Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

831 results about "Ethylene vinyl alcohol copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene vinyl alcohol (EVOH) is a formal copolymer of ethylene and vinyl alcohol. Because the latter monomer mainly exists as its tautomer acetaldehyde, the copolymer is prepared by polymerization of ethylene and vinyl acetate to give the ethylene vinyl acetate (EVA) copolymer followed by hydrolysis.

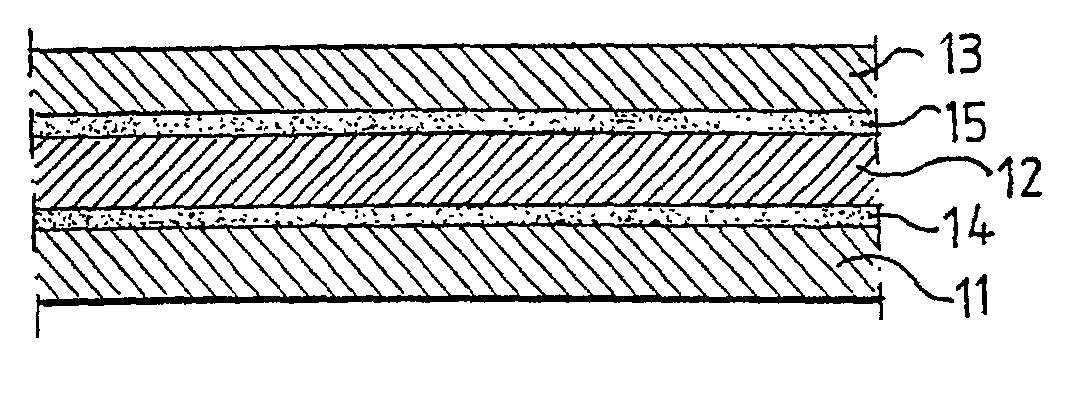

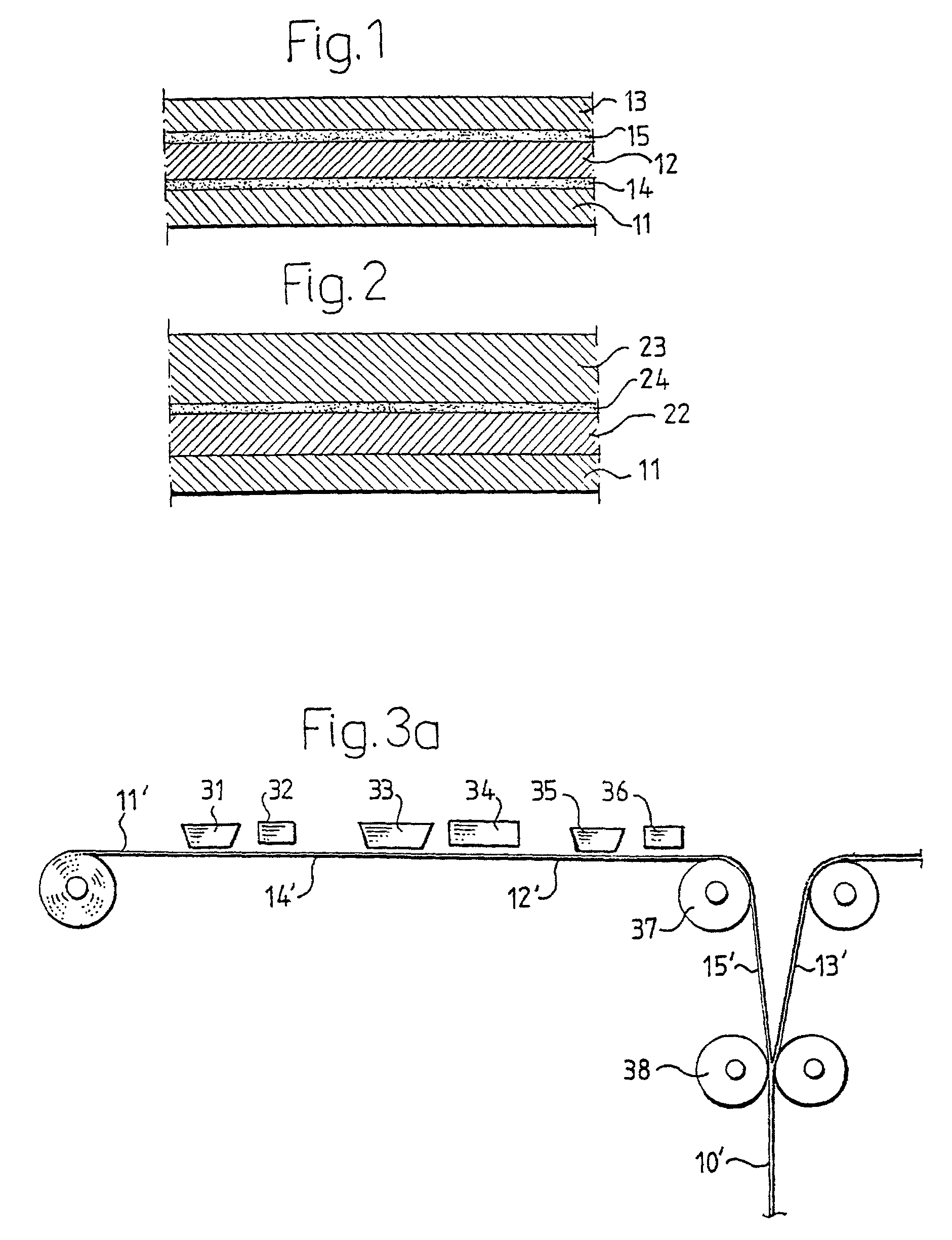

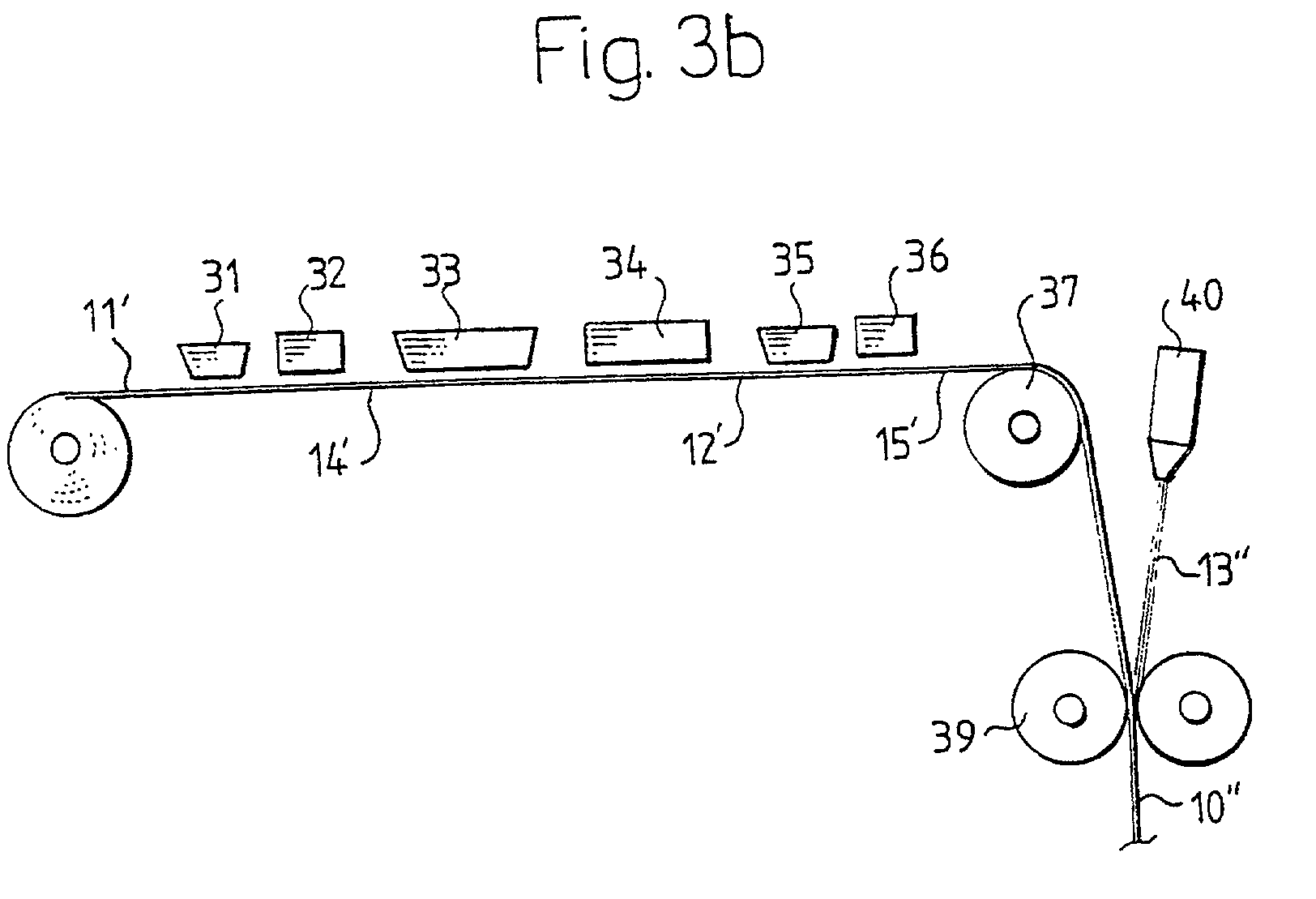

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

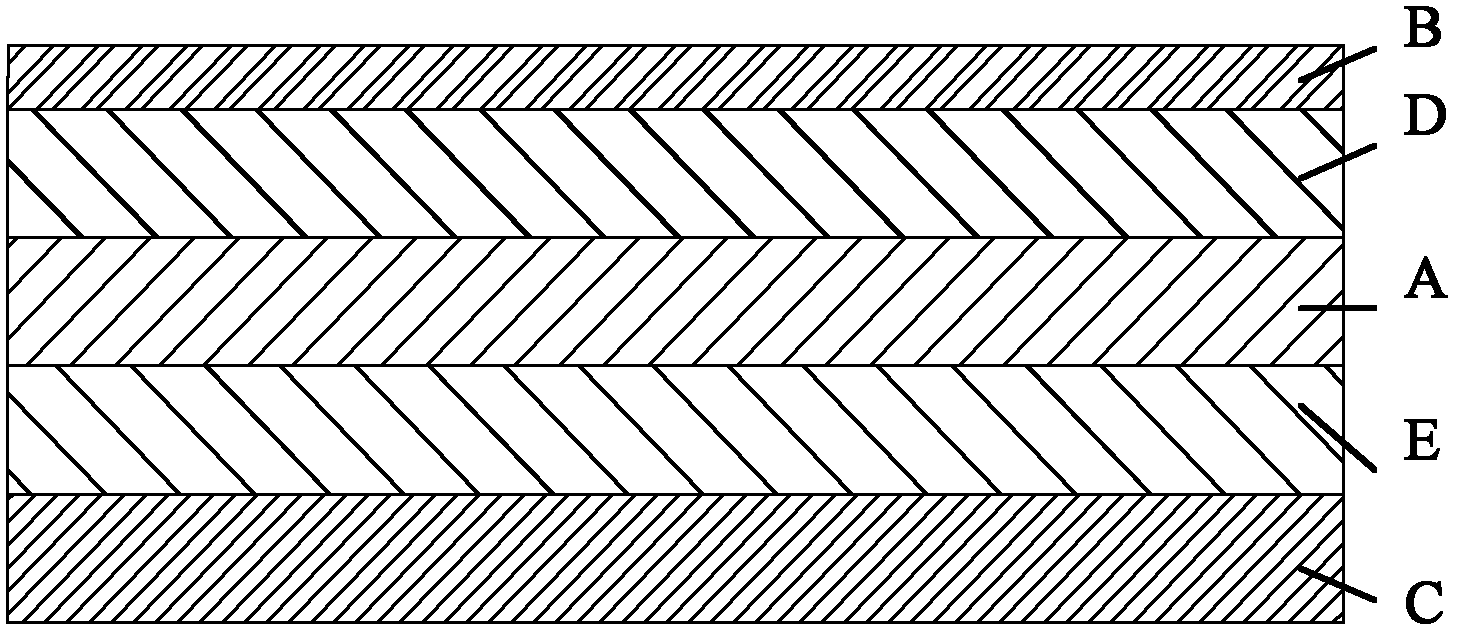

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

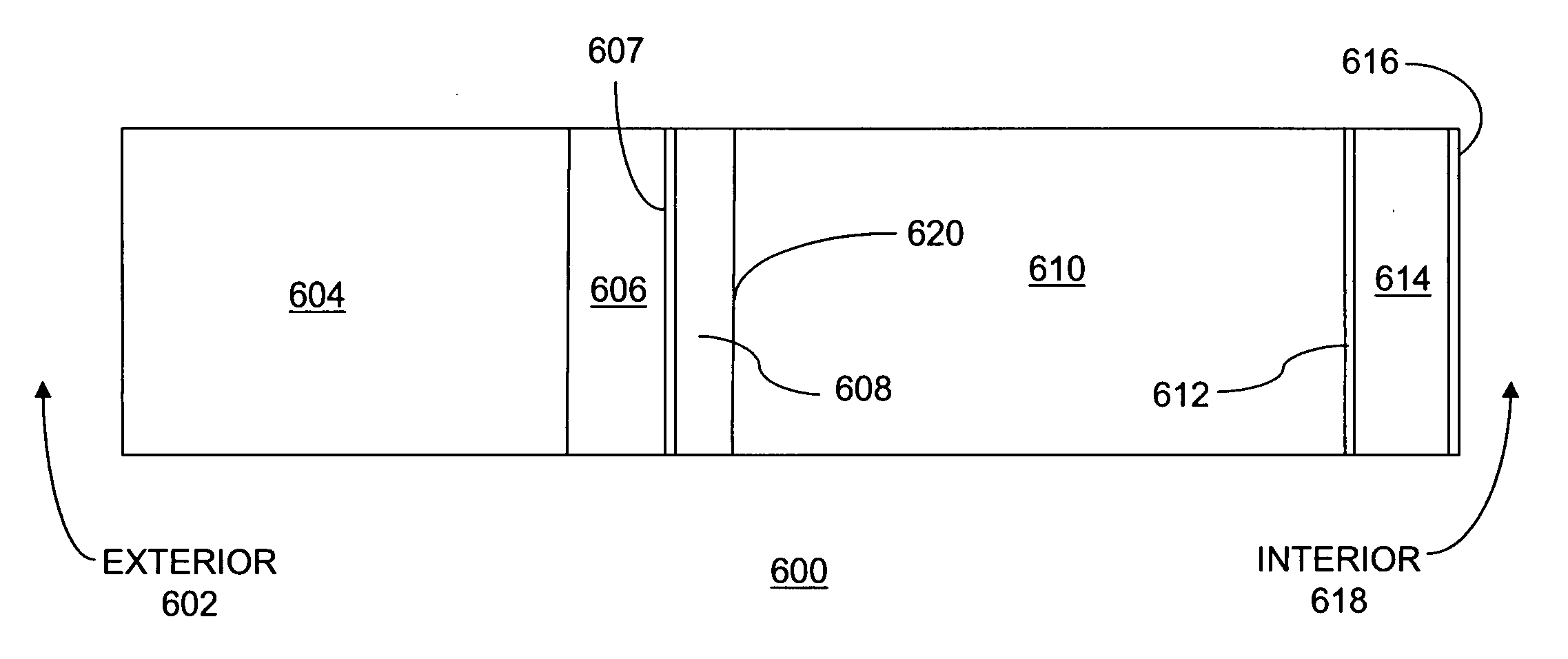

Building material having adaptive vapor retarder

InactiveUS20070015424A1Excellent water vapor permeabilitySynthetic resin layered productsConstructions elementsPolymer sciencePolymer

A laminated article includes a substrate of a building material; and an adaptive vapor retarder film adhered to the substrate. The film is selected as being at least one from the group consisting of: ethylene vinyl alcohol (EVOH), EVOH coextruded or laminated with at least a second polymer, a blended polymer comprising EVOH, or a combination of these materials.

Owner:CERTAINTEED CORP

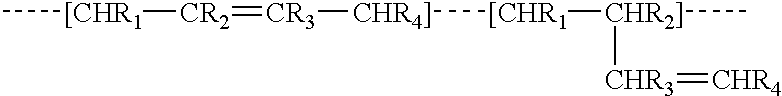

Resin composition and multi-layer structures

ActiveUS20050147778A1Improved melt stabilityInhibit deteriorationNon-fibrous pulp additionSynthetic resin layered productsStructural unitEthylene

Provided is a resin composition comprising 1-99% by weight of a modified ethylene-vinyl alcohol copolymer (C) having an ethylene content of 5-55 mol %, which contains a specific structural unit (I) in an amount of 0.3-40 mol % and can be obtained by reacting an ethylene-vinyl alcohol copolymer (A) with a monofunctional epoxy compound (B) having a molecular