Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259results about How to "Lower equivalent series resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

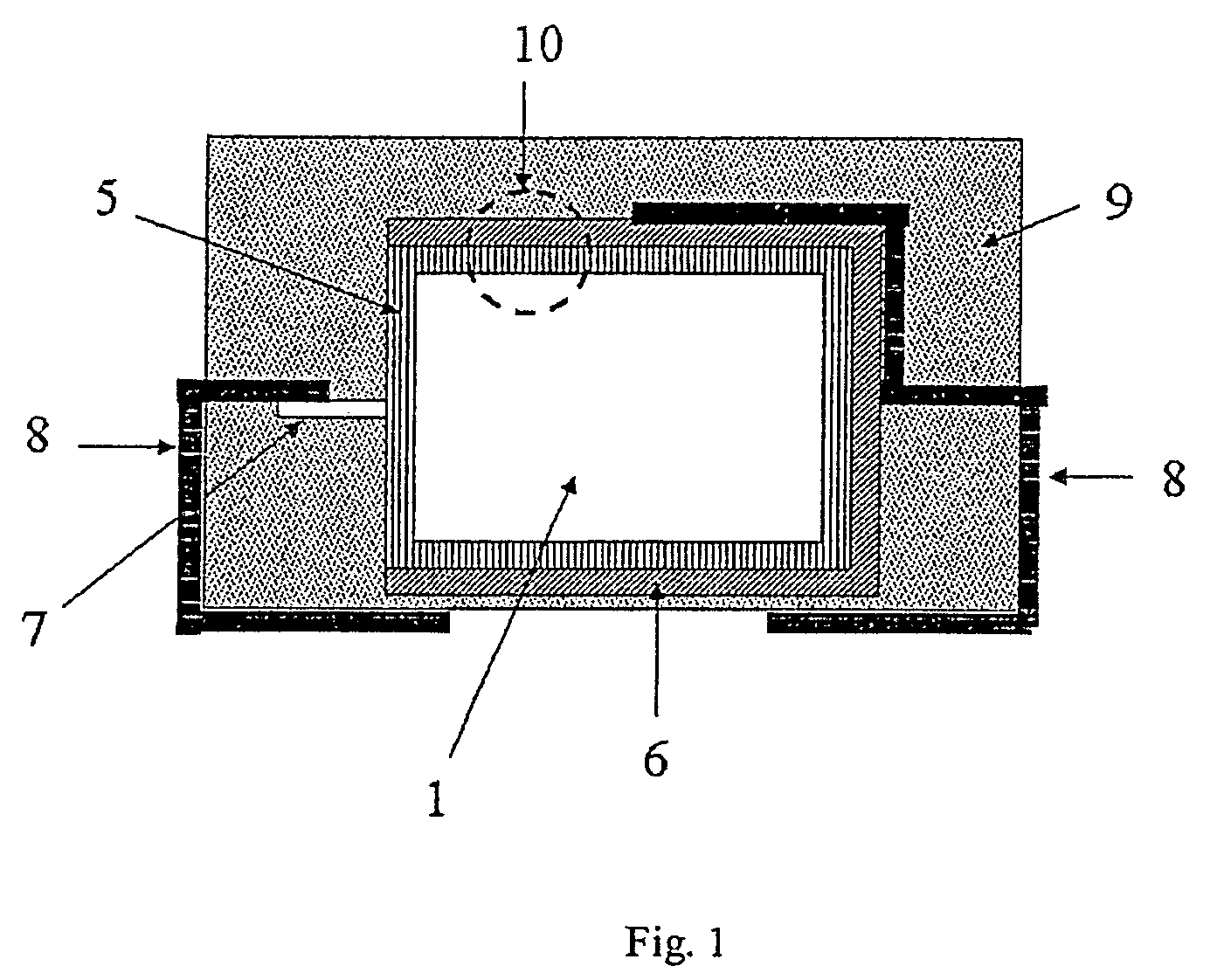

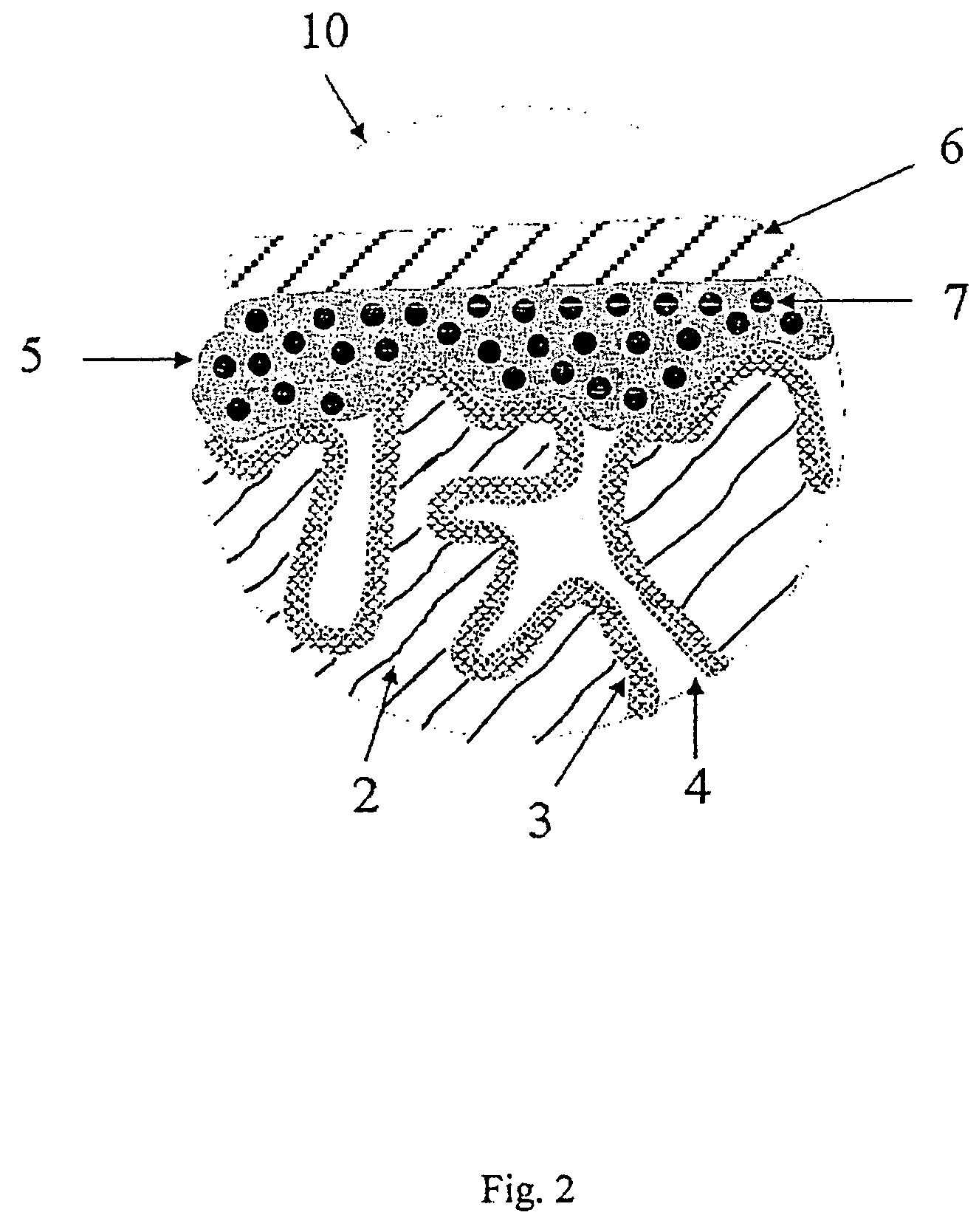

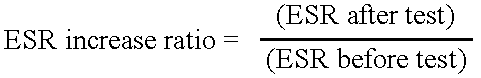

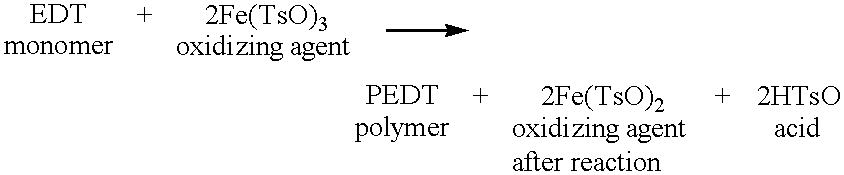

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

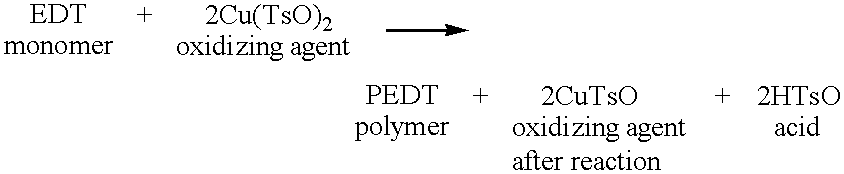

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

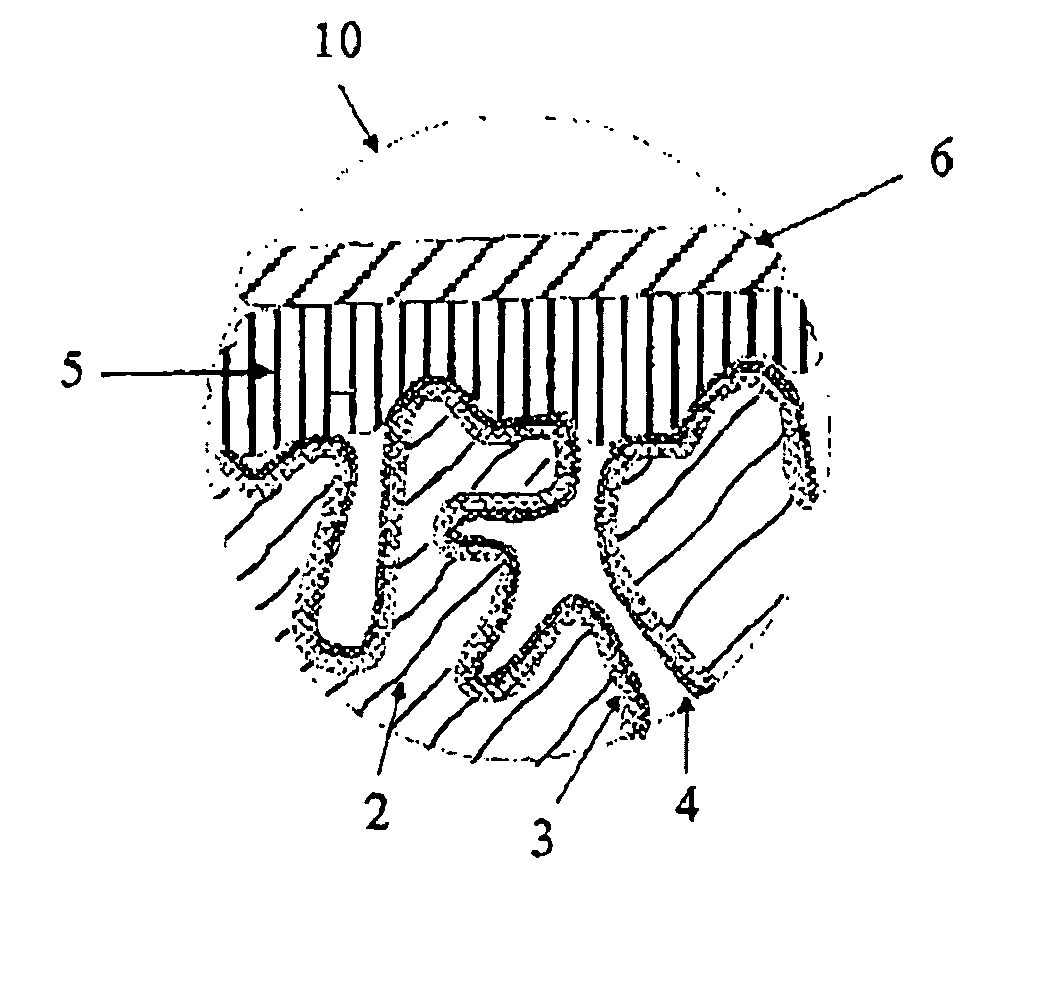

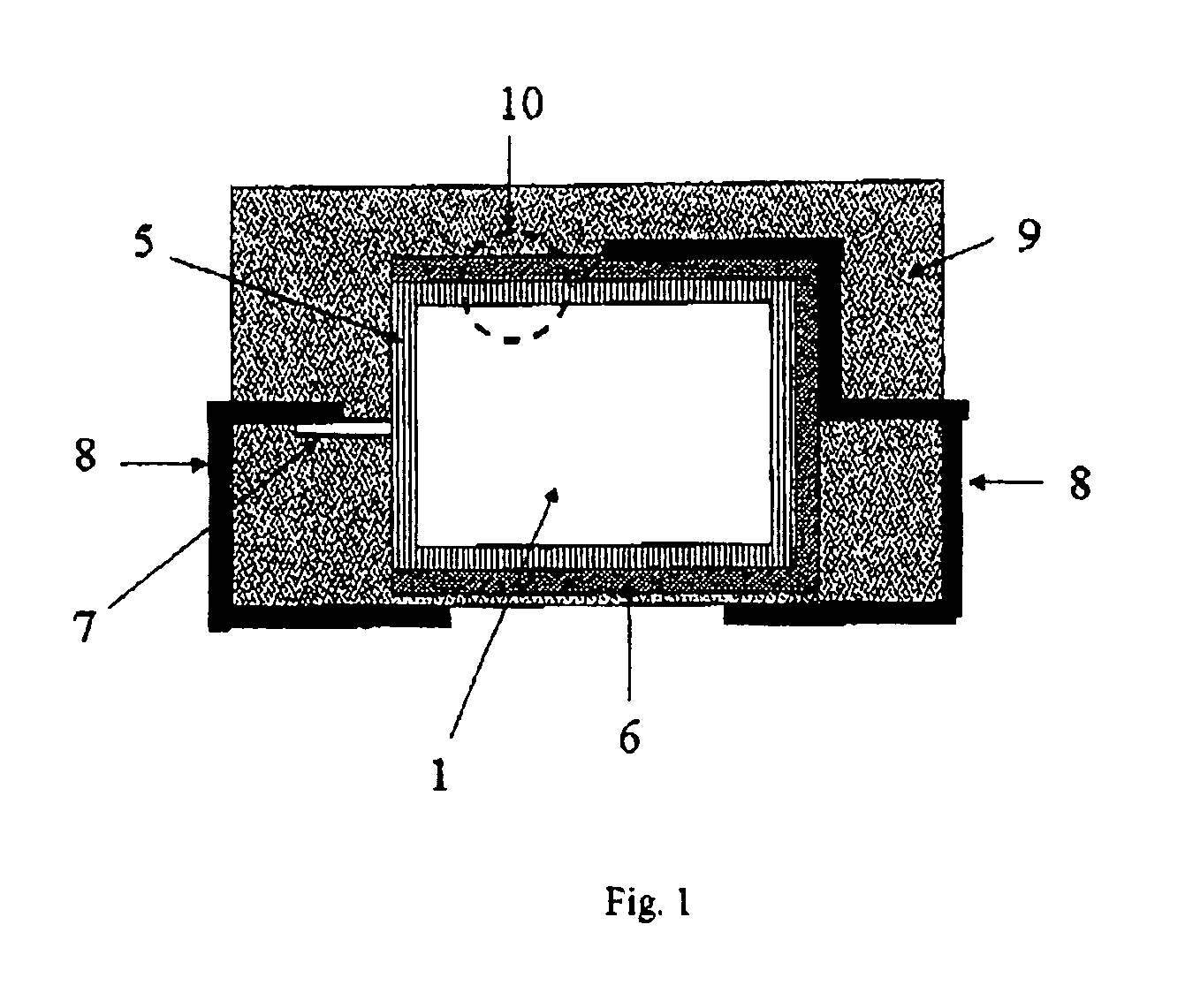

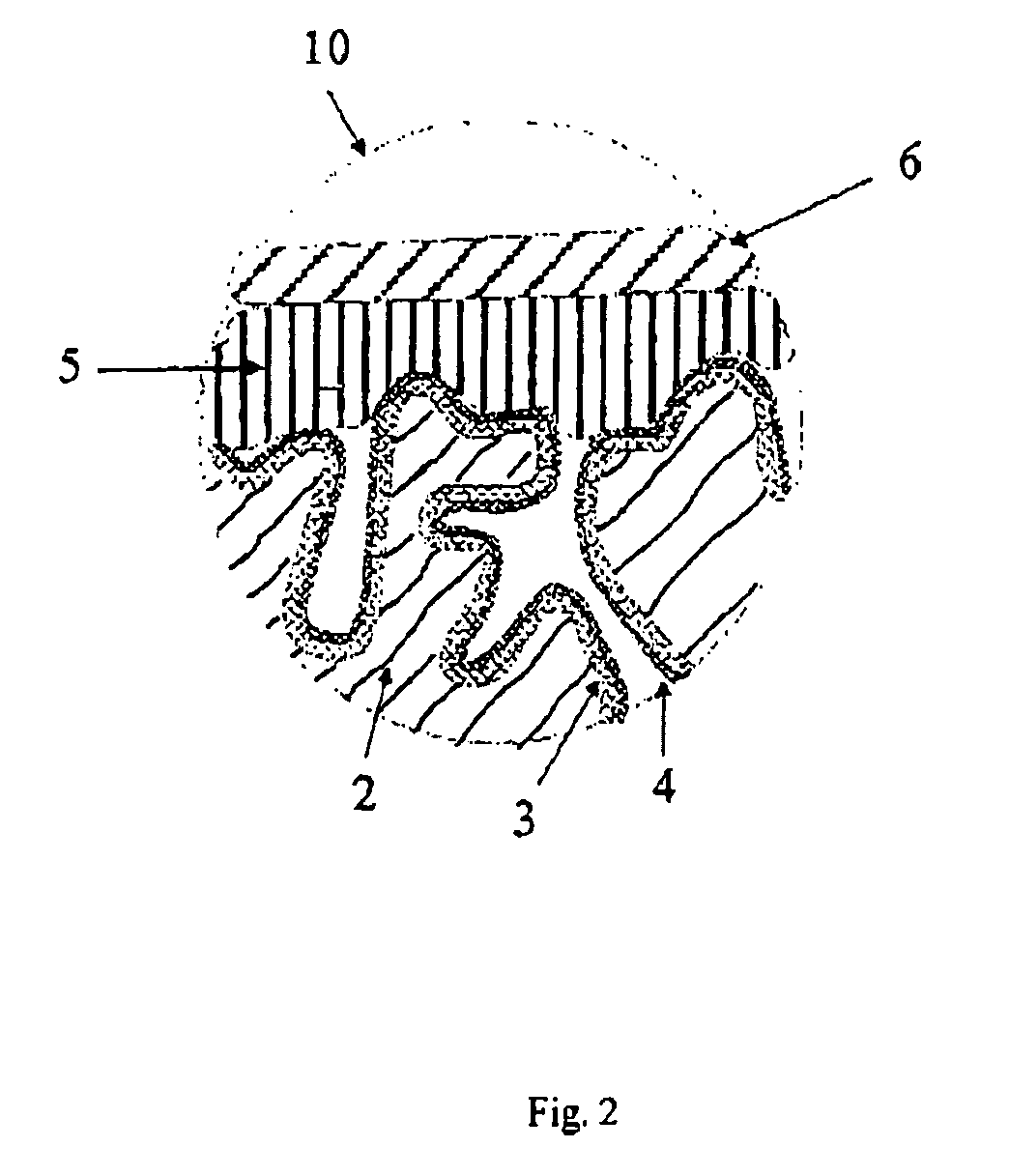

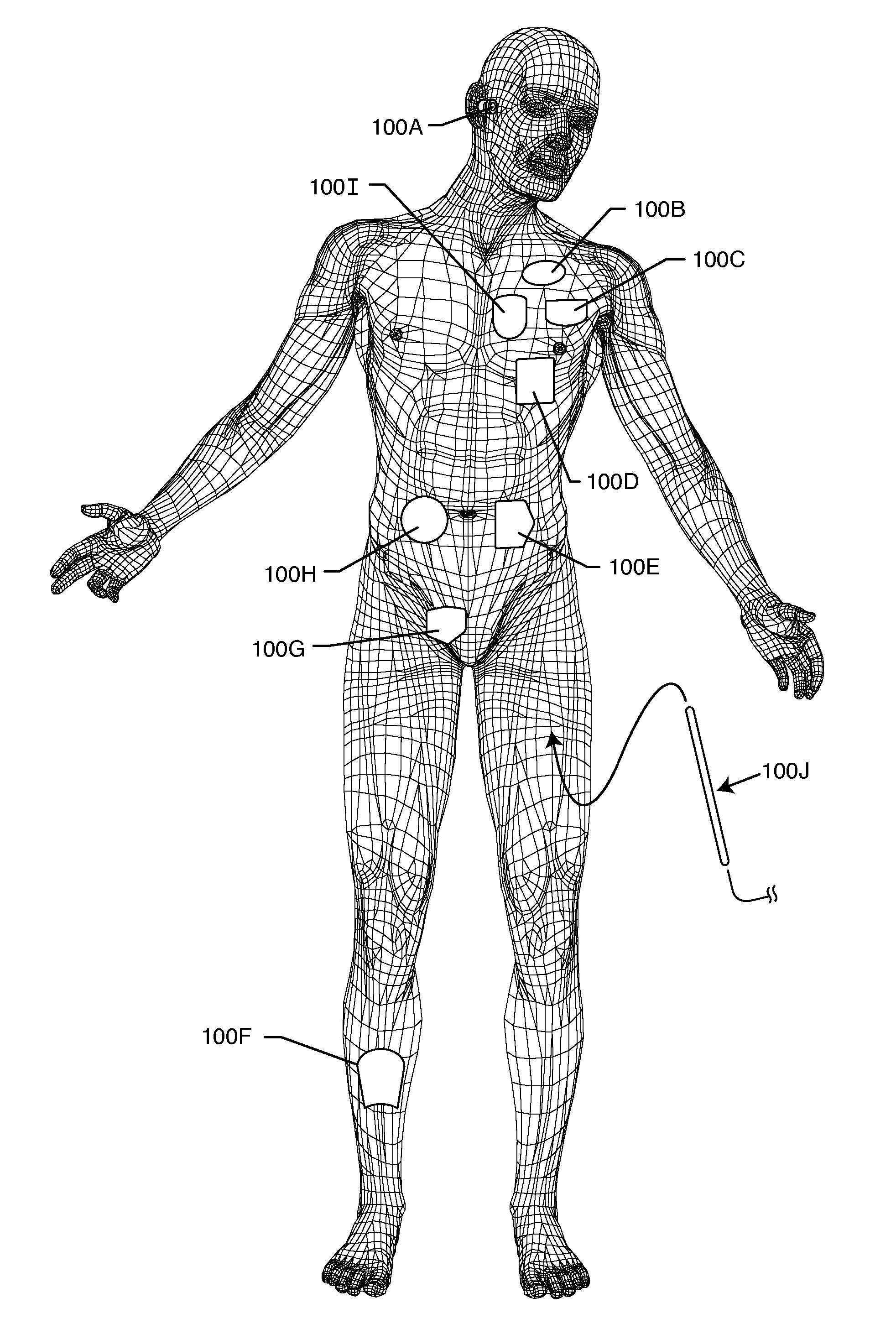

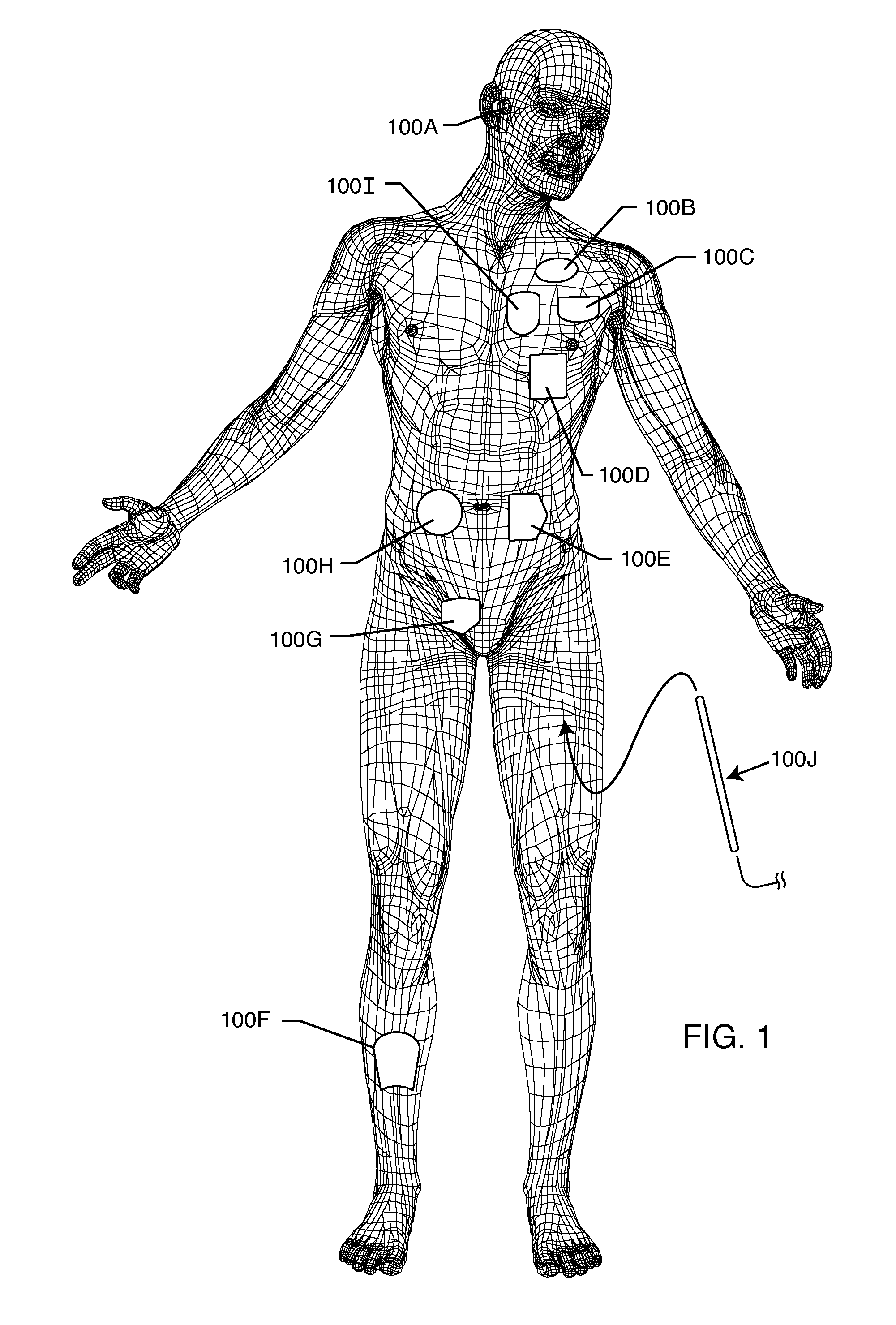

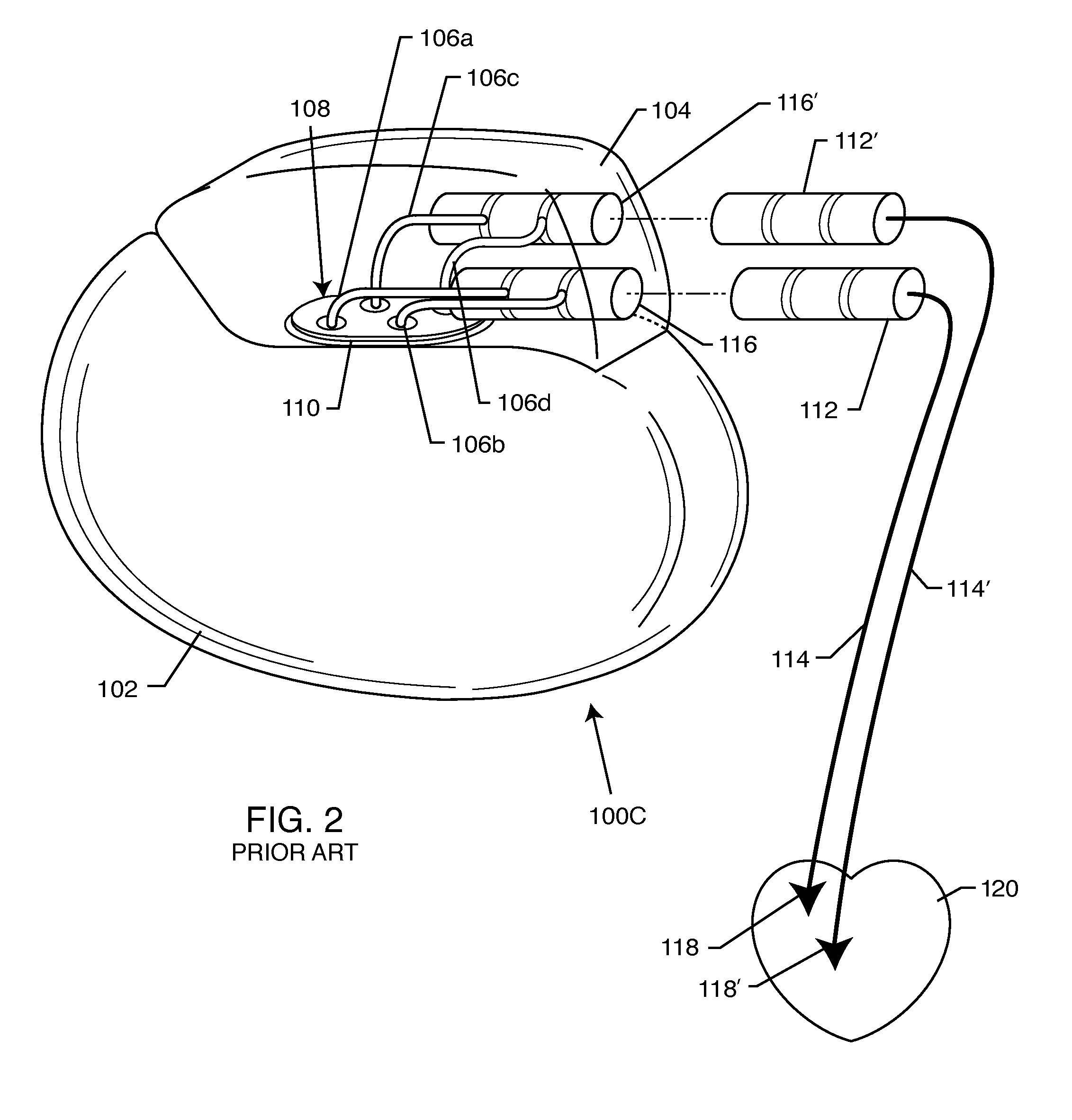

Implantable medical device having flat electrolytic capacitor with laser welded cover

