Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128 results about "Beam pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

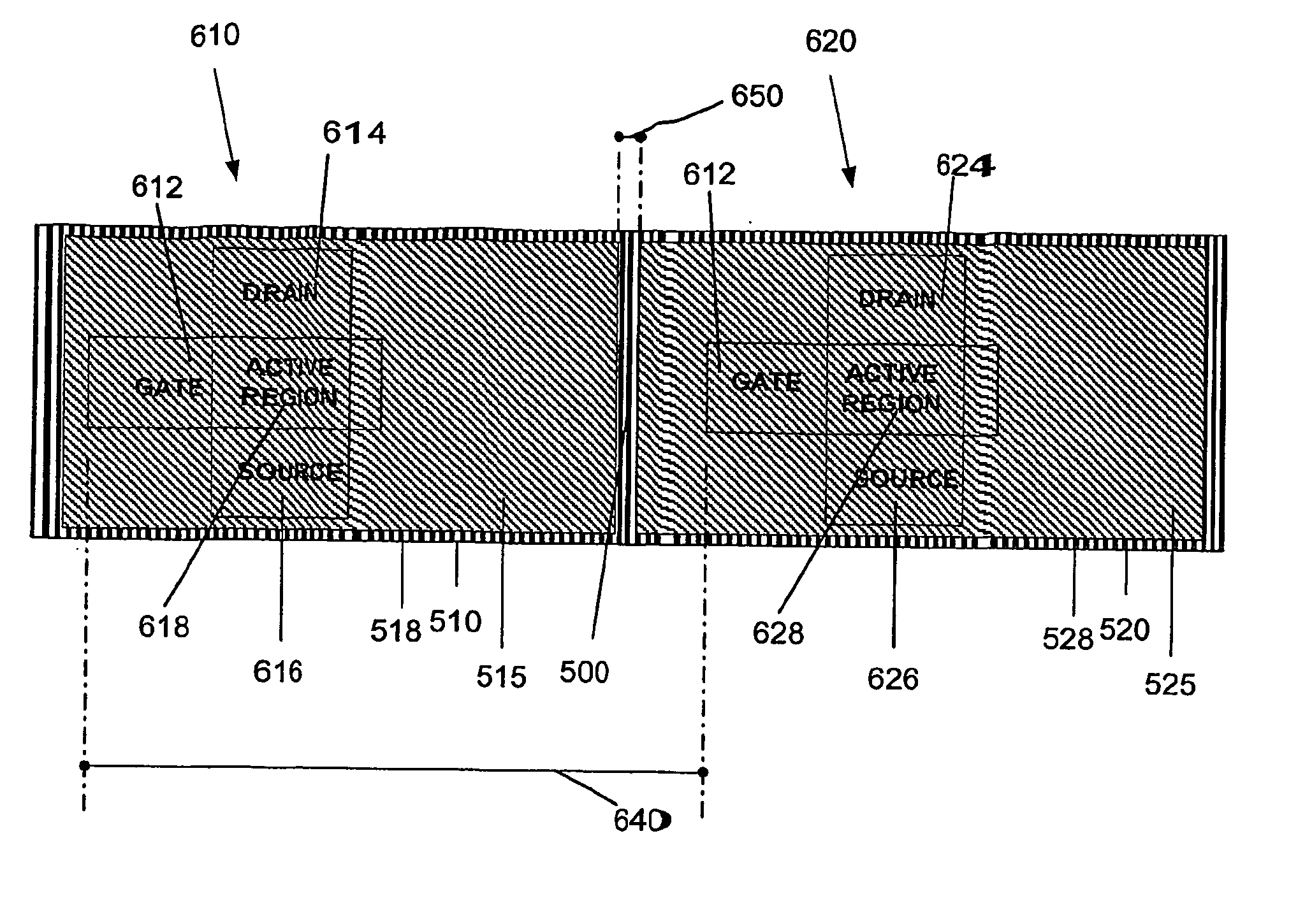

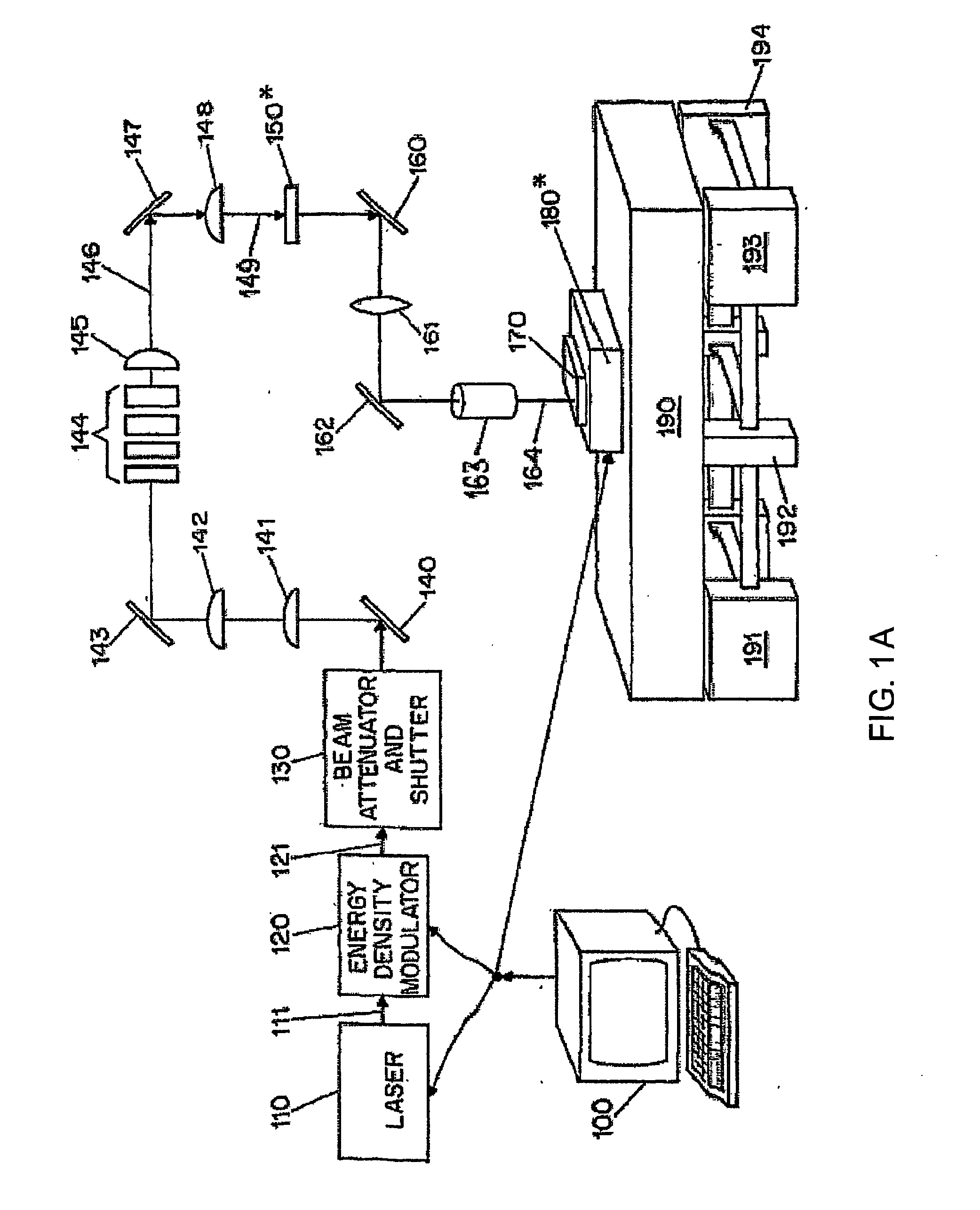

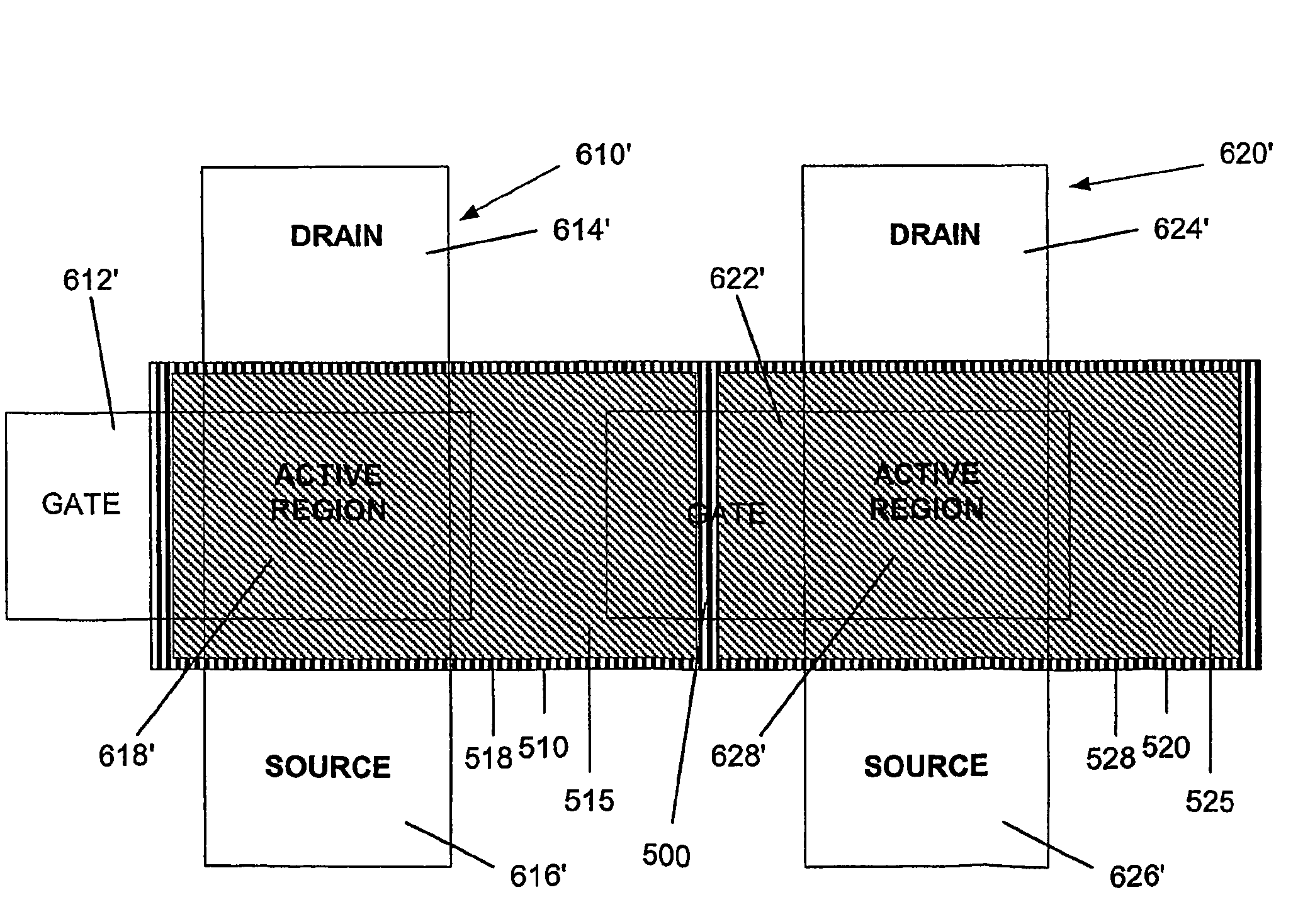

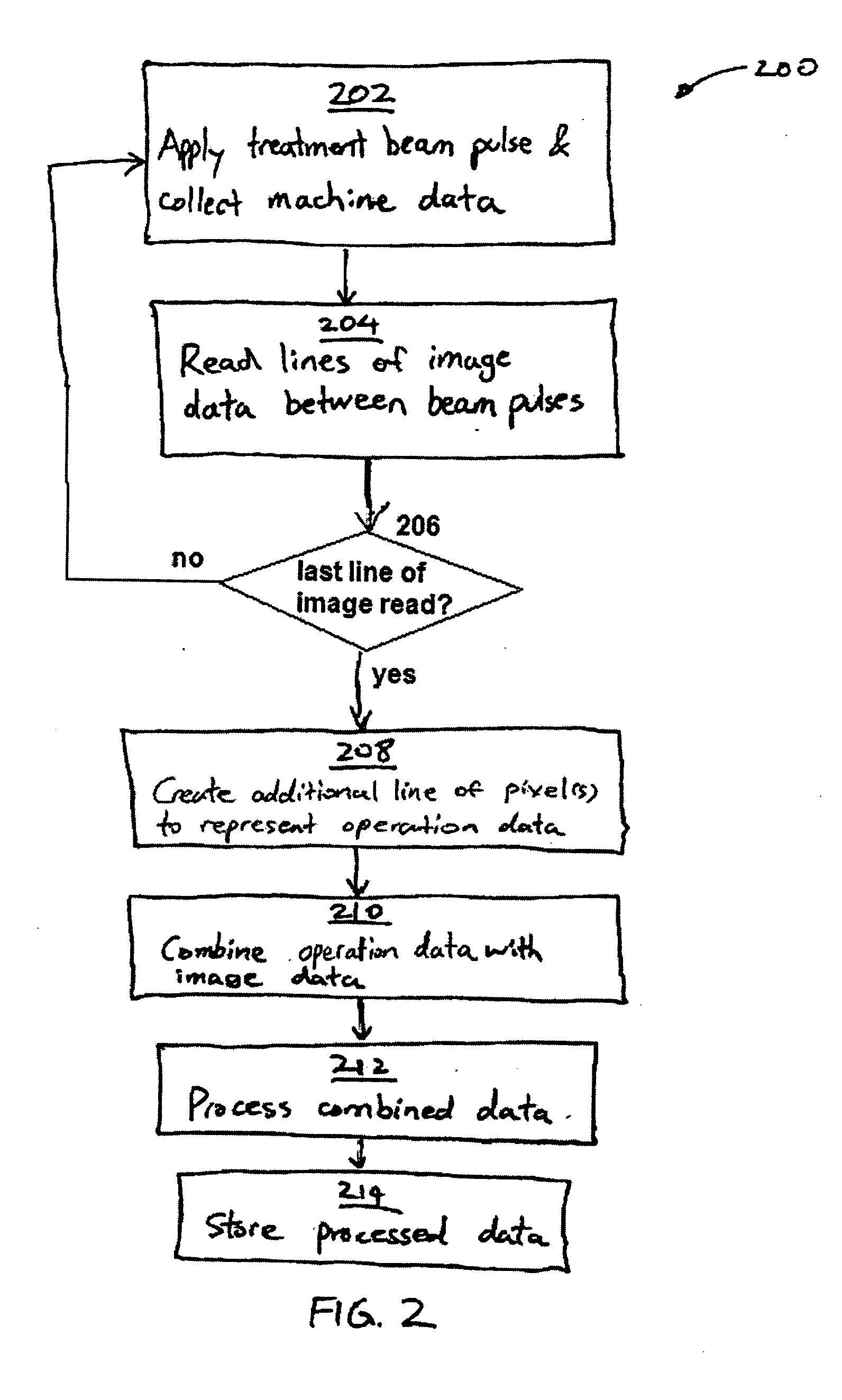

Process and system for laser crystallization processing of film regions on a substrate to minimize edge areas, and a structure of such film regions

InactiveUS20060030164A1Increase speedSmall sizeTransistorLaser detailsLaser crystallizationCrystallization

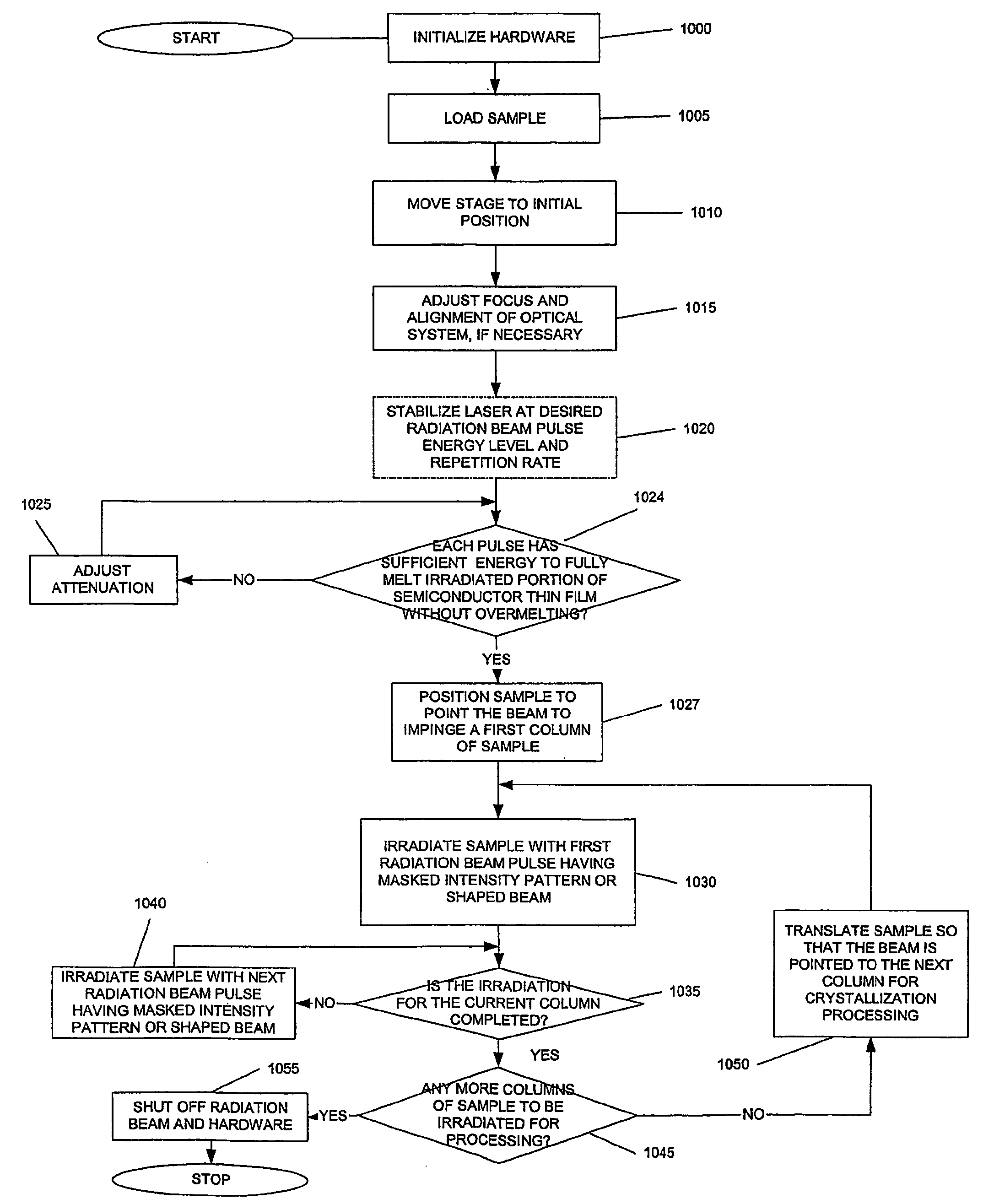

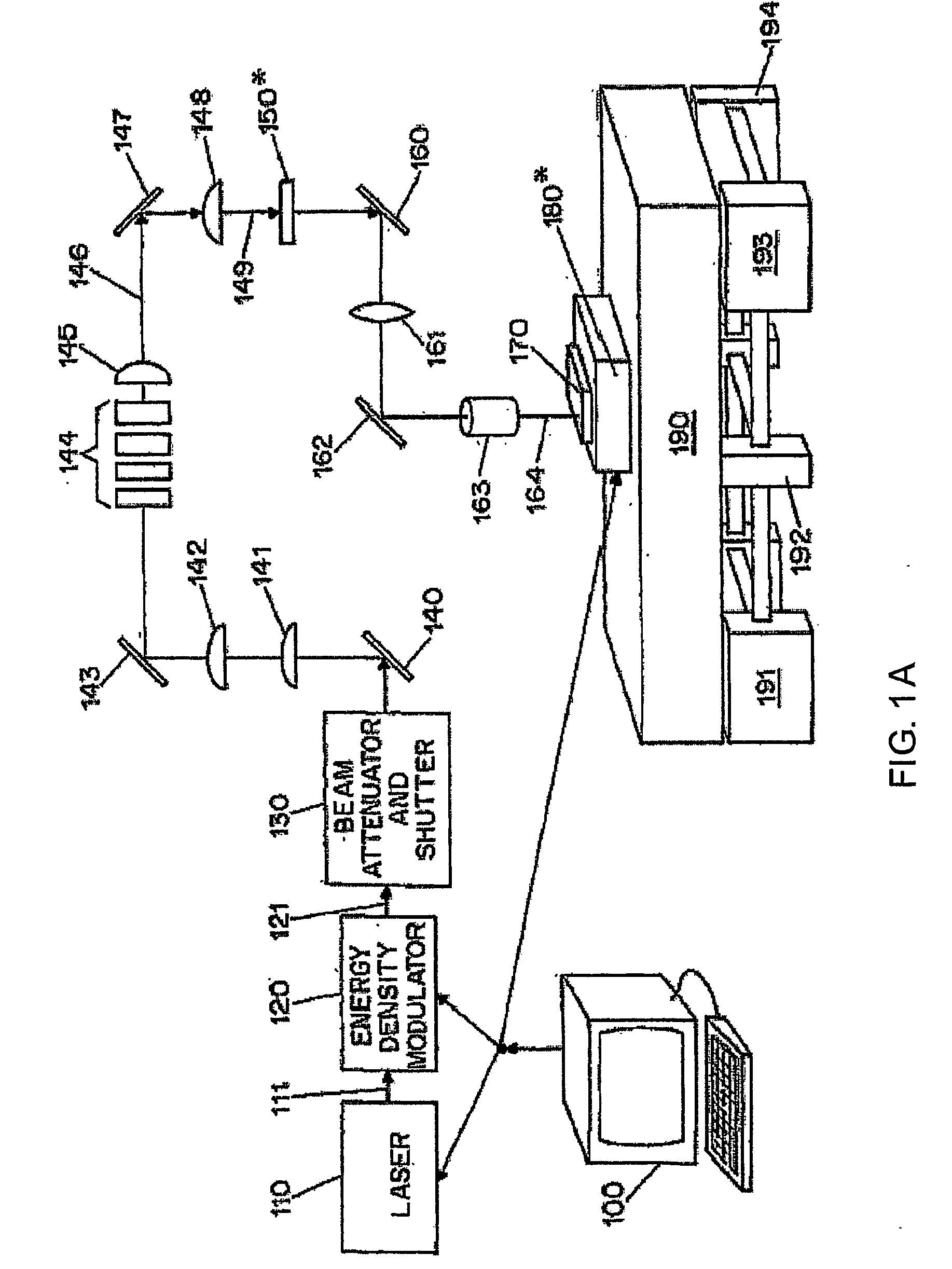

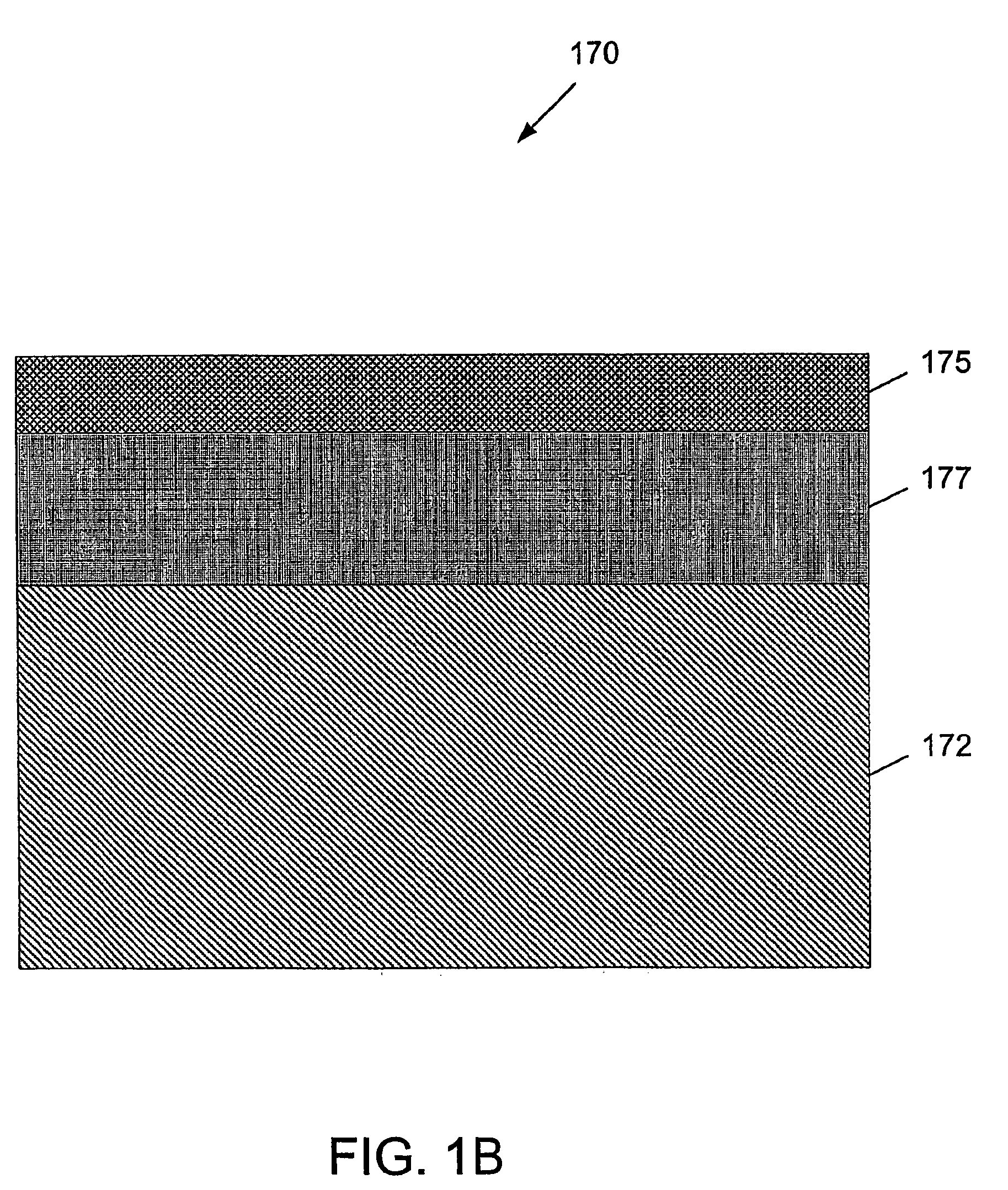

A process and system for processing a thin film sample are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. The beam pulse is then masked to produce at least one masked beam pulse, which is used to irradiate at least one portion of the thin film sample. With the at least one masked beam pulse, the portion of the film sample is irradiated with sufficient intensity for such portion to later crystallize. This portion of the film sample is allowed to crystallize so as to be composed of a first area and a second area. Upon the crystallization thereof, the first area includes a first set of grains, and the second area includes a second set of grains whose at least one characteristic is different from at least one characteristic of the second set of grains. The first area surrounds the second area, and is configured to allow an active region of a thin-film transistor (“TFT”) to be provided at a distance therefrom.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

