Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23283 results about "Oxygen gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

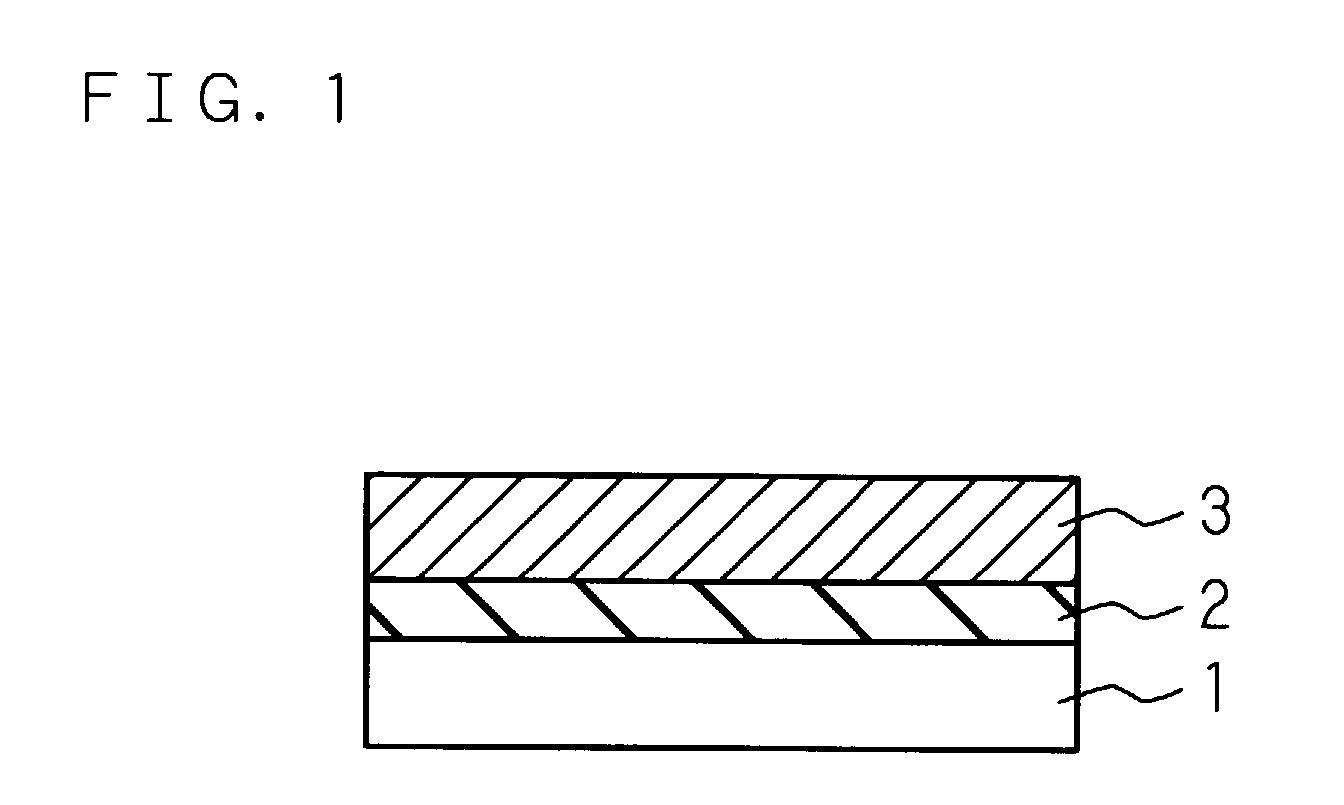

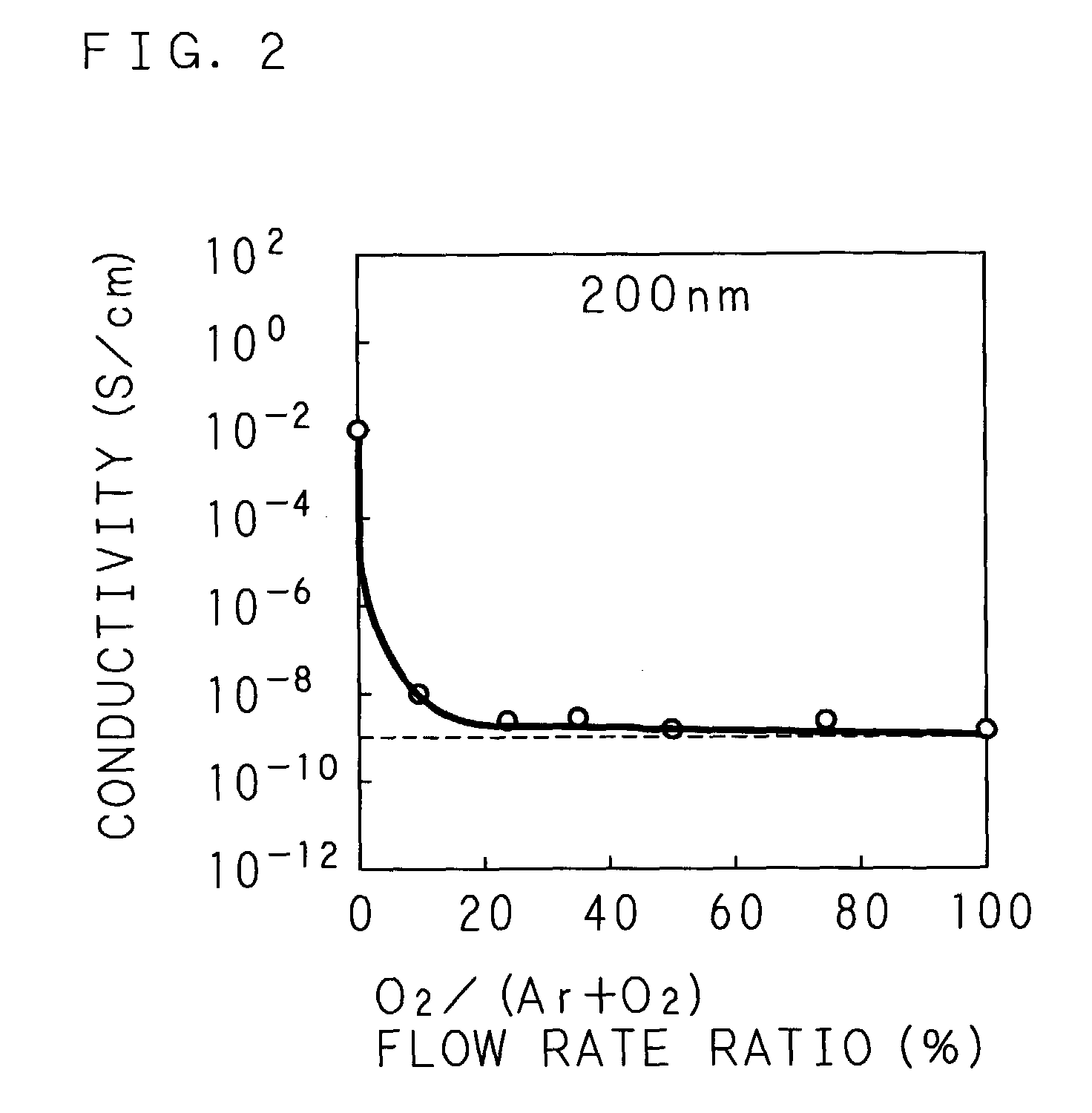

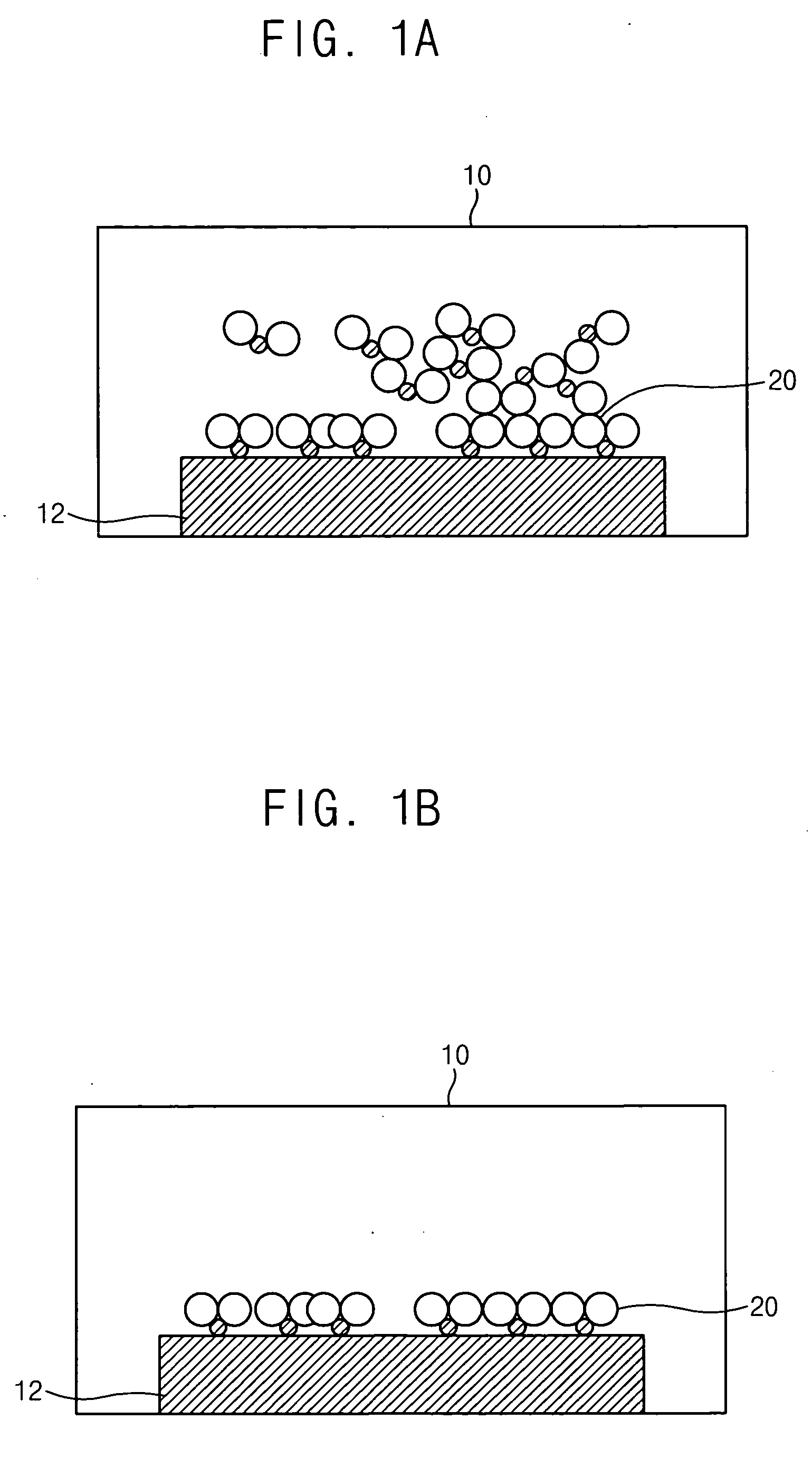

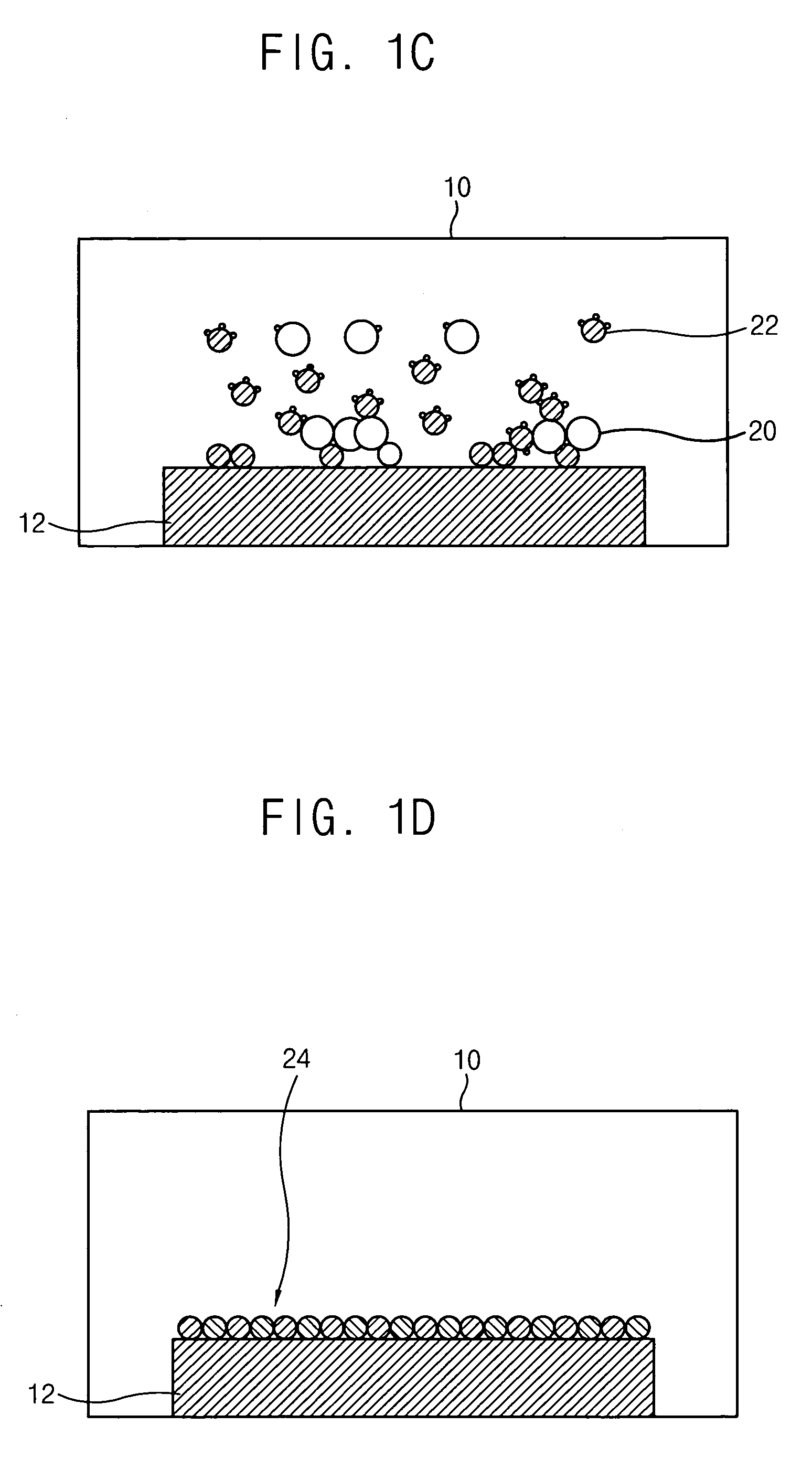

Method for forming ZnO film, method for forming ZnO semiconductor layer, method for fabricating semiconductor device, and semiconductor device

InactiveUS7049190B2High crystallinityLow costTransistorPolycrystalline material growthX-rayElectrical resistivity and conductivity

A ZnO buffer layer having an electric conductivity of 1×10−9 S / cm or lower or alternatively a ZnO buffer layer having a diffraction peak of a crystal face other than (002) and (004) in X-ray diffraction is formed on a substrate by sputtering. A ZnO semiconductor layer is formed on the ZnO buffer layer. The ZnO semiconductor layer is formed under the condition that the flow rate ratio of an oxygen gas in a sputtering gas is lower than that in the formation of the ZnO buffer layer.

Owner:SANYO ELECTRIC CO LTD

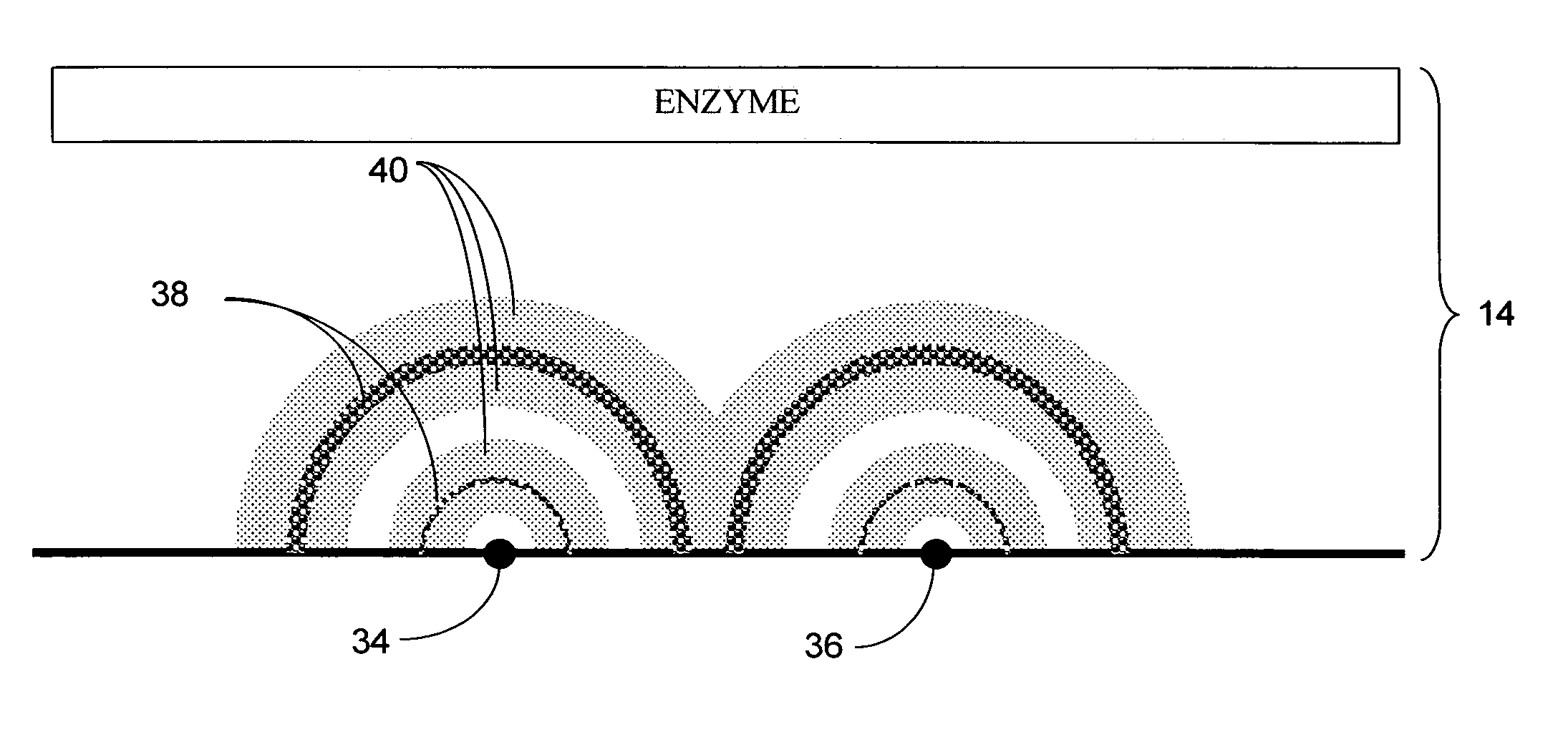

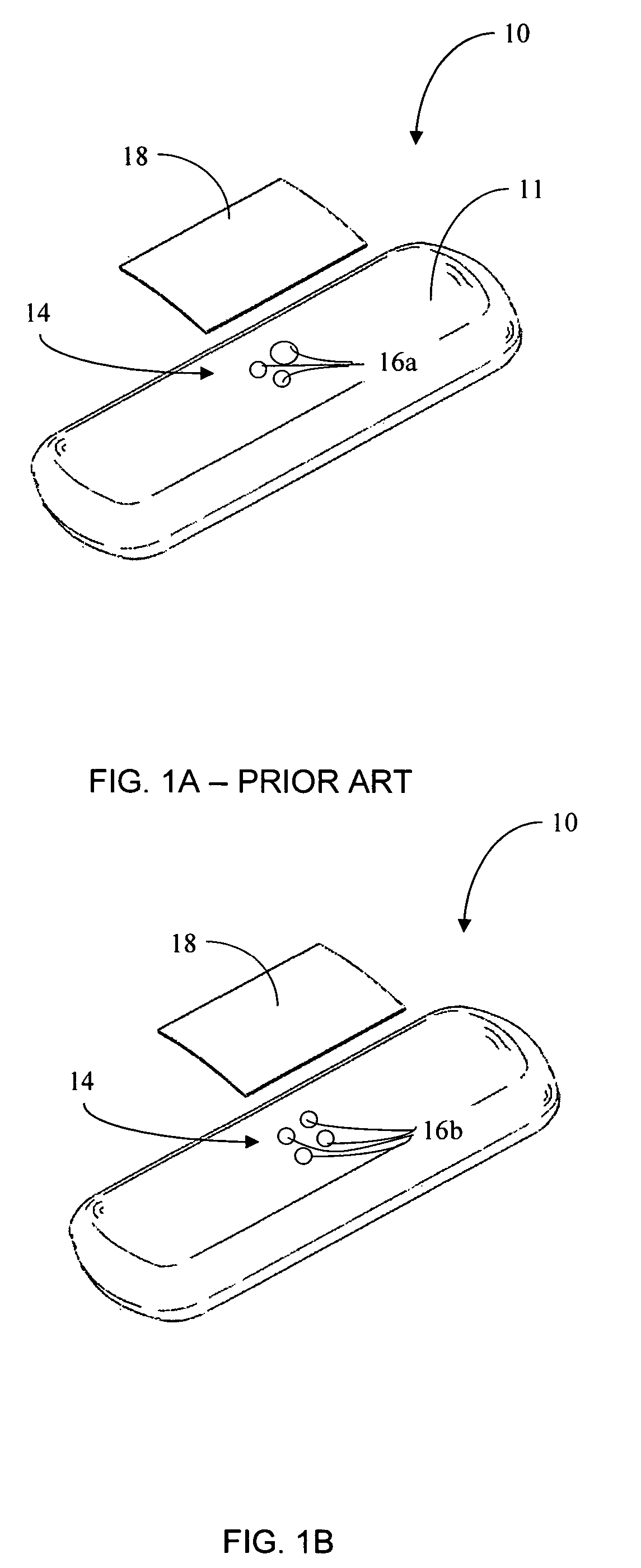

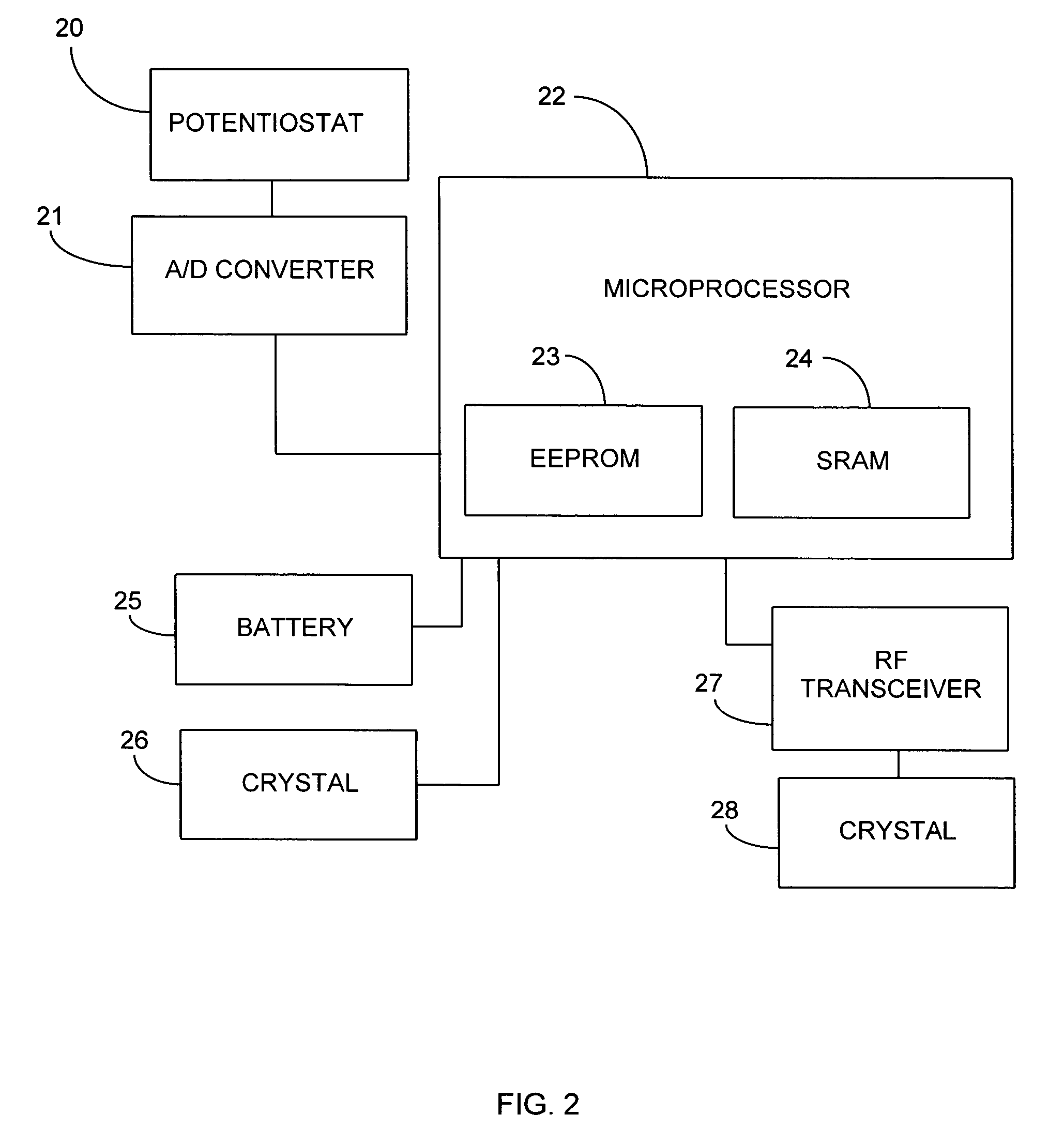

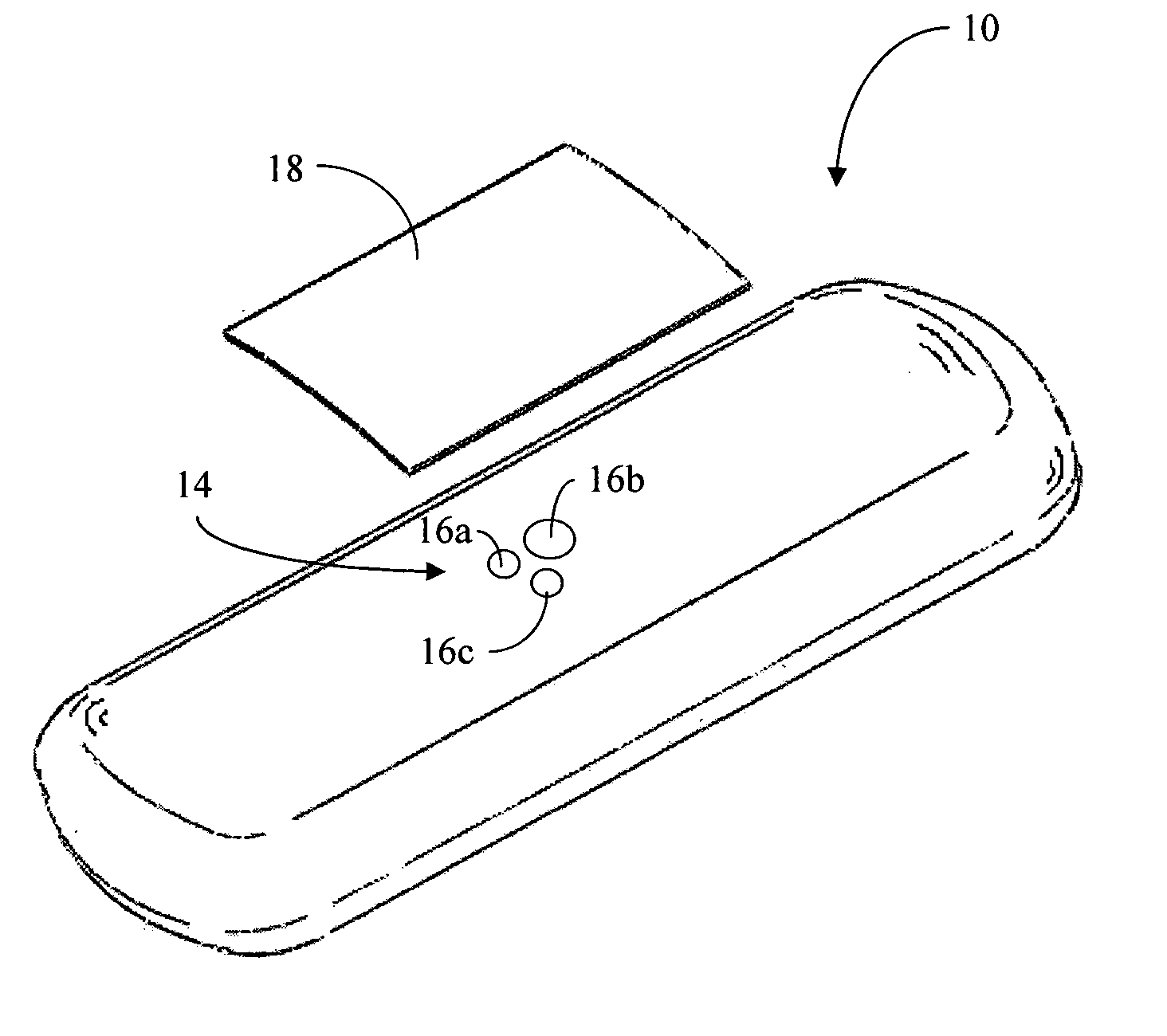

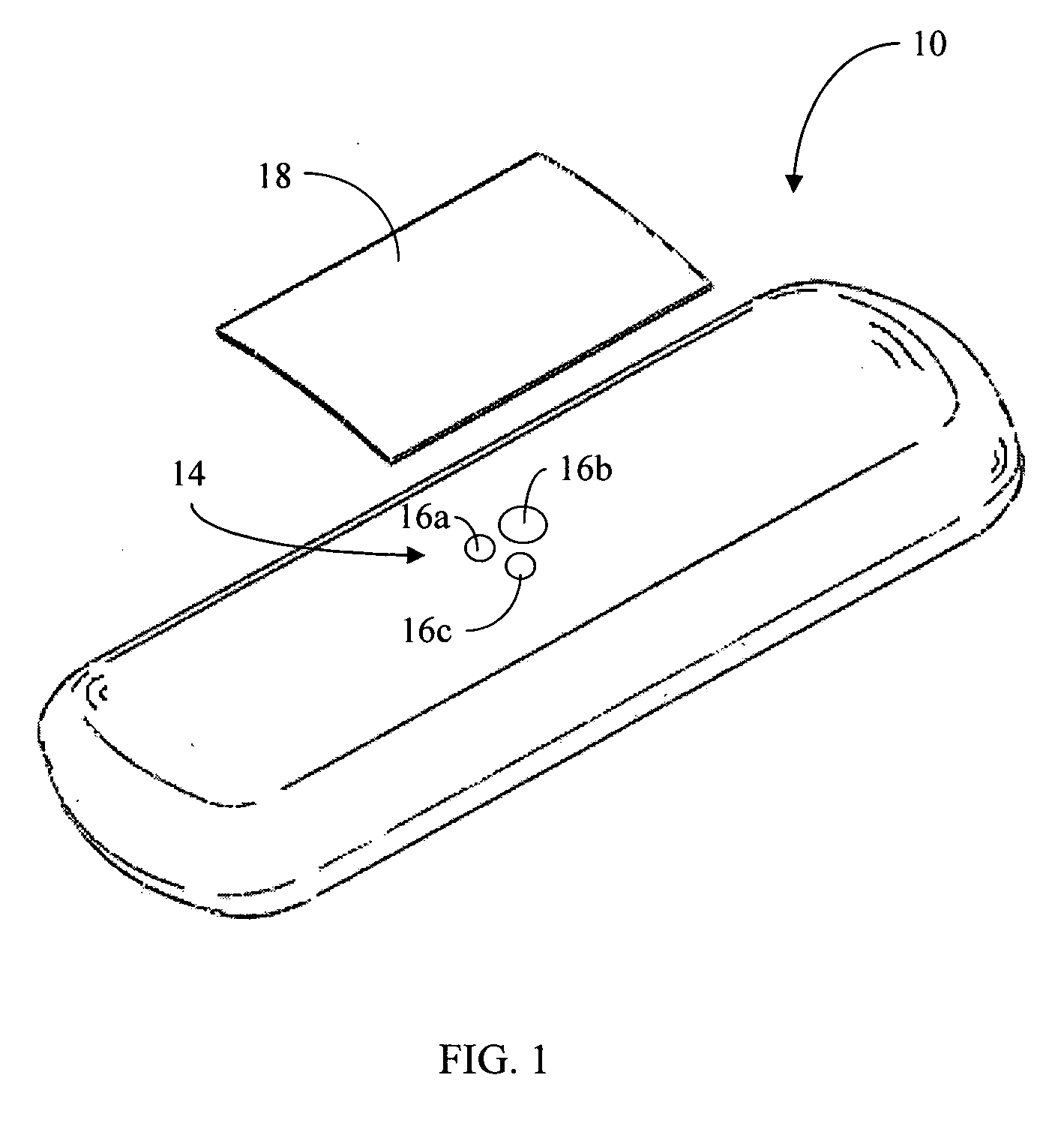

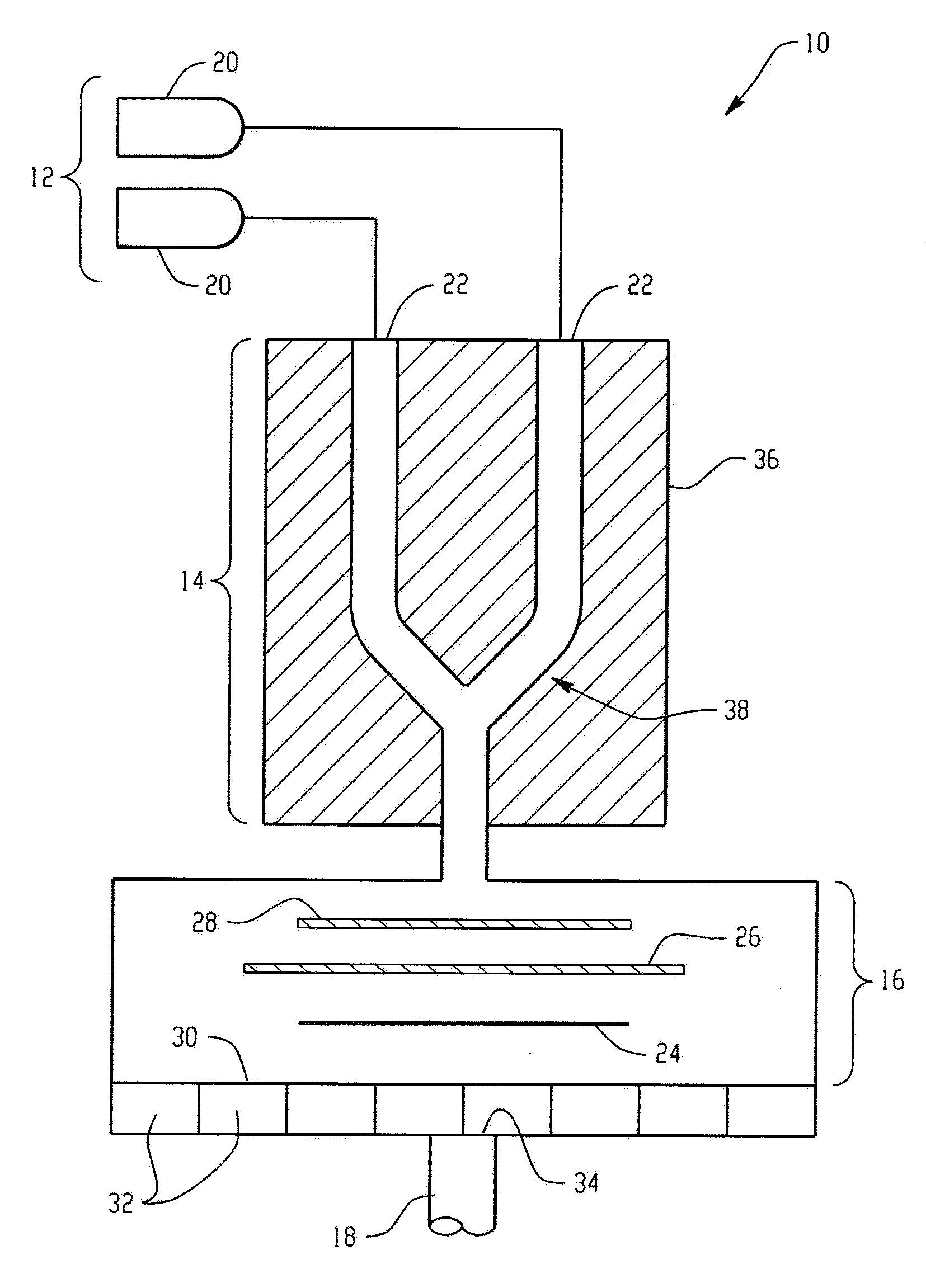

Electrochemical sensors including electrode systems with increased oxygen generation

ActiveUS7108778B2Immobilised enzymesBioreactor/fermenter combinationsAnalyteElectrochemical gas sensor

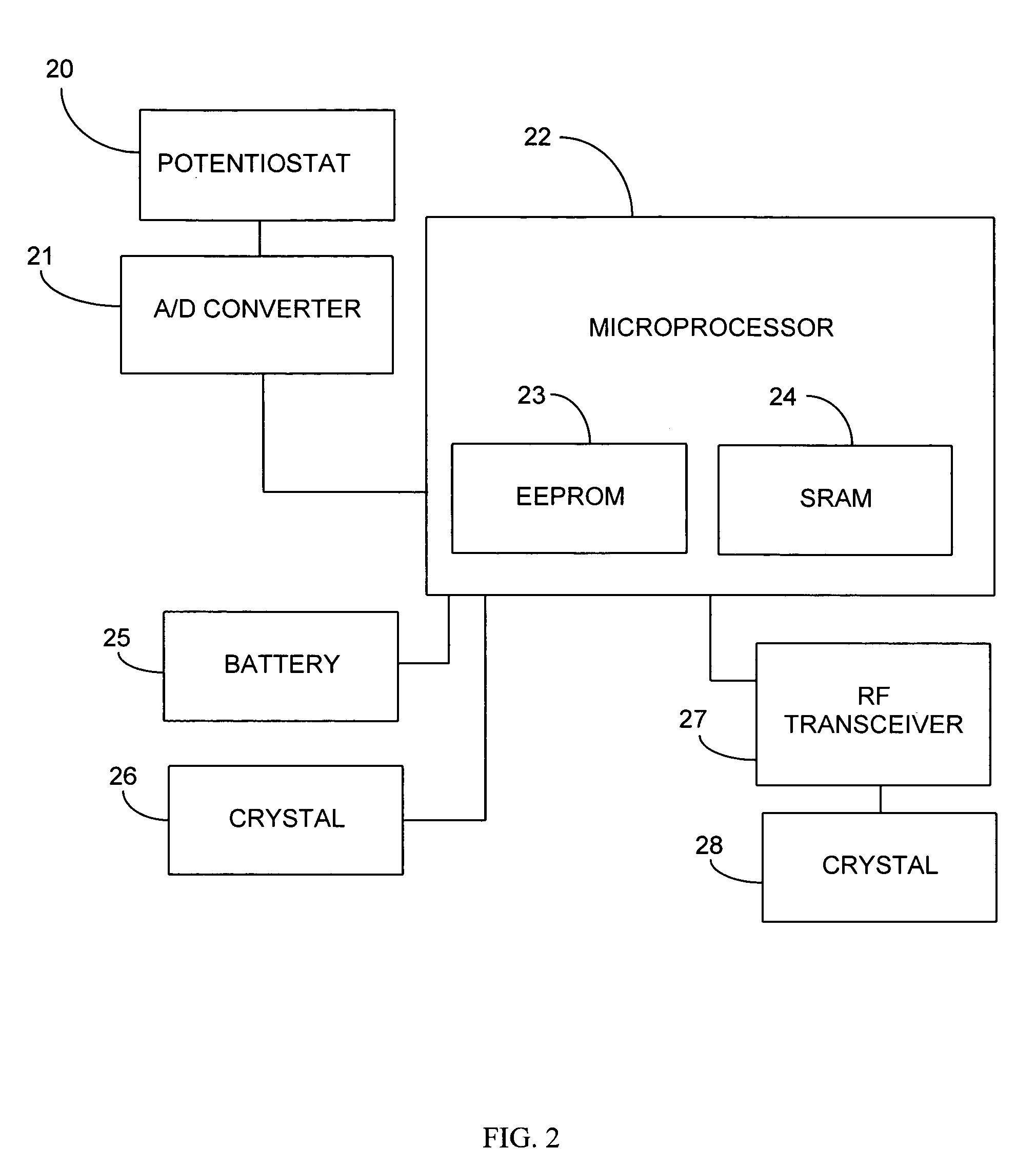

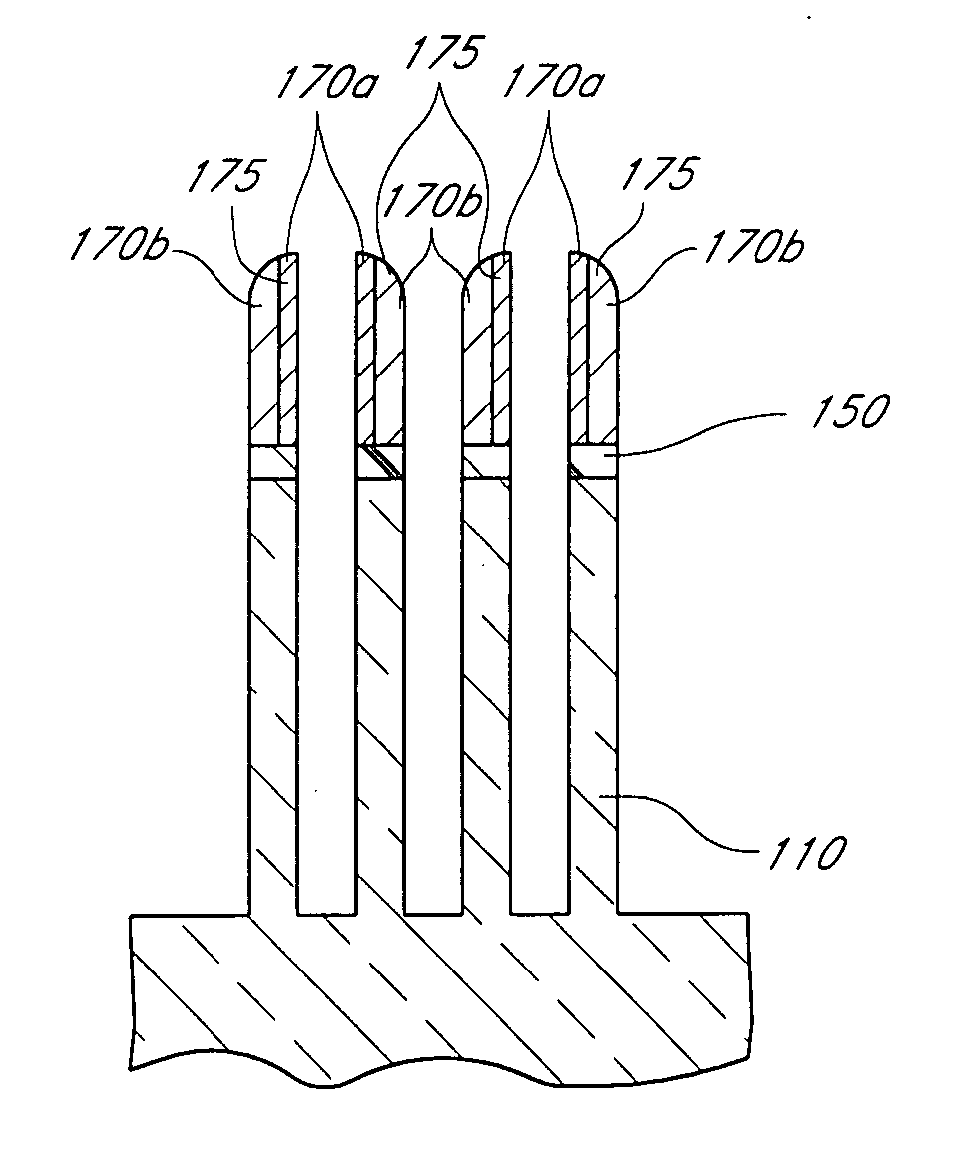

The present invention relates generally to systems and methods for increasing oxygen generation in electrochemical sensors in order to overcome the oxygen limitations. The preferred embodiments employ electrode systems with at least two electrodes in relatively close proximity to each other; wherein at least one electrode is configured to generate oxygen and at least one other electrode is configured to sense an analyte or a product of a reaction indicative of the concentration of analyte. The oxygen generated by the oxygen-generating electrode is available to the catalyst within a membrane system and / or the counter electrode, thereby enabling the electrochemical sensors of the preferred embodiments to function even during ischemic conditions.

