Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

363results about How to "Reduce the amount of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable medical device having flat electrolytic capacitor with laser welded cover

InactiveUS6118652ALower equivalent series resistanceIncrease capacitanceLiquid electrolytic capacitorsHeart defibrillatorsElectrical batteryFibrillation

An implantable medical device such as a defibrillator is described. The device includes an hermetically sealed housing containing a flat electrolytic capacitor and an energy source such as a battery. The battery is connected to the capacitor and provides charge thereto. The capacitor stores the charge at a relatively high voltage. The charge stored in the capacitor is discharged through a defibrillation lead to a site on or in the heart when fibrillation of the heart is detected by the implantable medical device. Methods of making and using the implantable medical device, the capacitor, and their various components are disclosed.

Owner:MEDTRONIC INC

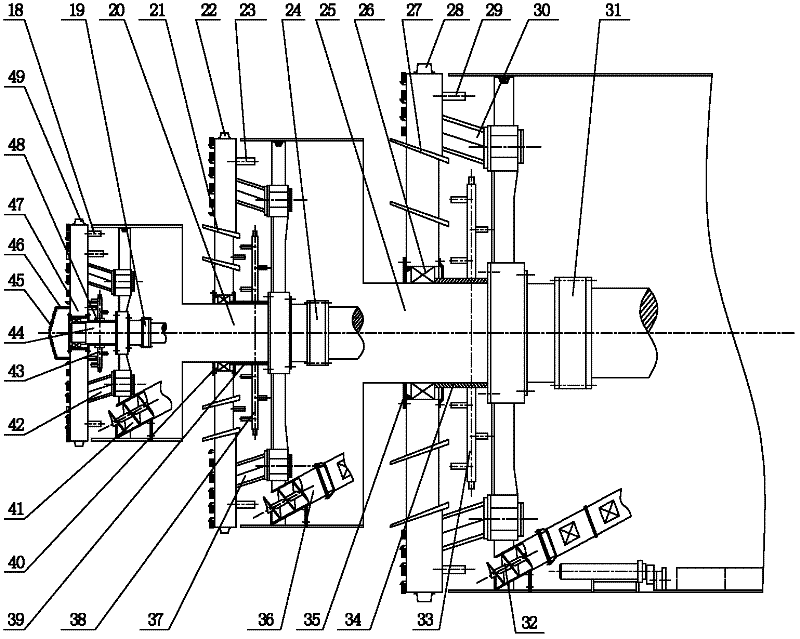

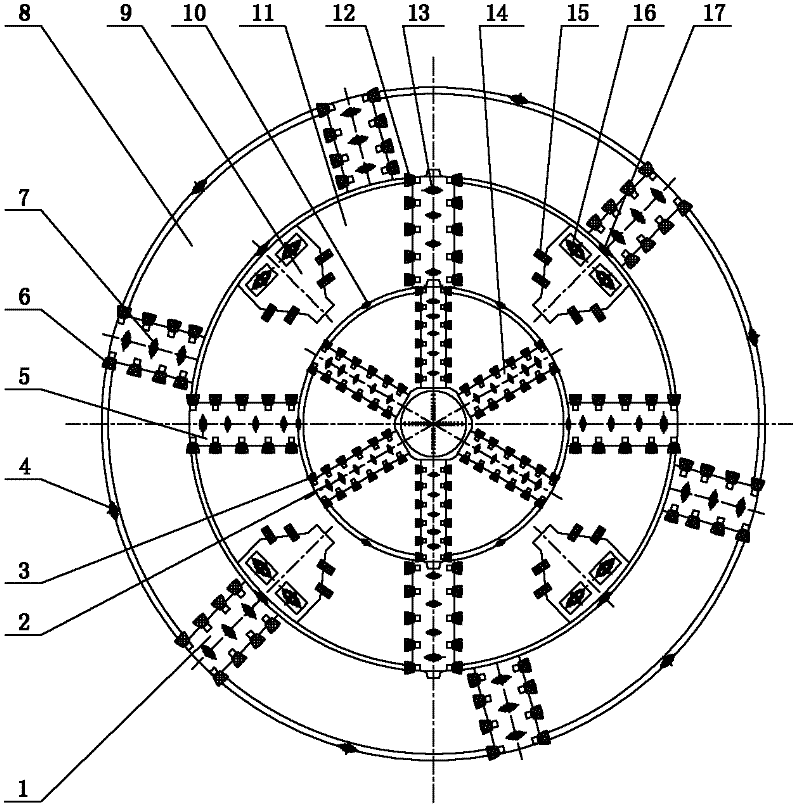

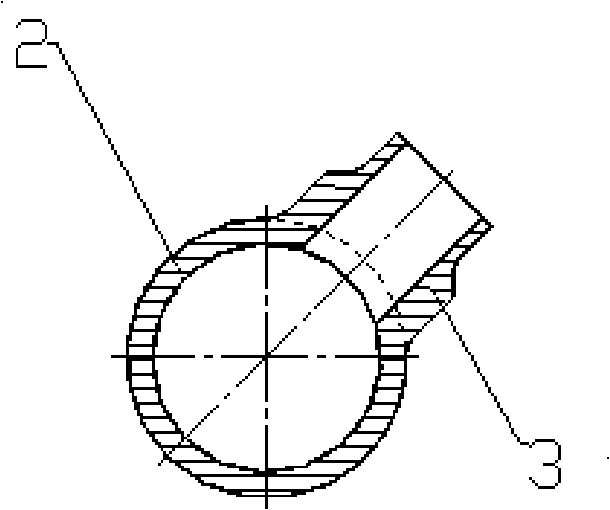

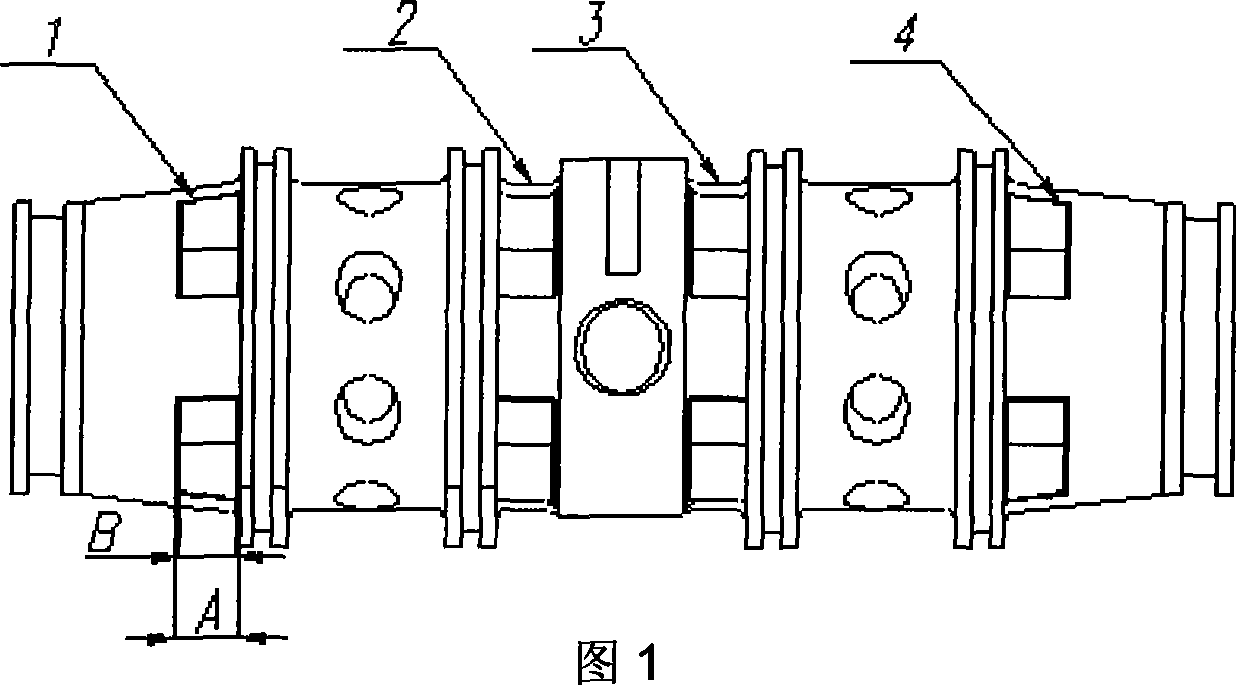

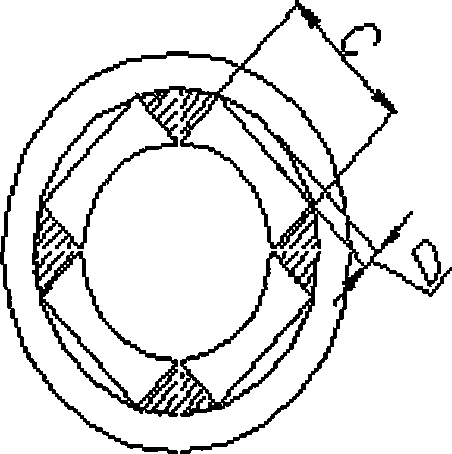

Multistage-separation progressive shield cutter head

InactiveCN102536254ASpeed up the flowEasy control of earth pressure balanceTunnelsEngineeringShield tunneling

The invention discloses a multistage-separation progressive shield cutter head which comprises a plurality of flexible shield cutter heads. During the work, a central shield cutter head primary rotation shaft clutch is closed; a power main shaft drives a primary cutter head to rotate to cut rocks; and at the same time, a rear hydraulic device pushes a central cutter head to tunnel ahead. When a certain distance is tunneled, a primary clutch is separated; after partial components are reassembled, a secondary clutch is closed and a secondary cutter head starts to tunnel ahead; and repeatedly, the multistage cutter head progressive excavation is realized. Cutter heads of a shield tunneling machine of a multistage-separation progressive structure share the same power main shaft and are respectively provided with a central stirring device and an auger delivery chip removal device; and material bulks cut by the cutter heads are crushed and conveyed into a chip removal guiderail at the center of the shield machine.

