Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

745 results about "Evaporative cooler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An evaporative cooler (also swamp cooler, swamp box, desert cooler and wet air cooler) is a device that cools air through the evaporation of water. Evaporative cooling differs from typical air conditioning systems, which use vapor-compression or absorption refrigeration cycles. Evaporative cooling uses the fact that water will absorb a relatively large amount of heat in order to evaporate (that is, it has a large enthalpy of vaporization). The temperature of dry air can be dropped significantly through the phase transition of liquid water to water vapor (evaporation). This can cool air using much less energy than refrigeration. In extremely dry climates, evaporative cooling of air has the added benefit of conditioning the air with more moisture for the comfort of building occupants.

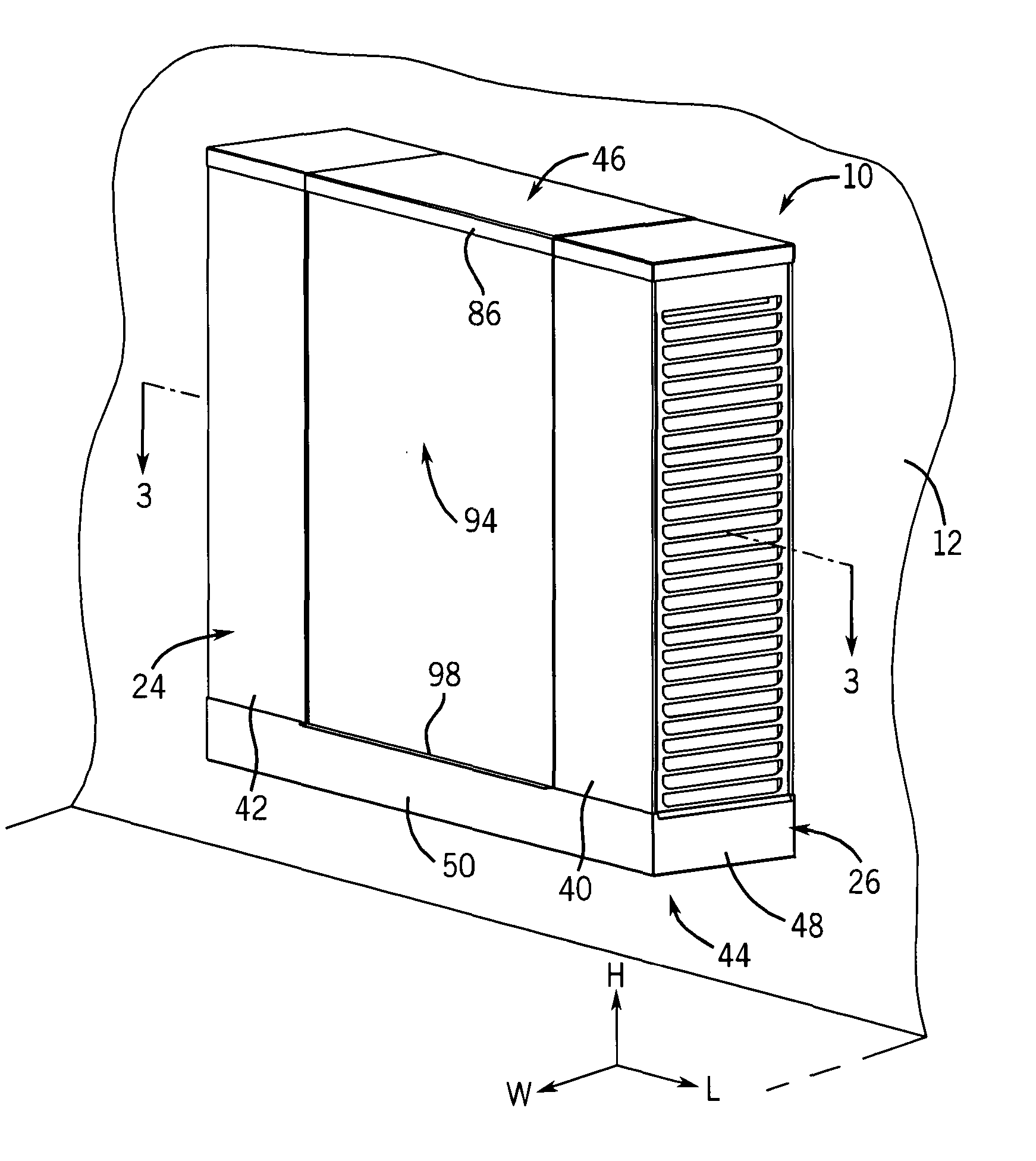

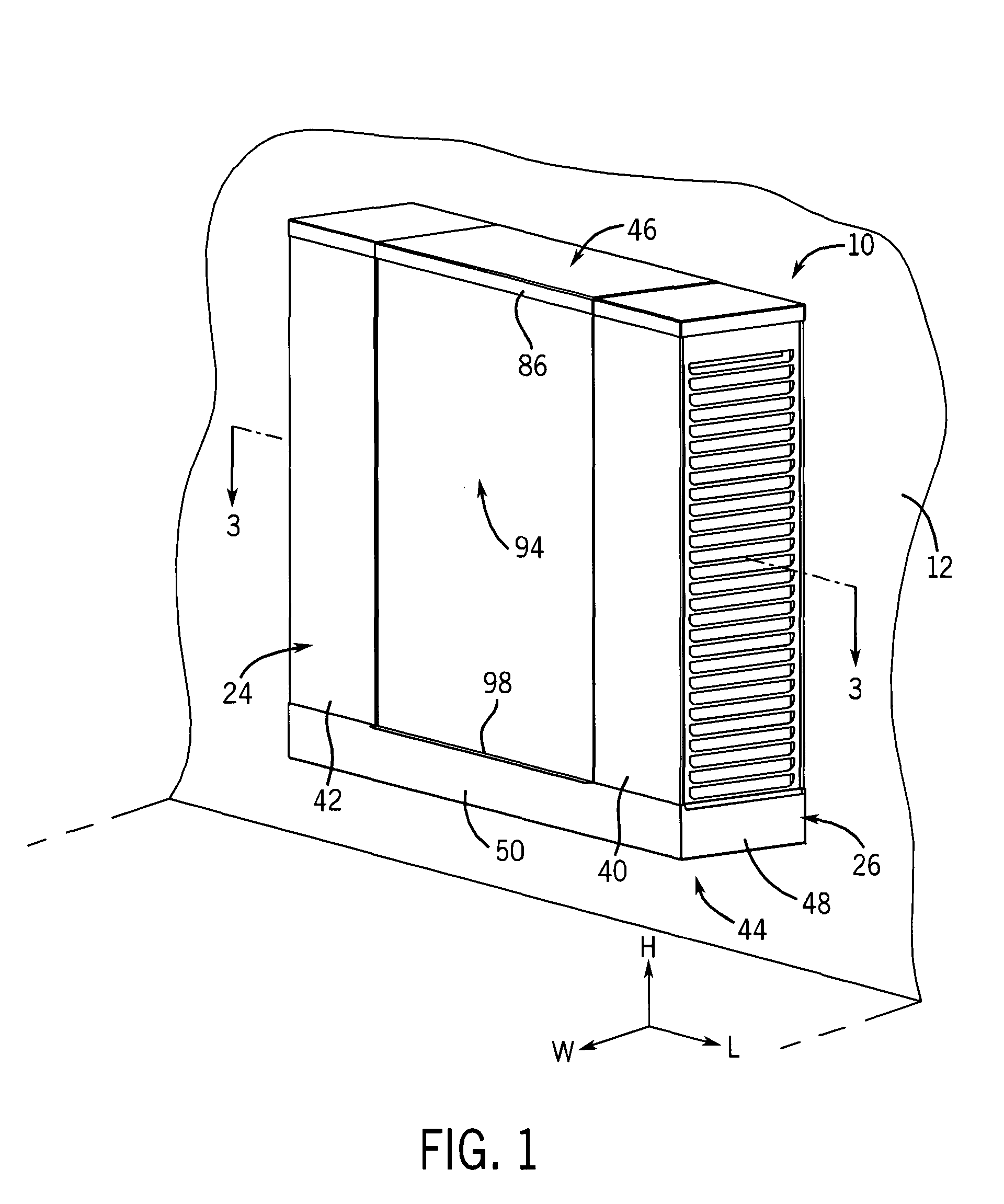

Low profile evaporative cooler housing

InactiveUS20050000241A1Domestic cooling apparatusHeating and ventilation casings/coversEvaporative coolerLouver