Owner:DEXCOM INC

Electrode systems for electrochemical sensors

ActiveUS20050115832A1Immobilised enzymesBioreactor/fermenter combinationsAnalyteOxygen utilization rate

The present invention relates generally to systems and methods for improved electrochemical measurement of analytes. The preferred embodiments employ electrode systems including an analyte-measuring electrode for measuring the analyte or the product of an enzyme reaction with the analyte and an auxiliary electrode configured to generate oxygen and / or reduce electrochemical interferants. Oxygen generation by the auxiliary electrode advantageously improves oxygen availability to the enzyme and / or counter electrode; thereby enabling the electrochemical sensors of the preferred embodiments to function even during ischemic conditions. Interferant modification by the auxiliary electrode advantageously renders them substantially non-reactive at the analyte-measuring electrode, thereby reducing or eliminating inaccuracies in the analyte signal due to electrochemical interferants.

Owner:DEXCOM

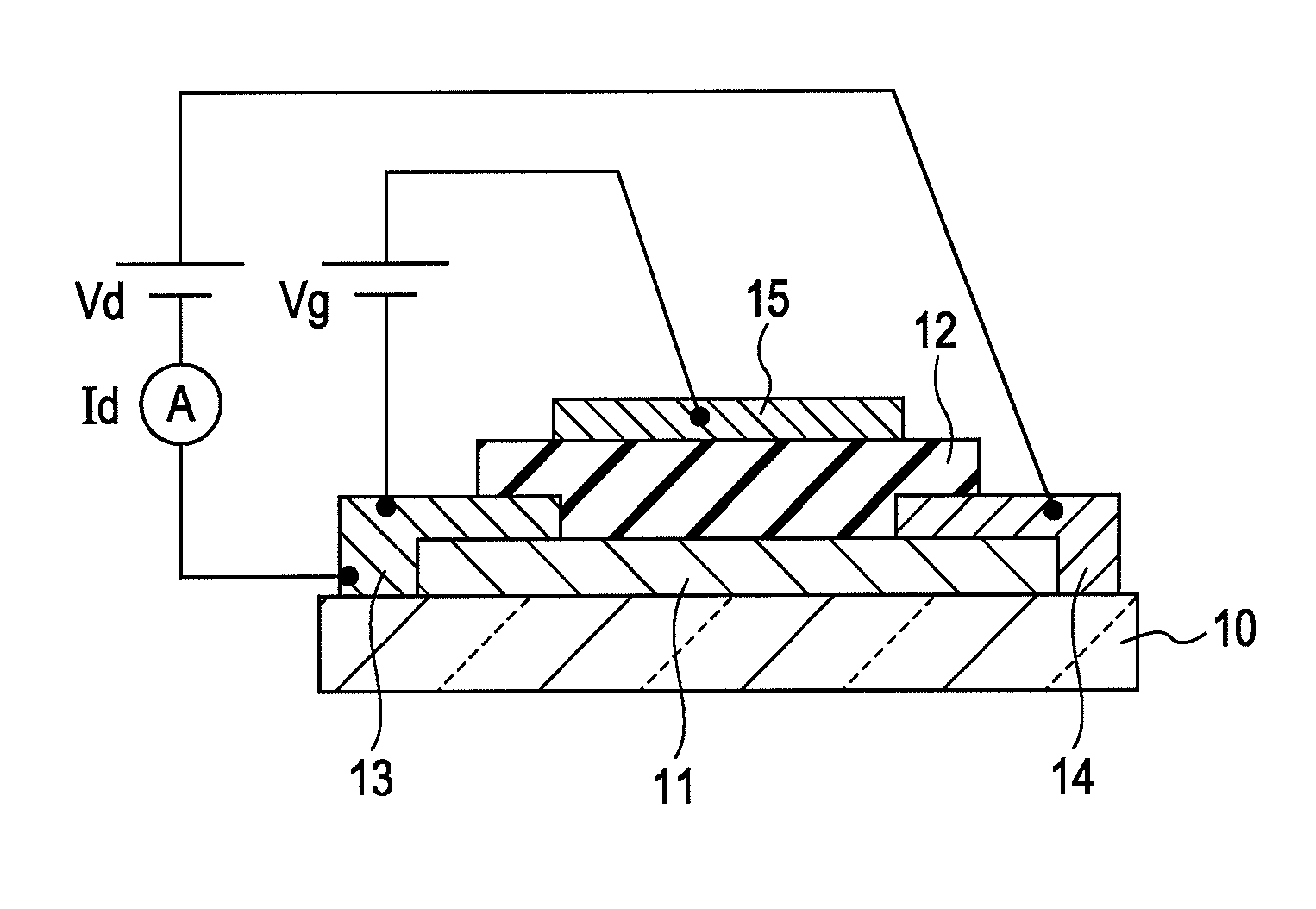

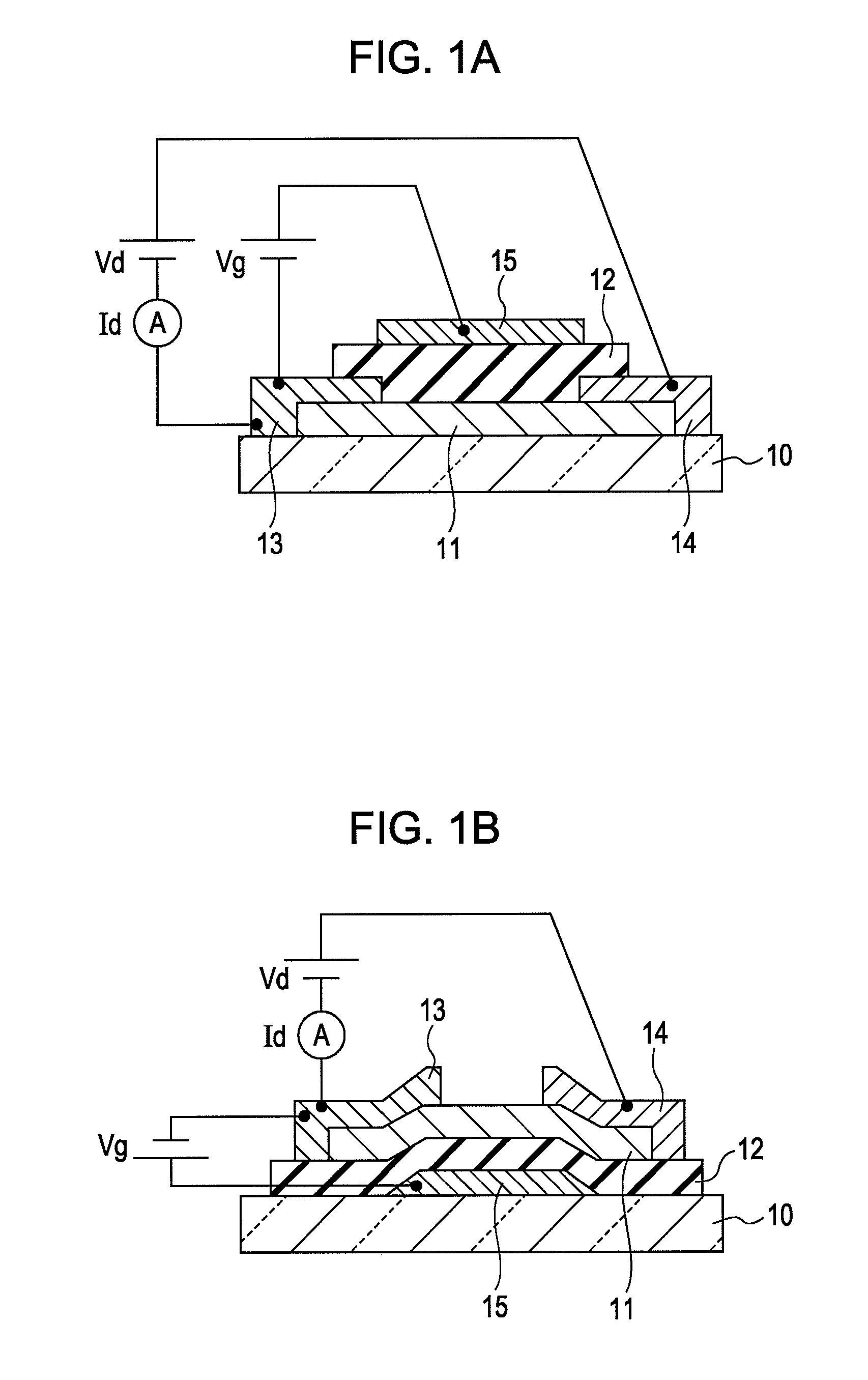

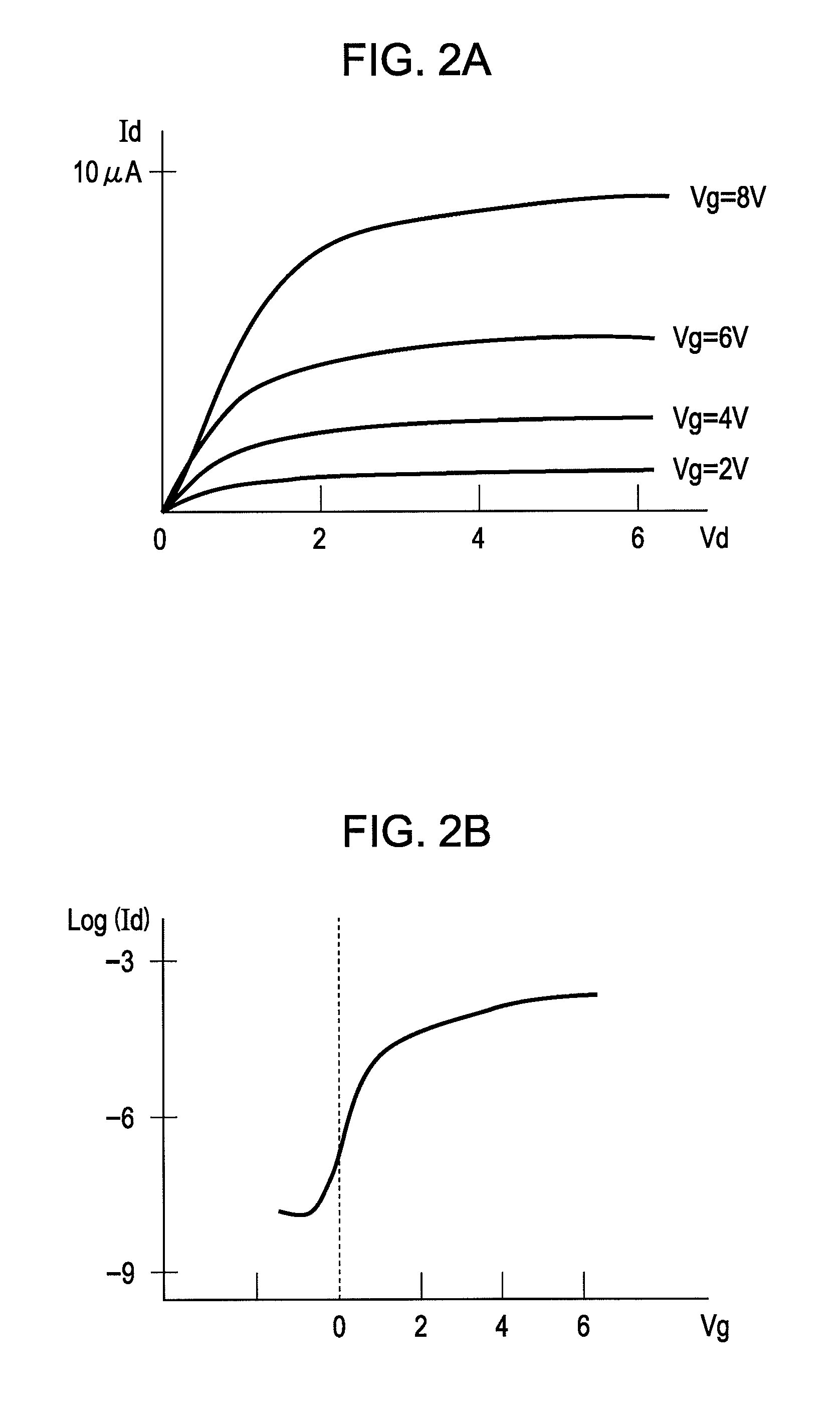

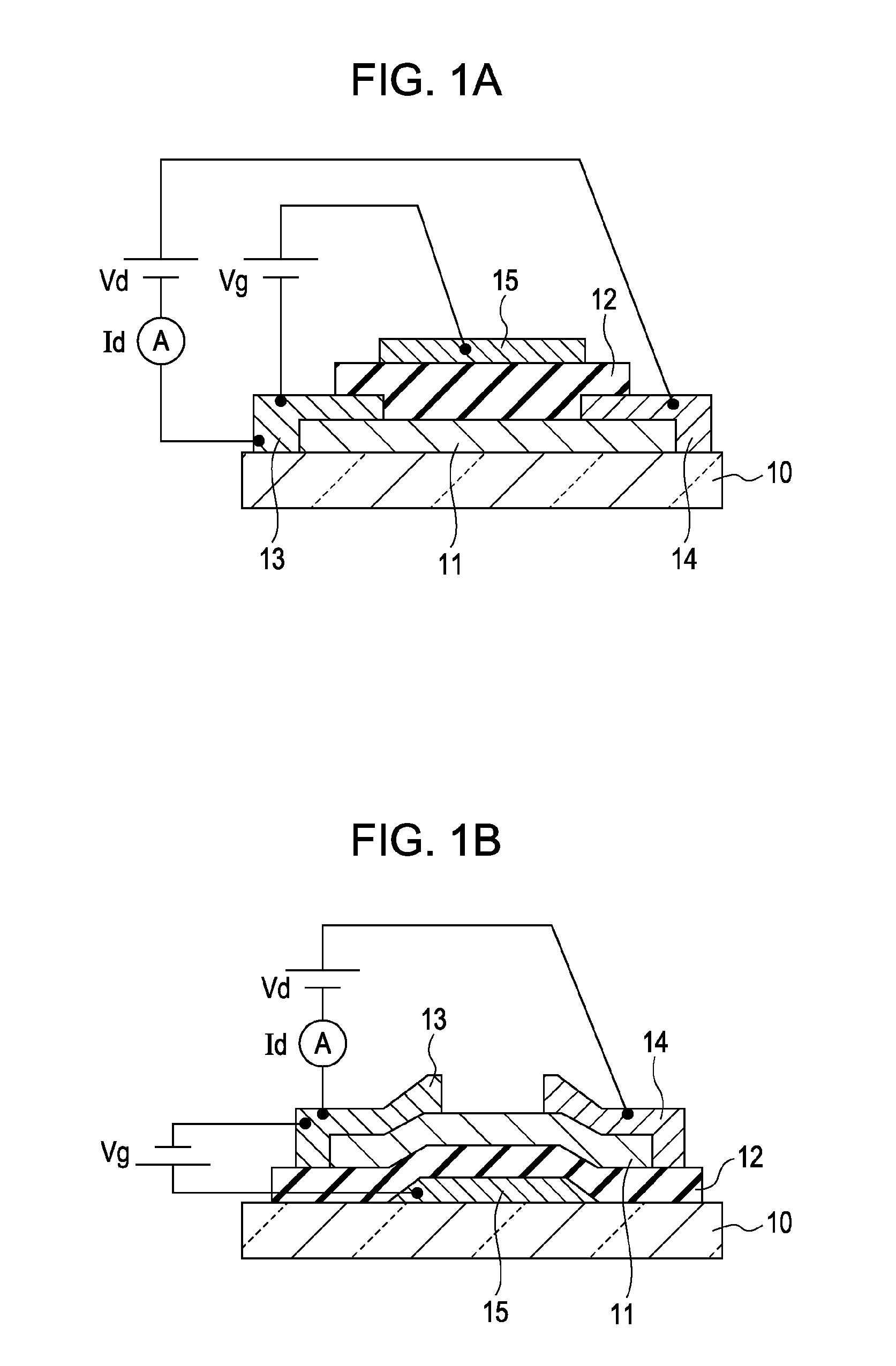

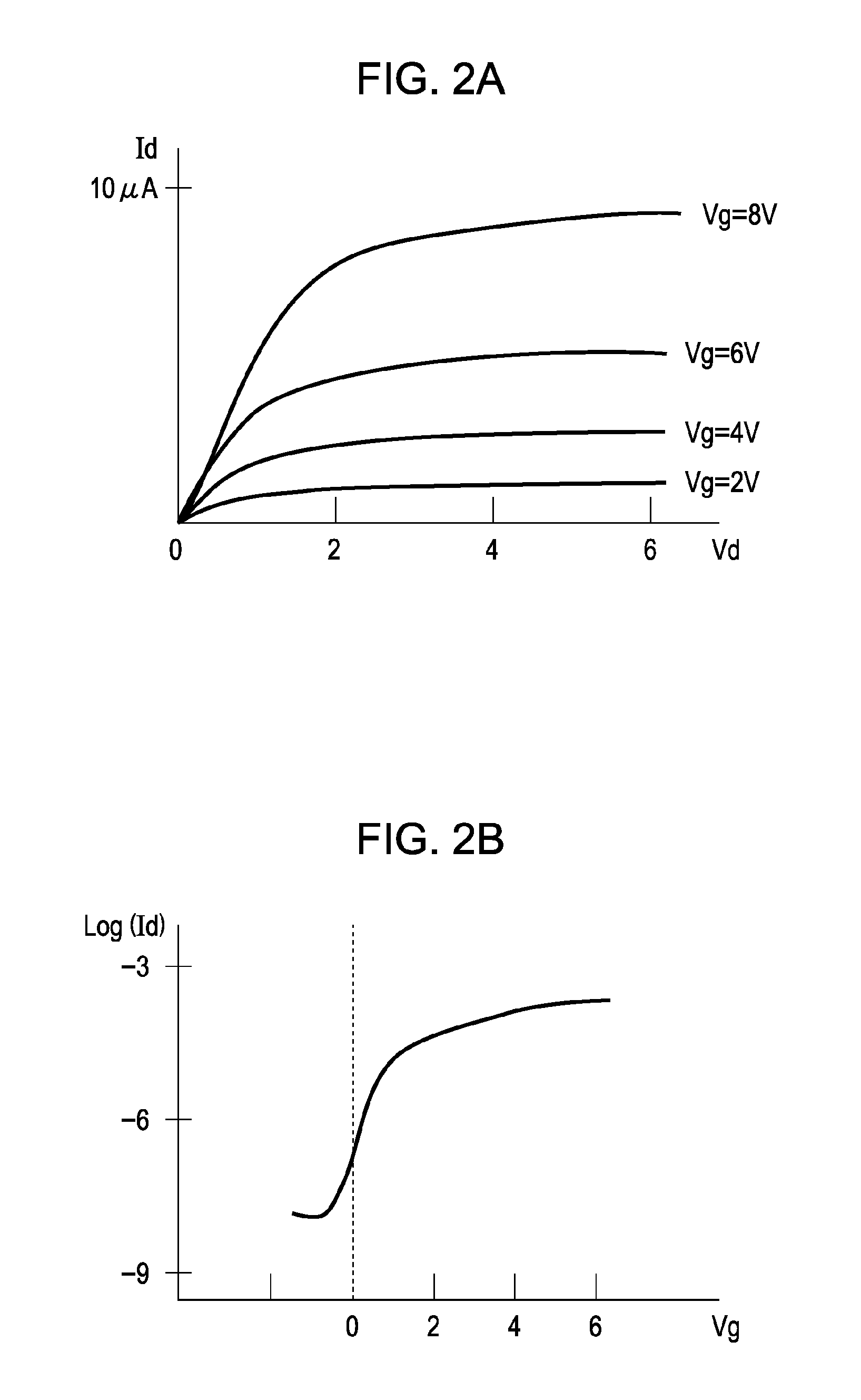

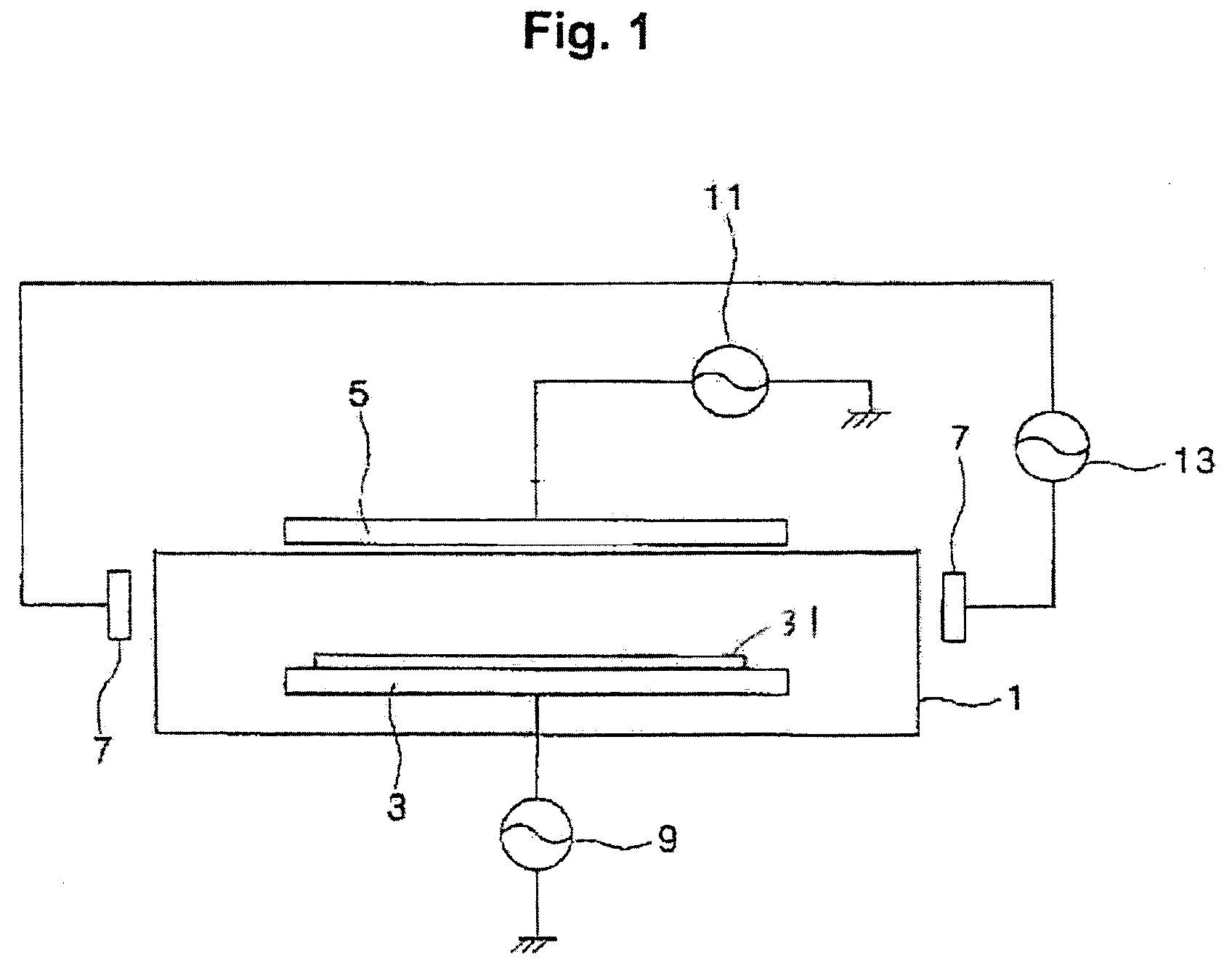

Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous oxide film

InactiveUS7791074B2Easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisHydrogen

An amorphous oxide containing hydrogen (or deuterium) is applied to a channel layer of a transistor. Accordingly, a thin film transistor having superior TFT properties can be realized, the superior TFT properties including a small hysteresis, normally OFF operation, a high ON / OFF ratio, a high saturated current, and the like. Furthermore, as a method for manufacturing a channel layer made of an amorphous oxide, film formation is performed in an atmosphere containing a hydrogen gas and an oxygen gas, so that the carrier concentration of the amorphous oxide can be controlled.

Owner:CANON KK

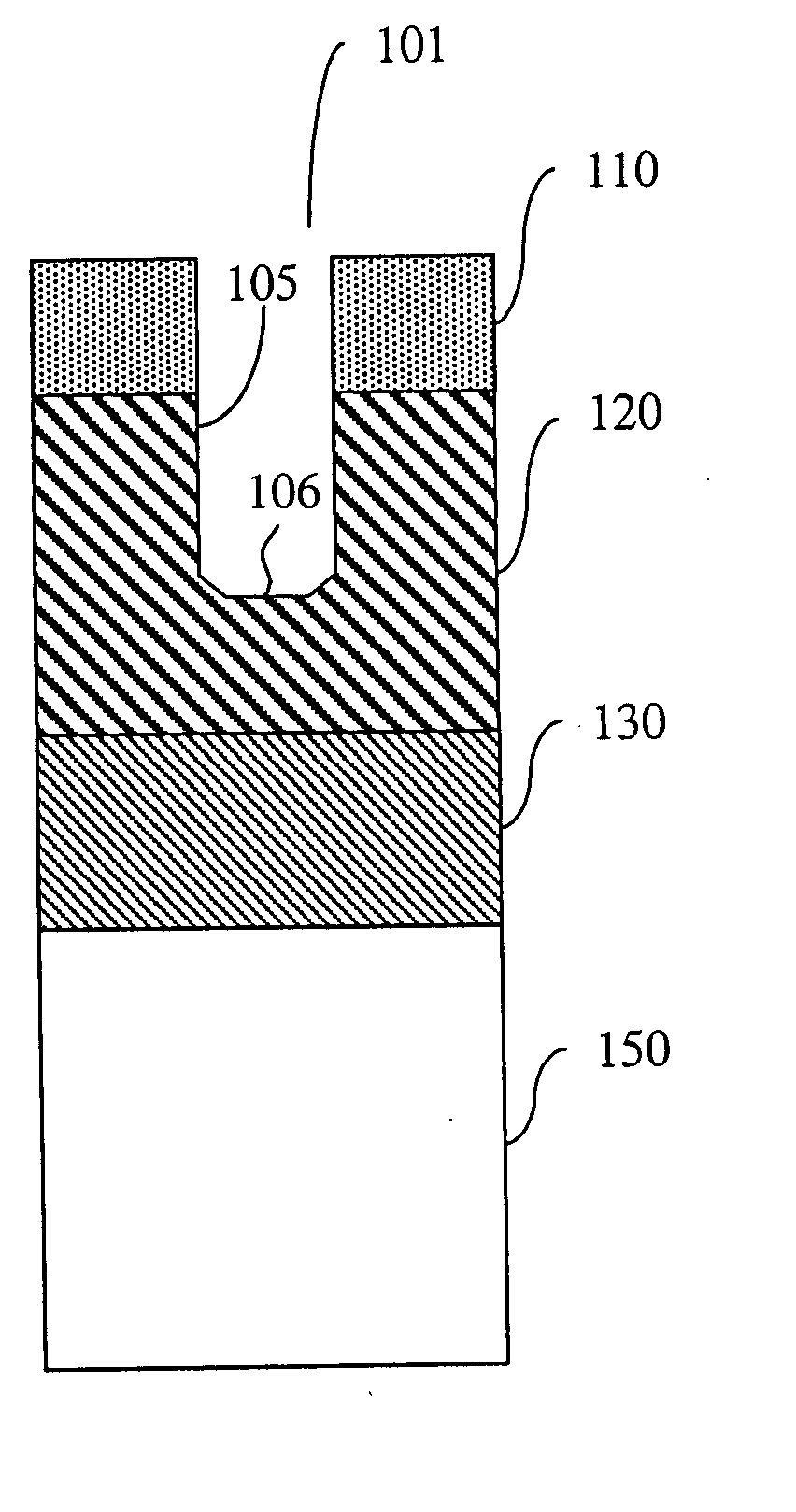

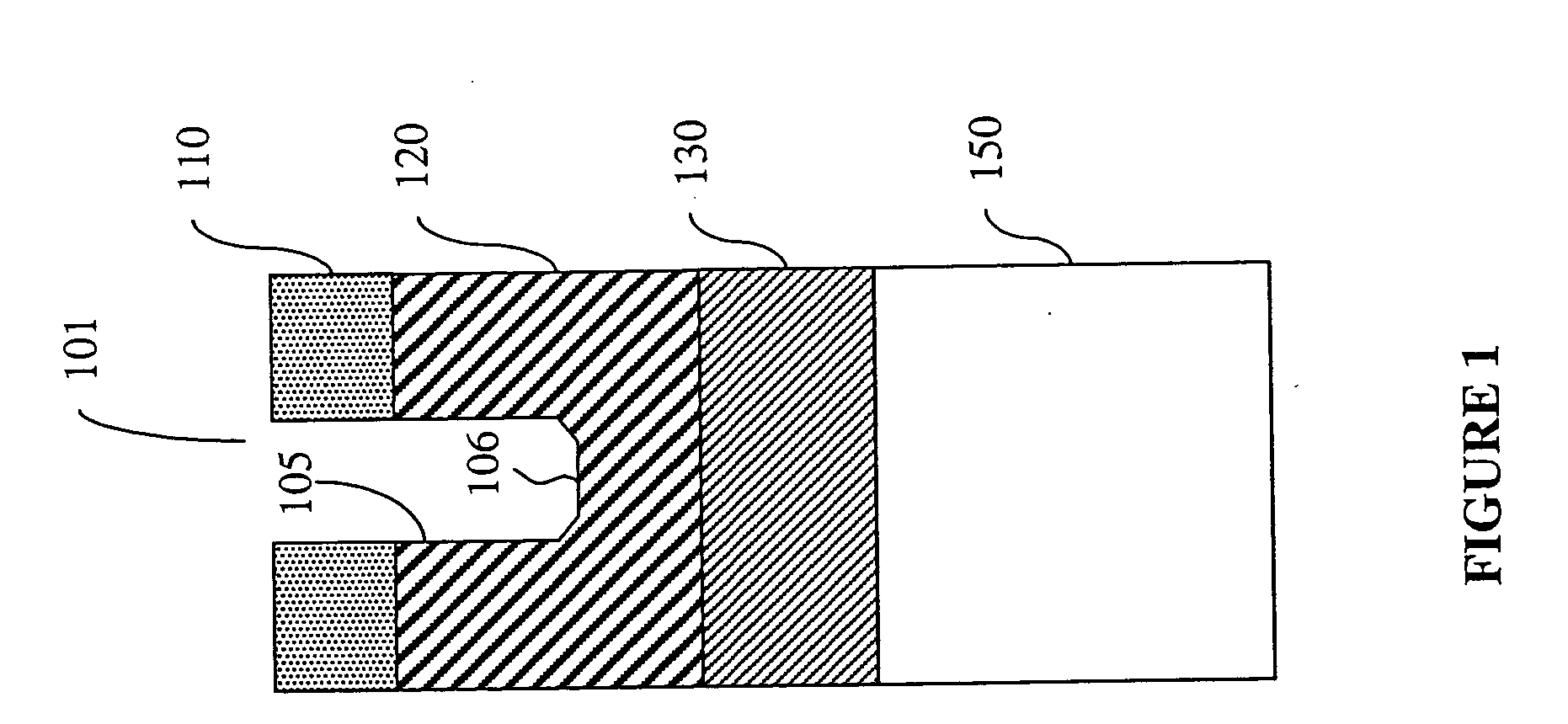

Integrated low K dielectrics and etch stops

InactiveUS6340435B1Decorative surface effectsSemiconductor/solid-state device detailsHydrogenFluorocarbon

A method of depositing and etching dielectric layers having low dielectric constants and etch rates that vary by at least 3:1 for formation of horizontal interconnects. The amount of carbon or hydrogen in the dielectric layer is varied by changes in deposition conditions to provide low k dielectric layers that can replace etch stop layers or conventional dielectric layers in damascene applications. A dual damascene structure having two or more dielectric layers with dielectric constants lower than about 4 can be deposited in a single reactor and then etched to form vertical and horizontal interconnects by varying the concentration of a carbon:oxygen gas such as carbon monoxide. The etch gases for forming vertical interconnects preferably comprises CO and a fluorocarbon, and CO is preferably excluded from etch gases for forming horizontal interconnects.

