Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

386 results about "Particle accelerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

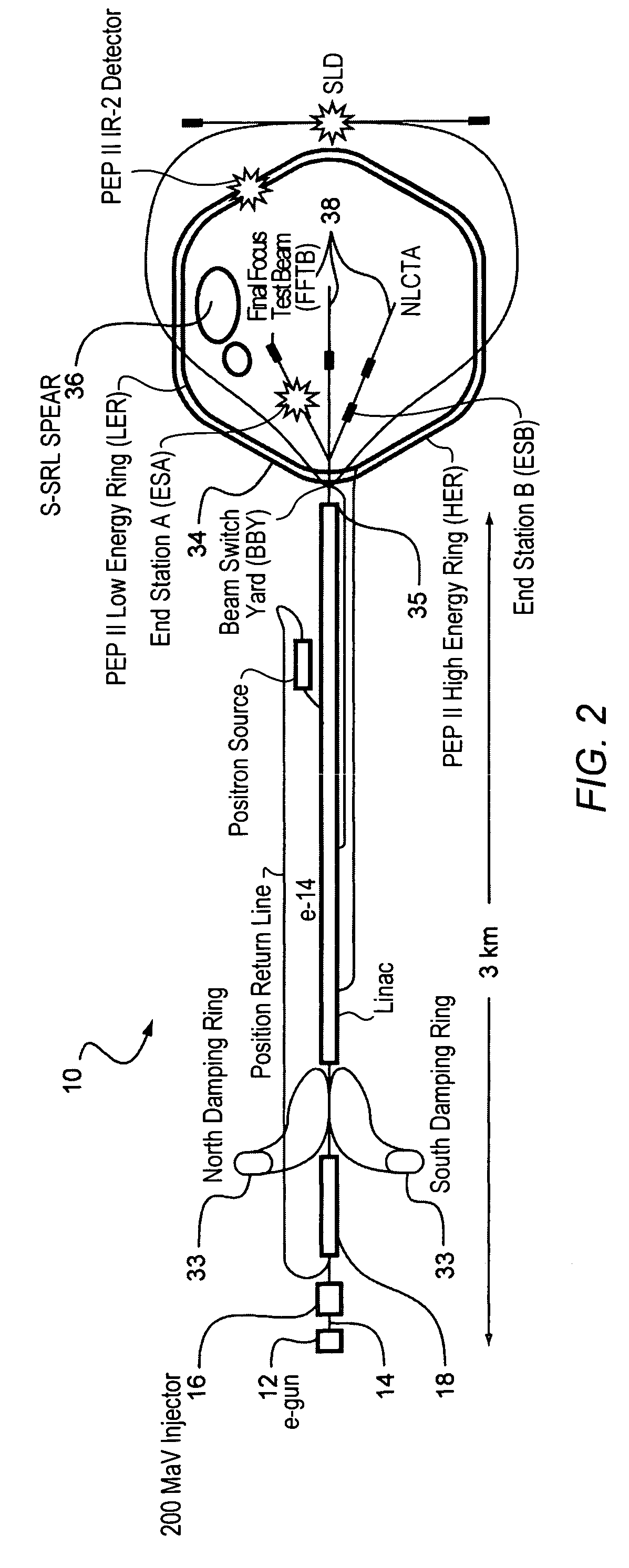

A particle accelerator is a machine that uses electromagnetic fields to propel charged particles to very high speeds and energies, and to contain them in well-defined beams. Large accelerators are used for basic research in particle physics. The most powerful accelerator currently is the Large Hadron Collider (LHC) near Geneva, Switzerland, built by the European collaboration CERN. It is a collider accelerator, which can accelerate two beams of protons to an energy of 6.5 TeV and cause them to collide head-on, creating center-of-mass energies of 13 TeV. Other powerful accelerators are KEKB at KEK in Japan, RHIC at Brookhaven National Laboratory, and the Tevatron at Fermilab, Batavia, Illinois. Accelerators are also used as synchrotron light sources for the study of condensed matter physics. Smaller particle accelerators are used in a wide variety of applications, including particle therapy for oncological purposes, radioisotope production for medical diagnostics, ion implanters for manufacture of semiconductors, and accelerator mass spectrometers for measurements of rare isotopes such as radiocarbon. There are currently more than 30,000 accelerators in operation around the world.

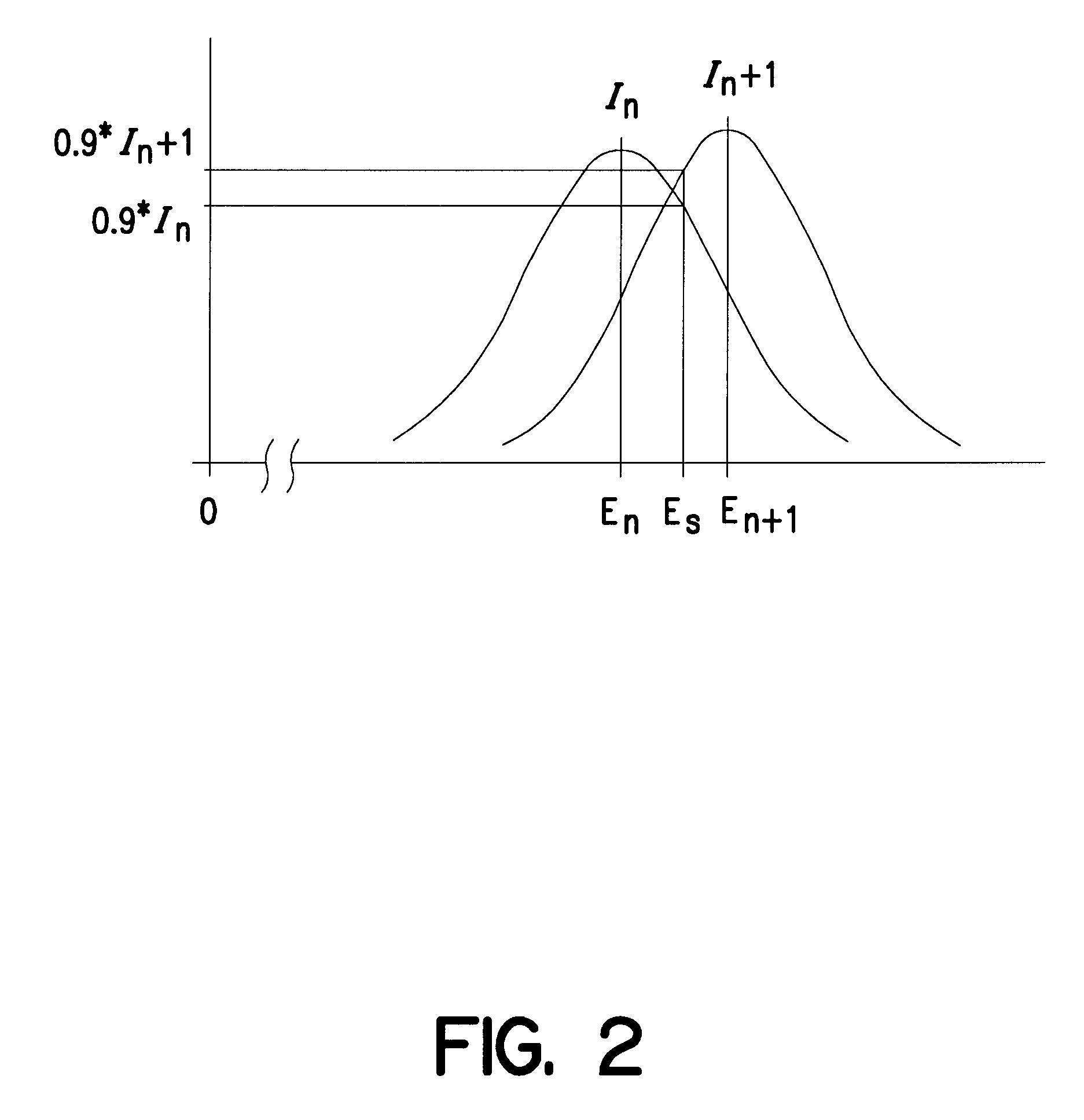

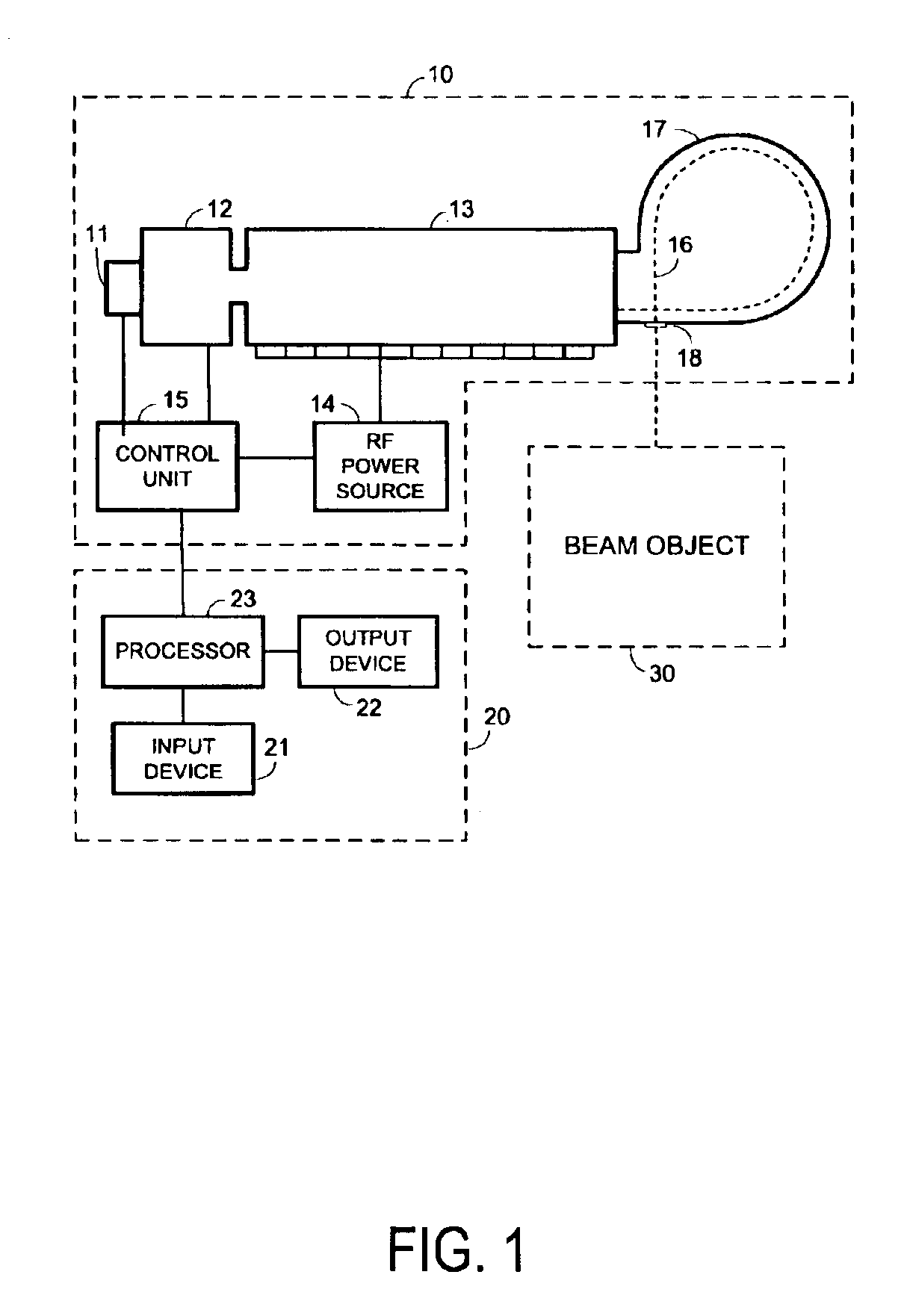

Device and method for regulating intensity of beam extracted from a particle accelerator

InactiveUS6873123B2Thermometer detailsStability-of-path spectrometersParticle acceleratorAccelerated particle

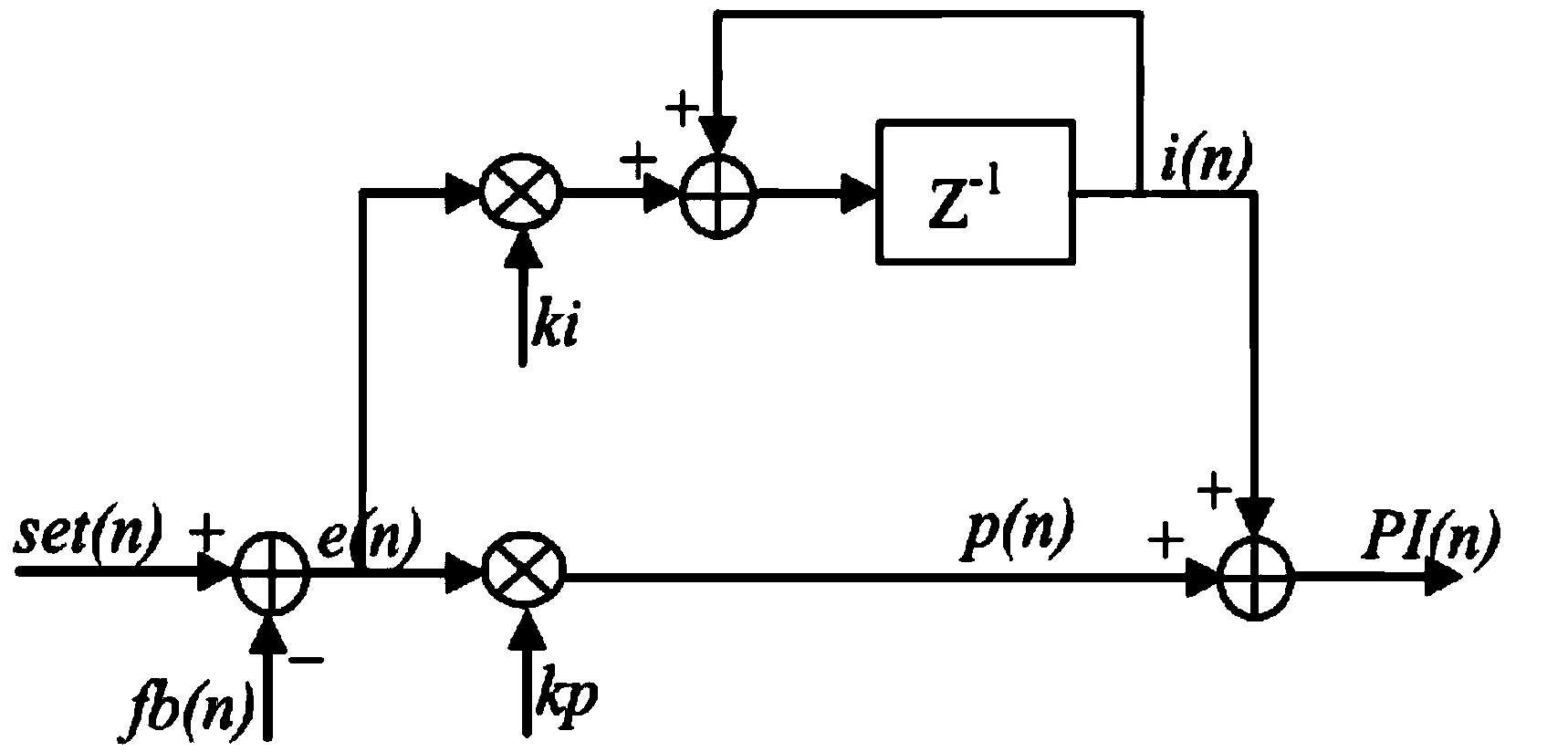

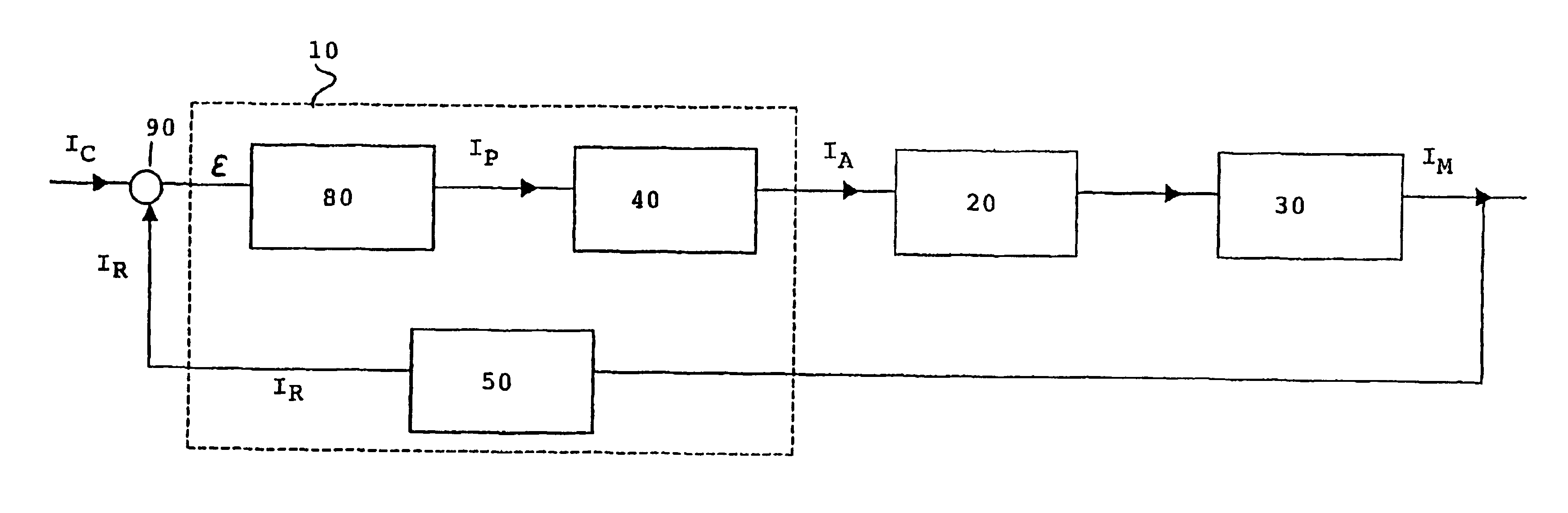

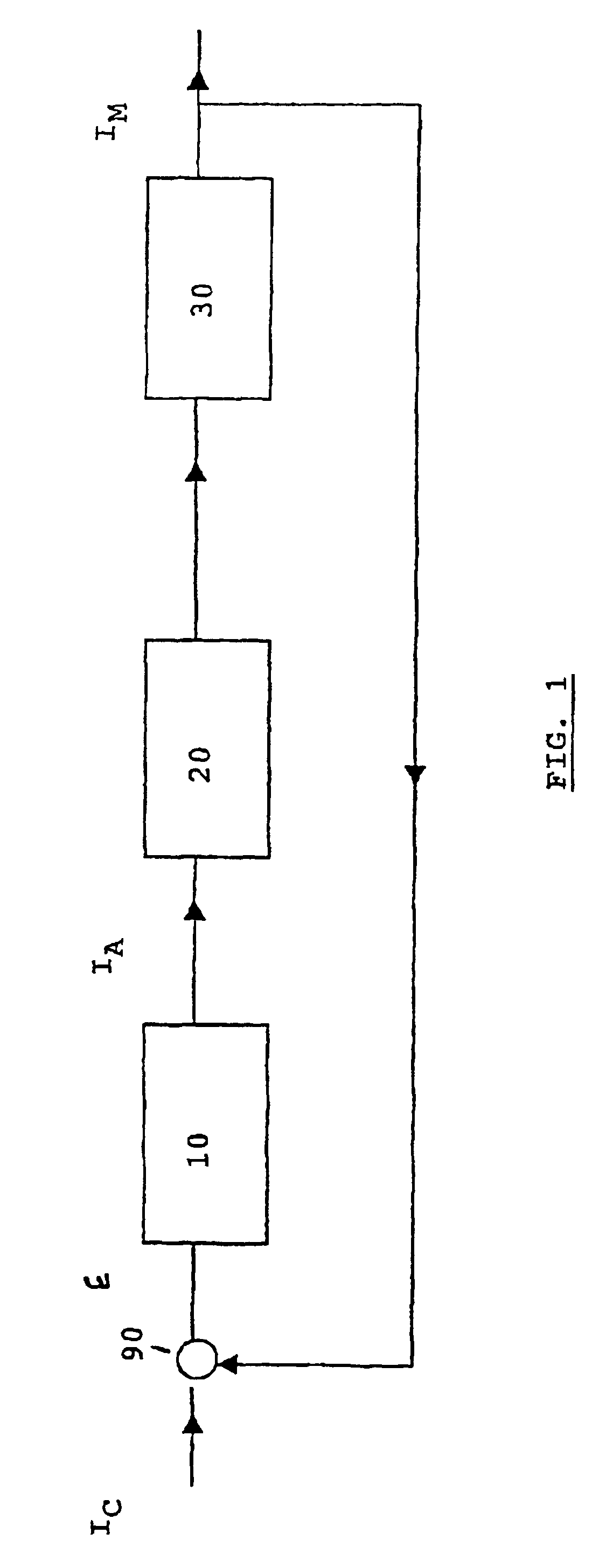

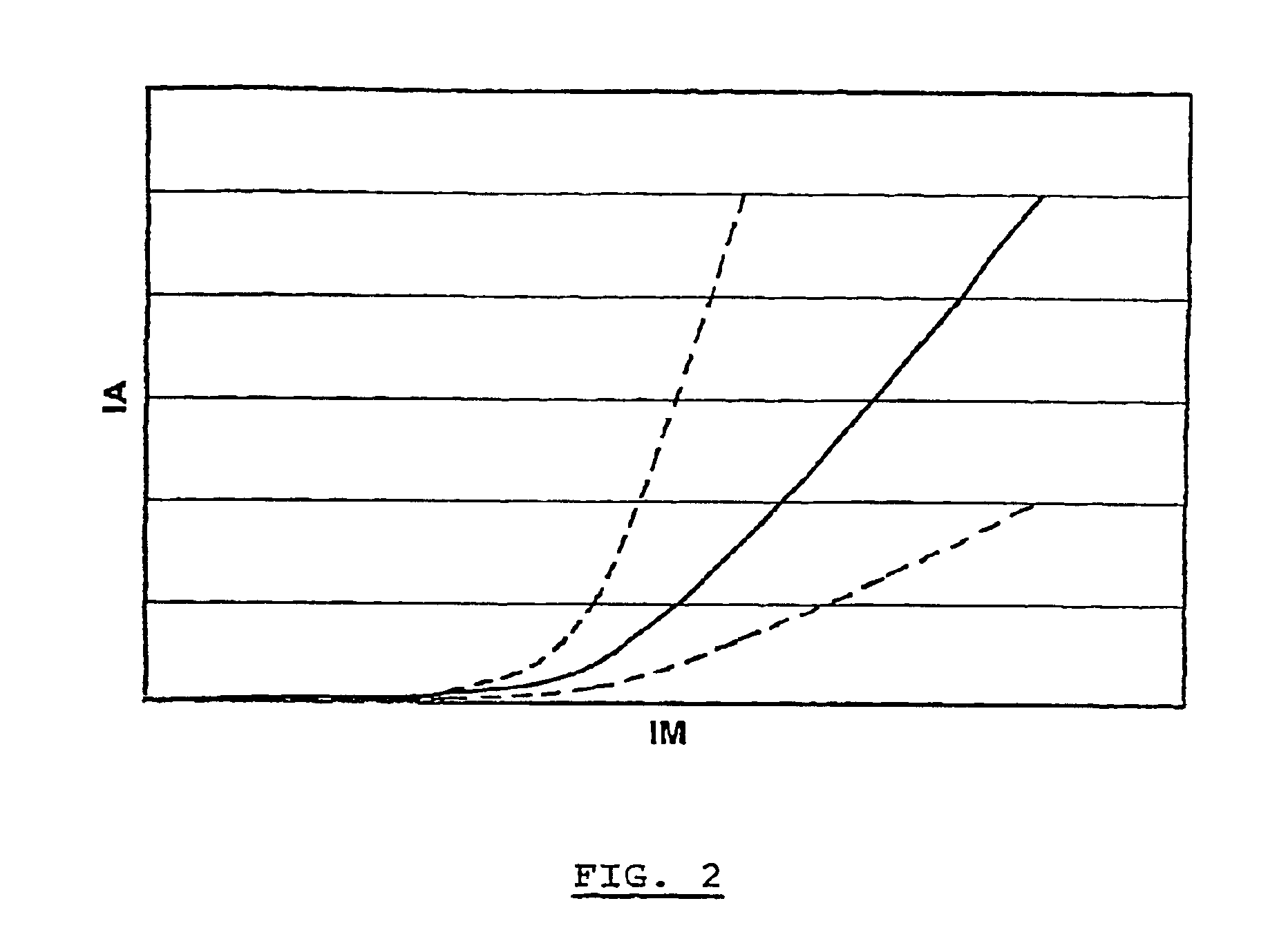

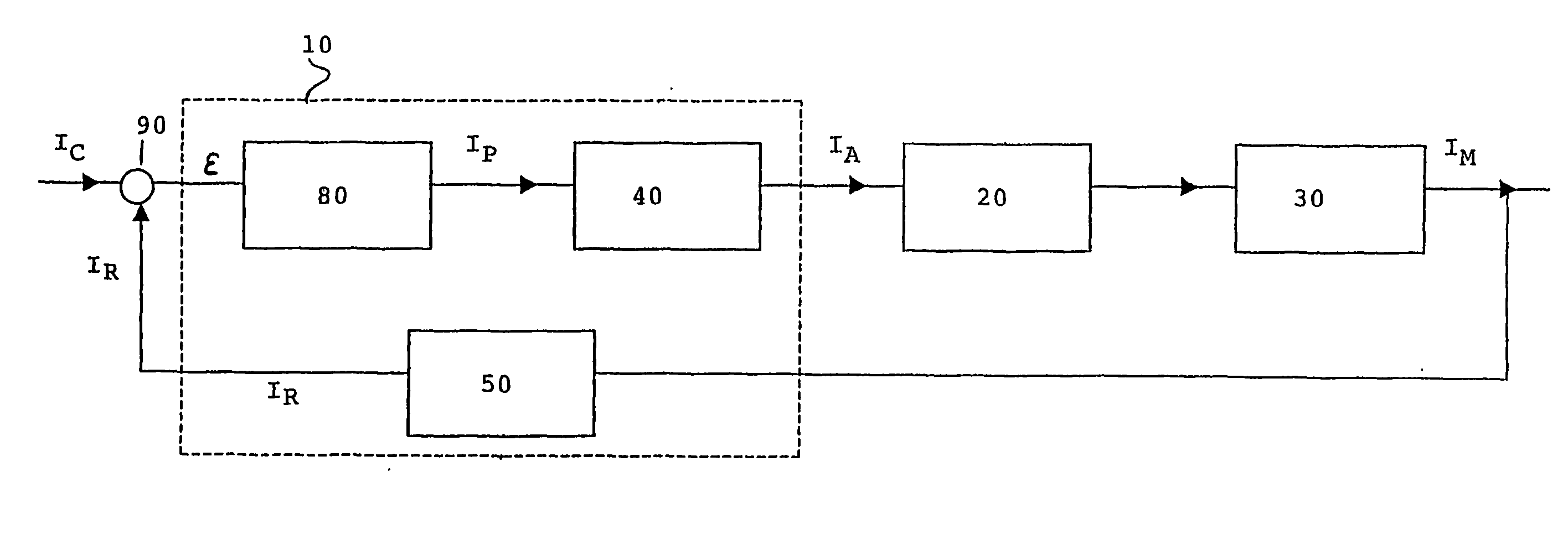

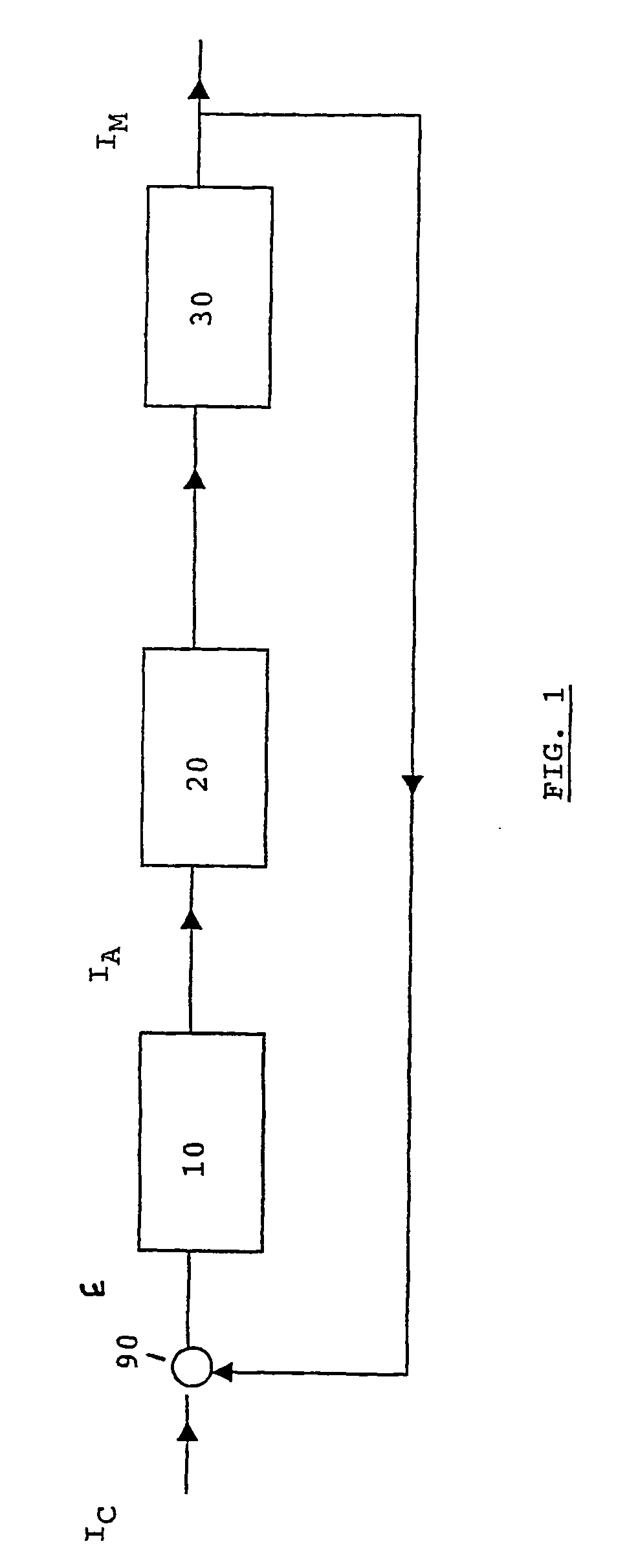

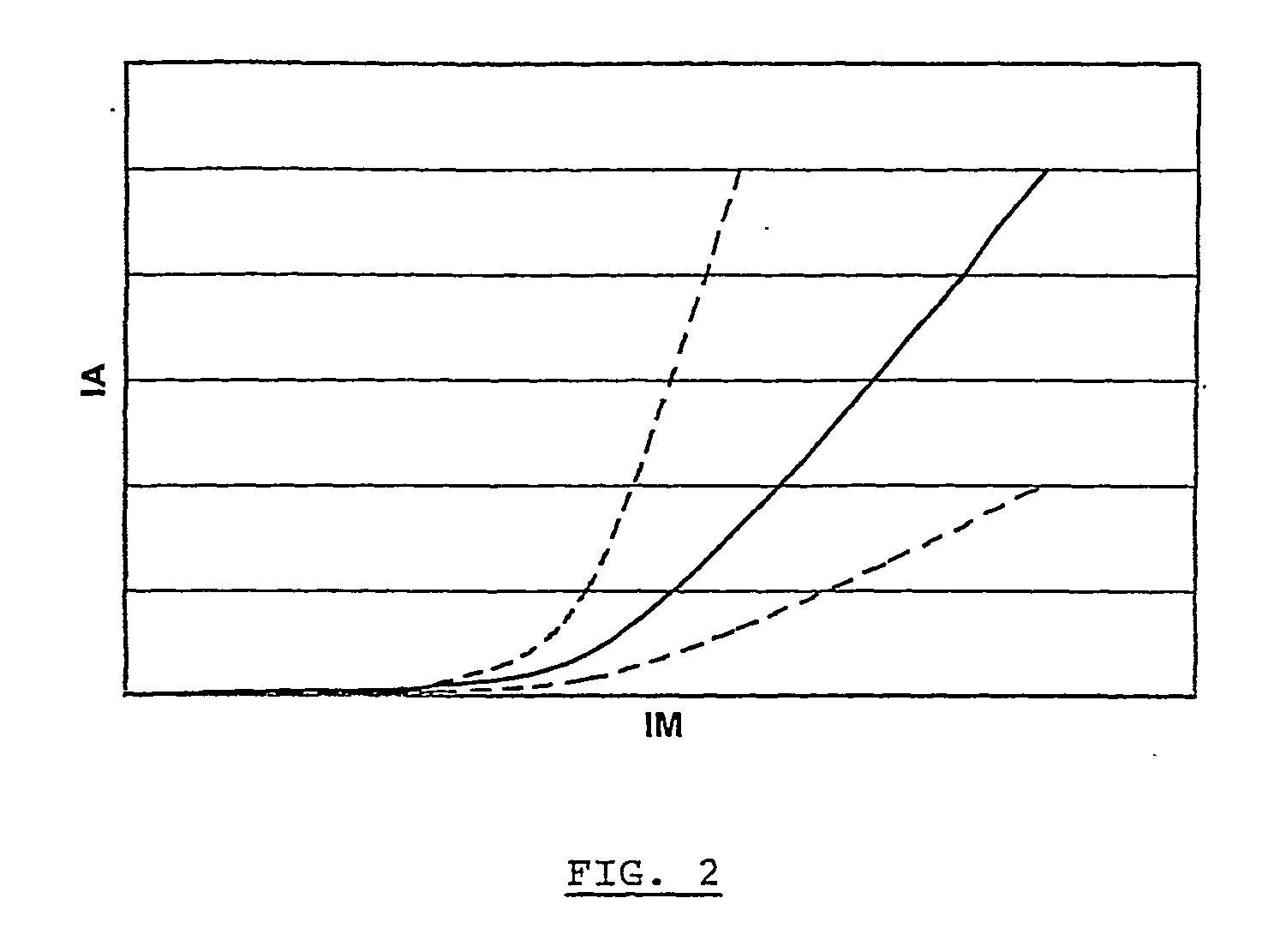

The invention concerns a device (10) for regulating the intensity of a beam extracted from a particle accelerator, such as a cyclotron, used for example for protontherapy, said particles being generated from an ion source. The invention is characterized in that it comprises at least: a comparator (90) determining a difference ε between a digital signal IR representing the intensity of the beam measured at the output of the accelerator and a setpoint value IC of the beam intensity: a Smith predictor (80) which determines on the basis of the difference ε, a correct value of the intensity of the beam IP; an inverted correspondence table (40) supplying, on the basis of the corrected value of the intensity of the beam IP, a setpoint value IA for supply arc current from the ion source (20).

