Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Excellent water vapor permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

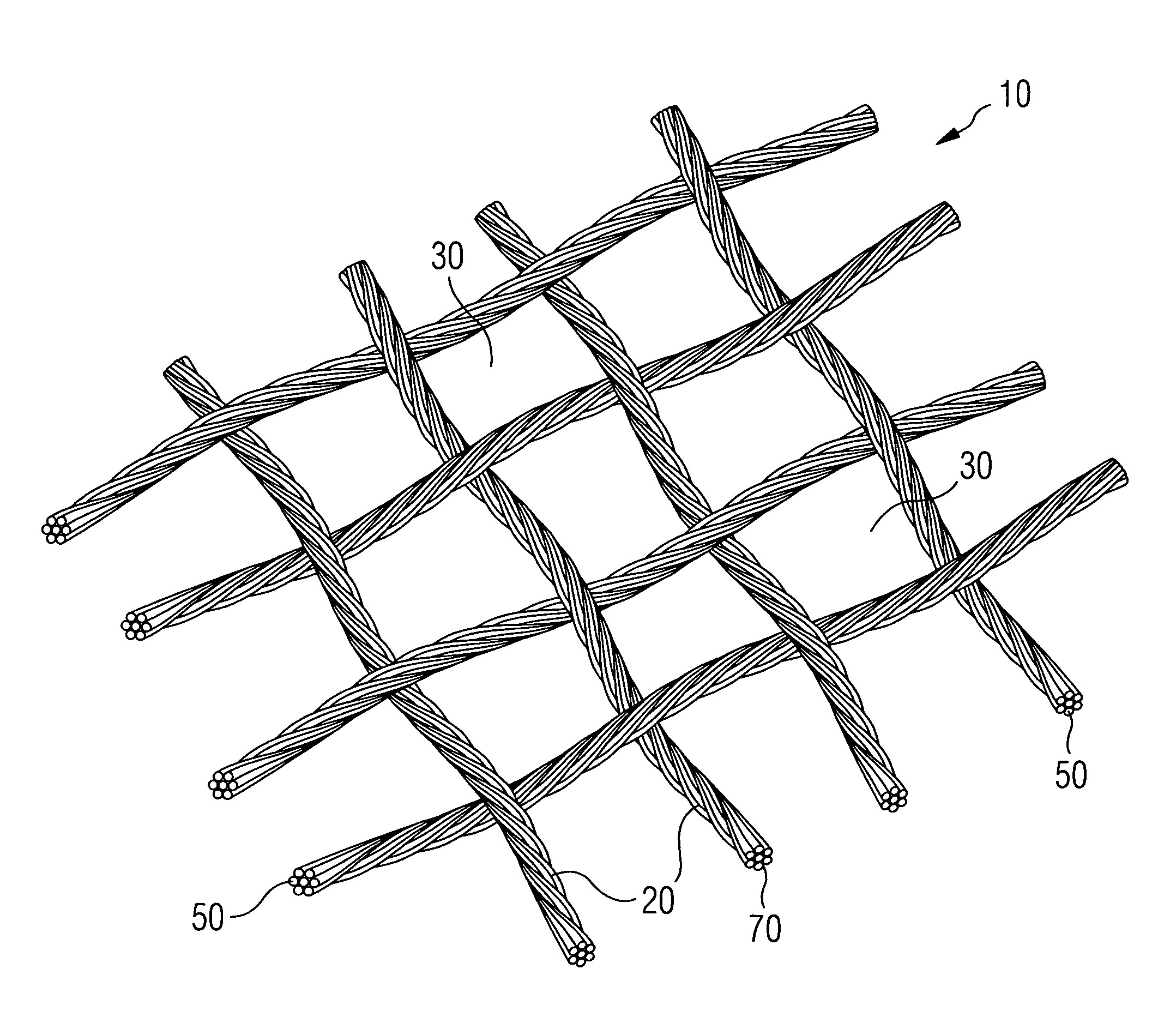

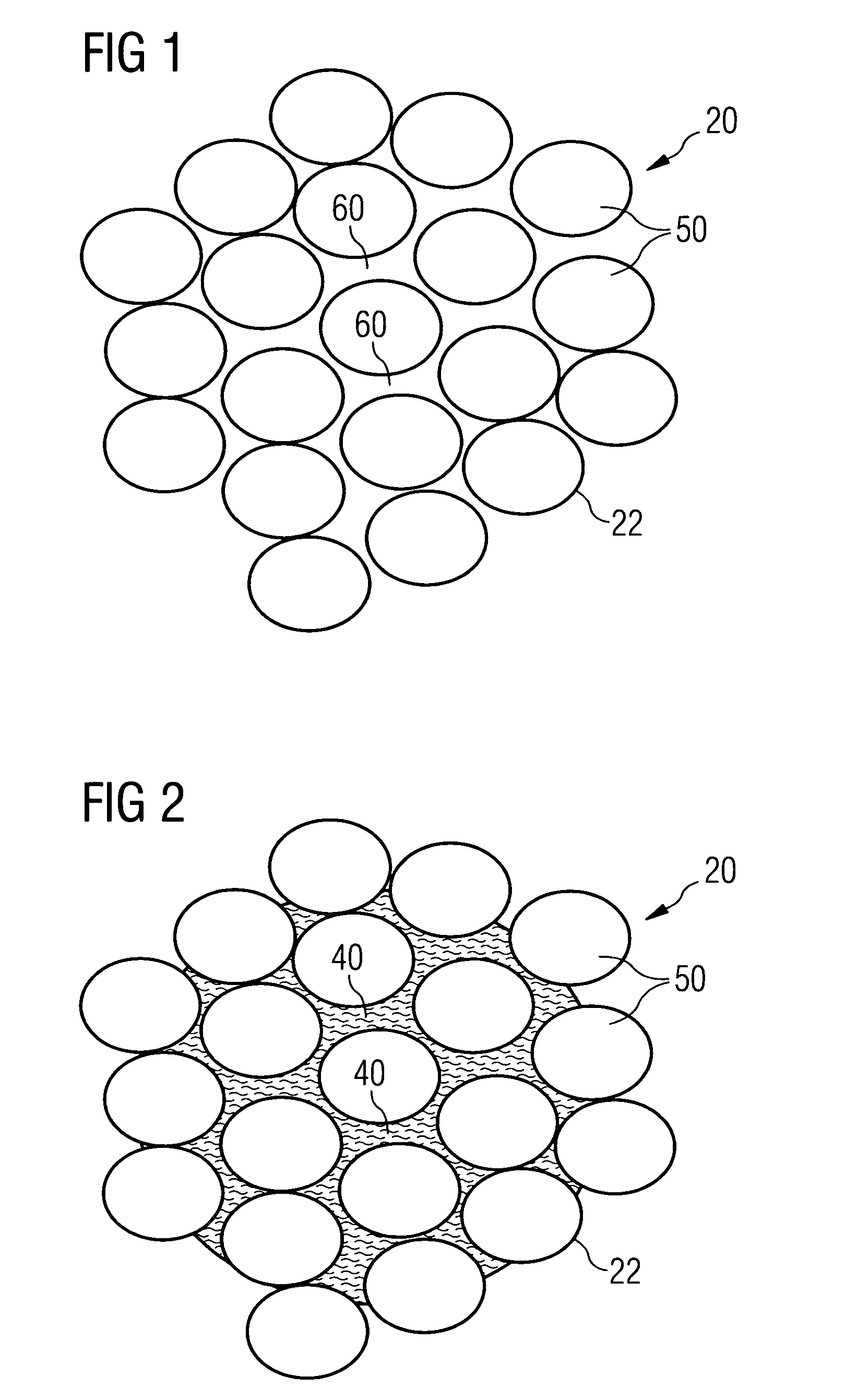

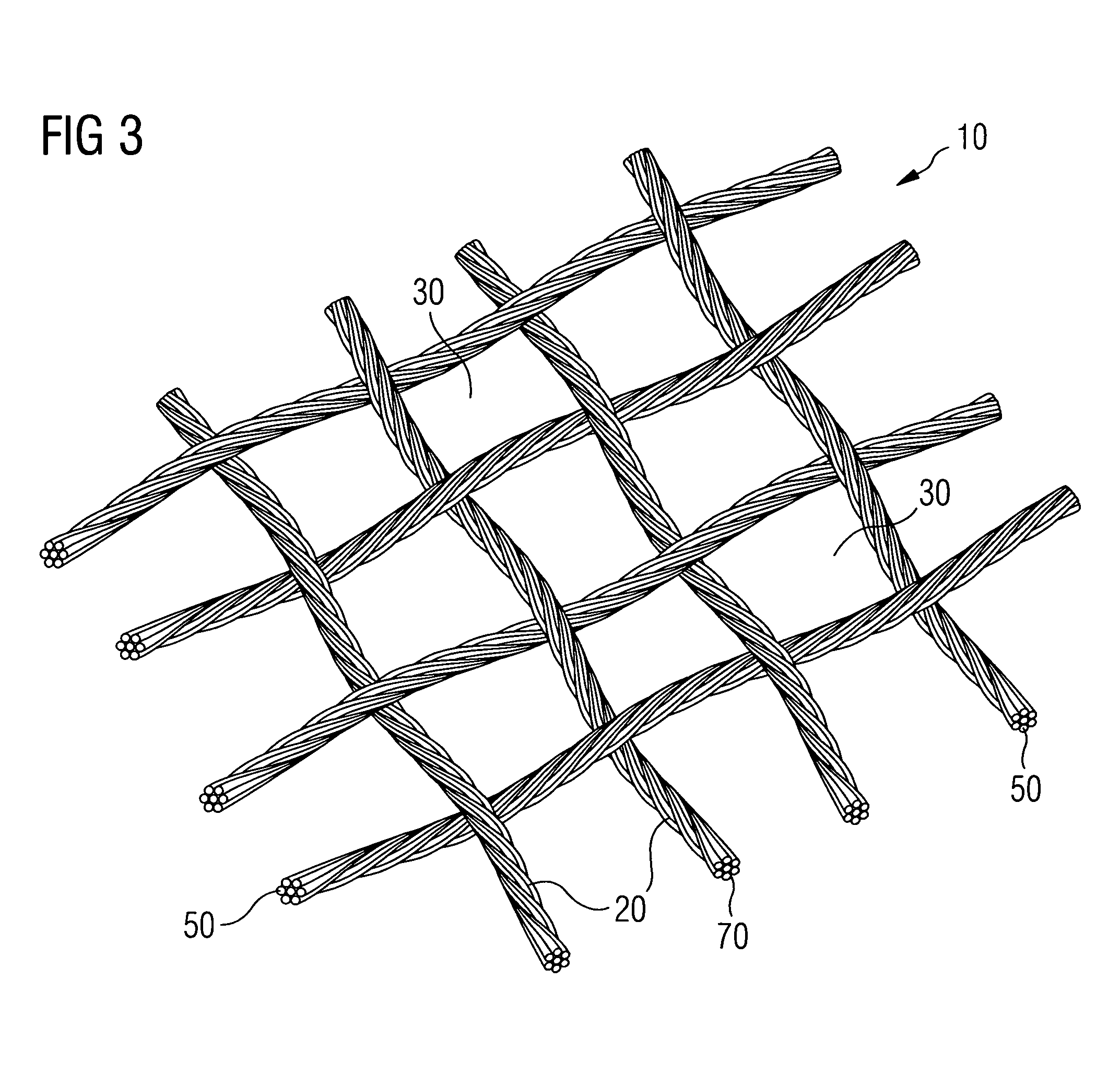

Fabric and Fabric Laminate

InactiveUS20100255270A1Feel goodImprove gripNatural cellulose pulp/paperPretreated surfacesYarnFiber

The present invention provides a fabric and a fabric structure made of yarns with reduced water absorption. The fabric comprises yarns and interstices between the yarns, the interstices between the yarns having an average width of greater than 100 μm. At least one of the yarns is comprised of multiple fibers. Said at least one yarn has voids between the fibers wherein the voids are filled up with a polymer material. The interstices remain open and the size of the interstices is the same as before the treatment. The filling of the voids between the fibers with the polymer material prevents the absorption of water into said voids and therefore leads to reduced water absorption of the fabric. The polymer material is substantially only located within the voids of the yarn and has embedded the fibers within the outer surface of said yarn.

Owner:STUEBIGER WERNER

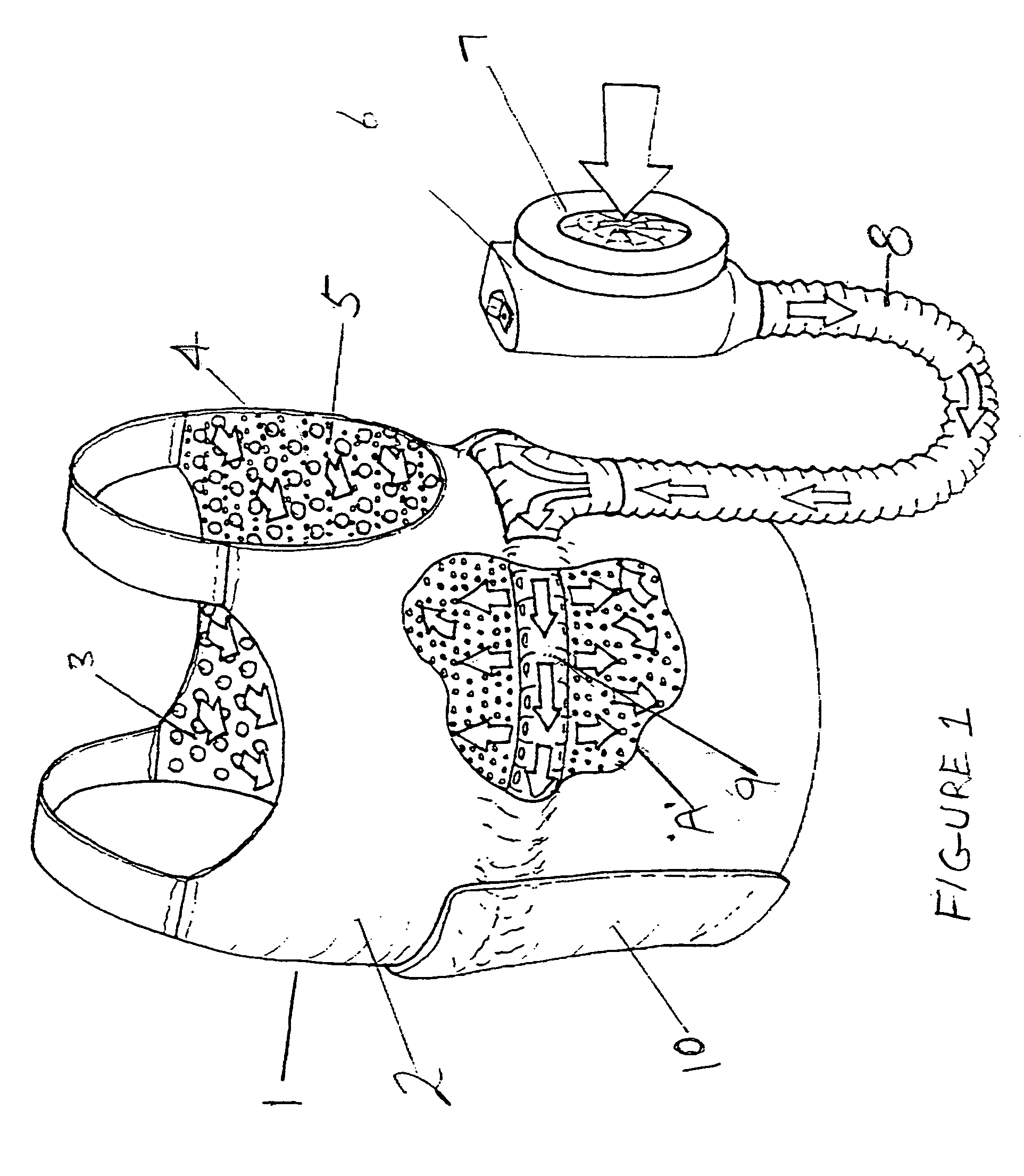

Gas distribution garment

InactiveUS20060026743A1Good cooling efficiencyImprove cooling efficiencyChemical protectionHeat protectionBiomedical engineeringGas supply

A garment for cooling the body of a wearer is described which comprises a substantially gas impermeable first substrate and a gas-permeable second substrate attached to form a cavity. At least one of the first and second substrates comprising a plurality of raised protrusions on a surface within the cavity, and the gas permeable second substrate comprising a plurality of raised protrusions on the surface external to the cavity and proximate to the body of the wearer. The cavity is adapted to be connected to a gas supply such that the gas flows into the cavity and exits the cavity through the gas permeable second substrate. The cooling garment is light weight and conformable, and may be non-tethered for portability.

