Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Energy Density Maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

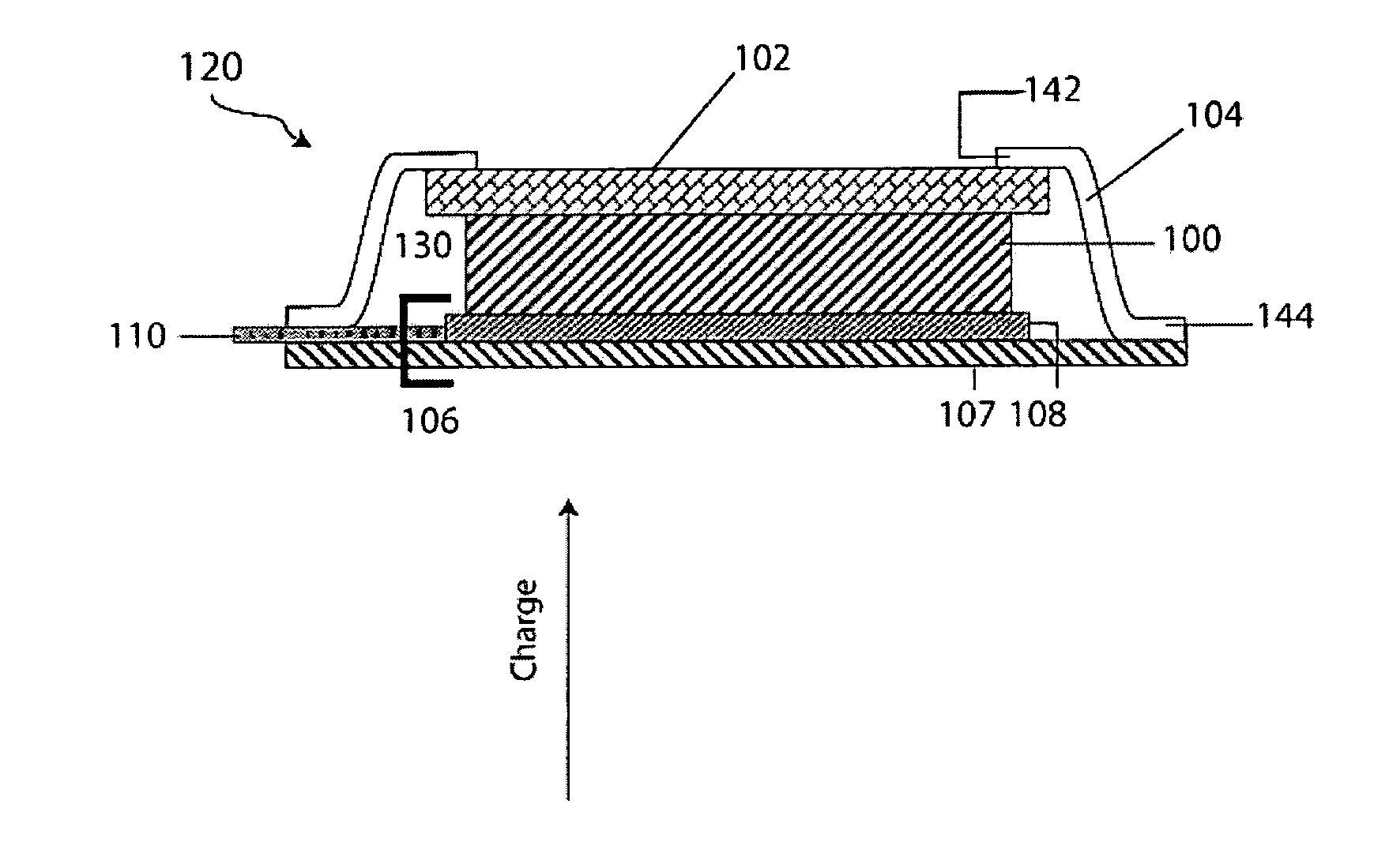

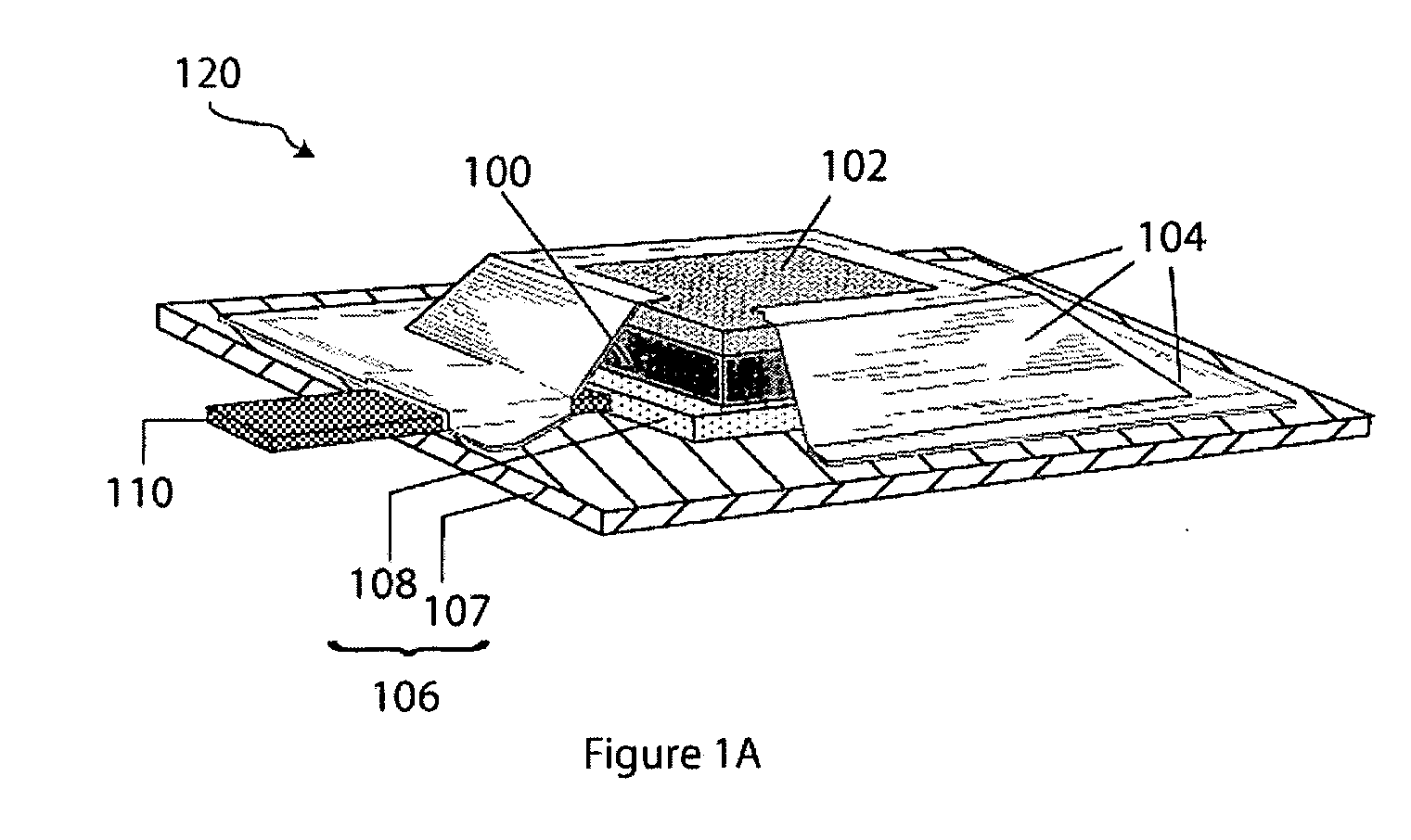

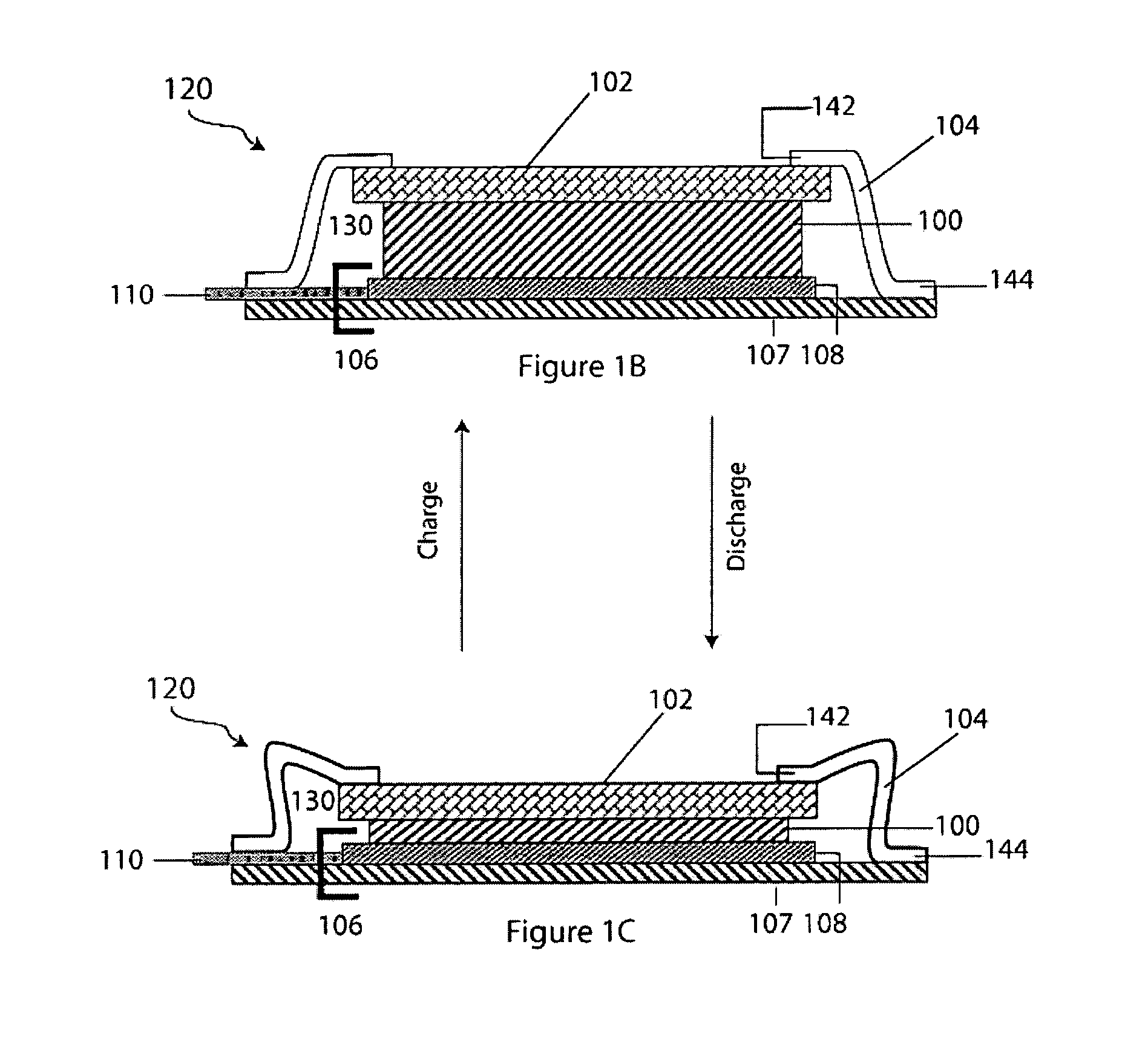

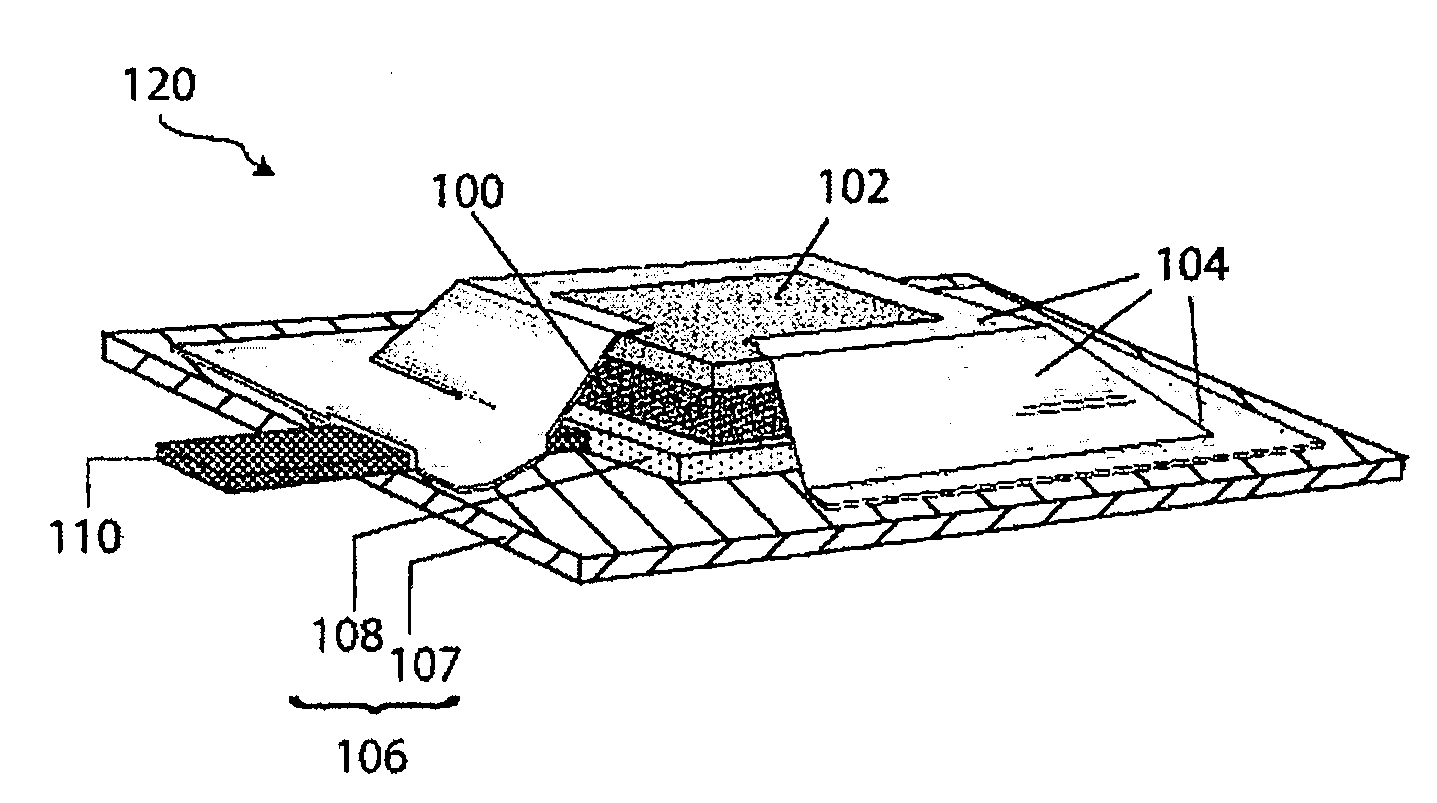

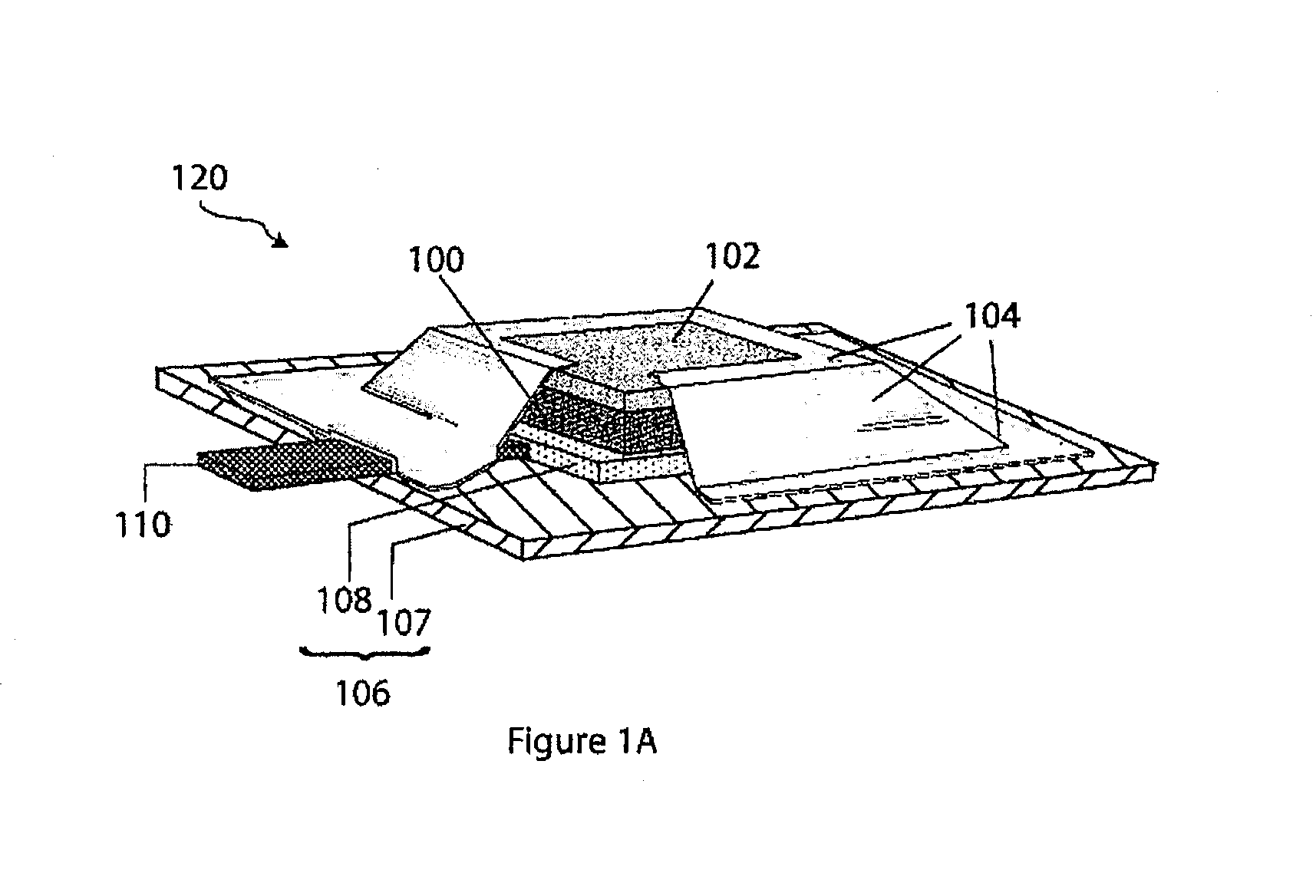

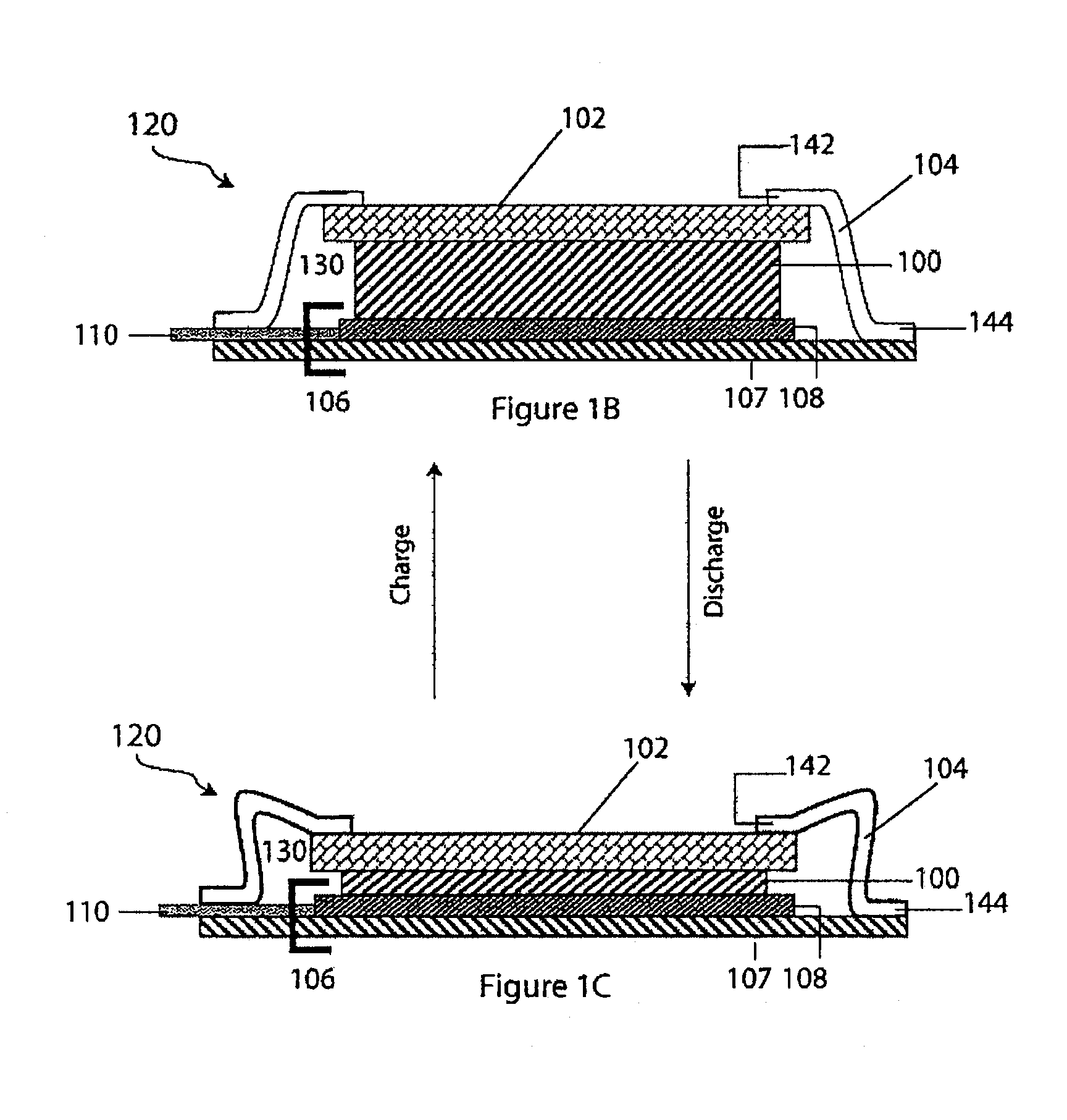

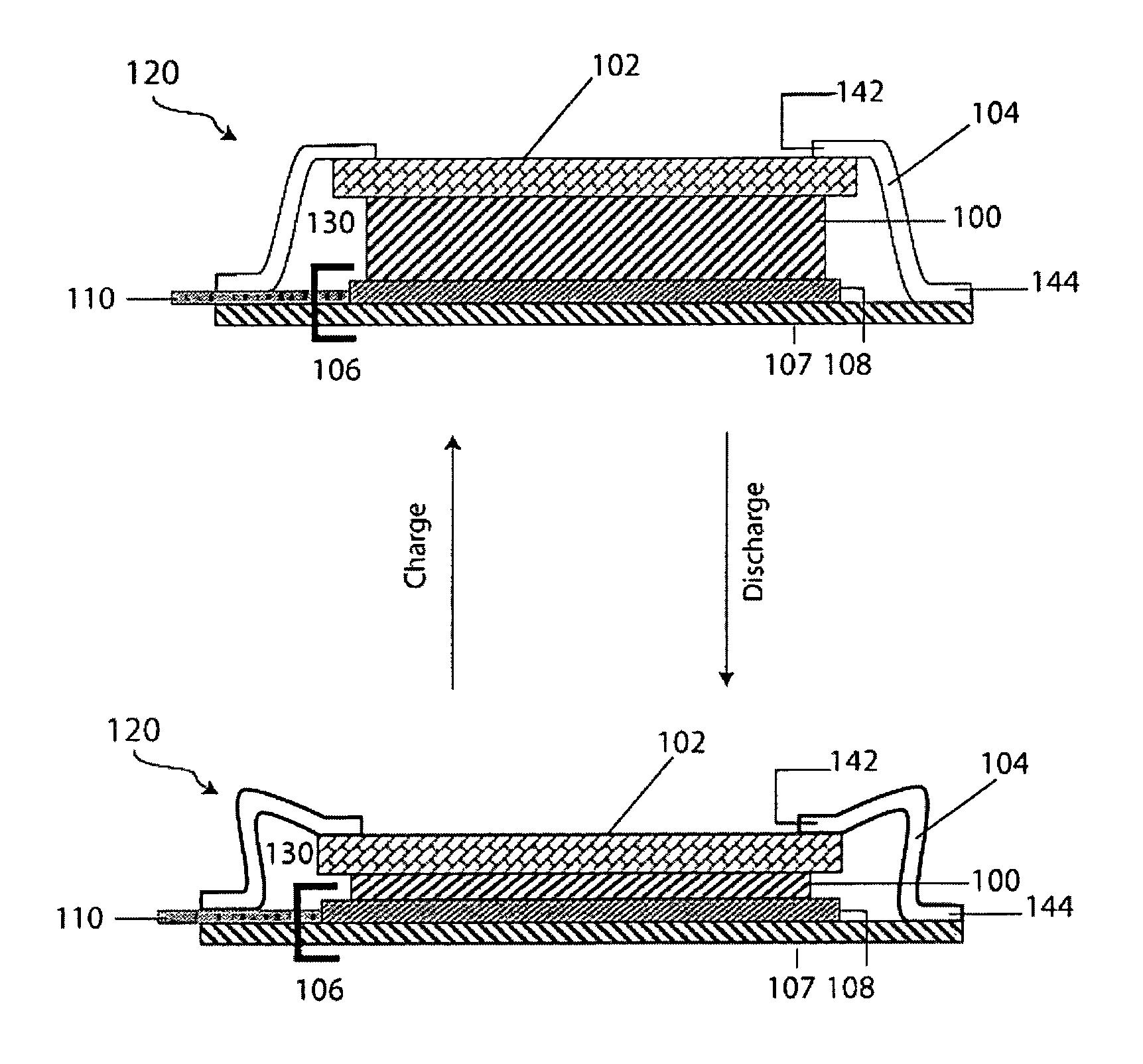

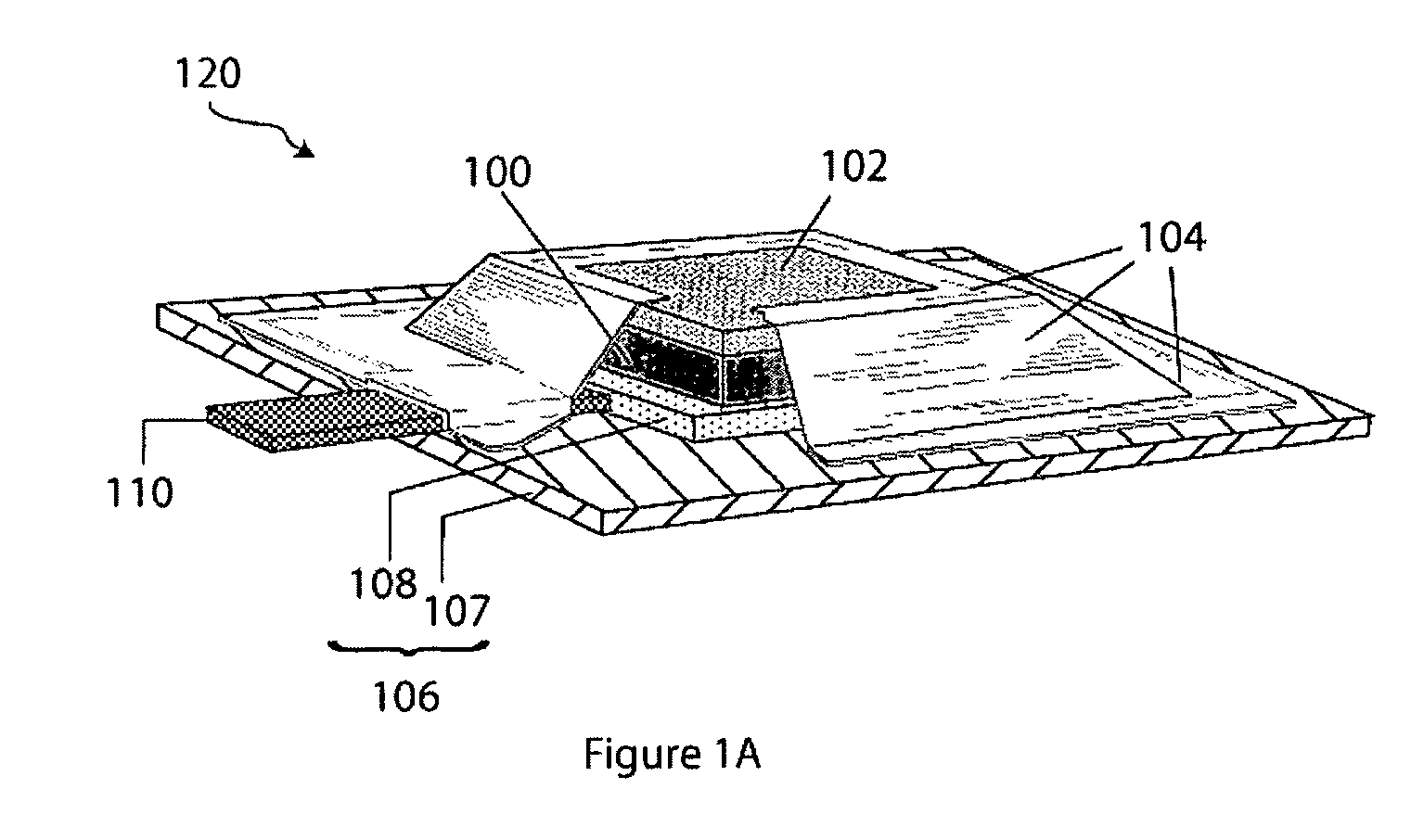

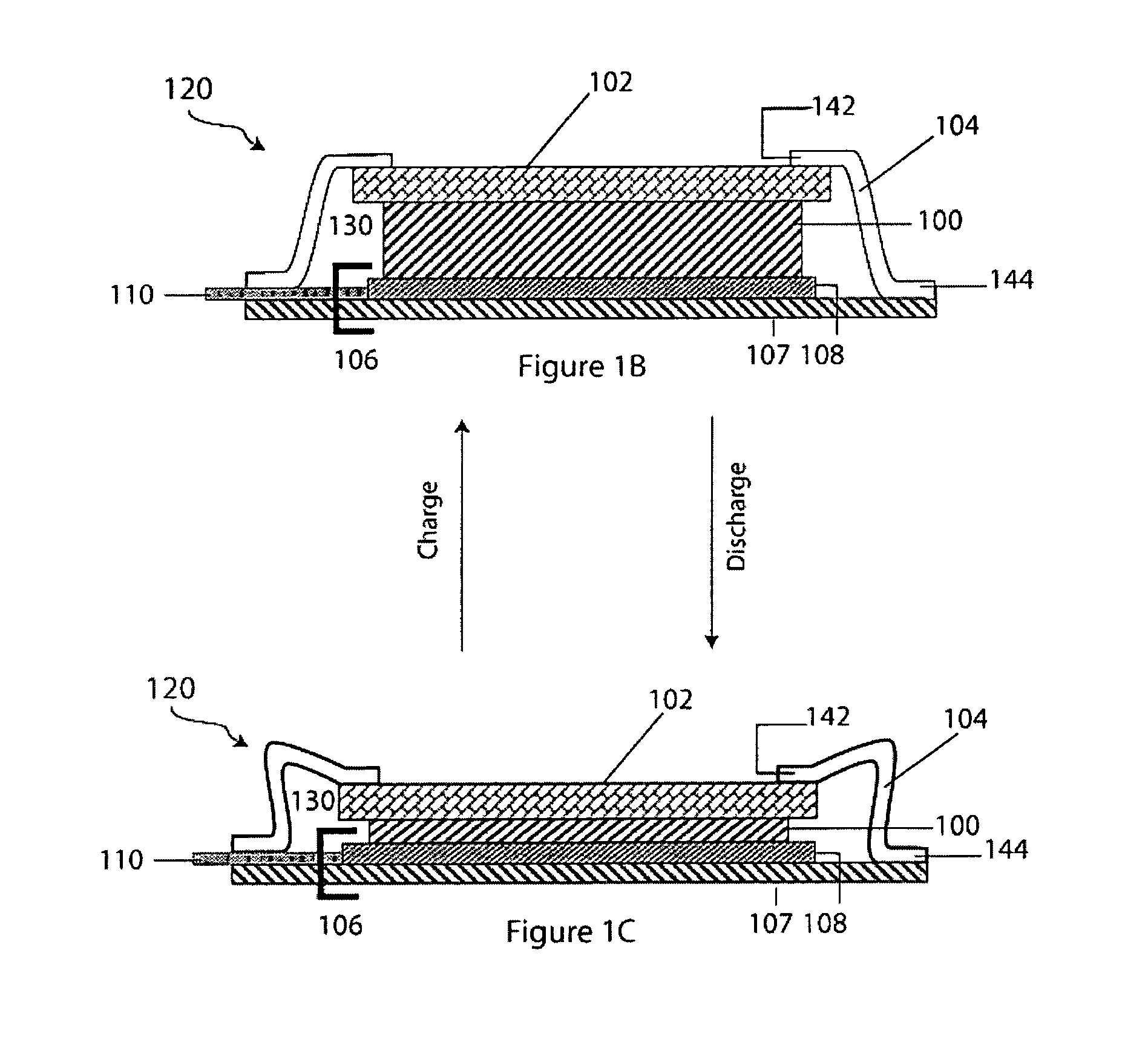

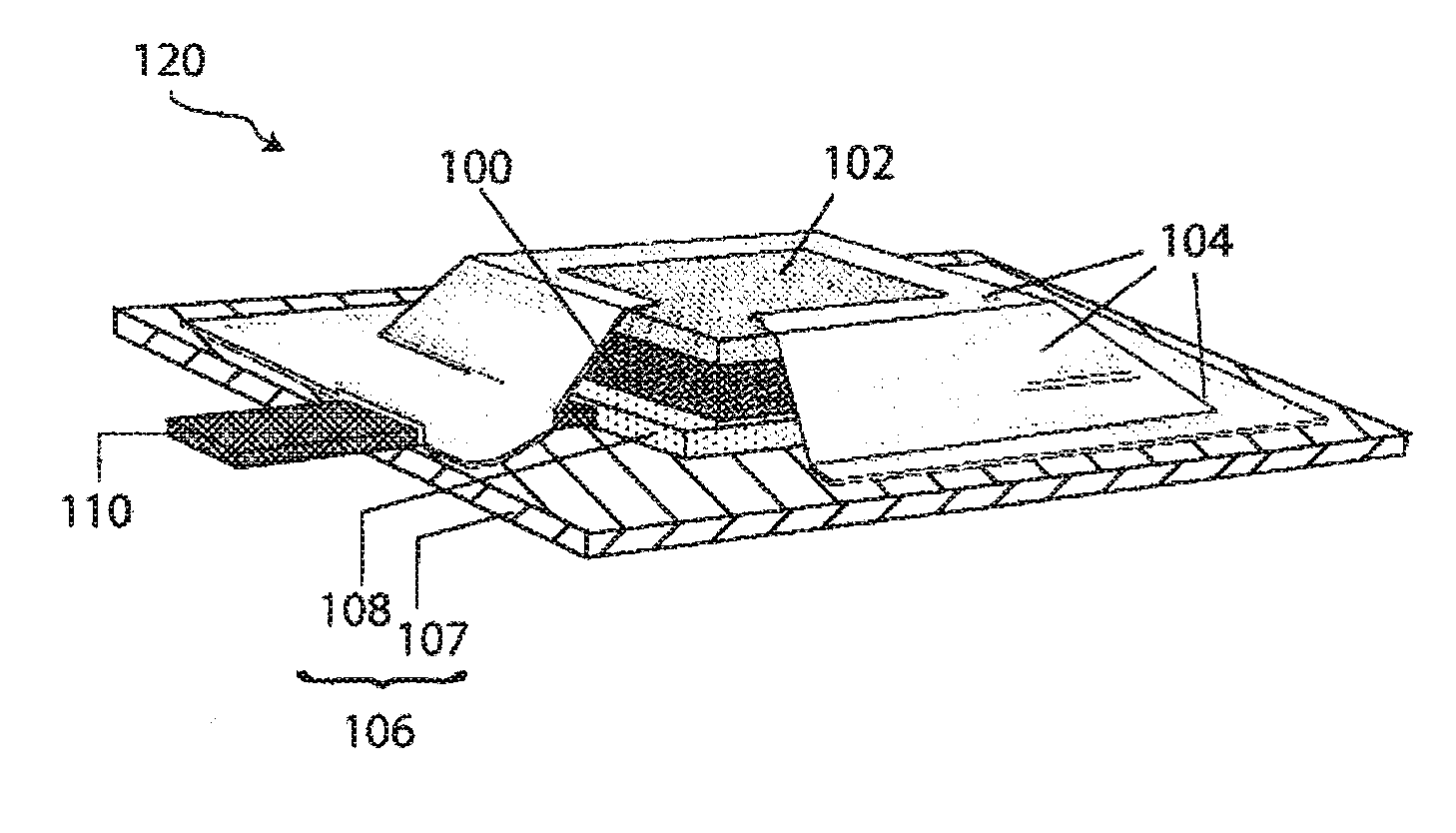