Owner:ION BEAM APPL

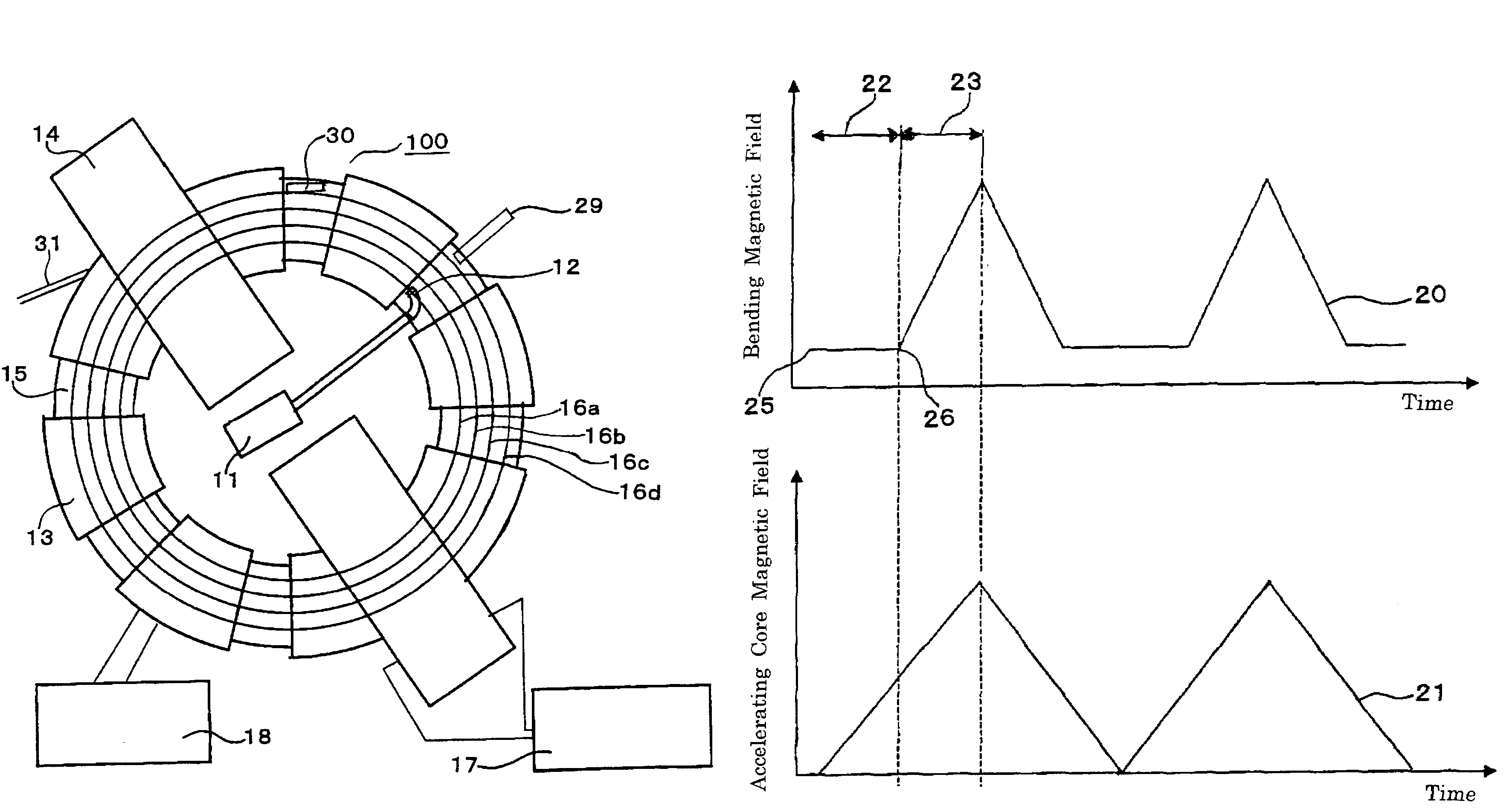

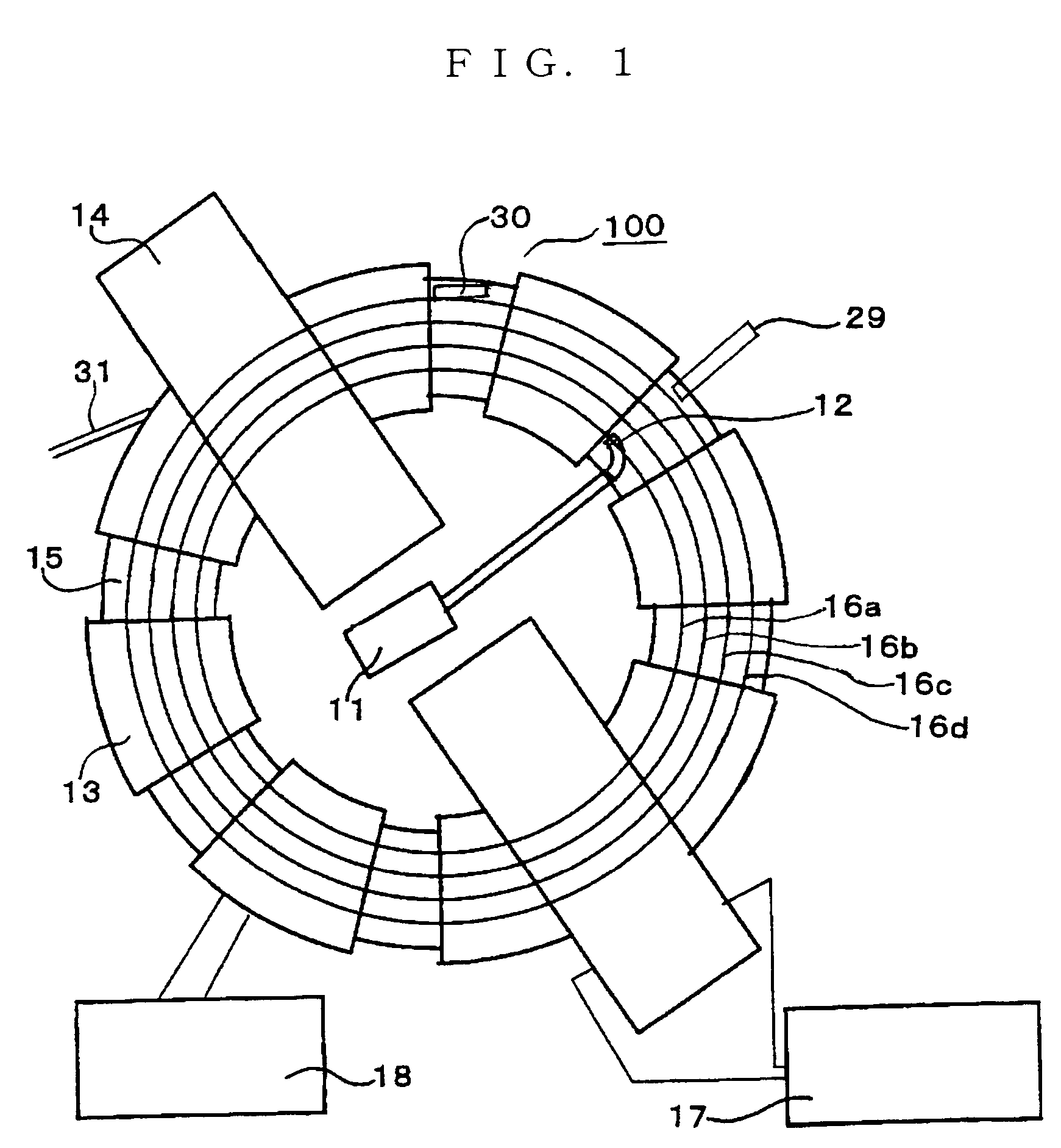

Charged particle accelerator

InactiveUS7259529B2High strengthQuality improvementMagnetic induction acceleratorsParticle acceleratorStart time

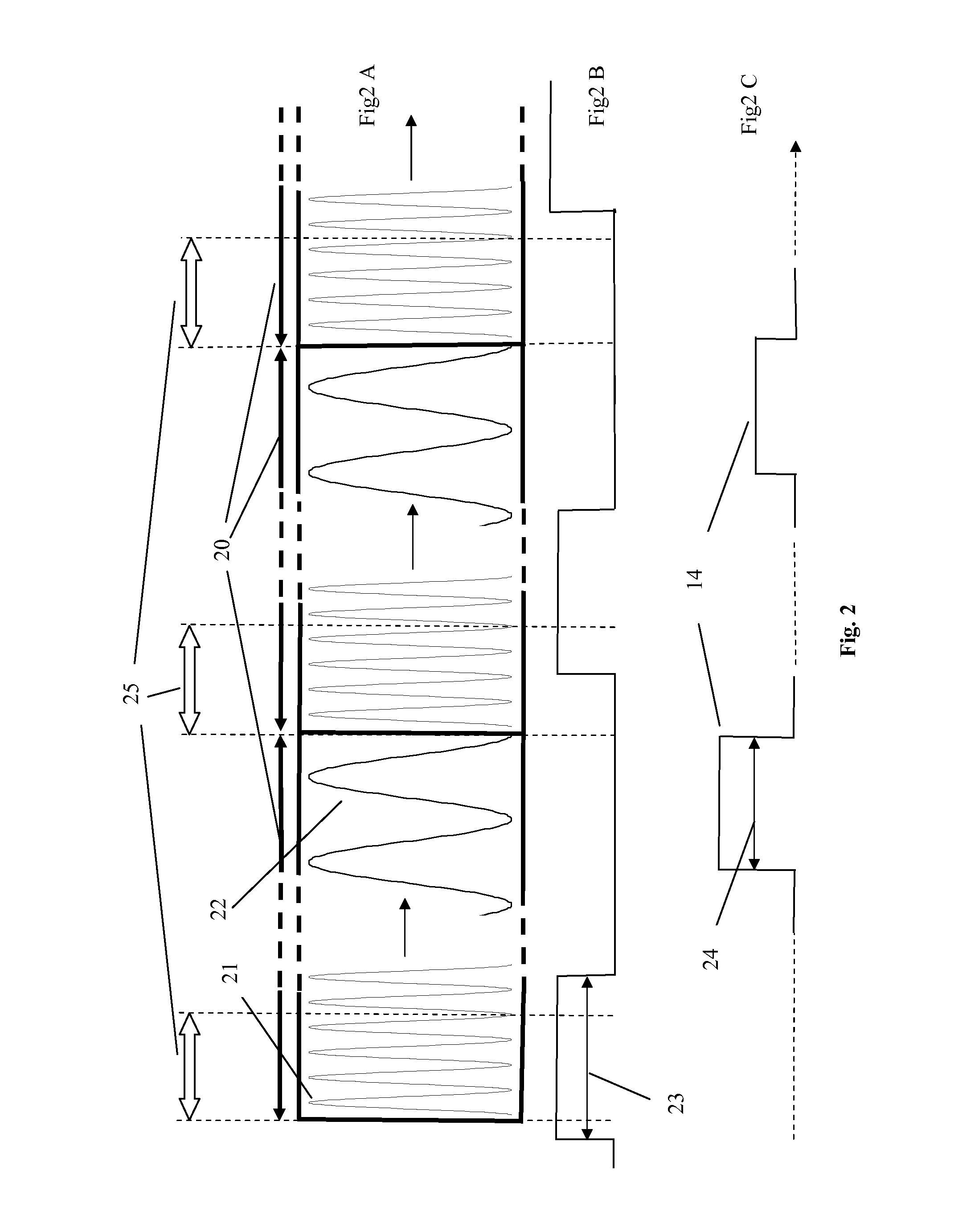

The present invention provides a charged particle accelerator comprising a charged particle generating apparatus, a bending magnet, accelerating means and a vacuum duct, wherein first and second acceleration periods (22), (23) are provided, accelerating electric field of the accelerating means is applied from the start time (25) of the first acceleration period (22) until the end time of the second acceleration period (23), and bending magnetic field is applied at a fixed value during the first accelerating period while, during the second acceleration period, it is applied so as to increase until the end time of the second acceleration period. Accordingly, there is provided a compact and high power charged particle accelerator which can perform large-current acceleration.

Owner:MITSUBISHI ELECTRIC CORP

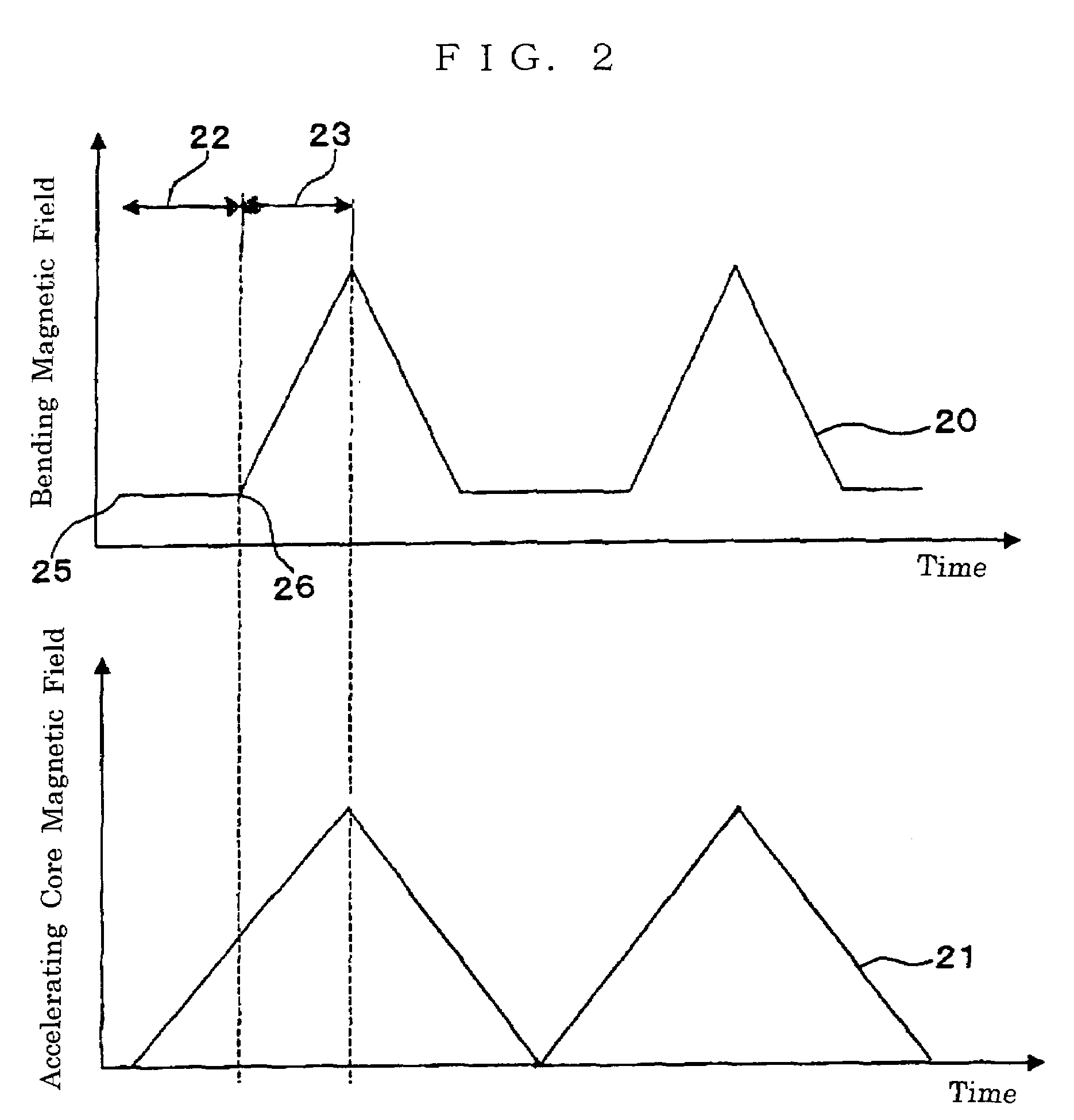

Biomarker generator system

ActiveUS7476883B2Efficient dosingEfficient productionMaterial analysis using wave/particle radiationIsotope delivery systemsChemical synthesisMicroreactor