InactiveUS6118652ALower equivalent series resistanceIncrease capacitanceLiquid electrolytic capacitorsHeart defibrillatorsElectrical batteryFibrillation

An implantable medical device such as a defibrillator is described. The device includes an hermetically sealed housing containing a flat electrolytic capacitor and an energy source such as a battery. The battery is connected to the capacitor and provides charge thereto. The capacitor stores the charge at a relatively high voltage. The charge stored in the capacitor is discharged through a defibrillation lead to a site on or in the heart when fibrillation of the heart is detected by the implantable medical device. Methods of making and using the implantable medical device, the capacitor, and their various components are disclosed.

Owner:MEDTRONIC INC

Solid electrolyte capacitor and method for manufacturing the same

InactiveUS6229689B1Increase resistanceImprove efficiencyHybrid capacitor electrolytesLiquid electrolytic capacitorsOrganic sulfonic acidProduct layer

A solid electrolyte capacitor having a solid electrolyte layer that is formed of a polymeric product layer of a polymerizable monomer. The polymeric product layer is doped with an organic sulfonic acid selected from the group consisting of an aromatic polysulfonic acid, an organic sulfonic acid having a hydroxy group, an organic sulfonic acid having a carboxyl group, an alicyclic sulfonic acid, and a benzoquinone sulfonic acid.

Owner:TOKIN CORP

Process for the production of electrolyte capacitors

ActiveUS8058135B2Lower equivalent series resistanceHeat stableSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceElectrolysis

