Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392 results about "Single crystal superalloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

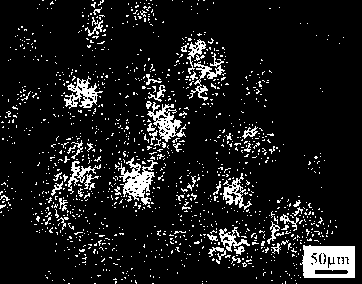

Metallic coating for single crystal alloys

InactiveUS20110256421A1Polycrystalline material growthMolten spray coatingSingle crystal superalloySingle crystal

A metallic coating for use in a high temperature application is created from a nickel base alloy containing from 5.0 to 10.5 wt % aluminum, from 4.0 to 15 wt % chromium, from 2.0 to 8.0 wt % tungsten, from 3.0 to 10 wt % tantalum, and the balance nickel. The metallic coating has particular utility in protecting single crystal superalloys used in high temperature applications such as turbine engine components.

Owner:UNITED TECH CORP

Ni-based single crystal superalloy

The object of the present invention is to provide an Ni-based single crystal super alloy capable of improving strength by preventing precipitation of a TCP phase at high temperatures. This object is achieved by an Ni-based single crystal super alloy having a composition comprising 5.0-7.0 wt % of Al, 4.0-10.0 wt % of Ta, 1.1-4.5 wt % of Mo, 4.0-10.0 wt % of W, 3.1-8.0 wt % of Re, 0-0.50 wt % of Hf, 2.0-5.0 wt % of Cr, 0-9.9 wt % of Co and 4.1-14.0 wt % of Ru in terms of its weight ratio, with the remainder consisting of Ni and unavoidable impurities.

Owner:NAT INST FOR MATERIALS SCI +1

Apparatus and method for direct writing of single crystal super alloys and metals

InactiveUS20160258045A1TurbinesAdditive manufacturing apparatusTemperature controlSingle crystal superalloy

Apparatus and methods for direct writing of single crystal super alloys and metals are provided. In one method, a substrate is heated to a pretermined temperature below its melting point, and a laser is used to form a melt pool on a surface of a substrate. The substrate is positioned on a base plate, and the laser and the base plate are movable relative to each other, with the laser being used for direct metal deposition and the substrate is heated to a temperature below its melting point. A superalloy powder is introduced to the melt pool, and the temperature of the melt pool is controlled to maintain a predetermined thermal gradient on a solid and liquid interface of the melt pool so as to form a single crystal deposit on the substrate.

Owner:GENERAL ELECTRIC CO +1

High-strength hot-corrosion-resistant Ni-based single crystal superalloy and preparation method

InactiveCN103966671AImprove high temperature mechanical propertiesExcellent hot corrosion resistancePolycrystalline material growthFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the field of single crystal superalloys, particularly to a high-strength hot-corrosion-resistant Ni-based single crystal superalloy and a preparation method, and is mainly applied to high-temperature components applied to various marine environments and turbine high-temperature components of ground industrial gas turbines. The superalloy comprises chemical components in percentage by weight as follows: 11-15% of Cr, 5-9% of Co, 0.5-2.0% of Mo, 3.0-5.0% of W, 4.5-7.0% of Ta, 3.5-5.6% of Al, 2.3-3.7% of Ti and the balance of Ni. A vacuum induction furnace is used for smelting, a mother alloy is cast firstly, and then the high-strength hot-corrosion-resistant single crystal superalloy is prepared according to a single crystal growth technology and a heat treatment system. The Cr and refractory metallic elements with higher content are selected, but the content of the Ti element is reduced. Meanwhile, the crystal boundary is eliminated through a single crystal technology, so that the hot corrosion resistance, the high-temperature mechanical property and the structure stability of the alloy are further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Superalloy compositions with improved oxidation performance and gas turbine components made therefrom

Single crystal superalloy compositions and components made from such compositions are provided. One composition consists essentially of, in weight percent, from about 4 to about 7 percent chromium; from about 8 to about 12 percent cobalt; from about 1 to about 2.5 percent molybdenum; from about 3 to about 6 percent tungsten; from about 2 to about 4 percent rhenium; from about 5 to about 7 percent aluminum; from about 0 to about 1.5 percent titanium; from about 6 to about 10 percent tantalum; from about 0.08 to about 1.2 percent hafnium; no more than about 0.0002 percent sulfur; no more than about 0.007 percent zirconium; and the balance nickel.

Owner:HONEYWELL INT INC

Nickel base single crystal superalloy with low cost and low density

ActiveCN102732750AImprove durabilityImprove tensile propertiesPolycrystalline material growthSingle crystal growth detailsSingle crystal superalloySingle crystal

A nickel base single crystal superalloy with low cost and low density comprises, in percentage by weight, 2.5-4.5% of Cr, 7.0-11.0% of Co, 0.5-2.3% of Mo, 5.0-7.5% of W, 7.0-10.0% of Ta, 3.3-4.5% of Re, 5.0-7.0% of Al, 0-0.5% of Ti, 0-0.2% of Hf, 0-0.05% of C, 0-0.01% of B, and the balance being Ni. Compared with the conventional nickel base single crystal superalloys, the nickel base single crystal superalloy in the invention has excellent stress rupture property and tensile property and the cost is reduced obviously.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