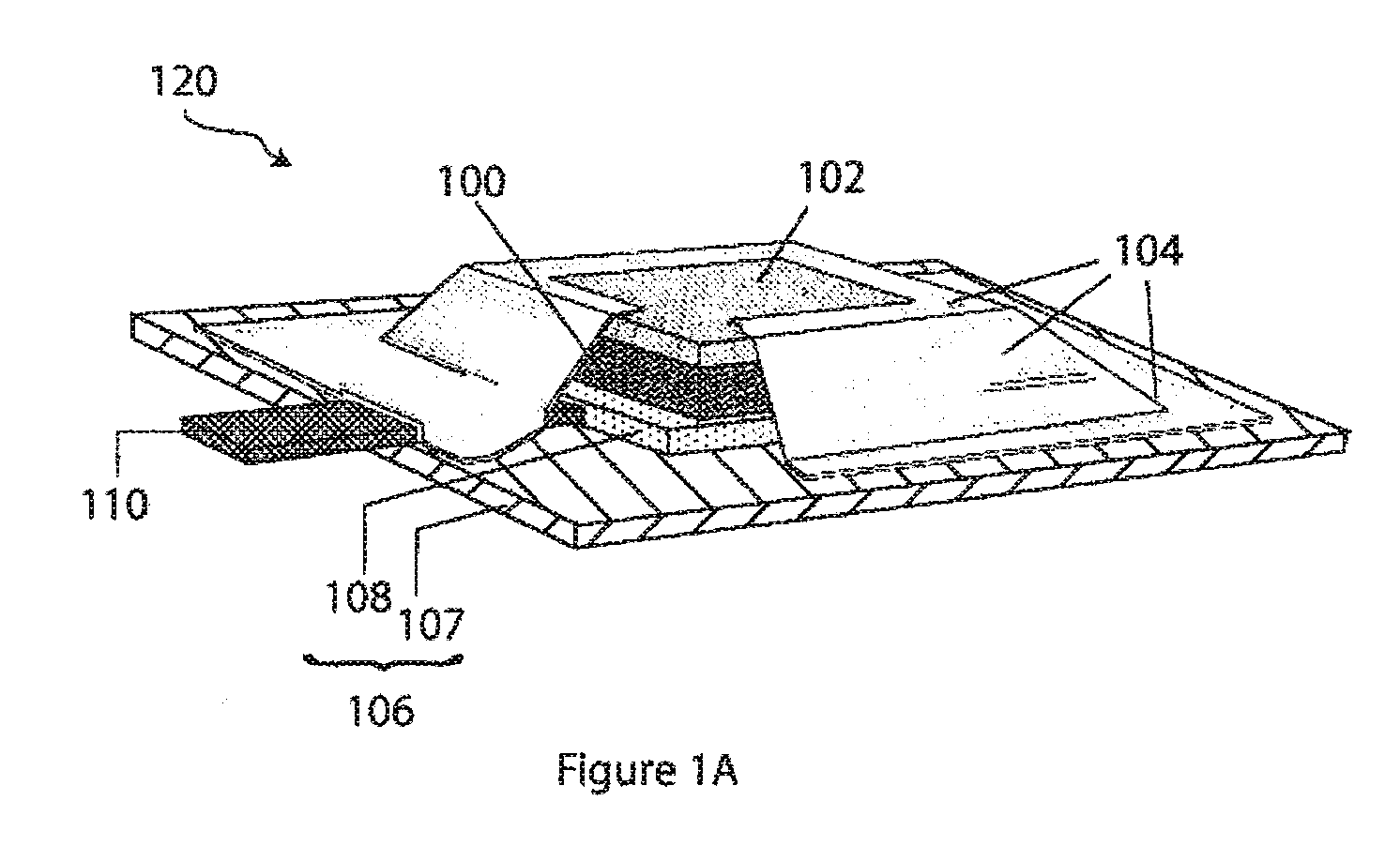

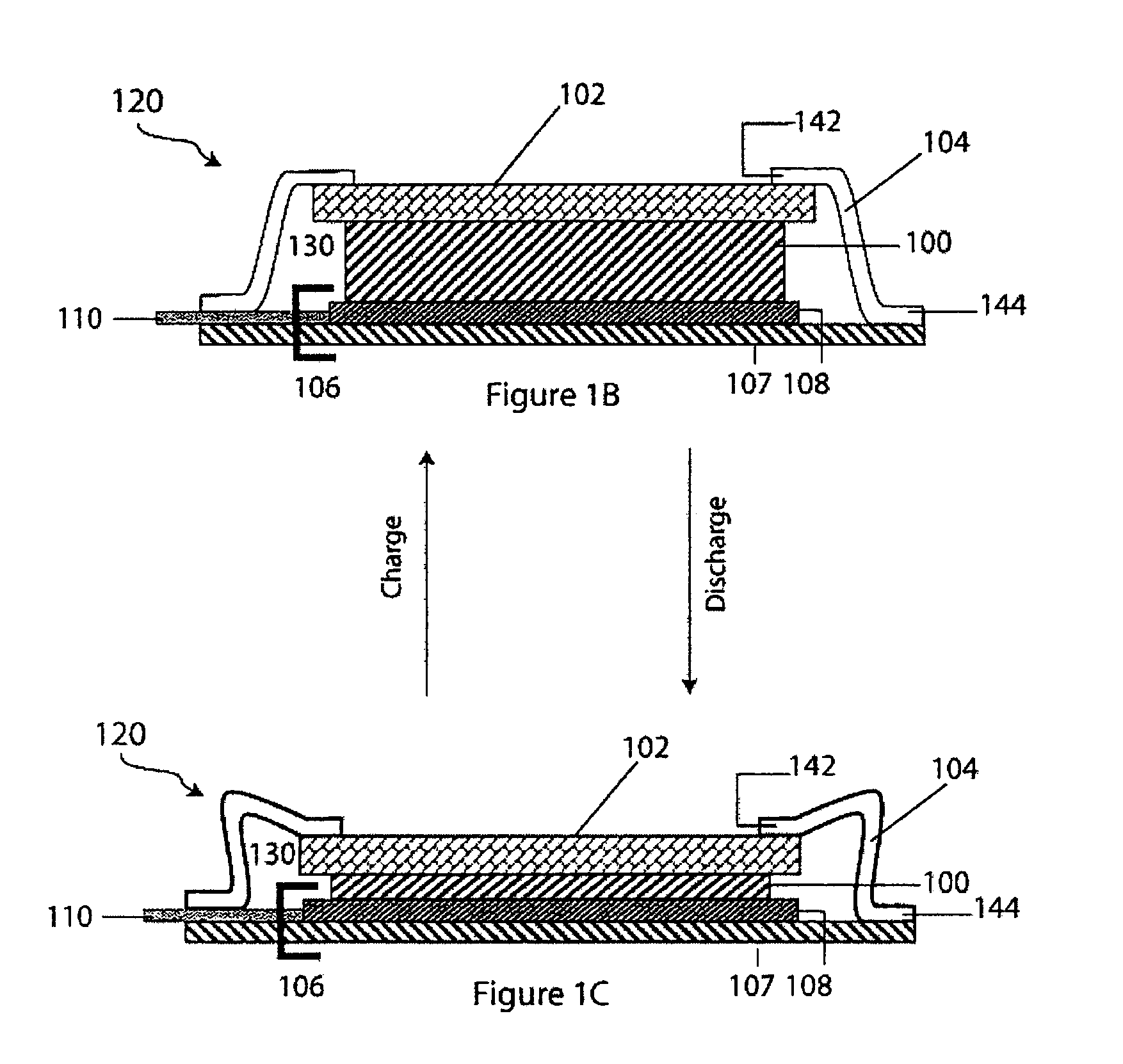

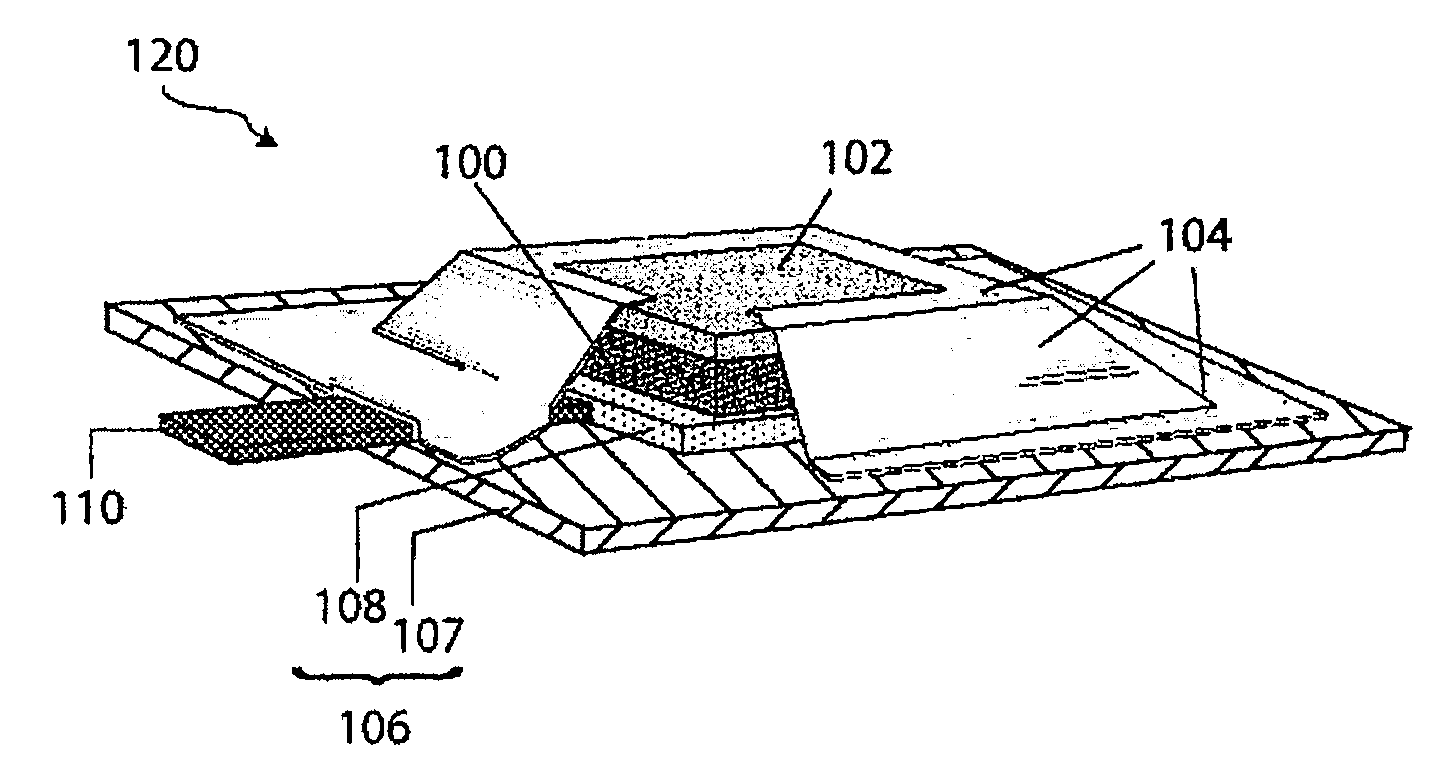

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

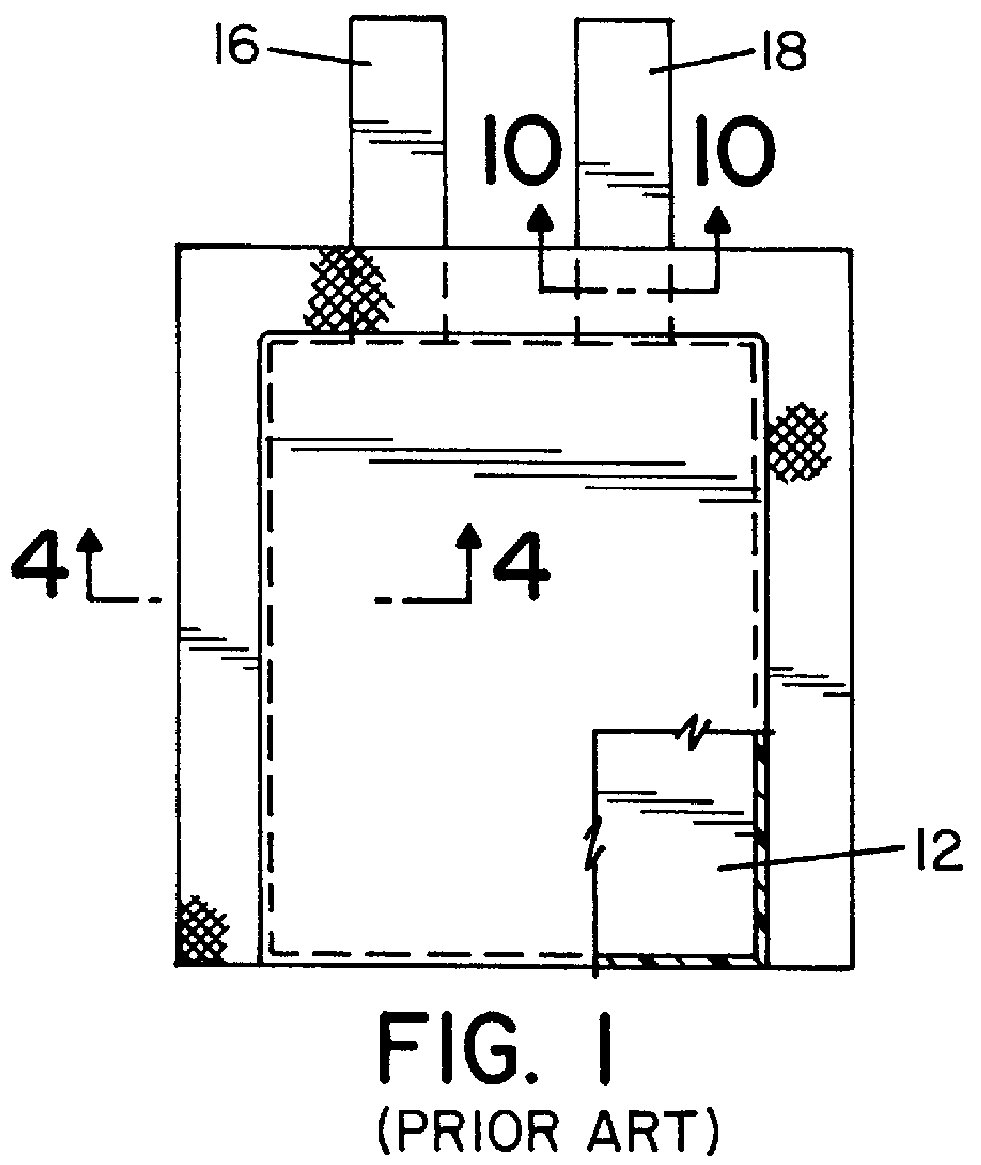

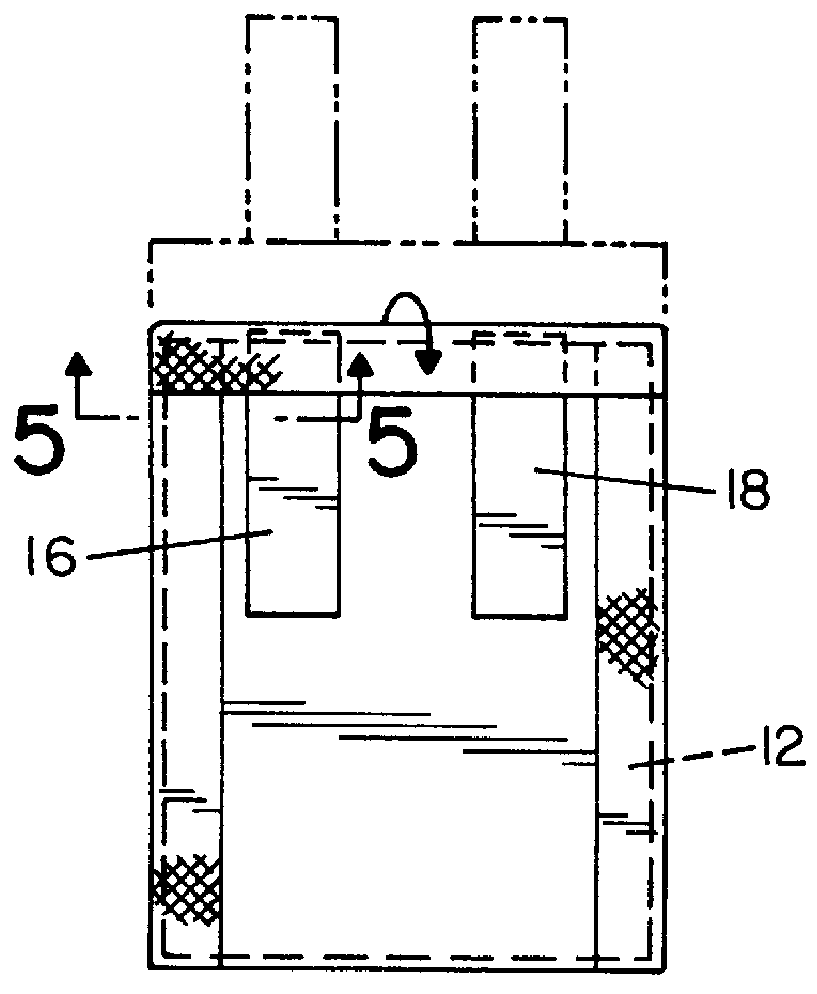

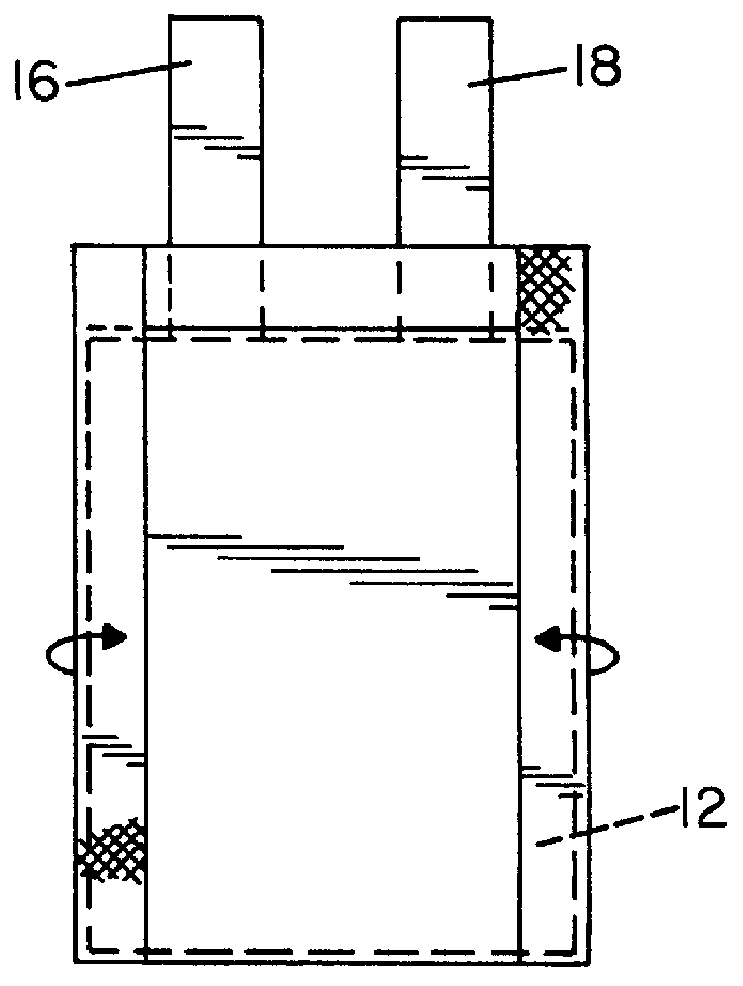

Flexible packaging for polymer electrolytic cell and method of forming same

InactiveUS6145280AEnergy Density MaximizationShrink the necessary spaceSmall-sized cells cases/jacketsPrimary cellsEngineeringMechanical engineering

