Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204results about "Specific isotope recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

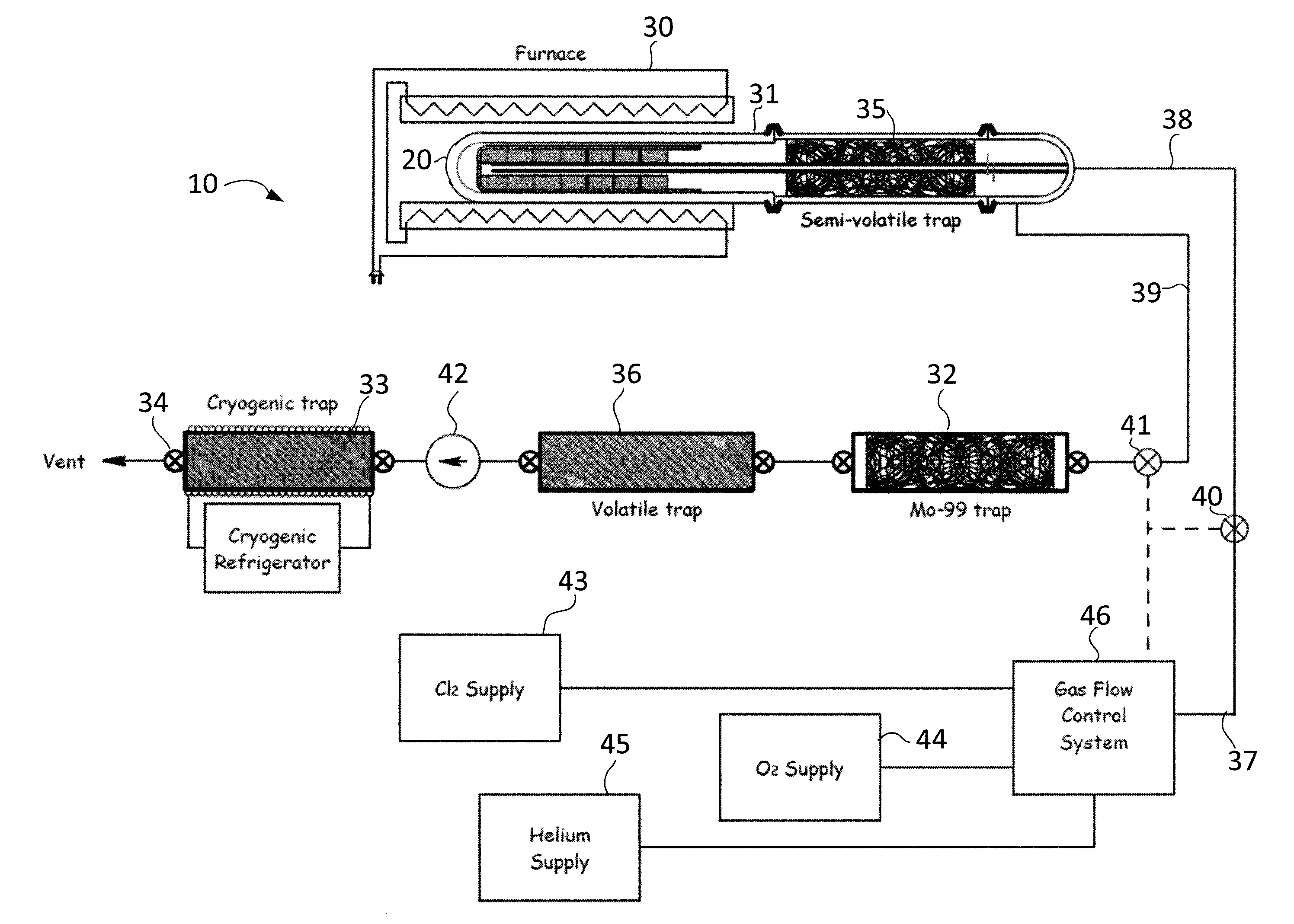

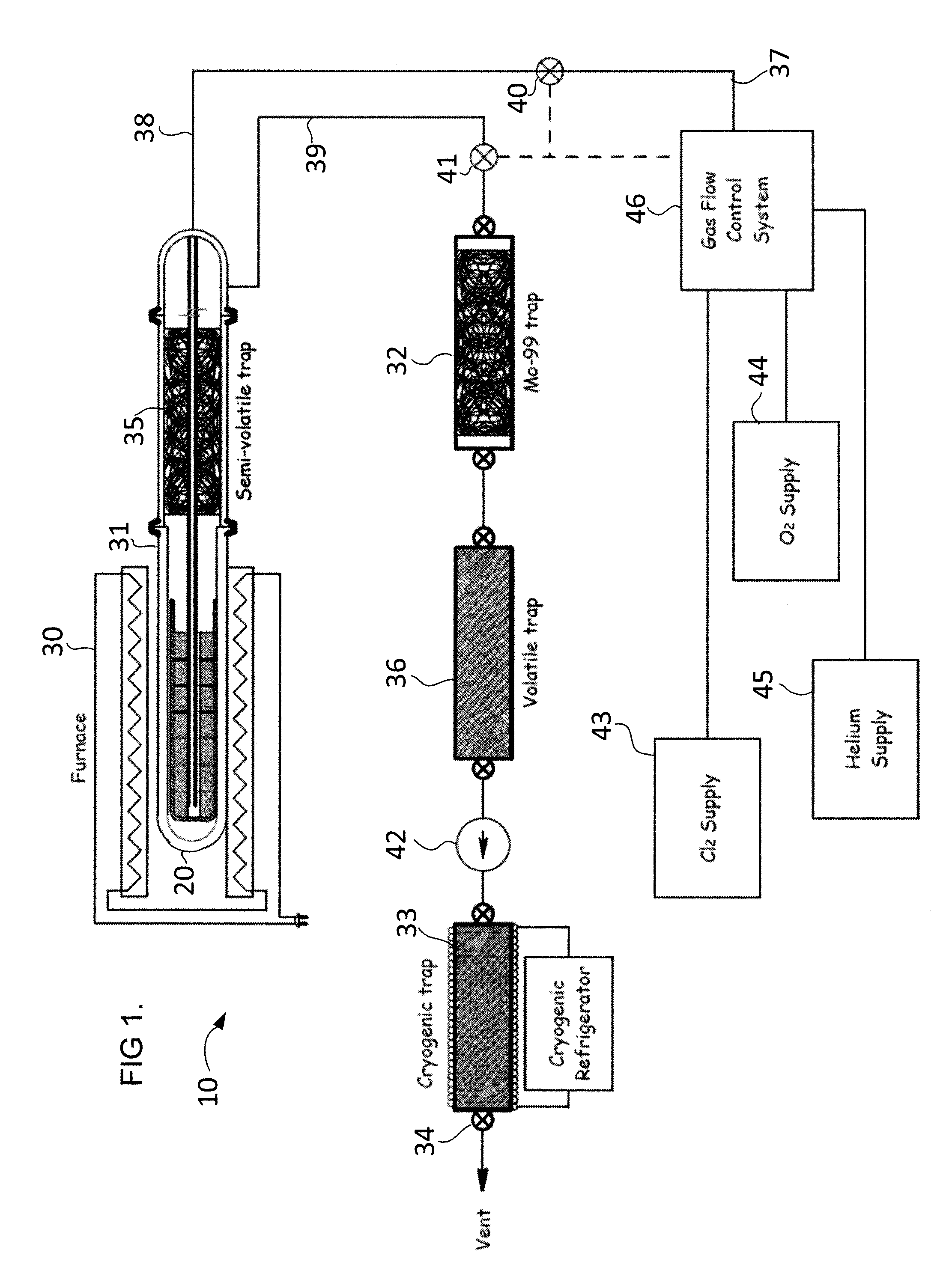

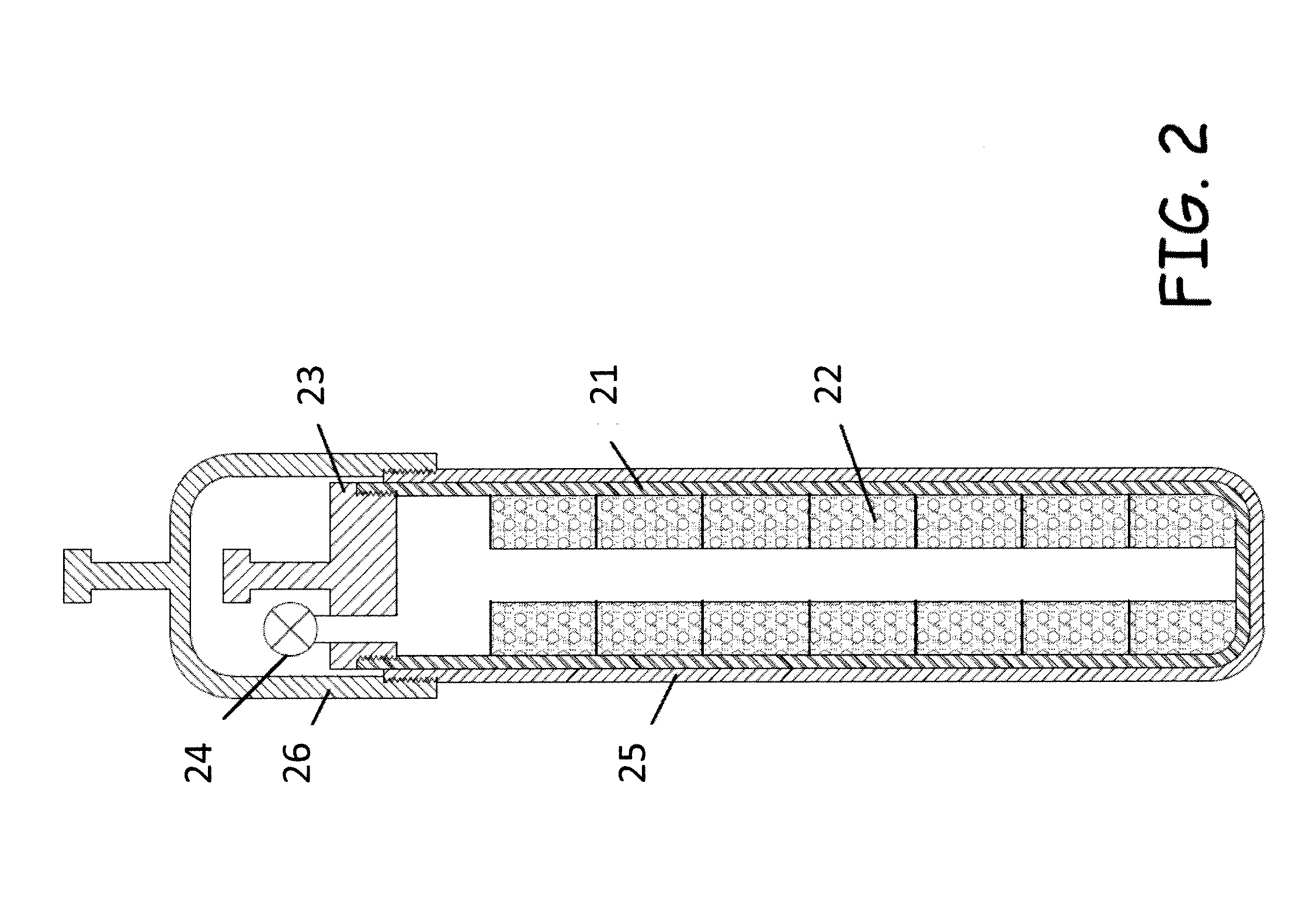

Methods and apparatus for selective gaseous extraction of molybdenum-99 and other fission product radioisotopes

ActiveUS20110305309A1Less capital equipmentRapid productionSpecific isotope recoveryConversion outside reactor/acceleratorsChemistryGaseous substance

Methods and apparatus are provided for producing and extracting Mo-99 and other radioisotopes from fission products that overcome the drawbacks of previously-known systems, especially the excessive generation of radioactive wastes, by providing gas-phase extraction of fission product radioisotopes from a nuclear fuel target using a mixture including halide and an oxygen-containing species with heat to convert the fission product radioisotopes to gas (e.g., Mo-99 to MoO2Cl2 gas). The gaseous species are evacuated to a recovery chamber where the radioisotopes solidify for subsequent processing, while the substantially intact uranium target made available for further irradiation and extraction cycles.

Owner:GENERAL ATOMICS

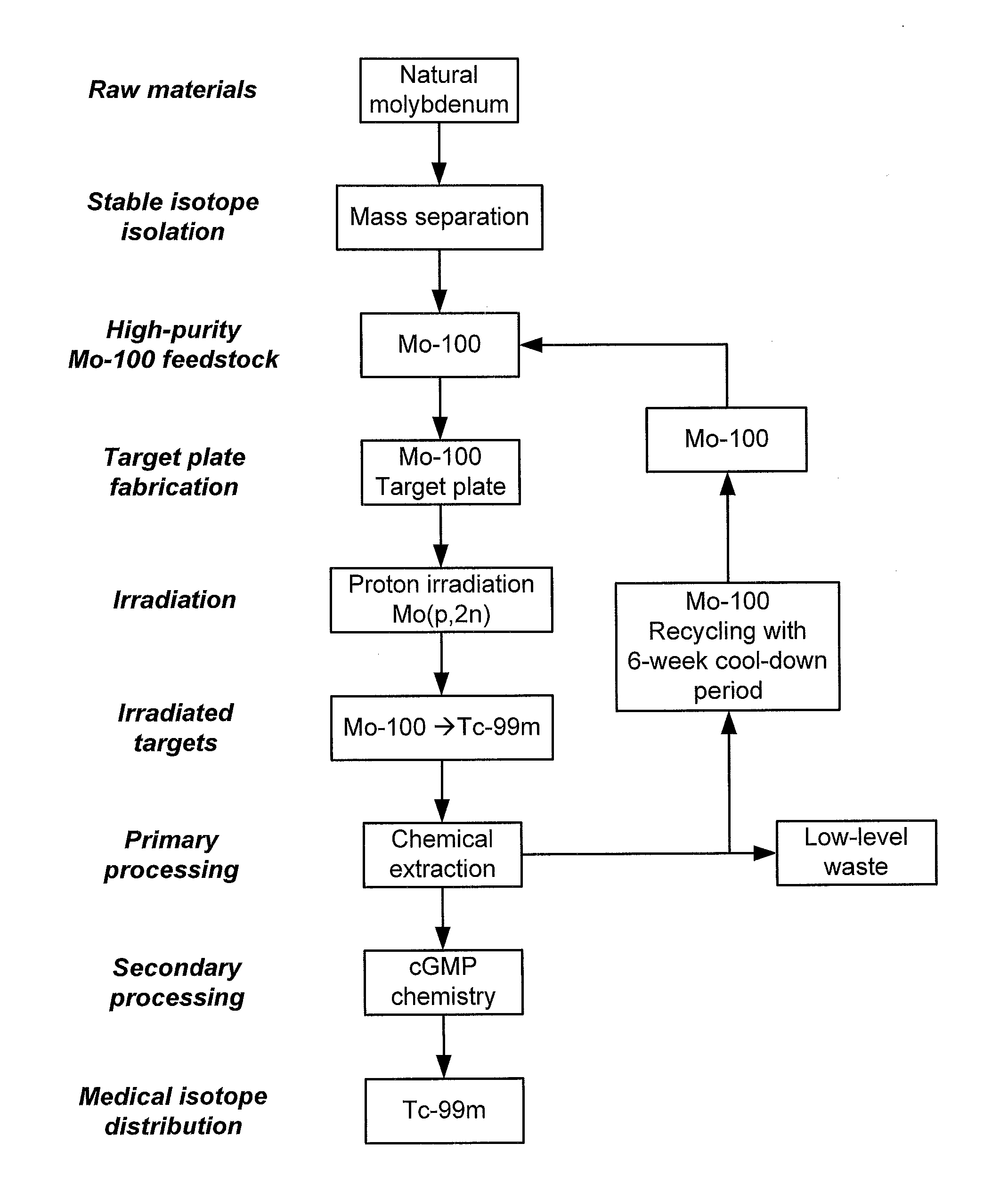

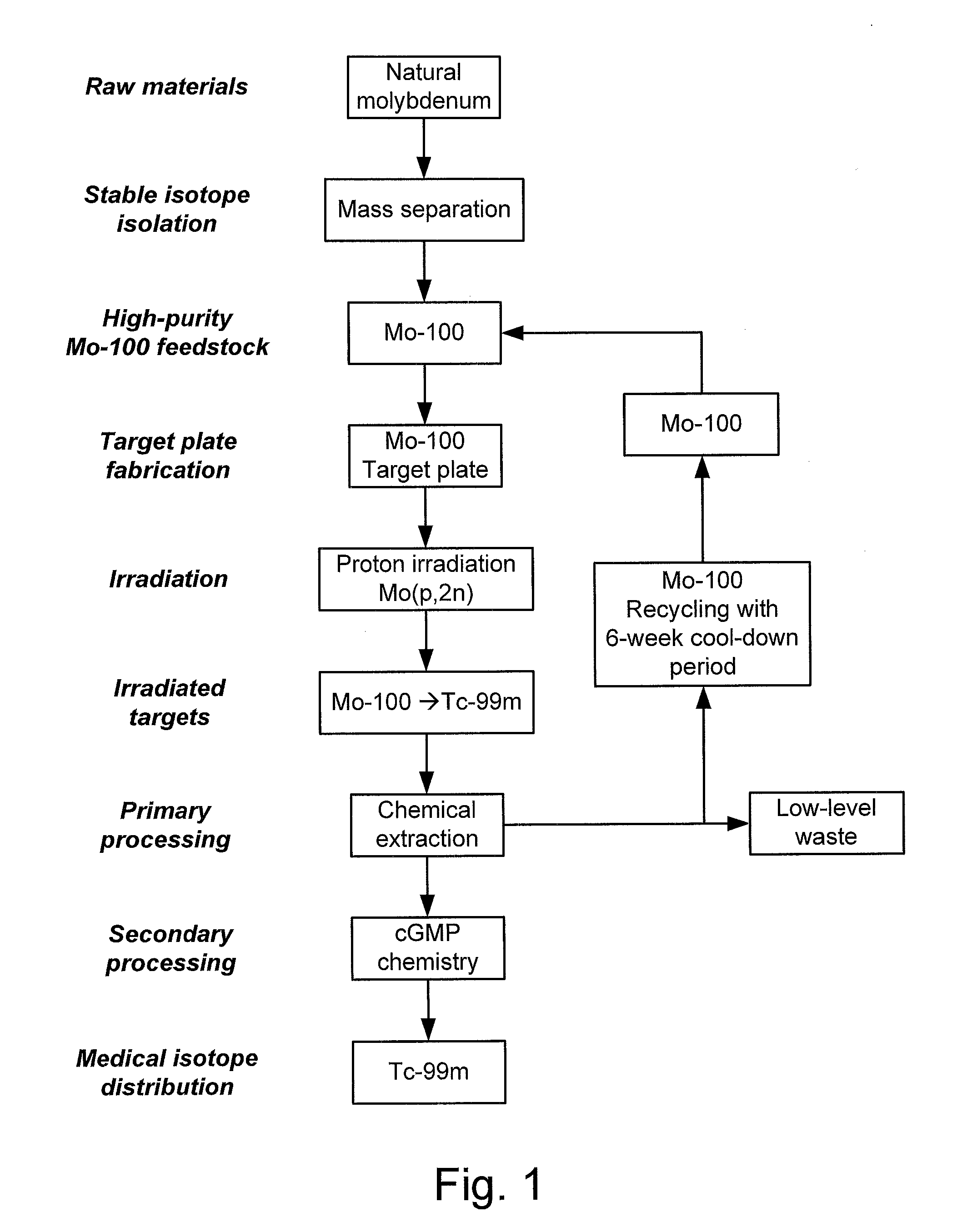

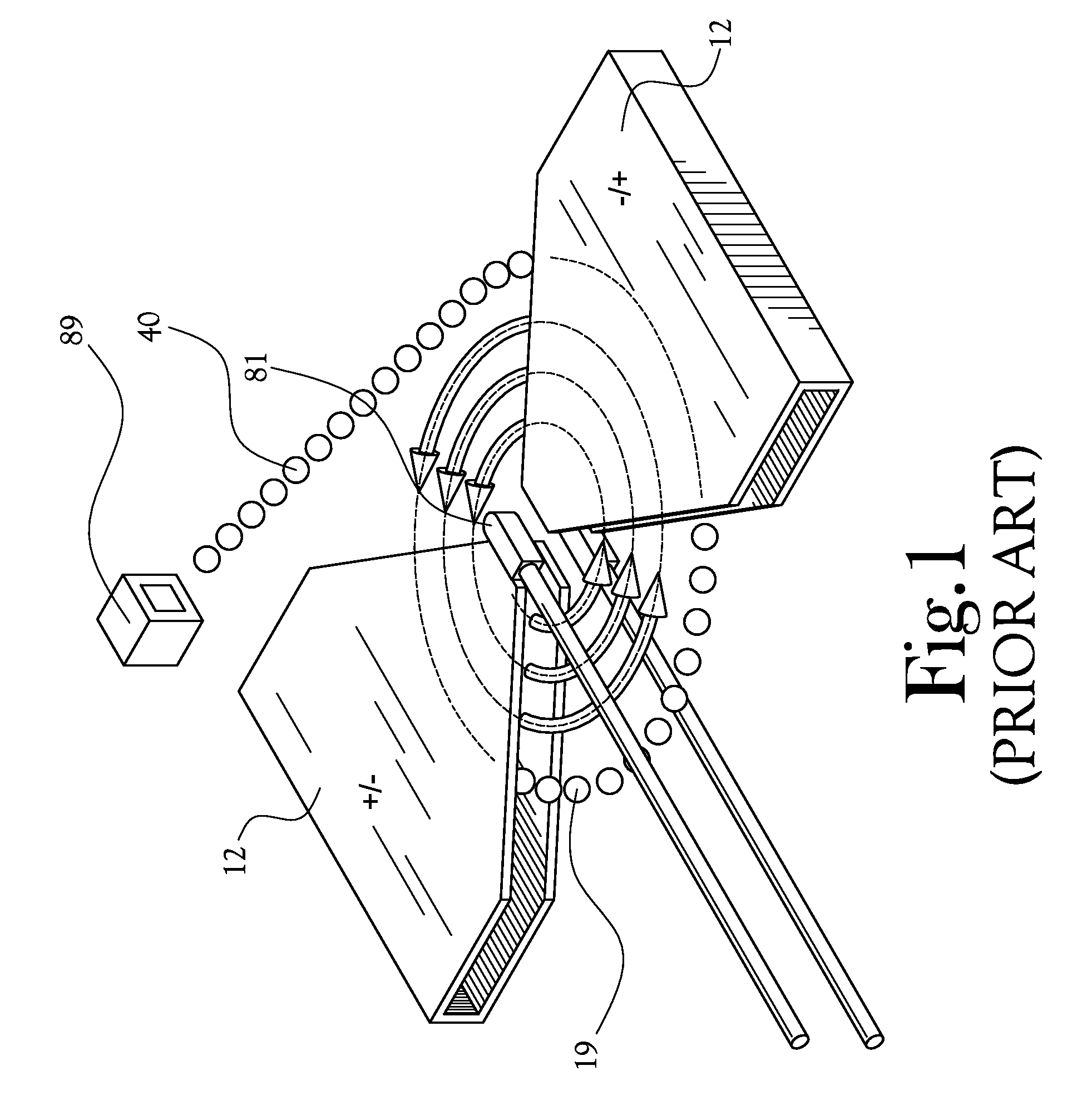

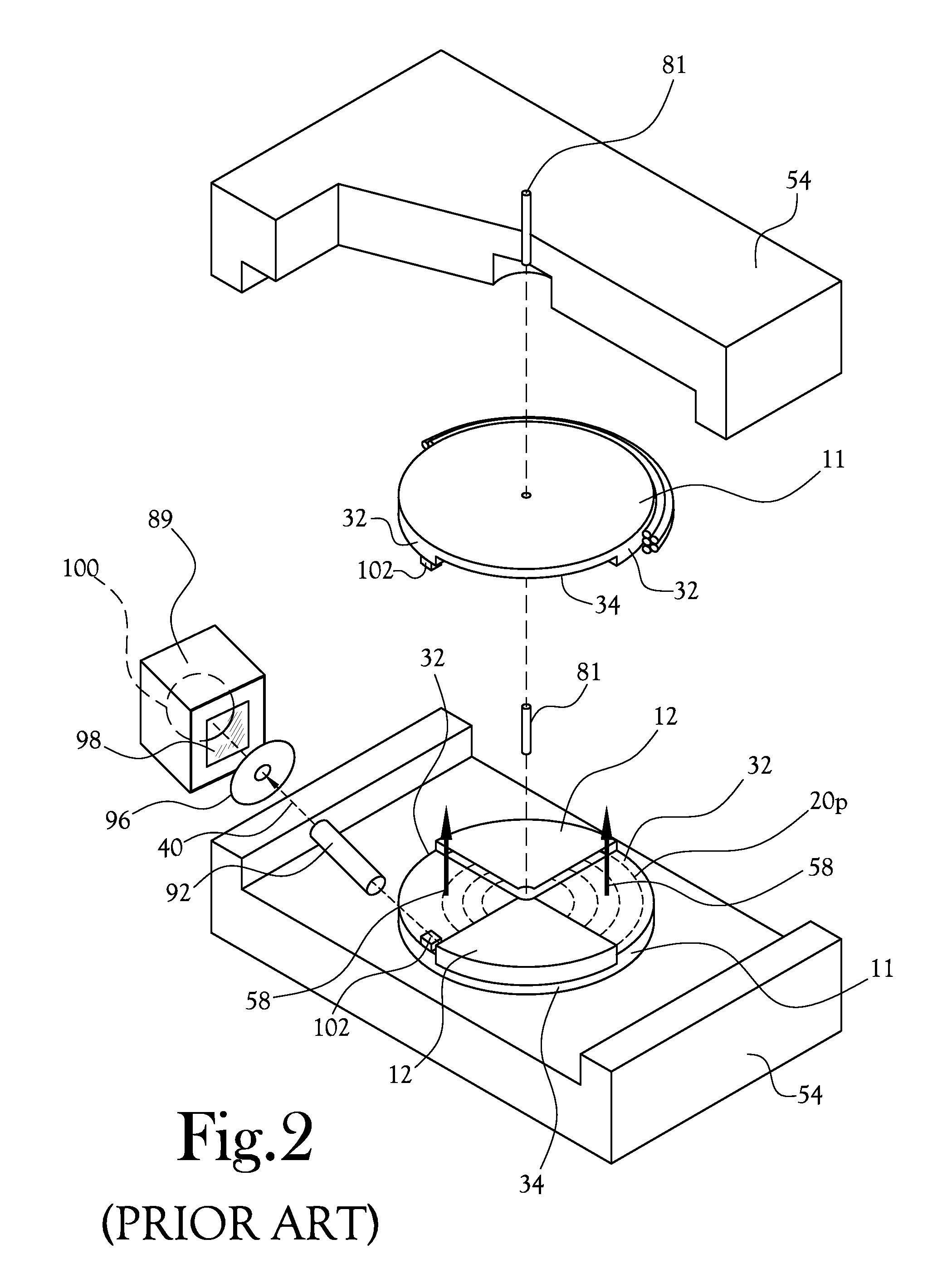

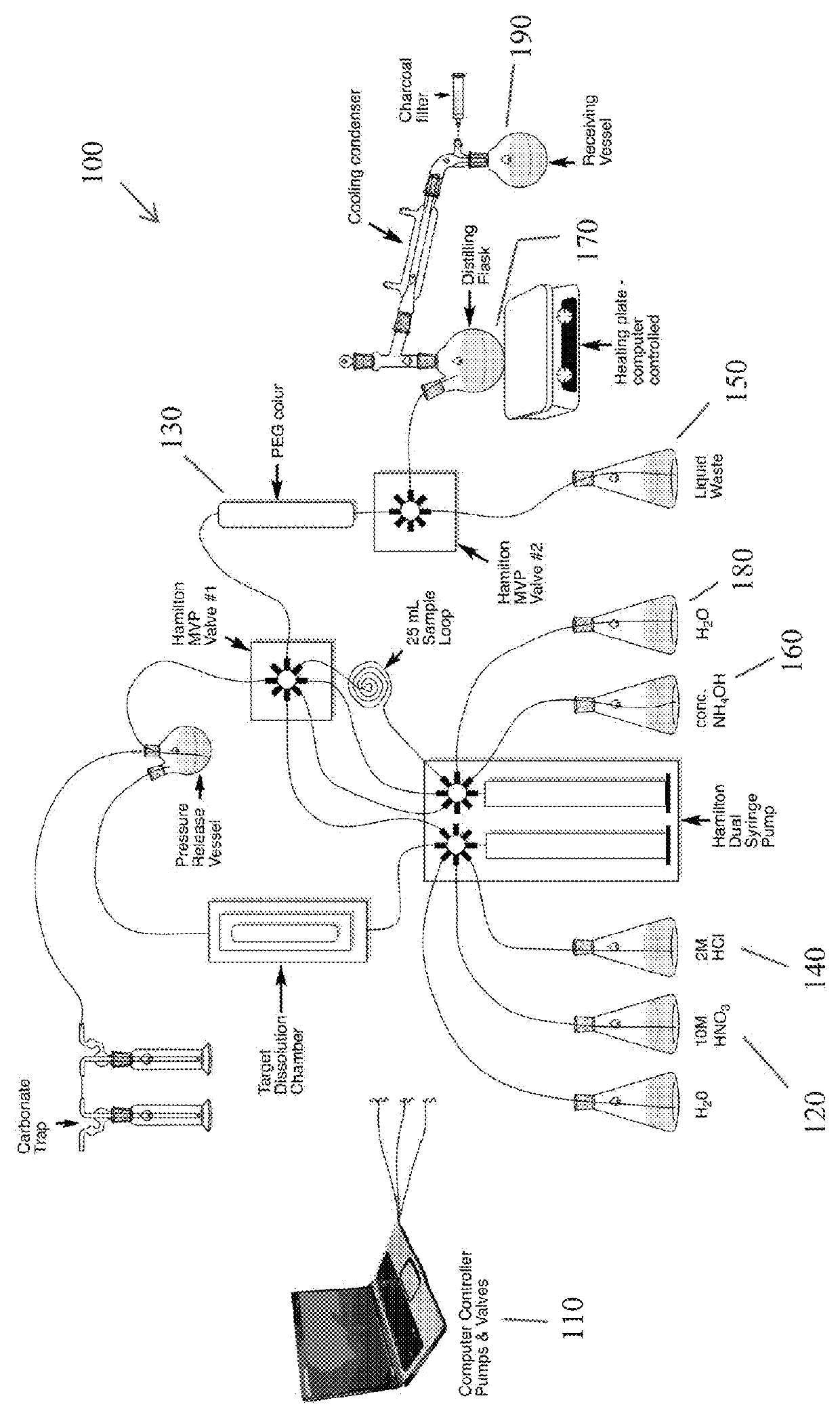

Processes, systems, and apparatus for cyclotron production of technetium-99m

A process for producing technetium-99m from a molybdenum-100 metal powder, comprising the steps of:(i) irradiating in a substantially oxygen-free environment, a hardened sintered target plate coated with a Mo-100 metal, with protons produced by a cyclotron;(ii) dissolving molybdenum ions and technetium ions from the irradiated target plate with an H2O2 solution to form an oxide solution;(iv) raising the pH of the oxide solution to about 14;(v) flowing the pH-adjusted oxide solution through a resin column to immobilize K[TcO4] ions thereon and to elute K2[MoO4] ions therefrom;(vi) eluting the bound K[TcO4] ions from the resin column;(vii) flowing the eluted K[TcO4] ions through an alumina column to immobilize K[TcO4] ions thereon;(viii) washing the immobilized K[TcO4] ions with water;(ix) eluting the immobilized K[TcO4] ions with a saline solution; and(x) recovering the eluted Na[TcO4] ions.

