Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Chrome alum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

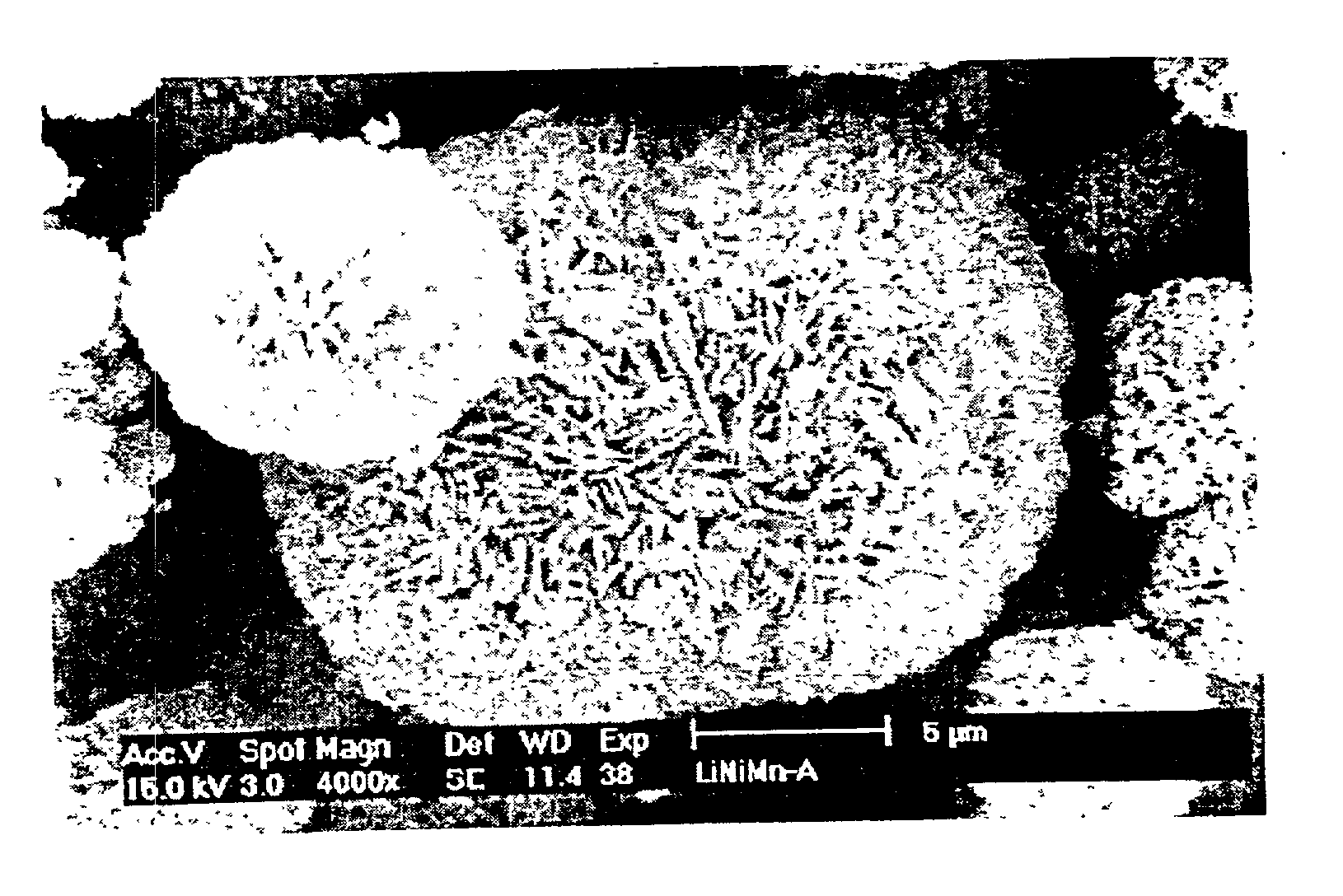

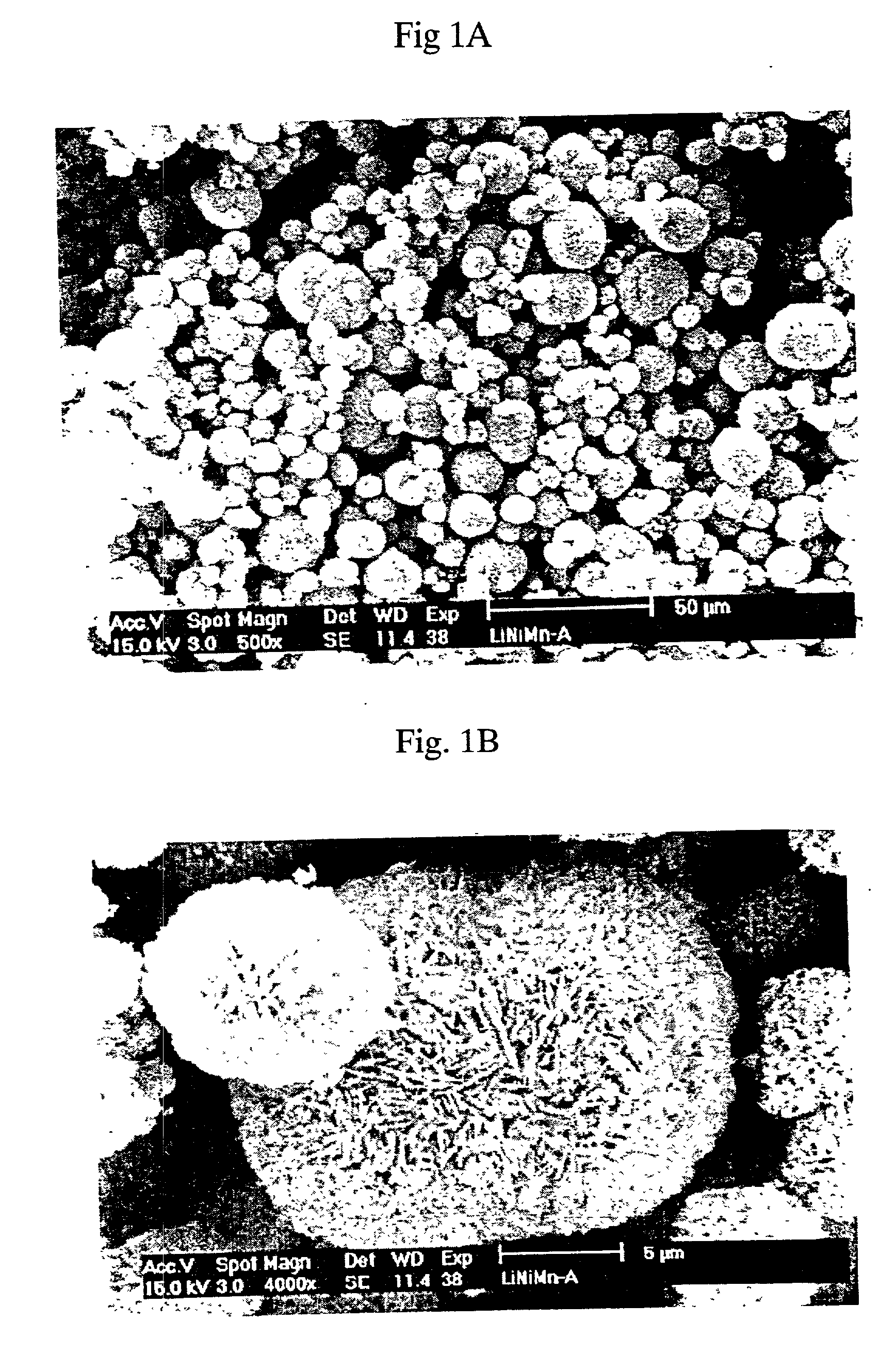

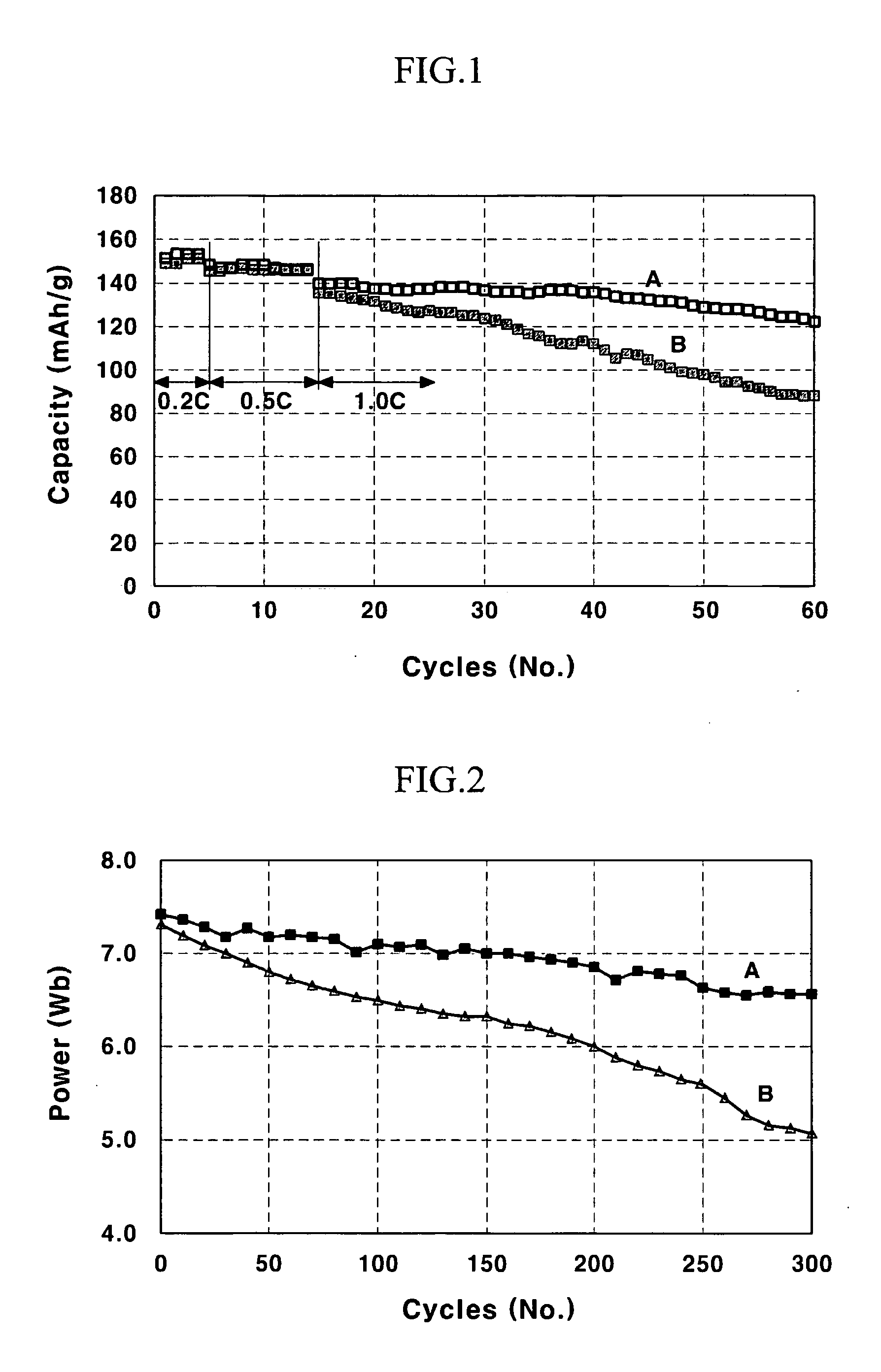

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS20020055042A1Improve thermal stabilityElectrode manufacturing processesZirconium compoundsPhysical chemistryLithium battery

