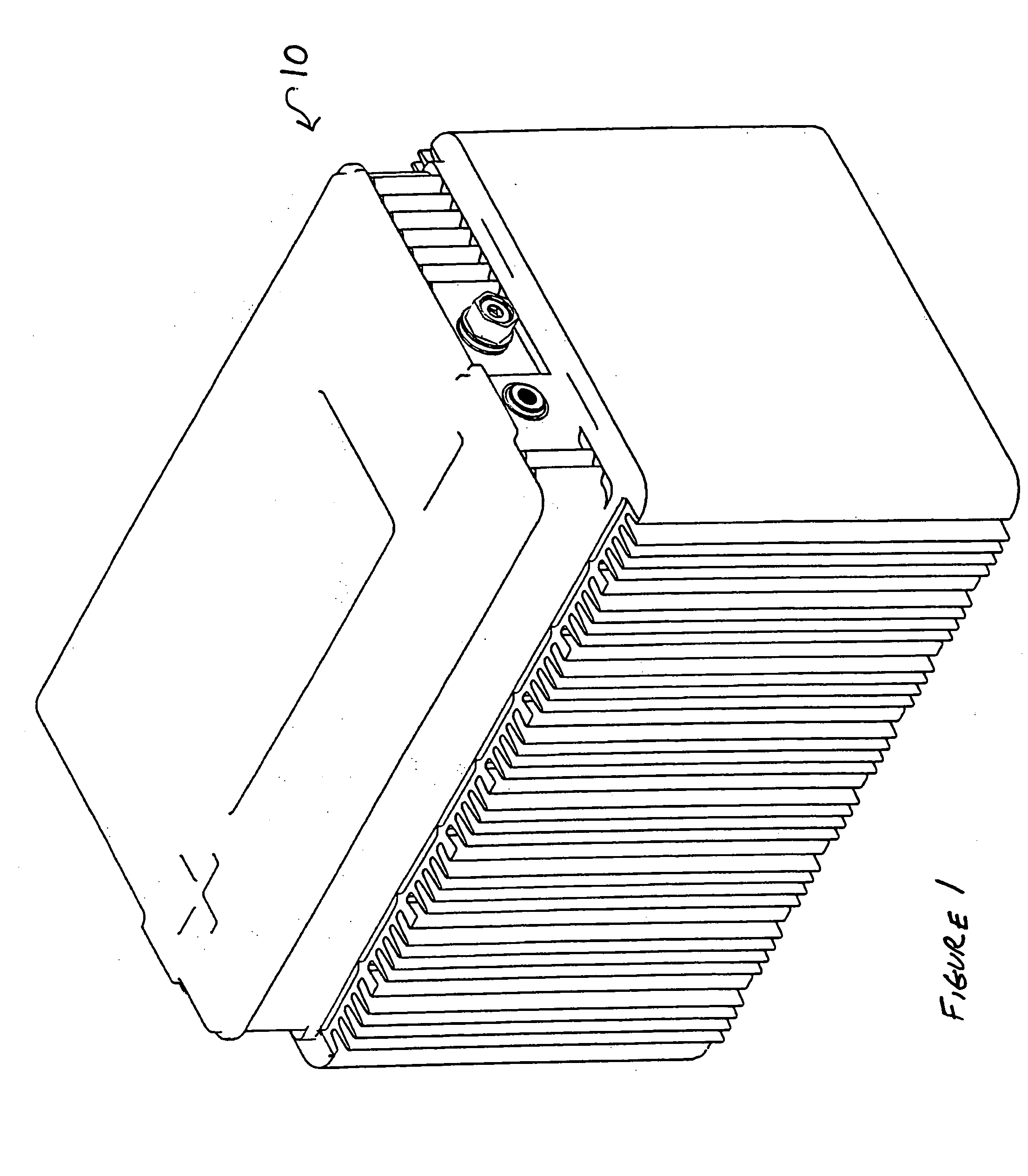

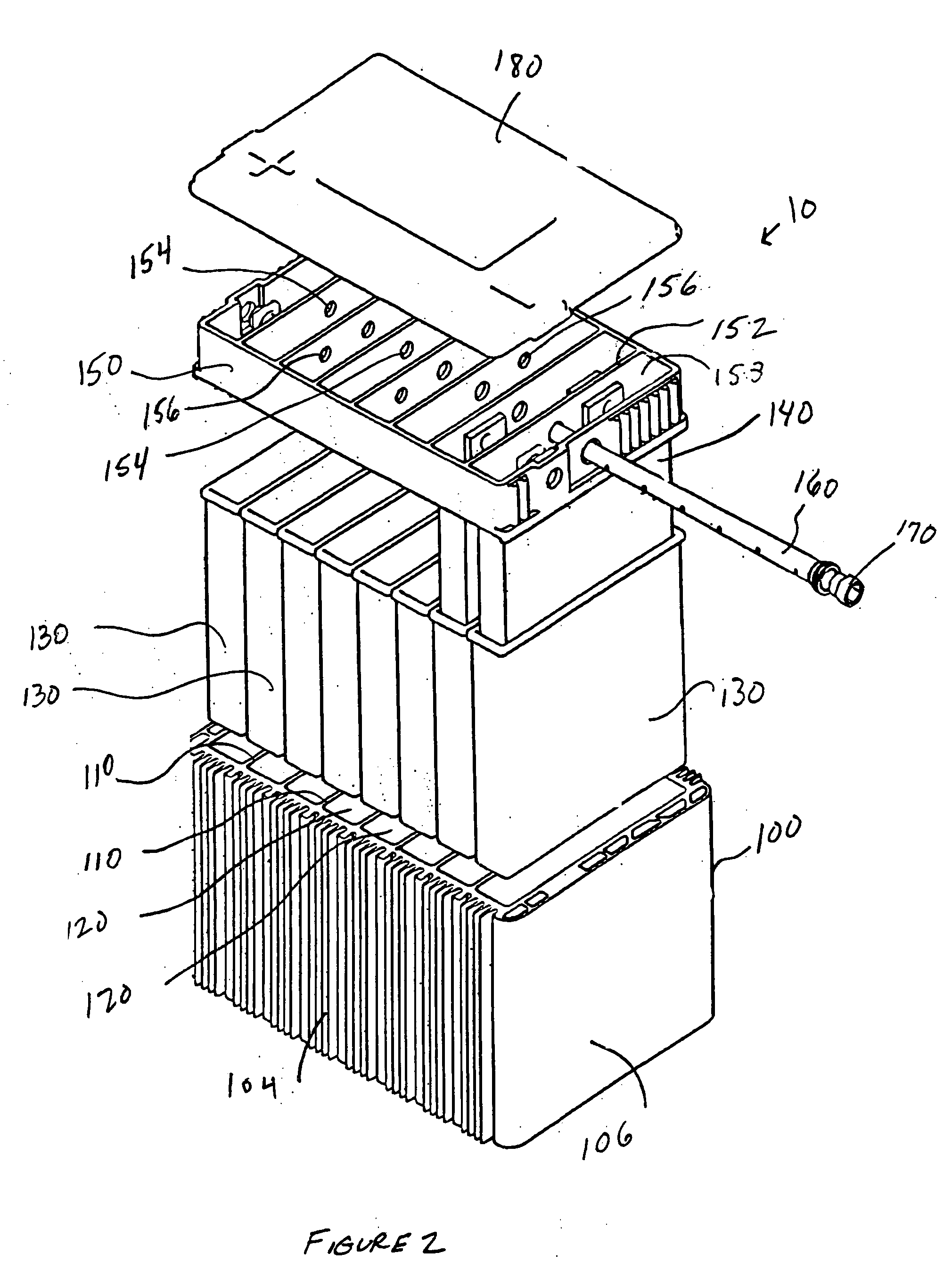

Battery assembly with heat sink

InactiveUS20050255379A1Improve thermal conductivityJackets/cases materialsFlat cells groupingEngineeringElectrochemical cell

A multi-cell battery comprising a housing having one or more partitions dividing the housing into a plurality of regions. A dielectric material lines the surfaces of the housing within each of the regions and an electrochemical cell is disposed within each of the regions. The housing is used as a heat sink to draw heat away from the individual electrochemical cells during operation.