Owner:XIAN RUITE RAPID MFG ENG +1

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

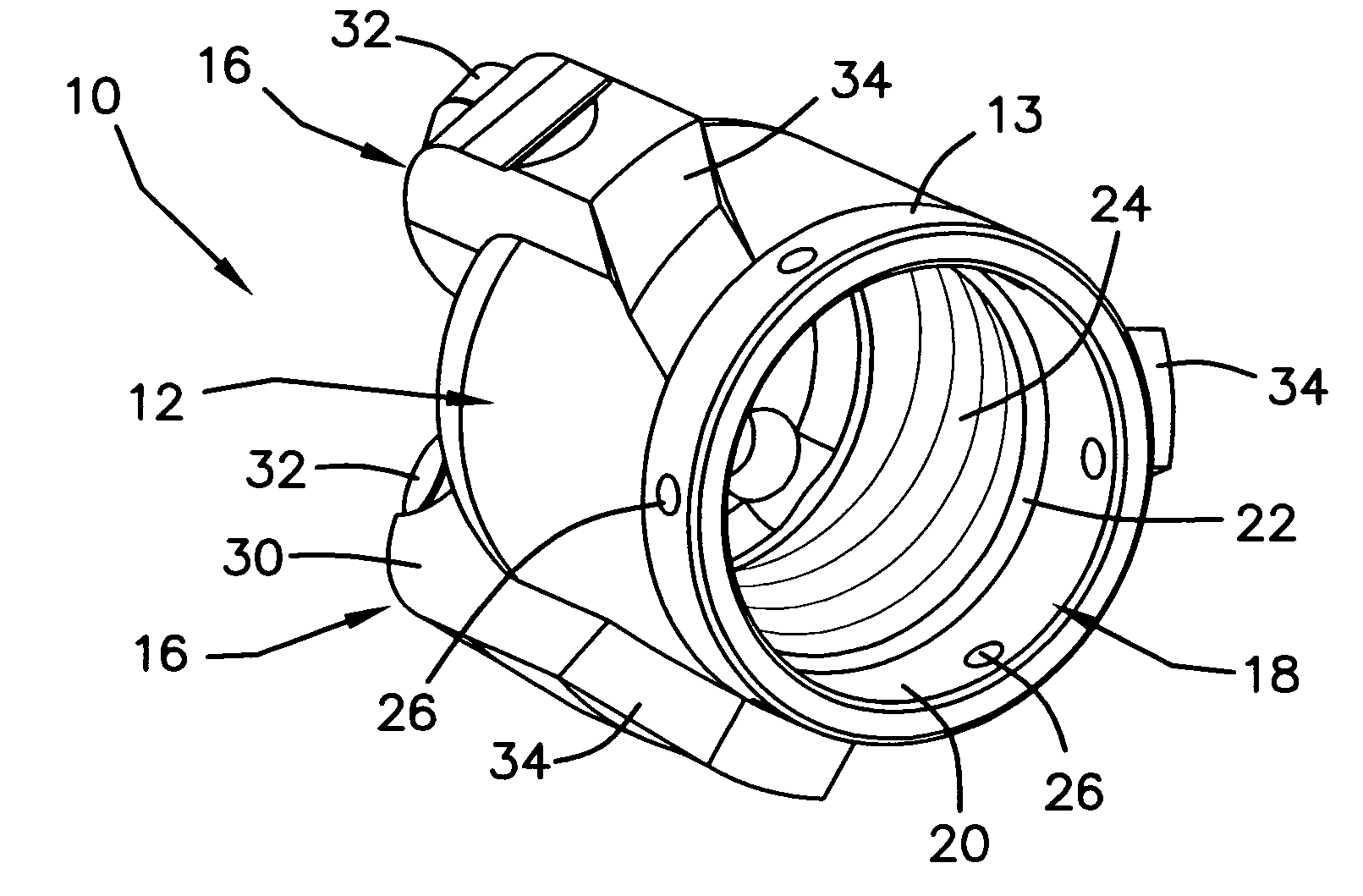

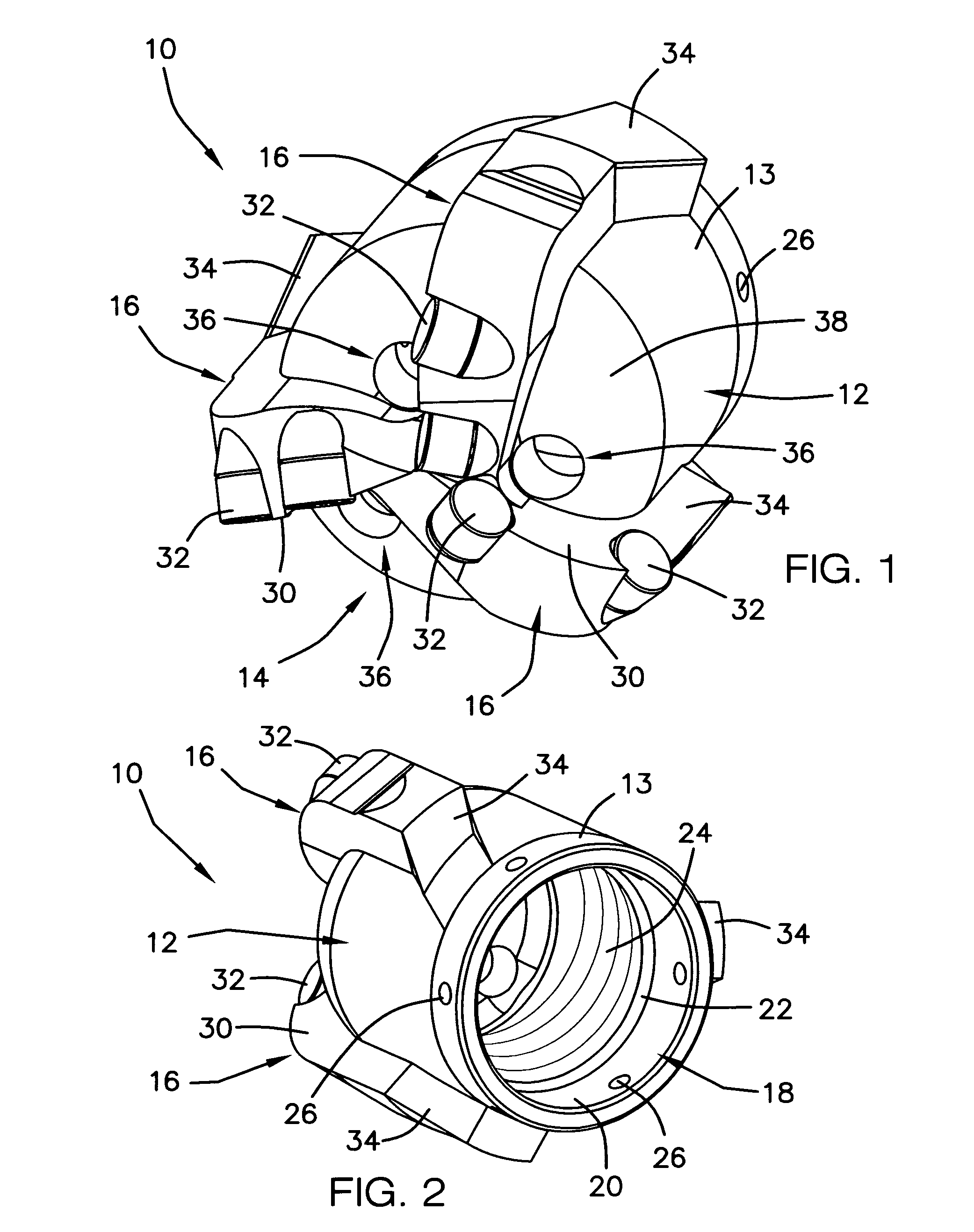

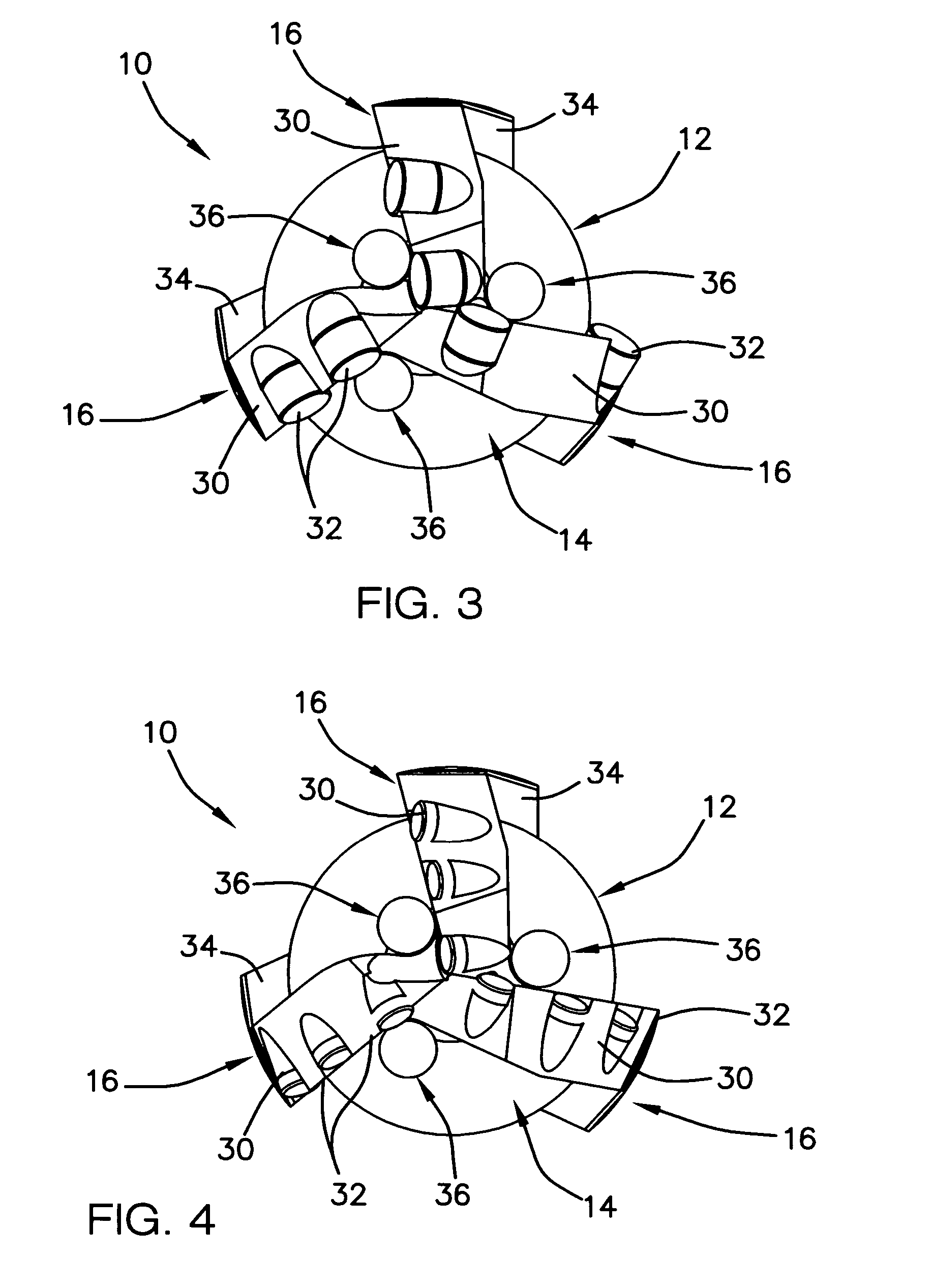

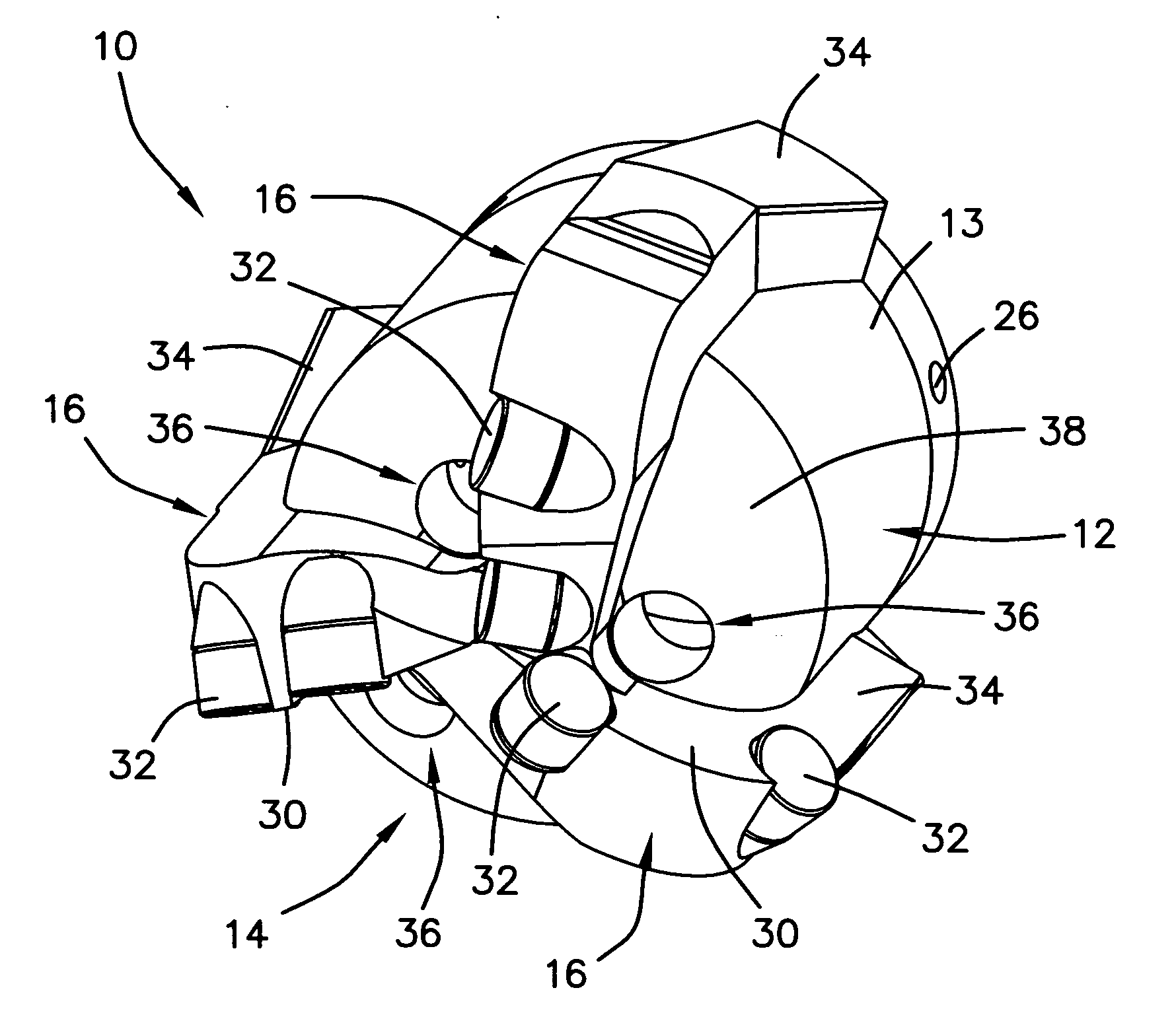

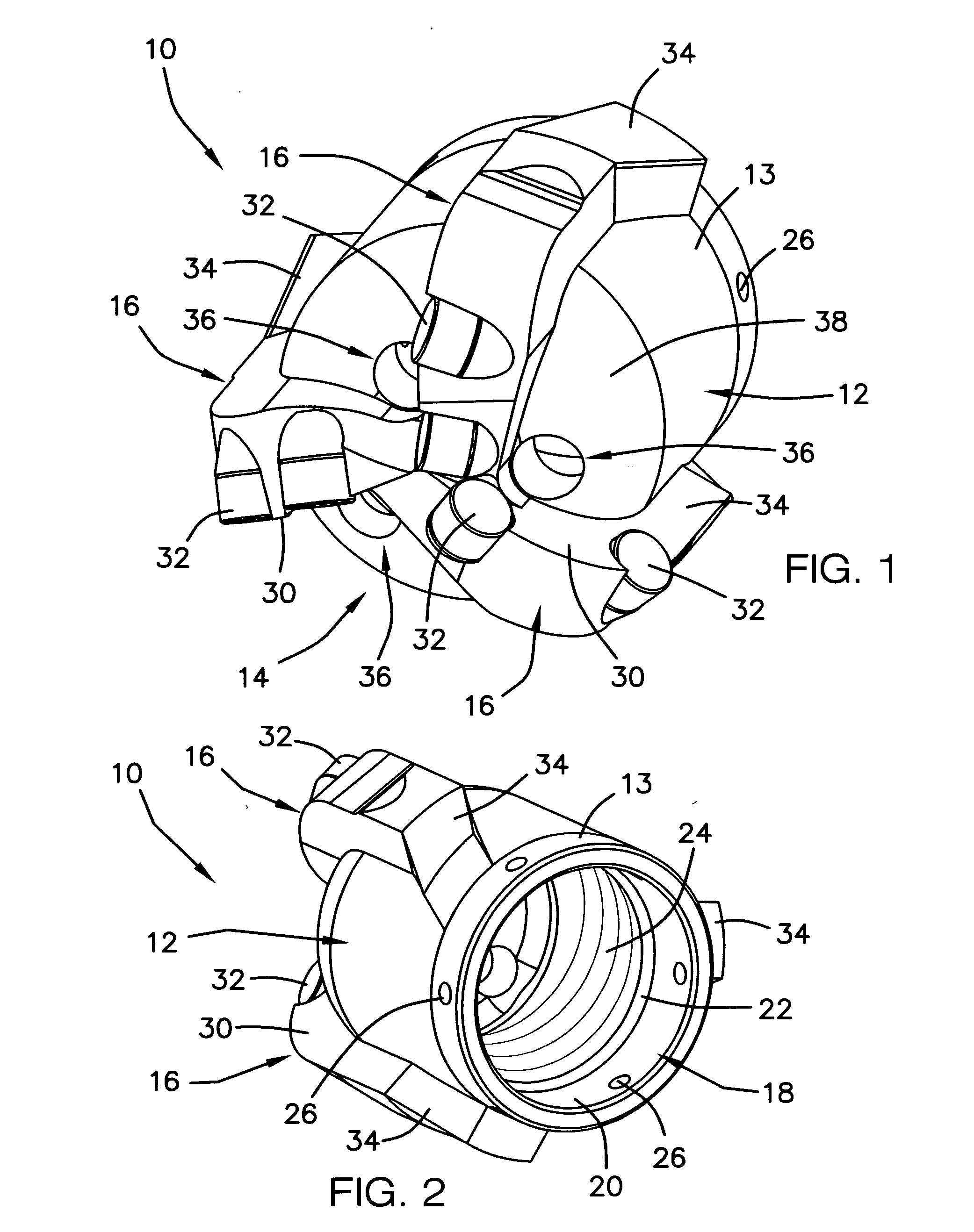

Bits for use in drilling with casting and method of making the same

InactiveUS7117960B2Reduce manufacturing costShallow depthDrill bitsDrilling rodsMechanical engineeringOil well

Bits for use in drilling with a well completion string having a bit body and a cutting face that includes a plurality of sets of cutter elements mounted on the cutting face. The bit body has a central longitudinal bore having an integrated female non-shouldered, standard oilfield completion string thread. The bits are designed with minimal cutter coverage, and this combined with the integrated completion string thread allows for economical completion of a well with high ROP expected from a PDC type bit. In an additional embodiment, a bit comprises a bit body and a cutting face having integrated cutting structures.

Owner:WHEELER JAMES L +1

Bits for use in drilling with casing and method of making the same

InactiveUS20050103530A1Reduce manufacturing costShallow depthDrill bitsDrilling rodsEngineeringMechanical engineering

Bits for use in drilling with a well completion string or the like are provided. The bits comprise a bit body and a cutting face that includes a plurality of sets of cutter elements mounted on the cutting face. The bit body has a central longitudinal bore having an integrated female non-shouldered, standard oilfield completion string thread. This thread arrangement allows the bit to be secured directly to any standard completion string, well casing. The bits are designed with minimal cutter coverage, and this combined with the integrated completion string thread allows economical completion of a well with the high ROP expected from a PDC type bit. In an additional embodiment, a bit comprises a bit body and a cutting face having integrated cutting structures. The bit body has a central longitudinal bore having an integrated female non-shouldered, standard oilfield completion string thread. A unique bit manufacturing technique is also provided.

Owner:WHEELER JAMES L +1

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

Automobile hub isothermal forging and spinning forming process

InactiveCN102814621AReduce consumptionHigh precisionMetal-working apparatusWheelsTemperature controlCasting defect

The invention relates to an automobile hub isothermal forging and spinning forming process which mainly overcomes casting defects of proneness to shrinkage and looseness, low mechanical property and the like of a traditional metal mold casting blank forming method and overcomes the shortcoming that an automobile hub is large in machining allowance, high in production cost and difficult in wide application. The technical scheme includes that the process includes: cutting an aluminum alloy rod to a blank; preheating the blank to the temperature of 460 DEG C to 500 DEG C and then keeping the temperature for 1 hour; forging and pressing the blank for 3-4 times under a forging press to manufacture a pre-forging blank; preheating a die; placing the pre-forging blank into the forging die (controlling the die temperature at 400-450 DEG C) under a 1500t forging press, and performing isothermal forging for 2-3 times again to enable an aluminum alloy hub to be formed primarily; and spinning for precise forming. By the forming process, product manufacturing precision and strength are enhanced, and the forming process belongs to precise forming and is capable of effectively saving production cost and improving mechanical property of the hub.

Owner:韦光东

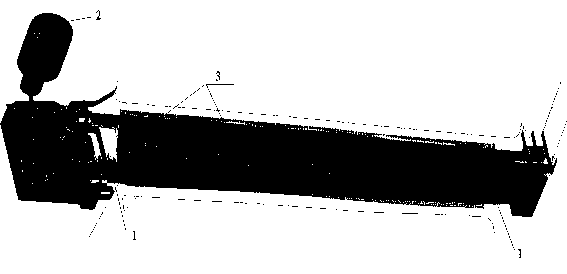

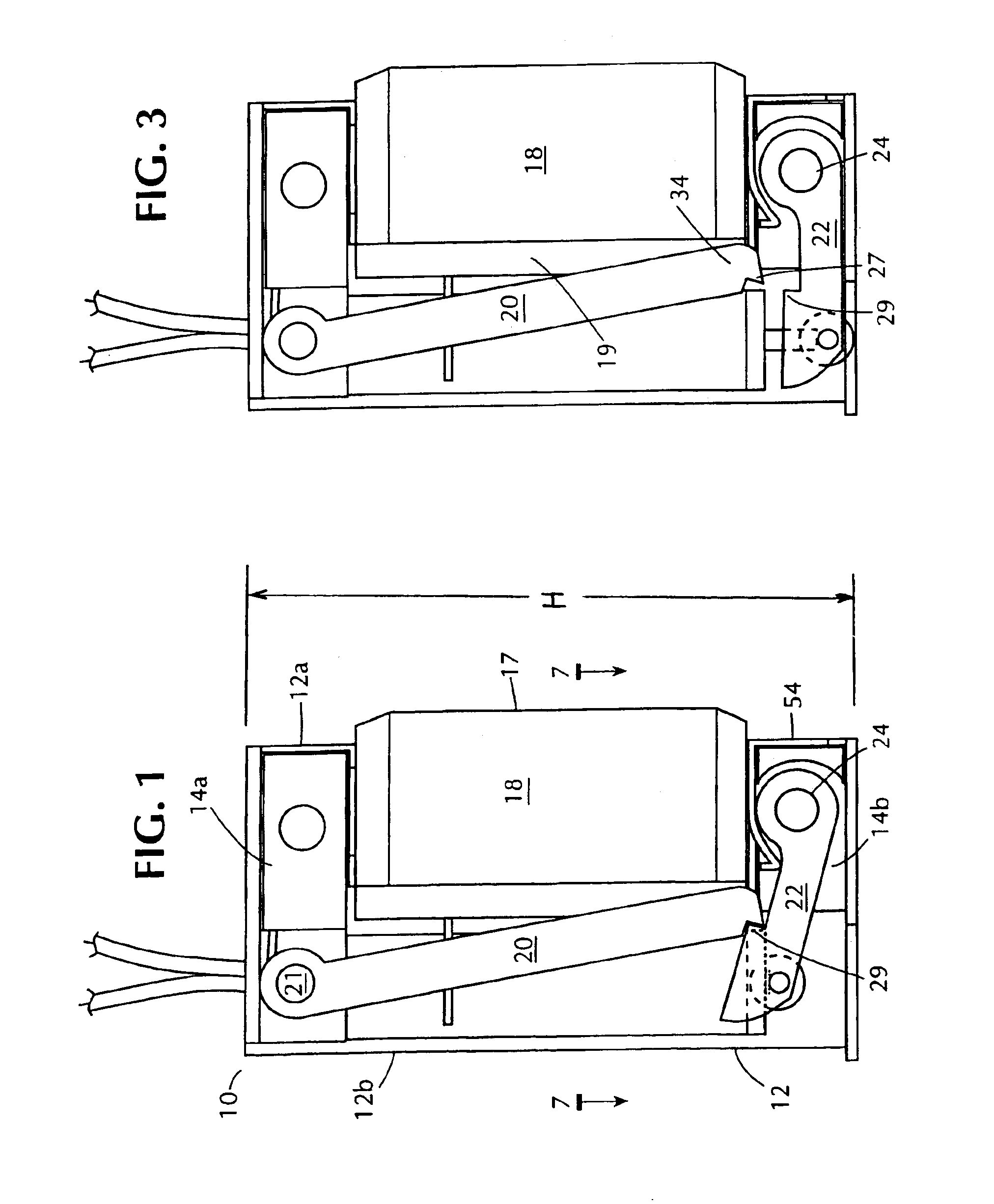

Electronically-operable door strike with guard clip, springless solenoid and face plate

InactiveUS6935663B2Reduce amountProblem can be overcomeNon-mechanical controlsBuilding repairsEngineeringMagnetism

An electronically-operable door strike employing a guard clip for deterring picking of the locking mechanism therein, a springless solenoid designed to avoid the undesirable build-up of residual magnetism and which incorporates air gaps for dissipating heat, thus prolonging the useful life of the solenoid, and a face plate for mounting the strike into a door jamb.

Owner:TRINE ACCESS TECH

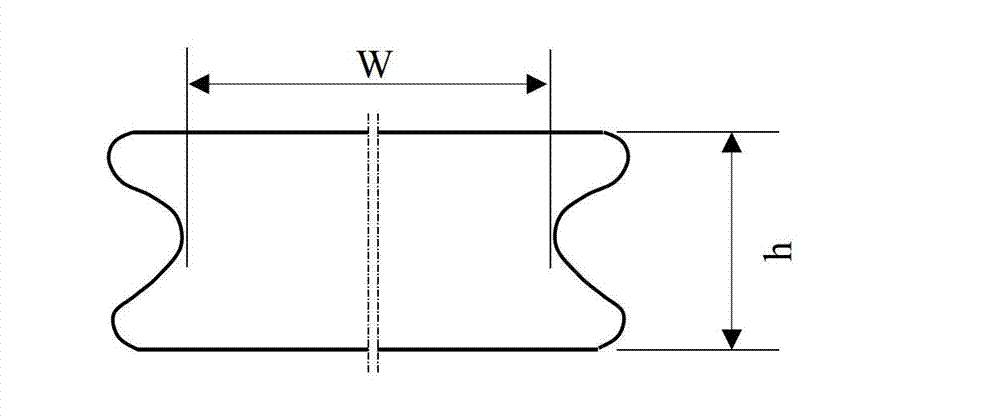

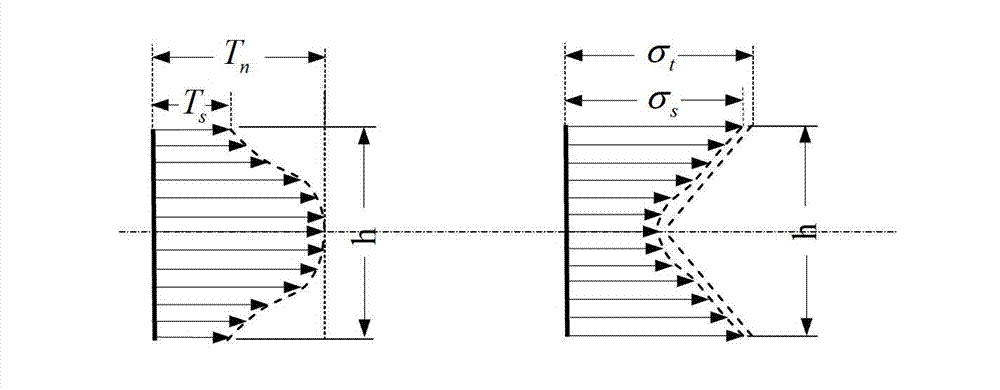

Press forming die set and method

A die set for press-forming a blank of thin metallic sheet. The die set has a punch and a blank holder. The blank holder has a first bead for restraining an edge of the blank with a constant force. The first bead is disposed further to an inside than a second bead for restraining the edge of the blank with a force that varies during pressing of the blank.