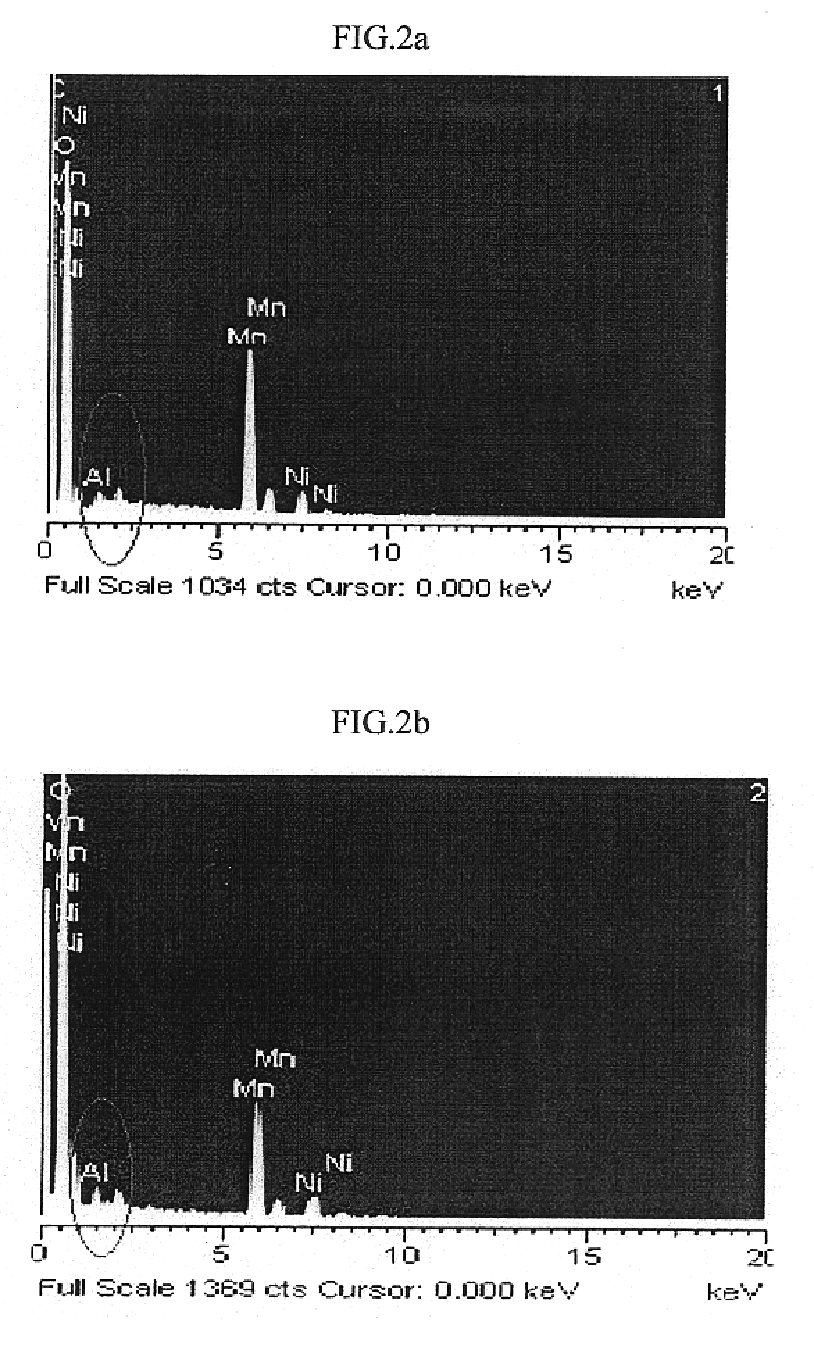

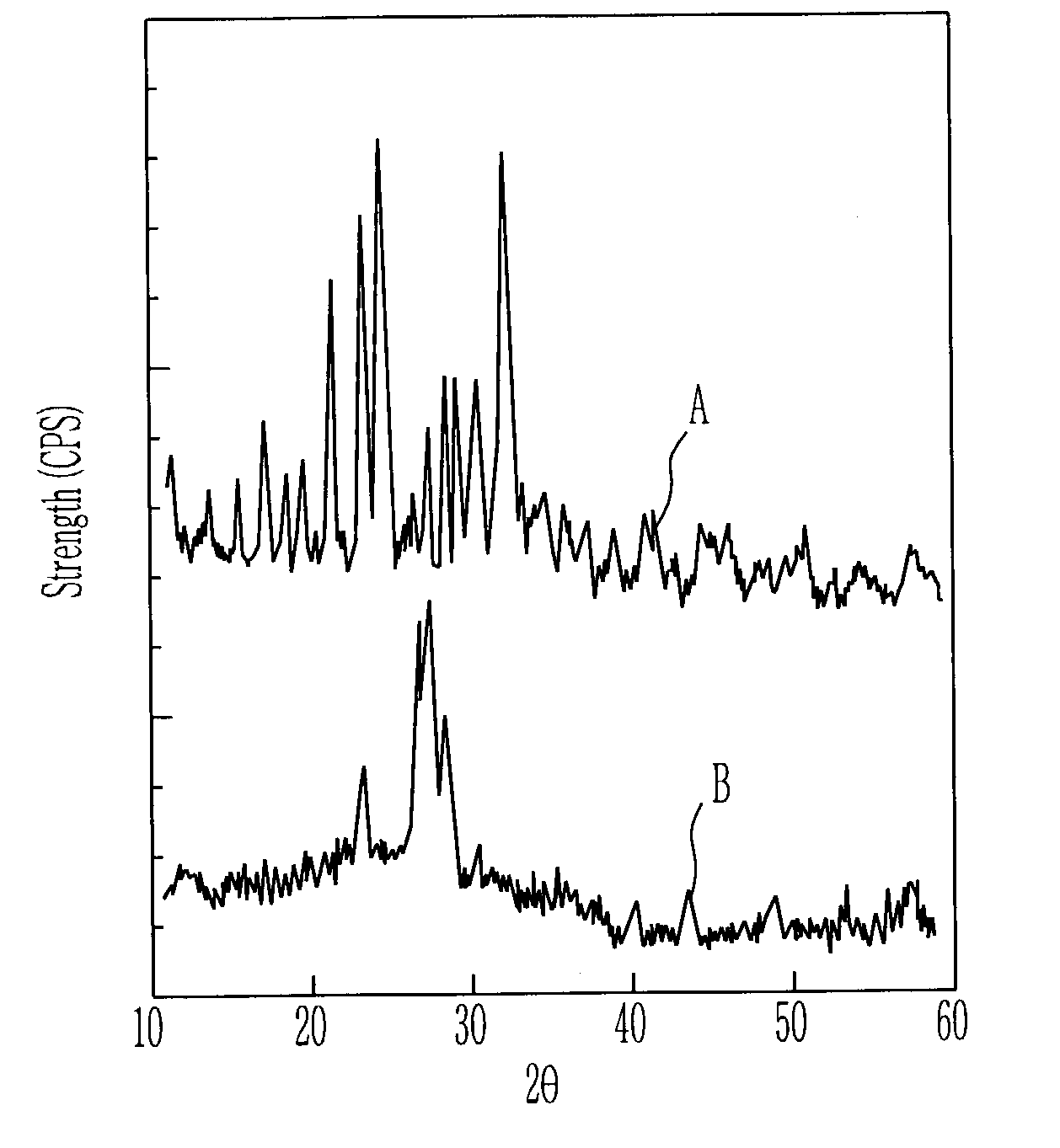

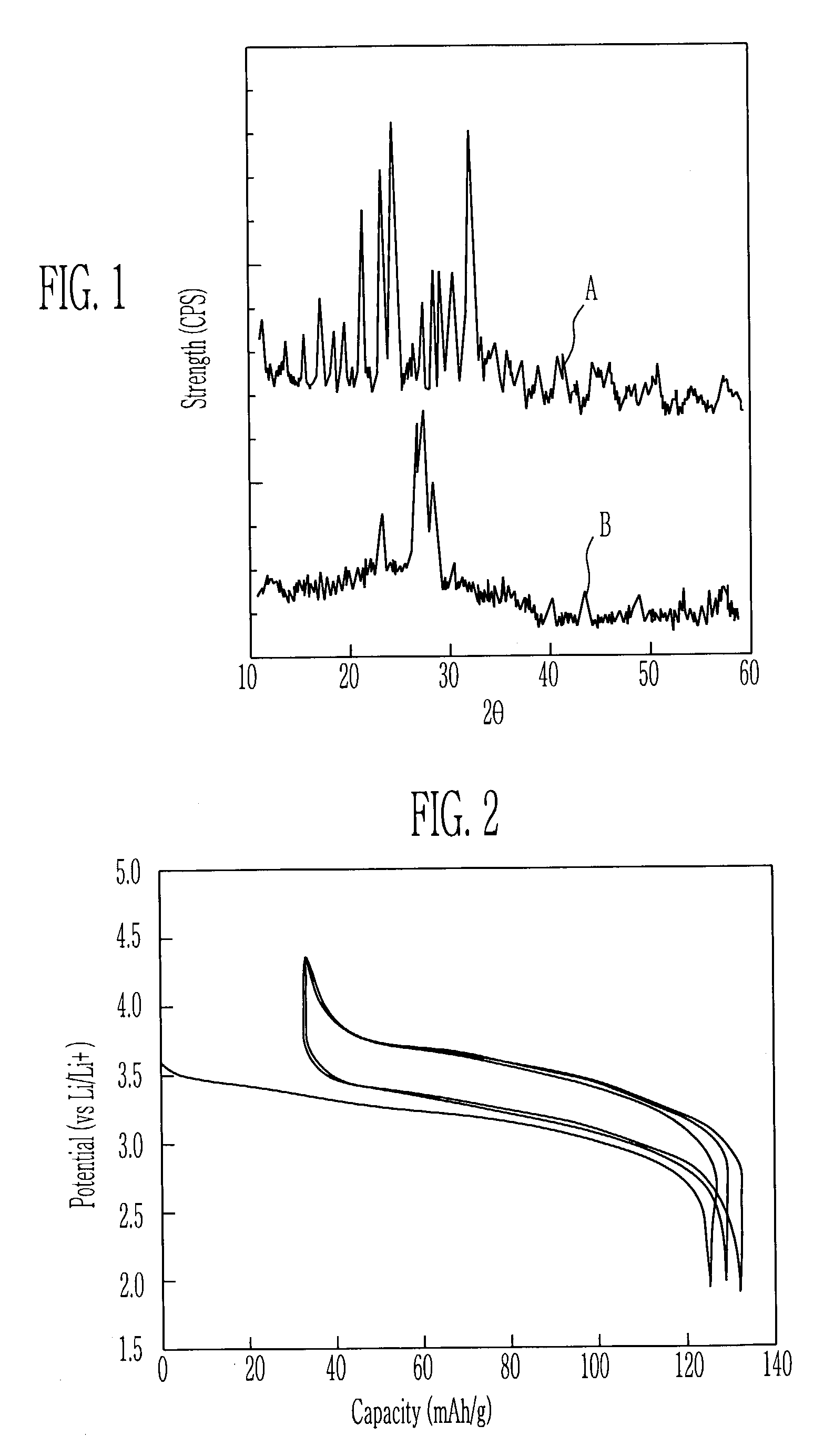

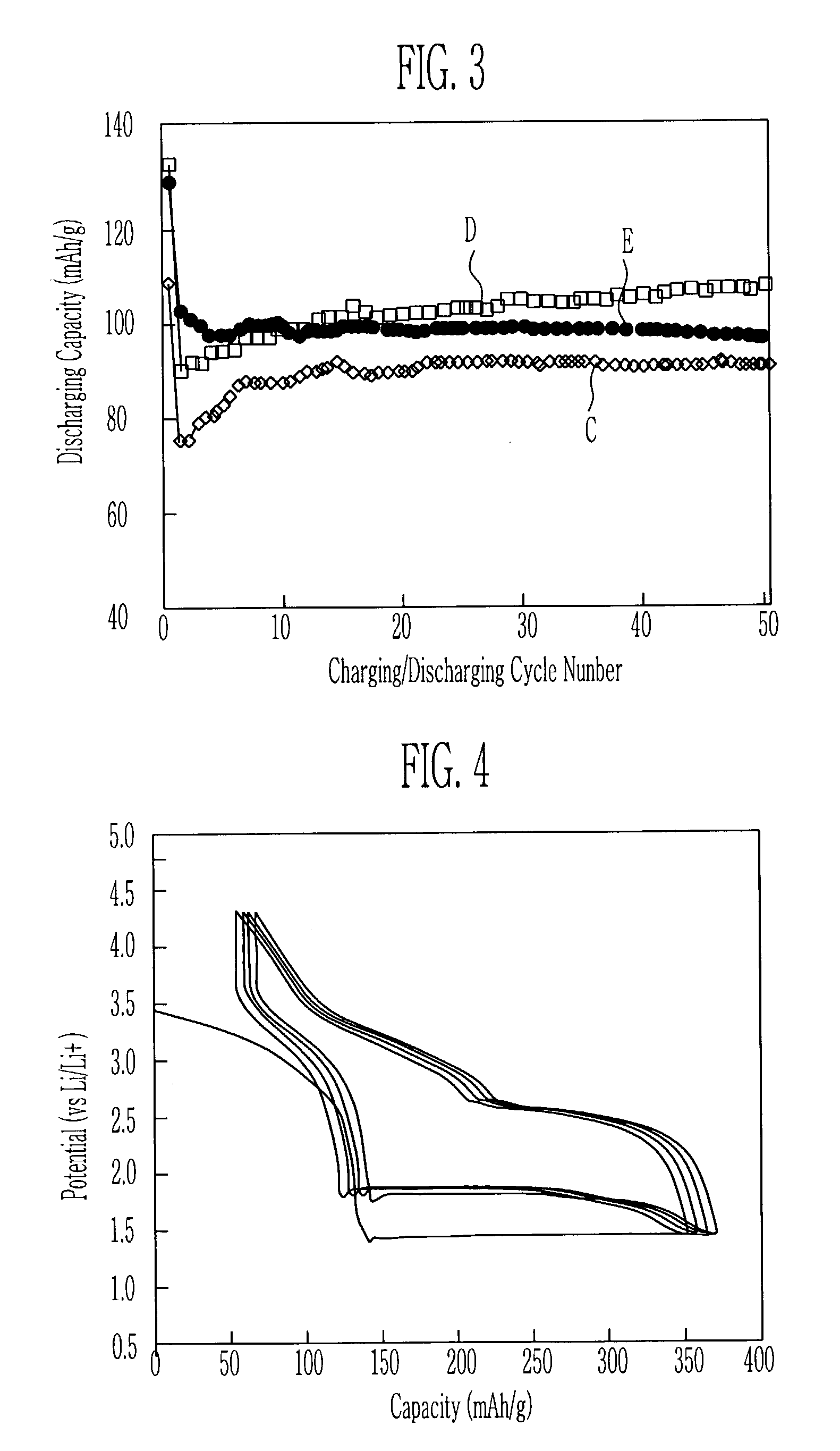

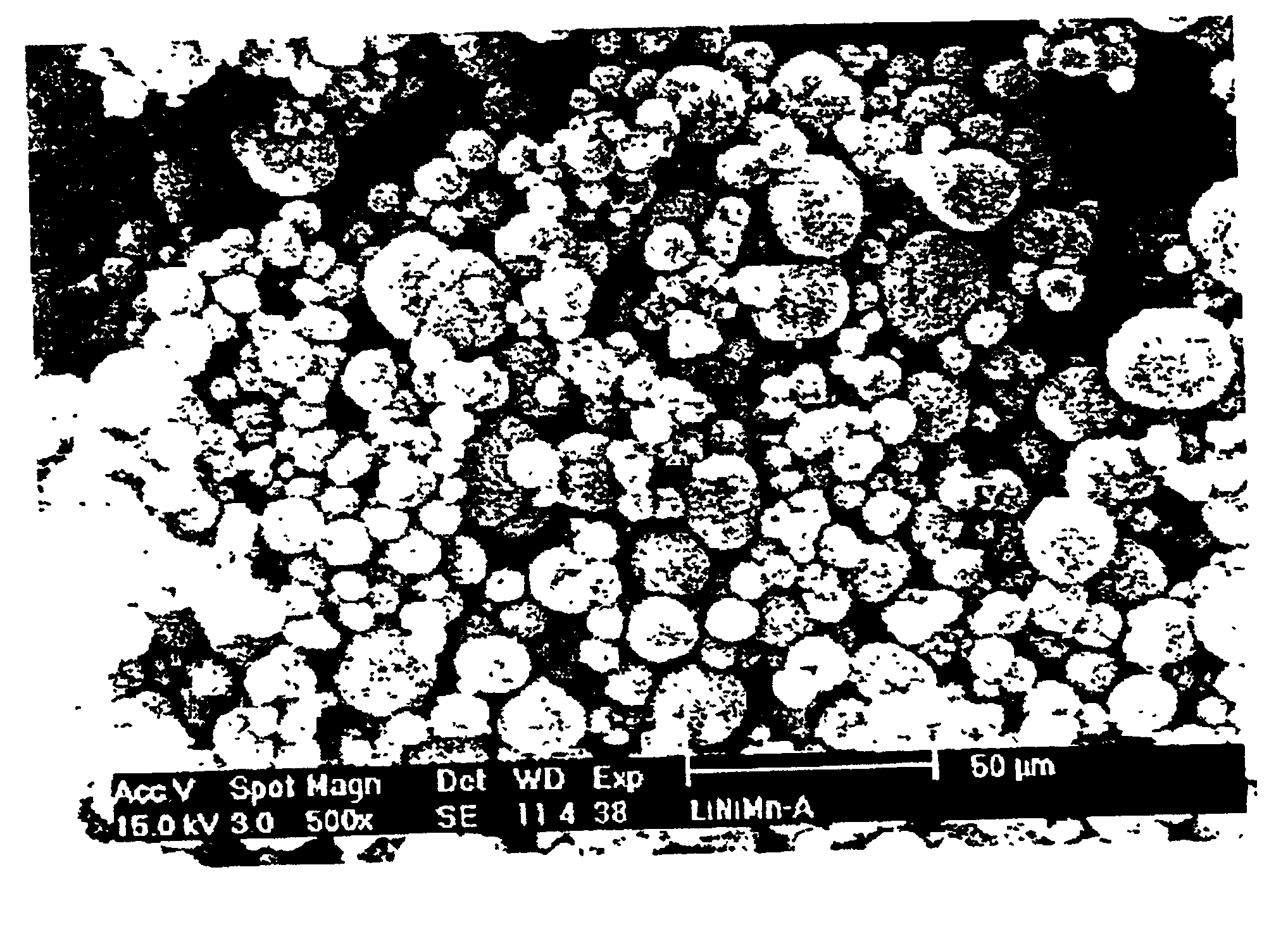

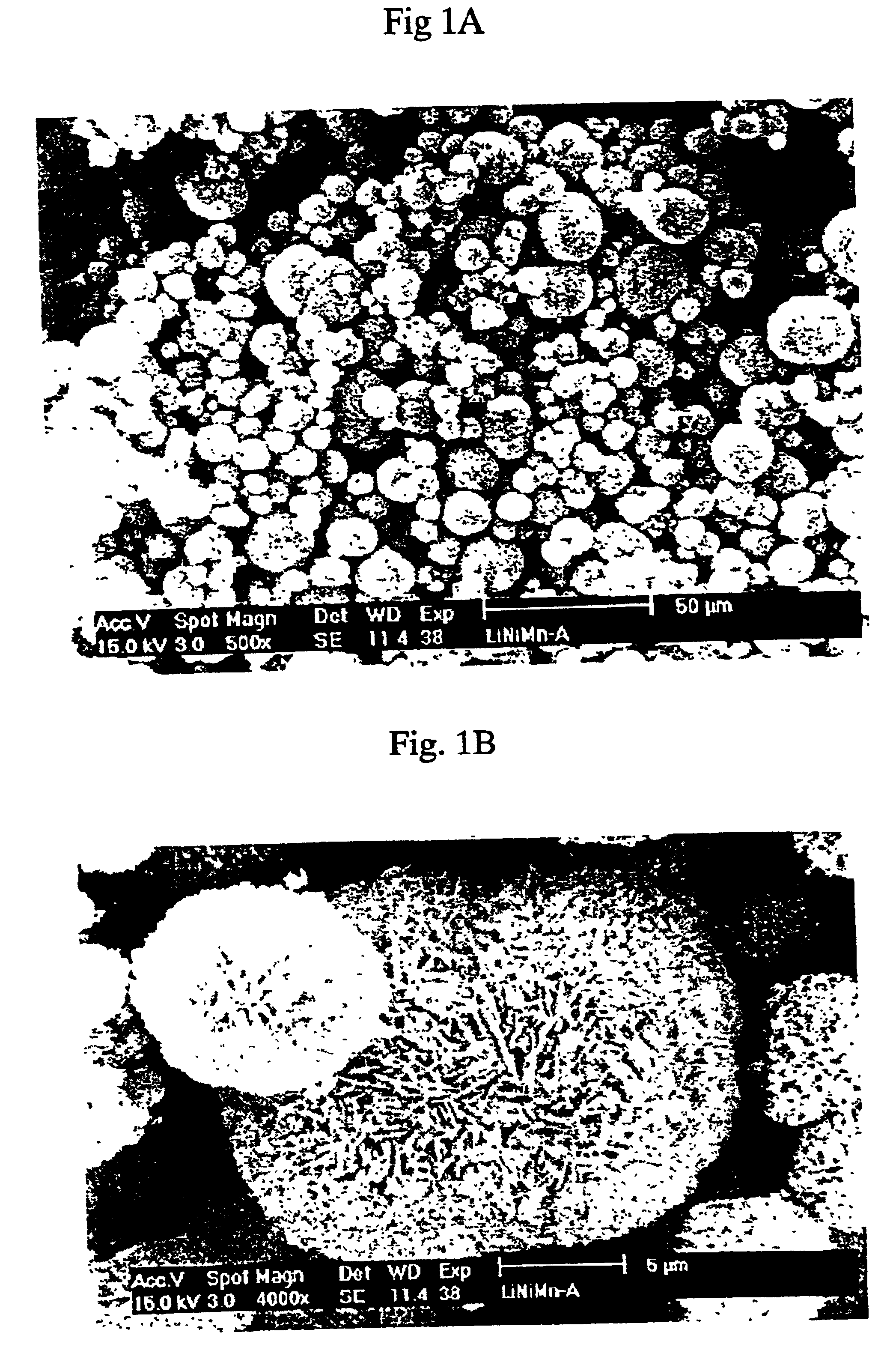

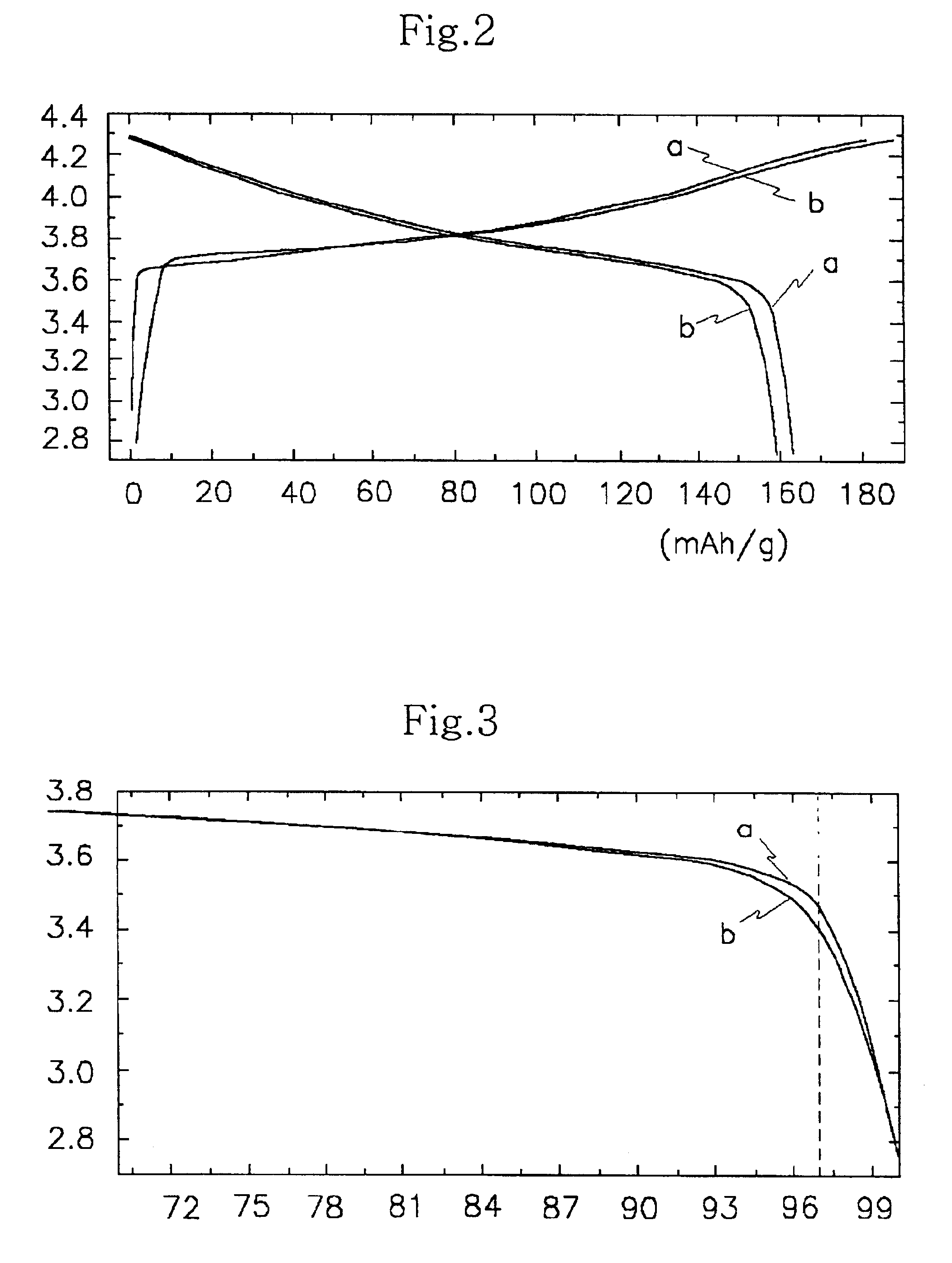

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 andl a metal oxide or composite metal oxide layer formed on the compound. <table-cwu id="TABLE-US-00001"> <number>1< / number> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="OFFSET" colwidth="42PT" align="left" / > <colspec colname="1" colwidth="77PT" align="left" / > <colspec colname="2" colwidth="98PT" align="center" / > <row> <entry>< / entry> <entry>< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyF2< / entry> <entry>(1)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyS2< / entry> <entry>(2)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aFa< / entry> <entry>(3)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aSa< / entry> <entry>(4)< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> < / tgroup> < / table-cwu> (where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, IPu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<=y<=0.99, 0<=,z<=0.5, and 0<=a<=0.5)

Owner:SAMSUNG SDI CO LTD

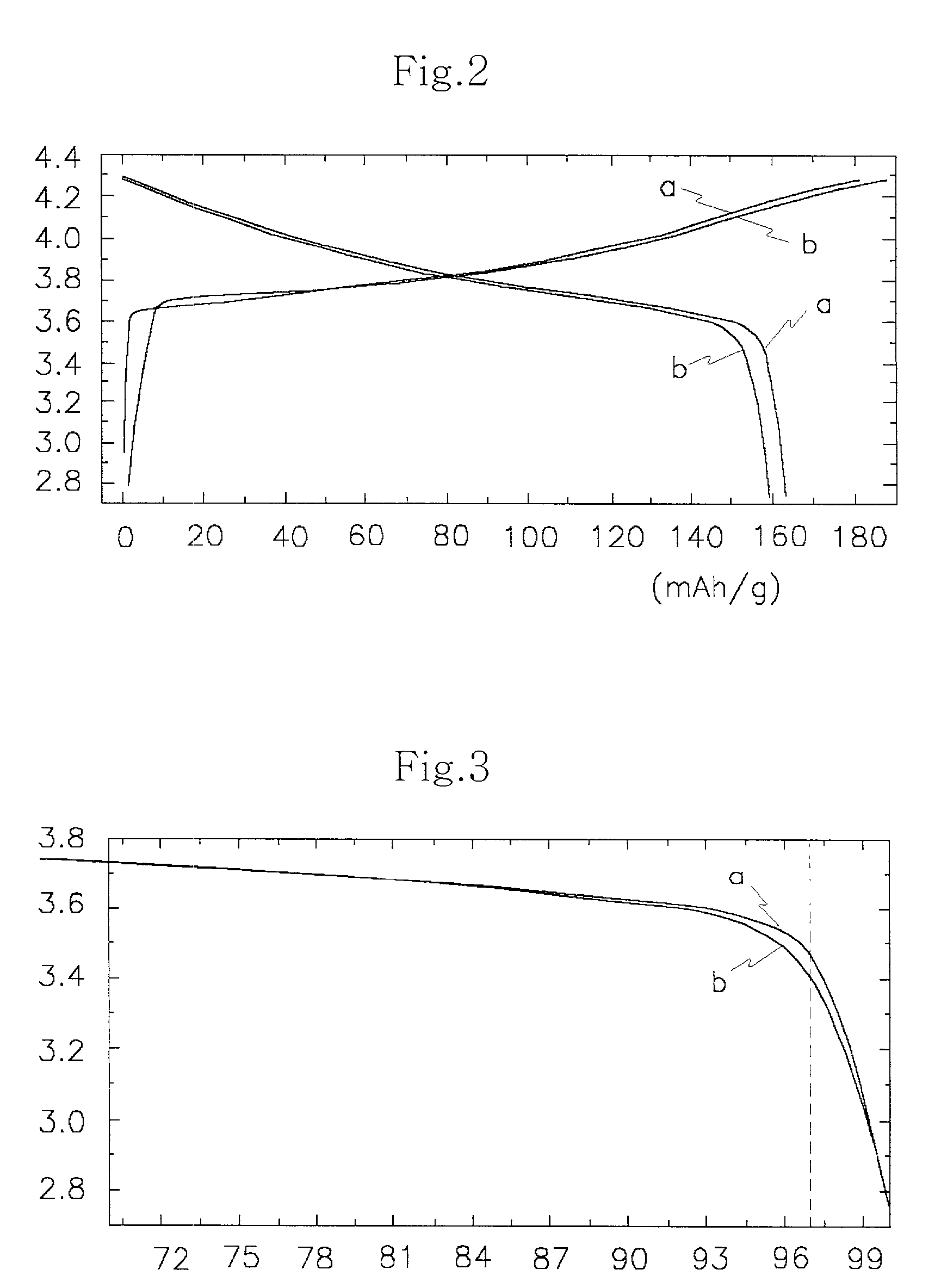

Method of preparing positive active material for rechargeable lithium batteries

InactiveUS6949233B2Improved cycle life characteristicsHigh discharge rateElectrode manufacturing processesPhosphatesPhysical chemistryHeat treated

