Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Neptunium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neptunium is a chemical element with the symbol Np and atomic number 93. A radioactive actinide metal, neptunium is the first transuranic element. Its position in the periodic table just after uranium, named after the planet Uranus, led to it being named after Neptune, the next planet beyond Uranus. A neptunium atom has 93 protons and 93 electrons, of which seven are valence electrons. Neptunium metal is silvery and tarnishes when exposed to air. The element occurs in three allotropic forms and it normally exhibits five oxidation states, ranging from +3 to +7. It is radioactive, poisonous, pyrophoric, and can accumulate in bones, which makes the handling of neptunium dangerous.

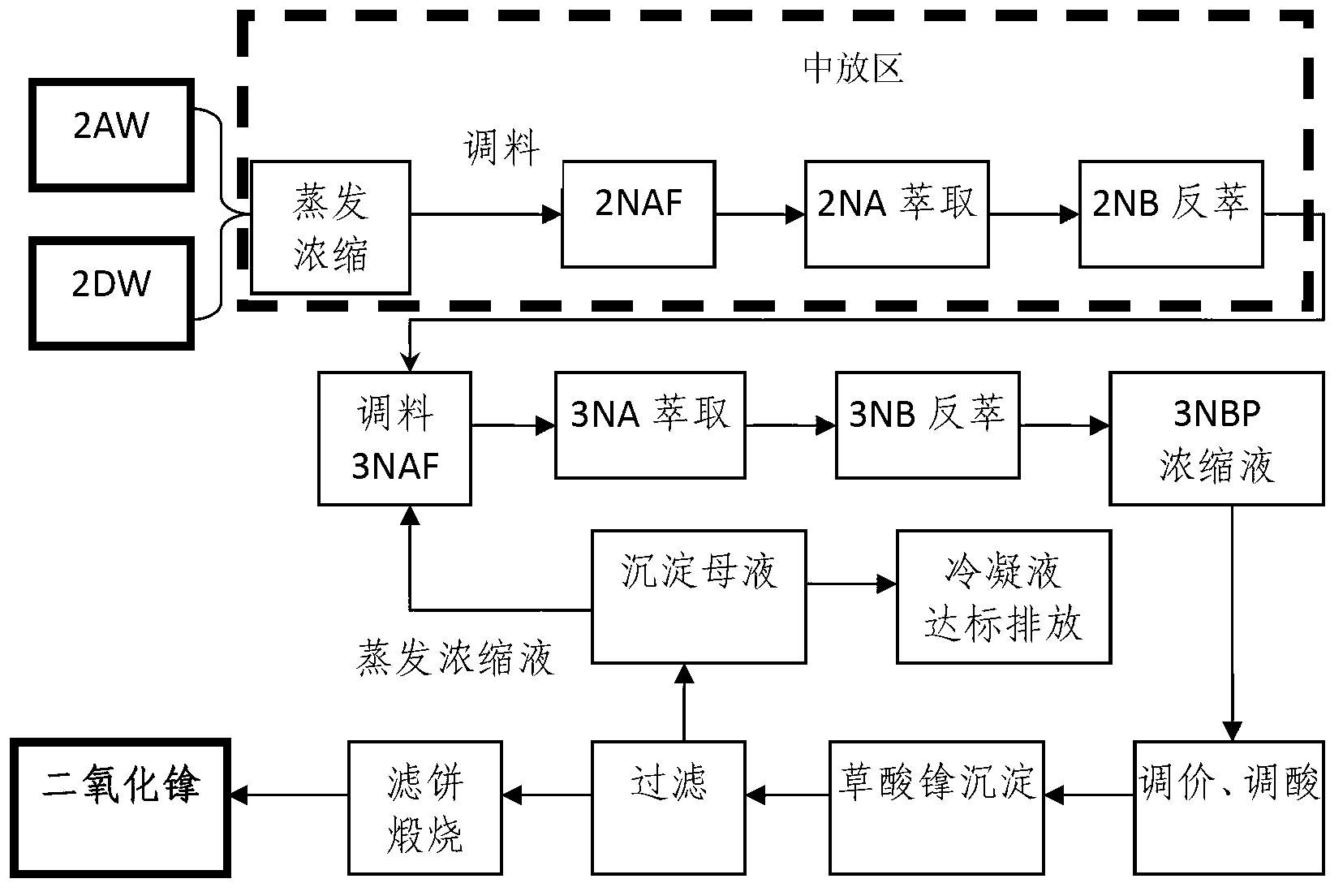

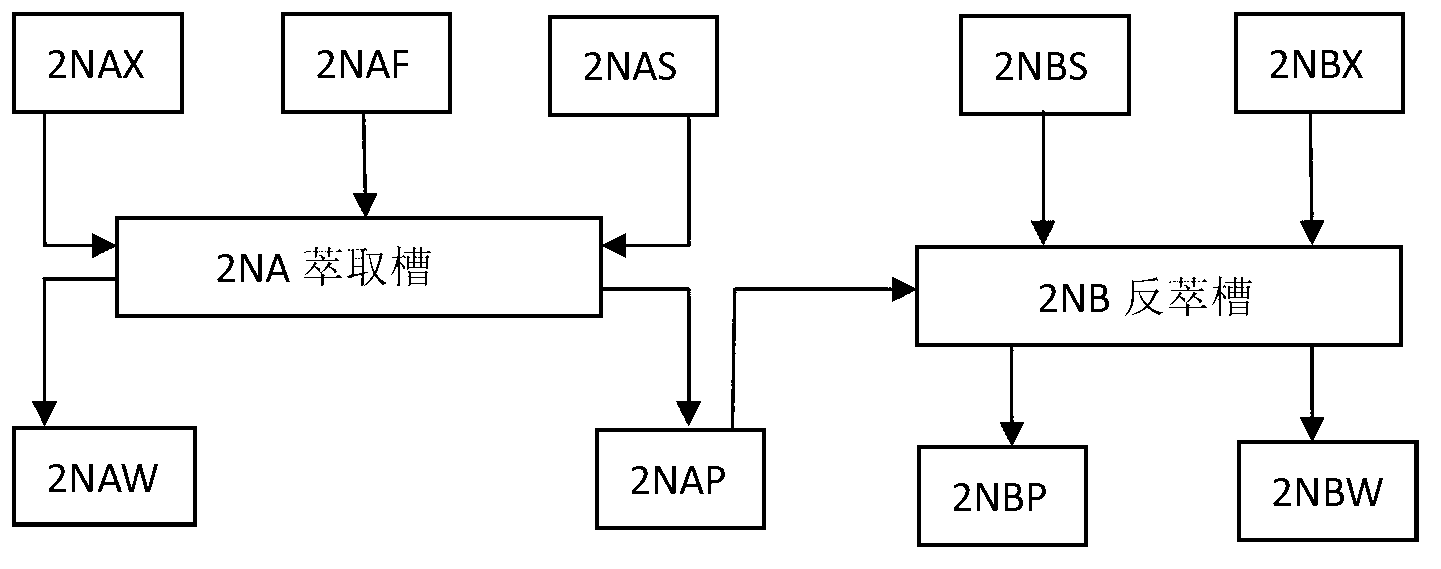

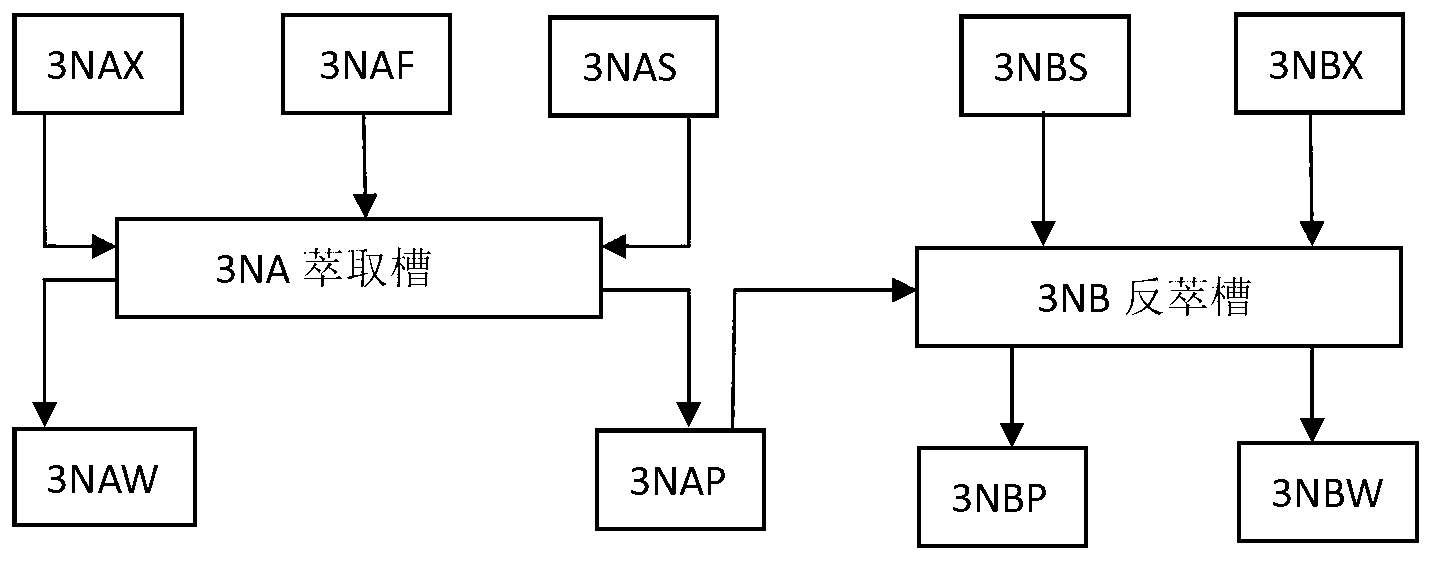

Process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow

ActiveCN103305702AHigh recovery rateValence stableProcess efficiency improvementRadioactive decontaminationOxalate precipitationEngineering

The invention belongs to the technical field of nuclear fuel reprocessing and discloses a process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow. The process comprises the primary neptunium purification process and the secondary neptunium purification process; the process comprises the following steps: by taking 30 volume percent of TBP-kerosene as an extraction agent, extracting Np, U and Pu to the organic phase, and allowing the fission fragments to enter the aqueous phase; adding a reducing agent and an extraction agent into the organic phase, reversely extracting the Np to the aqueous phase; further extracting uranium and plutonium, and performing oxalate precipitation, filtering and calcining on the obtained aqueous phase product to obtain the purified neptunium oxide solid. The process has the advantages that the neptunium recovery rate is over 98 percent, and the uranium and plutonium removal coefficient in neptunium is high.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

