Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "Fluorinated gases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated gases (F-gases) are man-made gases that can stay in the atmosphere for centuries and contribute to a global greenhouse effect. There are four types: hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulfur hexafluoride (SF₆) and nitrogen trifluoride (NF₃).

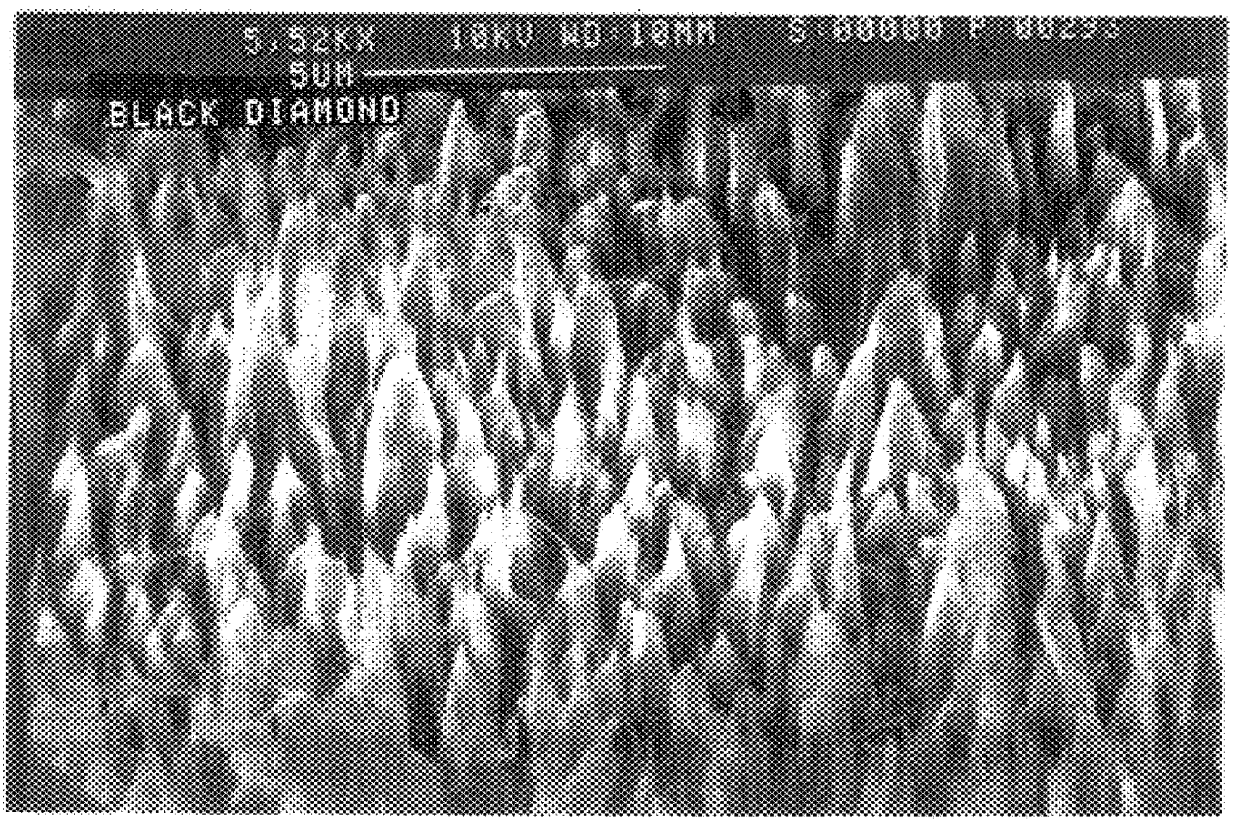

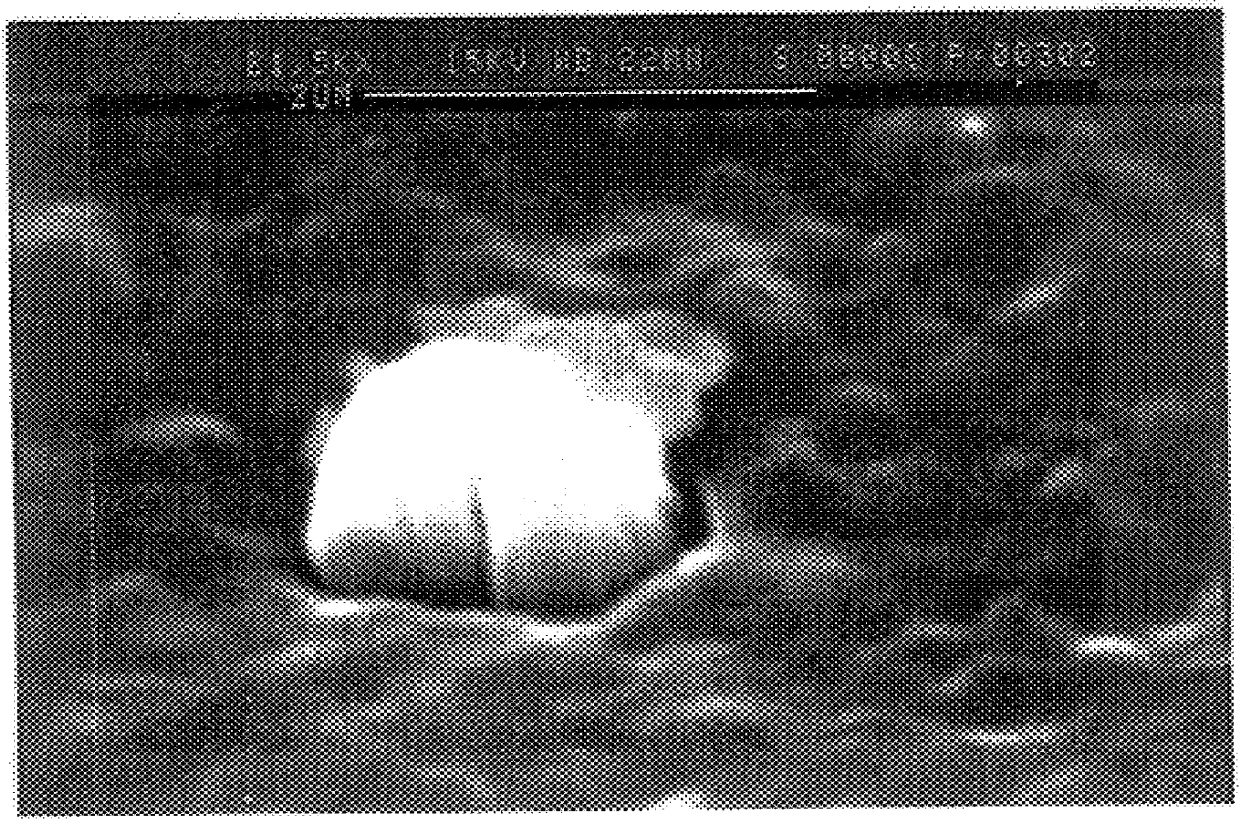

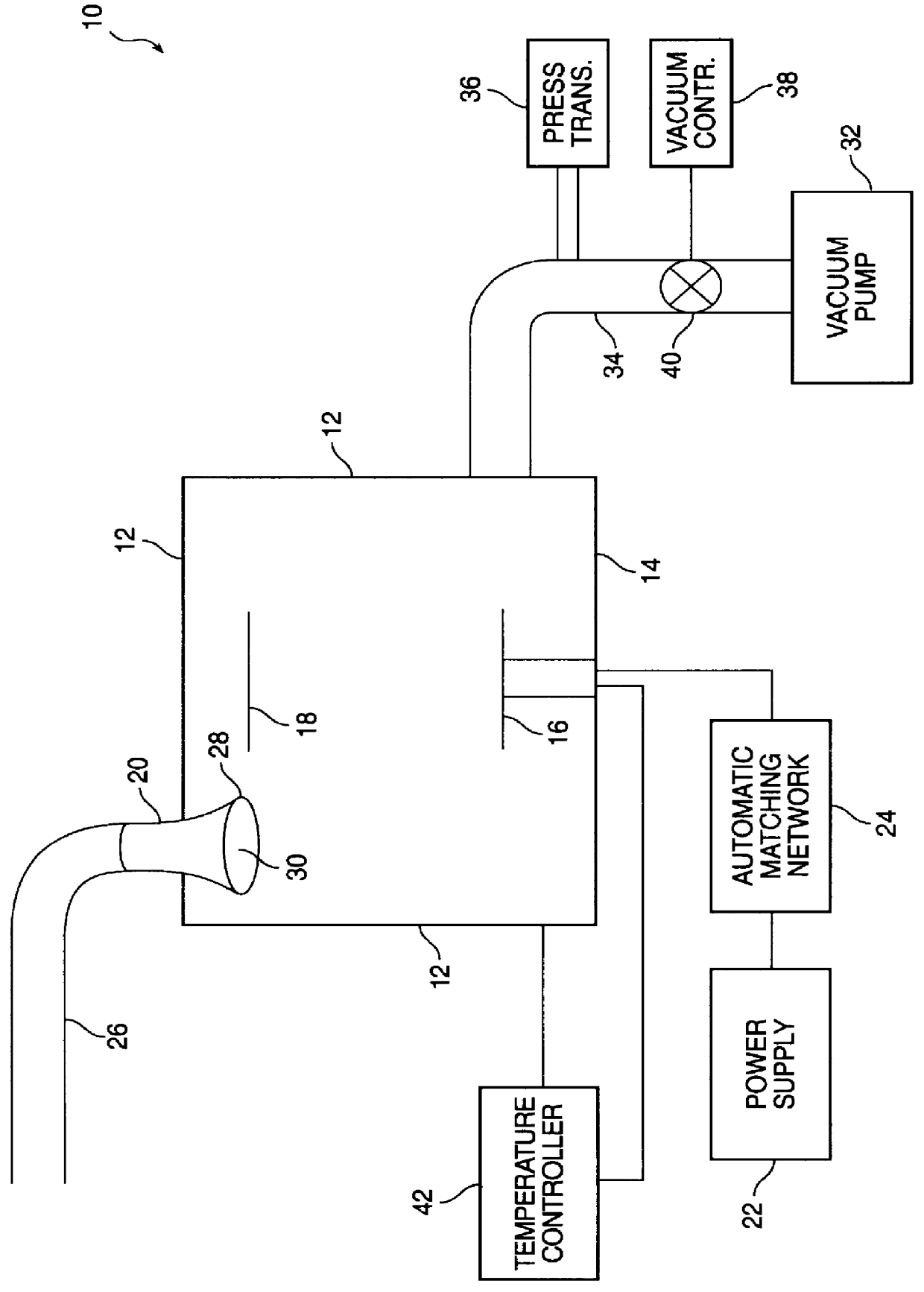

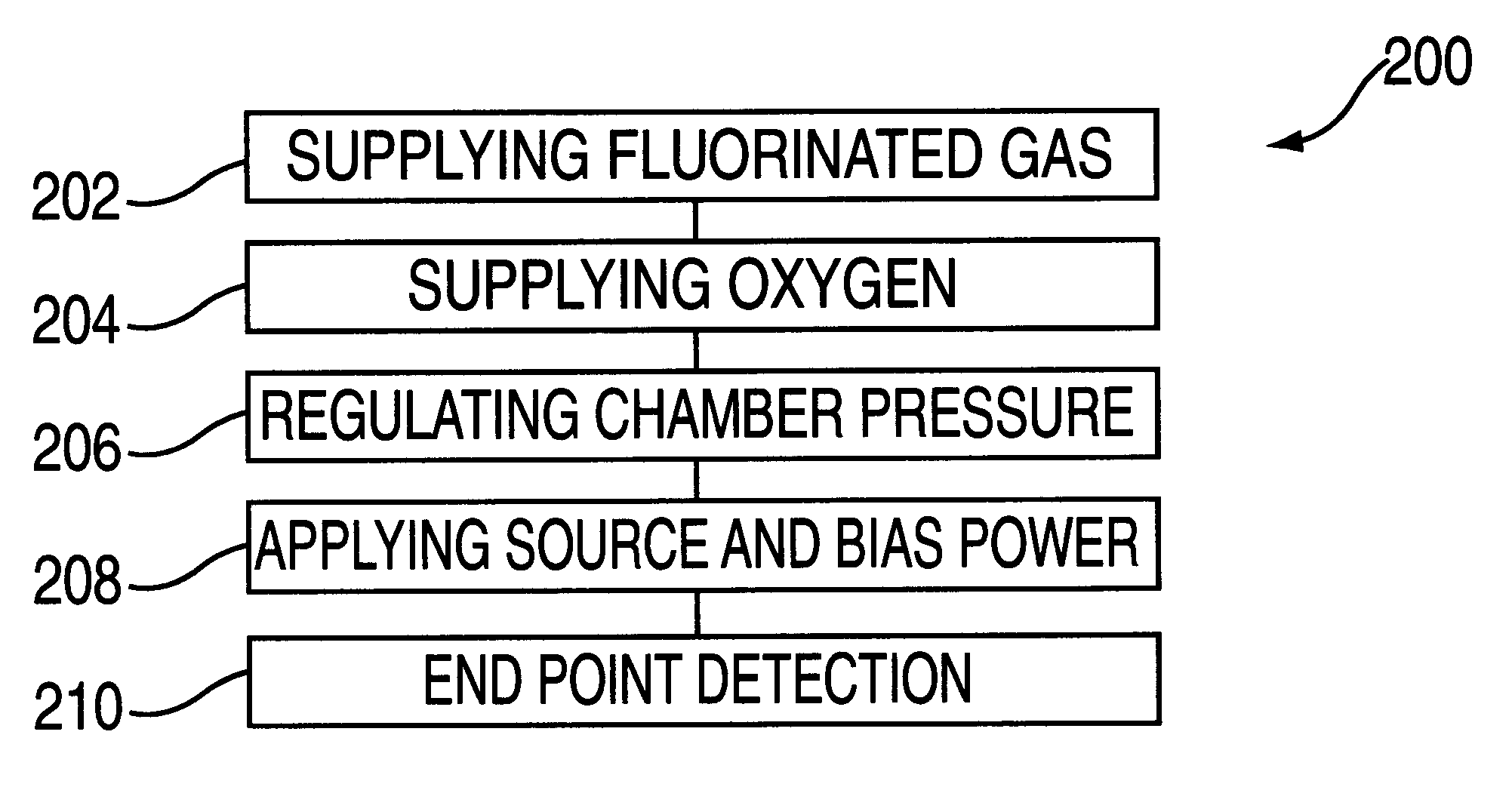

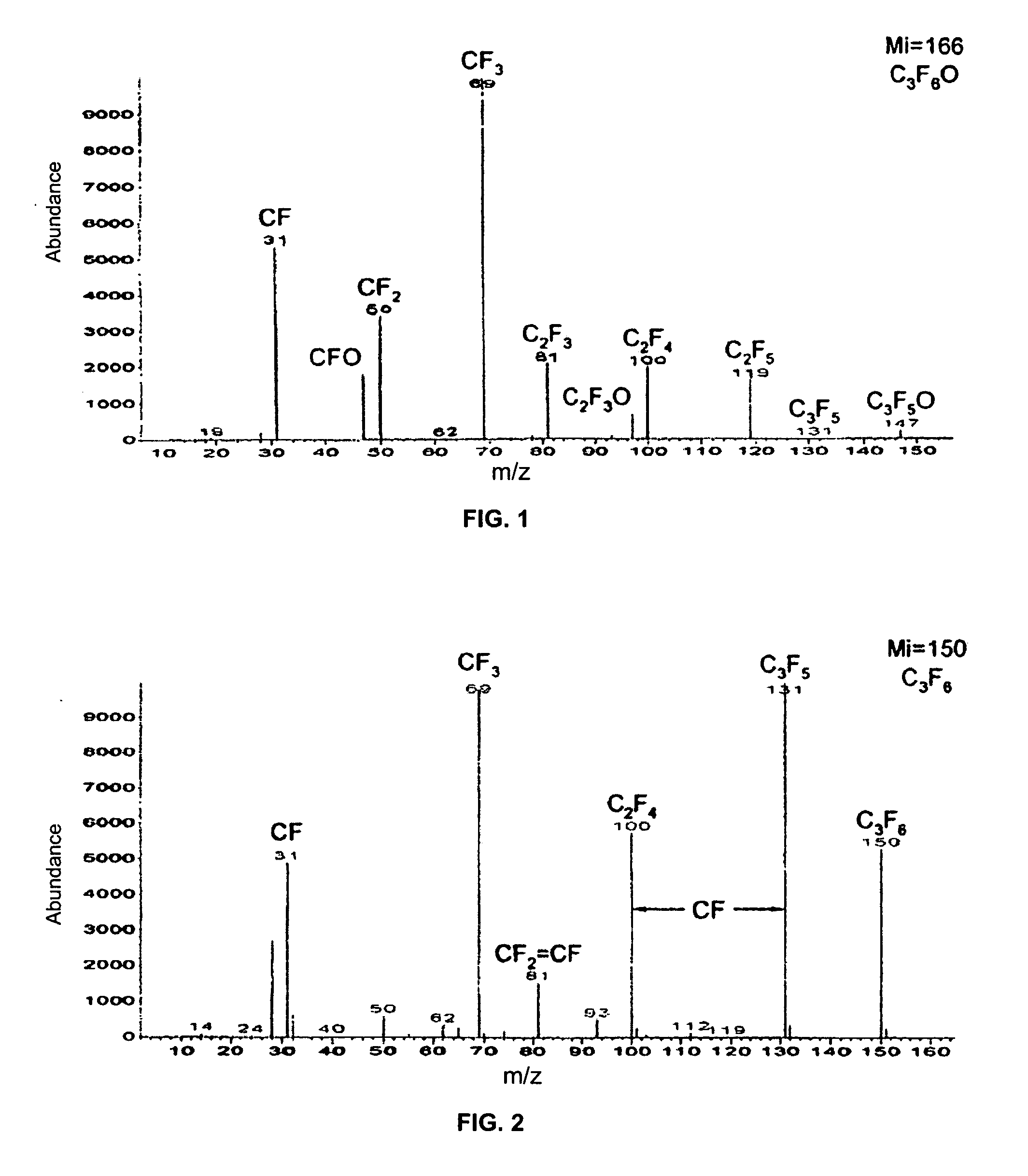

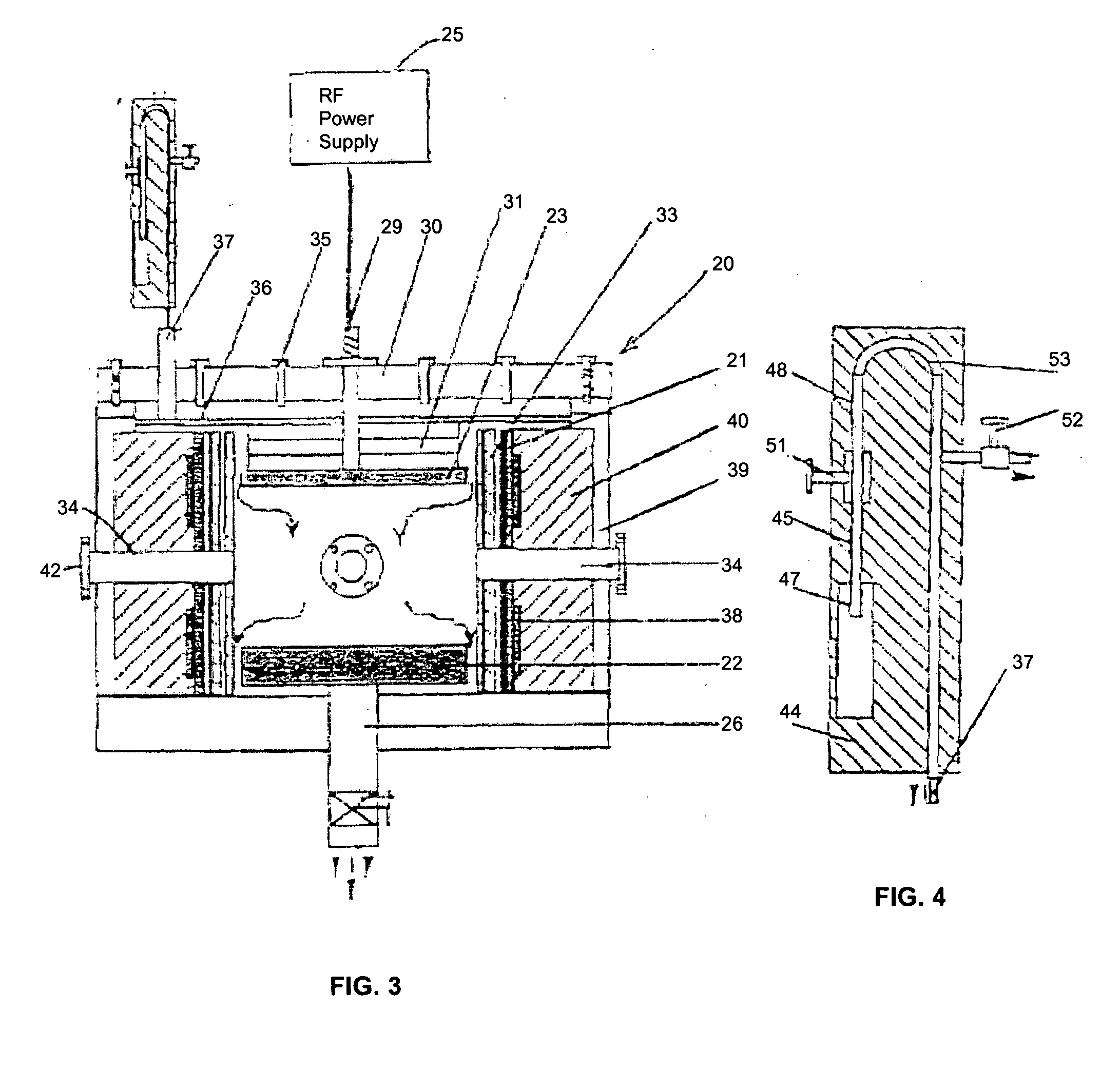

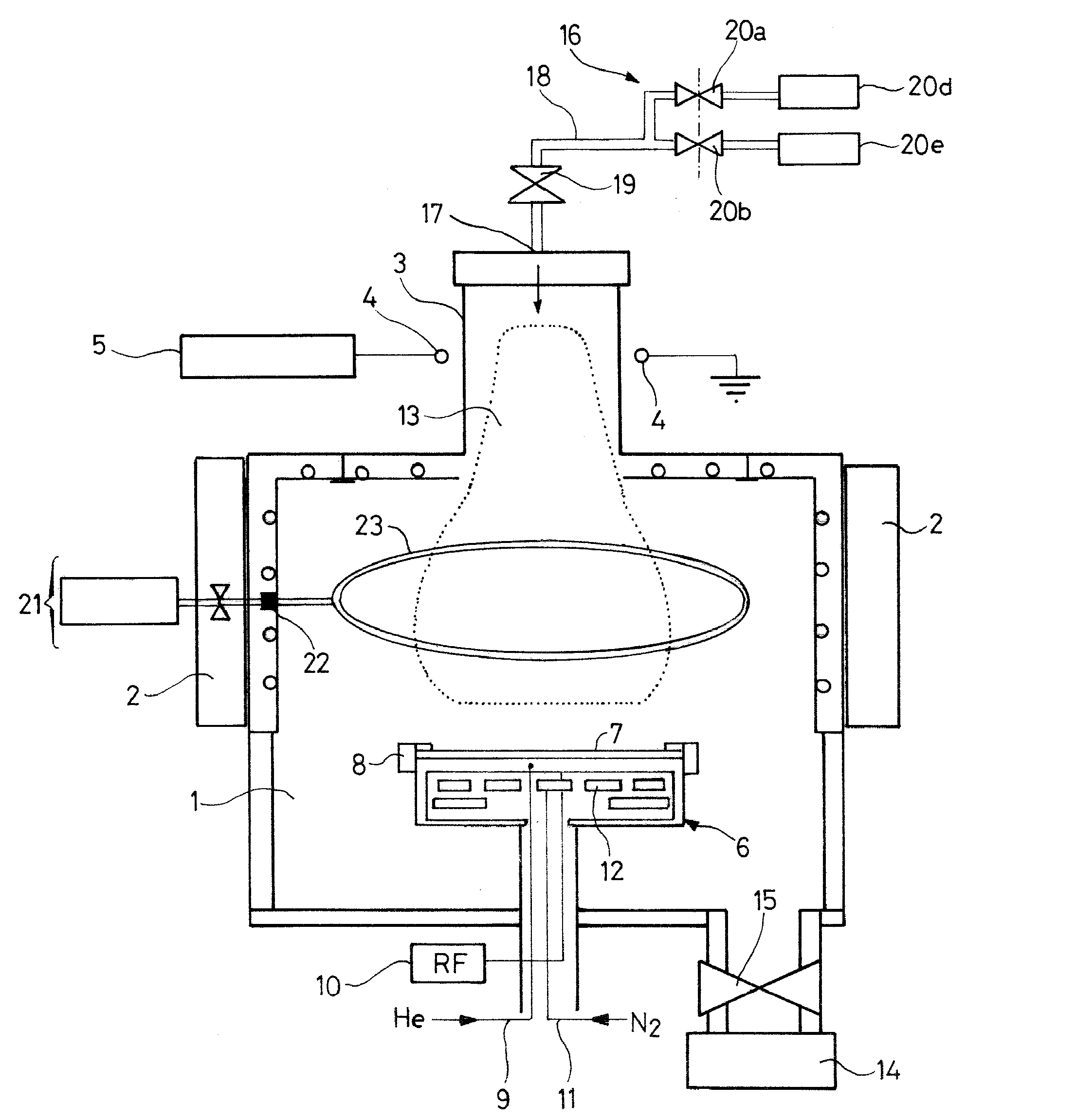

Method of polishing CVD diamond films by oxygen plasma

InactiveUS6013191APolycrystalline material growthAfter-treatment detailsFluorinated gasesOxygen plasma

A method for polishing the surface of a diamond film with a low power density plasma in a reactor which comprises disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, providing power to the reactor so that the power density in the reactor is between about 1.0 watts / cm2 and about 1.1 watts / cm2 for a first duration, and maintaining temperature in the reactor at between about 200 DEG to about 400 DEG . The method may alternatively comprise disposing a sputter gas such as Ar,O2 or N2 in the reactor, providing power to the reactor so that the power density in the reactor is between about 3.0 watts / cm2 and about 7.5 watts / cm2 for a first duration, and performing a sputter etch, disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, and providing power to the reactor so that the power density in the reactor is between about 1.5 watts / cm2 and about 3.0 watts / cm2 for a second duration.