Owner:NGK SPARK PLUG CO LTD

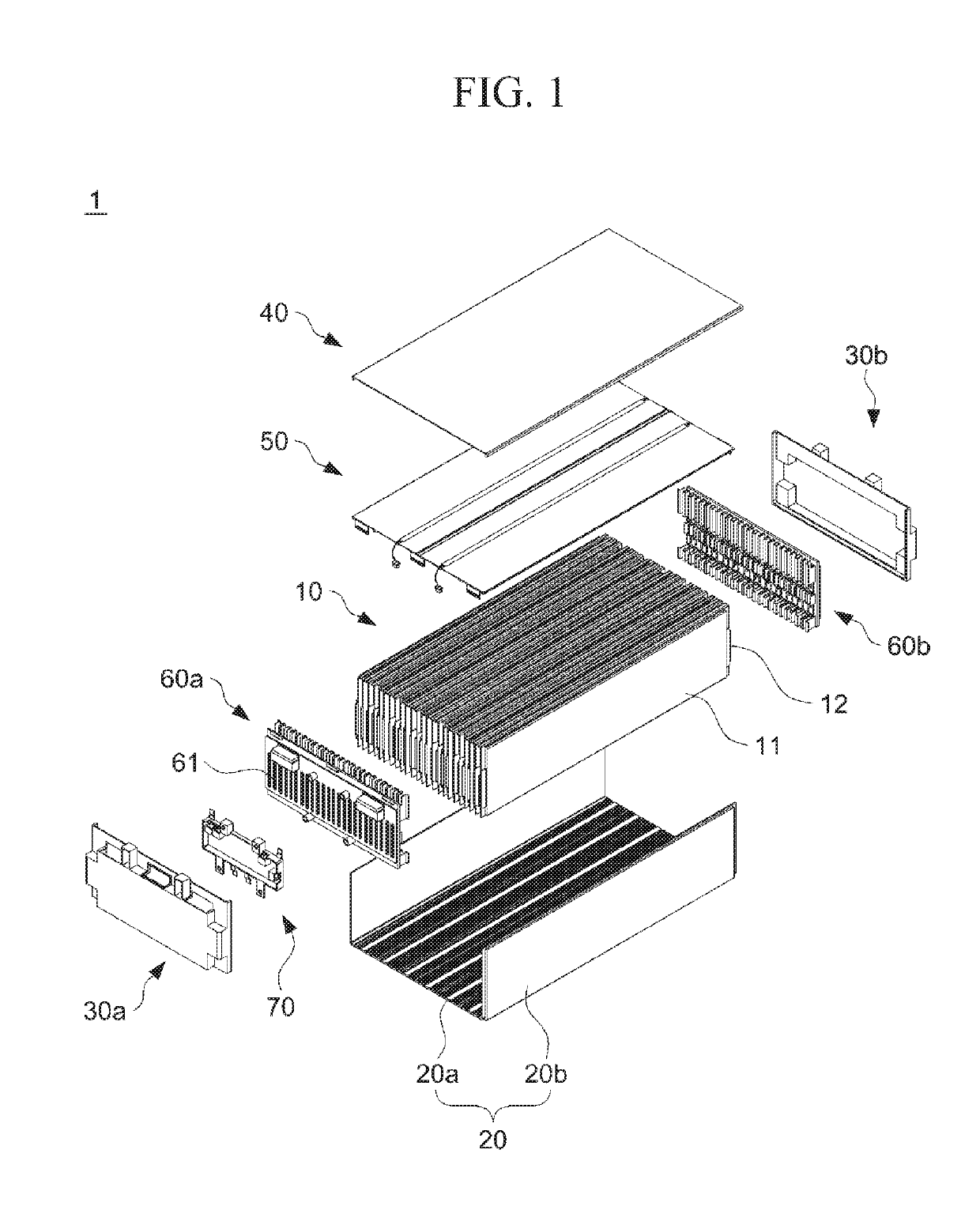

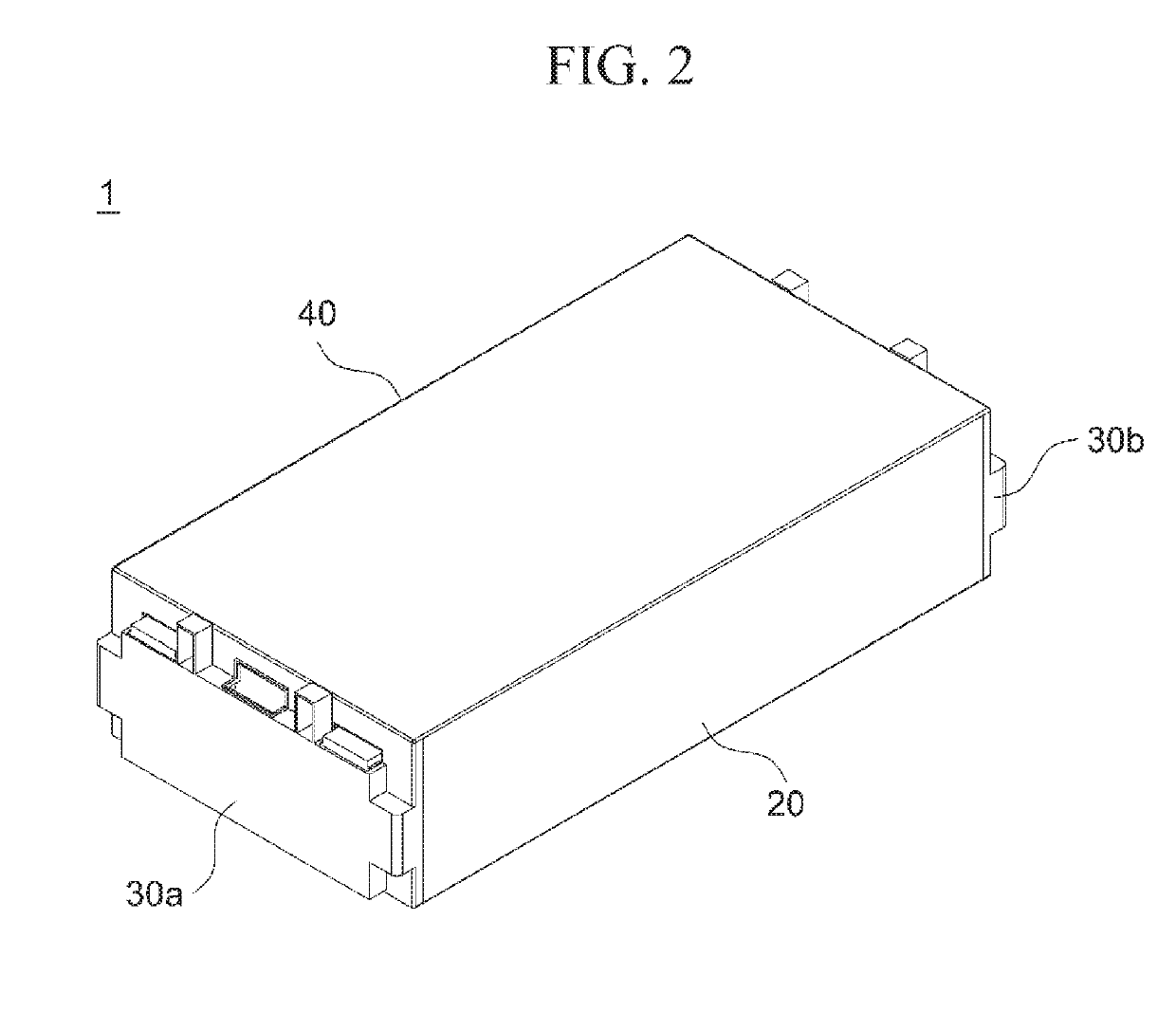

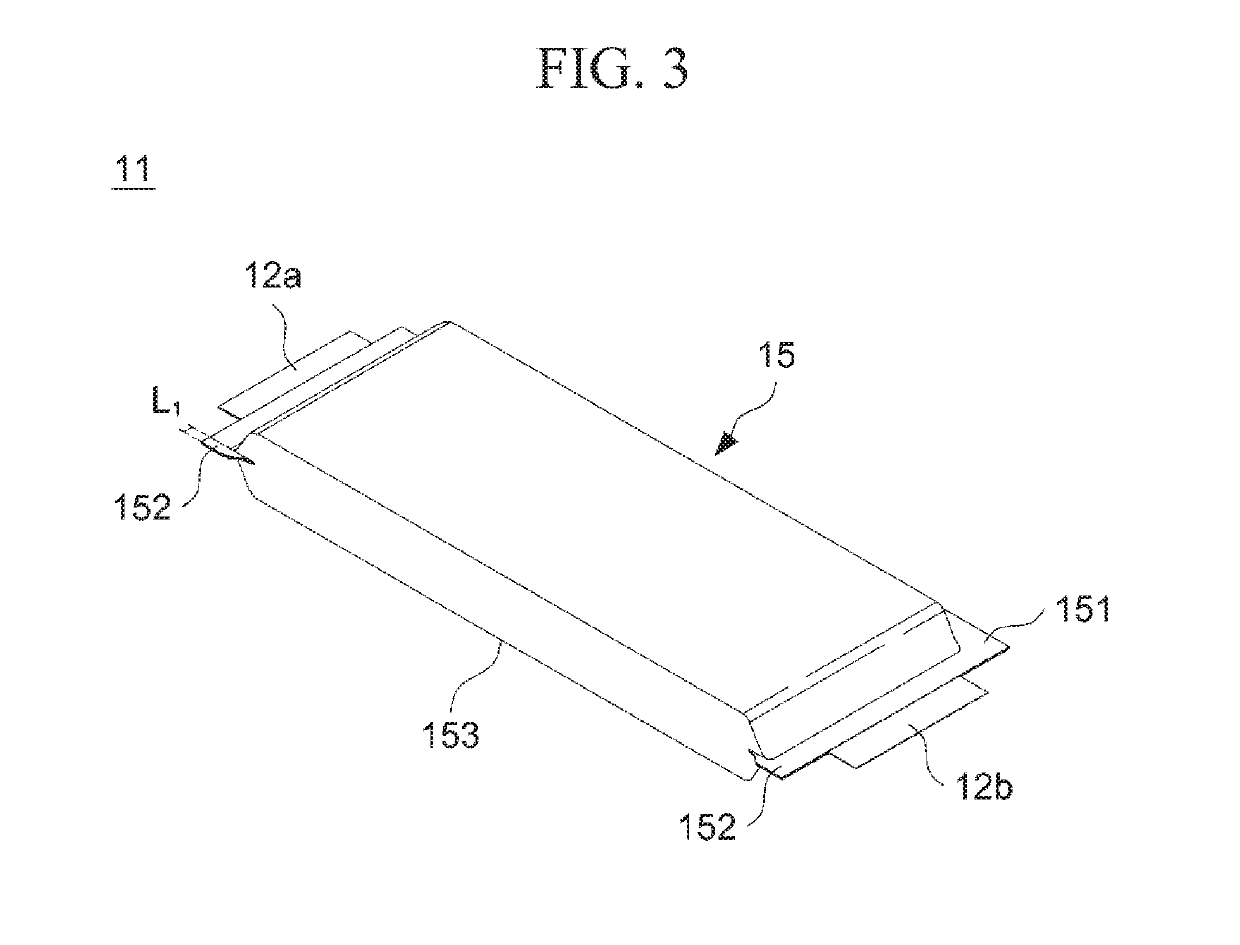

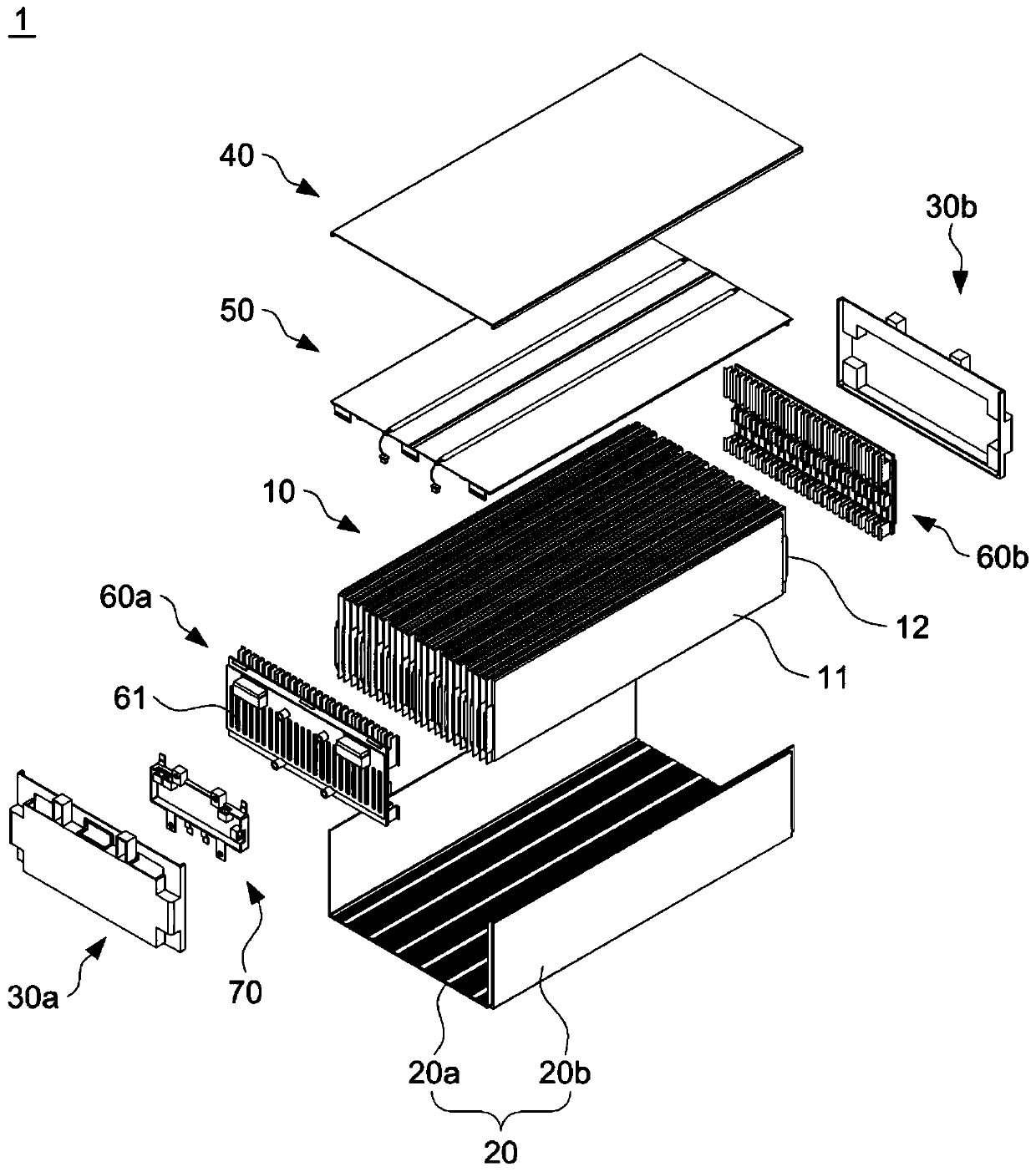

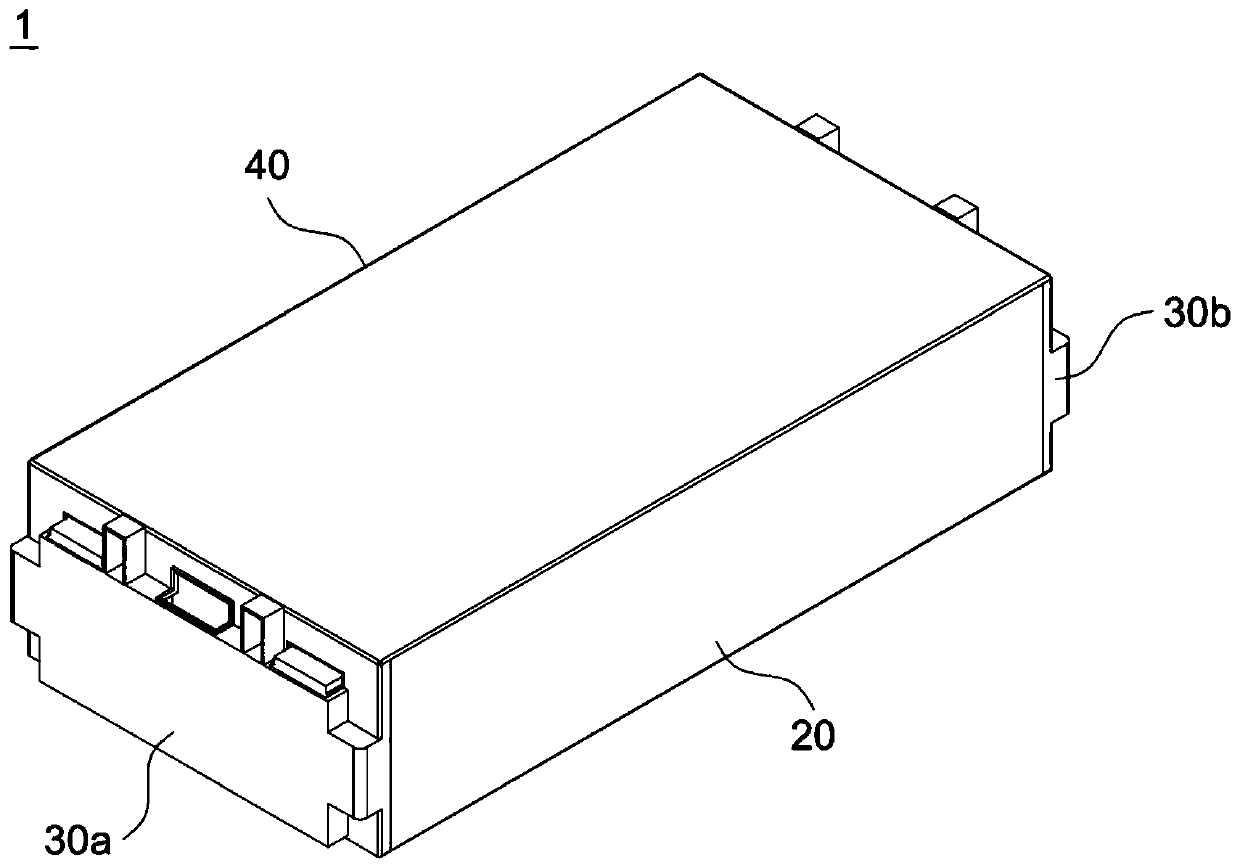

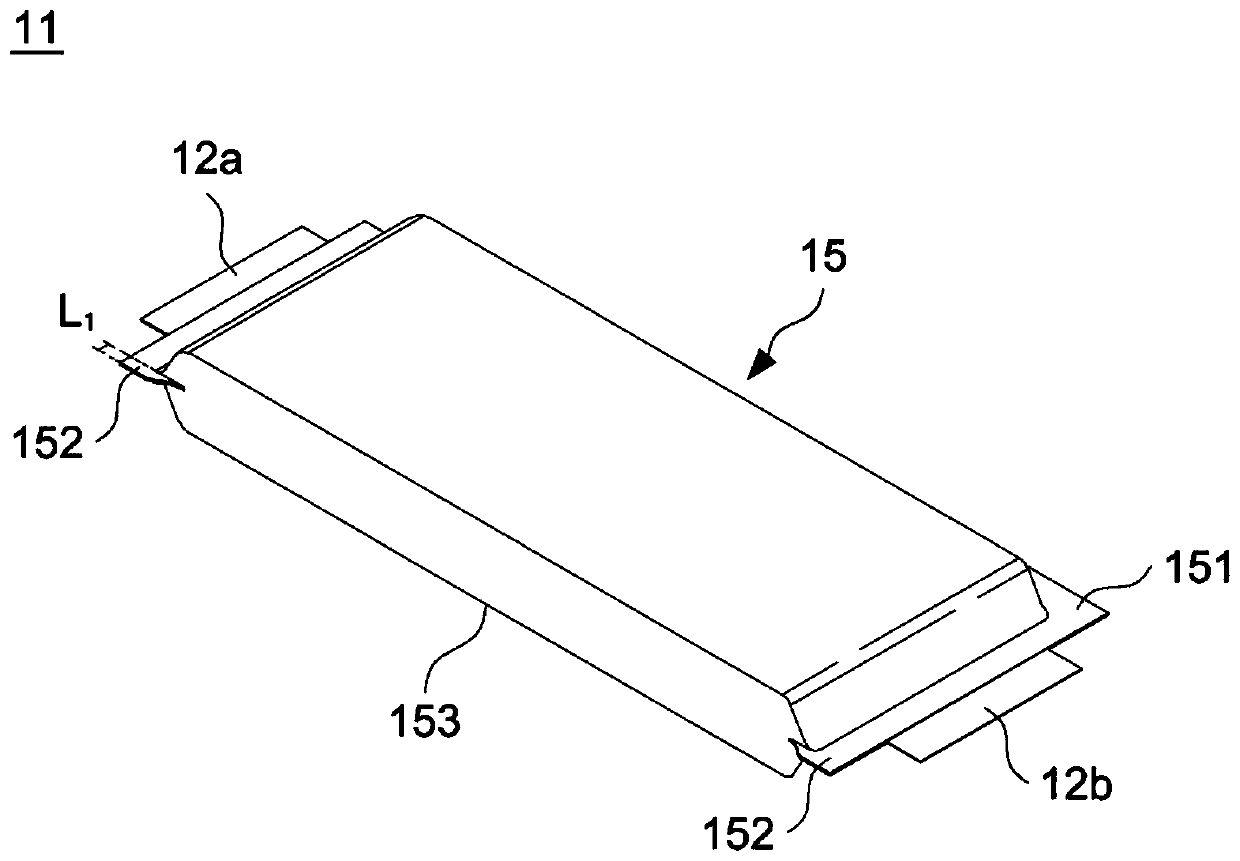

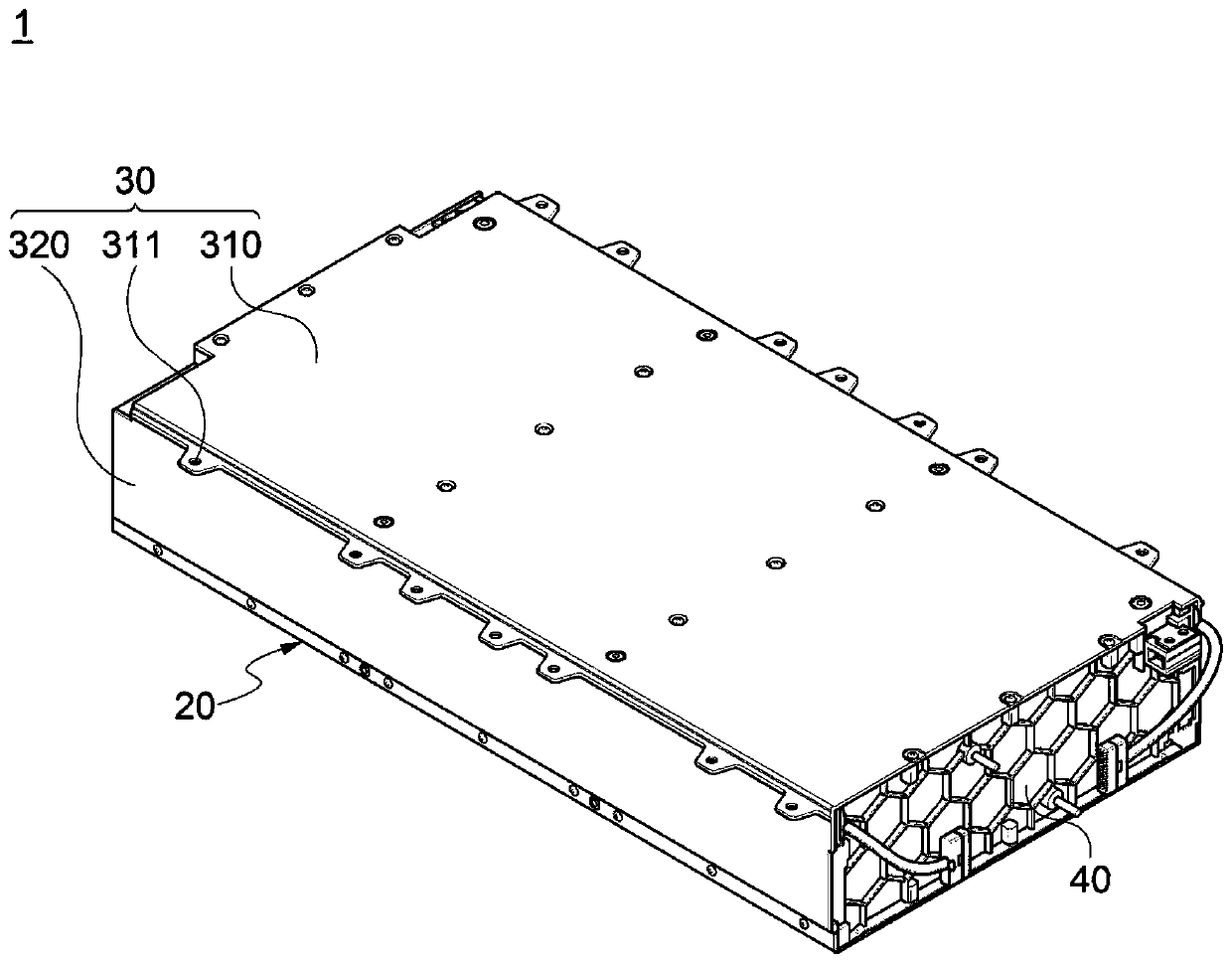

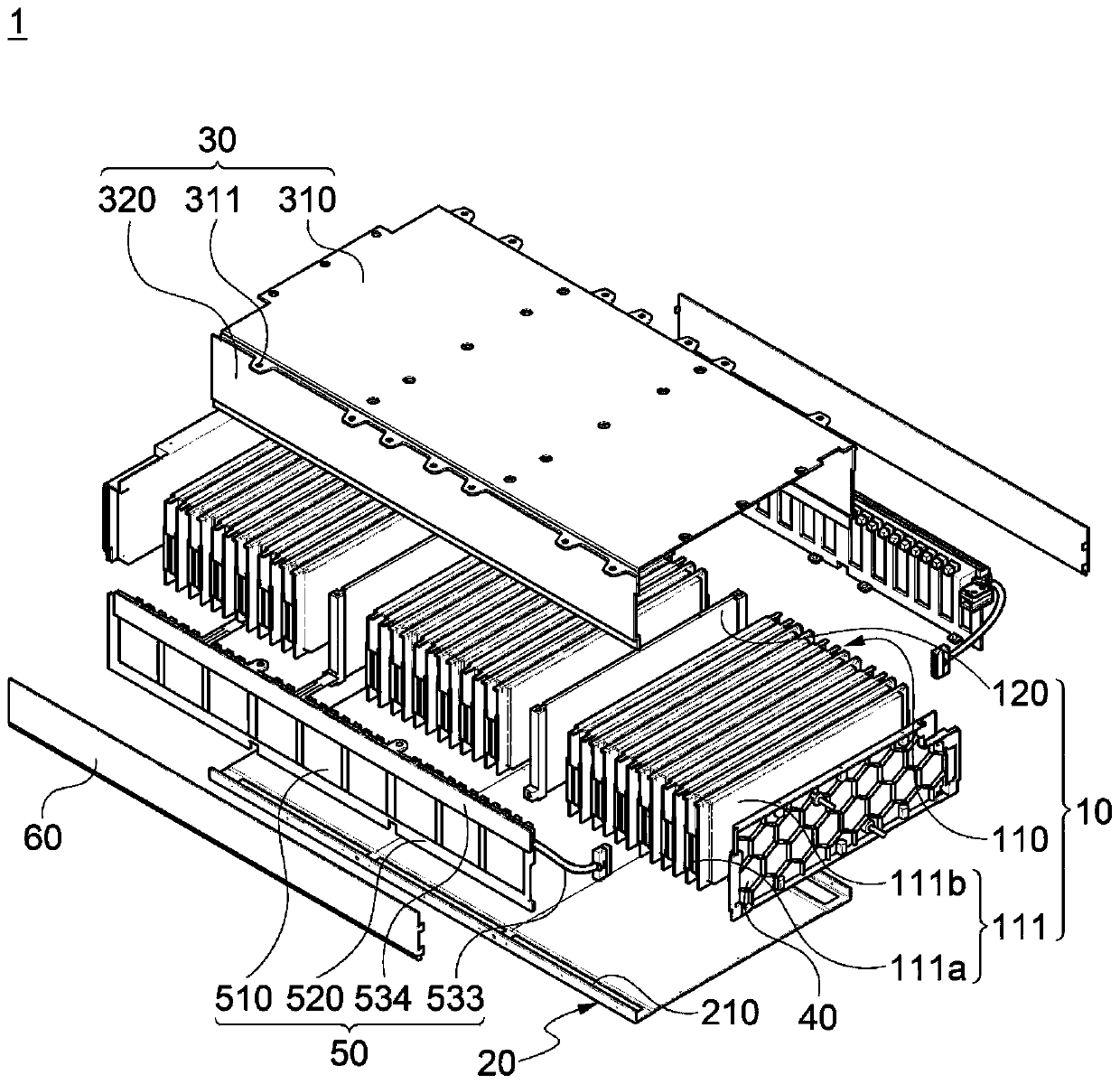

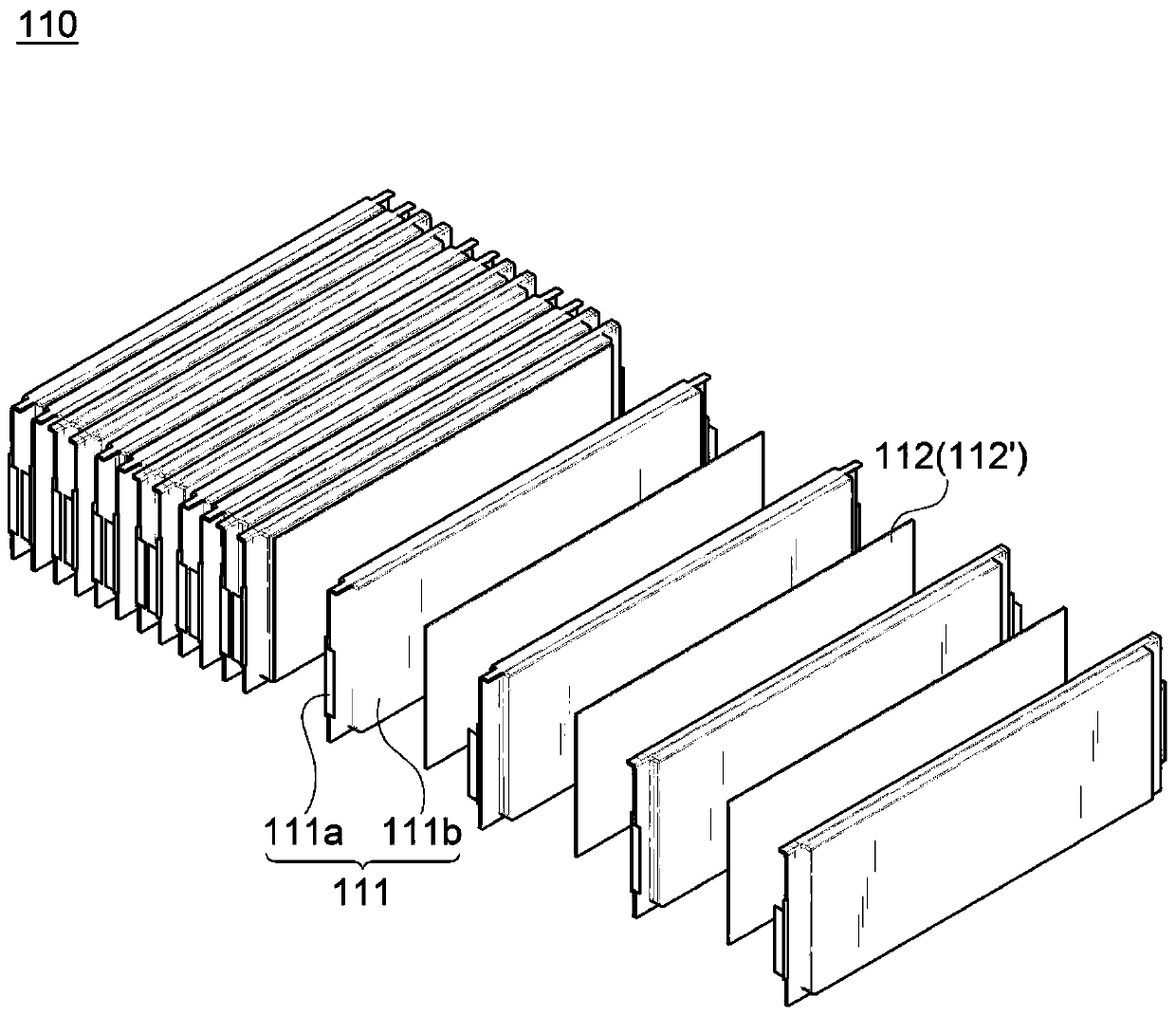

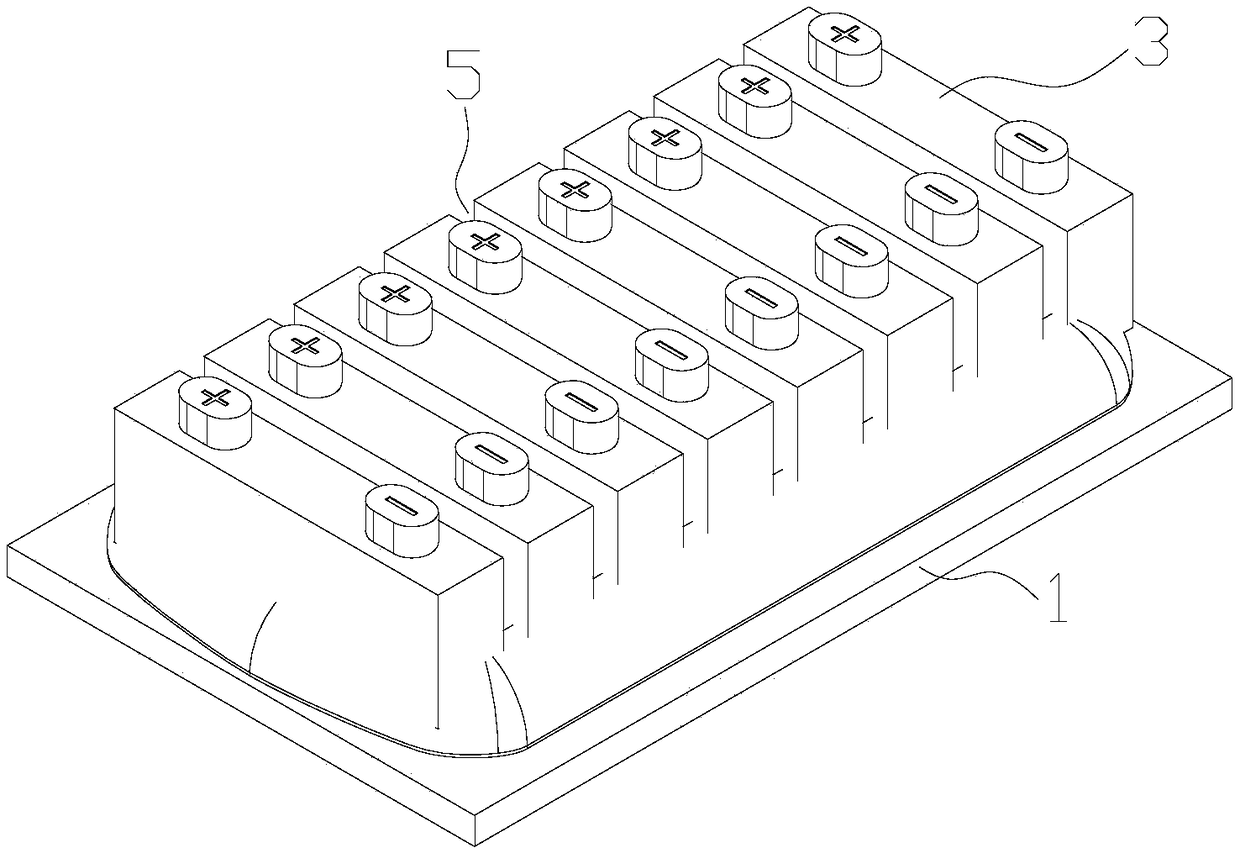

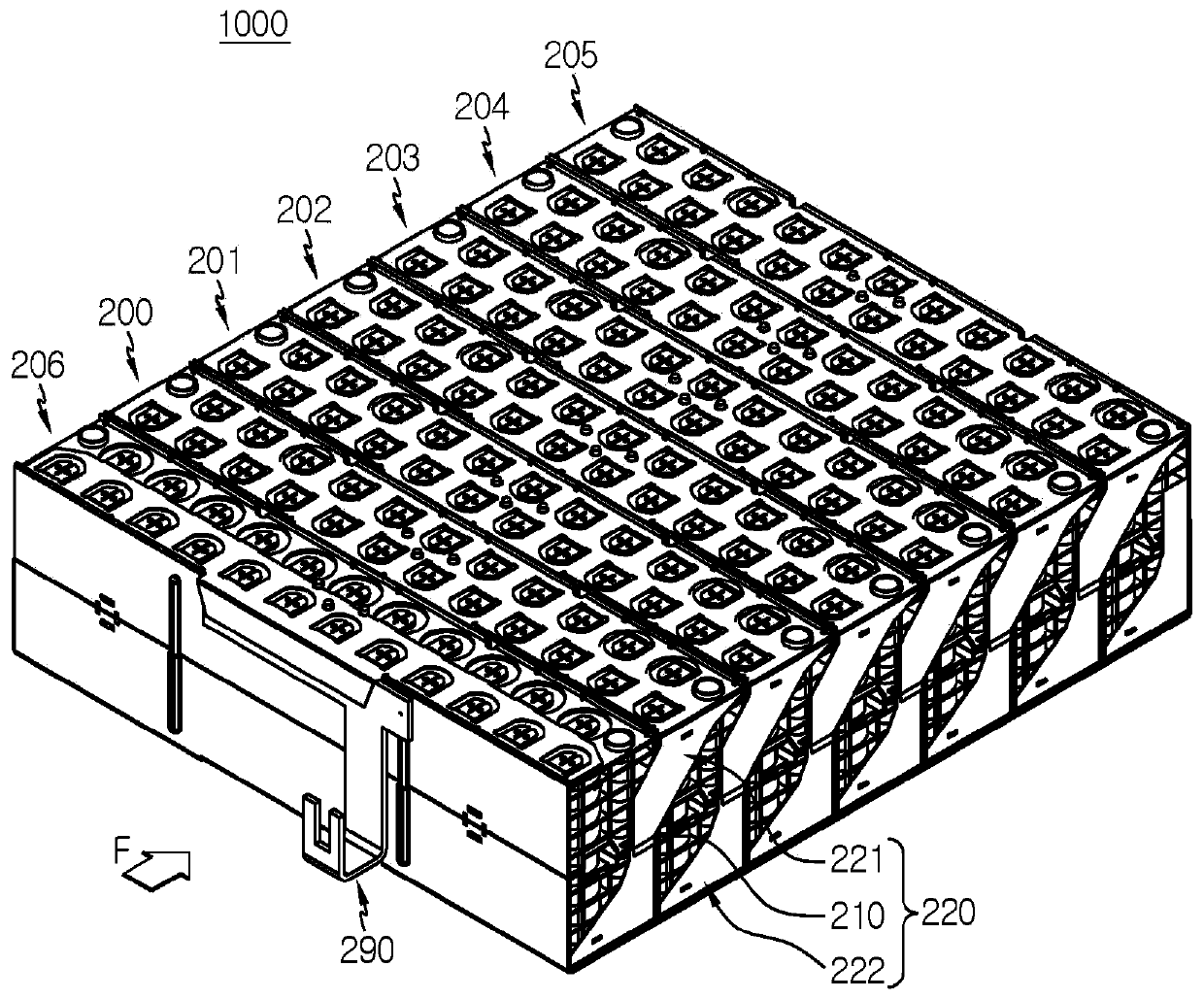

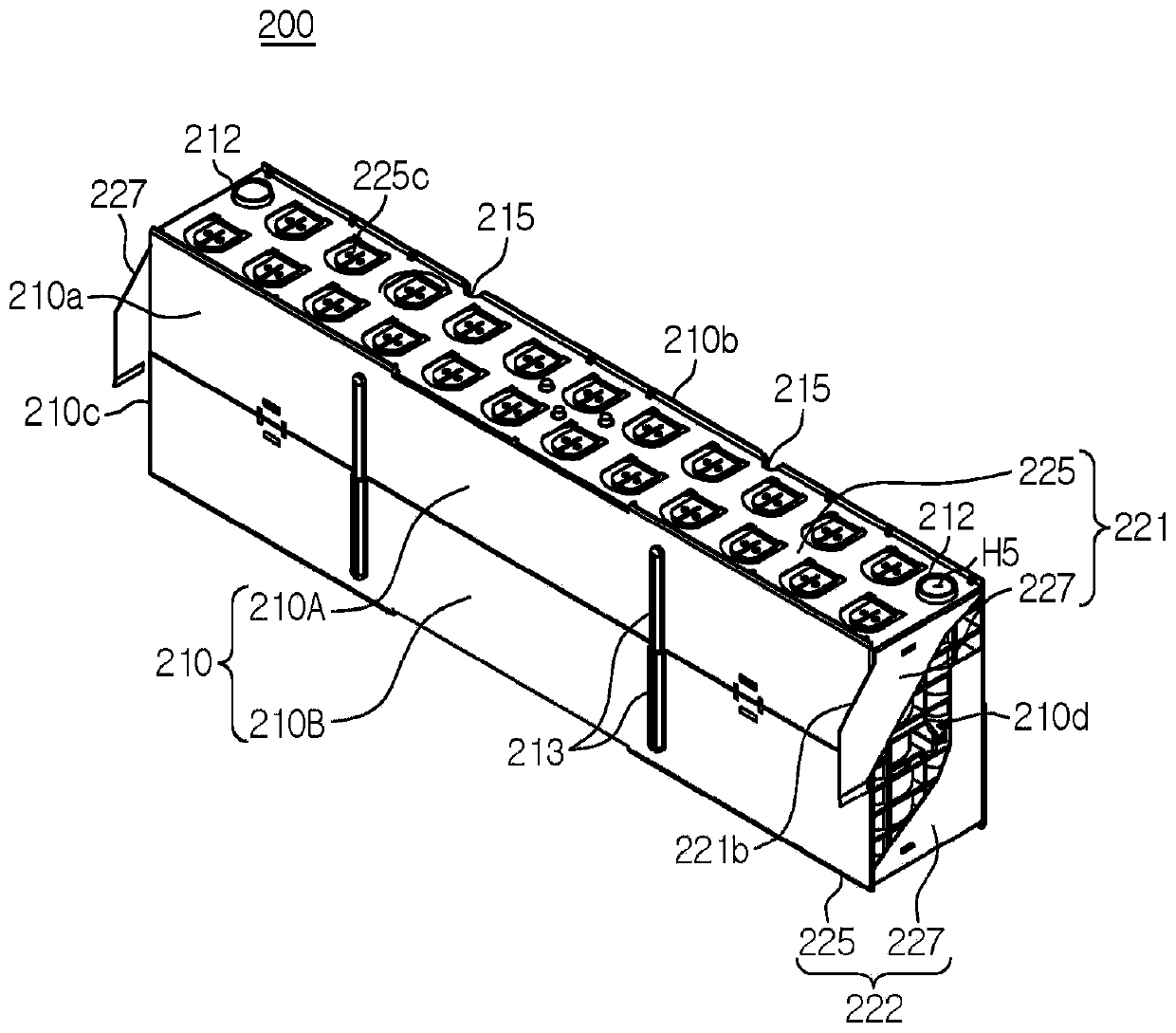

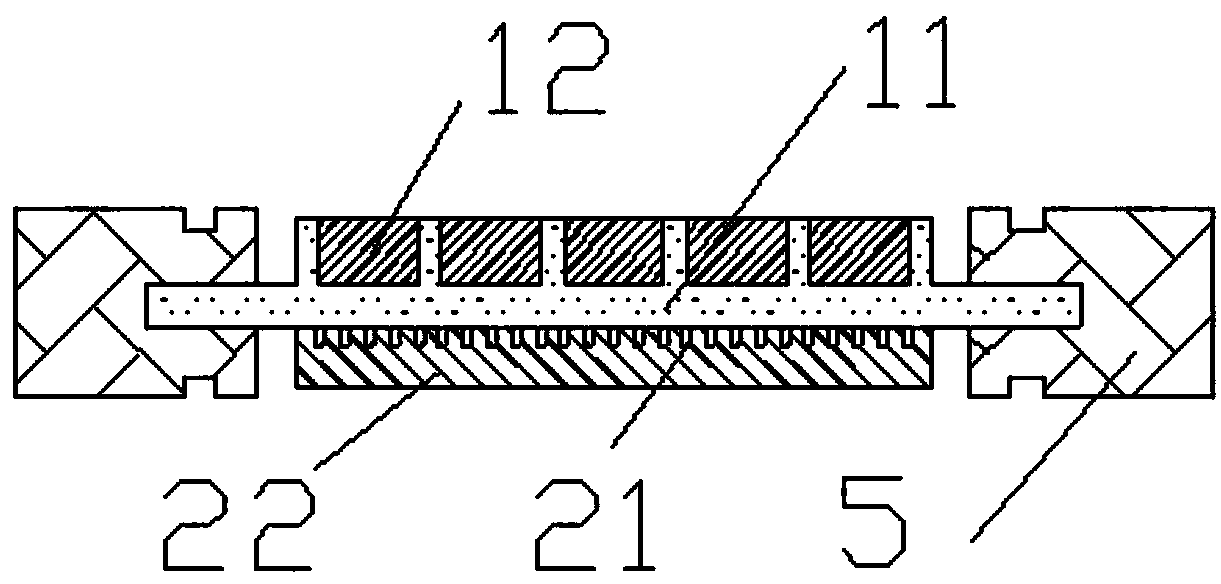

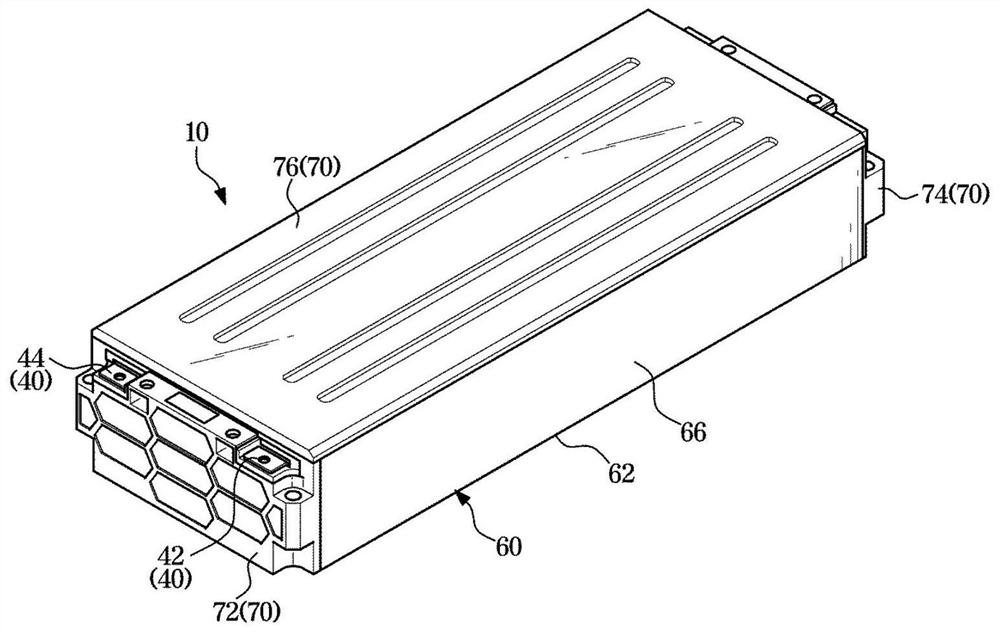

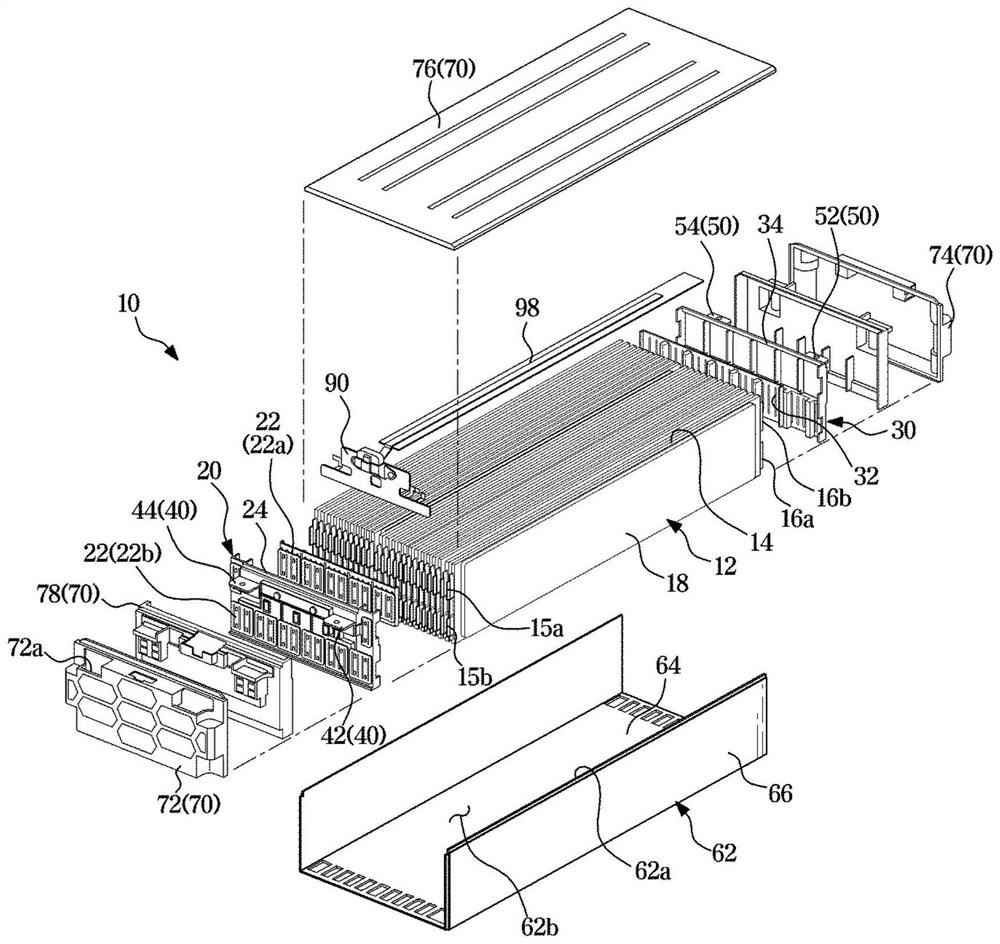

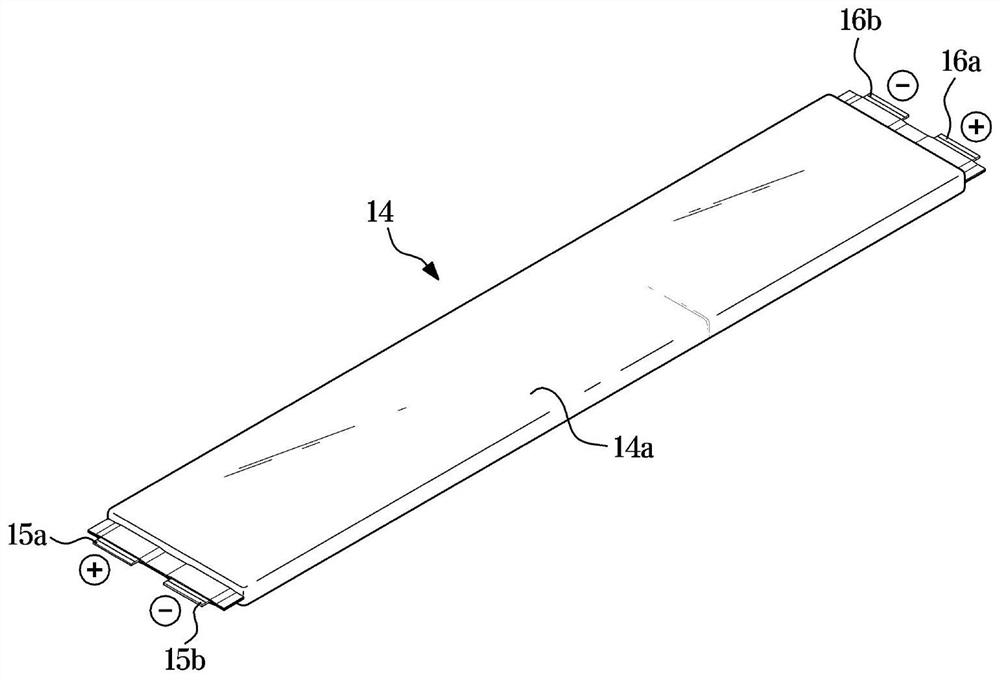

Battery module and manufacturing method thereof

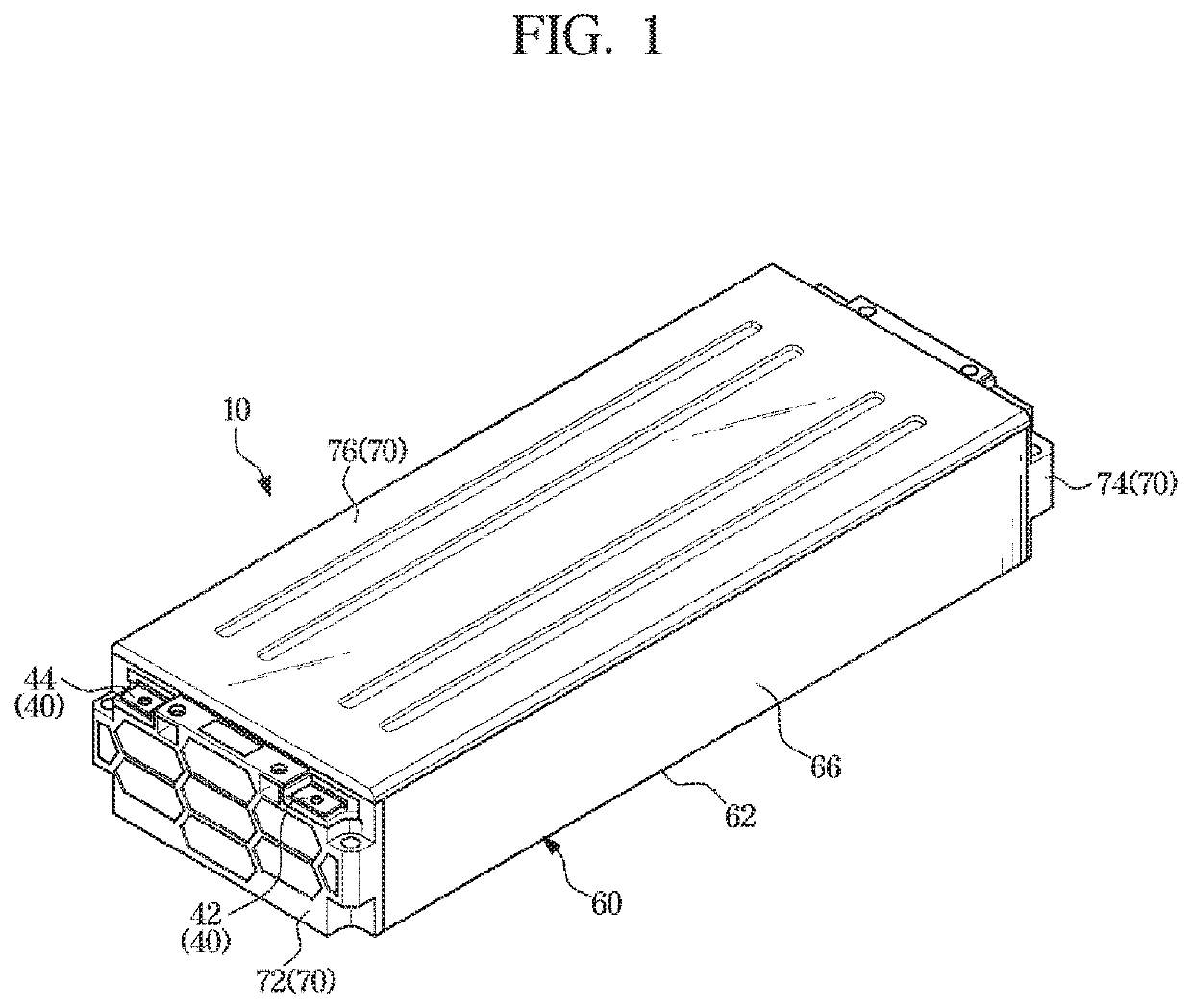

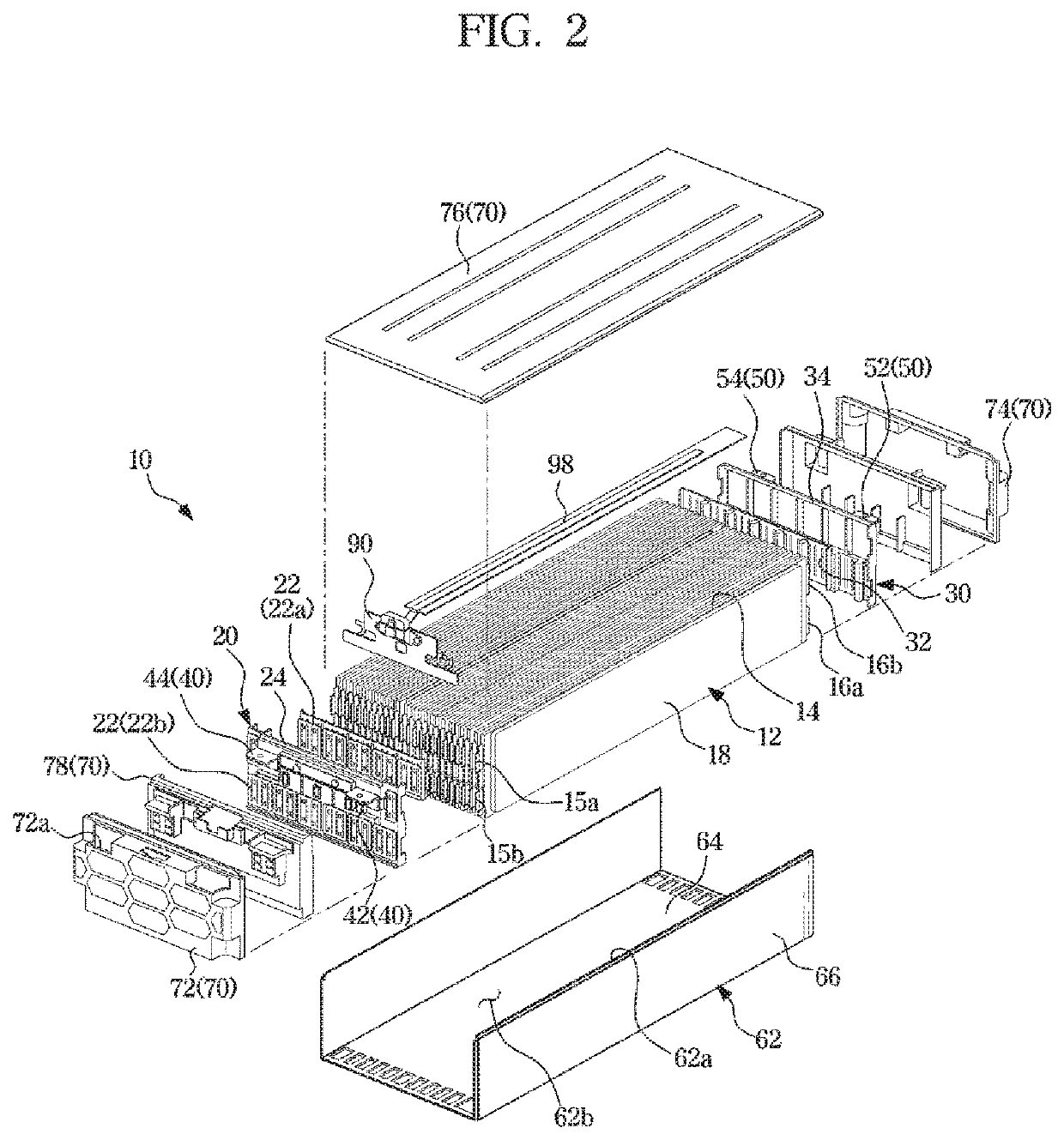

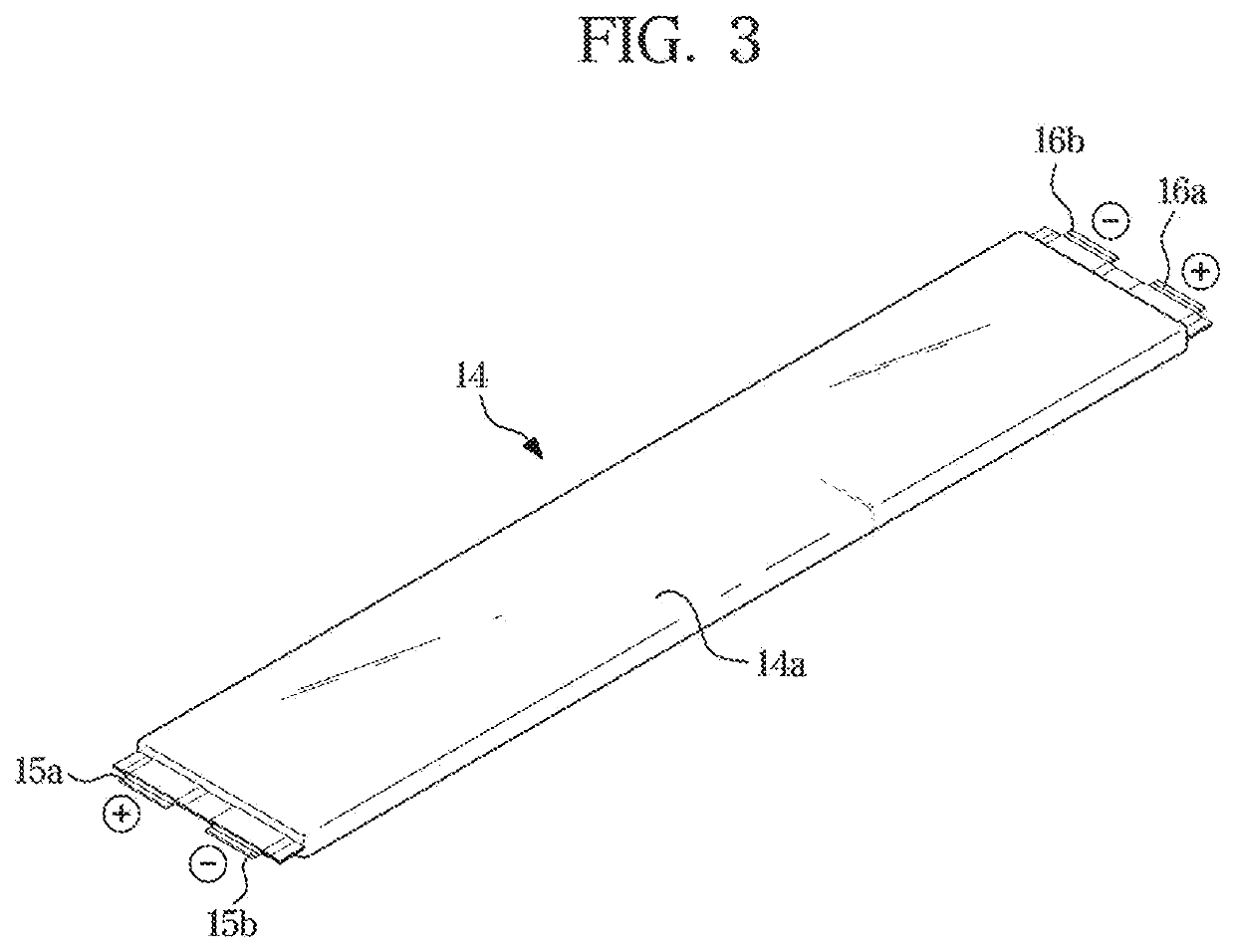

PendingUS20190198952A1Improve workabilityLow costSecondary cellsCell lids/coversEngineeringBattery cell

The present invention provides a battery module, which includes: a battery group formed by stacking a plurality of battery cells, each of which includes electrode tabs; a cooling housing including a cooling plate located corresponding to one side of sides of the battery group, in which the electrode tabs are not extended, and side plates located on both sides of the battery group perpendicular to the one side of the sides, thus to house the battery group; a cover plate located on the other side of the battery group; and a front cover part and a rear cover part, which are located at outermost front and rear of the battery group on both sides in a direction in which the electrode tabs are extended.