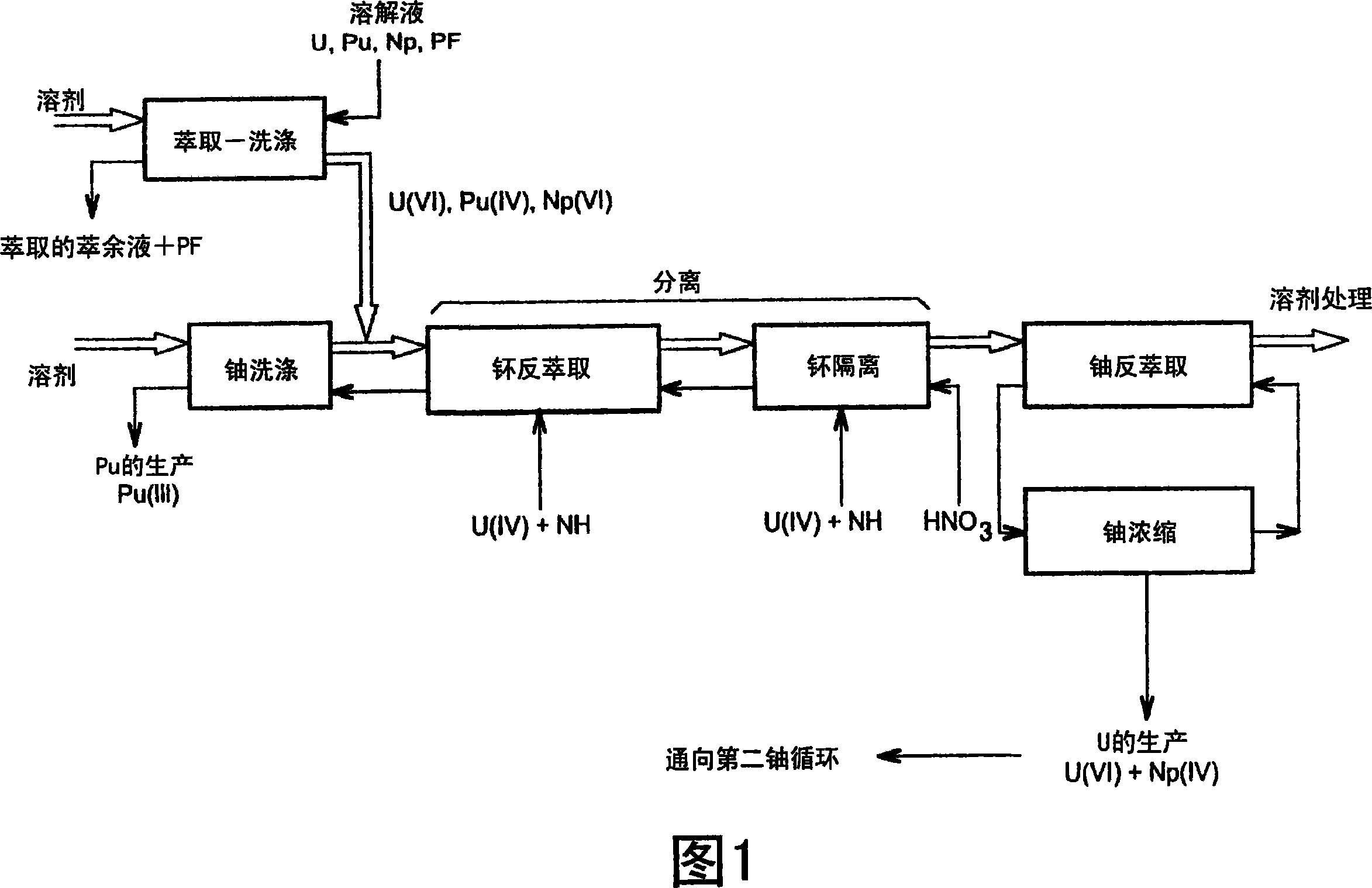

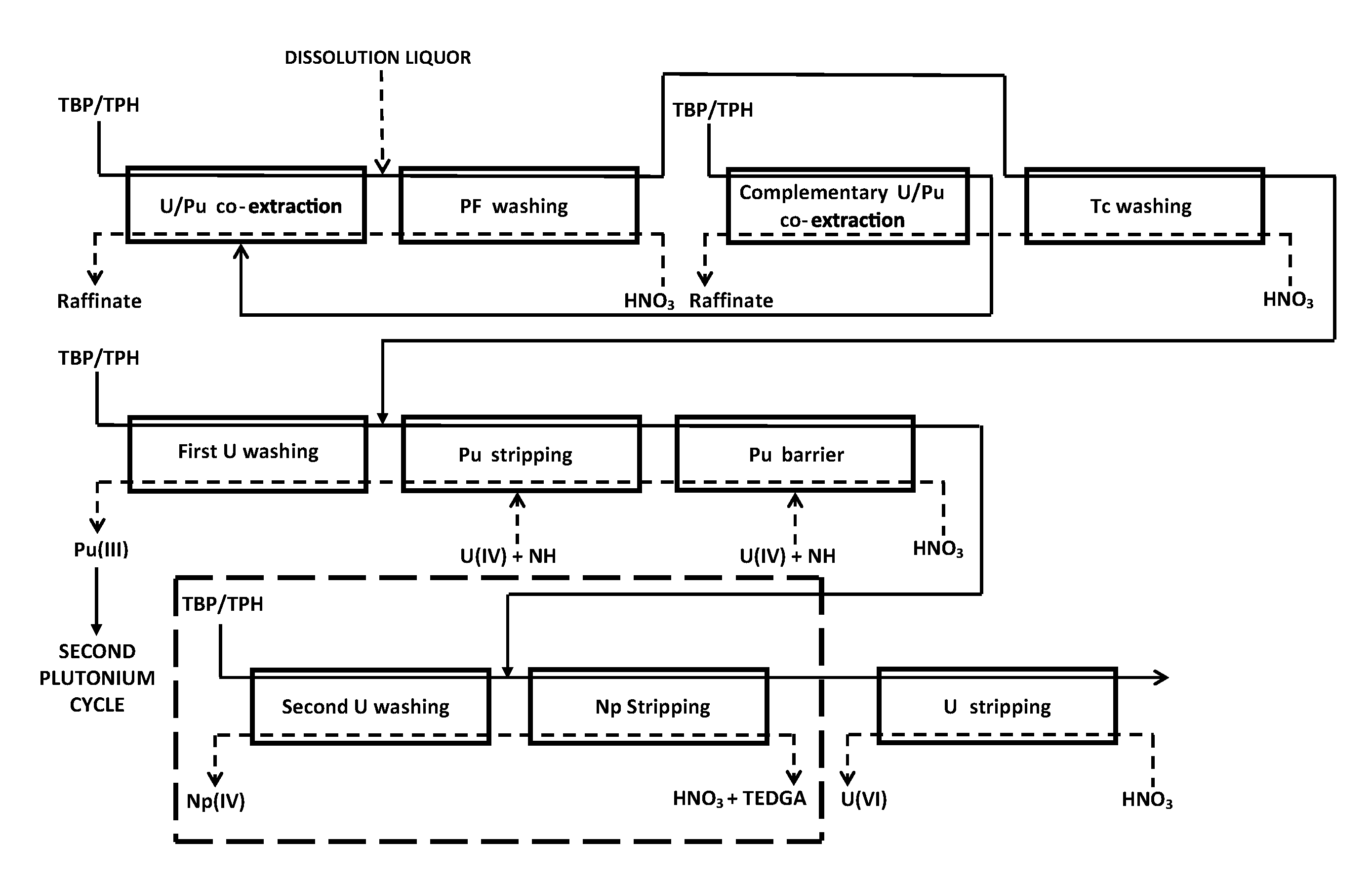

Improvement of the purex method and uses thereof

ActiveCN101088129AEfficient separationNuclear energy generationRecycling and recovery technologiesSolventPu element

The procedure consists of separating the uranium, plutonium, other actinides and fission products from the spent fuel in a nitric acid solution, separating the uranium from the plutonium in two separate flows by extracting the plutonium from the solvant phase in a nitric acid aqueous solution with a reducing agent, and then concentrating the solution containing the uranium (III). Part of the concentrated solution is used to extract the actinides (IV) present in the oxidated state, the actinides (IV) being neptunium (IV), thorium (IV) and / or plutonium (IV).

Owner:ORANO RECYCLAGE

Methods of producing and recovering plutonium-238

InactiveUS20110265605A1Conversion outside reactor/acceleratorsOrganophosphorous compoundsPlutonium-238

Methods of producing plutonium-238 are disclosed. One method includes dissolving neptunium-237 in a nitric acid solution to produce a neptunium target solution, subjecting the neptunium target solution to neutron radiation to produce plutonium-238, and removing the plutonium-238 from the neptunium target solution. A second method includes exposing a solution of neptunium-237 to neutron radiation to produce plutonium-238, complexing the plutonium-238 with an organophosphorus compound, and separating the plutonium-238 / organophosphorus compound complex from the solution of neptunium-237. A third method includes dissolving neptunium-237 to form a neptunium-237 target solution, exposing the neptunium-237 to thermal neutrons to produce plutonium-238, utilizing an organophosphorus compound to complex the plutonium-238 and the organophosphorus compound, extracting the plutonium-238 / organophosphorus compound complex from the irradiated neptunium target solution, and recovering the plutonium-238.

