Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Small absorption cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

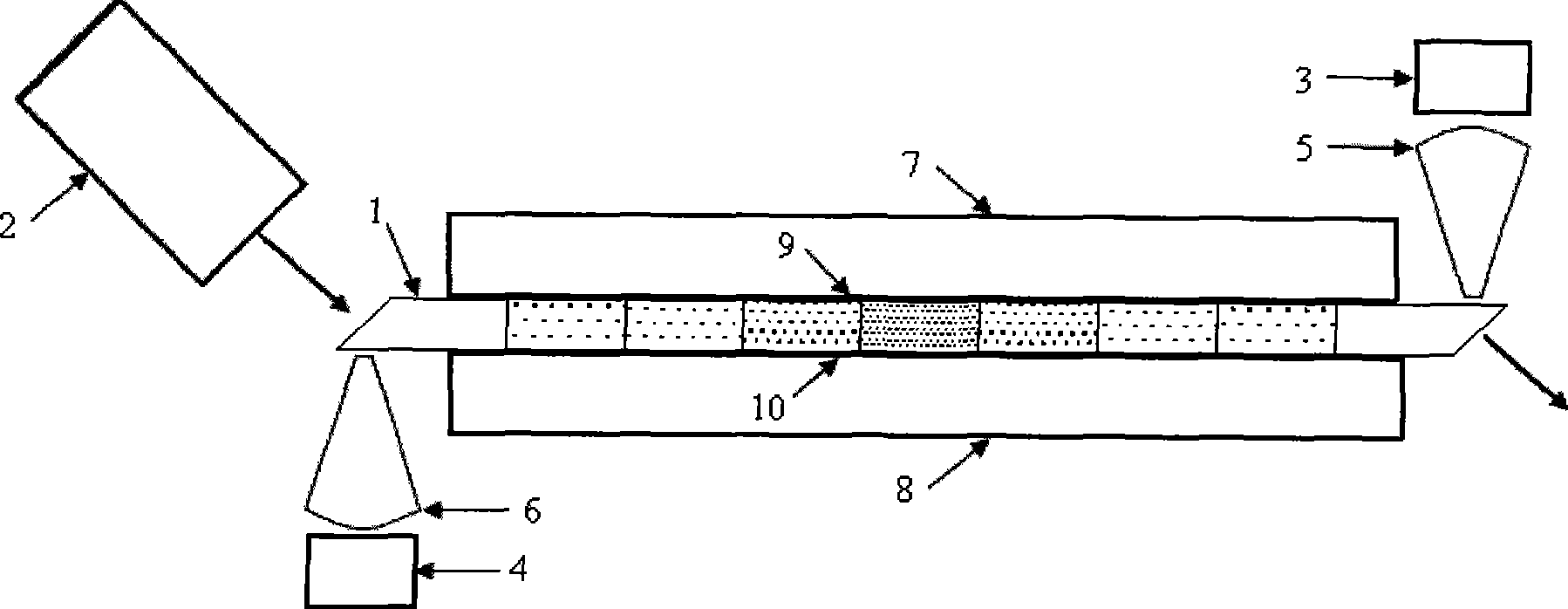

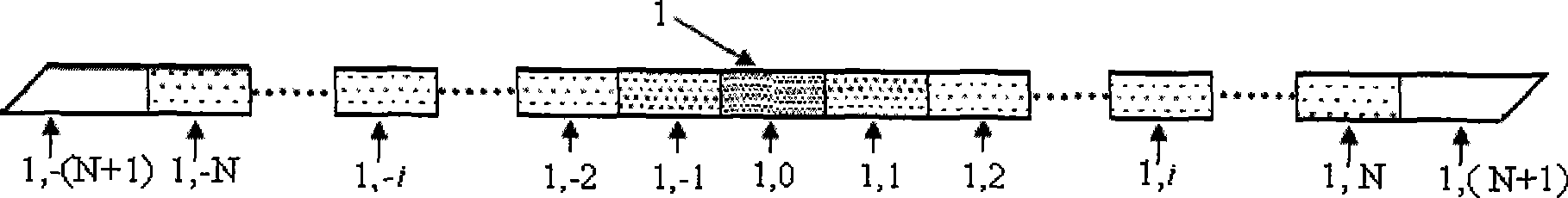

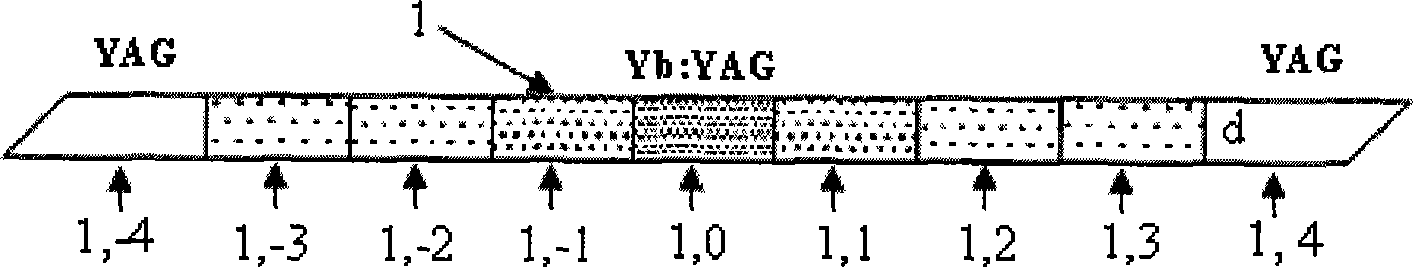

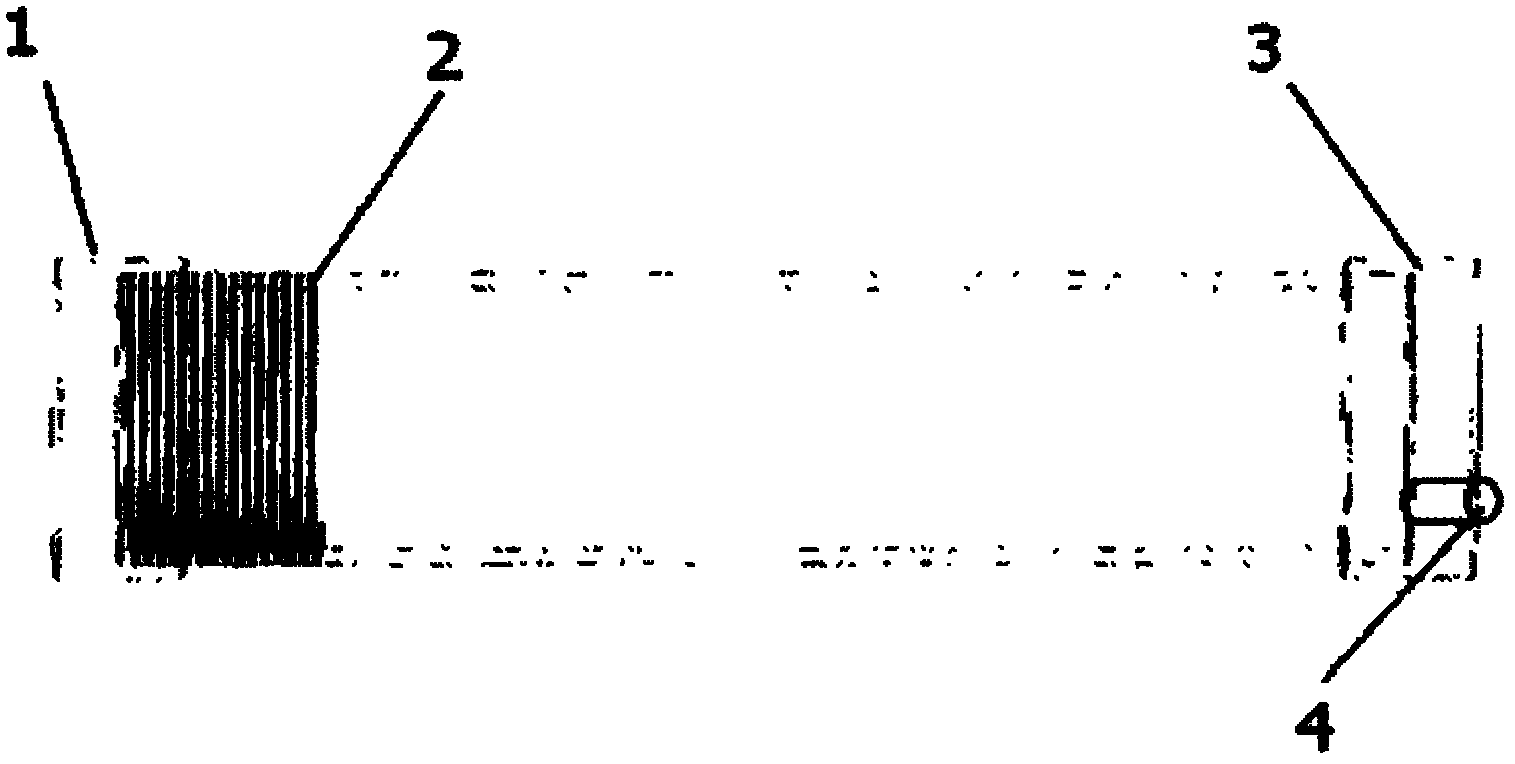

Terminal surface pump order variant grade doping composite plate laser amplifier

The present invention discloses an end pumped order variable gradient adulterate composite lath laser amplifier, which comprises a laser gain medium, seed source, pumping source, coupling lens duct, lath cooling heat sink and indium transition layer, characterized in that the laser gain medium is N-order order variable gradient adulterate composite ceramic lath and is composed by 2N+3 segments that is sub-lath in middle section that has highest luminous ion concentration decreases, each N segment sub-lath with luminous ion concentration decreases gradually towards two ends, and sub-lath with zero adulterate on two ends, wherein N is positive integer. The present invention can improve temperature distribution homogeneity and decrease biggest thermal stress, and further realize laser output of high average power and high beam quality.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

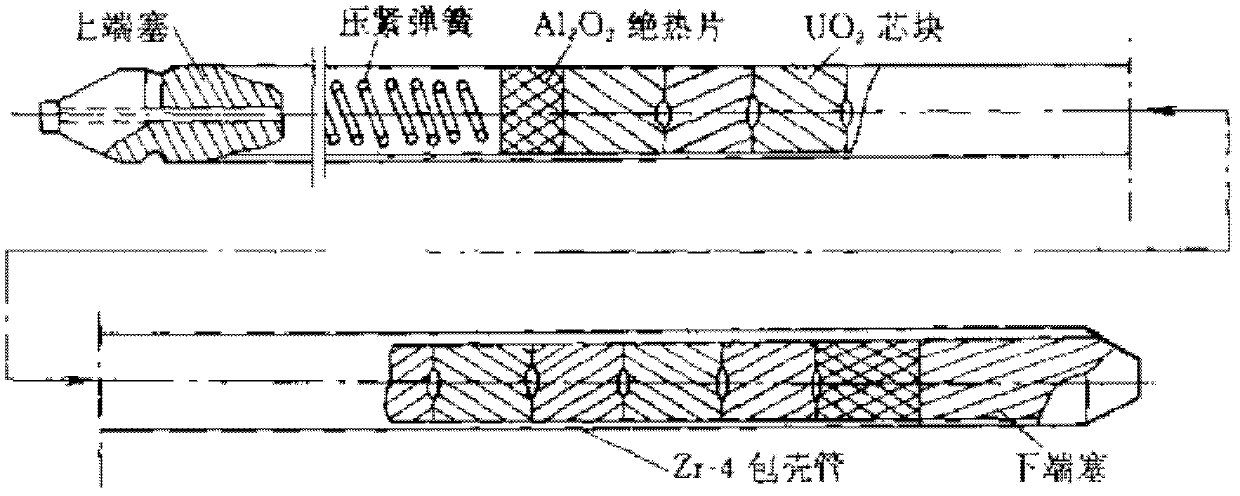

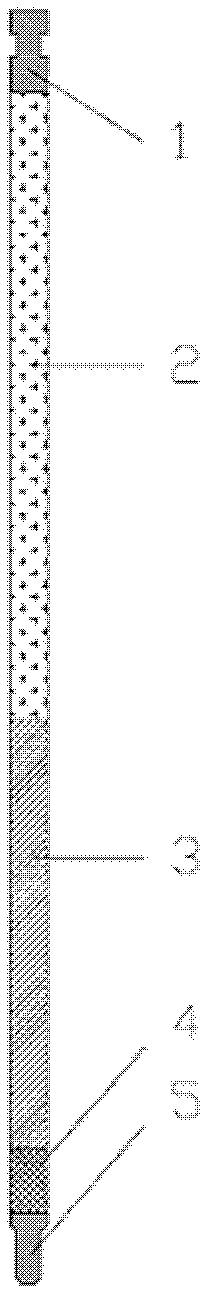

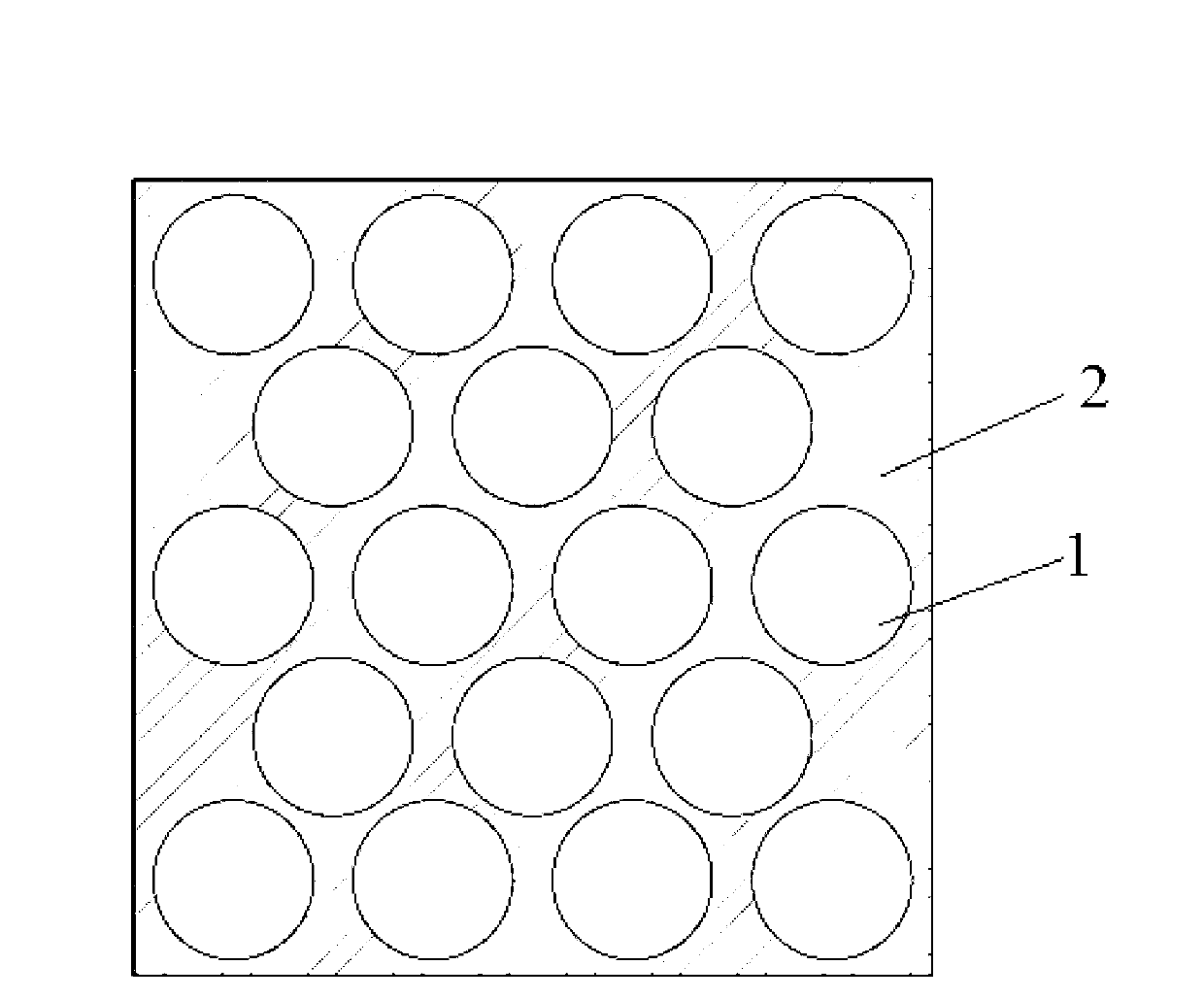

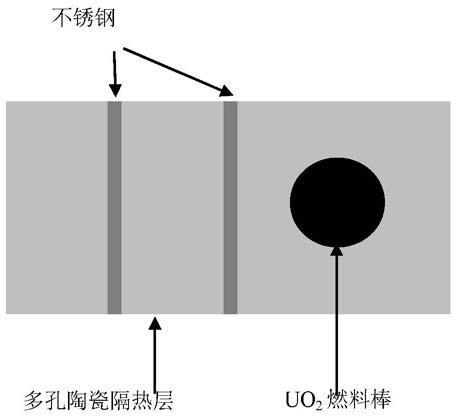

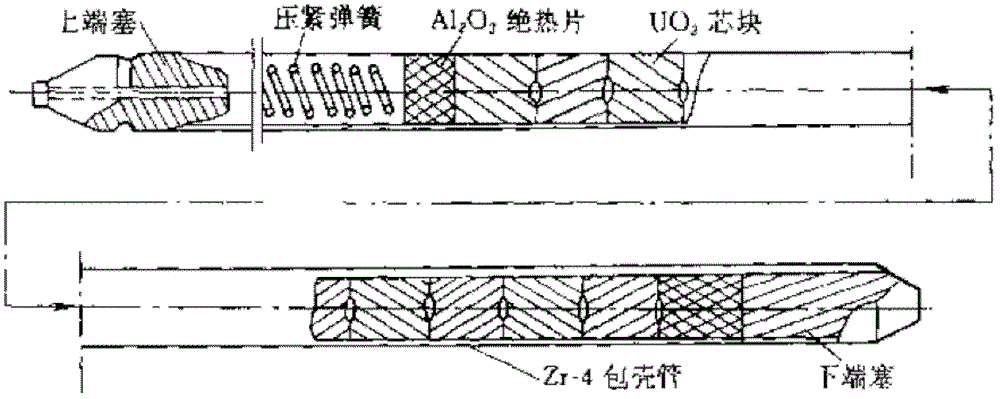

Nuclear fuel rod with ceramic cladding and metallic pellet

ActiveCN103295652AImprove mechanical propertiesReduce breakageOptical rangefindersNuclear energy generationHeat conductingComposite ceramic

The invention aims at providing a nuclear fuel rod with ceramic cladding and metallic pellet. The nuclear fuel rod with ceramic cladding and metallic pellet has the advantages that the heat-conducting property of the nuclear fuel rod can be improved, the central temperature of the fuel pellet is lowered or the fuel power density is effectively improved, the fuel rod cladding mechanical property, corrosion resistance and radiation resistance are greatly improved, the breakage rate of the fuel rod is lowered, the discharge burnup of the fuel rod is remarkably increased and the fuel utilization rate is greatly improved; meanwhile, the fuel rod has good neutronics performance, and can be widely used in a fast reactor or a thermal reactor. The cladding of the nuclear fuel rod provided by the invention is a SiCf / SiC composite ceramic material cladding, the metallic fuel pellet adopts a U-Zr or U-Pu-Zr alloy fuel pellet; a gap between the cladding and the fuel pellet is filled with low-melting-point metal; and a lengthened air cavity is designed at the upper part of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