Owner:SK ON CO LTD

Compliant seal structures for protected active metal anodes

ActiveUS8048570B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingFuel and secondary cellsOptoelectronicsMoisture

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholytes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS20080182157A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesIonBackplane

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholytes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

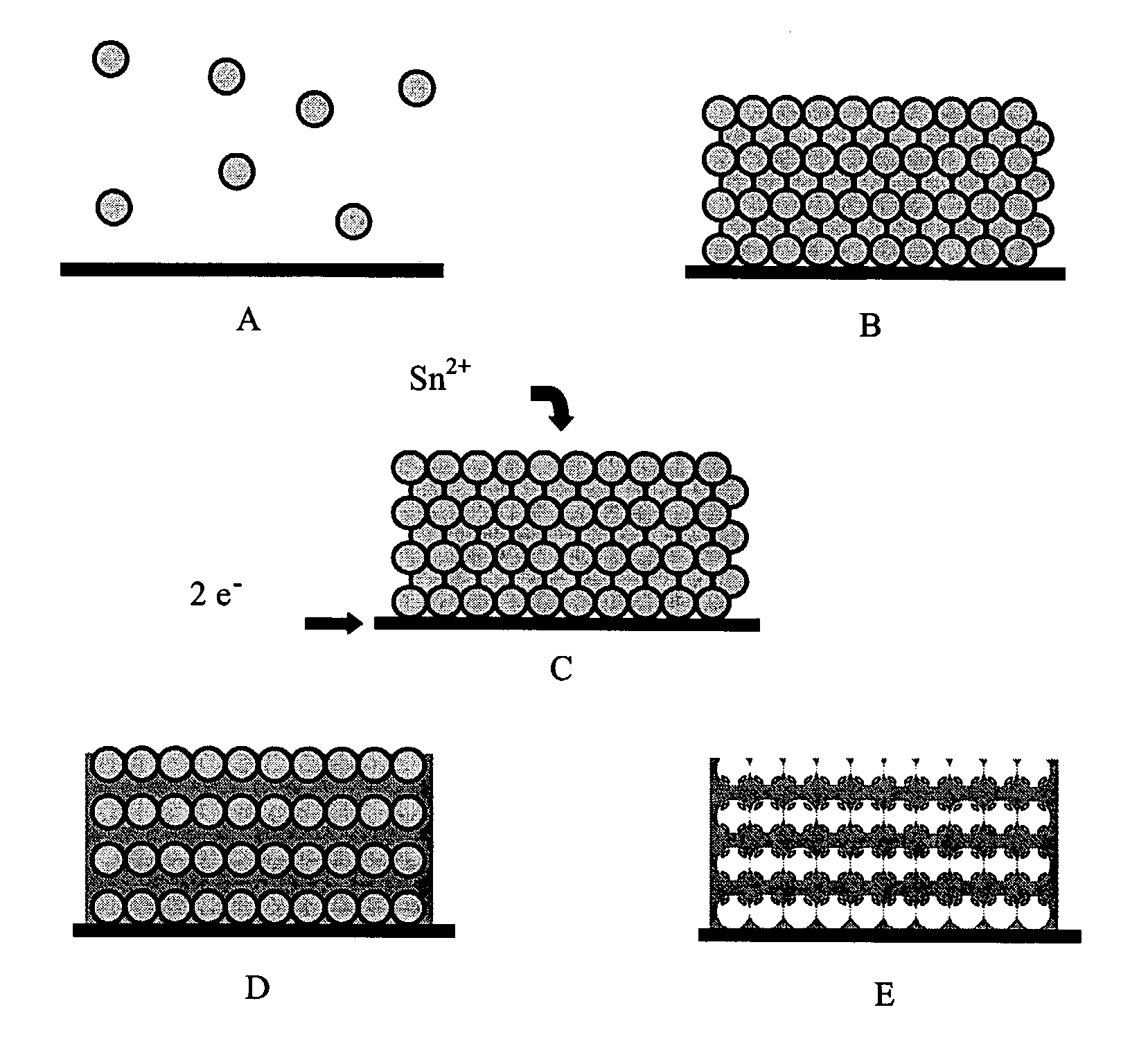

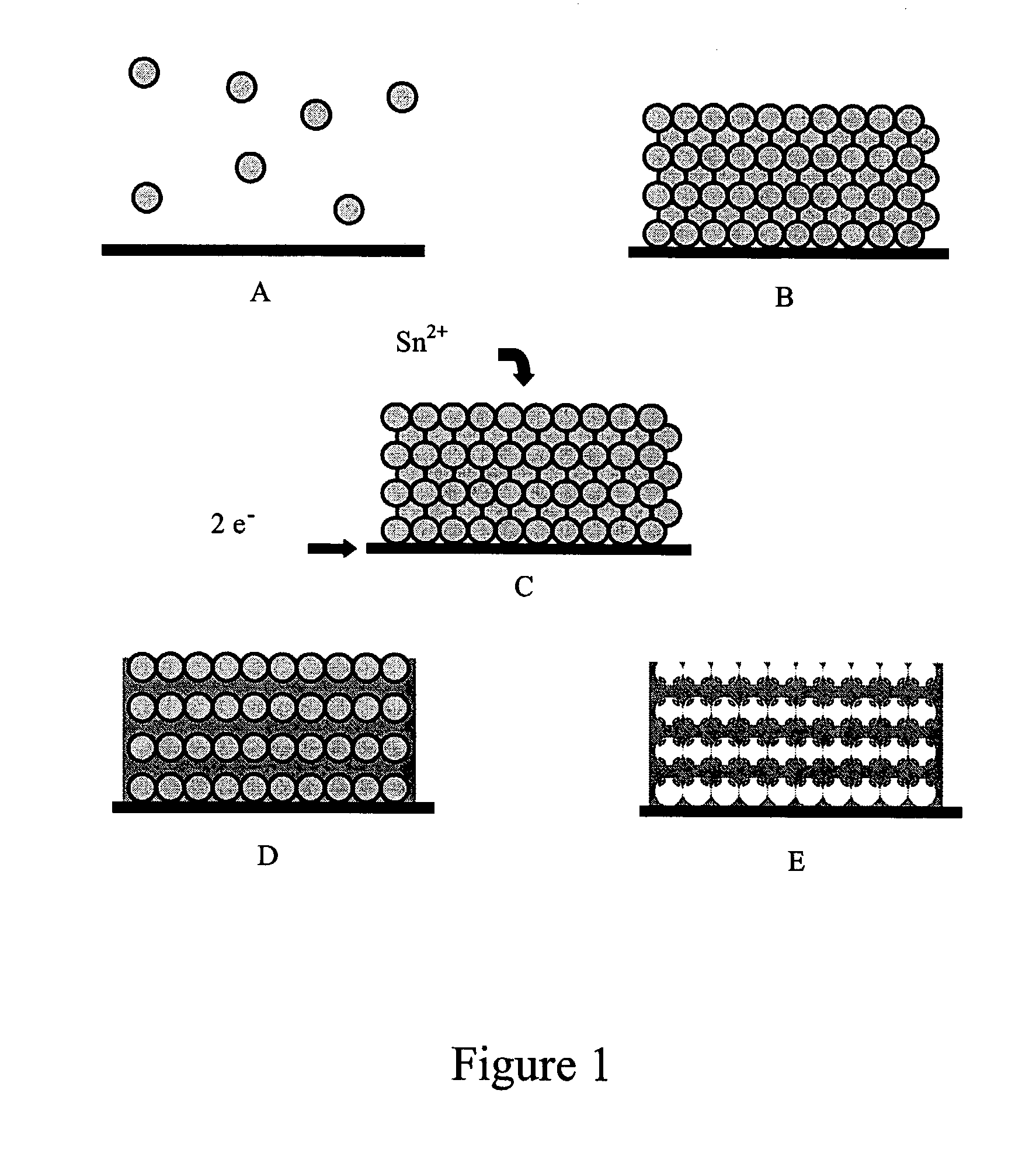

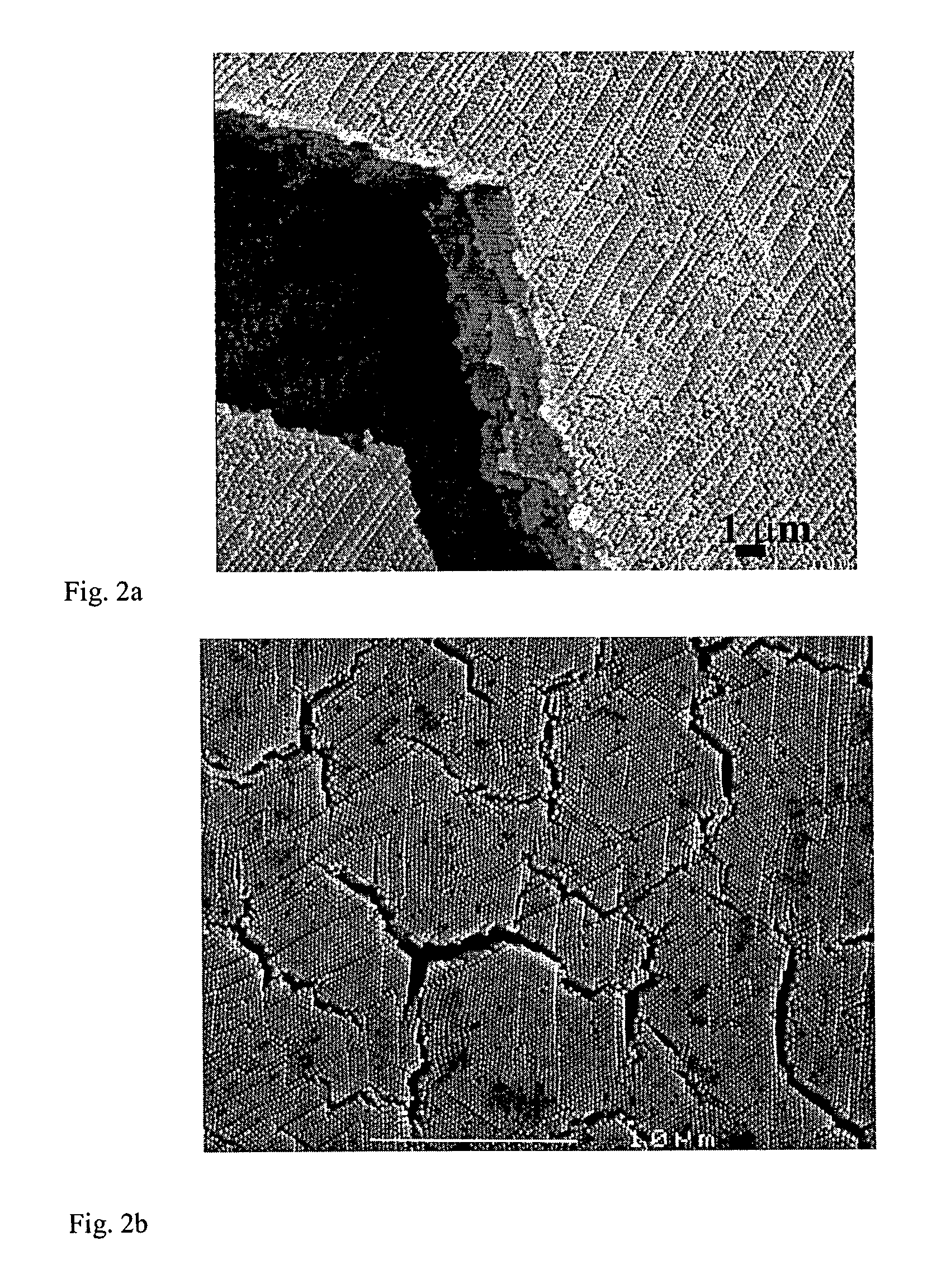

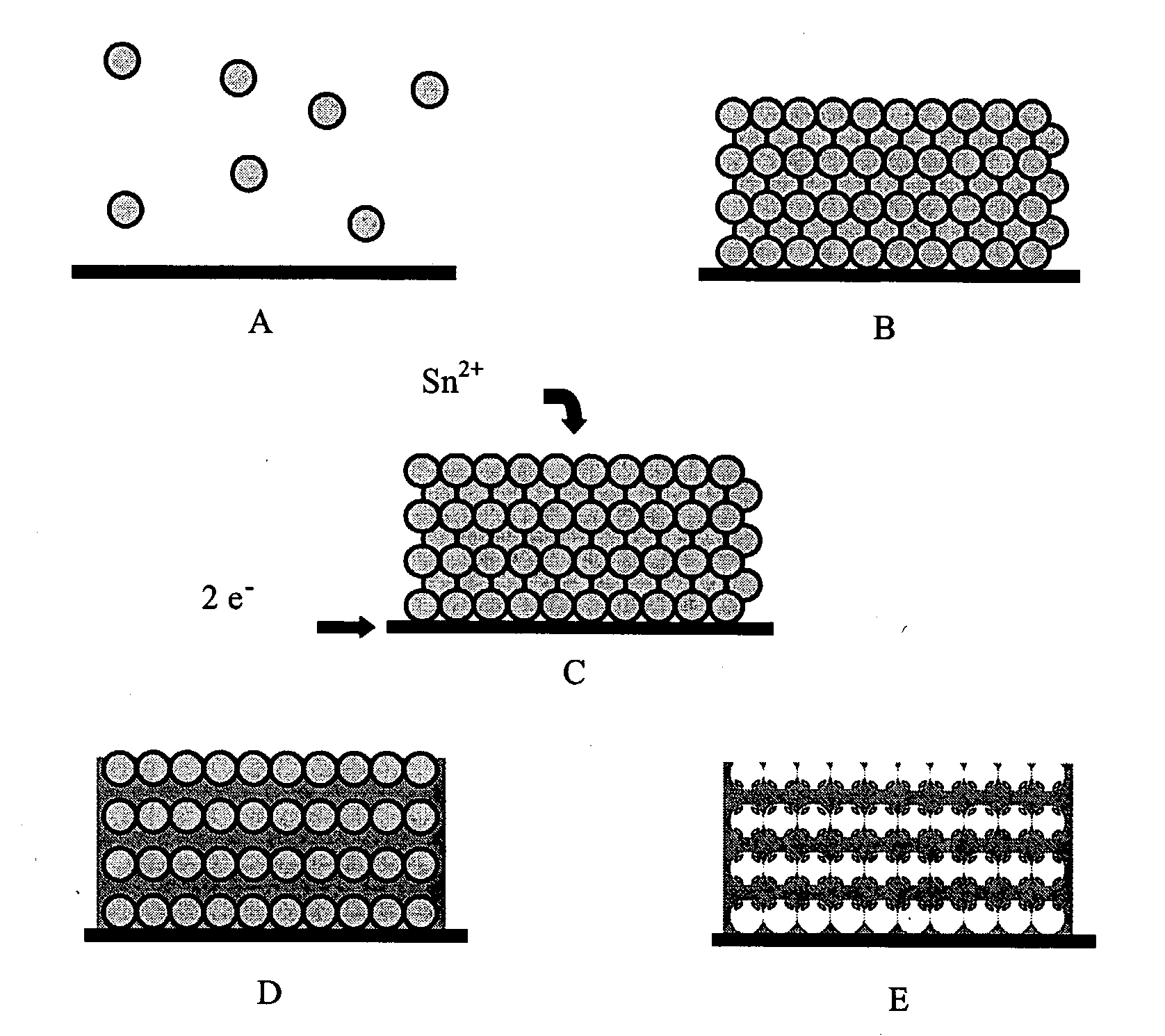

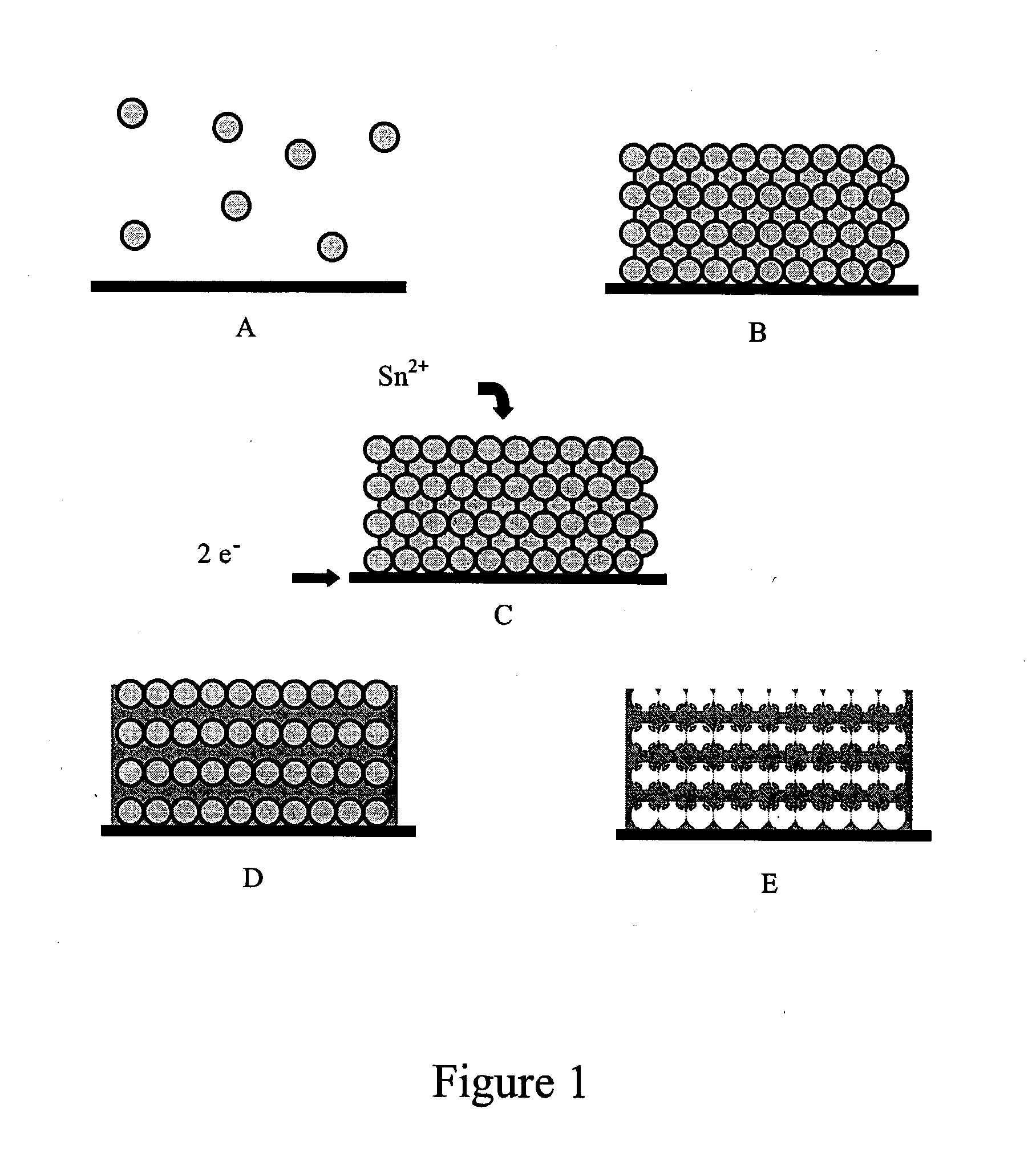

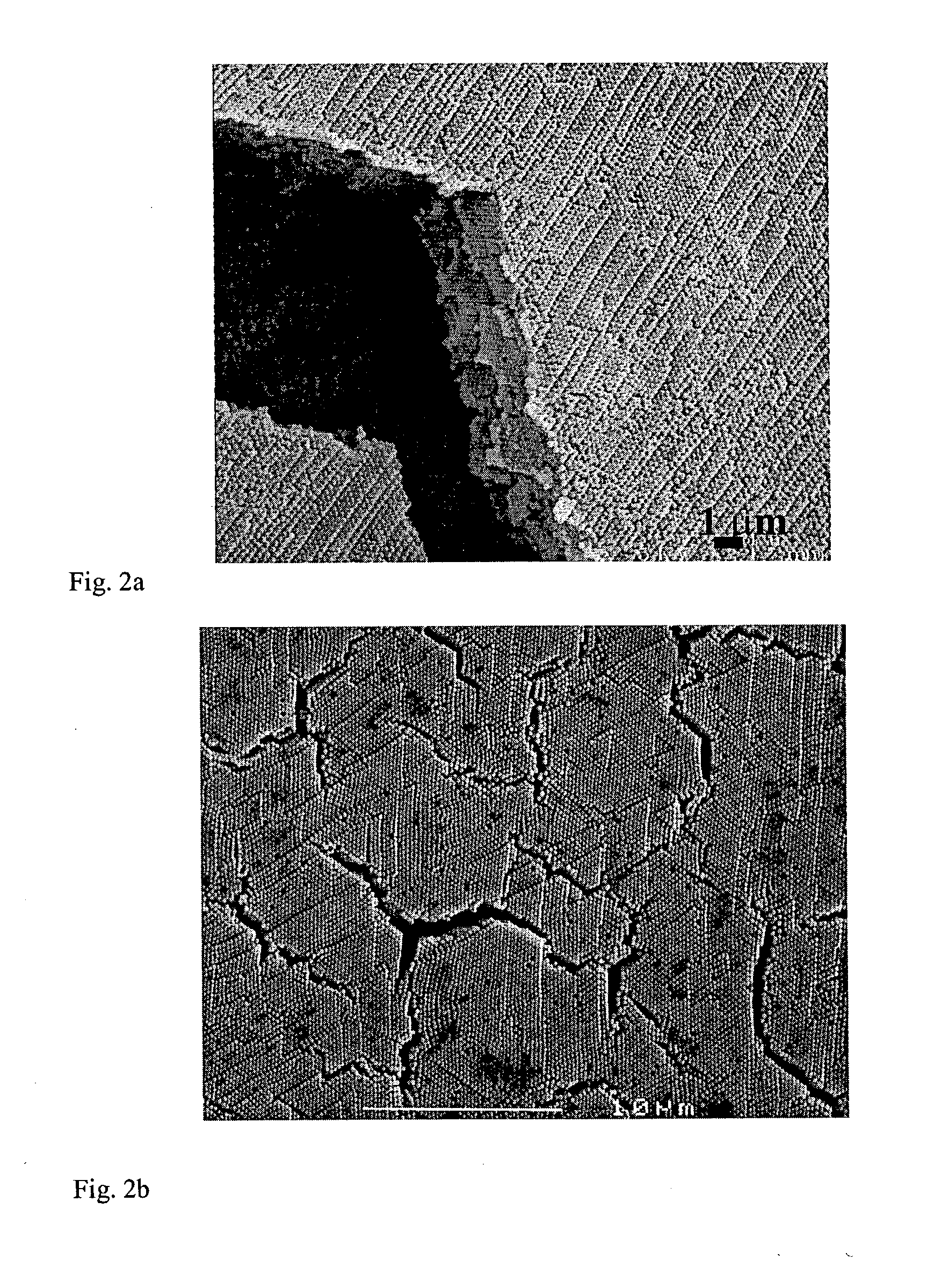

Colloidal sphere templates and sphere-templated porous materials

ActiveUS8137525B1Reduce crackingSpecific charge capacityDuplicating/marking methodsActive material electrodesColloidNanostructured metal

A method of making colloidal sphere templates and the sphere-templated porous materials made from the templates. The templated porous materials or thin films comprise micron and submicron-scaled spheres in ordered, disordered, or partially ordered arrays. The invention is useful in the synthesis of submicron porous, metallic tin-based and other high capacity anode materials with controlled pore structures for application in rechargeable lithium-ion batteries. The expected benefits of the resulting nanostructured metal films include a large increase in lithium storage capacity, rate capability, and improved stability with electrochemical cycling.

