Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

515results about How to "Reduce tooling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

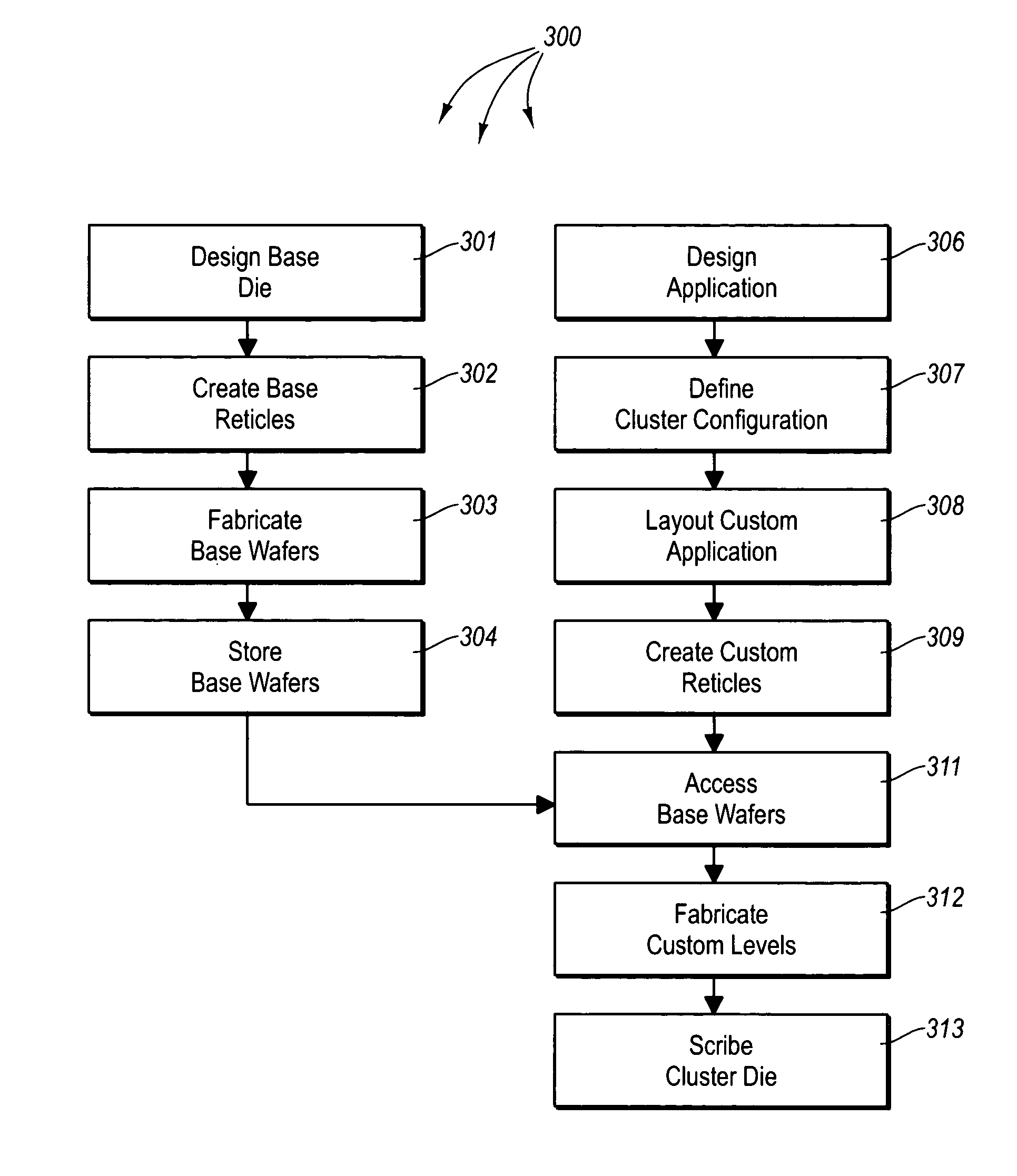

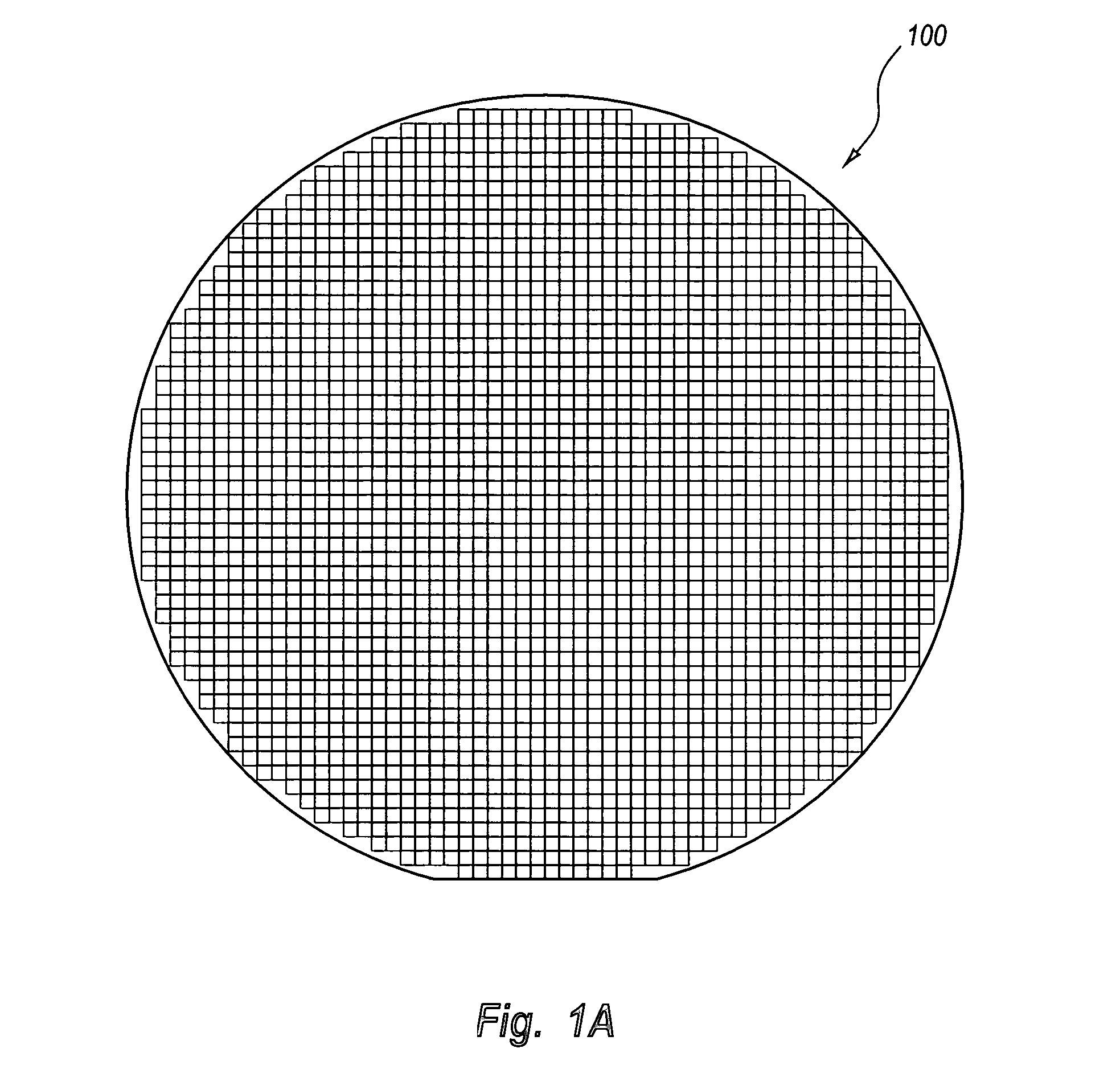

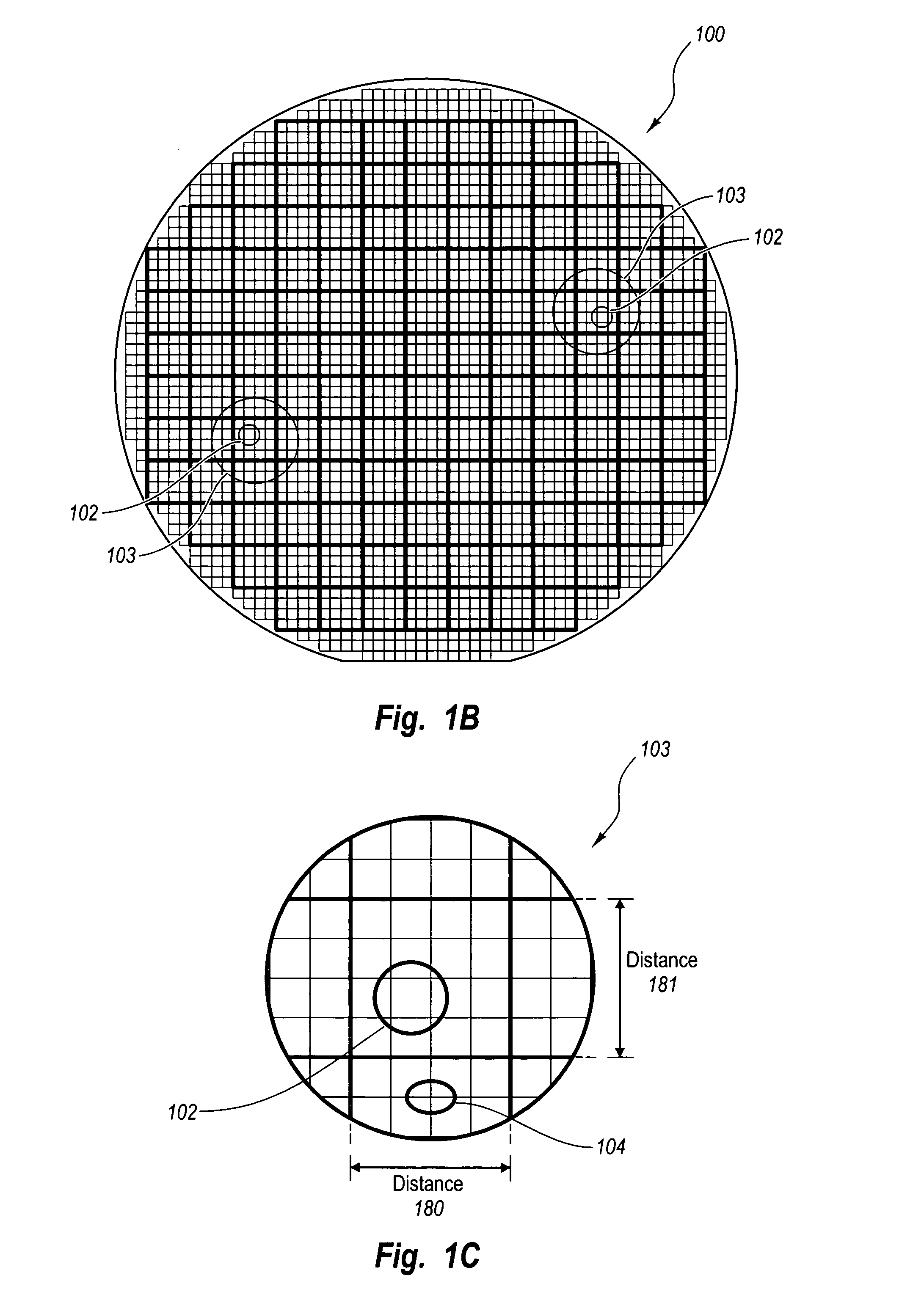

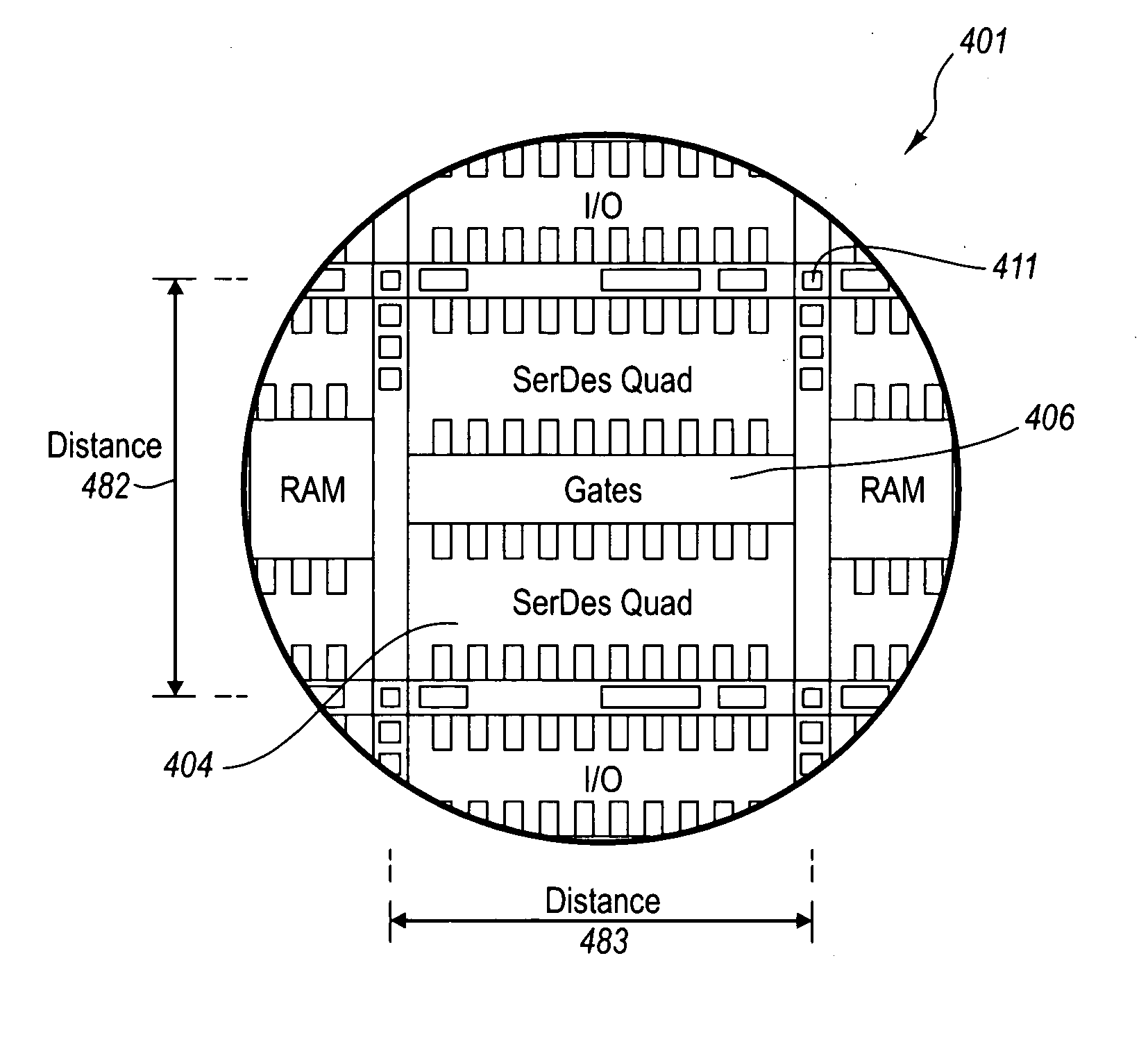

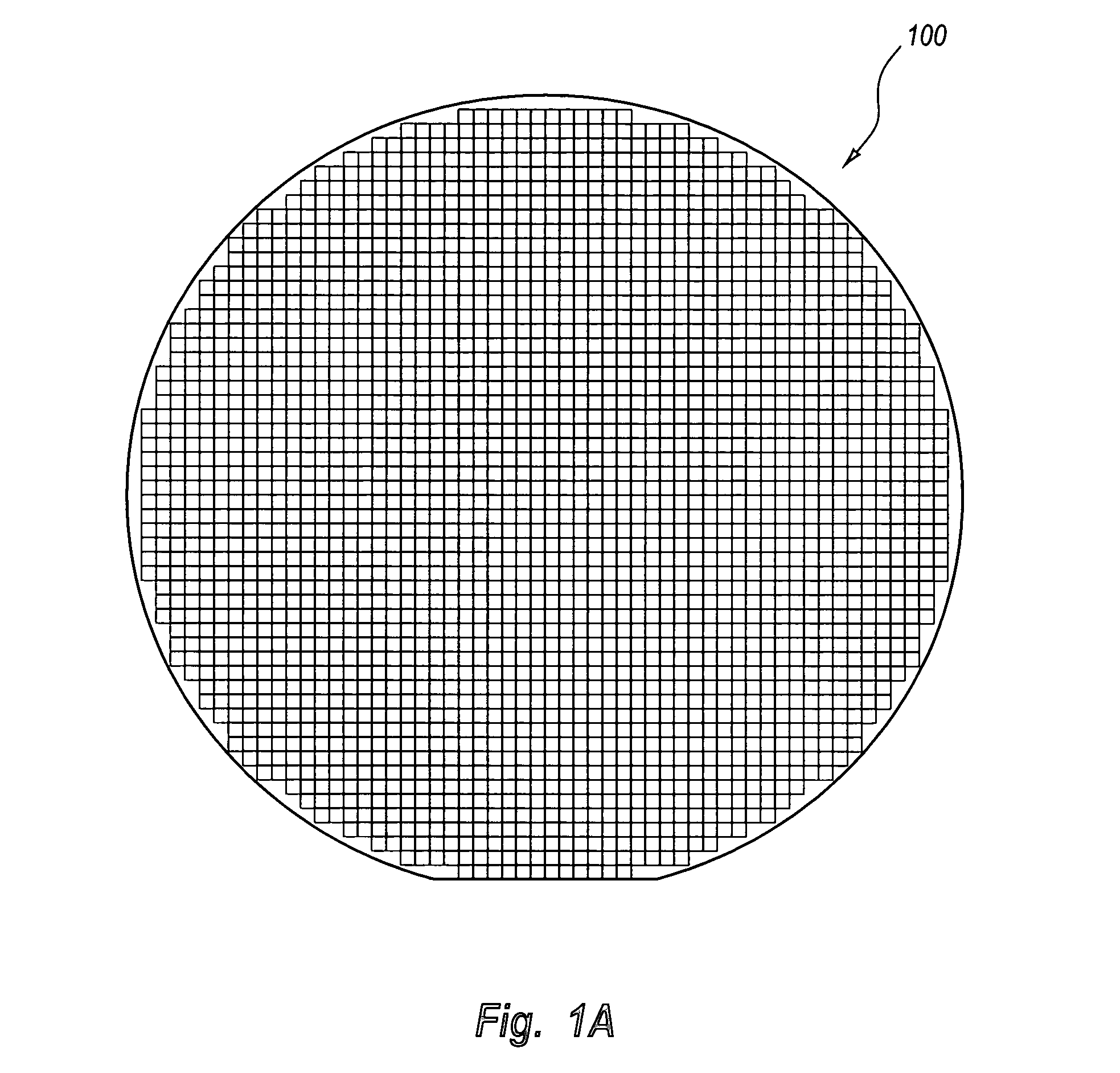

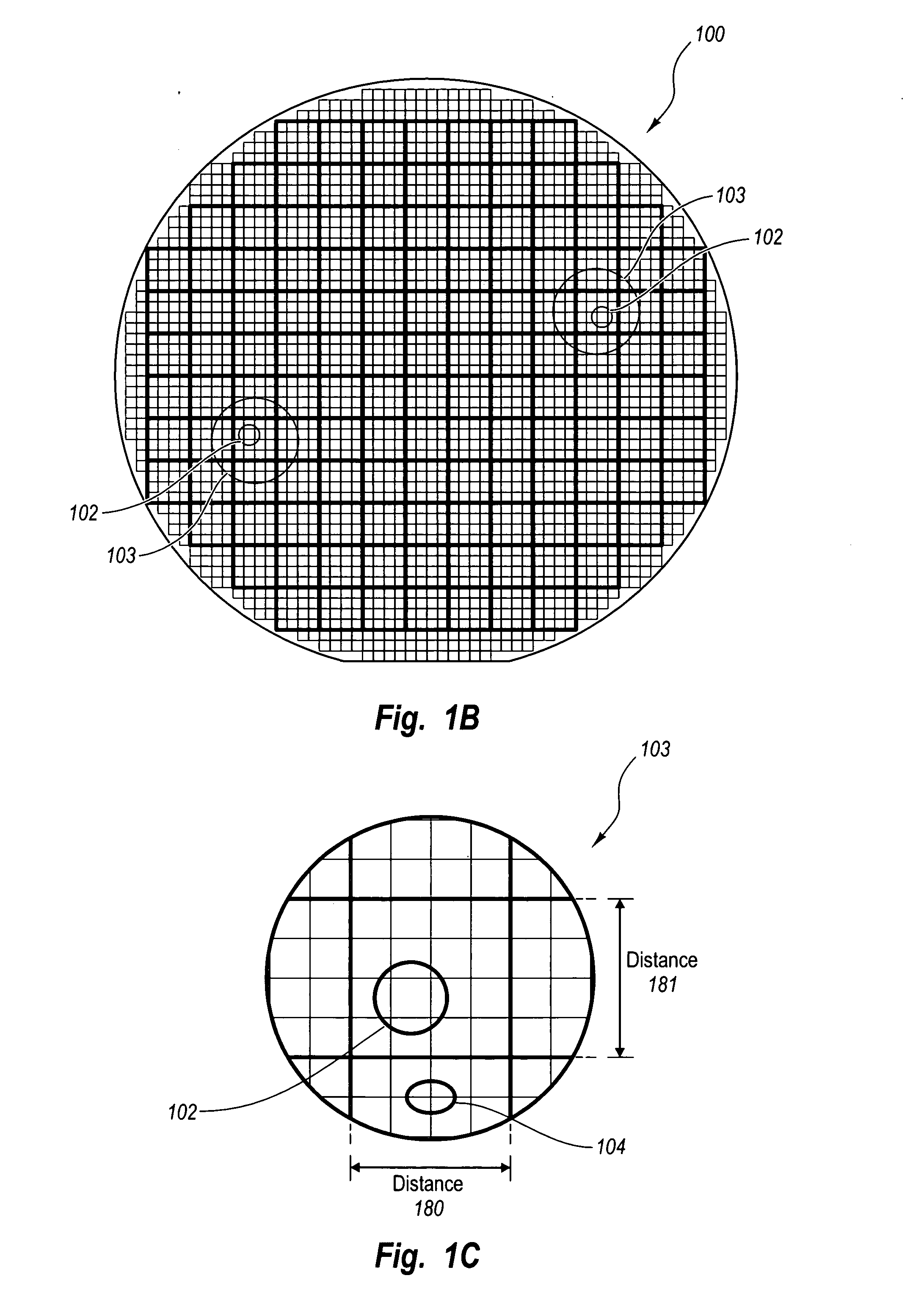

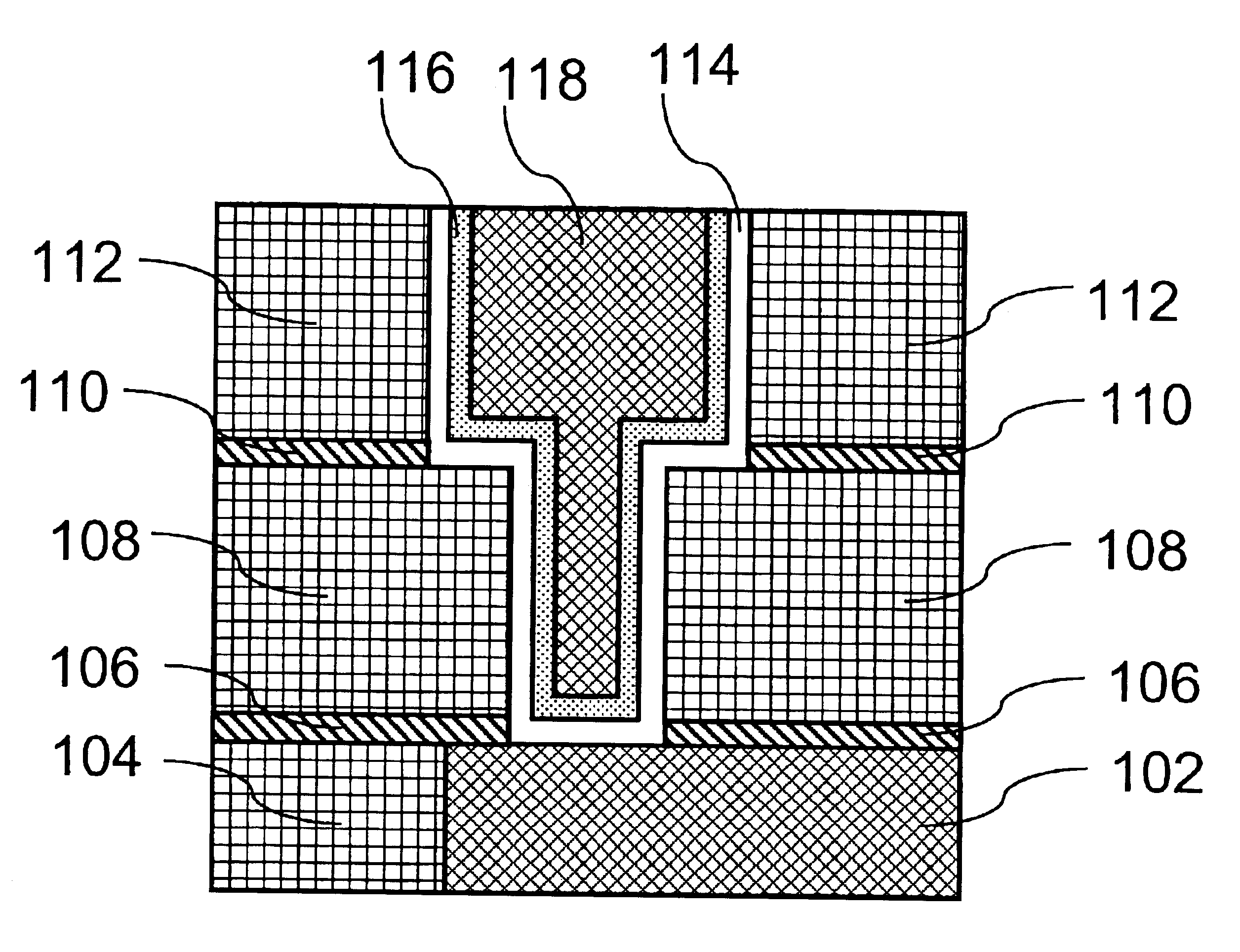

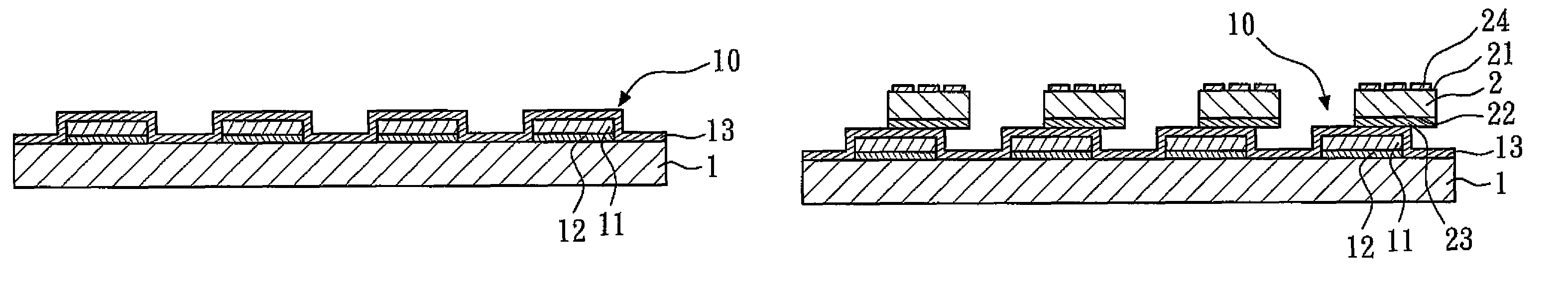

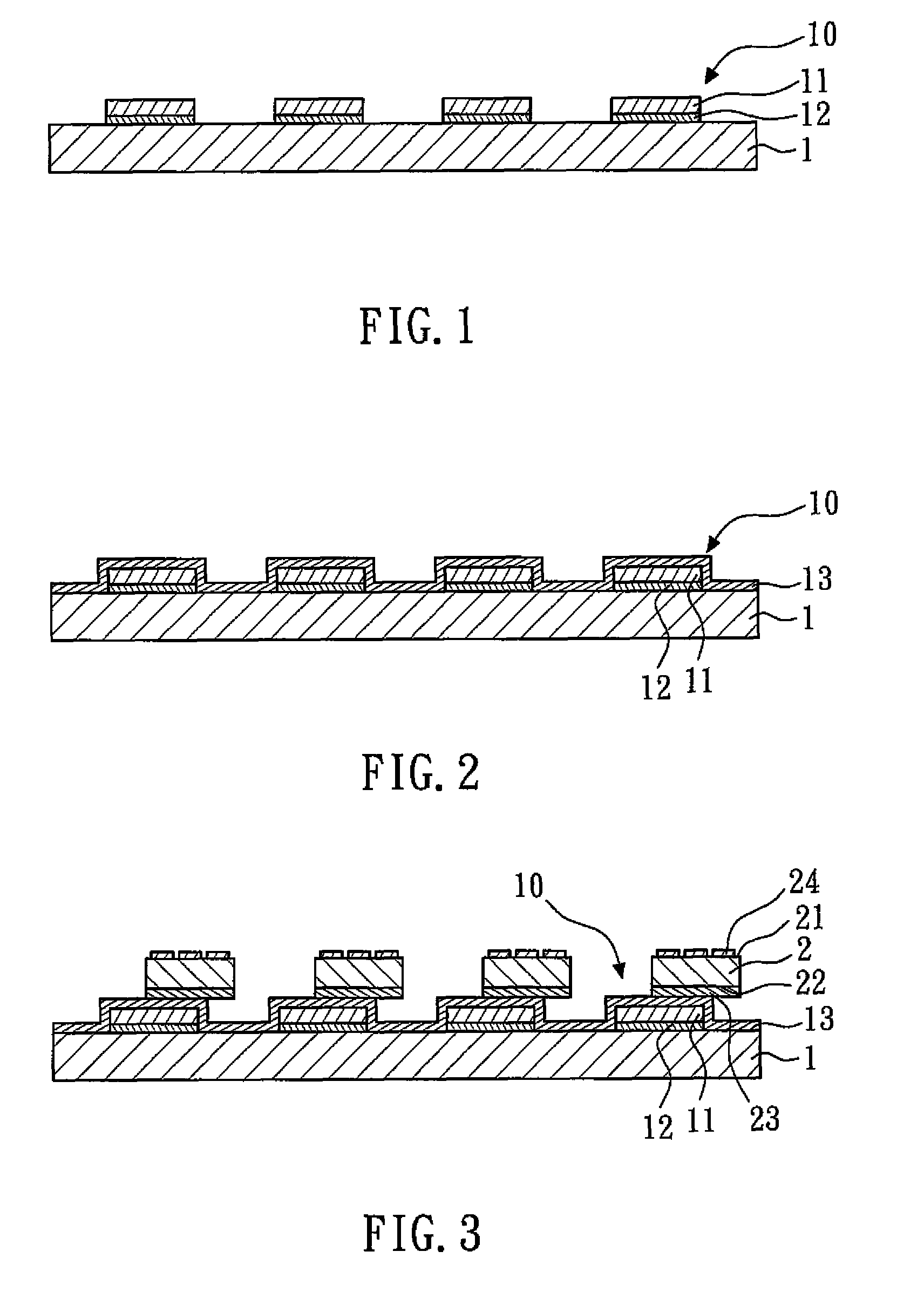

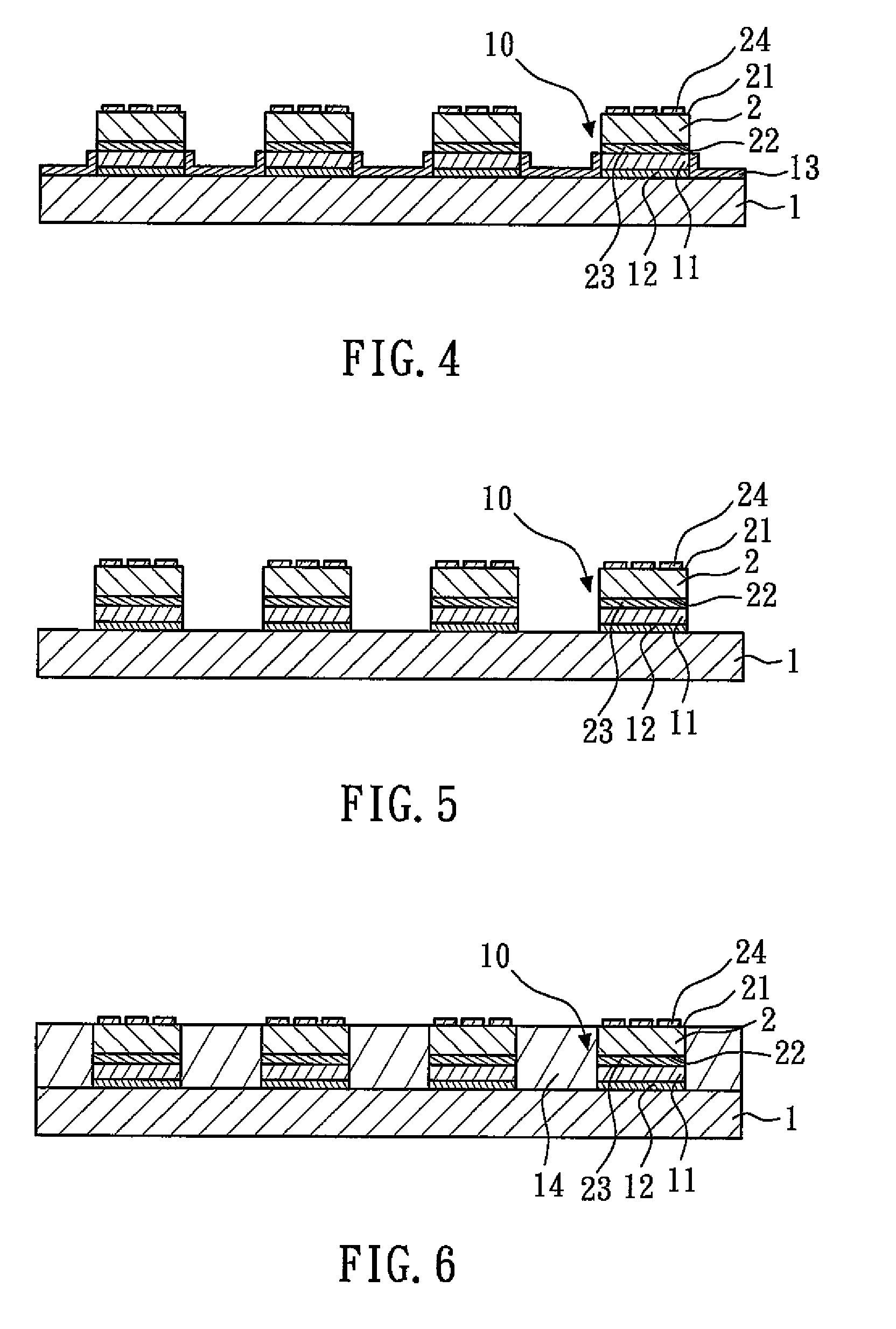

Structured ASIC device with configurable die size and selectable embedded functions

ActiveUS7337425B2Reduce the numberReduce tooling costsSemiconductor/solid-state device detailsSolid-state devicesGeneral purposeChip size

One embodiment of the present invention provides for a master or universal base and base tooling which addresses the general purpose Structured ASIC requirements. Another embodiment of the present invention provides for a common set of base tooling from which the master / universal base is created as well as additional custom bases with customized selection and quantity of embedded Platform ASIC functions. Embodiments can utilize conventional Structured ASIC architecture and processing and are compatible with traditional probing and packaging.

Owner:SEMICON COMPONENTS IND LLC

Structured ASIC device with configurable die size and selectable embedded functions

ActiveUS20050273749A1Reduce number of baseCost reductionSemiconductor/solid-state device detailsSolid-state devicesEmbedded systemChip size

One embodiment of the present invention provides for a master or universal base and base tooling which addresses the general purpose Structured ASIC requirements. Another embodiment of the present invention provides for a common set of base tooling from which the master / universal base is created as well as additional custom bases with customized selection and quantity of embedded Platform ASIC functions. Embodiments can utilize conventional Structured ASIC architecture and processing and are compatible with traditional probing and packaging.

