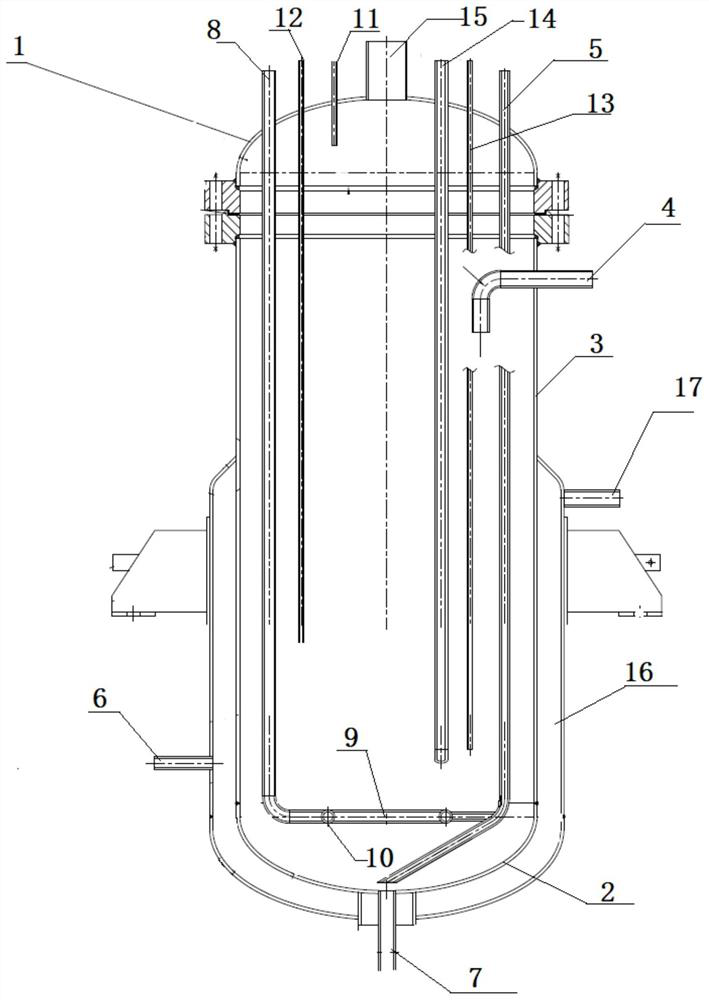

Device and method for adjusting valence states of neptunium and plutonium in hot chamber

A technology of valence state and inner cylinder, which is applied to the device of plutonium valence state and adjusts the field of neptunium, can solve the problems of uncertainty and potential safety hazards, and achieve the effect of reliable performance, long service life and convenient operation of the manipulator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Take a certain volume of Pu-containing feed solution, in which the reducing agent concentration is 0.1-0.3mol / L. Use the above-mentioned price adjustment device to adjust Pu to tetravalent, adjust the concentration of nitric acid to 2-3mol / L, and the nitrous acid in the feed liquid to be lower than 5mmol / L.

[0063] Experimental use N 2 o 4 The valence state of ions is adjusted by bubbling, the reaction process is stable, there is no bumping and spraying state, the temperature of the liquid during the seasoning process does not exceed 50°C, and the valence state of the ions in the liquid and the content of the reducing agent and nitric acid are tested respectively during the price adjustment process and after the end of the price adjustment Concentrations are in line with the requirements of the next step process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com