Owner:ADVANCED REFRACTORY TECH INC

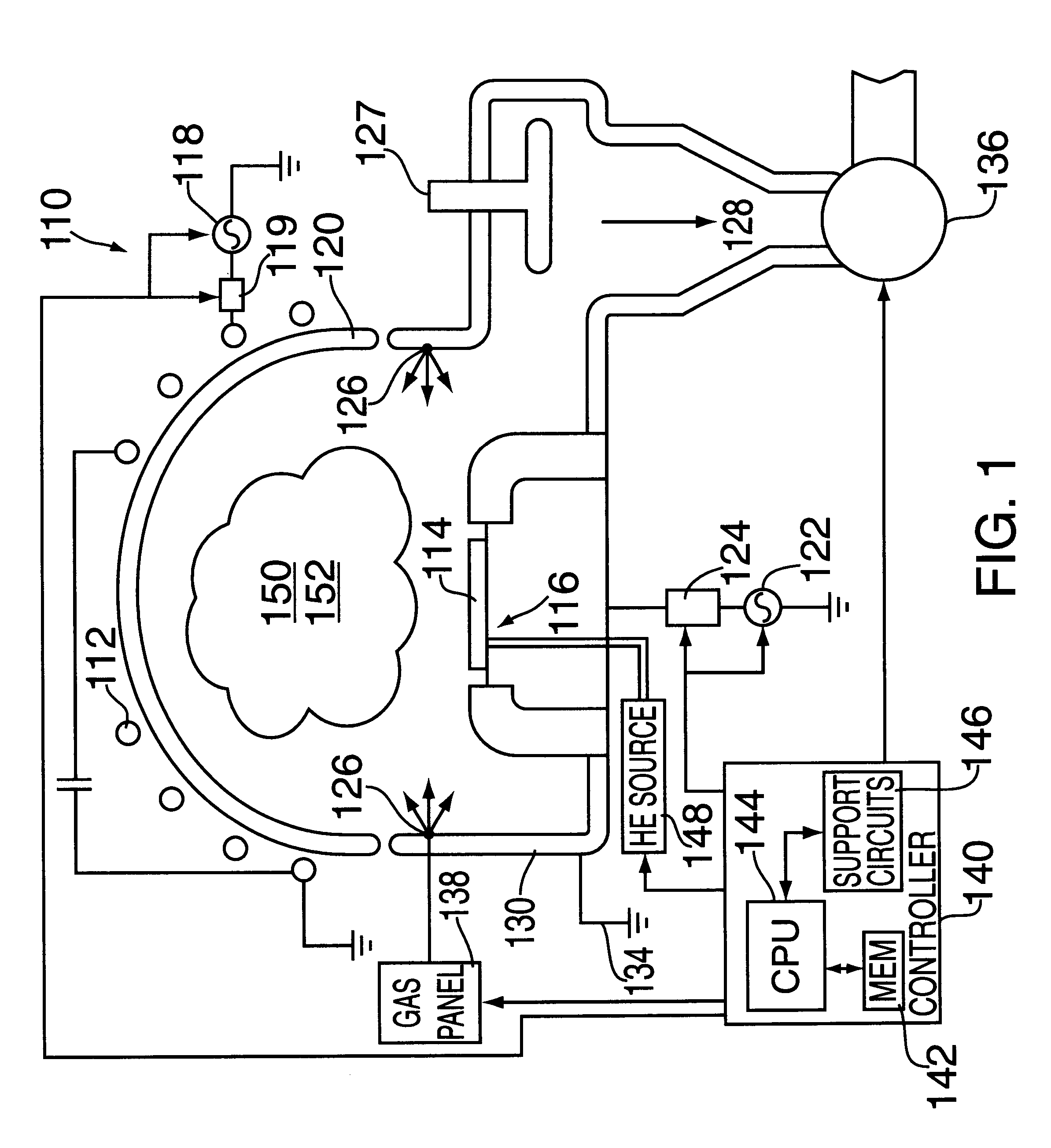

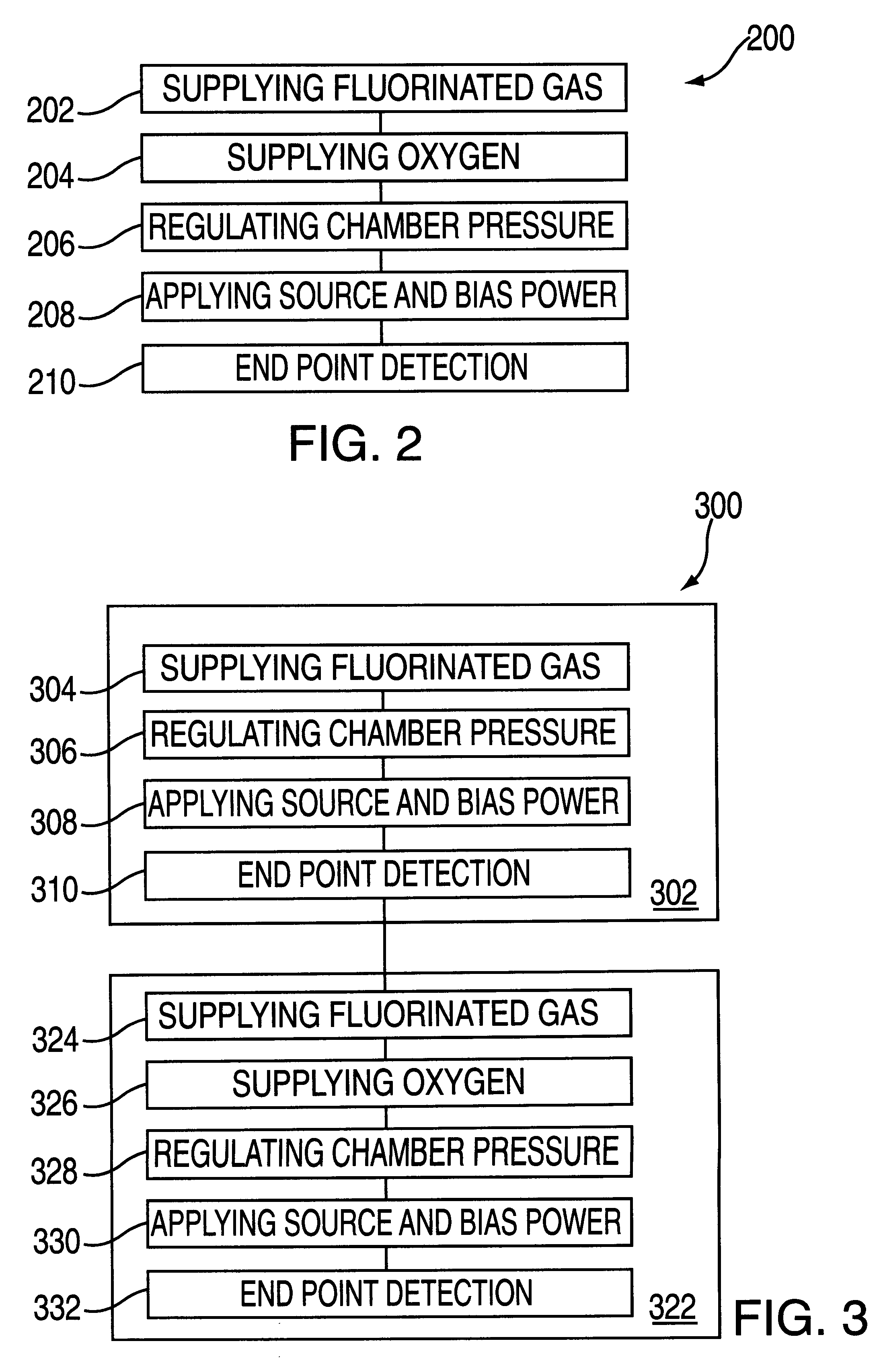

Plasma processing of tungsten using a gas mixture comprising a fluorinated gas and oxygen

InactiveUS6277763B1Good choiceElectric discharge tubesVacuum gauge using ionisation effectsFluorinated gasesProduct gas

Owner:APPLIED MATERIALS INC

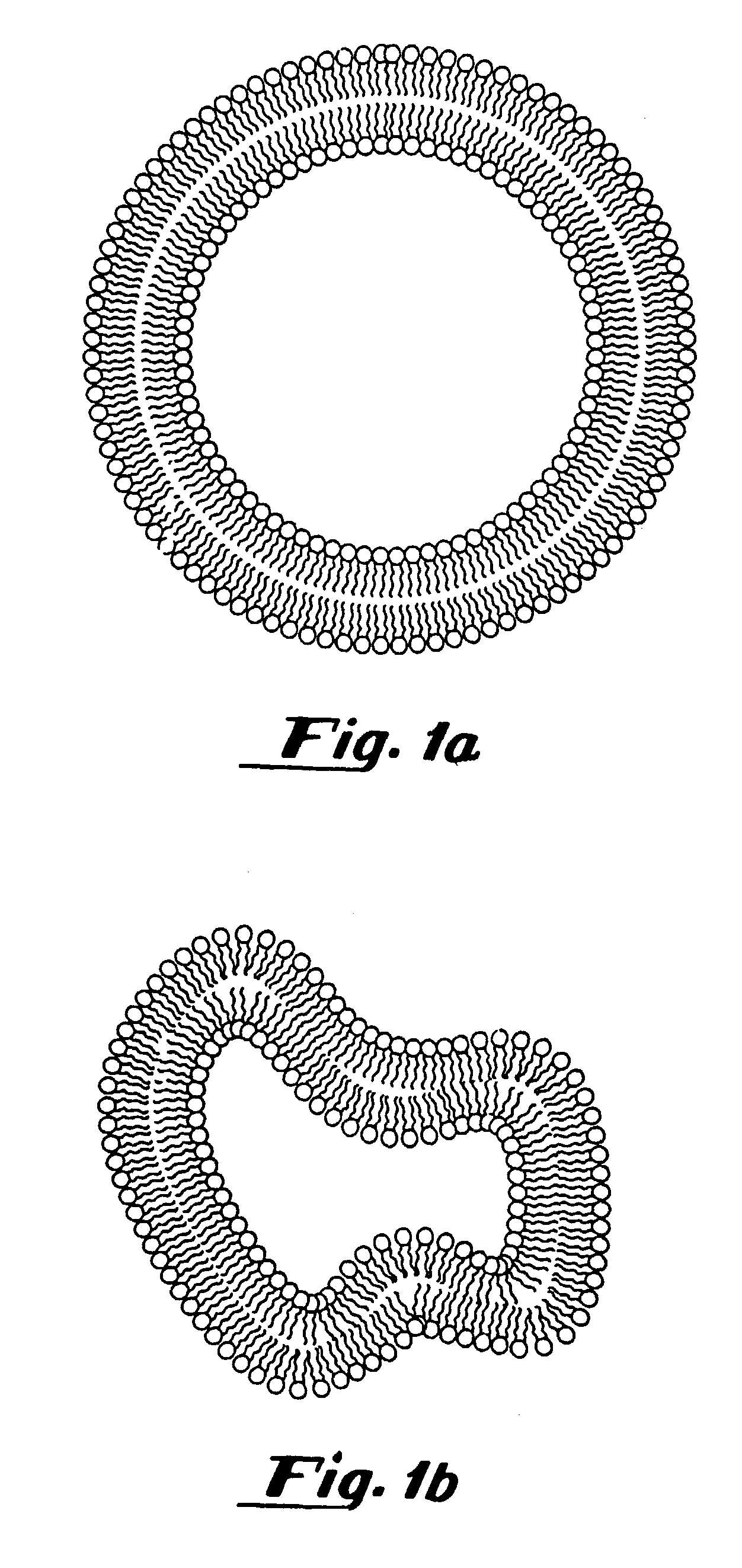

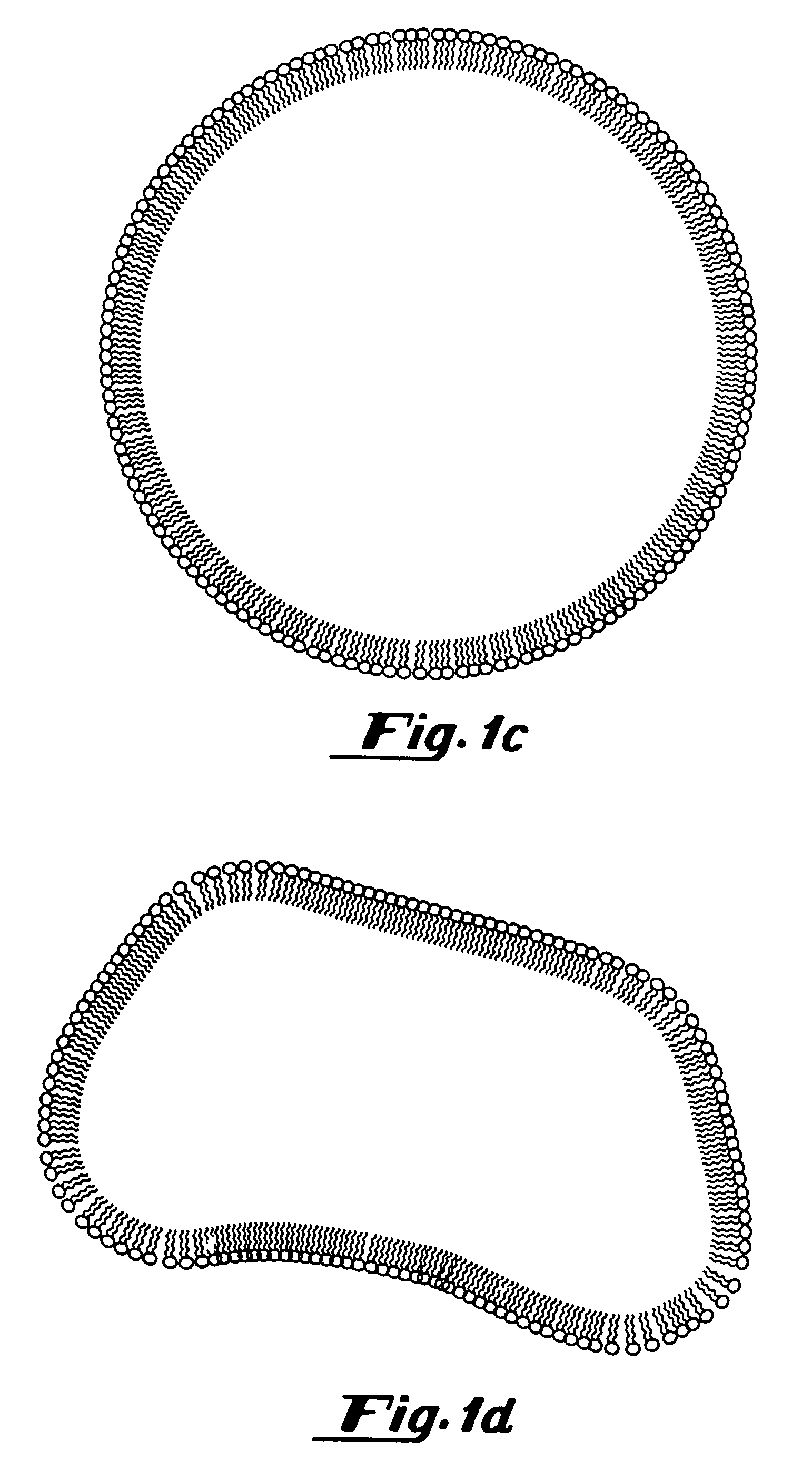

Oxygen delivery agents and uses for the same

InactiveUS7105151B2Ultrasonic/sonic/infrasonic diagnosticsPowder deliveryFluorinated gasesOxygen delivery

