Process for enhancing hygiene performance of superfine-fiber synthetic leather

A technology of ultra-fine fiber and hygienic performance, applied in fiber processing, textiles and papermaking, etc., can solve the problems of inability to permanently improve hygienic performance, physical filling and inability to wash with water, etc., and achieve the effect of improving hygienic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

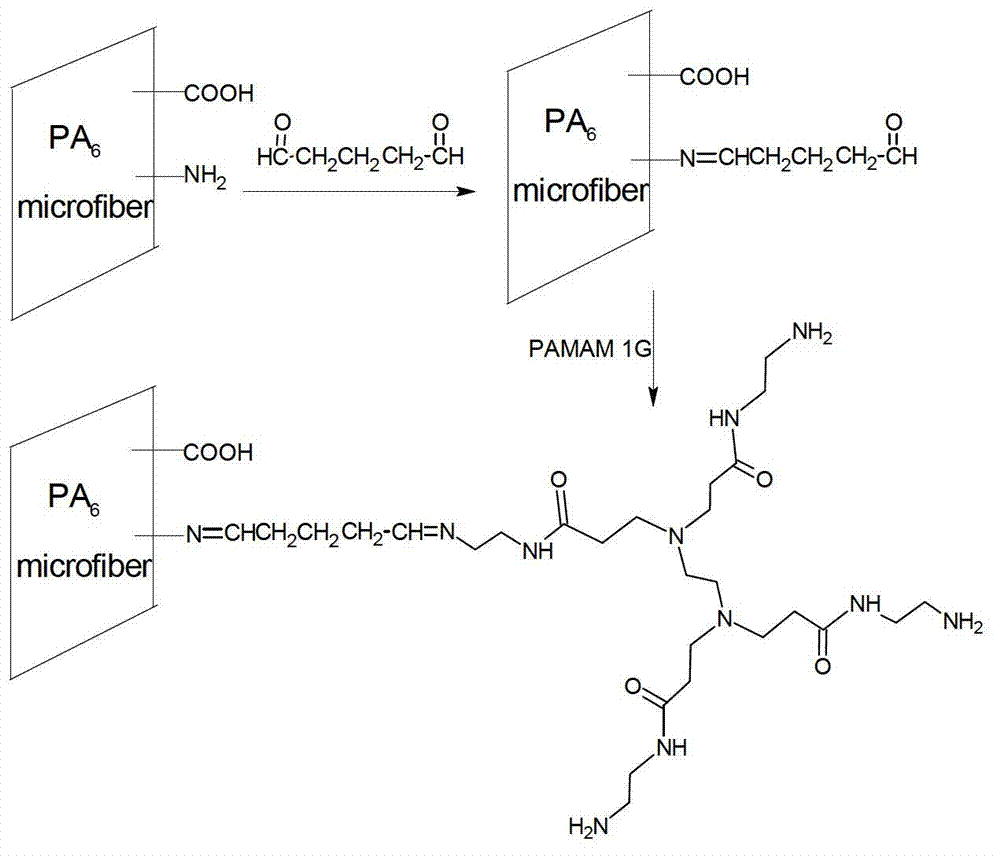

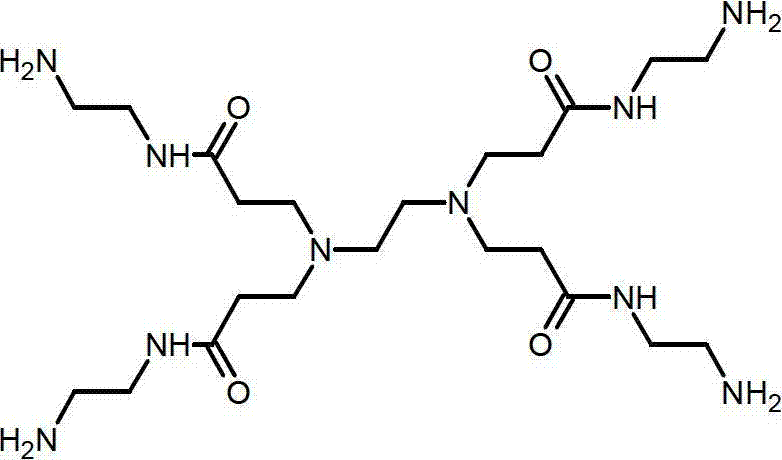

[0034] A kind of technique specific implementation steps of improving the hygienic performance of microfiber synthetic leather is as follows:

[0035] The microfiber synthetic leather base cloth after opening is subjected to acid treatment, water washing, glutaraldehyde modification, salt water washing, cross-linking 1G PAMAM, dealdehyde treatment, warm water washing and then drying in sequence, specifically including the following steps:

[0036] Step 1: In the case of a liquid ratio of 50, add superfine fiber synthetic leather and concentrated sulfuric acid with a mass concentration of 98% to the drum for 2 hours at a temperature of 35°C, where the amount of concentrated sulfuric acid is the weight of the base cloth 10%;

[0037] Step 2: Wash the base fabric treated in Step 1 at room temperature for 3 times (0.5h / time);

[0038] Step 3: adjust the pH of the bath solution to 6, and wash the base cloth with glutaraldehyde with a mass concentration of 25% at 25°C for 3 hours, ...