Owner:TRIUMF

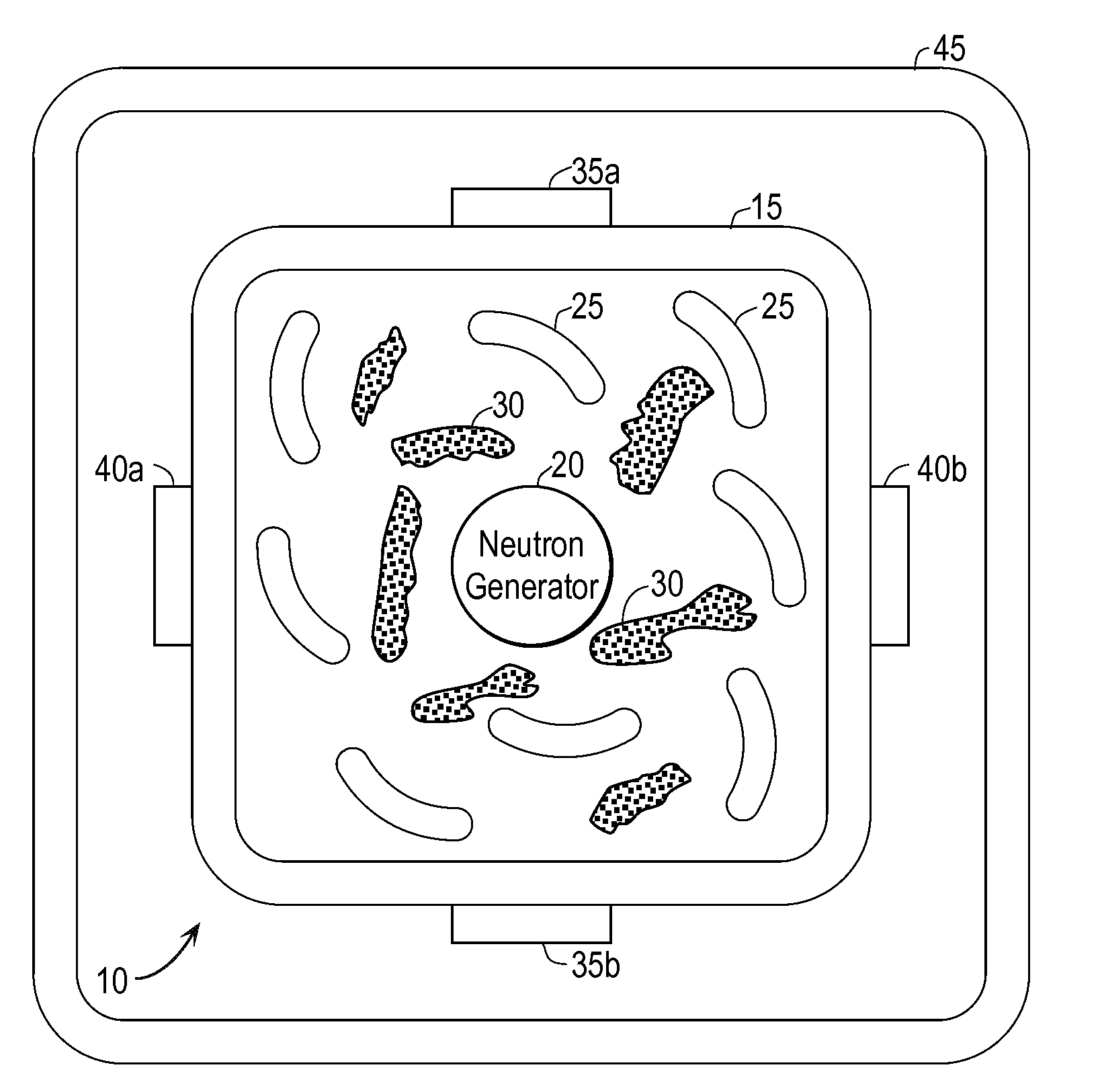

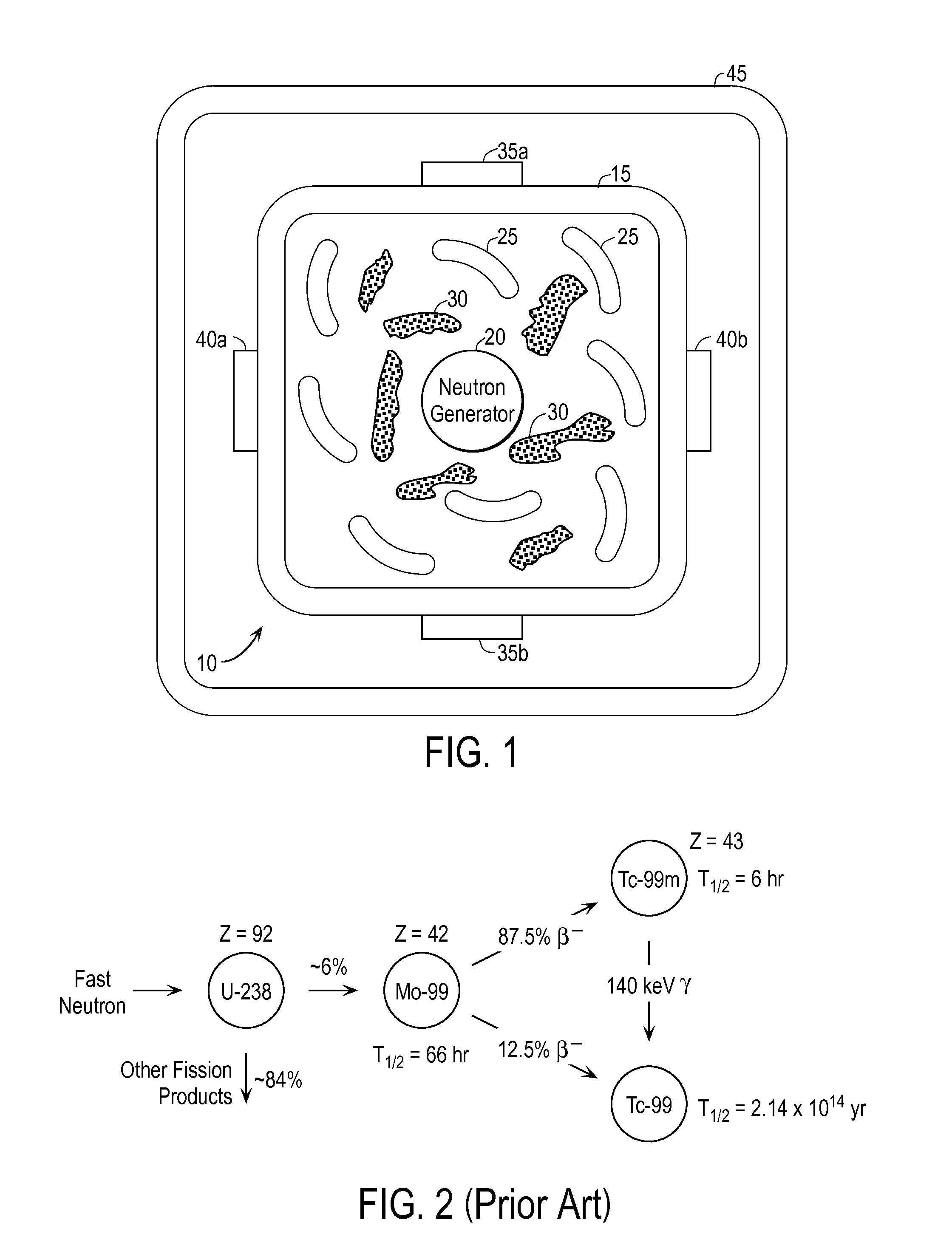

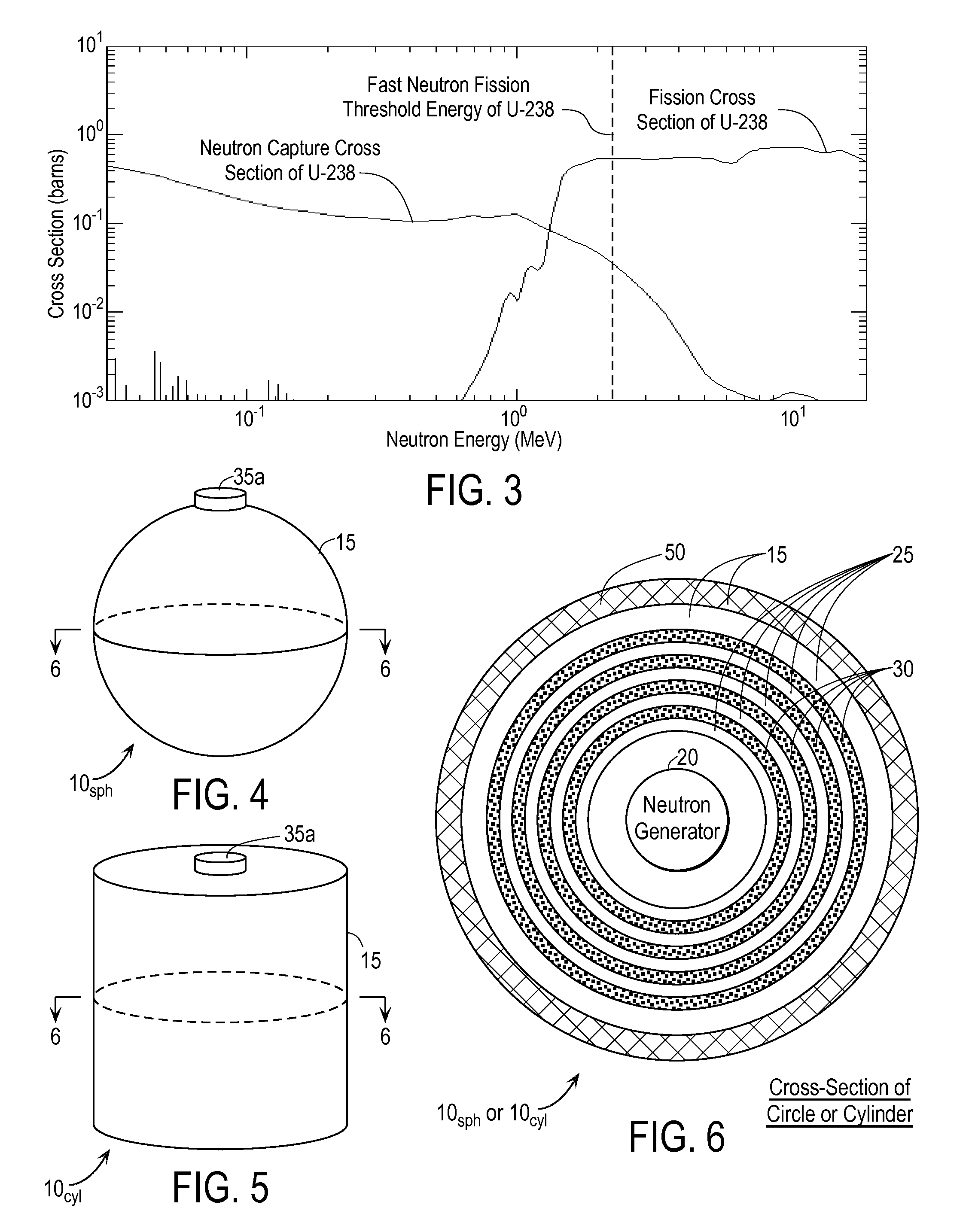

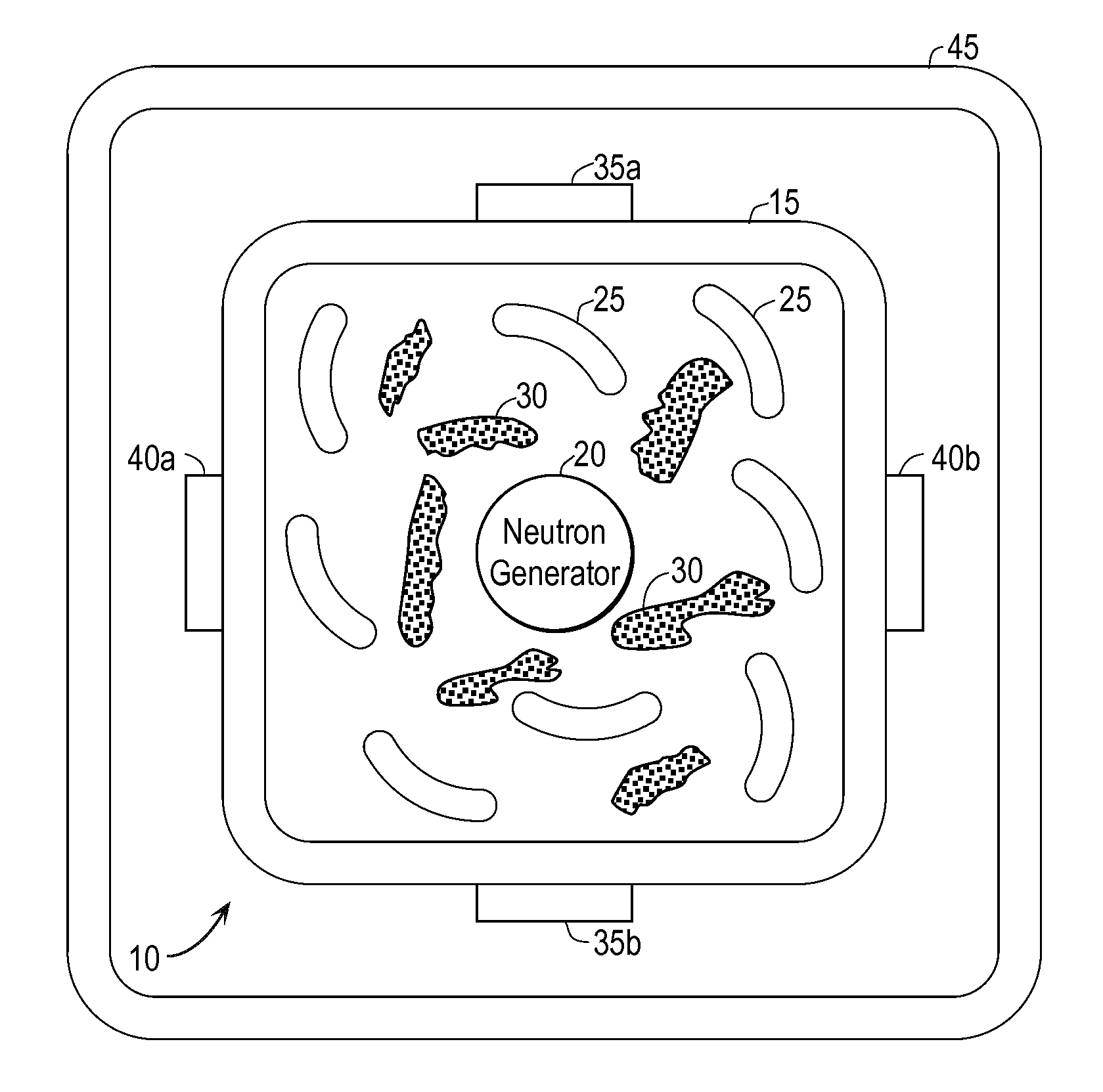

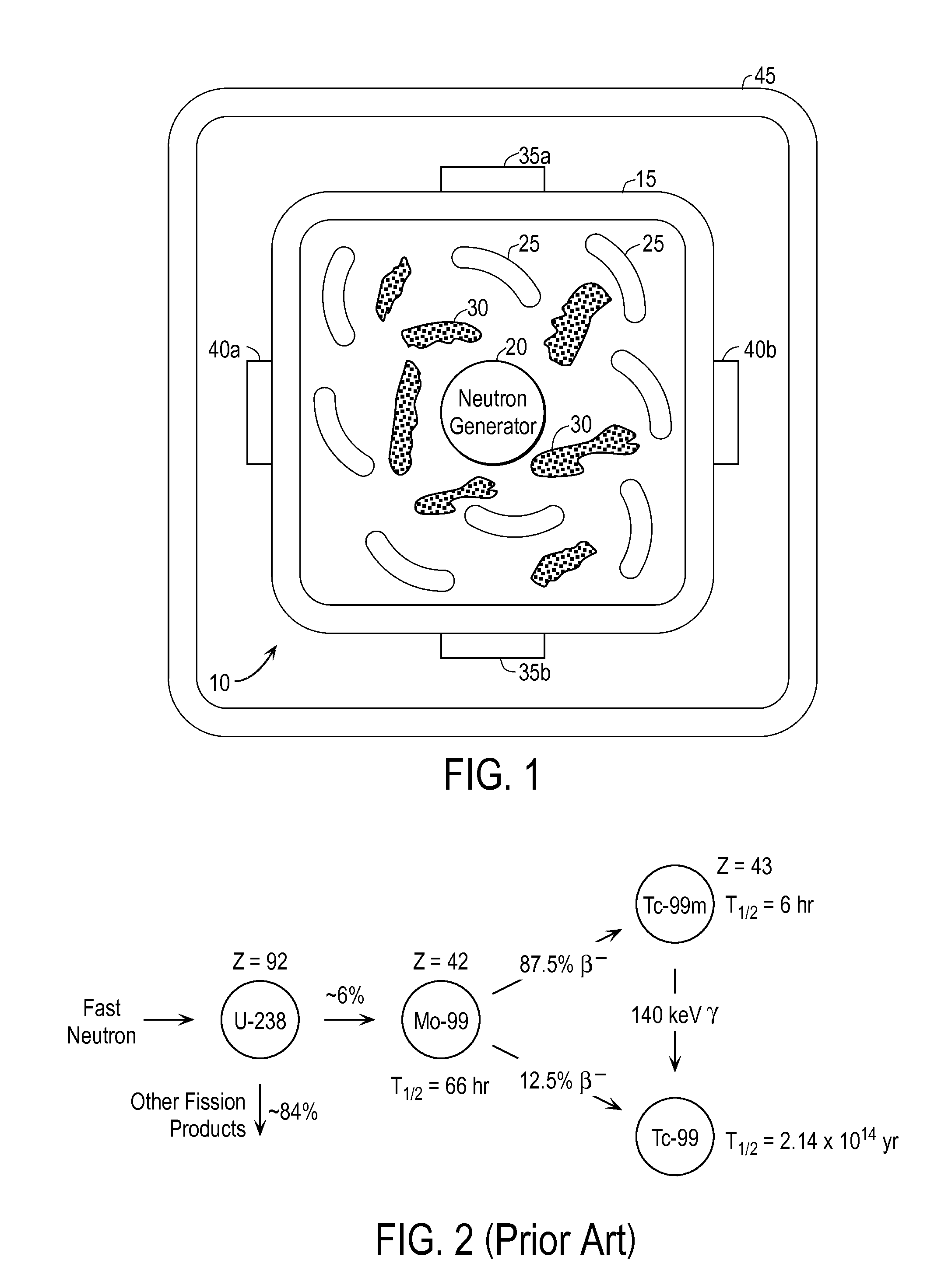

Techniques for On-Demand Production of Medical Isotopes Such as Mo-99/Tc-99m and Radioactive Iodine Isotopes Including I-131

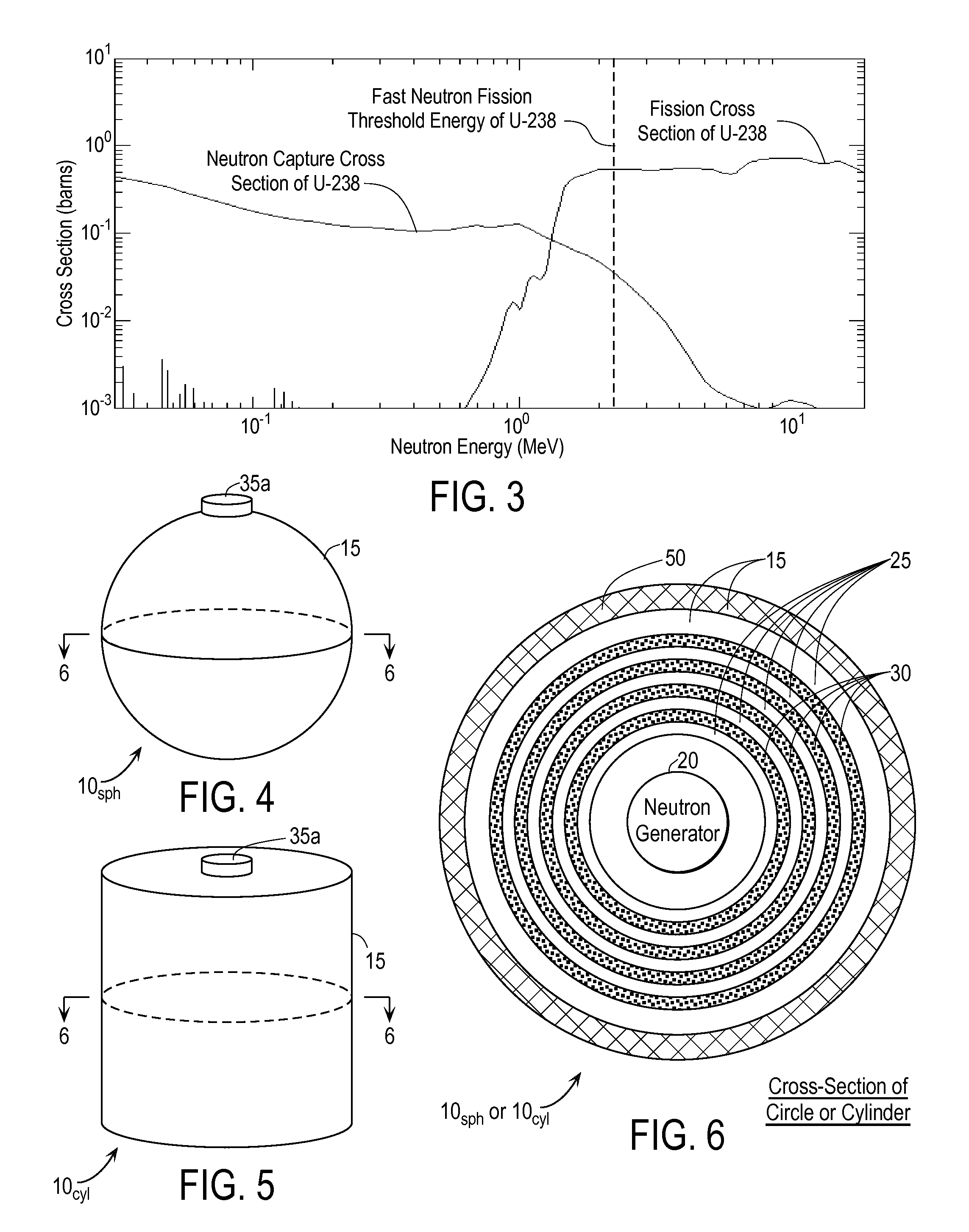

InactiveUS20110280356A1Minimize neutron absorptionReduce productionSpecific isotope recoveryConversion outside reactor/acceleratorsRadio isotopesNuclear engineering

A system for radioisotope production uses fast-neutron-caused fission of depleted or naturally occurring uranium targets in an irradiation chamber. Fast fission can be enhanced by having neutrons encountering the target undergo scattering or reflection to increase each neutron's probability of causing fission (m, f) reactions in U-238. The U-238 can be deployed as layers sandwiched between layers of neutron-reflecting material, or as rods surrounded by neutron-reflecting material.

Owner:GLOBAL MEDICAL ISOTOPE SYTEMS LLC +1

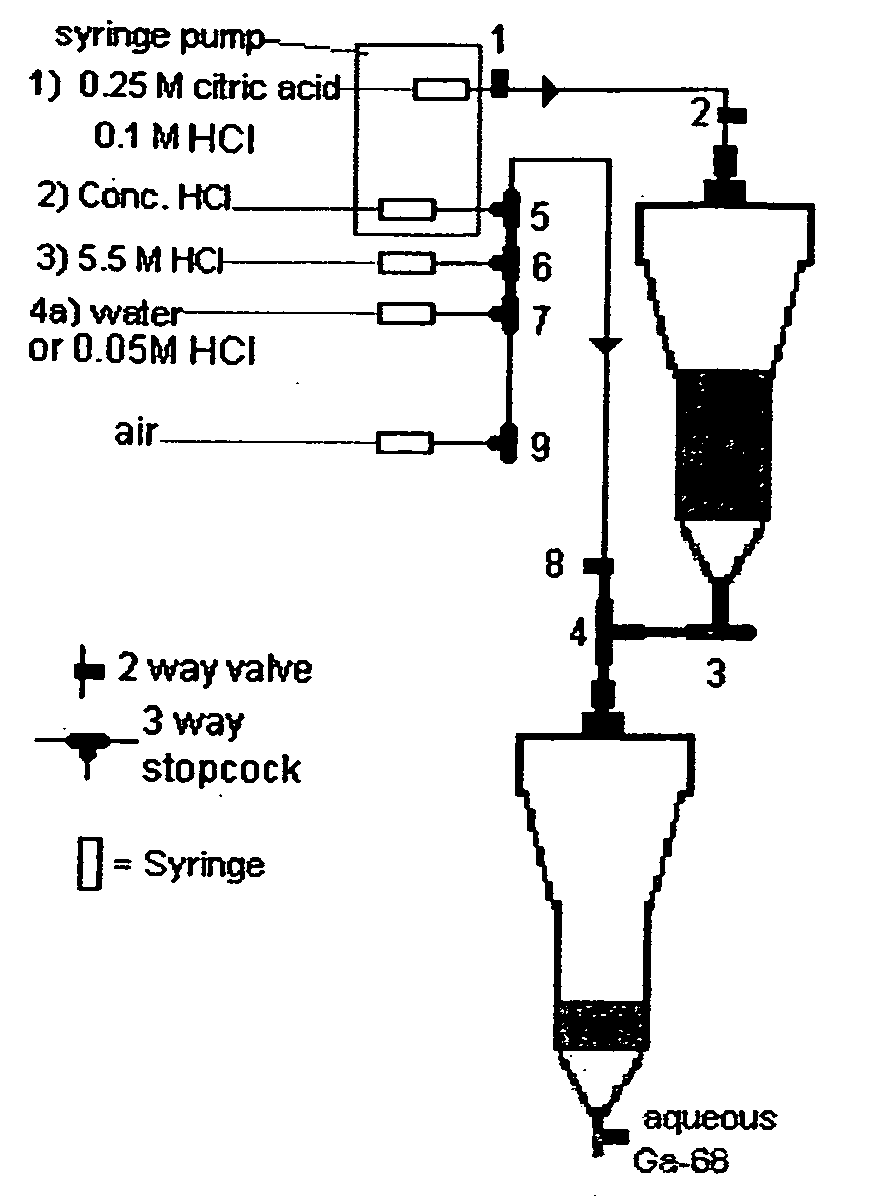

Separation of germanium-68 from gallium-68

InactiveUS20070207075A1High specific activitySpecific isotope recoveryTransuranic element compoundsCarboxylic acidGallium alloy

A method for separating germanium-68 from gallium-68 using an anion exchange resin and a chelating / complexing agent containing a plurality of carboxylic acid groups and at least three carbon atoms to the first solution is disclosed together with a generator apparatus for providing a source of gallium-68.

Owner:LOS ALAMOS NATIONAL SECURITY

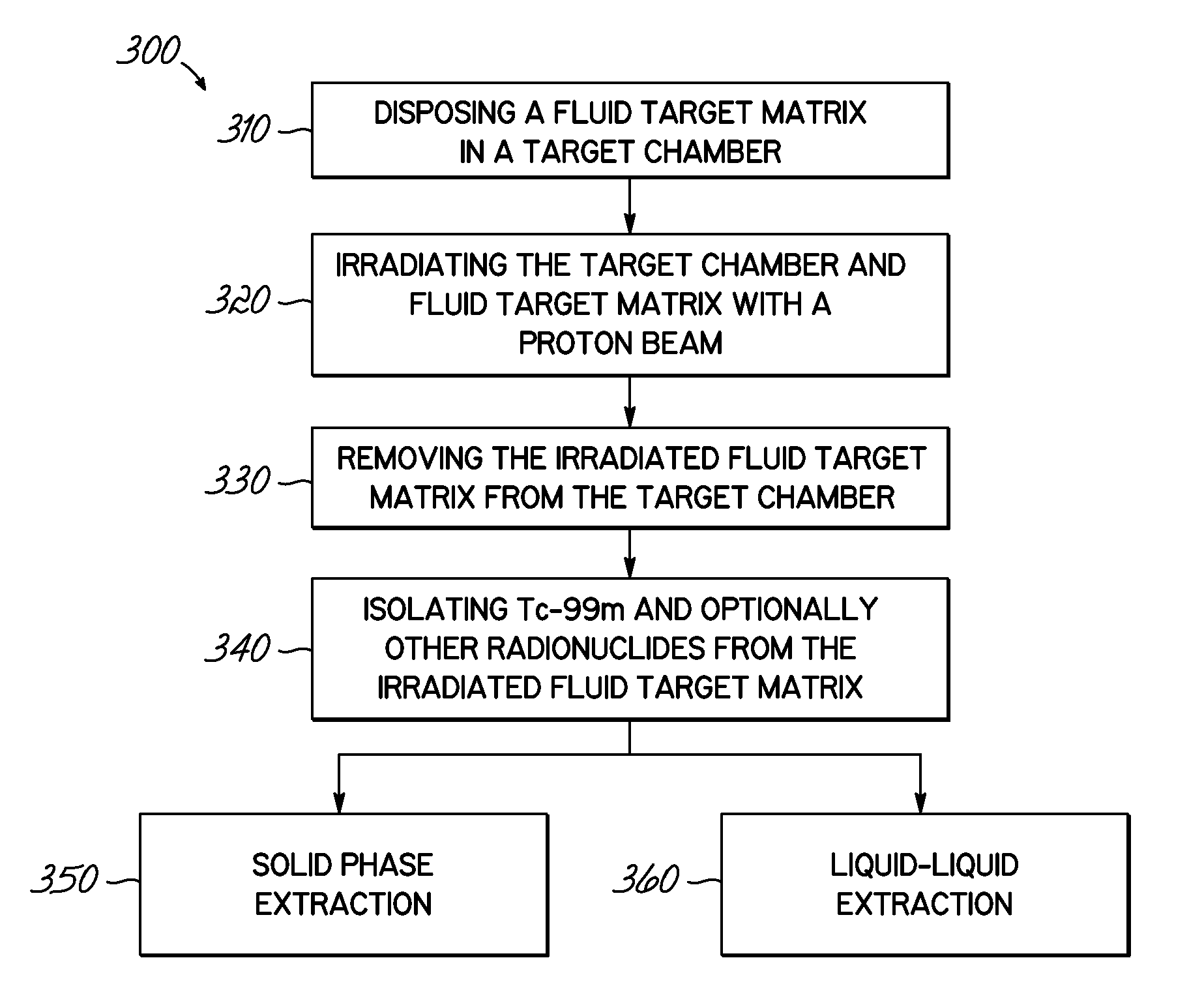

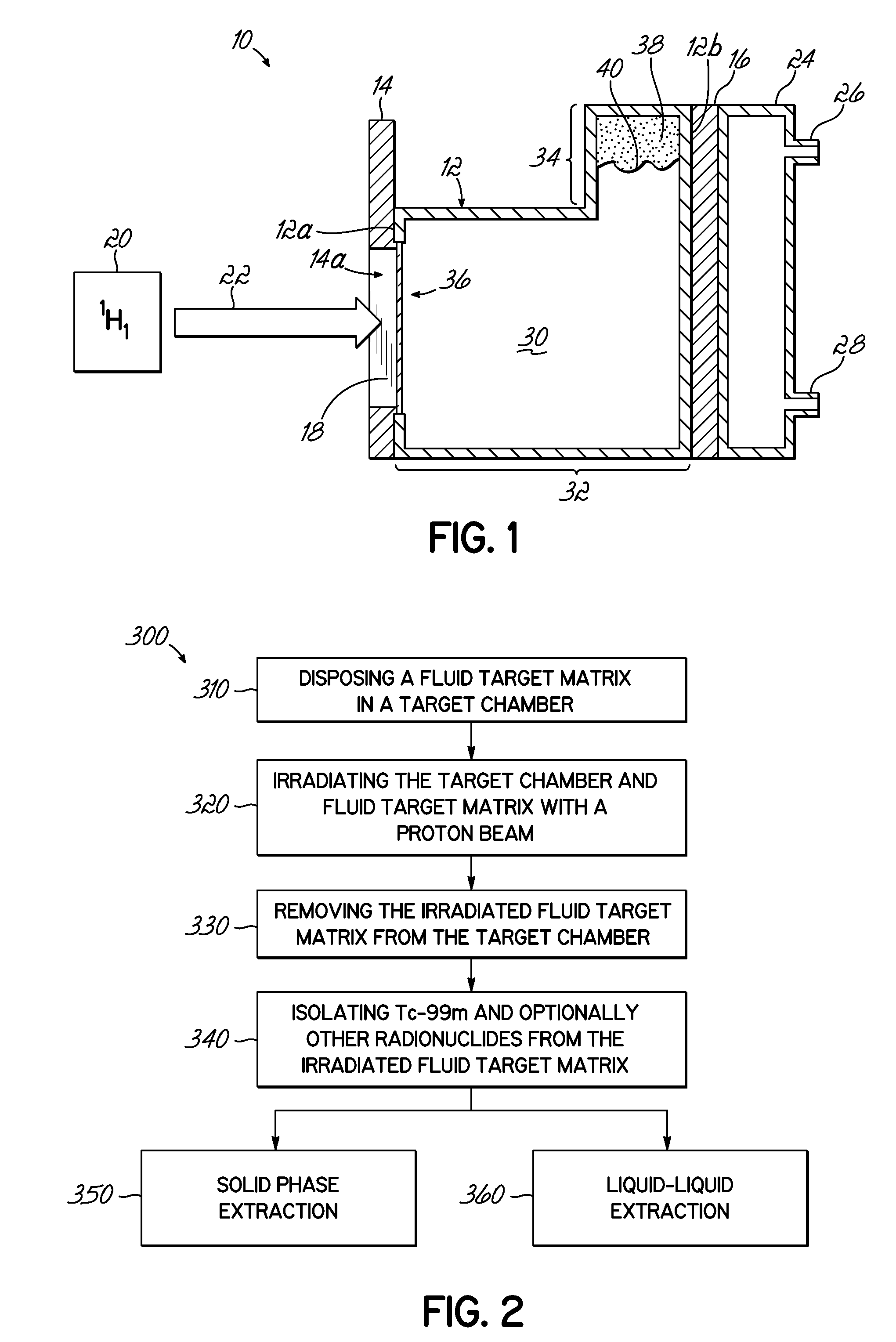

Tc-99m PRODUCED BY PROTON IRRADIATION OF A FLUID TARGET SYSTEM

InactiveUS20110280357A1Specific isotope recoveryConversion outside reactor/acceleratorsProtonIrradiation

Owner:TCNET

Techniques for On-Demand Production of Medical Radioactive Iodine Isotopes Including I-131

InactiveUS20110286565A1Avoid short travelEnhance fast fissionSpecific isotope recoveryConversion outside reactor/acceleratorsIodineIsotope

A system for radioisotope production uses fast-neutron-caused fission of depleted or naturally occurring uranium targets in an irradiation chamber. Fast fission can be enhanced by having neutrons encountering the target undergo scattering or reflection to increase each neutron's probability of causing fission (n, f) reactions in U-238. The U-238 can be deployed as one or more layers sandwiched between layers of neutron-reflecting material, or as rods surrounded by neutron-reflecting material. The gaseous fission products can be withdrawn from the irradiation chamber on a continuous basis, and the radioactive iodine isotopes (including I-131) extracted.