Owner:SEMICON COMPONENTS IND LLC

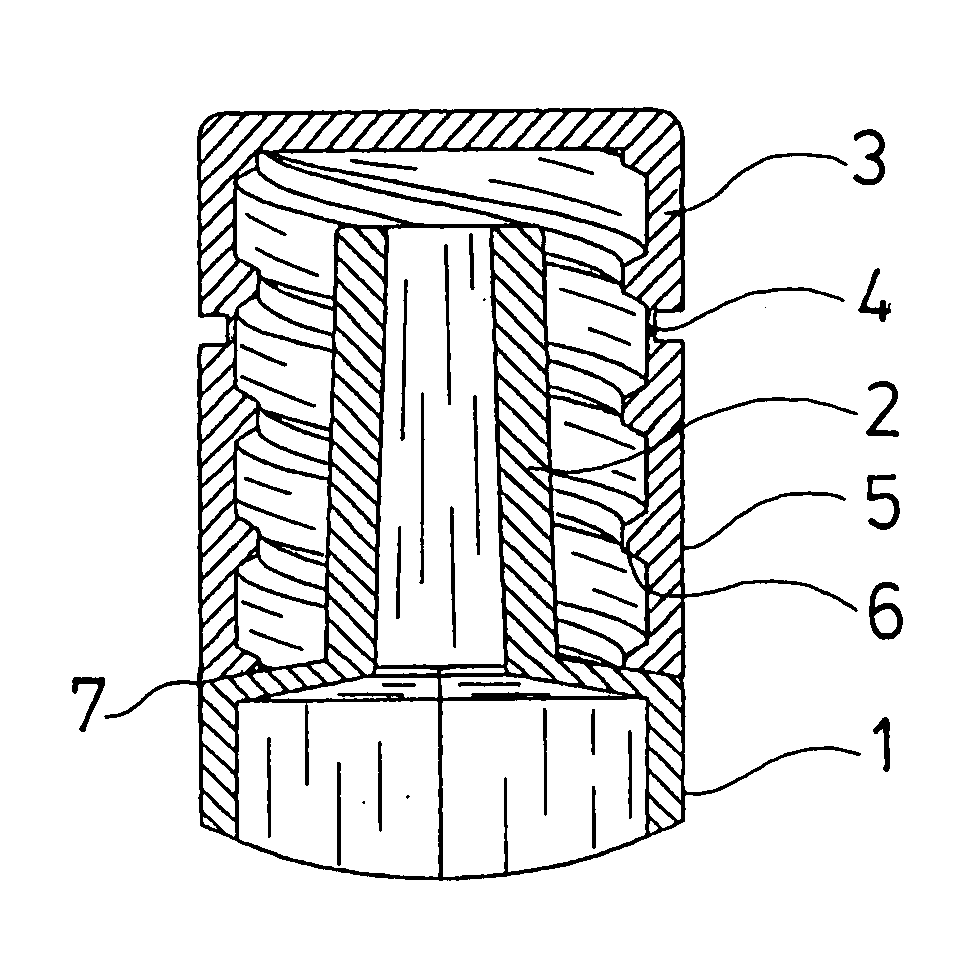

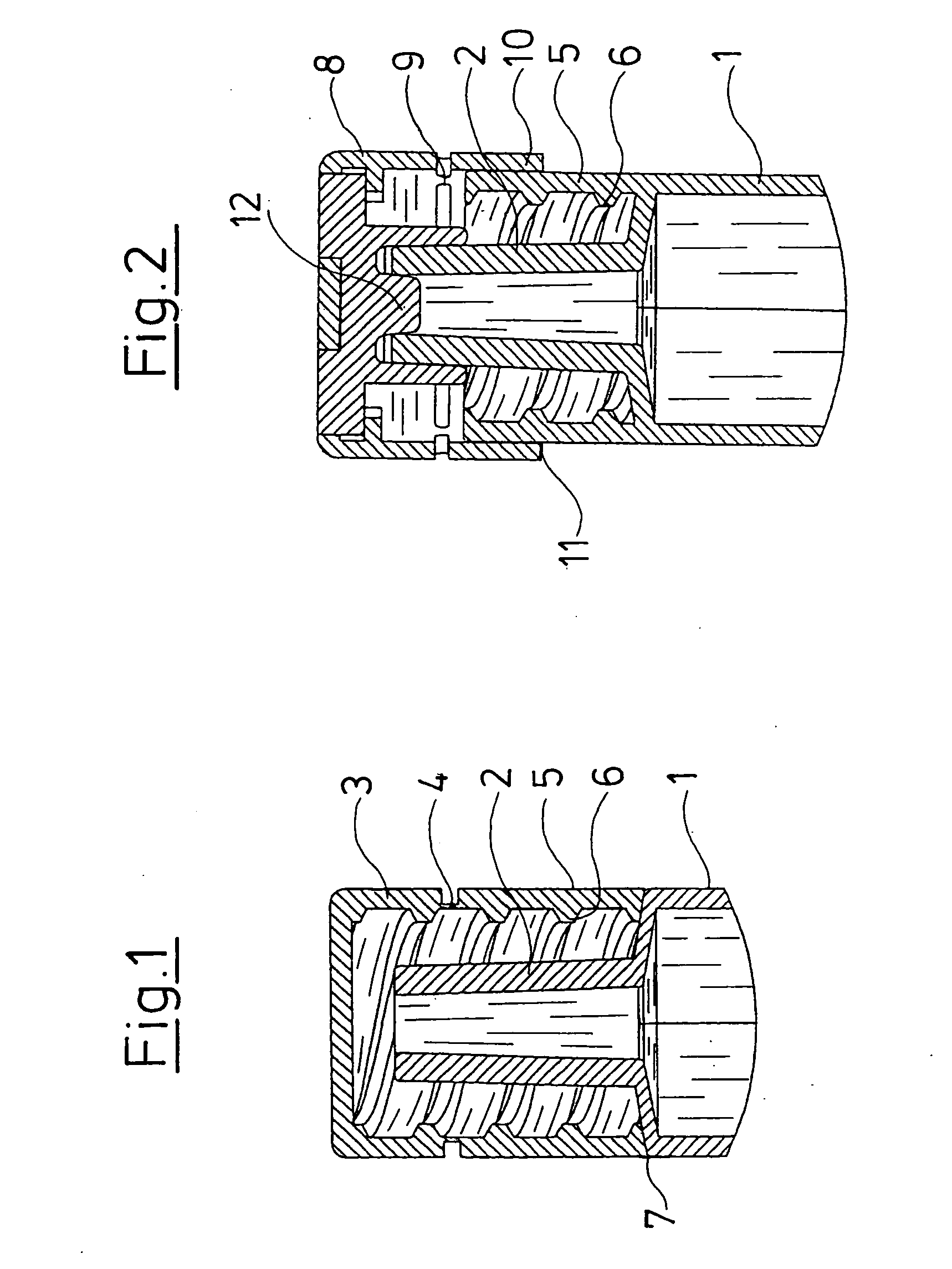

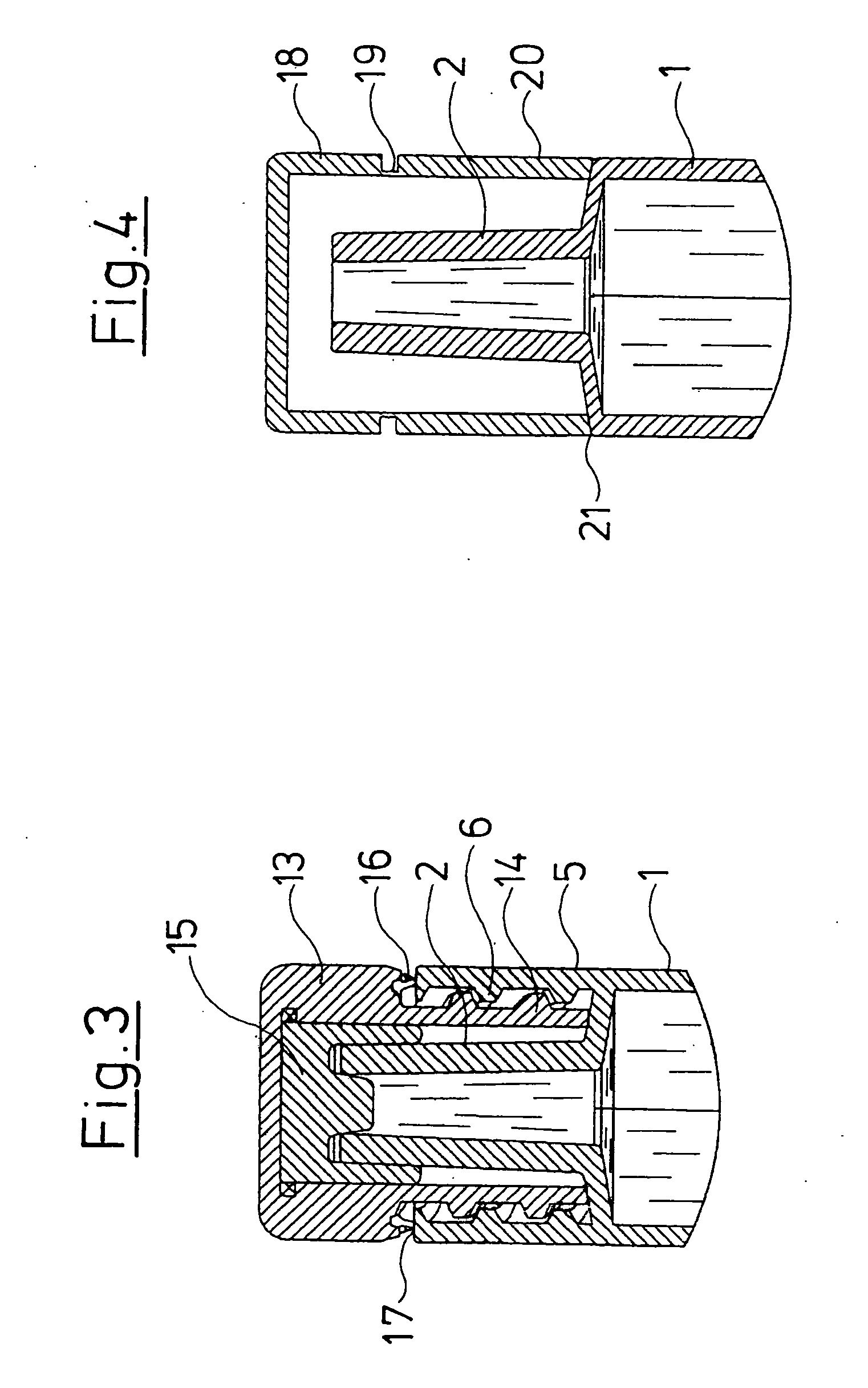

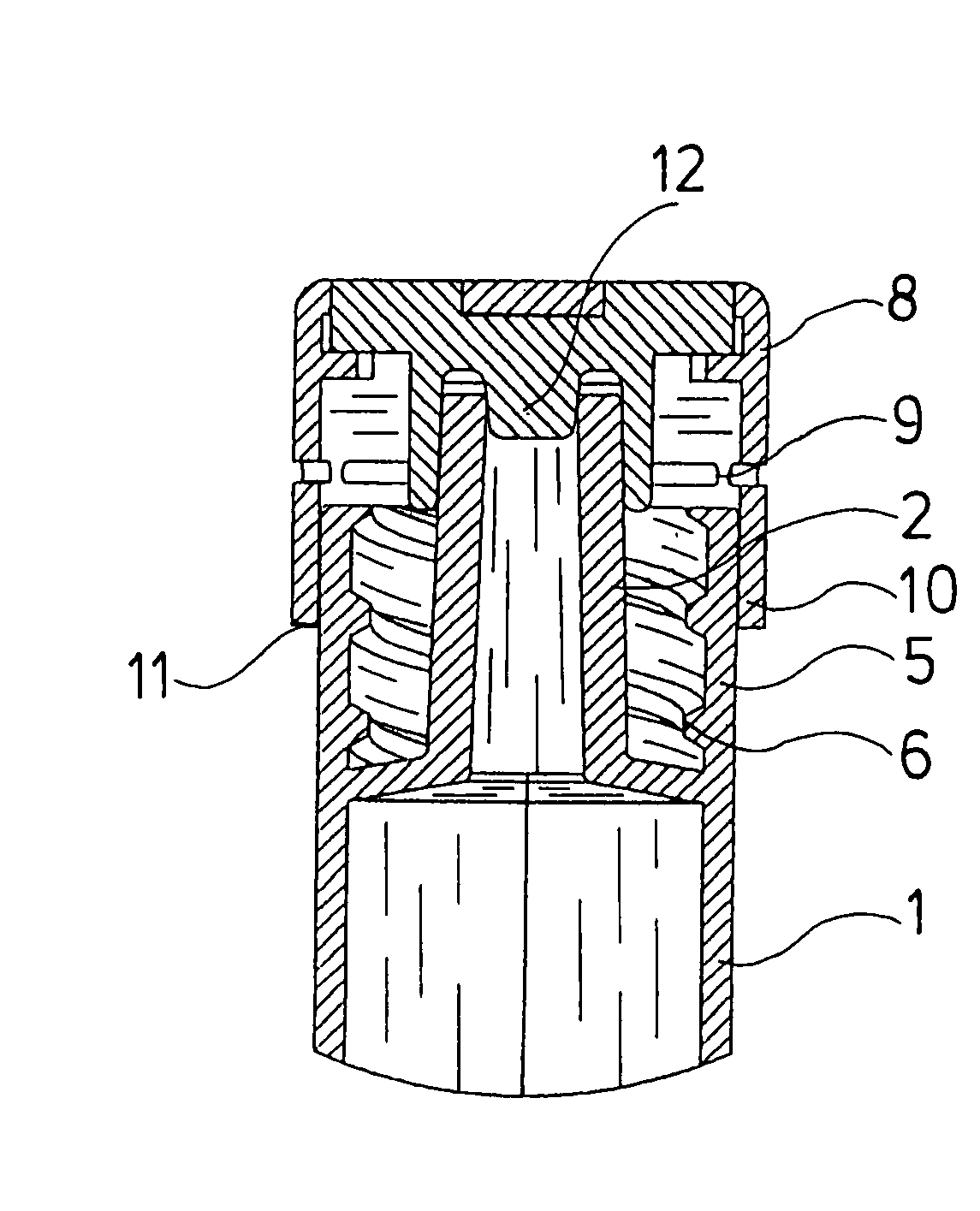

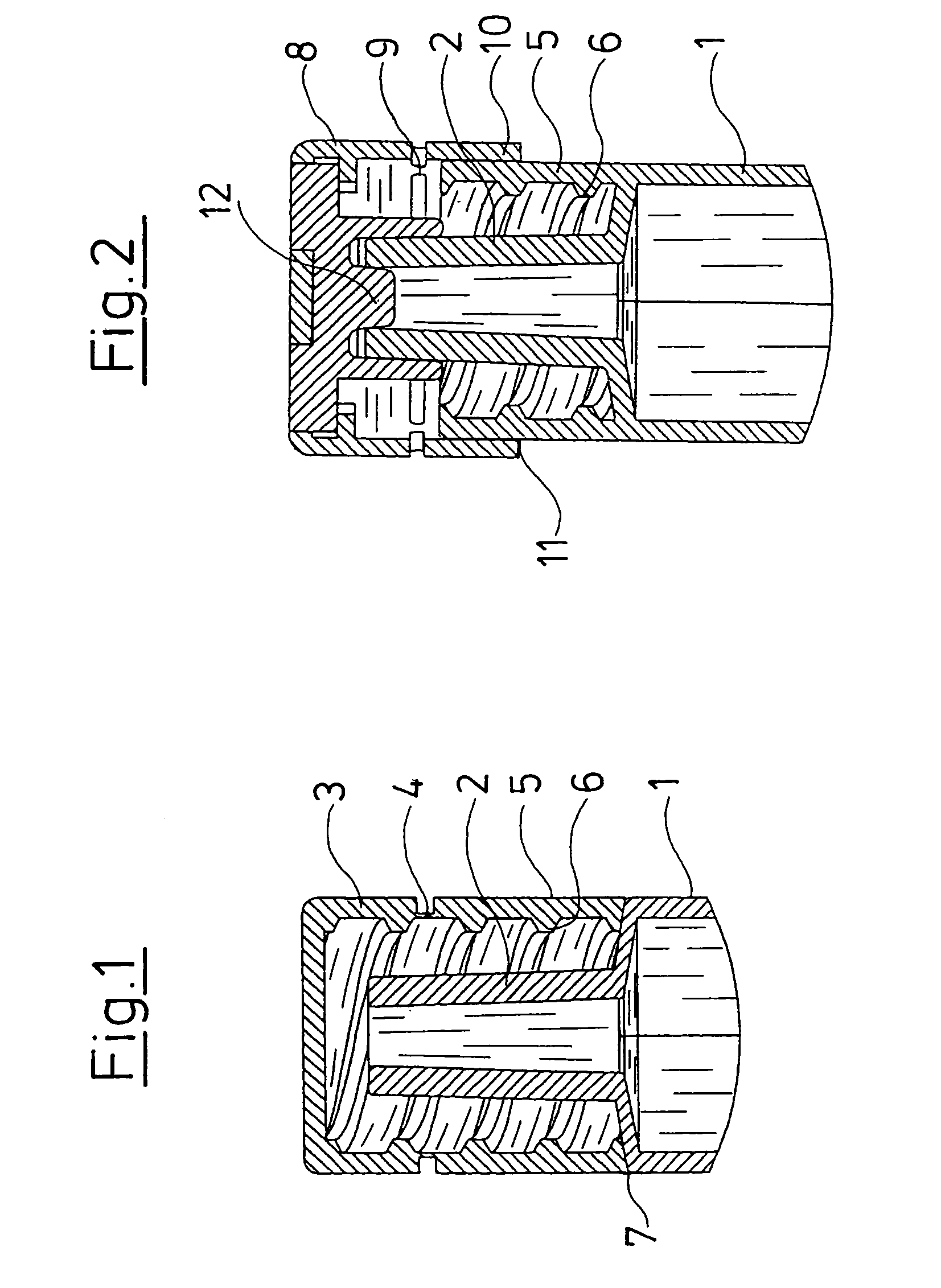

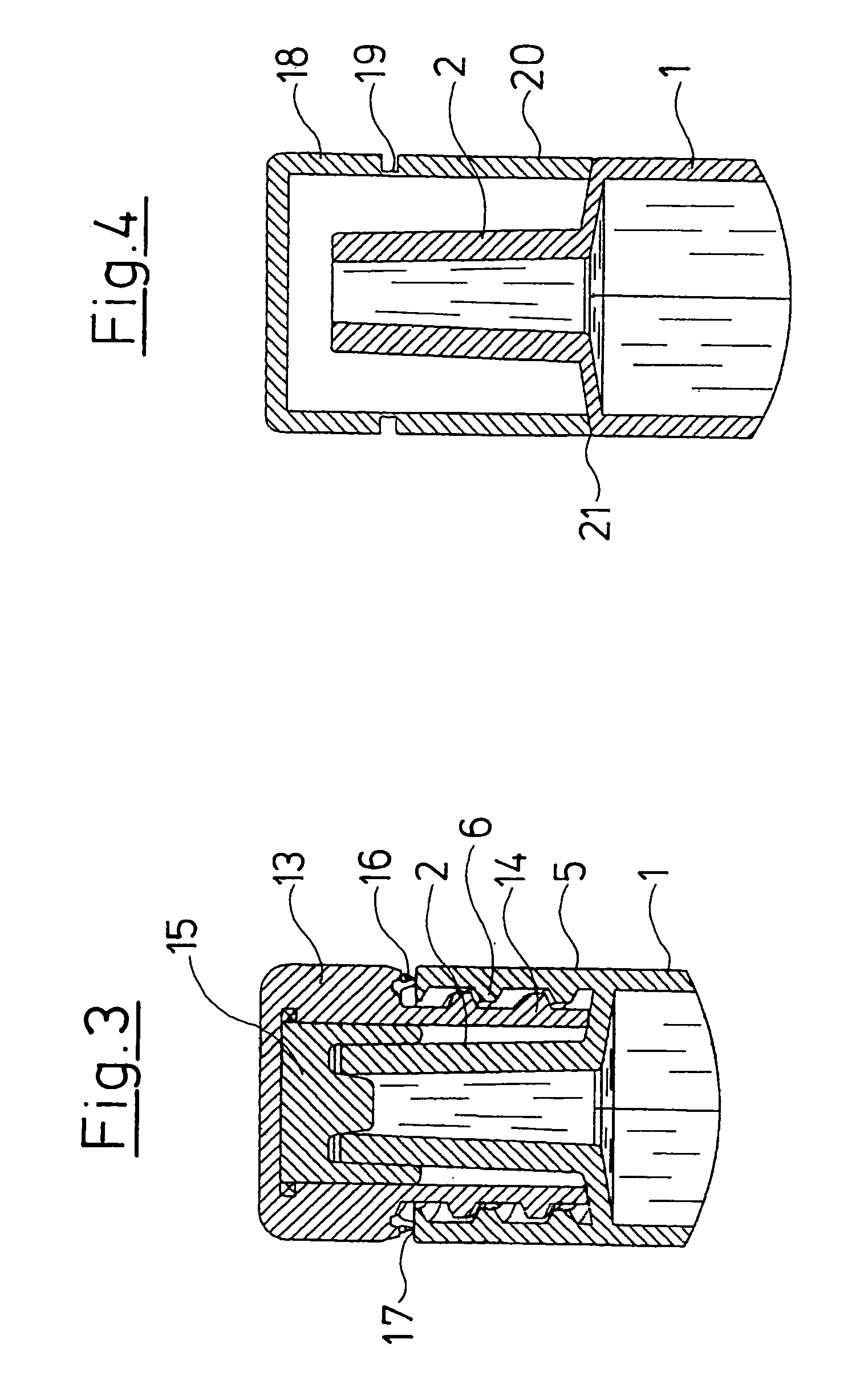

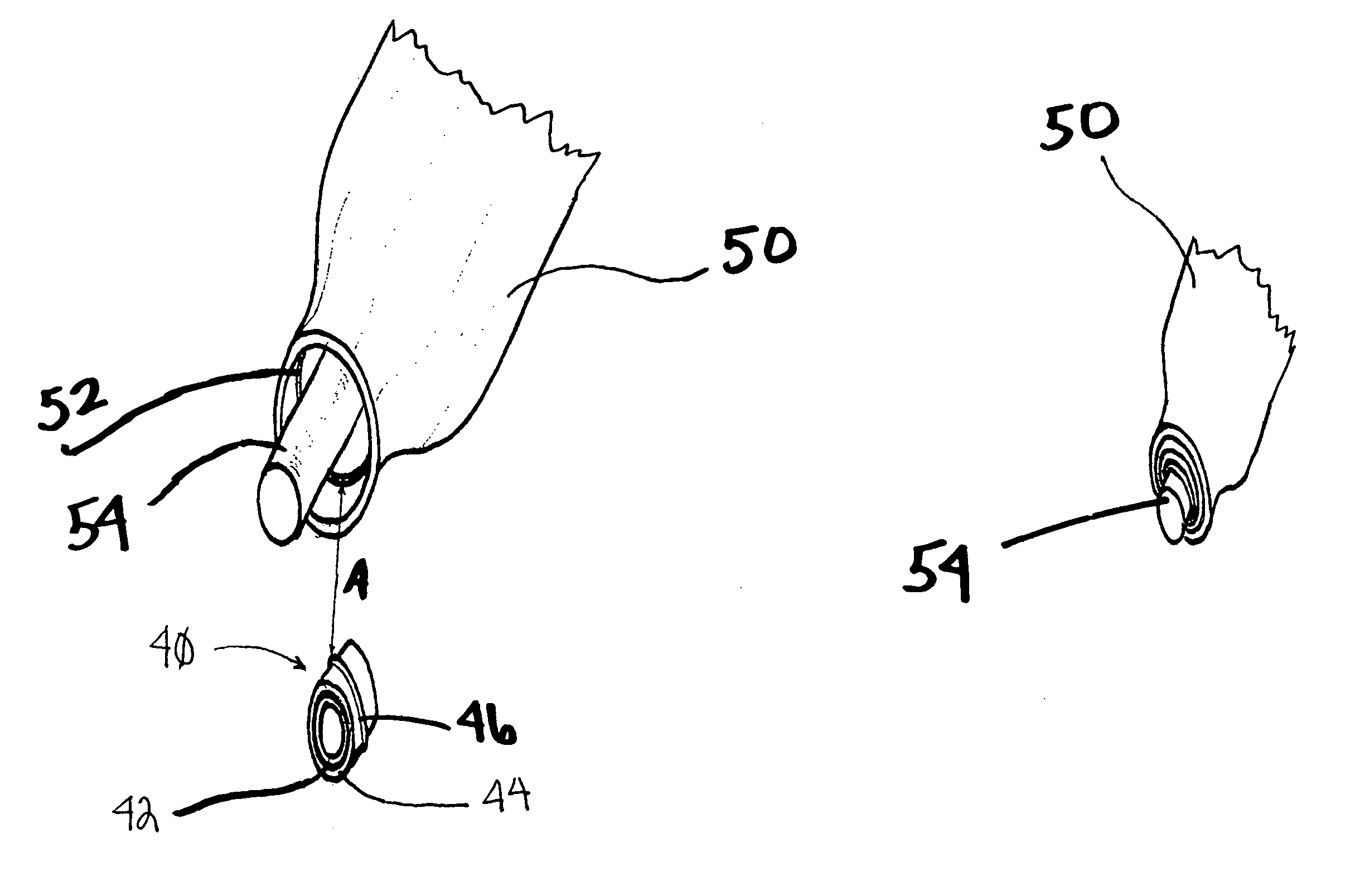

Tamper-evident closure for a syringe

ActiveUS20040116858A1Improve toleranceFirmly connectedClosuresInfusion syringesBiomedical engineeringSyringe

The tamper-evident closure is provided for a syringe with a Luer connection or a Luer lock connection, wherein at least the connection end consists of plastic. A cap which is connected to the syringe via at least one frangible web. The cap and the frangible web together with a fixation component are formed as one piece as a plastic injection molded part and are connected to the connection end of the syringe by way of welding.

Owner:TRANSCOJECT

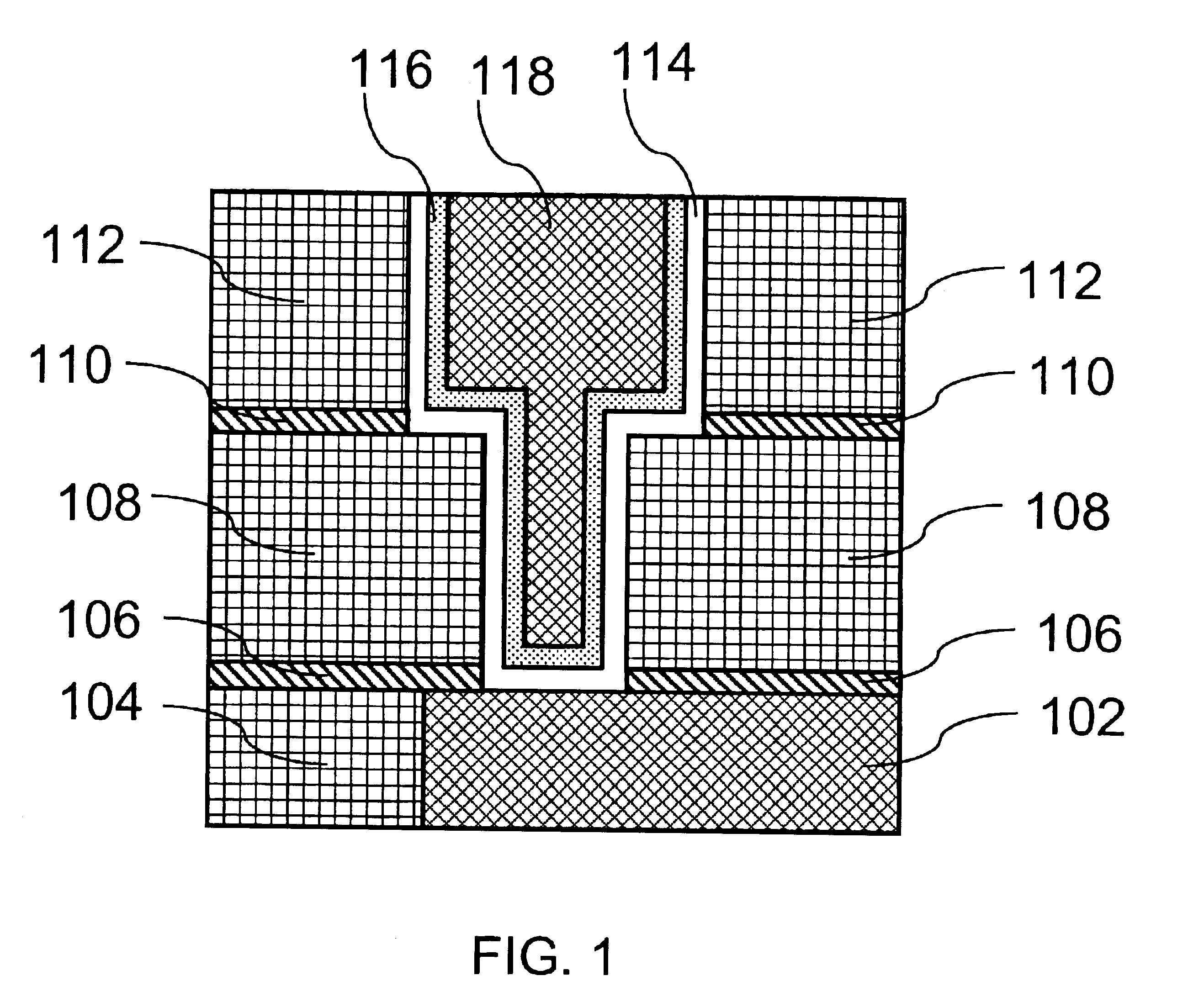

Atomic layer deposition methods for forming a multi-layer adhesion-barrier layer for integrated circuits

InactiveUS6955986B2Enhance layeringReduce tooling costsSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitMetal alloy

A process produces a layer of material which functions as a copper barrier layer, adhesion layer and a copper seed layer in a device of an integrated circuit, particularly in damascene or dual damascene structures. The method includes a step of depositing a diffusion barrier layer over a dielectric, a step of depositing a layer of graded metal alloy of two or more metals, and a step of depositing a copper seed layer, which step is essentially a part of the step of depositing the alloy layer.

