Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "PUREX" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PUREX is a chemical method used to purify fuel for nuclear reactors or nuclear weapons. It is an acronym standing for Plutonium Uranium Redox EXtraction. PUREX is the de facto standard aqueous nuclear reprocessing method for the recovery of uranium and plutonium from used ("spent", or "irradiated") nuclear fuel. It is based on liquid–liquid extraction ion-exchange.

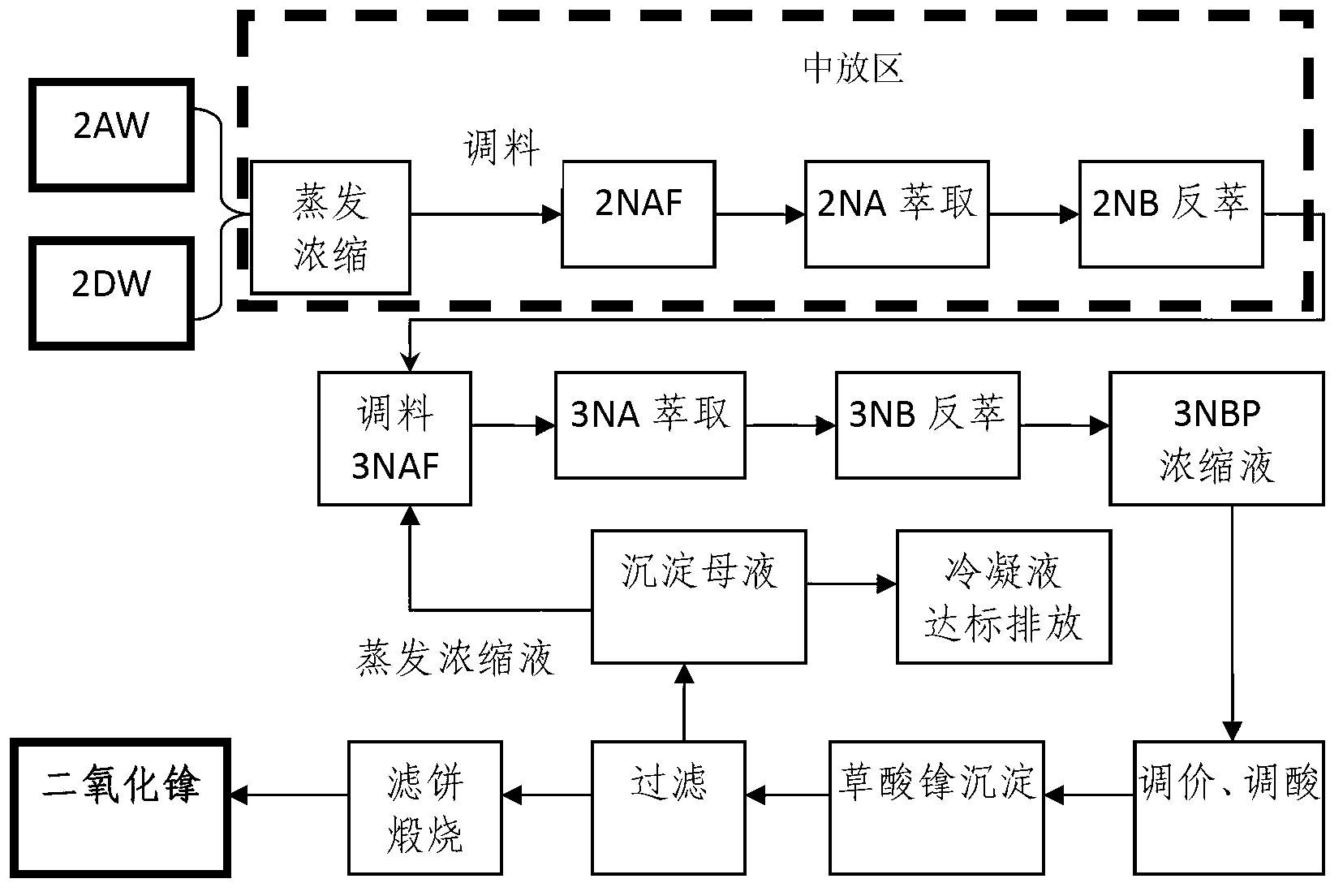

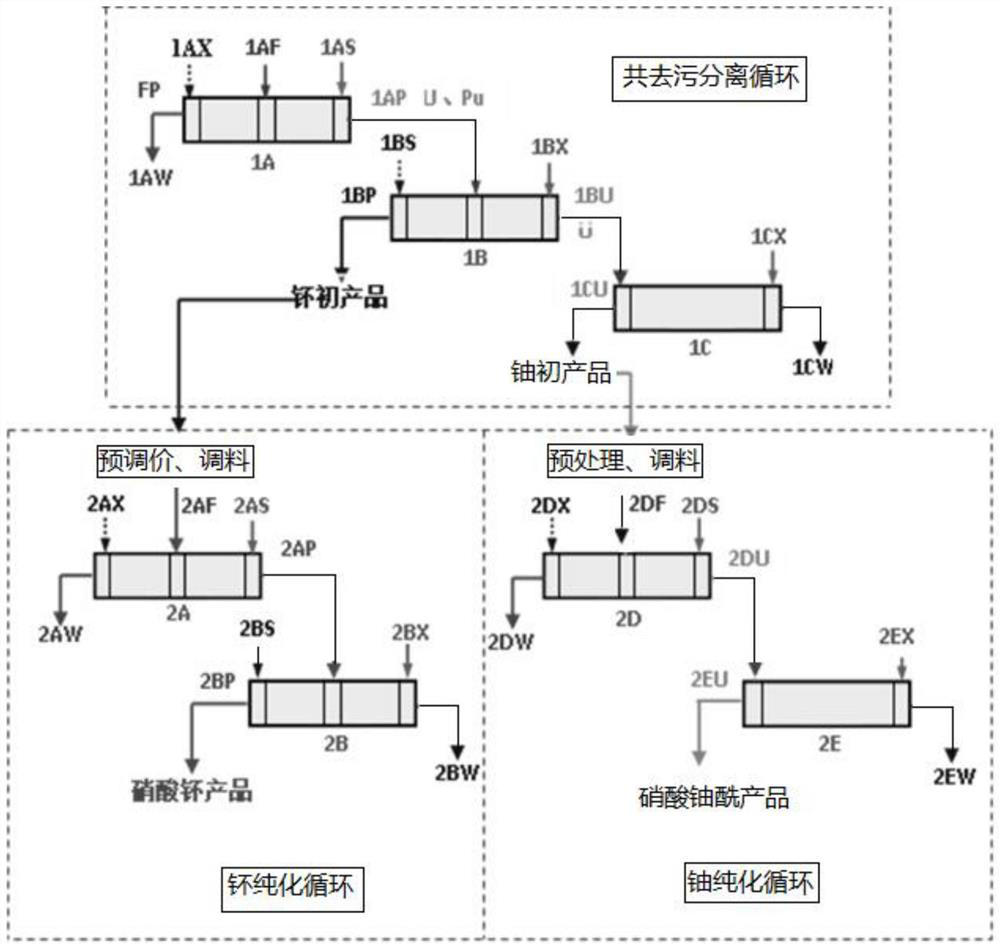

Process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow

ActiveCN103305702AHigh recovery rateValence stableProcess efficiency improvementRadioactive decontaminationOxalate precipitationEngineering

The invention belongs to the technical field of nuclear fuel reprocessing and discloses a process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow. The process comprises the primary neptunium purification process and the secondary neptunium purification process; the process comprises the following steps: by taking 30 volume percent of TBP-kerosene as an extraction agent, extracting Np, U and Pu to the organic phase, and allowing the fission fragments to enter the aqueous phase; adding a reducing agent and an extraction agent into the organic phase, reversely extracting the Np to the aqueous phase; further extracting uranium and plutonium, and performing oxalate precipitation, filtering and calcining on the obtained aqueous phase product to obtain the purified neptunium oxide solid. The process has the advantages that the neptunium recovery rate is over 98 percent, and the uranium and plutonium removal coefficient in neptunium is high.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Uranium (U) and plutonium (Pu) separation technology in Purex process

ActiveCN103451455AStrong complexing abilityStrong reductionLiquid solutions solvent extractionRadioactive decontaminationPUREXSeparation technology

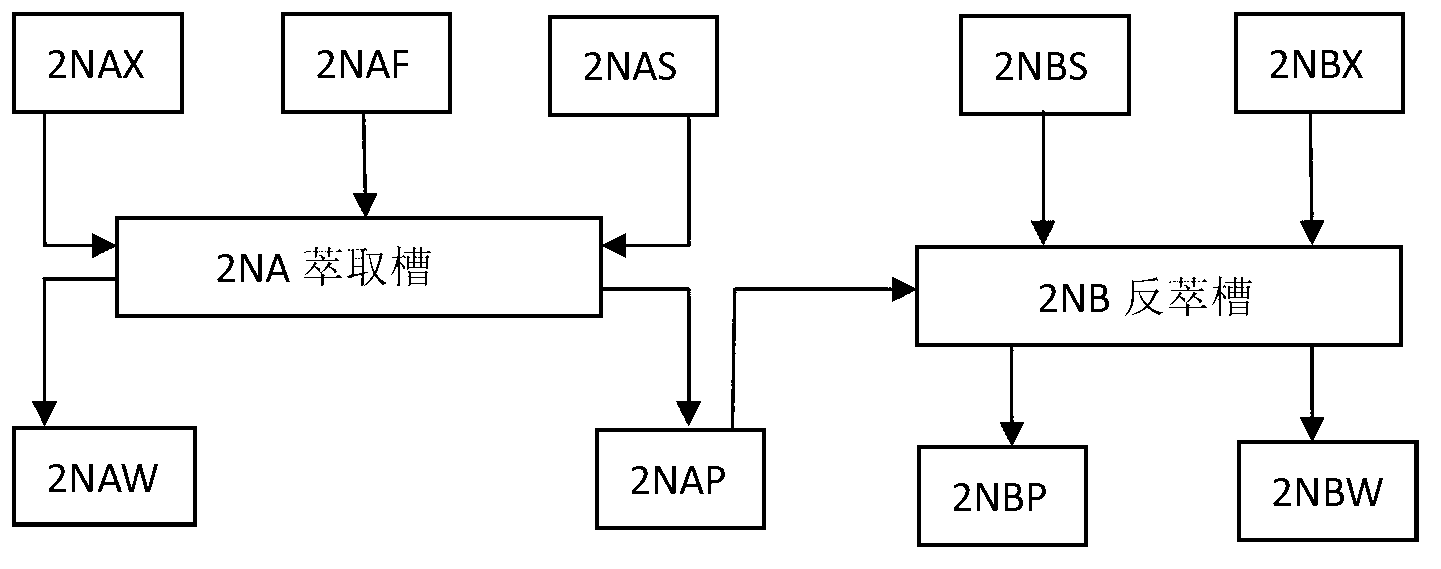

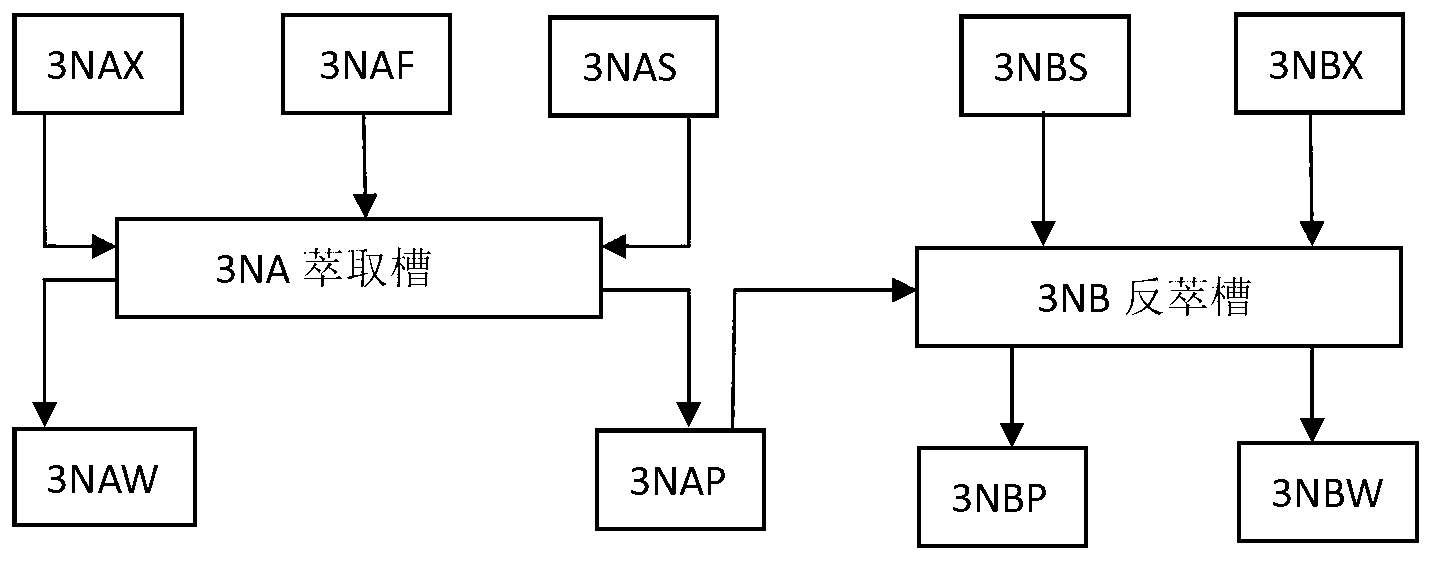

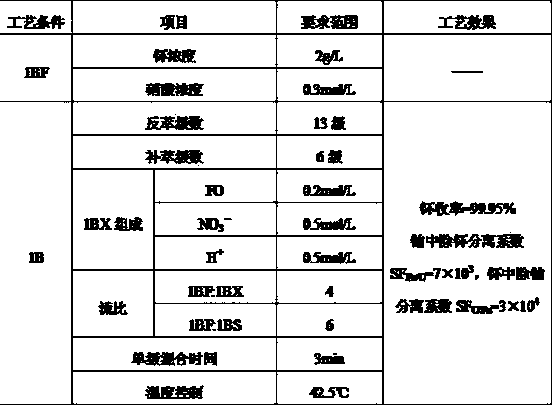

The invention belongs to the technical field of nuclear fuel postprocessing, and discloses a uranium (U) and plutonium (Pu) separation technology in a Purex process. According to the uranium and plutonium separation technology, Pu (IV) in 1BF material flow is reduced to Pu (III) in 1B tank by use of reducing agent 1BX and supplement extractant 1BS to enable plutonium to get into an aqueous phase and uranium to be retained in an organic phase, and uranium and plutonium separation is realized. The reducing agent 1BX which is used comprises 0.1-0.2 mol / L of formaldoxime, 0.35-0.5 mol / L of NO<3-> and 0.35-0.5 mol / L of H<+>; the flow ratio of 1BF:1BX is 1-4, and the flow ratio of 1BF:1BS is 4-6. The uranium and plutonium separation technology has the characteristics that the plutonium recovery rate is high, and the purification coefficients of removal of plutonium from uranium and removal of uranium from plutonium are large.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method of separating uranium from irradiated nuclear fuel

