Adsorbents for Radioisotopes, Preparation Method Thereof, and Radioisotope Generators Using the Same

a radioisotope and radioisotope technology, applied in the direction of filtration separation, alkali metal sulfites/sulfates, separation processes, etc., can solve the problems of increasing the cost of production, reducing the yield, and increasing the difficulty of production of high-quality radioactive zirconium molybdate gel on a commercial scale through so many steps, etc., to achieve excellent physical stability, stable physical properties, and high adsorption performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

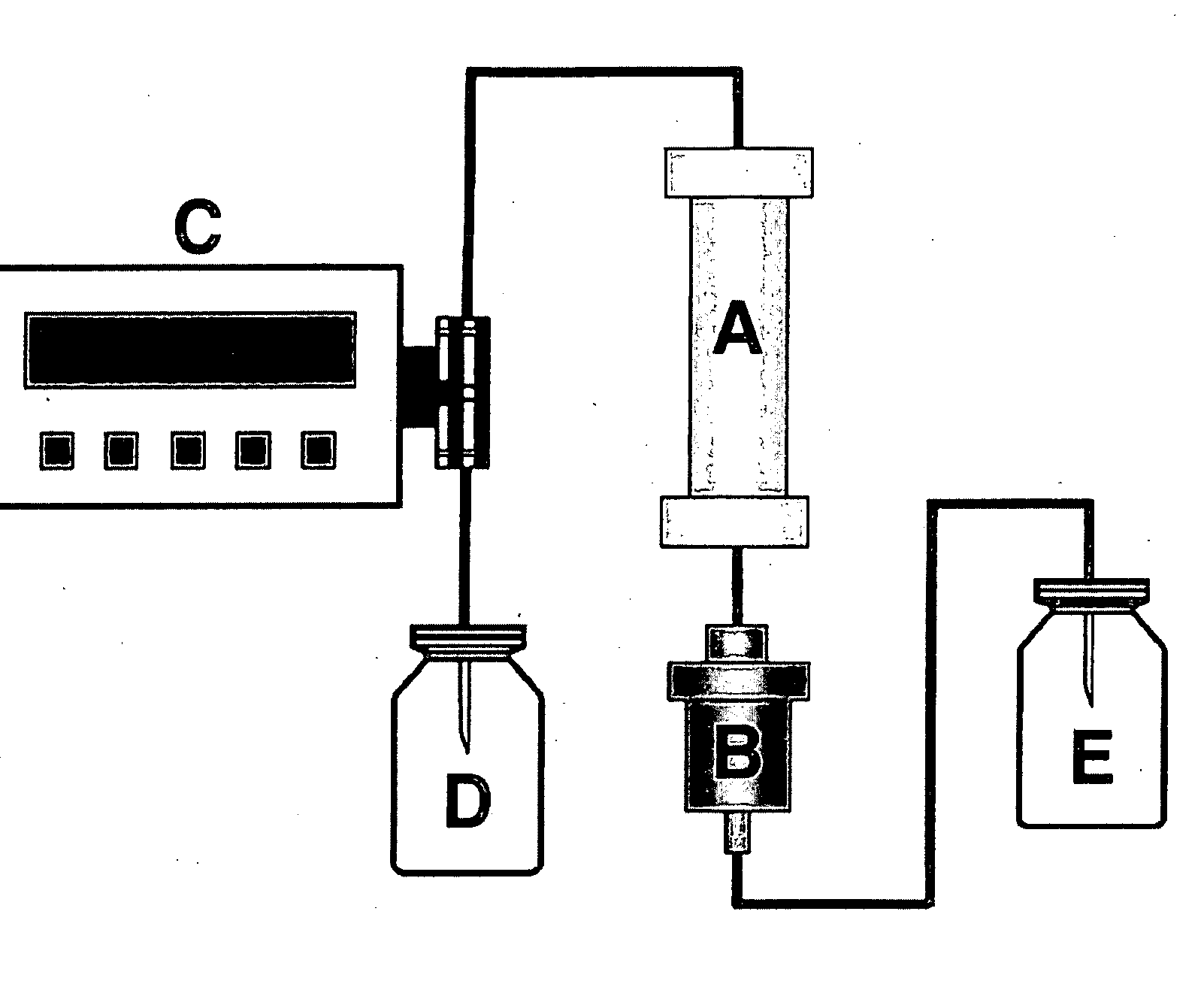

Method used

Image

Examples

example 1

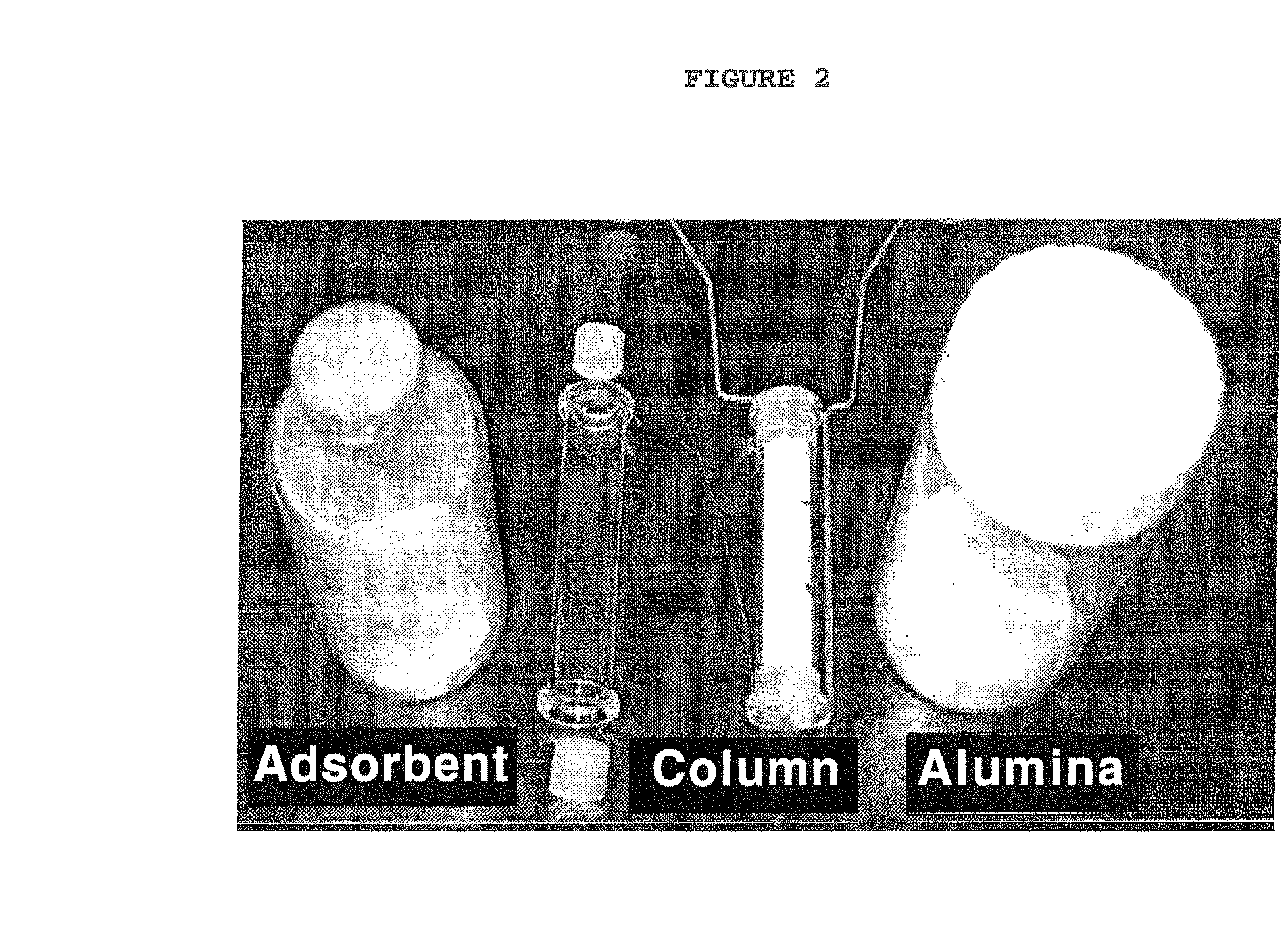

Preparation of Sulfated Alumina 1

[0062]In a vessel, 7.64 of ASB was dissolved in 15 of octanol, slowly added with 0.58 of anhydrous sulfuric acid with stirring for 10 min, and was then reacted for 2 hours. The solution thus obtained was slowly added with a solution comprising 0.65 of 0.14 M hydrochloric acid and 1.94 of ethanol, allowed to stand at room temperature for 24 hours, washed with acetone and ethanol in turn, and dried at 90° C. for 24 hours, thus obtaining a ceramic material composed of milk-white or light brown particles. The material thus obtained was dried, powdered using a mortar and pestle, boiled along with acetone, dried at 80° C. for 24 hours, and then stored in a sealed state.

example 2

Preparation of Sulfated Alumina 2