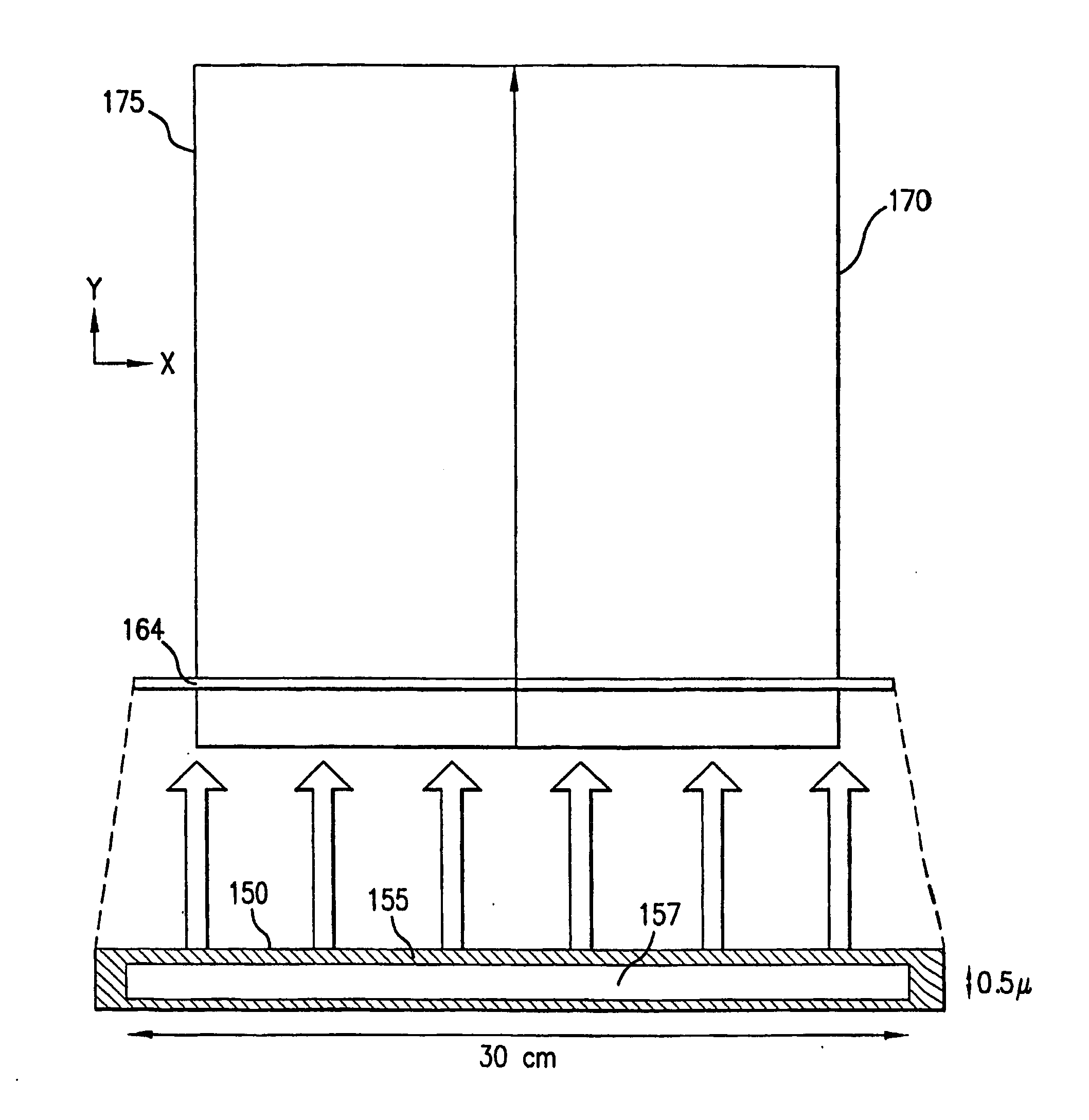

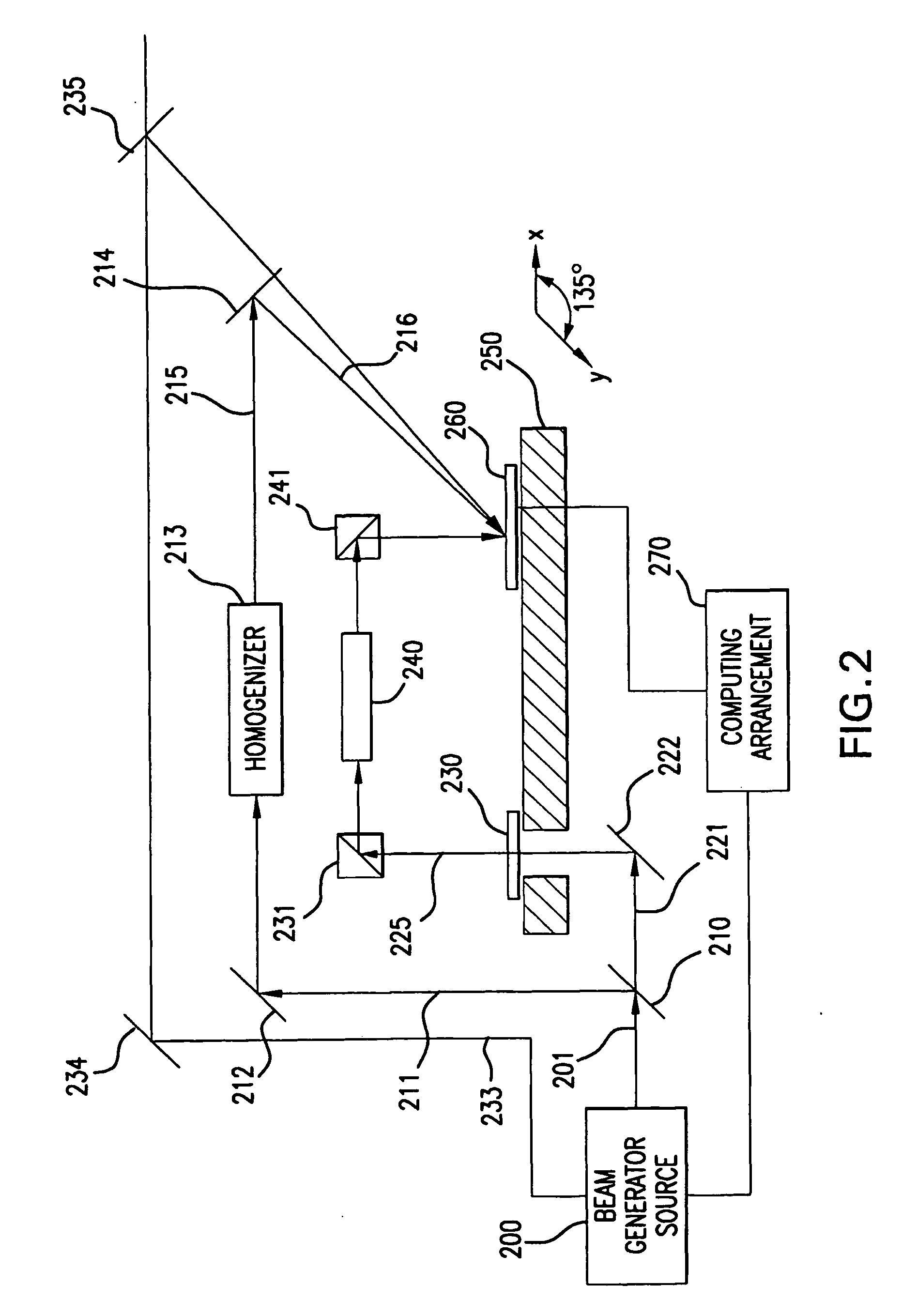

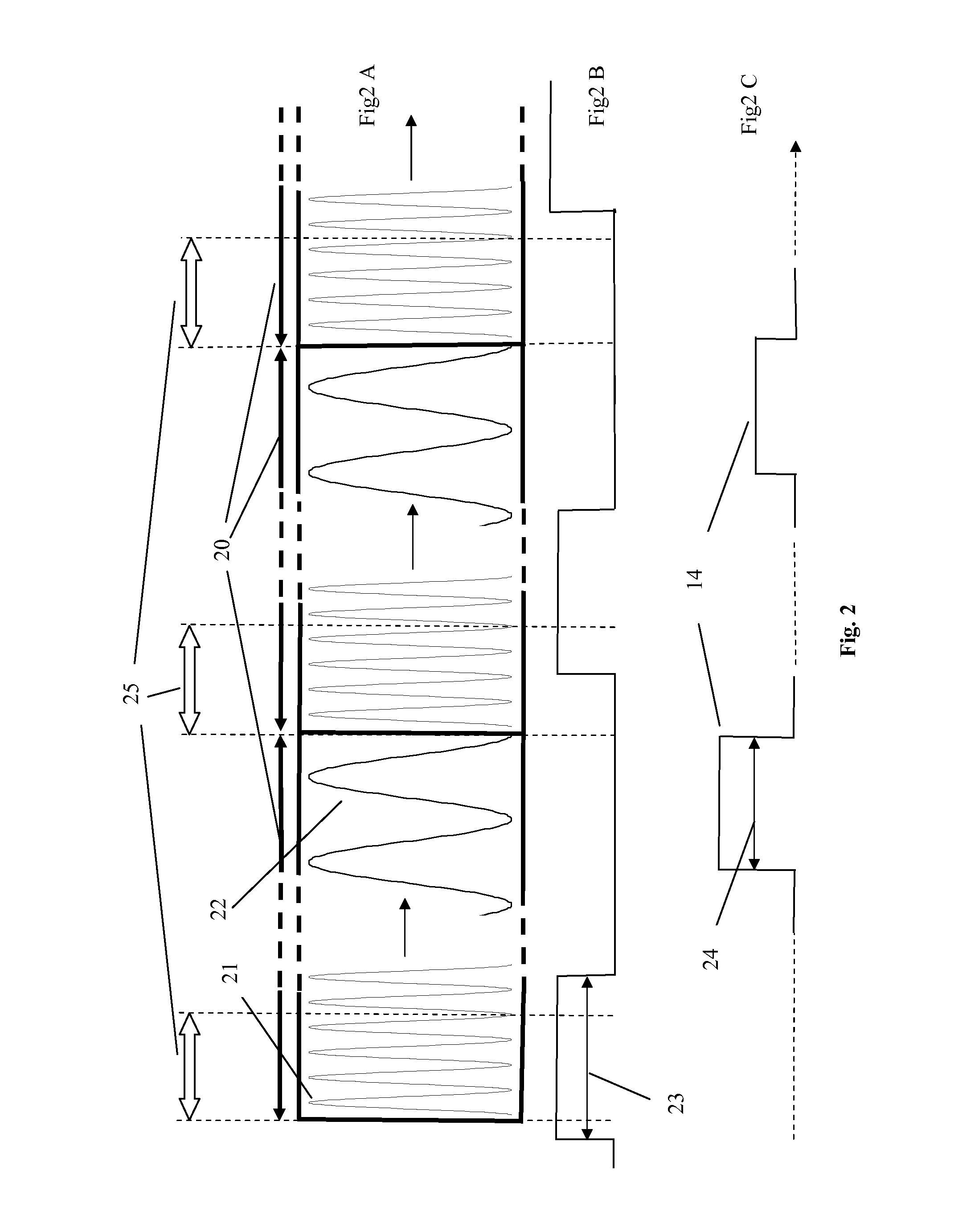

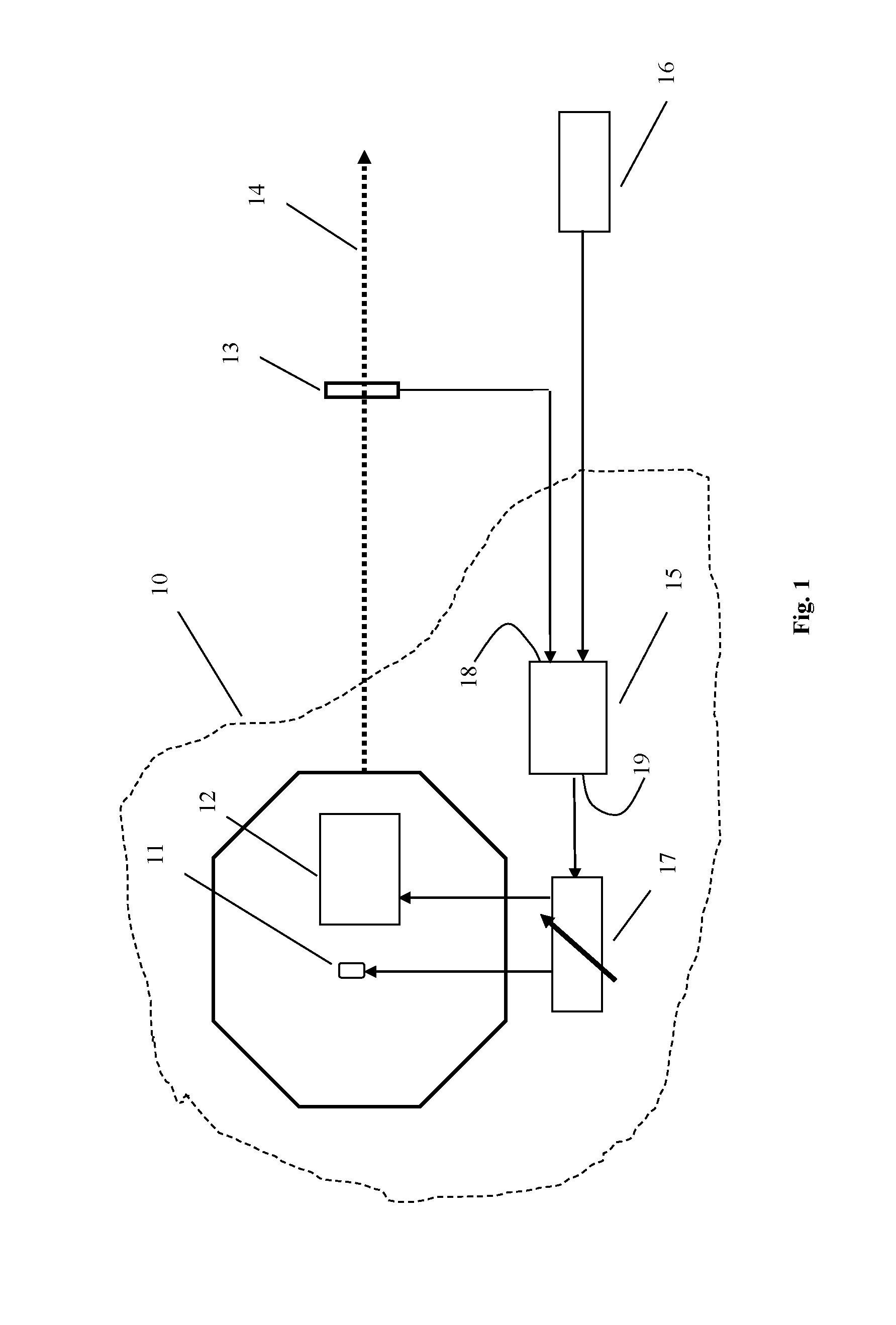

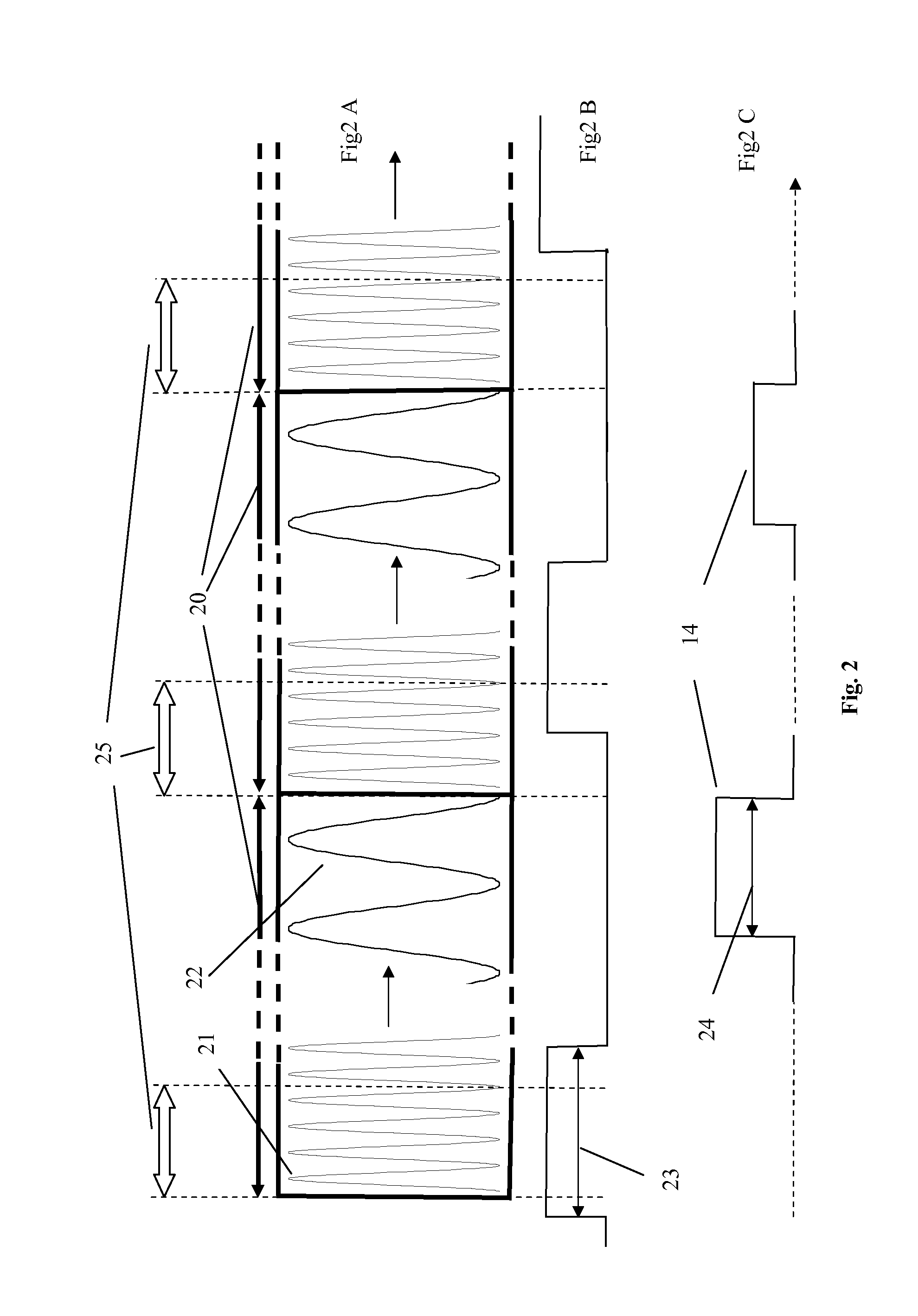

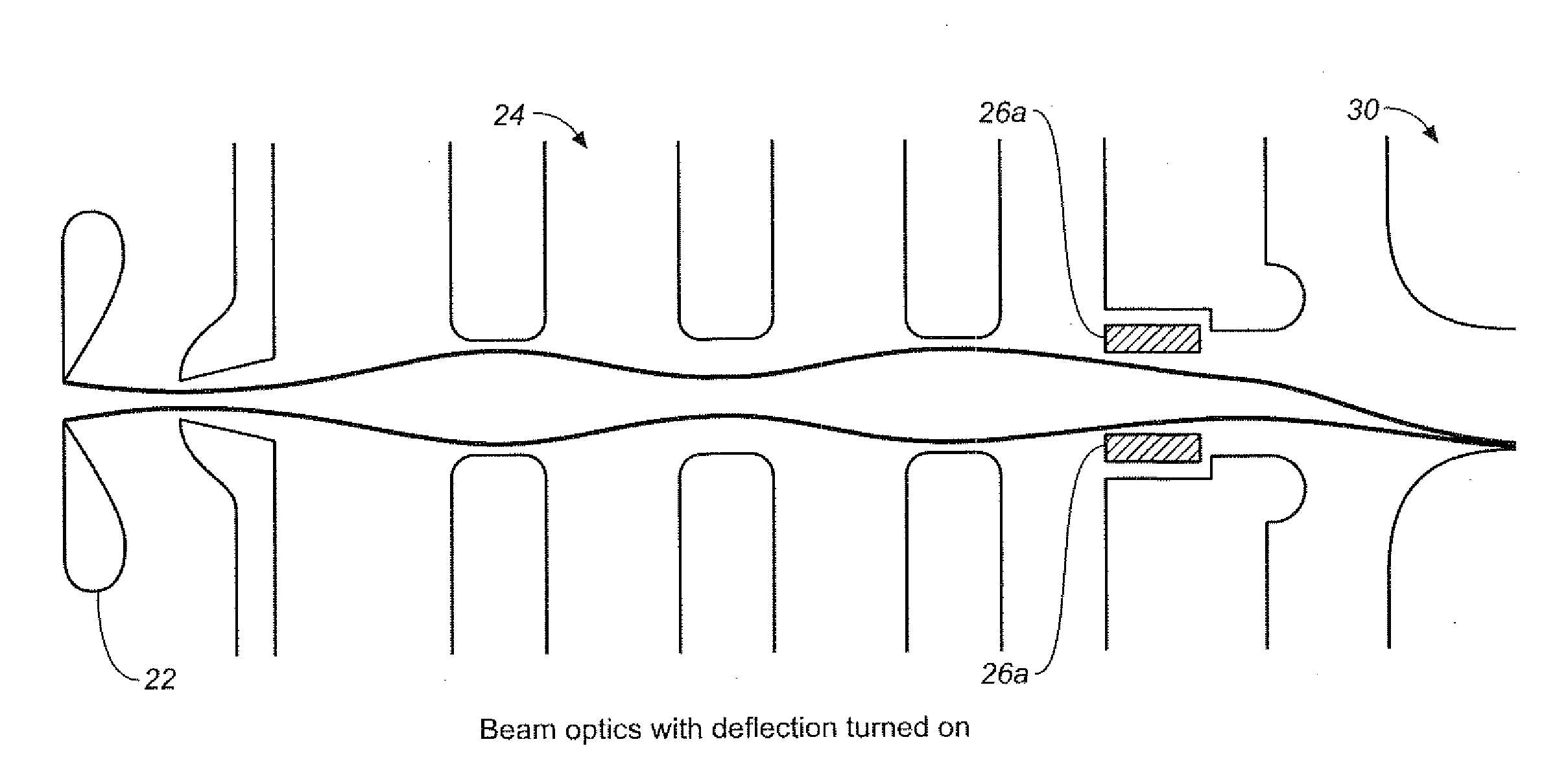

Processes and systems for laser crystallization processing of film regions on a substrate utilizing a line-type beam, and structures of such film regions

ActiveUS20070010104A1Similar performanceAvoid radiationAfter-treatment apparatusFrom solid stateLaser crystallizationIrradiation

Process and system for processing a thin film sample, as well as at least one portion of the thin film structure are provided. Irradiation beam pulses can be shaped to define at least one line-type beam pulse, which includes a leading portion, a top portion and a trailing portion, in which at least one part has an intensity sufficient to at least partially melt a film sample. Irradiating a first portion of the film sample to at least partially melt the first portion, and allowing the first portion to resolidify and crystallize to form an approximately uniform area therein. After the irradiation of the first portion of the film sample, irradiating a second portion using a second one of the line-type beam pulses to at least partially melt the second portion, and allowing the second portion to resolidify and crystallize to form an approximately uniform area therein. A section of the first portion impacted by the top portion of the first one of the line-type beam pulses is prevented from being irradiated by trailing portion of the second one of the line-type beam pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