Owner:MIPOD NUCLEAR +1

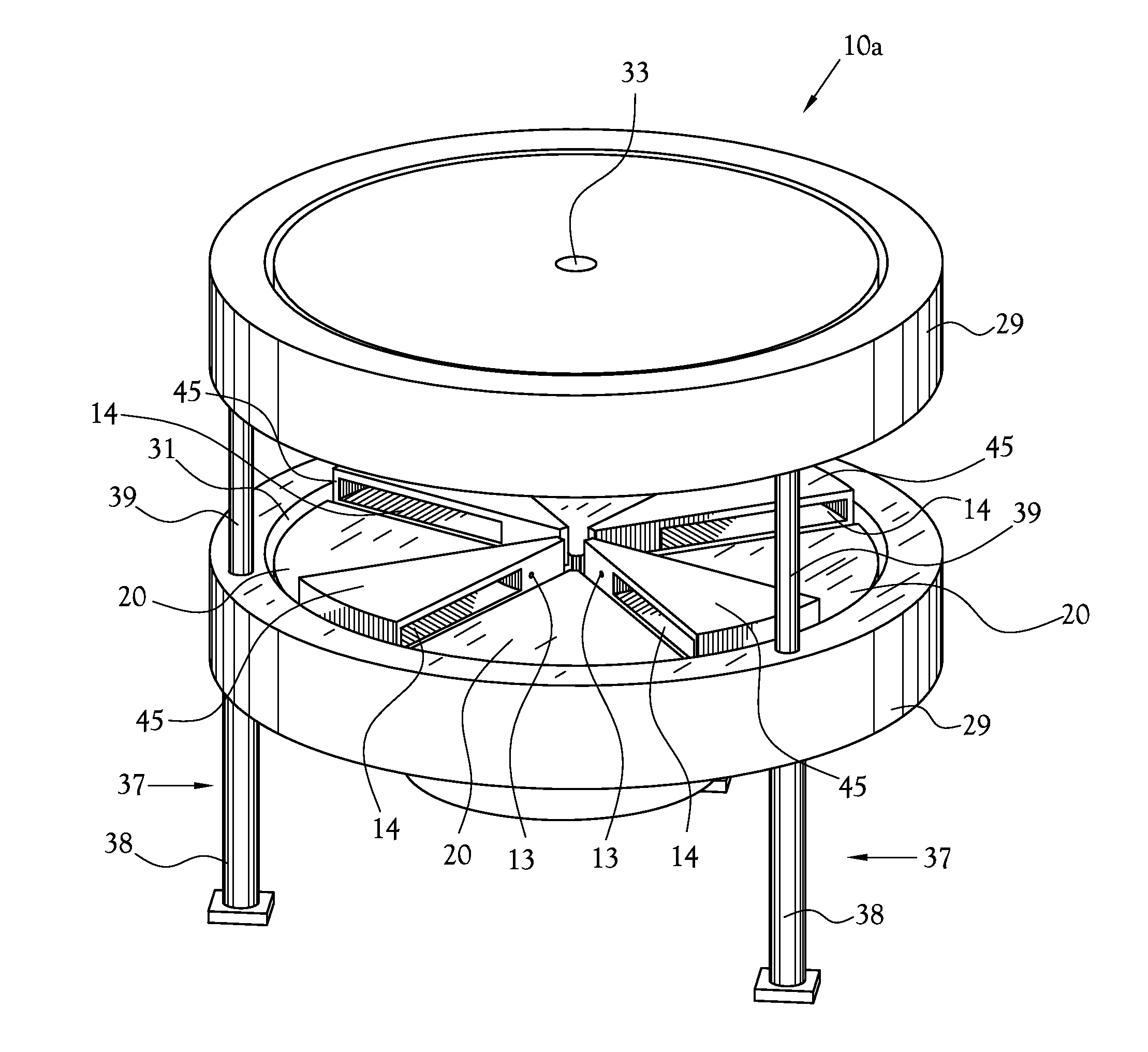

Biomarker Generator

ActiveUS20100127188A1Reduce in quantityLess stringent infrastructure requirementSpecific isotope recoveryMaterial analysis using wave/particle radiationChemical synthesisMicroreactor

An improved biomarker generator and a method suitable for efficiently producing short lived radiopharmaceuticals in quantities on the order of a unit dose. The improved biomarker generator includes a particle accelerator and a radiopharmaceutical micro-synthesis system. The micro-accelerator of the improved biomarker generator is optimized for producing radioisotopes useful in synthesizing radiopharmaceuticals in quantities on the order of one unit dose allowing for significant reductions in size, power requirements, and weight when compared to conventional radiopharmaceutical cyclotrons. The radiopharmaceutical micro-synthesis system of the improved biomarker generator is a small volume chemical synthesis system comprising a microreactor and / or a microfluidic chip and optimized for synthesizing the radiopharmaceutical in quantities on the order of one unit dose allowing for significant reductions in the quantity of radioisotope required and the processing time when compared to conventional radiopharmaceutical processing systems.

Owner:BEST ABT INC

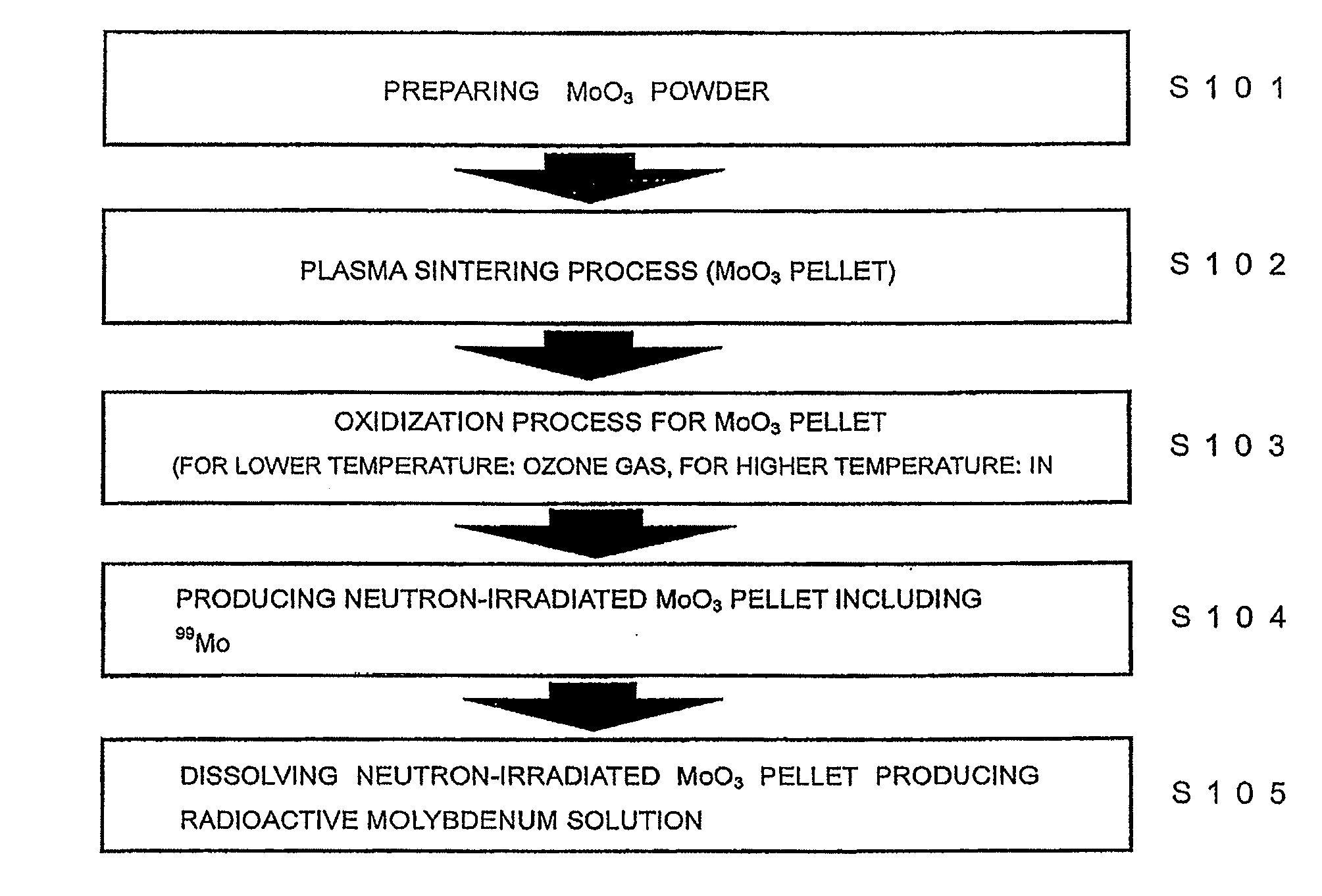

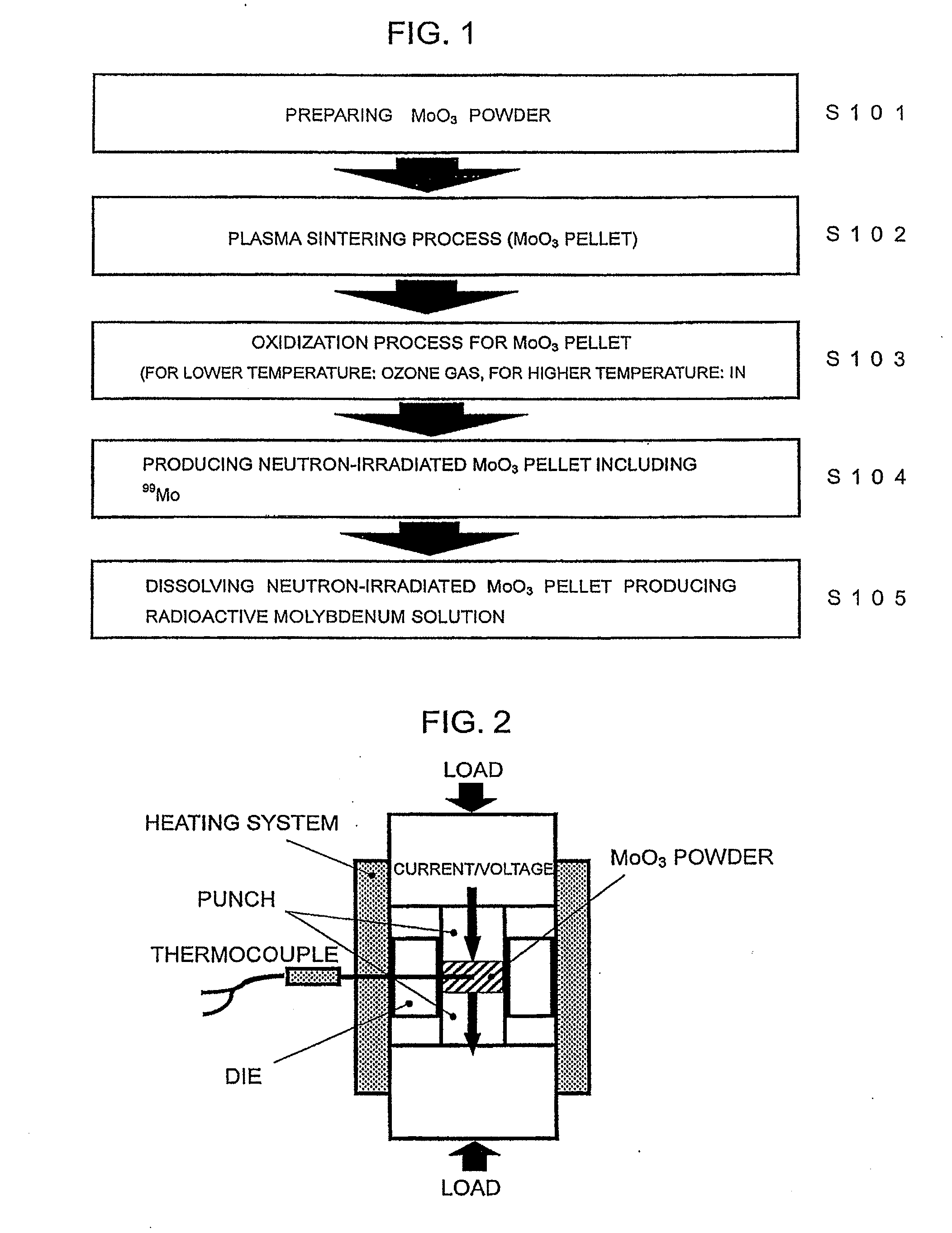

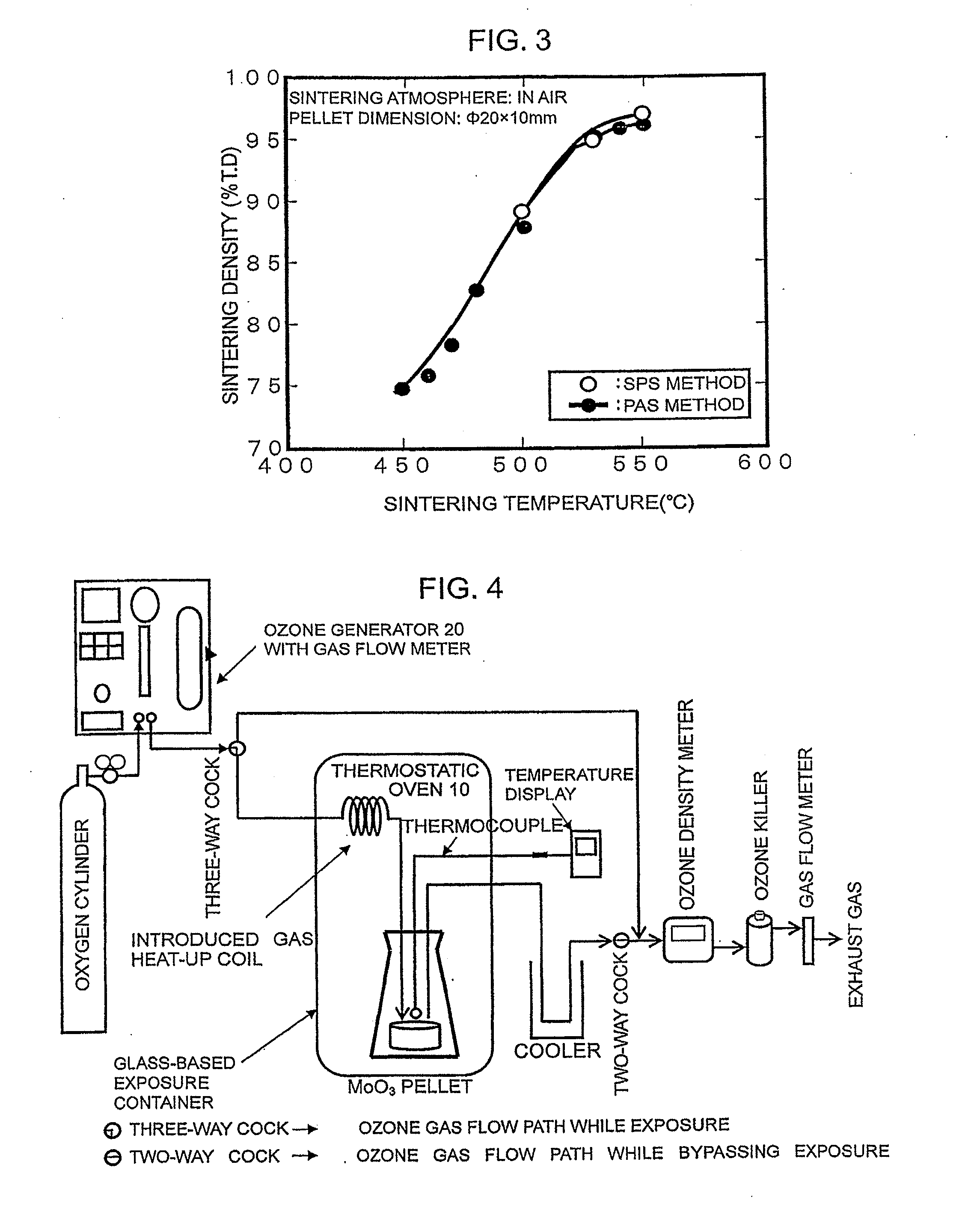

Method of producing radioactive molybdenum

InactiveUS20130136221A1Reduce the amount requiredSpecific isotope recoveryConversion outside reactor/acceleratorsHigh densityNeutron

To provide a method of producing radioactive molybdenum solution suitable for extracting 99mTc to be used as radioactive diagnostic drug by way of establishing a production process for high-density MoO3 pellets with a lower amount of insoluble content when dissolving the pellets. The method has the steps of: preparing MoO3 powder, fabricating a MoO3 pellet by filling said MoO3 powder in a heated die and sintering in an air, oxidizing said MoO3 pellet, producing neutron-irradiated MoO3 pellets by irradiating a neutron on said oxidized MoO3 pellet, and obtaining radioactive molybdenum solution by dissolving said neutron-irradiated MoO3 pellet.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

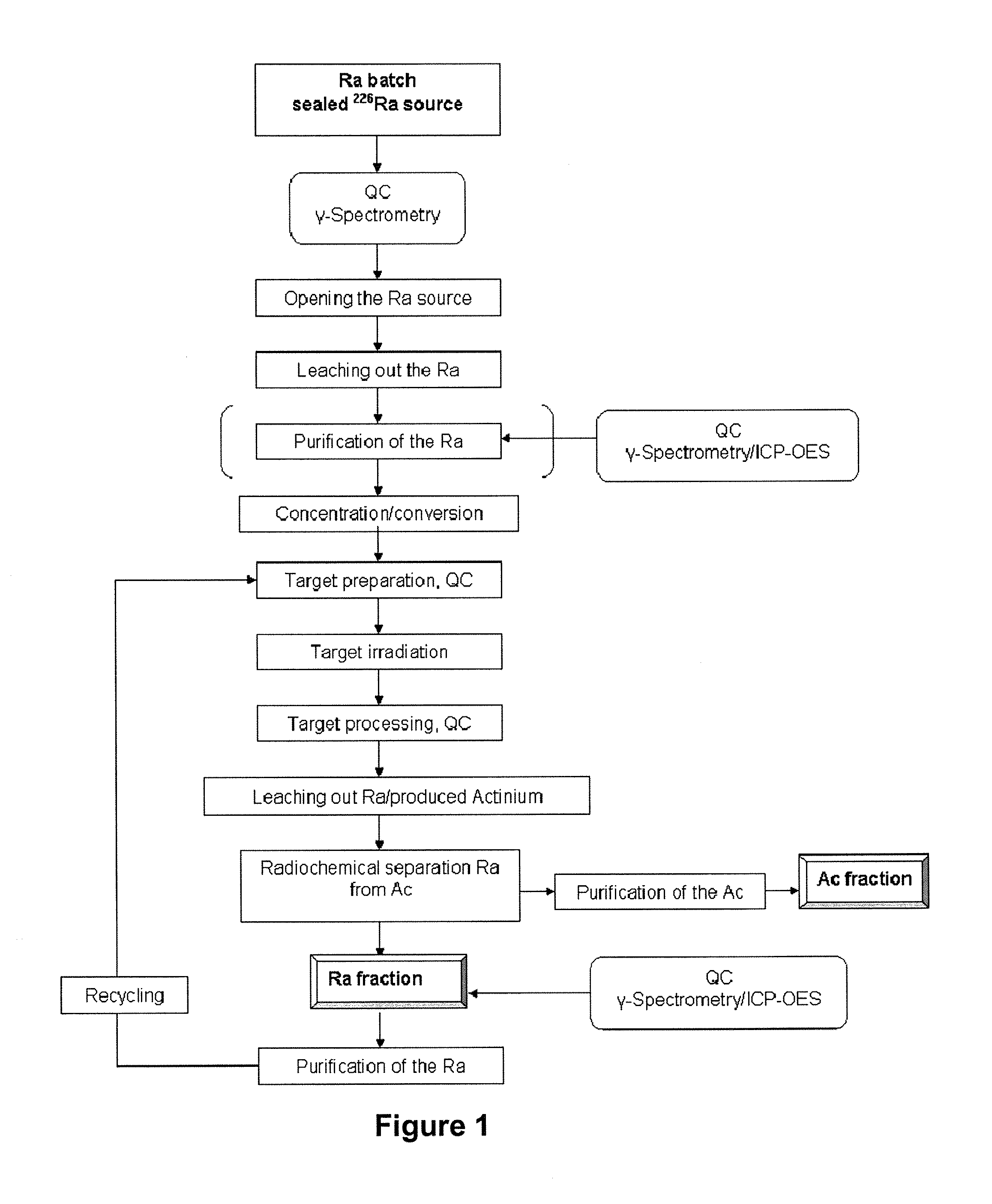

Method for producing actinium-225 and isotopes of radium and target for implementing same

The invention relates to the field of nuclear technology and radiochemistry, more specifically to the production and isolation of radionuclides for medical purposes. The method for producing actinium-225 and isotopes of radium comprises irradiating a solid block of metallic thorium of a thickness of 2 to 30 mm, which is contained within a hermetically sealed casing made of a material which does not react with thorium, with a flow of accelerated charged particles with high intensity. The irradiated metallic thorium is removed from the casing and is either heated with the addition of lanthanum and the distillation of radium or is dissolved in nitric acid with the recovery of actinium-225 by extraction. A target for implementing this method consists of blocks of metallic thorium of a thickness of 2 to 30 mm, which are contained within a hermetically scaled casing made of different materials which do not react with thorium.

Owner:UCHREZHDENIE ROSSIJSKOJ AKADI NAUK INSTITUT JADERNYKH ISSLEDOVANIJ RAN IJAI RAN

Method for the chemical separation of GE-68 from its daughter Ga-68

InactiveUS20090001283A1Specific isotope recoveryMaterial analysis using wave/particle radiationCITRATE ESTERTetrachloride

The present invention is directed to a generator apparatus for separating a daughter gallium-68 radioisotope substantially free of impurities from a parent gernanium-68 radioisotope, including a first resin-containing column containing parent gernanium-68 radioisotope and daughter gallium-68 radioisotope, a source of first eluent connected to said first resin-containing column for separating daughter gallium-68 radioisotope from the first resin-containing column, said first eluent including citrate whereby the separated gallium is in the form of gallium citrate, a mixing space connected to said first resin-containing column for admixing a source of hydrochloric acid with said separated gallium citrate whereby gallium citrate is converted to gallium tetrachloride, a second resin-containing column for retention of gallium-68 tetrachloride, and, a source of second eluent connected to said second resin-containing column for eluting the daughter gallium-68 radioisotope from said second resin-containing column.

Owner:LOS ALAMOS NATIONAL SECURITY

Production of actinium-227 and thorium-228 from radium-226 to supply alpha-emitting isotopes radium-223, thorium-227, radium-224, bismuth-212

InactiveUS20140226774A1Region can be greatHigh affinitySpecific isotope recoveryConversion outside reactor/acceleratorsRadium-224Actinium

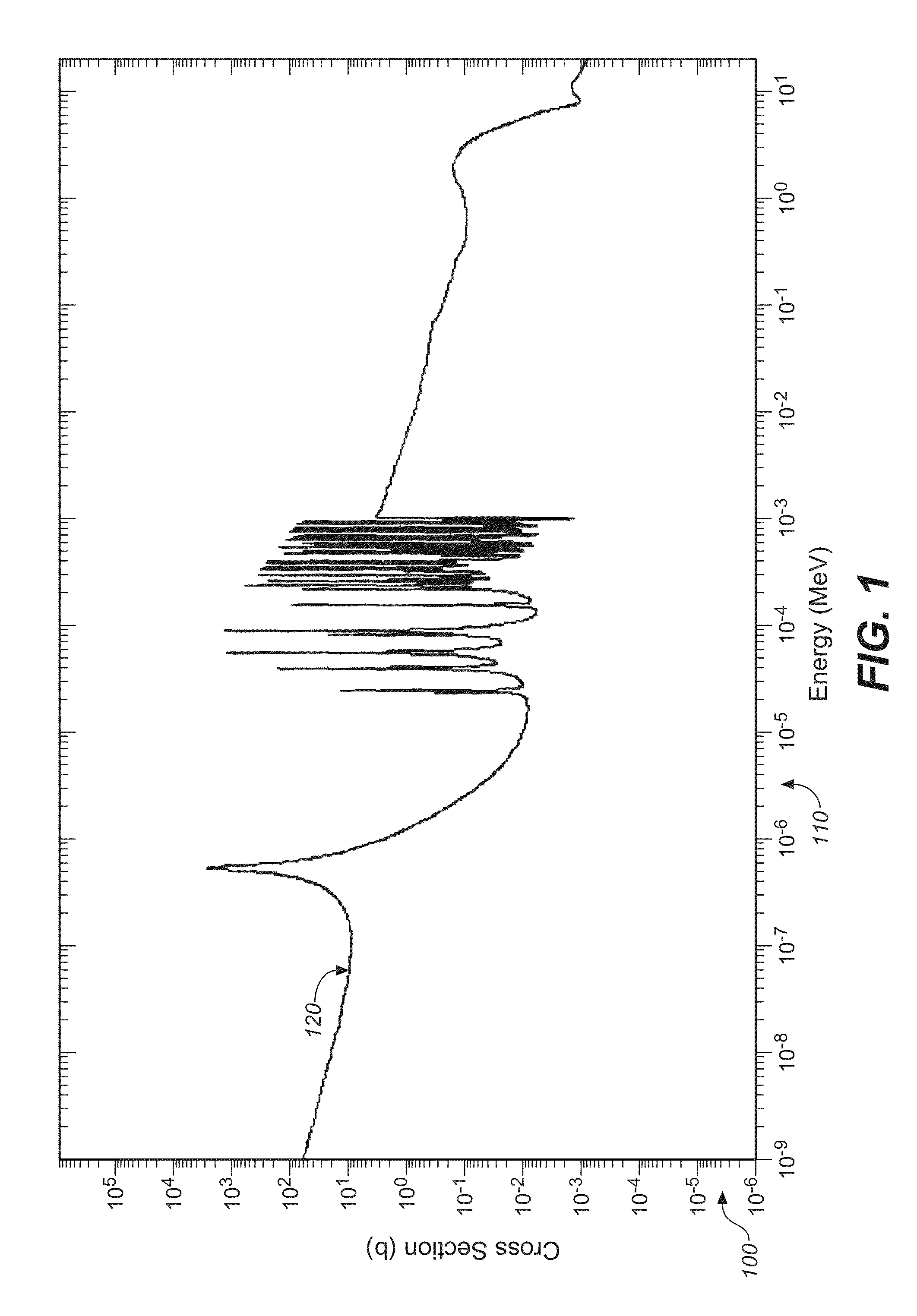

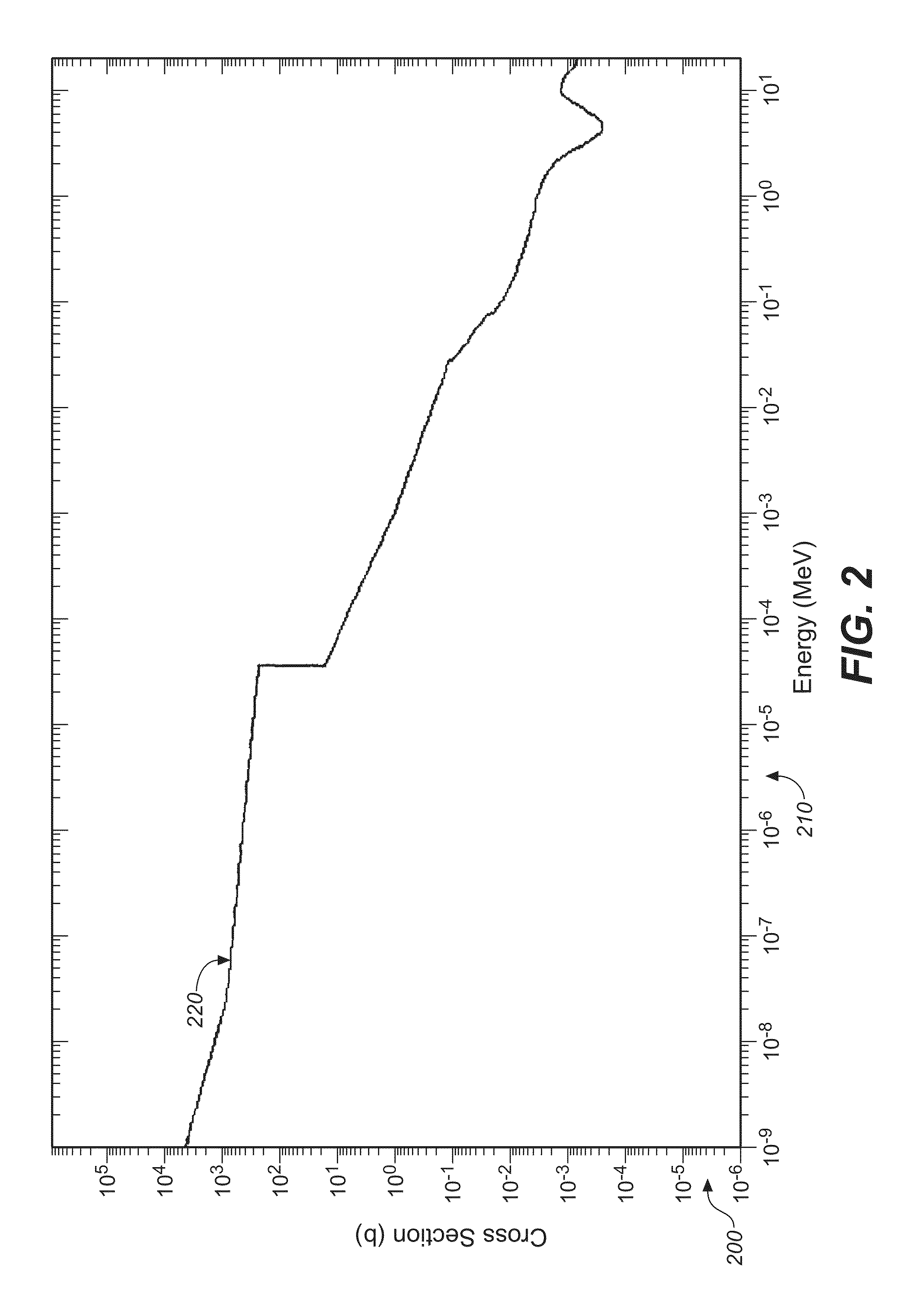

An actinium-227 production device having a plurality of metallic or ceramic caplets, each enclosing a radium-226 compound in redundantly nested sealed cylinders. The radium-226 compound is compacted into a disk and diluted with heat transporting ceramic materials. A thermal neutron shield including spectrum shaping materials to protect actinium-227 produced from exposure to thermal neutrons is included along with a strong neutron absorber to shape the neutron spectrum such that radium-226 nuclei are exposed to neutrons in the higher epithermal energy groups upon entry into the target with an energy of between 20 eV and 1 KeV.

Owner:THORENCO MEDICAL ISOTOPES

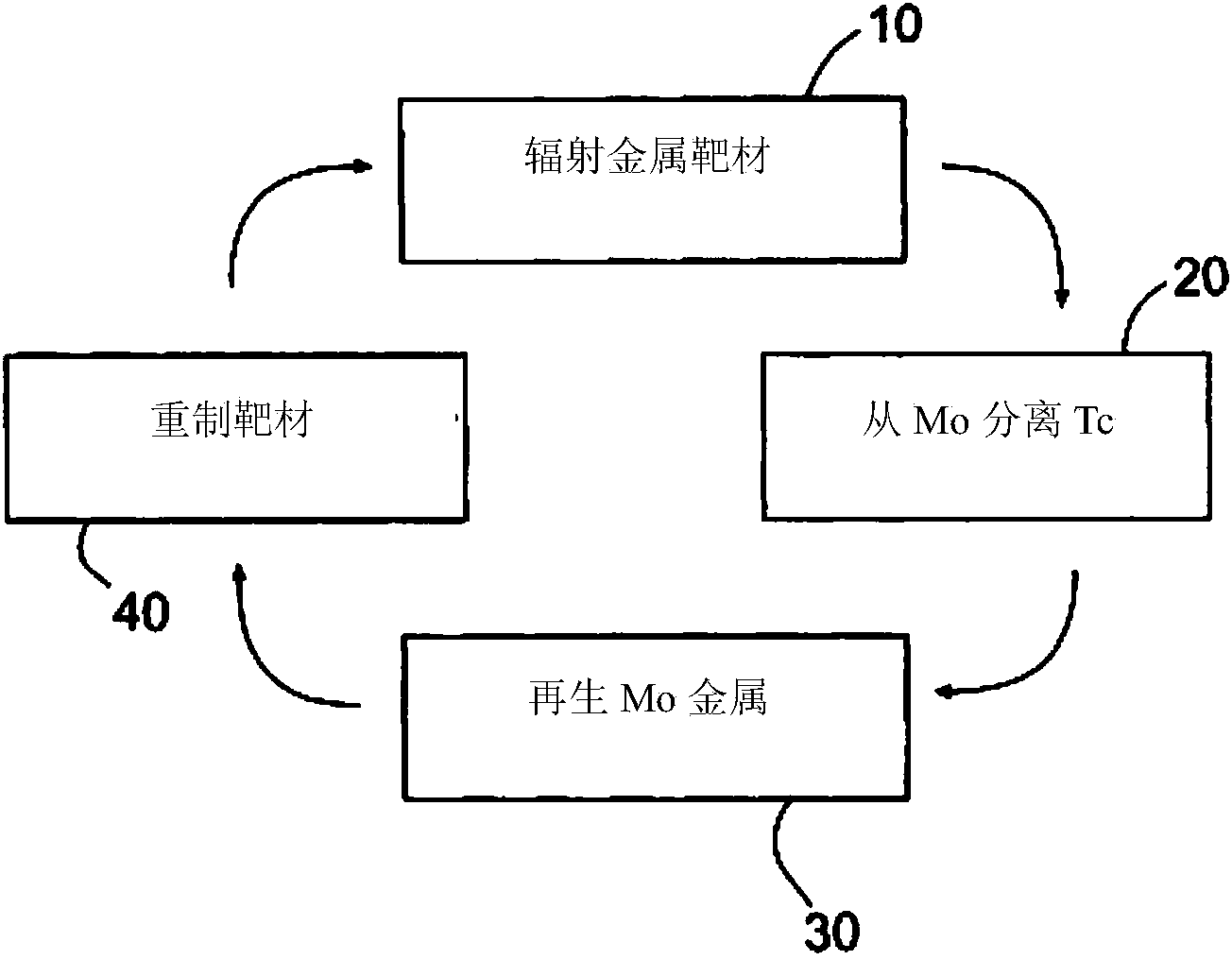

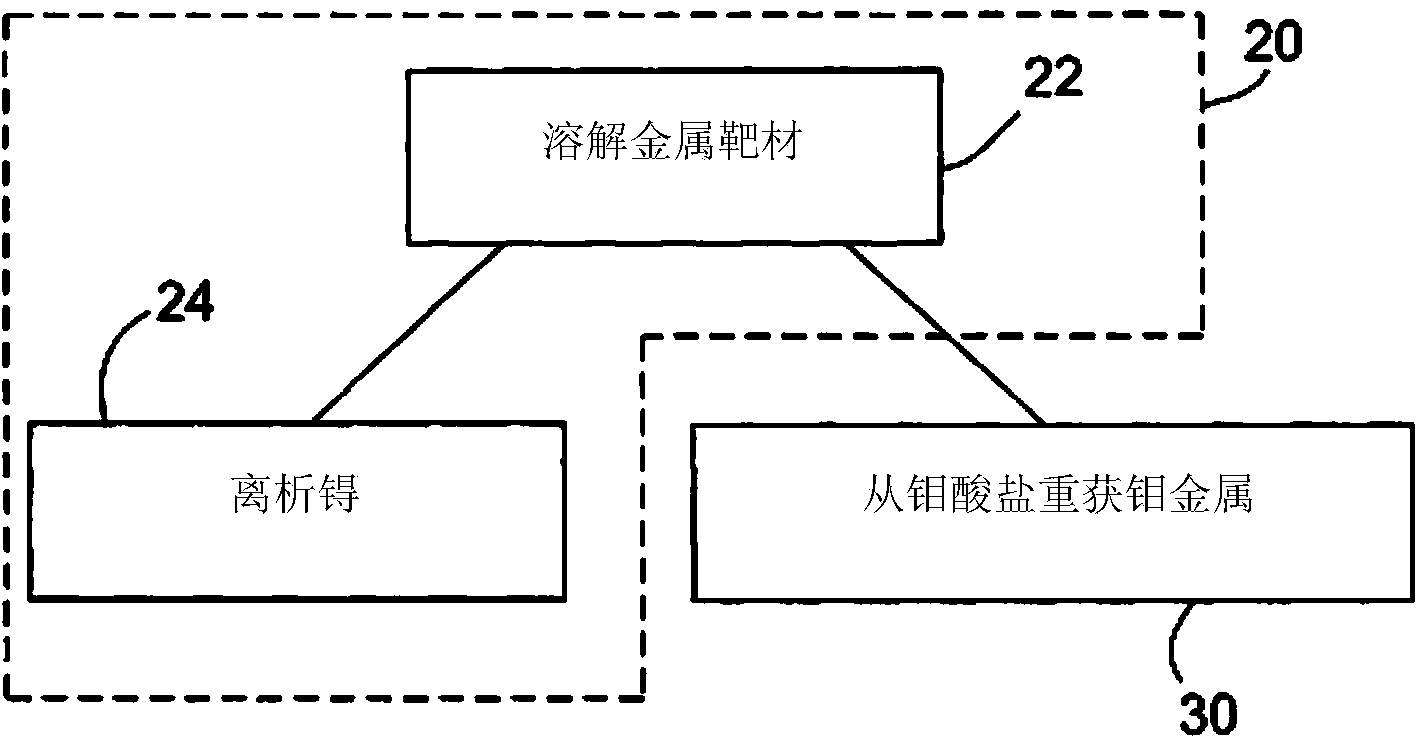

Production of technetium from a molybdenum metal target

InactiveCN103733270ASpecific isotope recoveryConversion outside reactor/acceleratorsMolybdateTechnetium

Recycling of isotopically enriched molybdenum metal targets that are suitable for the large scale cyclotron production of 99mTc or 94mTc includes the charged particle irradiation of an enriched molybdenum metal target to produce a technetium isotope, separation of the technetium isotope following irradiation of the molybdenum, re-claiming the molybdenum metal and reformation of the molybdenum target for a further irradiation step. This process may then be repeated. Separation of the technetium isotope preferably is achieved by oxidative dissolution of the molybdenum thereby removing it from a target support plate, and forming molybdate and pertechnetate. The technetium isotope is isolated by various means, such as the ABEC process. To reuse the molybdenum, additional steps of isolating the molybdate and reducing it back to molybdenum metal are required. The recovered molybdenum metal may then be reformed as a target for example by pressing or pressing and sintering, followed by bonding to a target support plate.

