Method for extracting technetium from nuclear fuel post-treatment waste liquid

A technology for nuclear fuel and waste liquid, applied in the direction of improving process efficiency, can solve problems such as unfavorable purification of technetium products, and achieve the effect of small amount of radioactive waste and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

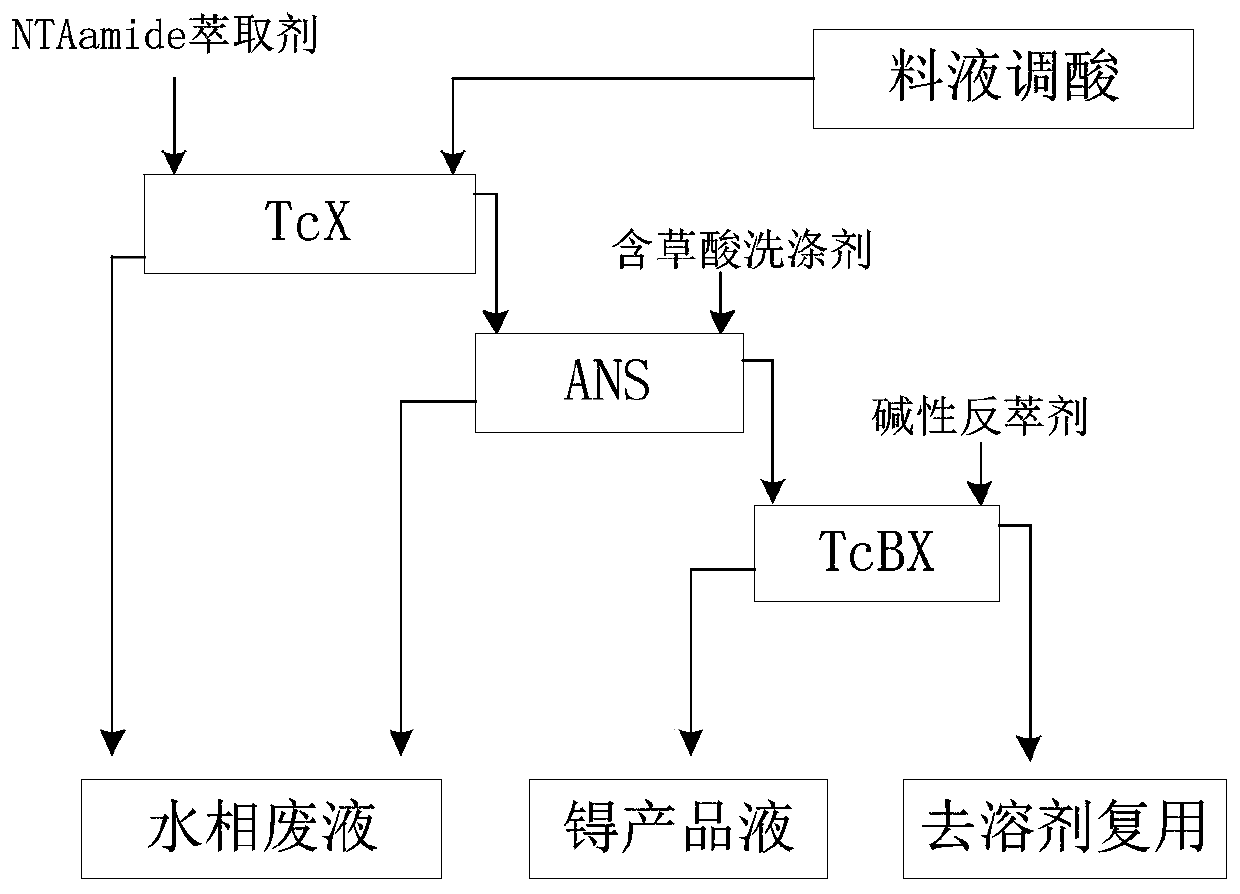

[0031] Using the method for extracting technetium of the present invention to extract technetium from a certain nuclear fuel reprocessing waste liquid, the main steps are as follows:

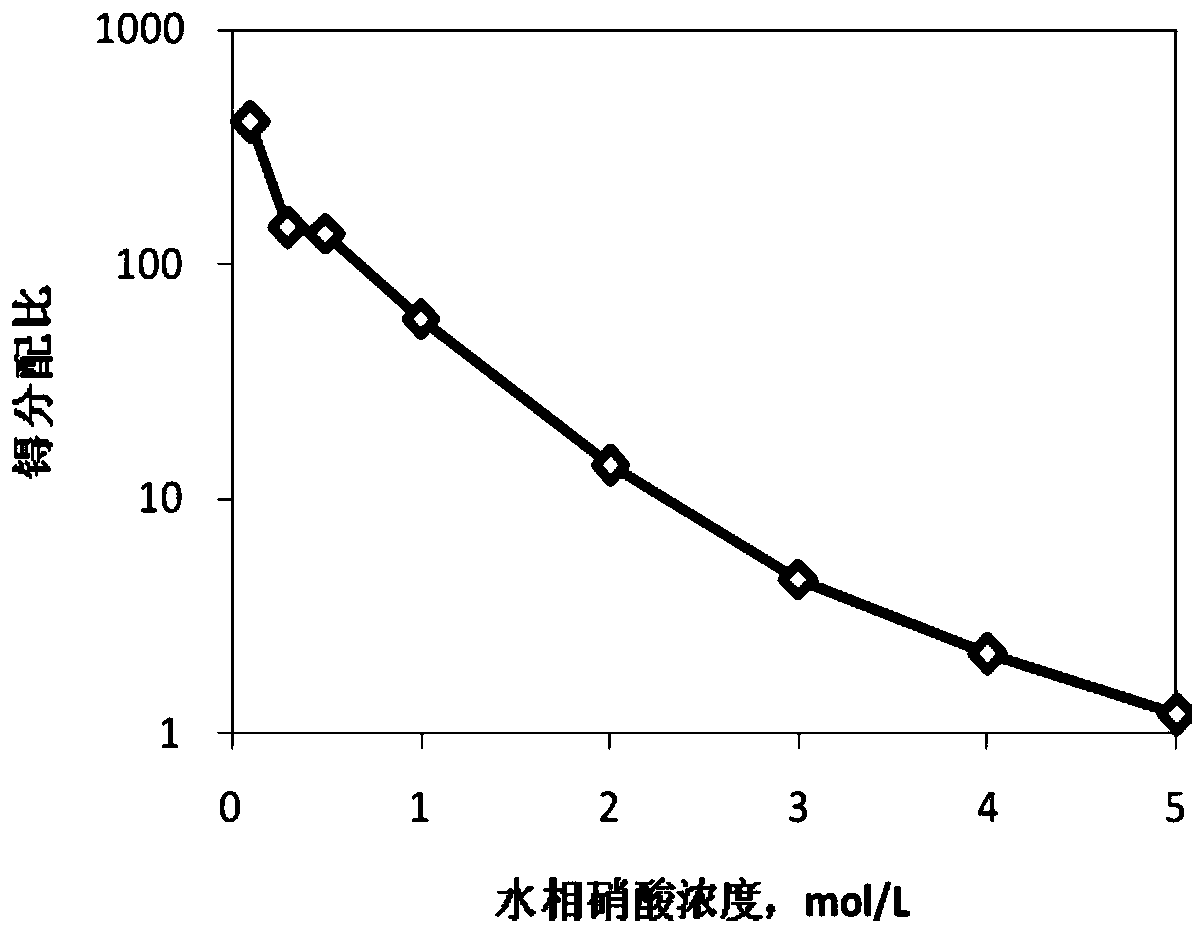

[0032] (1) acid adjustment: the concentration of nitric acid containing pertechnetate radical nitric acid waste liquid is adjusted to 0.5mol / L;