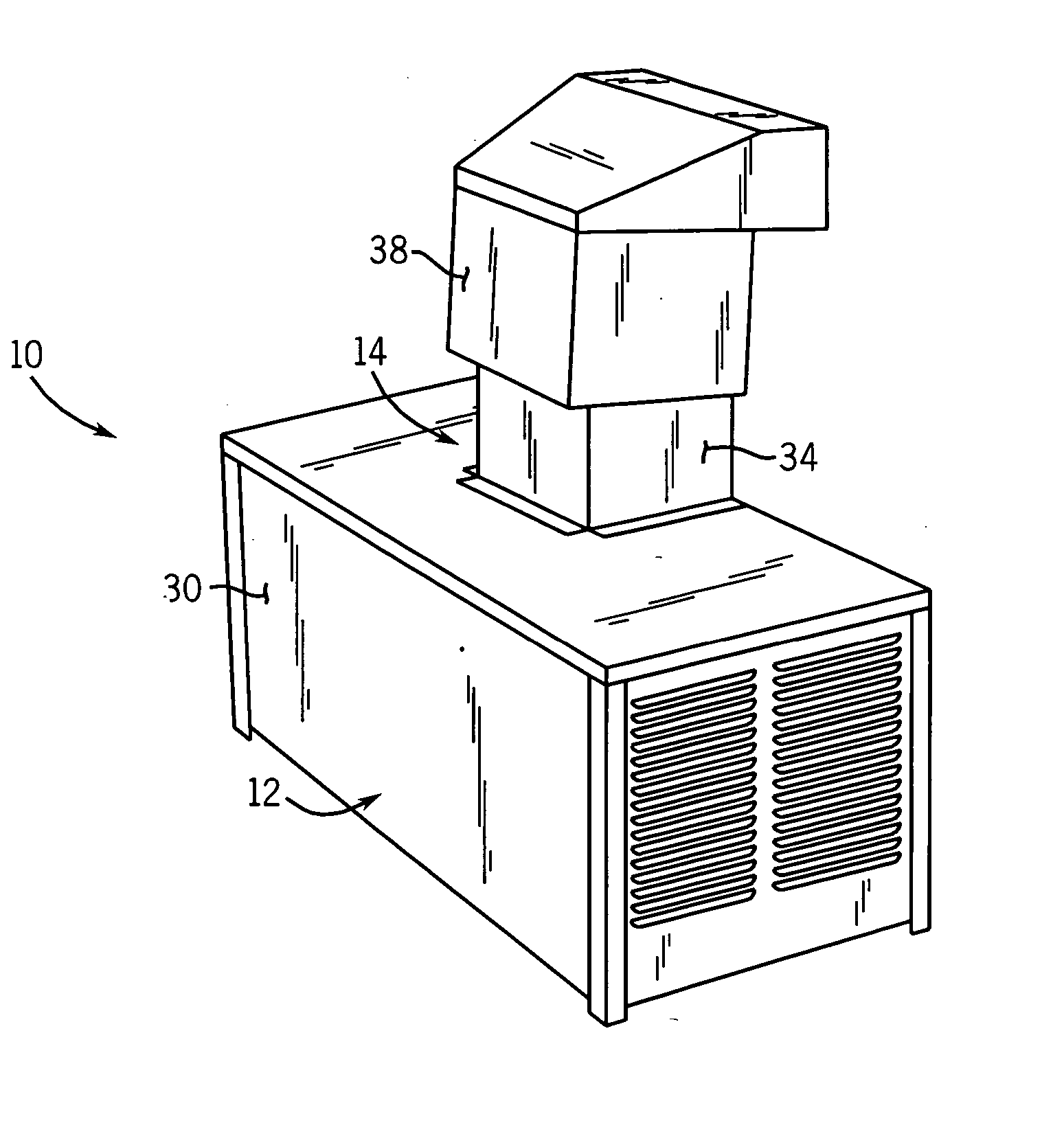

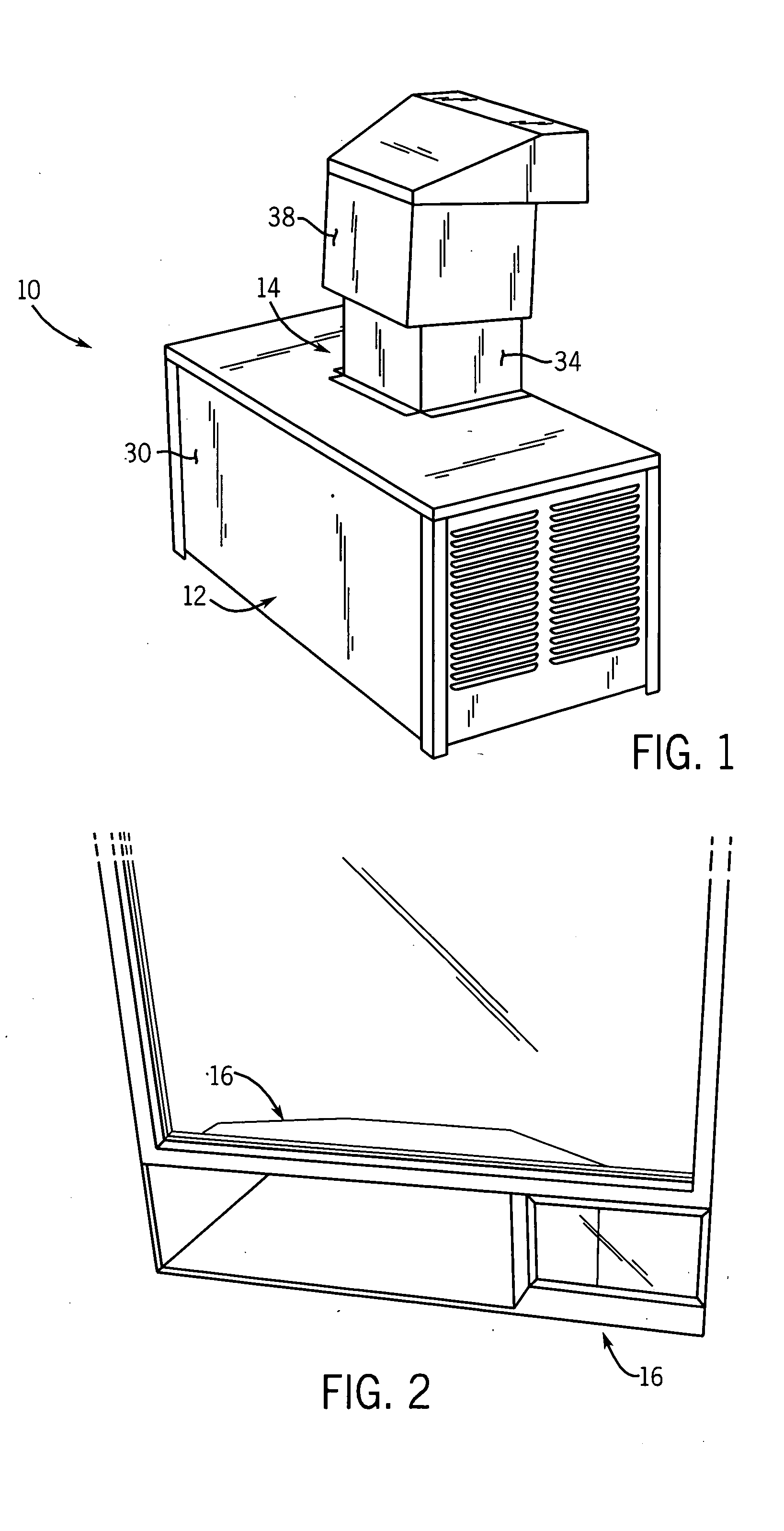

A low profile evaporative cooler housing for attachment to a building includes a front panel, and an opposing rear panel that may have an extension that extends into a wall of the building. A first and second louver may extend between the front and rear panels.