Owner:ASM INTERNATIONAL

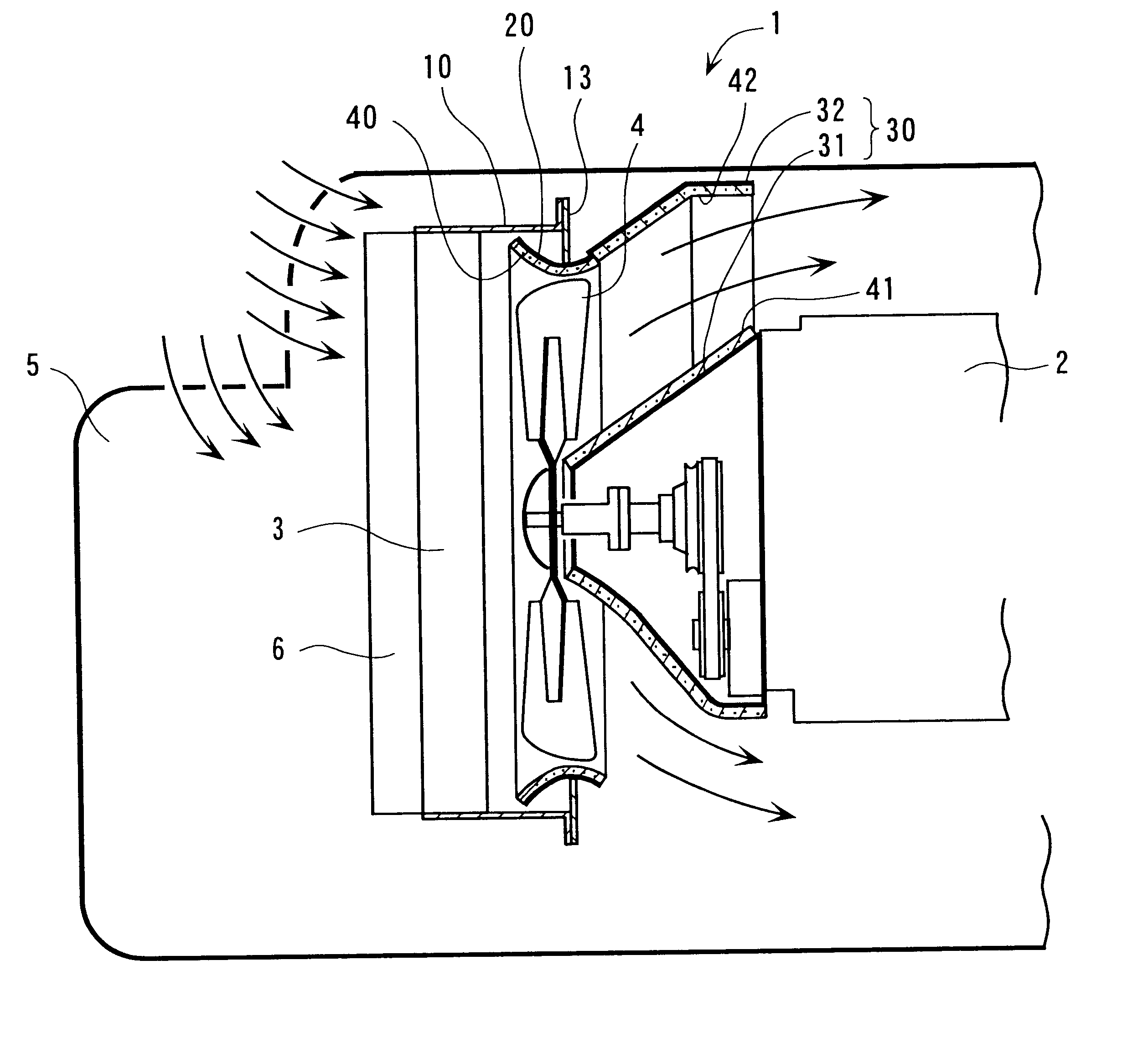

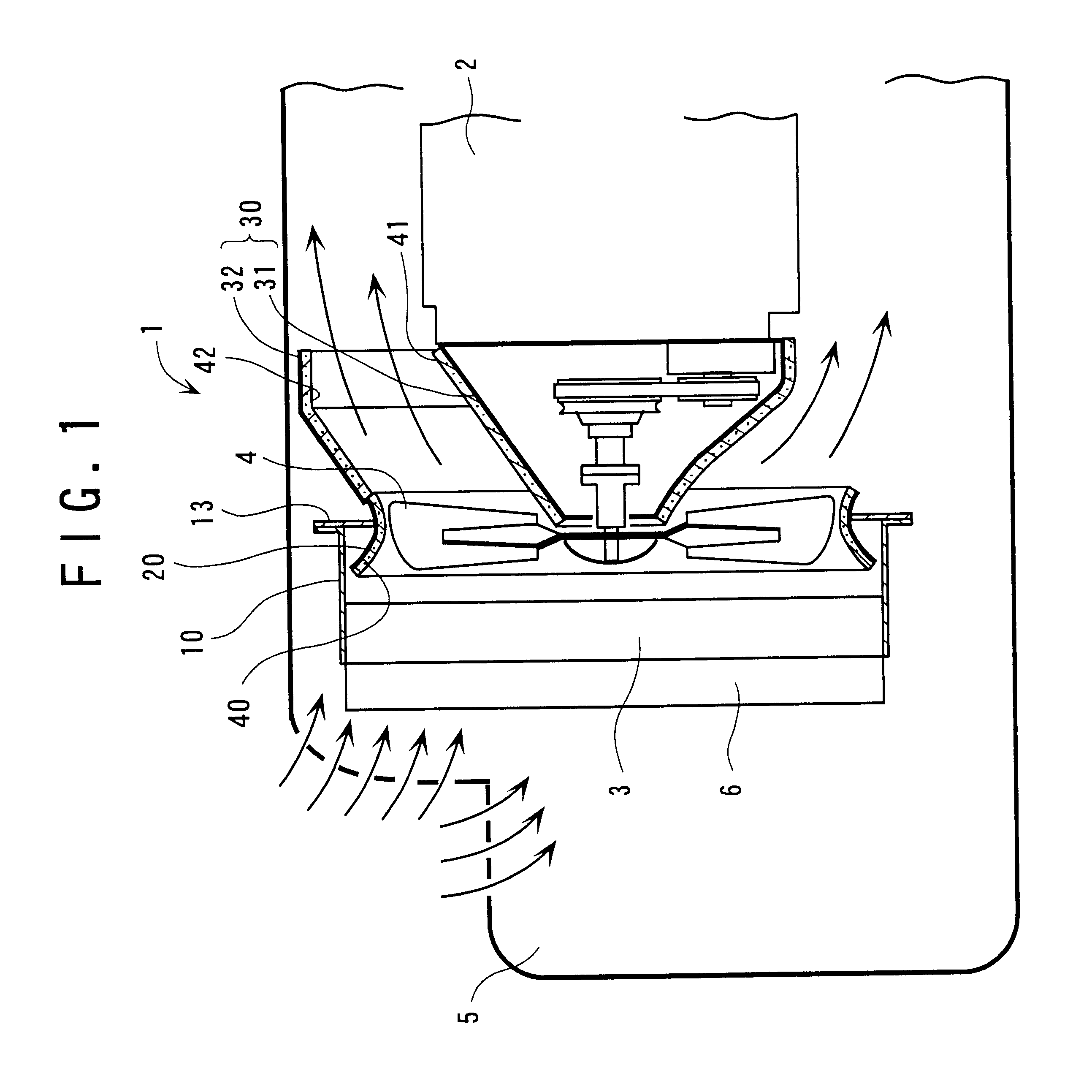

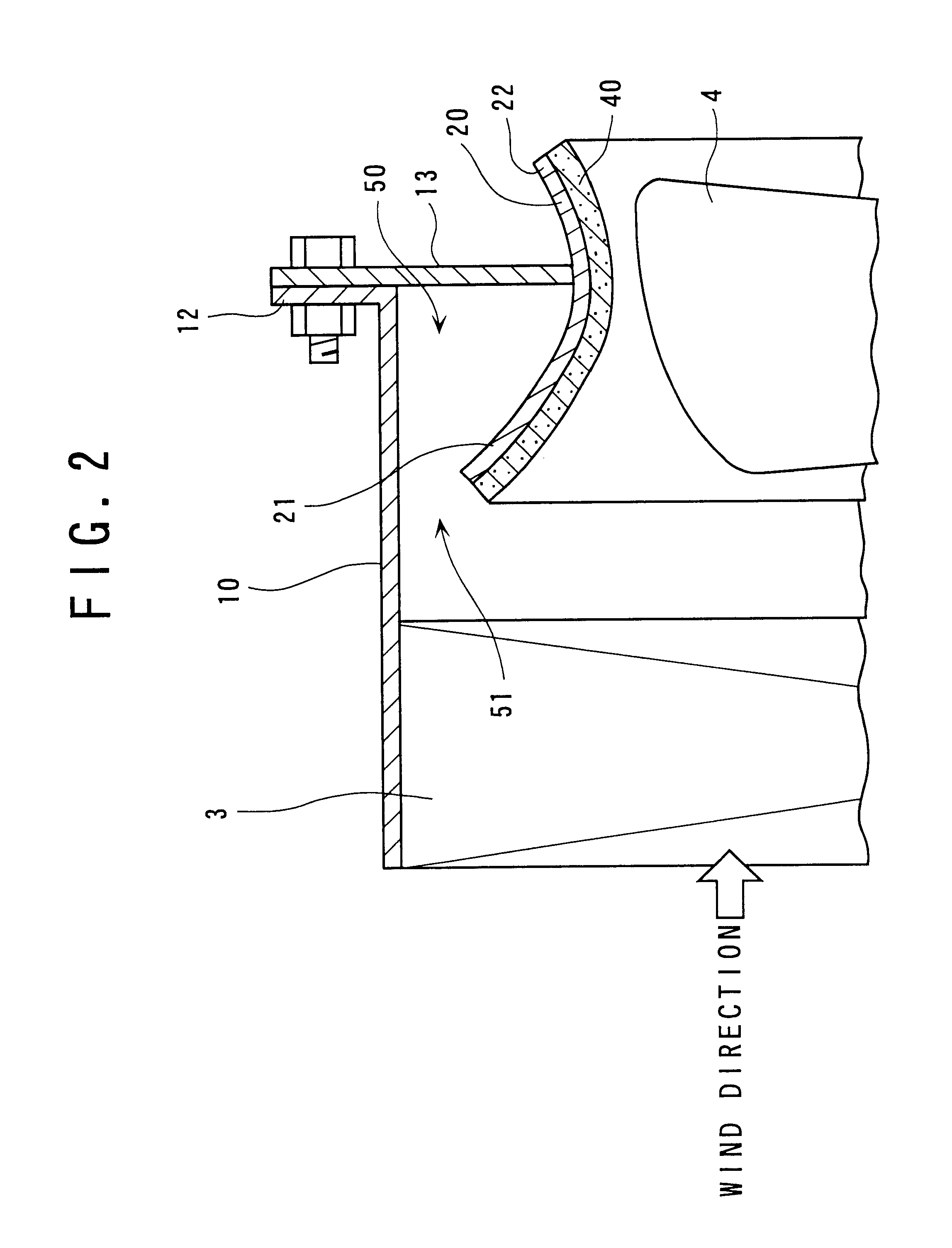

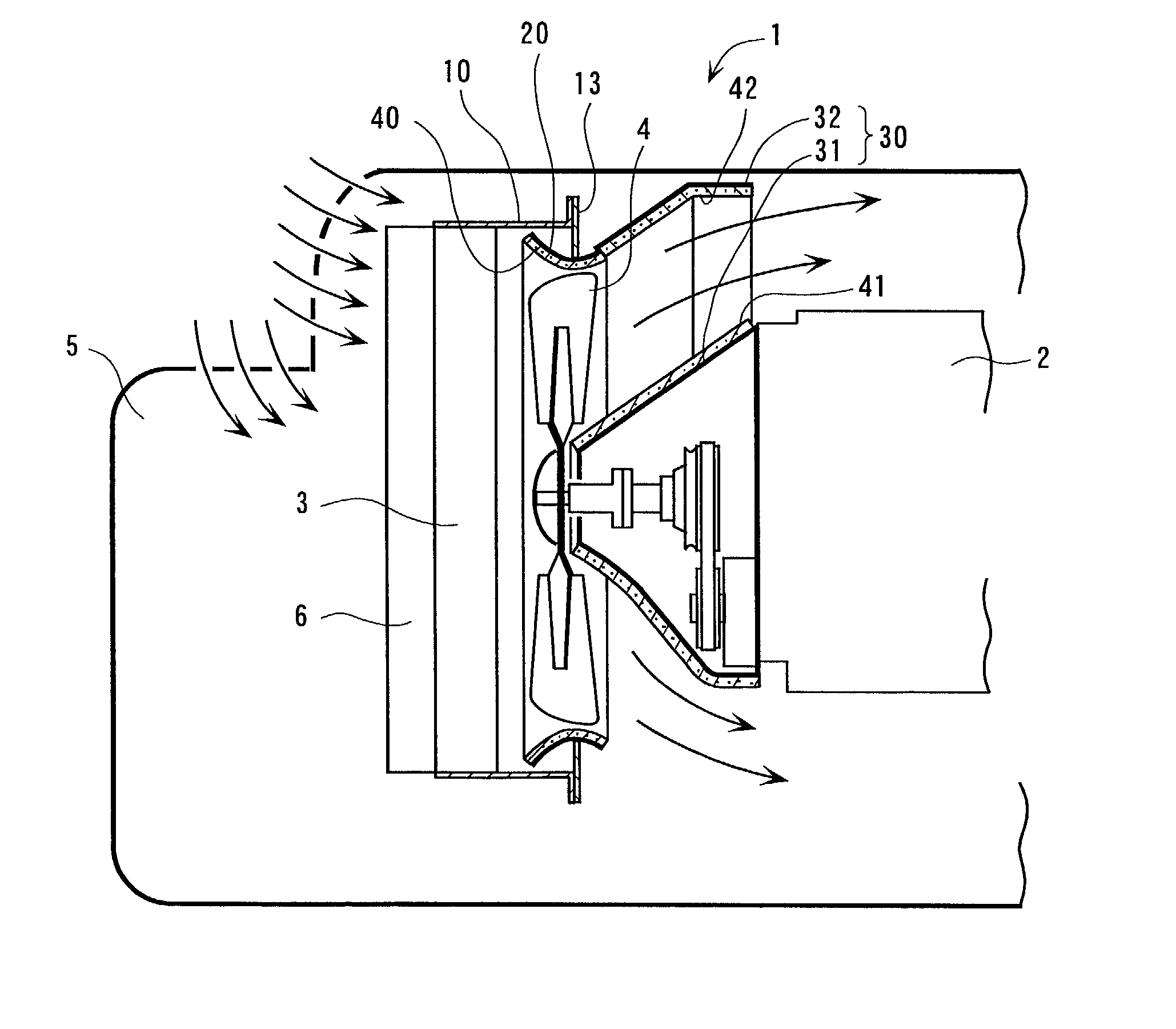

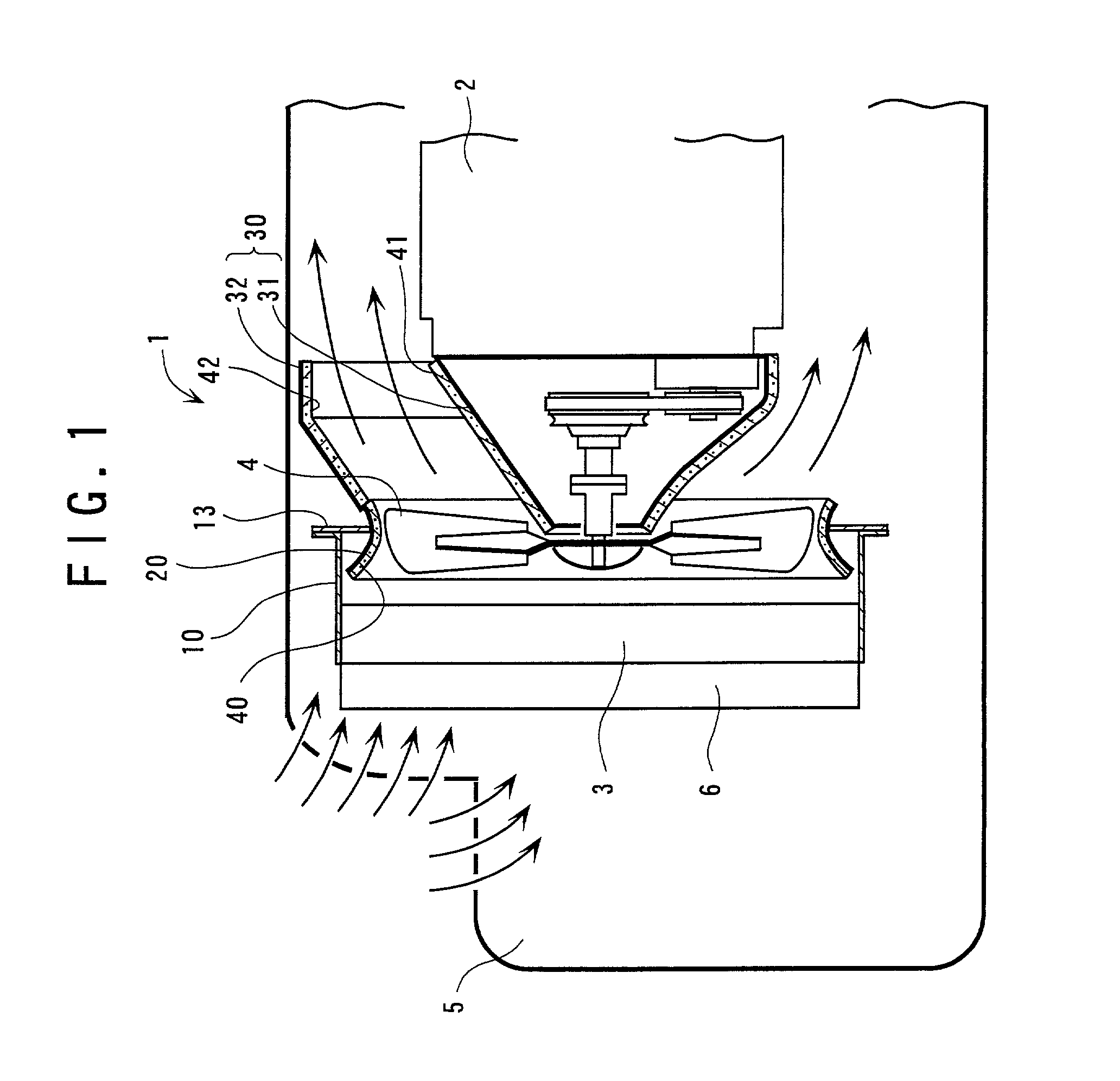

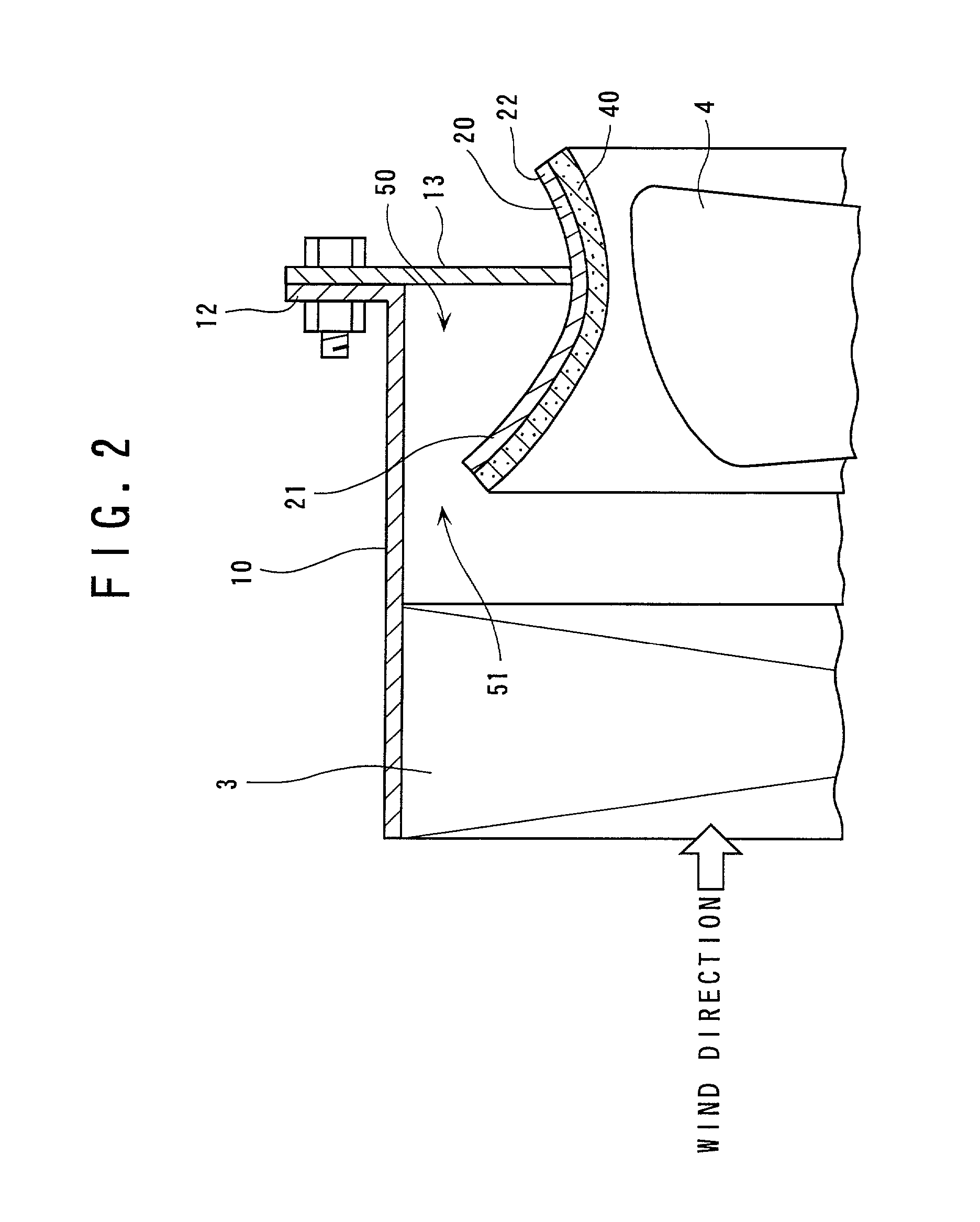

Noise reduction mechanism of fan device and molding method of porous damping material therefor

InactiveUS6454527B2Effective dampingMeet the noisePump componentsBlade accessoriesEngineeringNoise reduction

Porous damping material (40) is attached to an entire inner circumference of the fan shroud (20) opposing to an end of a fan (4) and is exposed to opposing space without using conventional perforated metal. Accordingly, jet noise caused by strong swirl between the fan (4) and the fan shroud (20) can be damped by the damping material (40) and impulsive sound scarcely occurs. Thus, both of the impulsive sound and the jet noise can be effectively damped, thereby securely reducing noise. The pours member (401) constituting the porous damping material (40) is a die-molding product made by a die (150) having a cavity (153).

Owner:KOMATSU LTD

Noise reduction mechanism of fan device and molding method of porous damping material therefor

InactiveUS20020015640A1Effective dampingMeet the noisePump componentsBlade accessoriesEngineeringNoise reduction

Porous damping material (40) is attached to an entire inner circumference of the fan shroud (20) opposing to an end of a fan (4) and is exposed to opposing space without using conventional perforated metal. Accordingly, jet noise caused by strong swirl between the fan (4) and the fan shroud (20) can be damped by the damping material (40) and impulsive sound scarcely occurs. Thus, both of the impulsive sound and the jet noise can be effectively damped, thereby securely reducing noise. The pours member (401) constituting the porous damping material (40) is a die-molding product made by a die (150) having a cavity (153).

Owner:KOMATSU LTD

Tamper-evident closure for a syringe

ActiveUS7374555B2Improve toleranceFirmly connectedClosuresInfusion syringesBiomedical engineeringSyringe

The tamper-evident closure is provided for a syringe with a Luer connection or a Luer lock connection, wherein at least the connection end consists of plastic. A cap which is connected to the syringe via at least one frangible web. The cap and the frangible web together with a fixation component are formed as one piece as a plastic injection molded part and are connected to the connection end of the syringe by way of welding.

Owner:TRANSCOJECT

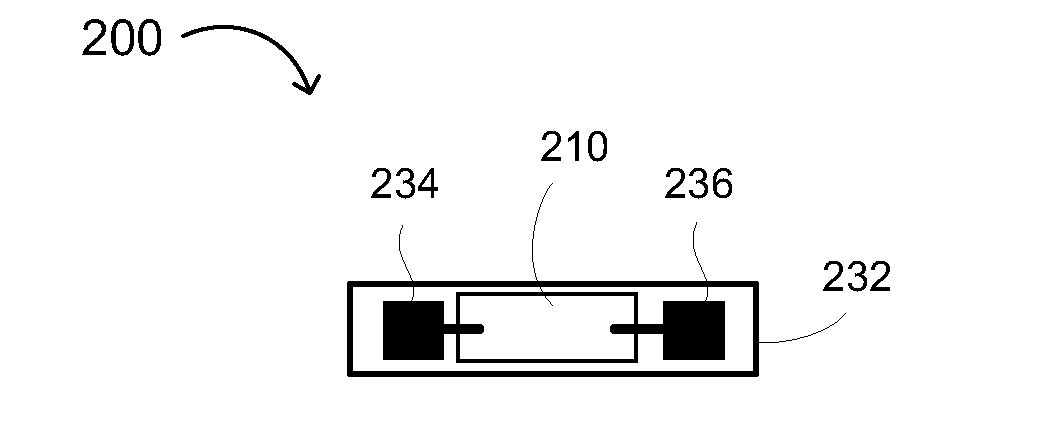

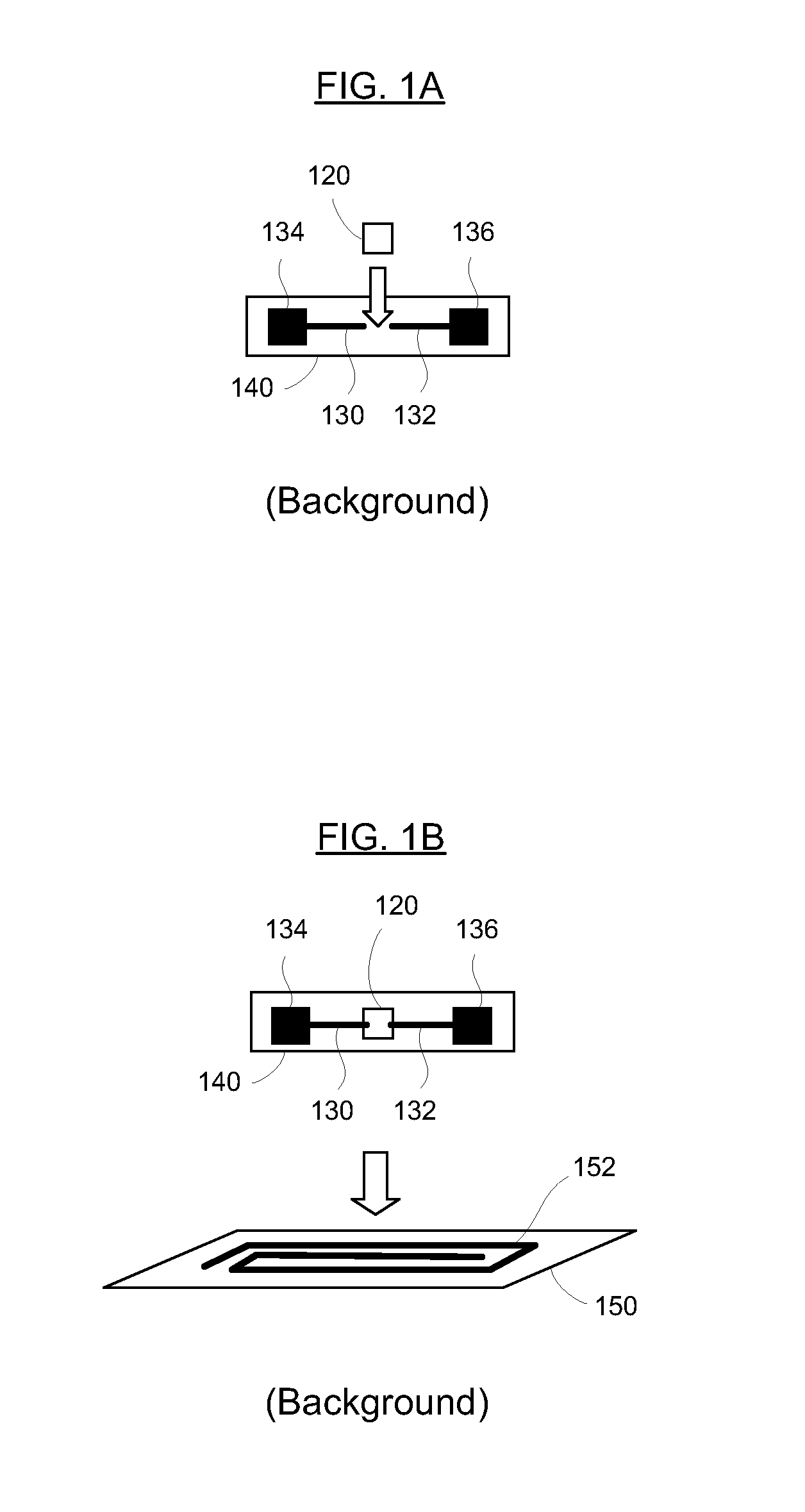

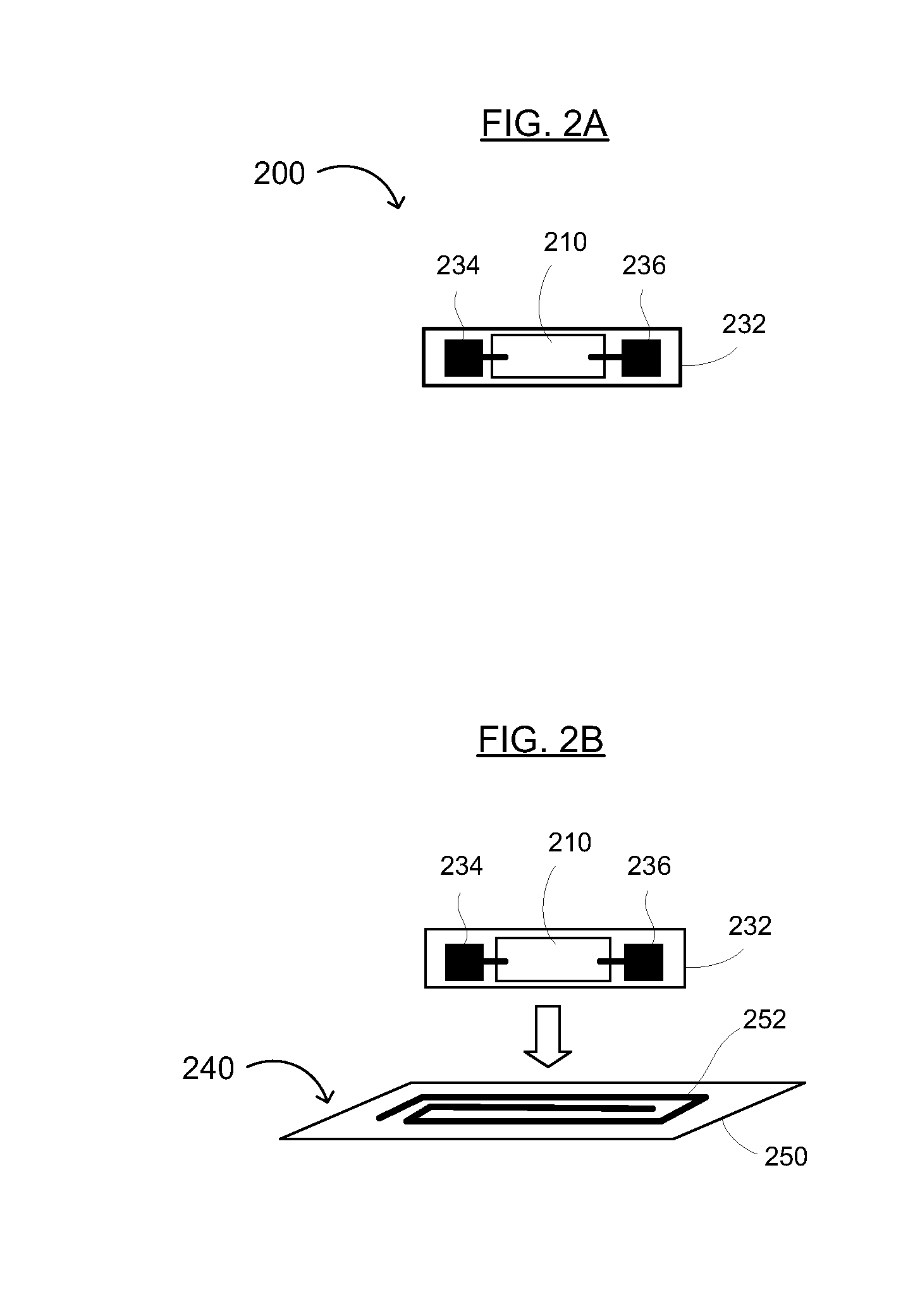

Wireless Devices Including Printed Integrated Circuitry and Methods for Manufacturing and Using the Same

InactiveUS20090095818A1Leverage low capital expenditure and operating costLow costPrinted circuit manufactureSubscribers indirect connectionElectricityElectrical devices

Printed integrated circuitry and attached antenna and / or inductor for sensors, electronic article surveillance (EAS), radio frequency (RF) and / or RF identification (RFID) tags and devices, and methods for its manufacture. The tag generally includes printed integrated circuitry on one carrier and an antenna and / or inductor on another carrier, the integrated circuitry being electrically coupled to the antenna and / or inductor. The method of manufacture generally includes of printing an integrated circuit having a plurality of first pads on a carrier, forming an antenna and / or inductor having a plurality of second pads on a substrate, and attaching at least two of the first pads of the printed integrated circuit to corresponding second pads of the antenna and / or inductor. The present invention advantageously provides a low cost RFID tag capable of operating at MHz frequencies that can be manufactured in a shorter time period than conventional RFID tags that manufacture all active electrical devices on a conventional wafer.

Owner:ENSURGE MICROPOWER ASA

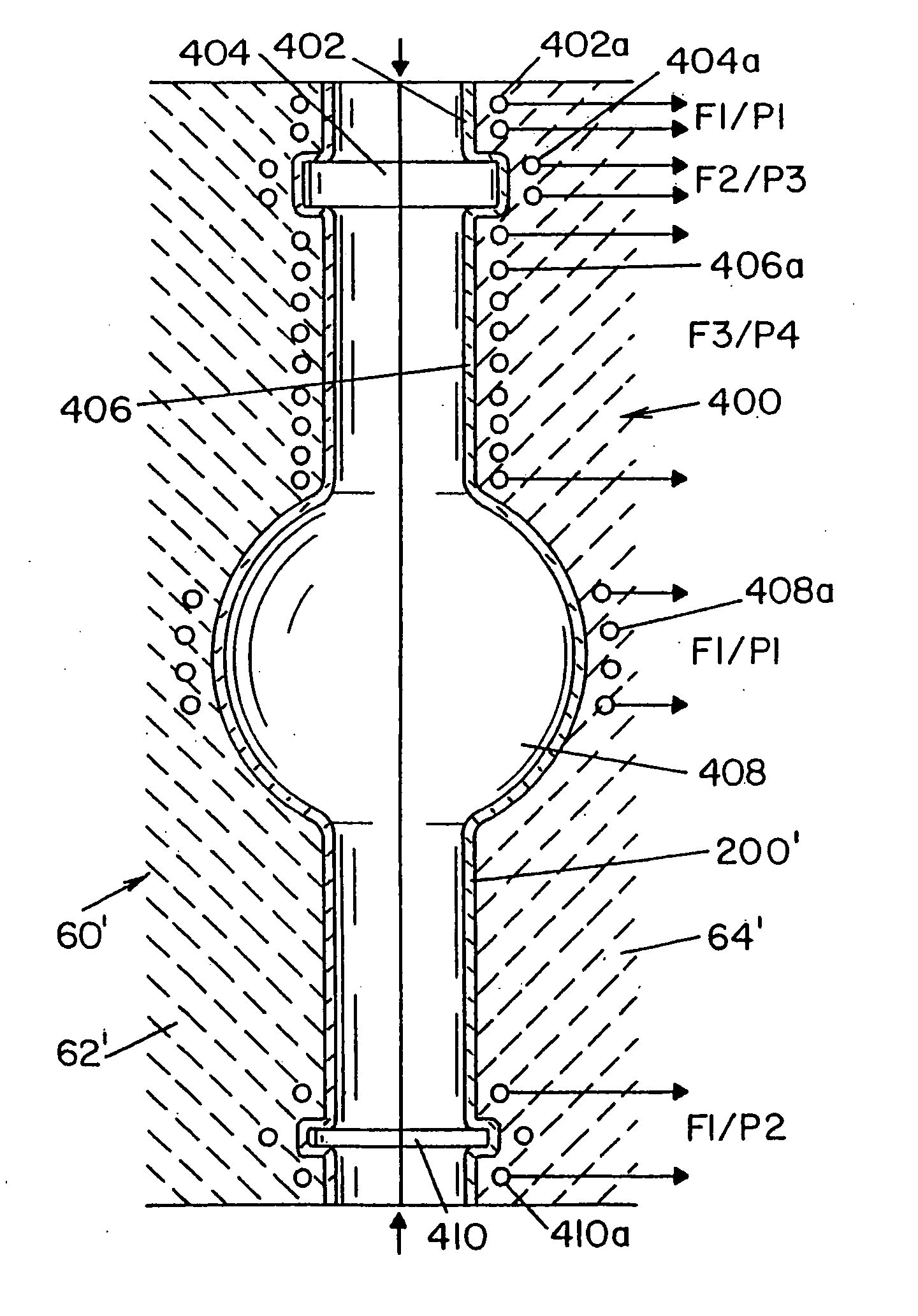

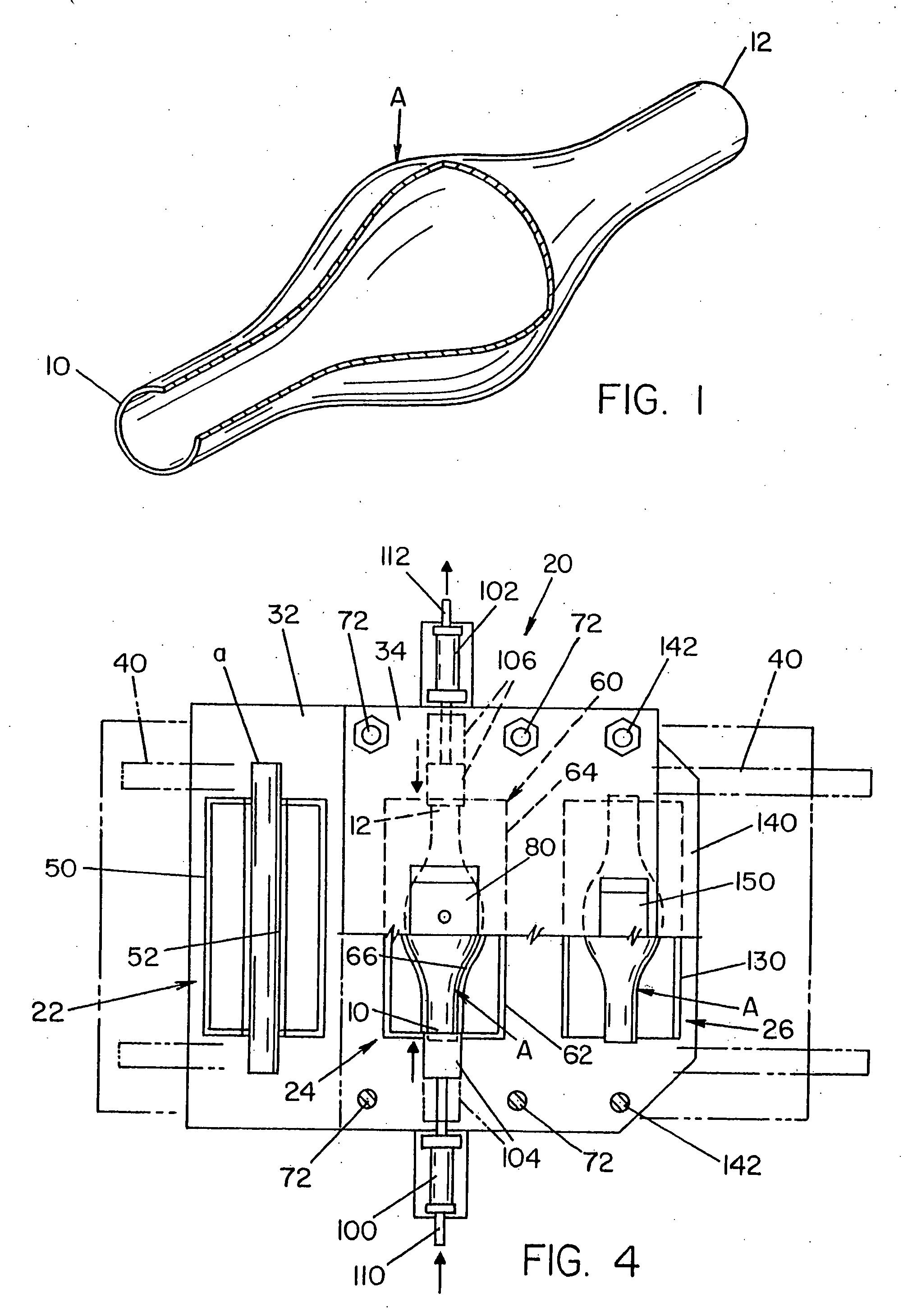

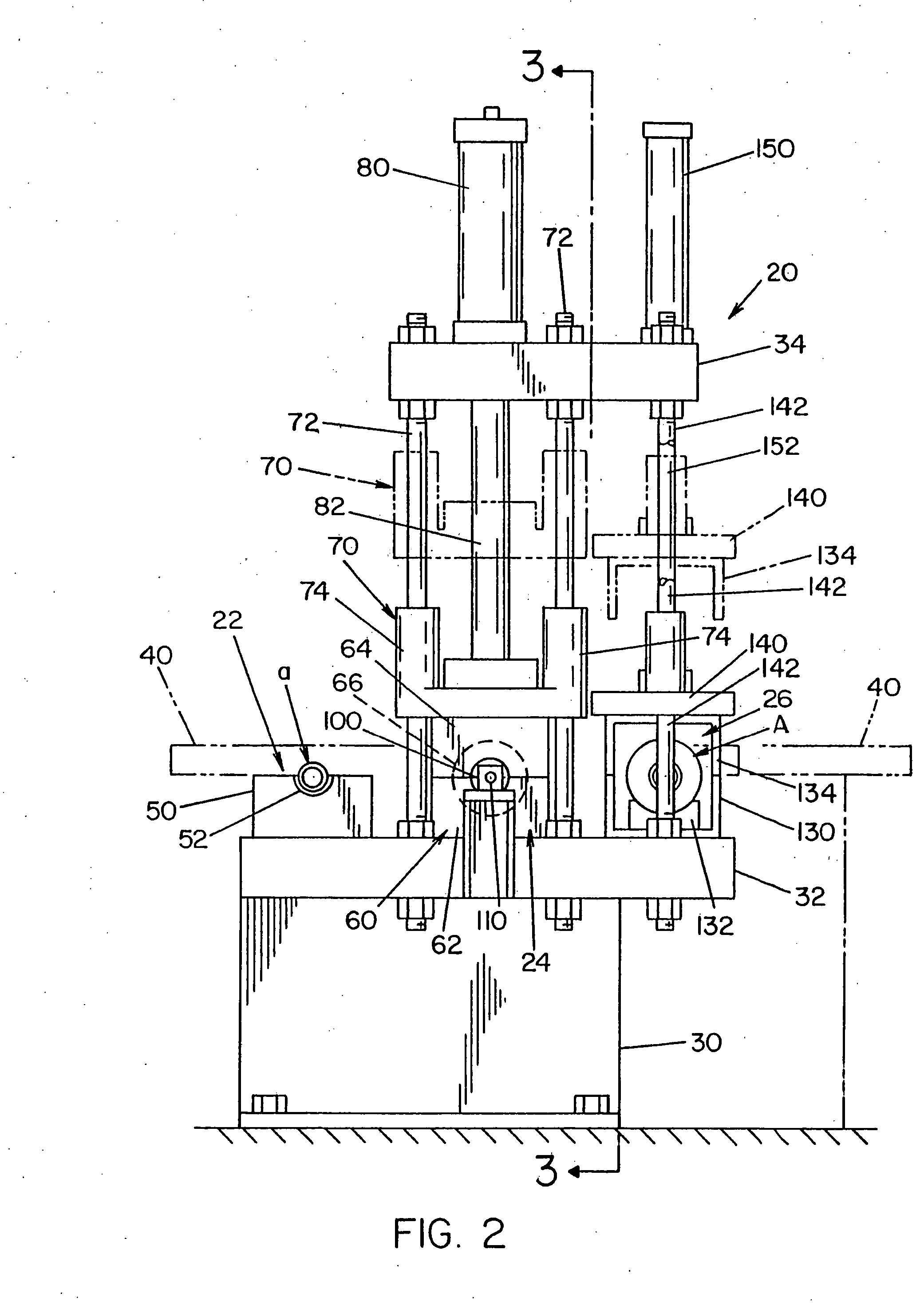

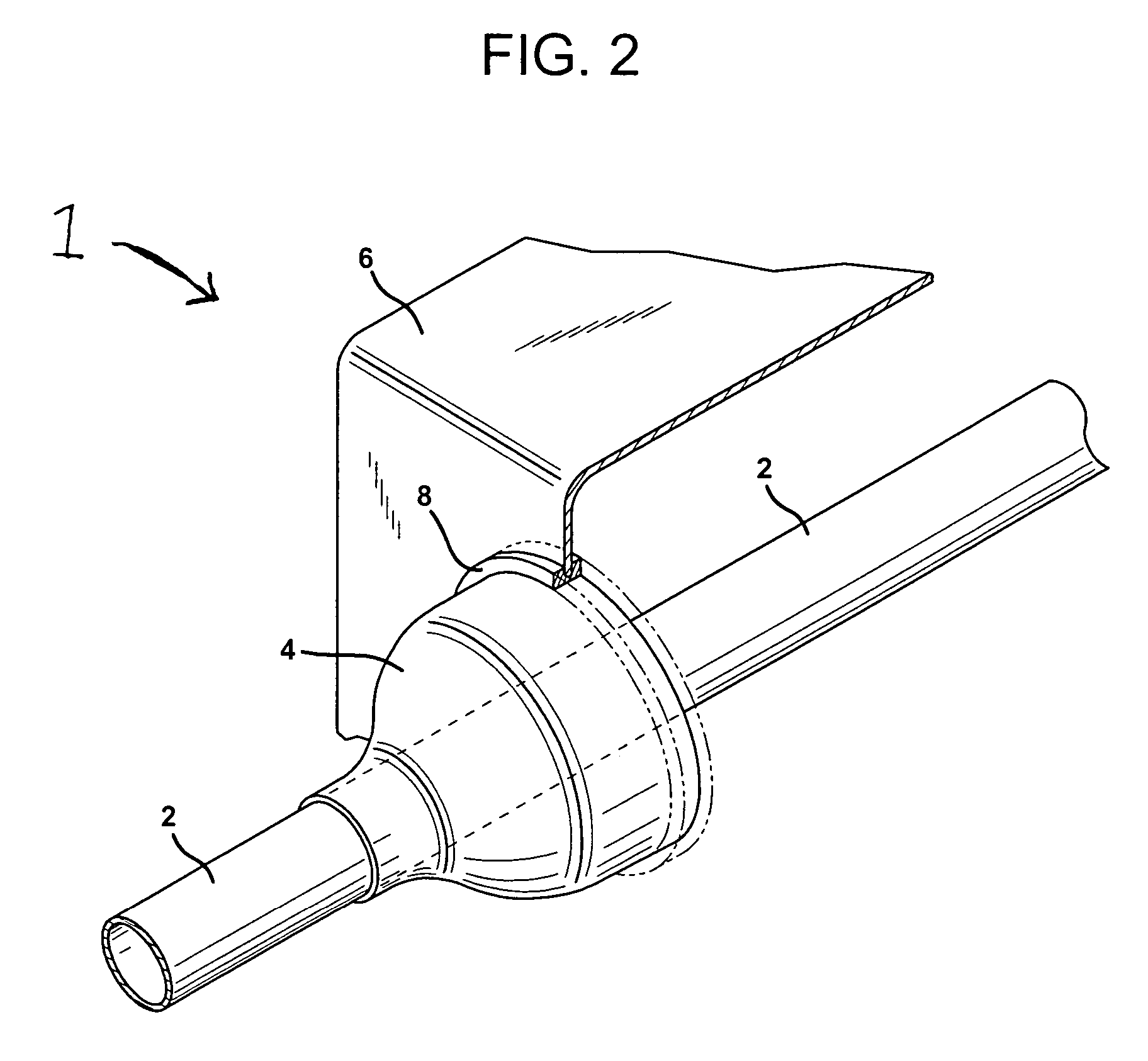

Method of forming a tubular blank into a structural component and die therefor

InactiveUS20040200550A1Reduce tooling costsImprove design flexibilityShaping toolsFurnace typesHigh pressureMetal

A method of forming an elongated metal blank into a structural component having a predetermined outer configuration. The method includes providing a shape imparting cavity or shell section formed from a rigid material which includes an inner surface defining the predetermined shape, placing the metal blank into the cavity or shell section, and forming the metal blank into the component by heating axial portions of the metal blank and forcing a fluid at a high pressure into the metal blank until the metal blank at least partially conforms to at least a portion of the inner surface of the cavity or shell section to form the structural component.

