Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Excellent hot corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni Co Cr Al Y Si B coating layer capable of resisting thermal corrosion and its preparation method

InactiveCN1536033AExcellent thermal corrosion resistanceCorrosion weight gain is smallCoatingsHigh resistanceIon deposition

The present invention relates to coating technology, in the concrete, it discloses a NICoCrAlYSiB hot corrosion resisting high-temp. protection coating and its preparation method. Its element content composition includes: Co 28-35 wt%, Cr 17-23 wt%, Al 5-12 wt%, Y 0.1-0.6 wt%, Si 0.9-1.1 wt%, B 0.02-0.04 wt% and the rest is Ni. Said invention adopts electric arc ion deposition technique to prepare said protection coating, and as compared with existent technology said invented protection coating has highest resistance to hot corrosion and high temp. oxidative property, and its preparation process is low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

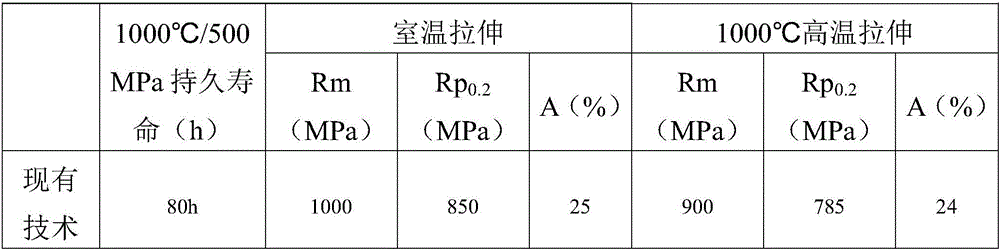

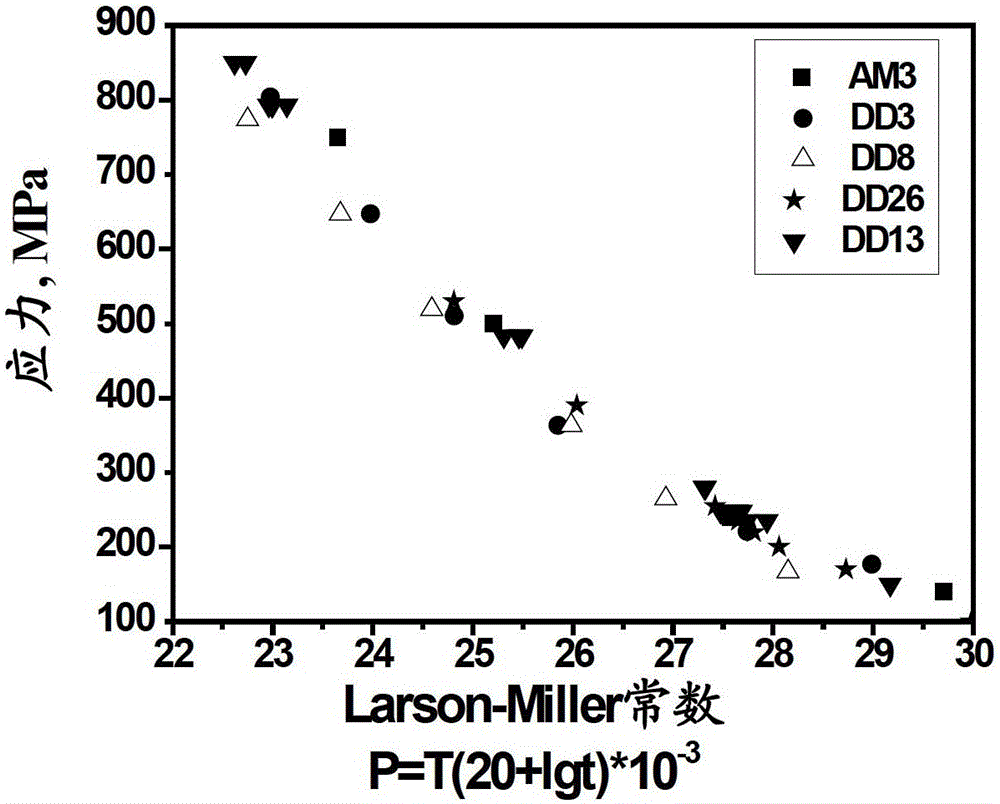

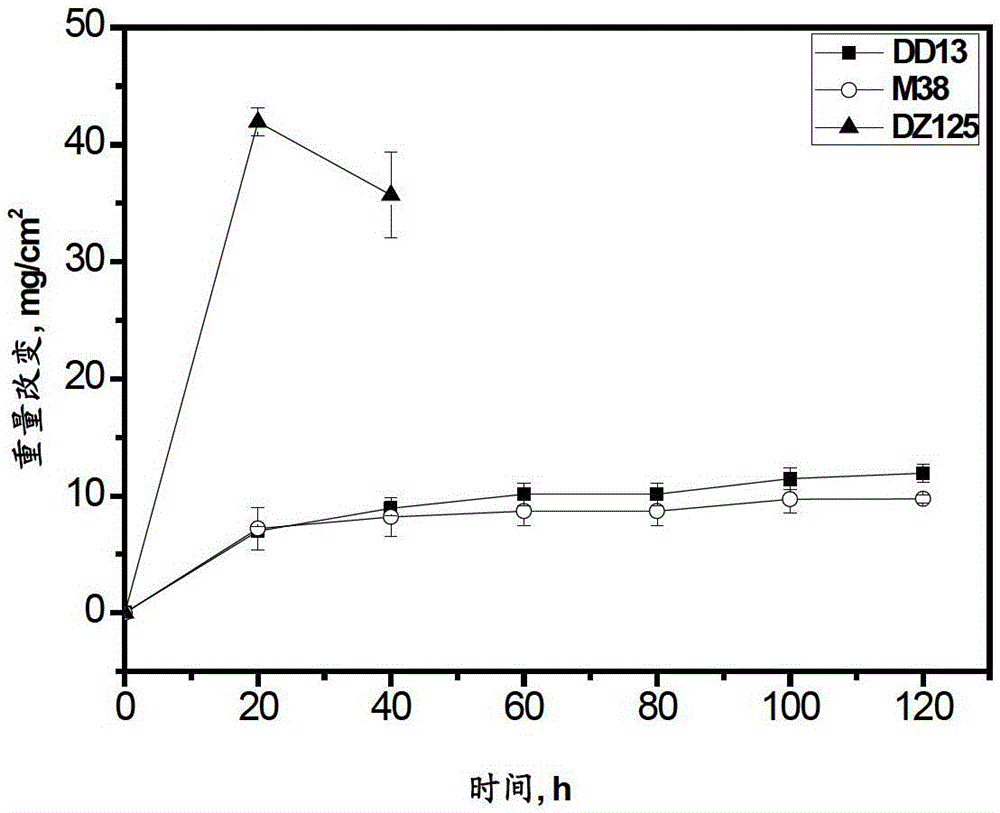

High strength antithermal corrosion low segregation directional high temp alloy

ActiveCN101089215AImprove mechanical propertiesImprove organizational structureSlow coolingSuperalloy

This invention relates to high-strength thermal abrasion resistance high-temperoducre alloy with low segregation and directional solidification properties. Its constitutions are (wt.%): Co9-12, Cr11-16, Mo1-3, W4-7, Al4-7, Ta4-7, Ti0-2, Re2-3, C0.01-0.15, 0.005-0.02 and Ni as the rest. The heat treatment for directional solidification steps are: 1240+-10deg.C for 0.5Hrs; 1260+-10deg.C for 0.5Hrs; 1280+-10deg.C for 4Hrs; air cooling to room temperature; 1120+-10deg.C for 4-1 Hrs; slow cooling to 1080+-10deg.C for 4Hrs; air cooling to room temperature; 900+-10deg.C; air cooling to room lemperature. This invention alloy can meet the requirement strength for design of turbine blade of aircraft engine but also has excellent thermal abrasion resistance property. The plane with the turbine blade of aircraft engine can be used for high altitude flight and flight in corrosion environment obove turbine blade of aircraft engine can be used for high altitude flight and flight in corrosion environment above sea.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process for preparing nickel-base superalloy

ActiveCN102808113AElimination of lateral grain boundariesImprove organizationPolycrystalline material growthSingle crystal growth detailsSmelting processRoom temperature

The invention discloses a process for preparing nickel-base superalloy. The superalloy consists of the following components in percentage by weight: 22.5 to 24.5 percent of Cr, 7.0 to 8.0 percent of Co, 6.5 to 7.5 percent of W, 3.0 to 4.0 percent of Mo, 1.2 to 1.8 percent of Al, 1.5 to 2.5 percent of Ti, 2.0 to 3.0 percent of Nb, 1.0 to 2.0 percent of Mn, 2.0 to 4.0 percent of Fe, 0.02 to 0.08 percent of B, 0.5 to 1.5 percent of Ce, less than or equal to 0.1 percent of C, less than or equal to 0.2 percent of Si, less than or equal to 0.008 percent of P, less than or equal to 0.008 percent of S and the balance of Ni. The process for preparing the nickel-base superalloy comprises a smelting process and a heat treatment process, wherein the smelting process comprises the steps of: smelting master alloy by using a vacuum induction furnace, and performing directional solidification in a liquid metal directional furnace to prepare directional column crystal alloy, wherein the vacuum degree of the directional furnace is about (1-5)*10<-4>mmHg, the pouring temperature is 1,580 to 1,600 DEG C, the drawing speed is 4 to 8mm / min, the temperature gradient is 75 to 85 DEG C / cm, and the temperature of liquid tin is 250 to 350 DEG C; the heat treatment process comprises the following steps of: heating the column crystal alloy obtained through smelting to 1,240 to 1,260 DEG C, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; heating to 1,150 to 1,170, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; and heating to 930 to 950 again, preserving heat for 8 to 12 hours and performing air cooling to room temperature.

Owner:南通大地电气股份有限公司

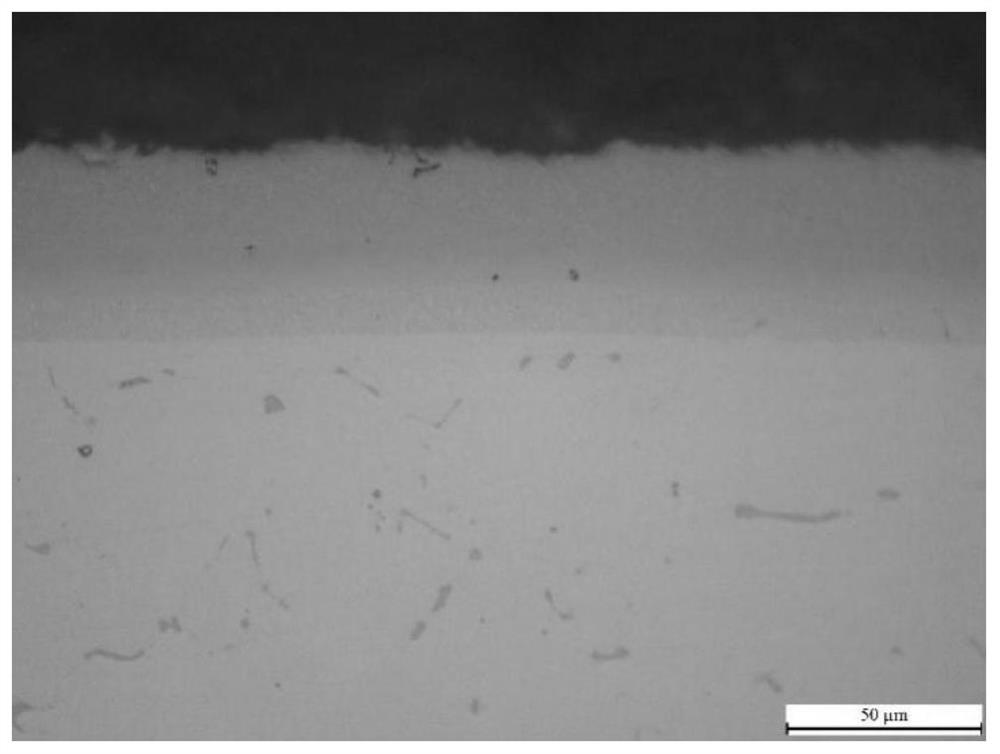

High-temperature oxidation resistant and corrosion resistant glass ceramic composite coating and preparation technology thereof