Owner:RGT UNIV OF CALIFORNIA

Compliant seal structures for protected active metal anodes

ActiveUS8404388B2Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

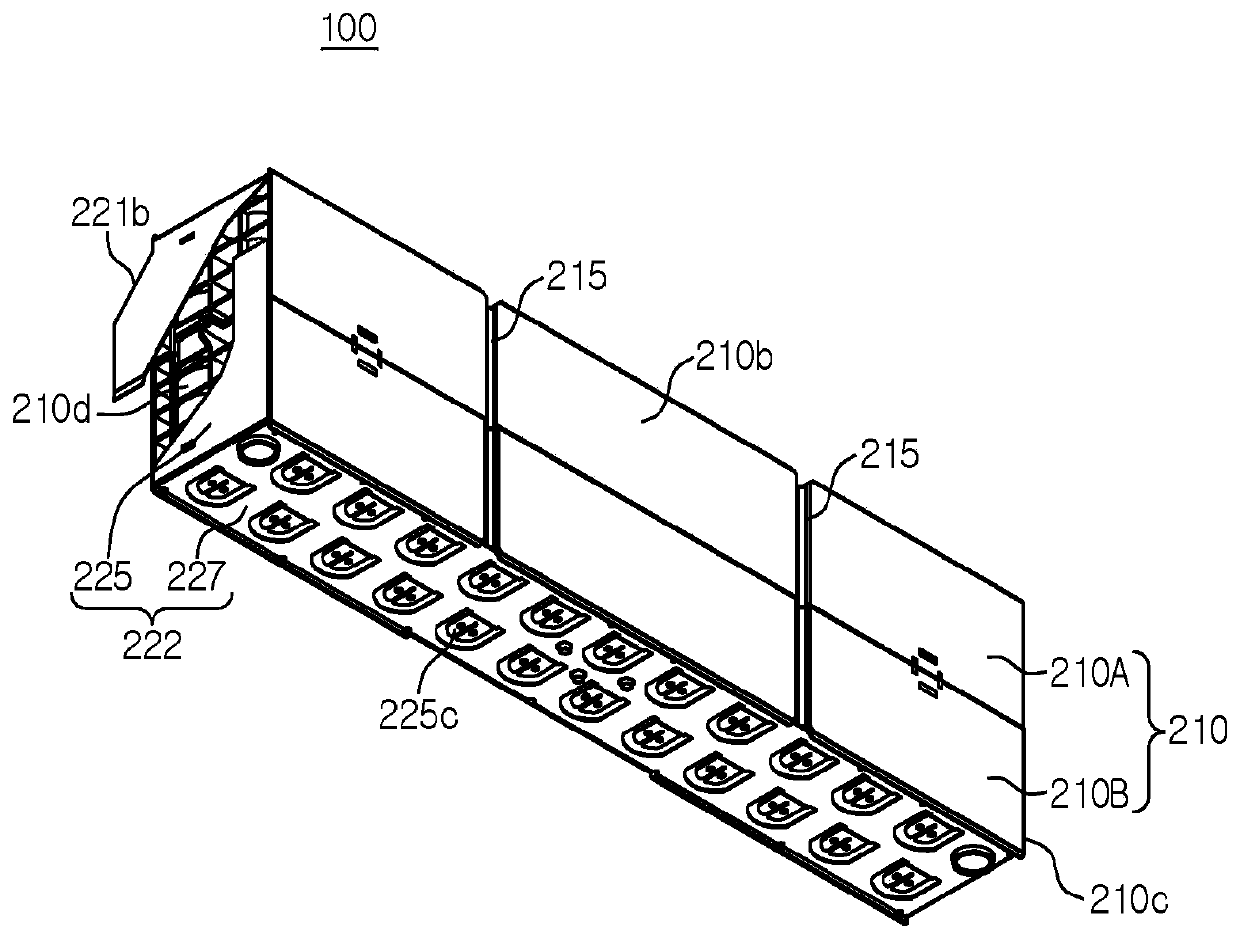

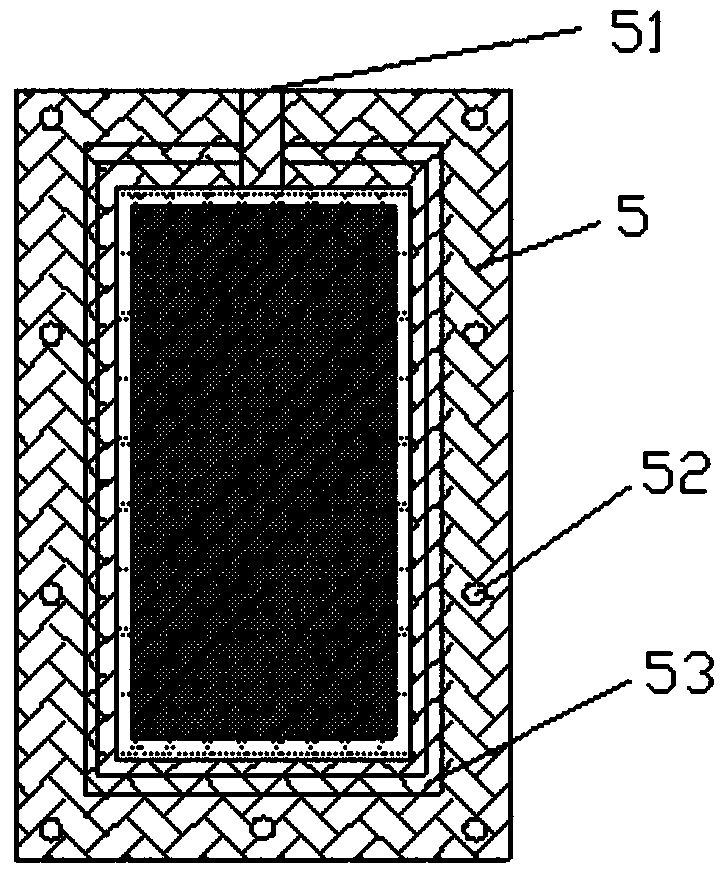

Battery module and manufacturing method thereof

PendingUS20200067040A1Improve structural rigidityPrevent module structureBattery isolationSecondary cellsEngineeringMechanical engineering

The present invention provides a battery module including: a battery group including a plurality of battery cells stacked with each other; a cooling plate which is located in contact with one side of the battery group to cool the plurality of battery cells; and a case which is located on the other side of the battery group so as to surround the battery group, wherein the case comprises an upper cover located on the other side of the battery group; and side covers which vertically extend from the upper cover so as to surround side portions of the plurality of battery cells from which electrode tabs protrude.

Owner:SK ON CO LTD

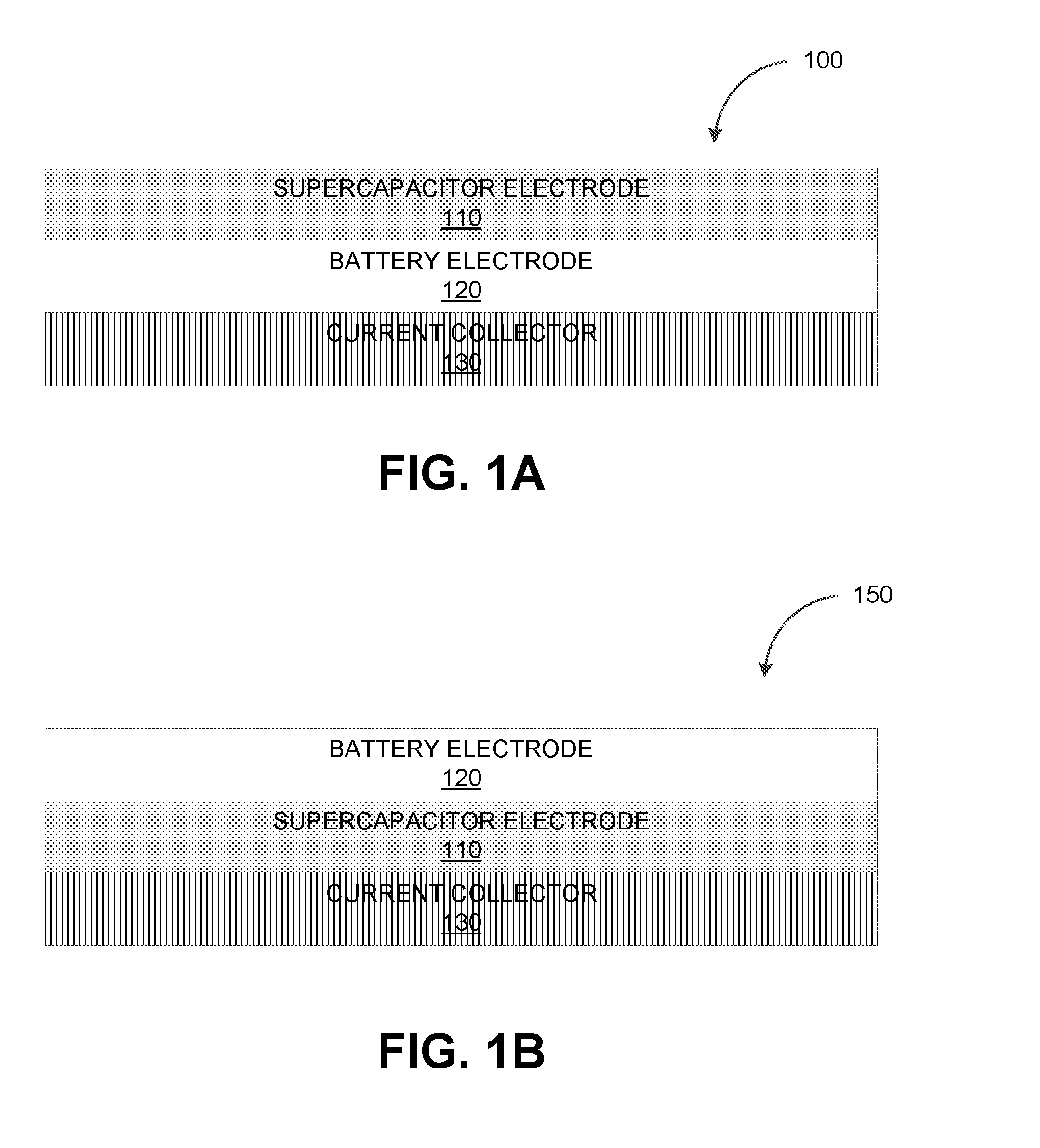

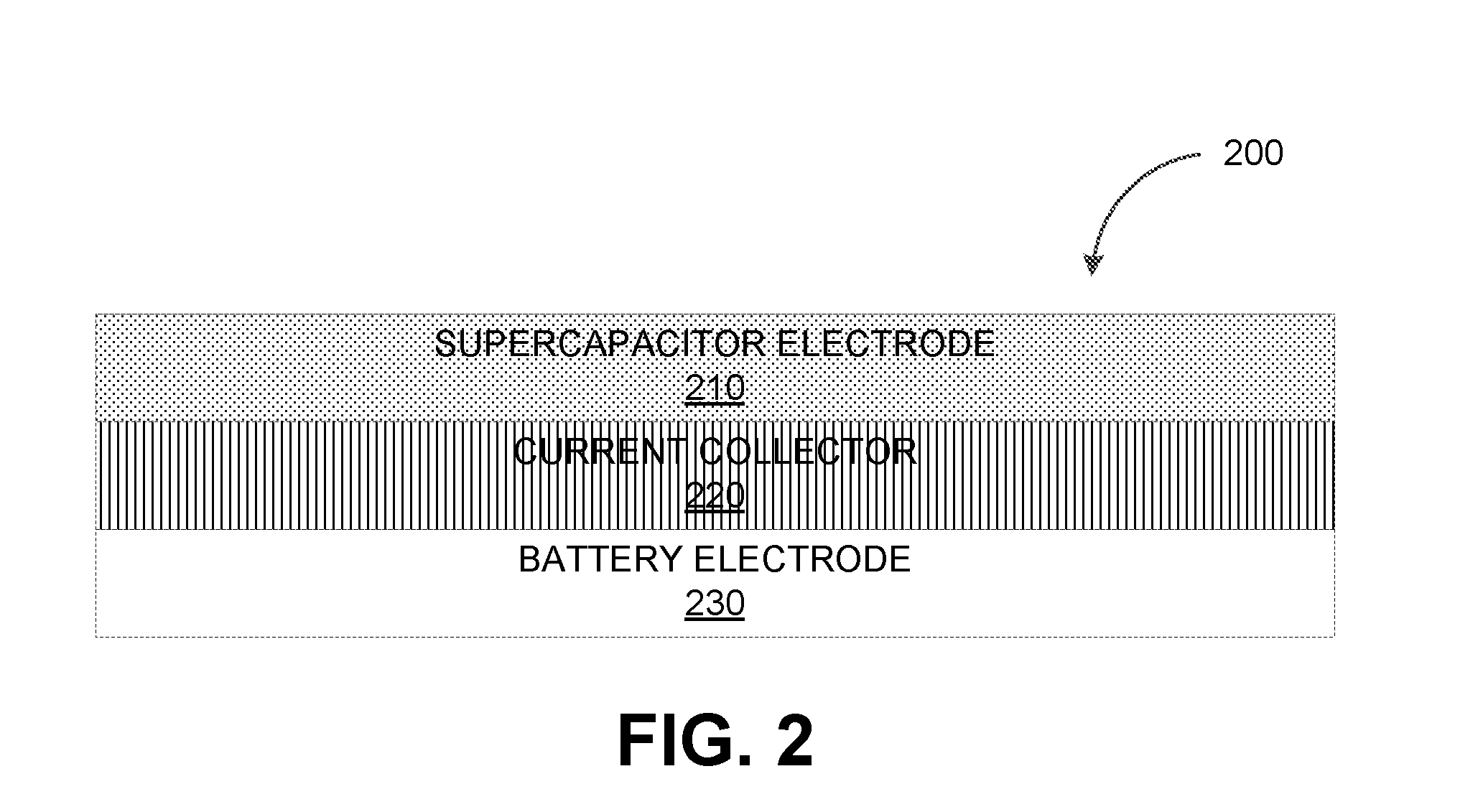

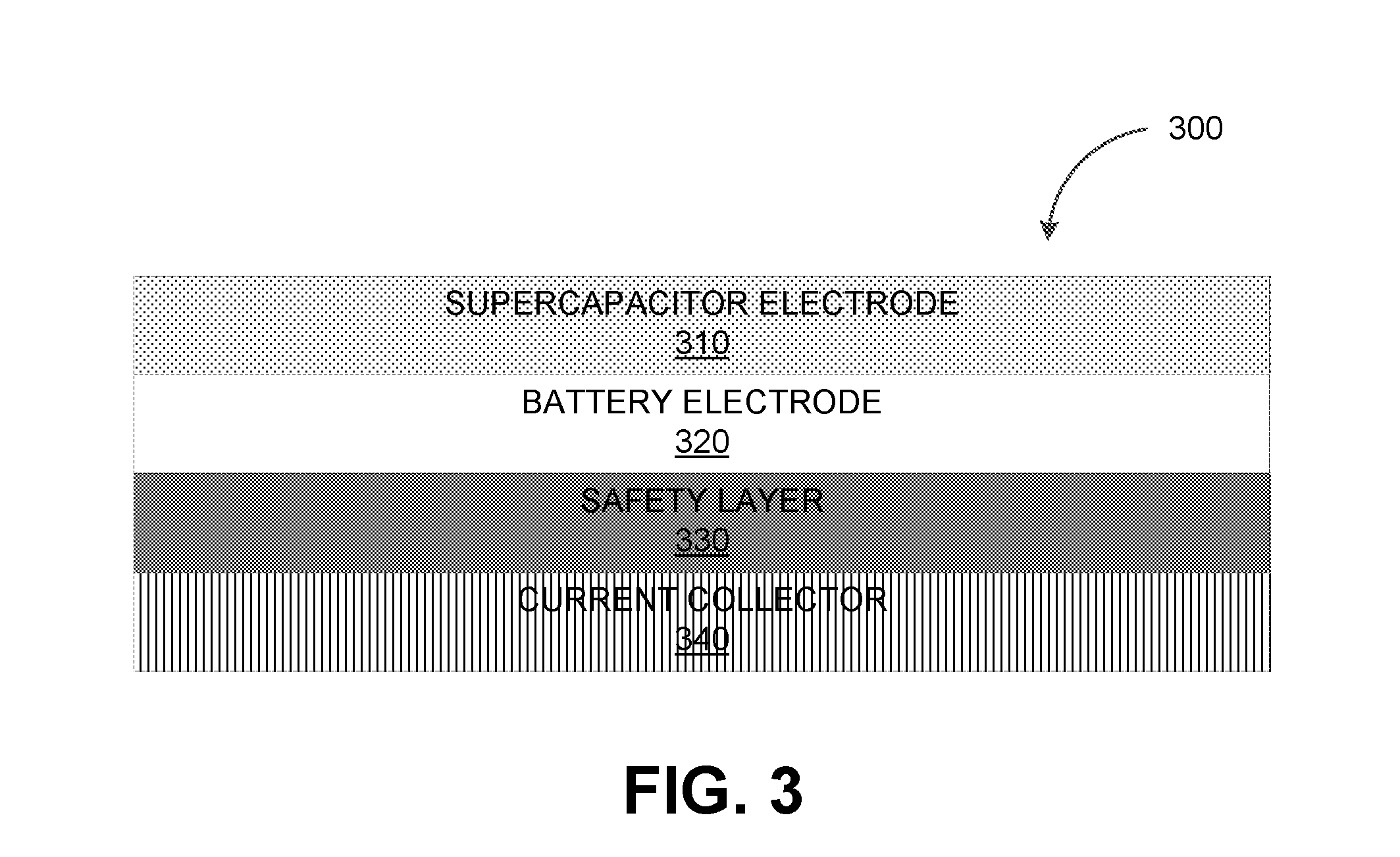

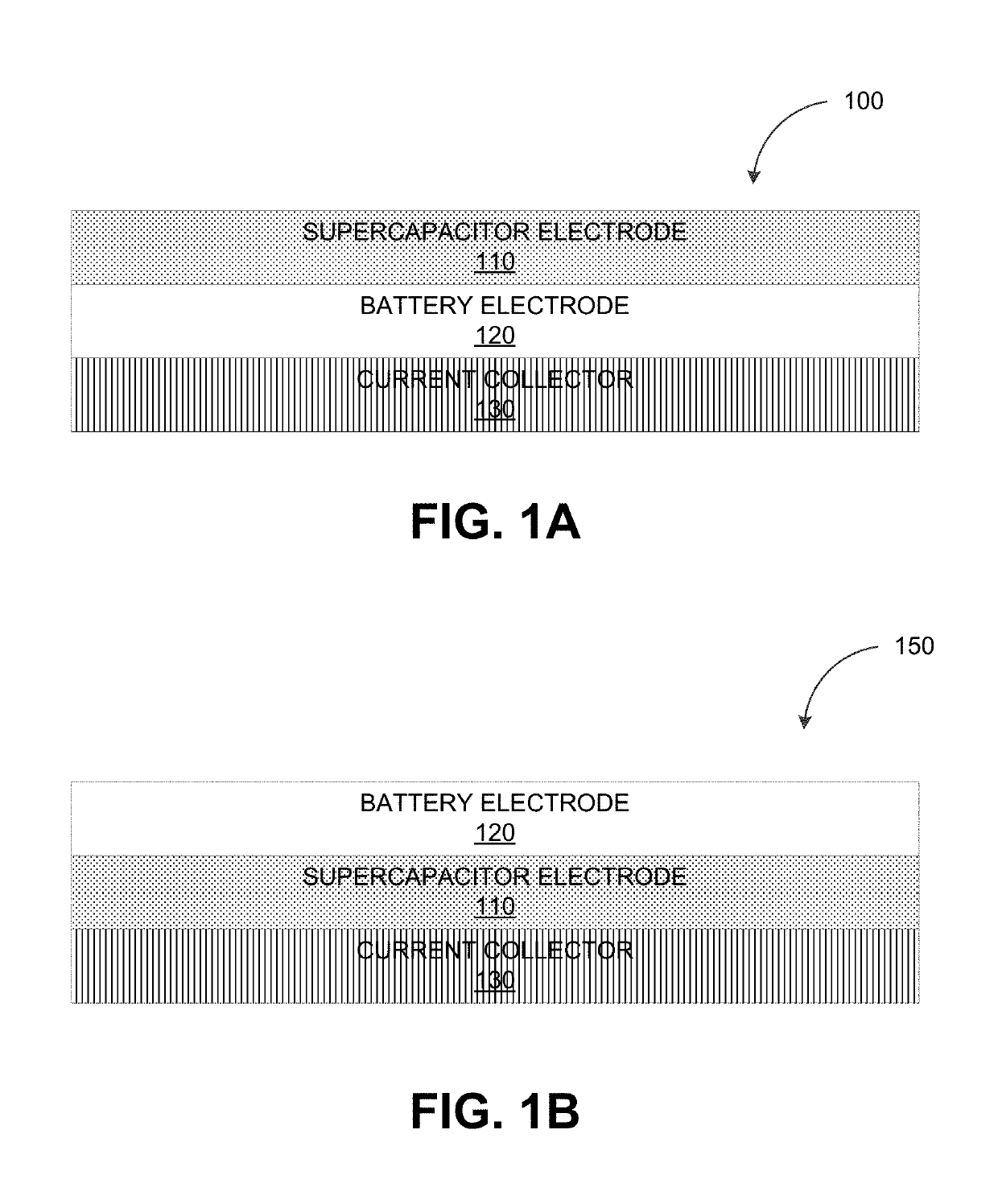

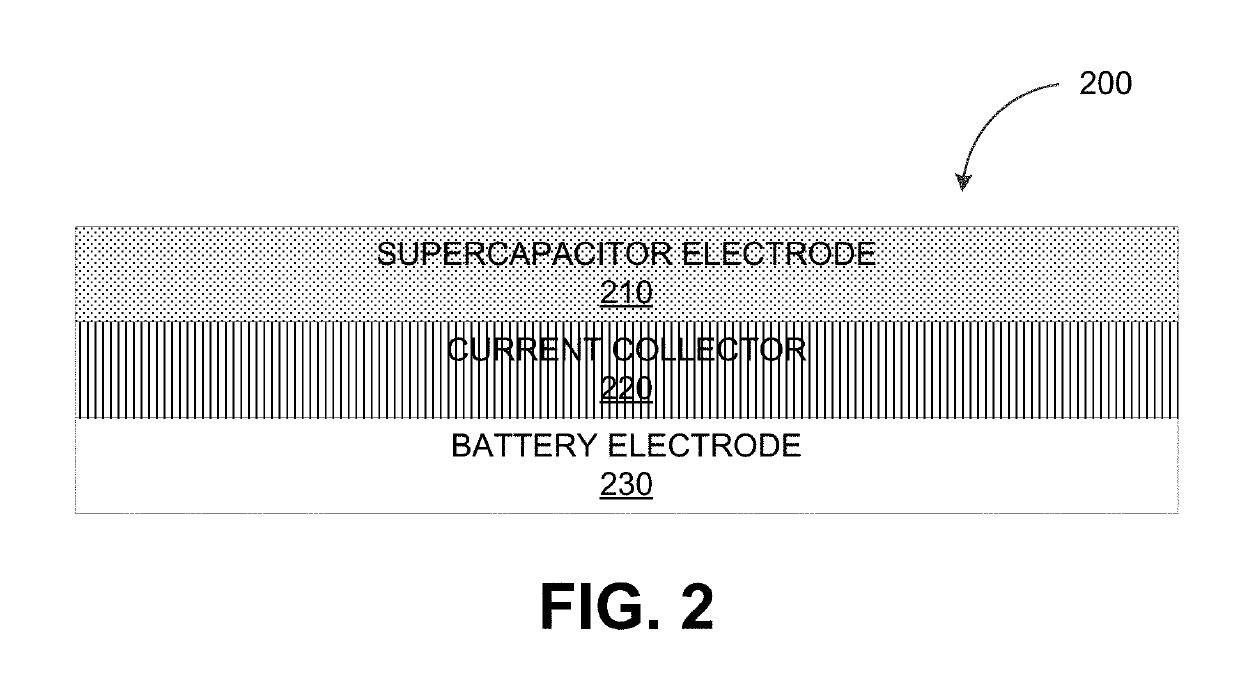

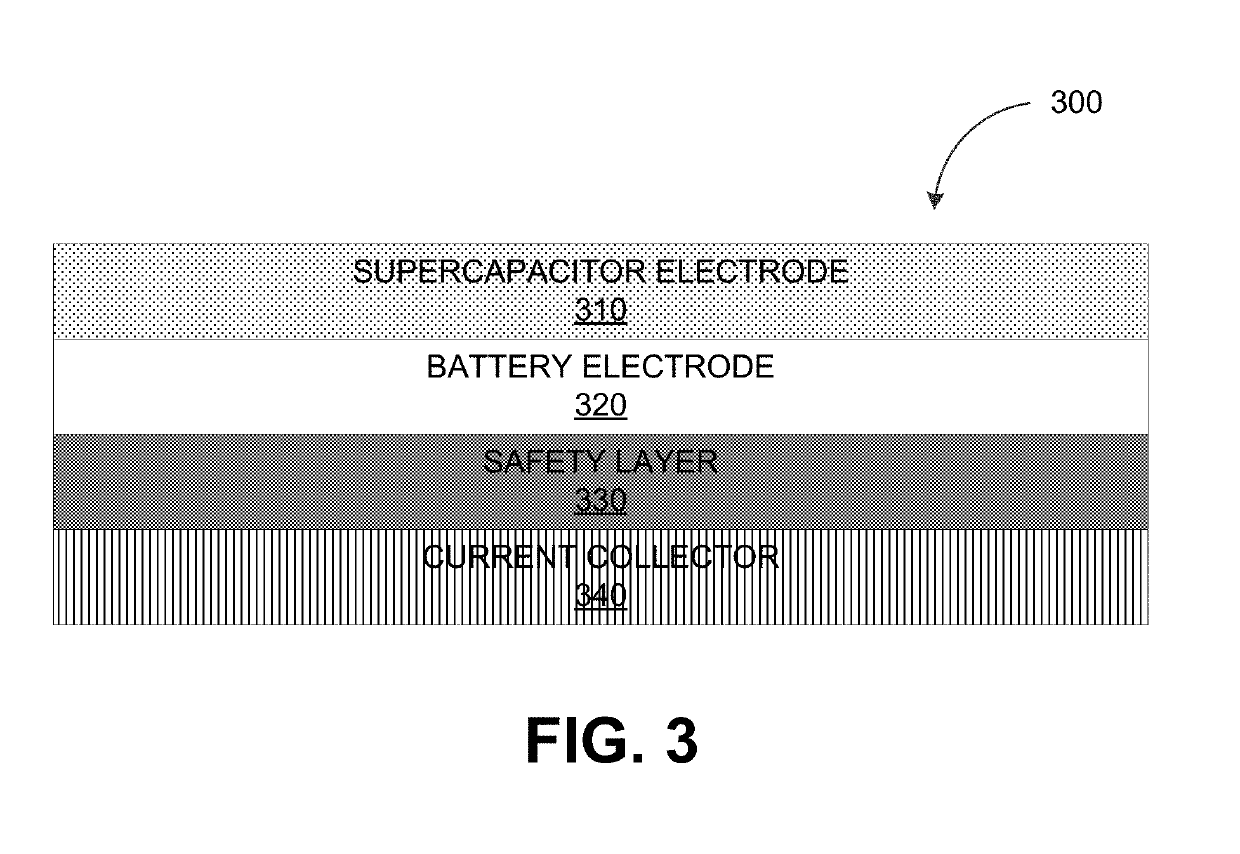

Battery and supercapacitor hybrid

InactiveUS20160365613A1Improve power densityIncrease chanceHybrid capacitor separatorsHybrid capacitor electrolytesSupercapacitorEngineering

A battery and supercapacitor hybrid can include a first hybrid electrode. The first hybrid electrode can include a first electrode, a first current collector, and a first supercapacitor. The battery and supercapacitor hybrid can further include a second hybrid electrode and a separator interposed between the first hybrid electrode and the second hybrid electrode.

Owner:AMERICAN LITHIUM ENERGY CORP

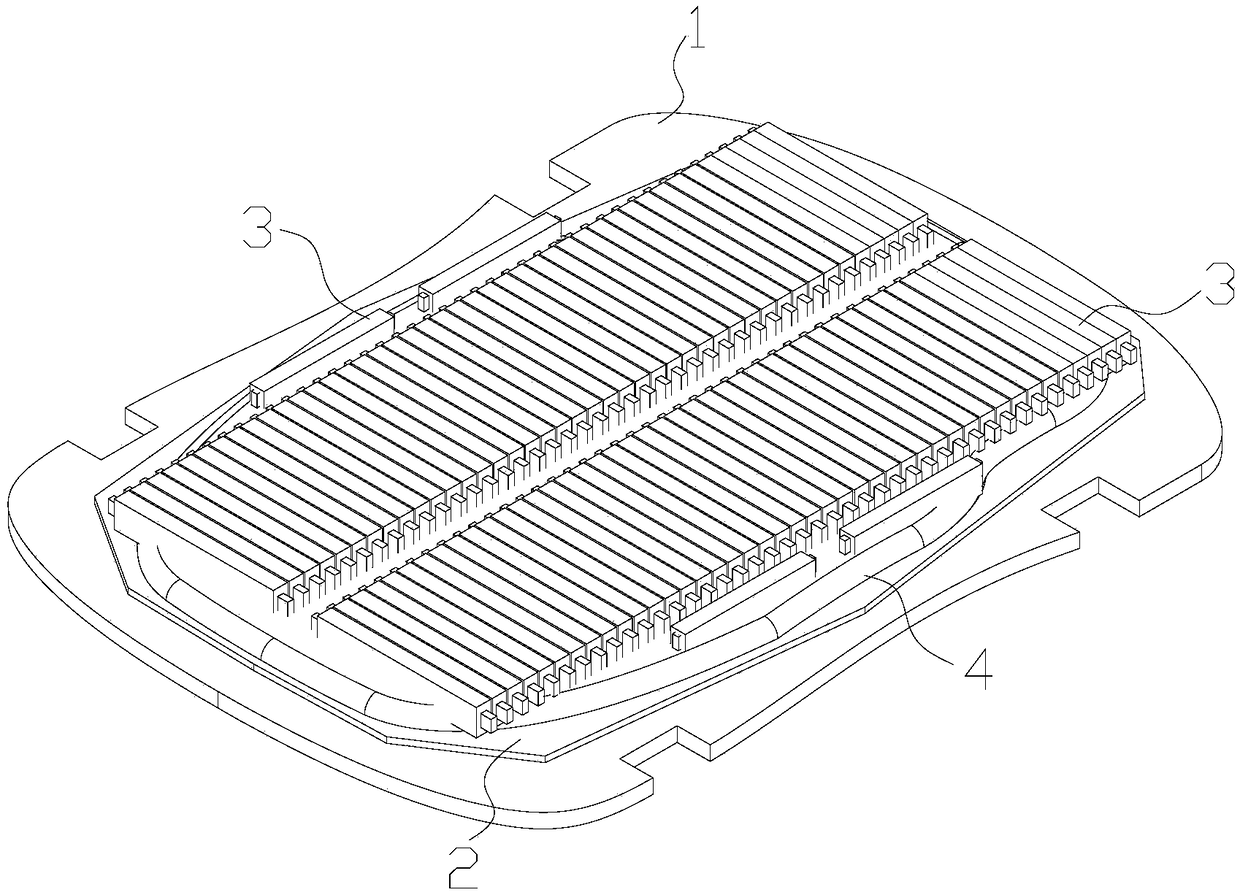

Battery module and its manufacturing method

PendingCN109994798AEnergy Density MaximizationMiniaturizationSecondary cellsCell lids/coversBattery cellBattery pack

The present invention provides a battery module, which includes: a battery group formed by stacking a plurality of battery cells, each of which includes electrode tabs; a cooling housing including a cooling plate located corresponding to one side of sides of the battery group, in which the electrode tabs are not extended, and side plates located on both sides of the battery group perpendicular tothe one side of the sides, thus to house the battery group; a cover plate located on the other side of the battery group; and a front cover part and a rear cover part, which are located at outermost front and rear of the battery group on both sides in a direction in which the electrode tabs are extended.