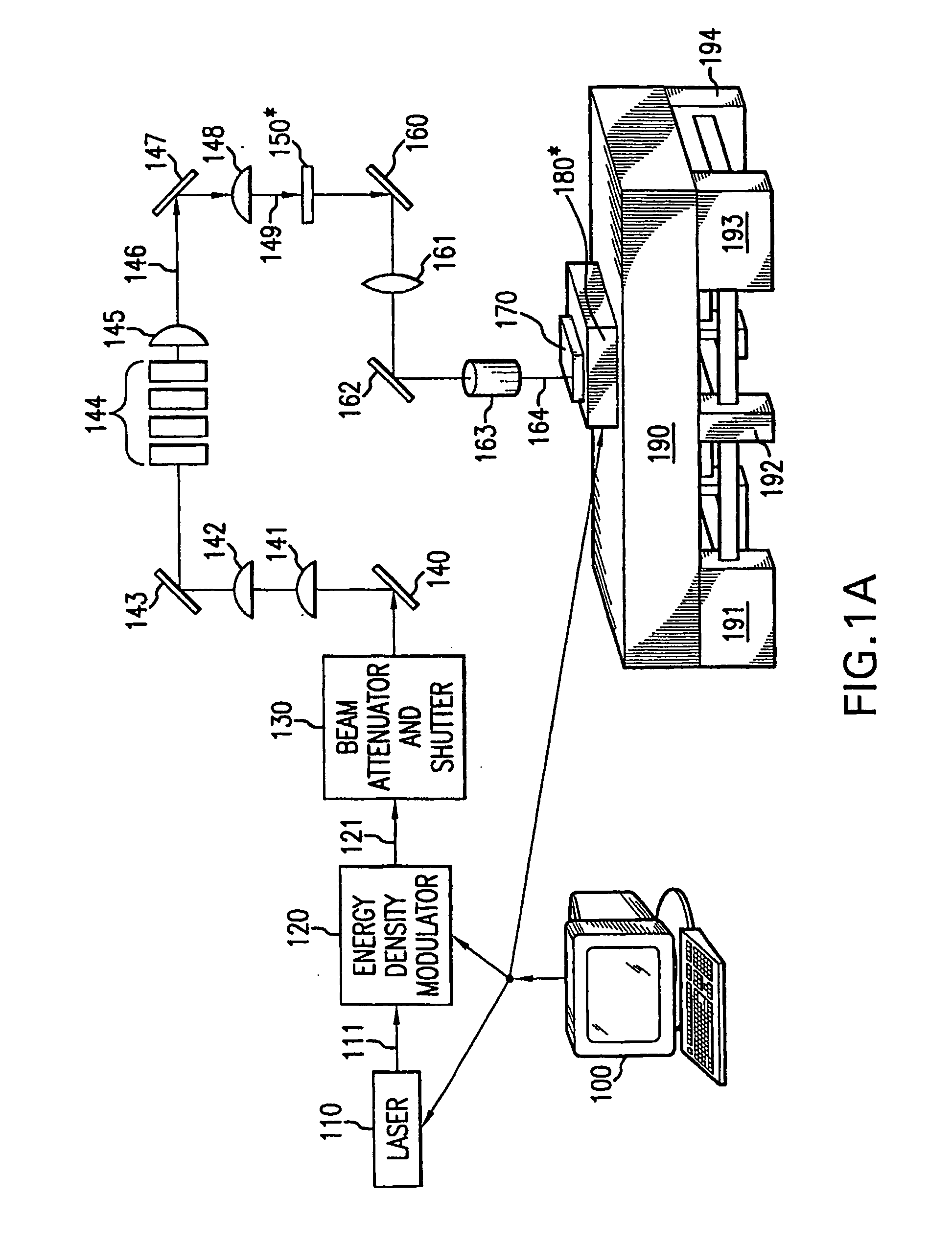

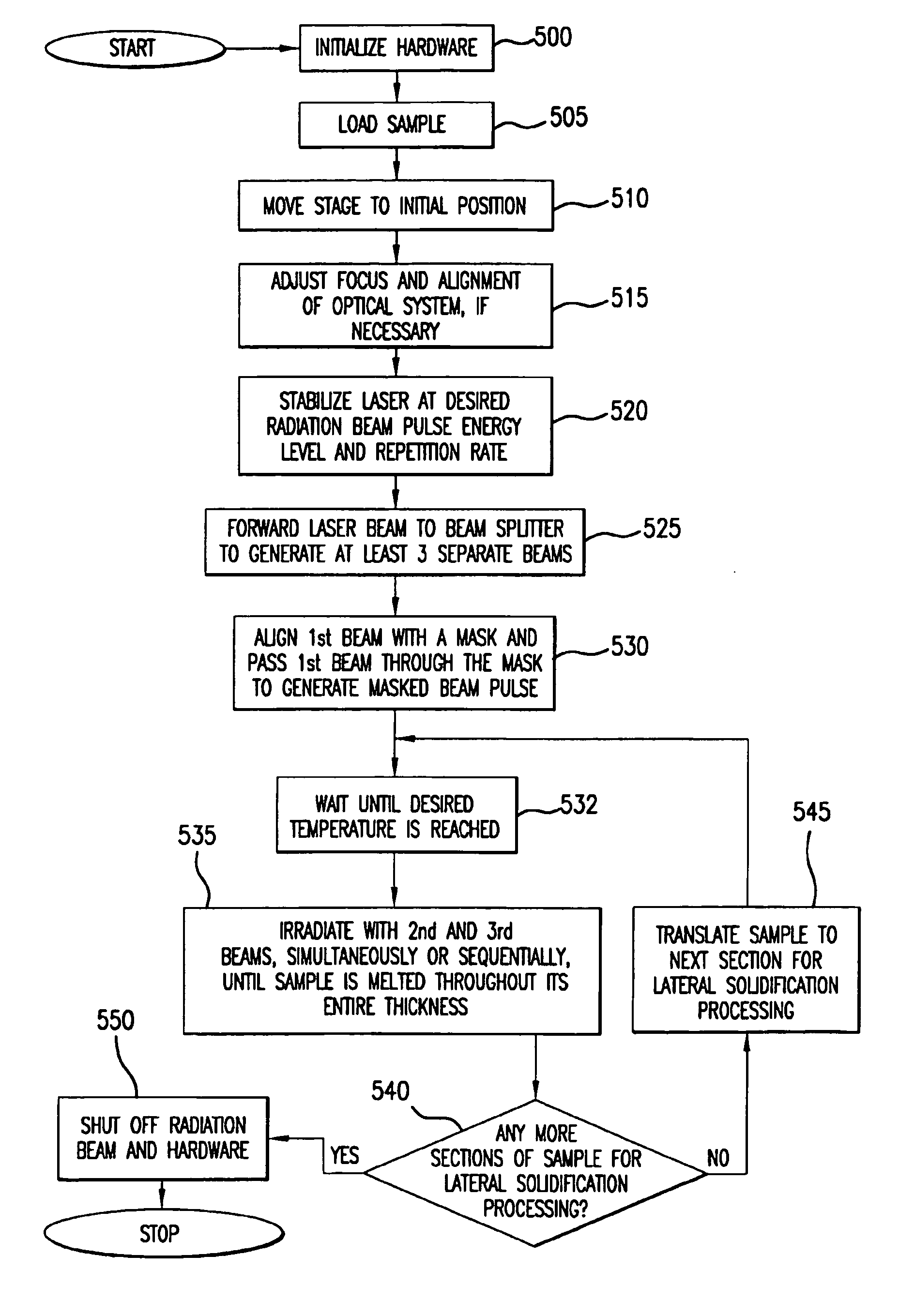

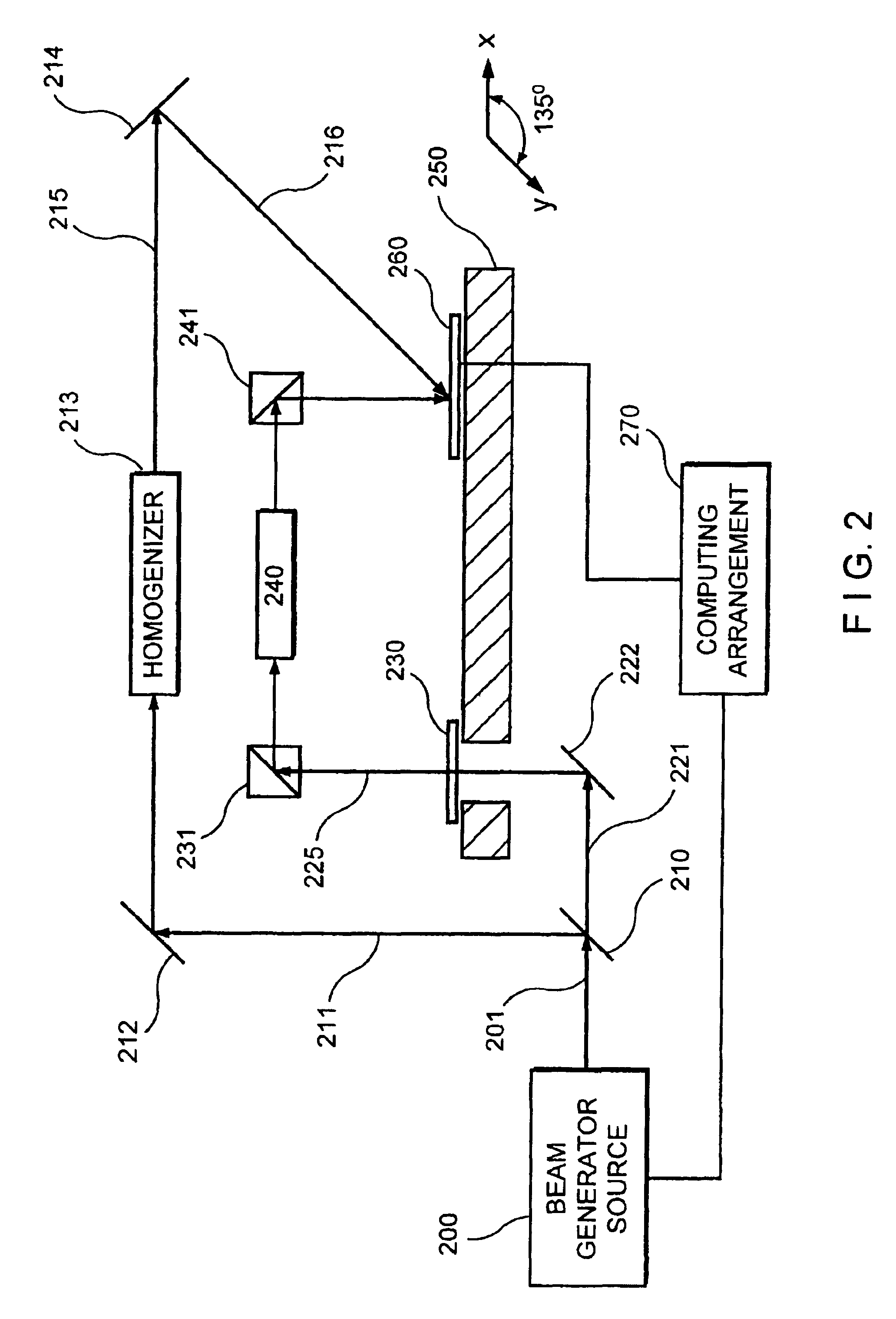

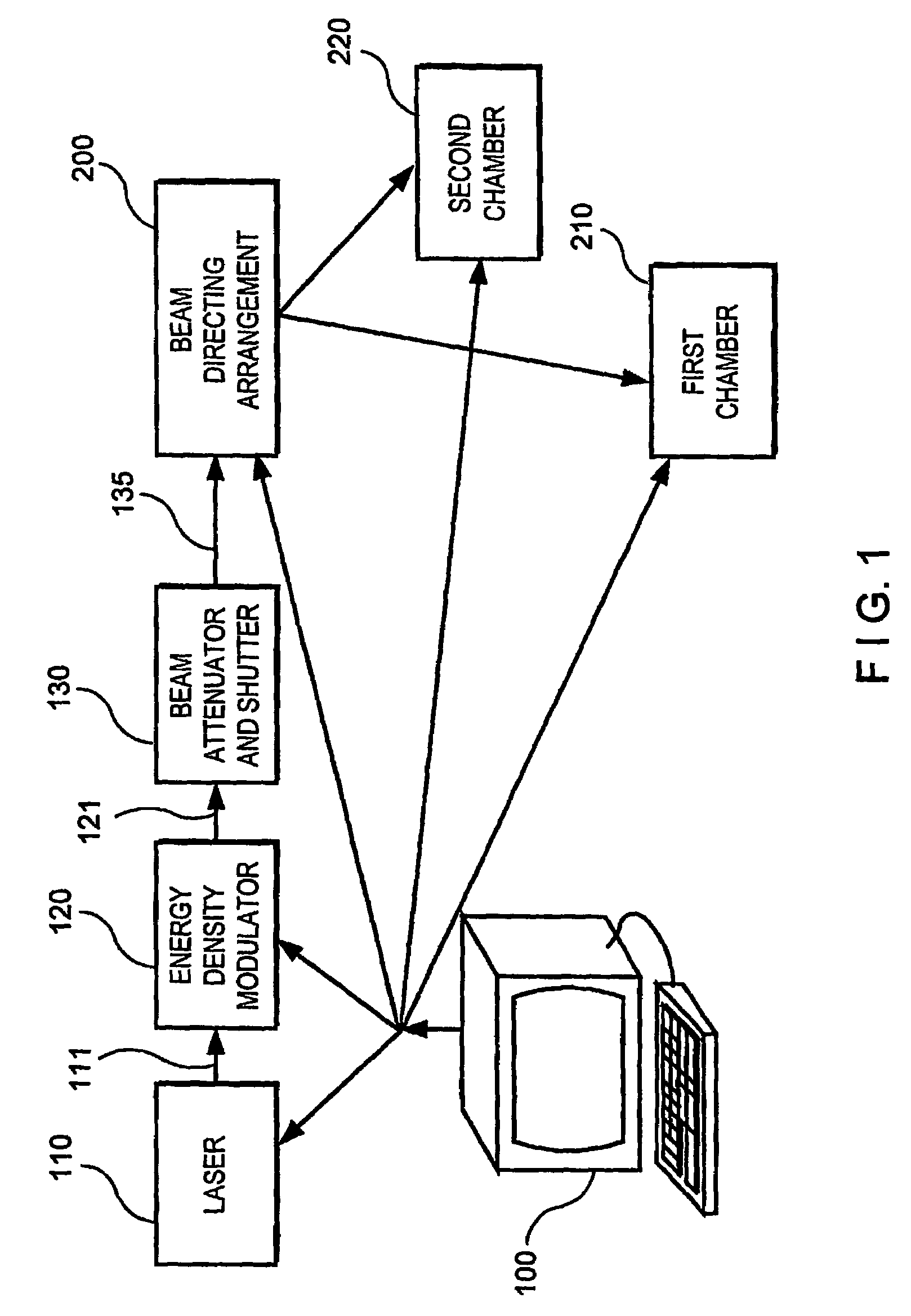

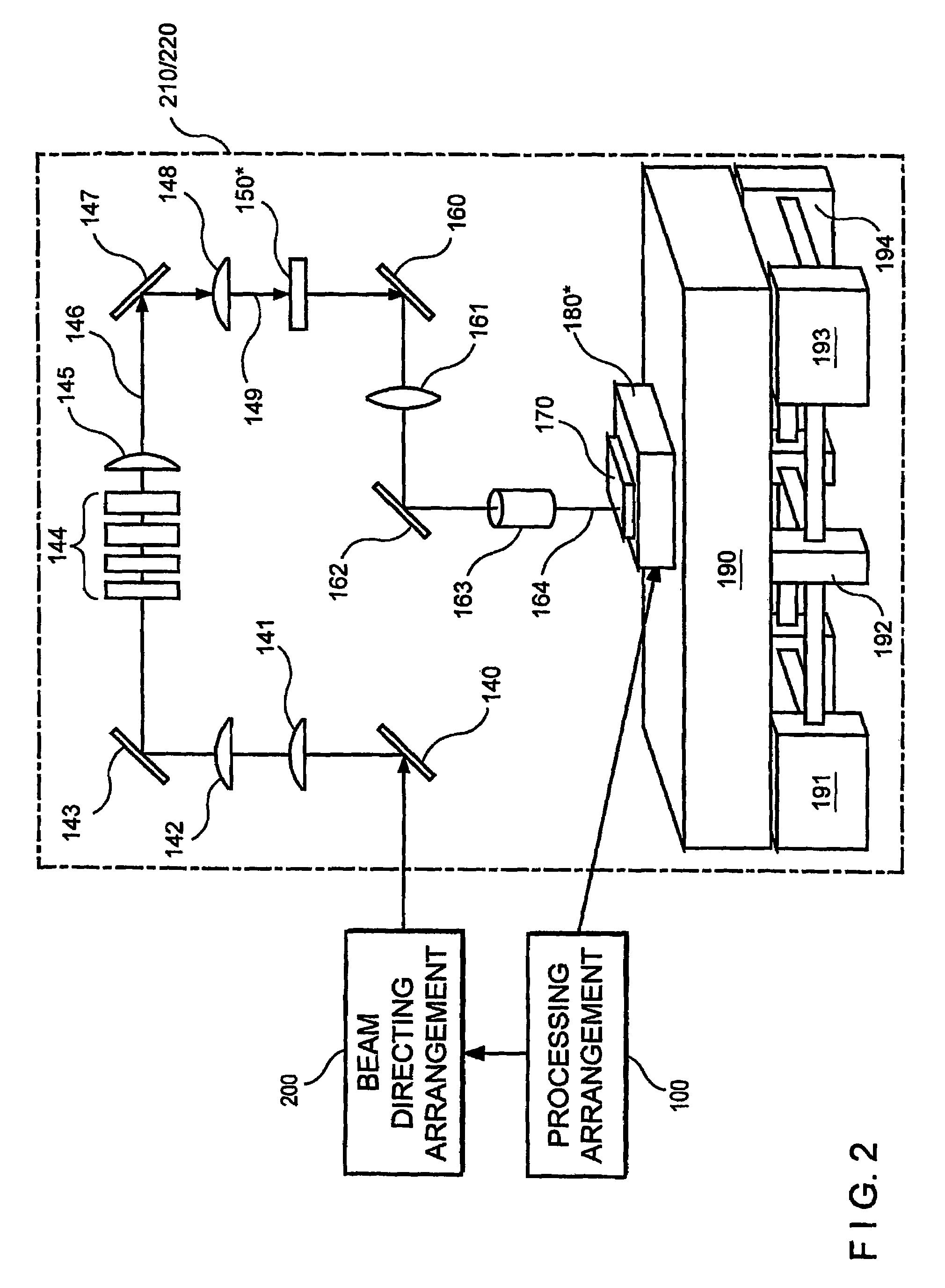

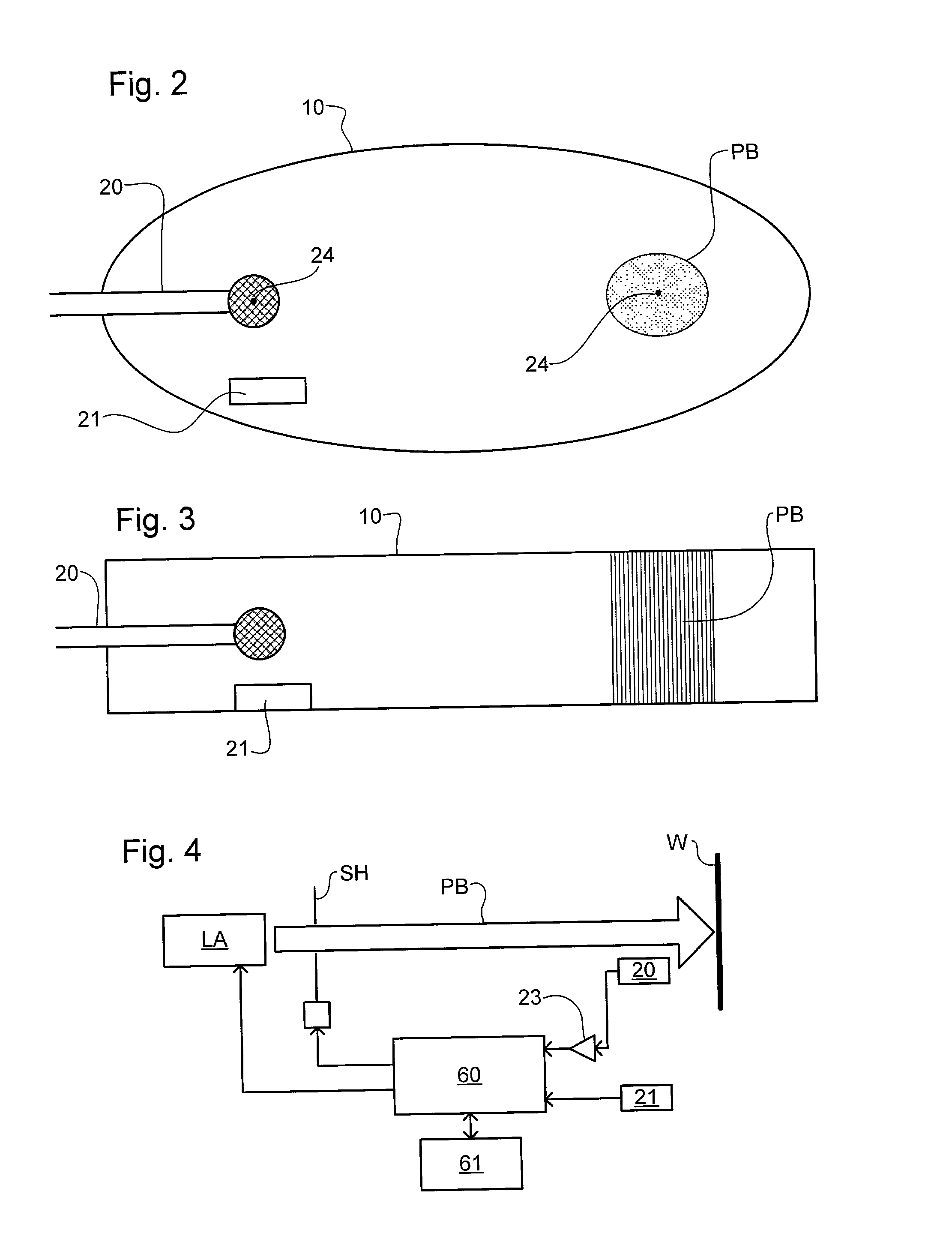

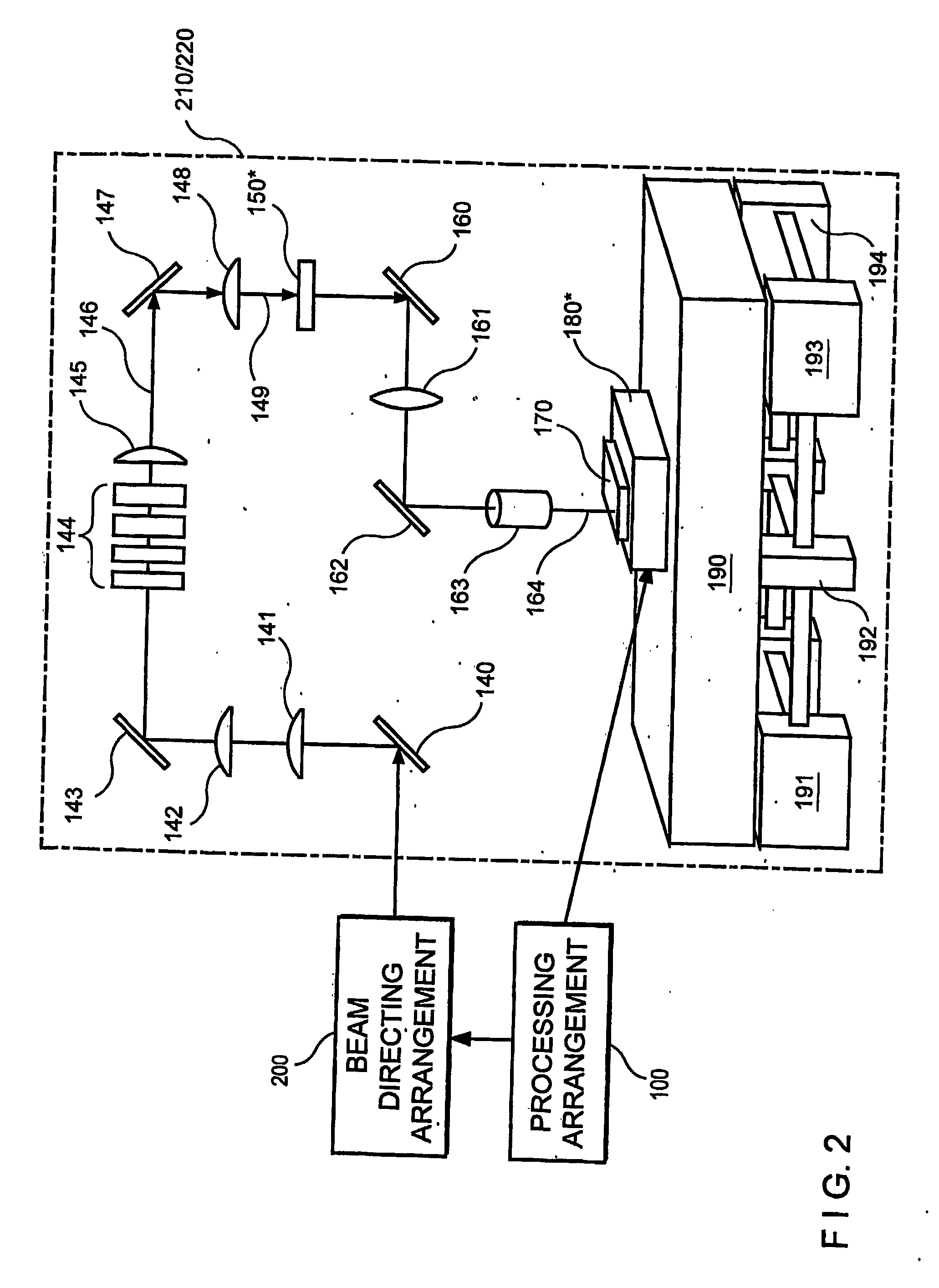

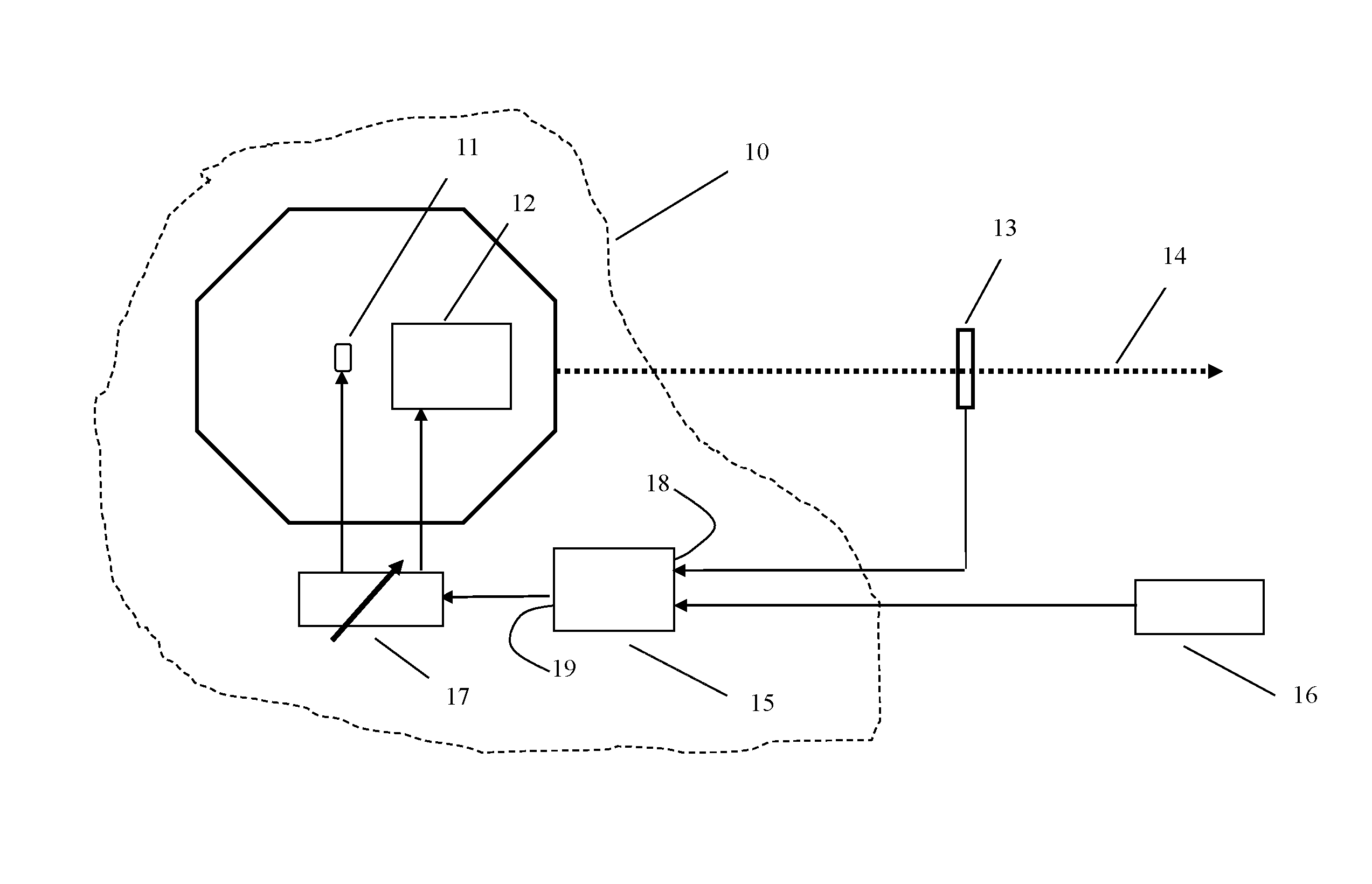

System and process for providing multiple beam sequential lateral solidification

InactiveUS20070032096A1Extended service lifeEmission reductionSolid-state devicesSemiconductor/solid-state device manufacturingLight beamIrradiation

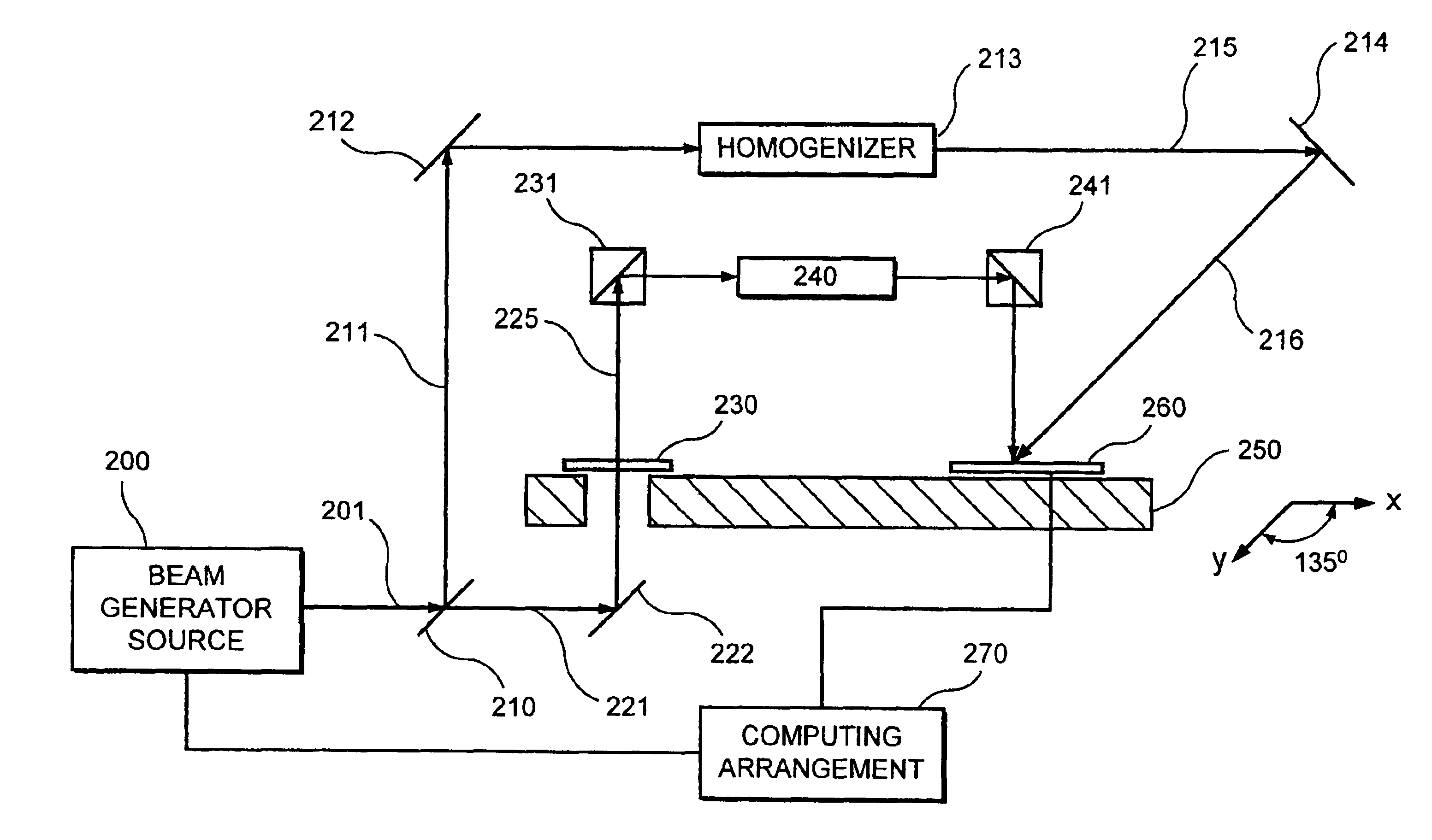

A process and system for processing a thin film on a sample are provided. In particular, a plurality of separated beams each including beam pulses are generated. At least one first beam of the separated beams is forwarded through a mask to irradiate and heat the thin film sample prior to further irradiation. At least one second beam of the separated beams is then forwarded through a mask to further irradiate the thin film sample. Additional separated beams are sent through a mask to produce and further irradiate the thin film until the combined intensity of the beams impinging on the sample is sufficient to melt a section of the thin film throughout its entire thickness.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