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

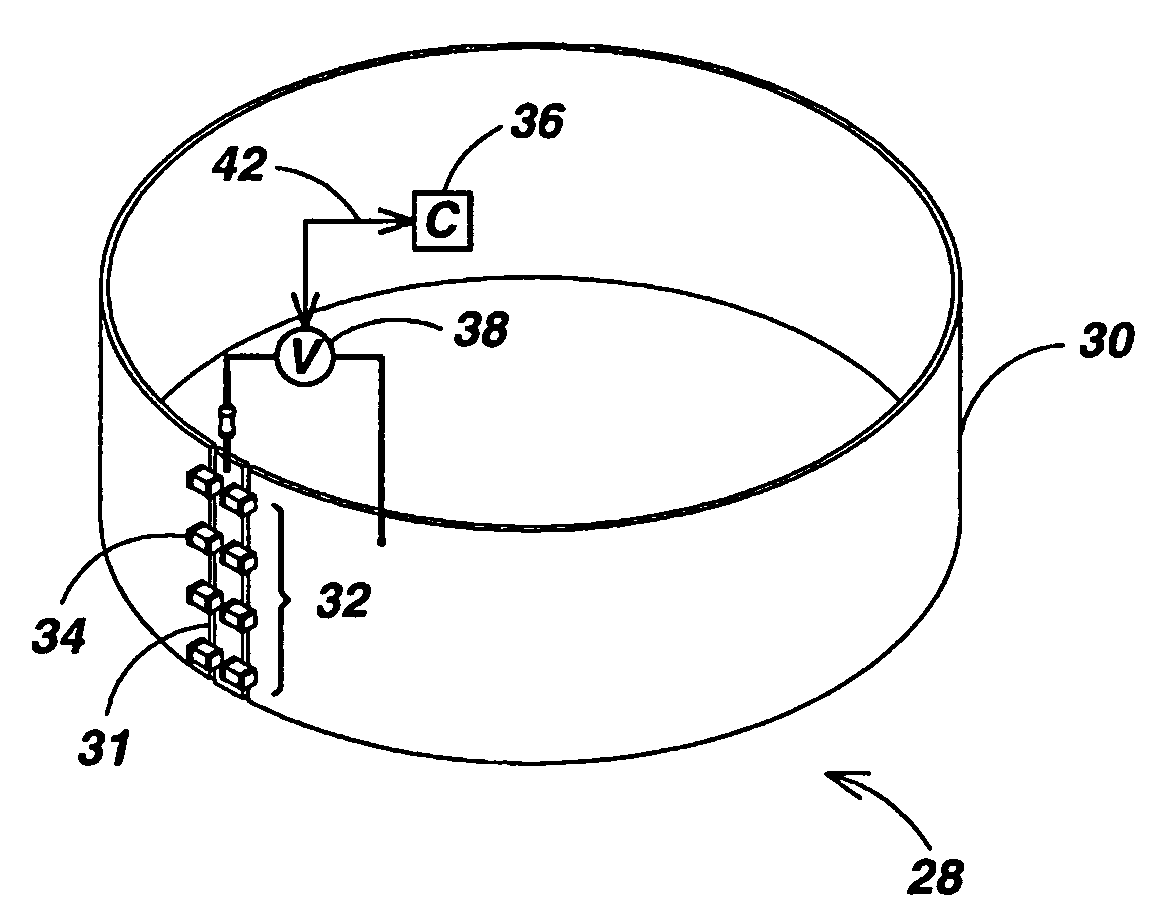

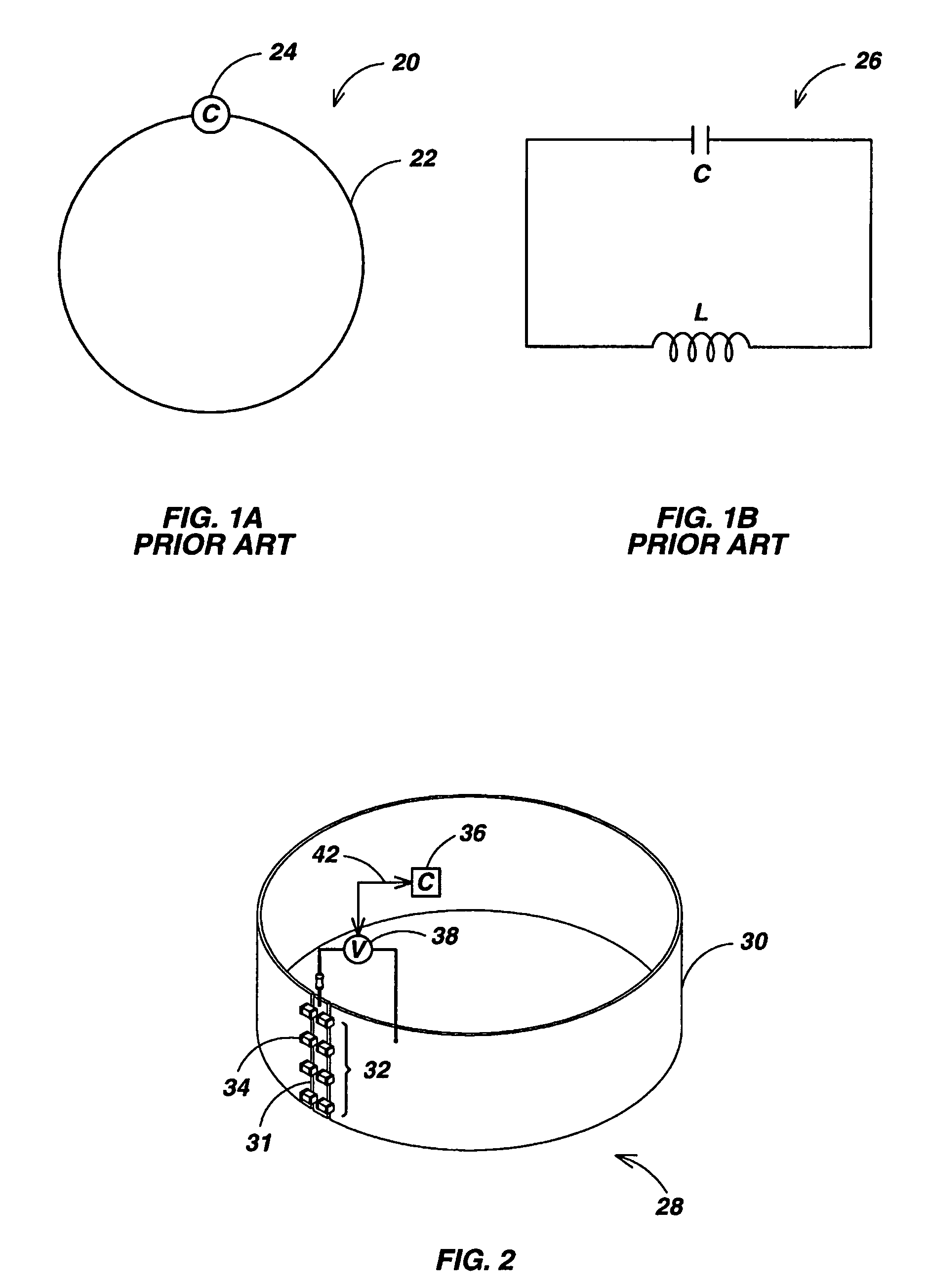

Shielded network for an active medical device implantable lead

InactiveUS20110054582A1Increase the equivalent series resistanceLower equivalent series resistanceSpinal electrodesMultiple-port networksPassive networksElectromagnetic shielding

A shielded component or network for an active medical device (AMD) implantable lead includes (1) an implantable lead having a length extending from a proximal end to a distal end, all external of an AMD housing, (2) a passive component or network disposed somewhere along the length of the implantable lead, the passive component or network including at least one inductive component having a first inductive value, and (3) an electromagnetic shield substantially surrounding the inductive component or the passive network. The first inductive value of the inductive component is adjusted to a account for a shift in its inductance to a second inductive value when shielded.

Owner:WILSON GREATBATCH LTD

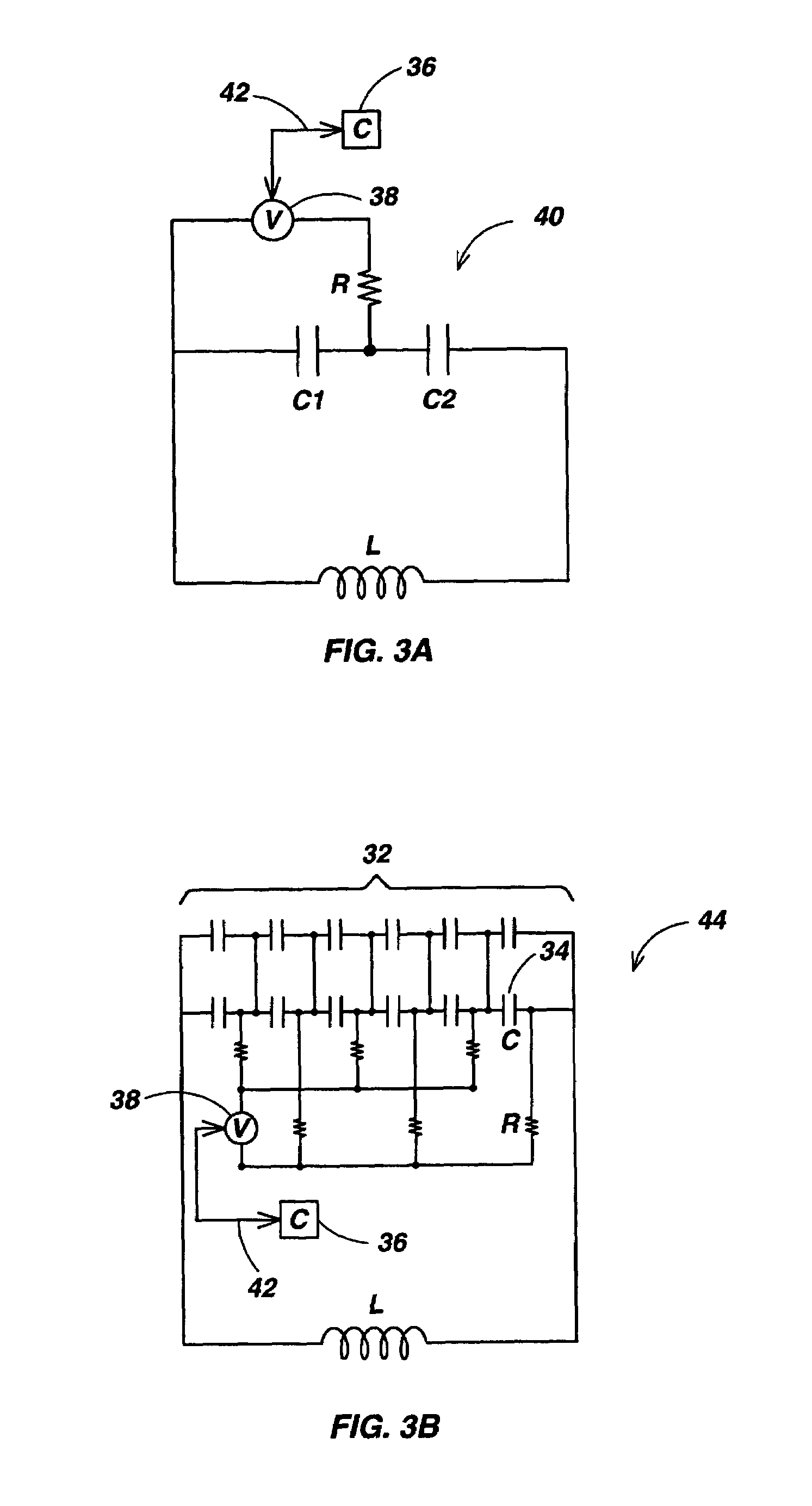

Compact self-tuned electrical resonator for buried object locator applications

ActiveUS7276910B2Improved efficiency and induced output powerLower equivalent series resistanceDetection of traffic movementResonatorsCapacitanceElectrical conductor

A self-tuning resonator for use in a transmitter apparatus for inducing alternating currents in a buried conductor. The resonator is dynamically tuned at frequencies below 500 kHz by exploiting the inherent voltage-variability of net capacitance in multilayer ceramic capacitors. The transmitter apparatus provides improved efficiency and induced output power suitable for use in a man-portable locator system, providing a very high magnetic field output from a physically small battery-powered resonator at frequencies under 500 kHz. The resonator exhibits a very low equivalent series resistance (ESR) and is adaptively returned to a predetermined resonant frequency responsive to any changes in resonance arising from phenomena such as component heating, thereby supporting very high tank circuit currents from battery-powered source to produce very high magnetic flux output.

Owner:SEEK TECH

Solid electrolytic capacitor and method for manufacturing same

InactiveUS7154743B2Lower equivalent series resistanceImprove conductivitySolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisNiobium

A solid electrolytic capacitor comprises an anode formed of at least one metal selected from tantalum, niobium, titanium and tungsten, and a dielectric layer, an electrolytic layer and a cathode disposed on the anode, wherein the cathode comprises a mixed layer containing a first material consisting of silver particles having an average particle diameter (median diameter) of not less than 2 μm, a second material consisting of conducting carbon particles and / or silver particles having an average particle diameter (median diameter) of 1 μm or less and a binding agent.

Owner:SANYO ELECTRIC CO LTD

Solid electrolytic capacitor and method for producing the same

ActiveUS7388741B2Increase capacitanceLower equivalent series resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitanceConductive polymer