[0063]In a vessel, 7.64 of ASB was dissolved in a mixture comprising 5 of ethanol and 10 of octanol, slowly added with 0.58 of anhydrous sulfuric acid with stirring for 10 min, and then reacted for 20 min. In another vessel, 0.65 of 0.14 M hydrochloric acid was added to 1.94 of ethanol and then stirred. Thereafter, the reacted ASB solution was slowly added with the solution comprising hydrochloric acid and ethanol, allowed to stand at room temperature for 24 hours, and then dried at 90° C. for 24 hours, thus obtaining a ceramic material composed of milk-white or light brown particles. The material thus obtained was powdered using a mortar and pestle, washed with acetone and ethanol in turn, dried at 90° C. for 24 hours, and then stored in a sealed state.

example 3

Preparation of Sulfated Alumina 3

[0064]In a vessel, 7.94 of ASB was dissolved in 4.5 of isobutanol, slowly added with 4.5 of ethanol with stirring for 10 min, slowly added with 0.58 of anhydrous sulfuric acid with stirring for 1 hour, and then reacted for 1 hour. In another vessel, 0.54 of 0.14 M hydrochloric acid was added to 1.62 of ethanol and then stirred. Thereafter, the reacted ASB solution was slowly added with the solution comprising hydrochloric acid and ethanol, allowed to stand at room temperature for 24 hours, and dried under conditions of 80° C. for 24 hours, 130° C. for 24 hours, and 150° C. for 24 hours, thus obtaining a ceramic material composed of milk-white or light brown particles. The material thus obtained was powdered using a mortar and pestle, washed with acetone, boiled with acetone, dried at 80° C. for 24 hours, and then stored in a sealed state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| half life | aaaaa | aaaaa |

| half life | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com