Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Excellent high temperature mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

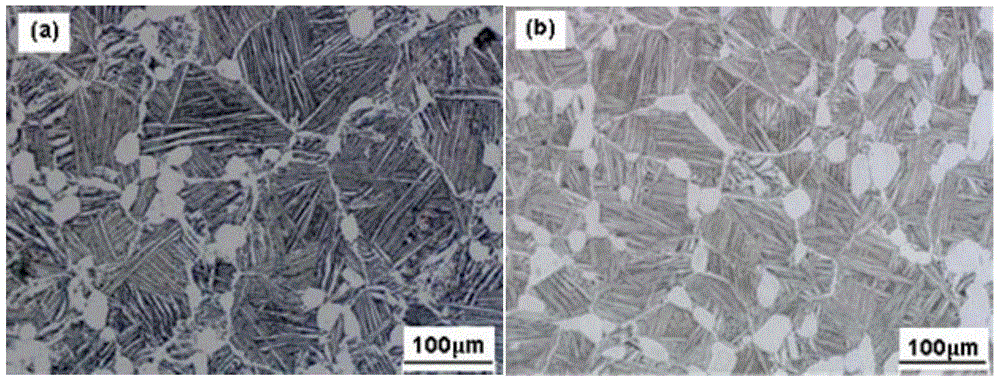

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

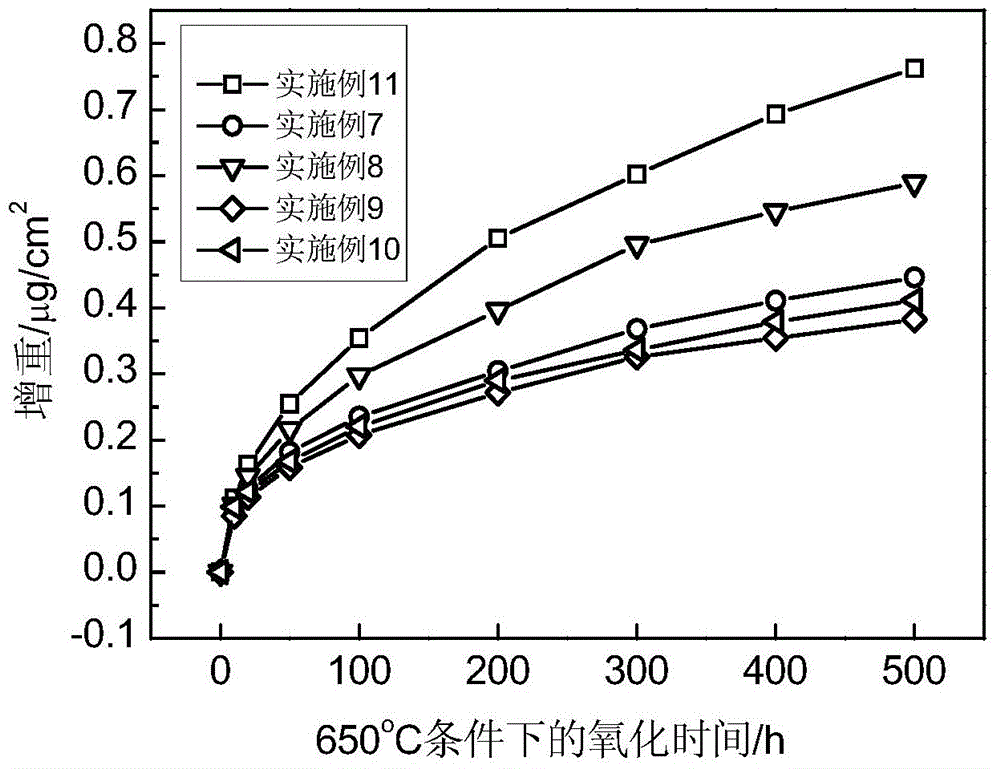

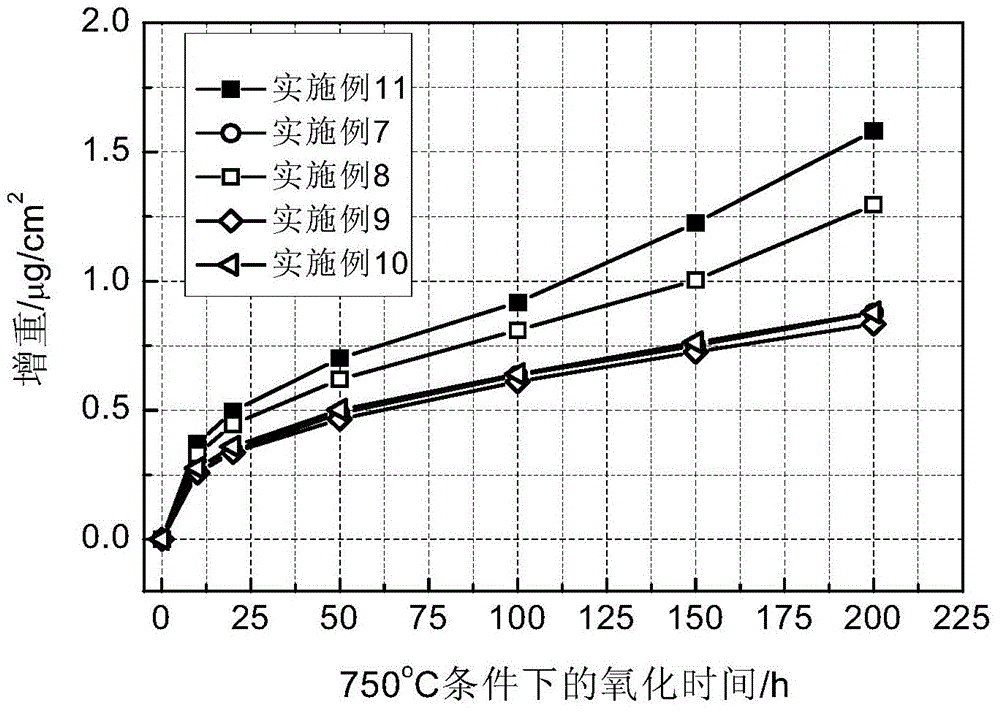

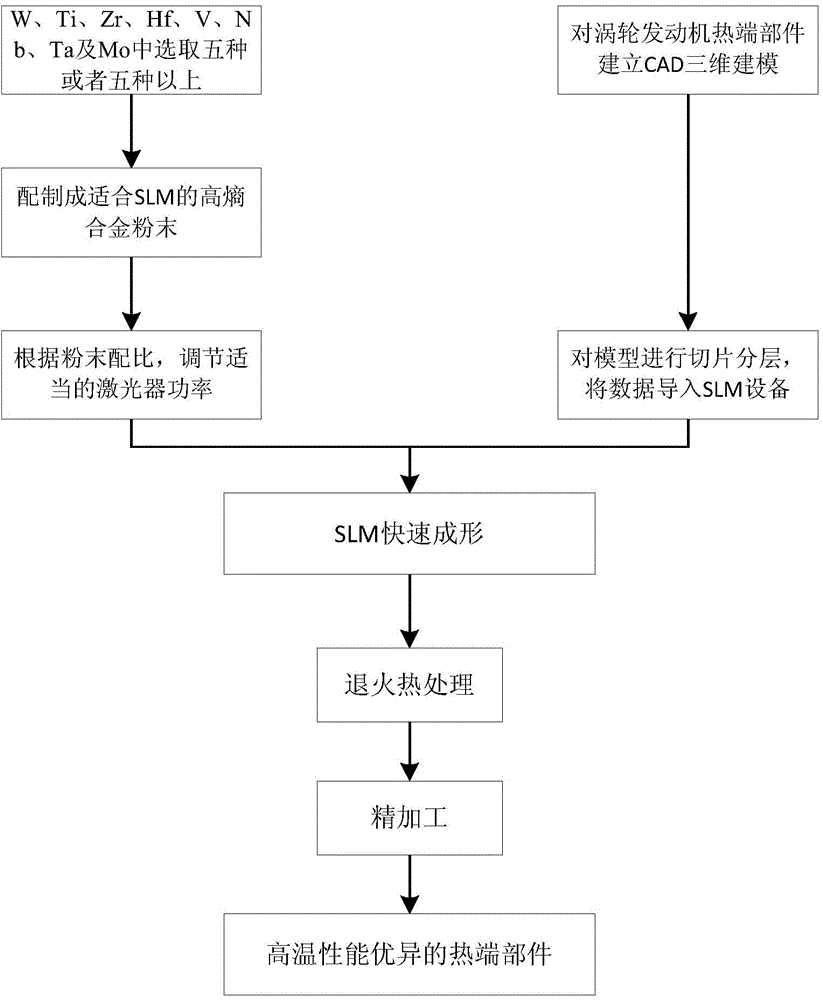

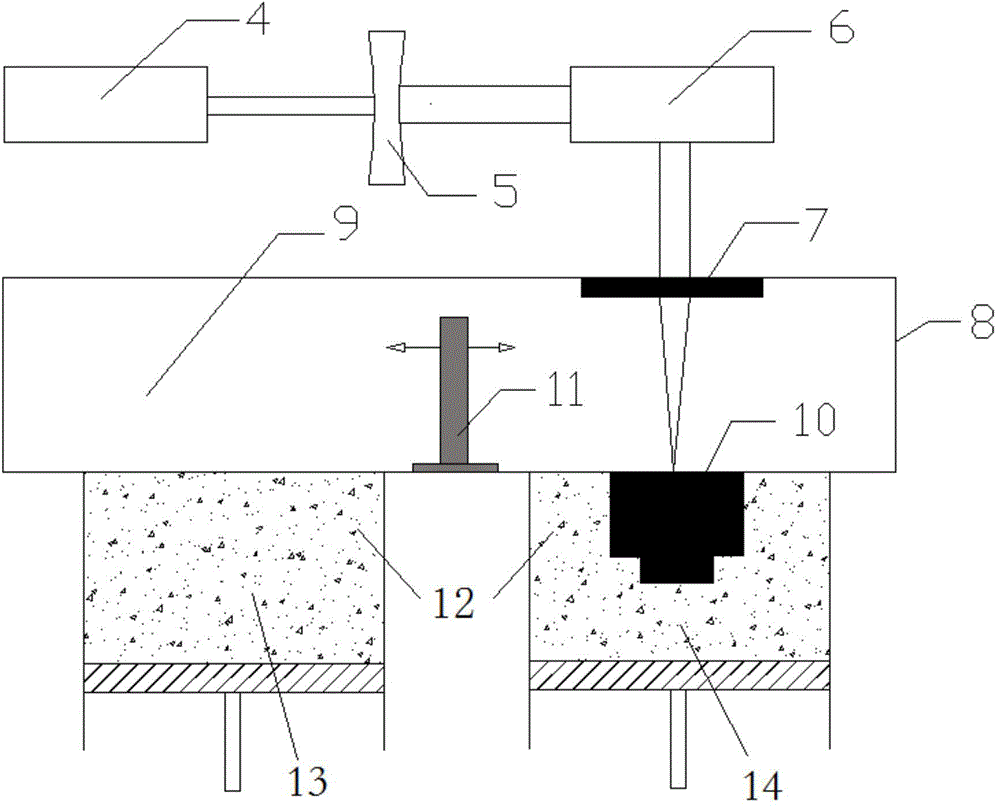

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

ActiveCN104308153AMeet the requirements of gas temperature to form a large thrustSatisfy the requirement of increasing the gas temperature to form a large thrustTurbinesIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a high-entropy alloy hot-end part manufacturing method of a turbine engine on the basis of selective laser melting and belongs to the technical field of manufacture of hot-end parts of the turbine engine. The high-entropy alloy hot-end part manufacturing method includes firstly selecting five or more of eight kinds of high-melting metal powder of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder uniformly according to a certain mole ratio to obtain high-entropy alloy powder; setting up a three-dimensional solid model of a hot-end part of the turbine engine, slicing and layering by software to obtain profile data of various sections, and importing the data into a quick forming device; quickly forming a hot-end part blank of the turbine engine by the SLM technology; thermally treating and finely processing the blank to obtain the high-temperature high-entropy alloy hot-end part of the turbine engine. The formed hot-end part of the turbine engine has high compactness and excellent high temperature performance, has high forming accuracy and surface accuracy and can be quickly and accurately manufactured.