Owner:BATTELLE ENERGY ALLIANCE LLC

Uranium purification method for simultaneously removing neptunium and plutonium in nuclear fuel Purex post-treatment process

ActiveCN107130121AReduce extractionGood removal effectNuclear energy generationRecycling and recovery technologiesPurification methodsEvaporation

The invention belongs to the technical field of nuclear fuel post-treatment, and relates to a uranium purification method for simultaneously removing neptunium and plutonium in the nuclear fuel Purex post-treatment process. The uranium purification method sequentially comprises the following steps that firstly, evaporation and concentration pretreatment is conducted, a uranium rough product from the Purex post-treatment procedure uranium plutonium codecontamination separating cycle is subjected to evaporation and concentration pretreatment, accordingly, Np(IV) in the uranium rough product is adjusted to Np (V) and Np (VI); secondly, a reducing agent is adopted for reducing, a concentrated solution obtained in the first step is cooled to the room temperature, then the reducing agent is added, then Pu (IV) and Pu (VI) in the concentrated solution are reduced into Pu (III), and Np (VI) is reduced into Np (V); and thirdly, organic solvent extraction is conducted, the acidity of the solution obtained in the second step is adjusted, extraction is conducted in an extractor with an organic solvent containing tributyl phosphate in a multi-level manner, wherein the organic solvent containing the tributyl phosphate is divided into multiple parts to be added at different extraction levels. By utilization of the uranium purification method, the Np and the Pu can be removed at the same time through one uranium purification cycle, and qualified uranium products are obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Tetravalent plutonium ion extraction method

ActiveCN110894578AImprove extraction abilityFast extractionGroup 5/15 element organic compoundsProcess efficiency improvementPhenanthrolineDiluent

The invention relates to the technical field of nuclear fuel circulation and waste liquid treatment, and discloses a tetravalent plutonium ion extraction method, which comprises steps of: mixing a phenanthroline derivative represented by a formula (1) and a diluent to form an organic phase, and extracting tetravalent plutonium ions from an aqueous phase. The aqueous phase is an acidic aqueous solution containing tetravalent plutonium ions. The phenanthroline derivative is used as an extracting agent, tetravalent plutonium is selectively extracted from the aqueous phase containing various actinide ions, the extraction capacity is high, the extraction speed is high, particularly, the tetravalent plutonium extraction and separation efficiency is very high from a nitric acid aqueous solution containing pentavalent neptunium and hexavalent uranium, the extraction rate can reach 99% at most, and the method has a good application prospect in the field of nuclear industry waste liquid treatment.

Owner:ZHEJIANG UNIV

Criticality prevention devices and methods in nuclear fuel production

The invention concerns a vessel for processing, transfer, accumulation and / or transfer of material containing civilian or military origin plutonium, in the form of plutonium oxide, carbide and / or nitride. The plutonium is preferably present in a concentration not higher than a guaranteed maximum between 20 and 50% wt. in said material, possibly with other actinides such as americium, neptunium, or curium. Said material is preferably in form of powder, granulate and / or tablets. The vessel comprises a volume of 20 to 70 liters for containing said material, demarcated at least by two substantially parallel walls, these two walls being separated by a distance e between 8 and 15 cm. The invention concerns also an enclosure comprising analogous geometrically safe criticality-preventing means (bottom-catcher), a fuel production plant comprising a set of such vessels, preferably installed in a set of said enclosures, as well as a nuclear fuel production process carried out in a set of such vessels, preferably installed in a set of said enclosures.

Owner:BELGONUCLEAIRE SA

Rapid neptunium separating method

The invention discloses a rapid neptunium separating method. The method comprises the steps that neptunium is reduced and reextracted to a water phase through a multi-stage reverse flow reduction andreextraction process, uranium and plutonium are reserved in an organic phase, and neptunium separation and extraction are achieved. Rapid separation of neptunium from uranium and plutonium is achieved, the extraction technological time is shortened, the technological process of separating and extracting neptunium is simplified, and the difficulty of purifying neptunium from follow-up processes (neptunium purification cycle and plutonium purification cycle) is lowered.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for processing spent nuclear fuel comprising a step for decontaminating uranium (VI) from at least one actinide (IV) by complexing this actinide (IV)

ActiveUS20160314861A1Nuclear energy generationRecycling and recovery technologiesNeptuniumNuclear fuel

A method for processing a spent nuclear fuel is disclosed which includes a step for decontaminating uranium(VI) from one or more actinides(IV) and more specially from neptunium and / or plutonium, by complexing this (these) actinide(s)(IV). This method includes a step for decontaminating uranium (VI) from at least one actinide(IV), which decontaminating step comprises at least one operation for stripping the actinide(IV) from an organic phase, not miscible with water, and wherein uranium(VI) and the actinide(IV) are present, by putting the organic phase into contact with an aqueous phase comprising nitric acid and at least one complexing agent which more strongly complexes actinides(IV) than uranium(VI), and then separating the organic phase from the nitric aqueous phase, wherein the at least one complexing agent is a diglycolamide.

Owner:ORANO RECYCLAGE +1

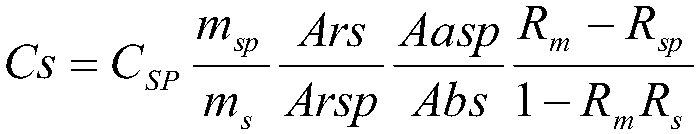

Method for determining contents of uranium, neptunium and plutonium in PUREX posttreatment flow 1AW by liquid chromatography-mass spectrometry

InactiveCN108226327ARealize automatic separation and determinationAccurate analysisComponent separationRadioactive agentMass Spectrometry-Mass Spectrometry

The invention belongs to the technical field of radioactive substance analysis, and relates to a method for determining the contents of uranium, neptunium and plutonium in PUREX posttreatment flow 1AWby liquid chromatography-mass spectrometry. The method comprises the following steps: (1) dilution and valence adjustment: diluting a 1AW solution with a diluent, and adding an oxidant to adjust thevalence of the plutonium; (2) determination of the uranium and the neptunium: performing chromatography separation and mass spectrometry detection on a diluted valence-adjusted solution of the 1AW, and drawing a working curve by an external standard method for quantification of the uranium and the neptunium; (3) determination of the plutonium: preparing two parts of 1AW diluted valence-adjusted solution, adding a 242Pu diluent into one part, performing chromatography separation and mass spectrometry detection in sequence, and calculating the content of the plutonium according to determinationresults of the abundance of two parts of solution 239Pu and 242Pu. Through adoption of the method disclosed by the invention, the contents of the uranium, the neptunium and the plutonium in a nuclearfuel PUREX posttreatment flow 1AW can be analyzed more accurately and precisely, and the influence of radioactivity on the analysis operation is eliminated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Experiment device for research of actinide elementdiffusionin high-level radioactive waste repository

The invention belongs to field of research of high-level radioactive wastegeological disposal, and particularly relates to an experiment device for the research of actinide elementdiffusion ina high-level radioactive waste repository. The experiment device comprises a diffusion chamber (1) and a locking mechanism (2); the interior of the diffusion chamber (1) is filled with a porous material (3); the diffusion chamber (1) is fixed on the outer surface of a stock solution bottle (4) and is communicated with the interior of the stock solution bottle (4); a connector (5) used for being connected with thediffusion chamber (1) is arranged on the stock solution bottle (4); the diffusion chamber (1) is provide with a bottom cover (6); the bottom cover (6) is locked to the connector (5) through the locking mechanism (2). The experiment device can be operated for a long time, and is suitable for migration experiments of uranium, neptunium and plutonium.