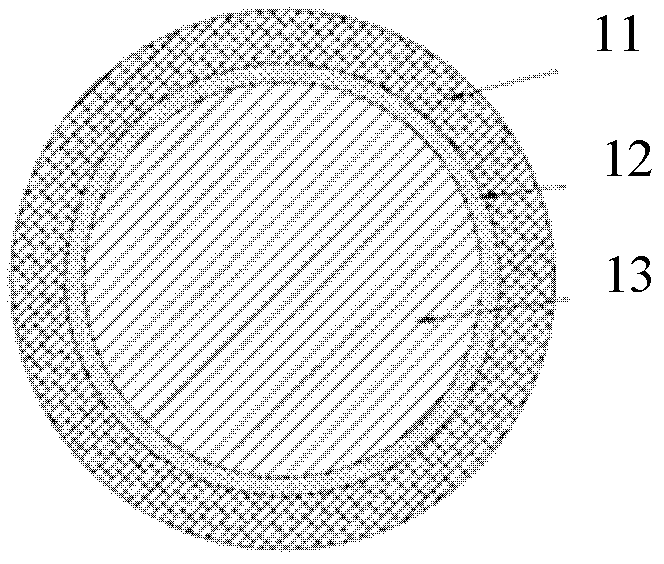

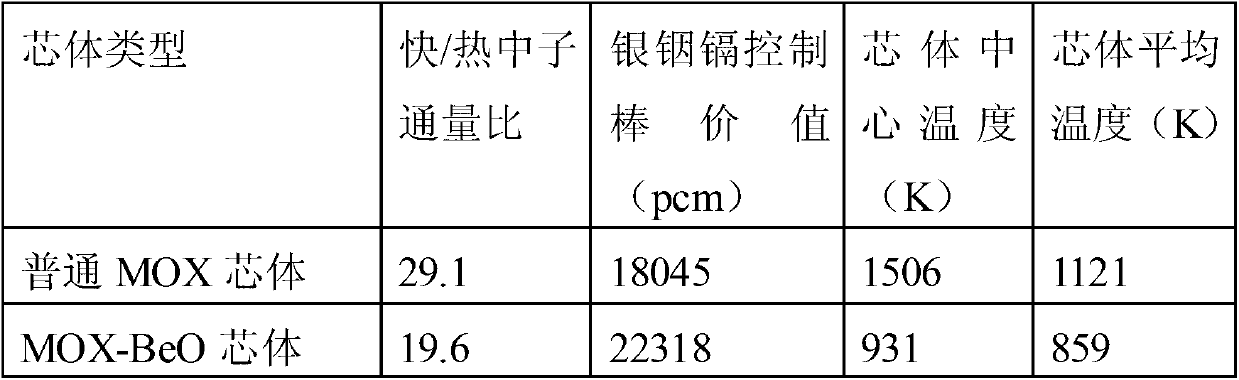

Performance-modified oxide ceramic core body for thermal neutron reactor, and preparation method thereof

ActiveCN103214231AHigh thermal conductivitySmall absorption cross sectionNuclear energy generationReactor fuel susbtancesOxide ceramicNeutron energy spectrum

The present invention provides a performance-modified oxide ceramic core body for a thermal neutron reactor, and a preparation method thereof. According to the present invention, a second phase material is added to an oxide ceramic core body, and the added second phase material forms a continuous phase in the oxide ceramic core body to obtain a performance-modified oxide ceramic core body, wherein the mass of the second phase material is 0.3-15% of the total mass of the performance-modified oxide ceramic core body; the preparation steps comprise: raw material preparation, mixing, green compacting and sintering; compared with the common core body with no specified component addition, the performance-modified oxide ceramic core body for the thermal neutron reactor has a low temperature; and the fuel assembly adopting the core body has the following characteristics that: a neutron energy spectrum is softened, a ratio of a fast neutron flux to a thermal neutron flux in the assembly is reduced by about 35%, and a reactivity value of a neutron absorption body is increased by about 25%.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

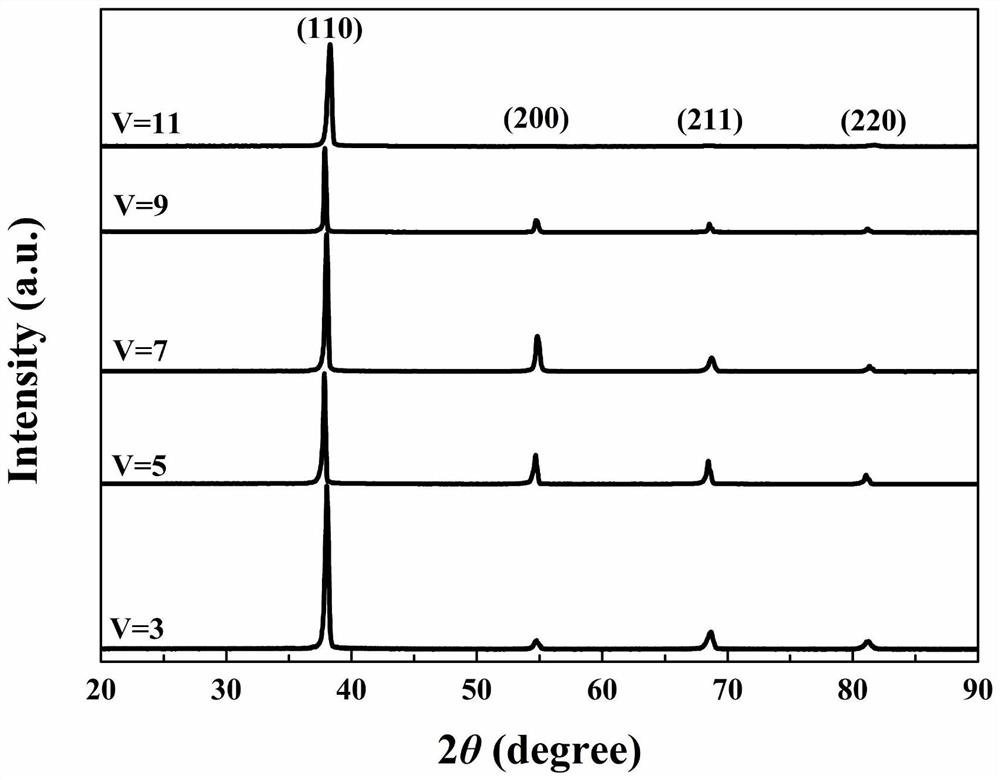

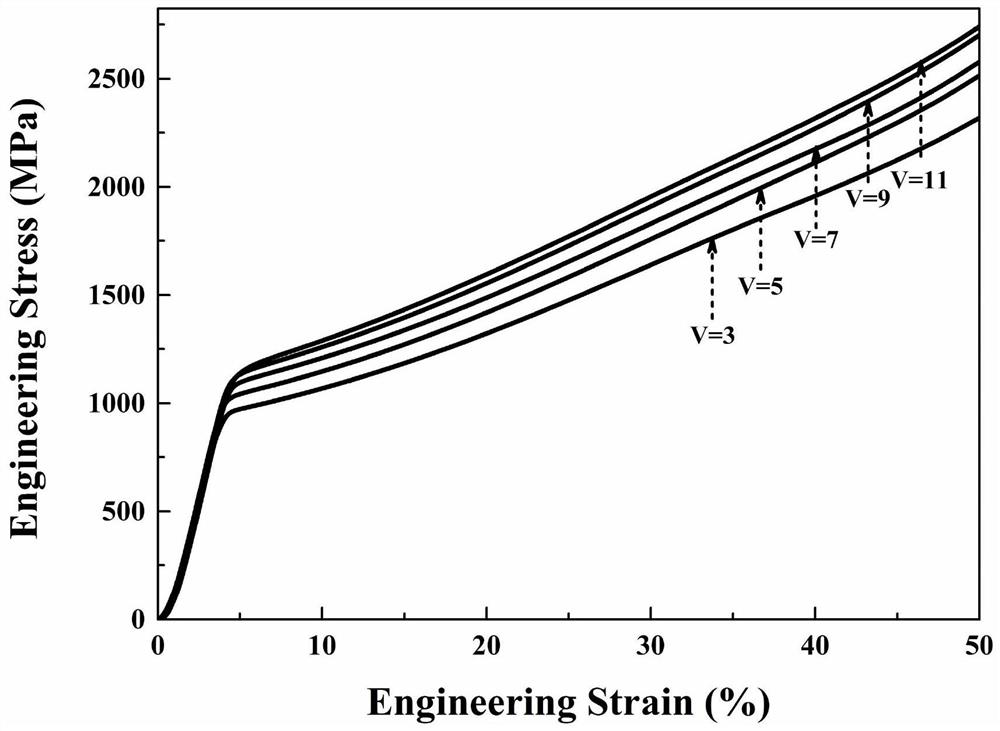

Refractory high-entropy alloy material with high plasticity and low neutron absorption section and preparation method thereof

InactiveCN112708817AHigh melting pointExcellent high temperature mechanical propertiesOptical rangefindersNuclear energy generationHigh entropy alloysUltimate tensile strength

The invention relates to a refractory high-entropy alloy material with high plasticity and low neutron absorption cross section and a preparation method thereof, and belongs to the technical field of high-entropy alloys. The high-entropy alloy material is AlVTiNbZr high-entropy alloy, wherein the atomic percent of an aluminum element is 5%-10%, the atomic percent of a V element is 3%-15%, the atomic percent of a Ti element is 20%-40%, the atomic percent of an Nb element is 25%-35%, and the atomic percent of a Zr element is 20%-35%. The AlVTiNbZr high-entropy alloy is of a single-phase BCC structure. The AlVTiNbZr high-entropy alloy is obtained in a vacuum arc melting mode, has a high theoretical melting point, low alloy density, high room-temperature yield strength and deformation plasticity, can resist deformation failure in the service process, and brings sufficient safety margin in the service process.