weight of not more than 500, and 1-99% by weight of a thermoplastic resin (T1) other than (C). Moreover, a multilayer structure in which the resin composition and a thermoplastic resin (T2) are laminated is also provided. Thus, a resin composition superior in barrier properties, transparency, stretchability, flexibility, flexing resistance and interlayer adhesiveness and various kinds of molded articles made thereof are provided.

Owner:KURARAY CO LTD

Barrier coating for thermoplastic films

The present invention generally relates to a barrier coating composition for application to a thermoplastic film comprising (a) a nano-clay additive in an amount from about 1 wt % to 50 wt % of said barrier coating, wherein said nano-clay additive comprises untreated nano-clay platelets; and (b) a base coating in an amount from about 50 wt % to 99 wt % of said barrier coating, wherein said base coating comprises a polymer selected from the group consisting of polyvinylidene chloride (PVdC), poly(vinyl)alcohol (PVOH), ethylene vinyl alcohol (EVOH), acrylate copolymers and mixtures thereof.

Owner:JINDAL FILMS AMERICAS LLC

Heat shrinkable multilayer film and tube with improved adhesion after orientation

Multilayer laminated shrink films that have good interlayer adhesion comprise at least three layers, a first layer comprising a polymer selected from the group consisting of polyamides, ethylene vinyl alcohol copolymers and mixtures thereof, a second adhesive layer consisting essentially of a blend of a functionalized polymer component, an ethylene copolymer component and a tackifier and a third layer comprising a polymer selected from the group consisting of polyethylene homopolymers, ethylene copolymers, polypropylene homopolymers, propylene copolymers, polyesters, polyamides, polyvinyl chloride, polycarbonates, and mixtures thereof The adhesive layer is positioned between and contacts the first and third layers.