Owner:阿尔伯塔大学董事会

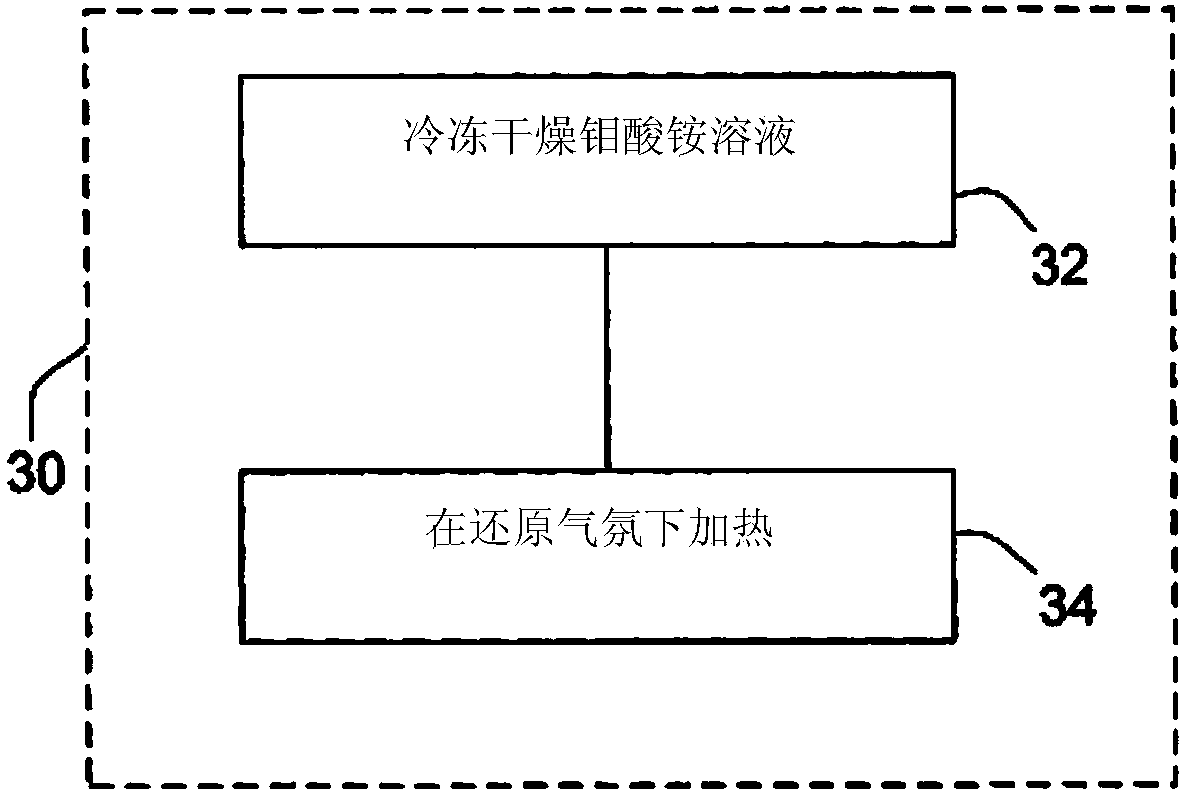

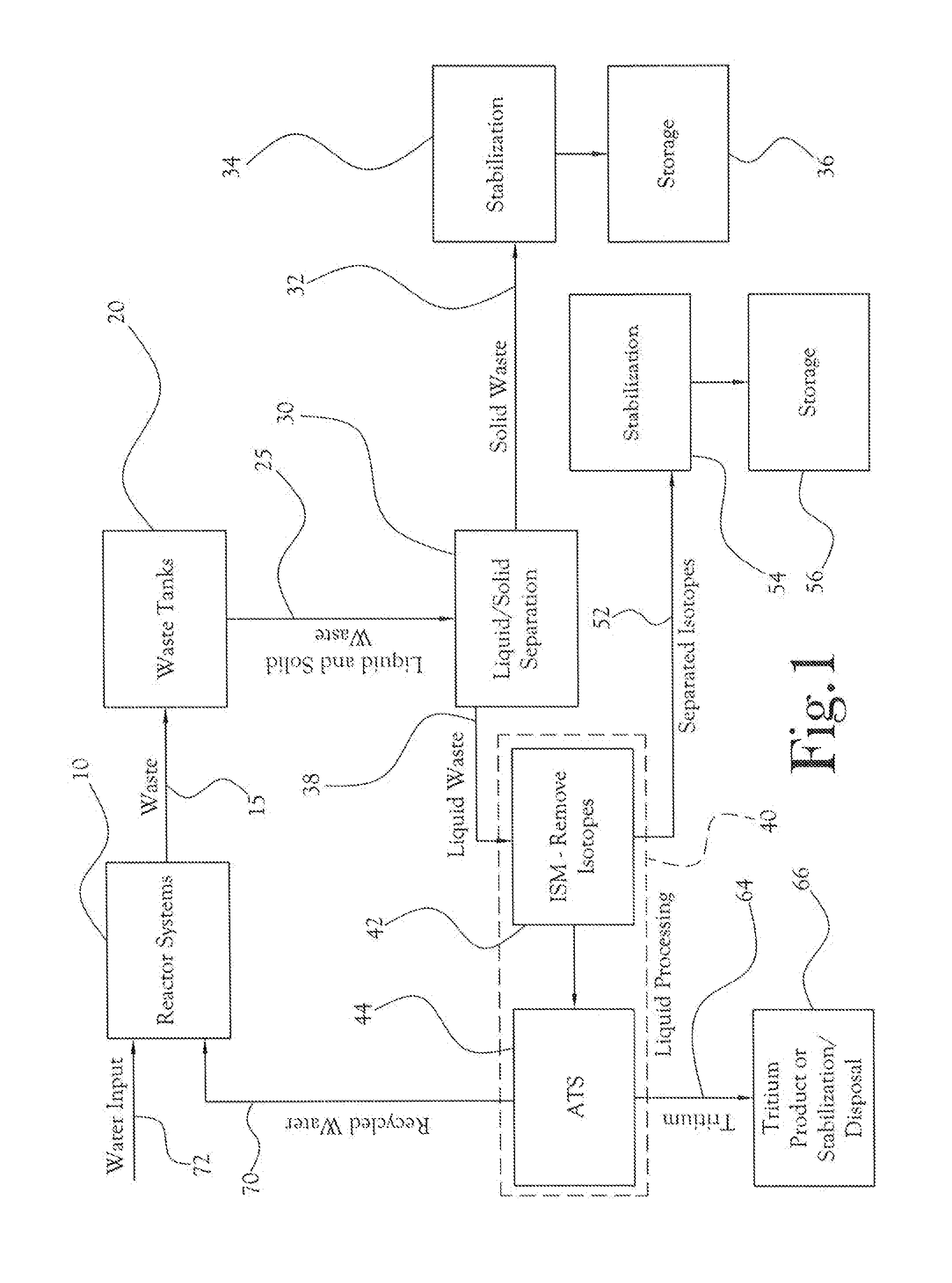

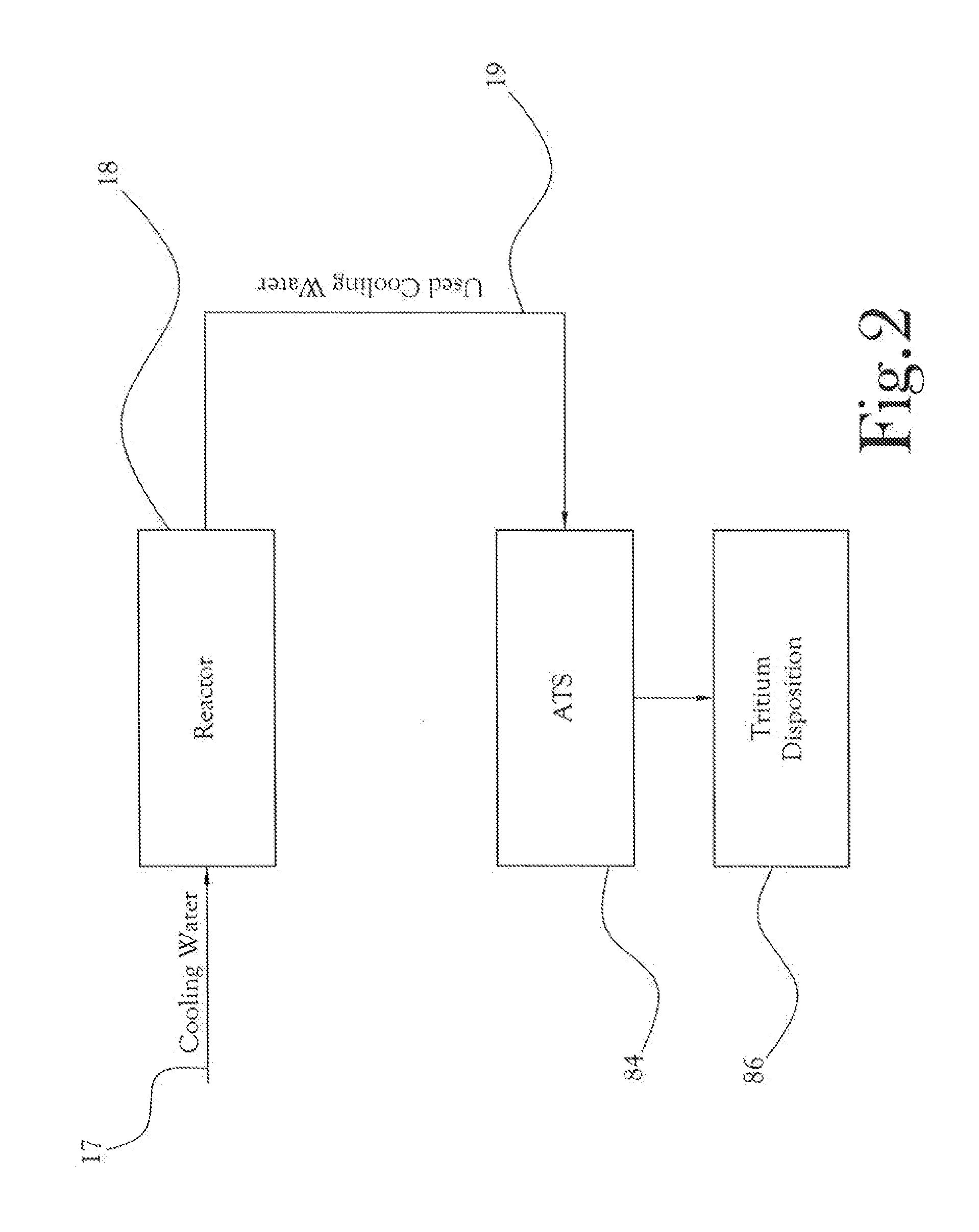

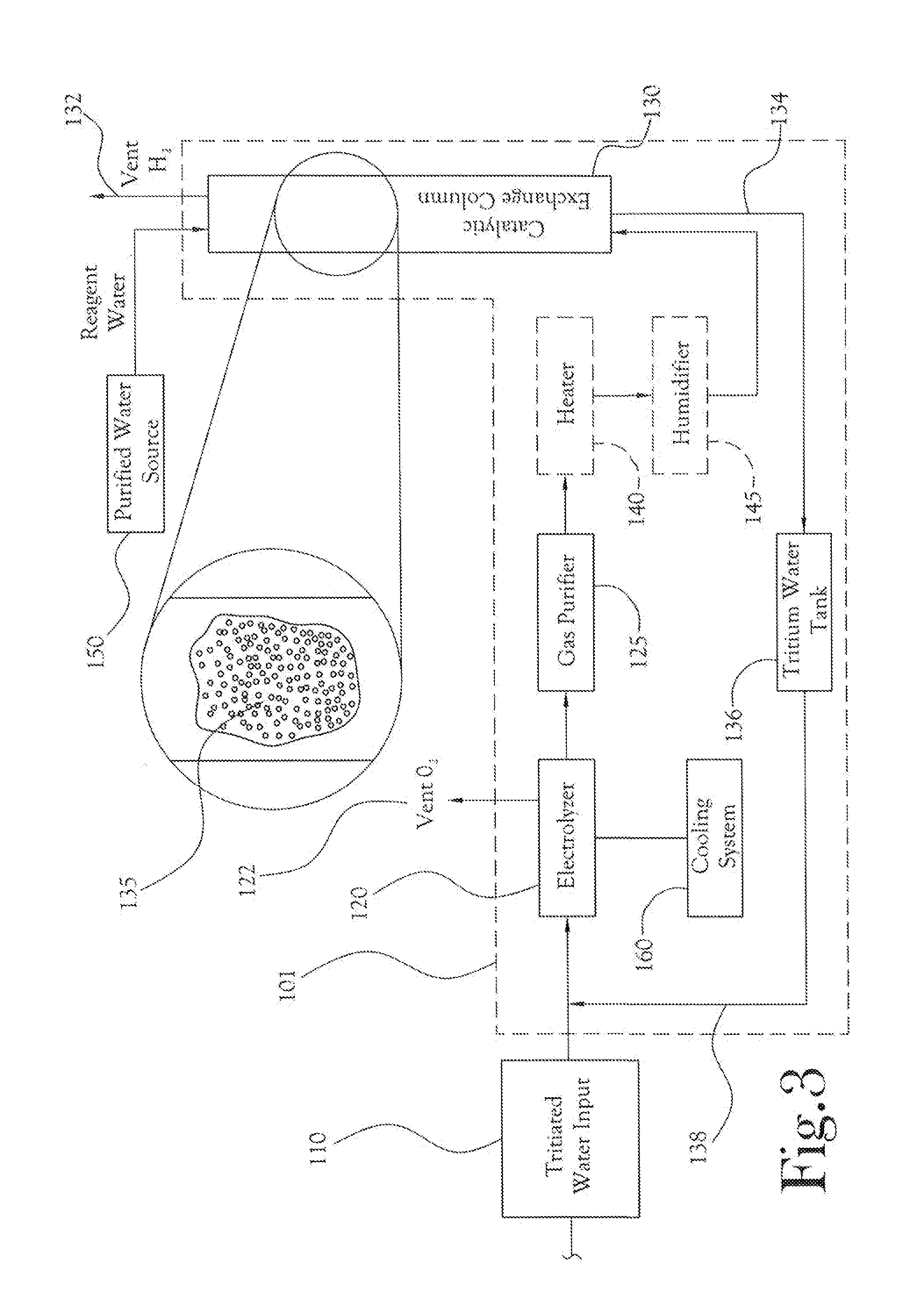

Advanced Tritium System for Separation of Tritium from Radioactive Wastes and Reactor Water in Light Water Systems

InactiveUS20130336870A1Process stabilityIncrease wasteSpecific isotope recoveryTransuranic element compoundsElectrolysisHydrophobic polymer

Systems, methods, and processes for a high throughput, low concentration processing of low activity tritiated light water include the electrolysis of at least some of the tritiated water to produce hydrogen and tritium gas. The hydrogen and tritium gas produced by electrolysis in some cases are combined with heated water vapor to increase throughput and passed through a liquid phase catalytic exchange column, which generally includes a catalyst that includes palladium coated with a hydrophobic polymer. As the hydrogen and tritium gas, along with heated water vapor, rise through the LPCE column, the tritium is retained on the catalyst. Deionized wash water passes down the column (i.e., in the opposite direction of the flow of the hydrogen gas and heated water vapor) and carries the retained tritium out of the LPCE column. Useful in separating tritium from radioactive waste materials and from the water from nuclear reactors.

Owner:KURION INC

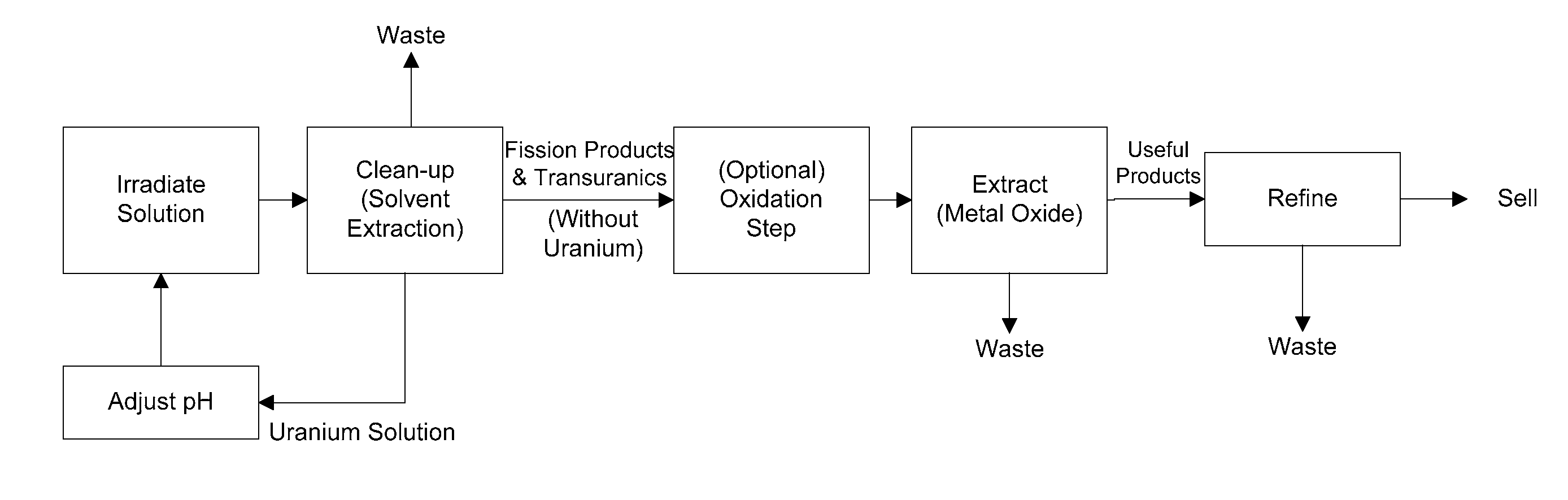

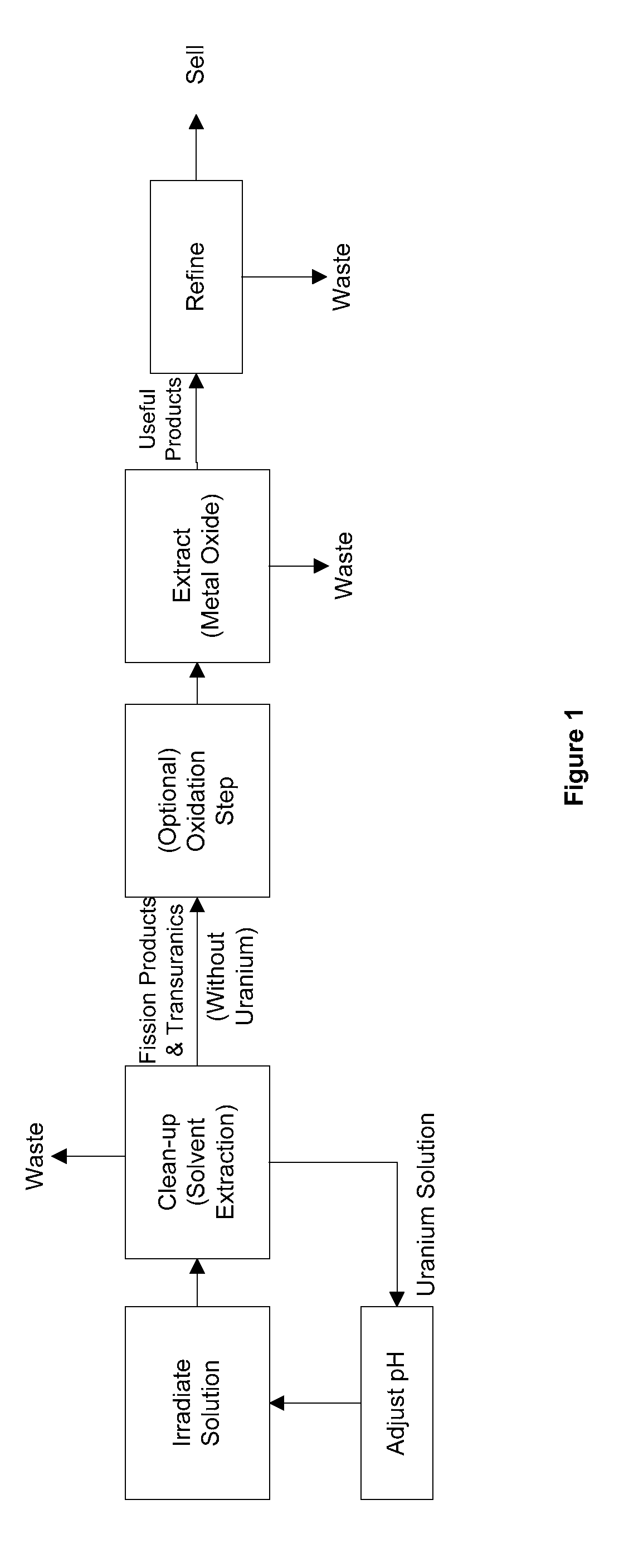

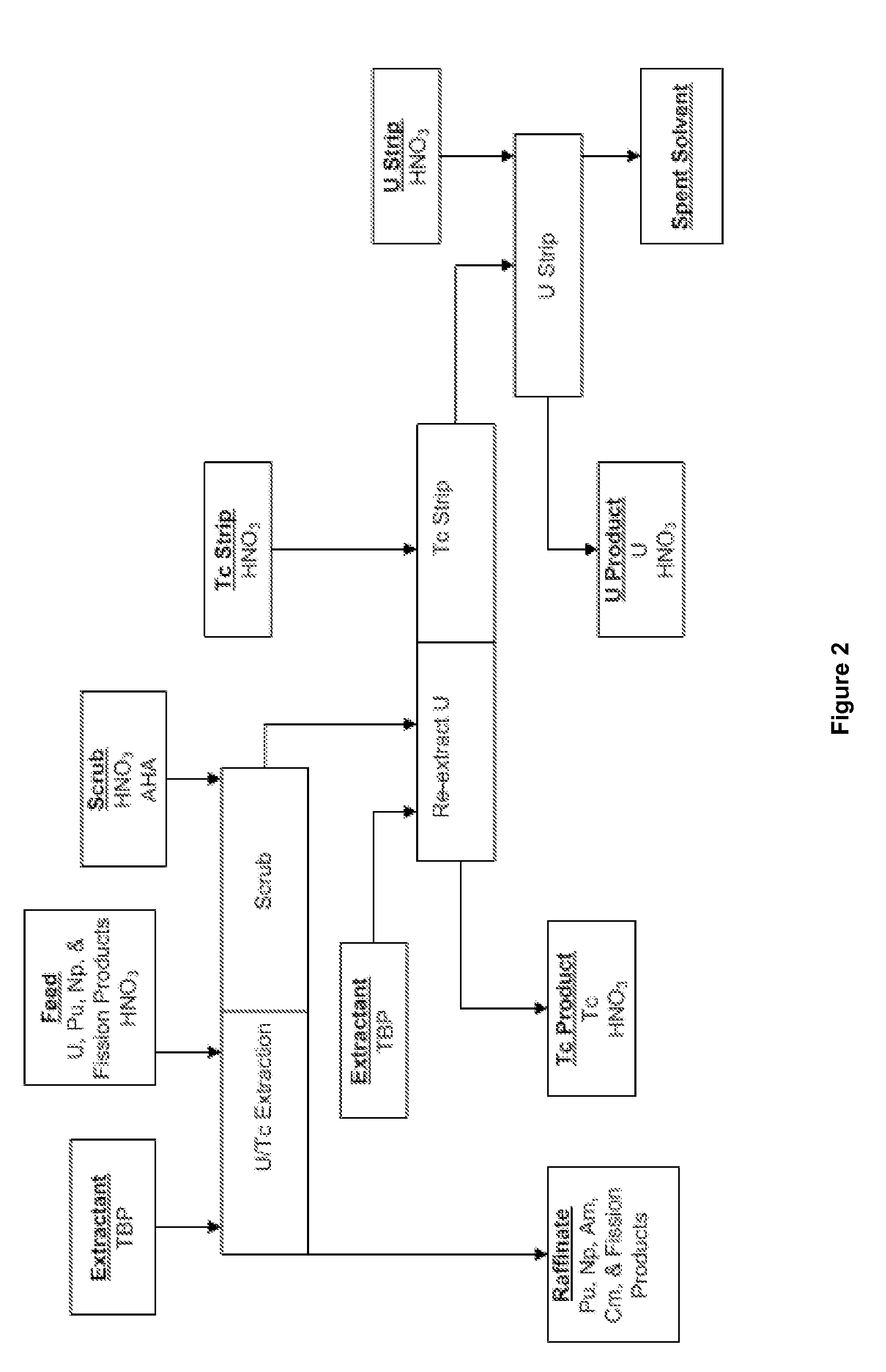

Methods of separating medical isotopes from uranium solutions

Provided are methods to separate an isotope from a first solution including uranium. The methods may include (a) cleaning the first solution to form a second solution including the uranium and a third solution including the isotope; (b) oxidizing the third solution to form an oxidized isotope; and (c) separating the oxidized isotope.

Owner:SHINE TECH LLC

Process for isolation and purification of astatine-211

InactiveUS20160053345A1Specific isotope recoveryTransuranic element compoundsBismuthAutomated method