Owner:CHONGQING UNIV

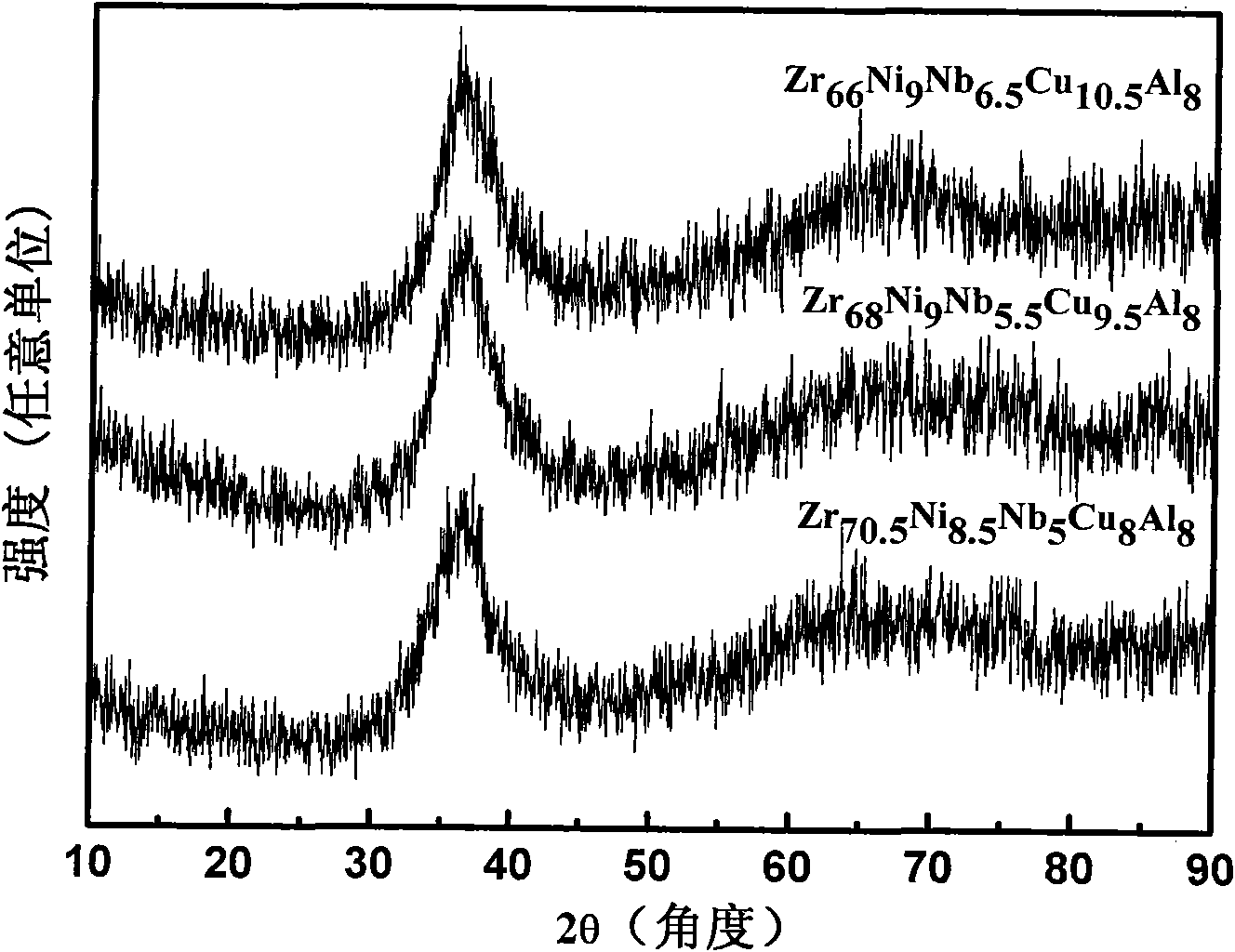

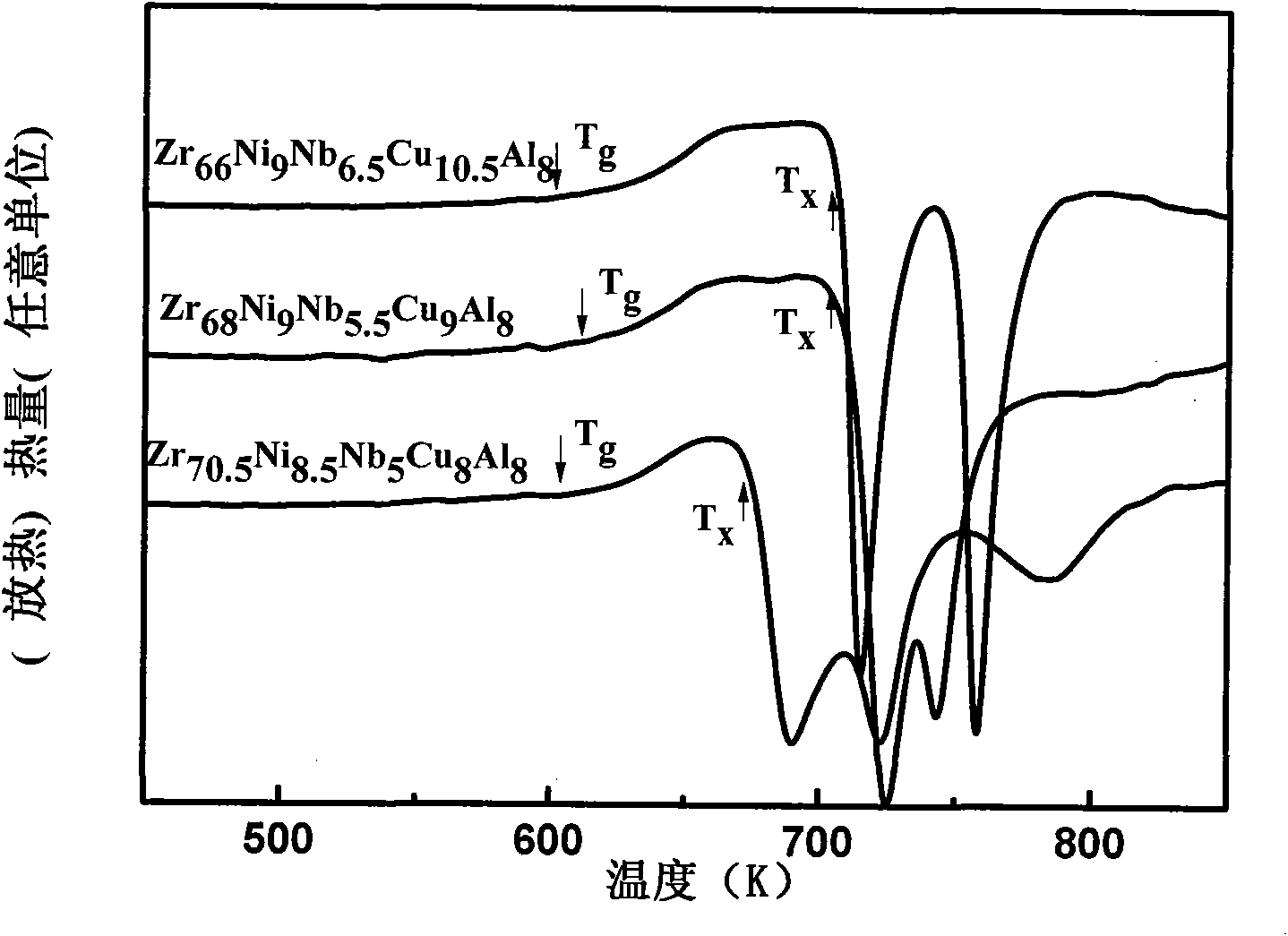

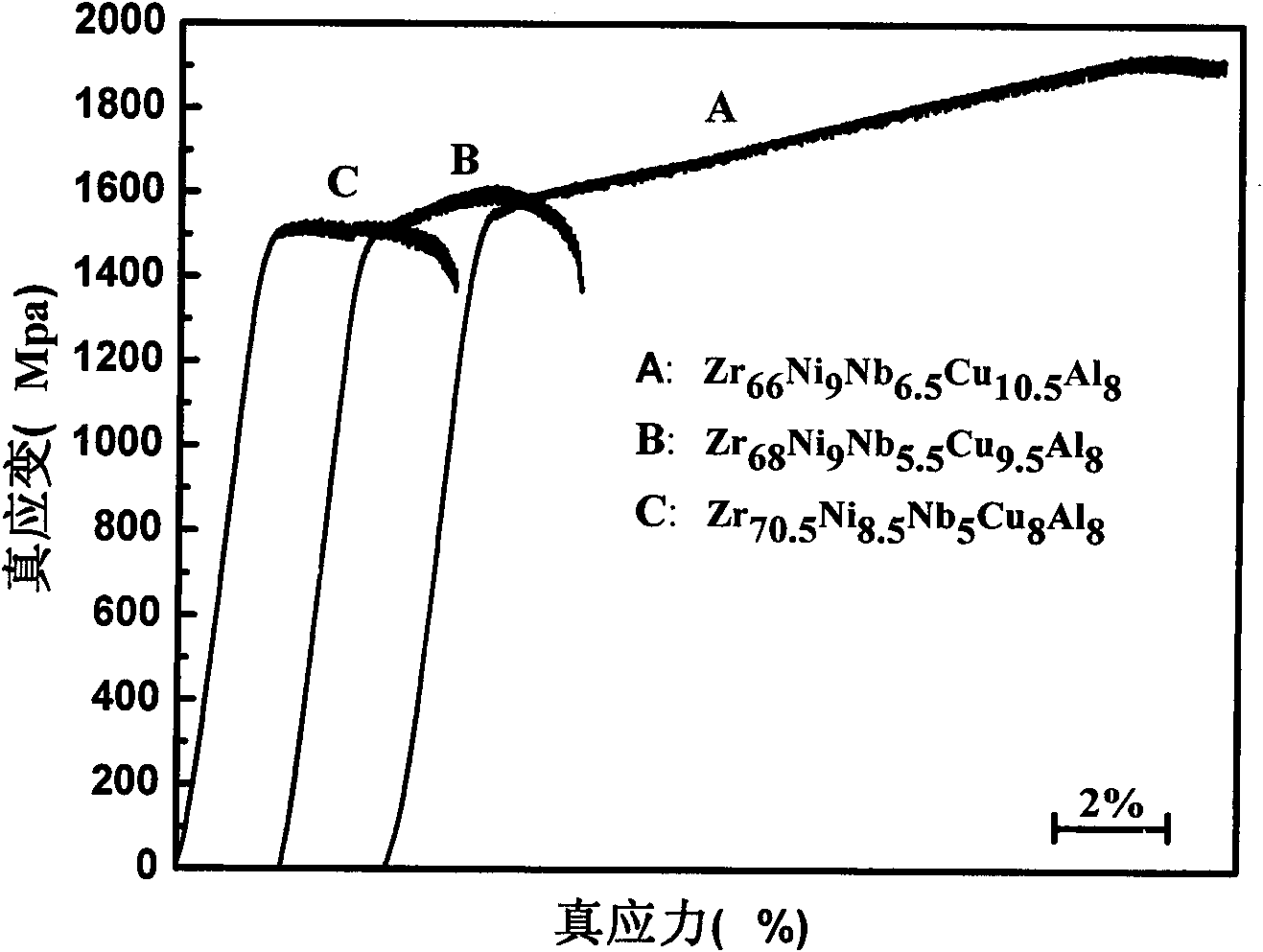

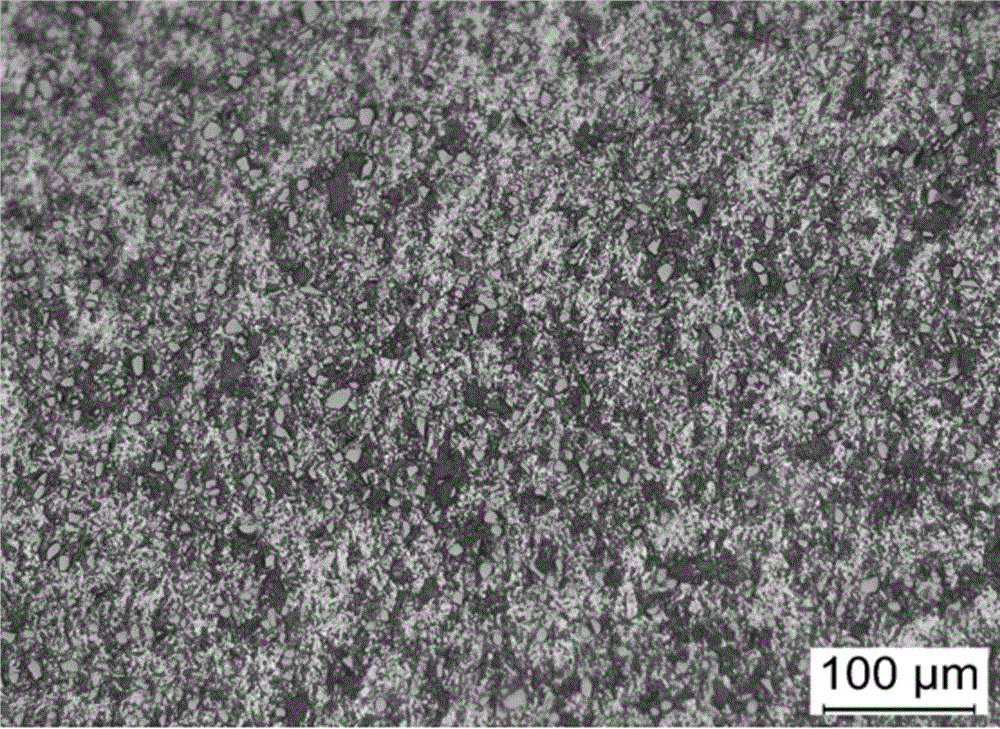

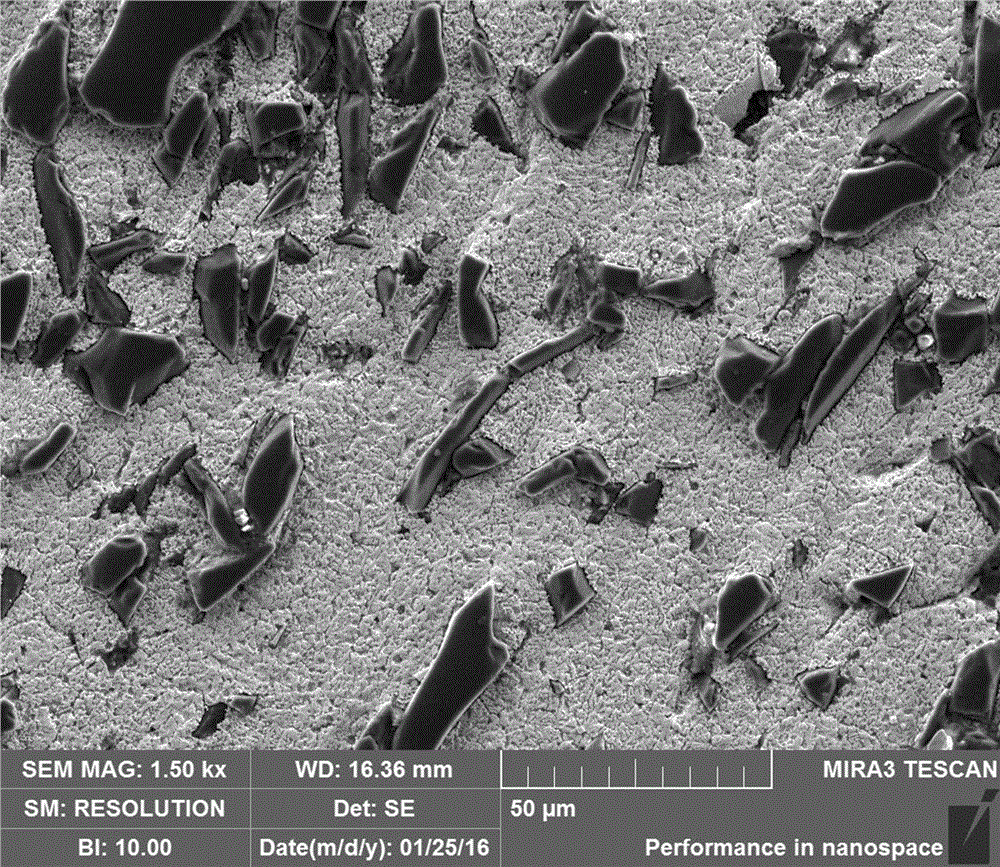

Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content

The invention relates to a Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content. The Zr-Cu-Ni-Al-Nb bulk amorphous alloy includes the following chemical components (atom percent): 66-72 Zr, 7.0-10.0 Ni, 3.0-7.0 Nb, l6.0-10.0 Al and 8.0-12.0 Cu. The material can form a bulk amorphous alloy under the ordinary casting condition, the required critical cooling rate is low, the thermal stability is good and a wide surfusion phase region is provided; under the condition that the atom percent of Zr is not lower than 66 percent, the corrosive resistance of the bulk amorphous alloy to various acid, alkali and salt is enhanced and the specific weight of the alloy is reduced; the plastic deformation property of the bulk amorphous alloy is enhanced by adding a proper amount of Nb elements, and the compression plastic deformation amount at the room temperature is higher than 7 percent; and meanwhile, the alloy has good corrosive resistance in high-temperature and high pressure water at 300-400 DEG C and in steam, proper mechanical property and lower atomic heat neutron absorption cross section.

Owner:UNIV OF SCI & TECH BEIJING

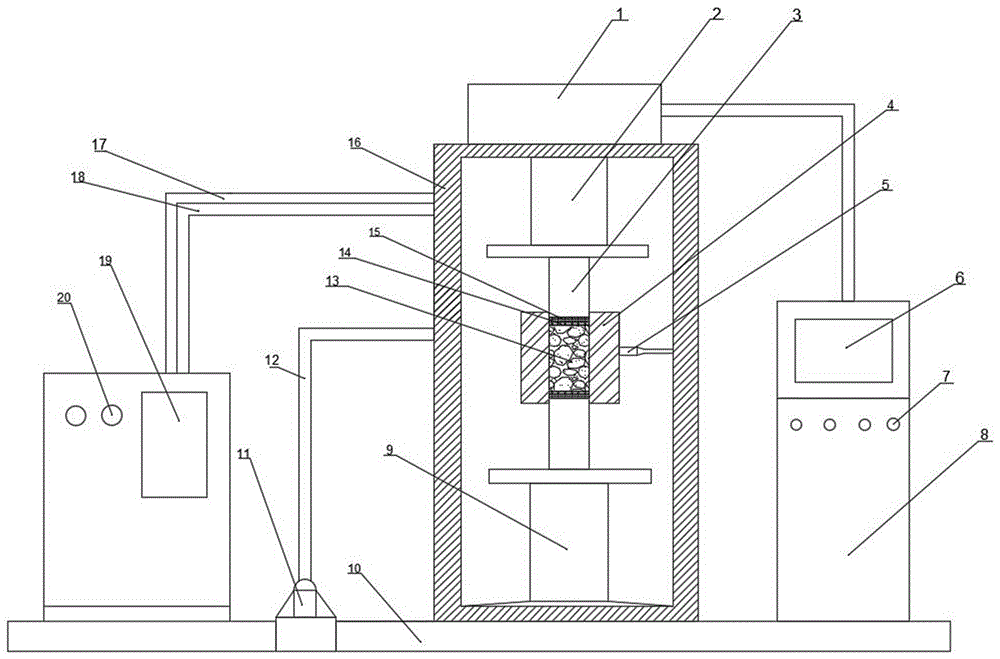

Preparation method of copper-based neutron absorbing material

InactiveCN105950897ASmall absorption cross sectionImprove plasticityNuclear energy generationReactors manufactureBoron carbideMixed materials

The invention discloses a preparation method of a copper-based neutron absorbing material. Specifically, the spark plasma sintering technique is used for applying pulse currents to mixed powder materials, so that joule heat and point discharge plasma are generated between particles, and the particles are made to melt locally to be connected in a metallurgical bonding mode; and the chemical materials used in the preparation process mainly include copper powder, boron carbide powder, absolute ethyl alcohol, hydrochloric acid, hydrofluoric acid, deionized water, graphite paper, sand paper and diamond paste. The preparation method comprises the steps of pretreatment of the copper powder, pretreatment of the boron carbide powder, weighing of the raw materials, ball milling of mixed materials, filling of powder, prepressing of a mold, spark plasma sintering for preparation, cleaning of the surface of a sample, detection and analysis of the sample and the like. The compactness of the prepared copper-based neutron absorbing material can reach 99% or over, the boron carbide in the copper-based neutron absorbing material is distributed in a dispersed mode, the bending strength can reach 350+ / -5 MPa, and the neutron absorbing performance can reach 98%.

Owner:TAIYUAN UNIV OF TECH

ZrC inert matrix dispersed pellet nuclear fuel as well as preparation method and application thereof

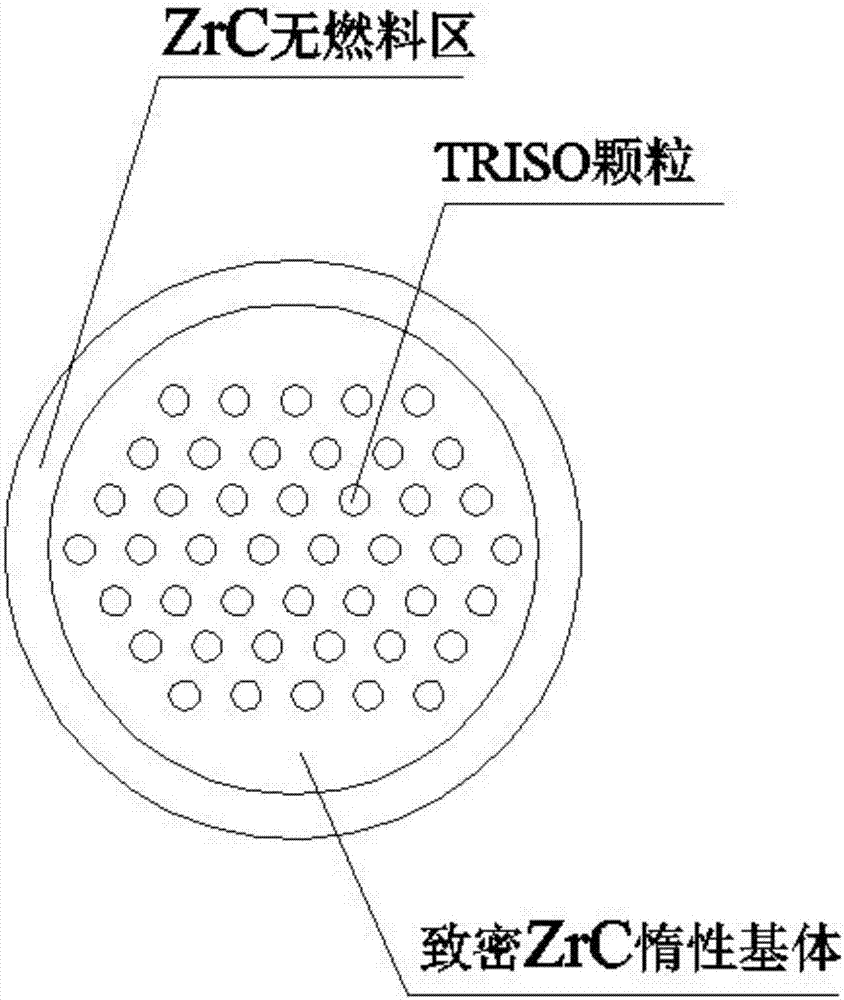

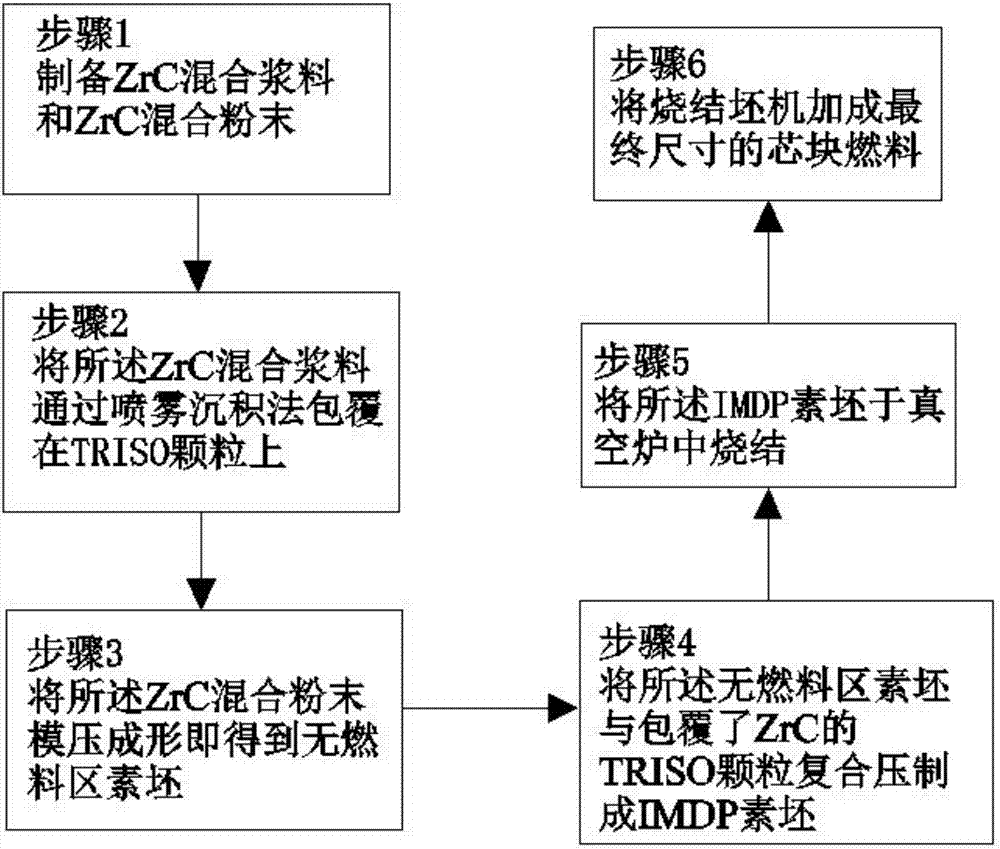

ActiveCN107093468AImprove fault tolerance performanceImprove securityNuclear energy generationReactors manufactureVacuum furnaceReactor safety

The invention discloses ZrC inert matrix dispersed pellet nuclear fuel as well as a preparation method and application thereof and aims at solving the problems in the prior art that since thermal conductivity of an inert matrix of dispersed nuclear fuel is reduced rapidly under the irradiation condition, fault-tolerant performance is reduced and reactor safety is influenced. The ZrC inert matrix dispersed pellet nuclear fuel comprises the inert matrix, a fuel element and a fuel-free zone protective layer, wherein the inert matrix is ZrC, and the fuel-free zone protective layer is made from ZrC. The preparation method comprises the following steps: coating ZrC mixed slurry on TRISO particles by virtue of a spray deposition process to form a compact ZrC inert matrix, carrying out mould pressing on ZrC mixed powder to form a fuel-free zone biscuit, then carrying out complex pressing on the inert matrix and the fuel-free zone biscuit to form an IMDP biscuit, then sintering the IMDP biscuit in a vacuum furnace at high temperature, cooling the furnace, and then carrying out machining on a sintered billet according to the required size, so that a fuel assembly in a water reactor and a high temperature gas cooled reactor is obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