InactiveUS6960326B1Simplified cutting stepsReduce stepsTransuranic element compoundsNuclear energy generationHydrogen fluorideFluoride

The invention provides a method of separating uranium from at least fission products in irradiated nuclear fuel, said method comprising reacting said irradiated nuclear fuel with a solution of ammonium fluoride in hydrogen fluoride fluorinating said reacted irradiated nuclear fuel to form a volatile uranium fluoride compound and separating said volatile uranium fluoride compound from involatile fission products. The invention thus provides a reprocessing scheme for irradiated nuclear fuel. The method is also capable of reacting, and breaking down Zircaloy cladding and stainless steel assembly components. Thus, whole fuel elements may be dissolved as one thereby simplifying procedures over conventional Purex processes.

Owner:NEXIA SOLUTIONS

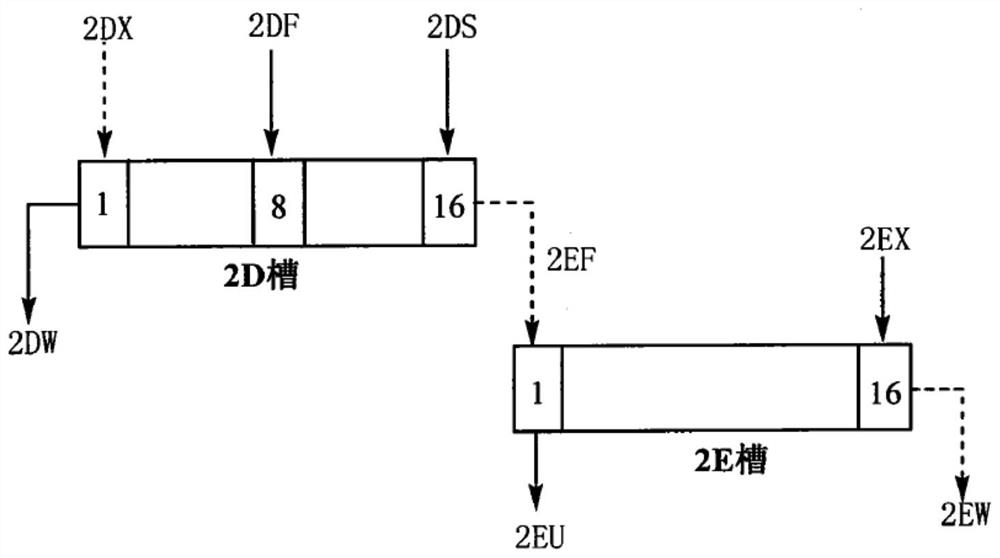

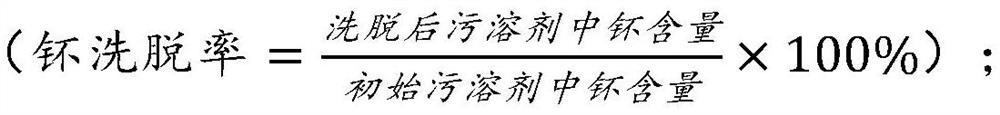

Method for cycle purification of uranium in Purex process

ActiveCN102290111AQuick restoreNo increase in solid waste volumeProcess efficiency improvementInorganic non-surface-active detergent compositionsMonomethyl hydrazineHydroxylamine

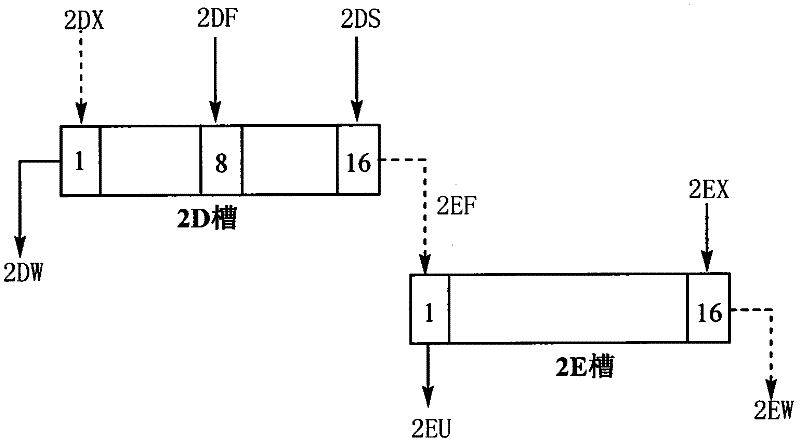

The invention discloses a method for cycle purification of uranium in a Purex process. The method comprises the following steps of: pretreating 1CU feed liquor, seasoning, and further purifying plutonium by using a washing agent in a two-dimensional (2D) tank, wherein the used washing agent in the 2D tank is a mixed solution of dimethyl hydroxylamine, monomethyl hydrazine and nitric acid, the concentration of the dimethyl hydroxylamine is 0.01 to 0.1mol / L, the concentration of the monomethyl hydrazine is less than or equal to 0.15mol / L, and the concentration of the nitric acid is 0.8 to 1.2mol / L. The dissipation factor (DF) (Pu / U) in the 2D tank is more than 1,000, and the content of the plutonium in 2EU feed liquor reaches a uranium product index.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for separating U (uranium) from Pu (plutonium) in Purex process

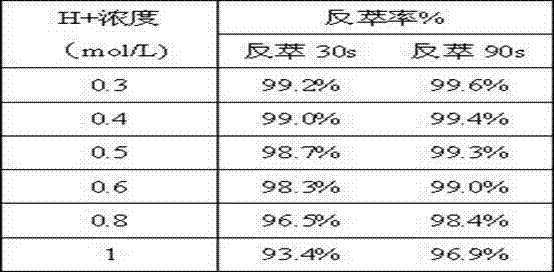

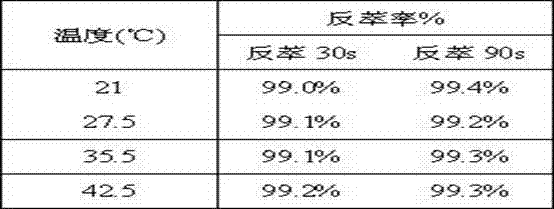

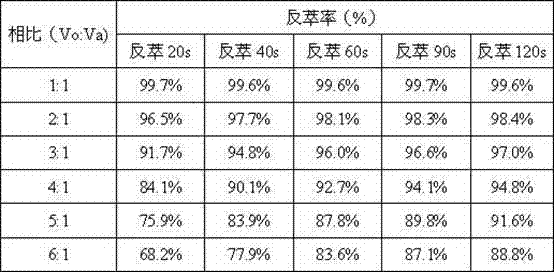

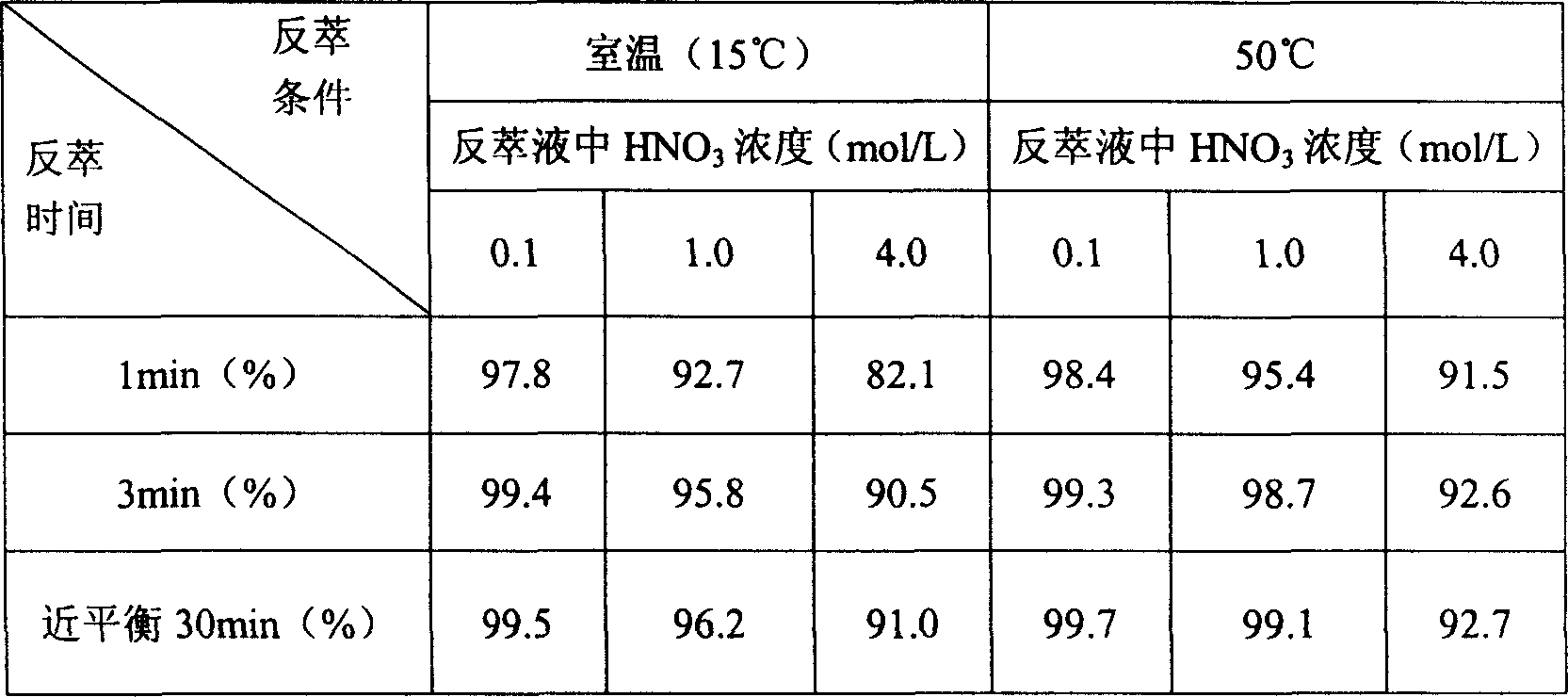

The invention which belongs to the technical field of radioactive post-treatment concretely relates to a method for separating U from Pu in a Purex process. The method comprises the following steps: 1, removing nuclear reaction splinters except U and Pu; 2, coextracting codecontaminated U and Pu to a TBP (tributyl phosphate) / kerosene mixed liquor with a volume percentage of 30%; and 3, adding a reducing agent HSC (hydroxysemicarbazide) to the mixed liquor in step 2, and fully mixing to back-extract Pu (III) which is reduced from Pu (IV) in an organic phase to an aqueous solution of hydrogen nitrate, wherein the ratio of the molar concentration of the HSC in an aqueous phase solution to the molar concentration of Pu in an organic phase solution is 5-60, the volume ratio of the organic phase solution to the aqueous phase solution is 1:1-6:1, the temperature is 21-42.5DEG C, and the concentration of H<+> is 0.3-1mol / L. A technical scheme provided by the invention allows Pu (IV) in the organic phase to be rapidly reduced and back-extracted to the aqueous phase, the reaction time is two magnitudes shorter than the reaction time of the prior art, the technological process is simplified, and the separation efficiency is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