Owner:WL GORE & ASSOC INC

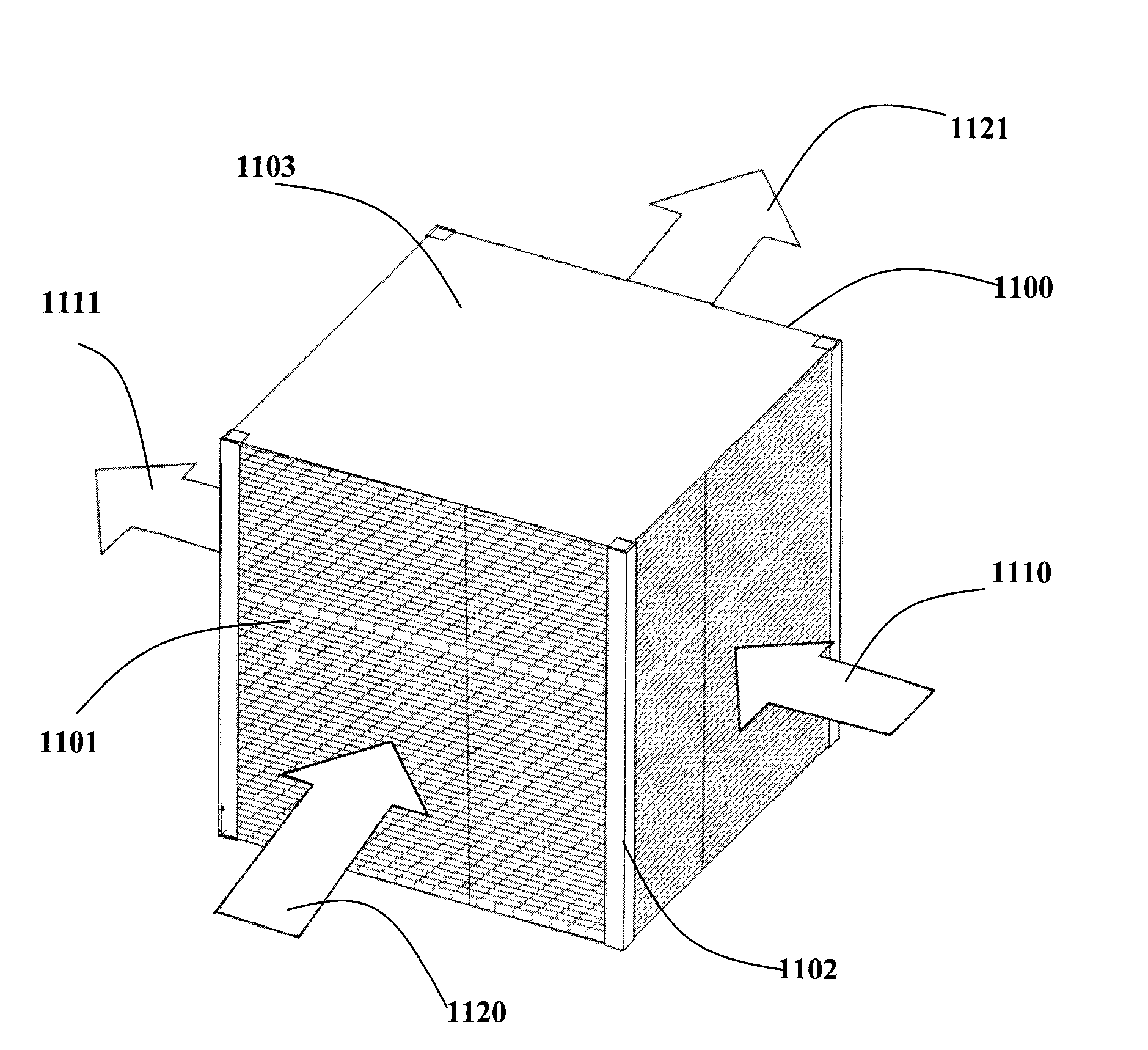

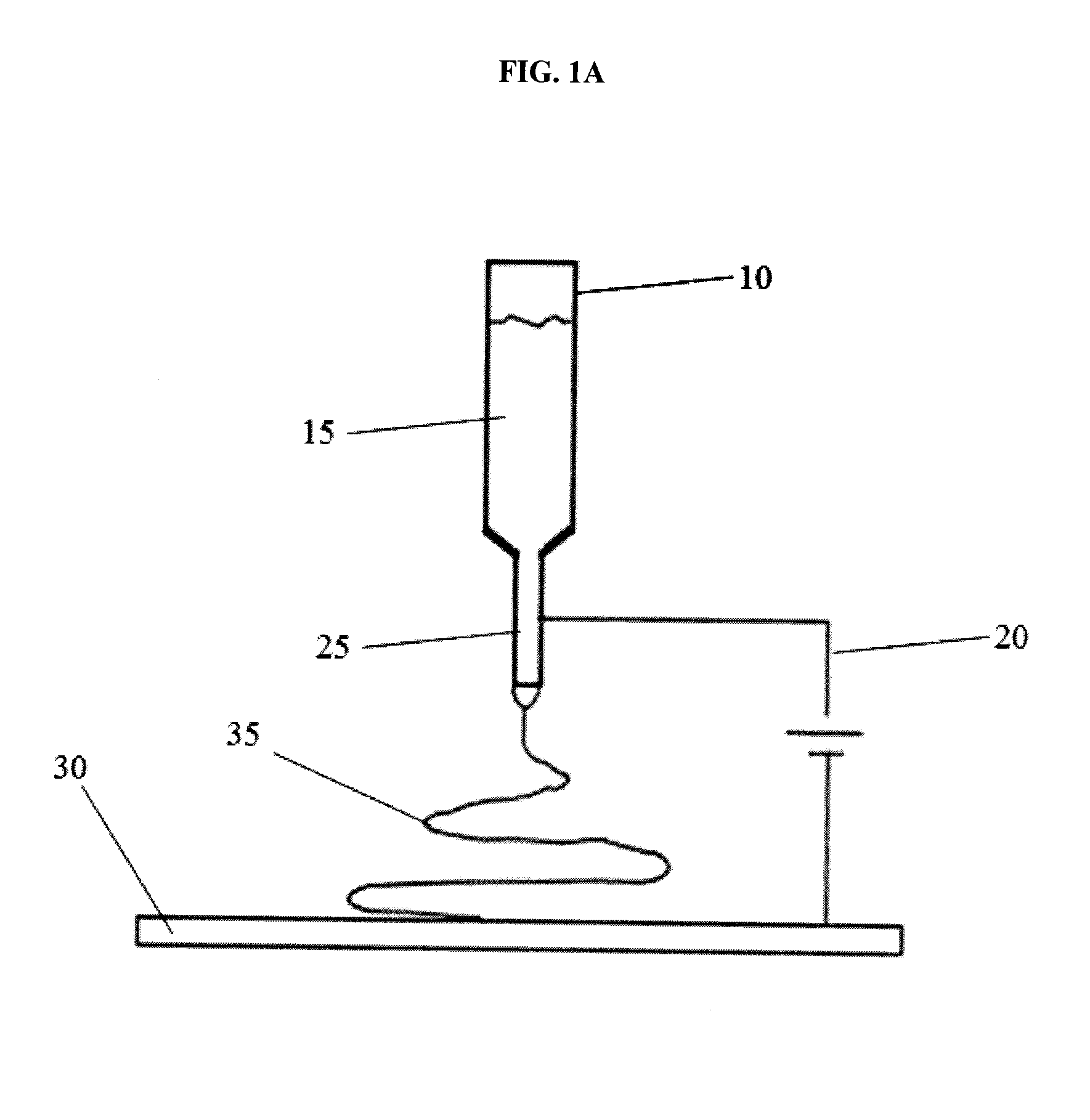

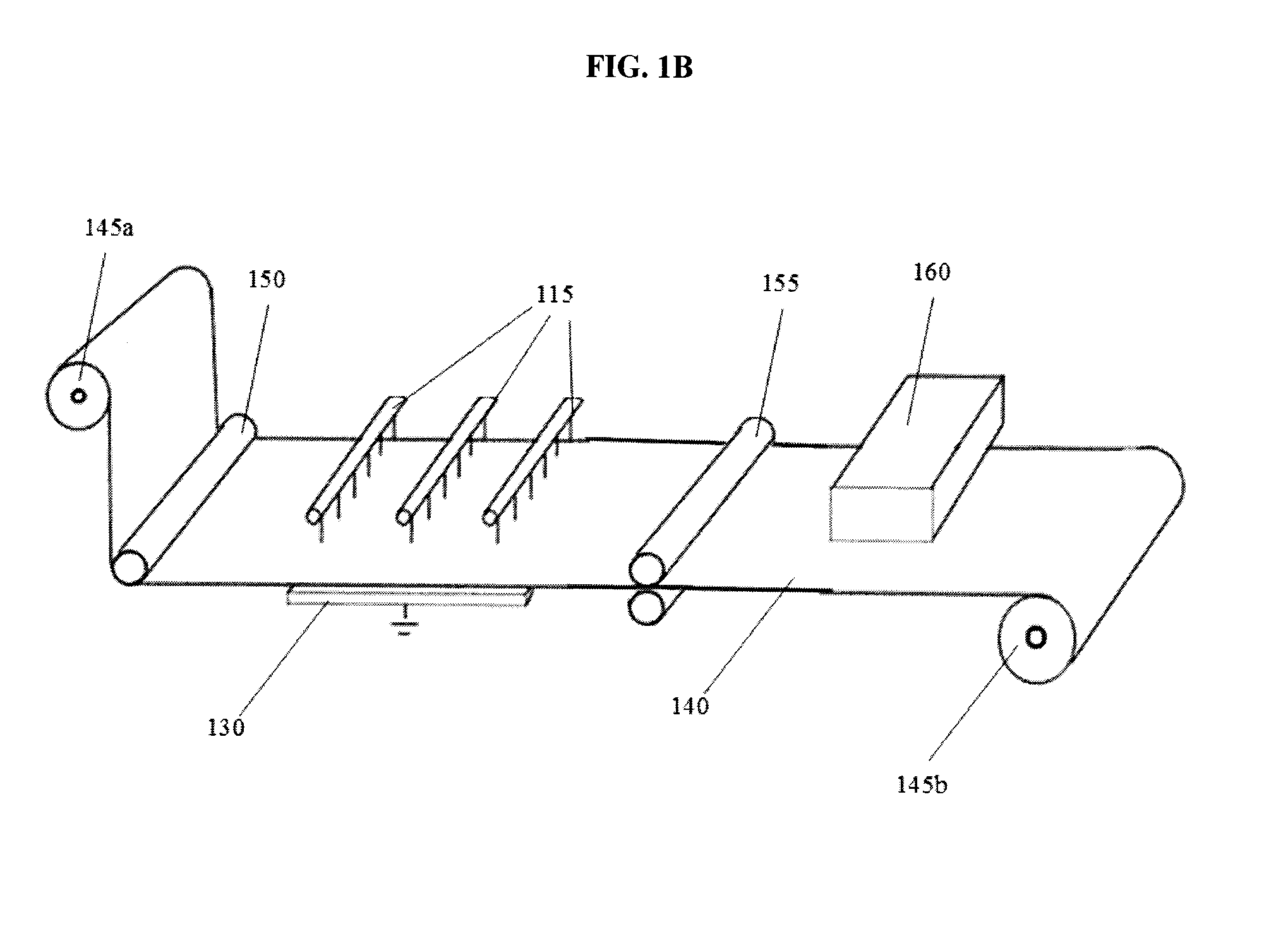

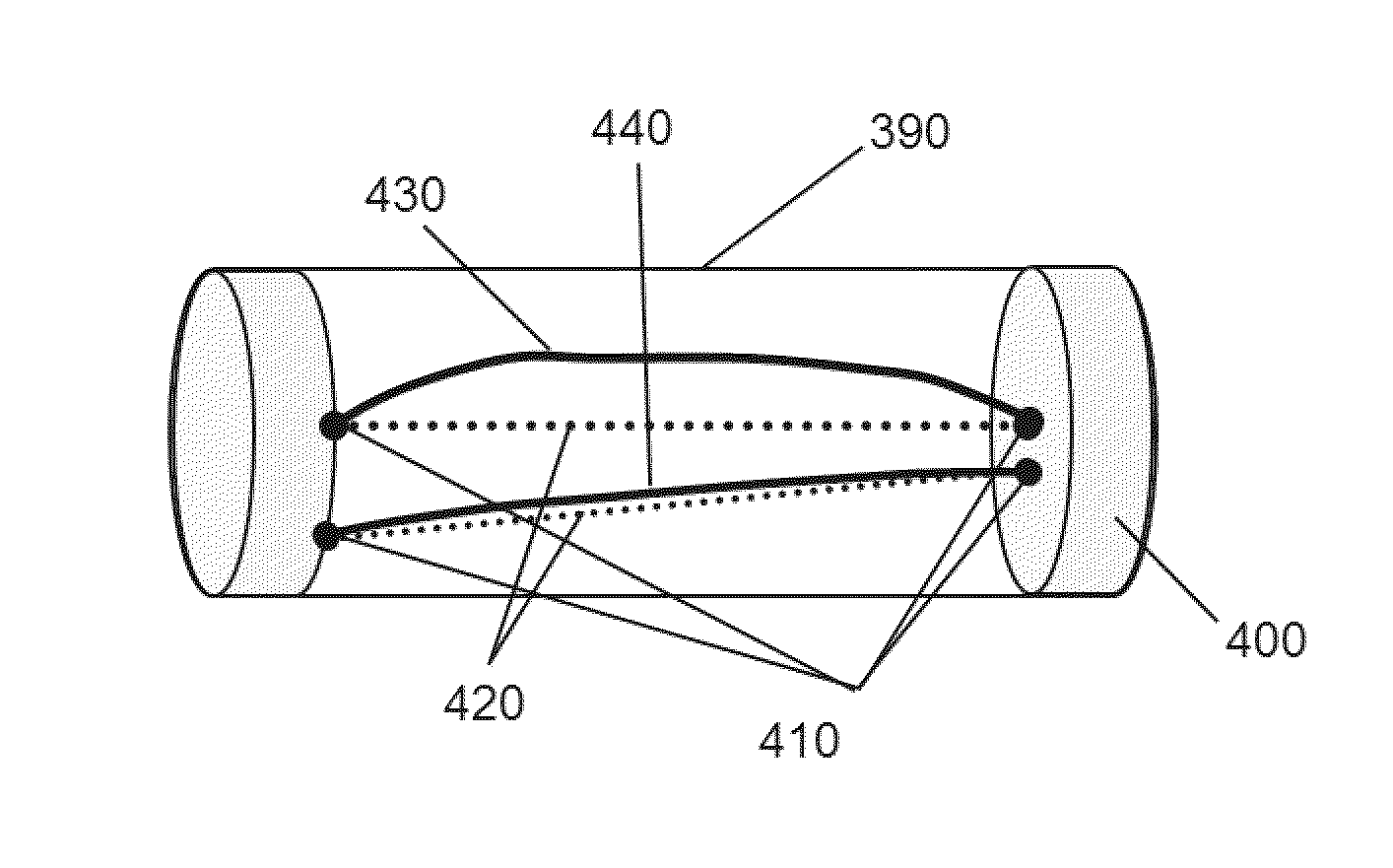

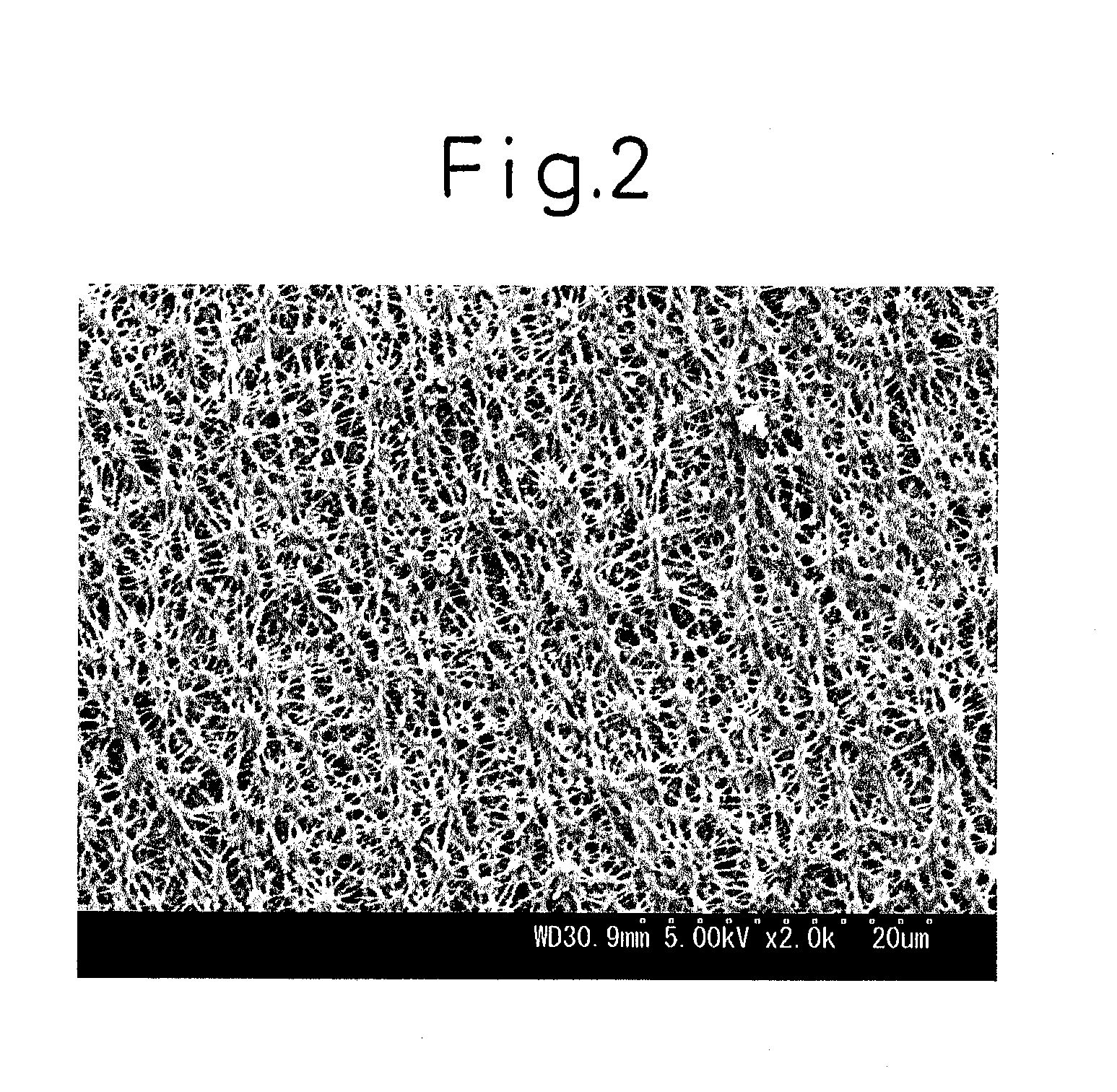

Selective water vapour transport membranes comprising a nanofibrous layer and methods for making the same

ActiveUS20140319706A1Low costHighly water vapour permeableSpace heating and ventilationUsing liquid separation agentFiberCompression molding

A water vapour transport membrane comprises a nanofibrous layer disposed on a macroporous support layer, the nanofibrous layer coated with a water permeable polymer. A method for making a water vapour transport membrane comprises forming a nanofibrous layer on a macroporous support layer and applying a water permeable polymer to the nanofibrous layer. The water permeable polymer can be applied for so that the nanofibrous layer is substantially or partially filled with the water permeable polymer, or so that the coating forms a substantially continuous layer on one surface of the nanofibrous layer. In some embodiments of the method, the nanofibrous layer is formed by electro-spinning at least one polymer on at least one side of the porous support layer. In some embodiments, the support layer is formable and the method further comprises forming a three-dimensional structure from the water vapour transport membrane, for example, by compression molding, pleating or corrugating.

Owner:CORE ENERGY RECOVERY SOLUTIONS INC

Internal wall anticorrosive coating for sea water evaporating installation

InactiveCN1709999AConducive to on-site constructionImprove water resistanceEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to endophragm anticorrosion dope of carbon steel material vaporizing equipments in seawater desalting craft of low temperature and multiple effect distillation. It mainly comprises basic materials, pigment, padding, auxiliary agent and solvent. The basic materials are one or more than one kind of epoxy resin and painthydroxybenzene modified thermostable resins. The painthydroxybenzene modified thermostable resins are one or more than one kind of painthydroxybenzene silicon resin, painthydroxybenzene furol resin and painthydroxybenzene titanium resin got from chemical modification of painthydroxybenzene distilled from fresh paint; the color padding is one or more than one kind of titanium oxide powder, talcum powder, mica powder, mica ferric oxide, gas phase silicon dioxide, silica flour, porcelain powder and bentonite. The dope is solidified at room temperature. It has excellent permeability resistance of water, seawater and vapor at high temperature and is suitable to anticorrosion of low temperature.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

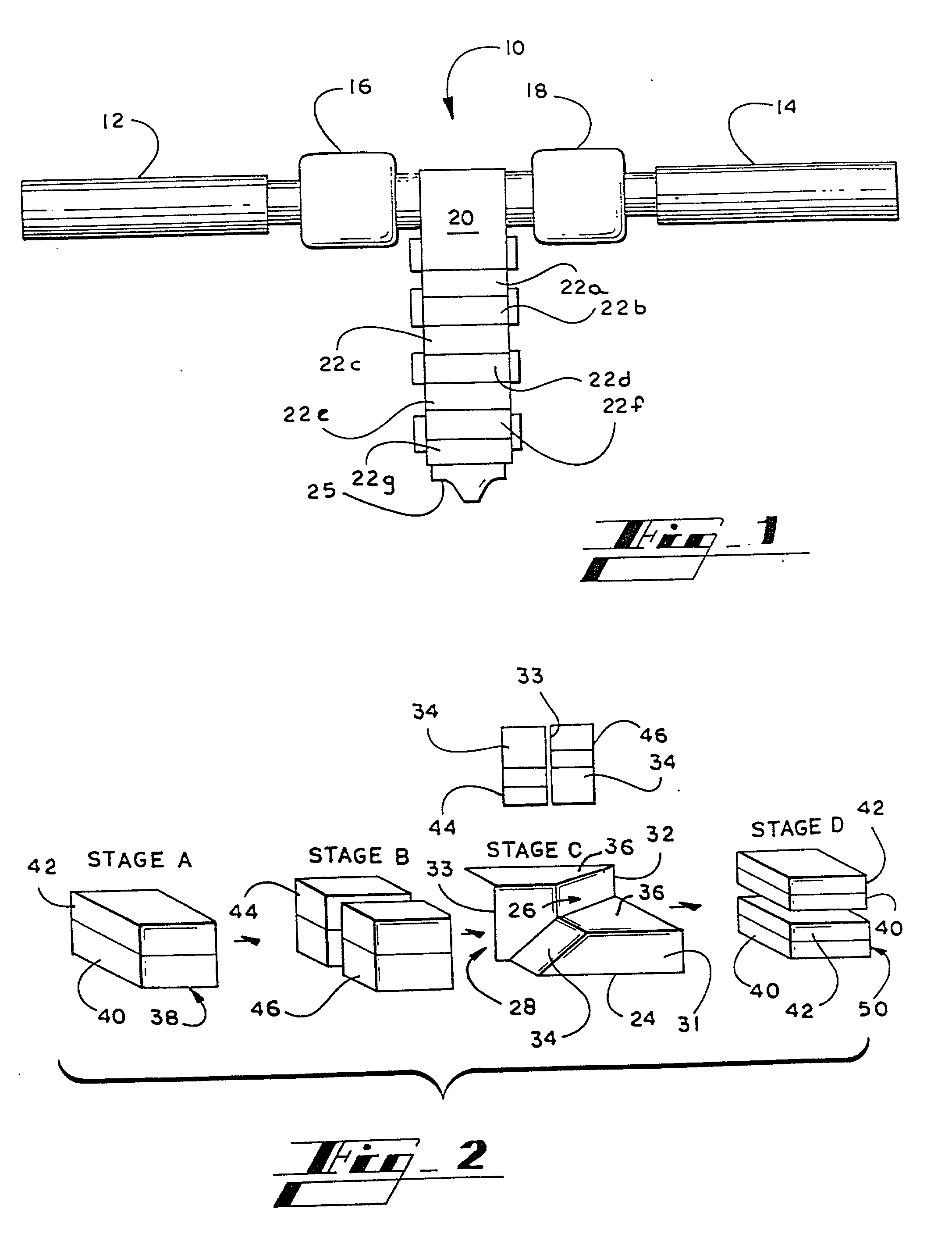

Water degradable microlayer polymer film and articles including same

InactiveUS20020127385A1High strengthSufficient breathabilitySynthetic resin layered productsAbsorbent padsParticulatesLinear low-density polyethylene

A microlayer polymer film comprising a plurality of coextruded microlayers including a non-degradable layer comprising a non-water degradable, melt-extrudable polymer and degradable layer comprising a water degradable, melt-extrudable polymer. The microlayer polymer film degrades when soaked in water and is suitable as a covering material for disposal items such as flushable diapers. The microlayer polymer film is also breathable and is a barrier to small amounts of water. A suitable non-water degradable, melt-extrudable polymer is linear low density polyethylene filled with a particulate filler. A suitable water degradable, melt-extrudable polymer is polyethylene oxide.

Owner:KIMBERLY-CLARK WORLDWIDE INC

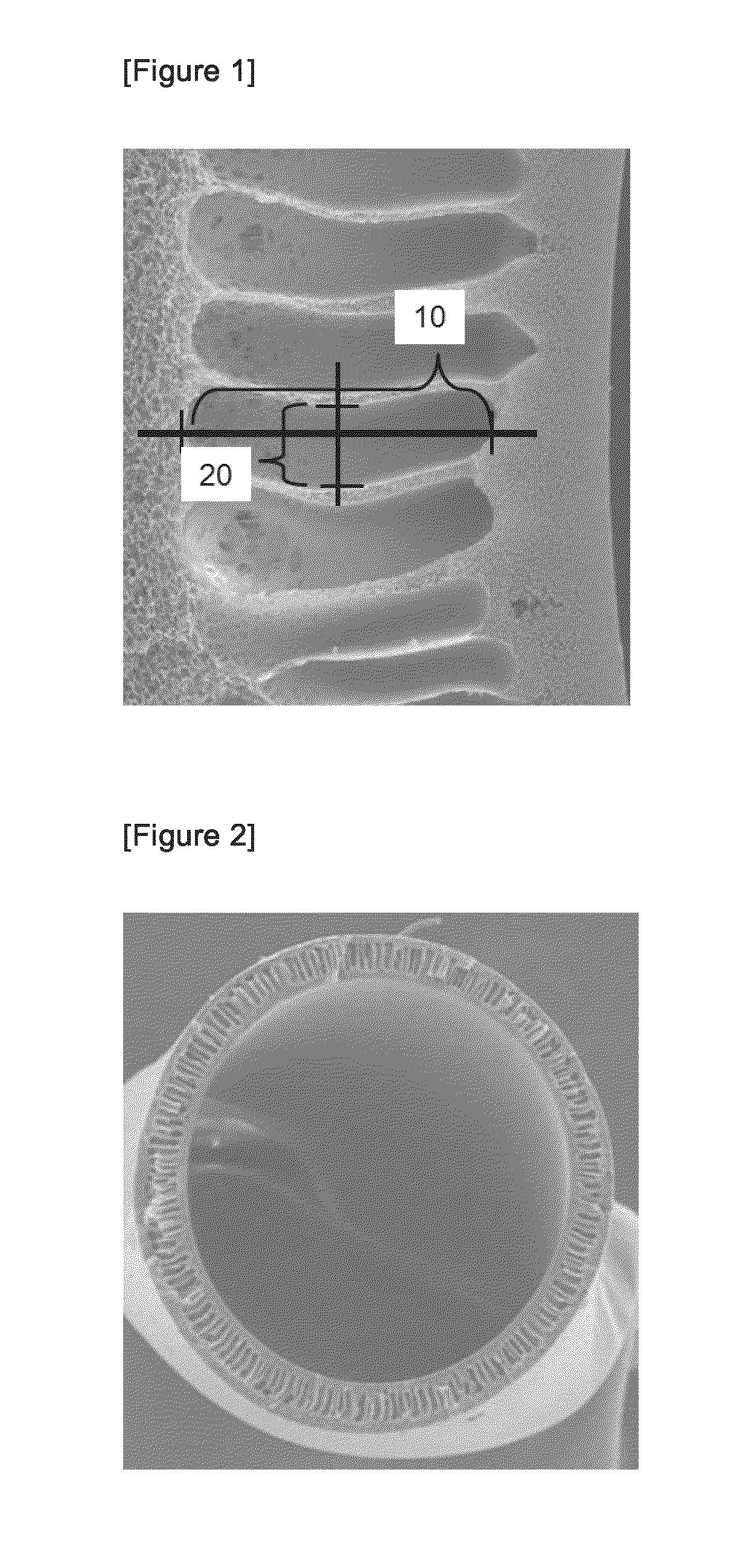

Water-vapor-permeable membrane, hollow-fiber membrane, and hollow-fiber membrane module

ActiveUS20120174790A1Excellent water vapor permeabilityReduce air leakageMembranesLighting and heating apparatusWater vapor permeabilityWater vapor

A water vapor permeable membrane is provided comprising a dense layer and a support layer that are adjacent to each other, wherein the dense layer contains voids with a void length of 0.1 μm or less and the dense layer has a thickness of 0.1 μm or more and 2 μm or less while in the support layer, void (a), i.e. the void with the largest length in the 2 μm thick region measured from the boundary between the dense layer and the support layer into the support layer, has a length of 0.3 μm or more and void (b), i.e. the void with the largest length in the region ranging between 2 μm and 4 μm measured from the boundary into the support layer, has a length of 0.5 μm or more, the length of the void (b) being larger than that of the void (a). A water vapor permeable membrane having both a high water vapor permeability and a low air leakage is provided.