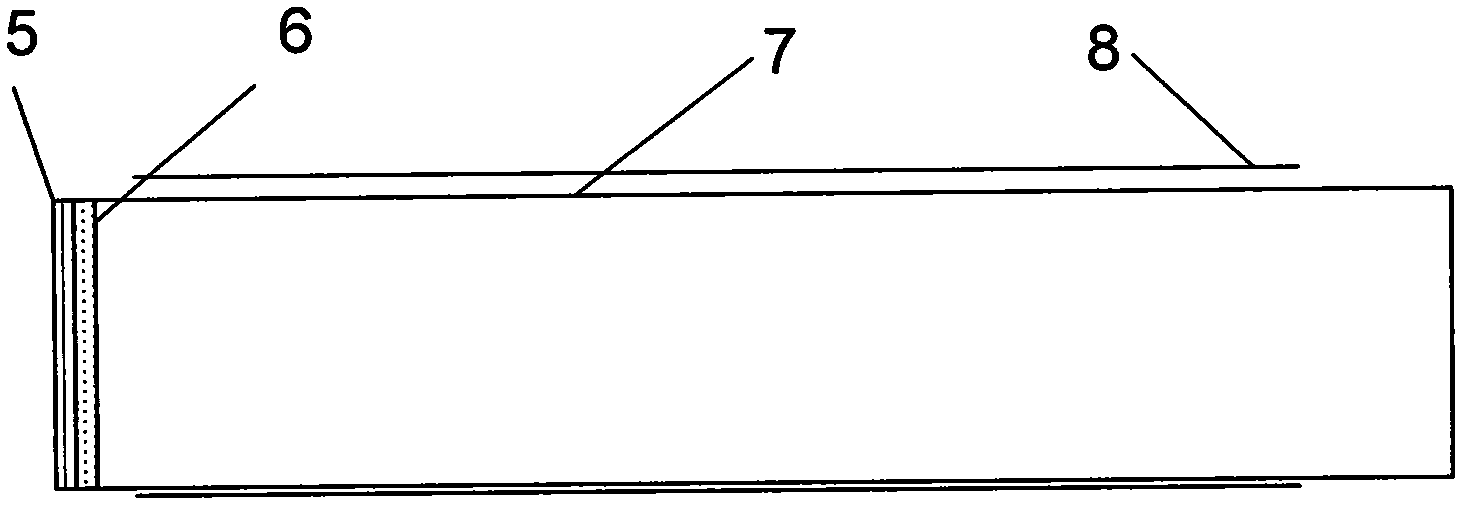

Portable neutron detection device

ActiveCN102253404ASmall absorption cross sectionImprove detection efficiencyMeasurement with scintillation detectorsEngineeringPhotomultiplier

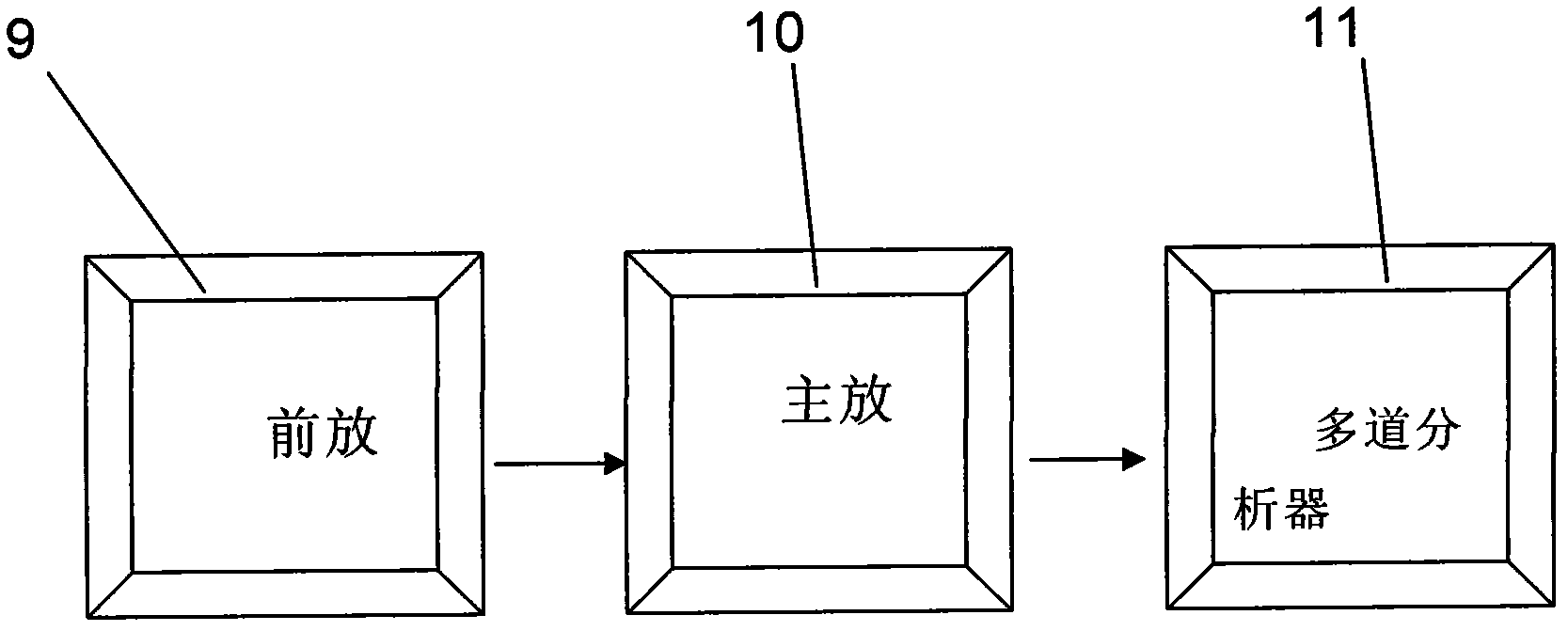

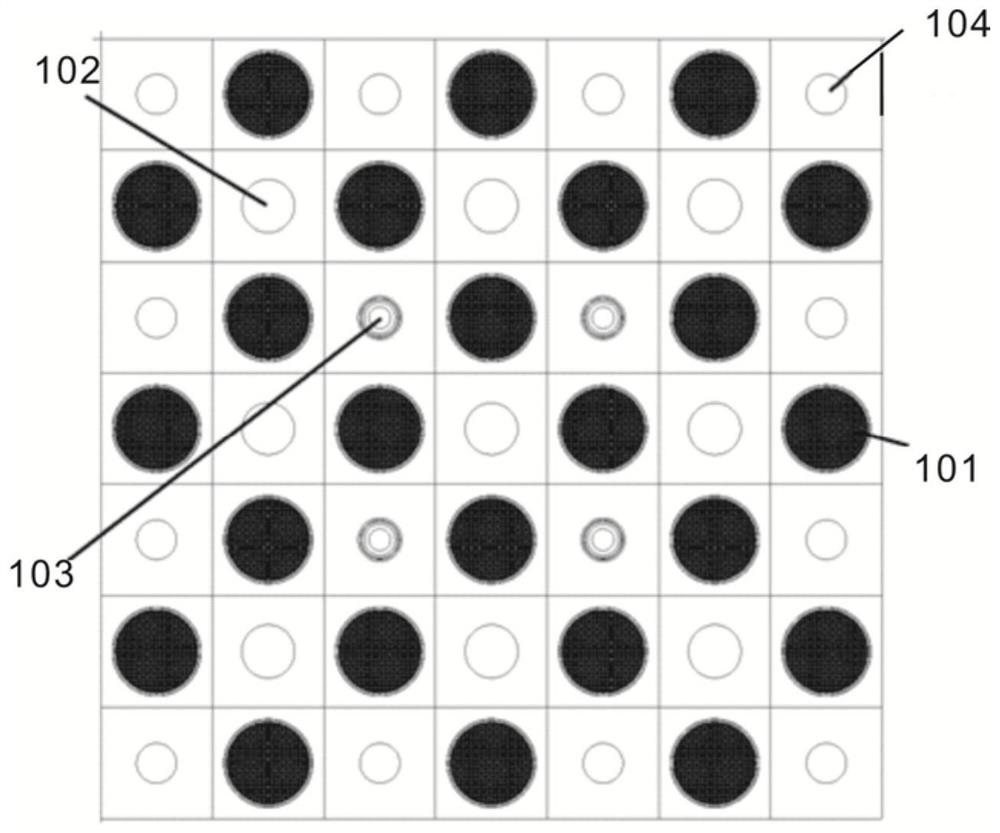

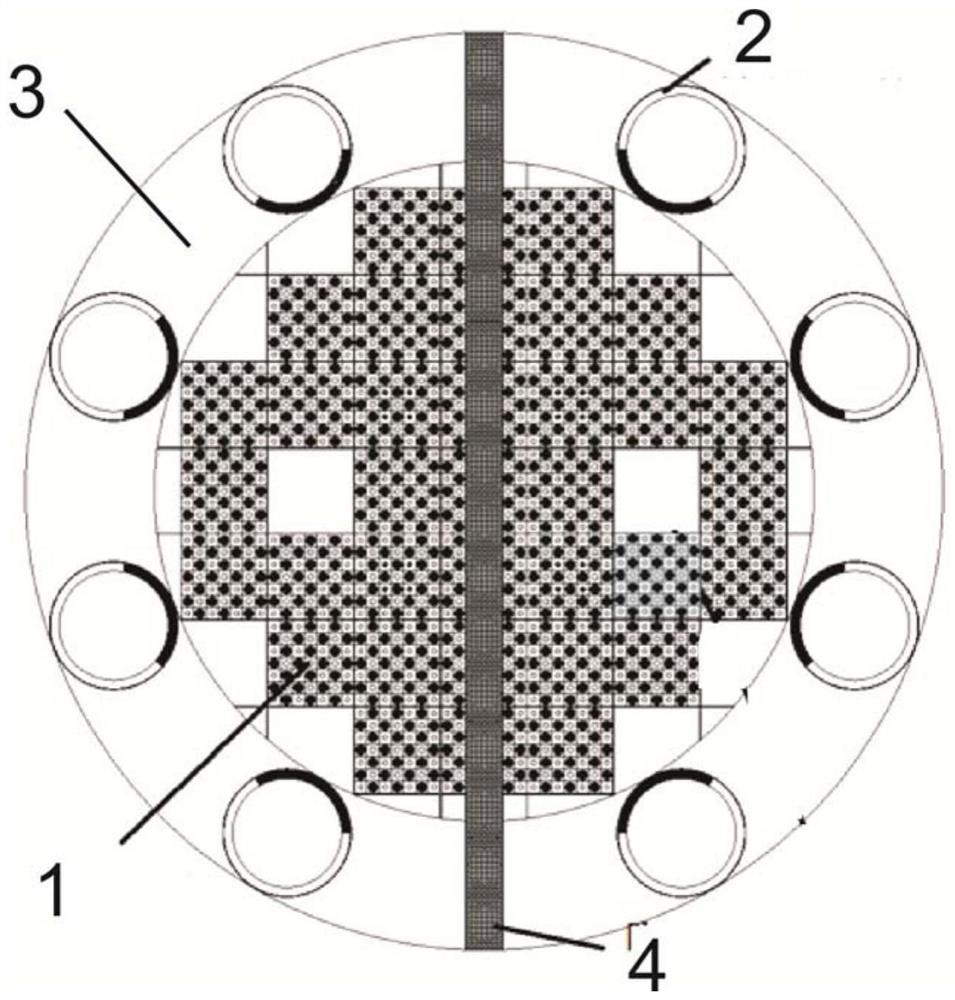

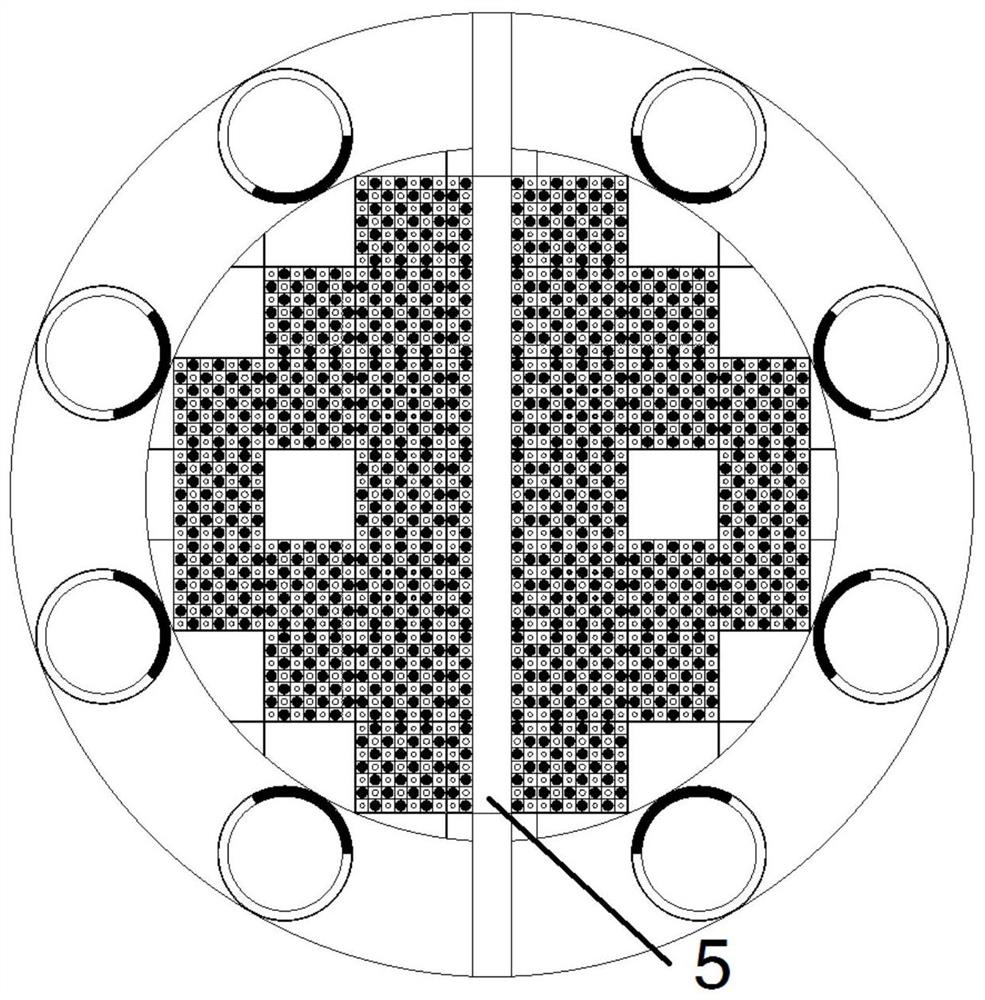

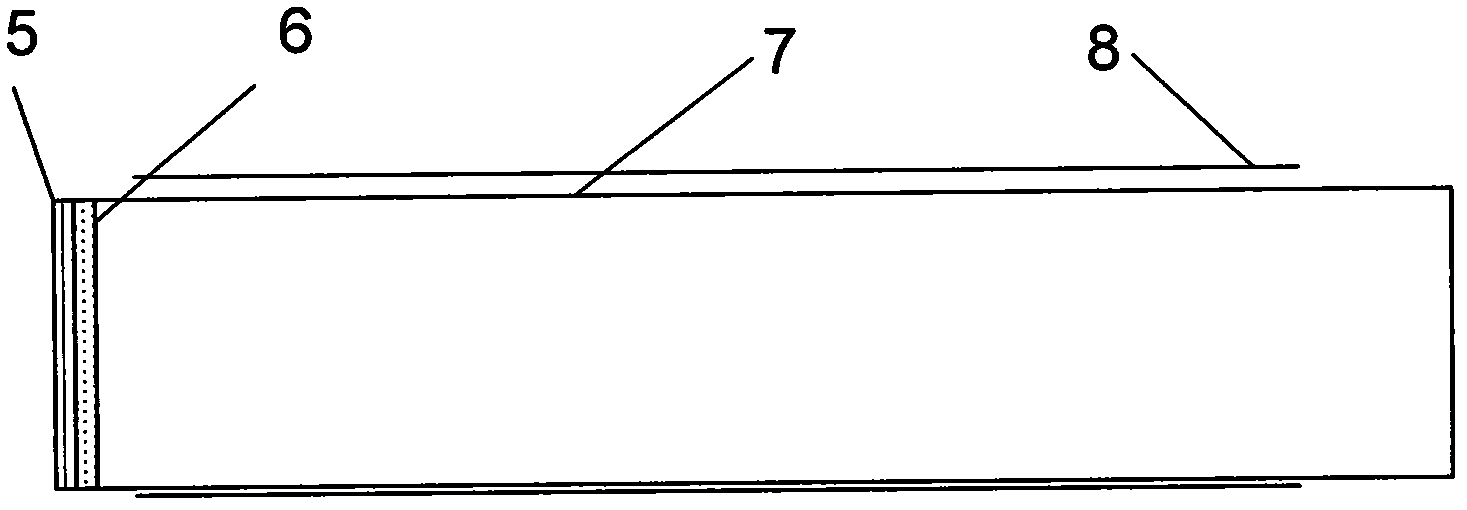

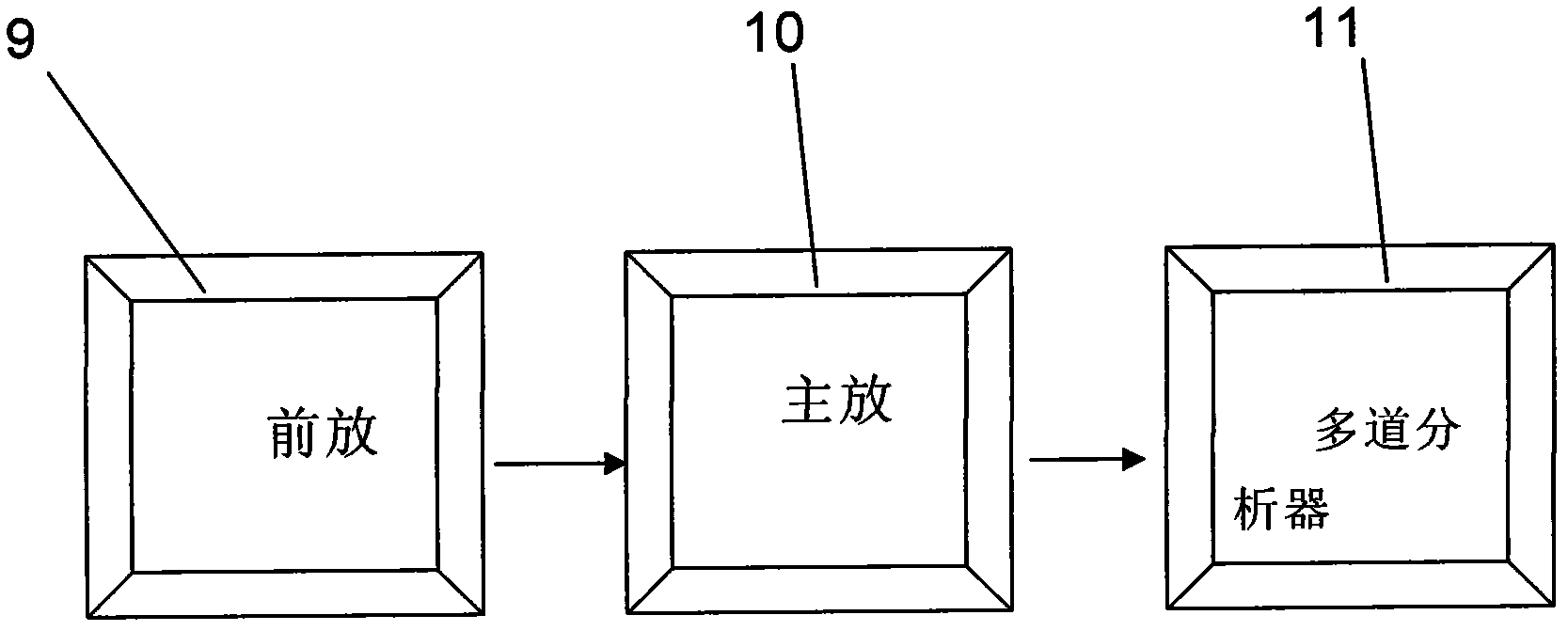

The invention relates to a portable neutron detection device. The device comprises an outer sleeve (2), as well as a neutron scintillator conversion screen (5), a photoconductive material (6), an end window photomultiplier (7) and a base (3) which are sequentially arranged in the outer sleeve (2) and are in compression fitting joint, wherein an output port (4) extruding at the outer end of the base (3) is formed at one end of the end window photomultiplier (7), and connected with a preamplifier (9), a main amplifier (10) and a multi-channel analyzer (11) in sequence through leads; a screwable protective cover (1) with an inner thread is arranged at the front end of the outer sleeve (2); the protective cover (1) and the outer sleeve (2) are made of an aluminum material; the screwing progress can be adjusted by rotating the protective cover (1); and a magnetic shielding material (8) is coated on the outer surface of the end window photomultiplier (7). The portable neutron detection device can effectively shield an outer optical signal, has high efficiency in neutron detection, and is simple in structure and convenient to carry.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Preparation method of SiC-based multi-phase ceramic solidified body for radioactive graphite solidification treatment