ActiveCN103469207AThe preparation process is non-toxicNo pollution in the processMicron scaleMetallic materials

The invention relates to an inorganic high temperature protection coating technology, particularly to a high-temperature oxidation resistant and corrosion resistant glass ceramic composite coating which can be used for components made of titanium alloy and other metallic materials and a preparation technology of the composite coating. The coating is formed through uniformly dispersing and distributing micron scale ceramic particle phase and nanoscale metal / oxide mixed powder into a glass matrix phase, the glass matrix phase is formed through performing high temperature conversion on sodium silicate water glass or potassium silicate water glass, the micron phase ceramic particle phase accounts for 15-60 wt% of the glass ceramic composite coating, and the nanoscale metal / oxide mixed powder accounts for 0.5-5 wt% of the glass ceramic composite coating. The coating preparation technology comprises the steps of coating material preparation, coating material spraying and high temperature processing. The glass ceramic composite coating, provided by the invention, is compact, has no holes, has higher strength and breaking tenacity, and has good binding force with a titanium alloy matrix and thermal expansion coefficient matched with the titanium alloy matrix, thereby having excellent anti-thermocycling thermal shock performance, high-temperature oxidation resistance and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nickel-based high temperature alloy and manufacturing method thereof

ActiveCN106636760AImprove creep resistanceImprove organizational stabilitySolution treatmentImpurity

The invention discloses a nickel-based high temperature alloy and a manufacturing method thereof. The nickel-based high temperature alloy comprises the following components in percentage by weight: 0.06-0.15% of C, 0.25-0.55% of Si, 0.40-0.95% of Mn, 0.05-3.00% of Fe, 1.0-5.0% of Co, 0.05-0.50% of Al, 0.01-0.09% of Ti, 20.0-24.0% of Cr, 0.01-0.40% of Nb, 0.90-3.0% of Mo, 12.0-15.0% of W, 0.10-1.0% of Re, 0.001-0.009% of B, 0.8-2.0% of Ce, 0.8-1.8% of Ru, 0.3-3.0% of Hf, 2.0-5.0% of Ta, 0.05-0.35% of V and the balance of nickel and inevitable impurities. The nickel-based high temperature alloy disclosed by the invention has the advantages that materials are prepared in a certain proportion, homogenization treatment is carried out on the alloy for three times, high temperature forging is carried out on the alloy, and solution treatment, heat preservation and cooling are carried out; and by adopting the technical scheme of the invention, the strength, fatigue resistance and corrosion resistance of the alloy at high temperature can be effectively improved.

Owner:宁国市华成金研科技有限公司

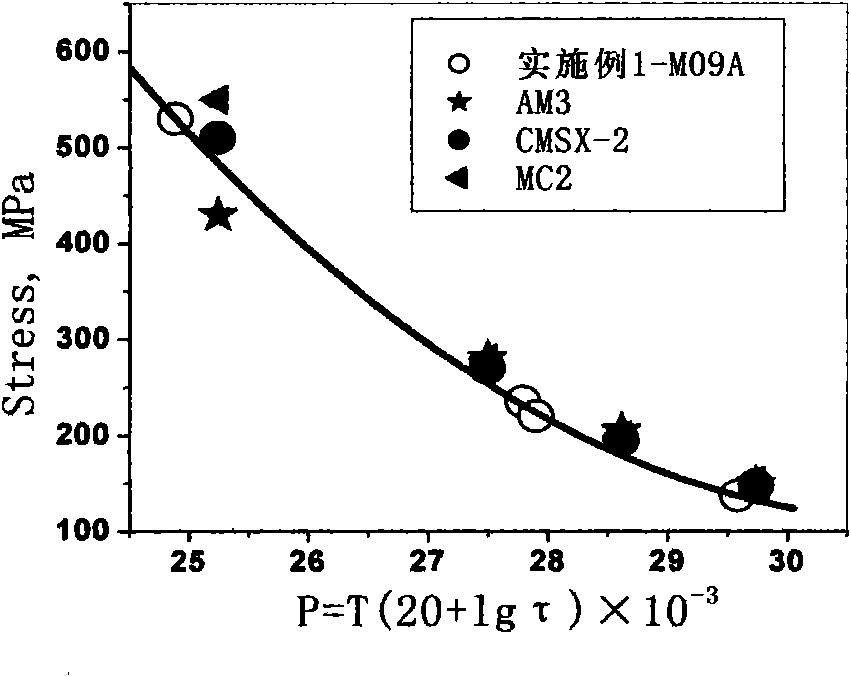

High-strength corrosion-resistant nickel-based monocrystal superalloy

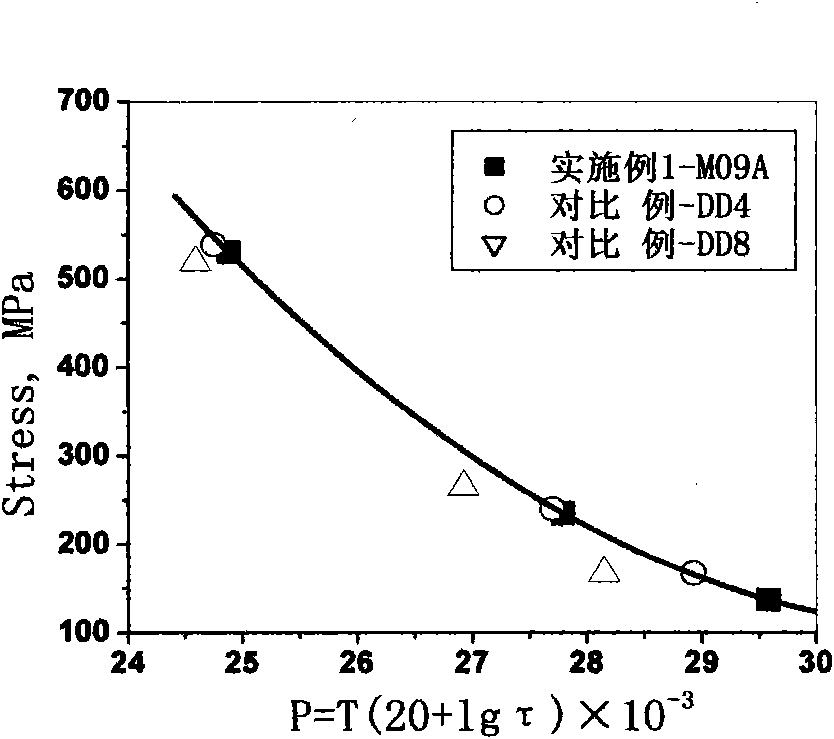

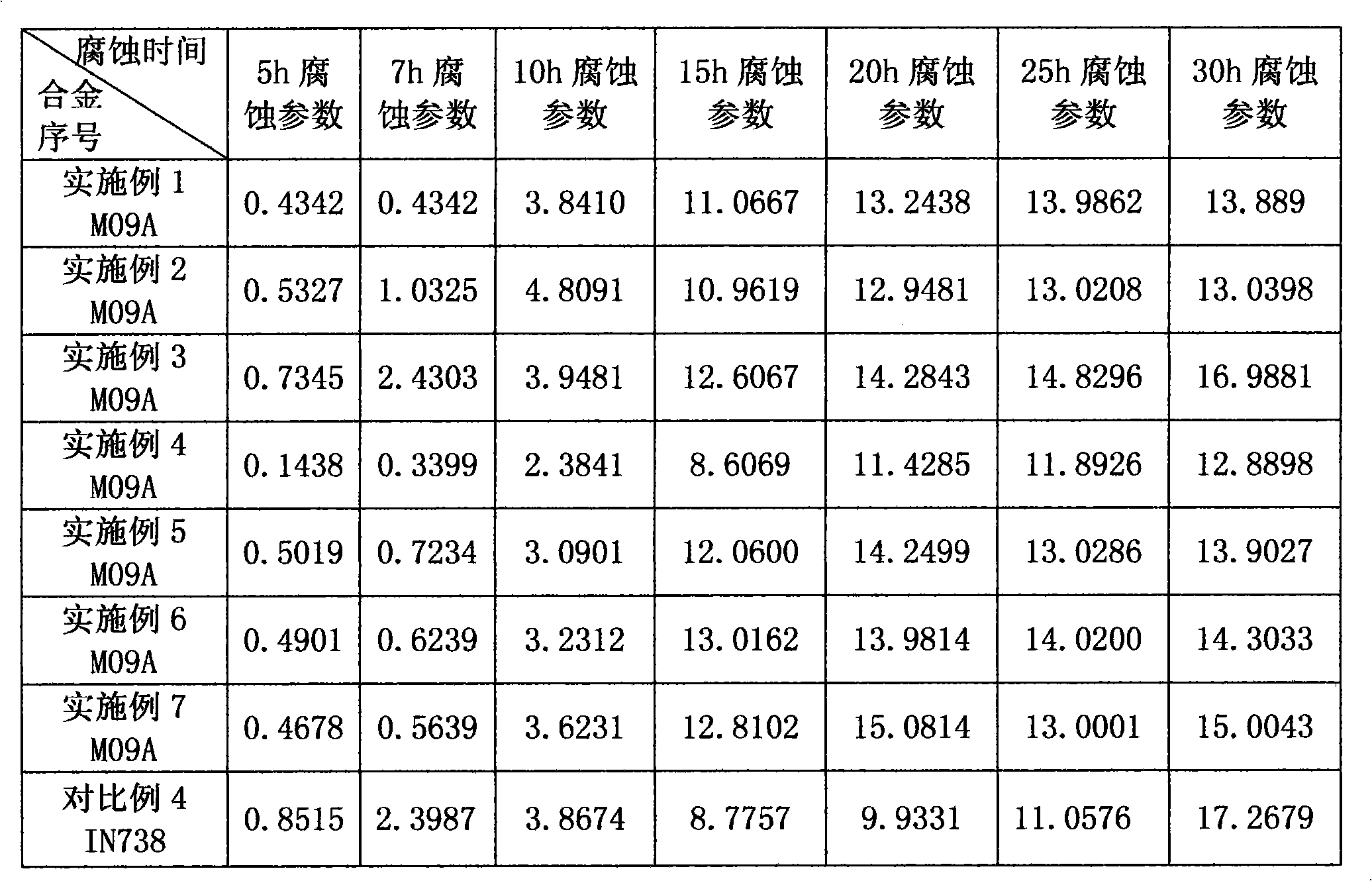

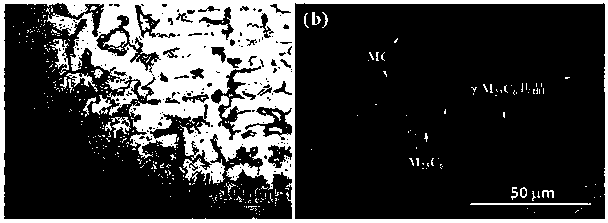

InactiveCN101857931AImprove corrosion resistanceDecreased tissue stabilityChemical compositionSingle crystal superalloy

The invention relates to a novel high-temperature alloy material, in particular to a high-strength corrosion-resistant nickel-based monocrystal superalloy M09A. The superalloy comprises the following chemical compositions (by weight percent): 11.0-15.0 percent of Cr, 8.0-9.0 percent of Co, 1.8-2.2 percent of Mo, 3.5-4.4 percent of W, 5.0-6.0 percent of Ta, 4.0-5.4 percent of Al, 2.5-3.5 percent of Ti, 0.004-0.007 percent of B, 0.01-0.03 percent of C, and the balance of Ni. The alloy material of the invention has good high-temperature resistance, good hot corrosion resistance and structural stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