Owner:HOT METAL GAS FORMING IP2 INC +1

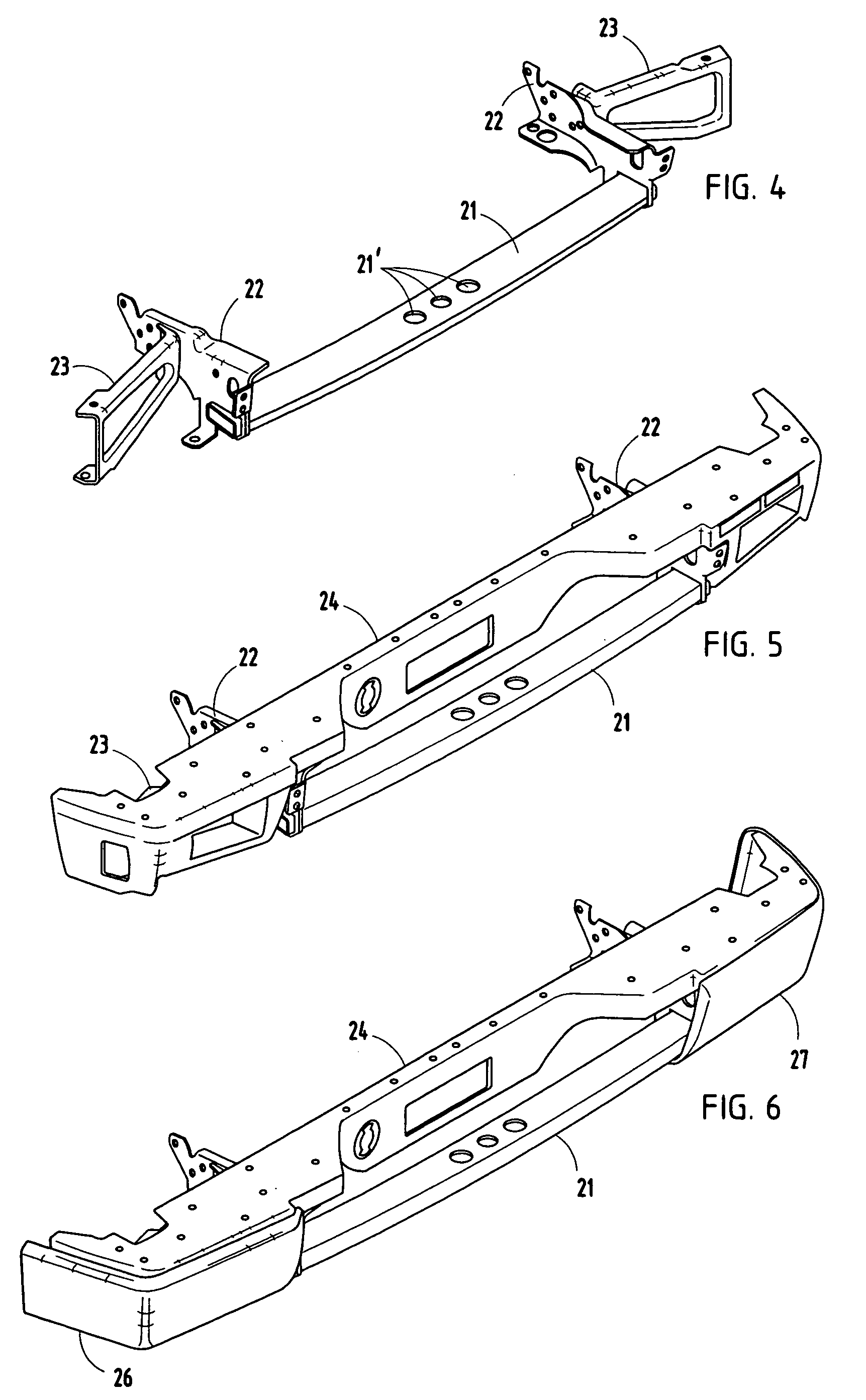

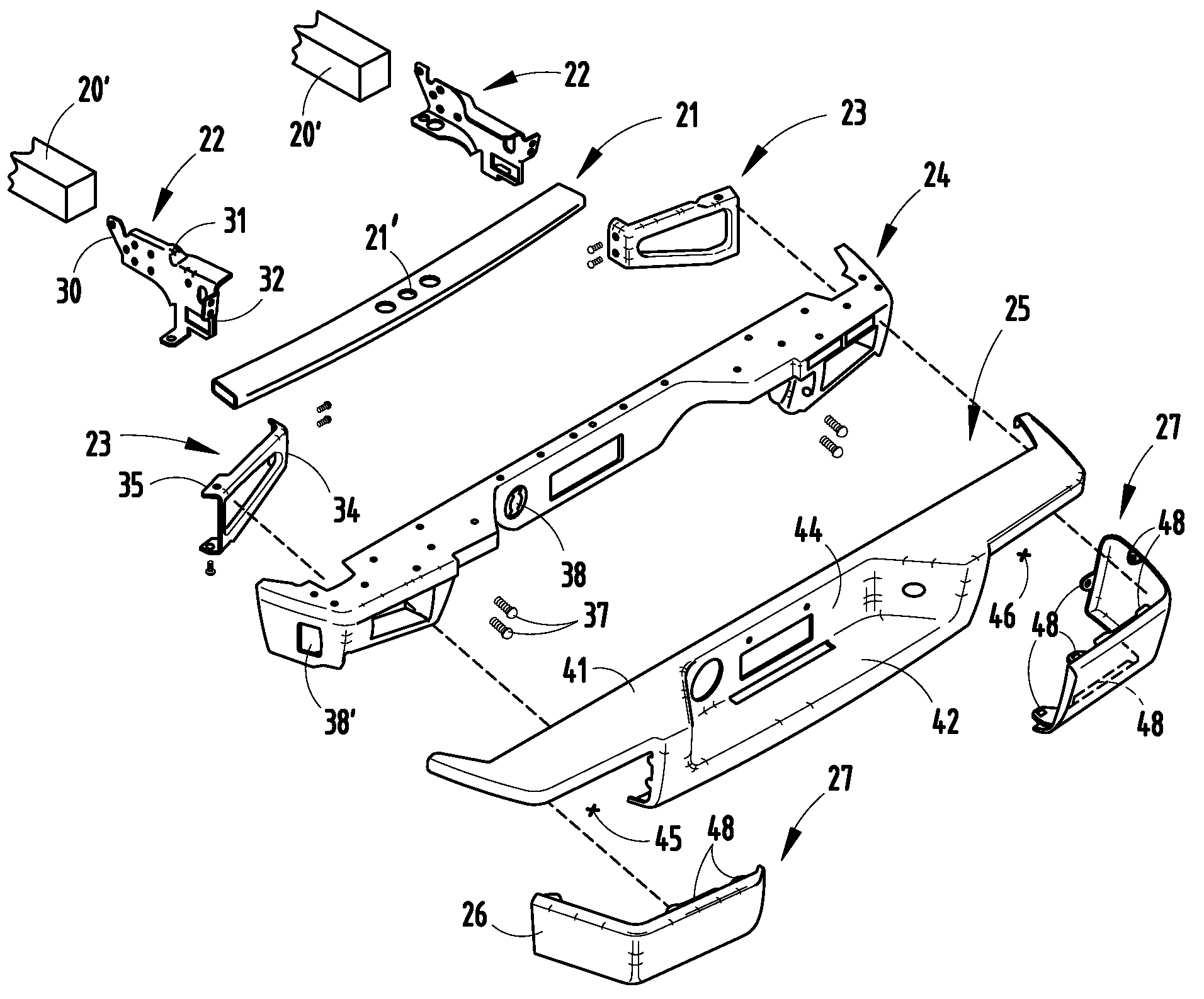

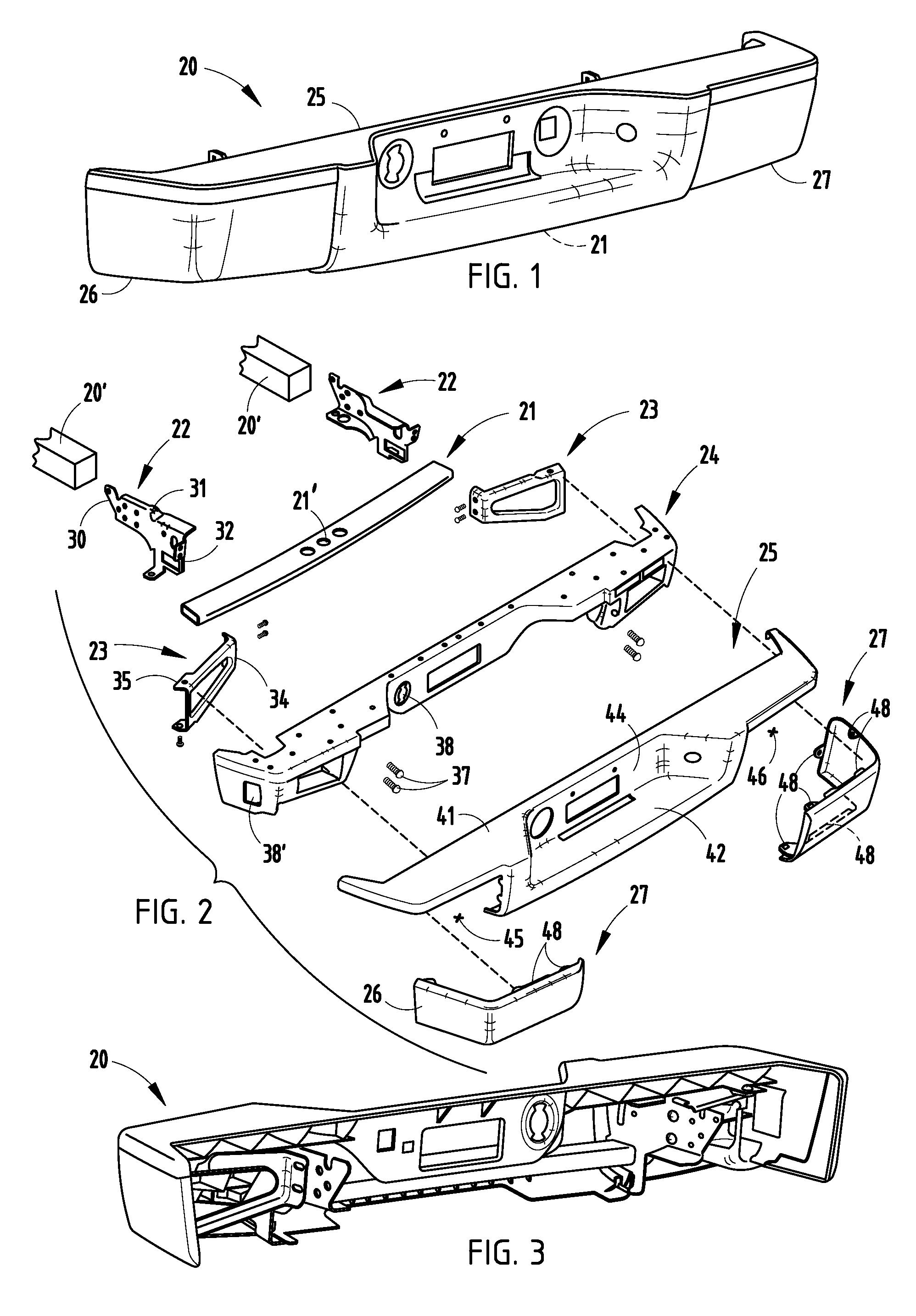

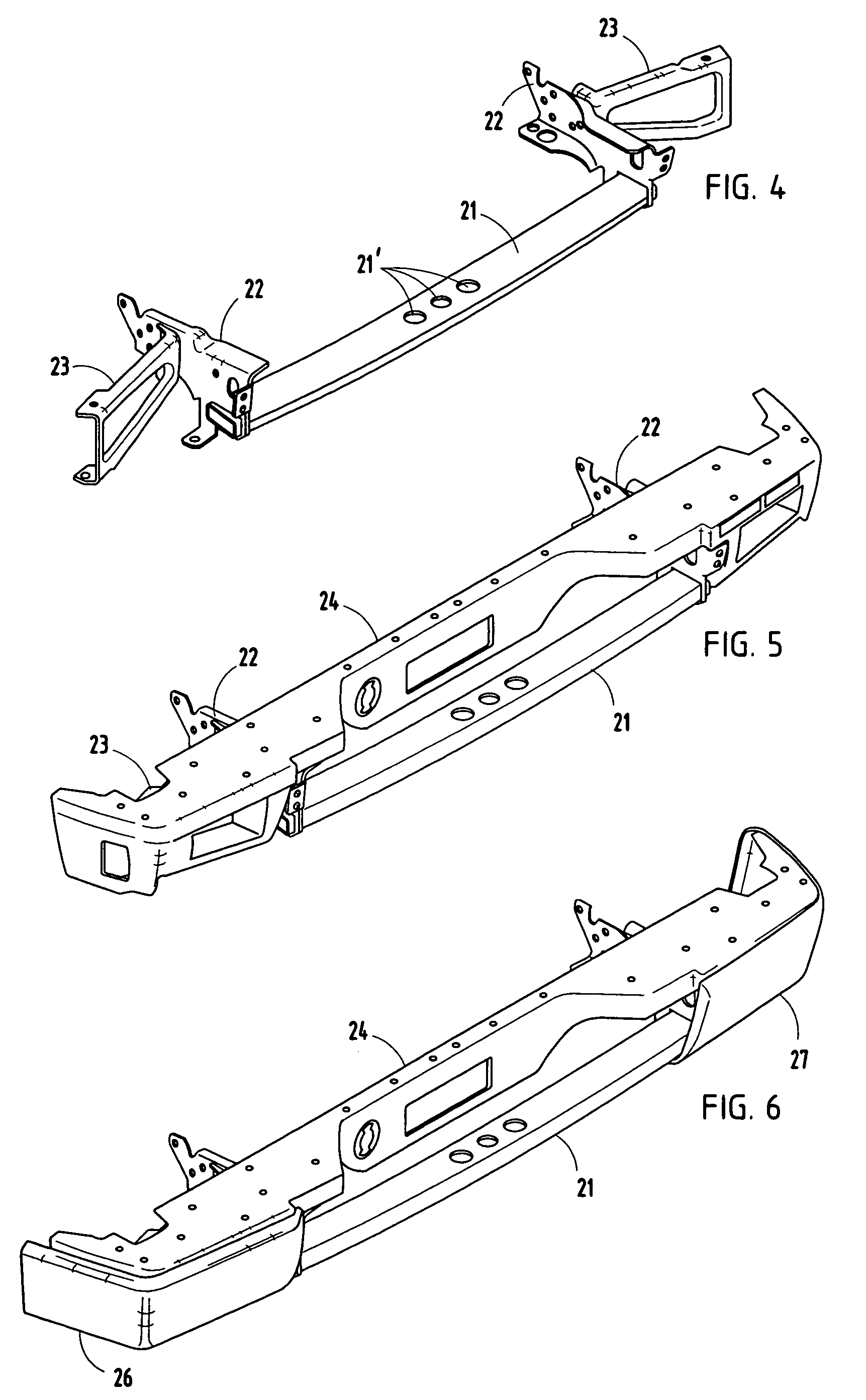

Hybrid bumper with trim

A hybrid bumper system includes a polymeric reinforcement beam with end sections and structural covers attached to the ends sections to considerably strengthen the end sections. Bracketry stably supports the reinforcement beam on a vehicle frame. A fascia covers at least part of the reinforcement beam but leaves a portion of the structural covers in a visible position. The structural covers are treated for aesthetics, such as by painting, chroming, or other surface treatment. In one aspect, the beam includes a molded polymeric beam component, structural L-shaped covers attached to its end sections, and a tie bar along it rear side that stiffens and rigidifies a center of the polymeric beam component. In another aspect, a tow bar or rail-to-rail metal reinforcement beam front system (or rear with tow bar) is incorporated.

Owner:SHAPE CORP

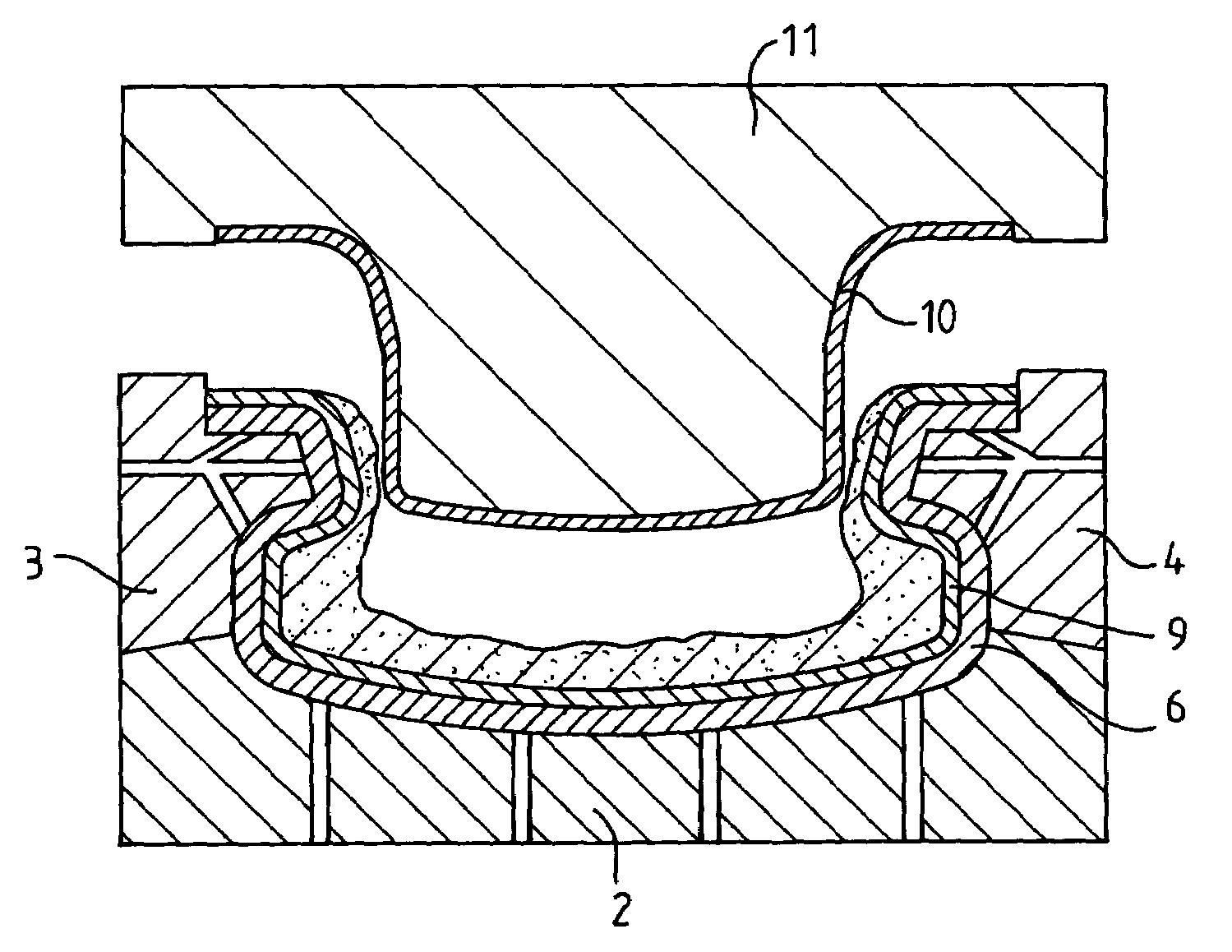

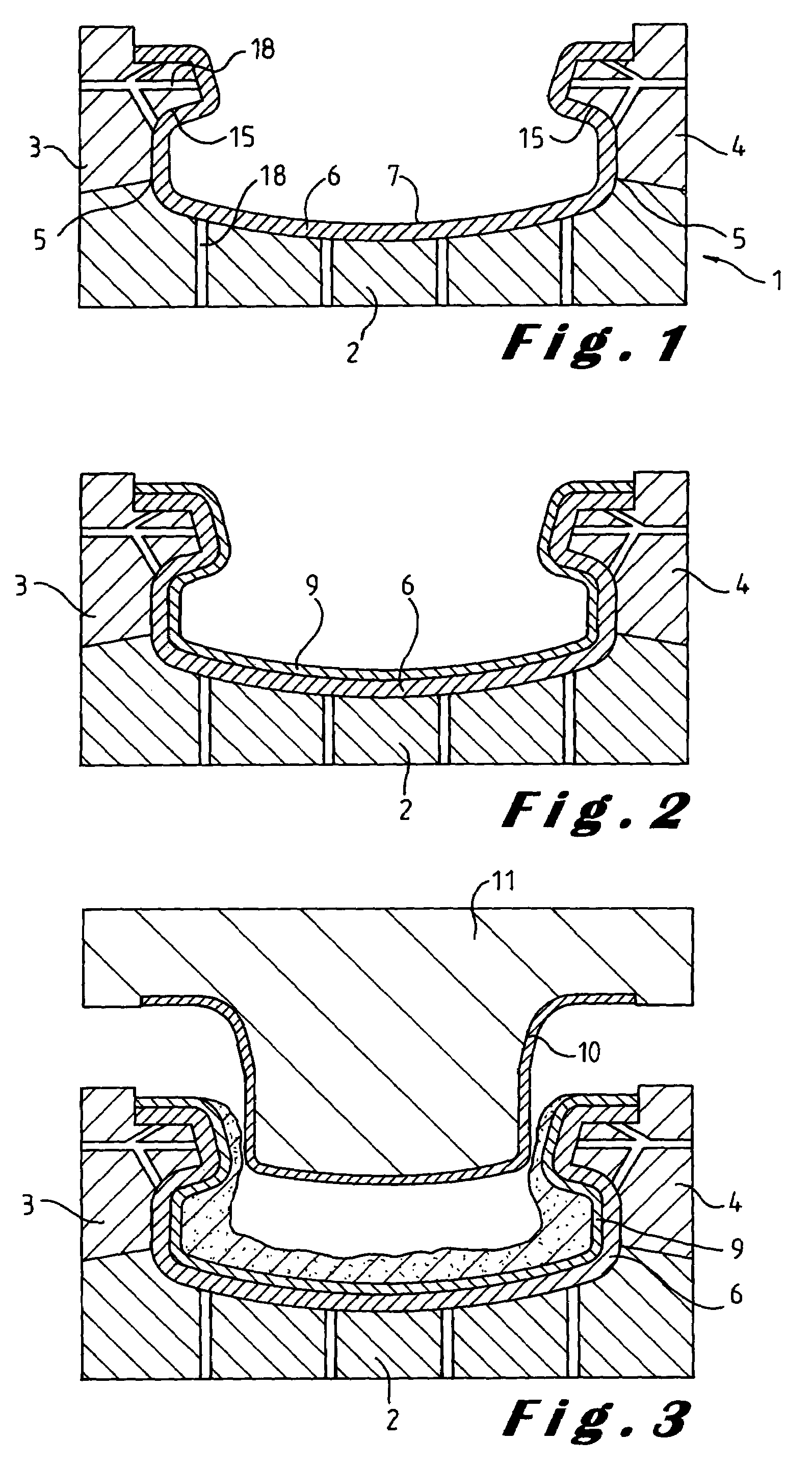

Method and mould for manufacturing a moulded article comprising at least an elastomeric polyurethane skin

InactiveUS7192543B2Similar design freedomSolve the real problemMouldsLaminationElastomerShell molding

For manufacturing a moulded article comprising at least an elastomeric polyurethane skin (9) and optionally a structural backing layer (10) and an intermediate foam layer (12) a mould is used having at least a first mould part (1) comprising at least two mutually movable mould sections (2-4). The skin (9) is moulded with its front against a surface (7) of the first mould part (1) by applying at least one reactive polyurethane mixture to this mould surface. In order to prevent the seam between the mutually movable mould sections (2-4) of the first mould part to leave traces on the front of the moulded skin (9), the first mould part (1) further comprises a removable, flexible liner (6) which is positioned onto these mould sections to cover at least partially the seam therebetween. Since the first mould part (1) comprises mutually movable mould sections (2-4), the design freedom is increased and it is not required to transfer the skin to another mould for providing relatively rigid backing layers to the back of this skin.

Owner:RECTICEL AUTOMOBIL SYSTEME GMBH

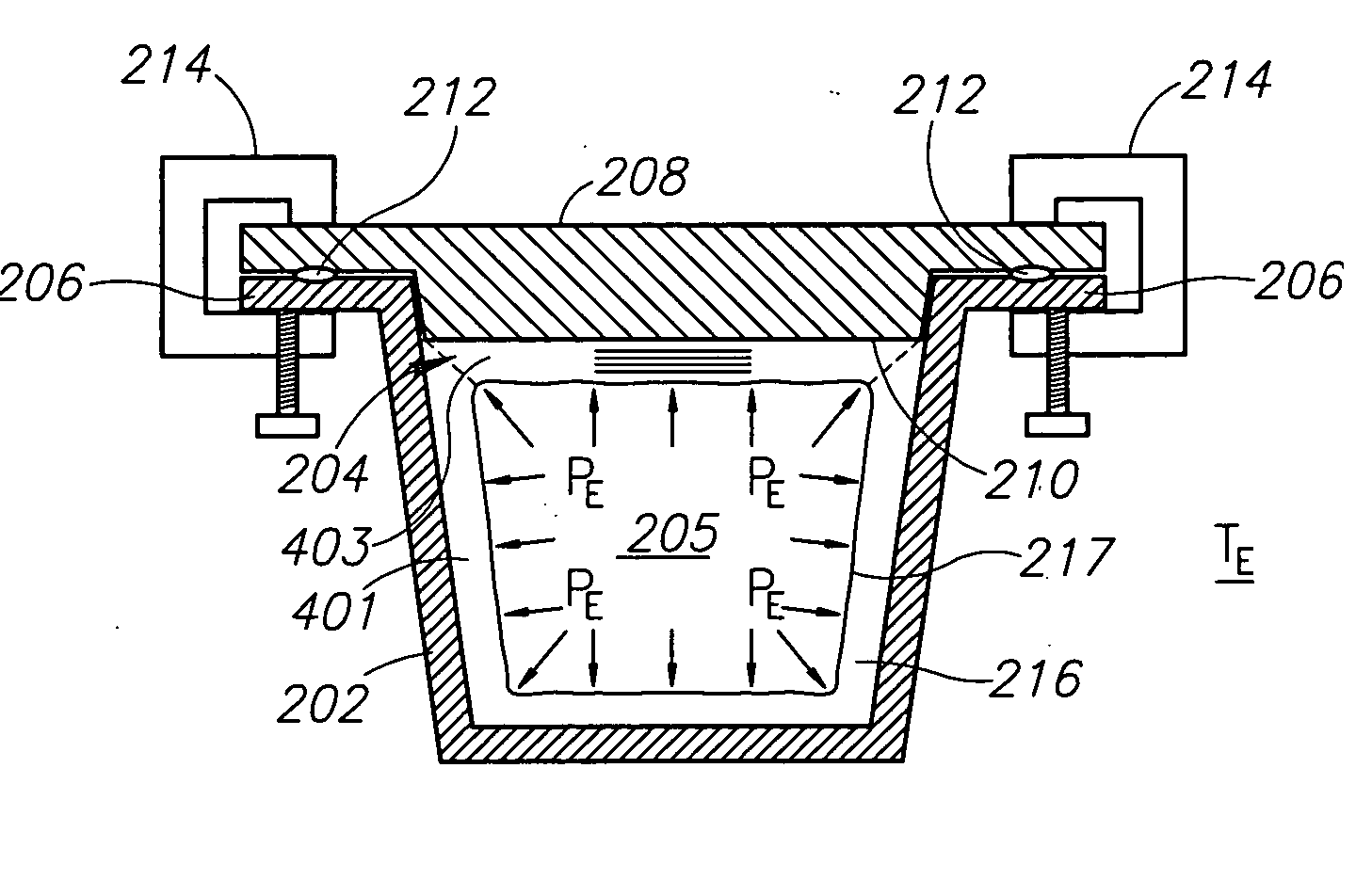

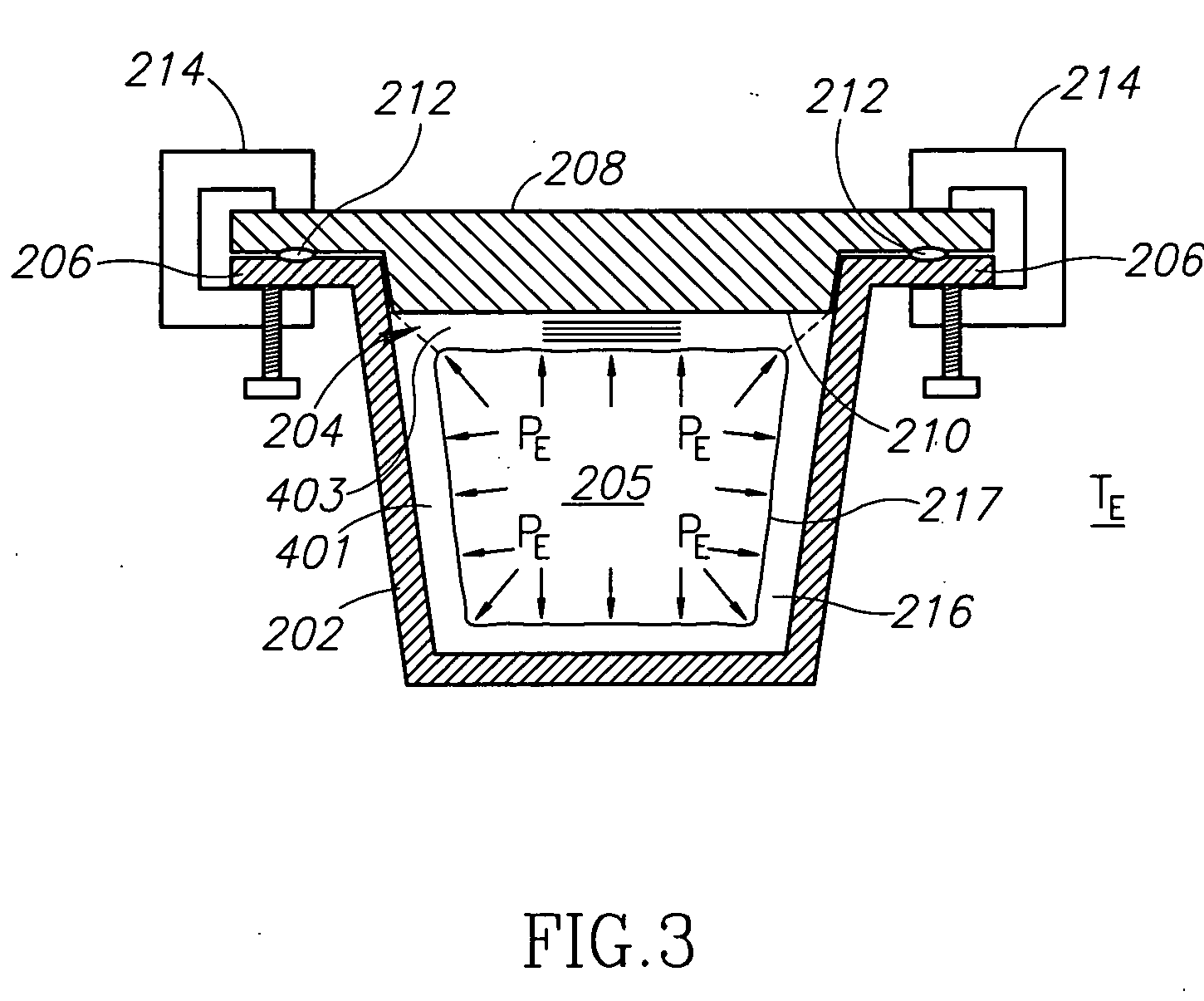

Apparatus and methods for fabrication of composite components

InactiveUS20070080481A1Improve efficiencyReduce tooling costsConfectionerySweetmeatsMaterials science

Apparatus and methods for fabrication of composite components are disclosed. In one embodiment, an apparatus for fabricating a component from a composite material includes a containment member having an internal volume adapted to receive the composite material, and a lid member. An expandable member is disposed within the internal volume adjacent to the composite material, the expandable member being inflatable within the internal volume and adapted to apply an elevated pressure against the composite material that urges the composite material against at least one of the containment member and the lid member. The containment member, the lid member, and the expandable member are further adapted to withstand at least one of the elevated pressure and an elevated temperature suitable for curing the composite material.

Owner:THE BOEING CO

Indexable Type Cutting Tool

InactiveUS20080003072A1Improve cutting performanceSimply and quickly and precisely fastenedThread cutting toolsWood turning toolsFluteEngineering

An indexable type cutting tool comprises a drill having a shank and a drill body which extends from the shank, the drill body being defined with body flutes, and being formed with an insert seat which has seat side surfaces and a seat bottom surface and body flank surfaces and body thinning surfaces; a drill insert fitted into the insert seat of the drill body, having cutting edges and an insert bottom surface which is brought into close contact with the seat bottom surface, formed with insert flutes and insert side surfaces which are brought into close contact with the seat side surfaces, and defined with a through-hole which passes through the insert side surfaces; and a fastening screw for fastening the drill insert fitted into the insert seat to the drill.

Owner:KORLOY

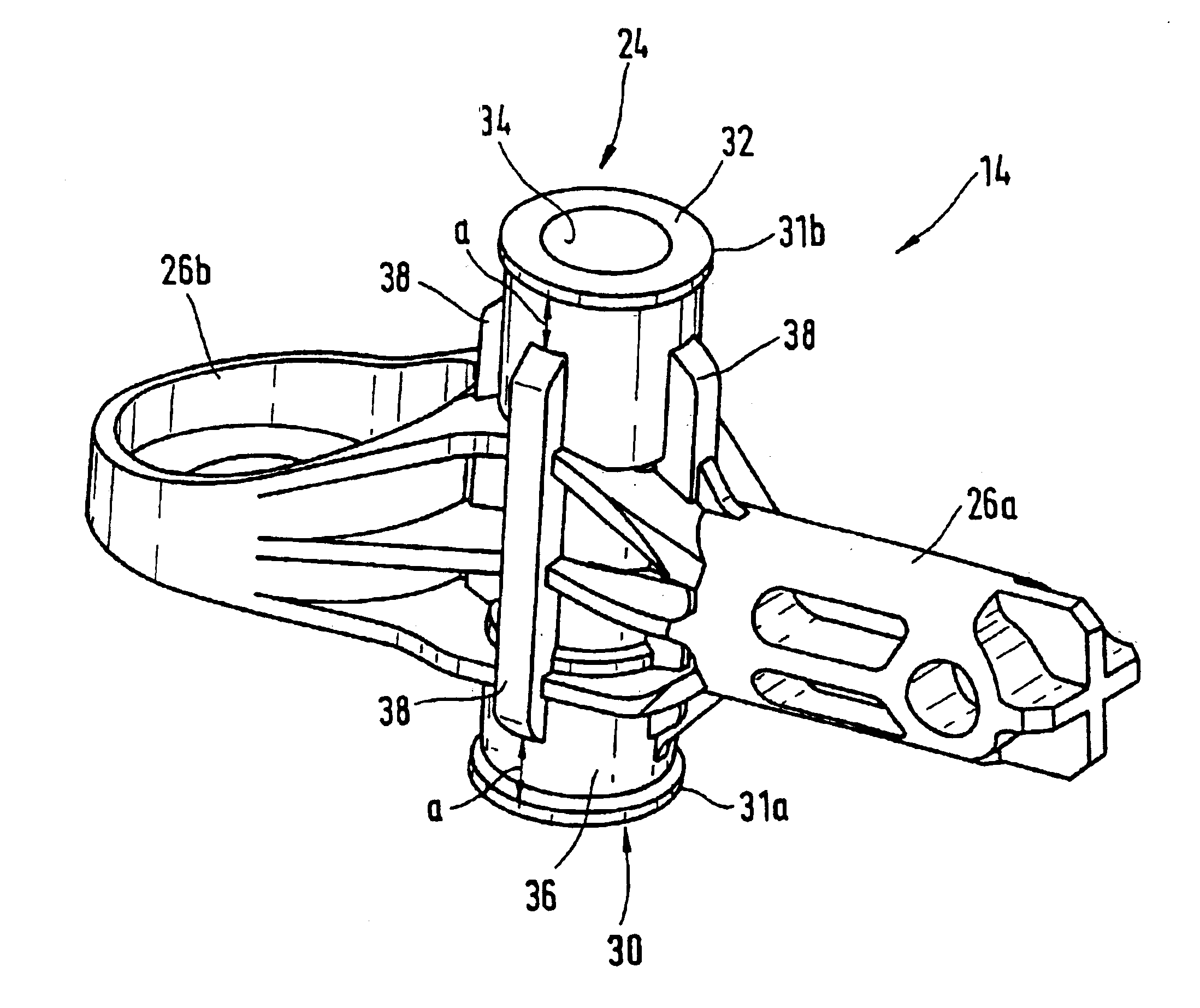

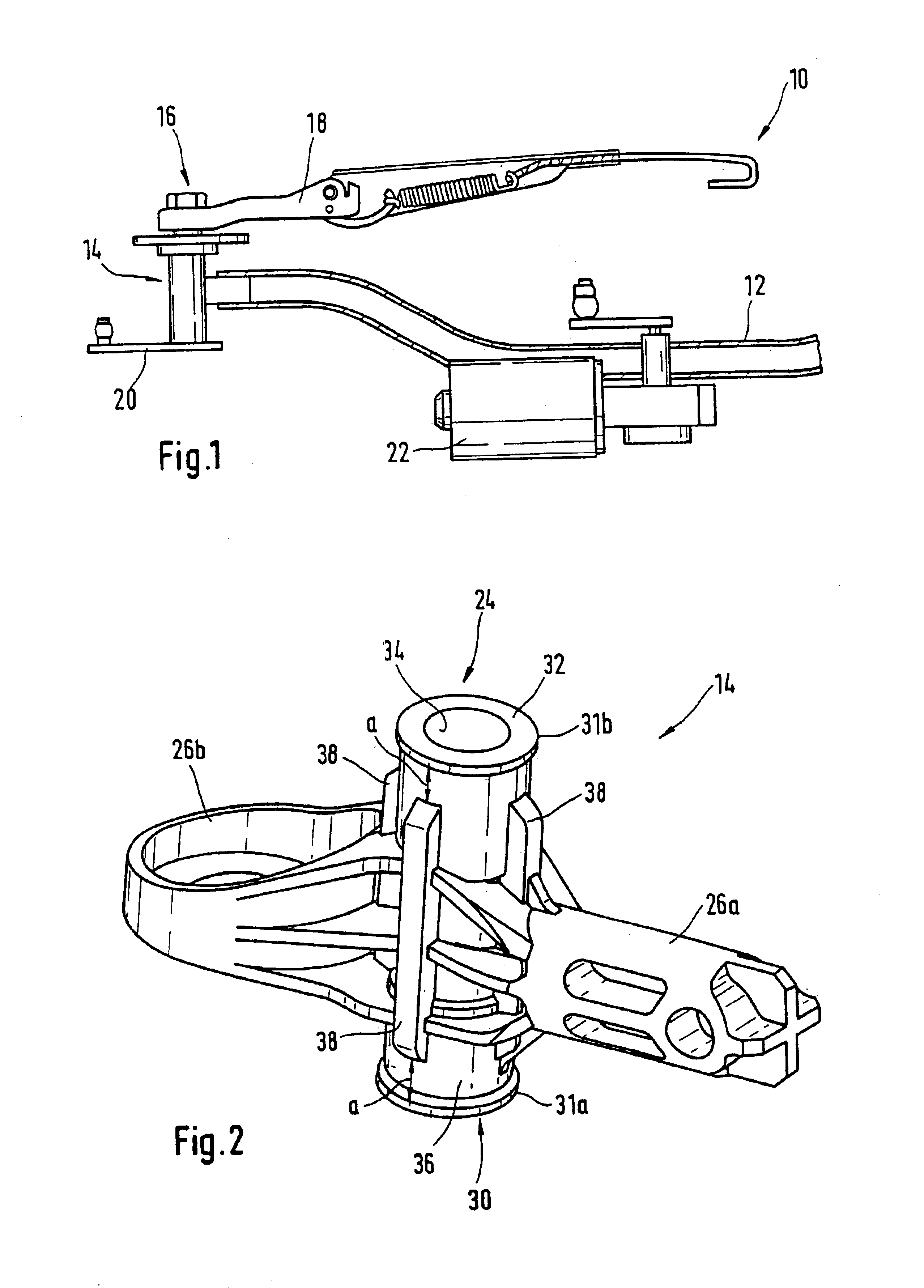

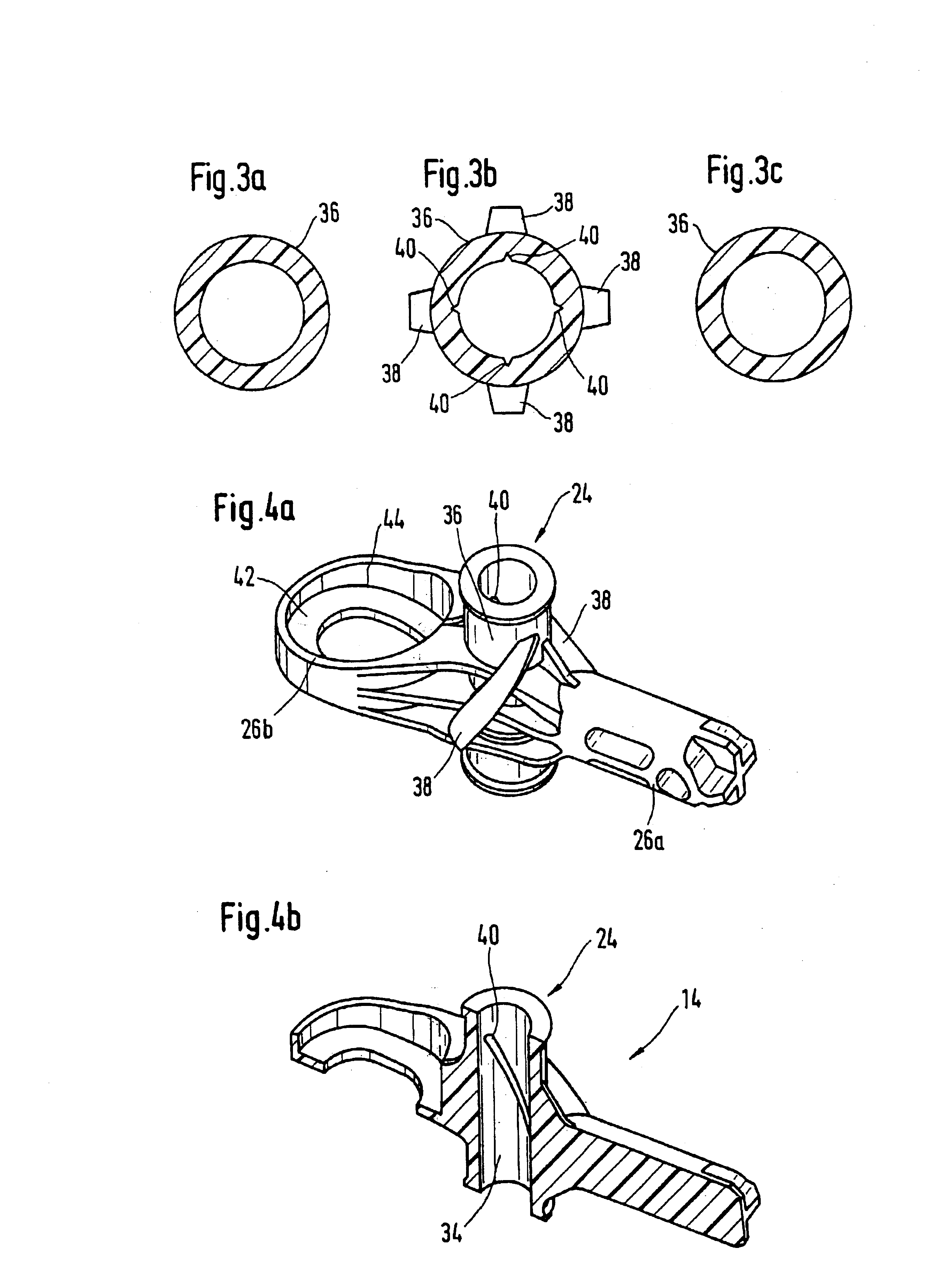

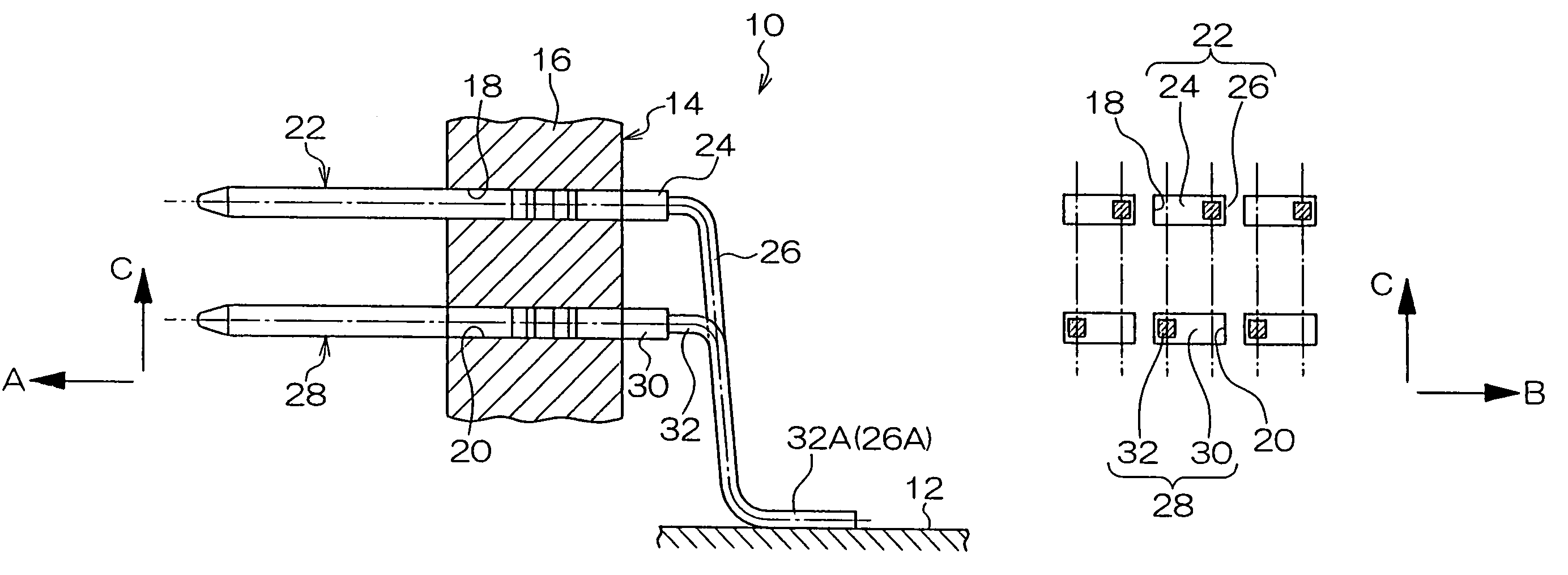

Windshield wiper, especially for motor vehicles and method for production of said windshield wiper

InactiveUS6883966B2Reduce tooling costsSmall diameterCrankshaftsCrossheadsMobile vehicleMotor vehicle part

A windshield wiper system, and a method for producing such a system, in particular for a motor vehicle, having at least one wiper bearing (14) substantially comprising an injection-moldable material, in particular plastic, in which a wiper shaft (16) is supported at least in such a way that it can swing back and forth, and in the region of the wiper shaft (16), the wiper bearing (14) has a substantially hollow-cylindrical segment (24) on whose inner surface (34) at least one groove (40) is provided; at least one, in particular riblike, accumulation of material (38) is provided on the outer surfaces of the hollow-cylindrical segment (24), which accumulation is disposed in the radially outward direction of the groove (40) relative to the axis of rotation of the wiper shaft (16).

