Small prismatic annular air-cooled micro-reactor core system with densely arranged coolant channels

A coolant and prismatic technology, which is applied in the field of small prismatic annular gas-cooled micro-reactor core systems, can solve problems such as affecting the functions of control rod cladding and other internal components of the reactor, affecting the safety of the core, etc., and achieves a moderation ratio of High, improve the temperature rise margin, prevent the effect of fission product release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are introduced below in conjunction with accompanying drawings:

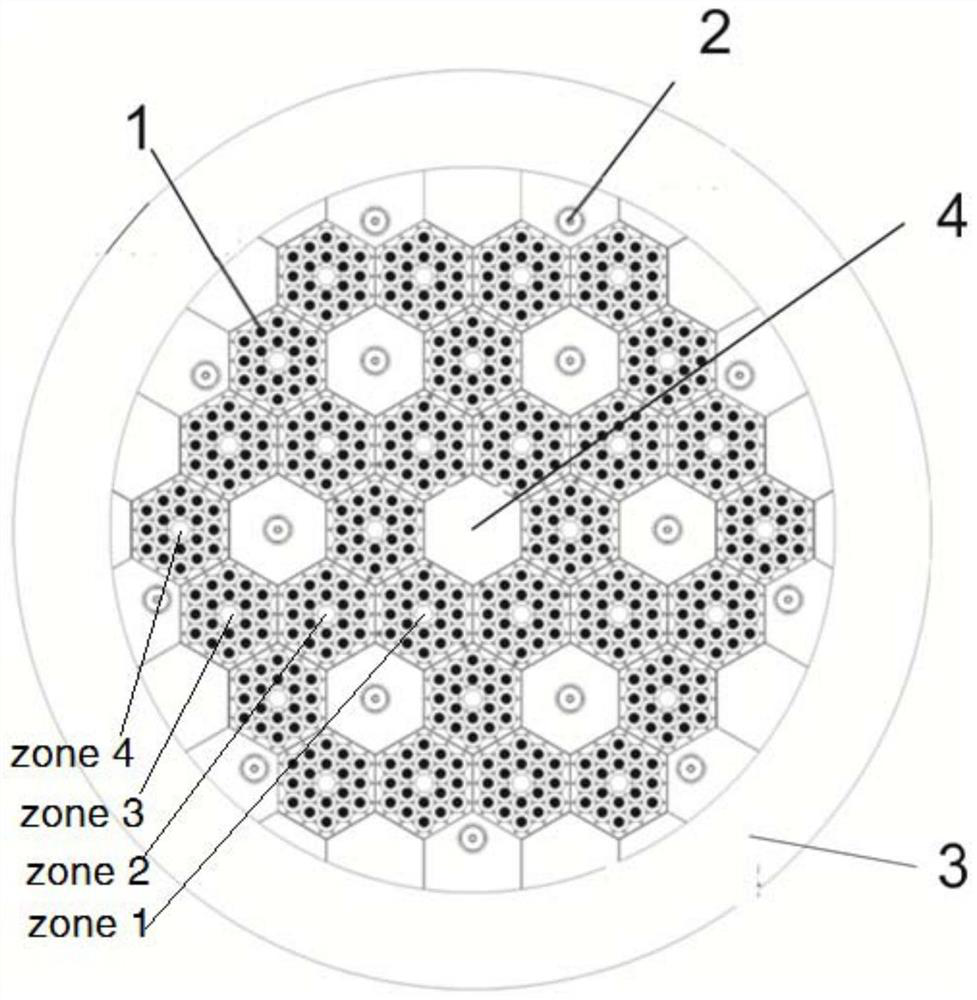

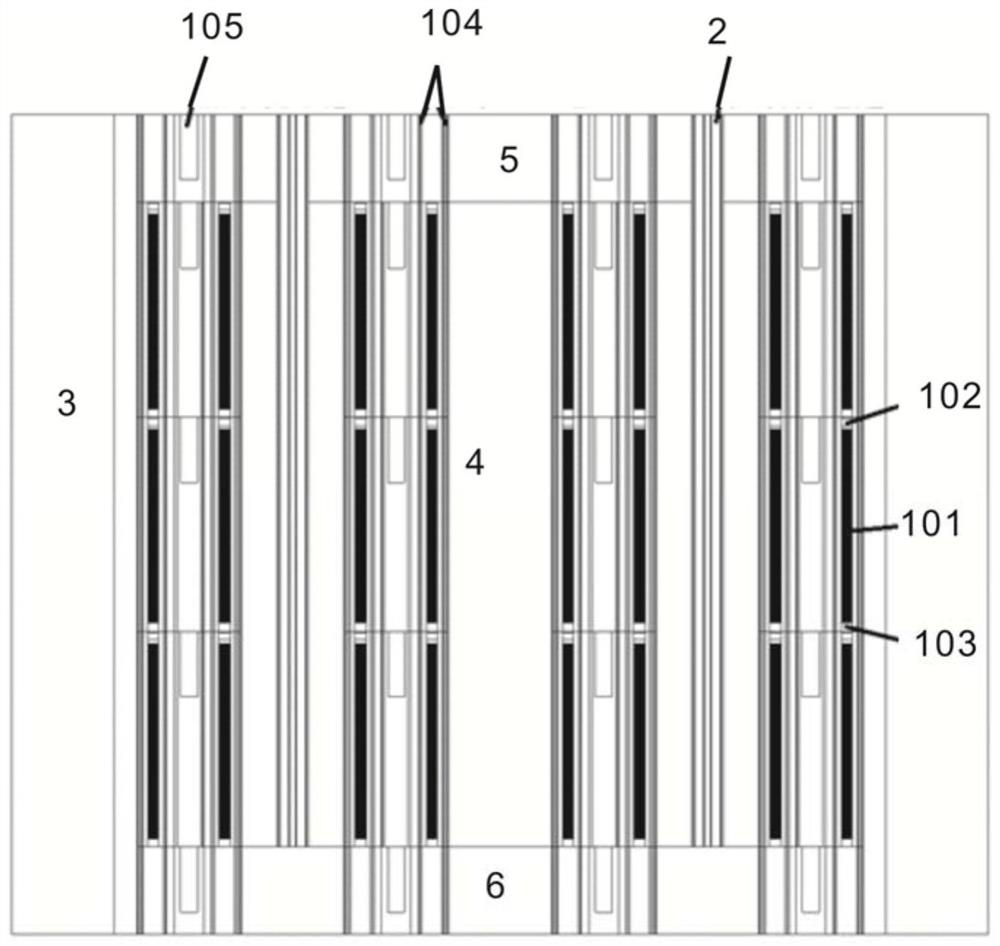

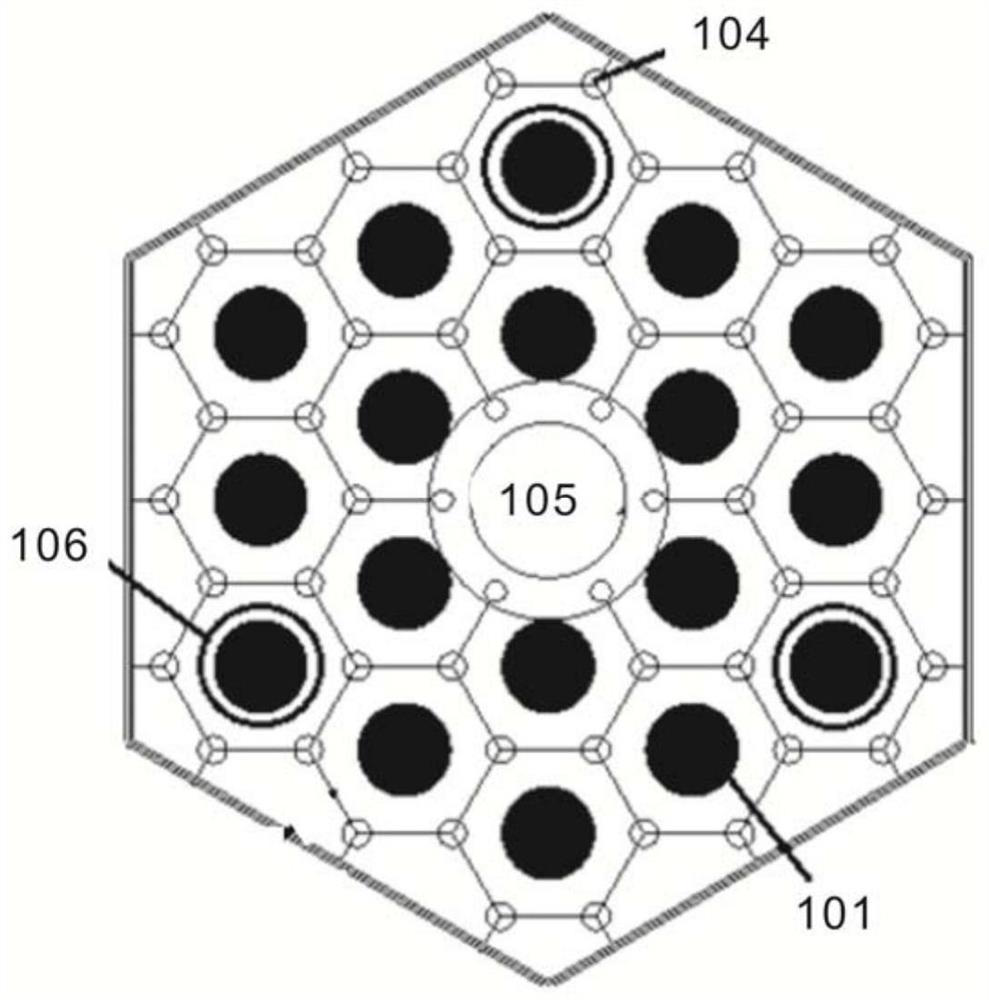

[0032] The present invention provides a small-scale prismatic annular air-cooled micro-reactor core system with densely arranged coolant passages, comprising a fuel assembly 1, a control rod assembly 2 and a reflection layer; the fuel assembly 1 is in the shape of a hexagonal prism, including Regularly arranged fuel rod passages and coolant passages 104; six coolant passages 104 are evenly and symmetrically arranged around each fuel rod passage to reduce the maximum fuel temperature; the reflective layer includes an upper reflective layer 5, a lower reflective layer 6, a side Reflector 3 and internal reflector 4; the upper reflector 5, lower reflector 6 and side reflector 3 wrap the core; the internal reflector 4 is arranged at the center of the core to prevent the core temperature from being too high; The fuel assembly 1 is arranged around the inner reflection layer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com