Owner:TORAY IND INC

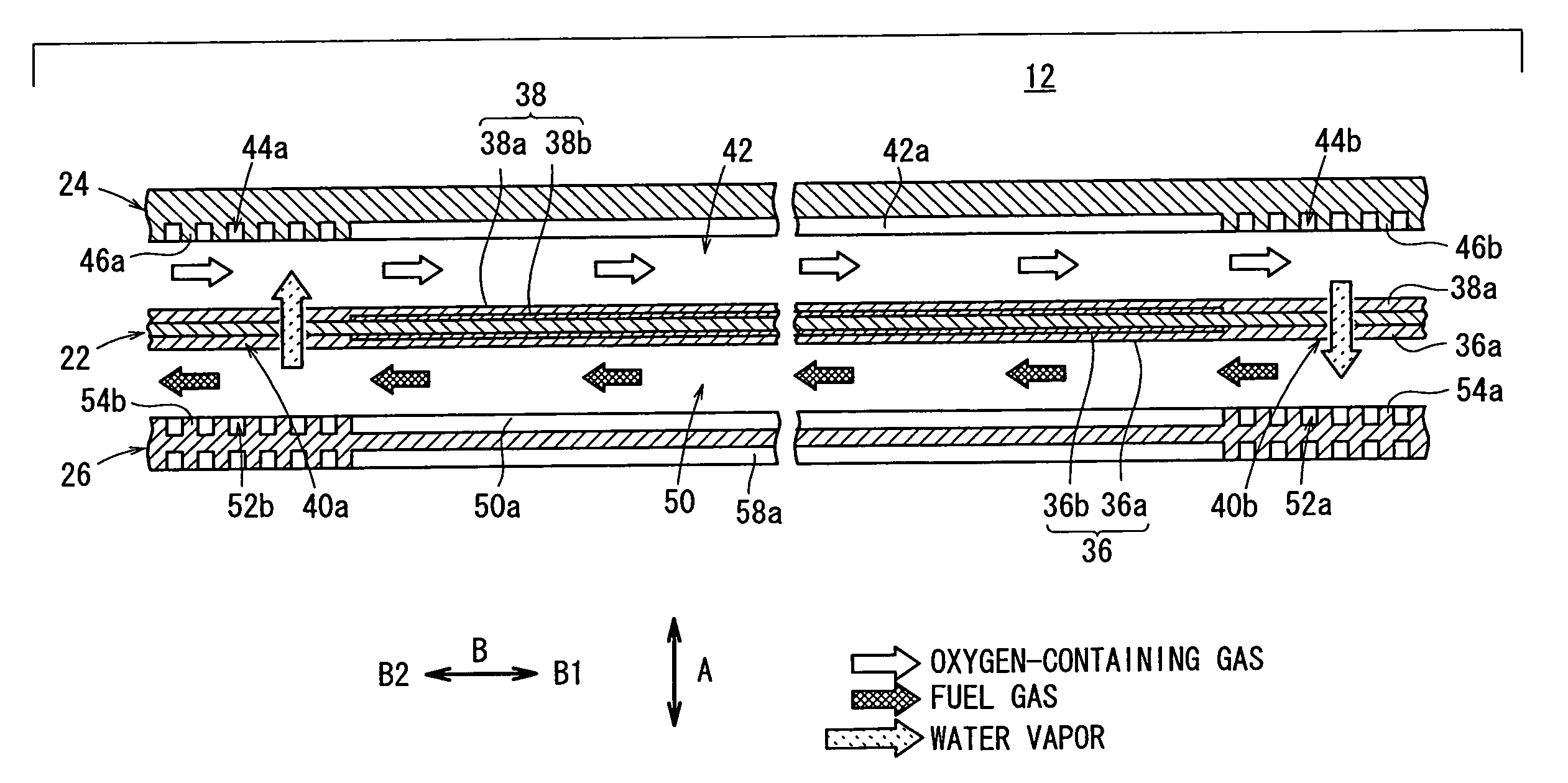

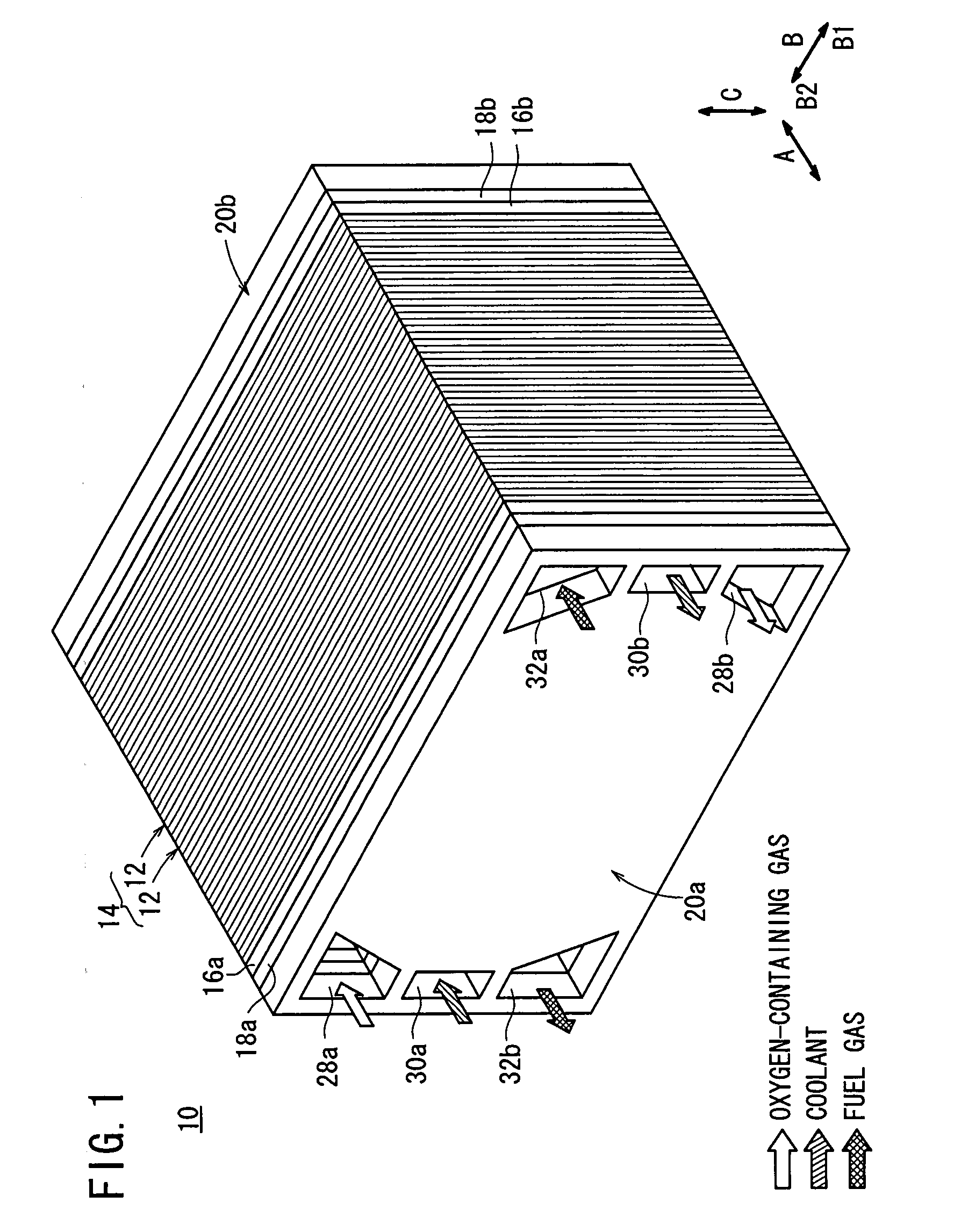

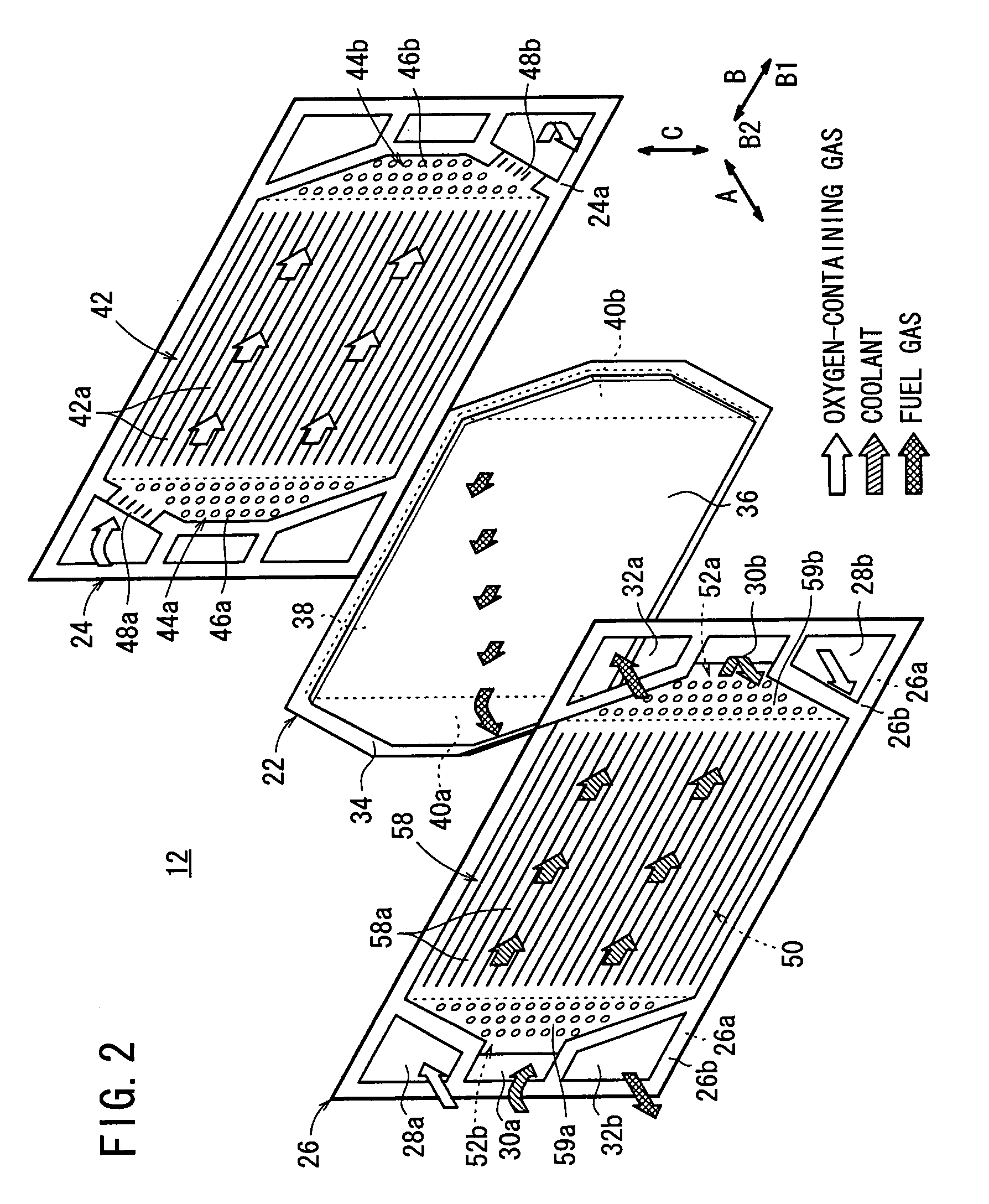

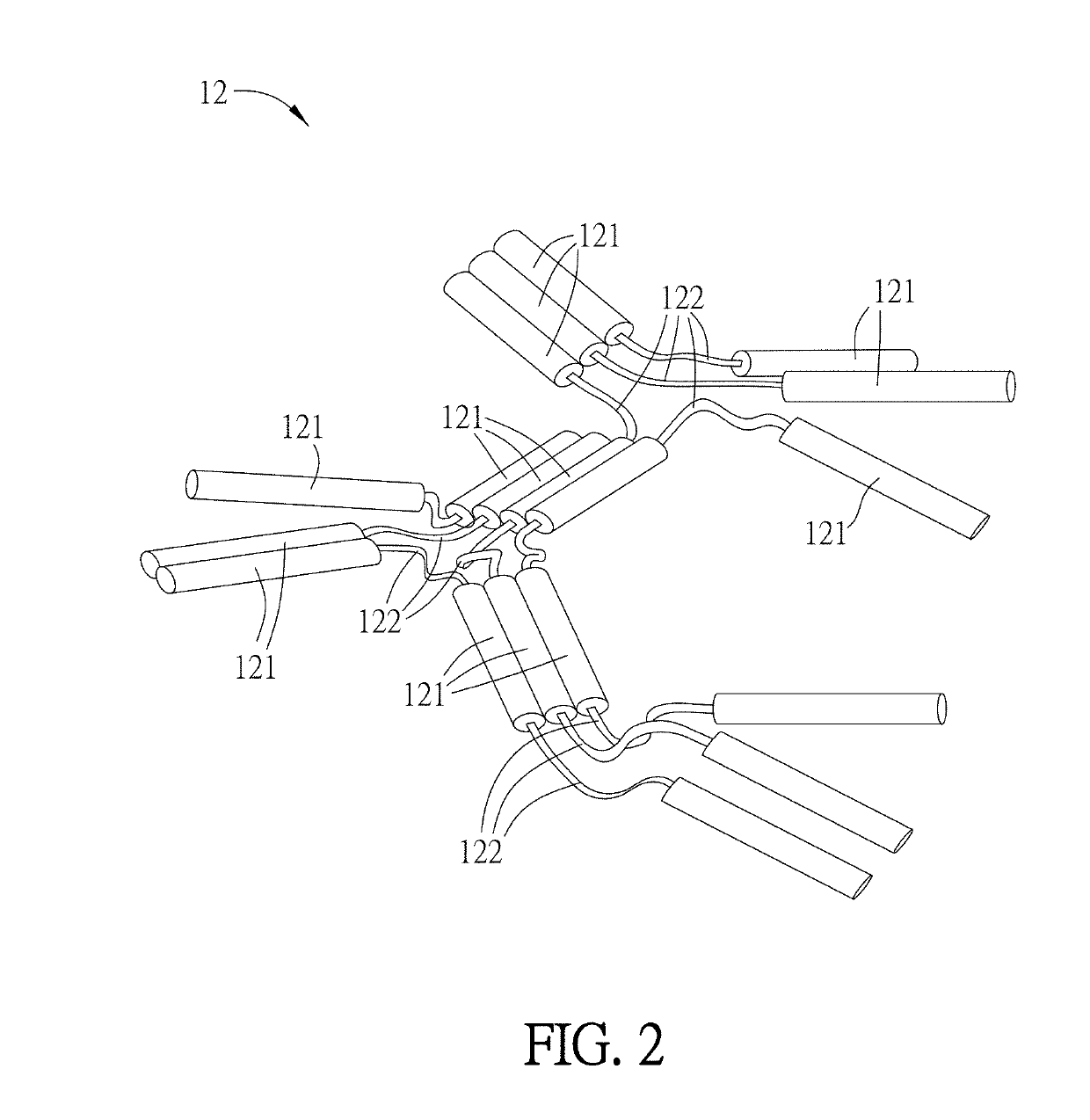

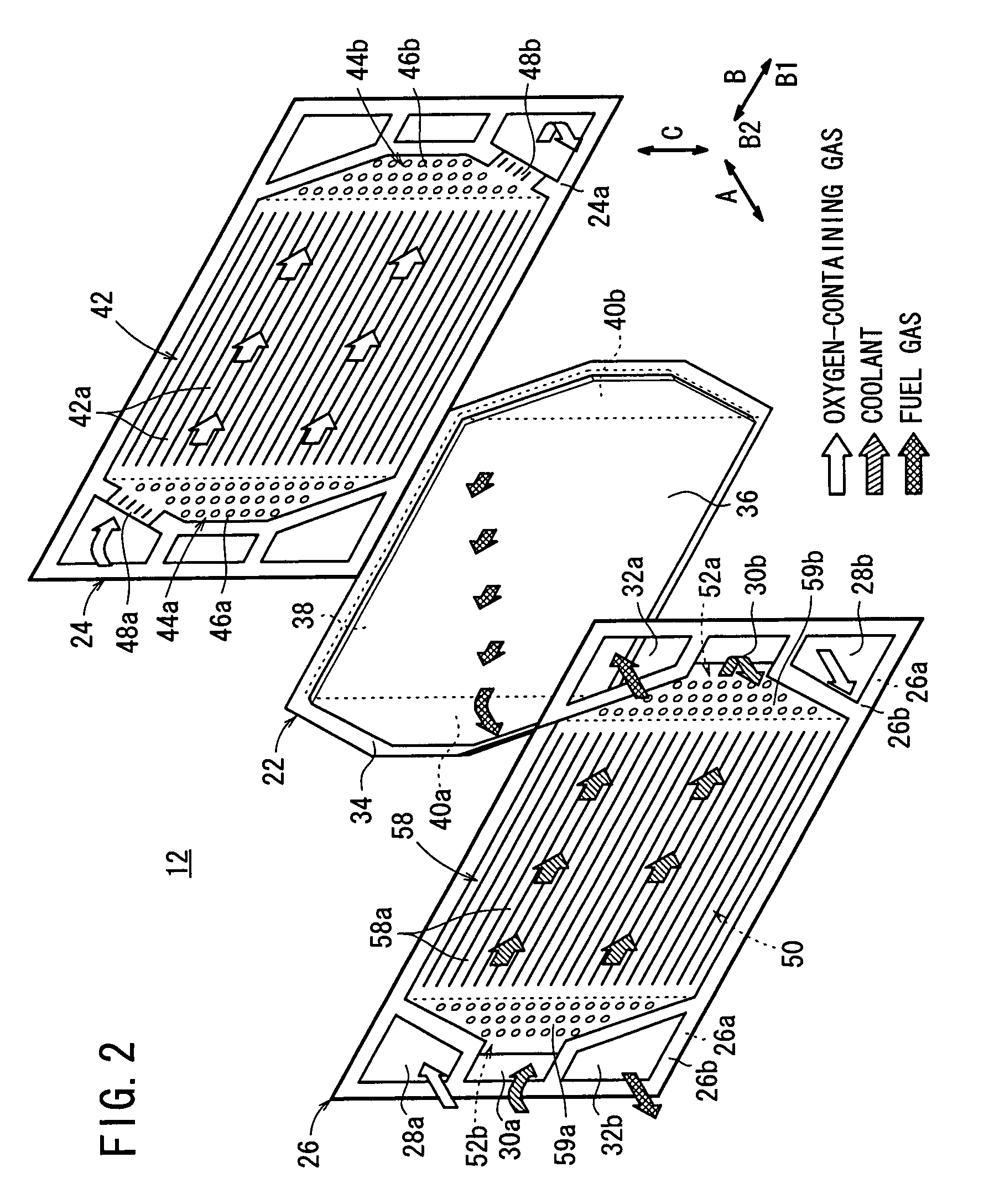

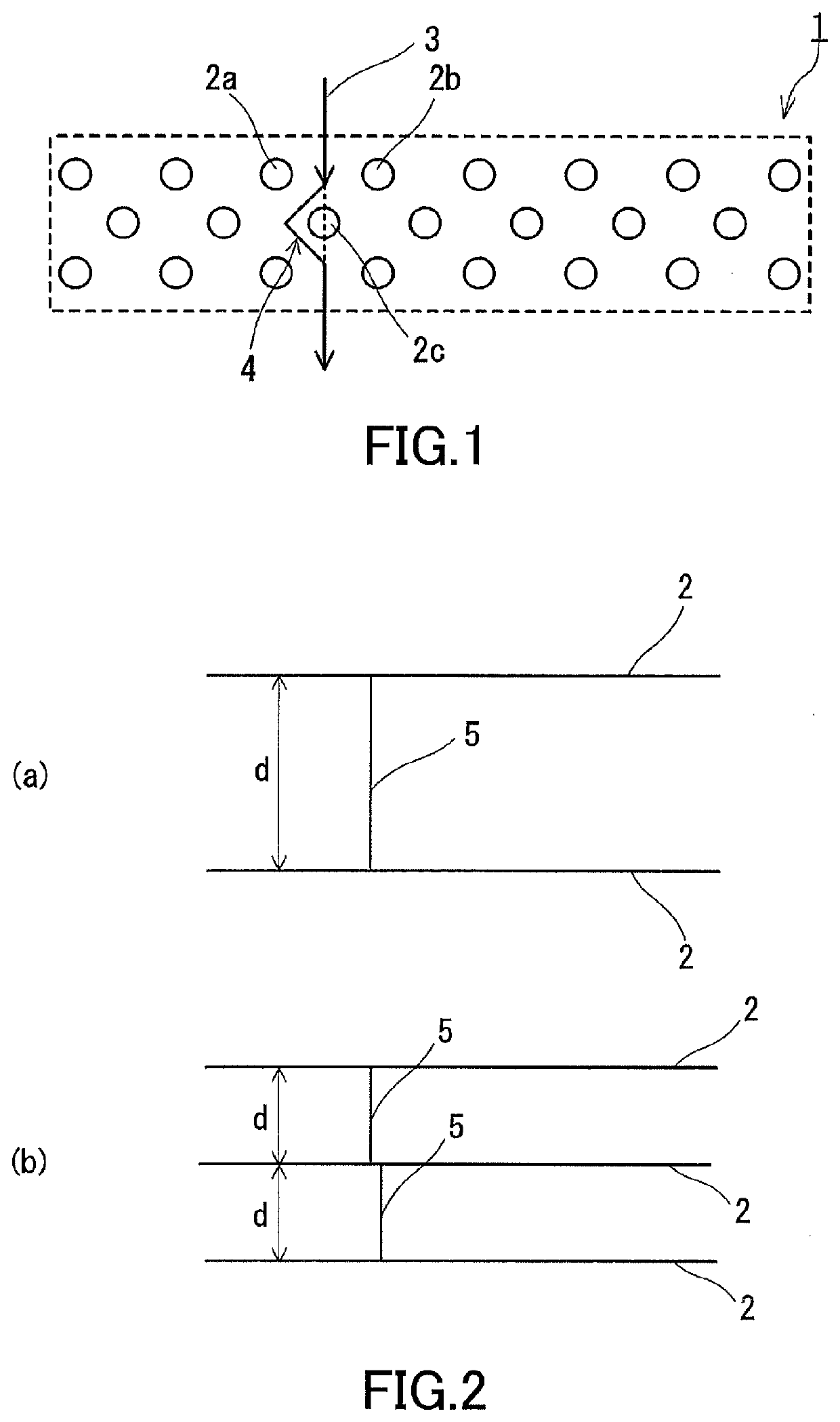

Fuel cell

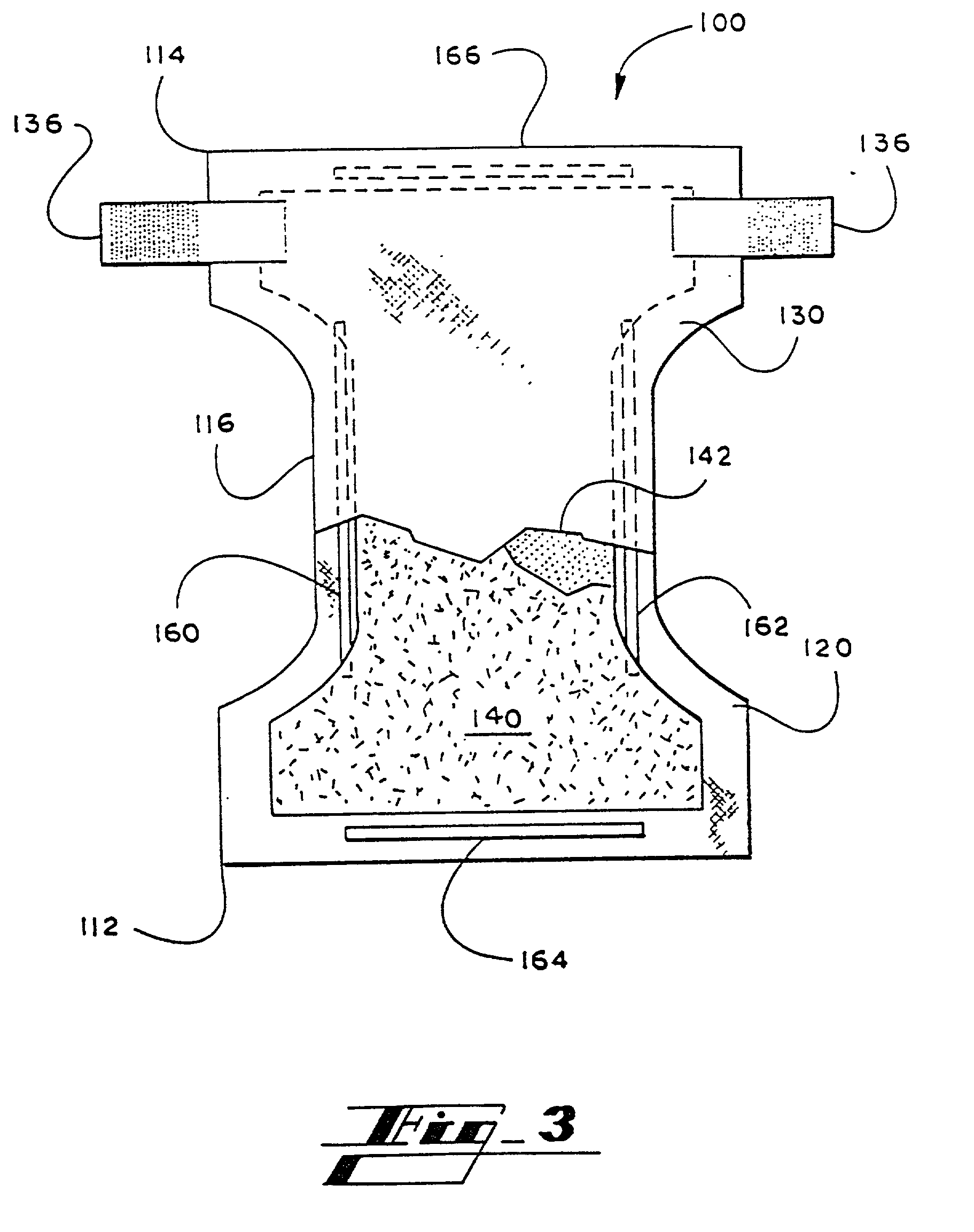

InactiveUS20070207371A1Compact structureDesired water vapor permeabilityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A power generation cell includes a membrane electrode assembly, and first and second separators sandwiching the membrane electrode assembly. The first separator includes an oxygen-containing gas flow field. An inlet buffer area is provided between the oxygen-containing gas flow field and an oxygen-containing gas supply passage, and an outlet buffer area is provided between the oxygen-containing gas flow field and an oxygen-containing gas discharge passage. Plural columnar resistance members are provided within the inlet buffer area and the outlet buffer area. The membrane electrode assembly further includes first and second humidification sections.