InactiveCN107500775AExcellent high temperature mechanical propertiesGood chemical stabilityRadioactive decontaminationRadiation stabilityPolyvinyl alcohol

The invention discloses a preparation method of a SiC-based multi-phase ceramic solidified body used for radioactive graphite solidification treatment, and the preparation method is characterized by comprising the following steps: using silicon powder, graphite powder, MgO and Al (OH) 3 as raw materials, preparing MgAl2O4 powder, preparing Si-C powder, preparing SiC-MgAl2O4 multi-phase powder, adding polyvinyl alcohol, performing sol-granulating, shaping and glue discharging, vacuum hot-pressing sintering and the like to obtain the SiC-based multi-phase ceramic solidified body at low temperature. The SiC-based multi-phase ceramic solidified body with excellent anti-radiation stability, chemical stability, mechanical stability and thermal stability is prepared from the safe and cheap raw materials by a simple and practical vacuum hot-pressing sintering technique at the low temperature. The prepared SiC-based multi-phase ceramic solidified body is particularly suitable for the ceramic solidification treatment of high-radioactive activity graphite waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

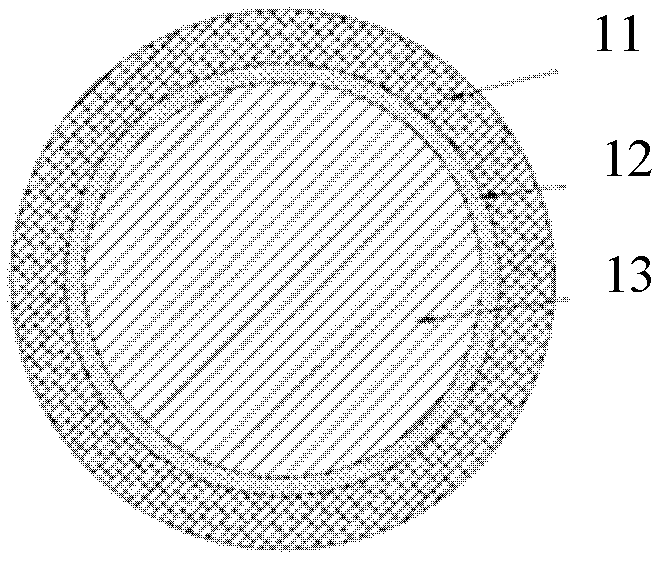

ZrC and UO2 composite fuel pellet as well as preparation method and application of ZrC and UO2 composite fuel pellet

ActiveCN108417279ASmall absorption cross sectionImprove securityNuclear energy generationReactors manufactureLubricantMaterials science

The invention discloses a ZrC and UO2 composite fuel pellet as well as a preparation method and application of the ZrC and UO2 composite fuel pellet and aims at solving the problem that UO2 is super-low in heat conductivity to result in relatively low safety performance of a fuel assembly in the prior art. The ZrC and UO2 composite fuel pellet disclosed by the invention is prepared by sintering raw materials including UO2 and ZrC at high temperature, wherein the enrichment degree of 235U in UO2 is 1%-5%, and the dosage of ZrC does not exceed 10vol% of total quantity of UO2 and ZrC. The preparation method disclosed by the invention comprises the steps: uniformly mixing UO2, ZrC and a lubricant according to a certain proportion, carrying out high-temperature sintering, carrying out furnace cooling, then, taking out a sample, and processing the sample to the required shape and size. By using the ZrC and UO2 composite fuel pellet disclosed by the invention, the heat conductivity of UO2 canbe effectively increased, so that the safety performance of the fuel assembly is improved. The preparation method disclosed by the invention is simple and convenient to operate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Modularized transverse prism type air-cooled micro-reactor core system

PendingCN113270208AEnsure safetyAvoid erosionNuclear energy generationShieldingInherent safetyGraphite

The invention discloses a modularized transverse prism type air-cooled micro-reactor core system which comprises a fuel assembly, a drum control rod, an absorber ball and a reflecting layer; the reflecting layer covers a reactor core formed by the fuel assembly; the drum control rod is arranged on the side reflecting layer; the reactor core is provided with a central graphite ribbon; an absorber ball channel is arranged in the central graphite ribbon; the fuel assembly is provided with fuel rod channels, coolant channels and beryllium oxide rods which are regularly arranged at intervals so as to enhance moderation. The system has the beneficial effects that the fuel is microencapsulated by the ceramic so that the fuel is prevented from being eroded; the system has the advantages of high heat capacity, high temperature resistance, high heat conductivity, high slowing-down ratio, small thermal neutron absorption cross section and the like; the inherent safety of automatic thermal shutdown only depending on temperature negative feedback is achieved; the drum control rod and the absorber ball not only can effectively control reactivity and ensure the safety of the reactor core, but also can save space, so that the reactor core system and the reactor can be arranged in a common container and are convenient to transport.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Porous rare earth titanate heat-isolating material and preparation method and application thereof

The invention relates to a porous rare earth titanate heat-isolating material and a preparation method and an application thereof. The porous rare earth titanate heat-isolating material is of a porousstructure and the composition of the material is (Re2O3)X(TiO2)(1-X), wherein Re is at least one of Y and lanthanide elements, and X is equal to 0.2-0.8, preferably 0.4-0.7. The porosity of the porous rare earth titanate heat-isolating material is 10-90% and the pore diameter is 0.1-500 microns.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

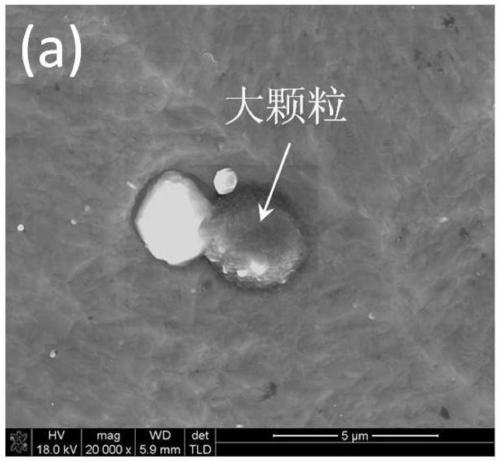

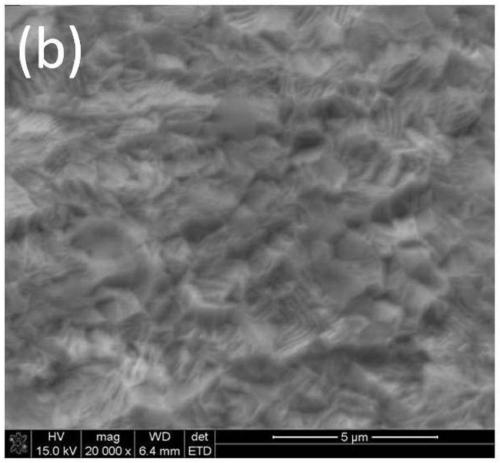

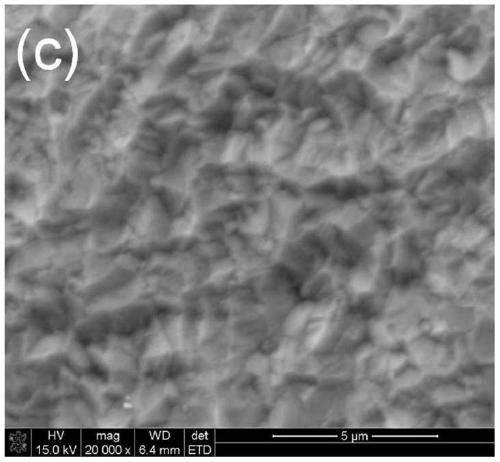

Zirconium alloy coating with high burnup and long service life and preparation method of zirconium alloy coating

ActiveCN109811316AImprove compactnessHigh fuel consumptionVacuum evaporation coatingSputtering coatingZirconium alloyBinding force

The invention relates to a zirconium alloy coating with high burnup and long service life and a preparation method of the zirconium alloy coating. Zirconium alloy is a fuel element cladding material,the coating is a metal Cr coating, the purity of metal Cr is 99.95%, and the thickness of the coating is 1-10 microns. The zirconium alloy coating is mainly used for improving the corrosion resistanceand high temperature oxidation resistance of a zirconium alloy cladding so as to improve the inherent safety of a fuel element and prolong the refuelling cycle. The invention also provides the preparation method of the zirconium alloy coating. By optimizing the method, better coating binding force and a fine coating surface structure are obtained.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

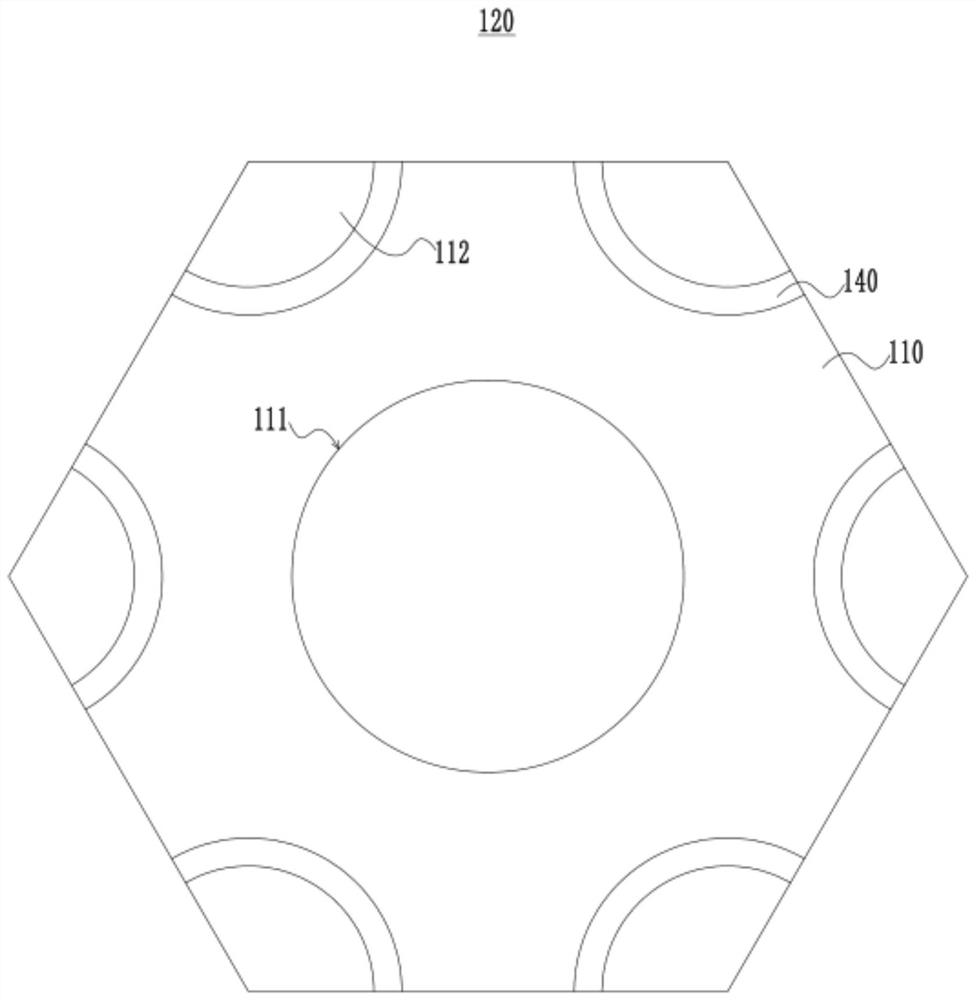

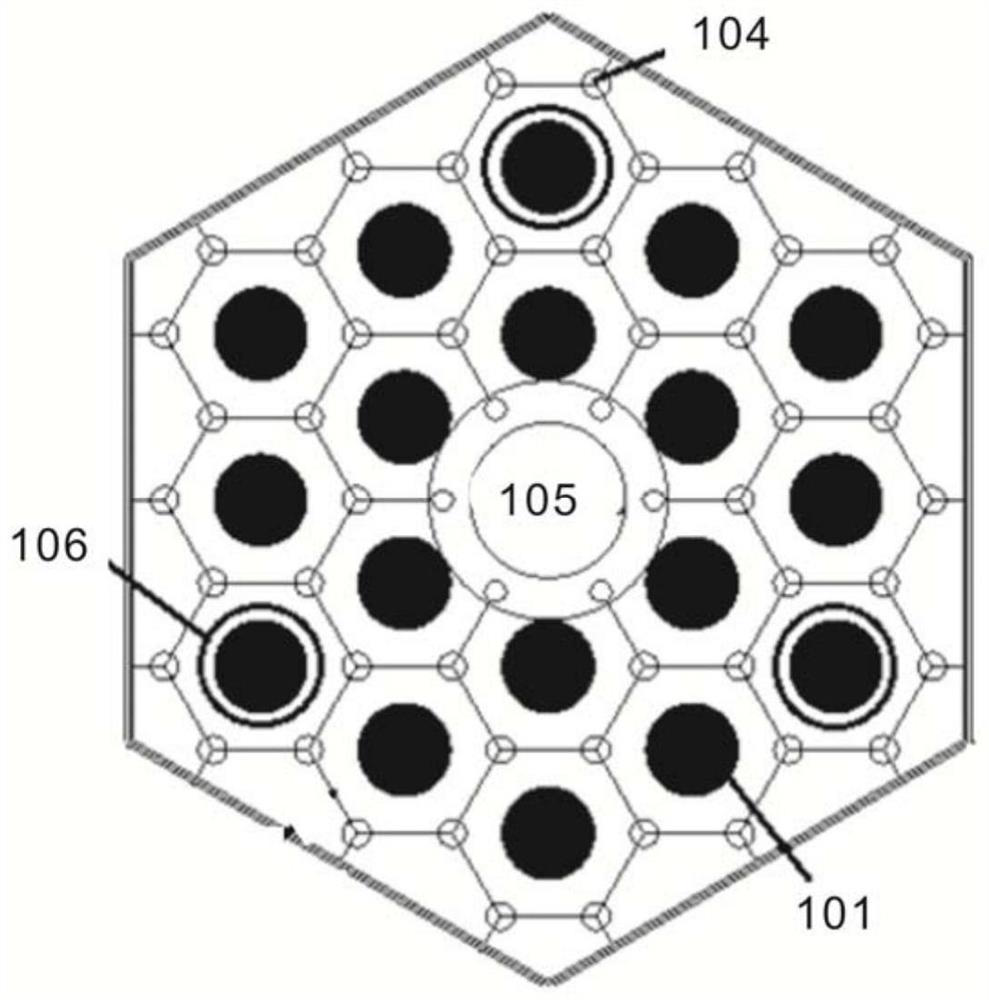

Compact reactor core applied to land mobile power supply and land mobile power supply

PendingCN114283953AIncrease powerCompact structureNuclear energy generationShieldingNuclear reactorUranium carbide

The invention provides a compact reactor core applied to a land mobile power supply and the land mobile power supply, relates to the technical field of nuclear reactors, and is designed for solving the problem that the structure of the existing land small-sized gas-cooled nuclear reactor is not compact enough. The compact reactor core applied to the land mobile power supply comprises a reactor core active area, a reflecting layer wrapping the periphery of the reactor core active area and a pressure bearing layer wrapping the periphery of the reflecting layer, the reactor core active area comprises a plurality of hexagonal fuel elements, and the plurality of fuel elements are closely arranged in a honeycomb shape; the center of the fuel element is a fuel rod with a circular cross section, and the hexagon is a coolant inlet channel; the fuel rod comprises uranium carbide fuel; the cooling agent is helium and xenon mixed gas. The land mobile power supply comprises the compact reactor core applied to the land mobile power supply. The compact reactor core applied to the land mobile power supply and the land mobile power supply provided by the invention are more compact in structure on the premise of the same power.

Owner:SHANGHAI JIAO TONG UNIV

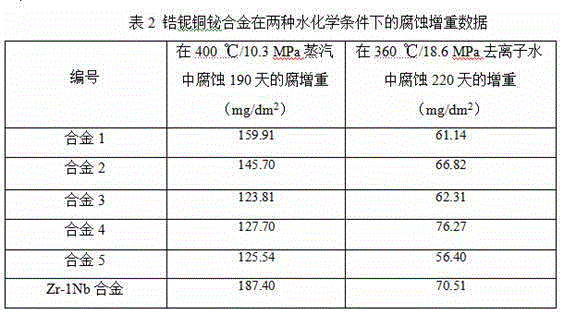

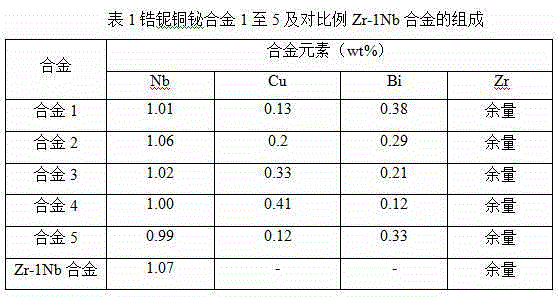

Zirconium/niobium/copper/bismuth alloy for fuel cladding of nuclear power plant

InactiveCN105018794AGood corrosion resistanceSmall absorption cross sectionOptical rangefindersNuclear energy generationAlloy elementZirconium alloy

The invention relates to a zirconium / niobium / copper / bismuth alloy used as such structural materials as a fuel cladding of a pressurized water reactor nuclear power plant and a positioning grillwork strip, and belongs to the technical field of zirconium alloy materials. The zirconium alloy comprises the following chemical components in percentage by weight: 0.7-1.2% of Nb, 0.05-0.6% of Cu, 0.05-1.0% of Bi, and the balance of Zr. The preferential range of the alloy elements is as follows: 0.8-1.2% of Nb, 0.1-0.4% of Cu, and 0.1-0.4% of Bi. The zirconium alloy is excellent in corrosion resistance in superheated steam of 400 DEG C / 10.3 MPa and de-ionized water of 360 DEG C / 18.6 MPa, is obviously superior to a Zr-1Nb alloy, is excellent in machinability, and can be used as such core structural materials as the fuel element cladding and the positioning grillwork strip in a pressurized water reactor of the nuclear power plant.