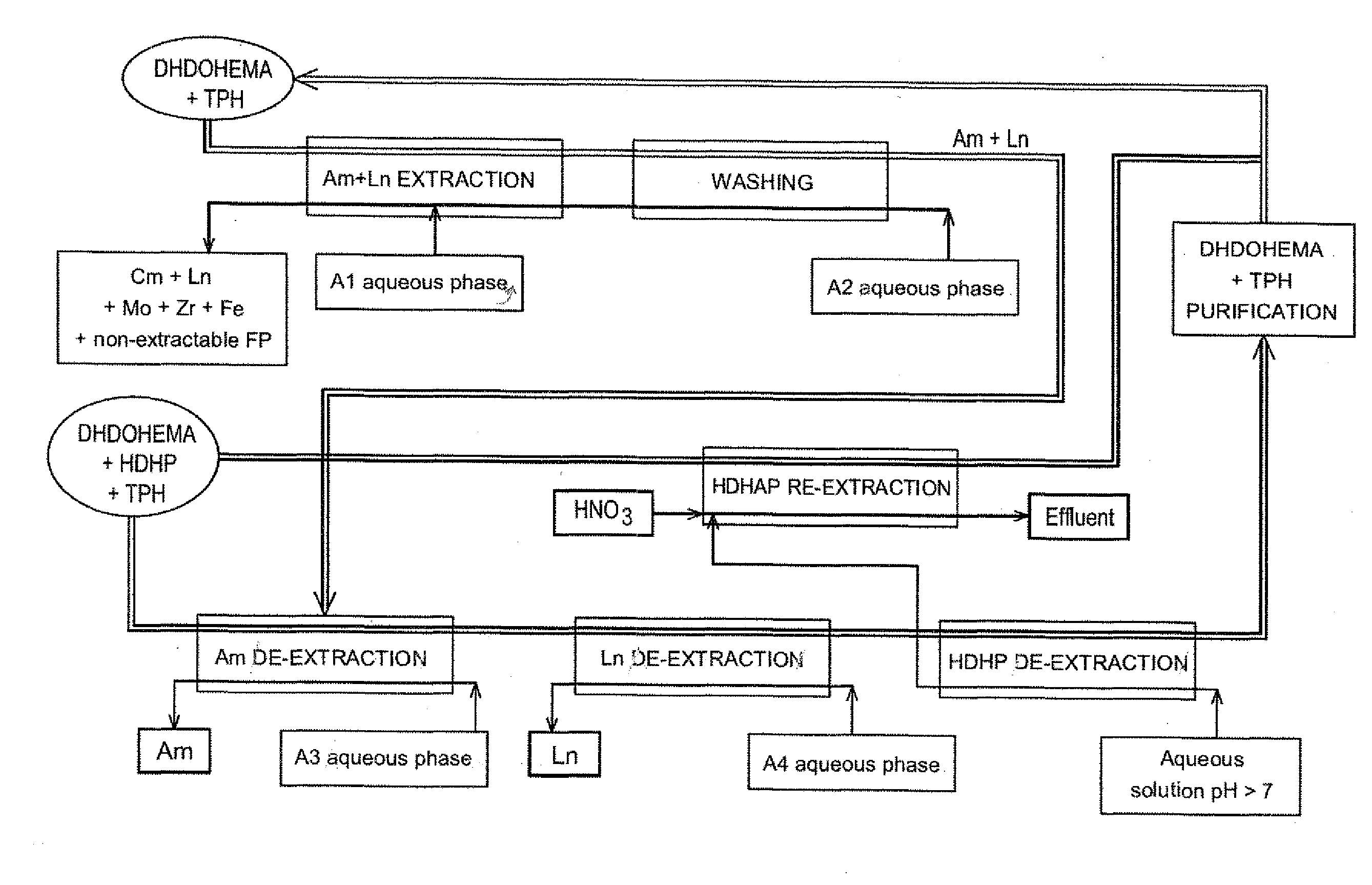

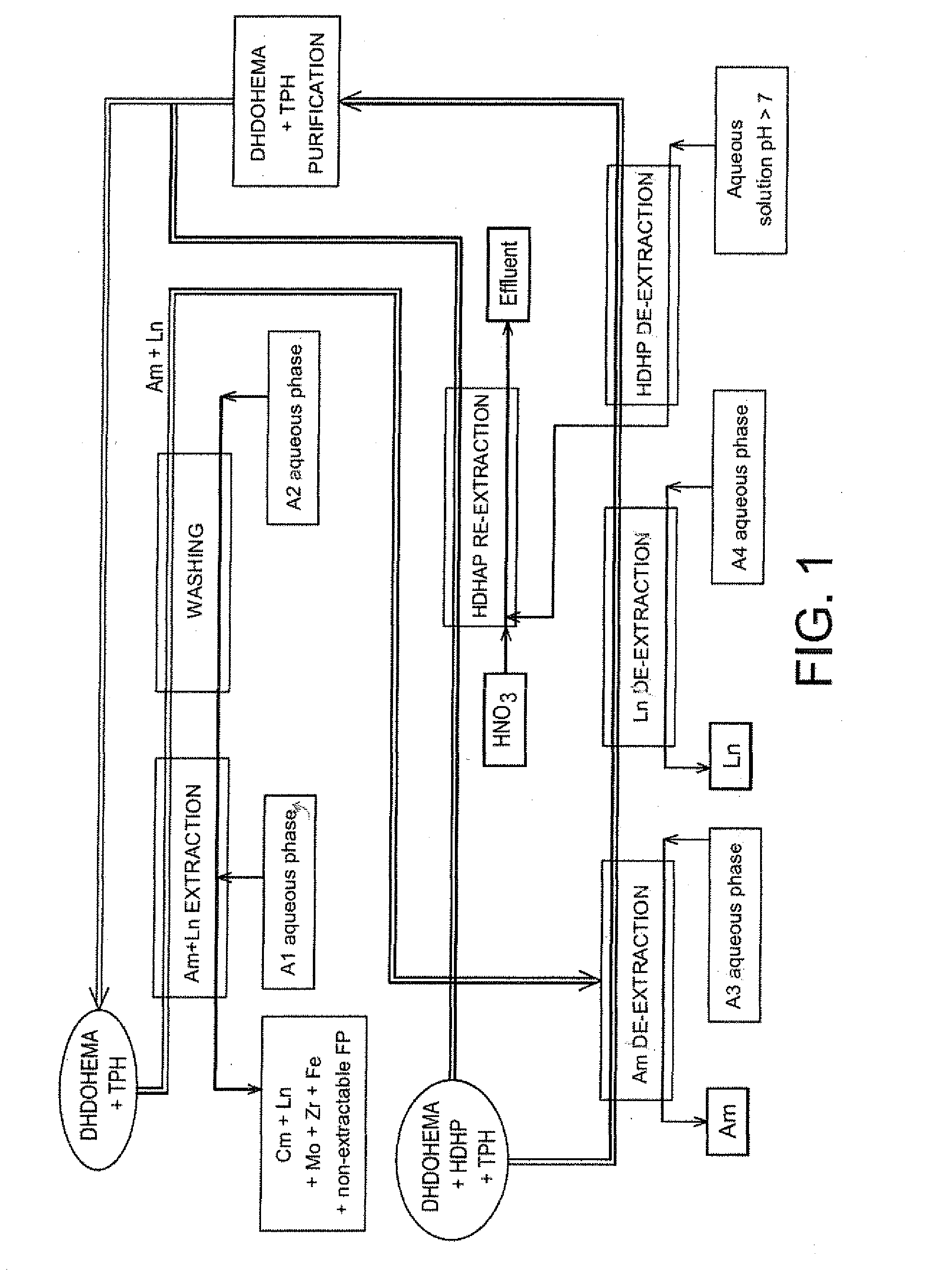

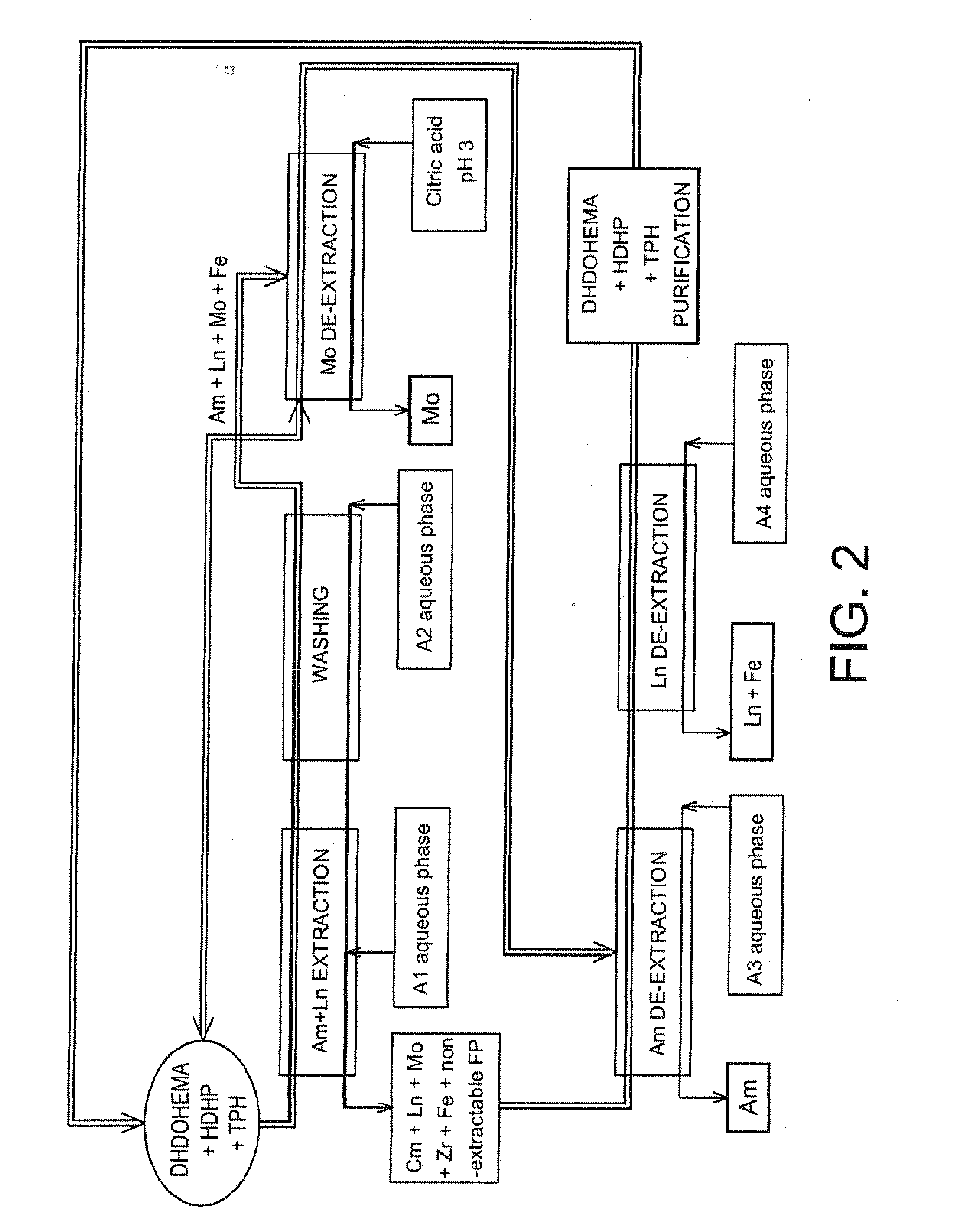

Increase in the separation factor between americium and curium and/or between lanthanides in a liquid-liquid extraction operation

ActiveUS20120160061A1Improved separation factorEasy to separateNuclear energy generationNuclear elementsSeparation factorRare earth

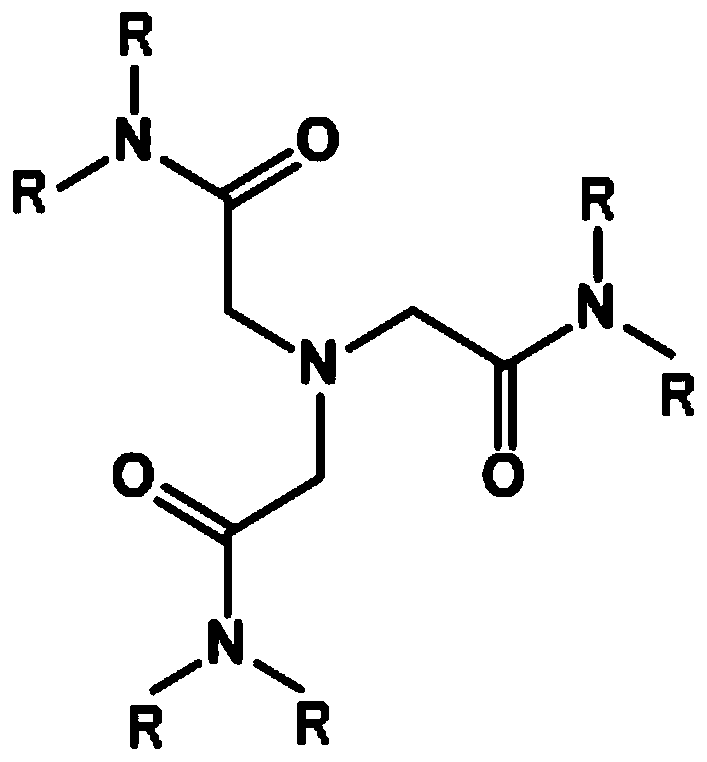

A method using diglycolamide for increasing the separation factor between americium and curium and / or between lanthanides during an extraction operation. The operation comprising putting an acid aqueous phase, in which are found the americium, curium and / or lanthanides, in contact with an organic phase non-miscible with water, containing at least one extractant in an organic diluent. The aqueous and organic phases are then separated, and the diglycolamide is added to the aqueous phase. This method can be used for processing and recycling irradiated nuclear fuels, in particular for selectively recovering americium from high activity aqueous solutions such as raffinates stemming from the processing of irradiated nuclear fuels with a PUREX or COEX™ method; processing of rare earth ores of the monazite, xenotime or bastnaesite type, in order to facilitate separation of <<lightweight>> rare earths from <<heavy>> rare earths and of yttrium, or that of two rare earths with adjacent or close atomic numbers.