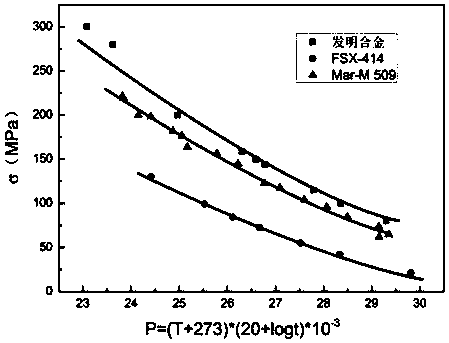

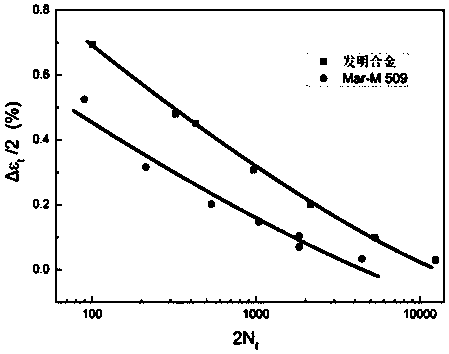

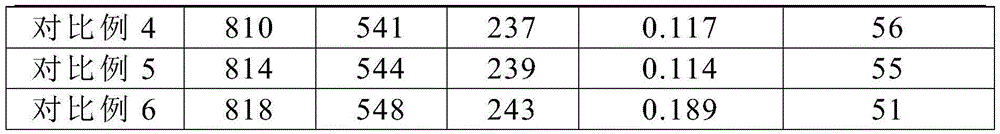

Cobalt-based high temperature alloy, preparation method thereof and application in heavy-duty gas turbine

The invention discloses a cobalt-based high temperature alloy, a preparation method thereof and application in a heavy-duty gas turbine, and belongs to the technical field of casting isometric crystalcobalt-based high temperature alloy. The alloy comprises chemical compositions of, 22.0-25.0% of Cr, 9.0-11.0% of Ni, 5.4-6.4% of W, 0.7-1.3% of Mo, 3.0-4.0% of Ta, 0.47-0.65% of C, 0.15-0.25% of Ti,0.05-0.2% of Al, 0.06-0.35% of Zr, 0-0.1% of Mn, 0-0.4% of Si, 0.005-0.015% of B, and the balance Co. The cobalt-based high temperature alloy has excellent mechanical properties, physical and chemical properties and high temperature structural stability, and is suitable for heavy-duty gas turbine guide blade materials for ground and ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and manufacturing method thereof

InactiveCN109371288AExcellent high temperature durabilityLow Re elementPolycrystalline material growthAfter-treatment detailsRheniumChemical composition

The invention discloses a low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and a manufacturing method thereof. The alloy comprises the followingchemical components of, in percentage by weight, 9.0-12.0% of Cr, 8.0-11.0% of Co, 0.2-1.5% of Mo, 4.5-7.0% of W, 3.5-5.5% of Al, 2.0-4.0% of Ti, 4.5%-6.5% of Ta, 0.1-0.3% of Hf, 1.2-2.0% of Re, andthe balance Ni. The high-temperature endurance performance is superior to that of the PWA1483 alloy, the Re element is low, and good thermal corrosion resistance is achieved; compared with the existing nickel-based single-crystal high-temperature alloy, the content of the Cr element in the alloy component is relatively high, the alloy component has relatively high thermal corrosion resistance; thealloy has good high-temperature endurance performance, the high-temperature performance is superior to that of PWA1483, and the creep time of the 982 DEG C / 100 Mpa is larger than or equal to 5000h.

Owner:DONGFANG TURBINE CO LTD

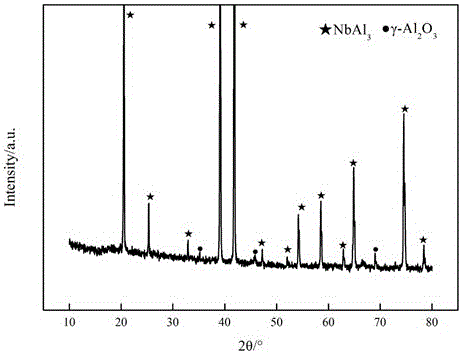

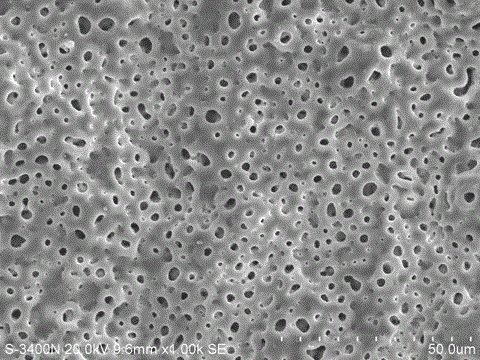

Method for preparing composite coating by adopting multi-stage pack cementation aluminizing in combination with micro-arc oxidation

ActiveCN106637071AImprove bindingReduce stressSurface reaction electrolytic coatingSolid state diffusion coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing a composite coating by adopting multi-stage pack cementation aluminizing in combination with micro-arc oxidation and belongs to the technical field of high-temperature protective coatings. A continuous and smooth NbAl3 aluminized layer is obtained firstly on a substrate with a multi-stage pack cementation aluminizing technology; a micro-arc oxidation electrolyte is regulated by adding film-forming agent sodium fluoride, modifier sodium tungstate, stabilizer EDTA-2Na and rare-earth salt yttrium nitrate; and a uniform and regular porous Al2O3 ceramic film layer is prepared on the NbAl3 aluminized layer, and the Al2O3 / NbAl3 composite coating is obtained. The Al2O3 / NbAl3 composite coating has the characteristics of good bonding performance, uniform coating and excellent high-temperature hot corrosion resistance, the coating with different thicknesses can be obtained by controlling pack cementation aluminizing time and temperature as well as the electrolyte and electrical parameters of the micro-arc oxidation, the process is simple, and the controllability is high.

Owner:GUANGXI UNIV +1

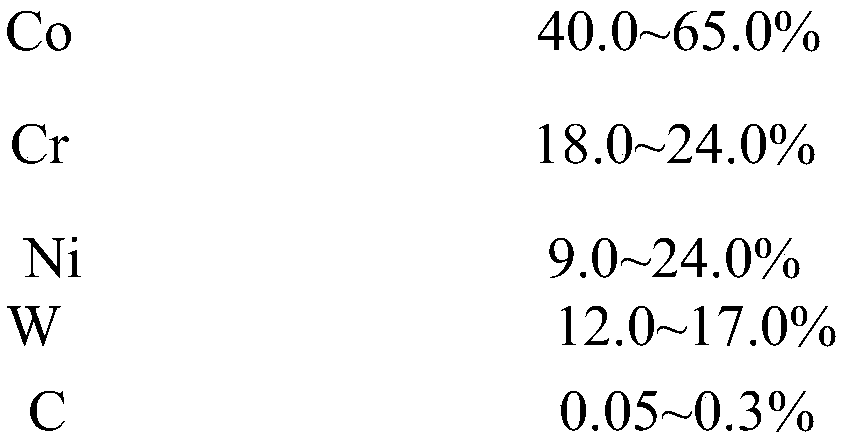

High-temperature-resistant turbocharger turbine wheel

InactiveCN105603260AImprove high temperature performanceLight in massBlade accessoriesMachines/enginesTurbine wheelSuperalloy

The invention relates to a high-temperature-resistant turbocharger turbine wheel. The turbocharger turbine wheel comprises a turbine body, wherein the turbine body comprises a ceramic filling part and a metal layer arranged on an outer layer of the ceramic filling part; the metal layer is made of cobalt-based high-temperature alloy; and the cobalt-based high-temperature alloy consists of the following components (in percentage by mass): 0.15-0.3% of C, 8-15% of Ni, 15-25% of Cr, 10-15% of W, 0.3-1% of Mo, 0.5-3% of Nb, 0.3-1% of Ta, 0.1-0.8% of Ti, 0.003-0.008% of B, 0.1-0.8% of Zr, 0.05-0.5% of rare earth elements, not more than 3% of Fe and the balance of Co and inevitable impurity elements. According to the turbocharger turbine wheel, the high-temperature usage performance of the turbine wheel is improved to a certain extent and the effects of absorbing sound, reducing noise and reducing turbine wheel mass can be achieved.

Owner:NINGBO TIANGE AUTOMOBILE PARTS CO LTD

Heat barrier composite plating and preparation technique thereof

InactiveCN101358363AReduce surface roughnessHigh bonding strengthElectrophoretic depositionThermal conductivity

The invention discloses a heat barrier composite cladding layer which consists of a MCrAlY alloy adhesive layer, a NiAl alloy barrier layer, a ZrO2-CeO2 ceramic layer and an Al2O3 protective layer; the NiAl alloy barrier layer is arranged between the MCrAlY alloy adhesive layer and the ZrO2-CeO2 ceramic layer, and the Al2O3 protective layer is arranged on the surface of the ZrO2-CeO2 ceramic layer. The invention adopts a preparation process integrated with electrophoretic deposition, high-speed electrical spray-plating and plasma arc plating layer scanning, and has the advantages of simple operation method, quite low preparation cost, capability of realizing industrialized production and the like, and the prepared heat barrier composite cladding layer also has the advantages of low heat conductivity, low roughness of the cladding layer surface, high integration strength of the cladding layer and the matrix, good hot corrosion resistance performance, good hot oxidation resistance performance and the like, solves the difficulties of poor high-temperature oxidation resistance and high-temperature corrosion resistance of high temperature resistant parts, and prolongs the service life of the high temperature resistant parts.

Owner:SHANGHAI UNIV OF ENG SCI

Nickel-based superalloy

The invention discloses a nickel-based superalloy, which consists of the following components in percentage by weight: 22.5 to 24.5 percent of Cr, 7.0 to 8.0 percent of Co, 6.5 to 7.5 percent of W, 3.0 to 4.0 percent of Mo, 1.2 to 1.8 percent of Al, 1.5 to 2.5 percent of Ti, 2.0 to 3.0 percent of Nb, 1.0 to 2.0 percent of Mn, 2.0 to 4.0 percent of Fe, 0.02 to 0.08 percent of B, 0.5 to 1.5 percent of Ce, less than or equal to 0.1 percent of C, less than or equal to 0.2 percent of Si, less than or equal to 0.008 percent of P, less than or equal to 0.008 percent of S and the balance of Ni.