Owner:SHANGHAI UNIV

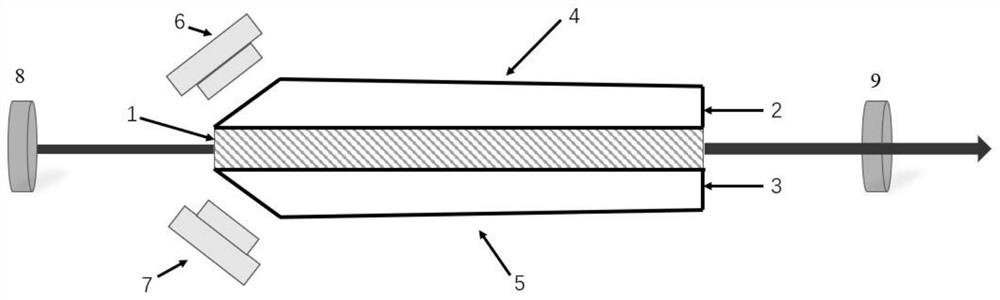

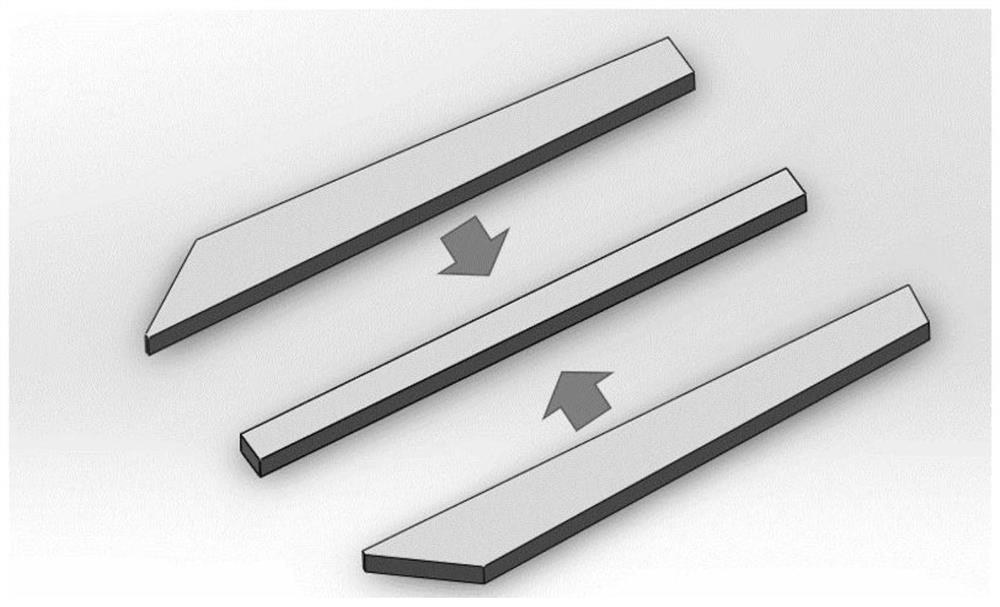

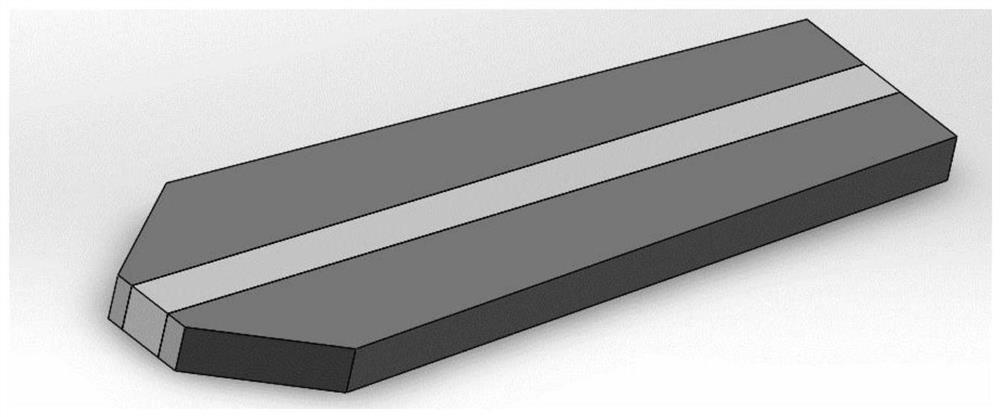

Structure for increasing one-way gain through angular side pumping and implementation method

InactiveCN111769431ASmall emission cross sectionEmission cross section is smallOptical resonator shape and constructionActive medium shape and constructionLight beamEngineering

The invention discloses a structure for increasing one-way gain by side pumping and an implementation method. A non-absorptive cladding material is bonded on the outer side of a gain medium, so that pumping light is reflected on an upper reflecting surface, a lower reflecting surface and side surfaces of a cladding; and the two side surfaces have a relative angle, the light travels back and forthalong the gain medium while being reflected by the side surfaces, so that the light can pass through the gain medium for multiple times, the absorption of the gain medium is increased, and the size ofthe gain medium is effectively reduced while the pumping light absorption frequency is increased. Because the pump light is reflected for multiple times and passes through the gain medium, the energydistribution of the pump light is more uniform, the cladding material has high thermal conductivity, the temperature gradient of the gain medium can be effectively reduced, the possibility of damaging a device is reduced, and the quality of an output light beam is improved.

Owner:BEIJING UNIV OF TECH

Nuclear Fuel Rods Using Ceramic Clad Metal Pellets

ActiveCN103295652BImprove mechanical propertiesReduce breakageOptical rangefindersNuclear energy generationComposite ceramicHeat conducting

The invention aims at providing a nuclear fuel rod with ceramic cladding and metallic pellet. The nuclear fuel rod with ceramic cladding and metallic pellet has the advantages that the heat-conducting property of the nuclear fuel rod can be improved, the central temperature of the fuel pellet is lowered or the fuel power density is effectively improved, the fuel rod cladding mechanical property, corrosion resistance and radiation resistance are greatly improved, the breakage rate of the fuel rod is lowered, the discharge burnup of the fuel rod is remarkably increased and the fuel utilization rate is greatly improved; meanwhile, the fuel rod has good neutronics performance, and can be widely used in a fast reactor or a thermal reactor. The cladding of the nuclear fuel rod provided by the invention is a SiCf / SiC composite ceramic material cladding, the metallic fuel pellet adopts a U-Zr or U-Pu-Zr alloy fuel pellet; a gap between the cladding and the fuel pellet is filled with low-melting-point metal; and a lengthened air cavity is designed at the upper part of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Preparation technology of neptunium oxide target pellet

ActiveCN106847353AConvenient chemical dissolutionImprove dissolution rateNuclear energy generationReactors manufacturePartial oxidationStearic acid

The invention belongs to the field of nuclear material preparation and provides a preparation technology of a neptunium oxide target pellet for solving the problems that an existing preparation technology of a neptunium oxide target is relatively low in overall neptunium loading capacity, relatively high in production cost and relatively complicated in process. The technology comprises the following steps: (1) taking neptunium oxide powder and magnesium oxide powder as a target pellet material; (2) taking out part of neptunium oxide powder and mixing with the magnesium oxide powder to obtain preliminarily mixed powder; (3) adding the remaining neptunium oxide powder and further mixing with stearic acid to obtain mixed powder; (4) carrying out cold press molding to prepare a target pellet body; and (5) carrying out pressureless sintering to prepare the neptunium oxide target pellet. The preparation technology has the advantages of being simple in technological process and low in cost; the prepared neptunium oxide target pellet is high in overall neptunium loading capacity and high in neutron utilization rate, has relatively high thermal conductivity and good in-pile irradiation performance, and is convenient to chemically dissolve and extract and suitable for massive production of 238Pu fuel.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

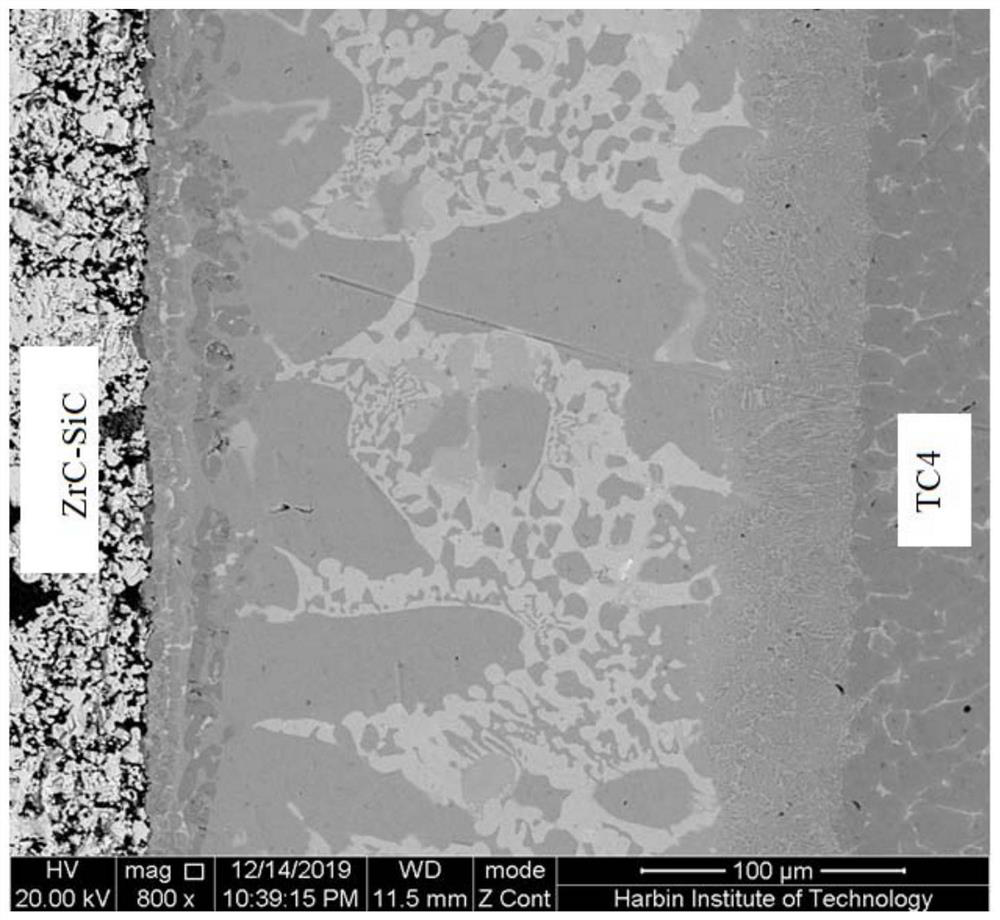

ZrC-SiC ceramic and TC4 titanium alloy brazing method

ActiveCN112427759AReduce the proportionSmall expansion coefficientSoldering auxillary devicesGraphiteGraphene

The invention discloses a ZrCSiC ceramic and TC4 titanium alloy brazing method, and relates to a ZrCSiC ceramic and TC4 titanium alloy brazing method. The problems that when existing ZrCSiC ceramic and TC4 titanium alloy are brazed, wettability of brazing filler metal to a base metal is poor, brittle compounds are prone to being generated in brazing seams, a metal base metal is excessively dissolved, and connector residual stress is large are solved. The method comprises the steps: adding ZrH2 powder into Cu powder, wherein graphene grows on the surface of the Cu powder, and adding ZrH2 for tabletting to obtain a brazing filler metal foil; and performing brazing after assembling. According to the method, the vertical few-layer graphene grows on the surface of the Cu powder in situ, so thatthe reinforced composite brazing filler metal containing the graphene is prepared, the proportion of brittle compounds in brazing seams is reduced, the joint residual stress is relieved, and the wettability of the brazing filler metal to base metal is improved. Generation of the brittle compounds is avoided, and the problem of excessive dissolution of the base metal is solved. The method is suitable for brazing the ZrCSiC ceramic and the TC4 titanium alloy.

Owner:HARBIN INST OF TECH

Zr-Ni brazing filler metal used for nuclear reactor core structure brazing and preparing method and application of Zr-Ni brazing filler metal

InactiveCN108907509ASmall absorption cross sectionImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaNuclear reactor coreNuclear reactor

The invention discloses Zr-Ni brazing filler metal used for nuclear reactor core structure brazing and a preparing method and application of the Zr-Ni brazing filler metal, and relates to Zr-Ni brazing filler metal and the preparing method and application of the Zr-Ni brazing filler metal. In order to solve the problem that in existing brazing filler metal for reactor Zr4 alloy structure piece brazing, the Be element is hypertoxic, the Zr-Ni brazing filler metal is prepared from, by mass ratio, 82%-84% of Zr and the balance Ni. According to the preparing method, raw materials are weighed, washed and dried to be placed into a crucible; and electric arc melting is carried out, cutting is carried out to form sheets, and the Zr-Ni brazing filler metal is obtained. The melting point of the Zr-Ni brazing filler metal is similar to the melting point of Zr-Be brazing filler metal, the brazing temperature can be reduced, the Ni element in the brazing filler metal is non-toxic, and therefore processing, producing and use are easier. The Zr-Ni brazing filler metal is suitable for welding a Zr4 alloy.

Owner:HARBIN INST OF TECH

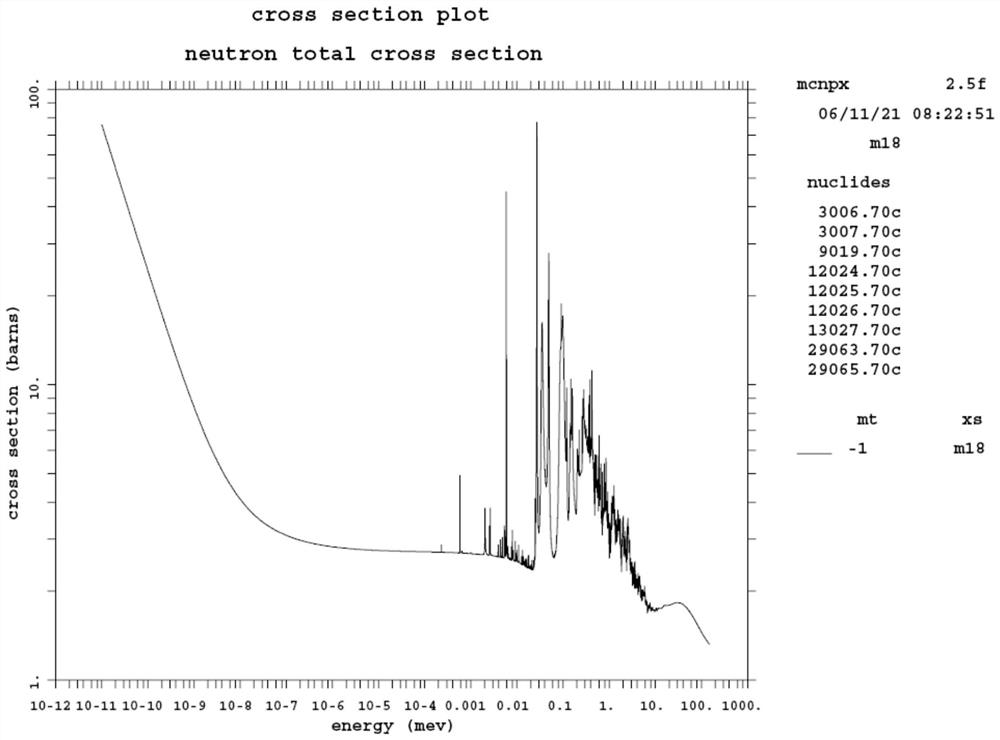

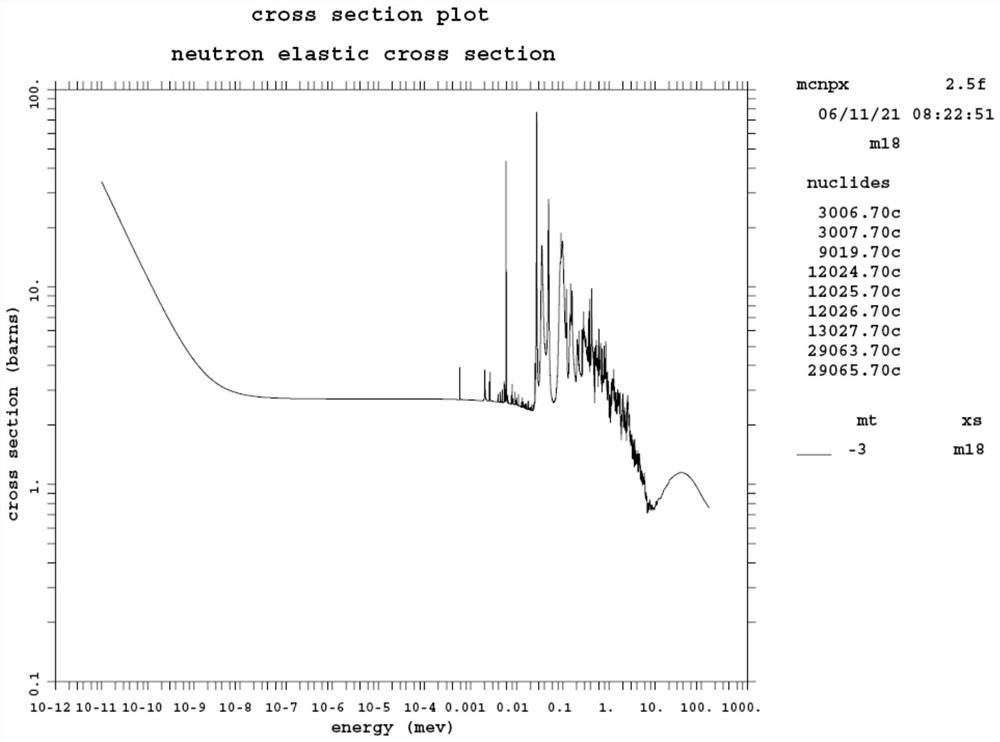

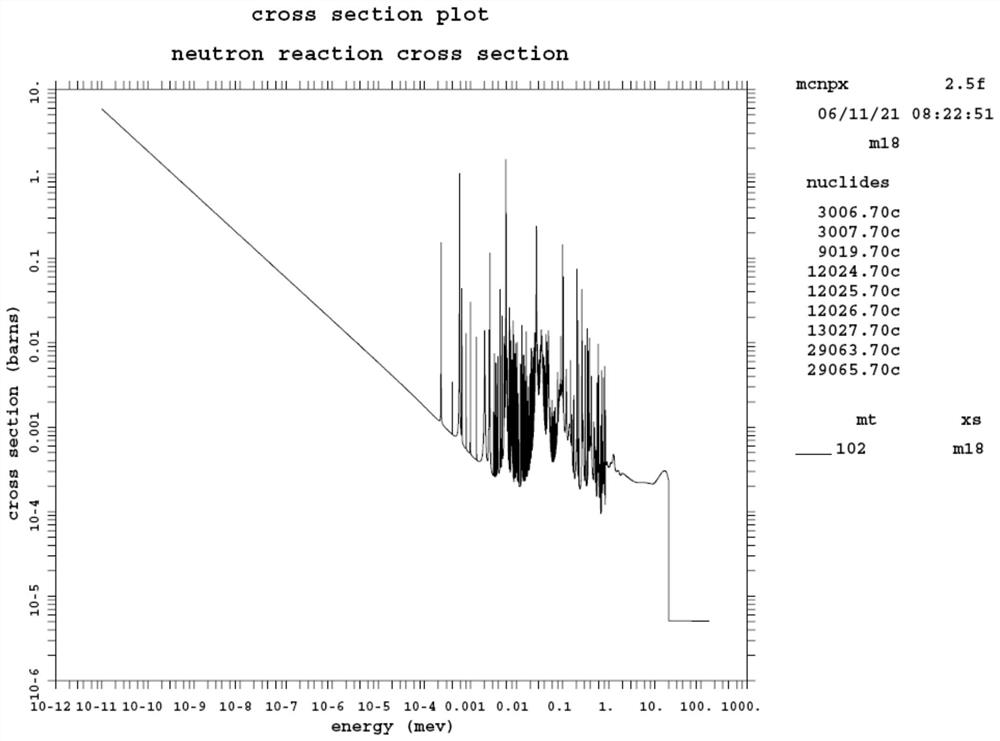

Neutron deceleration composite material

PendingCN113897526ALow radioactivityFree from harmX-ray/gamma-ray/particle-irradiation therapyAluminum fluorideMulti material