Owner:EI DU PONT DE NEMOURS & CO

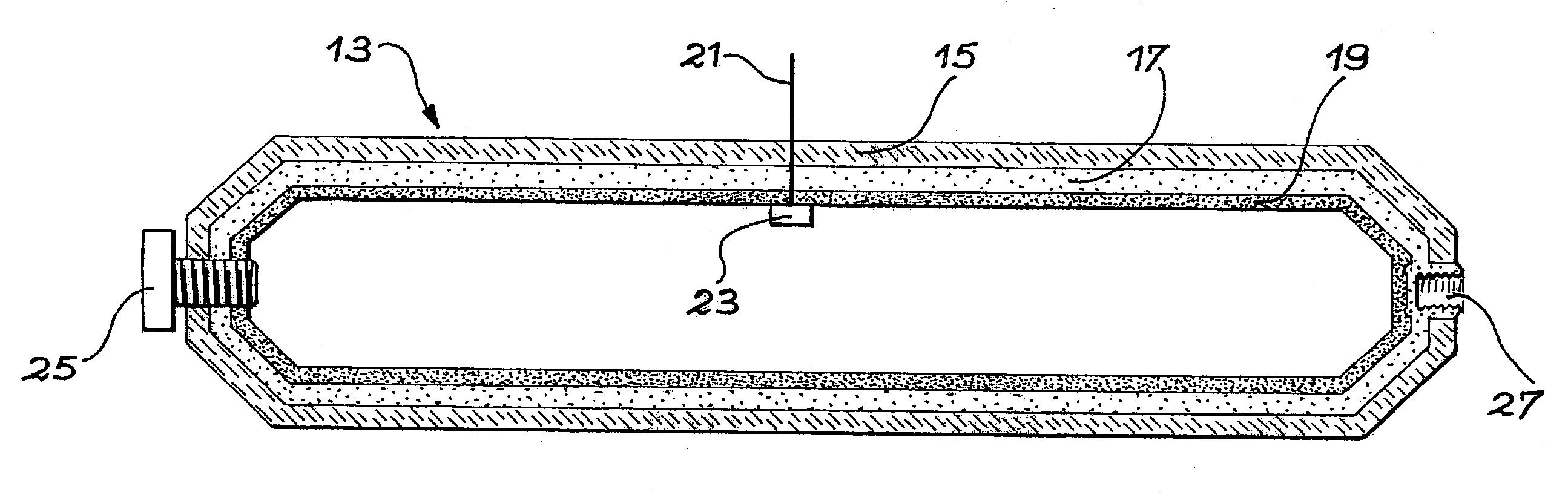

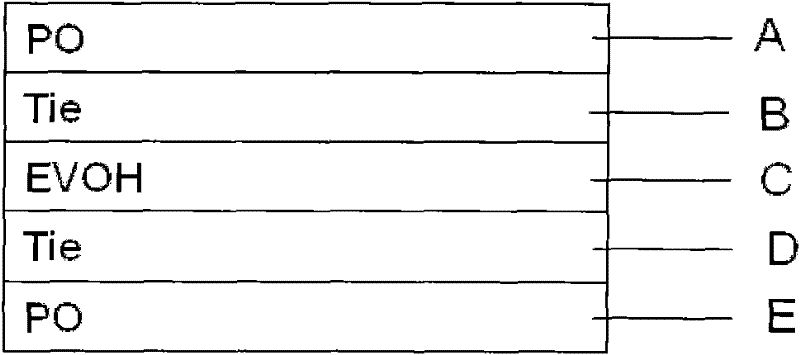

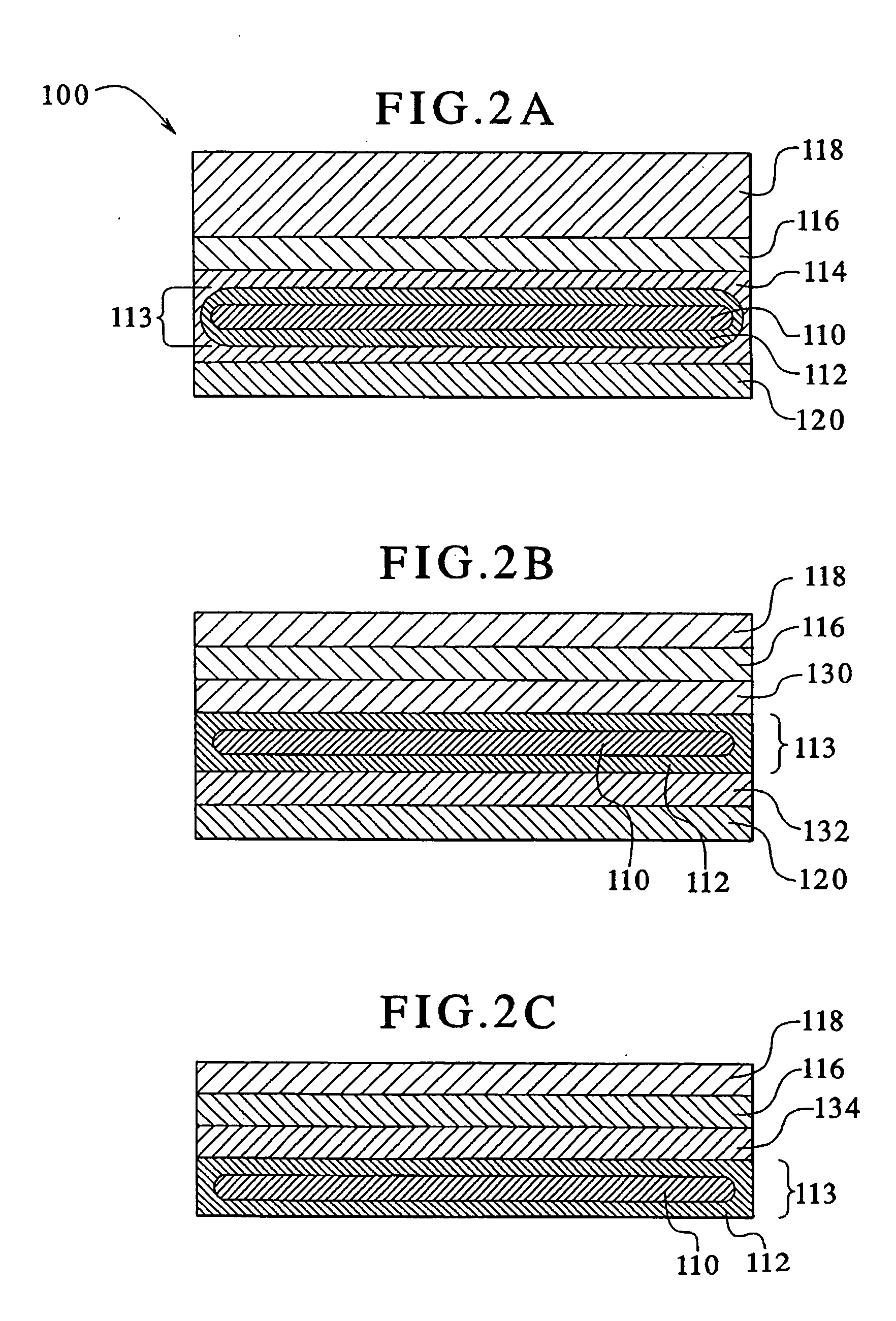

Multilayered polymer structure for medical products

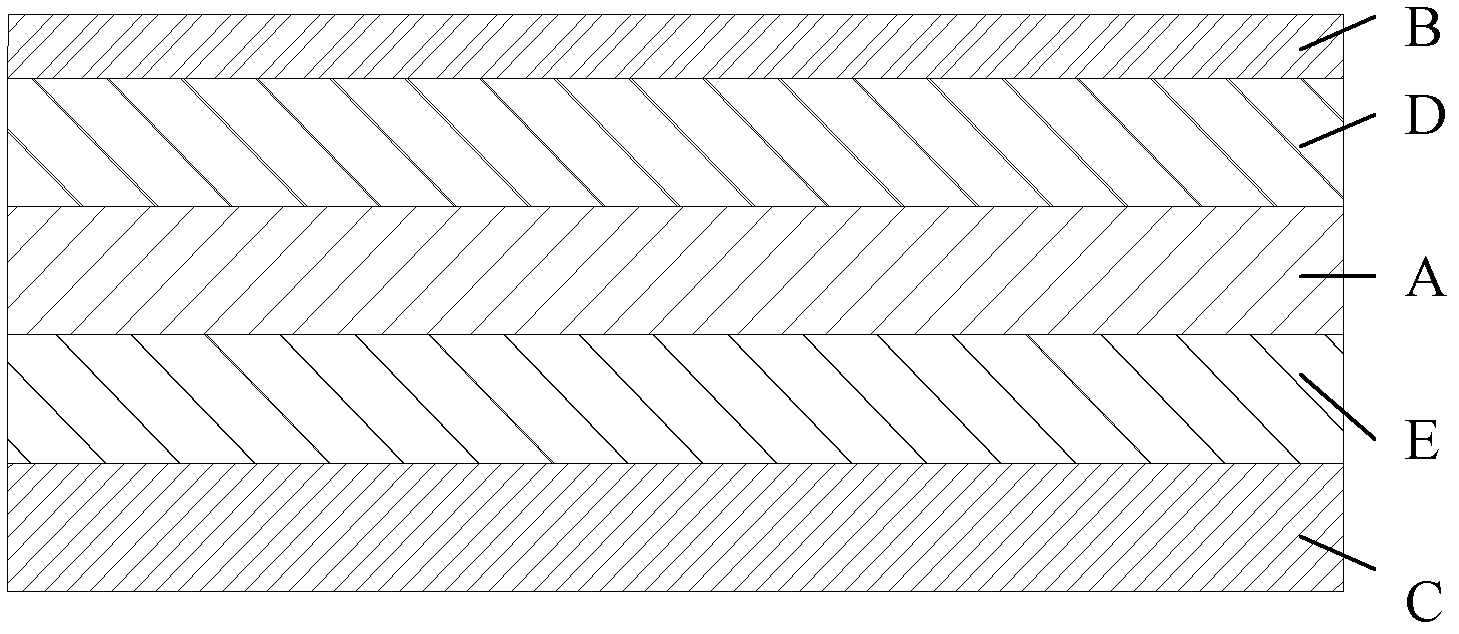

The present invention provides a multiple layer structure (10) for fabricating medical products. The layer structure (10) has a core layer (14) of an ethylene vinyl alcohol copolymer having an ethylene content of about 25-45 mole percent, a solution contact layer of a polyolefin positioned on a first side of the core layer, an outer layer (12) positioned on a second side of the core layer opposite the solution contact layer (16), the outer layer (12) being selected from the group consisting of polyamides, polyesters and polyolefins; two tie layers (18)-one of each adhered to the first and second sides of the core layer (14) and positioned between the solution contact layer (16) and the core layer (14) and between the outer layer (12) and the core layer (14), and wherein the structure (10) is produced in a cast coextrusion process.

Owner:BAXTER INT INC

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

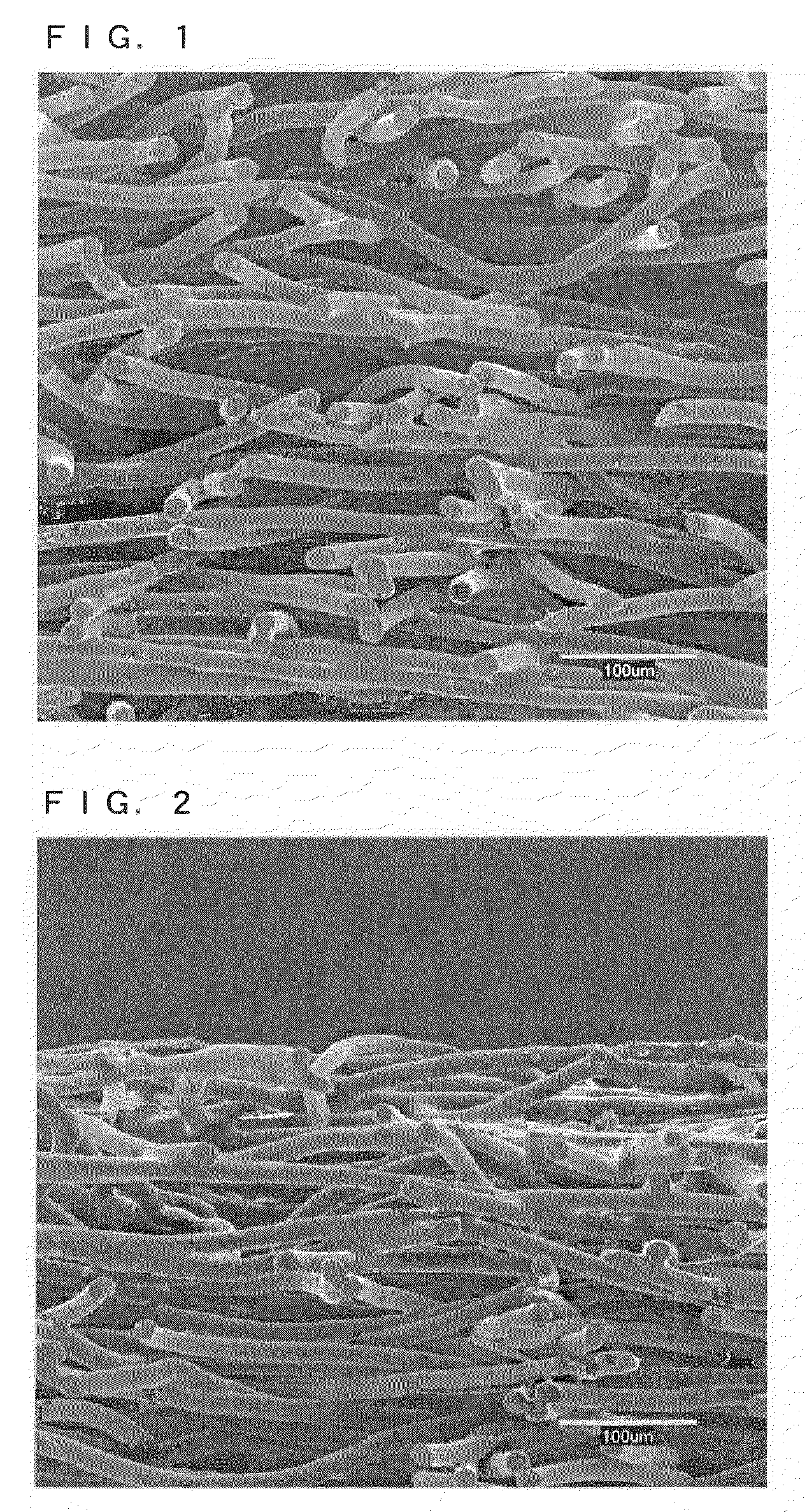

Molded object having nonwoven fibrous structure

ActiveUS20090130939A1Increased bending stressImprove toughnessErasing devicesConstruction materialPolyesterApparent density

To prepare a shaped product comprising a thermal adhesive fiber under moisture and having a fiber aggregate nonwoven structure. In the shaped product, the thermal adhesive fibers under moisture are melted to bond to fibers constituting the fiber aggregate nonwoven structure and the bonded fiber ratio is not more than 85%. The shaped product has an apparent density of 0.05 to 0.7 g / cm3, a maximum bending stress of not less than 0.05 MPa in at least one direction, and a bending stress of not less than ⅕ of the maximum bending stress at 1.5 times as large as the bending deflection at the maximum bending stress. The moistenable-thermal adhesive fiber may be a sheath-core form conjugated fiber comprising a sheath part comprising an ethylene-vinyl alcohol-series copolymer and a core part comprising a polyester-series resin. Such a shaped product can be used for a building board or the like since the shaped product has a high bending stress although the product is light and has a low density.