Owner:XI AN JIAOTONG UNIV

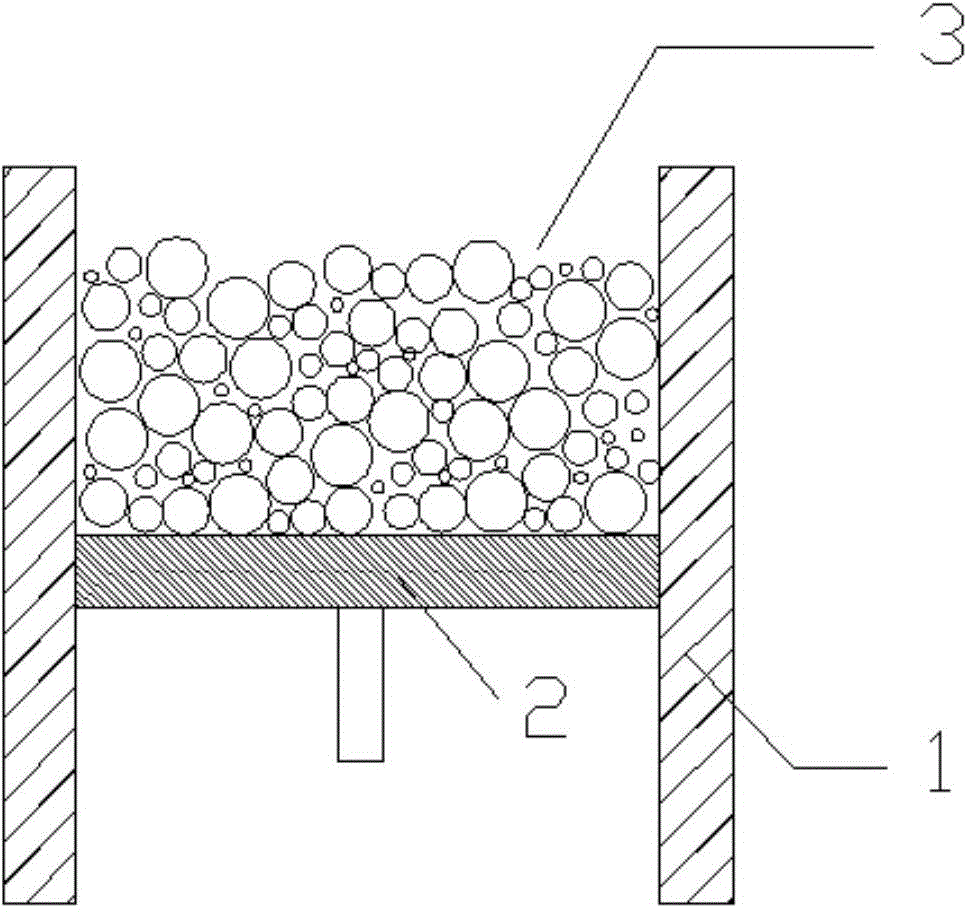

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to a castable for preparing a high-temperature ceramic wear-resistant lining, which contains 10-25% of fused mullite with a particle size of 3-5mm, and 20-45% of fused mullite with a particle size of 1-3mm. 3-7% of andalusite with a particle size of 0.1mm-1mm, 8-25% of platy corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum, and pure calcium aluminate with a particle size of <0.074mm 2-10% of cement, 2-6% of silicon micropowder, and 2-10% of alumina micropowder. The castable can be applied to the intersection of blast furnace hot air pipe and air supply branch pipe, etc. where thermal shock stability is high. The lining made of it has good thermal stability, high temperature air erosion resistance, good thermal shock resistance, It has the advantages of long life cycle, simple manufacturing method, short construction period, environmental protection and pollution-free, low cost, and easy industrial production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