Owner:CEREVAST THERAPEUTICS

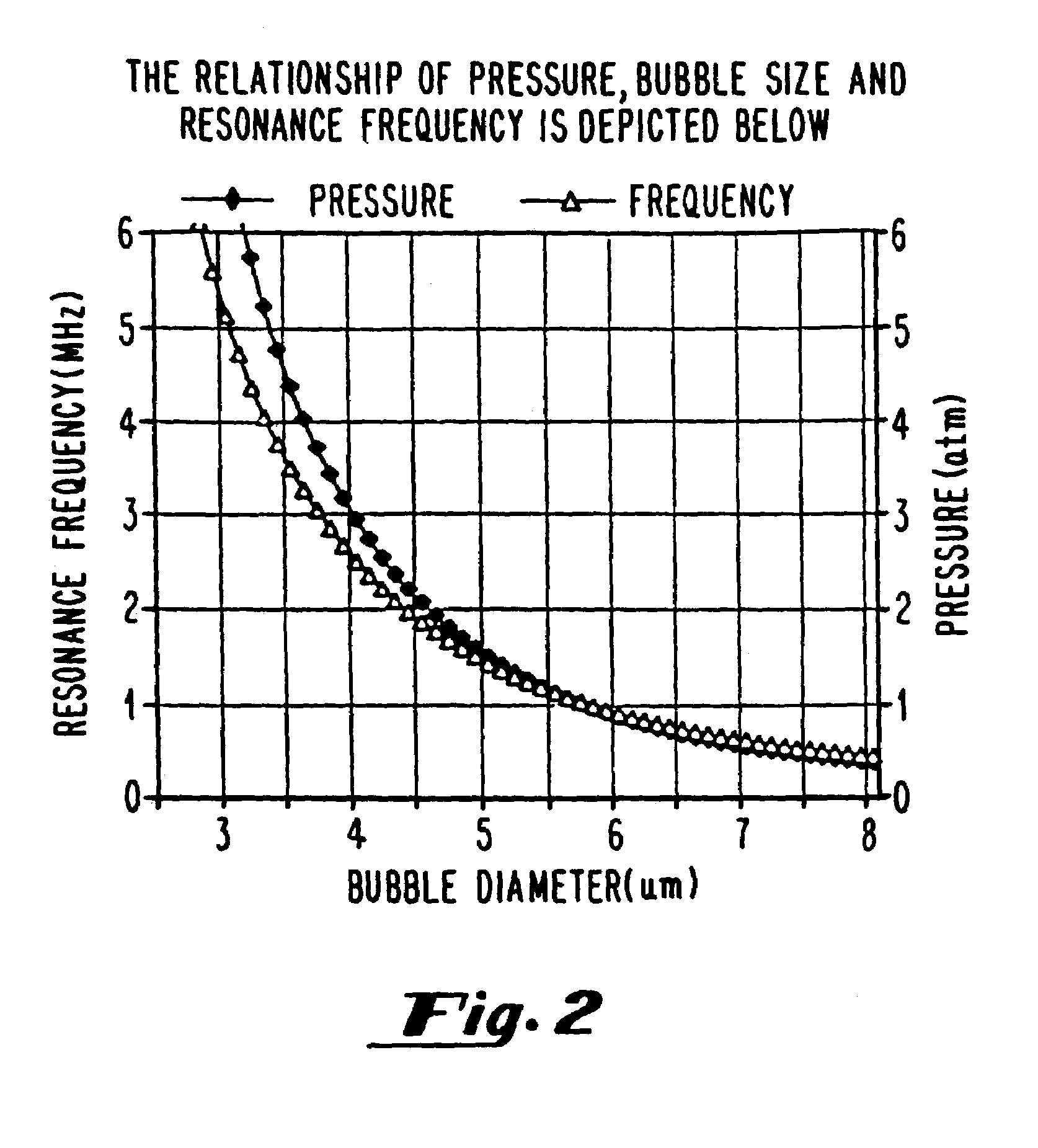

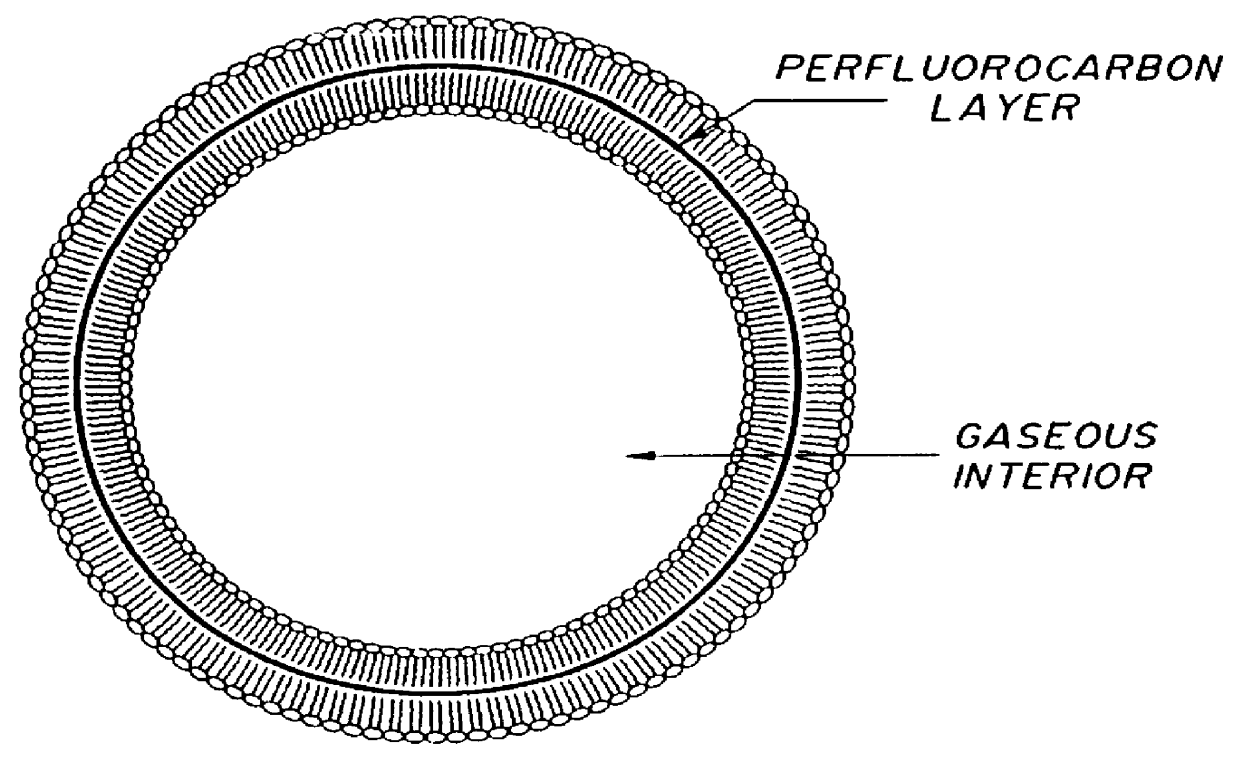

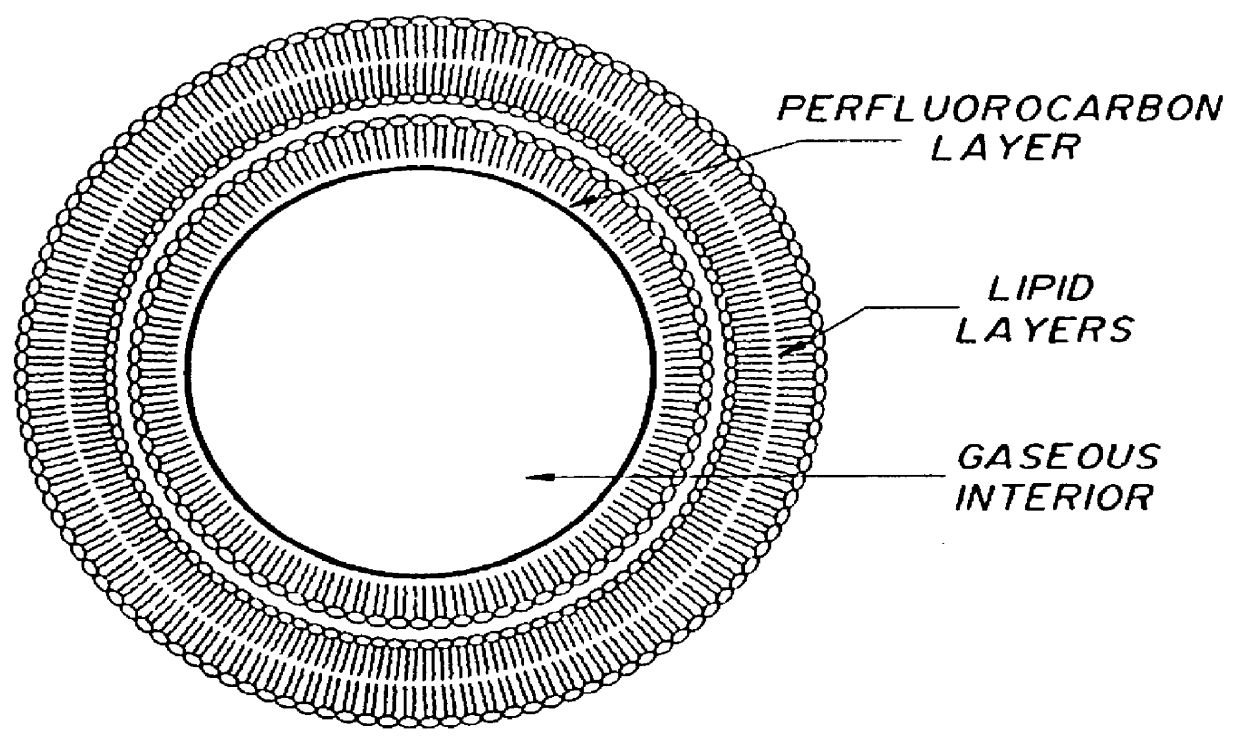

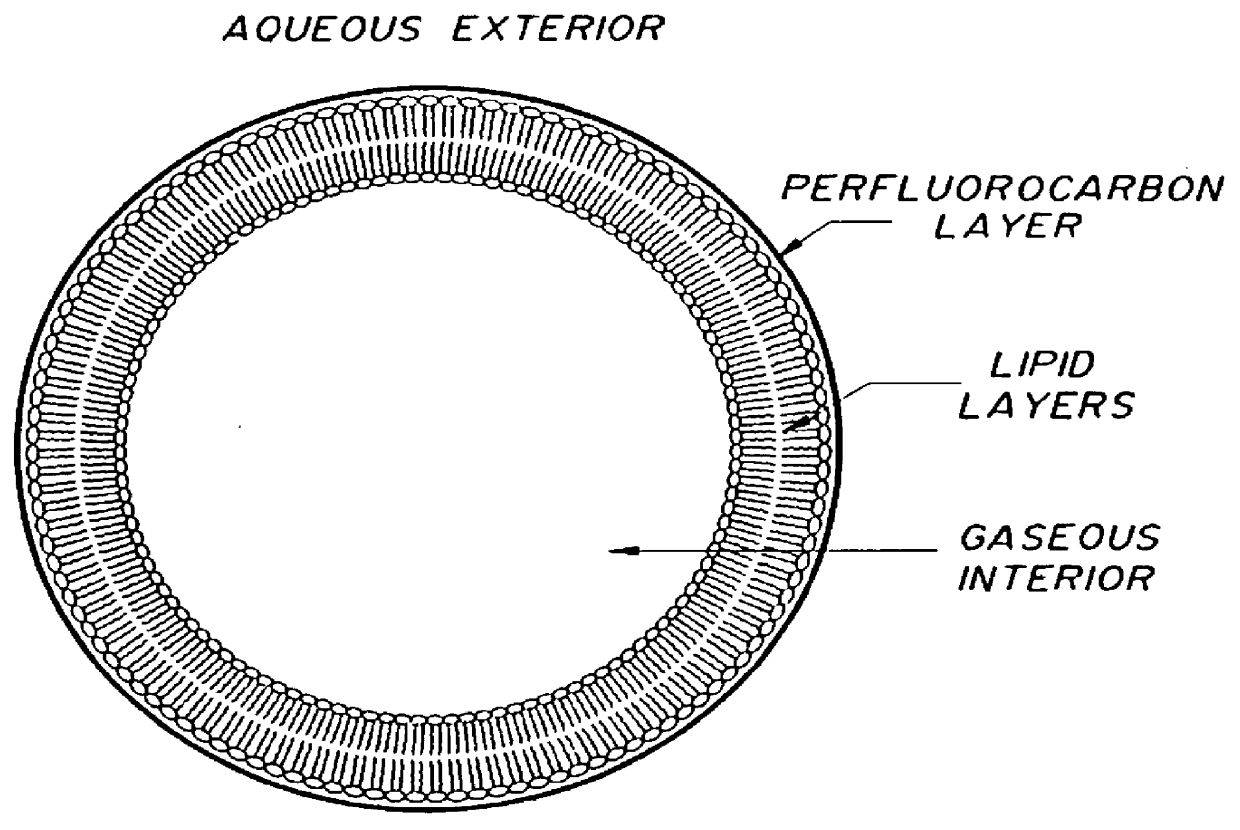

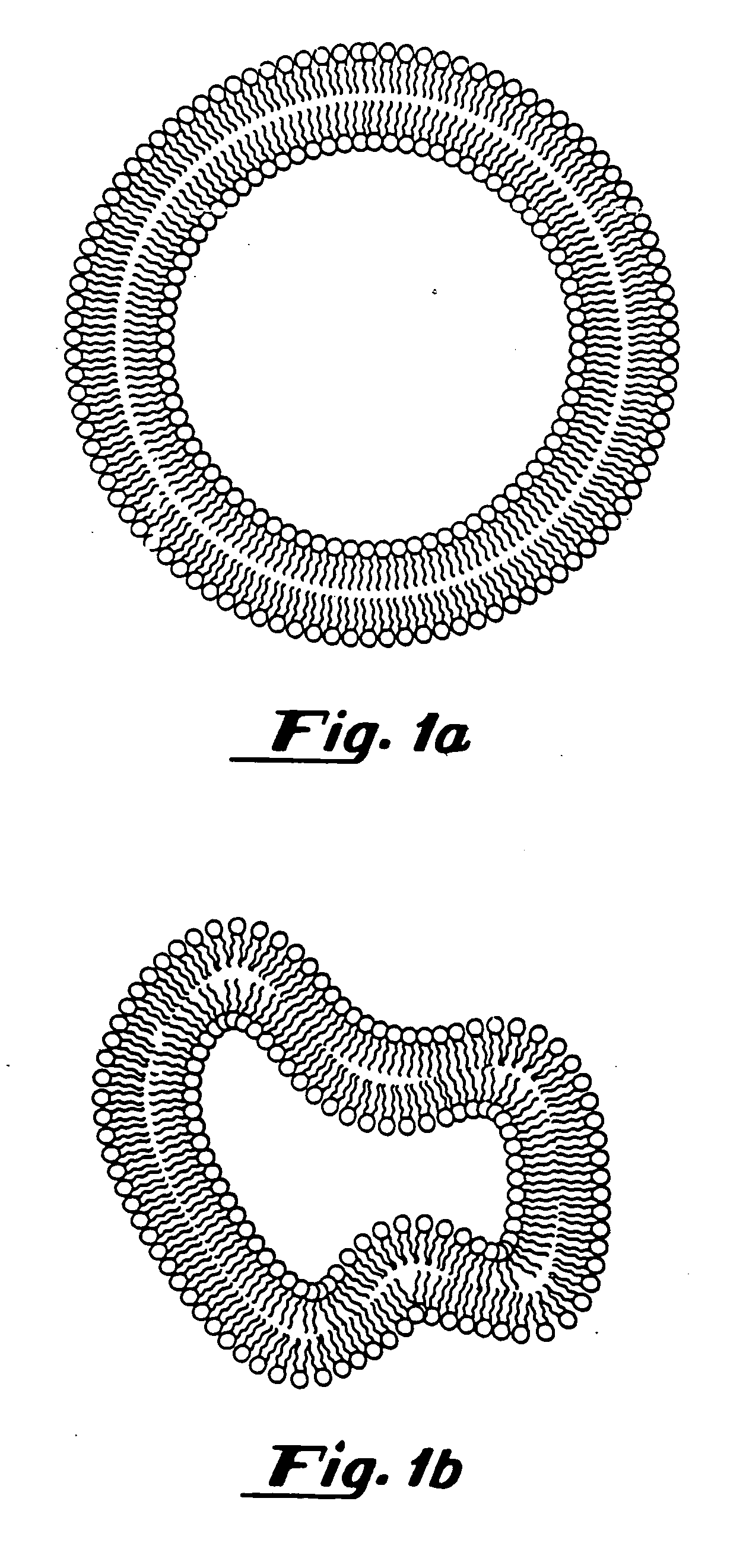

Method of computed tomography using fluorinated gas-filled lipid microspheres as contrast agents

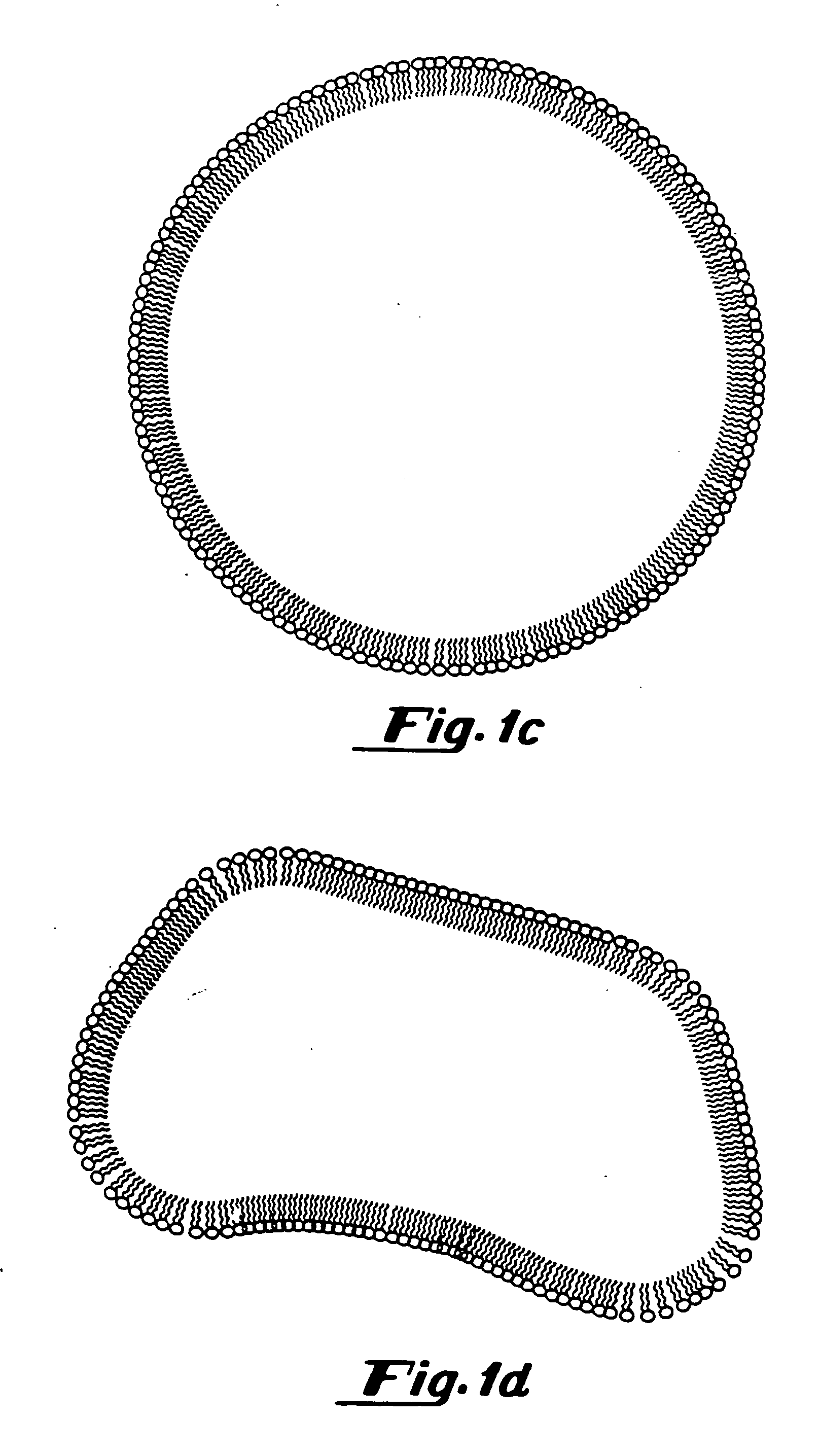

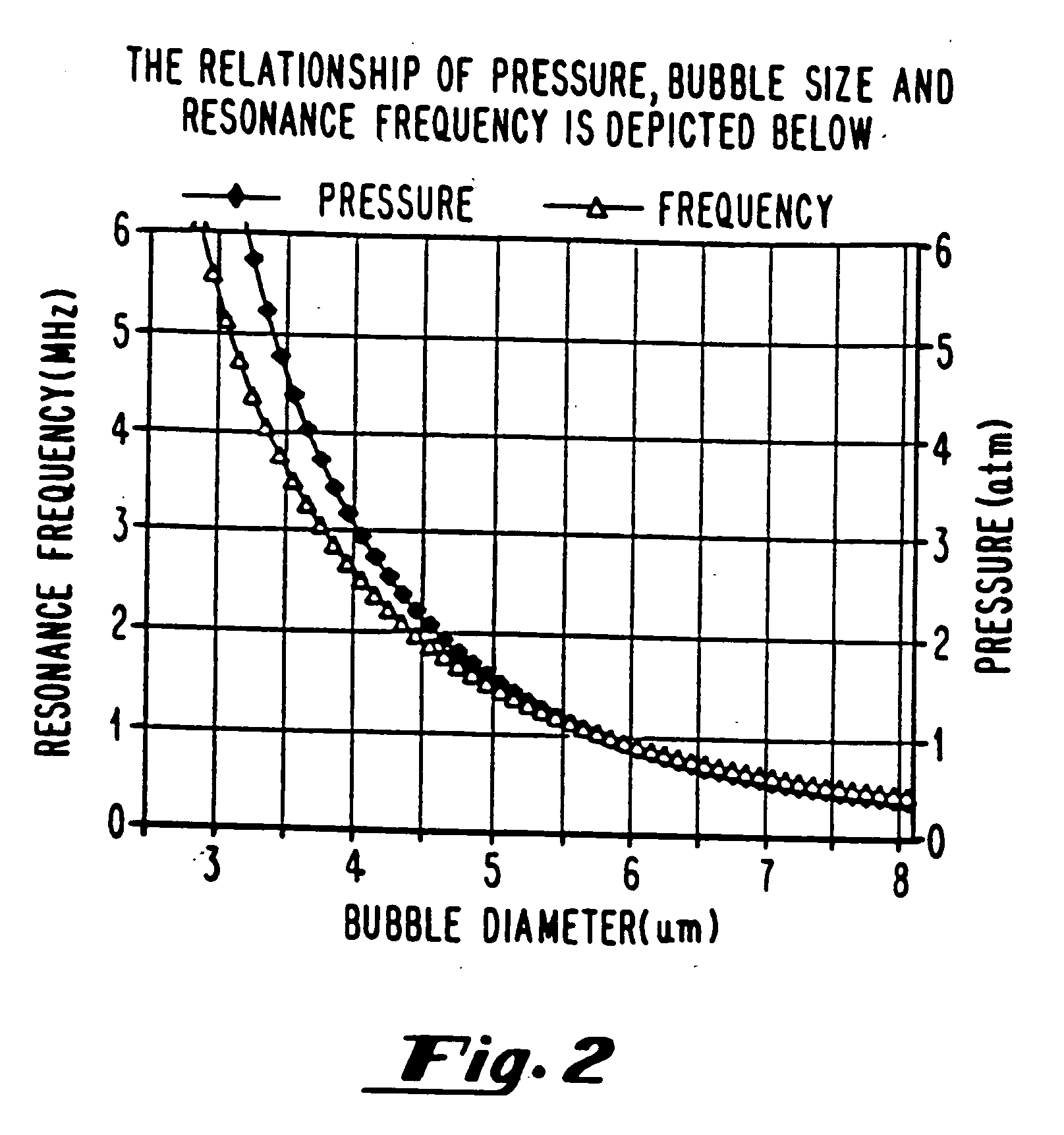

InactiveUS6117414ALow densityEnhance the imageUltrasonic/sonic/infrasonic diagnosticsPowder deliveryLipid formationFluorinated gases

Novel gas filled microspheres useful as computed tomography (CT) contrast agents. The microspheres are prepared from a gas and / or a gaseous precursor, and one or more stabilizing compounds.

Owner:IMARX THERAPEUTICS

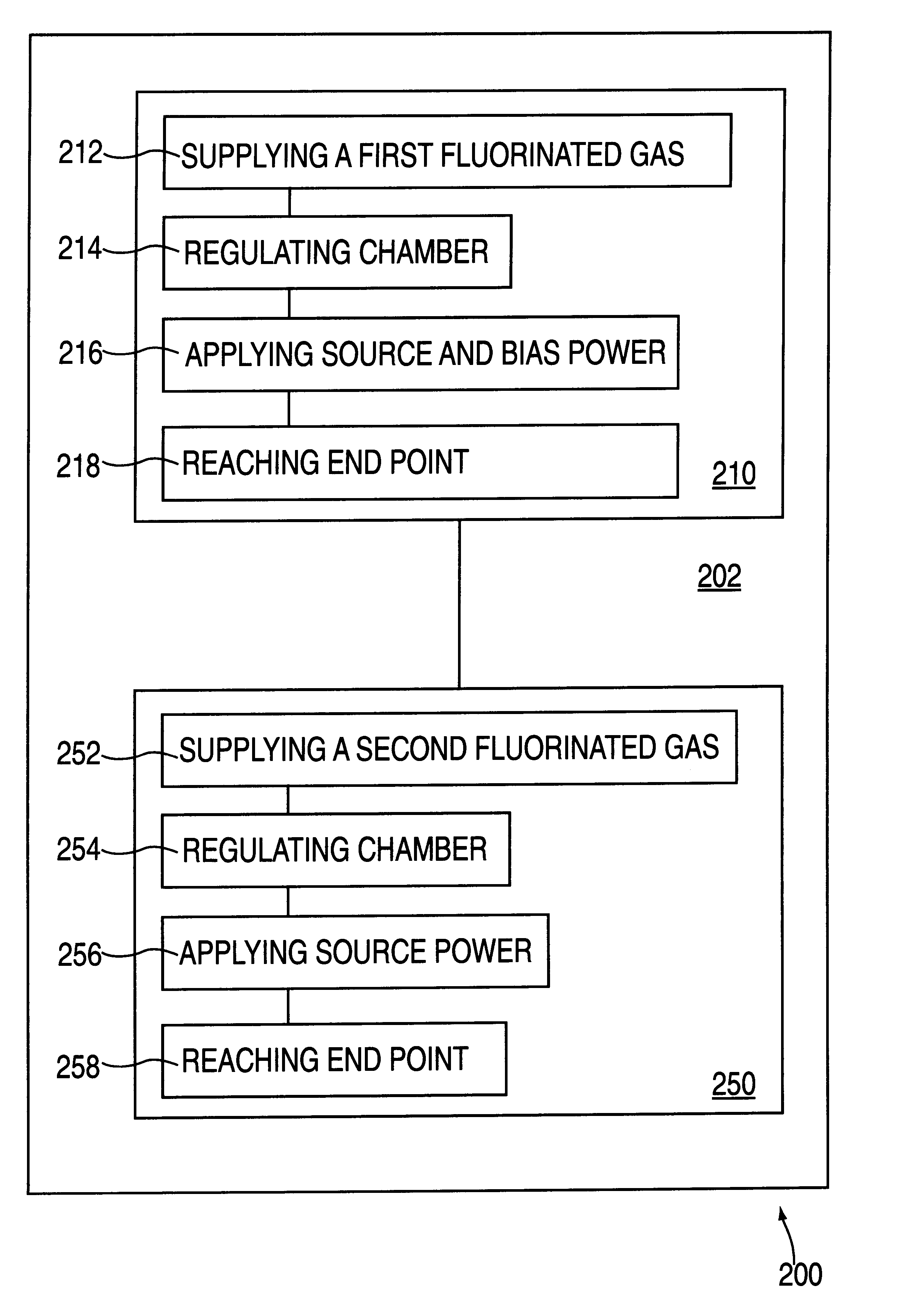

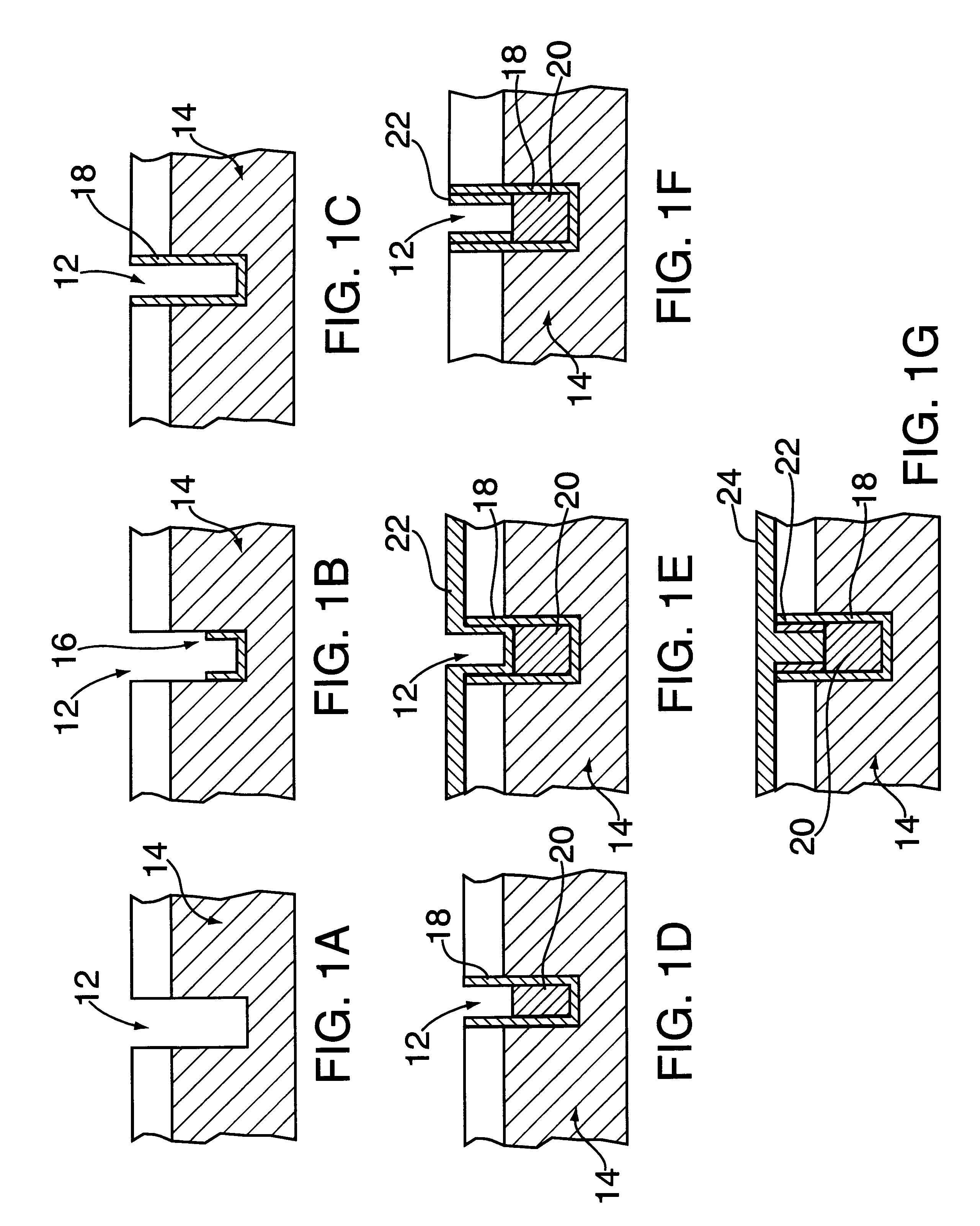

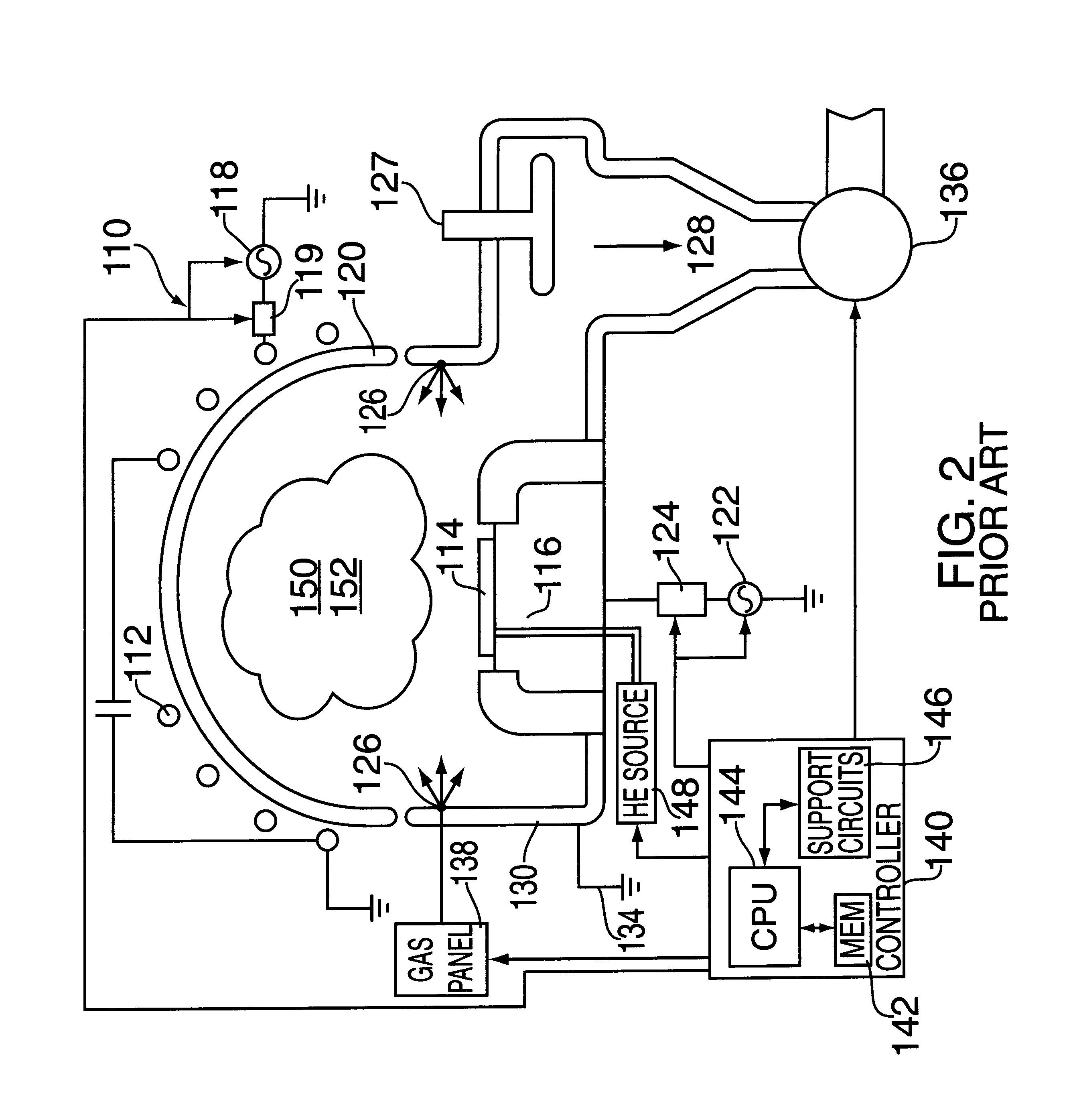

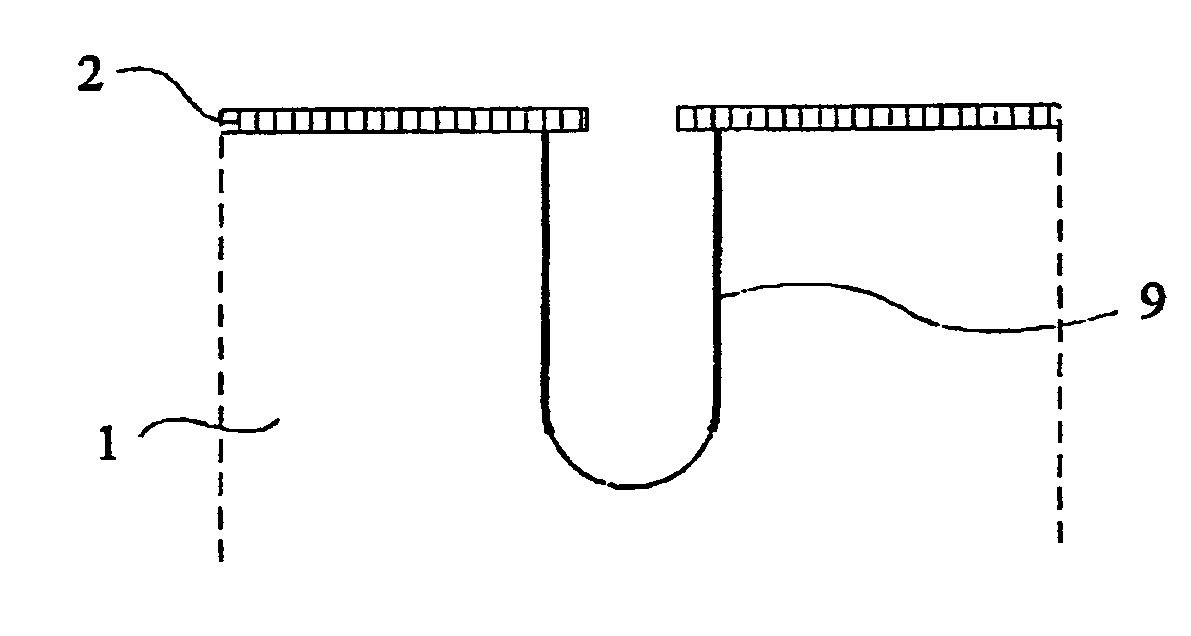

Method and apparatus for sequentially etching a wafer using anisotropic and isotropic etching