Owner:KURARAY CO LTD

Ultra high oxygen barrier films and articles made therefrom

Oxygen barrier films exhibiting high oxygen scavenging capability suitable for extended shelf-life, packaging applications. These films comprise a polyamide homopolymer, copolymer, or blends thereof; an ethylene vinyl alcohol copolymer; an oxidizable polydiene; and at least one metal salt catalyst. These films are particularly suited to making high barrier, retortable packaging structures such as pouches, containers etc. Such articles are useful for packaging a variety of oxygen-sensitive foods, beverage, medical and health care products.

Owner:ADVANSIX RESINS & CHEM LLC

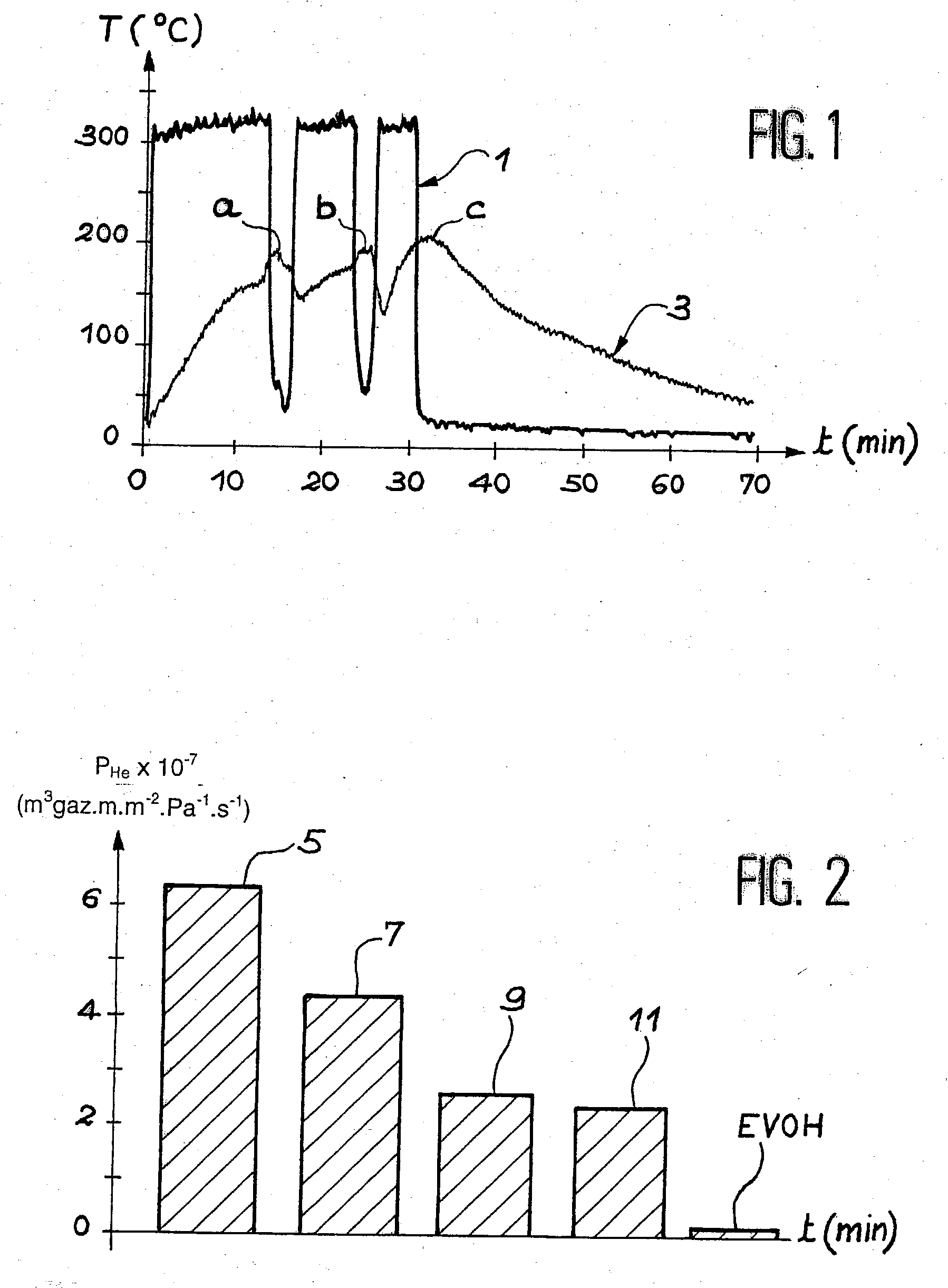

Mulitlayer thermoplastic structure for gas tank

InactiveUS20030175457A1Avoid the needControlling the riskUnderstructuresRecord information storageThermoplasticMelt flow index

This invention relates to a multiple layer thermoplastic structure, use of the said structure for manufacturing a tank, and a tank comprising the said structure. Multi-layer thermoplastic structure of the said invention comprising at least one layer composed of an ethylene-vinyl alcohol copolymer with a density of between 0.94 and 1.4, and a melt flow index of between 1.3 and 4.2 g / 10 minutes at a temperature between 170 and 240° C. It is used for manufacturing gas tanks.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Nanocomposite blend composition having super barrier property

InactiveUS7138452B2High mechanical strengthImprove barrier propertiesPigmenting treatmentFlexible coversPolyolefinPolyvinyl alcohol

The present invention relates to a nanocomposite blend composition having superior barrier properties, and more particularly to a nanocomposite blend composition comprising a polyolefin resin; one or more nanocomposites having barrier properties, selected from an ethylene-vinyl alcohol (EVOH) / intercalated clay nanocomposite, a polyamide / intercalated clay nanocomposite, an ionomer / intercalated clay nanocomposite, and a polyvinyl alcohol (PVA) / intercalated clay nanocomposite; and a compatibilizer. This nanocomposite blend composition has superior mechanical strength and superior barrier properties to oxygen, organic solvent, and moisture. Also, it has superior chemical barrier properties and is applicable to single / multi-layer blow molding and film processing.

Owner:LG CHEM LTD

Resin composition and multilayer structure

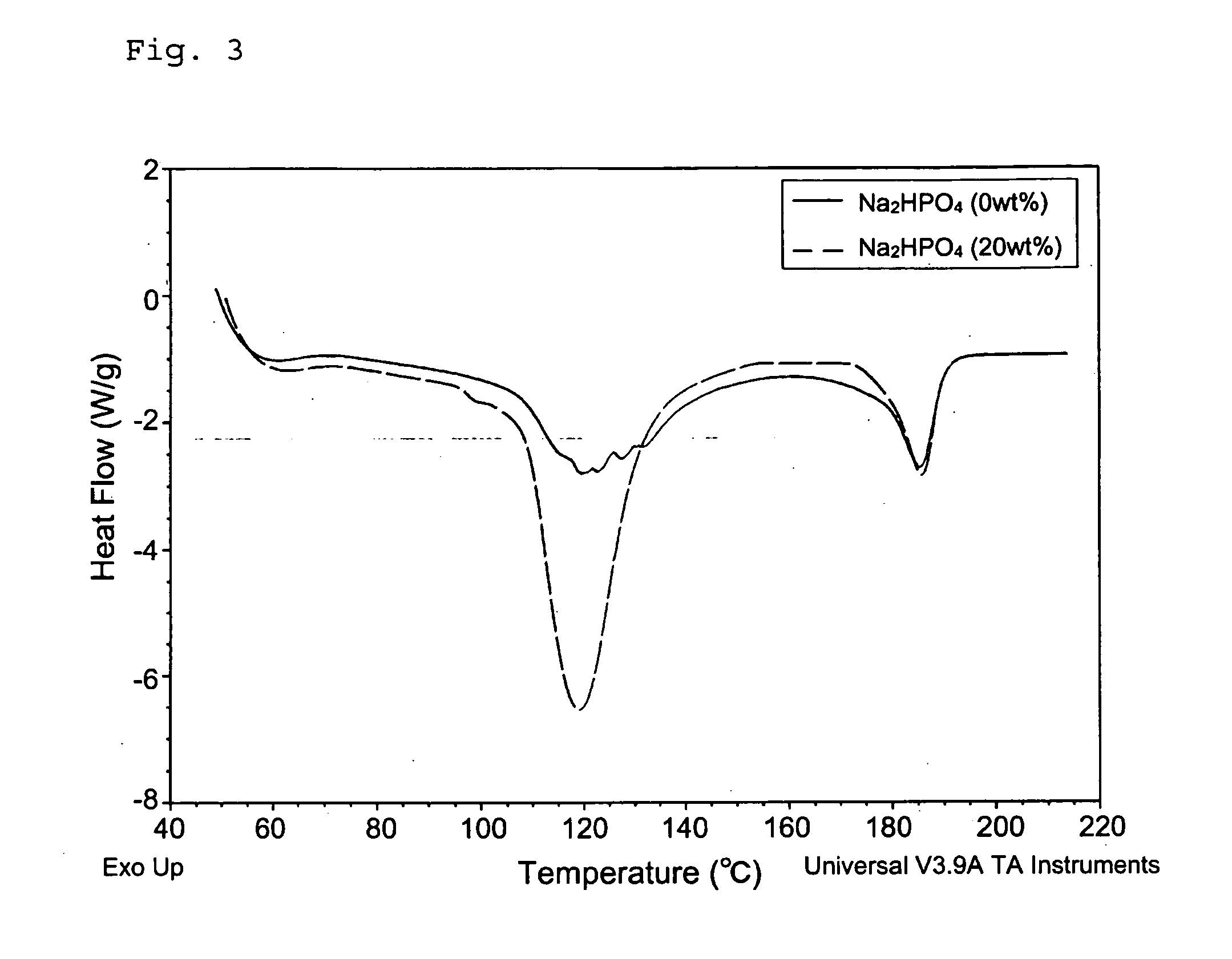

InactiveUS20070275197A1Excels in gas barrier property and moisture resistanceMultilayer structure being prevented from deterioration in gas barrier propertiesSynthetic resin layered productsOrganic dyesPhosphoric acidMoisture resistance

To provide a resin composition including: an ethylene-vinyl alcohol copolymer (A) having an ethylene content of from 15 to 65 mol % and a saponification degree of at least 95 mol %, a phosphoric acid salt (B) which can form a hydrate, and a conjugated polyene compound (C) having a boiling point of at least 150° C., wherein the resin composition comprises from 50 to 99 parts by weight of (A), from 1 to 50 parts by weight of (B) and from 0.00001 to 1 parts by weight of (C), based on 100 parts by weight of the total amounts of (A) and (B). This resin composition excels in gas barrier property and also in moisture resistance at high temperatures and high humidities. Therefore, it is suitable for food packaging containers to be retorted.