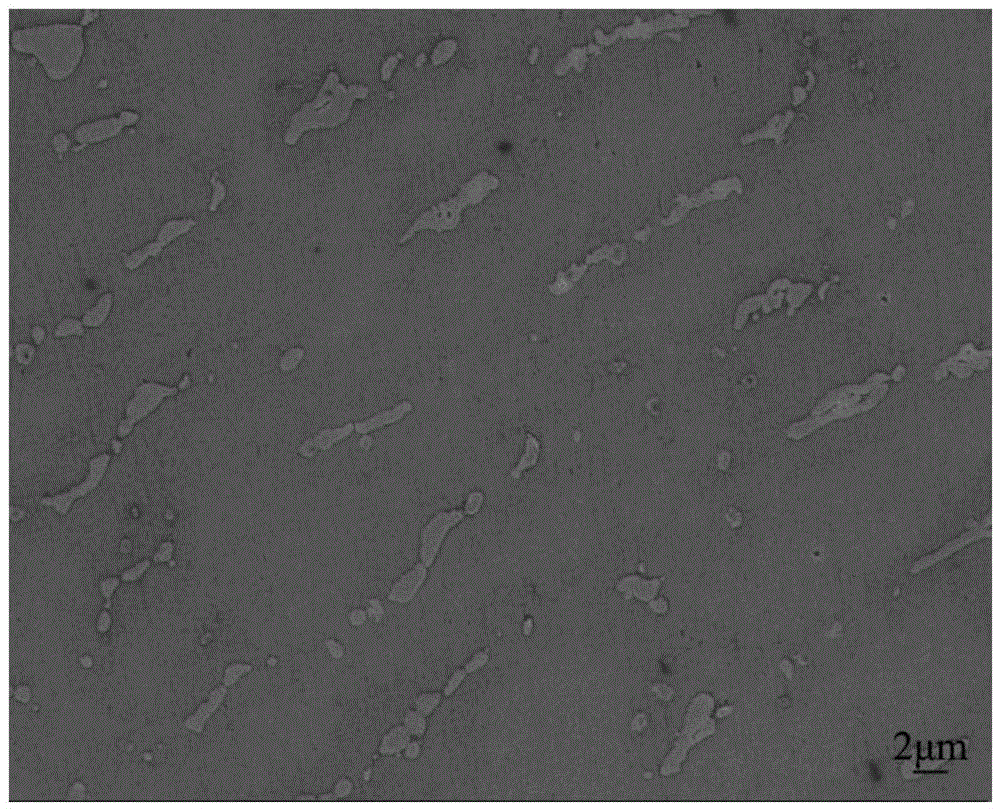

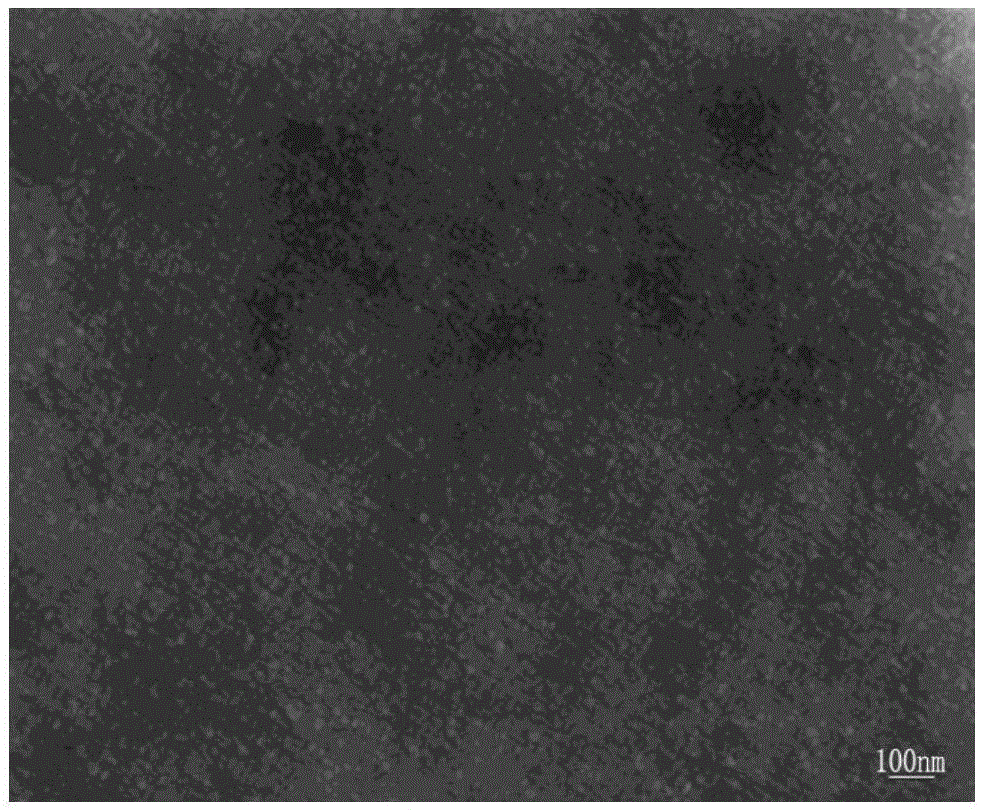

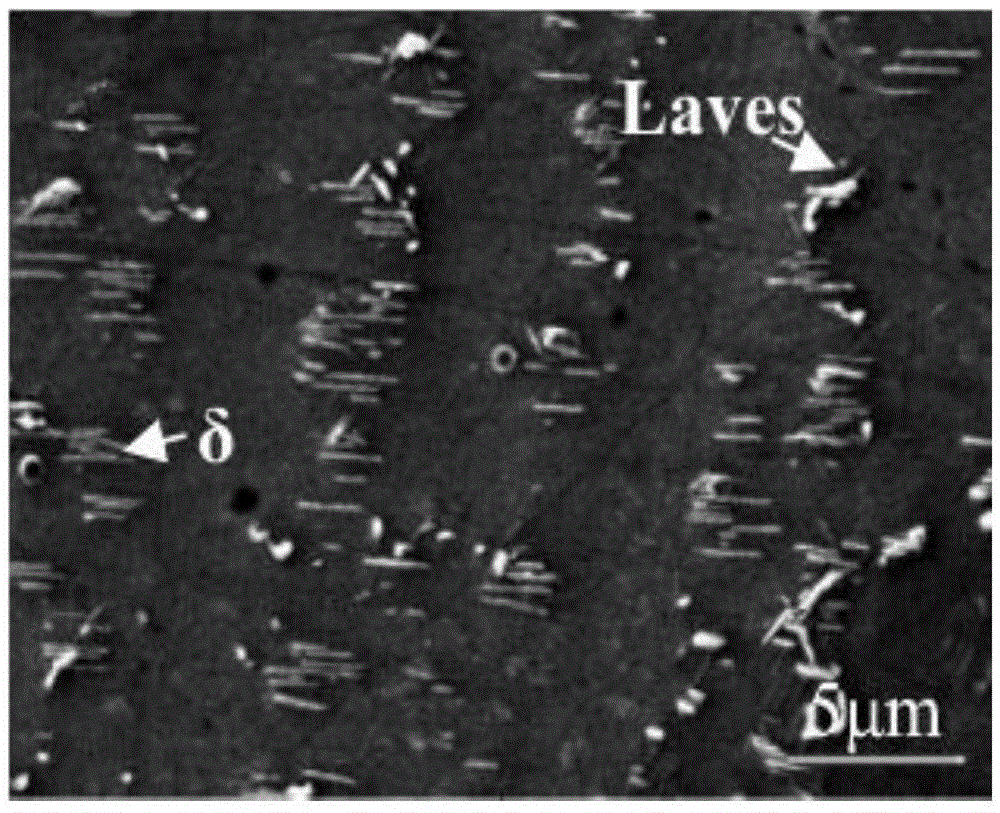

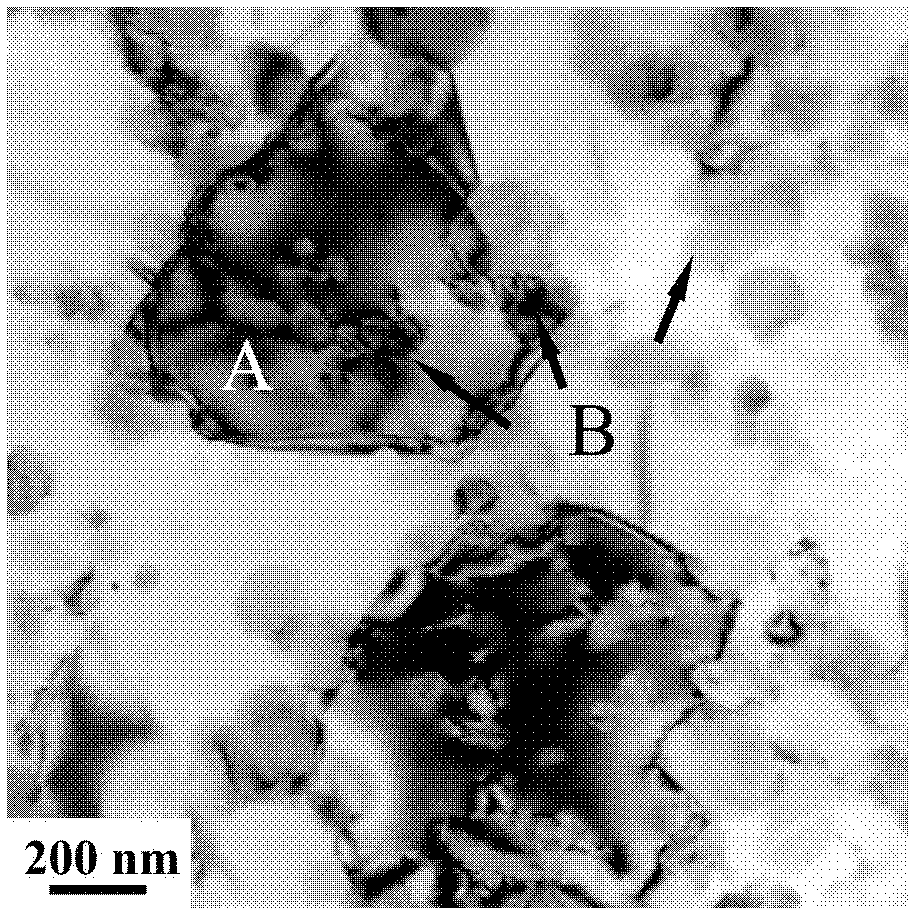

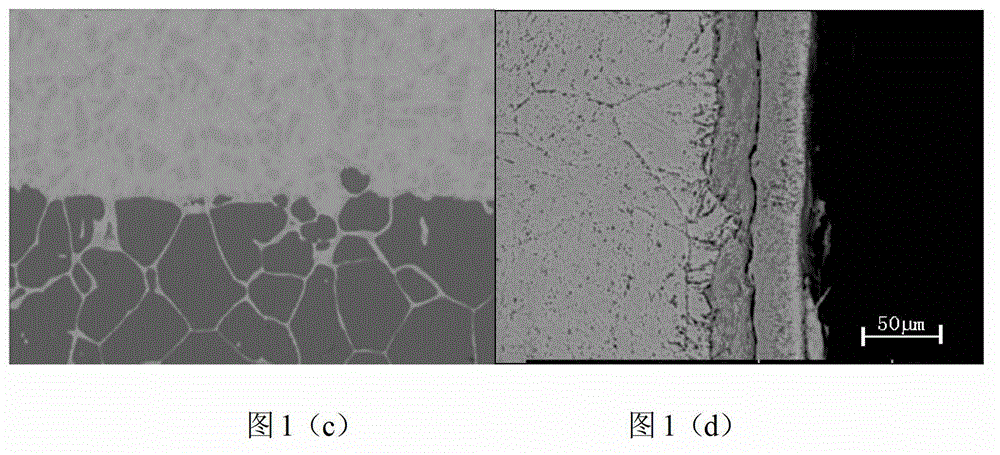

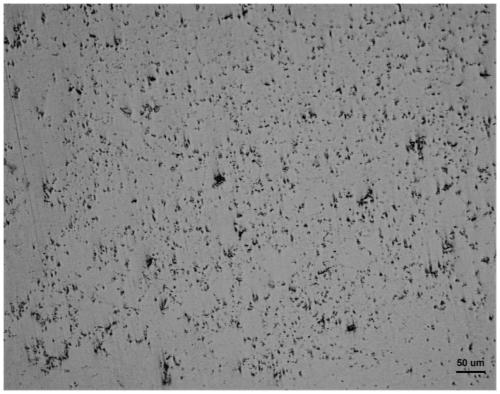

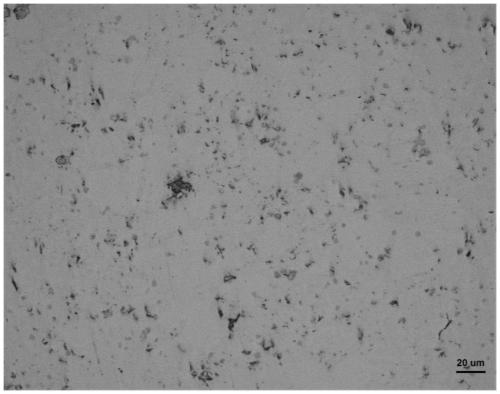

Preparation method of material increase manufactured nickel-based high-temperature alloy reserved with Laves phase

ActiveCN105543747AShorten the manufacturing cycleFast preparationMetallic material coating processesFree coolingSuperalloy

The invention provides a preparation method of a material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase. GH4169 high-temperature alloy with the Laves phase distributed in a dispersed particle shape is prepared through the preparation method, and compared with industrial forged and cast isometric crystal high-temperature alloy, the high-temperature mechanical properties, especially the high-temperature creep property, the high-temperature endurance life and the like are greatly improved. The preparation method comprises the following steps that firstly, in a processing rood, GH4160 high-temperature alloy powder or wire materials are processed through a high-energy beam heat source to be continuously melted and deposited on a base plate, so that the GH4169 high-temperature alloy reserved with the Laves phase is prepared; secondly, the prepared GH4169 high-temperature alloy reserved with the Laves phase is naturally cooled in the processing room and taken out after the temperature of the GH4169 high-temperature alloy is below 100 DEG C; and thirdly, two stages of heat treatment is conducted on the GH4169 high-temperature alloy which is taken out of the processing and reserved with the Laves phase in sequence, the first stage is completed by conducting heat preservation for 8-24 hours under the condition that the GH4169 high-temperature alloy is heated to the temperature of 700-740 DEG C, then the second stage is completed by cooling the GH4169 high-temperature alloy to the temperature below 600-640 DEG C along with a heat preservation furnace and then conducting heat preservation for eight hours, and finally air cooling is conducted till the indoor temperature is reached, so that the material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

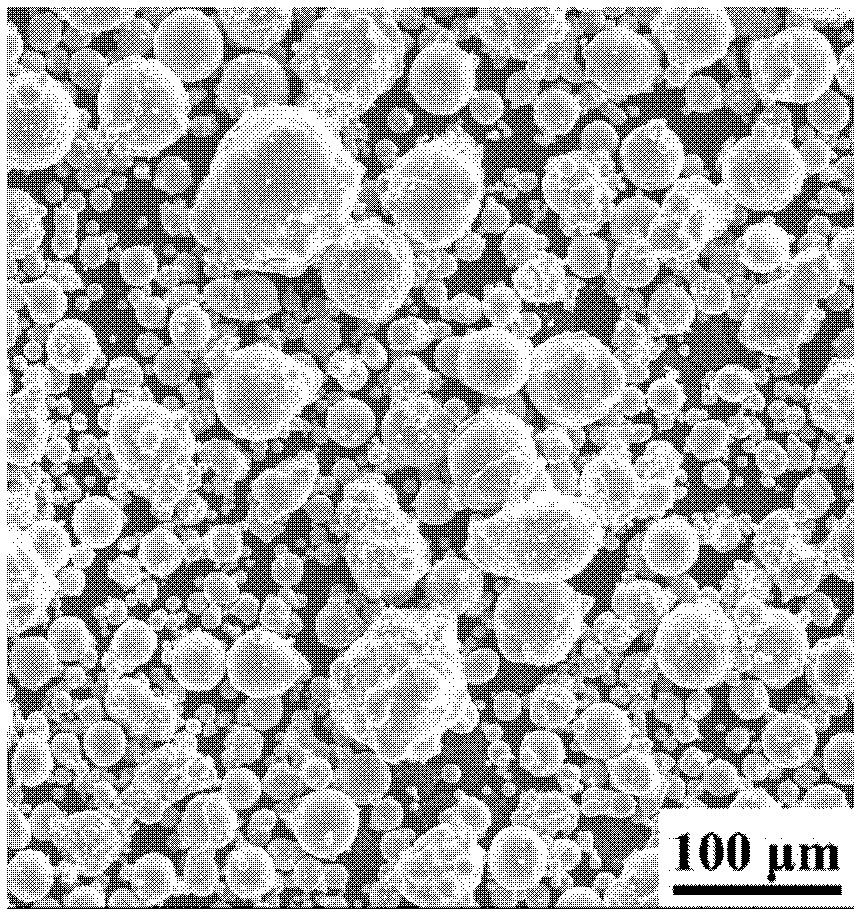

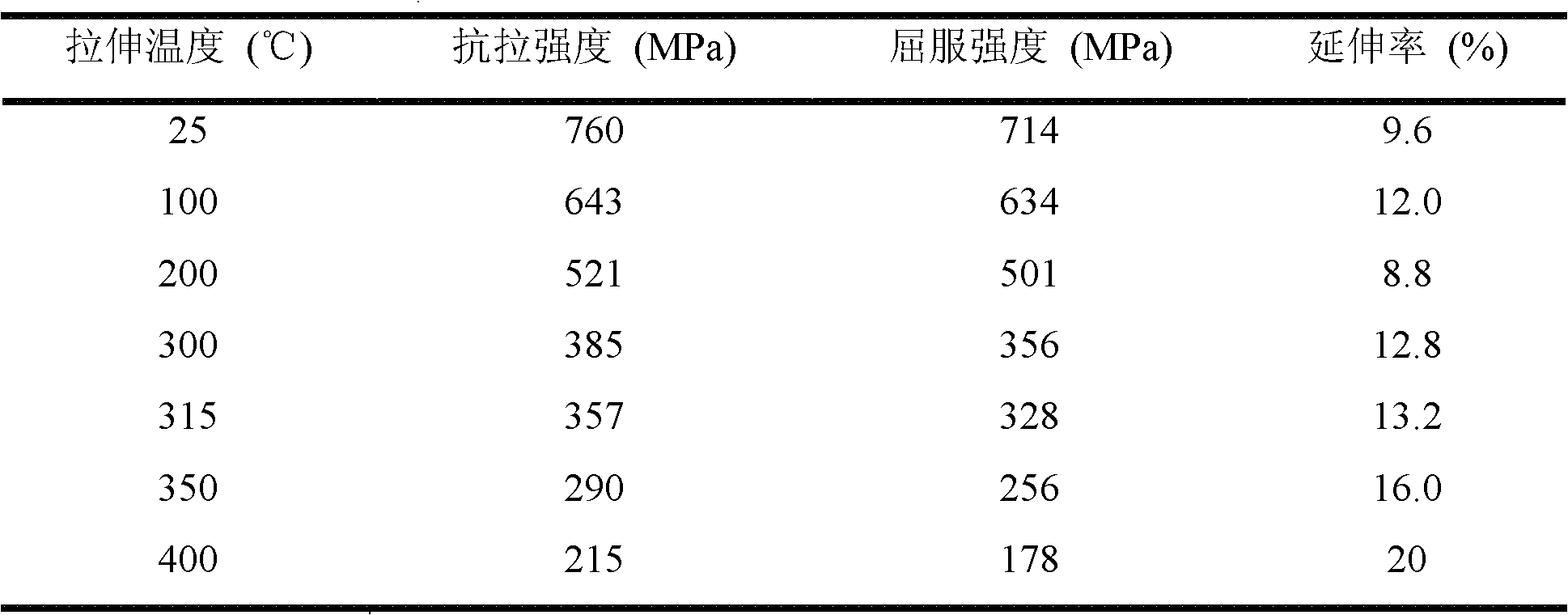

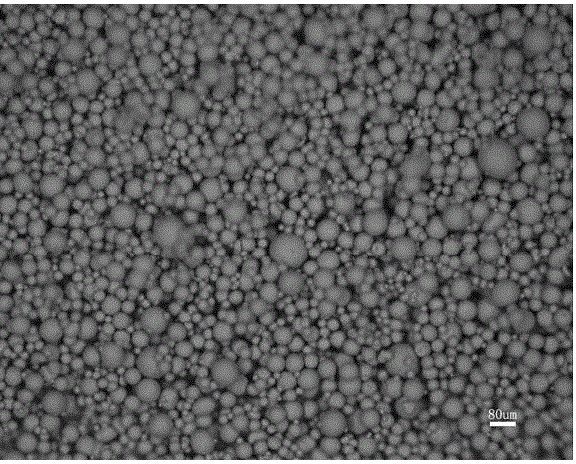

Preparation method of nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet

InactiveCN102660716AExcellent high temperature mechanical propertiesImprove corrosion resistanceNanoparticleRoom temperature

The invention relates to a preparation method of an aluminum alloy sheet, particularly a preparation method of a nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet. The invention aims to solve the problems of complex technique, high cost and multiple defects in the existing method for preparing the compacted large-size aluminum alloy sheet, and the problem of poor mechanical properties of the prepared Al-Fe-Cr-Ti-Re alloy sheet at room temperature and high temperature. The method comprises the following steps: proportioning materials, and preparing spherical alloy powder from the refined and degassed melt by a gas atomization method; and sequentially carrying out cool isostatic pressing, canning vacuum degassing, hot isostatic pressing, hot extrusion and rolling on the alloy powder to obtain the nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet. The invention is mainly used for preparing the Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet.