Owner:SAMSUNG SDI CO LTD

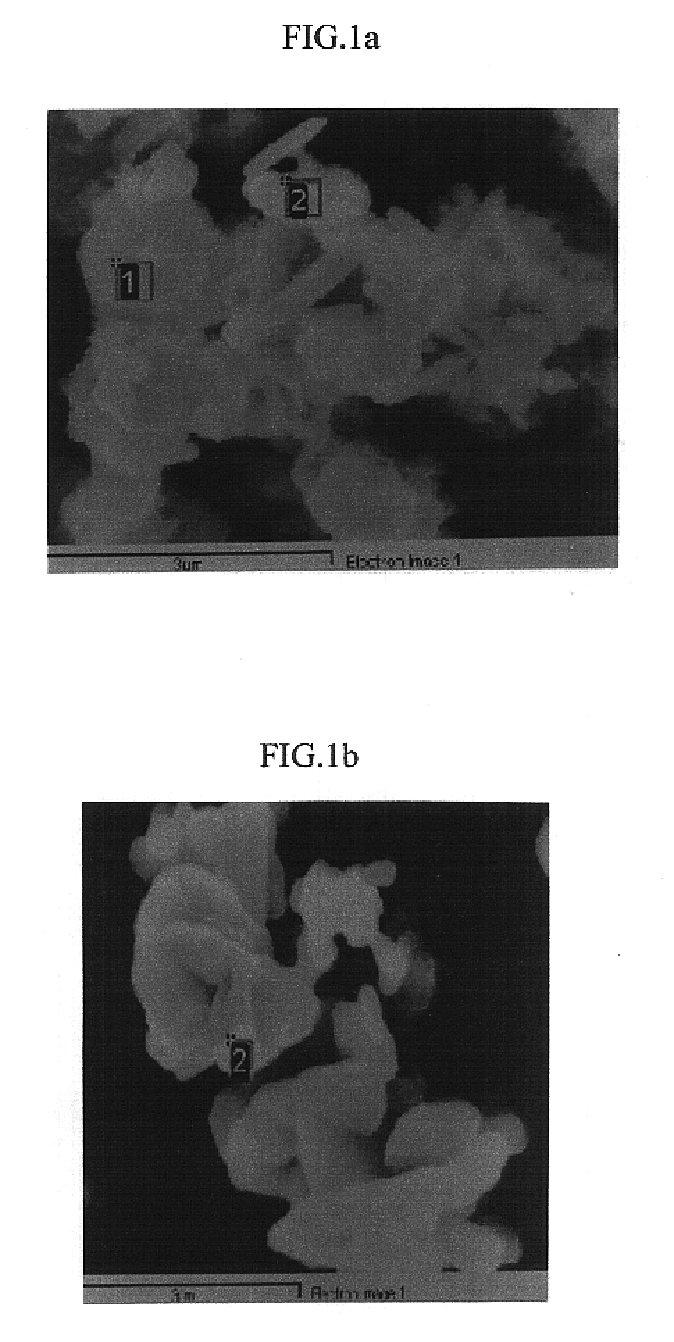

Cathode active material for lithium secondary cell and method for manufacturing the same

ActiveUS6986968B2Good electrochemical propertiesEasy to getPhosphatesSulfur compoundsChemical treatmentLithium

A cathode active material for a lithium secondary cell used in a cellular phone is disclosed. The cathode active material for the lithium secondary cell and the method the same having a high capacity and a long lifetime, different from LiCoO2 and LiMn2O4, Li(Ni, Co)O2, and V-system oxide that has been researched as the active material for substituting LiCoO2 are provided. The cathode active material for the lithium secondary cell in the next formula 1 is obtained by heating or chemically treating diadochite [Fe2(PO4)(SO4)(OH).6H2O] that is the mineral containing PO43−, SO42−, and OH−.LiaFebMc(PO4)x(SO4)y(OH)z (1)In the formula, M is at least one element selected from a radical consisting of Mg, Ti, Cr, Mn, Co, Ni, Cu, Zn, Al, and Si, with 0≦a, c≦0.5, 1≦b≦2, 0.5≦x, y, z≦1.5.

Owner:ELECTRONICS & TELECOMM RES INST

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS6737195B2Improve thermal stabilityElectrode manufacturing processesZirconium compoundsMaterials scienceMetal

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 and a metal oxide or composite metal oxide layer formed on the compound.(where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, Pu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<y<=0.99, 0<=z<=0.5, and 0<=A≤0.5).

Owner:SAMSUNG SDI CO LTD

Alkali/Transition Metal Halo-And Hydroxy-Phosphates And Related Electrode Active Materials

InactiveUS20100276632A1Increase capacityImprove cycle performancePhosphatesFluoride preparationHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(SO4)2Zd.

Owner:VALENCE TECH INC

Alkali/Transition Metal Halo-And Hydroxy-Phosphates And Related Electrode Active Materials

InactiveUS20070190425A1Increase capacityImprove cycle performancePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(XY4)2Zd.

Owner:BARKER JEREMY +2

Alkali-iron-cobalt phosphates and related electrode active materials

InactiveUS7422823B2Increase capacityImprove cycle performancePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesLithiumPhosphate

Owner:VALENCE TECH INC

Alkali-transition metal phosphates having a +3 valence non-transition element and related electrode active materials

ActiveUS7482097B2Increase capacityImprove cycle performancePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesLithiumPhosphate

This invention relates to electrode active materials, electrodes, and batteries. In particular, this invention relates to active materials comprising lithium or other alkali metals, transition metals, +3 oxidation state non-transition elements, and phosphates or similar moieties.

Owner:RIL USA INC +1

Aluminium polychlorosulphates, process for their preparation and use thereof

Aluminum polychlorosulphates having the general formula (I)whereM represents an alkali metall, m, n, p represent the number of moles per mole of aluminum, so that1.74<=l<=2.25,0.01<=n<=0.17,0.32<=p<=1.49, andl+m+2n=p+3,their use as coagulation and flocculation agents, and their preparation process by reaction, at room temperature, of an alkali metal basic compound, such as Na2CO3, NaHCO3, NaOH, K2CO3, KHCO3 and KOH, and an alkali metal sulphate or sulphuric acid with an aluminum polychloride or polychlorosulphate having the general formula(I')where1.1<=1'<=1.44,n'<=0.10,p'<p(p of formula (I)), andl'+m'+2n'=p'+3.

Owner:POZZOLI BERNARDO

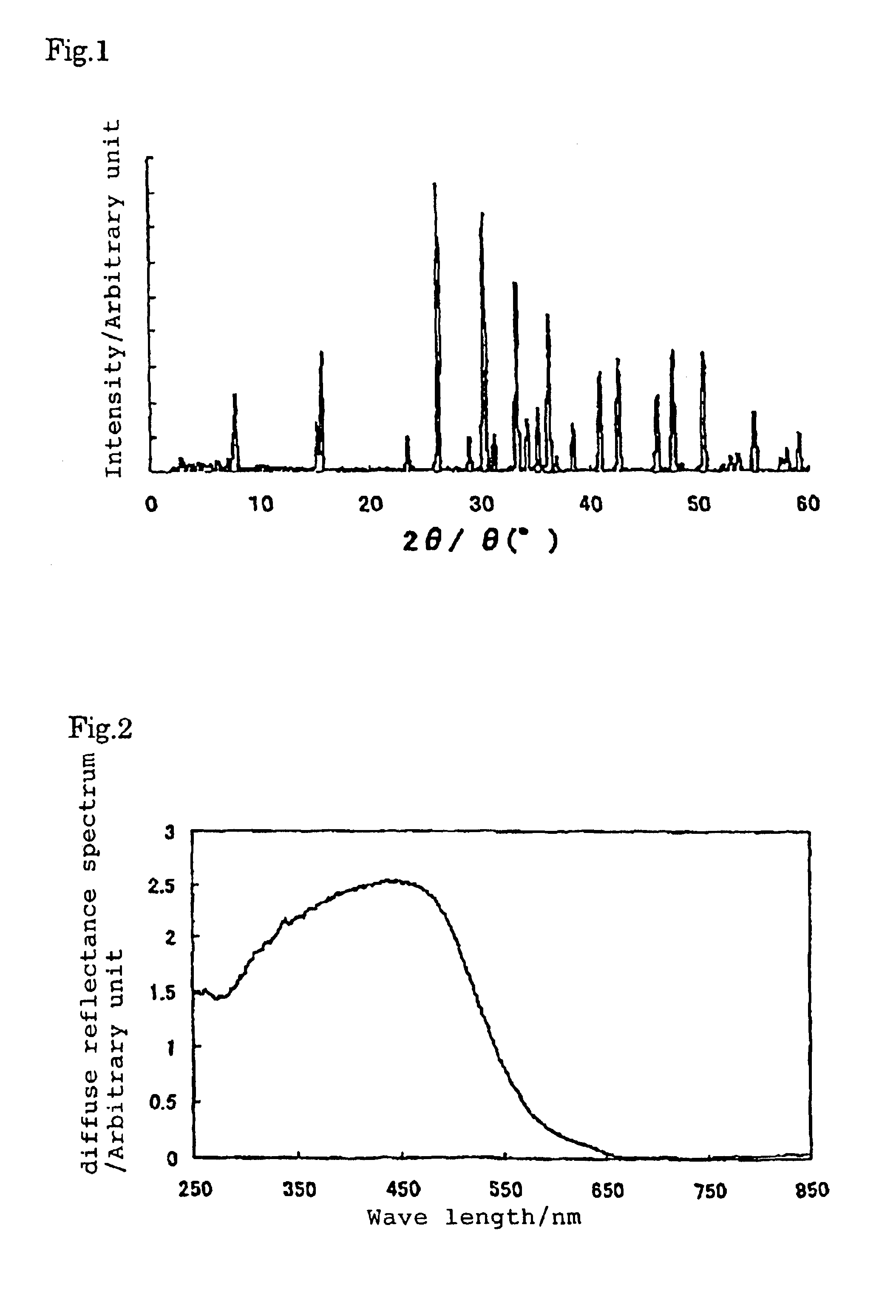

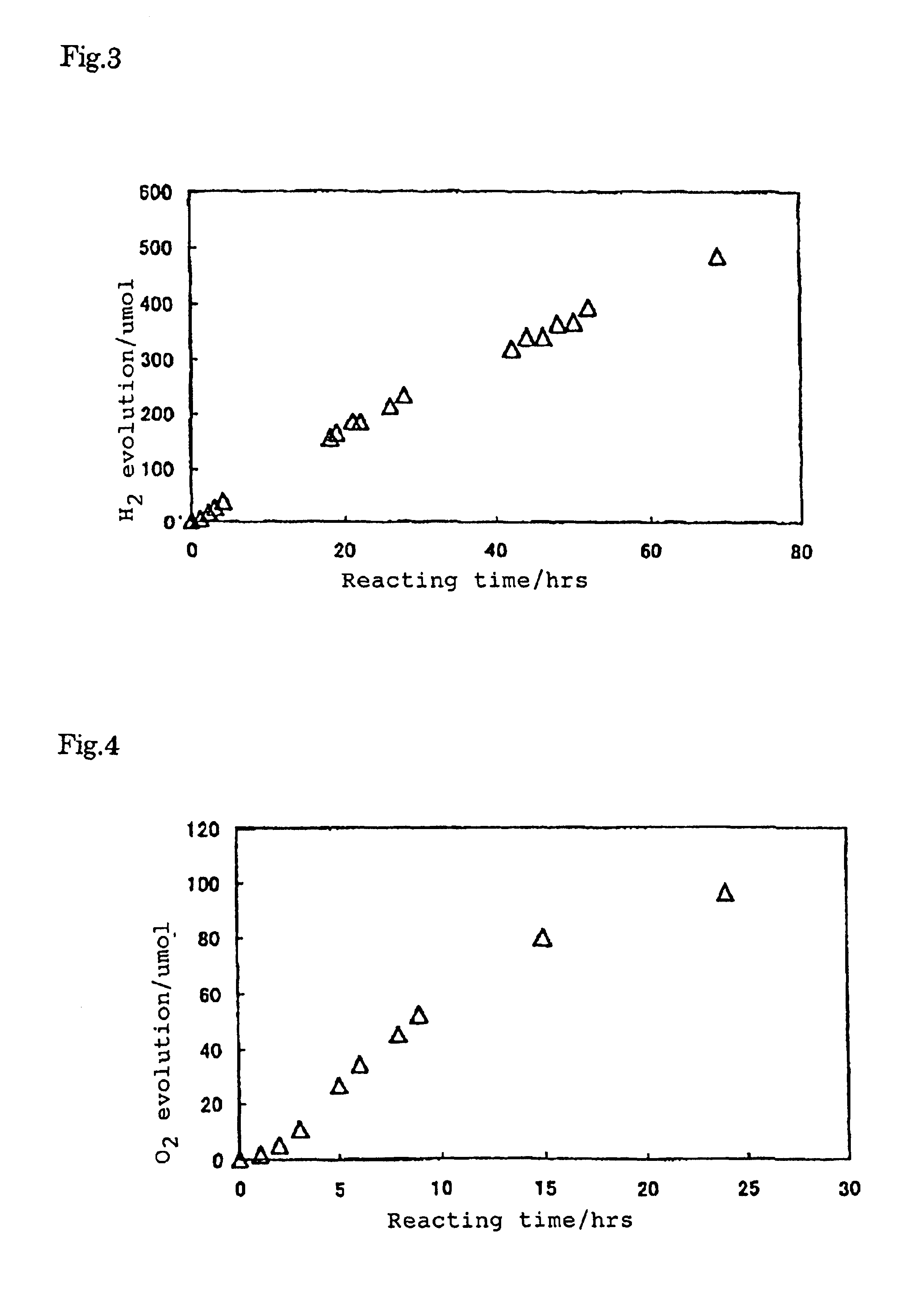

Oxysulfide photocatalyst for decomposition of water by visible light

InactiveUS6838413B2Sulfate/bisulfate preparationCatalyst activation/preparationRare-earth elementDecomposition

A photocatalyst which comprises an oxysulfide containing at least one transition metal; a preferable photocatalyst which also comprises a rare earth element such as Sm in addition to the above and wherein the transition metal is at least one selected from the group consisting of Ti and Nb; a more preferable photocatalyst which further comprises a promoter comprising a transition metal such as Pt loaded on each of the above photocatalyst; and a catalyst for use in the decomposition of water by a light which comprises one of the above oxysulfide photocatalysts.