Owner:ROBERT BOSCH GMBH

Hybrid bumper with trim

A hybrid bumper system includes a polymeric reinforcement beam with end sections and structural covers attached to the end sections to considerably strengthen the end sections. Bracketry stably supports the reinforcement beam on a vehicle frame. A fascia covers at least part of the reinforcement beam but leaves a portion of the structural covers in a visible position. The structural covers are treated for aesthetics, such as by painting, chroming, or other surface treatment. In one aspect, the beam includes a molded polymeric beam component, structural L-shaped covers attached to its end sections, and a tie bar along its rear side that stiffens and rigidifies a center of the polymeric beam component. In another aspect, a tow bar or rail-to-rail metal reinforcement beam front system (or rear with tow bar) is incorporated.

Owner:SHAPE CORP

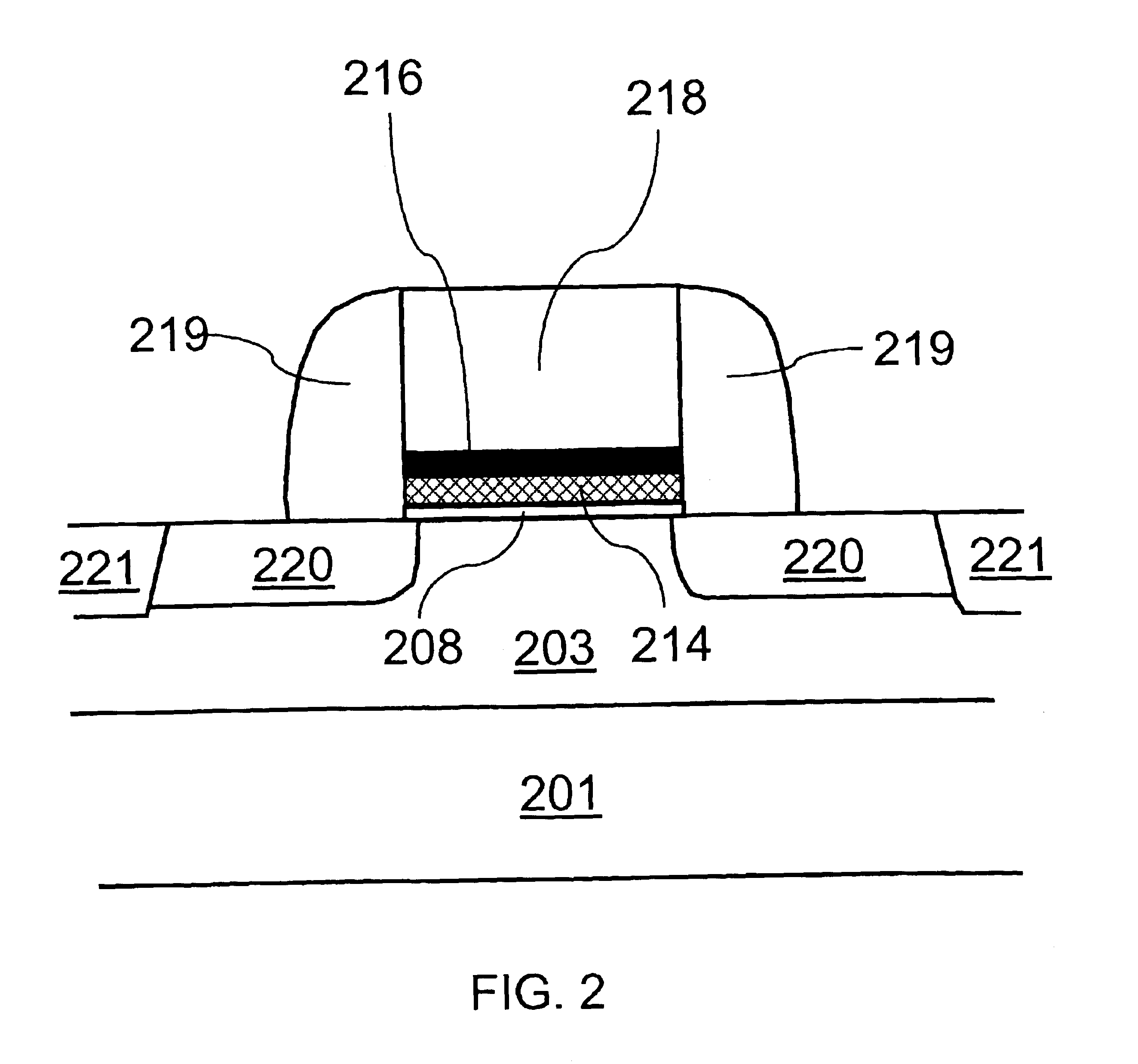

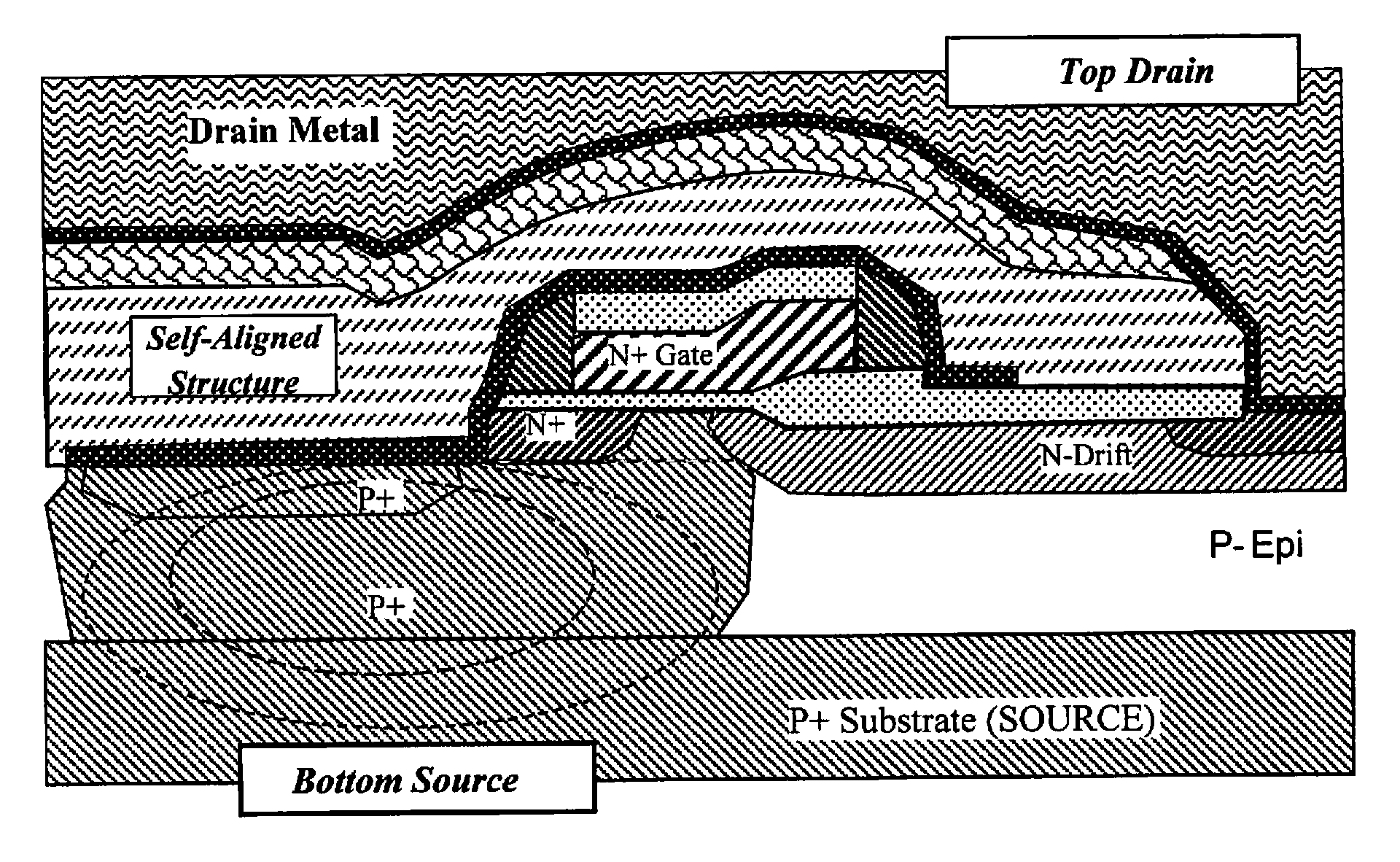

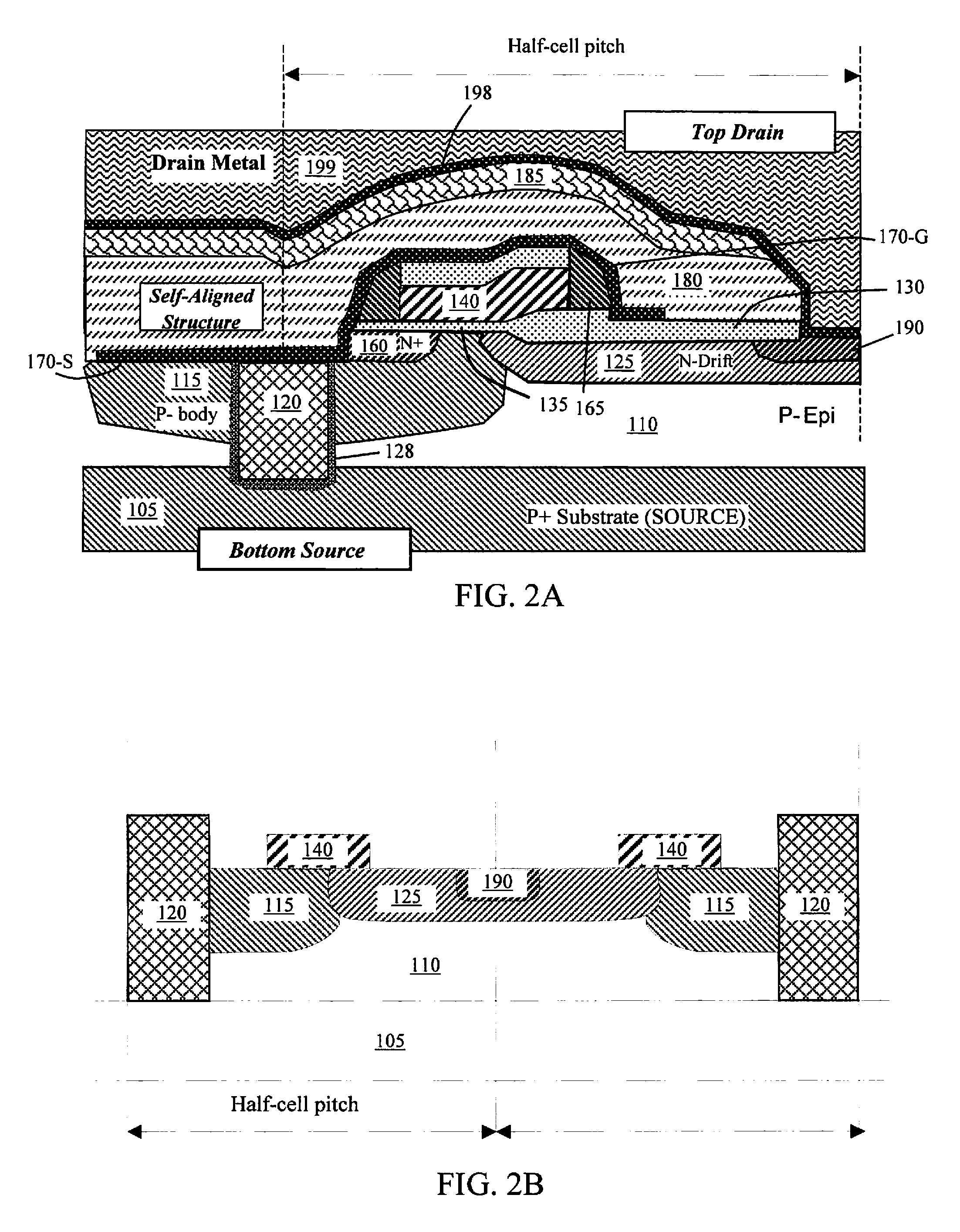

Top drain ldmos

ActiveUS20120273879A1Reduced cell pitchReduce tooling costsSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSCurrent channel

In an embodiment, this invention discloses a top-drain lateral diffusion metal oxide field effect semiconductor (TD-LDMOS) device supported on a semiconductor substrate. The TD-LDMOS includes a source electrode disposed on a bottom surface of the semiconductor substrate. The TD-LDMOS further includes a source region and a drain region disposed on two opposite sides of a planar gate disposed on a top surface of the semiconductor substrate wherein the source region is encompassed in a body region constituting a drift region as a lateral current channel between the source region and drain region under the planar gate. The TD-LDMOS further includes at least a trench filled with a conductive material and extending vertically from the body region near the top surface downwardly to electrically contact the source electrode disposed on the bottom surface of the semiconductor substrate.

Owner:ALPHA & OMEGA SEMICON INC

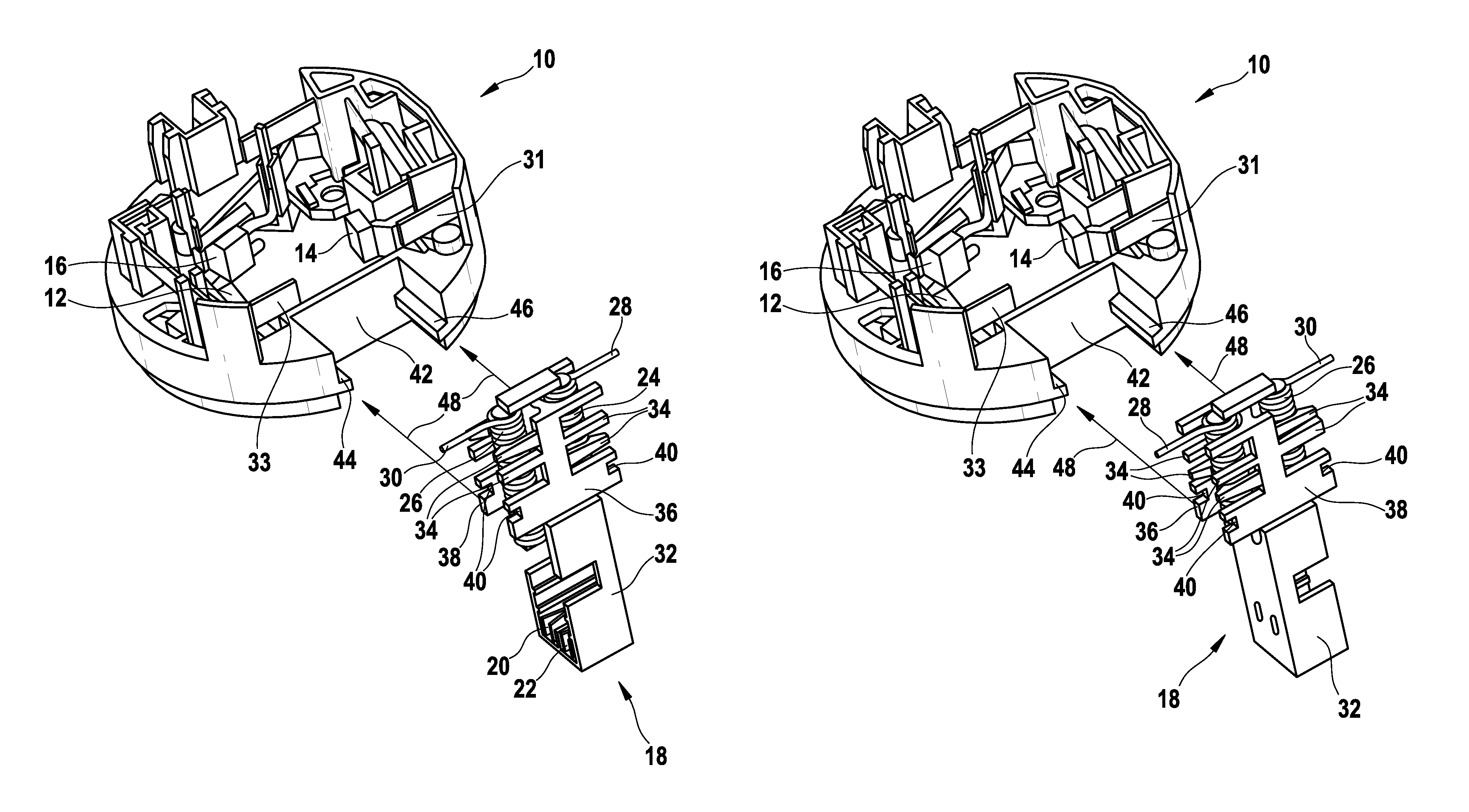

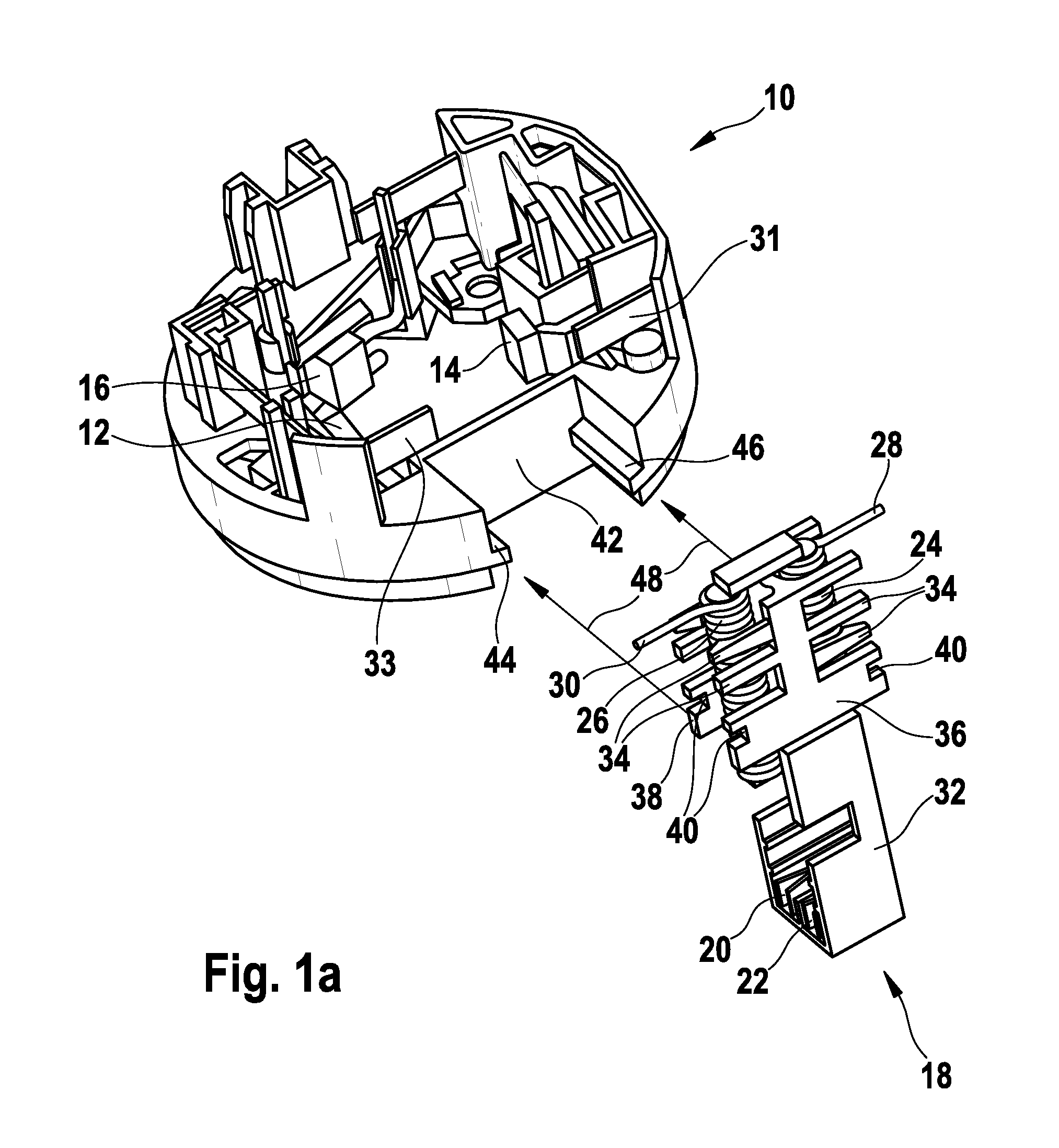

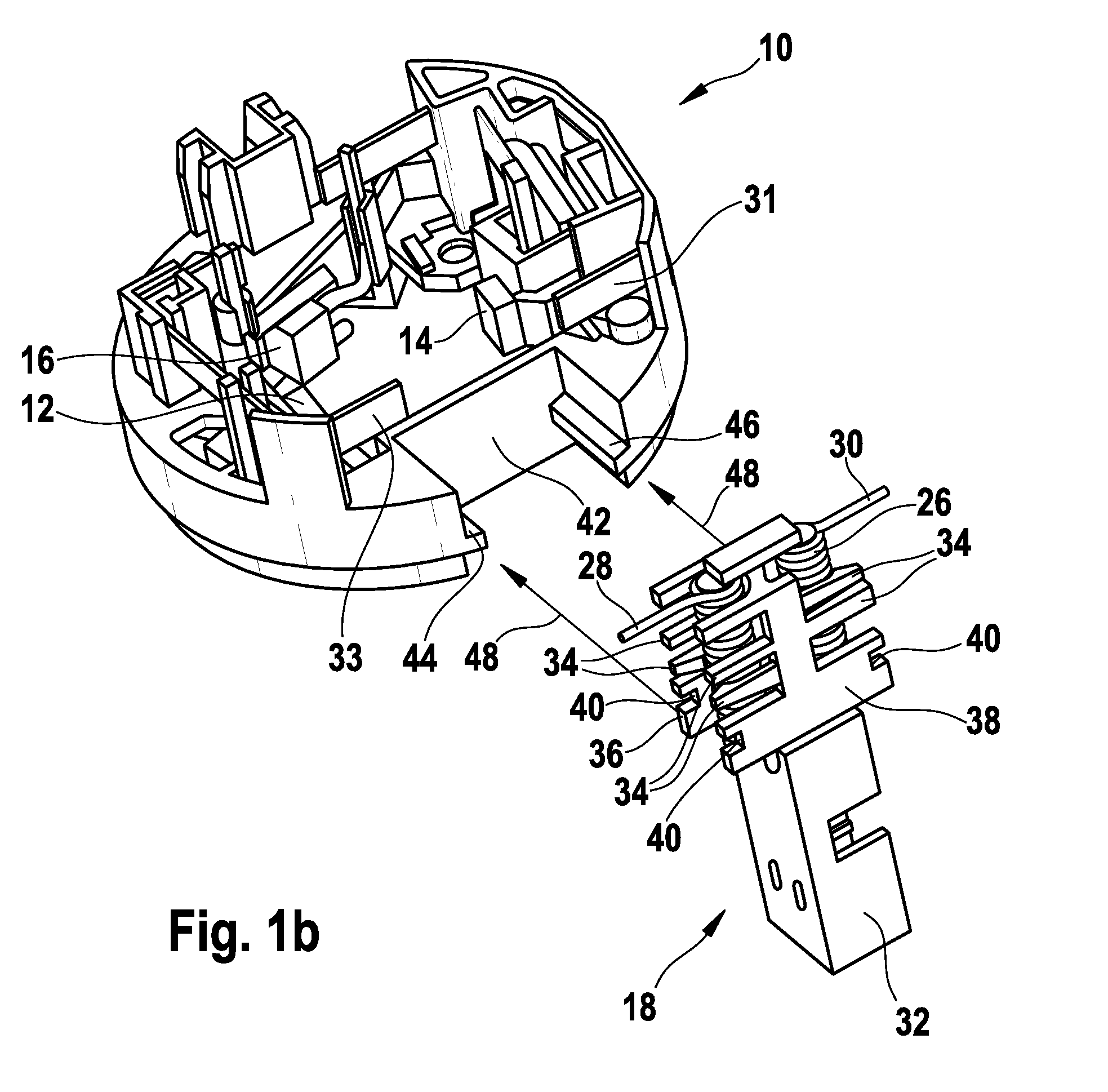

Electric drive

InactiveUS7898141B2Variety of tools andReliably producedRotary current collectorVehicle cleaningElectricityDrive shaft

An electric drive, in particular a wiper drive for vehicles, is proposed, with an electric driving motor in a motor housing (50), a brush holder (10) projecting into the motor housing (50), an anti-interference module (18) which is connected electrically and mechanically to the brush holder (10) and is intended for the electrical connection and interference protection of the motor, and with a gear mechanism (52) which is attached to the motor housing (50), at least partially accommodates the anti-interference module (18) and is designed in accordance with the predetermined position of the output shaft (53) with respect to the drive shaft (58). According to the invention, the diversity of components of the electric drive and therefore, in particular, the diversity of tools for producing the components are reduced by the anti-interference module (18) and the brush holder (10) being equipped with corresponding retaining means (40, 44) which permit the installation of a structurally identical anti-interference module (18) on the brush holder (10) in two installation positions rotated through 180°.

Owner:ROBERT BOSCH GMBH

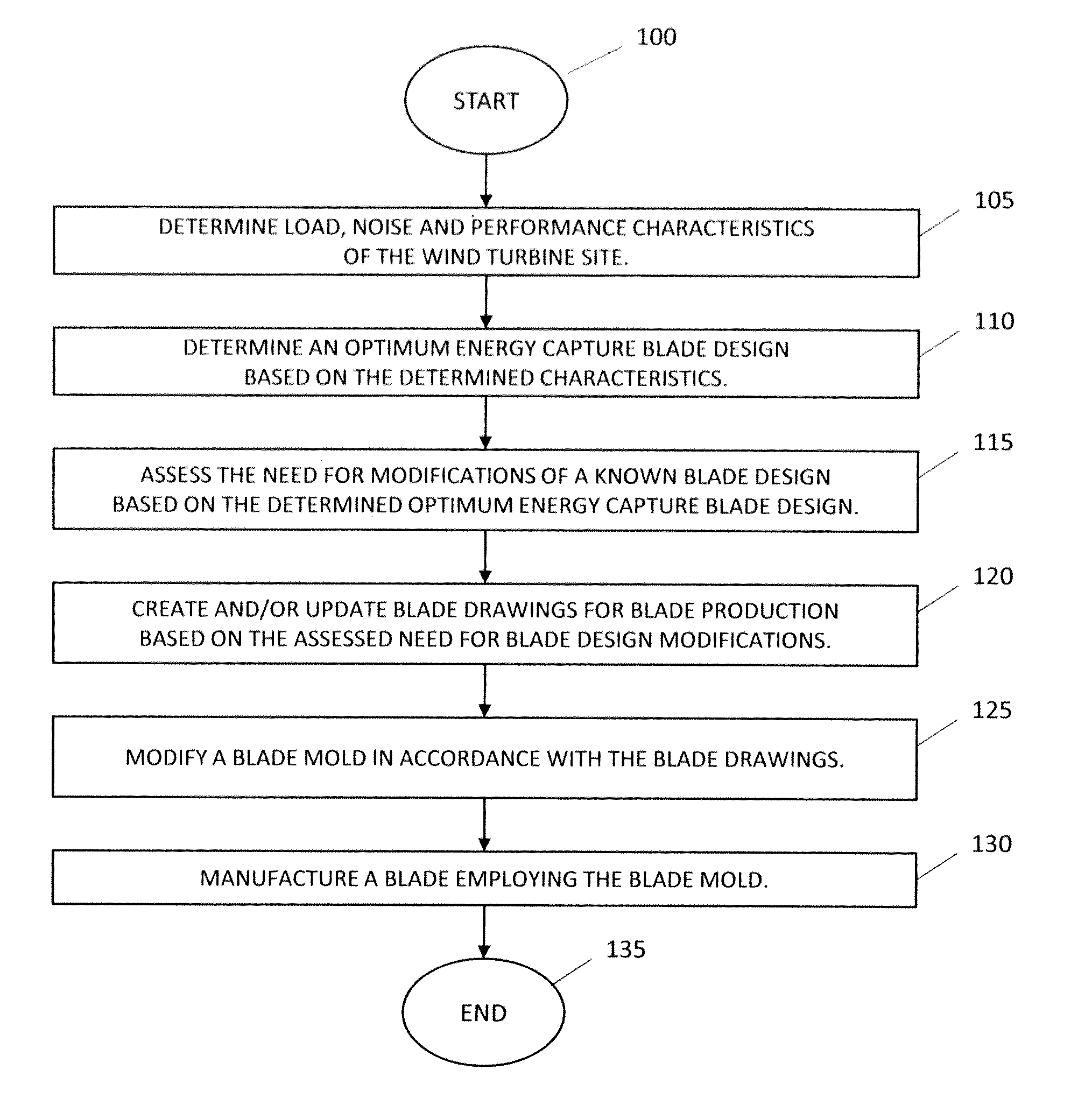

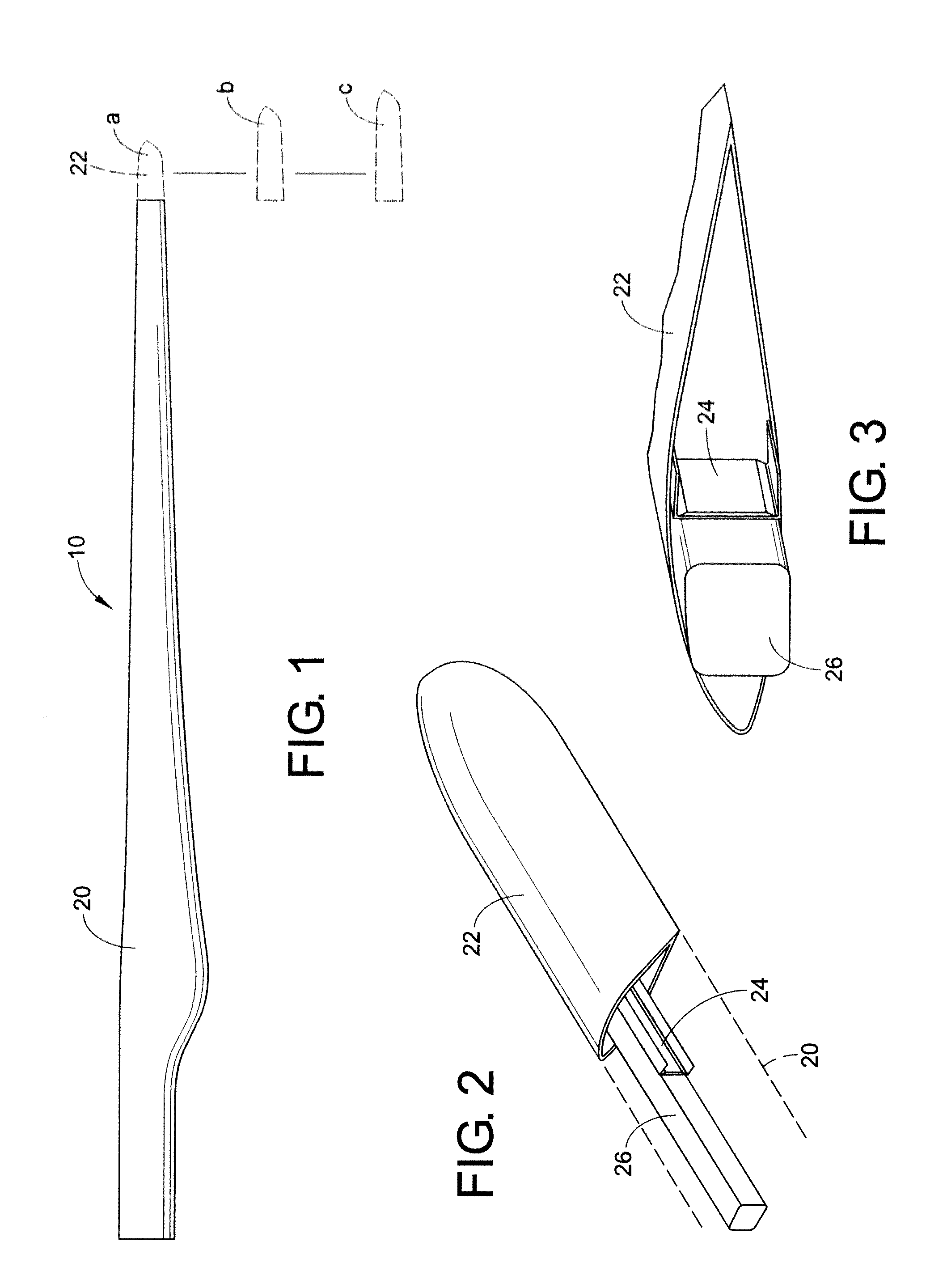

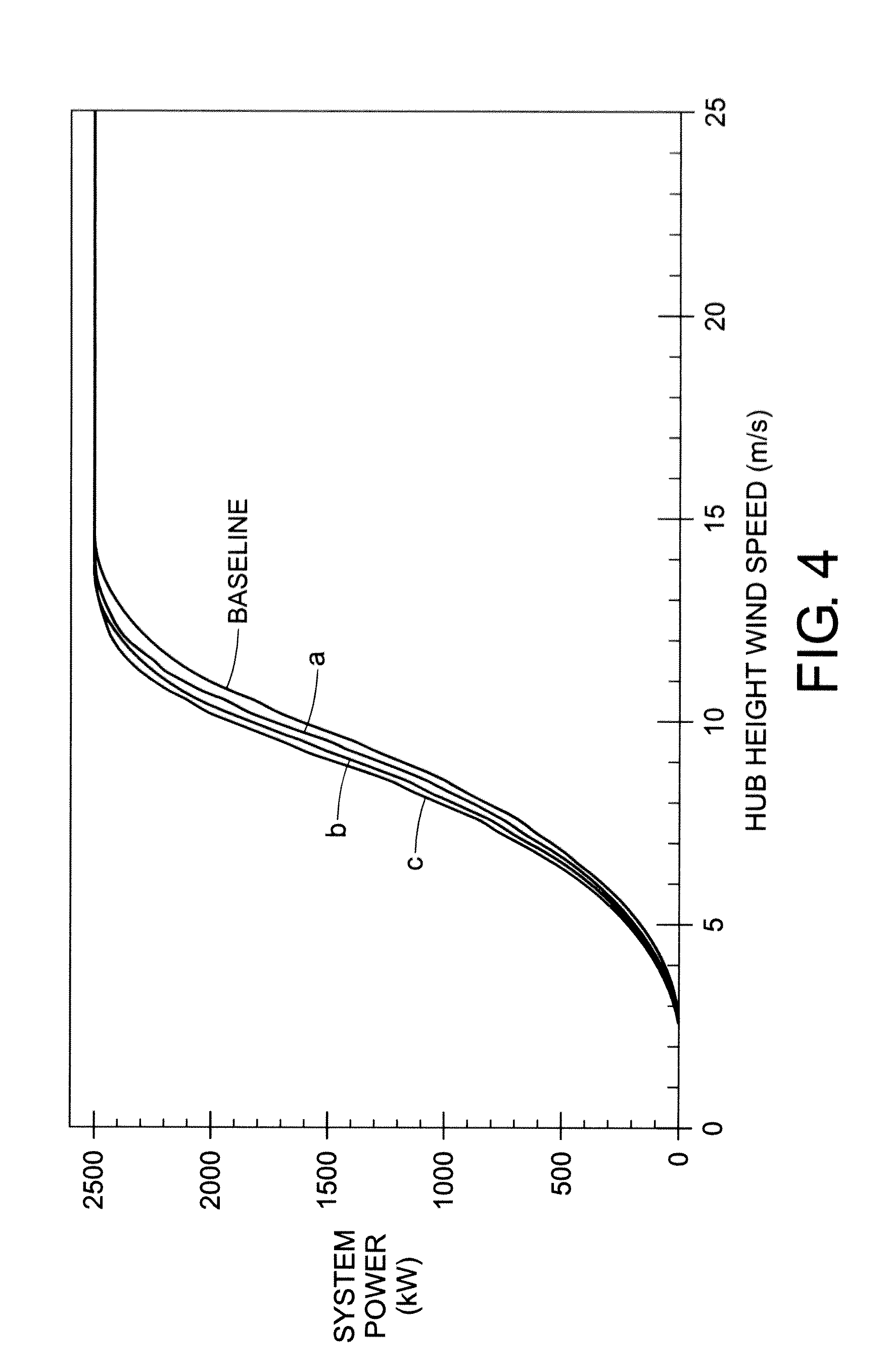

Method for site specific energy capture optimization through modular rotor blade tip extension

InactiveUS20120093627A1Firmly connectedEasy to removeFinal product manufactureWind motor assemblyUnderwaterModularity

A power generating system wherein a turbine (34) is mounted on top of a tower (30) or tethered underwater. The turbine (34) includes a rotor having a main blade (20) connected to a rotor hub (40) and an extender blade tip (22, 22′) attached to the main blade (20). During manufacture, the optimum energy-capture is determined using site-specific conditions of one or more of air density, wind speed, extreme wind, wind shear, noise and turbulence intensity. The extender blade tip (22, 22′) is chosen from a number of extender blade tips having a length that is the closest to the determined optimum energy-capture. The chosen extender blade tip is attached to the main blade either during manufacture or on-site. Alternatively, a one piece blade is produced based on information determined from the site specific conditions. The tip of such one piece blade can be customized based on the information obtained.