Owner:HONDA MOTOR CO LTD

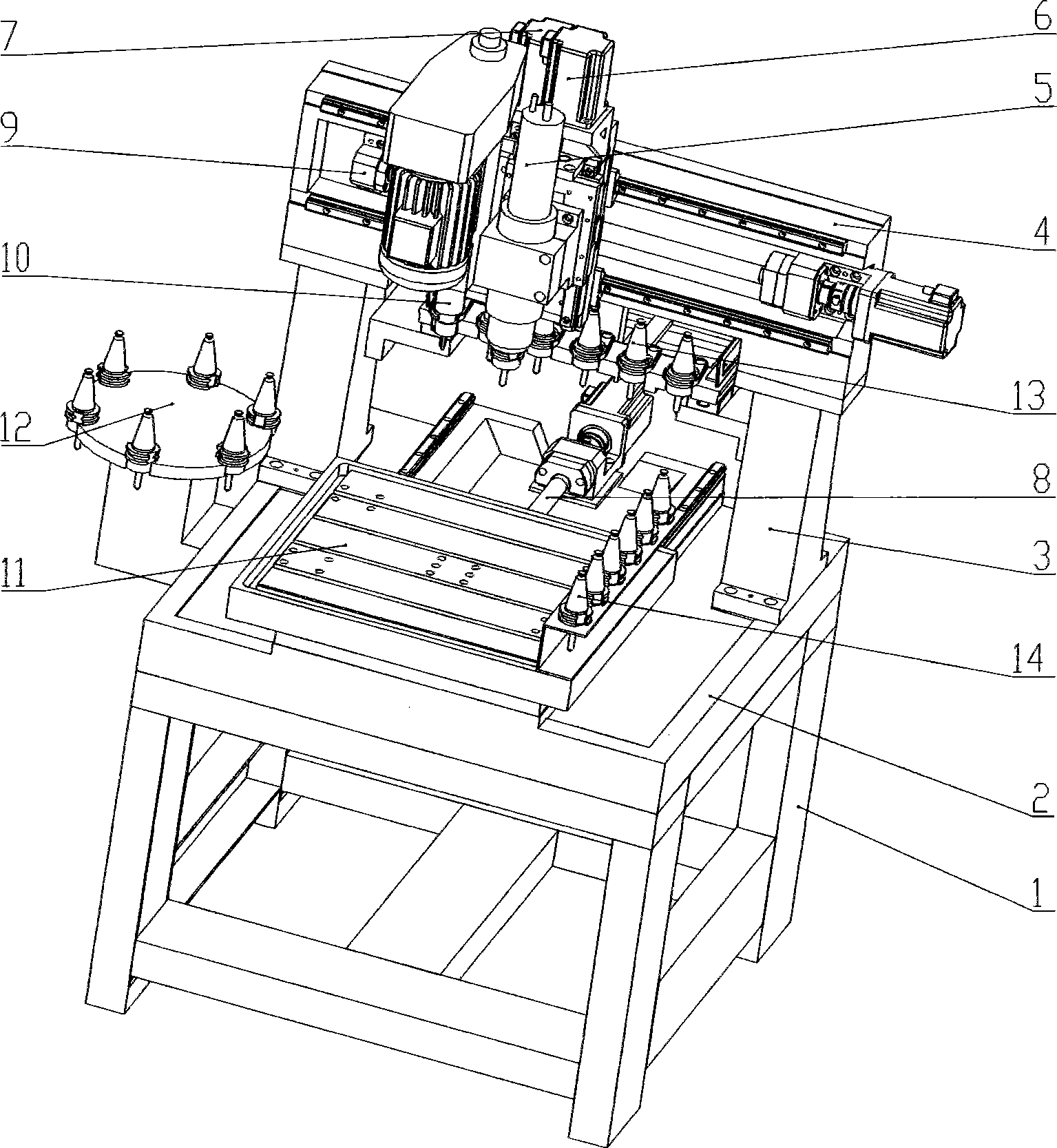

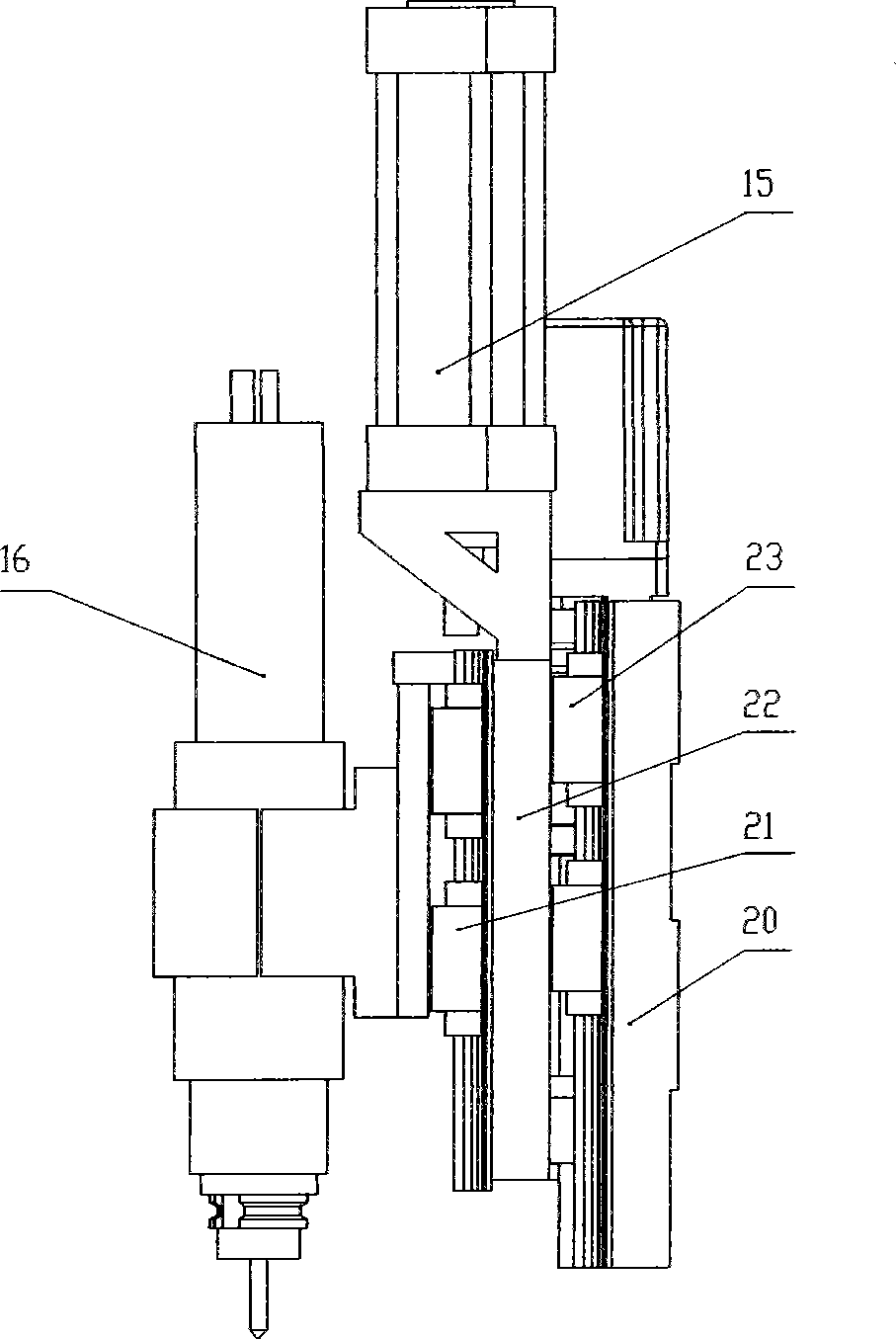

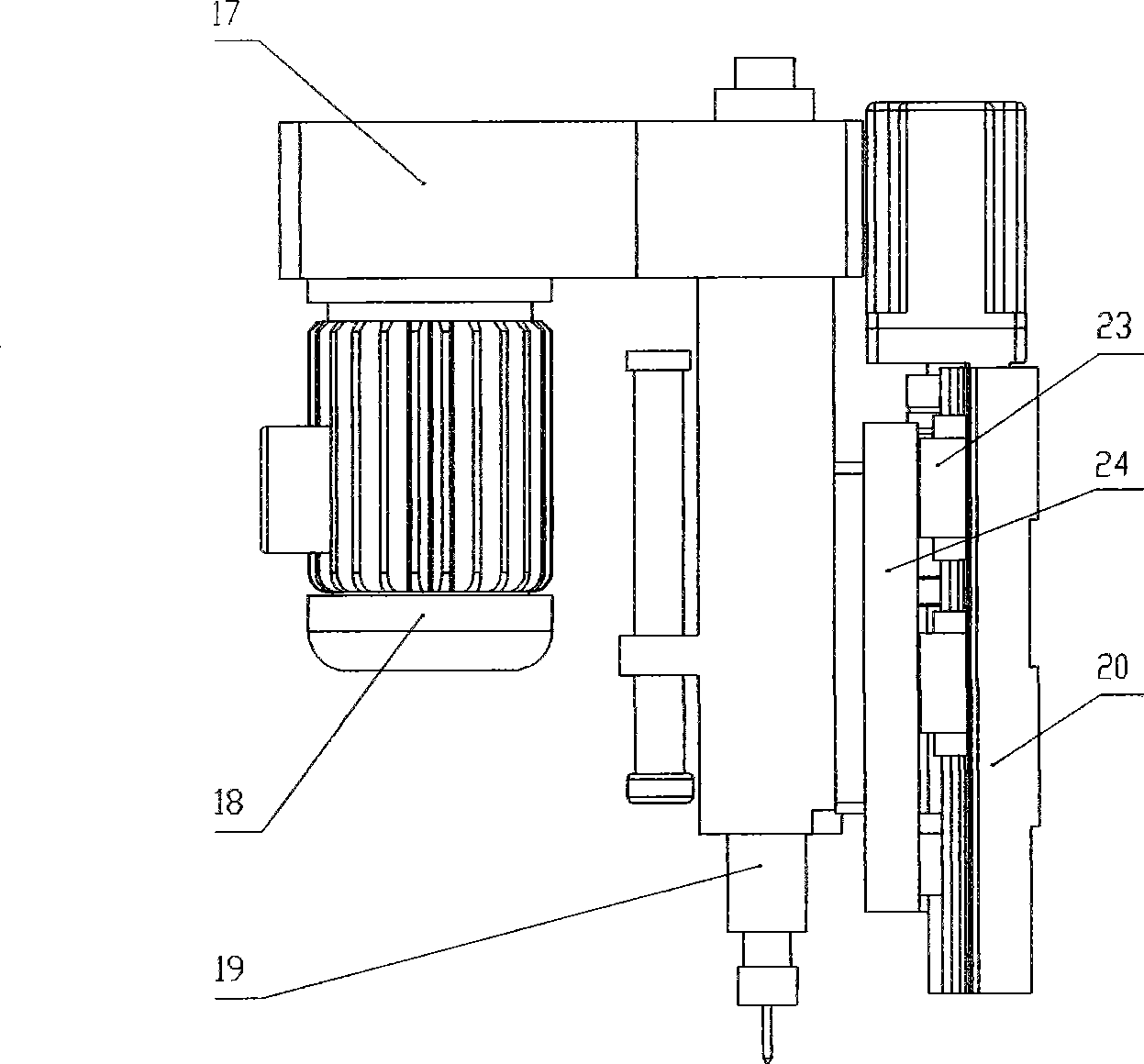

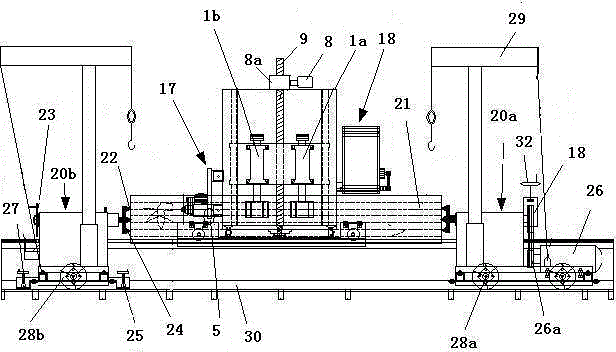

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

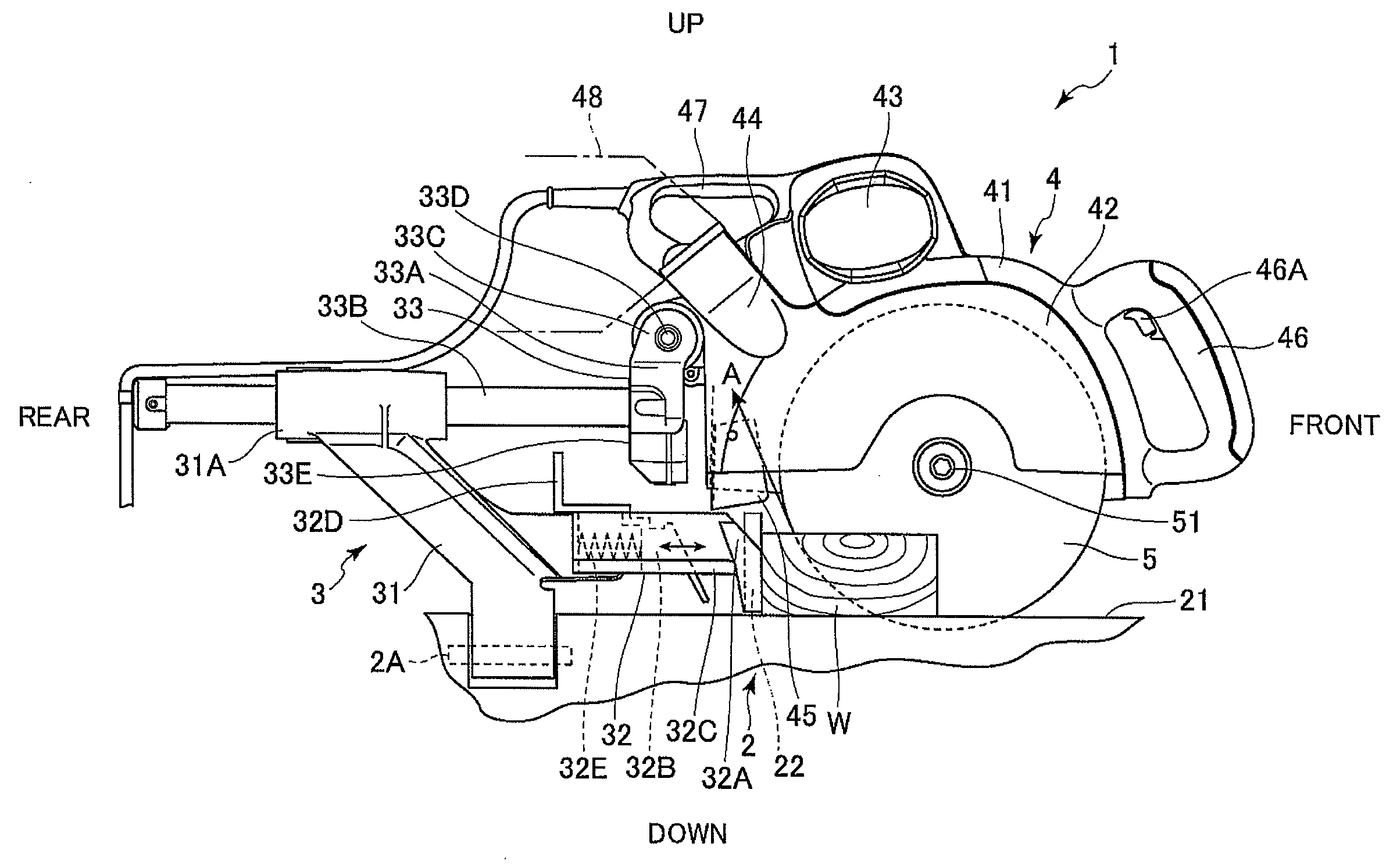

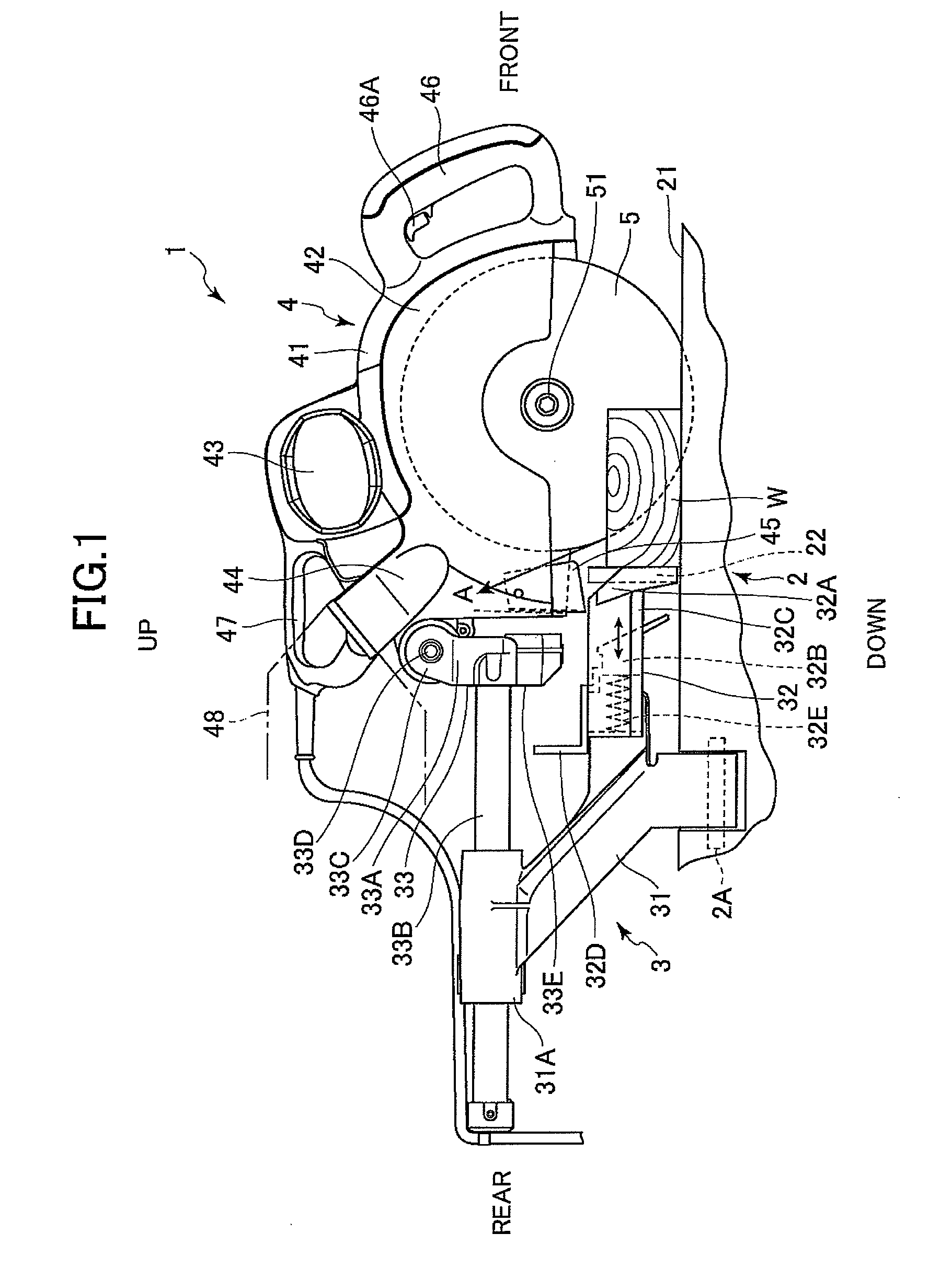

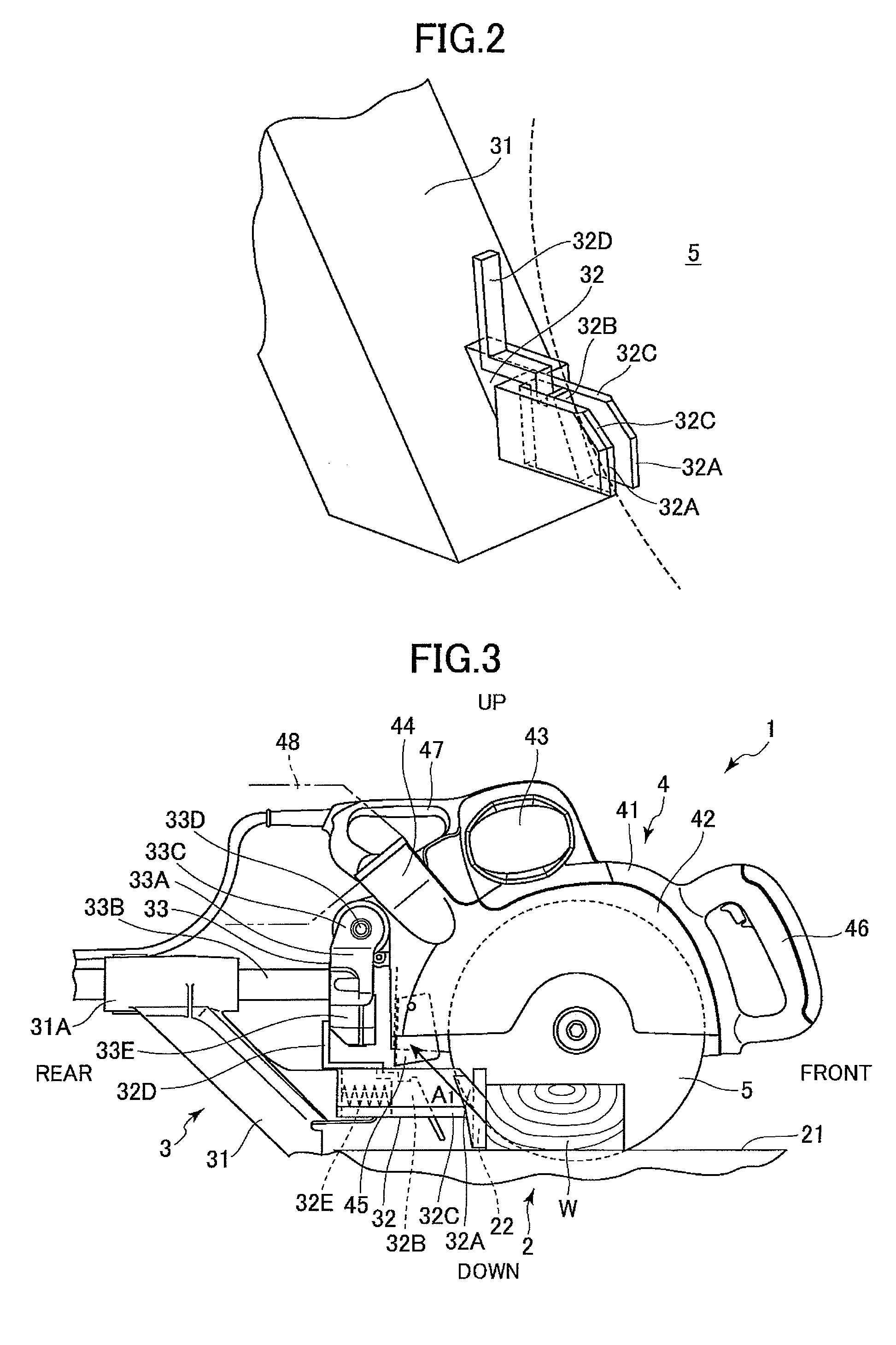

Miter Saw Having Slide Mechanism

InactiveUS20070163409A1Reduce the amount of cuttingMetal sawing devicesMetal sawing accessoriesMechanical engineering

A miter saw capable of reducing scattering amount of cutting chips at a terminal phase of cutting operation. The miter saw includes a base section for supporting a workpiece, a cutting section, and a support section for supporting the cutting section. The support section includes a slide support part extending from the base section, and a pivot support part for pivotally movably supporting the cutting section. The cutting section includes a cutting chip inflow part. A guard extends from the slide support part. The guard has a slope portion for guiding cutting chips toward the inflow part. The slope portion is positioned on an extension of an intersection line defined between the base section and a saw blade and is movable in the direction of the intersection line.