Owner:HUZHOU TEACHERS COLLEGE

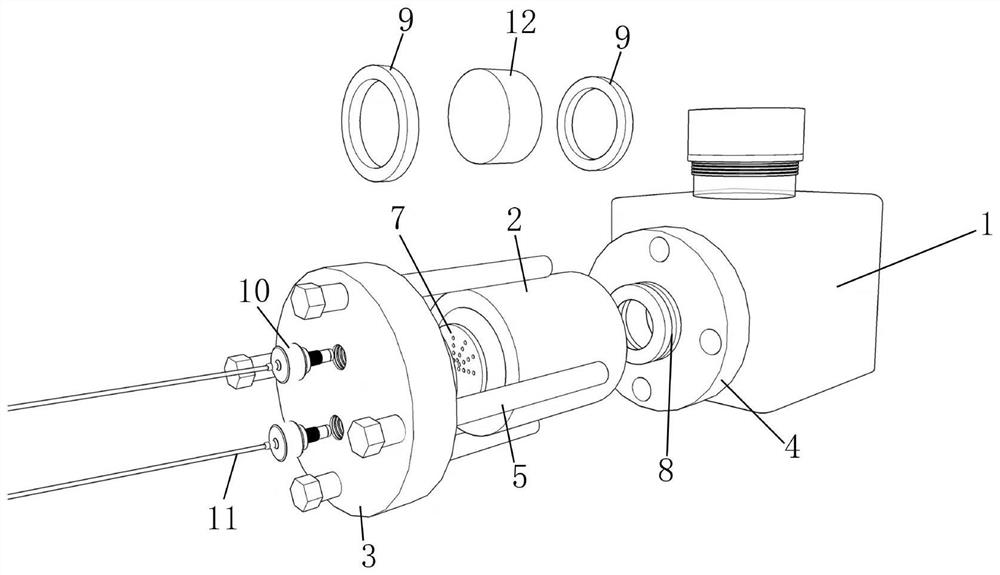

Carbon fiber tube X-ray fluorescence sample cell

ActiveCN110632112AHigh temperature resistantAnti-frictionMaterial analysis using wave/particle radiationFiberCarbon fibers

The invention discloses a carbon fiber tube X-ray fluorescence sample cell. The carbon fiber tube X-ray fluorescence sample cell comprises a sample cell main body and a joint; the sample cell main body is a carbon fiber tube; the joint is composed of a sleeve, a sealing ring and a base; internal threads are arranged in the sleeve; corresponding external threads are arranged outside the base; and the sealing ring located in the middle can be squeezed when the threads are matched and pressed, so that the sealing is achieved. The carbon fiber tube X-ray fluorescence sample cell provided by the invention has relatively small absorption on X-ray fluorescence, does not introduce errors in post-processing of conventional analysis of uranium, neptunium, plutonium and other elements, and meanwhile,the carbon fiber X-ray fluorescence sample cell has good radiation resistance, good acid and organic corrosion resistance, strong mechanical property and excellent comprehensive performance.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Process for the synthesis of a mixed peroxide or hydroxo-peroxide of an actinyl and of at least one doubly, triply or quadruply charged metal cation, mixed peroxide or hydroxo-peroxide thus obtained and uses thereof

ActiveUS20160314858A1Nuclear energy generationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMixed oxideUranyl

A process is described for synthesizing a mixed peroxide or hydroxo-peroxide of an actinyl and at least one cation X1, wherein the actinyl is a uranyl or neptunyl and the at least one cation X1 is a di-, tri- or tetra-charged metal cation. This process includes the reaction in a solvent of a salt of the at least one cation X1 with a compound C2 selected from mixed peroxides and hydroxo-peroxides of the actinyl and of at least one singly charged cation X2, whereby compound C2 is converted to the peroxide or hydroxo-peroxide by replacement of the at least one cation X2 by said at least one cation X1. Also disclosed is a process for synthesizing a mixed oxide of an actinide selected from uranium and neptunium, and of at least one metal able to form a di-, tri- or tetra-charged cation, which implements the preceding synthesis process. The disclosure further relates to a mixed peroxide or hydroxo-peroxide of an actinyl and of at least one di-, tri- or tetra-charged metal cation, and the use thereof for the preparation of a mixed oxide of an actinide and of at least this metal.

Owner:ORANO RECYCLAGE

Preparation technology of neptunium oxide target pellet

ActiveCN106847353AConvenient chemical dissolutionImprove dissolution rateNuclear energy generationReactors manufacturePartial oxidationStearic acid

The invention belongs to the field of nuclear material preparation and provides a preparation technology of a neptunium oxide target pellet for solving the problems that an existing preparation technology of a neptunium oxide target is relatively low in overall neptunium loading capacity, relatively high in production cost and relatively complicated in process. The technology comprises the following steps: (1) taking neptunium oxide powder and magnesium oxide powder as a target pellet material; (2) taking out part of neptunium oxide powder and mixing with the magnesium oxide powder to obtain preliminarily mixed powder; (3) adding the remaining neptunium oxide powder and further mixing with stearic acid to obtain mixed powder; (4) carrying out cold press molding to prepare a target pellet body; and (5) carrying out pressureless sintering to prepare the neptunium oxide target pellet. The preparation technology has the advantages of being simple in technological process and low in cost; the prepared neptunium oxide target pellet is high in overall neptunium loading capacity and high in neutron utilization rate, has relatively high thermal conductivity and good in-pile irradiation performance, and is convenient to chemically dissolve and extract and suitable for massive production of 238Pu fuel.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Preparation method of organic-phase plutonium and organic-phase neptunium standard solution

ActiveCN106932421AMeet the needs of direct measurementMaterial analysis by measuring secondary emissionHydrofluoric acidEvaporation

The invention belongs to the technical field of analysis of uranium, neptunium and plutonium in radioactive liquid and particularly relates to a preparation method of an organic-phase plutonium and organic-phase neptunium standard solution. The preparation method includes the following steps of preparation of nitric acid-hydrofluoric acid, preparation of an organic-phase reagent, aampling of standard substances, dissolution of a standard plutonium substance sample, plutonium sample evaporation, preparation of an organic-plutonium standard, neptunium standard sampling, neptunium standard sample evaporation, organic-phase addition and preparation of organic-phase neptunium standard. The uncertainty of the organic-phase plutonium standard prepared by adopting the method is 0. 069%, and the uncertainty of the organic-phase neptunium standard is 1.08%. The preparation method can be used for preparation of relevant series standard solutions in a method for direct determination of the low-concentration uranium, neptunium and plutonium in posttreatment samples and thus meets the need for direct determination of organic phases uranium, neptunium and plutonium in posttreatment process feed liquors.