Owner:UNIV OF WASHINGTON

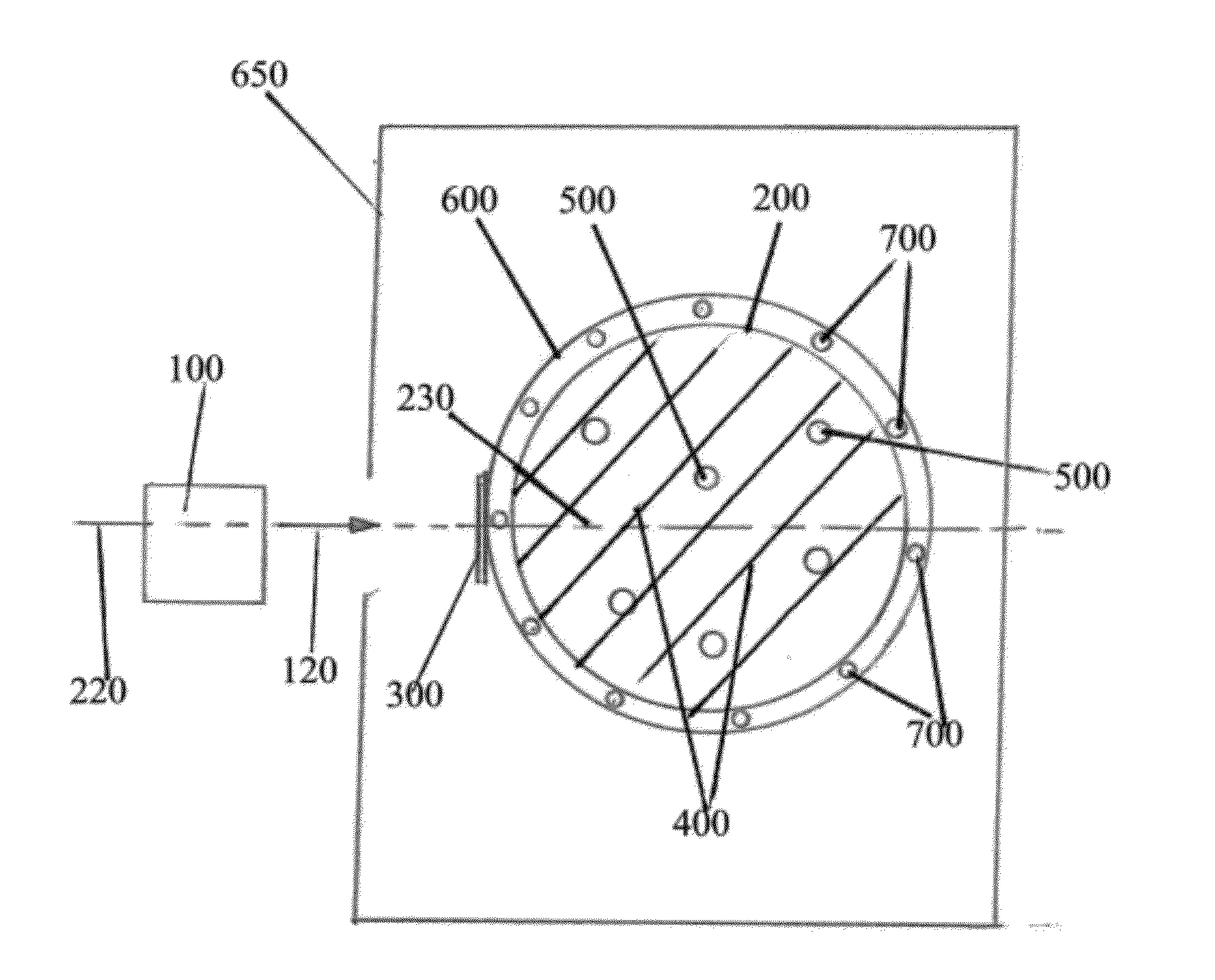

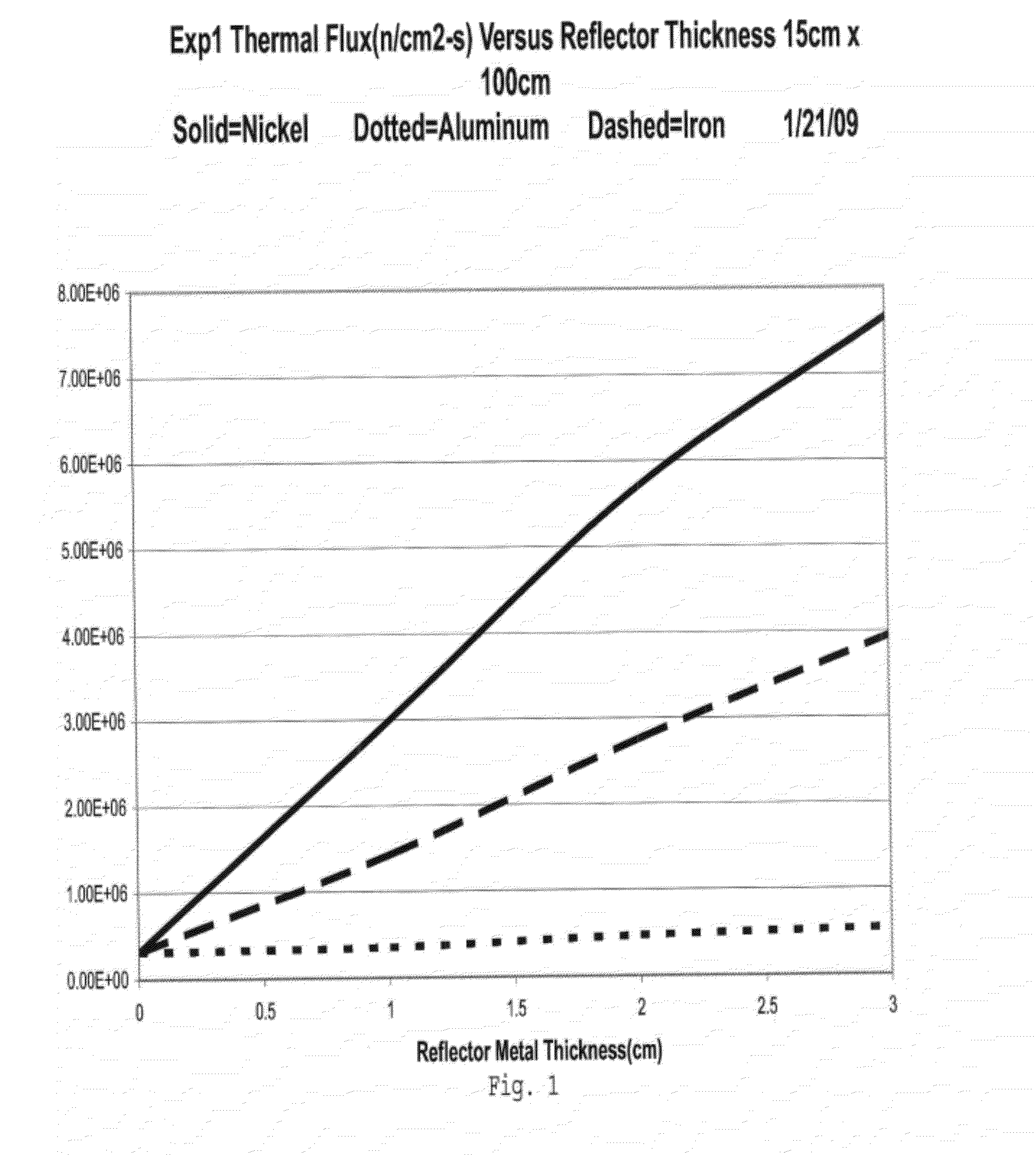

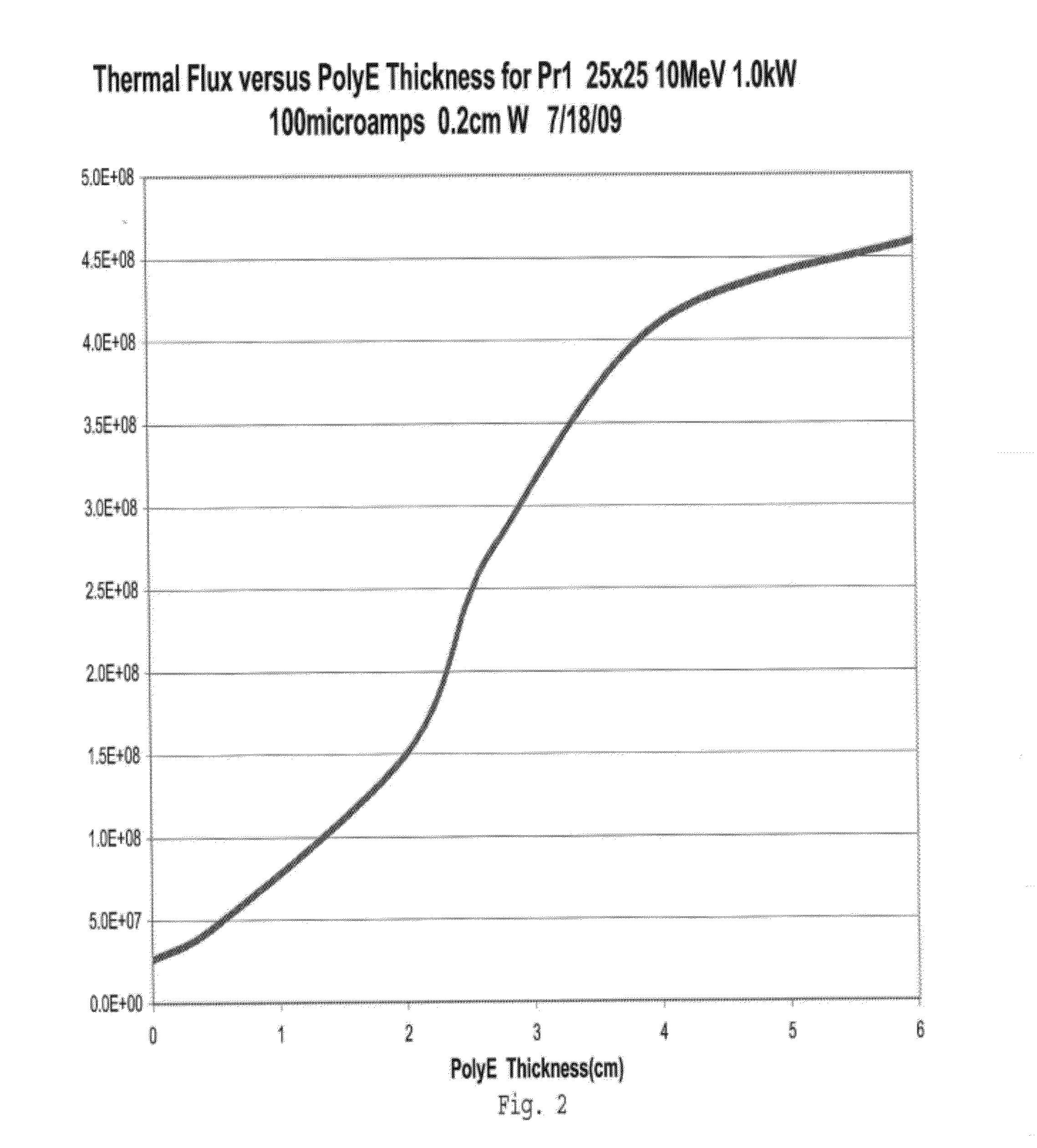

Very Large Enhancements of Thermal Neutron Fluxes Resulting in a Very Large Enhancement of the Production of Molybdenum-99 Including Spherical Vessels

InactiveUS20120121053A1Enhancement of the neutron fluxEnhanced neutron fluxSpecific isotope recoveryConversion outside reactor/acceleratorsThermal neutron fluxElectron

A large enhancement of neutron flux is realized when a primary target of D2O and H2O is contained in a vessel, is irradiated by an electron beam incident on a gamma converter and where the vessel is enclosed within a neutron reflector material including Nickel and Polyethylene. A very large enhancement of neutron flux is realized when a secondary target of LEU is mixed with the primary target resulting in a very large enhanced production of Molybdenum-99. The primary target and the secondary target is contained in cylindrical or spherical vessels.

Owner:SCHENTER ROBERT E +1

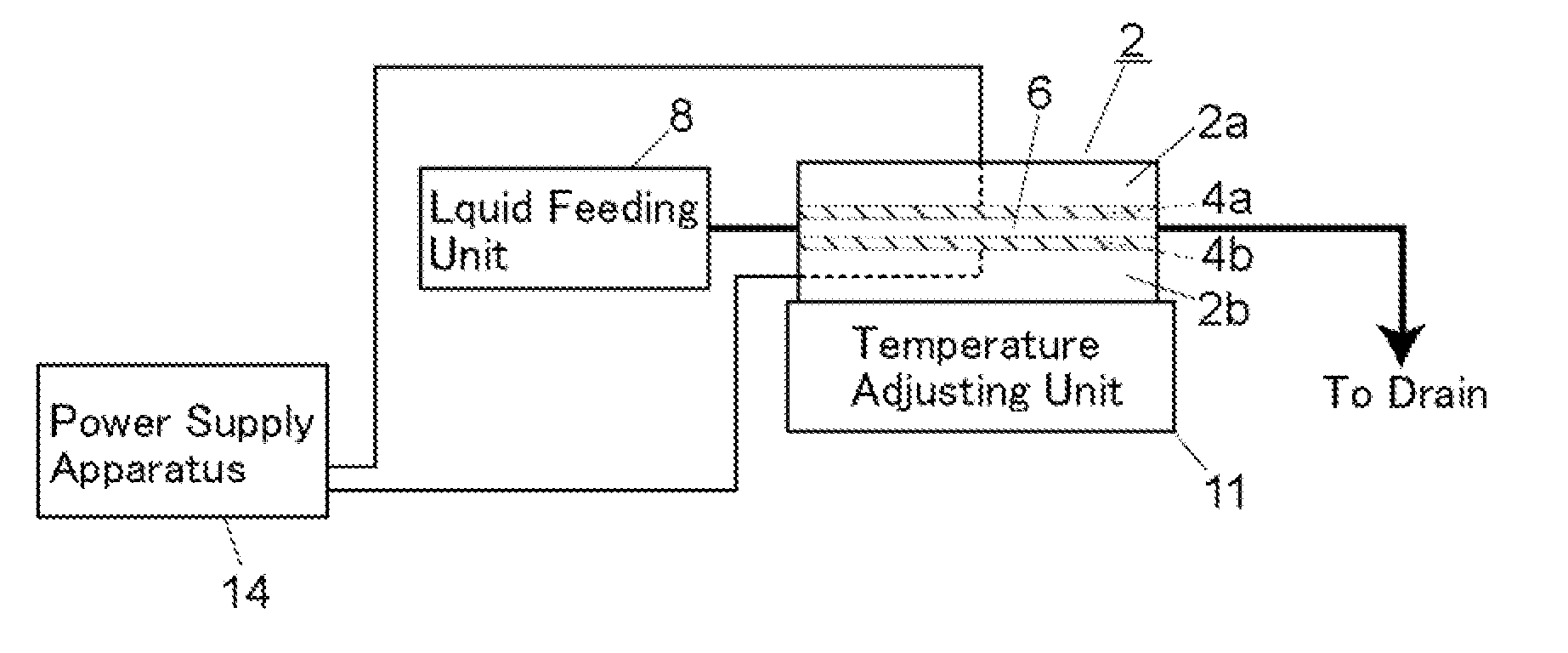

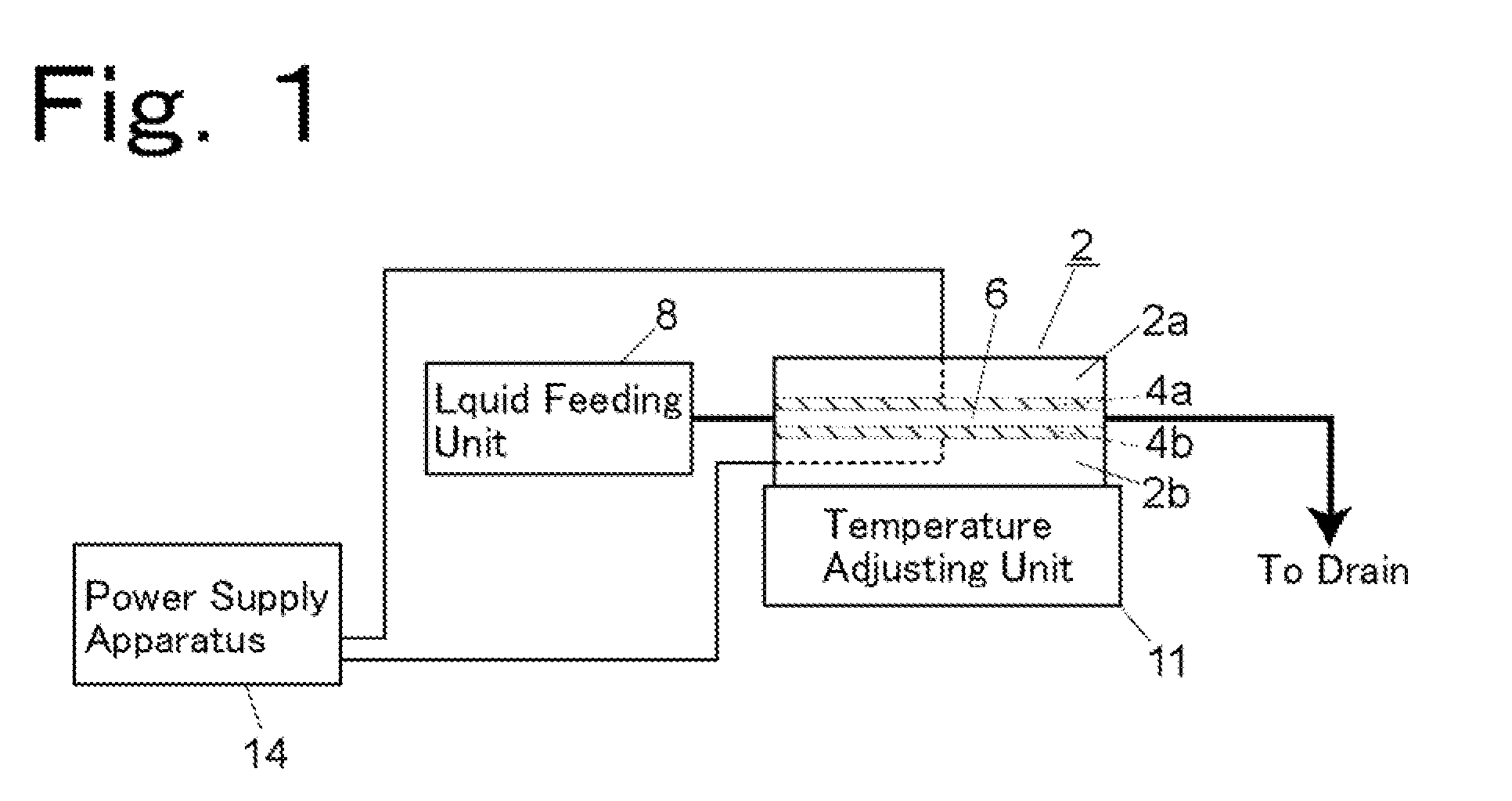

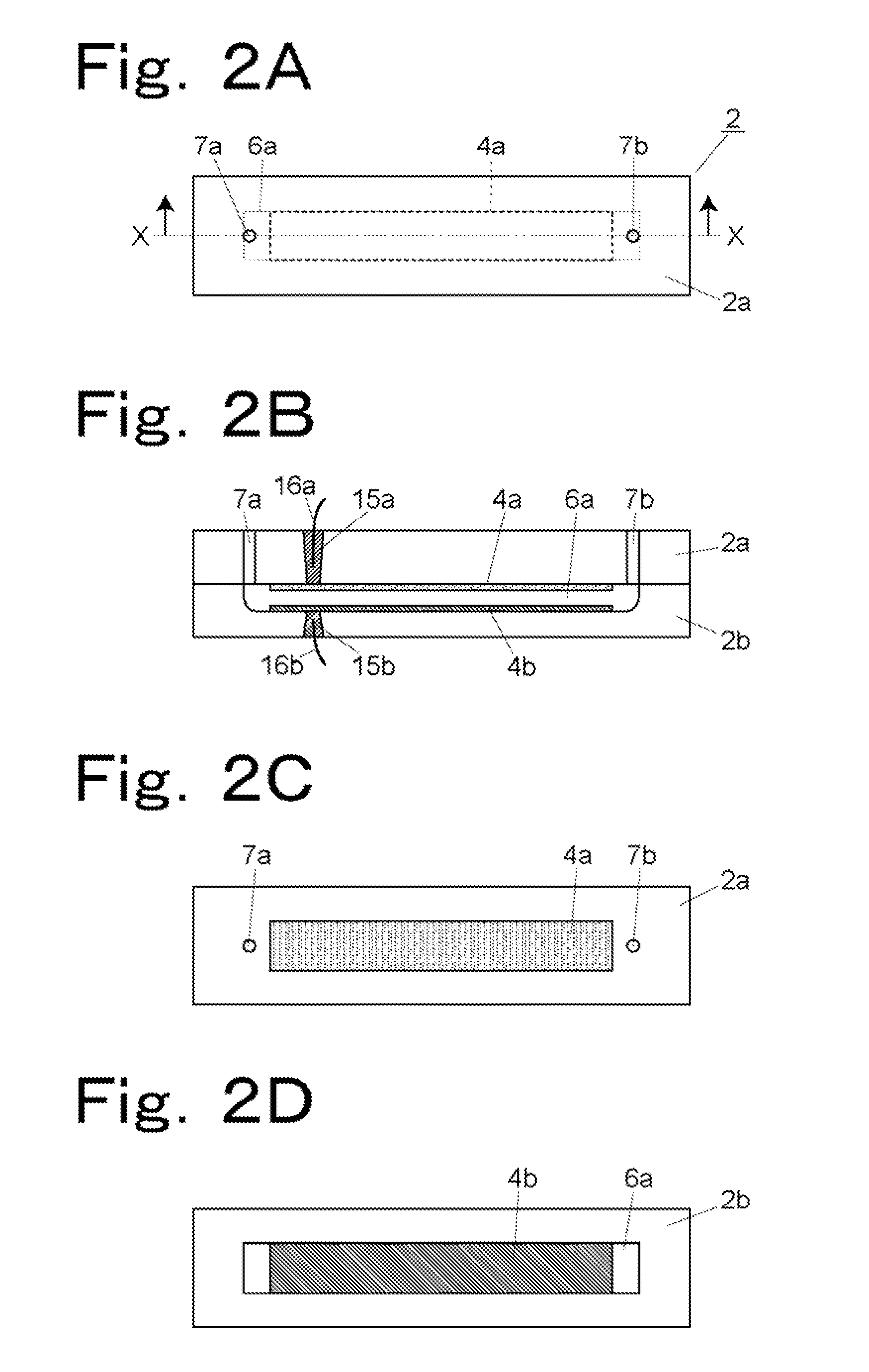

Flow cell, apparatus for concentrating radioactive fluoride anion, and method of concentrating radioactive fluoride anion

InactiveUS20110100840A1High concentration rateLiquid-tightness within the channel is highSpecific isotope recoveryElectrostatic separatorsHydrofluoric acidFluoride

A flowcell 2 is constituted of insulating substrates 2a and 2b. The two substrates 2a and 2b have been directly bonded to each other by a bonding method for attaining tenacious bonding, for example, anodic bonding or hydrofluoric acid bonding. A channel 6 has been formed at the interface between the substrates 2a and 2b. Part of the substrate 2a which faces the channel 6 has a carbon electrode 4a formed thereon by sintering a pasty carbon material, the electrode 4a extending along the channel 6. On the other hand, the substrate 2b has a groove 6a serving as the channel 6, and has an electrode 4b made of a metal film formed on a bottom surface of the groove 6a.

Owner:SHIMADZU CORP +1

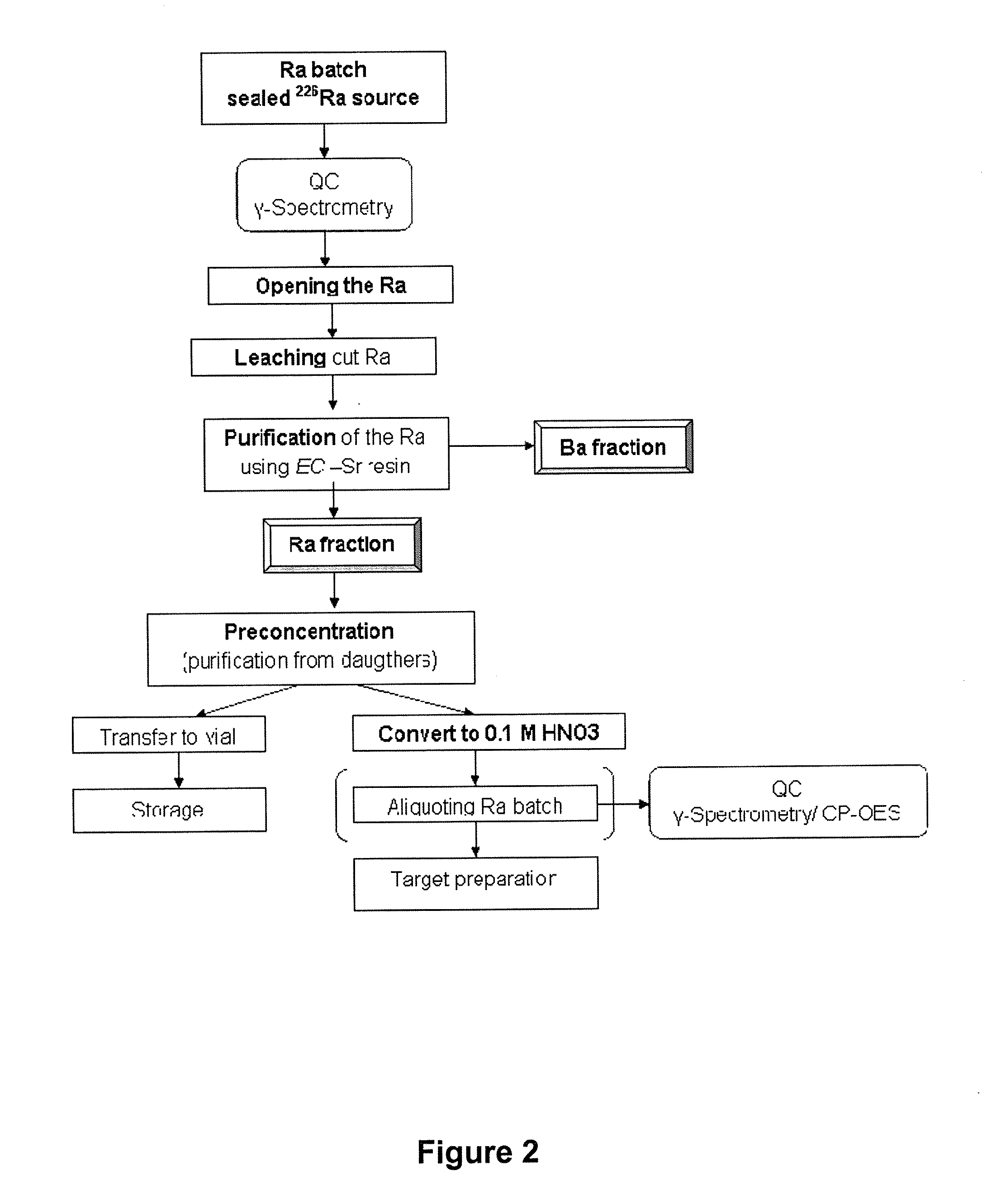

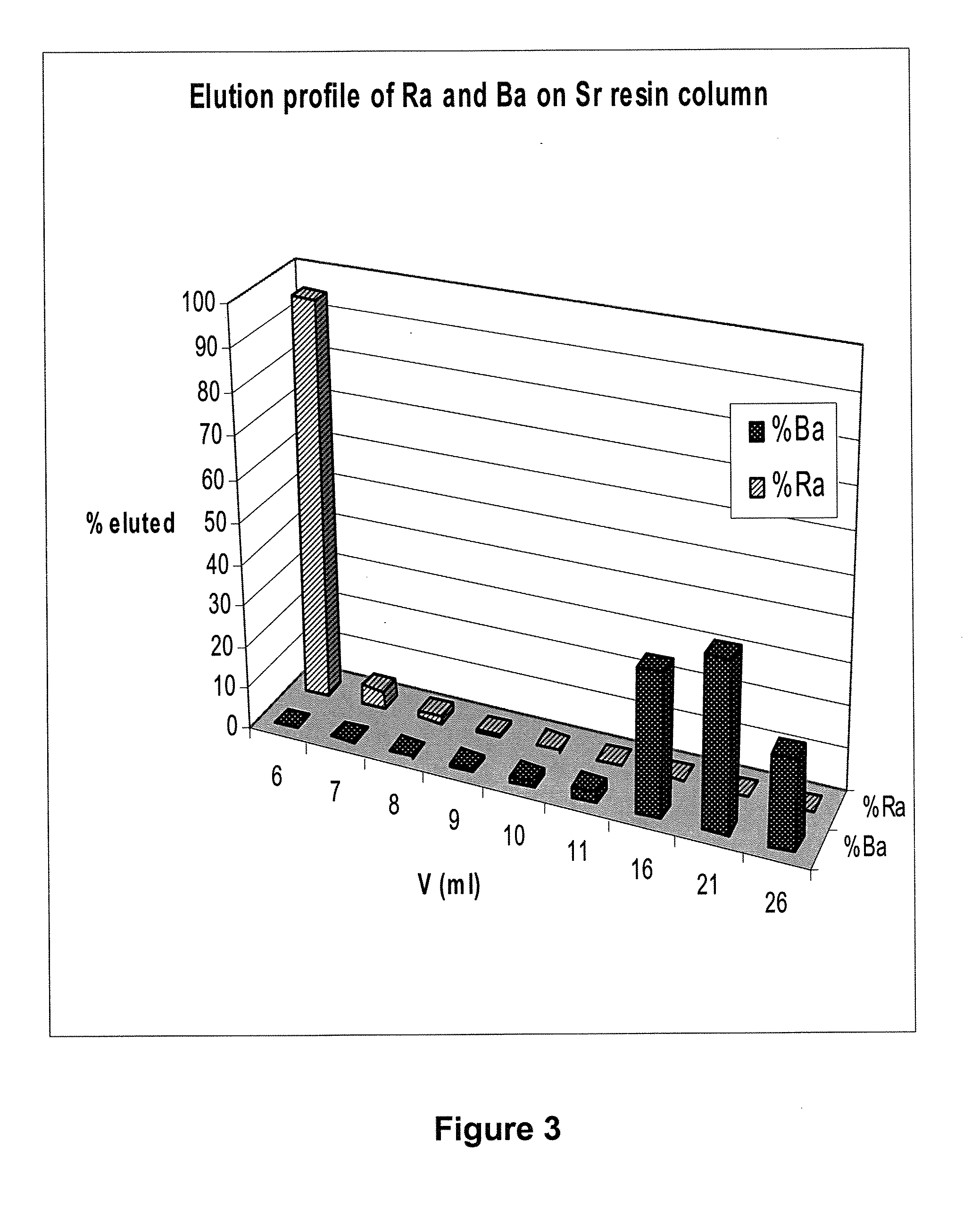

Method for the purification of radium from different sources

The present application is directed to a method for the purification of Radium, in particular 226Ra, for target preparation for an essentially pure 225Ac production from available radioactive sources, using an extraction chromatography in order to separate chemically similar elements such as Ba, Sr, and Pb from the desired Ra; wherein said extraction chromatography has an extractant system on the basis of a crown ether. The invention is further related to a method for recycling of 226Ra, for target preparation for 225Ac production from radium sources irradiated with accelerated protons (p,2n), after separation of the produced 225AC. In this method a combination of the above extraction chromatography and a cation exchange chromatography is used. The obtained 226Ra is essentially free of the following chemical contaminants consisting of Ag, Al, As, Be, Bi, Ca, Cd, Co, Cr, Cu, Fe, Ga, K, Li, Mg, Mn, Na, Ni, Pb, Sr, V, Zn, and Ba.

Owner:ACTINIUM PHARMA

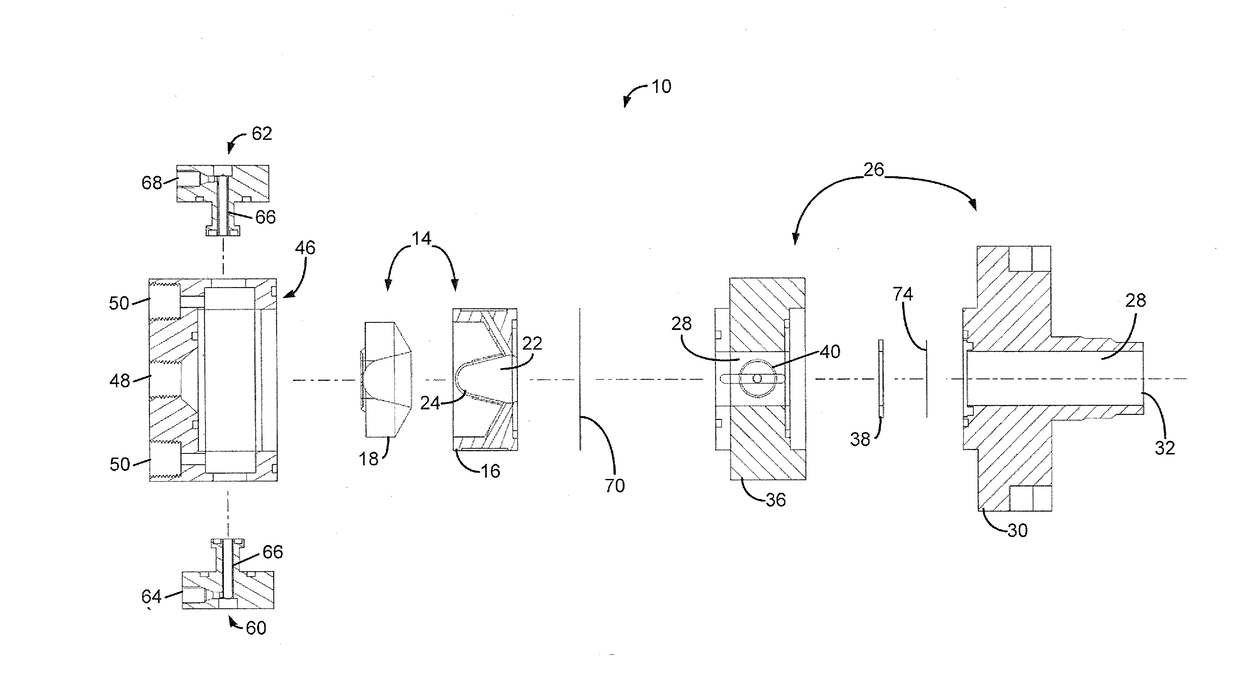

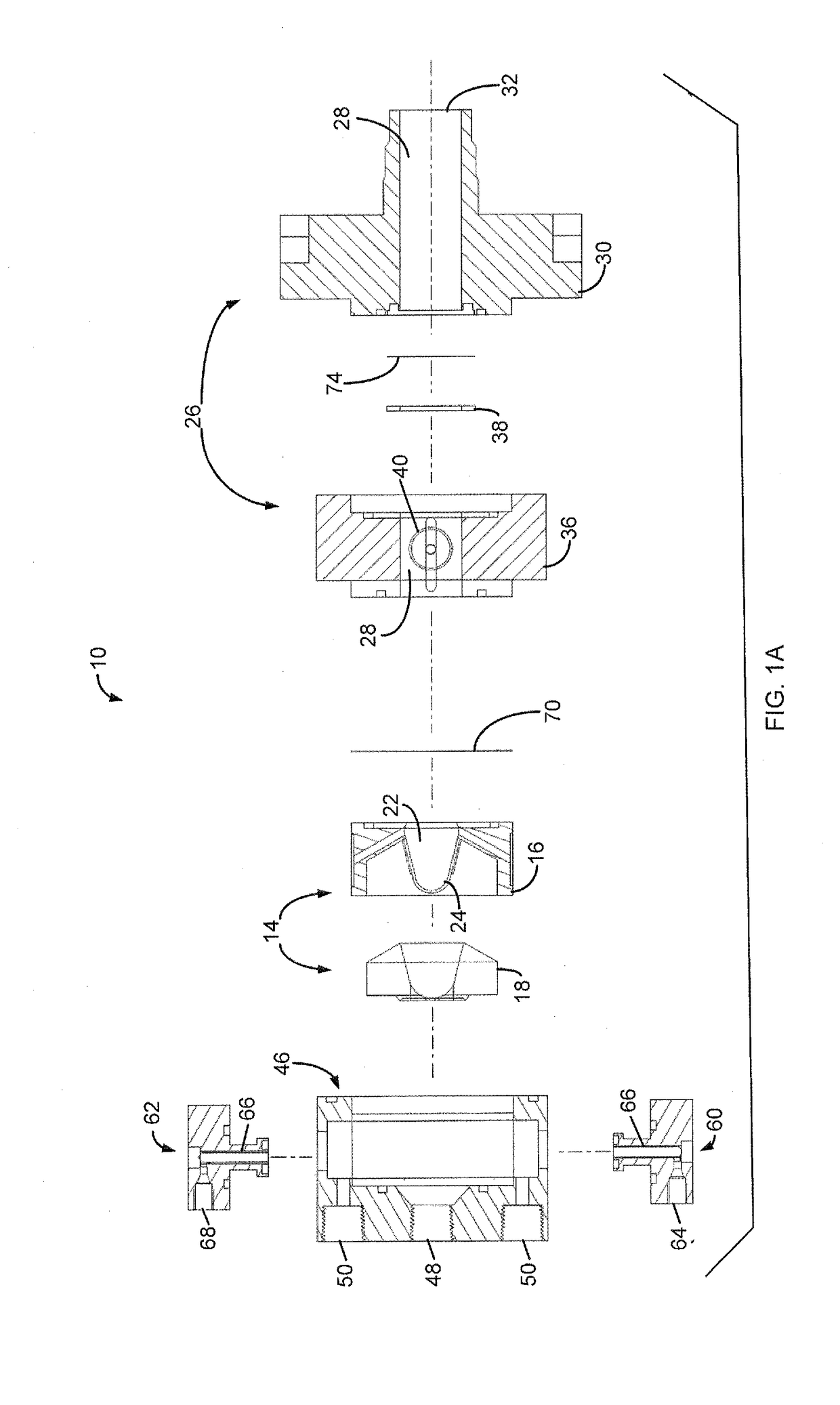

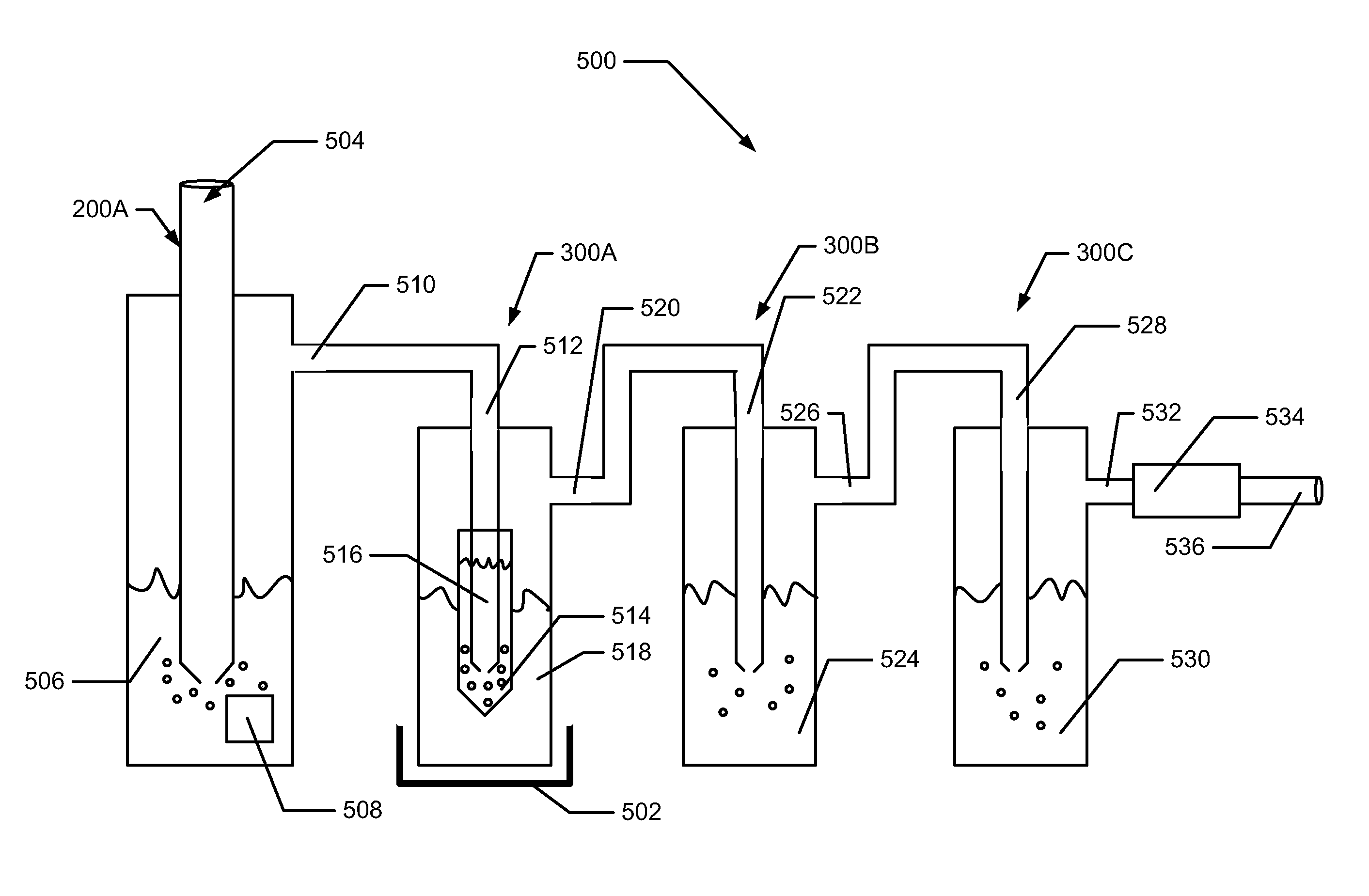

Solution target for cyclotron production of radiometals

ActiveUS20170221594A1Improve heat transfer characteristicsMaximize heat transferIon-exchange process apparatusSpecific isotope recoveryParticle beamProton

Methods of producing and isolating 68Ga, 89Zr, 64Cu, 63Zn, 86Y, 61Cu, 99mTc, 45Ti, 13N, 52Mn, or 44Sc and solution targets for use in the methods are disclosed. The methods of producing 68Ga, 89Zr, 64Cu, 63Zn, 86Y, 61Cu, 99mTc, 45Ti, 13N, 52Mn, or 44Sc include irradiating a closed target system with a proton beam. The closed target system can include a solution target. The methods of producing isolated 68Ga, 89Zr, 64Cu, 63Zn, 86Y, 61CU, 99mTC, 45-Ti, 52Mn, or 44Sc by ion exchange chromatography. An example solution target includes a target body including a target cavity for receiving the target material; a housing defining a passageway for directing a particle beam at the target cavity; a target window for covering an opening of the target cavity; and a coolant gas flow path disposed in the passageway upstream of the target window.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC +1

Method of producing radionuclides

ActiveUS20130170593A1Reduce exposureReduce radiation exposureSpecific isotope recoveryConversion outside reactor/acceleratorsNeutron irradiationRadioactive decay

The invention relates to a method of producing radionuclides. According to the method, a target medium comprising at least a target nuclide material is irradiated in an irradiation zone with neutron irradiation. Radionuclides form in the target nuclide material as a result of the irradiation, and at least some of the formed radionuclides are ejected from the target nuclide material. The ejected radionuclides are then captured and collected in a carbon-based recoil capture material which does not have an empty cage structure at crystallographic level.