Owner:HONDA MOTOR CO LTD

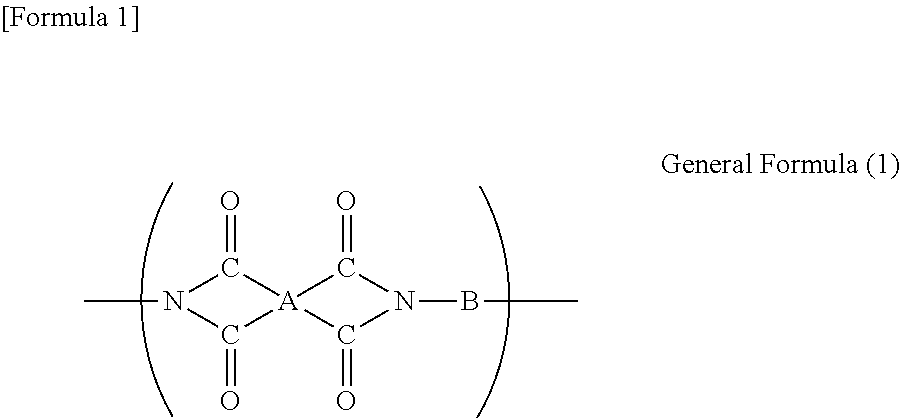

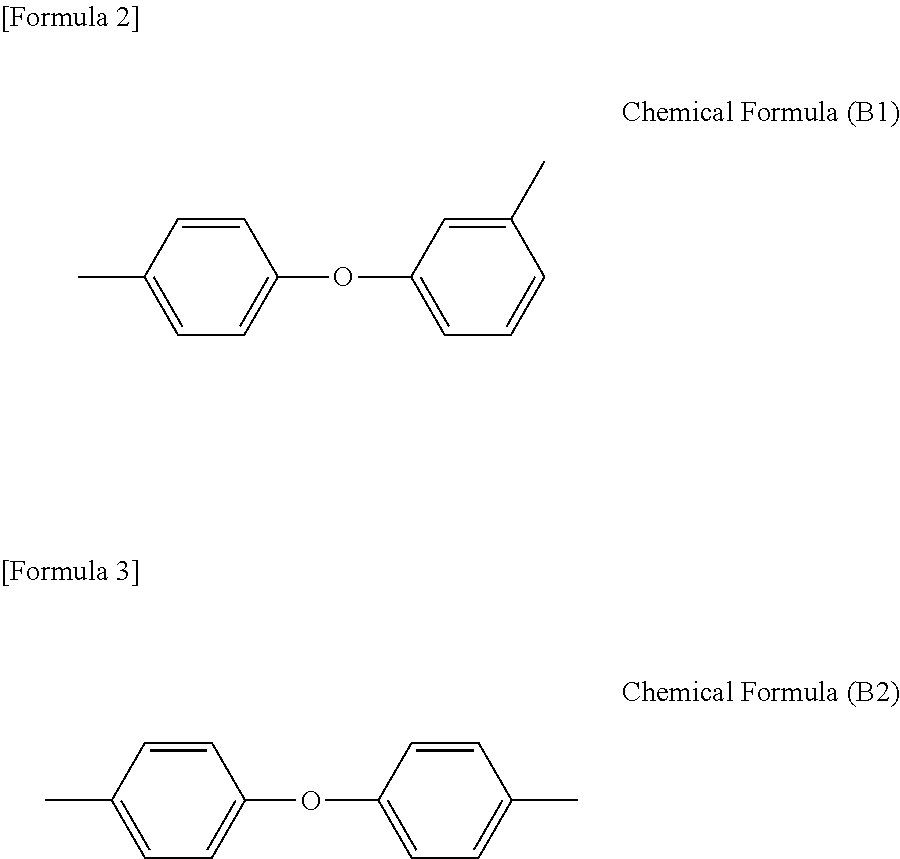

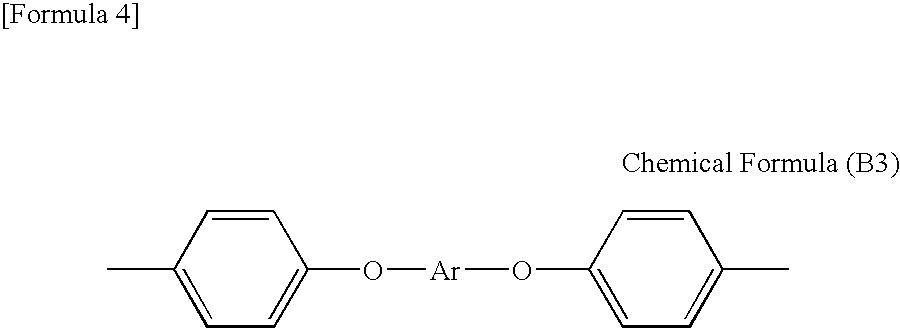

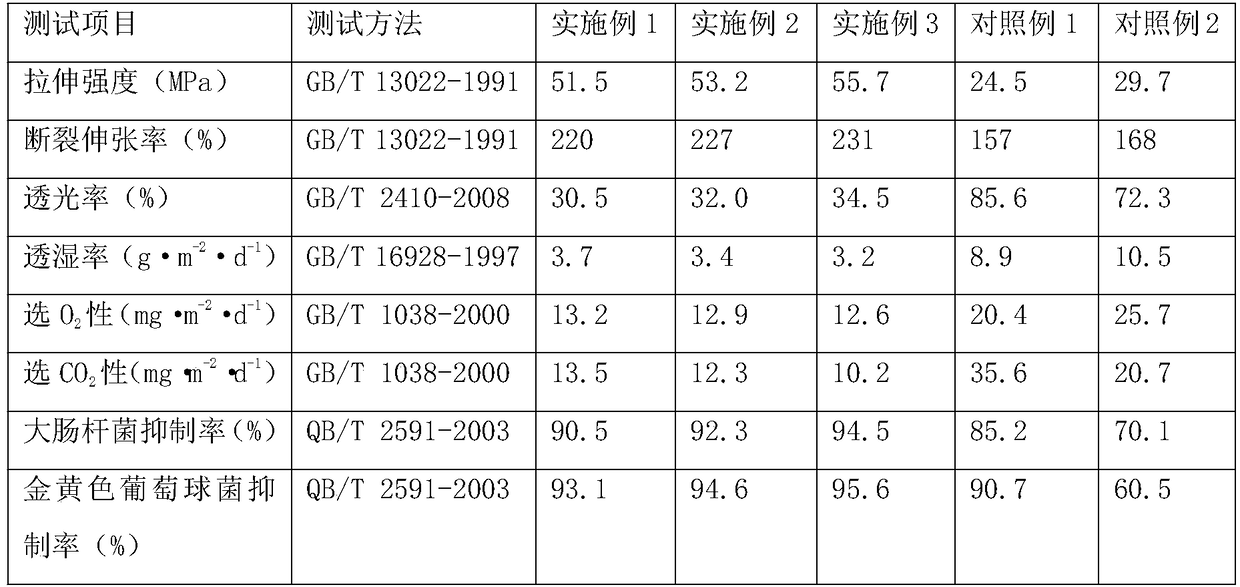

Polyimide gas separation membrane and gas separation method

InactiveUS20110000367A1Excellent water vapor permeabilityIncrease resistanceSemi-permeable membranesIsotope separationDiaminodiphenyl etherCarboxylic acid

Disclosed are a gas separation membrane and a gas separation method in which at least one species of organic vapor is separated and recovered from an organic vapor mixture using the gas separation membrane. The gas separation membrane is made of an aromatic polyimide composed of a tetracarboxylic acid component consisting of an aromatic ring-containing tetracarboxylic acid and a diamine component comprising 10 to 90 mol % of a combination of (B1) 3,4′-diaminodiphenyl ether and (B2) 4,4′-diaminodiphenyl ether at a B1 to B2 molar ratio, B1 / B2, ranging from 10 / 1 to 1 / 10, and 10 to 90 mol % of other aromatic diamine.

Owner:UBE IND LTD

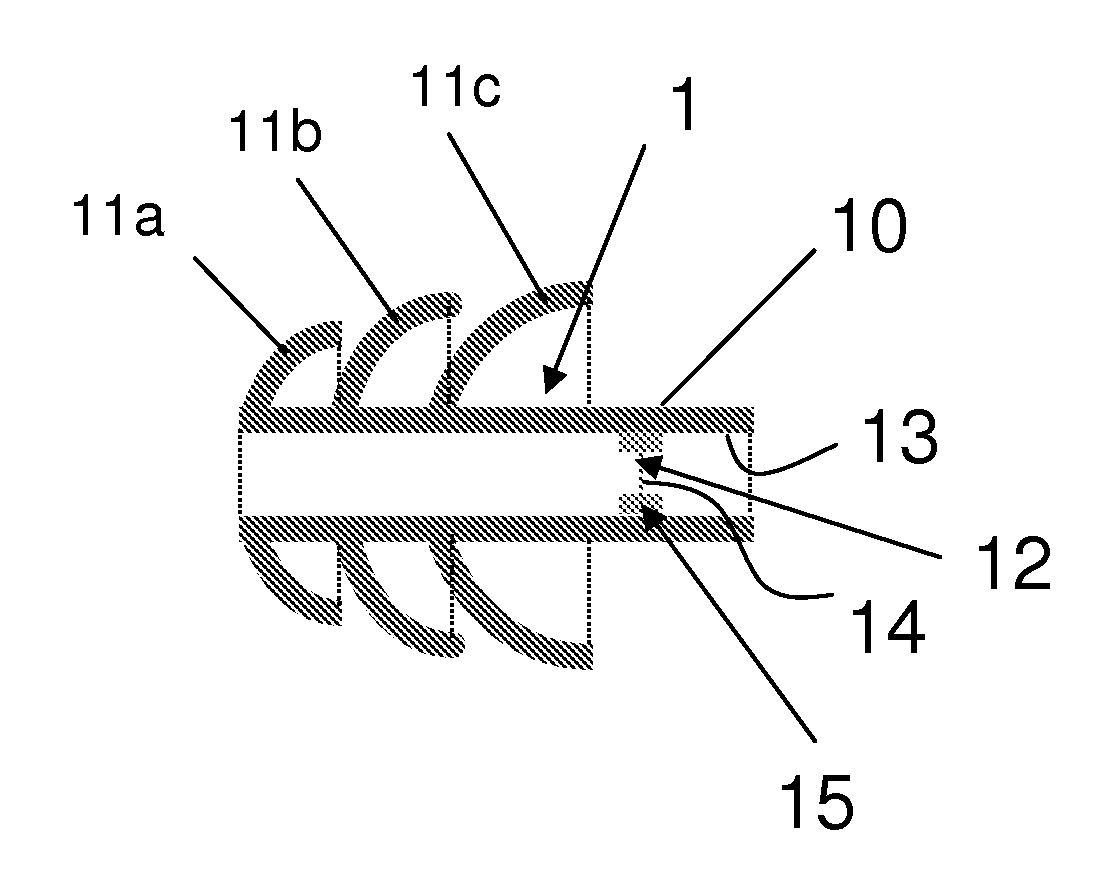

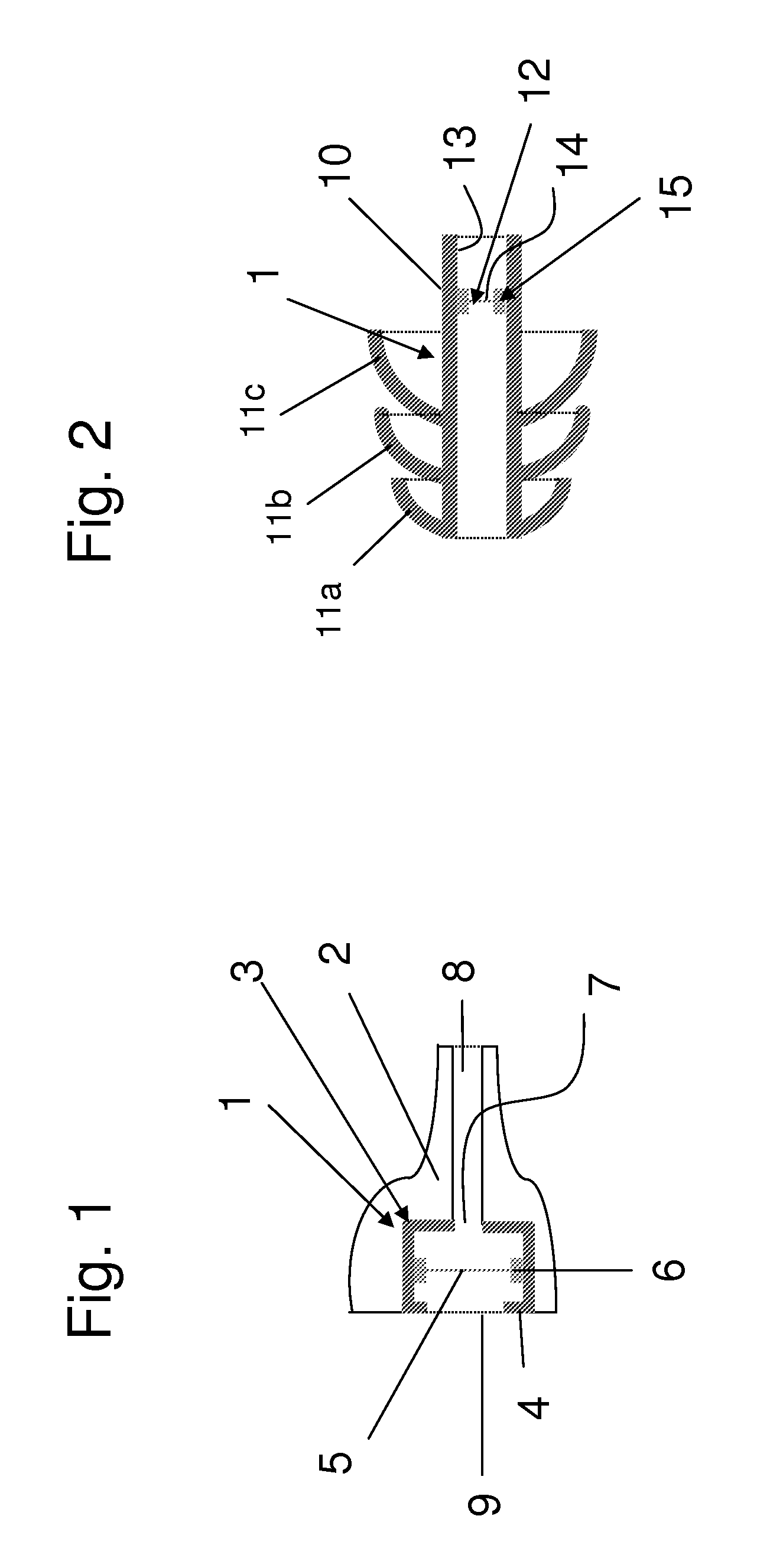

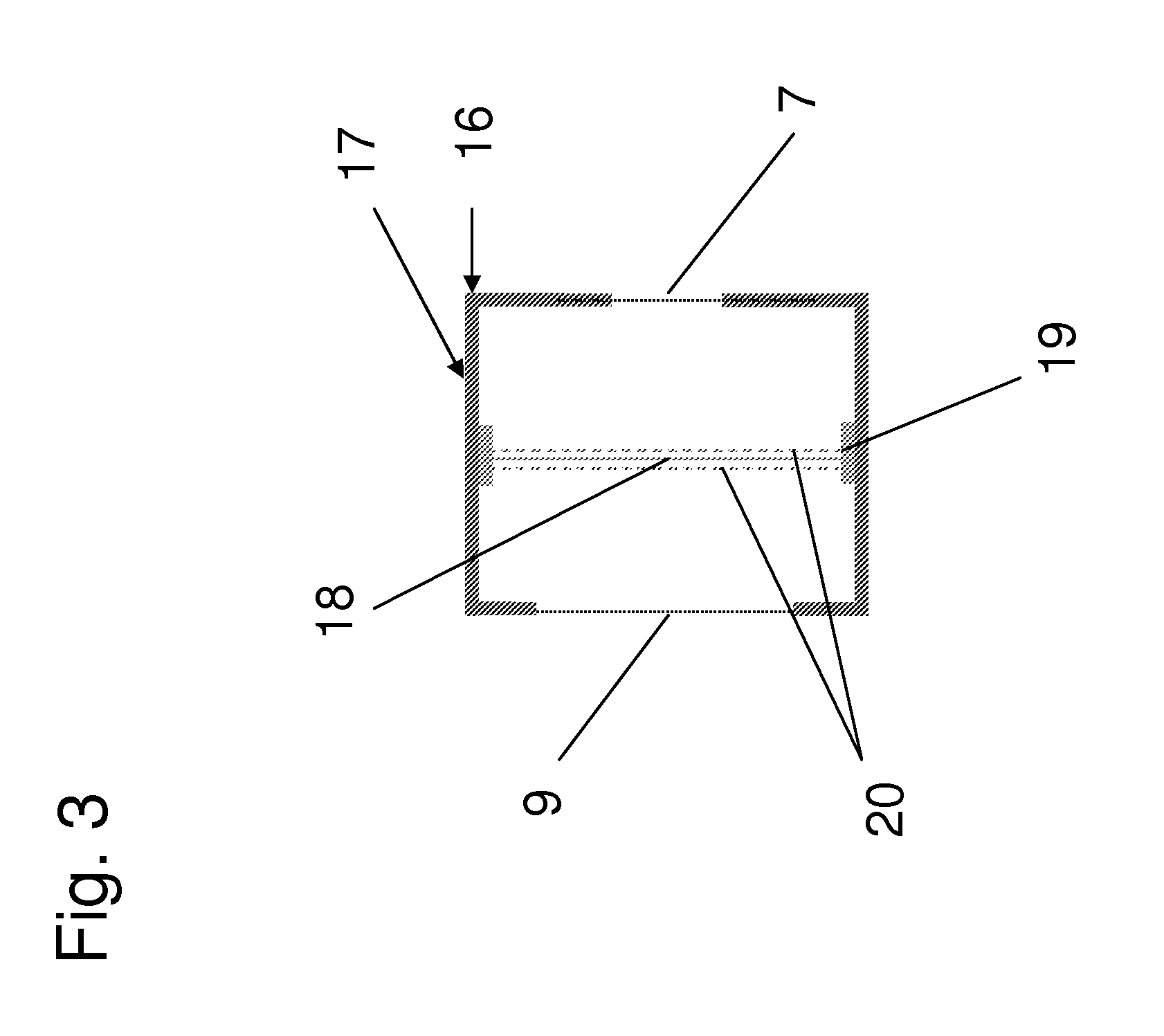

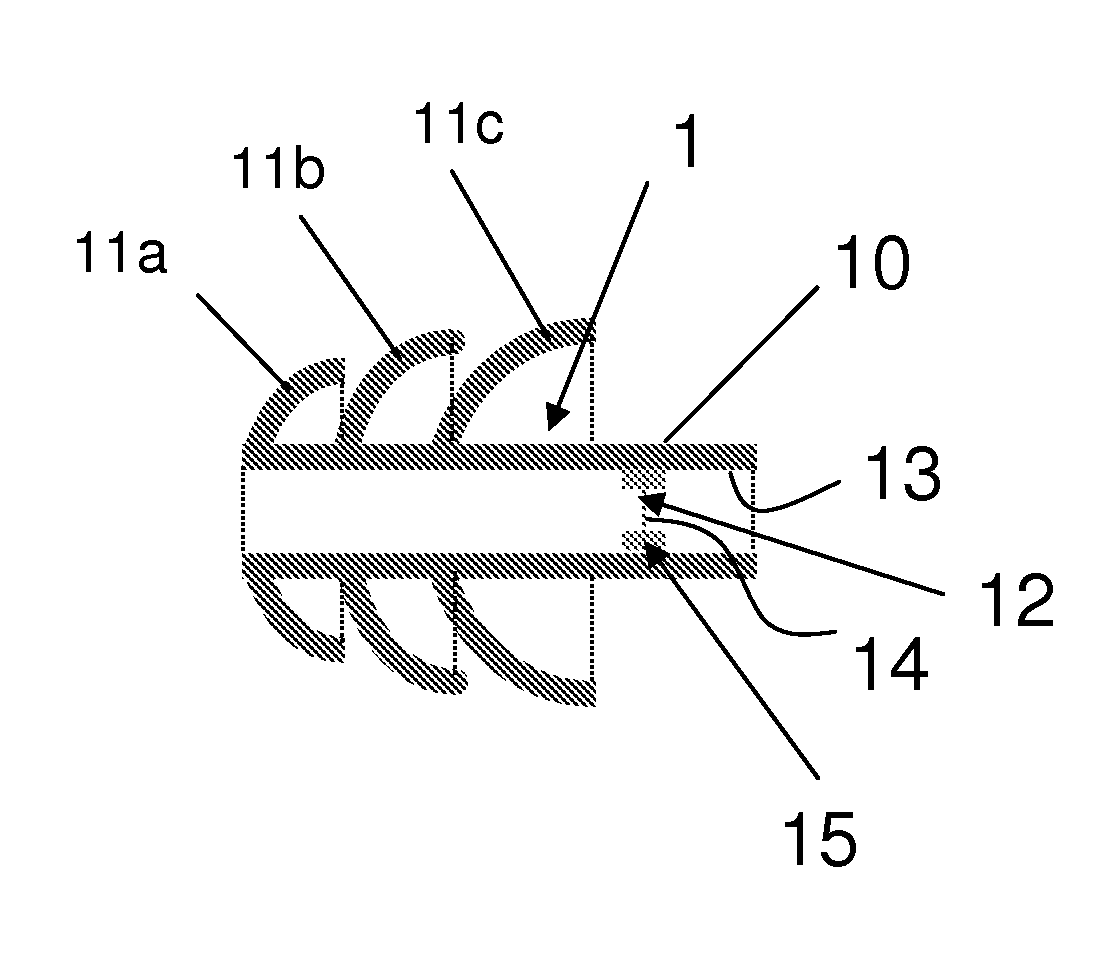

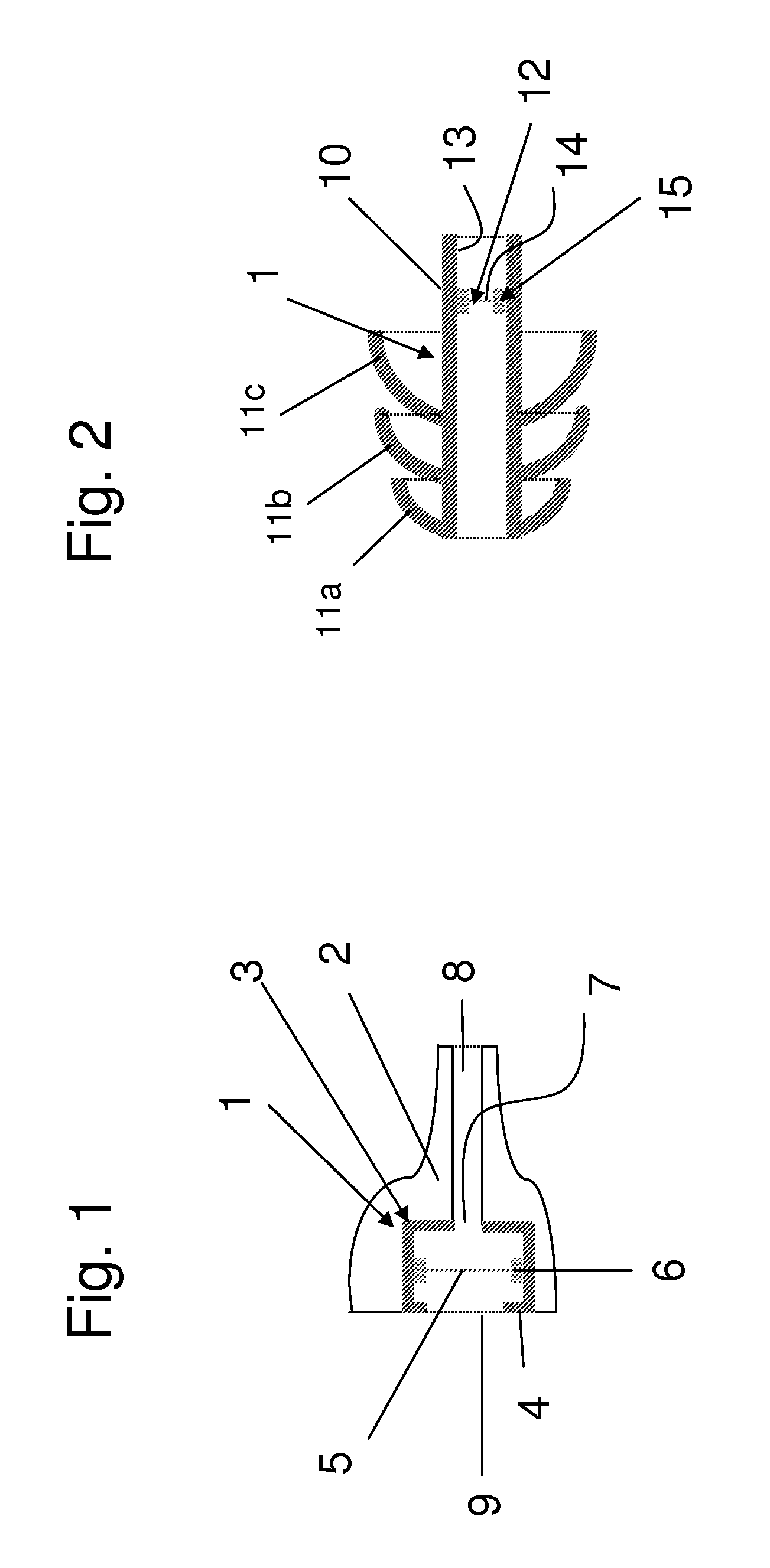

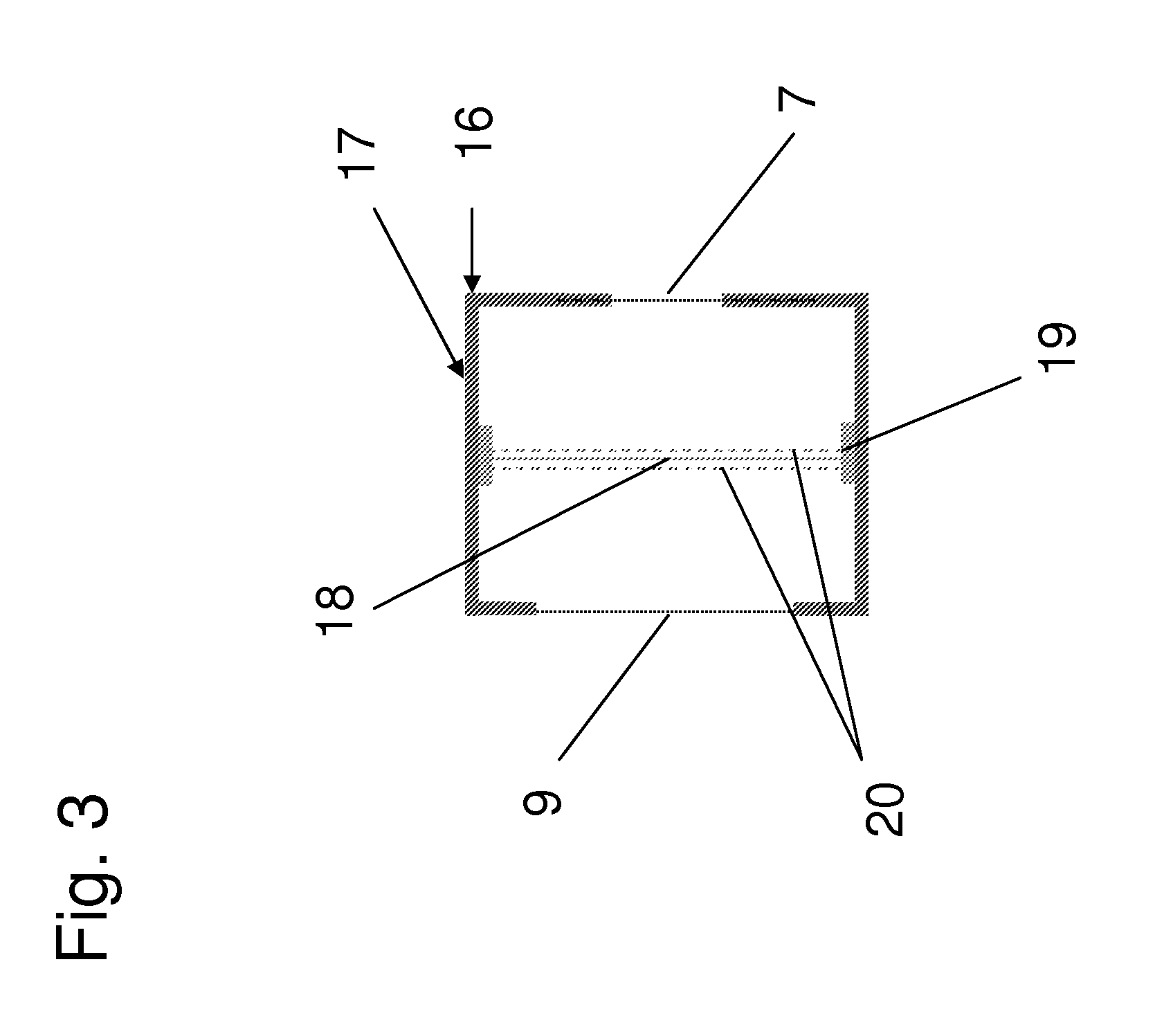

Ear protector with a sound damping filter, sound damping filter for such an ear protector as well as method for manufacturing a sound damping filter for such an ear protector

ActiveUS20130126262A1Characteristic is also fixedExcellent water vapor permeabilityStethoscopeEarplugsUltrasound attenuationWater vapor

An ear protector (1) with a sound damping filter (3), comprises a membrane (5). The membrane is composed of a material that permits the transmission of air and water vapour with respect to the ear from the into the outside of the ear protector, the membrane is pre stressed mounted in the filter, enabling a bigger surface and hence bigger air and water transport at same sound attenuation.