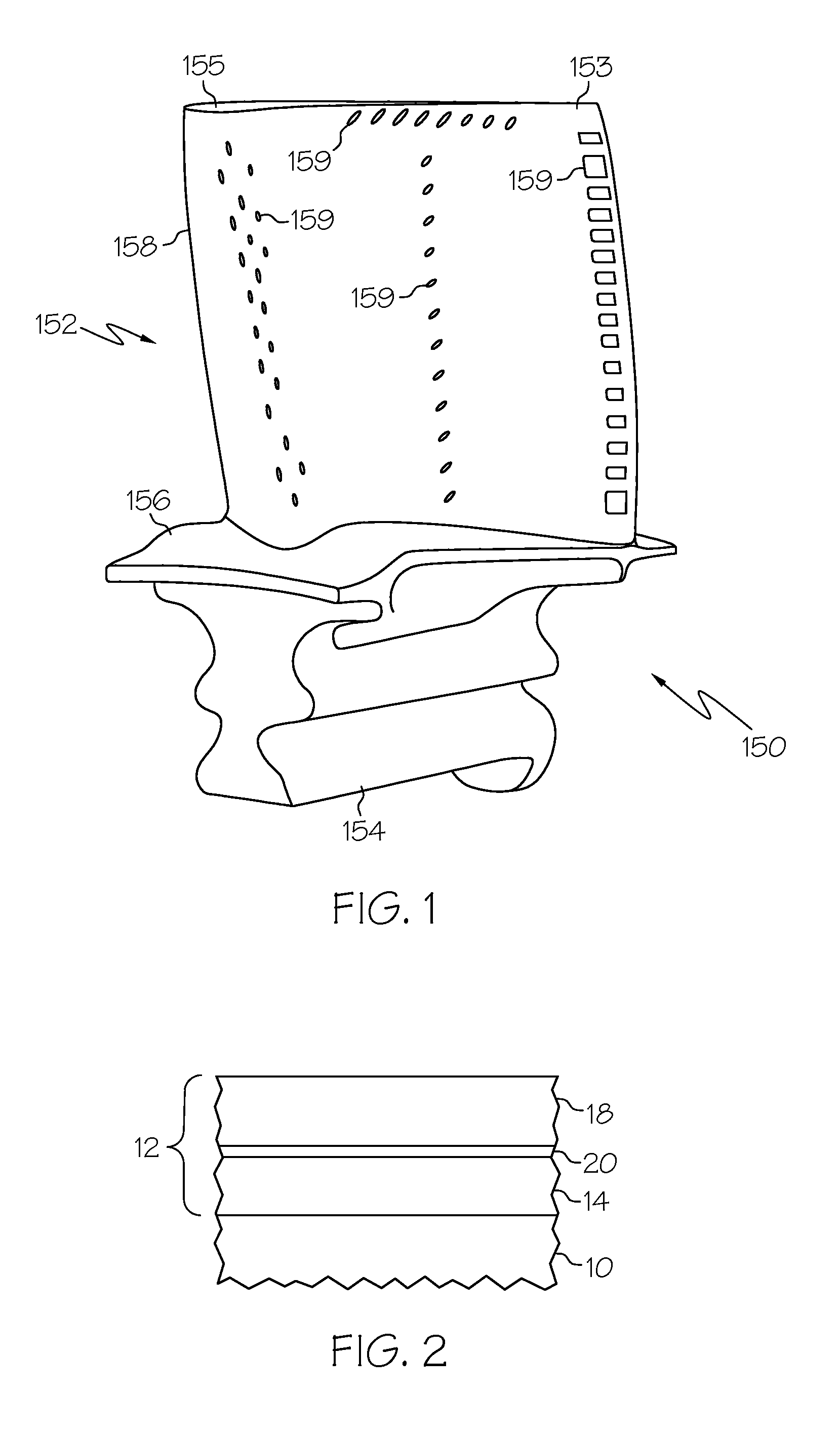

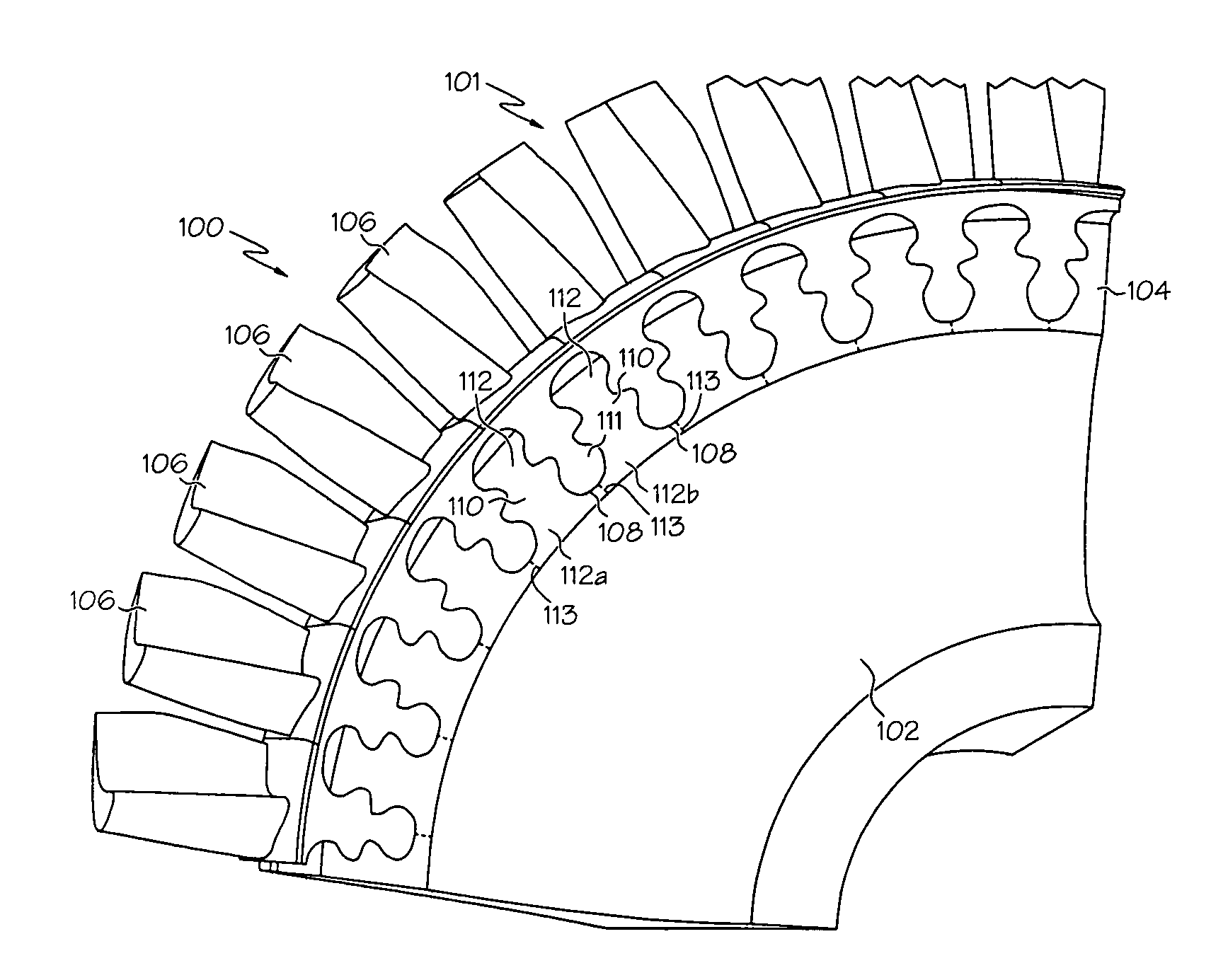

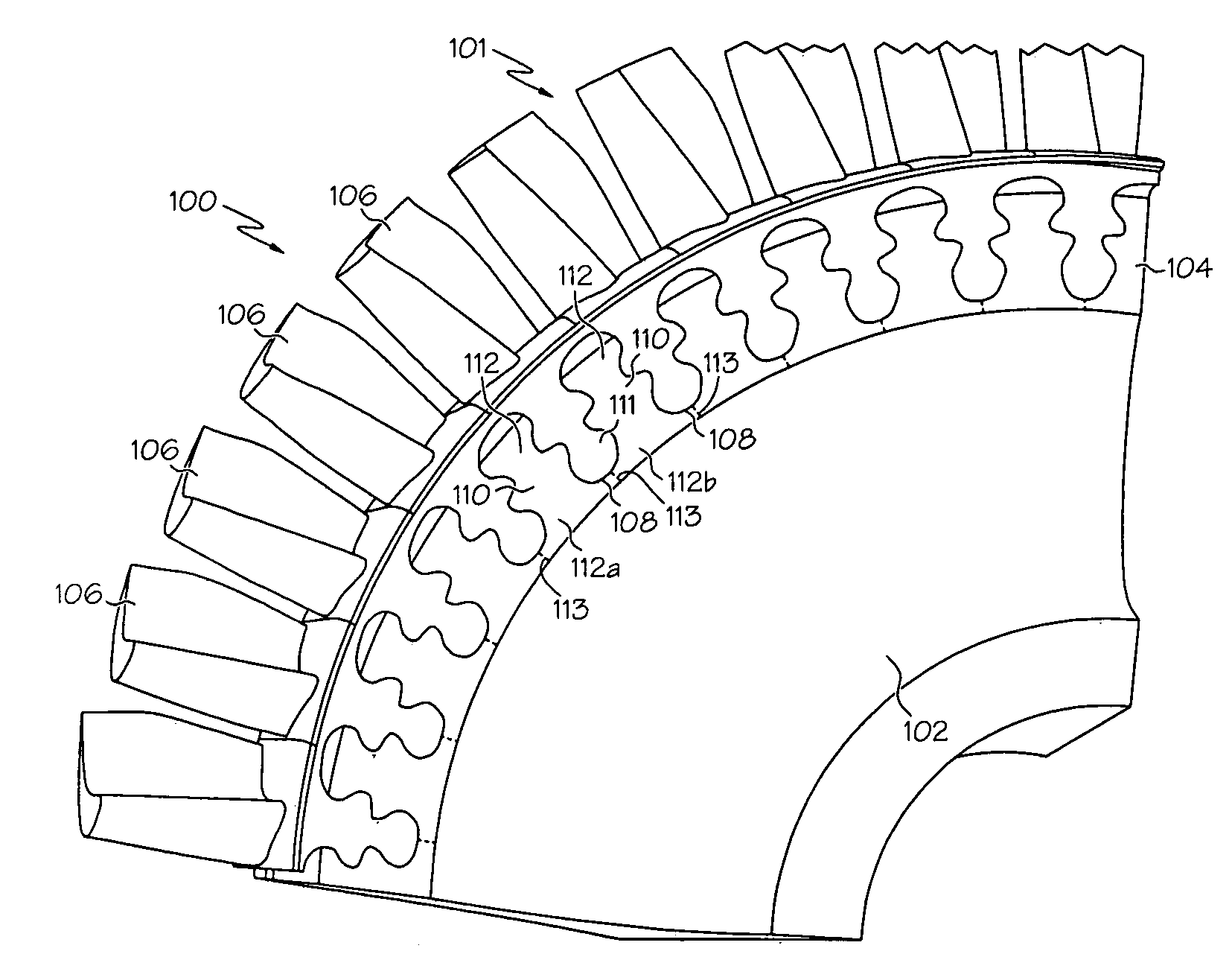

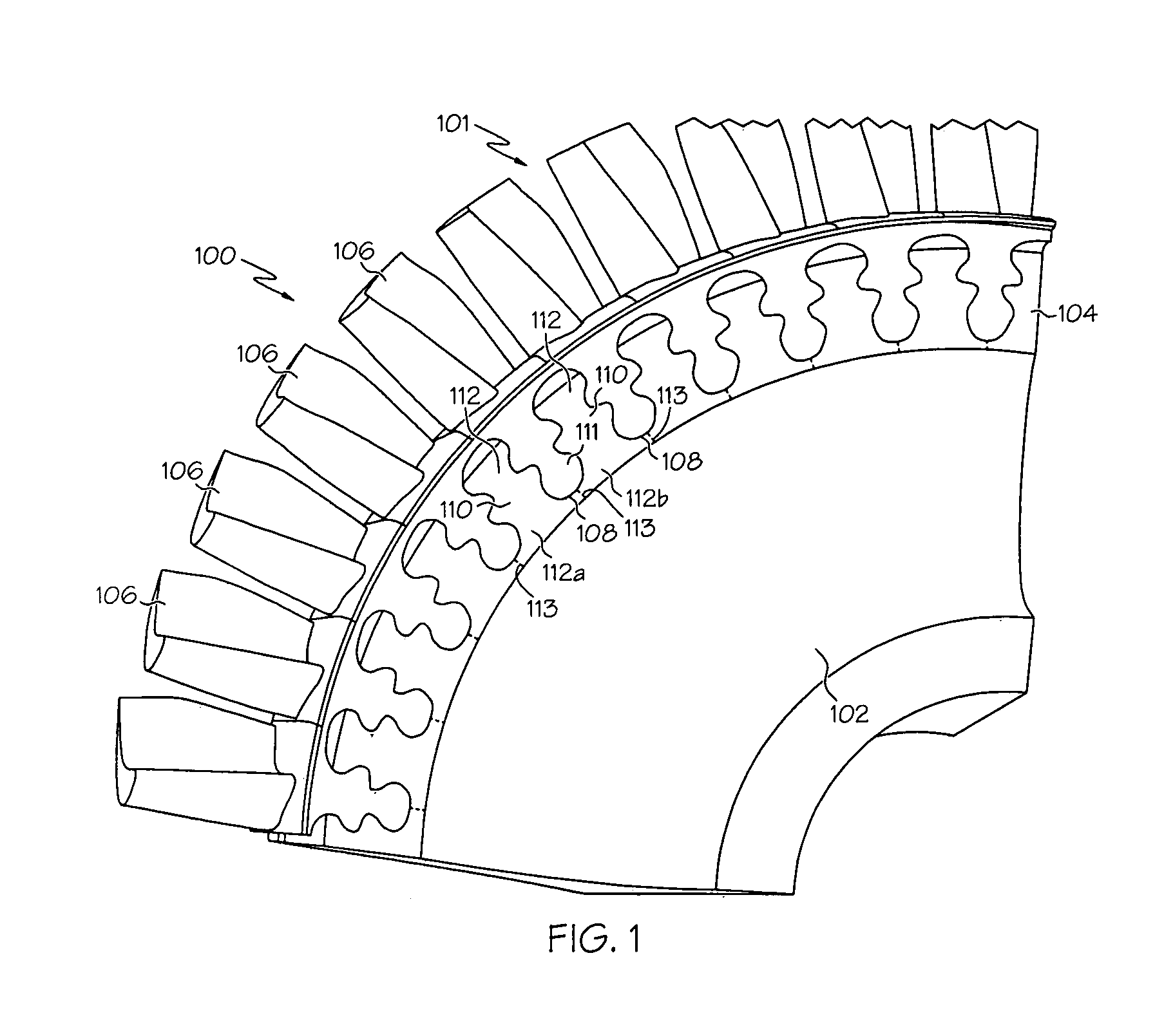

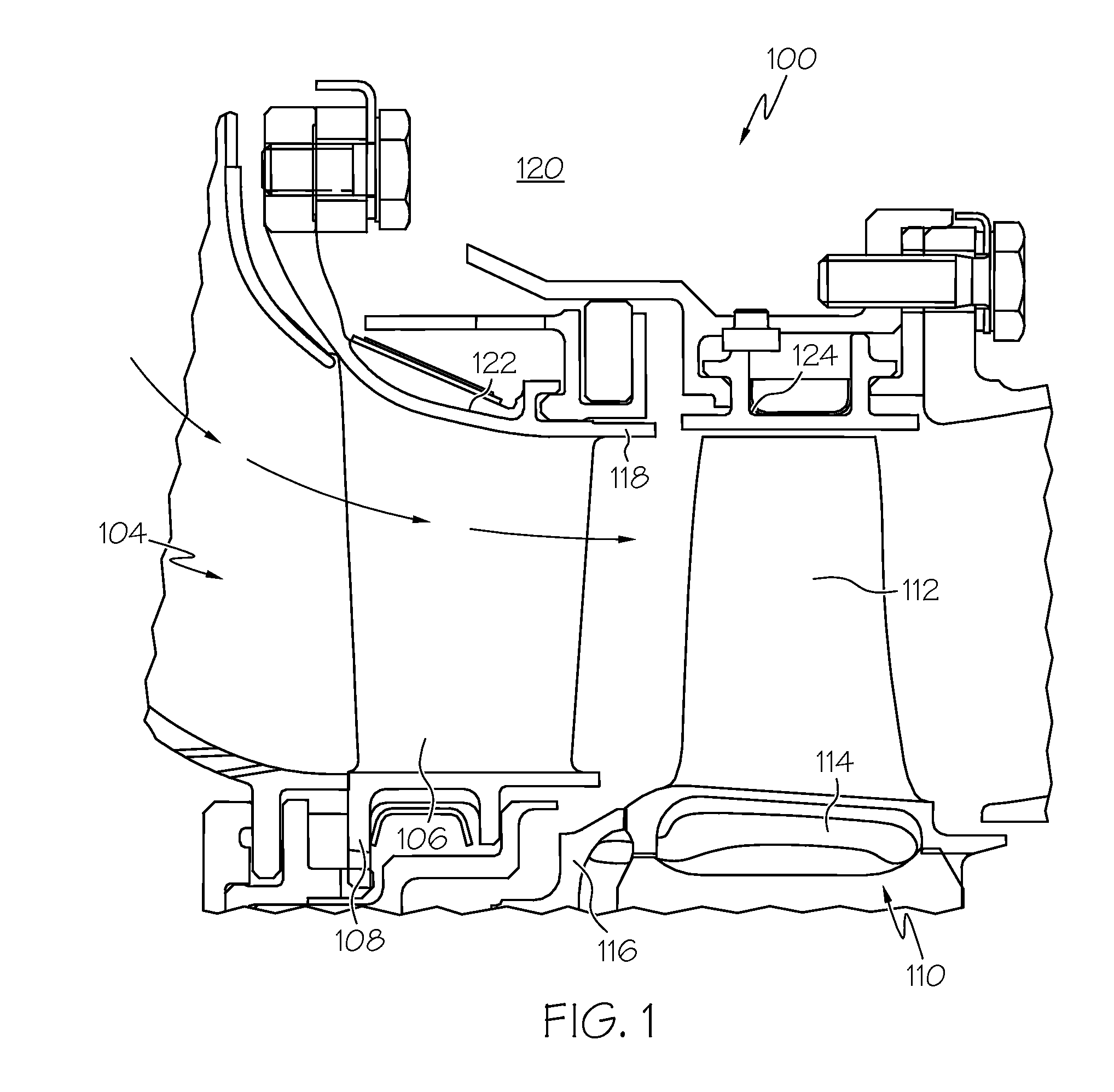

Turbine components and methods of manufacturing turbine components

Turbine components are provided. In an embodiment, by way of example, a hub and a ring are included. The hub comprises a first material. The ring is bonded to the hub. The ring comprises a plurality of arc segments forming a ring, each arc segment comprising a second material comprising a single crystal superalloy material having a predetermined primary orientation and a predetermined secondary orientation, each predetermined primary orientation of each arc segment being substantially equal, and each predetermined secondary orientation of each arc segment being substantially equal, each arc segment adjacent another arc segment, and the adjacent arc segments having a predetermined crystallographic mismatch therebetween. Methods of manufacturing are also provided.

