Refractory high-entropy alloy material with high plasticity and low neutron absorption section and preparation method thereof

A high-entropy alloy and high plasticity technology, applied in the field of high-entropy alloys, can solve problems such as high theoretical melting point, high room temperature yield strength and deformation plasticity, and poor room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

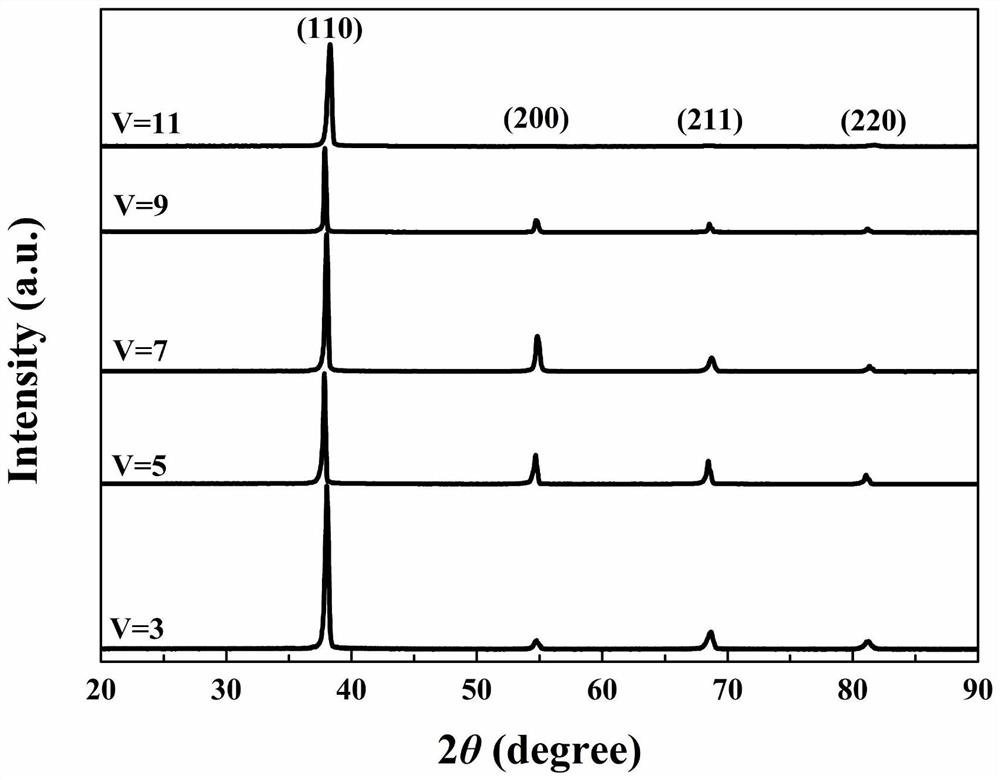

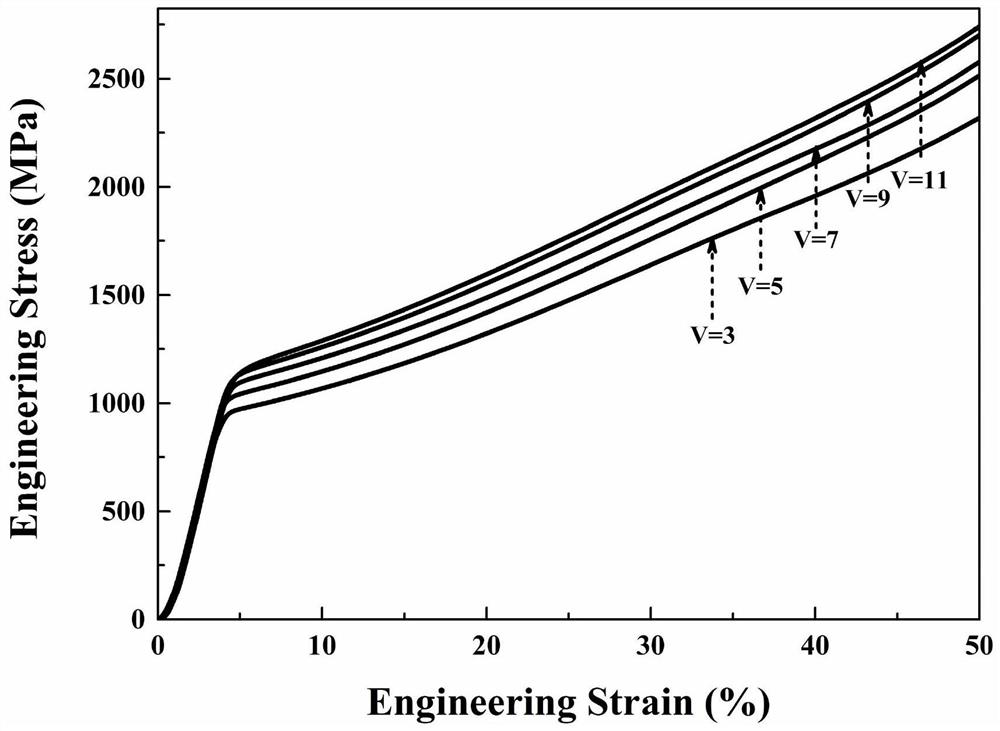

[0020] Example 1: Refractory AlVTiNbZr high-entropy alloy material with high plasticity and low neutron absorption cross section, recorded as Nb according to atomic percentage 31 Ti 37-x Zr 26 Al 6 V x , where x=3, the AlVTiNbZr high-entropy alloy has a single-phase body-centered cubic structure;

[0021] A method for preparing a refractory high-entropy alloy material with high plasticity and low neutron absorption cross-section, the specific steps are as follows:

[0022] (1) Use sandpaper or grinder to polish and remove the oxide scales on five kinds of raw material surfaces of Al, V, Ti, Nb and Zr, and use ethanol to clean up; wherein Al, V, Ti, Nb, Zr are all purity greater than 99.77wt% Block;

[0023] (2) Five raw materials of Al, V, Ti, Nb and Zr are sequentially added into the vacuum arc melting furnace in order of melting point from low to high; ensure that the low melting point material is located at the bottom of the melting vessel;

[0024] (3) Vacuum to 6×10...

Embodiment 2

[0027] Embodiment 2: Refractory AlVTiNbZr high-entropy alloy material with high plasticity and low neutron absorption cross section, recorded as Nb according to atomic percentage 31 Ti 37-x Zr 26 Al 6 V x , where x=5, the AlVTiNbZr high-entropy alloy has a single-phase BCC structure;