Owner:CHAMPION COOLER CORP +2

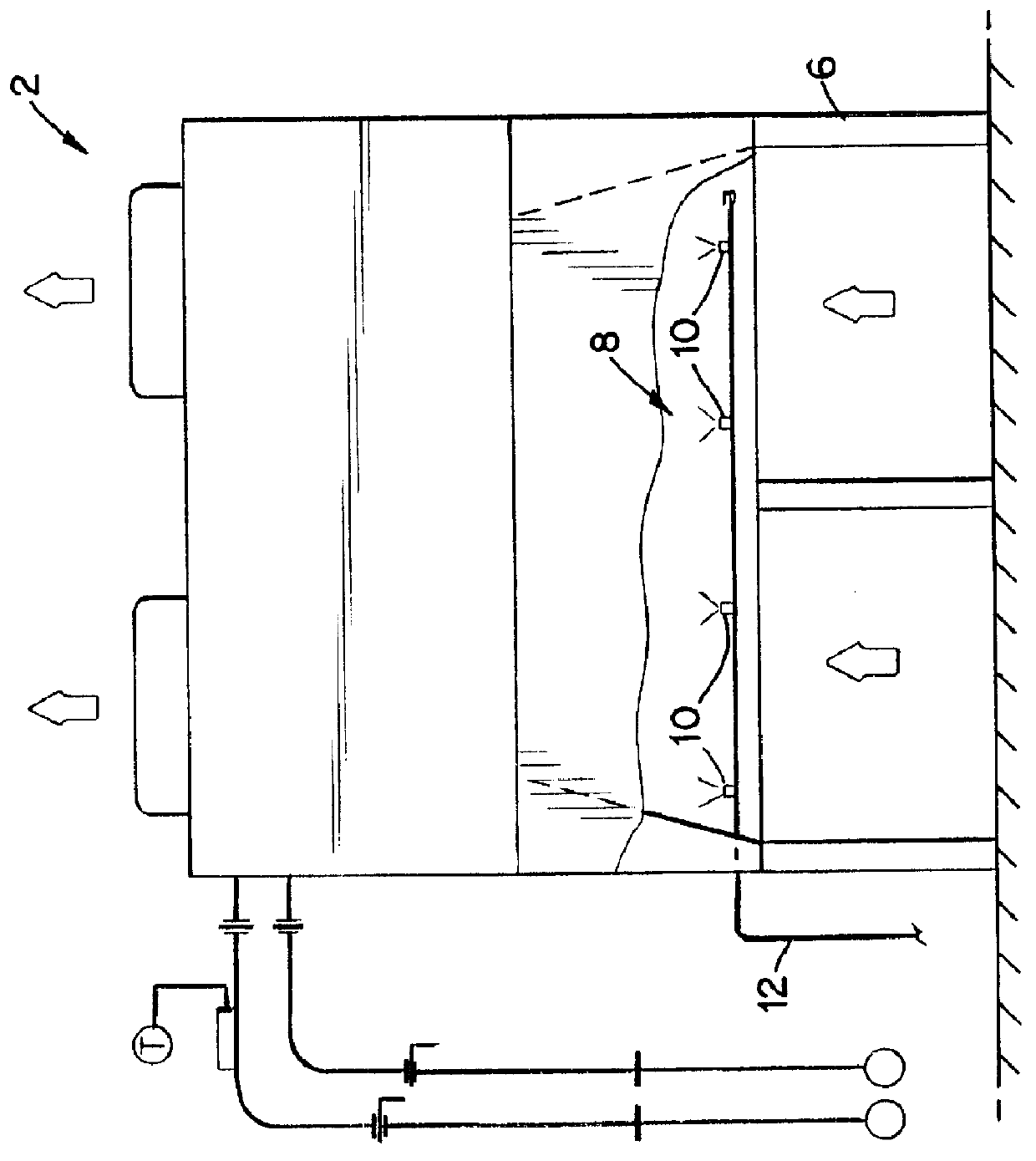

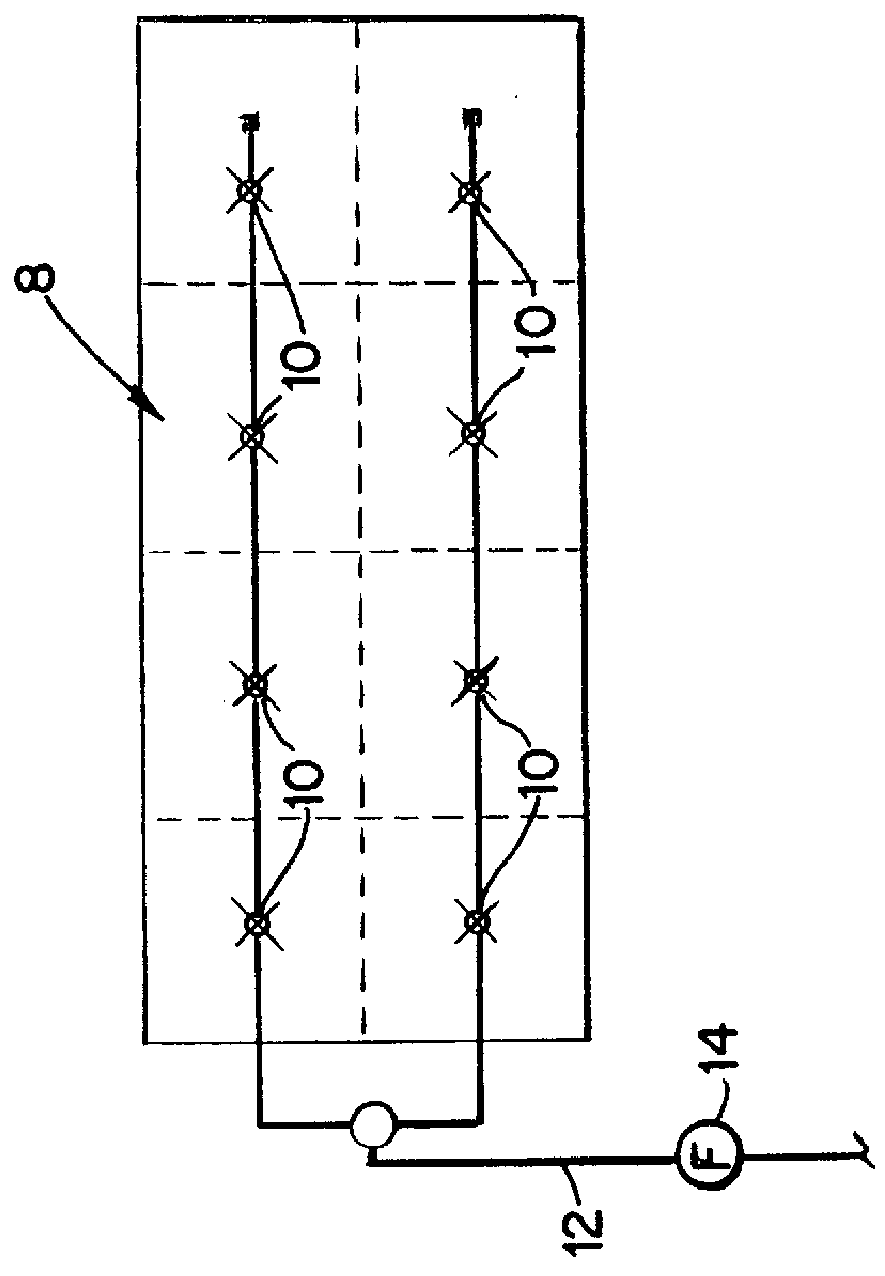

Indirect supplemental evaporation cooler

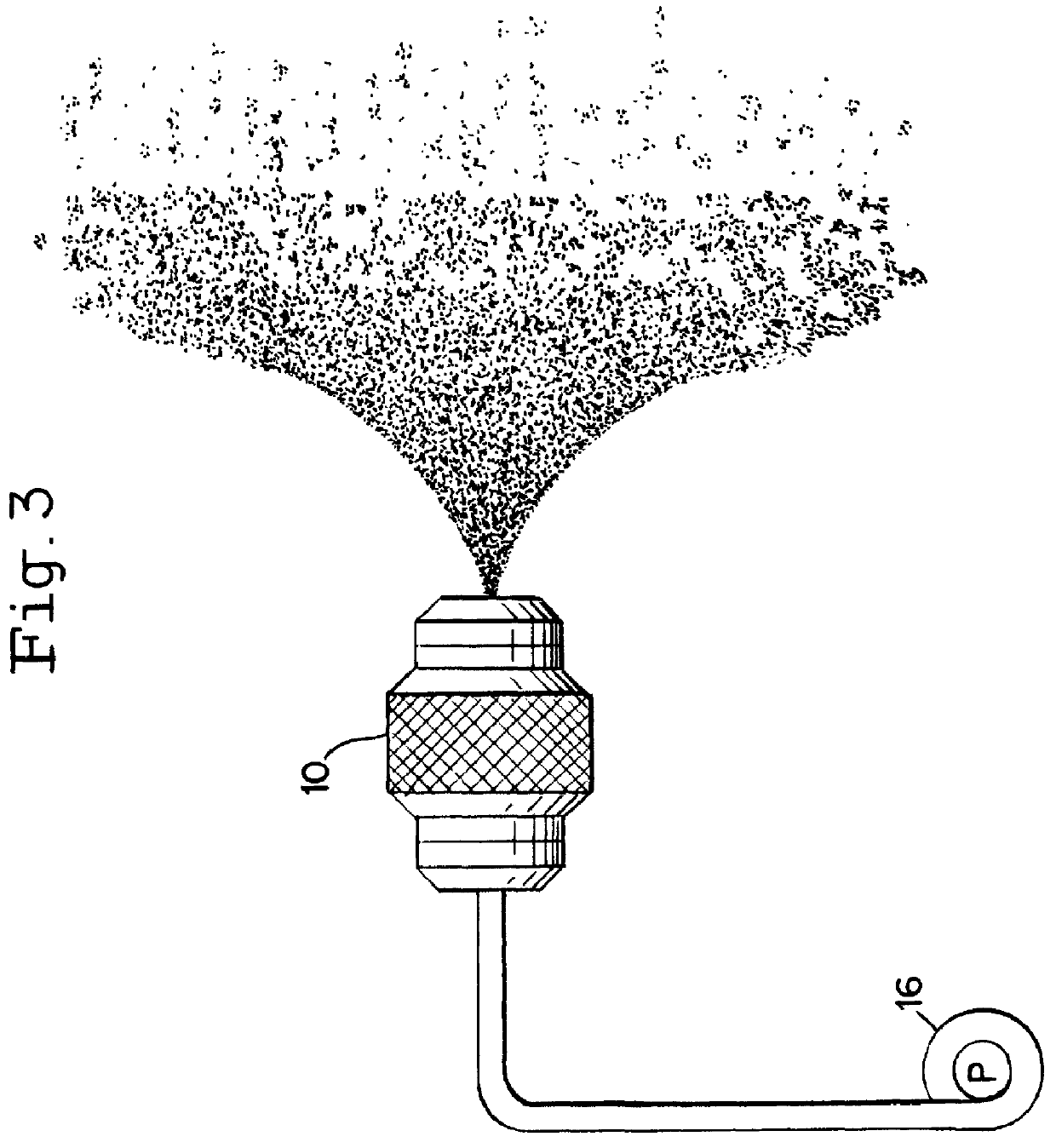

InactiveUS6141986ARemove heatEasy to eliminateFree-cooling systemsStationary conduit assembliesEvaporative coolerEvaporation

A cooler for an air conditioning system or other system having a heated surface to be cooled has an array of nozzles for issuing a fine spray of liquid. A fan of the cooler induces flow of air over a surface to be cooled, the nozzles issuing into the flow of air the fine spray at a distance from the heated surface such that the liquid of the fine spray is fully evaporated prior to contact with the heated surface. Drop sizes of 20 to 30 microns are typical.