Owner:HONEYWELL INT INC

Diffusion bond mixture for healing single crystal alloys

A diffusion bond mixture paint and method for repairing a single-crystal superalloy article that minimizes the amount of braze alloy applied to the article. The amount of boron and eutectic brittle borides of the wide gap brazing processes is minimized, resulting in a more robust repair. The braze paint includes an alloy powder mixture, a binder, and a carrier to thin the paint.

Owner:HONEYWELL INT INC

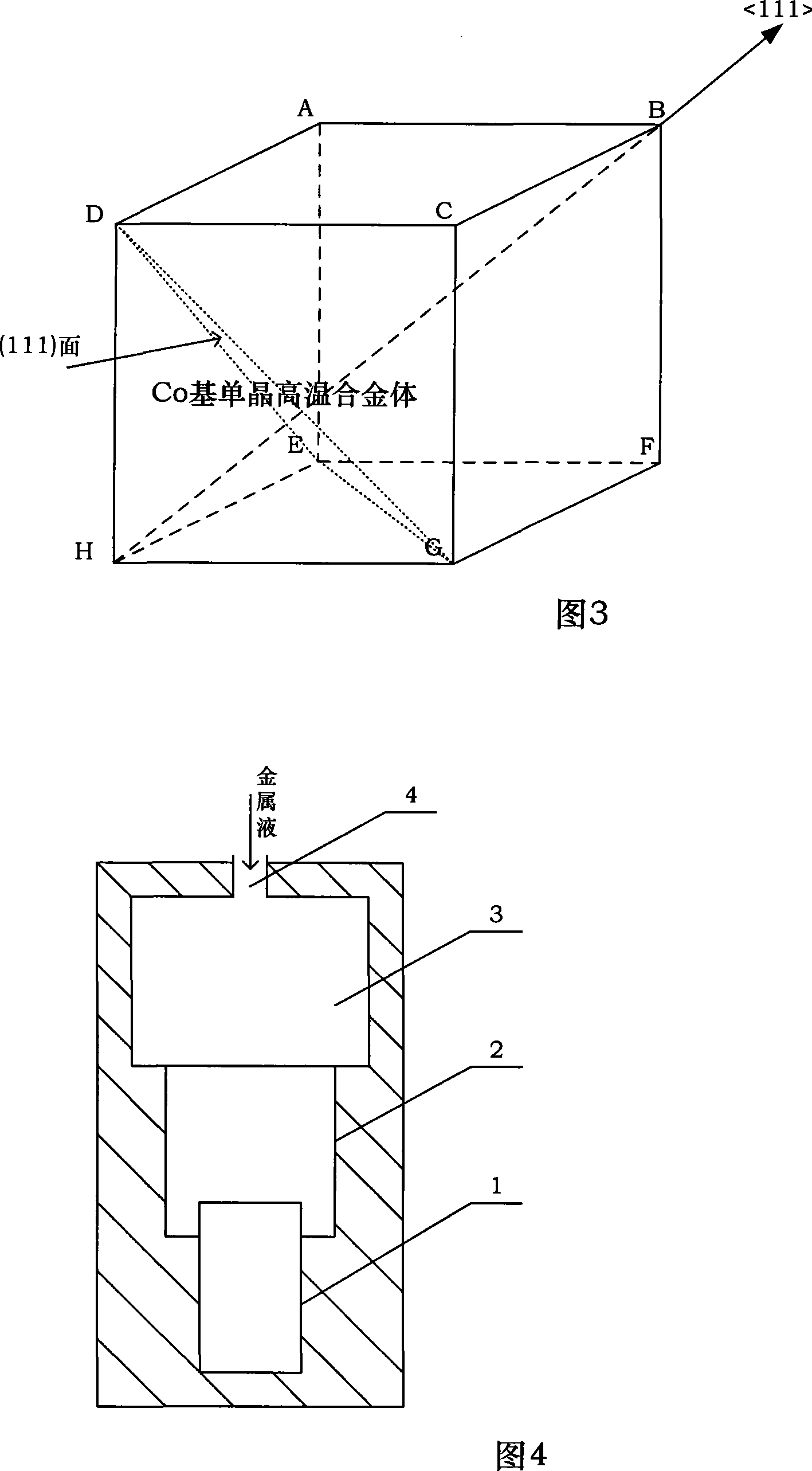

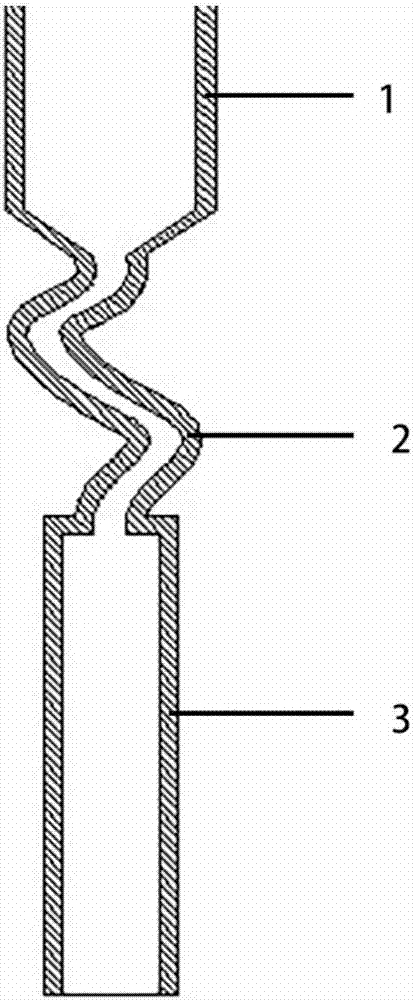

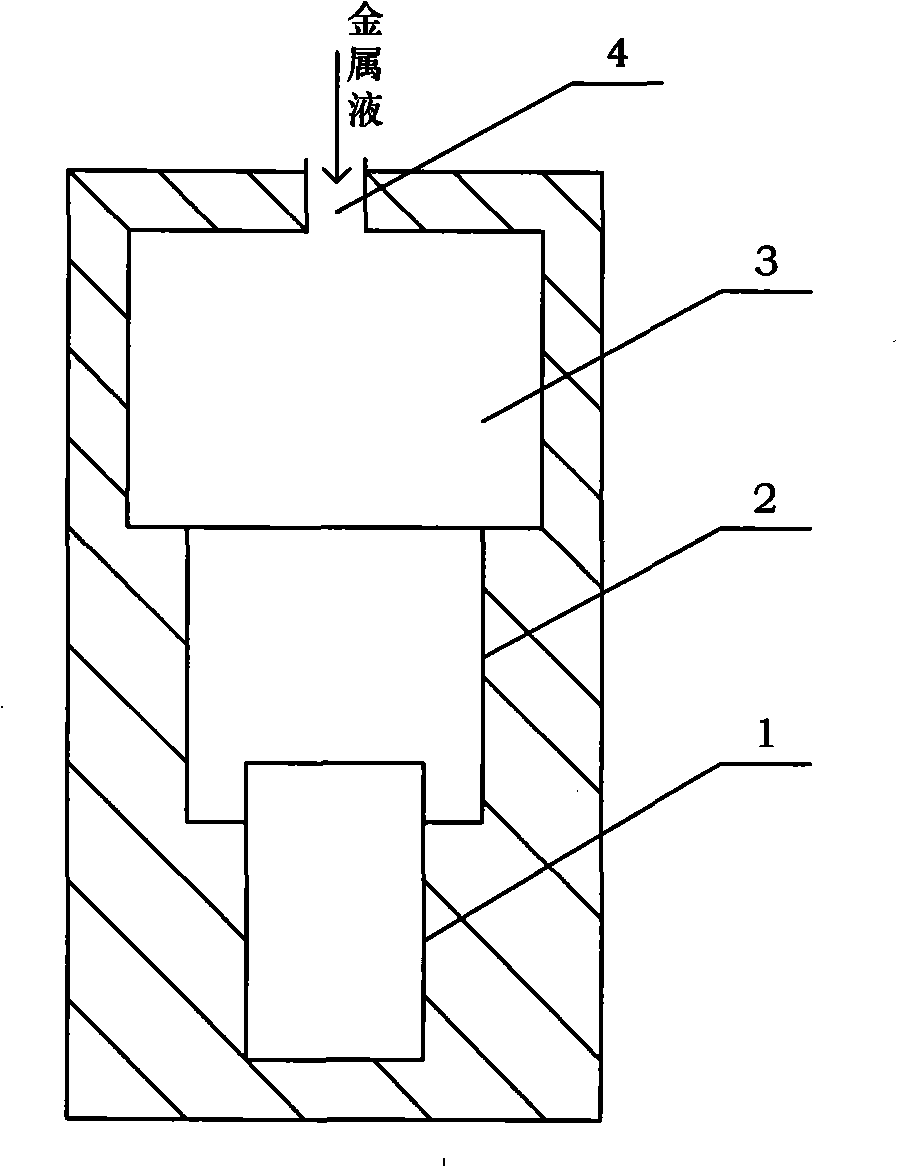

Method for preparing Co based single-crystal refractory alloy by employing combination of seed crystal method and screw selecting method

The present invention discloses a method adopting a seed crystal method combined with a spiral crystal selecting method to prepare Co-based single crystal superalloy. seed crystal with certain crystal orientation is directionally cut on a Co-based single crystal superalloy body; the seed crystal is put into one end of a spiral crystal selecting machine wax mold; the other end of the spiral crystal selecting machine wax mold is connected with a part wax mold; ceramic refractory slurry is smeared outside the seed crystal, the spiral crystal selecting machine wax mold and the part wax mold; a ceramic mold shell with the seed crystal is prepared through dewaxing and roasting; the ceramic mold shell is cast and molded in a single crystal furnace to prepare Co-based single crystal superalloy materials. The single crystal preparation technology of the present invention can accurately control the crystal orientation and microstructure of single crystal, so as to prepare the Co-based single crystal superalloy materials of good quality.