Owner:KURARAY CO LTD

Ultra High Barrier Aseptic Film and Package

InactiveUS20110027428A1Ready-for-oven doughsSynthetic resin layered productsPolymer scienceInter layer

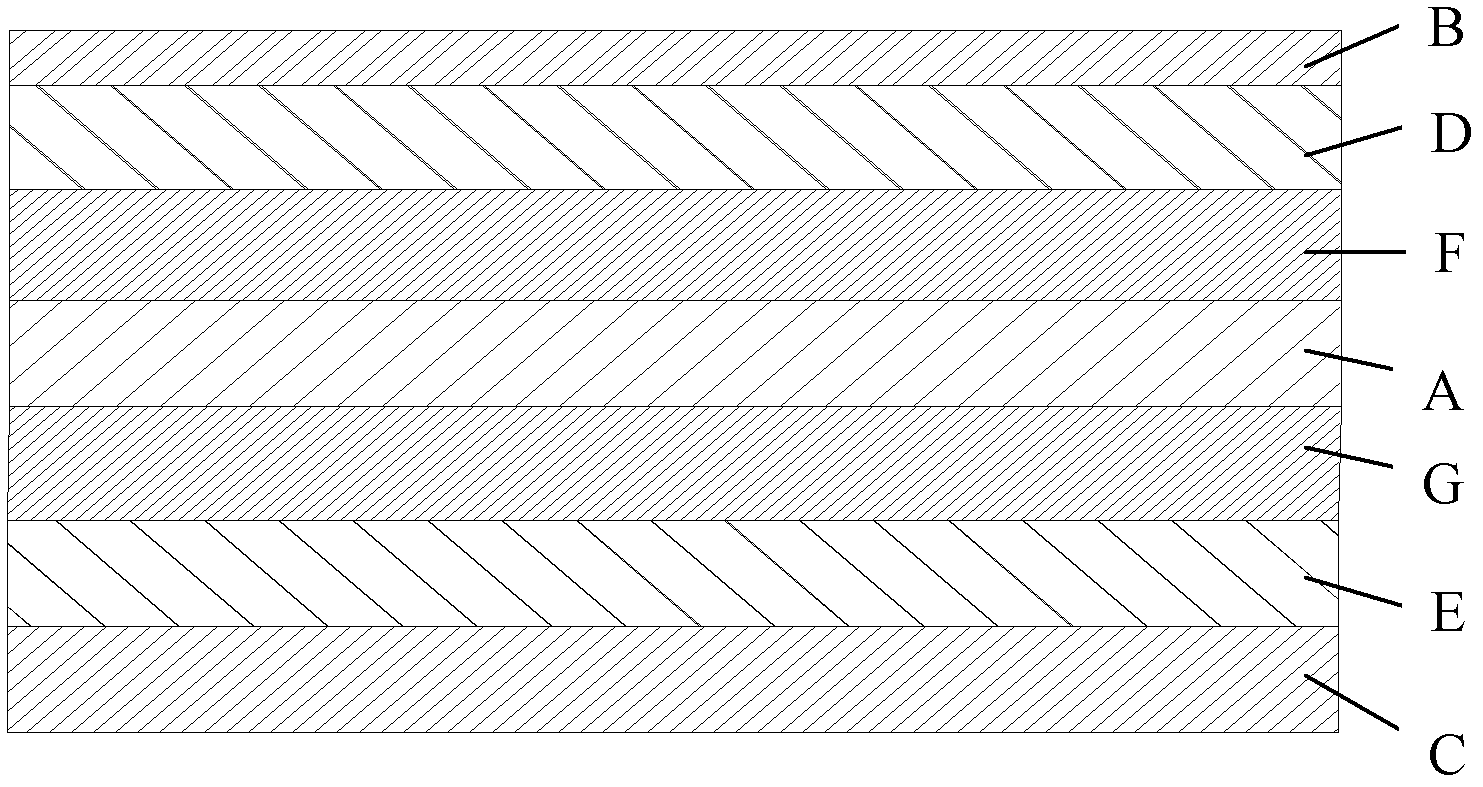

A coextruded multilayer film includes a core layer including a polyamide; two intermediate layers each including an ethylene vinyl alcohol copolymer; a first and second outer layer each including an olefinic copolymer or an amorphous cyclic olefin copolymer; and two tie layers each adhering an intermediate layer to a respective outer layer; the ethylene vinyl alcohol copolymer of the first intermediate layer having a mole % ethylene at least 5 greater than the mole % ethylene of the ethylene vinyl alcohol copolymer of the second intermediate layer An aseptic package includes a sterilized food product, and a sterilized pouch in which the sterilized food product is disposed, the sterilized pouch including the film of the invention. A method of making an aseptic package is also disclosed.

Owner:CRYOVAC ILLC

Highly obstructed multilayer coextrusion thermal shrink film

InactiveCN102555379AHigh tensile strengthExcellent oxygen barrier propertiesFlexible coversWrappersPolyolefinPolyamide

The invention discloses a highly obstructed multilayer coextrusion thermal shrink film which comprises a heat sealing layer, an outer surface layer, an obstruction layer and a bonding layer, wherein the heat sealing layer, the outer surface layer and the obstruction layer are contacted with a packaged object, and the bonding layer connects the outer surface layer, the heat sealing layer and the obstruction layer; the heat sealing layer comprises polyolefin resin; the outer surface layer comprises polyethylene with middle density and the like; the obstruction layer comprises at least one layer of one out of ethylene-vinyl alcohol copolymer or polyamide or the mixture of the two; and the structure of the multilayer coextrusion thermal shrink film has 5-9 layers. The highly obstructed multilayer coextrusion thermal shrink film has good oxygen obstruction performance and higher tensile strength, and even objects sensitive to air cannot suffer from the risk that the color is changed or even aged or the food flavor is changed due to entrance of oxygen after being stored for a longer time. Furthermore, the structure of the outer layer can improve the optical property, the mechanical property, the surface printing capability and the stretching capability, and resist high temperature sealing and burning.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

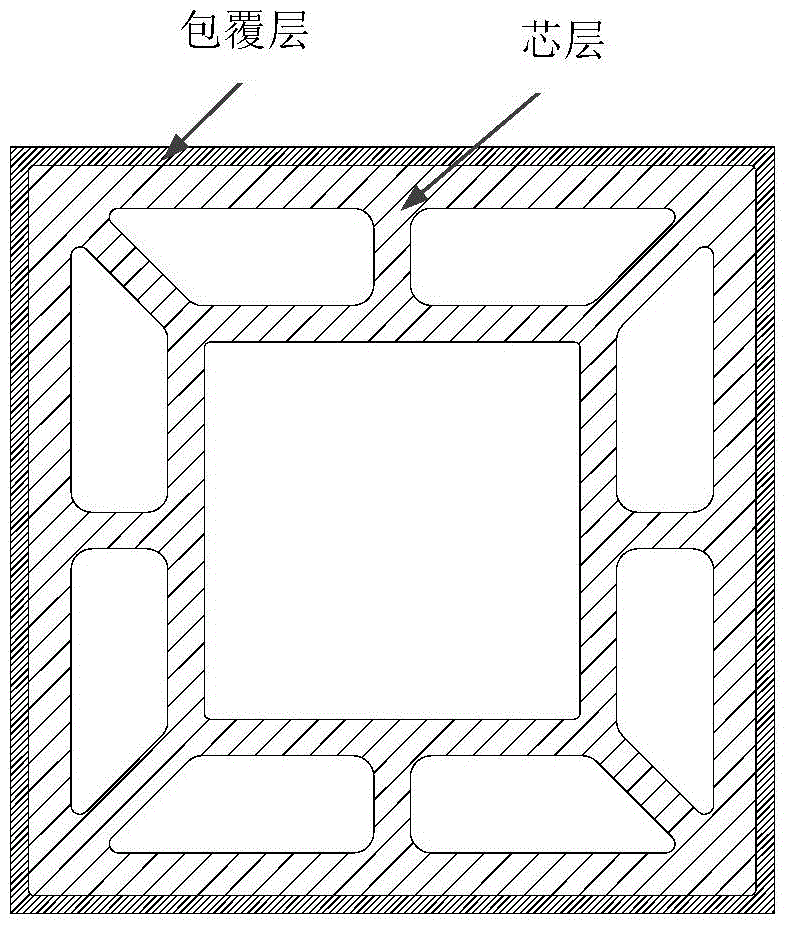

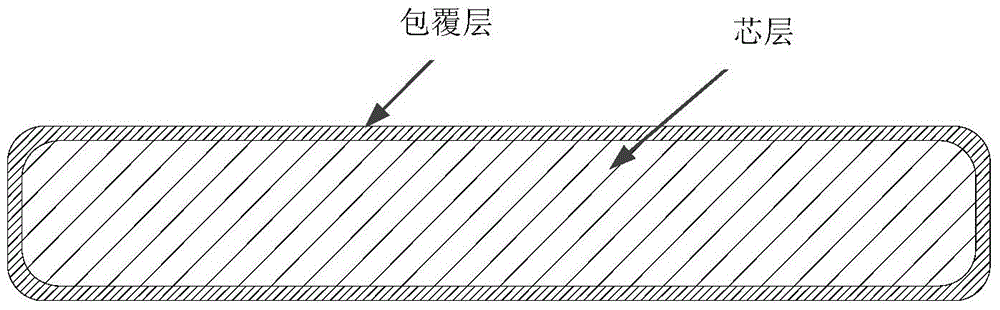

High strength wood-plastic coated coextruded composite material and preparation method thereof

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Multi-Layer Structure and Process for Production Thereof

InactiveUS20080003390A1Nice appearanceExcellent gas barrier propertiesSynthetic resin layered productsThin material handlingSolubilityPolyolefin

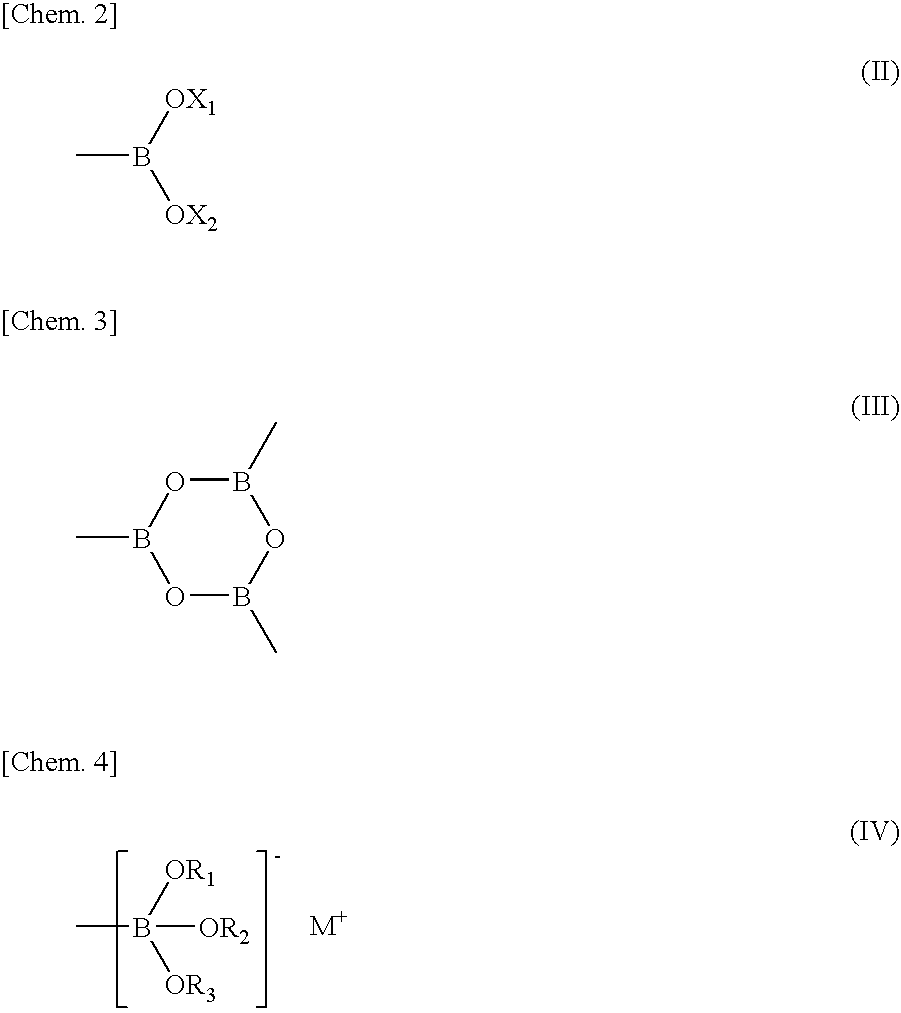

A multi-layer structure comprising a layer of an ethylene-vinyl alcohol copolymer (A), a layer of a carboxylic acid-modified polyolefin (B), a layer of a thermoplastic resin (C) having a solubility parameter of 11 or less, and a layer of a resin composition (E), wherein the resin composition (E) comprises an ethylene-vinyl alcohol copolymer (A), a carboxylic acid-modified polyolefin (B), a thermoplastic resin (C) and a thermoplastic resin (D) having at least one functional group selected from the group consisting of a boronic acid group and boron-containing groups capable of being converted into a boronic acid group in the presence of water, and the layer of an ethylene-vinyl alcohol copolymer (A) is laminated with the layer of a thermoplastic resin (C) or the layer of a resin composition (E) through the layer of a carboxylic acid-modified polyolefin (B). This provides a multi-layer structure which allows effective reuse of regrind and which is excellent in impact resistance and gas barrier properties.