InactiveUS6221784B1Decorative surface effectsSemiconductor/solid-state device manufacturingFluorinated gasesAnisotropic etching

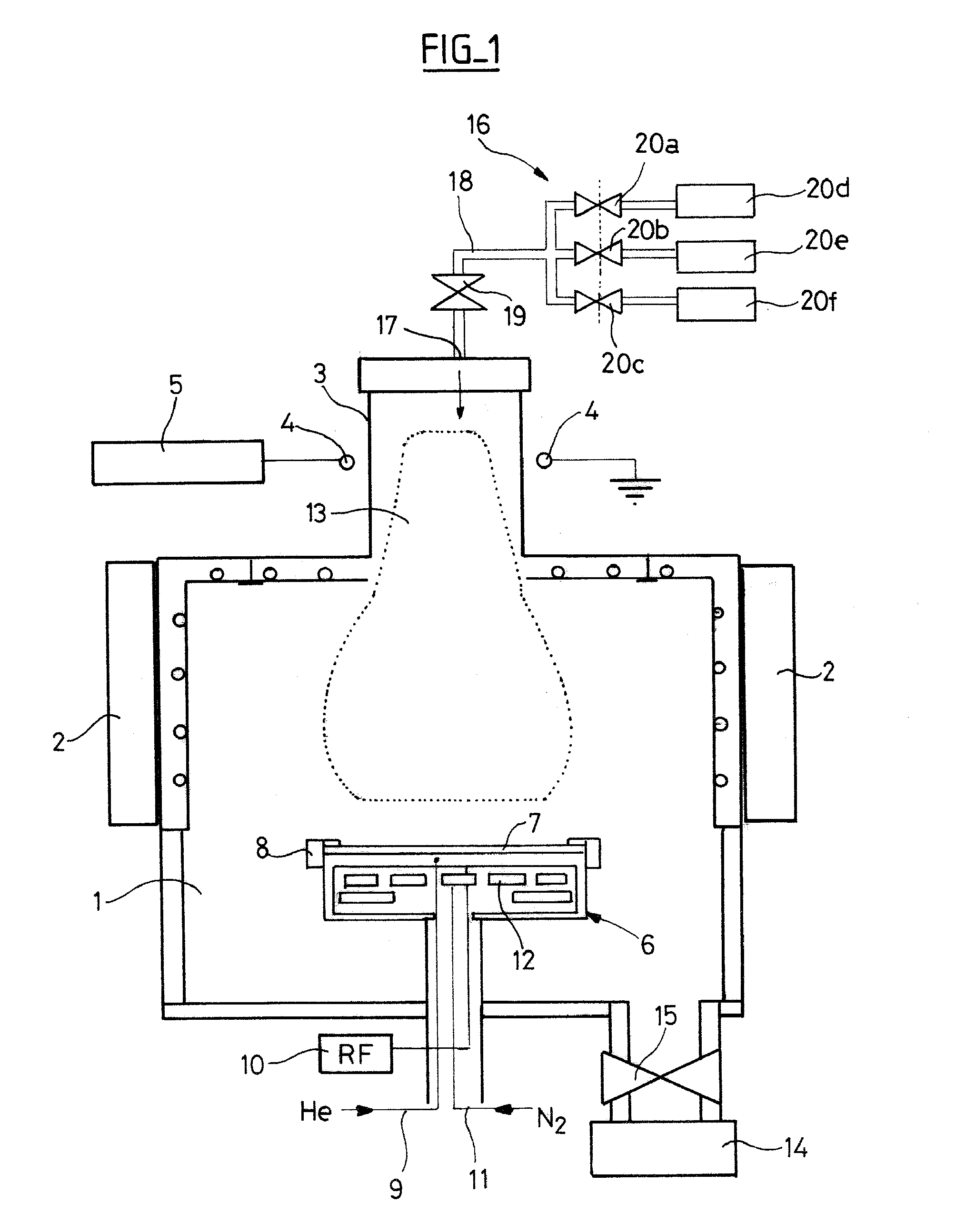

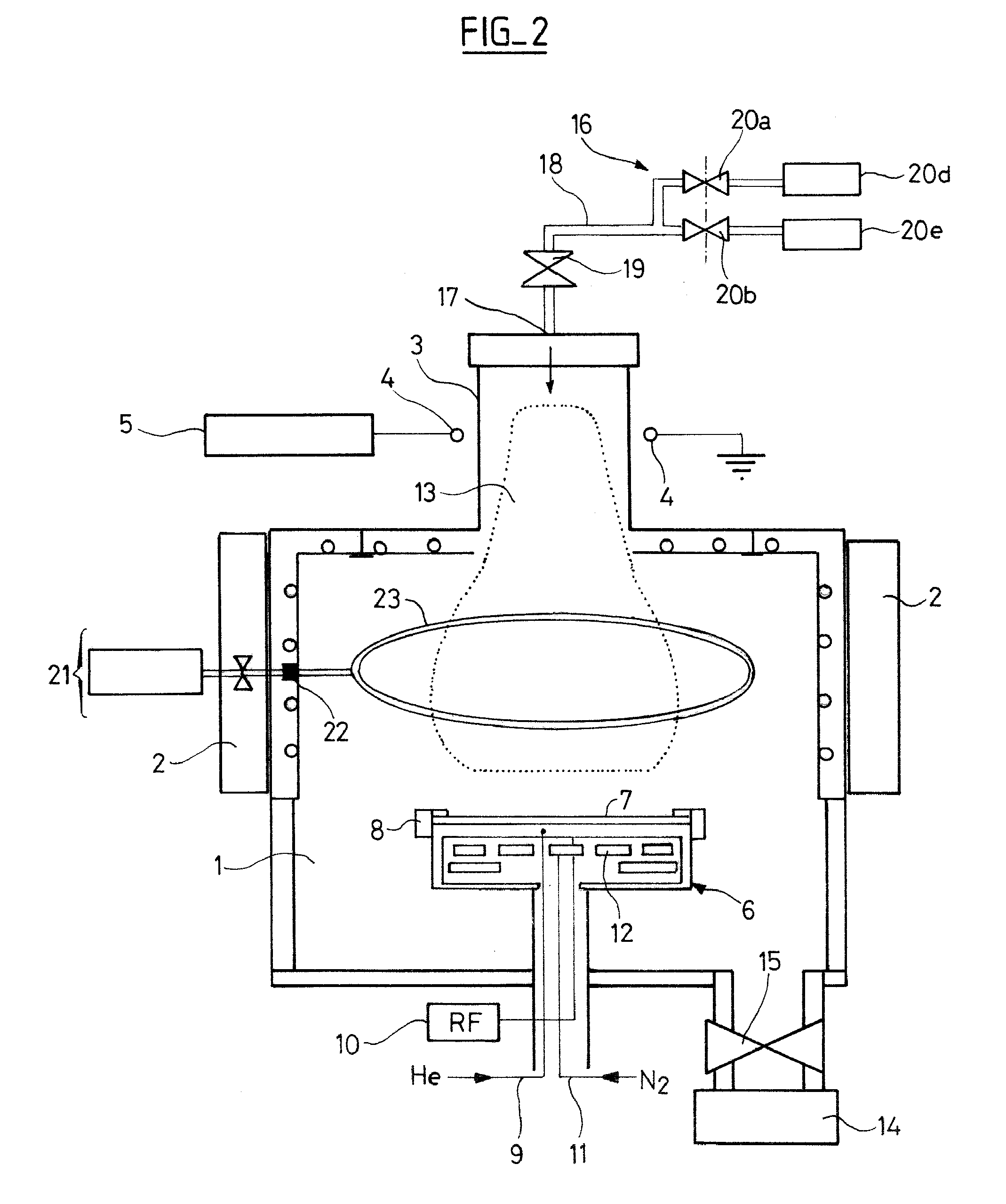

An apparatus and method for in-situ etching of a substrate comprising both a polysilicon layer and an overlying dielectric layer. An embodiment of the method comprises an anisotropic etch of the dielectric layer in a chamber using a first fluorinated gas (such as CF4, NF3, SF6, and the like) as an etch gas to expose at least a portion of underlying polysilicon layer. Following the anisotropic etch and without removing the substrate from the chamber, i.e., in situ, an isotropic etch is preformed on the underlying polysilicon layer using a second fluorinated gas (such as CF4, NF3, SF6, and the like) as an etch gas.

Owner:APPLIED MATERIALS INC

Oxygen delivery agents and uses for the same

InactiveUS20070059248A1Ultrasonic/sonic/infrasonic diagnosticsRespiratorsFluorinated gasesOxygen delivery