Owner:BEIHANG UNIV

Method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment

ActiveCN108624959AOvercome the need to set up a spiral crystal selector to suppress the formation of miscellaneous crystals below the remelting interface inside the seed crystalOvercoming the problem of stray crystal formation below the remelt interfacePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses a method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment. The method is characterized in that the original structurestate of seed crystal is converted into a uniform structure from a thick seed crystal structure through a solid-solution thermal treatment way, so that a structure on the upper part of a mushy zone under a melting-back interface forms a complex network shaped structure in a seed crystal single-crystal preparation process; un-melted solid phases are connected with each other to improve ability ofresisting deformation, so that flow speed when melt is poured to the upper end of the seed crystal does not need to limit, and therefore, the purpose of removing a spiral crystal selector structure ina mould shell is achieved. In a process of preparing the single-crystal high-temperature alloy, the seed crystal re-melting region is completely inhibited to form mixed crystal, so that the structureof the corresponding mould shell is simplified, mechanical degree and assembly precision of shell making are improved, and cost is reduced, and therefore, the defect of using a spiral crystal selecting section in the mould shell in a process of producing single-crystal high-temperature alloy by repeatedly using seed crystal is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

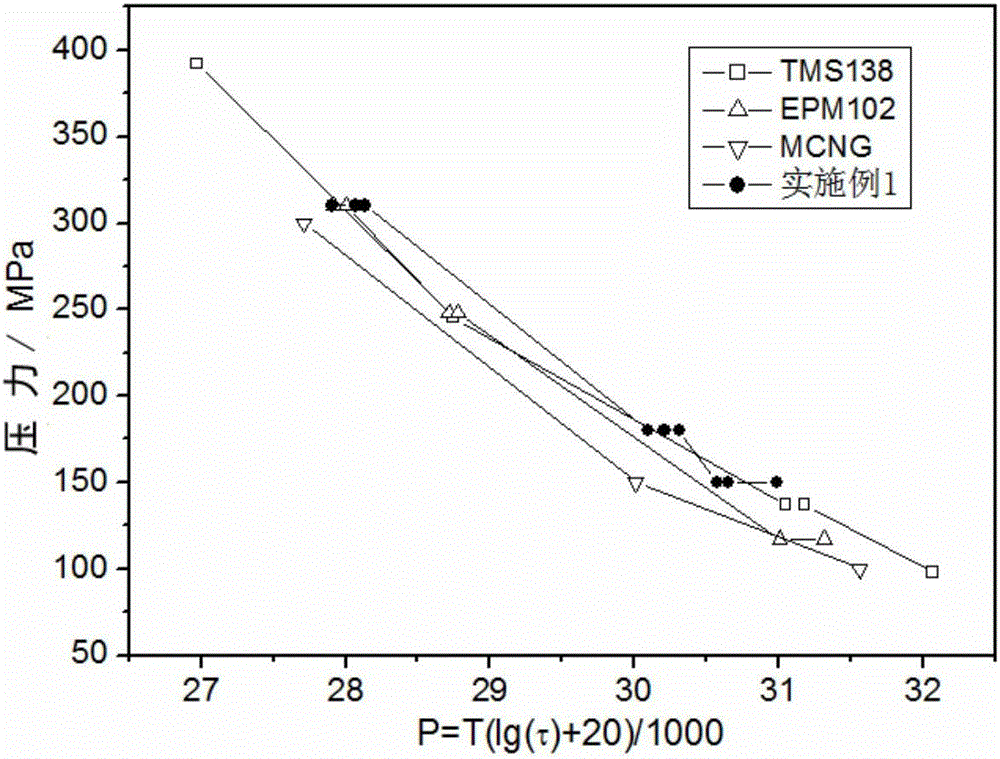

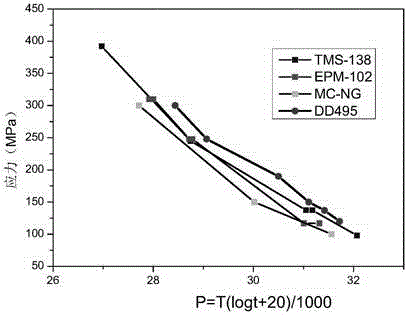

High-strength and tissue stable nickel-base single crystal superalloy and preparation method thereof

InactiveCN106756249AEasy to useSimple processPolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

The invention relates to the field of high-strength single crystal superalloys and particularly provides a high-strength and tissue stable nickel-base single crystal superalloy with the temperature capability reaching to 1,150 DEG C. The high-strength and tissue stable nickel-base single crystal superalloy is mainly suitable for blade materials, used at the temperature of 1,100 DEG C or above, of an aero-engine. The superalloy comprises chemical components (wt%): 3%-5% of Cr, 6%-13% of Co, 6%-8% of W, 0.1%-2% of Mo, 4.5%-6% of Re, 2%-4% of Ru, 5.5%-6.5% of Al, 6%-10% of Ta, 0%-0.2% of Hf and the balance Ni. A preparation method comprises the steps that the temperature gradient range of a single crystal growth furnace is 40K / cm-80K / cm, the pouring temperature is 1,480 DEG C-1,550 DEG C, the mold shell temperature and the pouring temperature keep consistent, and a single crystal blade or a test bar is prepared within the growth rate range of 4mm / min-8mm / min; and then, solid solution homogenization treatment, high-temperature aging treatment and low-temperature aging treatment are carried out so that the superalloy can have high endurance strength. The service life of the superalloy is 100 h or longer under the endurance condition of 1,140 DEG C / 137 MPa, and the endurance strength of the superalloy is equivalent to that of an EPM102 alloy; the high-temperature tissue stability is good; and a heat treatment window is wide, and solution treatment is easy to control.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified advanced high strength single crystal superalloy composition

The present invention relates to an improved single crystal nickel base superalloy and a process for making same. The single crystal nickel base superalloy has a composition comprising 3 to 12 wt % chromium, up to 3 wt % molybdenum, 3 to 10 wt % tungsten, up to 5 wt % rhenium, 6 to 12 wt % tantalum, 4 to 7 wt % aluminum, up to 15 wt % cobalt, up to 0.05 wt % carbon, up to 0.02 wt % boron, up to 0.1 wt % zirconium, up to 0.8 wt % hafnium, up to 2.0 wt % niobium, up to 1.0 wt % vanadium, up to 0.7 wt % titanium, up to 10 wt % of at least one element selected from the group consisting of ruthenium, rhodium, palladium, osmium, iridium, platinum, and mixtures thereof, and the balance essentially nickel. The single crystal nickel base superalloy has a microstructure which is pore-free and eutectic γ–γ′ free and which has a gamma prime morphology with a bimodal γ′ distribution.

Owner:RTX CORP

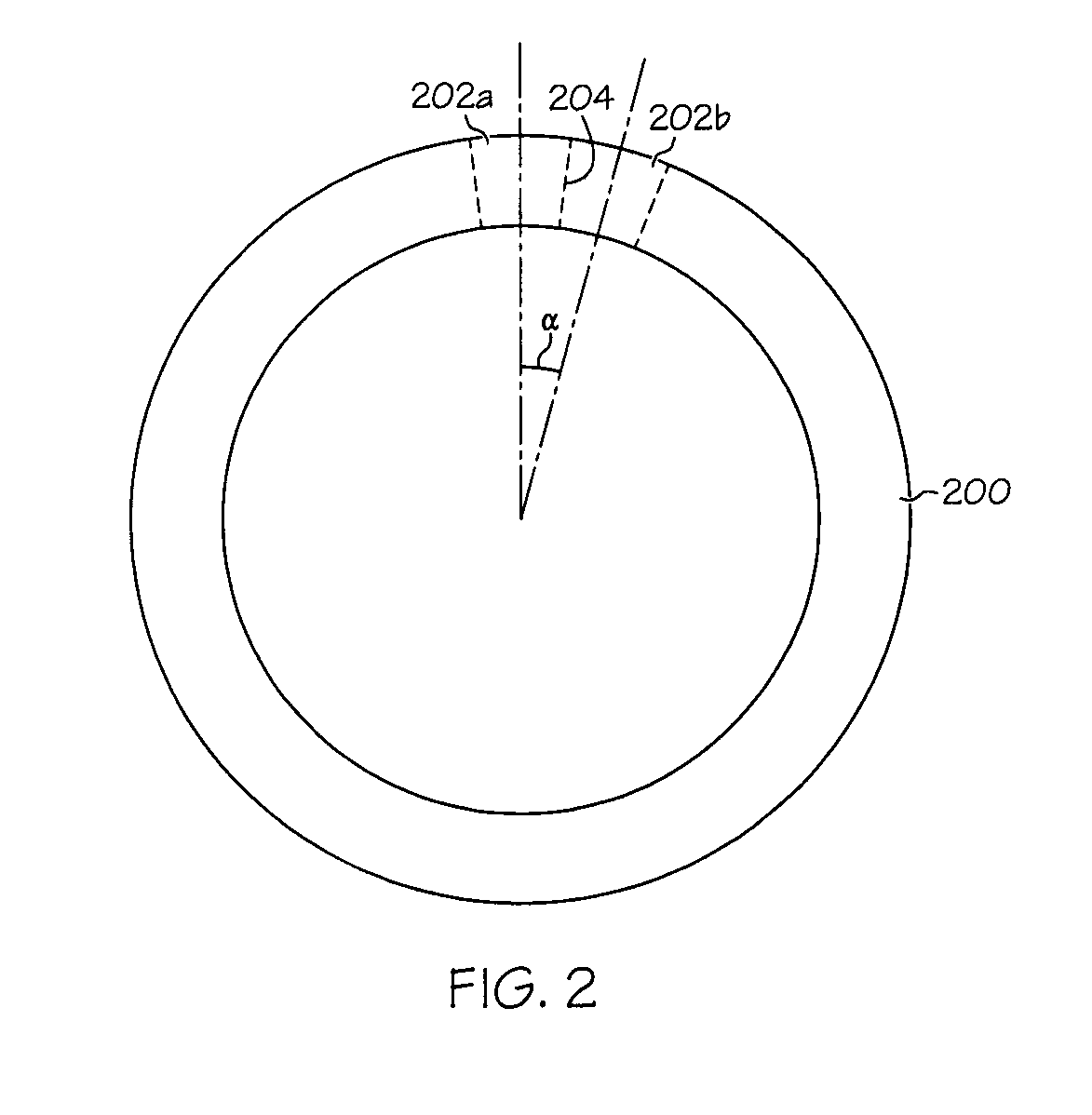

Crystal selection method for accurately controlling single-crystal orientation

ActiveCN107059133ANo change in microstructureNo significant increase in preparation costsPolycrystalline material growthFrom frozen solutionsSingle crystal superalloyCrystal orientation

The invention relates to a crystal selection method for accurately controlling single-crystal orientation. The crystal selection method comprises the following steps: putting short seed crystals into a mold shell, and forming an include angle of 0-45 degrees between secondary dendritic crystal orientation of the short seed crystals and a normal direction of a casting leaf body; and pouring melt mother alloy into a mold shell, maintaining the temperature, and drawing downwards at a speed of 50um / s-100um / s so as to obtain a single-crystal orientated single-crystal high-temperature alloy sample after the crystal drawing is finished. The primary dendritic crystal orientation of the prepared single-crystal high-temperature alloy sample deviates from the axial direction by an angle alpha, and the secondary dendritic crystal orientation deviates from the normal direction of the casting leaf body by an angle beta, wherein alpha is equal to 0-5 degrees, and beta is equal to 0-45 degrees.

Owner:苏州高晶新材料科技有限公司

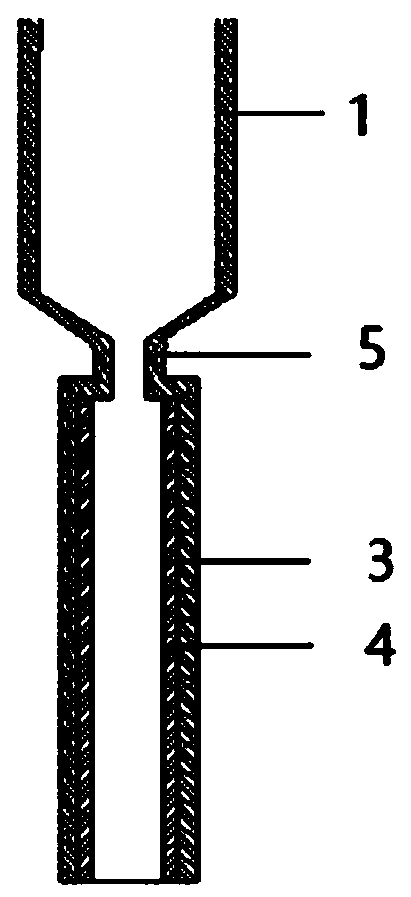

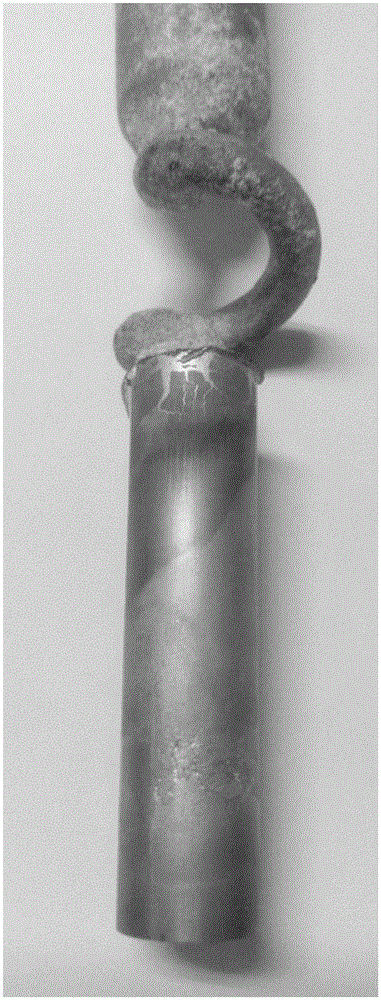

Method of repeatedly using seed crystals to prepare monocrystalline high-temperature alloy