Owner:SOUTH AFRICA NUCLEAR ENERGY +1

Radioactive fluorine anion concentrating device and method

InactiveUS20100101943A1Large specific surface areaLower the volumeSpecific isotope recoveryCellsMetallic materialsFluoride

A radioactive fluoride anion concentrating device capable of concentrating 18F− ions speedily and efficiently. A flow cell (11) is composed of a metal plate electrode (21), an insulating sheet (23) and a carbon plate electrode (25) located so that the sides of electrodes may be opposed to each other with the insulating sheet (23) inserted between them. An example of the plate metal plate electrode (21) is obtained by forming a film of metallic material on an insulation plate, and an example of the insulating sheet (23) is a PDMS from which a groove being a channel (26) having a thickness of ≦500 μm is cut out. The thickness of the sheet is desirably about 100 μm. The upper and lower sides of the flow cell (11) are fixed by fixing jigs (27) and (29).

Owner:SHIMADZU CORP +1

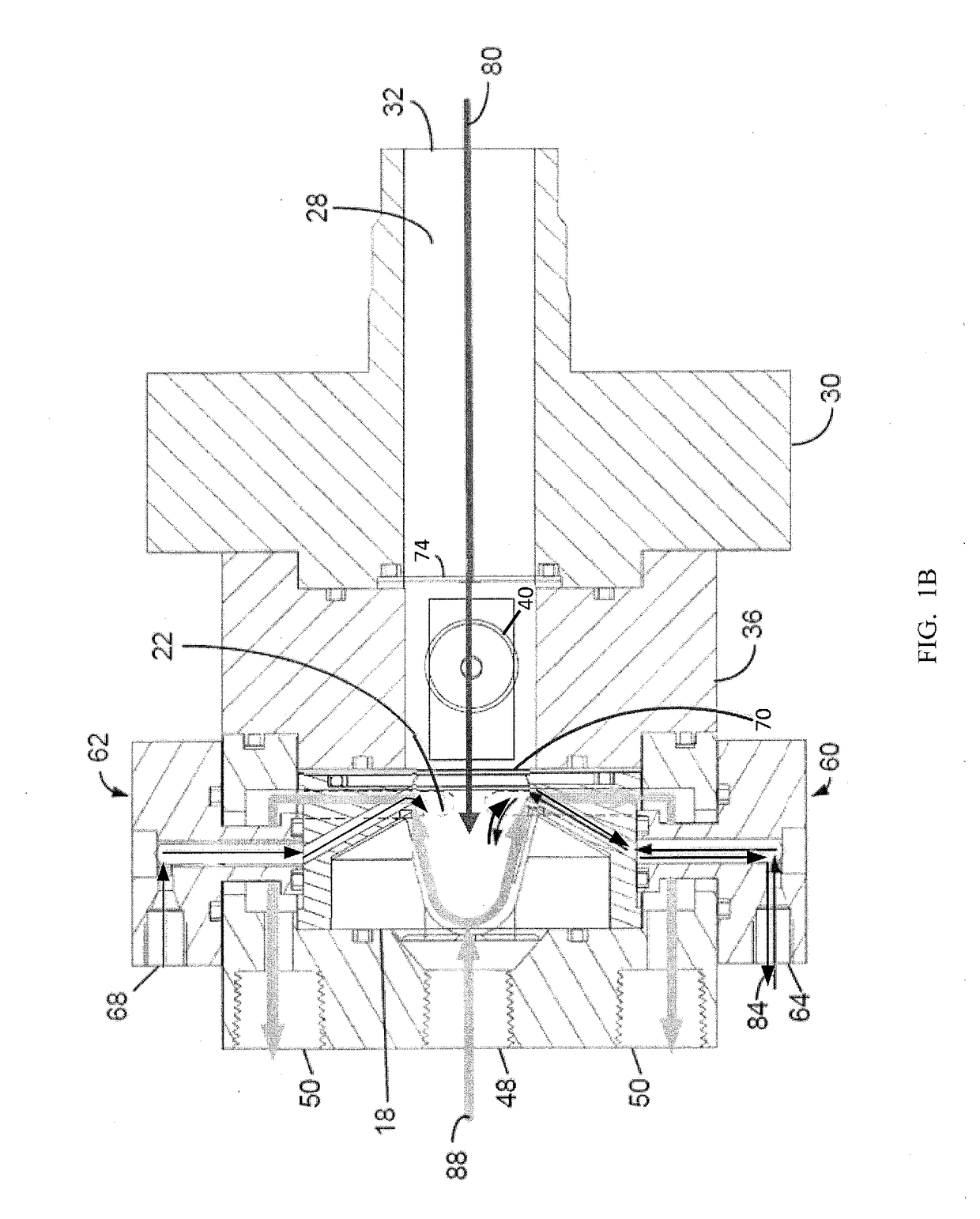

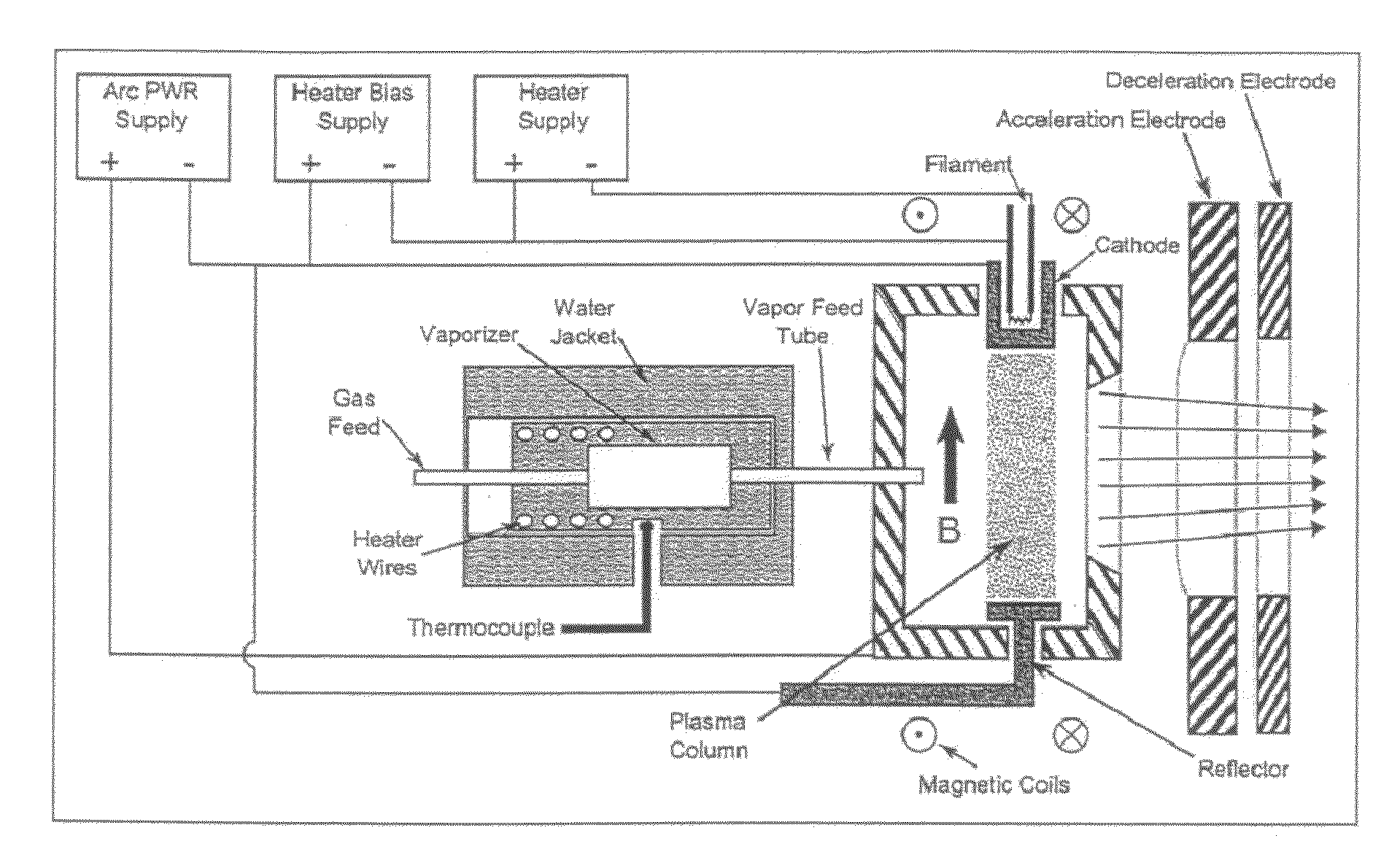

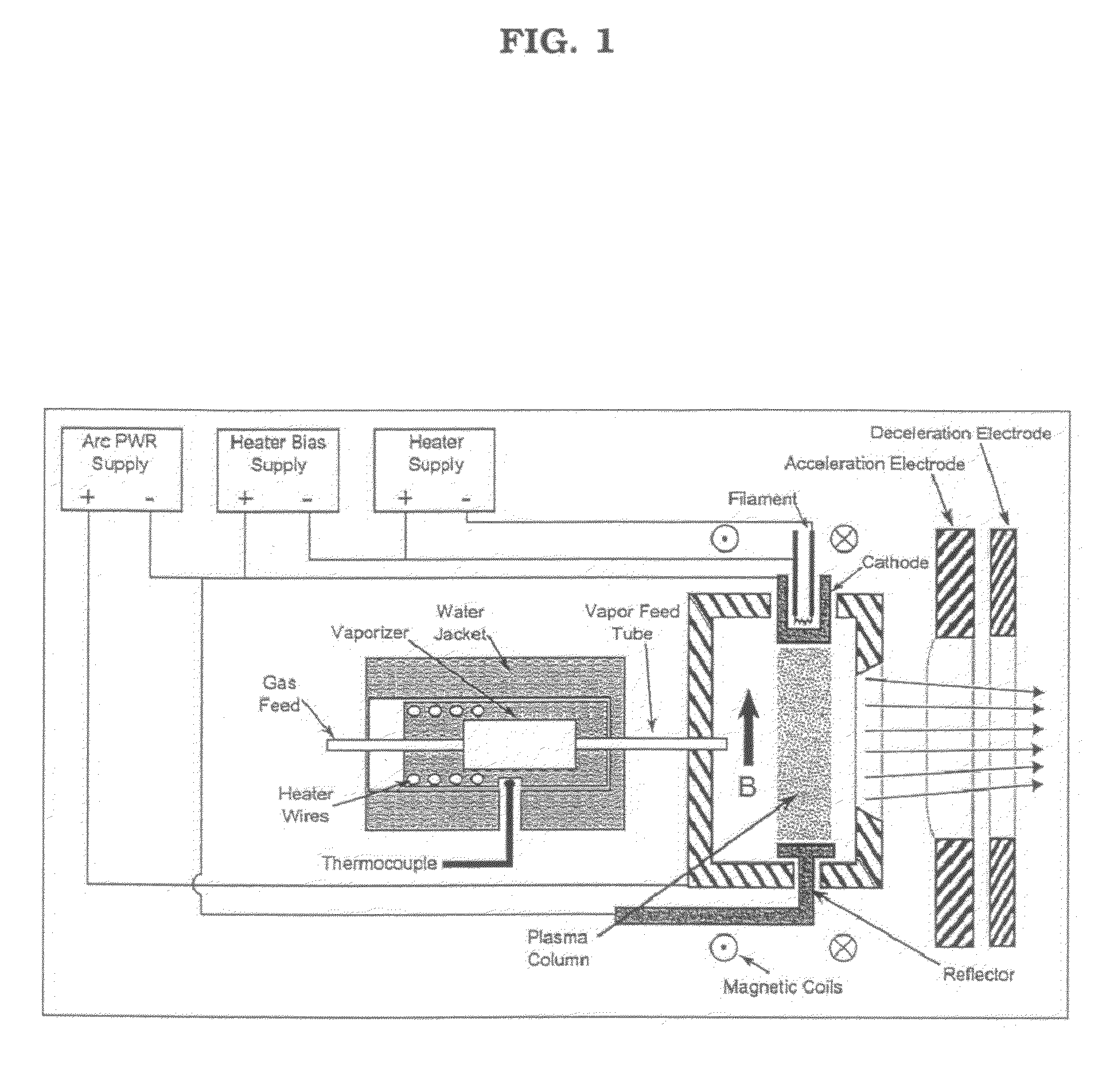

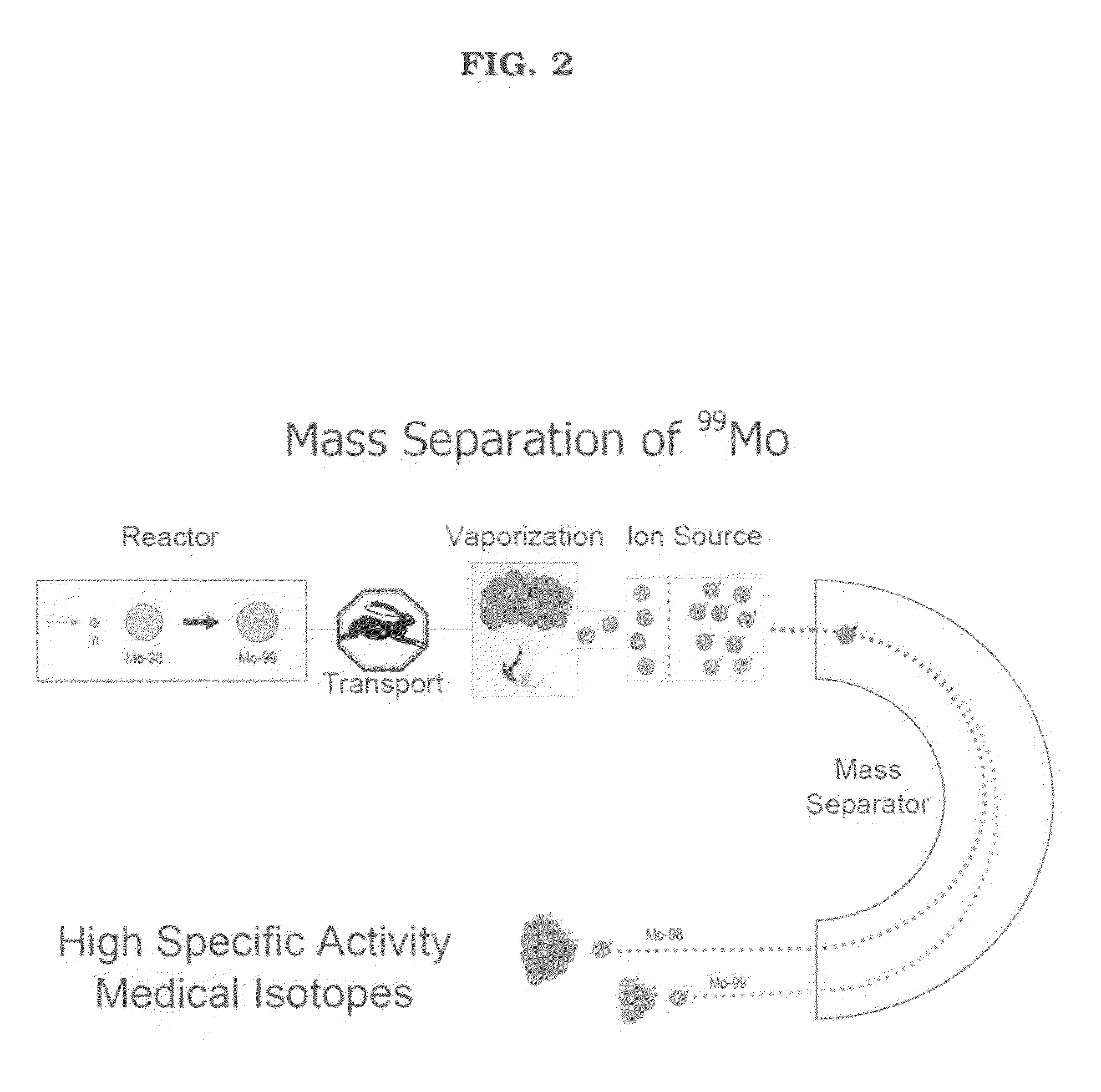

Method and apparatus for isolating the radioisotope molybdenum-99

InactiveUS20110079108A1High activitySpecific isotope recoveryChemical/physical/physico-chemical processesIsotopeRadioactive decay

A method of isolating 99Mo produced using a (n,γ) reaction according to example embodiments may include vaporizing a source compound containing 98Mo and 99Mo. The vaporized source compound may be ionized to form ions containing 98Mo and 99Mo. The ions may be separated to isolate the ions containing 99Mo. The isolated ions containing 99Mo may be collected with a collector. Accordingly, the isolated 99Mo may have a relatively high specific radioactivity and, in turn, may be used to produce the diagnostic radioisotope, 99mTc, through radioactive decay.