Owner:CEREVAST THERAPEUTICS

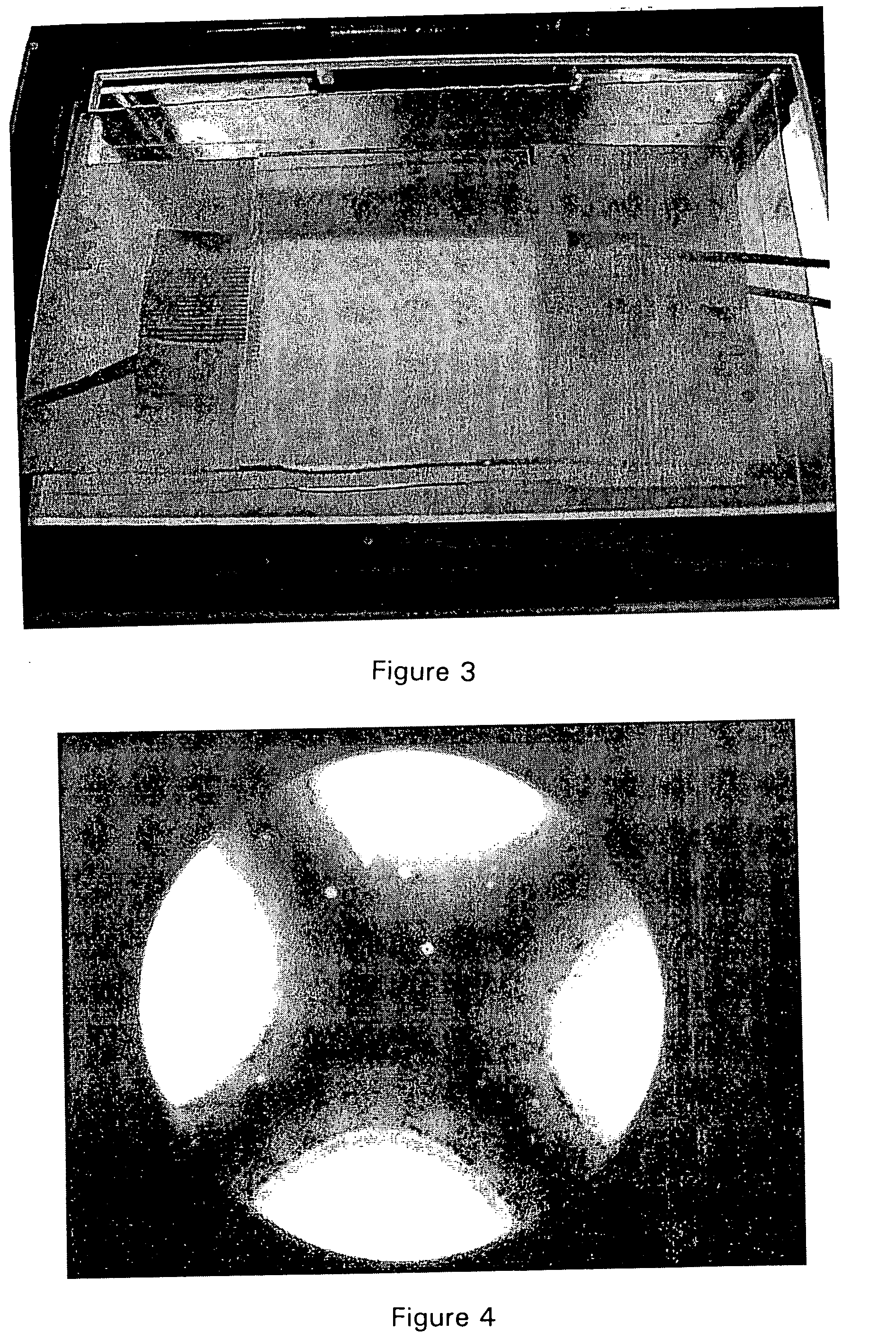

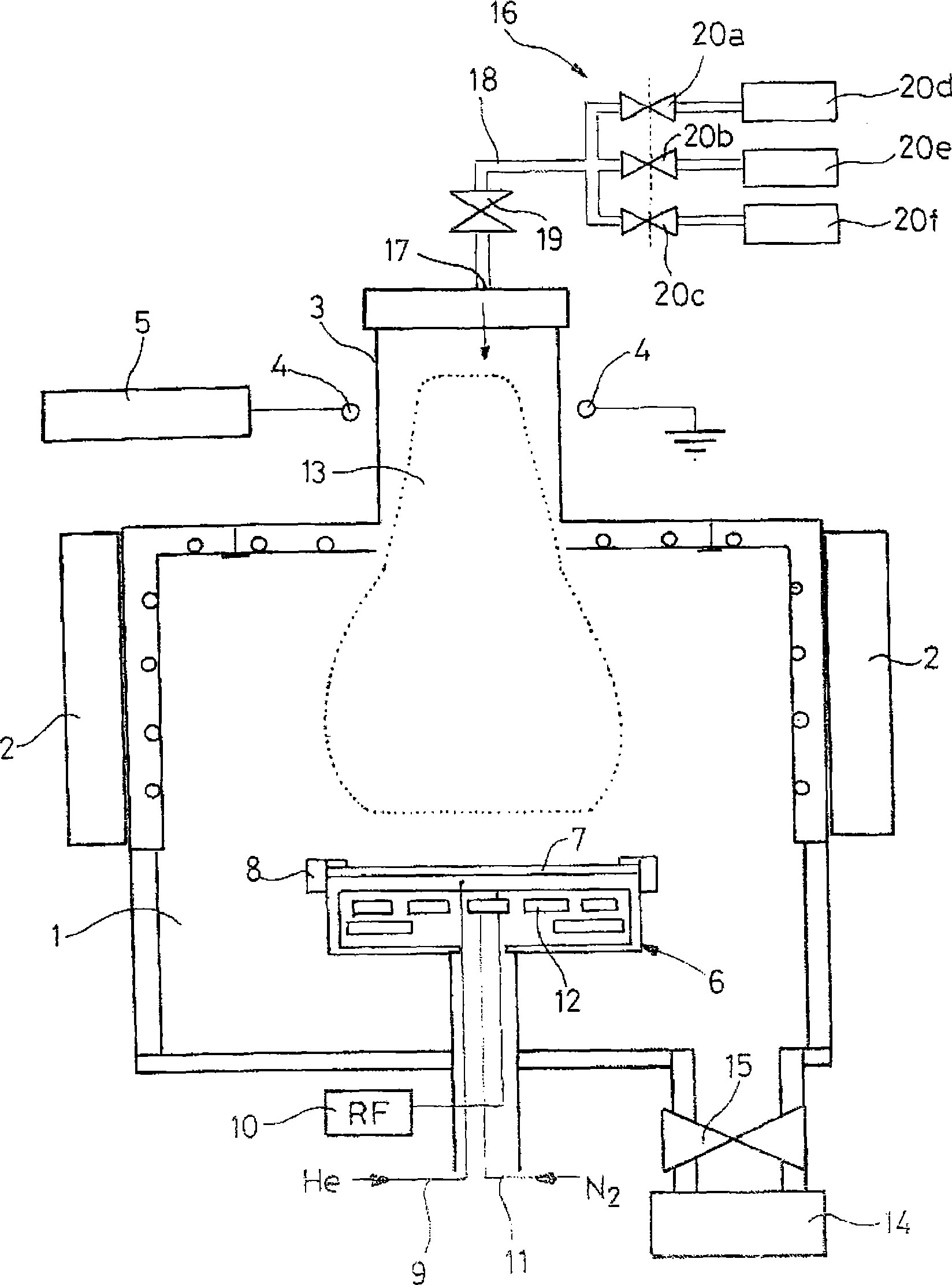

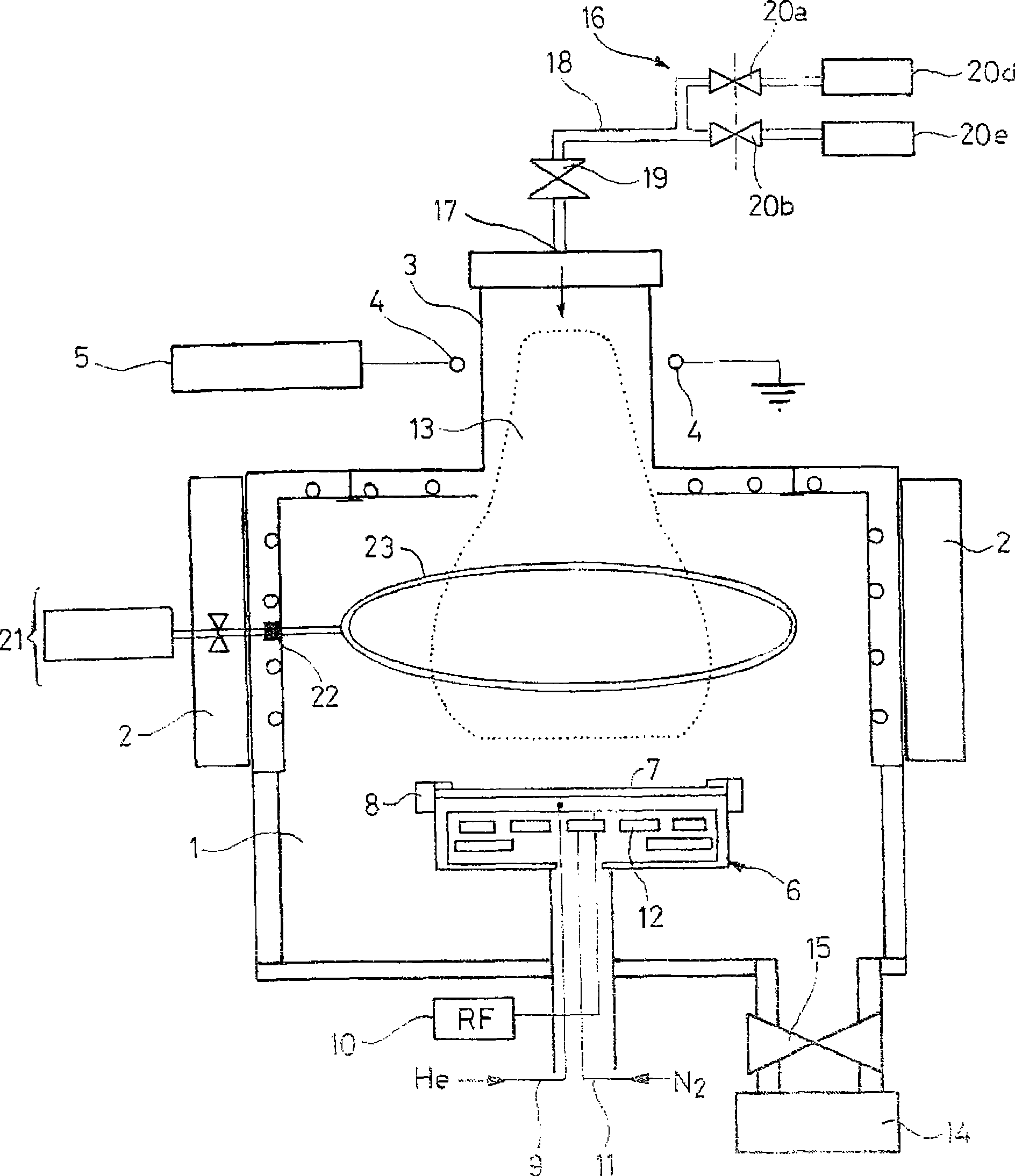

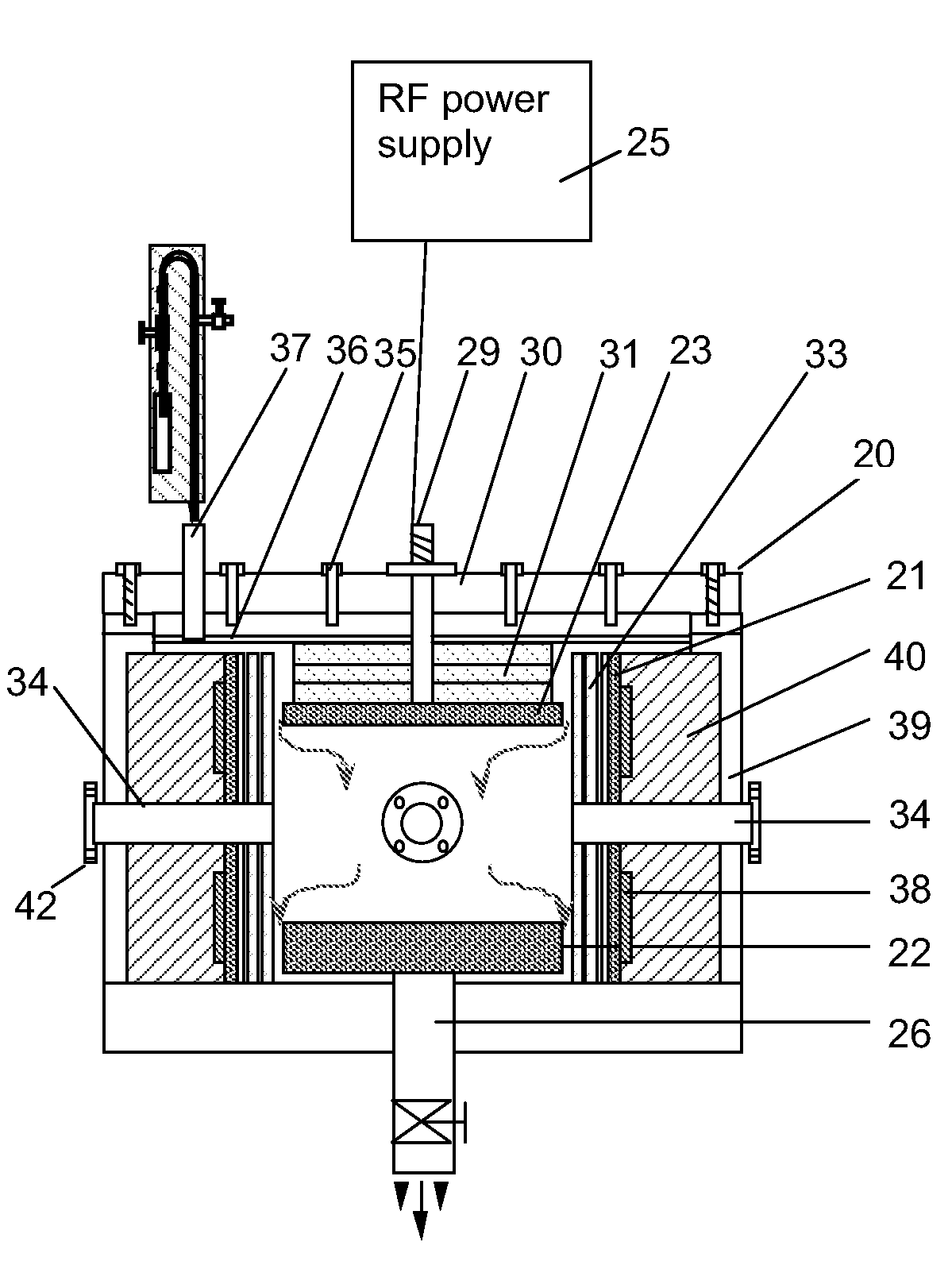

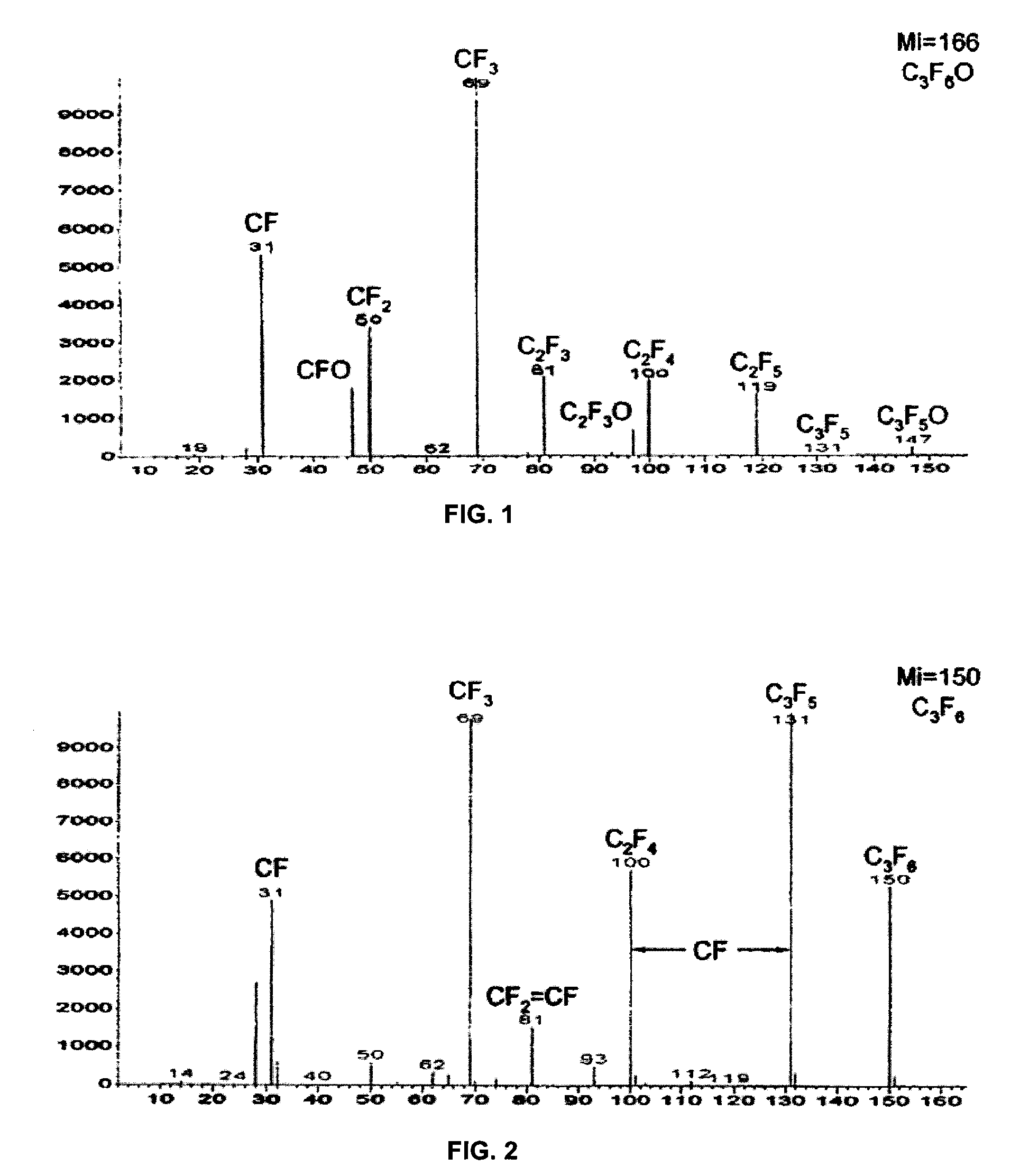

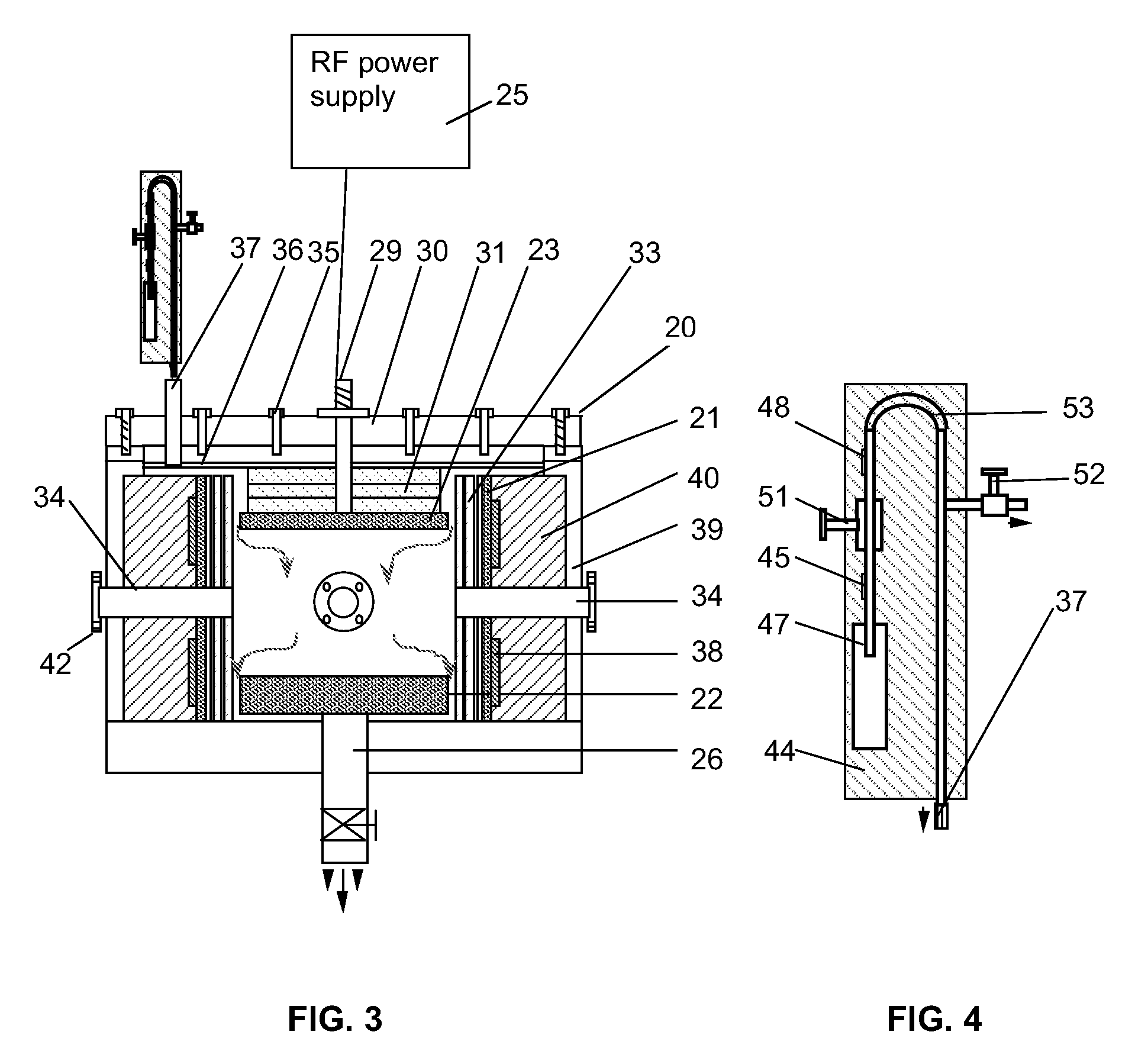

RF plasma-enhanced deposition of fluorinated films

InactiveUS20070172666A1Avoid stickingPrevent and minimize surface oxidationSynthetic resin layered productsPretreated surfacesFluorinated gasesPolymer science

Low- or atmospheric pressure RF plasma-enhanced thin film deposition methods are provided for the deposition of hydrophobic fluorinated thin films onto various substrates. The methods include at least two steps. In the first step, RF plasma-mediated deposition is used to deposit a fluorinated film onto a substrate surface. In a second step, plasma-generated active sites on the fluorinated film are quenched by reacting them with stable fluorinated gas-phase molecules in situ, in the absence of plasma, to provide a hydrophobic fluorinated thin film having a very low oxygen content. In some instances the hydrophobic fluorinated thin films have an atomic oxygen concentration of no more than about 3%.

Owner:WISCONSIN ALUMNI RES FOUND

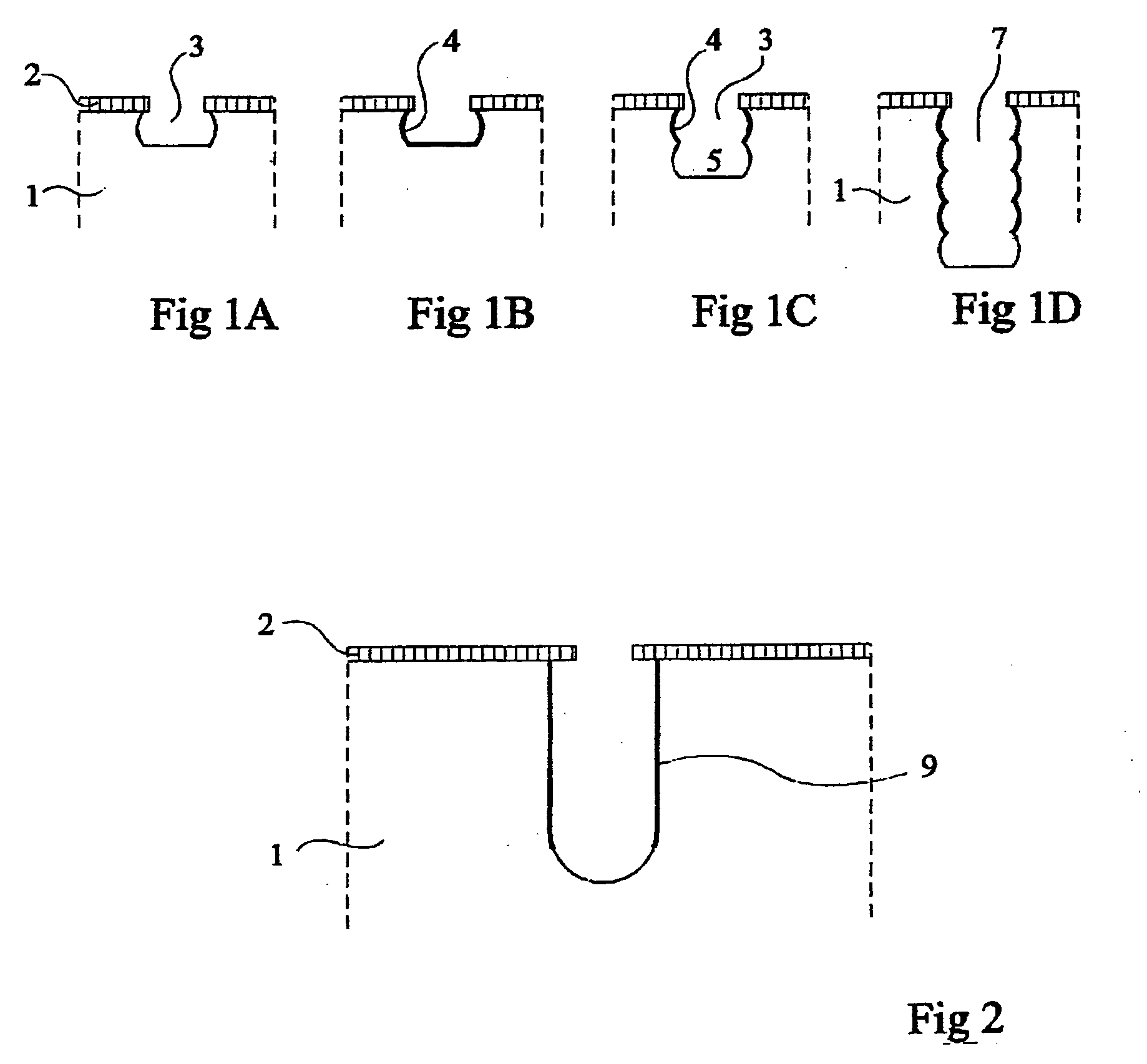

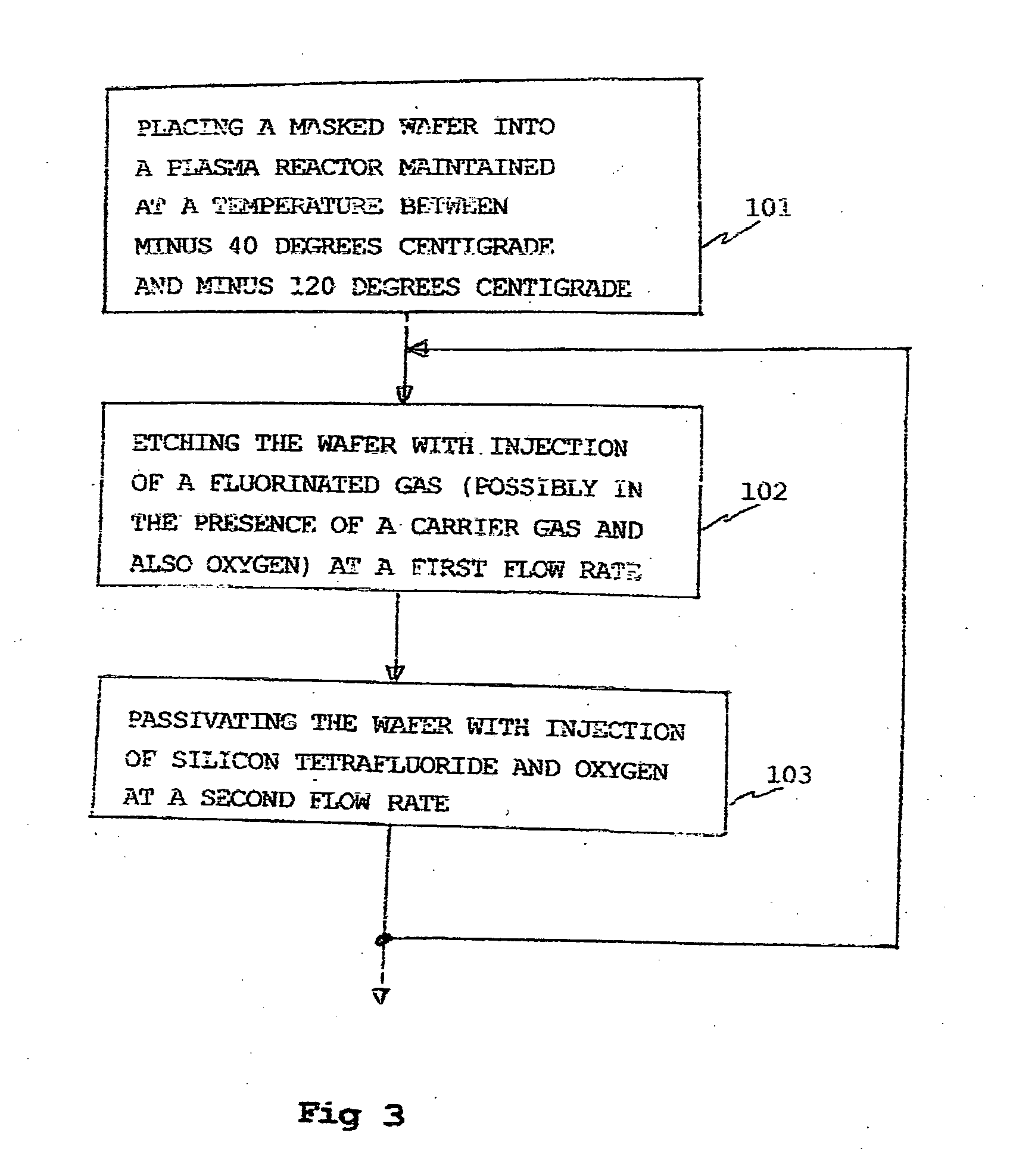

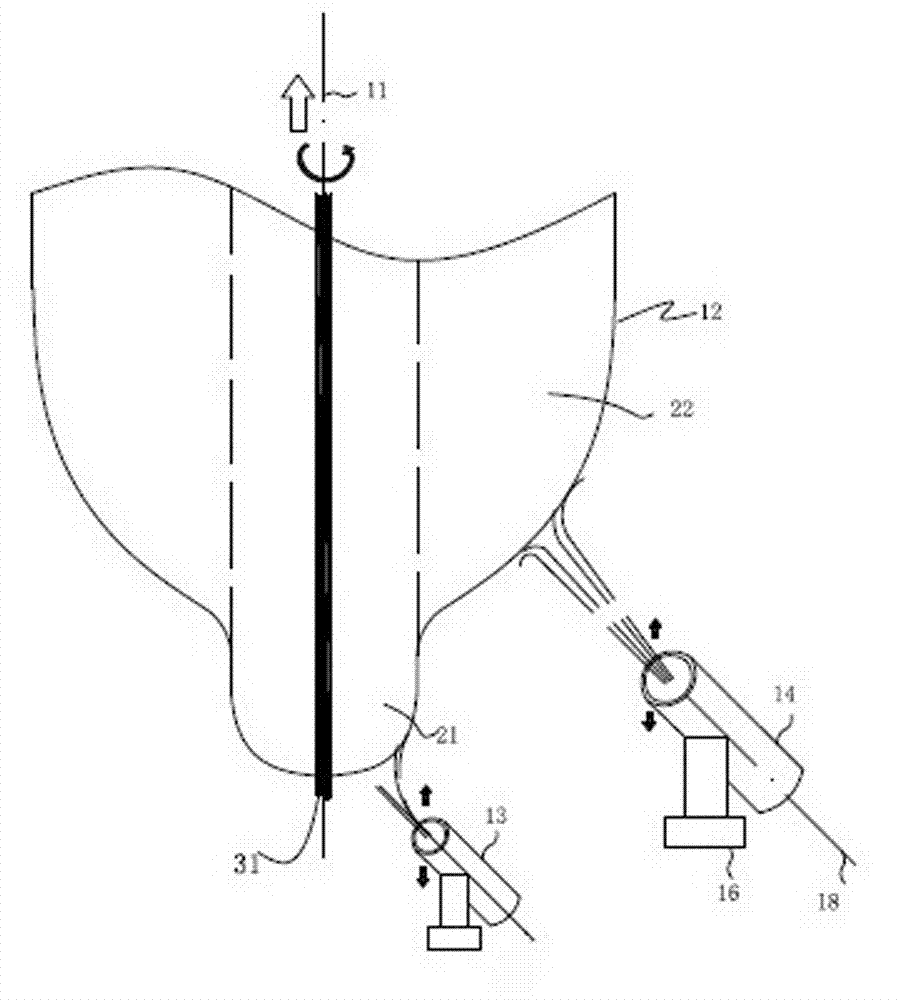

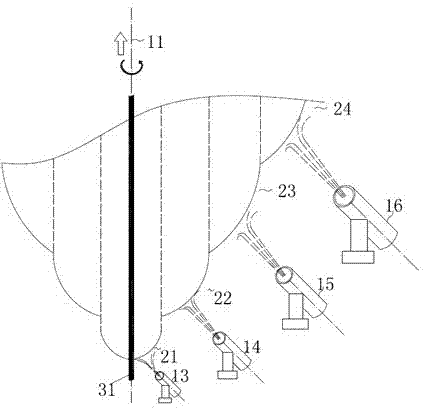

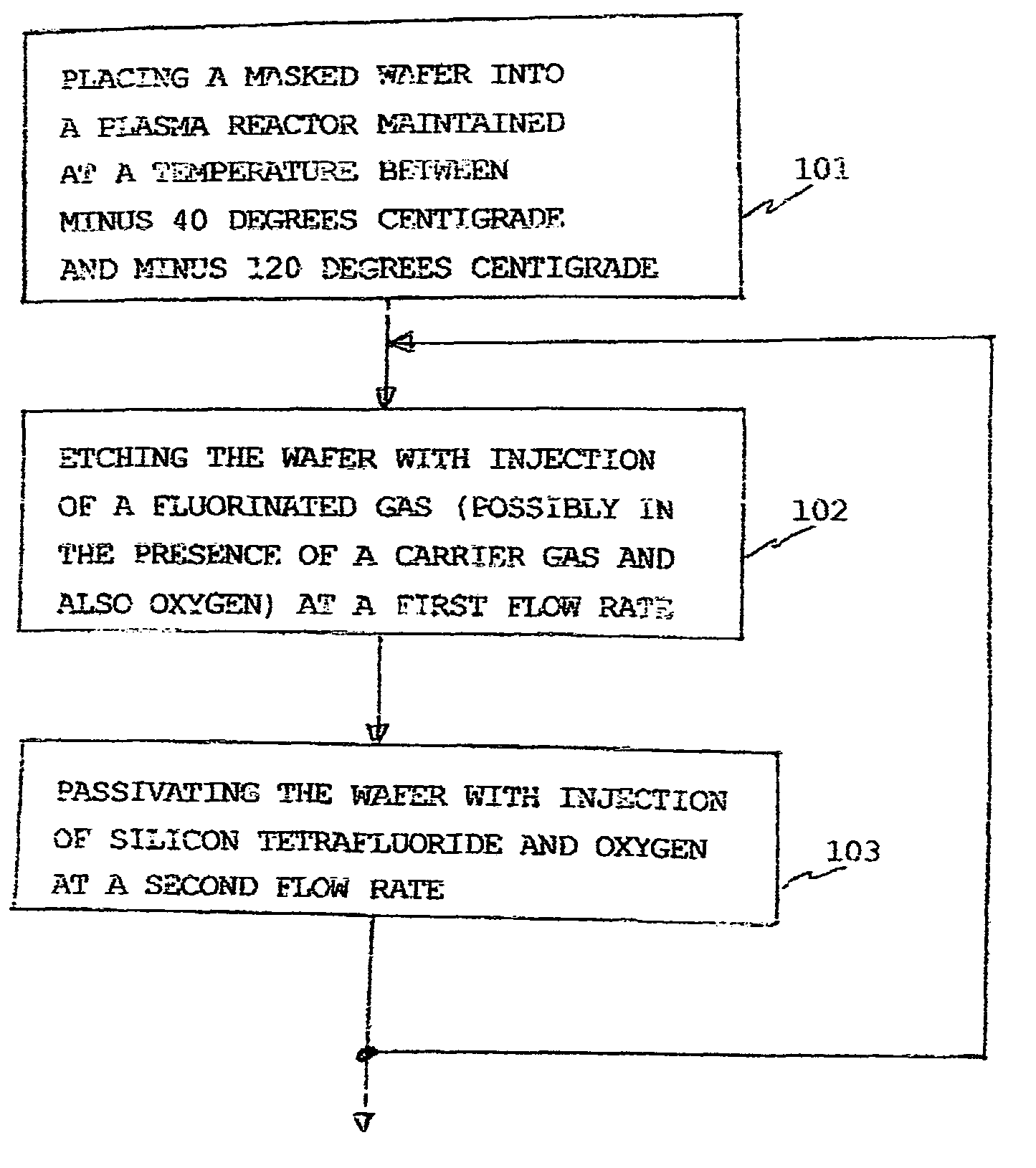

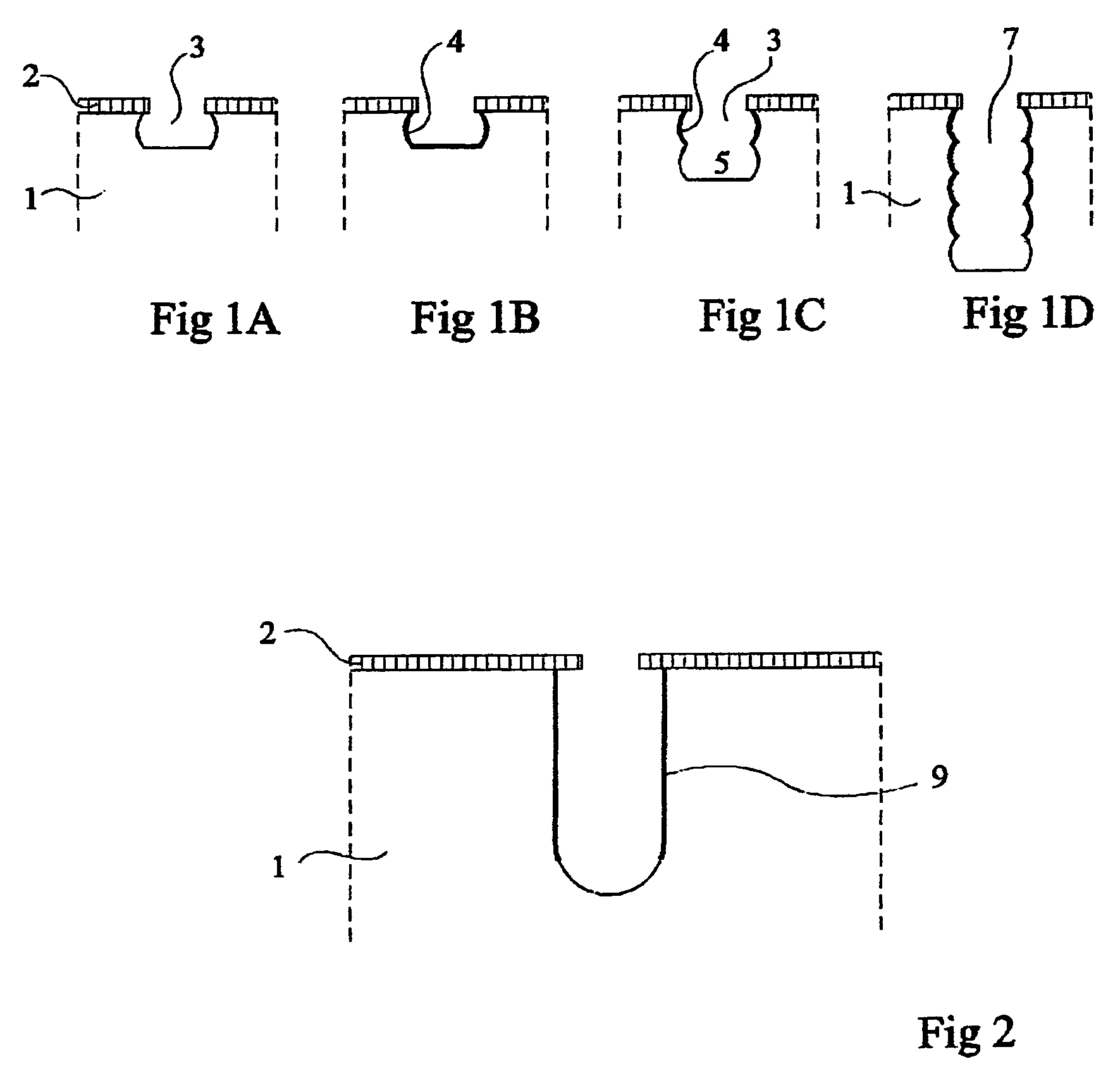

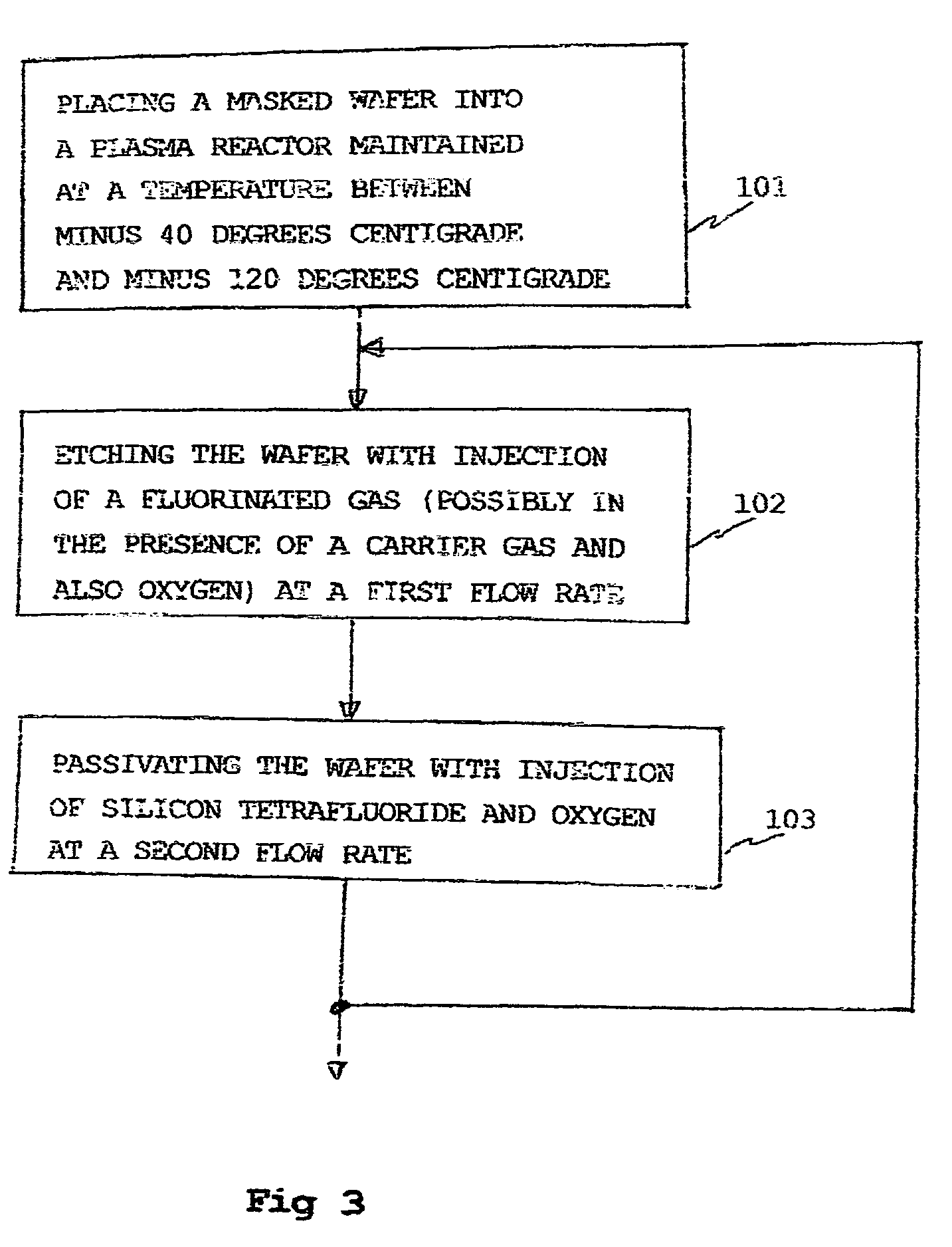

Deep anisotropic silicon etch method

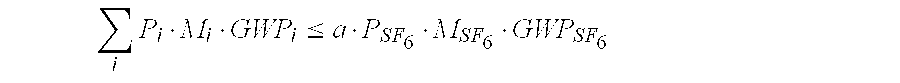

ActiveUS20080293250A1Eliminate disadvantagesDecorative surface effectsSemiconductor/solid-state device manufacturingFluorinated gasesSilicon tetrafluoride

A method of anisotropic plasma etching of a silicon wafer, maintained at a temperature from −40° C. to −120° C., comprising alternated and repeated steps of:etching with injection of a fluorinated gas, into the plasma reactor, andpassivation with injection of silicon tetrafluoride, SiF4, and of oxygen into the plasma reactor, the flow rate of the gases in the plasma reactor being on the order of from 10% to 25% of the gas flow rate during the etch step.