Owner:SK ON CO LTD

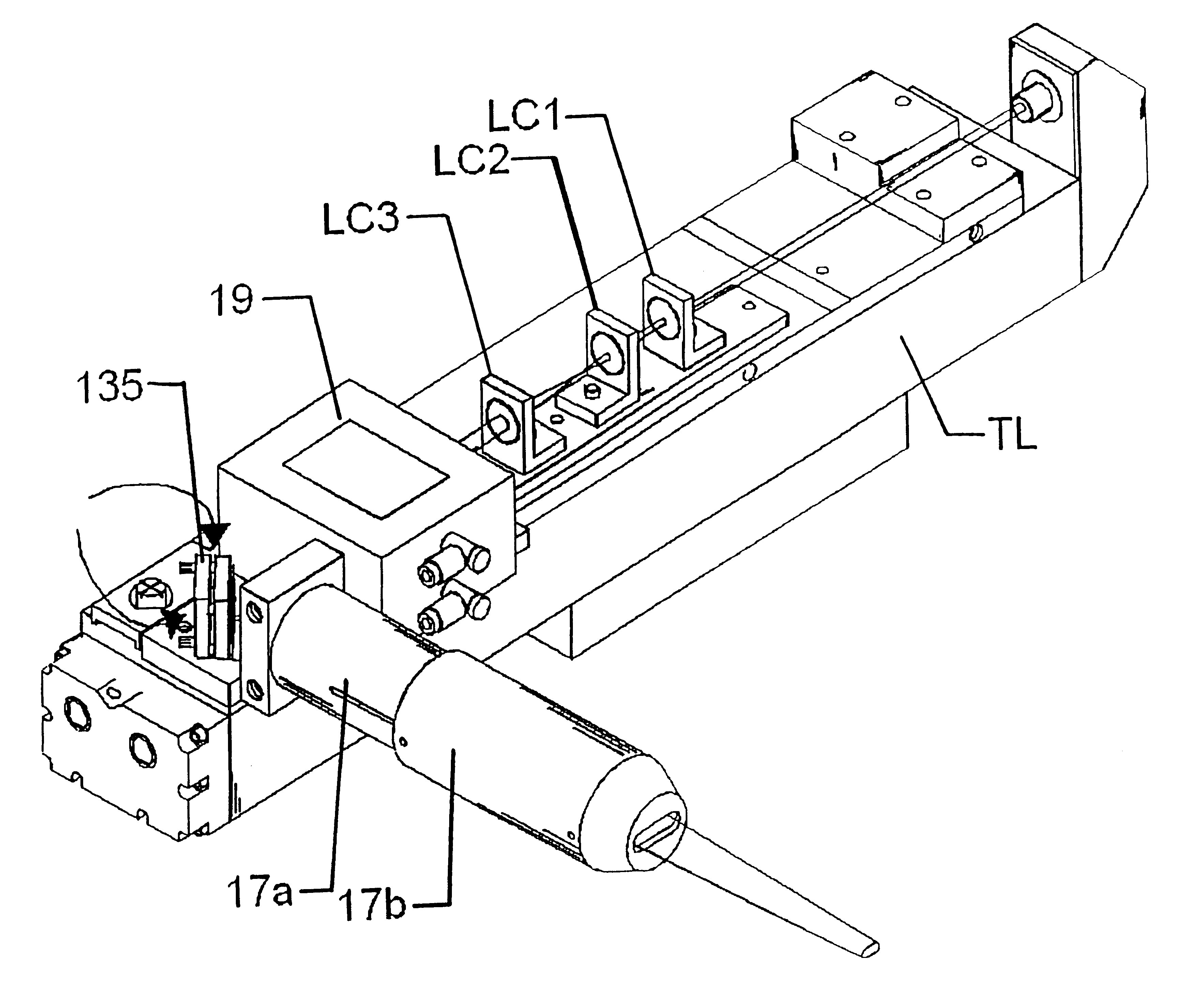

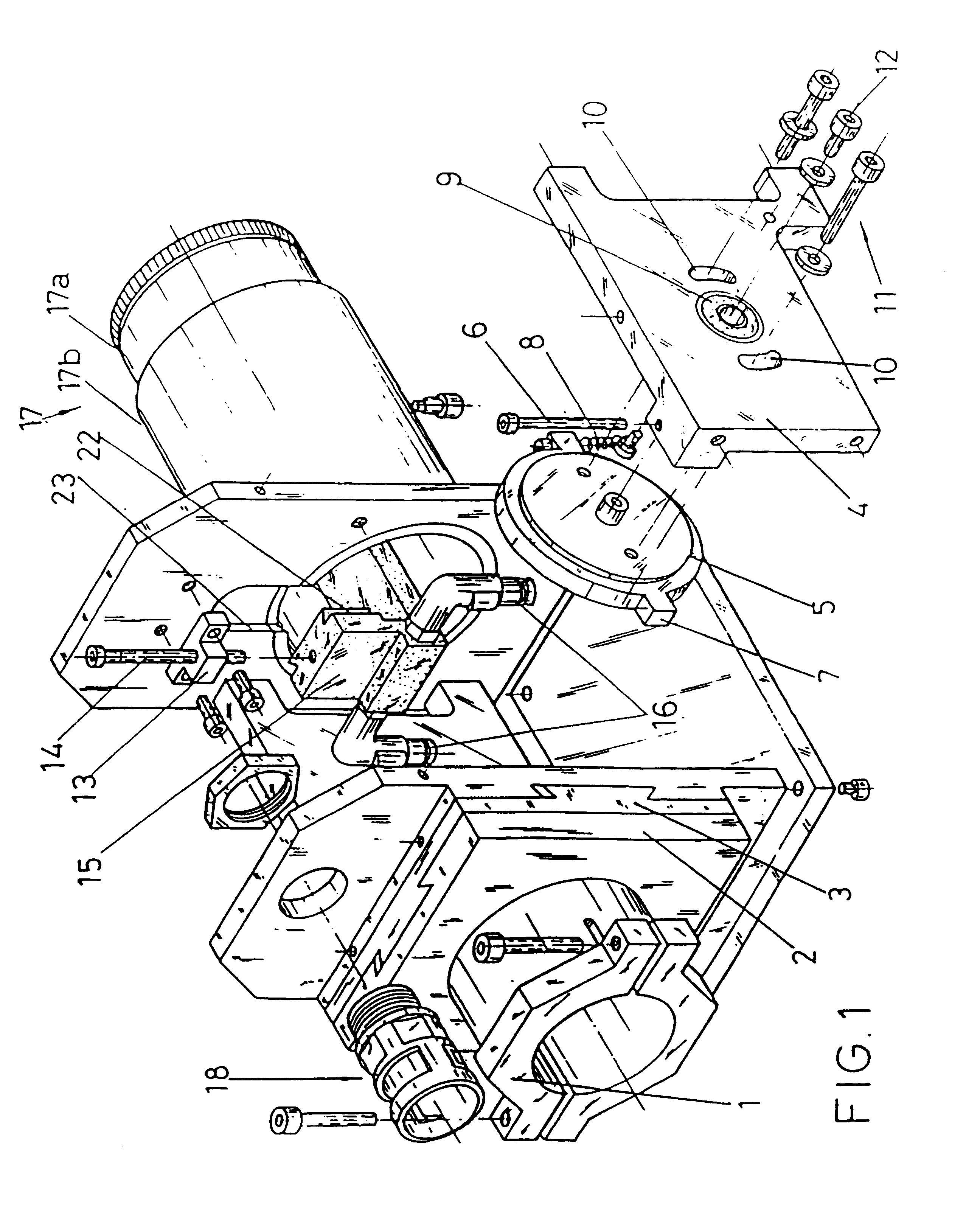

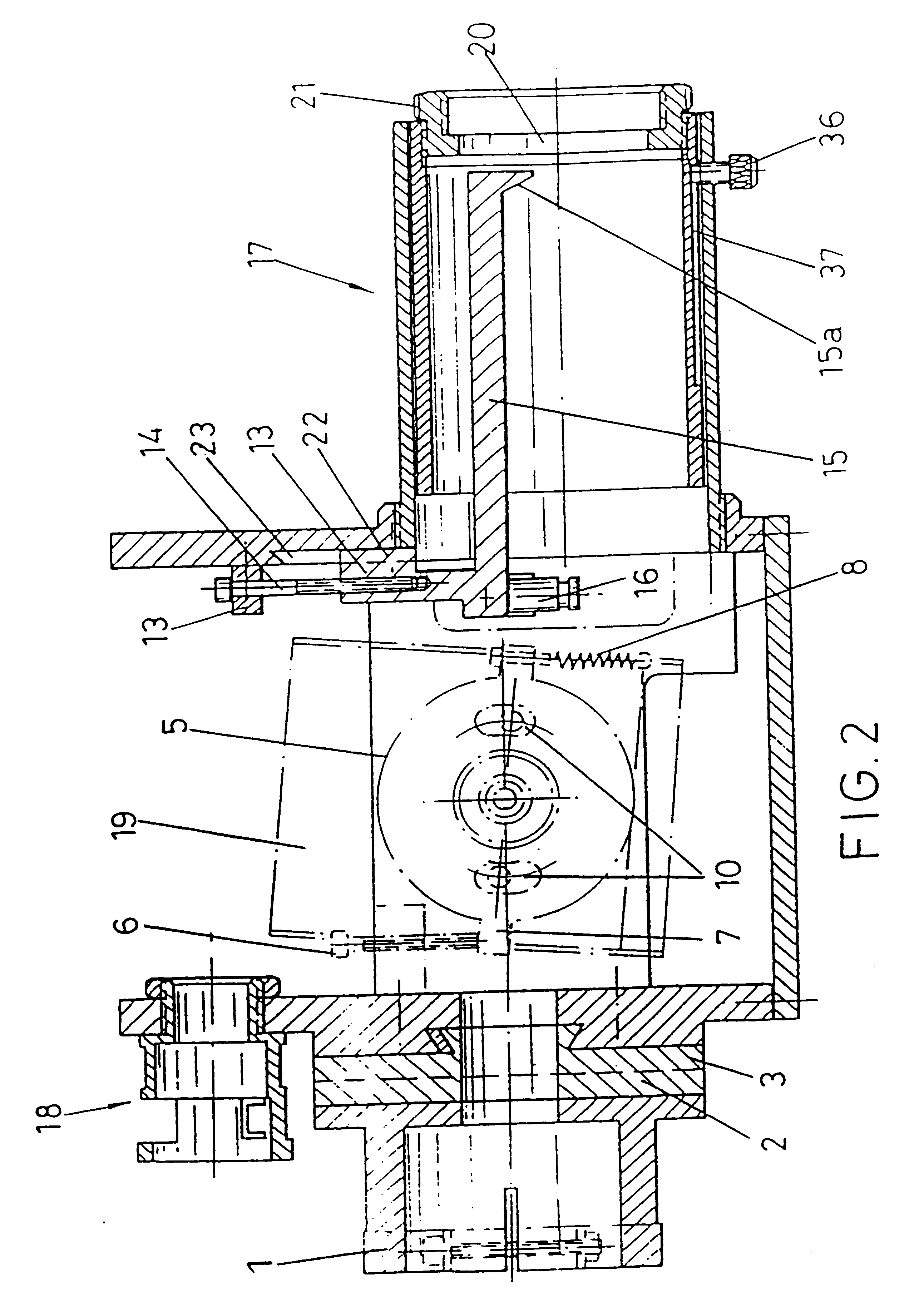

Laser system for marking or perforating

InactiveUS6201209B1Easy to adjustImprove securityLaser beam welding apparatusOptical elementsLight beamPhysics

A laser system for marking or perforating, including a laser tube and a head having an adjustable optical system with at least one focusing lens. The telescopic tube, a system of lenses for the light beam correction, and a deflexion system are integrally provided with the laser tube. In order to easily optimize the focal distance, a focusing lens is situated in a mobile tube of the telescopic tube which includes a mobile tube (17b) and a fixed tube (17a).

Owner:MACSA ID

Colloidal sphere templates and sphere-templated porous materials

ActiveUS20120067728A1Increase capacityIncrease ratingsDuplicating/marking methodsActive material electrodesColloidElectrochemistry

A method of making colloidal sphere templates and the sphere-templated porous materials made from the templates. The templated porous materials or thin films comprise micron and submicron-scaled spheres in ordered, disordered, or partially ordered arrays. The invention is useful in the synthesis of submicron porous, metallic tin-based and other high capacity anode materials with controlled pore structures for application in rechargeable lithium-ion batteries. The expected benefits of the resulting nanostructured metal films include a large increase in lithium storage capacity, rate capability, and improved stability with electrochemical cycling.

Owner:RGT UNIV OF CALIFORNIA

Battery module and manufacturing method thereof

ActiveCN110854319AMaximize space utilizationEnergy Density MaximizationBattery isolationSecondary cellsEngineeringMechanical engineering

The invention relates to a battery module and a manufacturing method thereof. The battery group including a plurality of battery cells stacked with each other; a cooling plate which is located in contact with one side of the battery group to cool the plurality of battery cells; and a case which is located on the other side of the battery group so as to surround the battery group, wherein the casecomprises an upper cover located on the other side of the battery group; and side covers which vertically extend from the upper cover so as to surround side portions of the plurality of battery cellsfrom which electrode tabs protrude.

Owner:SK ON CO LTD

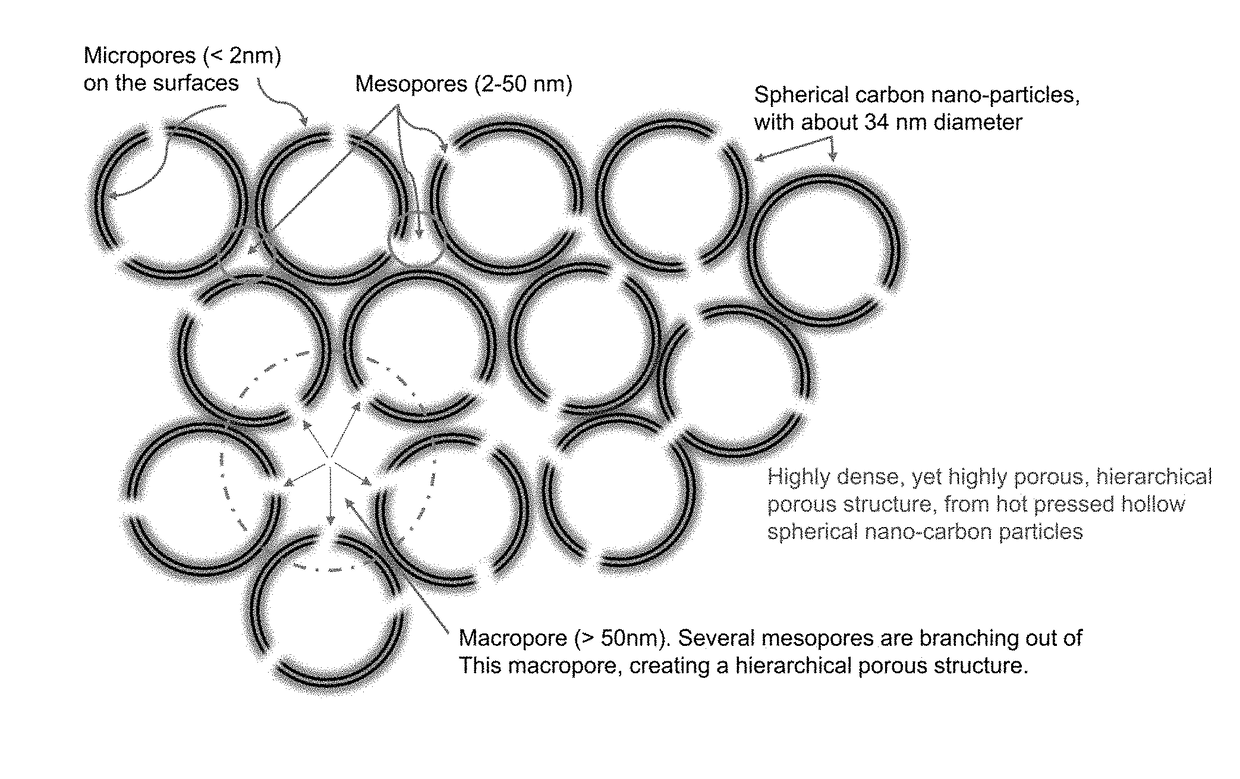

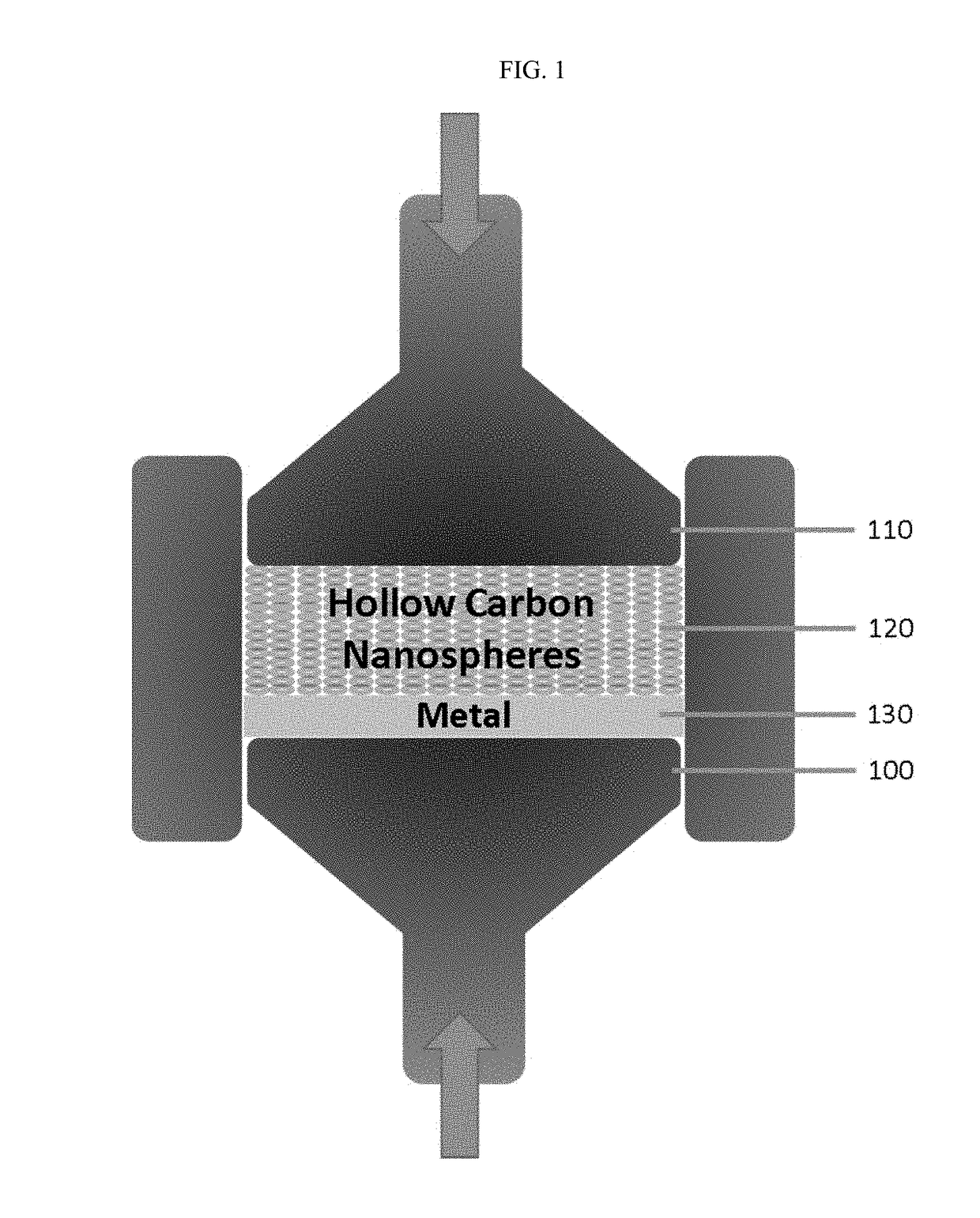

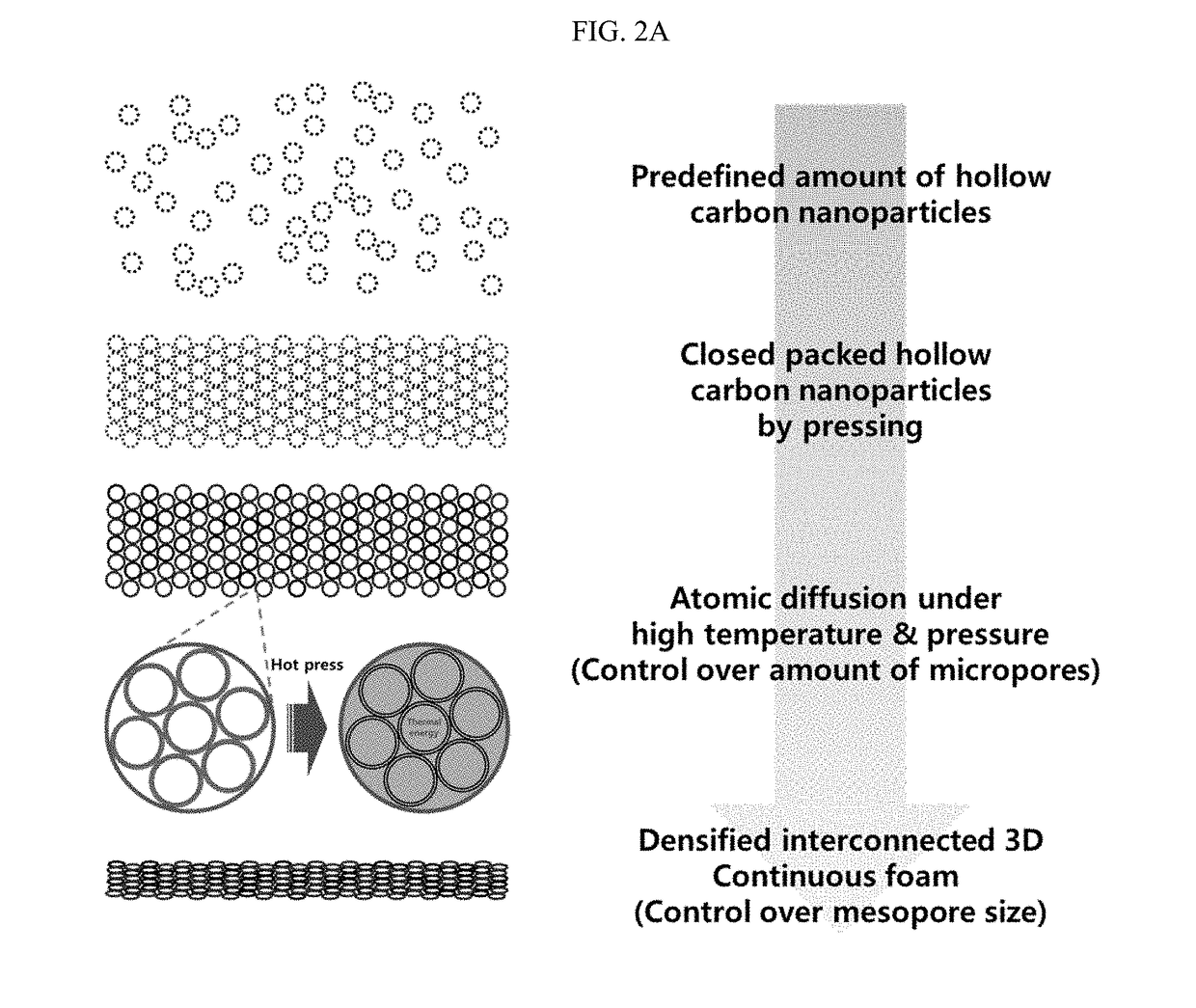

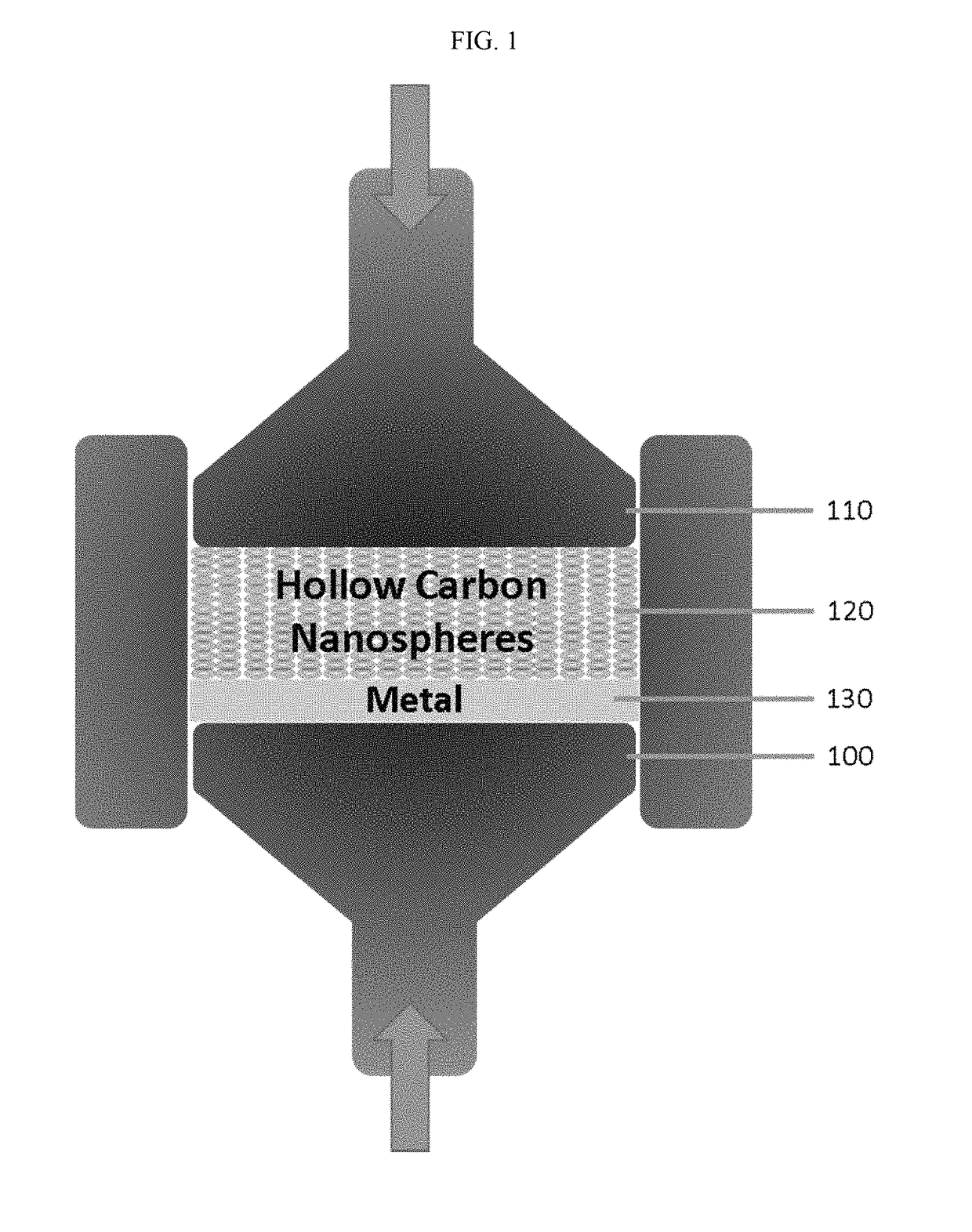

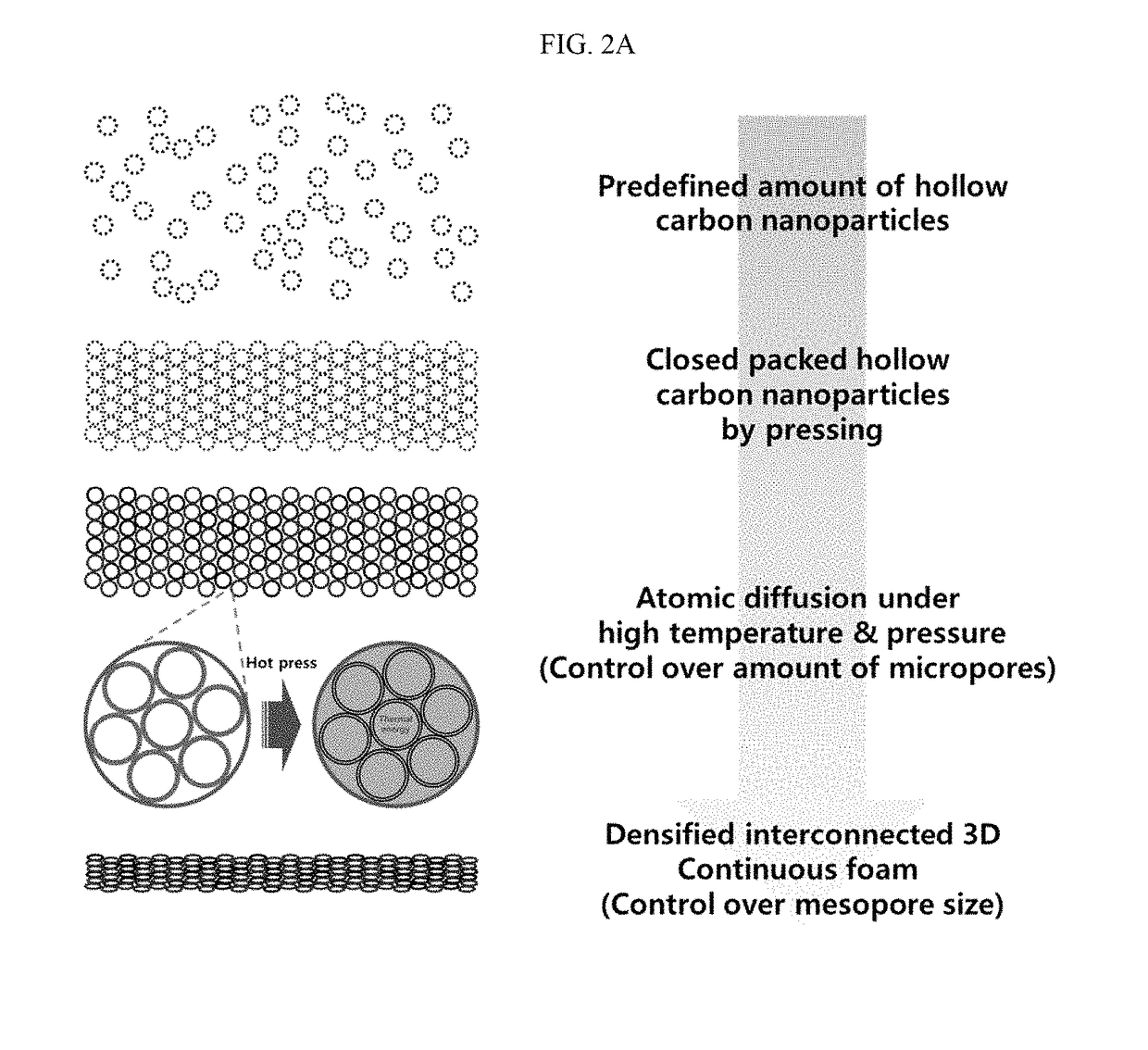

Highly dense nano-carbon foam with controlled porosity synthesized from hollow carbon nanoparticles

InactiveUS20170297923A1Reducing and eliminating conductive additive and binderReduce the amount requiredLayered productsCarbon preparation/purificationPorosityCarbon Nanoparticles

Hot pressing hollow carbon nanoparticles results in a nano-carbon foam that can be used for energy storage, carbon dioxide capture or water desalination.