Owner:KOKI HLDG CO LTD

Manufacturing method of super-thick steel plate

ActiveCN103111464AReduced compression ratio requirementsLarge amount of deformationTemperature control deviceMetal rolling arrangementsThick plateIndustrial engineering

The invention discloses a manufacturing method of a super-thick steel plate (thickness is 60 millimeters) and belongs to the steel plate production field of metallurgical industry. The manufacturing method of the super-thick steel plate comprises the following steps: firstly, sending a plate blank which is heated to a certain temperature and removed an oxide scale to cooling space to conduct forced cooling, surface temperature cooling a phase transition temperature of the super-thick plate material above Ar 1, then by short time temperature returning, the surface temperature rising to the range between 780 DEG C and 880 DEG C, and sending the plate bland to a rolling mill to roll as soon as possible; when the surface temperature of the plate blank being higher than 880 DEG C, needing to conduct the forced cooling again, and then conducting the subsequent rolling. A cooling-temperature returning-rolling process can be repeated for many times if needed till rolling to the needed thickness of the super-thick steel plate. The manufacturing method of a super-thick steel plate can increase dependent variable of the central area by increasing temperature difference between a surface layer and the central area and has the advantages of being beneficial to refining central organization and improving impact toughness, beneficial to removing center porosity of the super-thick plate, and capable of reducing double strand shape on lateral sides of the super-thick plates. The manufacturing method of a super-thick steel plate further has the advantages of being saving in investment, and flexible to operate.

Owner:UNIV OF SCI & TECH BEIJING

Expansion soil ecological modifying agent and construction method

The present invention relates to technology of utilizing chemical reagent in treating expansion soil. The ecological expansion soil modifying agent consists of CMA weak acid resin liquid, water and active lime through full stirring. The ecological expansion soil modifying agent is sprayed to the surface in 1-3 times and penetrated into soil. Through ion exchange, gluing and curing, the expansion soil is altered in the structural characteristic, has raised strength and raised water stability, and is changed into non-expansion soil permanently. The said technology is simple, and the modified soil may be greened. The technology of the present invention is suitable for highway, railway, water engineering and other engineering.

Owner:陈永烽

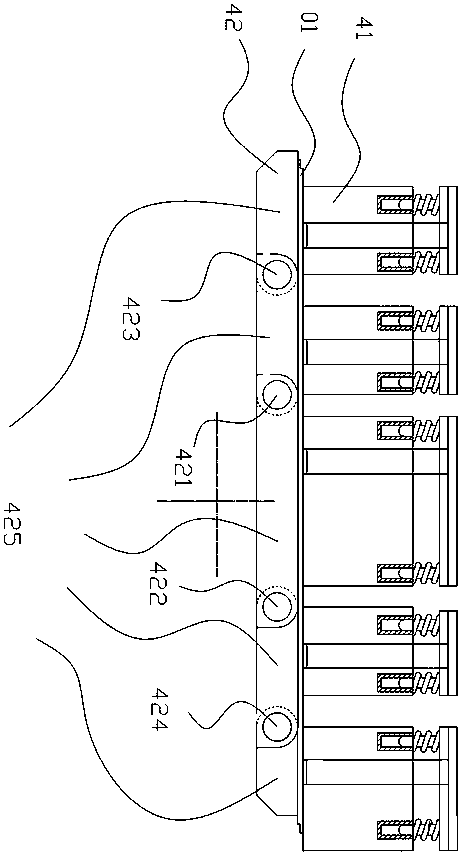

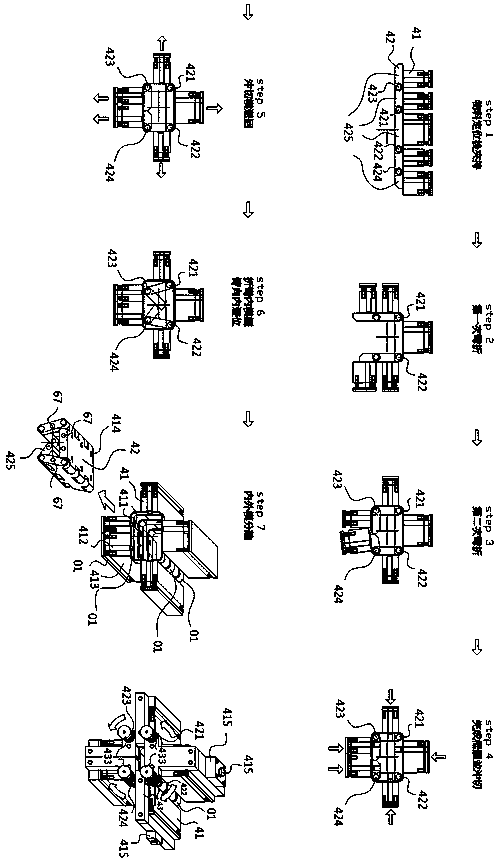

Bending and cutting integrated machine and method thereof

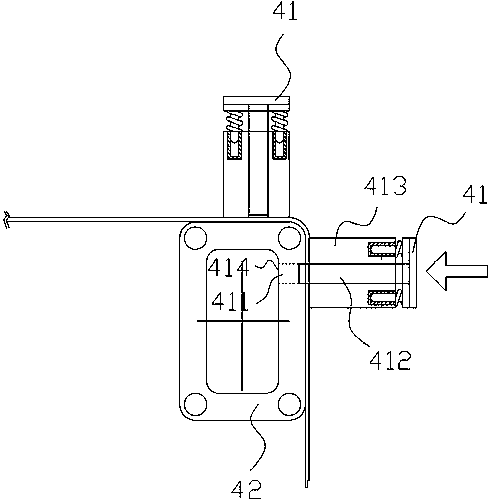

PendingCN107597968AReduce dependenceImprove segmental processingShaping toolsOther manufacturing equipments/toolsNumerical controlPunching

The invention relates to a bending and cutting integrated machine and a method thereof. A punching or cutting unit carries out punching or cutting operation before bending forming or after the bendingforming, and the punching or cutting unit applies force to a punching cutter through a punching driving device (415) to prompt the punching cutter to carry out shape and hole punching on a workpiece,or carries out shape and hole machining on the workpiece through a cutting tool on a numerical control mechanical arm when bending external moulds (41) and bending internal moulds (42) clamp the workpiece and are closed, it is avoided that the precision of a hole and a bend angle of each workpiece is reduced due to resetting after demoulding.

Owner:东莞市健耀烨电子科技有限公司

Cutting preparation method of nickel-based single-crystal alloy seed crystal for casting

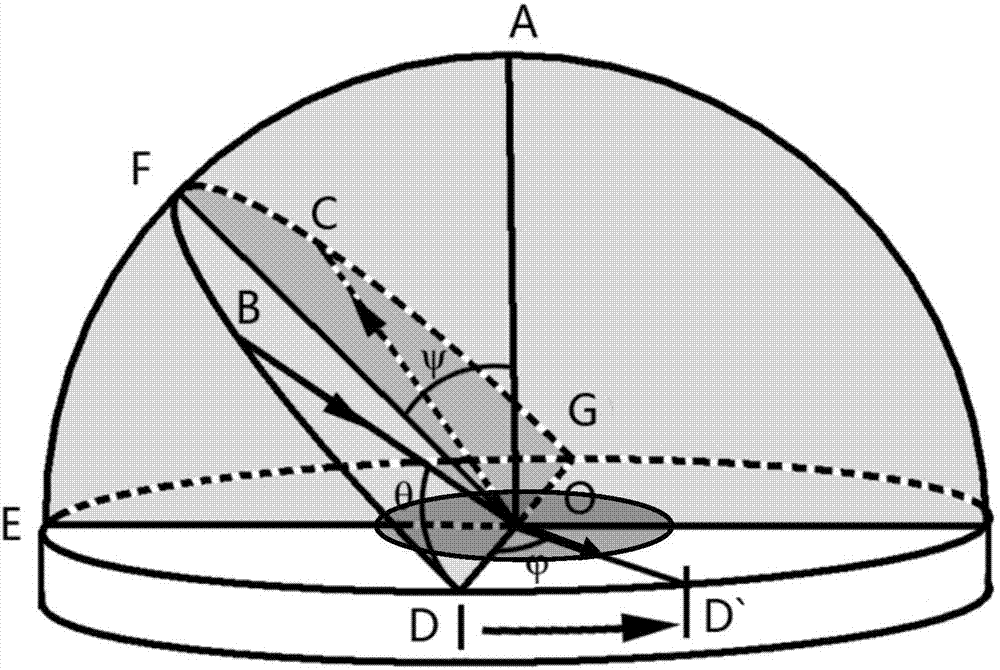

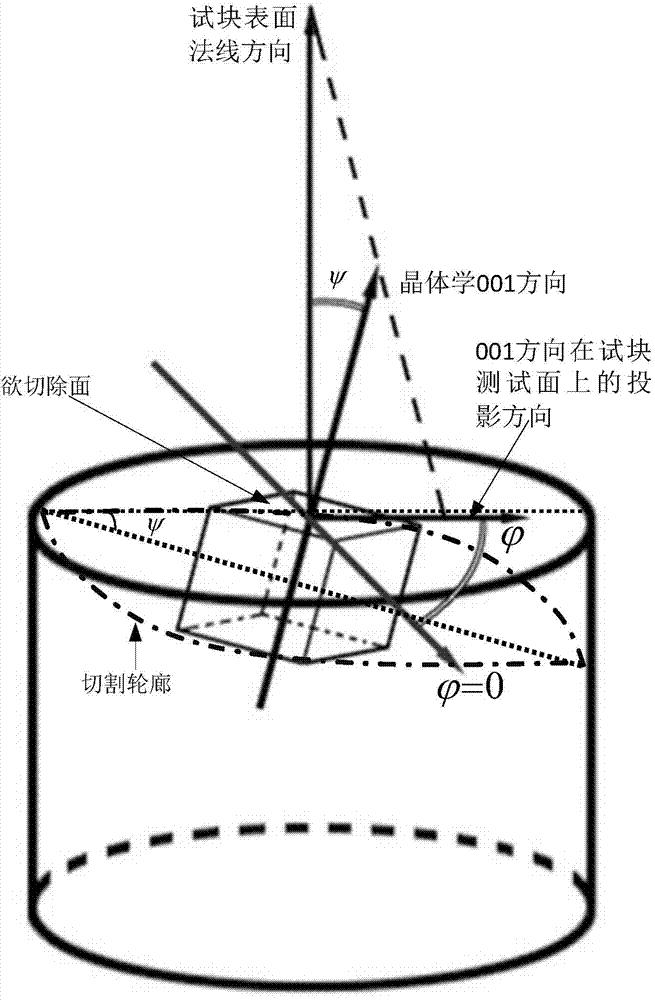

ActiveCN104846441AOrientation requirements are lowReduce the amount of cuttingPolycrystalline material growthFrom frozen solutionsWire cuttingX-ray

The invention discloses a cutting preparation method of a nickel-based single-crystal alloy seed crystal for casting. The cutting preparation method comprises the following steps of firstly machining a test rod or test plate which is used for preparing a seed crystal to obtain a test block with an upper parallel section and a lower parallel section, and carrying out polishing treatment on one of the parallel sections of the test block to obtain a polished surface; fixing the test block with the polished surface upward in the center of a rotating disc of an X-ray stress tester, marking a direction on the polished surface of the test block; determining an X-ray diffraction angle of a test block material, and scanning the psi angle and angle of the test block by utilizing the X-ray stress tester; carrying out the single-crystal directional cutting of the psi angle and an deflection angle by utilizing a wire cutting machine; finally preparing the seed crystal. The cutting preparation method disclosed by the invention has excessively low requirement on the orientation of an original single-crystal test rod, can directly obtain the seed crystal with orientational characteristics of (001), (011) and (111) through cutting and is low in processing cost. The seed crystal obtained through cutting has the advantages of high accuracy, good repeatability, high surface smoothness and no reprocessing.

Owner:成都航大新材料有限公司

Circular deep foundation ditch concrete pile arranging support and major structure inversing construction method

InactiveCN101457526AEasy constructionFast progressExcavationsBulkheads/pilesIndustrial constructionSoil horizon

The invention belongs to the construction method of a deep foundation pit of industrial construction, particularly relates to a reverse operating construction method of a round deep foundation pit concrete piling support and a main structure and solves the problem that the existing construction method of the deep foundation pit is not suitable for complex geological condition and the construction cost is too high. The construction method comprises the following steps: the center of the foundation pit is adopted as the center and the outer sides of the position of the main structure are respectively distributed with pilings; the top parts of the pilings are poured with crown bore beams which connects the top parts of the pilings into one body; the first section of the foundation pit is excavated, reverse operation is carried out to the outer layer of the first section of the main structure; the outer layer of the first section of the main structure and the pilings are integrated by the crown bore beams so as to form a primary support of the foundation pit; the foundation pit is excavated by sections, reverse operating construction of the outer layer of the main structure is carried out by sections, which form a foundation pit support together; and normal operating construction is carried out to the inner layer of the main structure. The invention is applicable to poor geological condition and is particularly applicable to structural diversity of the soil layer in the depth range of excavation of earthwork, thus ensuring the stability of the soil body of the main structure in the construction period, greatly reducing the cost of construction measures and improving the construction speed.

Owner:MCC TIANGONG GROUP

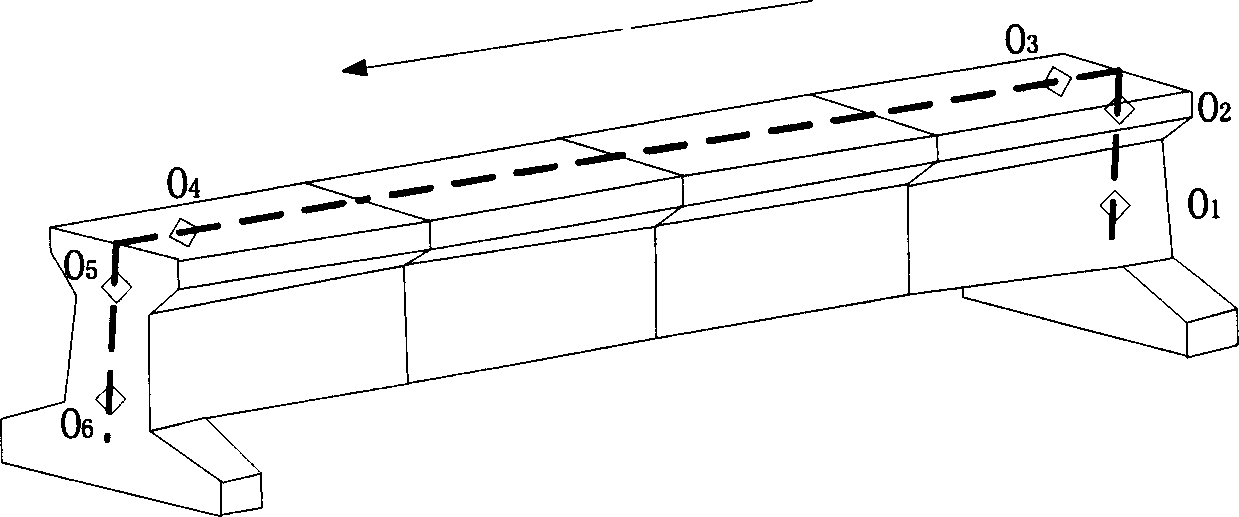

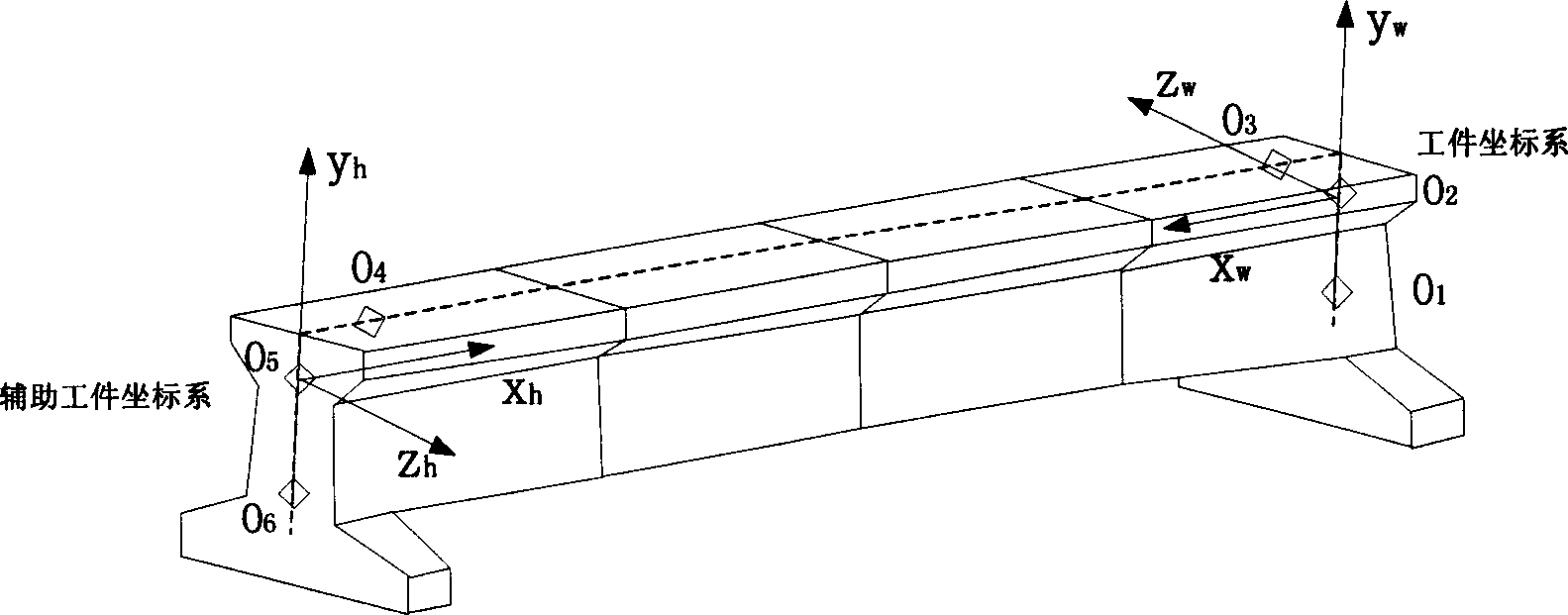

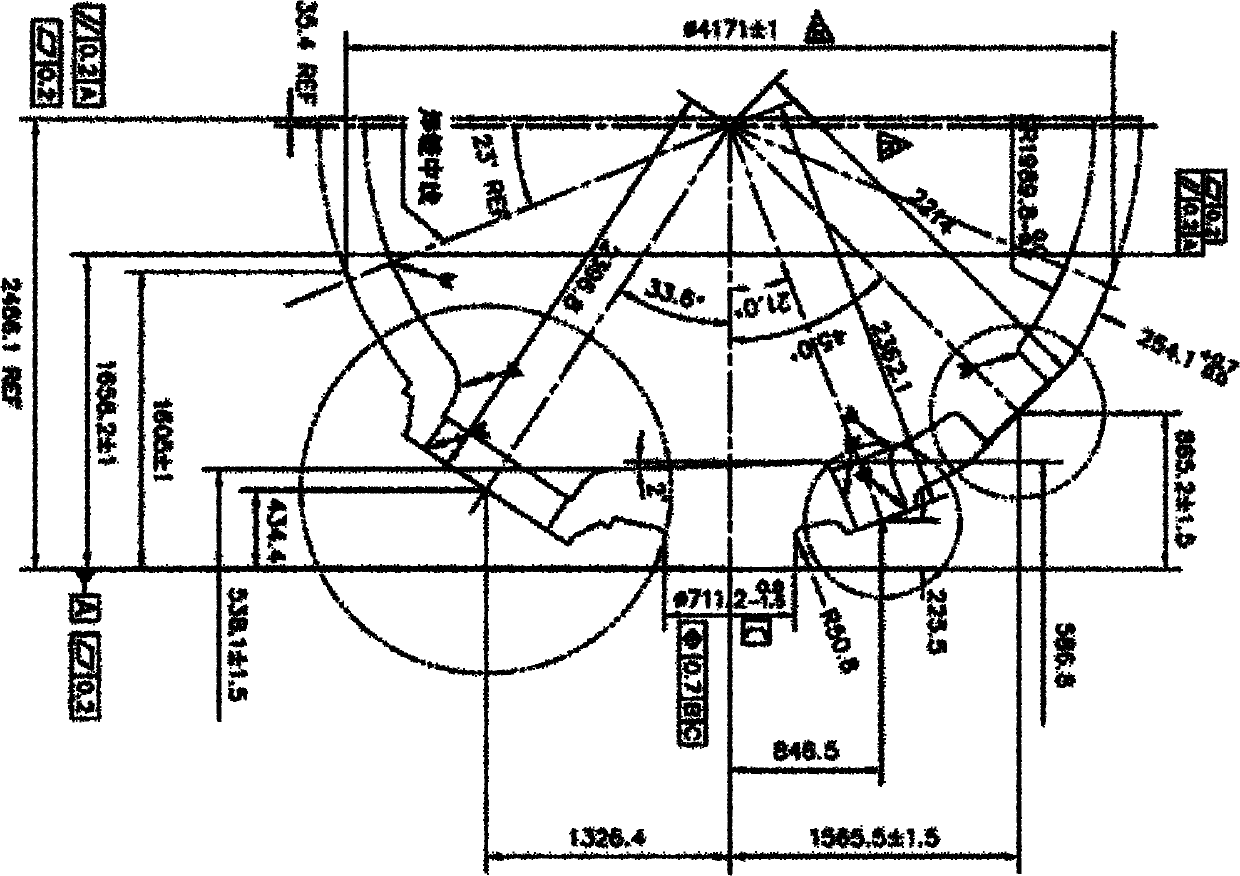

Locating method for large size work pieces in machine work

InactiveCN1446666ASimplify tightening positioning requirementsEasy to compileAutomatic control devicesMeasurement/indication equipmentsNumerical controlMeasurement device

A method for searching the machining position of large workpiece includes such steps as primary fixing on machine-tool, measuring the 2D coordinates of 6 points on the workpiece by the optical reading head on the mainshaft of machine-tool and moving the numerally controlled machine-tool comparing them with theoretical 3D coordinate of said 6 points on CAD model of the workpiece, homogenizing and optimizing the errors to obtain the coordinates of the workpiece in the coordinate system of machine-tool, regulating the position of workpiece in CAD / CAM system, and generating actual machining program. Its advantage is high productivity.