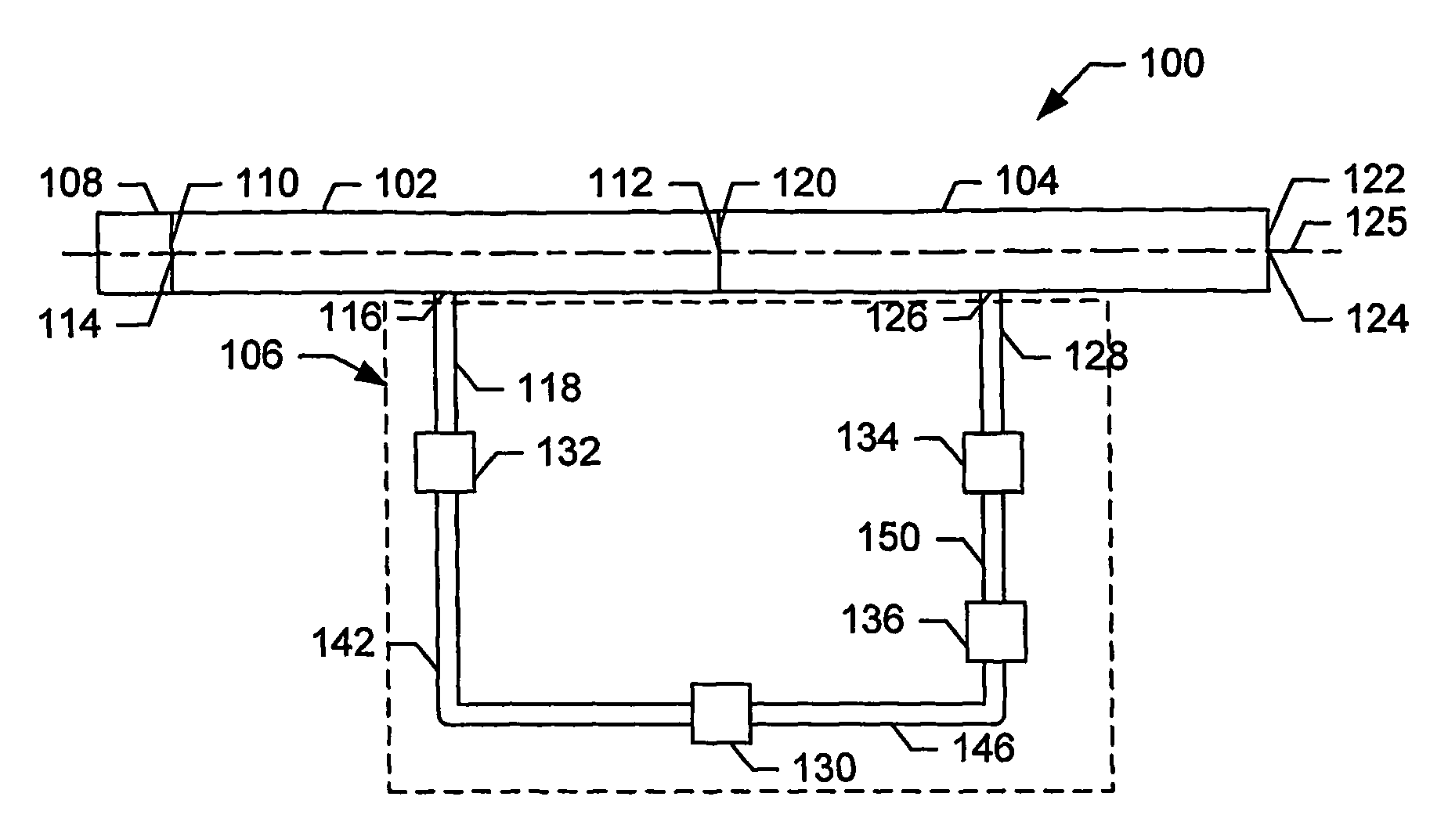

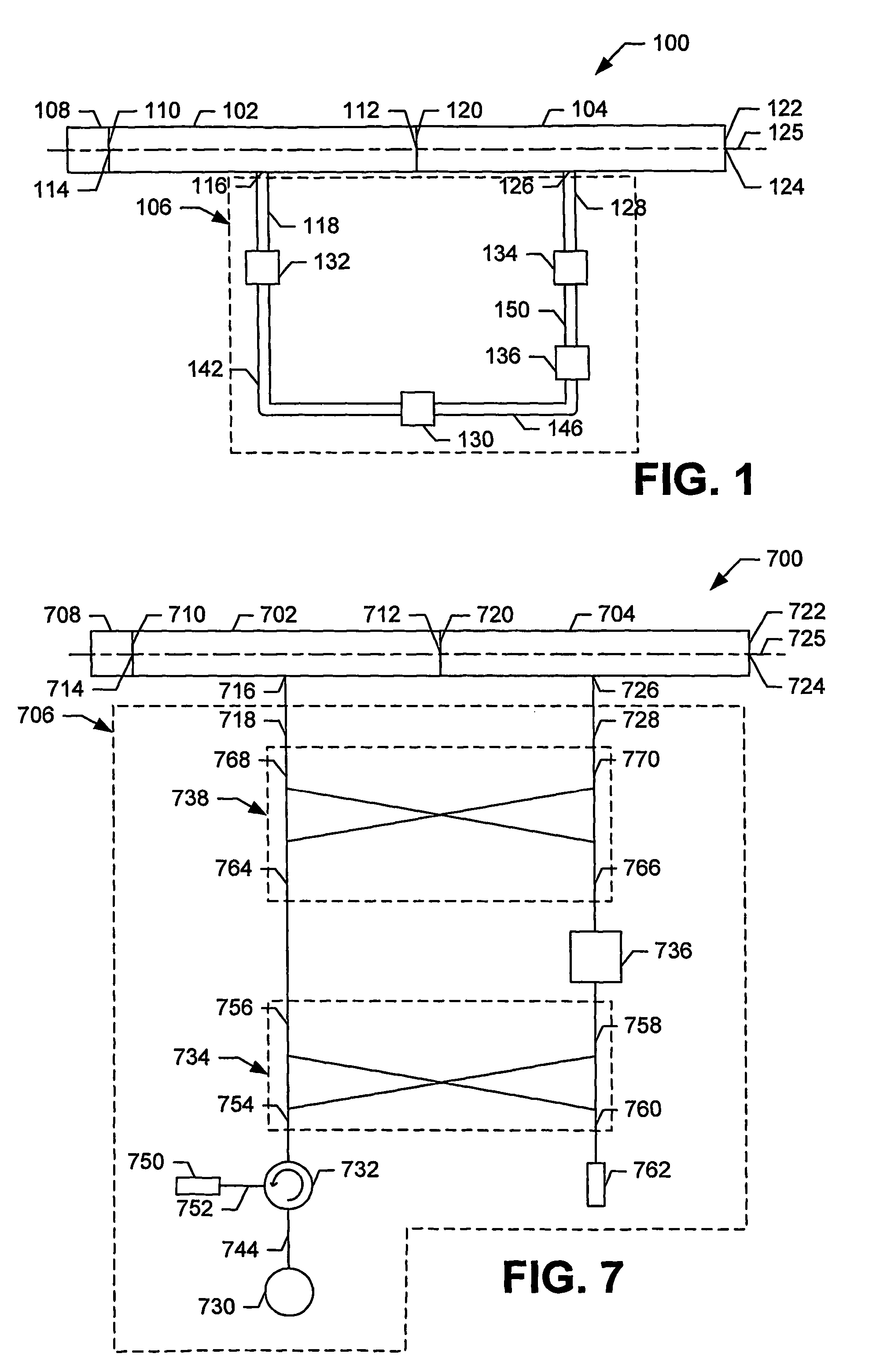

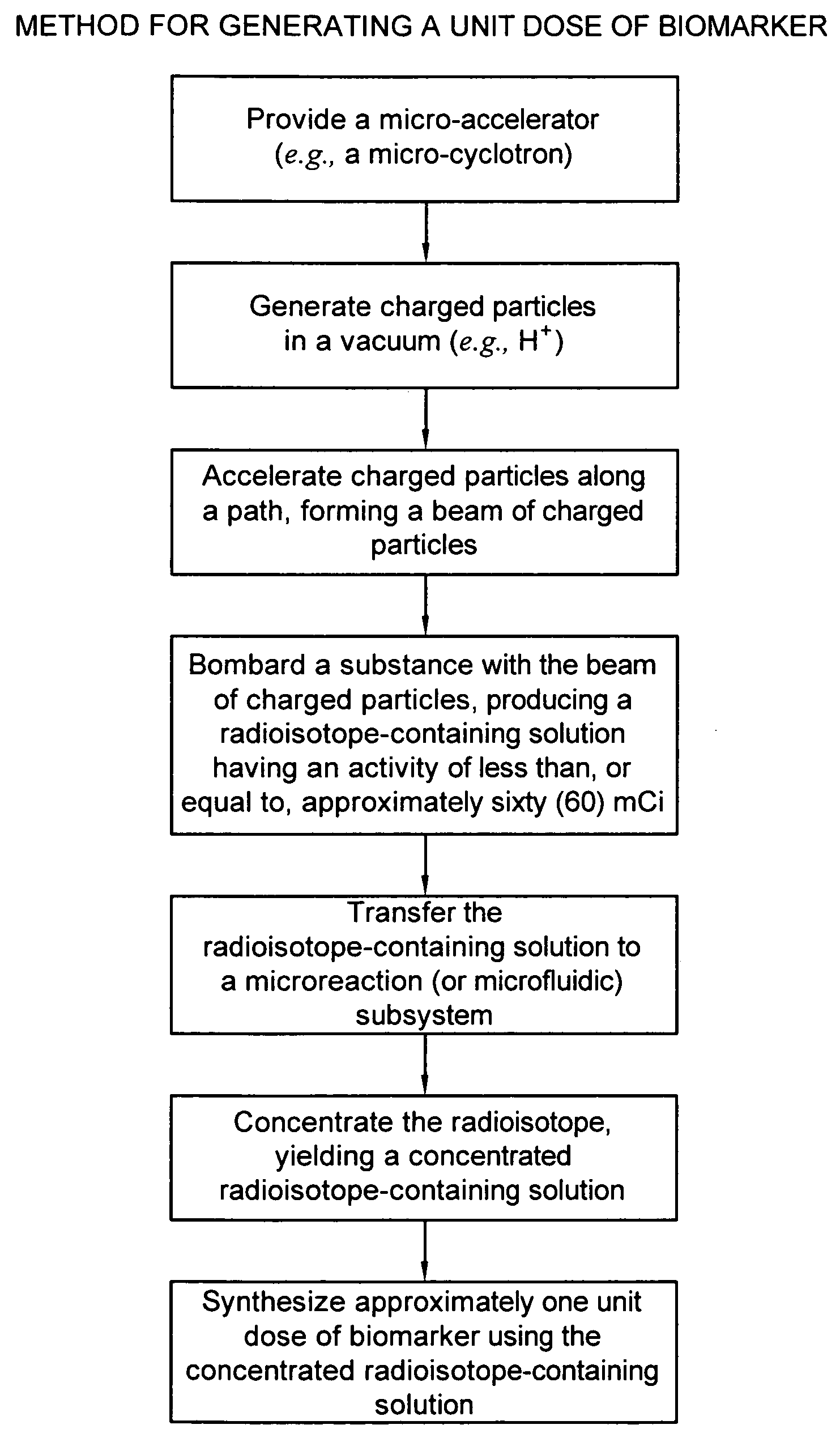

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

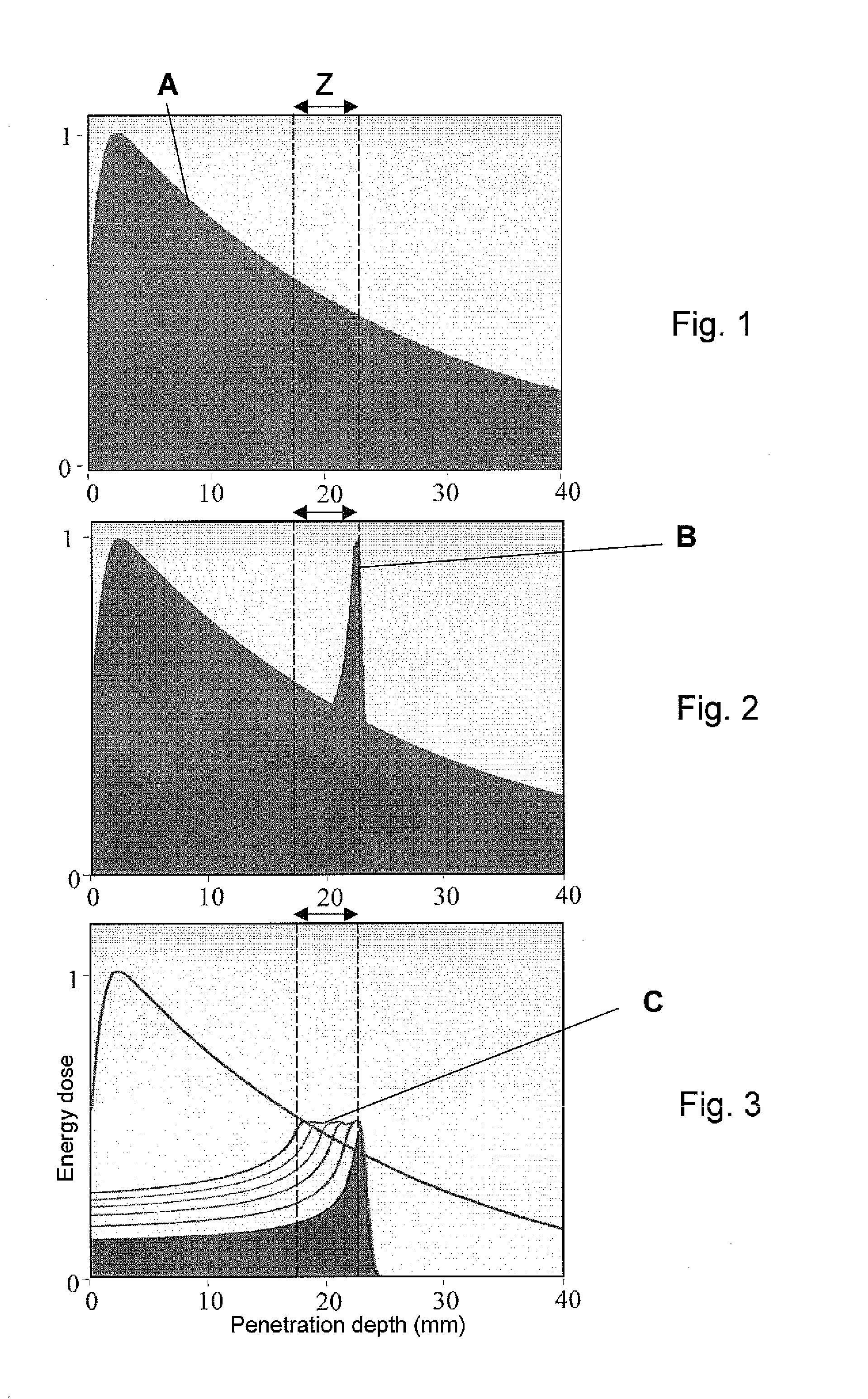

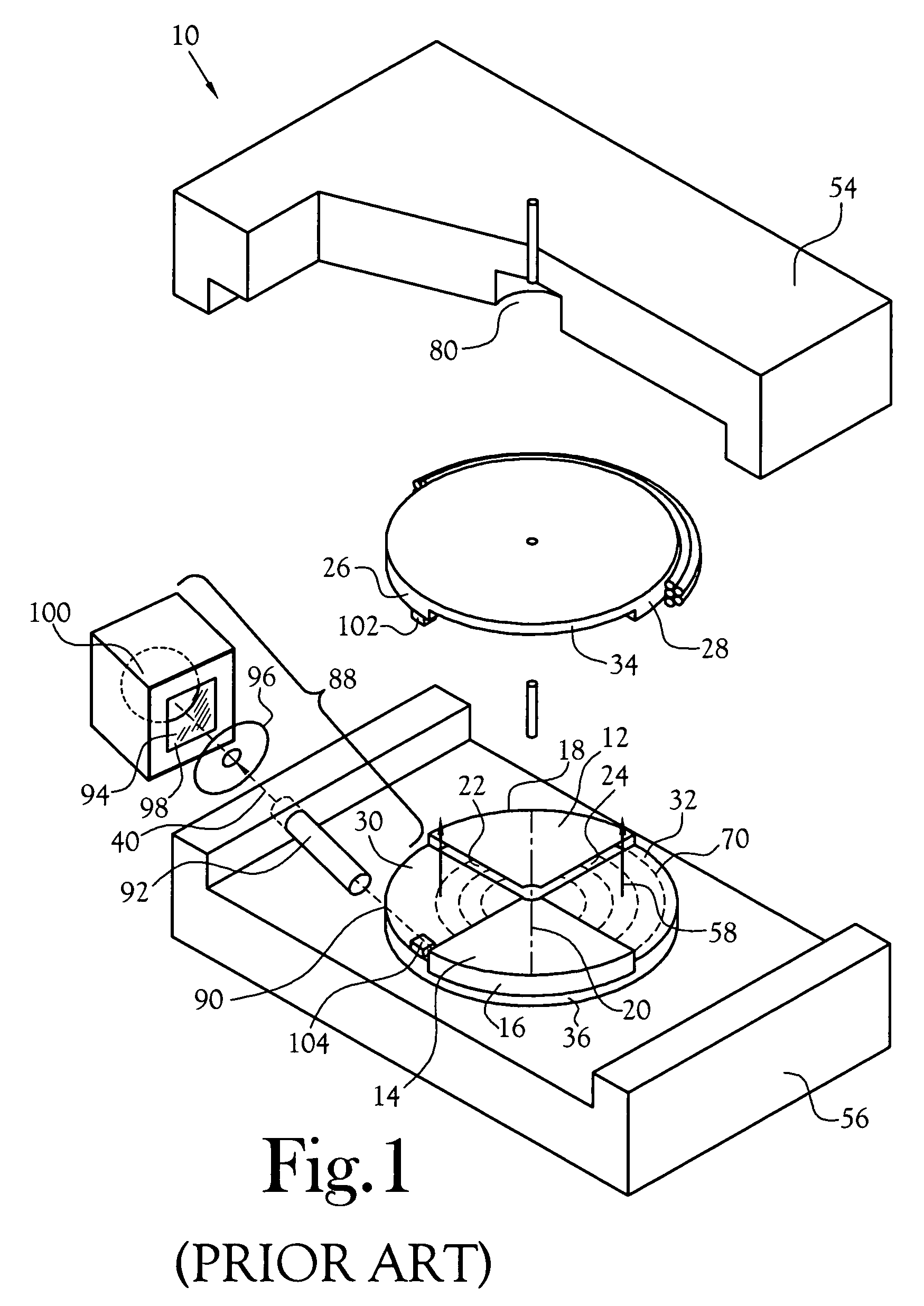

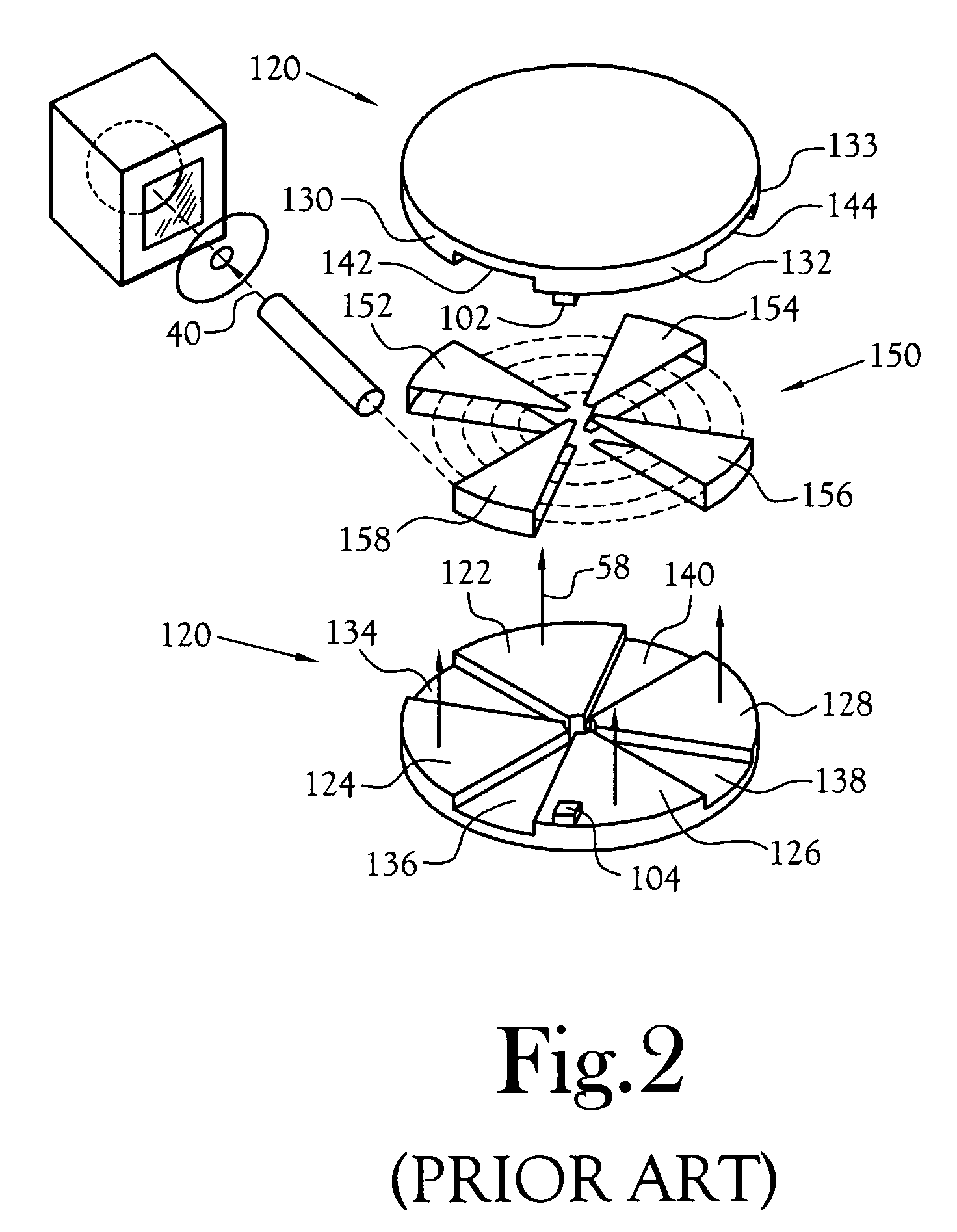

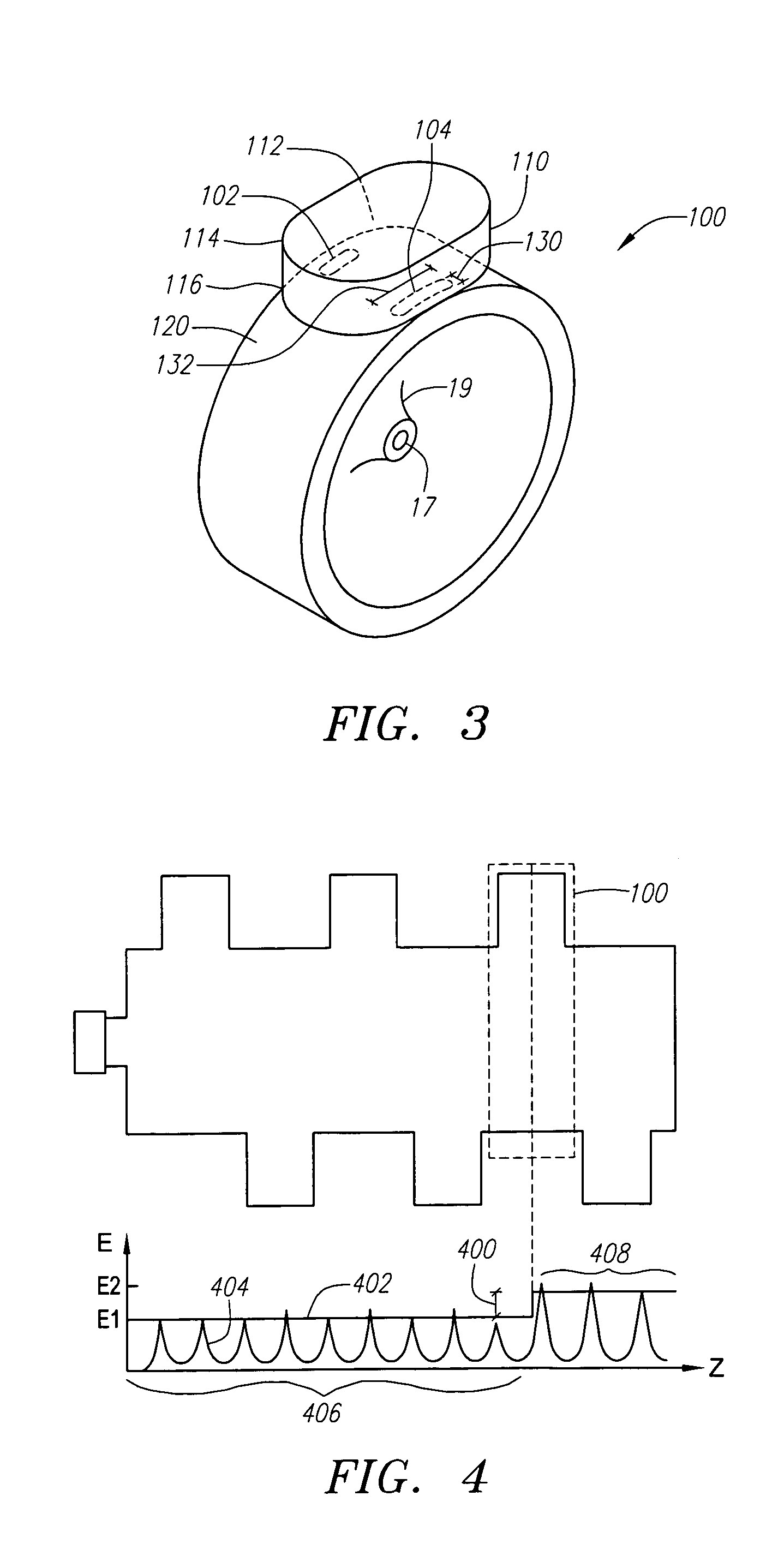

Device for varying the energy of a particle beam extracted from an accelerator

InactiveUS6433336B1Radiation/particle handlingElectrode and associated part arrangementsLower limitParticle accelerator

A device for varying the energy of a particle beam extracted from a fixed-energy particle accelerator includes a block of energy degrading material positioned in the path of the particle beam. The block of energy degrading material is preferably in the form of a ring arranged on a wheel. The ring is of a staircase configuration, having discrete steps defining a thickness between parallel entry and exit faces. According to one aspect of the invention, the block is configured so that the particle beam energy variation reaches a maximum at the edges of each step. This upper limit is also the lower limit of the next step. Thus, continuous energy variation is possible despite the fact that the thickness of the block varies in discrete steps.

Owner:ION BEAM APPL

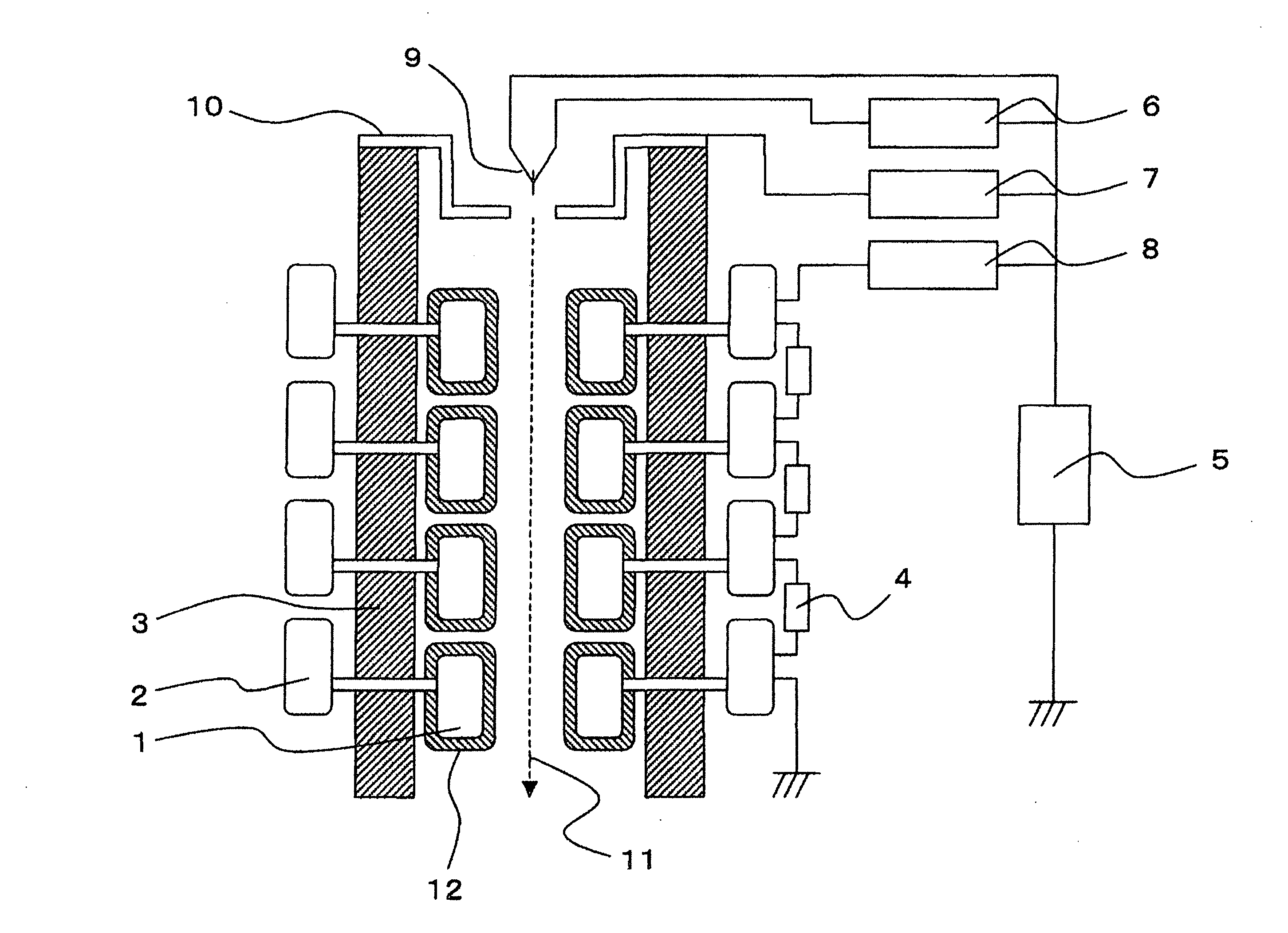

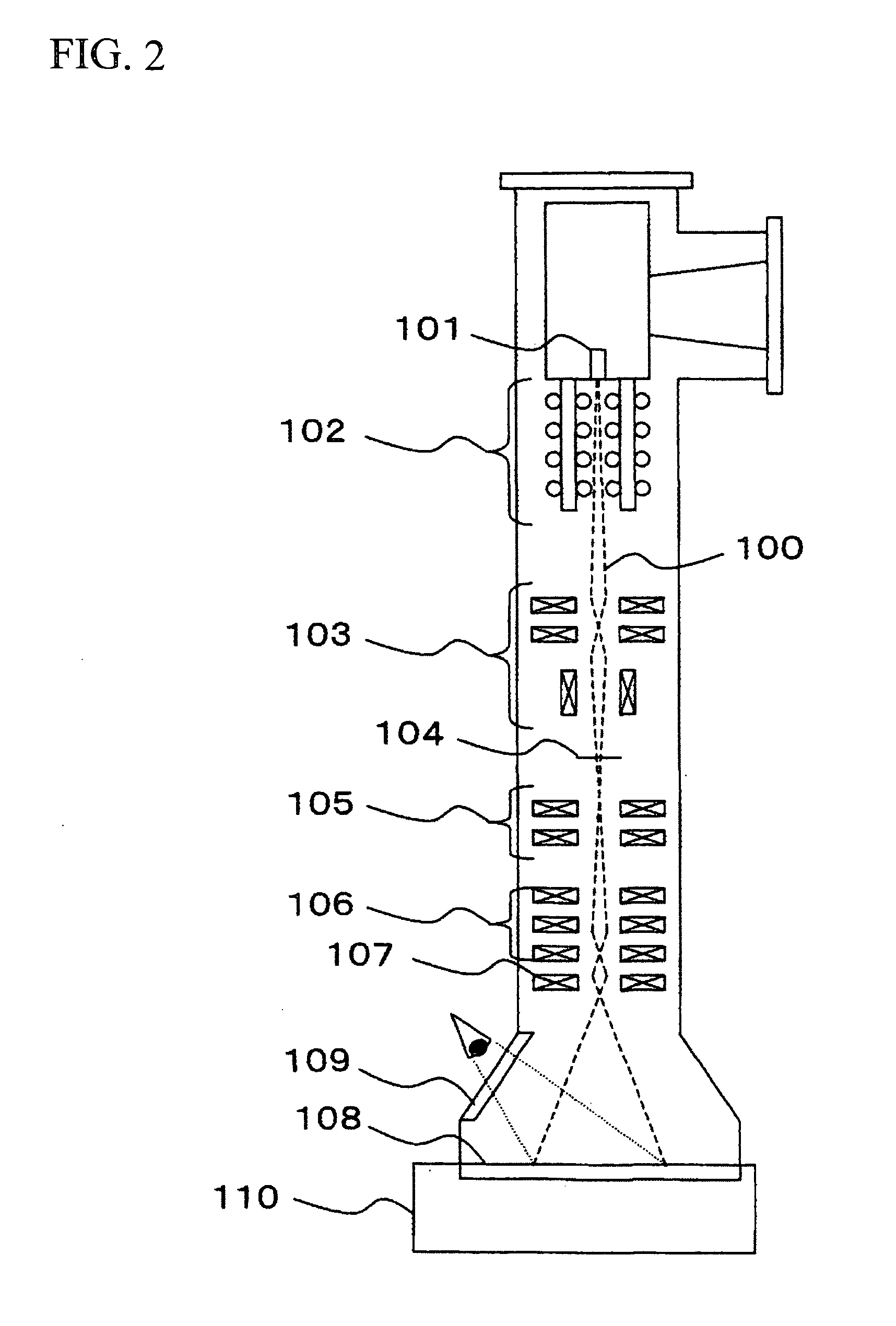

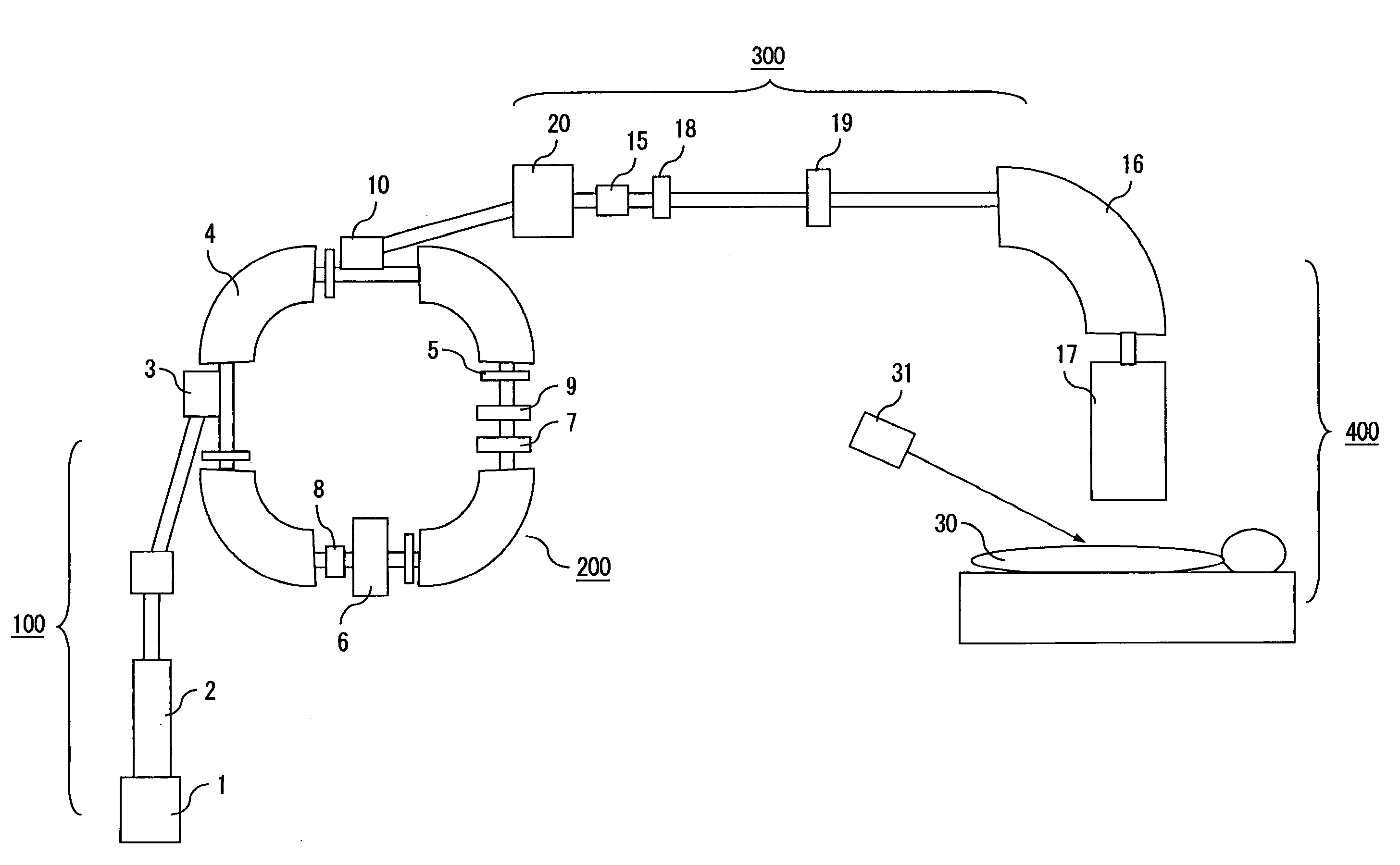

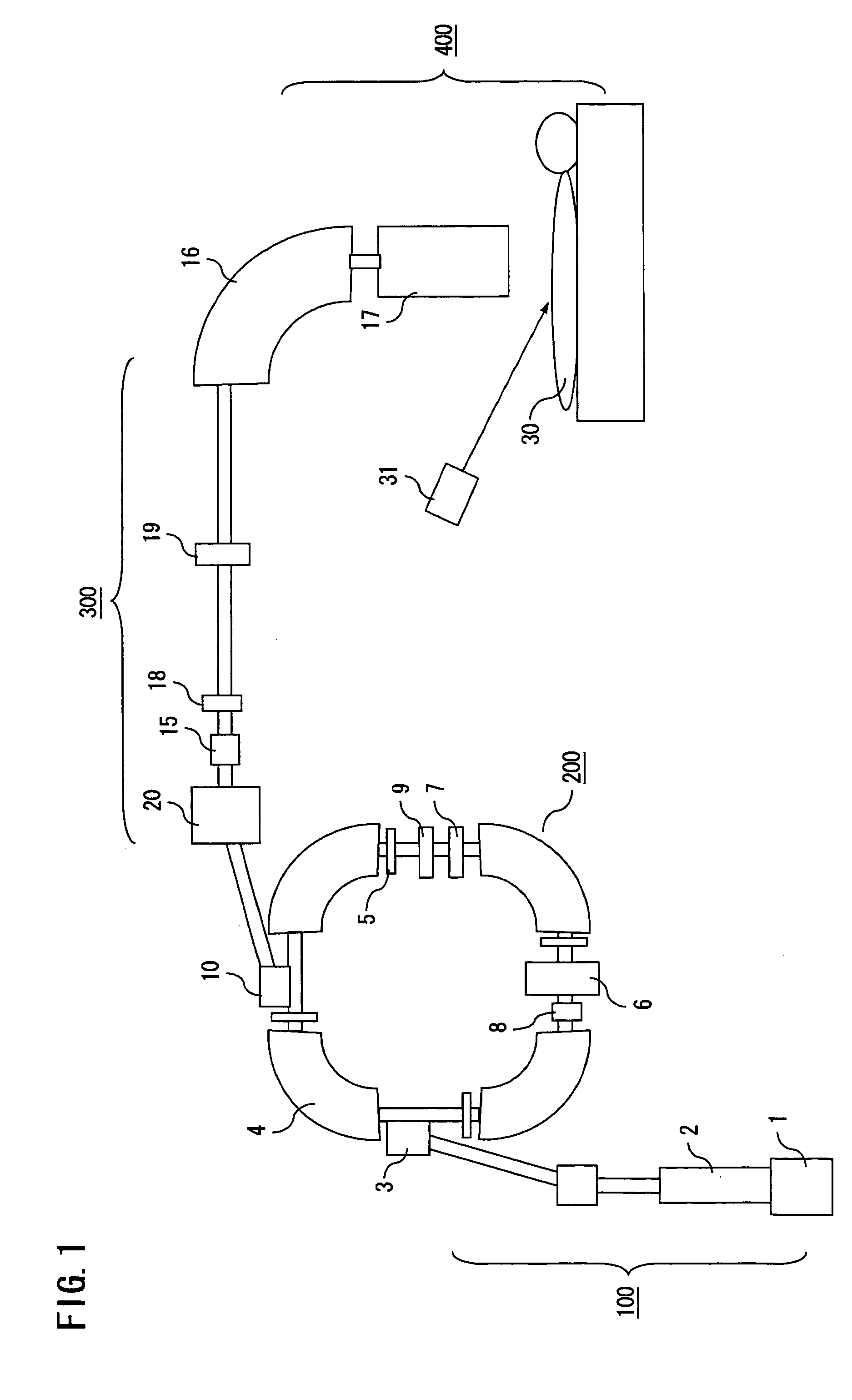

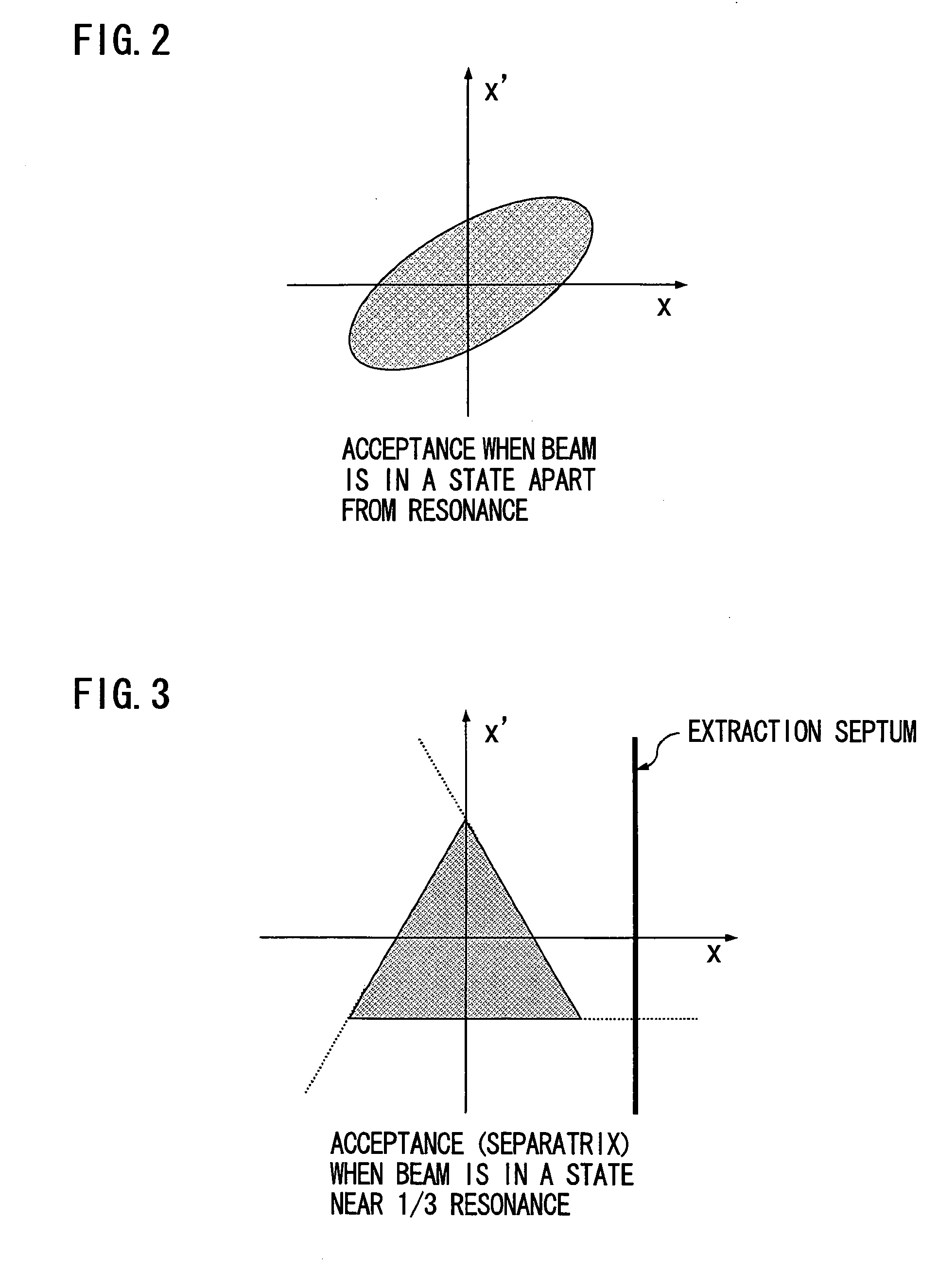

Charged-particle beam accelerator, particle beam radiation therapy system using the charged-particle beam accelerator, and method of operating the particle beam radiation therapy system

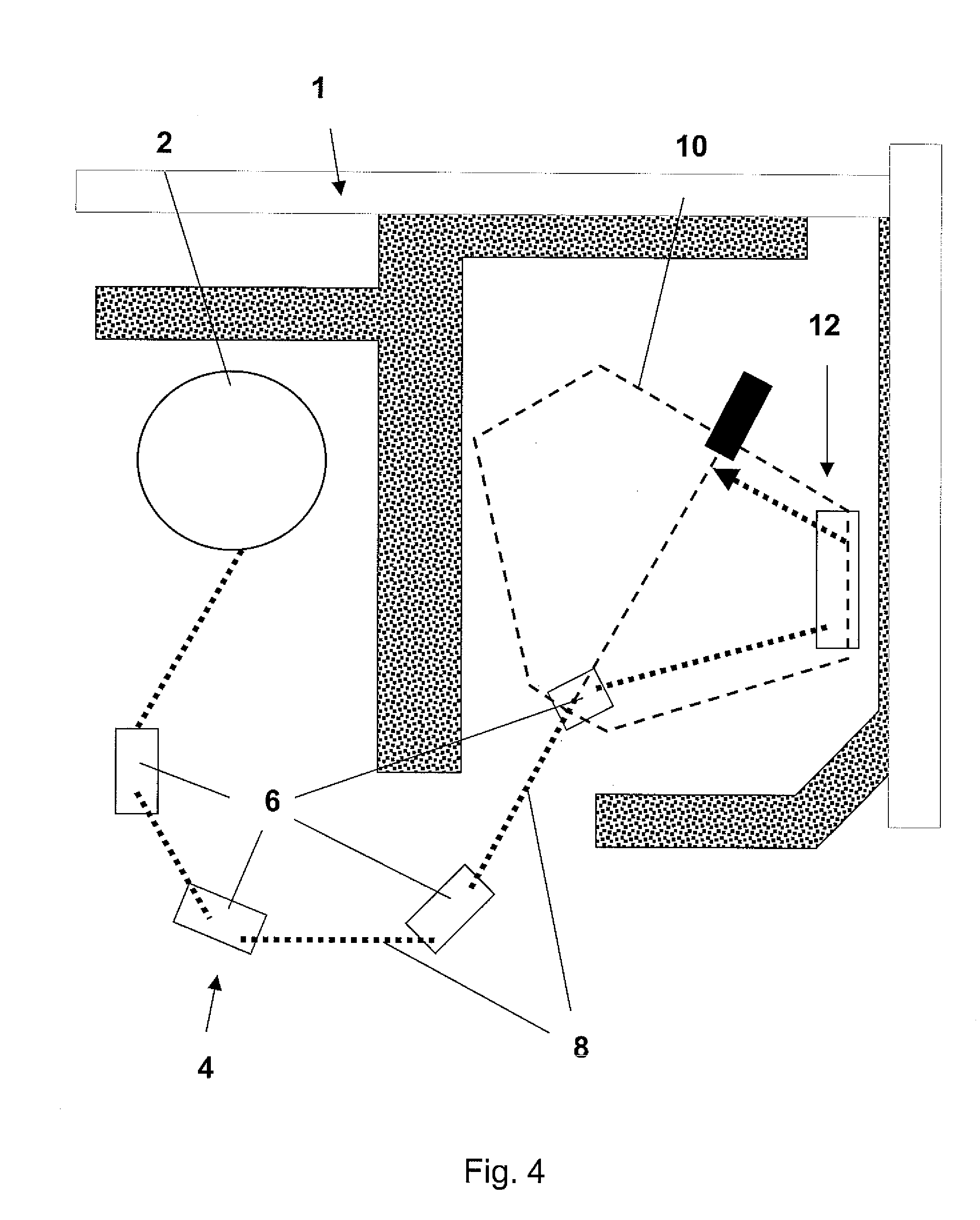

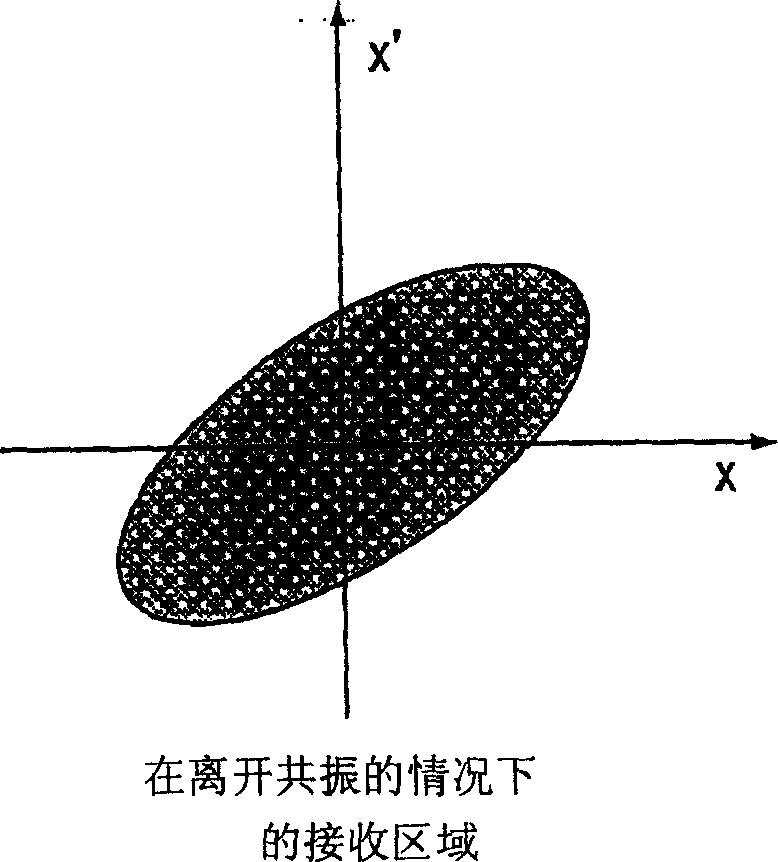

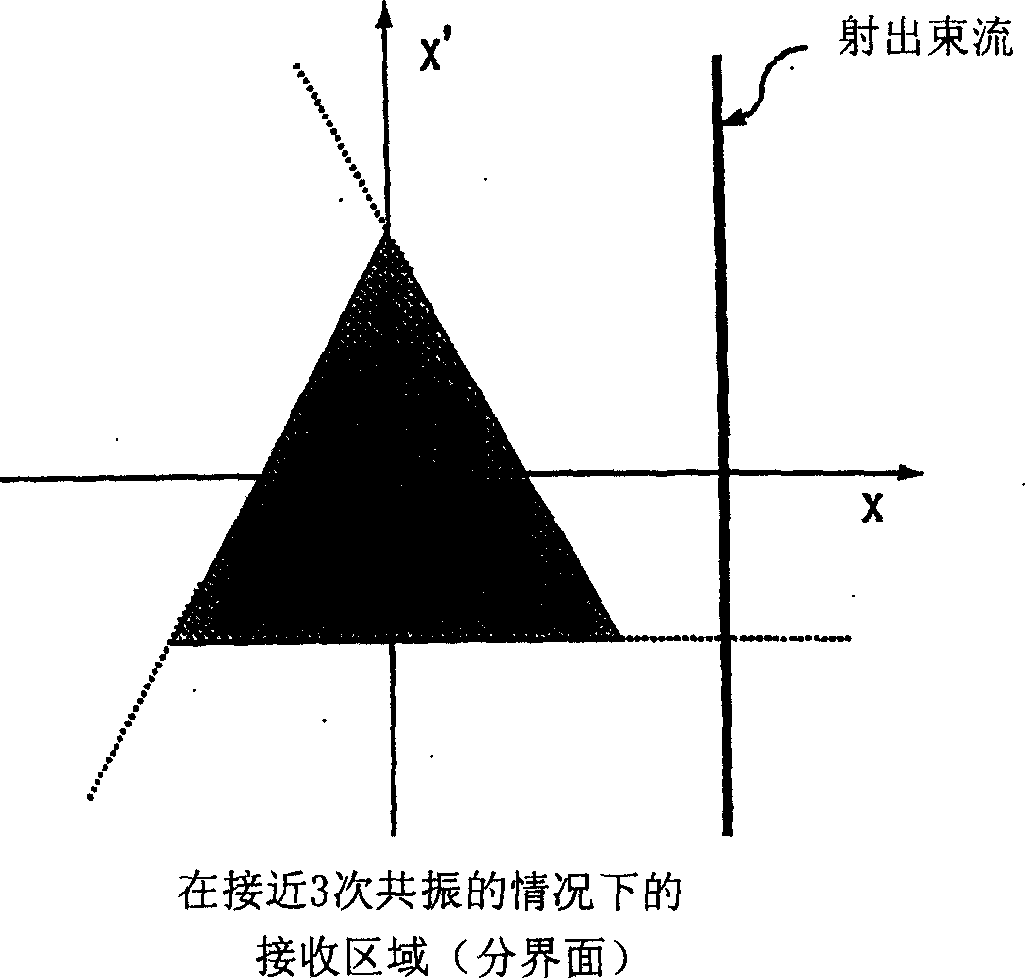

ActiveUS7122978B2Easy to identifyMagnetic induction acceleratorsMagnetic resonance acceleratorsParticle acceleratorResonance

A charged-particle beam accelerator includes an RF-KO unit for increasing the amplitude of betatron oscillation of a charged-particle beam within a stable region of resonance and an extraction quadrupole electromagnet unit for varying the stable region of resonance. The RF-KO unit is operated within a frequency range in which the circulating beam does not go beyond a boundary of the stable region of resonance, and the extraction quadrupole electromagnet unit is operated with appropriate timing as required for beam extraction so that the charged-particle beam is extracted with desired timing.