Owner:JAPAN SCI & TECH CORP

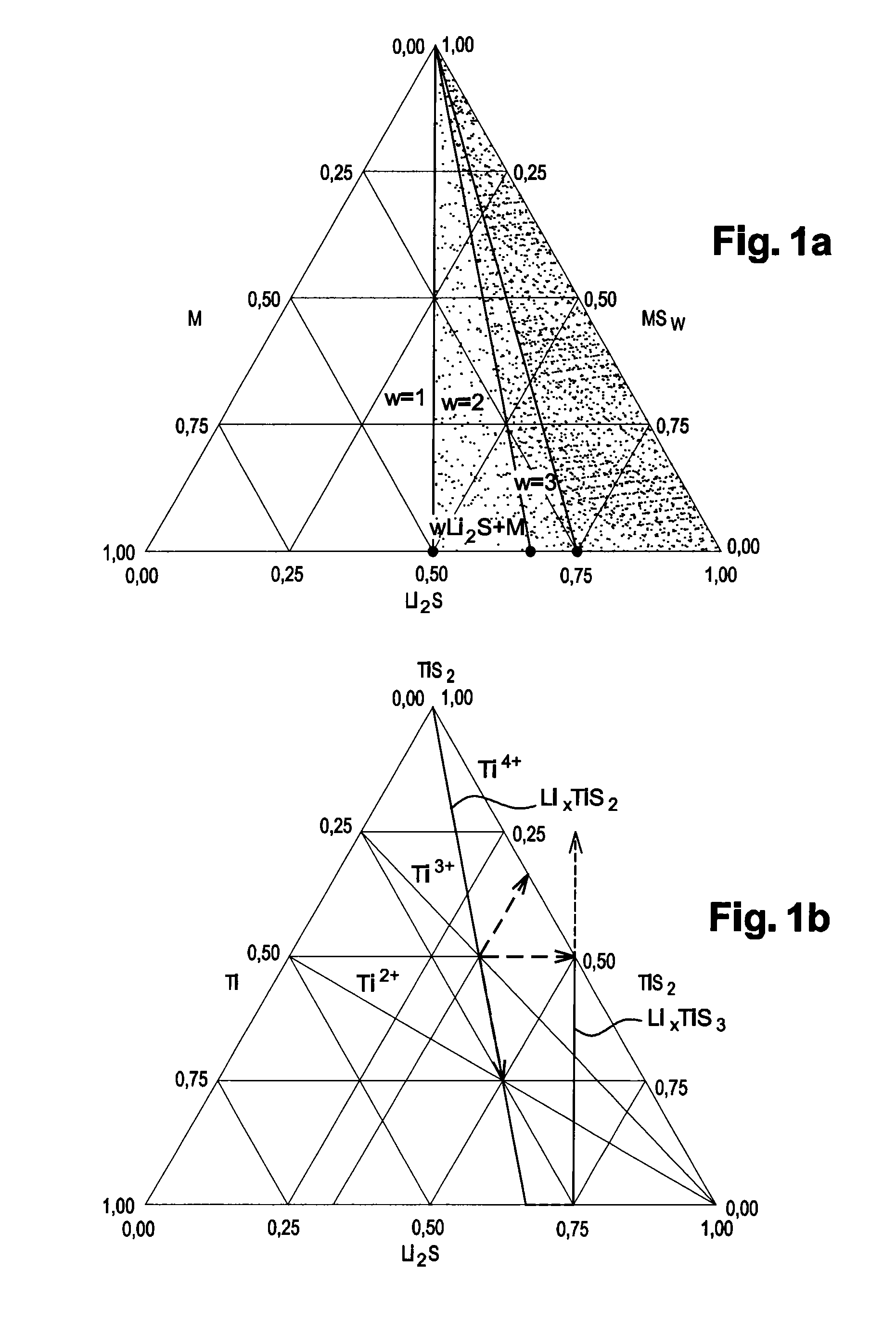

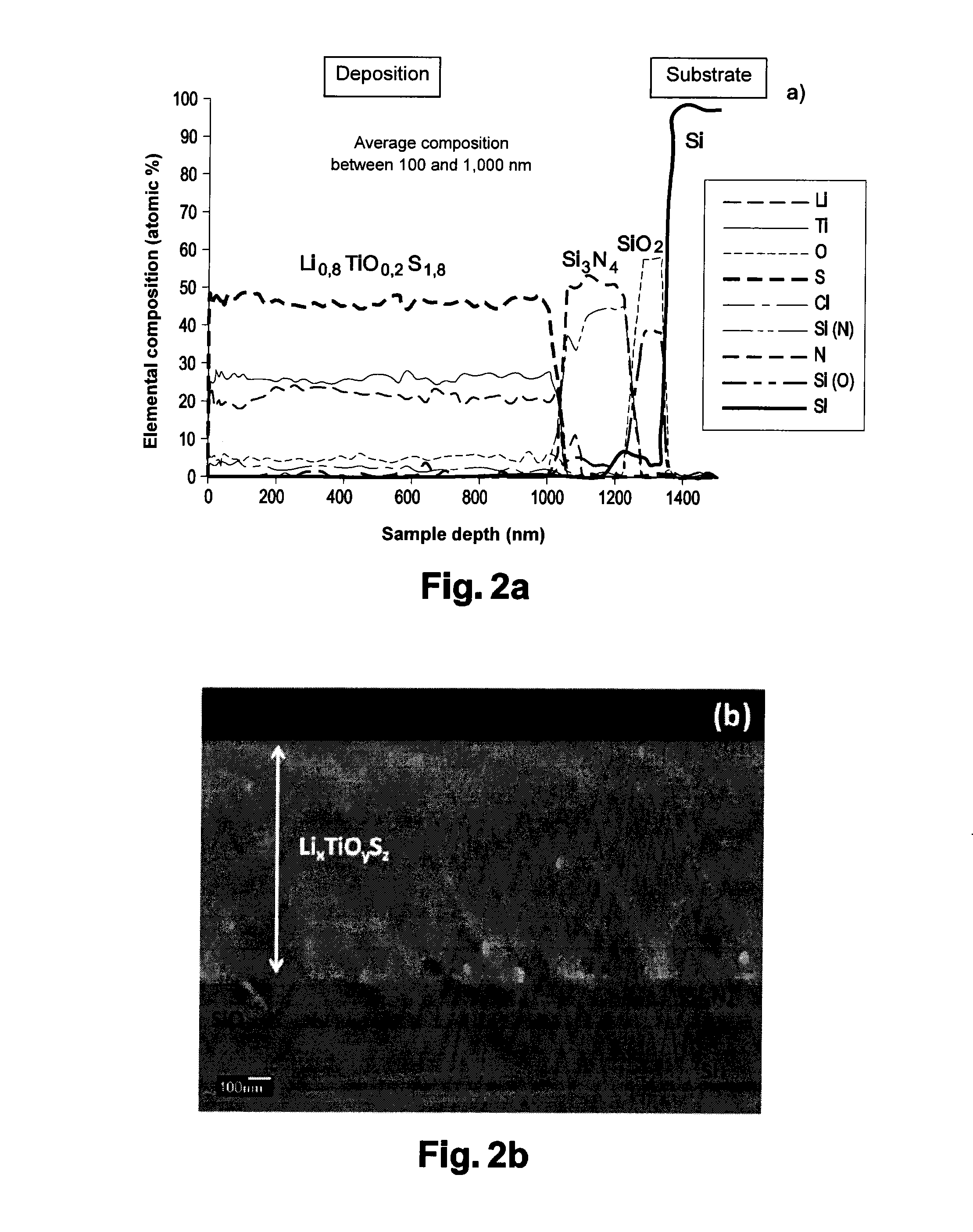

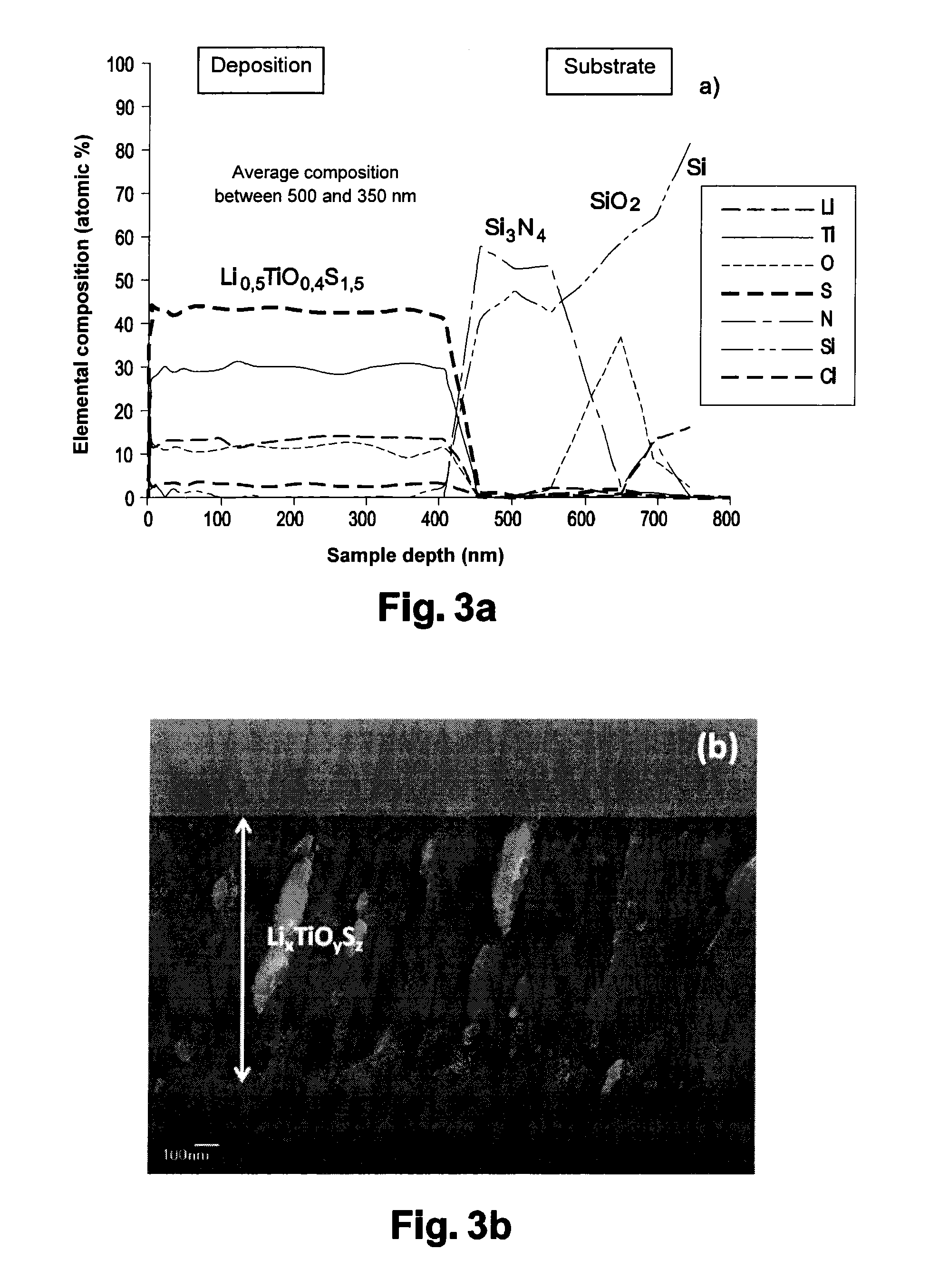

Method for preparing an amorphous film made from lithiated metal sulfide or oxysulfide

InactiveUS20160111709A1Increase usable capacityLower potentialFinal product manufactureSulfur compoundsMetallic sulfideInorganic sulfide

A method of preparing an amorphous film of lithiated metal sulfide or oxysulfide of formula LiαM(O1-βSβ)γ using a lithiated target material:M being advantageously selected from the group comprising Al, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ge, Zr, Nb, Mo, Ag, Cd, In, Sn, Sb, Ta, W, Pb, Bi, and mixtures thereof; andα≧0.5;1≧β≧⅔;2≧α / γ≧⅓.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

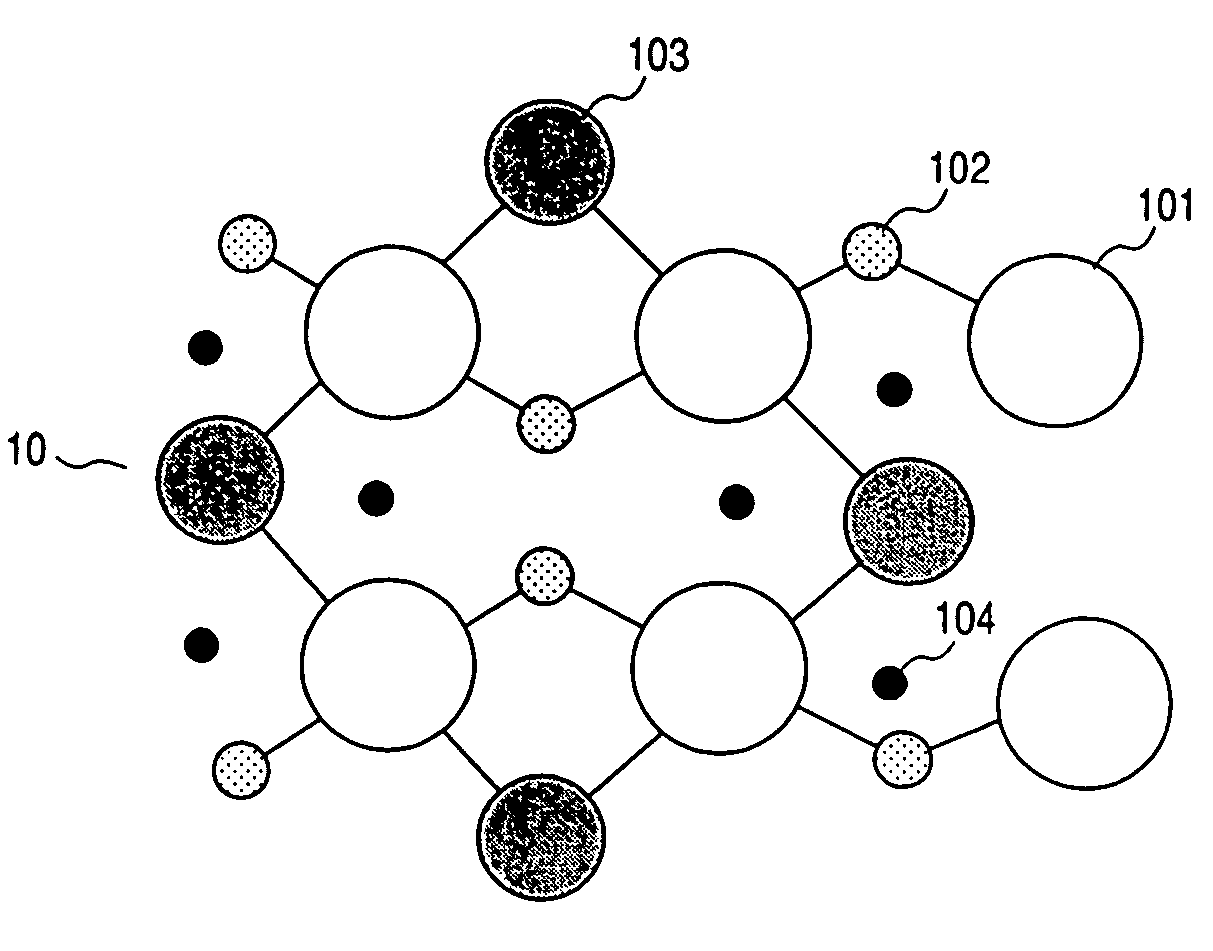

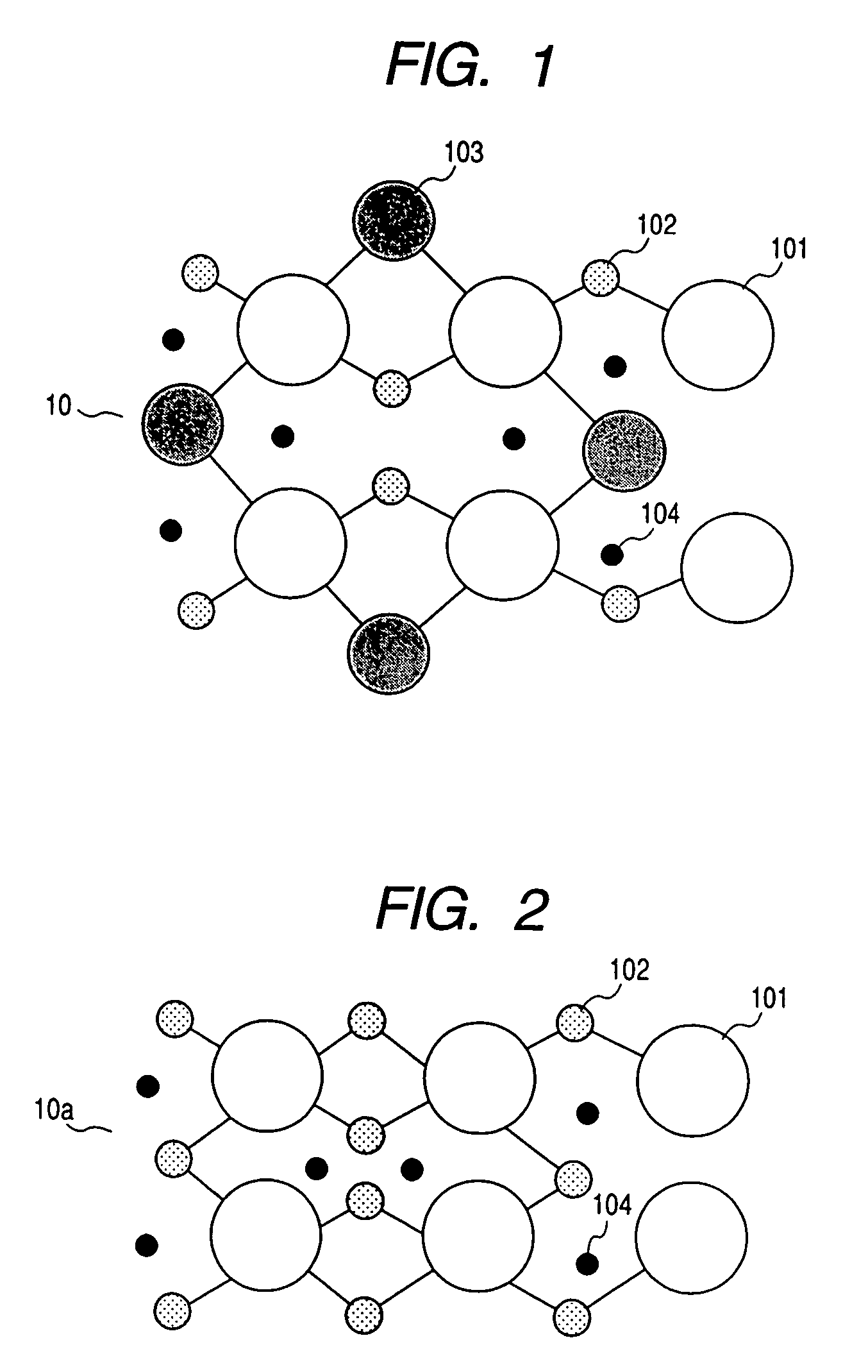

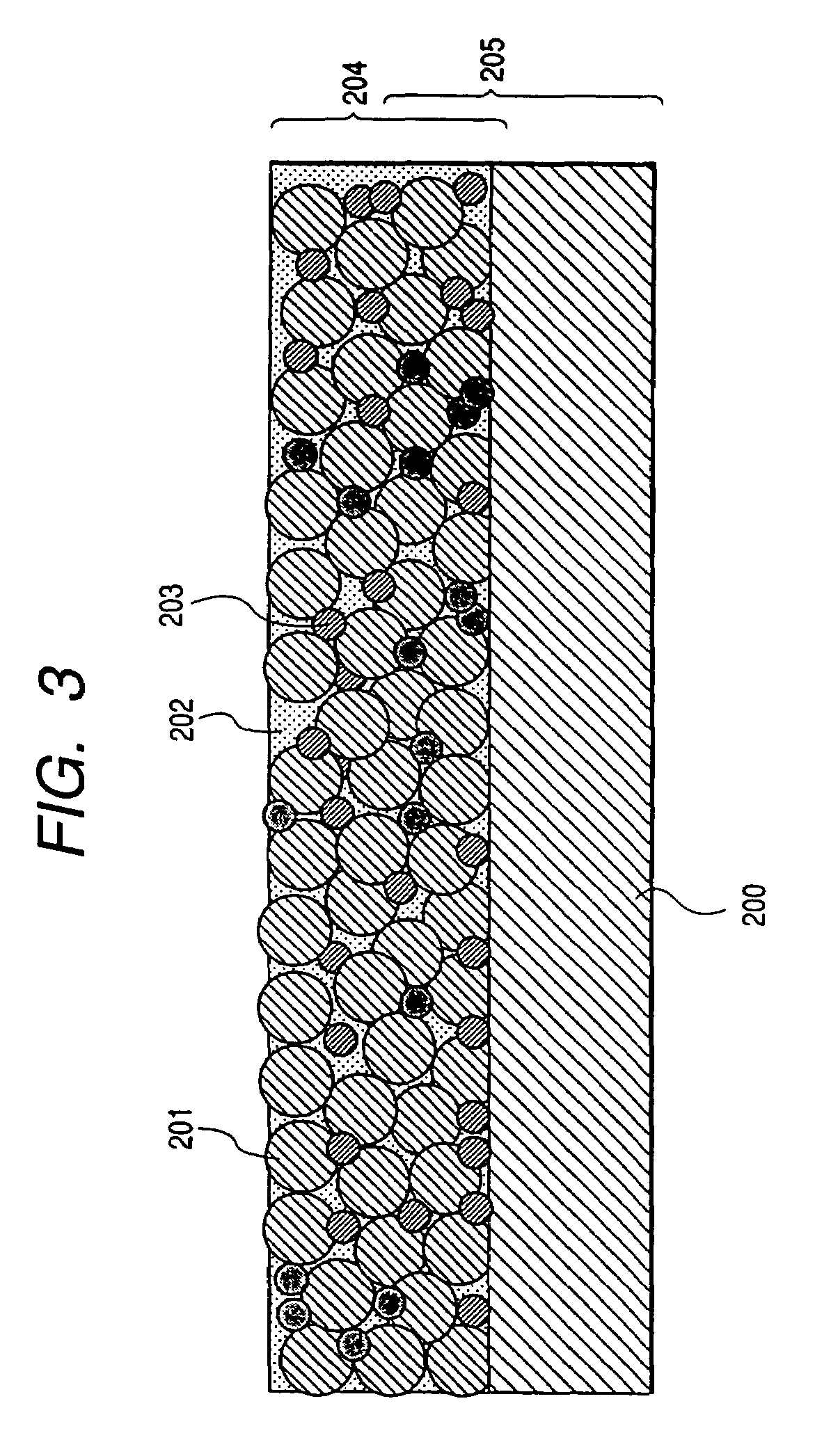

Electrode structure production process

InactiveUS7491378B2Increase capacityImprove efficiencyMaterial nanotechnologyFinal product manufactureLithiumSulfur

Owner:CANON KK

Adsorbents for Radioisotopes, Preparation Method Thereof, and Radioisotope Generators Using the Same

InactiveUS20090277828A1Improve physical stabilityImprove adsorption capacitySpecific isotope recoverySulfate/bisulfate preparationSorbentIsotope