Owner:X NTH INC

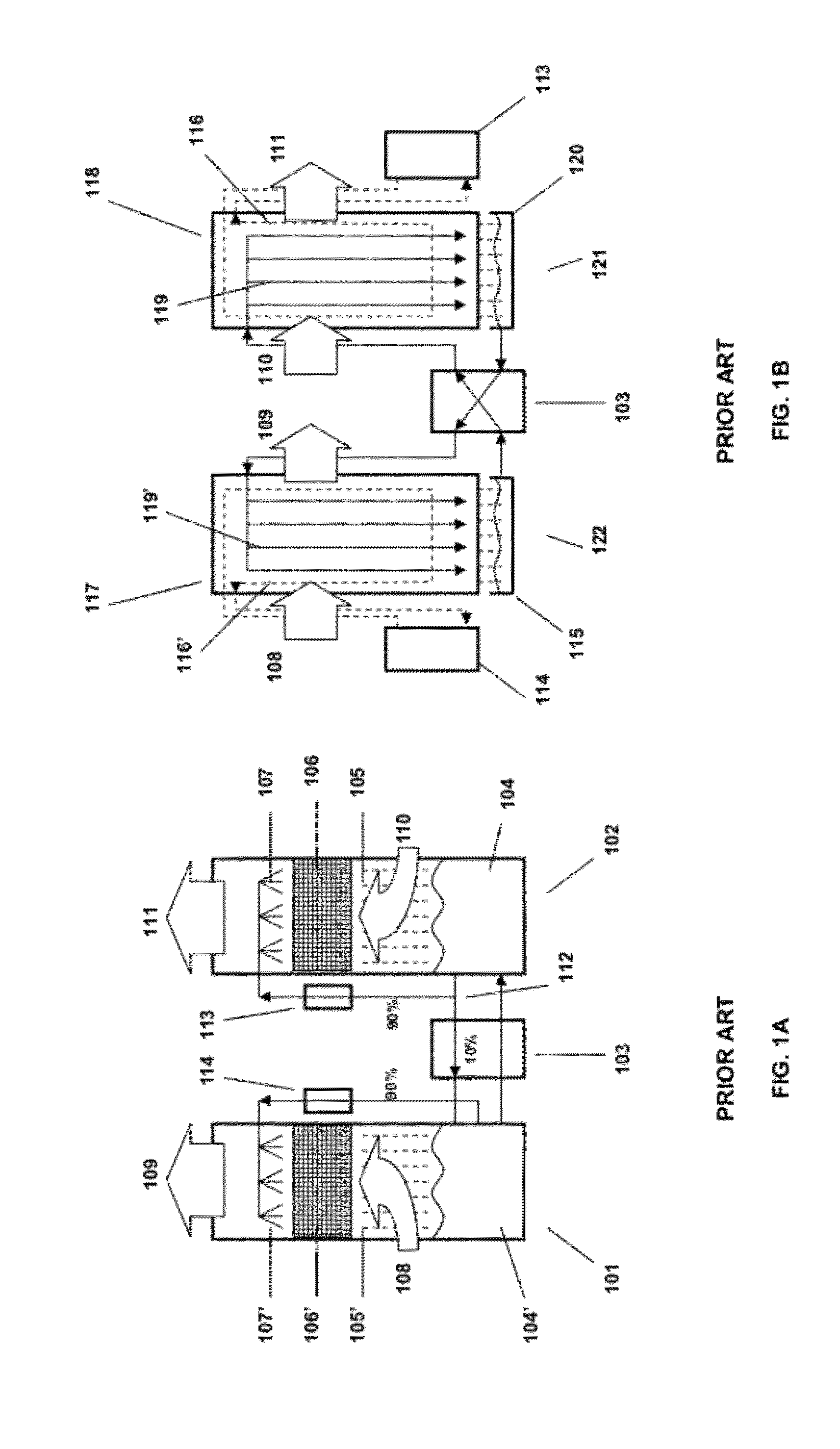

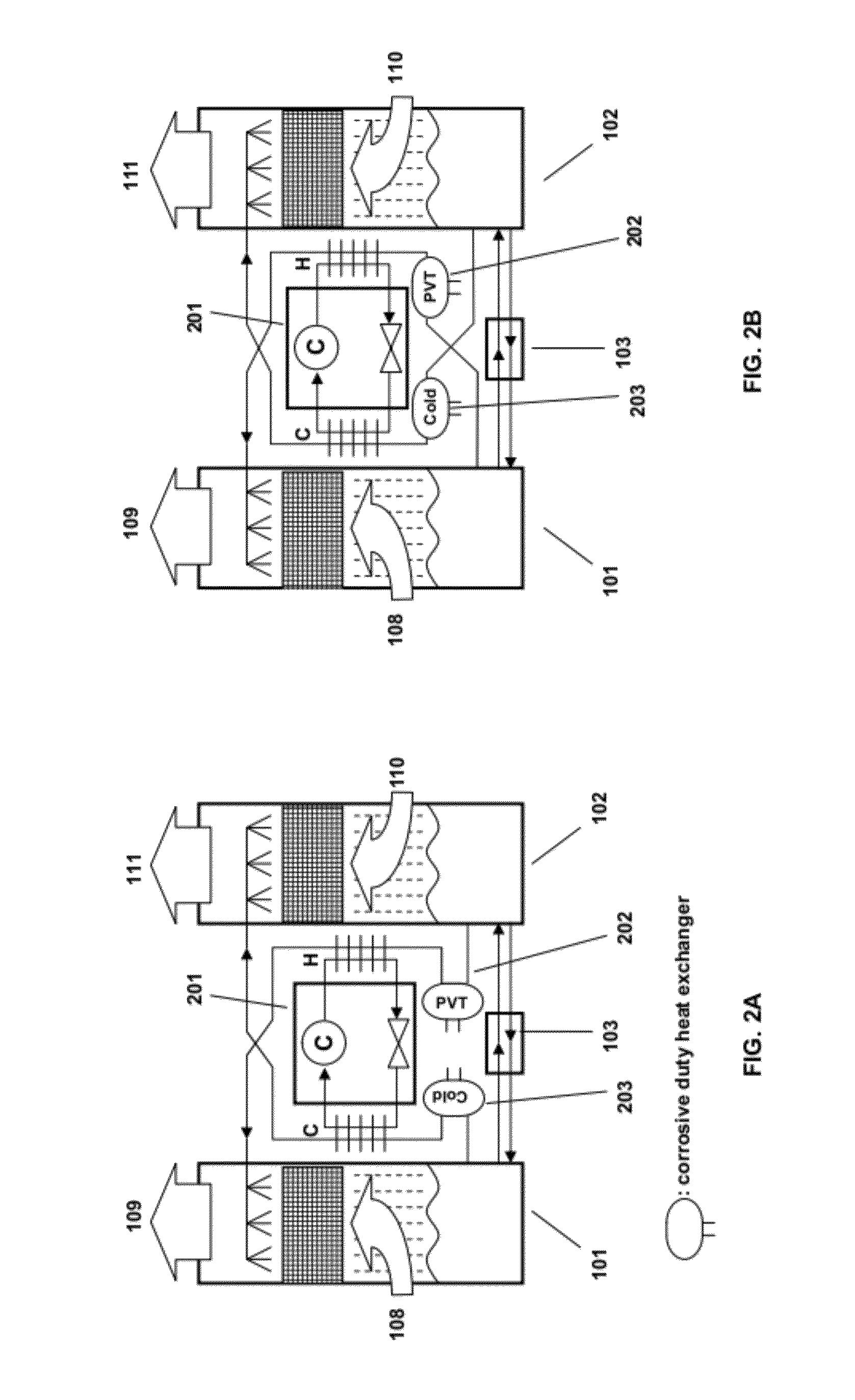

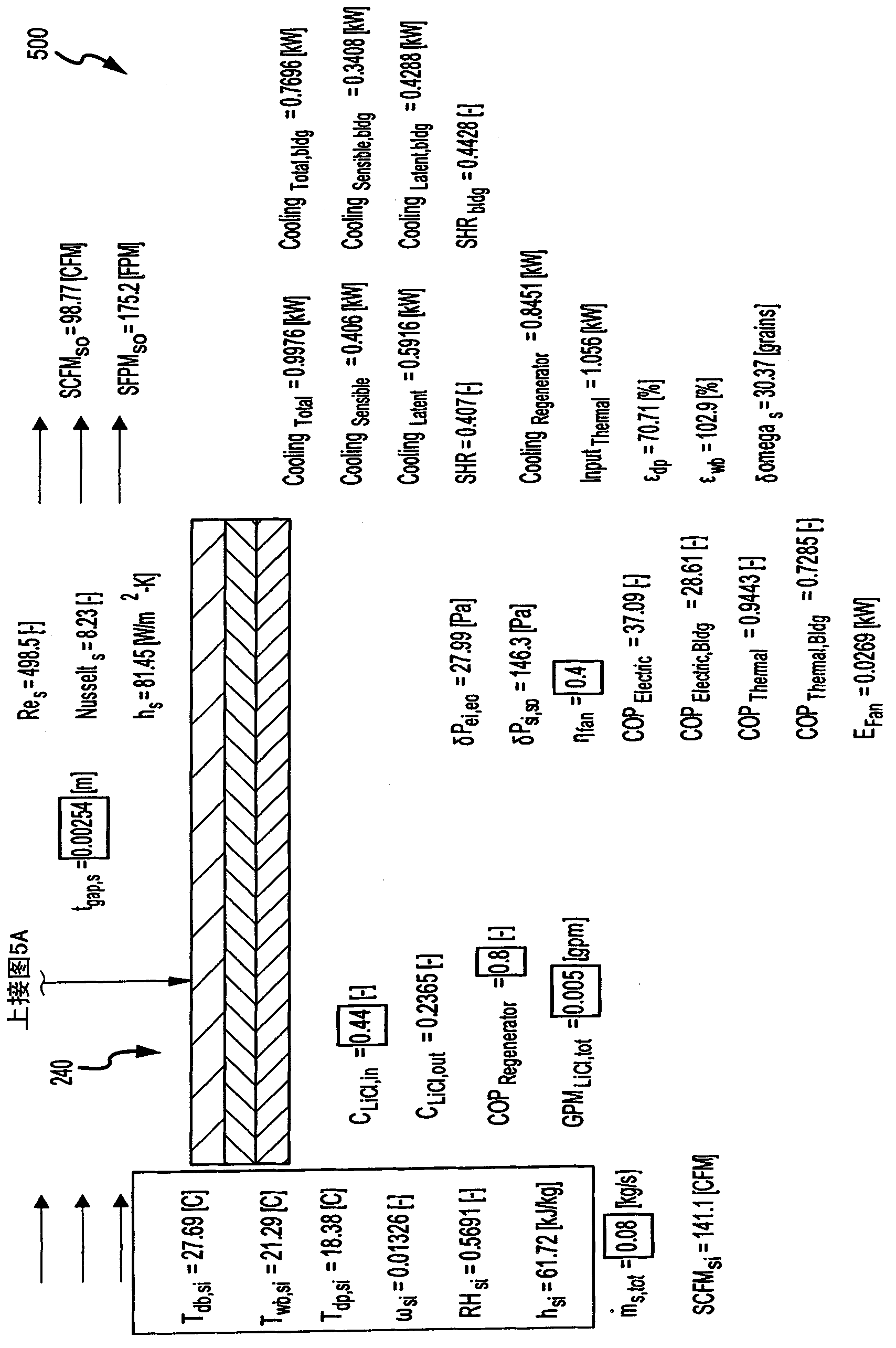

Desiccant air conditioning methods and systems using evaporative chiller

Methods and systems are provided for air conditioning, capturing combustion contaminants, desalination, and other processes using liquid desiccants.