Owner:DYNAMIC EAR

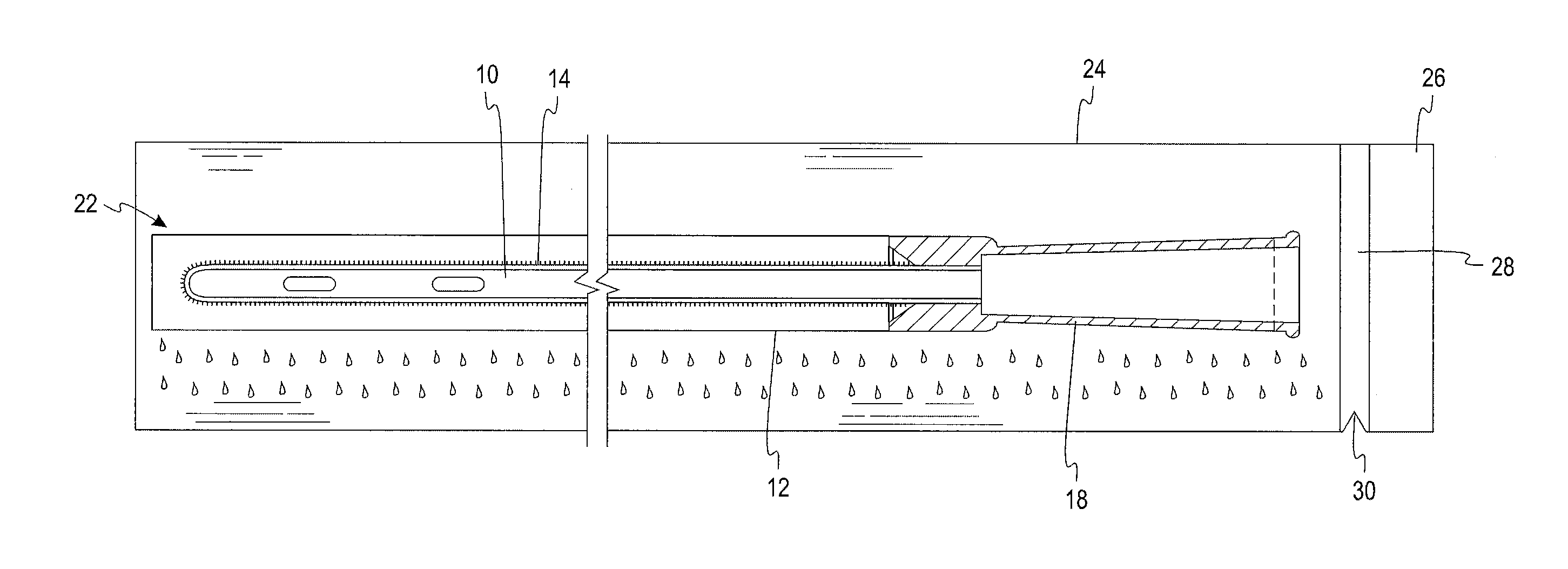

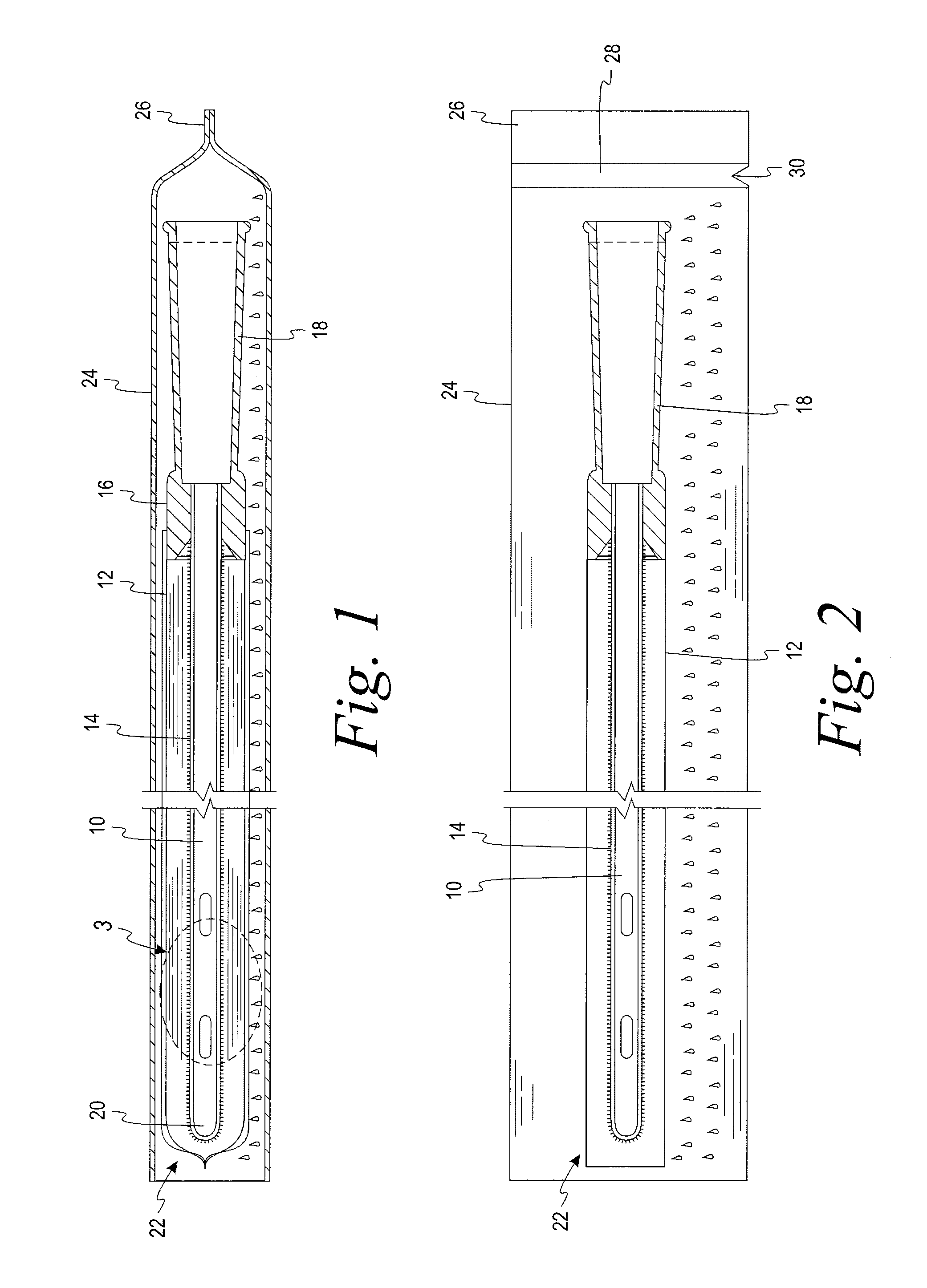

Vapor hydrated medical device with low surface energy sleeve

InactiveUS20150265801A1Reduce wetnessReduce sliminessDiagnosticsSurgical needlesHydrophilic coatingWater vapor

A medical device such as a catheter in a liquid and vapor impermeable package, the device being contained in a low surface energy sleeve or compartment that is liquid impermeable and vapor permeable. Water vapor molecules from a liquid provided within the package exteriorly of the sleeve or compartment migrate across the sleeve or compartment to an interior thereof, thereby creating and maintaining a moist environment for the device, which may include activating a hydrophilic coating of the catheter. Water molecules are transported through the sleeve from an exterior of the sleeve or compartment to the interior of the sleeve compartment. Upon removal of the device from the package, the exterior of the sleeve or compartment is drier to the touch.

Owner:HOLLISTER INCORPORAED

Water-vapor-permeable waterproof composite fabric, waterproof textile article containing same and processes for producing same

InactiveCN1460068AWater pressure resistantExcellent resistance to water pressureSynthetic resin layered productsTextiles and paperElastomerWater vapor

A water-vapor-permeable waterproof composite fabric having high flexibility, water pressure resistance and water laundering resistance is constituted from a substrate fabric and a polyether-ester elastomer (PEE-A) film layer laminated to the substrate fabric through a polyether-ester elastomer (PEE-B) binder layer, each of PEE-A and PEE-B including polyalkylene glycol residues, alkyleneglycol residues and dicarboxylic acid residues, in which composite fabric, (1) the PEE-A contains 5 to 25 % by mass of polyethyleneglycol residues, (2) the PEE-A film layer is 5 to 5 mu thick, (3) the PEE-B has a melting temperature of at least 20 DEG C below that of the PEE-A and (4) the PEE-B binder layer is present in an amount of 2 to 20 g / m<2>.

Owner:TEIJIN LTD

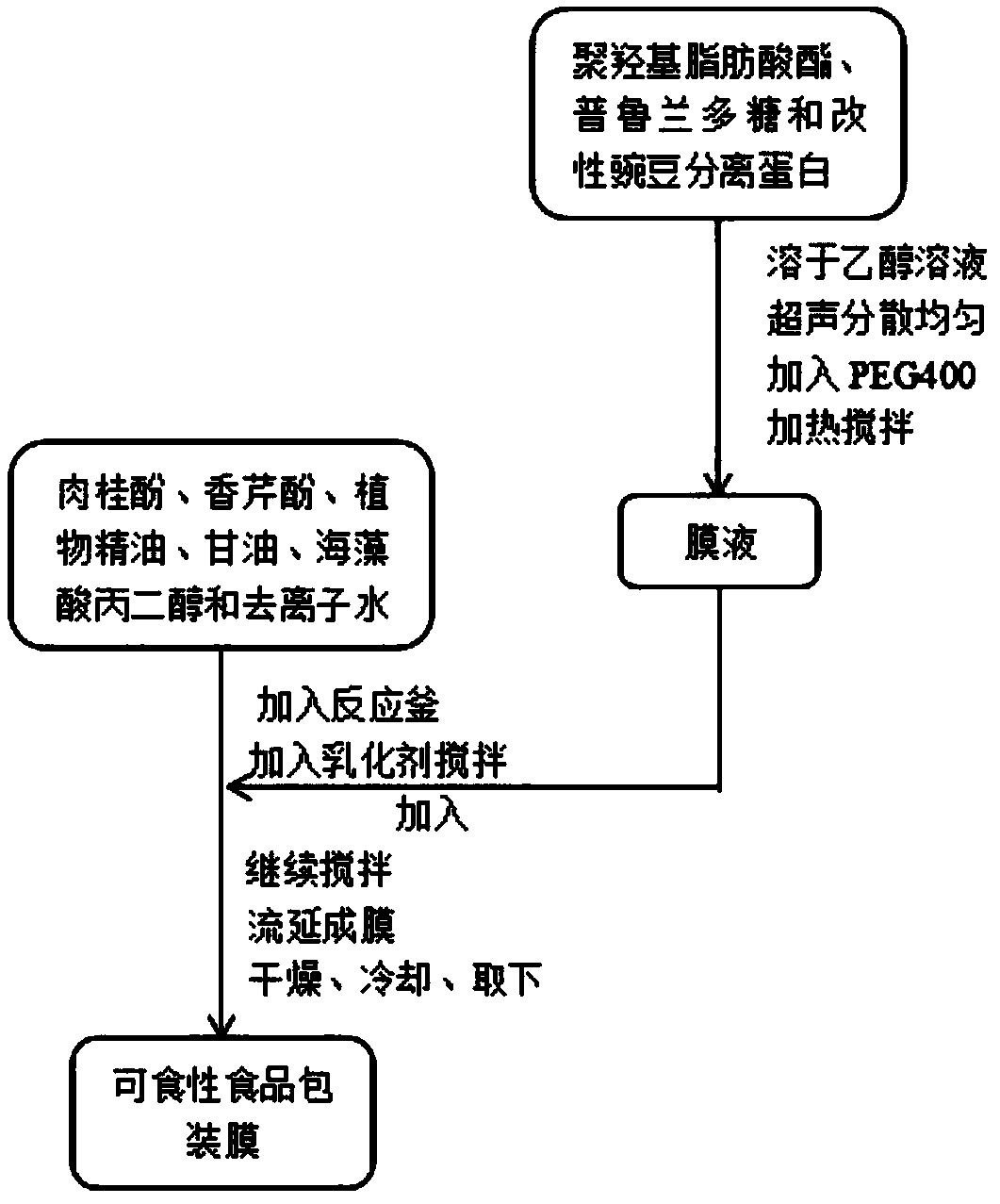

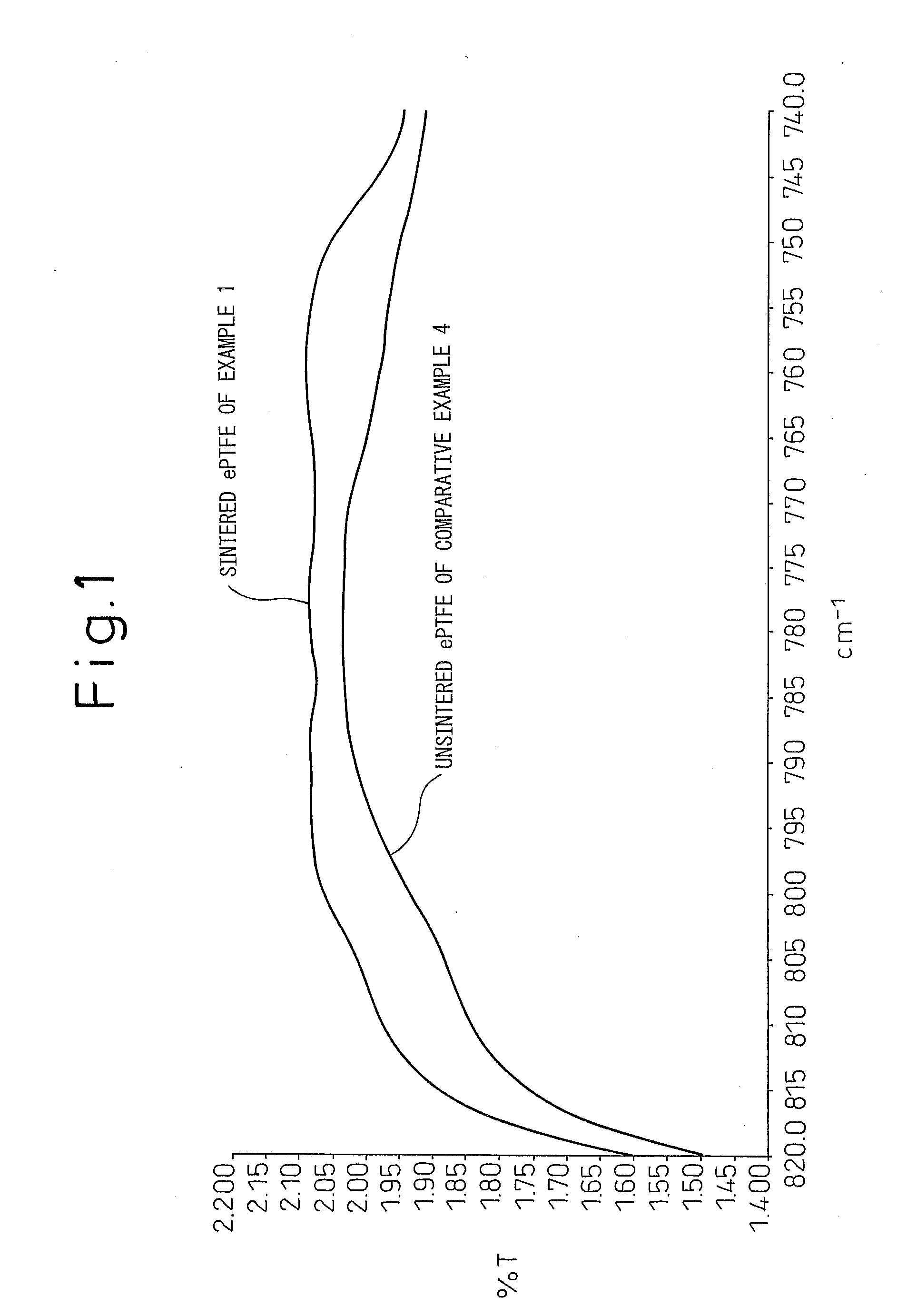

Edible food packaging film and preparation method and application thereof

The invention provides an edible food packaging film which is prepared from the following raw materials in parts by weight: 50-70 parts of polyhydroxyalkanoate, 30-50 parts of Pulullan, 30-50 parts ofmodified pea protein isolate, 20-30 parts of cinnamon phenol, 20-30 parts of carvacrol, 10-20 parts of plant essential oil, 5-10 parts of glycerinum, 1-5 parts of an emulsifier, 1-10 parts of propylene glycol alginate and 100-140 parts of deionized water. The edible food packaging film prepared by the invention is a microbial copolymerized ester, can be degraded and eaten, and has a relatively good water and oxygen-resistant ability. By adding the modified pea protein isolate, the mechanical property and heat resistance of a film material are enhanced, and the edible food packaging film is wide in application.

Owner:深圳市绿源兴环保科技有限公司

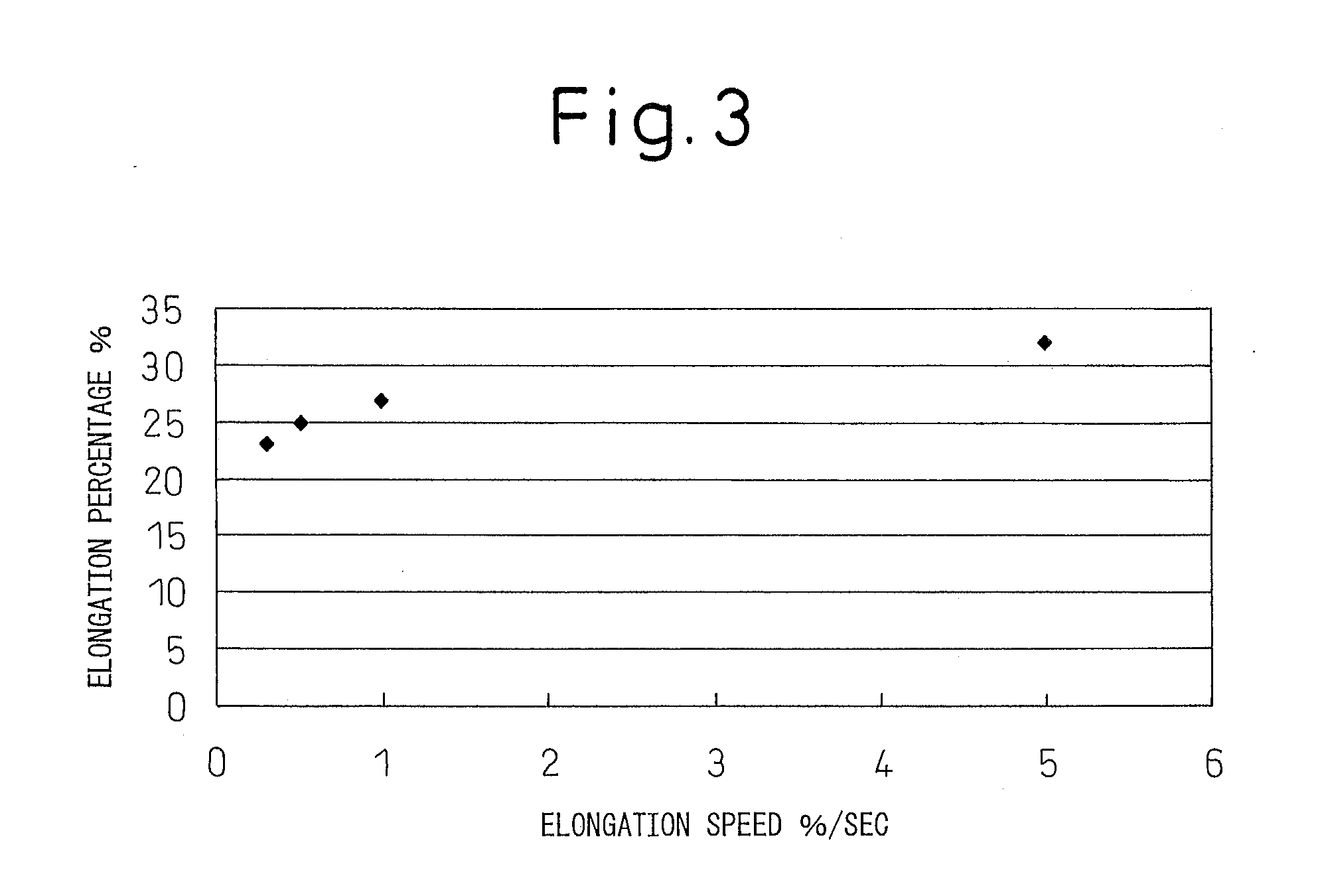

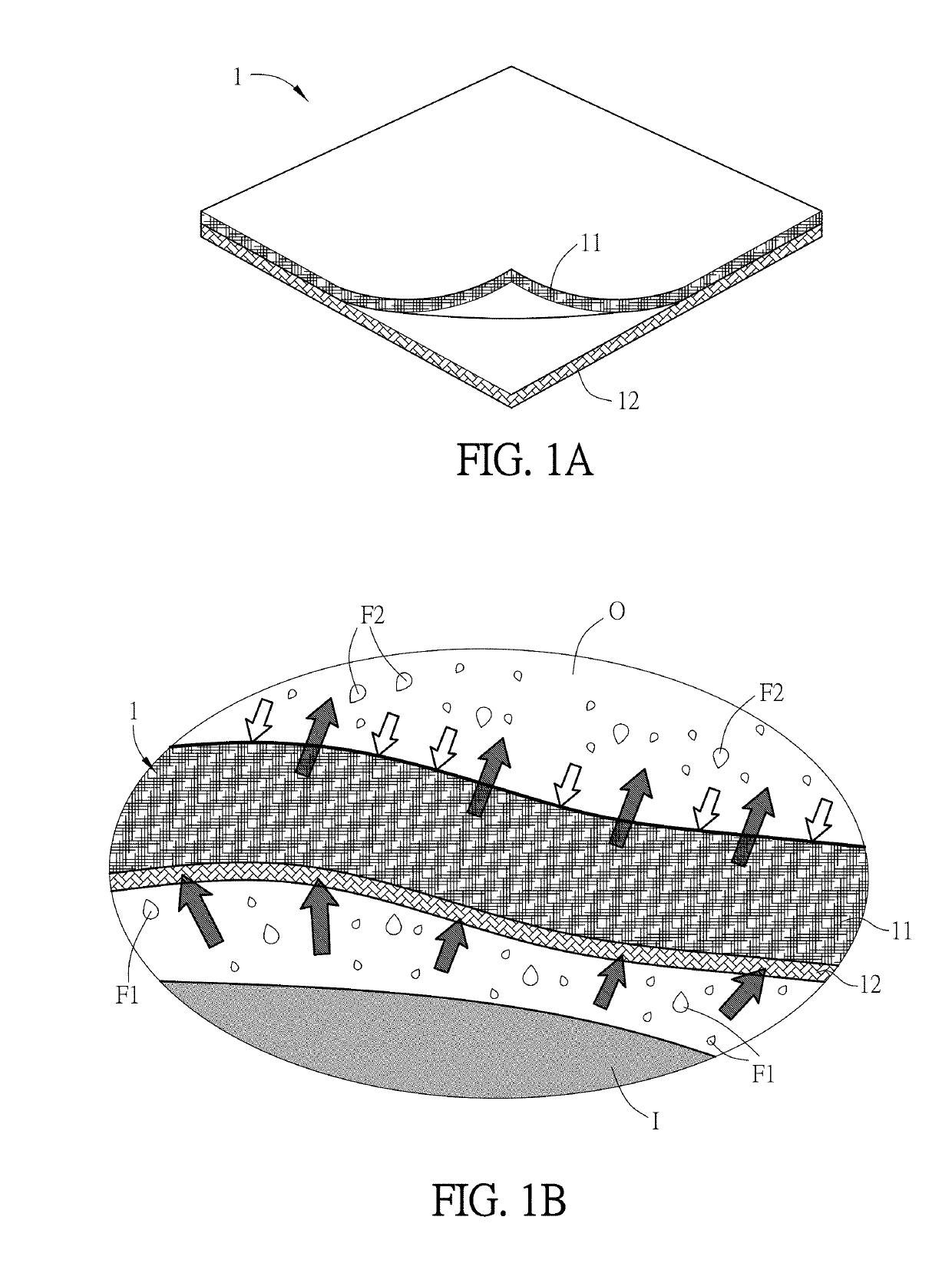

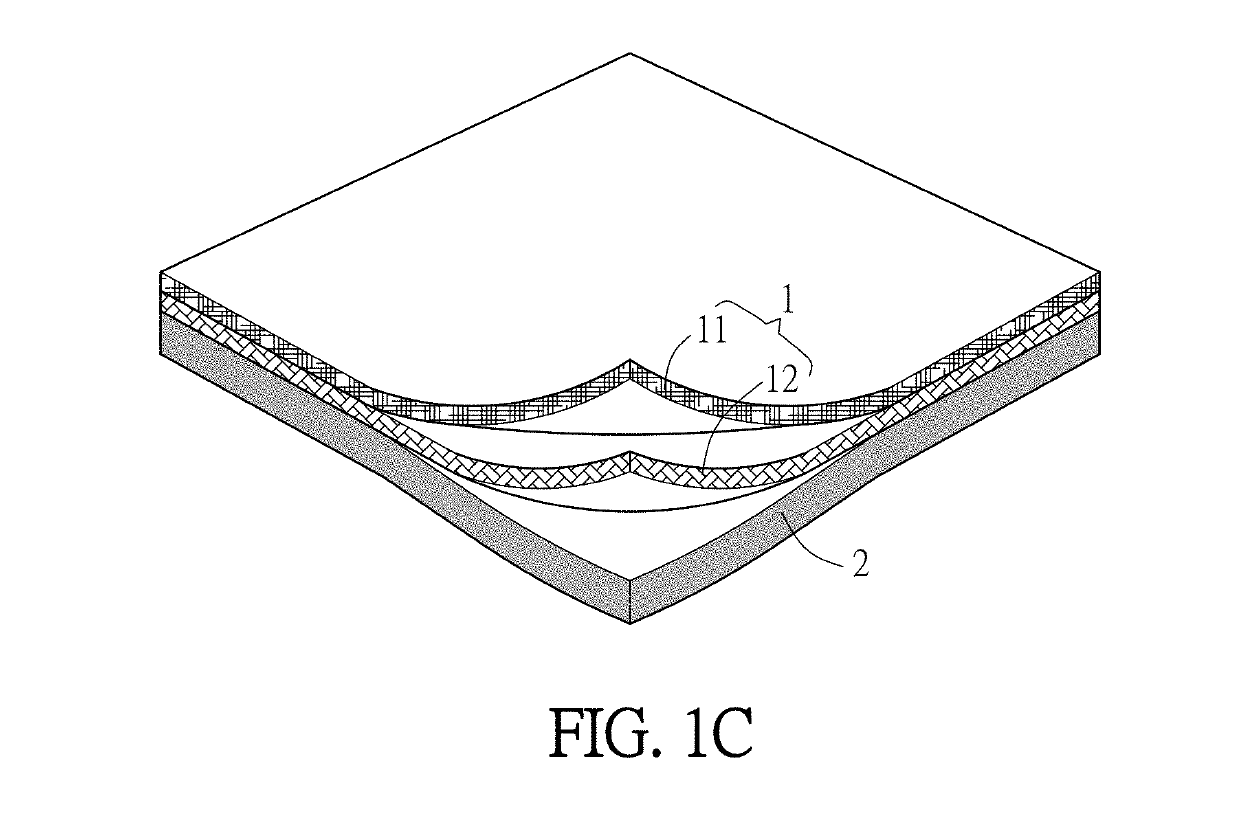

Elastic Composite Film and Composite Fabric and Production Processes Thereof

InactiveUS20090042473A1High elongationExcellent water vapor permeabilityWarp knittingPretreated surfacesComposite filmStress strength