Owner:ORANO RECYCLAGE +1

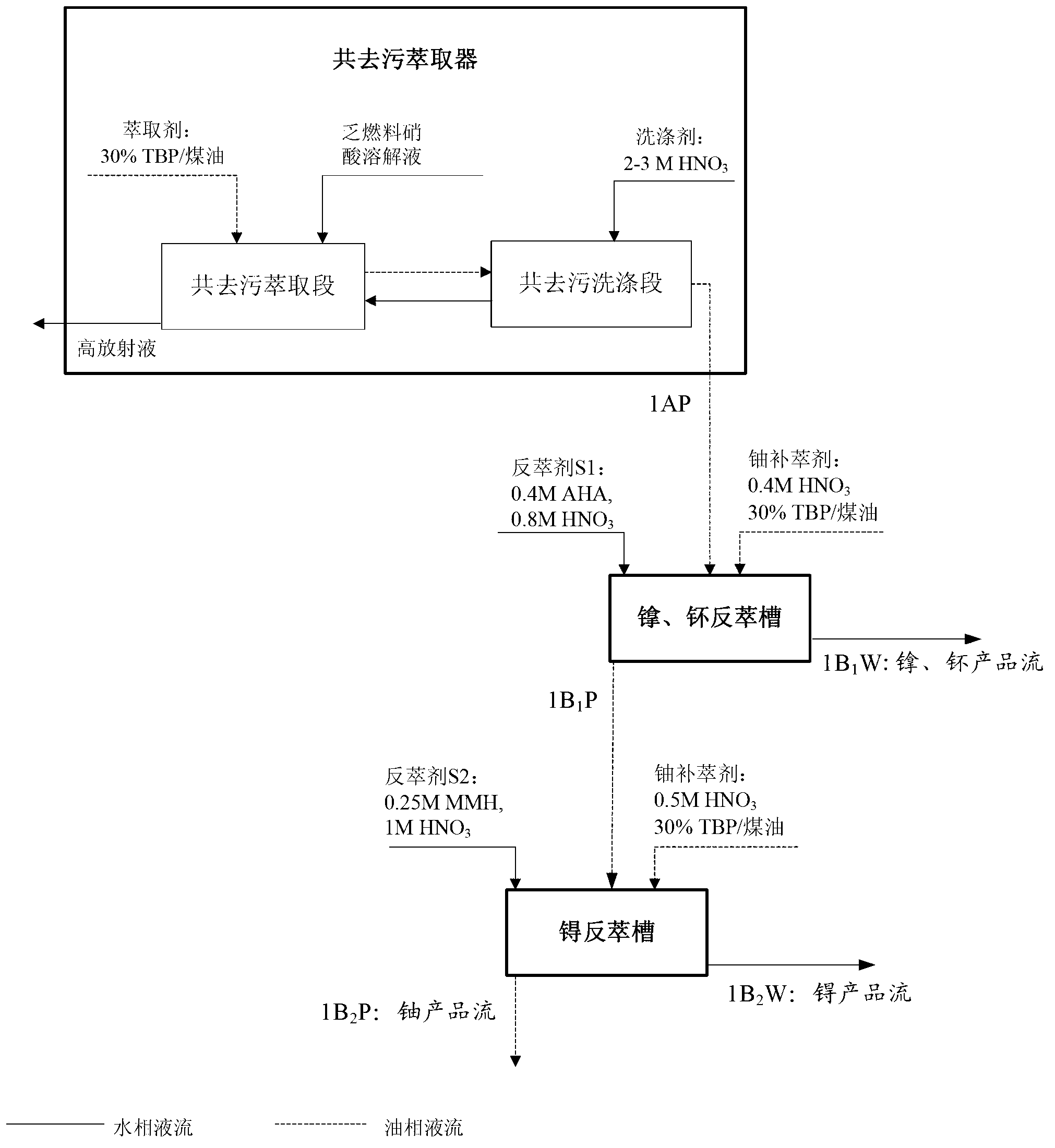

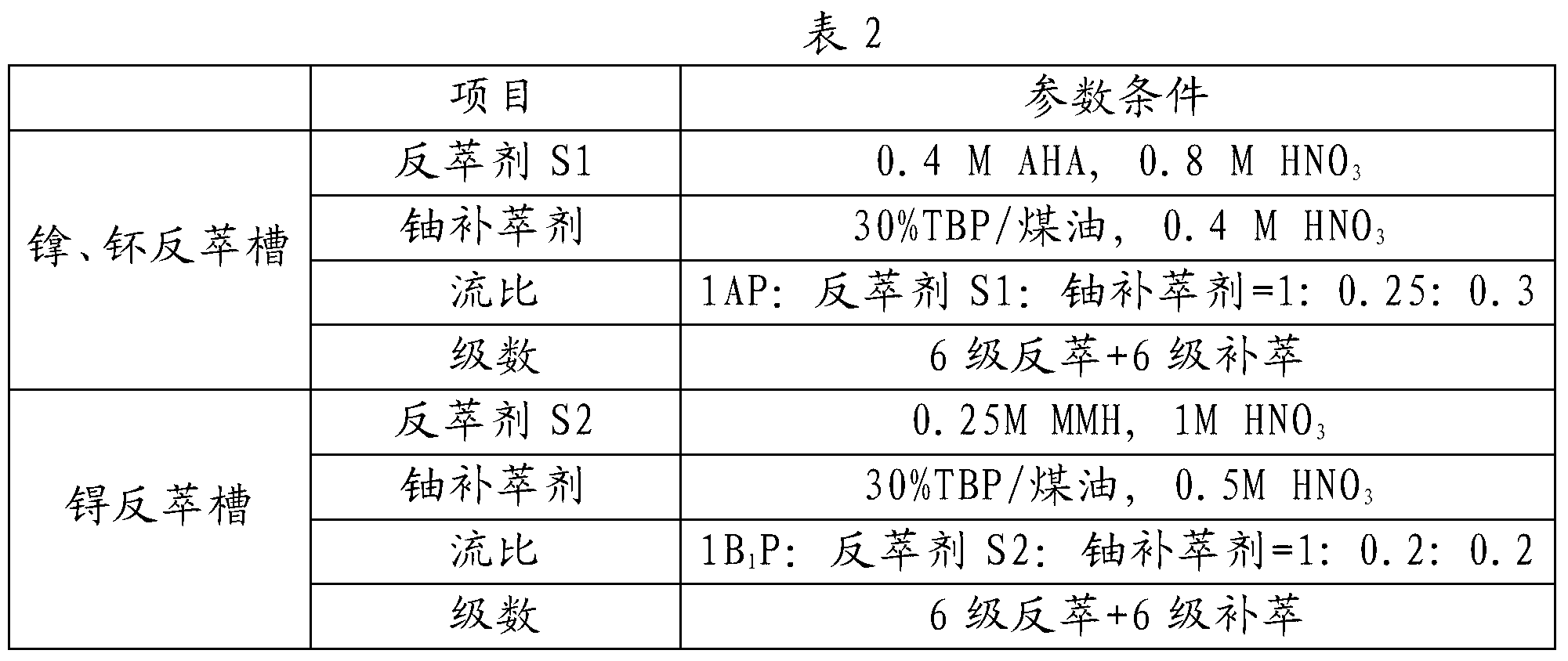

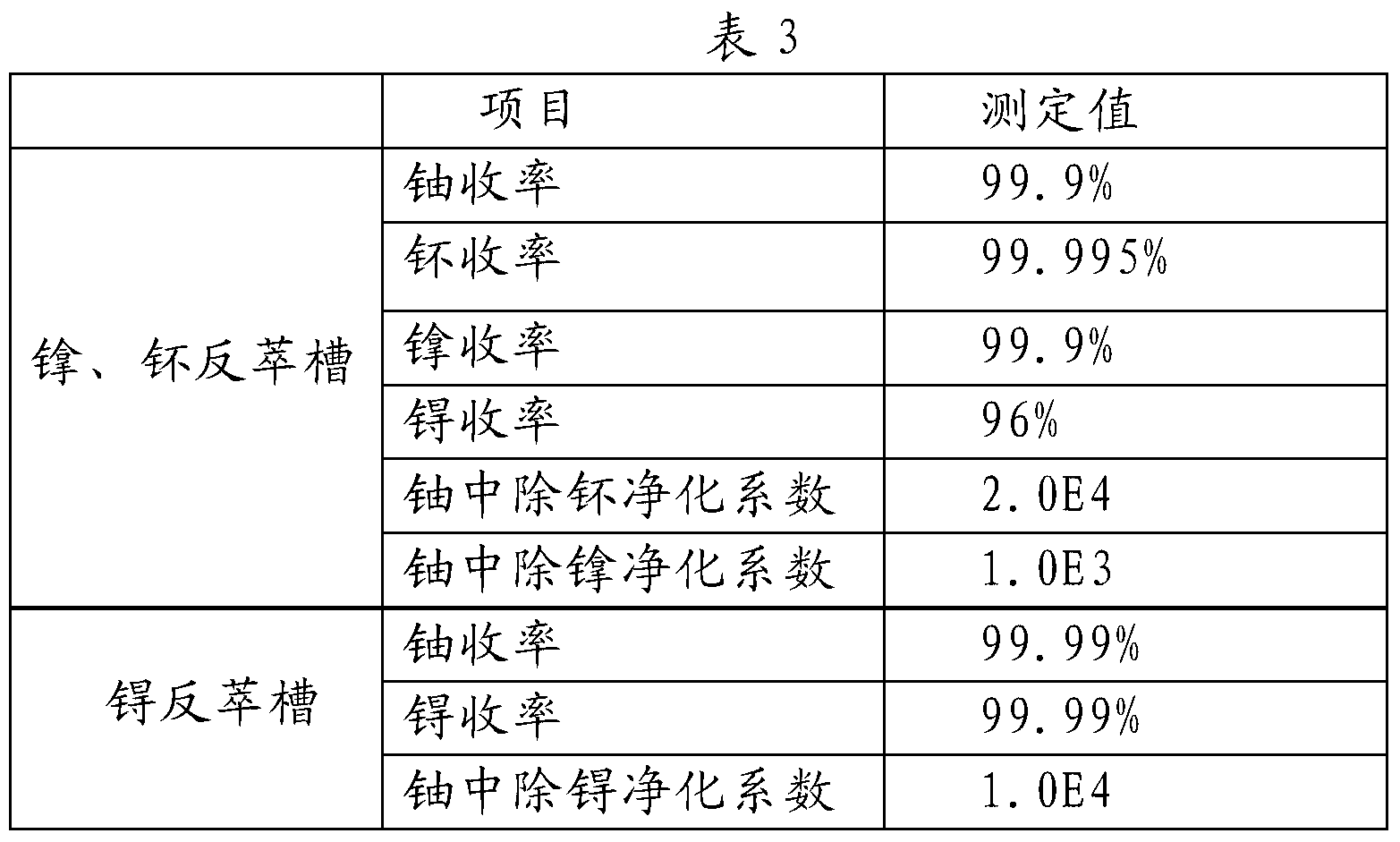

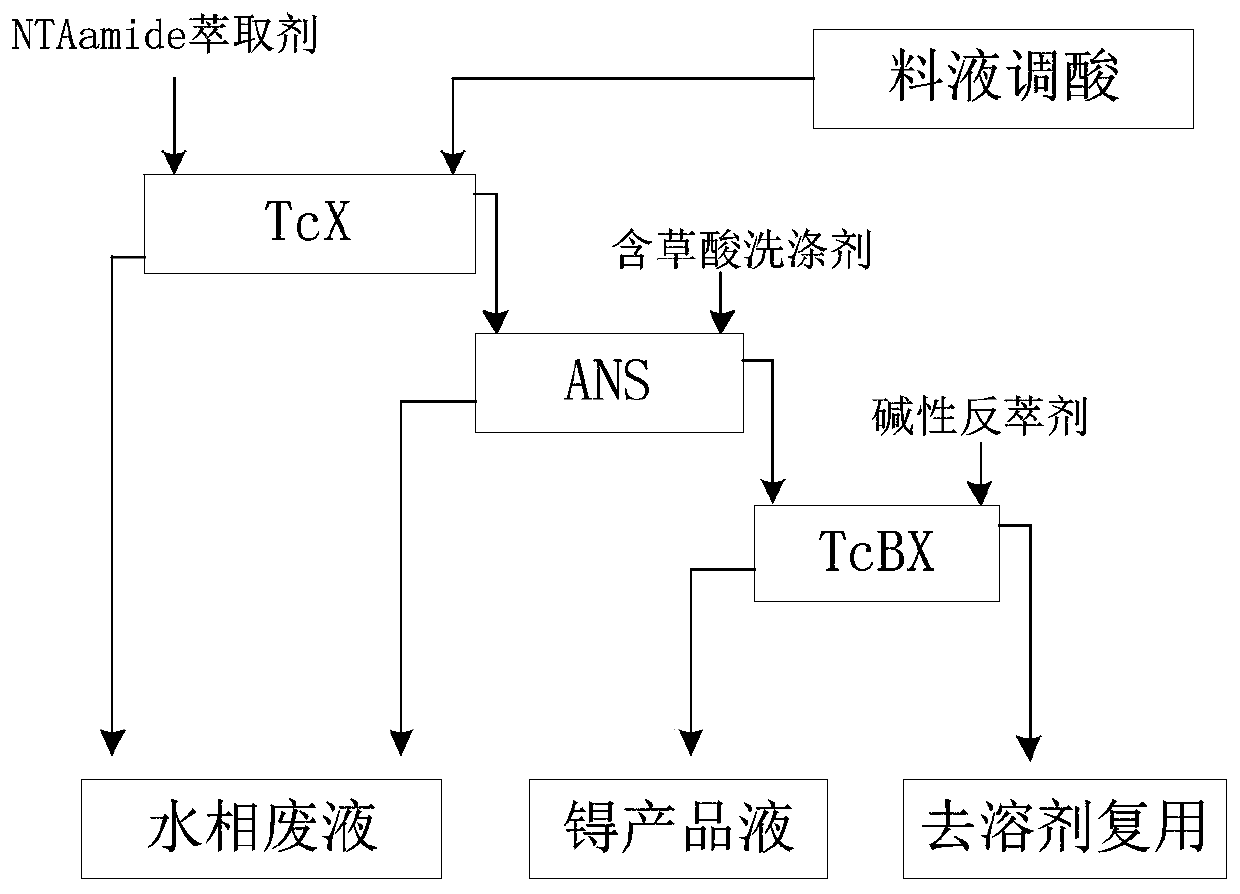

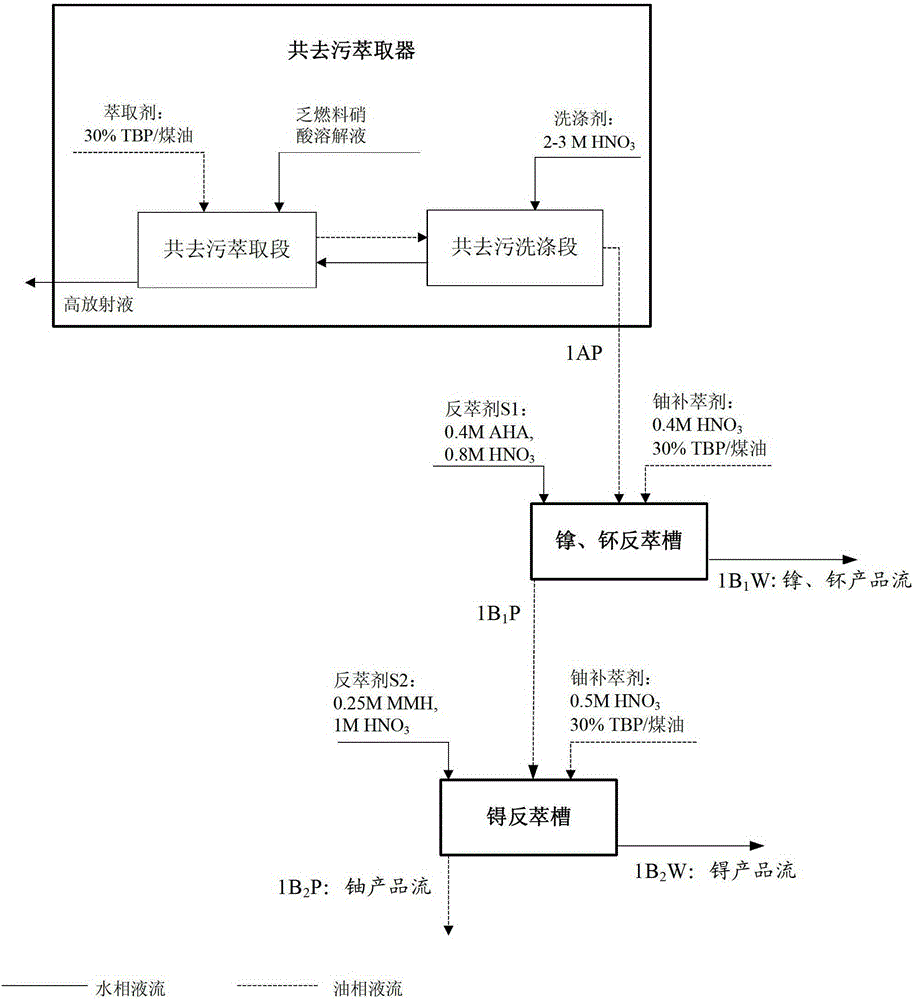

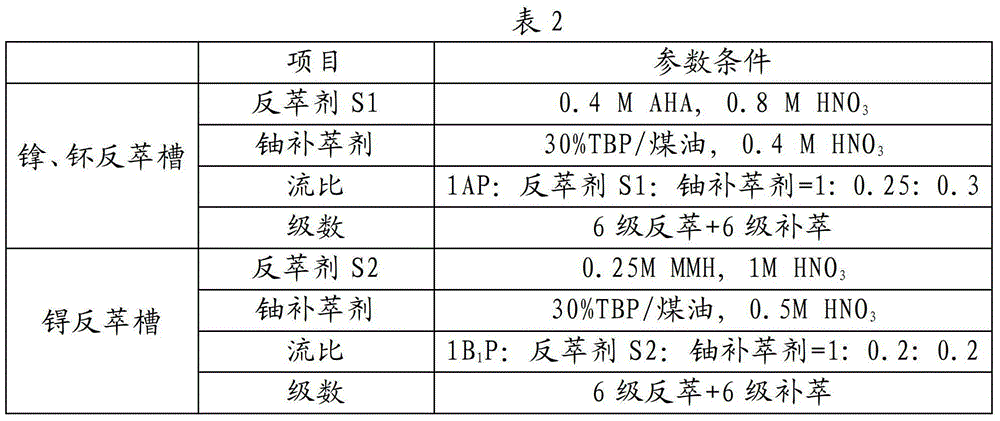

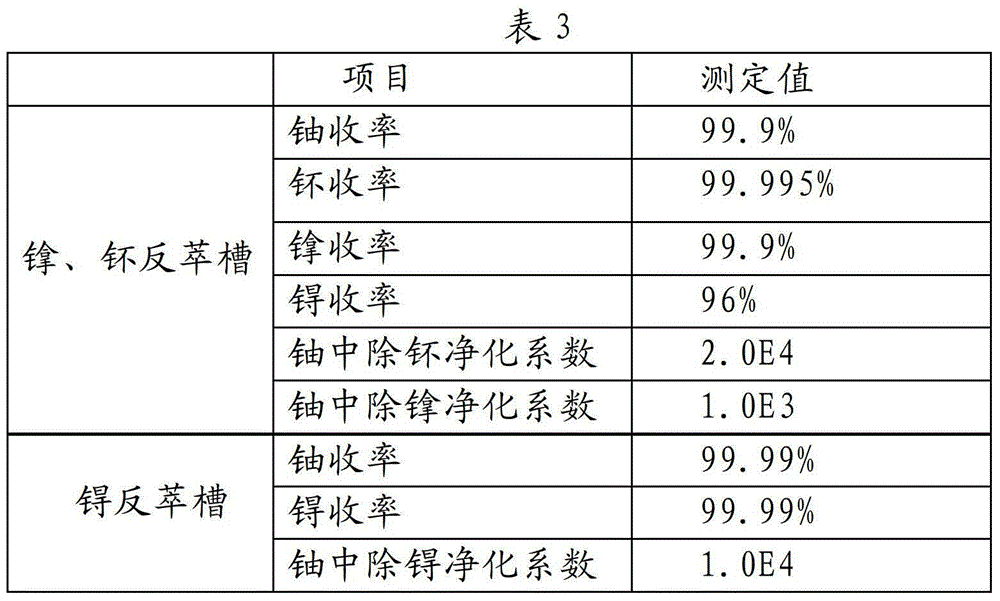

PUREX process for separating technetium

ActiveCN103325431AStep-by-step restore implementationGo simpleRadioactive decontaminationTechnetiumSalt free

The invention relates to a PUREX process for separating technetium. The PUREX process includes the steps: (1) co-decontamination and co-extraction: co-extracting uranium, plutonium, neptunium and the technetium in spent fuel nitric acid solution into an organic phase and washing co-extraction liquid; (2) plutonium and neptunium reverse extraction: reversely extracting the plutonium and the neptunium in the co-extraction liquid into a water phase by reverse extraction agents S1 containing AHA and then adding uranium supplement extraction agents for supplement extraction to obtain the water phase containing the plutonium and the neptunium and an oil phase containing the uranium and the technetium; (3) technetium reduction and reverse extraction: reducing and reversely extracting the technetium in the oil phase containing the uranium and the technetium into the water phase by reverse extraction agents S2 containing reducing agents and then