Owner:HARBIN INST OF TECH

Prepn process of in-situ grain reinforced refractory aluminium-base composite material

The in-situ grain reinforced refractory aluminum-base composite material consists of Si 11-13 wt%, Mg 0.5-1.5 wt%, Cu 0.8-1.3 wt%, Ni 0.5-1.5 wt%, and TiB2 1-20 wt% except Al. The preparation process includes the following steps: 1. adding ZL102 alloy and Al-Si intermediate alloy or industrial pure aluminum into crucible, melting, heating and covering with covering agent; 2. mixing KFB4 and KTiF6, stoving and adding into the melt via stirring; 3. taking out the side product after reaction, adding industrial pure Mg, Al-Ni intermediate alloy and Al-Cu intermediate alloy, scumming, pumping vacuum and letting stand; and 4. low pressure casting formation. The composite material of the present invention has reinforcing TiB2 grains with clean interface and even distribution, excellent structure and performance, excellent high temperature strength, high plasticity and high modulus, and the present invention is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

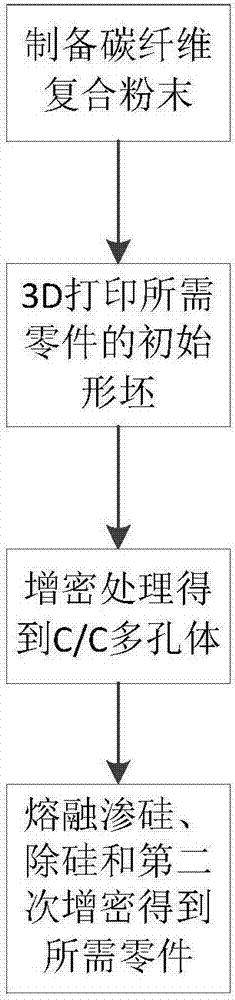

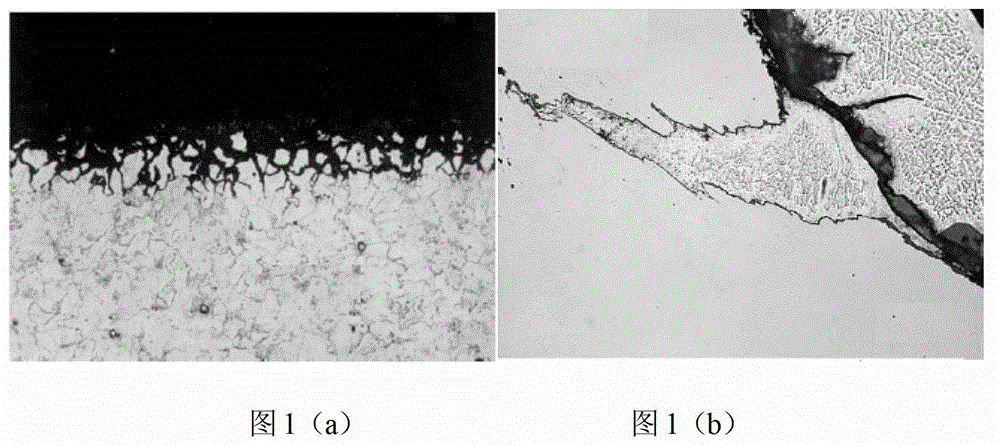

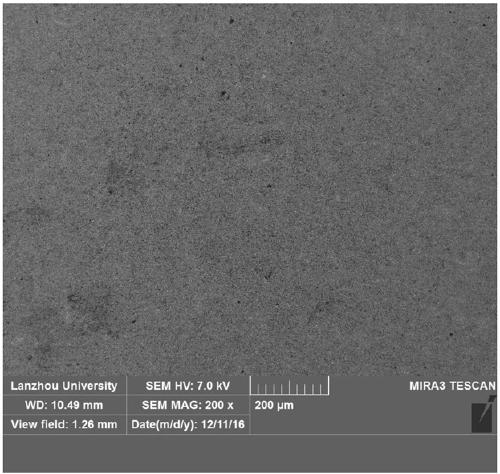

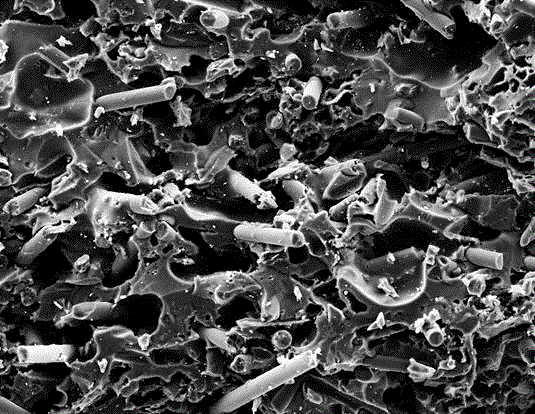

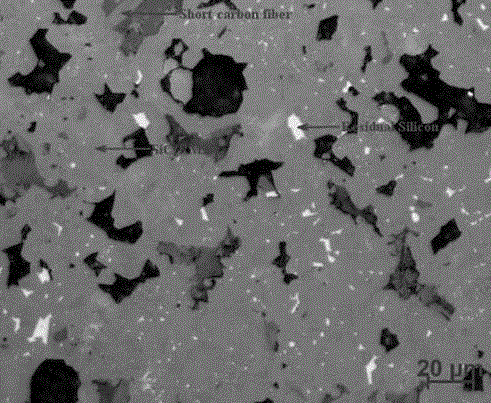

Method for preparing C/C-SiC composite part and product prepared through method

ActiveCN106927846AEvenly distributedAvoid damageAdditive manufacturing apparatusFiberSolvent evaporation

The invention belongs to the field of composites, and discloses a method for preparing a C / C-SiC composite part and a product prepared through the method. The method comprises the following steps that firstly, carbon fiber / phenolic resin composite powder is prepared by using a solvent evaporation method; secondly, according to a three-dimensional model of the part, the carbon fiber composite powder is molded into an initial molded blank by means of the 3D printing technology; thirdly, the initial molded blank is subjected primary densification and a C / C porous body is obtained; fourthly, the C / C porous body is subjected to a molten silicon infiltration reaction, high-temperature desilication and secondary densificaiton, and the final C / C-SiC part is obtained. By means of the method, the C / C-SiC composite part with a complex structure can be shaped in a near-net mode, the method is short in production period and low in cost, and the C / C-SiC composite part obtained through the method is low in residual silicon content and has excellent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation of FeAl intermetallic compound porous material

The invention relates to a preparation method for FeAl intermetallic compound porous material, which belongs to the field of inorganic porous material. The technical problem solved by the invention is to provide the preparation method for the FeAl intermetallic compound porous material with a pore structure having higher controllability. The method comprises the following steps: firstly preparing a porous supporting body and composite slurry; then coating the surface of the porous supporting body with the composite slurry; and sintering and cooling down the porous supporting body in the vacuum atmosphere to obtain the FeAl intermetallic compound porous material. The method capable of regulating the porous structure of the porous material is characterized by a short flow, low cost and low energy consumption. The porous material has excellent resistance to high temperature sulfurization, resistance to high temperature oxidation and thermal shock, good mechanical performance at a high temperature, good processability and solderability, and the like. Therefore, the FeAl intermetallic compound porous material has bright application prospect.

Owner:CHENGDU INTERMENT TECH

Method of preparing water-soluble mold core

InactiveCN101229574ANo pollution in the processGood water solubilityFoundry moulding apparatusSolubilityResin matrix

The invention pertains to a casting moulding technical field, which relates to improvement of a technical mold core for casting and molding resin matrix composites. The steps in the invention are the following: preparing aqueous solution of a bonder-adding aggregate-adding plaster powder-defoaming-casting moulding- drying- post-processing. Solidification has advantages of room temperature curing and good temperature endurance, good water solubility at room temperature and no environmental pollution.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

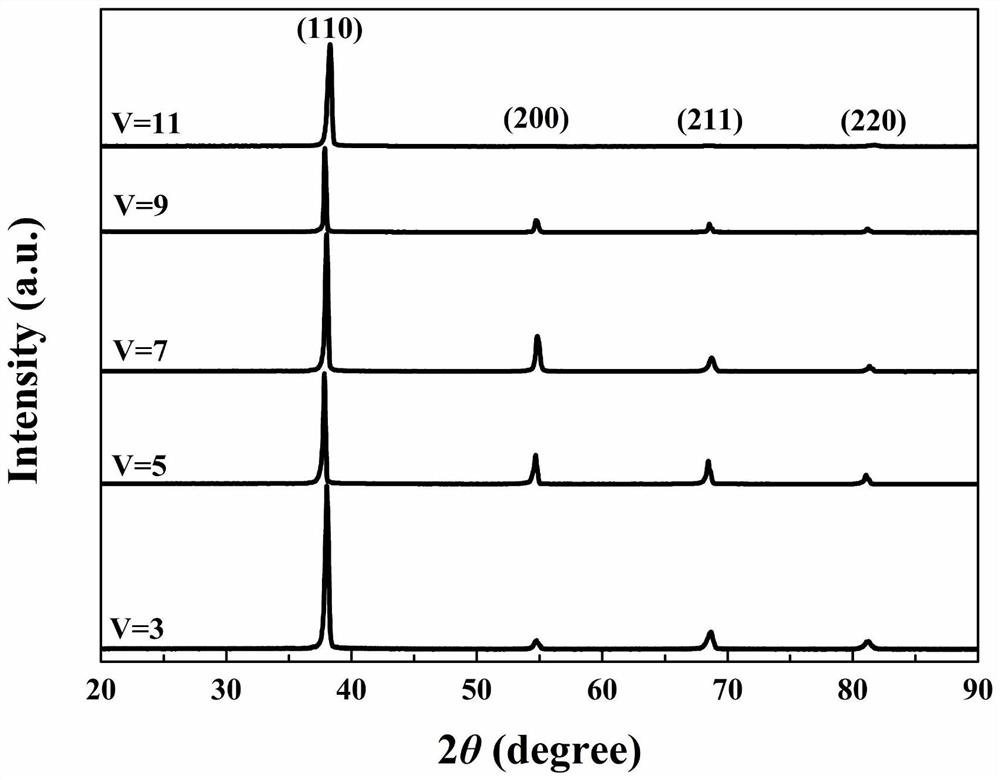

Refractory high-entropy alloy material with high plasticity and low neutron absorption section and preparation method thereof

InactiveCN112708817AHigh melting pointExcellent high temperature mechanical propertiesOptical rangefindersNuclear energy generationHigh entropy alloysUltimate tensile strength

The invention relates to a refractory high-entropy alloy material with high plasticity and low neutron absorption cross section and a preparation method thereof, and belongs to the technical field of high-entropy alloys. The high-entropy alloy material is AlVTiNbZr high-entropy alloy, wherein the atomic percent of an aluminum element is 5%-10%, the atomic percent of a V element is 3%-15%, the atomic percent of a Ti element is 20%-40%, the atomic percent of an Nb element is 25%-35%, and the atomic percent of a Zr element is 20%-35%. The AlVTiNbZr high-entropy alloy is of a single-phase BCC structure. The AlVTiNbZr high-entropy alloy is obtained in a vacuum arc melting mode, has a high theoretical melting point, low alloy density, high room-temperature yield strength and deformation plasticity, can resist deformation failure in the service process, and brings sufficient safety margin in the service process.