An elastic composite film provided with a sintered ePTFE film and an elastomeric resin layer, produced by continuously forming the elastomeric resin layer on at least one side of the sintered ePTFE film, continuously elongating the resulting multilayer film at less than the yield point of the expanded, sintered, porous film and at an elongation factor of 1.3 times or more in the biaxial directions, or in the uniaxial direction without contracting in the direction perpendicular to the direction of elongation, and relaxing the resulting elongated multilayer film, wherein when the composite film is elongated by 10% in the longitudinal and / or transverse direction, the tensile stress strength of the composite film is 2.5 N / 15 mm or less, and / or the elongation percentage of the composite film in the longitudinal and / or transverse direction is 30% or more and the elongation recovery rate is 70% or more.

Owner:JAPAN GORE TEX INC

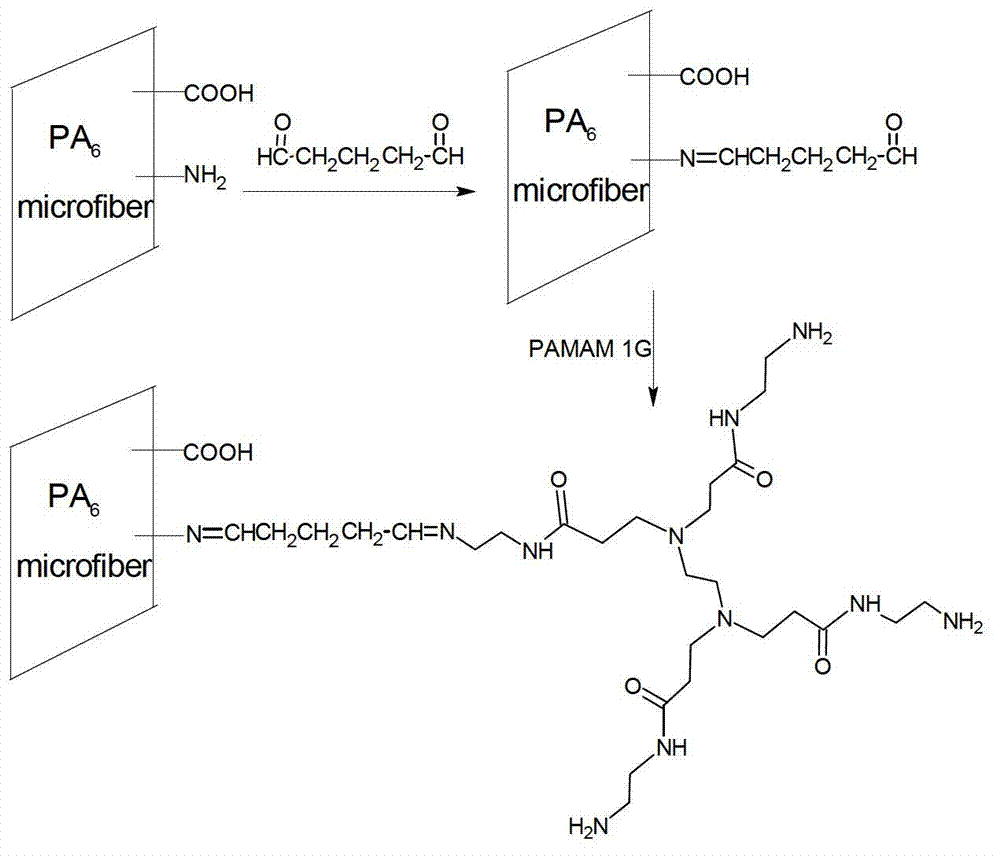

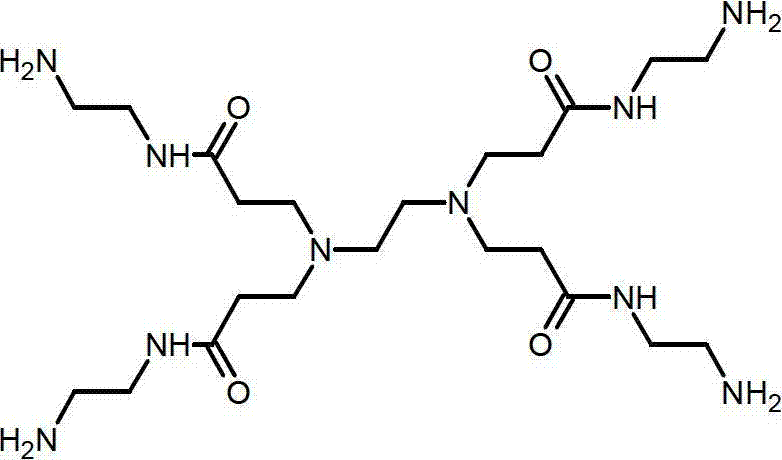

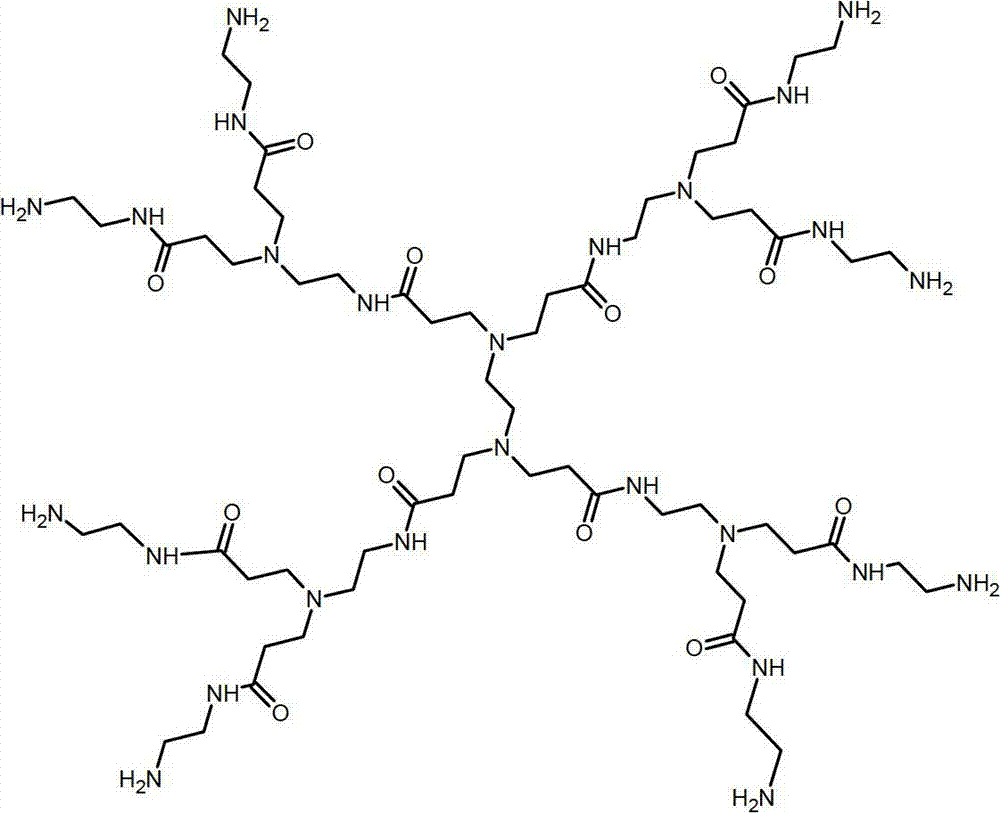

Process for enhancing hygiene performance of superfine-fiber synthetic leather

ActiveCN102758356AAdd active functional groupsImprove hygieneFibre treatmentFiber compositionPolymer

The invention relates to a process for enhancing hygiene performance of superfine-fiber synthetic leather. The process comprises the following steps of: firstly, adding 10%-15% of concentrated sulfuric acid with mass concentration of 98% under the situation that a liquor ratio is 50, and repeatedly washing resultant at a normal temperature after the reaction; adjusting the pH value of the resultant to 6-8, reacting glutaraldehyde with mass concentration of 25% with base cloth at a temperature of 20-50 DEG C, and repeatedly washing resultant with saline at the normal temperature; adding multi-amino polymer in the resultant, and performing crosslink on the mutli-amino polymer and the resultant at a temperature of 20-50 DEG C and with the pH being 6-8, wherein the mole ratio of the multi-amino polymer to the glutaraldehyde is 1:1-1:2; and finally, adding 1%-4% of aldehyde eliminating agent in resultant, reacting the agent and the resultant for 1-2 hours at a temperature of 30-50 DEG C, washing the resultant in water at a temperature of 30-50 DEG C, and drying the resultant. The process provided by the invention utilizes the two-step glutaraldehyde method to crosslink the base cloth and the multi-amino polymer to form the composite of the base cloth, the glutaraldehyde and the multi-amino polymer, so that active functional groups of the base cloth are enhanced, and the hygiene performance of the superfine fiber composition leather is permanently enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

Controlled release transdermal patch for preventing and treating cardiovascular and cerebrovascular system diseases and preparation method thereof

InactiveCN101810596AGood film formingExcellent water vapor permeabilityOrganic active ingredientsOil/fats/waxes non-active ingredientsTransdermal patchComposite film

The invention relates to a controlled release transdermal patch for preventing and treating cardiovascular and cerebrovascular system diseases, which consists of a protectively layer, a medicine release layer, a medicine storage layer and a back lining layer through being sequentially overlapped, wherein the protectively layer is siliconized anti-sticking paper or a polyethylene film or a siliconized polyester film, the back lining layer is an aluminum foil, an aluminum foil and polyethylene composite film or a polyester composite film, the medicine releasing layer is prepared from 3 to 8 percent of cyclovimbuxine D, 60 to 70 percent of pressure sensitive adhesive substrates, 5 to 10 percent of composite transdermal penetrating agents, 20 to 30 percent of plasticizing agents and 1 to 3 percent of cross-linking agents, the medicine storage layer consists of 8 to 15 percent of the cyclovimbuxine D, 50 to 60 percent of the pressure sensitive adhesive substrates, 1 to 5 percent of composite transdermal penetrating agents, 20 to 30 percent of plasticizing agents and 1 to 3 percent of cross-linking agents. The patch of the invention is prepared by an organic solvent dispersing method, the preparation process is simple, the prepared patch has the exact curative effect, stable quality, high safety and convenient use, and is applicable to the long-time prevention and treatment of the cardiovascular and cerebrovascular diseases.

Owner:GUANGZHOU UNIVERSITY OF CHINESE MEDICINE

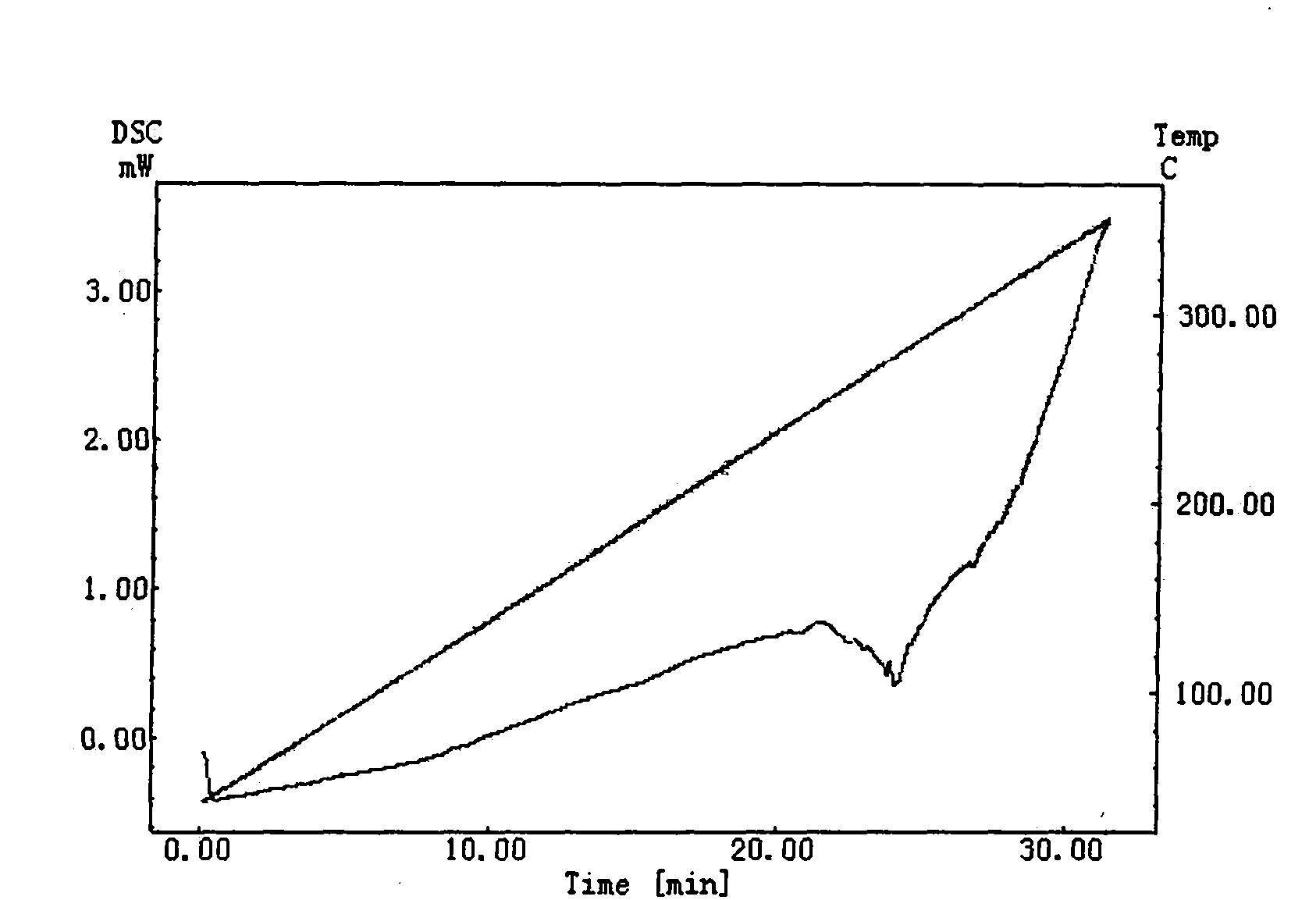

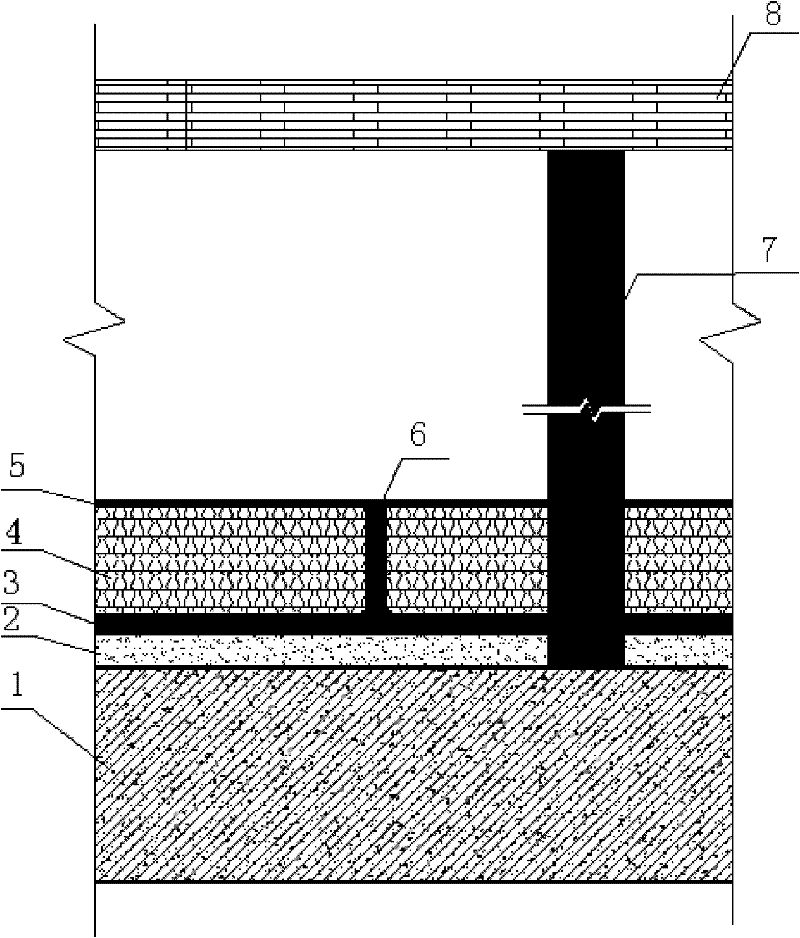

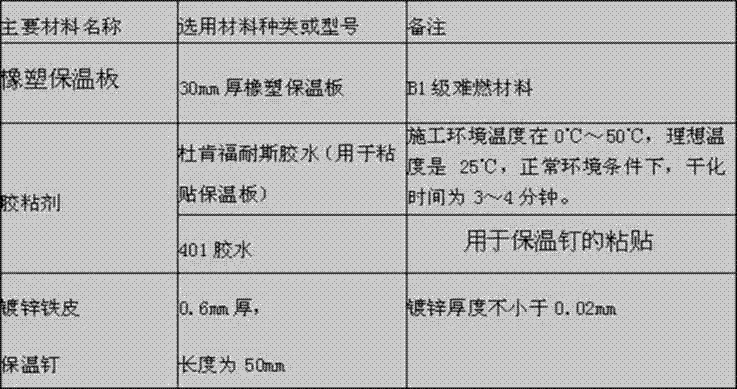

Three-dimensional floor building insulating system and construction method thereof

ActiveCN102635168AReduce energy consumptionImprove insulation effectHeat proofingFlooring insulationsThermal insulationWiring diagram

The invention provides a three-dimensional floor building insulating system, aiming to provide a three-dimensional floor building insulating system which is stable in thermal insulation property, compatible with a wall body insulating system and advantageous for bringing an air conditioning system into play, and a construction method thereof. The three-dimensional floor building insulating systemis implemented according to the following technical proposal: the three-dimensional floor building insulating system further comprises a floor ground insulating system which is connected to the wall body insulating system; the floor ground insulating system comprises a prefabricated slab surface structure base layer, a waterproof base layer with a flashing slope formed by plastering cement grout and a multi-layer waterproof coating connected with the waterproof base layer; and a rubber-plastic insulation board connected to the floor board by a sticking insulation nail is arranged on the multi-layer waterproof coating. The construction method comprises the following steps of: unreeling wires on the ground according to an integrated wiring diagram of pipelines under the floor board, planning and designing elevated floor board supporting points, plastering a plurality of waterproof layers also serving as closed layers, sticking the insulation nail and laying the insulation board on the floor ground. The three-dimensional floor building insulating system and the wall body insulating system supplement each other to provide all-around thermal insulation measures.

Owner:CHENGDU SIXTH CONSTR ENG

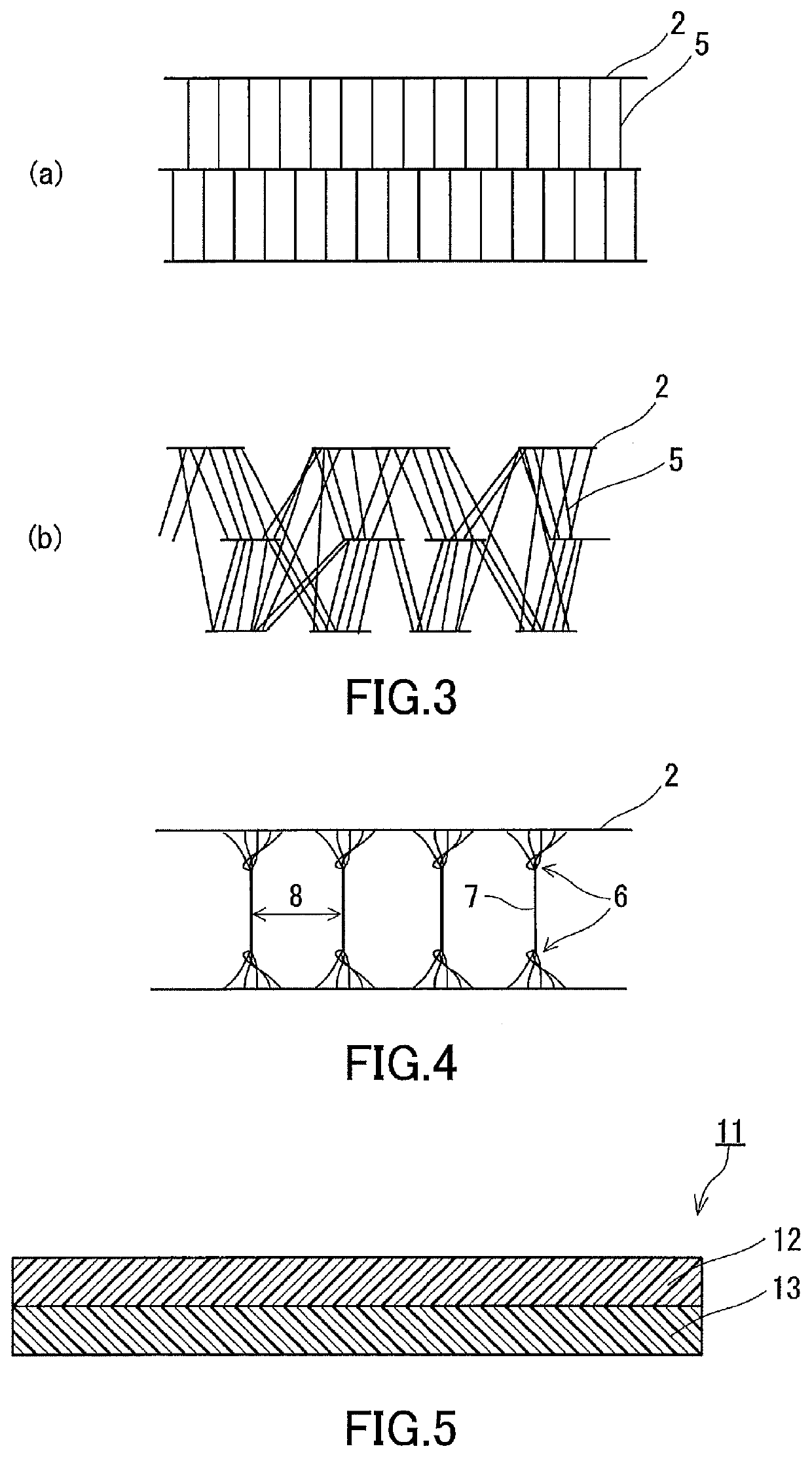

Composite textile product

InactiveUS20190099989A1Good water-vapor permeabilityExcellent water-vapor permeability and waterproof abilitySynthetic resin layered productsClothingsPolyamideEngineering

Owner:YIE CHENG TEXTILE ENTERPRISE CO LTD

Fuel cell

InactiveUS8003278B2Efficient humidificationCompact structureFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A power generation cell includes a membrane electrode assembly, and first and second separators sandwiching the membrane electrode assembly. The first separator includes an oxygen-containing gas flow field. An inlet buffer area is provided between the oxygen-containing gas flow field and an oxygen-containing gas supply passage, and an outlet buffer area is provided between the oxygen-containing gas flow field and an oxygen-containing gas discharge passage. Plural columnar resistance members are provided within the inlet buffer area and the outlet buffer area. The membrane electrode assembly further includes first and second humidification sections.