adding uranium supplement extraction agents for supplement extraction to obtain a water phase containing the technetium and an oil phase containing the uranium, wherein the oil phase containing the uranium enters a subsequent uranium purification process. The neptunium, the plutonium and the technetium are reduced step by step through a step-by-step reduction method, the technetium can be separated out, the trend of elements is simpler and more uniform, all the reducing agents are salt-free reagents, remaining reagents are easily damaged, and the subsequent process is less affected.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

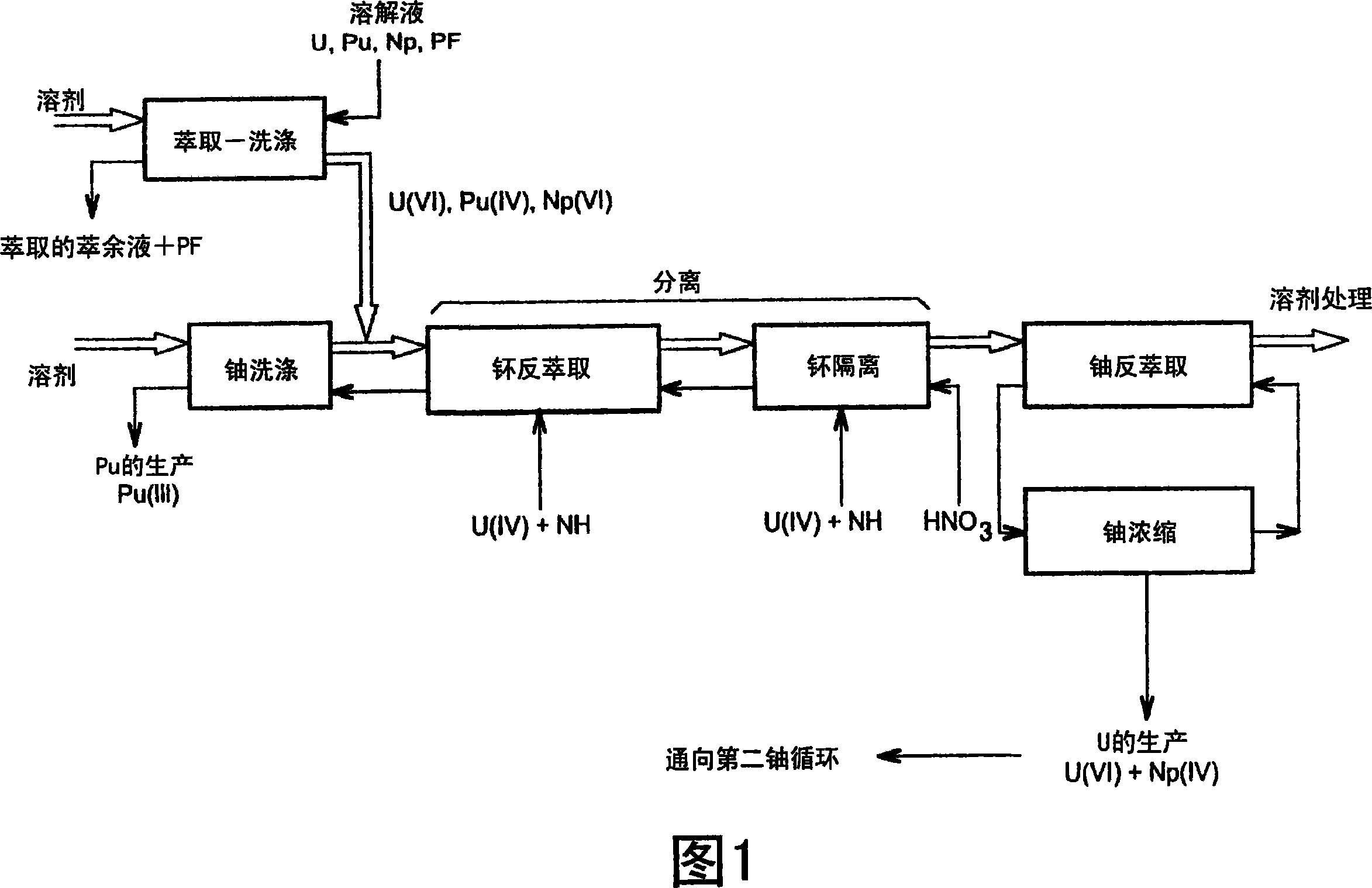

Improvement of the purex method and uses thereof

ActiveCN101088129AEfficient separationNuclear energy generationRecycling and recovery technologiesSolventPu element

The procedure consists of separating the uranium, plutonium, other actinides and fission products from the spent fuel in a nitric acid solution, separating the uranium from the plutonium in two separate flows by extracting the plutonium from the solvant phase in a nitric acid aqueous solution with a reducing agent, and then concentrating the solution containing the uranium (III). Part of the concentrated solution is used to extract the actinides (IV) present in the oxidated state, the actinides (IV) being neptunium (IV), thorium (IV) and / or plutonium (IV).