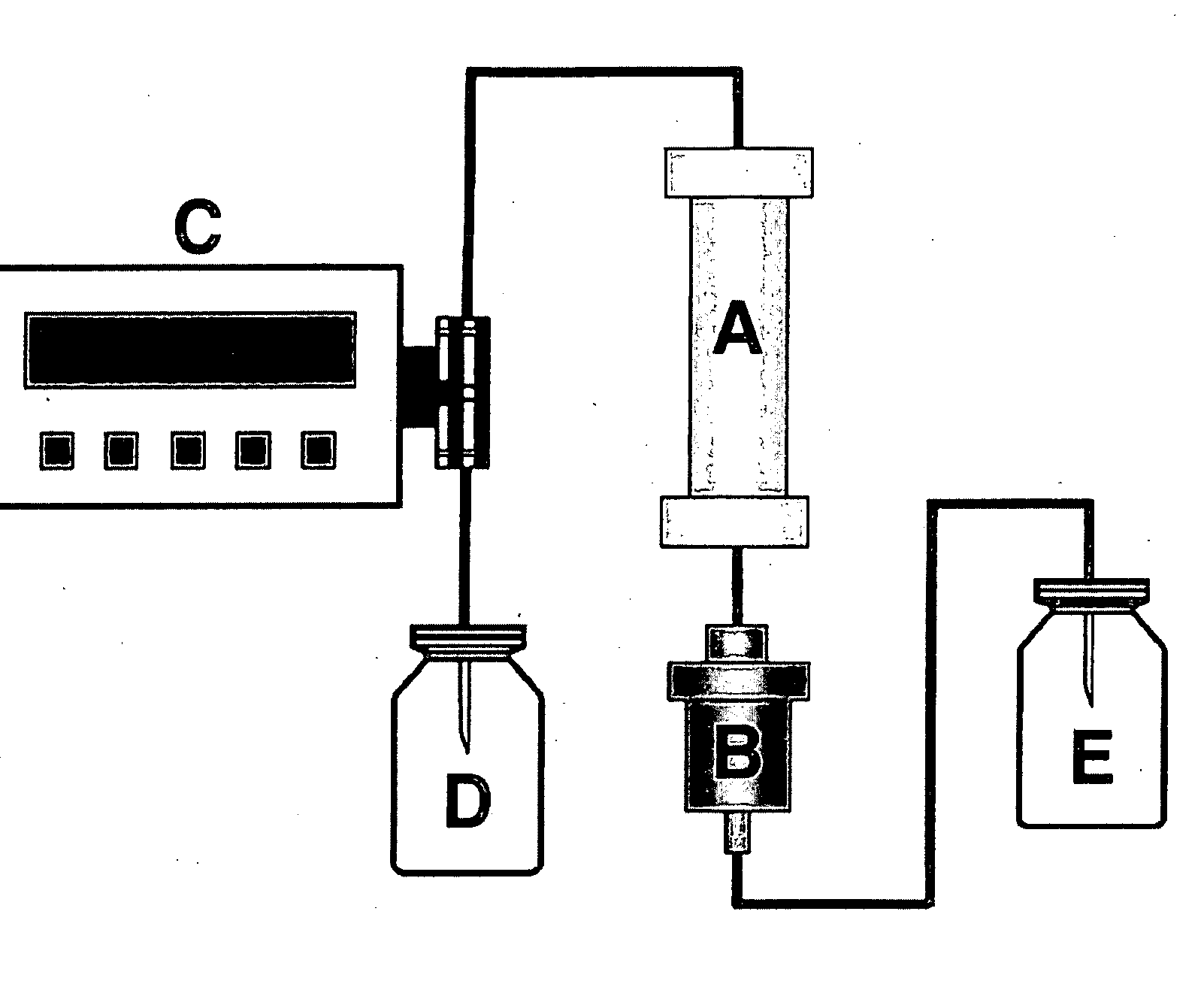

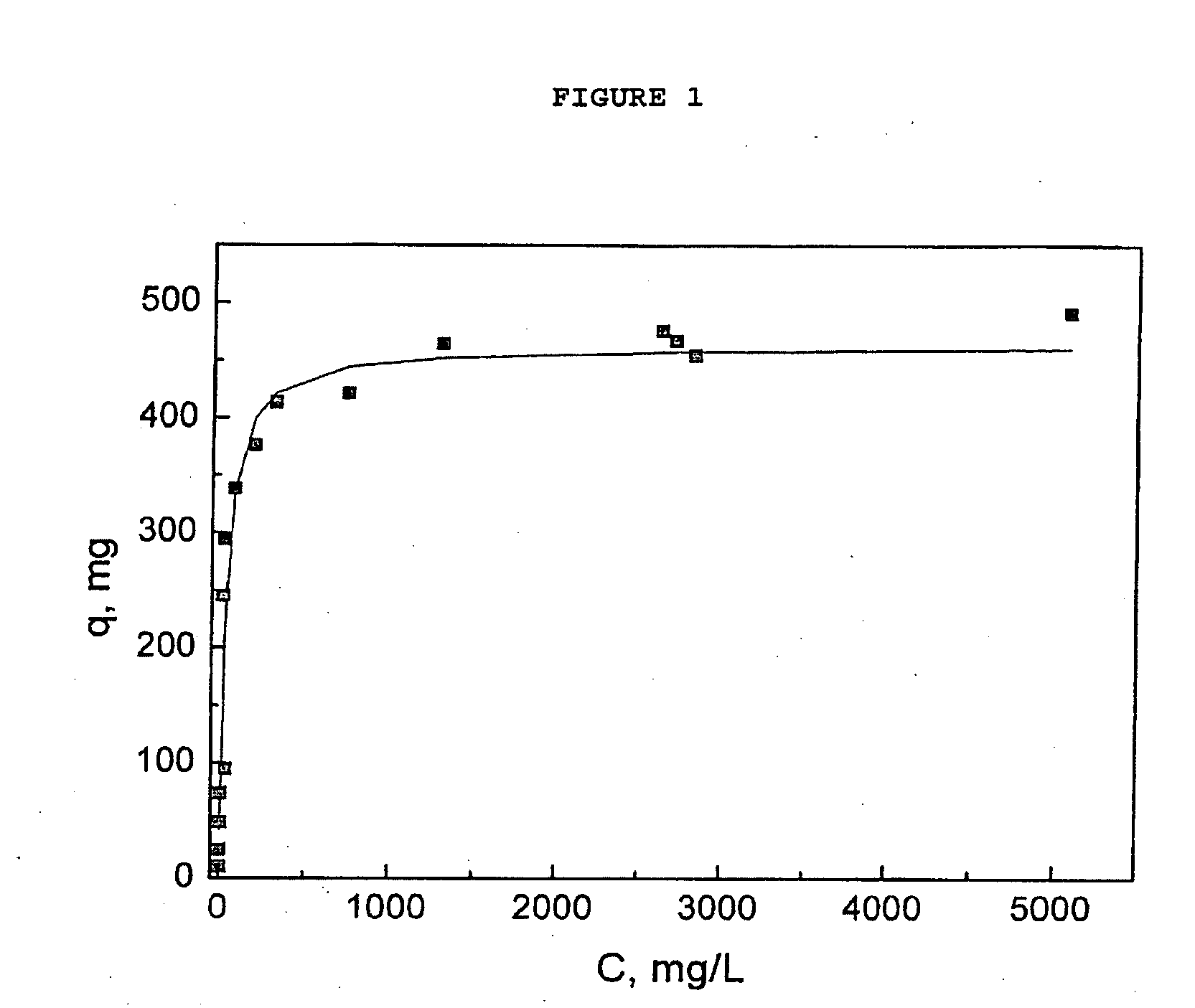

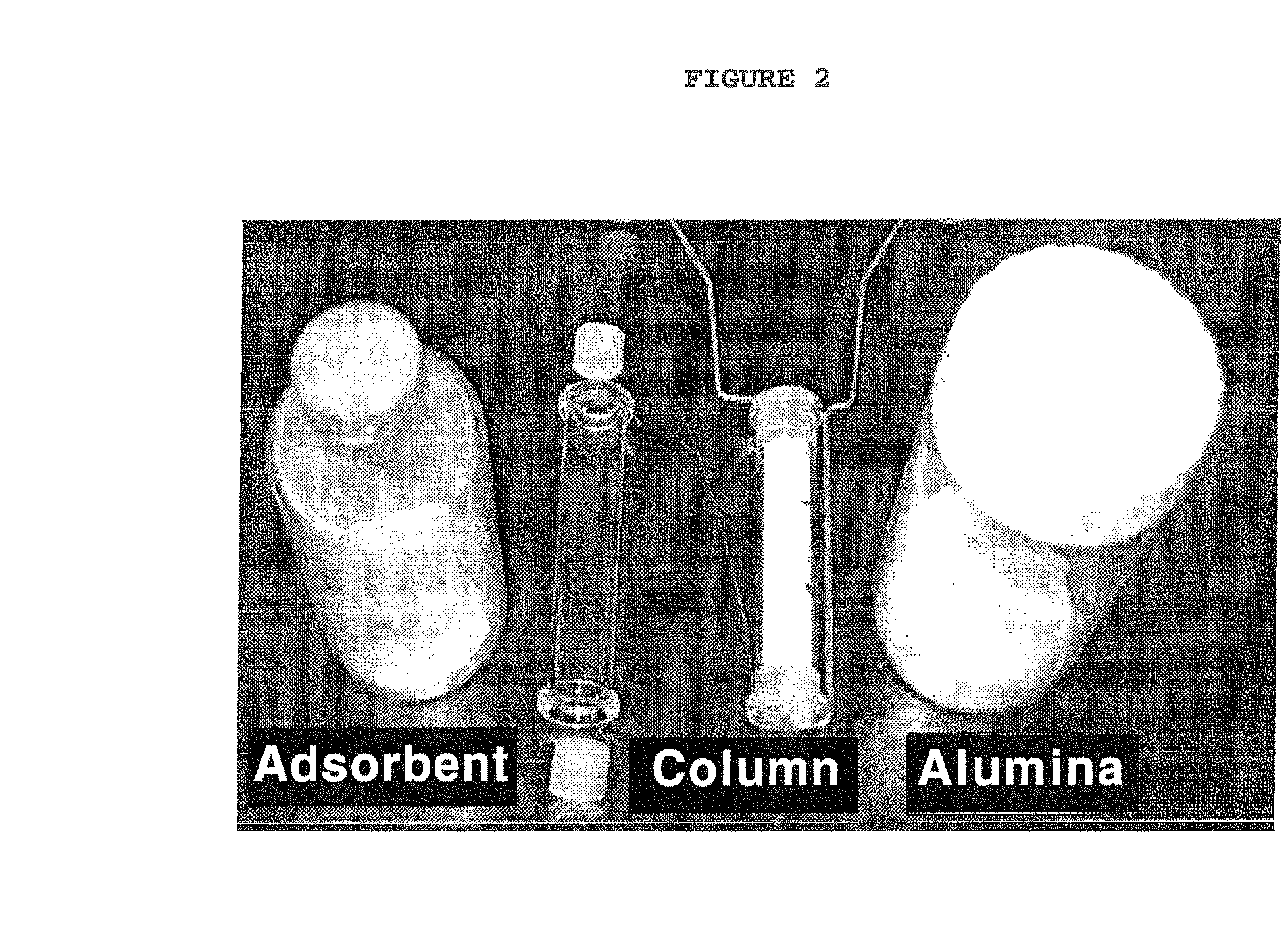

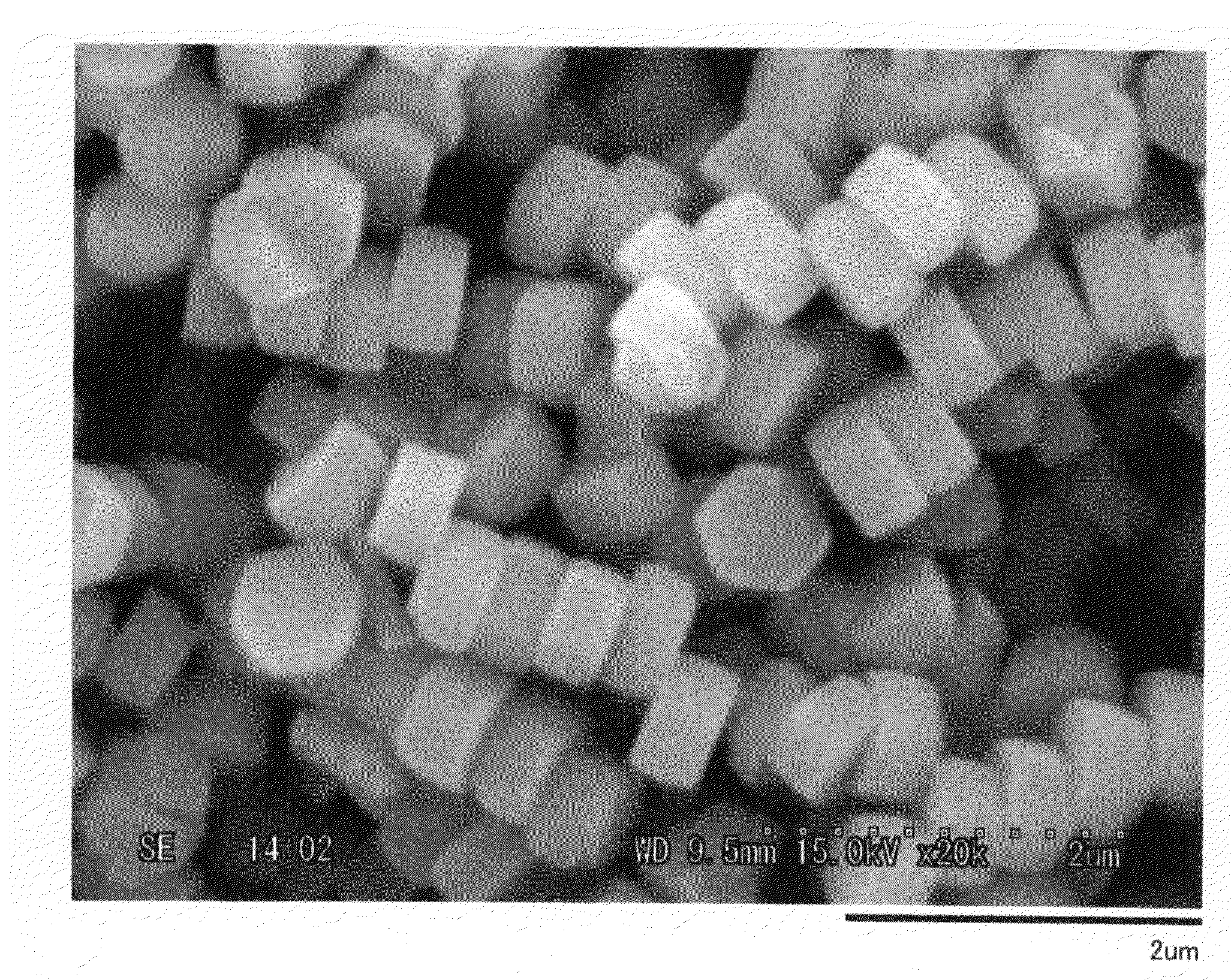

Disclosed is a novel adsorbent for use in a 99Mo / 99mTc generator, which is a medical diagnostic radioisotope generator, and in a 188W / 188Re generator, which is a therapeutic radioisotope generator. The adsorbent composed of sulfated alumina or alumina-sulfated zirconia exhibits adsorption capacity superior to that of conventional adsorbents, and is stable and is thus loaded in a dry state in an adsorption column so that the radioisotope 99Mo or 188W can be adsorbed. Thus, it is possible to miniaturize the column, and such a miniaturized column is small, convenient to use, and highly efficient, and extracts a radioisotope satisfying the requirements for pharmaceuticals, and thus can be useful for radioisotope generators extracting 99mTc or 188Re.