Owner:中核四0四成都核技术工程设计研究院有限公司

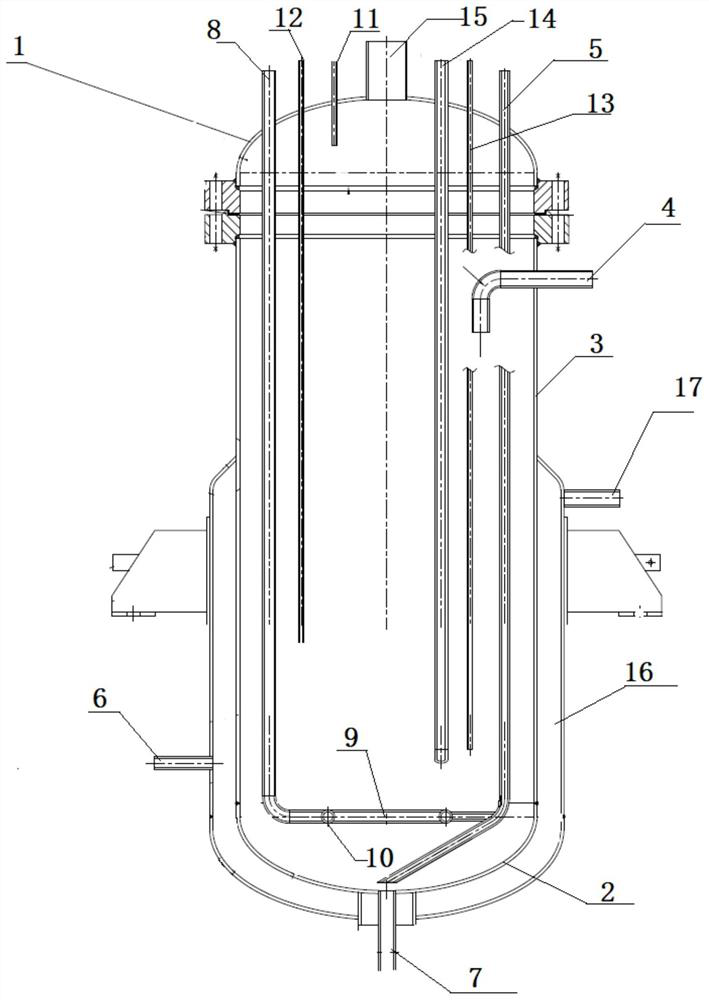

Neptunium dioxide-plutonium dioxide dissolver for hot chamber

ActiveCN111199808AEffective dissolutionQuick changeNuclear energy generationRecycling and recovery technologiesFuel reprocessingStrong acids

The invention belongs to the technical field of spent fuel aftertreatment, and particularly relates to a neptunium dioxide-plutonium dioxide dissolver for a hot chamber, which is used for dissolving aneptunium target containing neptunium and plutonium elements in the hot chamber, and comprises a strong acid-resistant and high temperature-resistant dissolving tank (1). A heating device is arrangedat the periphery of the dissolving tank (1); a cleaning pipe (4) used for adding nitric acid into the dissolving tank (1), a feeding pipe (5) used for adding a dissolving solution, a bubbling pipe (6) used for introducing disturbing gas into the dissolving solution in the dissolving tank (1), and a discharging pipe (7) used for discharging the dissolving solution are arranged on the dissolving tank (1) in a penetrating manner; the integral electrode (14) is arranged in the dissolving tank (1) in a replaceable and penetrating manner; and a control system for remotely operating the replacementof the integral electrode (14) is also included. The dissolver can be applied to a hot chamber to dissolve a neptunium target; the dissolution reaction can be remotely operated through a manipulator in the hot chamber; and the neptunium target is fully dissolved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for analyzing trace neptunium content in large amount of uranium in nuclear fuel post-treatment process

InactiveCN111380943ASmall amount of sampleReduce distractionsPreparing sample for investigationMaterial analysis by electric/magnetic meansFuel reprocessingNeptunium

The invention belongs to the technical field of analytical chemistry, and relates to a method for analyzing the content of trace neptunium in a large amount of uranium in a nuclear fuel aftertreatmentprocess. The analysis method sequentially comprises the following steps: (1) taking a sample with a certain volume, and adding concentrated nitric acid to adjust the concentration of nitric acid to 1-2 mol / L; (2) adding a ferrous aminosulfonate solution into the sample, uniform mixing, and standing for a period of time; (3) adding an extraction agent into the sample for extraction, performing centrifugal separation, removing a water phase, and retaining an organic phase; (4) washing the organic phase with a washing solution for 2-5 times, removing the water phase after each washing, and retaining the organic phase; (5) diluting the organic phase with isopropanol, and analyzing the diluted organic phase with ICP-MS provided with an organic sample injection system. By utilizing the method for analyzing the trace neptunium content in the large amount of uranium in the nuclear fuel post-treatment process, the analysis of the trace neptunium content in the large amount of uranium in the nuclear fuel post-treatment process can be simply, conveniently, quickly and accurately carried out with less required sample amount and little interference.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for extracting and separating trace neptunium in liquid sample

InactiveCN108051283AHigh recovery rateImprove extraction efficiencyPreparing sample for investigationOxalateElement analysis

The invention relates to a method for extracting and separating trace neptunium in a liquid sample, and belongs to the technical field of trace analysis sample pretreatment. According to the method, mainly trioctylamine is used as an extraction filling material, and the concentration of a leaching nitric acid solution is strictly controlled, such that the high distribution coefficient and the strong adsorption ability for neptunium are ensured while the interference caused by high abundance uranium is removed so as to achieve the good extraction and separation effect; the hot mixed acid solution of oxalic acid and nitric acid is used as an eluant, and the concentration of the mixed acid solution is strictly controlled, such that the neptunium recovery rate is high so as to achieve the goodconcentration effect; and with the extraction and separation method, the trace neptunium in the liquid sample can be simply and rapidly separated and concentrated, the trace neptunium analysis sensitivity under the uranium matrix interference can be improved, and the method has advantages of stable and reliable neptunium analysis result and good reproducibility.

Owner:中国人民解放军陆军防化学院

Systems and methods for efficiently preparing plutonium-238 with high isotopic purity

InactiveUS20140133616A1Efficient preparationInhibit side effectsSpecific isotope recoveryConversion outside reactor/acceleratorsDistillationIsotope

A method for preparing plutonium-238 (Pu-238) using reactor may include irradiating a liquid containing a neptunium-237 (Np-237) based compounds with neutrons to convert a portion of the Np-237 based compound to a Np-238 based compound; retaining the liquid containing the resulting mixture for a sufficient amount of time for the Np-238 based compound to at least partially convert to a plutonium-238 (Pu-238) based compound. The method further may include separating the Pu-238 based compound from the neptunium based compounds using distillation or chemical method.