Embodiment 2

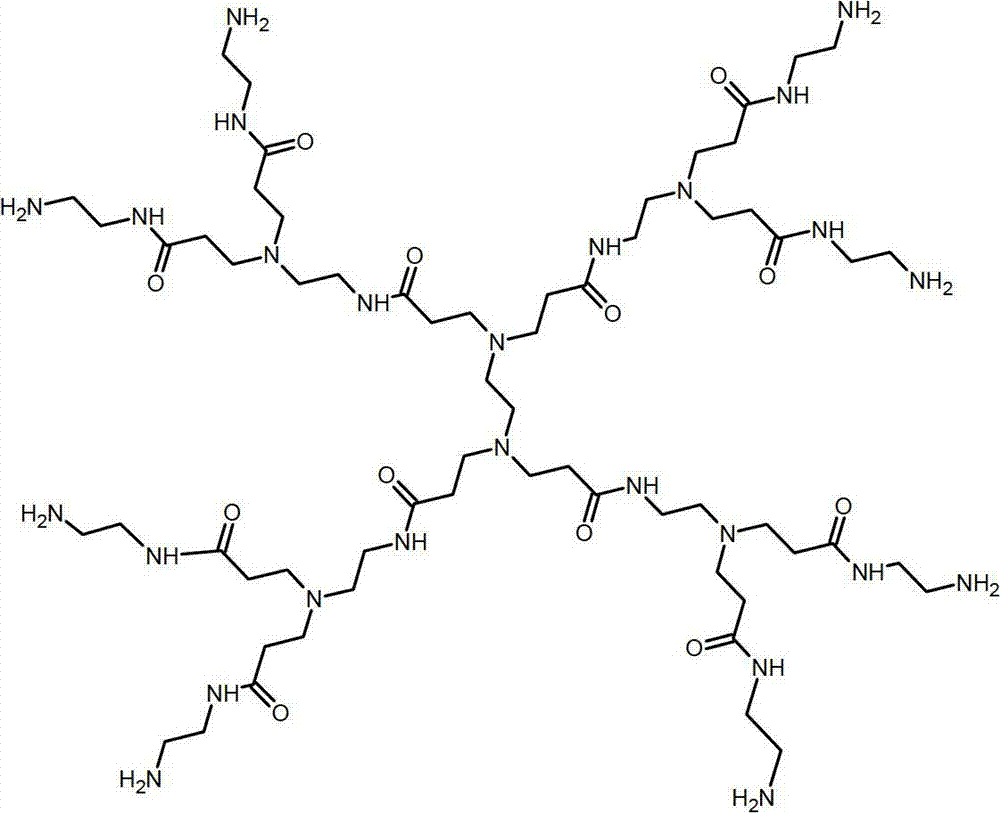

[0045] A kind of technique specific implementation steps of improving the hygienic performance of microfiber synthetic leather is as follows:

[0046] The microfiber synthetic leather base cloth after opening is subjected to acid treatment, water washing, glutaraldehyde modification, salt water washing, cross-linking 2G PAMAM, dealdehyde treatment, warm water washing and drying in sequence;

[0047] Step 1: In the case of a liquid ratio of 50, add superfine fiber synthetic leather and concentrated sulfuric acid with a mass concentration of 98% to the drum for 4 hours at a temperature of 45°C, where the amount of concentrated sulfuric acid is the weight of the base cloth 15%;

[0048] Step 2: Wash the base fabric treated in Step 1 with water 4 times at room temperature (0.5h / time);

[0049] Step 3: adjust the pH of the bath solution to 7, and wash the base cloth with glutaraldehyde with a mass concentration of 25% at 25°C for 5 hours, and the amount of glutaraldehyde is 15% (b...

Embodiment 3

[0055] A kind of technique specific implementation steps of improving the hygienic performance of microfiber synthetic leather is as follows:

[0056] The microfiber synthetic leather base cloth after fiber opening is sequentially acid-treated, washed with water, modified with glutaraldehyde, washed with salt water, cross-linked with 3G PAMAM, washed with warm water, and then dried;

[0057] Step 1: In the case of a liquid ratio of 50, add superfine fiber synthetic leather and concentrated sulfuric acid with a mass concentration of 98% to the drum for 4 hours at a temperature of 45°C, where the amount of concentrated sulfuric acid is the weight of the base cloth 12%;

[0058] Step 2: Wash the base fabric treated in Step 1 at room temperature for 3 times (0.5h / time);

[0059] Step 3: adjust the pH of the bath liquid to 7, and act on the washed base cloth with glutaraldehyde at 25°C with a mass concentration of 25% for 3 hours, and the glutaraldehyde dosage is 12% (based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com