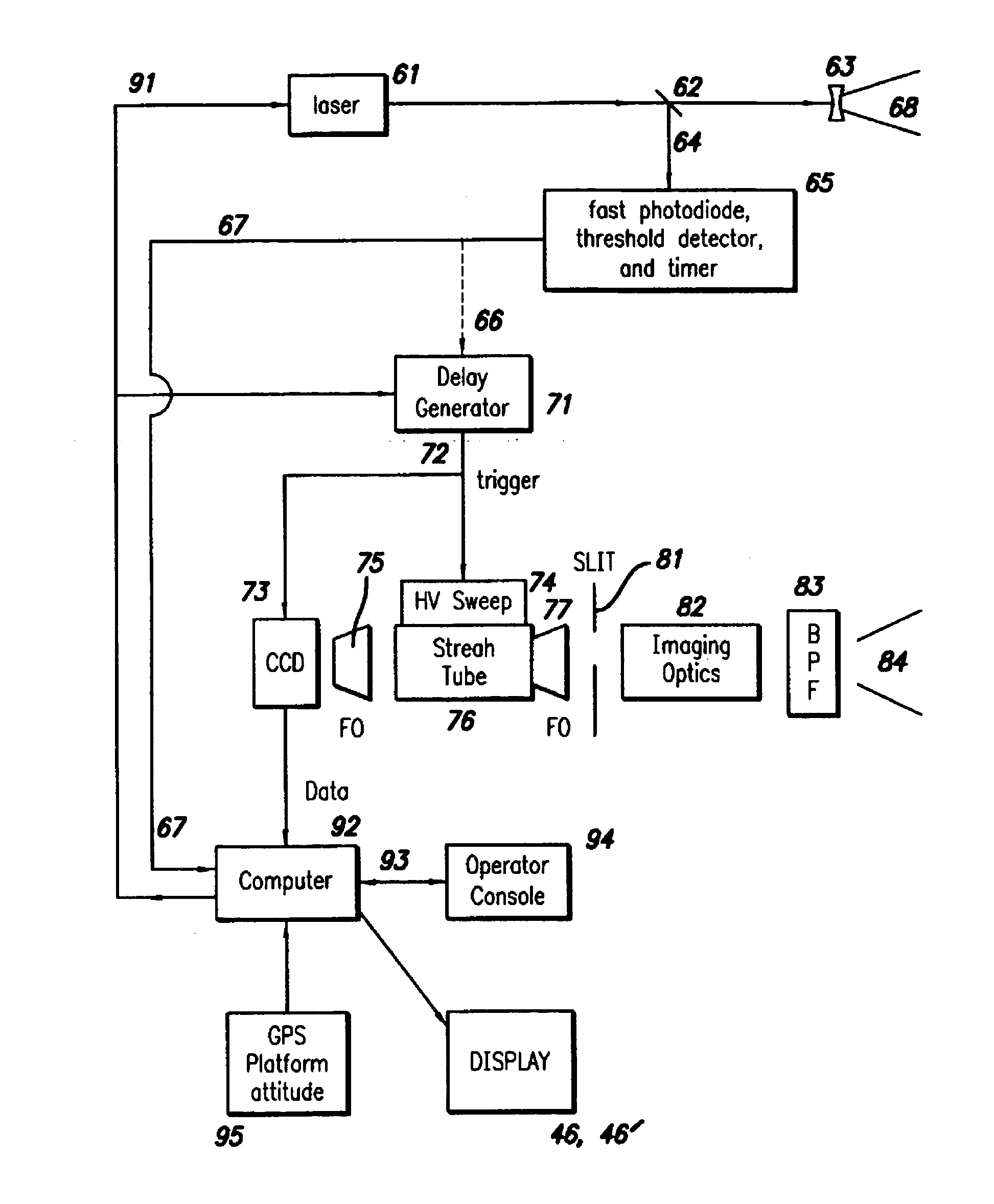

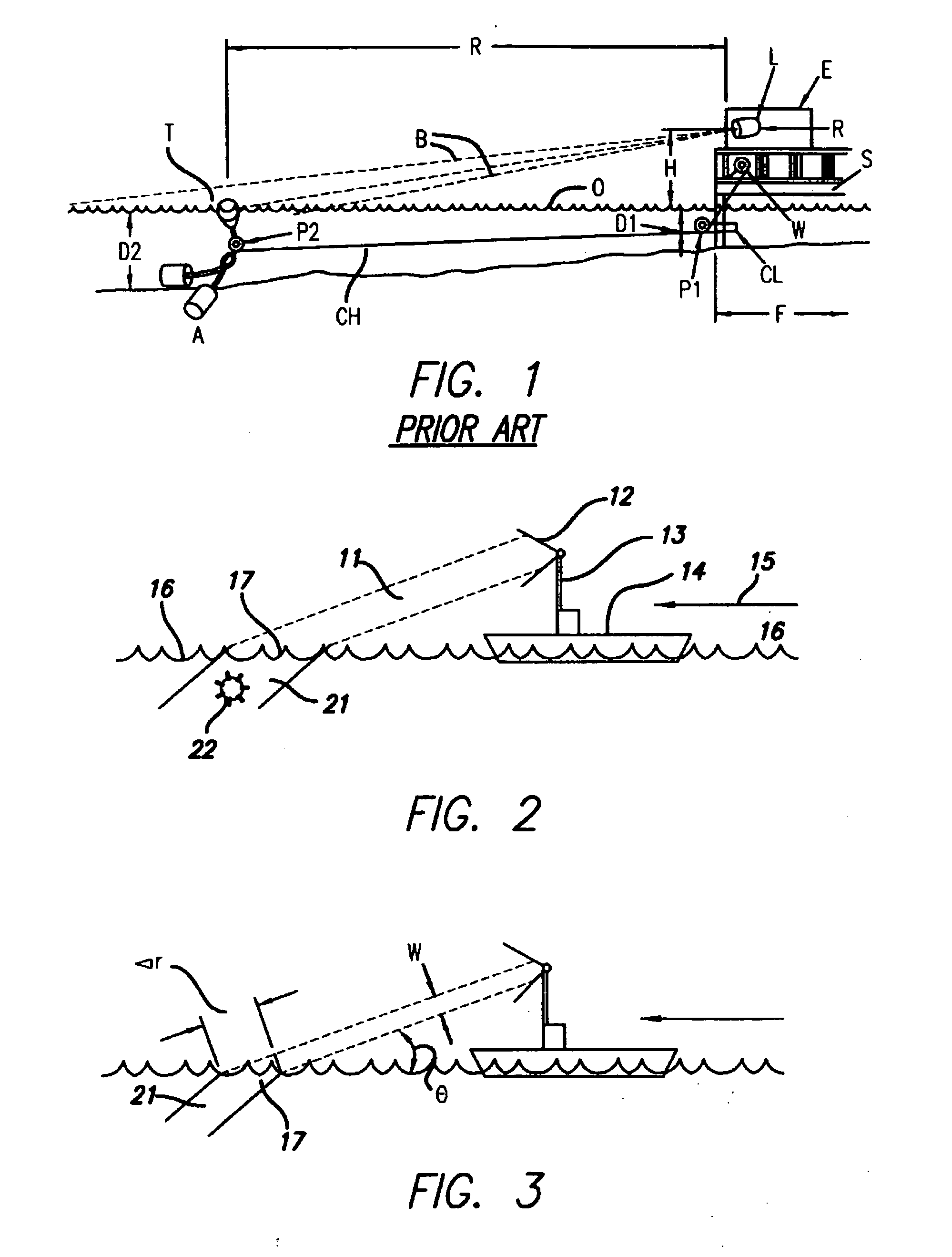

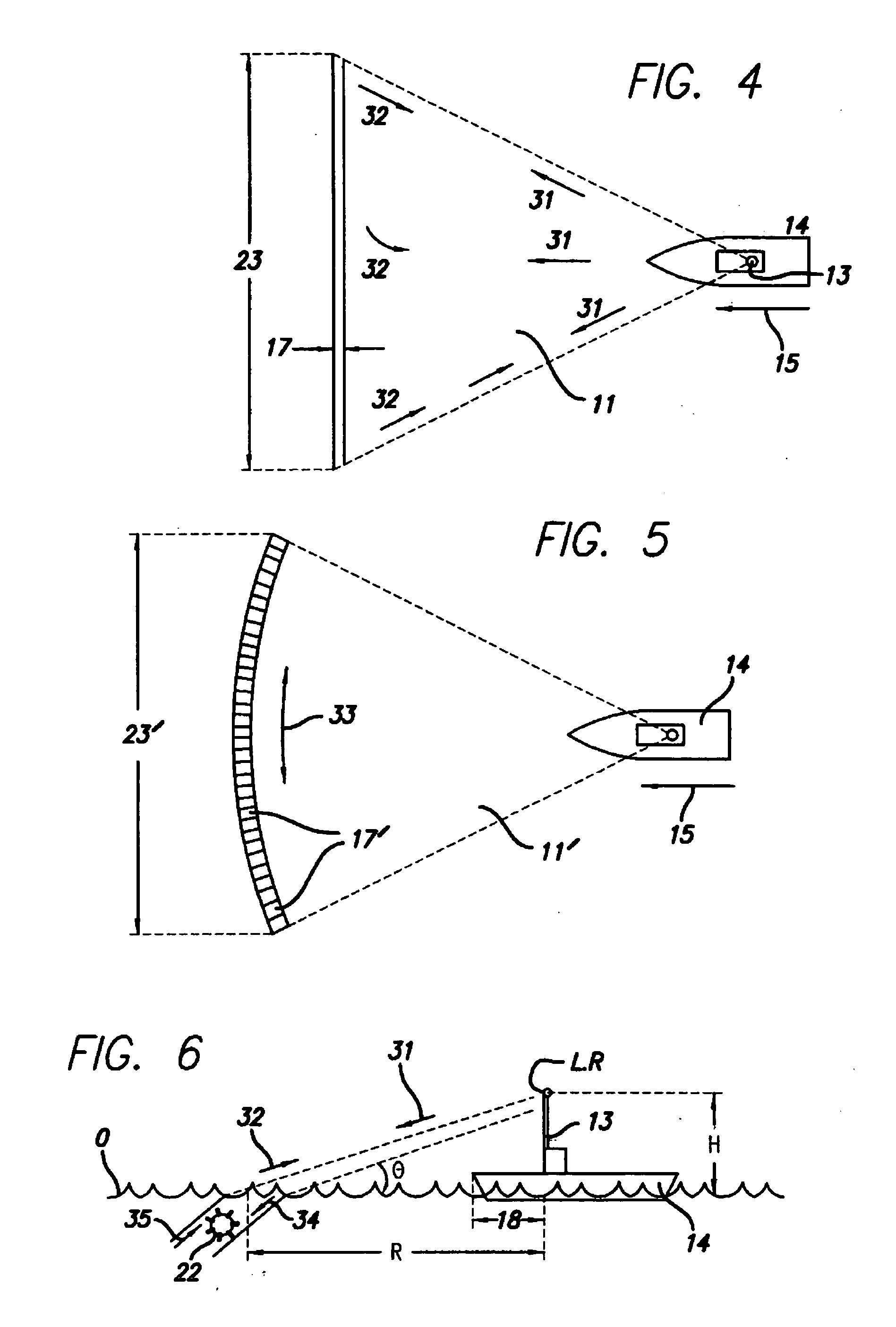

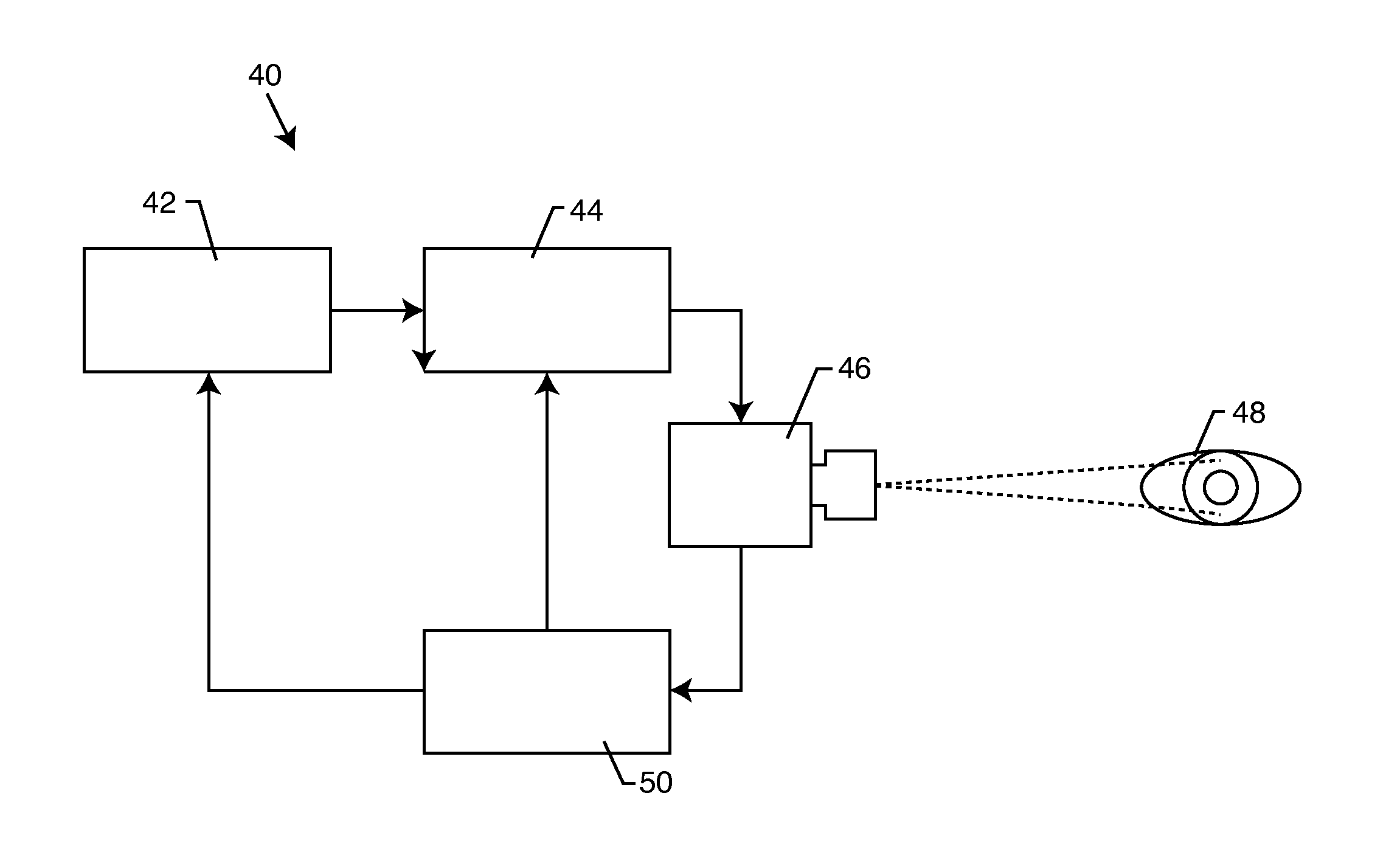

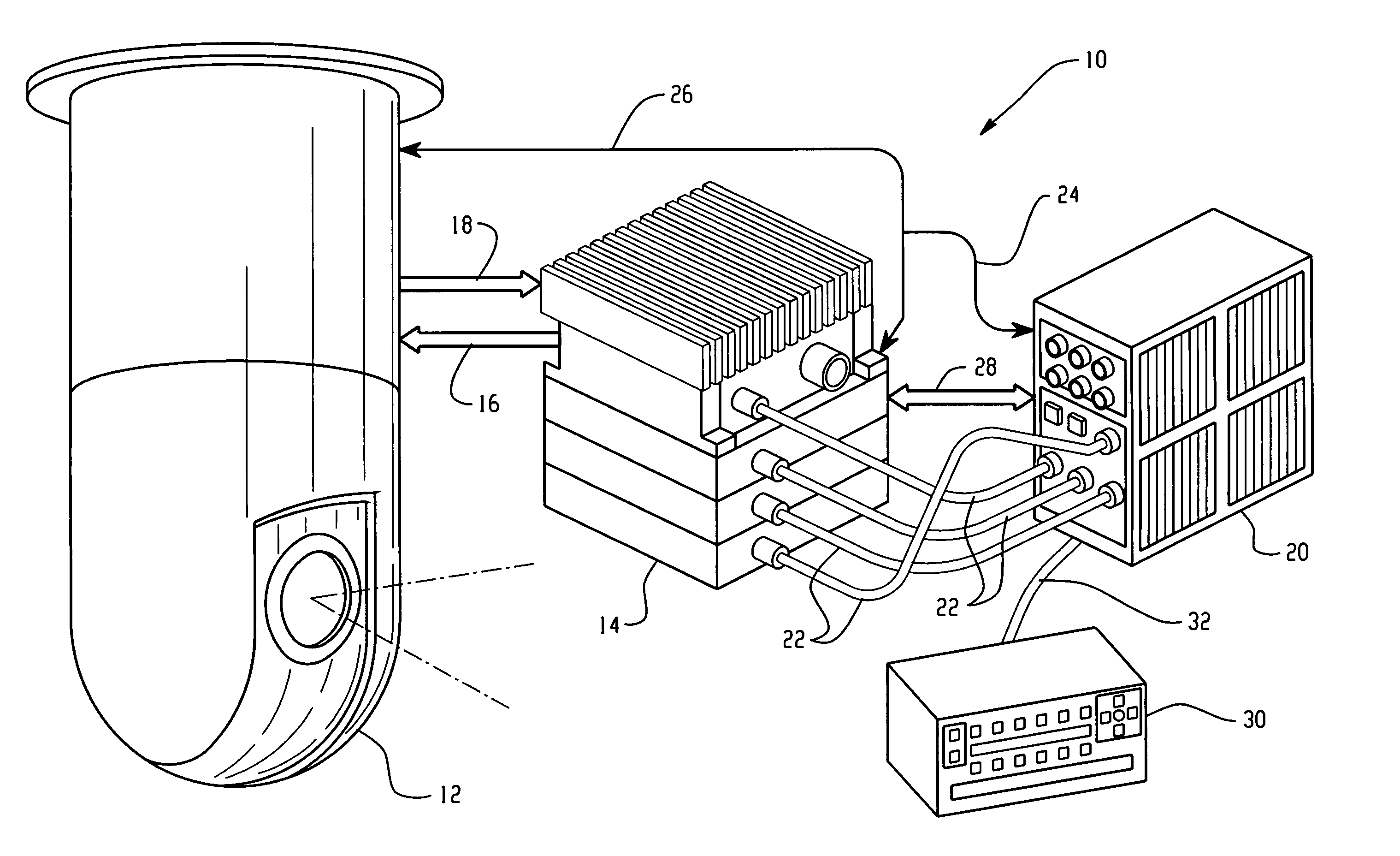

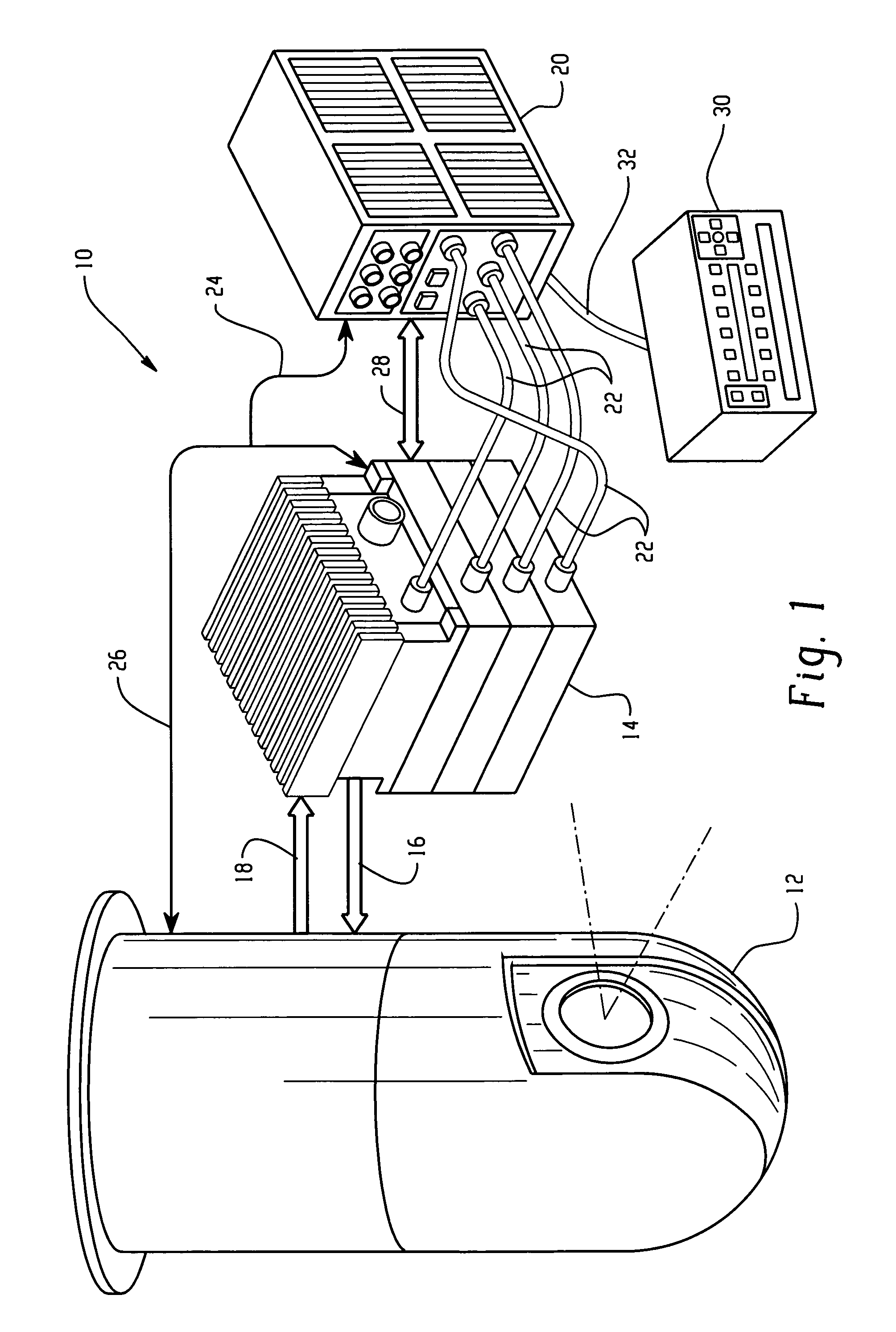

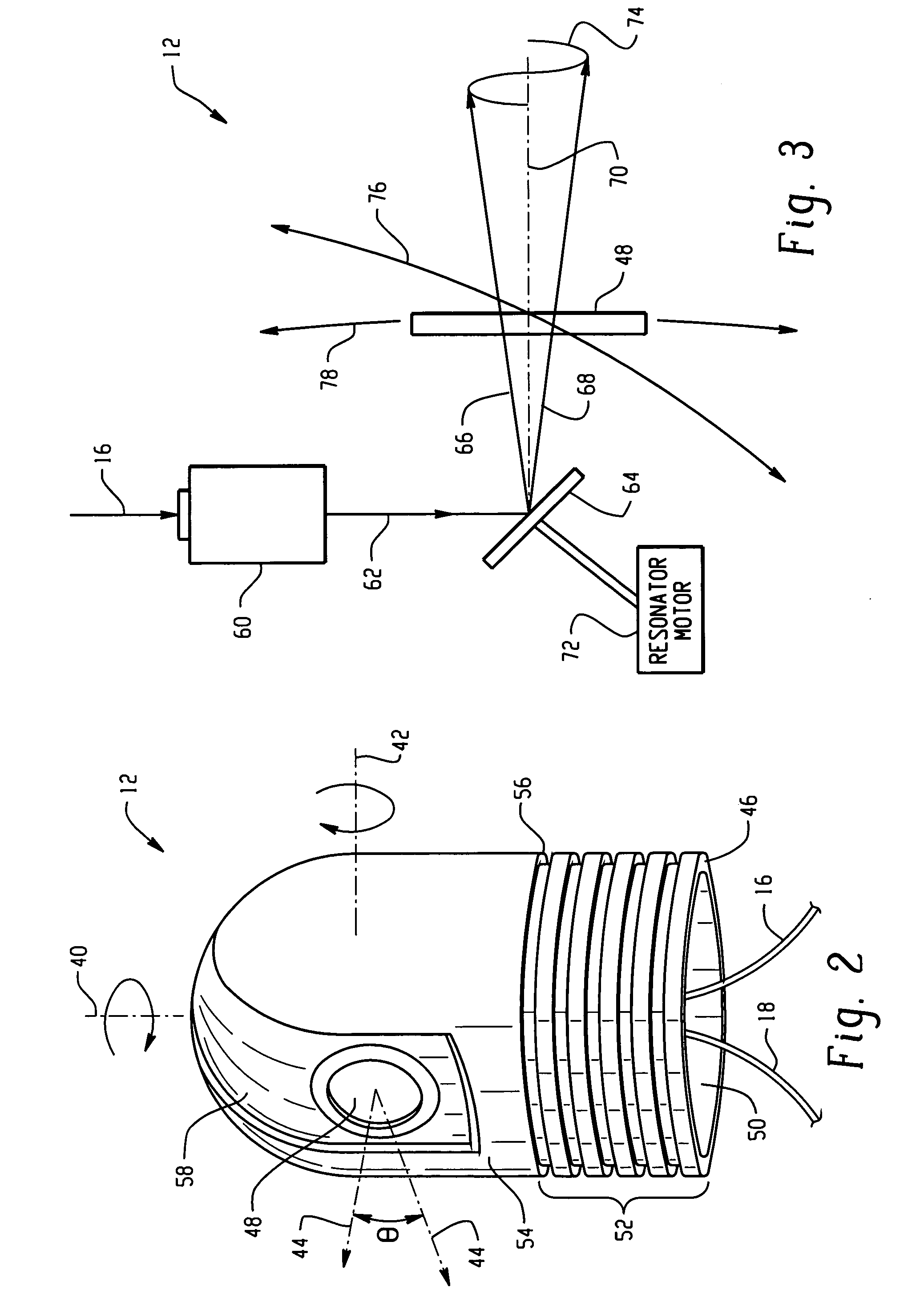

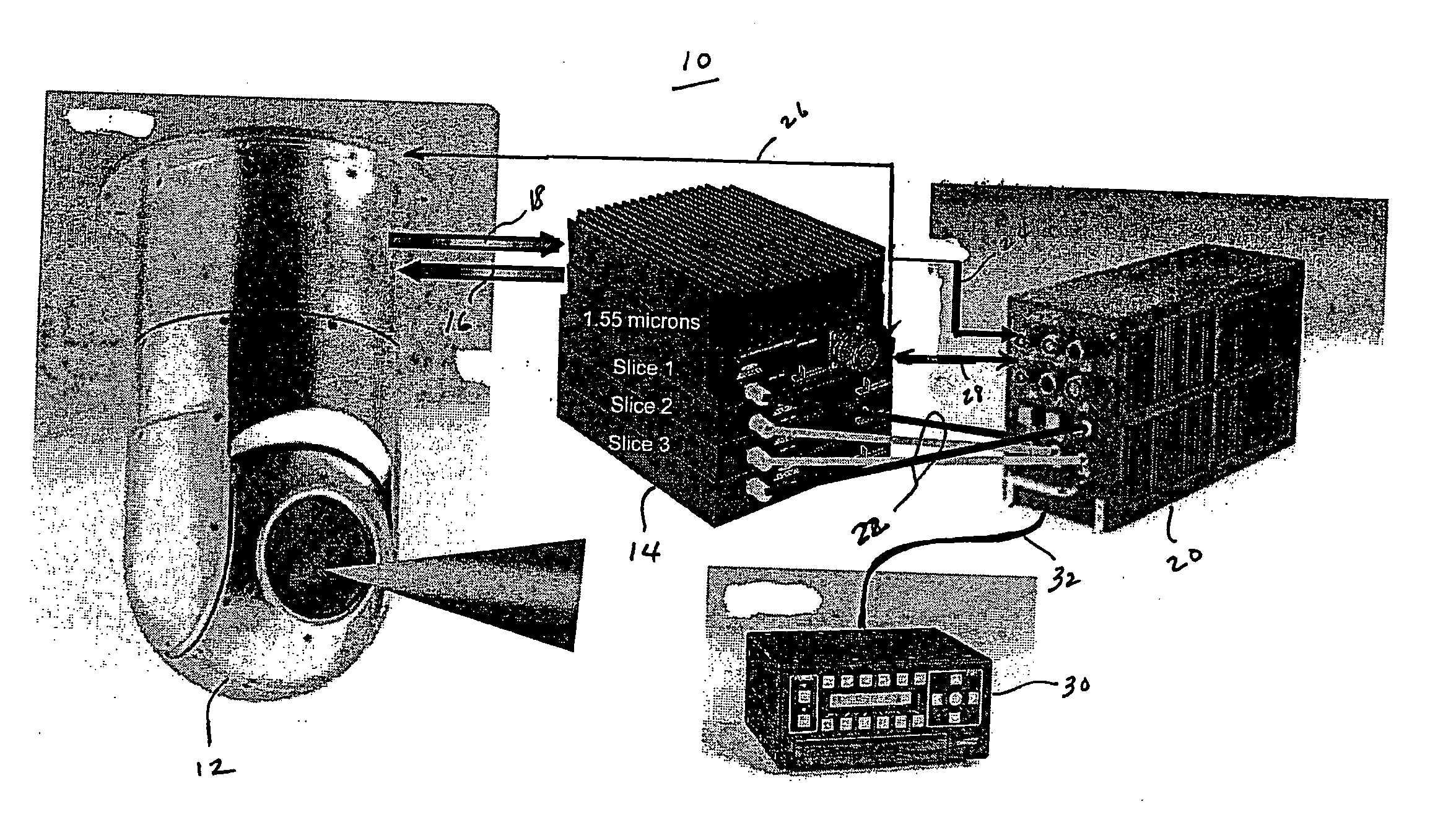

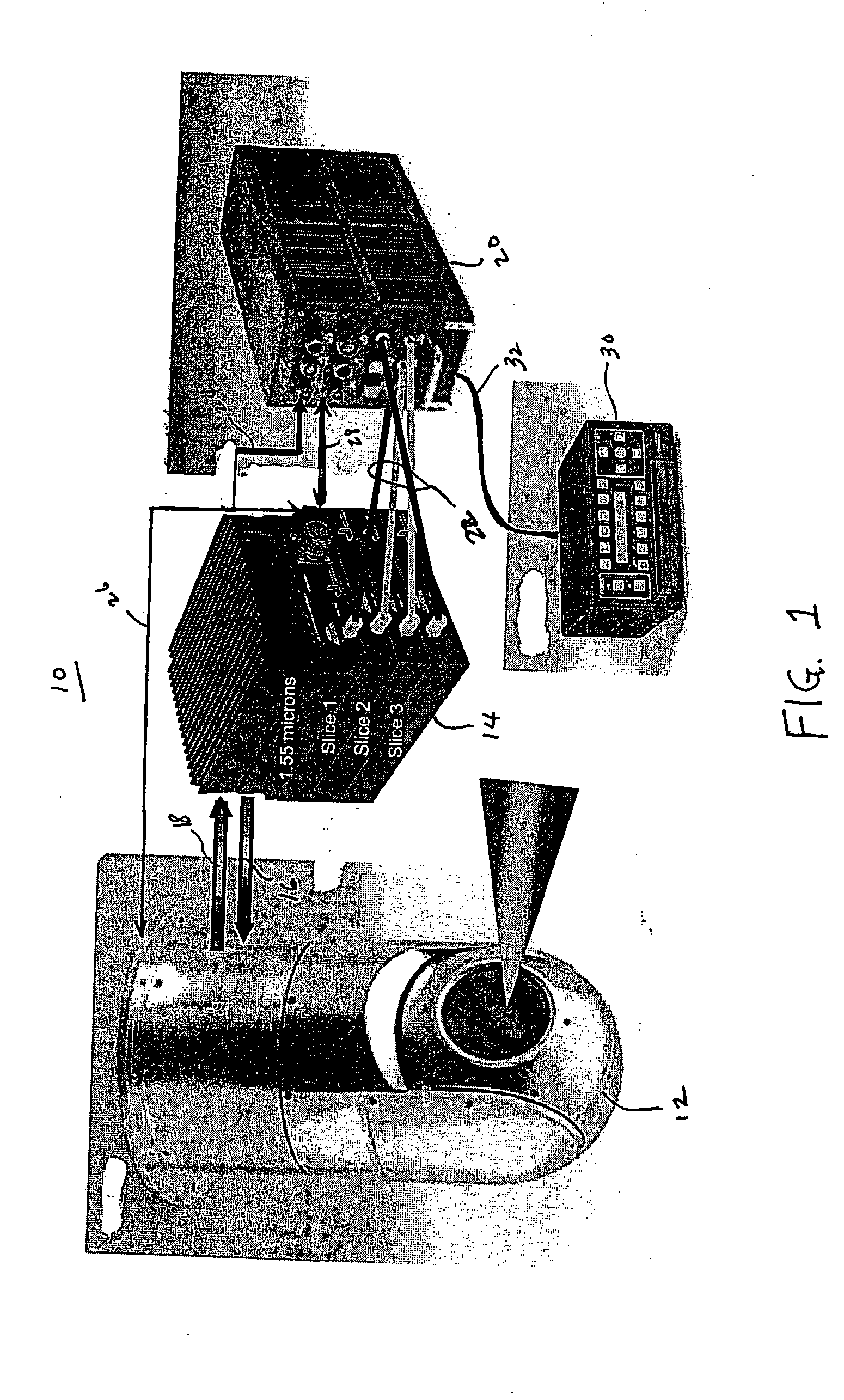

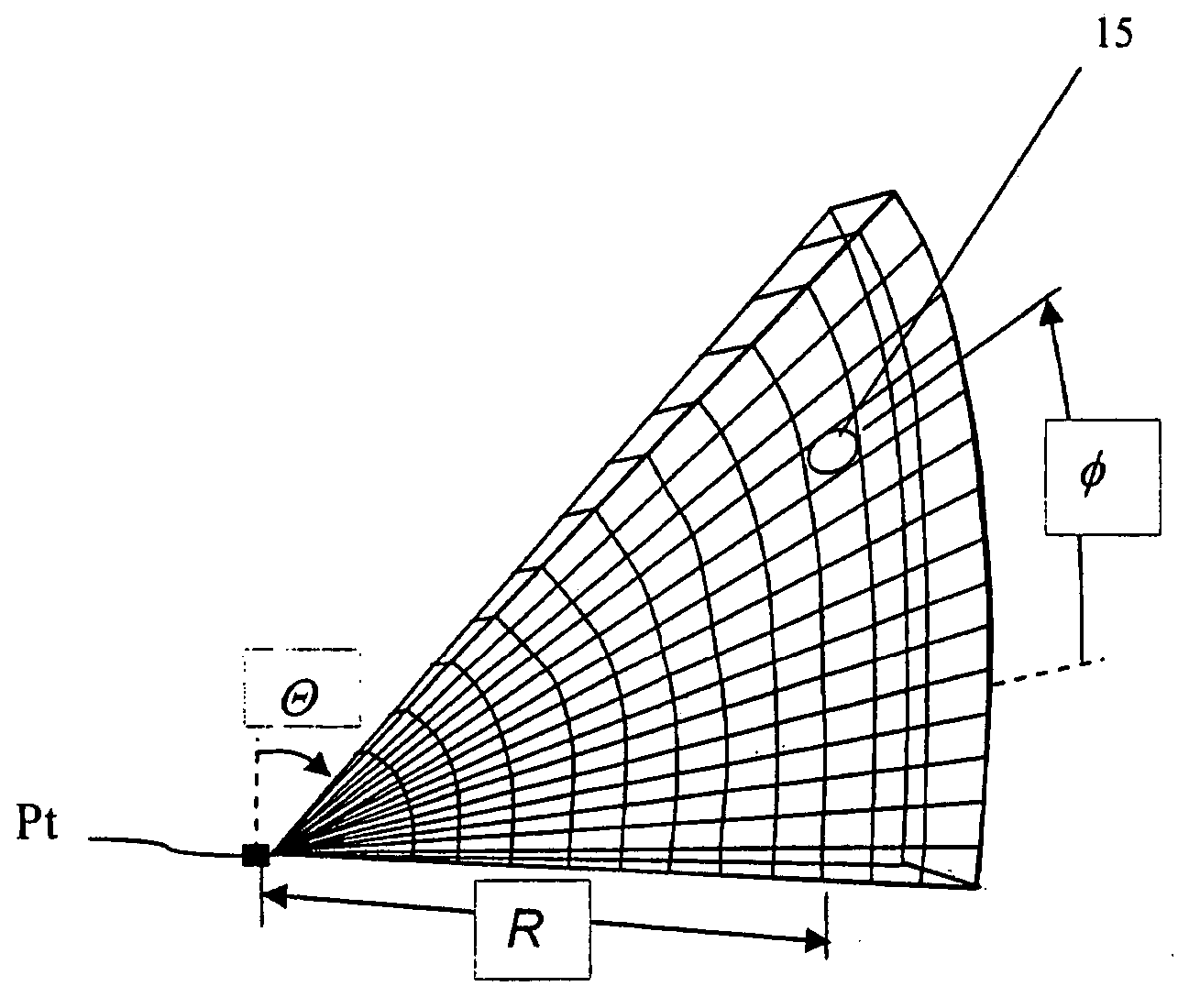

Lidar with streak-tube imaging, including hazard detection in marine applications; related optics

InactiveUS20070035624A1Full coverageOptimize geometryColor television detailsClosed circuit television systemsRadar3d image

The system and method relate to detection of objects that are submerged, or partially submerged (e. g. floating), relative to a water surface. One aspect of the invention emits LIDAR fan-beam pulses and analyzes return-pulse portions to determine water-surface orientations and derive submerged-object images corrected for refractive distortion. Another defines simulated images of submerged objects as seen through waves in a water surface, prepares an algorithm for applying a three-dimensional image of the water surface in refractive correction of LIDAR imaging through waves—and also models application of the algorithm to the images, and finally specifies the LIDAR-system optics. Yet another emits nearly horizontal pulses to illuminate small exposed objects at tens of kilometers, detects reflected portions and images successive such portions with a streak-tube subsystem. Still others make special provisions for airborne objects.

Owner:ARETE ASSOCIATES INC

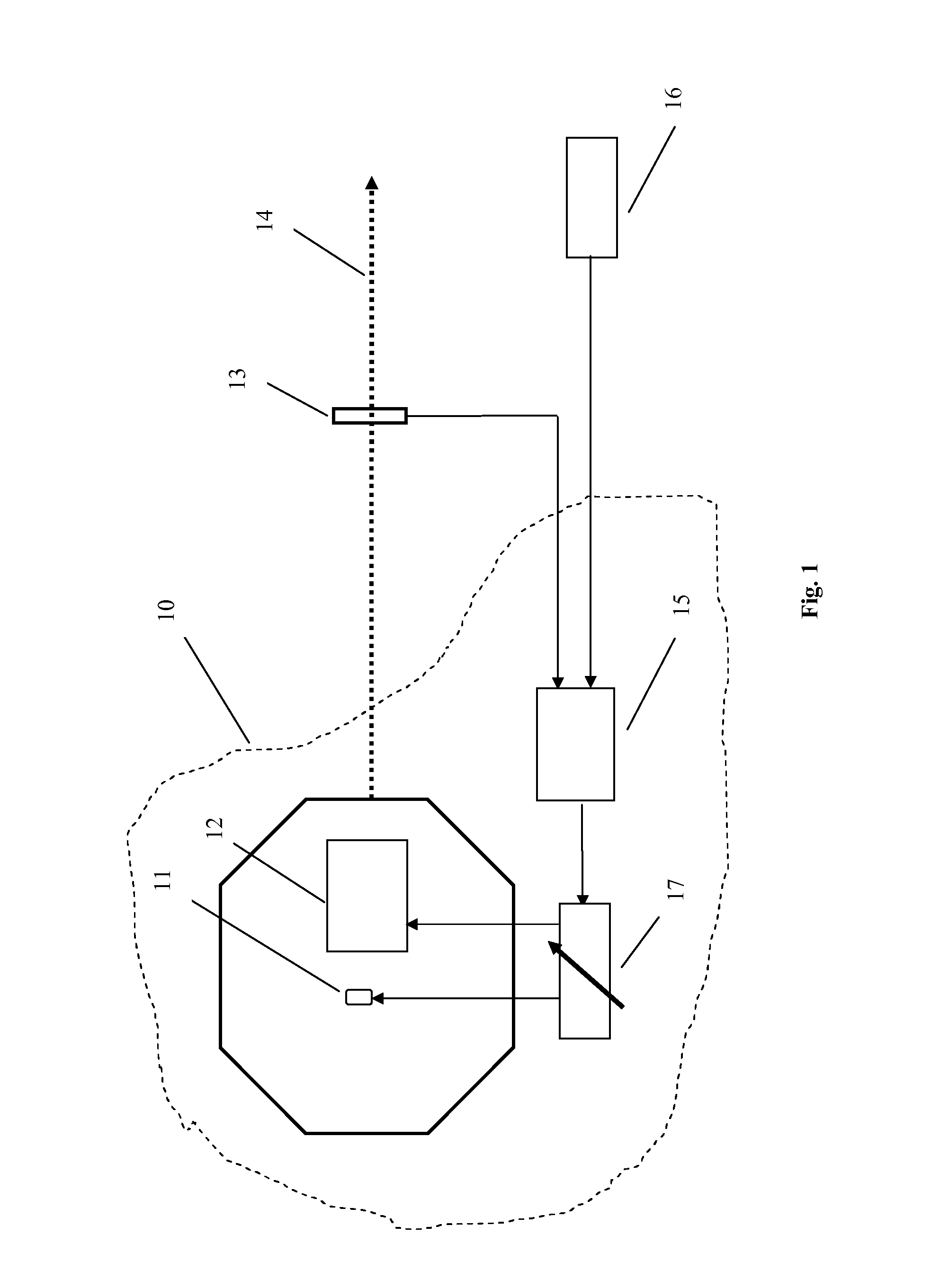

System and process for retina phototherapy

A system and process for treating retinal diseases includes passing a laser light beam through an optical lens or mask to optically shape the light beam. The light beam is applied to at least a portion of the retina. Due to the selected parameters of the laser light beam pulse length, power and duty cycle, the laser light beam can be applied to substantially the entire retina, including the fovea, without damaging retinal or foveal tissue, while still attaining the benefits of retinal photocoagulation.

Owner:OJAI RETINAL TECH

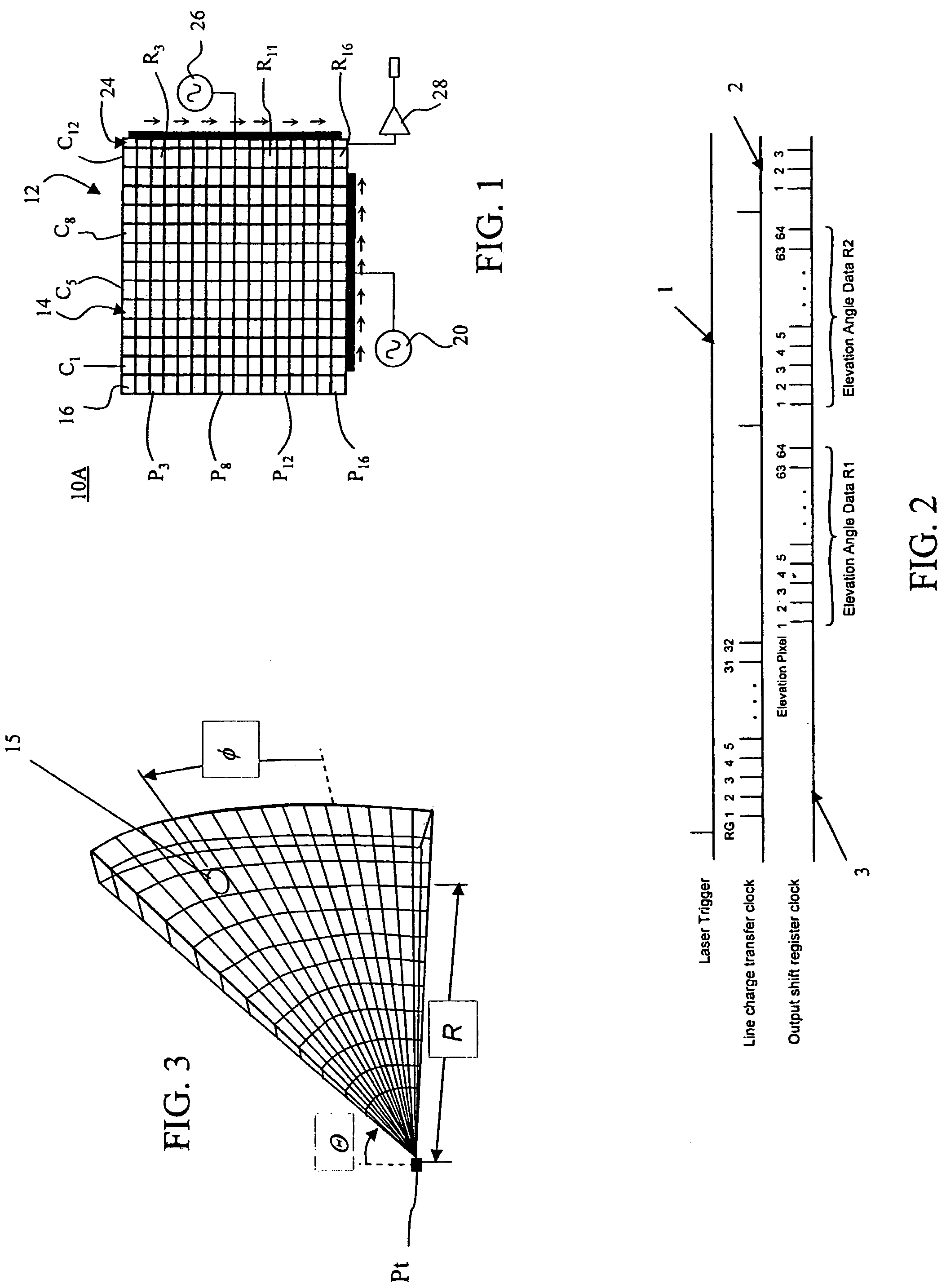

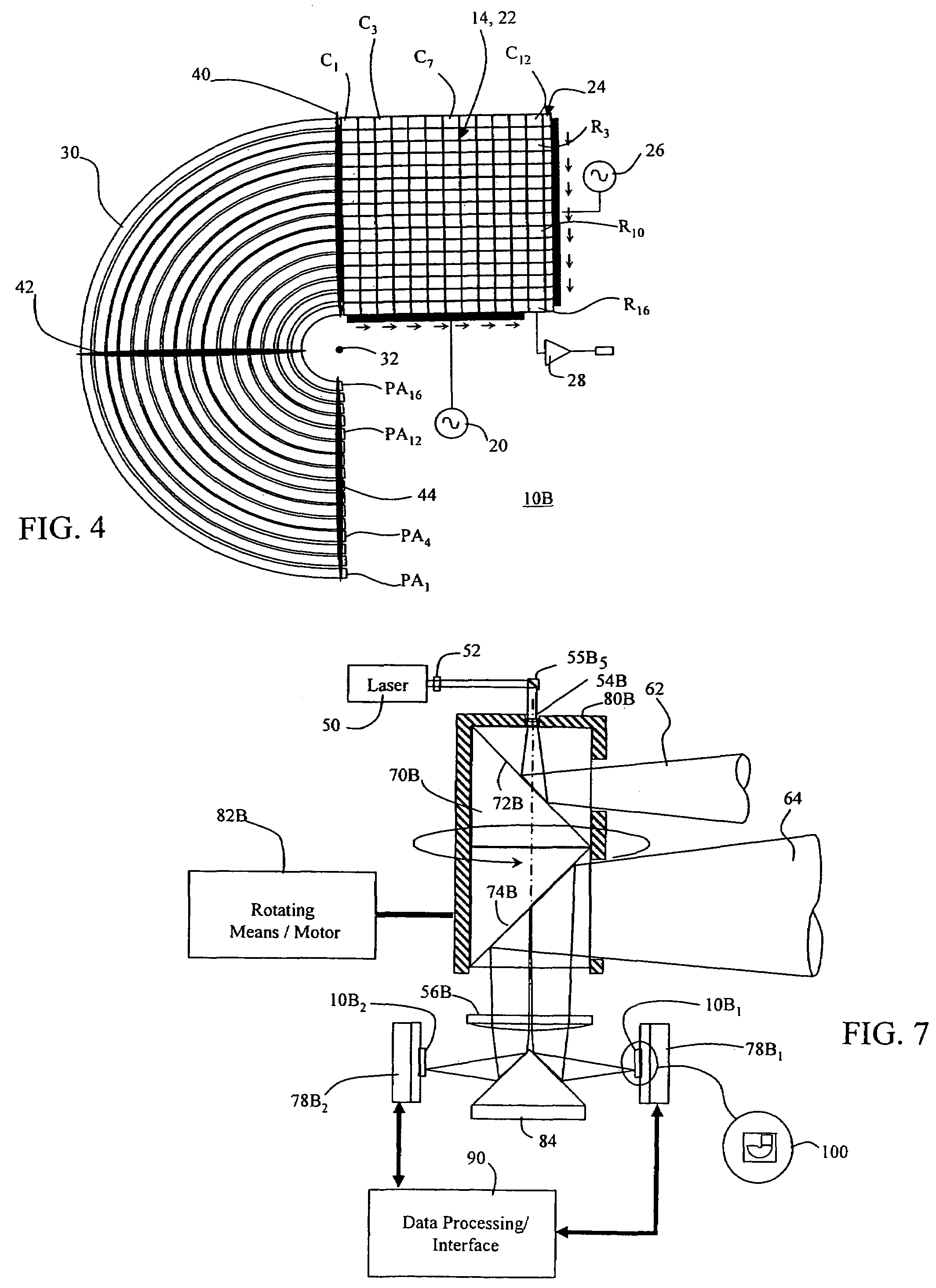

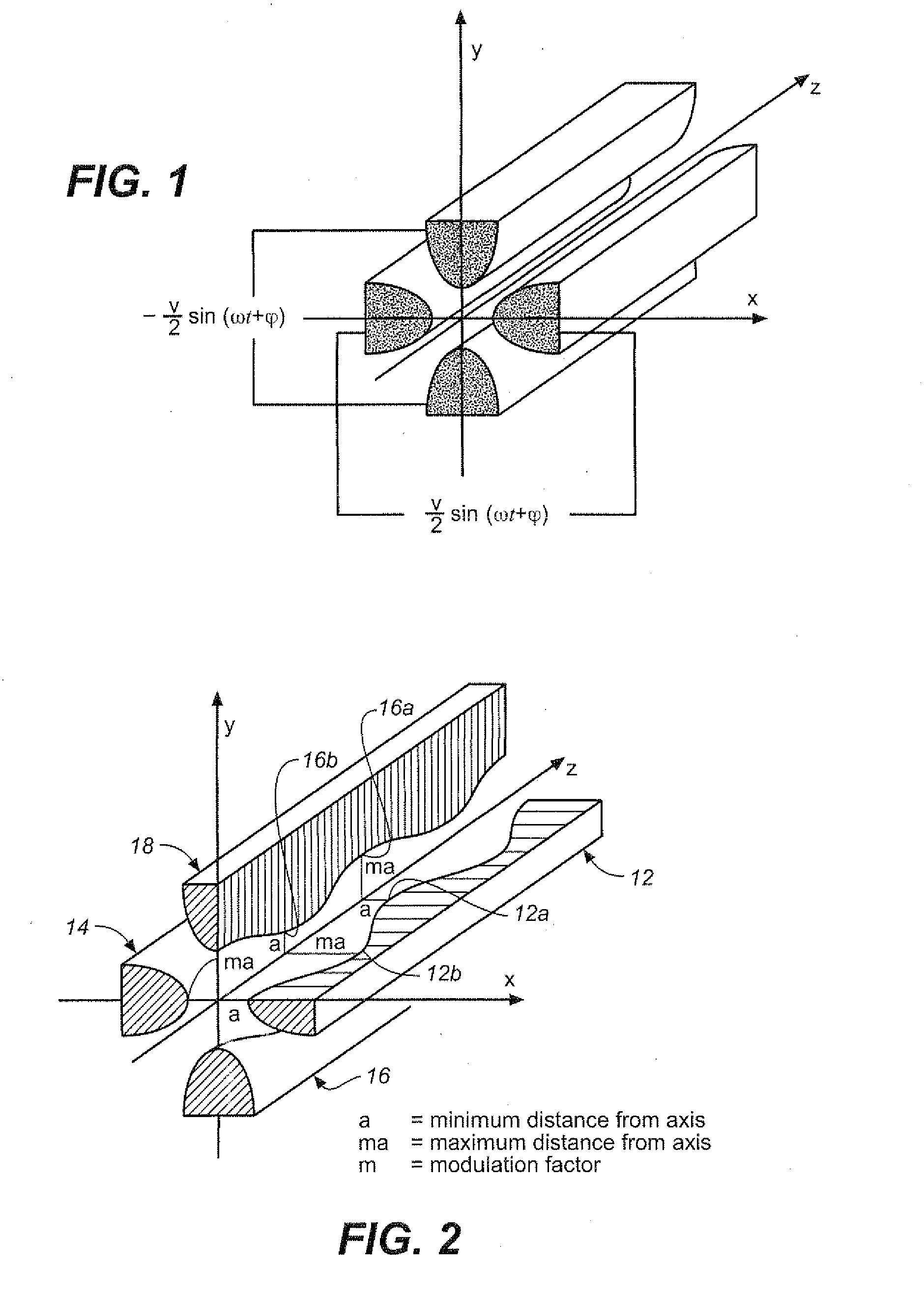

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulation radiation field intensity patterns for radiotherapy

ActiveUS8306184B2X-ray apparatusMaterial analysis by transmitting radiationElectron sourceLight beam

