A special four-functional group ultra-flexible linear phenolic curing agent for heavy-duty powder coatings, its synthesis method and application

A technology of phenolic curing agent and powder coating, which is applied in the direction of powder coating, anti-corrosion coating, epoxy resin coating, etc. It can solve the problems that no patent publications have been found, and the molecular functionality cannot be increased, so as to achieve excellent compactness and comprehensive performance. Excellent, functionality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A four-functional ultra-flexible linear phenolic curing agent for heavy-duty powder coatings. The phenolic curing agent is synthesized by two-step chemical reactions:

[0044] The first step is the synthesis of basic epoxy resin A; the second step is the synthesis of four-functional ultra-flexible phenolic curing agent B;

[0045] Wherein, the synthetic raw material composition of described basic epoxy resin A and mole fraction thereof are as follows:

[0046] Epoxy resin E-51 1 part;

[0047] 0.25 parts of dihydrazide compounds;

[0048] The synthetic raw material composition of described phenolic solidifying agent B and its mole fraction are as follows:

[0049] 0.25 parts of basic epoxy resin A;

[0050] 1 part of bisphenol A;

[0051] Ammonium salt catalyst 0.001 part.

[0052] The epoxy resin is E-51 type liquid epoxy resin; or, the molecular formula of the dihydrazide compound is [H2NNH-CO-(CH2)n-CO-HNNH2], wherein n=4-10, n The larger the value, the better ...

Embodiment 2

[0062] A four-functional ultra-flexible linear phenolic curing agent for heavy-duty powder coatings. The phenolic curing agent is synthesized by two-step chemical reactions:

[0063] The first step is the synthesis of basic epoxy resin A; the second step is the synthesis of four-functional ultra-flexible phenolic curing agent B;

[0064] Wherein, the synthetic raw material composition of described basic epoxy resin A and mole fraction thereof are as follows:

[0065] Epoxy resin E-51 2 parts;

[0066] 0.25 parts of dihydrazide compounds;

[0067] The synthetic raw material composition of described phenolic solidifying agent B and its mole fraction are as follows:

[0068] 0.25 parts of basic epoxy resin A;

[0069] 2 parts of bisphenol A;

[0070] Ammonium salt catalyst 0.001 part.

