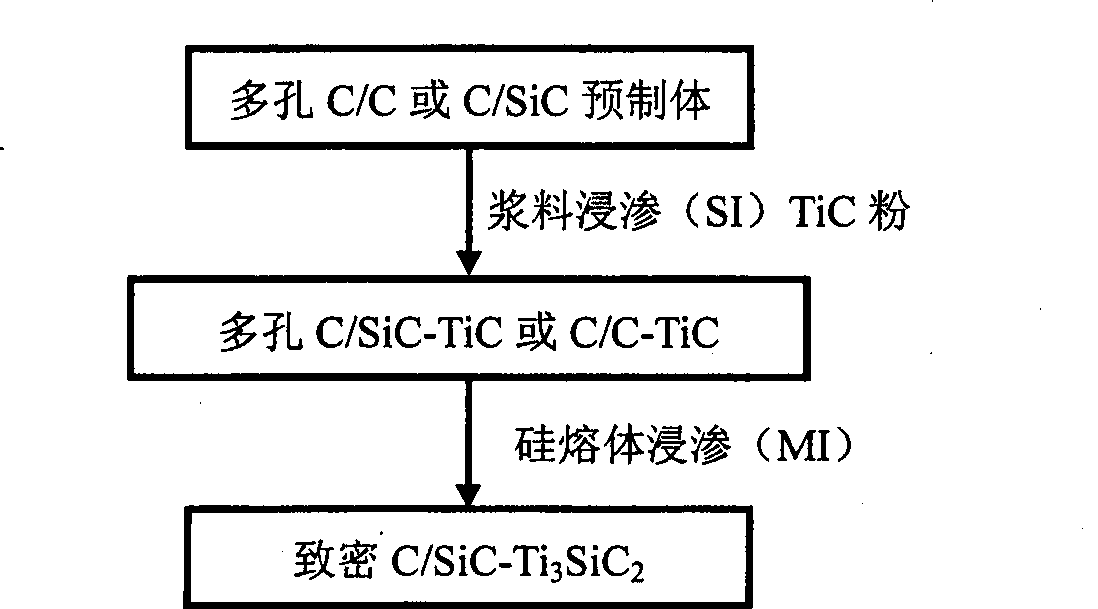

Process for producing composite material of Ti3SiC2 modified C/SiC

A composite material and modification technology, applied in the field of preparation of modified C/SiC composite materials, can solve the problems of low use temperature and poor toughness, and achieve the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Select a three-dimensional needle-punched porous C / C composite material as a prefabricated body, and its density is 1.3g / cm 3 , with an open porosity of 35vol.%, ultrasonically cleaned and dried for later use. Add 1.5g of sodium carboxymethyl cellulose and 150g of TiC powder with a particle size of 1μm to 300g of distilled water at a temperature of 50°C, stir evenly, pour into a ball mill jar, and add a total weight of 903g of corundum balls with a particle size of 5 to 12mm Ball milled for 10 hours to make slurry. Slurry impregnation adopts vacuum impregnation combined with pressure infiltration. Put the open container with the slurry and the three-dimensional needle-punched C / C composite material prefabricated body into the airtight container respectively, and evacuate to keep the absolute pressure of the airtight container at 5.0×10 2 Pa, then submerge the preform in the slurry and continue vacuuming; when the absolute pressure in the container is 5.0×10...

Embodiment 2

[0020] Example 2: Select a two-dimensional needle-punched porous C / C composite material as a preform, and its density is 1.5g / cm 3, with an open porosity of 23vol.%, ultrasonically cleaned and dried for later use. Add 3g of sodium carboxymethyl cellulose and 300g of TiC powder with a particle size of 2μm to 300g of distilled water at a temperature of 60°C, stir evenly, pour into a ball mill jar, add 603g of corundum balls with a particle size of 5 to 12mm in total weight for ball milling 5h to make slurry. Slurry impregnation adopts vacuum impregnation combined with pressure infiltration. Put the open container with the slurry and the two-dimensional needle-punched C / C composite prefabricated body into the airtight container respectively, and vacuumize to keep the absolute pressure in the airtight container at 1.0×10 3 Pa, then submerge the prefabricated body in the slurry and continue vacuuming; when the absolute pressure in the container is 1.0×10 3 At Pa, air is introduc...