Owner:CLIPPER WINDPOWER INC

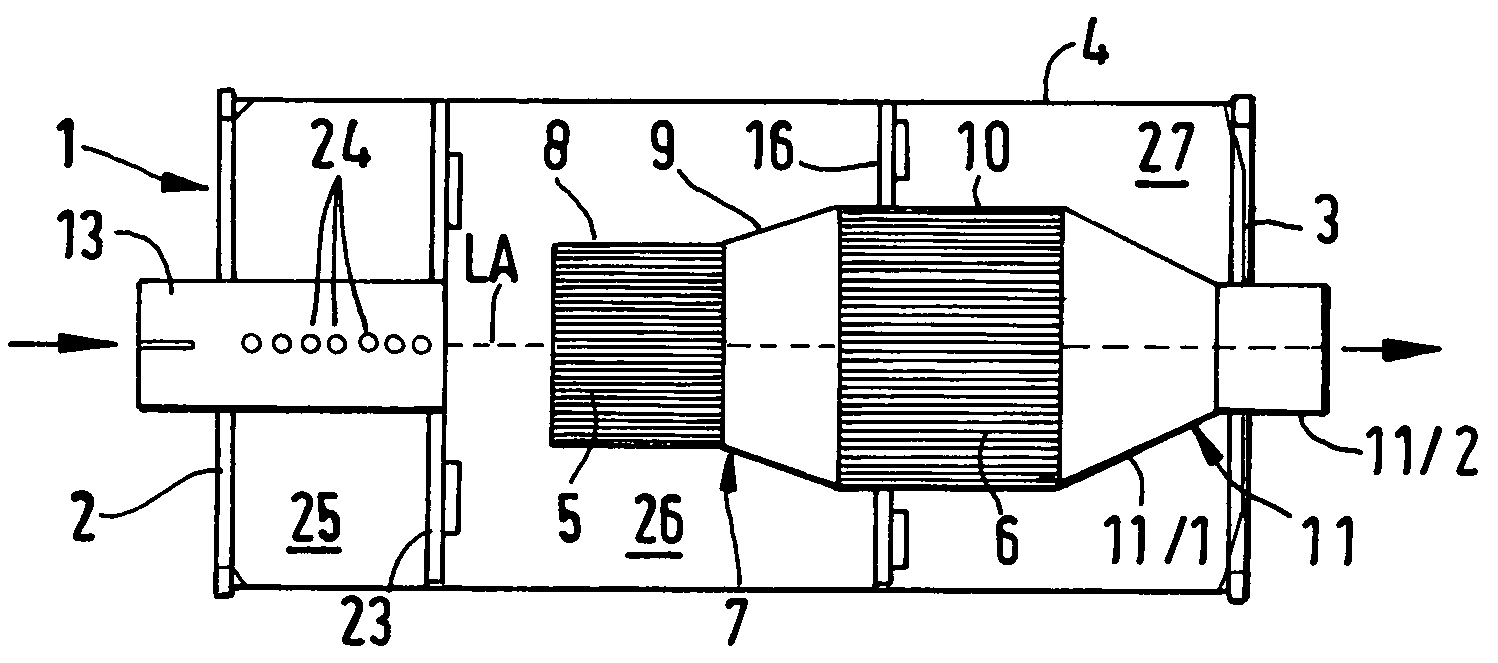

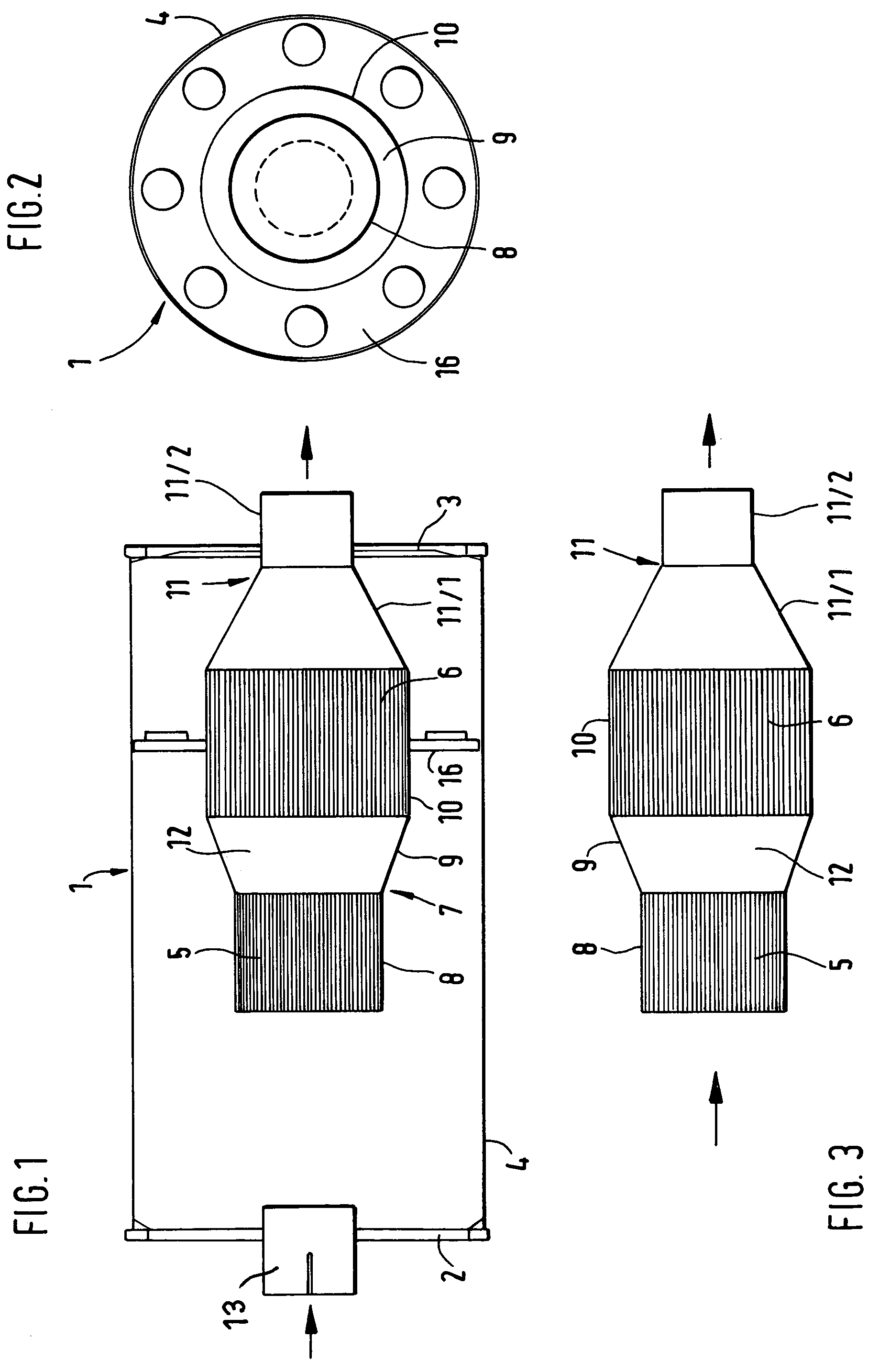

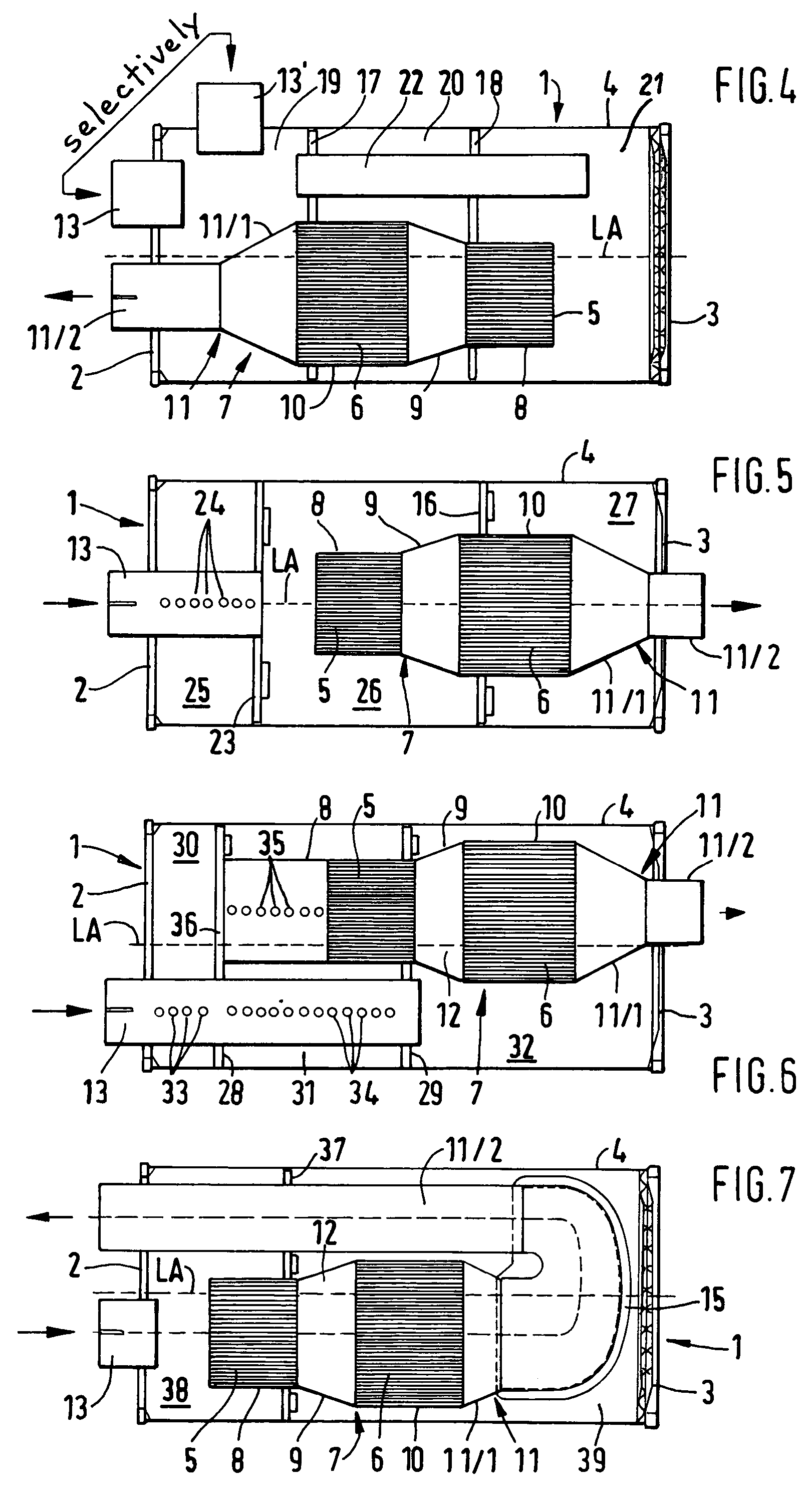

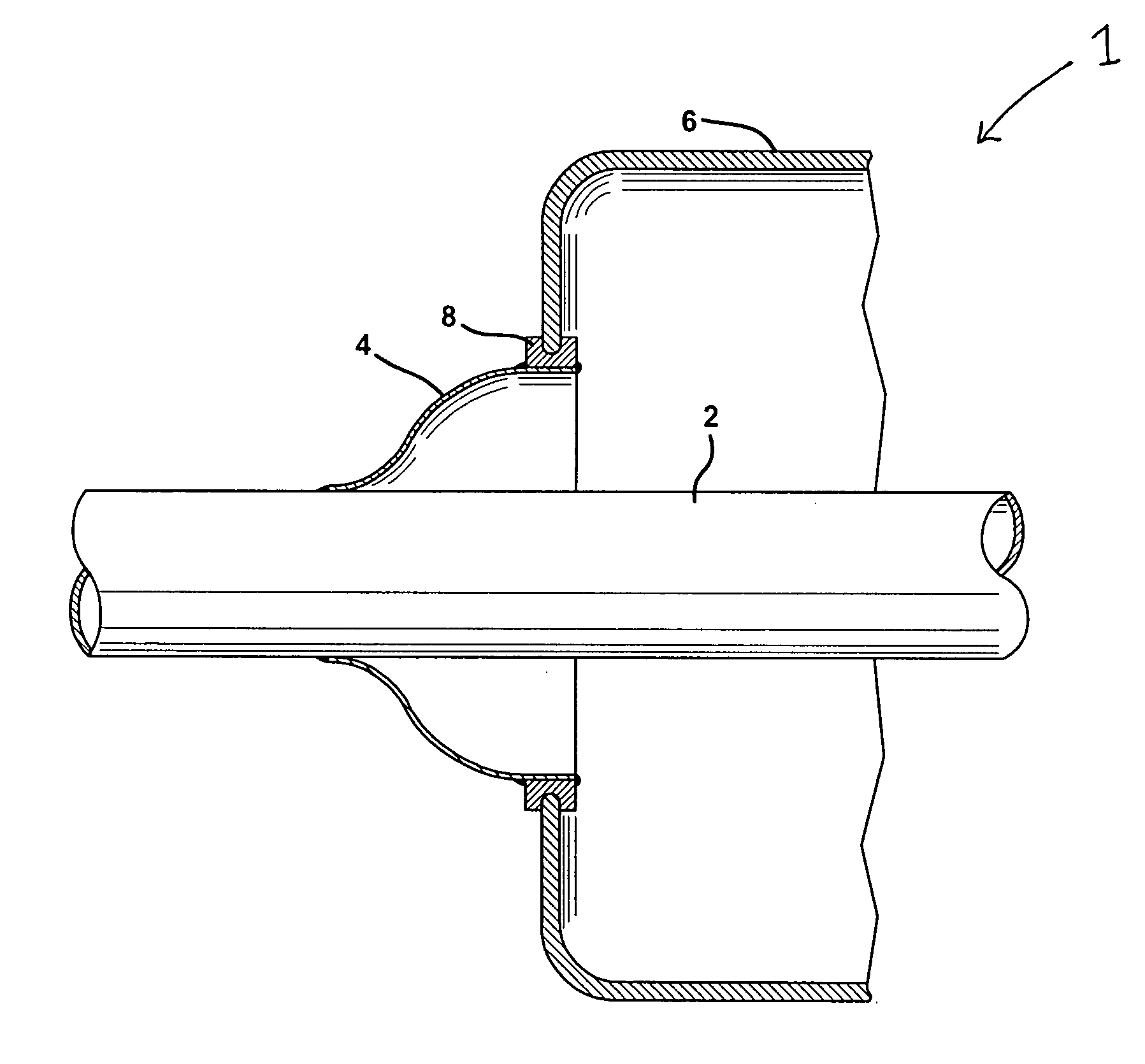

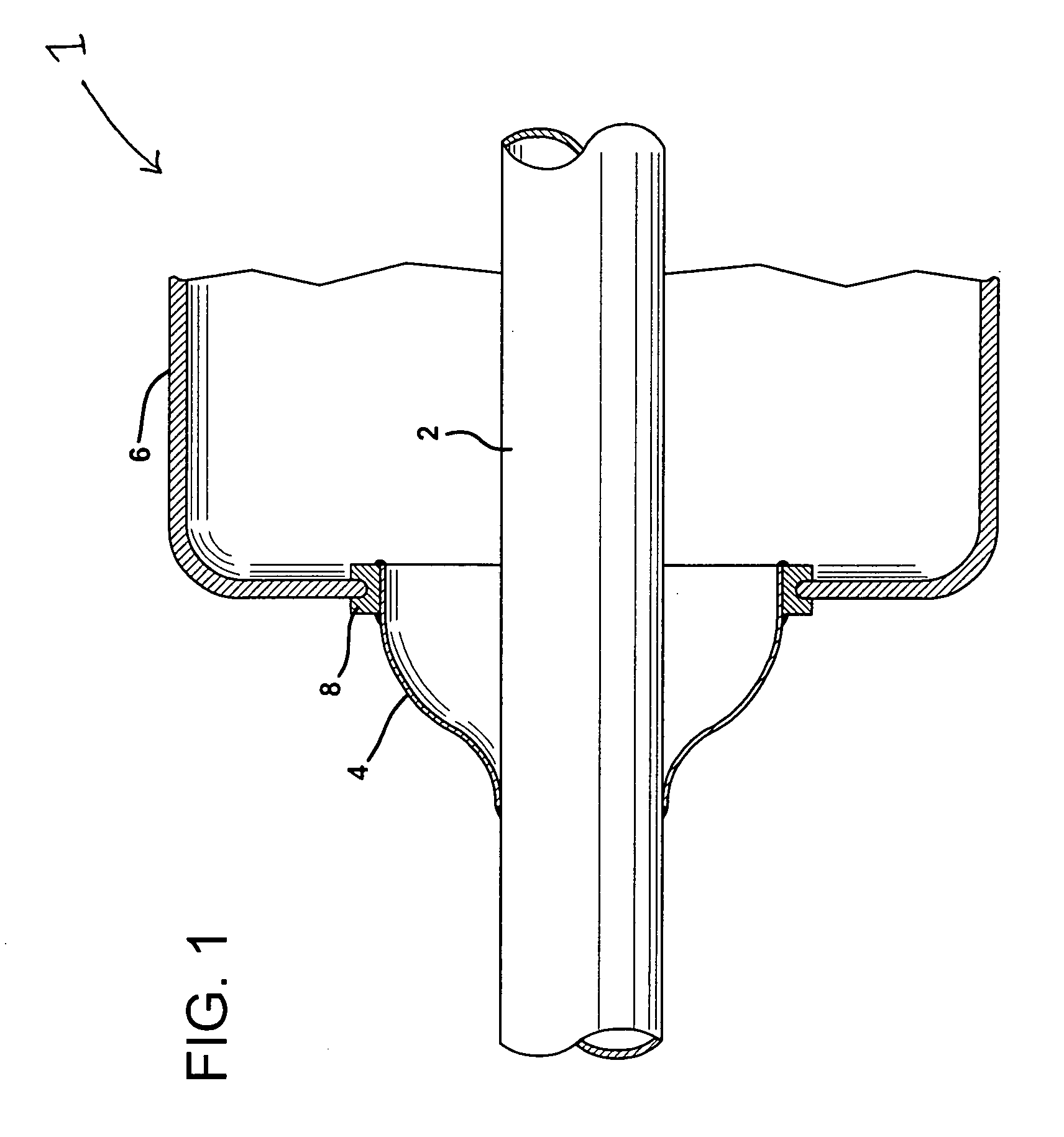

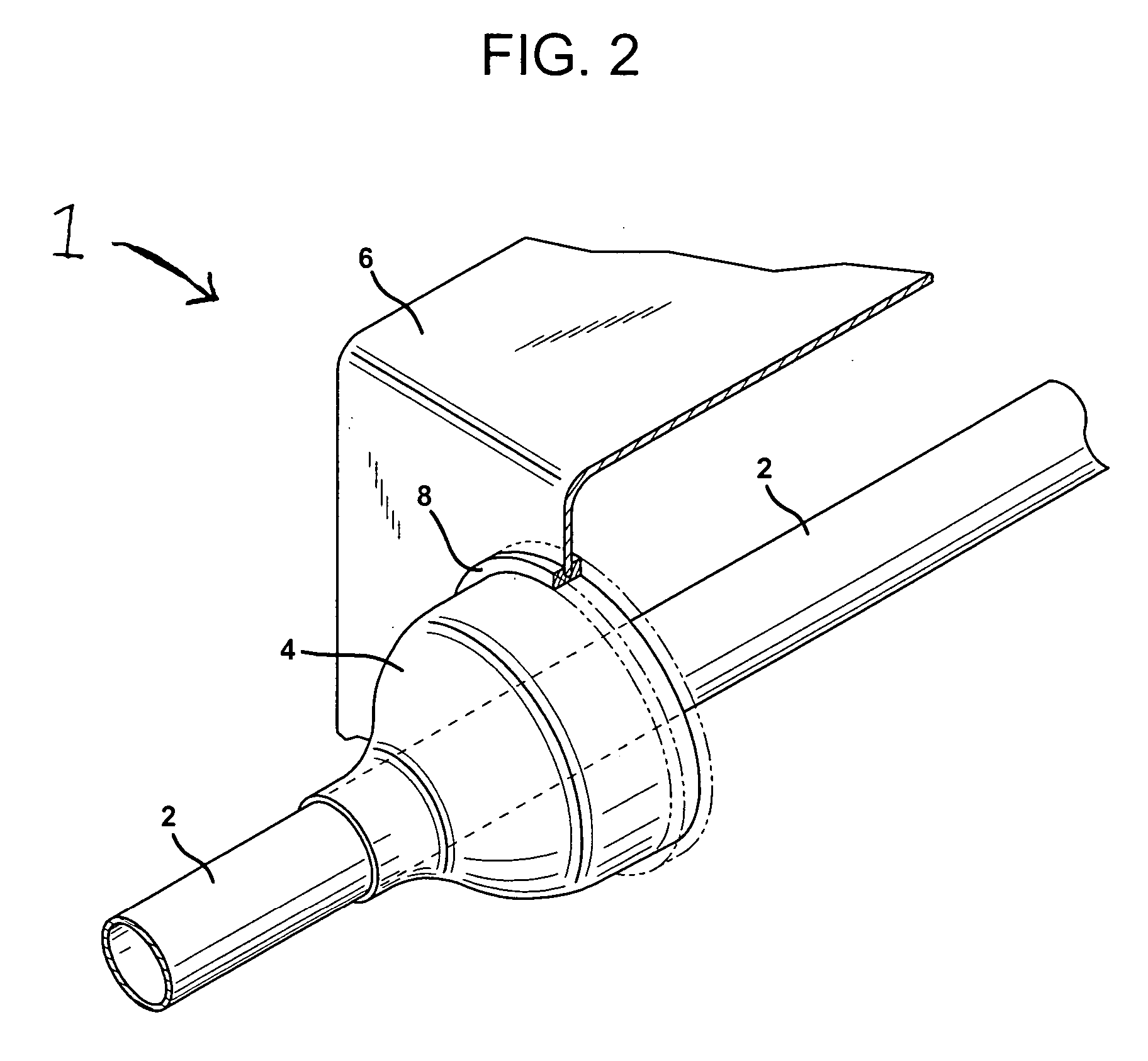

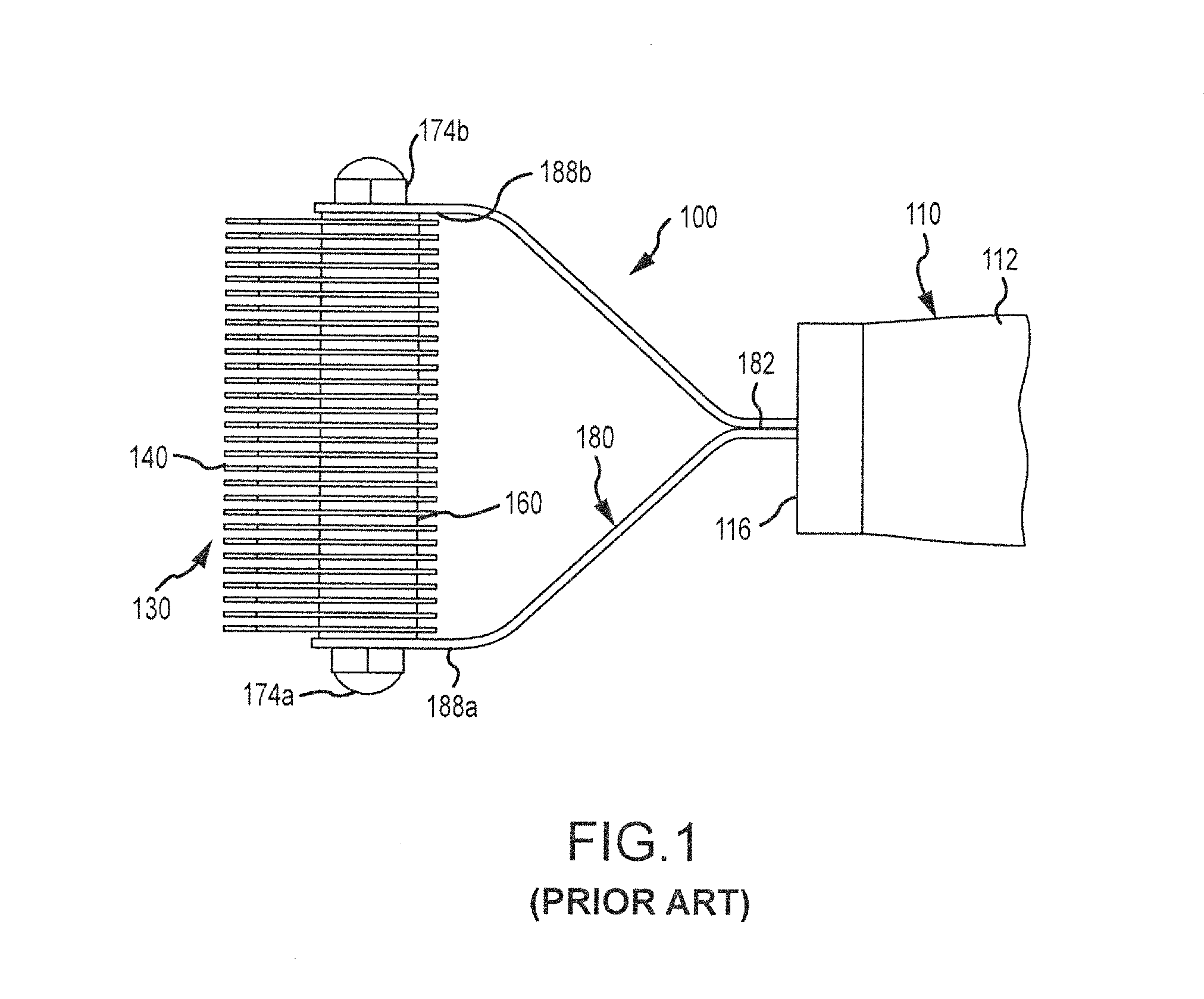

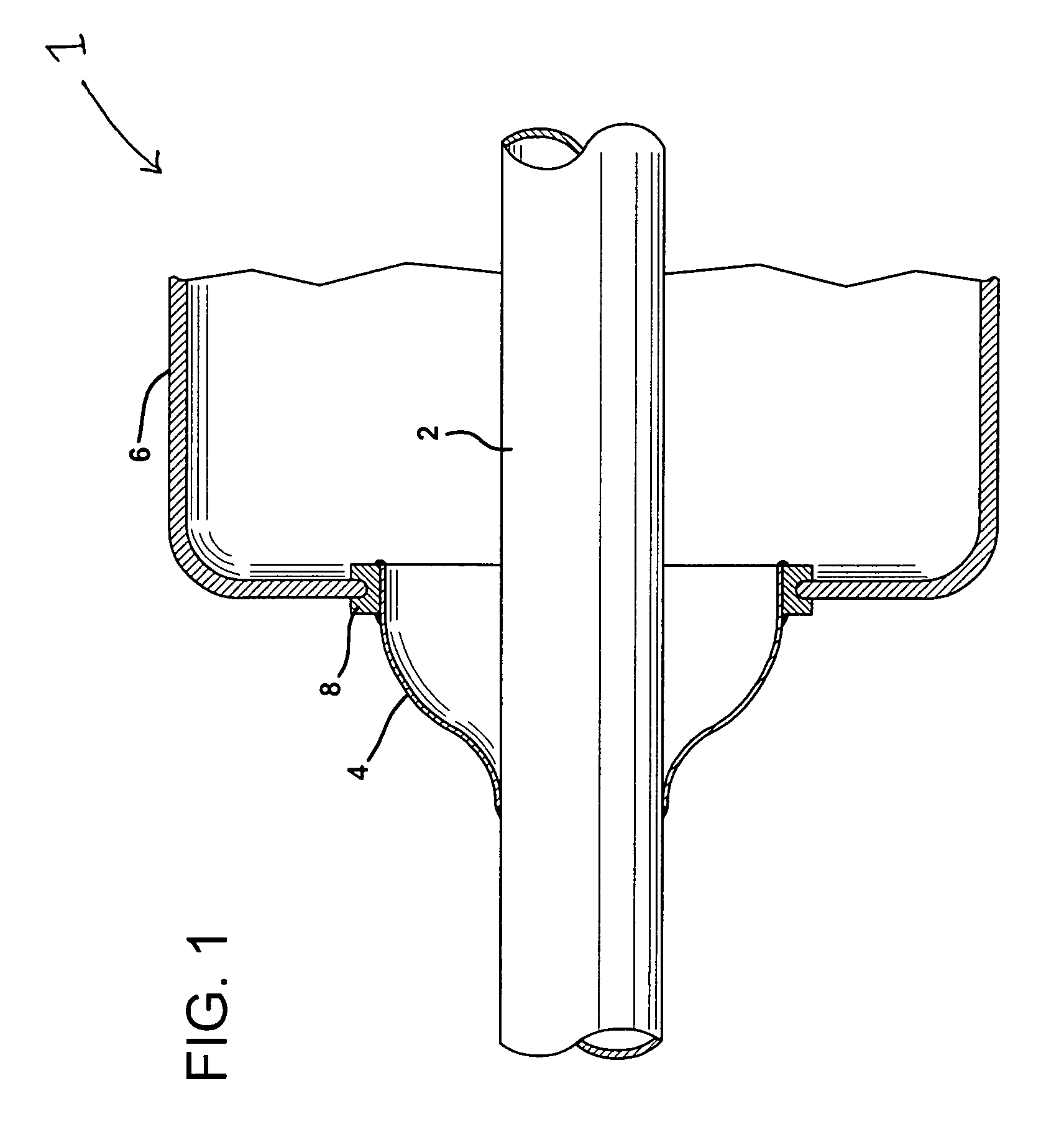

Combination exhaust gas post treatment/muffler device in the exhaust gas section of an internal combustion engine

ActiveUS7273592B2Reduce material costsReduce tooling costsCombination devicesSilencing apparatusExhaust gasExhaust fumes

A combination exhaust gas post treatment / muffler device in the exhaust gas section of an internal combustion engine is provided. The exhaust gas post treatment within the muffler, which forms sulfuric acid, takes place in at least one exhaust gas post treatment / muffler module, and only that housing thereof through which flows exhaust gas that is to be cleaned is produced from ferritic or austenitic stainless steel, thus making it possible to produce the outer walls of the muffler, as well as any inner element thereof, such as a transverse wall, that is disposed externally of the exhaust gas post treatment / muffler module of unalloyed sheet steel that is coated with aluminum or some other material.