Owner:OVONIC BATTERY CO INC

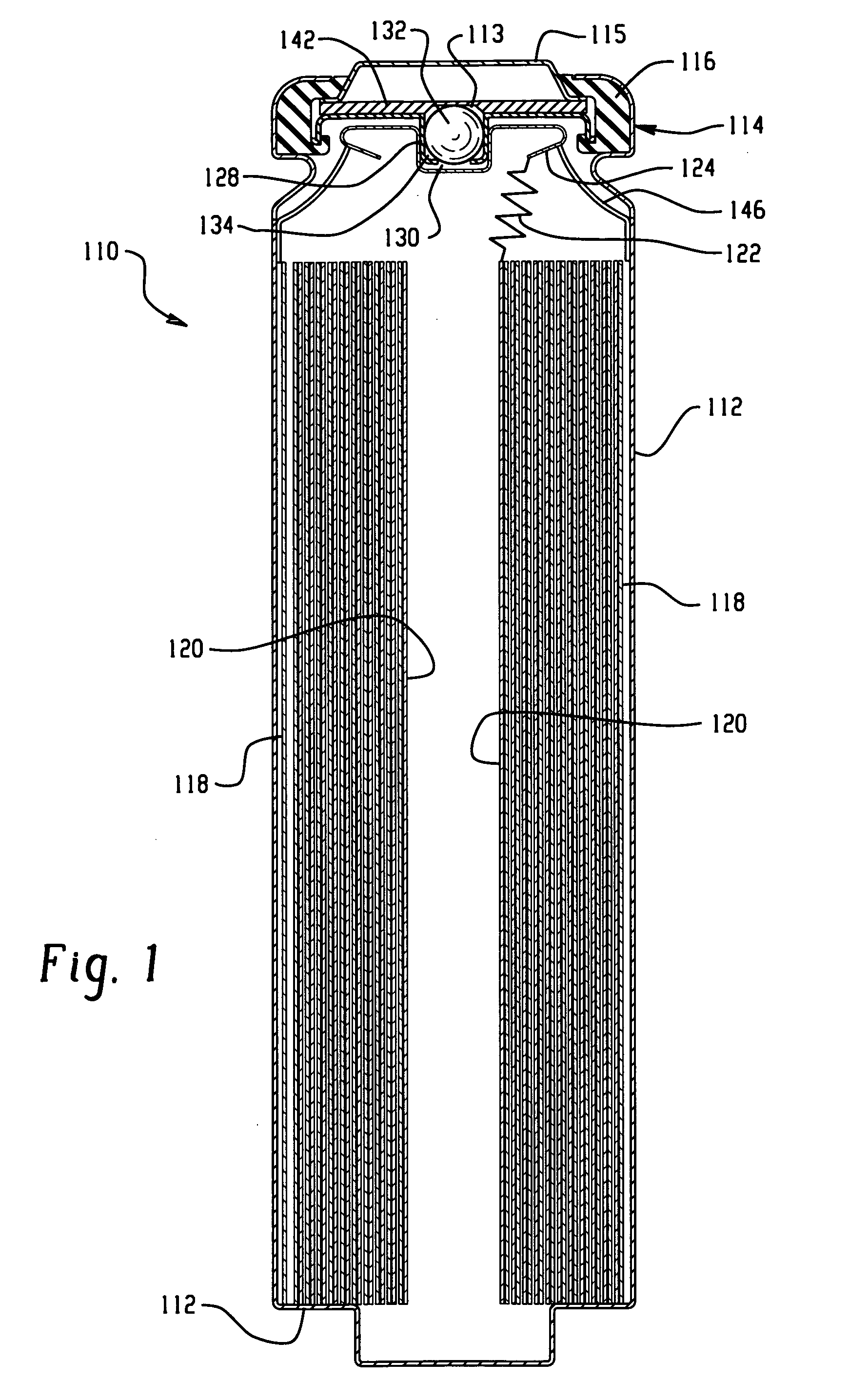

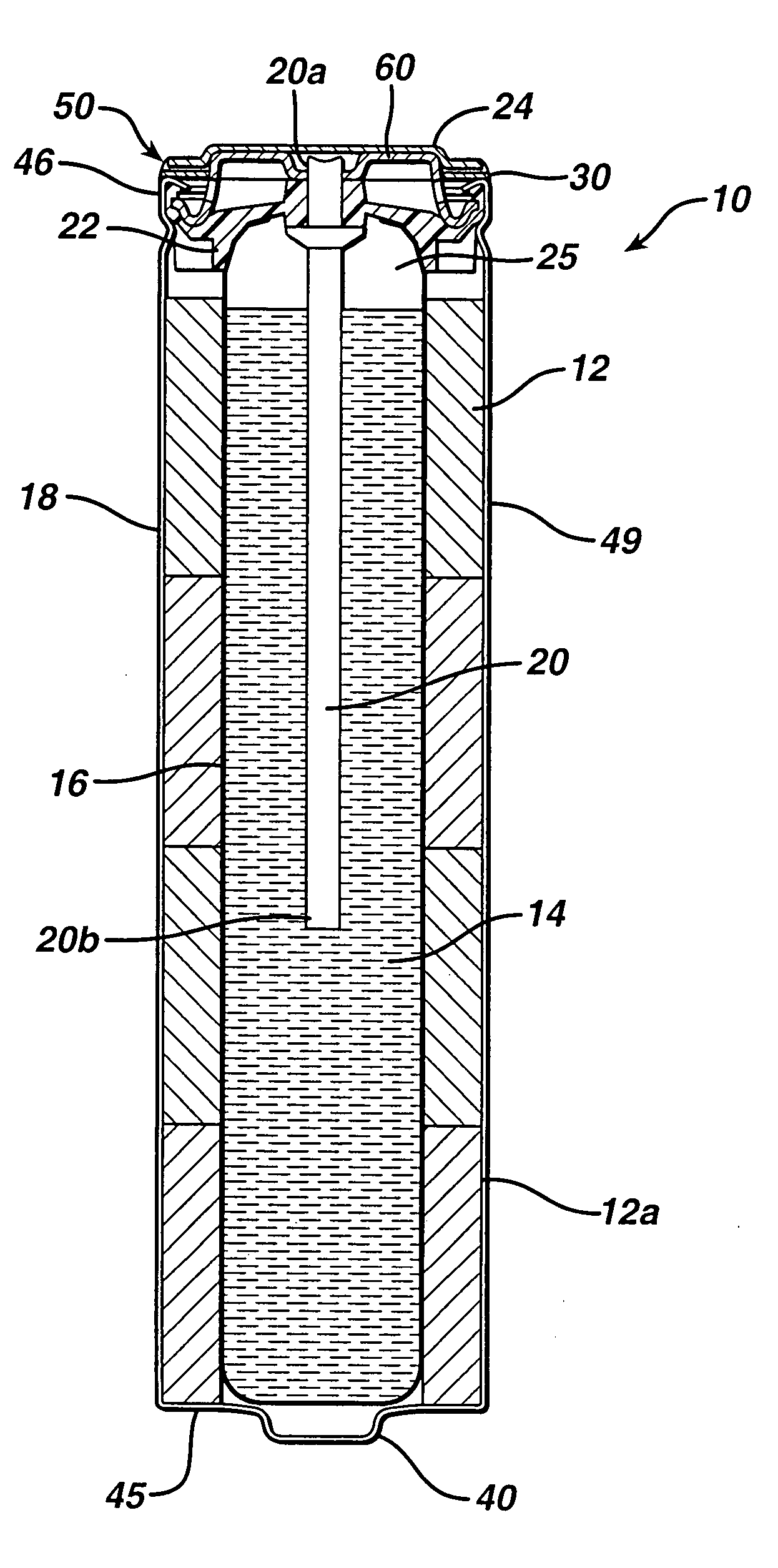

Electrochemical cell with positive container

InactiveUS20080026288A1Improve utilization efficiencyIncrease battery capacityFinal product manufactureElectrode carriers/collectorsSpiral woundEngineering

An electrochemical cell, particularly an electrochemical cell having a container with a positive polarity. In one embodiment, the cell is a primary cell that includes an electrode assembly having a lithium negative electrode and a positive electrode, preferably comprising iron disulfide. The cell is provided with a spiral wound electrode assembly with a portion of the positive electrode contacting the container. The positive electrode current collector contacts the container in one embodiment. The negative electrode includes an electrically conductive member that electrically contacts a cover of the cell and provides the cover with a negative polarity. In a preferred embodiment, the electrically conductive member makes pressure contact with a portion of the cell cover. A method of manufacturing such a cell is also provided.