Owner:CHONGQING UNIV

Radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi

ActiveCN102943209AImprove radiation resistanceExcellent high temperature mechanical propertiesTemperature resistanceCorrosion

The invention belongs to the technical field of heat-resistant alloy, and specifically relates to radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi. The steel comprises the components in weight percentage: 0.05-0.2% of C, 9.0-12.0% of Cr, 1.0-3.0% of Si, 0.3-3.0% of Mn, 1.0-3.0% of W, 0.1-0.4% of V, 0.03-0.3% of Ta, 0.03-0.15% of N, less than or equal to 0.05% of Al, less than or equal to 0.05% of Ti and the balance of Fe. According to the invention, the content of Si is increased; part of C element is replaced by N; the precipitation of Cr23C6 is reduced so as to ensure the Cr content in matrix, so that a rich Si compact oxide film is formed on the surface when the material serves in the Pb and Pb-Bi under high temperature, and a structure is protected to be free of lead corrosion; activating elements Mo, Ni and Nb are replaced by W, Mn and Ta, so that the low activation is ensured, and the irradiation resistance performance is improved; the types and appearance of the precipitated phase can be controlled according to a reasonable proportion between the C+N content and V+Ta content, so as to ensure the high-temperature performance in the serving process; and the novel martensite heat-resistant steel which serves under a strong radiation condition and has high-temperature resistance, lead corrosion resistance and irradiation resistance can be obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Water-soluble core mold material for forming filament-wound case and preparation method of water-soluble core mold material

InactiveCN102827445AExcellent high temperature mechanical propertiesMeet the requirements of curing molding processFiberTemperature resistance

The invention relates to a water-soluble core mold material for forming a filament-wound case and a preparation method of the water-soluble core mold material. The water-soluble core mold material for forming the filament-wound case comprises composite binder aqueous solution and core mold packing, and the composite binder aqueous solution comprises polyvinyl pyrrolidone binder aqueous solution and polyvinyl alcohol binder aqueous solution. The polyvinyl pyrrolidone binder aqueous solution accounting for 20-80Wt% of the total mass of the composite binder aqueous solution is mixed with the polyvinyl alcohol binder aqueous solution to prepare the composite binder aqueous solution. The addition quantity of the water-soluble high-polymer binder aqueous solution is 0.05-0.5 time of the weight of the core mold packing. The preparation method includes steps of preparing the polyvinyl pyrrolidone binder aqueous solution; preparing the polyvinyl alcohol binder aqueous solution; preparing the composite binder aqueous solution; preparing the packing; mixing the materials; filling and forming; drying and solidifying; and demoulding and machining. The density and the compressive strength of a core mold prepared by the method can be adjusted according to service conditions, and the core mold is good in temperature resistance, room-temperature water-soluble collapsibility and fracture toughness, and is free of environmental pollution.

Owner:中国航天科工集团第六研究院41所

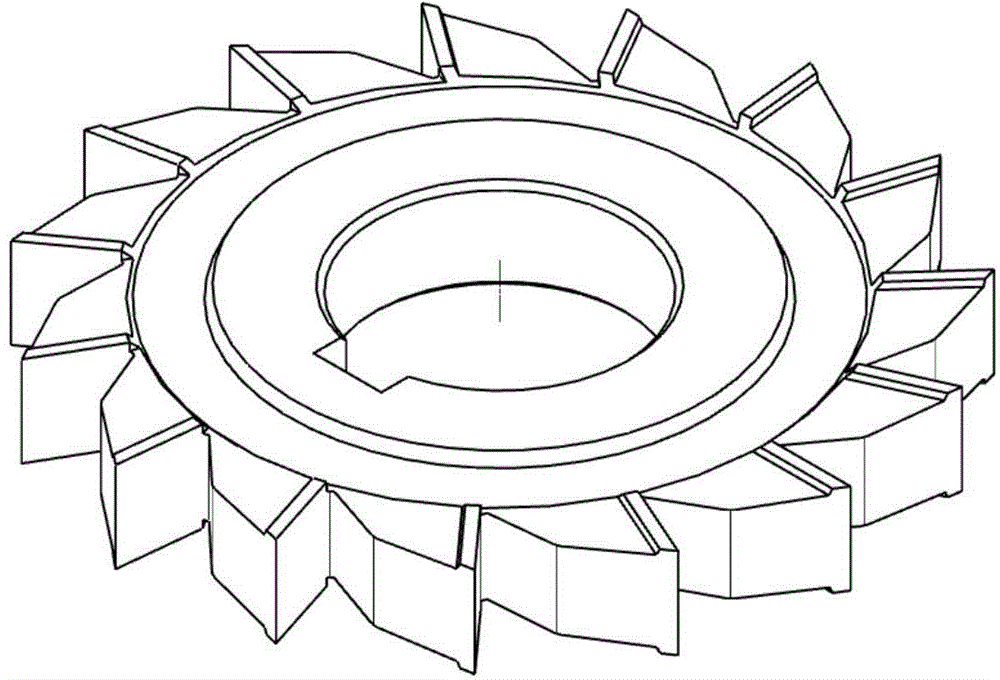

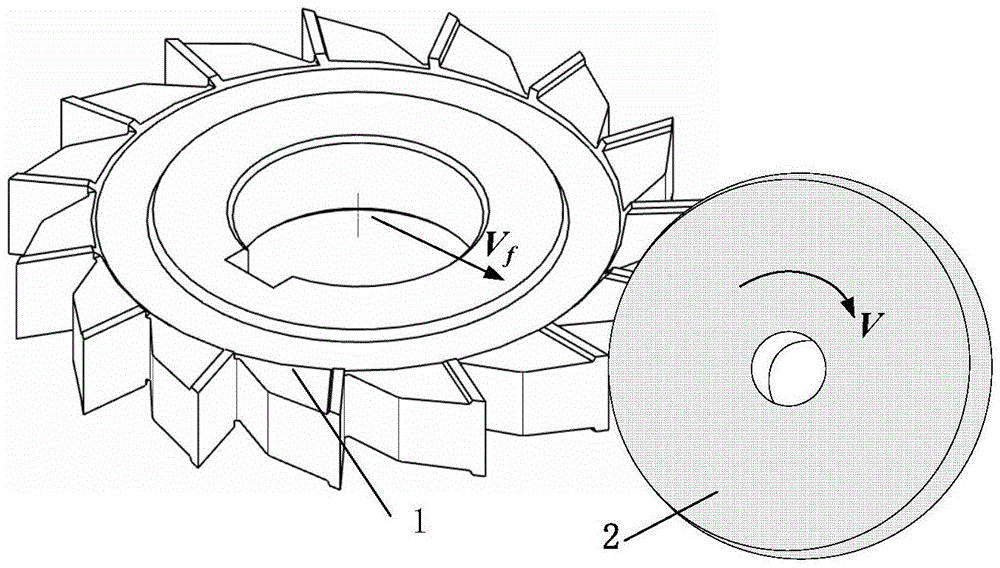

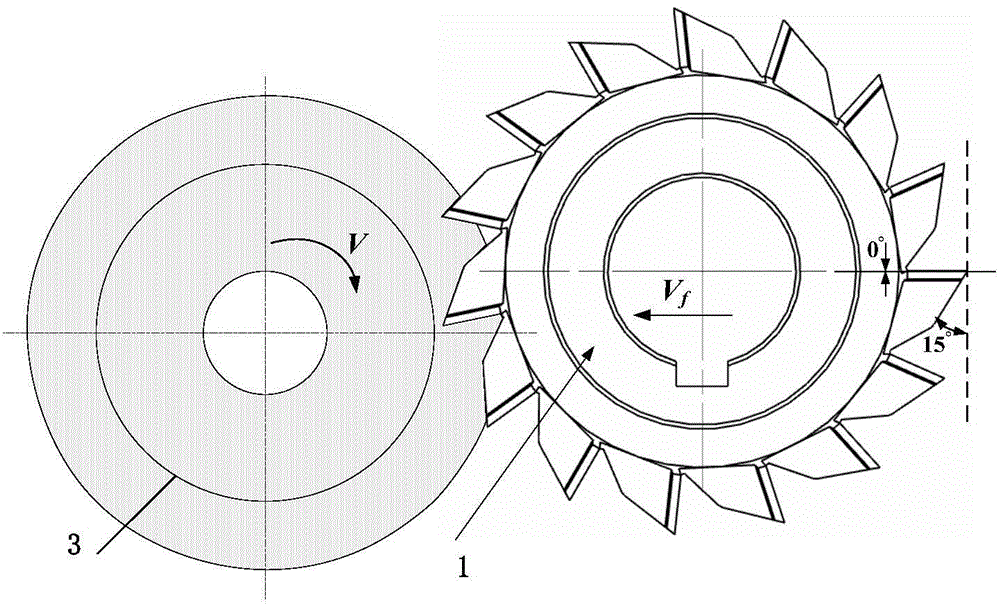

Integral full-ceramic super dense-tooth three-edge milling cutter and manufacturing method thereof

InactiveCN104889466AHigh hardnessImprove wear resistanceMilling cuttersMilling cutterTitanium carbonitride

The invention discloses an integral full-ceramic super dense-tooth three-edge milling cutter and a manufacturing method thereof. The integral full-ceramic super dense-tooth three-edge milling cutter comprises a three-edge milling cutter body; the three-edge milling cutter body is connected with a cutter handle through a keyway hole in the center of the three-edge milling cutter body, and comprises a main cutting edge and two side cutting edges; the front angle of the main cutting edge is (-10)-0 degree; the rear angle of the main cutting edge is 5-15 degrees; the rear angles of the two side cutting edges are 2-5 degrees respectively; the three-edge milling cutter body has 10-20 teeth, has a diameter of 50-200 mm, and is made of titanium carbonitride based metal ceramic. Through the adoption of the integral full-ceramic super dense-tooth three-edge milling cutter, high-speed and super high-speed machining can be realized, the material removing rate is improved, and the machining cost is reduced; when the total radial cutting depth remains unchanged, the radial cutting depth of a single cutting edge, the cutting force and the cutter abrasion can be reduced; the service life of the integral full-ceramic super dense-tooth three-edge milling cutter is effectively prolonged, the cutter replacement times are reduced, and the machining efficiency is improved. Compared with an indexable milling cutter, the integral full-ceramic super dense-tooth three-edge milling cutter has the advantages of being high in rigidity, positioning precision, and repeated sharpening property; moreover, the machining quality can be improved, and the machining cost is reduced.