Owner:MITSUBISHI ELECTRIC CORP

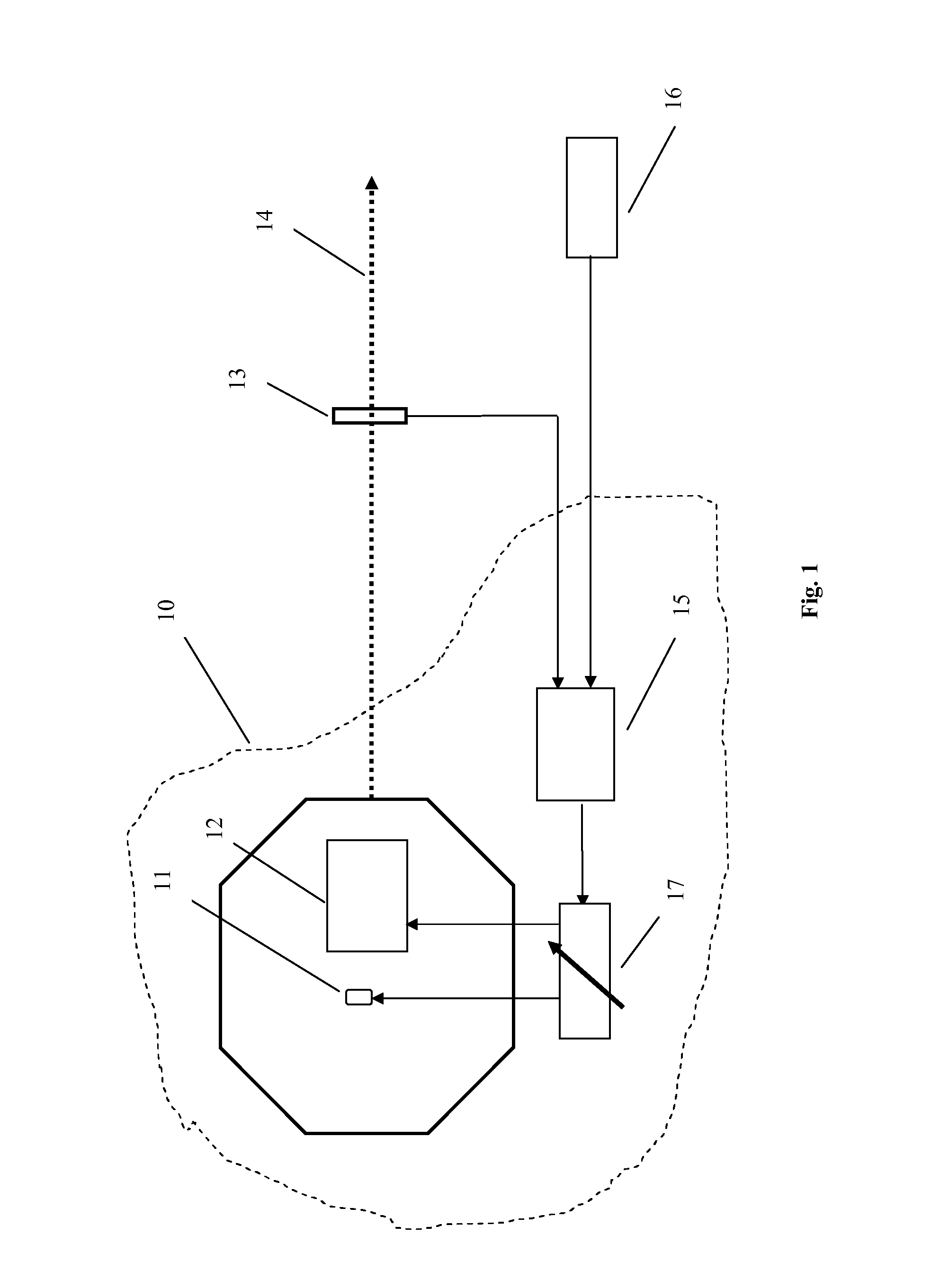

Device and method for regulating intensity of beam extracted from a particle accelerator

InactiveUS20040155206A1Thermometer detailsElectrode and associated part arrangementsElectric arcParticle accelerator

The invention concerns a device (10) for regulating the intensity of a beam extracted from a particle accelerator, such as a cyclotron, used for example for protontherapy, said particles being generated from an ion source. The invention is characterised in that it comprises at least: a comparator (90) determining a difference epsilon between a digital signal IR representing the intensity of the beam measured at the output of the accelerator and a setpoint value IC of the beam intensity: a Smith predictor (80) which determines on the basis of the difference epsilon, a corrected value of the intensity of the beam IP; an inverted correspondence table (40) supplying, on the basis of the corrected value of the intensity of the beam IP a setpoint value IA for supplying arc current from the ion source (20).

Owner:ION BEAM APPL

Biomarker generator system

ActiveUS20080067413A1Efficient dosingEfficient productionIsotope delivery systemsMaterial analysis using wave/particle radiationMicroreactorParticle accelerator

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

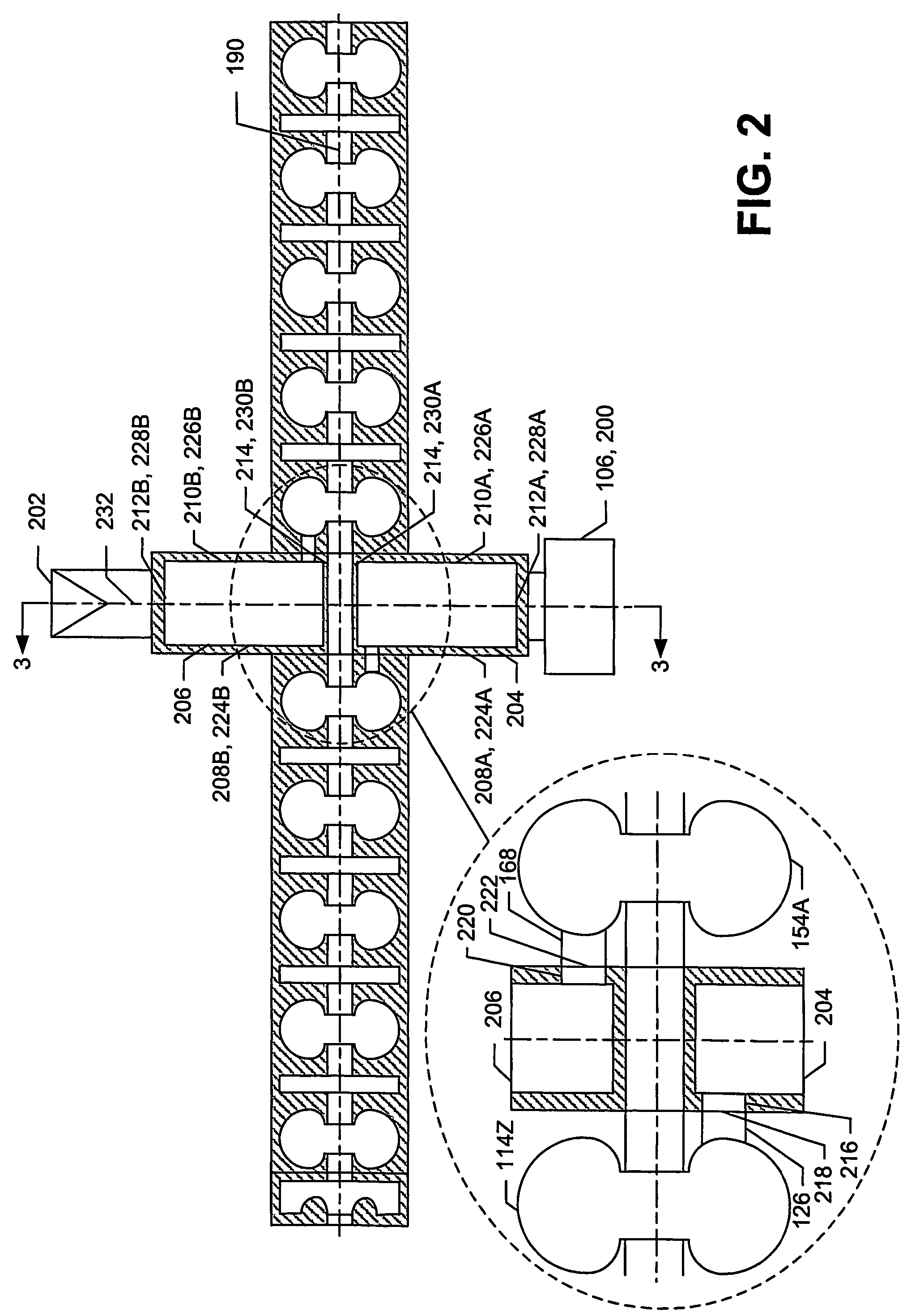

Standing wave particle beam accelerator

ActiveUS7339320B1Enhanced interactionWide bandwidthLinear acceleratorsKlystronsCapacitanceParticle accelerator

An accelerator for accelerating a particle beam includes a main body having a plurality of electromagnetic cavities coupled in series, and a first coupling body having a first side cavity coupled to one of the electromagnetic cavities through a first opening, and to another of the electromagnetic cavities through a second opening, wherein the first opening and the second opening have different configurations. The accelerator further includes a pair of conductive capacitively coupled noses secured to side walls of the first coupling body, wherein the pair of noses have equal lengths.

Owner:HONEYWELL INT INC +1

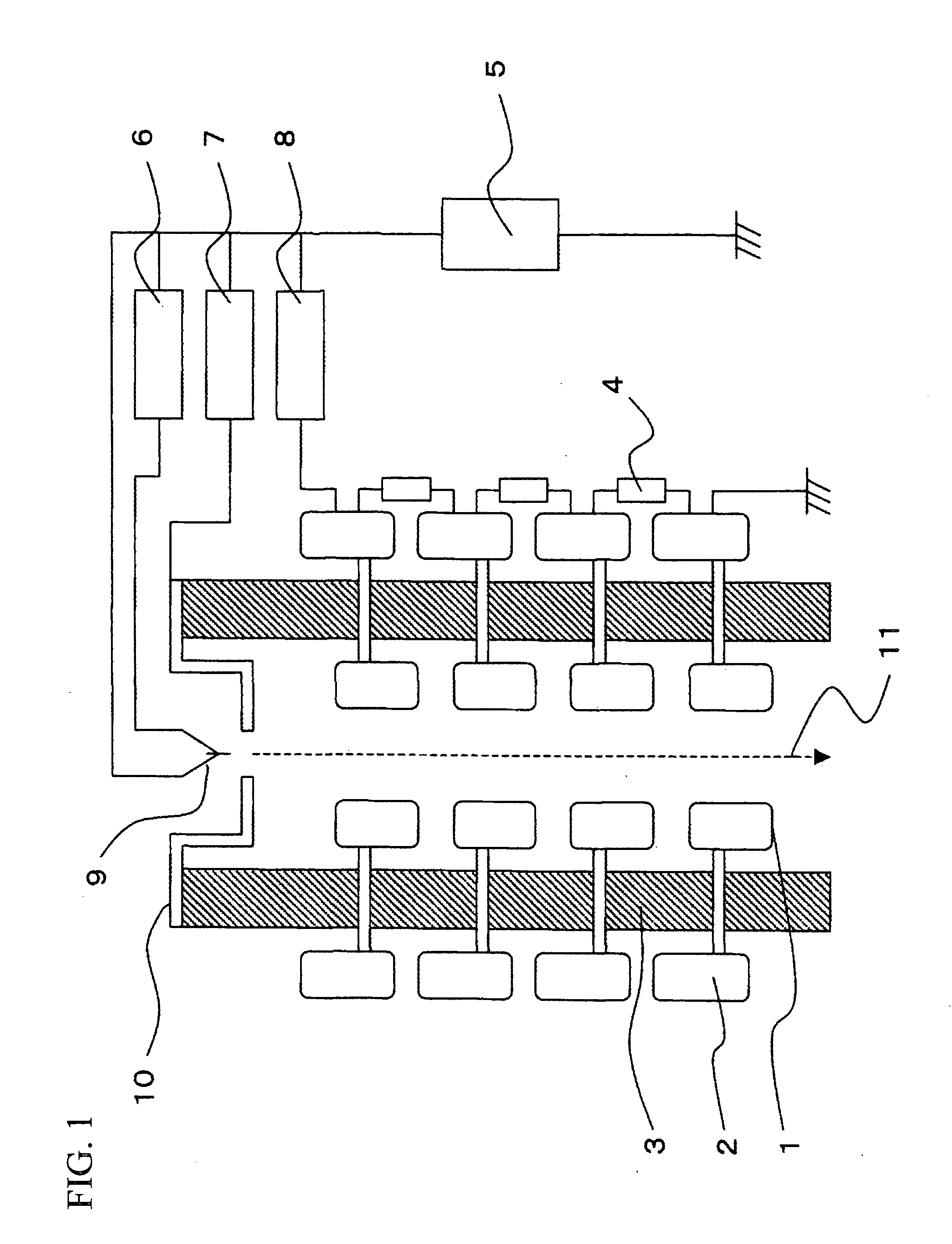

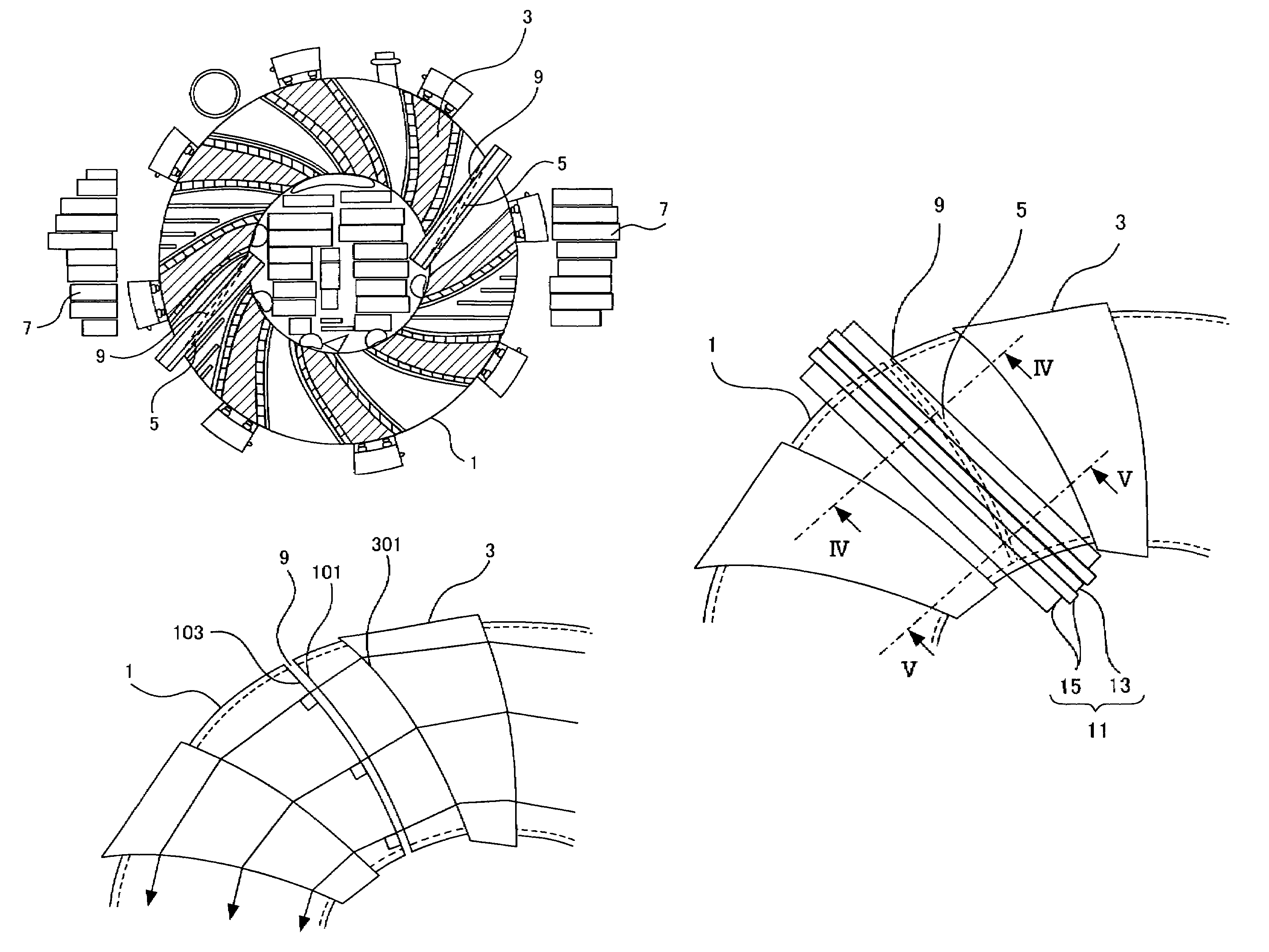

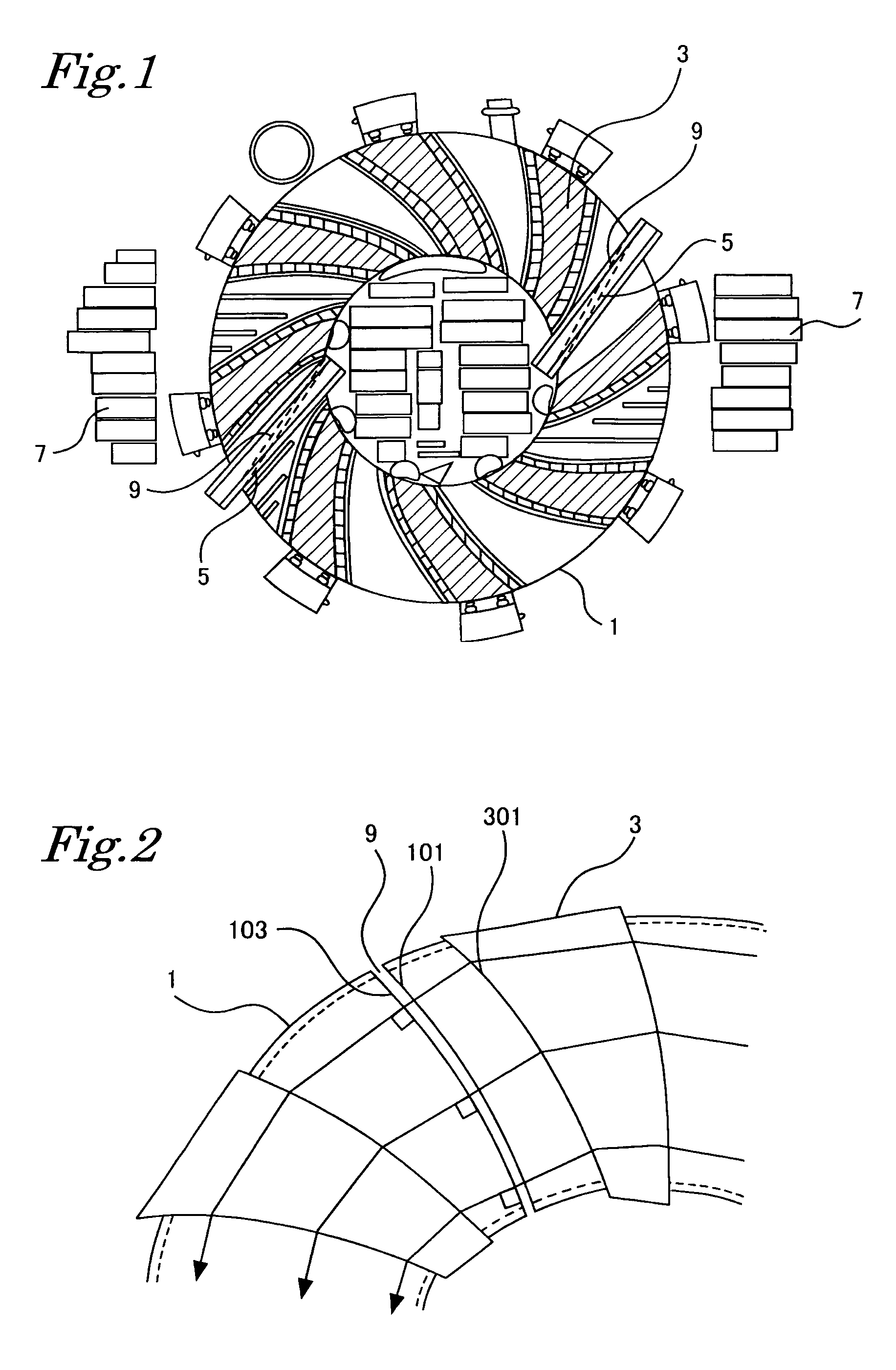

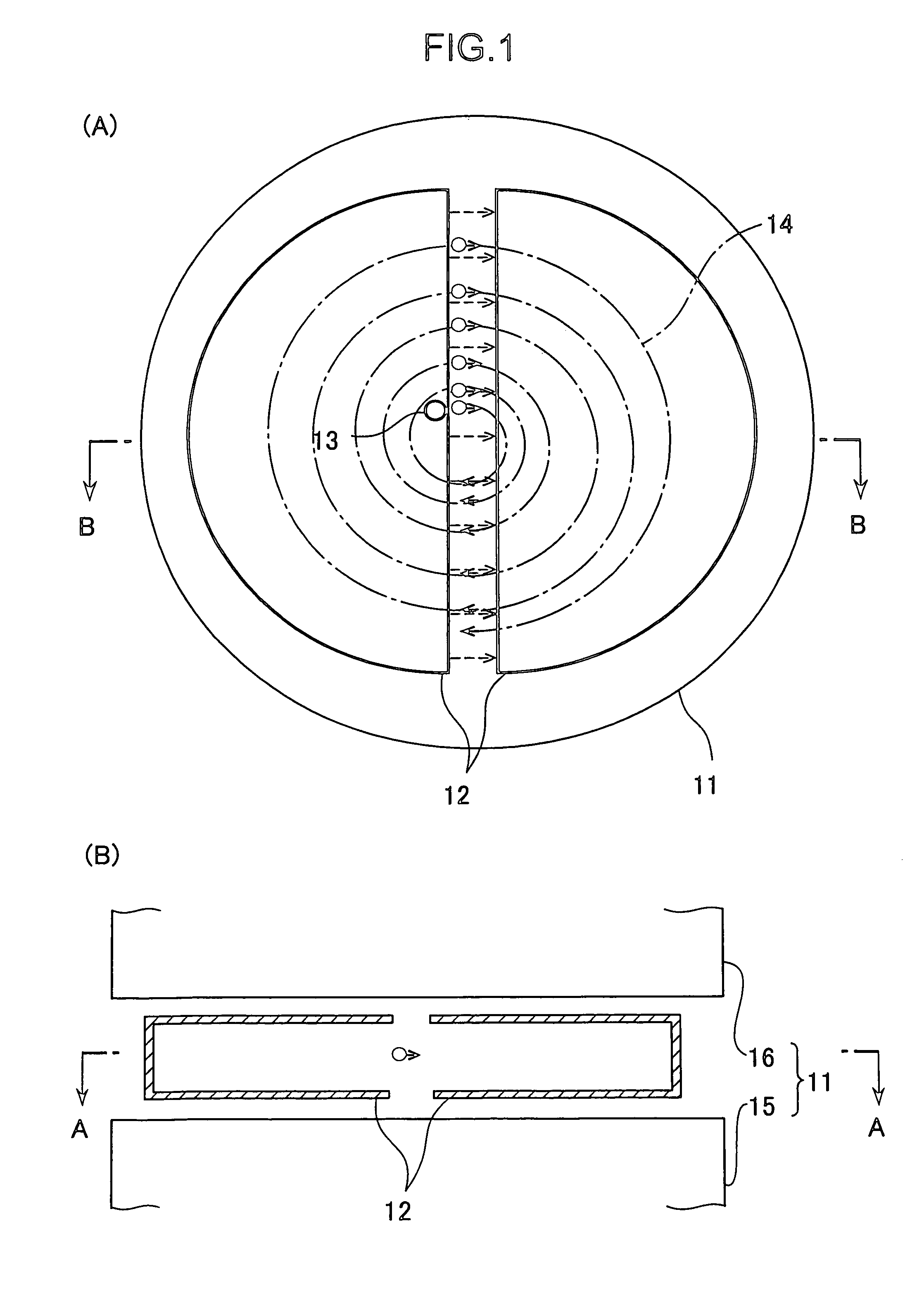

Particle beam accelerator

ActiveUS7332880B2Reduce lossesStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsParticle acceleratorParticle beam

The present invention provides a particle beam accelerator for accelerating charged particles along a traveling direction of the charged particles. The invention provides a particle beam accelerator, in which the charged particle beam deflected by spiral-shaped-deflecting electromagnet 3, is accelerated by an accelerating unit 5, the charged particle beam circulating in an annular vacuum passageway of a vacuum duct 1 a plurality of times differing in orbit. And gap 9 is formed in the accelerating unit 5 of the vacuum duct 1, and gap-constituting face of the vacuum duct 1 is formed to be perpendicular to each of the traveling directions of the charged particle beam orbiting on a first orbit and on a second orbit. In the above accelerator, vibrations of the charged particle beam can be brought under control and loss of the charged particle beam can be reduced.

Owner:MITSUBISHI ELECTRIC CORP

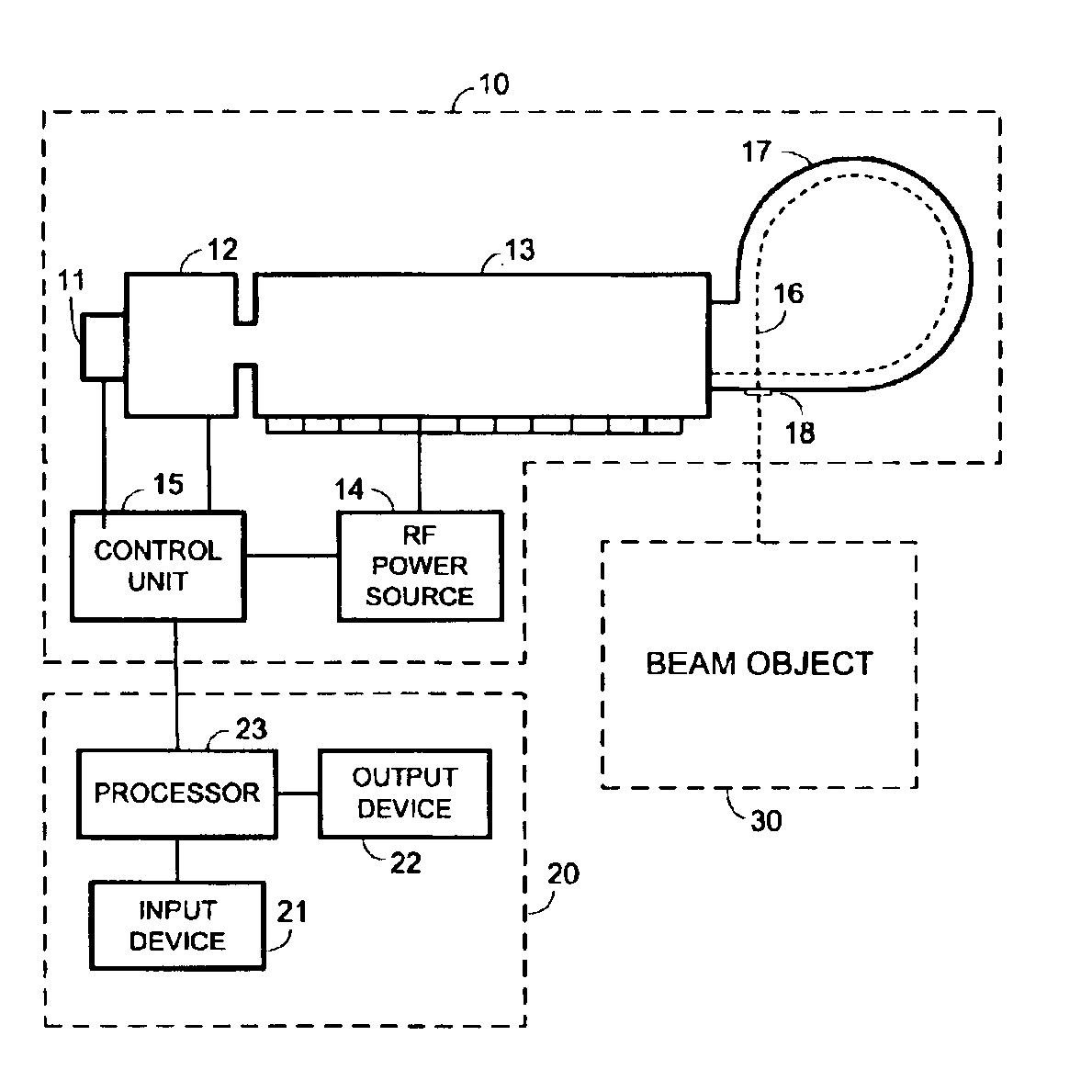

System and method of applying adaptive control to the control of particle accelerators with varying dynamics behavioral characteristics using a nonlinear model predictive control technology

ActiveUS7184845B2Efficient collisionMore accurateAcceleratorsAdaptive controlParticle acceleratorIdentifying Variable

The present invention provides a method for controlling nonlinear control problems within particle accelerators. This method involves first utilizing software tools to identify variable inputs and controlled variables associated with the particle accelerator, wherein at least one variable input parameter is a controlled variable. This software tool is further operable to determine relationships between the variable inputs and controlled variables. A control system that provides variable inputs to and acts on controller outputs from the software tools tunes one or more manipulated variables to achieve a desired controlled variable, which in the case of a particle accelerator may be realized as a more efficient collision.

Owner:ROCKWELL AUTOMATION TECH

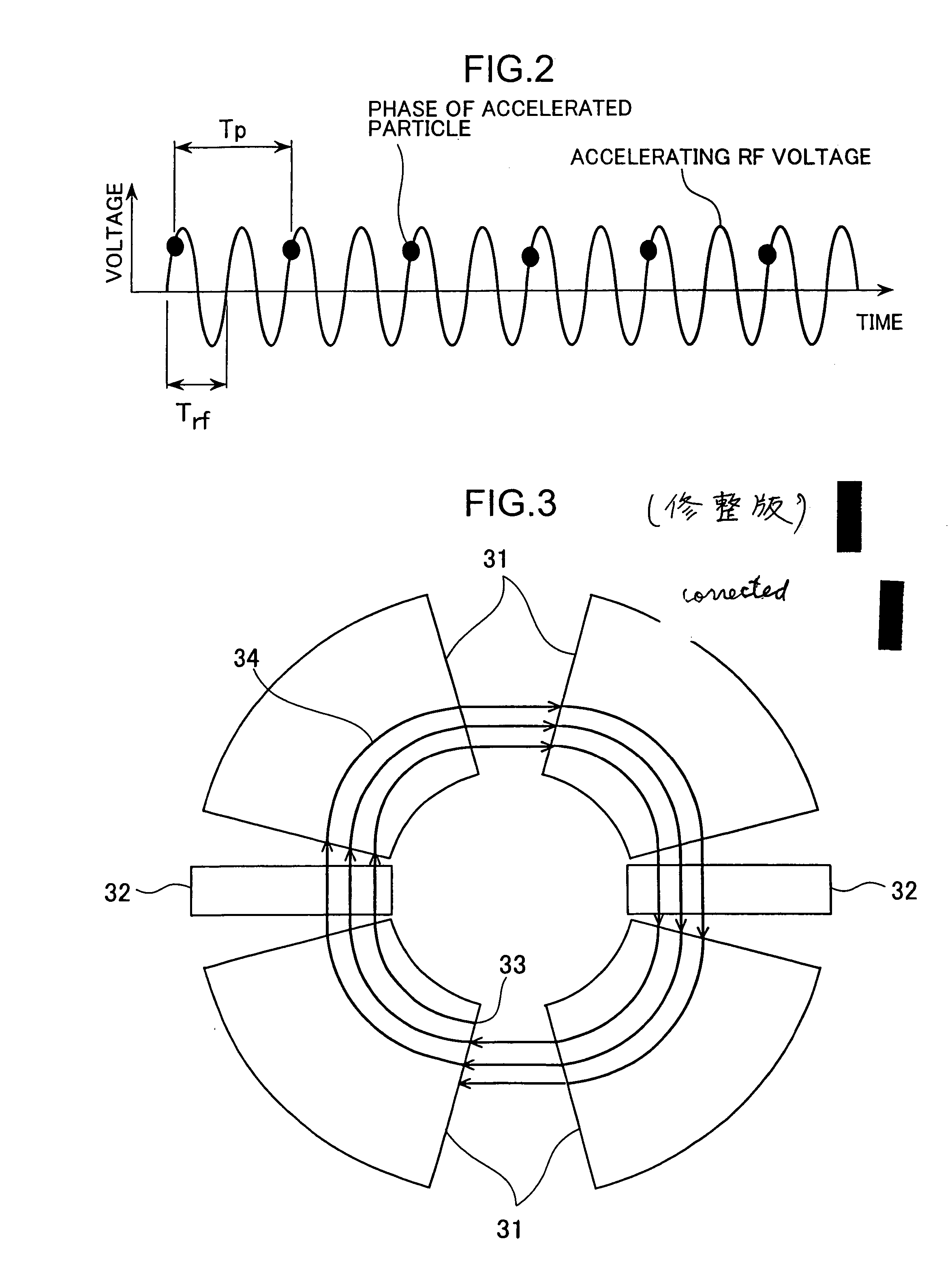

Spiral orbit charged particle accelerator and its acceleration method

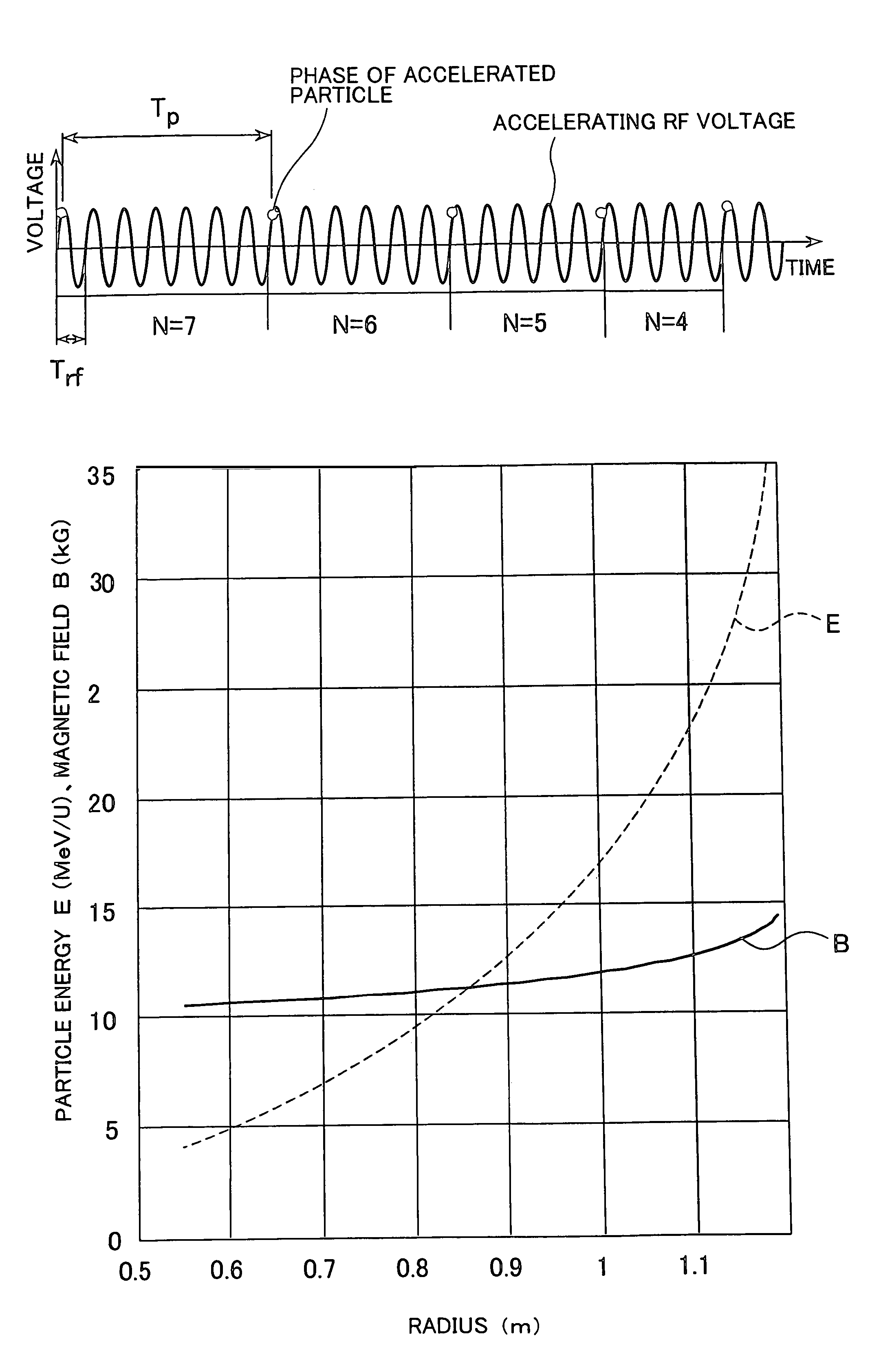

InactiveUS7262565B2High energyIncreasing magnet sizeMagnetic resonance acceleratorsKlystronsParticle acceleratorHarmonic

According to the present invention, a non-isochronous magnetic field distribution in which the magnetic field increases as the radius increases is formed and a distribution of fixed-frequency accelerating RF voltage is formed, said non-isochronous magnetic field distribution and said distribution of fixed-frequency accelerating RF voltage being formed so that a harmonic number defined as a ratio of the particle revolution period to the period of the accelerating RF voltage decreases in integer for every particle revolution.

