Nickel-based high temperature alloy and manufacturing method thereof

A technology of nickel-based superalloys and manufacturing methods, which is applied in the field of superalloys, can solve problems such as not being able to meet the needs of scientific and technological progress, and not degrade surface properties, and achieve the effects of improving structural stability and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a nickel-based superalloy. The alloy includes the following components in weight percentage: C0.10%, Si 0.35%, Mn 0.65%, Fe 0.22%, Co 1.8%, Al 0.25%, Ti 0.05%, Cr 22.4%, Nb 0.20%, Mo 1.5% , W 13%, Re 0.30%, B 0.005%, Ce 1.1%, Ru 1.2%, Hf 0.8%, Ta2.5%, V 0.15%, S 0.005%, P 0.007%, N 0.02%, the balance is nickel and unavoidable impurities;

[0027] The preparation method of above-mentioned alloy comprises the steps:

[0028] The first step is to select raw materials according to a certain ratio, and all raw materials should use low S and P raw materials as much as possible;

[0029] In the second step, alloy ingots conforming to the composition are formed by vacuum induction melting and casting.

[0030] In the third step, the alloy is subjected to three homogenization treatments, the temperature of the first homogenization is 1000°C, the time is 20 hours, the heating and cooling rates above 300°C are both 200°C / h, and the second homogenization...

Embodiment 2

[0036] The difference between this embodiment and Example 1 is that the content of each substance is not the same. Specifically, in this embodiment, the nickel-based superalloy includes the following components in weight percentage: C 0.15%, Si 0.55%, Mn 0.95%, Fe3.00%, Co5.0%, Al 0.50%, Ti0.09%, Cr 24.0%, Nb0.40%, Mo 3.0%, W15.0%, Re1.0%, B 0.009%, Ce 2.0%, Ru 1.8%, Hf 3.0%, Ta 5.0%, V 0.35%, the balance is nickel and unavoidable impurities.

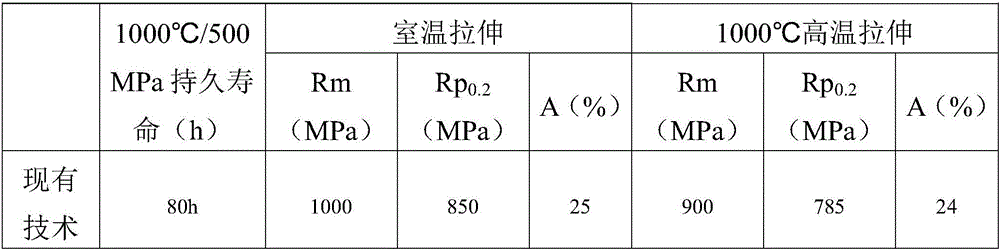

[0037] Samples were taken from the test block and stretched at room temperature and 1000°C. At room temperature, its tensile strength Rm was 1200MPa, Rp0.2 was 1010MPa, and the elongation rate was 31%. At 1000°C, its tensile strength Rm1115MPa, Rp0. 2 The range is 988MPa, the elongation range is 29%, and the duration of the 1000°C, 500MPa endurance test is 98h.

Embodiment 3

[0039] The difference between this example and Example 1 is that the content of each substance is not the same. Specifically, in this example, the nickel-based superalloy includes the following components in weight percentage: C 0.08%, Si 0.30%, Mn 0.45%, Fe 0.10%, Co 1.5%, Al 0.10%, Ti 0.03%, Cr 20.5%, Nb 0.05%, Mo 1.0%, W 12.5%, Re 0.15%, B 0.003%, Ce 0.9% , Ru 0.9%, Hf 0.5%, Ta 2.2%, V 0.08%, the balance is nickel and unavoidable impurities.

[0040]Samples were taken from the test block and stretched at room temperature and 1000°C. At room temperature, its tensile strength Rm was 1189MPa, Rp0.2 was 1001MPa, and the elongation rate was 31%. At 1000°C, its tensile strength Rm1112MPa, Rp0. 2 The range is 987MPa, the range of elongation is 29%, and the endurance time of 1000℃, 500MPa endurance test is 99h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com