Edible food packaging film and preparation method and application thereof

A technology of food packaging film and edible properties, which is applied in the field of edible food packaging film, can solve the problems of low polarity and low strength, and achieve the effects of enhancing mechanical properties and heat resistance, improving usability, and enhancing liking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

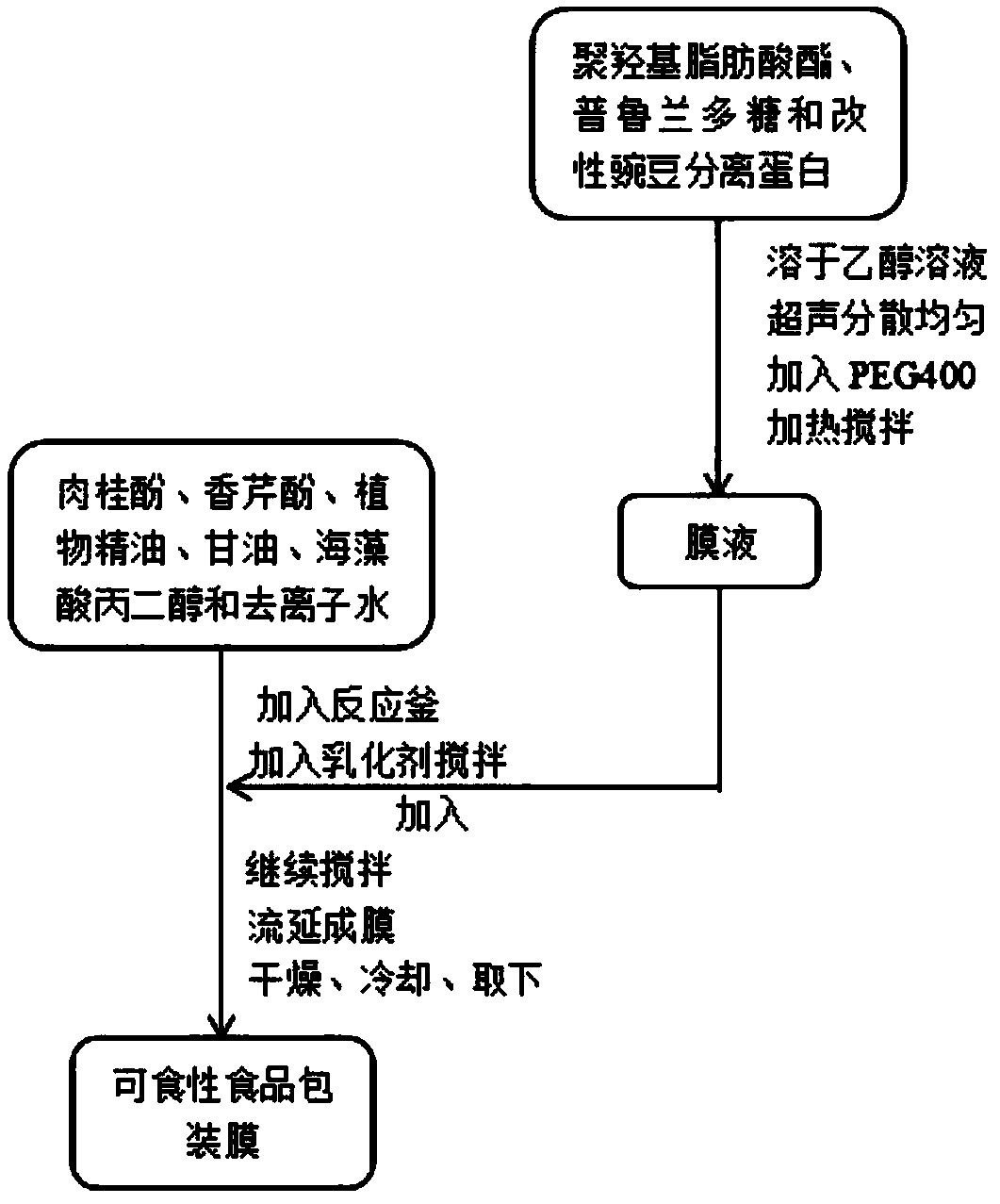

Method used

Image

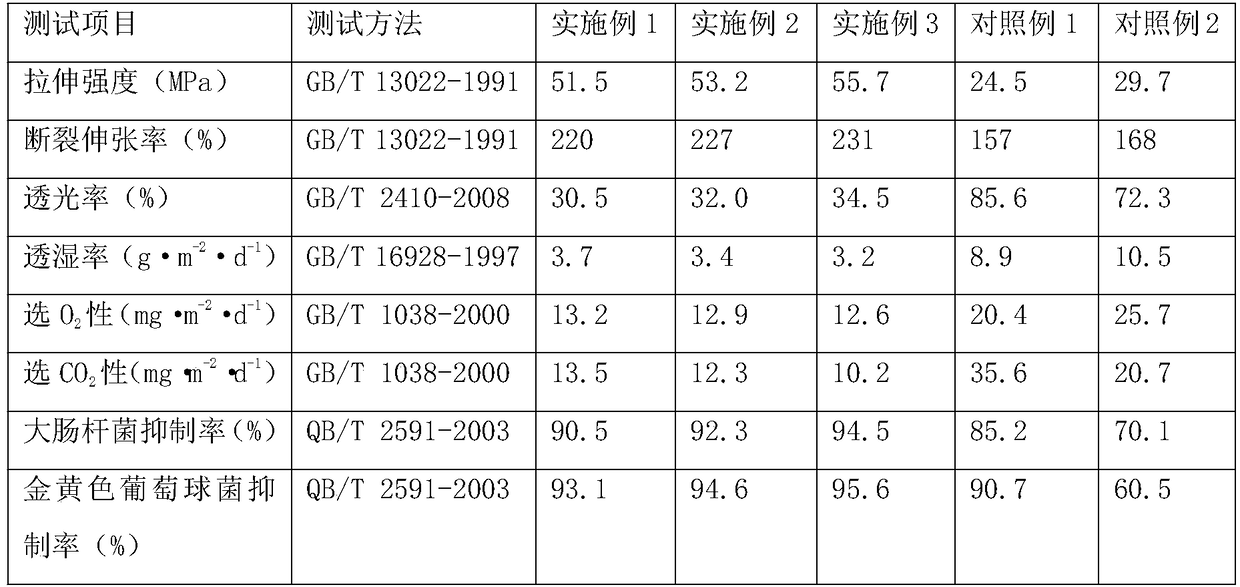

Examples

Embodiment 1

[0024] The preparation of embodiment 1 edible food packaging film

[0025] Ingredients: 50 parts of polyhydroxyalkanoate, 30 parts of pullulan, 30 parts of modified pea protein isolate, 20 parts of cinnamon phenol, 20 parts of carvacrol, 10 parts of peppermint oil, 5 parts of glycerin, lauryl 1 part of calcium benzenesulfonate, 1 part of propylene glycol alginate, 100 parts of deionized water;

[0026] Preparation of modified pea protein isolate:

[0027] Dissolve pea protein isolate in phosphate buffer, stir well, add tri(dodecyl alcohol) ester and tri(hexadecanyl alcohol) ester and dithiothreitol, then add polyethylene glycol monomethyl ether, and keep at room temperature After reacting for 3 hours, add NaOH solution to adjust the pH to 7, put it into a dialysis bag with a molecular weight cut-off of 12000D-15000D for dialysis, freeze-dry the product, wash the obtained powder with ethanol for 3 times, and dry it at room temperature to obtain, with a yield of 70 %.

[0028...

Embodiment 2

[0031] The preparation of embodiment 2 edible food packaging films

[0032] Ingredients: 70 parts of polyhydroxyalkanoate, 50 parts of pullulan, 40 parts of modified pea protein isolate, 30 parts of cinnamon, 30 parts of carvacrol, 10 parts of rose oil, 10 parts of lemon oil, 10 parts of glycerin , 5 parts of sodium alkylbenzene sulfonate, 10 parts of propylene glycol alginate, 140 parts of deionized water;