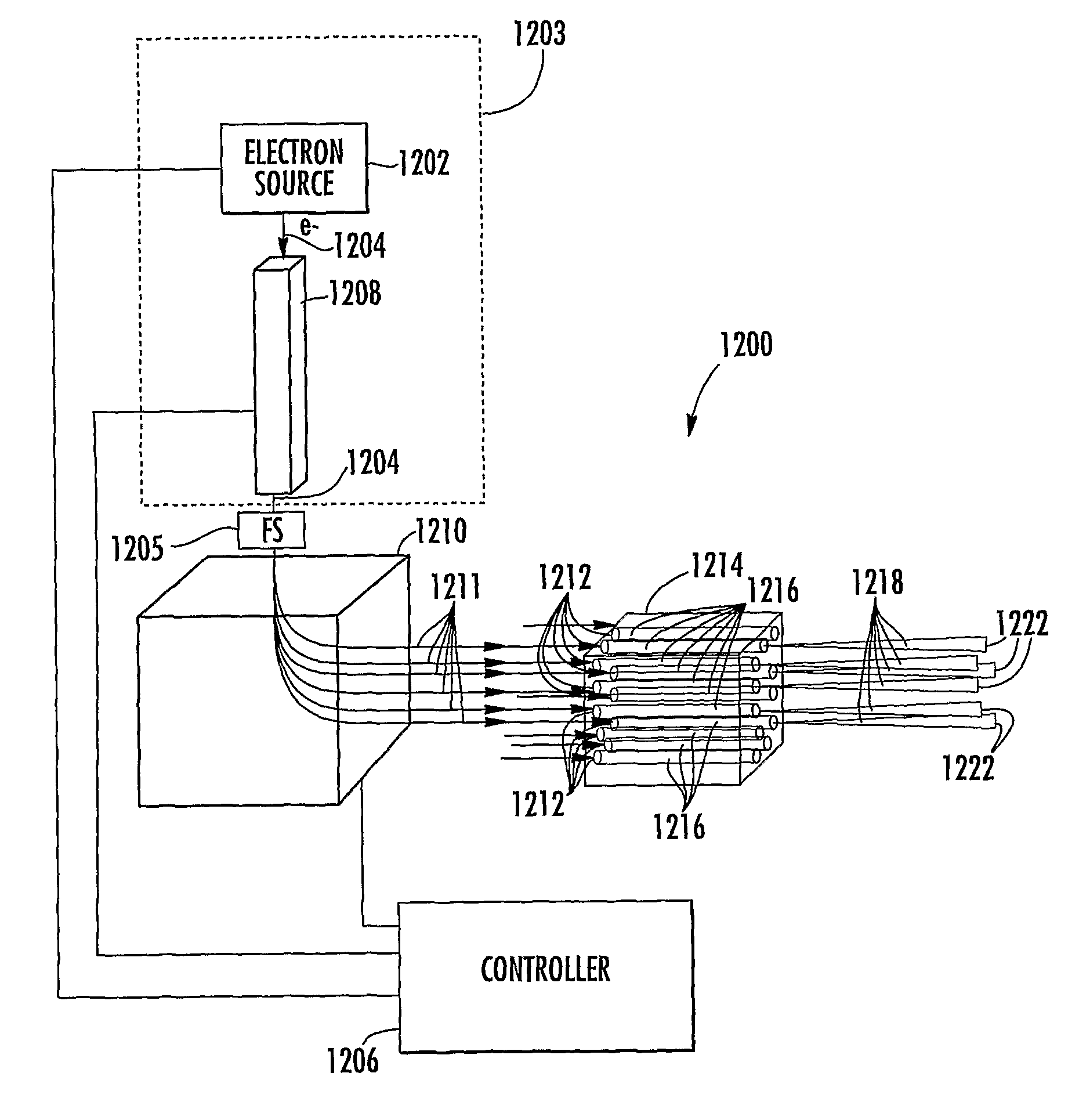

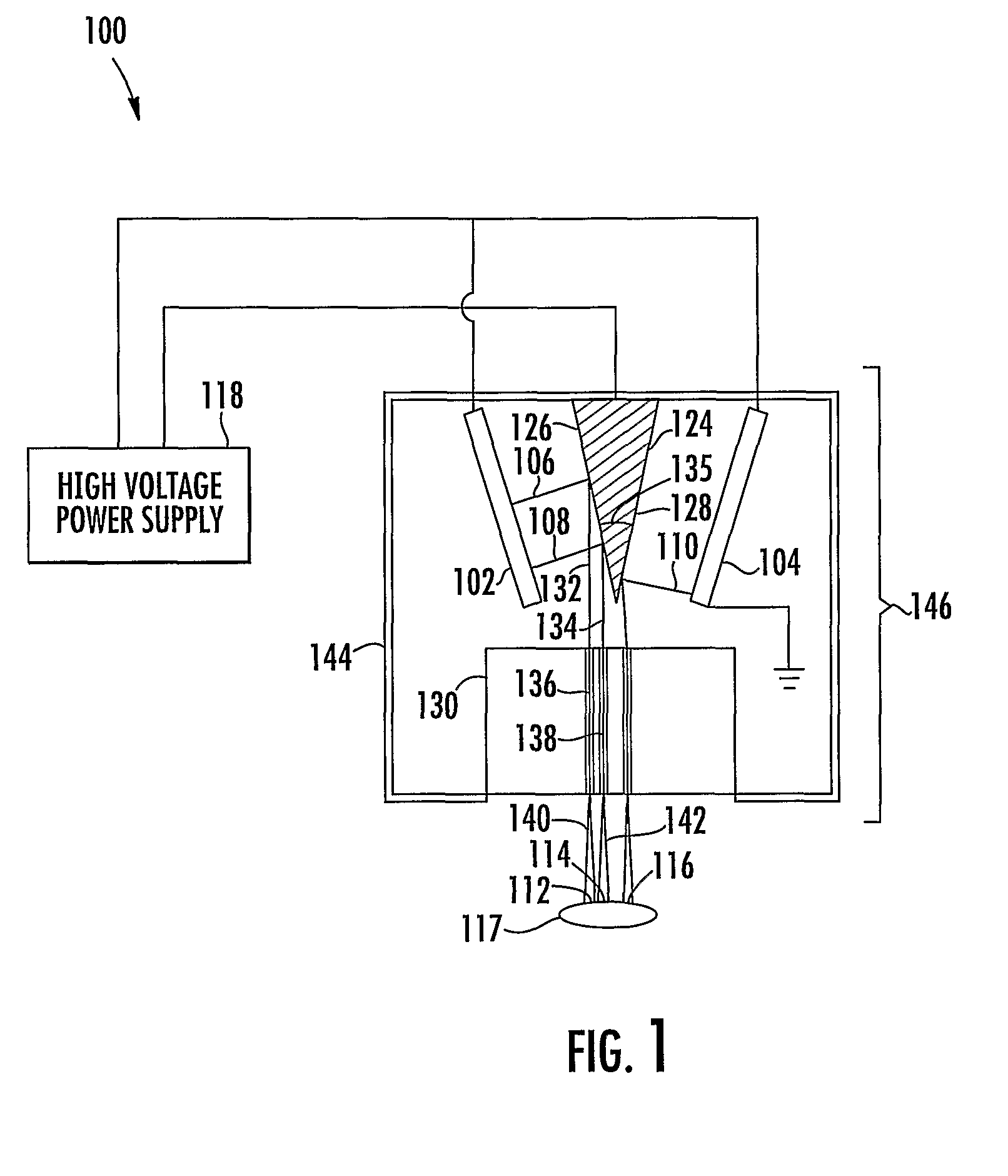

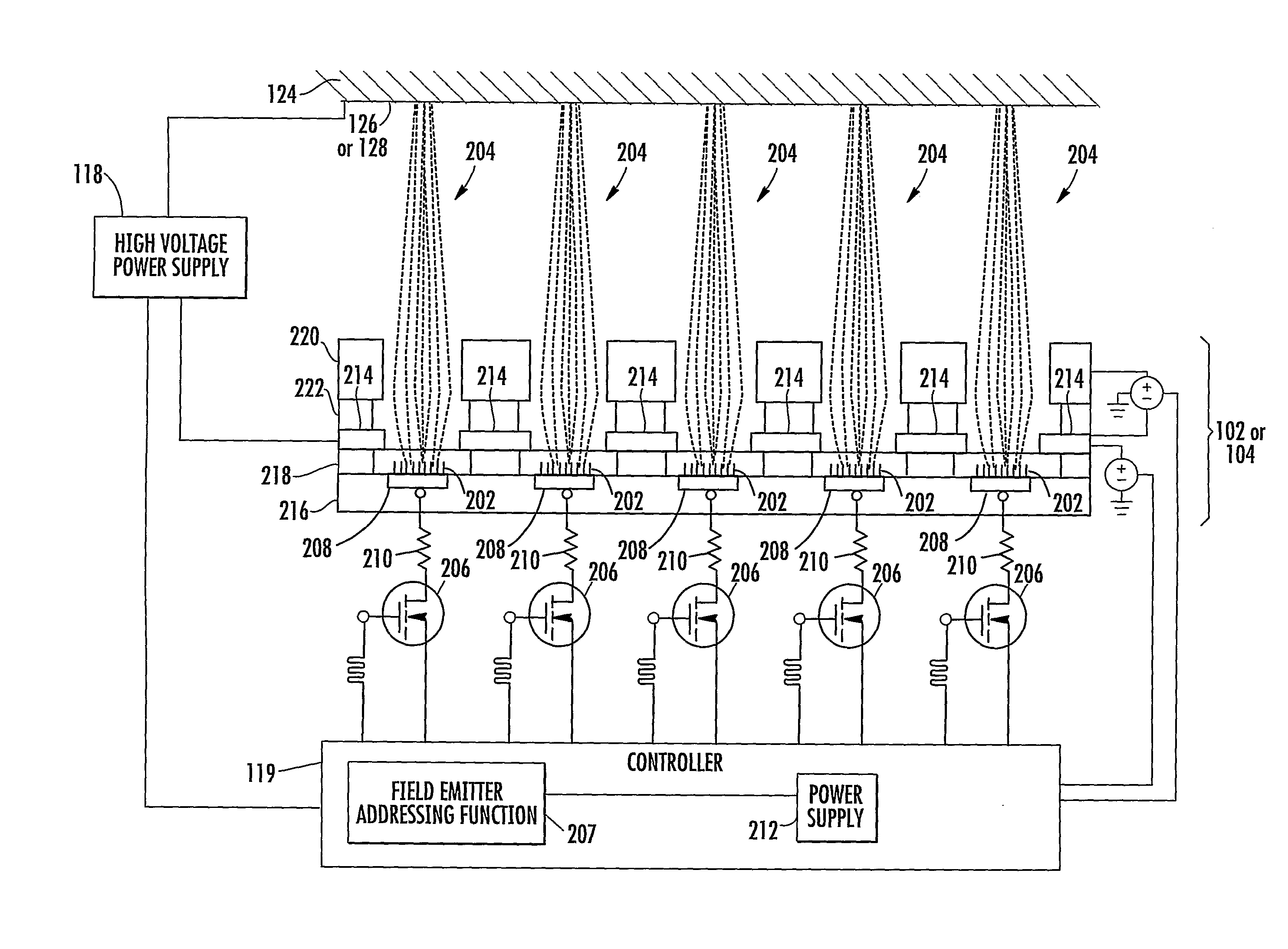

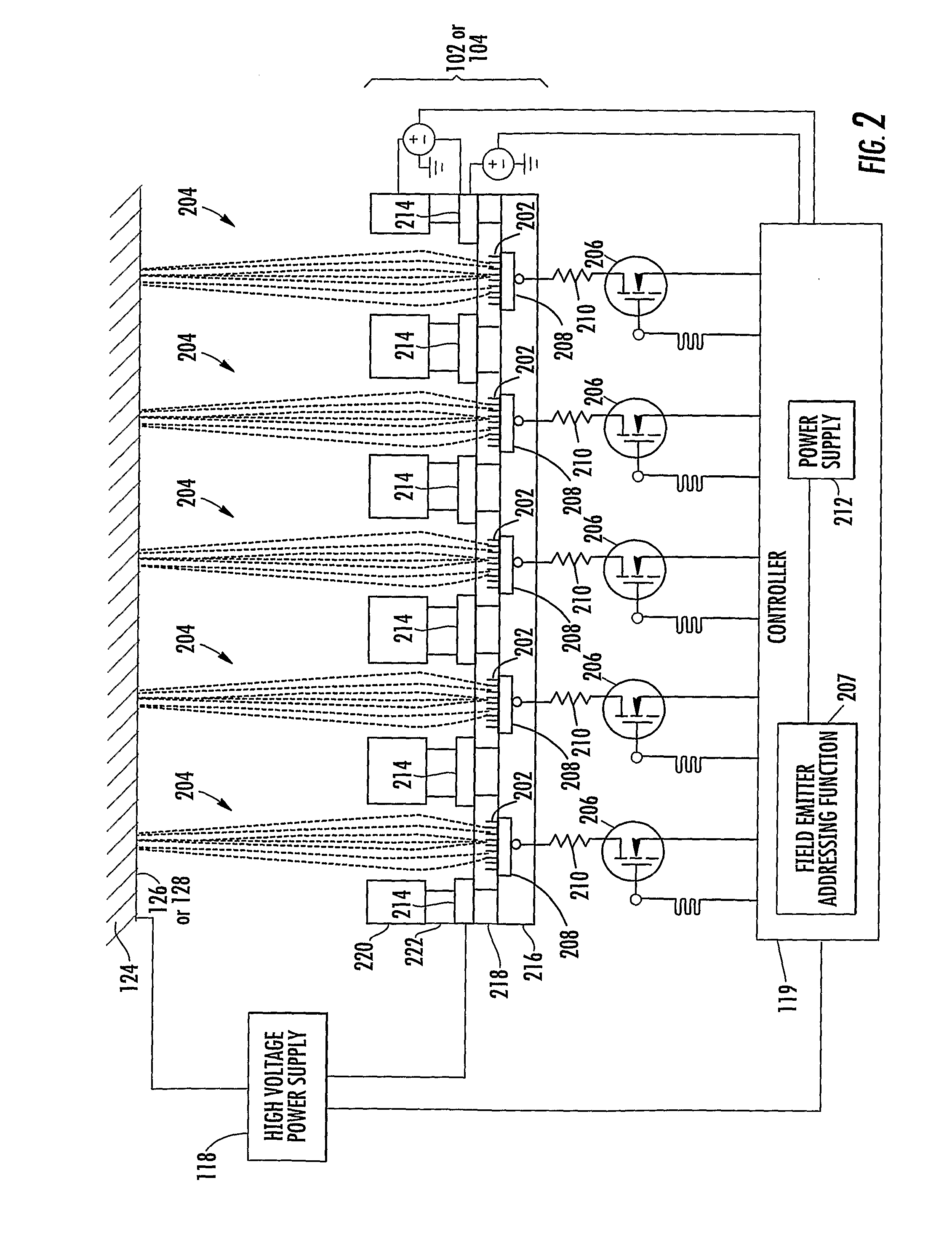

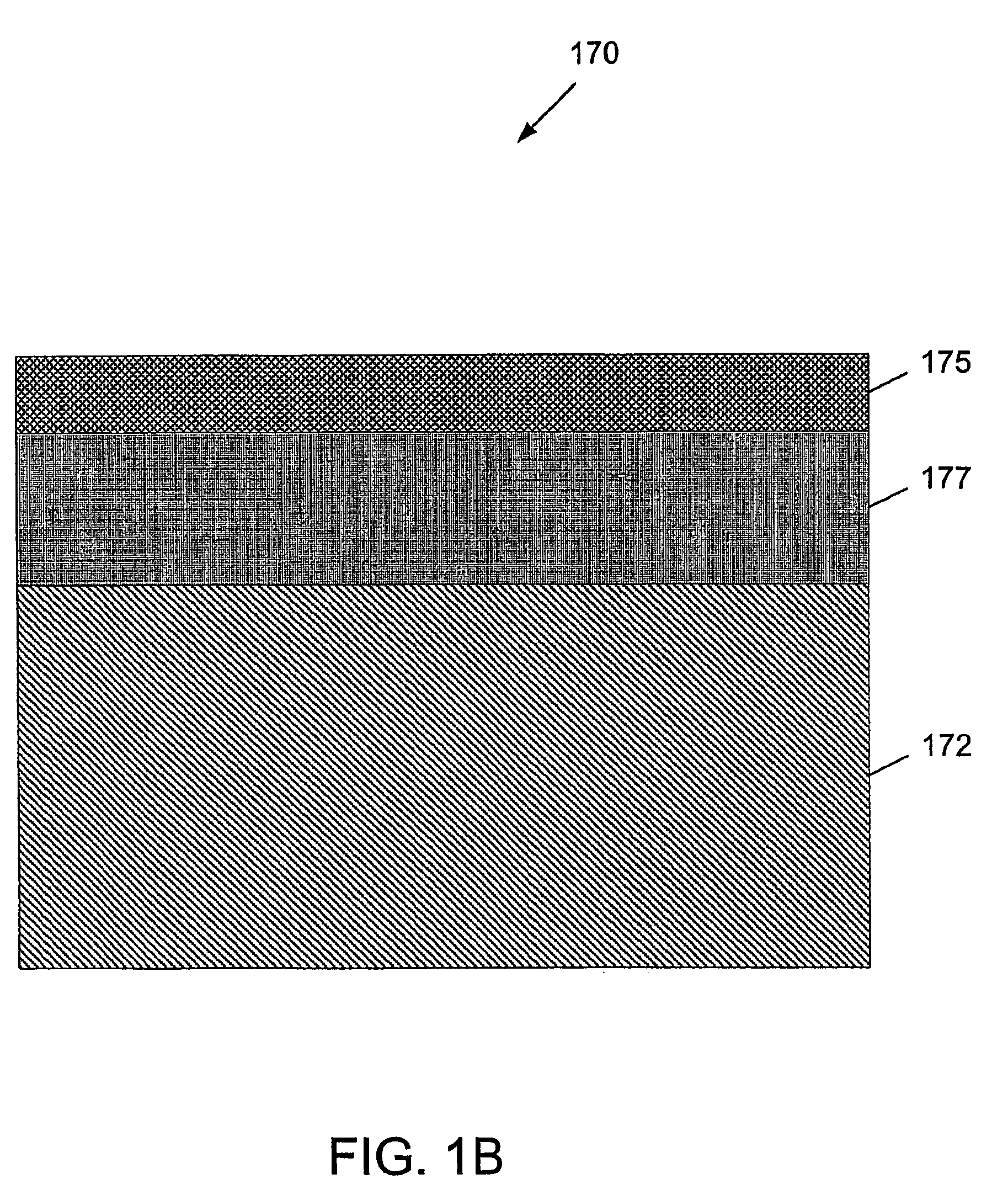

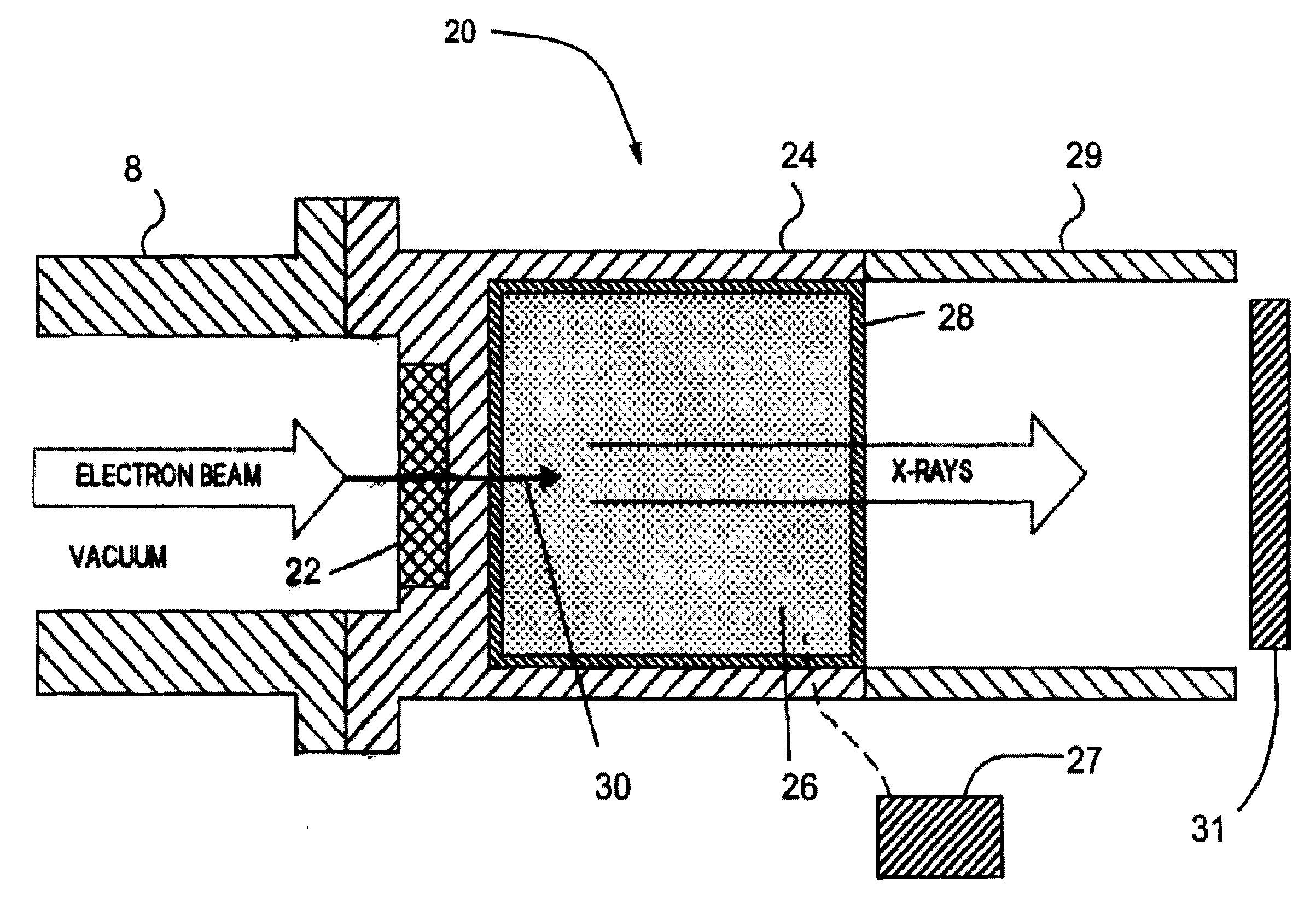

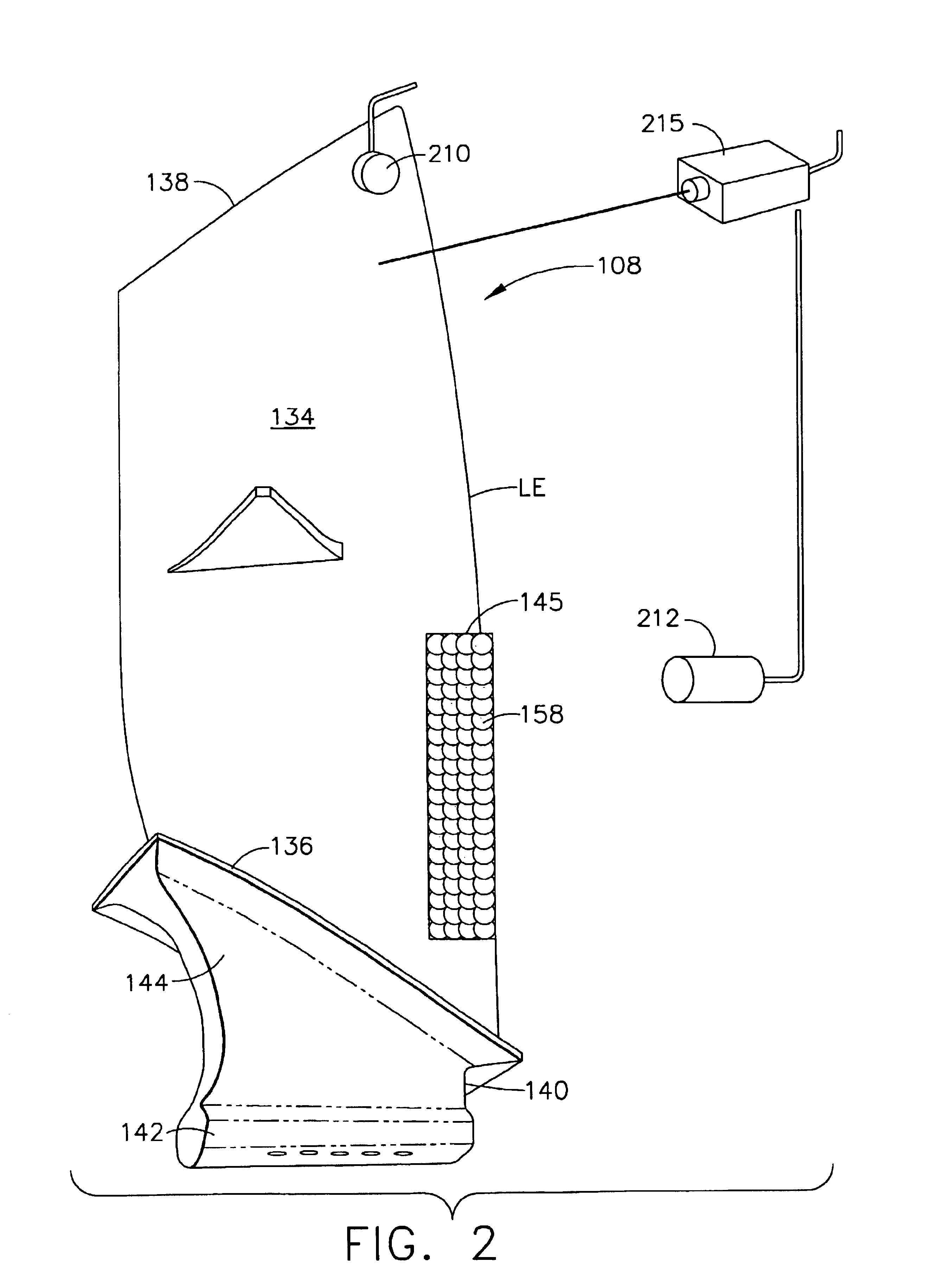

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulating radiation field intensity patterns for radiotherapy are disclosed. One exemplary pre-clinical system may include addressable electron field emitters (102, 104) that are operable to emit a plurality of electron pixel beams (106, 108, 110). Each electron pixel beam may correspond to an x-ray target (124) and x-ray pixel beam collimation aperture (136, 138) to convert a portion of energy associated with the electron pixel beam to a corresponding x-ray pixel beam (140, 142). Further, the x-ray pixel beam array collimator (130) forms a one-to-one correspondence between individual electron pixel beam and its corresponding x-ray pixel beam. One exemplary clinical system may include a high-energy electron source (1203), an n-stage scanning system (1210), x-ray pixel beam targets (1212), and an x-ray pixel beam array collimator (1214). A controller (1206) may sequentially direct electron beam pulses to predetermined x-ray pixel targets and produce an electronically controlled radiation field direction, pattern; and intensity pattern.

Owner:DUKE UNIV +1

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulation radiation field intensity patterns for radiotherapy

ActiveUS20100260317A1Handling using diaphragms/collimetersX-ray tube with very high currentSoft x rayElectron source

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulating radiation field intensity patterns for radiotherapy are disclosed. One exemplary pre-clinical system may include addressable electron field emitters (102, 104) that are operable to emit a plurality of electron pixel beams (106, 108, 110). Each electron pixel beam may correspond to an x-ray target (124) and x-ray pixel beam collimation aperture (136, 138) to convert a portion of energy associated with the electron pixel beam to a corresponding x-ray pixel beam (140, 142). Further, the x-ray pixel beam array collimator (130) forms a one-to-one correspondence between individual electron pixel beam and its corresponding x-ray pixel beam. One exemplary clinical system may include a high-energy electron source (1203), an n-stage scanning system (1210), x-ray pixel beam targets (1212), and an x-ray pixel beam array collimator (1214). A controller (1206) may sequentially direct electron beam pulses to predetermined x-ray pixel targets and produce an electronically controlled radiation field direction, pattern; and intensity pattern.

Owner:DUKE UNIV +1

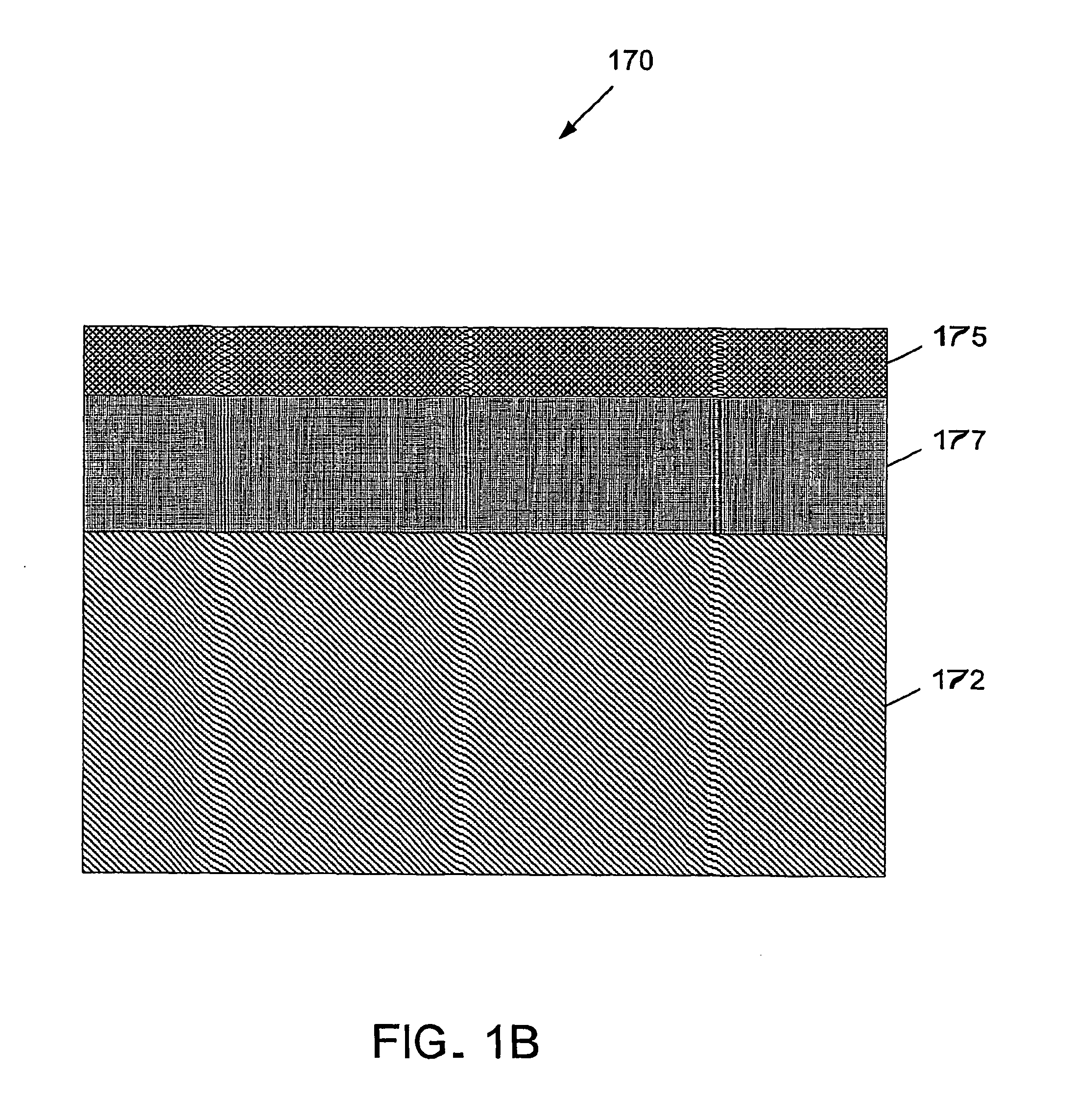

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS20050202654A1Increase speedUniform materialAfter-treatment apparatusTransistorLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

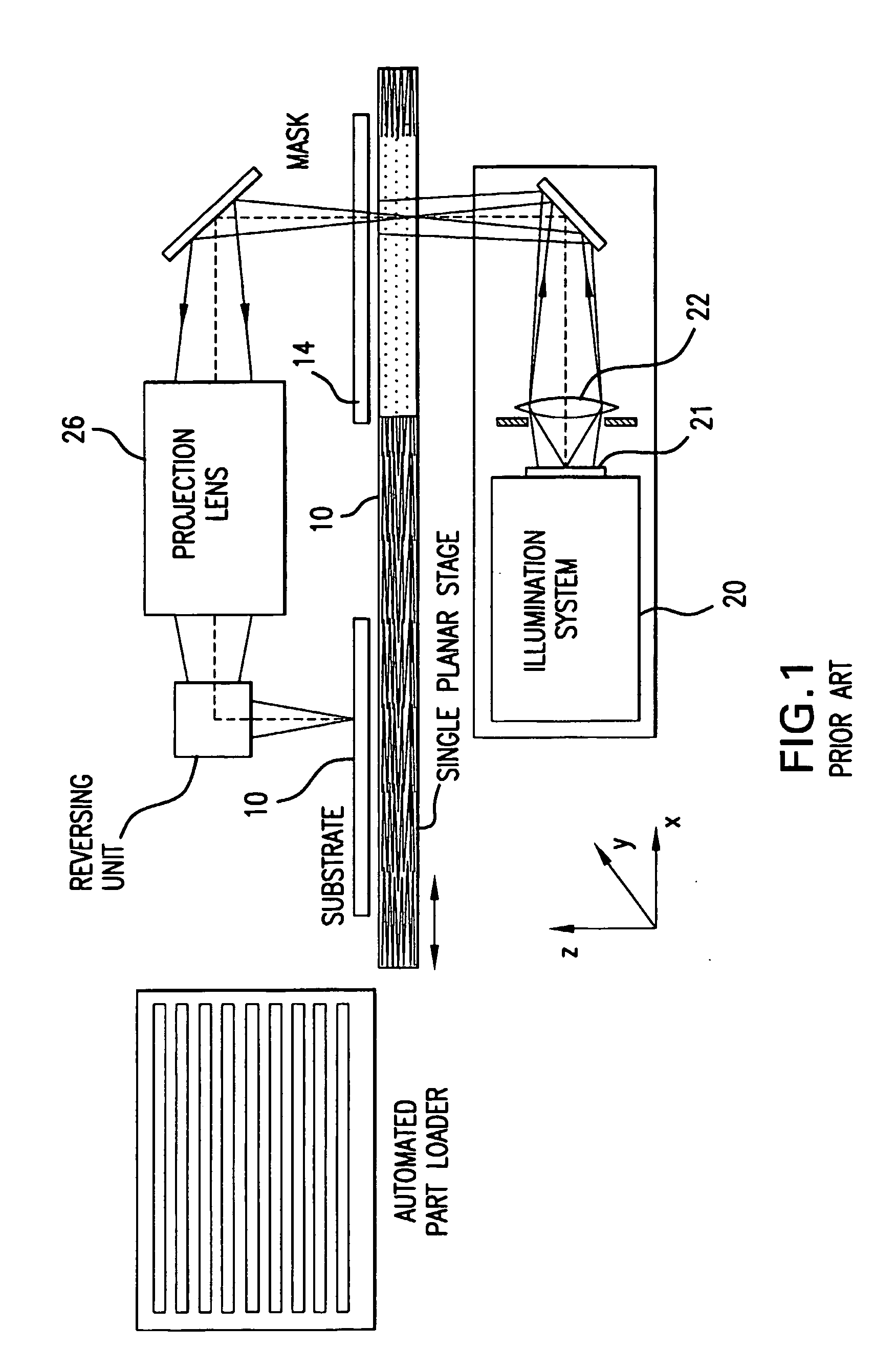

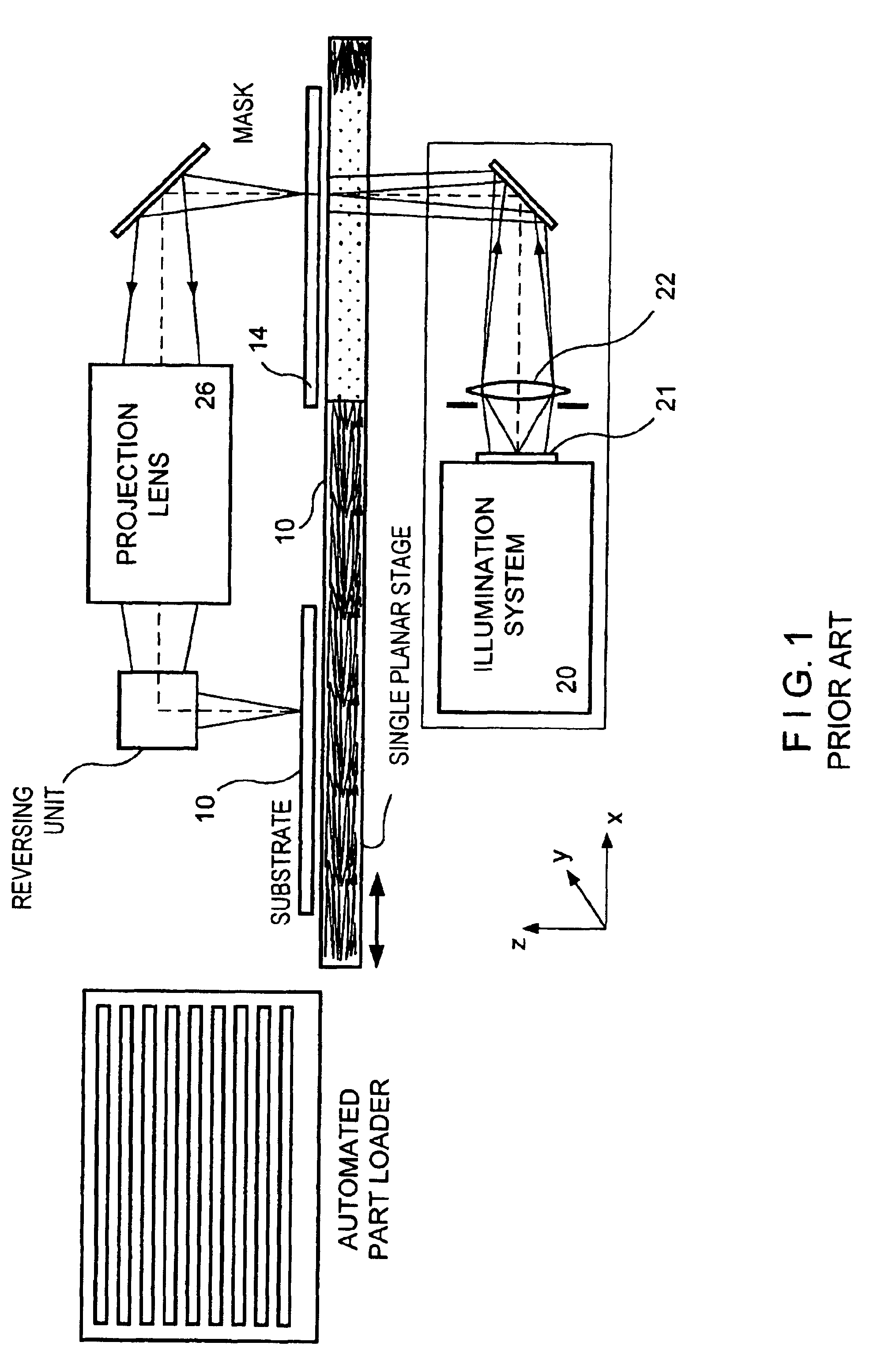

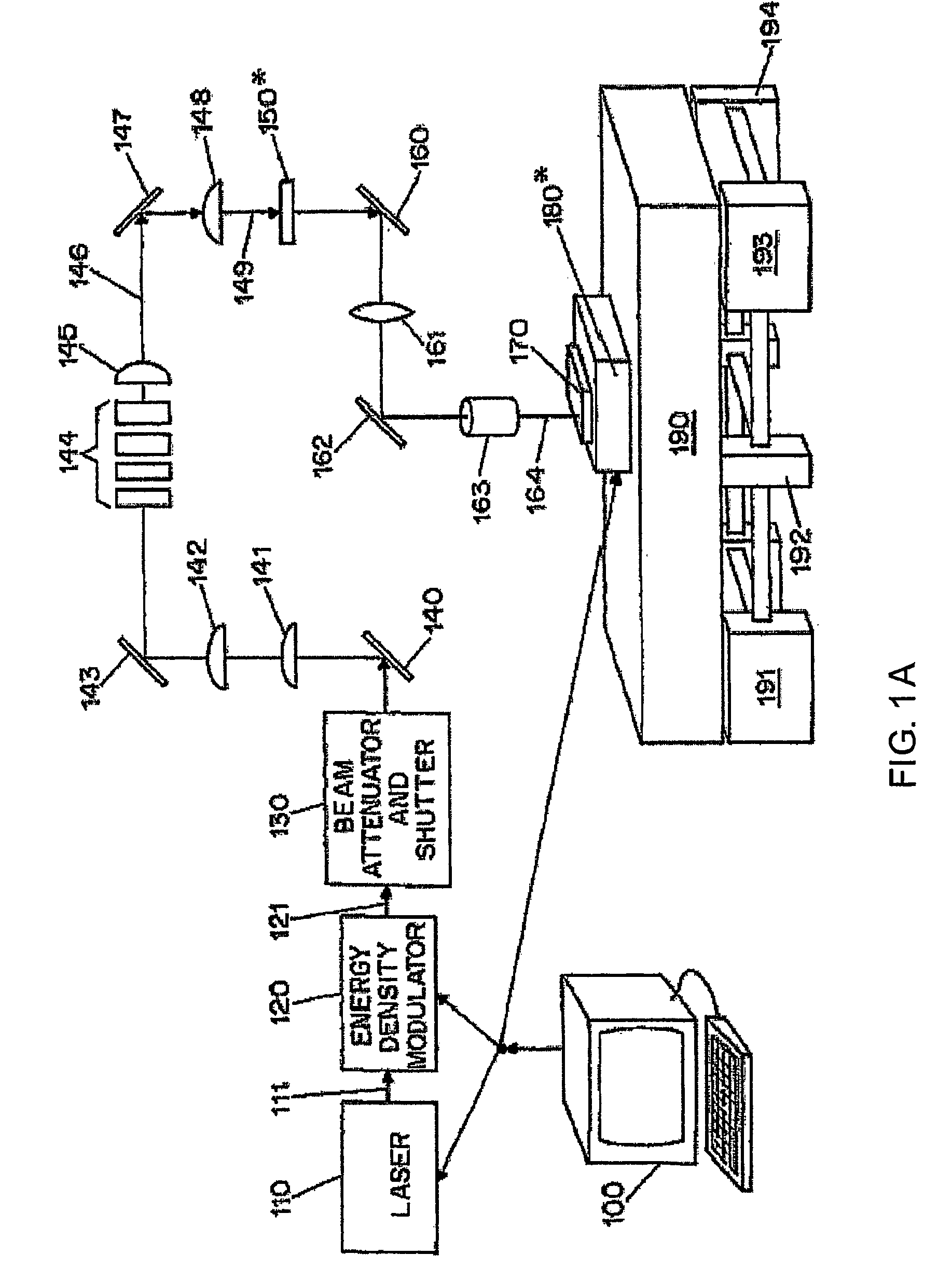

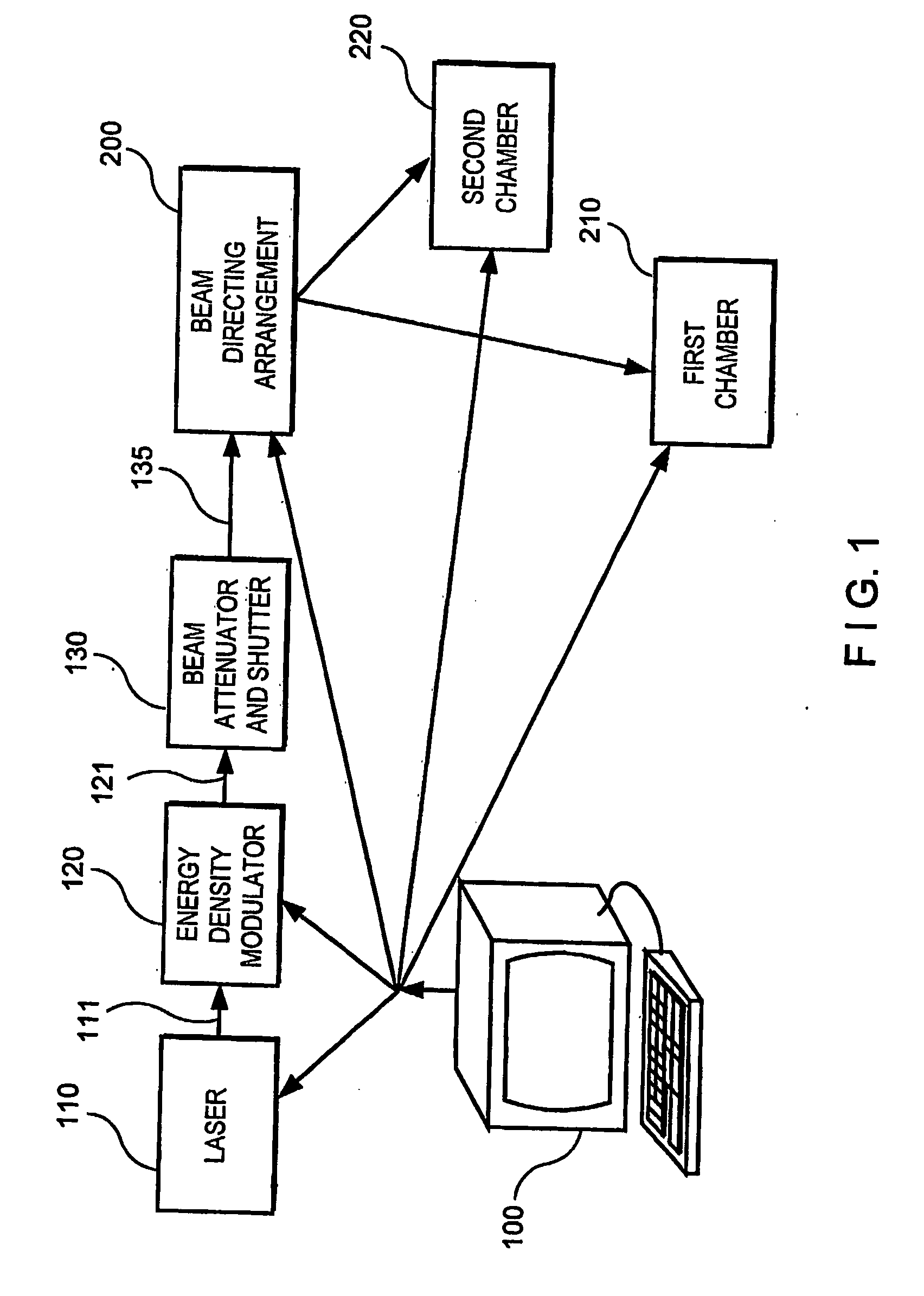

Process and mask projection system for laser crystallization processing of semiconductor film regions on a substrate