Owner:TONGJI UNIV

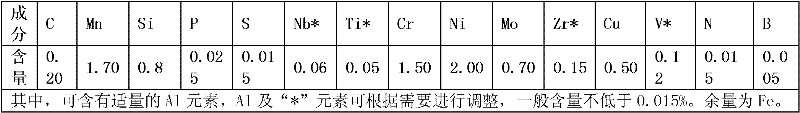

Forging method for water chamber head of steam generator of third-generation nuclear power station

InactiveCN102554084AReduce processing difficultyReduce the amount of cuttingMetal-working apparatusNuclear powerNuclear engineering

The invention discloses a forging method for a water chamber head of a steam generator of a third-generation nuclear power station, which is used for forging the water chamber head of the steam generator of the third-generation nuclear power station. The internal spherical radius of the water chamber head is no less than 1500mm, the water chamber head comprises a bent section, a straight section and a nozzle, and double vacuum steel ingots are used as raw materials. The forging process includes the steps: firstly, cogging; secondly, combined forging; and thirdly, rotating extrusion. A megaton free forging press is used for forging the double vacuum steel ingots into cylindrical billets, and then the internal shape of a forging is forged by means of rotating extrusion through a mould. The forging manufactured by the forging method can meet the technical requirement of the water chamber head, water chamber head forging materials are compact, reasonable in metal flow line distribution and not easy to crack, difficulty in machining is reduced, metal cutting output is less, and machining difficulty and cost can be reduced.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Combined shaping mold

ActiveCN101244443AMeet the technical requirements of productionReduce the amount of cuttingShaping toolsFilling rateMetal cutting

The invention discloses a composite forming die for production of elbow, satisfying the high requirements of shape and position dimensions of superior elbow, which comprises an upper die, a bottom die and a core die; wherein, the core die is made by metal; the spatial filling rate of core die filling tube interior is above 95%. The composite forming die has the advantages of satisfying the high technical requirements of shape and position dimensions of superior elbow, good performance and metal structure of tube body, low machining difficulty, small amount of metal cutting, light weight of semifinished product piece, circular bending part of elbow, good feature of bending back arc thickness reduction, good feature of nominal wall thickness, good feature of minimum wall thickness, preventing non-roundness and thickness reduction of bending part, and being applicable to a plurality of superior elbows requiring the high demands of shape and position dimensions, compared with the prior elbow made by the method of machining.

Owner:ERZHONG GROUP DEYANG HEAVY EQUIP

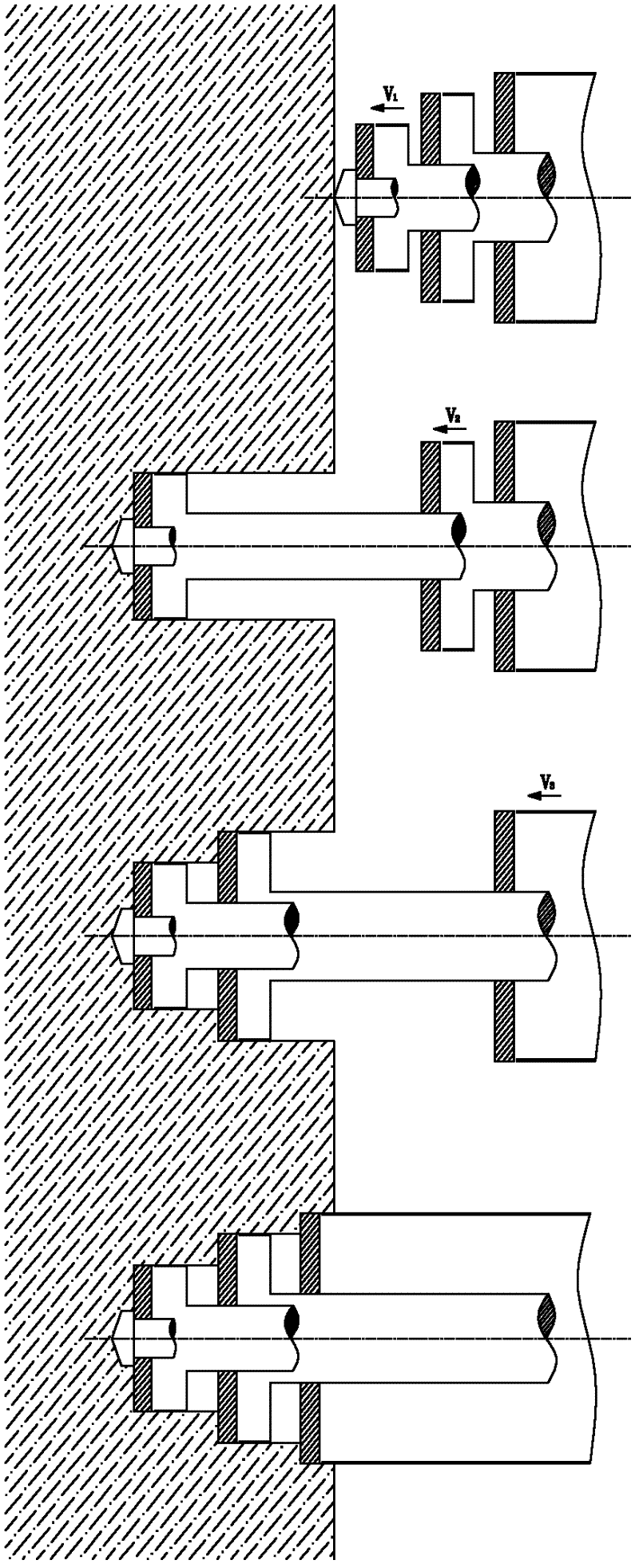

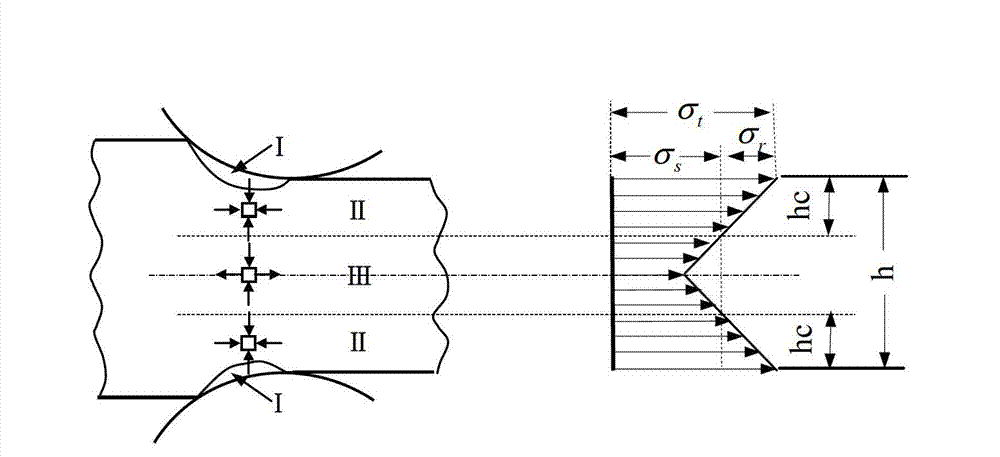

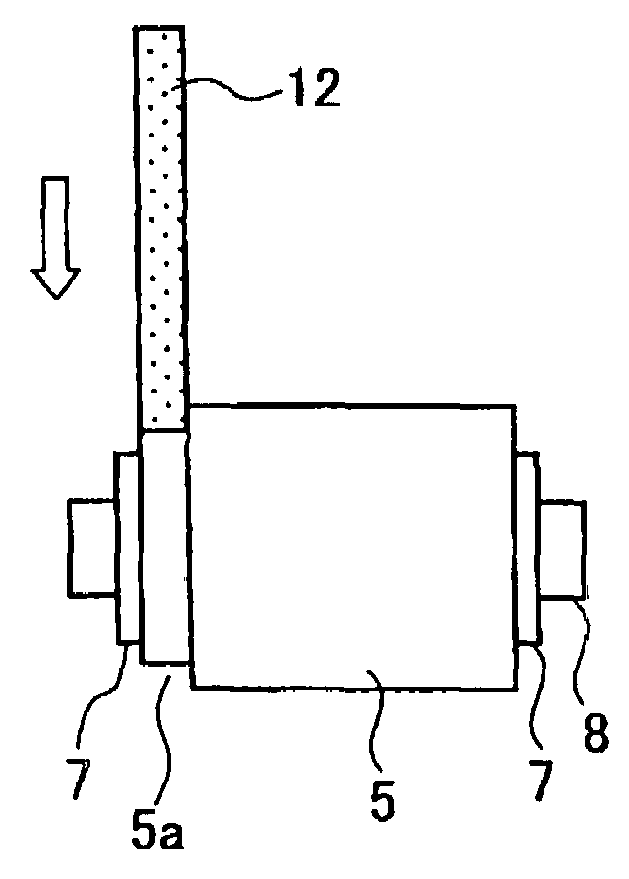

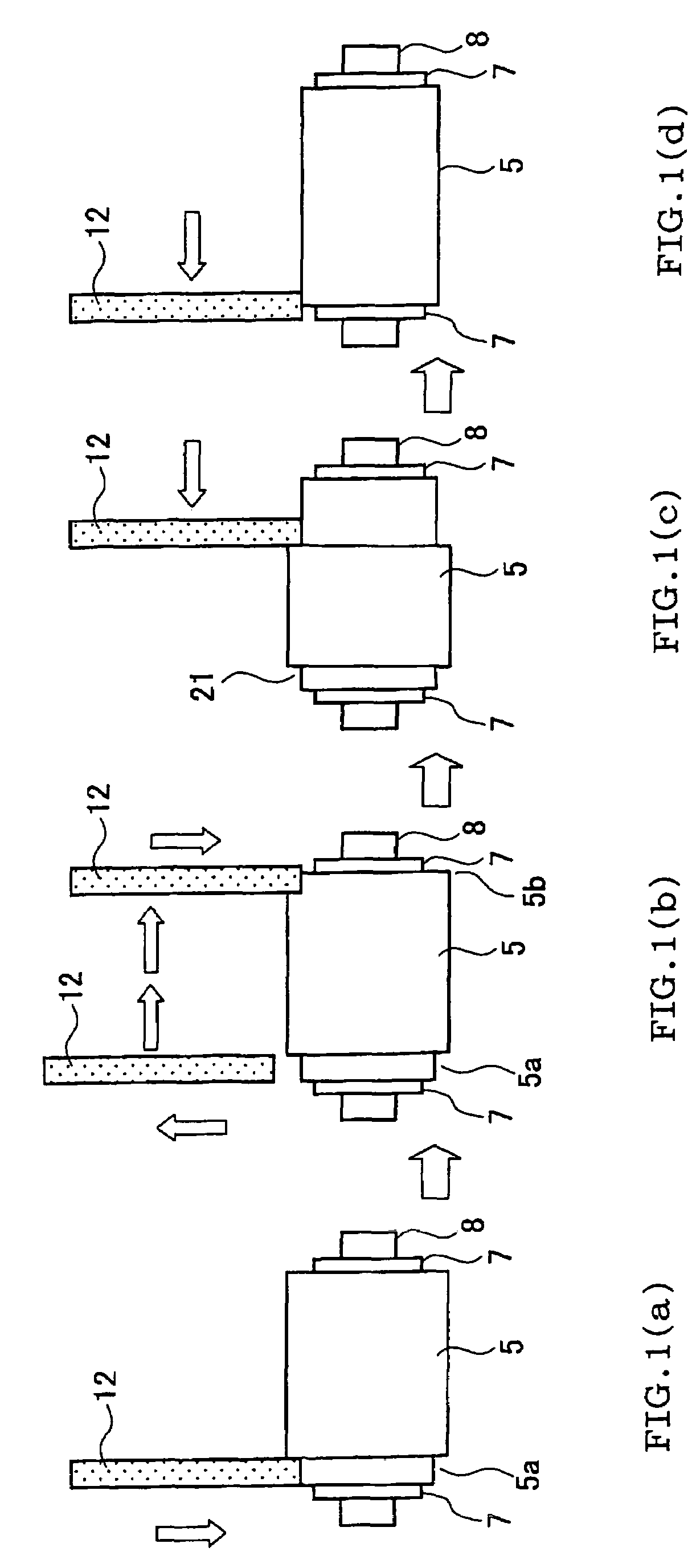

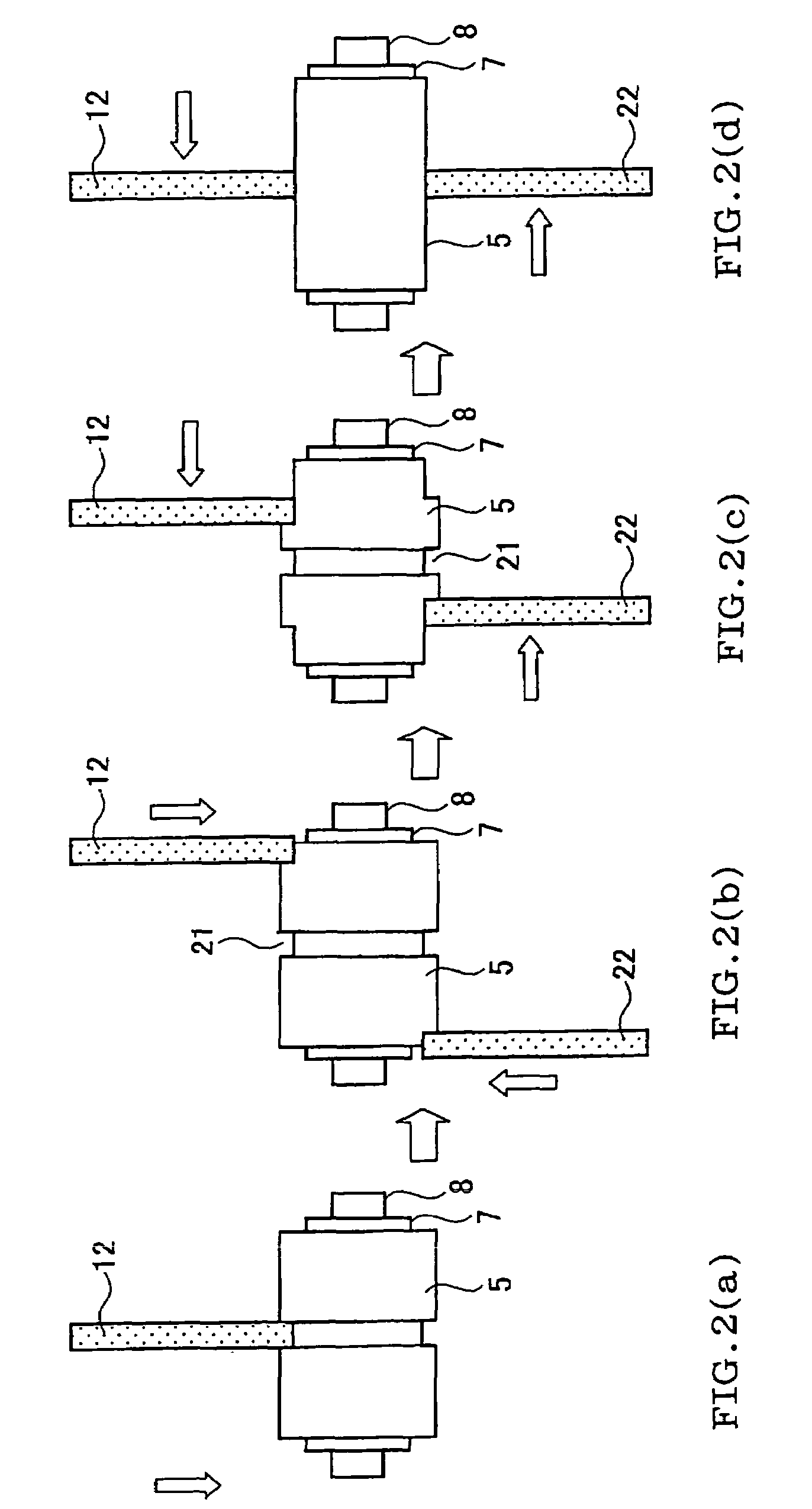

Grinding method

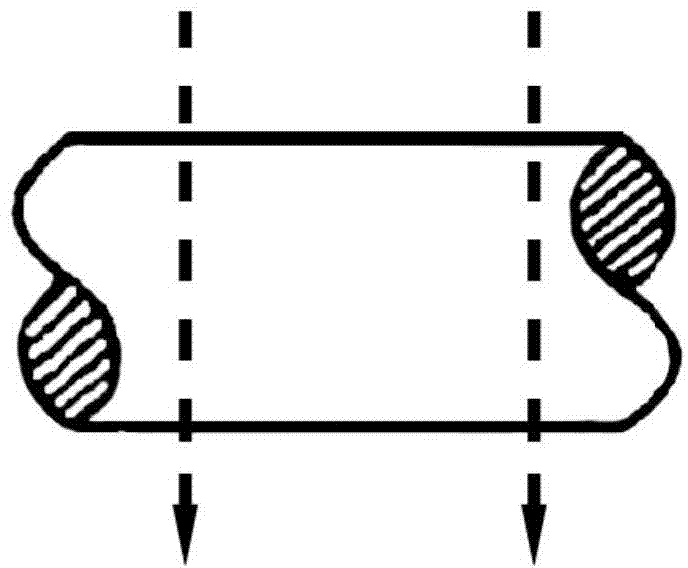

ActiveUS7452263B2Reduce the amount of cuttingAmountRevolution surface grinding machinesGrinding feed controlRotational axisEngineering

A method of grinding the outer circumferential surface of a workpiece 5 formed of a hard and brittle material into a predetermined shape using a grinding wheel while rotating the workpiece 5 is disclosed. The method includes plunge grinding the workpiece 5 at an arbitrary portion (plunge ground portion 21) in the longitudinal direction of the workpiece 5 by causing the grinding wheel to come in contact with the workpiece 5 in a direction which intersects a rotational axis 8 of the workpiece 5, and traverse grinding the workpiece 5 toward the plunge ground portion 21 by moving the grinding wheel relative to the workpiece 5 in a direction parallel to the rotational axis 8 of the workpiece 5. This allows the outer circumferential surface of the workpiece made of a hard and brittle material, such as a honeycomb structure used for a DPF, to be ground into a predetermined shape in a short time, and prevents occurrence of chipping during grinding.

Owner:NGK INSULATORS LTD

Manufacturing method for decorated eyeglass frame or eyeglass leg

The invention discloses a manufacturing method for a decorated eyeglass frame or eyeglass leg, comprising the steps of molding and processing, wherein the step of molding comprises the step of puttingdecoration and plastic raw materials into a molding cavity of a die mold, once die-casting a hard base material, and the step of processing comprises the step of machining the base material to manufacture the final eyeglass frame or eyeglass leg. Compared with the traditional manufacturing method of eyeglass frame or eyeglass leg, the invention has the advantages that a same eyeglass frame or eyeglass leg can be molded with a double-color or multi-color effect, the processing efficiency and processing quality are higher and the method is more environment-friendly because the processing needsno glue or solvent.