Owner:KURARAY CO LTD

High-separation multilayer joint-extrusion shrink film

InactiveCN102642359AImprove barrier propertiesIncrease oxygenFlexible coversWrappersSurface layerWater vapor

The invention discloses a high-separation multilayer joint-extrusion shrink film, which comprises an outer surface layer, a separation layer, a heat sealing layer and two bonding layers. The two bonding layers are respectively located between the separation layer and the outer surface layer and between the separation layer and the heat sealing layer, the separation layer is made of one of or a combination of two of ethylene vinyl alcohol (EVOH) resin, polyvinylidene chloride resin and modified polyamide resin, the thickness of the separation layer is 10%-45% of the total thickness, the thickness of the outer surface layer is 3%-5% of the total thickness, the thickness of the heat sealing layer is 25%-35% of the total thickness, the thickness of the bonding layers is 10%-30% of the total thickness, and the number of the separation layer is one or three. The outer surface layer of the film is made of high-melting-point resin to overcome the shortcoming that users are easy to burn during a using process of products, simultaneously oxygen and water vapor separation performance are good, the anti-puncturing effect and heat sealing strength are good, and the high-separation multilayer joint-extrusion shrink film can be suitable to vacuum shrink package of chilled pork, cheese products and seafood products.

Owner:张建岭

Preserving a hemoglobin blood substitute with a transparent overwrap

InactiveUS7041800B1High purityExtended shelf lifePeptide/protein ingredientsMetal layered productsPolyolefinMedicine