The invention discloses a neutron deceleration composite material. The neutron deceleration composite material comprises a mixed material, a material which accounts for 0.1-5% of the weight of the mixed material and contains a 6Li element, and Cu which accounts for 0.1-5% of the weight of the mixed material, and the mixed material comprises one or a mixture of more of Al, MgF2 and AlF3; the mixed material comprises the following components in percentage by mass: 10-95% of pure aluminum powder, 20%-80% of aluminum fluoride powder, 0.1%-15% of magnesium fluoride powder; the material containing the < 6 > Li element is < 6 > LiF powder; the mixed material further comprises pure magnesium powder, and the mass percent of the pure magnesium powder is 0.1-5%. The radioactivity of the material can be attenuated to an exemption level or below within a short time when the material is decommissioned at the last stage of the device or equipment, and the neutron deceleration composite material has obvious advantages in the aspects of radioactive waste disposal method and economy.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +1

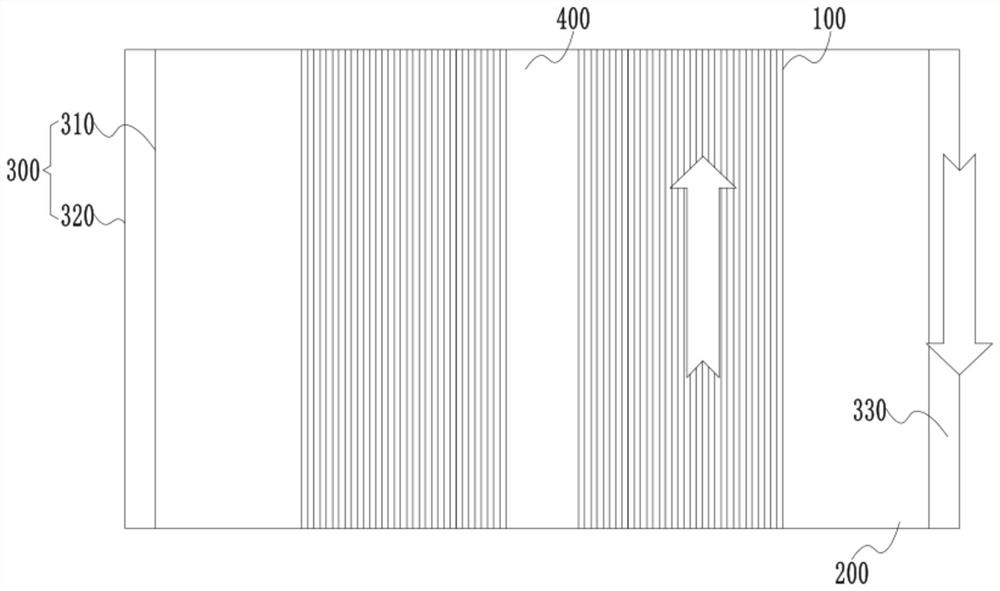

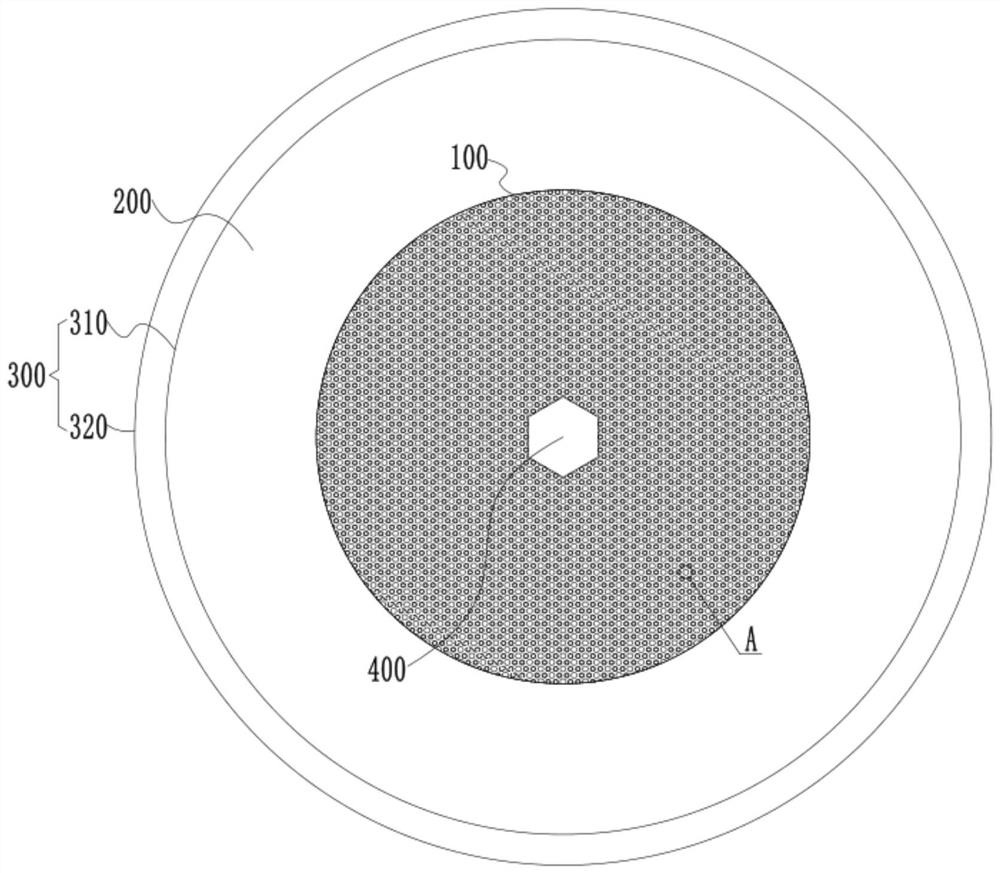

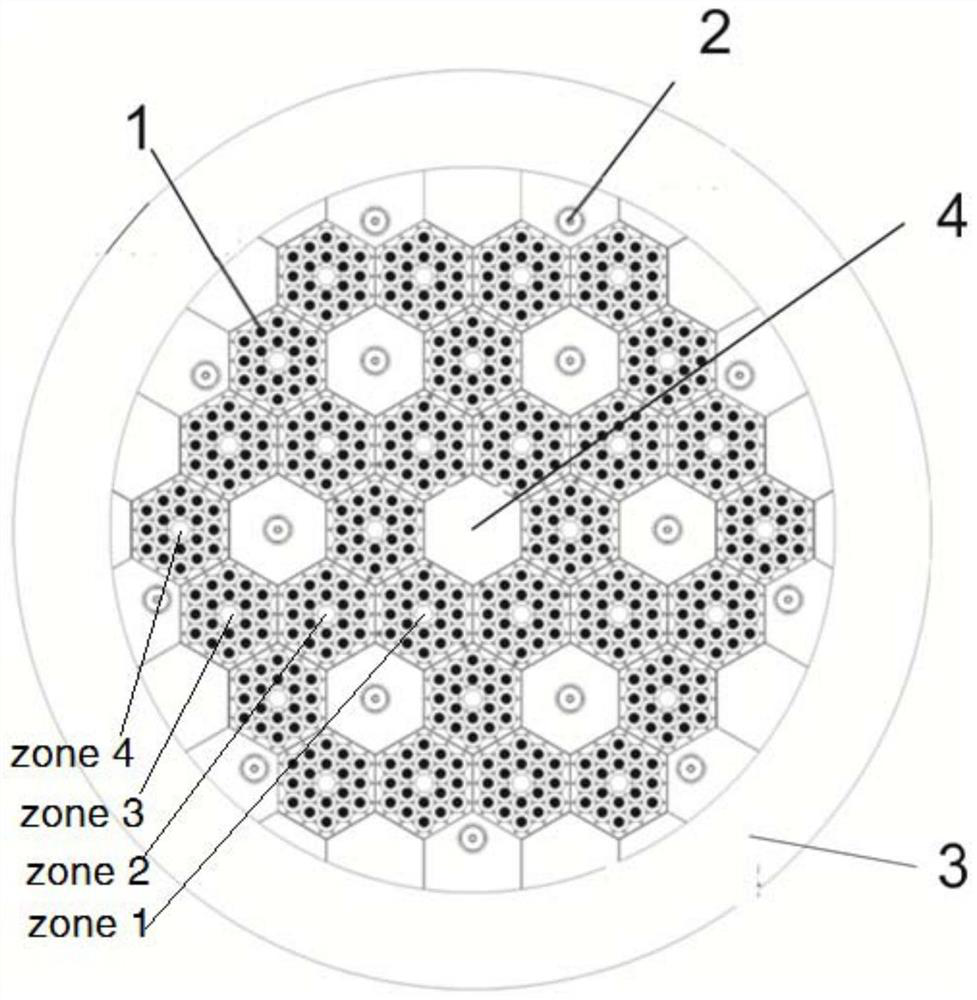

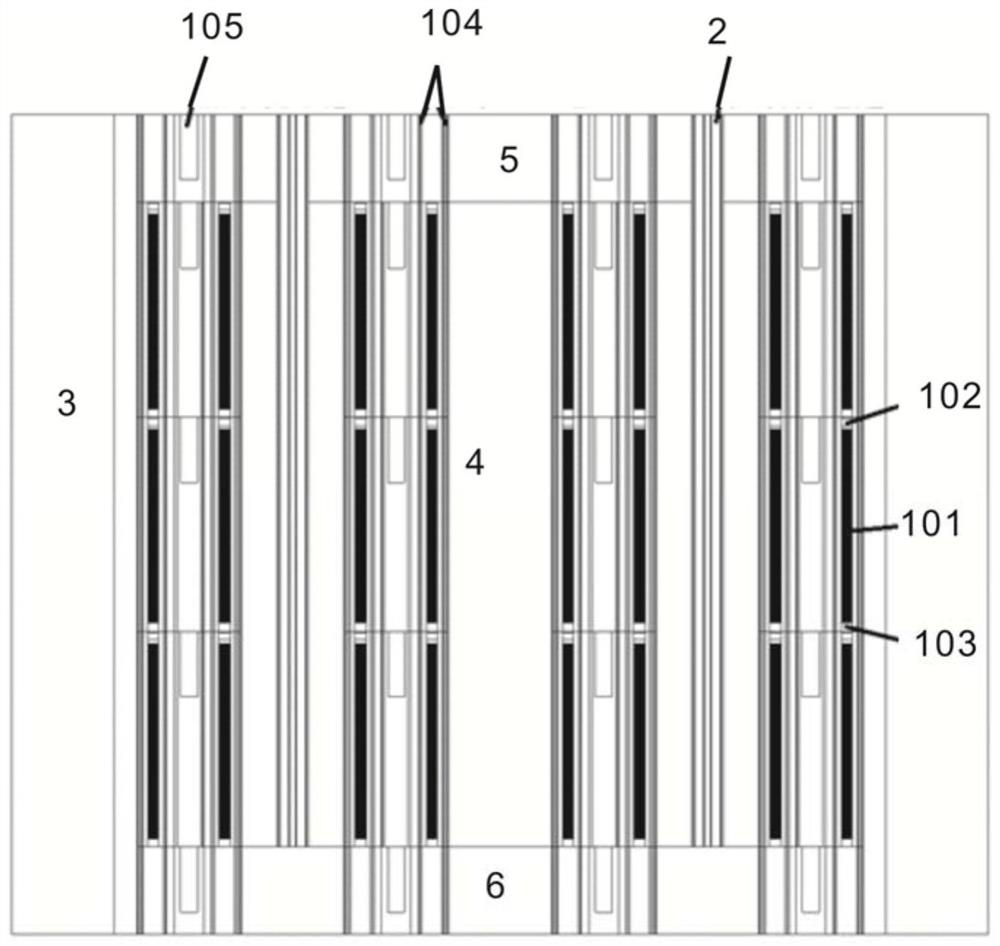

Small prismatic annular air-cooled micro-reactor core system with densely arranged coolant channels

PendingCN113270206AIncreased cooling capacityReduce the maximum temperatureNuclear energy generationShieldingProcess engineeringStructural engineering

The invention discloses a small prismatic annular air-cooled micro-reactor core system with densely arranged coolant channels. The small prismatic annular air-cooled micro-reactor core system comprises a fuel assembly, a control rod assembly and a reflecting layer; the fuel assembly comprises a fuel rod channel and a coolant channel; a coolant channel is arranged around each fuel rod channel to reduce the maximum temperature of the fuel; the reflecting layer comprises an upper reflecting layer, a lower reflecting layer, a side reflecting layer and an inner reflecting layer; the inner reflecting layer is arranged in the center of the reactor core to prevent the temperature of the center of the reactor core from being too high; the fuel assembly is arranged around the inner reflecting layer; the control rod assembly includes an emergency cold shut-down rod surrounded by the fuel assembly and a regulation control rod disposed at the side reflecting layer. The system has the beneficial effects that the cooling agent channels are uniformly and densely arranged so that the cooling capacity of the fuel assembly is enhanced; and the arranged inner reflecting layer is beneficial to reducing the highest temperature of the reactor core and improving the temperature rise allowance of the reactor core so that the safety of the reactor core is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

A zrc and uo 2 Composite fuel pellets and its preparation method and application

ActiveCN108417279BSmall absorption cross sectionImprove securityNuclear energy generationReactors manufactureProcess engineeringLubricant

The invention discloses a ZrC and UO2 composite fuel pellet as well as a preparation method and application of the ZrC and UO2 composite fuel pellet and aims at solving the problem that UO2 is super-low in heat conductivity to result in relatively low safety performance of a fuel assembly in the prior art. The ZrC and UO2 composite fuel pellet disclosed by the invention is prepared by sintering raw materials including UO2 and ZrC at high temperature, wherein the enrichment degree of 235U in UO2 is 1%-5%, and the dosage of ZrC does not exceed 10vol% of total quantity of UO2 and ZrC. The preparation method disclosed by the invention comprises the steps: uniformly mixing UO2, ZrC and a lubricant according to a certain proportion, carrying out high-temperature sintering, carrying out furnace cooling, then, taking out a sample, and processing the sample to the required shape and size. By using the ZrC and UO2 composite fuel pellet disclosed by the invention, the heat conductivity of UO2 canbe effectively increased, so that the safety performance of the fuel assembly is improved. The preparation method disclosed by the invention is simple and convenient to operate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Zirconium alloy

InactiveCN110964946AReduce hydrogen absorptionSmall absorption cross sectionOxygen ionsZirconium alloy

The invention provides a zirconium alloy. The zirconium alloy comprises by weight 1.1%-2.1% of Nb, 0.2%-1.5% of Sn, 0.02%-0.1% of Cr, 0.01%-0.1% of Ni, 0.02%-0.1% of Ce and the balance of Zr. Nb is added into the zirconium alloy, and Nb is an alloy element which can improve corrosion resistance and mechanical property of the zirconium alloy; N is a harmful impurity element in the zirconium alloy due to the fact that N3- can replace oxygen ions in oxide crystal lattices and generate additional vacancy, after Sn is added into the zirconium alloy, N3- and oxygen ion vacancy attempt to be reservednear Sn3+; ions, and mobility is poor after the three components are combined, so that vacancy mobility is reduced, and Sn can counteract harmful effects of N and improve corrosion resistance; Cr andNi are further added into the zirconium alloy, Cr can effectively improve the creep resistance of the high alloy, and Ni can effectively improve the high-temperature steam corrosion resistance of thehigh alloy.

Owner:FOSHAN UNIVERSITY

Preparation method of SIC-based composite phase ceramic solidified body for radioactive graphite solidified treatment

InactiveCN107500775BExcellent high temperature mechanical propertiesGood chemical stabilityRadioactive decontaminationRadiation stabilityPolyvinyl alcohol

The invention discloses a preparation method of a SiC-based multi-phase ceramic solidified body used for radioactive graphite solidification treatment, and the preparation method is characterized by comprising the following steps: using silicon powder, graphite powder, MgO and Al (OH) 3 as raw materials, preparing MgAl2O4 powder, preparing Si-C powder, preparing SiC-MgAl2O4 multi-phase powder, adding polyvinyl alcohol, performing sol-granulating, shaping and glue discharging, vacuum hot-pressing sintering and the like to obtain the SiC-based multi-phase ceramic solidified body at low temperature. The SiC-based multi-phase ceramic solidified body with excellent anti-radiation stability, chemical stability, mechanical stability and thermal stability is prepared from the safe and cheap raw materials by a simple and practical vacuum hot-pressing sintering technique at the low temperature. The prepared SiC-based multi-phase ceramic solidified body is particularly suitable for the ceramic solidification treatment of high-radioactive activity graphite waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of preparation method of SIC-based composite phase ceramic solidified body

ActiveCN110423120BGood chemical stabilityImprove thermal conductivityRadioactive decontaminationPolyvinyl alcoholHeat stability

The invention discloses a method for preparing a SiC-based multiphase ceramic solidified body, which is characterized in that the steps are: using ZnO, CaO, Al 2 o 3 , SiO 2 As a raw material, ZCAS glass is obtained by ball milling, drying, calcining, ball milling, and drying; SiC-ZCAS composite powder is obtained by ball milling, drying, and calcining using silicon powder, graphite, and ZCAS glass as raw materials; Adding polyvinyl alcohol sol, mixing, granulating, and pressing to shape; heat-treating the shaped green body and sintering it in a vacuum hot-pressing sintering furnace to obtain a SiC-based multiphase ceramic solidified body. The invention adopts safe and cheap raw materials, simple and practical vacuum hot pressing sintering technology, and prepares a SiC-based multiphase ceramic solidified body with excellent radiation resistance stability, chemical stability, mechanical stability and thermal stability at a relatively low temperature. The SiC-based multiphase ceramic solidified body prepared by the invention is suitable for safe treatment of high-radioactive graphite waste produced by decommissioning of nuclear reactors.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Portable neutron detection device

ActiveCN102253404BSmall absorption cross sectionImprove detection efficiencyMeasurement with scintillation detectorsEngineeringPhotomultiplier

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A kind of max phase ceramic matrix dispersed pellet nuclear fuel and its preparation method and application