Owner:ORANO RECYCLAGE

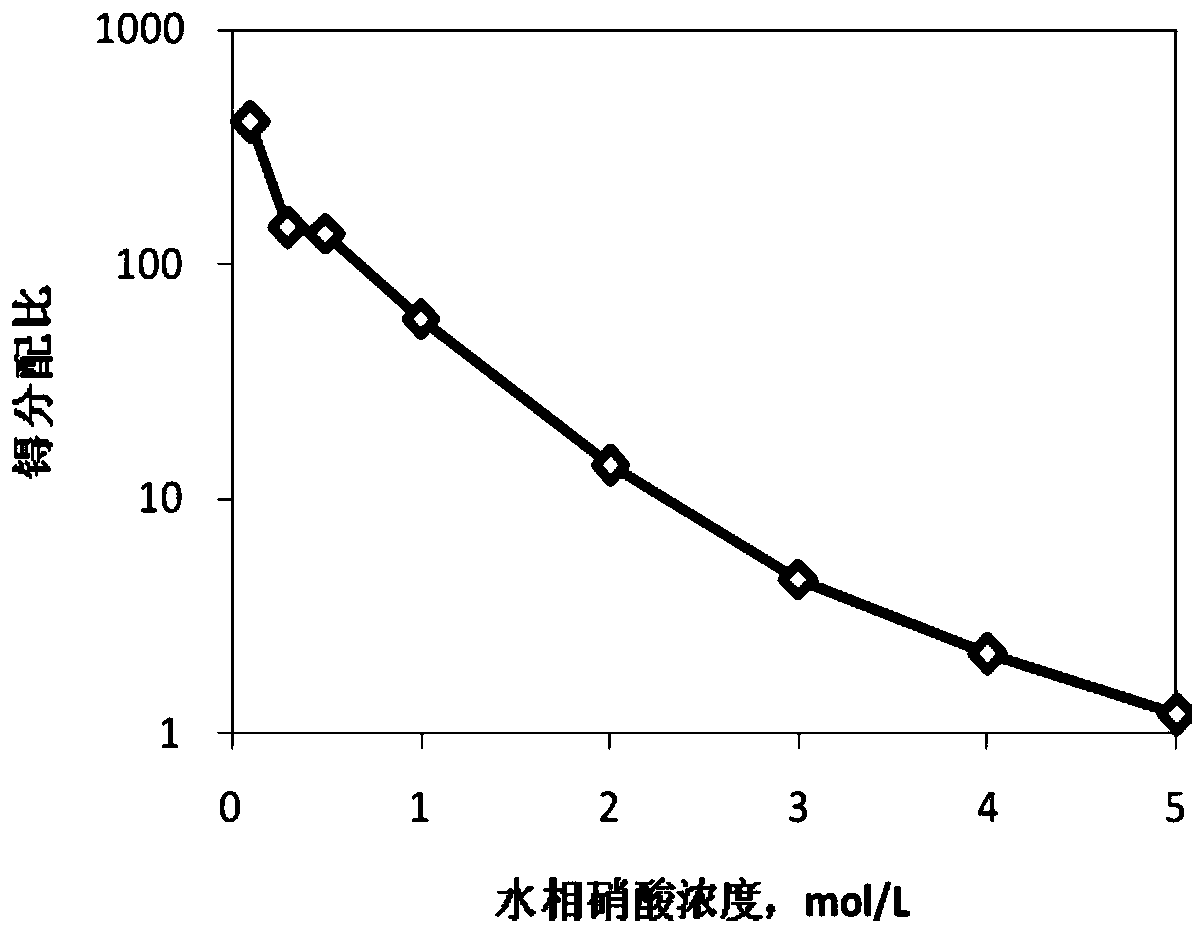

Method for extracting palladium from high-level liquid waste

ActiveCN101713026AMinimizeAchieve simplicityProcess efficiency improvementLiquid wasteAfter treatment

The invention provides a method for extracting palladium from high-level liquid waste, which belongs to the technical field of radioactive waste after treatment. The high-level liquid waste adopts nitric acid system, and the method comprises the following concrete steps of: a, adequately mixing the high-level liquid waste with extract phase; b, separating extract phase containing palladium from the mixture after extraction equilibrium; c, washing the separated extract phase containing palladium; d, repeating steps b and c 1 to 5 times; e, adding stripping agent to the washed extract phase containing palladium to perform back extraction; and the method is characterized in that triisobutyl phosphine sulfide (TiBPS) is adopted as extracting agent, and thinning agent is added for preparing the extract phase. The method has the following advantages: a, the extracting ratio of palladium in the nitric acid system is high by using TiBPS as extracting agent; b, the concentration range of adaptable nitric acid is wide, Purex process can be directly linked, mixtion is not required in the extraction process, and waste minimization and processing equipment simplification can be realized; c, the selectivity is good; and d, back extraction is easy.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

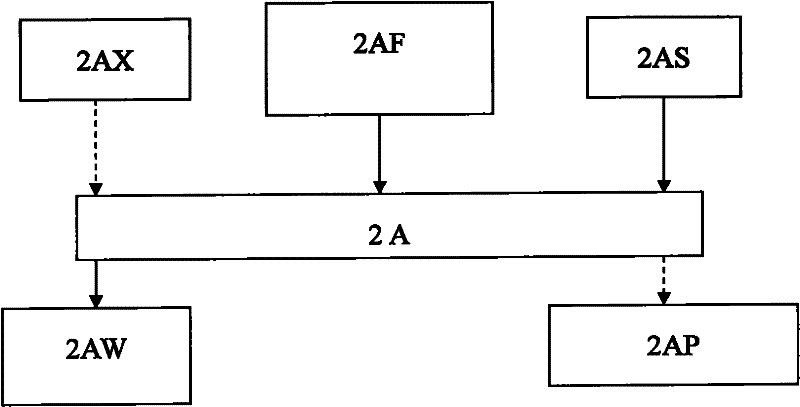

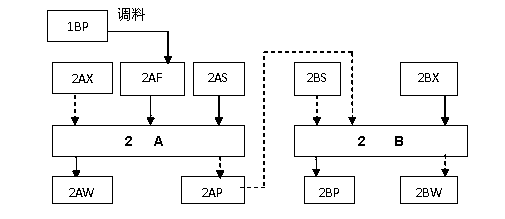

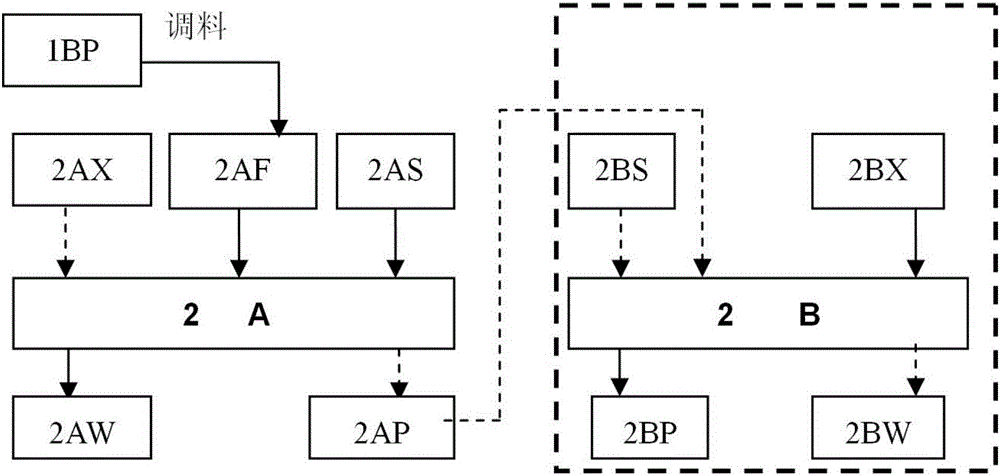

Method for improving 2A process plutonium concentration multiple in Purex flow

The invention belongs to the technical field of nuclear fuel reprocessing, and in particular relates to a method for improving 2A process plutonium concentration multiple in a Purex flow. By the method, the 2AF feed acidity is improved to be 3.8-5mol / L, and a flow ratio of 2AF to 2AX to 2AS is (7-8):1:(0.4-0.5). By the method, the plutonium concentration of the 2AP can be more than 10g / L.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for detecting radiolysis behavior of 30% TBP (Tri-Butyl-Phosphate)-kerosene

ActiveCN102778522AShort irradiation timeComponent separationColor/spectral properties measurementsFuel reprocessingPhosphate

The invention discloses a method for detecting radiolysis behavior of 30% TBP (Tri-Butyl-Phosphate)-kerosene, belonging to the technical field of post-treatment of spent fuel. The method comprises the following steps of: using a radiolysis source to carry out radiolysis on an extraction system in a Purex procedure; subsequently detecting the radiolysis products, i.e. DBP (Dibutyl Phthalate), MBP (Myelin Basic Protein) and carbonyl compounds. The method is characterized in that the radiolysis source is 238Pu. With the adoption of the method, the influence of alpha radiolysis on the TBP-kerosene system can be obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Uranium purification method for simultaneously removing neptunium and plutonium in nuclear fuel Purex post-treatment process

ActiveCN107130121AReduce extractionGood removal effectNuclear energy generationRecycling and recovery technologiesPurification methodsEvaporation

The invention belongs to the technical field of nuclear fuel post-treatment, and relates to a uranium purification method for simultaneously removing neptunium and plutonium in the nuclear fuel Purex post-treatment process. The uranium purification method sequentially comprises the following steps that firstly, evaporation and concentration pretreatment is conducted, a uranium rough product from the Purex post-treatment procedure uranium plutonium codecontamination separating cycle is subjected to evaporation and concentration pretreatment, accordingly, Np(IV) in the uranium rough product is adjusted to Np (V) and Np (VI); secondly, a reducing agent is adopted for reducing, a concentrated solution obtained in the first step is cooled to the room temperature, then the reducing agent is added, then Pu (IV) and Pu (VI) in the concentrated solution are reduced into Pu (III), and Np (VI) is reduced into Np (V); and thirdly, organic solvent extraction is conducted, the acidity of the solution obtained in the second step is adjusted, extraction is conducted in an extractor with an organic solvent containing tributyl phosphate in a multi-level manner, wherein the organic solvent containing the tributyl phosphate is divided into multiple parts to be added at different extraction levels. By utilization of the uranium purification method, the Np and the Pu can be removed at the same time through one uranium purification cycle, and qualified uranium products are obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for extracting technetium from nuclear fuel post-treatment waste liquid

ActiveCN110144471AImplement extractionAchieve purificationProcess efficiency improvementLiquid wasteOxalate

The invention provides a method for extracting technetium from a nuclear fuel post-treatment waste liquid. The method comprises the following steps of (1), adjusting nitric acid concentration of nitric acid waste liquid containing high technetium acid radical to 2 mol / L; (2), extracting the high-technetium acid radical ions in the waste liquid, and separating to obtain an organic phase; (3), washing the organic phase obtained in the step (2) by adopting an oxalic acid-containing nitric acid solution; and (4), reversely extracting technetium in the organic phase by using an alkaline aqueous solution to obtain a technetium product solution. According to the method, extraction and purification of technetium in the nuclear fuel post-treatment nitric acid waste liquid are effectively realized;the method for extracting technetium is simple to operate, and can be applied to a traditional PUREX flow post-treatment plant, the concentration and the concentration of nitric acid of technetium inthe treated object can be higher, the composition of the waste liquid can be relatively complicated, and the generation amount of a radioactive waste in the treatment process is smaller.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY +1

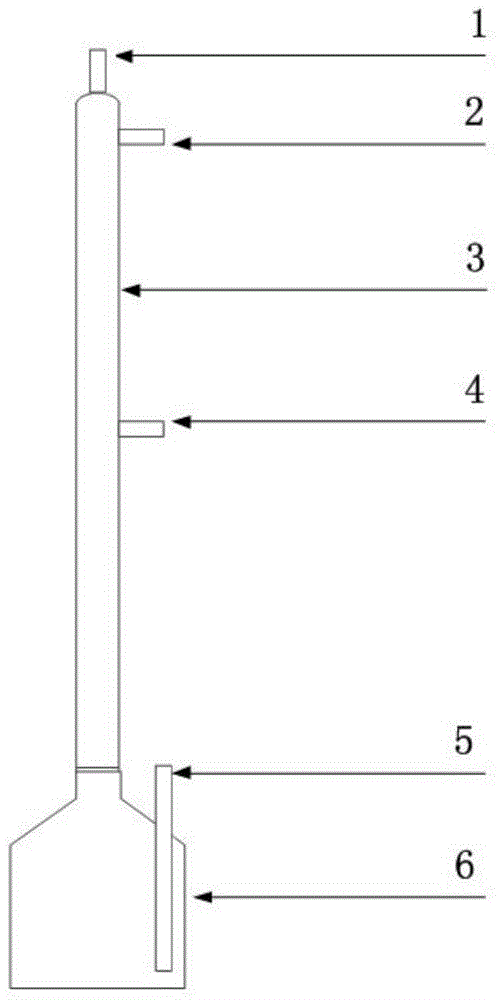

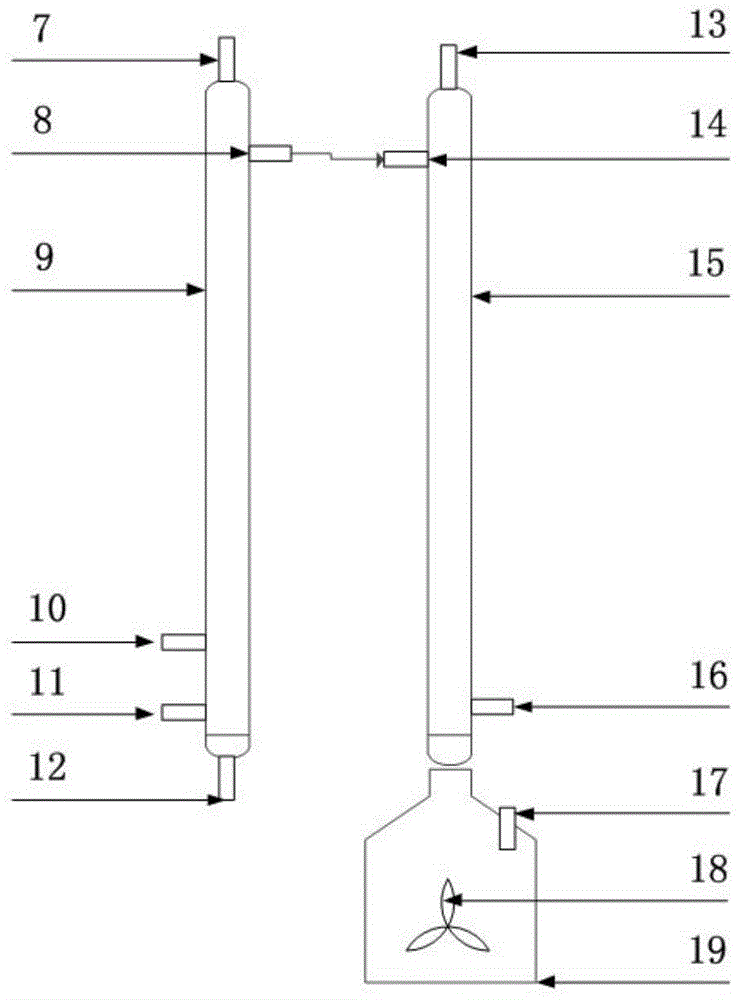

BP price-adjusting, degassing and acid-adjusting integrated device and method in Purex process

