Cutting preparation method of nickel-based single-crystal alloy seed crystal for casting

A technology of nickel-based single crystal and seed crystal, which is applied in the field of precise directional cutting and preparation of seed crystal, can solve the problems of single crystal blade high-temperature service performance degradation and difficulty in obtaining blades, etc., and achieve simple cutting equipment, good repeatability, and seed crystal The effect of high crystal precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

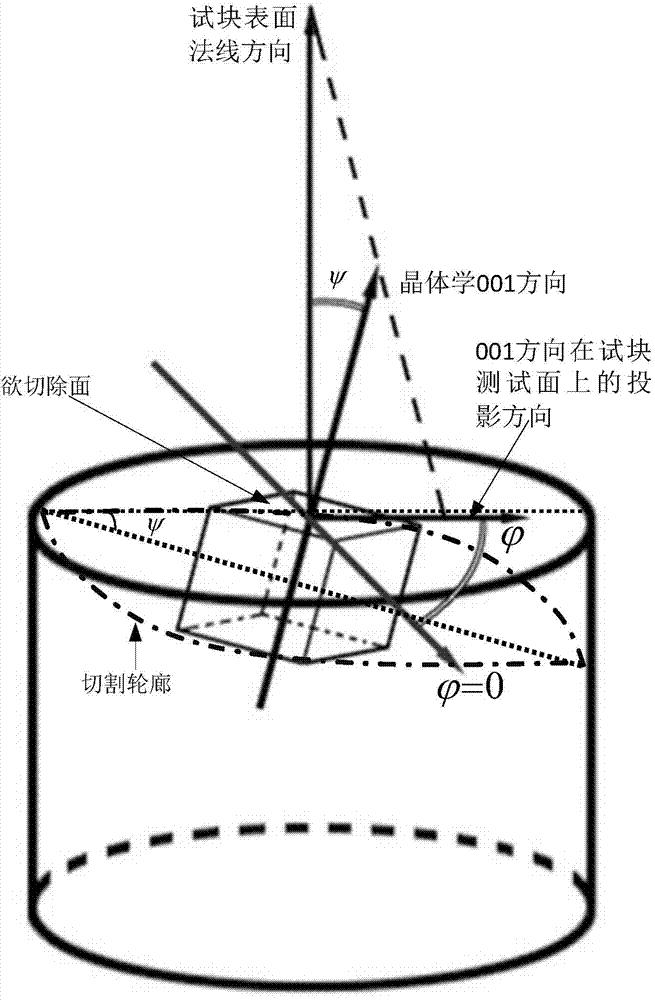

[0028] The method for cutting and preparing the nickel-based single crystal alloy seed crystal for casting provided by the present invention has the following specific steps:

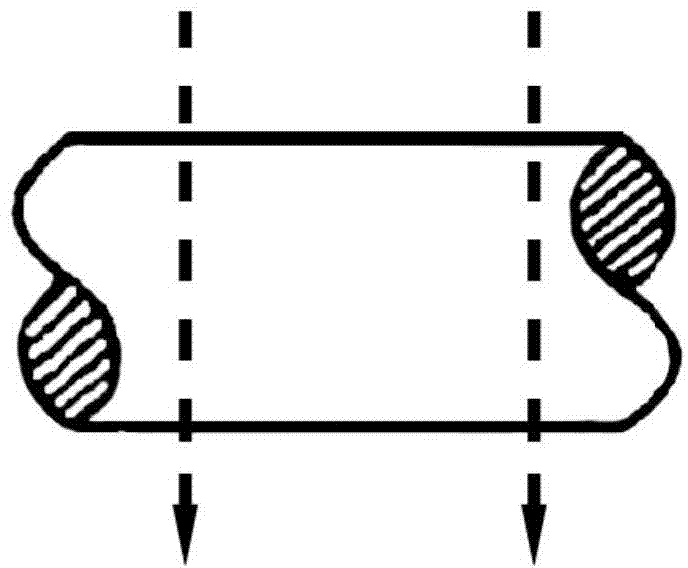

[0029] In the first step, the test bar or plate used for preparing the seed crystal is machined to obtain a test block with upper and lower parallel sections, such as figure 1 As shown, cut the test bar or test plate along the dotted line to obtain a test block whose upper and lower surfaces are parallel. One of the parallel sections of the test block is polished to obtain a polished surface.