Owner:NAT INST OF RADIOLOGICAL SCI

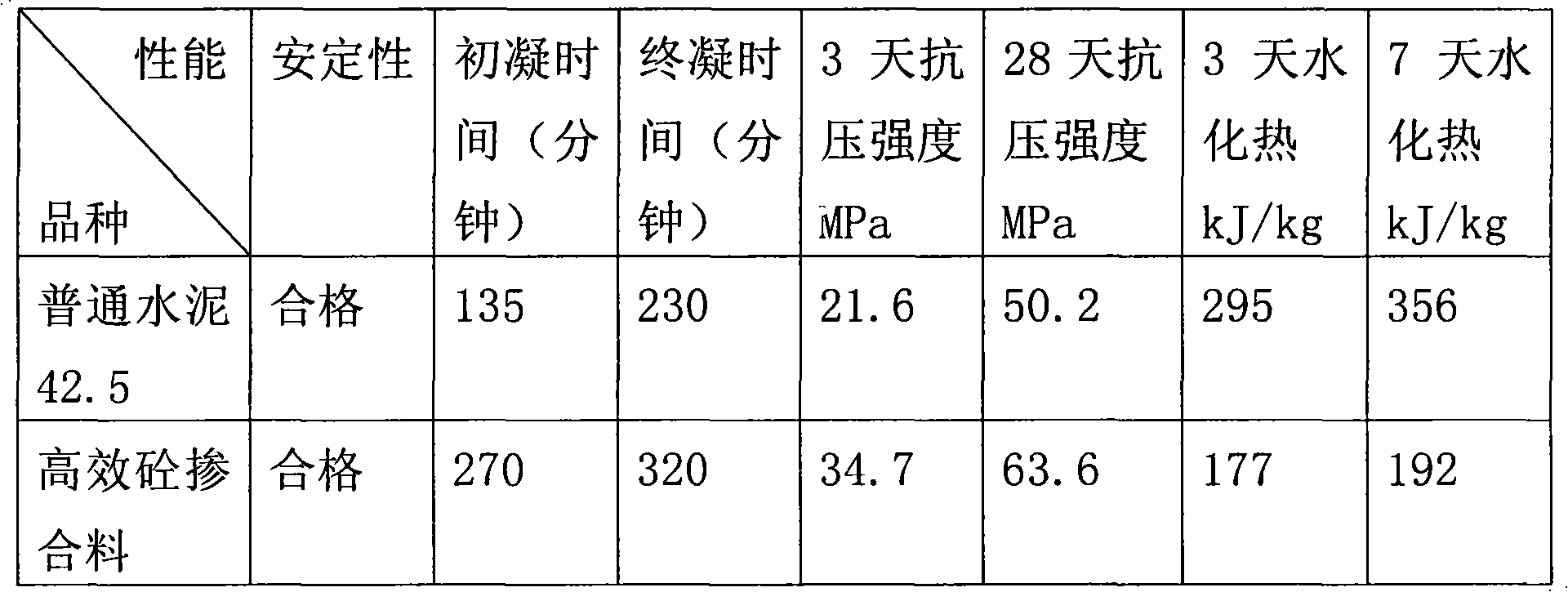

Premixed and pumped heavy concrete

InactiveCN101676239AGuaranteed homogeneityGuaranteed uniformitySolid waste managementApparent densityParticle accelerator

The invention relates to a premixed and pumped heavy concrete which comprises 80-93 parts by weight of heavy aggregate, 6-15 parts by weight of cement materials, 2-5 parts by weight of water, less than 0.4 part by weight of concrete additive and less than 0.01 part by weight of function regulator. The apparent density of the concrete is more than 3500kg / m<3>, the mixture has no phenomena of lamination and segregation, and the concrete has good cohesion and plasticity protection, thereby being applicable to long-distance pumping. The concrete selects a high-performance concrete admixture and can avoid the occurrence of cracks of the large-volume concrete caused by hydration heat of cement. The concrete is applicable to an anti-radiation heavy concrete engineering with the thickness of morethan 1500mm. The concrete can be widely used in shielding places of nuclear reactors, medical particle accelerators, customs inspection, scientific research laboratories and other applications of therelated nuclear industry and the radioactive isotope technology.

Owner:HUNAN NO 6 ENG CO LTD

Multi-energy particle accelerator

Some embodiments include operation of an accelerator waveguide to accelerate particles to a first energy within the waveguide, wherein a prebuncher coupled to the waveguide outputs particle bunches having a first phase, change of a phase at which particle bunches will be output from the prebuncher from the first phase to a second phase, and operation of the accelerator waveguide to accelerate particles to a second energy within the waveguide, wherein the prebuncher outputs particle bunches having the second phase. Further aspects provide change of a resonant frequency of the prebuncher from a first frequency to a second frequency. According to still further aspects, the prebuncher includes a prebuncher cavity and change of the resonant frequency comprises change of a shape of the prebuncher cavity.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Multi-section particle accelerator with controlled beam current

InactiveUS7208890B2Reducing and eliminating reflectionEasy transferLinear acceleratorsKlystronsParticle acceleratorAccelerated particle

Owner:SCANTECHIBS IP HLDG

Rod-loaded radiofrequency cavities and couplers

InactiveUS20080068112A1Effective dampingResonatorsCoupling devicesParticle acceleratorAccelerated particle

This invention relates to radiofrequency (rf) cavities and couplers that comprise metallic or dielectric rods to provide specified concentration of field patterns for the operating modes in the interaction region, for applications in particle accelerators, pulsed rf power sources, amplifiers, mode converters and power couplers.

Owner:DULY RES

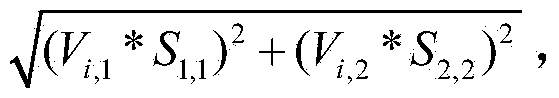

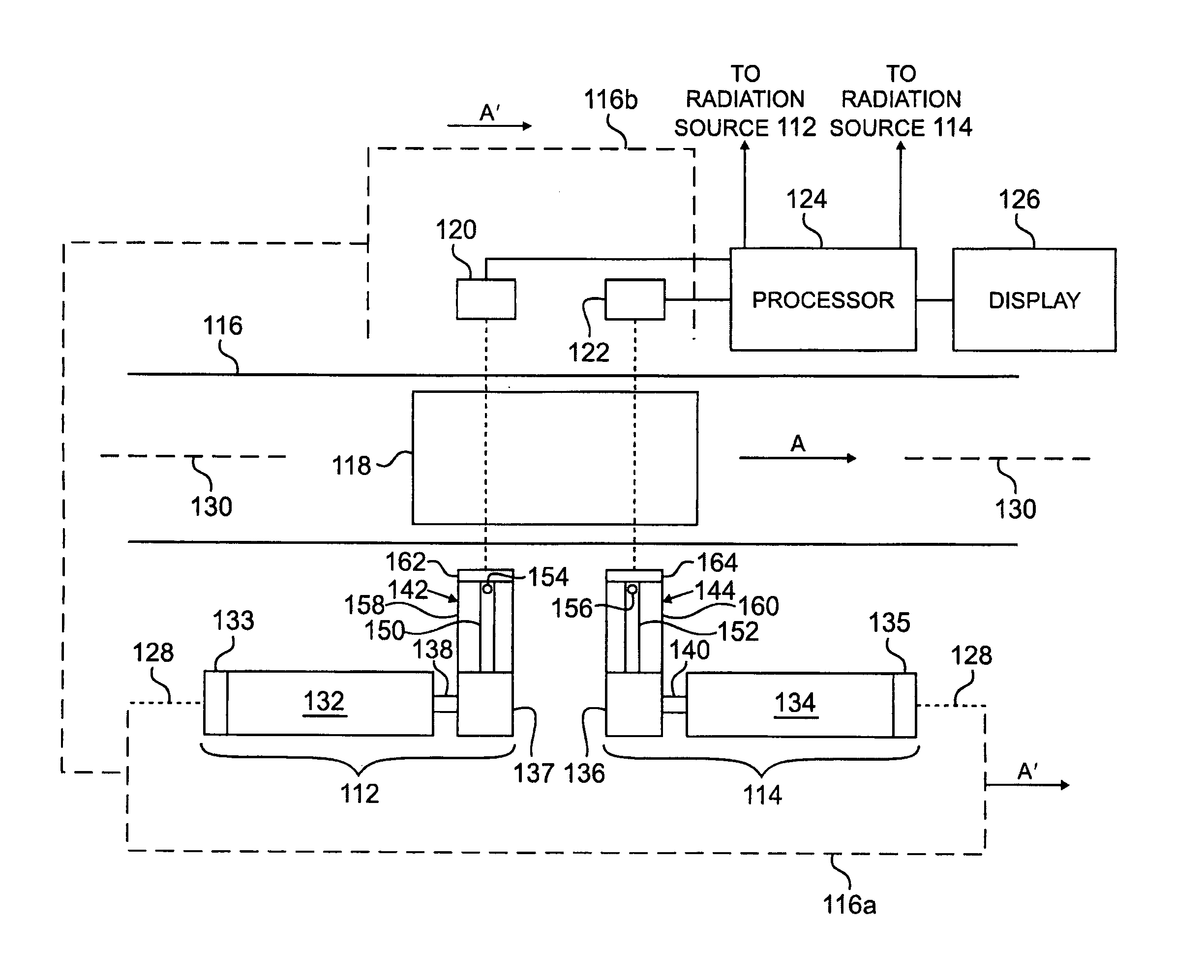

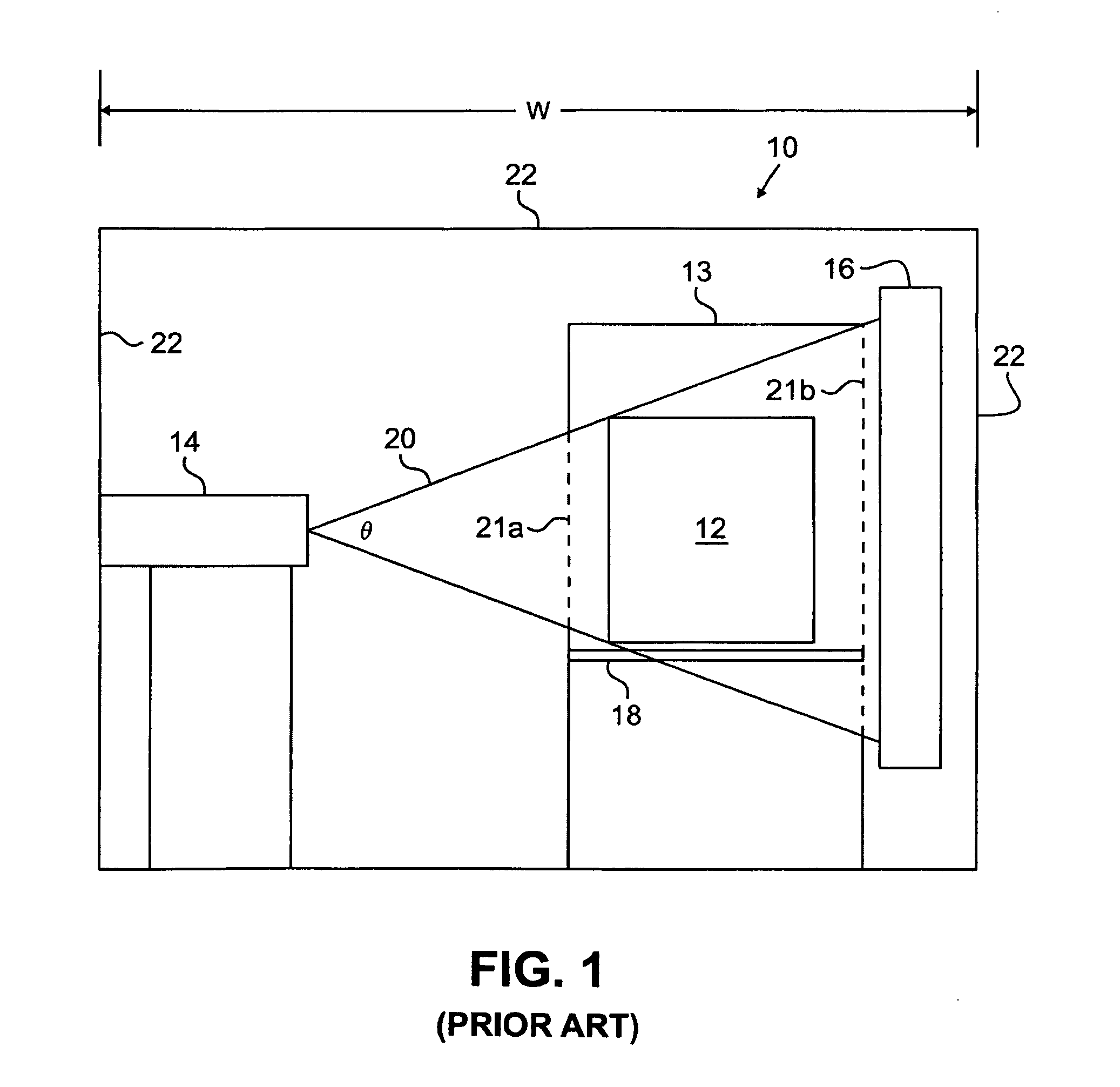

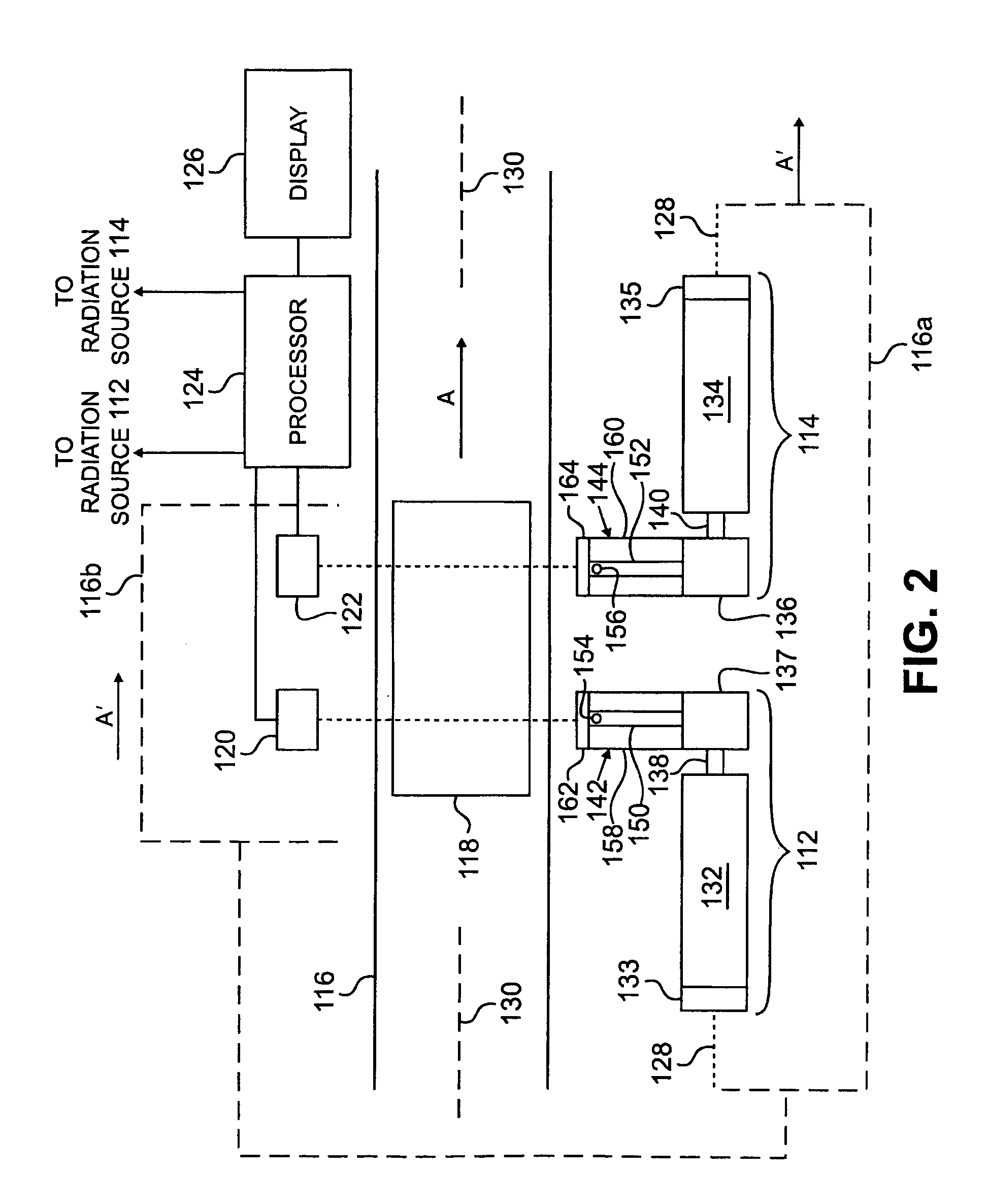

Compact, interleaved radiation sources

ActiveUS20100127169A1Improve compactionCompact X-ray scanning systemStability-of-path spectrometersMaterial analysis by optical meansParticle acceleratorBending magnets

Compact, dual energy radiation scanning systems are described comprising two particle beam accelerators, each configured to accelerate charged particles to different energies, positioned parallel to a direction of movement of an object to be inspected. The accelerator may be positioned perpendicular to a plane of the conveying system, instead. Bend magnet systems bend each charged particle beam toward a respective target. Alternatively, a single dual energy accelerator capable of accelerating charged particles to at least two different energies is positioned parallel to the direction of movement of the object, or perpendicular to a plane of the conveying system. A single bend magnet system is provided to bend each accelerated charged particle beam toward the same target. The particle beams may be bent through an orbit chamber. Two separate passages may be defined through at least part of the orbit chamber, one for charged particles having each energy.

Owner:VAREX IMAGING CORP

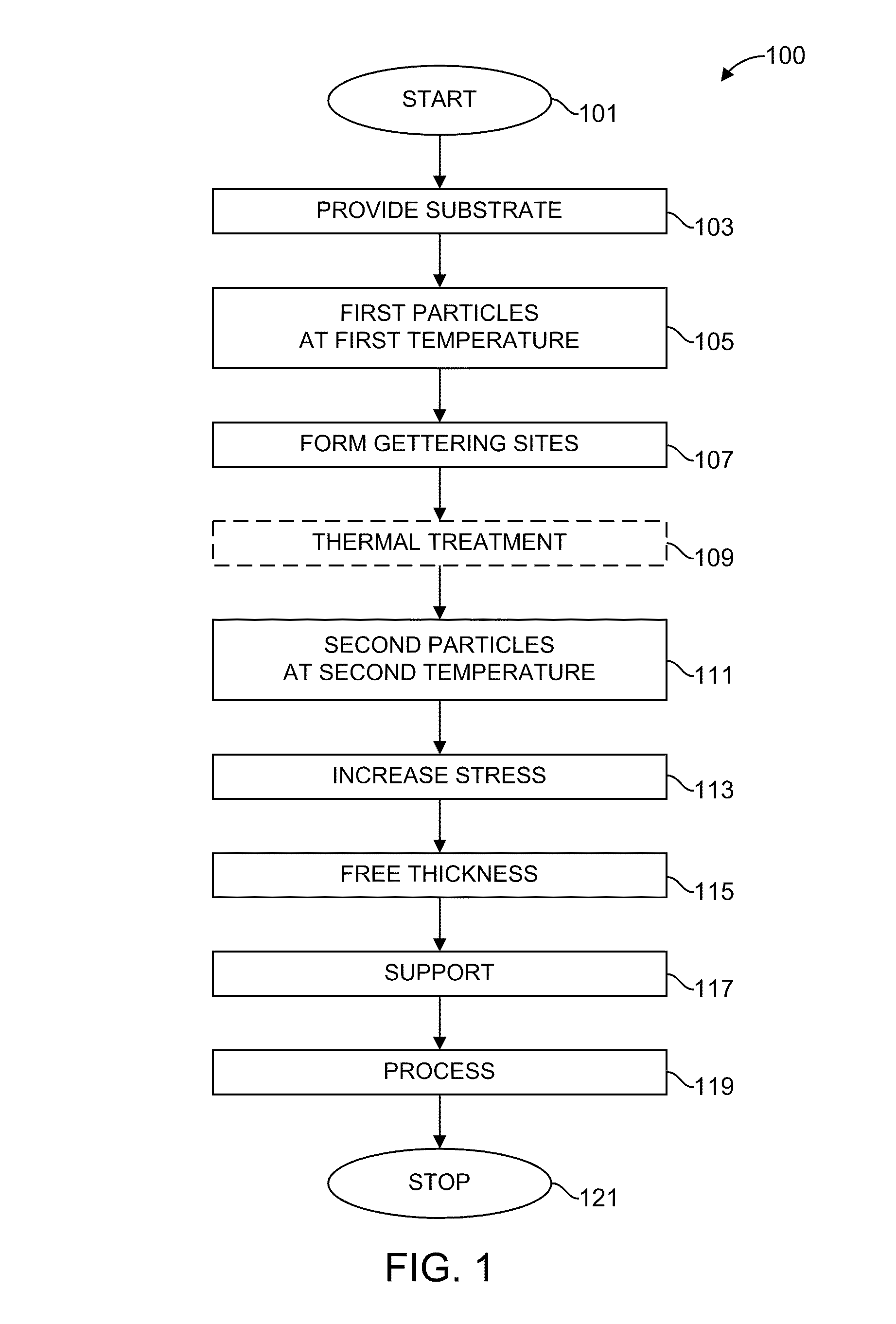

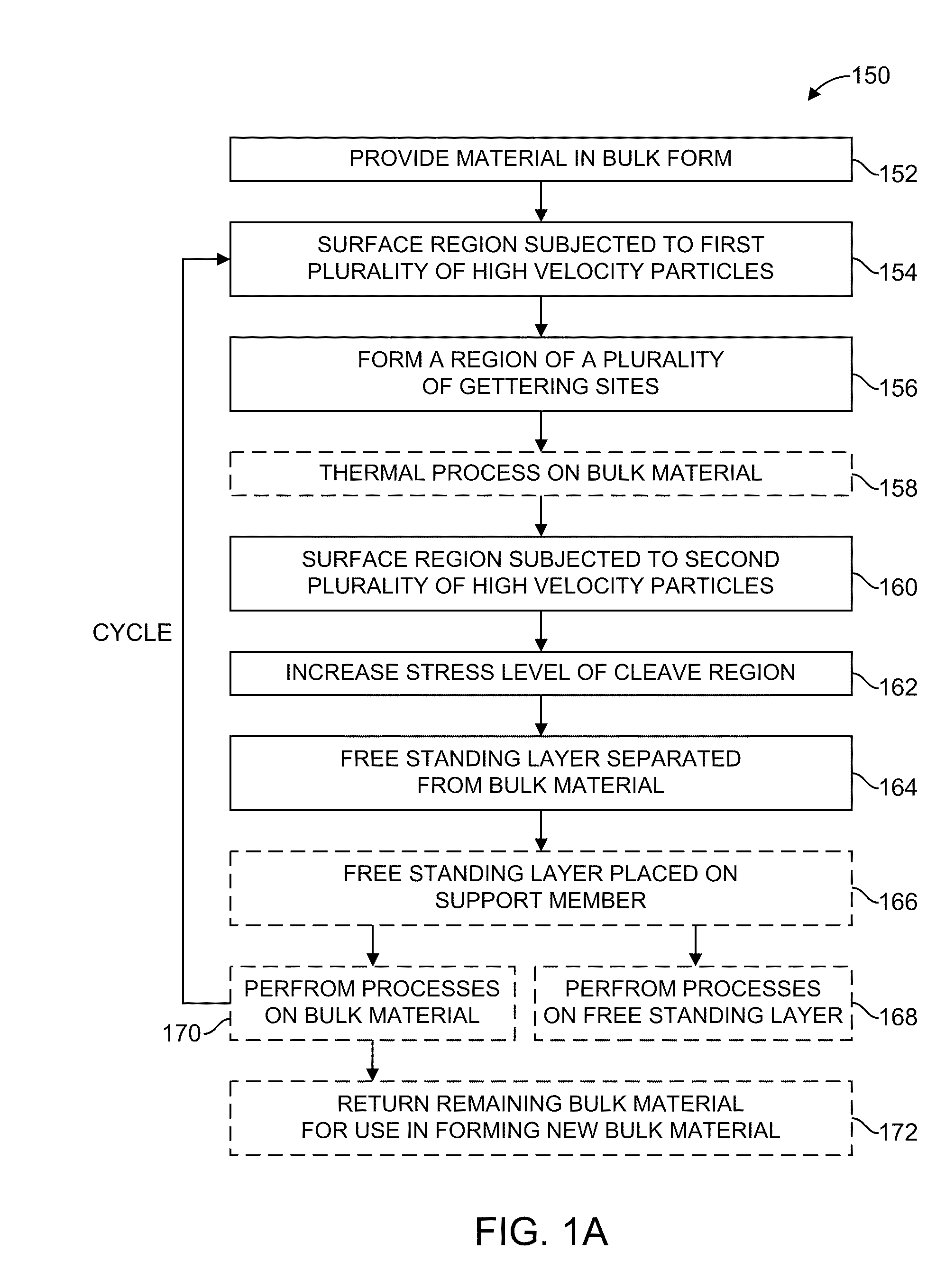

Techniques for forming thin films by implantation with reduced channeling

ActiveUS20100317140A1Improve uniformityChanneling effect can be reducedElectric discharge tubesSemiconductor/solid-state device manufacturingParticle acceleratorParticle beam

Embodiments of the present invention relate to the use of a particle accelerator beam to form thin films of material from a bulk substrate. In particular embodiments, a bulk substrate having a top surface is exposed to a beam of accelerated particles. Then, a thin film of material is separated from the bulk substrate by performing a controlled cleaving process along a cleave region formed by particles implanted from the beam. To improve uniformity of depth of implantation, channeling effects are reduced by one or more techniques. In one technique, a miscut bulk substrate is subjected to the implantation, such that the lattice of the substrate is offset at an angle relative to the impinging particle beam. According to another technique, the substrate is tilted at an angle relative to the impinging particle beam. In still another technique, the substrate is subjected to a dithering motion during the implantation. These techniques may be employed alone or in combination.

Owner:SILICON GENERAL CORPORATION

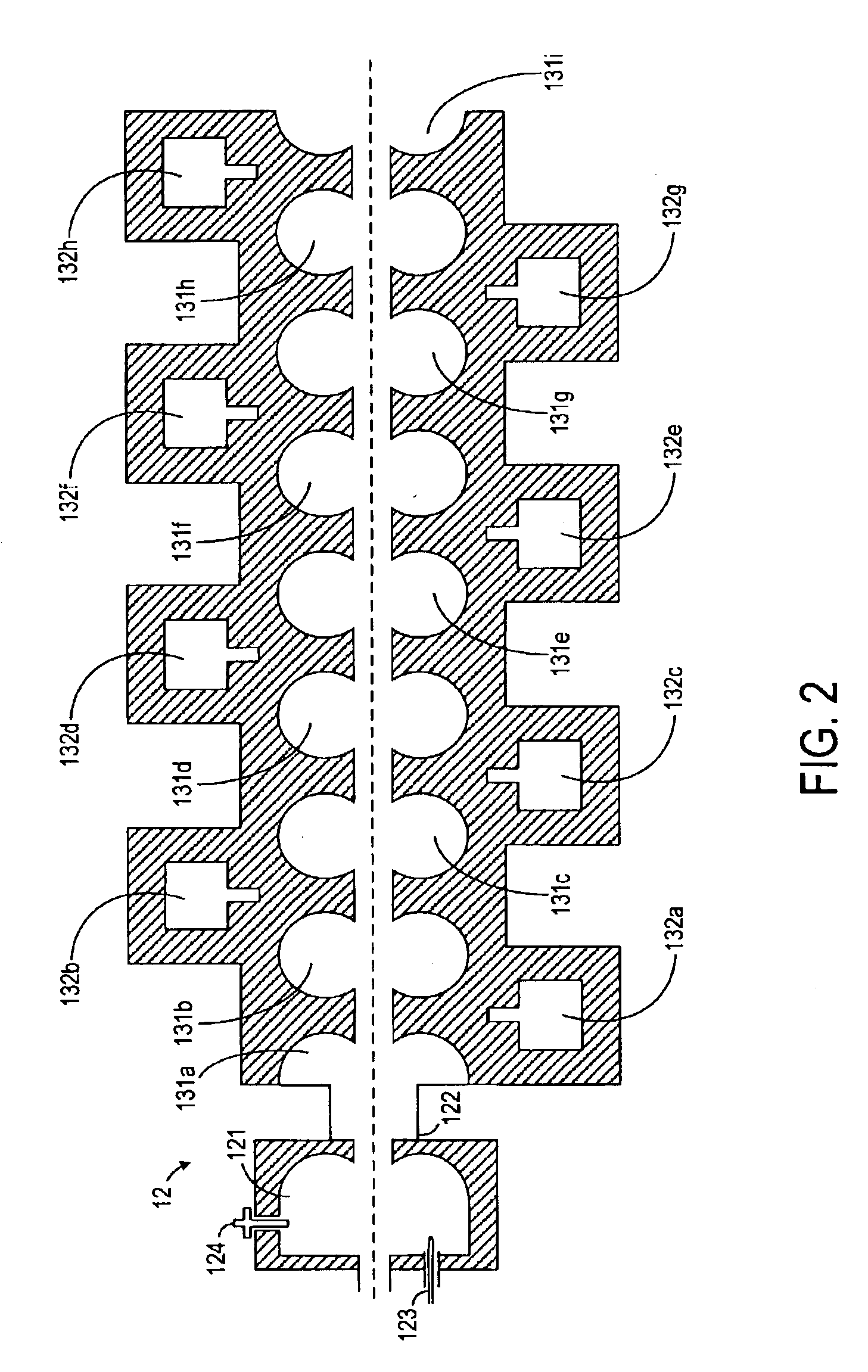

Slot resonance coupled standing wave linear particle accelerator

InactiveUS20090302785A1Improve effectivenessLinear acceleratorsKlystronsParticle acceleratorPhase difference

A slot resonance coupled, linear standing wave particle accelerator. The accelerator includes a series of resonant accelerator cavities positioned along a beam line, which are connected by resonant azimuthal slots formed in interior walls separating adjacent cavities. At least some of the slots are resonant at a frequency comparable to the resonant frequency of the cavities. The resonant slots are offset from the axis of the accelerator and have a major dimension extending in a direction transverse to the radial direction with respect to the accelerator axis. The off-axis resonant slots function to magnetically couple adjacent cavities of the accelerator while also advancing the phase difference between the standing wave in adjacent cavities by 180 degrees in addition to the 180 degree phase difference resulting from coupling of the standing wave in each cavity with the adjacent slot, such that the signals in each cavity are in phase with one another and each cavity functions as a live accelerating cavity. The resonance frequency of the slot is the comparable to the resonance frequency of the cavities, resulting in coupling of the cavities while also eliminating the need for side-cavity or other off-axis coupling cavities.