InactiveCN104789782AReduce consumptionEasy to handleNuclear energy generationRecycling and recovery technologiesProcess engineeringEngineering

The invention relates to a nuclear fuel reprocessing method in order to solve the problems that more devices are adopted, actual operation is complex, excessive nitric oxide is consumed, the economy is low and the like when a U / Pu separation section of the Purex process adopts nitric oxide for price adjustment, and provides a BP price-adjusting, degassing and acid-adjusting integrated device and method in a Purex process. The device comprises a filler column and a feed liquid receiving tank, wherein a BP feed liquid inlet and an NO2 feed port are formed in the filler column, a tail gas outlet is formed in the top, and a feed pipe extending to the feed liquid receiving tank is arranged on the feed liquid receiving tank. The method comprises steps of Pu price adjustment, nitrous acid removal and acid adjustment. According to the BP price-adjusting, degassing and acid-adjusting integrated device in the Purex process, nitric oxide price adjustment equipment is successfully simplified, the overall design of the adopted technological process is remarkably optimized, the nitric oxide consumption and the tail gas treatment quantity are remarkably reduced, the economy is remarkably improved, and a large quantity of costs is saved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Uranium and plutonium separation technology in Purex process

The invention belongs to the technical field of irradiated fuel reprocessing and discloses a uranium and plutonium separation technology in a Purex process. According to the technology, in a 1B tank, a reducing agent 1BX and a fill extraction agent 1BS are used for reducing Pu (IV) in 1BF feed liquid into Pu (III), so that plutonium enters a water phase, and uranium is reserved in an organic phase; therefore, the uranium and the plutonium are separated. The used reducing agent 1BX comprises 0.1-0.2mol / L of N-hydroxyl-1-hydrazine carbomite, 0.35-0.5mol / L of NO<3-> and 0.35-0.5mol / L of H<+>; the fill extraction agent 1BS is 30% TBP- kerosene containing 0.6-1mol / LHNO3. The technology has the characteristics of high plutonium yield, good uranium and plutonium separation effect and high technology safety factor without needing adding a holding reducing agent.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for selectively recovering americium from a nitric aqueous phase

ActiveUS20120152059A1Easy to separateNuclear energy generationTransuranic element compounds preparationLanthanideRaffinate

A method with which americium may be selectively recovered from a nitric aqueous phase containing americium, curium and fission products including lanthanides and yttrium, but which is free of uranium, plutonium and neptunium or which only contains these three last elements in trace amounts. The method is applicable for treatment and recycling of irradiated nuclear fuels, in particular for removing americium from raffinates stemming from methods for extracting and purifying uranium and plutonium such as the PUREX and COEX™ methods.

Owner:ORANO RECYCLAGE +1

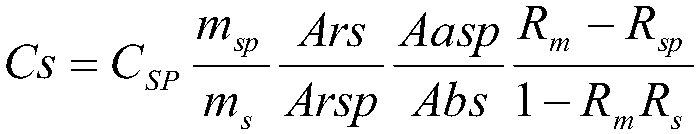

Method for determining contents of uranium, neptunium and plutonium in PUREX posttreatment flow 1AW by liquid chromatography-mass spectrometry

InactiveCN108226327ARealize automatic separation and determinationAccurate analysisComponent separationRadioactive agentMass Spectrometry-Mass Spectrometry

The invention belongs to the technical field of radioactive substance analysis, and relates to a method for determining the contents of uranium, neptunium and plutonium in PUREX posttreatment flow 1AWby liquid chromatography-mass spectrometry. The method comprises the following steps: (1) dilution and valence adjustment: diluting a 1AW solution with a diluent, and adding an oxidant to adjust thevalence of the plutonium; (2) determination of the uranium and the neptunium: performing chromatography separation and mass spectrometry detection on a diluted valence-adjusted solution of the 1AW, and drawing a working curve by an external standard method for quantification of the uranium and the neptunium; (3) determination of the plutonium: preparing two parts of 1AW diluted valence-adjusted solution, adding a 242Pu diluent into one part, performing chromatography separation and mass spectrometry detection in sequence, and calculating the content of the plutonium according to determinationresults of the abundance of two parts of solution 239Pu and 242Pu. Through adoption of the method disclosed by the invention, the contents of the uranium, the neptunium and the plutonium in a nuclearfuel PUREX posttreatment flow 1AW can be analyzed more accurately and precisely, and the influence of radioactivity on the analysis operation is eliminated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

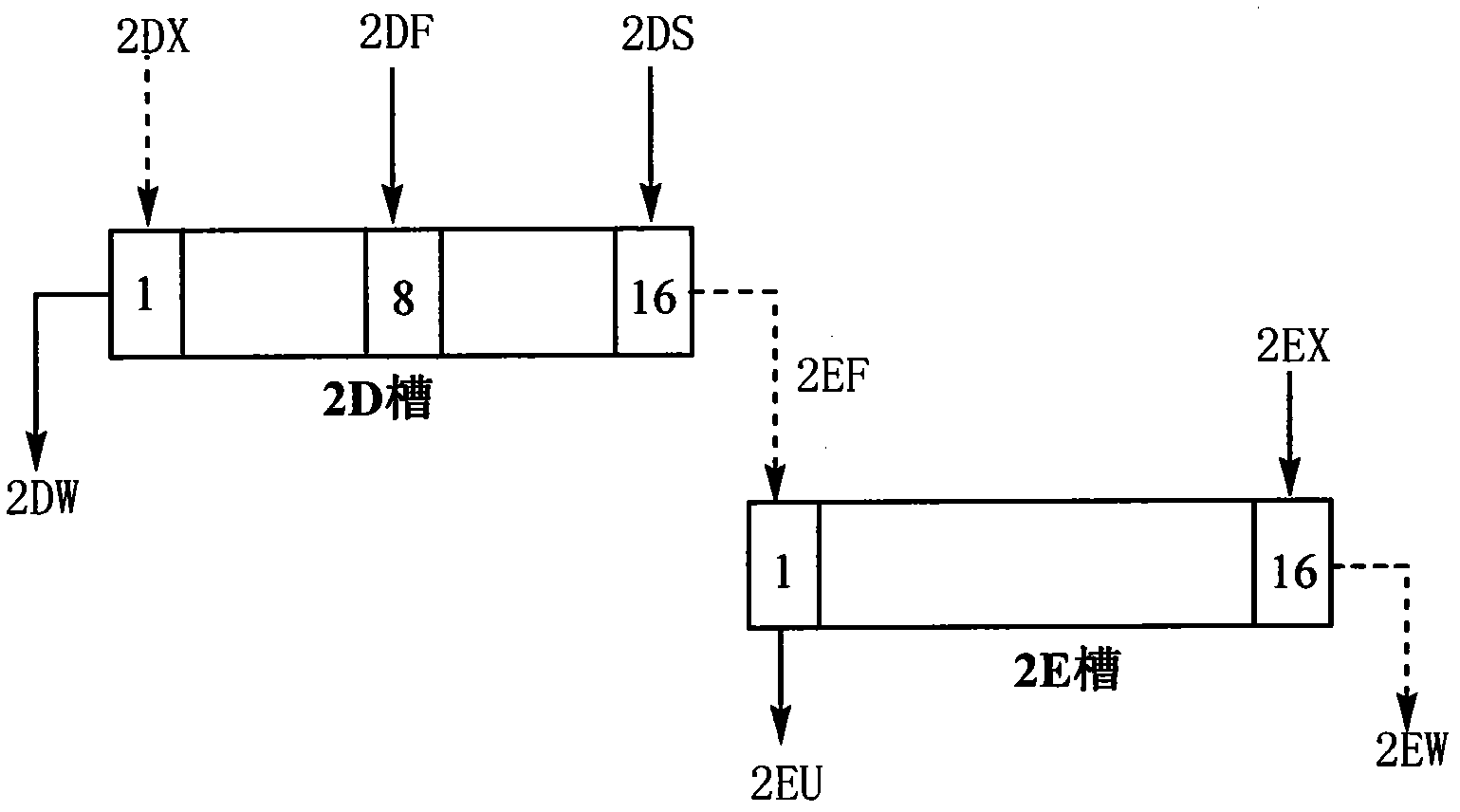

Ruthenium purifying technology in plutonium purification cycle of Purex process

The invention belongs to the technical field of nuclear fuel postprocessing, and discloses a ruthenium purifying technology in a plutonium purification cycle of a Purex process; according to the ruthenium purifying technology, extraction agent 2AX and detergent 2AS are added in 2A tank for removing a small amount of ruthenium element in 2AF material liquid, the used extraction agent 2AX comprises 30%TBP (Tri-Butyl-Phosphate) / kerosene, the detergent 2AS is an aqueous solution with C(HNO3) being 0.5-1.5 mol / L, the flow ratio of 2AF:2AX is 3.5-6, the extraction count is 8-10 grades and the washing grade is more than 6 grades. The ruthenium purifying technology can further purify the ruthenium, and can improve the quality of a final plutonium product of the Purex process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for separating uranium from plutonium in Parex procedure

InactiveCN1229814CSimplify process conditionsIncrease separation speedNuclear energy generationRecycling and recovery technologiesReducing agentNuclear fuel

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for uranium purification circulation in Purex process

InactiveCN112342409AImprove purification effectImprove the purification factorNuclear fuelSemicarbazide

The invention belongs to the technical field of nuclear fuel post-treatment, and relates to a method for uranium purification circulation in a Purex process. The method comprises the steps that aftera uranium crude product liquid 1CU is pretreated and blended, plutonium is further removed from an obtained 2DF in a 2D tank in the uranium extraction process by using a washing agent 2DS, and the washing agent 2DS contains a nitric acid solution with semicarbazide. The method for uranium purification circulation in the Purex process is used, the problems existing in an existing method for uraniumpurification circulation in the Prex process can be solved, the purification effect of plutonium removal in uranium purification circulation is improved, and the purification coefficient DF(Pu / U) ofplutonium removal in uranium is increased.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A purex process for separating technetium

ActiveCN103325431BStep-by-step restore implementationGo simpleRadioactive decontaminationTechnetiumSalt free

The invention relates to a PUREX process for separating technetium. The PUREX process includes the steps: (1) co-decontamination and co-extraction: co-extracting uranium, plutonium, neptunium and the technetium in spent fuel nitric acid solution into an organic phase and washing co-extraction liquid; (2) plutonium and neptunium reverse extraction: reversely extracting the plutonium and the neptunium in the co-extraction liquid into a water phase by reverse extraction agents S1 containing AHA and then adding uranium supplement extraction agents for supplement extraction to obtain the water phase containing the plutonium and the neptunium and an oil phase containing the uranium and the technetium; (3) technetium reduction and reverse extraction: reducing and reversely extracting the technetium in the oil phase containing the uranium and the technetium into the water phase by reverse extraction agents S2 containing reducing agents and then adding uranium supplement extraction agents for supplement extraction to obtain a water phase containing the technetium and an oil phase containing the uranium, wherein the oil phase containing the uranium enters a subsequent uranium purification process. The neptunium, the plutonium and the technetium are reduced step by step through a step-by-step reduction method, the technetium can be separated out, the trend of elements is simpler and more uniform, all the reducing agents are salt-free reagents, remaining reagents are easily damaged, and the subsequent process is less affected.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for extracting palladium from high-level liquid waste

ActiveCN101713026BHigh palladium extraction ratioHigh extraction ratioProcess efficiency improvementLiquid wasteAfter treatment

The invention provides a method for extracting palladium from high-level liquid waste, which belongs to the technical field of radioactive waste after treatment. The high-level liquid waste adopts nitric acid system, and the method comprises the following concrete steps of: a, adequately mixing the high-level liquid waste with extract phase; b, separating extract phase containing palladium from the mixture after extraction equilibrium; c, washing the separated extract phase containing palladium; d, repeating steps b and c 1 to 5 times; e, adding stripping agent to the washed extract phase containing palladium to perform back extraction; and the method is characterized in that triisobutyl phosphine sulfide (TiBPS) is adopted as extracting agent, and thinning agent is added for preparing the extract phase. The method has the following advantages: a, the extracting ratio of palladium in the nitric acid system is high by using TiBPS as extracting agent; b, the concentration range of adaptable nitric acid is wide, Purex process can be directly linked, mixtion is not required in the extraction process, and waste minimization and processing equipment simplification can be realized; c, the selectivity is good; and d, back extraction is easy.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