Owner:OPK BIOTECH

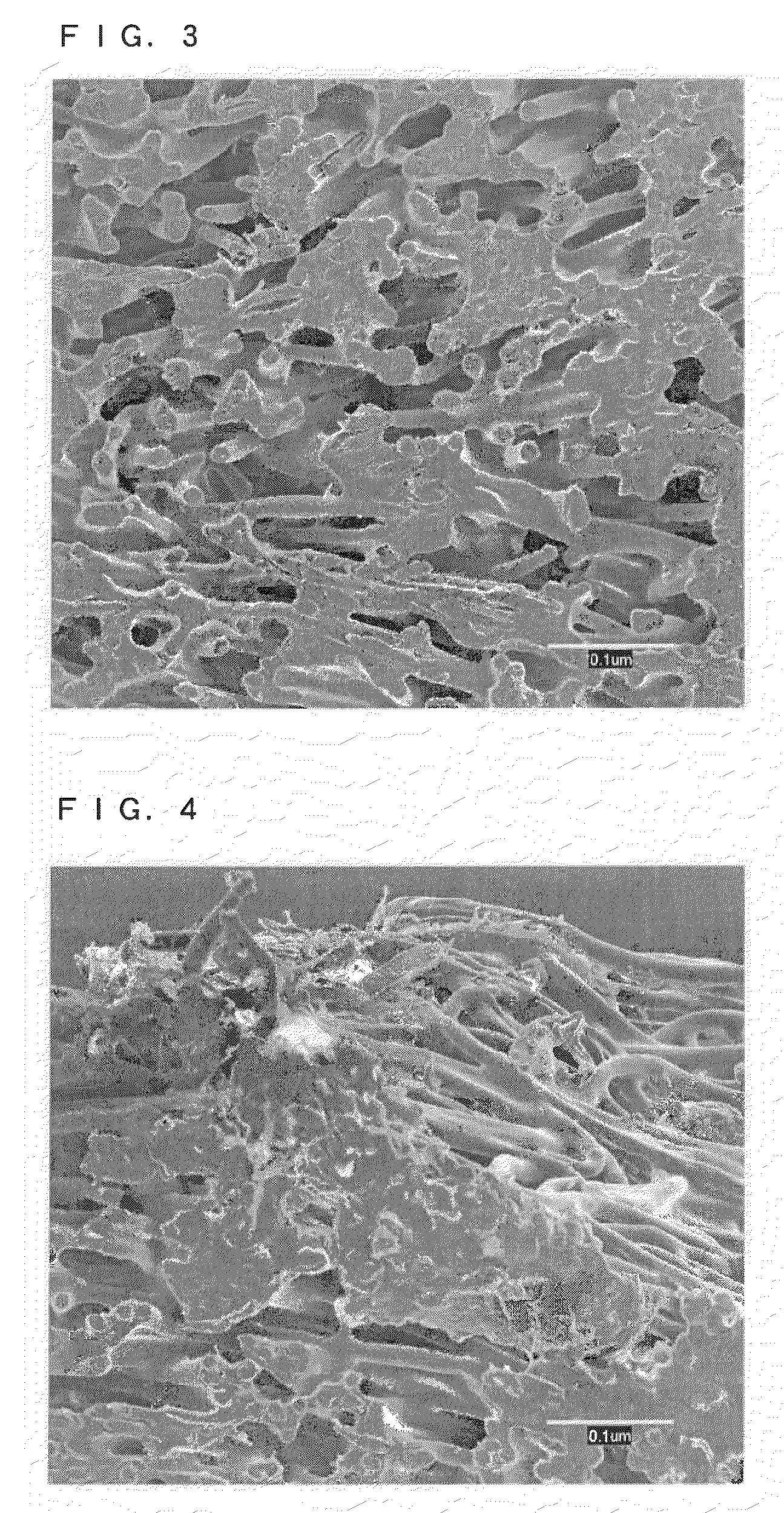

Film, inner liner for tire, and tire using the same

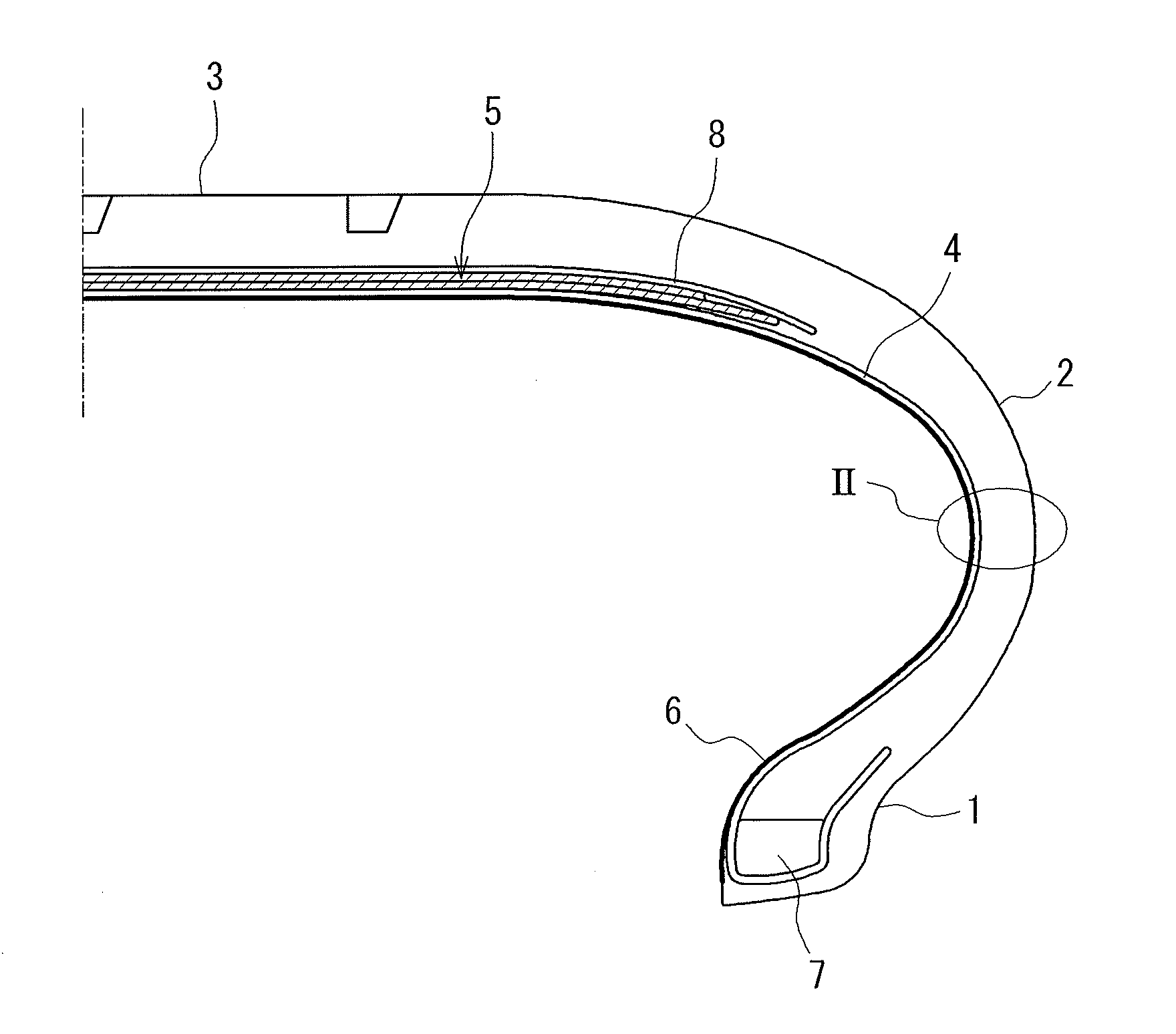

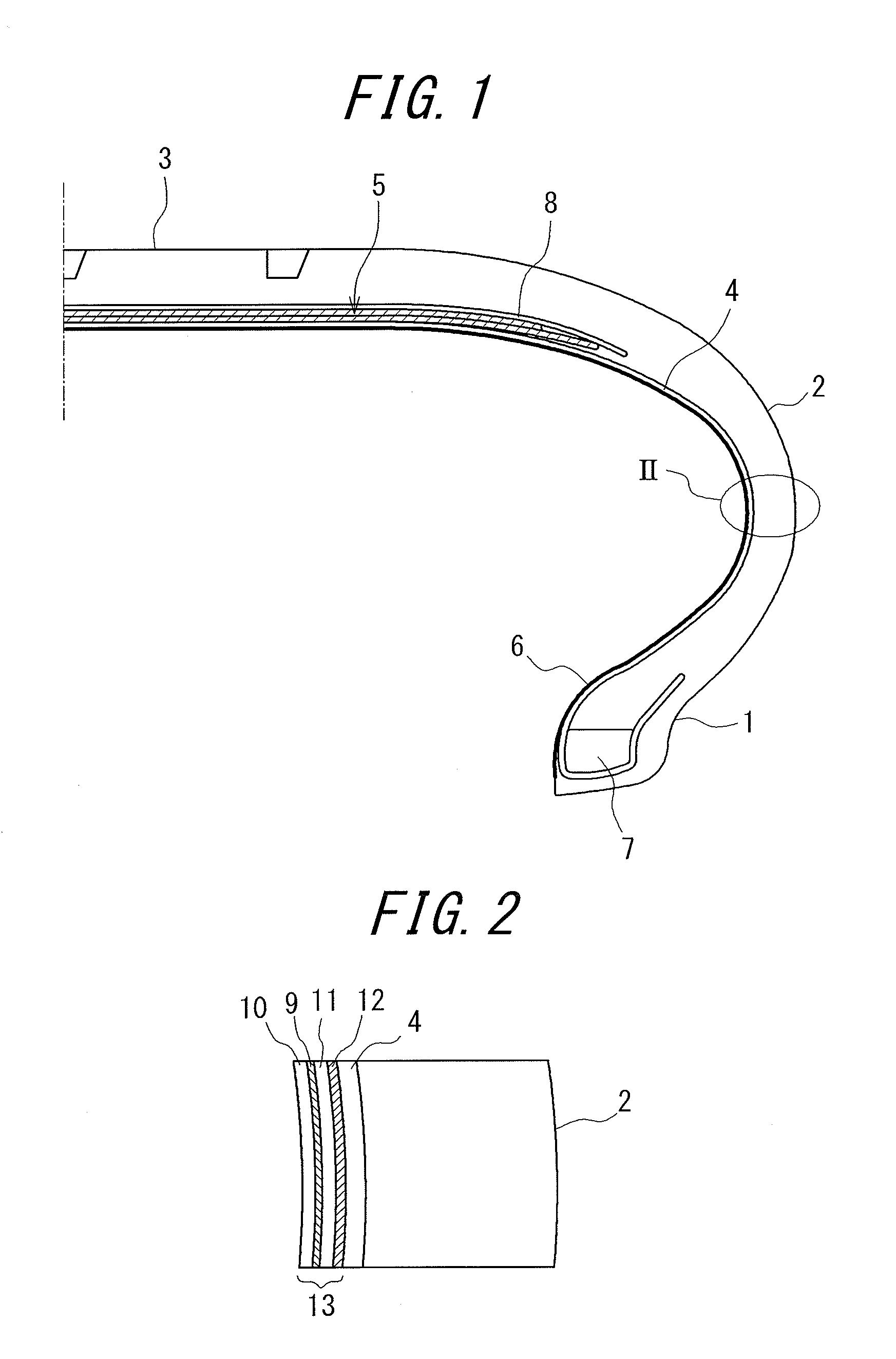

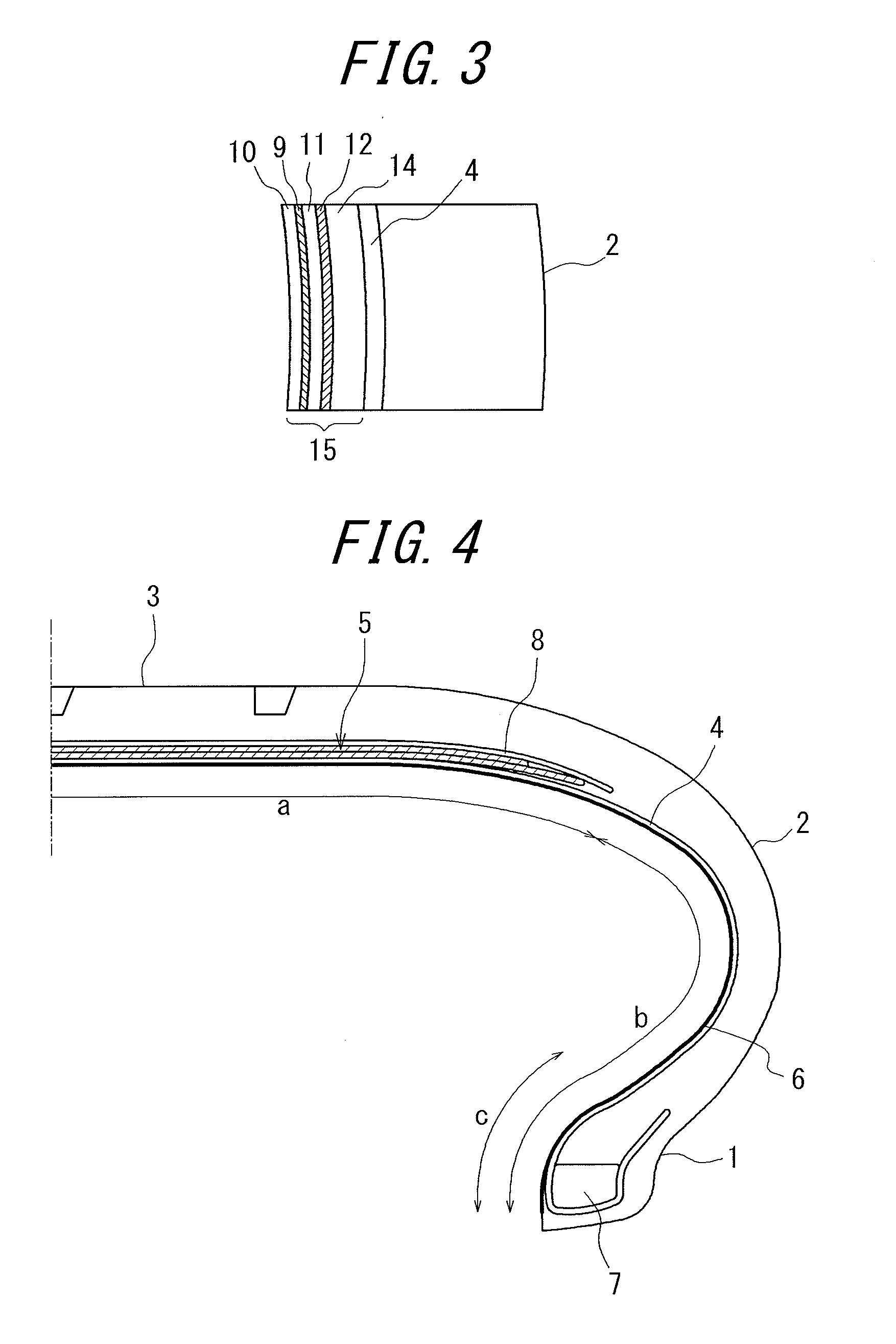

InactiveUS20110024015A1Excellent gas barrier propertiesImprove bending resistanceWithout separate inflatable insertsWith separate inflatable insertsInternal pressureEngineering

An object of the present invention is to provide: a film which is applicable to a tire, has excellent gas barrier properties and bending resistance, allows weight of a tire to be reduced with improving internal pressure retainability of the tire at both the brand-new stage and the used stage thereof, and is capable of demonstrating good gas barrier properties without breaking especially in a running condition at a relatively low temperature in winter time or the like; an inner liner for tire, using the film; and a tire provided with the inner liner for tire. The film of the present invention comprises at least a layer composed of resin composition (D) produced by dispersing viscoelastic substance (C) in a resin containing modified ethylene-vinyl alcohol copolymer (B) obtained by subjecting ethylene-vinyl alcohol copolymer (A) to a reaction, wherein 100% modulus at −30° C. of the viscoelastic substance (C) is smaller than 6 MPa. The inner liner for tire, and the tire, of the present invention are an inner liner for tire, using said film, and a tire provided with said inner liner for tire, respectively.

Owner:BRIDGESTONE CORP +1

Oxygen scavenging polymer compositions containing ethylene vinyl alcohol copolymers

InactiveUS6793994B2Low oxygen permeabilityHigh oxygen scavengingFlexible coversWrappersPolyolefinPolymer science

Oxygen barrier polymer compositions exhibiting high oxygen scavenging capability suitable for extended shelf-life, packaging applications. These polymer compositions comprise at least one ethylene vinyl alcohol copolymer, at least one oxidizable polydiene, and at least one metal salt catalyst. The polymer products are particularly suited to making barrier packaging articles such as monolayer or multi-layer films, sheets, tubes, pipes, thermoformed containers and coinjection / coextrusion blow molded bottles comprising PET, polyolefin or polycarbonate as structural layers. Such articles are useful in a variety of oxygen-sensitive food, beverage, pharmaceutical and health care product packaging applications.

Owner:HONEYWELL INT INC

Dimensionally stable sterilizable coextruded film for aseptic packaging

InactiveUS20070110853A1Good physical propertiesHigh densityFruit and vegetables preservationLayered product treatmentPolymer sciencePolyamide

A coextruded multilayer film includes a core layer including an ethylene vinyl alcohol copolymer; two intermediate layers each including a polyamide; a first outer layer comprising an amorphous cyclic olefin copolymer; a second outer layer comprising an amorphous cyclic olefin copolymer or an olefinic copolymer; and two tie layers each adhering an intermediate layer to a respective outer layer. An aseptic package includes a sterilized food product, and a sterilized pouch in which the sterilized food product is disposed, the sterilized pouch including the coextruded multilayer film of the invention. A method of making an aseptic package is also disclosed.

Owner:CRYOVAC ILLC

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN101081653AReduce consumptionReduce thicknessFlexible coversWrappersPolyesterPolymer science

The present invention discloses one kind of multilayer high blocking film for packing liquid material, the multilayer high blocking film includes polyethylene-based heat sealing layer(s), blocking polymer layer(s) preferably of ethylene-vinyl alcohol copolymer, PVA or polyvinylidene dichloride; and protecting layer(s) of polypropylene, polyester, etc. It has the total thickness below 80 micron, preferably of 55-65 micron. The present invention discloses also the making process of the multilayer high blocking film.