Owner:ROTH TECHN AUSTRIA +1

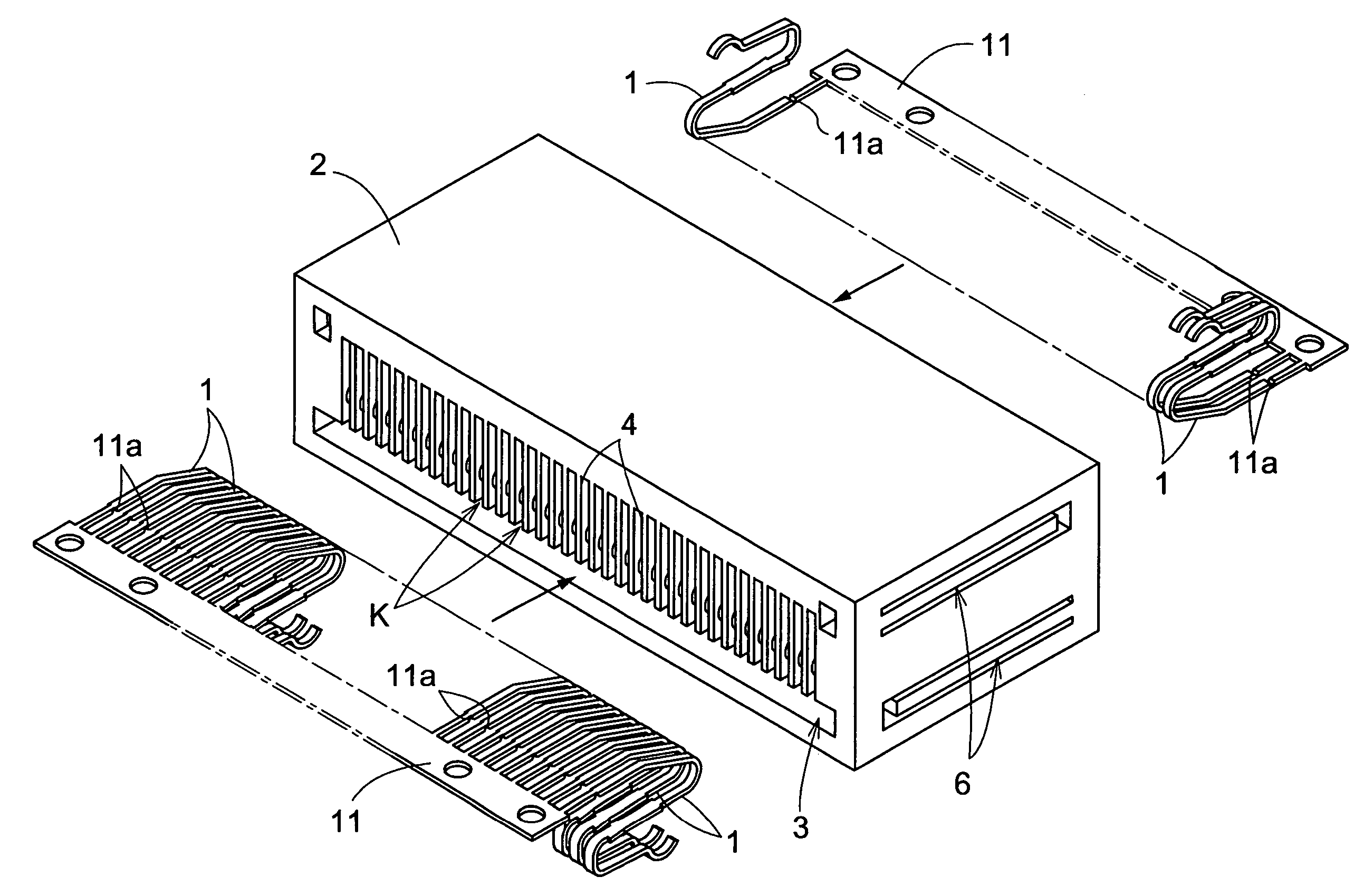

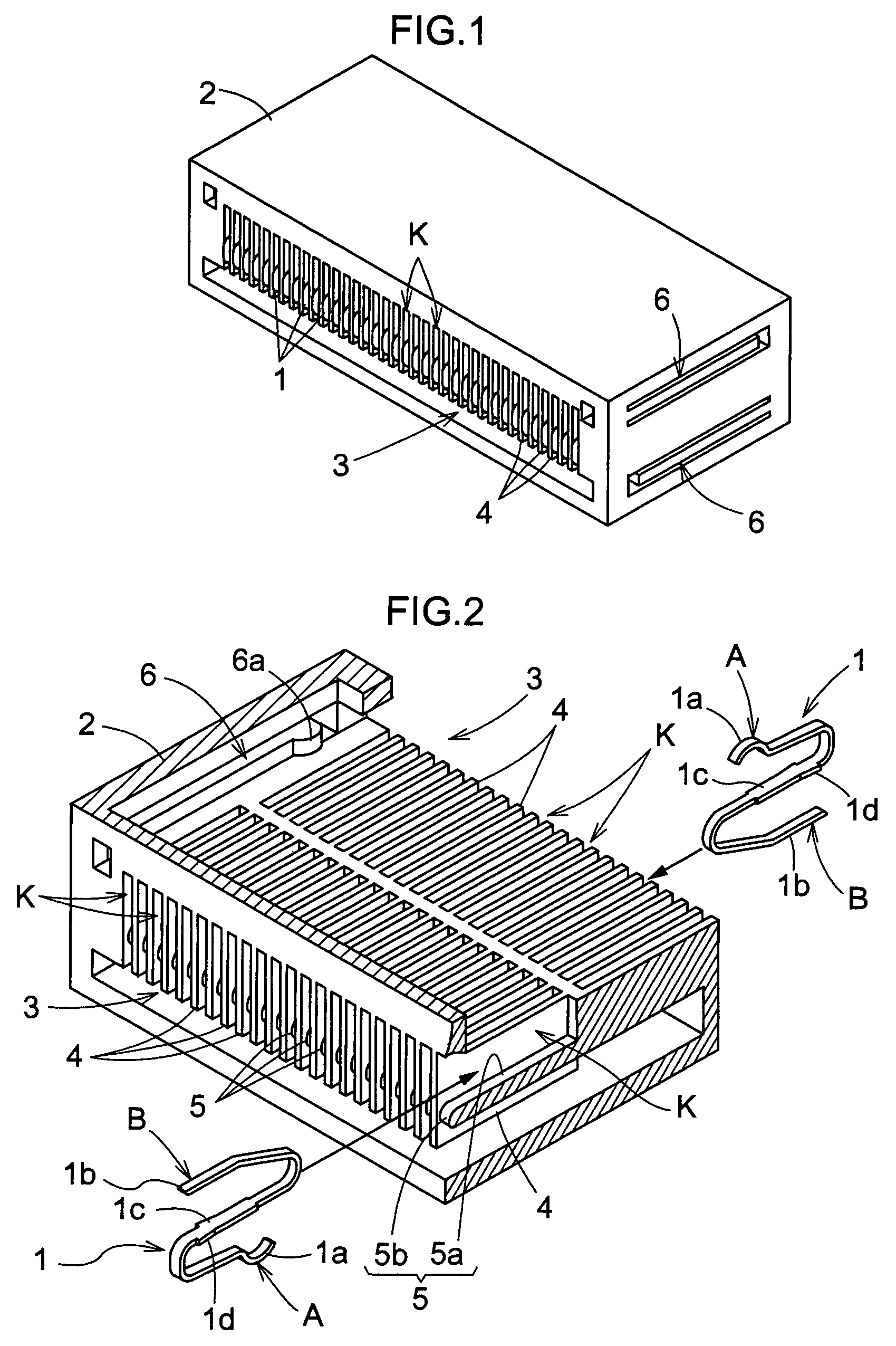

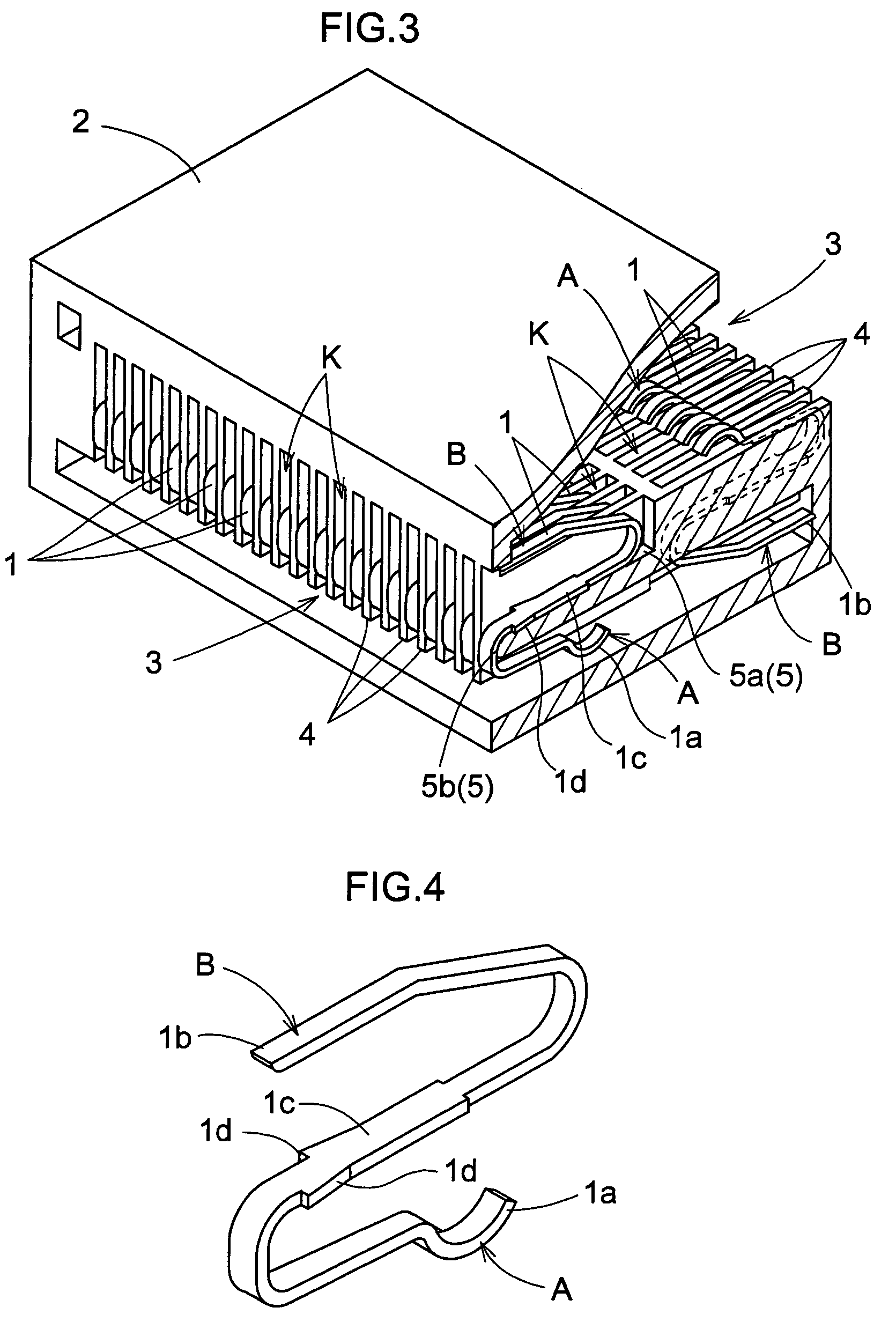

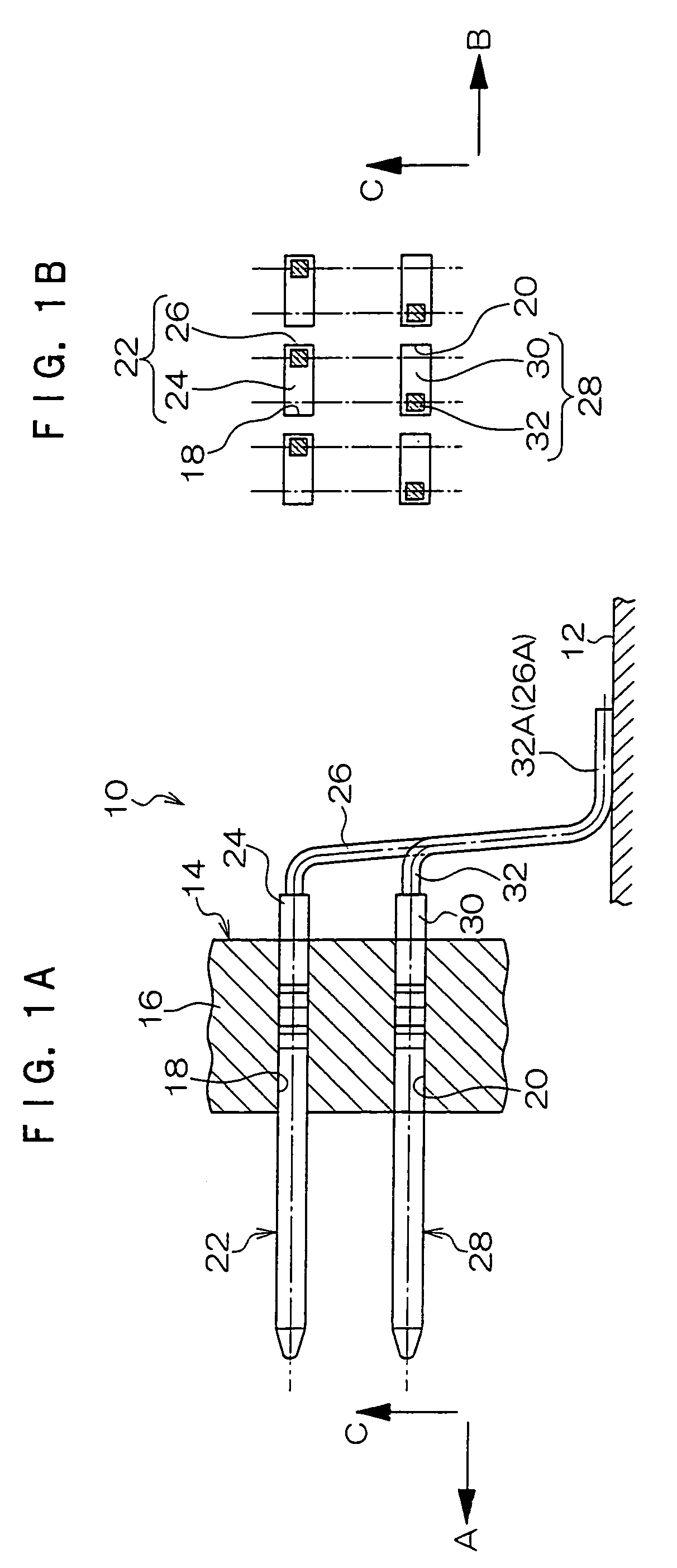

Connector

InactiveUS7137849B2Compactness savingSave spaceCoupling contact membersTwo-part coupling devicesEngineeringElectrical and Electronics engineering

Disclosed are contact members which have elastically deformable points of contact formed in two locations, and a main connector body for insulating and holding a plurality of contact members arranged at intervals in a width direction with the points of contact in the two locations of the respective contact members being in the same positions as seen in the direction of arrangement. The main connector body includes a pair of socket portions for receiving board ends defining land electrodes in two rows corresponding to the points of contact of the respective contact members lying in the same positions as seen in the direction of arrangement, so that the land electrodes are in pressure contact with the corresponding points of contact.

Owner:HOSIDEN CORP

Bumper/muffler assembly

InactiveUS20050023076A1Easy to optimizeSimple designSilencing apparatusMachines/enginesThin metalEngineering

A bumper / muffler assembly is provided comprising a bumper; and a muffler having an outer shell. The outer shell may be formed from a non-high impact resistant material, such as a thin metal or a composite material. The muffler may comprise a separate element from the bumper, which is coupled thereto, or is formed as an integral part of the bumper.

Owner:OCV INTELLECTUAL CAPITAL LLC

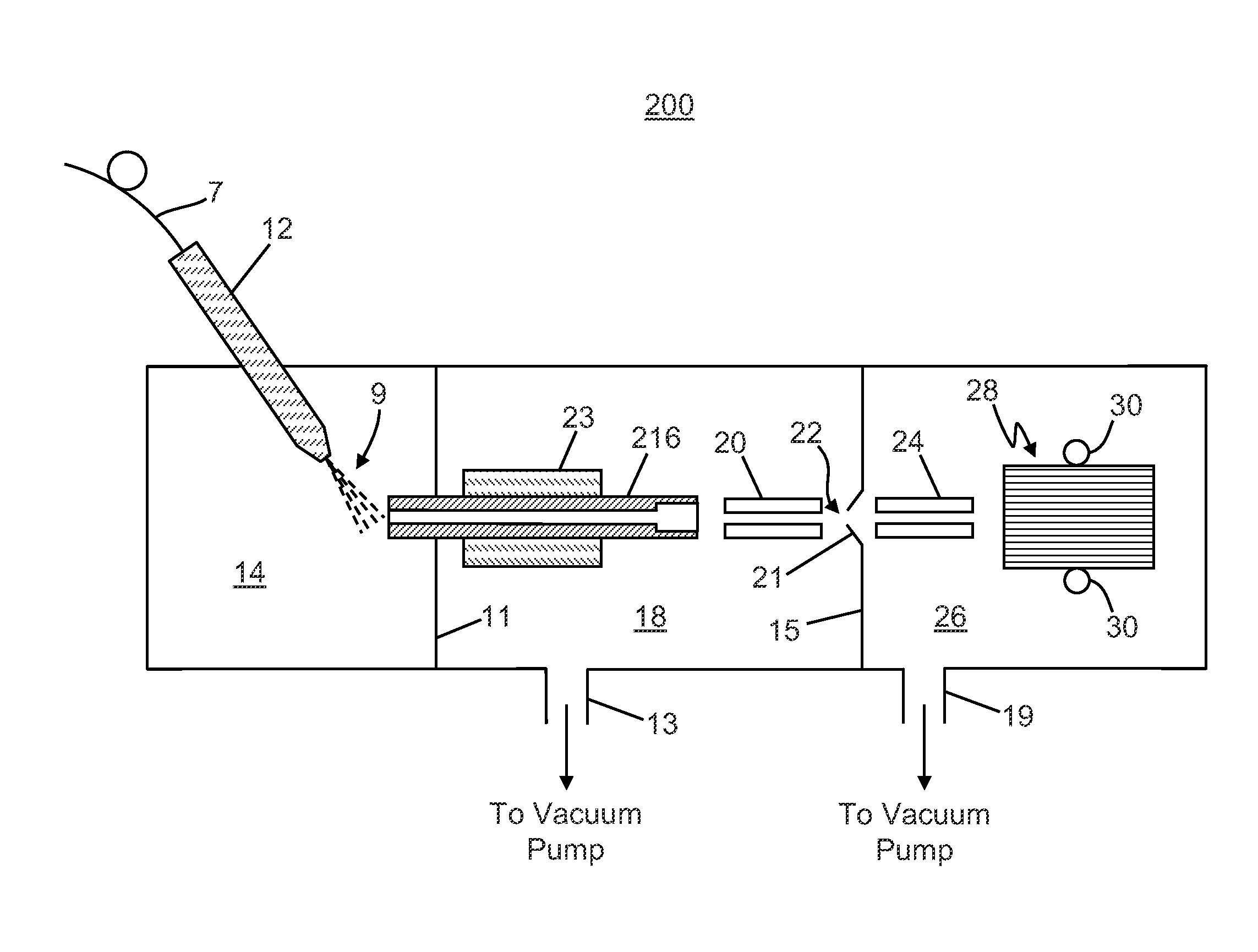

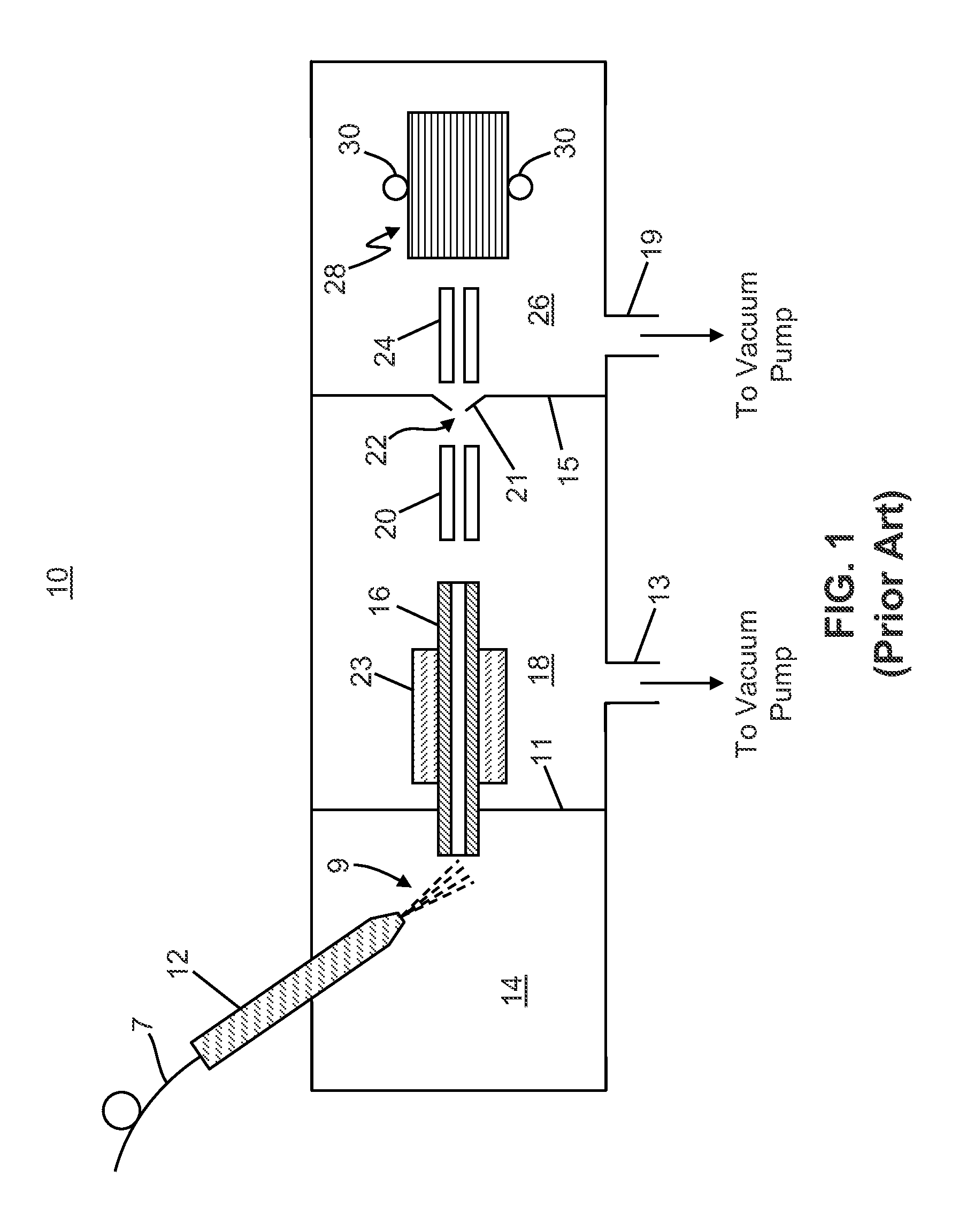

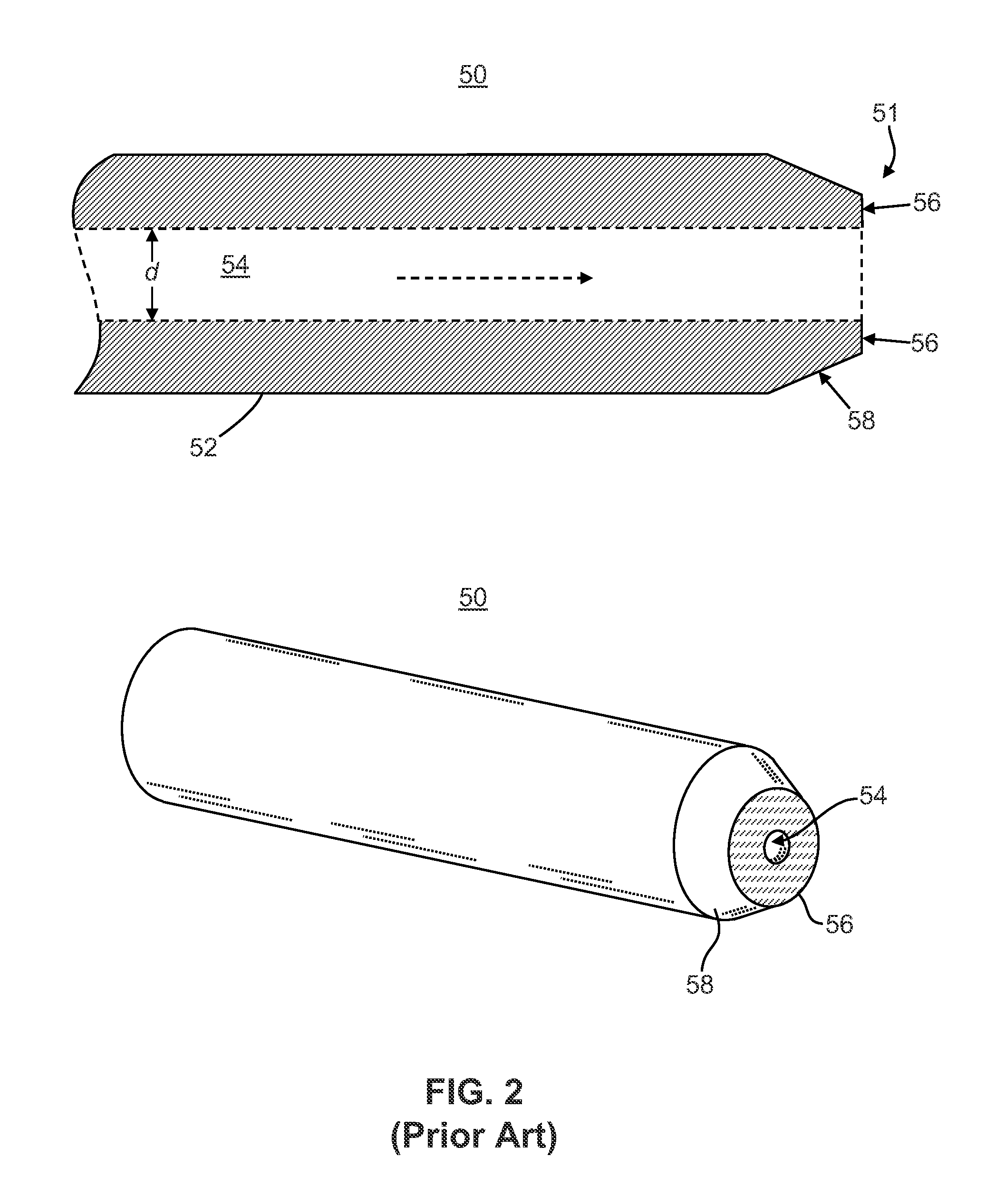

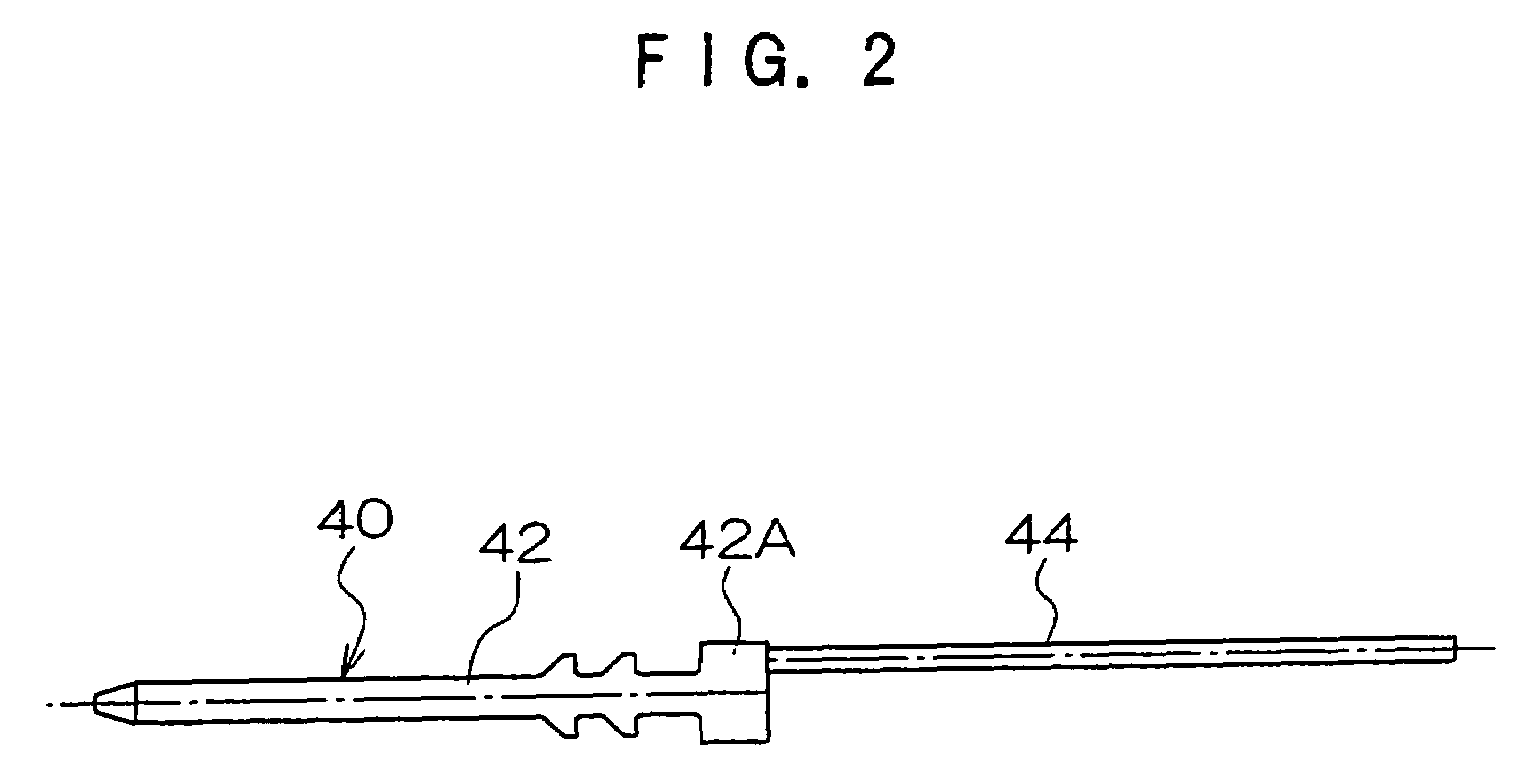

Method and apparatus for an ion transfer tube and mass spectrometer system using same

ActiveUS8242440B2Spread the wordReduce generationSamples introduction/extractionIsotope separationIon transferCapillary Tubing

A method for analyzing a sample comprising the steps of: generating ions from the sample within an ionization chamber at substantially atmospheric pressure; entraining the ions in a background gas; transferring the background gas and entrained ions to an evacuated chamber of a mass spectrometer system using a single-piece capillary having an inlet end and an outlet end, wherein a portion of the capillary adjacent to the outlet end comprises an inner diameter that is greater than an inner diameter of an adjoining portion of the capillary; and analyzing the ions using a mass analyzer of the mass spectrometer system.

Owner:THERMO FINNIGAN

Indexable type cutting tool

InactiveUS7997836B2Reduce tooling costsReduce manufacturing costThread cutting toolsWood turning toolsFluteEngineering