Owner:APPLIED MATERIALS INC

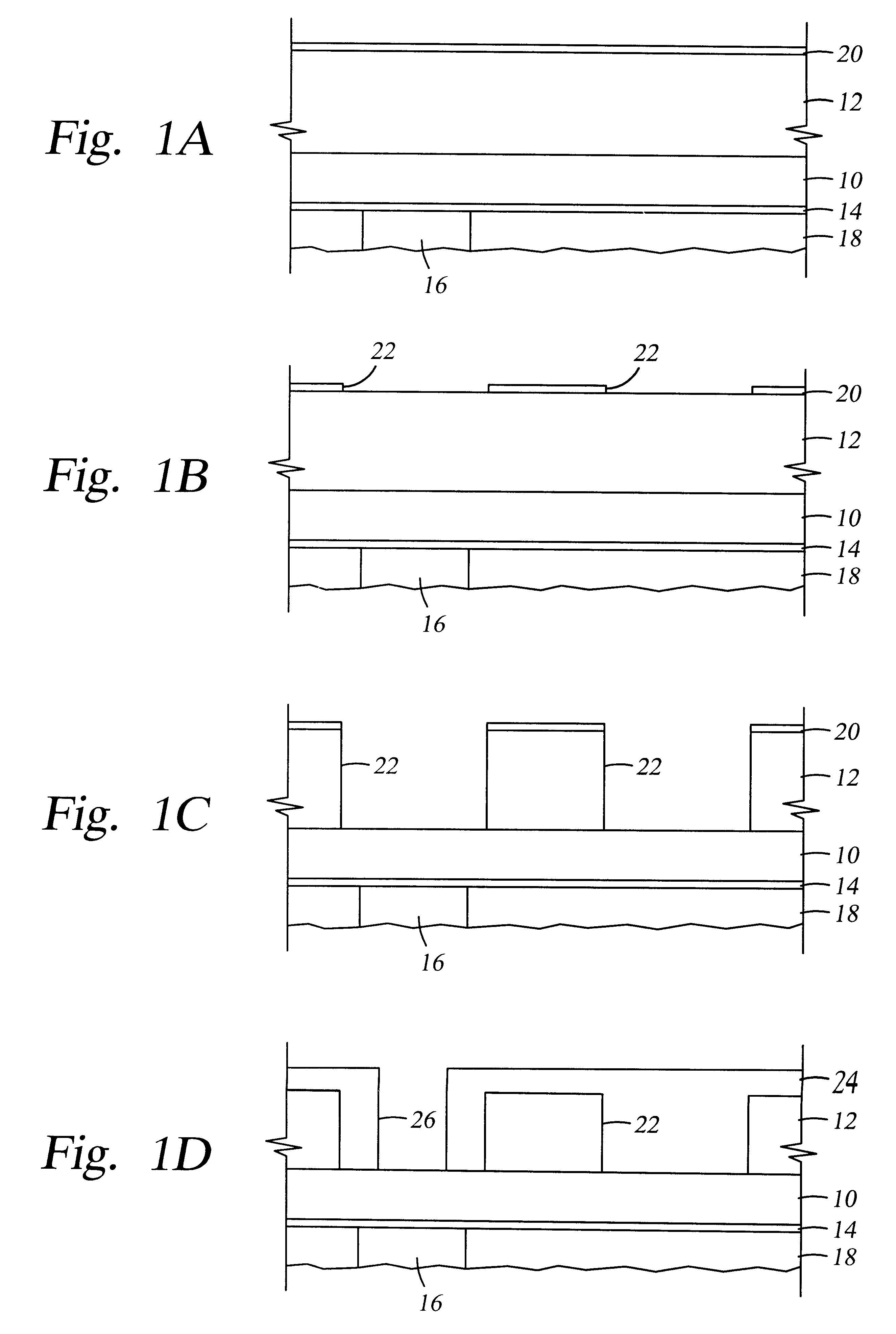

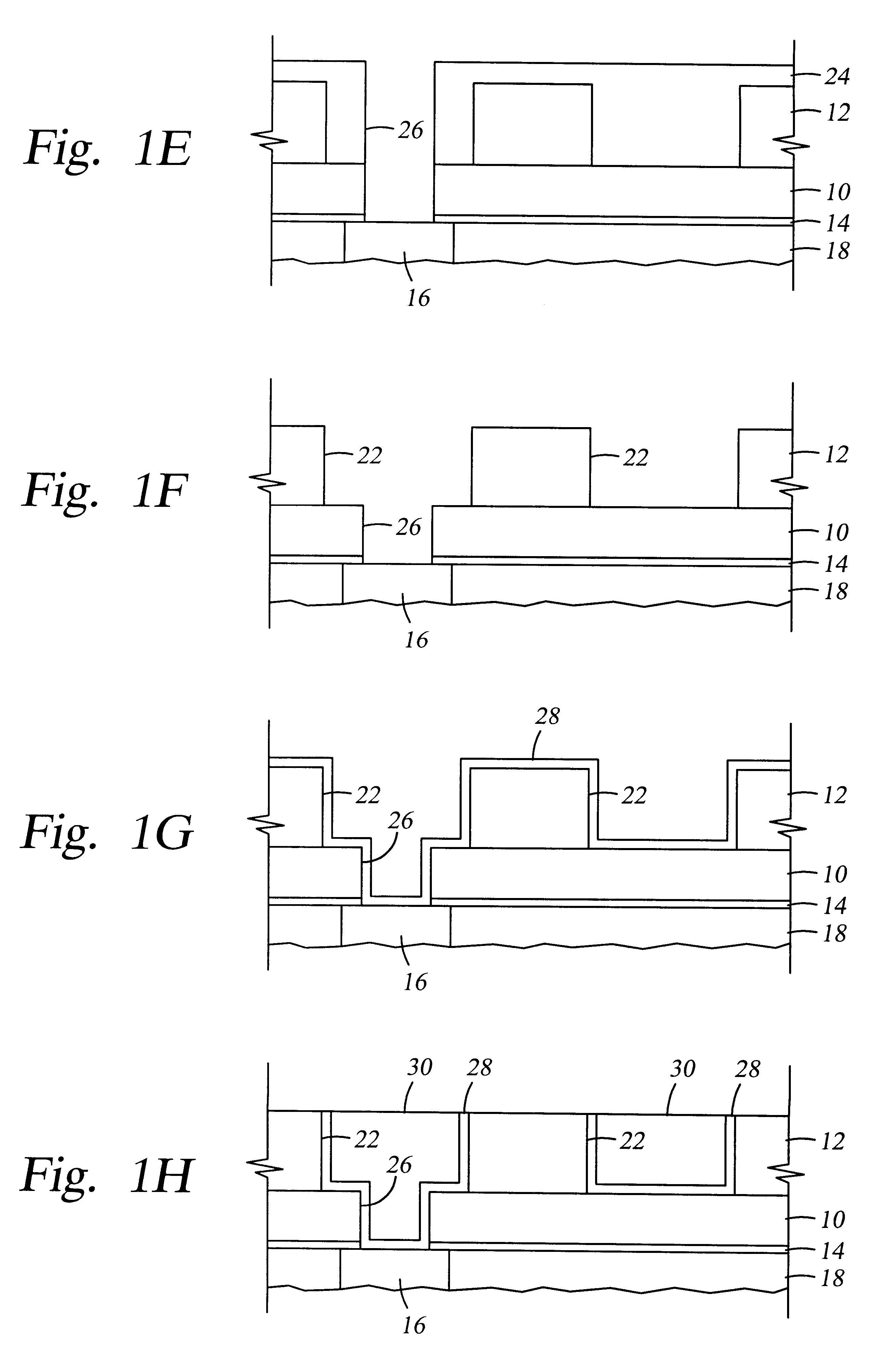

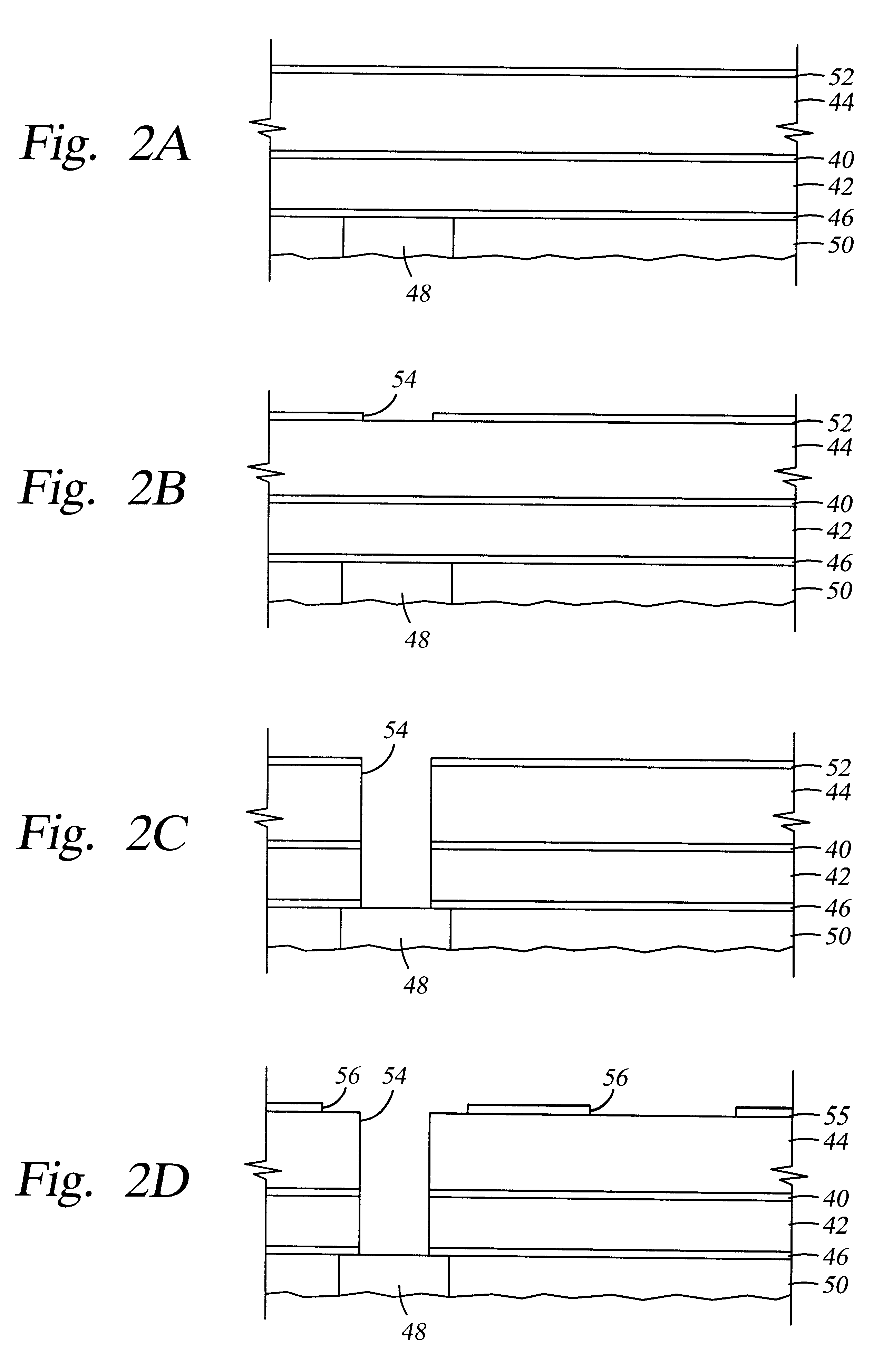

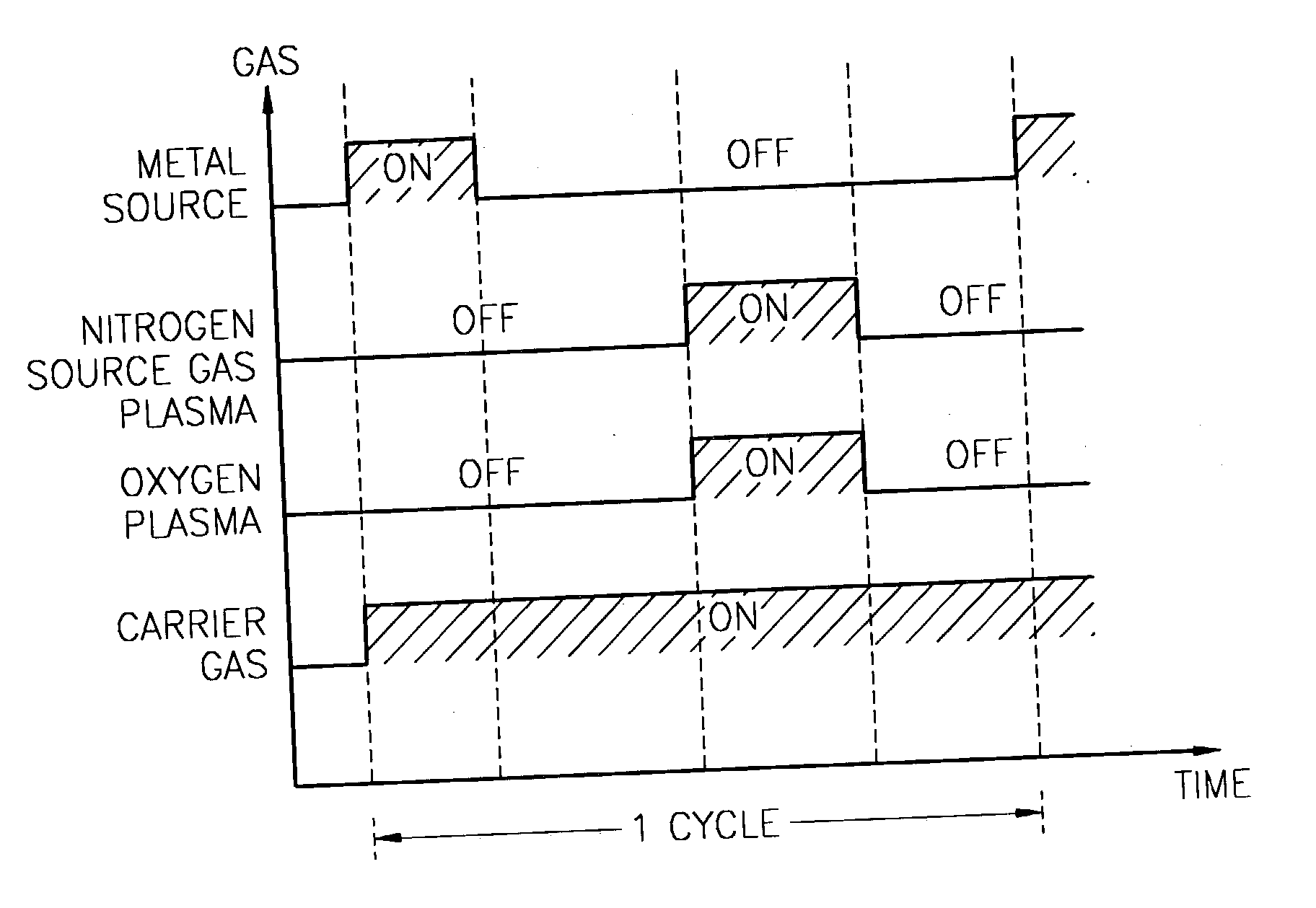

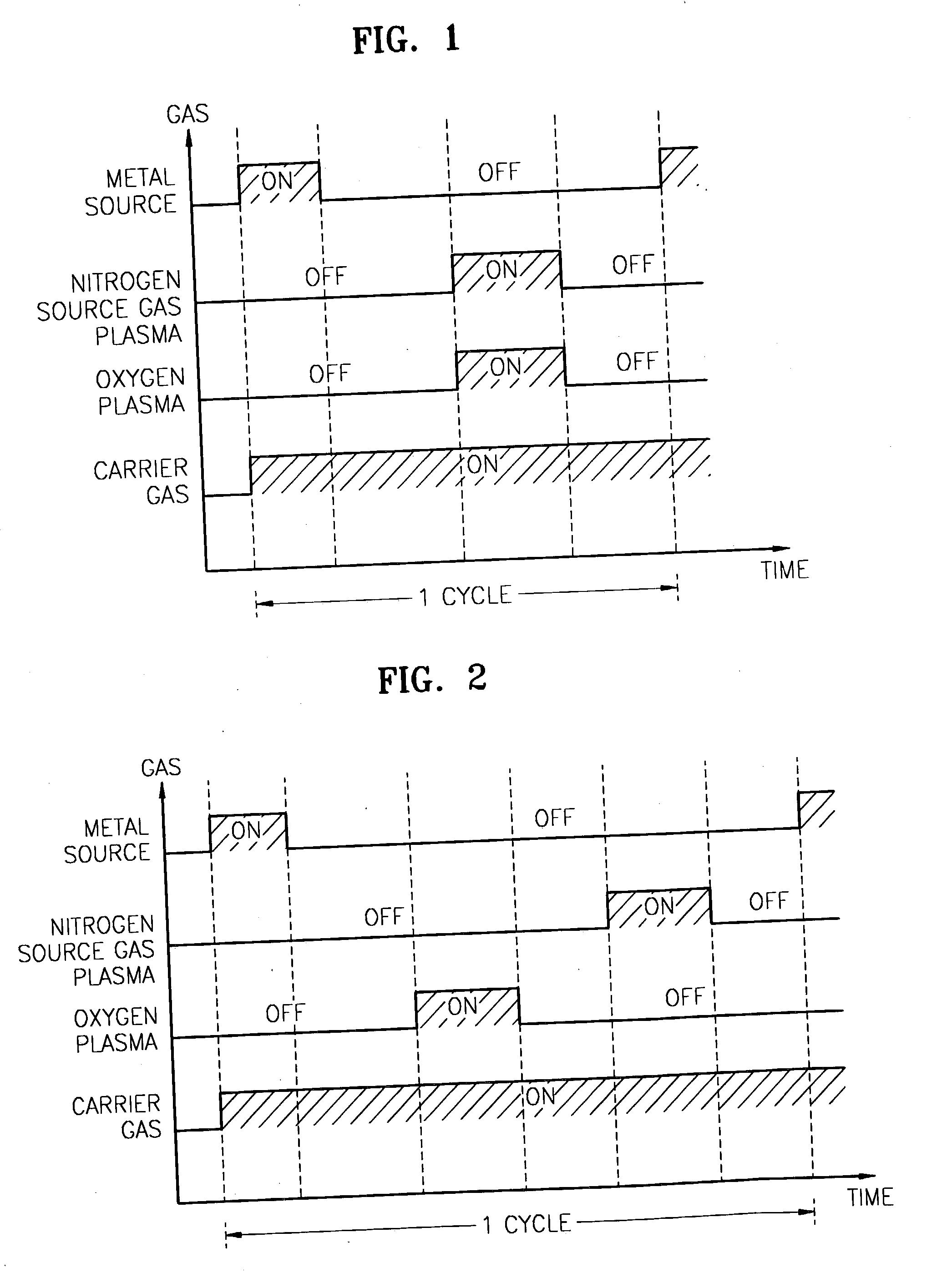

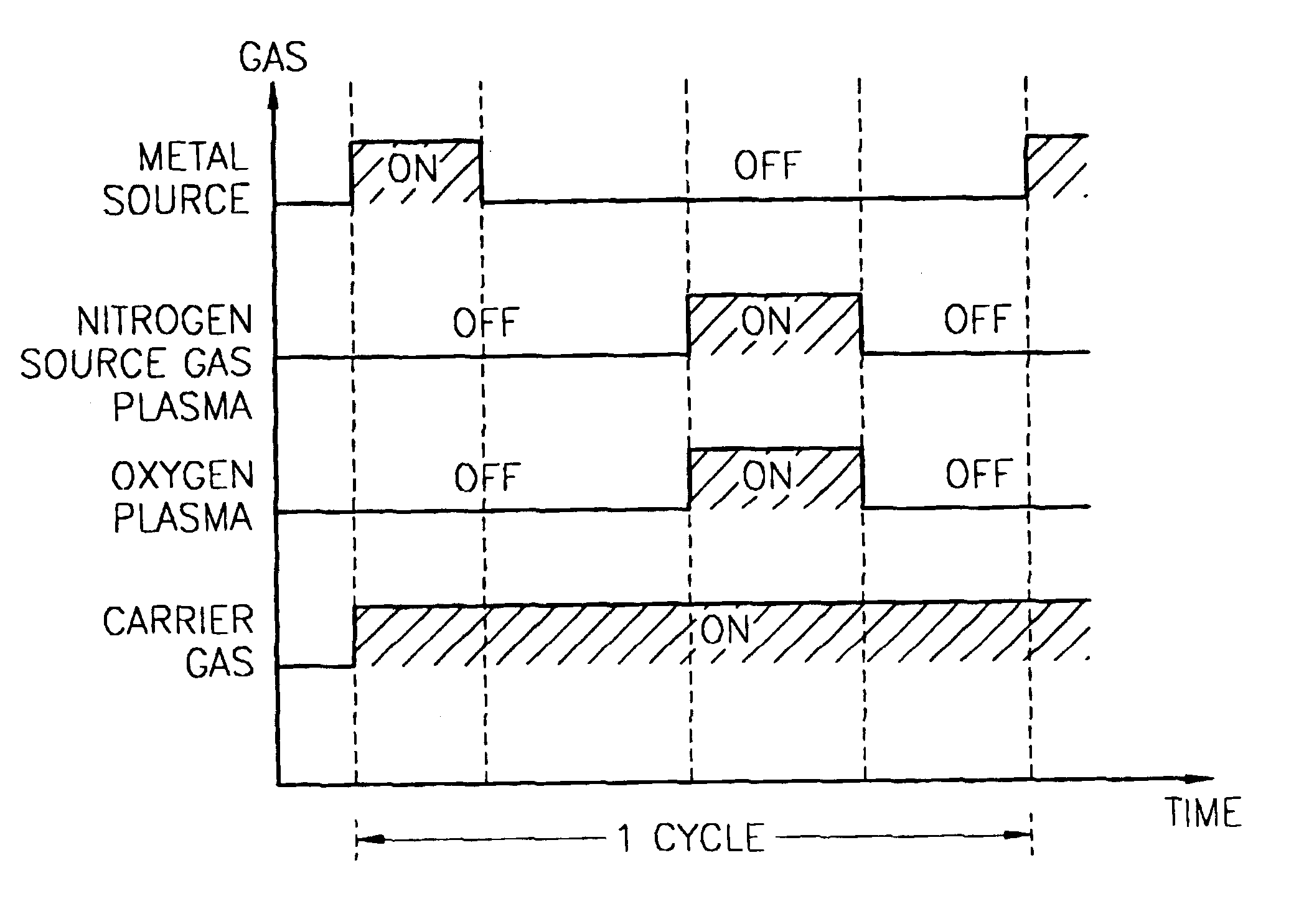

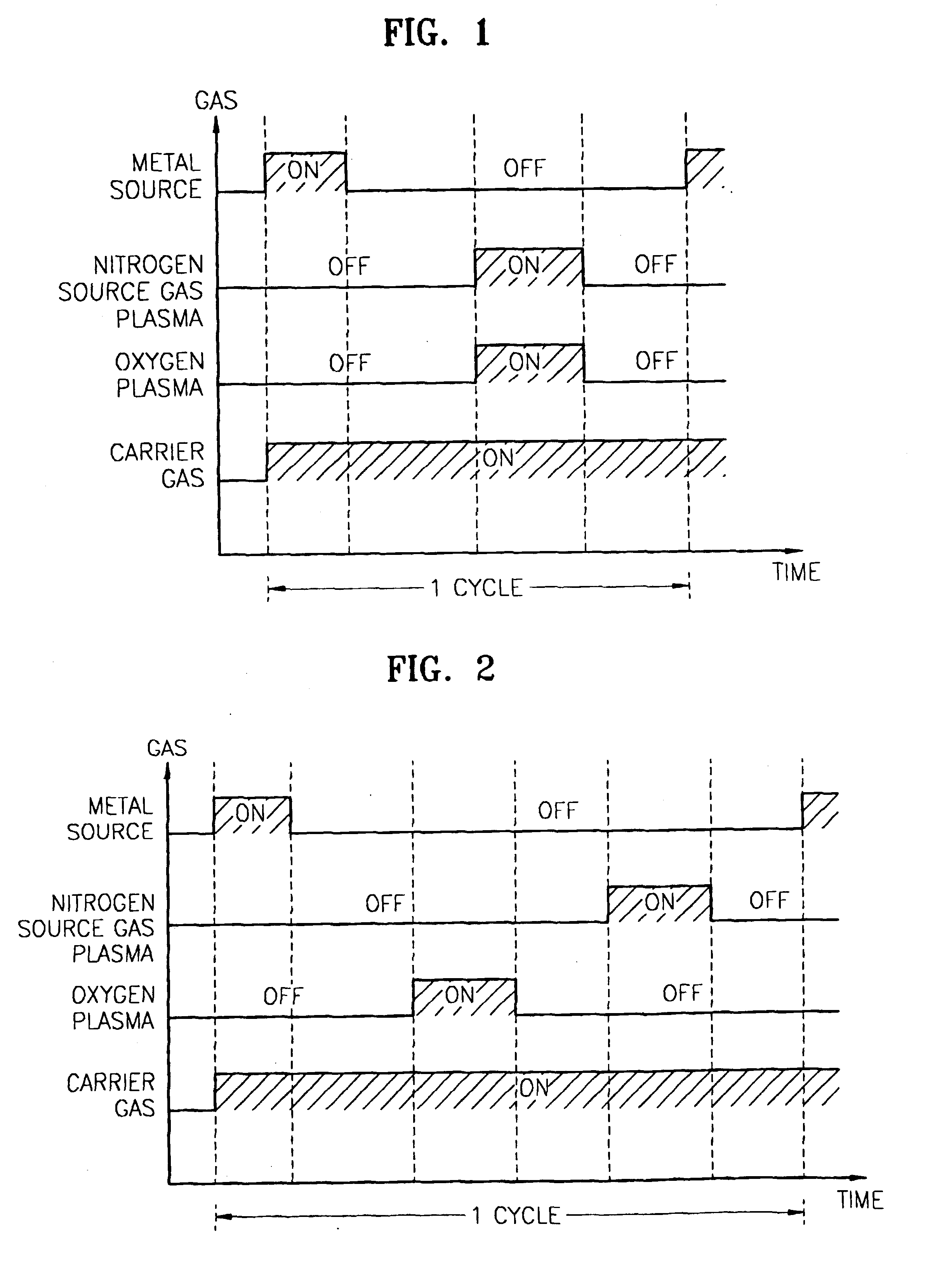

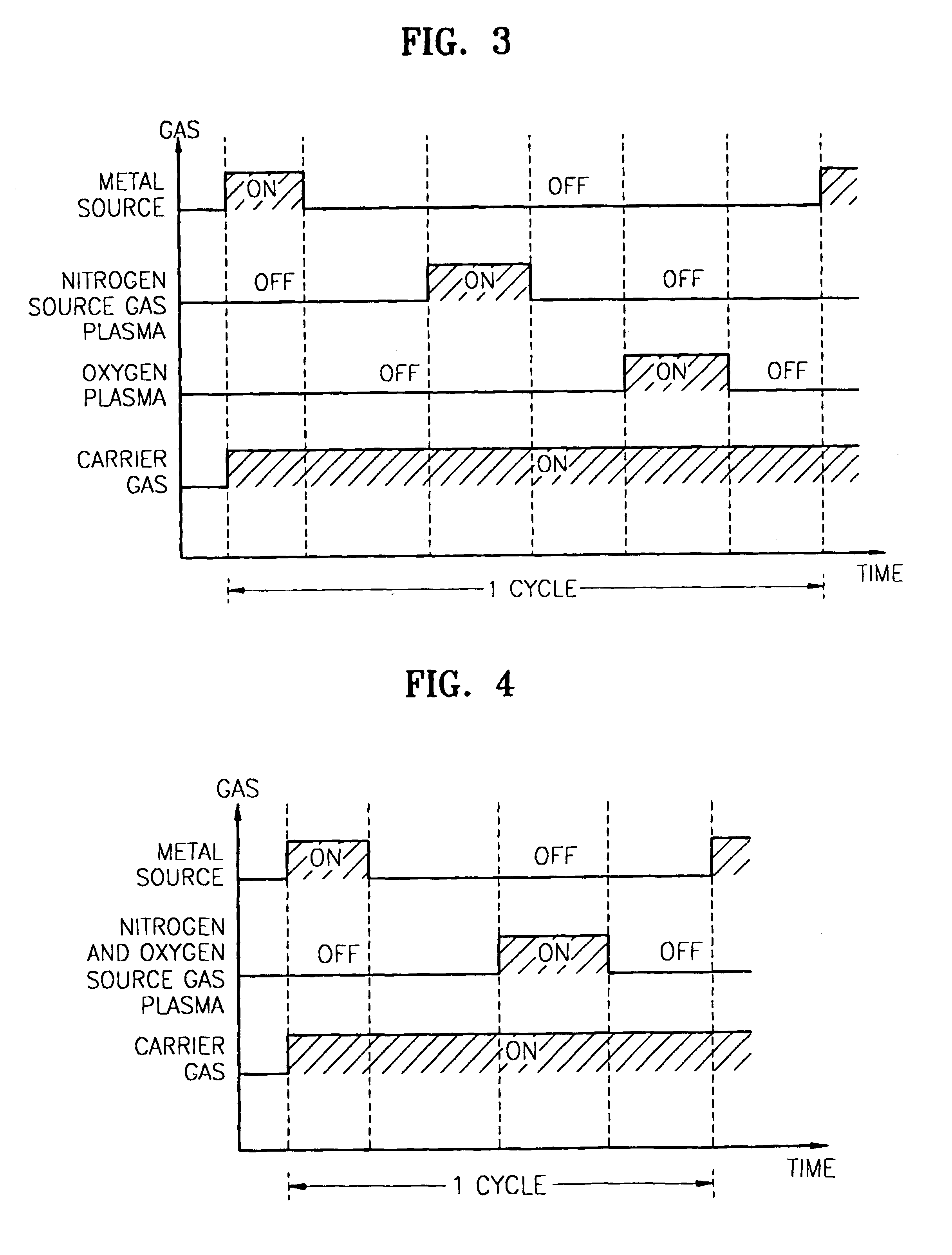

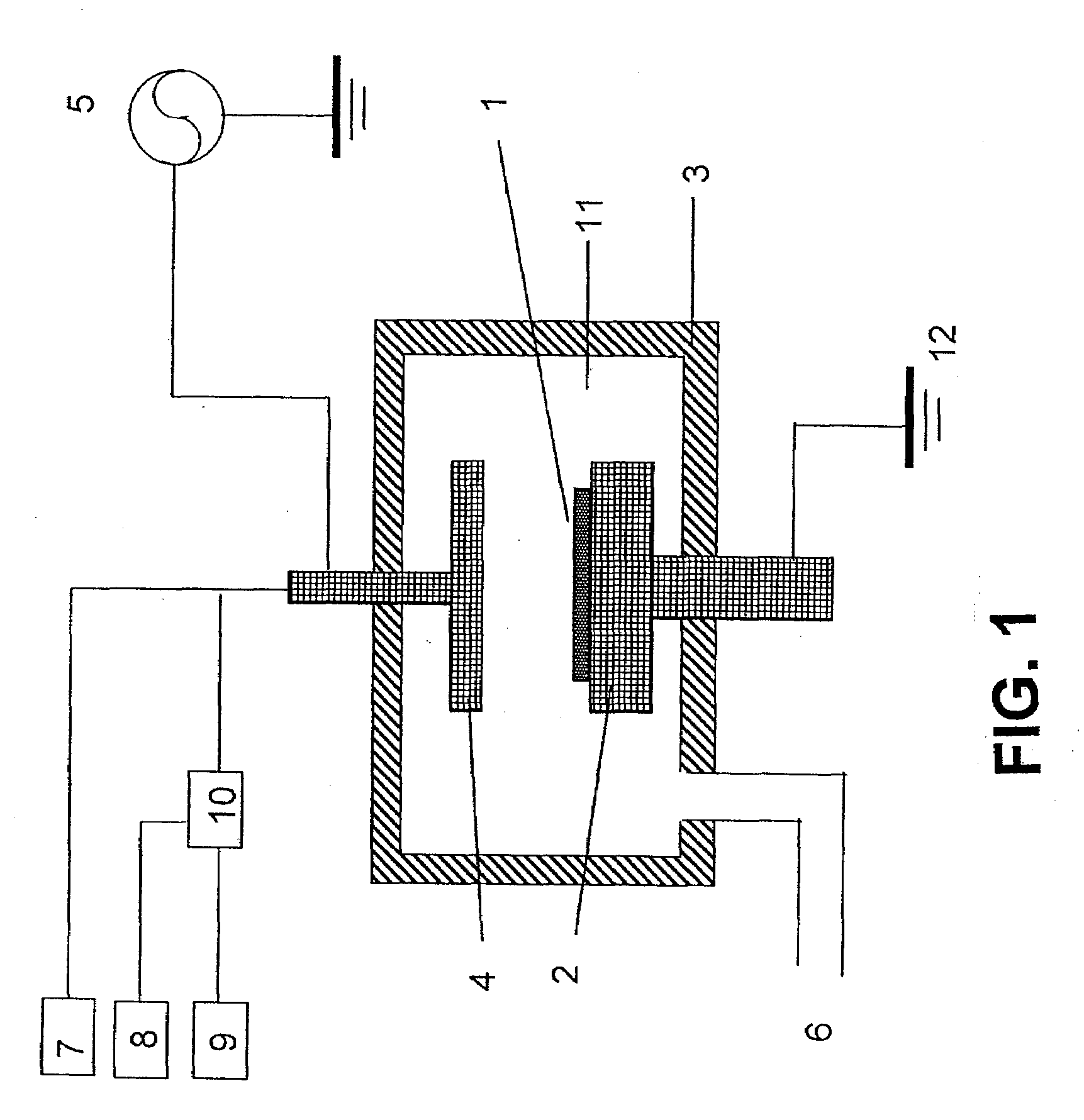

Method for forming introgen-containing oxide thin film using plasma enhanced atomic layer deposition

InactiveUS20040077182A1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateNitrogen source