Owner:NANTONG BEICHENG SCI & TECH ENTREPRENEURIAL MANAGEMENT

High-temperature alloy material and preparation method thereof

The invention discloses a high-temperature alloy material and a preparation method thereof, comprising C: 0.05-0.15%, Cr: 20.5-23.00%, Mo: 8.00-10.00%, Co: 0.50-2.50%, W: 0.20 to 1.00%, Fe, 17.00 to 20.00%, B: 0.001 to 0.010%, the balance being Ni and unavoidable impurities. The high-temperature alloy prepared by the invention has a uniform structure, and the slag material used for electroslag remelting is processed with a reasonable ratio to improve the purity of the material, so that the plasticity and impact toughness of the alloy material are enhanced at low temperature, room temperature and high temperature. The amount of deformation and the method of multiple fires are forged into materials, so that the structure of the turbine blade is uniform and has excellent fracture toughness. The alloy material produced by the present invention has a tensile strength σb≥700N / mm at room temperature. 2 ; Yield strength σ0.2≥320N / mm 2 ; Elongation δ5≥50%; High temperature (816±3℃) creep rupture test ≥103N / mm 2 , breaking time ≥ 25h, elongation δ5 ≥ 60%, meeting the performance requirements of turbine blades.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

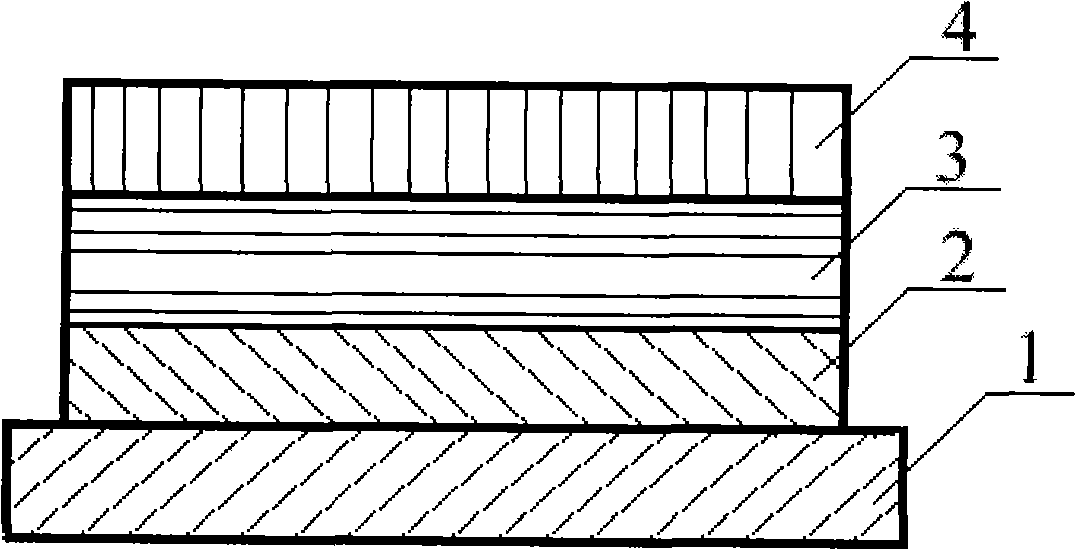

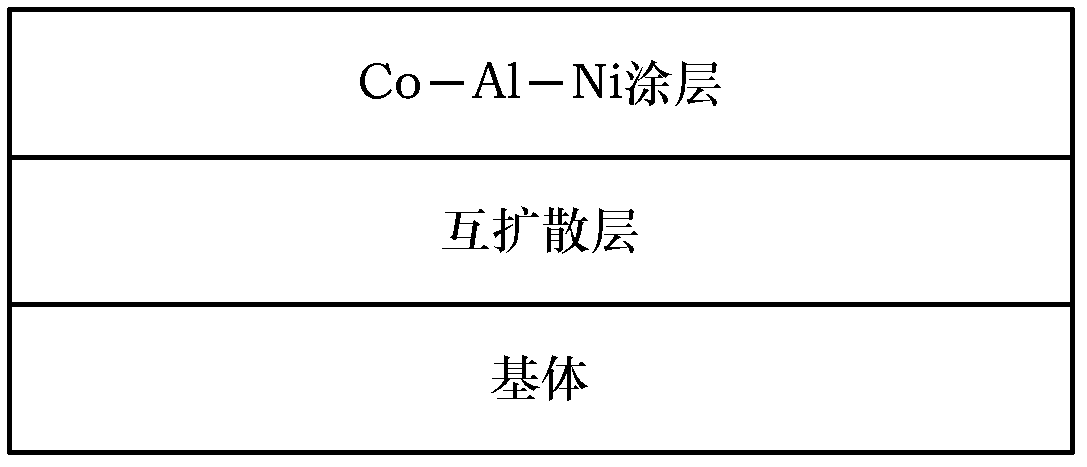

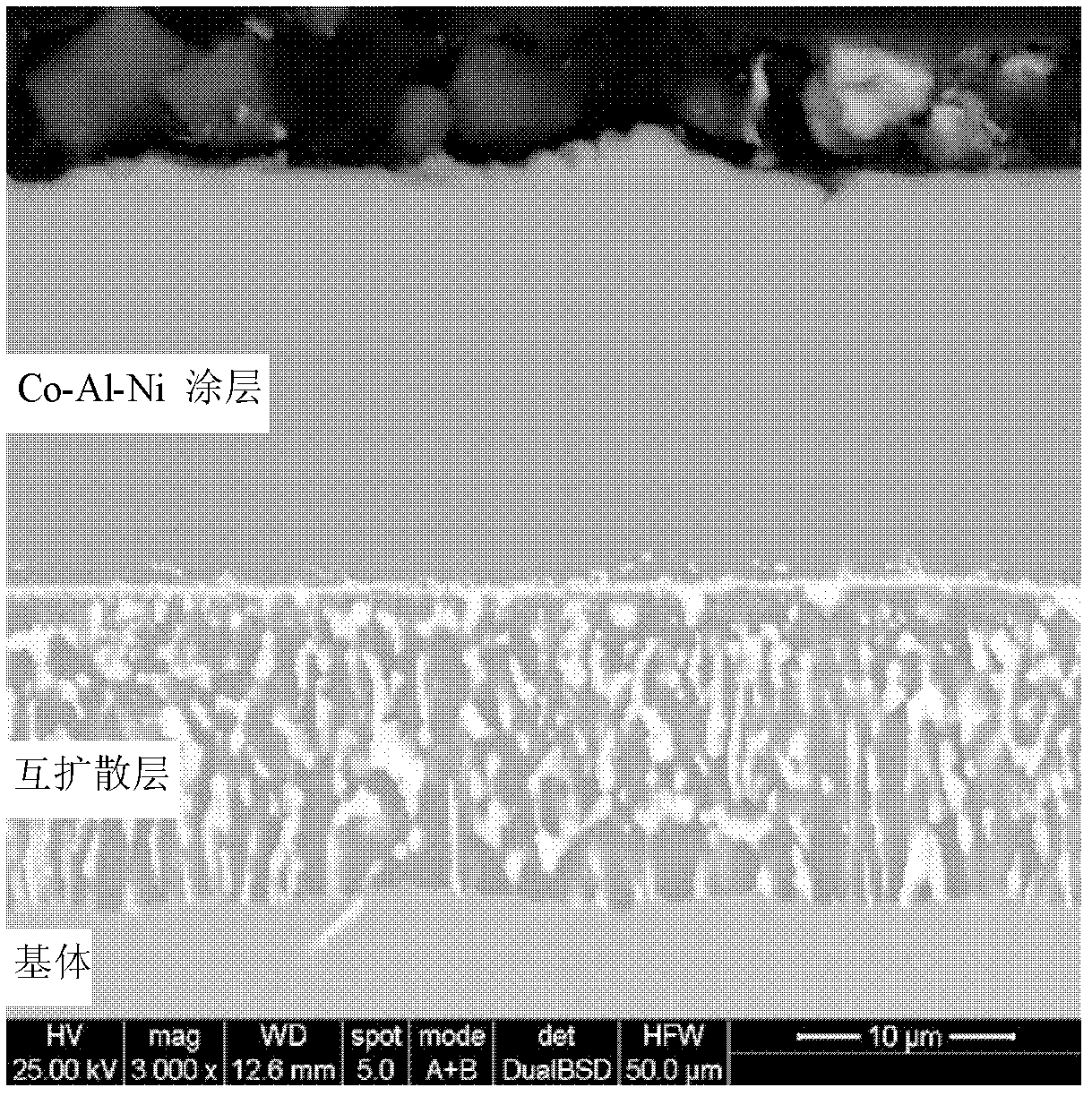

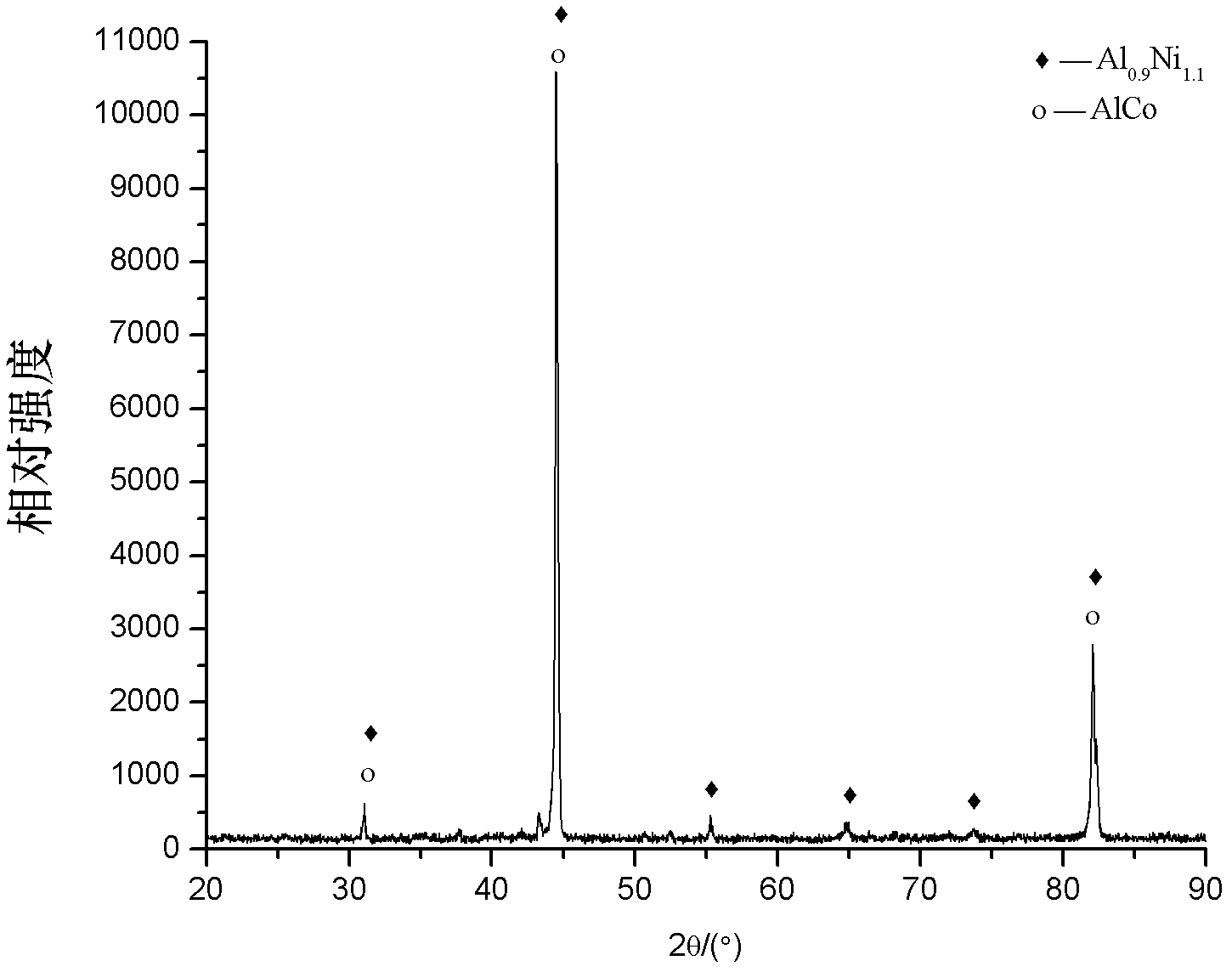

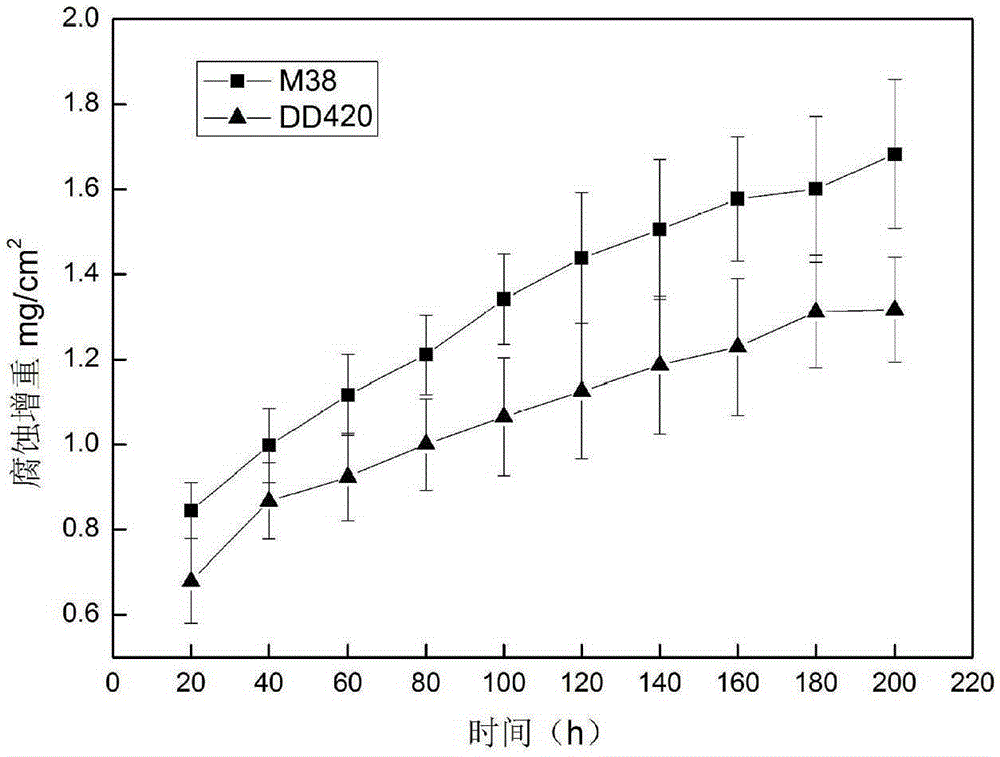

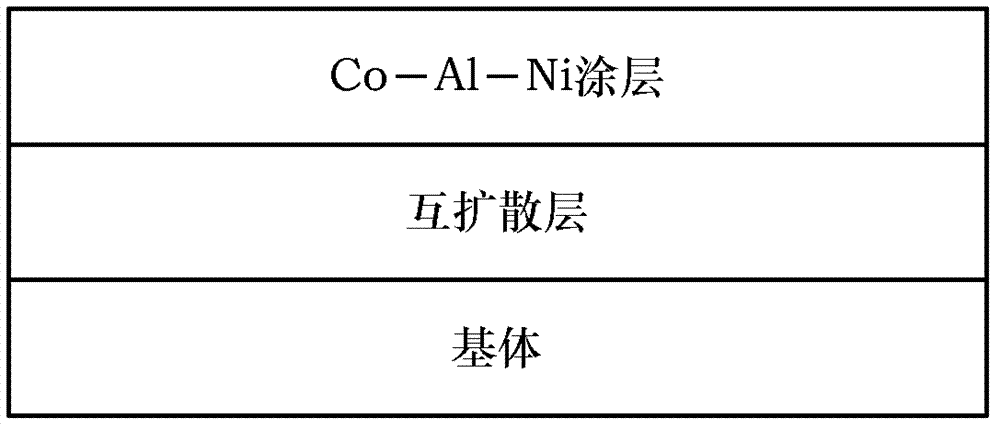

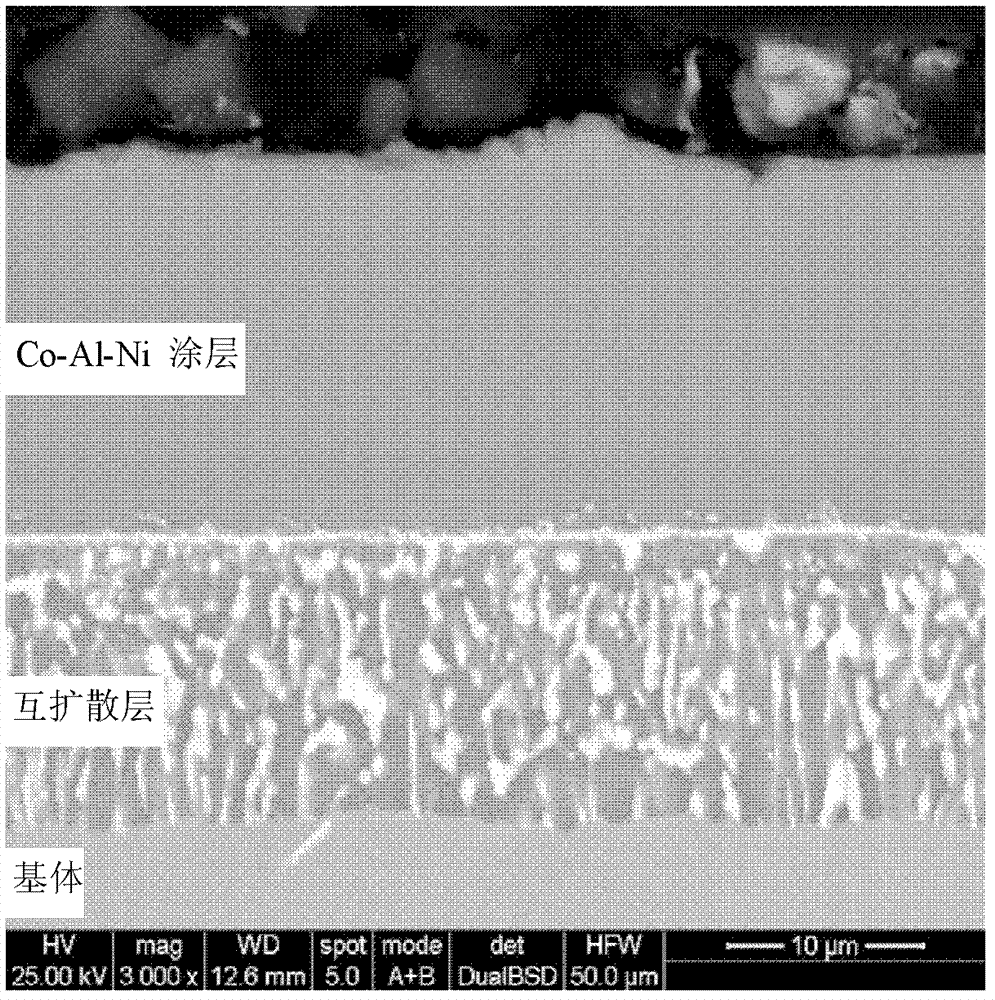

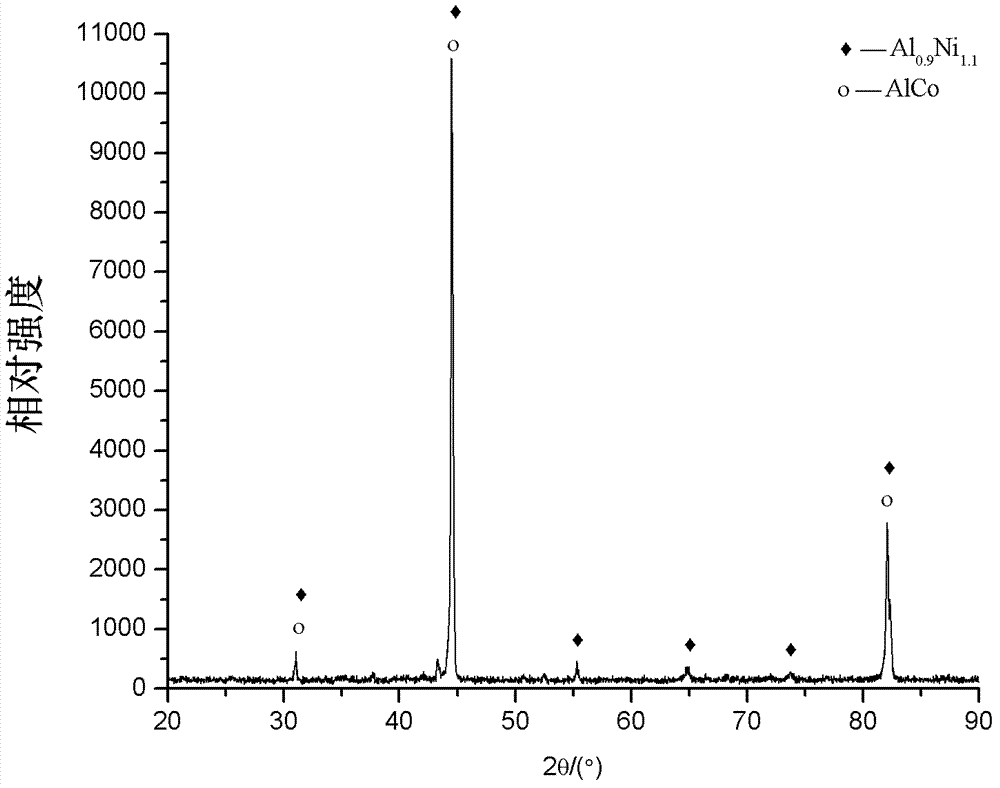

Method of preparing CoAlNi coating on Ni-based high-temperature alloy through pack cementation

InactiveCN102424948AThe process is simple and easy to controlReduce manufacturing costSolid state diffusion coatingSuperalloyHot Temperature

The invention discloses a method of preparing a CoAlNi coating on Ni-based high-temperature alloy through pack cementation. The thickness of the CoAlNi coating is 10-30mu m, and the CoAlNi coating contains two phases Al0.9Ni1.1 and AlCo. A continuous and dense Al2O3 oxide layer can be formed through high-temperature oxidation of the prepared CoAlNi coating at 1050 DEG C so as to prevent further oxidation of the coating and a substrate and improve the resistance of the substrate against the high-temperature oxidation. The prepared CoAlNi coating has good resistance against hot corrosion at thehigh temperature of 900-950 DEG C.