Owner:SHANDONG UNIV

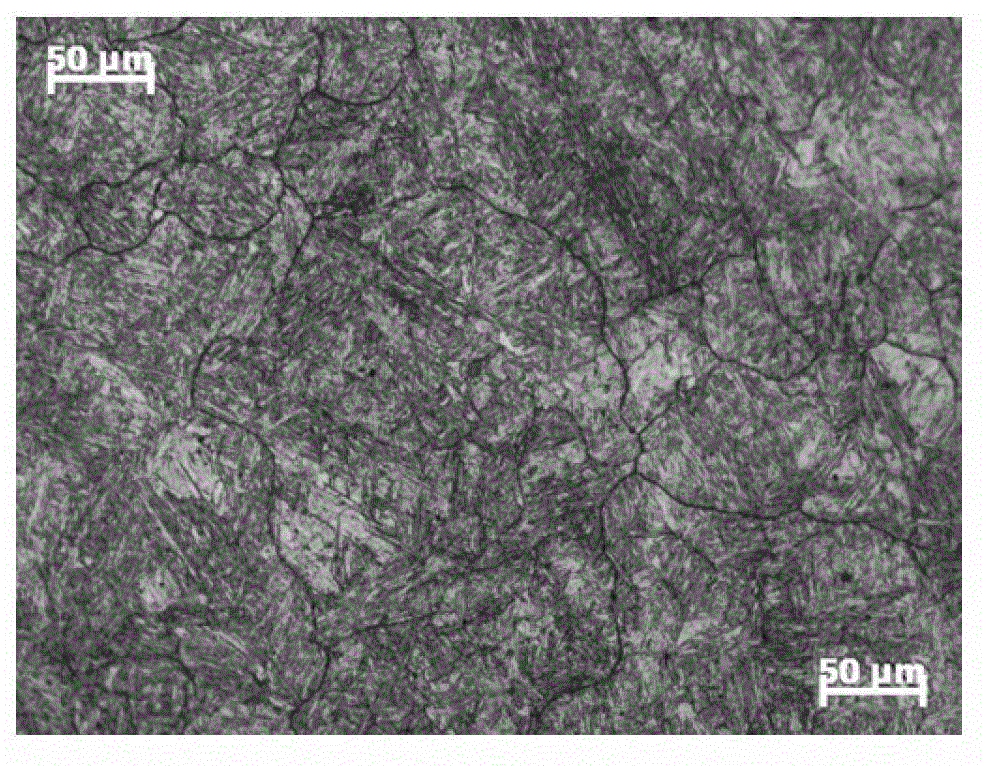

Heat treatment process of nickel base single crystal superalloy

InactiveCN104746145AImprove durabilityRaise the initial melting temperaturePolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

The invention discloses a heat treatment process of nickel base single crystal superalloy. A differential thermal analysis method and metallographic test method are used to determine the incipient melting temperature of the alloy at 1280 DEG C; and an optical metalloscope is used for observation of the microstructure of alloy after different solid solution treatments, and the stress rupture properties of the alloy are tested. The results show that optimum heat treatment process of the alloy is as below: 1245 DEG C / 2h, AC+1275 DEG C / 4h, AC+1100 DEG C / 2h, AC+850 DEG C / 24h, AC. The single crystal superalloy treated by the process has excellent durability, and creep rupture life reaching 159.35h under 980 DEG C and 235MPa.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

ActiveCN109666815AHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

The invention discloses a preparation method and application of a MAX-phase enhanced nickel-based high-temperature lubricating composite material. The preparation method comprises the following steps:carrying out mechanical mixing on Ti powder, Si powder and TiC powder; preparing loose block-shaped Ti3SiC2 ceramic through a powder metallurgy method; then carrying out crushing and ball-milling treatment on the prepared loose block-shaped Ti3SiC2 ceramic, so as to obtain Ti3SiC2 ceramic powder; then carrying out mechanical mixing on the sieved Ti3SiC2 powder and NiAl powder; compacting and molding; and finally, preparing a block-shaped NiAl-Ti3SiC2 composite material through hot-pressing sintering, wherein the phase content of NiAl and Ti3SiC2 in the block-shaped NiAl-Ti3SiC2 composite material is 60 to 90 percent and 10 to 40 percent respectively. The NiAl composite high-temperature lubricating material is prepared by adopting the powder metallurgy method and the self-lubricating performance of hot-pressing sintering and synthesis in the composite material is better than that of Ti3SiC2-phase ceramic of graphite and MoS2; and meanwhile, an NiAl alloy has excellent corrosion resistance and abrasion resistance, and has good sintering performance, so that NiAl alloy powder is selected as a matrix of the composite material.

Owner:咸阳瞪羚谷新材料科技有限公司

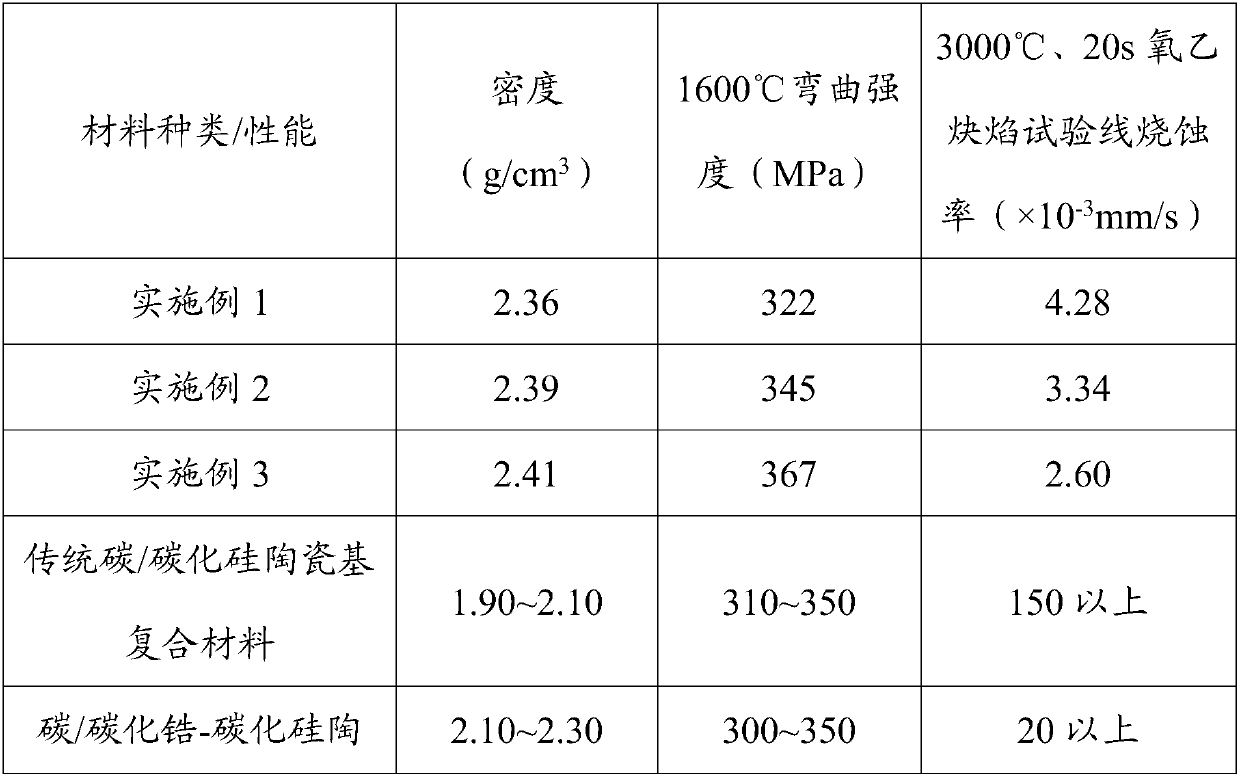

Ceramic matrix composite material and preparation method thereof

ActiveCN110028330AStrong chemical bondGive full play to the synergistic antioxidant effectCarbon fibersHafnium

The invention provides a ceramic matrix composite material and a preparation method thereof, wherein a carbon fiber preform is used as a skeleton, and is immersed in a hafnium-tantalum-silicon ternarycomposite phose ceramic precursor solution, and curing and cracking are performed to prepare the composite material. According to the preparation method, a pyrolytic carbon interface layer is prepared on a carbon fiber preform by using a chemical vapor infiltration method, matrix densification treatment is performed by using a hafnium-tantalum-silicon ternary composite phose ceramic precursor impregnation cracking method, and finally pore sealing treatment is performed by using a chemical vapor infiltration method. According to the present invention, the method has characteristics of simple process and short development period; and the prepared ultra-high temperature ceramic matrix composite material has the uniform distribution of various components of the matrix, has characteristics ofultra-high-temperature resistance, oxidation resistance and ablation resistance, can be used as the high temperature thermal structure material for hypersonic vehicles and rocket propulsion systems, and has broad application prospects.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of in-situ generated mullite whisker ceramic material

The invention discloses a preparation method of an in-situ generated mullite whisker ceramic material. According to the preparation method, coal gangue and high bauxite are used as raw materials, polycrystal mullite fibers are added and used as seed crystals, chlorine trifluoride is added and used as a whisker growth catalyst, and generation of mullite whiskers in the sintering process is promoted; the crystal structure of acidized potassium feldspar is damaged, the liquid-phase formation temperature of a ceramic blank system is lowered, fusion of substances in ceramic blank is promoted, formation and growth of mullite crystals are promoted, the aim of lowering the ceramic sintering temperature is achieved, and energy consumption is lowered; through gel injection molding and two-segment high-temperature sintering, in-situ generated mullite whiskers develop completely, a three-dimensional network structure is formed in the ceramic material, the ceramic material has high porosity, a gelinjection molding technology is adopted at the same time, the pore distribution state of final ceramic can be adjusted and controlled, and the light heat insulation performance of the ceramic materialis improved.

Owner:马鞍山科润冶金材料有限公司

Method for preparing carbon fiber toughened silicon carbide wood-ceramics

InactiveCN106478121AGood chemical stabilityExcellent high temperature mechanical propertiesCarbon fibersFreeze-drying

The invention belongs to the field of preparation of silicon carbide wood ceramics and discloses a method for preparing carbon fiber toughened silicon carbide wood-ceramics. The method comprises the steps: putting 4-6 parts (in parts by mass) of wood flour, 4-6 parts of carbon fibers and 15-20 parts of thermosetting phenolic resin into a dissolution equivalent of water so as to prepare slurry, wherein the sum of parts (by mass) of the wood flour and parts (by mass) of the carbon fibers is 10 parts; pouring the prepared slurry into a metal container, and carrying out freeze drying in freeze drying equipment, so as to prepare a carbon fiber reinforcement; subjecting the prepared carbon fiber reinforcement to mold-pressing forming, so as to prepare biscuits; subjecting the prepared biscuits to carbonization and reacting siliconizing sequentially, thereby obtaining the carbon fiber toughened silicon carbide wood-ceramics. According to the method disclosed by the invention, the disadvantages of the silicon carbide wood ceramics in the prior art that the volume shrinkage is high during the carbonization of the biscuits, deformation and cracking are easy, and the toughness of products is poor are overcome, the involved raw materials are readily available, and the process is simple and feasible.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Beryllium-free molten salt reactor core using beryllium oxide for moderating

PendingCN106981319AImproved neutron economyHigh heavy nuclei contentNuclear energy generationShieldingNeutron economyMolten salt reactor

The invention provides a beryllium-free molten salt reactor core using beryllium oxide for moderating, the molten salt reactor core is characterized by comprising a fuel grid and a reflective layer grid, the reflective layer grid is arranged outside the fuel grid, and surrounds the fuel grid, and the grid uses the beryllium oxide as a moderator. The beryllium in the beryllium oxide in the molten salt reactor core has (n, 2n) neutron multiplication reaction, reactor core neutron economy is improved, and design of a high proliferation thorium molten salt reactor can be designed.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

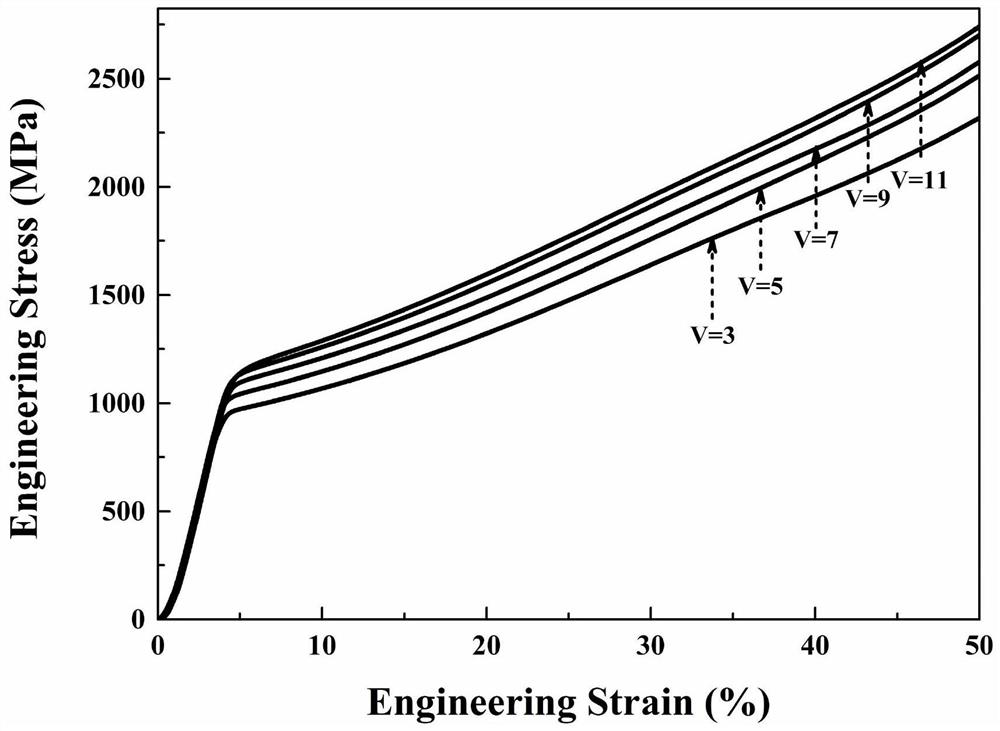

Isothermal superplastic deformation method for micro/nano particulate reinforced titanium matrix composite