Owner:FARTECH

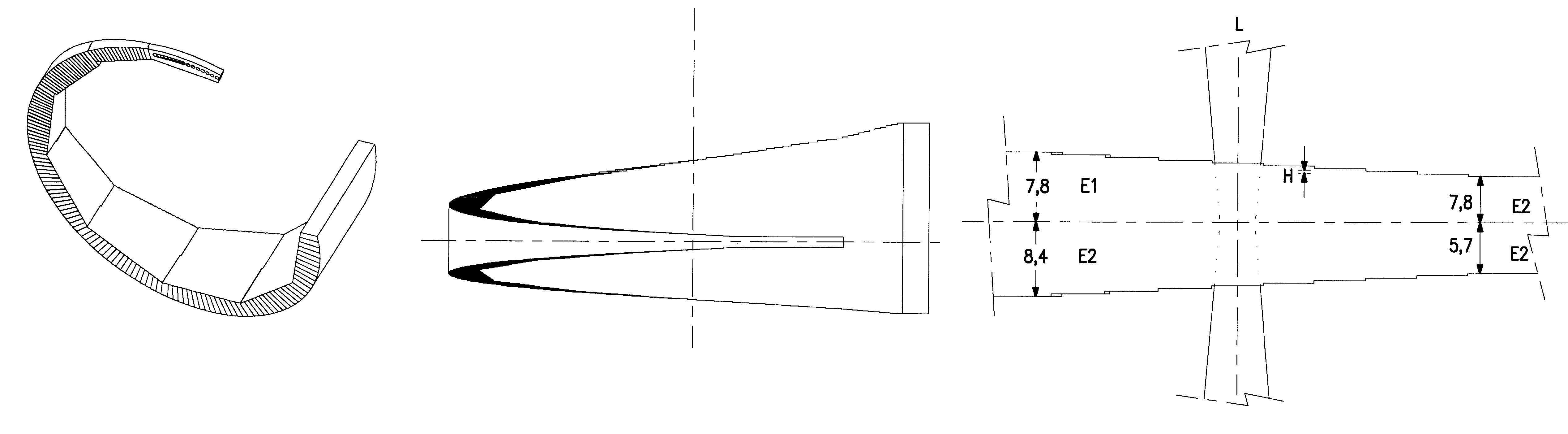

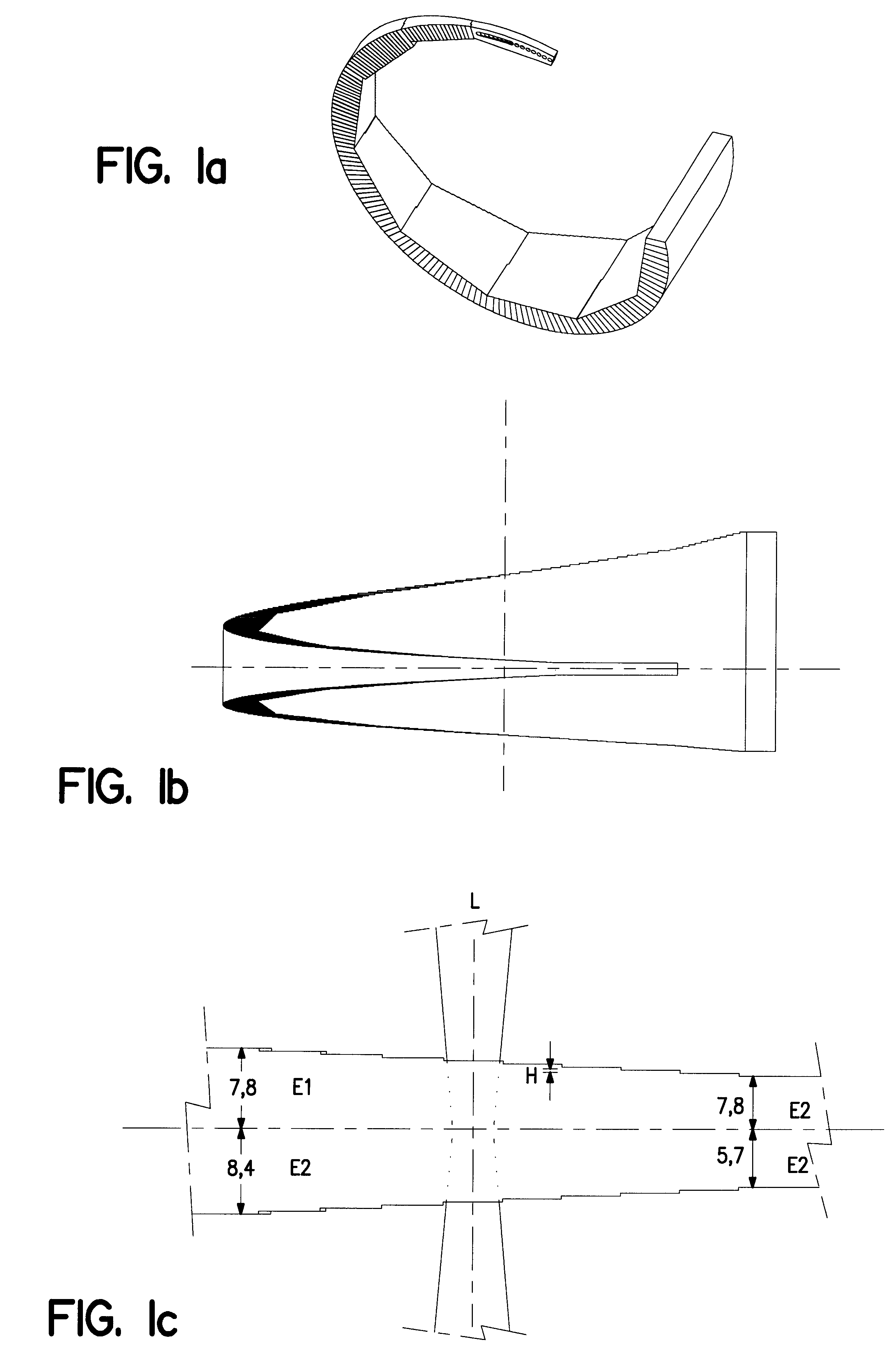

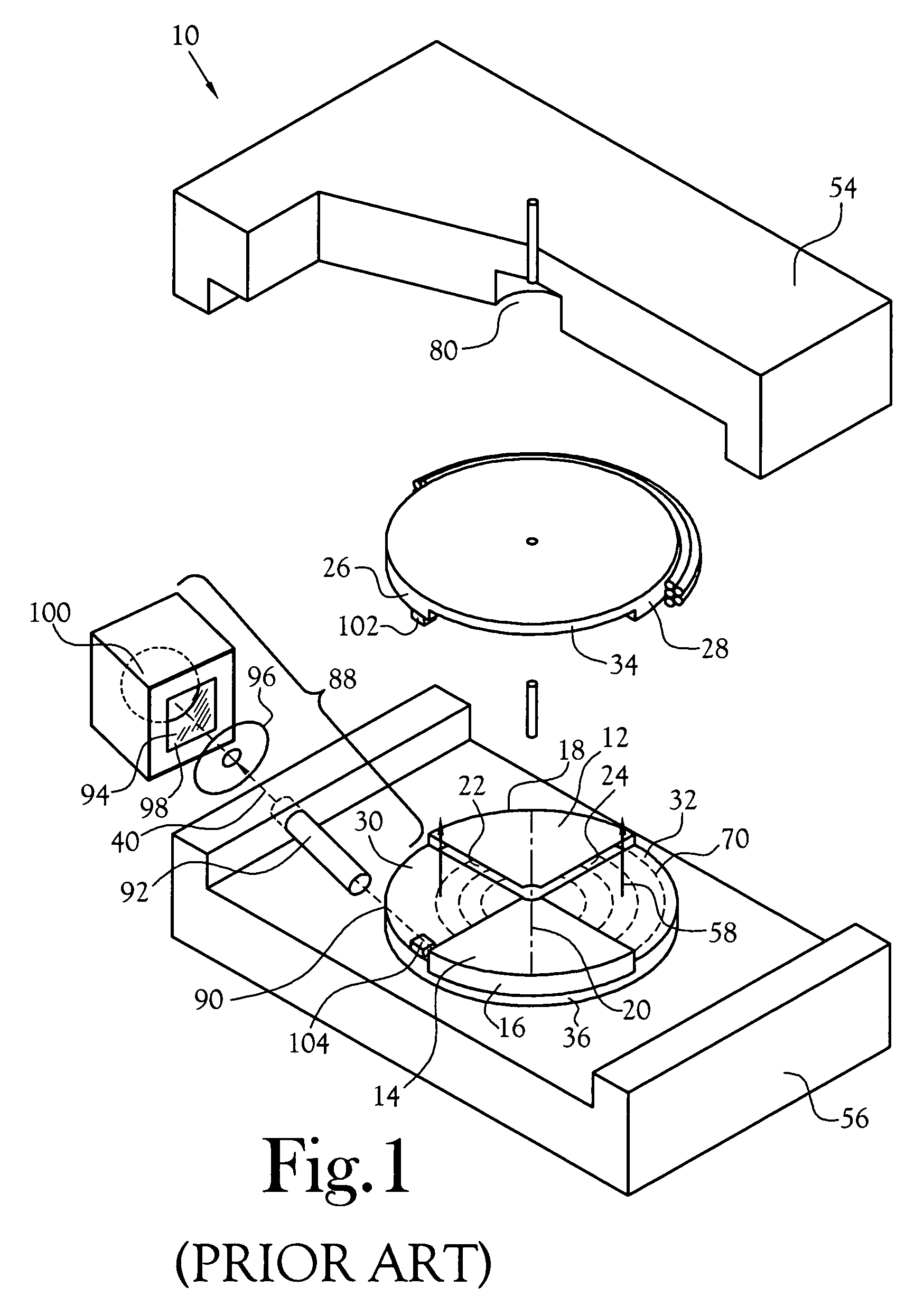

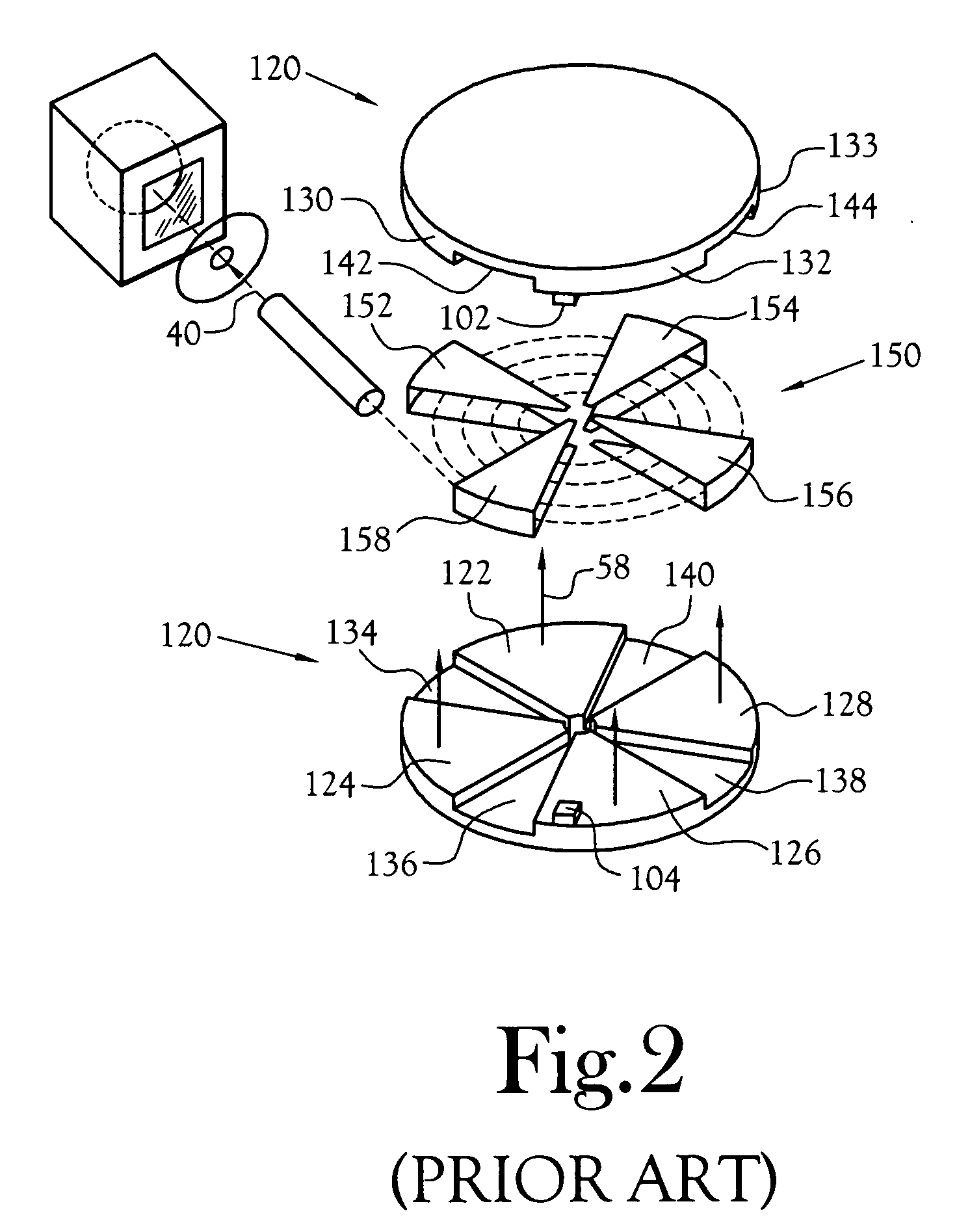

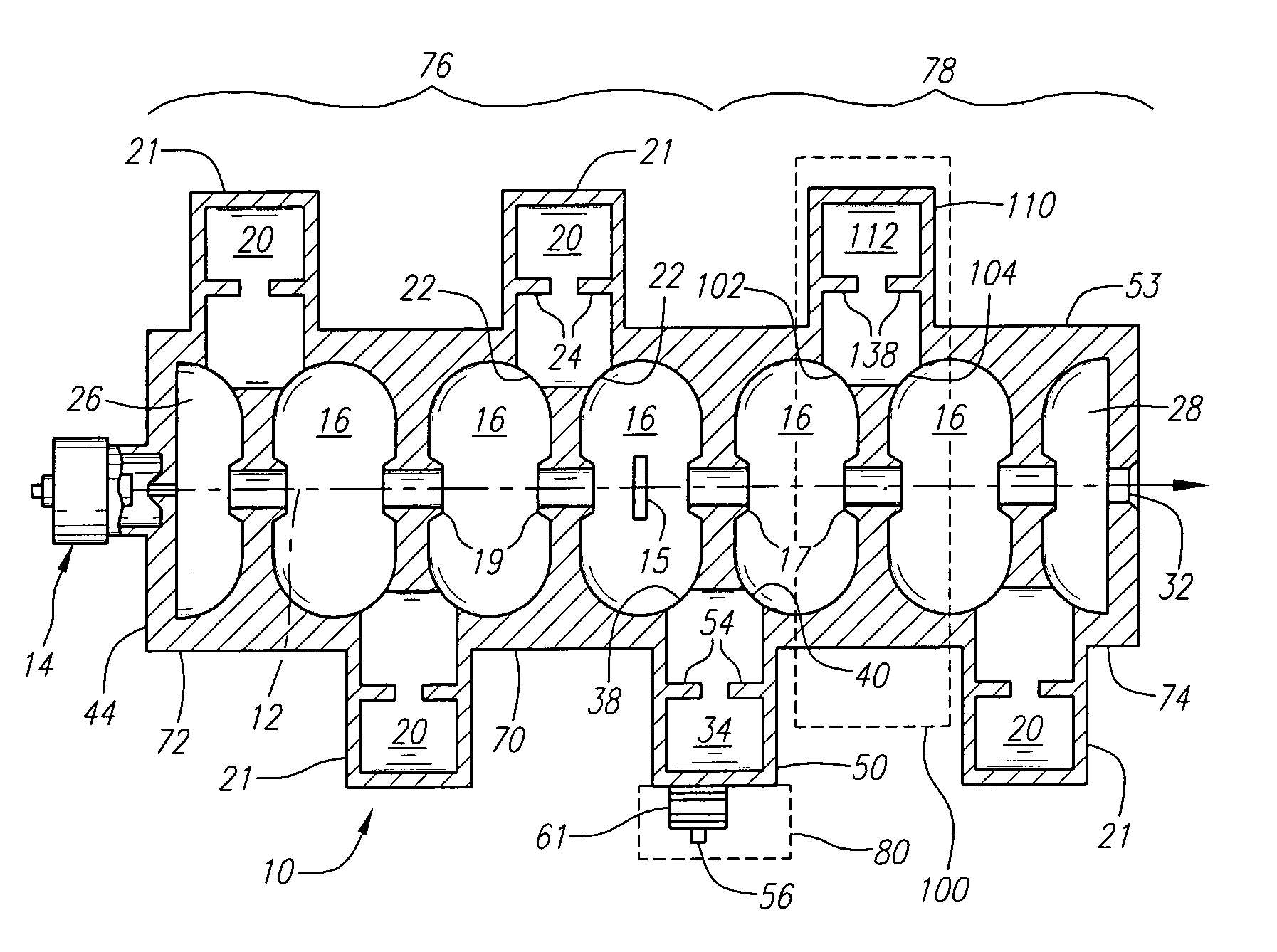

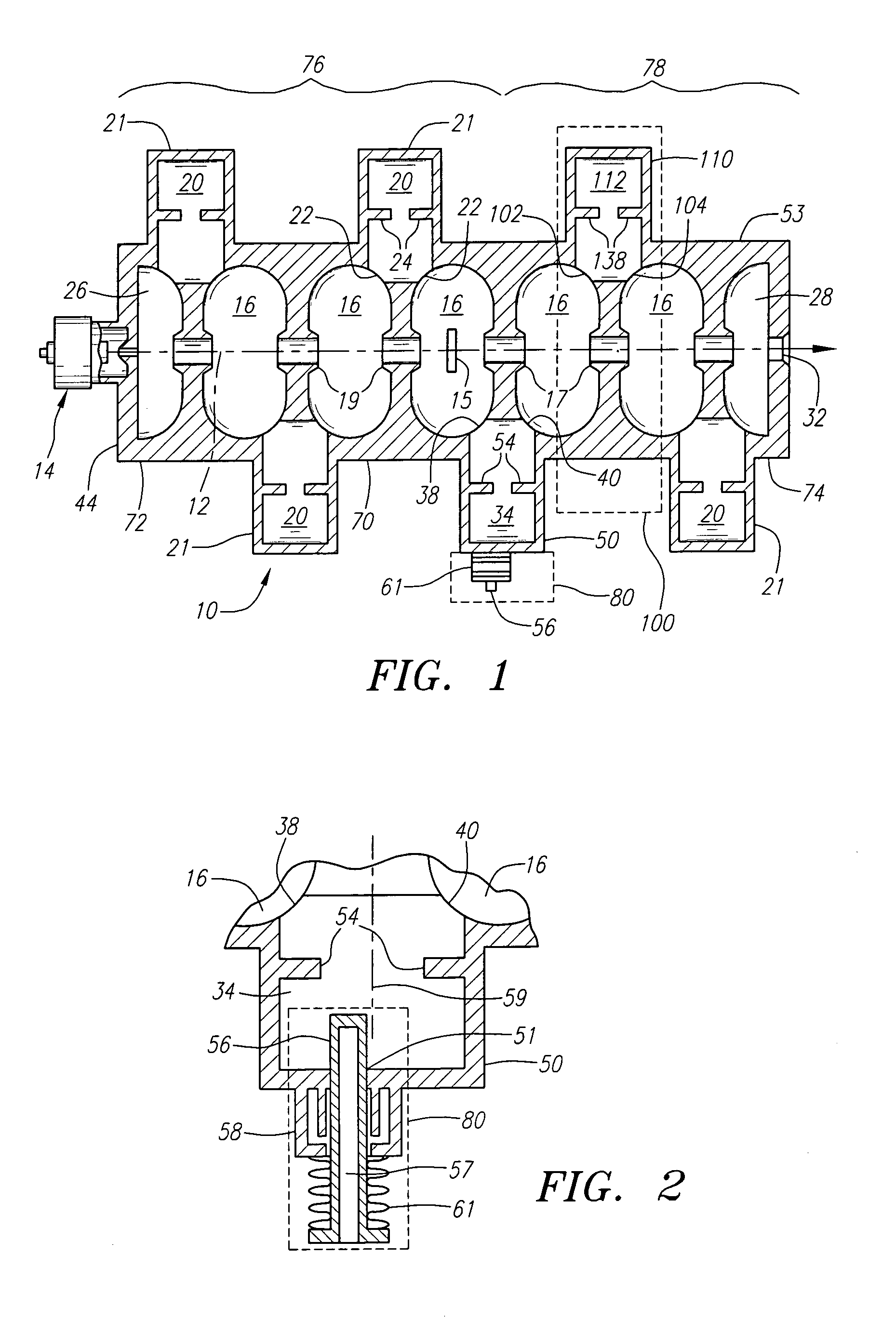

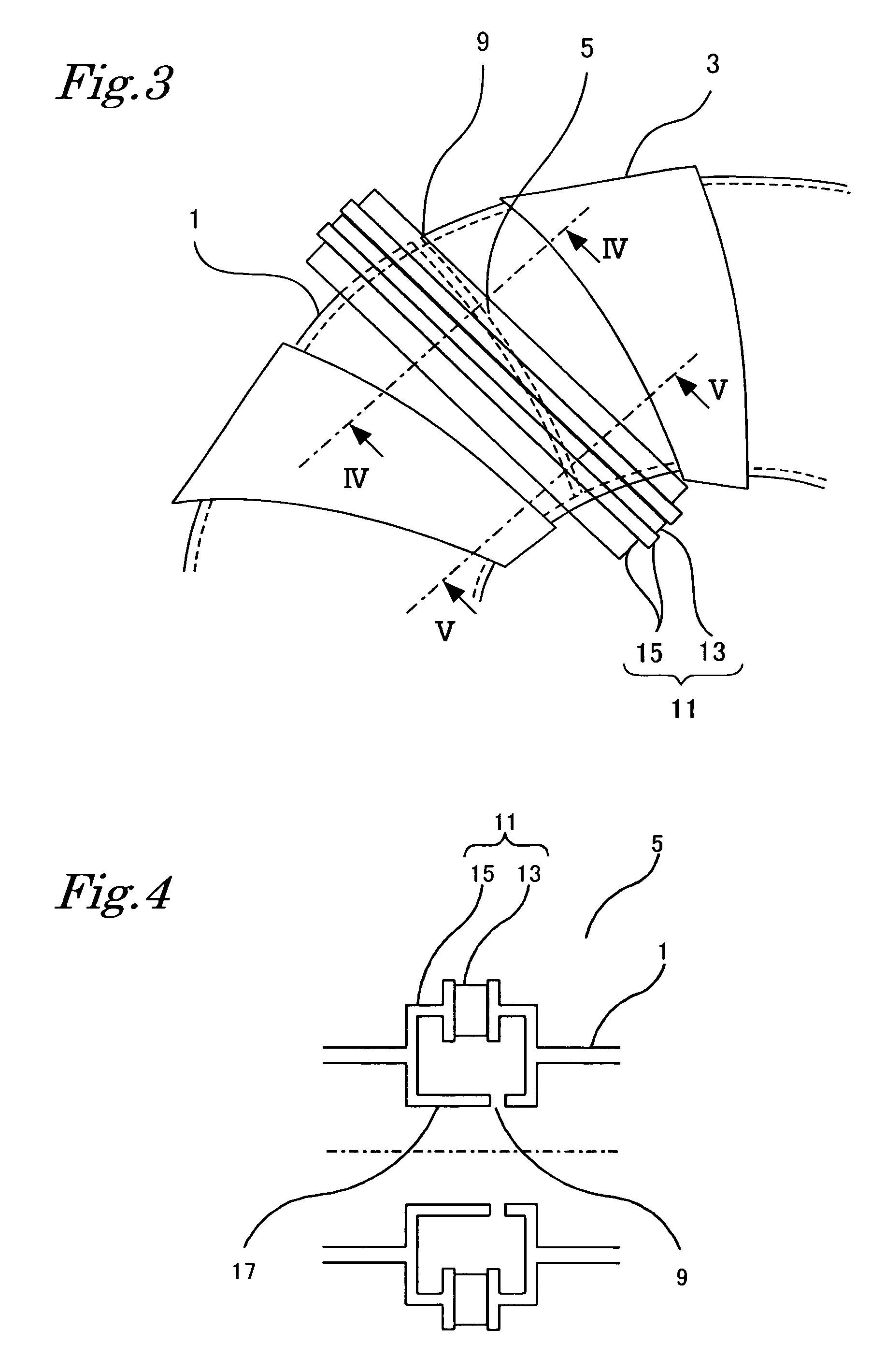

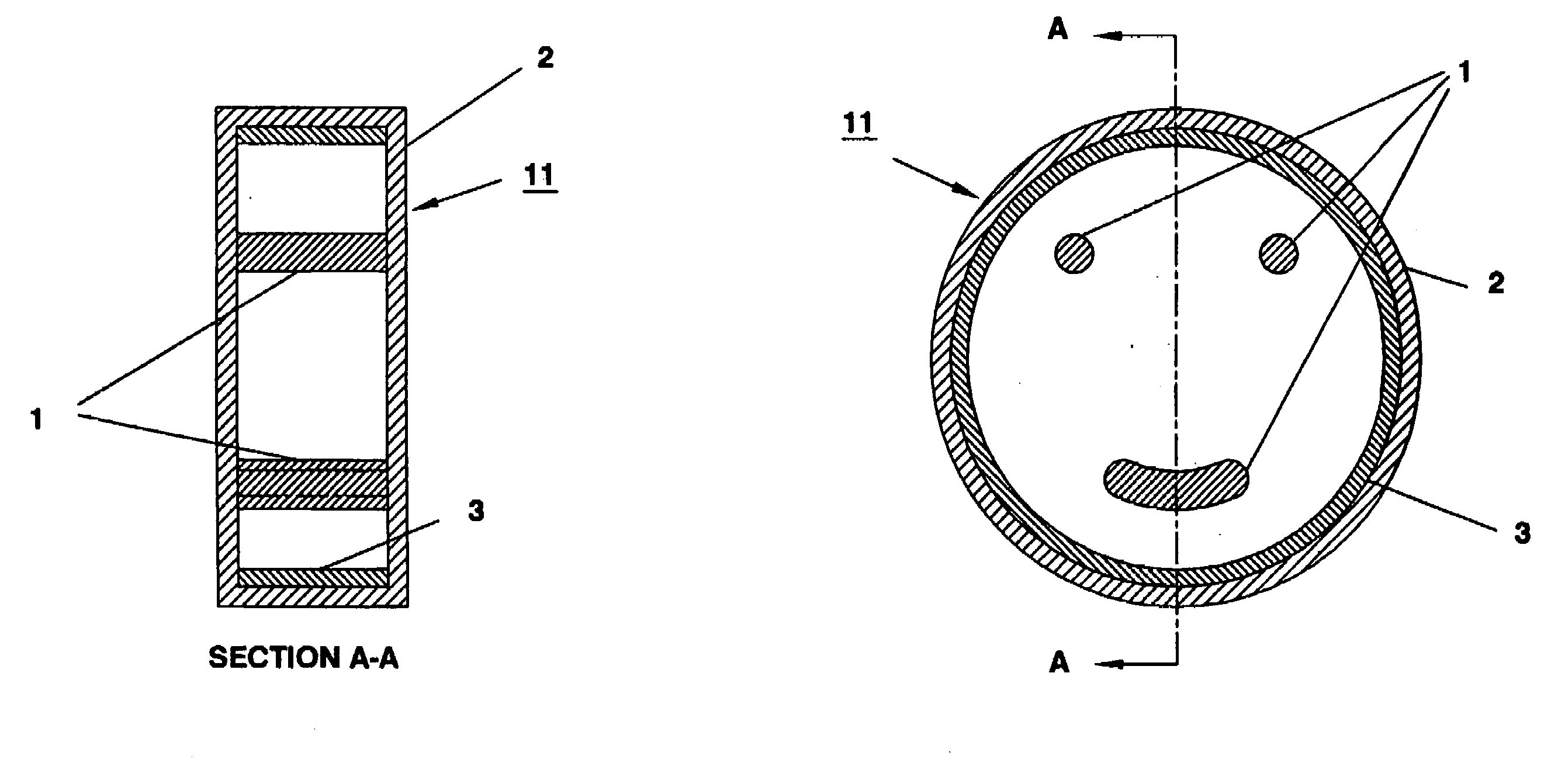

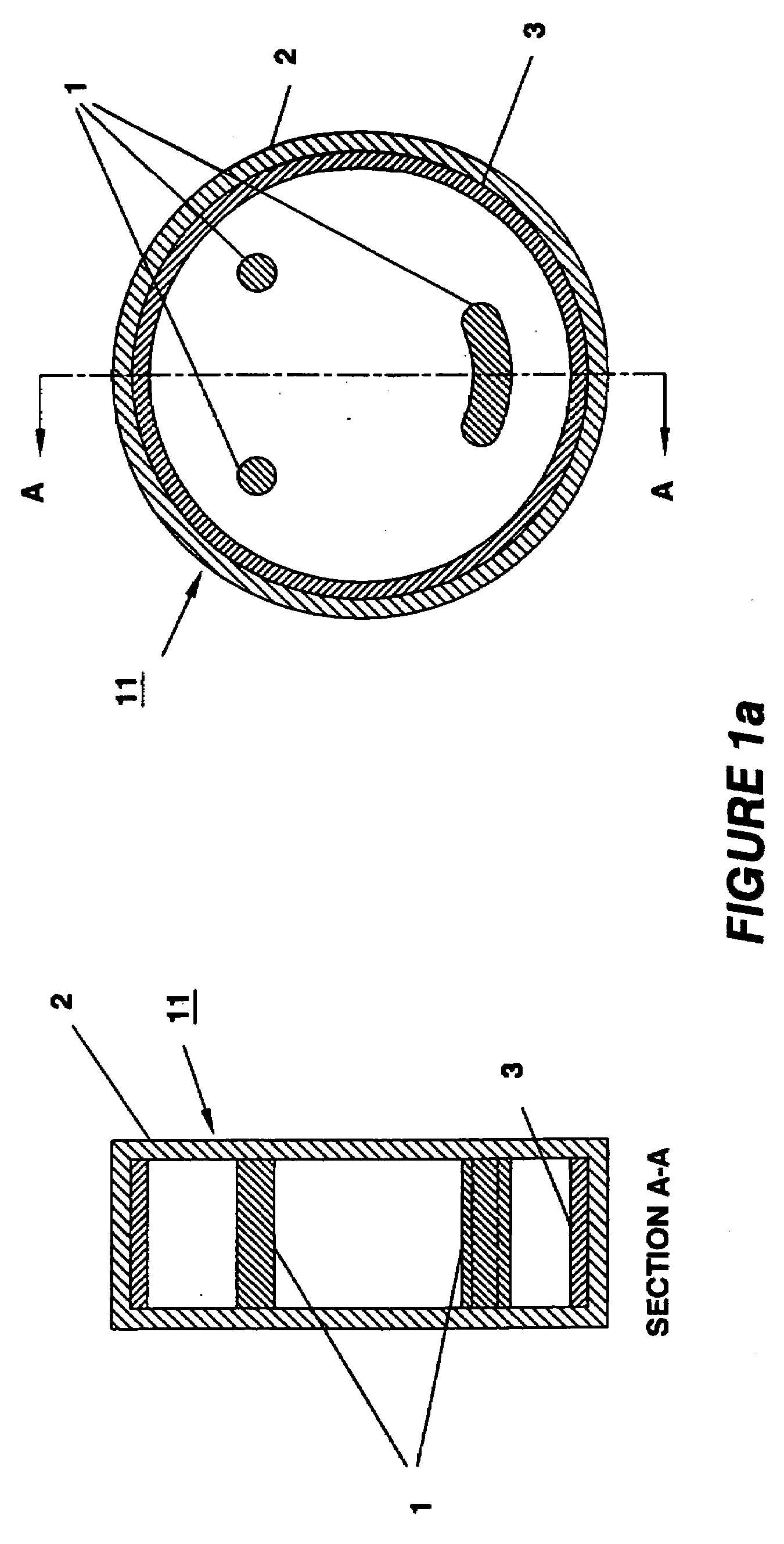

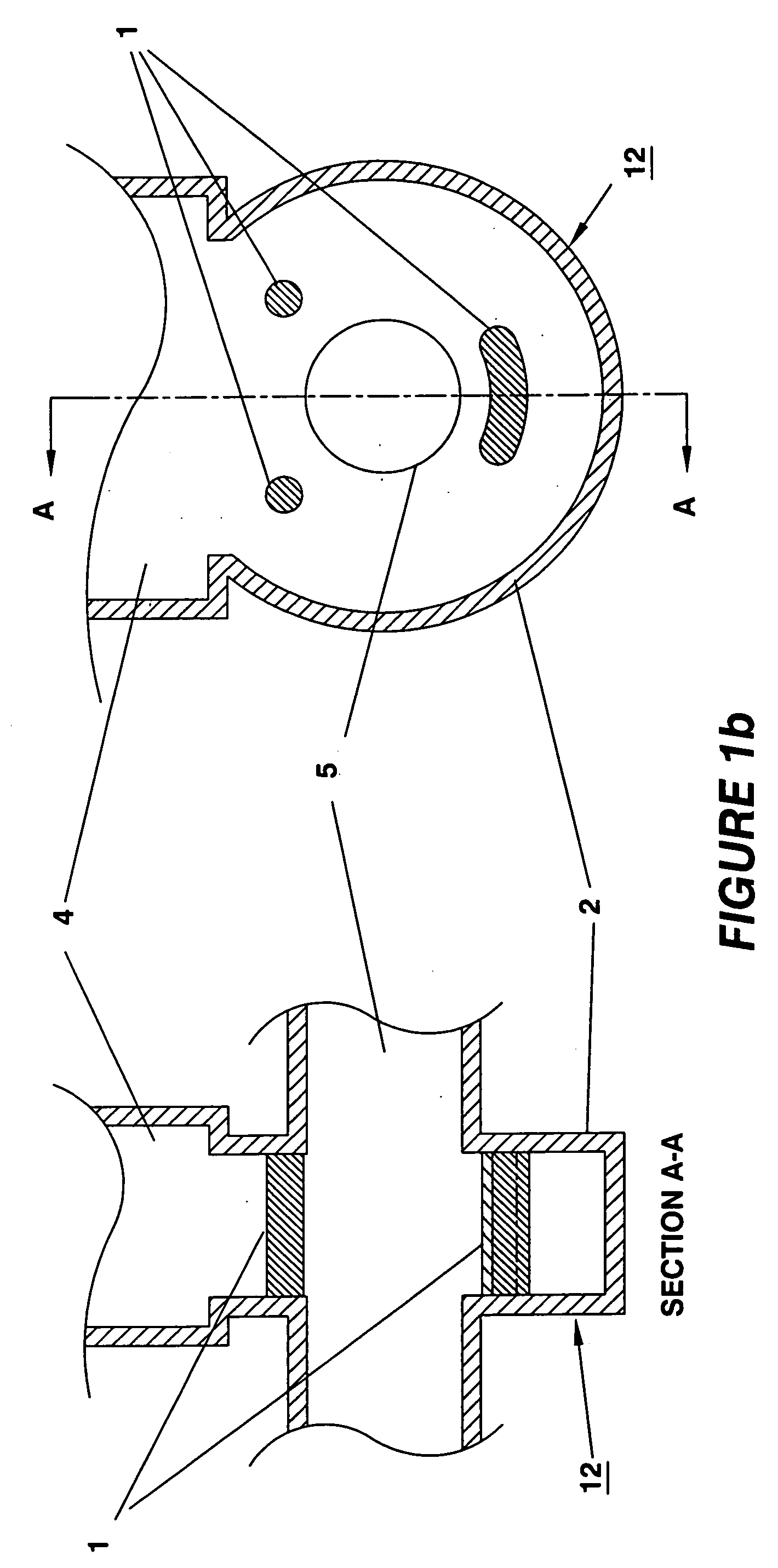

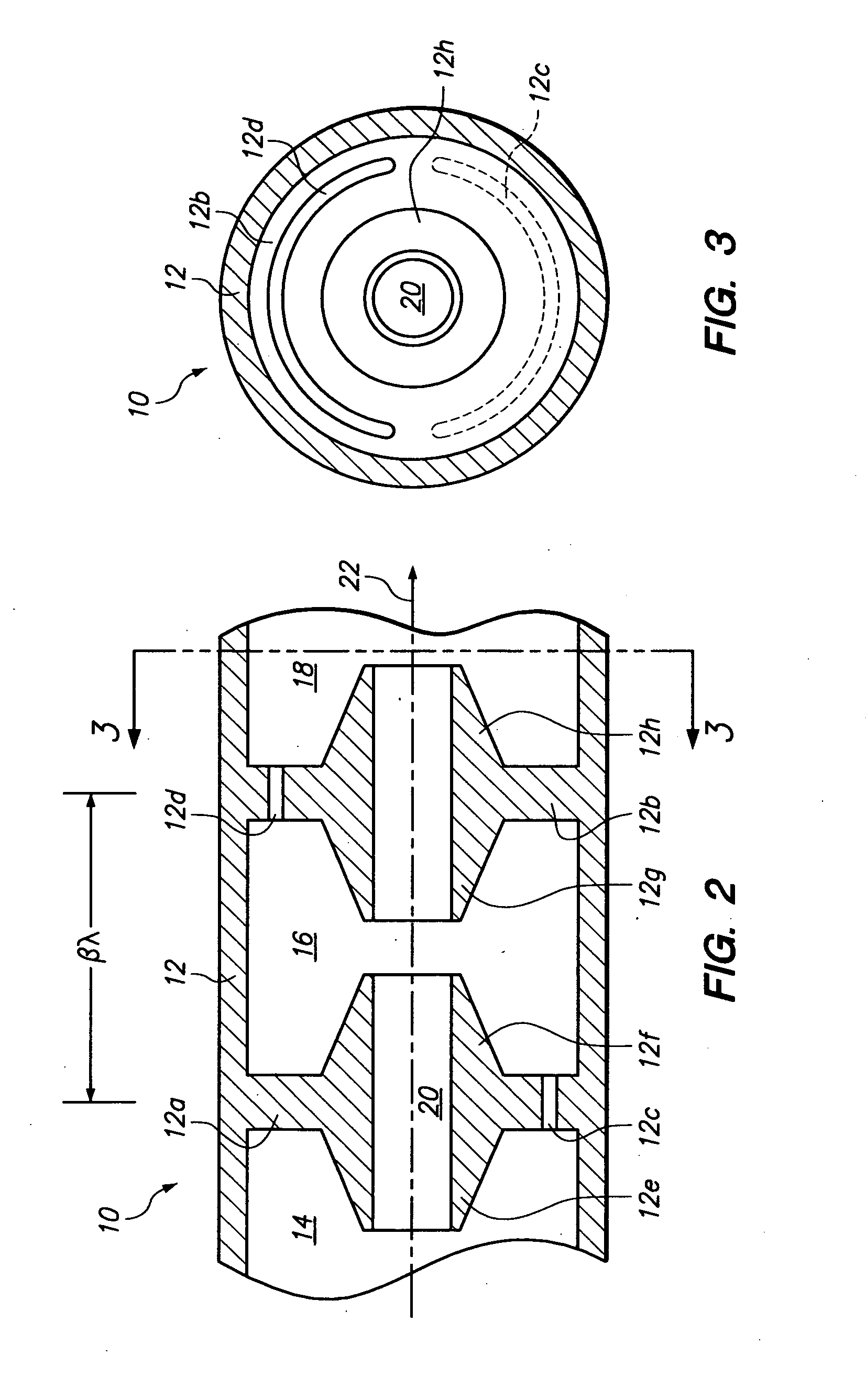

Target foil for use in the production of [18f] using a particle accelerator

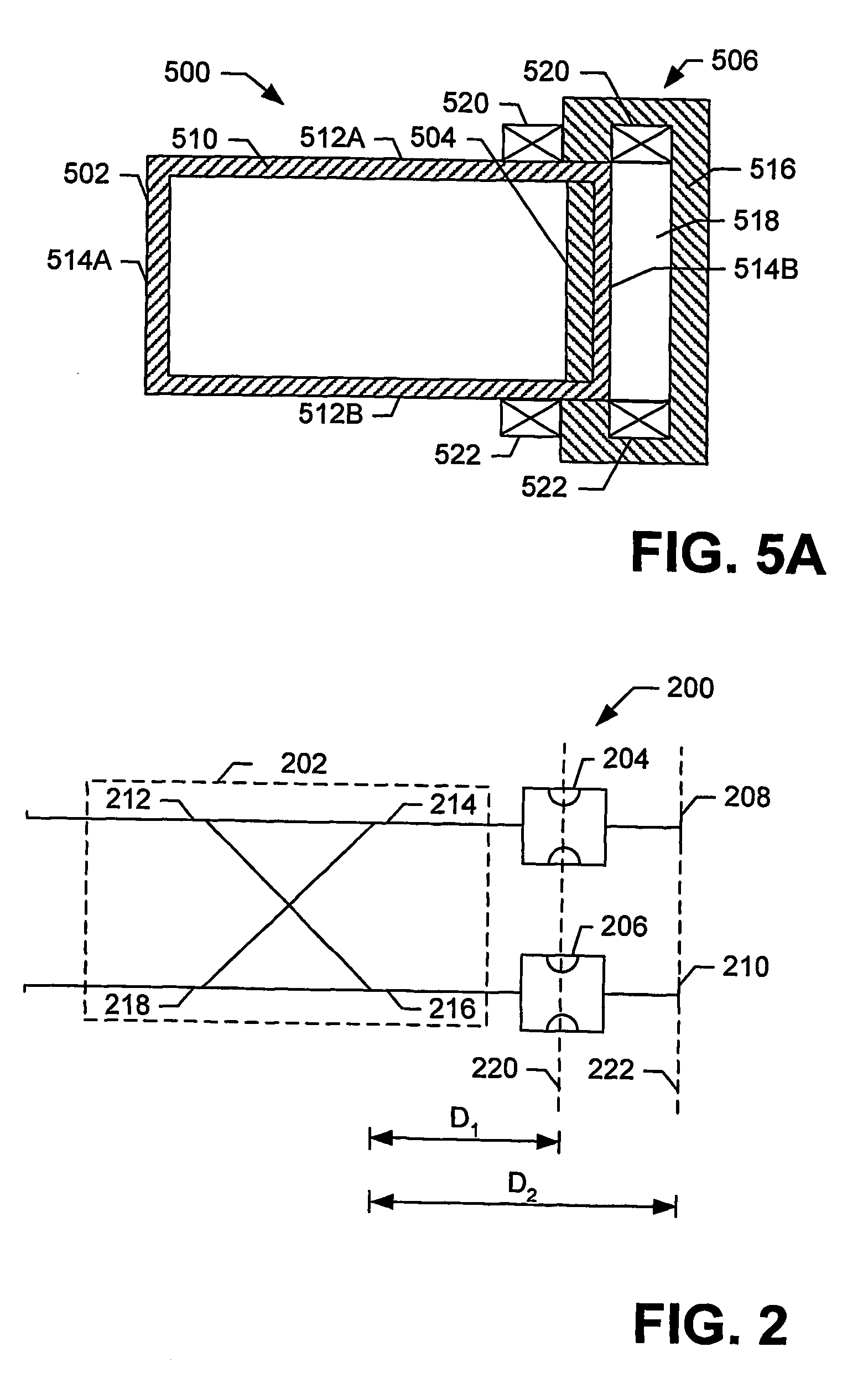

InactiveUS20090052628A1High strengthConversion outside reactor/acceleratorsX-ray tube electrodesParticle acceleratorNiobium