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

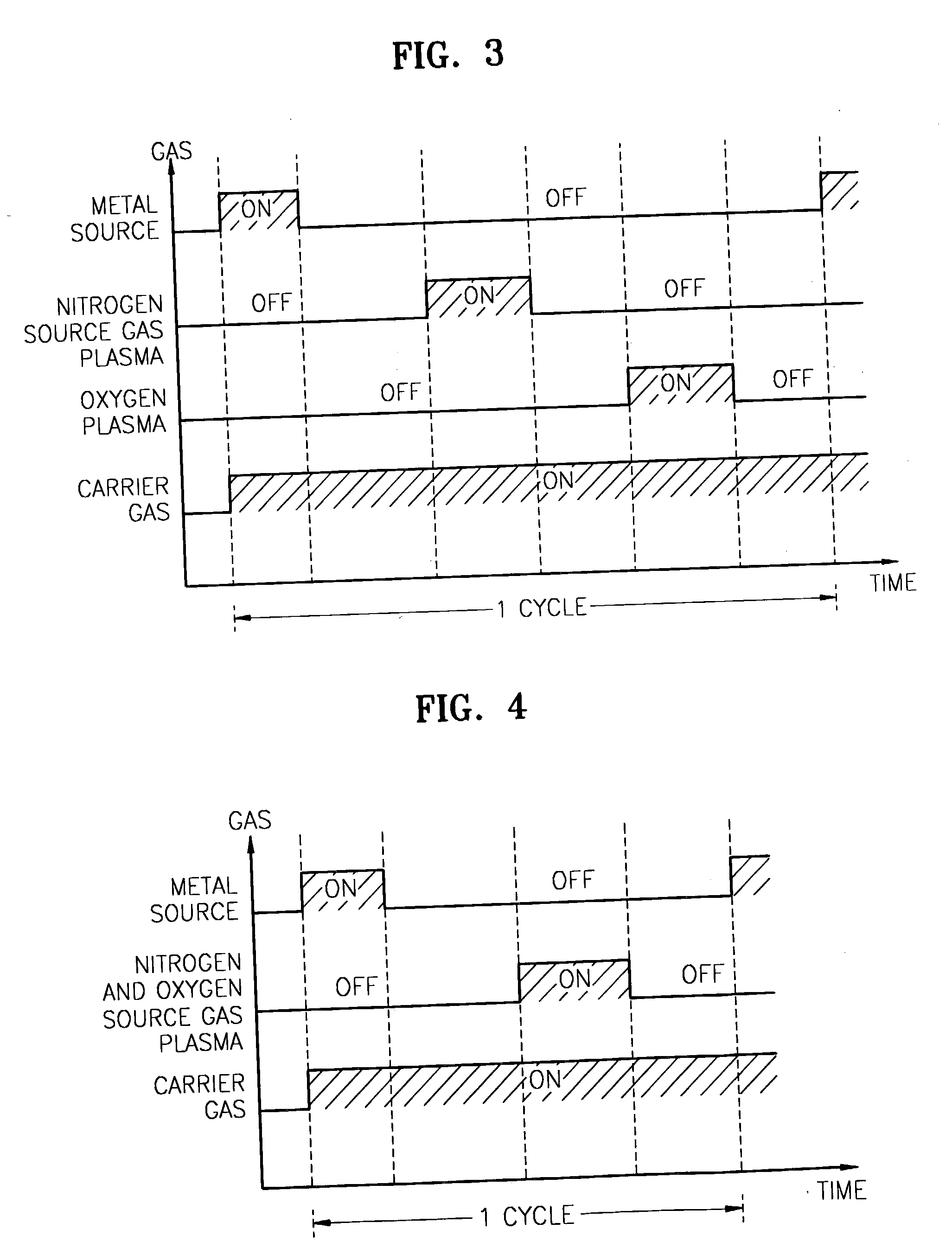

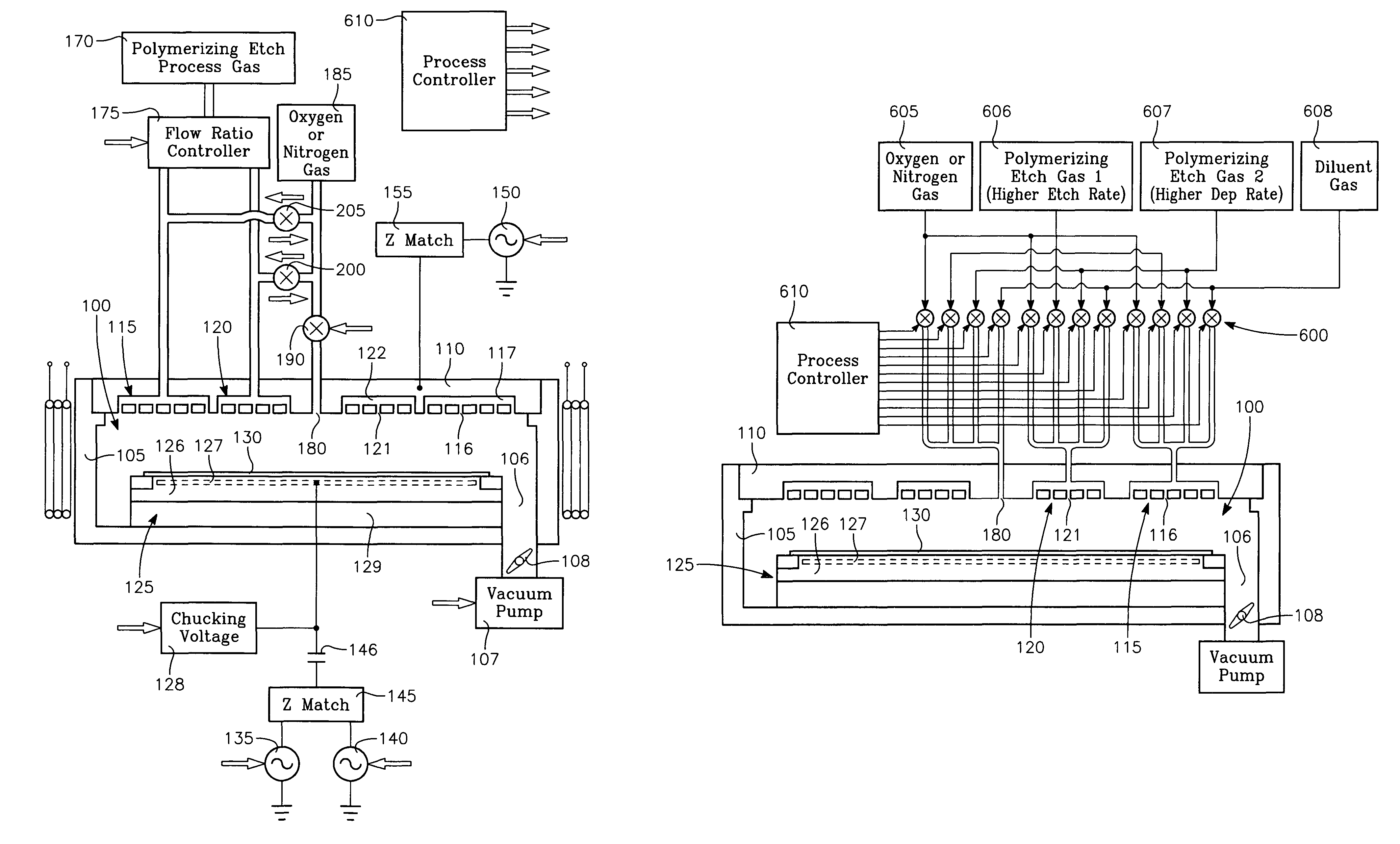

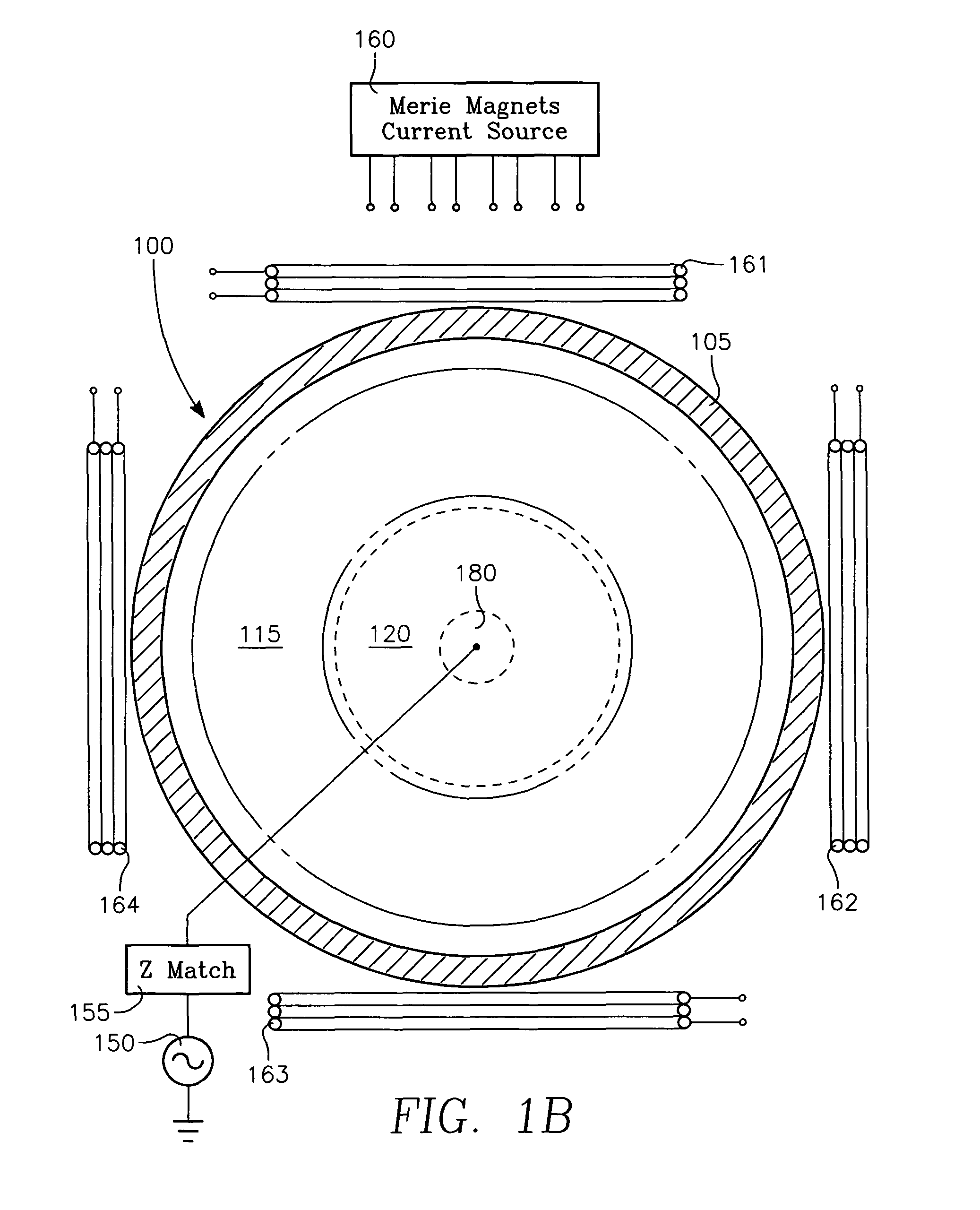

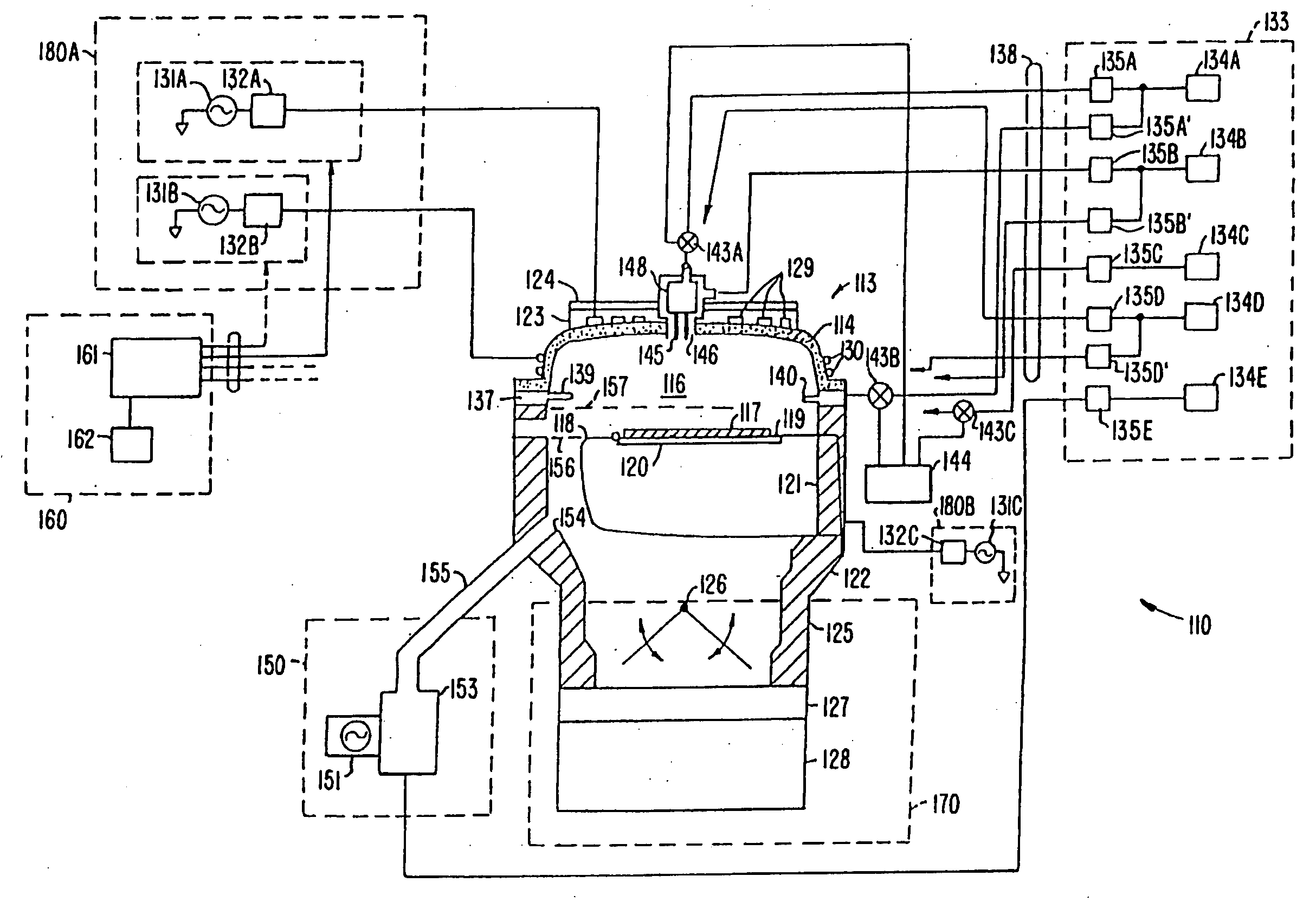

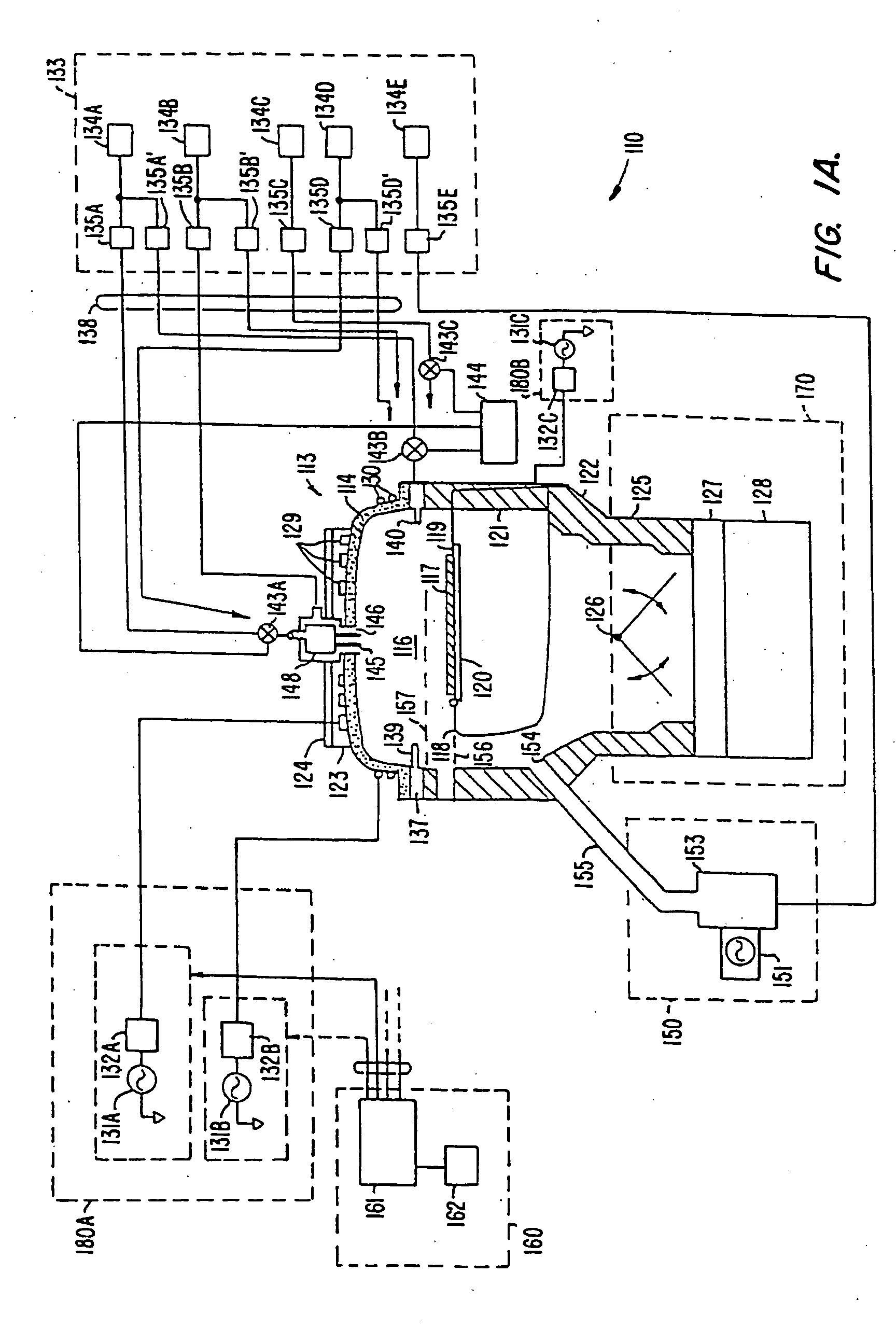

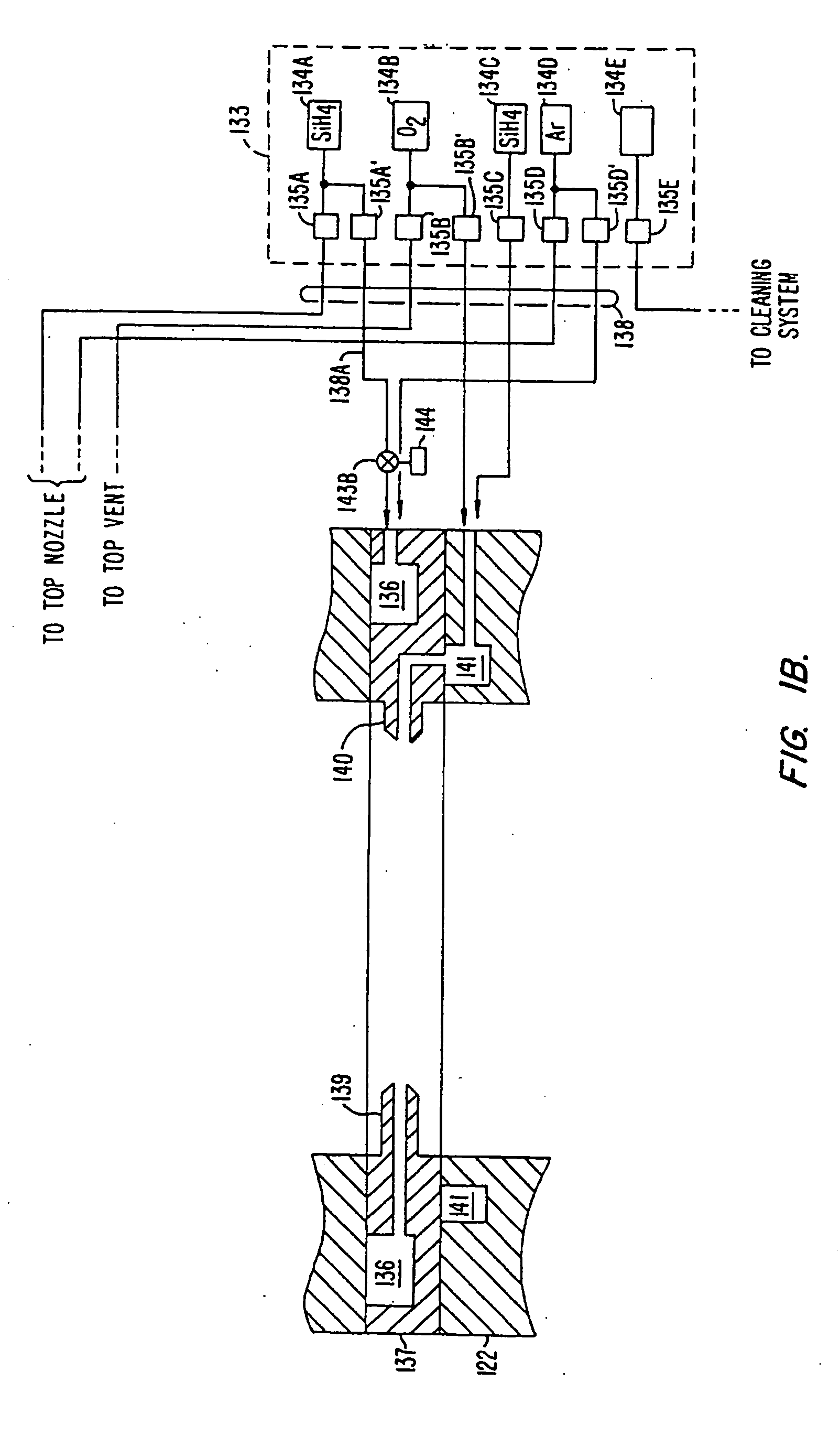

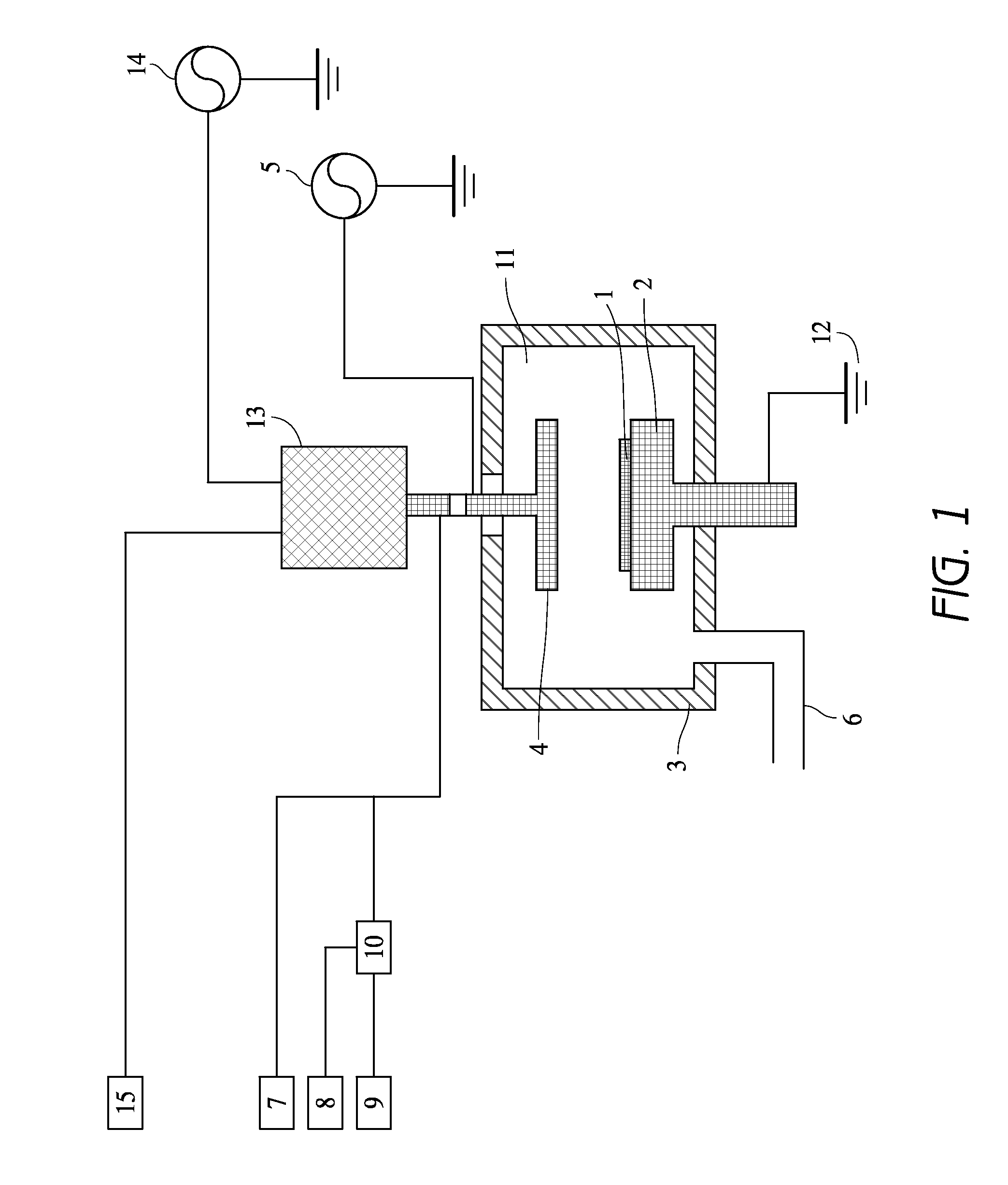

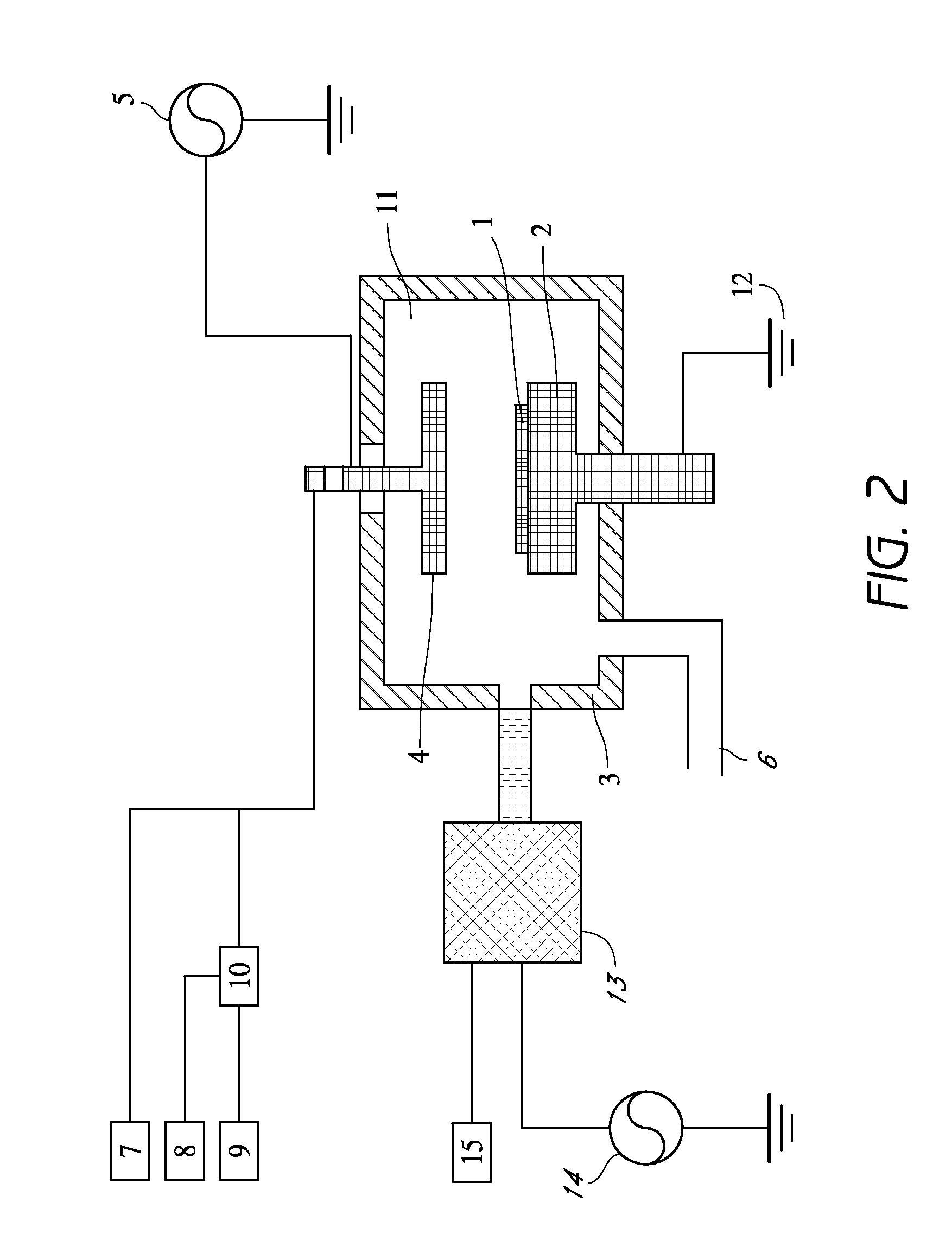

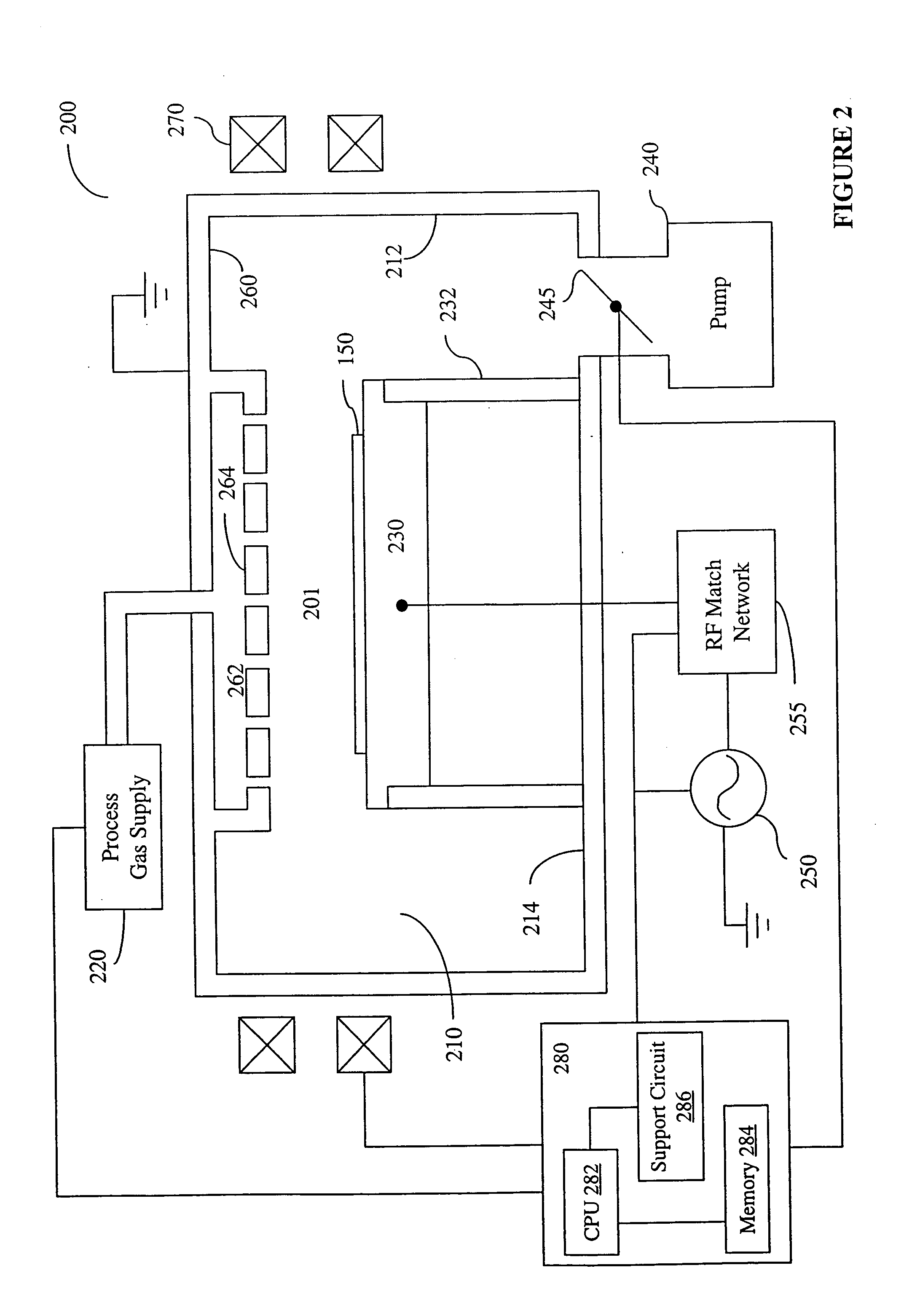

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

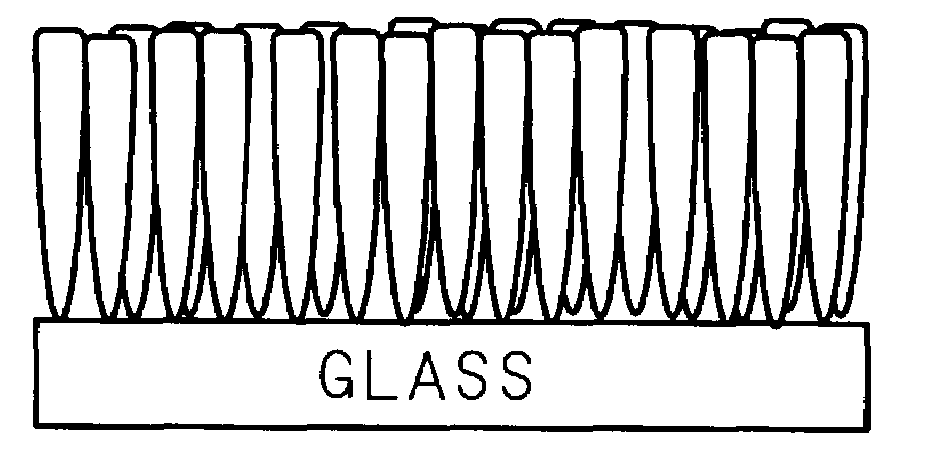

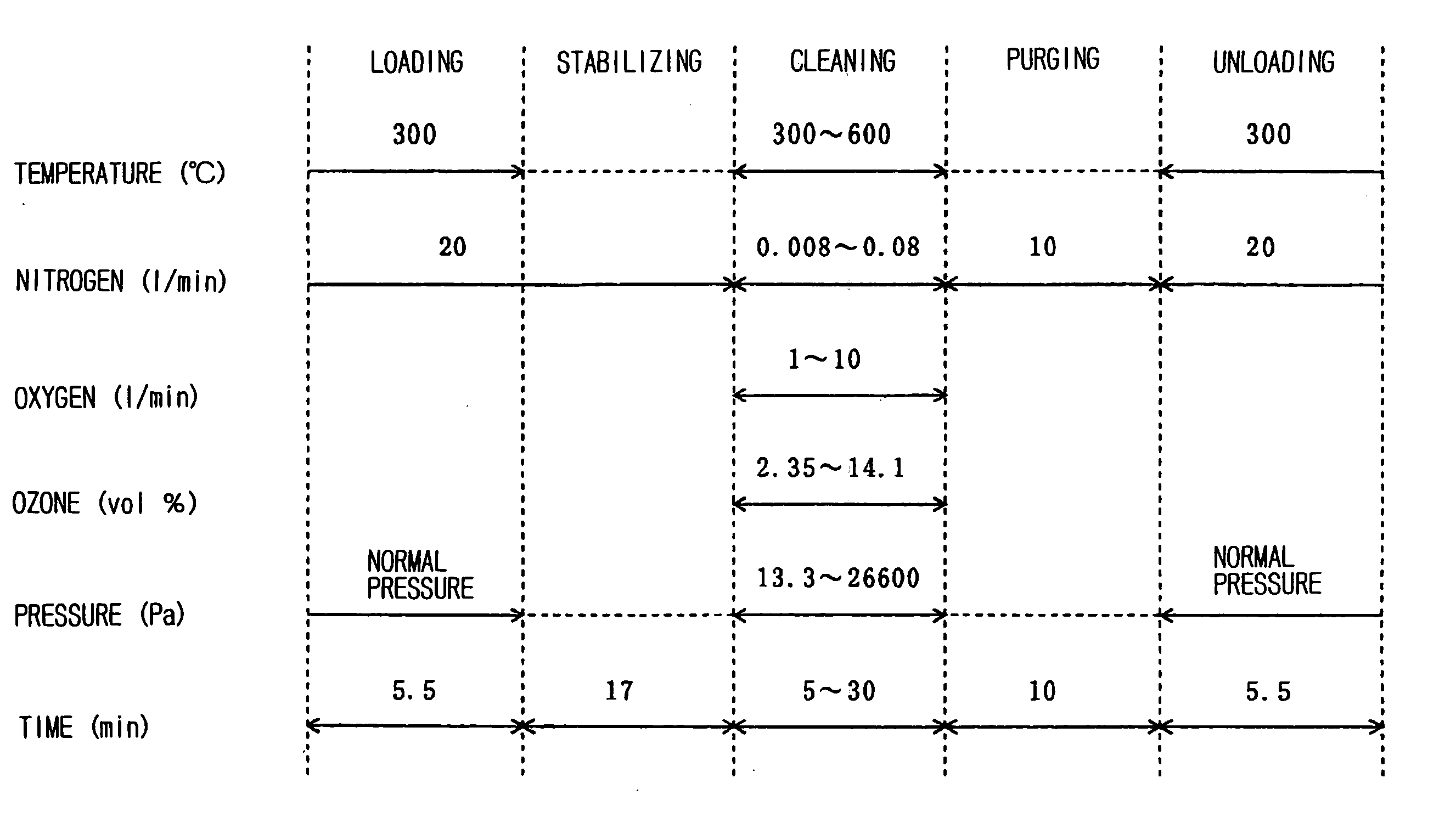

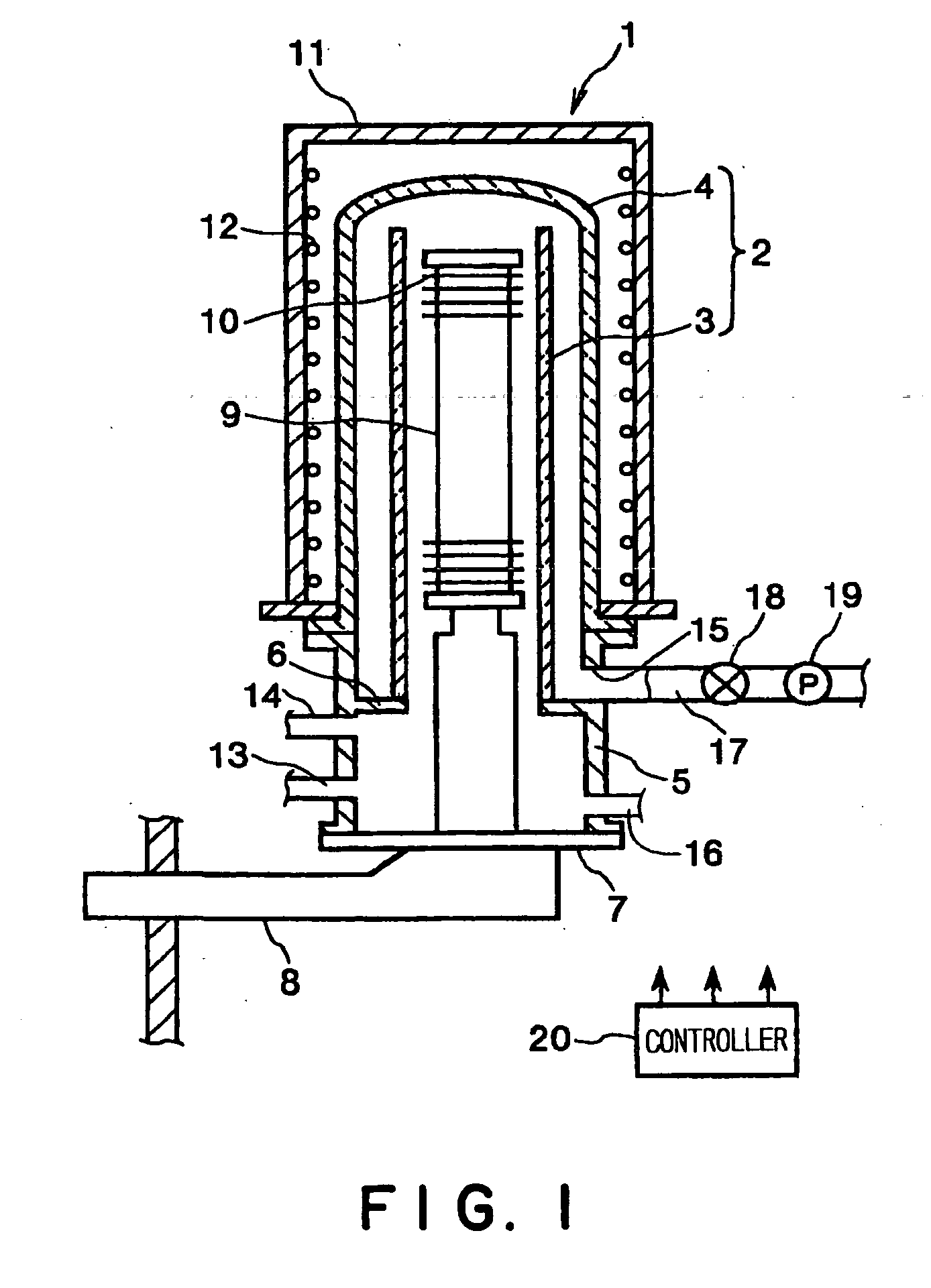

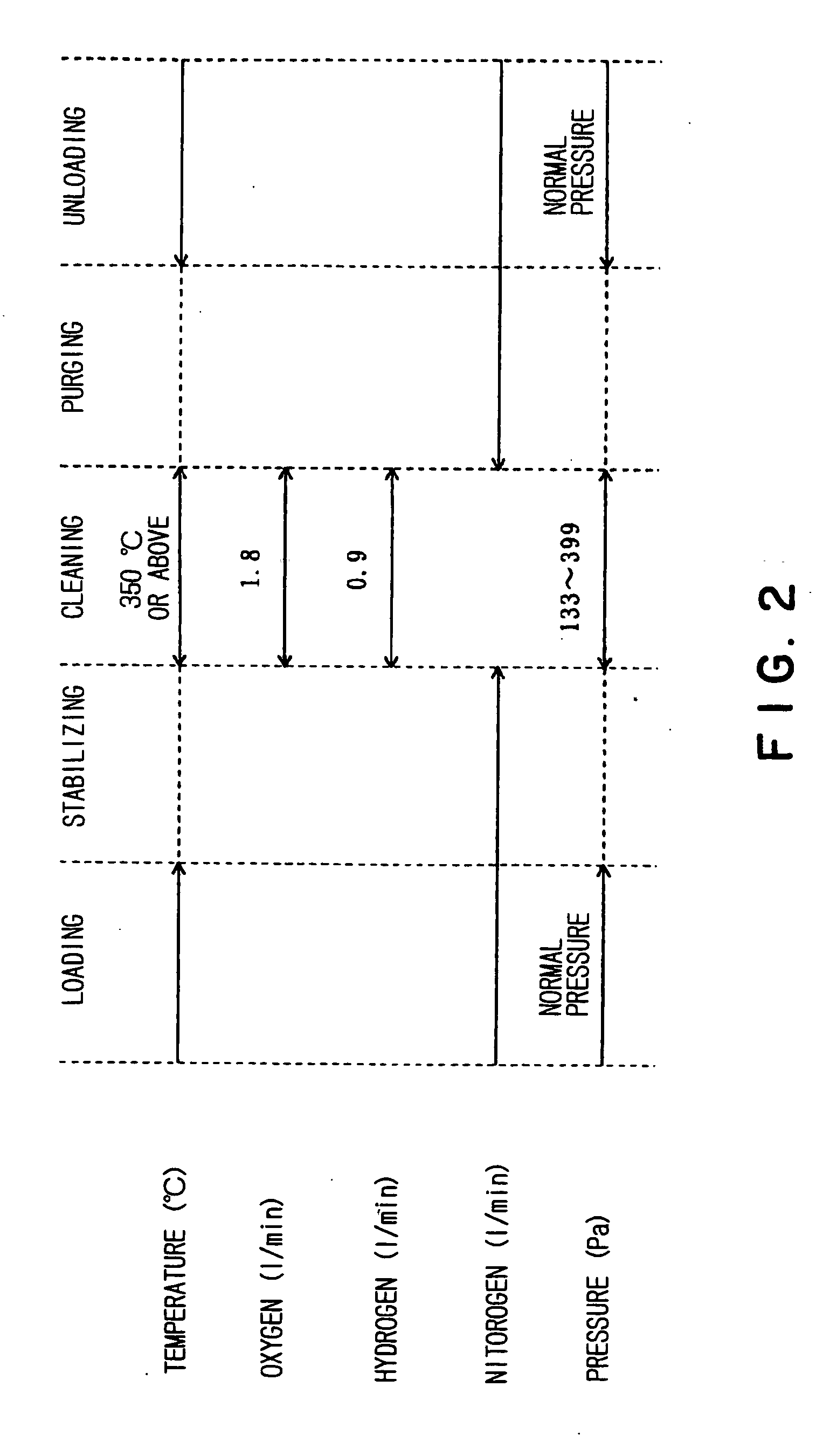

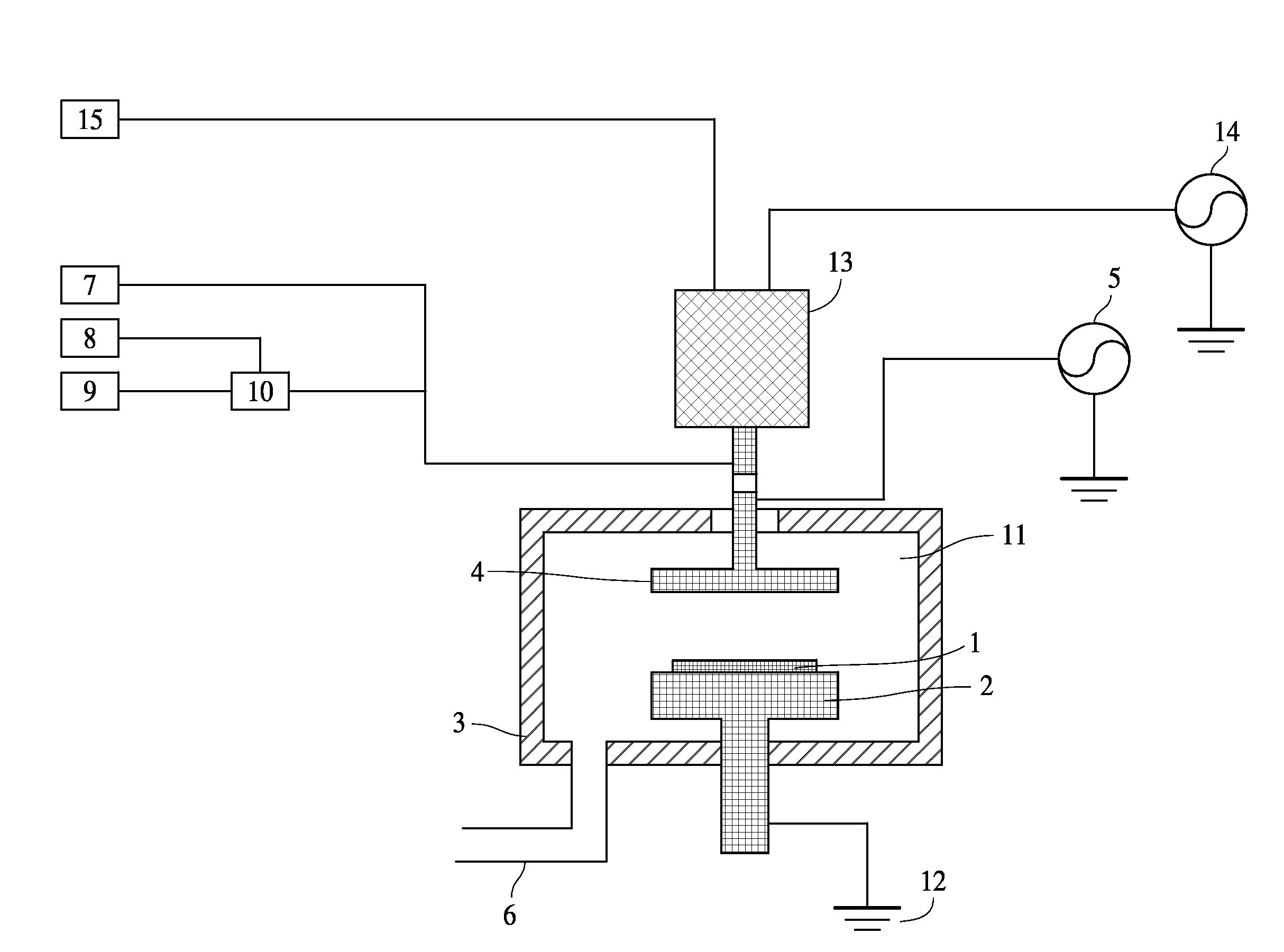

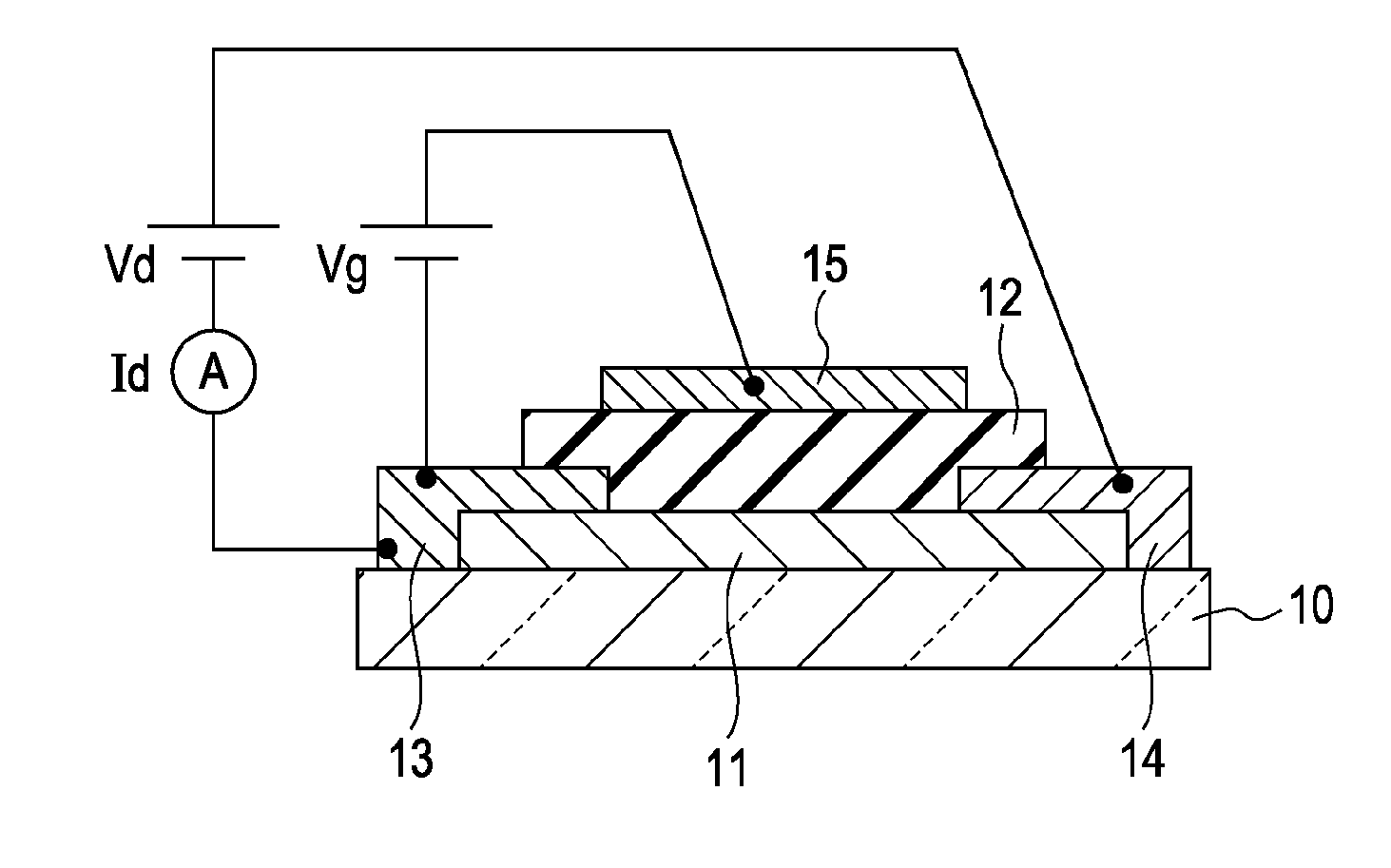

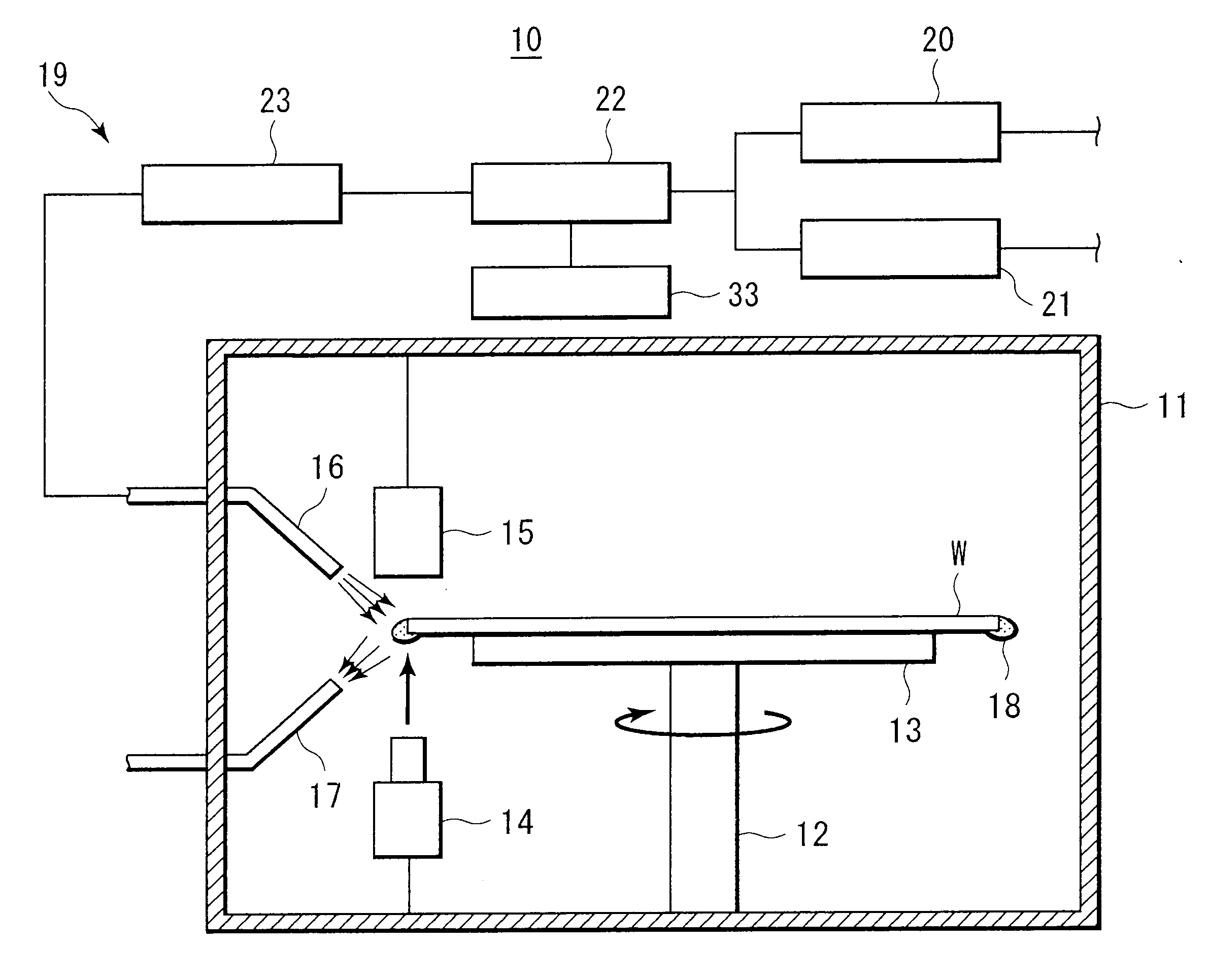

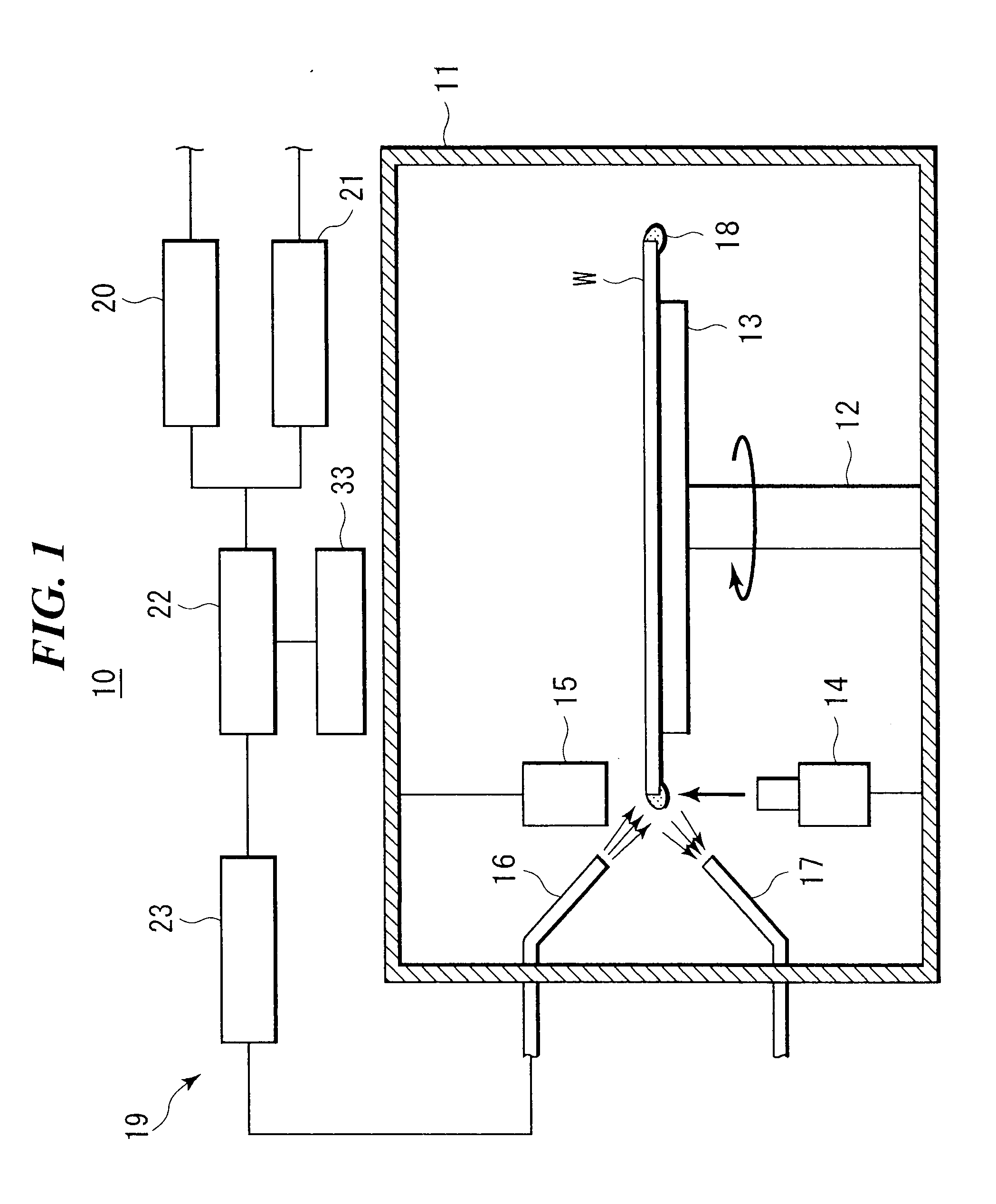

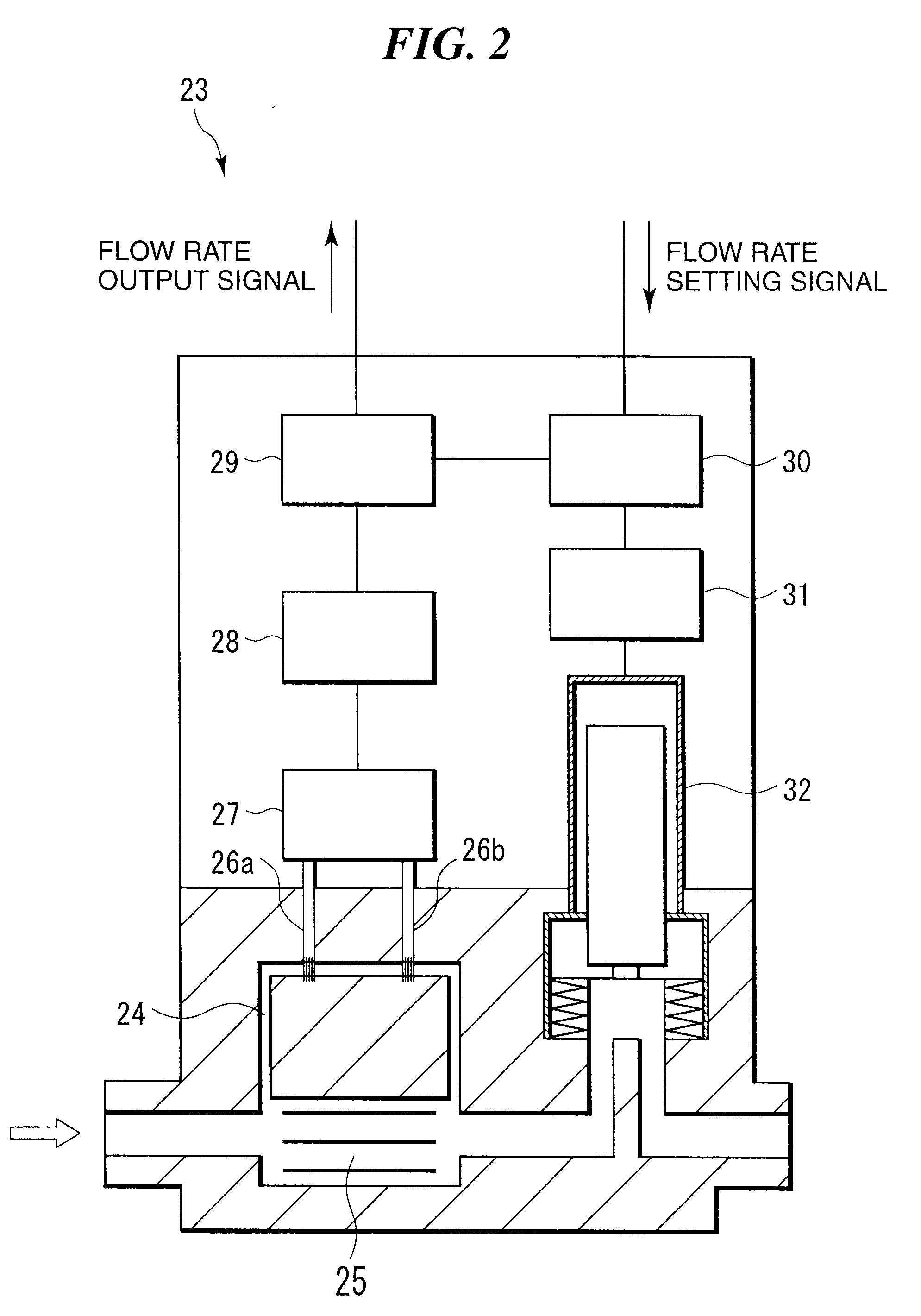

Method and apparatus for treating article to be treated

InactiveUS20040219793A1Efficient removalShort timeAfter-treatment detailsSemiconductor/solid-state device manufacturingCombustionHydrogen

A thermal treatment apparatus 1 includes a reaction tube 2 for containing wafers 10 contaminated with organic substances having a heater 12 capable of heating the reaction tube; a first gas supply pipe 13 for carrying oxygen gas into the reaction tube 2; and a second gas supply pipe 14 for carrying hydrogen gas into the reaction tube 2. Oxygen gas and hydrogen gas are supplied through the first gas supply pipe 13 and the second gas supply pipe 14, respectively, into the reaction tube 2, and the heater 12 heats the reaction tube 2 at a temperature capable of activating oxygen gas and hydrogen gas. A combustion reaction occurs in the reaction tube 2 and thereby the organic substances adhering to the wafers 10 are oxidized, decomposed and removed.

Owner:TOKYO ELECTRON LTD

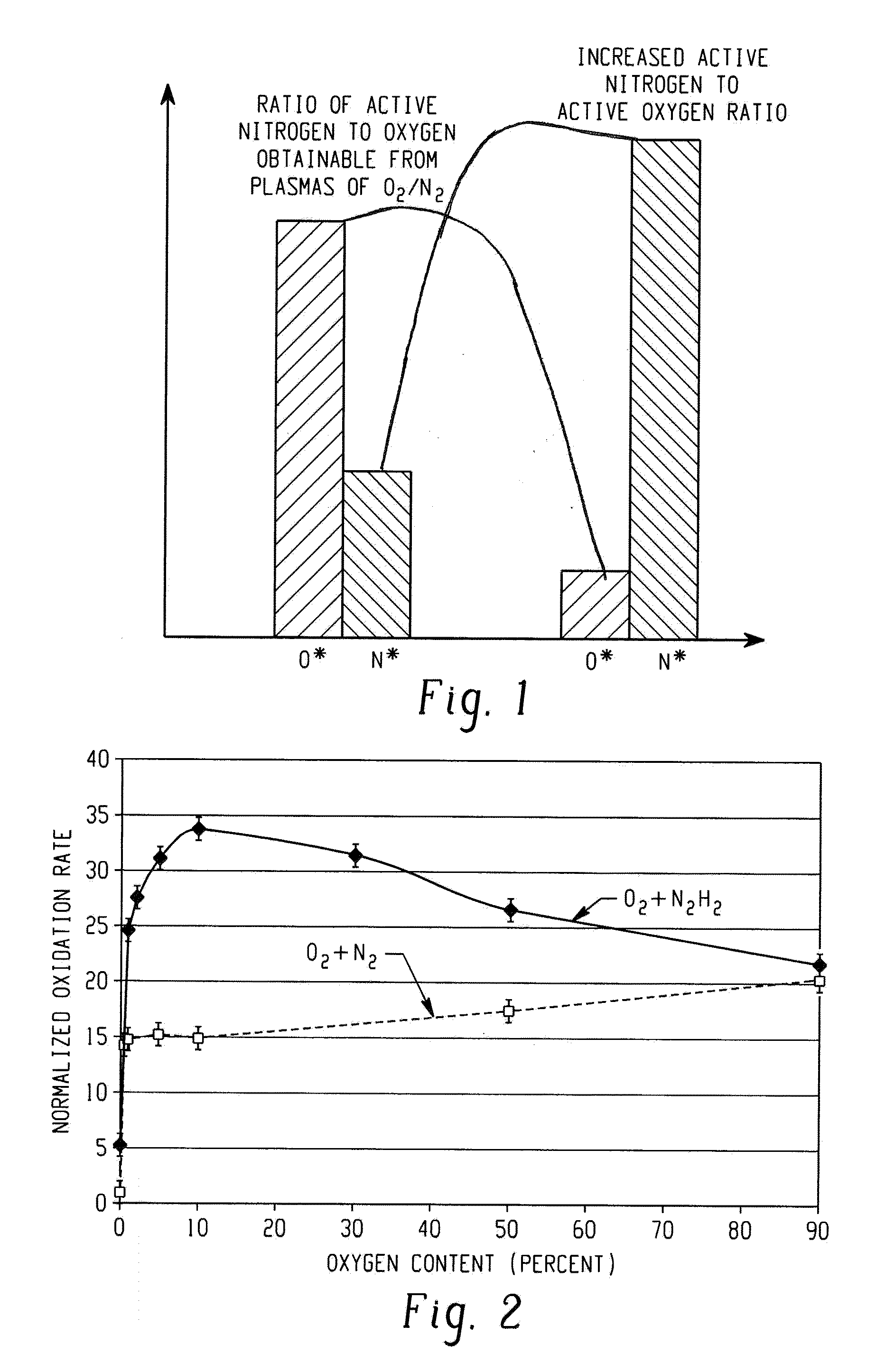

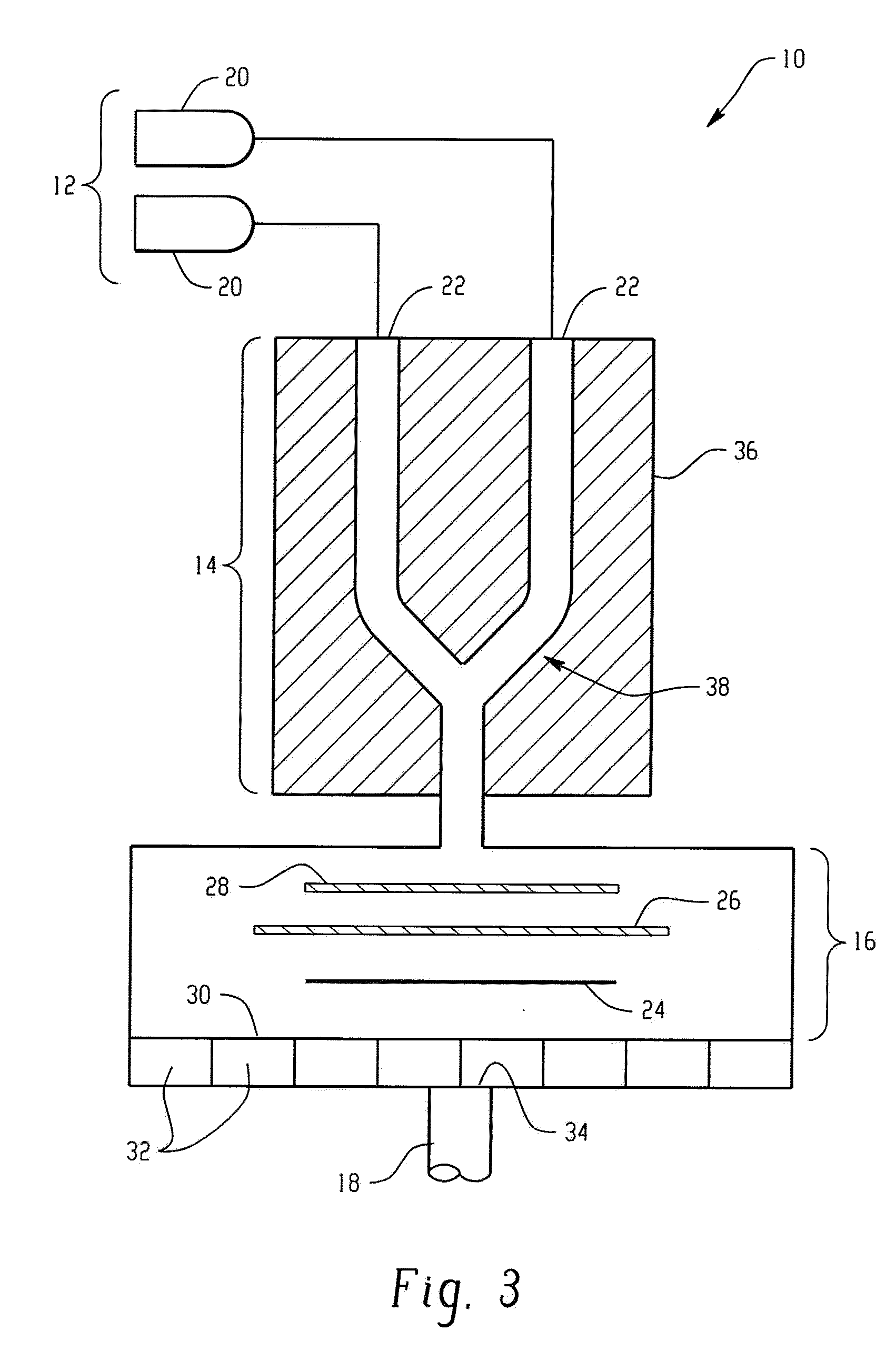

Front end of line plasma mediated ashing processes and apparatus

InactiveUS20100130017A1Increased formationElectric discharge tubesSemiconductor/solid-state device manufacturingResistFront end of line