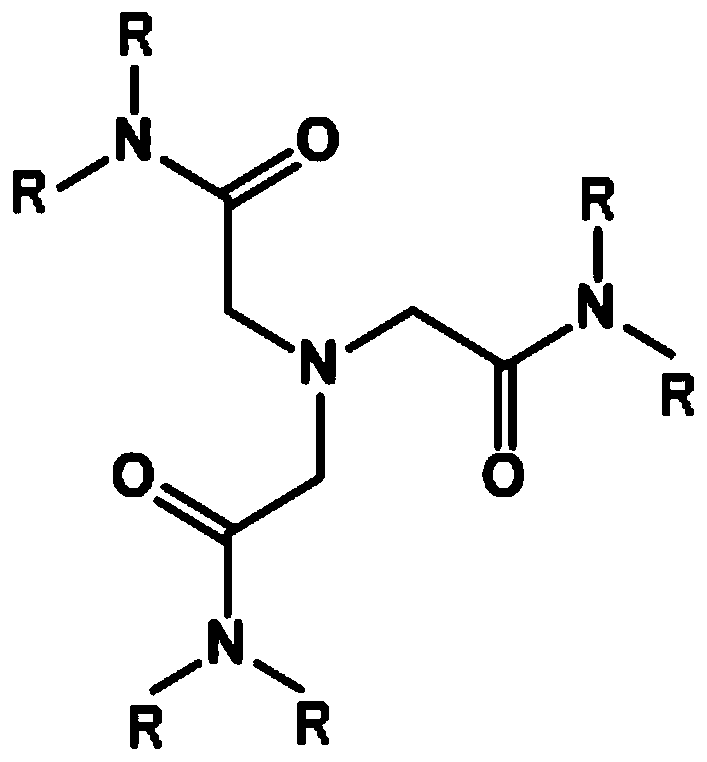

[0033] (2) technetium extraction: use protonated tris(N'N-di-n-octylacetamido)amine as extractant (the alkyl group is a straight-chain alkyl group with 8 carbon atoms), and use kerosene as diluent The waste liquid is extracted and separated to obtain an organic phase; the concentration of the tris(N'N-di-n-octylacetamido)amine in the organic phase is 0.1mol / L;

[0034] (3) Tetravalent actinide element impurity washing: adopt the nitric acid solution containing oxalic acid to wash the organic phase that step (2) obtains, and the concentration of described oxalic acid is 0.2mol / L;

[0035] (4) Technetium back-extraction: Back-extract the technetium in t...

Embodiment 2

[0038] Using the method for extracting technetium of the present invention to extract technetium from a certain nuclear fuel reprocessing waste liquid, the main steps are as follows:

[0039] (1) acid adjustment: the concentration of nitric acid containing pertechnetate radical nitric acid waste liquid is adjusted to 1mol / L;

[0040] (2) technetium extraction: use protonated tris(N'N-di-n-decylacetamido)amine as extractant (the alkyl group is a straight-chain alkyl group with 12 carbon atoms), and use kerosene as diluent The waste liquid is extracted and separated to obtain an organic phase; the concentration of the tris(N'N-di-n-decylacetamido)amine in the organic phase is 0.2mol / L;

[0041] (3) Washing of tetravalent actinide impurities: the organic phase obtained in step (2) is washed with nitric acid solution containing oxalic acid, and the concentration of said oxalic acid is 0.1mol / L;

[0042] (4) Technetium back-extraction: Back-extract the technetium in the organic ph...

Embodiment 3

[0045] Using the method for extracting technetium of the present invention to extract technetium from a certain nuclear fuel reprocessing waste liquid, the main steps are as follows:

[0046](1) acid adjustment: the concentration of nitric acid containing pertechnetate radical nitric acid waste liquid is adjusted to 0.75mol / L;

[0047] (2) technetium extraction: use protonated tris(N'N-di-n-butylacetamido)amine as extractant (the alkyl group is a straight-chain alkyl group with 4 carbon atoms), and use kerosene as diluent The waste liquid is extracted and separated to obtain an organic phase; the concentration of the tris(N'N-di-n-butylacetamido)amine in the organic phase is 0.05mol / L;

[0048] (3) Tetravalent actinide element impurity washing: adopt the nitric acid solution containing EDTA to wash the organic phase that step (2) obtains, and the concentration of described EDTA is 0.3mol / L;

[0049] (4) Technetium back-extraction: back-extract the technetium in the organic ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com