Lead-carbon supercapacitor

A supercapacitor, lead-carbon technology, applied in capacitors, electrolytic capacitors, double-layer capacitors, etc., can solve the problems of not meeting the requirements of auxiliary power supply, limiting the application range of capacitors, and not reaching energy storage batteries, etc., so as to avoid softening Shedding, compact structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Reference Figure 9 As shown, the lead-carbon supercapacitor of the present invention includes a positive plate, a carbon negative plate, five lead-carbon bipolar plates 4, a diaphragm 3 and an electrolyte between adjacent plates; the diaphragm 3 is AGM Separator, the electrolyte is dilute sulfuric acid electrolyte; according to the orderly arrangement and assembly of the positive plate, multiple lead-carbon bisexual plates 4 and carbon negative plates, an acid-resistant rubber sealing strip 6 is arranged between the plates, and the fixing bolts 7 are used to position the electrodes The plate is pressed and fixed to prepare the lead-carbon supercapacitor of the embodiment, and the nominal voltage is 12 volts.

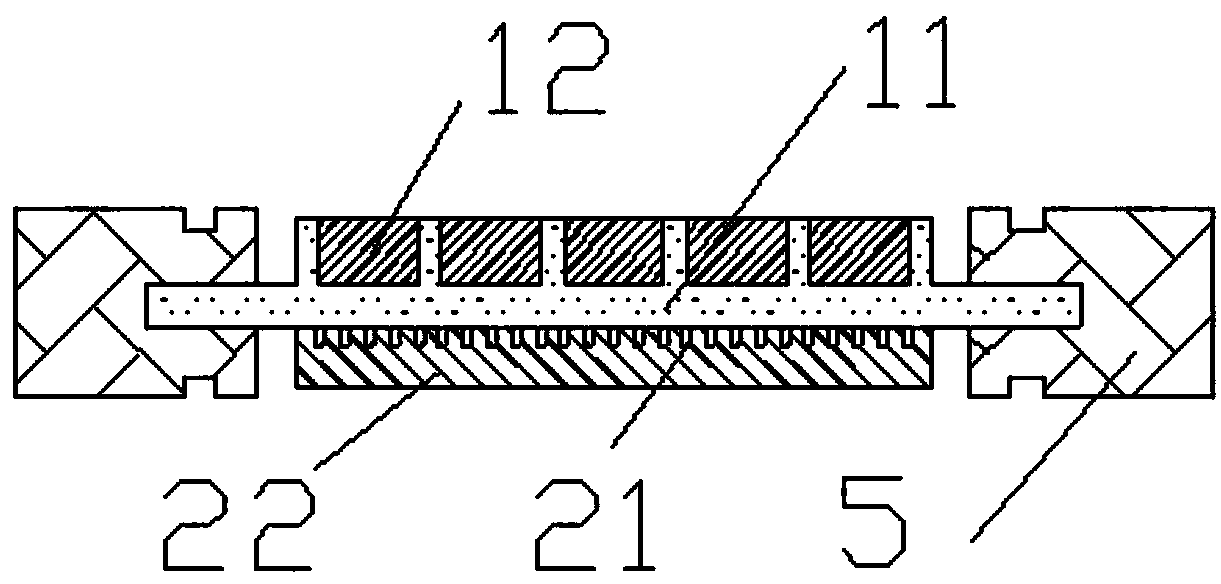

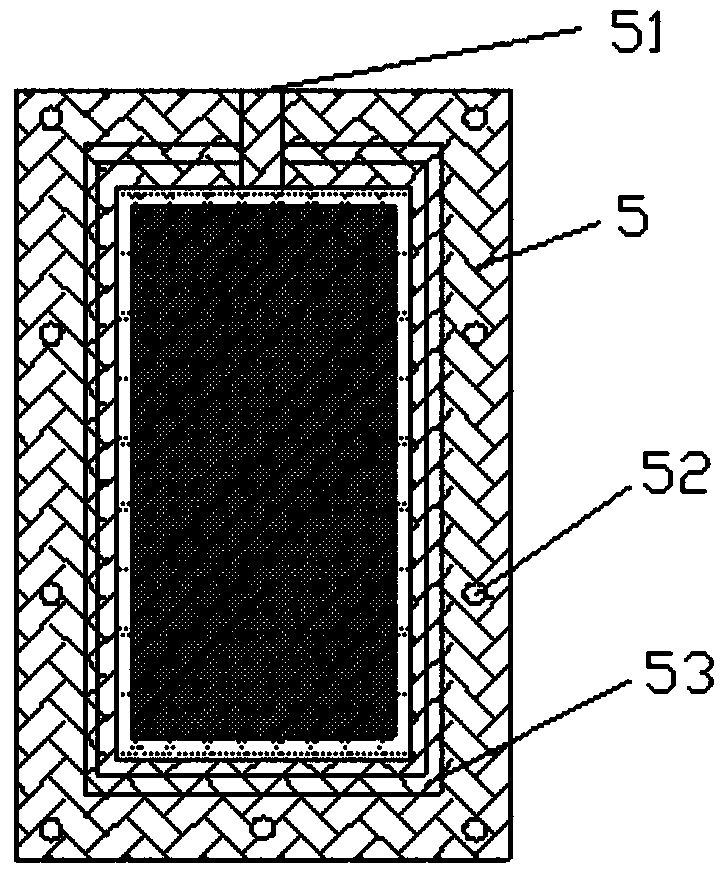

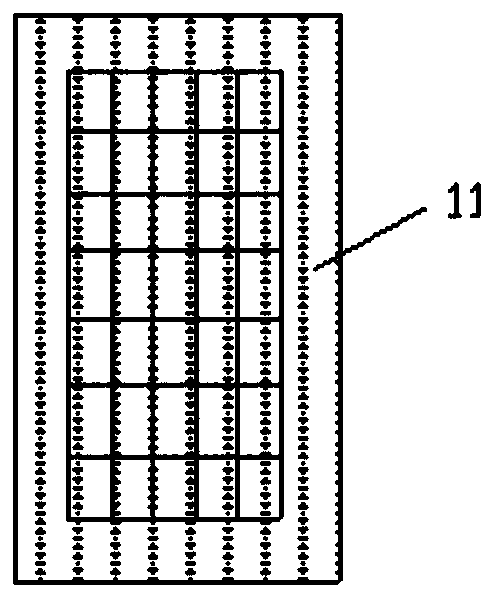

[0046] combine figure 1 , figure 2 and Figure 2a As shown, the lead-carbon bipolar plate 4 is composed of a plastic frame 5, a current collector 11, a positive electrode active material 12 and a carbon negative electrode 2; the current collector 1...

Embodiment 2

[0058] Embodiment 2: The lead-carbon supercapacitor of the present invention adopts two lead-carbon bipolar plates, and the corresponding nominal voltage is 6 volts. combine figure 1 , figure 2 and Figure 2b As shown, the front of the current collector 11 is designed with a rhombus grid, and its grid size is: 120mm×80mm×1.0mm (length×width×depth).