Owner:EVEREADY BATTERY CO INC

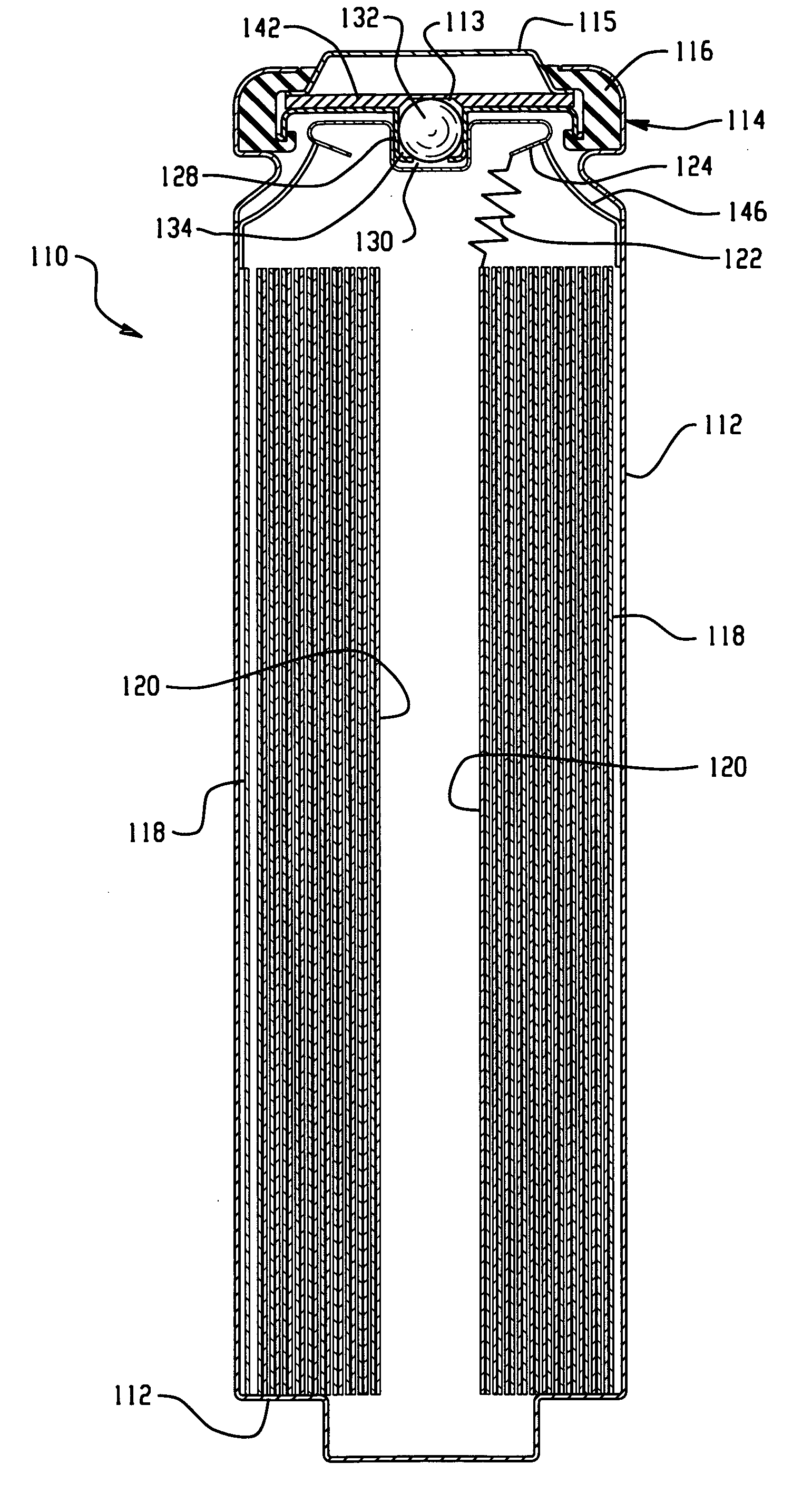

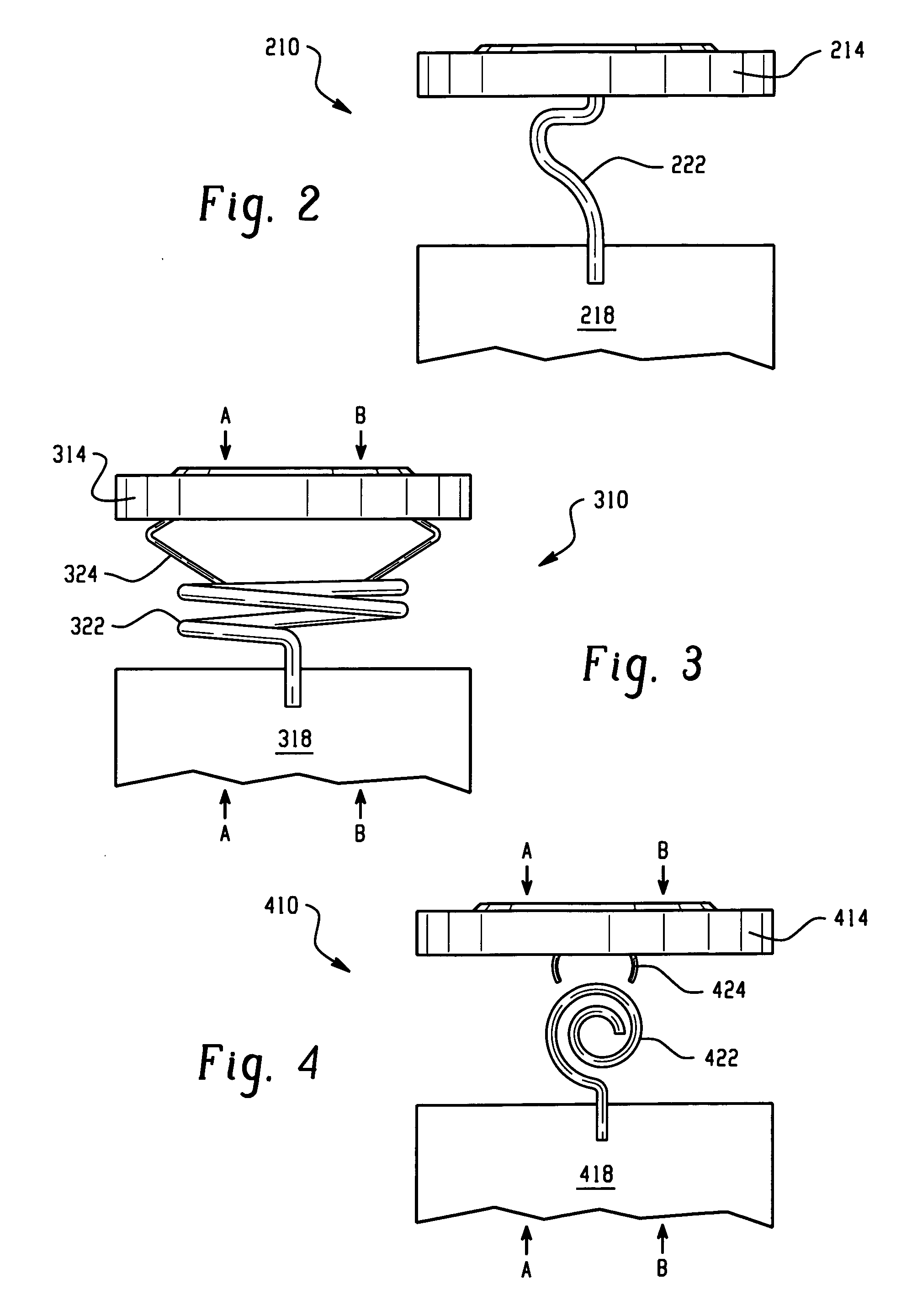

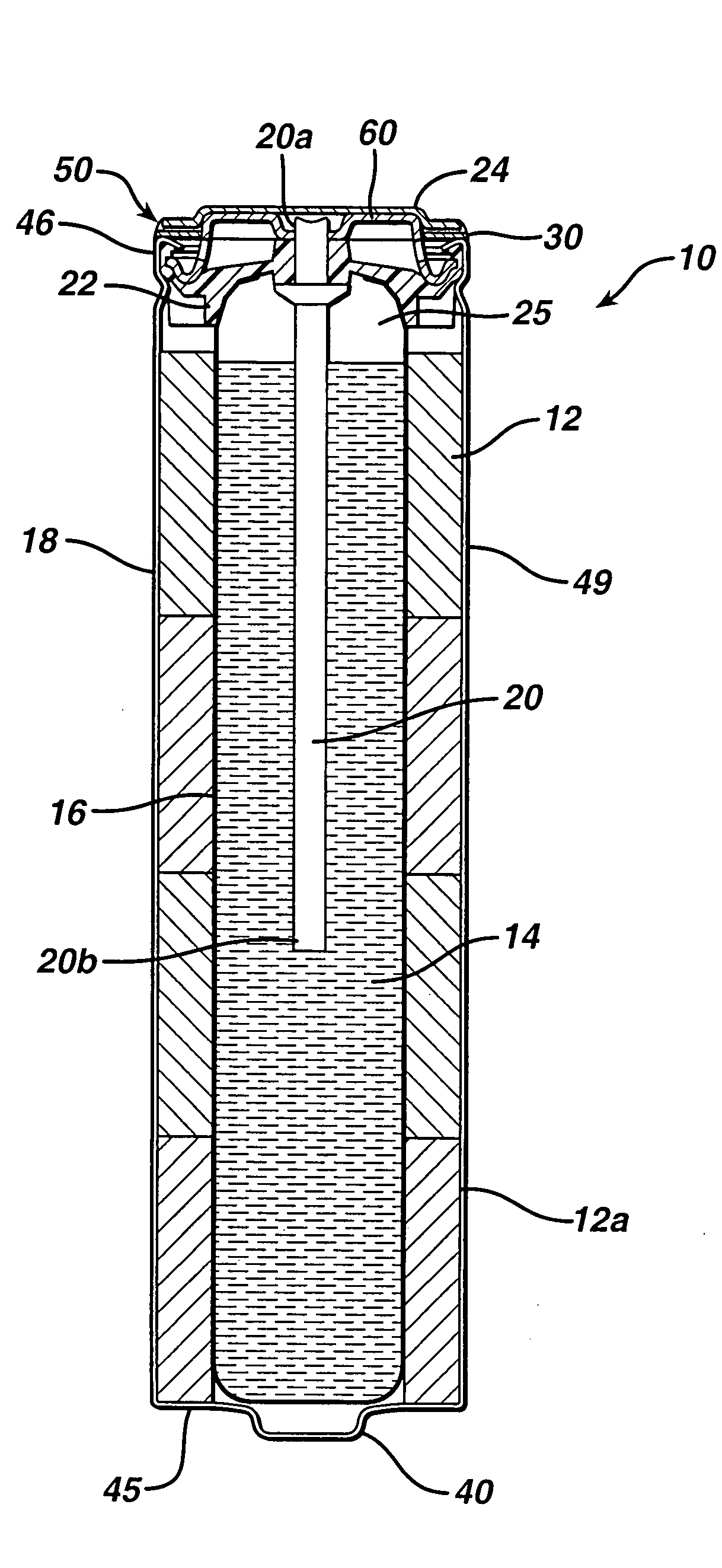

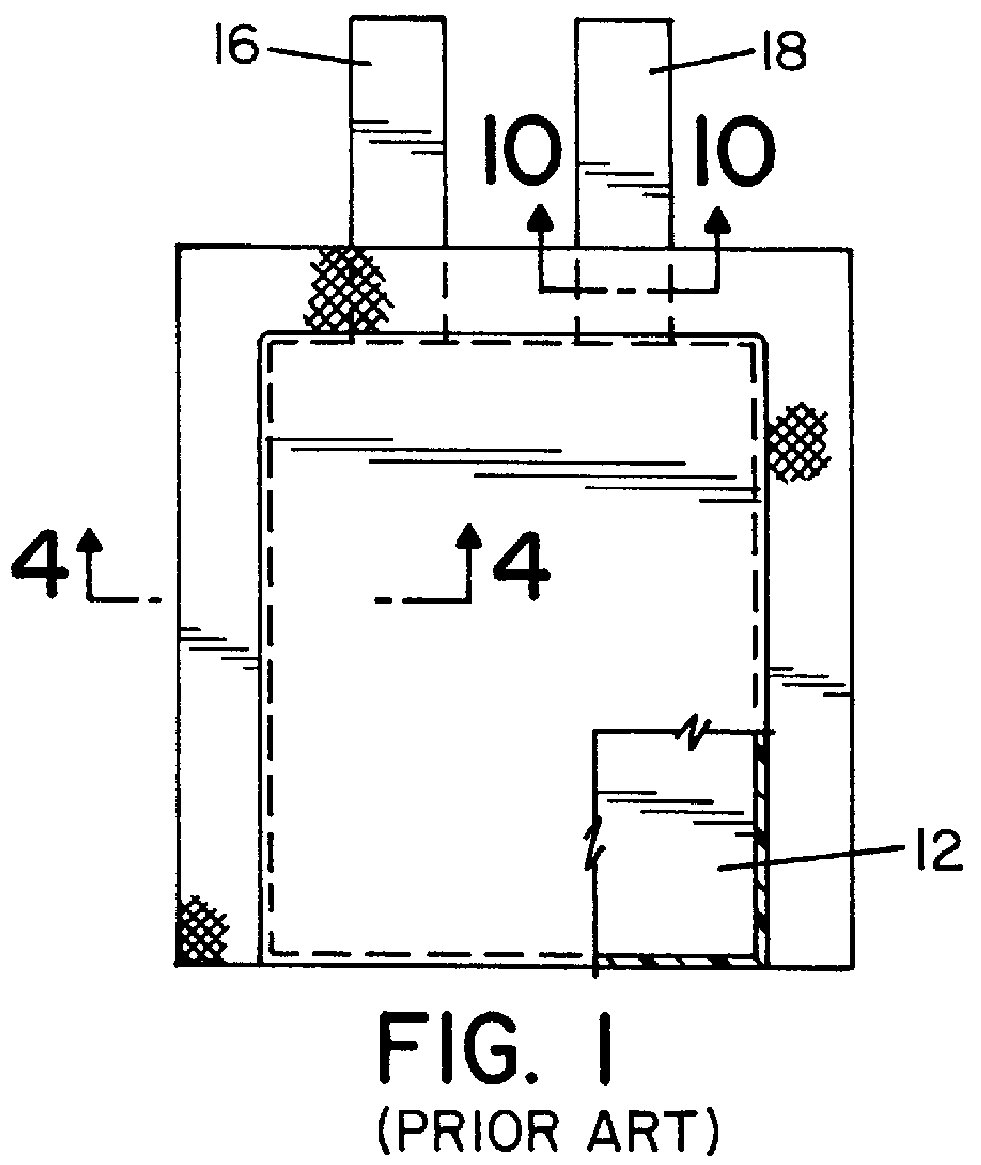

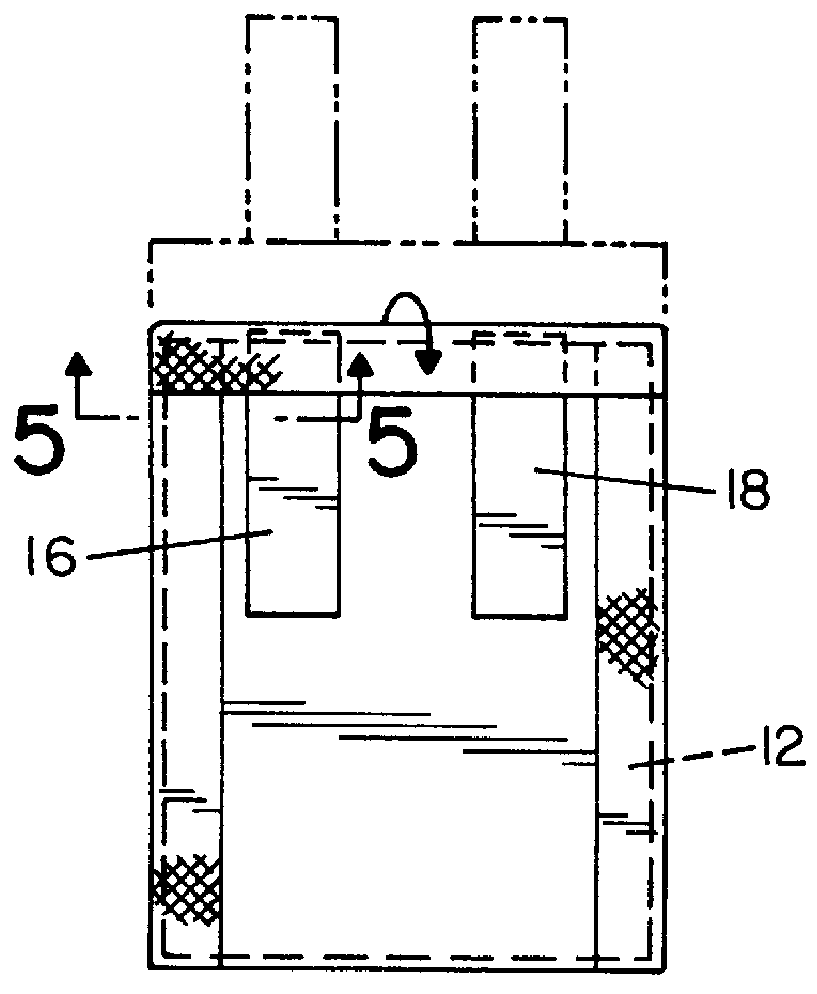

Electrical battery assembly and method of manufacture

InactiveUS7070881B2Reliable functionEnsure uniformityElectrotherapyCell seperators/membranes/diaphragms/spacersElectricityElectrical battery

The invention provides electrical storage battery assemblies and related methods for assembling such batteries. A battery assembly includes positive and negative electrode sheets and separator sheets sandwiched together and wrapped around a central mandrel to provide a spiral sandwich electrode assembly. The electrode assembly is housed inside a case that includes a case housing open at two ends and covers closing the two openings. The central mandrel of the electrode assembly is in electrical contact with one of the electrode sheets and a first battery terminal that passes through the case. A projecting member on the central mandrel provides the electrical connection between the electrode and the first battery terminal. The other electrode is in electrical contact with the case. A first insulator lies between the electrode assembly and the projecting member. A second insulator is positioned between the projecting member and the case.