Owner:KOREA ATOMIC ENERGY RES INST

Alunite Type Compound Particles, Manufacturing Process Thereof and Use Thereof

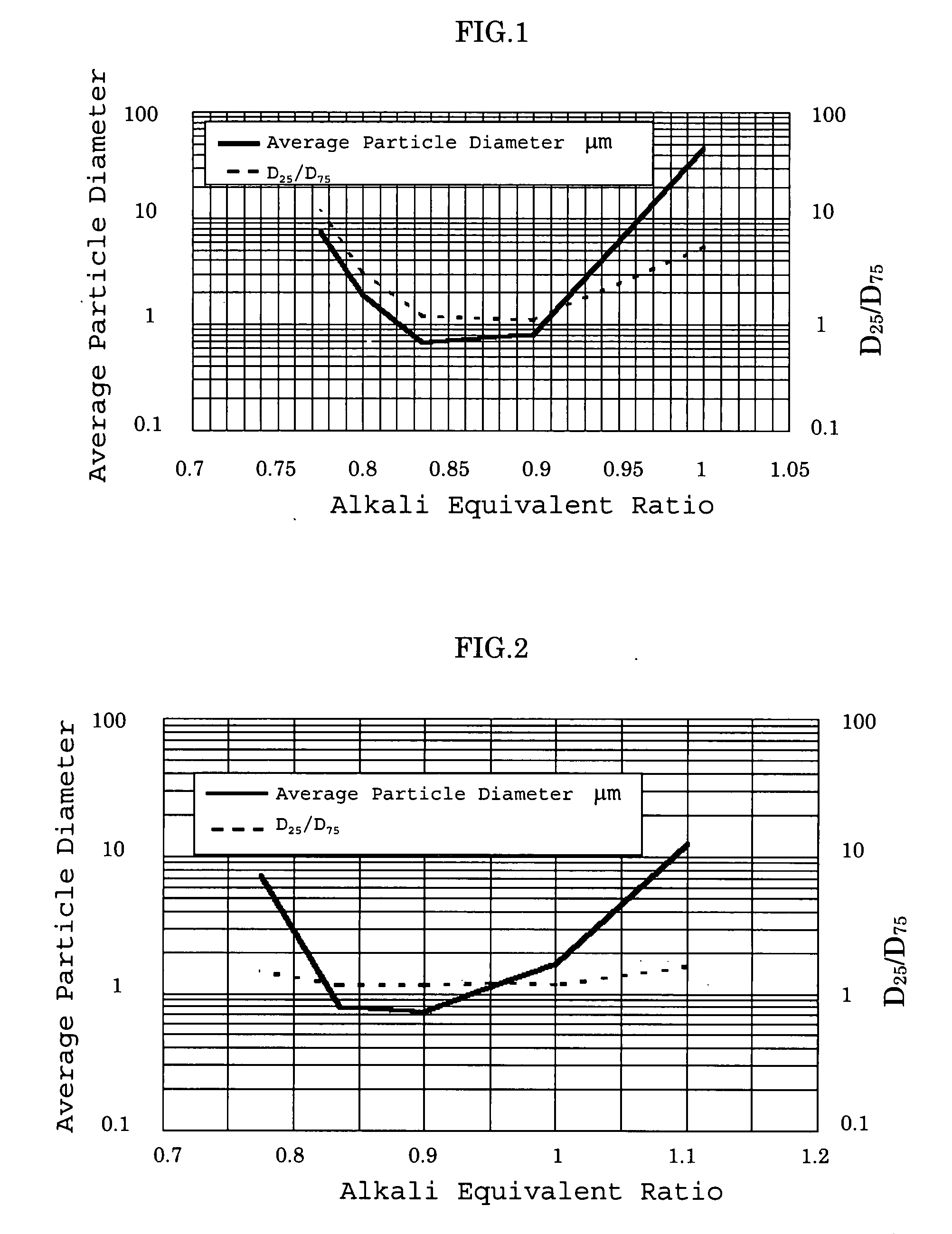

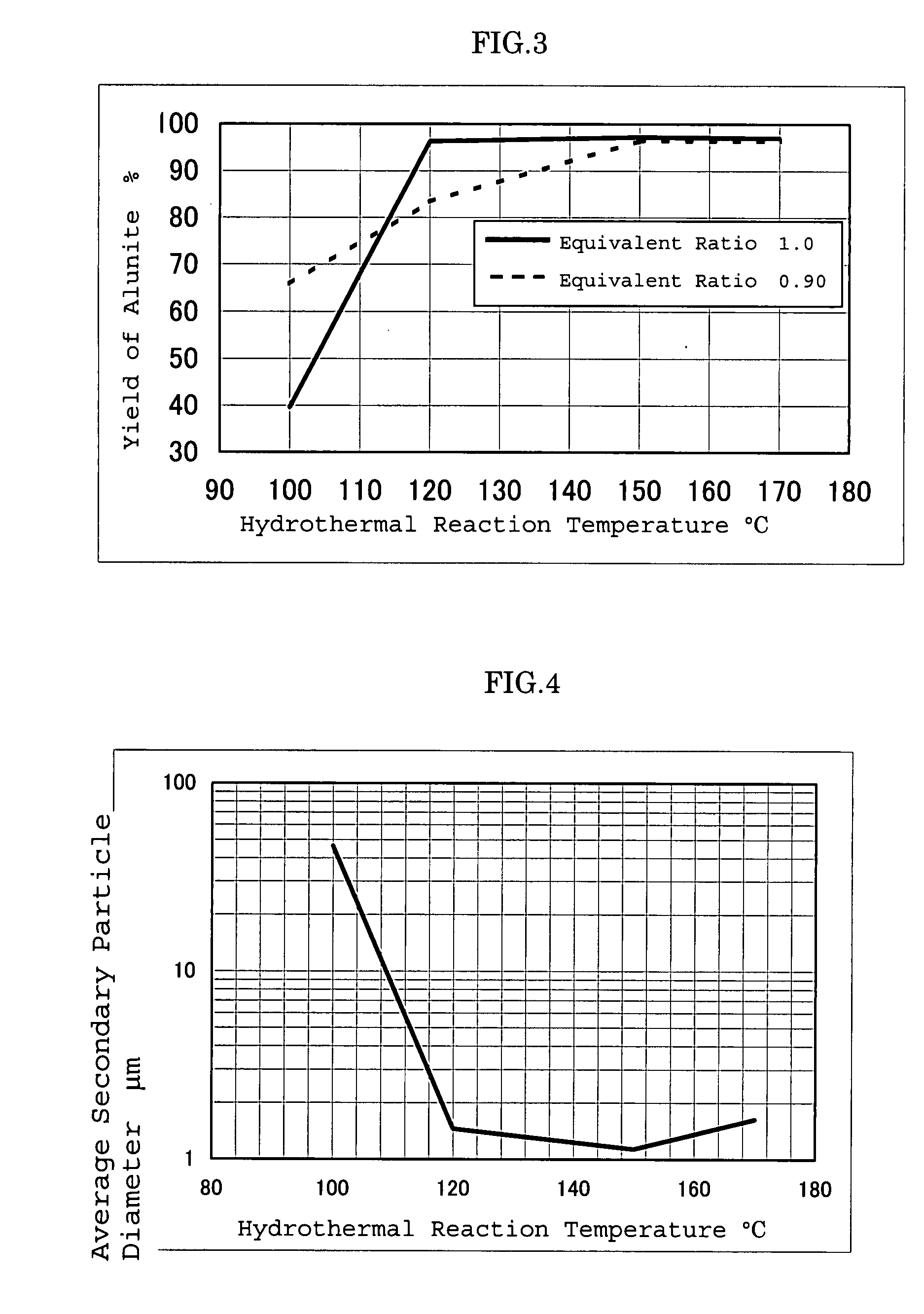

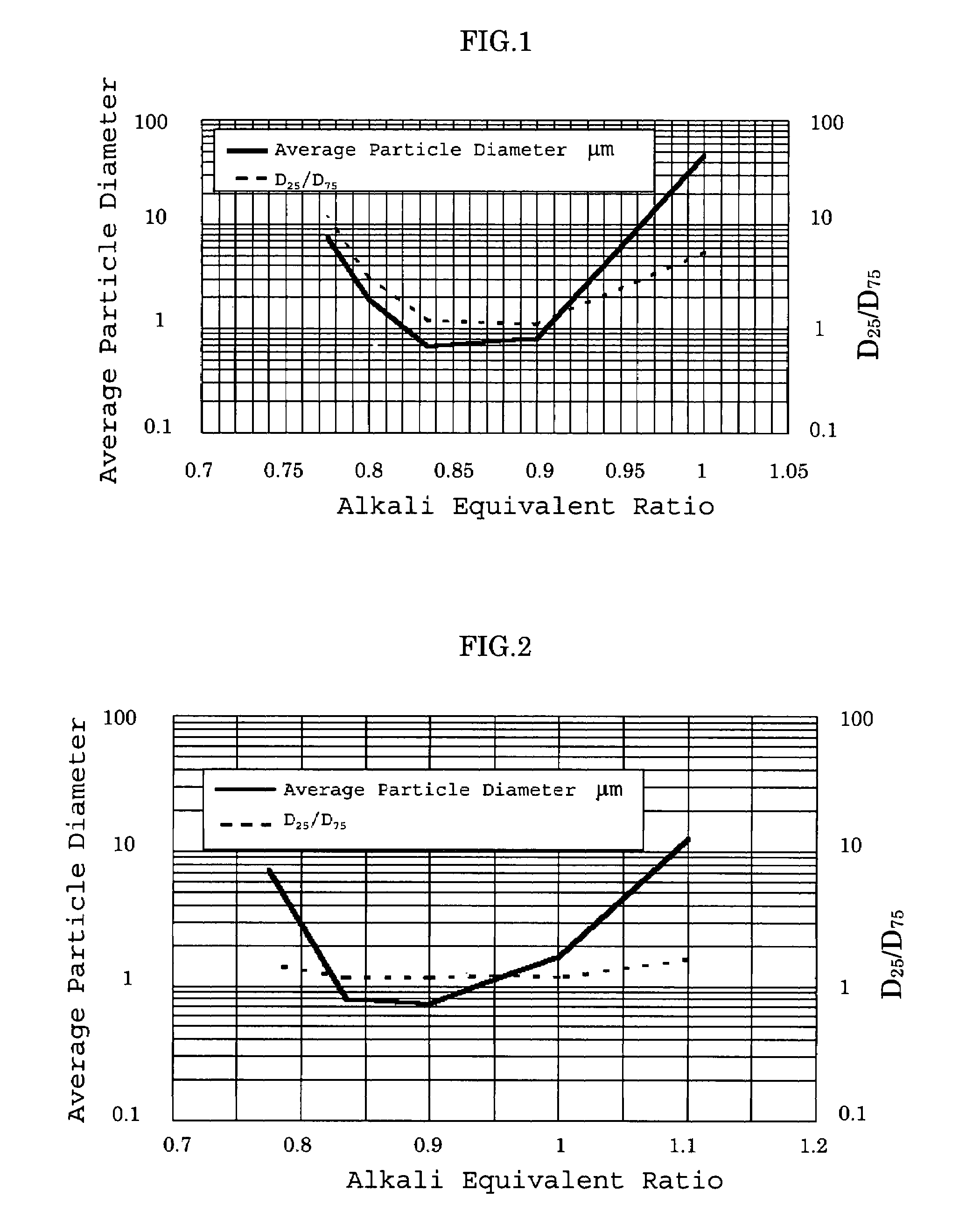

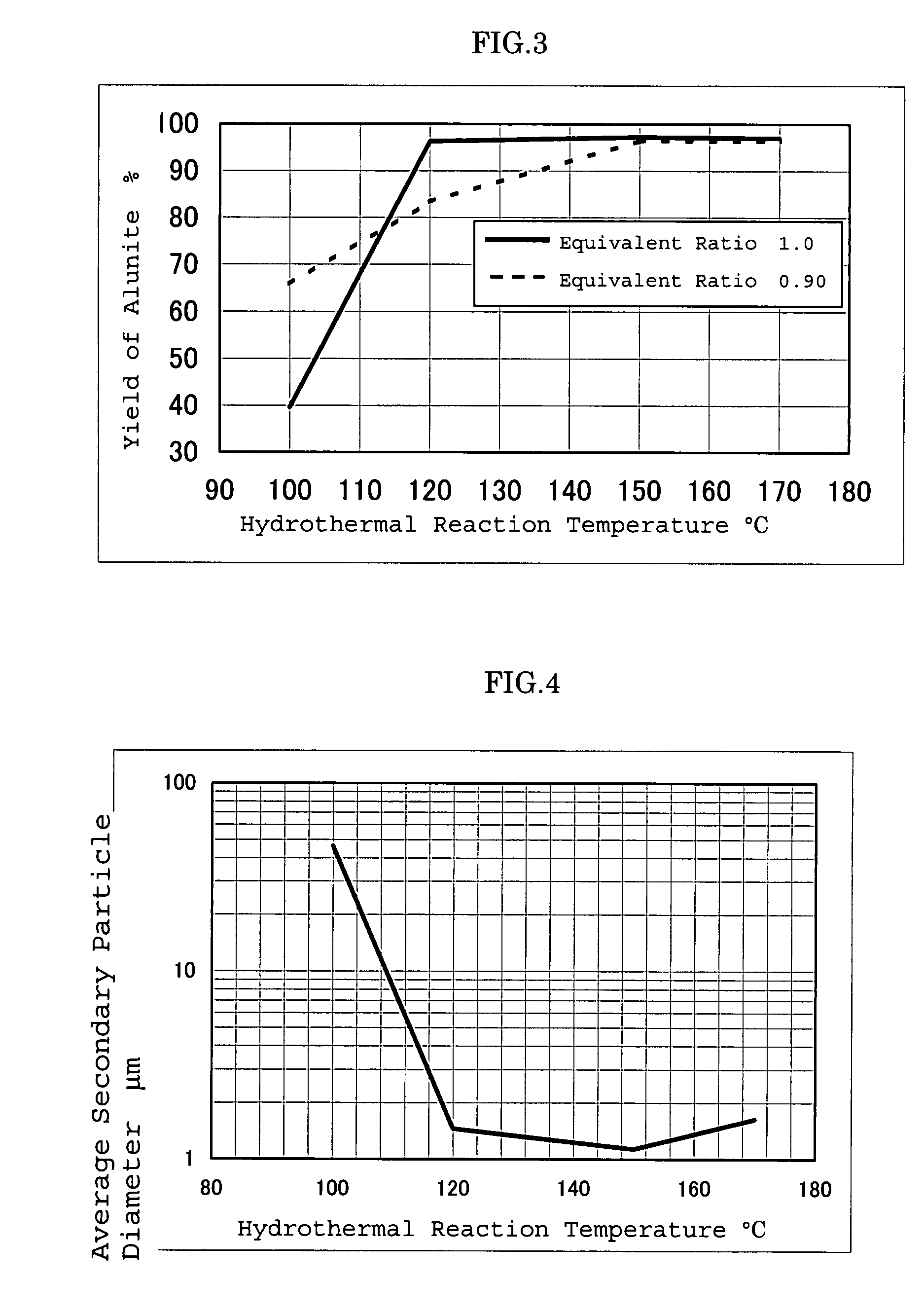

InactiveUS20090012223A1Low costGood reproducibilityPigmenting treatmentSulfate/bisulfate preparationAluniteParticle-size distribution

Alunite type compound particles represented by the following general formula (I) and having a specific value of D75 / D25 when D25 is the particle diameter of particles which account for 25% of the total and D75 is the particle diameter of particles which account for 75% of the total in the cumulative particle size distribution curve measured by a laser diffraction method:Ma[Al1-xM′x]3(SO42−)y(OH)z.mH2O (I)wherein M is at least one cation selected from the group consisting of Na+, K+, NH4+ and H3O+, M′ is at least one cation selected from the group consisting of Cu2+, Zn2+, Ni2+, Sn4+, Zr4+ and Ti4+, and a, m, x, y and z satisfy 0.8≦a≦1.35, 0≦m≦5, 0≦x≦0.4, 1.7≦y≦2.5, and 4≦z≦7, respectively.The above particles of the present invention have a small average particle diameter, are spherical, disk-like or hexagonal and have an extremely narrow particle size distribution.

Owner:KYOWA CHEM IND

Alunite type compound particles, manufacturing process thereof and use thereof

Alunite type compound particles represented by the following general formula (I) and having a specific value of D75 / D25 when D25 is the particle diameter of particles which account for 25% of the total and D75 is the particle diameter of particles which account for 75% of the total in the cumulative particle size distribution curve measured by a laser diffraction method:Ma[Al1-xM′x]3(SO42−)y(OH)z.mH2O (I)wherein M is at least one cation selected from the group consisting of Na+, K+, NH4+ and H3O+, M′ is at least one cation selected from the group consisting of Cu2+, Zn2+, Ni2+, Sn4+, Zr4+ and Ti4+, and a, m, x, y and z satisfy 0.8≦a≦1.35, 0≦m≦5, 0≦x≦0.4, 1.7≦y≦2.5, and 4≦z≦7, respectively. The above particles of the present invention have a small average particle diameter, are spherical, disk-like or hexagonal and have an extremely narrow particle size distribution.

Owner:KYOWA CHEM IND

Oil Extractor and The Preparation Method Thereof

ActiveUS20130243685A1Reduce interfacial tensionFacilitate separation of oilWater cleaningOther chemical processesPotassium persulfateMicrowave

A method for preparing an oil extractor is provided. The method includes dissolving 0.1˜30% by weight of a potassium sulfate, 0.1˜30% by weight of a potassium persulfate, and 0.1˜30% by weight of a manganese sulfate in a solvent to form a solution; heating the solution to synthesize a compound by a microwave; cooling a temperature of the compound to a room temperature; and removing the solvent from the compound. An extractor prepared from the method is also provided.

Owner:NATIONAL TSING HUA UNIVERSITY

One-off manufacturing technology of chromium compounds and new products in many industries by liquid phase method of ferrochromium

The invention relates to a one-off manufacturing technology of chromium compounds and new products in many industries by a liquid phase method of ferrochromium and belongs to the technical field of new chemical materials with metallurgical products used as raw materials to manufacture chromium compounds, iron series pigments, new silicon materials, new photovoltaic materials and new energy. The technology provided by the invention is advanced, energy-saving and environmentally friendly, and there is no discharge of waste residues, exhaust gas or wastewater. High temperature and high pressure are not required. Ferrochromium is used as a raw material to produce products such as chromium compounds, pigments, new energy, new silicon carbon battery materials and the like by a liquid phase method at a time, thus forming a series of new high-end industrial chains and thoroughly changing situations of single application and pure production of ferrochromium in the prior art. The backward production technology that original chromate compound roasting production generates high pollution which is greatly harmful to the environment is changed. Production of chromate compounds has embarked on an energy-saving and high-efficiency development road. Diversified development and application fields of the ferrochromium industry are greatly expanded, international competitiveness of enterprises is greatly enhanced and national industrial upgrading and optimization and development are promoted. The technology provided by the invention is of great significance. The technology accords with requirements of modern green economic development and has great enterprises economic benefits, perfection benefits and social benefits.

Owner:唐翔

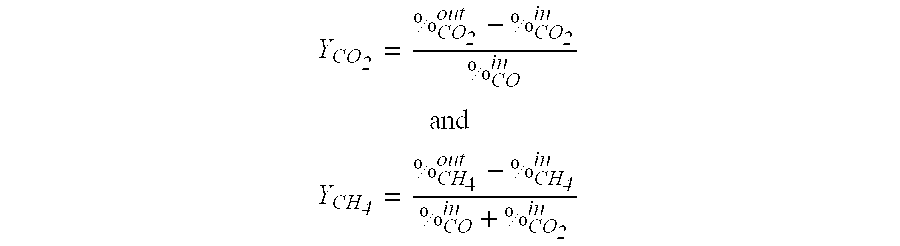

Catalyst for removal of sulfer from a gaseous stream

The present invention involves a process and materials for simultaneous desulfurization and water gas shift of a gaseous stream comprising contacting the gas stream with a nickel aluminate catalyst. The nickel aluminate catalyst is preferably selected from the group consisting of Ni2xAl2O2x+3, Ni(2−y)Ni0yAl2O(5−y), Ni(4−y)Ni0yAl2O(7−y), Ni(6−y)Ni0yAl2O(9−y), and intermediates thereof, wherein x≧0.5 and 0.01≦y≦2. Preferably, x is between 1 and 3. More preferably, the nickel containing compound further comprises Ni2xAl2O2x+3−zSz wherein 0≦z≦2x.

Owner:UOP LLC

Alkali/transition metal halo-and hydroxy-phosphates and related electrode active materials

InactiveUS8367036B2Increase capacityImprove cycle performancePhosphatesFluoride preparationHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(SO4)2Zd.

Owner:VALENCE TECH INC

Mixed metal oxide containing sulfur

InactiveUS20060269462A1Organic compound preparationHeterogenous catalyst chemical elementsSulfurDecomposition

Owner:EXXONMOBIL CHEM PAT INC

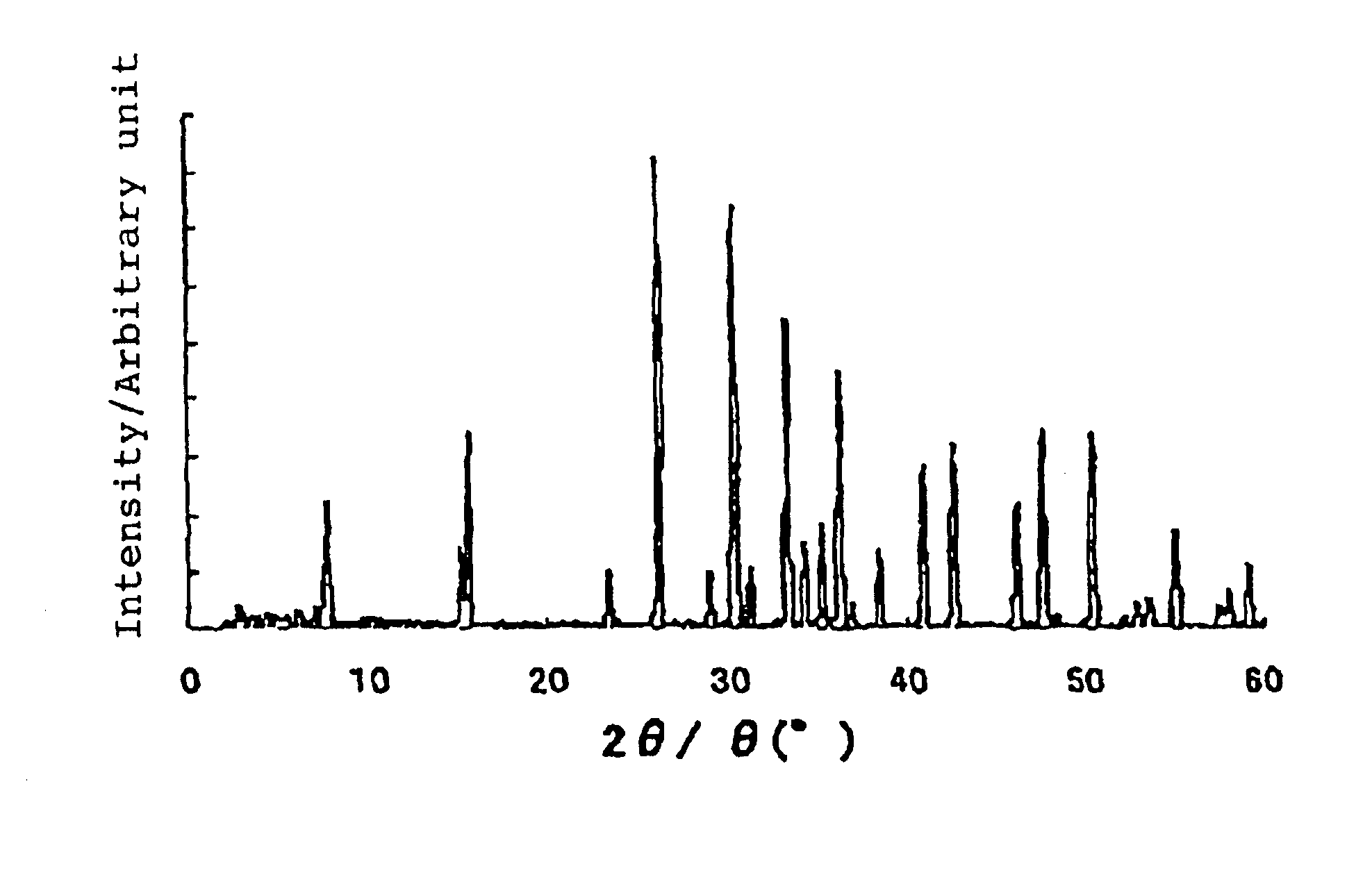

Positive active material for lithium secondary battery and method of preparing same

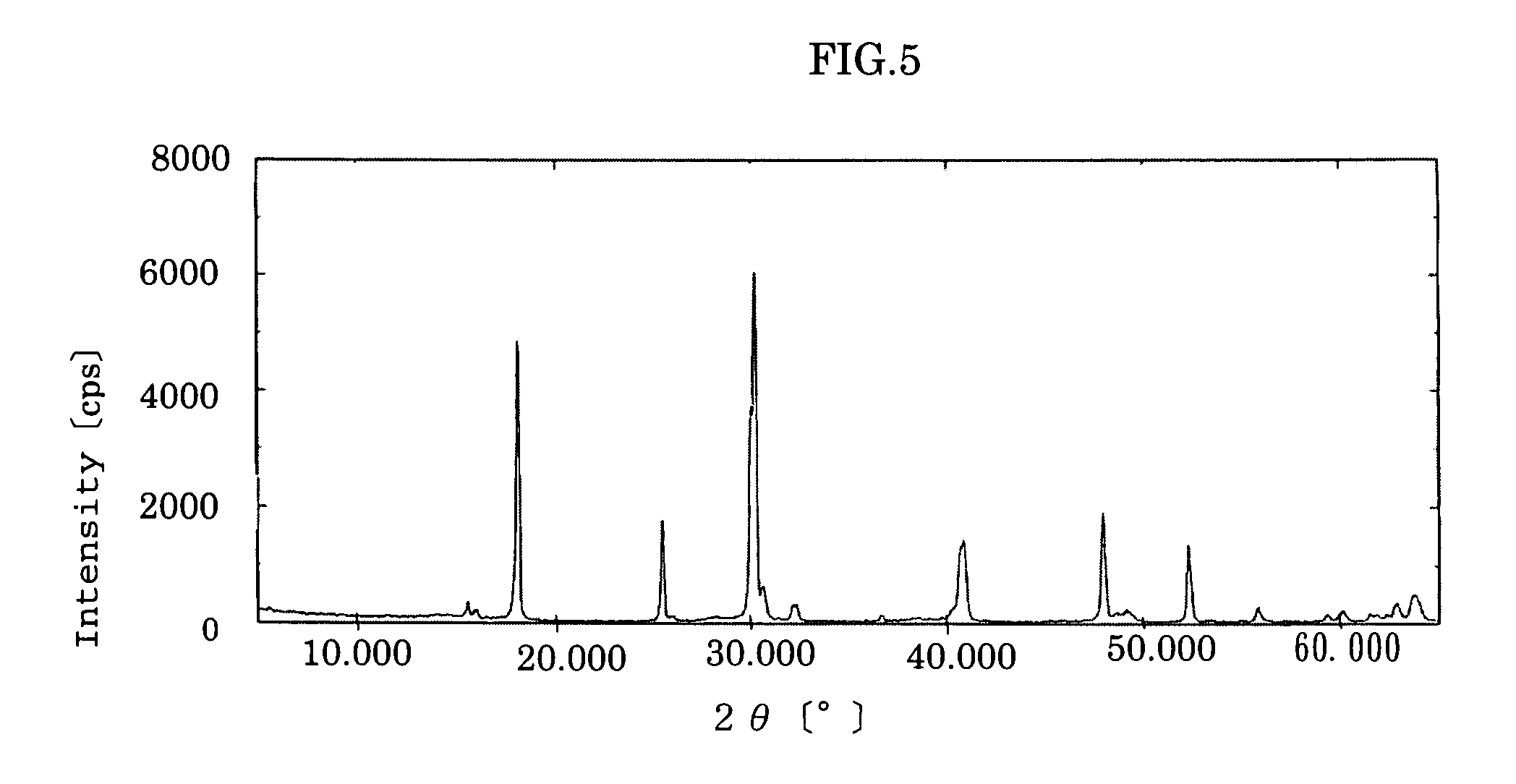

ActiveUS20050181281A1Improved cycle life characteristicsExcellent capacity and potential characteristicPhosphatesFluoride preparationCrystallographyLithium

Disclosed in a positive active material for a lithium secondary battery including a compound represented by formula 1 and having a 10% to 70% ratio of diffracted intensity of diffraction lines in 2θ=53° (104 plane) with respect to diffracted intensity of diffraction lines in the vicinity of 2θ=22° (003 plane) in X-ray diffraction patterns using a CoKα-ray,LixCoO2-yAy (1)wherein, x is from 0.90 to 1.04, y is from 0 to 0.5, and A is selected from the group consisting of F, S and P.

Owner:SAMSUNG SDI CO LTD

Mixed metal oxide containing sulfur

InactiveUS7173158B2Organic compound preparationHeterogenous catalyst chemical elementsDecompositionSulfur

Owner:EXXONMOBIL CHEM PAT INC

Simultaneous warm gas desulfurization and co-shift for improved syngas cleanup

ActiveUS20100135896A1Combustible gas catalytic treatmentSulfate/bisulfate preparationAluminateNickel

The present invention involves a process and materials for simultaneous desulfurization and water gas shift of a gaseous stream comprising contacting the gas stream with a nickel aluminate catalyst. The nickel aluminate catalyst is preferably selected from the group consisting of Ni2xAl2O2x+3, Ni(2−y)Ni0yAl2O(5−y), Ni(4−y)Ni0yAl2O(7−y), Ni(6−y)Ni0yAl2O(9−y), and intermediates thereof, wherein x≧0.5 and 0.01≦y≦2. Preferably, x is between 1 and 3. More preferably, the nickel containing compound further comprises Ni2xAl2O2x+3−zSz wherein 0≦z≦2x.

Owner:UOP LLC

Pretreatment agent for limulus test

ActiveUS7867722B2Improve accuracyInhibition is effectiveMagnesium halidesFluoride preparationAlkaline earth metalSulfate

A pretreatment agent for a sample to be subjected to Limulus assay comprising an alkali metal sulfate and / or an alkaline earth metal sulfate wherein the sulfate(s) has a final concentration of 20 mM or more when the sulfate(s) is allowed to contact with the sample, or an alkali metal halide and / or an alkaline earth metal halide wherein the halide(s) has a final concentration of from 0.4 M to 1.2 M or less when the halide(s) is allowed to contact with the sample, or a kit for Limulus assay reagent comprising thereof as a composing article.