Owner:刘建林

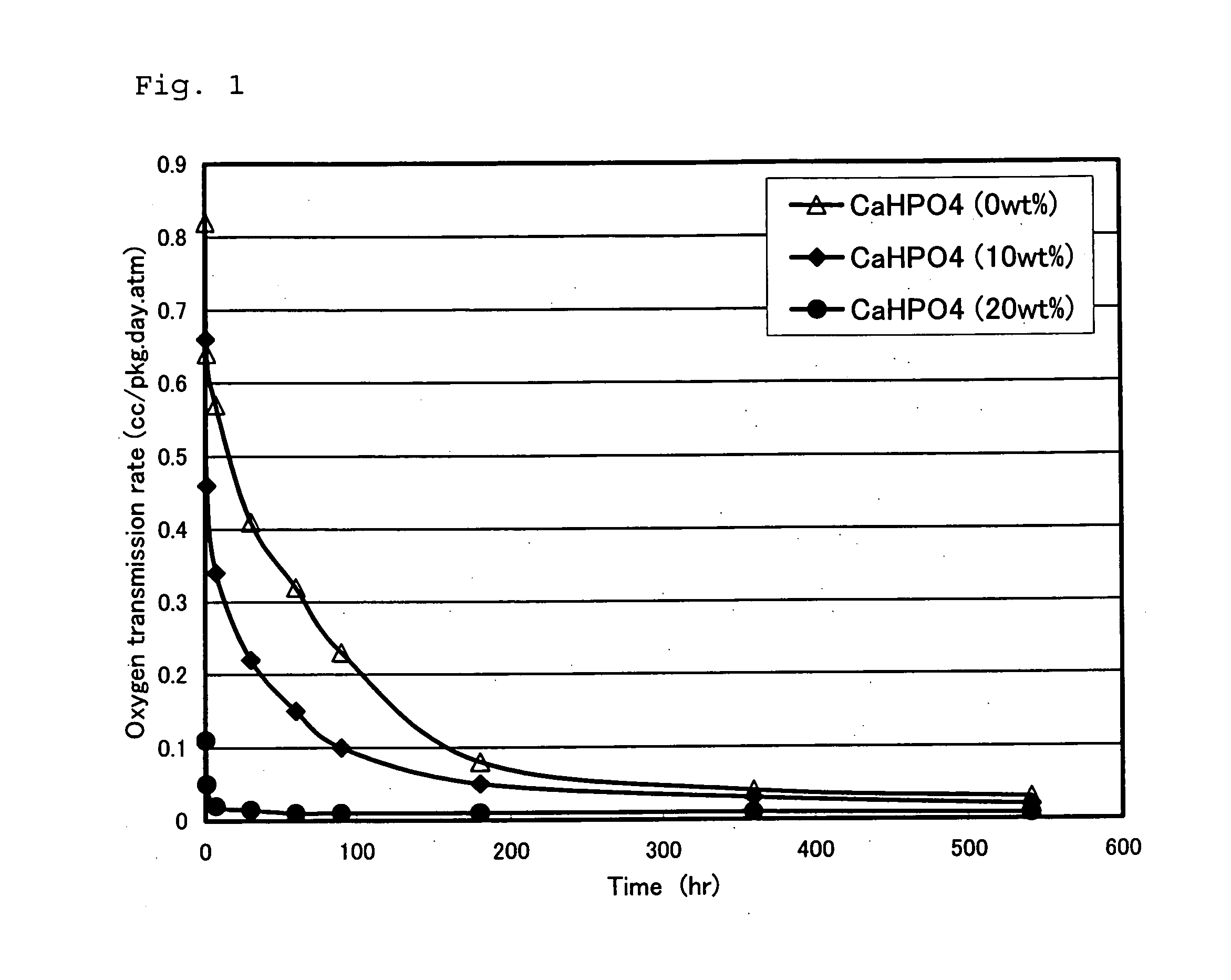

Nanocomposite composition having super barrier property and article using the same

InactiveUS7368496B2High mechanical strengthMaintain good propertiesPigmenting treatmentMaterial nanotechnologyIonomerBlow molding

A nanocomposite composition having superior barrier properties and an article comprising the same are provided. The nanocomposite composition includes: a polyolefin resin; a nanocomposite having barrier properties, and including intercalated clay and one or more resins having barrier properties, and a compatibilizer. The resin having barrier properties comprises an ethylene-vinyl alcohol copolymer, a polyamide, an ionomer, a polyvinyl alcohol, or a combination comprising one or more of the foregoing resins. The nanocomposite composition has superior mechanical strength and can form a strong barrier to oxygen, organic solvent, and moisture. Also, the nanocomposite composition has superior chemical barrier properties and can be used in single / multi-layer blow molding and film processing.

Owner:LG CHEM LTD

Resin composition and multilayer structure

ActiveUS7713614B2Excels in gas barrier property and moisture resistanceMultilayer structure being prevented from deterioration in gas barrier propertiesFilm/foil adhesivesSynthetic resin layered productsHigh humidityPhosphoric acid

To provide a resin composition comprising an ethylene-vinyl alcohol copolymer (A) having an ethylene content of from 15 to 65 mol % and a degree of saponification of 95 mol % or more, a phosphoric acid salt (B) which can form a hydrate, and a dispersing agent (C), wherein the dispersing agent (C) comprises at least one species selected from the group consisting of aliphatic acid salts, glycerol aliphatic acid esters and aliphatic acid amides, the resin composition comprises (A) and (B) in amounts of from 50 to 99 parts by weight and from 1 to 50 parts by weight, respectively, based on 100 parts by weight of (A) and (B) in total, and the resin composition comprises (C) in an amount of from 1 to 20 parts by weight based on 100 parts by weight of (B). This resin composition excels in gas barrier property and also in moisture resistance at high temperatures and high humidities. Therefore, it is suitable for food packaging containers to be retorted.

Owner:KURARAY CO LTD

Printed sterilizable laminate for aseptic packaging

A printed sterilizable laminate for aseptic packaging includes two films each including a core layer including ethylene vinyl alcohol copolymer, polymeric adhesive, or polyamide; first and second intermediate layers each including a polyamide; an outer layer including amorphous cyclic olefin copolymer, or a blend of amorphous cyclic olefin copolymer and at least one olefinic copolymer; an inner layer including olefinic copolymer, or a blend of an olefinic copolymer and amorphous cyclic olefin copolymer; and first and second tie layers adhering the intermediate layers to the outer and inner layers respectively; a printed image disposed on the outside surface of the first film, or the inside surface of the second film; and an adhesive that bonds the outer layer of the first coextruded film to the inner layer of the second coextruded film. An aseptic package, and a method of making an aseptic package are also disclosed.

Owner:CRYOVAC INC

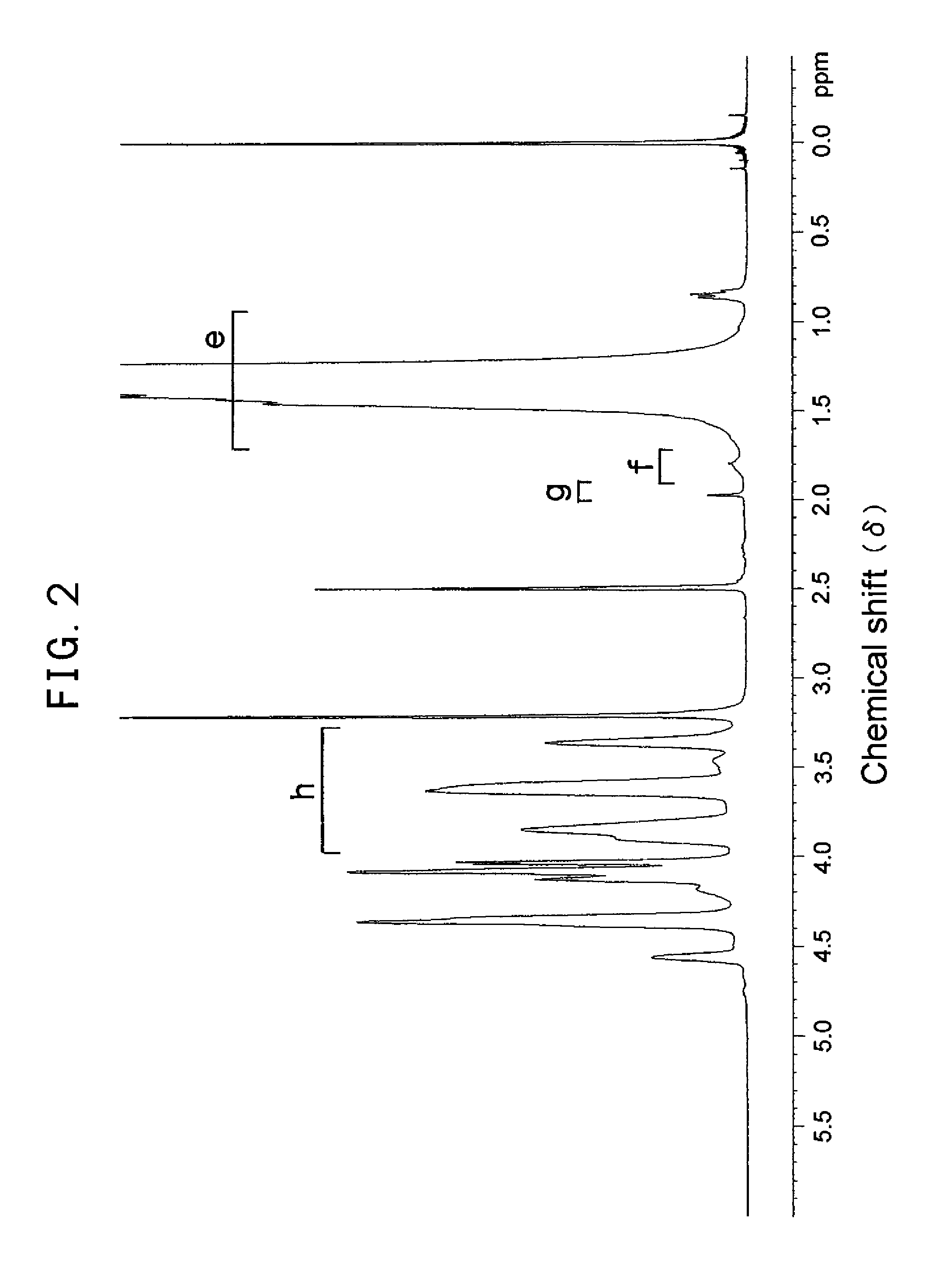

Method for producing ethylene-vinyl alcohol copolymer resin

InactiveUS6838029B2Good effectWell mixedColloidal chemistry detailsOrganic chemistryEthylene vinyl alcohol copolymer

Owner:KURARAY CO LTD

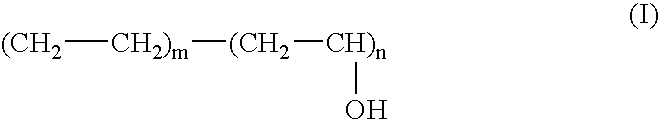

Ethylene-Vinyl Alcohol Copolymer Composition and Multilayer Structure Using the Same

ActiveUS20070196679A1Improvement of thermal stretchabilityGood formabilitySynthetic resin layered productsThin material handlingEtherVinyl ester

The present invention provides to an ethylene-vinyl alcohol copolymer composition excellent in neck-in reduction, stretching properties and further, gas barrier properties and a multilayer structure using the same. The ethylene-vinyl alcohol copolymer composition of the present invention is the blend of two or more ethylene-vinyl alcohol copolymers and at least one of the copolymers has the following structural unit (1). (wherein X represents any binding chain excluding an ether bond, each of R1 to R4 represents independently any substituent and n represents 0 or 1). Preferably, the ethylene-vinyl alcohol copolymer having the structural unit (1) is obtained by hydrolyzing of a copolymer of 3,4-diacyloxy-1-butene, a vinyl ester monomer and ethylene.

Owner:MITSUBISHI CHEM CORP

Sterilizable coextruded film for aseptic packaging

Owner:CRYOVAC ILLC

Encapsulated barrier for flexible films and a method of making and using the same

A film structure having an inner barrier layer comprised of a blend of a polyamide and ethylene vinyl alcohol copolymer. The polyamide is present in the blend in an amount of from 15-40%, and most preferably from 25-30%. The inner barrier layer is laminated on each side with a layer of a polyamide. The preferred polyamide is nylon, and particularly nylon 6. In a preferred embodiment, the film structure is layered with an oxide or ceramic layer. Included is a method of manufacturing the film and for using the film structure to package a product in a retort packaging process.

Owner:COVERIS FLEXIBLES UK

Thermoplastic resin composition

The present invention relates to a thermoplastic resin composition which excels in impact resistance, dimension stability and rigidity, and also excels in appearance, fluidity and paint film adhesion property, and further which is very useful as manufacturing materials for exterior parts of automobile. A thermoplastic resin composition comprising component (A): a polyamide resin; component (B): a hydrogenated product of block copolymer comprising vinyl aromatic polymer block (a) and conjugated diene based polymer block (b), and / or ethylene-α-olefin based block copolymer; component (C): a modified hydrogenated product of block copolymer comprising the vinyl aromatic polymer block (a) and the conjugated diene based polymer block (b), which hydrogenated product is modified by addition of an unsaturated acid and / or derivative thereof; component (D): a plate-like and / or needle-like inorganic filler; and component (F): an ethylene-vinyl alcohol copolymer and / or a partial saponified product of ethylene-vinyl acetate copolymer.

Owner:MITSUBISHI CHEM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com