Owner:NAT UNIV OF SINGAPORE

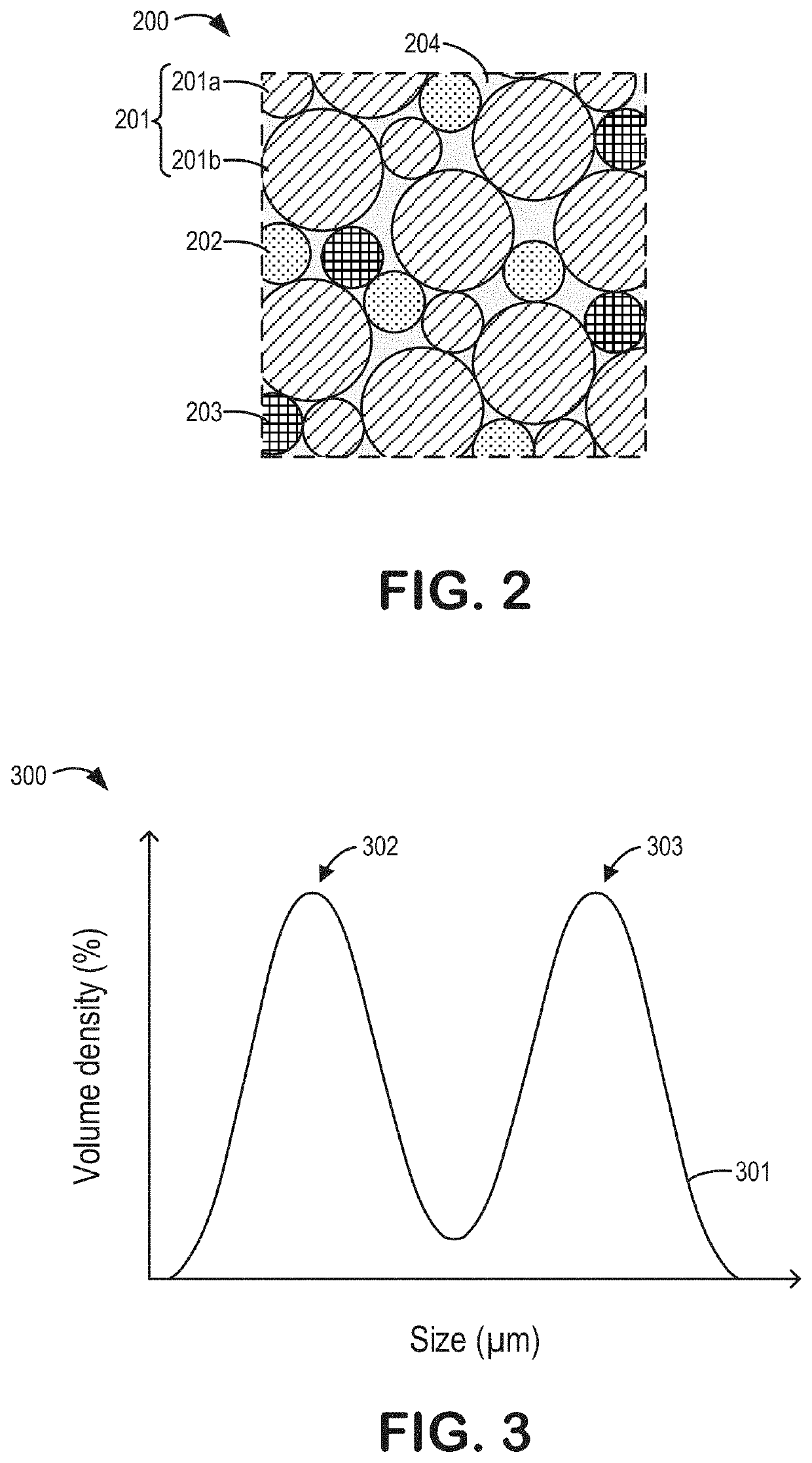

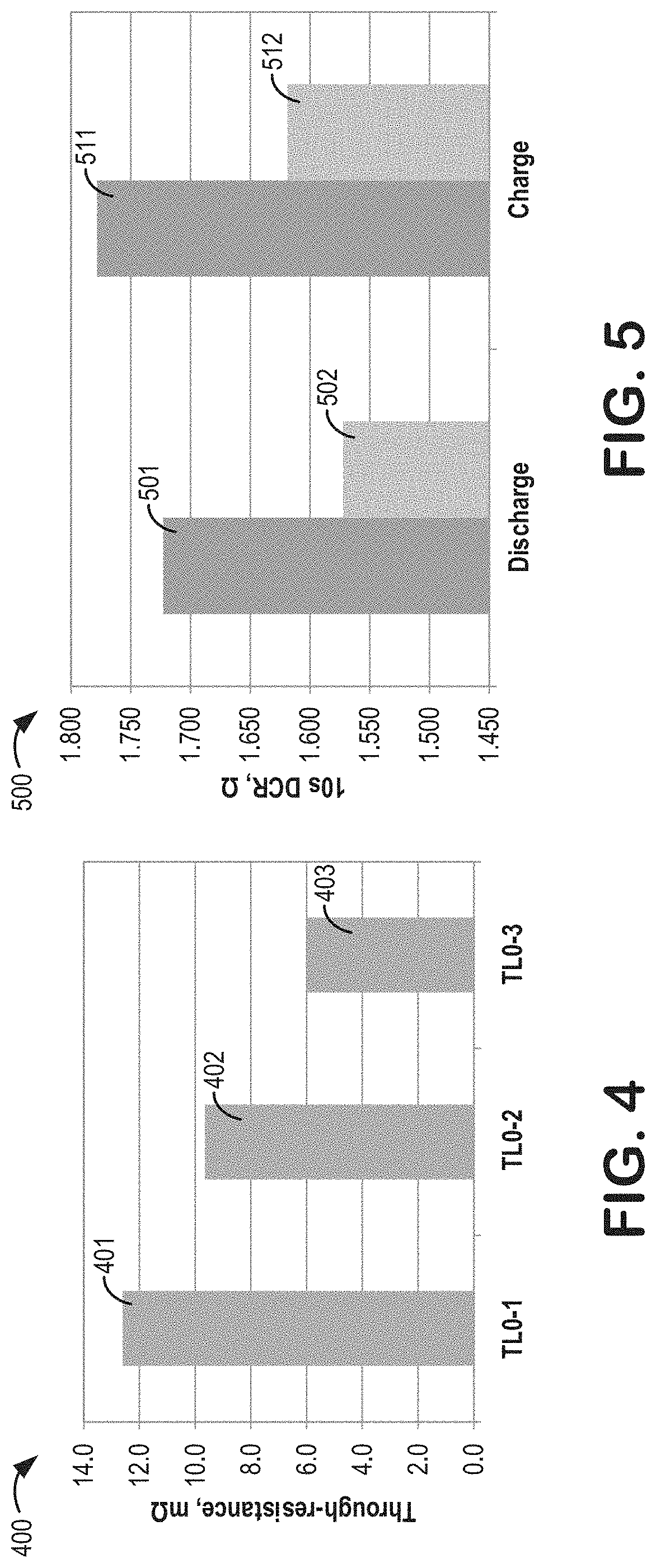

Positive electrode for secondary batteries and secondary battery including the same

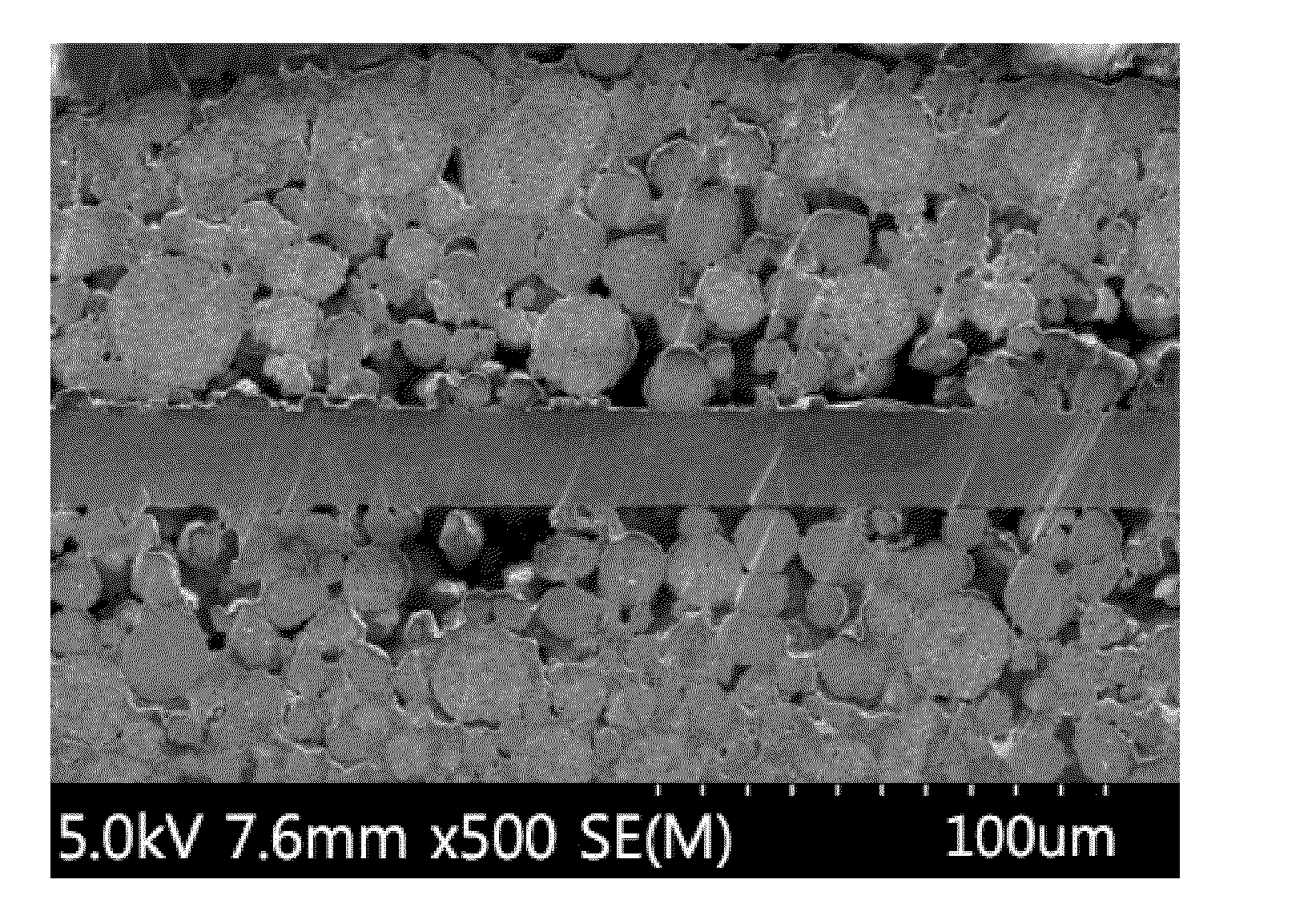

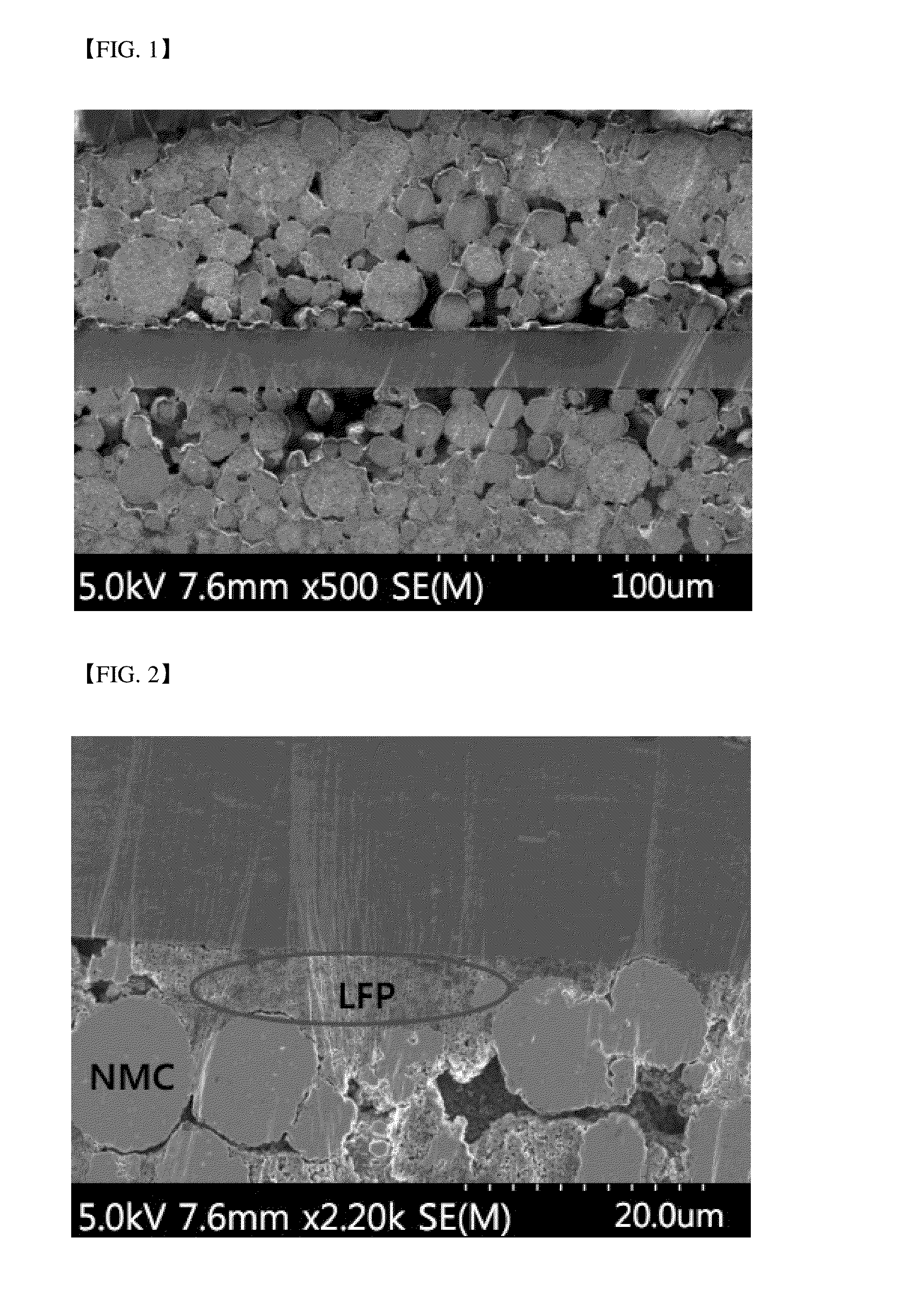

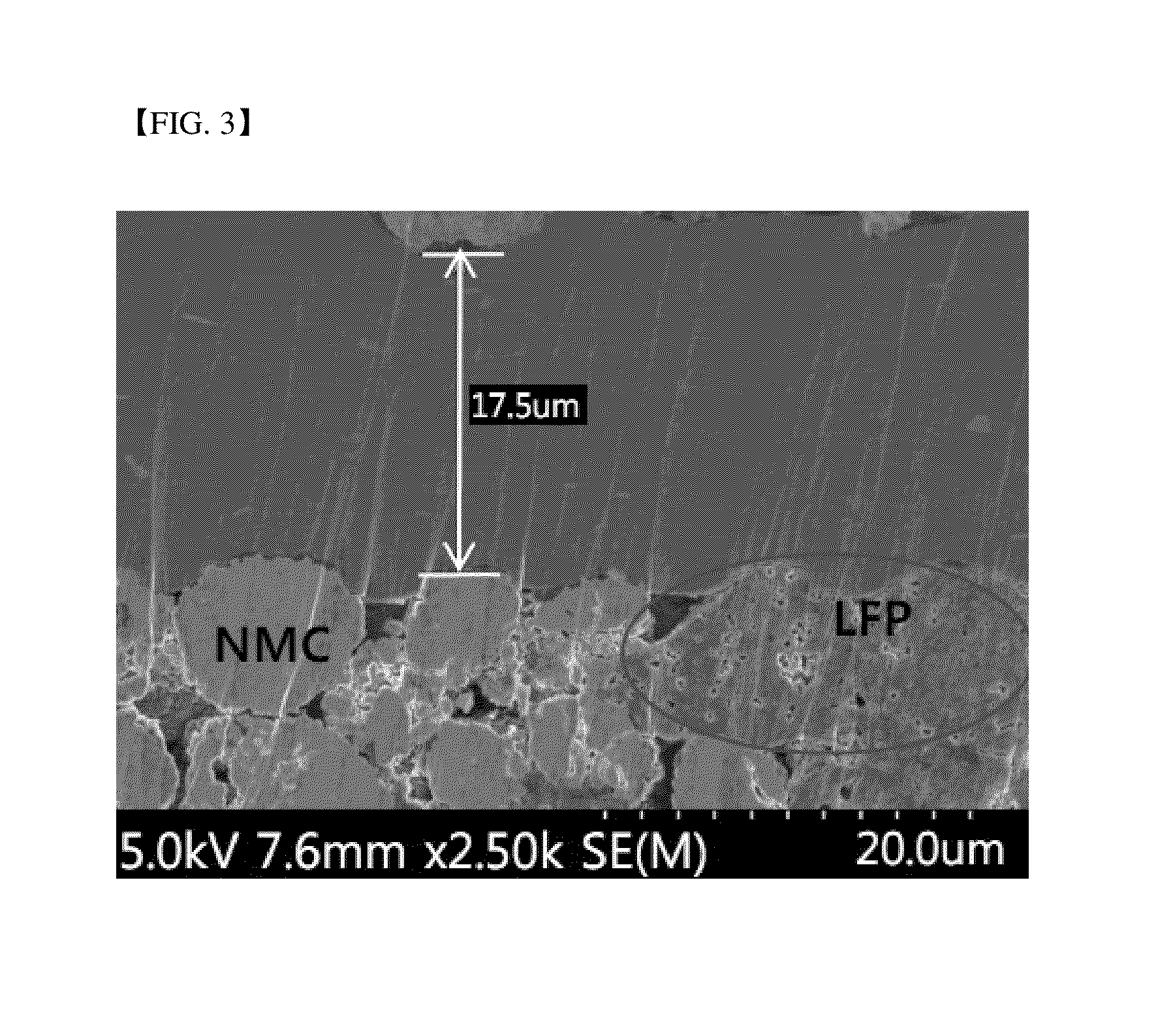

ActiveUS20160204423A1Diffusivility of lithium ions is increasedEnergy Density MaximizationPrimary cell to battery groupingElectrode rolling/calenderingLithium iron phosphateCrystal structure

Disclosed is a positive electrode for secondary batteries manufactured by coating and rolling a slurry for a positive electrode mix including positive electrode active material particles on a current collector, wherein the positive electrode active material particles include one or more selected from the group consisting of lithium iron phosphate particles having an olivine crystal structure and lithium nickel-manganese-cobalt composite oxide particles according to Formula 1, the lithium nickel-manganese-cobalt composite oxide particles existing as secondary particles formed by agglomeration of primary particles, in an amount of greater than 50% and less than 90% based on the total volume of lithium nickel-manganese-cobalt composite oxide, and the lithium iron phosphate particles existing as primary particles in an amount of greater than 50% and less than 100% based on the total volume of lithium iron phosphate

Owner:LG ENERGY SOLUTION LTD

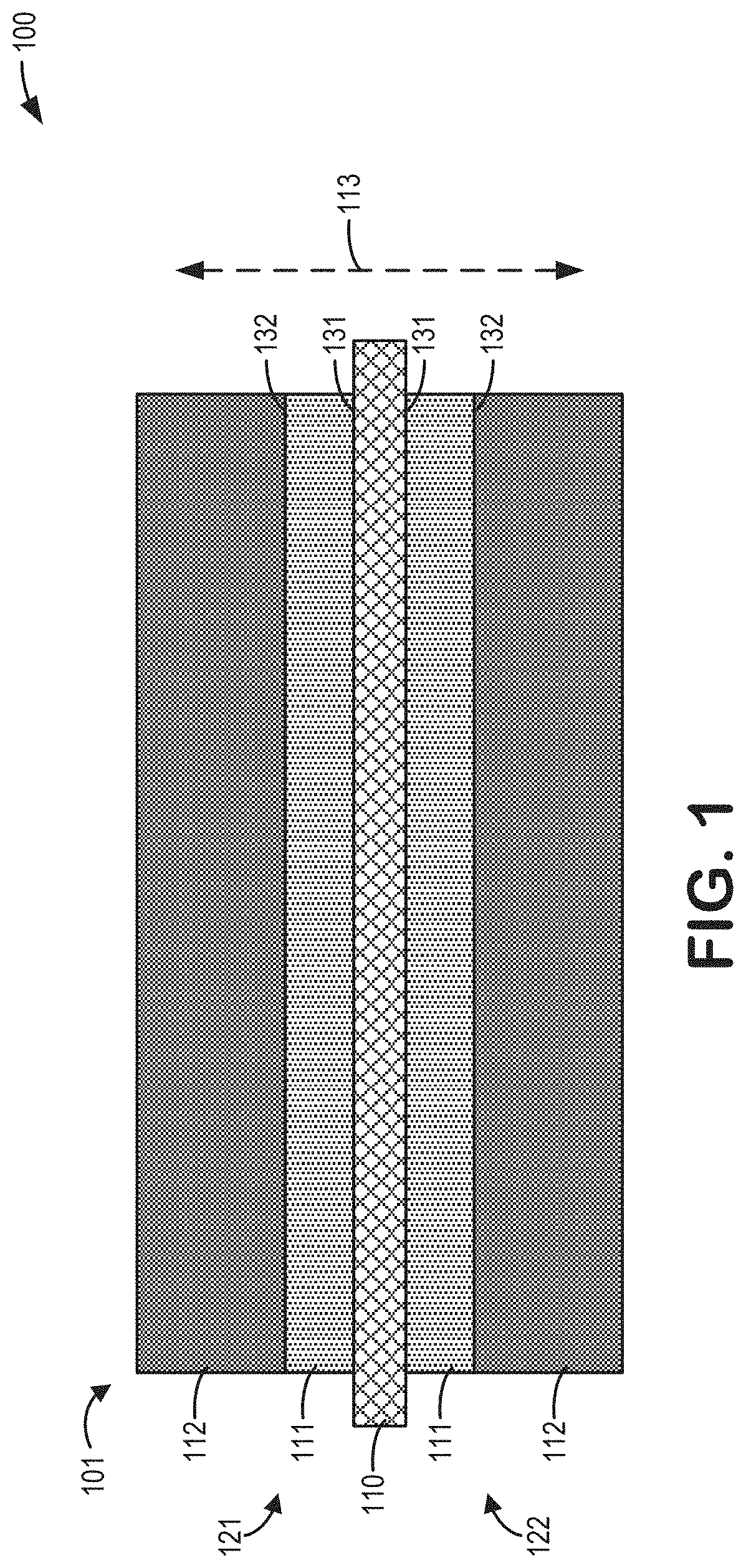

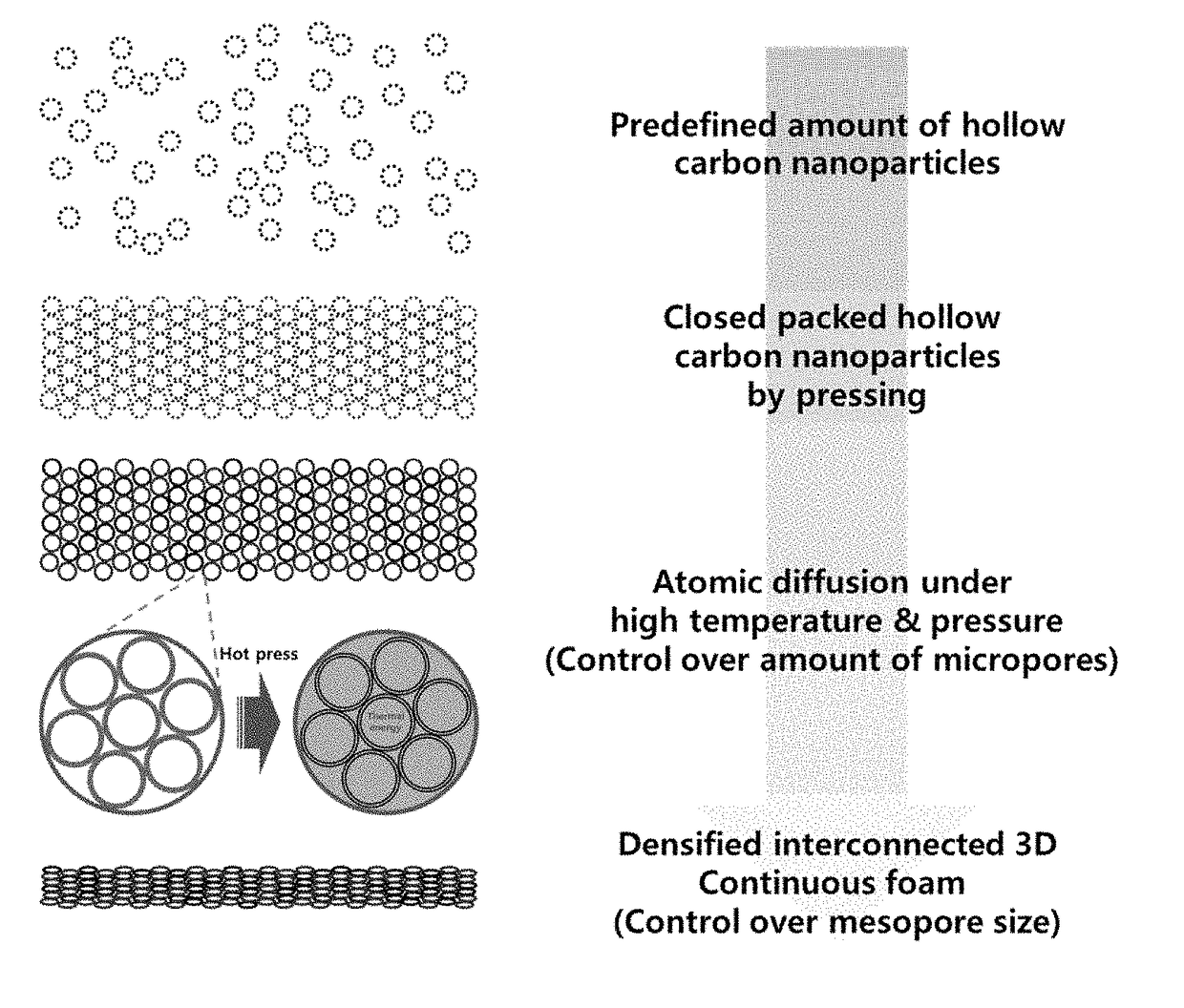

Multi-layered coated electrode for lithium-ion battery

ActiveUS20210399308A1Extended durationEnergy Density MaximizationElectrode rolling/calenderingElectrode carriers/collectorsInternal resistanceCoated electrodes

Systems and methods are provided for an electrode for a lithium-ion battery cell. In one example, the electrode may include a current collector having two opposing sides, at least one of the two opposing sides being configured with a first coating layer disposed on the current collector at a first loading, where the first coating layer may include a first binder in a first weight ratio, and a second coating layer disposed on the first coating layer at a second loading, where the second coating layer may include a second binder in a second weight ratio, wherein the first weight ratio may be greater than the second weight ratio, and a ratio of the first loading to the second loading may be less than 1:2. In this way, direct current internal resistance of the lithium-ion battery cell may be decreased while maintaining or increasing adhesion within the electrode.

Owner:A123 SYSTEMS LLC

Highly dense nano-carbon foam with controlled porosity synthesized from hollow carbon nanoparticles

ActiveUS9725322B2Reducing and eliminating conductive additive and binderReduce the amount requiredNanotechnologyCarbon preparation/purificationPorosityWater desalination

Hot pressing hollow carbon nanoparticles results in a nano-carbon foam that can be used for energy storage, carbon dioxide capture or water desalination.

Owner:NAT UNIV OF SINGAPORE

Battery core fixing structure for electric automobile and electric automobile

PendingCN109449338AReduce mechanical structureReduce weightElectric propulsion mountingSecondary cellsEnergy densityElectrical and Electronics engineering

The invention discloses a battery core fixing structure for an electric automobile. The fixing structure comprises an automobile chassis, a heat dissipation plate and a plurality of battery cores, wherein the heat dissipation plate is fixedly connected to the automobile chassis; the battery cores are arranged on the heat dissipation plate through a fixing material; each of the battery cores is a soft-packed battery core or a steel-shell battery core; and when each of the battery cores is the soft-packed battery core, a gap with 1-10 mm is reserved between the soft-packed battery cores. According to the battery core fixing structure for the electric automobile and the electric automobile provided by the invention, the heat dissipation efficiency is high; more battery cores can be arranged on the automobile chassis, and the energy density is high.

Owner:广州市垠瀚能源科技有限公司

Battery pack comprising connection plate

ActiveCN111406329AEnergy Density MaximizationReduce manufacturing costCurrent conducting connectionsBatteriesStructural engineeringMechanical engineering

Owner:LG ENERGY SOLUTION LTD

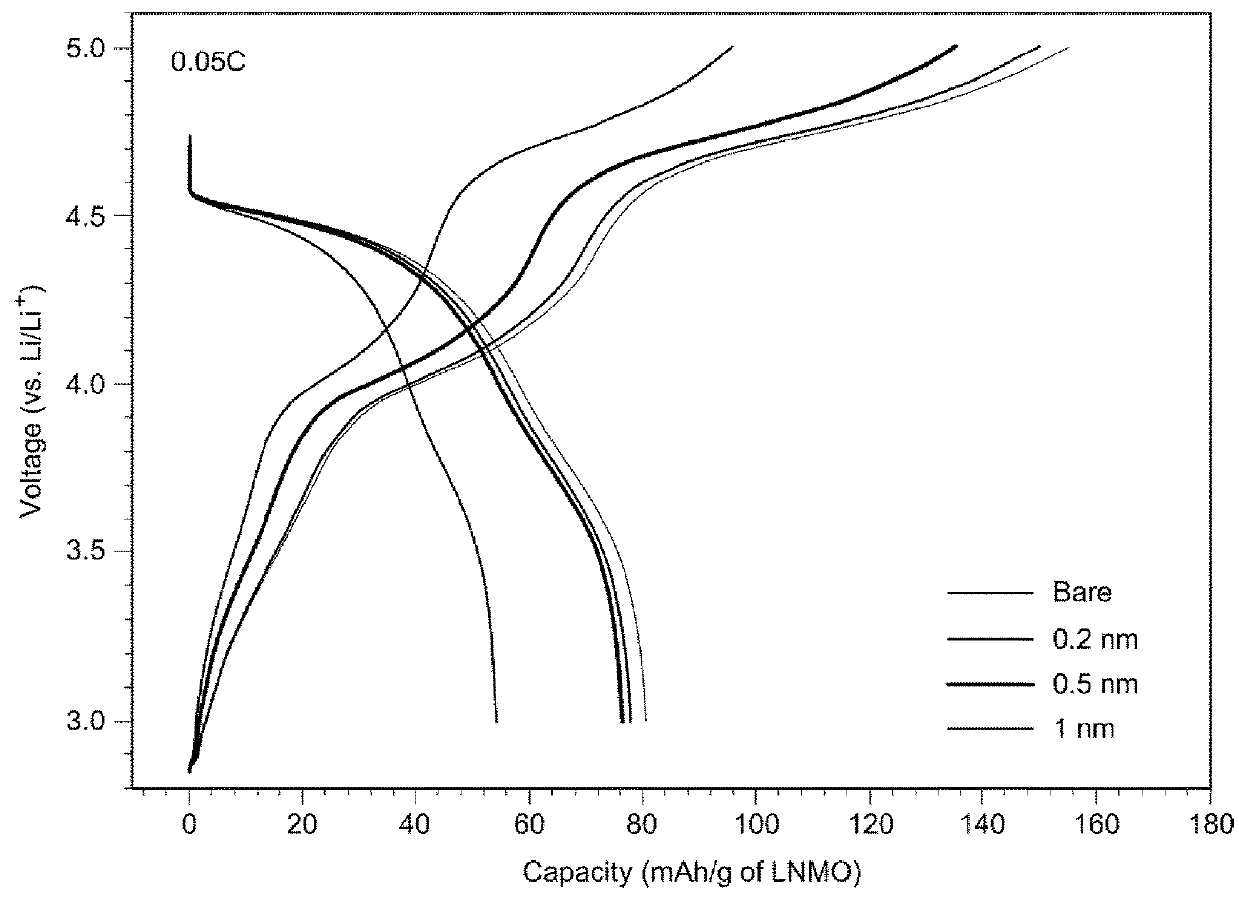

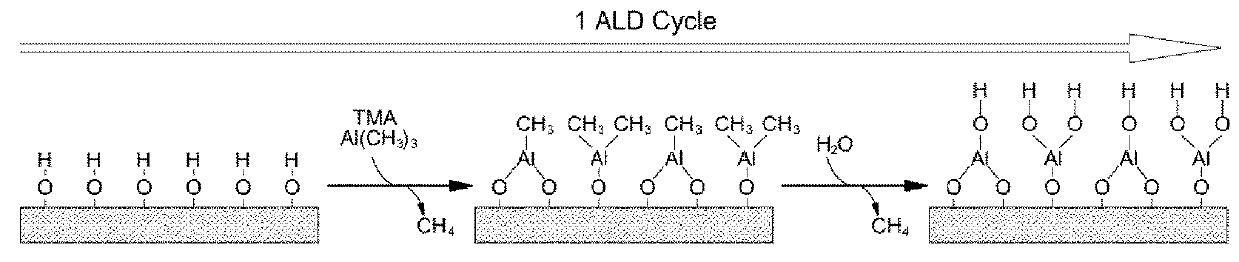

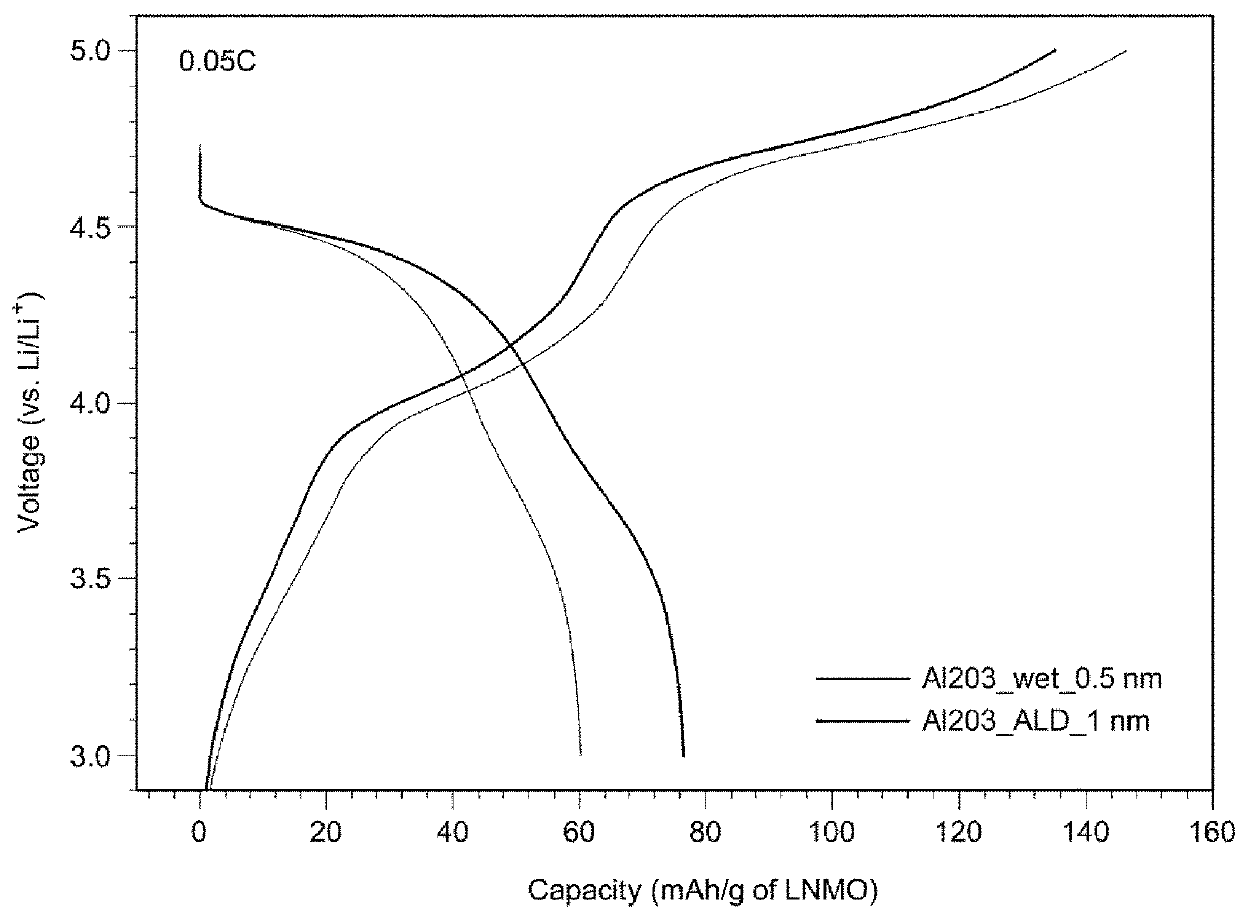

All solid battery with improved energy density and method of manufacturing the same

InactiveUS20180183095A1Suppress side-reactionsMaximize energy densitySolid electrolytesFinal product manufactureEnergy densitySide reaction

Disclosed are an all solid battery including a positive electrode layer including a positive electrode active material, a solid electrolyte and a conductive material coated with an insulator coating layer, an electrolyte layer, and a negative electrode layer and a method of manufacturing an all solid battery the same. In particular, the method includes: coating, by atomic layer deposition (ALD), a conductive material with an insulator by atomic layer deposition (ALD) to produce a conductive material surrounded by an insulator coating layer; producing a positive electrode layer including the conductive material coated with the insulator coating layer-formed conductive material, a positive electrode active material, and a solid electrolyte; and stacking and pressing the positive electrode layer produced above, an electrolyte layer and a negative electrode layer. The all solid battery can suppress side-reactions between the conductive material and the solid electrolyte, thereby advantageously maximizing energy density based on improved initial charge / discharge efficiency, and enhancing lifespan and power.

Owner:HYUNDAI MOTOR CO LTD +2

Lead-carbon supercapacitor

ActiveCN109637818ACompact structureReduce volumeHybrid capacitor electrodesDouble layer capacitorsAdhesiveHigh energy

The invention discloses a lead-carbon supercapacitor which comprises a positive plate, a carbon negative plate, a plurality of lead-carbon bipolar plates, diaphragms and electrolyte, wherein the diaphragms are arranged between adjacent polar plates. Each diaphragm is an AGM separator, and the electrolyte is a dilute sulfuric acid electrolyte. The positive plate, the plurality of lead-carbon bipolar plates and the carbon negative plate are sequentially arranged and assembled. Acid-resistant rubber sealing strips are arranged among the polar plates. The polar plates are positioned by fixing bolts, and then are pressed and fixed. Each lead-carbon bipolar plate is composed of a plastic frame, a current collector, a positive active material and a carbon negative electrode. A current collector is embedded into the plastic frame. The current collector is a lead plate of which the front surface is provided with a grid-shaped groove. The positive active substance is embedded in the groove, andthe back surface of the current collector is flat-plate-shaped. A carbon negative electrode is bonded by using an organic conductive adhesive. The supercapacitor is compact in structure and small in size, and has high power density and high energy density.

