Low rhenium and nickel-based single crystal high-temperature alloy and preparation method thereof

A high-temperature alloy, nickel-based single crystal technology, applied in nickel-based single-crystal superalloy and its preparation, high-performance nickel-based single-crystal superalloy and its preparation, low rhenium field, can solve the problem of reducing market competitiveness and deteriorating nickel-based single crystal The properties of crystal superalloys and the increase of alloy cost have been solved, so as to achieve the effects of wide melting temperature range, low alloy cost and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

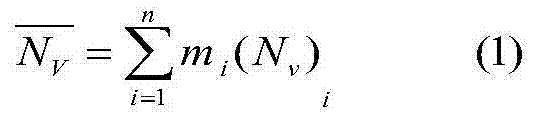

Method used

Image

Examples

Embodiment 1

[0040] (1) Alloy composition design

[0041] The low-rhenium nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.0%Cr, 7.5%Co, 1.5%Mo, 6.0%W, 6.0%Ta, 1.0%Re, 6.0%Al, 1.5%Ti, 0.15%Hf, 0.05%C, 0.004%B, 0.015%Y, the balance of Ni. The calculation results and the performance prediction parameters of typical first-generation and second-generation nickel-based single crystal superalloys are shown in Table 1.

[0042] Table 1 Prediction of main performance parameters of typical first-generation and second-generation nickel-based single crystal superalloys and design alloys

[0043]

[0044]

[0045] (2) Master alloy smelting

[0046] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was smelted by vacuum induction suspension in a water-cooled copper crucib...

Embodiment 2

[0054] (1) Alloy composition design

[0055] The low-rhenium nickel-based superalloy of the present invention has the following alloy components by mass percentage: 6.75%Cr, 7.25%Co, 1.3%Mo, 5.75%W, 5.8%Ta, 0.85%Re, 5.9%Al, 1.3%Ti, 0.12%Hf, 0.04%C, 0.003%B, 0.013%Y, the balance of Ni.

[0056] (2) Master alloy smelting

[0057] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was smelted by vacuum induction suspension in a water-cooled copper crucible, with a smelting power of 20Kw and a smelting time of 5 minutes.

[0058] (3) Master alloy casting rod preparation

[0059] After the master alloy was remelted in a non-consumable electric arc furnace, the master alloy casting rod was prepared by gravity casting in a copper mold, with a size of

[0060] (4) Single crystal preparation

[0061] The single cr...

Embodiment 3

[0065] (1) Alloy composition design

[0066] The low-rhenium nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.25%Cr, 7.75%Co, 1.7%Mo, 6.25%W, 6.2%Ta, 1.15%Re, 6.1%Al, 1.7%Ti, 0.18%Hf, 0.06%C, 0.005%B, 0.017%Y, the balance of Ni.

[0067] (2) Master alloy smelting

[0068] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was smelted by vacuum induction suspension in a water-cooled copper crucible, with a smelting power of 25Kw and a smelting time of 3 minutes.

[0069] (3) Master alloy casting rod preparation

[0070] After the master alloy was remelted in a non-consumable electric arc furnace, the master alloy casting rod was prepared by gravity casting in a copper mold, with a size of

[0071] (4) Single crystal preparation

[0072] The single cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com