Owner:BEIHANG UNIV

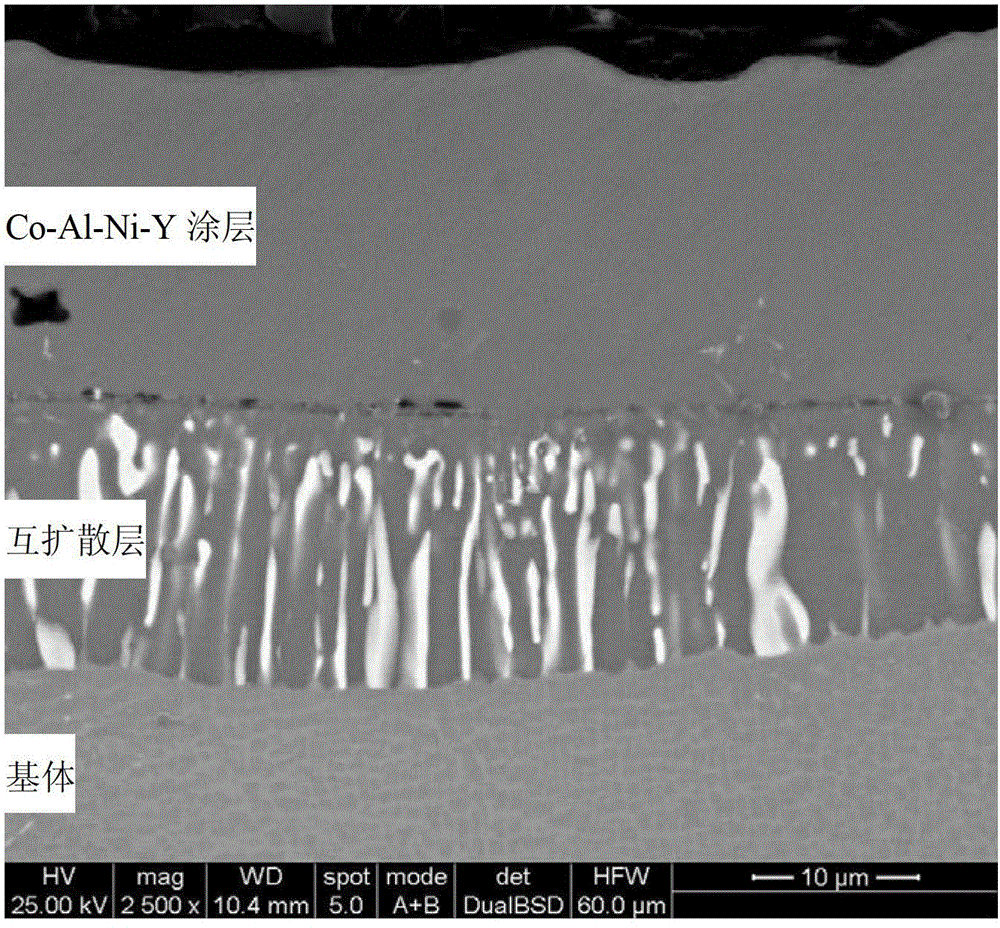

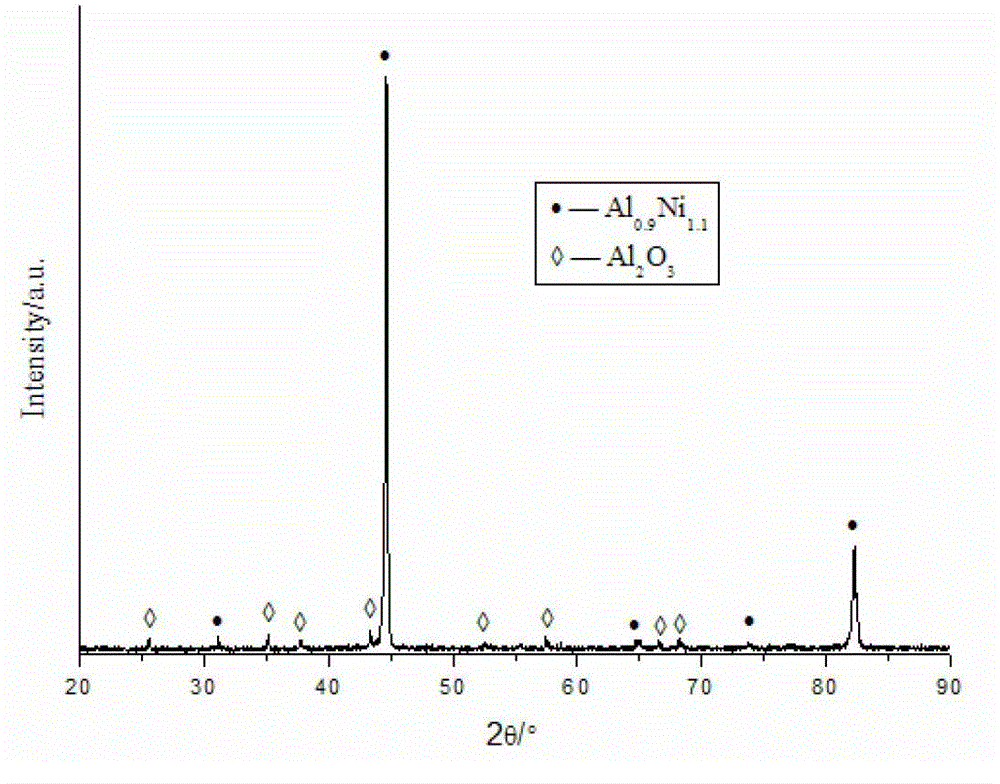

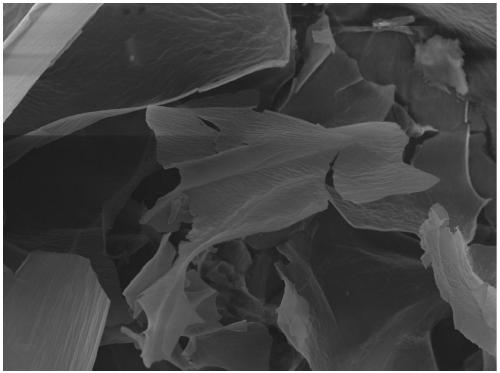

Method for preparing Y modified CoAlNi coating on Ni-based high temperature alloy by embedding infiltration process

InactiveCN103060747AThe process is simple and easy to controlReduce manufacturing costSolid state diffusion coatingSuperalloySolid solution

The invention discloses a method for preparing a Y modified CoAlNi coating on an Ni-based high temperature alloy by an embedding infiltration process. The thickness of the CoAlNiY coating is between 10 and 30 mu m. The CoAlNiY coating only comprises an Al0.9 Ni1.1 phase, wherein partial Ni atoms are replaced by Co atoms, and Y atoms exist in the Al0.9 Ni1.1 phase in the form of placeholder solid solution. Continuous and dense Al2O3 oxide layers can be formed on the prepared CoAlNiY coating C when the CoAlNiY coating is subjected to high-temperature cycle oxidation at the temperature of 1,050 DEG, so that the coating and a substrate can be prevented from being further oxidized, and the high-temperature cycle oxidation resistance of the substrate is improved. The CoAlNiY coating has higher thermal corrosion resistance at the high temperature of between 850 and 950 DEG C.

Owner:BEIHANG UNIV

Refractory Cr-base alloy

A high-temp Cr-base alloy used for refractory parts of heater contains C (0.01-0.5 wt.%), Si (0-2), Mn (0-2), W (10.1-18), Fe (10.1-30), Mo (0-3), Al (0-2), Ti (0-1.5) and Cr (rest). Its advantages are high smelting point, stable microscopic structure, and excellent high-temp strength and resistance to oxidation and hot corrosion.

Owner:马华政

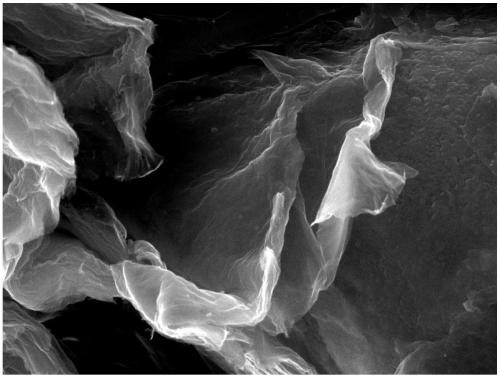

Preparation method of graphene-reinforced cobalt-based high-temperature alloy composite

The invention discloses a preparation method of a graphene-reinforced cobalt-based high-temperature alloy composite. The preparation method of the graphene-reinforced cobalt-based high-temperature alloy composite comprises the following steps that (1) cobalt-based high-temperature alloy powder and graphene are prepared; (2) the cobalt-based high-temperature alloy powder and the graphene are mixedto obtain cobalt-based high-temperature alloy powder containing graphene; (3) the cobalt-based high-temperature alloy powder containing graphene is dispersed in absolute ethyl alcohol to prepare cobalt-based high-temperature alloy and absolute ethyl alcohol dispersing liquid; (4) the cobalt-based high-temperature alloy and absolute ethyl alcohol dispersing liquid is dried to obtain a dry powder material; (5) the powder material is ball-milled into powder; and (6) the powder obtained after ball-milling is placed into a steel capsule, the steel capsule is heated to the temperature of 500-800 DEGC, and heat preservation is conducted for 2-5 hours. By adoption of the preparation method of the graphene-reinforced cobalt-based high-temperature alloy composite, the problem that due to the largecharacteristic difference between graphene and a cobalt-based high-temperature alloy matrix, the graphene cannot be evenly dispersed in cobalt-based high-temperature alloy easily is solved, and a newdirection is pointed out for the development of cobalt-based alloy.

Owner:北京石墨烯技术研究院有限公司

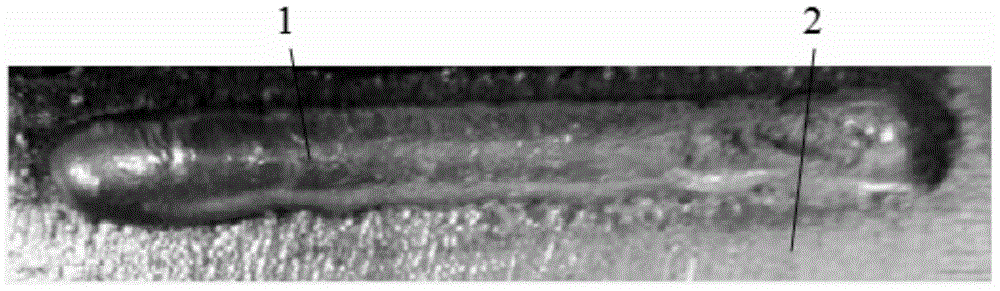

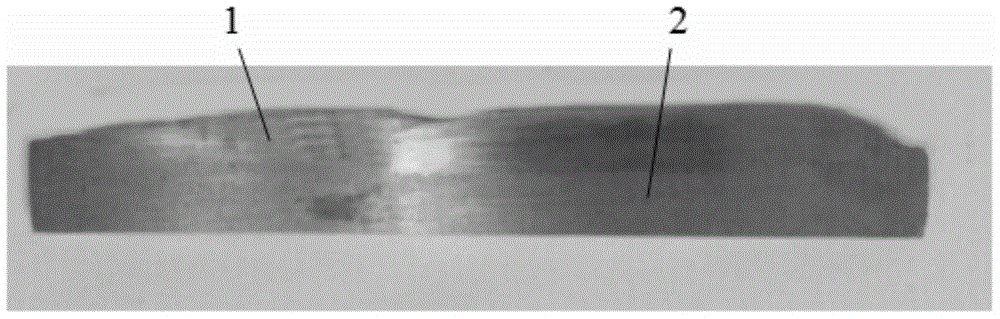

Manufacturing method for functionally gradient material capable of reinforcing tuyere

InactiveCN104404186AReduce crackingExtended service lifeMolten spray coatingArc welding apparatusFunctionally gradient materialHardness

The invention relates to a manufacturing method for a functionally gradient material capable of reinforcing a tuyere. The manufacturing method comprises the following steps: firstly, cleaning oil stain and dust on the inner wall and the small end of the copper matrix tuyere, and pre-heating to about 500 DEG C; overlaying a Ni202 transition layer on the copper matrix tuyere; overlaying a CoGrW reinforcing layer on the transition layer; performing sandblast texturing treatment on the reinforcing layer for enabling the surface to be flat, wherein the whole overlaying layer is 3 mm in thickness; plasma-spraying a ZrO2 thermal barrier coating with the thickness of 0.5 mm after the CoGrW reinforcing layer is preheated, in order to prevent the phenomenon that cracks exist in the CoGrW reinforcing layer during the use due to the different heat conductivity coefficient. According to the invention, the transition layer and the reinforcing layer are overlaid, the thermal barrier coating is plasma-sprayed, and the overlaying layer can reach the thickness and metallurgical bonding strength required for use, so that falling can be prevented during the use, the copper matrix tuyere can be protected by the thermal barrier coating during use, the cracking or falling of the reinforcing layer caused by thermal stress is reduced, the hardness is high, the abrasion resistance is excellent, the cost is low, the production efficiency is high, and the service life can reach 10 months.