The invention is directed to a novel foil for use as an entrance window foil during the production of [18F] by irradiation of [18O] using a particle accelerator. The foil is a high strength cobalt based alloy foil, thin film coated with an inert and refractory metal such as niobium.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA +1

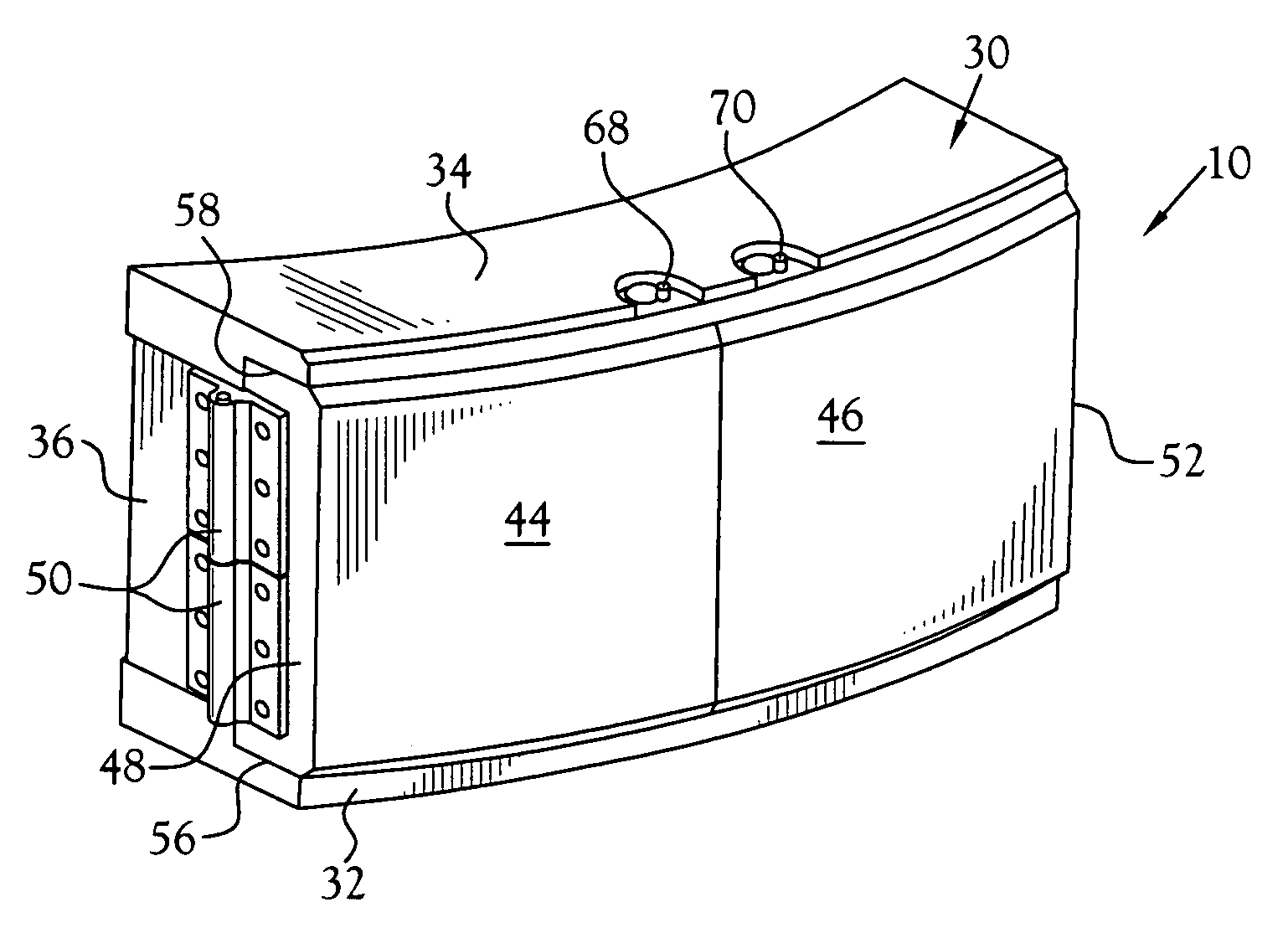

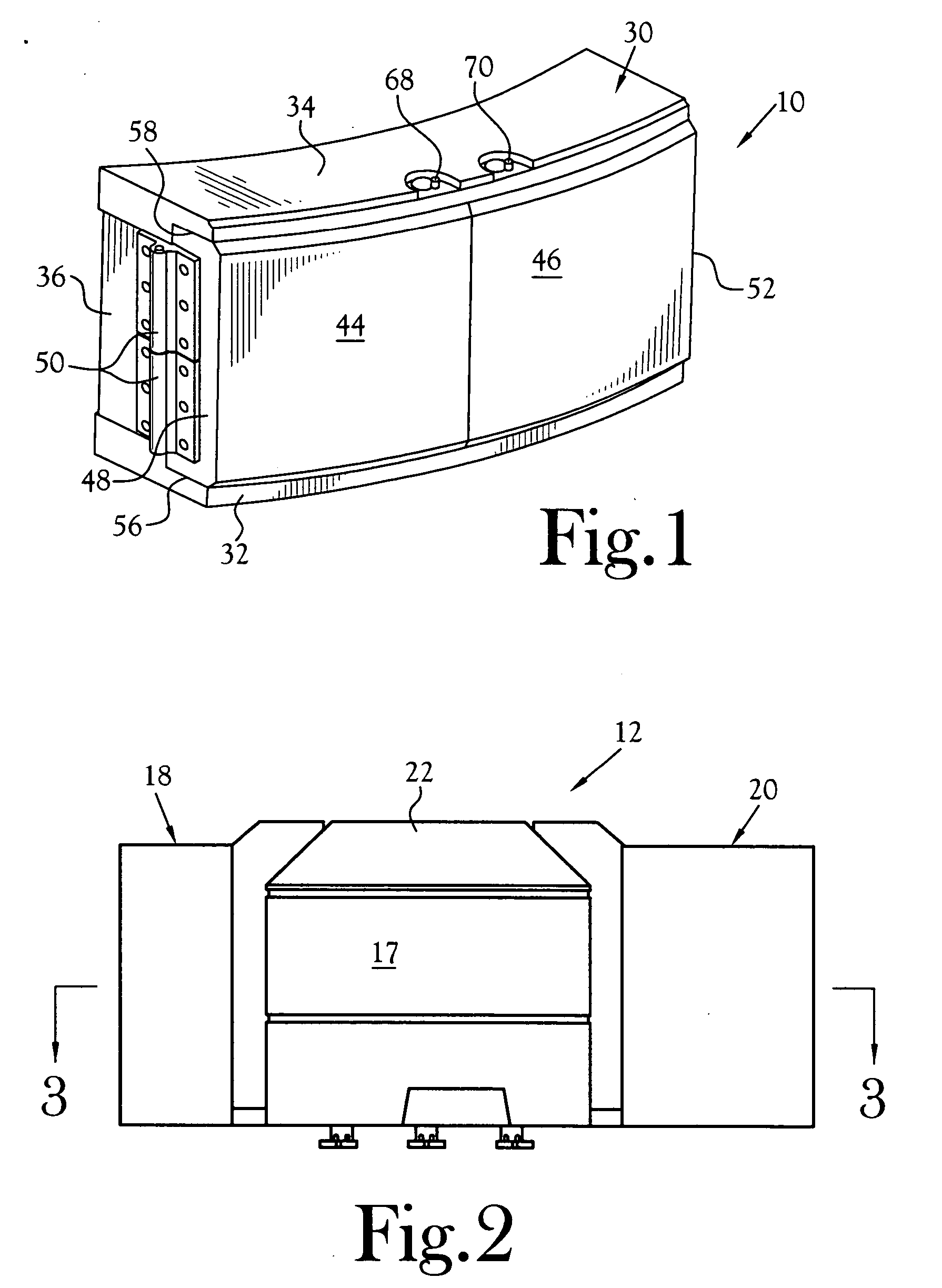

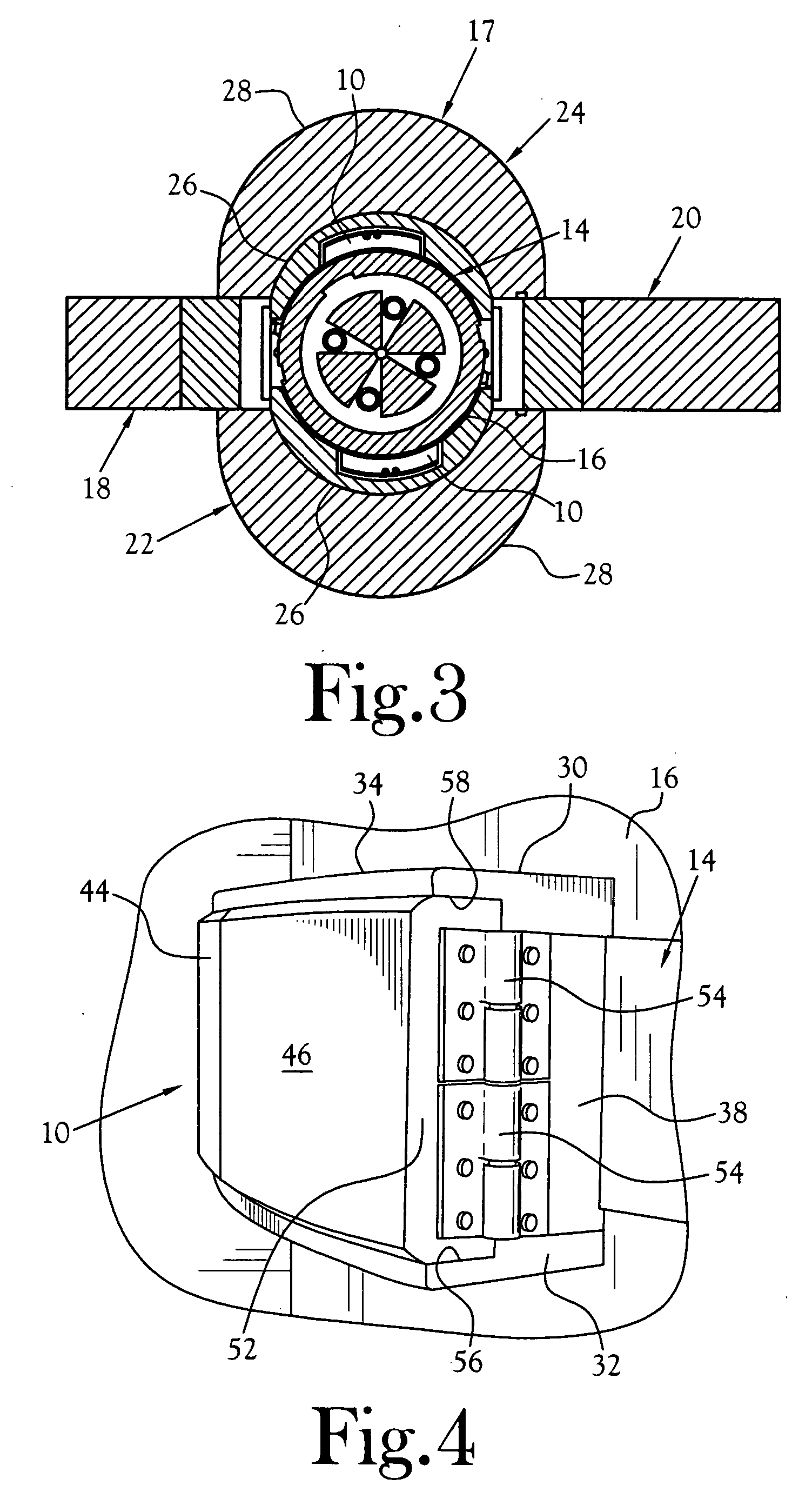

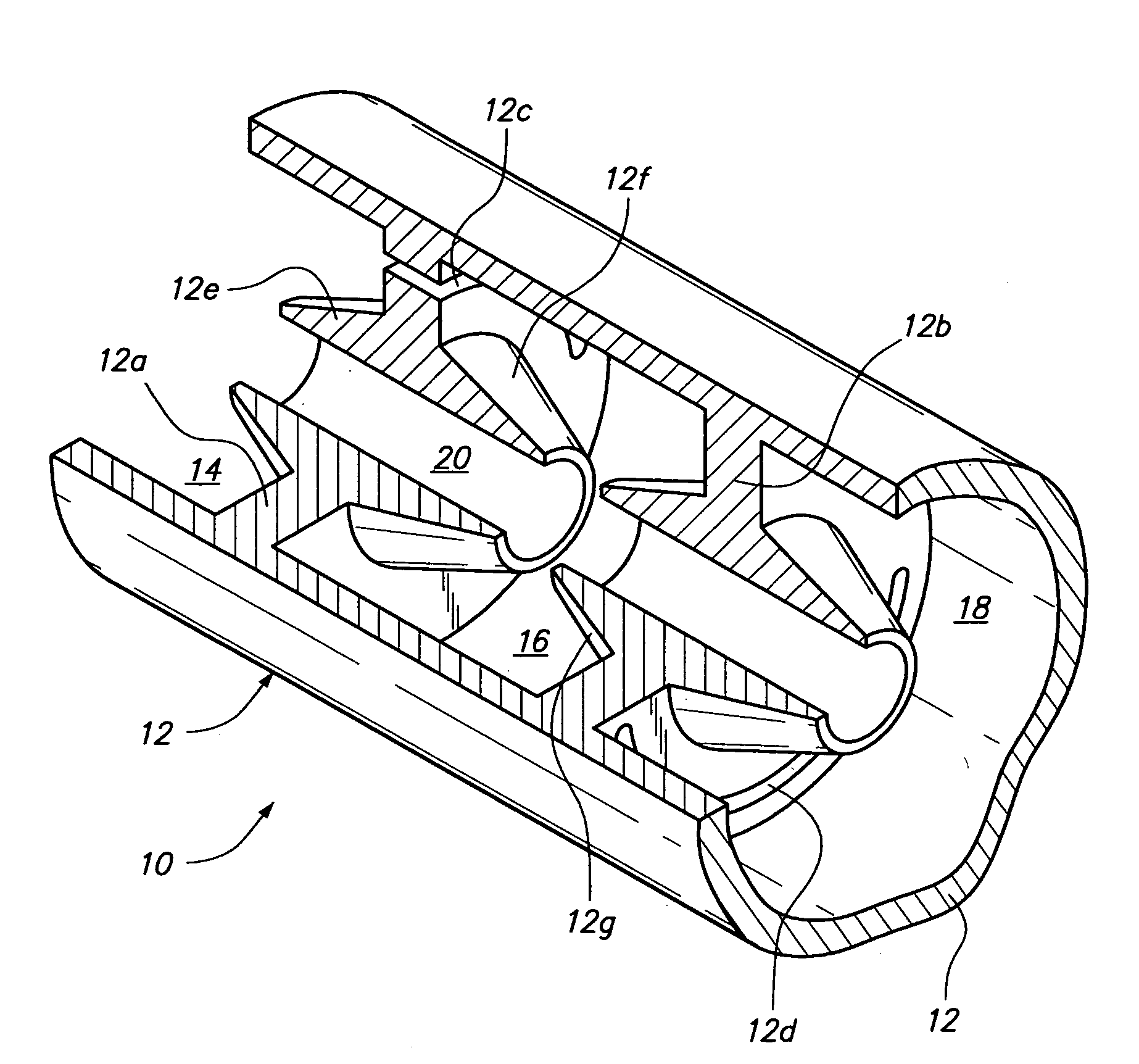

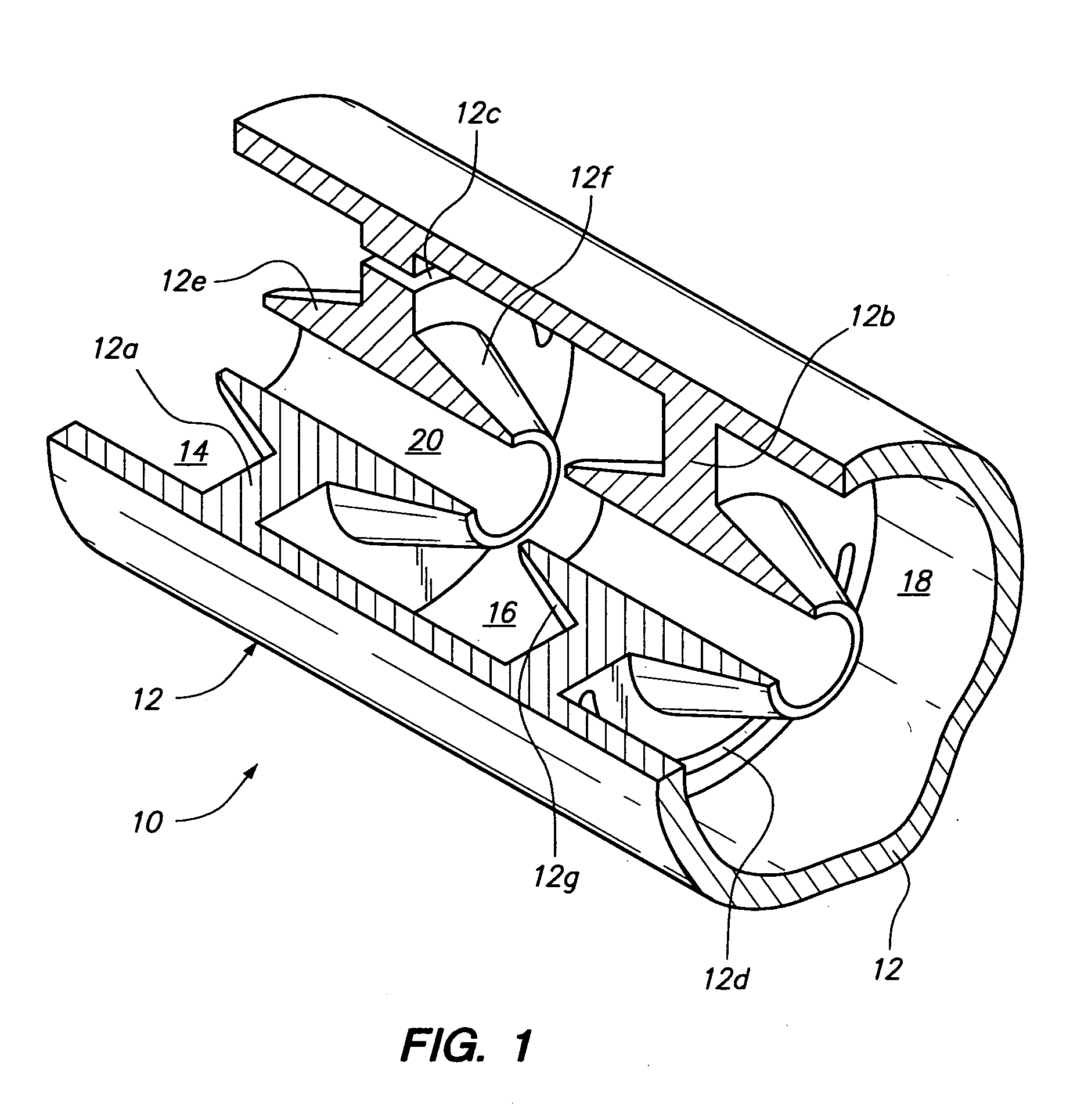

Closure for shielding the targeting assembly of a particle accelerator

ActiveUS20050218347A1Reduce radiationSmall and lightShieldingPortable shielded containersParticle acceleratorAccelerated particle

A closure (10) for shielding, and selectively providing access to, the targeting assembly of a particle accelerator of a radioisotope production system. The closure (10) includes at least one, and in one embodiment, first and second doors (44, 46), for selectively covering an opening in the housing of the particle accelerator which provides access to the targeting assembly. A door mounting assembly is also provided for mounting the first and second doors (44, 46) on the housing of the particle accelerator. In one embodiment the door mounting assembly includes a frame (30) for being secured about the opening in the particle accelerator accessing the targeting assembly. Further, in one embodiment the frame (30) and first and second doors (44, 46) are fabricated of copper.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Device And Method For Particle Beam Production

ActiveUS20120160996A1Transit-time tubesMagnetic resonance acceleratorsPulse beamParticle accelerator

The present invention relates to a pulsed beam particle accelerator which can be used for particle radiation therapy. More particular, a device and method are provided to control the number of particles within a beam pulse. The particle accelerator comprises means for varying the number of particles within each beam pulse of said pulsed ion beam from a minimum value to a maximum value as function of the value of a beam control parameter. For each particle irradiation the required number of particles for each beam pulse is controlled by defining a value for said beam control parameter based on calibration data.

Owner:ION BEAM APPL

Particle accelerator having wide energy control range

InactiveUS7208889B2Varying amountReduced strengthStability-of-path spectrometersLaser detailsParticle acceleratorEnergy control

A particle accelerator system for producing a charged particle beam having pulses of charged particles that have different energy levels from pulse to pulse. The system enables independent adjustment of the RF power delivered to first and second accelerating sections thereof without adjustment of the RF power generated by an RF source. Such independent adjustment enables the RF power provided to the first accelerating section to be maintained at a level appropriate for optimal particle capturing therein and for producing a tightly bunched beam of particles having different energy levels from pulse to pulse, while enabling the RF power provided to the second accelerating section to be varied in order to vary the energy levels of the charged particles of the charged particle beam from pulse to pulse.

Owner:SCANTECHIBS IP HLDG

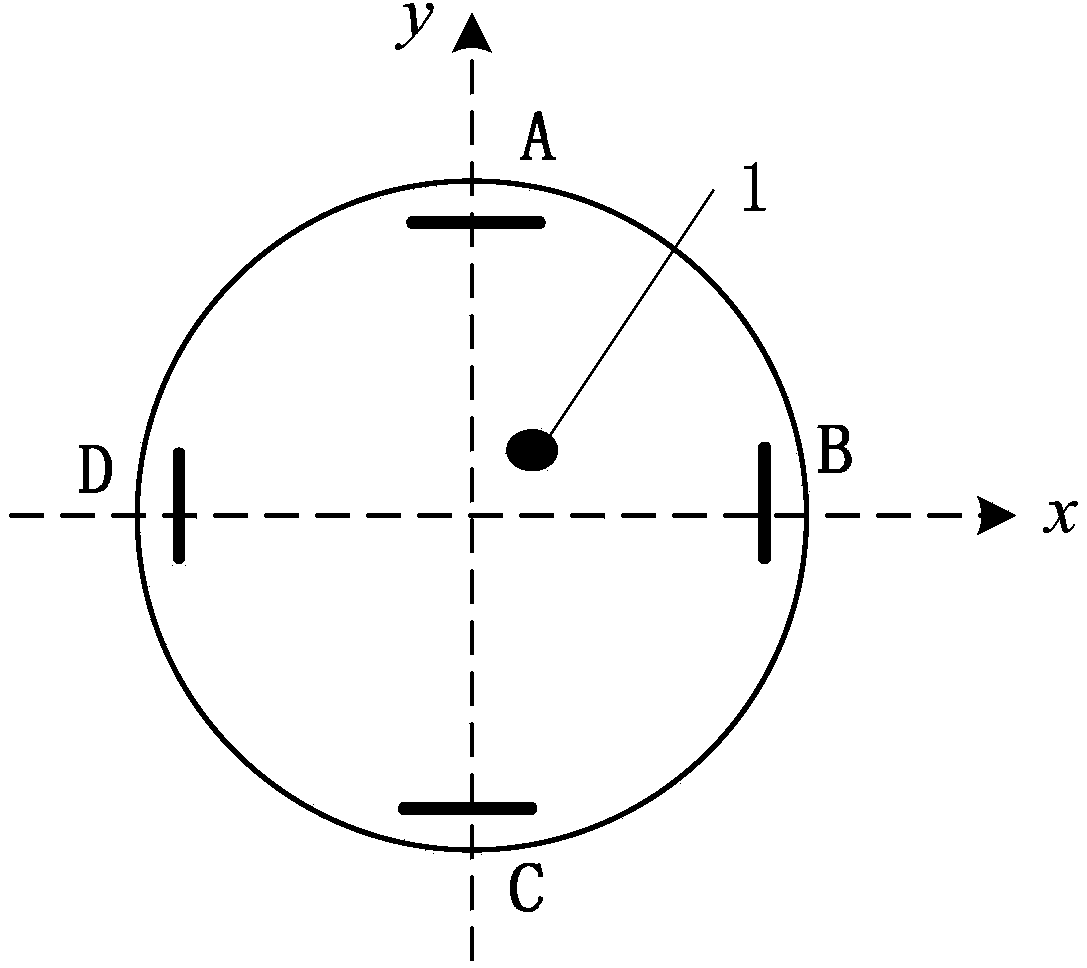

Method for measuring particle accelerator beam position

ActiveCN103809198ACancel noiseHigh measurement accuracyX/gamma/cosmic radiation measurmentParticle acceleratorNuclear engineering

The invention relates to a method for measuring a particle accelerator beam position. The method for measuring the particle accelerator beam position includes: step S1, sampling N electrode signals of N electrodes of a stripe beam position probe through N channels when the beam passes through the probe; step S2, making up an M*N matrix X for the N electrode signals, and analyzing the principal components of the matrix X; step S3, calculating to obtain beam signal induction amplitudes which are corresponding to the N electrodes one by one, and outputting the N beam signal induction amplitudes through the N channels; step S4, comparing the N beam signal induction amplitudes output from the N channels and calculating to obtain a position signal of the beam. According to the method for measuring the particle accelerator beam position, the electrode signals of the electrode probes are formed into the matrix and are processed simultaneously through a principal component analysis method, and accordingly the noise of each electrode signal is eliminated effectively, and the beam position measuring precision is effectively improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