Owner:MURATA MFG CO LTD

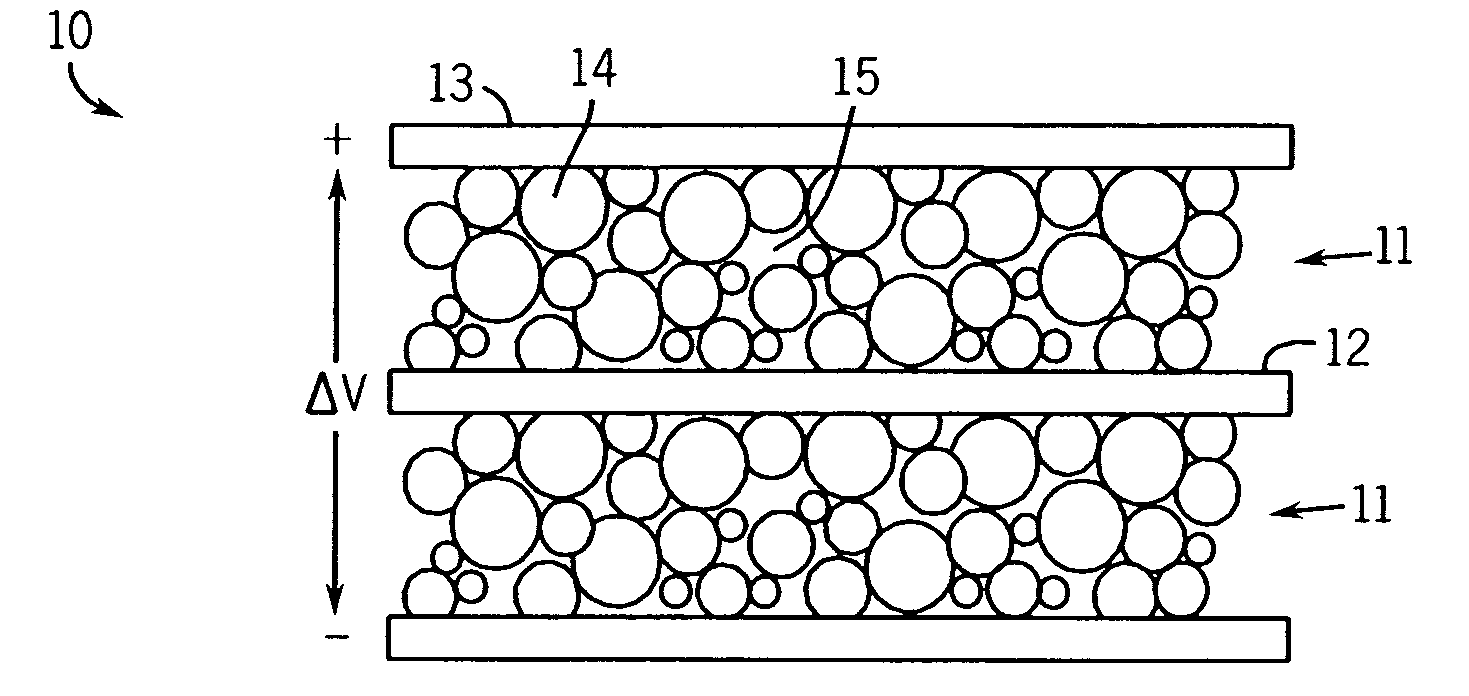

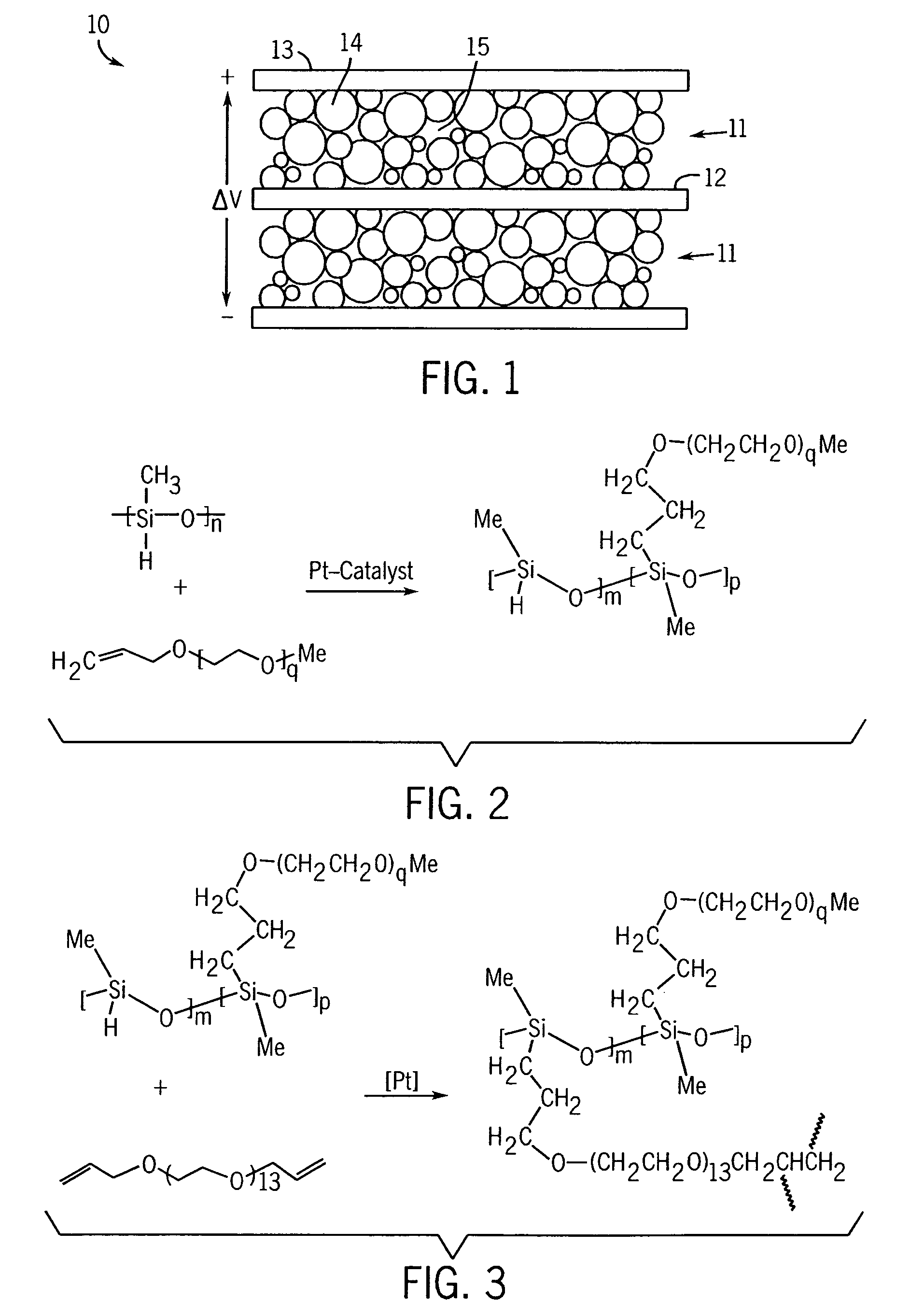

Electrochemical double-layer capacitor using organosilicon electrolytes

ActiveUS7466539B2Improve ionic conductivityHigh operating voltage and temperatureHybrid capacitor electrolytesHybrid capacitor electrodesPolymer capacitorPorous carbon

Disclosed are supercapacitors having organosilicon electrolytes, high surface area / porous electrodes, and optionally organosilicon separators. Electrodes are formed from high surface area material (such as porous carbon nanotubes or carbon nanofibers), which has been impregnated with the electrolyte. These type devices appear particularly suitable for use in electric and hybrid electric vehicles.

Owner:WISCONSIN ALUMNI RES FOUND

High capacitance anode and system and method for making same

InactiveUS6858126B1Lower equivalent series resistanceSacrificing capacitanceAnodisationElectrolysis componentsCapacitancePorosity

A method of producing electrodes for electrolytic capacitors by etching metal foil in a low pH etching electrolyte is disclosed. The low pH electrolyte is an aqueous solution, which comprises hydrochloric acid, glycerol, sodium perchlorate or perchloric acid, sodium persulfate and titanium (111) chloride. Anode foils etched according to the method of the invention maintain high capacitance gains, electrical porosity and strength. The electrical porosity of the etched foils is sufficiently high such that the overall Equivalent Series Resistance (ESR) is not increased in multilayer anodes configurations. Also described is a low pH electrolyte bath composition. Anode foils etched according to the present invention and electrolytic capacitors incorporating the etched anode foils are also disclosed.

Owner:PACESETTER INC

Graphene composite electrode and preparation method and application

ActiveCN103035409ALower equivalent series resistanceImprove stabilityLiquid electrolytic capacitorsCell electrodesCapacitanceComposite electrode

The invention provides a graphene composite electrode which comprises a current collector and electrode active materials arranged on the surface of the current collector, wherein the electrode active materials comprise graphene and manganese dioxide. The graphene is in a stratified structure and is arranged on the surface of the current collector, and the manganese dioxide is arranged on the surface of the graphene in the stratified structure. Mass percentage content of the graphene in the electrode active materials is 80%-90%. In addition, the invention further relates to a preparation method and an application of the graphene composite electrode. Oxidized graphene and the manganese dioxide are deposited on the current collector step by step, adhesion agents are not needed, and therefore equivalent series resistance of the whole electrode is reduced effectively, capacity and pseudocapacitance of an electric double-layer of the graphene and the manganese dioxide are developed simultaneously, and stability and conductivity of the electrode are well improved by addition of the graphene. In addition, through the method of electro-deposition, the electrode materials are directly deposited on an electrode plate, a complex coating process is saved, the process is simple, and time is short.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Solid electrolytic capacitor

ActiveUS8035953B2Lower equivalent series resistanceReduce the effective contact areaSolid electrolytic capacitorsLiquid electrolytic capacitorsCarbon layerElectrolysis

Owner:SANYO ELECTRIC CO LTD

Conductive polymer composition, method of producing the same, and solid electrolytic capacitor

ActiveUS20100091432A1Improve conductivityImprove waterproof performanceHybrid capacitor electrolytesSolid electrolytic capacitorsDopantConductive polymer

A conductive polymer composition with excellent water resistance and conductivity, and a solid electrolytic capacitor with low ESR, excellent reliability, and especially moisture resistance. The conductive polymer composition includes a conductive polymer, a polyanion that includes a hydrophilic group, where the polyanion functioning as a dopant of the conductive polymer. At least a part of the hydrophilic group of the polyanion is condensed with an epoxy group in a compound with one epoxy group. A solid electrolytic capacitor of the present invention includes the conductive polymer composition.

Owner:TOKIN CORP

Method for producing solid sheet type electrolytic capacitor

InactiveCN1649053AGood high frequency characteristicsLower equivalent series resistanceSolid electrolytic capacitorsCapacitor electrodesEpoxyAlloy

A manufacturing method for a solid plate electrolytic capacitor is to weld a strip Al foil to a stainless steel technical bar, the Al foil is coated with silicon resin or F resin to be divided into cathode and anode. The cathode part is immersed into a solution containing oxalamine and ammonium biphosphate plus 6-35v voltage, then again immersed in KMno4 solution to be dipped in a solution with Py and sulfosalt to form a pre-conductive layer on its surface as the anode, a stainless steel as the cathode to carry out constant current electrolyte in a mixed solution with Py and sulfosalt. The Al foil cathode is immersed in a solution containing oxalamine, ammonium biphosphate and sulfosalt plus 5-25v voltage to be coated with graphite and Ag to get single chip cores to be laminated, the anode is welded at that of an alloy lead frame, the cathode to the cathode to form a capacitor core to be molded and packaged with epoxy resin.