Front end of line (FEOL) plasma mediated ashing processes for removing organic material from a substrate generally includes exposing the substrate to the plasma to selectively remove photoresist, implanted photoresist, polymers and / or residues from the substrate, wherein the plasma contains a ratio of active nitrogen and active oxygen that is larger than a ratio of active nitrogen and active oxygen obtainable from plasmas of gas mixtures comprising oxygen gas and nitrogen gas. The plasma exhibits high throughput while minimizing and / or preventing substrate oxidation and dopant bleaching. Plasma apparatuses are also described.

Owner:LAM RES CORP

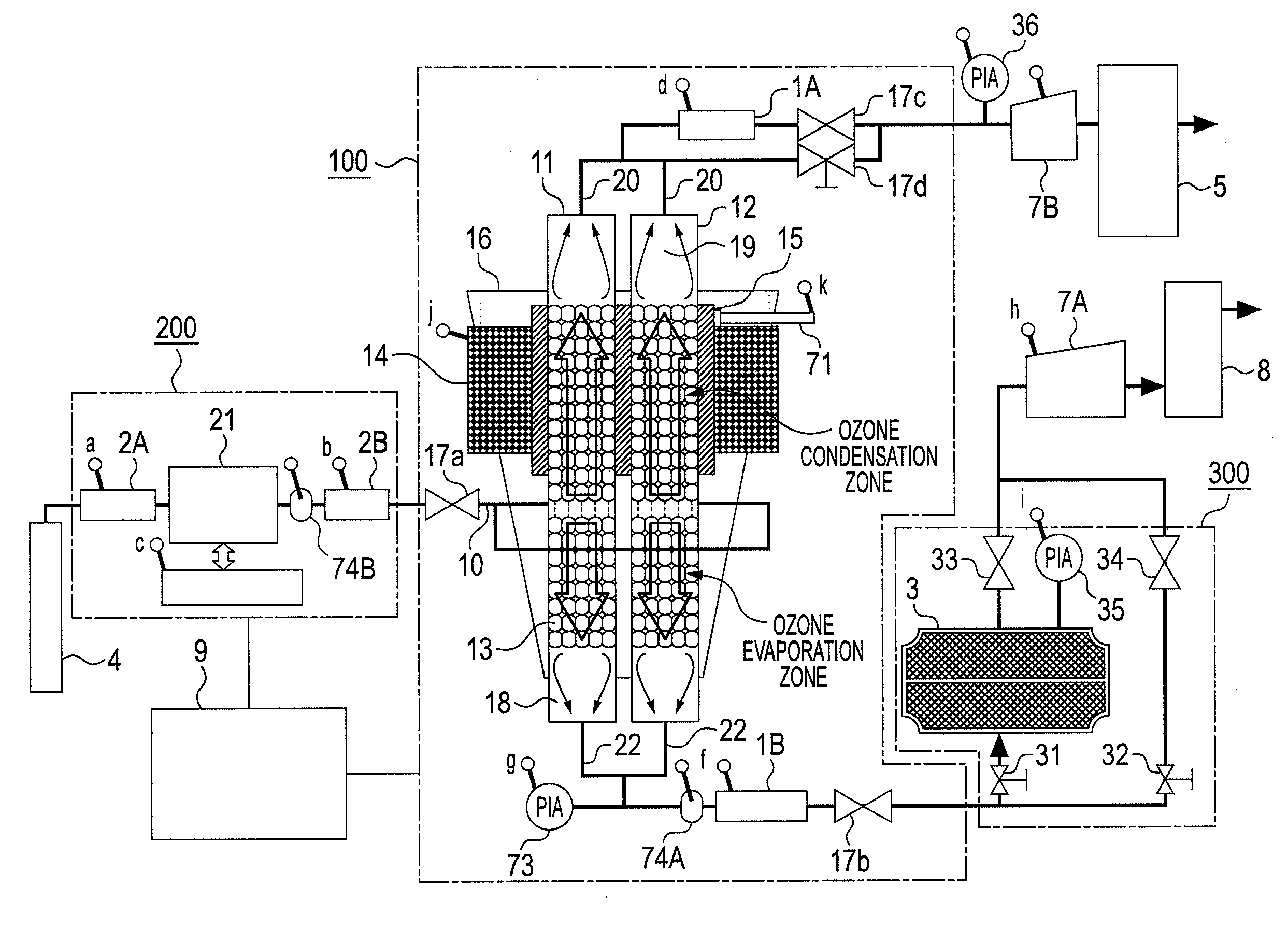

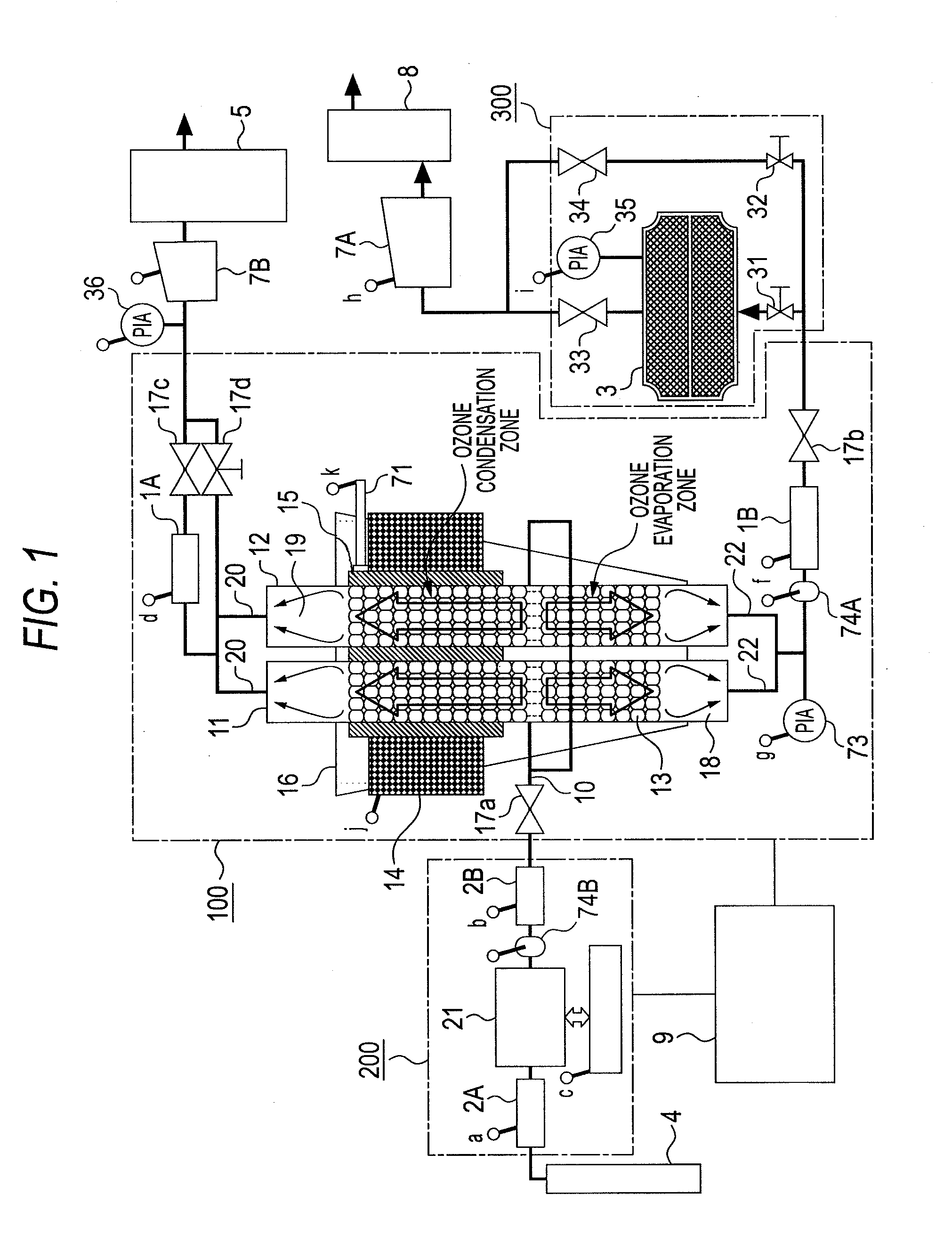

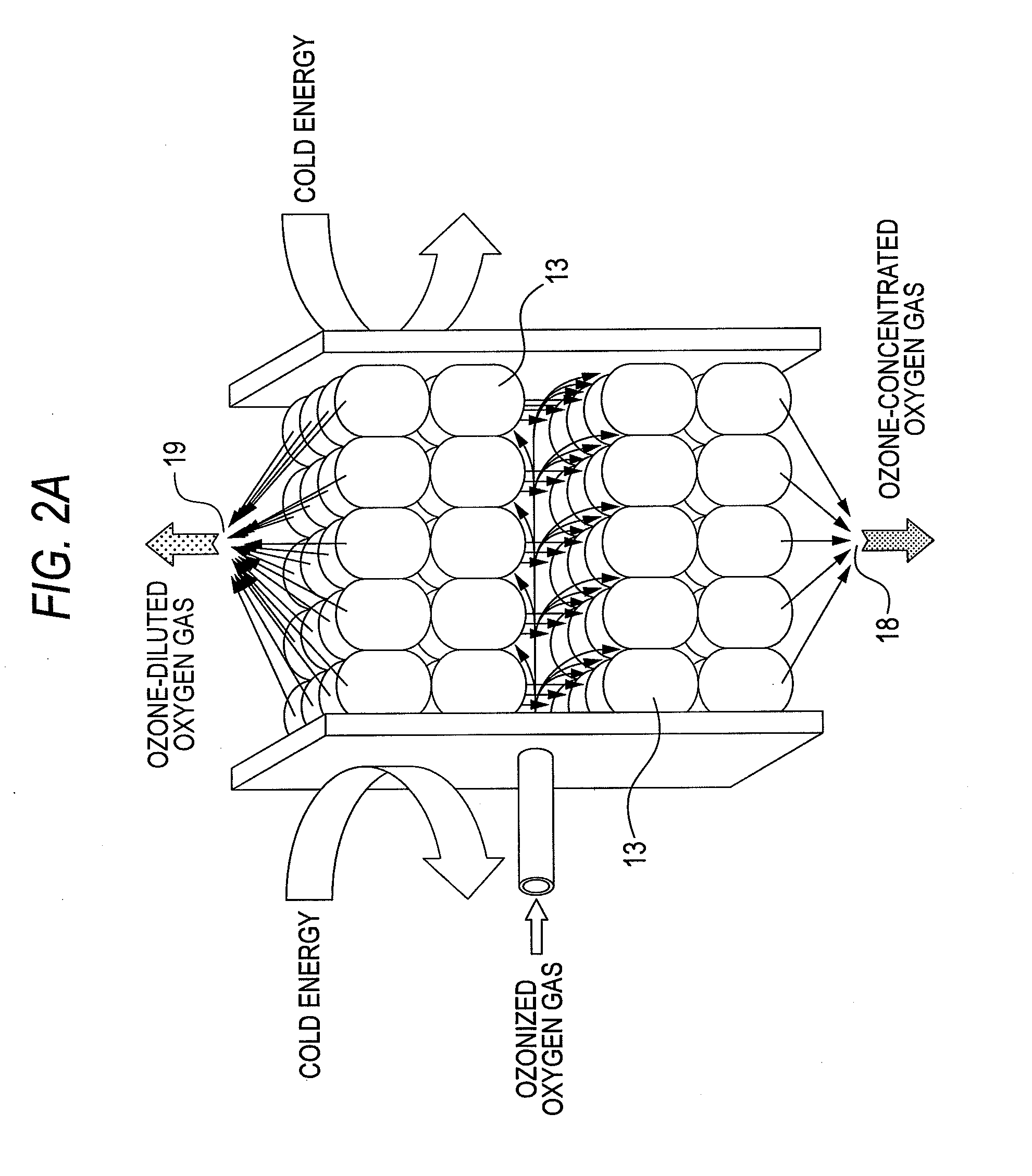

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

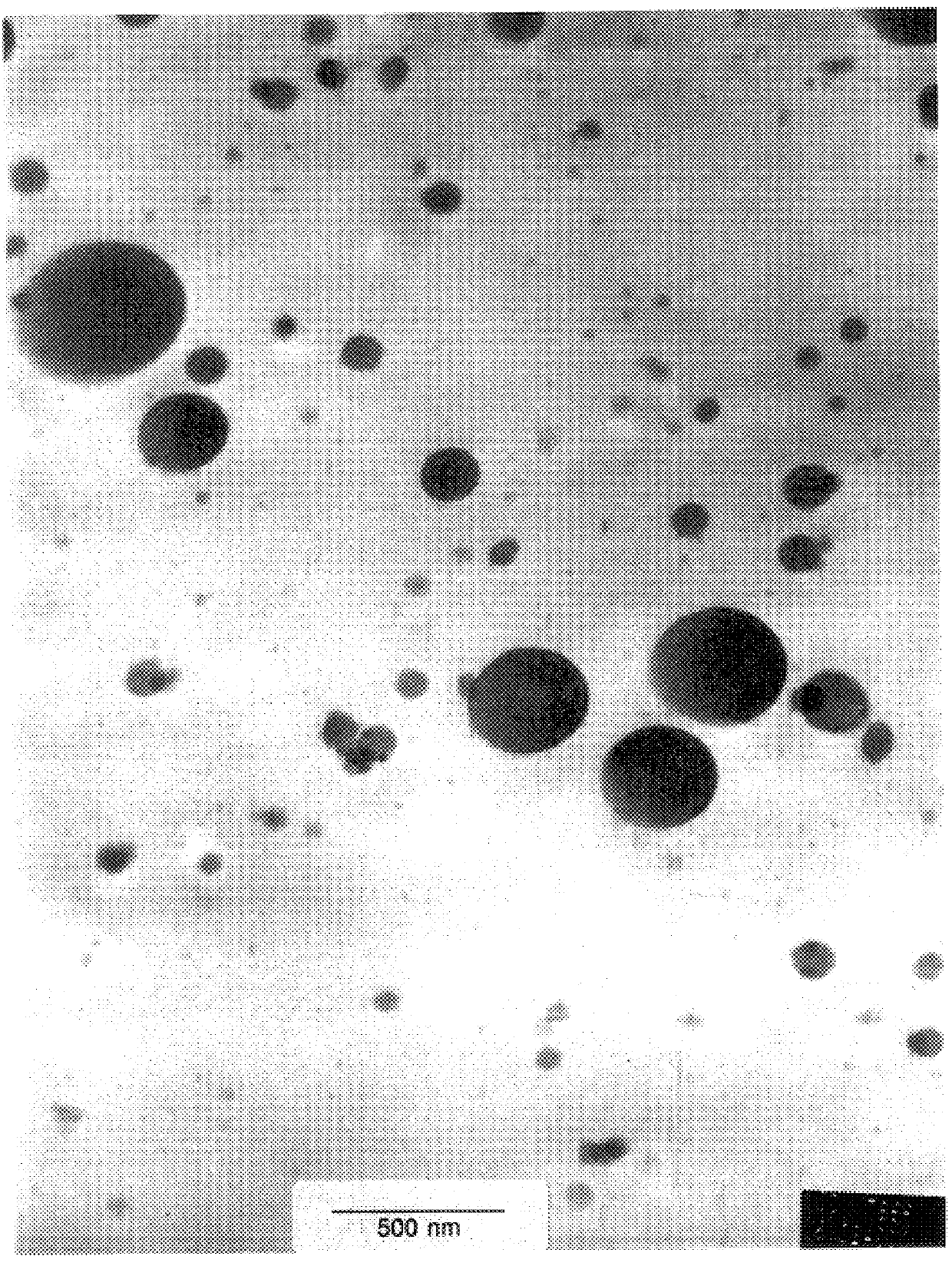

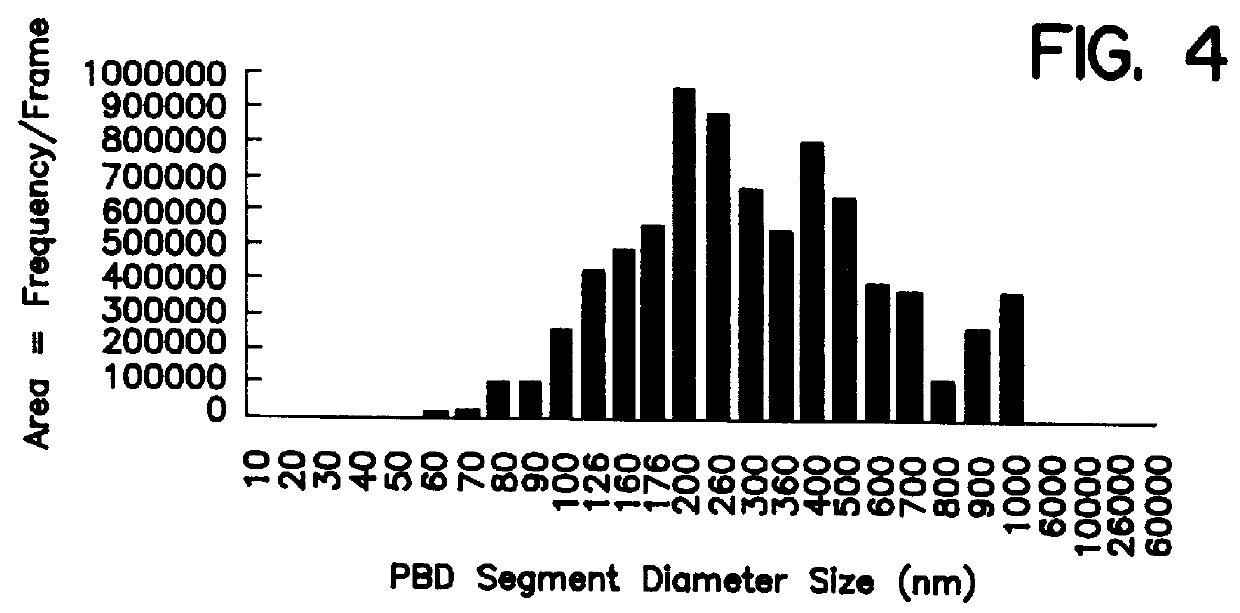

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Method of forming a layer and method of forming a capacitor of a semiconductor device having the same

InactiveUS20060063346A1Improve reliabilityLow costSemiconductor/solid-state device manufacturingCapacitorsKryptonDevice material

In a method of forming a layer using an atomic layer deposition process, after a substrate is loaded into a chamber, a reactant is provided onto the substrate to form a preliminary layer. Atoms in the preliminary layer are partially removed from the preliminary layer using plasma formed from an inert gas such as an argon gas, a xenon gas or a krypton gas, or an inactive gas such as an oxygen gas, a nitrogen gas or a nitrous oxide gas to form a desired layer. Processes for forming the desired layer may be simplified. A highly integrated semiconductor device having improved reliability may be economically manufactured so that time and costs required for the manufacturing of the semiconductor device may be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for forming nitrogen-containing oxide thin film using plasma enhanced atomic layer deposition

InactiveUS6723642B1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceNitrogen oxide