Owner:STMICROELECTRONICS SRL +2

Fluorinated precursors of superconducting ceramics, and methods of making the same

InactiveUS20050014032A1Quality improvementEliminate needLiquid/solution decomposition chemical coatingSuperconductor device manufacture/treatmentFluorinated gasesAlkaline earth metal

This invention provides a method of making a fluorinated precursor of a superconducting ceramic. The method comprises providing a solution comprising a rare earth salt, an alkaline earth metal salt and a copper salt; spraying the solution onto a substrate to provide a film-covered substrate; and heating the film-covered substrate in an atmosphere containing fluorinated gas to provide the fluorinated precursor.

Owner:BROOKHAVEN SCI ASSOCS

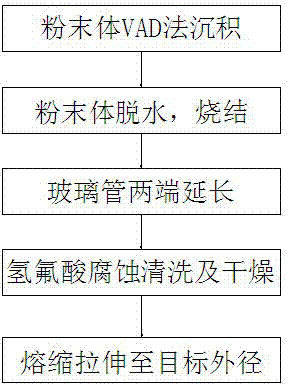

Method for preparing low water peak optical fiber preform

ActiveCN103663958AReduce manufacturing costImprove deposition efficiencyGlass making apparatusGlass productionFluorinated gasesHydrofluoric acid

The invention relates to a method for preparing a low water peak optical fiber preform, which comprises the following steps: (a) depositing powder containing SiO2, GeO2 and the like on a target bar through vapor axial deposition (VAD); (b) after the powder body is deposited on the target bar, withdrawing the target bar from the powder body; (c) mounting a holding mechanism at one end of the tubular powder body and a plug at the other end, feeding the powder body into a heating furnace filled with dewatering gas and heat-conducting gas by means of the holding mechanism, and dewatering and sintering the tubular powder body to obtain a tubular glass body; (d) welding extension tubes at both ends of the sintered tubular glass body, eroding in a liquid containing hydrofluoric acid, cleaning the central hole region and the external surface, and drying in a clean; (e) transferring the dried tubular glass body into an electrothermal furnace containing oxygen gas and fluorine-containing gas, and performing melting shrinkage; and (f) cladding the stretched glass bar in optical fibers or directly performing wire drawing to form optical fibers.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Method of forming a (CFx)n containing absorbent composition, intermediate materials employed in conducting the method and method of using the composition for preferential separation of a fluorine-containing gas from a gas stream containing the same

InactiveUS20040084793A1Other chemical processesTransportation and packagingCarbon monofluorideFluorinated gases

Method of forming a (CF.sub.X).sub.n containing adsorbent composition by combining a fine particle (CF.sub.X).sub.n starting material with a non-fluorinated carbonaceous material prior to the formation of a solid body and intermediate materials employed in conducting the method.

Owner:BOC GRP INC

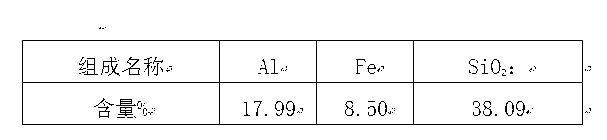

Method for producing superfine white carbon black, ferric hydroxide and aluminum oxide by using coal ash

InactiveCN103193238AHigh extraction rateImprove dissolution rateSilicaIron oxides/hydroxidesFerric hydroxideFluorinated gases

The invention belongs to a resourceful, economic and fine utilization method of coal ash, and relates to a method for producing superfine white carbon black, ferric hydroxide and aluminum oxide by using coal ash. The method comprises the following steps of: with the coal ash as a raw material and a sulfuric acid and caustic soda solution as a solvent, grinding the coal ash, heating to assist in dissolving the coal ash, carrying out acid leaching on the coal ash, and then, filtering and cleaning the coal ash to obtain a filtrate, wherein the filtrate is used for preparing the ferric hydroxide and the aluminum oxide, a filter cake obtained through leaching and filtering is used for preparing the superfine white carbon black, and a fluoride-contained gas generated through leaching is used for absorbing and preparing an AlF3 product. By using the method, the problem that the industrial application can not be realized because the traditional coal ash leaching way is low in useful substance leaching rate is better solved fundamentally, and the total useful substance dissolution rate of the coal ash can be increased from 15-20% to 75-85%, so that resourceful utilization, economic and fine utilization, product diversification and higher additional value of the coal ash can be realized.

Owner:宫毅 +2

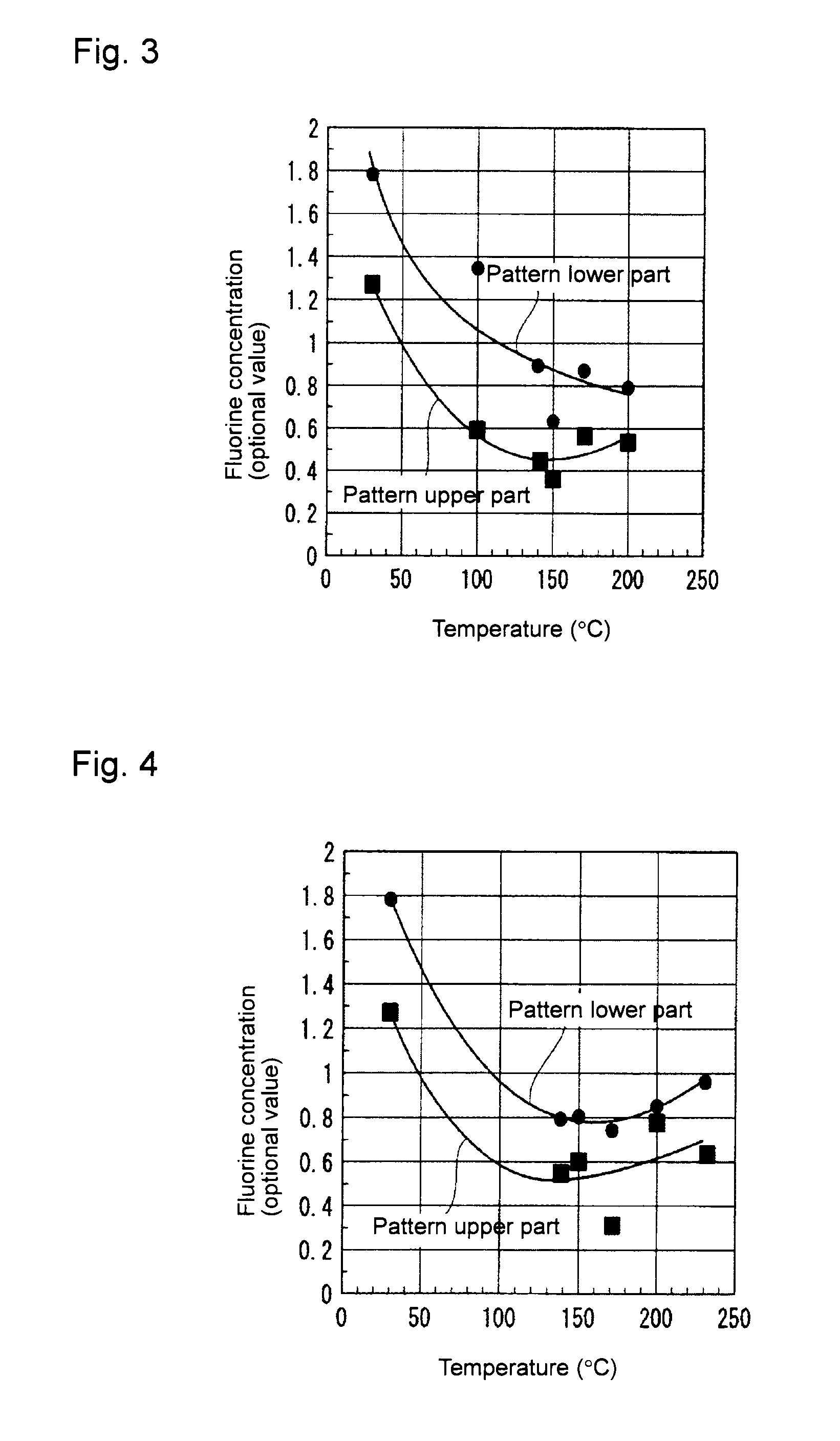

Anisotropic etching method

InactiveUS20070197039A1Less sensitiveClean etching methodElectric discharge tubesSemiconductor/solid-state device manufacturingFluorinated gasesSulfur hexafluoride

The present invention consists in a method for anisotropically etching a silicon substrate at very low temperature using a high-density fluorinated gas plasma, characterized in that the plasma is formed from a gas mixture comprising an etching gas containing fluorine, a passivating gas containing oxygen and a reaction gas comprising chlorine, and in which method the respective ratios of the flowrate of the passivating gas and the flowrate of the reaction gas to the flowrate of the etching gas are less than 0.15 by volume. The etching gas containing fluorine is preferably sulfur hexafluoride SF6, the passivating gas containing oxygen is preferably chosen from oxygen O2, ozone O3 and sulfur dioxide SO2, and the reaction gas comprising chlorine is preferably silicon tetrachloride SiCl4.

Owner:TEGAL CORP

Method for cleaning with fluorine compound

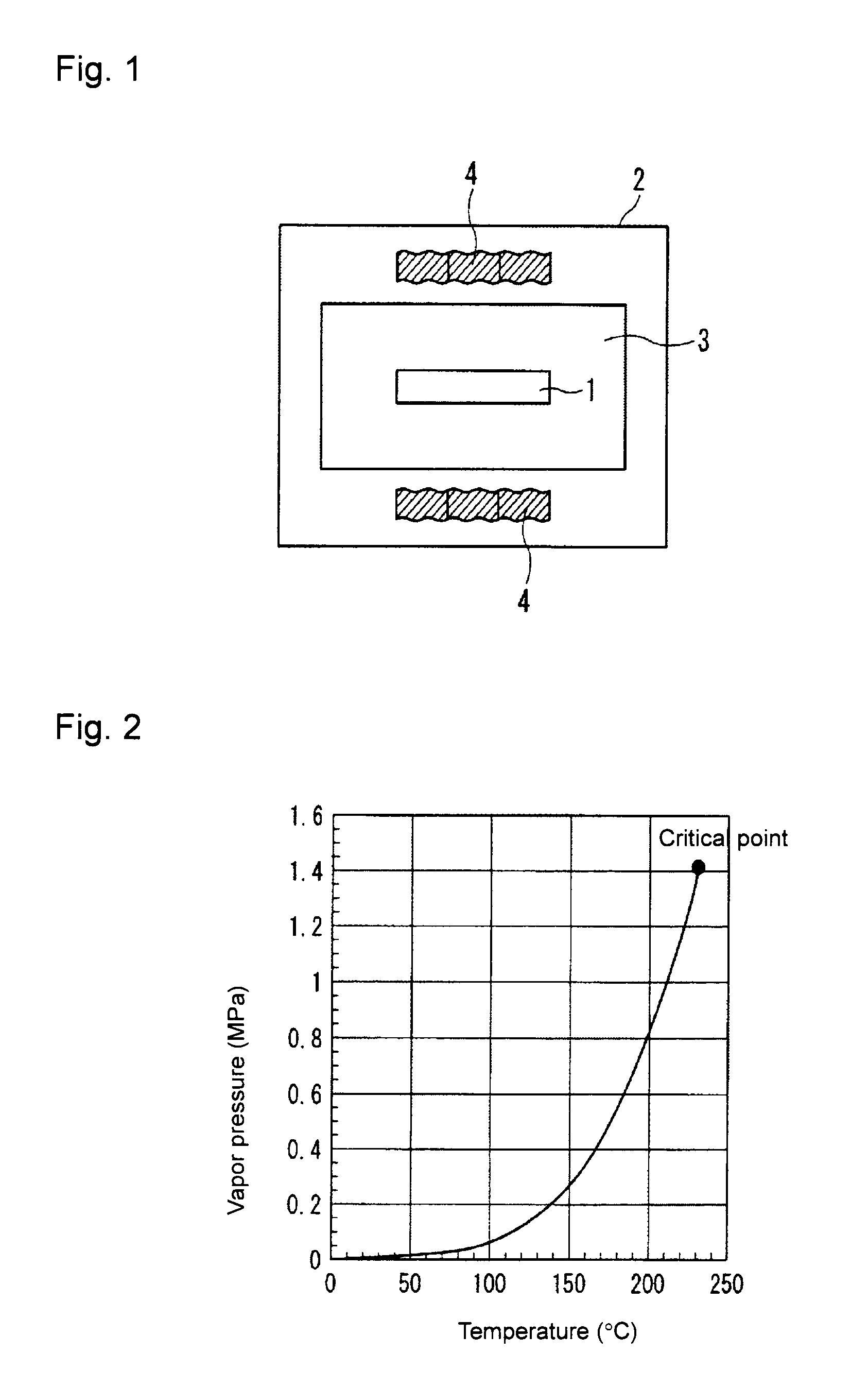

InactiveUS20110067733A1Lighting and heating apparatusNon-surface-active detergent compositionsFluorinated gasesLiquid state

To provide a cleaning method capable of favorably removing an object to be cleaned having a plasma polymer formed in a plasma etching step employing a fluorinated gas.A cleaning method comprising an immersion step of immersing an object 1 to be cleaned in a cleaning liquid (fluorinated solvent) 3 containing at least a fluorine compound, wherein in the immersion step, the temperature t of the cleaning liquid 3 is at least the lower one of the normal boiling point of the fluorine compound contained in the cleaning liquid 3 at 1 atm and 100° C., and the atmospheric pressure is such a pressure that the fluorine compound is in a liquid state at the temperature t. Further, a cleaning method comprising an immersion step of immersing an object to be cleaned having a plasma polymer formed in a plasma etching step employing a fluorinated gas, in a cleaning liquid containing a fluorinated compound, wherein the fluorinated compound has a linear or branched perfluoroalkyl group having a number of carbon atoms of at least 5.

Owner:ASAHI GLASS CO LTD

Fluorinated precursors of superconducting ceramics, and methods of making the same

InactiveUS7361377B2Quality improvementEliminate needPretreated surfacesLiquid/solution decomposition chemical coatingFluorinated gasesAlkaline earth metal

This invention provides a method of making a fluorinated precursor of a superconducting ceramic. The method comprises providing a solution comprising a rare earth salt, an alkaline earth metal salt and a copper salt; spraying the solution onto a substrate to provide a film-covered substrate; and heating the film-covered substrate in an atmosphere containing fluorinated gas to provide the fluorinated precursor.

Owner:BROOKHAVEN SCI ASSOCS

Method and Device For Representing the Microstructure of the Lungs

InactiveUS20080208038A1High expenditureSmall shrinkageBiocideMagnetic measurementsFluorinated gasesMedicine

The invention relates to an apparatus and a method for imaging the microstructure of an animal or human lung by way of introducing a fluoric contrast gas into the lung which is to be imaged; definition of the apparent diffusion coefficient of the contrast gas by way of diffusion weighted 19fluorine magnetic resonance tomography and based on the determined apparent diffusion coefficients; and imaging of the lung's microstructure.The current invention also describes a device for the implementation of the inventive method. The science of the current invention allows for the first time the production of a high resolution image of the microstructures of the lung through non-invasive measures, by way of fluorinated gases.

Owner:JOHANNES GUTENBERG UNIV

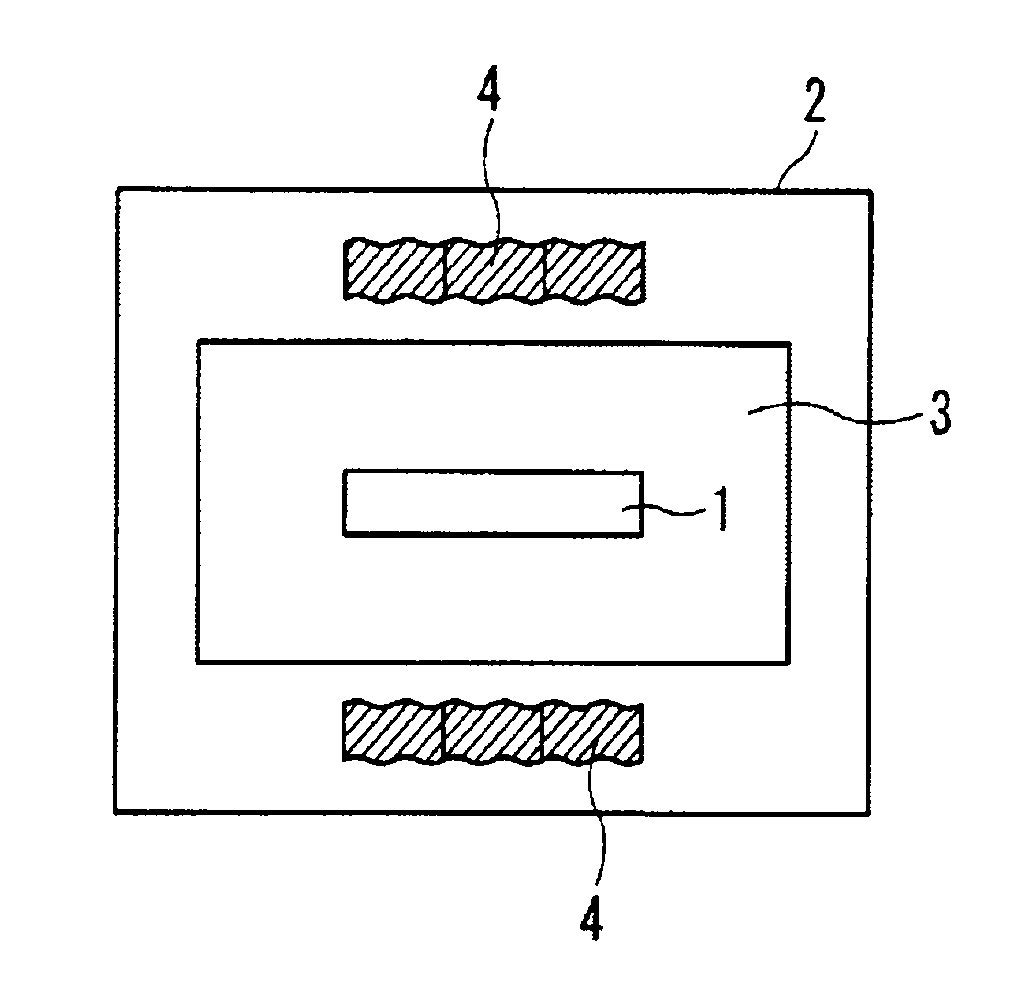

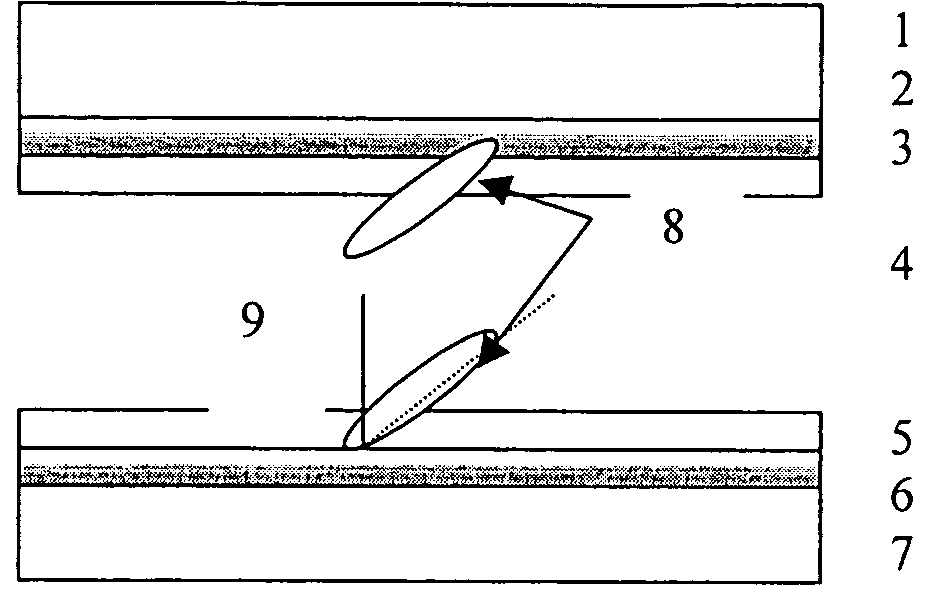

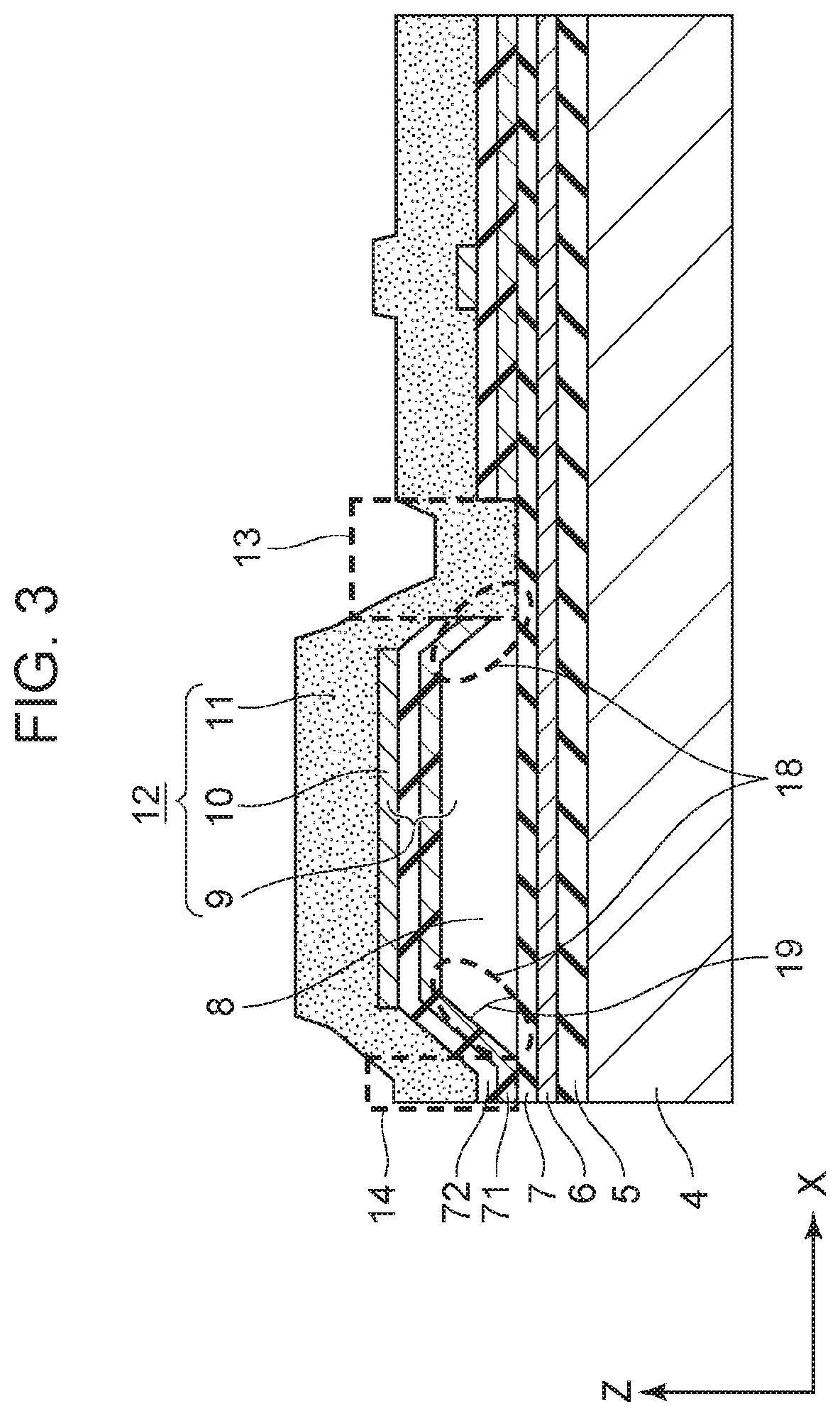

Liquid crystal display

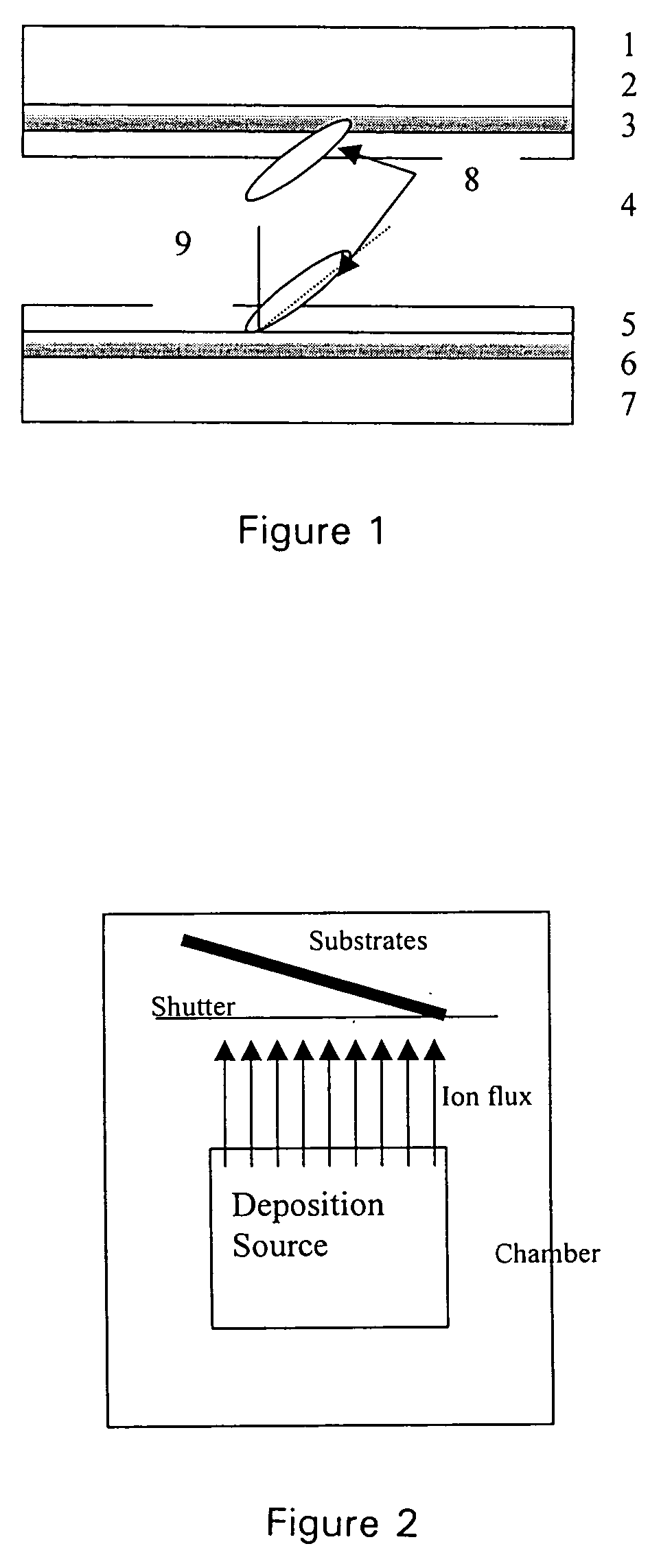

InactiveUS20050062921A1Improve light resistanceStable pretilt angleNon-linear opticsFluorinated gasesDiamond-like carbon

According to the invention there is provided a liquid crystal display device comprising at least two substrates, a homeotropic alignment film coated on said substrates, and a nematic liquid crystal mixture between adjacent substrates. A homeotropic alignment film in the form of a single Fluorinated-Diamond like Carbon (F-DLC) layer deposited onto the substrates with fluorinated gases by oblique plasma deposition method is disclosed.