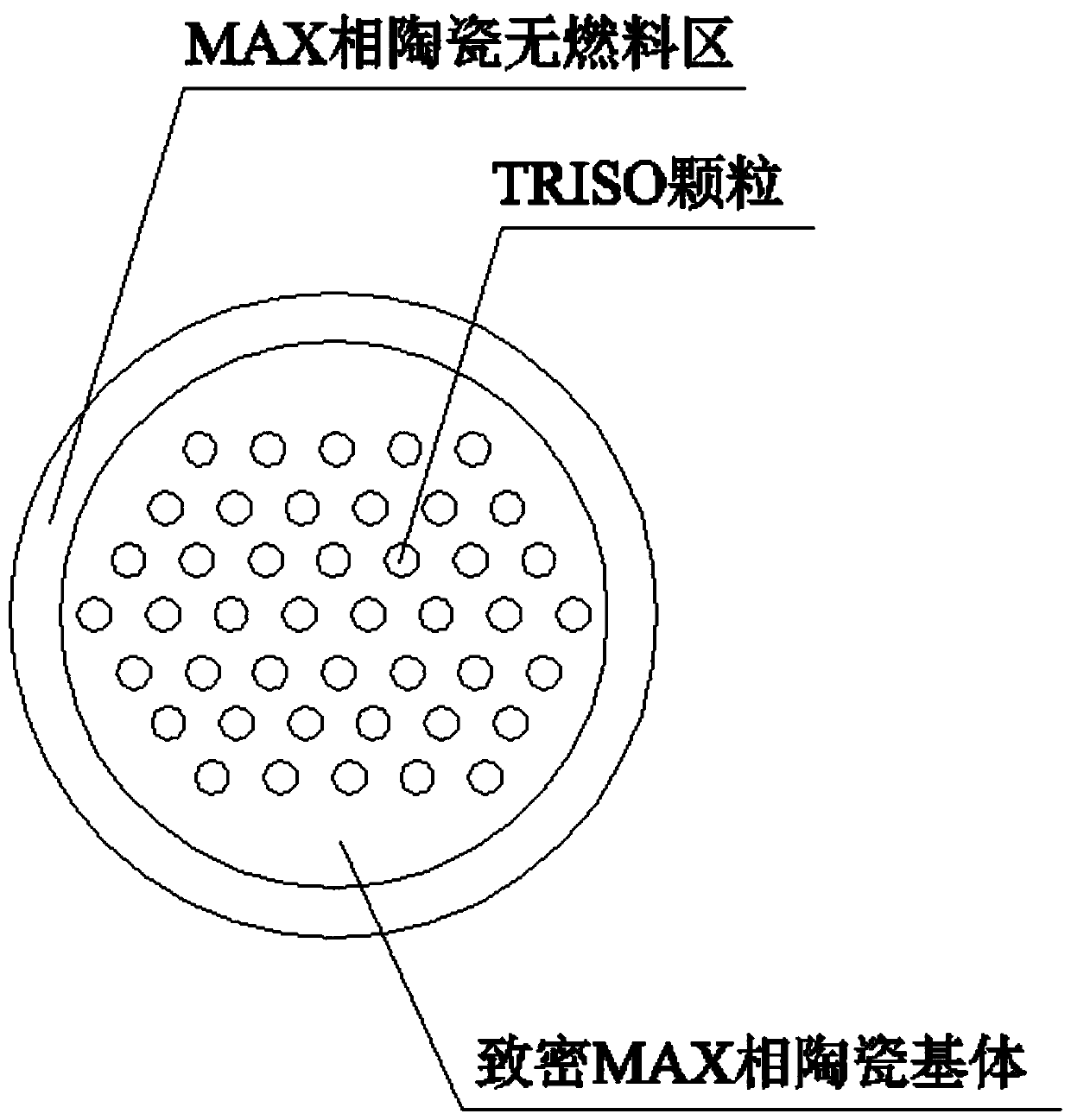

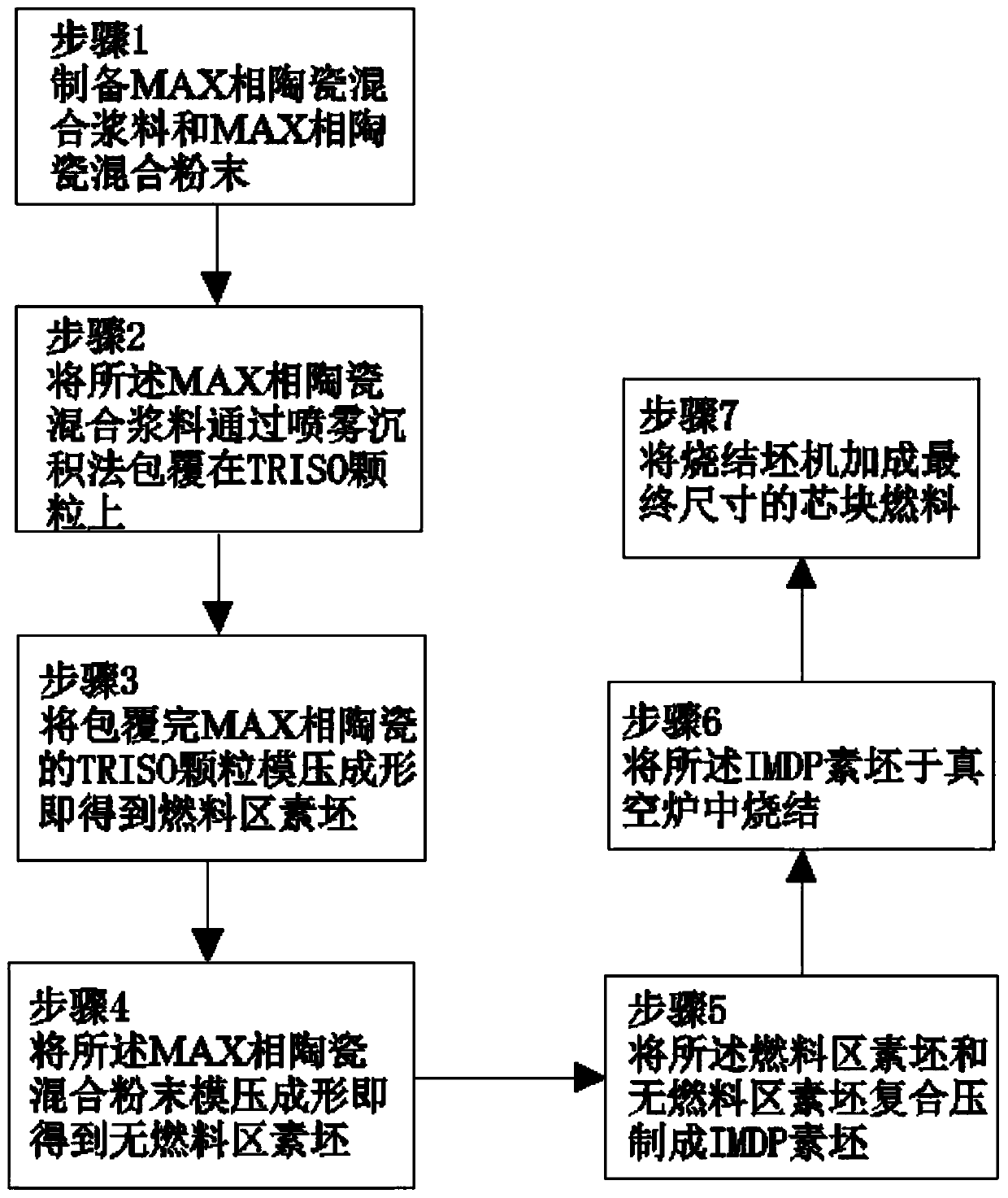

ActiveCN107180654BImprove fault tolerance performanceHigh melting pointNuclear energy generationReactor fuel susbtancesCompression moldingSlurry

The invention discloses MAX-phase-ceramic-matrix dispersion pellet nuclear fuel and a preparation method and application thereof and solves the problem that due to the fact that the heat conductivity of the inert matrix of dispersion nuclear fuel lowers fast under an irradiation condition, accident fault tolerance is lowered, and reactor safety is affected in the prior art. The MAX-phase-ceramic-matrix dispersion pellet nuclear fuel comprises a compact MAX-phase ceramic inert matrix, fuel elements and fuel-free-area protecting layer prepared by MAX-phase ceramic. The preparation method includes: wrapping TRISO particles with MAX-phase ceramic mixed slurry through a spray deposition method to form the compact MAX-phase ceramic inert matrix so as to prepare a fuel-area biscuit, performing compression molding on MAX-phase ceramic mixed powder to obtain a fuel-free-area biscuit, compositing and compressing the fuel-area biscuit and the fuel-free-area biscuit to obtain an IMDP (inert matrix dispersion pellet) biscuit, sintering the IMDP biscuit, and machining the sintered biscuit into a fuel component in a water reactor and a high-temperature gas cooled reactor.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of SiC-based composite ceramic solidified body

ActiveCN110423120AGood chemical stabilityImprove thermal conductivityRadioactive decontaminationRadiation stabilityPolyvinyl alcohol

The invention discloses a preparation method of a SiC-based composite ceramic solidified body, which is characterized by the following steps: taking ZnO, CaO, Al2O3 and SiO2 as raw materials, ball milling, drying, calcining, ball milling and drying to obtain ZCAS glass; using silicon powder, graphite and ZCAS glass as raw materials, ball milling, drying and calcining to obtain SiC-ZCAS composite powder; adding polyvinyl alcohol sol, mixing, granulating and pressing and forming; performing heat treatment on the formed blank body and placing the blank body into a vacuum hot-pressing sintering furnace for sintering, so as to obtain the SiC-based composite ceramic solidified body. The invention adopts safe and cheap raw materials, simple and practical vacuum hot pressing sintering technology is used to prepare the SiC-based composite ceramic solidified body with excellent radiation stability, chemical stability, mechanical stability and thermal stability at lower temperature. The SiC-basedcomposite ceramic solidified body prepared by the invention is suitable for safely treating high-radioactive graphite waste generated due to decommissioning of a nuclear reactor.

Owner:SOUTHWEAT UNIV OF SCI & TECH

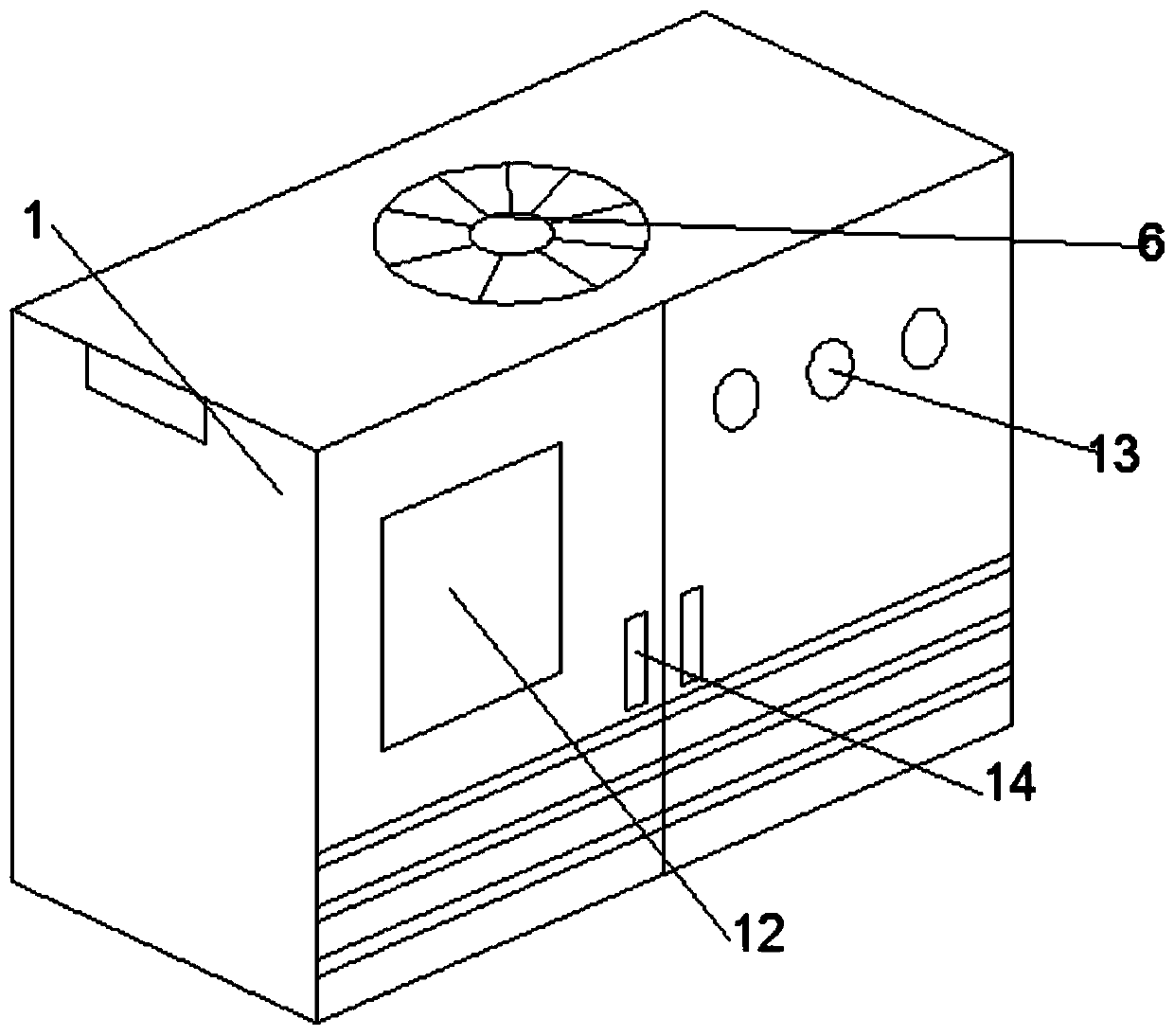

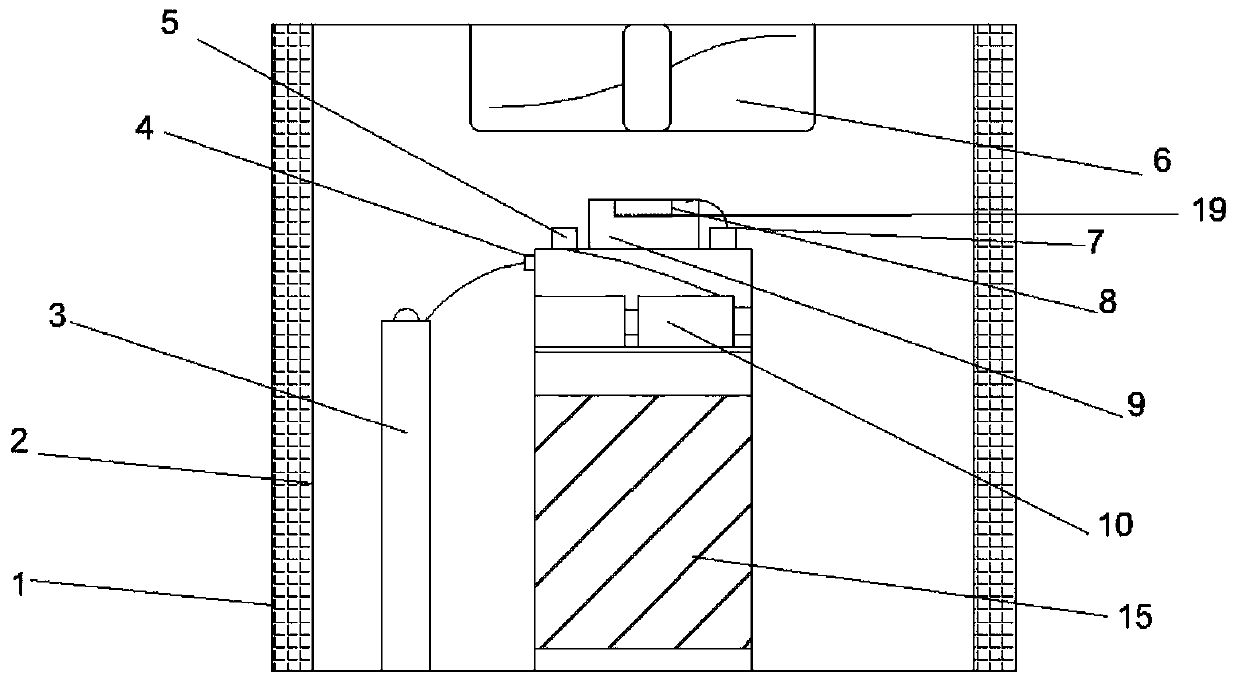

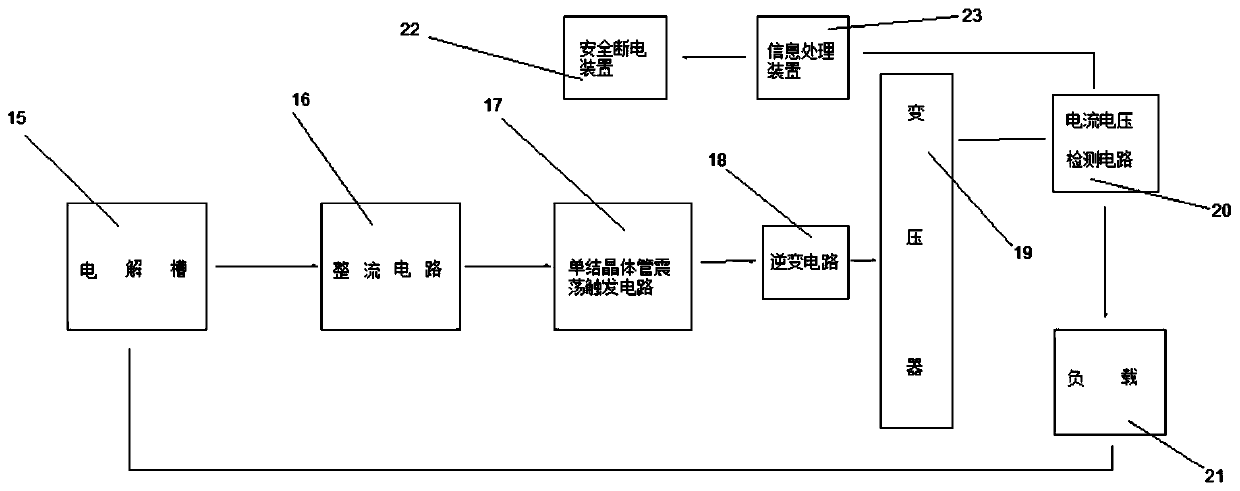

A method of electrolytic plating power supply

ActiveCN109194093BSmall absorption cross sectionInductive radioactivity is weakModifications for power electronicsAc-ac conversionTransformerHemt circuits

The invention discloses a method of an electrolytic plating power supply, including a main box, a coolant, an information processor, a signal switch, a current sense port, a heat-dissipating fan, a voltage detection port, a voltage regulator, an output port, current regulate component, ventilation fin, electronic touch display, safety signal lamp, insulated handle, electrolytic cell, rectify circuit, single junction transistor oscillation trigger circuit, inverter circuit, transformer, current voltage detection circuit, load, safety power-off device and information processing device. The invention has the advantages that: the design of the electrolytic plating power supply is reasonable, the information processor facilitates the sorting and merging of the obtained data and the sending of instructions to various circuit ports, The current detection port facilitates the control and detection of the output current and voltage, the current regulating module keeps the internal current stable, and the safety signal lamp facilitates the early warning of the user and the real-time expression of the internal running state.

Owner:双新电器(郑州)制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com