[0030] Polishing treatment conditions: use 60#, 180#, 400#, 800#, 1500# water-grinding sandpaper to polish one side of the parallel section of the test block in order to remove the processing residual stress on the surface.

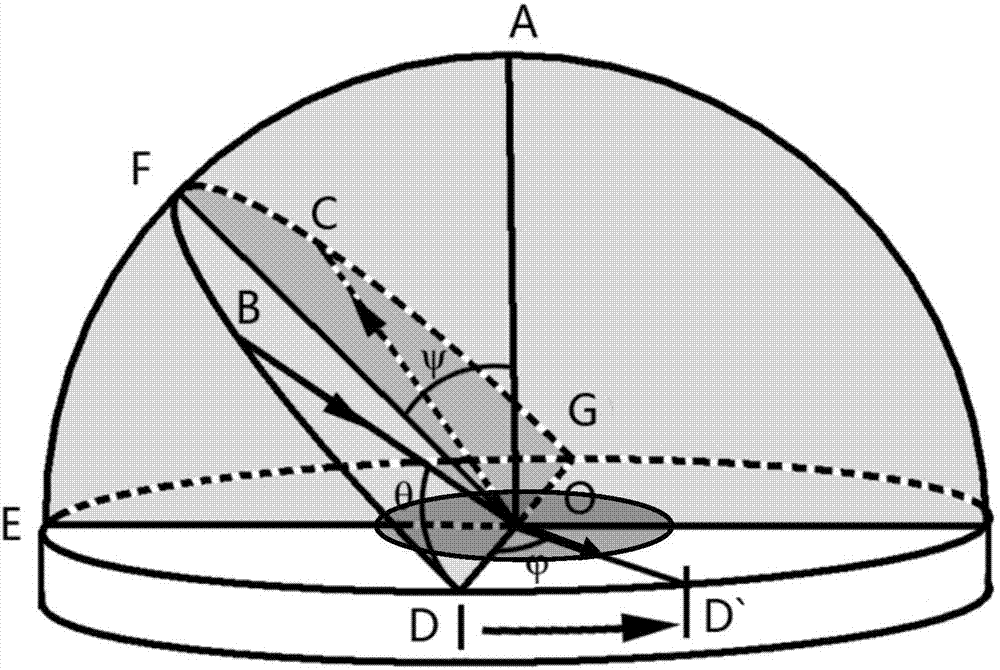

[0031] In the second step, the test block is fixed on the X-ray stress measuring instrument (manufactured by Handan Est Stress Technology Application Co., Ltd. X-ray stress tester 350AC) ...

Embodiment 1

[0043] The first step is to perform wire cutting on the cuboid test plate to be made into (001) direction seed crystals to obtain a test block (28×27×27mm) with upper and lower parallel sections, and one of the parallel sections of the test block is sequentially Use 60#, 180#, 400#, 800#, 1500# water abrasive paper to polish to obtain a polished surface.

[0044] The second step, such as figure 2 Fix the stable part of the test block on the X-ray stress measuring instrument (produced by Handan Este Stress Technology Application Co., Ltd. with point rotation The center of the turntable of the X-ray stress tester-350AC) with the function of the connection mechanism of the corner, and use a fine marker pen to make an initial mark on the polished surface of the test block, and the mark is the same as same direction;

[0045] The third step is to confirm that the 2θ angle (X-ray diffraction angle) of the tested block material is set to 79.6° by consulting relevant literature (...

Embodiment 2

[0051] first step, such as figure 1 Carry out wire cutting on the cuboid test plate to be made into (111) direction seed crystals to obtain two test blocks (29×25×34mm) with parallel sections on the upper and lower sides, and use 60# for one of the parallel sections of the test blocks , 180#, 400#, 800#, 1500# water-grinding sandpaper to polish to obtain a polished surface.

[0052] The second step, such as figure 2 Fix the stable part of the test block on the X-ray stress measuring instrument (produced by Handan Este Stress Technology Application Co., Ltd. with point rotation X-ray Stress Measuring Apparatus-350AC) with the function of the connecting mechanism of the angle, the center of the turntable, the polished side facing up, and use a fine marker pen to make initial marks on the polished surface of the test block, and the X-ray Stress Measuring Apparatus same direction;

[0053] The third step is to set the 2θ angle of the X-ray stress measuring instrument to 68.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com