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

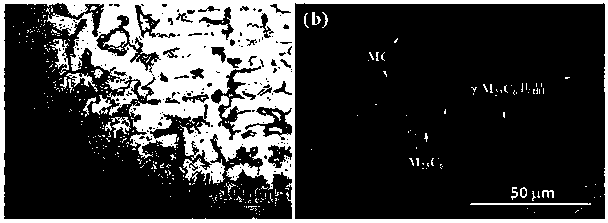

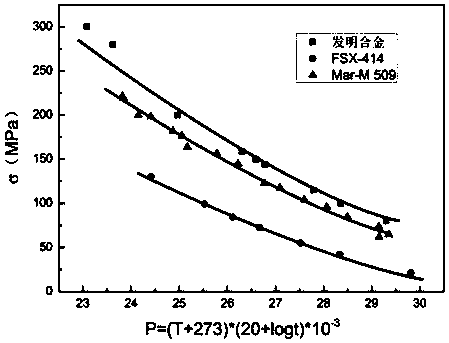

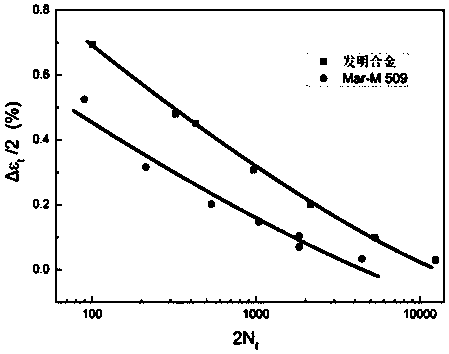

Cobalt-based high temperature alloy, preparation method thereof and application in heavy-duty gas turbine

The invention discloses a cobalt-based high temperature alloy, a preparation method thereof and application in a heavy-duty gas turbine, and belongs to the technical field of casting isometric crystalcobalt-based high temperature alloy. The alloy comprises chemical compositions of, 22.0-25.0% of Cr, 9.0-11.0% of Ni, 5.4-6.4% of W, 0.7-1.3% of Mo, 3.0-4.0% of Ta, 0.47-0.65% of C, 0.15-0.25% of Ti,0.05-0.2% of Al, 0.06-0.35% of Zr, 0-0.1% of Mn, 0-0.4% of Si, 0.005-0.015% of B, and the balance Co. The cobalt-based high temperature alloy has excellent mechanical properties, physical and chemical properties and high temperature structural stability, and is suitable for heavy-duty gas turbine guide blade materials for ground and ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

In-situ formed beta-Sialon combined corundum prefabricated member and production method thereof

InactiveCN102329126AExcellent high temperature mechanical propertiesImprove thermal shock resistanceChemical industryHydration reaction

The invention discloses an in-situ formed beta-Sialon combined corundum prefabricated member and a production method thereof. The prefabricated member is formed by adopting the following steps of: with elemental silicon powder, corundum particles and fine powder as raw materials and with hydrated alumina, activated alumina micropowder and silicon dioxide micropowder as binding agents, adding metal aluminum powder treated by adopting a sol-gel process; adding water, vibrating, pouring and forming; demoulding, curing and drying; and reacting and sintering in the nitrogen gas atmosphere to obtain the prefabricated member. The prefabricated member comprises the following components in parts by weight: 70-80 parts of corundum particles, 3-12 parts of alumina micropowder, 0-5 parts of silicon dioxide micropowder, 0.5-5 parts of hydrated alumina, 3-15 parts of elemental silicon powder, 0.3-2 parts of metal aluminum powder subjected to surface treatment and 0.05-0.30 part of organic water reducing agent as a dispersing agent, based on the total weight percentage of the raw materials. According to the invention, the defects of poor thermal shock resistance, poor stripping resistance, high temperature and low strength in the currently-general corundum-based castable are overcome; and the in-situ formed beta-Sialon combined corundum prefabricated member can be expected to be applied to ceramic cups of blast furnaces, ladle liners, permeable bricks for ladles, chemical industries and the like as well as has the characteristics of high strength, favorable stripping resistance and the like.

Owner:ZHENGZHOU UNIV

Preparation method of self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material

InactiveCN104529499AImprove high temperature stabilityHigh resistance to crystallization temperatureCarbon compositesSelf-healing

The invention relates to a preparation method of a self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material, which comprises the following steps: (1) preparing a polyborosilazane (PBSZ) precursor; dissolving the PBSZ precursor in a toluene solution under the protection of N2 to obtain a PBSZ toluene solution; transferring into a pipe furnace, crosslinking under the protection of N2, grinding and screening to obtain SiBNC precursor powder; (2) preparing SiC fibers into a prefabricated part, carrying out hot pressing on the SiBNC precursor powder and SiC fiber prefabricated part, cooling and demolding to obtain a composite material; and transferring into a pipe furnace in an N2 protective atmosphere to perform ceramization, and finally, sintering. The method is simple in technique, easy to operate and low in cost; and the prepared silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material is uniform and compact, has the advantages of favorable high-temperature stability and excellent oxidation resistance, and especially has self-healing performance.

Owner:DONGHUA UNIV

High-temperature alloy casting resistant to high-temperature hot corrosion

ActiveCN105349842AImprove mechanical propertiesGood long-term aging tissue stability at high temperatureFoundry mouldsFoundry coresMetallic materialsHigh-temperature corrosion

The invention belongs to the field of metal materials and relates to a high-temperature alloy casting which is resistant to high-temperature hot corrosion and is used for a part at the hot end of a gas turbine. Alloy comprises, by mass, 3.8%-6.0% of Al, 0.5%-3.5% of Ti, 10.0%-12.0% of Cr, 5.0%-7.0% of Ta, 8.0-10.0% of Co, 4.0%-7.0% of W, 1.0%-3.0% of Mo, 0-3.0% of Hf, 0-4% of Re, 0.02%-0.15% of C, 0.002-0.02% of B and the balance nickel. According to the high-temperature alloy casting resistant to high-temperature hot corrosion, the Al / Ti value, the content of Hf and the ratio of the content of Hf to the content of C and B are adjusted, so that the casting performance of the alloy is improved, and the high-temperature burning hot corrosion performance of the alloy is improved. Thus, the gas turbine high-temperature alloy more suitable for hollow blade casting is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing high-purity high-temperature alloys by using returned materials

InactiveCN110106374AConducive to environmental protectionReduce energy consumption and costsProcess efficiency improvementYttriumPre treatment

The invention discloses a method for preparing high-purity high-temperature alloys by using returned materials. The method is characterized by comprising the following steps in sequence: charging: pretreated high-temperature alloy returned materials are fed in a yttrium oxide crucible; and a door of a vacuum induction smelting furnace is closed; smelting: the vacuum induction smelting furnace is vacuumized to reach the furnace internal vacuum degree of 0.005-0.05 Pa; then, the smelting is started until all burdens are molten; when the burdens are heated to reach 1600-2000 DEG C, redundant argon in a hearth is extracted to maintain the hearth internal vacuum degree of 0.3-0.5 Pa; metal yttrium blocks are fed from a secondary feed port; the feeding quantity of the yttrium blocks is 0.01-0.2%of the weight of the high-temperature alloy returned materials; the refining is performed; and the molding by casting is performed after refining. The O and N contents of purified and smelted high-temperature alloys are reduced below 4 ppm; the purity reaches the level of high-quality and high-purity high-temperature alloy new materials; and the utilization rate of resources is increased.

Owner:BEIHANG UNIV +2

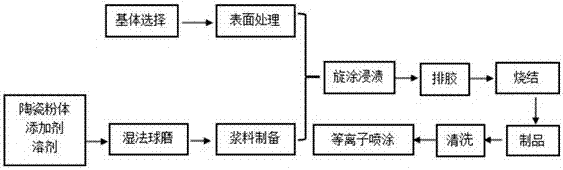

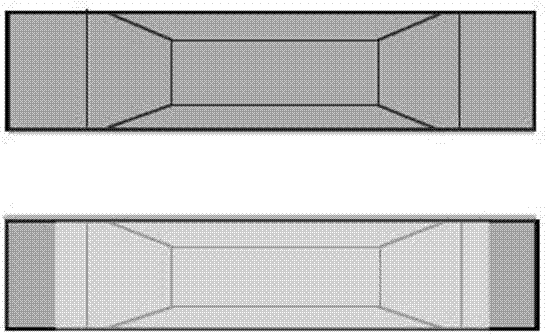

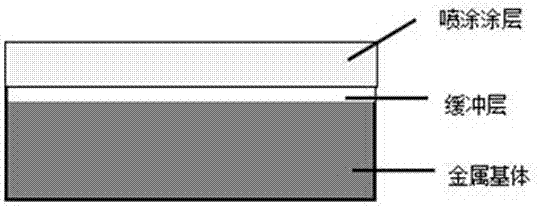

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

Low-resistivity silicon carbide ceramic and preparation method thereof

The invention relates to low-resistivity silicon carbide ceramic and a preparation method thereof. The low-resistivity silicon carbide ceramic comprises SiC, AlN, B4C and C, wherein the content of AlN is 1-5w%, the content of B4C is not more than 1w%, the content of C is 0-3w% and the balance is SiC.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of alpha-Al2O3/mullite multiphase ceramic fiber

InactiveCN110078482AAdd lessThe operation process is simple and controllableInorganic material artificial filamentsFiberNanoparticle

The invention provides a preparation method of an alpha-Al2O3 / mullite multiphase ceramic fiber. The preparation method comprises the following steps: mixing aluminum powder, aluminum salt and water, performing heating reflux at 110-200 DEG C till the aluminum powder reacts completely to form aluminum collosol, mixing the aluminum collosol prepared by the above method, silicasol, nano particle dispersing liquid and a spin finish aid, and performing aging, concentration, spinning and calcining to form the alpha-Al2O3 / mullite multiphase ceramic fiber, wherein the nano particle dispersing liquid is one or a combination of more than two of alpha-Al2O3 dispersing liquid, gamma-Al2O3 dispersing liquid or alpha-Fe2O3 dispersing liquid. A formation temperature difference of alpha-Al2O3 and a mullite crystal phase in the ceramic fiber is reduced by adding nano particles; and the dense ceramic fiber that is high in length, excellent in mechanical property and high in purity can be prepared at a lower temperature.