Owner:HONDA MOTOR CO LTD

Textiles Having Flame Protection Function

ActiveUS20190062571A1Increased flame protectionExcellent water vapor permeabilityFireproof paintsHeat resistant fibresGraphitePolymer chemistry

The invention relates to flame-retardant foam coatings for textile sheet products, wherein the coatings include plate-like expandable graphite which has a reduced salt content and a particle distribution with a proportion of >80 percent by weight having a diameter of at least 0.2 mm, and / or a minimum proportion of 70% having a mesh size of >50 mesh (0.3 mm), at least one binder and at least one foam stabilizer, and also processes for the production thereof, the use thereof for producing textile sheet products and also textile sheet products having such flame-retardant foam coatings.

Owner:SCHOELLER TEXTIL

Wet dressing for protecting skin and preparation method of wet dressing

The present invention provides a wet dressing for protecting skin. The wet dressing for protecting skin is prepared from halogenated nitrocellulose with a mass percentage concentration of 2-20%, hexamethylsilyl ether with a mass percentage concentration of 4-10%, C6-C9 alkanes with a mass percentage concentration of 2-8% and the balance ester solvent. The nitrocellulose is reacted with organic halides to form halogen-containing nitrocellulose, the halogen-containing nitrocellulose is dissolved in a mixed solvent of polar ester solvents, hexamethyldisilyl ether, and C6-C9 alkanes, the mixture is applied to damaged skin surfaces, the solvent evaporates, and the polymer forms a thin film to cover the skin surface, prevents external bacteria, water or other pollution sources from entering thedamaged skin, avoids infection of the affected area, and promotes wound healing. The wet dressing is non-irritating, has good skin affinity and durability, and can be used for care of large areas andirregular injuries.

Owner:SHANGHAI EAST HOSPITAL EAST HOSPITAL TONGJI UNIV SCHOOL OF MEDICINE

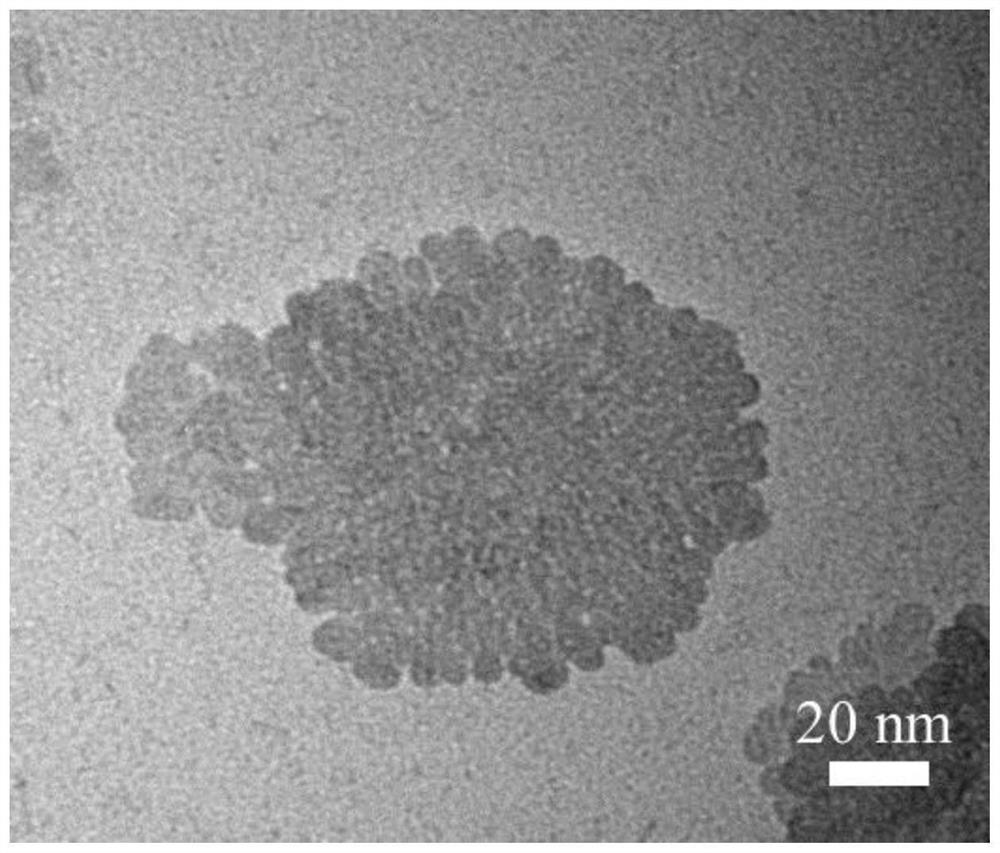

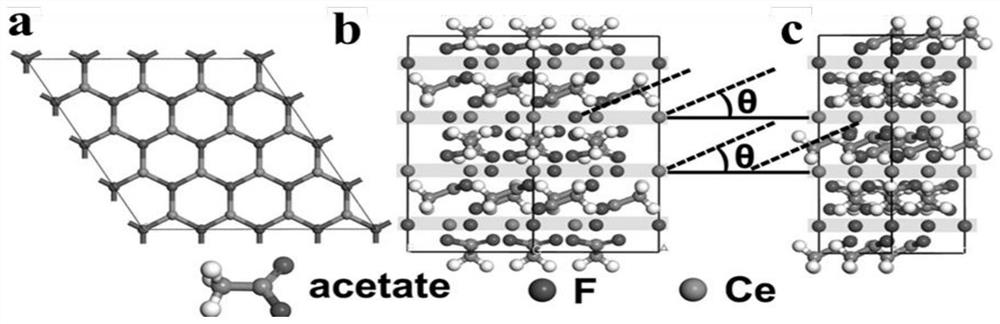

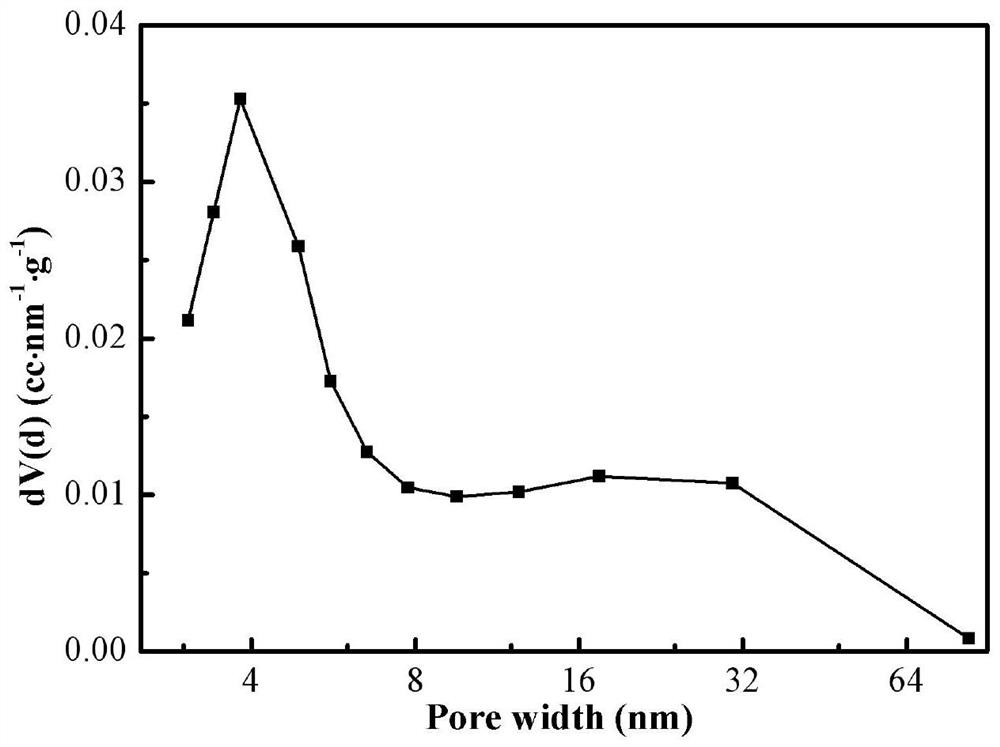

Cerium fluoride porous nanosheet regulated mixed matrix membrane, preparation method and application thereof

ActiveCN113896220AHigh selectivityImprove permeabilityMaterial nanotechnologySemi-permeable membranesPhysical chemistryMaterials science

The invention discloses a cerium fluoride porous nanosheet regulated mixed matrix membrane, a preparation method and application thereof, and belongs to the technical field of gas separation membranes. Specifically, the invention discloses a cerium fluoride porous nanosheet, which is formed by arranging fluorine-cerium monatomic layers and acetate radicals which are alternately stacked between the layers, wherein the fluorine-cerium monatomic layers are formed by arranging fluorine atoms and cerium atoms in a six-membered ring honeycomb form. The invention further provides a cerium fluoride porous nanosheet regulated mixed matrix membrane composed of the cerium fluoride porous nanosheet and a polymer matrix. The invention also provides a preparation method of the cerium fluoride porous nanosheet and a preparation method of the cerium fluoride porous nanosheet regulated mixed matrix membrane, wherein the preparation method is simple to operate. According to the invention, the cerium fluoride porous nanosheet filled polymer matrix membrane is applied to gas dehumidification / humidification, water vapor is permeated preferentially, and the high separation performance on water vapor is achieved.

Owner:TIANJIN POLYTECHNIC UNIV

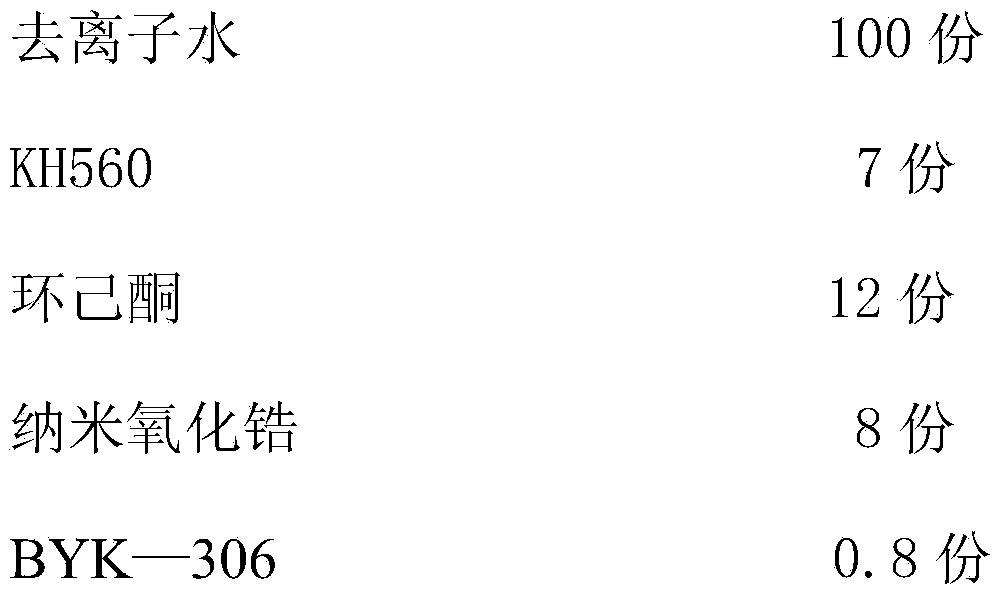

Finishing agent for improving water vapor permeability of fabric

InactiveCN104018347AExcellent water vapor permeabilityHarm reductionFibre treatmentCyclohexanoneWater vapor permeability

The invention belongs to the technical field of fabric modification and in particular relates to a finishing agent for improving the water vapor permeability of a fabric. The finishing agent is prepared from the following ingredients in part by weight: 5-10 parts of silane coupling agent, 12-15 parts of cyclohexanone, 6-10 parts of nanometer zirconia, 0.5-1.0 parts of leveling agent and 100 parts of ionized water. The fabric has high water vapor permeability after modification and finishing, has simple process, does not contain polytetrafluoroethylene and other organic polymers, and reduces harm of the traditional permeability modification process to human body or environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

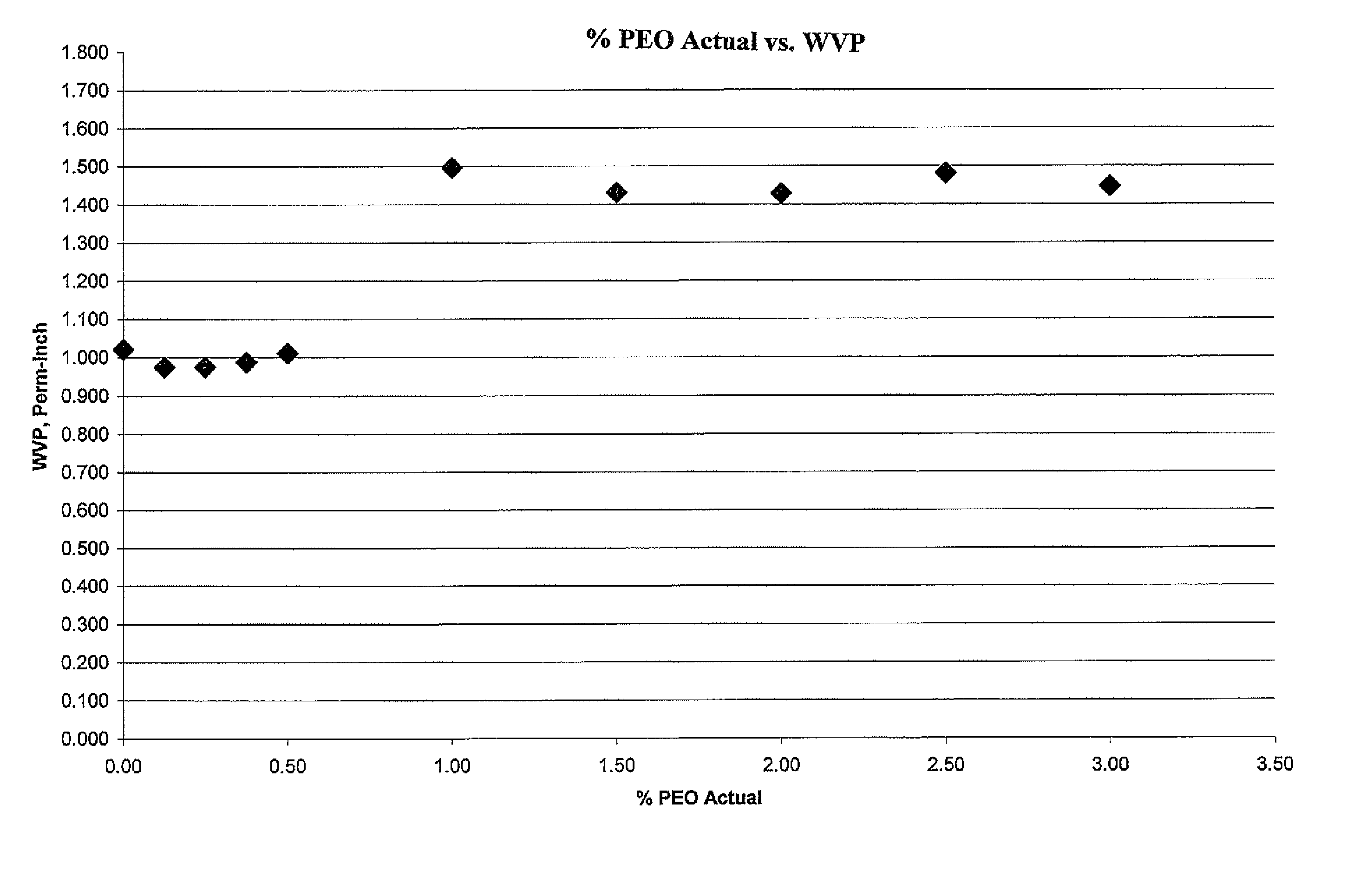

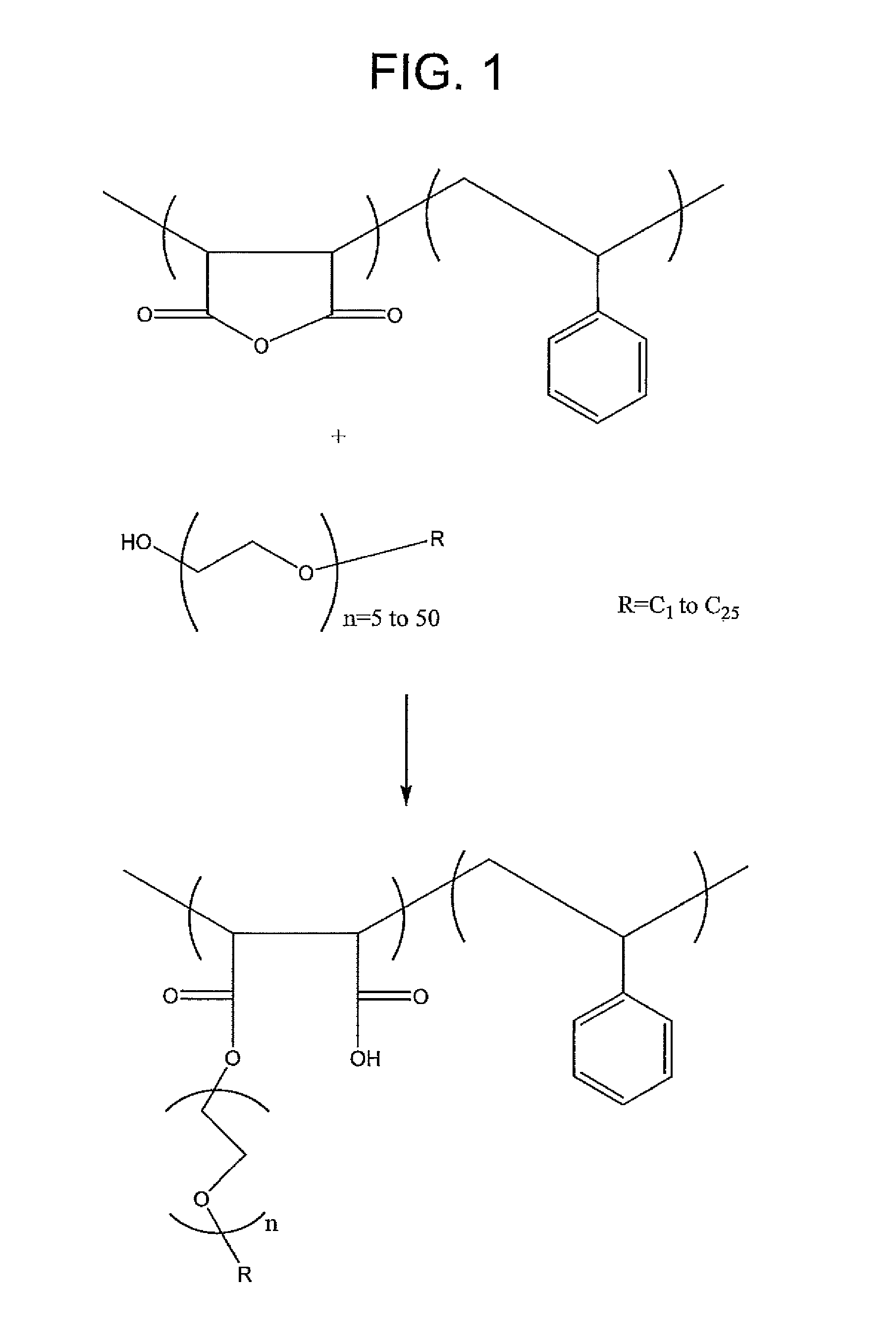

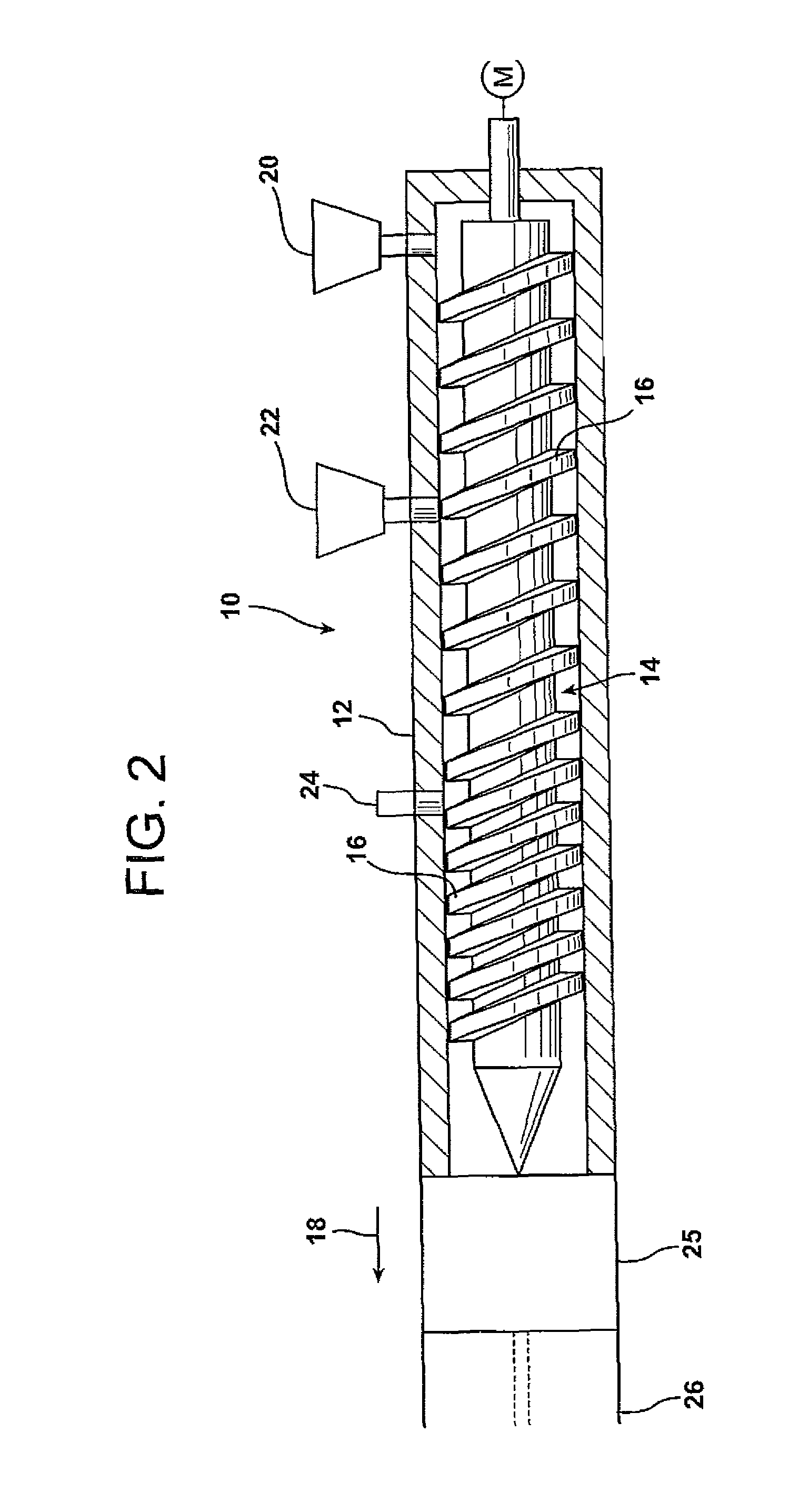

Polystyrene/polyethylene oxide copolymer for enhancing water vapor permeability in thermoplastic foam

ActiveUS8378001B2Excellent water vapor permeabilityLow global warming potentialFoundry mouldsFoundry coresThermoplasticSolubility

Polymeric foam and polymeric foam products that contain a foamable polymer material, at least one blowing agent, a polystyrene / polyethylene oxide copolymer, and optionally, an infrared attenuating agent, are provided. In exemplary embodiments, the blowing agent includes at least one hydrofluorocarbon blowing agent. The maleic anhydride-styrene copolymer grafted with polyethylene oxide provides a water vapor permeability of 1.1 perm inch or greater in the extruded foam product without detrimentally affecting physical or thermal properties of the product. Additionally, the copolymer of maleic anhydride-styrene grafted with polyethylene oxide has a positive affect on the processability of the blowing agent(s) in the composition by both widening the process window and enhancing the solubility of the blowing agent in the polymer melt. Thus, the polystyrene / polyethylene oxide copolymer present in the inventive composition acts as a cell enlarger, a plasticizer, and a processing aid. A method of forming an extruded foam product is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Porous polytetrafluoroethylene membrane, and waterproof air-permeable membrane and waterproof air-permeable member including the same

ActiveUS20200086282A1Excellent water vapor permeabilityImprove diffusivityMembranesSemi-permeable membranesPolymer scienceWater vapor permeability

A porous polytetrafluoroethylene (PTFE) membrane of the present disclosure has a water vapor permeability, as measured according to Japanese Industrial Standard (JIS) L 1099 (method B-1), of 150000 g / (m2·day) or more in a thickness direction of the membrane. The porous PTFE membrane of the present disclosure, when attached as a waterproof air-permeable membrane to a housing of an electrical component or electrical device, allows water vapor residing inside the housing to be quickly discharged out of the housing.