Owner:QUALLION

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

InactiveUS20070248879A1Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsConductive coatingZinc alloys

A primary alkaline battery includes a cathode including a nickel oxyhydroxide and an anode including zinc or zinc alloy particles. Performance of the nickel oxyhydroxide alkaline cell is improved by adding zinc fines to the anode and by including an oxidation resistant graphite in the cathode as well as in a conductive coating applied to the inside surface of the cell housing.

Owner:THE GILLETTE CO

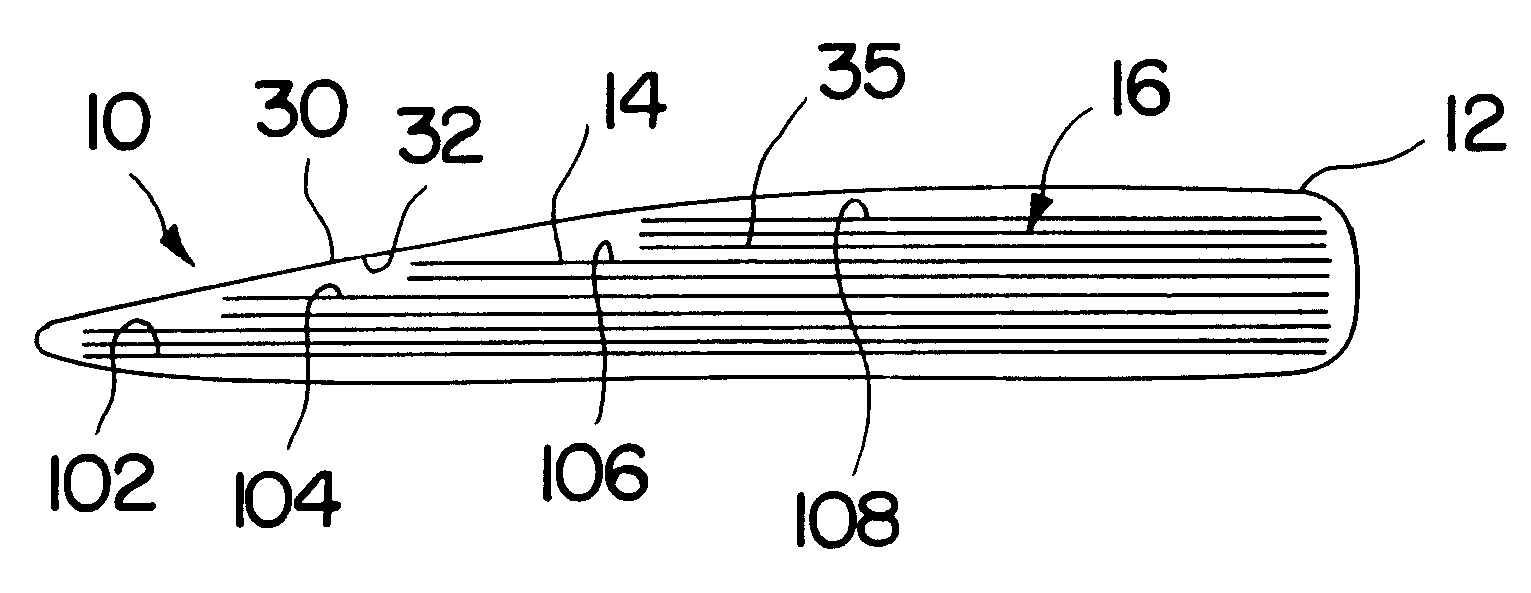

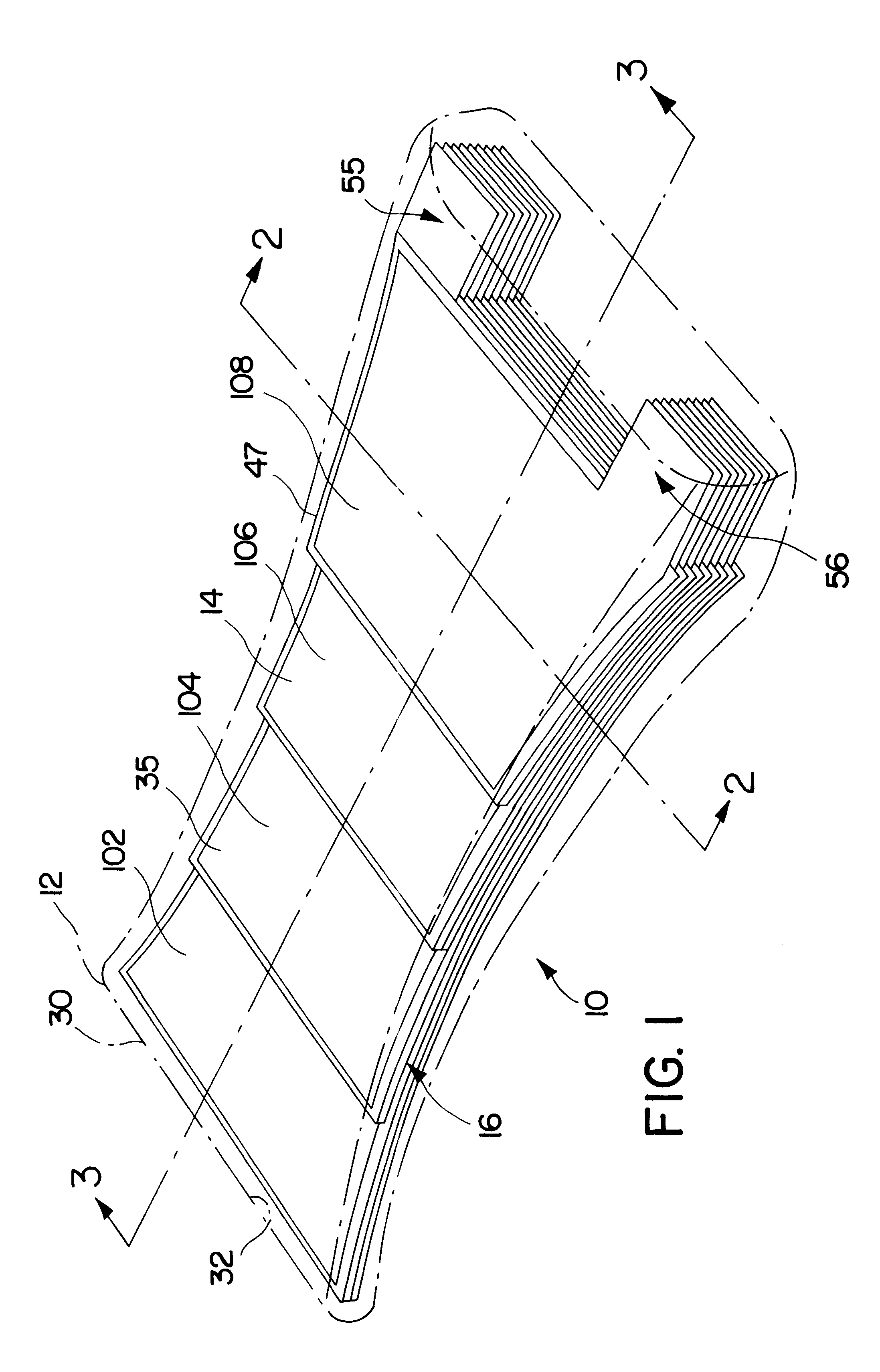