Owner:VARINTELLIGENTBVILTD

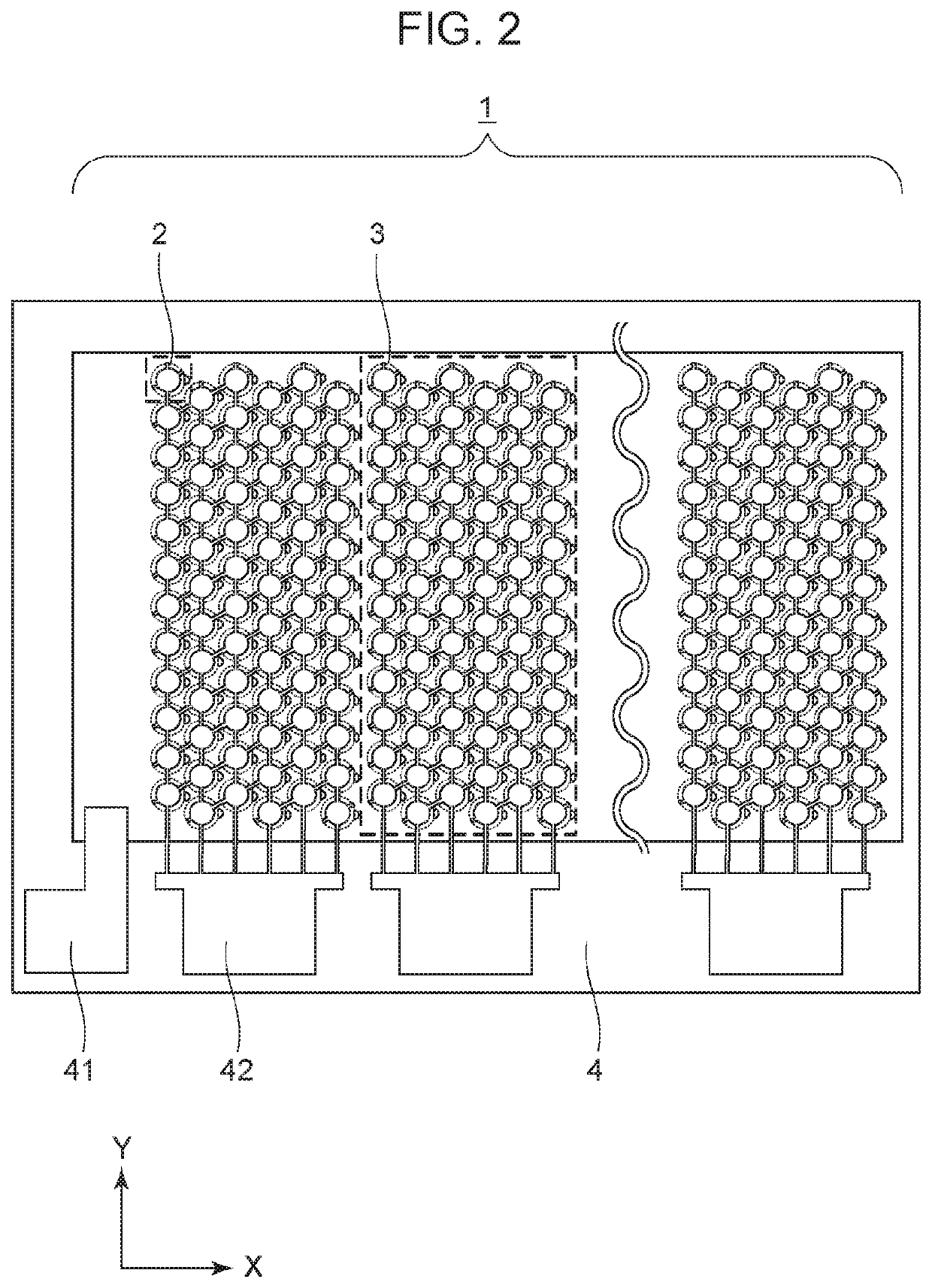

Method for producing hollow structure and hollow structure

ActiveUS20200123005A1Increase flow rateDecorative surface effectsSemiconductor electrostatic transducersFluorinated gasesFluorine containing

A method includes a step of forming a sacrificial layer on a first film, a step of forming a second film on the sacrificial layer, a step of forming an etching opening that extends through at least one of the first film and the second film so as to communicate with the sacrificial layer, and a step of forming a hollow portion by etching the sacrificial layer using a gas containing a fluorine-containing gas and hydrogen via the etching opening, wherein a composition ratio of silicon to nitrogen in a first region having a face in contact with the sacrificial layer is larger than a composition ratio of silicon to nitrogen in a second region not including the first region.

Owner:CANON KK

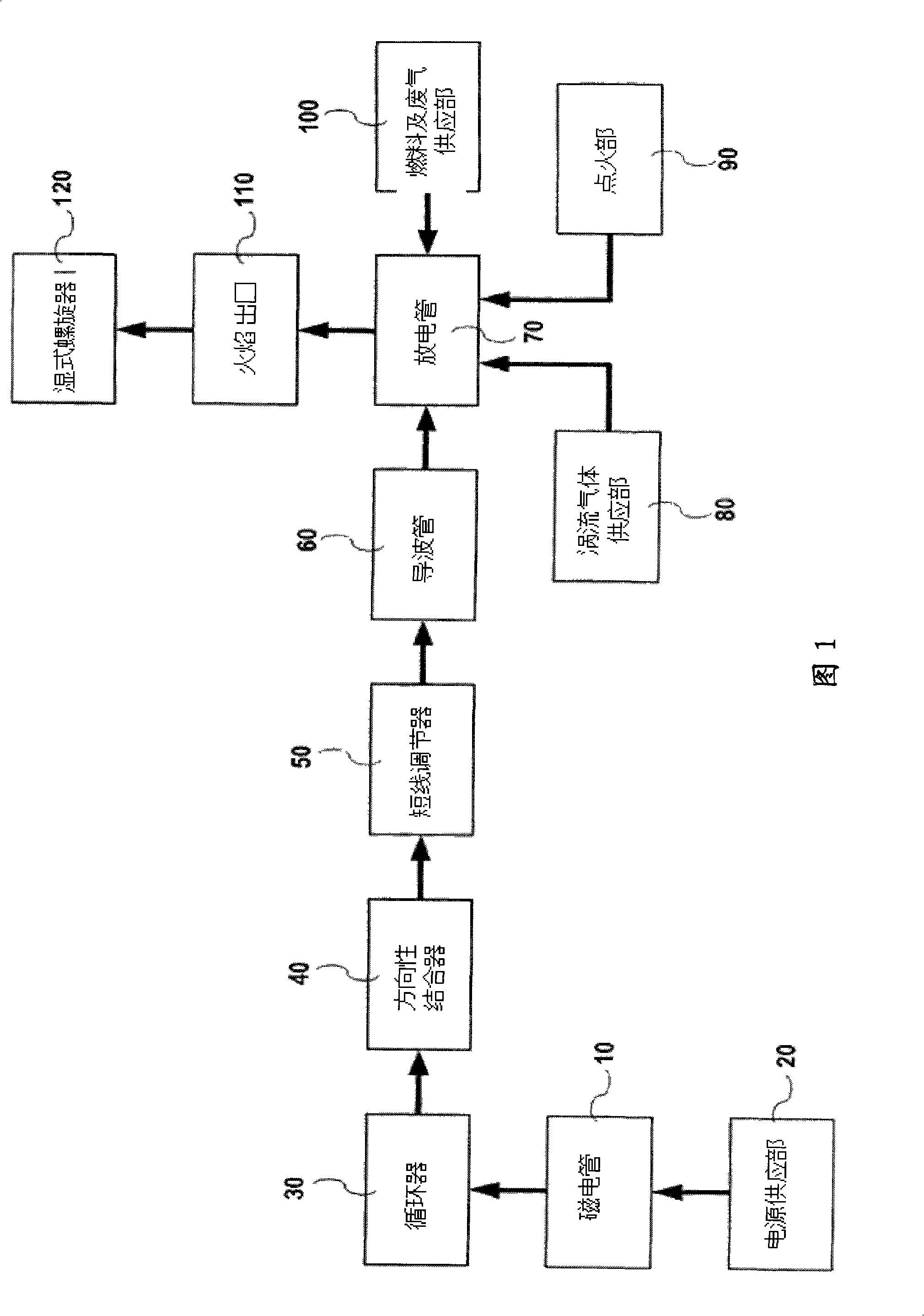

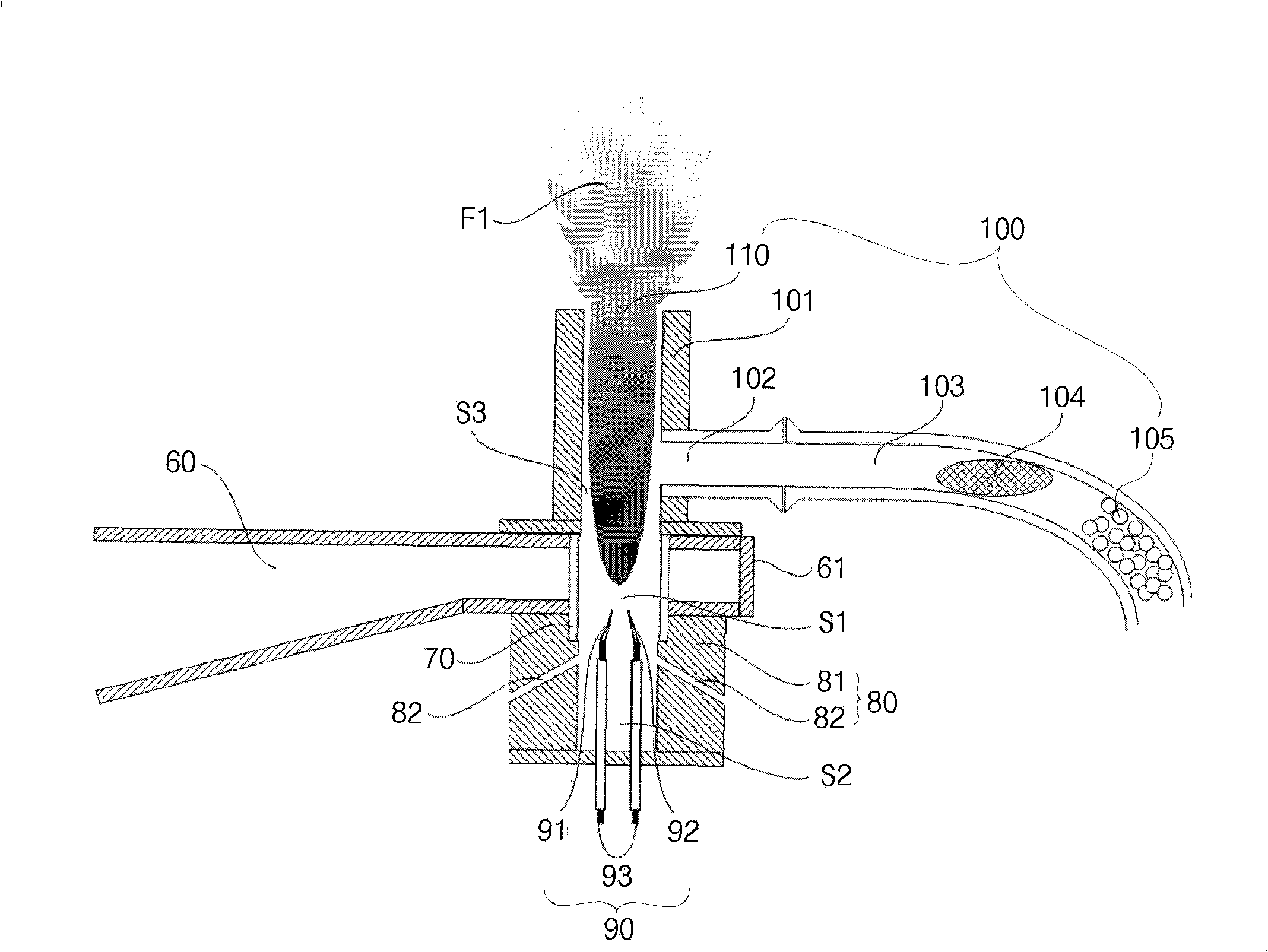

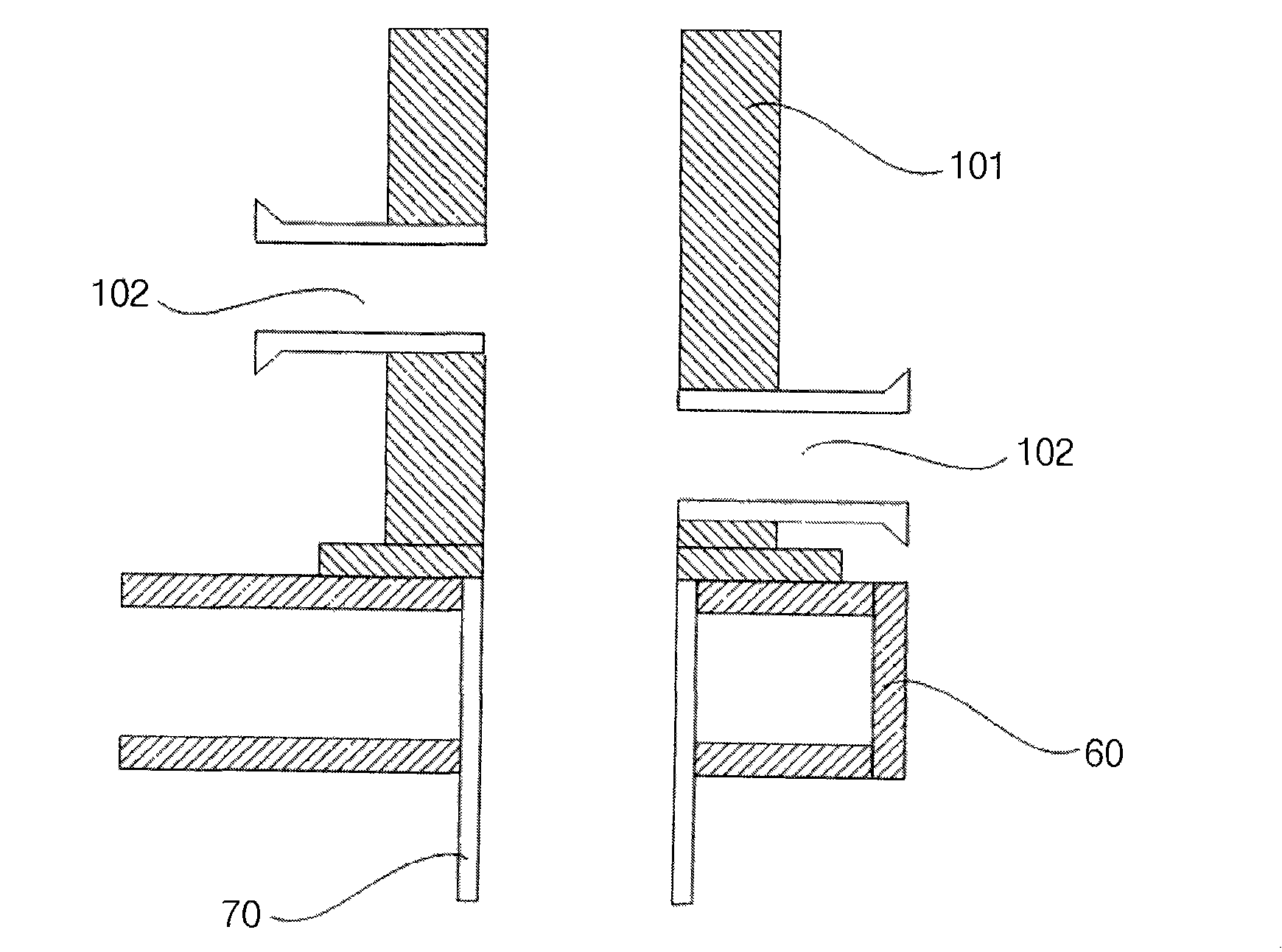

Device and method for eliminating fluorinated gases

InactiveCN101279187ADispersed particle separationEnergy based chemical/physical/physico-chemical processesFluorinated gasesChemical reaction

The invention relates to a device for removing fluorinated series gas and a method thereof. The device and the method of the invention is that: during the process of configuring, manufacturing and washing the high-tech industrial devices such as computers or semiconductors, etc. which use fluorinated serials gas, the gas polluted by the unreacted fluorinated series gas is led into plasmatorch with high temperature and high capacity to remove fluorinated series gas through thermal decomposition or plasmatorch chemical reaction.

Owner:严桓燮

Anisotropic etching method

InactiveCN101379600AEnhance or ensure integrityImprove practicalityElectric discharge tubesSemiconductor/solid-state device manufacturingFluorinated gasesOxygen

The subject of the present invention is a process for the anisotropic etching of a silcon substrate at very low temperature by a high-density fluorinated gas plasma, characterized in that the plasma is formed from a gas mixture comprising a fluorine-containing etching gas, an oxygen-containing passivation gas and a chlorine-containing reaction gas, in which process the respective ratios of the flow rate of the passivation gas and the flow rate of the reaction gas to the flow rate of the etching gas are less than 0.15 by volume. Preferably, the fluorine-containing etching gas is sulphur hexafluoride SF6, the oxygen-containing passivation gas is chosen from oxygen O2, ozone O3 and sulphur dioxide SO2, and the chlorine-containing reaction gas is silicon tetrachloride SiCl4.

Owner:ALCATEL LUCENT SAS

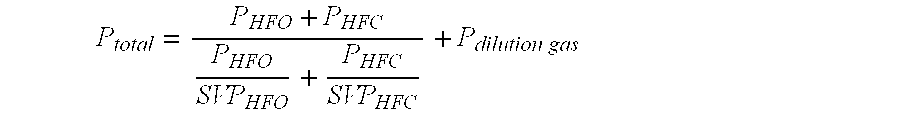

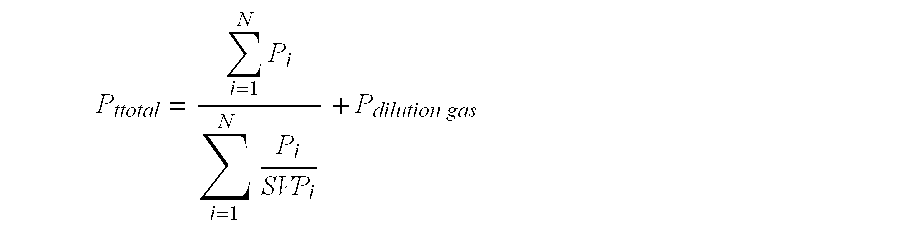

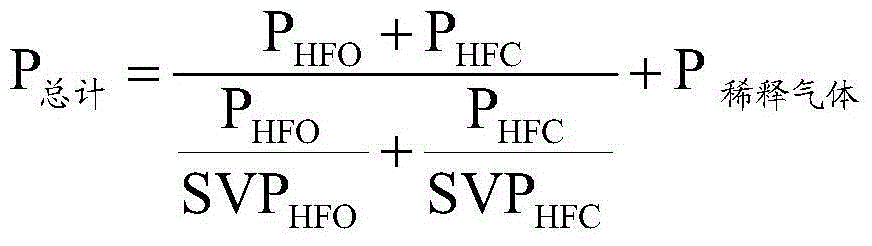

Mixture of hydrofluoroolefine and hydrofluorocarbide to improve the internal arc resistance in medium and high voltage electric apparatus

ActiveUS20140346145A1Low and zero impactGood arc resistanceSwitchgear arrangementsHigh-tension/heavy-dress switchesFluorinated gasesElectricity

The invention relates to the use of a mixture of a hydrofluoroolefin and a hydrofluorocarbon, optionally combined with another fluorinated gas, as an electrical insulation medium and / or an electric arc extinguishing medium in a medium-voltage electrical apparatus. The invention also relates to a medium- or high-voltage electrical apparatus in which such a mixture provides electrical insulation and / or electric arc extinguishing.

Owner:SCHNEIDER ELECTRIC IND SAS

Deep anisotropic silicon etch method

ActiveUS8012365B2Eliminate disadvantagesSemiconductor/solid-state device manufacturingMicrostructural device manufactureFluorinated gasesSilicon tetrafluoride

Owner:STMICROELECTRONICS SRL +2

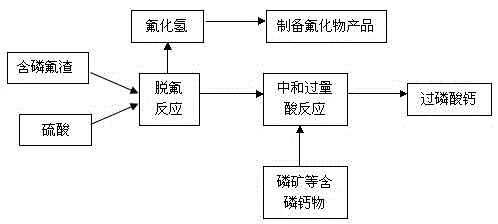

Method for recycling fluorine from phosphorus-containing fluorine slag and cogenerating calcium superphosphate

InactiveCN104370277AEfficient recyclingWell mixedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen fluorideFluorinated gasesSlurry

The invention discloses a method for recycling fluorine from a phosphorus-containing fluorine slag and cogenerating calcium superphosphate. The method comprises the following steps: adding a phosphorus-containing fluorine slag and concentrated sulfuric acid to a defluorination reaction tank according to the ratio of 1 to (0.6-1.1), stirring and reacting at 60-200 DEG C for 0.1-3 hours; recovering escaped fluorine-containing gas in the reaction process and preparing fluoride products such as hydrofluoric acid and the like to recover fluorine resources; stirring and reacting the phosphorus-containing fluorine slag and the concentrated sulfuric acid in the defluorination reaction tank for 0.1-3 hours; adding a phosphorus-containing calcium material to reaction slurry, stirring and reacting for 0.1-5 hours, and neutralizing free acids in the slurry; and drying the reactants after reacting, so as to obtain a calcium superphosphate product. Compared with the prior art, the method has the characteristics of being simple in process, mild in operation condition, high in recovery rate of phosphorus-fluorine resources, and free of 'three wastes' on the whole.