[0059] In this embodiment, the weight percent of each component in the organic conductive adhesive is: 25% of the conductive agent, 75% of the organic binder; wherein the conductive agent is a mixture of graphite and carbon black; the organic binder It is a mixture of styrene-butadiene rubber and neoprene. The ratio is: graphite 10%, carbon black 15%, styrene-butadiene rubber 37.5% and neoprene 37.5%.

[0060] In this embodiment, the size of the carbon negative electrode is: 120mm × 80mm × 2.0mm (length × width × thickness); the size of the stretched net collector is: 115mm × 75mm × 0.8mm (length × width × thickness), and its...

Embodiment 3

[0065] Embodiment 3: The lead-carbon supercapacitor of the present invention adopts twenty-three lead-carbon bipolar plates, and the corresponding nominal voltage is 48 volts. combine figure 1 , image 3 and Figure 3a As shown, in the supercapacitor with lead-carbon bipolar electrodes of this embodiment, the lead-carbon bipolar electrodes 4 adopt a circular design, and the size of the plates is: 170 mm in diameter and 8.0 mm in thickness; the plastic frame 5 has a width of 25 mm and a thickness of 8.0mm. The size of the current collector 11 is: 140mm in diameter, 2.5mm in thickness, its front is designed as a rectangular grid, the grid size: 110mm in diameter, 2.0mm in depth, and the rib width is 1.0mm.

[0066] combine Figure 4 , Figure 6 and Figure 6a As shown, the carbon negative electrode 2 in this embodiment adopts a circular design, and the size of the carbon negative electrode is 110 mm in diameter and 2.5 mm in thickness; the size of the stretched current col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com