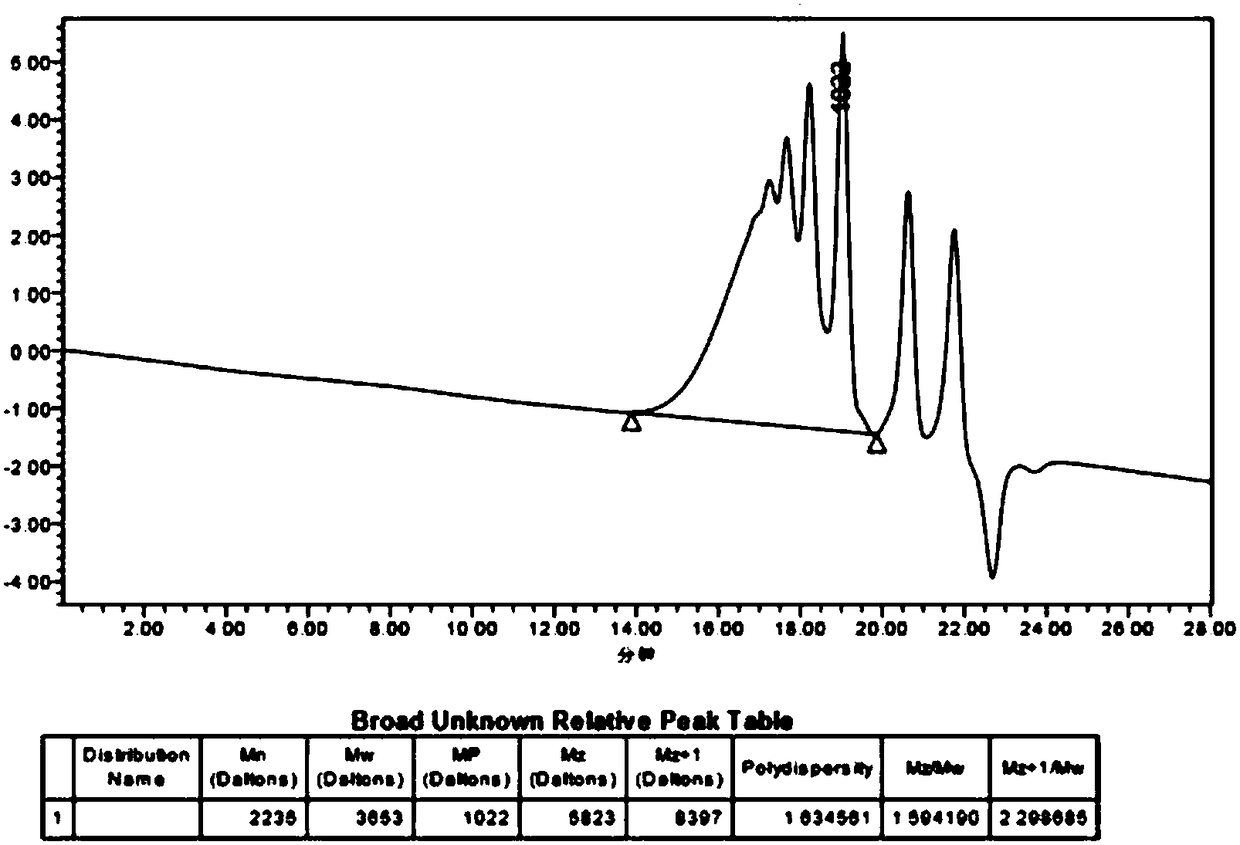

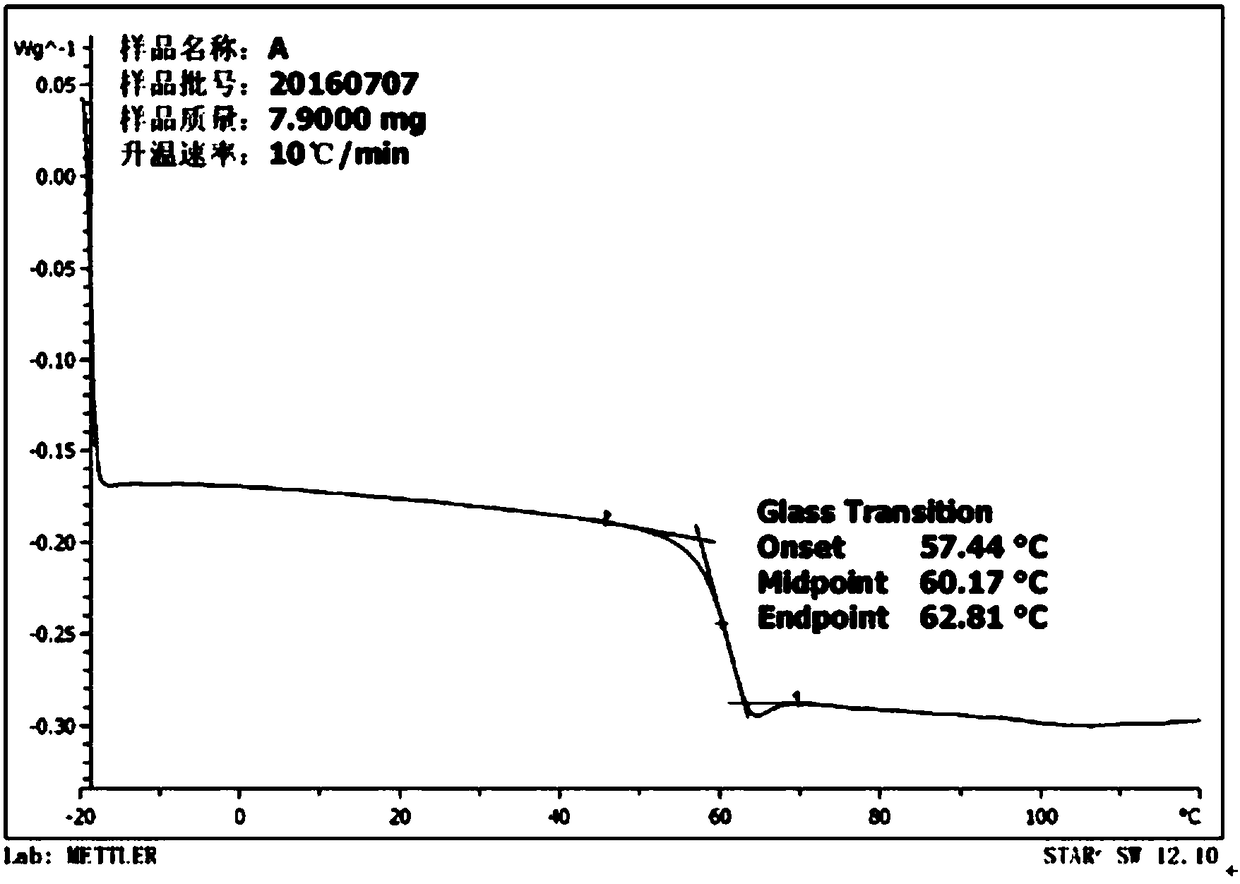

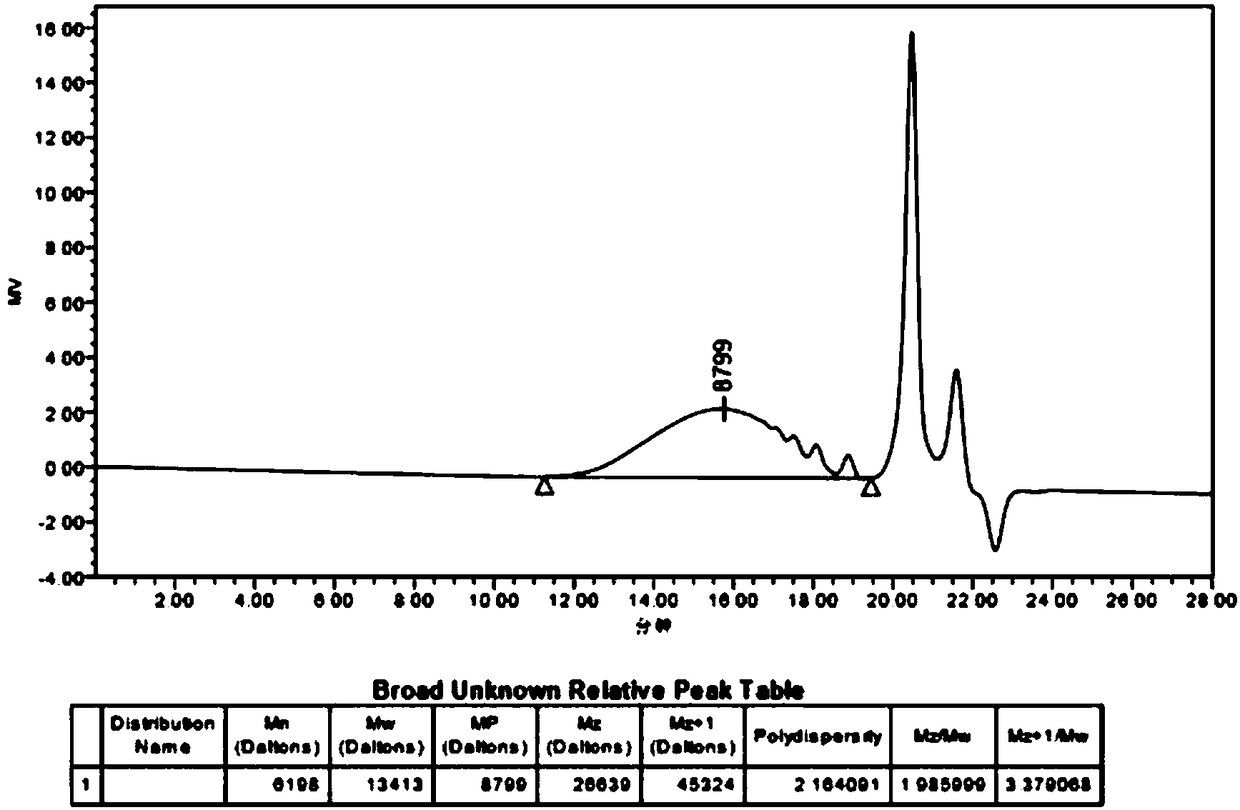

[0071] After testing, the number average molecular weight of the basic epoxy resin A is 2000-3000; the molecular weight distribution is 1.6-1.8; the glass transition temperature is 60±2°C; th...

Embodiment 3

[0084] A four-functional ultra-flexible linear phenolic curing agent for heavy-duty powder coatings. The phenolic curing agent is synthesized by two-step chemical reactions:

[0085] The first step is the synthesis of basic epoxy resin A; the second step is the synthesis of four-functional ultra-flexible phenolic curing agent B;

[0086] Wherein, the synthetic raw material composition of described basic epoxy resin A and mole fraction thereof are as follows:

[0087] Epoxy resin E-51 2.5 parts;

[0088] 0.25 parts of dihydrazide compounds;

[0089] The synthetic raw material composition of described phenolic solidifying agent B and its mole fraction are as follows:

[0090] 0.25 parts of basic epoxy resin A;

[0091] Bisphenol A 2.5 parts;

[0092] Ammonium salt catalyst 0.001 part.

[0093] After testing, the number average molecular weight of the basic epoxy resin A is 2000-3000; the molecular weight distribution is 1.6-1.8; the glass transition temperature is 60±2°C; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com