Owner:ADVANCED APPLIED PHYSICS SOLUTIONS

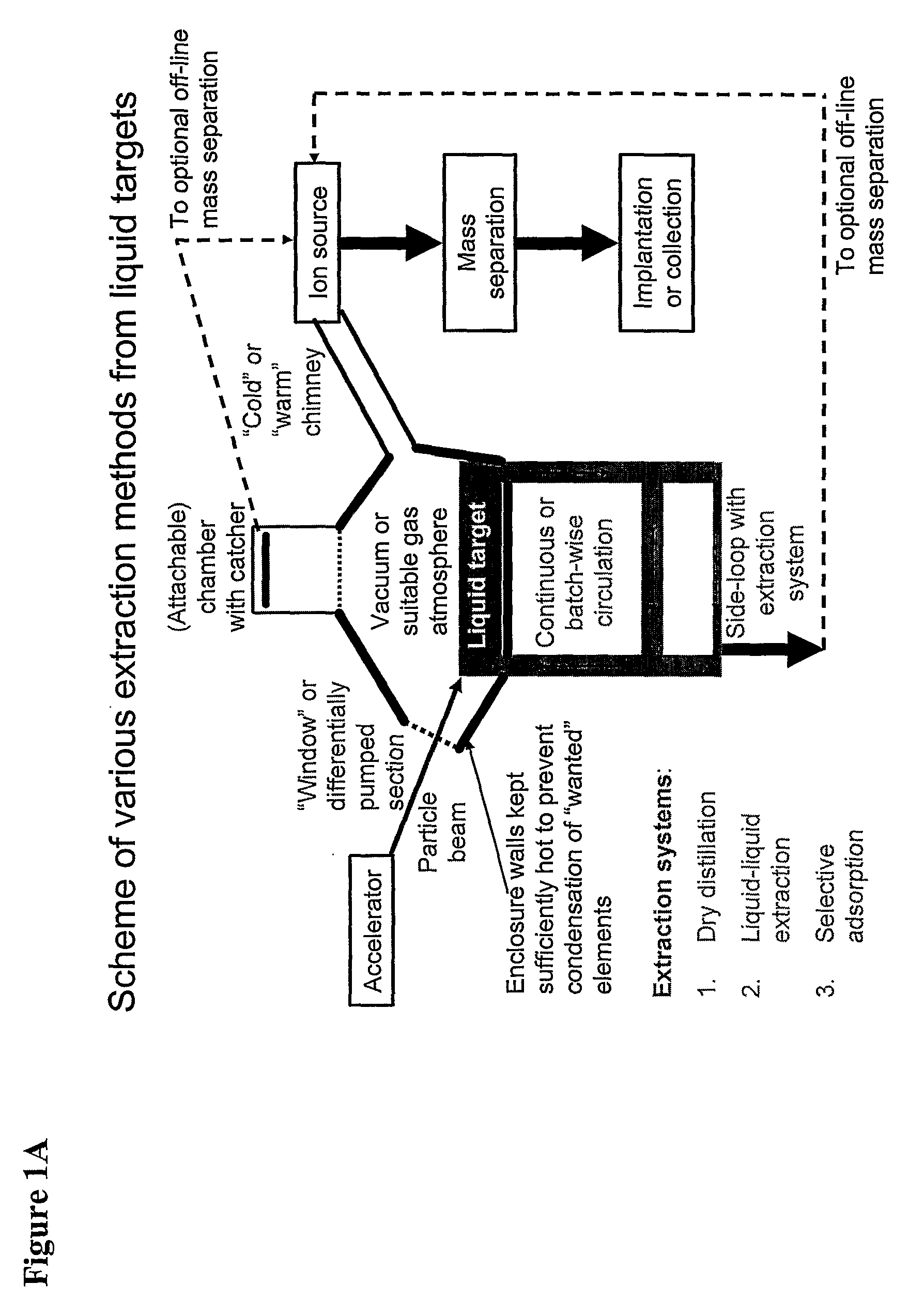

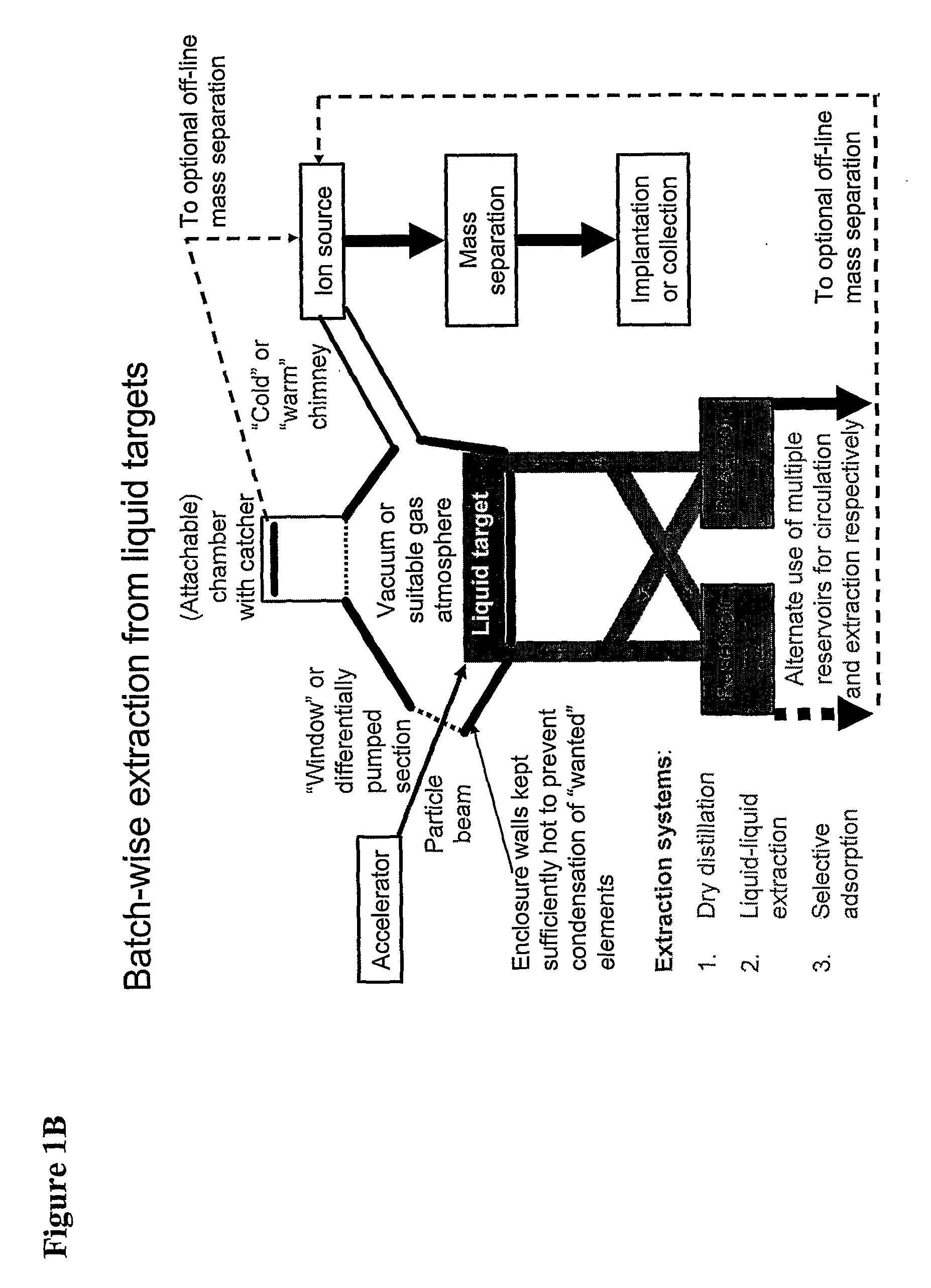

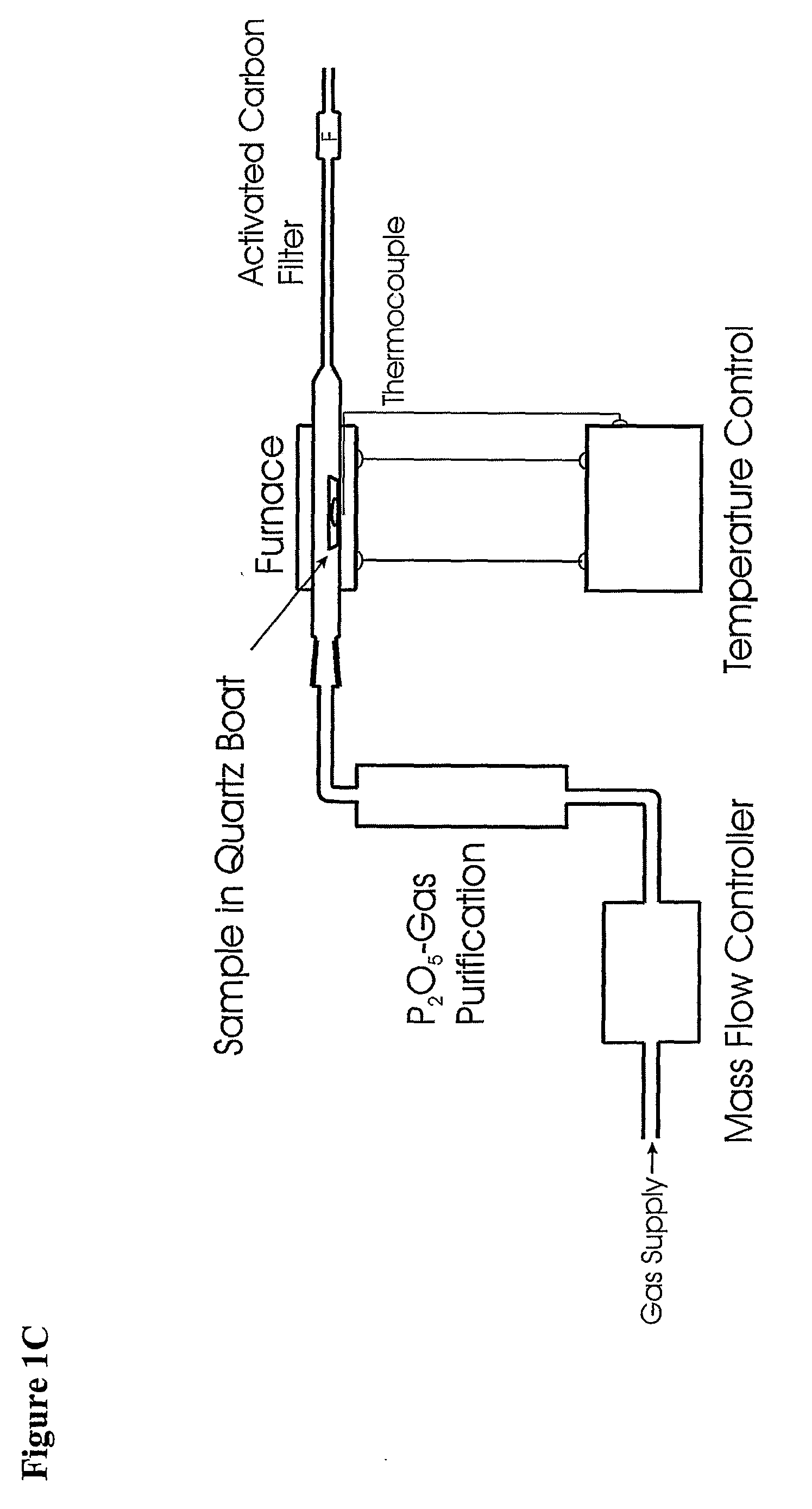

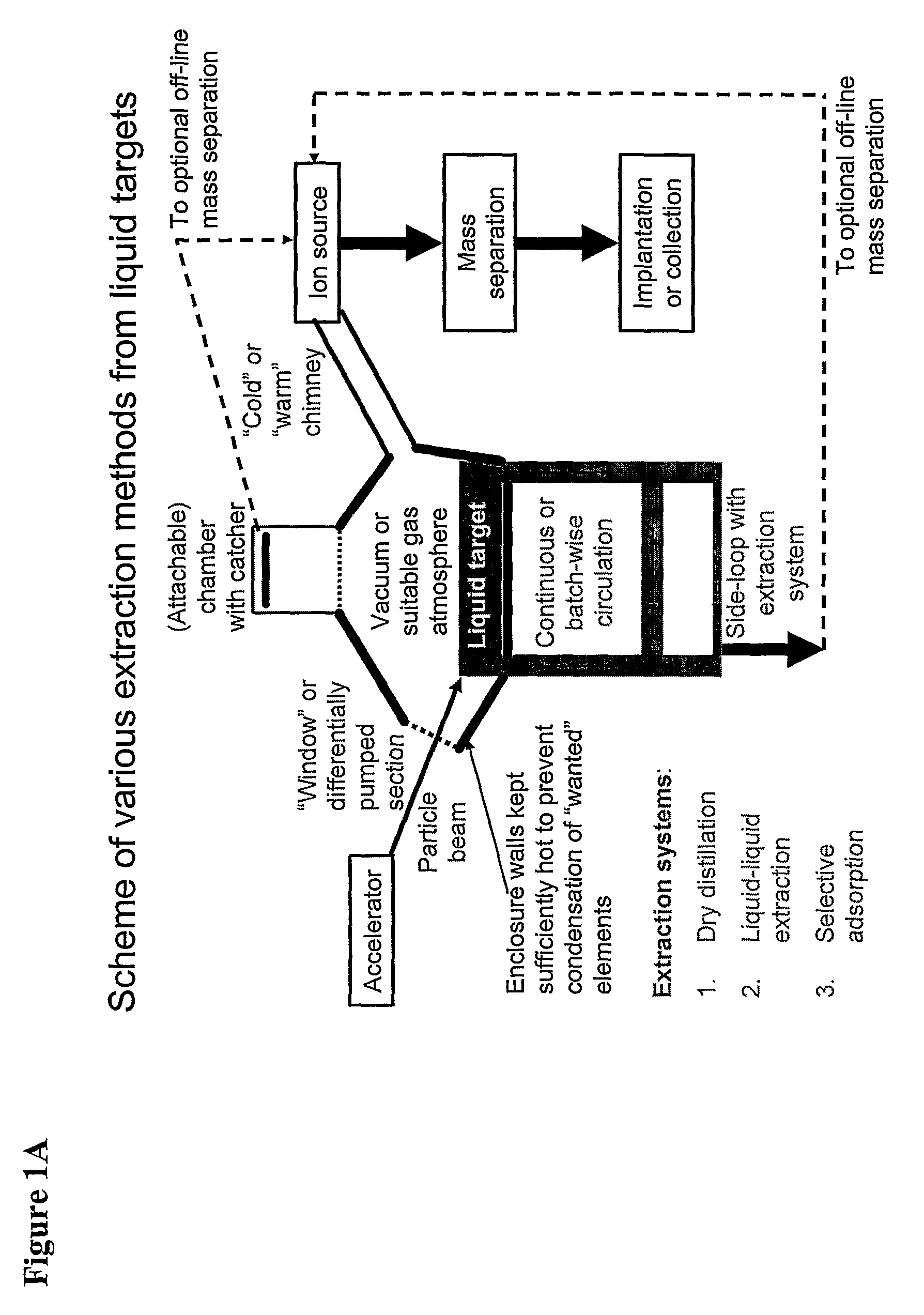

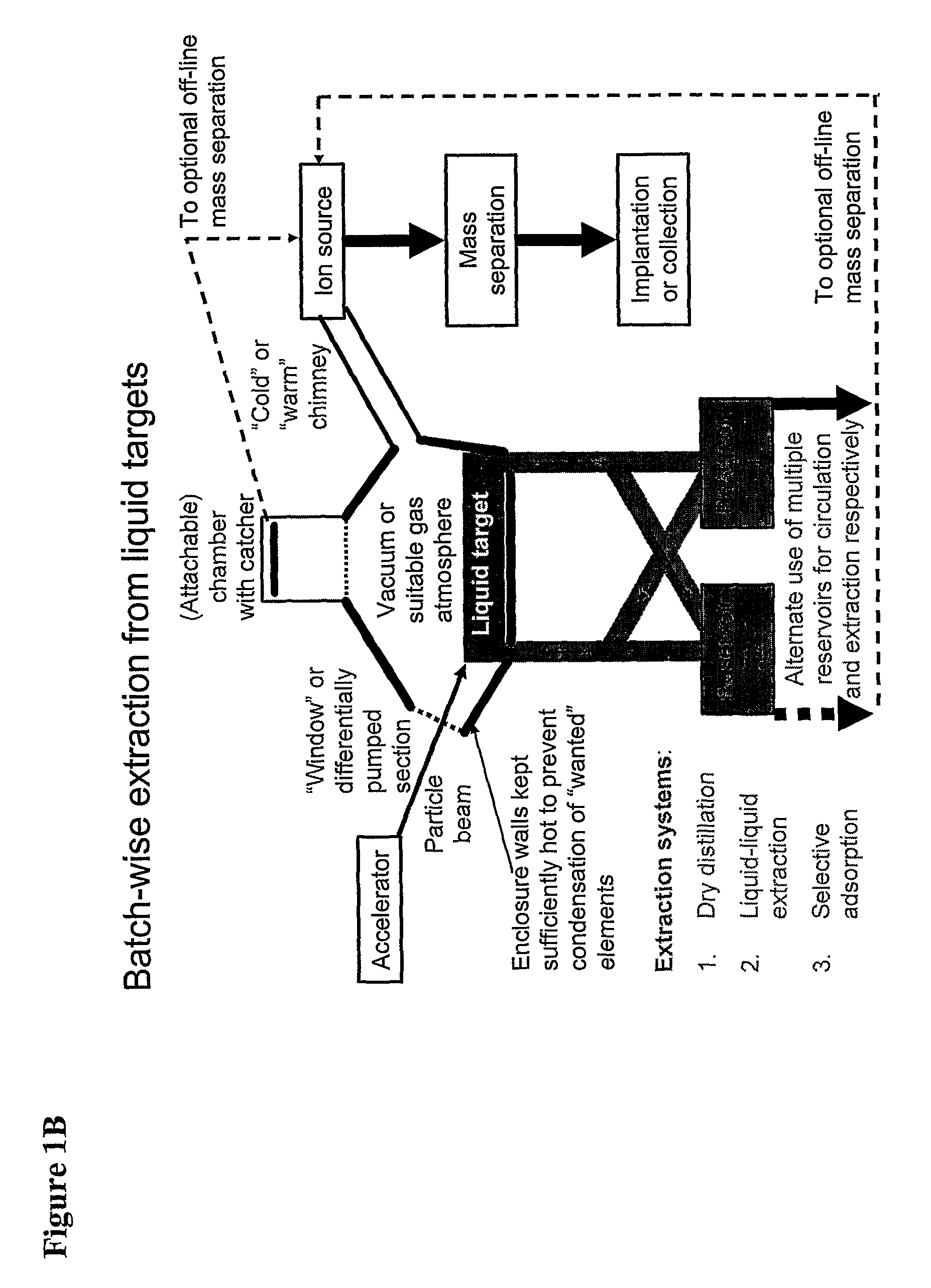

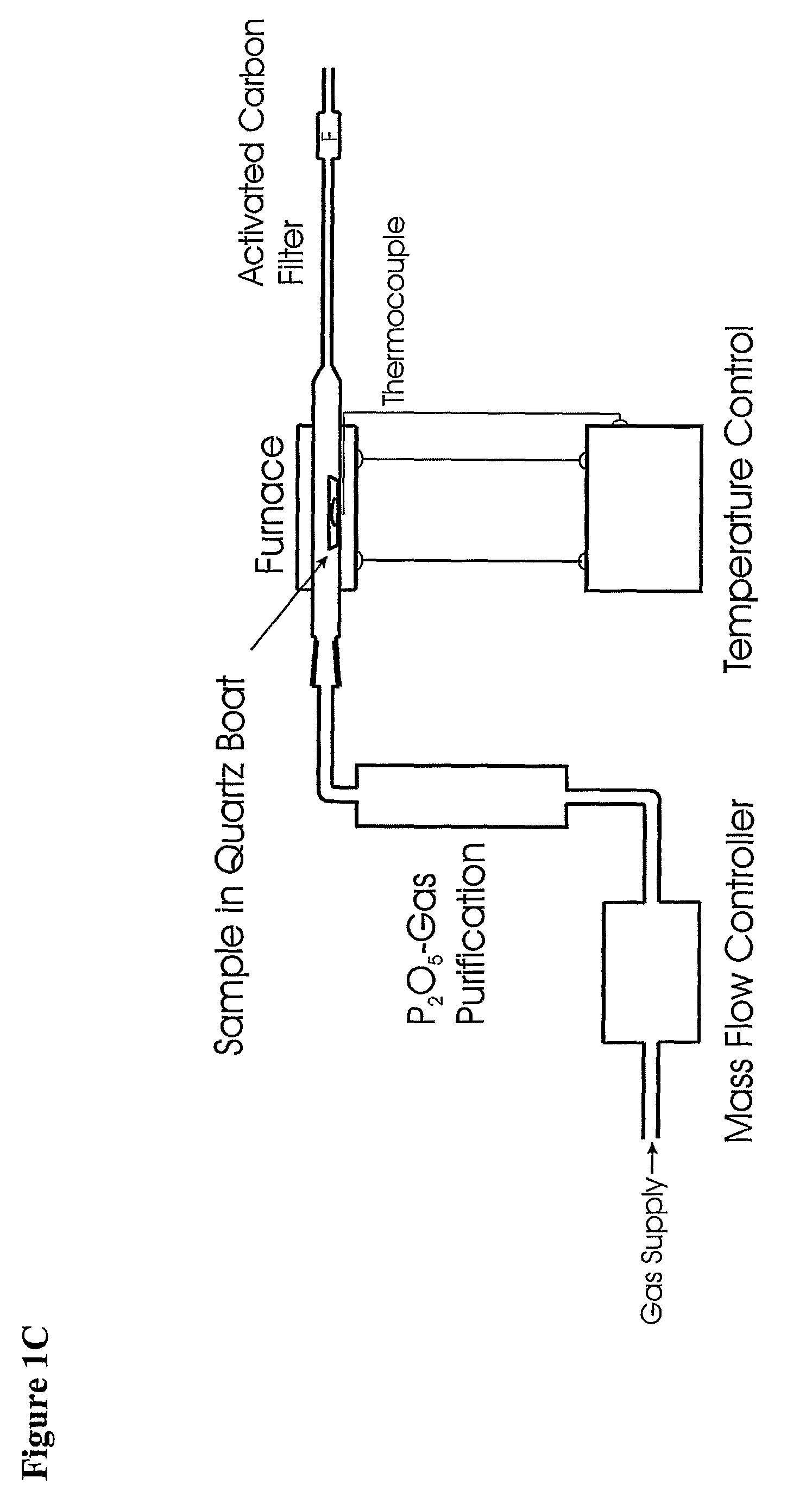

Method for production of radioisotope preparations and their use in life science, research, medical application and industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimized individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

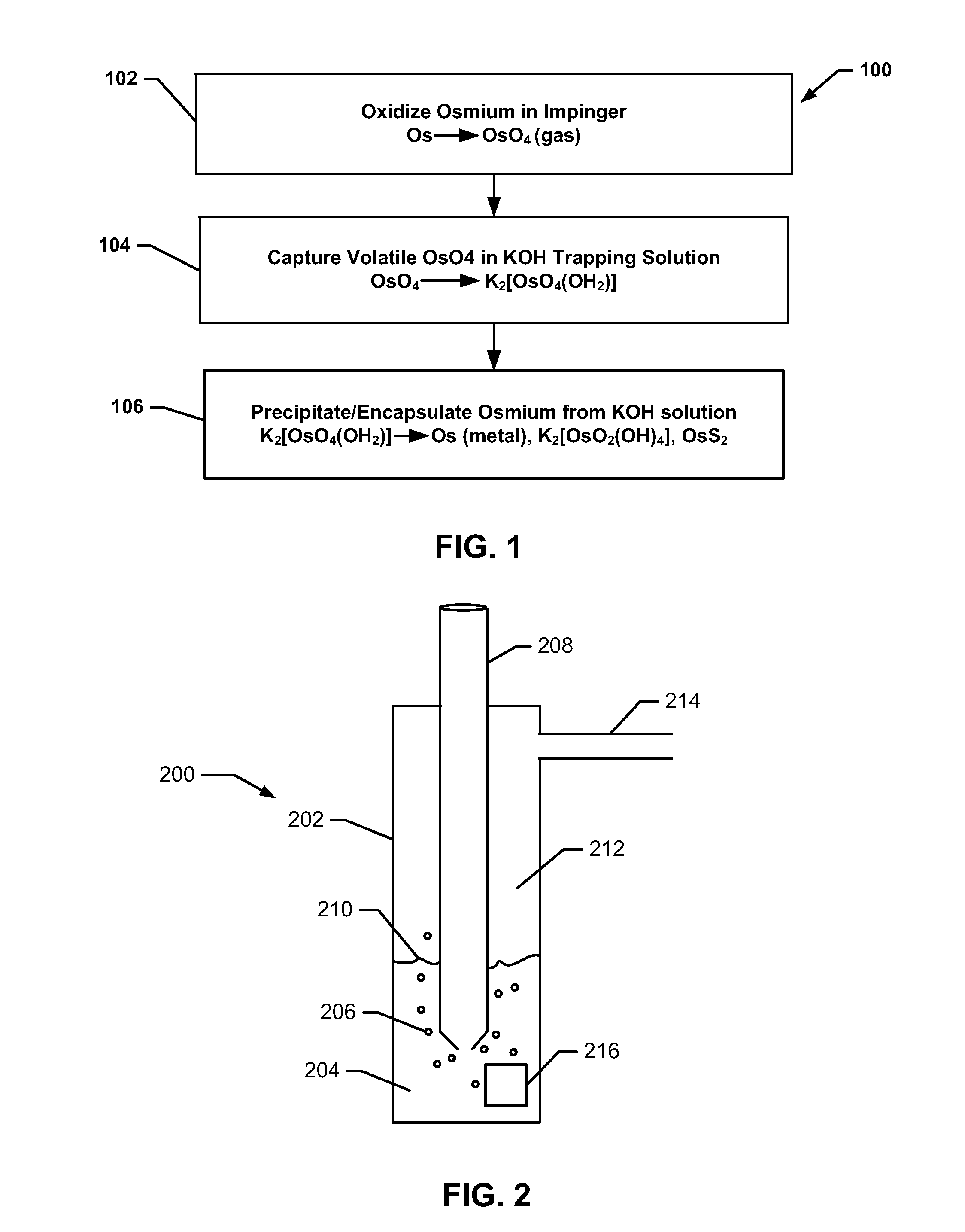

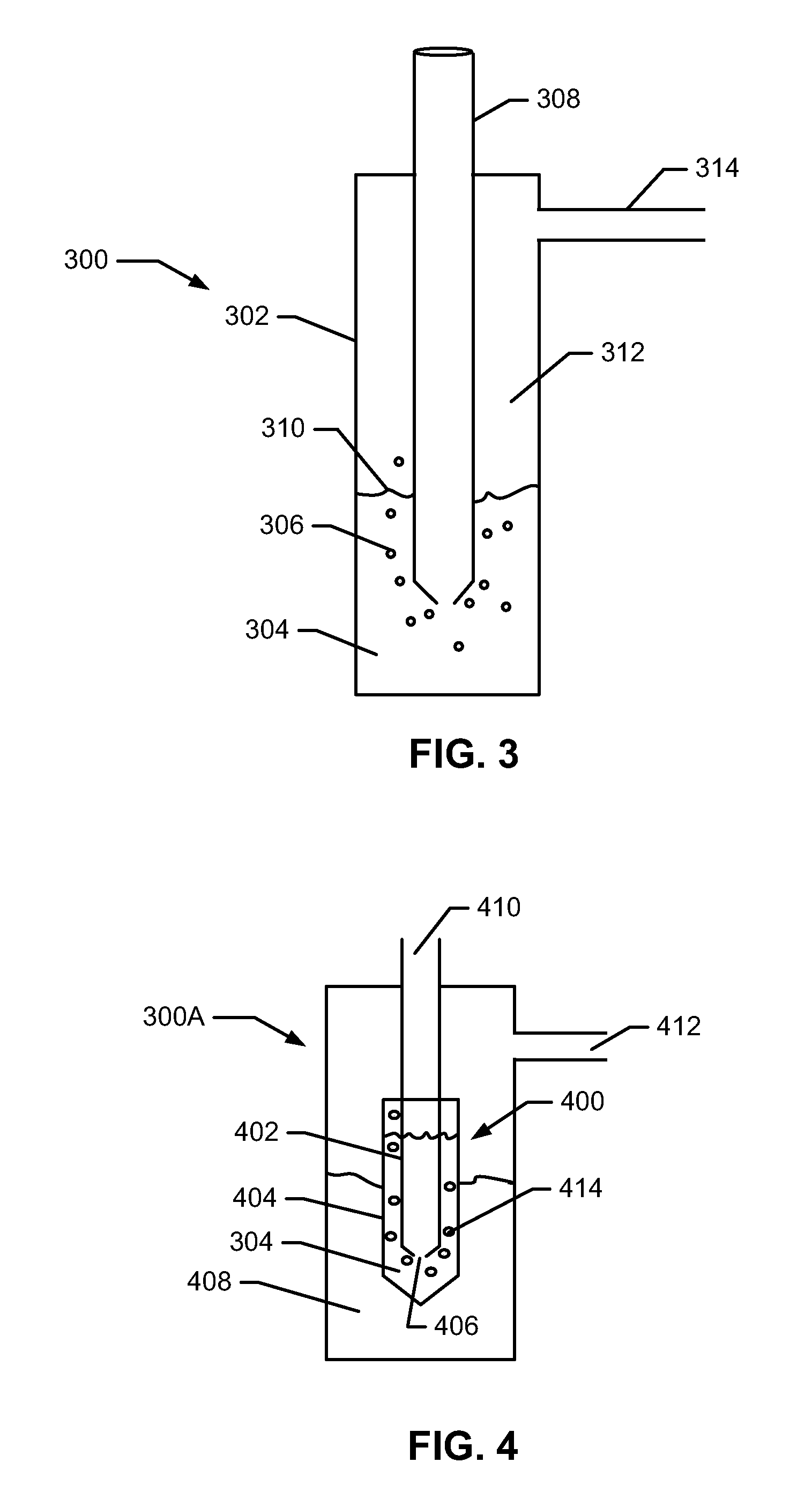

Method for separation of chemically pure os from metal mixtures

InactiveUS20130108525A1Minimize exposurePossibility is limitedSpecific isotope recoveryFrom normal temperature solutionsMetalOsmium

Owner:UNIVERSITY OF MISSOURI

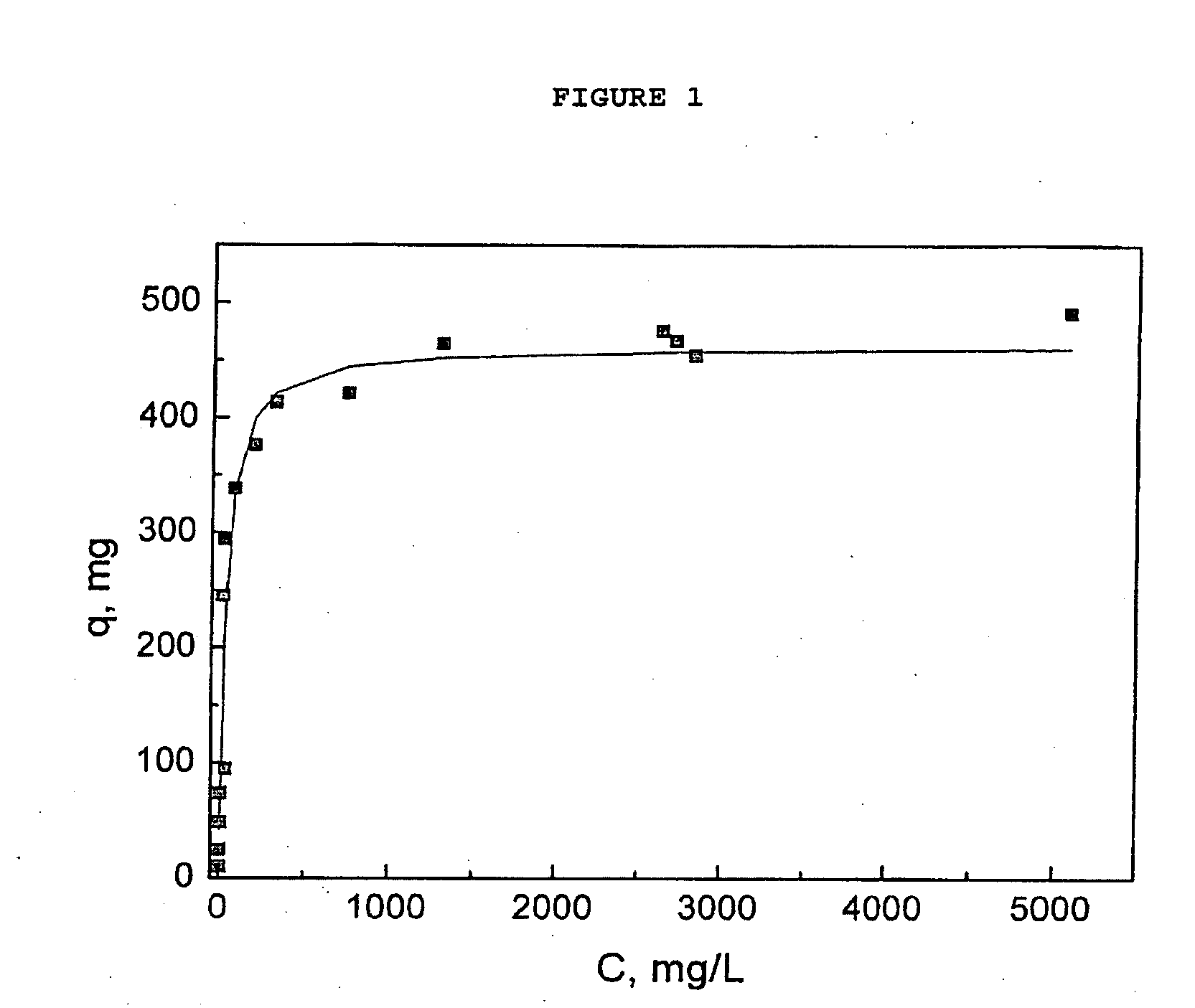

Adsorbents for Radioisotopes, Preparation Method Thereof, and Radioisotope Generators Using the Same

InactiveUS20090277828A1Improve physical stabilityImprove adsorption capacitySpecific isotope recoverySulfate/bisulfate preparationSorbentIsotope

Disclosed is a novel adsorbent for use in a 99Mo / 99mTc generator, which is a medical diagnostic radioisotope generator, and in a 188W / 188Re generator, which is a therapeutic radioisotope generator. The adsorbent composed of sulfated alumina or alumina-sulfated zirconia exhibits adsorption capacity superior to that of conventional adsorbents, and is stable and is thus loaded in a dry state in an adsorption column so that the radioisotope 99Mo or 188W can be adsorbed. Thus, it is possible to miniaturize the column, and such a miniaturized column is small, convenient to use, and highly efficient, and extracts a radioisotope satisfying the requirements for pharmaceuticals, and thus can be useful for radioisotope generators extracting 99mTc or 188Re.

Owner:KOREA ATOMIC ENERGY RES INST

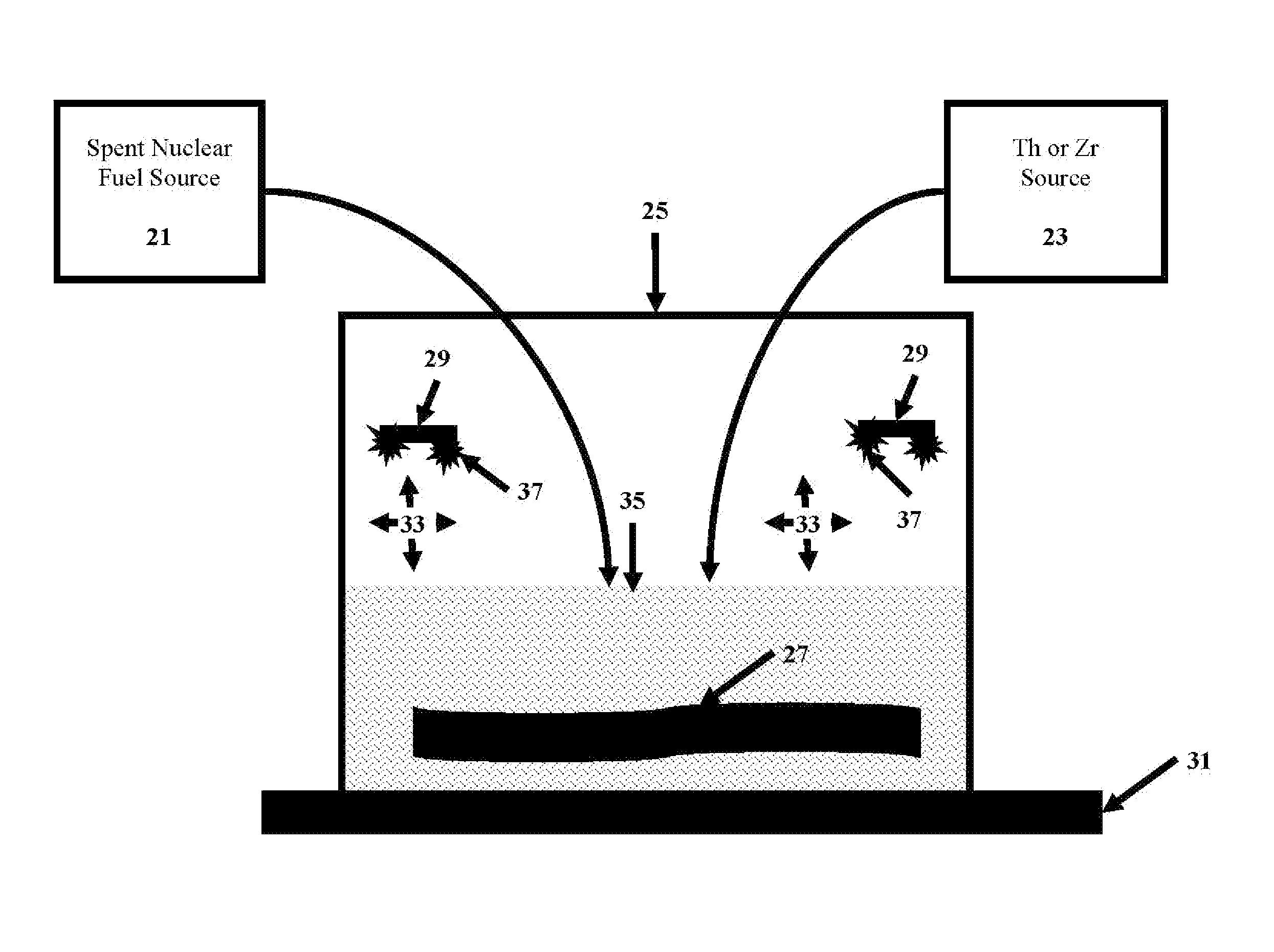

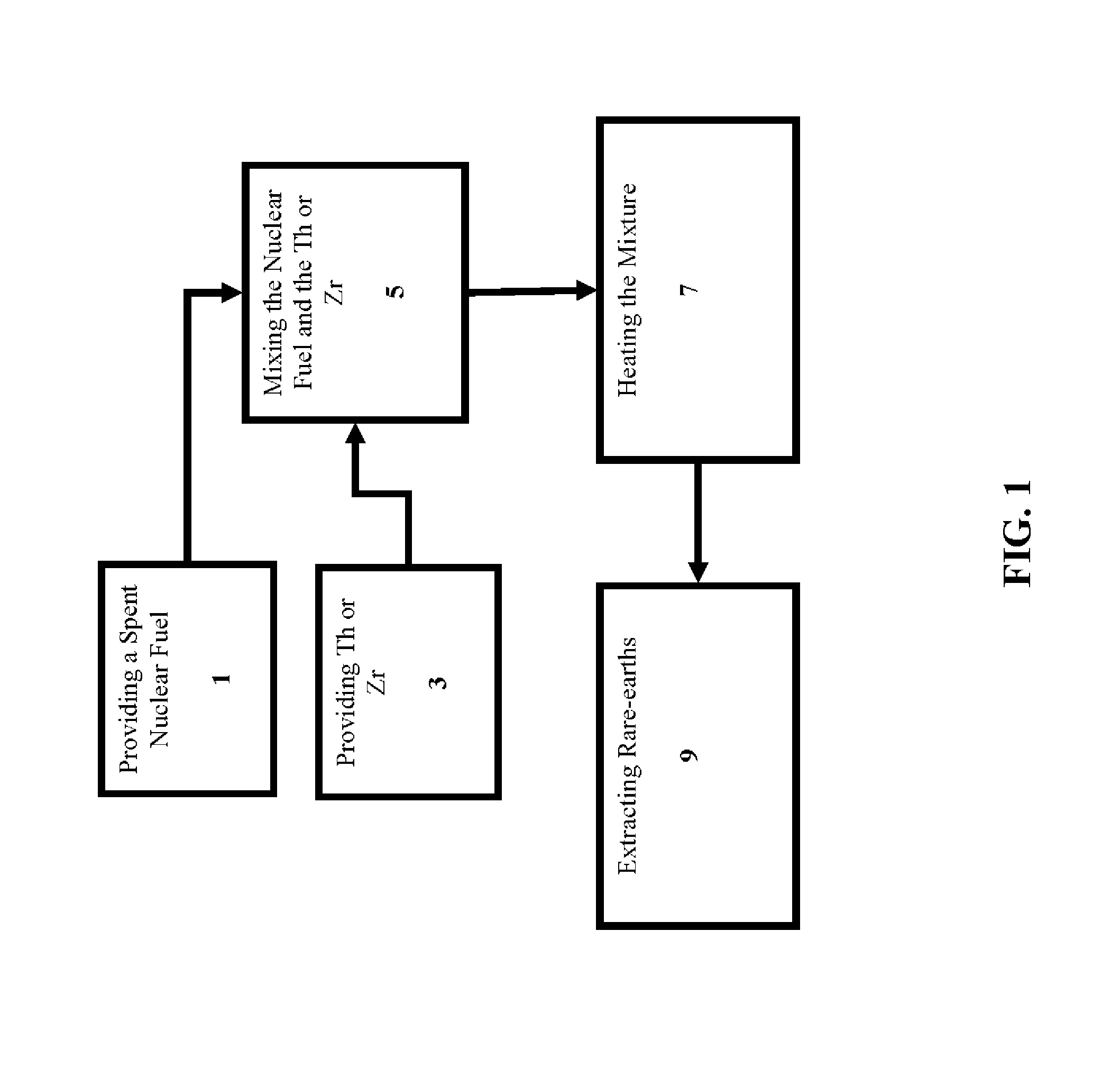

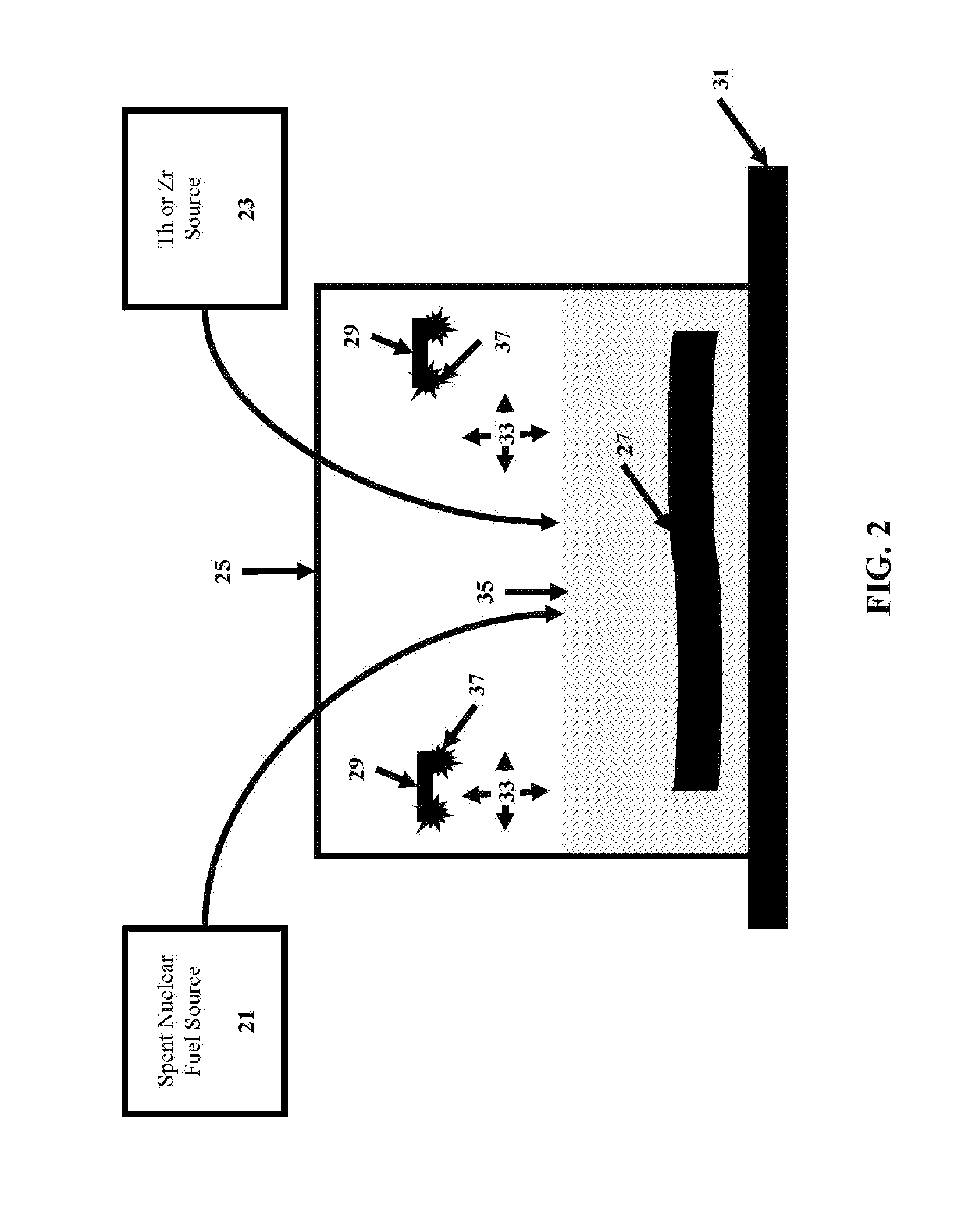

Separation of the rare-earth fission product poisons from spent nuclear fuel

ActiveUS9428401B1Specific isotope recoveryRare earth metal chloridesOxidation reductionRedox cycling