InactiveUS6961117B2Extended service lifeEmission reductionLaser detailsSemiconductor/solid-state device manufacturingLight beamLaser crystallization

A process and system for processing a silicon thin film on a sample are provided. In particular, an irradiation beam generator is controlled to emit irradiation beam pulses at a predetermined repetition rate. These irradiation beam pulses are then separated into a first set of beam pulses and a second set of beam pulses. The first set of beam pulses are caused to irradiate through a mask to produce a plurality of beamlets. The second set of beam pulses and the beamlets are caused to impinge and irradiate at least one section of the silicon thin film. When the second set of beam pulses and the beamlets simultaneously irradiate the section of the silicon thin film, this combination of the beamlets and second set of beam pulses provides a combined intensity which is sufficient to melt the section of the silicon thin film throughout an entire thickness of the section.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

System and method of identifying an object in a laser beam illuminated scene based on material types

Owner:ROSEMOUNT AEROSPACE

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity within arears in such regions and edge areas thereof, and a structure of film regions

ActiveUS20060060130A1Reduce perceptionKeep the same performanceTransistorPolycrystalline material growthLaser crystallizationThin membrane

A process and system for processing a thin film sample, as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit successive irradiation beam pulses at a predetermined repetition rate. Each irradiation beam pulse may be masked to define a first plurality of beamlets and a second plurality of beamlets. The first and second plurality of beamlets of each of the irradiation pulses being provided for impinging the film sample and having an intensity which is sufficient to at least partially melt irradiated portions of the section of the film sample. A particular portion of the section of the film sample is irradiated with the first beamlets of a first pulse of the irradiated beam pulses to melt first areas of the particular portion, the first areas being at least partially melted, leaving first unirradiated regions between respective adjacent ones of the first areas, and being allowed to resolidify and crystallize. After the irradiation of the particular portion with the first beamlets, the particular portion is again irradiated with the second beamlets of a second pulse of the irradiated beam pulses to melt second areas of the particular portion, the second areas being at least partially melted, leaving second unirradiated regions between respective adjacent ones of the second areas, and being allowed to resolidify and crystallize. The first irradiated and re-solidified areas and the second irradiated and re-solidified areas are intermingled with one another within the section of the film sample. In addition, the first areas correspond to first pixels, and the second areas correspond to second pixels.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

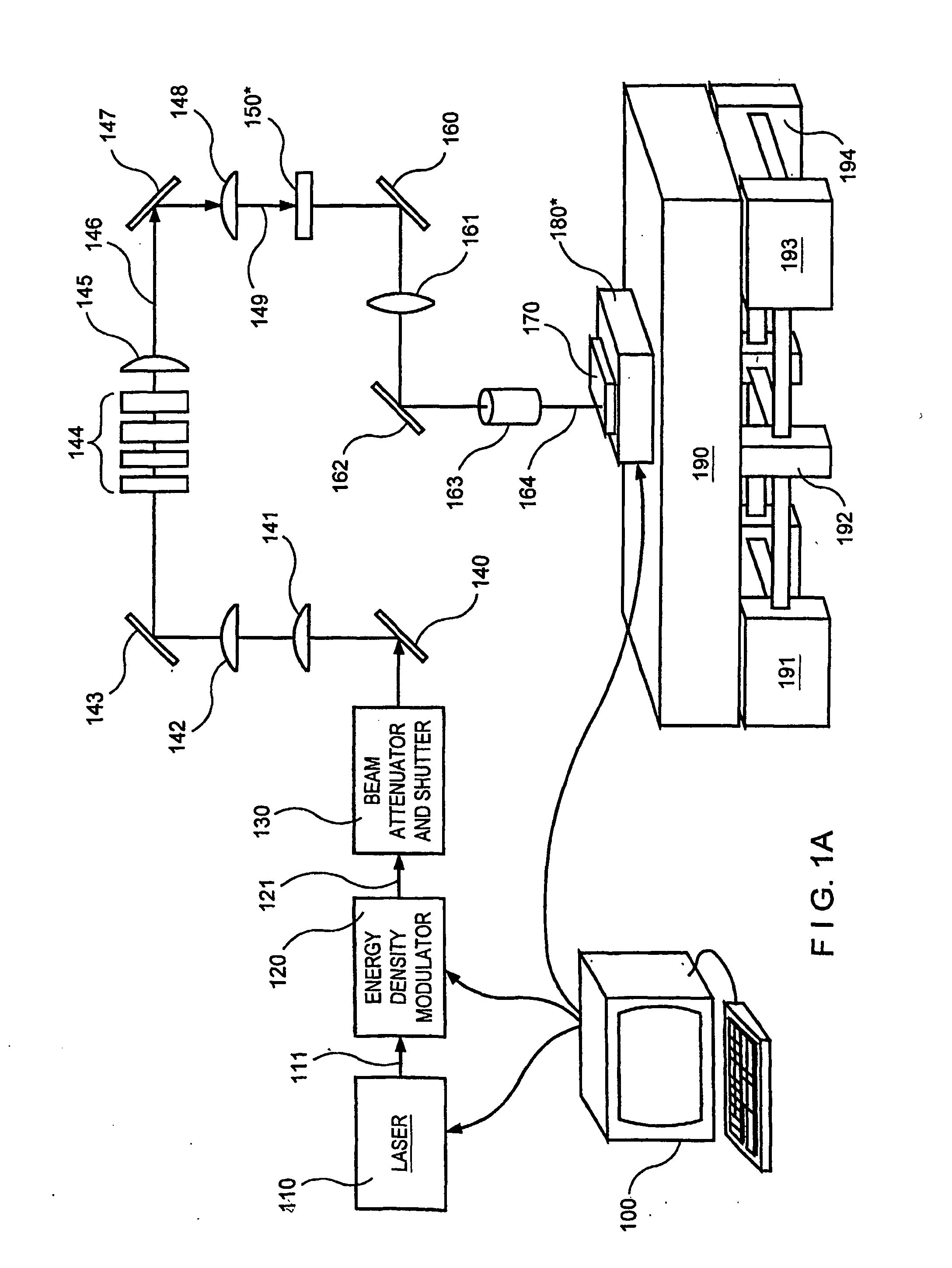

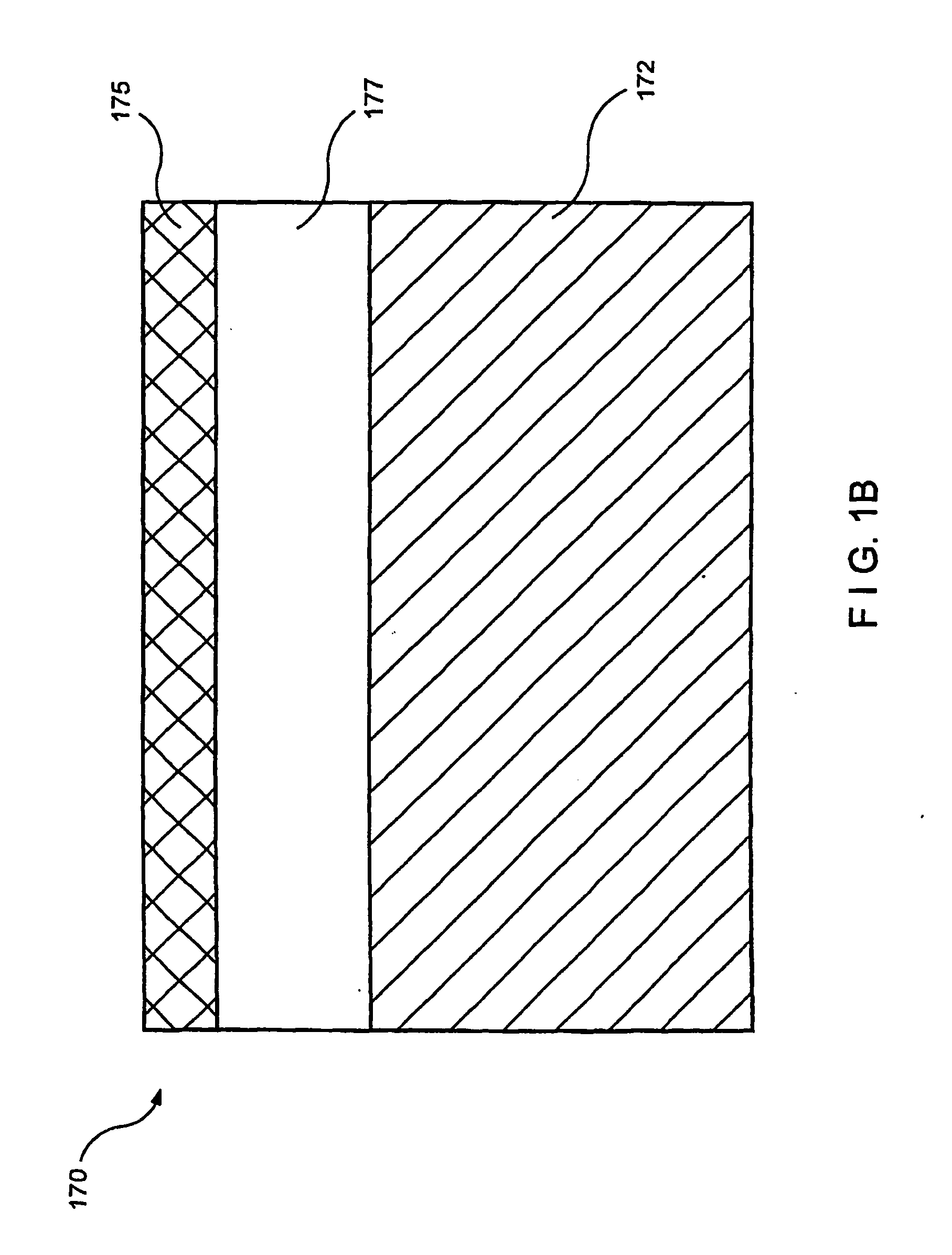

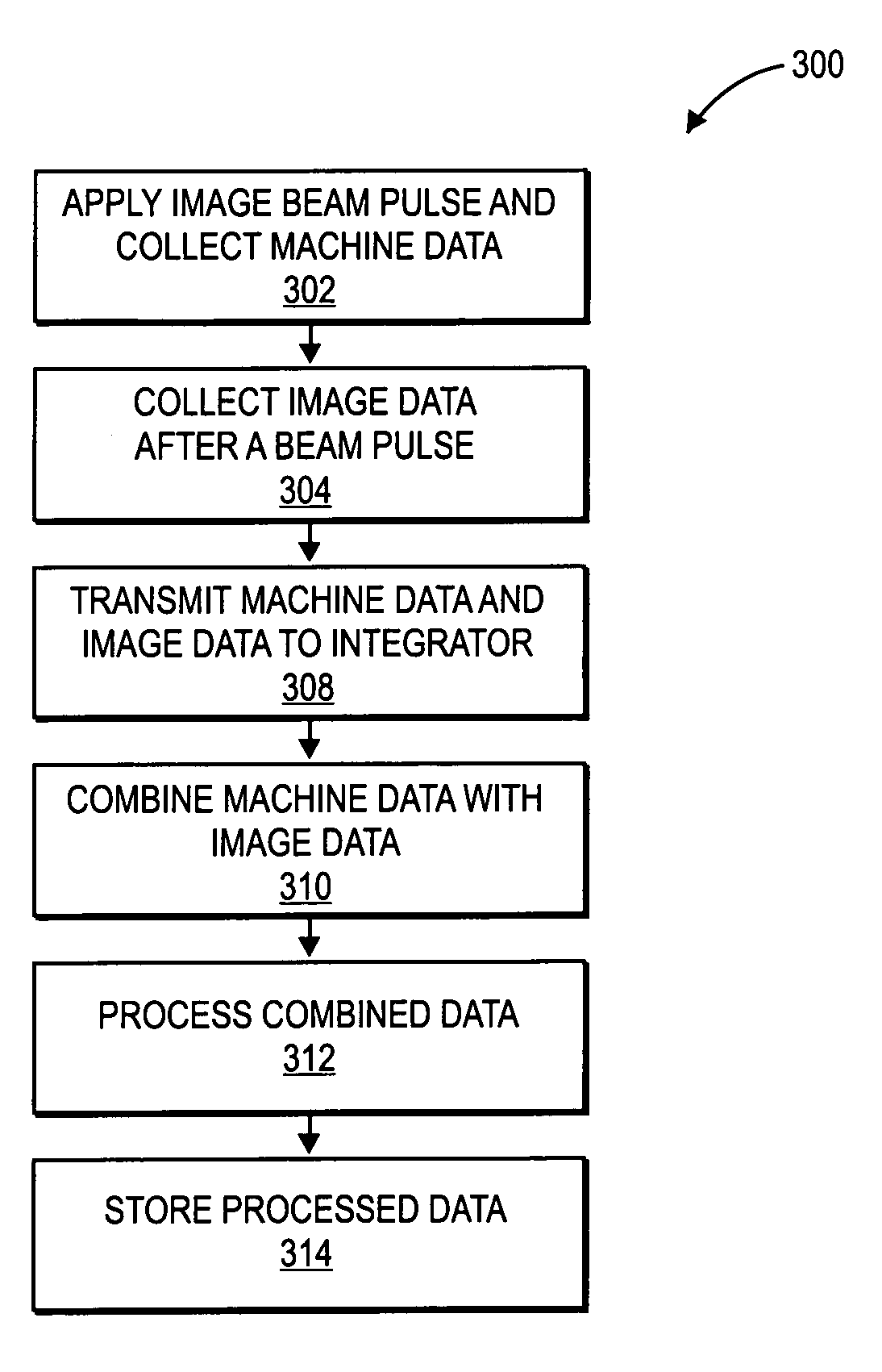

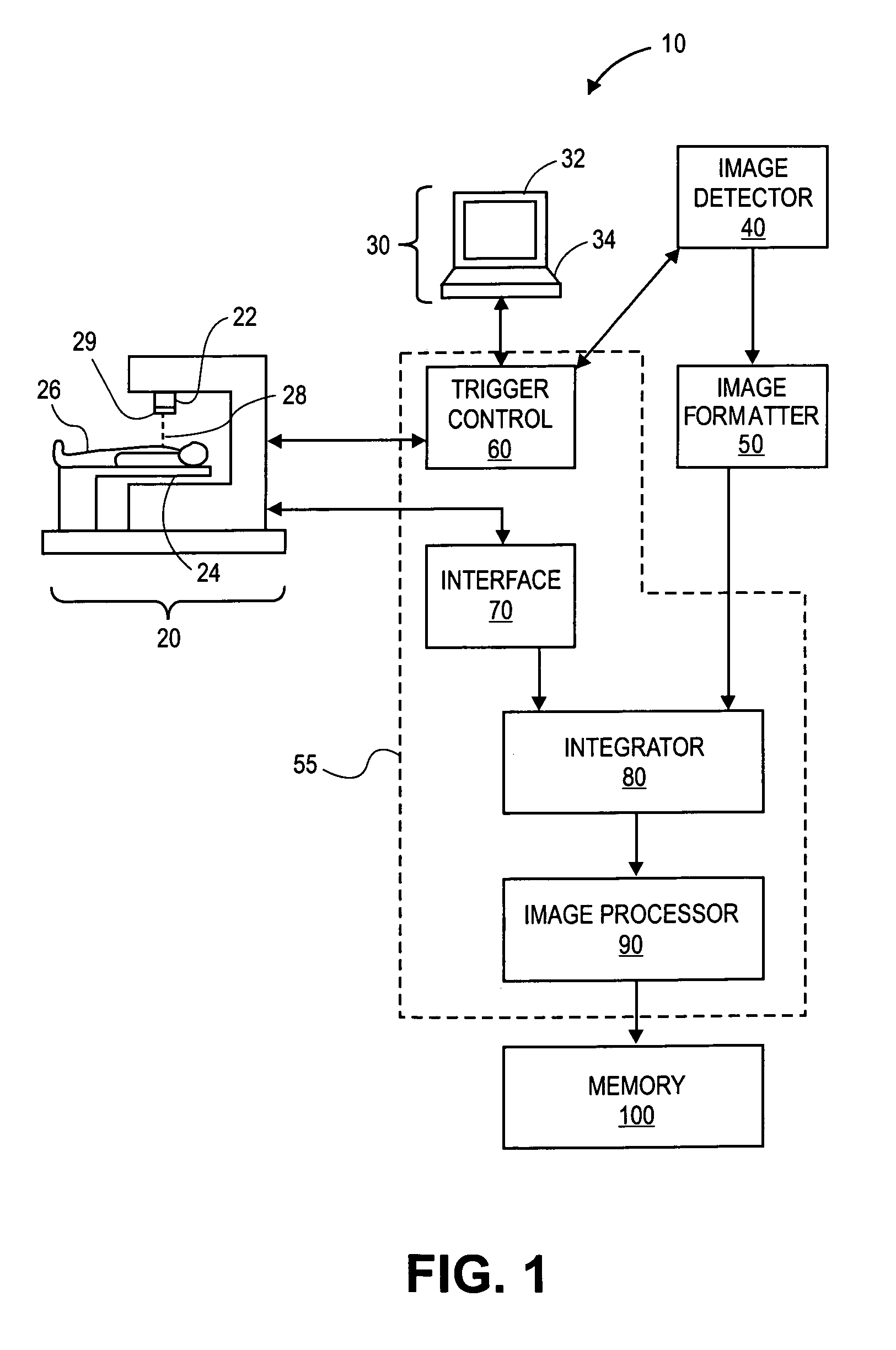

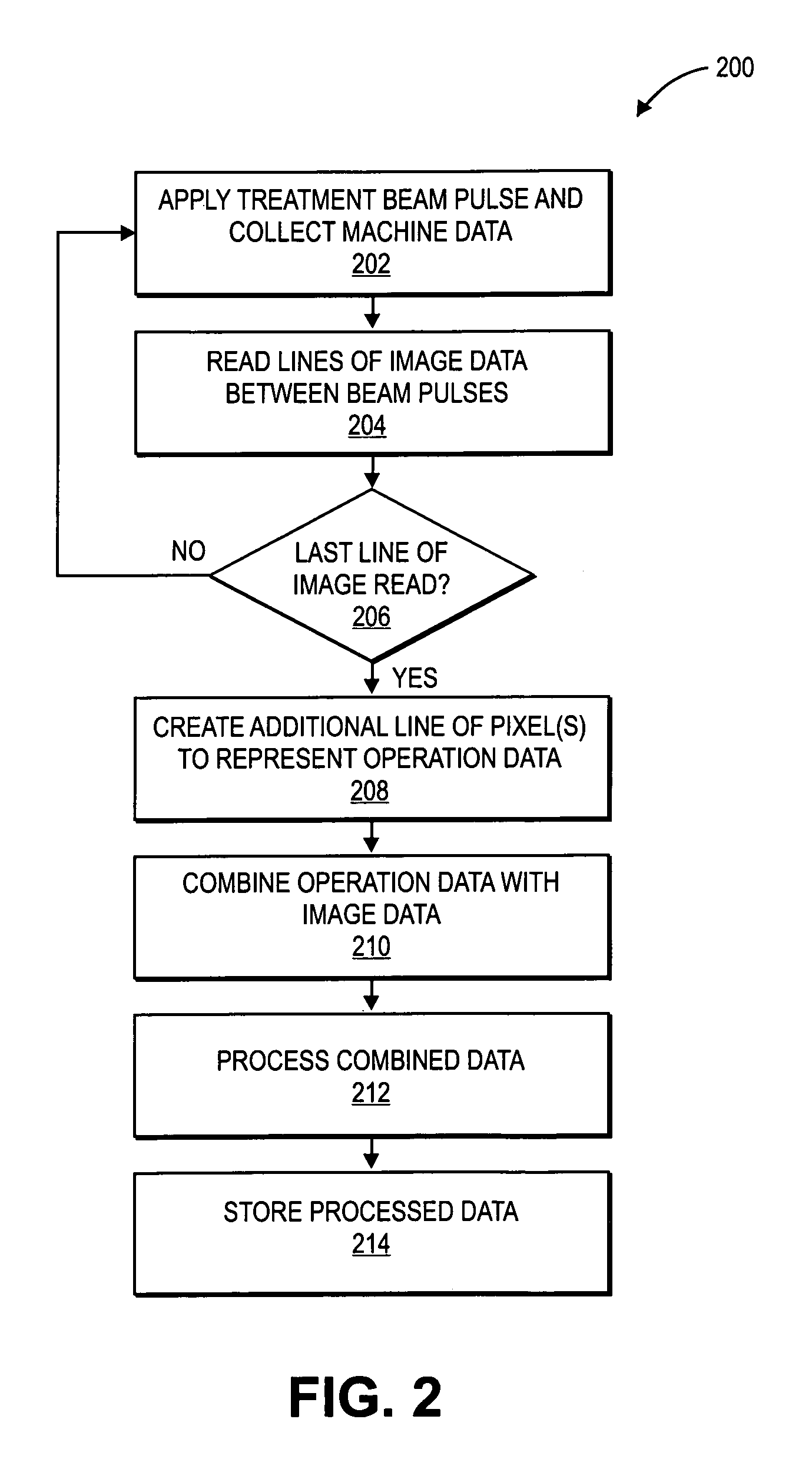

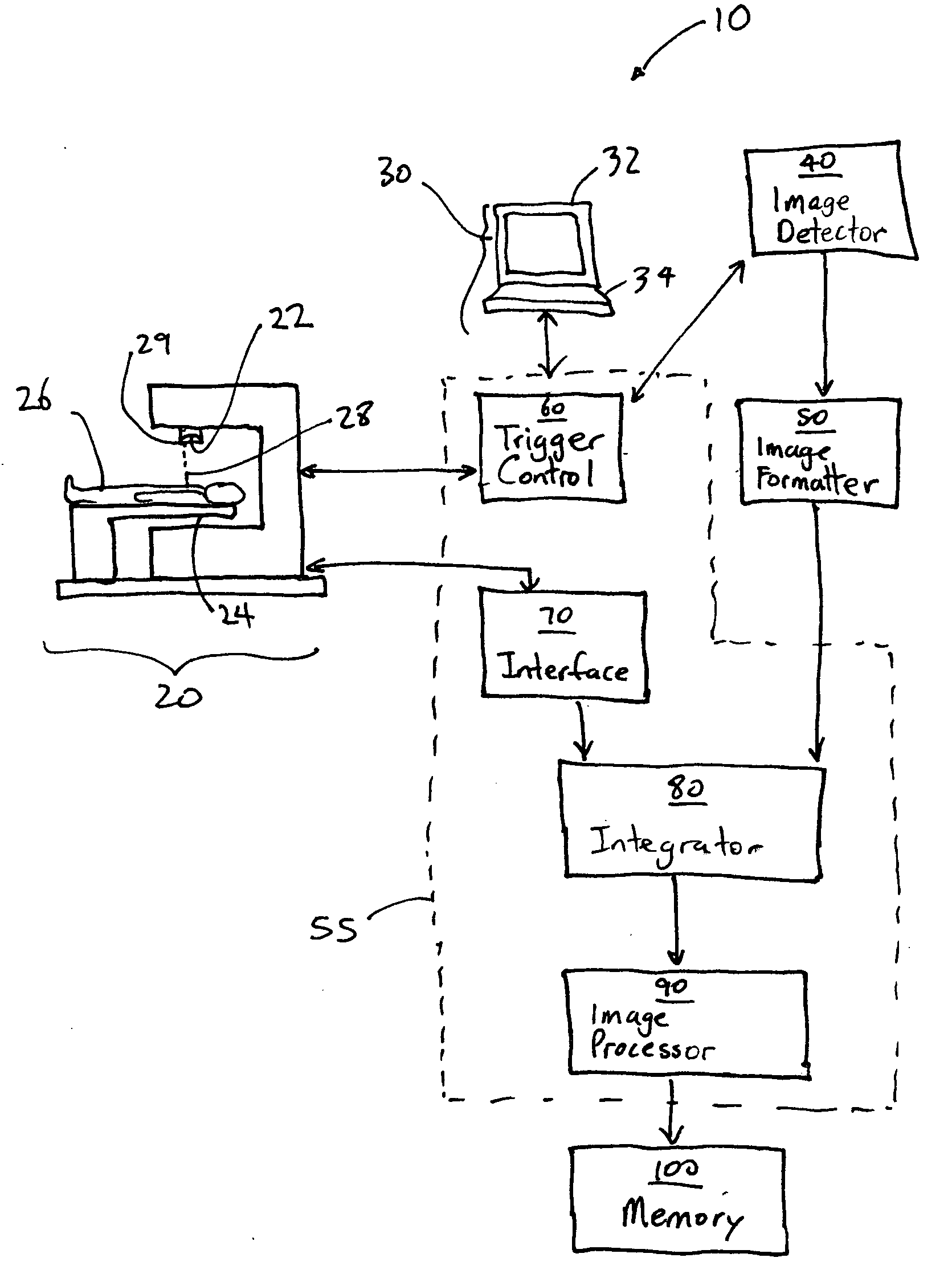

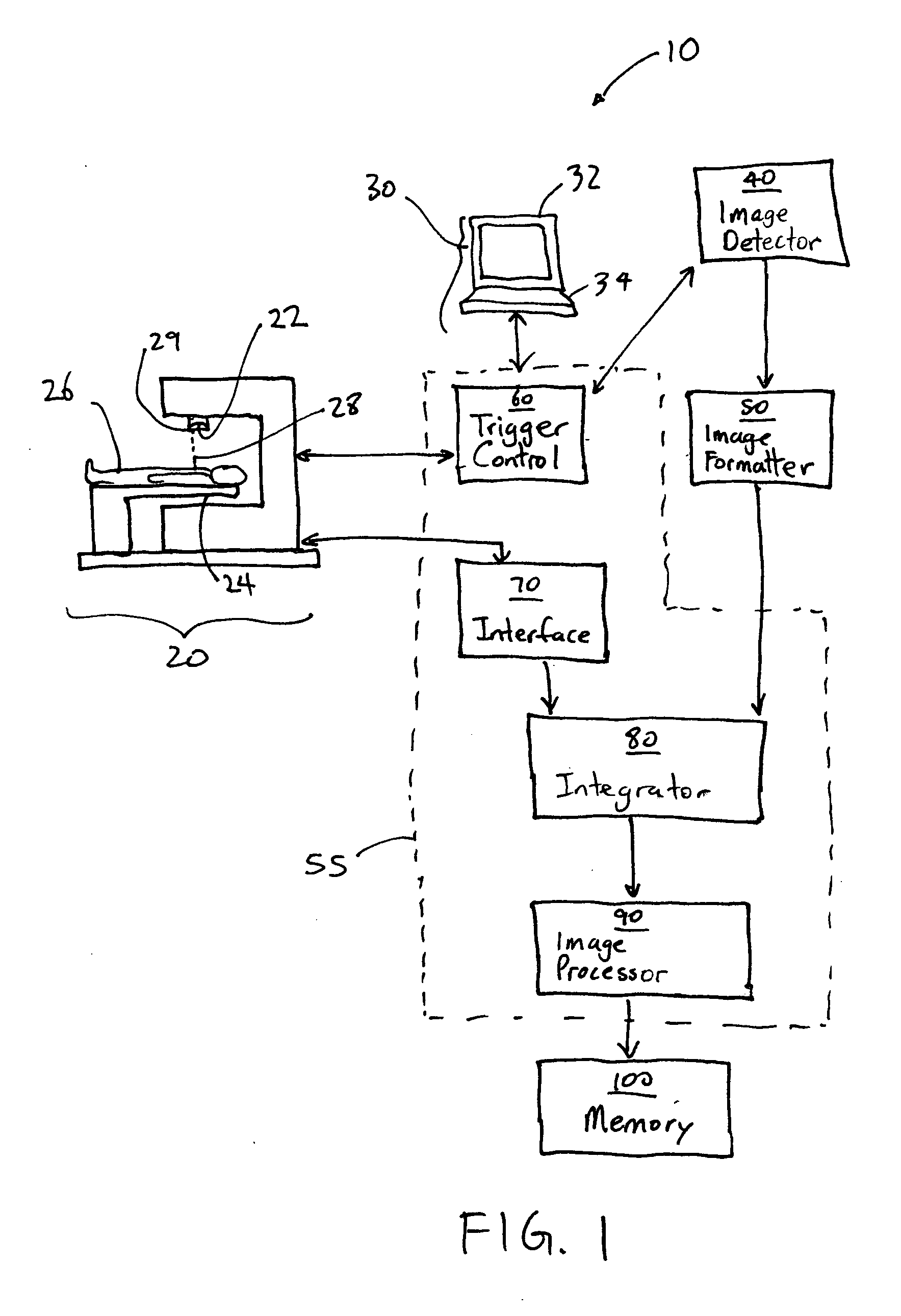

Systems and methods for processing data

InactiveUS6999555B2Reduce in quantityPrevents reduces of of and of dataComputerised tomographsTomographyBeam energyGantry angle

A method for processing data in a radiation procedure includes obtaining operation data, and formatting the operation data into a set of image data, wherein the operation data comprises one or a combination of a gantry angle, a patient position, a patient orientation, radiation dose rate, radiation dose fraction, beam pulse rate, beam energy, time when beam was activated, time when beam was deactivated, and beam variation (if any) during an image readout. Also machine axis information, machine status info and operation data from other systems like for instance the RPM system may be included. A method of processing data in a radiation procedure includes obtaining operation data, obtaining an image data, and combining the operation data with the image data in substantially real time.

Owner:VARIAN MEDICAL SYST INT AG

System and method of identifying an object in a laser beam illuminated scene based on material types

A method of identifying an object in a laser beam illuminated scene based on material types comprises the steps of: emitting a pulsed beam of laser energy, each beam pulse comprising a plurality of different discrete wavelength emission components; illuminating a predetermined scene with the pulsed beam; receiving return laser pulses from objects within the illuminated scene, each return laser pulse comprising return components corresponding to the plurality of different discrete wavelength emission components; determining spectral reflectance values for the plurality of return components of each return laser pulse; determining a material type for each return laser pulse of the illuminated scene based on the plurality of reflectance values of the corresponding return pulse; indexing each determined material type to a position in the illuminated scene; and identifying an object in the illuminated scene based on material types and indexed positions thereof in the scene. A counterpart system for carrying out the method is also disclosed.

Owner:ROSEMOUNT AEROSPACE

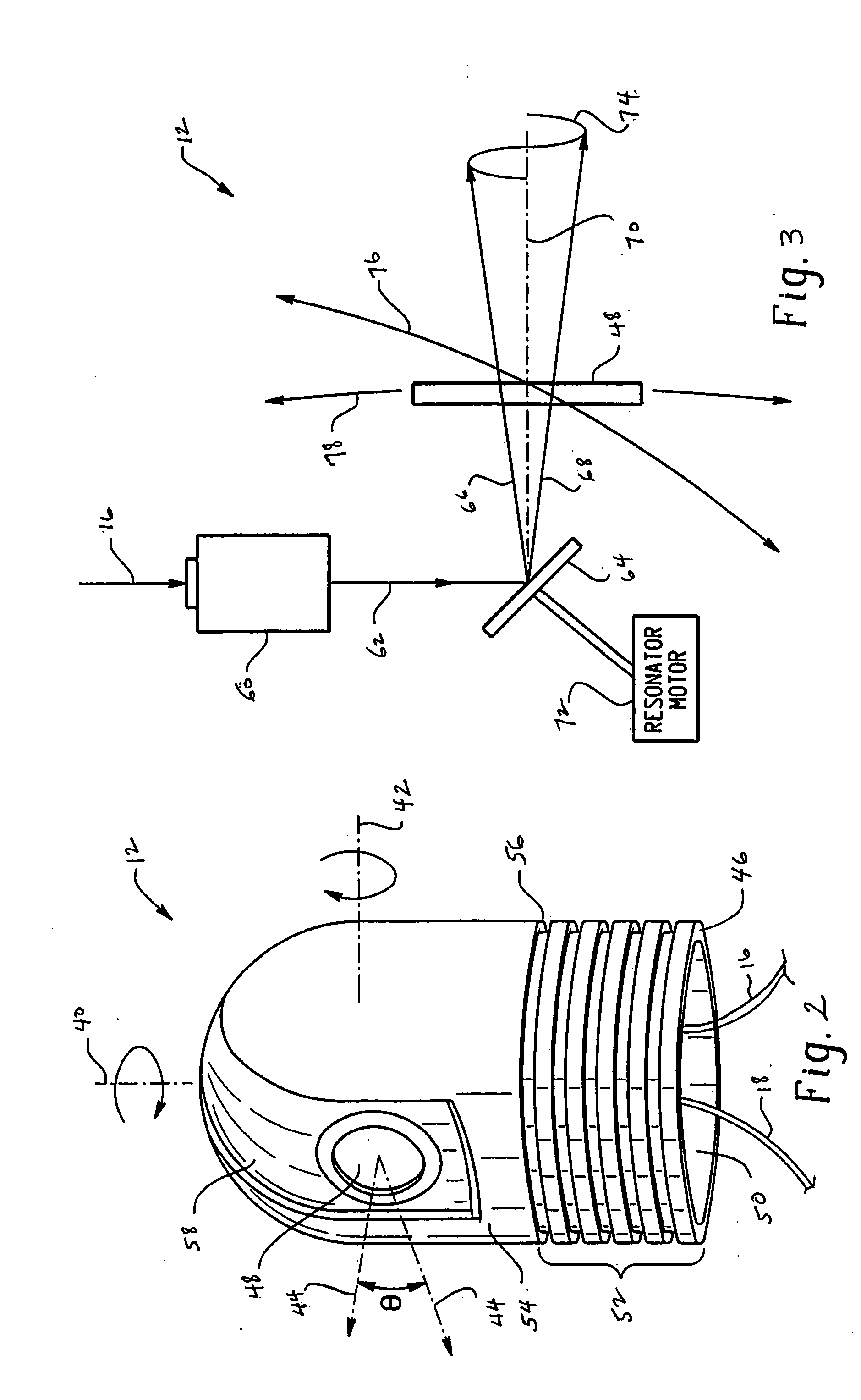

Flash ladar system

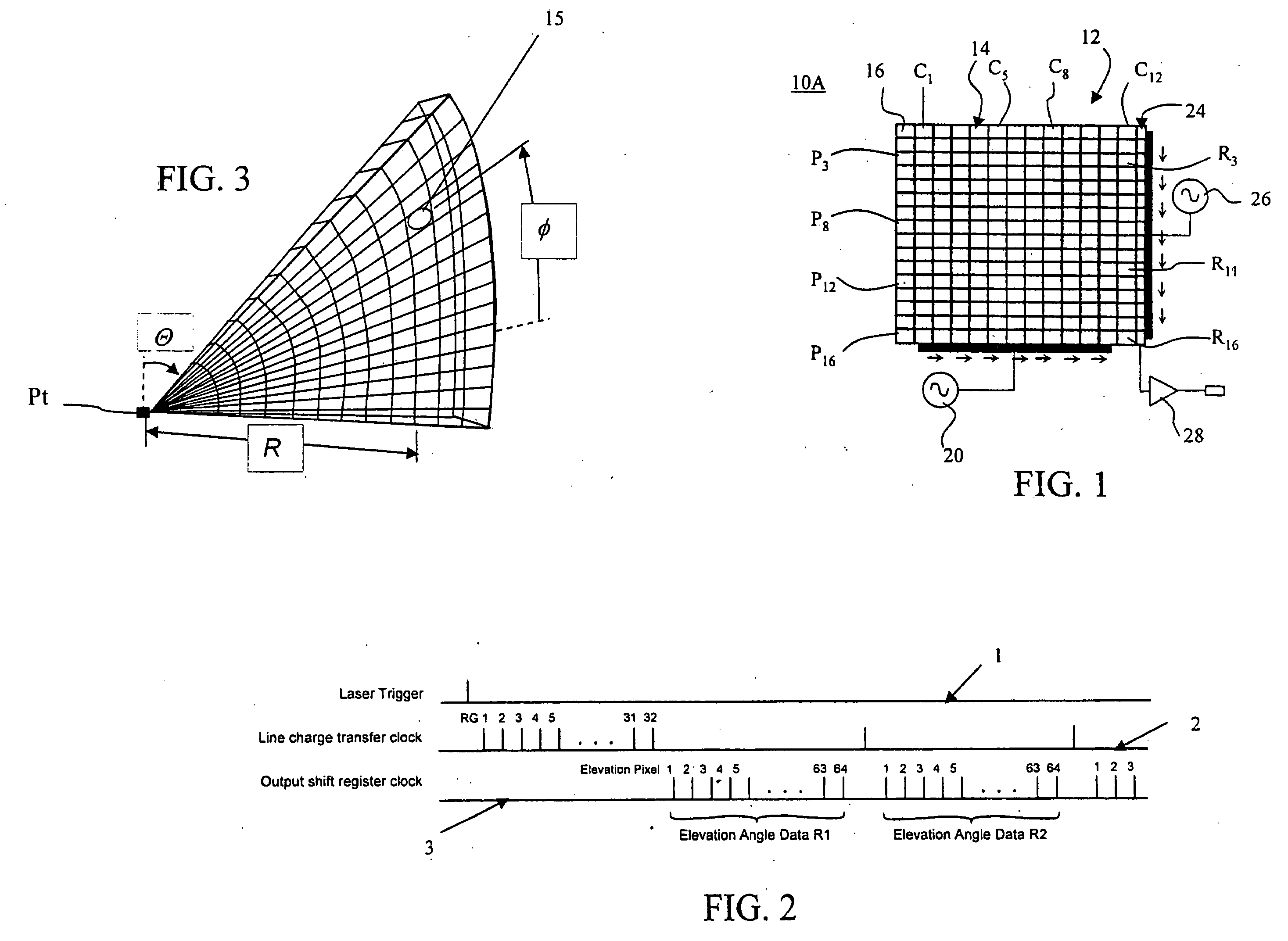

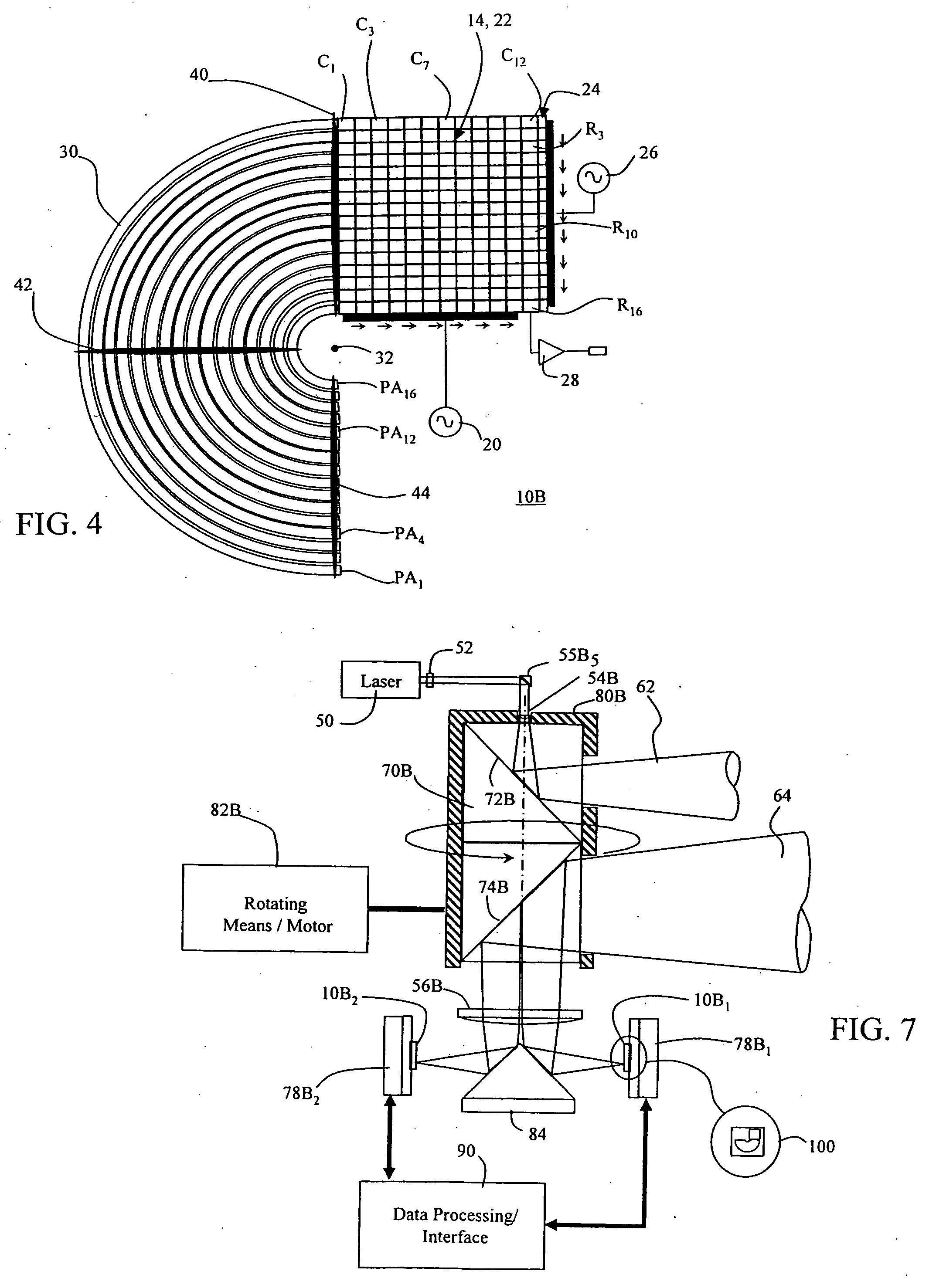

InactiveUS7135672B2Simple designReduce manufacturing costOptical rangefindersSolid-state devicesShift registerLight beam