Owner:XI AN JIAOTONG UNIV

Methods and apparatus for producing carbon cathodes

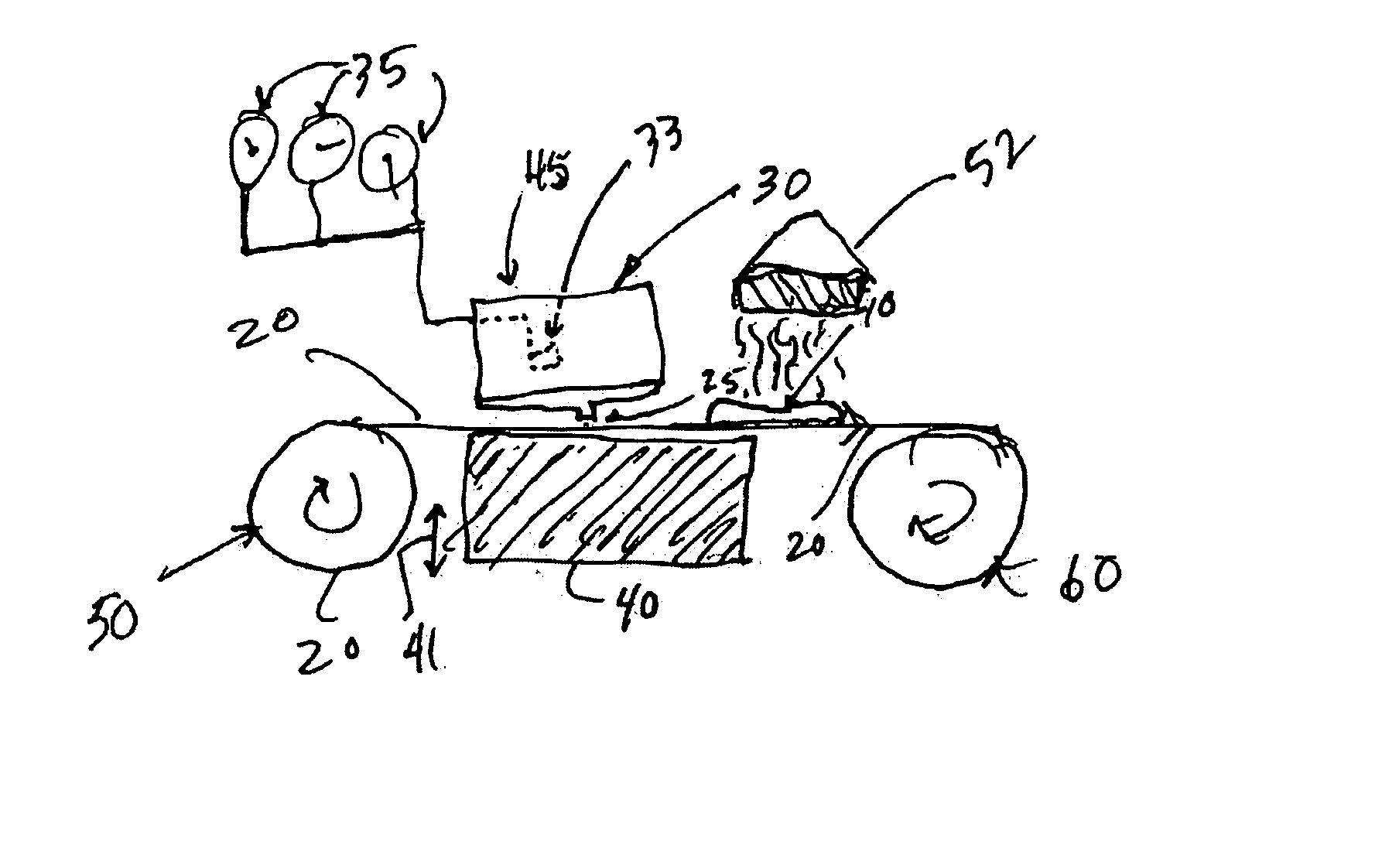

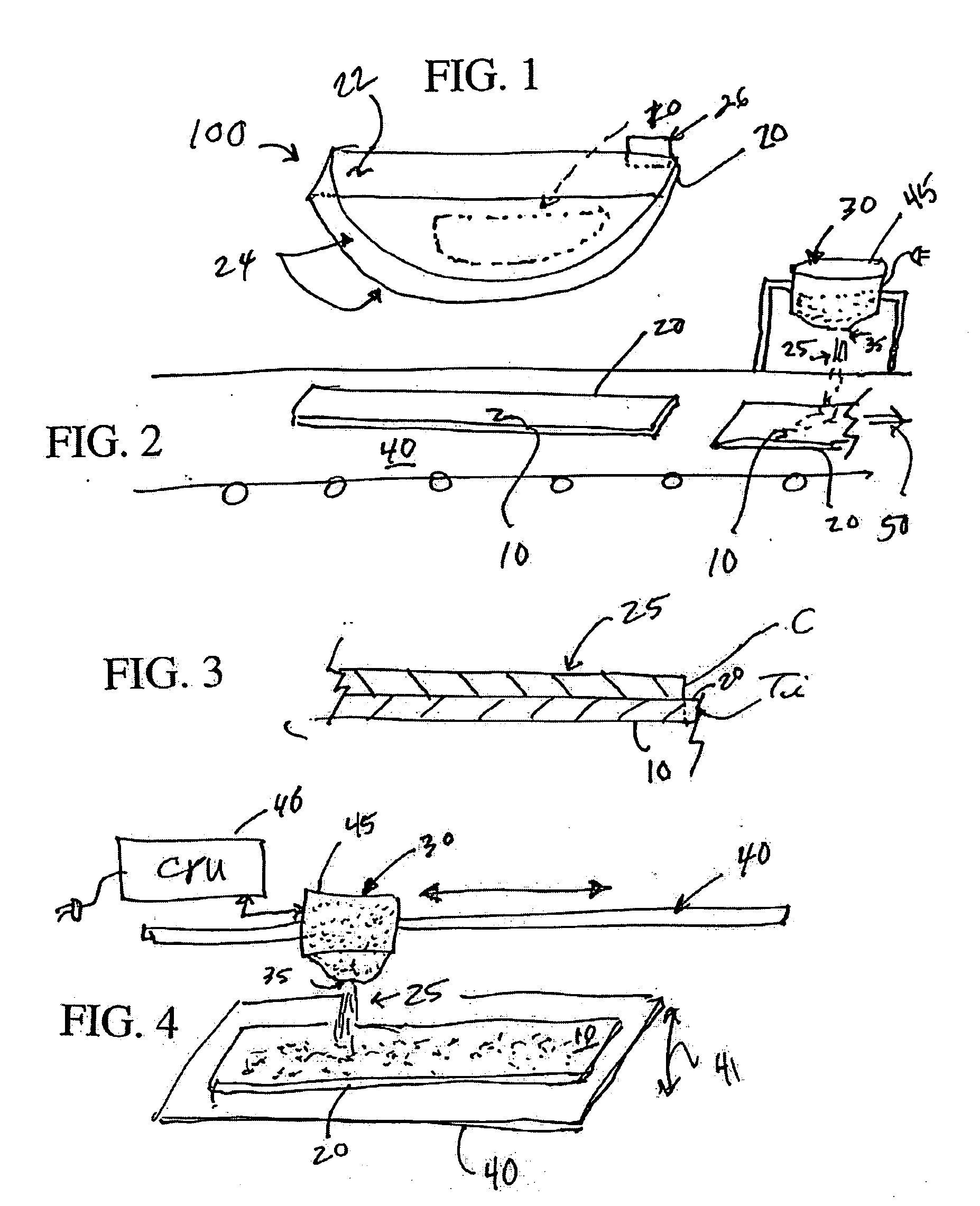

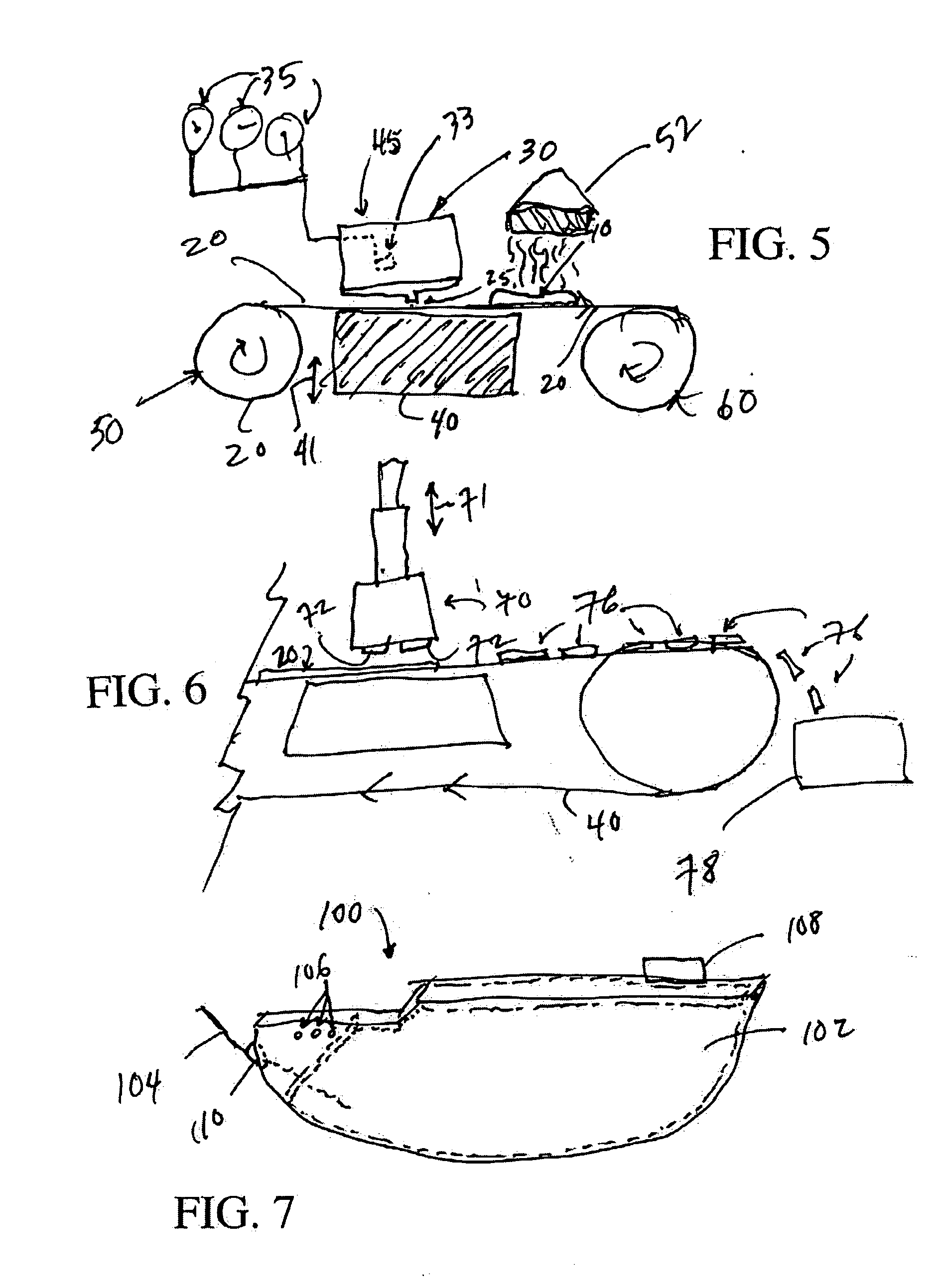

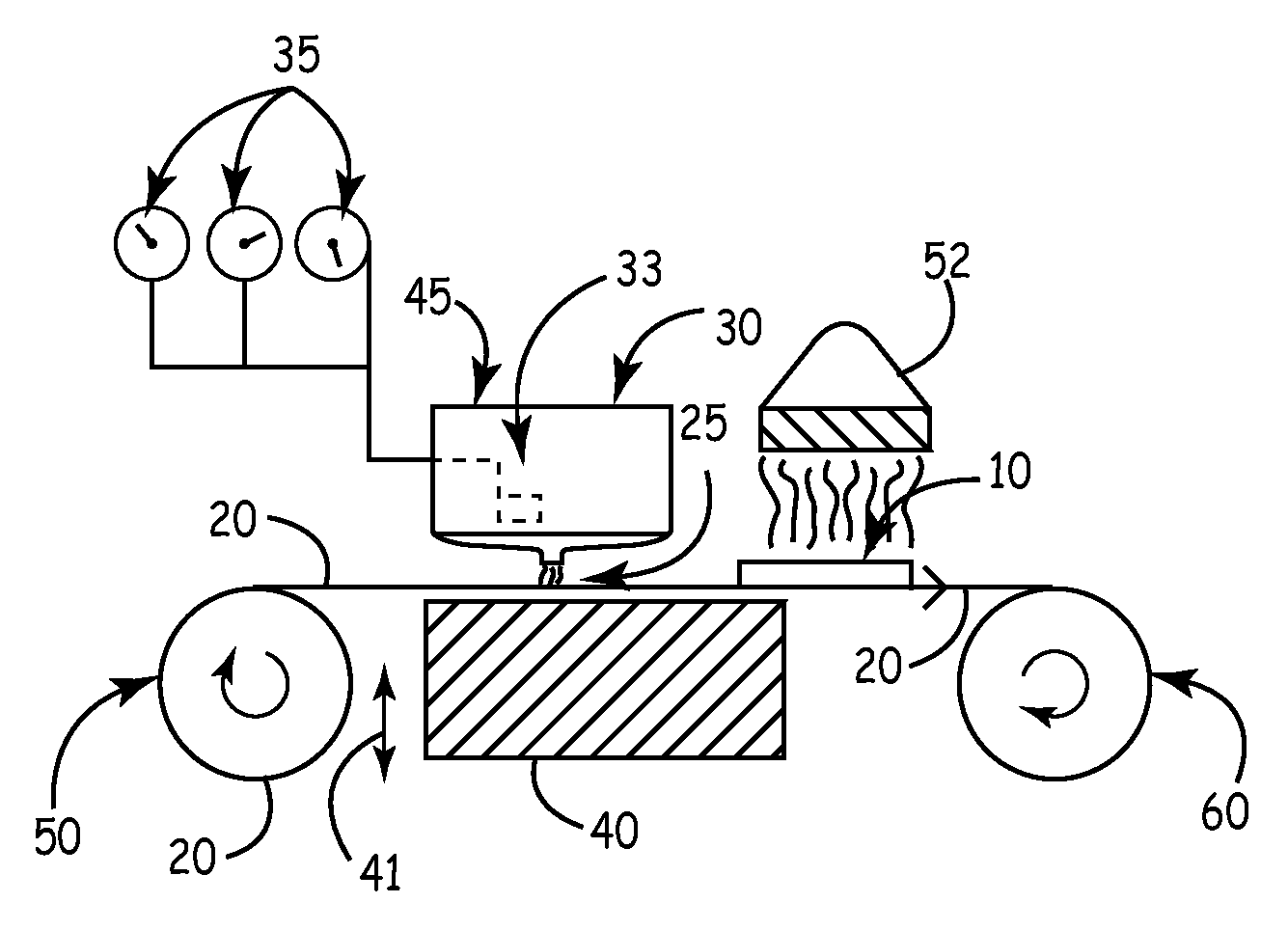

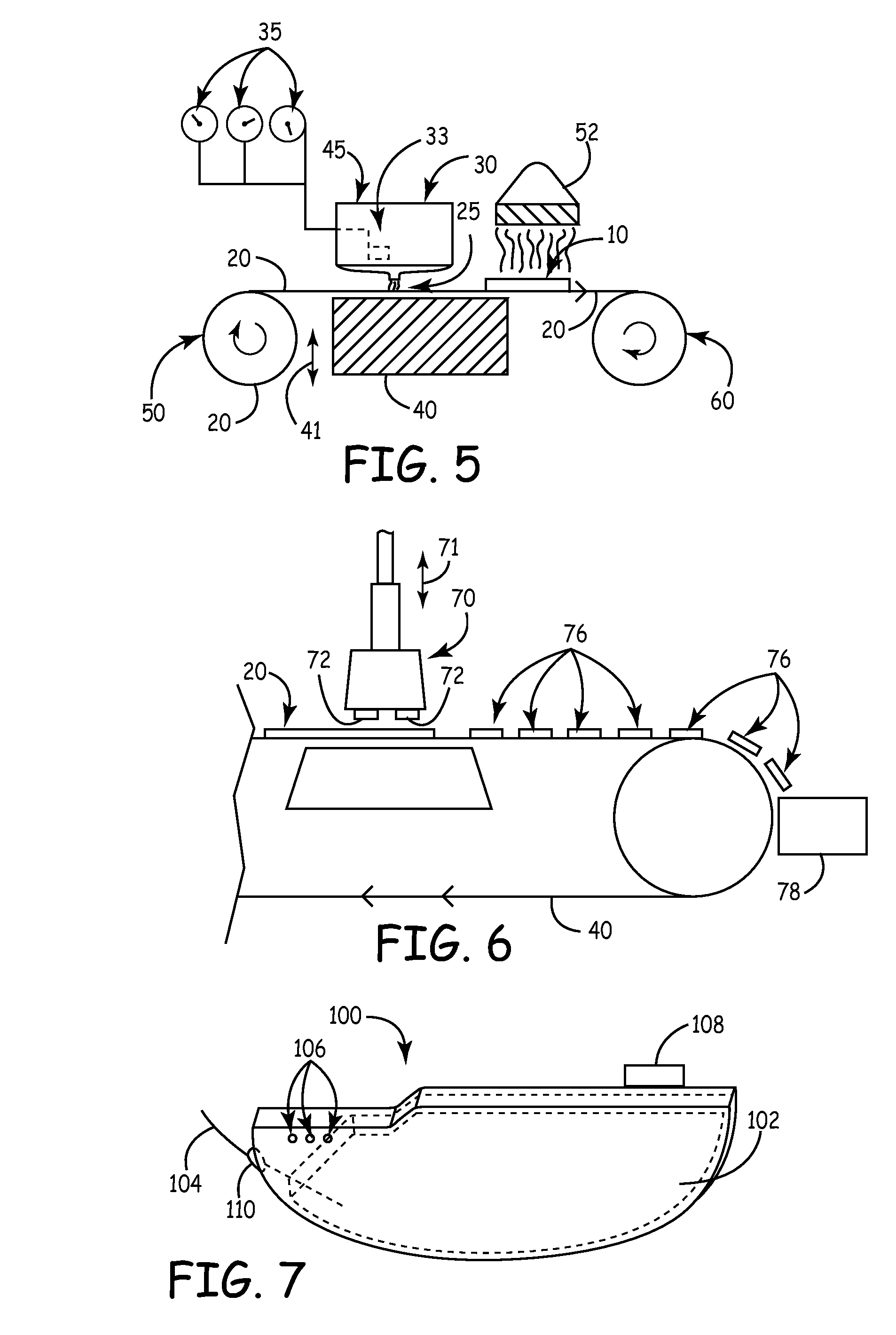

ActiveUS20050098242A1Efficient mass productionImprove consistencyElectrode thermal treatmentDouble layer capacitorsTitaniumMetal powder

The present invention provides improved cathodes and industrialized methods for producing such cathodes using an industrial dosing valve-based electrode coating fluid emitting technique. The family of cathodes according to the present invention can be produced so that they inhabit a pre-existing metallic surface such as an inner surface of a titanium casing adjacent but insulated from direct electrical communication from an anode. Foil-type valve metal anodes as well as porous valve metal anodes formed from metallic powders may be used in conjunction with the cathodes of the present invention.

Owner:MEDTRONIC INC +1

Antenna structure on IC and manufacturing method

InactiveCN1917285AReduce energy lossReduce lossSemiconductor/solid-state device manufacturingRadiating elements structural formsPhysicsCMOS

Under precondition without changing size of external diameter, the invention discloses integrated antenna on chip. The helix structural antenna possesses gradual changed widths of metal coils and spans of metal coils in order to reduce serial equivalent resistance of helix coils so as to reduce energy loss. Comparing with traditional antenna on chip, the disclosed antenna on chip possesses features of lowering influence of eddy current effect and approach effect in high frequency so as to reduce the said equivalent resistance Rs, and energy loss. The preparing technique is compatible to conventional CMOS technique.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Electrode of high-density super capacitor and method for manufacturing same

InactiveUS20120099244A1High densityLower equivalent series resistanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceElectrical resistance and conductance

Provided is a supercapacitor electrode that is coupled on one side or both sides of a collector, in which the supercapacitor electrode consists of a carbon material that forms an electric double layer, in which the carbon material consists of: a powder-shaped electrode active material; a powder-shaped conductive material; and a fibrous carbon material of a aspect ratio of 3-33. The supercapacitor electrode can be implemented into a high-capacitance or high-power supercapacitor together with low equivalent series resistance.

Owner:AMOGREENTECH CO LTD

Method for manufacturing electrode material of supercapacitor by cotton-stalk-based active carbon material

InactiveCN102730683ALarge specific surface areaGood capacitance characteristicsCarbon compoundsElectrolytic capacitorsCapacitanceSupercapacitor

The invention relates to a method for manufacturing an electrode material of a supercapacitor by a cotton-stalk-based active carbon material. The method comprises the following steps of: firstly removing skin and crushing a cotton stalk raw material, mixing and dipping with an activating agent, and carrying out processes of activation treatment, washing, drying and the like to obtain an active carbon electrode material required by the supercapacitor. The electrode material of the supercapacitor prepared by the method provided by the invention has higher specific surface area and excellent capacitance characters. An assembled simulation button type supercapacitor has higher specific capacitance, smaller equivalent series resistance, higher charge and discharge efficiencies and the like. The method disclosed by the invention is of important significance to increase an economical additional value of cotton stalk, realize sustainable development on the cotton stalk, improve the performance of supercapacitor and reduce the production cost.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Solid electrolytic capacitor

InactiveUS20050117280A1Lower equivalent series resistanceIncrease “ noncontact surface area ”Solid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

A solid electrolytic capacitor includes a capacitor element assembly, an anode lead and a cathode lead. The assembly includes a plurality of capacitor elements each consisting of a sintered valve metal chip, an anode wire projecting from the chip, a solid electrolytic layer formed on the chip, and a cathode layer formed on the electrolytic layer. The chip of each capacitor element is flat, having a thickness smaller than its length and width. The capacitor elements are stacked in a thickness direction of the chip so that the cathode layers of the respective capacitor elements are connected to each other. The anode wires are fixed to the anode lead. At least one of the cathode layers is directly connected to the cathode lead.