Owner:WENGFU (GRP) CO LTD

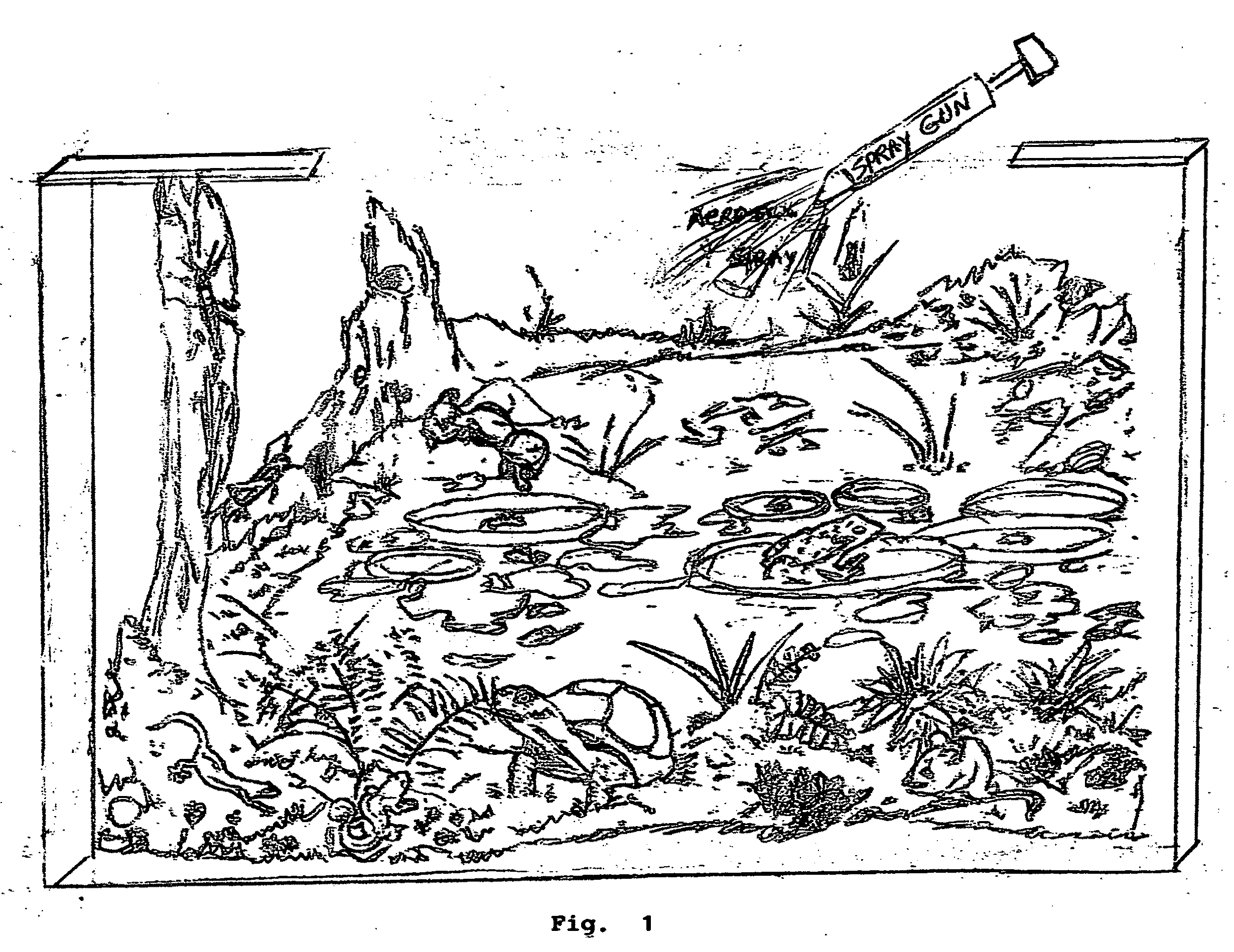

Method to scrub greenhouse gases from the atmosphere

InactiveUS20100005967A1Reduce buildEliminating fossil fuel useNitrous oxide captureGas treatmentFluorinated gasesAtmospheric air

Carbon dioxide, methane, nitrous oxide and three groups of fluorinated gases have been referred to as greenhouse gases and the most offensive gases in contributing to Global Warming This invention comprises the use of Titration and other chemical oxidation—reduction reactions in novel ways to scrub these gases from the Earth's atmosphere. The invention comprises identifying, developing, and spraying base aerosols to neutralize carbon dioxide, nitrous oxide, sulphur dioxide, and similar compounds whose oxides form acids when dissolved in water vapor. Acid-base titrations result in neutralization of the acid and the base. The formation of a salt and water typically are by-products. Salt precipitates such as CACO3—calcium carbonate or limestone settle into the oceans naturally forming limestone deposits which act as homes for microscopic sea life. Carbonic acid which results from CO2 being dissolved in water produces calcium carbonate when treated with a base. The invention proposes that by trials other natural salts may be identified which may safely be precipitated to the earth as it is important that the absorption into the Earth's environment occur with a minimum of deleterious effects. There exists a number of acids and The invention further comprises the novel use of vehicles such as space shuttles or a space station as delivery vehicles.

Owner:ABFY SELLERS GRP

Composite slagging agent for converter

InactiveCN102978329AReduce manufacturing costAvoid pollutionManufacturing convertersSteelmakingFluorinated gases

The invention discloses a composite slagging agent for a converter, which belongs to the technical field of slagging agents used in a converter steel-making process. The composite slagging agent comprises, by mass, 68 to 73 parts of calcium-free chromium slag, 12 to 15 parts of white corundum and 20 to 23 parts of limestone. The composite slagging agent for the converter provided by the invention does not contain CaF2, enables pollution to the atmosphere and the water resource by fluorine-containing gas and fluorinions to be avoided and integratedly utilizes waste calcium-free chromium slag which is difficult to recycle as a main raw material, so production cost for the slagging agent is substantially reduced, and elements like Cr and Fe in the calcium-free chromium slag are comprehensively utilized. According to the invention, formation time of the composite slagging agent is short and is reduced by about 30%, high production efficiency is realized, steel consumption is reduced by more than 3 Kg / t, consumption of slagging materials is reduced, and a substantial economic benefit is obtained.

Owner:高金菊

Mixture of a hydrofluoroolefin and hydrofluorocarbon for improving internal arc resistance in medium- and high-voltage electrical apparatuses

ActiveCN104137210ASwitchgear arrangementsHigh-tension/heavy-dress switchesFluorinated gasesElectricity

The invention relates to the use of a mixture including a hydrofluoroolefin and a hydrofluorocarbon, optionally combined with another fluorinated gas and a dilution gas, as an electrical insulation medium and / or an electric-arc extinguishing medium in a medium-voltage electrical apparatus. The invention also relates to a medium- or high-voltage electrical apparatus in which such a mixture provides electrical insulation and / or electric-arc extinguishing.

Owner:SCHNEIDER ELECTRIC IND SAS

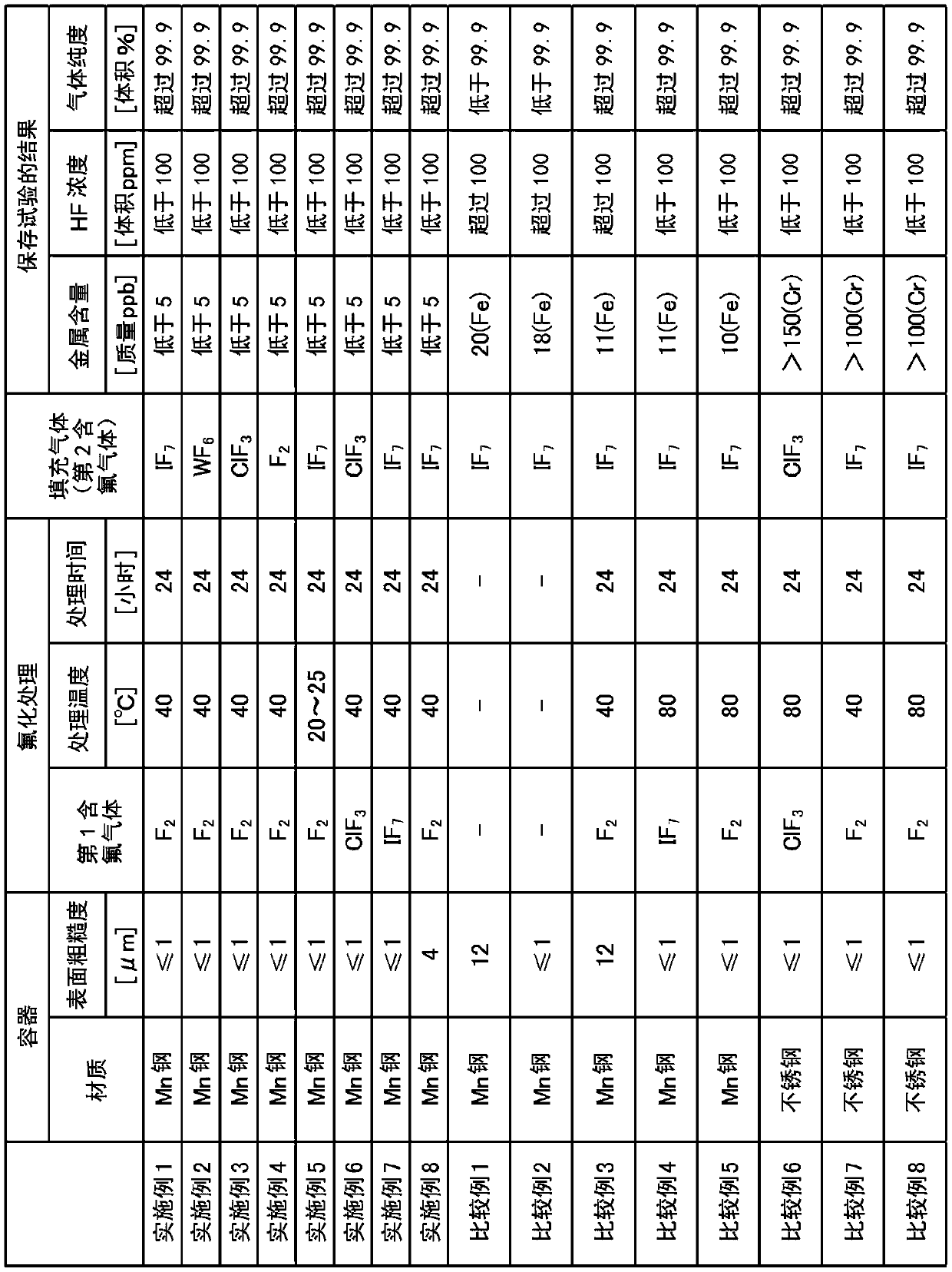

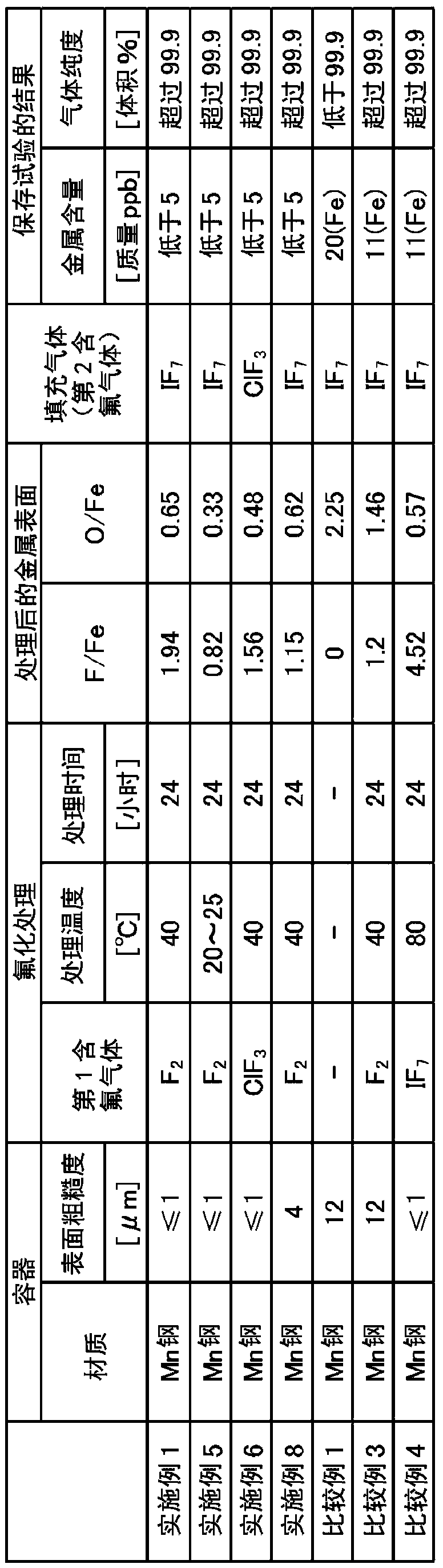

Method for manufacturing filled container, and filled container

ActiveCN110832106ALow purityAvoid mixingVessel manufacturingVessel wallsFluorinated gasesPhysical chemistry

A method for manufacturing a filled container is characterized by including: a step for preparing a metal-made storage container in which at least an inner surface thereof is formed from manganese steel and the surface roughness Rmax of the inner surface is 10 microns or less; a fluorination step for bringing the inner surface of the storage container into contact with a gas including at least onespecies of first fluorine-containing gas selected from the group consisting of ClF3, IF7, BrF5, F2, and WF6 at a temperature of 50 DEG C or less; a step for replacing the inside of the storage container with an inert gas; and a step for filling the inside of the storage container with at least one species of second fluorine-containing gas selected from the group consisting of ClF3, IF7, BrF5, F2,and WF6.

Owner:CENT GLASS CO LTD

RF plasma-enhanced deposition of fluorinated films

ActiveUS20090123639A1Low fluorescence backgroundLow oxygenPharmaceutical containersPretreated surfacesFluorinated gasesPolymer science

Low- or atmospheric pressure RF plasma-enhanced thin film deposition methods are provided for the deposition of hydrophobic fluorinated thin films onto various substrates. The methods include at least two steps. In the first step, RF plasma-mediated deposition is used to deposit a fluorinated film onto a substrate surface. In a second step, plasma-generated active sites on the fluorinated film are quenched by reacting them with stable fluorinated gas-phase molecules in situ, in the absence of plasma, to provide a hydrophobic fluorinated thin film having a very low oxygen content. In some instances the hydrophobic fluorinated thin films have an atomic oxygen concentration of no more than about 3%.

Owner:WISCONSIN ALUMNI RES FOUND

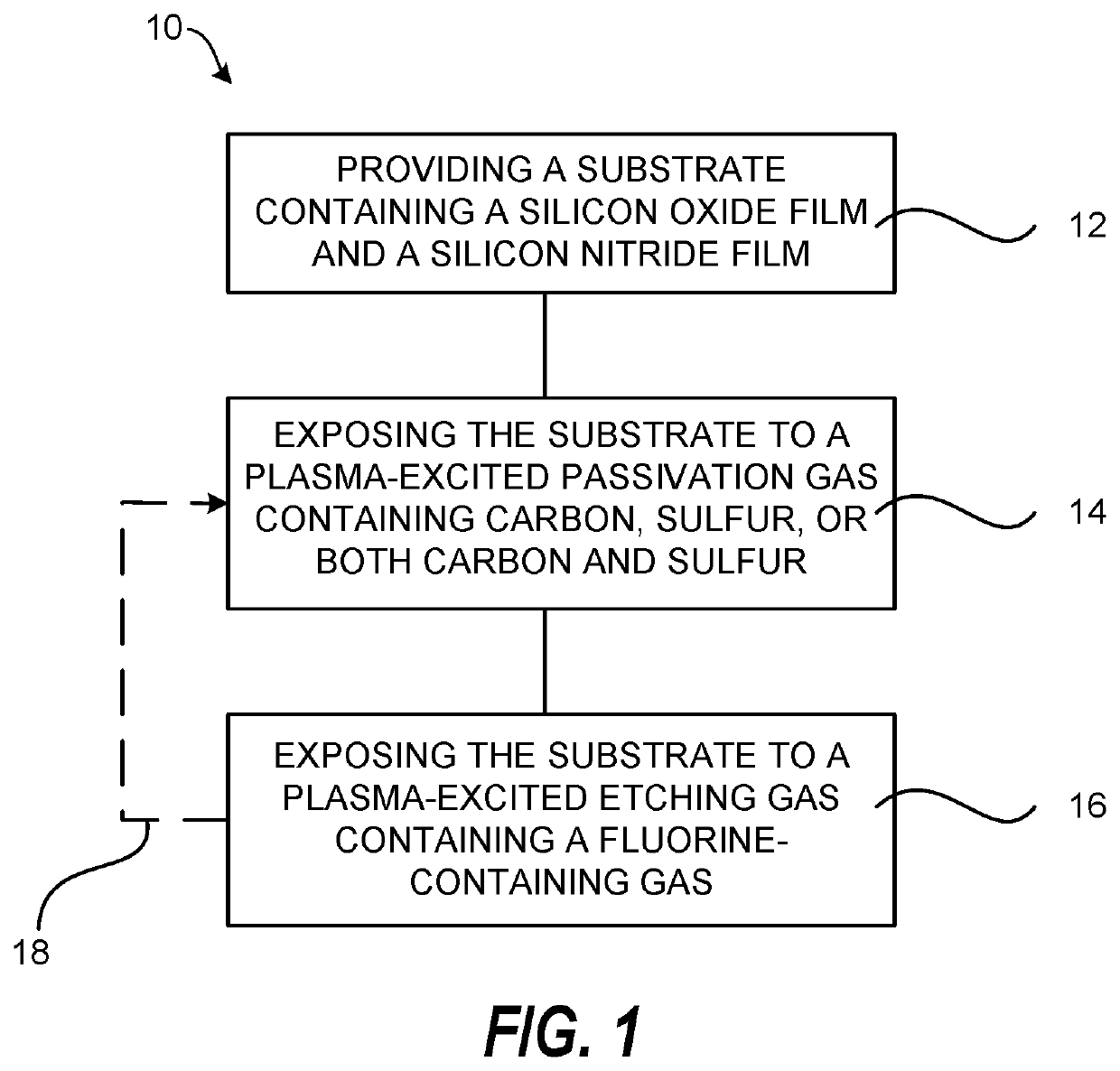

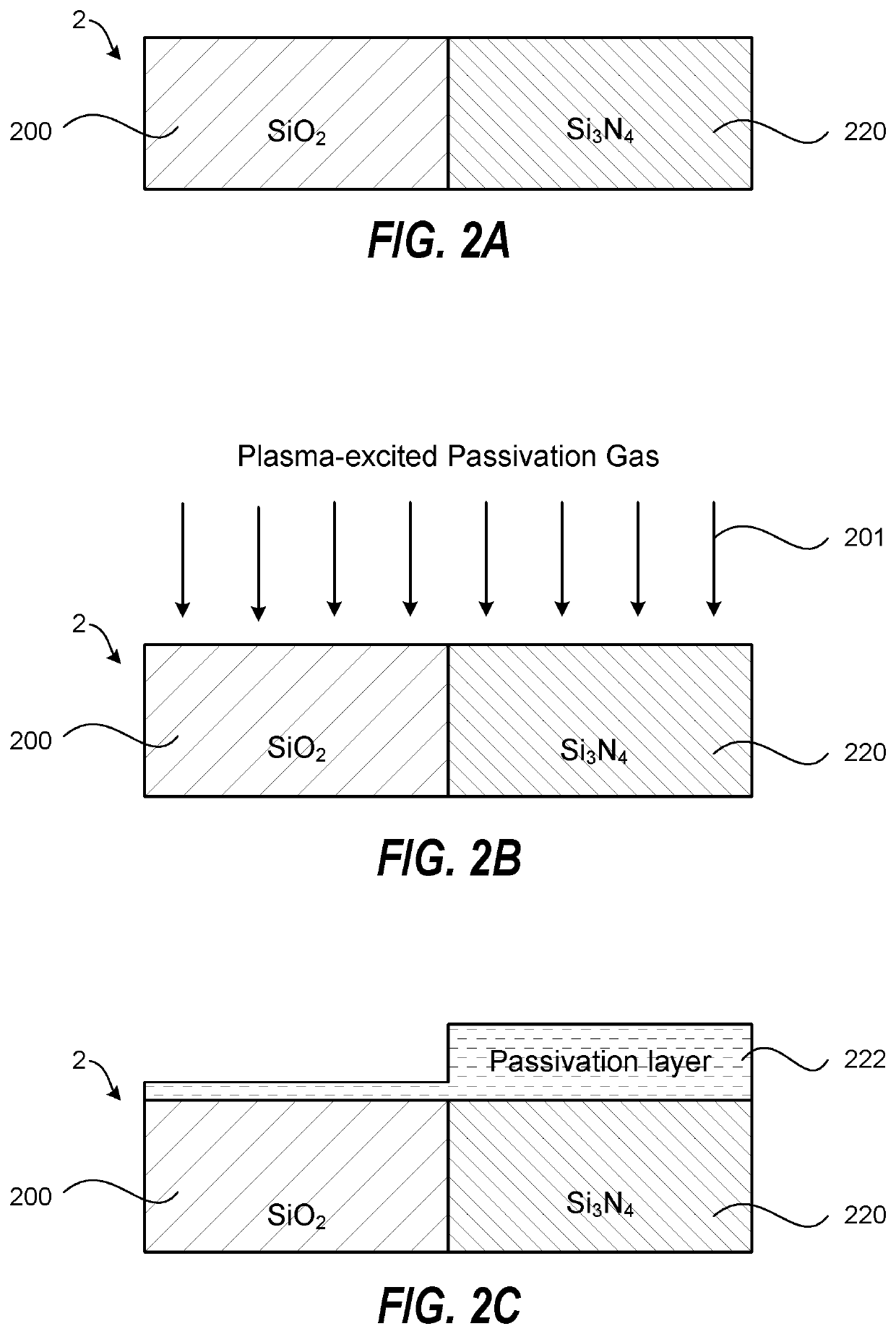

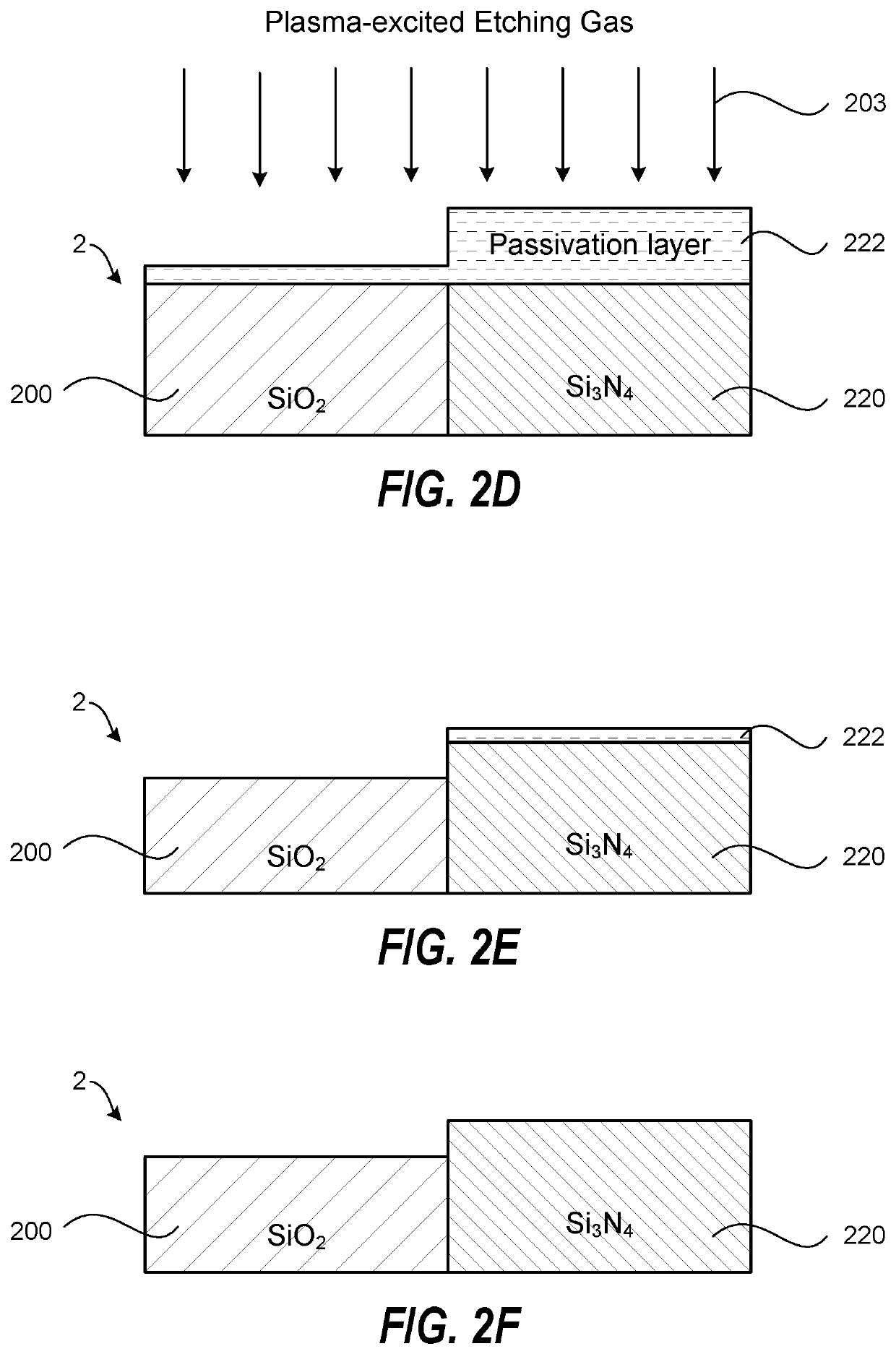

Independent control of etching and passivation gas components for highly selective silicon oxide/silicon nitride etching

ActiveUS20200321218A1Semiconductor/solid-state device manufacturingFluorinated gasesChlorofluorocarbon

A method for selective plasma etching of silicon oxide relative to silicon nitride is described. The method includes providing a substrate containing a silicon oxide film and a silicon nitride film, and selectively etching the silicon oxide film relative to the silicon nitride film by: a1) exposing the substrate to a plasma-excited passivation gas containing carbon, sulfur, or both carbon and sulfur, where the plasma-excited passivation gas does not contain fluorine or hydrogen, and b1) exposing the substrate to a plasma-excited etching gas containing a fluorine-containing gas. The method can further include, between a1) and b1), an additional step of a2) exposing the substrate to a plasma-excited additional passivation gas containing a fluorocarbon gas, hydrofluorocarbon gas, a hydrochlorocarbon gas, a hydrochlorofluorocarbon gas, or a hydrocarbon gas, or a combination thereof.

Owner:TOKYO ELECTRON LTD

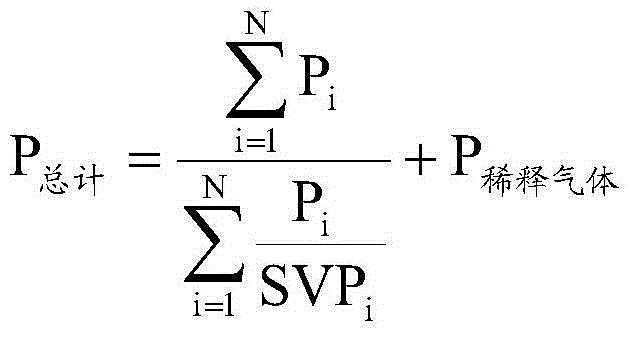

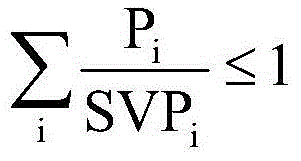

Method for Manufacturing Filled Container, and Filled Container

The method for producing a filled container of the present invention includes: providing a metal storage container, at least an inner surface of which is formed of a manganese steel and in which the inner surface has a surface roughness Rmax of 10 μm or less; performing fluorination by bringing the inner surface of the storage container into contact with a gas containing at least one first fluorine-containing gas selected from the group consisting of ClF3, IF7, BrF5, F2, and WF6 at 50° C. or lower; purging the inside of the storage container with an inert gas; and filling the inside of the storage container with at least one second fluorine-containing gas selected from the group consisting of ClF3, IF7, BrF5, F2, and WF6.

Owner:CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com