Owner:武汉钢铁有限公司 +1

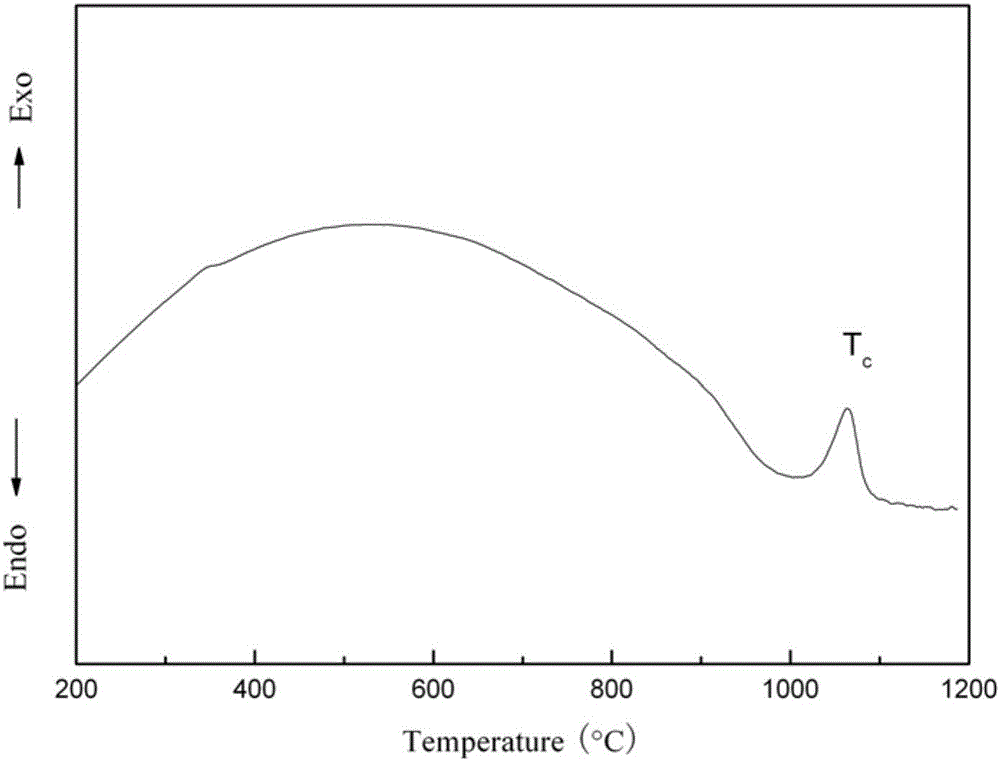

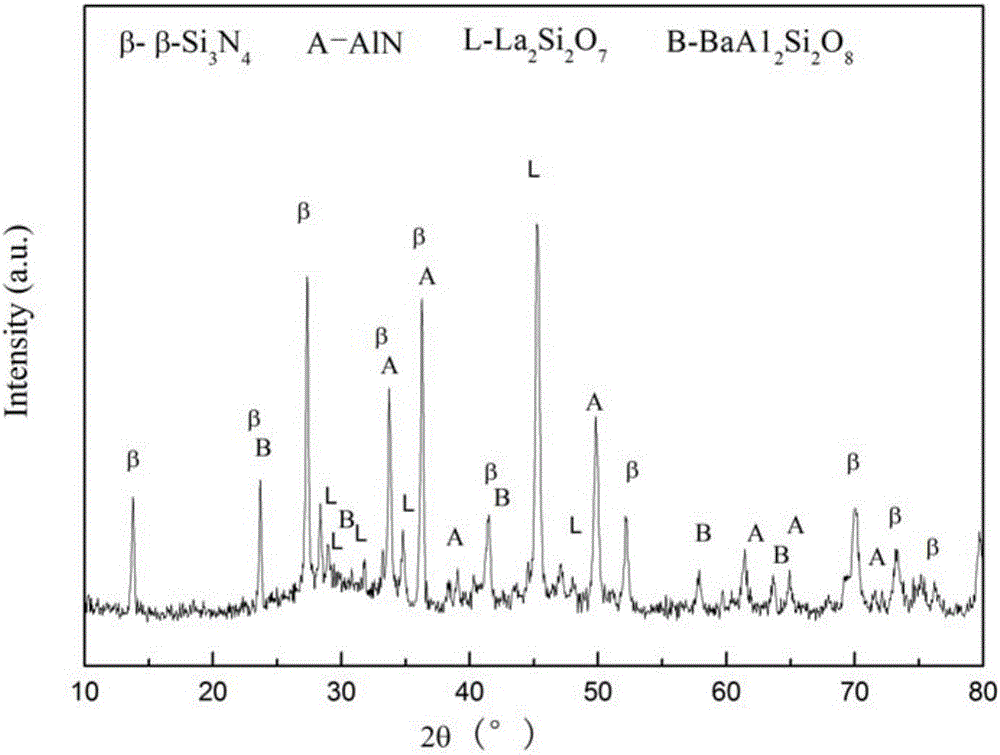

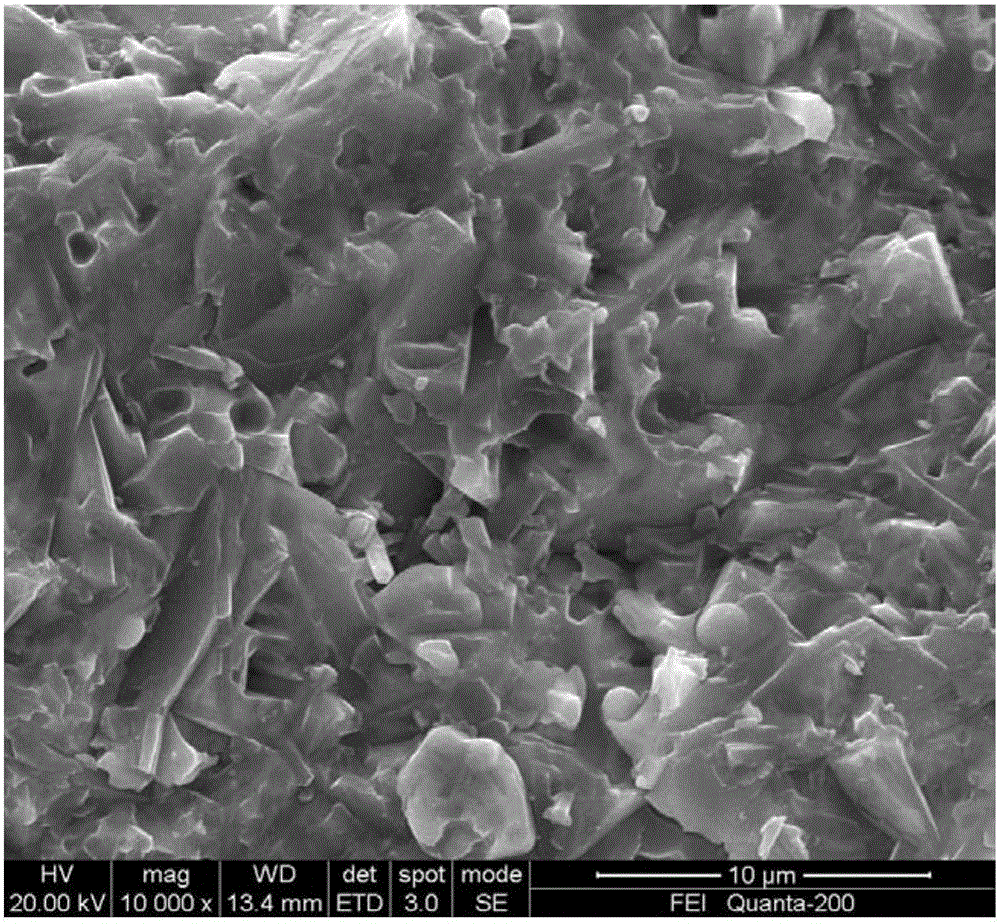

Self-enhancement-toughening silicon nitride/ aluminium nitride/ lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and preparing method of ternary composite material

InactiveCN106830690ASmall coefficient of thermal expansionExcellent hot corrosion resistanceSilicon nitrideLanthanum

The invention discloses a self-enhancement-toughening silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and a preparing method of the ternary composite material. The ternary composite material adopts lanthanum barium silicate glass powder, aluminum nitride powder and alpha-silicon nitride powder as raw materials, is prepared through blanking and sintering, and contains beta-silicon nitride rod-like crystal. The silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material has the advantages of being low in density, high in strength, high in fracture characteristic, high in dielectric constant, low in inflation coefficient, high in conductivity and the like. The preparing method of the ternary composite material is simple in preparing process and low in the glass melting temperature and the composite material sintering temperature, and the ternary composite material is friendly to environment and low in production cost. The prepared ternary composite material has a good application prospect, can partially replace an existing high temperature structure material, and is applied in the fields of national defense and military industries, electronic devices, high thermal conductivity ceramic baseplates, high-end ceramic parts and the like.

Owner:CENT SOUTH UNIV

Method for aluminizing and chromizing surface of nickel-based high-temperature alloy used on turbine blade or guider

InactiveCN112695271AImprove antioxidant capacityExcellent hot corrosion resistanceSolid state diffusion coatingTurbine bladeChromium coating

The invention discloses a method for aluminizing and chromizing the surface of a nickel-based high-temperature alloy used on a turbine blade or a guider. The method comprises the following steps: 1) preparing an aluminizing and chromizing agent; 2) pretreating the agent; 3) pretreating a part; 4) carrying out aluminizing and chromizing; and 5) post-treating the part containing an aluminum-chromium coating. The method mainly aims at the situation that in an environment with hot corrosion as a main damage form, chromium element can quickly generate a stable chromate layer, so that a single chromized layer and an aluminized and chromized layer have better hot corrosion resistance than a single aluminized layer. The oxidation resistance and the hot corrosion resistance are considered, and the aluminized and chromized layer has the optimal comprehensive corrosion resistance. According to the invention, a special formula and a unique atmosphere protection method are adopted, and the part is subjected to sufficient pretreatment and post-treatment, so that the obtained infiltrated layer has more excellent performance than an infiltrated layer manufactured by an existing method.