Owner:ROHM CO LTD

Graphene/elemental tin combined electrode plate and preparation method of same

ActiveCN103035877ALower equivalent series resistanceImprove power densityNon-aqueous electrolyte accumulator electrodesAdhesiveCvd graphene

The invention discloses a graphene / elemental tin combined electrode plate. The combined electrode plate comprises a current collector, graphene deposited on the surface of the current collector, and elemental tin dispersed on the surface of the graphene. According to the graphene / elemental tin combined electrode plate, the graphene and the elemental tin are directly deposited on the current collector. Compared with a traditional electrode plate added with an adhesive, the graphene / elemental tin combined electrode plate is lower in equivalent series resistance; and the power density of a battery can be effectively increased by use of the graphene / elemental tin combined electrode plate. The invention also provides a preparation method of the graphene / elemental tin combined electrode plate.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Solid electrolytic capacitor

InactiveUS7016179B2Increase “ noncontact surface area ”Small resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisCathode ray

A solid electrolytic capacitor includes a capacitor element assembly, an anode lead and a cathode lead. The assembly includes a plurality of capacitor elements each consisting of a sintered valve metal chip, an anode wire projecting from the chip, a solid electrolytic layer formed on the chip, and a cathode layer formed on the electrolytic layer. The chip of each capacitor element is flat, having a thickness smaller than its length and width. The capacitor elements are stacked in a thickness direction of the chip so that the cathode layers of the respective capacitor elements are connected to each other. The anode wires are fixed to the anode lead. At least one of the cathode layers is directly connected to the cathode lead.

Owner:ROHM CO LTD

Graphene/nano silicon combined electrode plate and preparation method of same

ActiveCN103035889ALower equivalent series resistanceImprove power densityNon-aqueous electrolyte accumulator electrodesNano siliconAdhesive

The invention discloses a graphene / nano silicon combined electrode plate. The combined electrode plate comprises a current collector, graphene deposited on the surface of the current collector, and nano silicon dispersed on the surface of the graphene. According to the graphene / nano silicon combined electrode plate, the graphene and the nano silicon are directly deposited on the current collector. Compared with a traditional electrode plate added with an adhesive, the graphene / nano silicon combined electrode plate is lower in equivalent series resistance; and the power density of a battery can be effectively increased by use of the graphene / nano silicon combined electrode plate. The invention also provides a preparation method of the graphene / nano silicon combined electrode plate.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method for tin-based/graphene composite anode material of lithium ion battery

ActiveCN104716313ALower equivalent series resistanceReduce manufacturing costCell electrodesSodium-ion batteryGraphene

The invention discloses a preparation method for a tin-based / graphene composite anode material of a lithium ion battery, relates to a preparation method for a composite anode material of a battery, and solves problems that a tin-based / graphene composite anode material is unlikely to be subjected to batch preparation and a current collector cannot realize one-side electrodeposition in an existing lithium ion battery. The preparation method comprises the following steps: 1, preparing a plating solution; 2, assembling a cathode device; 3, preprocessing the cathode device; 4, performing composite electrodeposition; 5, performing drying and reduction. The preparation method is used for preparing the tin-based / graphene composite anode material of the lithium ion battery.

Owner:HARBIN INST OF TECH

Two-dimensional transition metal dichalcogenide micro- supercapacitors

ActiveUS20190139713A1Stable and strong adhesionImprove cycle stabilityThin/thick film capacitorHybrid capacitor electrodesSputteringGas phase

The invention includes supercapacitors and methods of making supercapacitor by fabricating transition metal dichalcogenide (MX2) layers using a combination of magnetron sputtering followed by chemical vapor deposition.