[0033] Preparation of modified pea protein isolate:

[0034] Dissolve pea protein isolate in phosphate buffer, stir well, add vitamin C and dithiothreitol, then add polyethylene glycol monomethyl ether, react at room temperature for 3 hours, add NaOH solution to adjust the pH to 8, and put it into the intercepted Carry out dialysis in a dialysis bag with a molecular weight of 12000D-15000D, freeze-dry the product, wash the obtained powder three times with ethanol, and dry it at room temperature to obtain the obtained product with a yield of 82%.

[0035] Preparation of ...

Embodiment 3

[0038] The preparation of embodiment 3 edible food packaging films

[0039] Composition of raw materials: 60 parts of polyhydroxyalkanoate, 40 parts of pullulan polysaccharide, 40 parts of modified pea protein isolate, 25 parts of cinnamon phenol, 23 parts of carvacrol, 15 parts of clove oil, 7 parts of glycerin, N-12 3 parts of alkyl dimethylamine, 5 parts of propylene glycol alginate, 120 parts of deionized water;

[0040] Preparation of modified pea protein isolate:

[0041] Dissolve pea protein isolate in phosphate buffer, stir well, add butylated hydroxyanisole and dithiothreitol, then add polyethylene glycol monomethyl ether, react at room temperature for 3 hours, add NaOH solution to adjust the pH to 7.5 , put it into a dialysis bag with a molecular weight cut-off of 12000D-15000D for dialysis, freeze-dry the product, wash the obtained powder three times with ethanol, and dry it at room temperature to obtain the product with a yield of 90%.

[0042] Preparation of Edibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com