ActiveCN105839186AAvoid formingPolycrystalline material growthFrom frozen solutionsSingle crystal superalloySurface roughness

The invention discloses a method of repeatedly using seed crystals to prepare a monocrystalline high-temperature alloy. On the premise that the monocrystalline high-temperature alloy in needed orientation is ensured to be obtained, the seed crystals are used repeatedly, so that trouble of preparing brand-new seed crystals when the monocrystalline high-temperature alloy is produced by a seed crystal method at each time is avoided, and production cost is lowered remarkably. Studies on a seed crystal melting-back area misoriented crystal forming mechanism find that surface coarseness of the inner wall of a formwork seeding section and scouring of the seed crystals during alloy pouring are important factors which are neglected for a long time and have influence on misoriented crystals. By the method, the surface coarseness of the inner wall of the formwork seeding section can be lowered, speed of scouring the seed crystals during alloy pouring can be reduced, and forming of misoriented crystals in a melting-back area can be avoided effectively.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

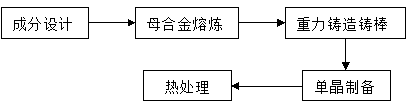

Low rhenium and nickel-based single crystal high-temperature alloy and preparation method thereof

InactiveCN103866392ARaise the initial melting temperatureWide melting temperature rangePolycrystalline material growthFrom frozen solutionsRheniumSingle crystal superalloy

The invention discloses low rhenium and nickel-based single crystal high-temperature alloy and a preparation method thereof. The alloy comprises the following raw materials by mass percent: 6.75-7.25% of Cr, 7.25-7.75% of Co, 1.3-1.7% of Mo, 5.8-6.2% of W, 5.8-6.2% of Ta, 0.85-1.15% of Re, 5.9-6.1% of Al, 1.3-1.7% of Ti, 0.12-0.18% of Hf, 0.04-0.06% of C, 0.003-0.005% of B, 0.010-0.020% of Y, and the balance of nickel. The method comprises the following preparation steps: smelting master alloy by using a vacuum induction furnace; preparing a master alloy rod by gravity casting; preparing a single-crystal test rod by adopting a seed crystal method through a Bridgeman directional solidification technology; carrying out thermal treatment on single crystal high-temperature alloy. The alloy disclosed by the invention is high in incipient melting temperature, wide in melting temperature range, small in solidification interval, low in alloy density, high in strength, good in oxidation resistance, good in phase stability and low in cost; a harmful phase is not easy to generate in long-term aging.

Owner:NANJING UNIV OF SCI & TECH +3

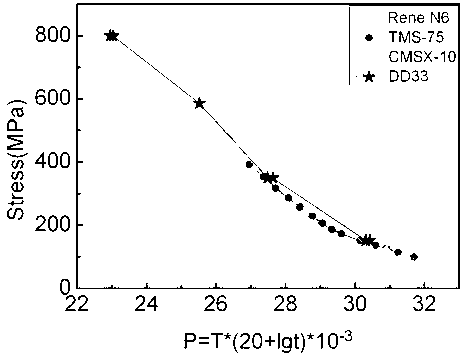

Third nickel-base high-temperature single crystal alloy in low cost

ActiveCN1966750AGood heat and corrosion resistanceImprove durabilitySingle crystal superalloySingle crystal

The invention belong to the field of nickel-based monocrystal superalloy, specifically a kind of low-cost third generation nickel-based monocrystal superalloy, which is mainly used for producing units bearing high stress under high temperature such as impeller blade in aero-motor. The chemical components of the alloy are (wt.%): Cr 2-4%,Co 11-13%,W 5-7%,Mo 0.5-2%,Re 3- 5%,Al 5-7%,Ta 6-10%,Hf 0.05-0.2%,and Ni as balance. The invention adopts vacuum induction melting for smelting, first smelting mother alloy with chemical components meeting the requirement, growing to monocrystal units. The following technological system for heating treatment is carried out before using: 1300DEG C / 8h,A.C.+1305DEG C / 15h,A.C.+1310DEG C / 8h, A.C.+1315DEG C / 24h,A.C.+1180DEG C / 4h,A.C.+870DEG C / 24h,A.C.. The alloy of the invention has the advantages of excellent persistence correspondent to that of third generation monocrystal superalloy CMSX-10, little Re content, low cost and good causticity resistance.