Owner:GENERAL ATOMICS

Separation method for separating neptunium from to-be-tested sample

ActiveCN111621652ACause incomplete separationHigh yieldComponent separationProcess efficiency improvementHydrogen fluorideSoil science

The embodiment of the invention provides a separation method for separating neptunium from a to-be-tested sample. The method includes the following steps that ammonium bifluoride is used as a dissolving agent, and the to-be-tested sample is dissolved; dissolution of the to-be-tested sample makes contact with a first extracting agent, and an organic phase containing the neptunium is obtained; the organic phase makes contact with a complexing agent, and a water phase containing the neptunium is obtained; and the neptunium is extracted from the water phase through a second extracting agent. The first extracting agent is bisamide podand. The method for separating the neptunium is suitable for separating the neptunium from rock, soil and river bottom sediment samples. According to the method for separating the neptunium, a trace amount of neptunium can be enriched from a system containing a large quantity of interference elements or ions, the separation and purification effect of the neptunium is improved, and therefore the detection and analysis precision of the neptunium is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Systems and methods for efficiently preparing plutonium-238 with high isotopic purity

InactiveUS9196389B2Efficient preparationInhibit side effectsSpecific isotope recoveryPlutonium halidesNuclear reactorIsotope

A method for preparing plutonium-238 (Pu-238) includes using a nuclear reactor in irradiating a liquid containing a neptunium-237 (Np-237) based compound with neutrons to convert a portion of the Np-237 based compound to a Np-238 based compound; retaining the liquid containing the resulting mixture for a sufficient amount of time for the Np-238 based compound to at least partially convert to a Pu-238 based compound; and separating the Pu-238 based compound from the neptunium based compounds using fractional distillation or a chemical separation method.

Owner:GENERAL ATOMICS

Experimental device for measuring nuclide diffusion parameters

PendingCN114459962ADiffusion is fastDiffusion slowDiffusion analysisPeristaltic pumpStructural engineering

The invention provides an experimental device for measuring nuclide diffusion parameters, and belongs to the field of nuclide migration research. Comprising a diffusion pool, a square bottle, a peristaltic pump and a sample bottle, the diffusion pool is composed of a bottom cover, a hollow cylinder, a locking mechanism, filter discs and a porous material soil block, the porous material soil block is placed in the hollow cylinder, the two sides of the porous material soil block are clamped and fixed through the filter discs, and a left bottom cover and a right bottom cover are installed on the two sides of the hollow cylinder respectively; the left bottom cover, the right bottom cover and the hollow cylinder are fixedly connected into a whole through a locking mechanism, and sealing washers are installed at the connecting positions of the hollow cylinder and the left bottom cover / the right bottom cover. The device is used for researching the diffusion behavior of radionuclides in a high-level radioactive waste repository, has the advantage of being easy to disassemble, and can be used for developing a penetration experiment method, researching weak-adsorbability nuclides, developing an internal diffusion experiment method, researching diffusion experiments of strong-adsorbability radionuclides (such as uranium, neptunium and plutonium) and measuring diffusion parameters.

Owner:HUZHOU TEACHERS COLLEGE

Device and method for adjusting valence states of neptunium and plutonium in hot chamber

ActiveCN111640520AOnline measurement of valenceOnline concentration measurementNuclear monitoringRecycling and recovery technologiesLiquid level measurementNeptunium

The invention discloses a device for adjusting valence states of neptunium and plutonium in a hot chamber. The device comprises an inner cylinder, a jacket cylinder, a sample feeding system, a discharging system, a sample online analysis system, a seasoning bubbling system, a liquid level measurement system, a temperature measurement system and a pressure measurement system. The device provided bythe invention is suitable for radioactive and strong corrosive places, can directly measure the light absorption value of a sample in the hot chamber, and utilizes the spectral absorption peaks of different substances to judge the ion valence state and other information in the feed liquid.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method and device for continuously adjusting neptunium valence and acidity in 1cu feed liquid in purex process

The invention relates to a method and a device for continuously adjusting the neptunium valence state and acidity in a 1CU feed liquid of a Purex process. The method comprises: adjusting the nitric acid concentration of the 1CU feed liquid to be 0.03-0.5mol / L; The neptunium in the liquid is oxidized to a high price; the 1CU feed liquid after the thermal insulation pretreatment is continuously cooled; the cooled 1CU feed liquid is continuously acid-adjusted to become the raw material liquid 2DF of the uranium purification cycle; in the above process, the heating and thermal insulation pretreatment The treatment process is carried out in the heating coil and the cooling process is carried out in the cooling coil to realize continuous production; the holding time of the heating and heat preservation pretreatment process is controlled by the flow rate of 1CU feed liquid, the diameter and length of the heating coil . The device includes a 1CU material and liquid temporary storage tank, a material and liquid transfer pump, a heating coil, a cooling coil and a static mixer. The beneficial effects of the present invention are as follows: the technical solution of the present invention can realize the continuous adjustment of neptunium valence state in 1CU, the process operation and control are very simple, and the tedious operation of the batch process is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method and device for continuously adjusting valence state and acidity of neptunium in Purex process 1CU feed liquid

The invention relates to a method and device for continuously adjusting the valence state and acidity of neptunium in a Purex process 1CU feed liquid. The method comprises the steps that the nitric acid concentration of the 1CU feed liquid is adjusted to be 0.03-0.5 mol / L; the 1CU feed liquid subjected to acid adjustment is subjected to heating and heat preservation continuous pretreatment to oxidize neptunium to the high valence; the 1CU feed liquid subjected to heat preservation pretreatment is continuously cooled; the cooled 1CU feed liquid is subjected to continuous acid adjustment to form raw material liquid 2DF for uranium purification circulation; in the process, the heating and heat preservation pretreatment process is carried out in a heating coil, and the cooling process is carried out in a cooling coil, so that continuous production is realized; the heat preservation time of the heating and heat preservation pretreatment process is controlled through the flow of the 1CU feed liquid as well as the diameter and length of the heating coil. The device comprises a 1CU feed liquid temporary storage tank, a feed liquid conveying pump, the heating coil, the cooling coil and a static mixer. The method and the device have the beneficial effects that according to the technical scheme, continuous adjustment of the valence state of neptunium in the 1CU can be achieved, process operation and control are very easy, and tedious operation of a batch process is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Solution stack for burning plutonium and transmutation of neptunium-237 or americium-241