Owner:SEIKAGAKU KOGYO CO LTD

Oil extractor and the preparation method thereof

ActiveUS8709375B2Reduce interfacial tensionEasy to separateWater cleaningOther chemical processesPotassium persulfateMicrowave

Owner:NATIONAL TSING HUA UNIVERSITY

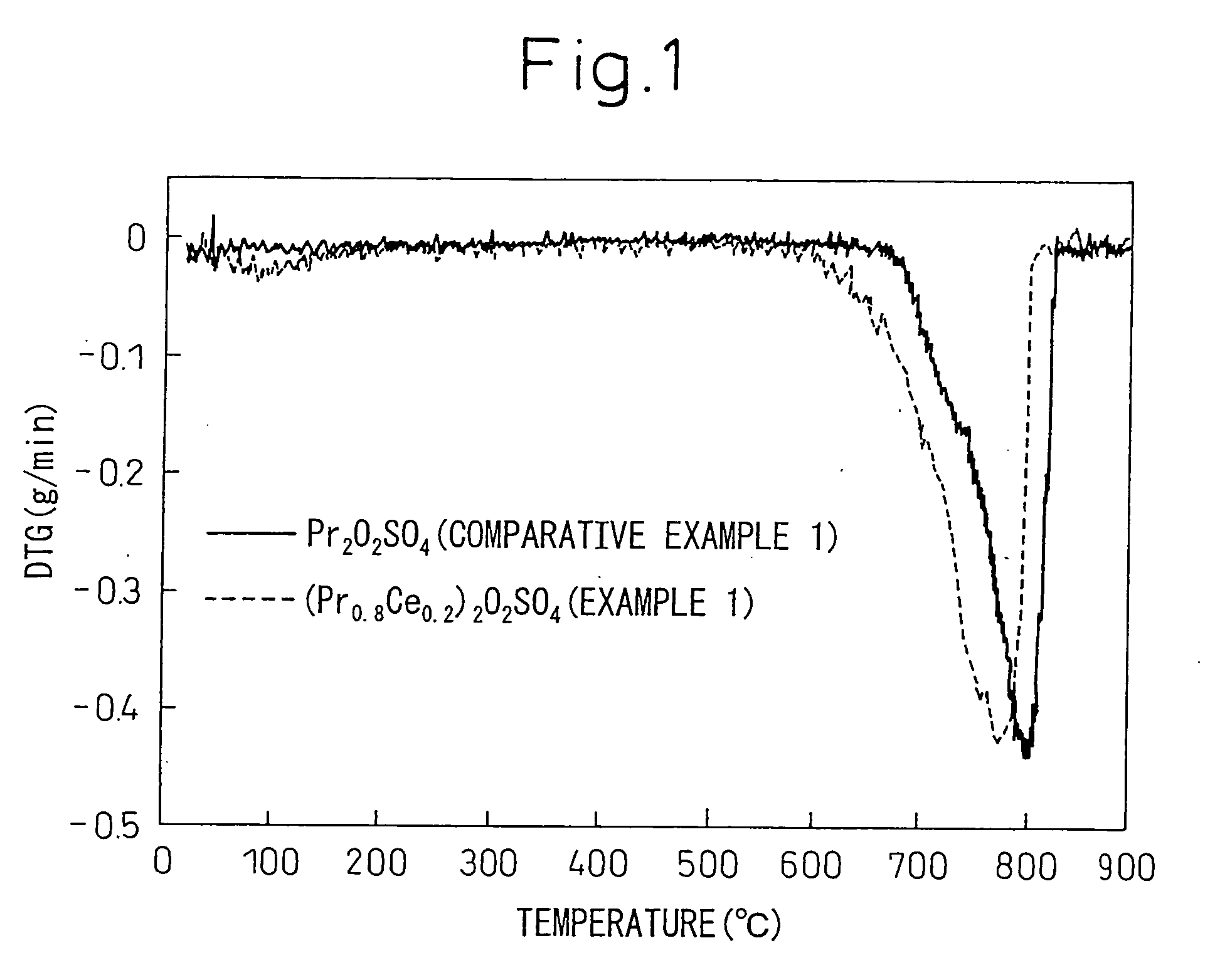

Oxygen storage/release material and exhaust gas purifying catalyst comprising the same

There is provided an oxygen storage / release material using a rare earth oxysulfate or oxysulfide, which has a high oxygen storage / release capacity even at lower temperatures. The oxygen storage / release material of the present invention comprises a compound consisting of Pr2O2SO4 and / or Pr2O2S in which at least a part of Pr is replaced with Ce.