Owner:辽宁红银金属有限公司

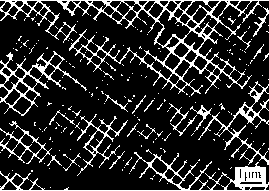

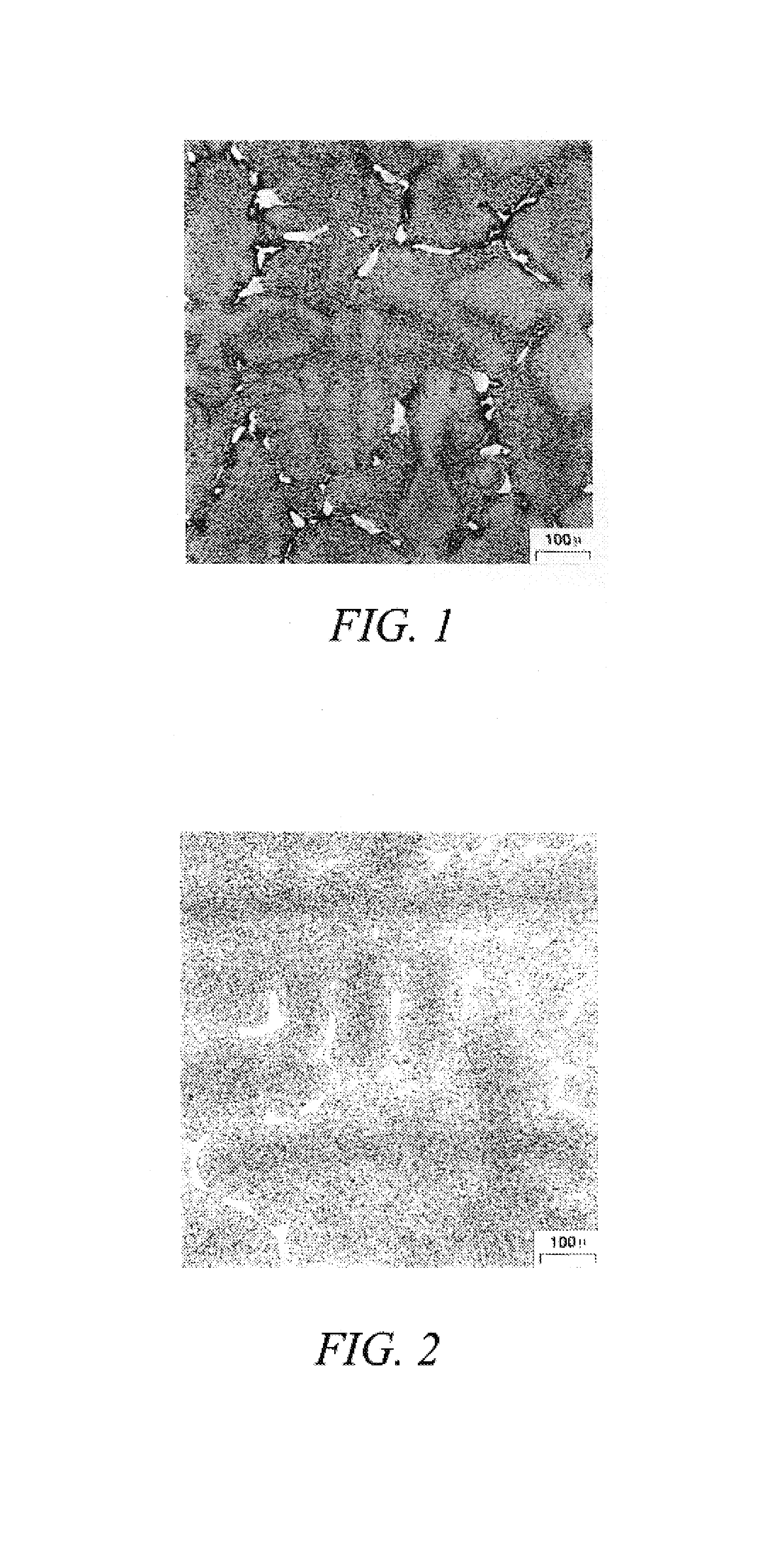

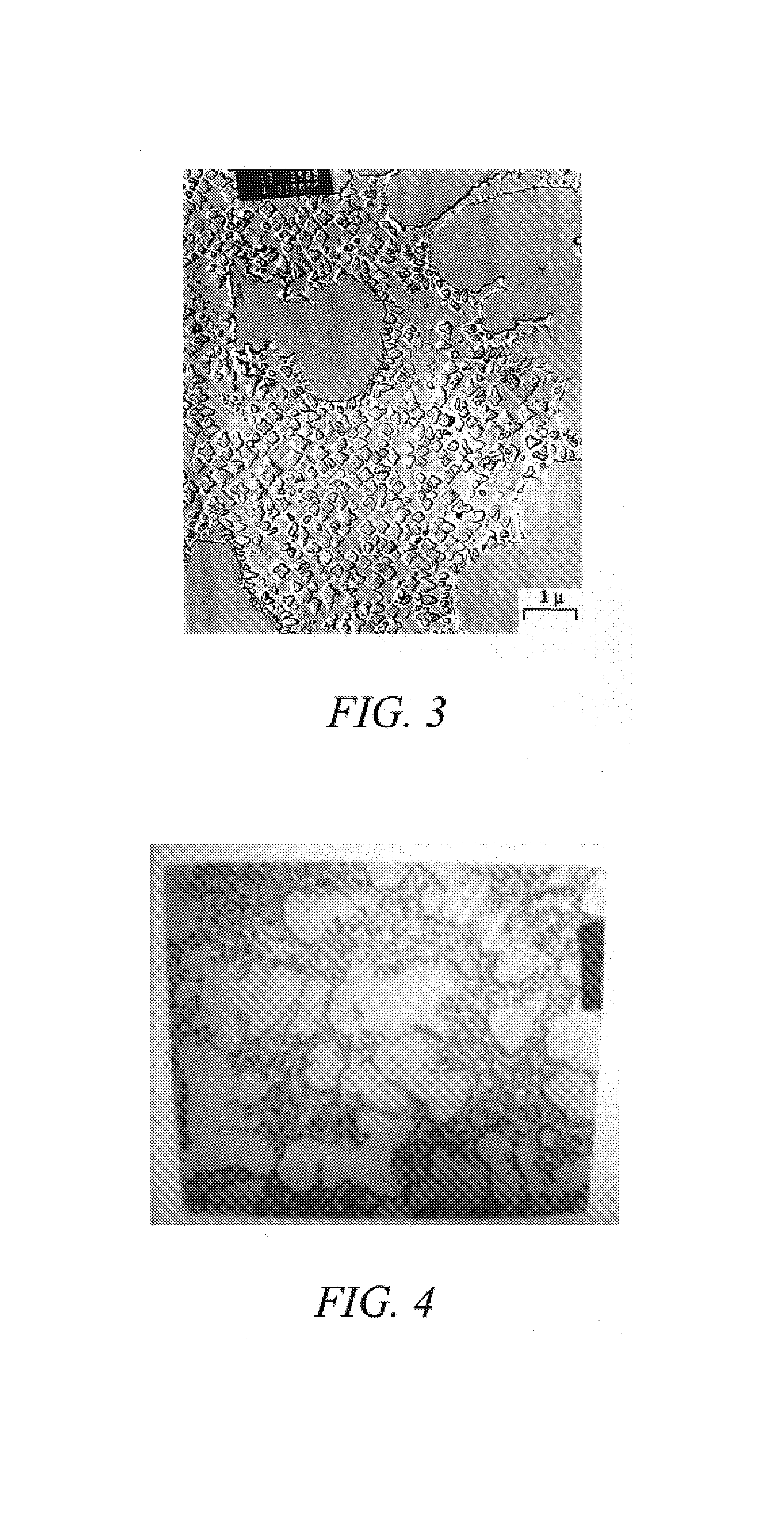

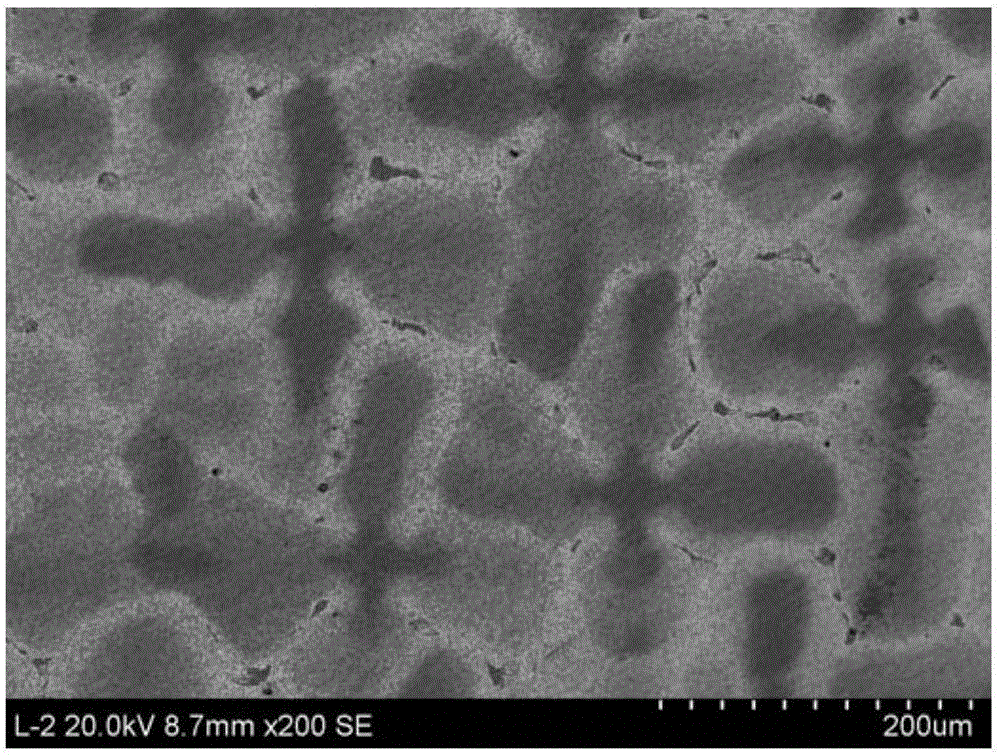

Method for preparing single crystal high temperature alloy block material through laser 3D printing

InactiveCN104947175ASmall dendritesIncrease thrust-to-weight ratioPolycrystalline material growthFrom solid stateSingle crystal superalloySingle crystal

The invention discloses a method for preparing a single crystal high temperature alloy block material through laser 3D printing and belongs to the technical fields of single crystal solidification and laser rapid forming. The method for preparing the single crystal high temperature alloy block material through the laser 3D printing comprises the following steps: firstly cutting a base material used for the laser 3D printing from a single crystal high temperature alloy material, then preheating the cut base material, carrying out surface remelting on the cut base material, and then observing a remelting microscopic structure; and based on a remelting technique, preparing the single crystal high temperature alloy block material through the laser 3D printing under the conditions that the base material is preheated to 0-800 DEG C, laser power is 200-500w, scanning speed is 30-3000mm / min, and powder feeding rate is 0.3-30g / min. The single crystal high temperature alloy prepared through the laser 3D printing can be used for developing a single crystal blade repairing technology and can also be used for developing a new single crystal high temperature alloy blade process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rhenium-free low-density high-performance nickel-based monocrystalline high-temperature alloy and heat treatment technology thereof

ActiveCN105200521ADurable cycle fatigue performanceDurable high temperature oxidation resistancePolycrystalline material growthAfter-treatment detailsRheniumChemical composition

The invention discloses a rhenium-free low-density high-performance nickel-based monocrystalline high-temperature alloy and a heat treatment technology thereof, and belongs to the field of nickel-based monocrystalline high-temperature alloys. The alloy comprises 6.0-8.0wt% of Cr, 8.0-10.0wt% of Co, 6.0-9.0wt% of W, 1.0-3.0wt% of Mo, 0-2wt% of Nb, 3.0-6.0wt% of Al, 1.0-3.0wt% of Ti, 1.0-5.0wt% of Ta, 0.02-0.06wt% of C, 0.001-0.003wt% of B, 0-0.02wt% of Ce, 0-0.01wt% of Y and the balance Ni. The alloy has excellent low-temperature, middle-temperature and high-temperature strength and antioxidation performances, has lasting and low-cycle fatigue behavior the same to that of a second monocrystalline high temperature alloy CMSX-4 with Re content of 3wt%, does not contain a noble element Re, reduces an alloy cost by 70% or more and reduces alloy density by about 3%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Turbine components and methods of manufacturing turbine components

Turbine components are provided. In an embodiment, by way of example, a hub and a ring are included. The hub comprises a first material. The ring is bonded to the hub. The ring comprises a plurality of arc segments forming a ring, each arc segment comprising a second material comprising a single crystal superalloy material having a predetermined primary orientation and a predetermined secondary orientation, each predetermined primary orientation of each arc segment being substantially equal, and each predetermined secondary orientation of each arc segment being substantially equal, each arc segment adjacent another arc segment, and the adjacent arc segments having a predetermined crystallographic mismatch therebetween. Methods of manufacturing are also provided.

Owner:HONEYWELL INT INC

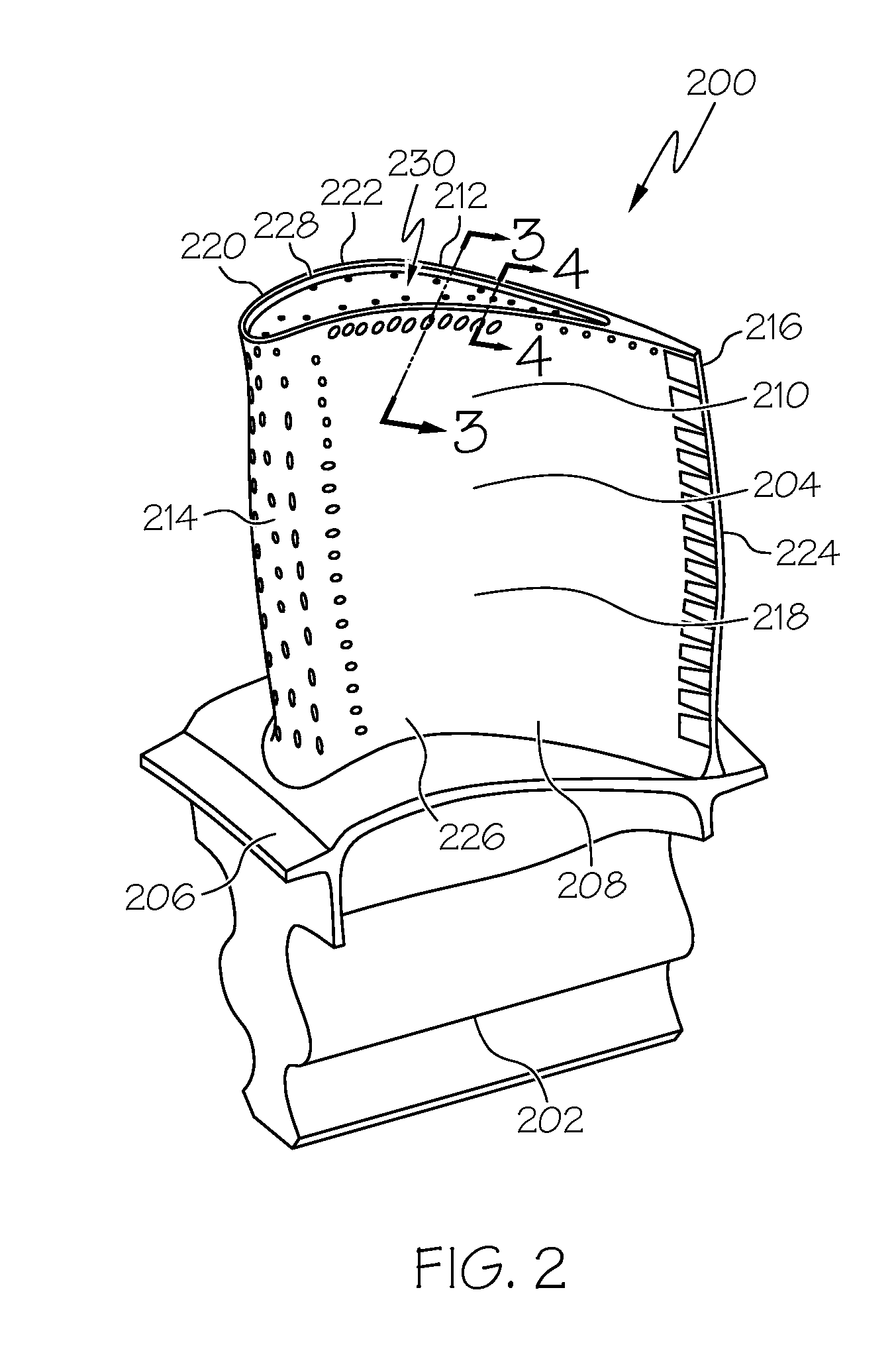

Blades, turbine blade assemblies, and methods of forming blades

Blades, turbine blade assemblies, and methods of forming blades are provided. The blade includes an airfoil including a convex suction side wall, a concave pressure side wall, a leading edge, a trailing edge, a root, and a tip, the convex suction side wall, the concave pressure side wall, and the tip each including interior surfaces that together define an internal cooling circuit, the airfoil including a single crystal superalloy, and a cladding layer disposed over the tip, the cladding layer including a zirconia grain stabilized platinum alloy.

Owner:HONEYWELL INT INC

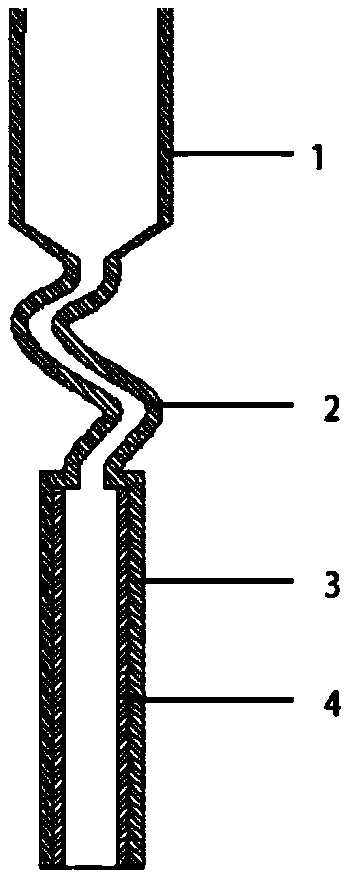

Method for preparing Ni based single-crystal refractory alloy by employing combination of seed crystal method and screw selecting method

InactiveCN101255606AImprove performancePolycrystalline material growthFoundry mouldsWaxSingle crystal superalloy

The invention discloses a method of preparing a Ni-based monocrystal high-temperature alloy through the crystallon method and the spiral crystal selection method, comprising: firstly a crystallon which is provided with a certain crystal orientation is cut directionally on the Ni-based monocrystal high-temperature alloy; the crystallon is extended into one side of a wax pattern of a spiral crystal selector; the other side of the wax pattern of the spiral crystal selector is connected with a parts wax pattern; and ceramics castable refractory is smeared on the outside of the crystallon, the wax pattern of the spiral crystal selector and the parts wax pattern; then a ceramics shuttering provided with the crystallon is manufactured via dewaxing and burning; and the Ni-based monocrystal high-temperature alloy material is teemed, shaped and manufactured by making use of the ceramics shuttering in a monocrystal furnace. The invention relates to a monocrystal preparation technology which can accurately control crystal orientation of the monocrystal and fine texture to manufacture the high quality Ni-based monocrystal high-temperature alloy material.