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

Method of self-cleaning of carbon-based film

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

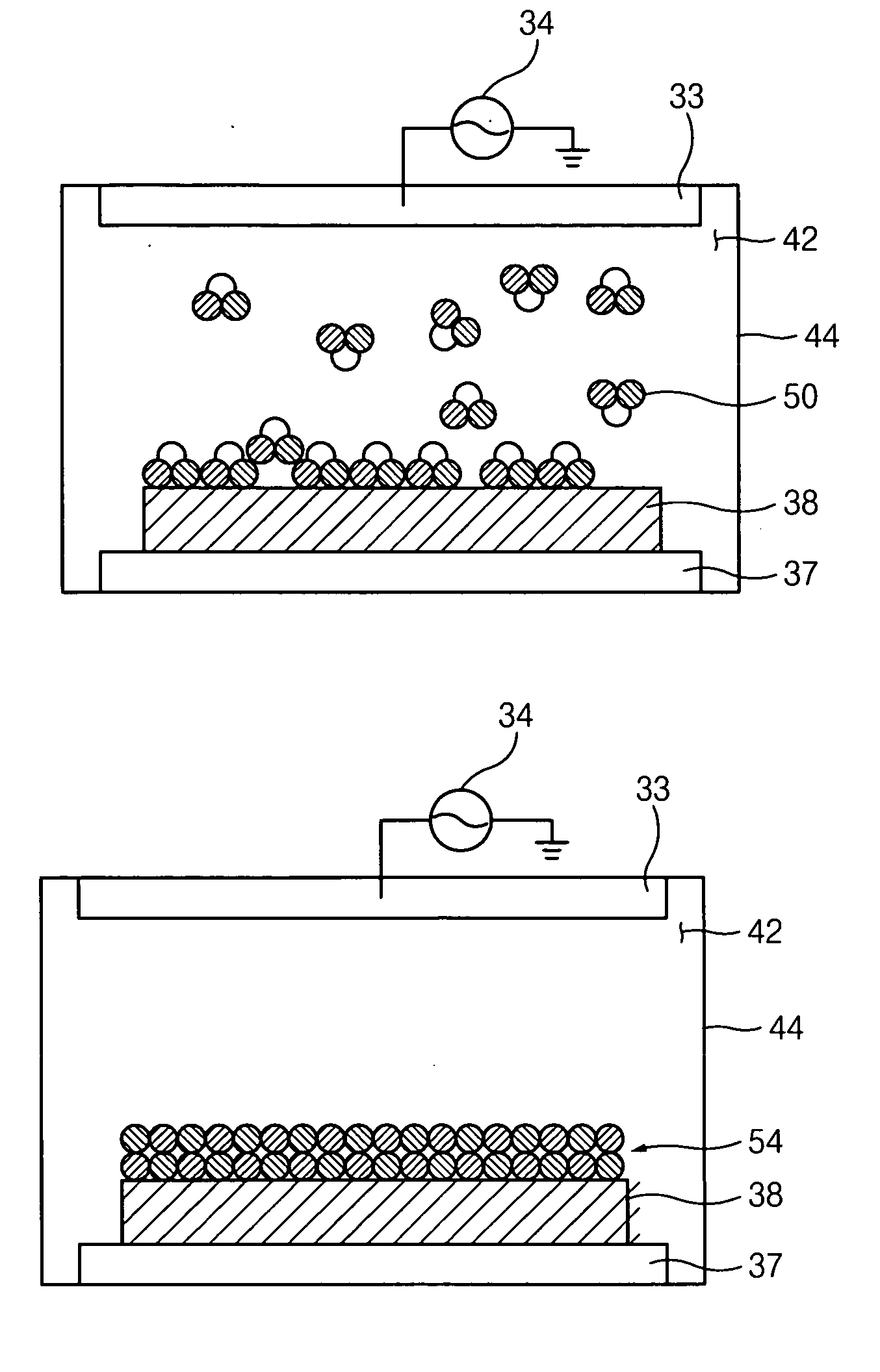

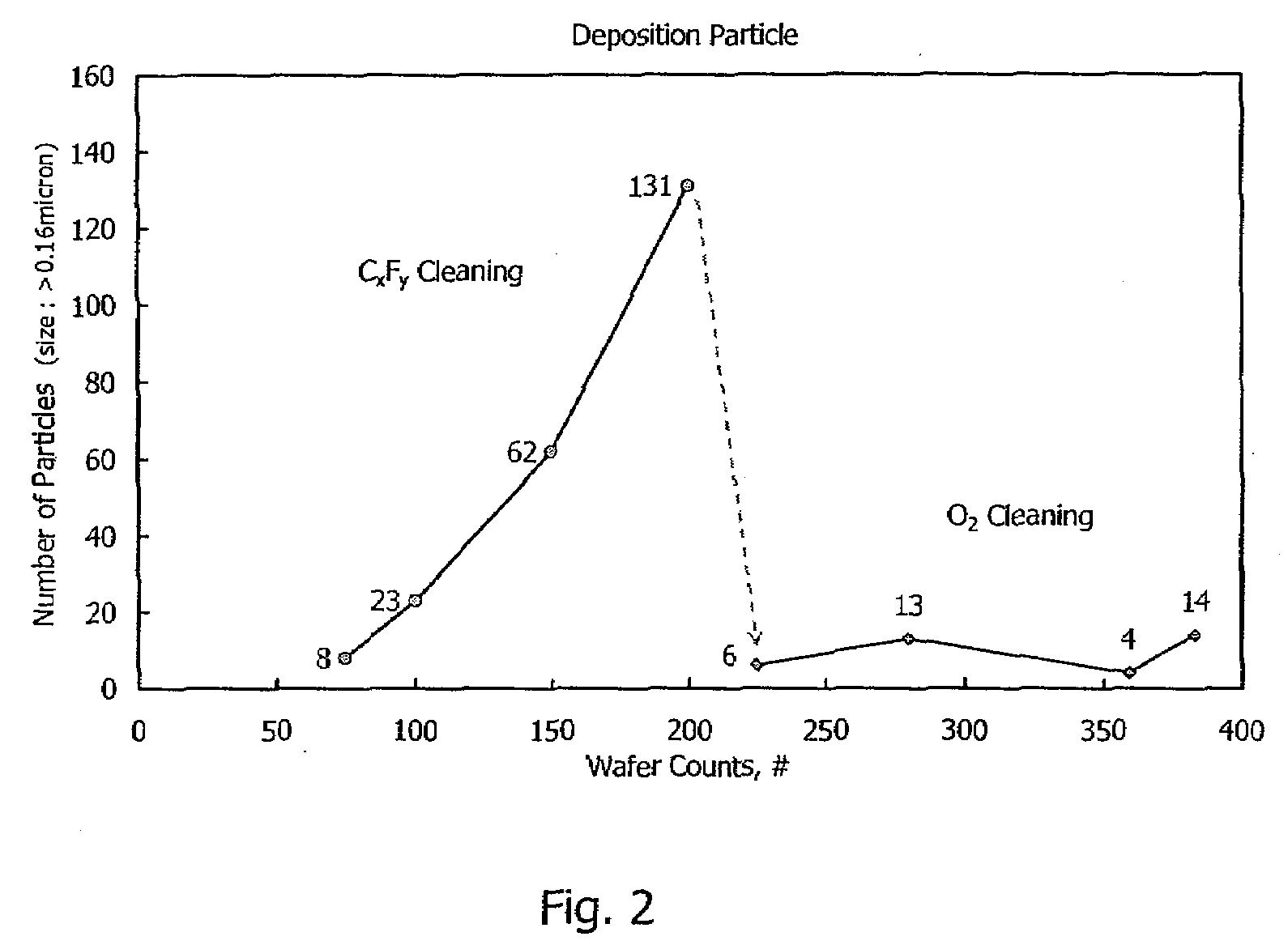

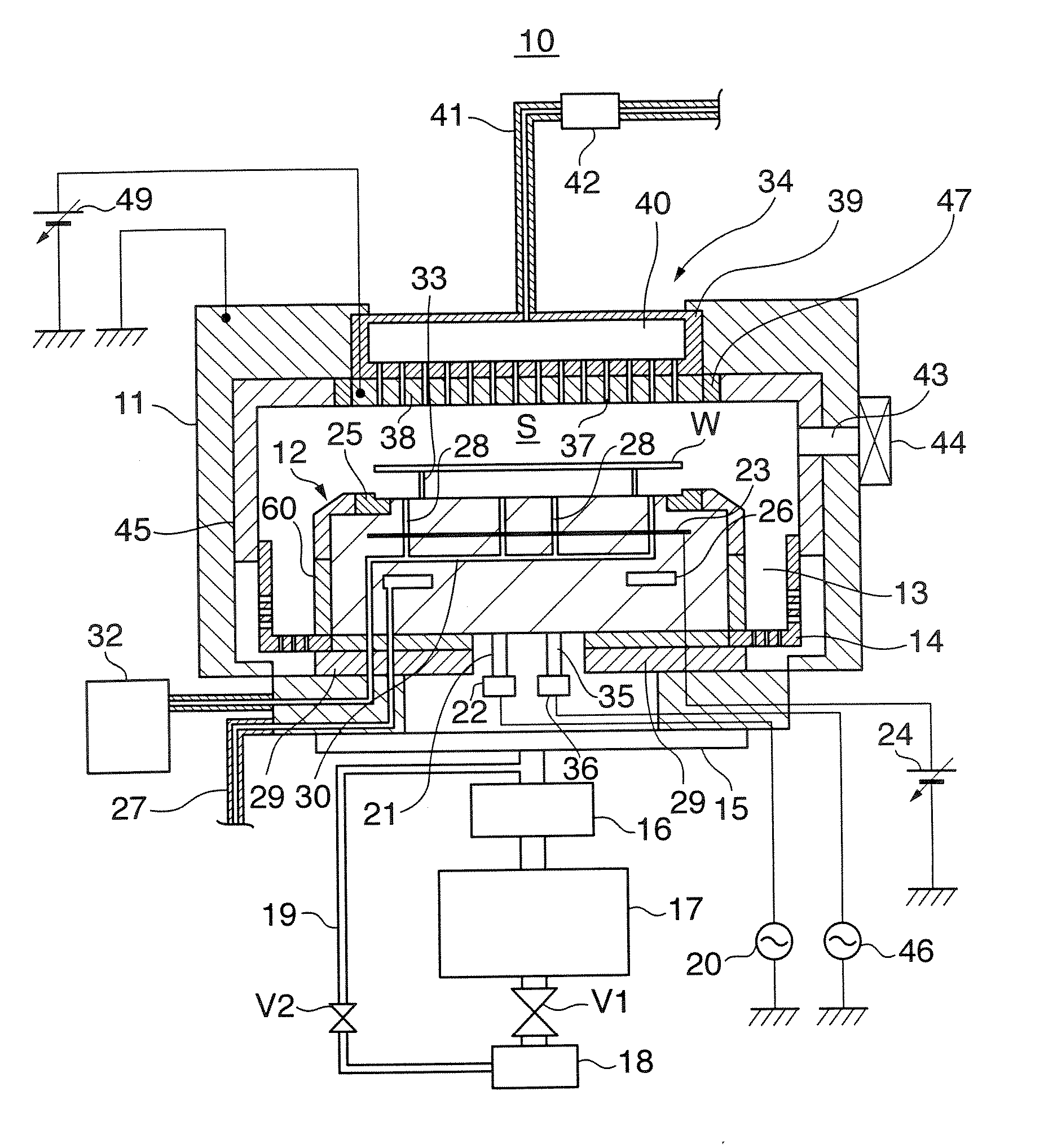

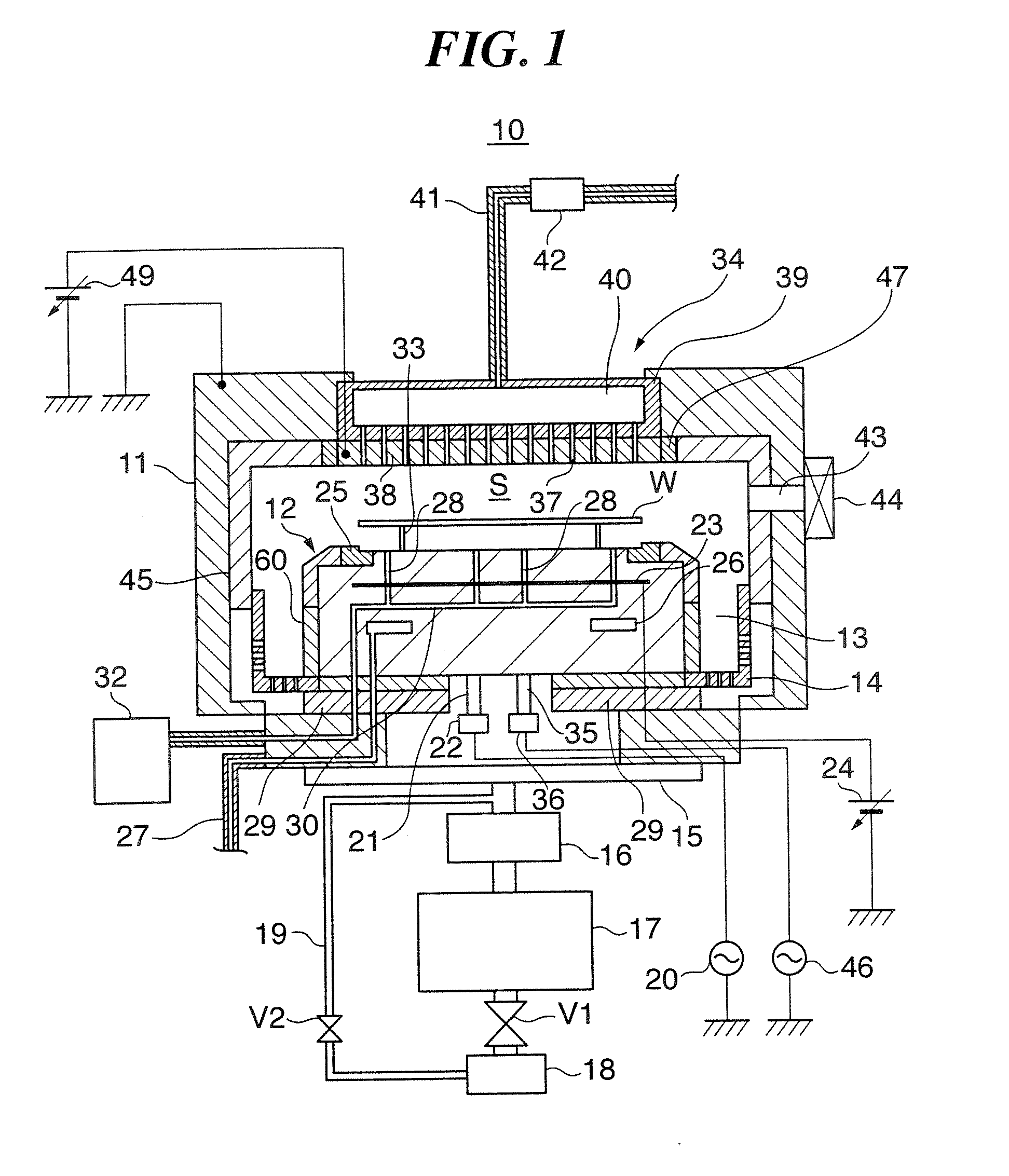

Method of cleaning substrate processing chamber, storage medium, and substrate processing chamber

ActiveUS20070186952A1Inhibition formationElectric discharge tubesHollow article cleaningElectricityReactive-ion etching

A method of cleaning a substrate processing chamber that enables formation of an oxide film on a surface of a processing chamber inside component to be prevented. A substrate processing chamber 11 has therein a processing space S into which a wafer W is transferred and carries out reactive ion etching on the wafer W in the processing space S. The substrate processing chamber 11 has an upper electrode plate 38 that comprises silicon and a lower surface of which is exposed to the processing space S. A dry cleaning is carried out on the upper electrode plate 38 using oxygen radicals produced from oxygen gas introduced into the processing space S. An oxide removal processing is carried out on the upper electrode plate 38 using fluorine ions and fluorine radicals produced from carbon tetrafluoride gas introduced into the processing space S.

Owner:TOKYO ELECTRON LTD

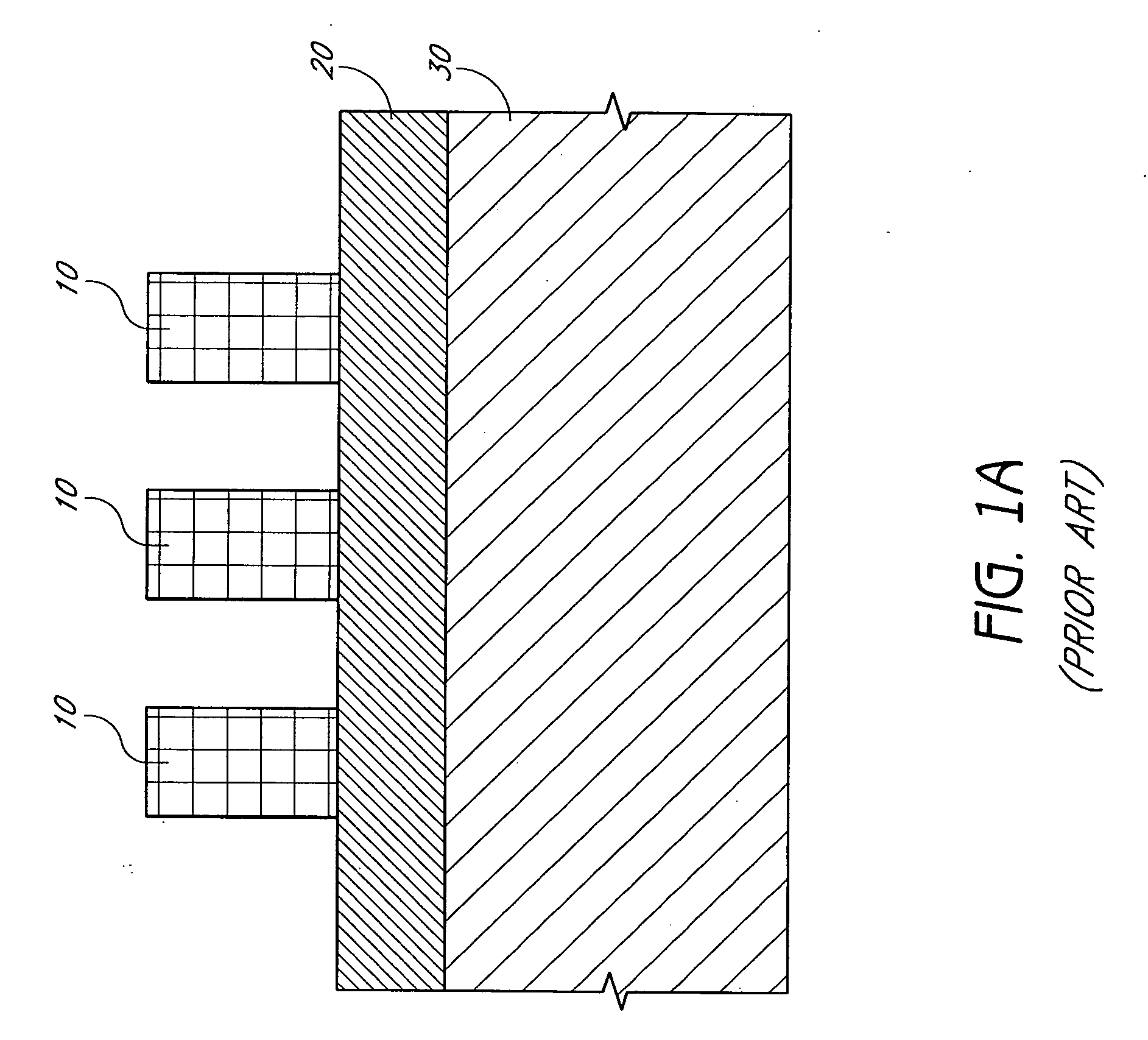

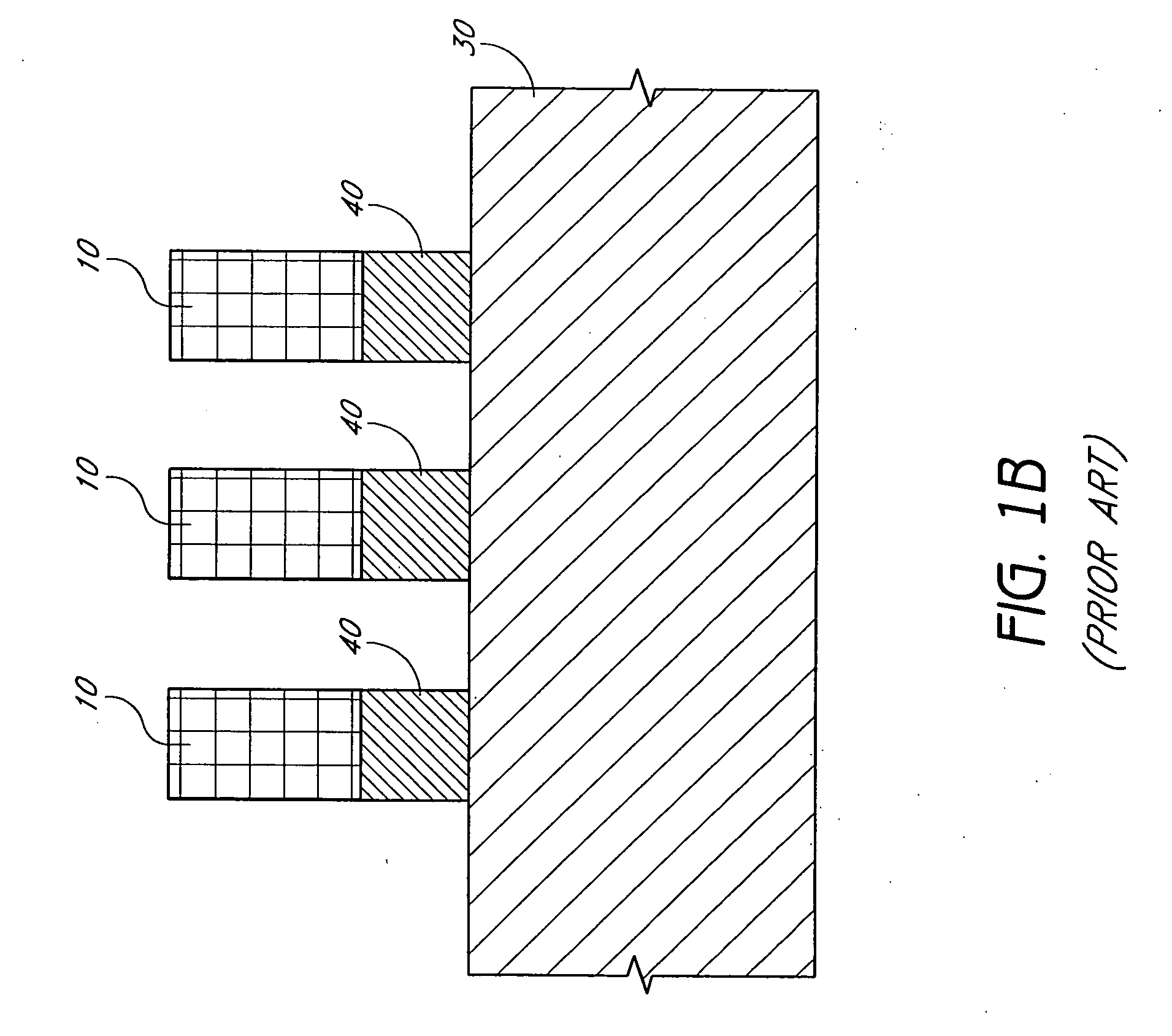

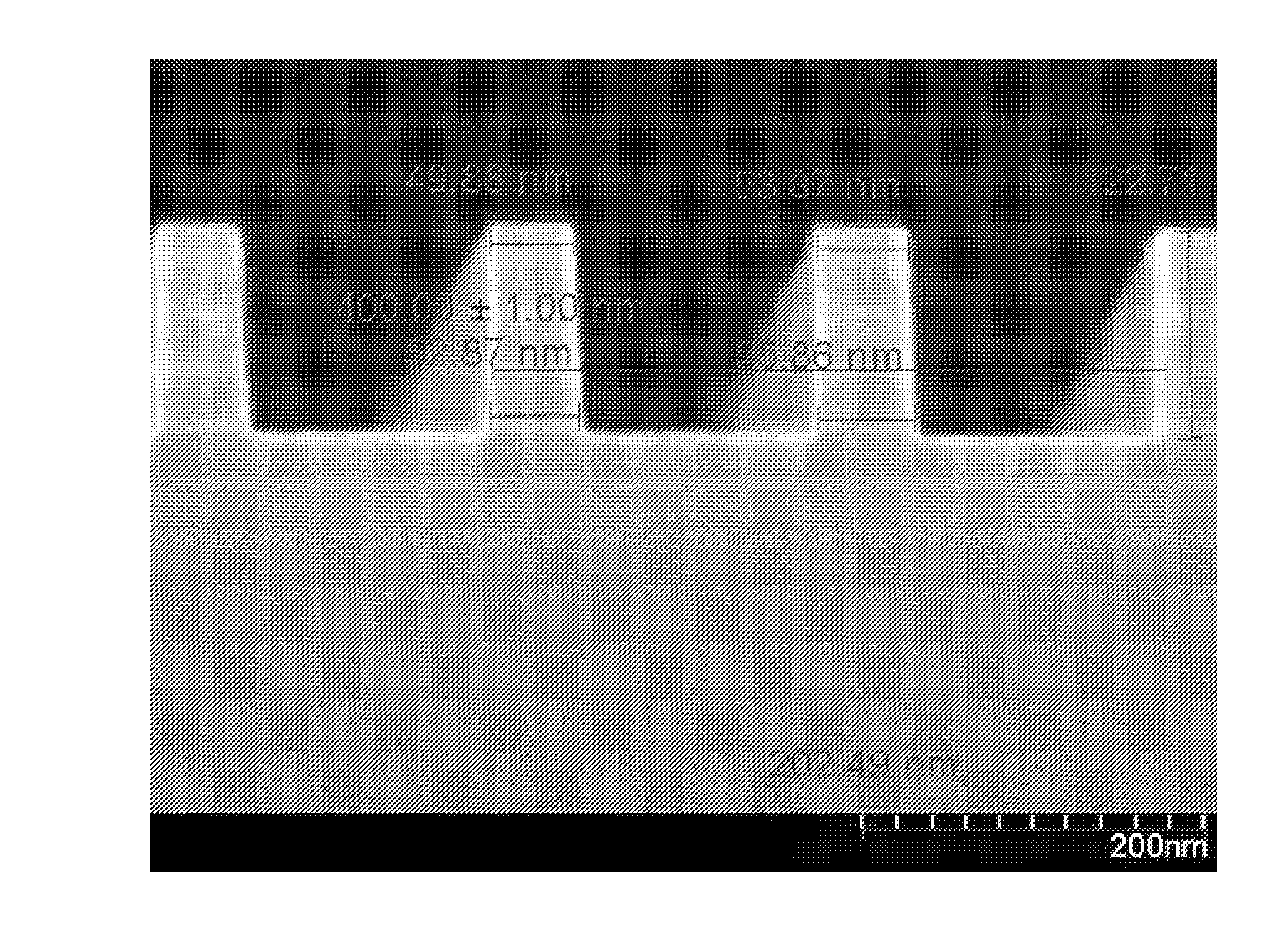

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20070049040A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

Method for activating reactive oxygen species for cleaning carbon-based film deposition

InactiveUS20090246399A1Liquid surface applicatorsElectrostatic cleaningNitrogenReactive oxygen species

A method of continuously forming carbon-based films on substrates includes: (i) forming a carbon-based film on a substrate in a reactor a pre-selected number of times; (ii) exciting an inert gas, an oxygen gas, and a nitrogen tri-fluoride gas to generate a plasma for cleaning; (iii) cleaning an inside of the reactor with the plasma after step (i) to remove particles accumulated during step (i) on the inside of the reactor.

Owner:ASM JAPAN

Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous oxide film

An amorphous oxide containing hydrogen (or deuterium) is applied to a channel layer of a transistor. Accordingly, a thin film transistor having superior TFT properties can be realized, the superior TFT properties including a small hysteresis, normally OFF operation, a high ON / OFF ratio, a high saturated current, and the like. Furthermore, as a method for manufacturing a channel layer made of an amorphous oxide, film formation is performed in an atmosphere containing a hydrogen gas and an oxygen gas, so that the carrier concentration of the amorphous oxide can be controlled.

Owner:CANON KK

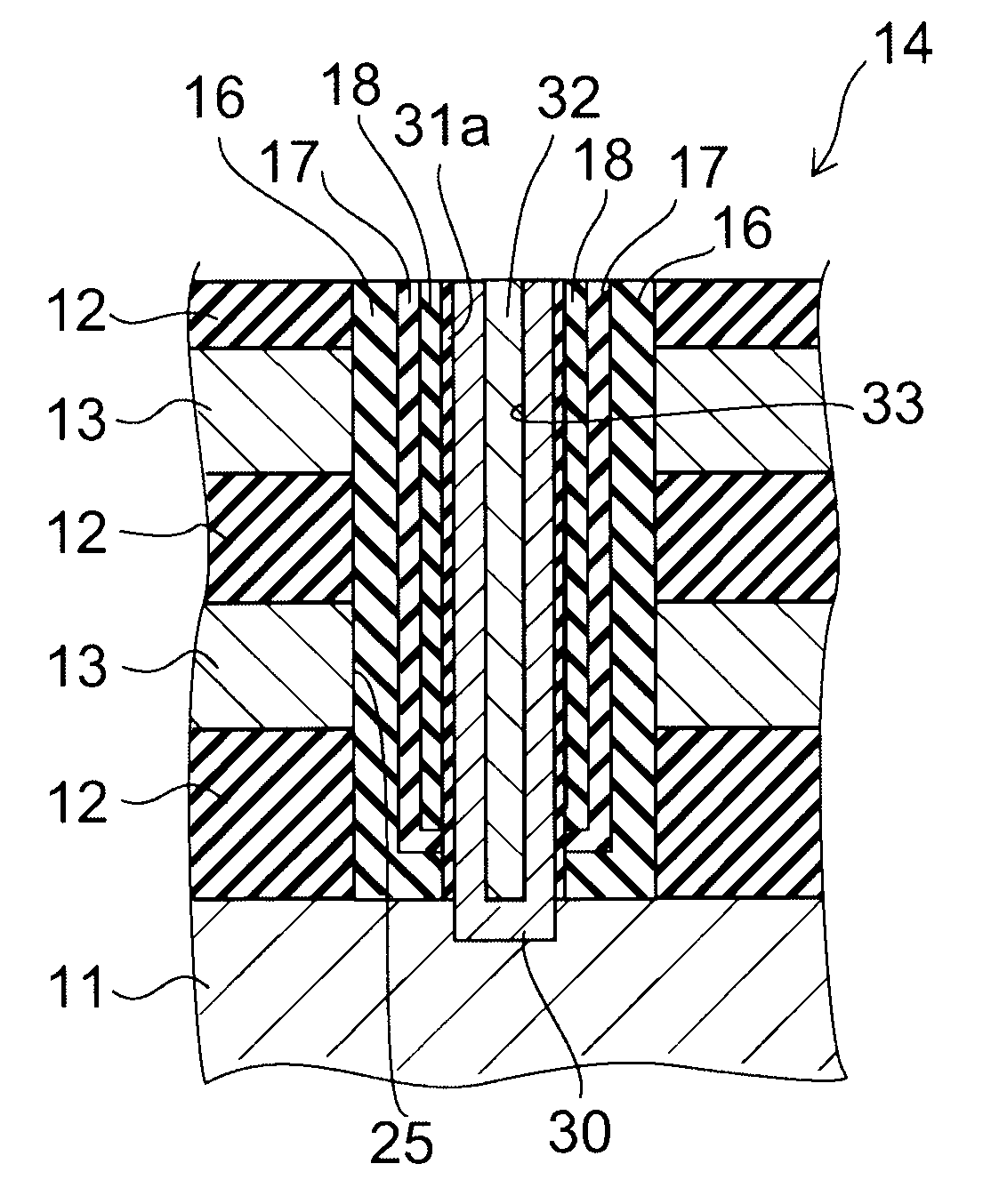

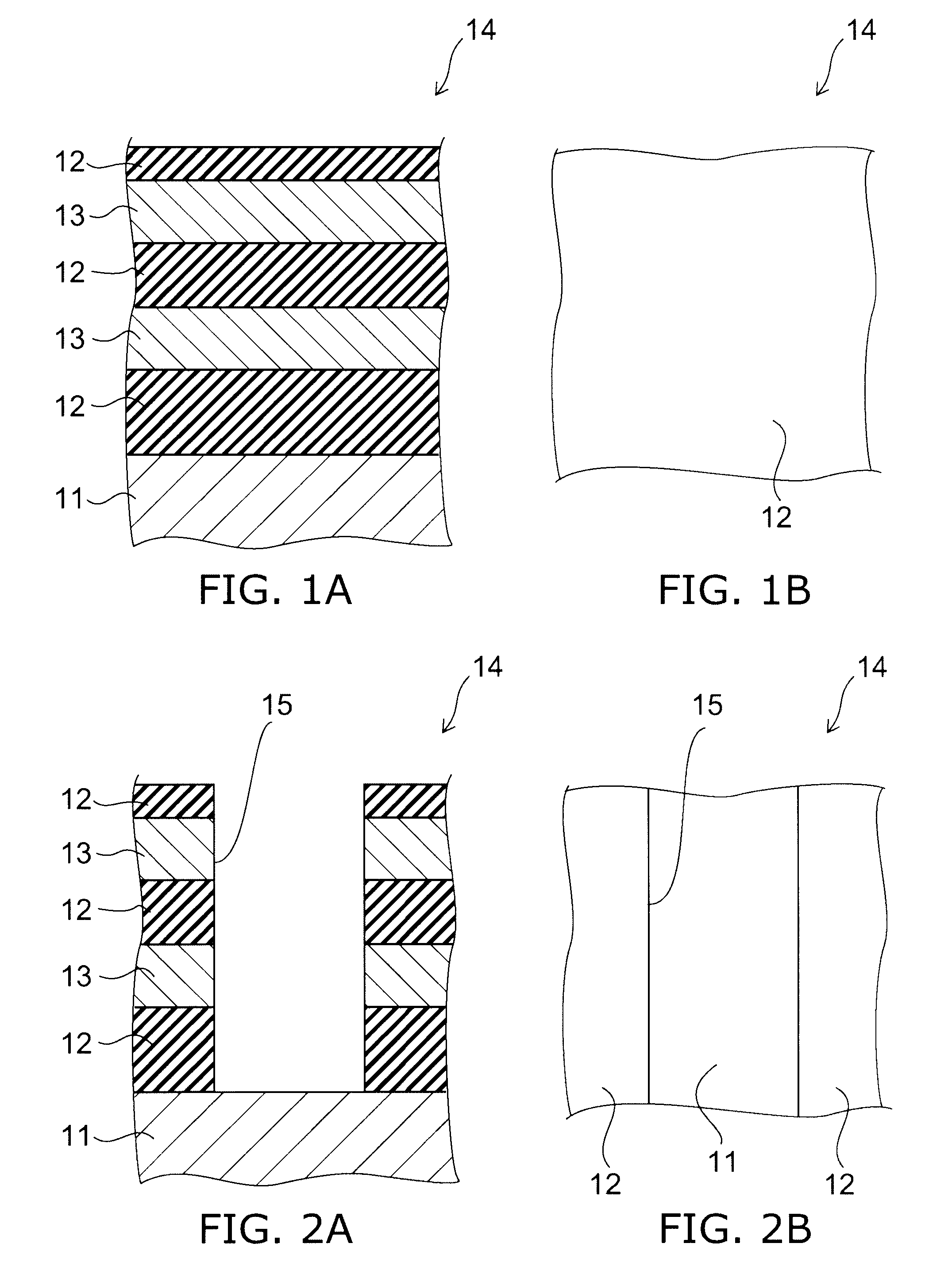

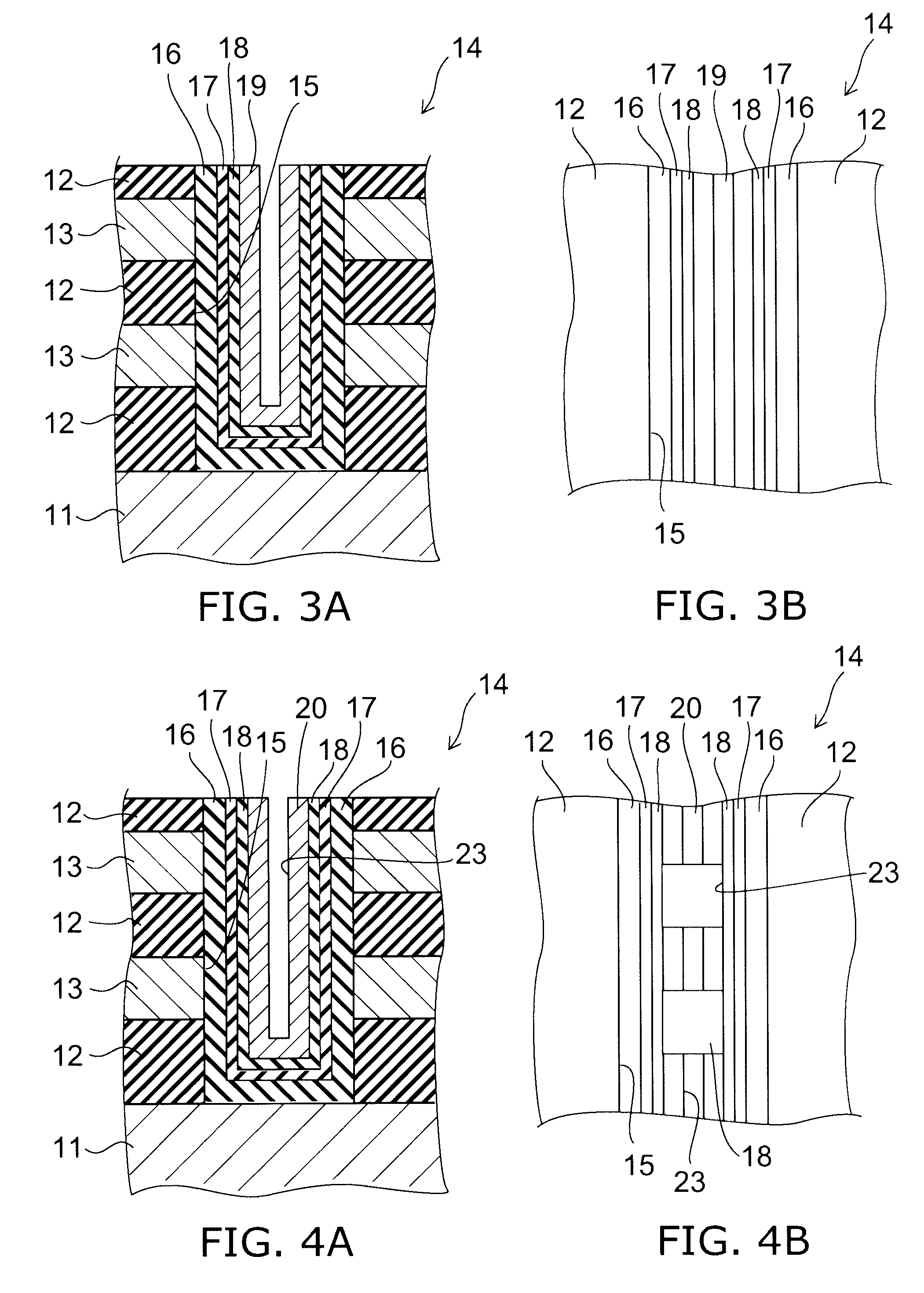

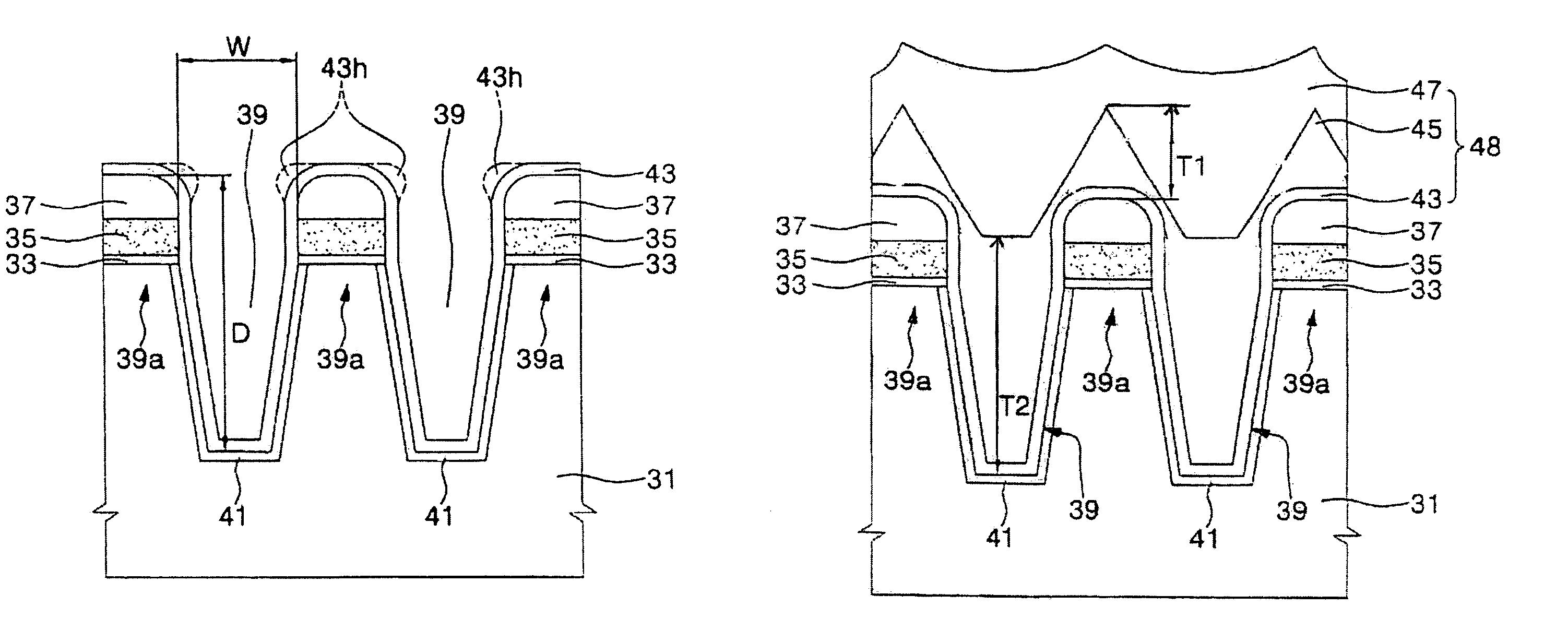

Nonvolatile semiconductor memory device and method for manufacturing the same

ActiveUS20100140684A1Solid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideThermal treatment

On a silicon substrate is formed a stacked body by alternately stacking a plurality of silicon oxide films and silicon films, a trench is formed in the stacked body, an alumina film, a silicon nitride film and a silicon oxide film are formed in this order on an inner surface of the trench, and a channel silicon crystalline film is formed on the silicon oxide film. Next, a silicon oxide layer is formed at an interface between the silicon oxide film and the channel silicon crystalline film by performing thermal treatment in an oxygen gas atmosphere.