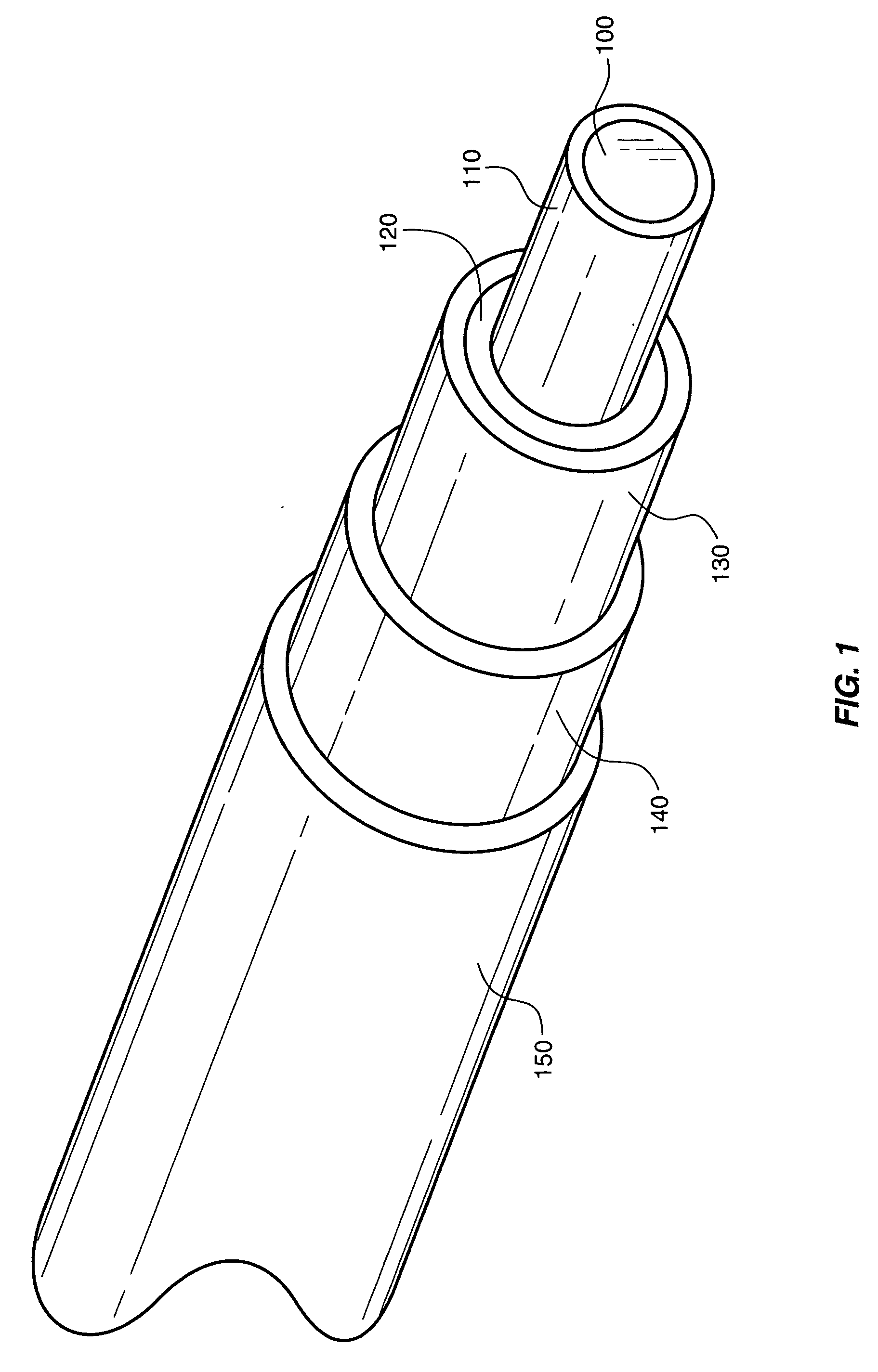

Thin-film electrochemical devices on fibrous or ribbon-like substrates and method for their manufacture and design

InactiveUS20050271796A1Increase capacityHigh voltageElectrode carriers/collectorsVacuum evaporation coatingFiberBand shape

The fabrication of functional thin-film patterns, such as solid-state thin-film batteries on substrates having fibrous, or ribbon-like or strip-like geometry is disclosed. The present invention relates additionally to the design and manufacture of multiple-layer and multi-function thin films.

Owner:ITN ENERGY SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com