Frost protection structure of wind power cooling system

A cooling system and wind power technology, applied in wind power generation, wind turbine components, wind turbines, etc., can solve problems such as the lowest temperature can only reach -35 ° C, the minimum survival temperature cannot be met, and the safety hazards of wind turbines can be achieved. Significant reduction, elimination of power limitation issues, effect of optimizing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

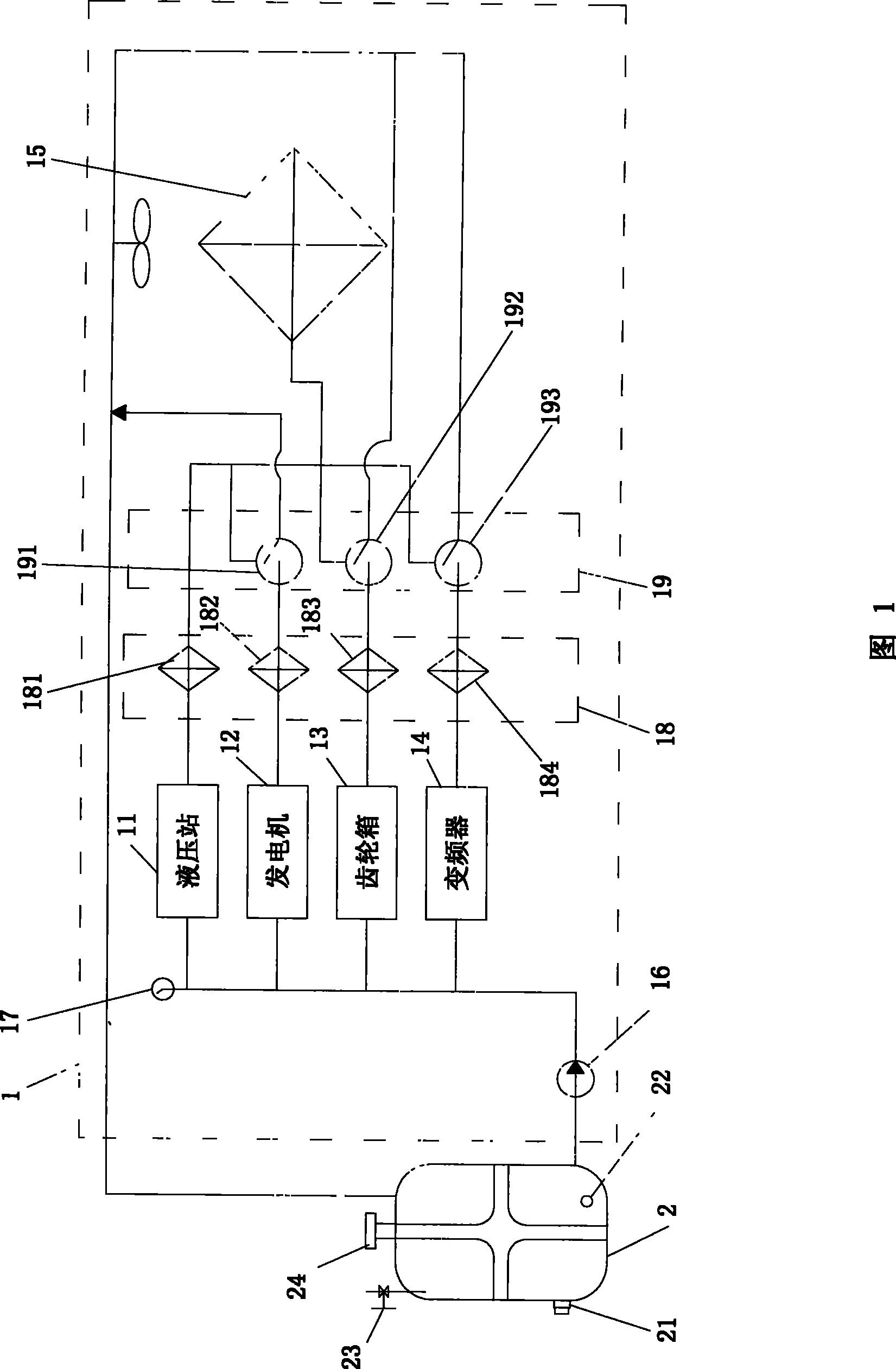

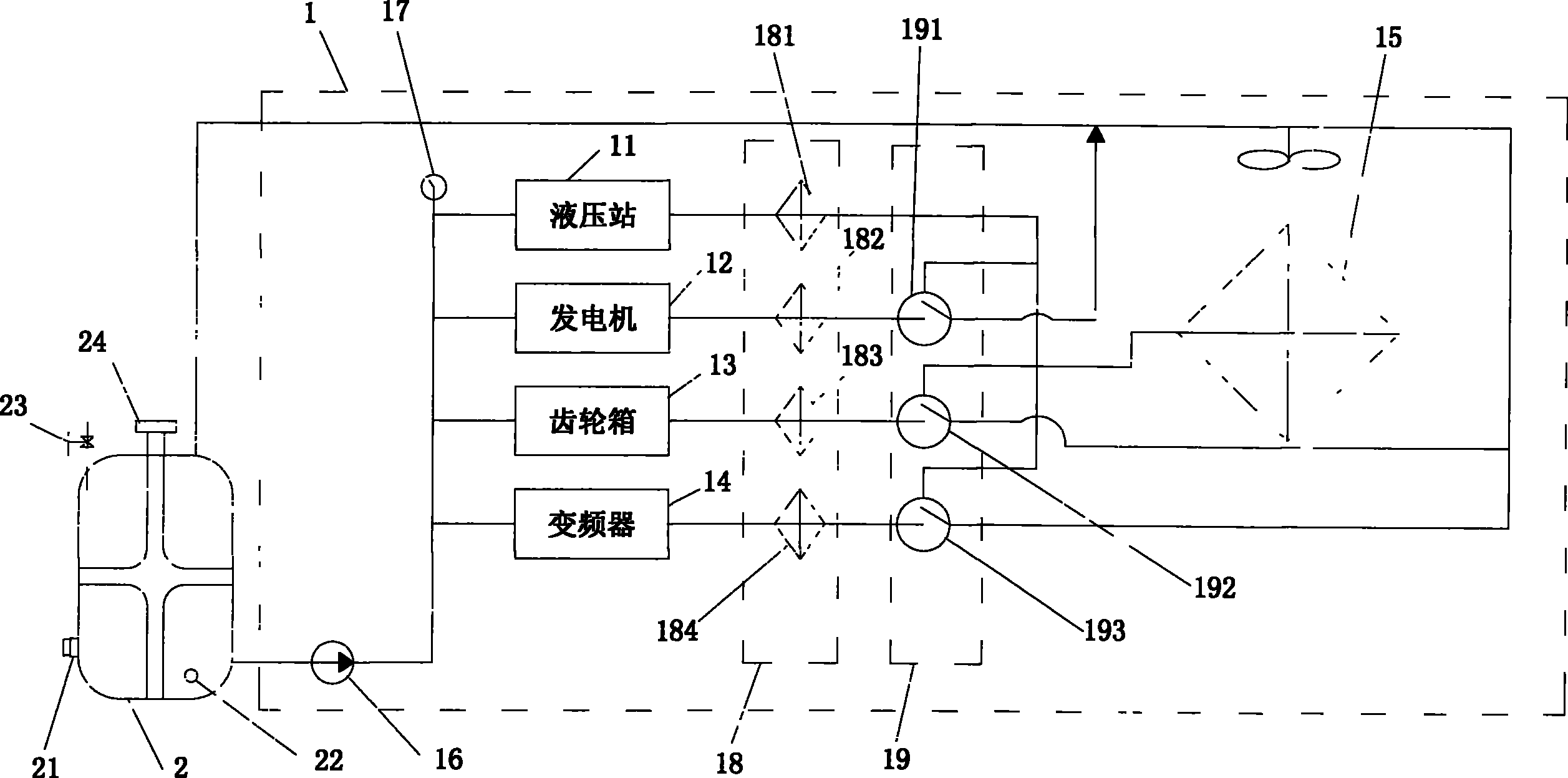

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] Please refer to Fig. 1, the antifreeze structure of the antifreeze structure of a kind of wind power cooling system of the present invention is shown among the figure, comprise a cooling system 1, this cooling system 1 comprises water pump 16, pressure gauge 17, hydraulic station 11, generator 12 , gear box 13, frequency converter 14, heat exchanger 18, thermostat 19 and cooler 15, also includes a reflowable, anti-freezing expansion tank 2 connected to the cooling system 1, the expansion tank 2 is set There is a heater 21 and a temperature sensor 22 is arranged inside it, one end of which is connected with the water pump 16 in the cooling system 1, and the other end is connected with the thermostat 19 in the cooling system 1, wherein:

[0017] The expansion water tank 2 is a corrugated container, such as a drum or a square bucket. The expansion water tank 2 also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com