Owner:KIOXIA CORP

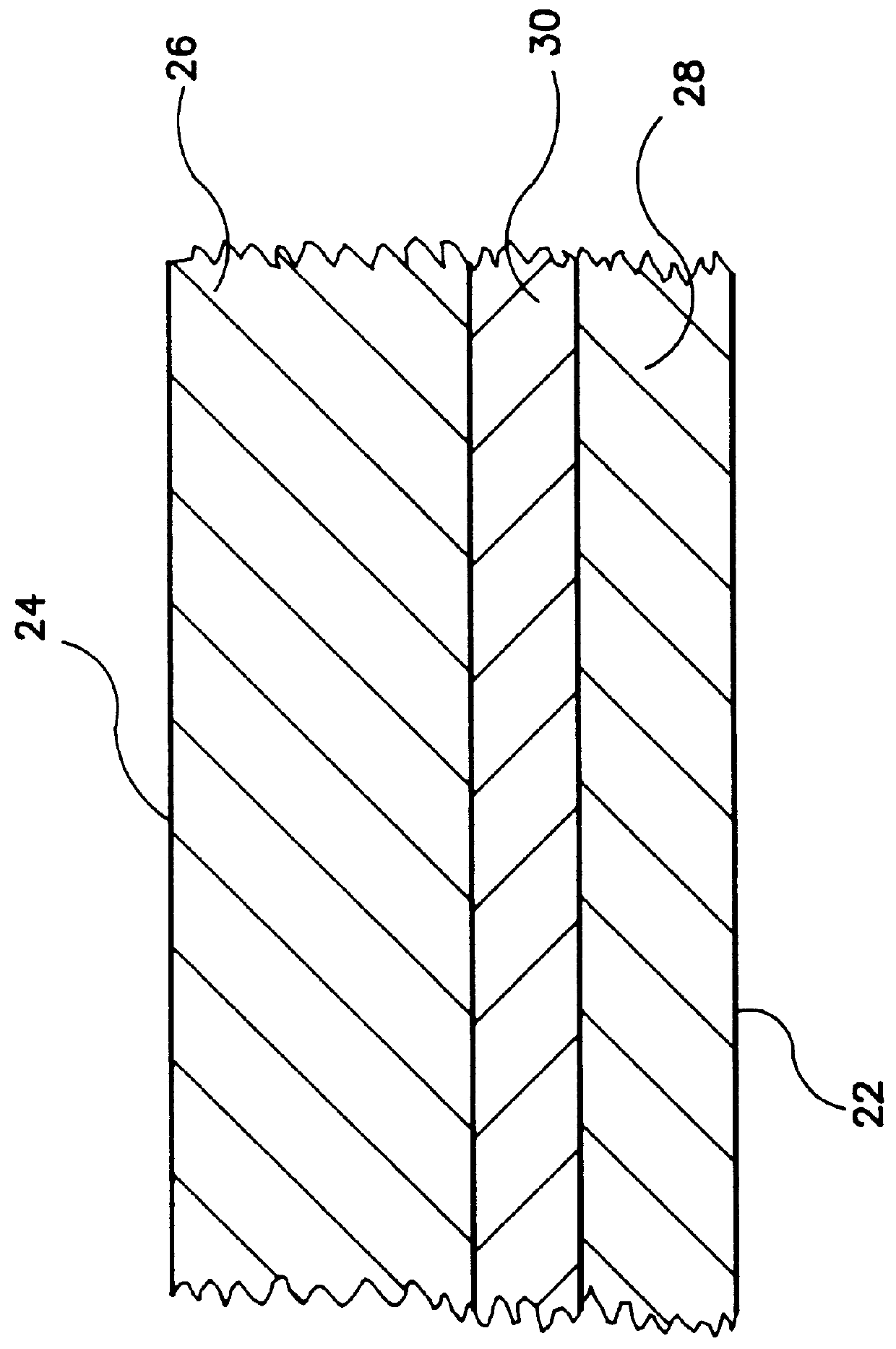

Oxygen scavenging condensation copolymers for bottles and packaging articles

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20080149593A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

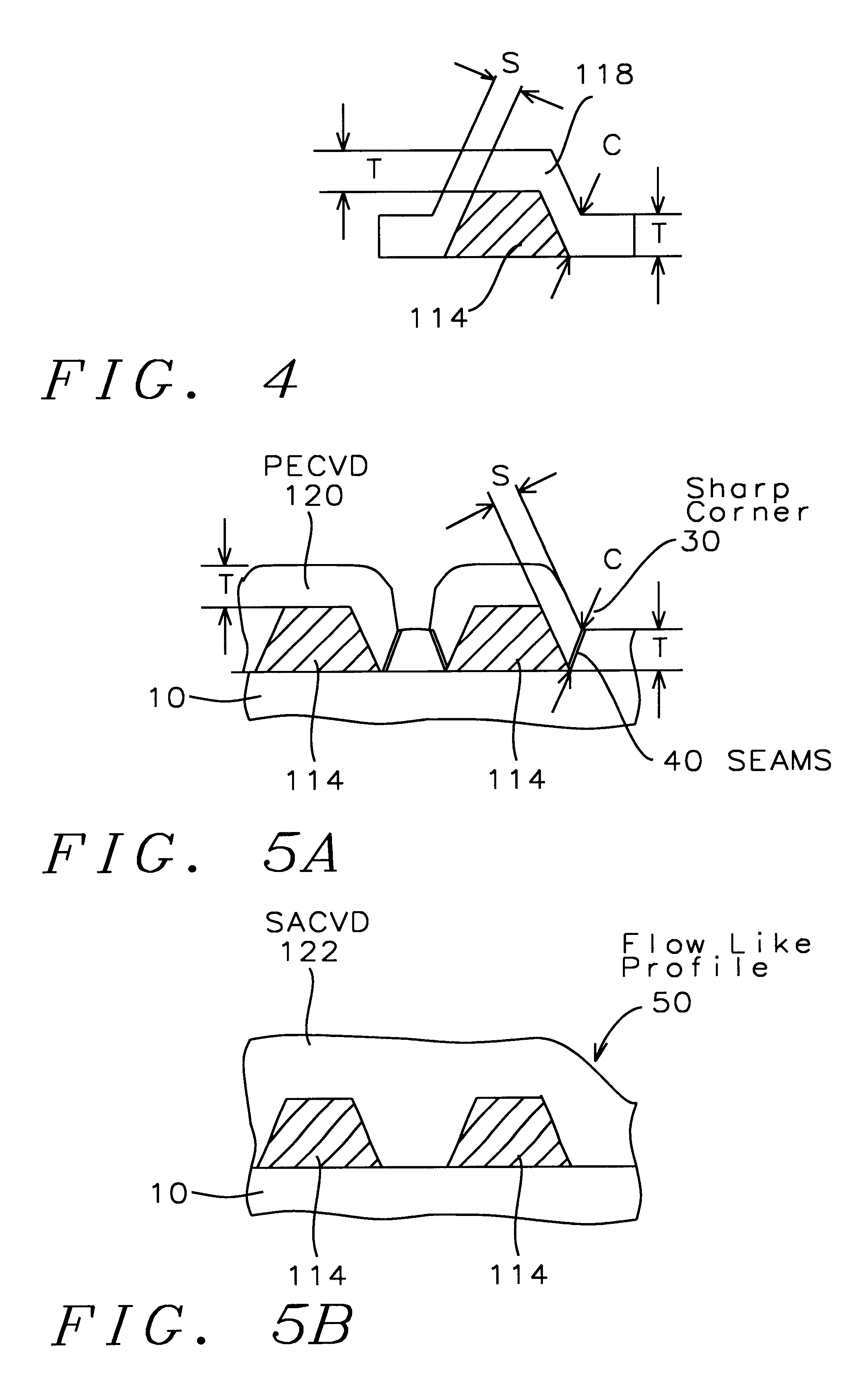

Method of silicon oxide and silicon glass films deposition

InactiveUS6197705B1Good step coverageImprove integrityPretreated surfacesSemiconductor/solid-state device manufacturingDielectricPlasma density

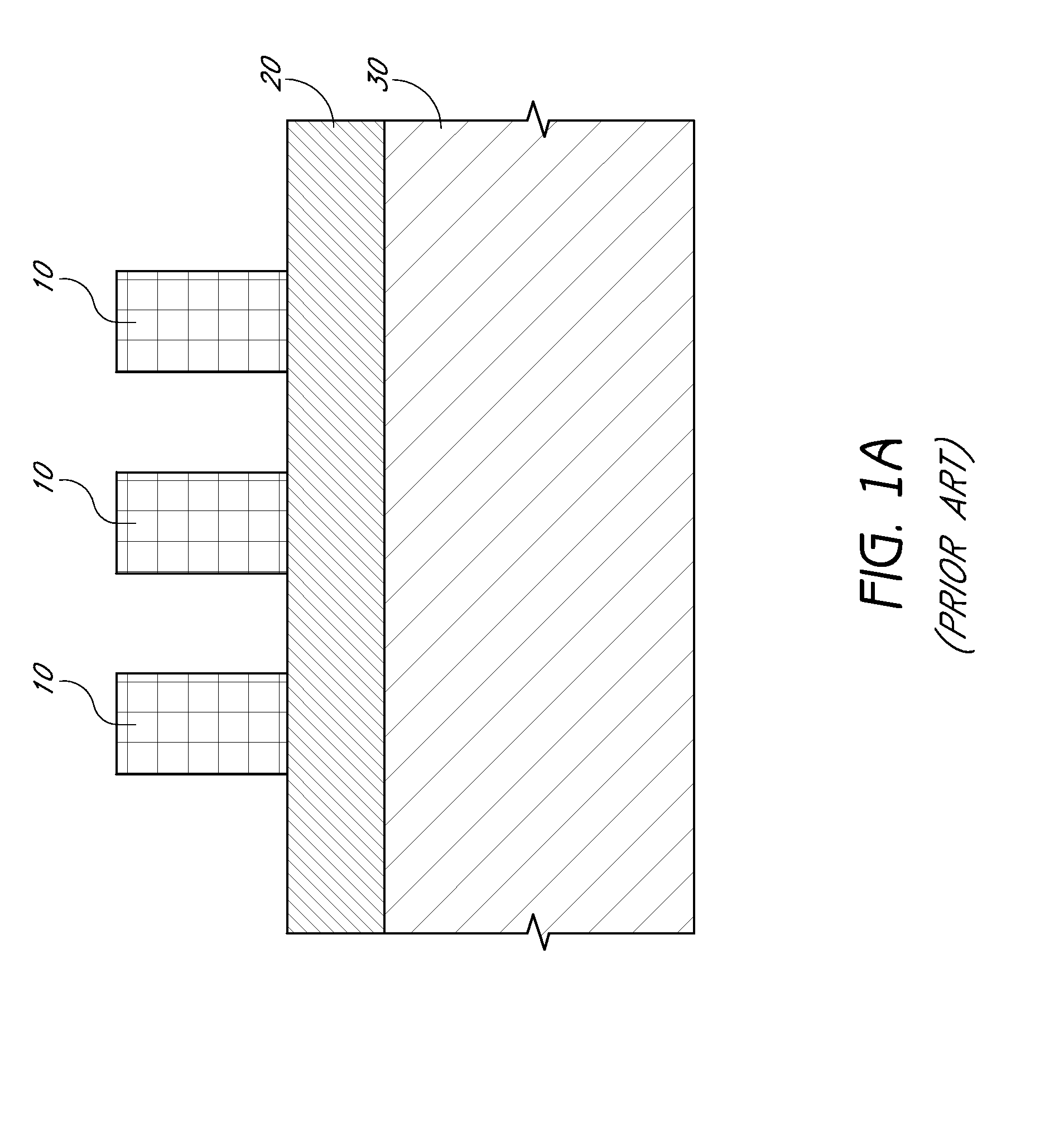

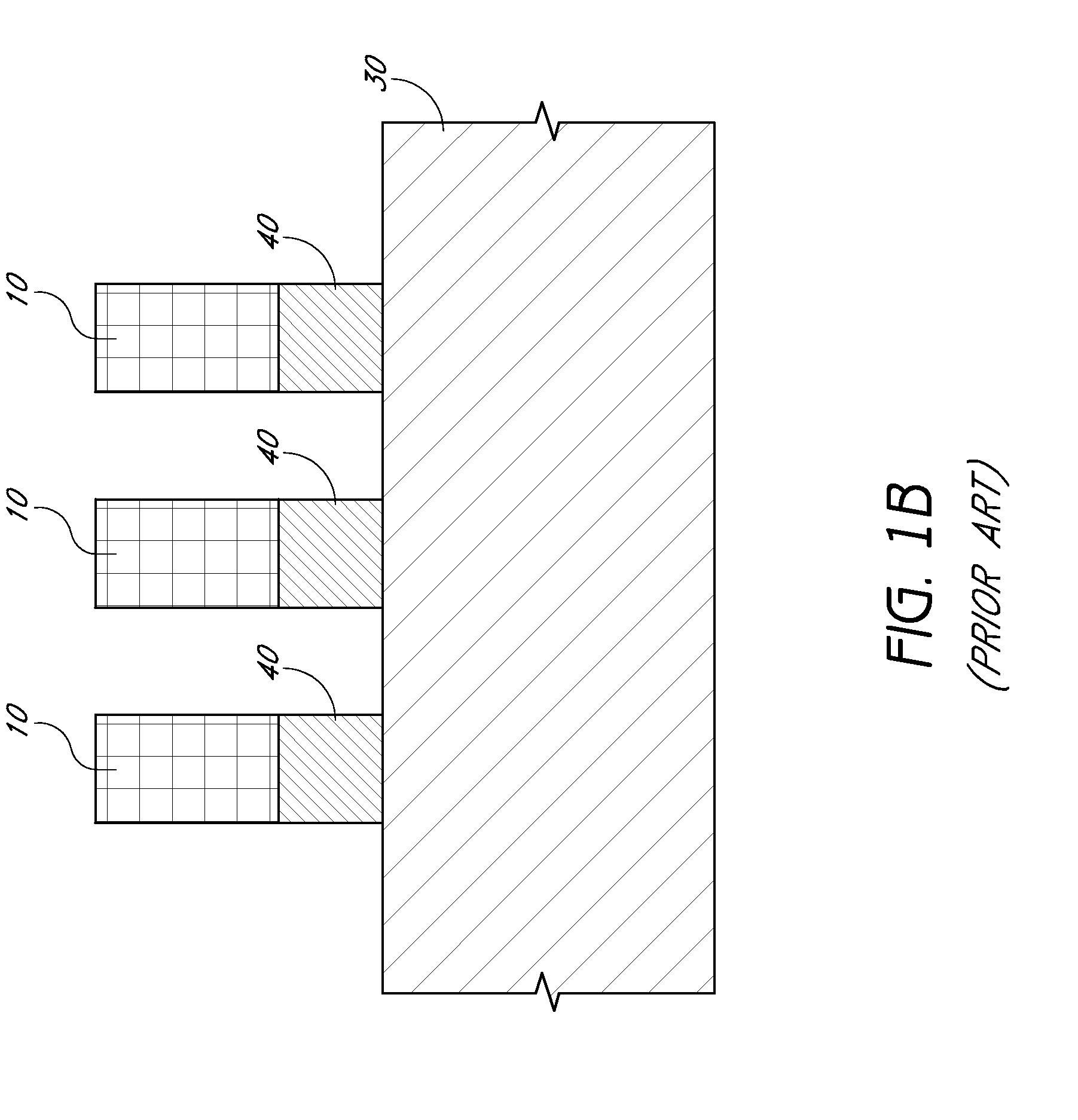

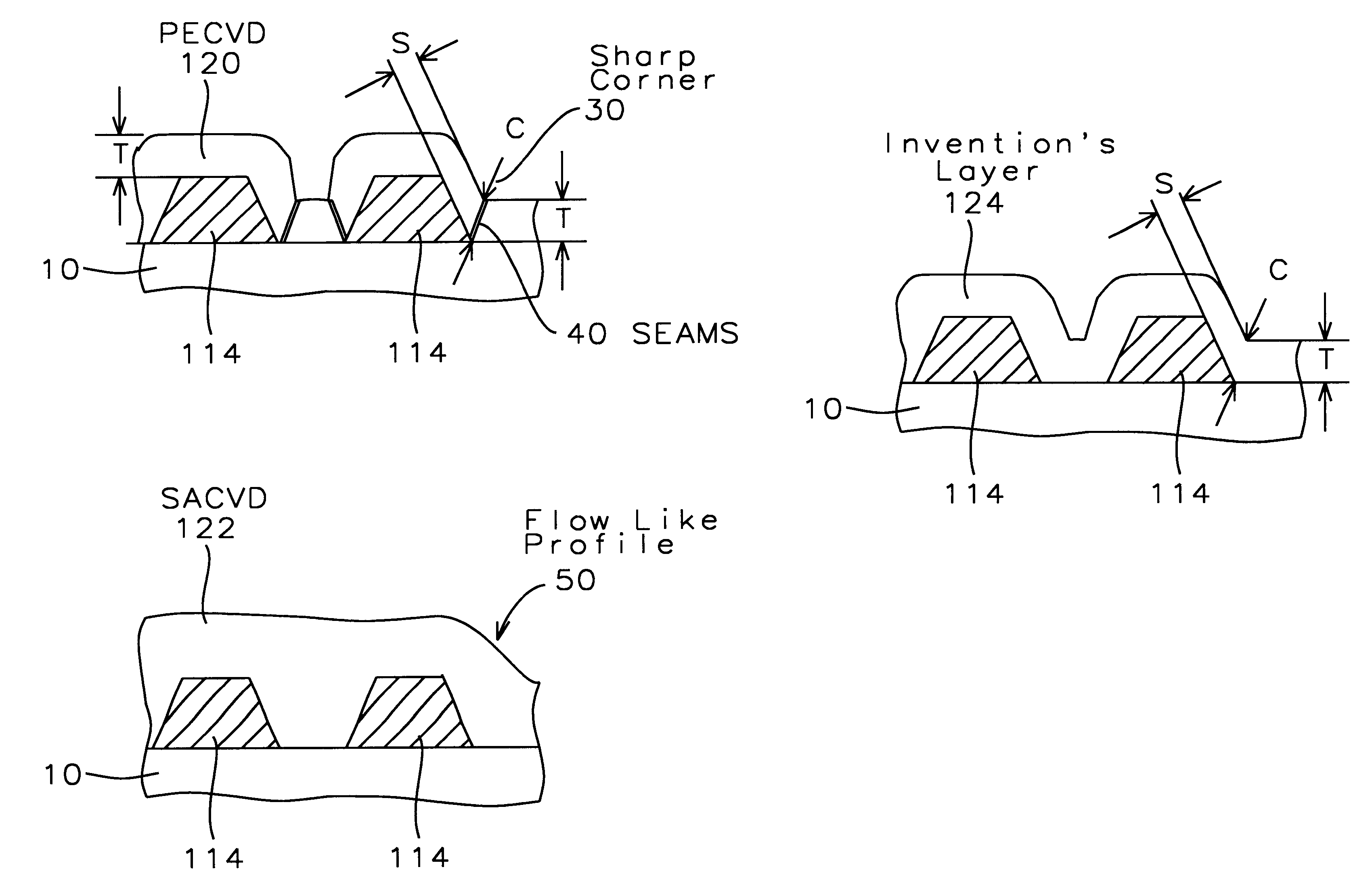

A method for fabricating a silicon oxide and silicon glass layers at low temperature using soft power-optimized Plasma-Activated CVD with a TEOS-ozone-oxygen reaction gas mixture (TEOS O3 / O2 PACVD) is described. It combines advantages of both low temperature Plasma-Enhanced Chemical Vapor Deposition (PECVD) and TEOS-ozone Sub-Atmospheric Chemical Vapor Deposition (SACVD) and yields a coating of silicon oxide with stable and high deposition rate, no surface sensitivity, good film properties, conformal step coverage and good gap-fill. Key features of the invention's O3 / O2 PACVD process are: a plasma is maintain throughout the entire deposition step in a parallel plate type reactor chamber, the precise RF plasma density, ozone concentration in oxygen and the deposition temperature. These features provide the reaction conditions for the proper O3 / O2 reaction mechanism that deposits a conformal silicon oxide layer. The process has significant implication for semiconductor device manufacturing involving the deposition of a dielectric over a conducting non-planar surface.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

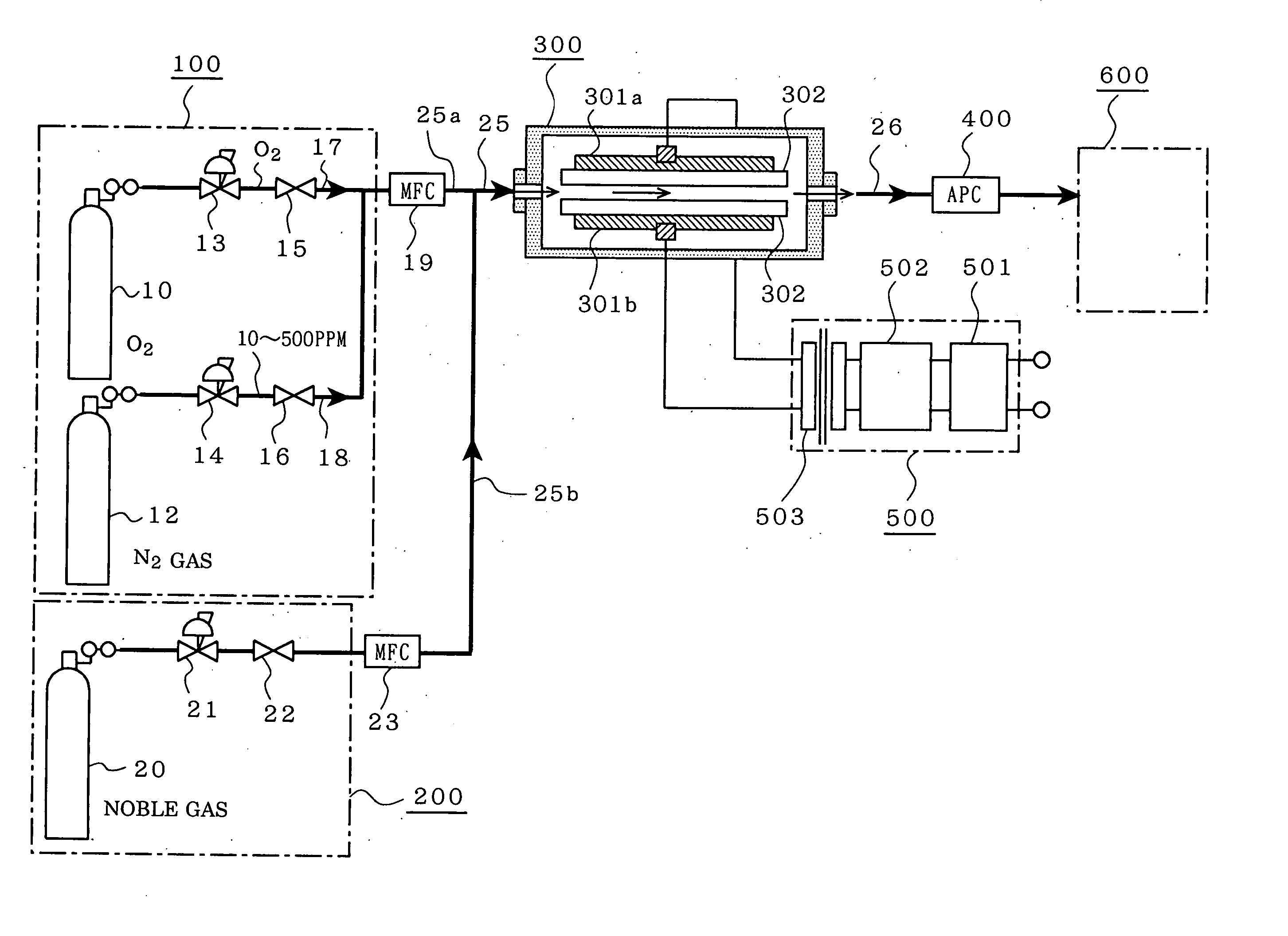

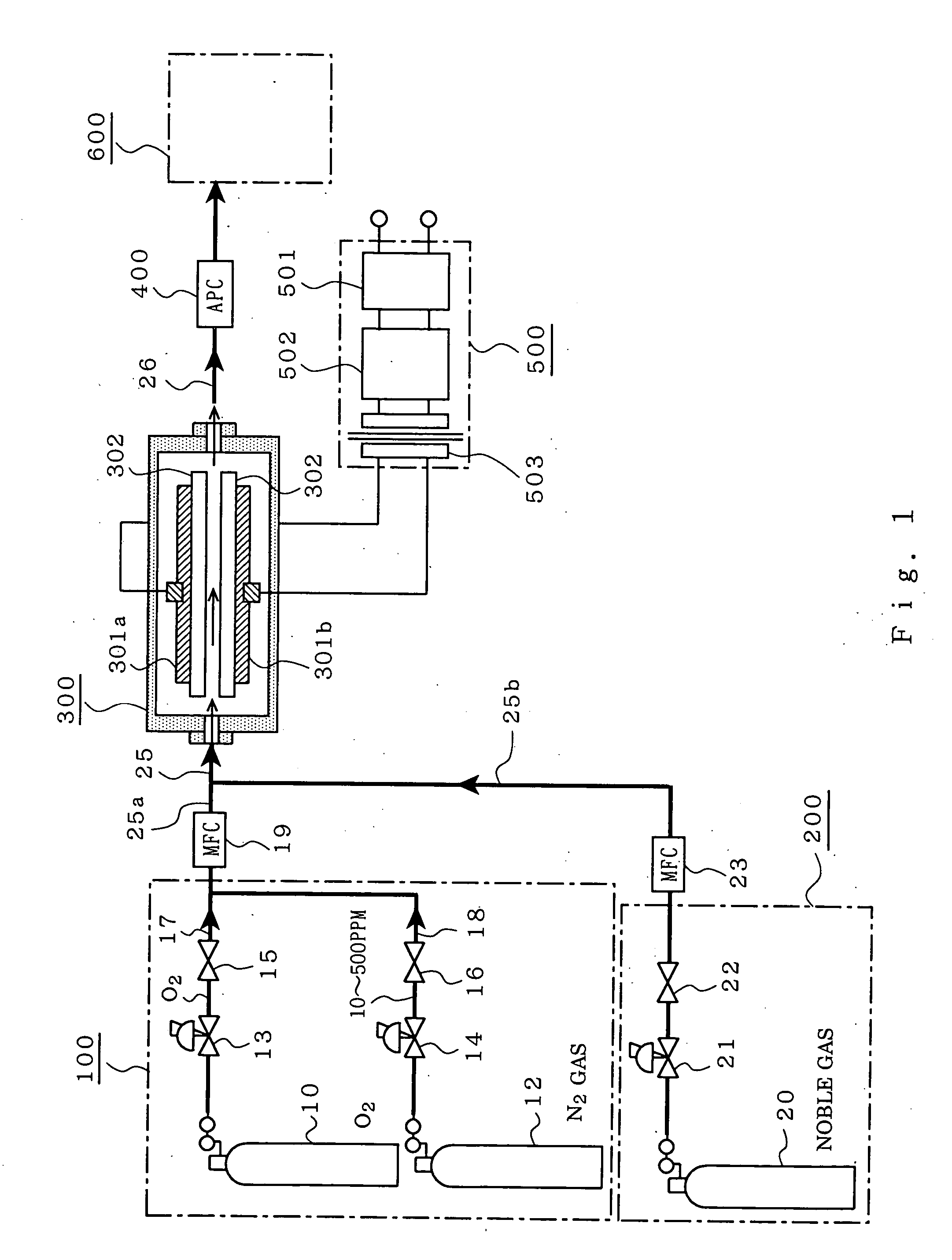

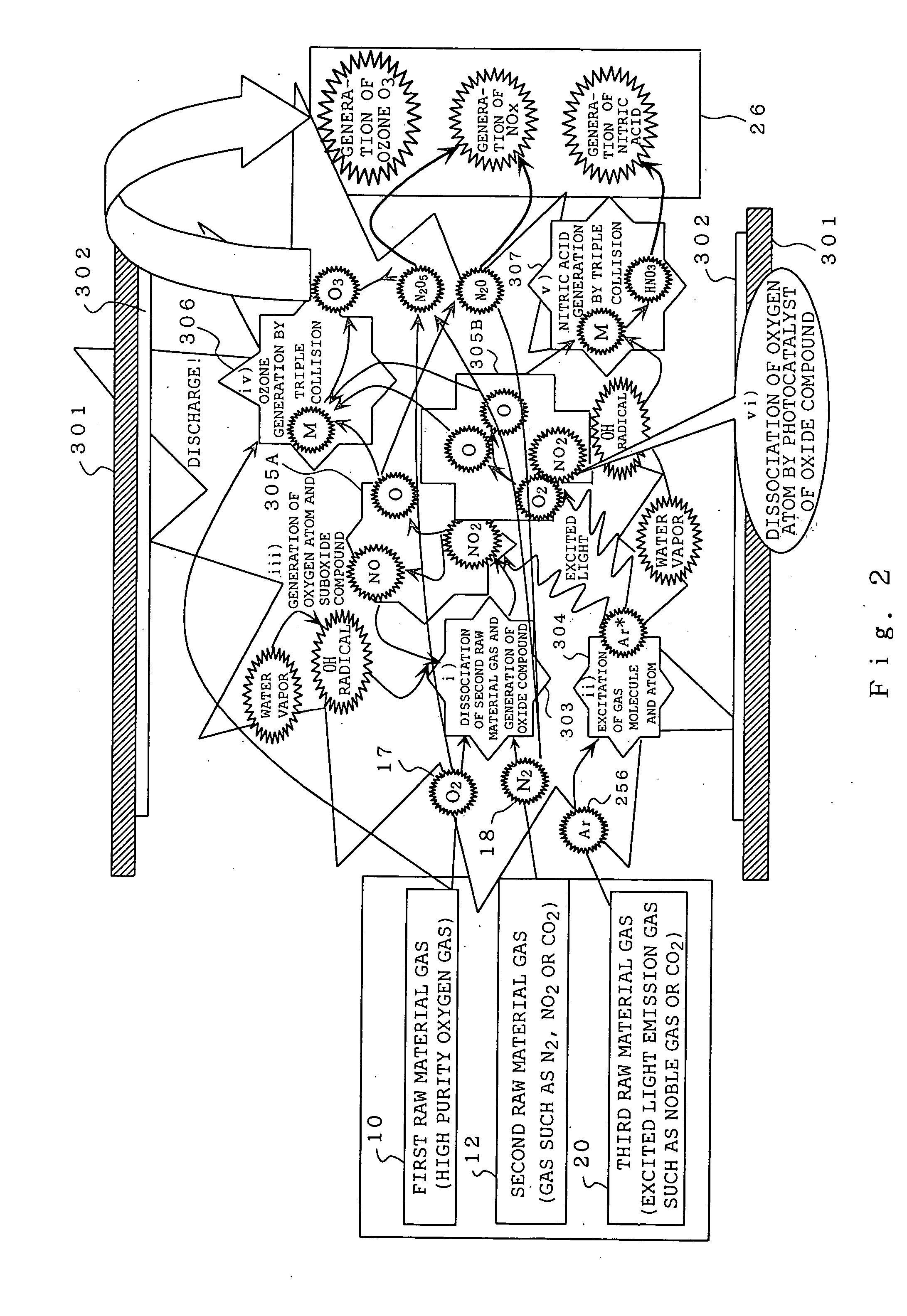

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Selective etching of carbon-doped low-k dielectrics

InactiveUS20050026430A1High selectivityReducing micro-loadingDecorative surface effectsVacuum evaporation coatingPlasma etchingChemistry

The present invention includes a process for selectively etching a low-k dielectric material formed on a substrate using a plasma of a gas mixture in a plasma etch chamber. The gas mixture comprises a fluorine-rich fluorocarbon or hydrofluorocarbon gas, a nitrogen-containing gas, and one or more additive gases, such as a hydrogen-rich hydrofluorocarbon gas, an inert gas and / or a carbon-oxygen gas. The process provides a low-k dielectric to a photoresist mask etching selectivity ratio greater than about 5:1, a low-k dielectric to a barrier / liner layer etching selectivity ratio greater about 10:1, and a low-k dielectric etch rate higher than about 4000 Å / min.

Owner:APPLIED MATERIALS INC

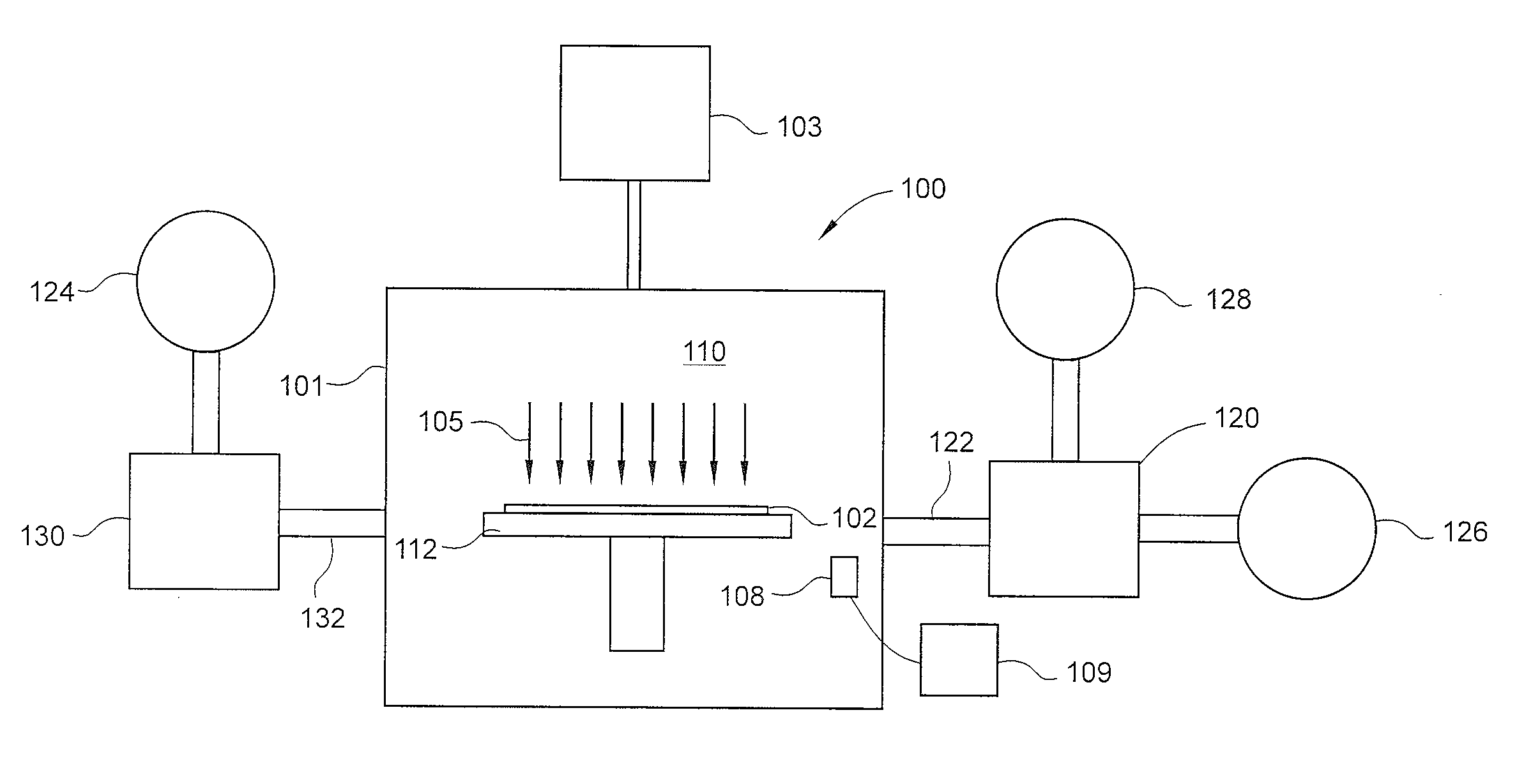

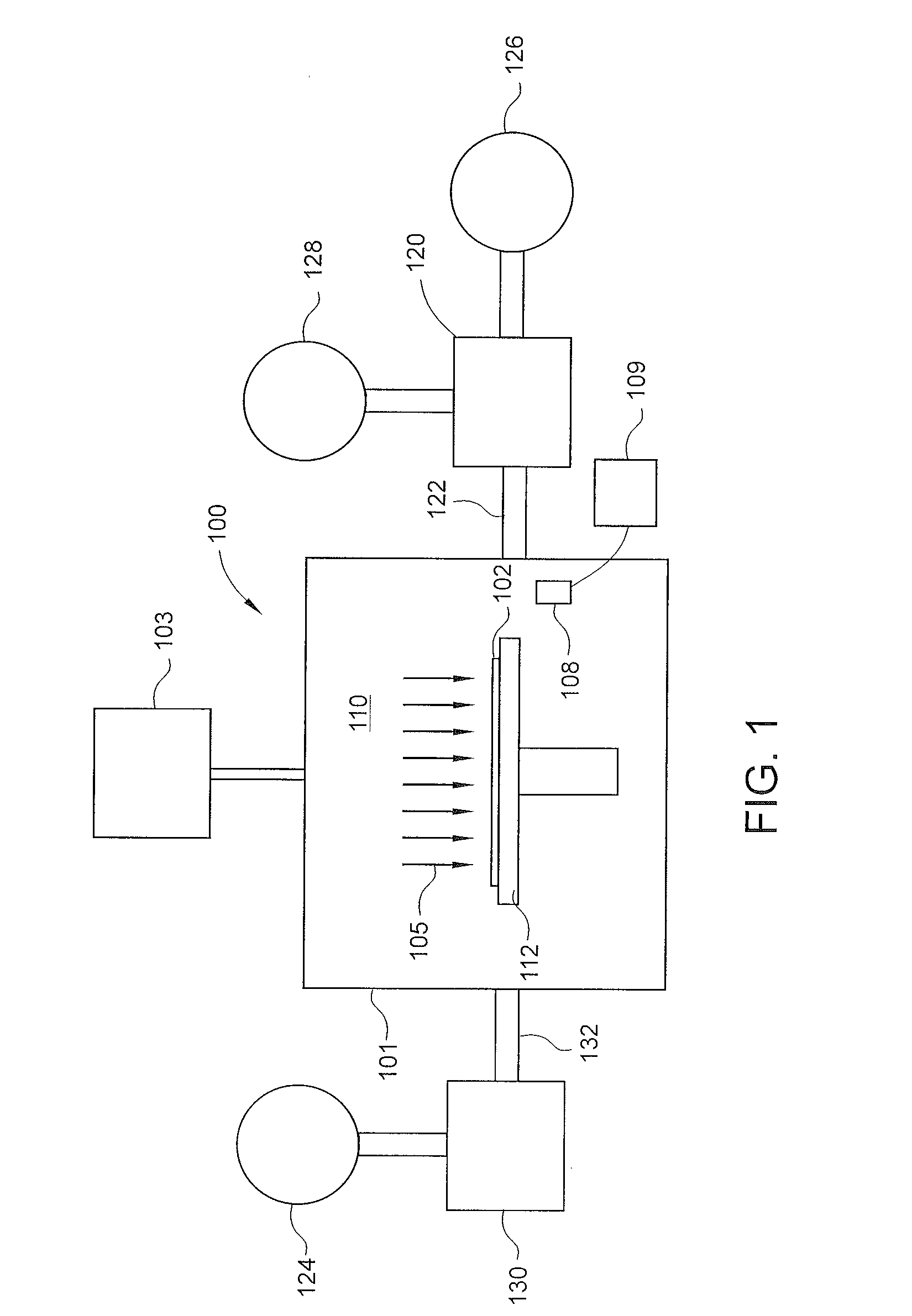

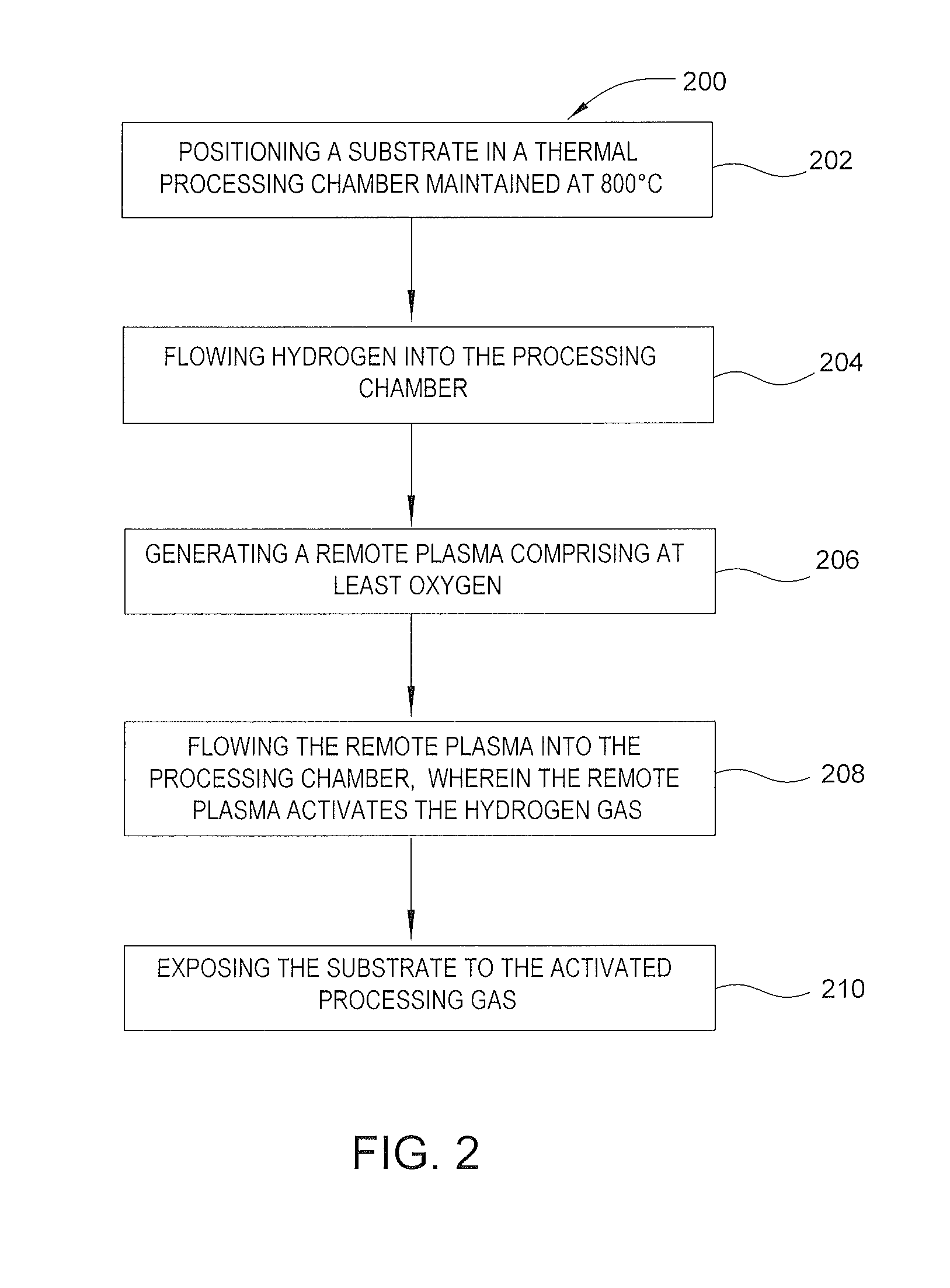

Apparatus and method for selective oxidation at lower temperature using remote plasma source

InactiveUS20140034632A1Reducing surface of metalHeater elementsSemiconductor/solid-state device manufacturingHydrogenRemote plasma

Devices and methods for selectively oxidizing silicon are described herein. An apparatus for selective oxidation of exposed silicon surfaces includes a thermal processing chamber with a plurality of walls, first inlet connection and a second inlet connection, wherein the walls define a processing region within the processing chamber, a substrate support within the processing chamber, a hydrogen source connected with the first inlet connection, a heat source connected with the hydrogen source, and a remote plasma source connected with the second inlet connection and an oxygen source. A method for selective oxidation of non-metal surfaces, can include positioning a substrate in a processing chamber at a temperature less than 800° C., flowing hydrogen into the processing chamber, generating a remote plasma comprising oxygen, mixing the remote plasma with the hydrogen gas in the processing chamber to create an activated processing gas, and exposing the substrate to the activated gas.