Owner:SUZHOU UNIV

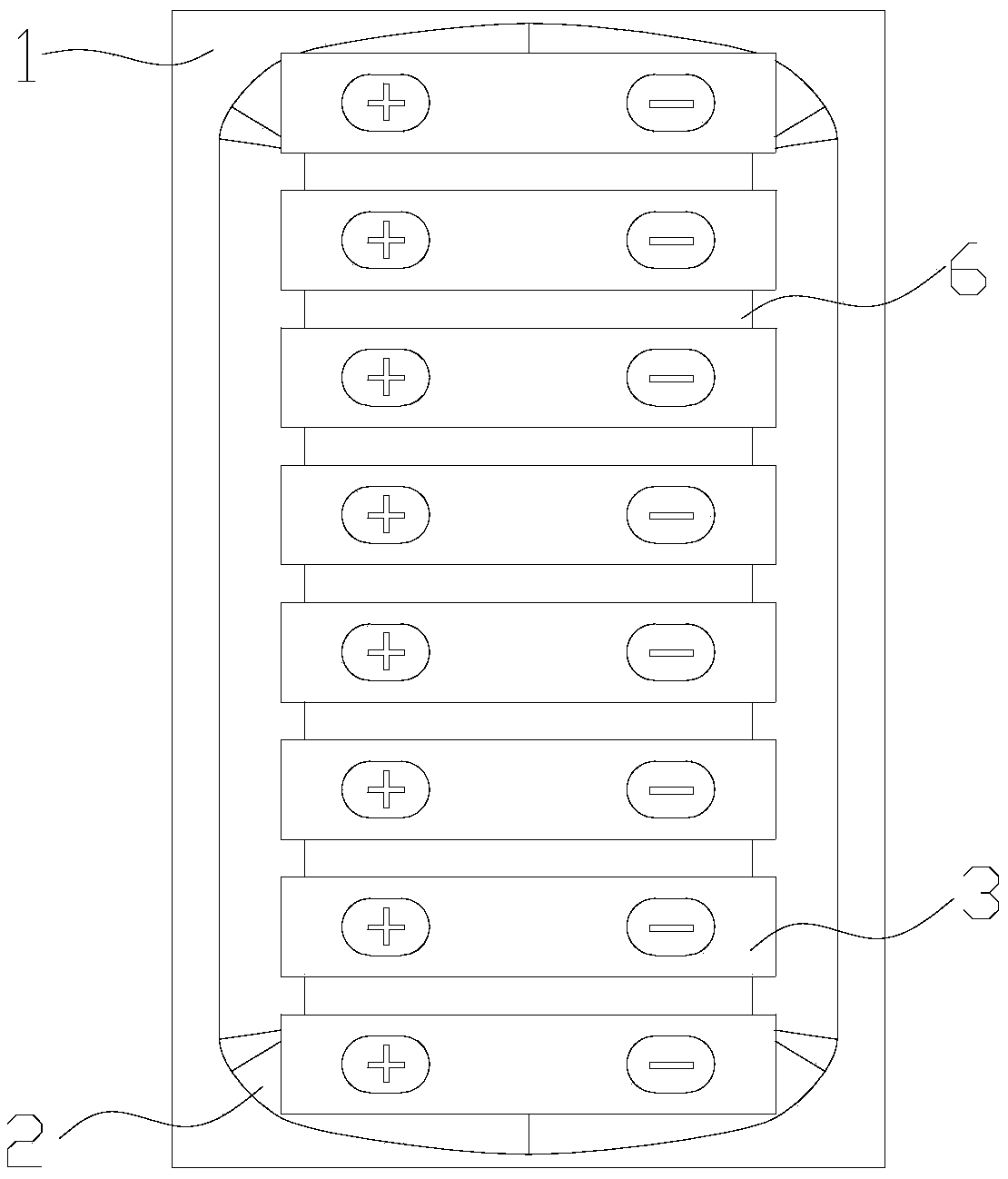

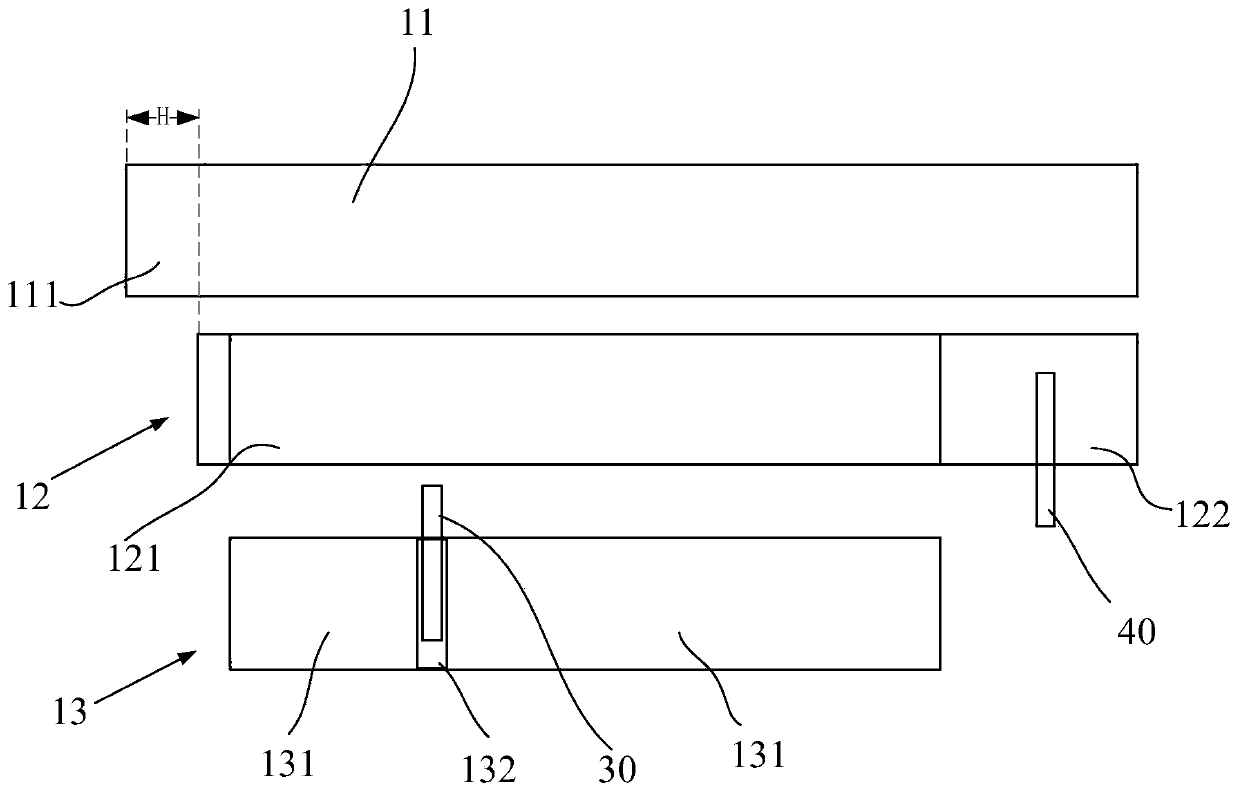

Battery system

PendingUS20210135182A1Energy Density MaximizationImprove cell structureSmall-sized cells cases/jacketsSecondary cellsPhysicsEngineering

A battery system includes a plurality of battery modules including battery cells in which electrode tabs having different polarities are formed at both ends thereof, wherein a plurality of battery cells are stacked. The plurality of battery modules includes: a first terminal having a first positive electrode terminal and a first negative electrode terminal, which are formed by connecting electrode tabs located at one end of the battery cells to each other among the plurality of electrode tabs; and a second terminal having a second positive electrode terminal and a second negative electrode terminal, which are formed by connecting electrode tabs located at the other end of the battery cells to each other among the plurality of electrode tabs. The first and second terminals of any one battery module of the plurality of battery modules are arranged to be electrically connected with the first and second terminals of battery modules adjacent to the any one battery module.

Owner:SK ON CO LTD

Battery and supercapacitor hybrid

InactiveUS20190260104A1Improve power densityIncrease chanceHybrid capacitor separatorsHybrid capacitor electrolytesSupercapacitorEngineering

A battery and supercapacitor hybrid can include a first hybrid electrode. The first hybrid electrode can include a first electrode, a first current collector, and a first supercapacitor. The battery and supercapacitor hybrid can further include a second hybrid electrode and a separator interposed between the first hybrid electrode and the second hybrid electrode.

Owner:AMERICAN LITHIUM ENERGY CORP

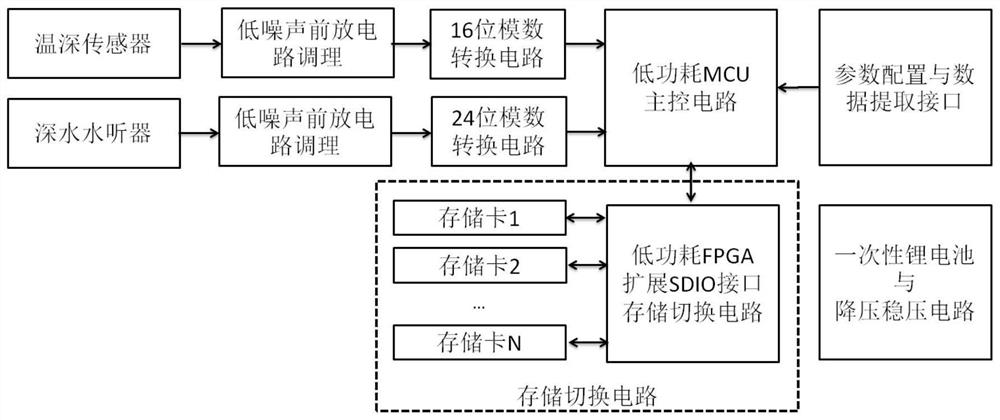

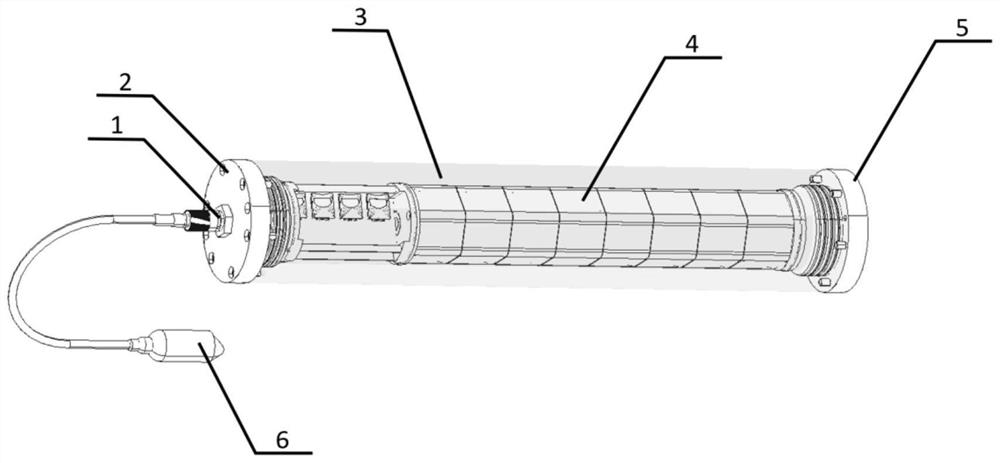

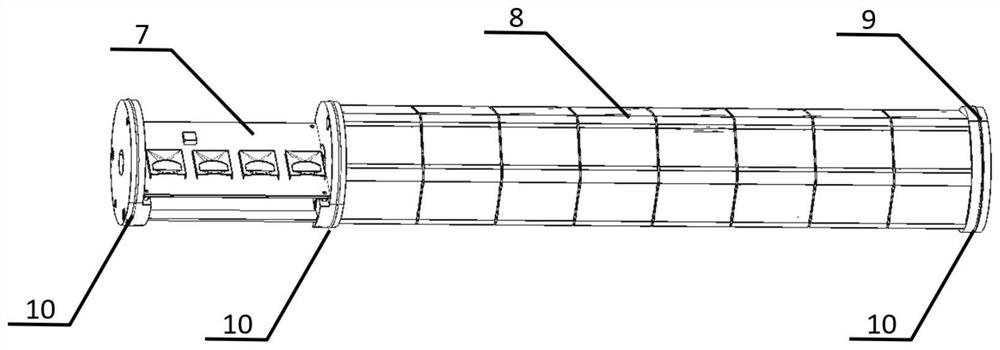

Large-capacity storage device for long-term and high-speed acquisition of underwater acoustic signals

PendingCN114863954ALong-term satisfactionMeet needsCarrier constructional parts dispositionRecord information storageMarine engineeringHemt circuits

The invention discloses a large-capacity storage device for long-term and high-speed acquisition of underwater acoustic signals. The device comprises an upper end cover, a lower end cover, a pressure-resistant cabin body, a deepwater sensor and a circuit module, the upper end cover and the lower end cover are respectively positioned at two ends of the pressure-resistant cabin; the upper end cover is provided with a watertight connector, and the upper end cover is connected with the deepwater sensor through the watertight connector. The deepwater sensor is used for collecting deepwater signals; the battery and circuit module is composed of a circuit board, a battery pack and a supporting frame. The circuit board is connected with the watertight connector; the circuit board is further connected with the battery pack and fixed to the supporting frame. The supporting frame is fixed to the upper end cover and makes contact with the interior of the pressure-resistant cabin through the elastic sealing ring. The invention provides a large-capacity storage device for long-term and high-speed acquisition of underwater acoustic signals, which can meet the requirements of myriameter pressure resistance, long-term and high-speed acquisition and storage of underwater acoustic signals.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

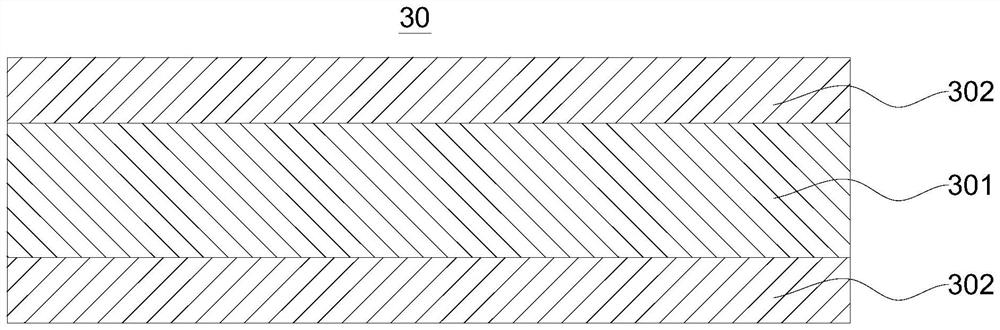

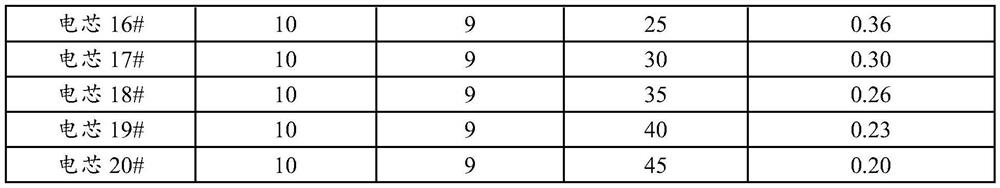

Battery cell, battery module and battery pack

PendingCN114883664AIncrease energy densityImprove securityCell seperators/membranes/diaphragms/spacersFinal product manufactureHigh energyPositive current

The invention discloses a battery cell, a battery module and a battery pack, and relates to the technical field of battery cells. The battery cell comprises a shell, a roll core and an electrolyte, the roll core and the electrolyte are arranged in the shell, and the roll core is formed by laminating or winding a positive plate, an isolating membrane and a negative plate which are arranged in a laminated manner; the positive plate comprises a positive current collector and a nickel-containing positive active material coated on the positive current collector, the positive current collector is a composite current collector comprising an insulating support layer and a conductive layer at least arranged on one side of the insulating support layer, the thickness of the insulating support layer is A, the unit is [mu] m, the weight percentage of a nickel element in the positive active material is I, and the unit is [mu] m. The unit is%; the thickness of the isolating membrane is F, and the unit is mu m; and the thickness A of the insulating support layer, the weight percentage I of the nickel element in the positive electrode active material and the thickness F of the isolating membrane satisfy 0.01 < = (A * F / I) / 1000 < = 3. The battery cell has the advantages of high energy density and high safety performance.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

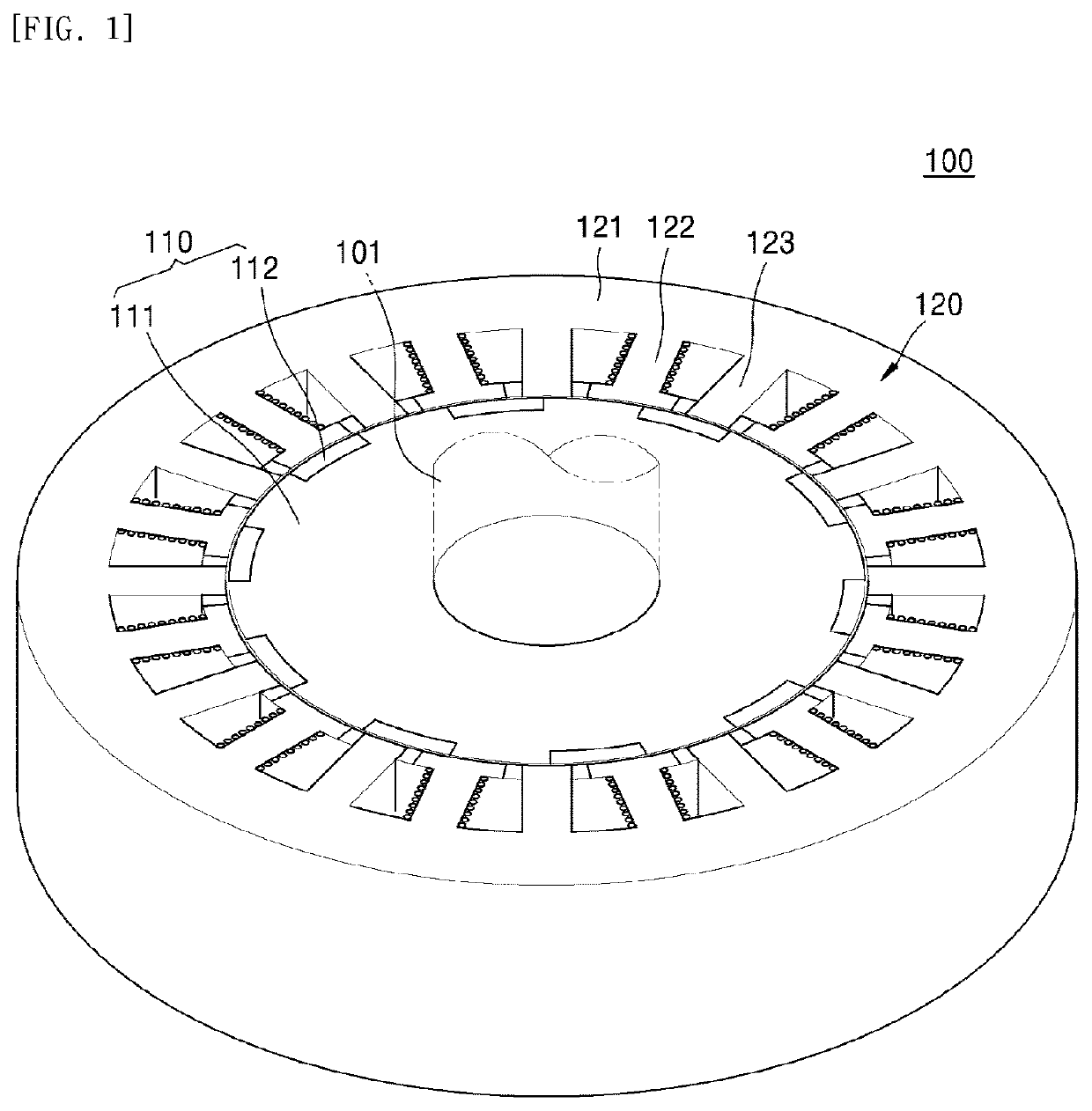

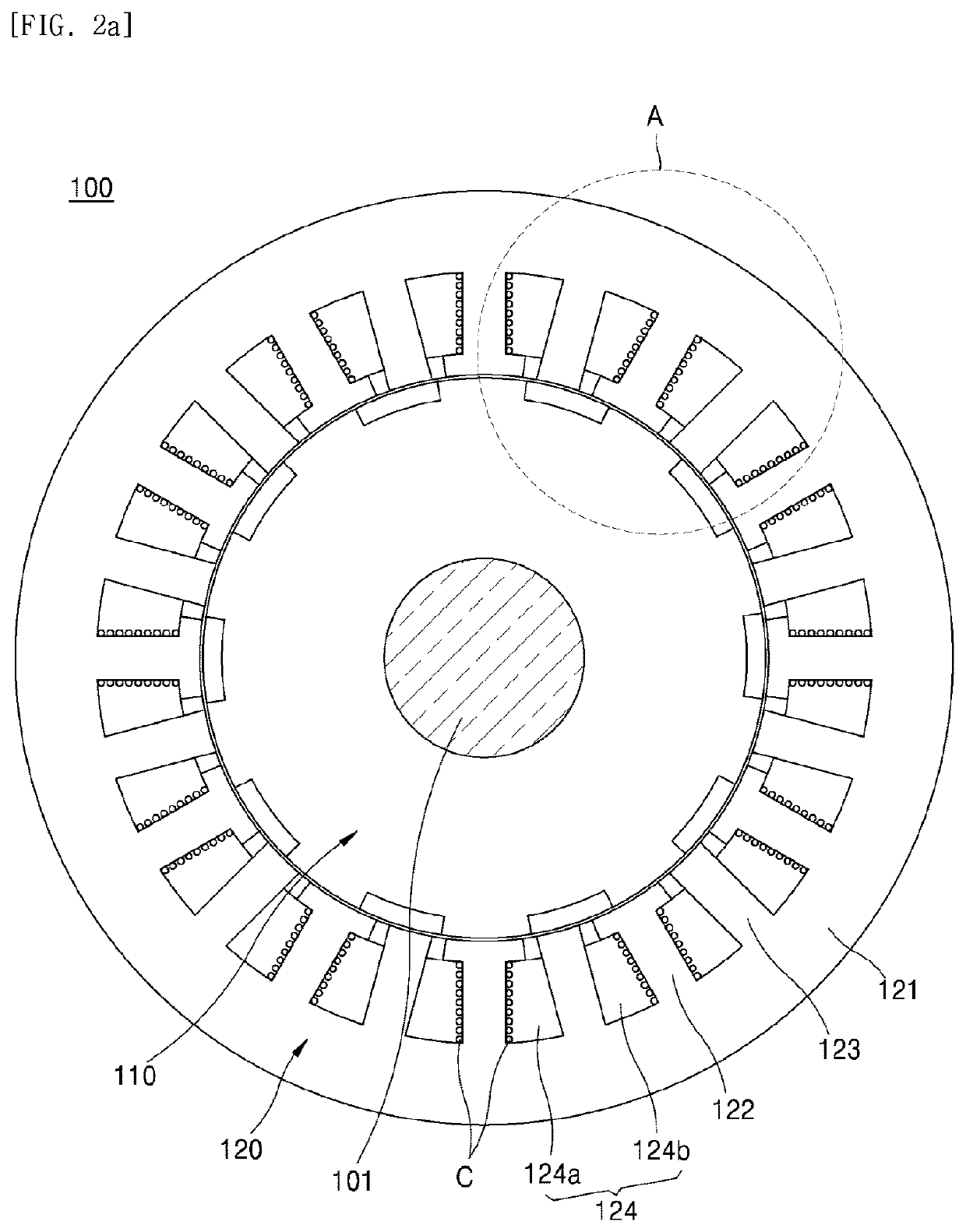

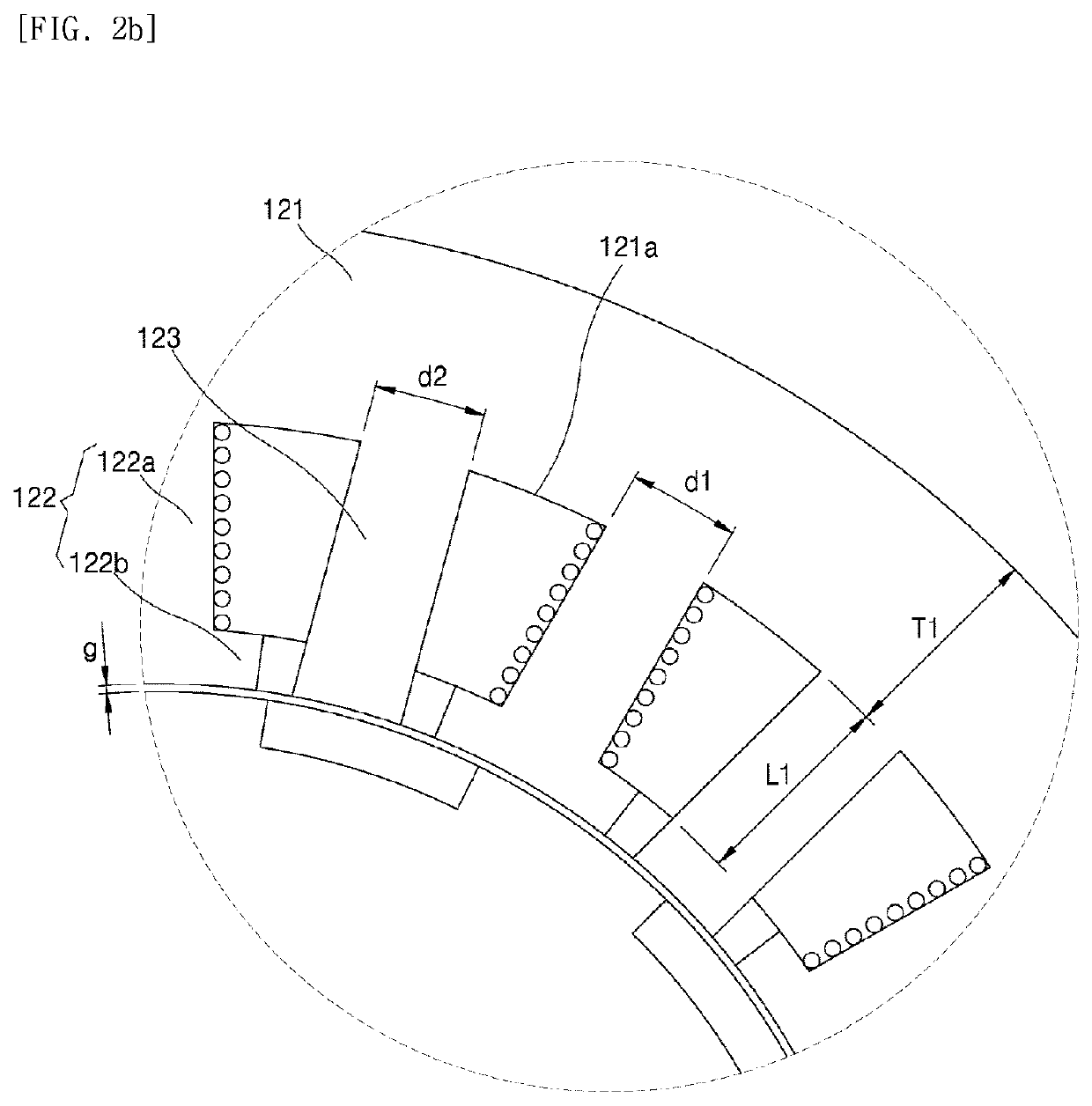

Stator and motor assembly including same

PendingUS20220052566A1Increase torqueHigh densityMagnetic circuit rotating partsMagnetic circuit stationary partsRotational axisElectric machinery

The present invention provides a stator and a motor assembly including the same. The stator includes: a stator core disposed outside a rotor core and having an inner surface inclined with respect to a rotation axis of a rotor; a plurality of coil-wound teeth extending from the inner surface of the stator core towards the rotation axis, wherein a coil is wound around each of the plurality of coil-wound teeth; and openings formed by sidewalls of the plurality of coil-wound teeth and the inner surface of the stator core, wherein a cross-sectional area of the openings changes along a direction of the rotation axis.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

Battery System

PendingCN112787021AEnergy Density MaximizationMinimize internal resistanceSmall-sized cells cases/jacketsBattery isolationMechanical engineeringBattery system

The invention relates to a battery system. The battery system includes a plurality of battery modules including battery cells in which electrode tabs having different polarities are formed at both ends thereof, wherein a plurality of battery cells are stacked. The plurality of battery modules includes: a first terminal having a first positive electrode terminal and a first negative electrode terminal, which are formed by connecting electrode tabs located at one end of the battery cells to each other among the plurality of electrode tabs; and a second terminal having a second positive electrode terminal and a second negative electrode terminal, which are formed by connecting electrode tabs located at the other end of the battery cells to each other among the plurality of electrode tabs. The first and second terminals of any one battery module of the plurality of battery modules are arranged to be electrically connected with the first and second terminals of battery modules adjacent to the any one battery module.

Owner:SK ON CO LTD

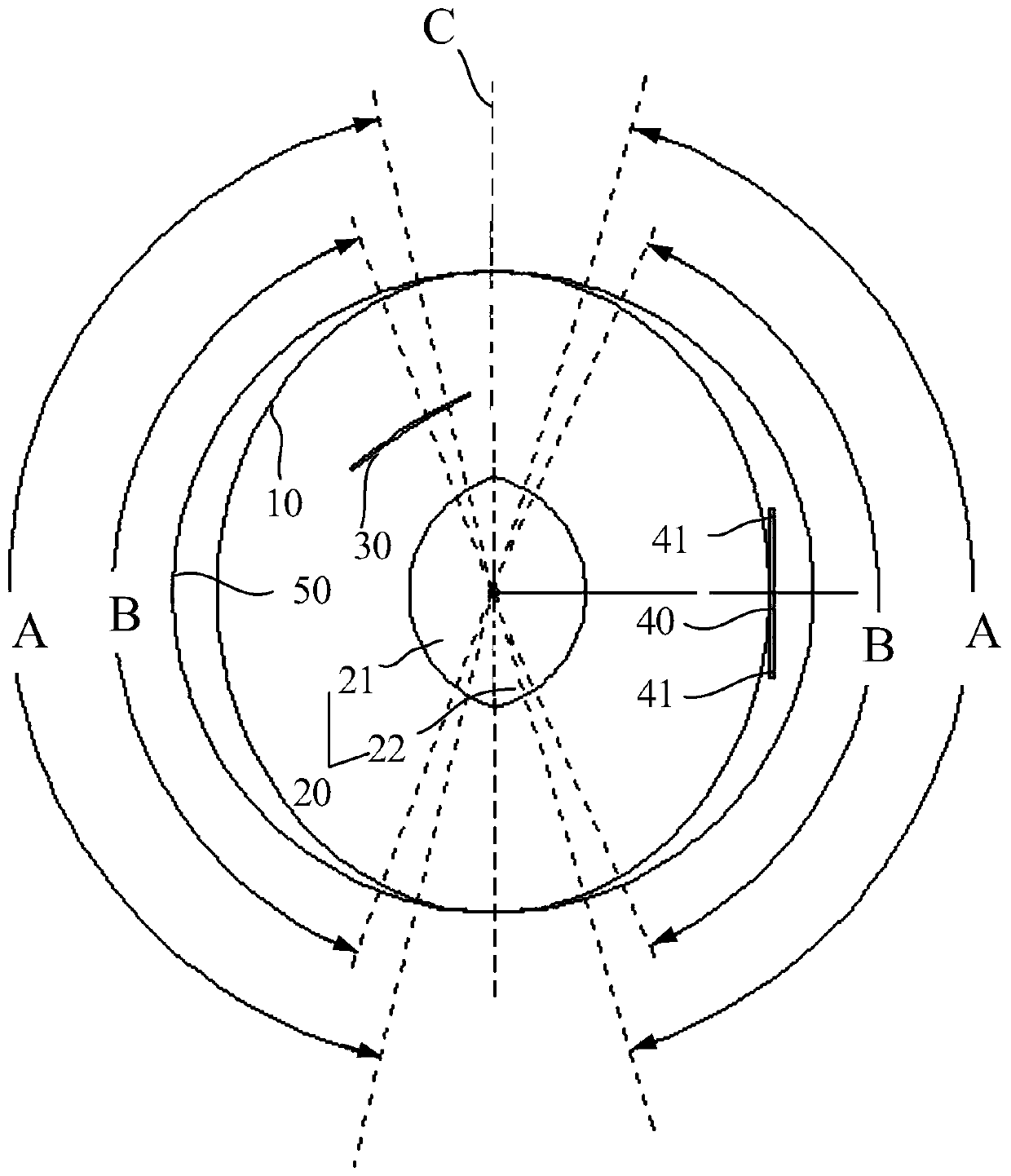

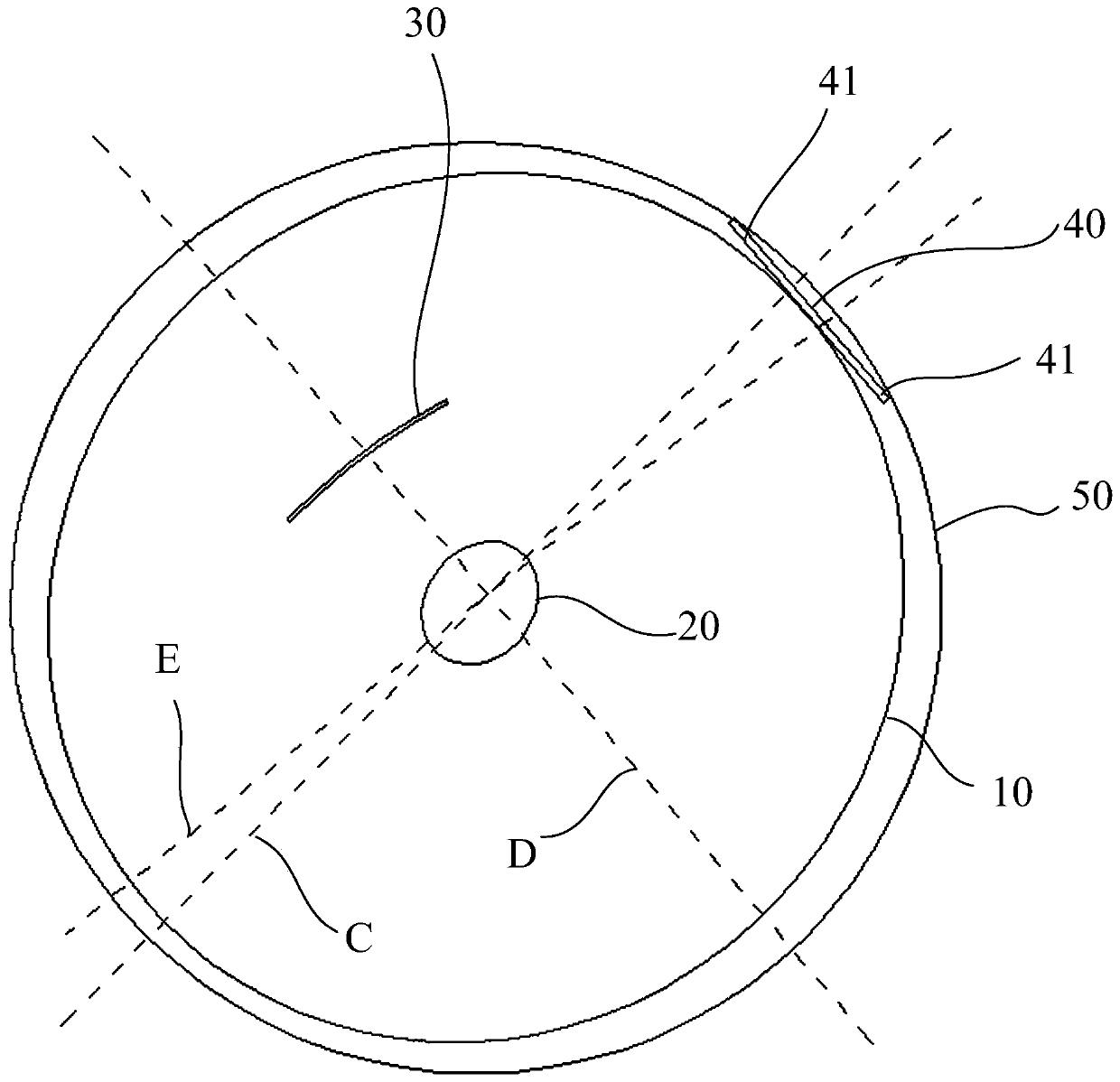

Manufacture method of winding core and winding core

InactiveCN109524723BSmall diameterSmooth entryFinal product manufactureCylindrical casing cells/batteryStructural engineeringMechanical engineering

The invention discloses a manufacturing method of a winding core and the winding core. In the manufacturing method of the winding core, the position of the negative electrode lug on the negative electrode sheet is adjusted until the negative electrode lug is aligned with the negative pole piece after winding. The included angle of the first direction of the above-mentioned winding frame is 15-165°, which avoids the superposition of the negative electrode lug in the long axis direction of the winding core, and can reduce the diameter of the winding core under the premise of ensuring the tightness rate, so that the winding core can be smoothly into the shell.

Owner:蜂巢能源(武汉)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com