A flash ladar system has a laser provided with beam focusing optics for directing a laser fan beam pulse to a scanning element that in turn directs the laser fan beam to a vertical region of space. Light reflected from an object in the vertical region of space is directed by a reflecting element to a sensor provided with a column of photosensitive pixels that connects to a charge storage matrix of non-photosensitive pixels. After an integration period electrical charges are shifted from the photosensitive region to an adjacent column in the charge storage region. The process of integrate and shift is repeated for multiple integration periods until the charge storage region is filled with charges whereupon a serial shift register removes the information to be processed by a data processor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

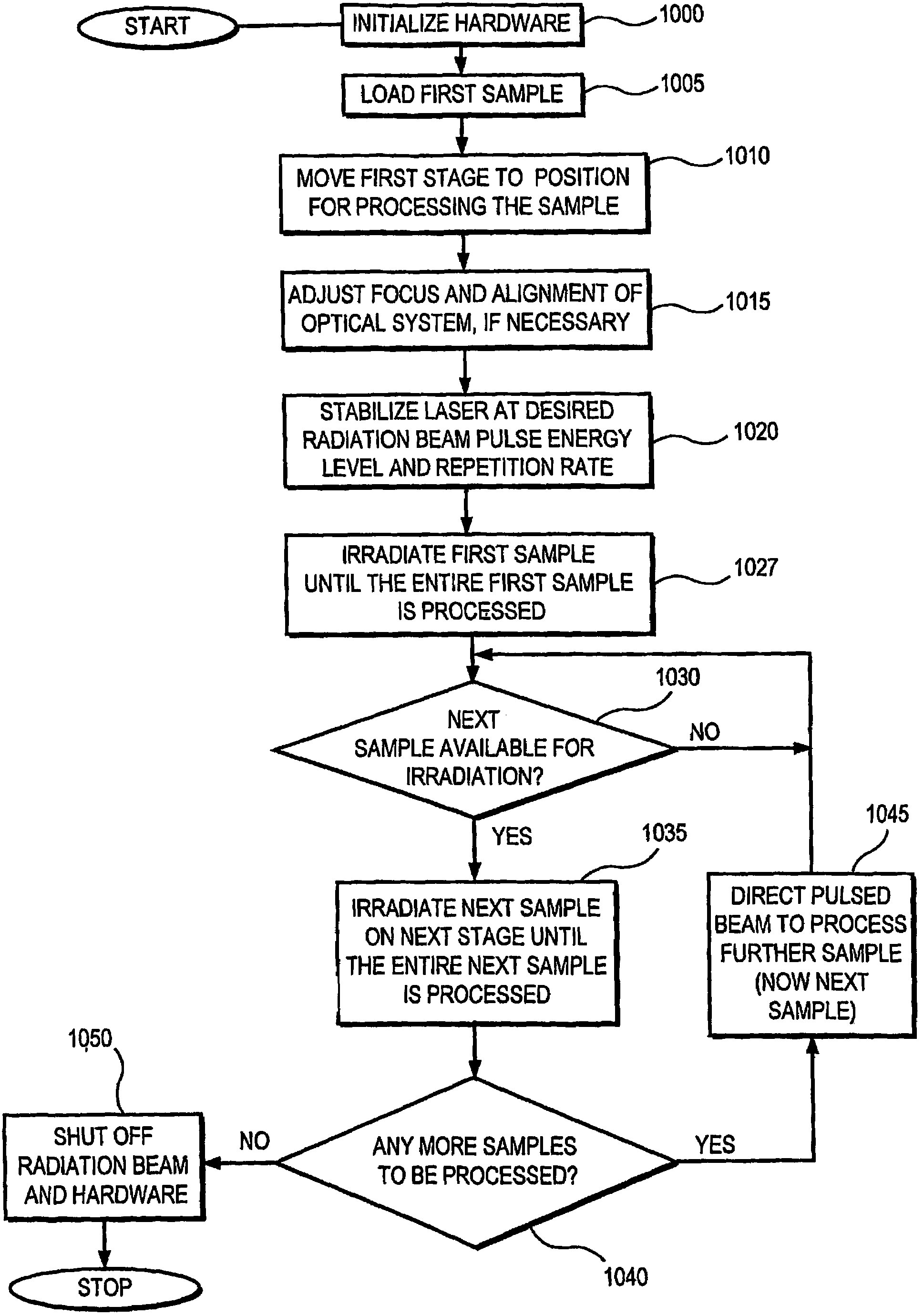

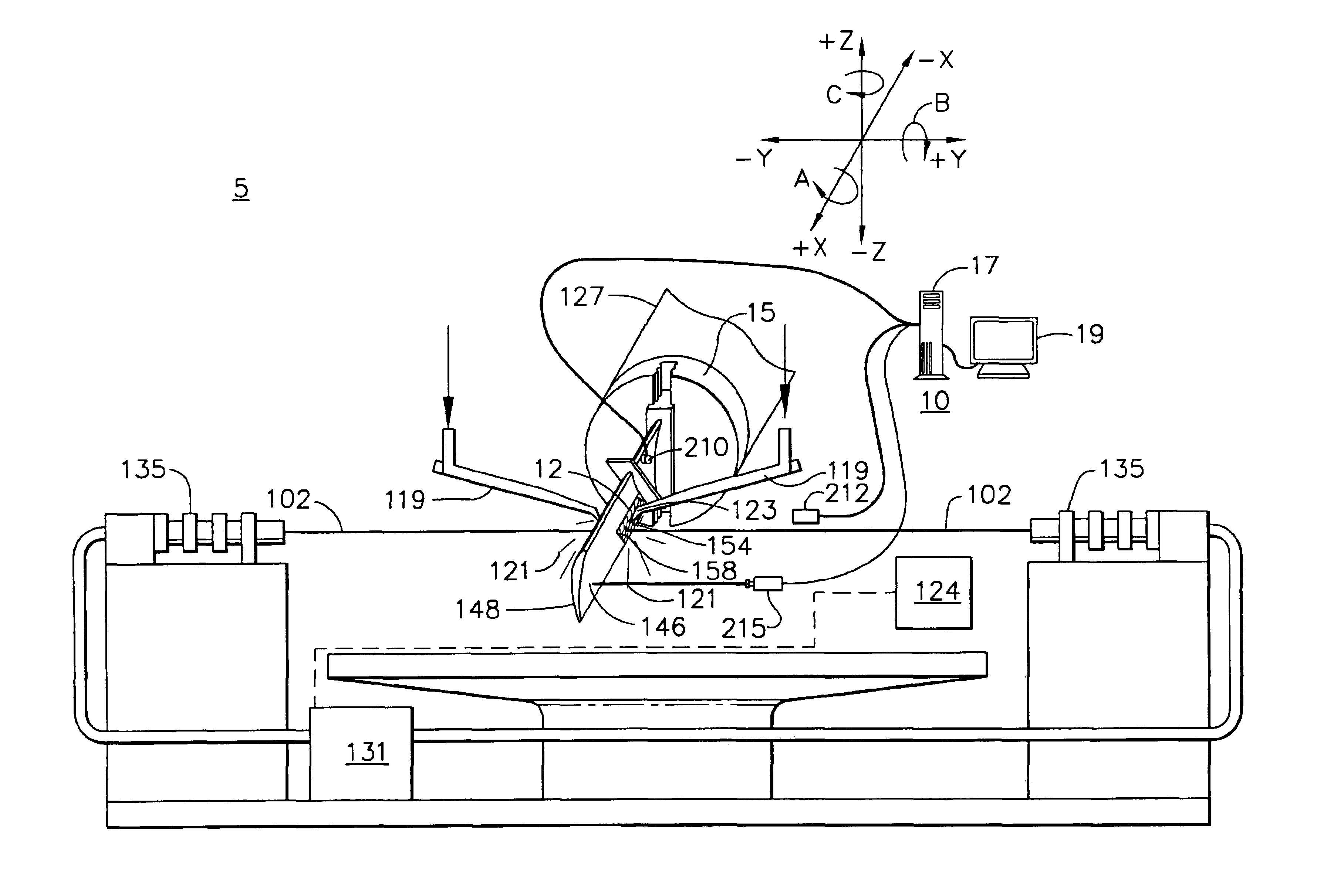

System and process for processing a plurality of semiconductor thin films which are crystallized using sequential lateral solidification techniques

A process and system are provided for processing at least one section of each of a plurality of semiconductor film samples. In these process and system, the irradiation beam source is controlled to emit successive irradiation beam pulses at a predetermined predetermined repetition rate. Using such emitted beam pulses, at least one section of one of the semiconductor film samples is irradiated using a first sequential lateral solidification (“SLS”) technique and / or a first uniform small grained material (“UGS”) techniques to process the such sections) of the first sample. Upon the completion of the processing of this section of the first sample, the beam pulses are redirected to impinge at least one section of a second sample of the semiconductor film samples. Then, using the redirected beam pulses, such sections) of the second sample are irradiated using a second SLS technique and / or a second UGS technique to process the at least one section of the second sample. The first and second techniques can be different from one another or substantially the same.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS7259081B2Increase speedUniform materialTransistorAfter-treatment apparatusLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

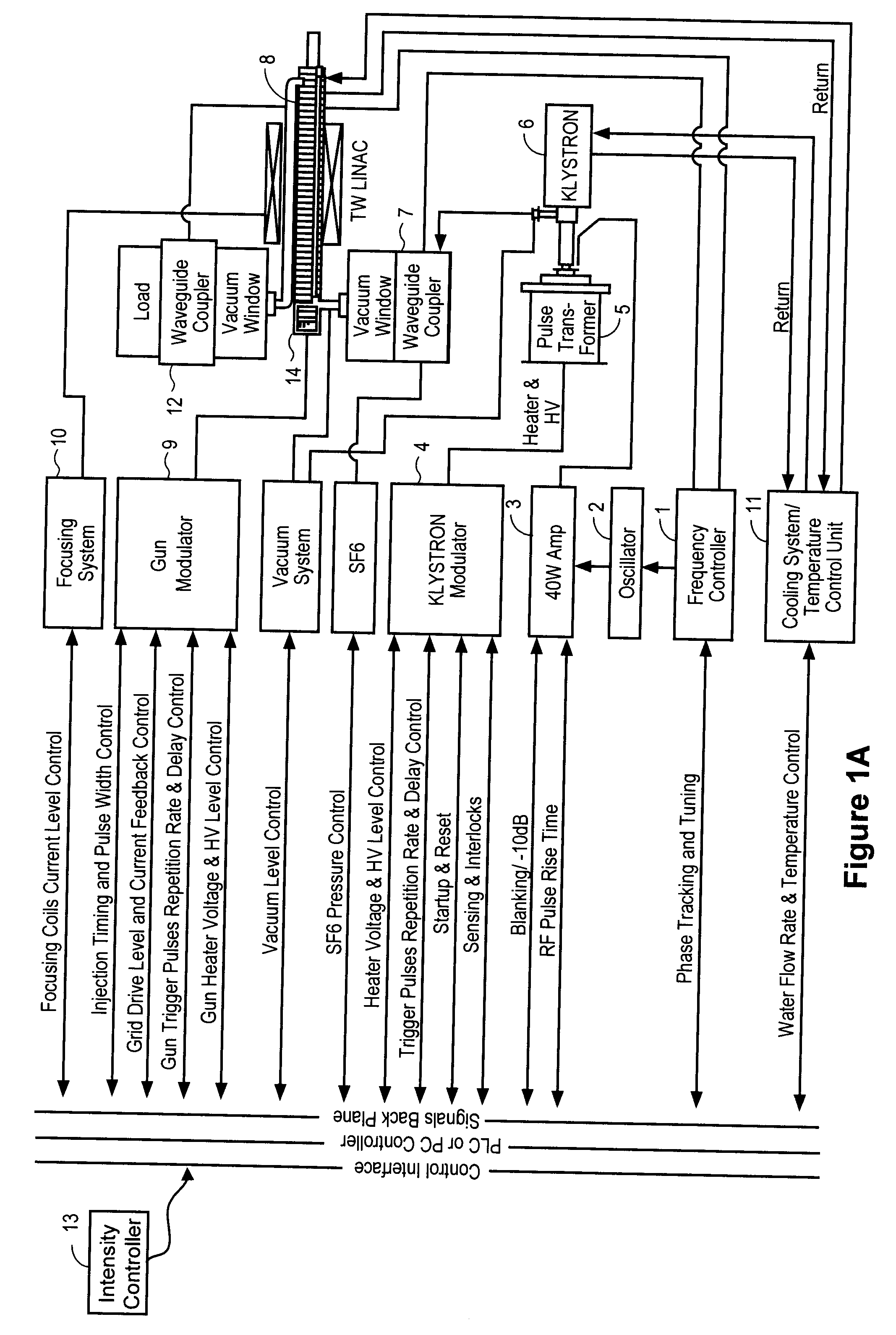

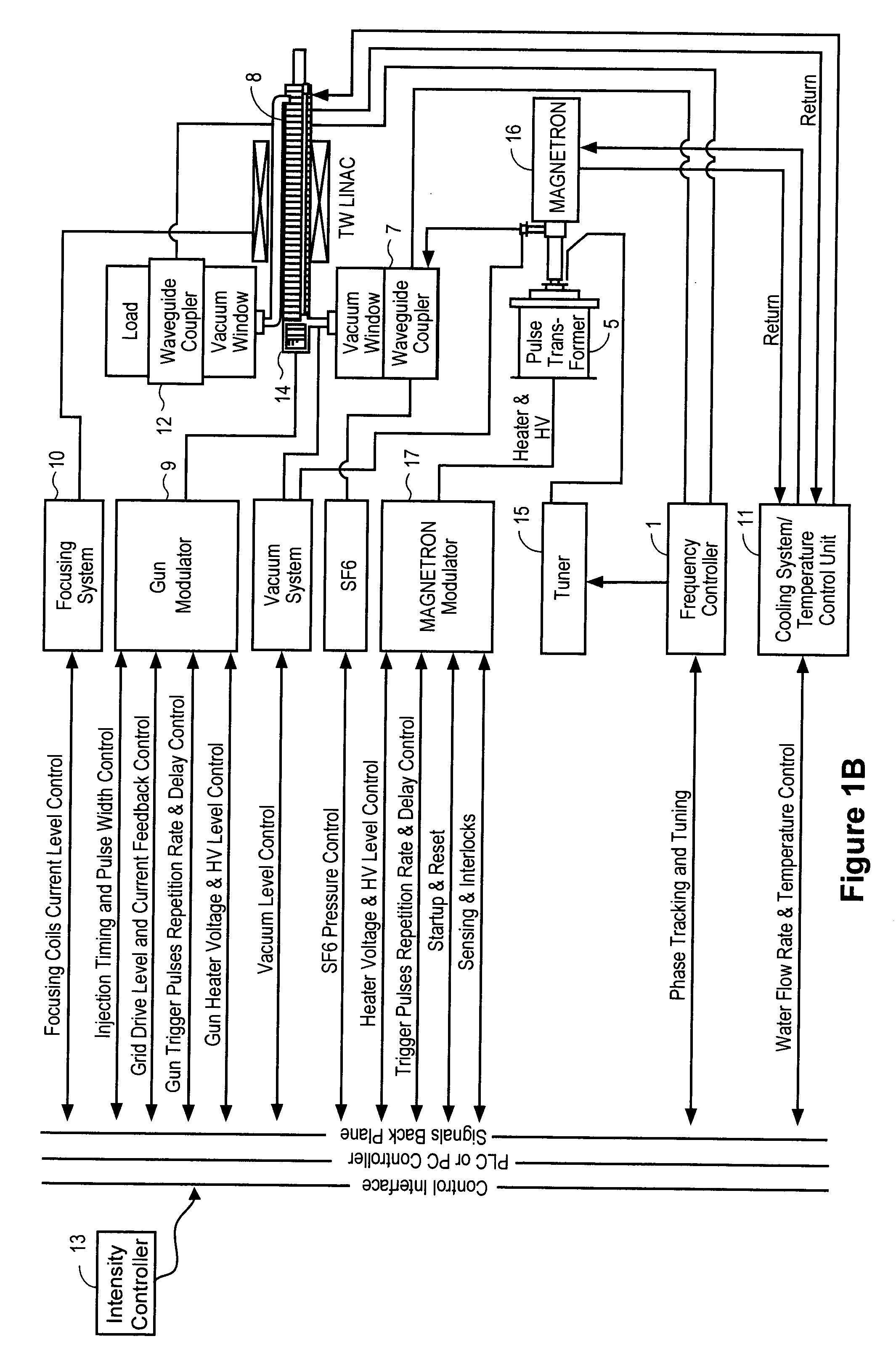

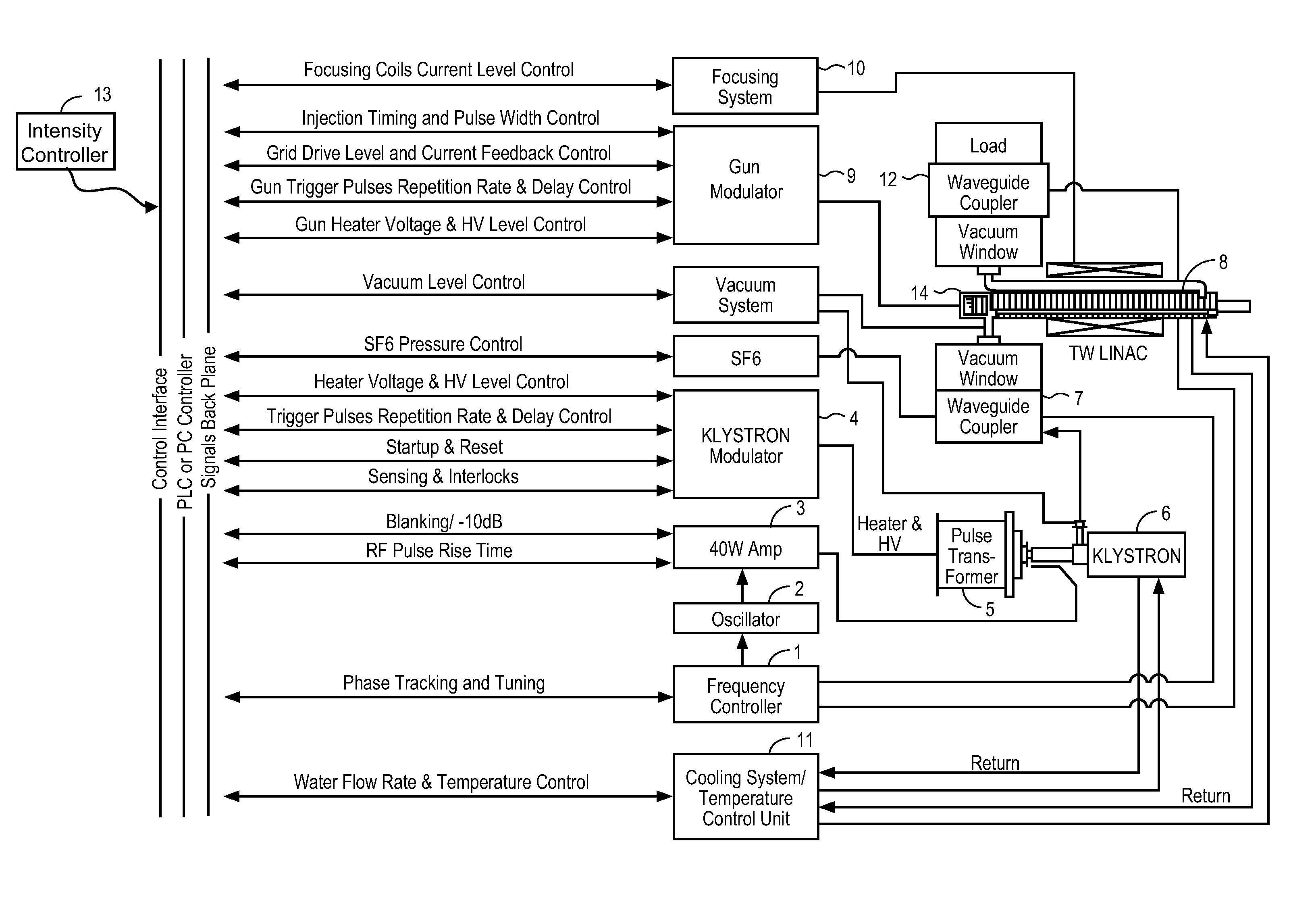

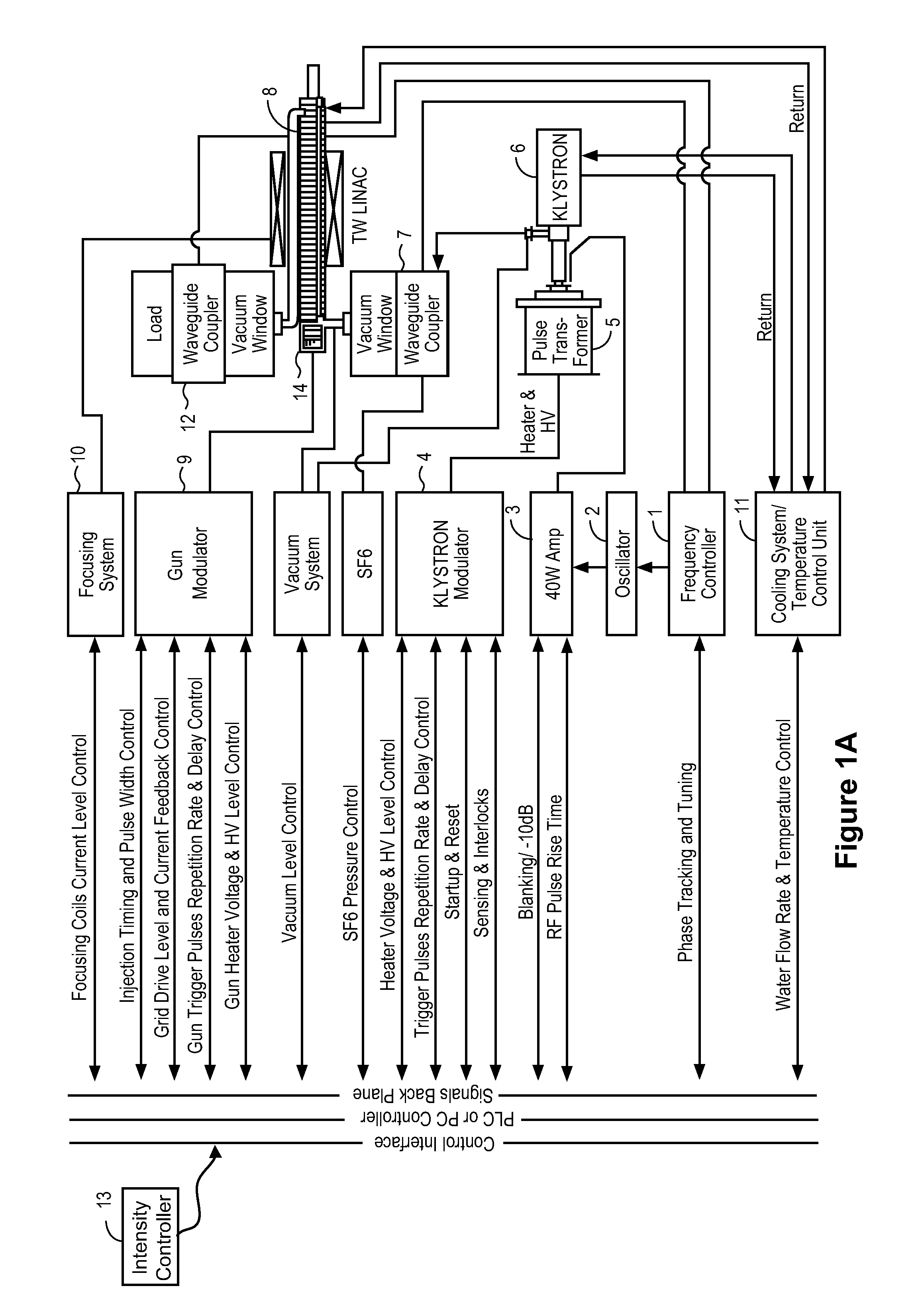

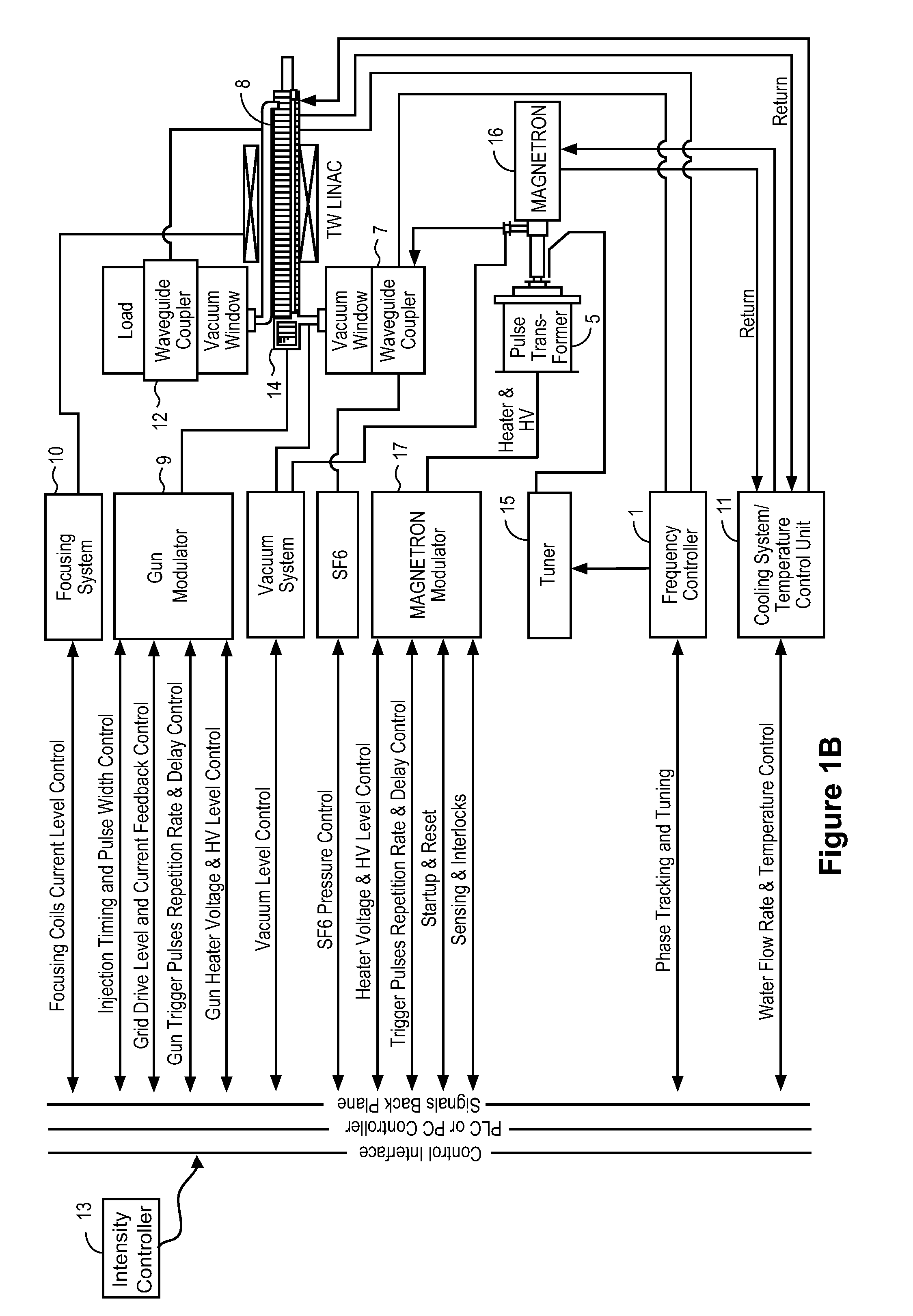

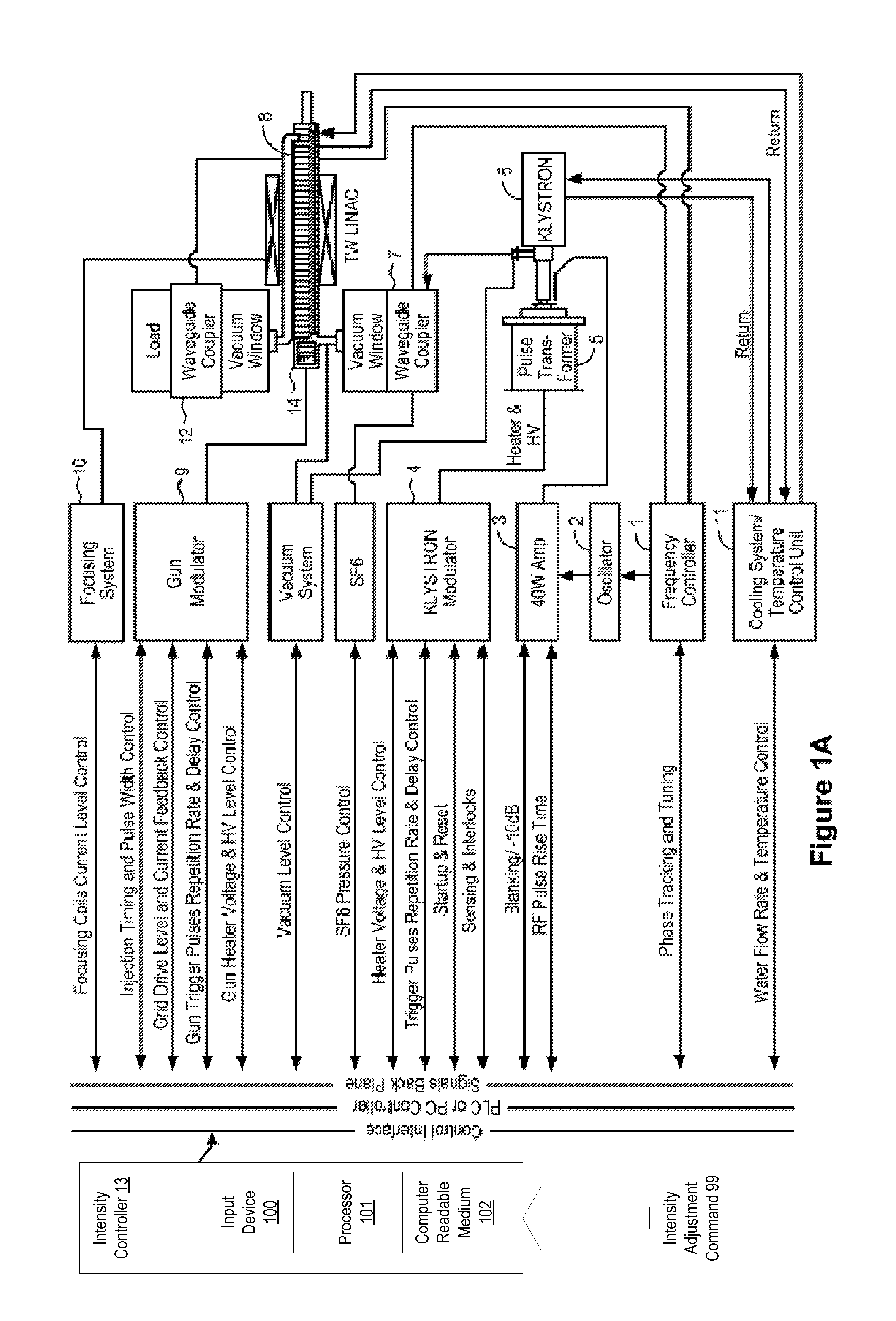

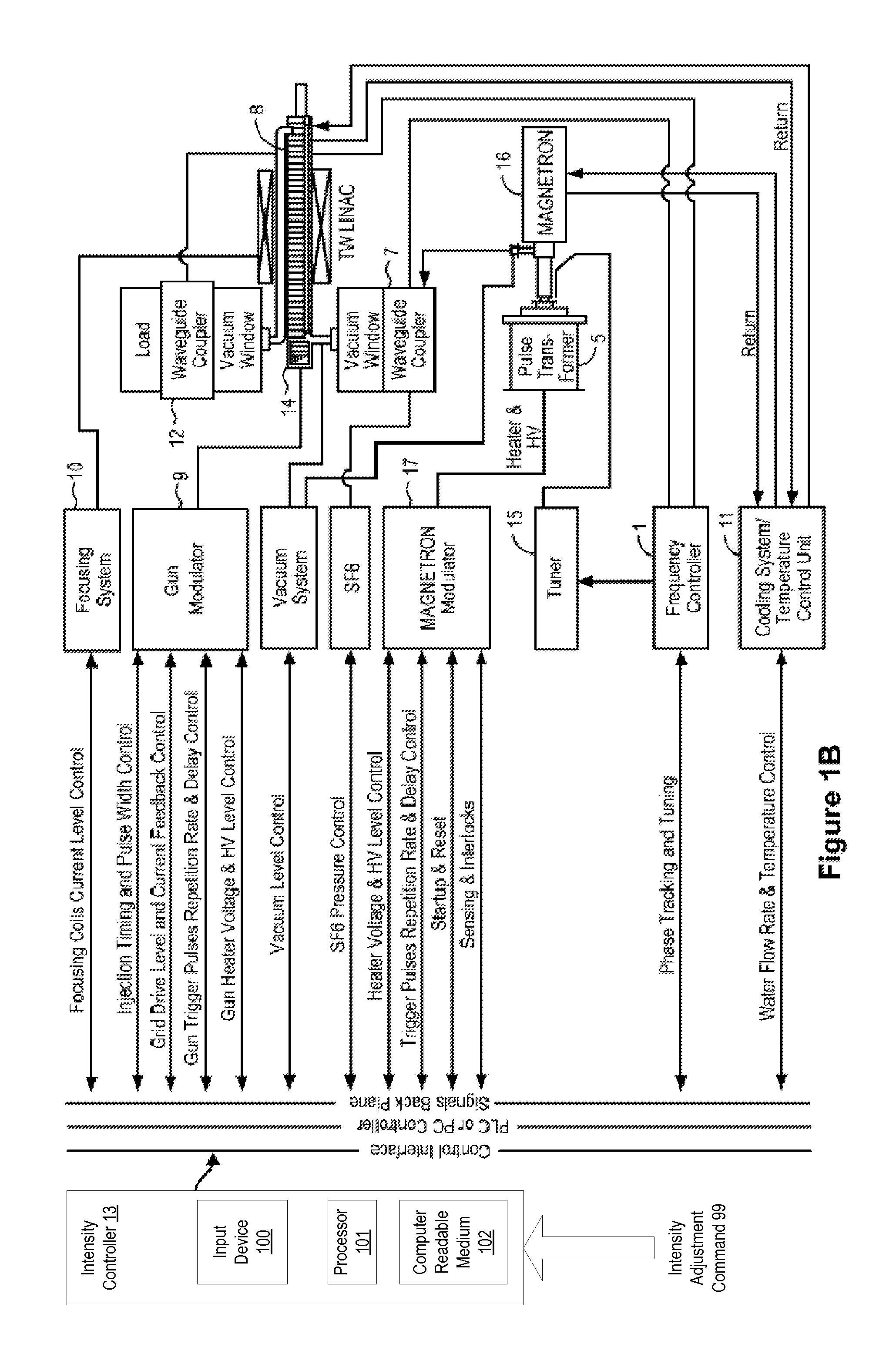

Systems and methods for cargo scanning and radiotherapy using a traveling wave linear accelerator based x-ray source using pulse width to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the width of the beam pulse, i.e., pulse width. The electron beams may be used to generate x-rays having selected doses and energies, which may be used for cargo scanning or radiotherapy applications.