The invention discloses a solution reactor used for the plutonium combustion and the neptunium-237 or the americium-241 transmutation. The solution reactor adopts plutonium or plutonium and americium in the spent fuel of the nuclear power plant as the fuel, and adopts neptunium-237 or americium-241 as the target. By adopting the solution reactor, the minor actinides which have long half life and high toxicity and can not be stored for a long time, such as the neptunium-237 or the americium-241, can be changed into nuclides with short half life and low toxicity through transmutation. Because the solution reactor adopts the spent fuel and can generate electricity at the low temperature, the cost-effectiveness and the security are high; the neutron provided by the plutonium combustion can extract plutonium-238 from the neptunium-237 solution target as the isotope battery, thereby the inexpensive energy is provided; the americium-242m extracted from the americium-241 solution target can be widely applied to the aerospace industry and the medical industry.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A device and method for adjusting the valence states of neptunium and plutonium in a hot chamber

ActiveCN111640520BAdjustable acidityMonitor pressure in real timeNuclear monitoringRecycling and recovery technologiesLiquid level measurementNeptunium

The invention discloses a device for adjusting the valence states of neptunium and plutonium in a hot chamber. The device comprises an inner cylinder, a clamping sleeve, a sample introduction system, a material discharge system, an online sample analysis system, a seasoning bubbling system, and a liquid level measurement system. systems, temperature measurement systems, pressure measurement systems. The device provided by the invention is suitable for use in radioactive and highly corrosive places, and can directly measure the light absorption value of the sample in the hot chamber, and use the spectral absorption peaks of different substances to judge the ion valence state and other information in the material liquid.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

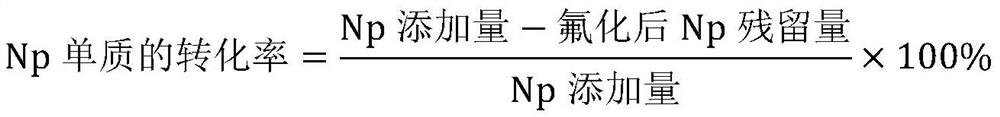

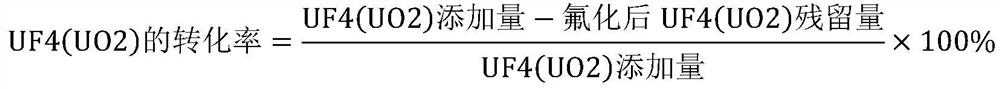

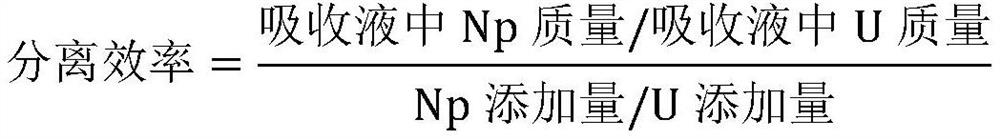

Method for separating uranium and neptunium through fluorination volatilization technology

PendingCN113881862AReduce chemical toxicityStable in natureProcess efficiency improvementPhysical chemistryReaction temperature

The invention provides a method for separating uranium and neptunium through a fluorinated volatilization technology. The method comprises the following steps that (1), air and water in a reactor are removed, the reactor is filled with a mixture A or a mixture B, the mixture A comprises a substance containing uranium elements and neptunium elements, the mixture B comprises a substance containing uranium elements, a substance containing neptunium elements and fused salt, the substance containing uranium elements comprises uranium elementary substance and / or uranium compound; and the substance containing neptunium elements is neptunium elementary substance and / or neptunium compound; (2), reaction products containing uranium elements are recycled; and (3) the residual product after the uranium elements are recycled is cooled to 350-600 DEG C, mixed gas of fluorine gas and inert gas is introduced, a reaction product containing neptunium elements is recycled; and the reaction temperature in the step 2 is higher than that in the step 3. The method has the advantages that the reaction speed is high, the conversion rate of uranium and neptunium is large, the separation efficiency of uranium and neptunium is high, side reactions are few, the separation selectivity is good, and serialization is easy.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow

ActiveCN103305702BHigh recovery rateValence stableProcess efficiency improvementRadioactive decontaminationOxalate precipitationEngineering

The invention belongs to the technical field of nuclear fuel reprocessing and discloses a process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow. The process comprises the primary neptunium purification process and the secondary neptunium purification process; the process comprises the following steps: by taking 30 volume percent of TBP-kerosene as an extraction agent, extracting Np, U and Pu to the organic phase, and allowing the fission fragments to enter the aqueous phase; adding a reducing agent and an extraction agent into the organic phase, reversely extracting the Np to the aqueous phase; further extracting uranium and plutonium, and performing oxalate precipitation, filtering and calcining on the obtained aqueous phase product to obtain the purified neptunium oxide solid. The process has the advantages that the neptunium recovery rate is over 98 percent, and the uranium and plutonium removal coefficient in neptunium is high.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A Neptunium Dioxide-Plutonium Dioxide Dissolver for Hot Chamber

ActiveCN111199808BEffective dissolutionQuick changeNuclear energy generationRecycling and recovery technologiesFuel reprocessingStrong acids

The invention belongs to the technical field of spent fuel reprocessing, and in particular relates to a neptunium dioxide-plutonium dioxide dissolver for a hot cell, which is used for dissolving neptunium targets containing neptunium and plutonium elements in a hot cell, including strong acid resistance A high-temperature dissolving tank (1), the periphery of the dissolving tank (1) is provided with a heating device; the dissolving tank (1) is also pierced with a cleaning pipe (4) for adding nitric acid into the dissolving tank (1), for adding and dissolving The feed pipe (5) of liquid, the bubbling pipe (6) that is used to pass into the disturbing gas in the solution in the dissolution tank (1), is used to discharge the discharge pipe (7) of solution; The integral electrode (14) which is installed inside the dissolving tank (1) is replaced; it also includes a control system for remote operation of the replacement of the integral electrode (14). The invention can be applied in a hot chamber to dissolve a neptunium target; the dissolution reaction can be remotely operated by a manipulator in the hot chamber; the neptunium target can be fully dissolved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for separating neptunium from uranium product by TEVA-UTEVA extraction chromatographic column

The invention discloses a method for separating neptunium (Np) from a uranium product by a TEVA-UTEVA extraction chromatographic column. The method comprises the following steps: (1) adding an acidic solution and a reducing agent into the uranium product to stabilize the neptunium into Np (IV), separating the neptunium from the uranium by a TEVA levextrel resin, and desorbing the neptunium by the mixed solution of nitric acid and oxalic acid; and (2) allowing the eluent to pass through a UTEVA extraction chromatographic column to further purify the neptunium. According to the method provided by the invention, the two separation processes only need one-time price adjustment and are simple; the method is high in recovery rate, precision and separation efficiency and stable in recovery; and the neptunium is separated from the uranium product with the ratio of the uranium to the neptunium of 106:1 by the TEVA-UTEVA extraction chromatographic column.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com