Owner:CENT SOUTH UNIV

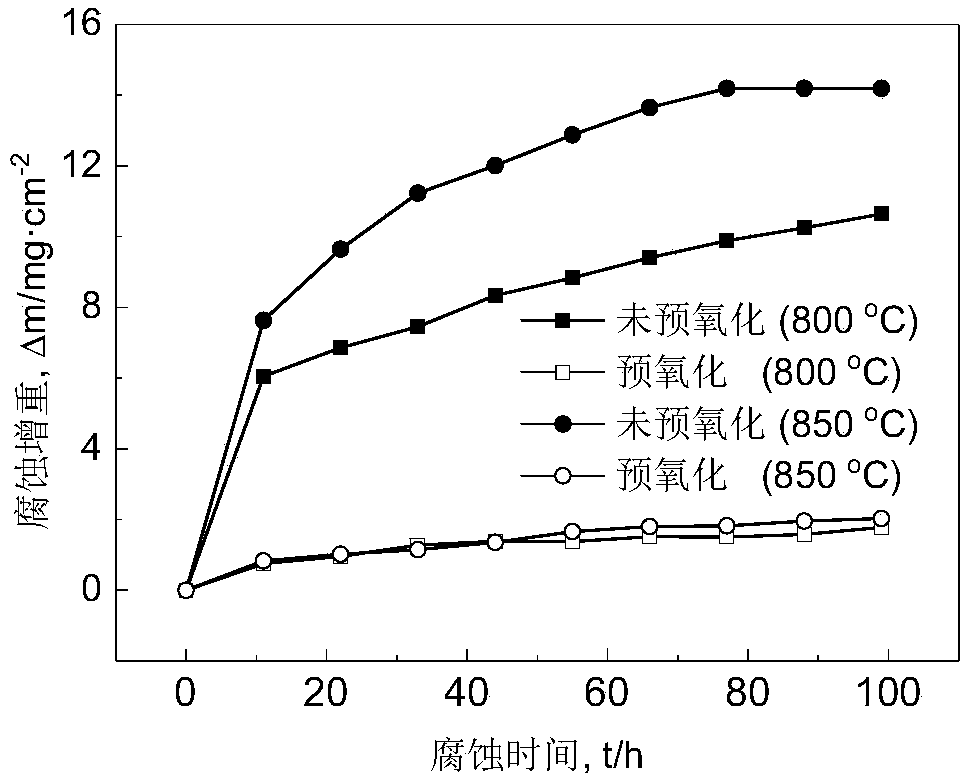

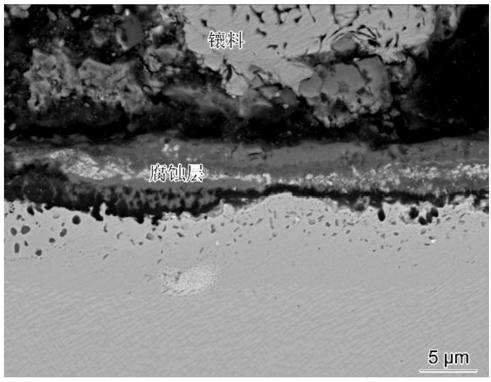

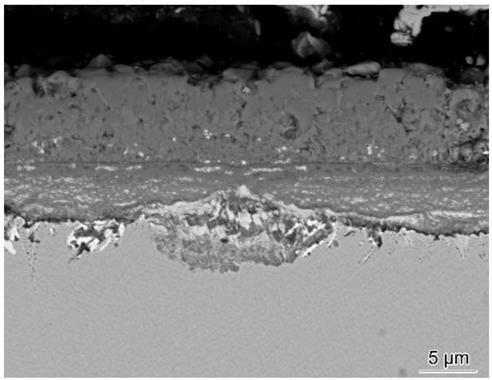

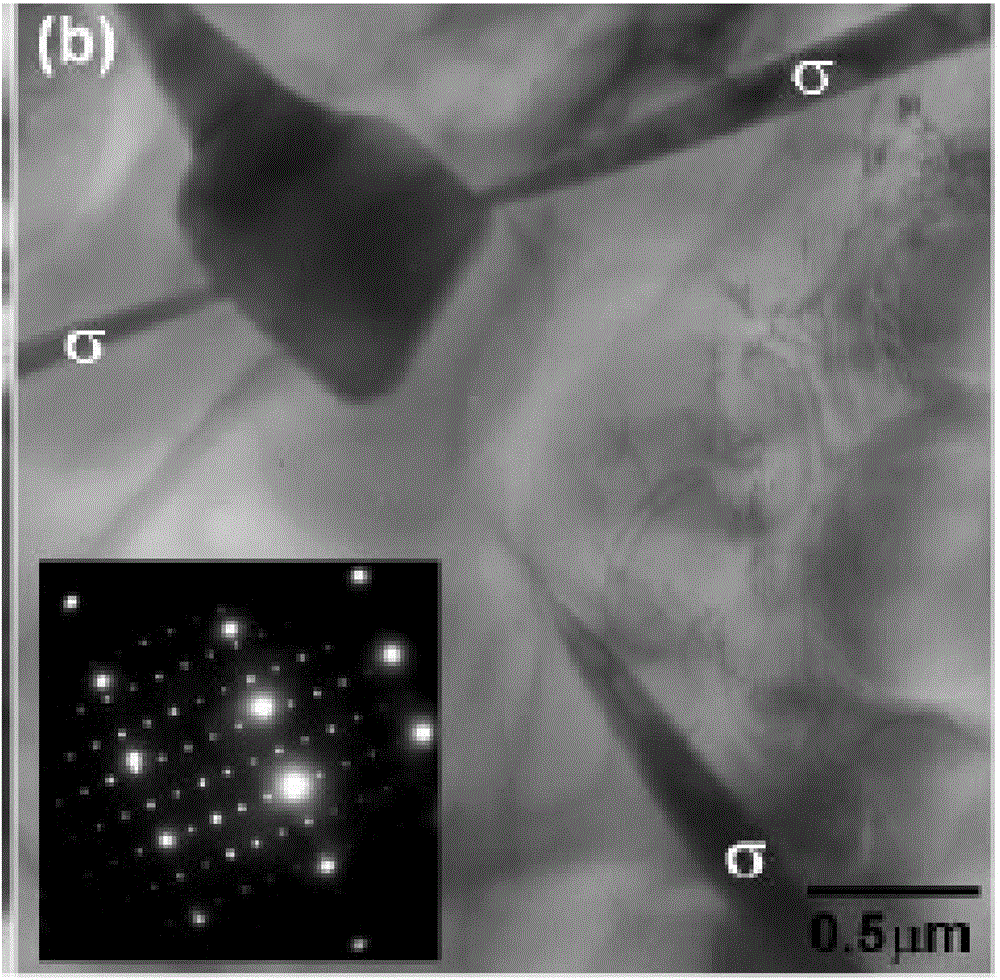

Method for improving hot corrosion resistance of Co-Al-W high temperature alloy by utilizing pre-oxidation

The invention discloses a method for improving hot corrosion resistance of Co-Al-W high temperature alloy by utilizing pre-oxidation. The method comprises the following steps: under atmospheric conditions, heating cobalt-based high temperature alloy to 950 DEG C and carrying out oxidation treatment for 50-100 hours to obtain a pre-oxidized layer with the thickness of 2-10 micrometers, wherein thethickness of an Al2O3 layer is 0.5-2 micrometers. The method disclosed by the invention has the advantages that the process is simple and the energy is saved. Compared with un-pre-oxidized alloy, thepre-oxidized alloy has the advantages that the pre-oxidized layer is structurally stable in a corrosive medium and the corrosive medium can be effectively prevented from entering the alloy matrix, sothat the corrosion weight gain of the alloy is significantly reduced by 80% or above and the hot corrosion resistance of the alloy is remarkably enhanced.

Owner:NORTHEASTERN UNIV

Thermal corrosion resistance nickel-based high-temperature alloy having stable structure

The purpose of the present invention is to provide a thermal corrosion resistance nickel-based high-temperature alloy having a stable structure, wherein the components of the alloy comprise, by wt%, 0.06-0.2% of C, less than or equal to 0.035% of B, 13.0-15.0% of Cr, 9.0-10.0% of Co, 1.2-1.8% of Mo, 3.5-4.1% of W, 2.8-3.4% of Al, 3.1-4.0% of Ta, 4.6-5.2% of Ti, less than or equal to 1.0% of Fe, less than or equal to 0.06% of Zr, and the balance of Ni, wherein the impurity P content is less than or equal to 0.005%, the impurity Si content is less than or equal to 0.2%, the impurity Pb content is less than or equal to 0.0005%, the impurity Bi content is less than or equal to 0.0001%, the impurity As content is less than or equal to 0.005%, the impurity Sn content is less than or equal to 0.002, and the impurity Sb content is less than or equal to 0.001%. According to the present invention, the alloy has high structure stability and good thermal corrosion resistance, is suitable for production of high-temperature combustion turbine components, and can be used for a long time in fuel gas corrosion environments.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ni-Co-Cr series single crystal superalloy and preparation method thereof

ActiveCN114058905AIncrease volume fractionExcellent high temperature mechanical propertiesPolycrystalline material growthAfter-treatment detailsPhase compositionSingle crystal

The invention provides a Ni-Co-Cr series single crystal superalloy and a preparation method thereof, and belongs to the technical field of nickel-based superalloys. The Ni-Co-Cr series single crystal superalloy provided by the invention comprises the following elements in atomic percent: 6-8% of Al, 7-9% of Ti, more than or equal to 13% and less than or equal to 17% of Al + Ti, 12-15% of Cr, 18-23% of Co, 1.5-2% of W and the balance being Ni. In phase composition, the Ni-Co-Cr series single crystal superalloy comprises a gamma matrix and a gamma' phase, and a volume fraction of the gamma' phase is 60-63%. According to the Ni-Co-Cr series single crystal superalloy provided by the invention, the volume fraction of the gamma' phase is relatively high, grain boundaries are eliminated, and high-temperature performance of the alloy is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Refractory Cr-base alloy

InactiveCN1151297CHigh melting pointHigh temperature compressive strengthOxidation resistantSuperalloy

A high-temp Cr-base alloy used for refractory parts of heater contains C (0.01-0.5 wt.%), Si (0-2), Mn (0-2), W (10.1-18), Fe (10.1-30), Mo (0-3), Al (0-2), Ti (0-1.5) and Cr (rest). Its advantages are high smelting point, stable microscopic structure, and excellent high-temp strength and resistance to oxidation and hot corrosion.

Owner:马华政

Ferritic heat-resistant steel used for coal-fired thermal power generation boiler piping and valve castings and preparation method thereof

ActiveCN105256247BImprove corrosion resistanceExcellent hot corrosion resistanceHeat resistanceRoom temperature

Owner:JIANGSU SHENGTAI VALVE CO LTD

A rhenium-containing high-strength hot-corrosion-resistant nickel-based single crystal superalloy

ActiveCN103436739BExcellent hot corrosion resistanceImprove durabilityRheniumSingle crystal superalloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method of preparing CoAlNi coating on Ni-based high-temperature alloy through pack cementation

InactiveCN102424948BThe process is simple and easy to controlReduce manufacturing costSolid state diffusion coatingSuperalloyHot Temperature

The invention discloses a method of preparing a CoAlNi coating on Ni-based high-temperature alloy through pack cementation. The thickness of the CoAlNi coating is 10-30mu m, and the CoAlNi coating contains two phases Al0.9Ni1.1 and AlCo. A continuous and dense Al2O3 oxide layer can be formed through high-temperature oxidation of the prepared CoAlNi coating at 1050 DEG C so as to prevent further oxidation of the coating and a substrate and improve the resistance of the substrate against the high-temperature oxidation. The prepared CoAlNi coating has good resistance against hot corrosion at the high temperature of 900-950 DEG C.

Owner:BEIHANG UNIV

A Ni-based Superalloy with Stable Structure and Anti-Hot Corrosion

ActiveCN104894434BExcellent hot corrosion resistanceGood long-term tissue stabilityImpurityGas turbines

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

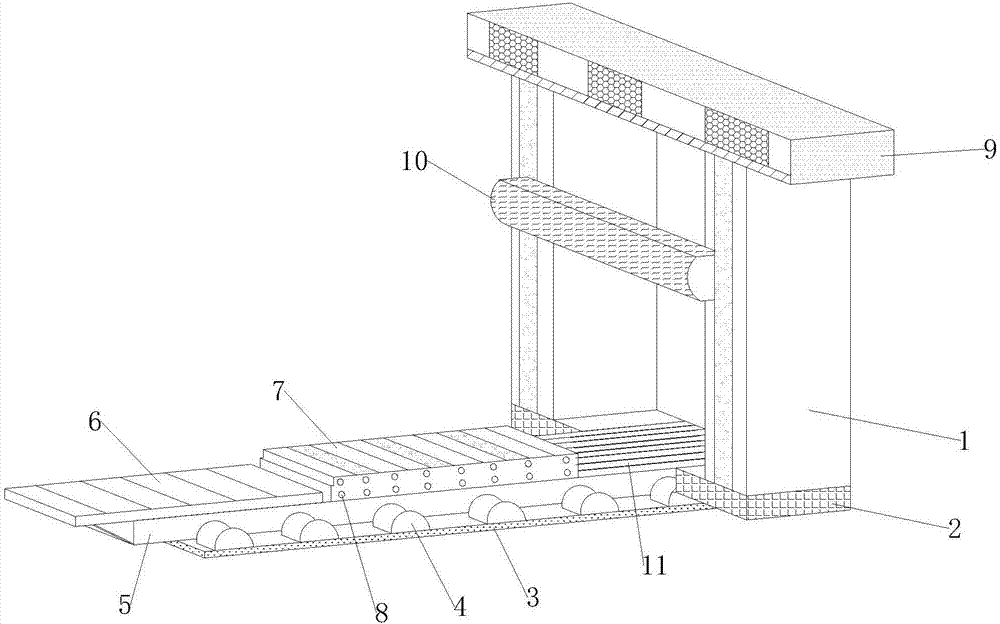

Manufacturing equipment of wear-resistant composite steel plate

InactiveCN107877051AImprove wear resistanceGood resistance to thermal fatigueWelding/cutting auxillary devicesAuxillary welding devicesWear resistantManufactured apparatus

The invention discloses a wear-resistant composite steel plate manufacturing equipment, which comprises a device main body and a pinch roller device. A steel base plate is arranged on the left side of the upper end of the device main body, and the bottom of the steel base plate is fixedly connected in the device main body. The middle end of the side is provided with a movable pressing plate, and the bottom of the moving pressing plate is movably connected in the main body of the device. The upper right side of the main body of the device is provided with a propulsion guide rail, and the bottom of the propelling guide rail is embedded in the main body of the device. The preheating temperature mainly depends on the quality grade and thickness of the steel plate, the method is flexible, and the preheating effect of the steel plate can be determined, so that the interface of the whole steel plate is heated evenly, and the phenomenon of local overheating in the area contacting the heat source is avoided. In the past, as the thickness and hardness of the steel plate increased, the cracks would also increase, which improved the overall connection of the steel plate and enhanced the quality.

Owner:WUXI WEI KELAI TECH CO LTD

A high-strength hot-corrosion-resistant nickel-based single crystal superalloy

ActiveCN103114225BExcellent hot corrosion resistanceImprove durabilityPolycrystalline material growthSingle crystal growth detailsSingle crystal superalloyAlloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com