Owner:邱湟鏻

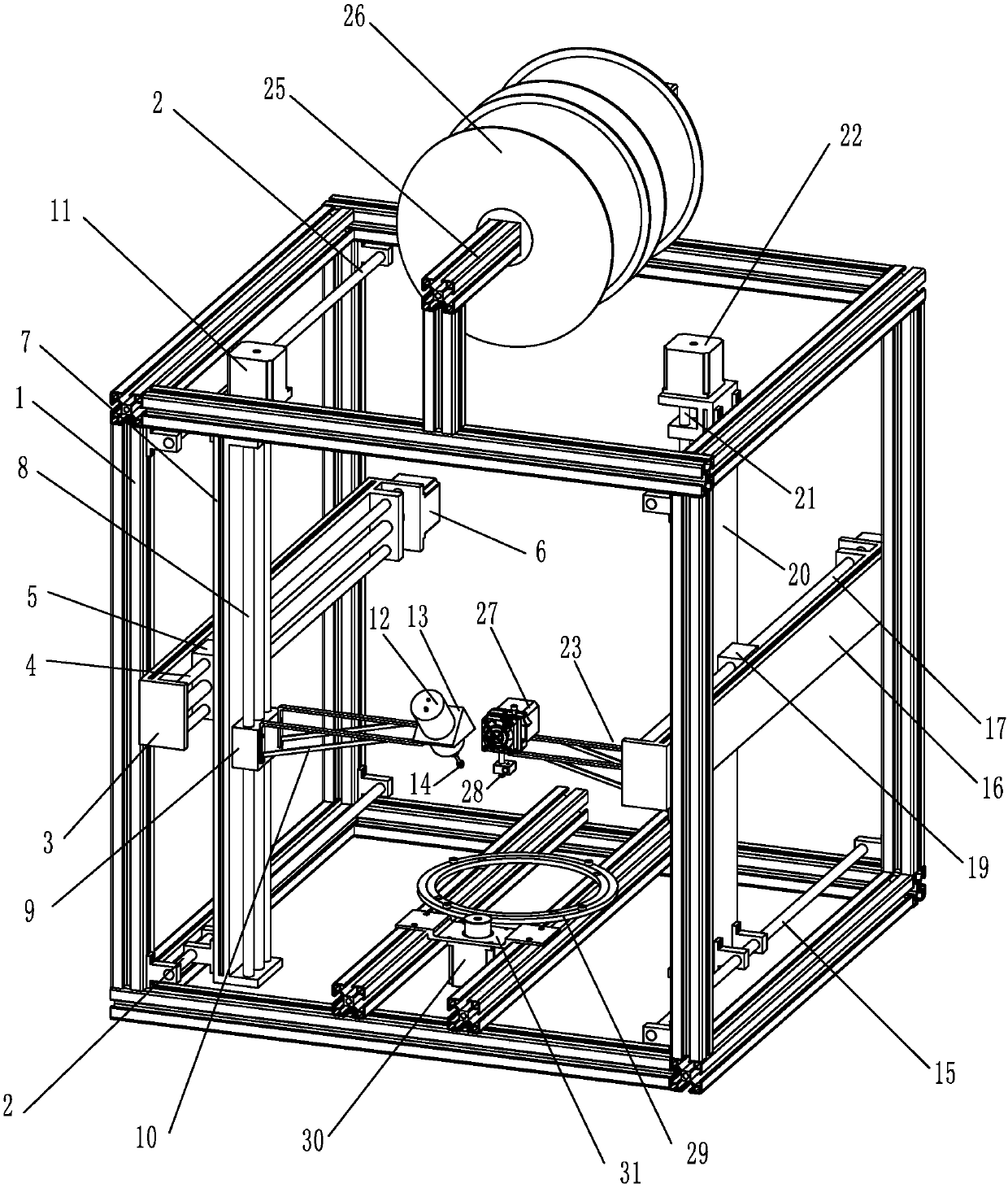

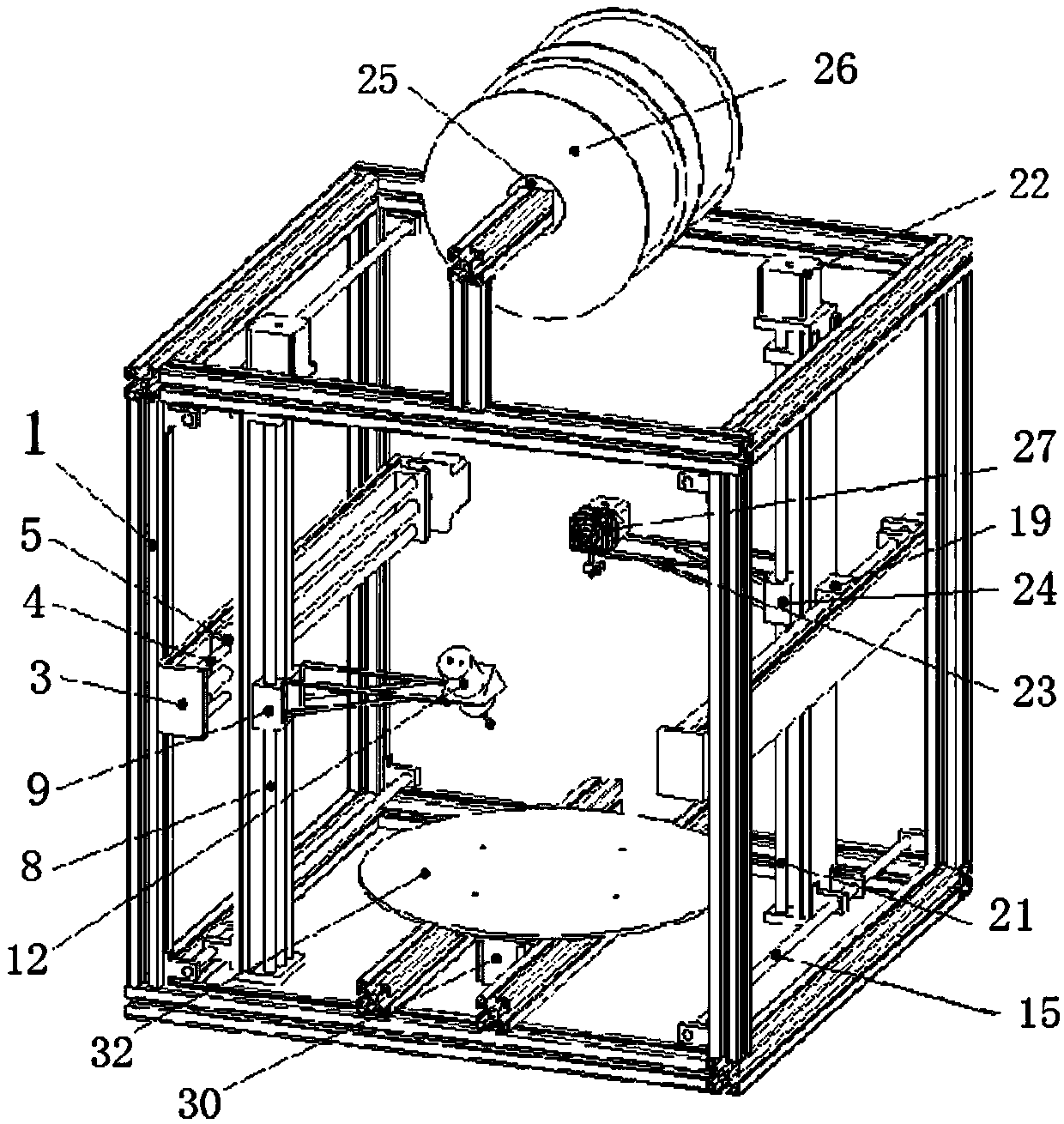

Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

PendingCN107672162AImprove flexibilityShorten the timeEdge grinding machinesAdditive manufacturing apparatusWear particleSurface roughness

The invention discloses a table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function, and relates to table top material increasing and decreasing wood-plastic composite 3D printers. In order to solve the problem that the shape accuracy, dimensional accuracy, surface quality and the like of parts are both limited by the single-layer printingthickness and plane printing accuracy in an existing 3D printing layer-by-layer stacking manufacturing mode, the table top material increasing and decreasing wood-plastic composite 3D printer comprises a rectangular frame (1) and further comprises a material decreasing assembly, a material increasing assembly and a material increasing and decreasing working platform. The material increasing and decreasing working platform is installed at the lower end of the rectangular frame (1) in a rotating mode. The material decreasing assembly and the material increasing assembly are installed on the rectangular frame (1). According to the table top material increasing and decreasing wood-plastic composite 3D printer, the wood-plastic composite is used as a manufacturing raw material to be stacked layer by layer, so that the material increase manufacturing technology is implemented; and a grinding wheel serves as a cutter in abrasive machining, and grinding wheel abrasive particles serve as cutting blades so that the size and shape accuracy and surface roughness needs required can be met. The table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function is used for wood-plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

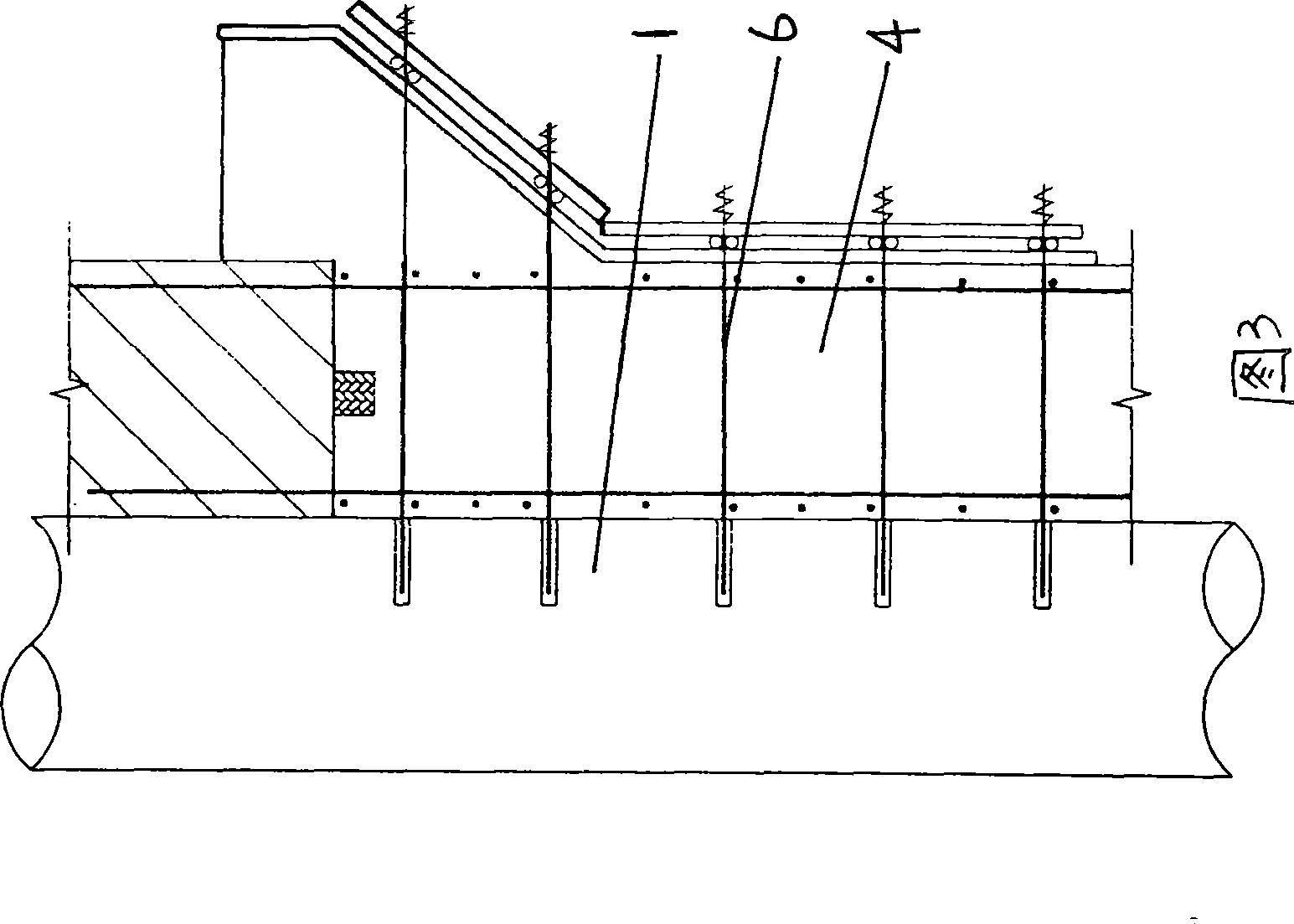

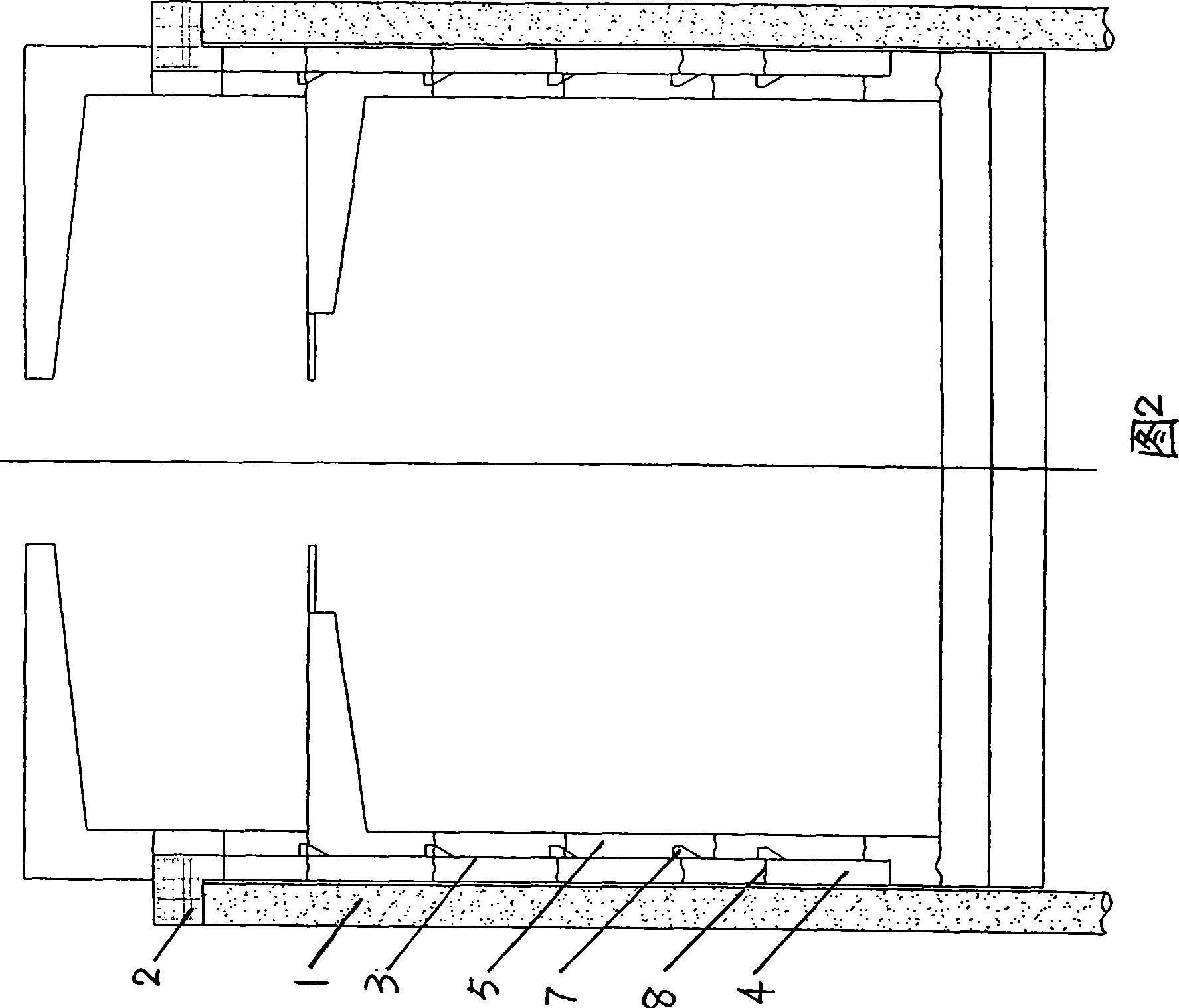

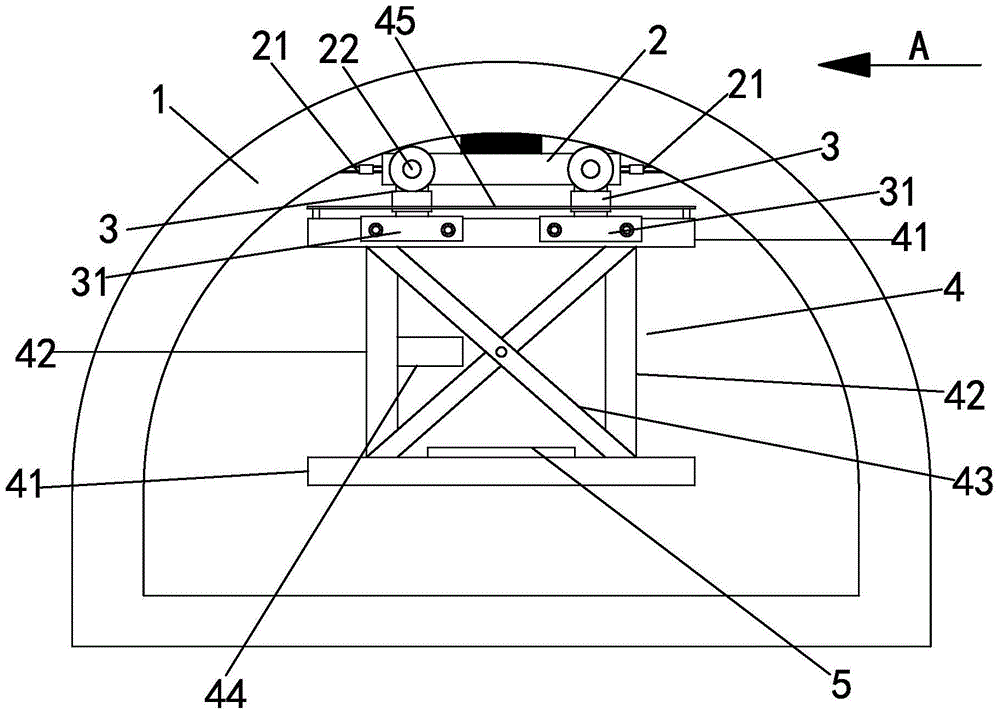

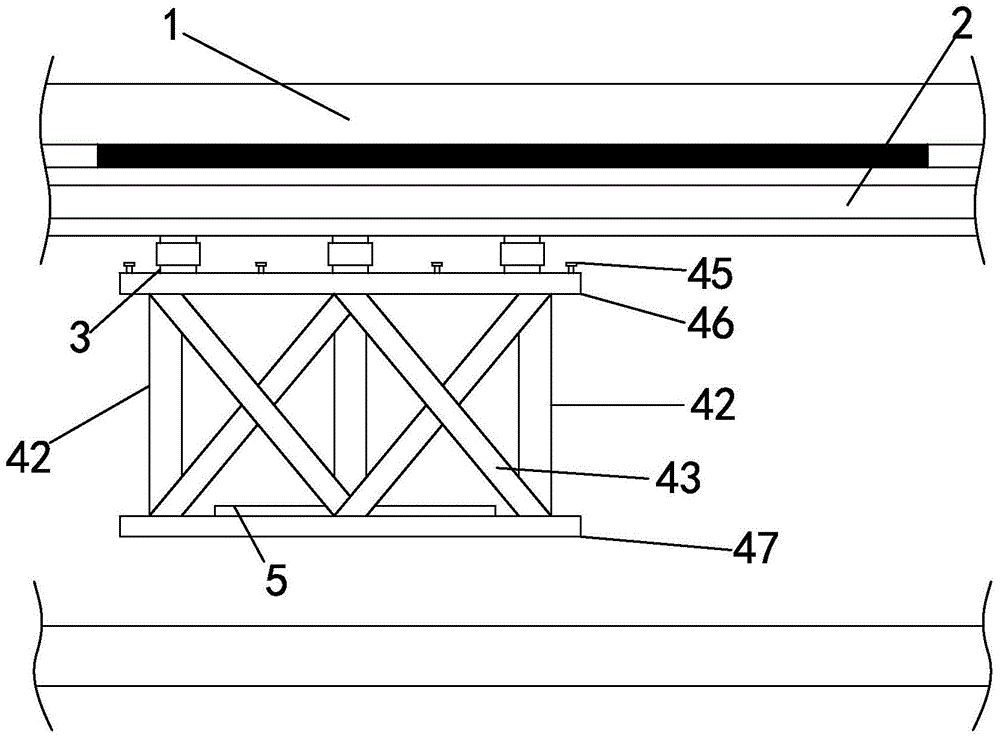

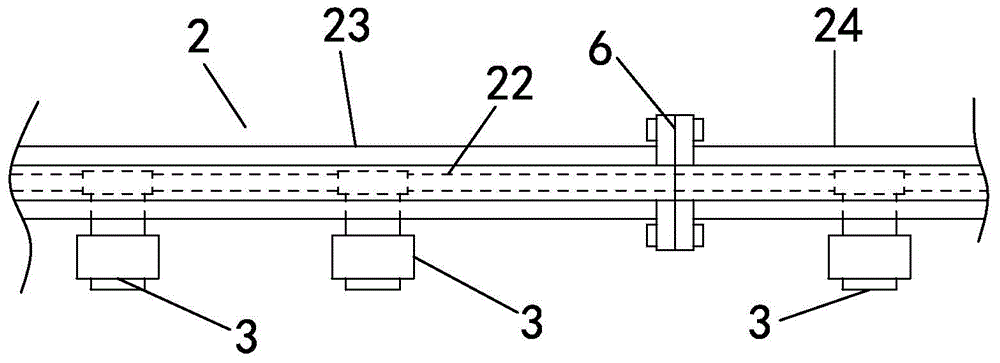

Rack for tunnel excavation and adit construction method applying rack

ActiveCN104533449AEasy to moveImprove work efficiencyUnderground chambersDrainageAditAutomatic control

The invention discloses a rack for tunnel excavation and an adit construction method applying the rack. The rack is automatically controlled through a cable, construction accuracy can be improved, the moving range of the rack can be adjusted, and the rack is very suitable for adit construction. In addition, a device fixing apparatus is added on the rack, movement of a part of machines and tools is facilitated, the machines and tools can be used in the construction process at any time anywhere, and the working efficiency of the adit construction and construction effect can be remarkably improved. The adit construction method applying the rack is characterized by comprising the following steps of (a) construction preparation, (b) opening plane arrangement, (c) spoil area site selection, (d) protection and greening of a spoil area site, (e) opening excavation, (f) main tunnel first-stage construction, (g) rack assembly and (h) main tunnel second-stage construction. The main tunnel construction is performed in a two-stage mode, mutual reference can be achieved in the construction process, and project quality can be improved.