Embodiment 3

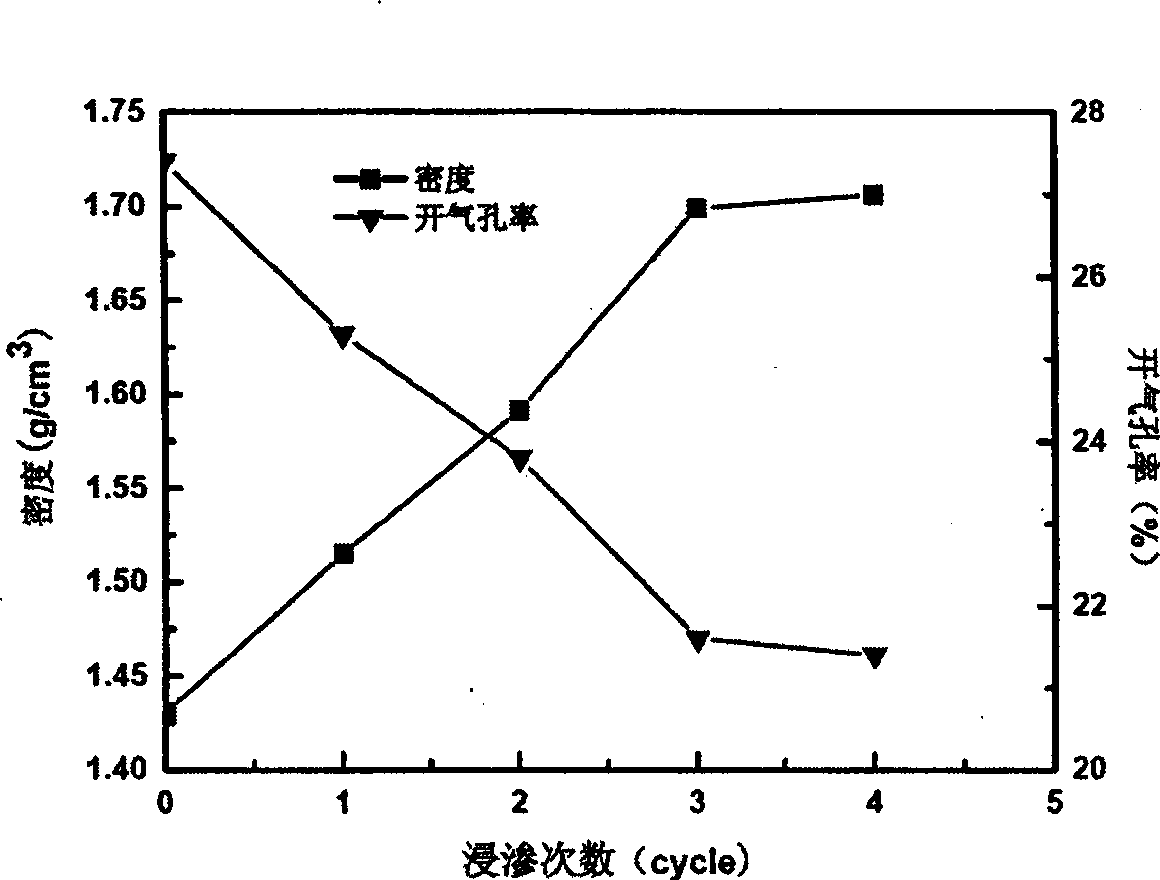

[0021] Example 3: Select a three-dimensional needle-punched porous C / C composite material as a prefabricated body, and its density is 1.49g / cm 3 , with an open porosity of 24vol.%, ultrasonically cleaned and dried for later use. Add 2.5g of sodium carboxymethyl cellulose and 250g of TiC powder with a particle size of 0.4μm to 300g of distilled water at a temperature of 70°C, stir well and pour it into a ball mill jar, and add a total weight of 1657g of corundum with a particle size of 5 to 12mm Ball milled for 30h to make slurry. Slurry impregnation adopts vacuum impregnation combined with pressure infiltration. Put the open container with the slurry and the three-dimensional needle-punched C / C composite material prefabricated body into the airtight container respectively, and vacuumize to keep the absolute pressure in the airtight container at 2.0×10 3 Pa, then submerge the preform in the slurry and continue vacuuming; when the absolute pressure in the container is 2.0×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com