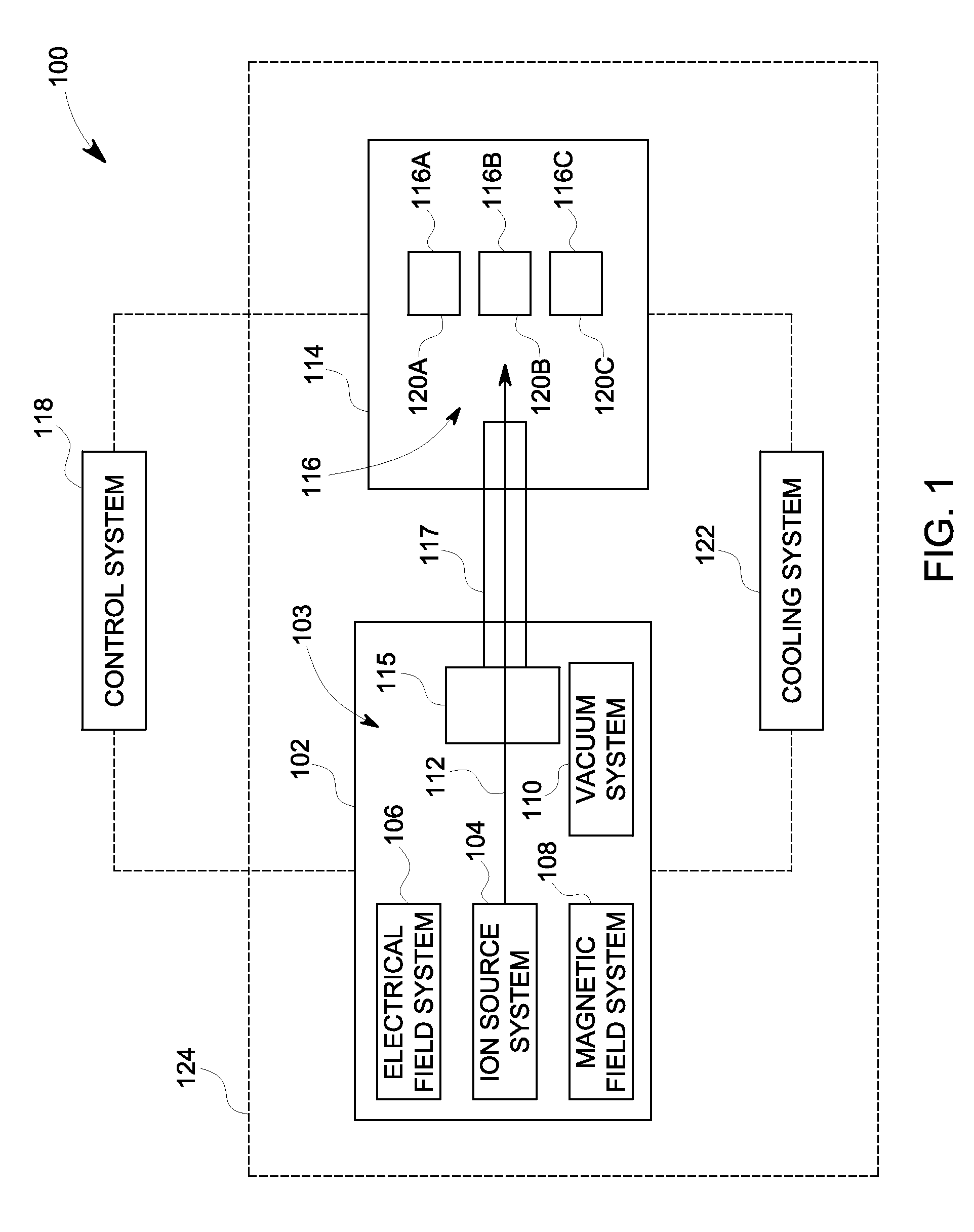

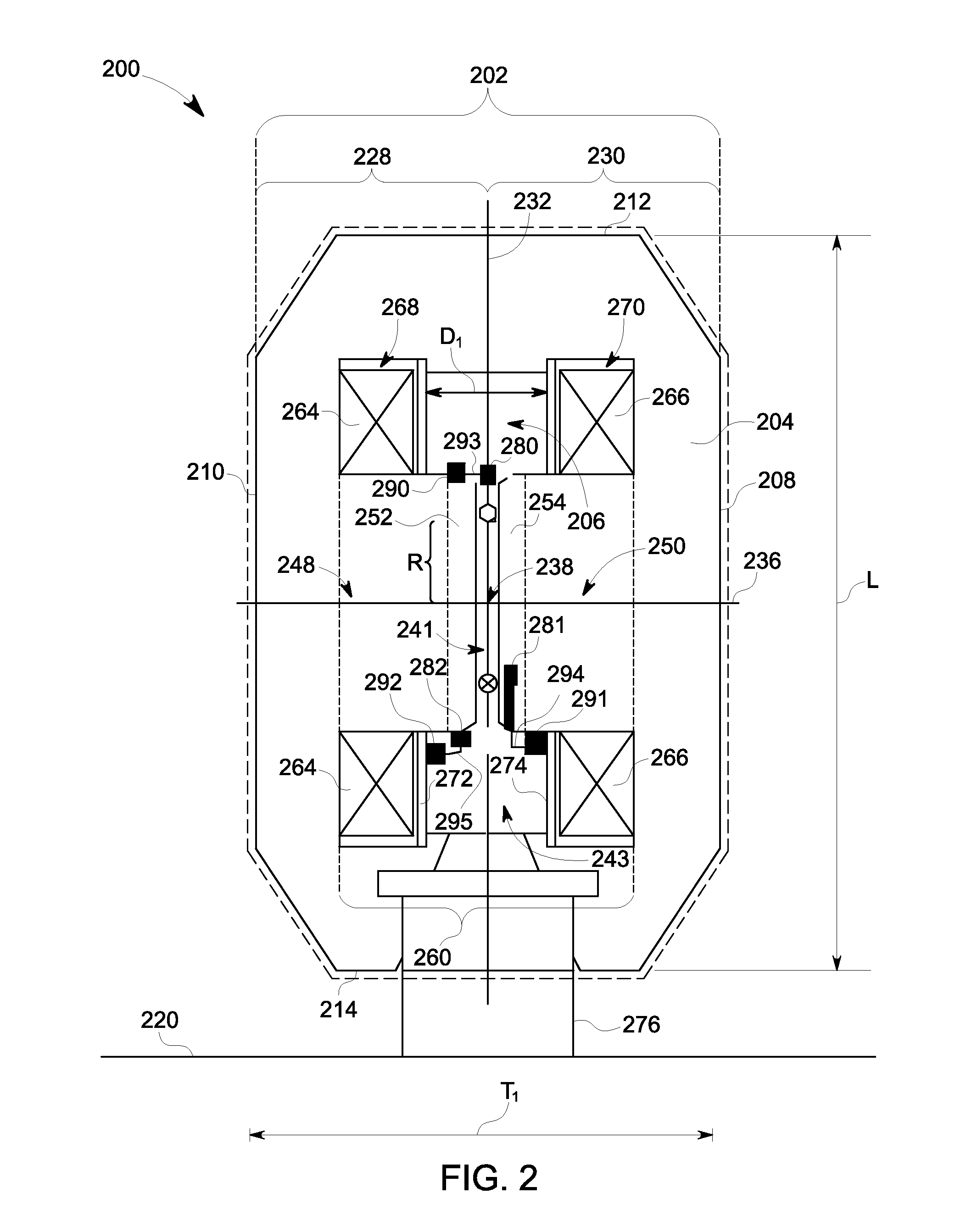

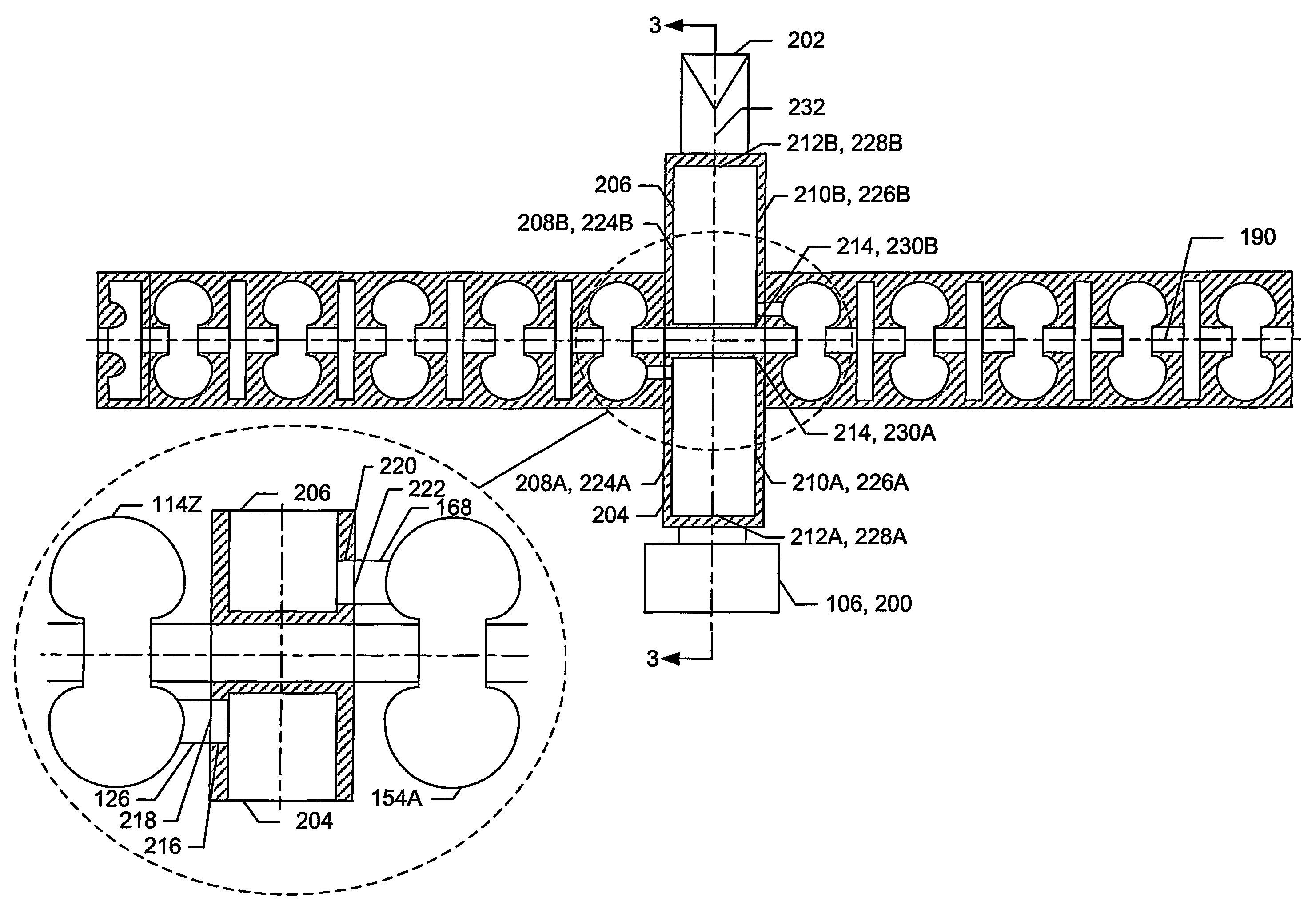

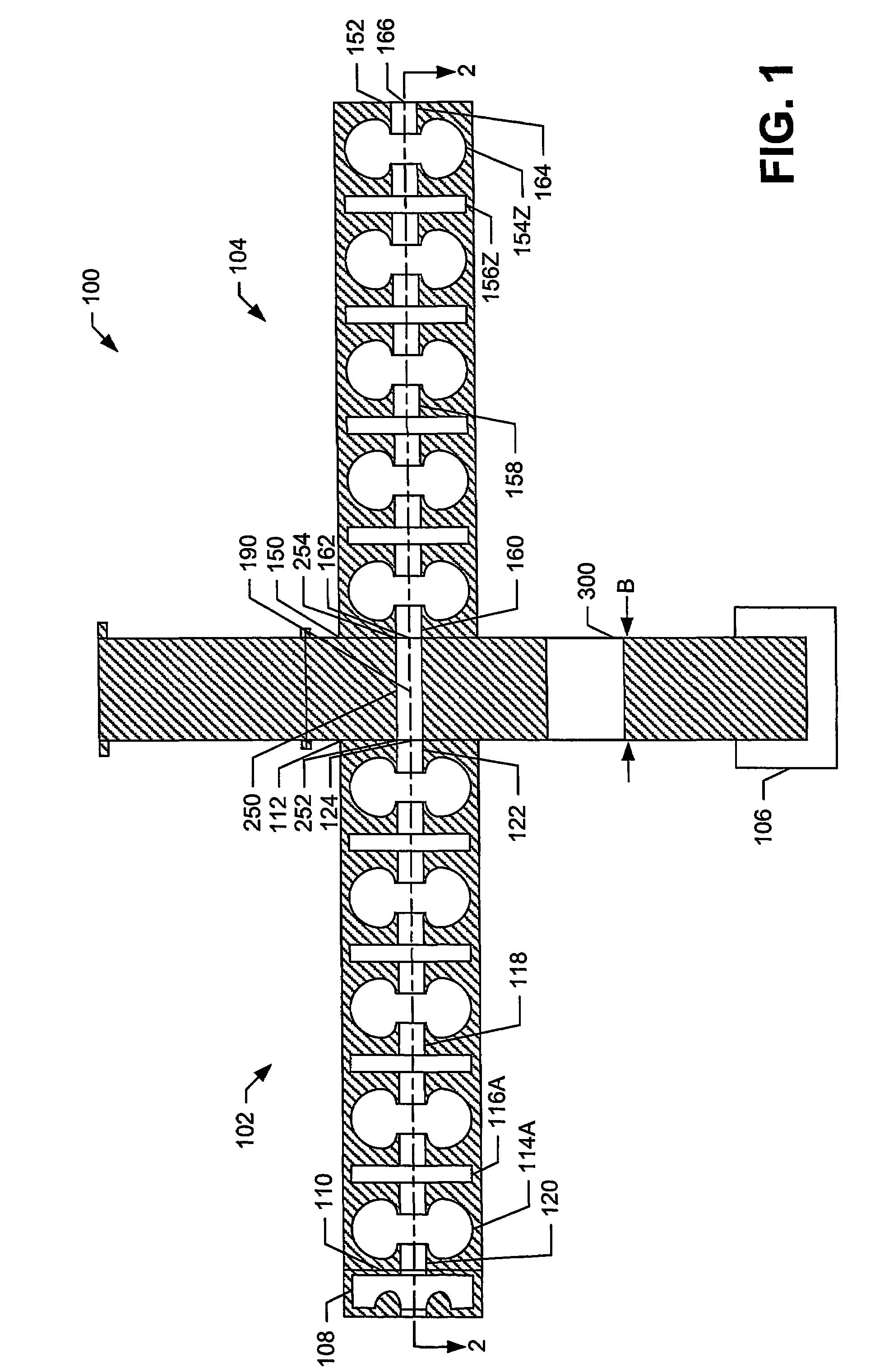

Particle accelerators having electromechanical motors and methods of operating and manufacturing the same

ActiveUS8653762B2Wave amplification devicesPiezoelectric/electrostriction/magnetostriction machinesParticle acceleratorElectricity

A particle accelerator including an electrical field system and a magnetic field system that are configured to direct charged particles along a desired path within an acceleration chamber. The particle accelerator also includes a mechanical device that is located within the acceleration chamber. The mechanical device is configured to be selectively moved to different positions within the acceleration chamber. The particle accelerator also includes an electromechanical (EM) motor having a connector component and piezoelectric elements that are operatively coupled to the connector component. The connector component is operatively attached to the mechanical device. The EM motor drives the connector component when the piezoelectric elements are activated thereby moving the mechanical device.

Owner:GENERAL ELECTRIC CO

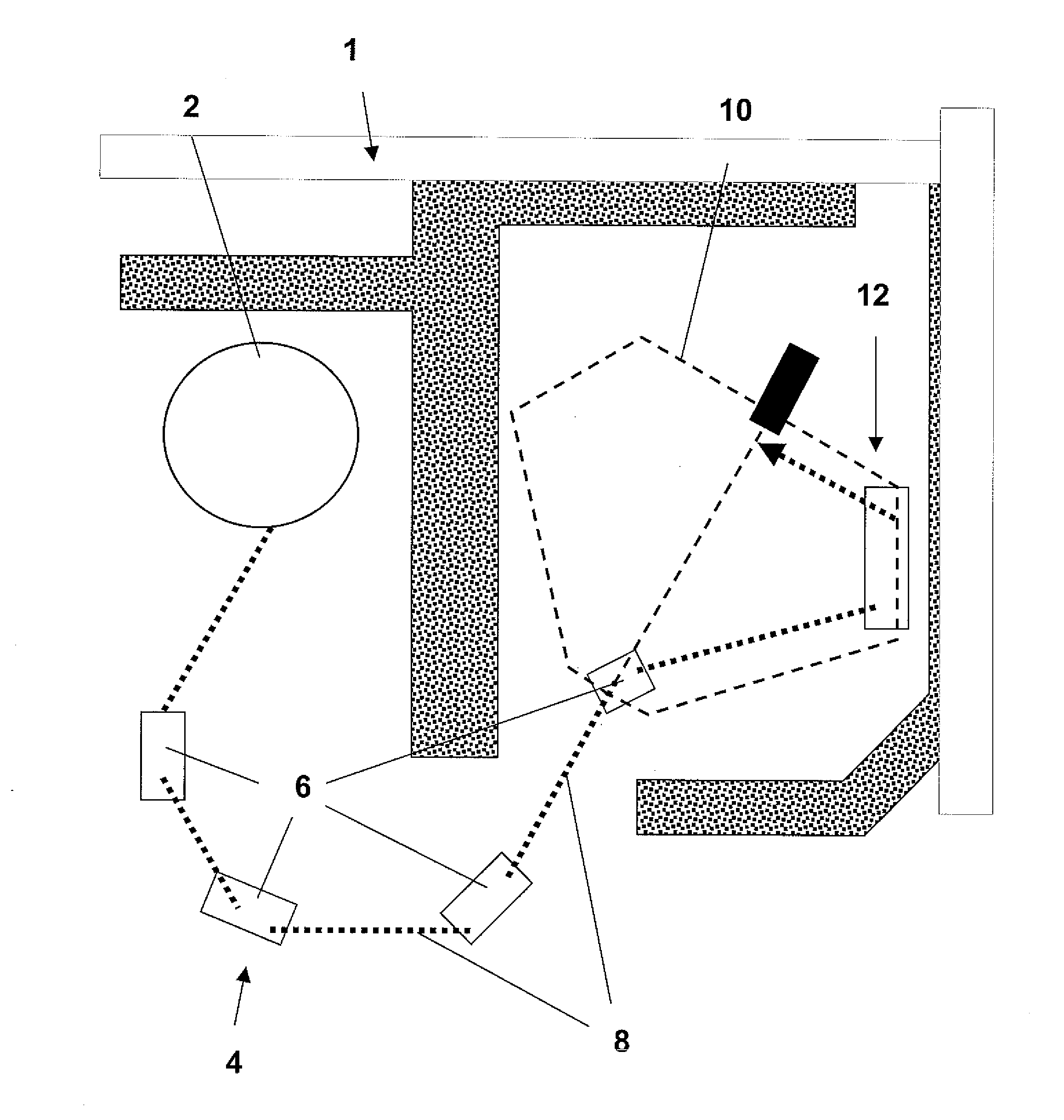

Irradiation System and Irradiation Method

InactiveUS20100117002A1Risk of corruptionRisk minimizationThermometer detailsStability-of-path spectrometersGratingTherapy planning

The system for irradiating patients with charged particles includes a raster scanning irradiation unit with a particle accelerator, a beam guide unit, and a 3D scanning system. It also contains a therapy planning system for generating therapy planning data, which include the energy and number of charged particles per raster point in each layer as derived from the derived dose distribution; a therapy control system, which converts the planning data generated by the therapy planning system into irradiation data and irradiation commands for the particle accelerator, the beam guide unit, and the 3D scanning system. The system further has a plurality of safety devices for ensuring that the therapy planning data have been converted correctly and for verifying the functionality of the system. The plurality of safety devices includes an evaluation unit, which checks the irradiation data and irradiation commands supplied by the therapy control system to the 3D scanning system to verify their therapy-specific plausibility.

Owner:VERW

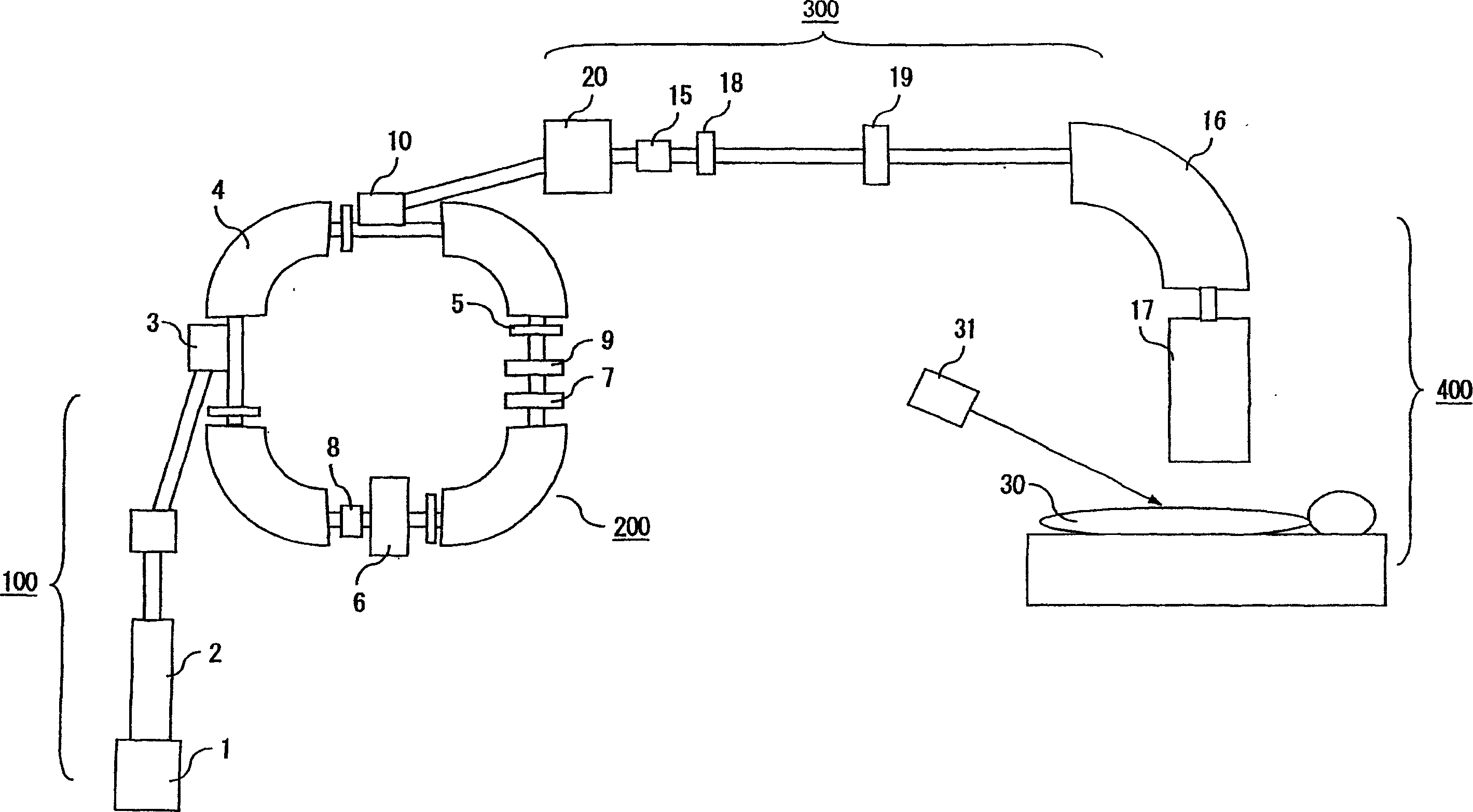

Charged-particle beam accelerator, particle beam radiation therapy system, and method of operating the particle beam radiation therapy system

ActiveCN1697587AEjaculation avoidanceReduce control objectsMagnetic resonance acceleratorsX-ray/gamma-ray/particle-irradiation therapyParticle acceleratorControl system

PROBLEM TO BE SOLVED: To provide a charged-particle beam accelerator having an electromagnet power source without needing simplification and the high reliability of beam emission control, reduction in the number of constituent apparatuses and high stability, and to provide a particle beam radiation therapy system using it.

Owner:MITSUBISHI ELECTRIC CORP

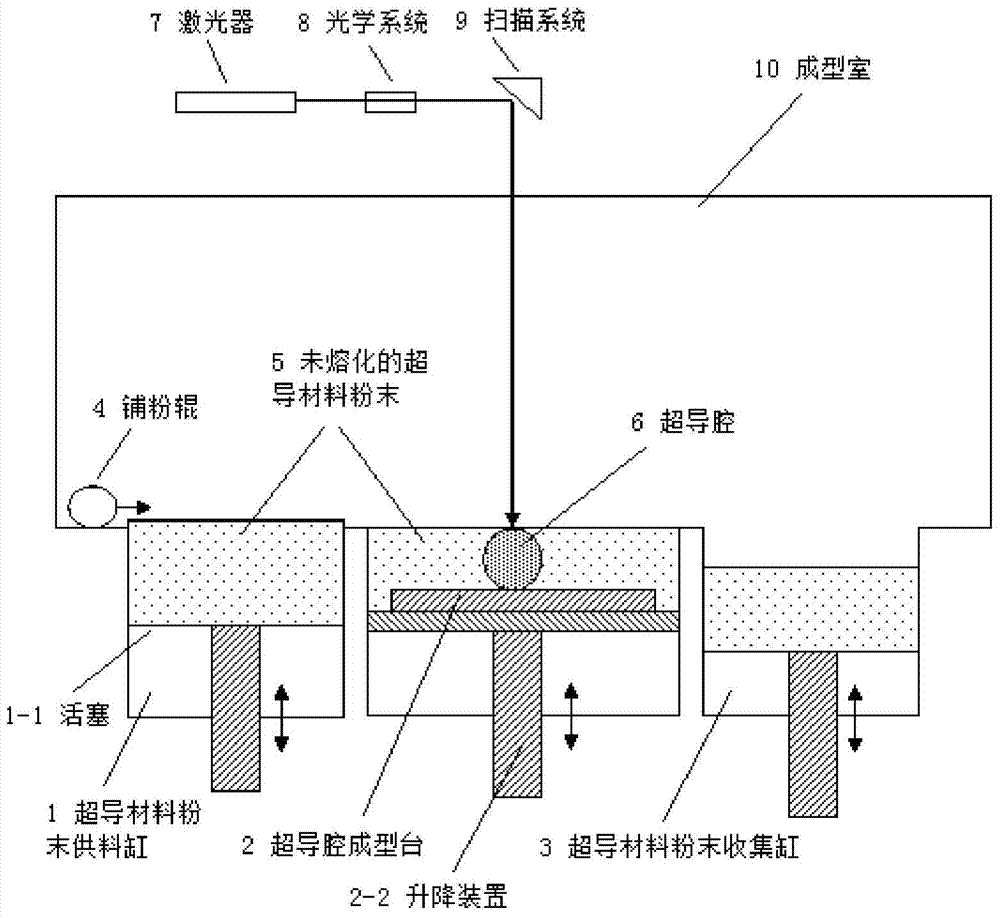

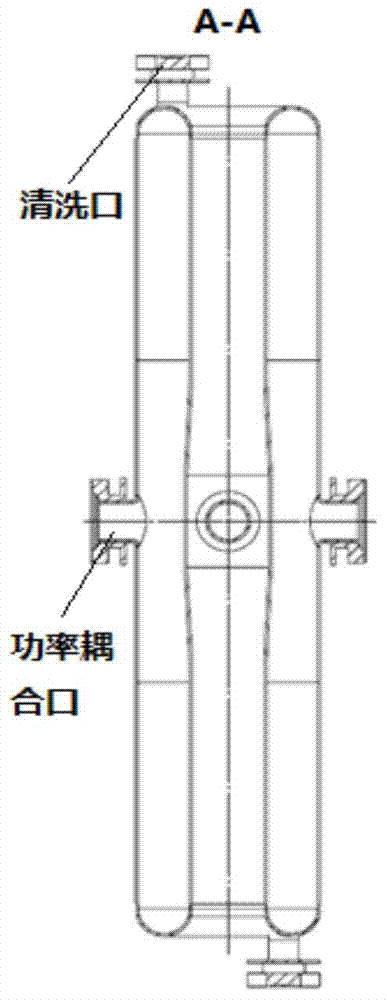

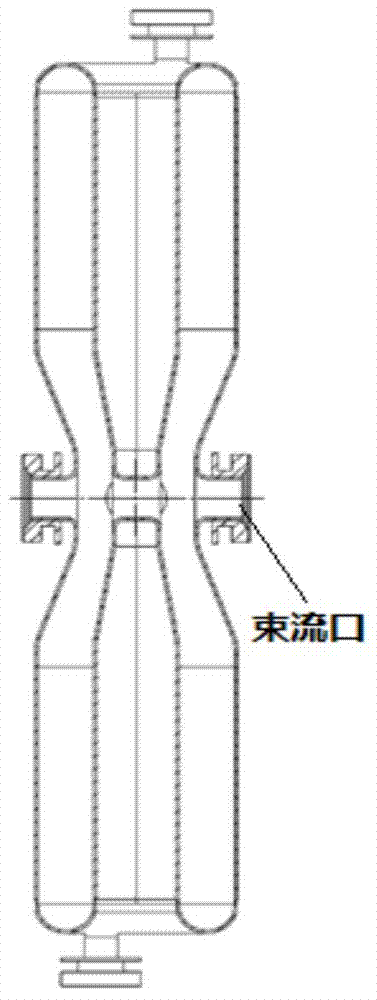

Manufacturing method of superconductor cavity

The invention belongs to the technical field of particle accelerators and particularly relates to manufacture of a radio frequency superconductor cavity. A manufacturing method of the superconductor cavity mainly comprises the following steps: (1) using superconductor materials as raw materials, (2) utilizing CAD software to generate a superconductor cavity model, and adopting layering software to layer the superconductor cavity model, (3) using an atmosphere control system to provide argon for a forming chamber, (4) laying powder of superconductor materials in the step (1) on a forming table of the forming chamber, (5) using a scanning control system to print laser energy onto a powder layer according to the description of a software model of a superconductor cavity slicing layer so as to generate a superconductor material slicing layer entity. The entity is a part of the superconductor cavity. A next slicing layer is processed continually on the first slicing layer entity until the whole superconductor cavity processing process is finished. Finally, mechanical polishing, chemical washing, high-temperature annealing, high-pressure super-pure water washing and super-clean chamber assembly are conducted. The method shortens the development cycle of the superconductor cavity, improves the finished product rate of the development of the superconductor cavity due to the fact that the whole superconductor cavity is free of welding joints, is free of restriction of stamping forming conditions and capable of improving the performance of the superconductor cavity, and reduces product cost due to the fact that surplus superconductor material powder can be used repeatedly.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Charged particle accelerator

InactiveUS20090224701A1Improve reliabilityDifficult to generateTransit-time tubesDirect voltage acceleratorsParticle acceleratorElectric discharge

In a charged particle accelerator, voltage of several tens of kV is applied between accelerating electrodes. In such a case, electric discharge is sometimes generated between the accelerating electrodes. In the charged particle accelerator, part or entirety of the accelerating electrodes is coated with an electric discharge suppressing layer made of ceramics or alloy having a high melting point as compared with metal. When impurity fine particles are accelerated by an electric field and collide with the electrodes, the electric discharge suppressing layer made of ceramics or alloy prevents metal vapor from being easily generated from the electrodes and an ionized plasma from being easily produced, thus suppressing electric discharge between the electrodes.

Owner:HITACHI HIGH-TECH CORP

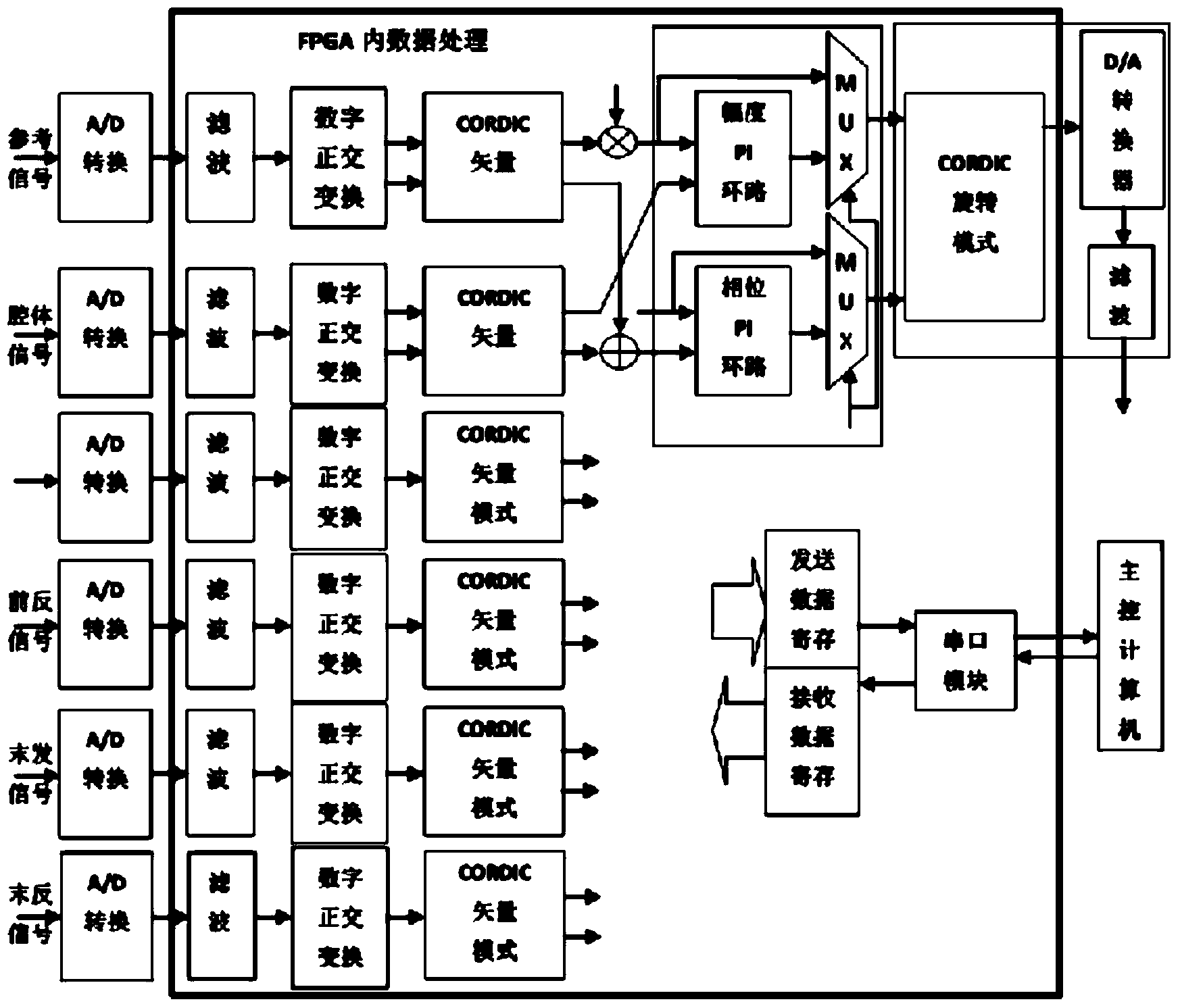

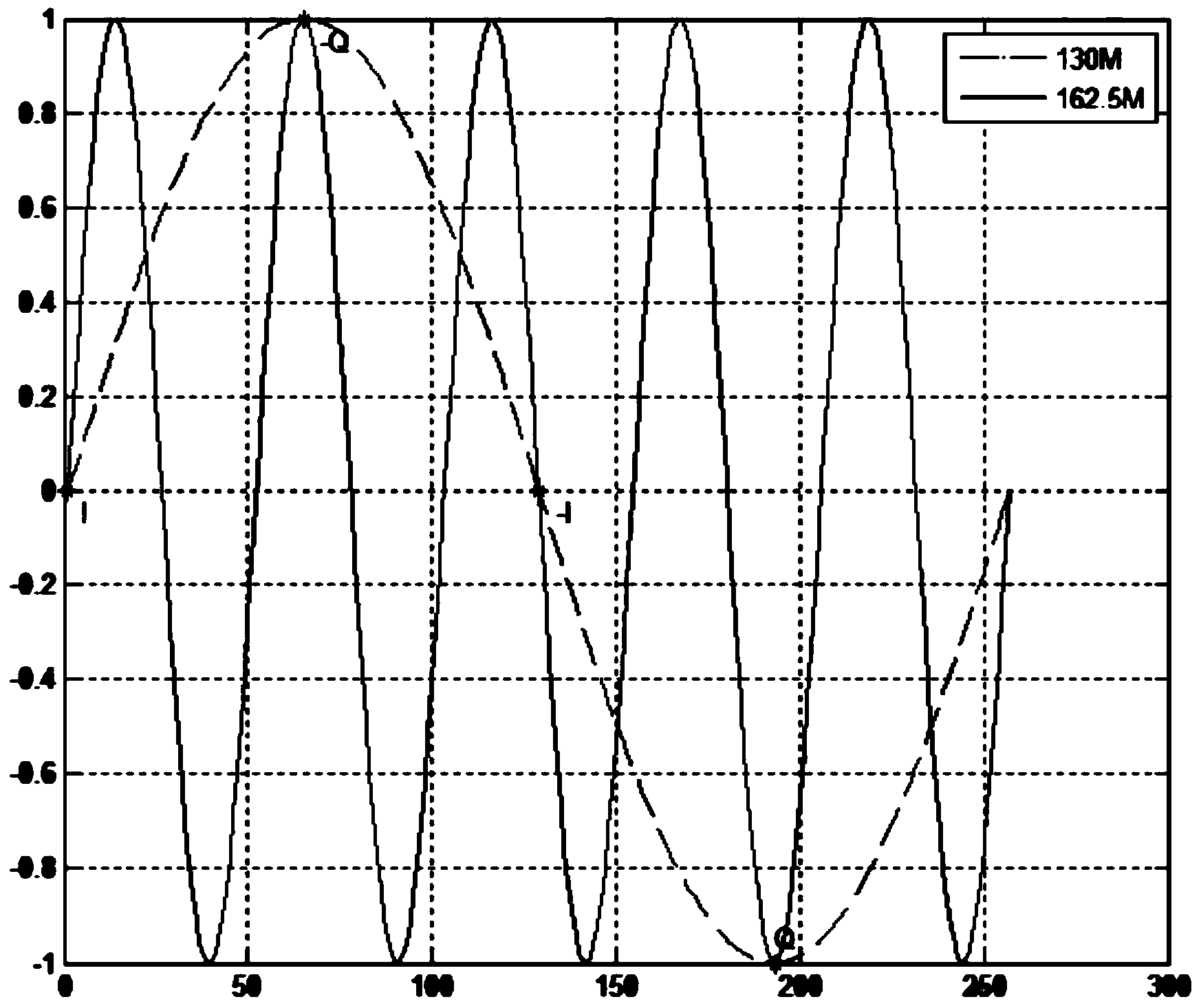

Power source low-level all-digital amplitude phase control system for high-energy particle accelerator and implementation method thereof

InactiveCN104333375AStable structureLess power consumptionPulse automatic controlLinear acceleratorsDigital signal processingLoop control

The invention relates to a power source low-level all-digital amplitude phase control system for a high-energy particle accelerator and an implementation method thereof. The method comprises cooperation of signal preprocessing, digital signal processing and digital loop control. An analog circuit component of the signal preprocessing comprises six signal processing channels and one clock processing channel integrated on an analog part, wherein each signal processing channel comprises an attenuator, an amplifier and a filter; and the clock processing channel comprises an attenuator, an amplifier, a filter, a frequency multiplier and a frequency divider. A digital circuit component of the digital signal processing and the digital loop control comprises three A / D (Analog to Digital) converters for sampling six paths of signals, one D / A (Digital to Analog) converter for generating signals and one FPGA (Field Programmable Gate Array) for the digital signal processing and the digital loop control, wherein the three A / D converters, the D / A converter and the FPGA are integrated on a digital part. Through adoption of the power source low-level all-digital amplitude phase control system, the physical structural parameters of a super conduction cavity can be controlled, and high stability of the amplitude and phase of a super conduction cavity driving energy field can be kept.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00000.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00001.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00002.png)