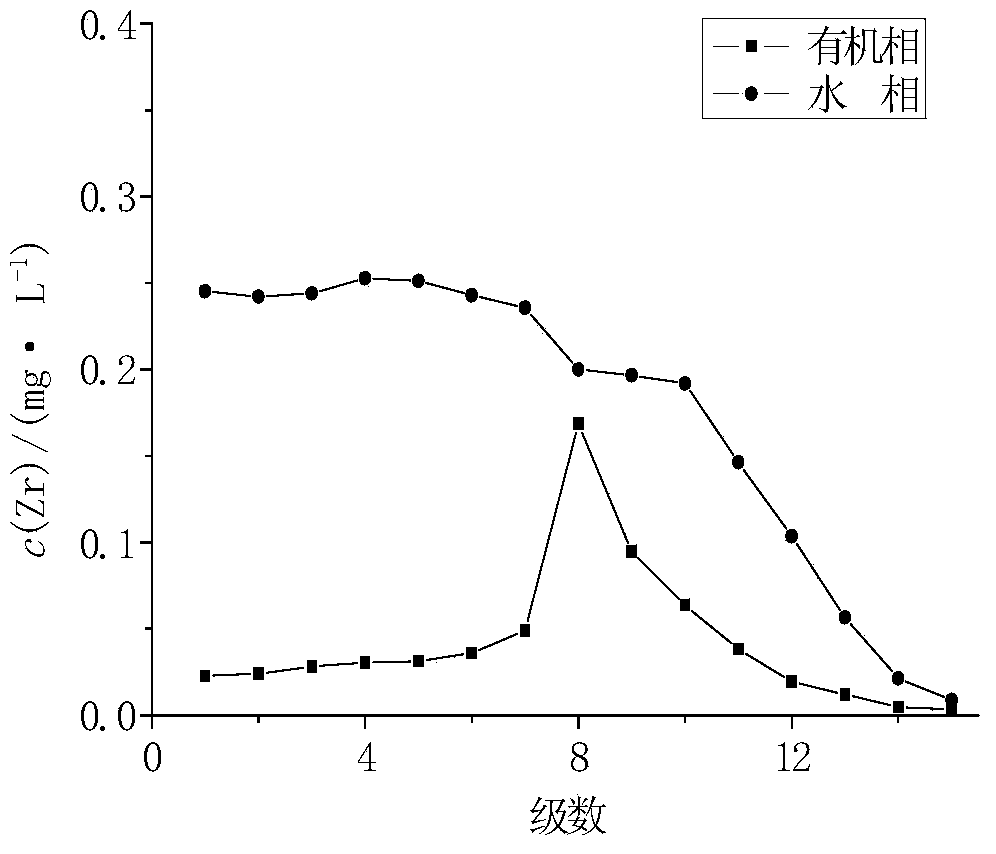

Process for purifying zirconium in Purex flow plutonium purification cycle

The invention belongs to the technical field of spent fuel post-treatment, and discloses a process for purifying zirconium in a Purex flow plutonium purification cycle. 30% tri-butyl-phosphate (TBP)-kerosene is adopted as an extraction agent 2AX in a 2A extractor, so as to recover uranium and plutonium and purify fission fragments. The process comprises an extraction section and a washing section; and the concentration of a nitric acid in a 2AF feed liquid is 3.5-3.7mol / L, and 2AS is an HNO3 solution of which the concentration is 0.8-0.85mol / L. The process has the advantages that the plutonium yield is greater than 99.9%, and the purification coefficient of zirconium is greater than 100.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Plutonium purification cycle process using formaldoxime as back extraction reagent

ActiveCN105913887AGood removal effectReduce usageNuclear energy generationReactor fuel elementsSalt freePu element

Belonging to the field of nuclear fuel reprocessing, the invention provides a plutonium purification cycle process using formaldoxime as a back extraction reagent to solve the problems of low plutonium concentration level, poor safety and the like in existing Purex process plutonium purification cycle adopting a salt-free reduction reagent. The process includes: a 2BX's formaldoxime concentration of 0.5-0.7mol / L, a 2BF's nitric acid concentration of 0.15-0.3mol / L, a 2BX's nitric acid concentration of 0.1-0.5mol / L, a flow ratio 2BF:2BX of 3-5:1, a back extraction level of more than 10, and a supplement extraction level of 3-5. The plutonium purification cycle process provided by the invention can realize plutonium concentration by more than 5 times during back extraction, the obtained plutonium product liquid has a plutonium concentration up to 60g / L, a high plutonium yield and good uranium removal effect can be achieved. Within a technological condition range, the process has good operation stability, and has good economical efficiency.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

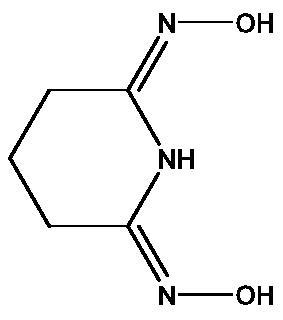

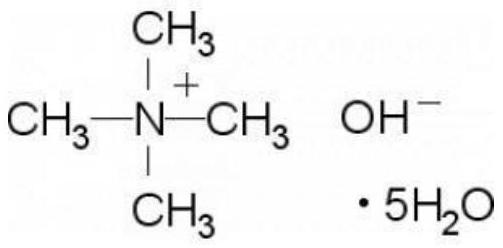

Elution method for reserved plutonium in PUREX process dirty solvent

ActiveCN111863300AGood elution recoveryMeet plutonium content requirementsNuclear energy generationRecycling and recovery technologiesTetramethylammonium hydroxideImide

The invention belongs to the technical field of radioactive waste treatment, and relates to an elution method for reserved plutonium in a PUREX process dirty solvent. The elution method comprises thestep of adding a solution containing glutaryl imide dioxime, tetramethylammonium hydroxide and NaOH into the dirty solvent for treatment. By utilizing the elution method for reserved plutonium in thePUREX process dirty solvent, plutonium can be better eluted and recovered from the PUREX process dirty solvent.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for cycle purification of uranium in Purex process

ActiveCN102290111BQuick restoreNo increase in solid waste volumeProcess efficiency improvementInorganic non-surface-active detergent compositionsMonomethyl hydrazineHydroxylamine

The invention discloses a method for cycle purification of uranium in a Purex process. The method comprises the following steps of: pretreating 1CU feed liquor, seasoning, and further purifying plutonium by using a washing agent in a two-dimensional (2D) tank, wherein the used washing agent in the 2D tank is a mixed solution of dimethyl hydroxylamine, monomethyl hydrazine and nitric acid, the concentration of the dimethyl hydroxylamine is 0.01 to 0.1mol / L, the concentration of the monomethyl hydrazine is less than or equal to 0.15mol / L, and the concentration of the nitric acid is 0.8 to 1.2mol / L. The dissipation factor (DF) (Pu / U) in the 2D tank is more than 1,000, and the content of the plutonium in 2EU feed liquor reaches a uranium product index.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Nuclear fuel dissolution

InactiveUS20030092954A1Reduce probabilityIncrease concentrationNuclear energy generationRecycling and recovery technologiesEngineeringDissolution

The invention comprises a method for the dissolution of spent nuclear fuel pins or contaminated cladding, the method comprising contacting together the pins and both nitric and fluoroboric acids which, preferably, are present in admixture. The combination of acids dissolves both cladding and fuel at an acceptable rate and provides a solution suitable for use in subsequent purification processes such as the Purex process.

Owner:NEXIA SOLUTIONS

Method and device for continuously adjusting neptunium valence and acidity in 1cu feed liquid in purex process

The invention relates to a method and a device for continuously adjusting the neptunium valence state and acidity in a 1CU feed liquid of a Purex process. The method comprises: adjusting the nitric acid concentration of the 1CU feed liquid to be 0.03-0.5mol / L; The neptunium in the liquid is oxidized to a high price; the 1CU feed liquid after the thermal insulation pretreatment is continuously cooled; the cooled 1CU feed liquid is continuously acid-adjusted to become the raw material liquid 2DF of the uranium purification cycle; in the above process, the heating and thermal insulation pretreatment The treatment process is carried out in the heating coil and the cooling process is carried out in the cooling coil to realize continuous production; the holding time of the heating and heat preservation pretreatment process is controlled by the flow rate of 1CU feed liquid, the diameter and length of the heating coil . The device includes a 1CU material and liquid temporary storage tank, a material and liquid transfer pump, a heating coil, a cooling coil and a static mixer. The beneficial effects of the present invention are as follows: the technical solution of the present invention can realize the continuous adjustment of neptunium valence state in 1CU, the process operation and control are very simple, and the tedious operation of the batch process is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method and device for continuously adjusting valence state and acidity of neptunium in Purex process 1CU feed liquid

The invention relates to a method and device for continuously adjusting the valence state and acidity of neptunium in a Purex process 1CU feed liquid. The method comprises the steps that the nitric acid concentration of the 1CU feed liquid is adjusted to be 0.03-0.5 mol / L; the 1CU feed liquid subjected to acid adjustment is subjected to heating and heat preservation continuous pretreatment to oxidize neptunium to the high valence; the 1CU feed liquid subjected to heat preservation pretreatment is continuously cooled; the cooled 1CU feed liquid is subjected to continuous acid adjustment to form raw material liquid 2DF for uranium purification circulation; in the process, the heating and heat preservation pretreatment process is carried out in a heating coil, and the cooling process is carried out in a cooling coil, so that continuous production is realized; the heat preservation time of the heating and heat preservation pretreatment process is controlled through the flow of the 1CU feed liquid as well as the diameter and length of the heating coil. The device comprises a 1CU feed liquid temporary storage tank, a feed liquid conveying pump, the heating coil, the cooling coil and a static mixer. The method and the device have the beneficial effects that according to the technical scheme, continuous adjustment of the valence state of neptunium in the 1CU can be achieved, process operation and control are very easy, and tedious operation of a batch process is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

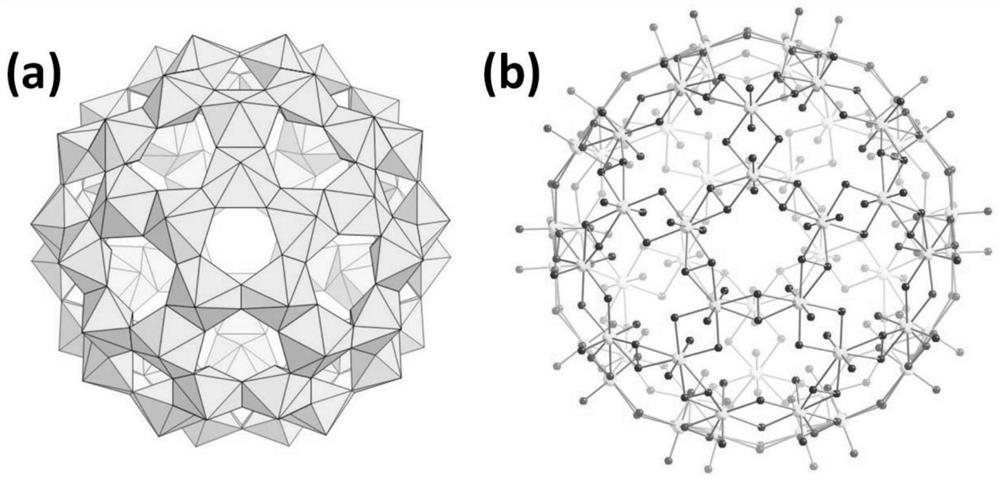

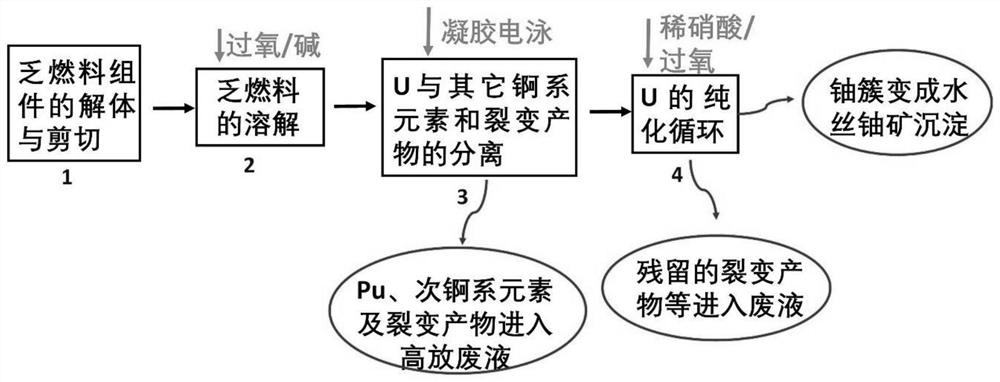

Spent fuel post-processing method based on uranium cluster compound

PendingCN114678149ARisk of nuclear proliferation noNo problems such as radiation decompositionNuclear energy generationRecycling and recovery technologiesFuel reprocessingUranium mine

The invention belongs to the technical field of spent fuel post-treatment, and particularly relates to a spent fuel post-treatment method based on a uranium cluster compound, which comprises the following steps: S1, disassembling and shearing a spent fuel assembly into small fuel rods; s2, dissolving the spent fuel by using hydrogen peroxide and an alkaline solution, and filtering to obtain a precipitate and a filtrate; s3, treating the filtrate obtained in the step S2 by utilizing gel electrophoresis, and separating to obtain a uranium cluster compound and a solution containing Pu, minor actinides and fission products; and S4, dilute nitric acid and hydrogen peroxide are added into the uranium cluster compound obtained in the step S3, uranium peroxide clusters are converted into hematite sediment, filtering is carried out, sediment is obtained, and separation of the uranium element is achieved. The spent fuel post-treatment process based on the uranium cluster compound has the advantages of being simple in process, small in corrosivity and the like, the risk of nuclear diffusion does not exist, and compared with a PUREX process, the spent fuel post-treatment process based on the uranium cluster compound has better economic benefits.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com