A method for the separation of the rare-earth fission product poisons comprising providing a spent nuclear fuel. The spent nuclear fuel comprises UO2 and rare-earth oxides, preferably Sm, Gd, Nd, Eu oxides, with other elements depending on the fuel composition. Preferably, the provided nuclear fuel is a powder, preferably formed by crushing the nuclear fuel or using one or more oxidation-reduction cycles. A compound comprising Th or Zr, preferably metal, is provided. The provided nuclear fuel is mixed with the Th or Zr, thereby creating a mixture. The mixture is then heated to a temperature sufficient to reduce the UO2 in the nuclear fuel, preferably to at least to 850° C. for Th and up to 600° C. for Zr. Rare-earth metals are then extracted to form the heated mixture thereby producing a treated nuclear fuel. The treated nuclear fuel comprises the provided nuclear fuel having a significant reduction in rare-earths.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

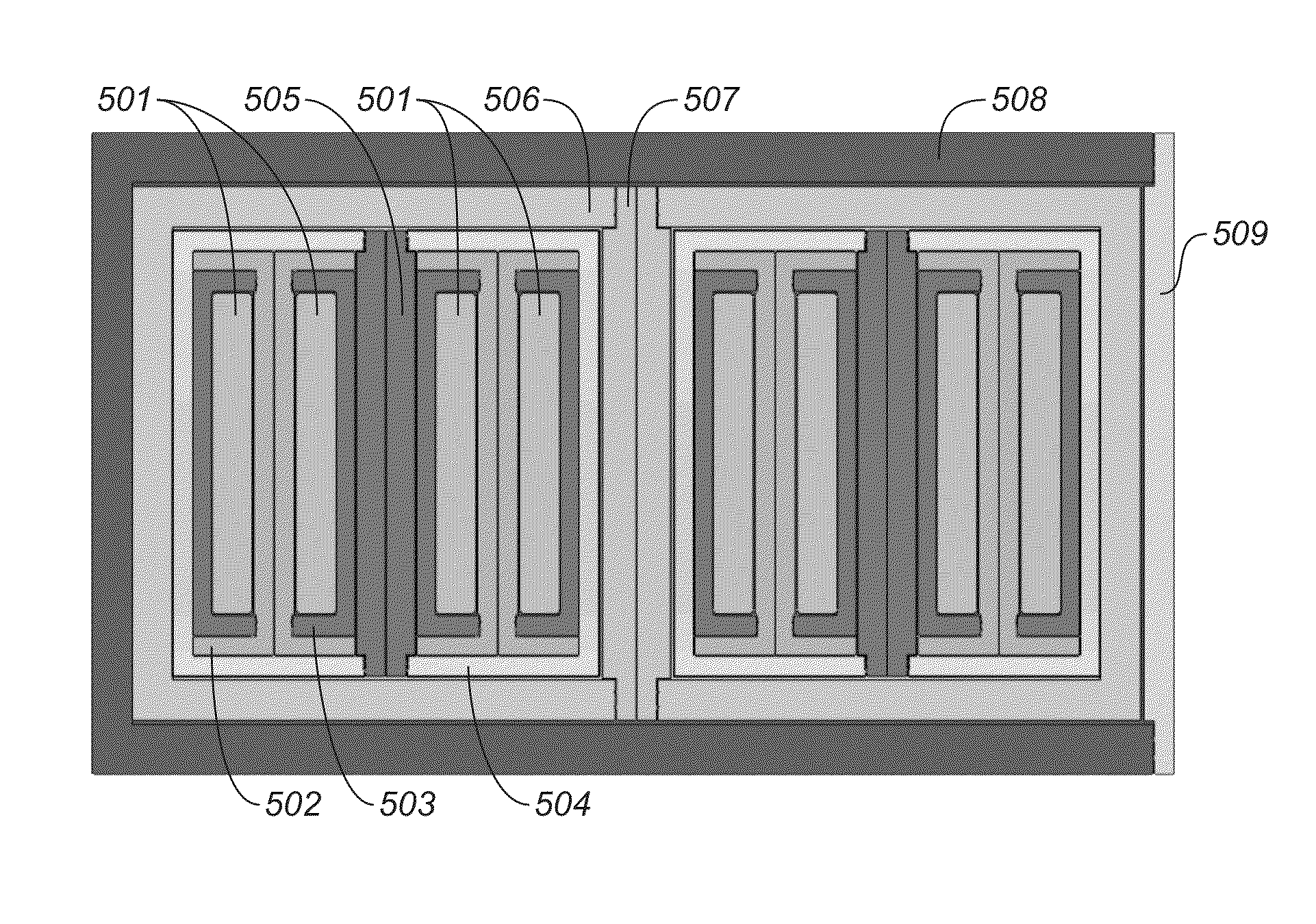

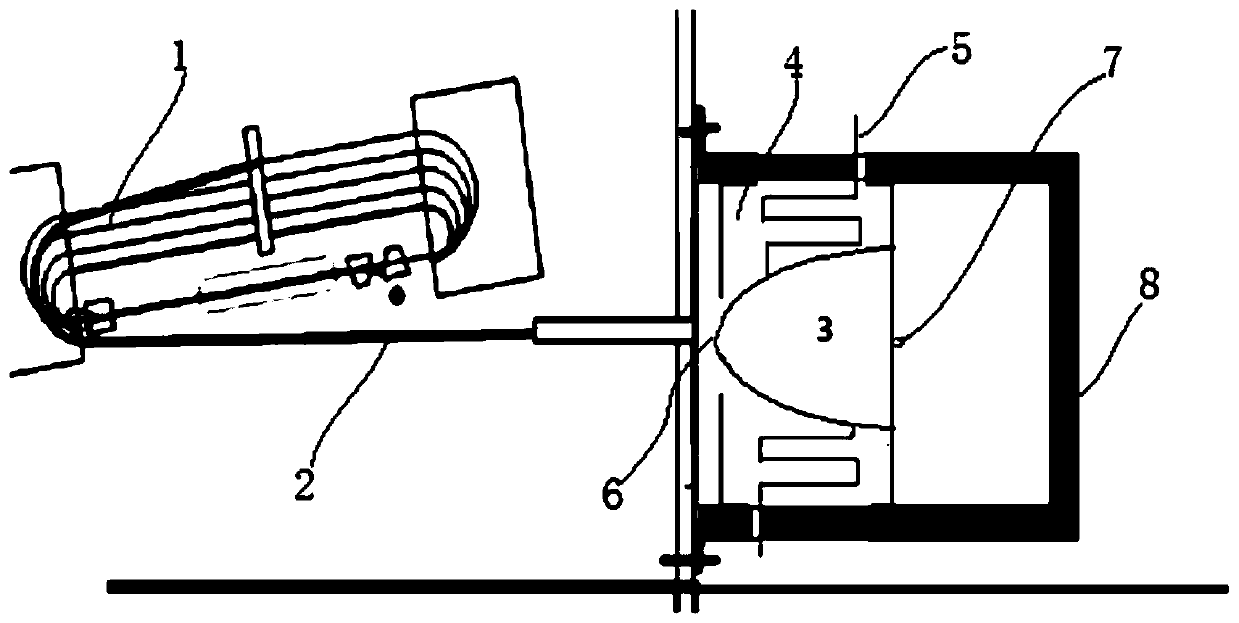

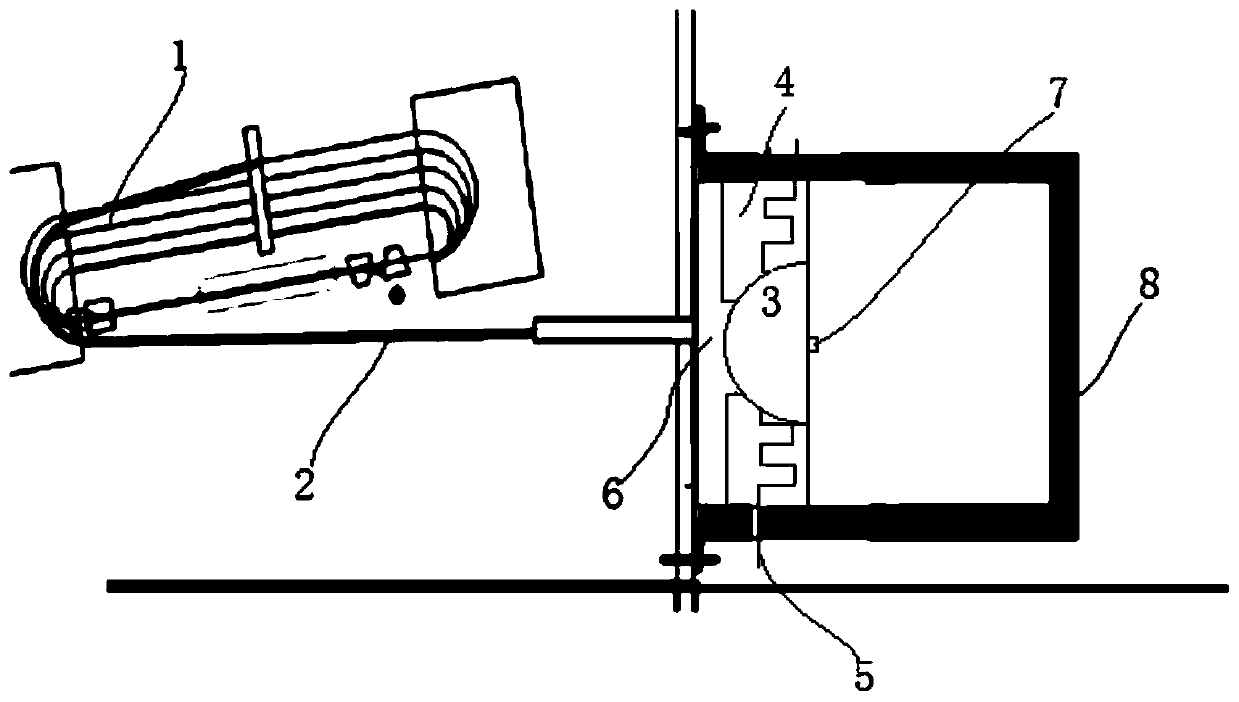

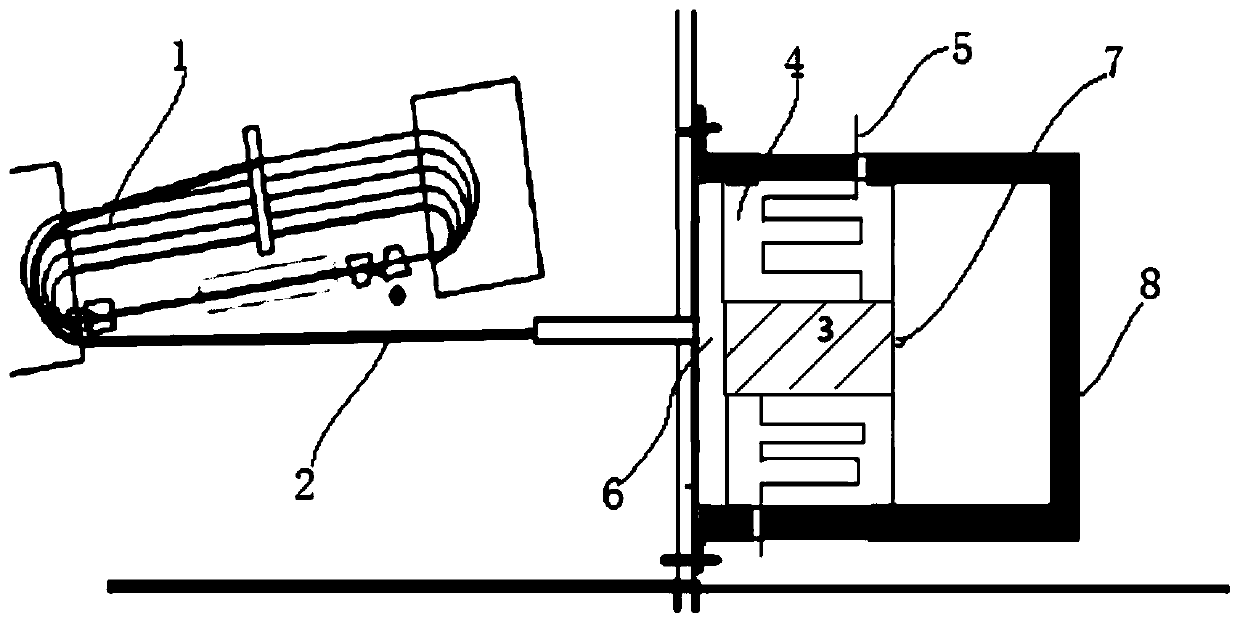

<99>Mo production method and <99>Mo production equipment based on bremsstrahlung and photonuclear reaction bifunctional target

PendingCN110473645AOvercoming strong self-attenuationIncrease productivitySpecific isotope recoveryIrradiation devicesSelf attenuationRadioactive decay

The invention belongs to the field of medical radioactive diagnosis nuclides, and relates to a <99>Mo production method and <99>Mo production equipment based on a bremsstrahlung and photonuclear reaction bifunctional target. In the prior art, the introduction of a conversion target can cause the low bremsstrahlung efficiency of a method for producing <99>Mo by using electron beams. A purpose of the present invention is to solve the problem in the prior art. According to the present invention, a high-energy electron beam emitted from an electron accelerator directly bombards an integrated bremsstrahlung and photonuclear reaction <100>Mo target; the production equipment comprises an electron accelerator, a target box, a target plate arranged in the target box, and a cooling system, wherein the target plate is a bremsstrahlung and photonuclear reaction bifunctional target plate, the bremsstrahlung and photonuclear reaction bifunctional target plate is a <100>Mo target, the target box hasan opening for the entering of an electron beam, and the electron beam enters the target box and directly bombards the bremsstrahlung and photonuclear reaction bifunctional target to produce <99>Mo. According to the present invention, by using the <100>Mo integrated bremsstrahlung and photonuclear reaction target, the strong self-attenuation on the bremsstrahlung twice in the traditional conversion target methods of high atomic number tungsten (W) and the like can be well overcome so as to greatly improve the production efficiency of <99>mo.

Owner:西安迈斯拓扑科技有限公司

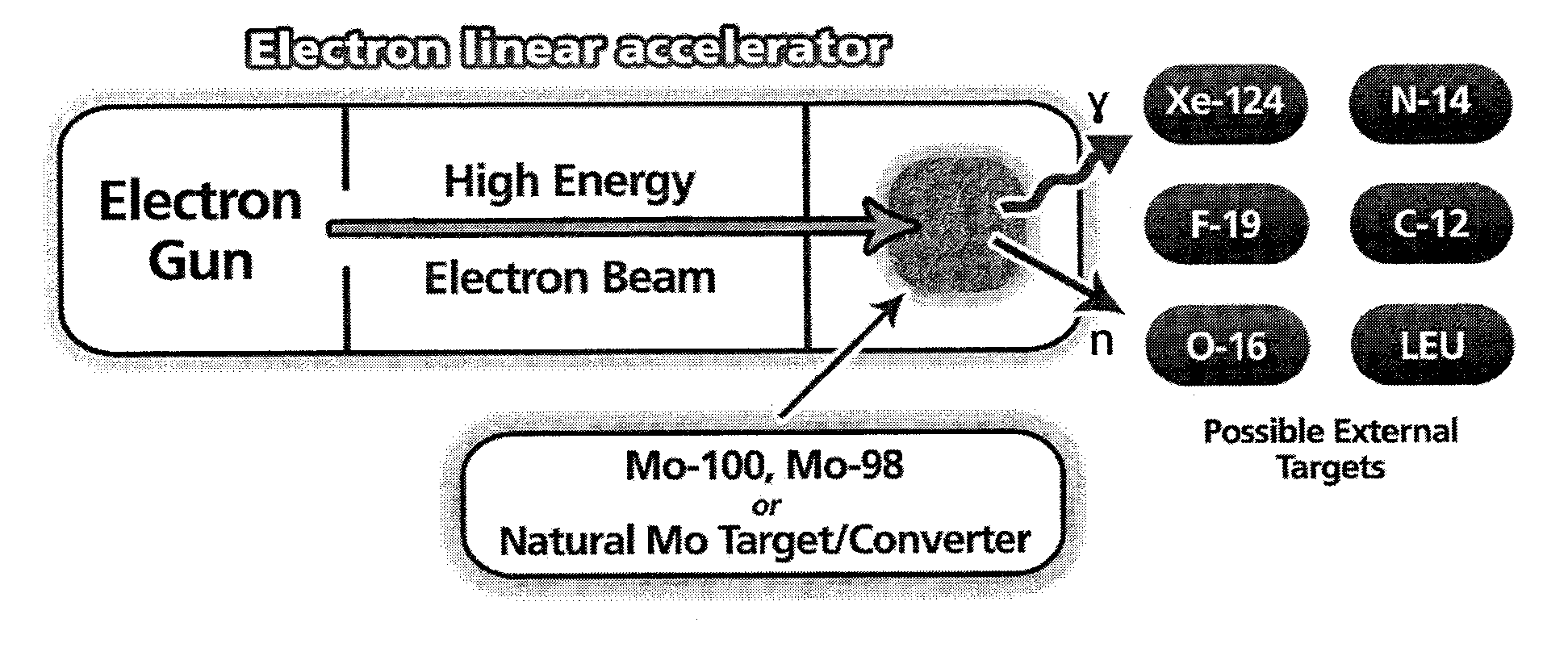

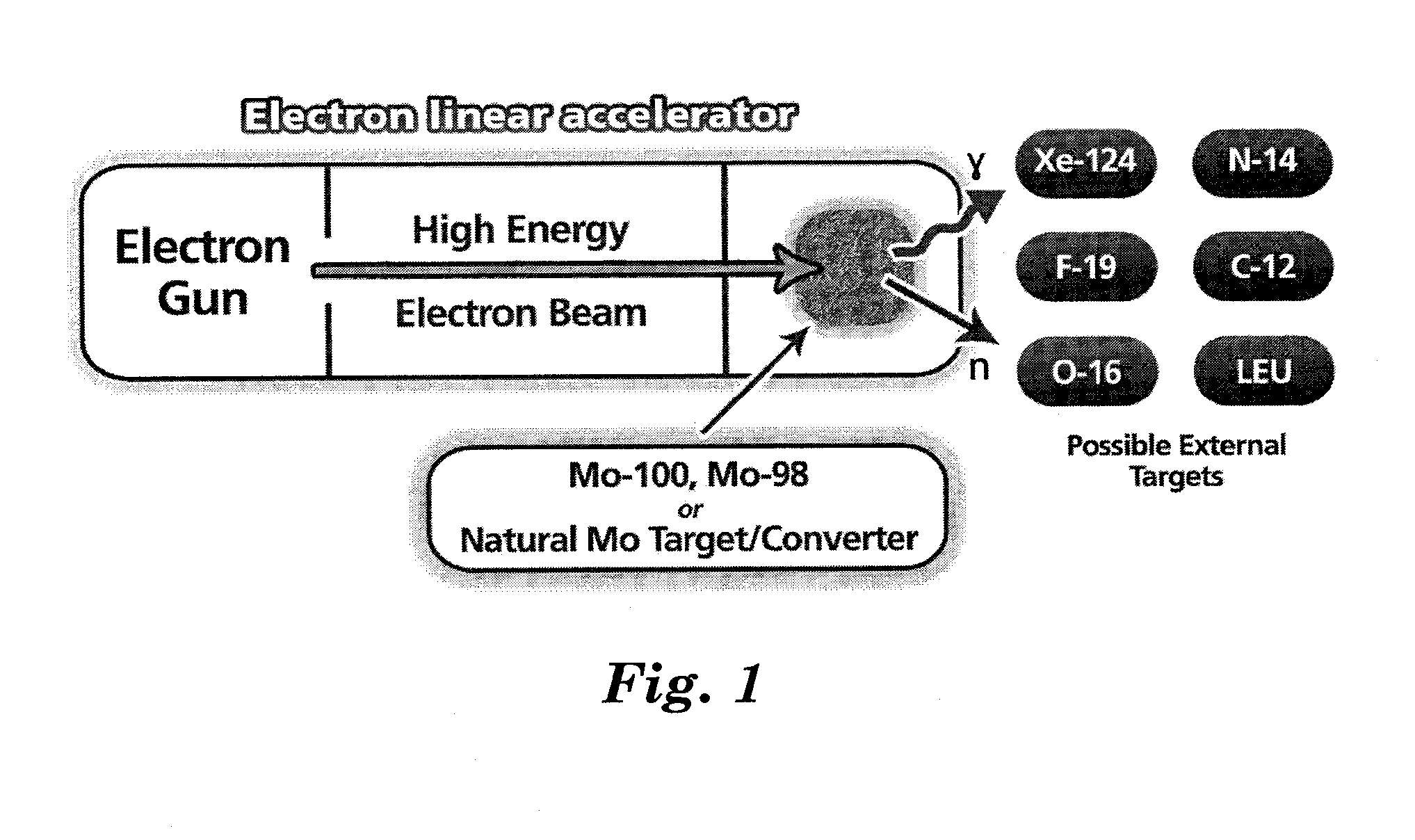

Molybdenum-converter based electron linear accelerator and method for producing radioisotopes

ActiveUS20140192942A1Specific isotope recoveryConversion outside reactor/acceleratorsNeutron captureDistilled water

The present invention provides a method for producing molybdenum-99 comprising: i) providing an electron accelerator; ii) providing a molybdenum converter / target unit (Mo-CTU) comprising one or more metallic components, wherein each one of said metallic components is made of a material selected from the group consisting of natural molybdenum, molybdenum-100, molybdenum-98, and mixtures thereof; iii) directing an electron beam generated via said electron accelerator onto said Mo-CTU to produce a braking radiation (bremsstrahlung); iv) employing said bremsstrahlung onto said Mo-CTU to produce molybdenum-99 and neutrons via a photo-neutron reaction; v) slowing down the neutrons produced in step iv) with a low atomic liquid, e.g. distilled water; and optionally vi) employing the neutrons produced in step iv) to produce a complementary amount of molybdenum-99 via a neutron capture reaction on said Mo-CTU. The invention further provides an apparatus for producing molybdenum-99.

Owner:B G NEGEV TECH & APPL LTD

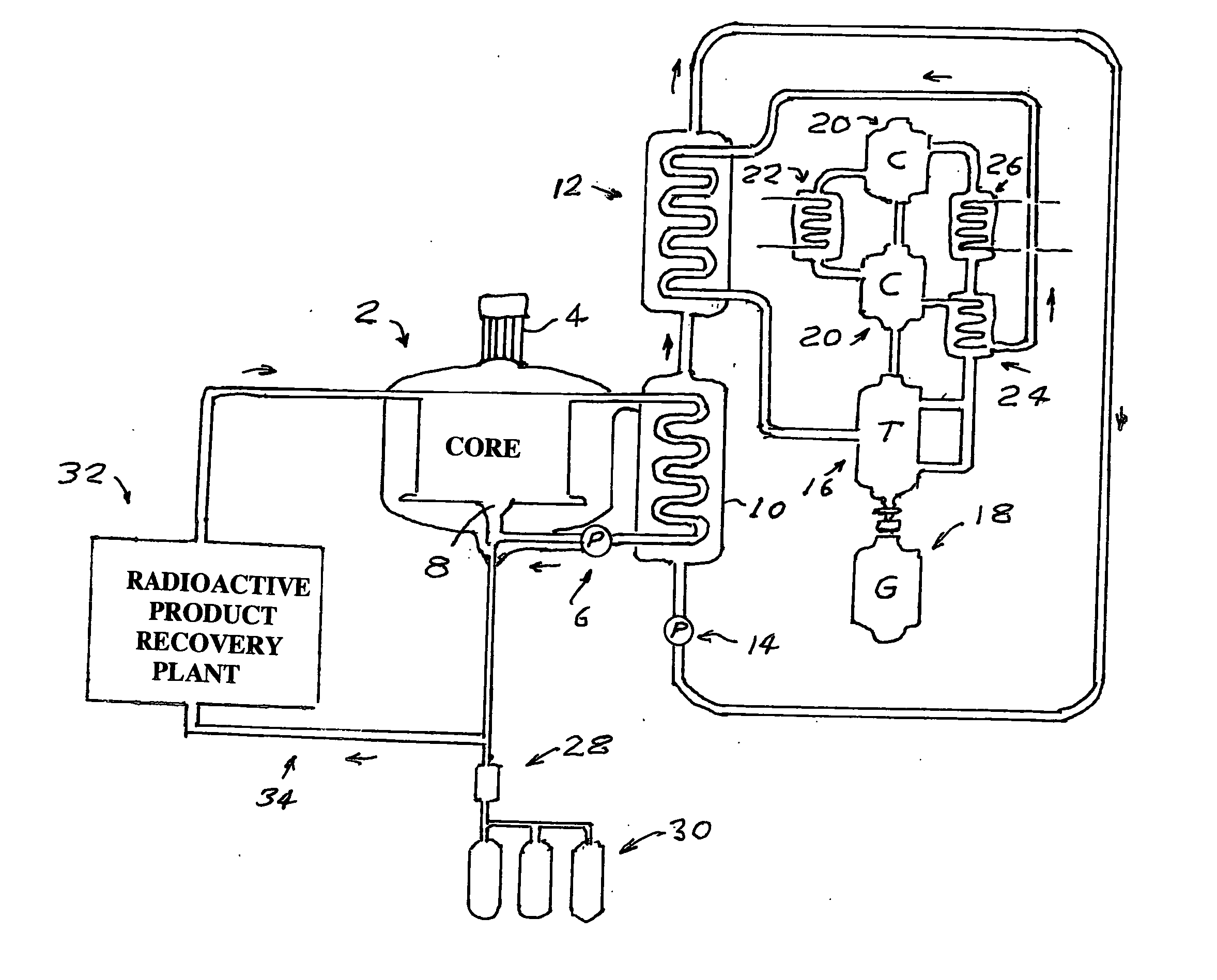

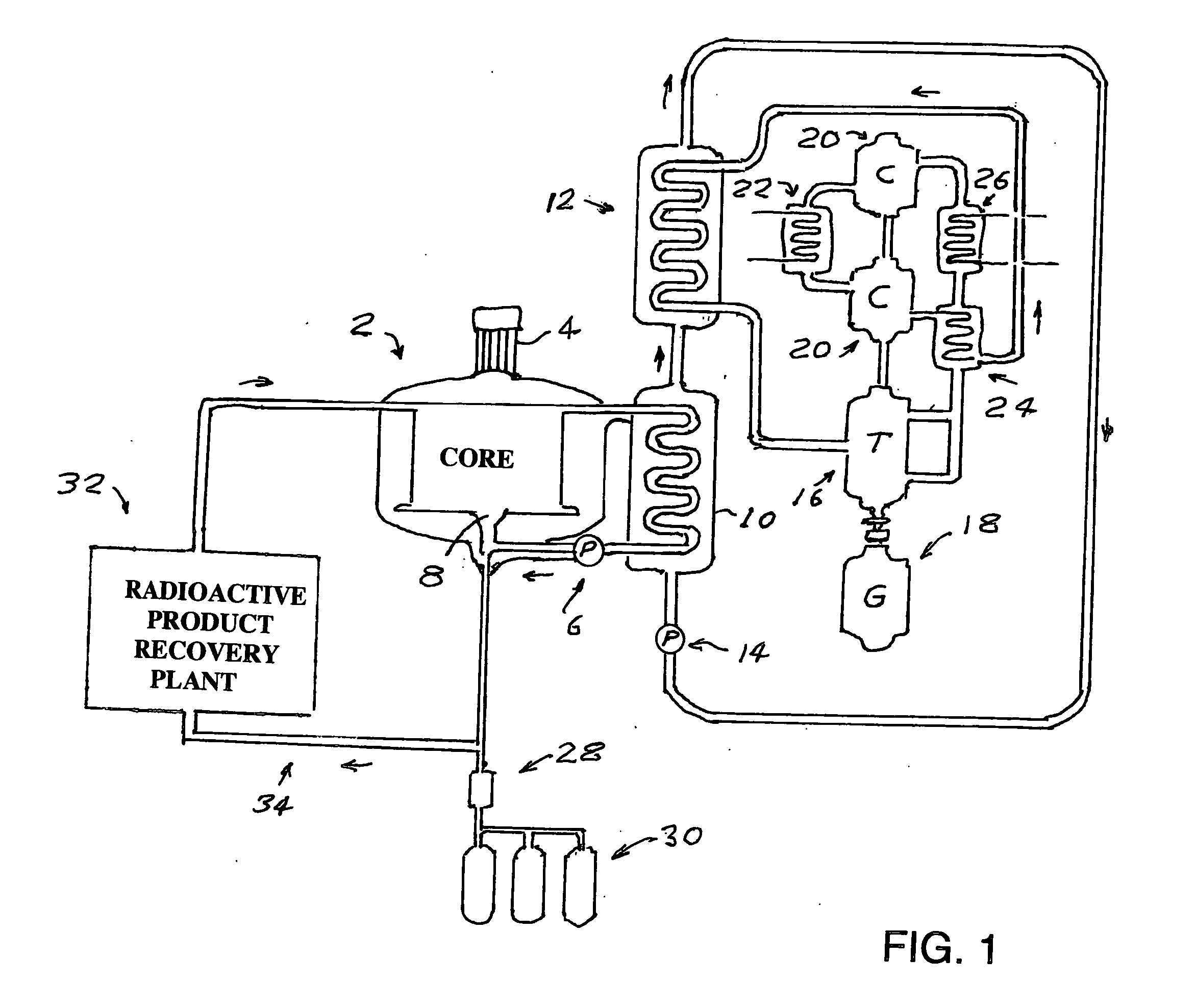

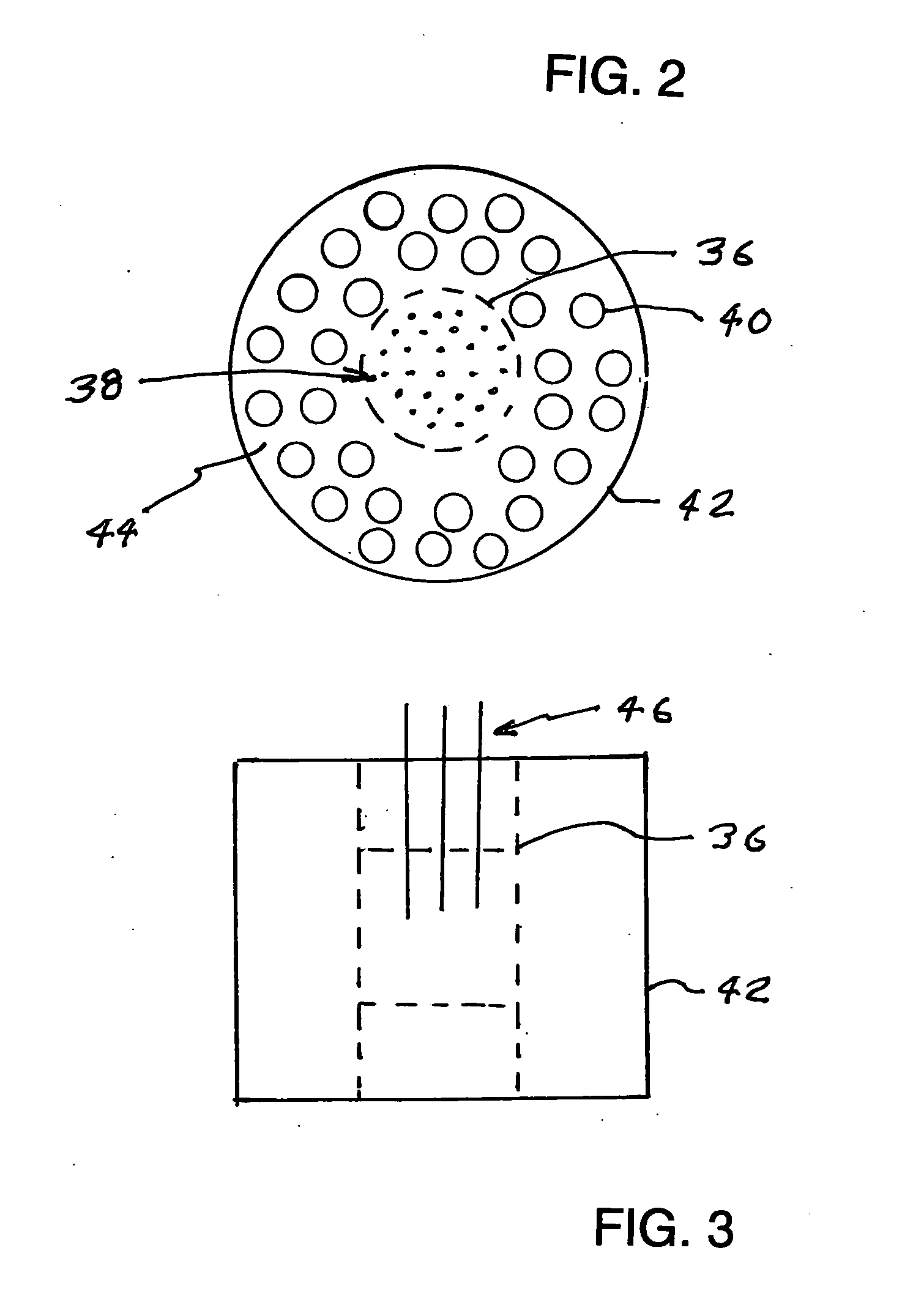

Liquid Lithium Cooled Fission Reactor for Producing Radioactive Materials

InactiveUS20140226775A1Increase productionEfficient rateSpecific isotope recoveryConversion outside reactor/acceleratorsRadioactive agentRapid processing

A liquid lithium-cooled fission reactor optimized for producing radioactive materials. The reactor is designed to enhance the availability of rare radioactive materials that have significant value for national defense, industrial research, and medical care. This invention has tangible design attributes that can be tailored to create one or more scarce and valuable radioactive materials. In particular, the reactor design is optimized for low-cost production of large quantities of radioactive tritium needed in national-defense and fusion-breeder programs. There are four core designs applied to this invention, all of which produce tritium and surplus heat that can generate byproduct electricity, thereby reducing the cost of radioactive-material production. Three of the embodiments furnish radioactive fission products, such as molybdenum-99, that can be extracted with high efficiency and rapid processing, thus fulfilling a critical supply and price shortfall in radioisotopes used for medical diagnosis and treatment.

Owner:NUCLEAR APPL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com