Owner:SHANDONG UNIV

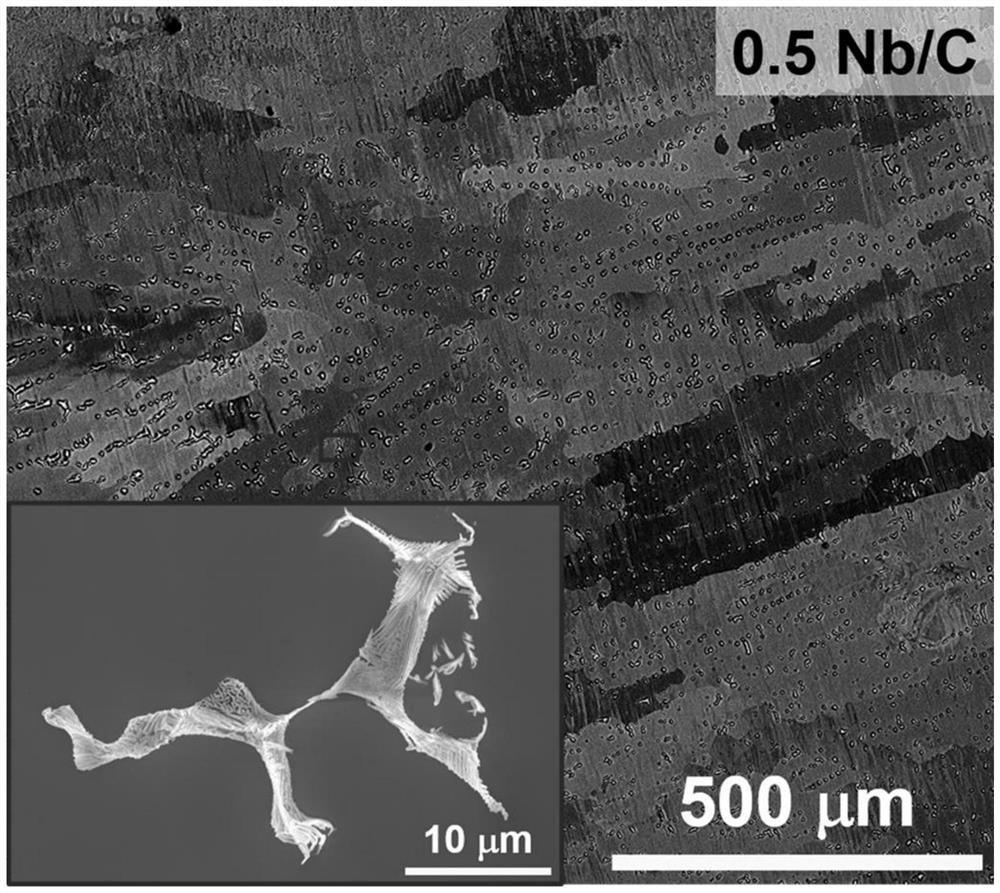

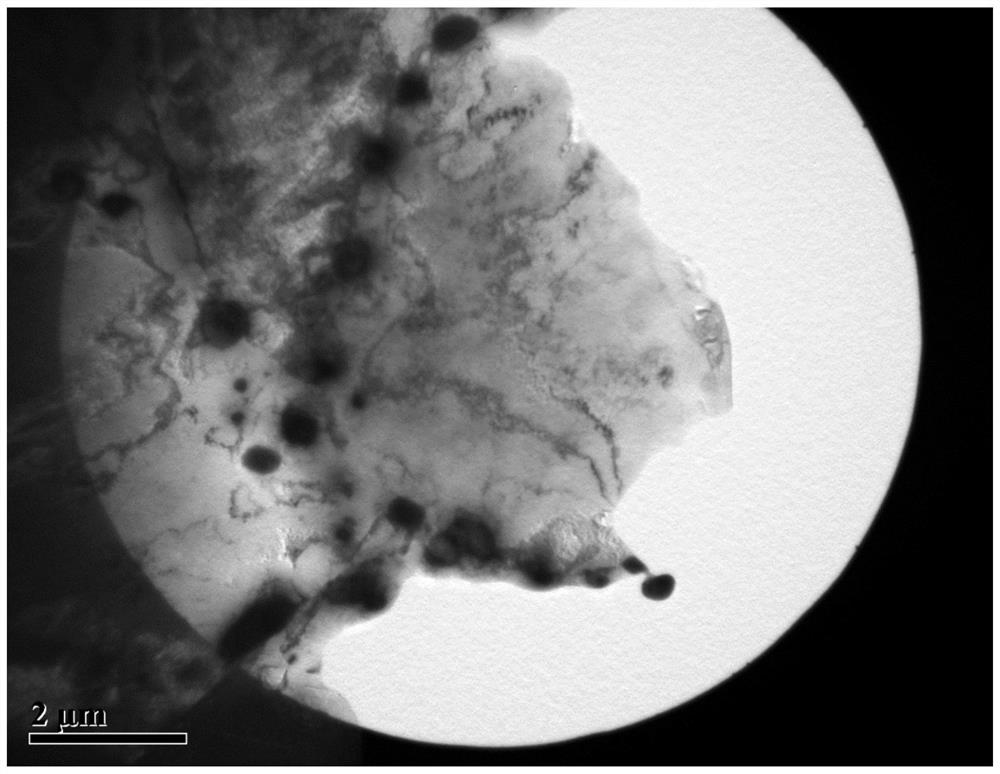

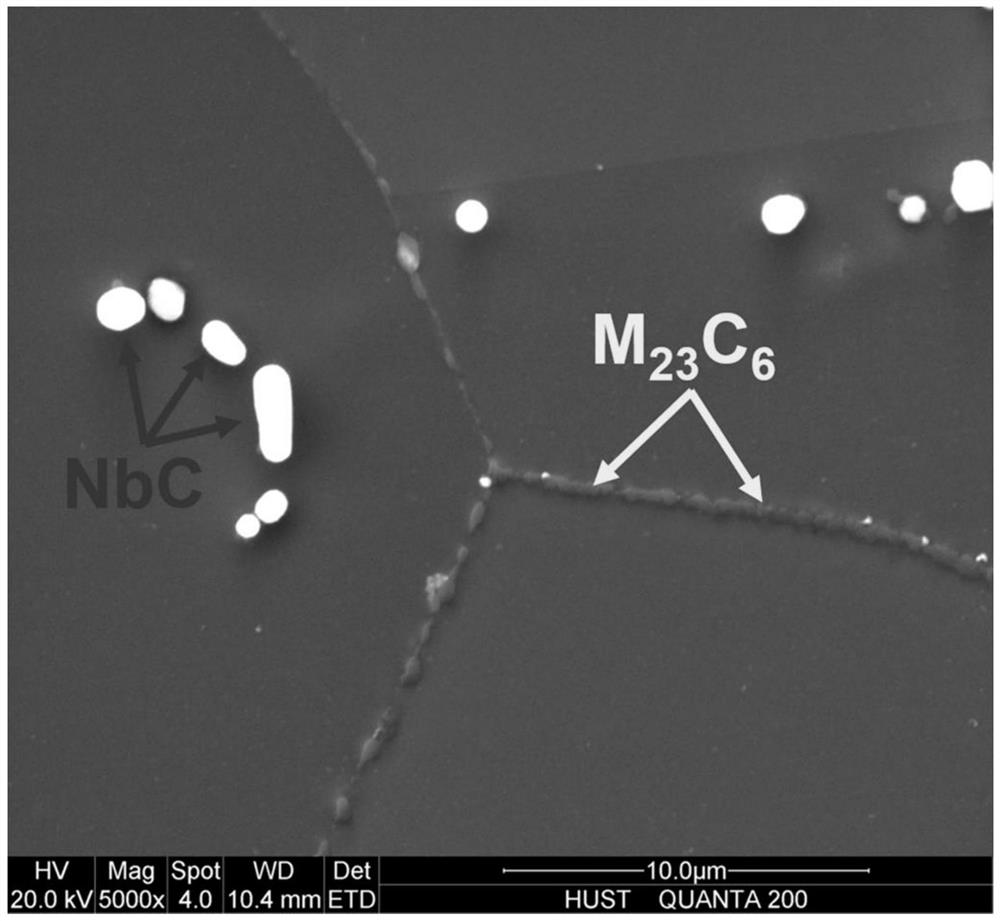

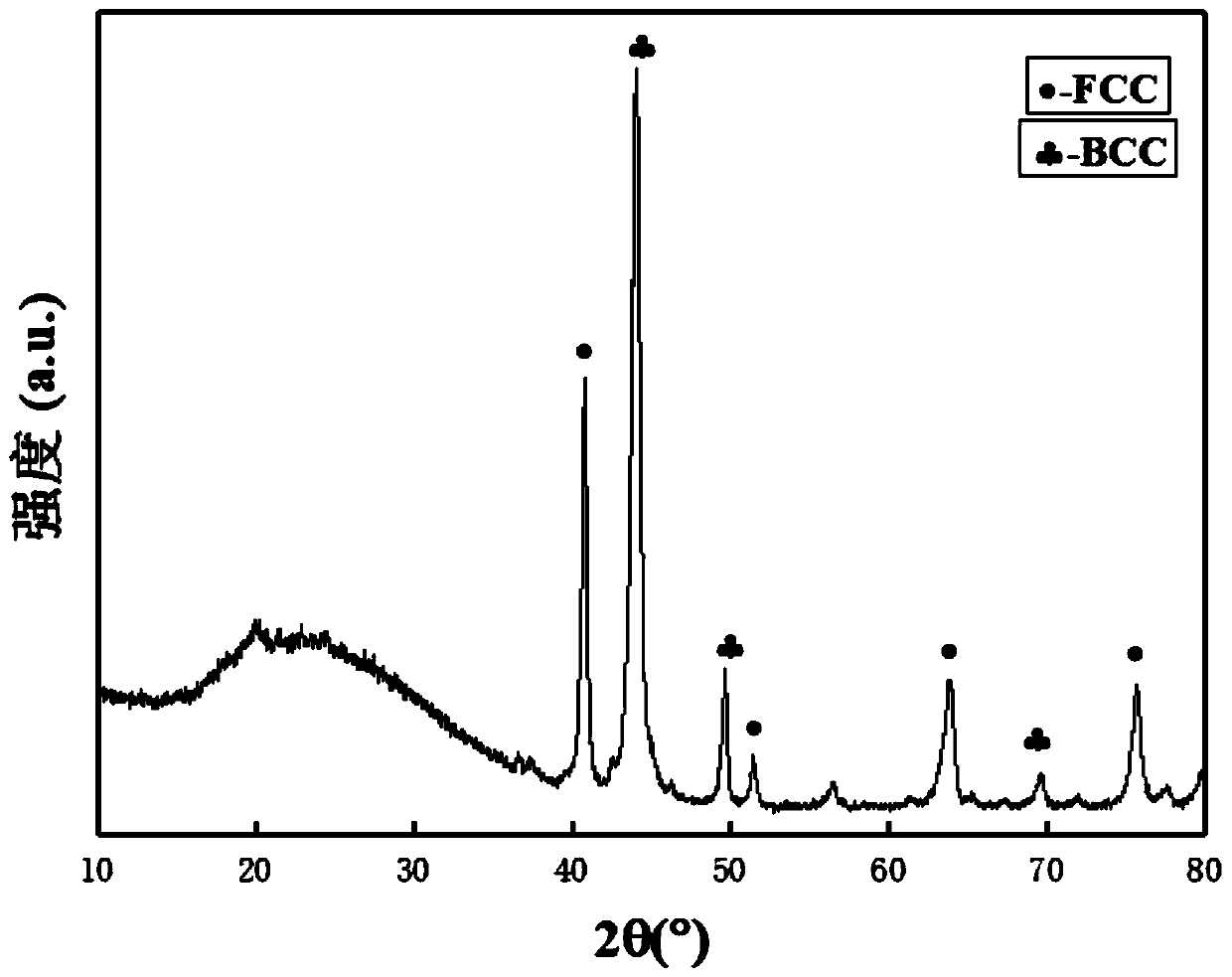

Precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and preparation method thereof

ActiveCN111621660AGood high temperature mechanical propertiesImprove mechanical propertiesHeat stabilityCarbide

The invention discloses a precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and a preparation method thereof, and belongs to the field of high-entropy alloy preparation. According to the method, a raw material composed of Cr, Fe, Co, Ni, Nb and Cr3C2 is fully smelted and mixed in an inert atmosphere and then subjected to solid solution agingtreatment, and the atomic percent and the atomic number of all the elements meet the requirements of 24.5% to 24.75% of Cr, 24.5% to 24.75% of Fe, 24.5% to 24.75% of Co, 24.5% to 24.75% of Ni, 0.5% to1% of Nb and 0.5% to 1% of C, wherein the atomic numbers of Cr, Fe, Co and Ni satisfy Cr = Fe = Co = Ni, and the atomic numbers of Nb and C satisfy Nb = C. According to the prepared alloy, a large number of spherical NbC carbide particles are dispersedly distributed in crystal grains, and a small number of M23C6 carbides are distributed on a crystal boundary. The crystal grains and carbide precipitated phases of the alloy have high thermal stability at high temperature, and have good effects on high-temperature structure stability and high-temperature mechanical properties of the alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

FeCrVTiMn high-entropy alloy and method for carrying out laser additive manufacturing by adopting same

InactiveCN109967733AImprove high temperature resistanceExcellent high temperature mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyNeutron irradiationNuclear power

The invention relates to the technical field of alloy powder and particularly relates to a FeCrVTiMn high-entropy alloy and a method for carrying out laser additive manufacturing of a complicated flowchannel structure by adopting the same. The FeCrVTiMn high-entropy alloy comprises: 20 to 23% of iron, 18 to 21% of chromium, 16 to 19% of vanadium, 17 to 20% of titanium and 20 to 23% of manganese.A nuclear power structure material manufactured by FeCrVTiMn high-entropy alloy powder for the laser additive manufacturing has excellent high-temperature resistance, excellent high-temperature mechanical properties, excellent neutron irradiation resistance and a cheap price.

Owner:中广核高新核材科技(苏州)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com