Owner:NAT UNIV CORP KUMAMOTO UNIV +1

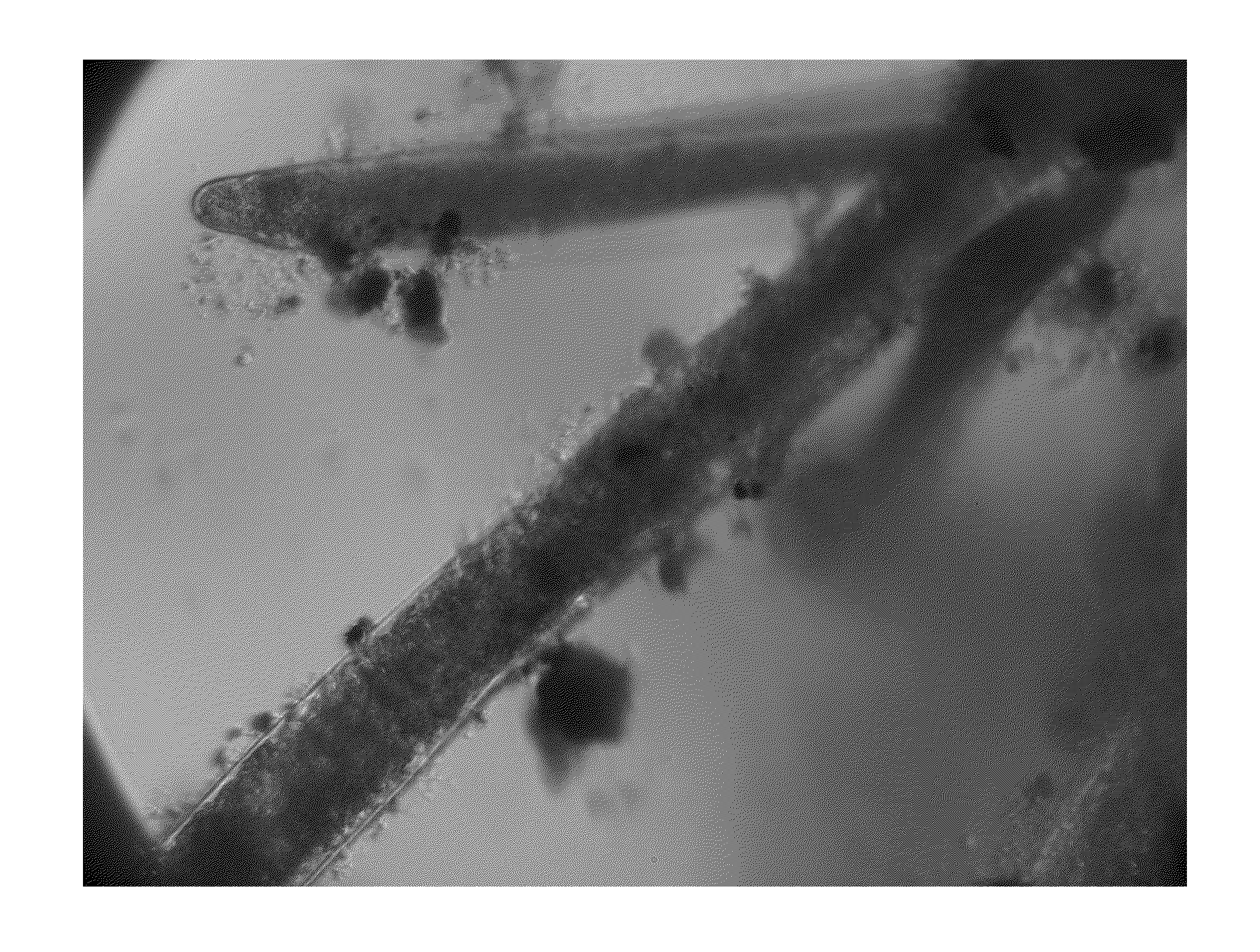

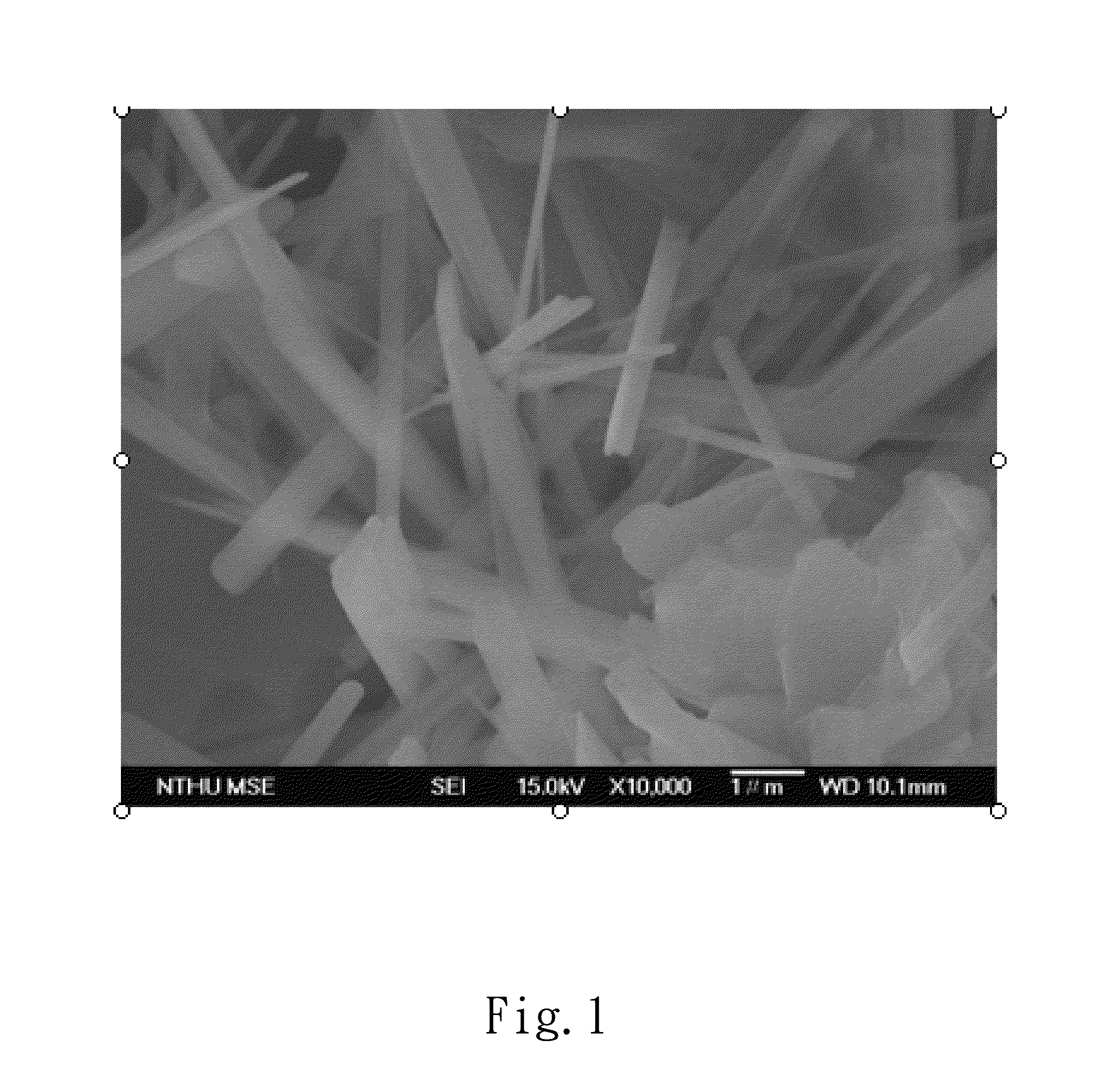

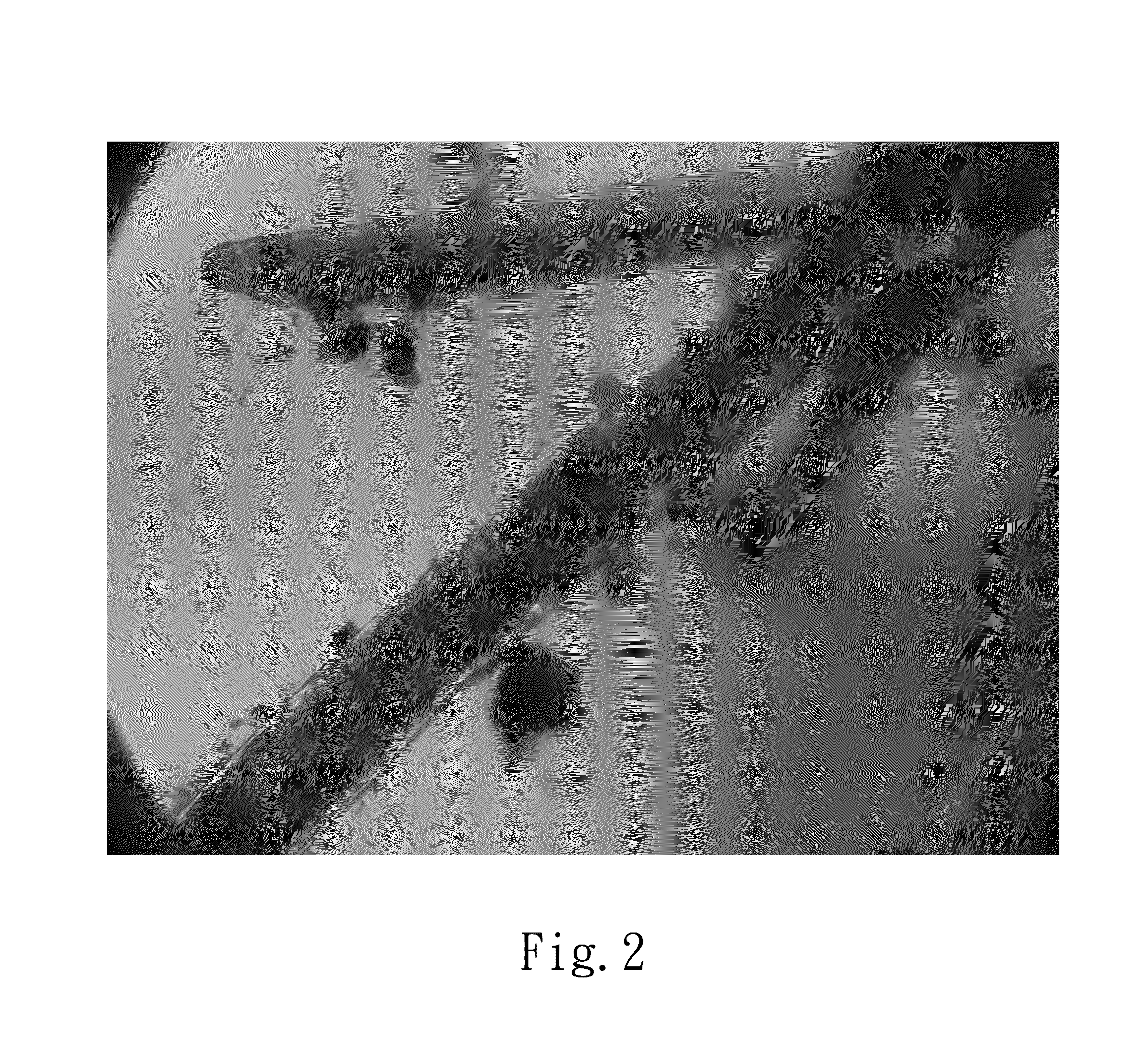

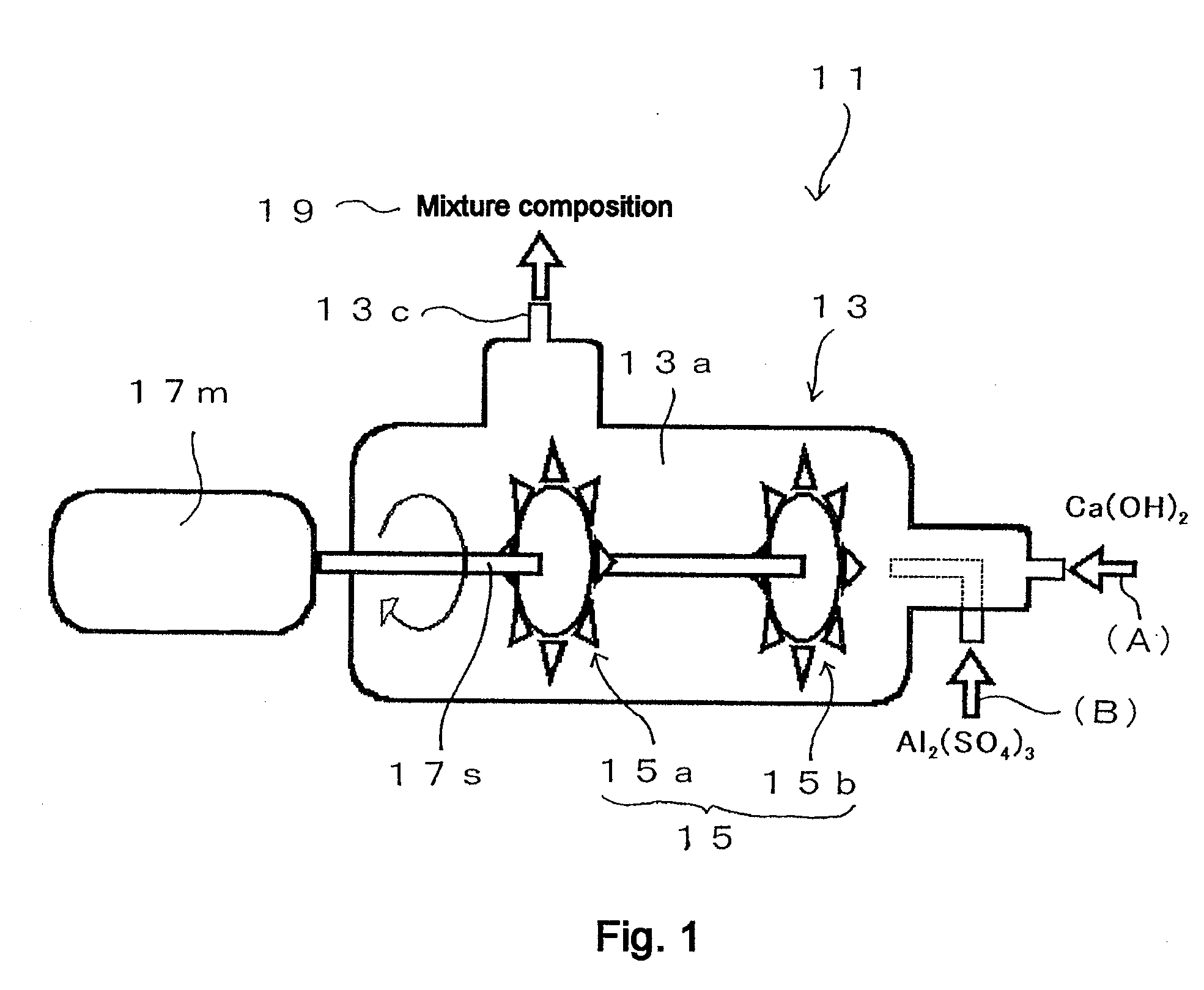

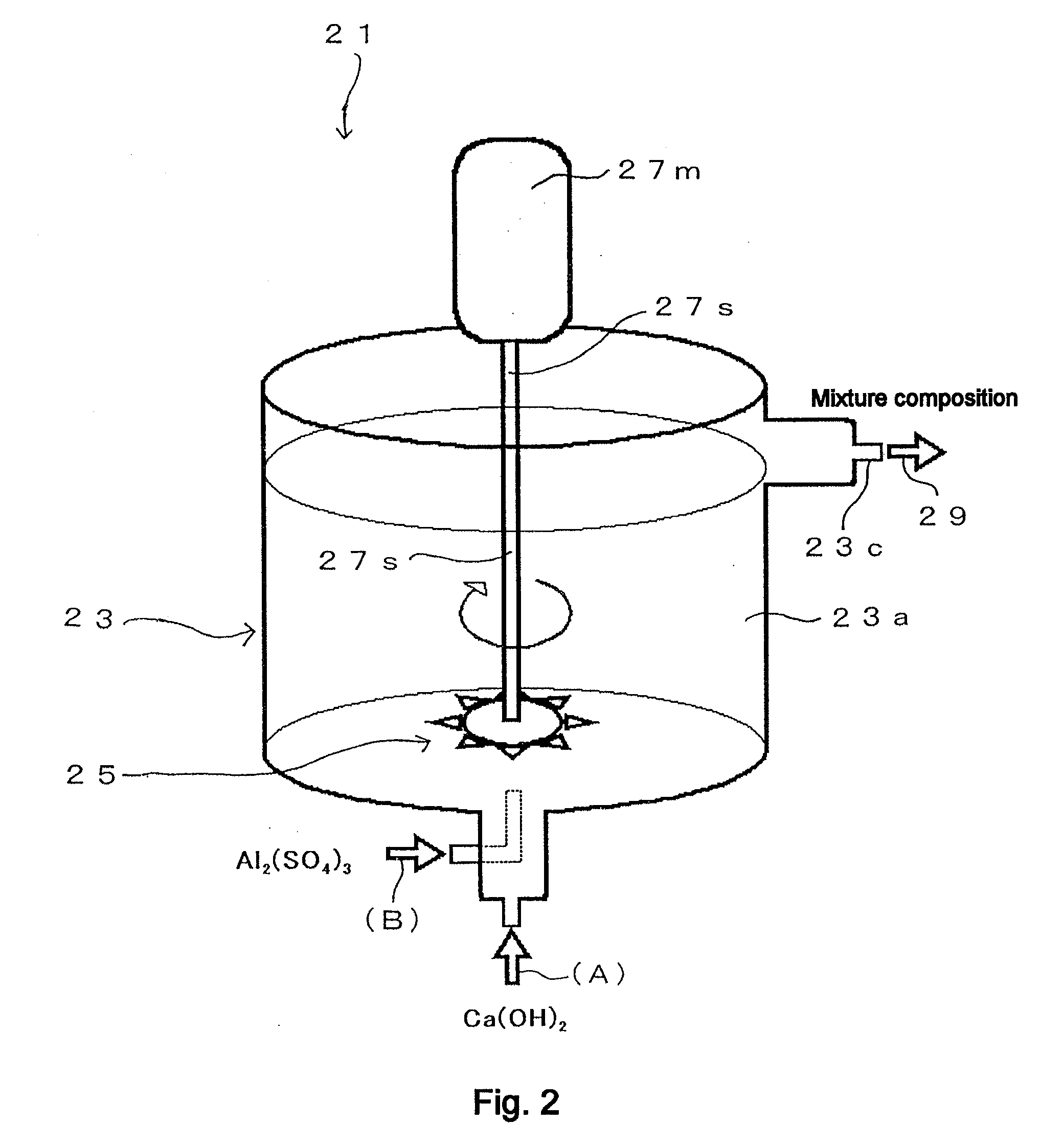

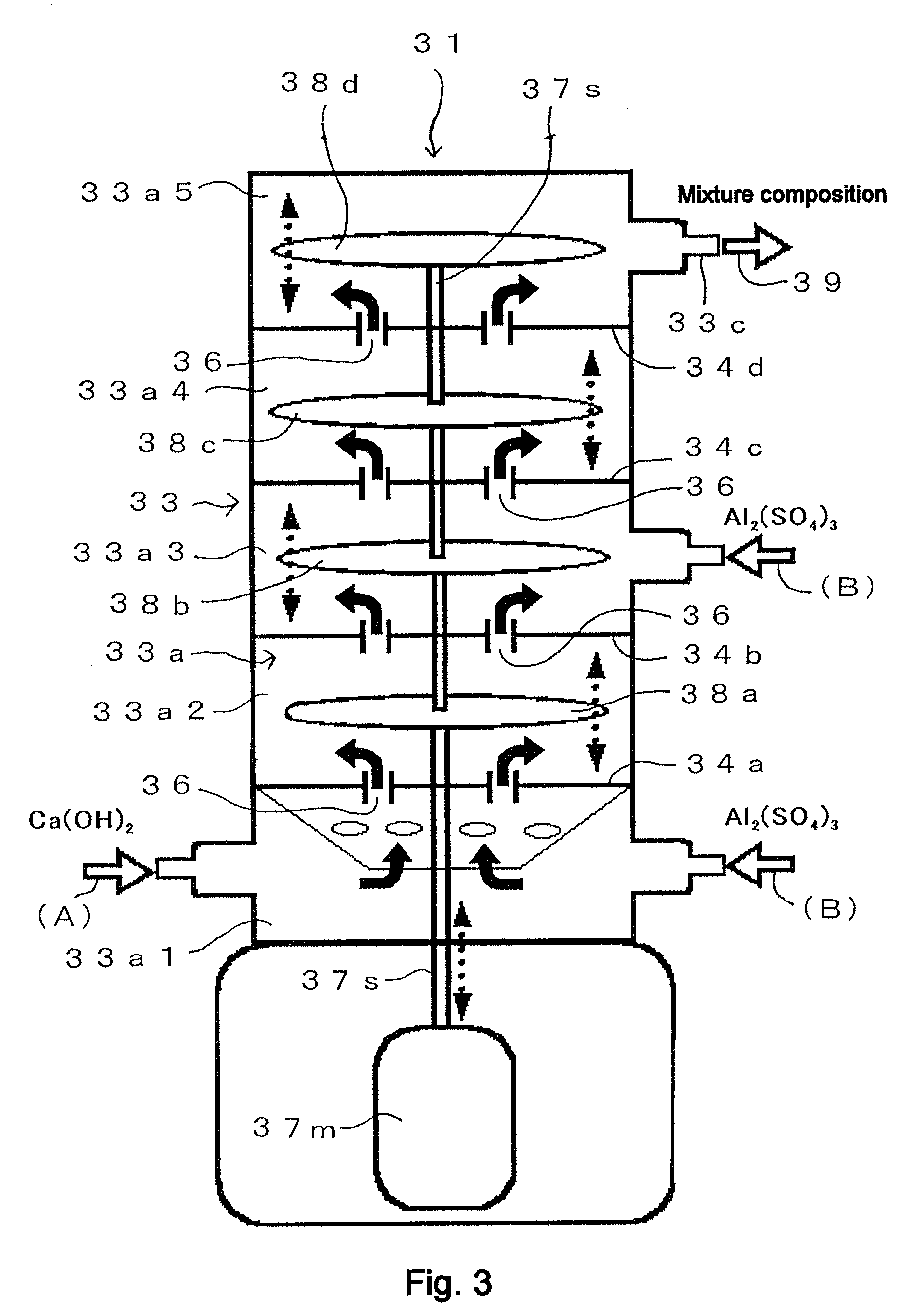

Process for producing calcium trisulfoaluminate and apparatus for use in said process

InactiveUS20070196264A1Small shapeStable productionPigmenting treatmentCoatings with pigmentsCalcium hydroxideAluminum sulphate

This invention provides a production process, which can stably produce high-quality satin white (calcium trisulfoaluminate) having very small and homogeneous particulate shapes suitable for incorporation into coated paper for printing, and an apparatus for use in said process. In this process for producing calcium trisulfoaluminate, a calcium hydroxide suspension (A) is reacted with an aqueous aluminum sulfate solution (B) to produce calcium trisulfoaluminate (C). The aqueous aluminum sulfate solution (B) is added in plurality of stages to the calcium hydroxide suspension (A). At least any one stage of the plurality of stages addition, addition of the aqueous aluminum sulfate solution (B) to the calcium hydroxide suspension (A) is carried out in such a manner that the aqueous aluminum sulfate solution (B) is continuously added to the calcium hydroxide suspension (A) being continuously transferred.

Owner:OJI PAPER CO LTD

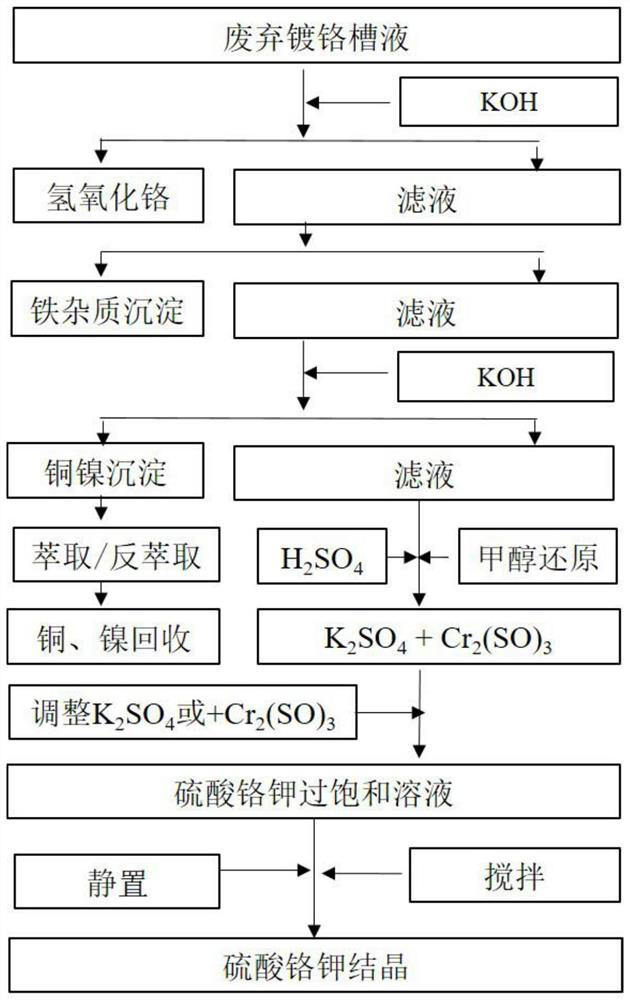

Disposal technology of waste chrome plating bath

ActiveCN113912119BHigh purityIncrease added valueChrome alumChromium(III) hydroxidePhysical chemistry

A process for disposing of a discarded chrome-plating bath. The KOH solution is slowly added to the discarded chrome-plating bath to react to obtain a chromium hydroxide precipitate and a filtrate, the chromium hydroxide precipitate is reacted with sulfuric acid to obtain a chromium sulfate solution, and the filtrate is subjected to impurity separation treatment and After the ion separation treatment, a solution containing chromium sulfate is reduced, and finally the chromium sulfate solution is combined and concentrated by heating to a supersaturated solution of potassium chromium sulfate, and crystallization is carried out on the basis of the supersaturated solution of potassium chromium sulfate to obtain potassium chromium sulfate. The invention has the characteristics of high recovery rate, high product purity, various recovery types, almost no acid and alkali salts discharged to the environment and the like.

Owner:SHANGHAI JIAOTONG UNIV +1

Chain inorganic oxide fine particle groups

InactiveUS7309457B2Solution value is not highImprove adhesionMaterial nanotechnologyAluminium silicatesSilica particleAntimonate

A chain antimony oxide fine particle group comprising antimony oxide fine particles which have an average particle diameter of 5 to 50 nm, are connected in the form of a chain and have an average connection number of 2 to 30 and preferably used for forming a hard coating film. The fine particle group can be prepared by a process comprising treating an alkali antimonate aqueous solution with a cation exchange resin to prepare an antimonic acid (gel) dispersion and then treating the dispersion with an anion exchange resin and / or adding a base to the dispersion. Also provided is a substrate with a film comprising a substrate and a hard coating film. The hard coating film includes a chain inorganic oxide fine particle group, in which inorganic oxide fine particles of 2 to 30 on the average are connected in the form of a chain, and a matrix. The inorganic oxide particles may be silica particles, silica-alumina particles being preferable, and porous particles and / or hollow particles having a cavity inside being more preferable.

Owner:JGC CATALYSTS & CHEM LTD

Preparation of suspensions

ActiveUS20140127117A1Quick mixLittle effectMaterial nanotechnologyNitrogen compoundsCoprecipitationHeat treated

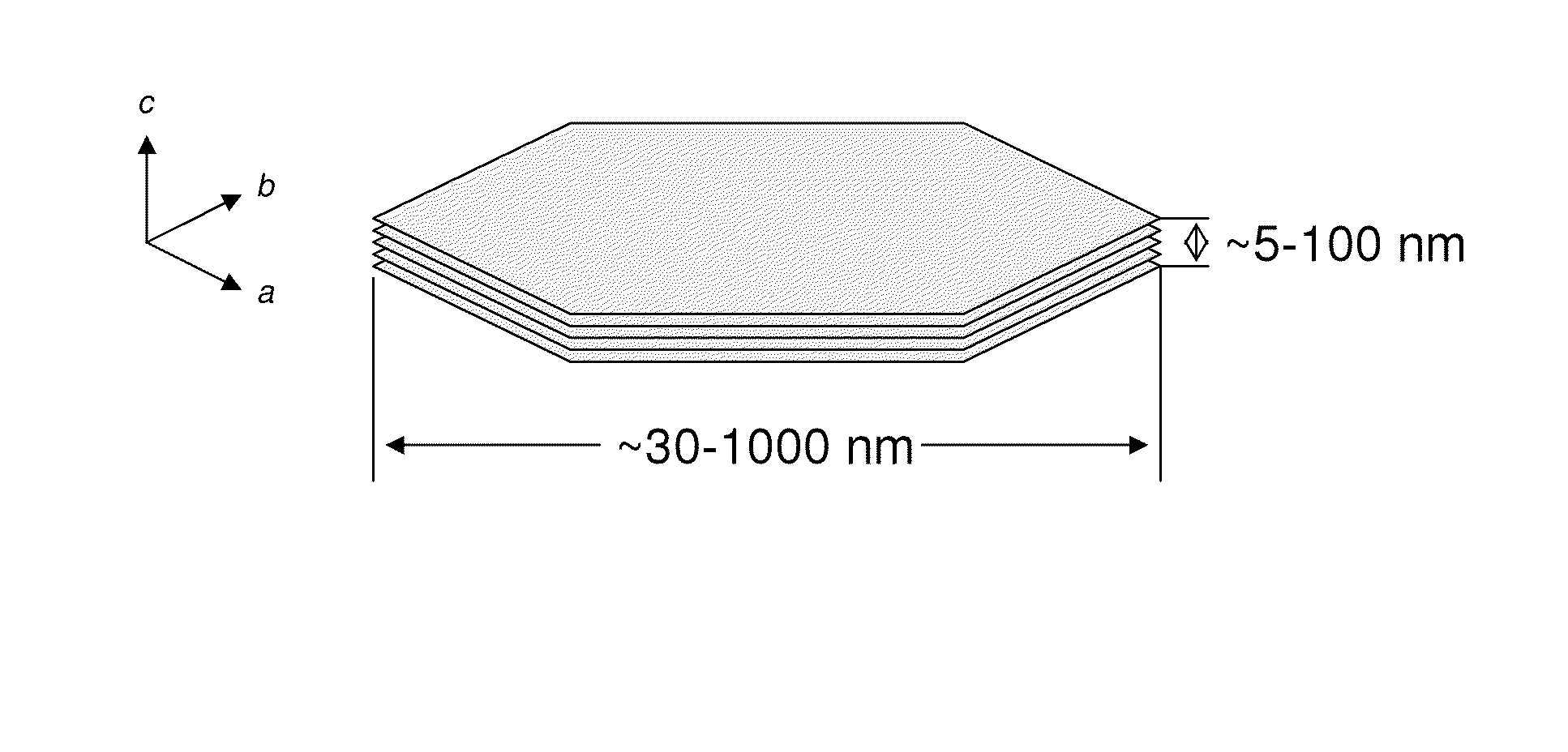

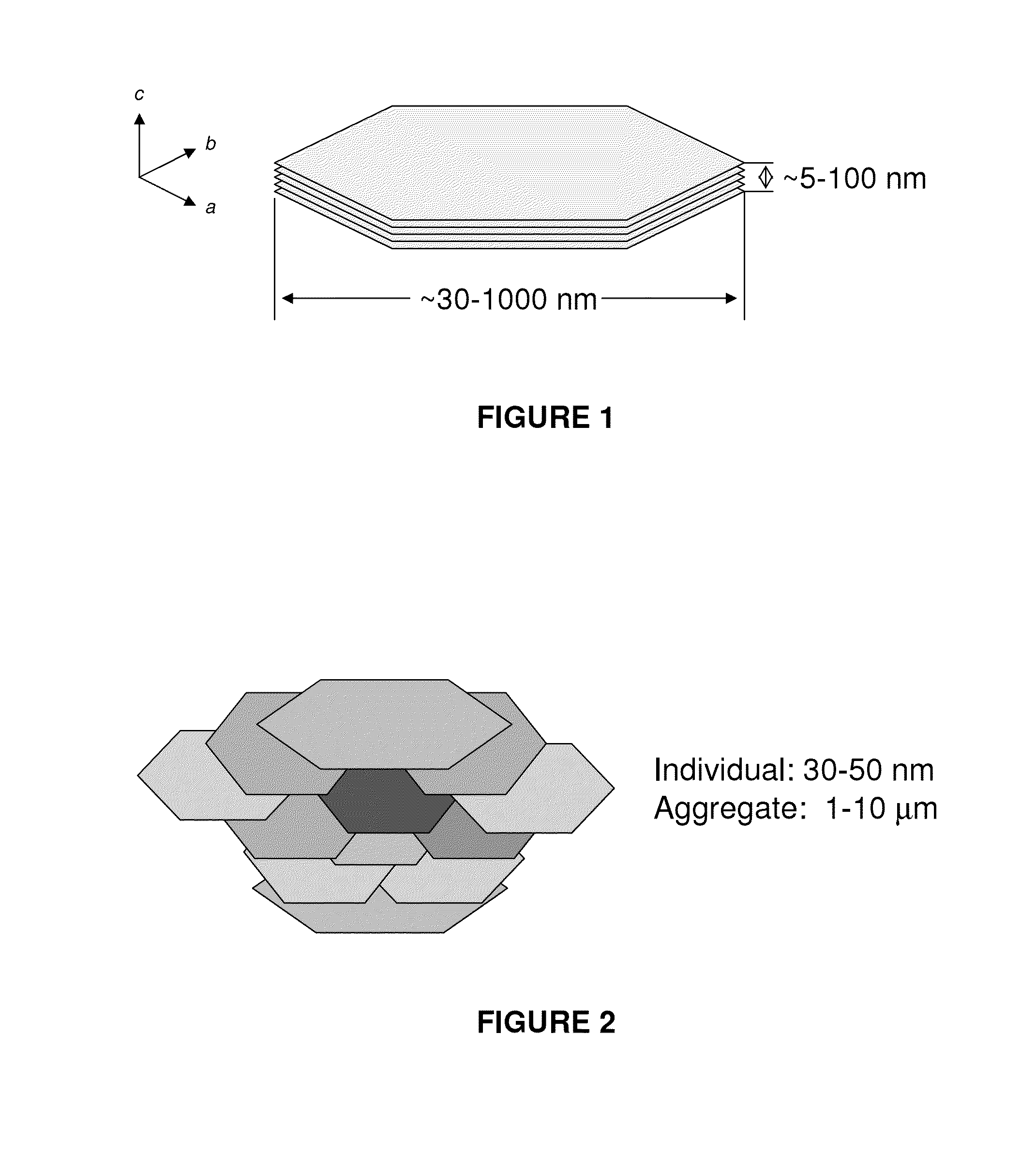

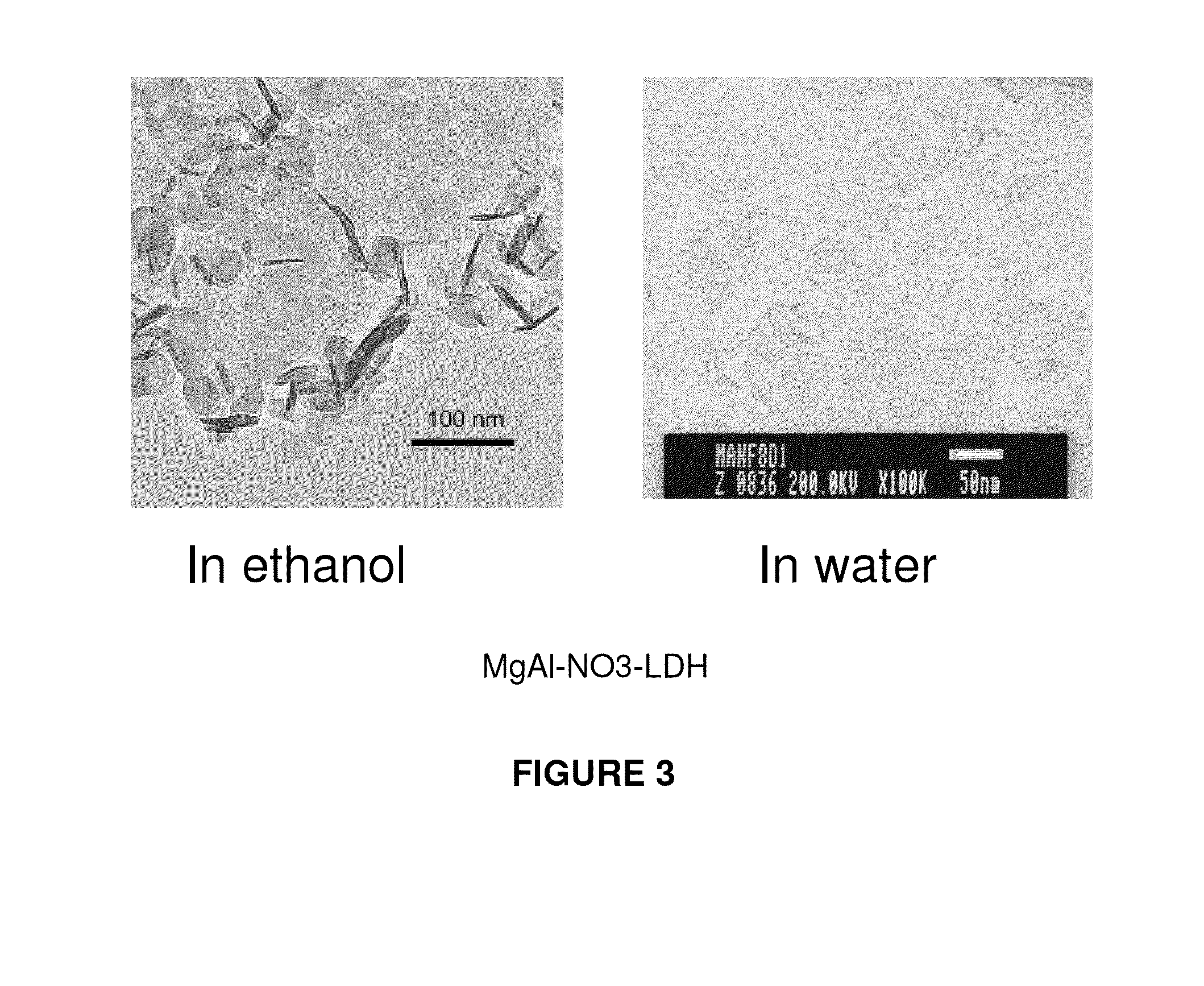

A method for preparing a suspension of LDH particles comprises the steps of preparing LDH precipitates by coprecipitation to form a mixture of LDH precipitates and solution; separating the LDH precipitates from the solution; washing the LDH precipitates to remove residual ions; mixing the LDH precipitates with water; and subjecting the mixture of LDH particles and water from step (d) to a hydrothermal treatment step by heating to a temperature of from greater than 80° C. to 150° C. for a period of about 1 hour to about 48 hours to form a well dispersed suspension of LDH particles in water.

Owner:THE UNIV OF QUEENSLAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com