Owner:CHENGLONG CONSTR GROUP

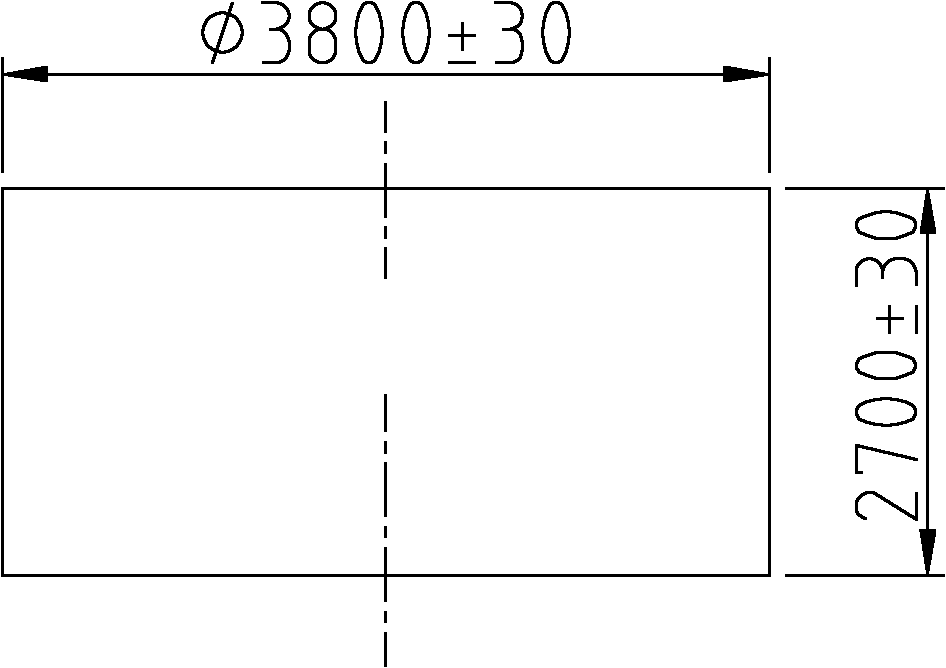

Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

ActiveCN102416463AAchieve the purpose of near-net shape in melting and castingHigh dimensional accuracyManufacturing technologySlag

The invention discloses an electroslag fusion casting manufacturing method for an annular plate of a hydraulic generator. The method is characterized by comprising the following steps of: 1) controlling slag systems and slag amount; 2) igniting; 3) selecting a crystallizer; 4) rotating the crystallizer by using a control system; 5) selecting power supply parameters; 6) controlling casting alloy components after fusion casting; and 7) selecting a casting thermal processing process. A near-net-shape forming annular plate manufacturing technology is provided for producing annular anti-tear steel plates for hydraulic generator seat rings, top covers and bottom rings at present; a rotatable crystallizer is used for electroslag fusion casting formation, so that technical requirements on production of the annular plate are met; and the produced annular plate has high laminated tearing resistance, higher fatigue resistance and higher crack generation and expansion resistance, and the quality and the performance of the annular plate are not lower than those of a specially-forged product which is made of the same material as that of the annular plate.

Owner:沈阳市盛华特种铸造有限公司

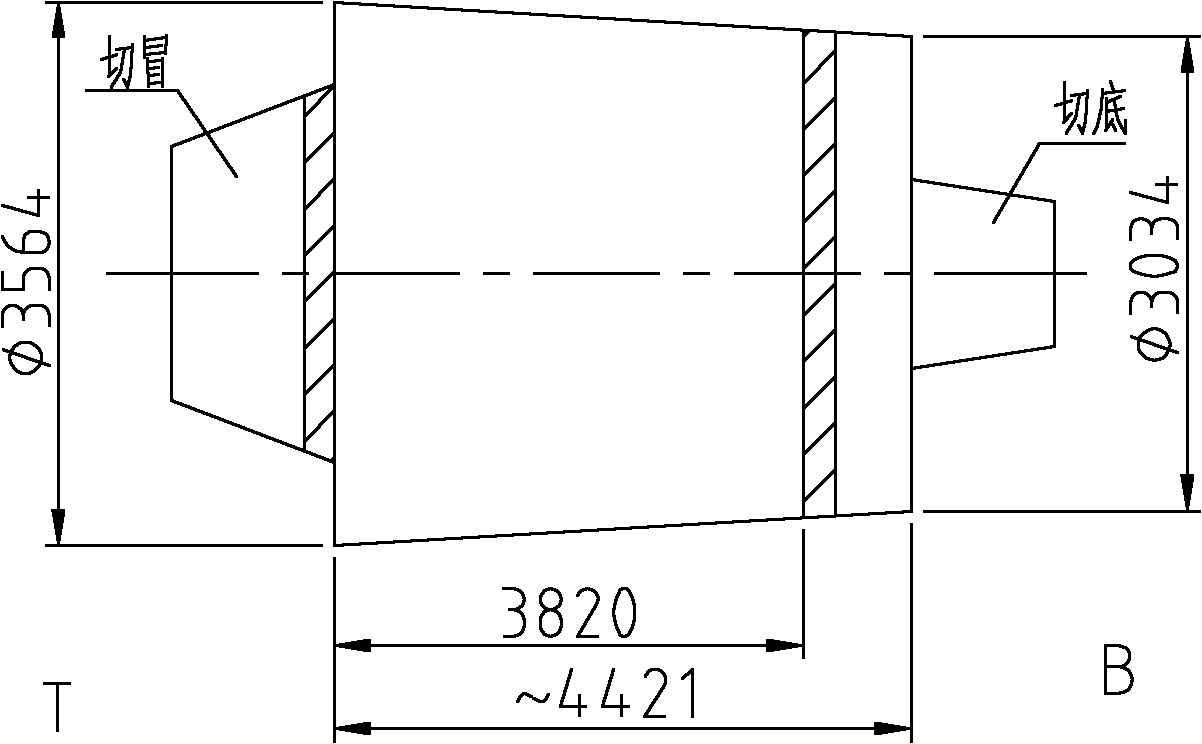

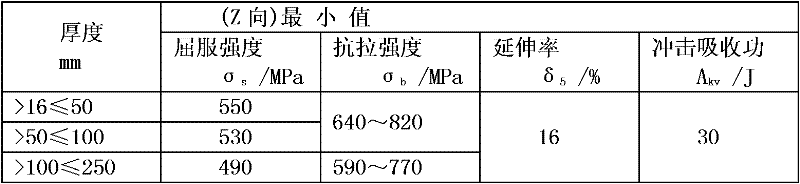

Forging method for pressure vessel bottom head transition section of second-generation nuclear power station and mould

InactiveCN102554088AReduce difficultyReduce the amount of cuttingForging/hammering/pressing machinesForgingNuclear power

The invention discloses a forging method for a pressure vessel bottom head transition section of a second-generation nuclear power station. The forging method is used for forging the pressure vessel bottom head transition section of the second-generation nuclear power station, the pressure vessel bottom head transition section comprises a straight section and a conical section, the inner diameter of the straight section is not less than 3000mm, the outer diameter of the straight section is not less than 4000mm, an inner hole of the conical section is provided with a bevel edge, the minimum inner diameter of the conical section is smaller than the inner diameter of the straight section, and the overall height of the conical section is not less than 2500mm. A megaton free forging press is used, and double-vacuum steel ingots are used as raw materials. The forging method includes the steps: firstly, primarily drawing; secondly, cogging; thirdly, upsetting, forging a central hole and pre-broaching; fourthly, secondarily drawing; fifthly, flattening a large end of a forging to form a conical hole of the forging; and sixthly, broaching. The forging manufactured by the forging method can meet the technical requirements of the pressure vessel bottom head transition section of the nuclear power station, and is compact, reasonable in metal flow line distribution and not easy to crack. The invention further discloses a special mould sleeve for the forging method.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