Owner:BEIHANG UNIV

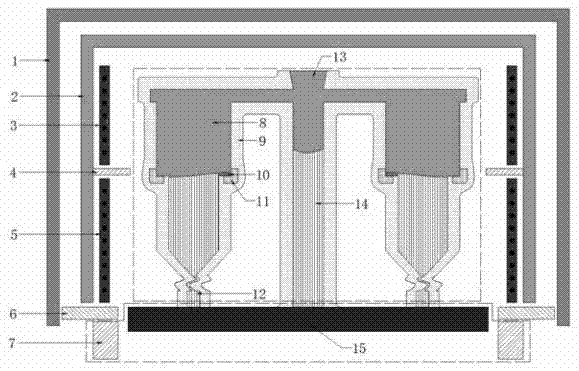

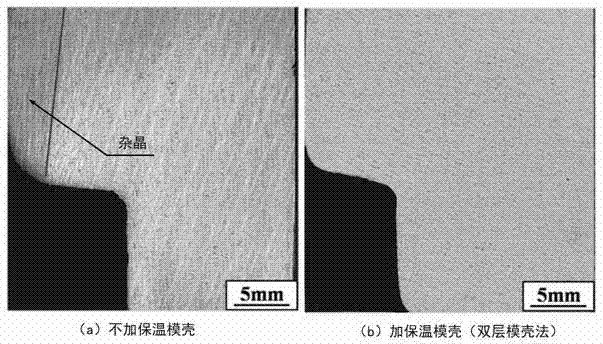

Method for controlling formation of foreign crystals at variable cross section

InactiveCN105436478AInhibition formationInhibitionPolycrystalline material growthFrom frozen solutionsSingle crystal superalloySingle crystal

The invention discloses a method for controlling the formation of foreign crystals at a variable cross section. According to the method, by using a double-layer mould case method at the variable cross section, the formation of foreign crystals at the variable cross section can be feasibly and effectively inhibited, a monocrystal structure is obtained at a relatively higher pulling speed, and a high-temperature alloy casting with excellent mechanical properties is obtained. A variable-cross-section casting directional-solidification device in the invention comprises a heating system, a casting system and a water cooling system, wherein directional solidification can be realized from bottom to top by pulling the casting system from a heating zone to a cooling zone. The double layer mould case method has an excellent effect of inhibiting the formation of foreign crystals, and is of important directive significance in manufacturing blades in groups, obtaining monocrystal high-temperature alloy blades with excellent properties and improving the production efficiency.

Owner:SHANGHAI UNIV

Non-rhenium nickel base single crystal superalloy and preparation method thereof

ActiveCN103436740ARaise the initial melting temperatureWide melting temperature rangePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses non-rhenium nickel base single crystal superalloy and a preparation method thereof. The non-rhenium nickel base single crystal superalloy comprises the following components in percentage by weight: 7.25-7.75% of Cr, 4.8-5.2% of Co, 1.8-2.2% of Mo, 7.8-8.2% of W, 6.3-6.7% of Ta, 6.0-6.2% of Al, 0.12-0.18% of Hf, 0.04-0.06% of C, 0.003-0.005% of B, 0.010-0.030% of Y, and the balance of Ni. The preparation method for the non-rhenium nickel base single crystal superalloy comprises the steps as follows: adopting a vacuum induction furnace to smelt the raw material into mother alloy, and preparing a mother alloy casting rod through gravity casting; adopting a seed crystal method to prepare a single crystal test bar within the temperature gradient of 150-250 K / cm and the withdrawing rate of 5-100 micron / s through a Bridgeman directional solidification technology; performing solution treatment on the single crystal superalloy for 2-4 h within the temperature range of 1,295-1,305 DEG C and performing air cooling, then performing high-temperature aging treatment on the single crystal superalloy for 2-4 h within the temperature range of 1,090-1,310 DEG C and performing air cooling; performing low-temperature aging treatment on the single crystal superalloy for 16-24 h within the temperature range of 850-890 DEG C and performing air cooling.

Owner:NANJING UNIV OF SCI & TECH

Nickel-based single-crystal high-temperature alloy connecting powder brazing filler metal as well as preparation method and application thereof

ActiveCN109420862AImprove mechanical propertiesSmall corrosionWelding/cutting media/materialsSoldering mediaChemical compositionSingle crystal superalloy

The invention discloses a nickel-based single-crystal high-temperature alloy connecting powder brazing filler metal as well as a preparation method and an application thereof, and belongs to the technical field of high-temperature alloy brazing materials. The brazing filler metal comprises the following chemical components (wt.%) of 10.0%-15.0% of Cr, 7.5%-13.5% of Co, 3.0%-8.5% of W, 0-4.5% of Al, 2.5%-5.5% of Mo, 2.5%-6.5% of Ti, 0-5.0% of Si, 0-2.0% of B, 0-3.0% of Fe and the balance Ni. The powder brazing filler metal is prepared by an atomization powder spraying method and is used for high-temperature alloy brazing connection. The brazing temperature is 1220-1320 DEG C, and the brazing time is 10-360 minutes. According to the powder brazing filler metal, the high-temperature performance brazing connection problem of a single crystal high-temperature alloy is solved and the important application value is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ni-based single crystal superalloy and alloy member using the same as base

Disclosed is a Ni-based single crystal superalloy having a composition consisting of, in mass percent, 5.0-7.0% of Al, 4.0-8.0% of Ta, 0-2.0% of Mo, 3.0-8.0% of W, 3.0-8.0% of Re, 0-0.50% of Hf, 3.0-6.0% of Cr, 0-9.9% of Co, 1.0-14.0% of Ru, 0.1-4.0% of Nb and the balance of Ni and unavoidable impurities. The present invention provides a Ni-based single crystal superalloy which suppresses the precipitation of the TCP phase at high temperatures, improves strength at high temperatures, and has oxidation resistance at high temperatures. The inventon aims to provide a Ni-based single crystal superalloy of high performance in strength and oxidation resistance at high temperatures, and further aims to provide a Ni-based single crystal superalloy having sufficient characteristic in a ''heat treatment window'' of not being negligent at the practical aspect.

Owner:NAT INST FOR MATERIALS SCI

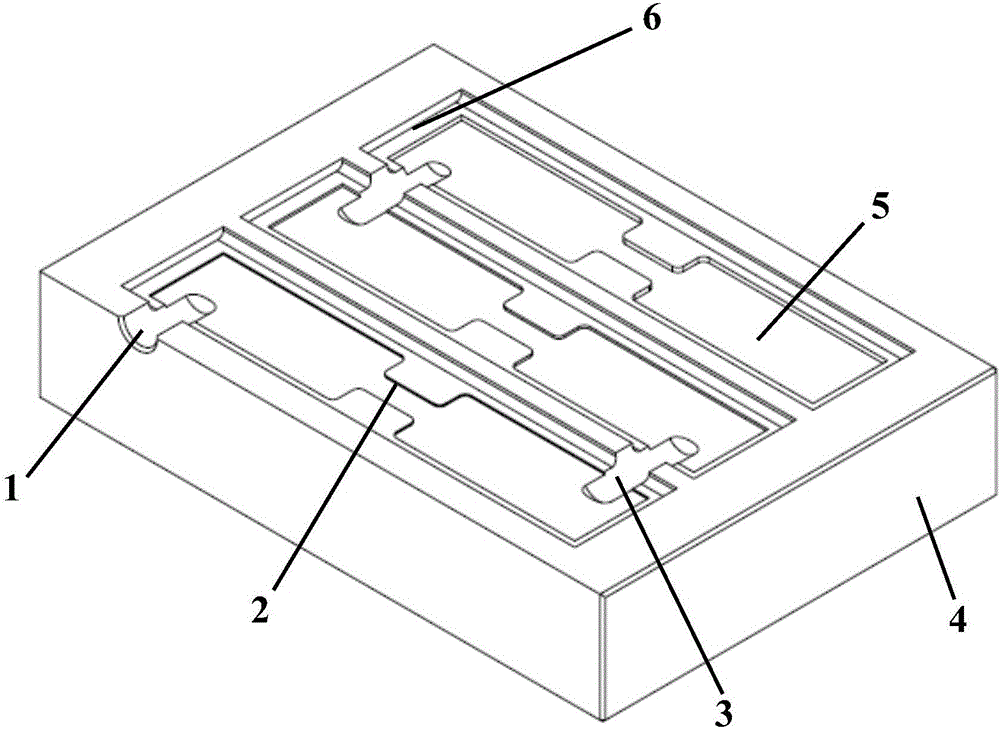

Preparation method of precision-investment casting single-crystal high-temperature alloy thin-wall sample

ActiveCN106001513AReduce the incidence of recrystallizationAvoid deformationPolycrystalline material growthFoundry mouldsInjection pressureTime range

The invention relates to a preparation method of a precision-investment casting single-crystal high-temperature alloy thin-wall sample. In the wax mould preparation process, a plate-shaped ceramic core is put into a mould, and the ceramic core is used as a support of wax; the mould is closed, the wax is injected into the mould, the injection pressure of the wax ranges from 5 bar to 8 bar, the temperature of the wax ranges from 60 DEG C to 80 DEG C, and the pressure maintaining time ranges from 60 s to 120 s; and wax moulds of a certain thickness are formed on the two sides of the plate-shaped ceramic core, and the wax moulds are closely attached to the surface of the ceramic core. According to the thickness of the designed thin-wall sample, the wax moulds on the two sides of the ceramic core are thinned, the rotating speed of a spindle is controlled to range from 500 r / min to 6,000 r / min, the feed speed is controlled to range from 30 mm / min to 450 mm / min, and the axial cutting depth is controlled to range from 0.03 mm to 0.5 mm. The wax moulds of the thin-wall sample are prepared, after a mould set is formed by the wax moulds of the thin-wall sample, a shell is prepared through shell coating, directional solidification pouring is completed in a vacuum induction single crystal furnace, and therefore the single-crystal high-temperature alloy precision casting thin-wall sample is prepared. According to the preparation method, the problems of short run and undercasting of the wax moulds in the deformation and directional solidification process in the mould pick-up and finishing process can be completely avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