[0028] A method for preparing a refractory high-entropy alloy material with high plasticity and low neutron absorption cross-section, the specific steps are as follows:

[0029] (1) Use sandpaper or grinder to polish and remove the oxide scales on five kinds of raw material surfaces of Al, V, Ti, Nb and Zr, and use ethanol to clean up; wherein Al, V, Ti, Nb, Zr are all purity greater than 99.77wt% Block;

[0030] (2) Five raw materials of Al, V, Ti, Nb and Zr are sequentially added into the vacuum arc melting furnace in order of melting point from low to high; ensure that the low melting point material is located at the bottom of the melting vessel;

[0031] (3) Vacuum to 6×10 -2 Below Pa...

Embodiment 3

[0034] Embodiment 3: Refractory AlVTiNbZr high-entropy alloy material with high plasticity and low neutron absorption cross section, recorded as Nb according to atomic percentage 31 Ti 37-x Zr 26 Al 6 V x , where x=7, the AlVTiNbZr high-entropy alloy has a single-phase BCC structure;

[0035] A method for preparing a refractory high-entropy alloy material with high plasticity and low neutron absorption cross-section, the specific steps are as follows:

[0036](1) Use sandpaper or grinder to polish and remove the oxide scales on five kinds of raw material surfaces of Al, V, Ti, Nb and Zr, and use ethanol to clean up; wherein Al, V, Ti, Nb, Zr are all purity greater than 99.77wt% Block;

[0037] (2) Five raw materials of Al, V, Ti, Nb and Zr are sequentially added into the vacuum arc melting furnace in order of melting point from low to high; ensure that the low melting point material is located at the bottom of the melting vessel;

[0038] (3) Vacuum to 6×10 -2 Below Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com