High strength wood-plastic coated coextruded composite material and preparation method thereof

A technology for coating co-extrusion and composite materials, which is applied in the direction of wood layered products, chemical instruments and methods, synthetic resin layered products, etc. The problems of poor mechanical properties of cladding co-extruded profiles and limiting the application range of wood-plastic composite materials can reduce the risk of falling off, improve the properties such as creep resistance and impact resistance, and improve the performance of impact resistance and creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

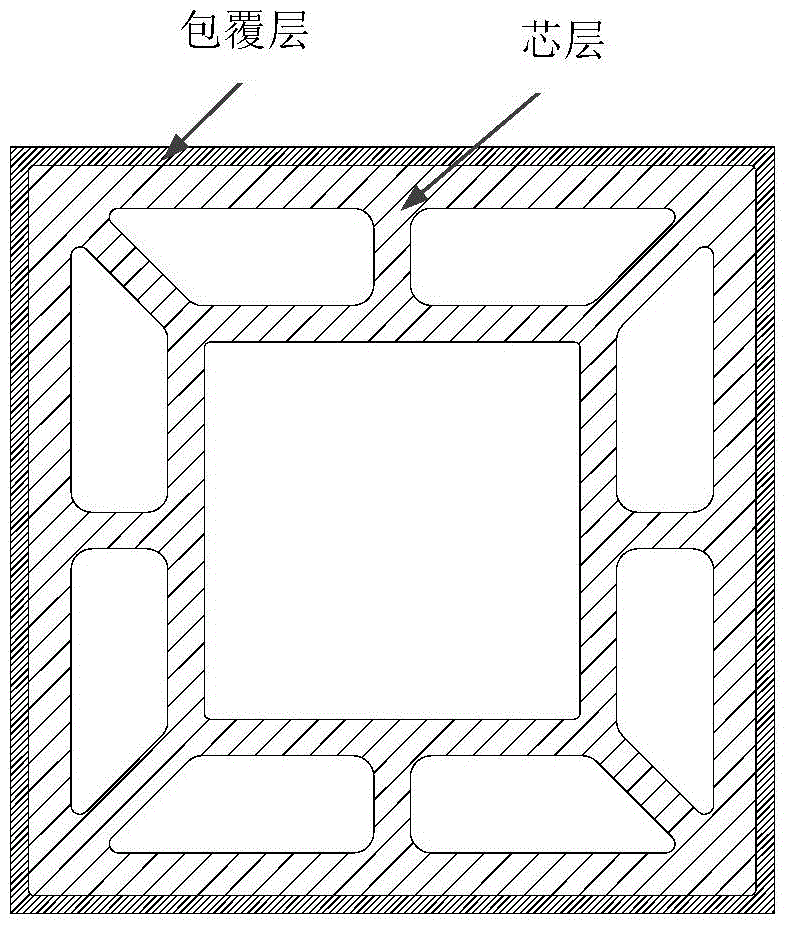

[0035] In this embodiment, the wood-plastic coated co-extruded profile is in the shape of a square column, and its cross-sectional schematic diagram is as follows figure 1 shown. The wood-plastic clad co-extrusion profile is composed of a cladding layer and a core layer, and the cladding layer is clad on the surface of the core layer through a co-extrusion process.

[0036] In terms of mass percentage, the core layer consists of the following components:

[0037] 55% wood fiber, and the length of the wood fiber is 0.1-4.0mm, and the aspect ratio is 10:1-100:1

[0038] Recycled Polyethylene 40%

[0039] Coupling agent - maleic anhydride grafted polyethylene 2%

[0040] Inorganic Filler - Calcium Carbonate 2%

[0041] Lubricant - Polyethylene Wax 1%.

[0042] In terms of mass percentage, the coating layer consists of the following components:

[0043] HDPE 40%

[0044] Polypropylene 10%

[0045] Ethylene-methyl acrylate copolymer 20%

[0046] Ethylene-vinyl alcohol copo...

Embodiment 2

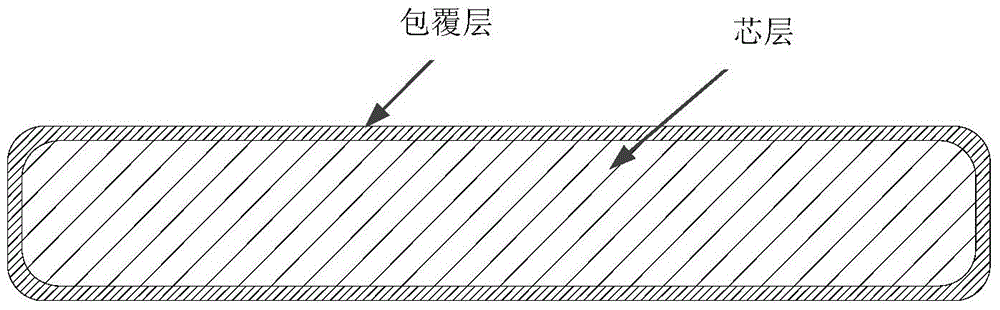

[0060] In this embodiment, the wood-plastic coated co-extruded profile is a solid floor, and its cross-sectional schematic diagram is as follows figure 2 shown. The plastic clad co-extrusion profile is composed of a cladding layer and a core layer, and the cladding layer is clad on the surface of the core layer through a co-extrusion process.

[0061] In terms of mass percentage, the core layer consists of the following components:

[0062] Bamboo fiber 50%, and the length of said bamboo fiber is 0.1~4.0mm, aspect ratio is about 10:1~100:1

[0063] Recycled Polyethylene 45%

[0064] Coupling agent - titanate 1.8%

[0065] Inorganic Filler - Talc 2.2%

[0066] Lubricant - 1% consisting of 40% by mass of stearic acid and 60% by mass of polyethylene wax.

[0067] In terms of mass percentage, the coating layer consists of the following components:

[0068] HDPE 55%

[0069] Polypropylene 7.5%

[0070] Ethylene-methyl acrylate copolymer 15.5%

[0071] Ethylene-vinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com