Owner:ACCURAY

Systems and methods for processing data

ActiveUS20050058237A1Reduce in quantityPrevents reduces of of and of dataRadiation/particle handlingComputerised tomographsBeam energyGantry angle

A method for processing data in a radiation procedure includes obtaining operation data, and formatting the operation data into a set of image data, wherein the operation data comprises one or a combination of a gantry angle, a patient position, a patient orientation, radiation dose rate, radiation dose fraction, beam pulse rate, beam energy, time when beam was activated, time when beam was deactivated, and beam variation (if any) during an image readout. Also machine axis information, machine status info and operation data from other systems like for instance the RPM system may be included. A method of processing data in a radiation procedure includes obtaining operation data, obtaining an image data, and combining the operation data with the image data in substantially real time.

Owner:VARIAN MEDICAL SYST INT AG

Laser crystallization and selective patterning using multiple beamlets

ActiveUS7300858B2Reduce perceptionKeep the same performanceTransistorPolycrystalline material growthLaser crystallizationLight beam

A process and system for processing a thin film sample, as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit successive irradiation beam pulses at a predetermined repetition rate. Each irradiation beam pulse may be masked to define a first plurality of beamlets and a second plurality of beamlets. The first and second plurality of beamlets of each of the irradiation pulses being provided for impinging the film sample and having an intensity which is sufficient to at least partially melt irradiated portions of the section of the film sample. A particular portion of the section of the film sample is irradiated with the first beamlets of a first pulse of the irradiated beam pulses to melt first areas of the particular portion, the first areas being at least partially melted, leaving first unirradiated regions between respective adjacent ones of the first areas, and being allowed to resolidify and crystallize. After the irradiation of the particular portion with the first beamlets, the particular portion is again irradiated with the second beamlets of a second pulse of the irradiated beam pulses to melt second areas of the particular portion, the second areas being at least partially melted, leaving second unirradiated regions between respective adjacent ones of the second areas, and being allowed to resolidify and crystallize. The first irradiated and re-solidified areas and the second irradiated and re-solidified areas are intermingled with one another within the section of the film sample. In addition, the first areas correspond to first pixels, and the second areas correspond to second pixels.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Traveling wave linear accelerator based x-ray source using pulse width to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the width of the beam pulse, i.e., pulse width.

Owner:ACCURAY

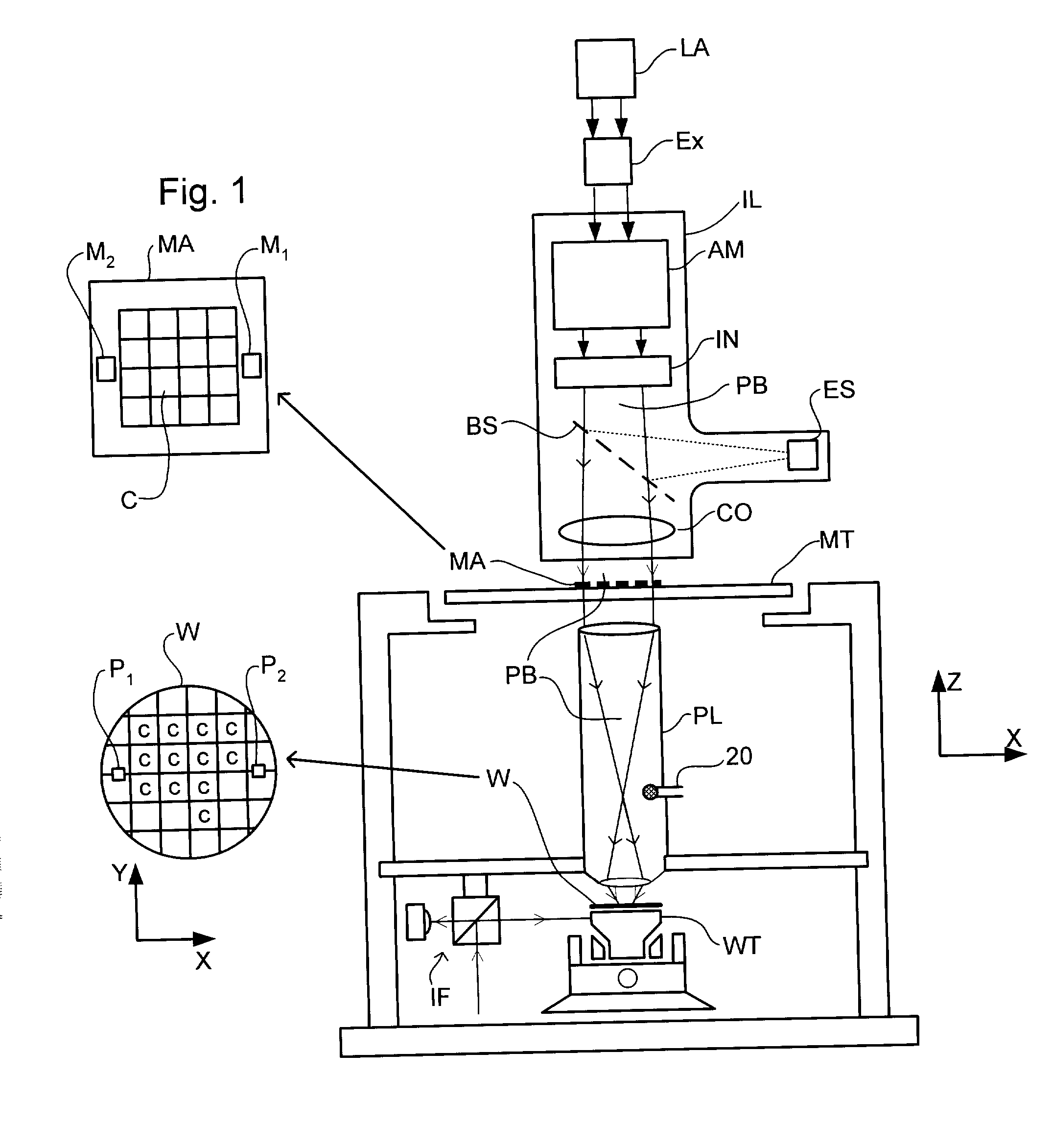

Lithographic apparatus, integrated circuit device manufacturing method, and integrated circuit device manufactured thereby

InactiveUS20020060296A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamBeam pulse

A microphone or other acoustic sensor is used to detect sound or other vibrations caused by the passage of pulses of radiation of a projection beam. The measured vibrations may be used to determine the intensity of the projection beam or the presence of contaminants. The vibrations are caused by absorption of the beam pulses in an absorptive gas or by objects, e.g. the substrate or mirrors in the projection lens, on which the projection beam is incident.

Owner:ASML NETHERLANDS BV

Device And Method For Particle Beam Production

ActiveUS20120160996A1Transit-time tubesMagnetic resonance acceleratorsPulse beamParticle accelerator

The present invention relates to a pulsed beam particle accelerator which can be used for particle radiation therapy. More particular, a device and method are provided to control the number of particles within a beam pulse. The particle accelerator comprises means for varying the number of particles within each beam pulse of said pulsed ion beam from a minimum value to a maximum value as function of the value of a beam control parameter. For each particle irradiation the required number of particles for each beam pulse is controlled by defining a value for said beam control parameter based on calibration data.

Owner:ION BEAM APPL

System and process for processing a plurality of semiconductor thin films which are crystallized using sequential lateral solidification techniques

InactiveUS20060134890A1Semiconductor/solid-state device manufacturingThin material handlingBeam sourceIrradiation

A process and system are provided for processing at least one section of each of a plurality of semiconductor film samples. In these process and system, the irradiation beam source is controlled to emit successive irradiation beam pulses at a predetermined predetermined repetition rate. Using such emitted beam pulses, at least one section of one of the semiconductor film samples is irradiated using a first sequential lateral solidification (“SLS”) technique and / or a first uniform small grained material (“UGS”) techniques to process the such sections) of the first sample. Upon the completion of the processing of this section of the first sample, the beam pulses are redirected to impinge at least one section of a second sample of the semiconductor film samples. Then, using the redirected beam pulses, such sections) of the second sample are irradiated using a second SLS technique and / or a second UGS technique to process the at least one section of the second sample. The first and second techniques can be different from one another or substantially the same.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Traveling wave linear accelerator based x-ray source using pulse width to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the width of the beam pulse, i.e., pulse width.

Owner:ACCURAY

Real time laser shock peening quality assurance by natural frequency analysis

InactiveUS6914215B2Efficient and reliable and repeatable qualityInexpensive and accurate and quickAnalysing solids using sonic/ultrasonic/infrasonic wavesBlade accessoriesQuality assuranceAcoustics

A real time method for quality control testing of a laser shock peening process of production workpieces by analysis of natural frequency shifts during the laser shock peening process. One particular embodiment includes laser shock peening surface of the production workpiece by firing a plurality of laser beam pulses on the surface and forming a plurality of corresponding plasmas, each one of the plasmas pulses having a duration in which the plasma causes a region having deep compressive residual stresses to form beneath the surface, measuring at least one natural frequency of the workpiece for each of the laser beam pulses, calculating natural frequency shifts from a baseline natural frequency for the measured natural frequencies for at least a portion of the laser beam pulses, and using the natural frequency shifts for accepting or rejecting the workpiece with respect to pass or fail criteria.

Owner:GENERAL ELECTRIC CO

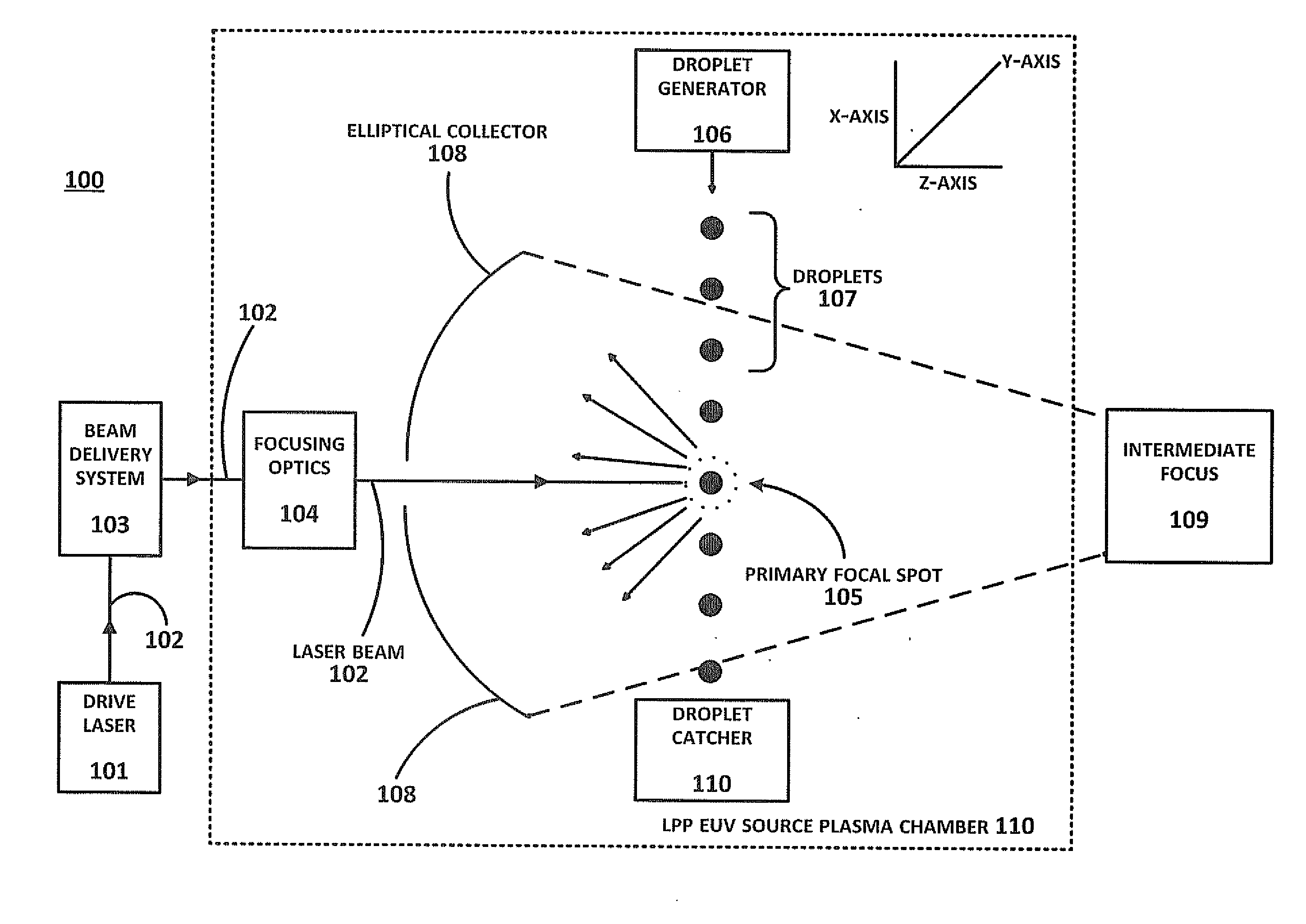

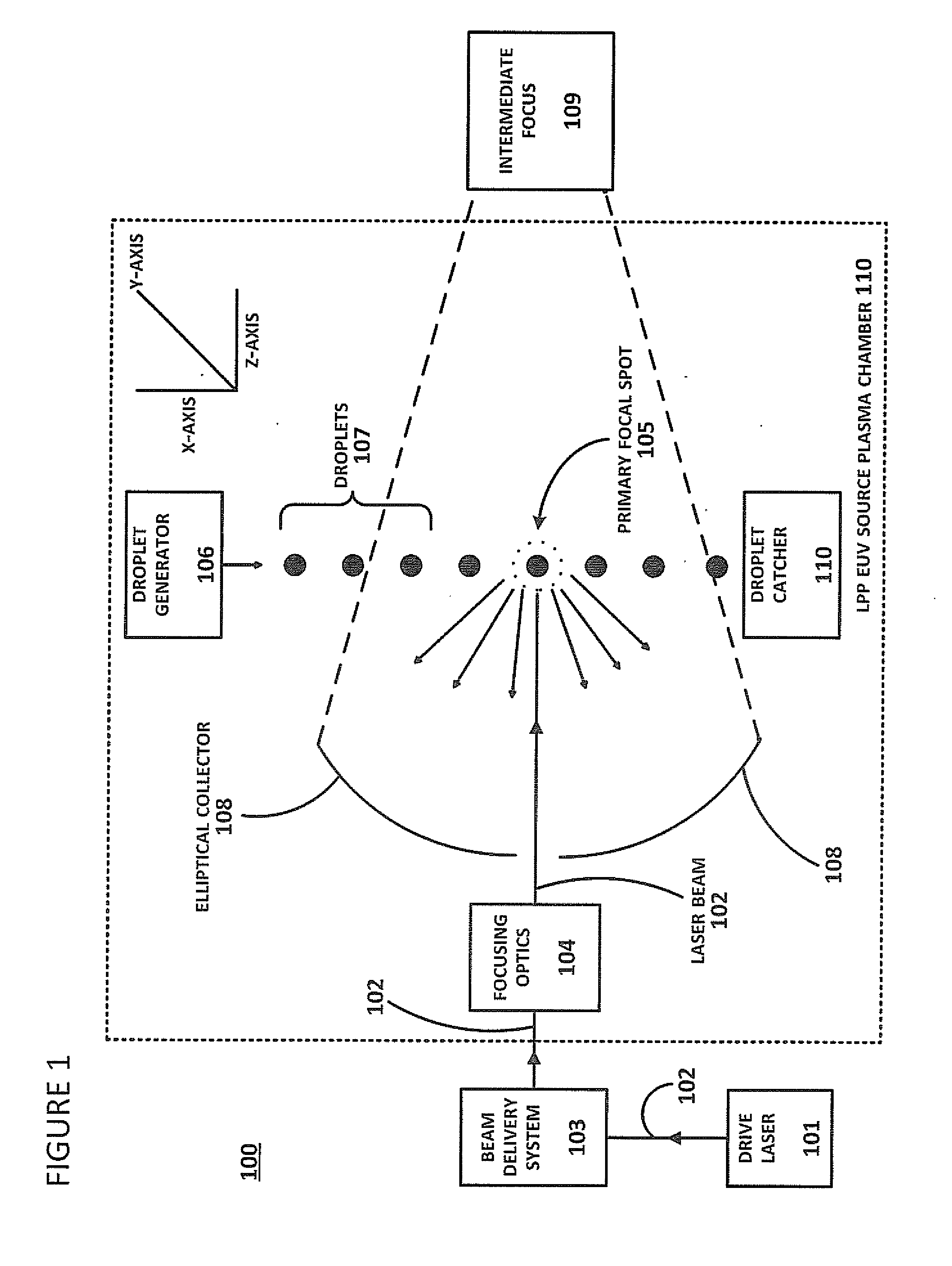

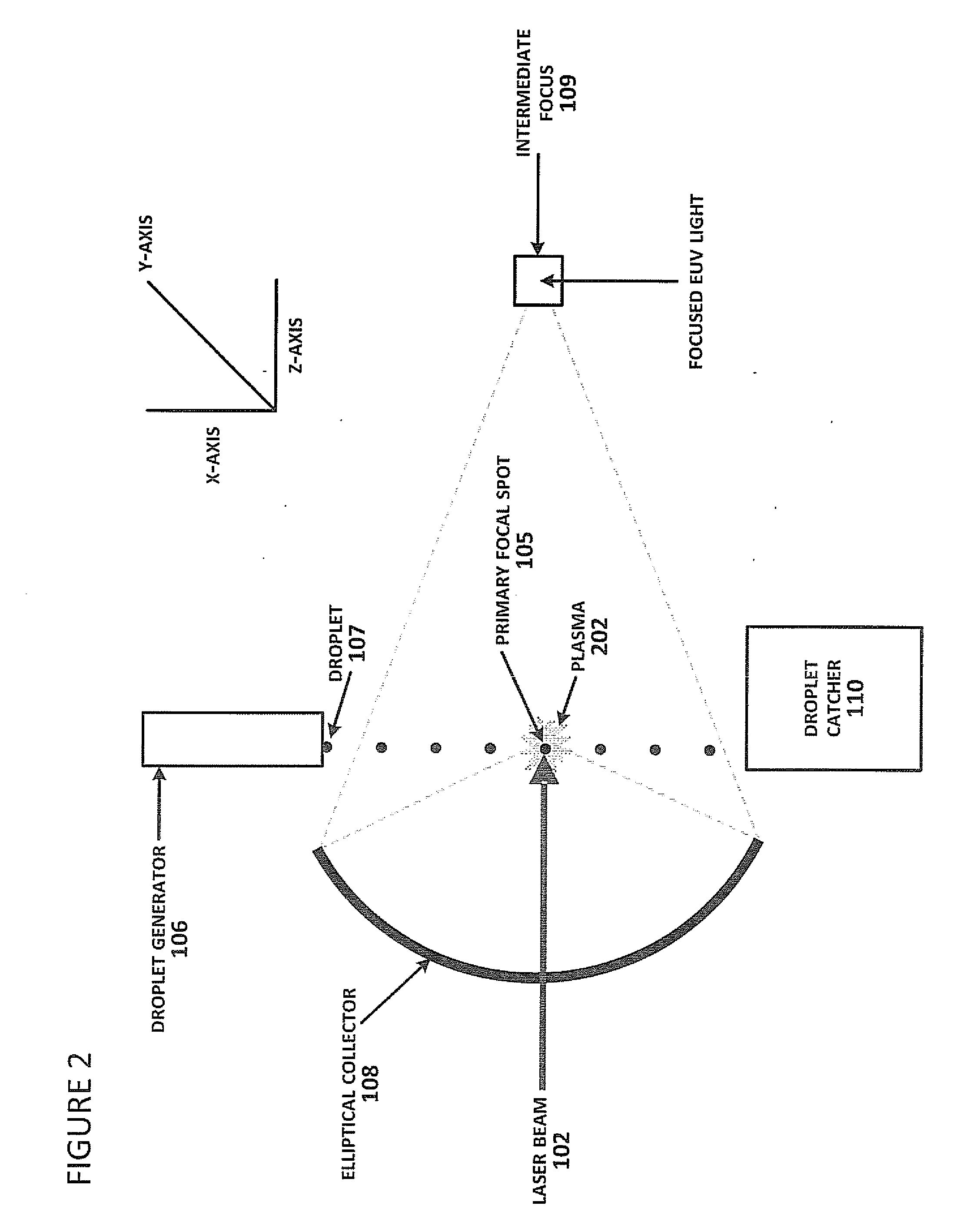

Method of Timing Laser Beam Pulses to Regulate Extreme Ultraviolet Light Dosing

ActiveUS20140191132A1Material analysis by optical meansPhotometry using electric radiation detectorsOptoelectronicsLighting system

Described herein are embodiments of a method to control energy dose output from a laser-produced plasma extreme ultraviolet light system by adjusting timing of fired laser beam pulses. During stroboscopic firing, pulses are timed to lase droplets until a dose target of EUV has been achieved. Once accumulated EUV reaches the dose target, pulses are timed so as to not lase droplets during the remainder of the packet, and thereby prevent additional EUV light generation during those portions of the packet. In a continuous burst mode, pulses are timed to irradiate droplets until accumulated burst error meets or exceeds a threshold burst error. If accumulated burst error meets or exceeds the threshold burst error, a next pulse is timed to not irradiate a next droplet. Thus, the embodiments described herein manipulate pulse timing to obtain a constant desired dose target that can more precisely match downstream dosing requirements.

Owner:ASML NETHERLANDS BV

Device and method for particle beam production

The present invention relates to a pulsed beam particle accelerator which can be used for particle radiation therapy. More particular, a device and method are provided to control the number of particles within a beam pulse. The particle accelerator comprises means for varying the number of particles within each beam pulse of said pulsed ion beam from a minimum value to a maximum value as function of the value of a beam control parameter. For each particle irradiation the required number of particles for each beam pulse is controlled by defining a value for said beam control parameter based on calibration data.

Owner:ION BEAM APPL

Flash ladar system

InactiveUS20060131486A1Simple designReduce manufacturing costOptical rangefindersInvestigating moving sheetsShift registerLight beam

A flash ladar system has a laser provided with beam focusing optics for directing a laser fan beam pulse to a scanning element that in turn directs the laser fan beam to a vertical region of space. Light reflected from an object in the vertical region of space is directed by a reflecting element to a sensor provided with a column of photosensitive pixels that connects to a charge storage matrix of non-photosensitive pixels. After an integration period electrical charges are shifted from the photosensitive region to an adjacent column in the charge storage region. The process of integrate and shift is repeated for multiple integration periods until the charge storage region is filled with charges whereupon a serial shift register removes the information to be processed by a data processor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

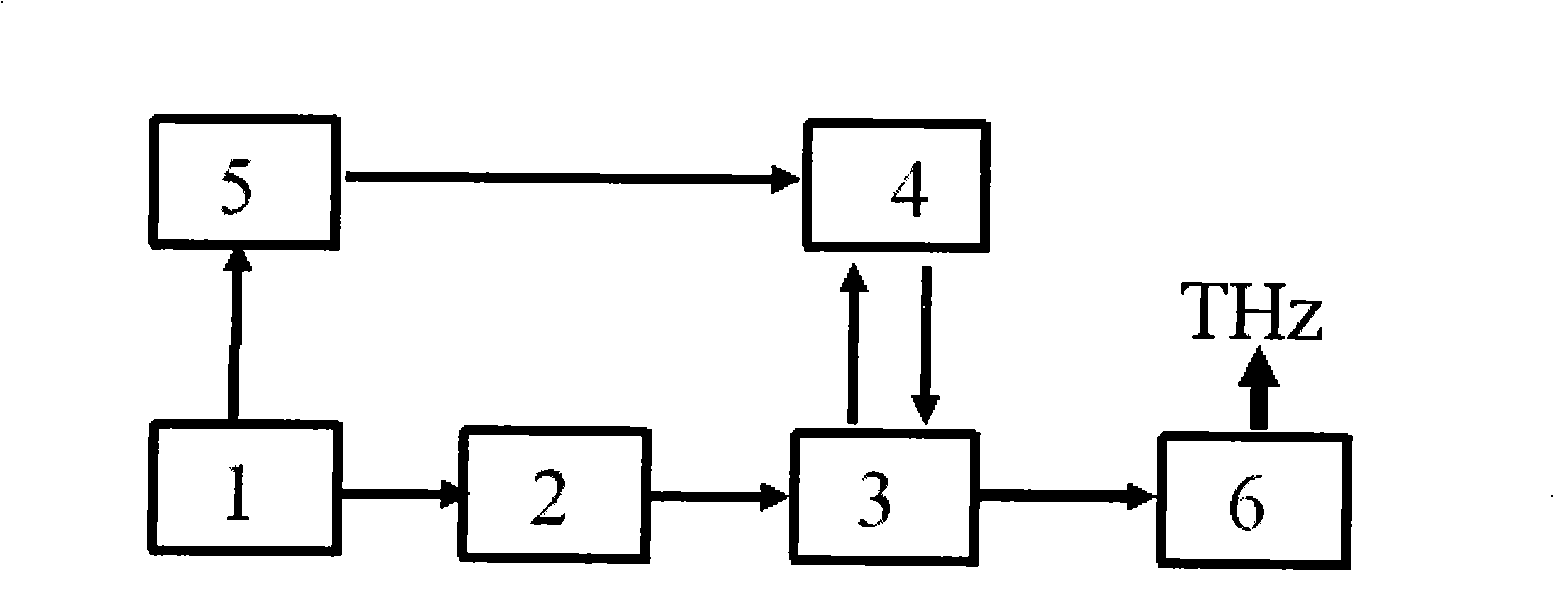

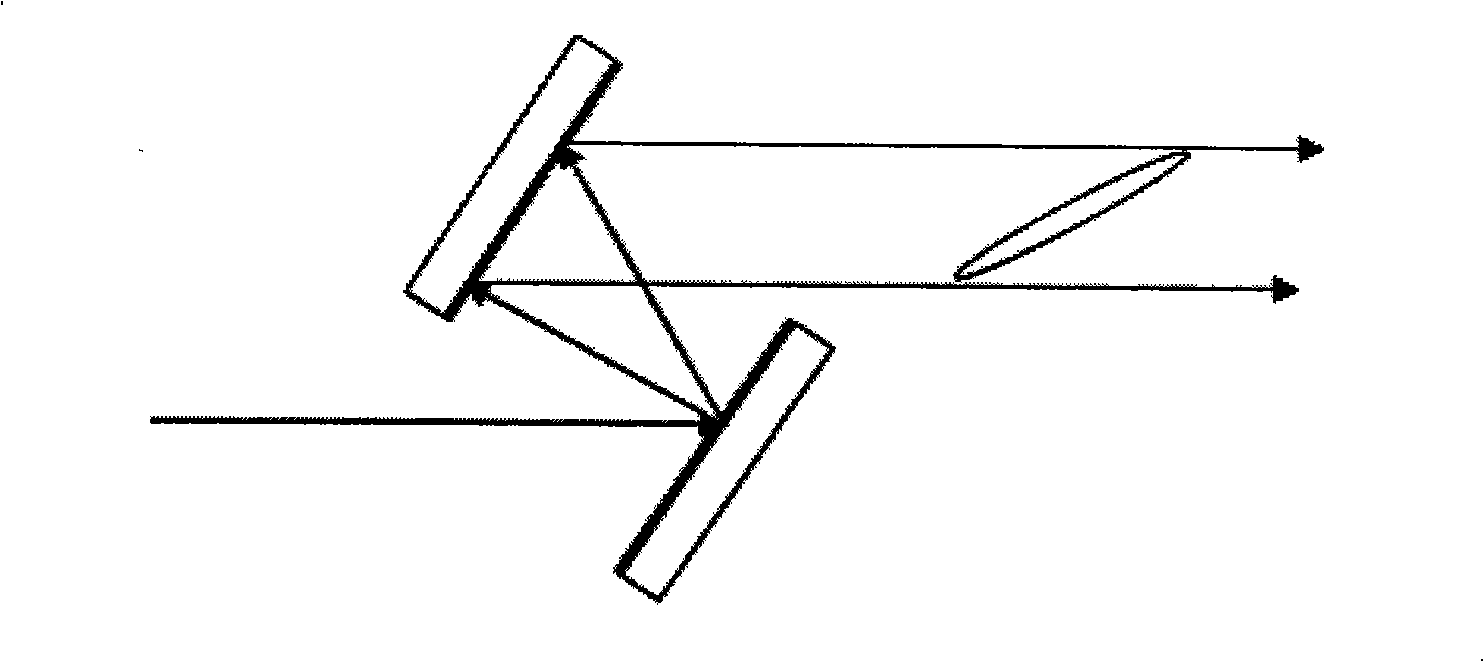

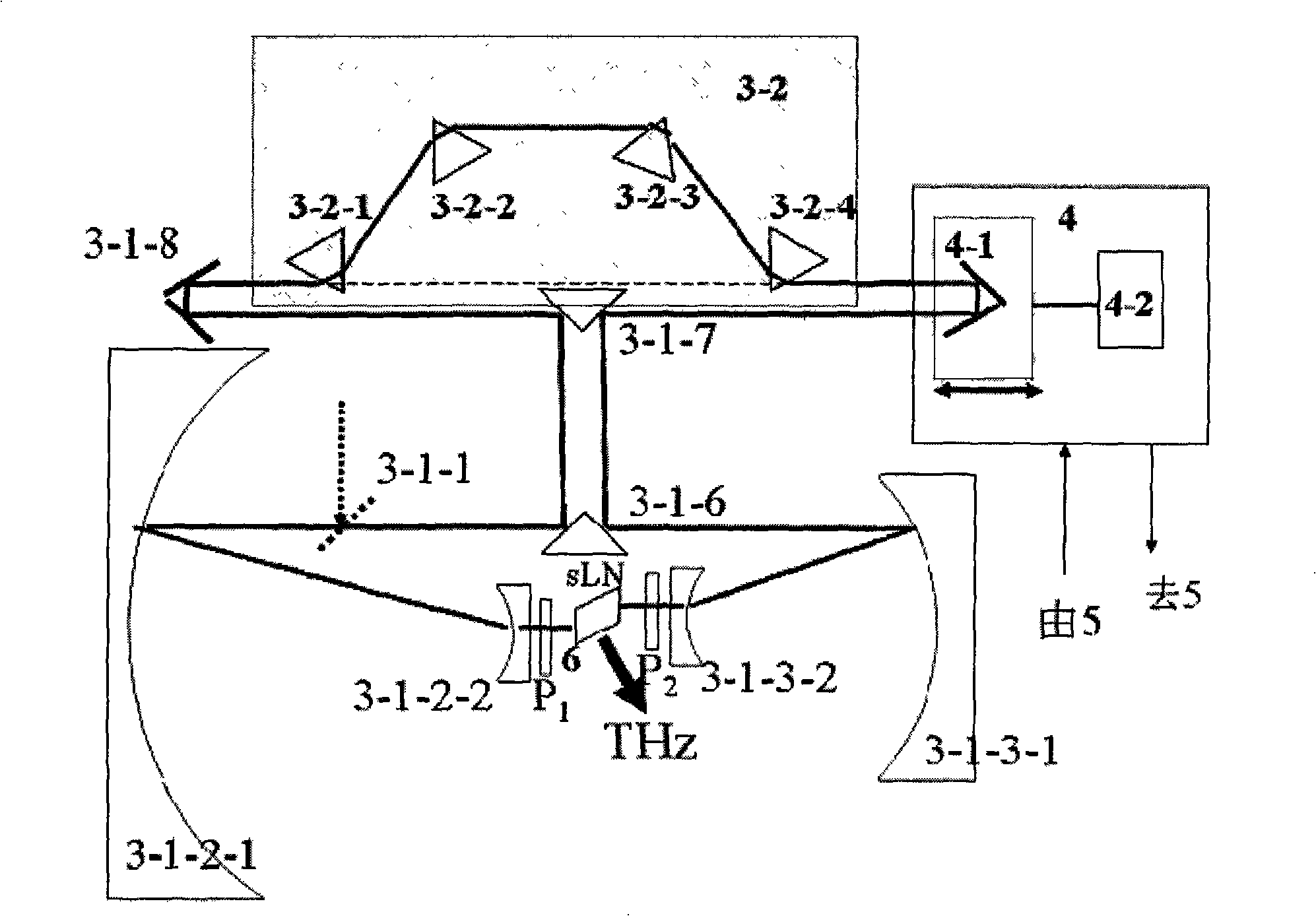

Pumping optical multiplexing high-efficiency generating high power THz radiation pulse source

InactiveCN101408708AIncrease profitHigh power operationLaser detailsTelescopesGratingTerahertz radiation

The invention discloses a high-power terahertz radiation pulse source which is efficiently generated by the multiplexing of pump light. The high-power terahertz radiation pulse source which is efficiently generated by the multiplexing of pump light comprises a photonic crystal fiber femtosecond laser amplifier, a beam pulse wave surface tiltometer and a dual-purpose dispersion compensator, a multiplexing cavity length matching control system, a pump light multiplexing cavity, a multiplexing cavity length adjustor and a terahertz radiation pulse emitter. The invention has the advantages that the photonic crystal fiber femtosecond laser amplifier is adopted; by using a multipass cavity structure and a grating for dispersion compensation and a beam pulse wave surface tilt method, the pump light utilization rate is improved; the theory limit that the efficiency of the pump light converted into THz radiation is extremely low is overcome, and the high-power running is realized; in addition, the invention has simple whole structure, good stability and low running cost.

Owner:TIANJIN UNIV

Sub-Nanosecond Beam Pulse Radio Frequency Quadrupole (RFQ) Linear Accelerator System

Sub-nanosecond single ion beam pulses are generated by means of one embodiment of the invention. In this embodiment, an ion source provides ions to a radio frequency quadrupole linear accelerator comprising electrodes. A power source is used to apply radio frequency alternating currents to the electrodes. A device is used to inject ions from the ion source to the accelerator, causing the accelerator to provide only a single sub-nanosecond output beam pulse at a time.

Owner:COMPACT PARTICLE ACCELERATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com