Owner:UNIVERSITY OF NORTH TEXAS

Design method for on-chip spiral inductor with the wearing metal conductor line width and gap

InactiveCN101017816AL value maximizationReduce lossSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorLine width

The invention provides a design method for chip spiral inductor with gradual-change metal conductor linewidth and span. Wherein, it calculates the linewidth wn and nearby conductor span sn by following formula: for odd N, wN+w1=wN-1+w2=...=2w(N+1) / 2=2w, sN-1+s1=sN-2+s2 =...=s(N+1) / 2+s(N-1) / 2=2s; for even N, wN+w1=wN-1+w2=...=w(N / 2)+1+wN / 2=2w, sN-1+s1= sN-2+s2=...=2sN / 2=2s; and wn+1>wn, sn+1>sn. This invention reduces vortex effect and near effect generated by spiral inductor at HF to decreases serial equivalent resistance and energy loss.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

Methods and apparatus for producing carbon cathodes

ActiveUS7687102B2Efficient mass productionImprove consistencyElectrode thermal treatmentElectrolytic capacitorsElectricityTitanium

The present invention provides improved cathodes and industrialized methods for producing such cathodes using an industrial dosing valve-based electrode coating fluid emitting technique. The family of cathodes according to the present invention can be produced so that they inhabit a pre-existing metallic surface such as an inner surface of a titanium casing adjacent but insulated from direct electrical communication from an anode. Foil-type valve metal anodes as well as porous valve metal anodes formed from metallic powders may be used in conjunction with the cathodes of the present invention.

Owner:MEDTRONIC INC +1

Electrode structure and method for manufacturing the electrode structure, and energy storage apparatus with the electrode structure

InactiveUS20120052400A1Low equivalent series resistanceHigh capacityAlkaline accumulatorsElectrolytic capacitorsCurrent collectorEngineering

Disclosed herein is an electrode structure for an energy storage apparatus. The electrode structure according to an exemplary embodiment of the present invention includes a current collector; and an active material layer formed in the current collector, wherein the active material layer includes: an active material; and a conductive material having a relatively higher content than that of the active material as being away from the current collector.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

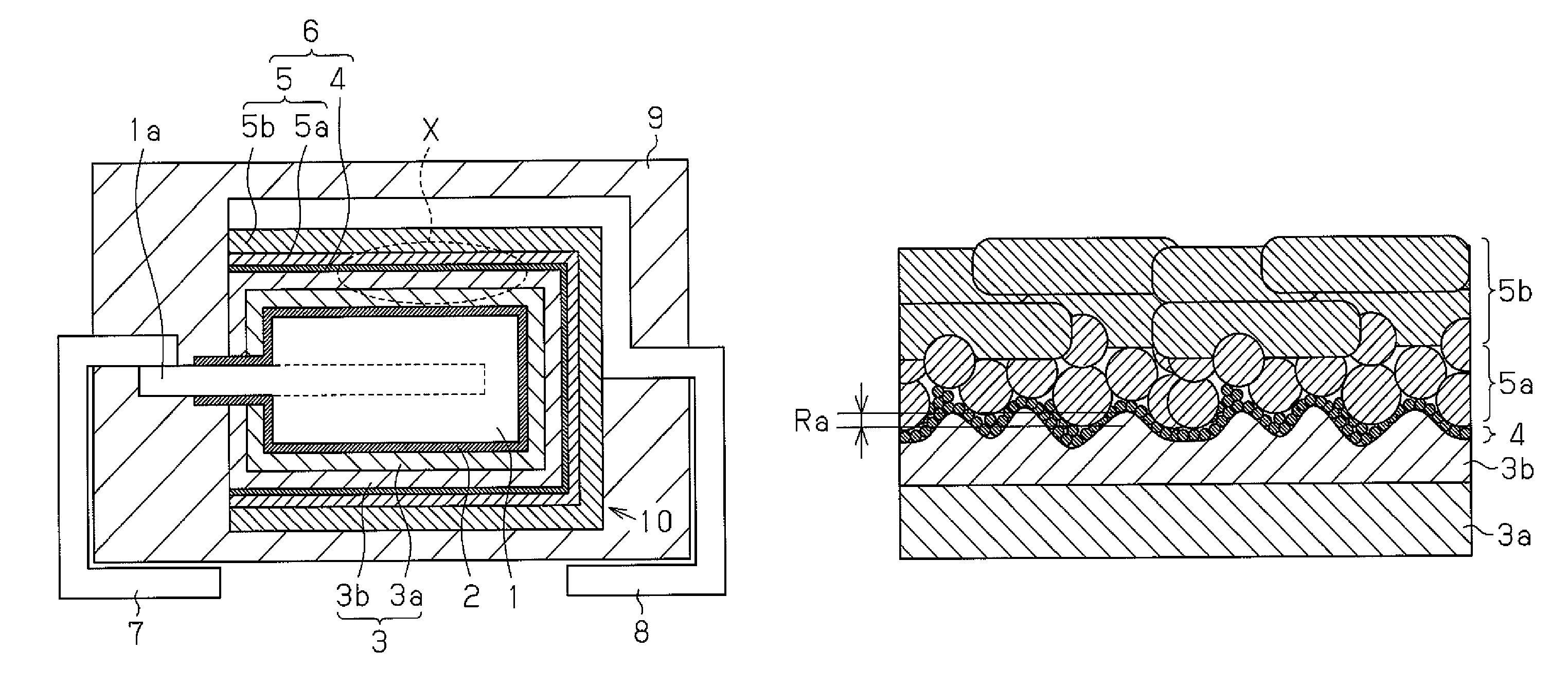

Electronic component and method of manufacturing the same

InactiveUS20100014217A1Small sizeLower equivalent series resistanceSolid electrolytic capacitorsCasings/cabinets/drawers detailsElectronic componentEquivalent series resistance

An electronic component includes a functional element, first and second collectors joined to the functional element, and an outer package integrally covering the functional element and the first and second collectors. The functional element has first and second end surfaces having circular shapes and a side surface having a cylindrical shape extending along a center axis. The element includes first and second electrode foils rolled about the center axis and exposed from the first and second surfaces, respectively. The outer package has first and second surfaces parallel to the first and second end surfaces of the functional element, and has first to fourth corners as seen from a direction of the center axis. The first corner is adjacent to the second corner. The first and second terminals are arranged at the first and second corners of the outer package, respectively. This electronic component can have a small size and a small height while reducing its equivalent series resistance.

Owner:PANASONIC CORP

Graphene/carbon nano tube/nickel electrode and preparation method and application of grapheme/carbon nano tube/nickel electrode

ActiveCN102760582AEasy to insertThe effect of complementary performance is goodElectrolytic capacitorsCell electrodesCarbon nanotubeNickel electrode

The invention belongs to the field of electrochemical materials, and discloses a grapheme / carbon nano tube / nickel electrode and a preparation method thereof. The preparation method of the composite material comprises the following steps: a graphene oxide and carbon nano tube mixed solution is prepared; a graphite oxide / carbon nano tube / nickel electrode is prepared through electrophoresis; and the grapheme / carbon nano tube / nickel electrode is prepared. The invention provides the preparation method of the grapheme / carbon nano tube / nickel electrode; as the graphite oxide / carbon nano tube material is directly deposited on an electrode plate, a complicated coating process can be omitted, the process is simple, and the time is short; in addition, equivalent series resistance (ESR) of the graphite oxide / carbon nano tube / nickel electrode is reduced, so that the power density of a super capacitor is increased more efficiently.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

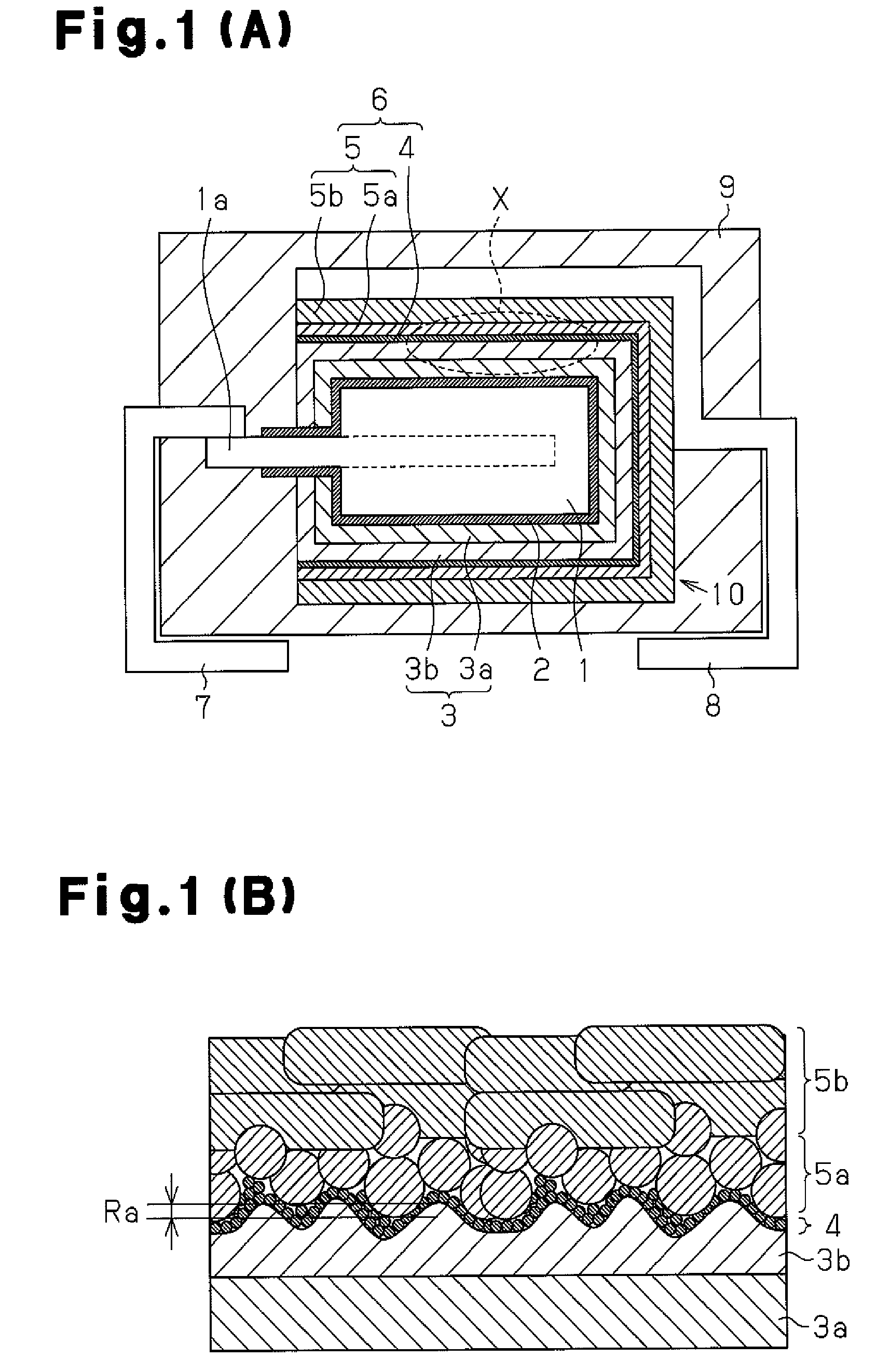

Solid electrolytic capacitor and method for manufacturing the same

ActiveUS20100202102A1Large capacitanceLower equivalent series resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitanceRough surface

A solid electrolytic capacitor includes an anode foil, a solid electrolyte provided on the anode foil and made of conductive polymer, and a cathode foil provided on the solid electrolyte and facing the anode foil across the solid electrolyte. The anode foil includes an anode base made of aluminum, a rough surface layer made of aluminum and provided on a surface of the anode base, and a dielectric oxide layer provided on the rough surface layer and contacting the solid electrolyte. The cathode foil includes a cathode base made of aluminum, and a nickel layer provided on a surface of the cathode base and contacting the solid electrolyte. The nickel layer faces the dielectric oxide layer of the anode foil across the solid electrolyte. The nickel layer is made of nickel and nickel oxide. This solid electrolytic capacitor has a large capacitance and a low equivalent series resistance while being inexpensive and highly reliable.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com