Owner:NITTO DENKO CORP

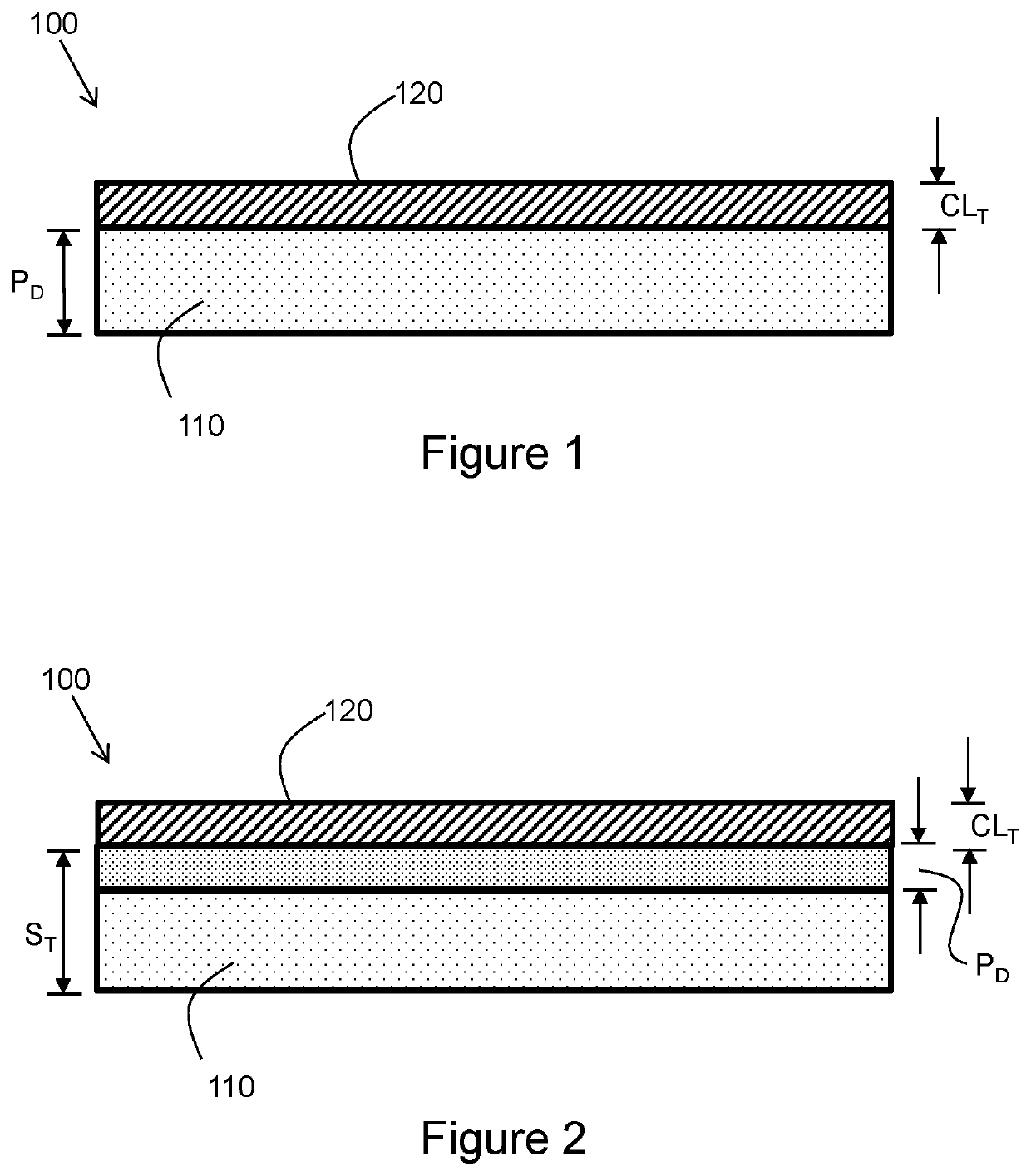

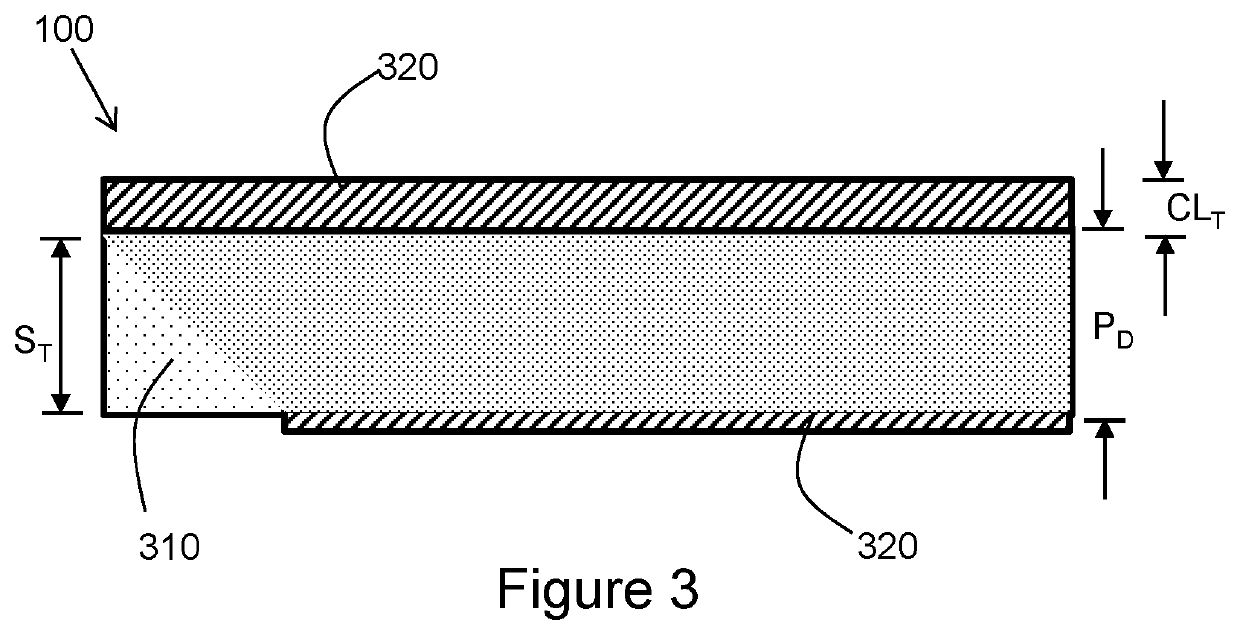

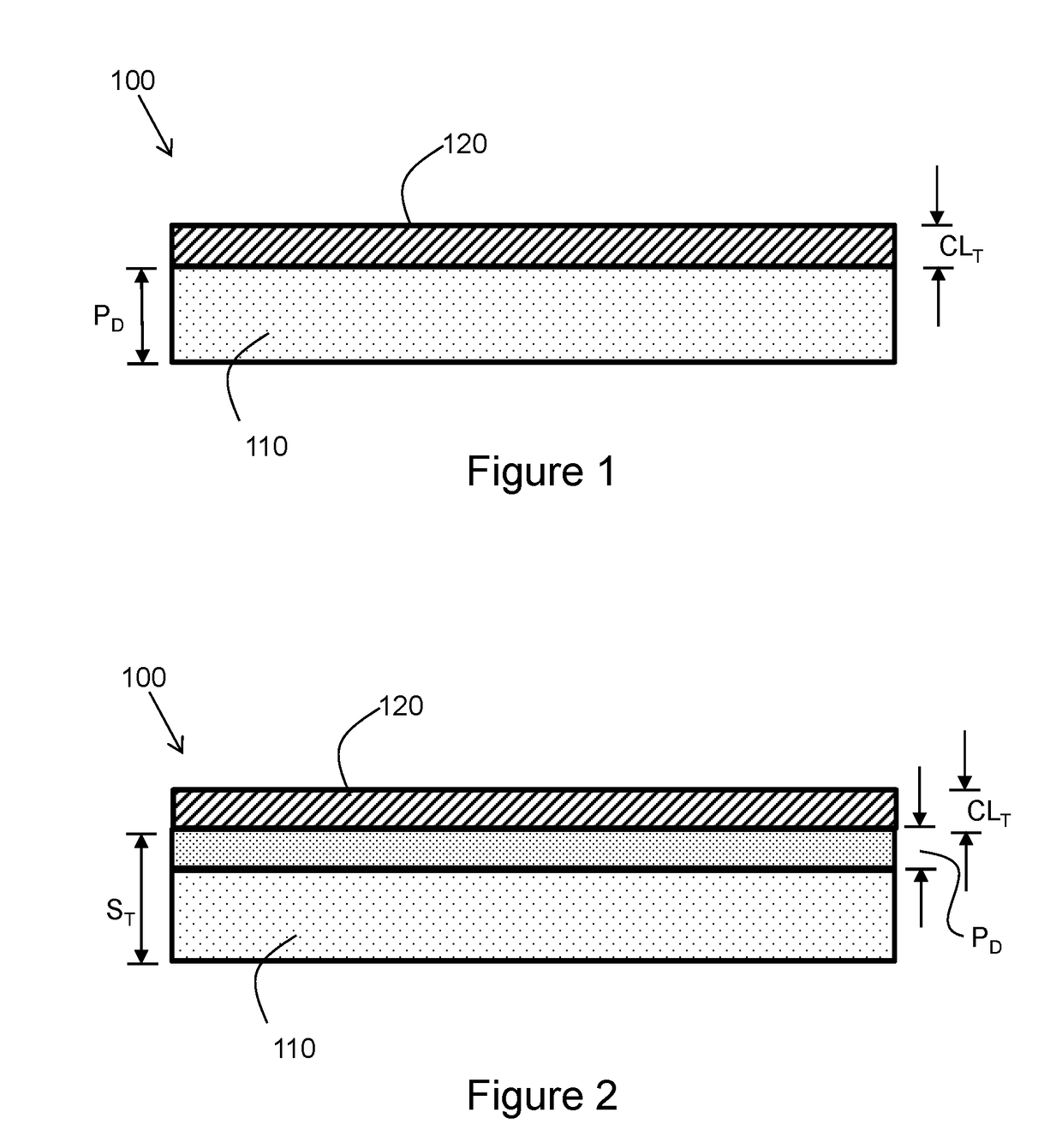

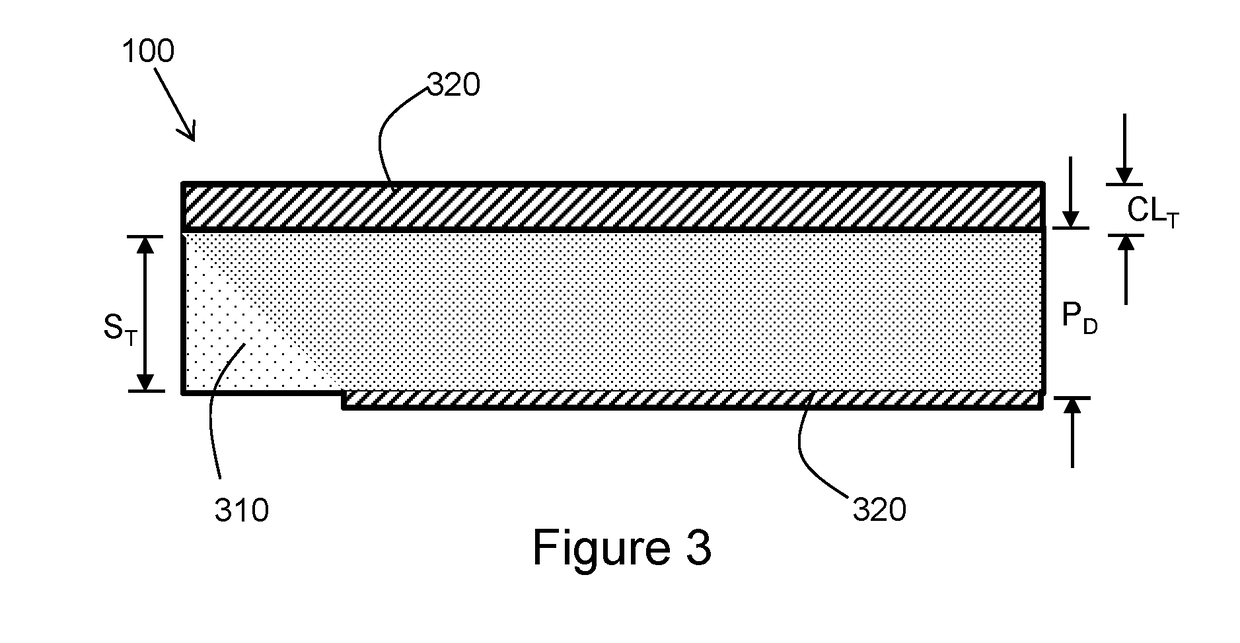

Vapor retarding building materials and methods for making them

ActiveUS11136755B2Low water vapor permeabilityExcellent water vapor permeabilitySynthetic resin layered productsConjugated diene hydrocarbon coatingsHydrophobic polymerWater vapor

The present disclosure relates generally to vapor retarding building materials and methods for making them. The present inventors have found simple and cost-efficient materials that have low water vapor permeability at low relative humidities and that can be provided as a coating on a building material substrate. Notably, in many embodiments, the materials can have high water vapor permeability at high relative humidities. In one embodiment, the disclosure provides vapor retarding articles comprising a building material substrate; and a polymeric coating layer coated on the building material substrate, the polymeric coating layer comprising an inorganic hydrophilic particulate filler dispersed in a continuous organic phase comprising a hydrophobic polymer, wherein the content of the filler is from about 30% to about 85% by weight of the polymeric coating layer, the vapor retarding article configured to have a water vapor permeance of no more than about 1 Perm at 25% relative humidity.

Owner:CERTAIN TEED LLC

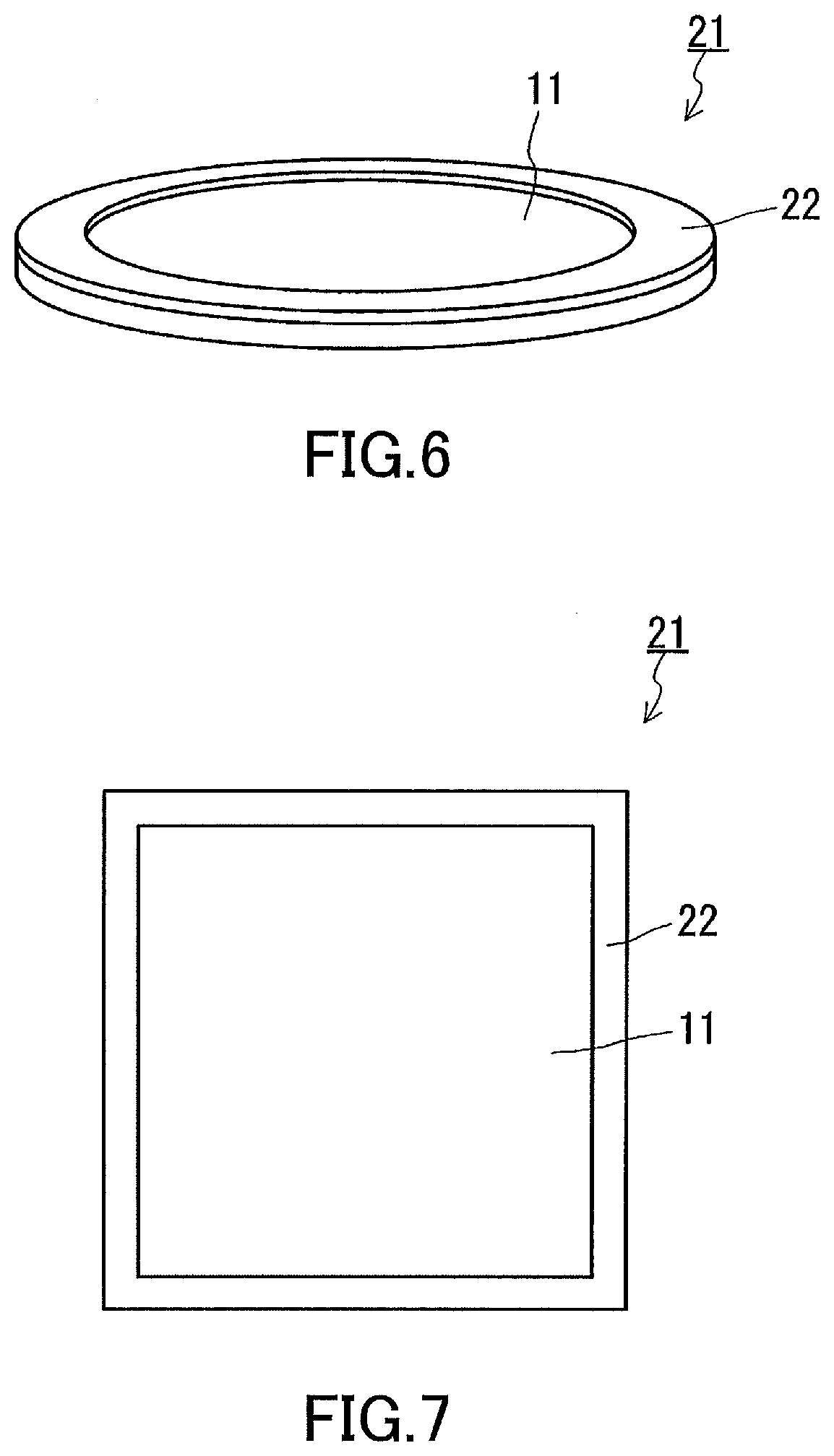

Ear protector with a sound damping filter, sound damping filter for such an ear protector as well as method for manufacturing a sound damping filter for such an ear protector

ActiveUS8689931B2Excellent water vapor permeabilityIncrease stickinessStethoscopeEarpiece/earphone attachmentsUltrasound attenuationWater vapor

An ear protector (1) with a sound damping filter (3), comprises a membrane (5). The membrane is composed of a material that permits the transmission of air and water vapor with respect to the ear from the into the outside of the ear protector, the membrane is pre stressed mounted in the filter, enabling a bigger surface and hence bigger air and water transport at same sound attenuation.

Owner:DYNAMIC EAR

Internal wall anticorrosive coating for sea water evaporating installation

InactiveCN1317345CConducive to on-site constructionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to endophragm anticorrosion dope of carbon steel material vaporizing equipments in seawater desalting craft of low temperature and multiple effect distillation. It mainly comprises basic materials, pigment, padding, auxiliary agent and solvent. The basic materials are one or more than one kind of epoxy resin and painthydroxybenzene modified thermostable resins. The painthydroxybenzene modified thermostable resins are one or more than one kind of painthydroxybenzene silicon resin, painthydroxybenzene furol resin and painthydroxybenzene titanium resin got from chemical modification of painthydroxybenzene distilled from fresh paint; the color padding is one or more than one kind of titanium oxide powder, talcum powder, mica powder, mica ferric oxide, gas phase silicon dioxide, silica flour, porcelain powder and bentonite. The dope is solidified at room temperature. It has excellent permeability resistance of water, seawater and vapor at high temperature and is suitable to anticorrosion of low temperature.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Vapor retarding building materials and methods for making them

ActiveUS20190003174A1Low costHigh water vapor permeabilitySynthetic resin layered productsConjugated diene hydrocarbon coatingsBuilding materialWater vapor permeation

The present disclosure relates generally to vapor retarding building materials and methods for making them. The present inventors have found simple and cost-efficient materials that have low water vapor permeability at low relative humidities and that can be provided as a coating on a building material substrate. Notably, in many embodiments, the materials can have high water vapor permeability at high relative humidities. In one embodiment, the disclosure provides vapor retarding articles comprising a building material substrate; and a polymeric coating layer coated on the building material substrate, the polymeric coating layer comprising an inorganic hydrophilic particulate filler dispersed in a continuous organic phase comprising a hydrophobic polymer, wherein the content of the filler is from about 30% to about 85% by weight of the polymeric coating layer, the vapor retarding article configured to have a water vapor permeance of no more than about 1 Perm at 25% relative humidity.

Owner:CERTAIN TEED LLC

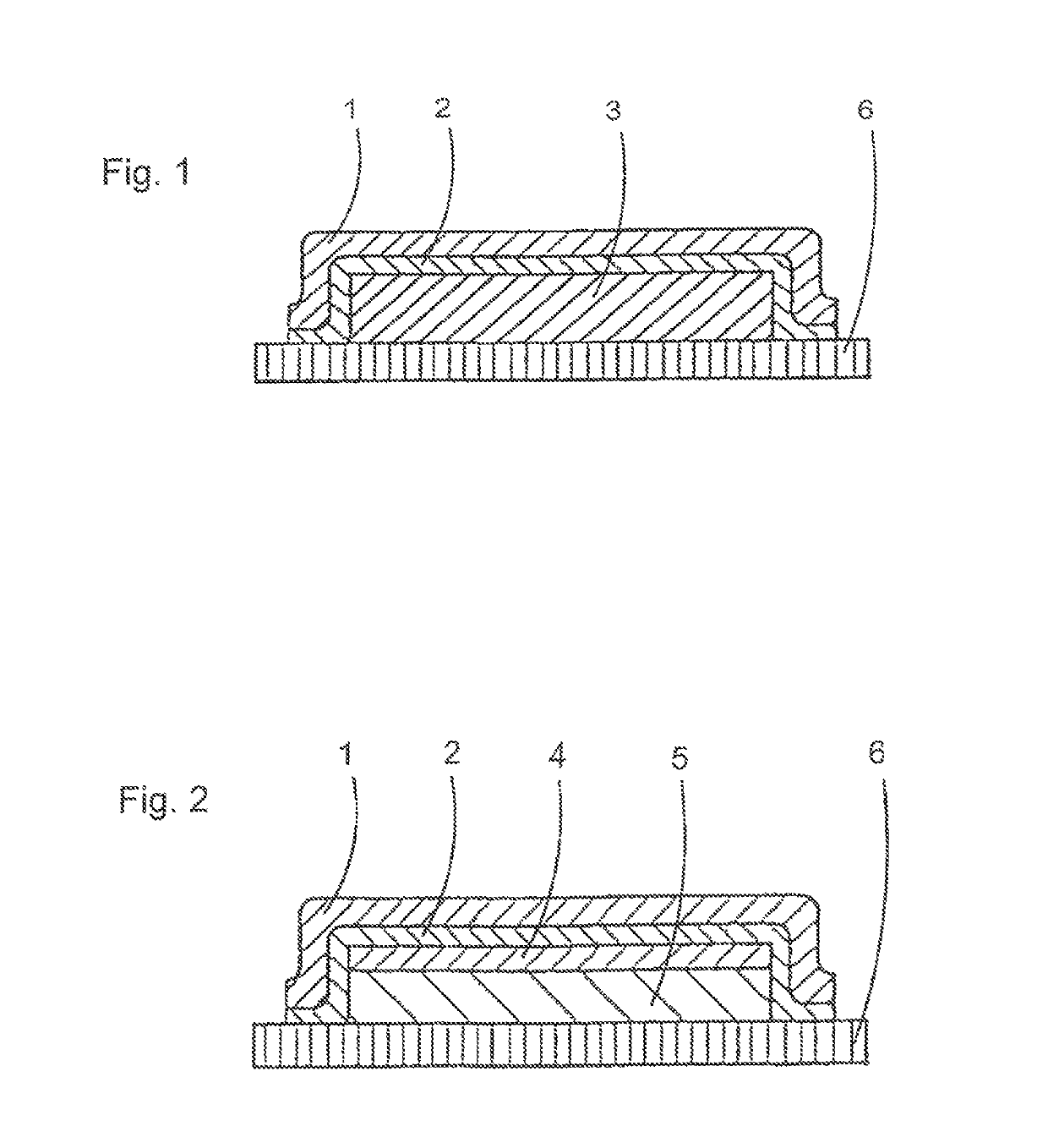

Over-patch having improved compatibility and a long adhesion duration and method for producing said over-patch

ActiveUS10335377B2Excellent water vapor permeabilityReduce occlusionCatheterAbsorbent padsWater vaporMedical product

The invention relates to a medical product for a fastening duration of at least 7 days having good skin compatibility. The medical product includes a central adhesive compartment (3) and an over-patch. The over-patch is free of active ingredients and is formed from a water-vapor-permeable back layer (1) and an adhesive polymer layer (2) that is free of active ingredients. The invention further relates to a method for the production of the foregoing medical product, and to kits of parts containing laminates of layers 1 and 2.

Owner:LTS LOHMANN THERAPIE-SYST AG

Finishing agent for improving fabric water vapor permeability

InactiveCN104358113AImprove water vapor permeabilityHigh water vapor permeabilityFibre treatmentIonKetone

The invention discloses a finishing agent for improving fabric water vapor permeability. The finishing agent comprises the following components in parts by weight: 2-3 parts of vinyl trimethoxy silane, 2-3 parts of a leveling agent, 1-2 parts of triethanolamine, 8-9 parts of cyclohexanone, 1-2 parts of vinyl trimethoxy silane, 60 parts of deionized water, 1-2 parts of iso-tridecanol oolyoxyethylene ether, 3-4 parts of nano zirconia and 1-2 parts of di-n-octyl-4-isothiazolin-3-ketone. The fabric finishing agent has the advantage that after being modified, a fabric has high water vapor permeability.

Owner:SUZHOU FUMEI TEXTILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com