Owner:APPLIED MATERIALS INC

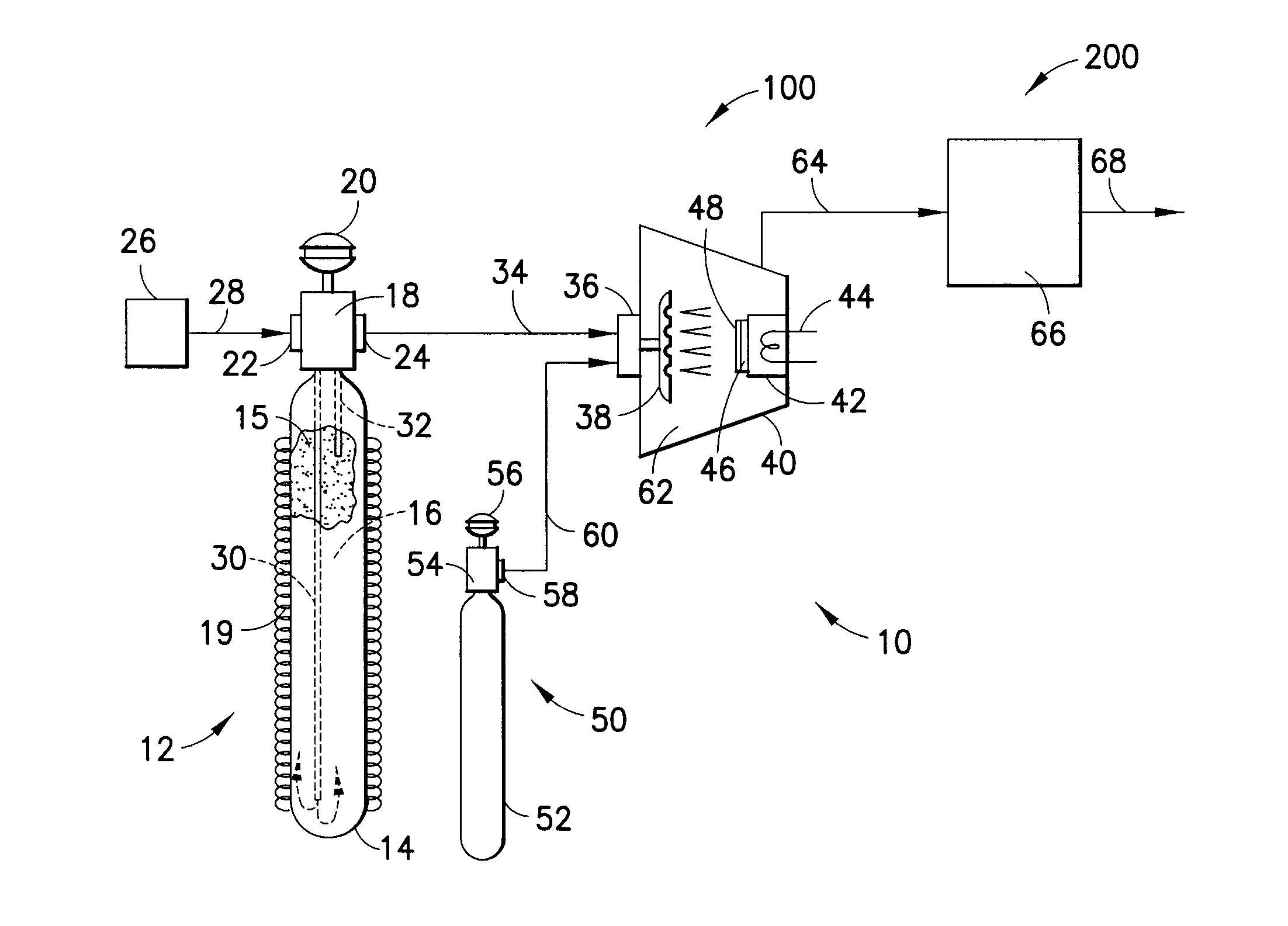

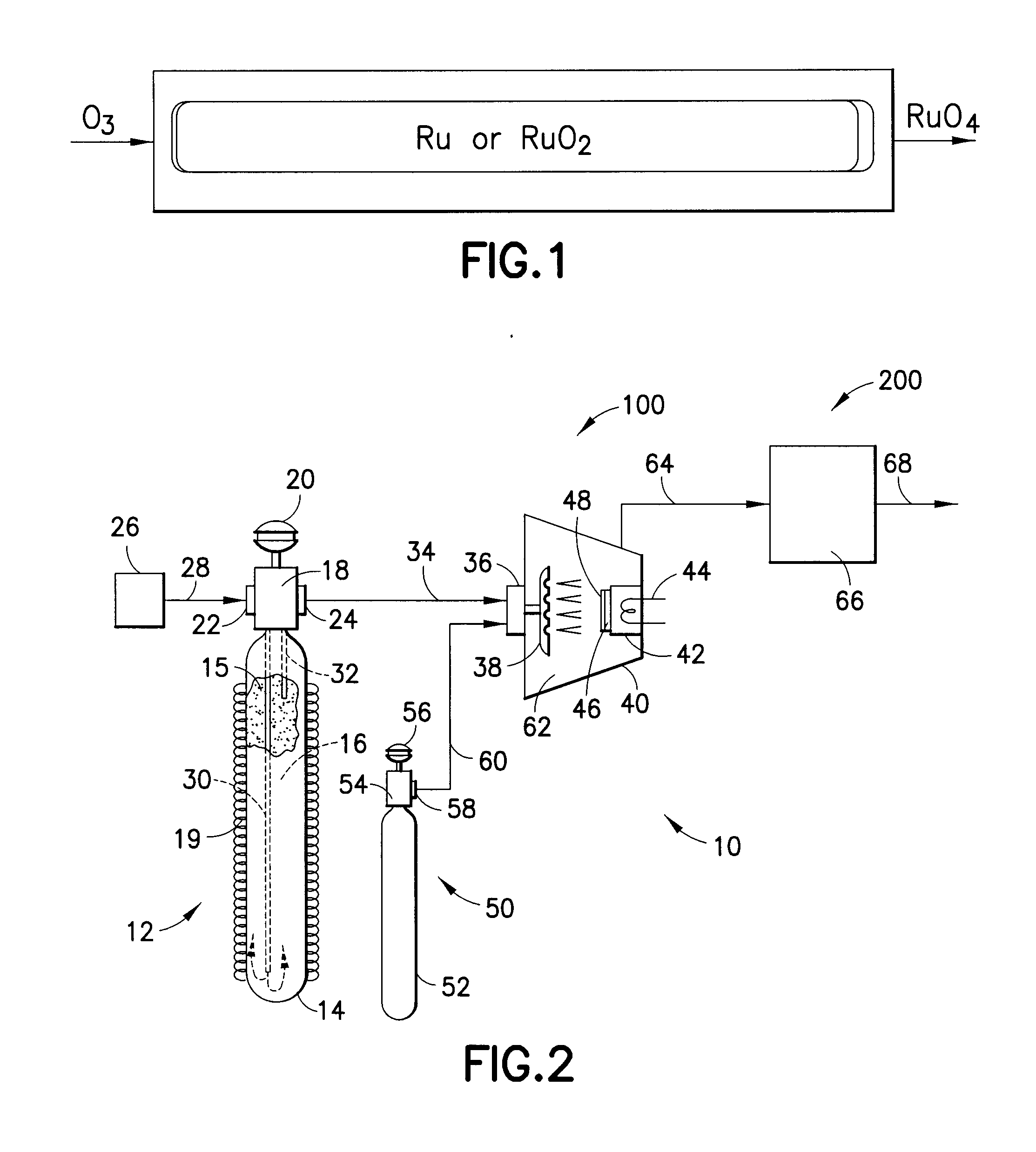

IN SITU GENERATION OF RuO4 FOR ALD OF Ru AND Ru RELATED MATERIALS

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

Apparatus and method for generating nitrogen oxides

InactiveUS20080176335A1Possible to useIncrease productionChemical analysis using combustionNitrogen compoundsCombustion chamberWorking temperature

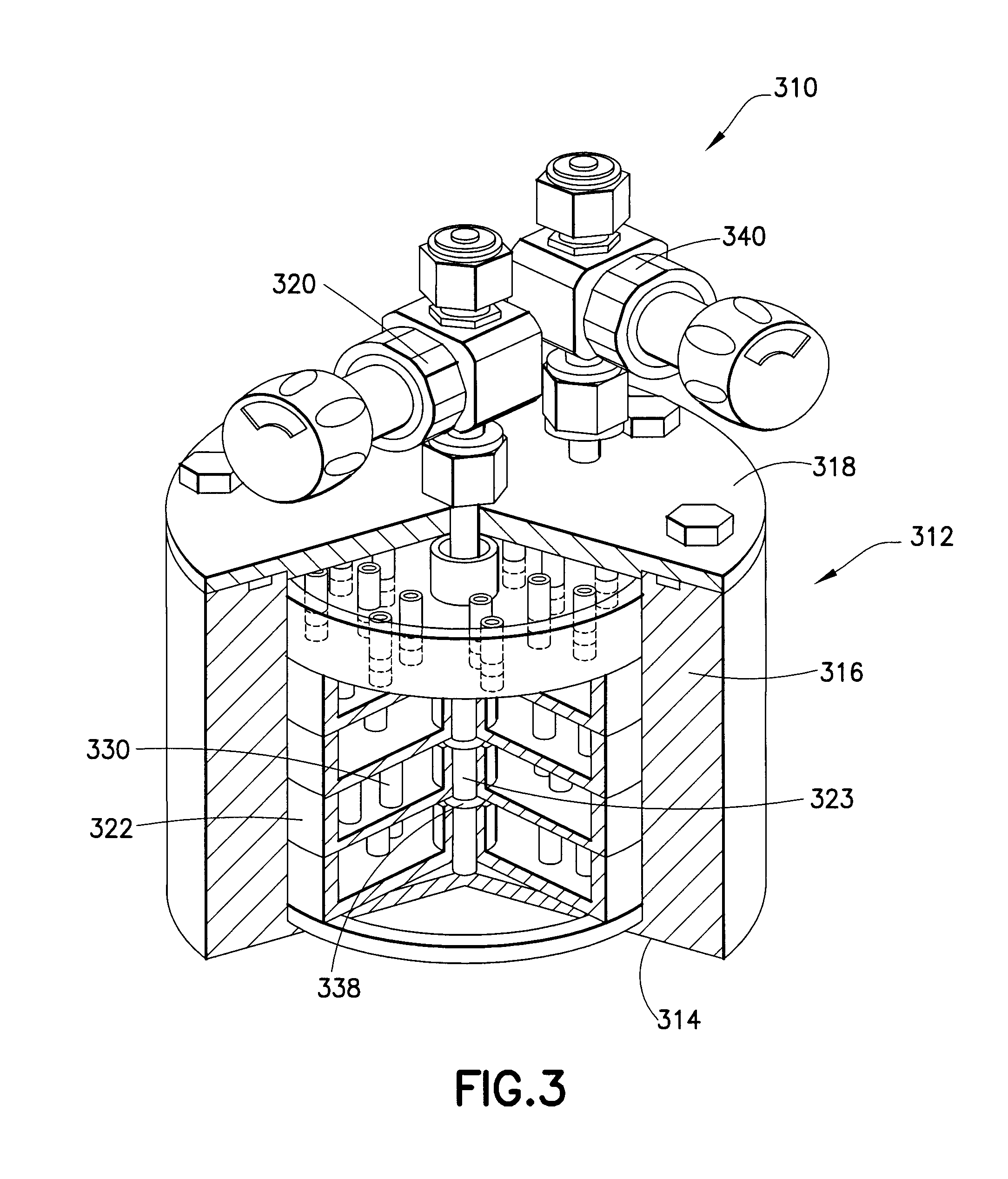

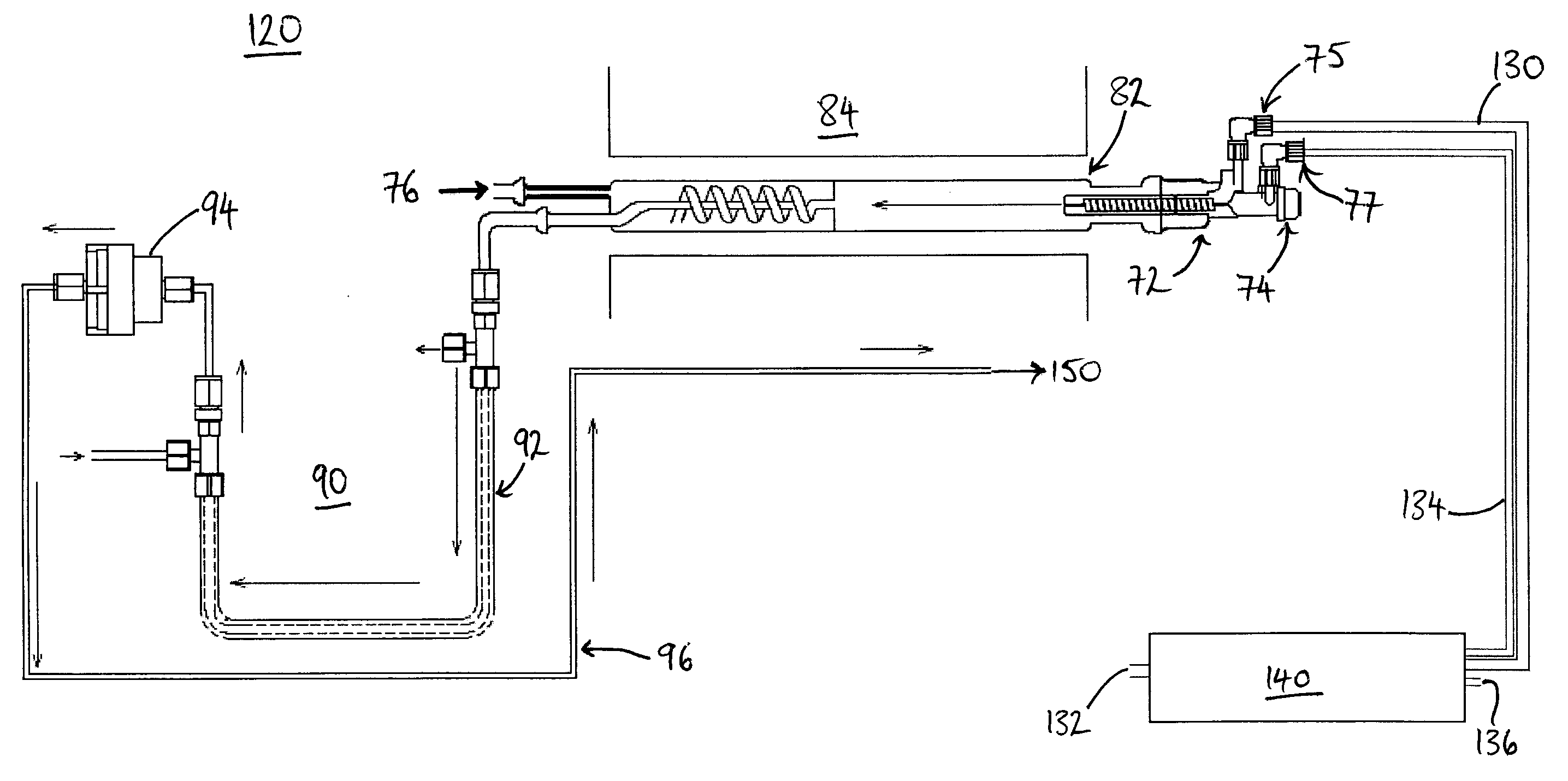

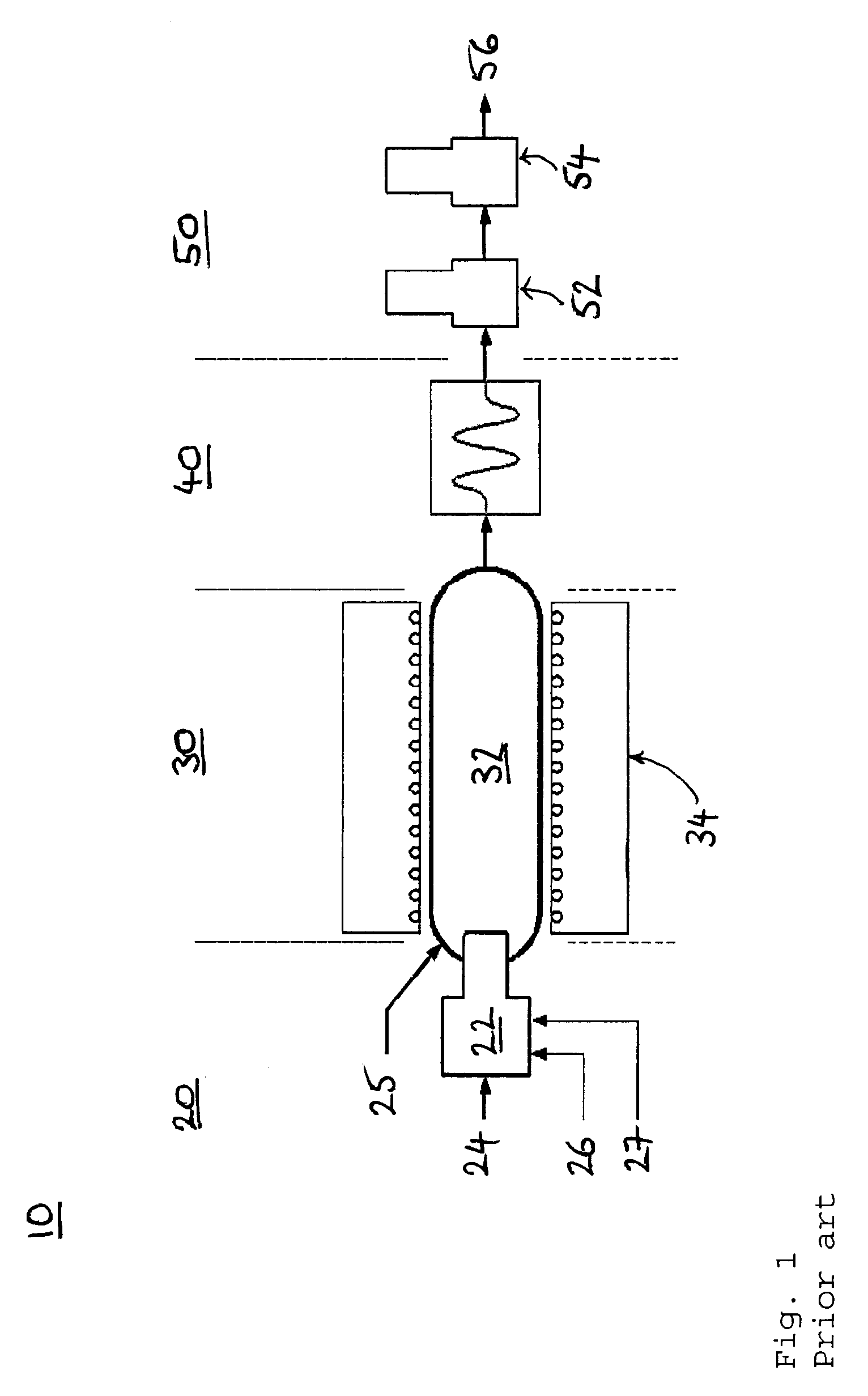

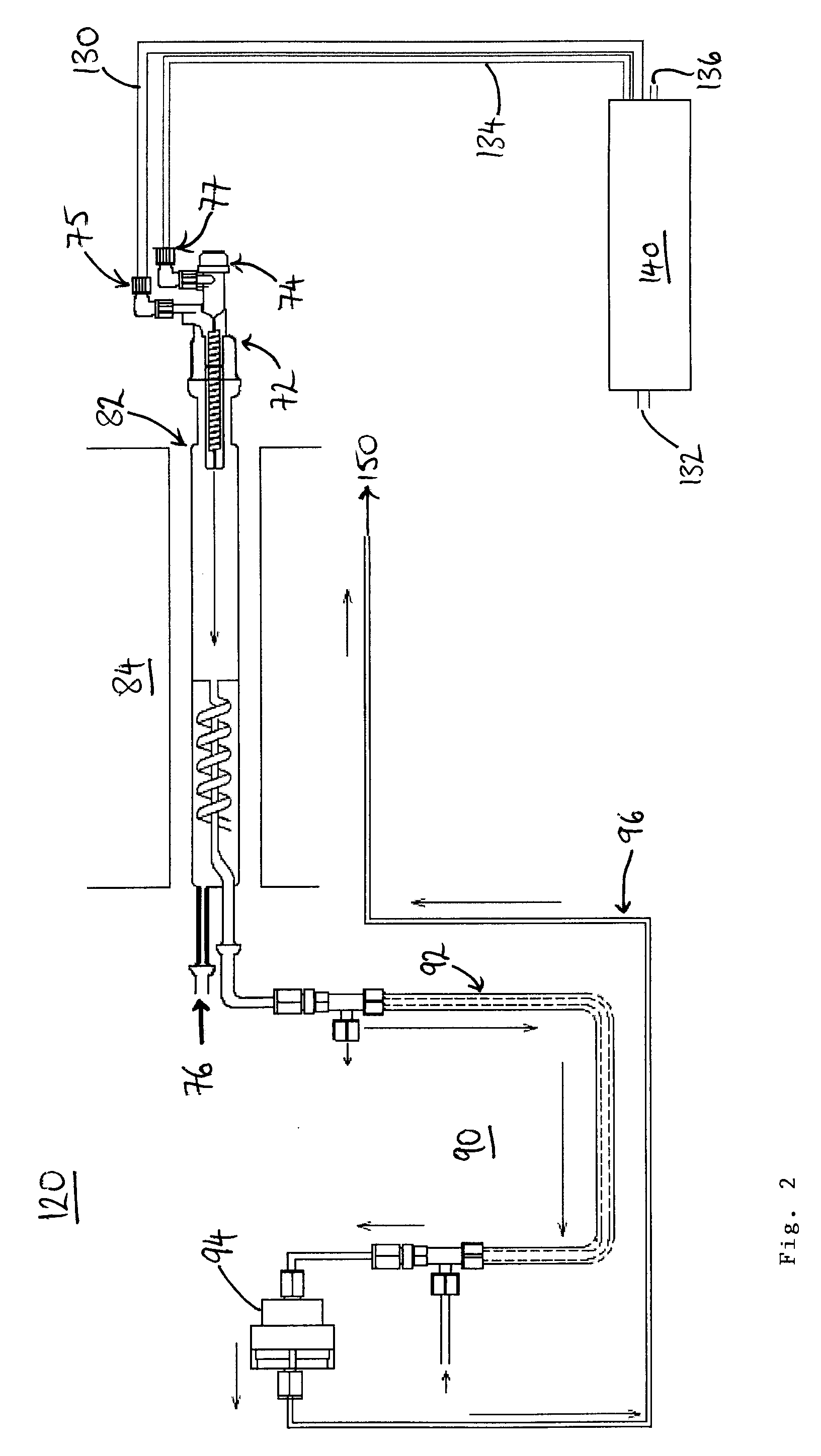

A combustion analyzer apparatus and method for combustion analysing a sample, the analyzer comprising a combustion chamber (82) for receiving a sample for combustion therein to form combustion products, and a fluid supply apparatus for supplying fluid(s) into the chamber. The fluid supply apparatus (130-140) comprises a nitrogen oxides (NOx) generating apparatus (140,190,210,240) and is arranged to supply NOx into the combustion chamber. A yield of sulphur dioxide in the combustion products may thereby be improved. The NOx generating apparatus may be operated at a raised working temperature. The NOx generating apparatus may be provided by an ozonator with a supply of nitrogen and oxygen. A Venturi tube arrangement (246) may draw the generated NOx into a (carrier or oxygen) gas line to the combustion chamber. Ozone may be supplied to the combustion products to convert nitrogen monoxide therein to nitrogen dioxide. The NOx and ozone may be supplied by a single device (210,240).

Owner:THERMO ELECTRON MFG

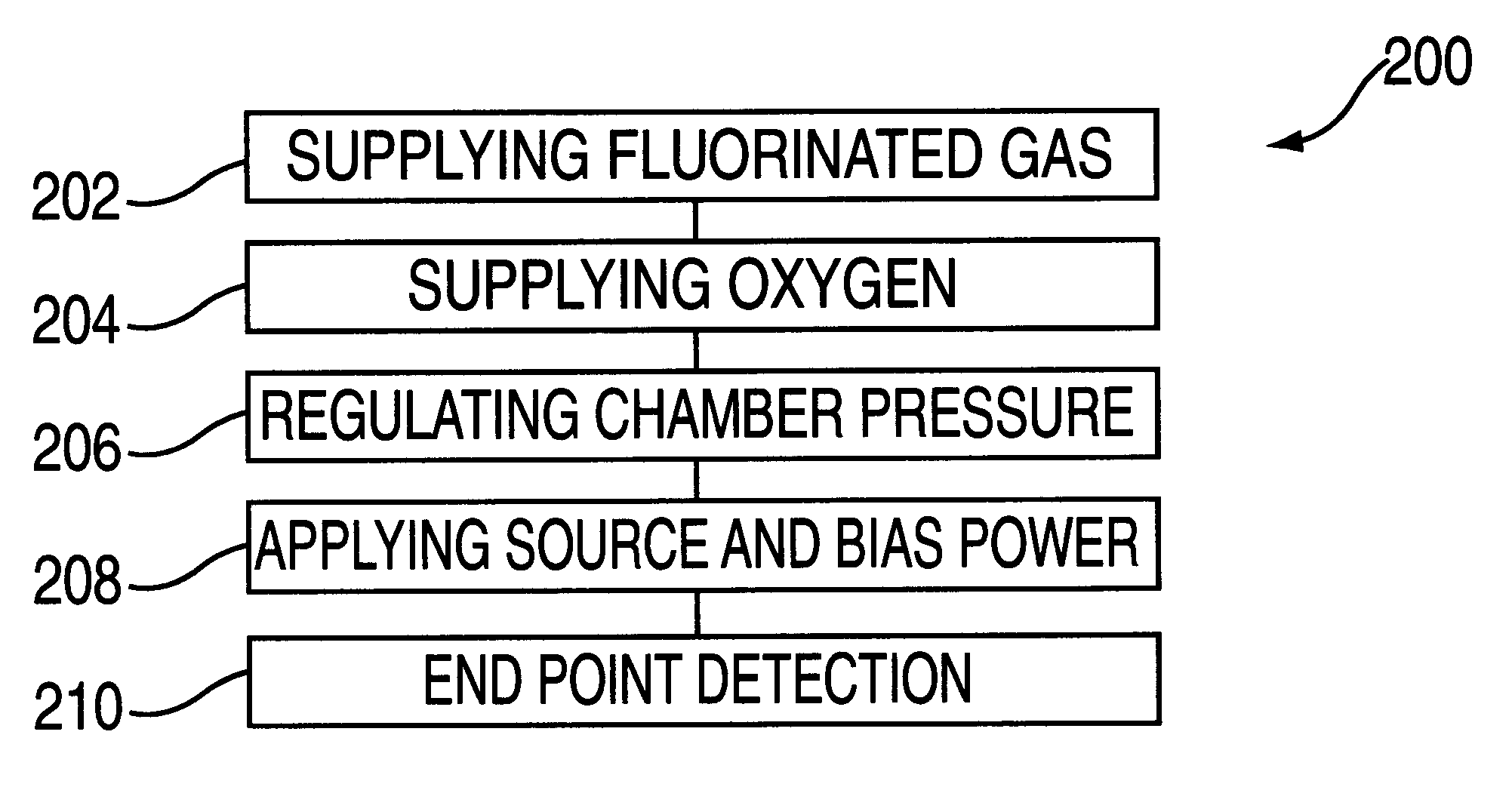

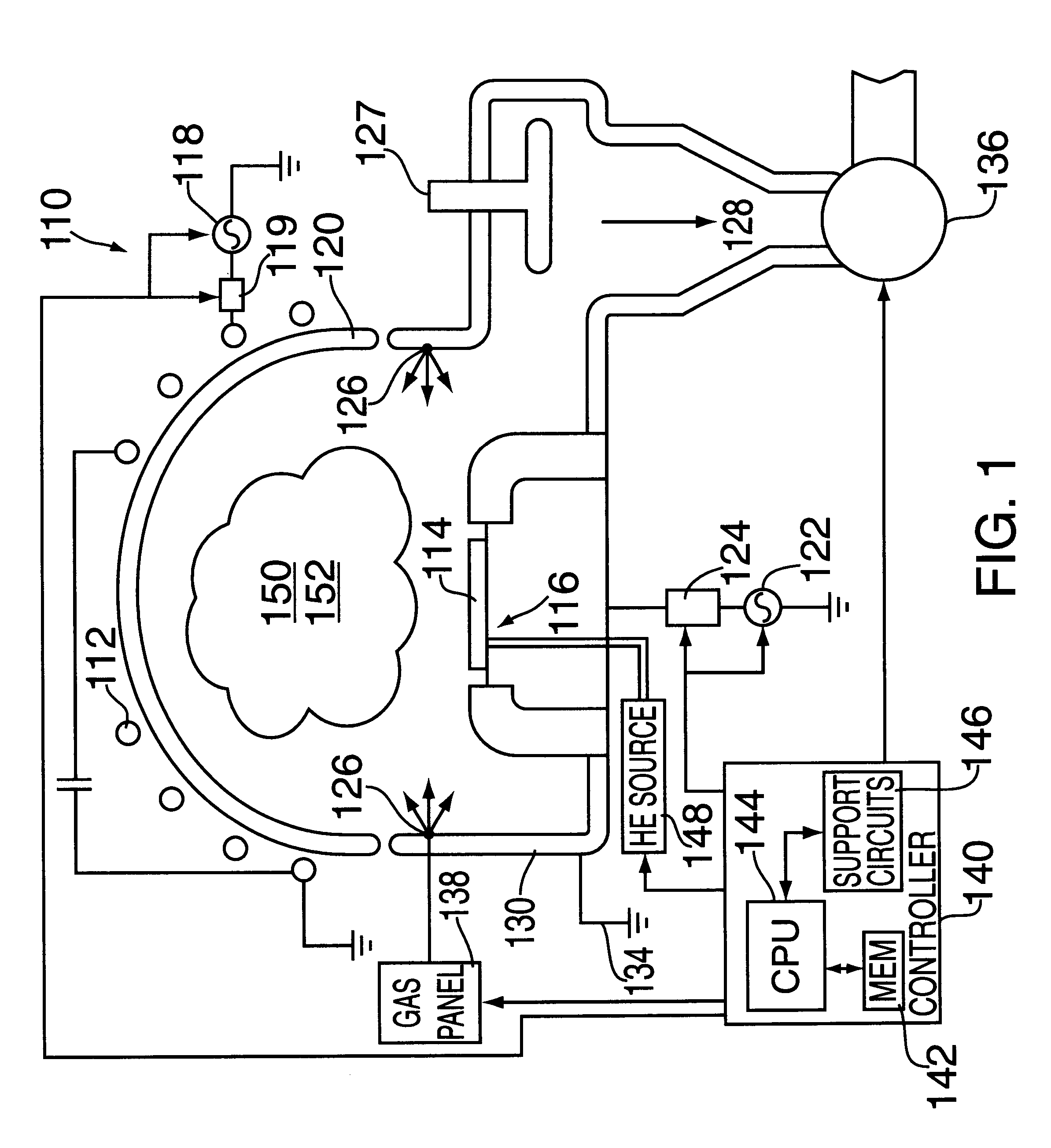

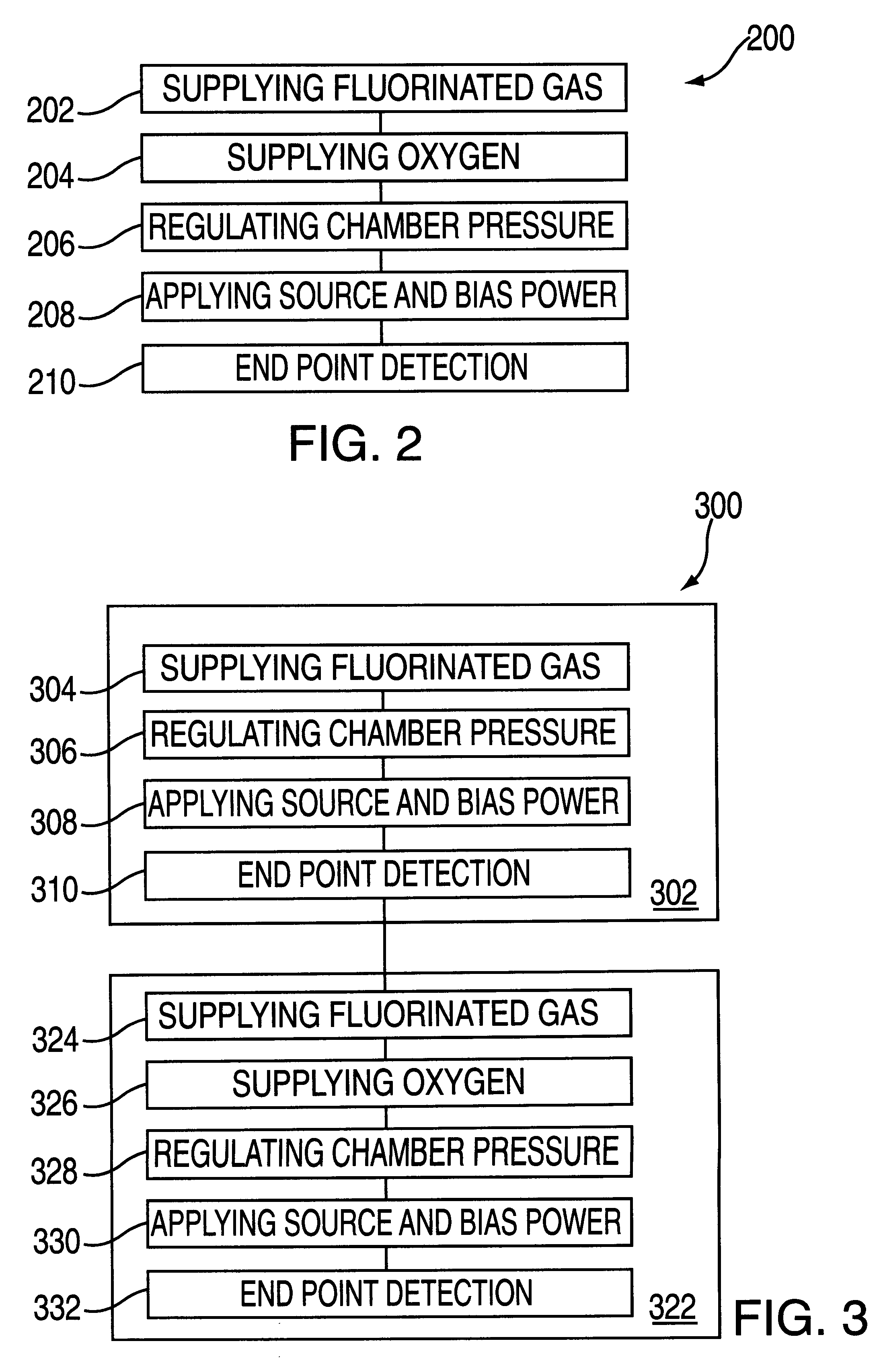

Plasma processing of tungsten using a gas mixture comprising a fluorinated gas and oxygen

InactiveUS6277763B1Good choiceElectric discharge tubesVacuum gauge using ionisation effectsFluorinated gasesProduct gas

Owner:APPLIED MATERIALS INC

Ozone gas concentration measurement method, ozone gas concentration measurement system, and substrate processing apparatus

ActiveUS20100119439A1Improve concentrationEasy to measurePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor/solid-state device manufacturingProduct gasGas concentration

An ozone gas concentration measurement method that can easily measure the concentration of ozone gas. A process gas containing ozone gas is produced from a raw gas containing oxygen gas. The number of moles of gas molecules contained in the process gas is measured. The concentration of the ozone gas contained in the process gas is calculated based on the number of moles of gas molecules contained in the process gas.

Owner:TOKYO ELECTRON LTD

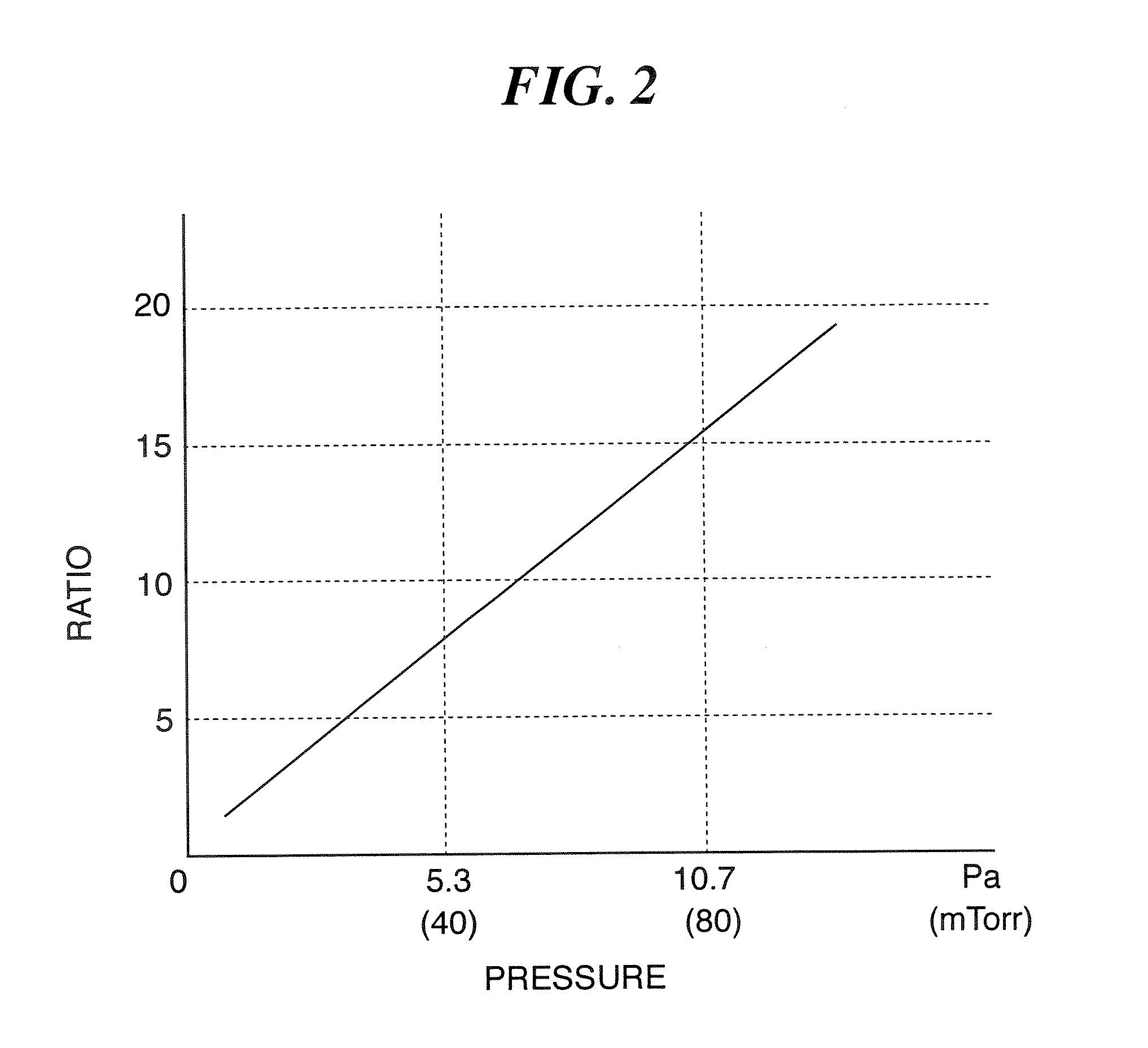

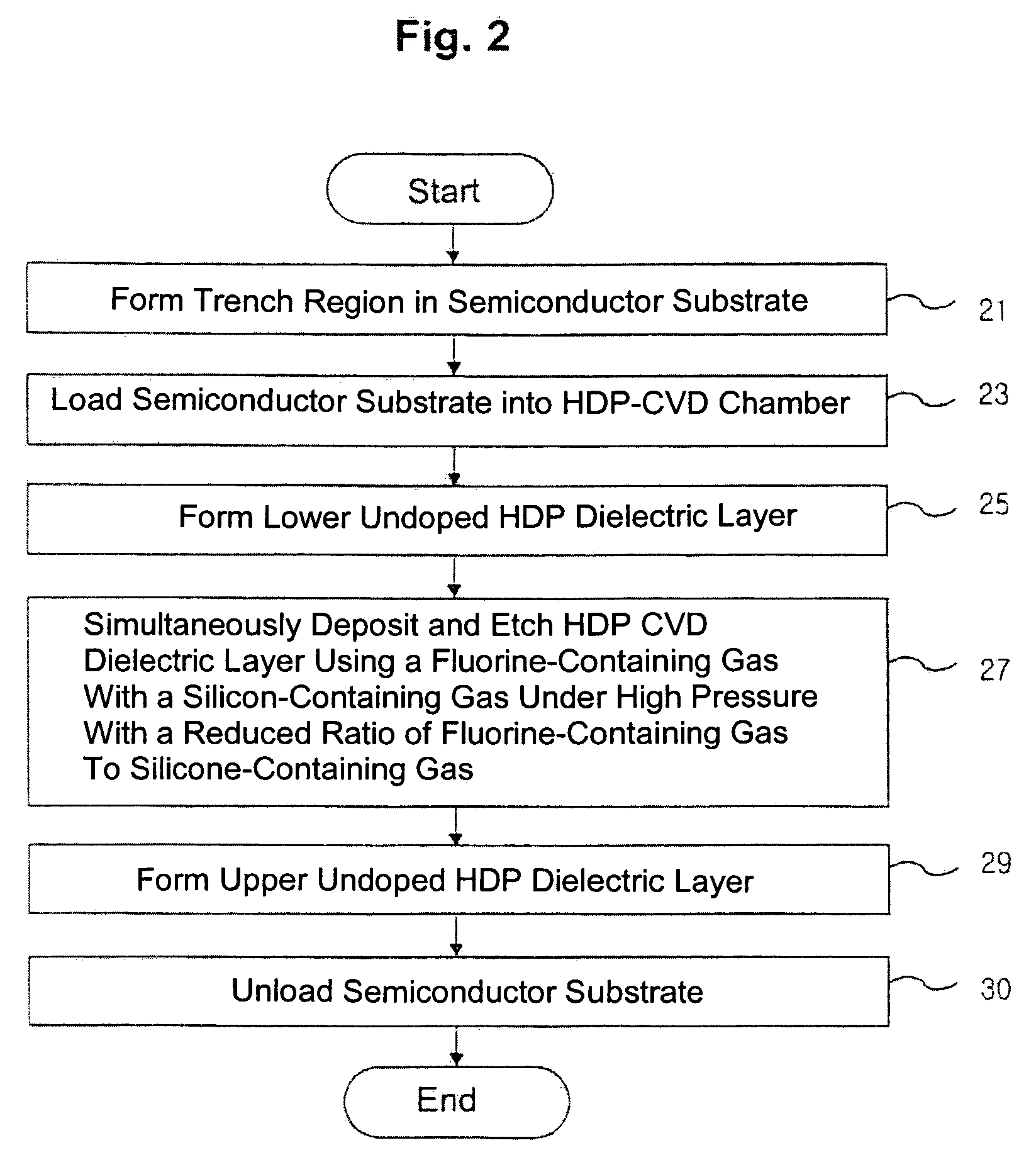

High-density plasma (HDP) chemical vapor deposition (CVD) methods and methods of fabricating semiconductor devices employing the same

InactiveUS7183214B2Reduce amountStrong Gap Filling CapabilitySemiconductor/solid-state device manufacturingPackaging toiletriesGas phaseDevice material

In one embodiment, a semiconductor substrate is placed into a process chamber. A gas mixture including a silicon-containing gas, a fluorine-containing gas, an inert gas, and an oxygen gas is introduced into the chamber at a pressure range of from about 30 mTorr to about 90 mTorr. During this time, deposition and etching processes are concurrently performed using a plasma to form a high-density plasma (HDP) insulating layer on the semiconductor substrate. A ratio of deposition to etching is from about 3:1 to about 10:1. A ratio of a flow rate of the fluorine-containing gas to a flow rate of the silicon-containing gas is less than about 0.9.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com