Wet dressing for protecting skin and preparation method of wet dressing

A wet dressing and skin protection technology, applied in the field of materials science, can solve the problems of non-waterproof film, slow drying, easy swelling and elution, etc., and achieve the effects of preventing bacterial infection, low cost, and less keratin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

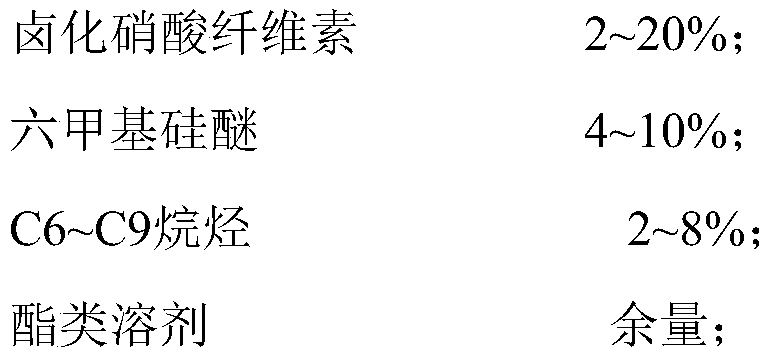

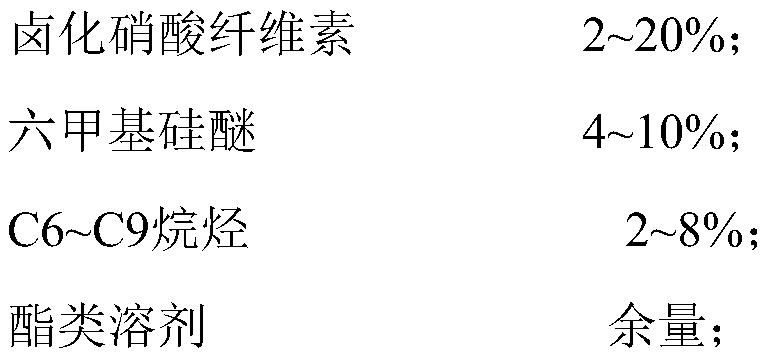

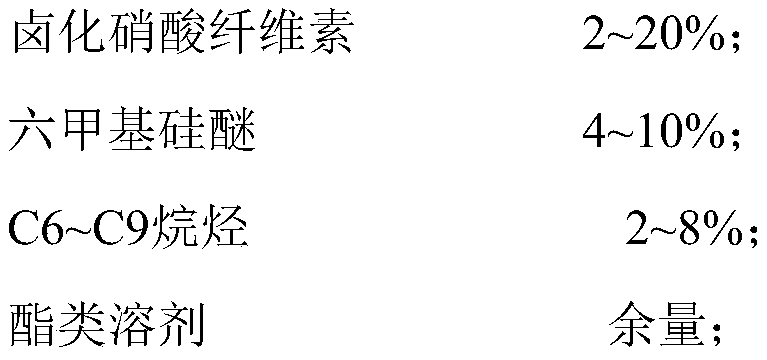

Method used

Image

Examples

Embodiment 1

[0043] 100g of pulverized refined cotton (more than 100 mesh) was soaked in 2000g of 32% sodium hydroxide aqueous solution at 26°C for 8 hours; put into an autoclave, evacuated to 0.02MPa, and added 310g of liquid methyl chloride. Raise the temperature to 58°C and keep it for 3 hours; feed nitrogen and add 0.2g of cobalt chloride as a catalyst, continue to raise the temperature to 78°C, keep it for 2.5 hours, distill and recover the excess etherification reagent, wash it with water, and dry it to obtain a Methylcellulose with an average molecular weight of 159kDa and a polydispersity index of 1.05.

[0044] Get above-mentioned methyl cellulose 60.5g and nitrating agent 377ml (the mass percent concentration of 34ml is 65% nitric acid solution, the mass percent concentration of 261ml is 98% sulfuric acid solution and 82ml deionized water) and mix in 1000ml glass kettle; Control reaction temperature 26°C, react for 20 minutes, when the nitrogen content of methyl cellulose reaches...

Embodiment 2

[0048] 100g of pulverized refined cotton (more than 100 mesh) was soaked in 1600g of 42% sodium hydroxide aqueous solution at 22°C for 7 hours; put into an autoclave, evacuated to 0.01MPa, and added 560g of liquid methyl chloride. Raise the temperature to 52°C and keep it for 4 hours; pass in argon and add 0.4g of manganese chloride as a catalyst, continue to raise the temperature to 83°C, keep it for 1.5 hours, distill and recover the excess etherification reagent, wash it with water, and dry it to get Methylcellulose with a number average molecular weight of 202kDa and a polydispersity index of 1.08.

[0049] Get methyl cellulose 58.5g and nitrating agent 580ml (the mass percentage concentration of 54ml is 65% nitric acid solution, the mass percentage concentration of 415ml is 98% sulfuric acid solution and 131ml deionized water) and mix in 1000ml glass kettle; Control reaction temperature is 30°C, react for 22 minutes, when the nitrogen content of methylcellulose reaches 9....

Embodiment 3

[0053] Put 100g of crushed wood pulp (above 100 mesh) at 20°C in 3600g of 40% sodium hydroxide aqueous solution for 9 hours; put it into an autoclave, feed argon, and add 380g of liquid propylene oxide . Raise the temperature to 51°C and keep it for 2 hours; add 0.5g of cobalt chloride as a catalyst, continue to heat up to 78°C, keep it for 2.5 hours, distill and recover the excess etherification reagent, wash with water, and dry to obtain a number average molecular weight of 208kDa, hydroxypropyl cellulose with a polydispersity index of 1.11.

[0054] Get above-mentioned hydroxypropyl cellulose 56.6g and nitrating agent 653.4ml (the mass percent concentration of 95ml is 65% nitric acid solution, the mass percent concentration of 430ml is 98% sulfuric acid solution and 128ml deionized water) and mix in 1000ml glass kettle; The reaction temperature is 30°C, react for 18 minutes, when the nitrogen content of hydroxypropyl cellulose reaches 10.0%, separate the mixed acid, stop t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com