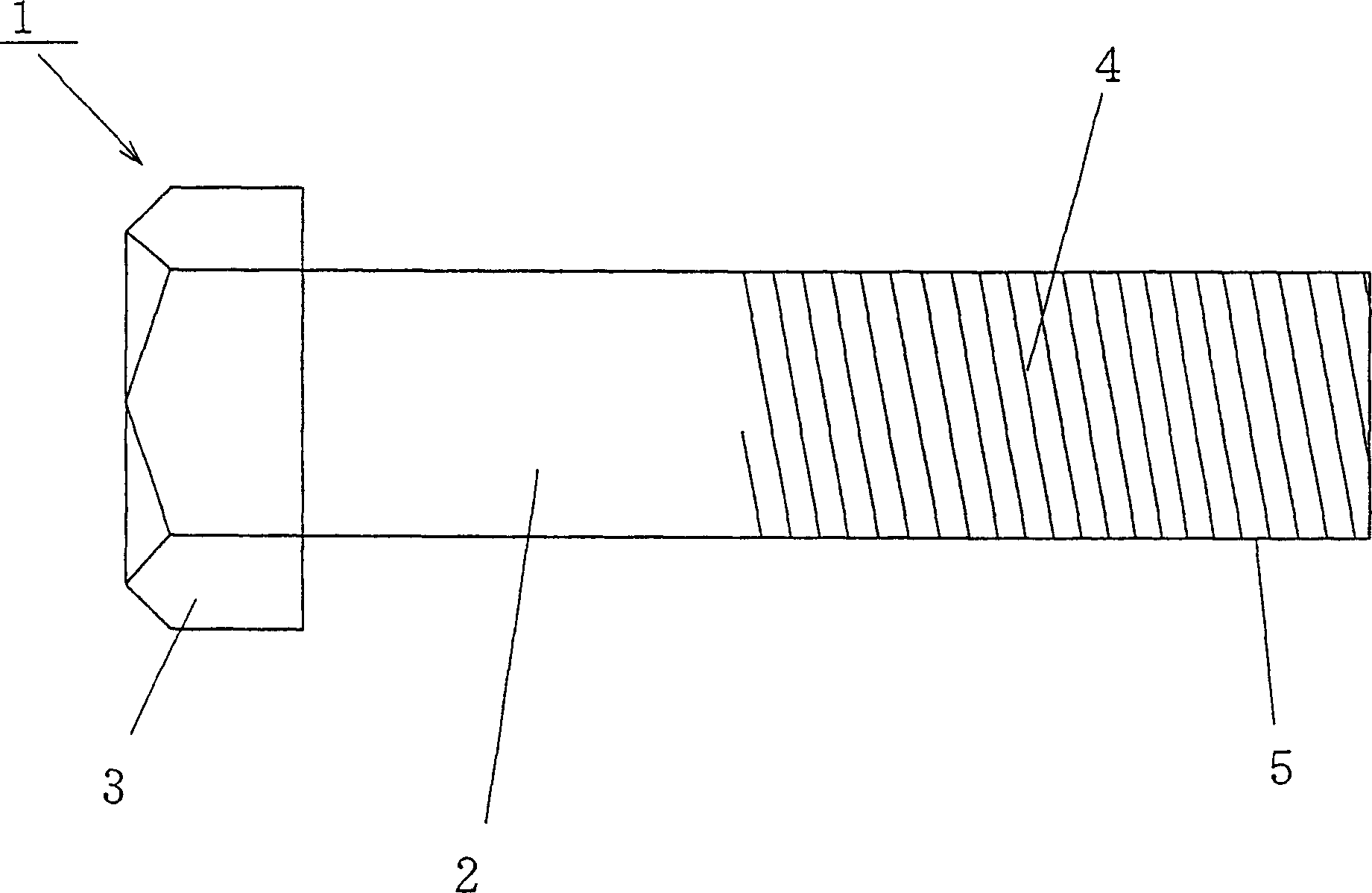

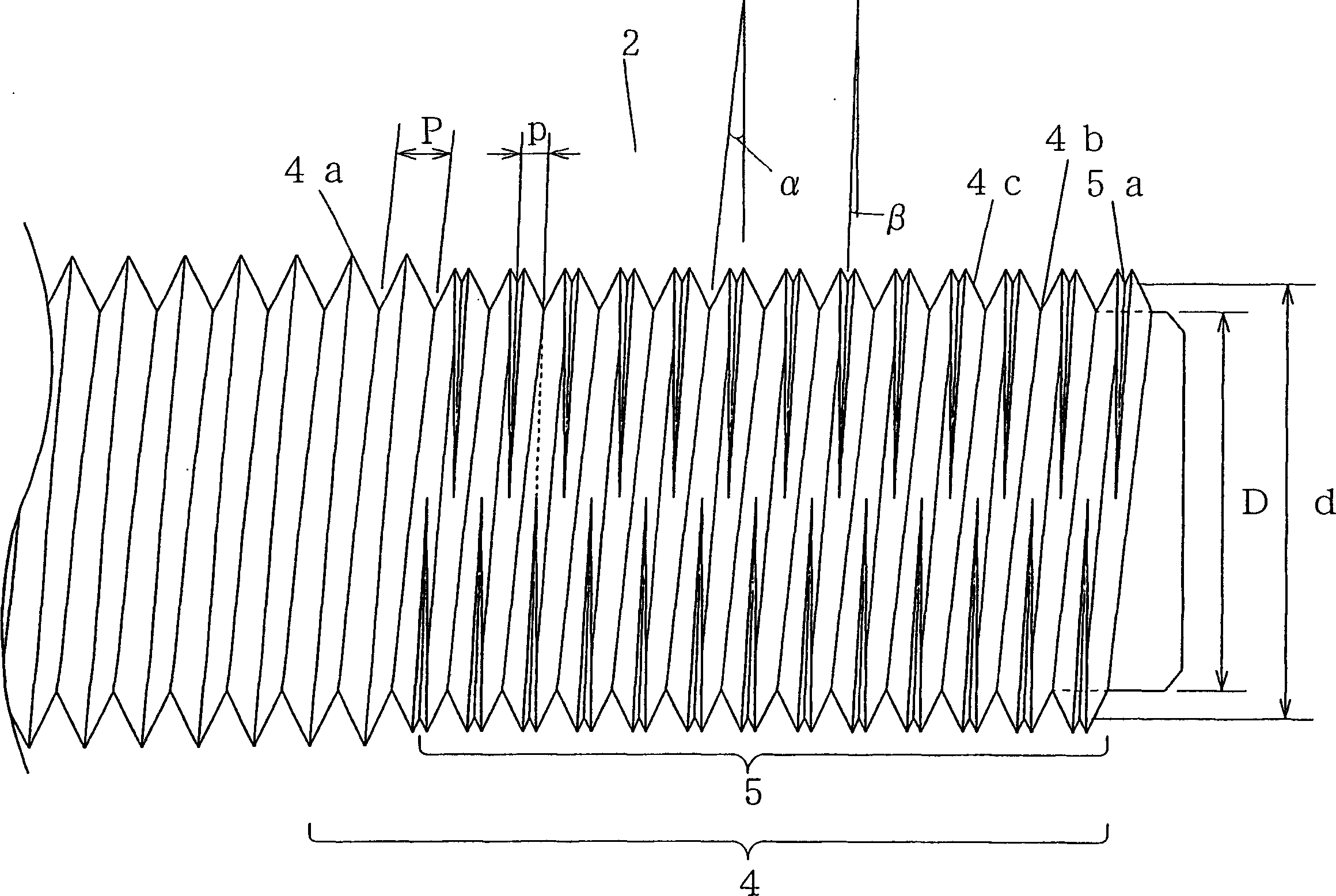

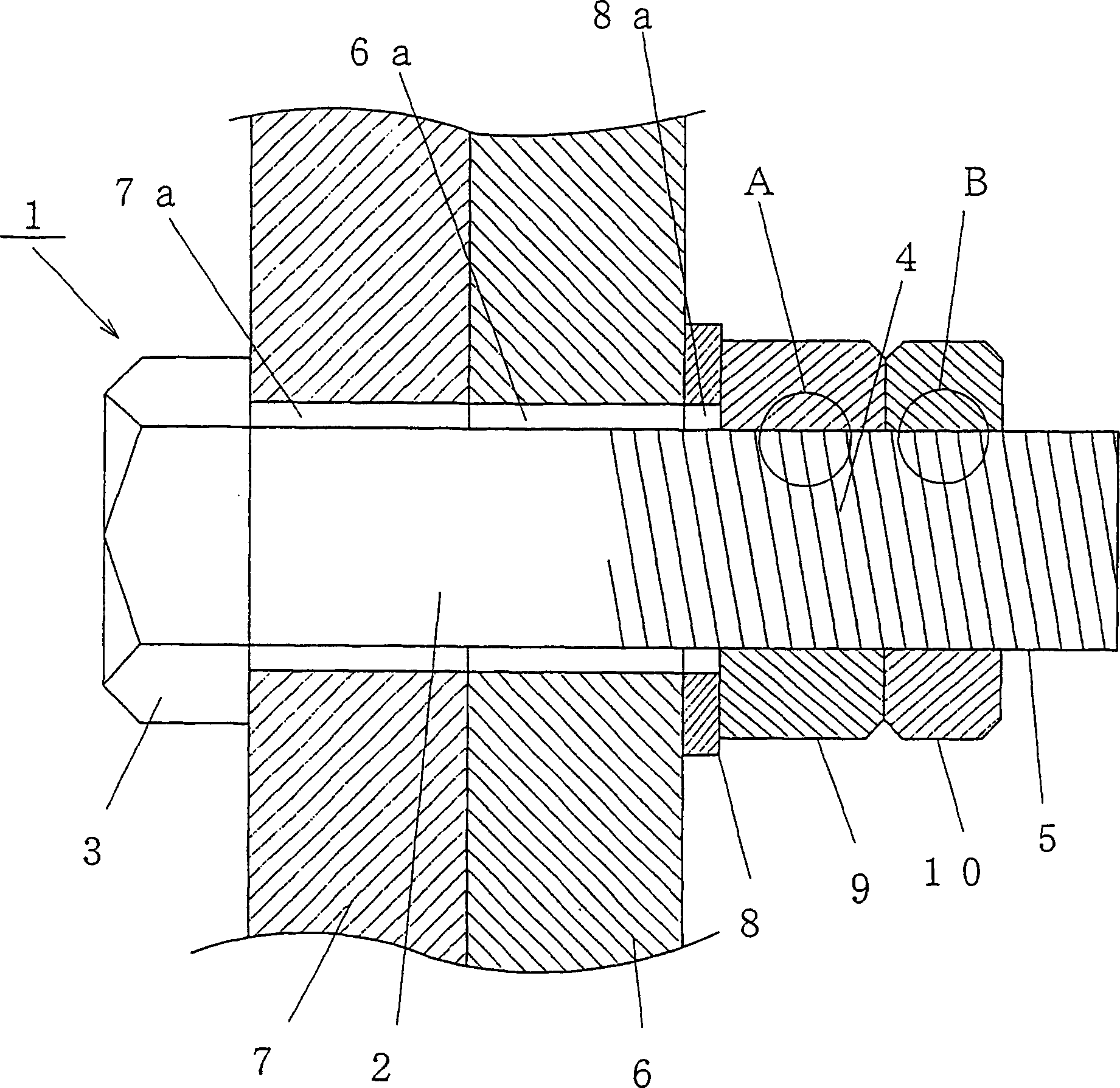

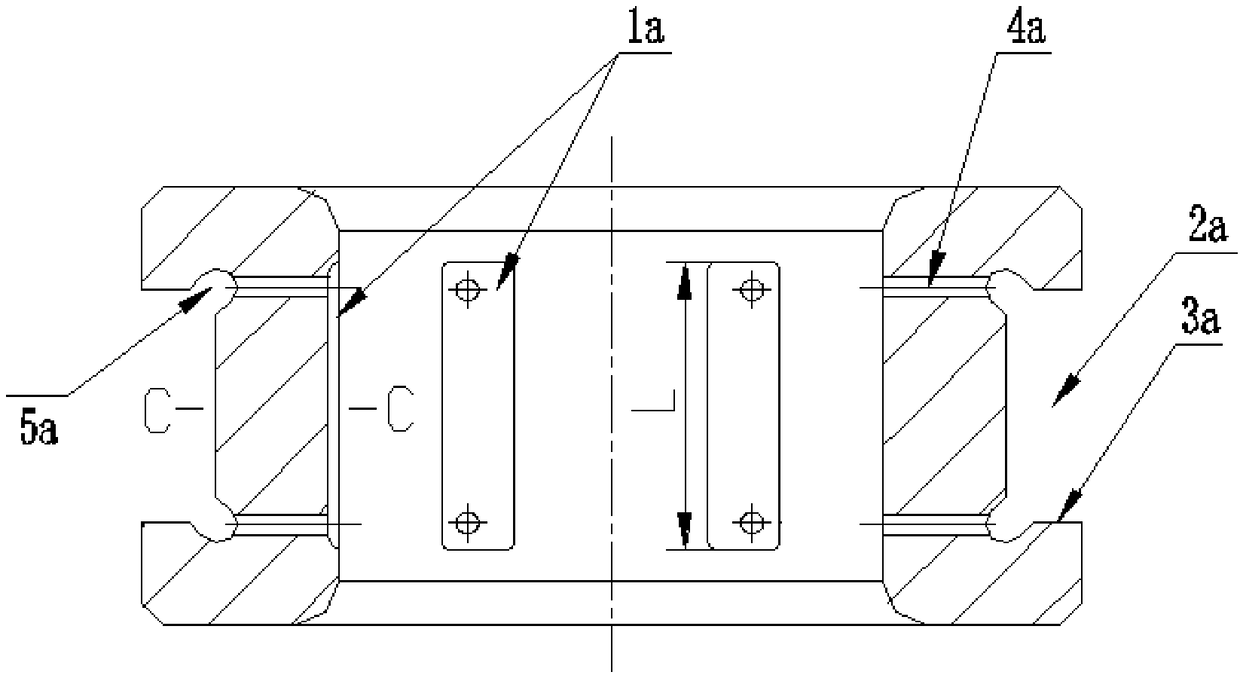

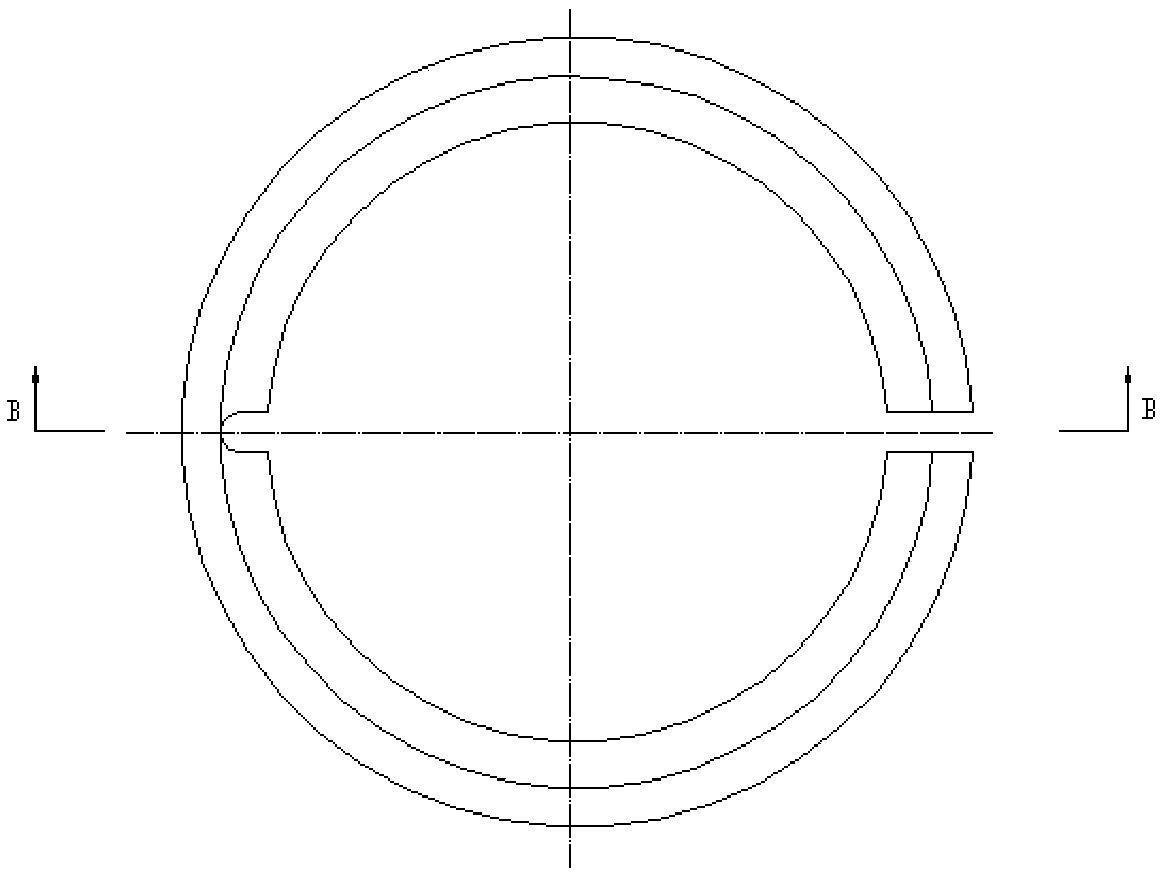

Bolt and method of mfg. bolt

InactiveCN1427926AIncrease profitIncrease production capacityNutsBoltsEngineeringCompressive strength

A bolt, comprising a coarse thread screw part with a pitch of (P) formed in an area ranging from the tip part to the specified part of a bolt shaft part and a fine thread screw part with a pitch of (P) (p=P / n, where n is the integer of 2 or more) formed by overlapping on the coarse thread screw part at least through the overall length of the coarse thread screw part of the bolt shaft part or through the area ranging from the tip part of the bolt shaft part to the specified part of the coarse thread screw part, whereby the bolt low in cost, mass-producible, excellent in synchronization of screw crests, high in compressive strength and shearing strength, making hard a nut threaded thereto to be loosened even if a large vibration load is applied thereto, and excellent in tightening force can be provided.

Owner:DAIKI IND +1

Mould for machining engine main shaft bearing inner ring with inner diameter oil groove and machining method

ActiveCN109483262ATight depth toleranceGuaranteed machining accuracyWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a mould for machining an engine main shaft bearing inner ring with an inner diameter oil groove and a machining method, and relates to a mould for machining a bearing inner ring and a machining method. The problem of poor machining accuracy of the inner diameter of a bearing inner ring and the size of an inner diameter oil groove is solved. The mould is composed of a mouldbase, a pressing plate and a connecting bolt; and a ring-shaped flange is arranged on a bearing plane. The machining method comprises the steps that an outer circumferential surface is milled softlybefore an inner circumferential surface is turned finally, the outer circumferential surface of an inner ring and one end face of the bearing inner ring are used as a positioning datum to machine theinner circumferential surface of the inner ring; milling of the inner diameter oil groove is performed after the finally turning of the inner circumferential surface of the inner ring; the bearing support flat face of the mould is used for positioning one end face of the bearing inner ring; and the outer circumferential surface positioned by the inner surface of the ring-shaped flange of the baseis used for machining the inner diameter oil groove. According to the mould for machining the engine main shaft bearing inner ring with the inner diameter oil groove, deformation caused by tightly clamping can be avoided, the machining method ensures the machining accuracy of the inner diameter oil groove, and the method is suitable for machining the engine main shaft bearing inner ring with the inner diameter oil groove.

Owner:AVIC HARBIN BEARING

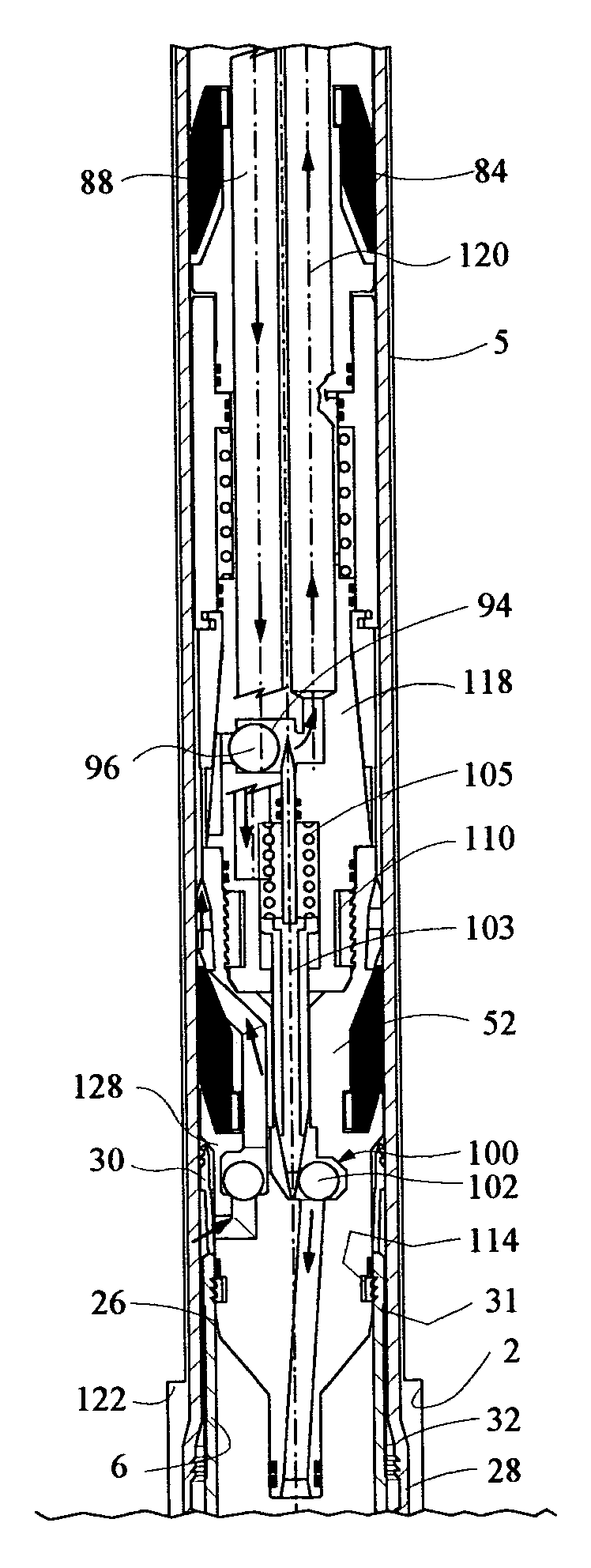

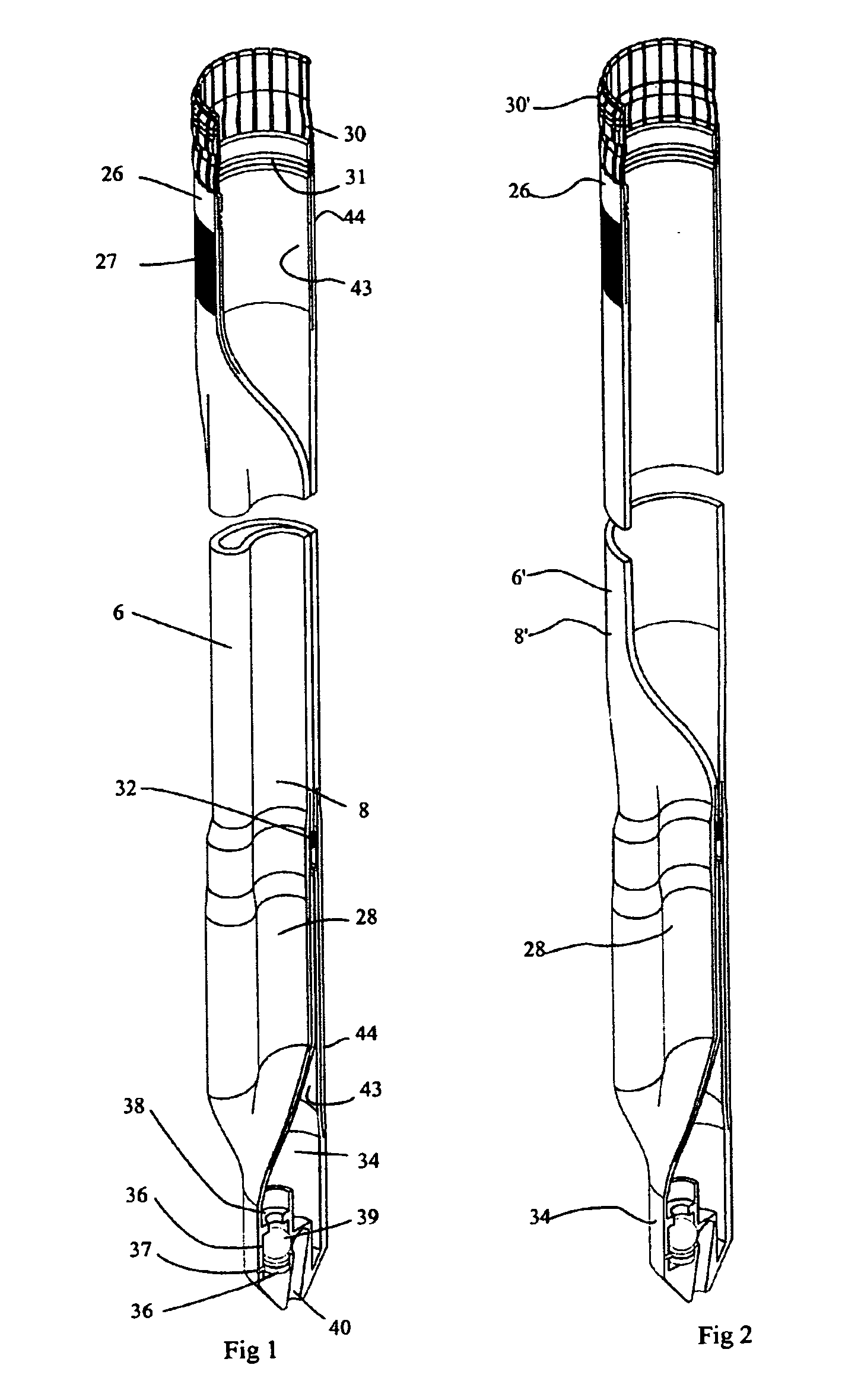

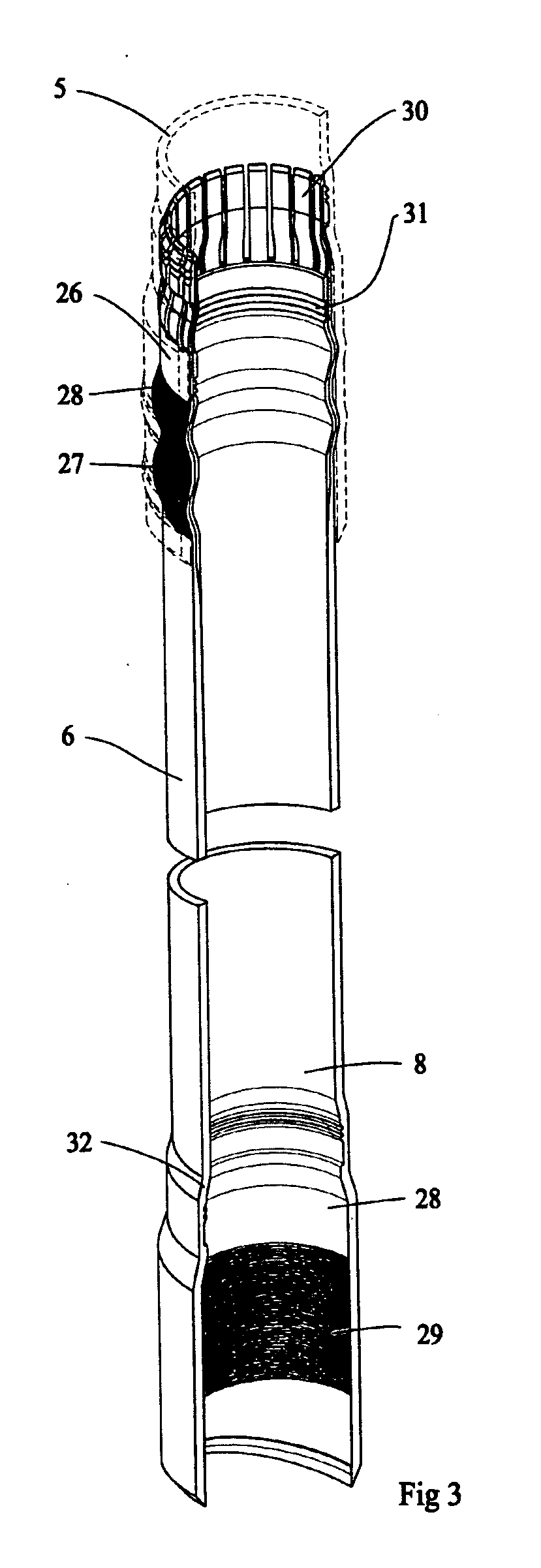

Method and system for tubing a borehole in single diameter

InactiveUS20060254778A1Reduce cutting volumeLarge freedomDrilling rodsConstructionsCasing stringEngineering

The invention concerns a method for casing a borehole which consists of successively lowering an unlimited plurality of strings of casing having a common diameter, the next one through the preceding one, to be installed one beneath the other and being sealingly connected. Thus a next casing (6) is lowered folded through the preceding casing (5) and the expansion process consists either in injecting pressurized fluid through the drillstring (54) towards the next casing (6) so as to re-inflate it, or the next casing (6) is a cylindrical pipe having a diameter smaller than the internal diameter of the preceding casing (5) and the expansion process consists in forcing a cylindrical gauge (52) from the top end (26) to the bottom bell (28) of the next casing (6) so as to increase its diameter to make it equal to the diameter of the preceding casing (5). The method can use a cementing shoe (34) and a metal-to-metal seal (29) between the casing string.

Owner:NOBILEAU PHILIPPE

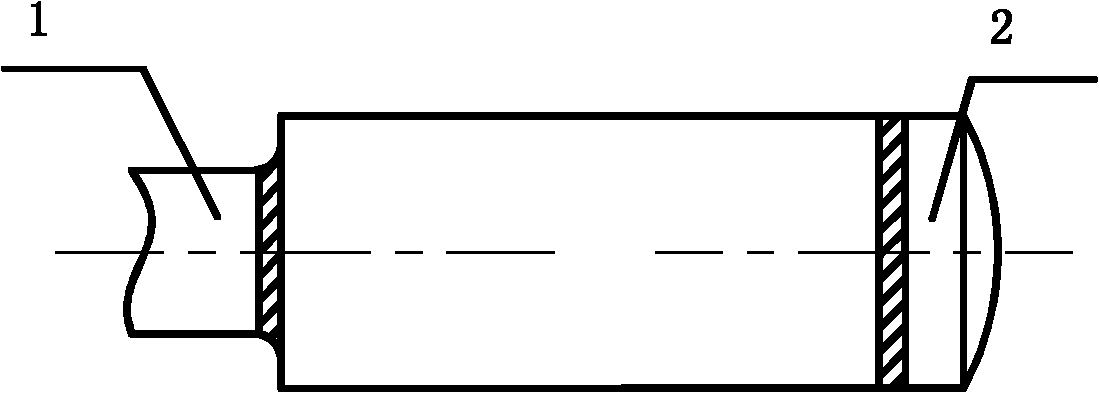

Valve housing used for opening square hole on electro-hydraulic servo valve in steam turbine power generation and processing method thereof

InactiveCN101446368AEasy to processReduce the amount of cuttingOperating means/releasing devices for valvesMultiple way valvesWire cuttingElectro hydraulic

The invention relates to a valve housing used for opening square holes on an electro-hydraulic servo valve in steam turbine power generation and a processing method thereof. The method is characterized by comprising the steps as follows: (1) two pairs of planes in proper size are milled in advance above a working edge of a processed valve housing, the size of the milled planes is slightly larger than the size of the square holes to be opened; (2) two pairs of square holes including a hole (1), a hole (2), a hole (3) and a hole (4) are cut out on the planes by linear cutting; and the intersection edges of the two pairs of square holes are crossed outside a valve core matching surface, so as to ensure complete opening. The valve housing of the electro-hydraulic servo valve used in the steam turbine power generation is processed by the method that a plane is milled on blank material in advance, and then the square holes are processed by the processing method of linear cutting. The plane which is milled in advance can reduce the cutting quantity and the abrasive magnitude of the linear cutting. The valve housing is simple for processing, saves a lot of time and improves the work efficiency.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com