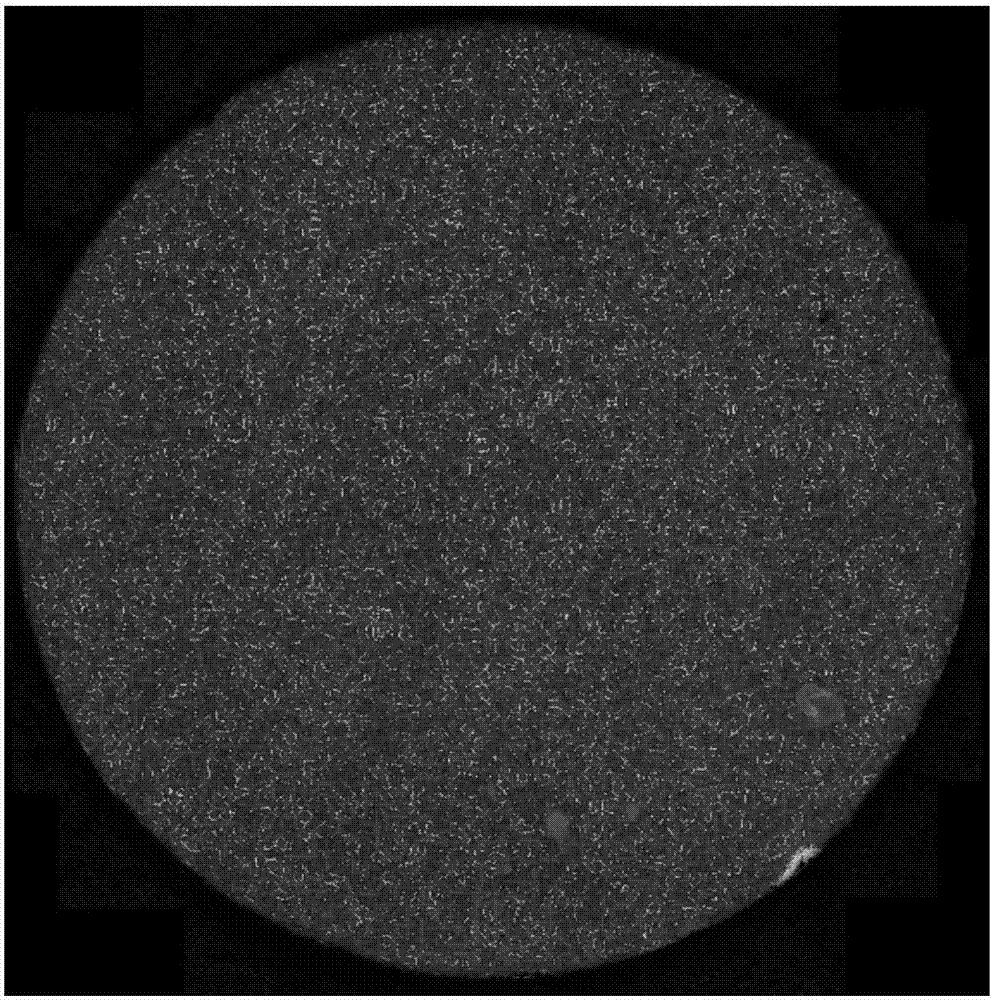

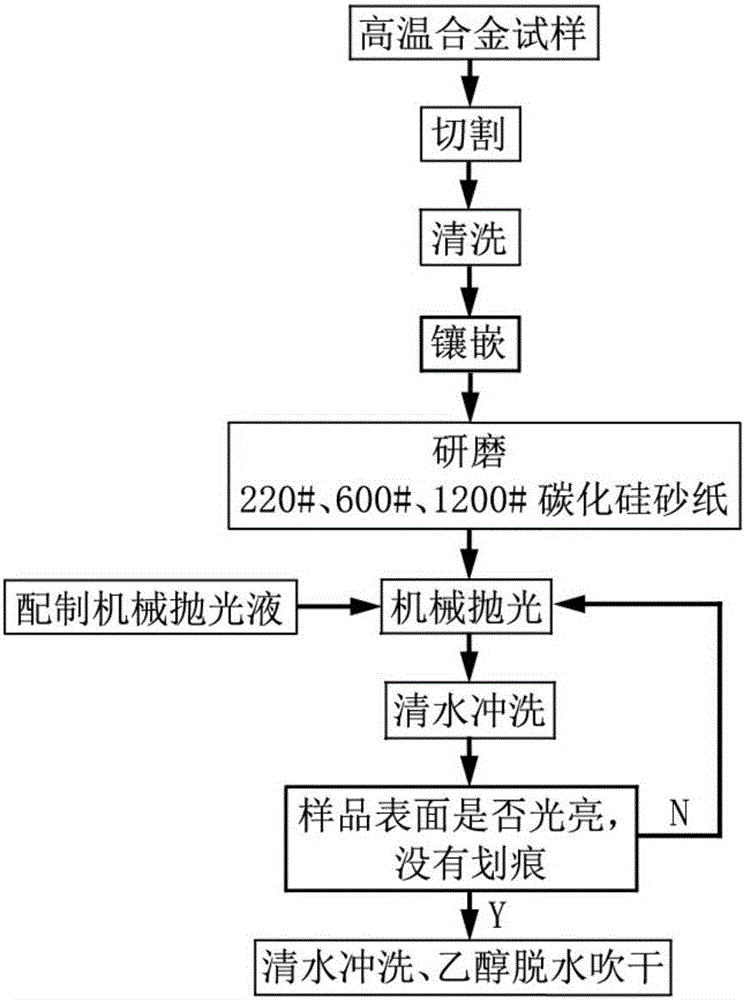

Mechanical polishing solution for preparing EBSD sample, preparation method and mechanical polishing method

InactiveCN105839111AEasy to prepareLow costPreparing sample for investigationPolishing compositions with abrasivesSingle crystal superalloyCrystal orientation

The invention discloses a mechanical polishing solution for preparing an EBSD sample, a preparation method and a mechanical polishing method, and belongs to the technical field of Ni-base single crystal superalloy crystal orientation analysis. The mechanical polishing method of the Ni-base single crystal superalloy EBSD sample is provided for solving the problems that the Ni-base single crystal superalloy EBSD sample is complex in preparation process, time-consuming, low in indexing rate and the like, and the mechanical polishing method with easy preparation of the polishing solution is easy and convenient to operate, low in cost, good in polishing effect and high in indexing rate. The polishing solution is composed of 25 wt%-30 wt% of colloidal silicon dioxide, 2 wt%-3 wt% of hydrogen peroxide, 1 wt%-2 wt% of oxalic acid, 2 wt%-3 wt% of glycerinum, and the balance a pH modifier and distilled water. The mechanical polishing method comprises the steps of (1) cutting, (2) cleaning, (3) inserting, (4) grinding and (5) mechanical polishing. The mechanical polishing method is easy to implement, low in energy consumption and suitable for preparation of the Ni-base single crystal superalloy EBSD sample.

Owner:XIAN THERMAL POWER RES INST CO LTD

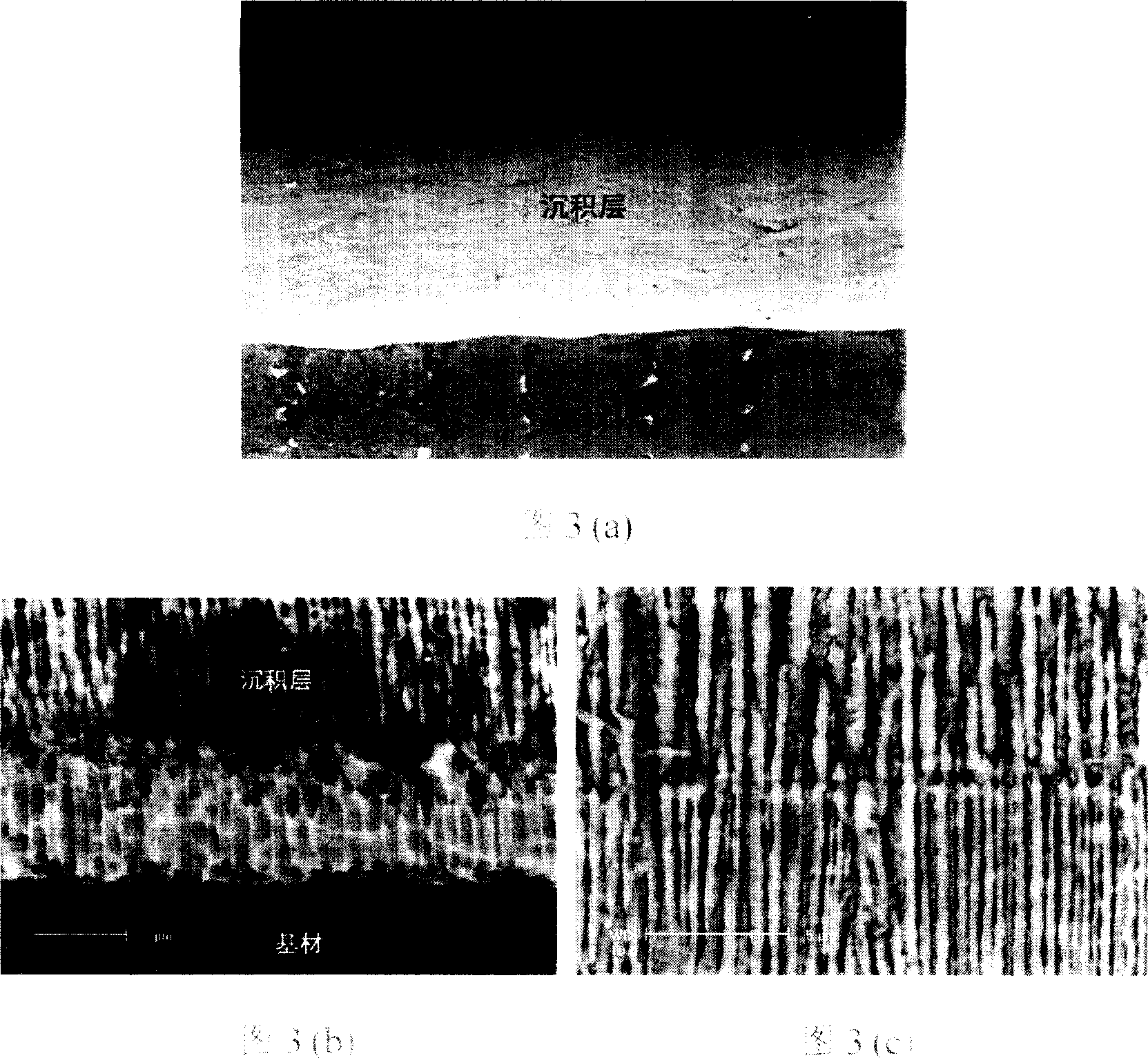

Directional freezing styloid or single-crystal nickel-base high-temperature alloy repairing or coating method

InactiveCN101126143ALittle thermal impactDoes not cause recrystallizationMolten spray coatingArc welding apparatusHeat-affected zoneSingle crystal superalloy

The invention belongs to a preparation technique of the metal surface settled layer, in particular to a method for preparing the directional solidification column crystal or single crystal settled layer which grows on the extension of the surface of the directional solidification column crystal or single crystal high temperature alloy. The proposal of the invention solves the problem of repairing and coating of the directional solidification column crystal or single crystal high temperature alloy; and to gain a compact and flawless directional solidification column crystal or single crystal settled layer which is matched with the directional solidification column crystal or single crystal. The invention discloses an extension high power differential arc spark metal deposition technique. The invention has the advantages of wide process window achieved by the extension high power differential arc spark metal deposition technique, no heat damage to the ferronickel high temperature alloy, narrow heat influence area or no heat influence area, being capable of effectively avoiding the phenomenon of heat flaw of the ferronickel high temperature, no complicated devices such as vacuum room needed and no preheating needed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Platinum group element reinforced high-thermal stability and high-strength nickel-based single-crystal high-temperature alloy

ActiveCN106636759AImprove thermal stabilityImprove durabilityPolycrystalline material growthFrom frozen solutionsChemical compositionSingle crystal superalloy

The invention discloses a platinum group element reinforced high-thermal stability and high-strength single-crystal high-temperature alloy and belongs to the technical field of nickel-based single-crystal high-temperature alloys. The alloy is prepared from the following chemical components in percentage by weight: 2 percent to 6 percent of Cr, 7 percent to 14 percent of Co, 1 percent to 3 percent of Mo, 4.5 percent to 6.5 percent of W, 4.7 percent to 6.7 percent of Al, 5 percent to 9 percent of Ta, 5.4 percent to 7 percent of Re, 2 percent to 5 percent of Ru, 1 percent to 3 percent of Ir, 0 to 0.2 percent of Hf, 0 to 0.2 percent of Y and the balance of Ni. The alloy has the advantages of high high-temprature tissue stability, excellent high-temprature strength, high anti-oxidization performance and the like and is especially suitable for manufacturing hot-end high-temperature parts in the fields of aviation, aerospace, energy sources and the like.

Owner:辽宁红银金属有限公司

Low density, high creep resistant single crystal superalloy for turbine airfoils

A nickel-base superalloy article for use in turbines has increased creep resistance and lower density. The superalloy article includes, as measured in % by weight, 6.0-12.0% Mo, 5.5-6.5% Al, 3.0-7.0% Ta, 0-15% Co, 2.0-6.0% Cr, 1.0-4.0% Re, 0-1.5% W, 0-1.5% Ru, 0-2.0%-Ti, 0-3.0% Nb, 0-0.2% Hf, 0-0.02% Y, 0.001-0.005% B, 0.01-0.04% C, and a remainder including nickel plus impurities.

Owner:NASA THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com