Owner:KORLOY

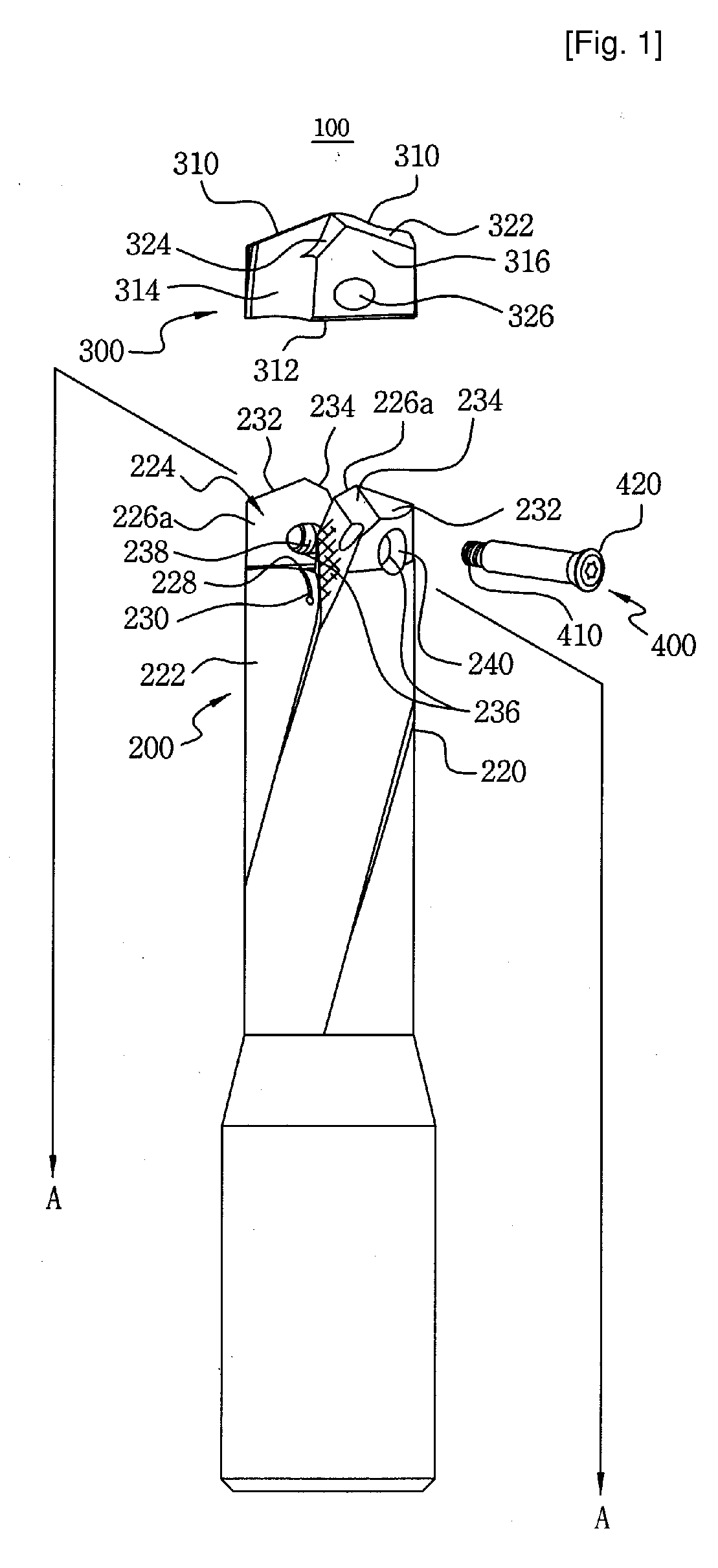

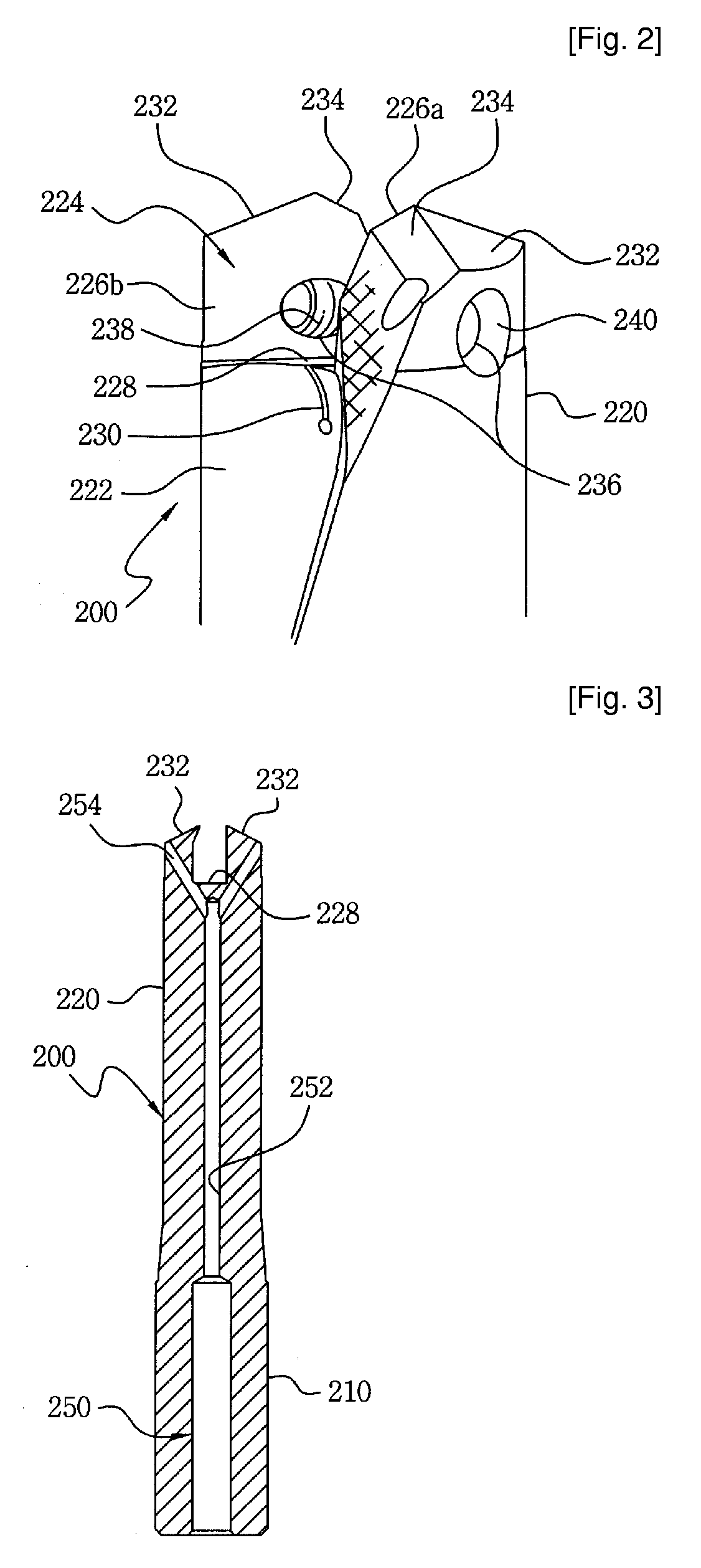

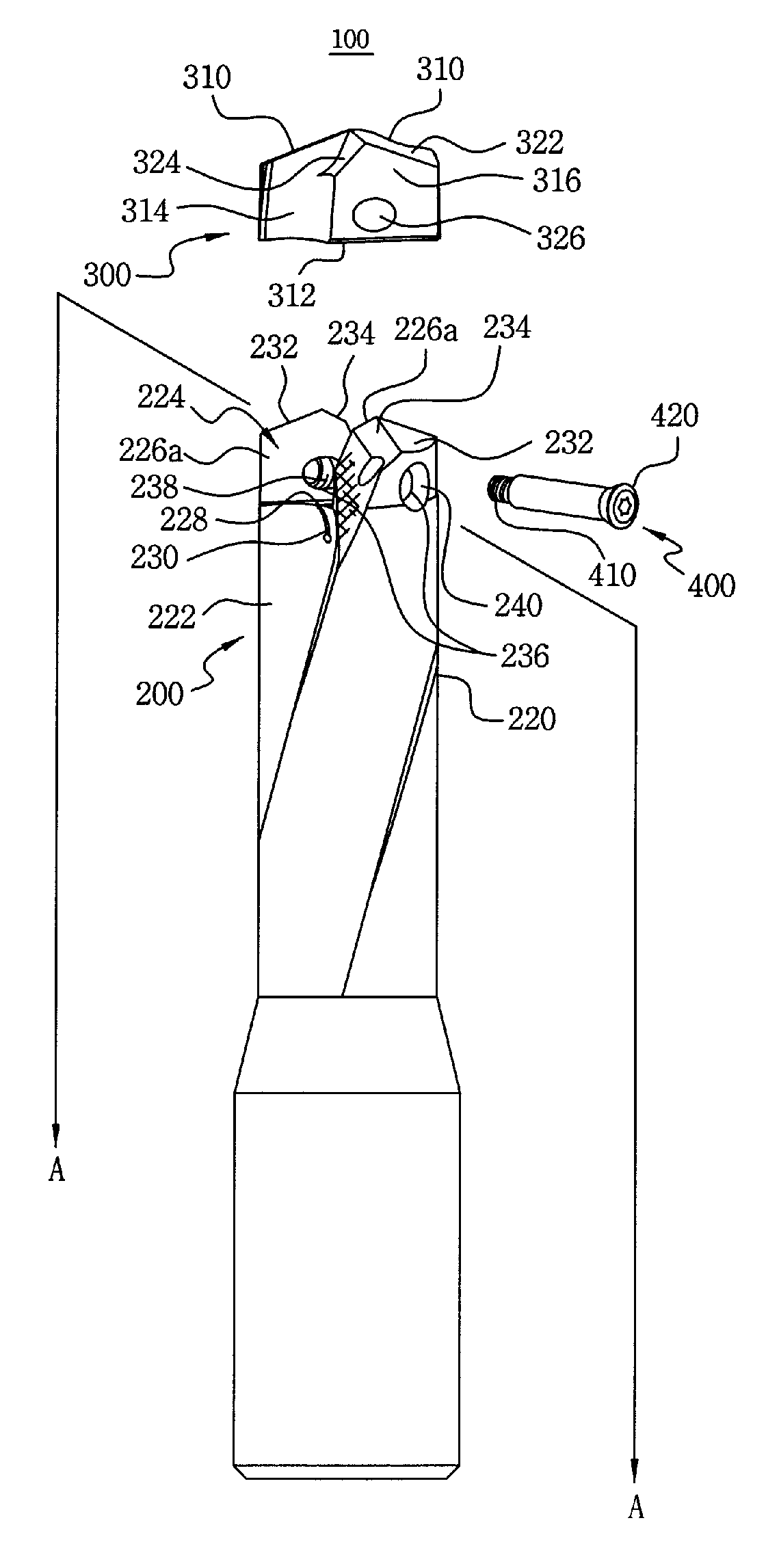

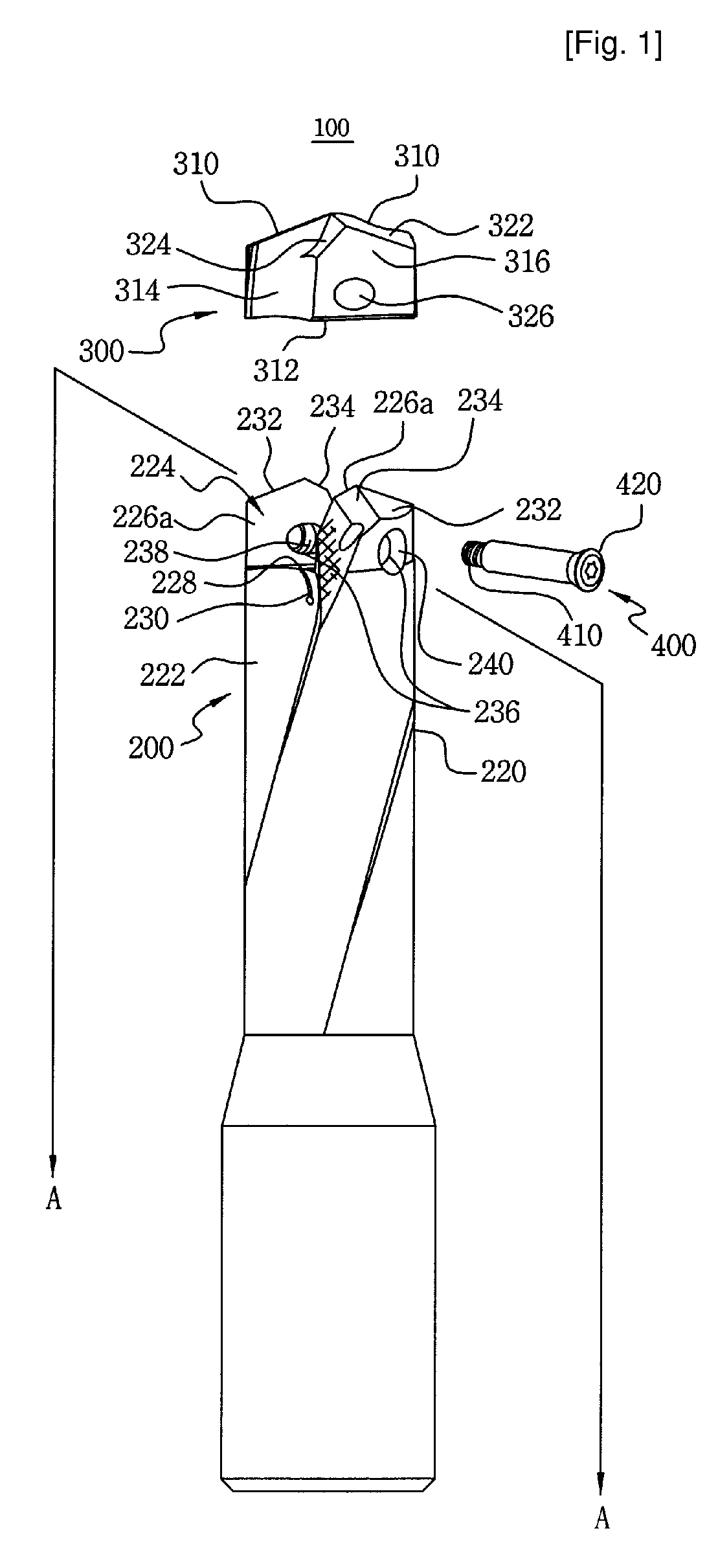

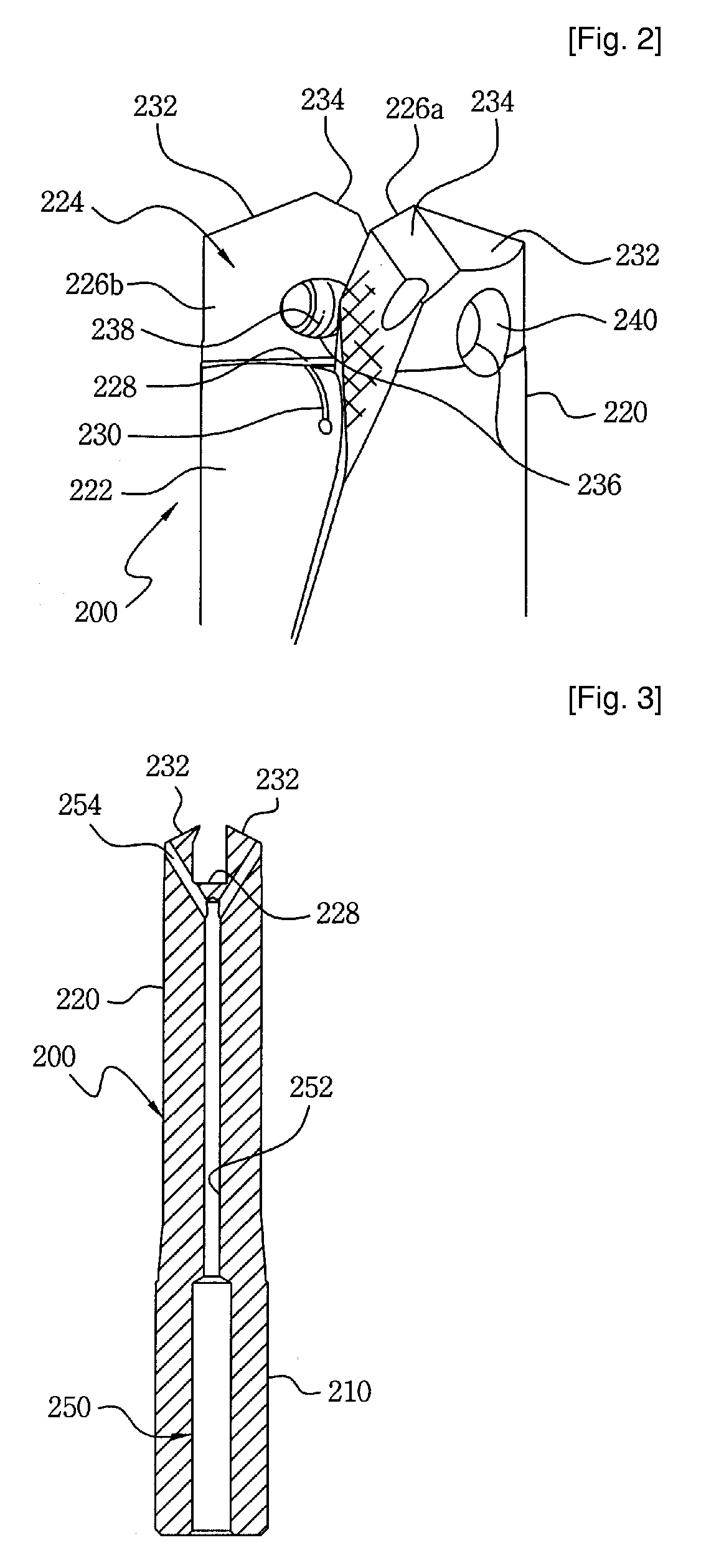

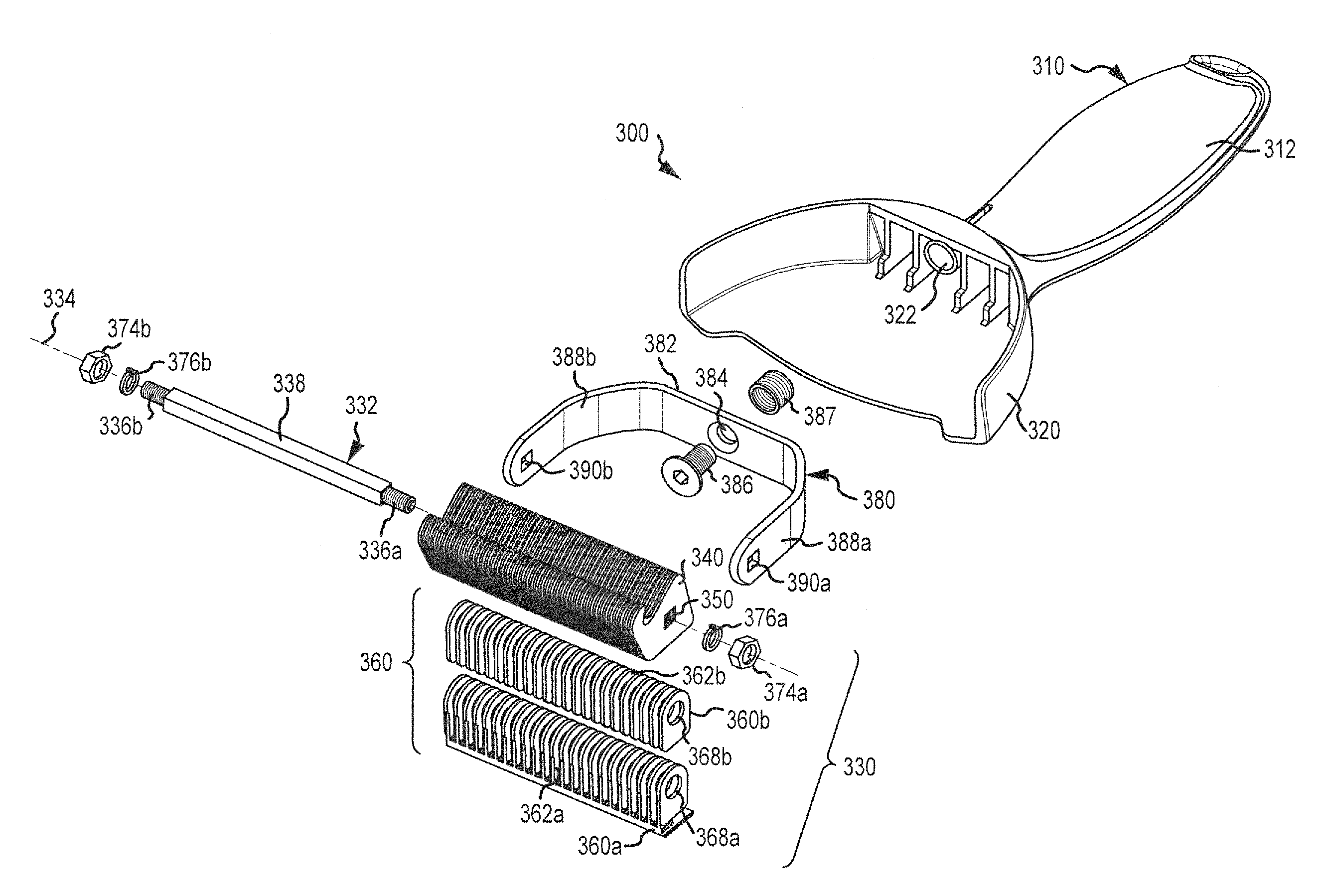

Grooming tool and method for the manufacture of a grooming tool

InactiveUS20120304938A1Less assembly timeLow costMetal working apparatusGrooming devicesCanis lupus familiarisManufacturing engineering

A grooming tool that includes a de-shedding rake and a method for assembling the de-shedding rake and the grooming tool. The grooming tool includes a handle portion, and the de-shedding rake is operatively attached to the handle portion. The de-shedding rake includes an axle, a spacer block disposed along the axle and having a plurality of spaced-apart slots and a plurality of de-shedding blades disposed along the axle and within the spaced-apart slots. The use of a spacer block to separate the de-shedding blades significantly reduces the assembly time and cost associated with manufacturing the grooming tool. The invention also includes a method for assembling the de-shedding rake and the grooming tool. The grooming tool is particularly useful for the grooming of furred animals such as dogs and cats.

Owner:TOPET INT

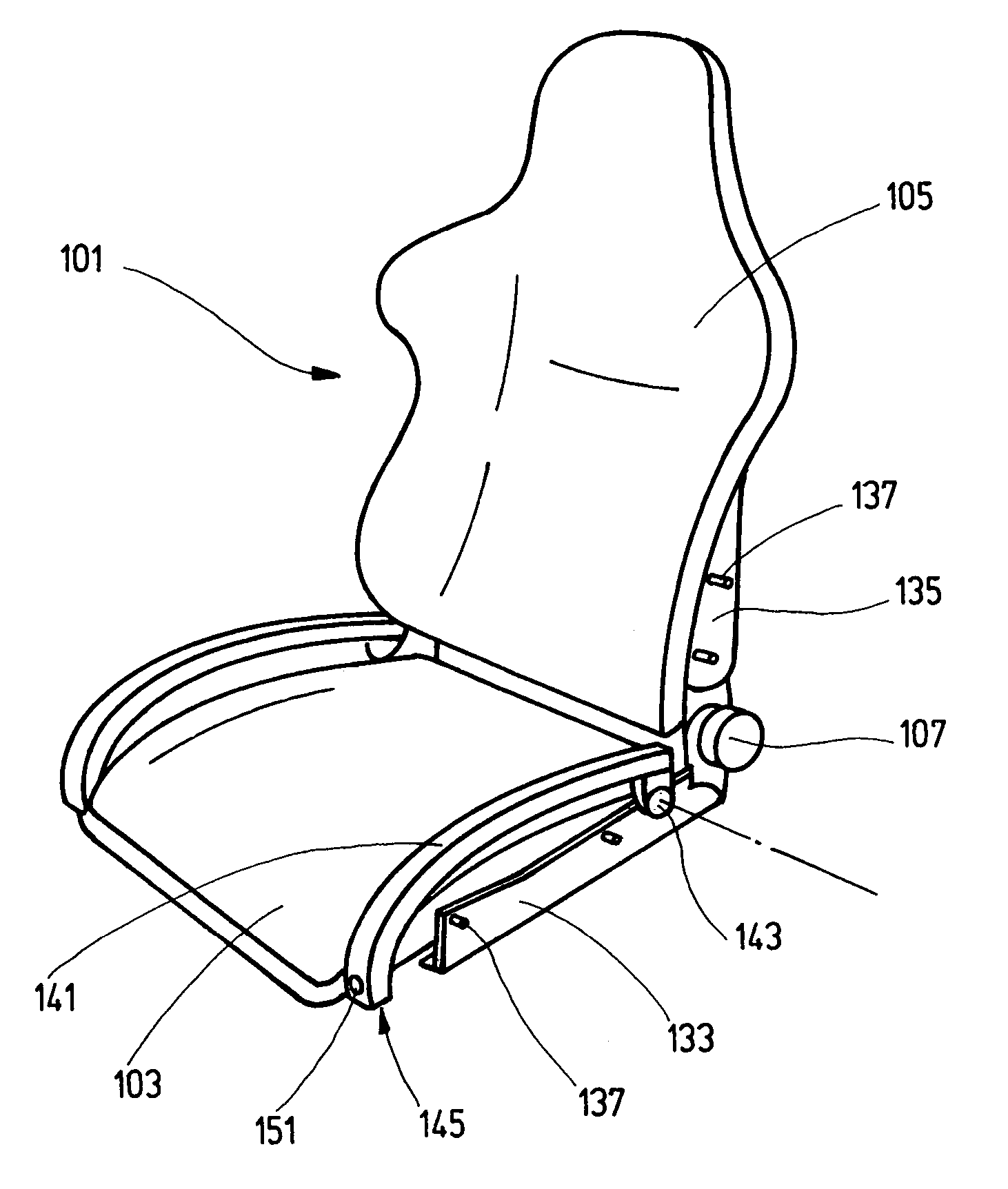

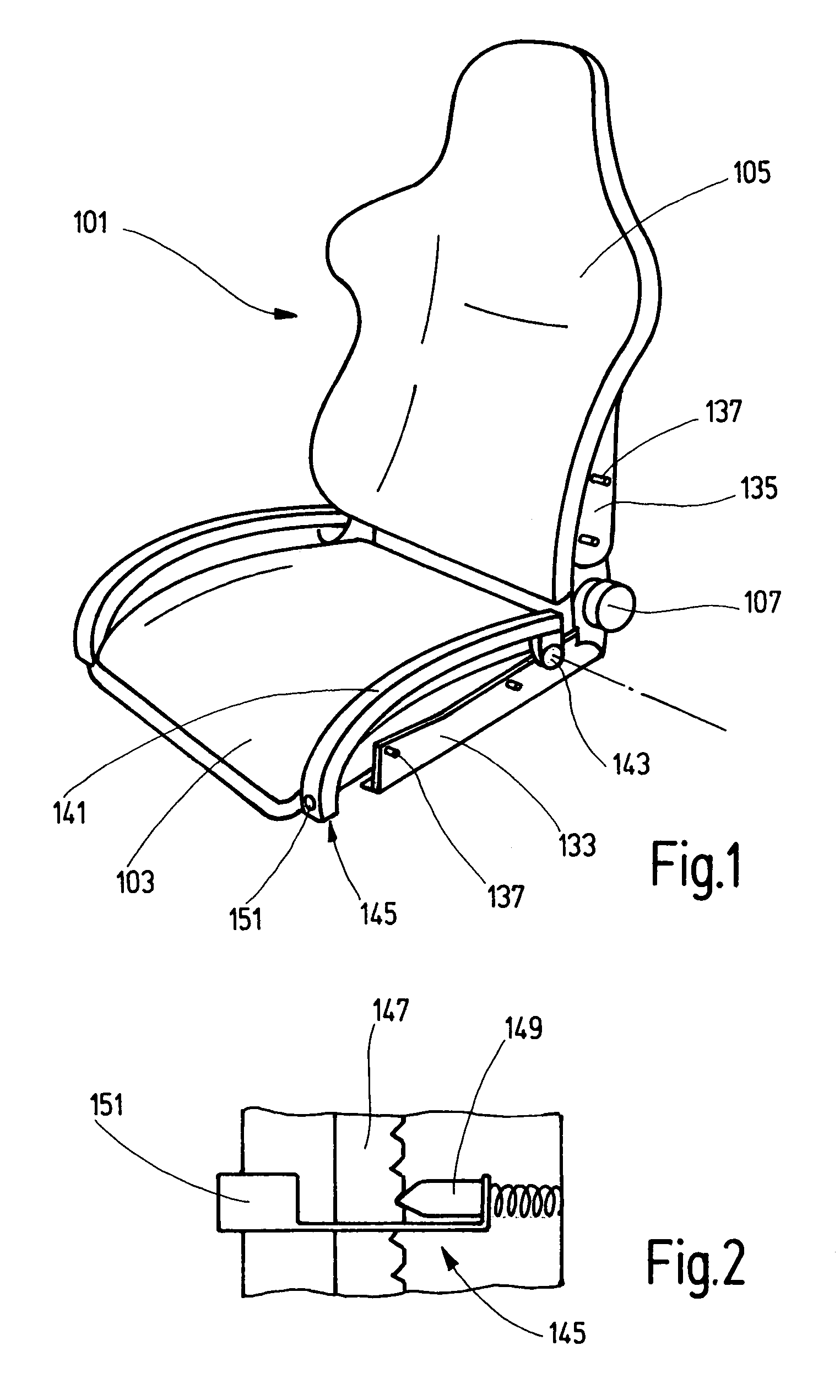

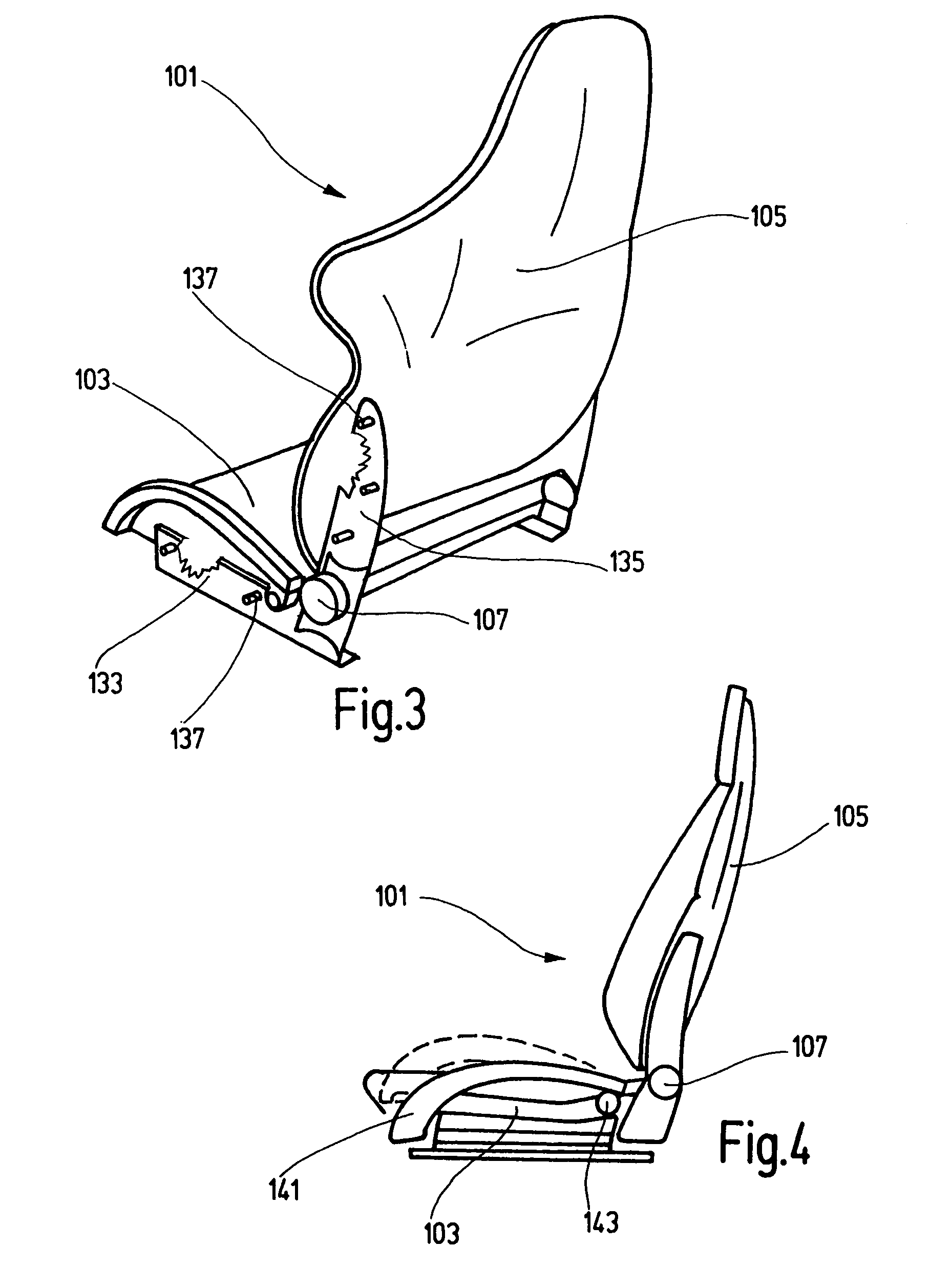

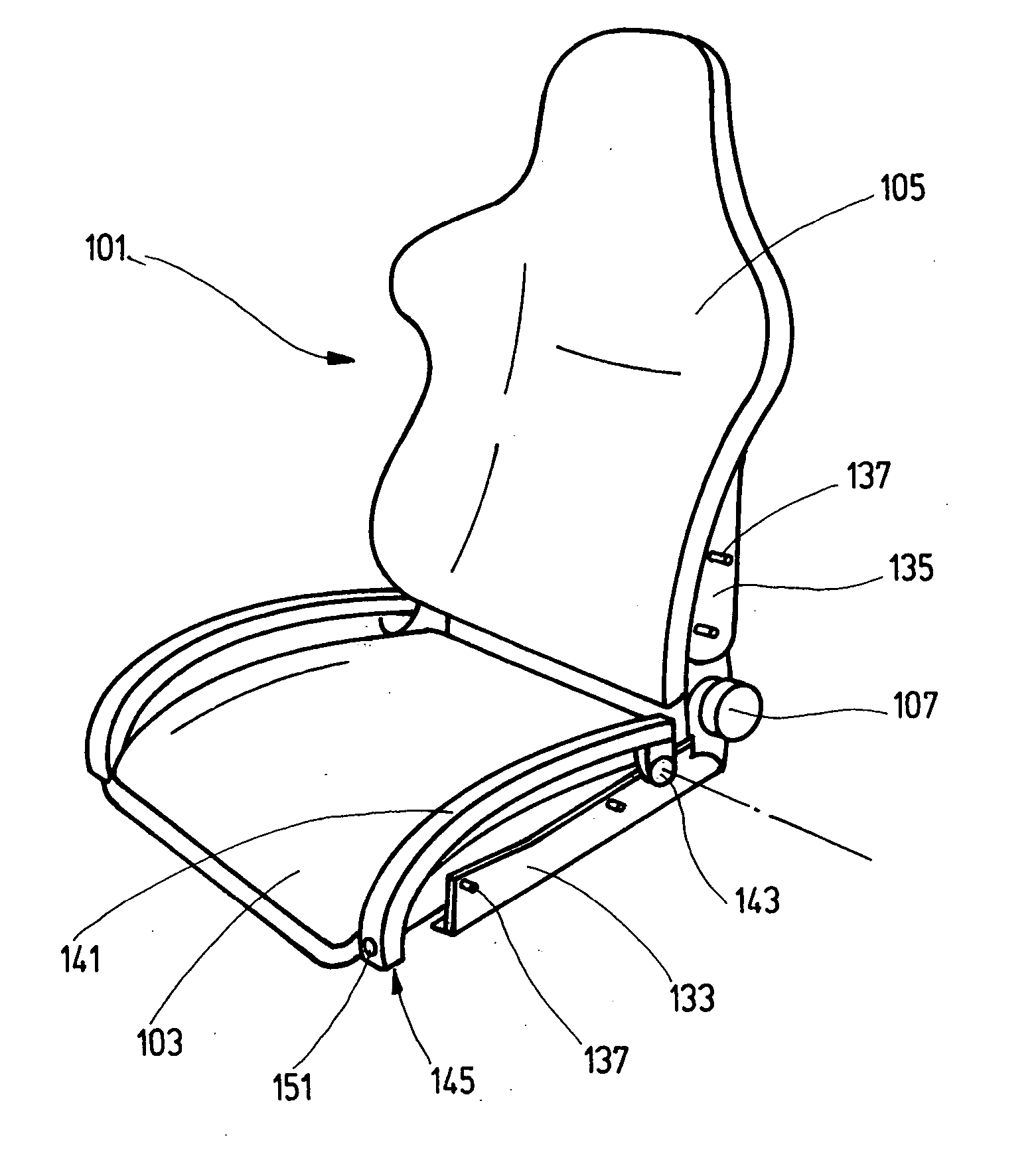

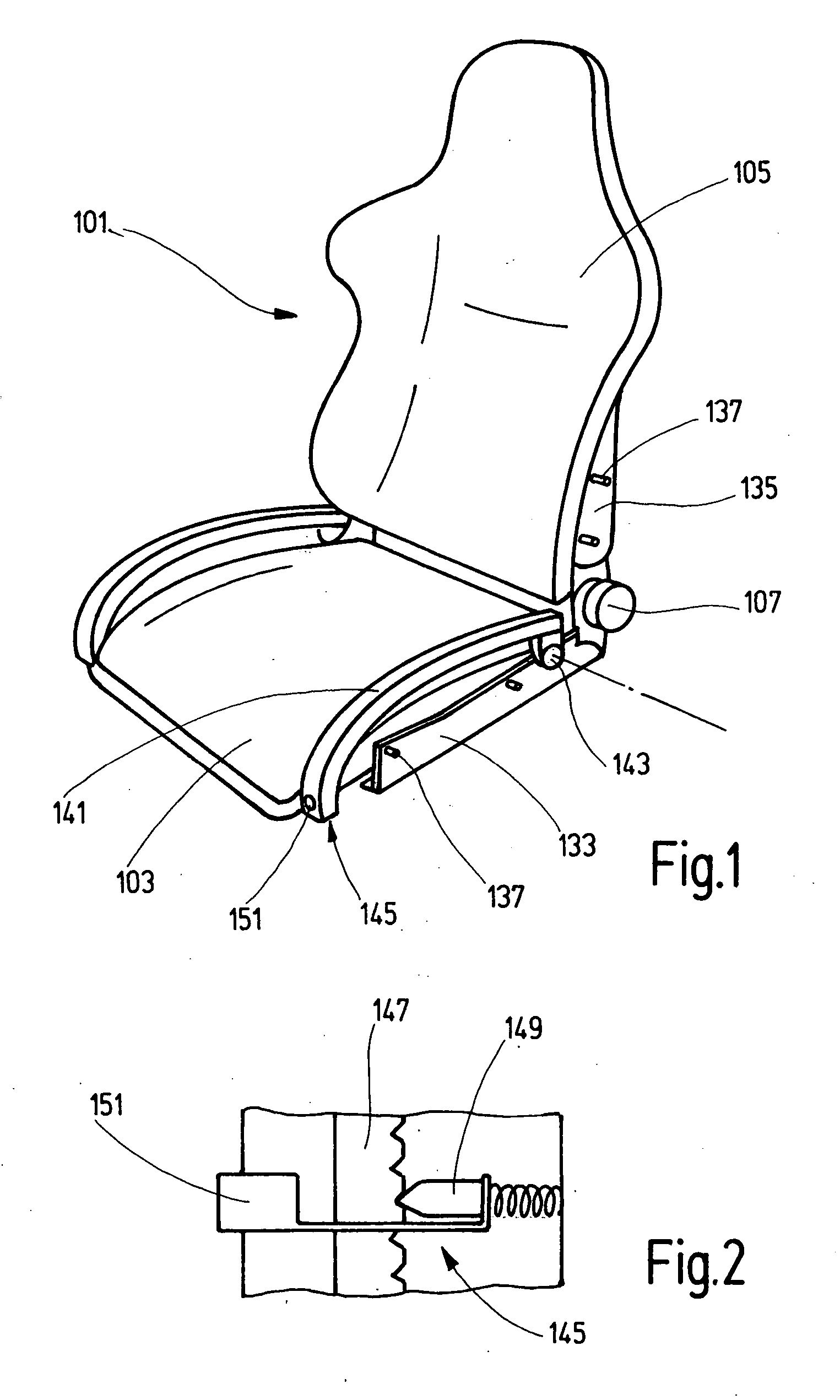

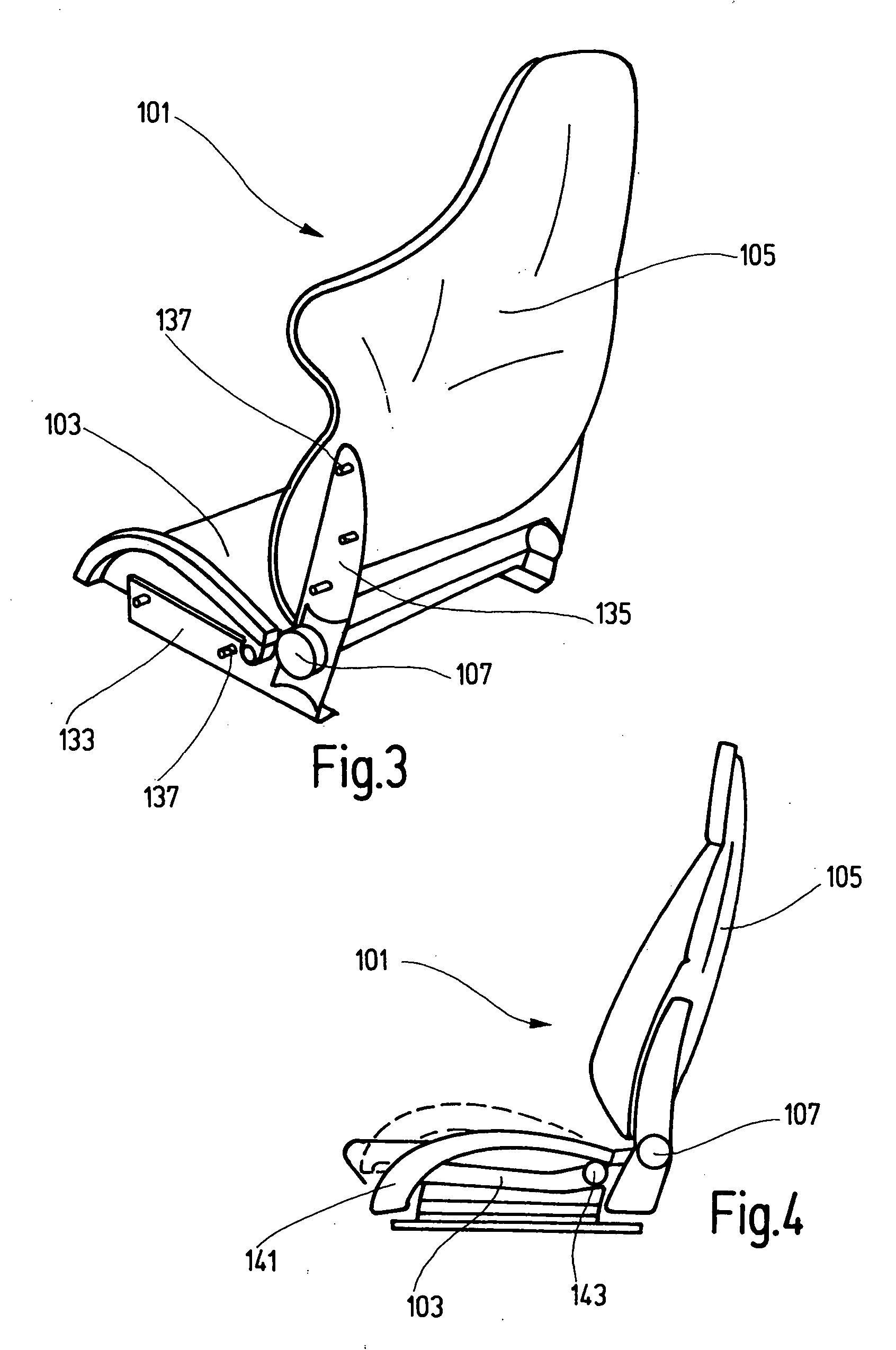

Sports seat for a vehicle, especially for a motor vehicle

ActiveUS7131697B2Reduce tooling costsImprove positionStoolsAdjustable chairsMobile vehicleMotorized vehicle

Owner:RECARO AUTOMOTIVE GMBH

Bumper/muffler assembly

InactiveUS7325652B2Simple designLess expensiveNon-rotating vibration suppressionSilencing apparatusThin metalMuffler

A bumper / muffler assembly is provided comprising a bumper; and a muffler having an outer shell. The outer shell may be formed from a non-high impact resistant material, such as a thin metal or a composite material. The muffler may comprise a separate element from the bumper, which is coupled thereto, or is formed as an integral part of the bumper.

Owner:OCV INTELLECTUAL CAPITAL LLC

Method of manufacturing terminal

InactiveUS7207809B2Reduce tooling costsImprove production accuracyContact member manufacturingCoupling device detailsEngineeringMechanical engineering

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

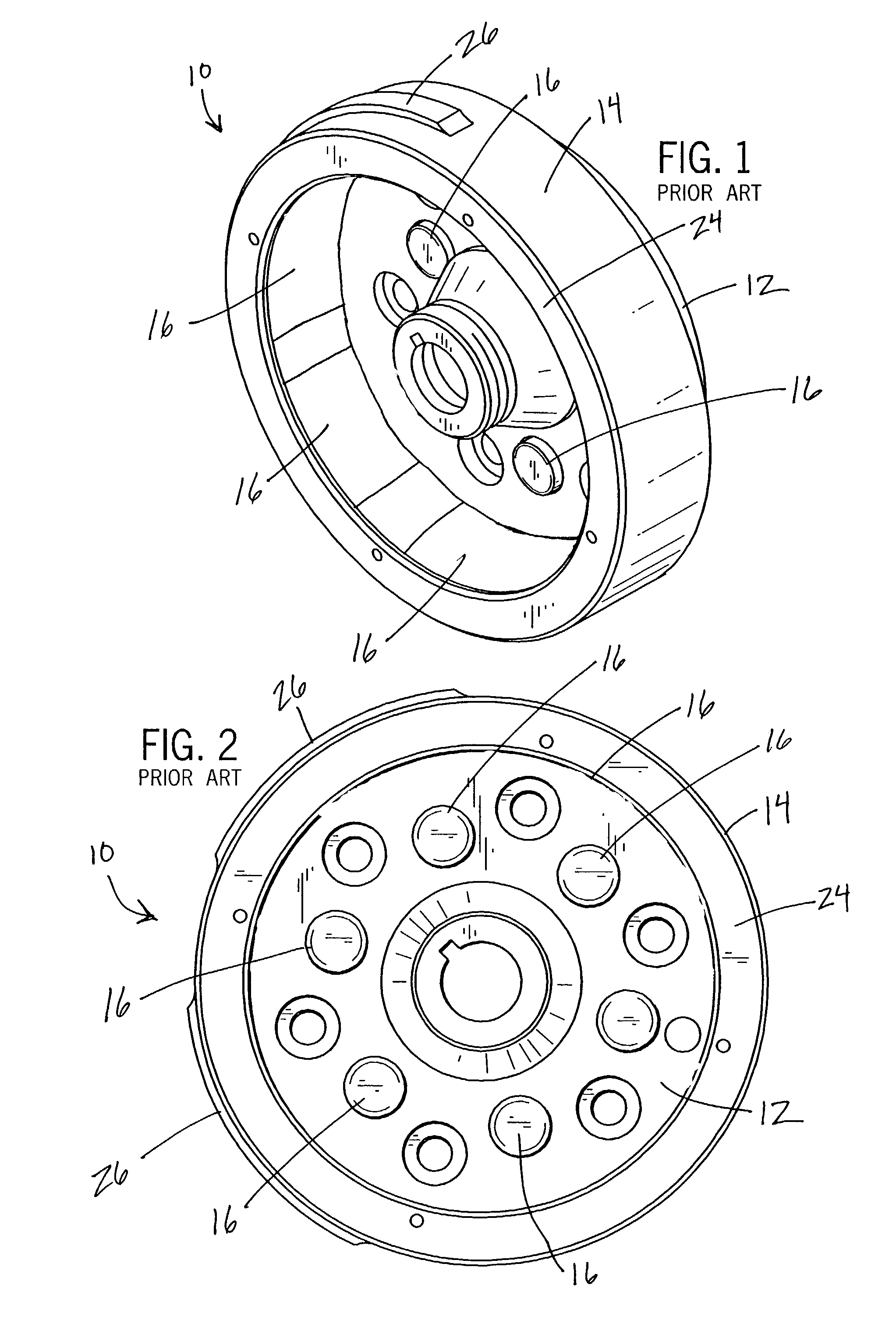

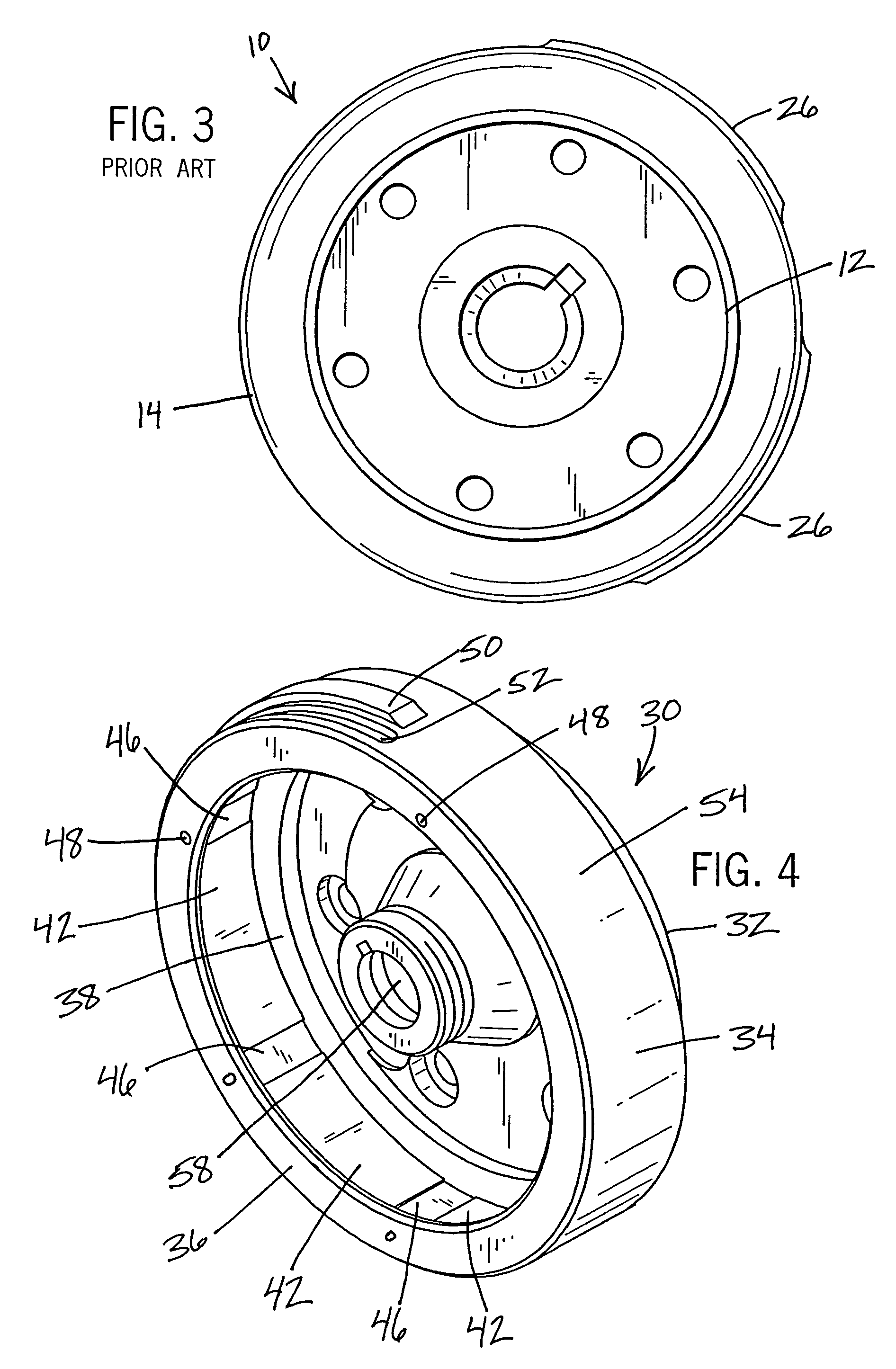

Machined rotor assembly and method of making same

InactiveUS7012349B1Reduction of tooling and assembly costHoop strength be strongMagnetic circuit rotating partsIgnition generator rotorUpper lipFastener

The present invention provides a single piece machined rotor comprising a shell having an upper lip and a lower lip, with a pocket formed between the upper lip and the lower lip for mounting magnets therein. The magnets are fixed in place within the inner sidewall of the rotor with an adhesive and spacers. The spacers are positioned between the magnets and are held in place on the shell of the rotor by fasteners. The spacers may be of any type of non-magnetic material that can absorb the heat of the engine. The rotor also preferably includes triggering protrusions and balancing cutouts machined into the shell of the rotor. The cutouts or grooves may be machined into the inner sidewall or the outer sidewall of the rotor. A plurality of timing teeth used for engine speed sensing maybe machined into the single piece rotor assembly. The present invention also contemplates a method of machining the entire rotor out of a single piece of material.

Owner:R E PHELSON COMPANY

Package and the method for making the same, and a stacked package

ActiveUS7811858B2Highly accurate placementImprove accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A package and the method for making the same, and a stacked package, the method for making the package includes the following steps: (a) providing a carrier having a plurality of platforms; (b) providing a plurality of dice, and disposing the dice on the platforms; (c) performing a reflow process so that the dice are self-aligned on the platforms; (d) forming a molding compound in the gaps between the dice, and (e) performing a cutting process so as to form a plurality of packages. Since the dice are self-aligned on the platforms during the reflow process, a die attach machine with low accuracy can achieve highly accurate placement.

Owner:ADVANCED SEMICON ENG INC

Sports seat for a vehicle, especially for a motor vehicle

ActiveUS20060082208A1Reduce tooling costsImprove comfortStoolsAdjustable chairsMobile vehicleEngineering

Owner:RECARO AUTOMOTIVE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com