Owner:COPELAND LP

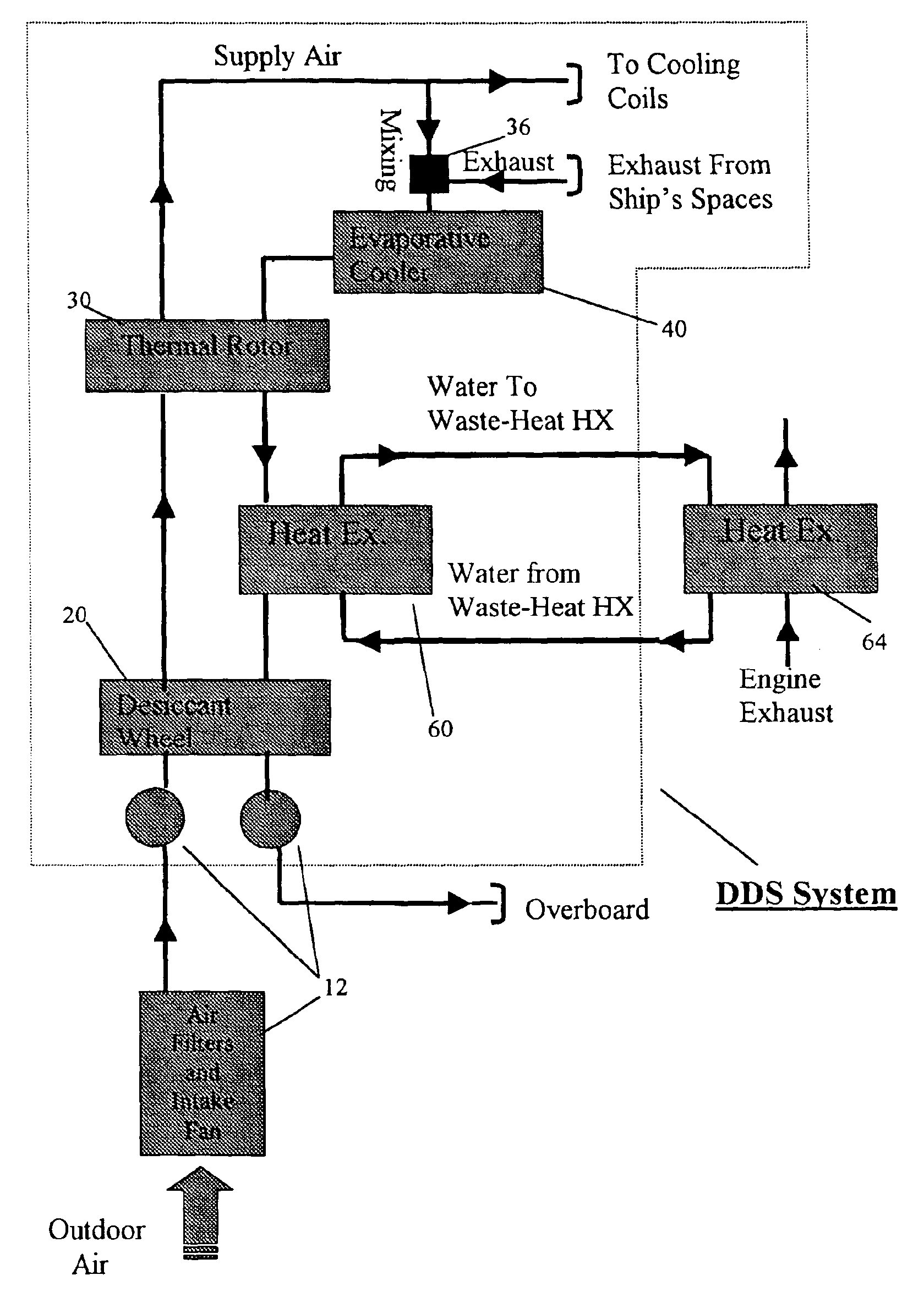

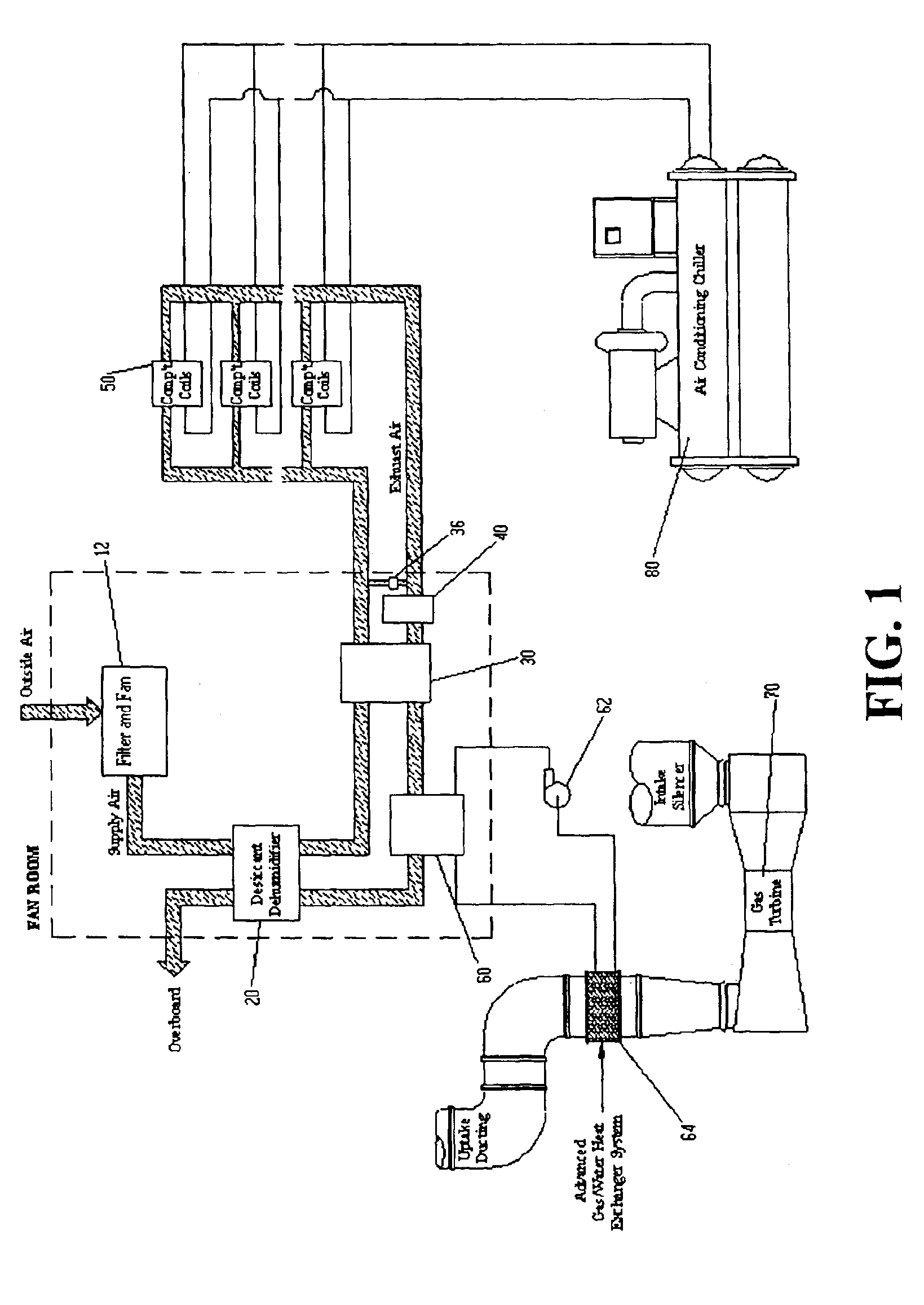

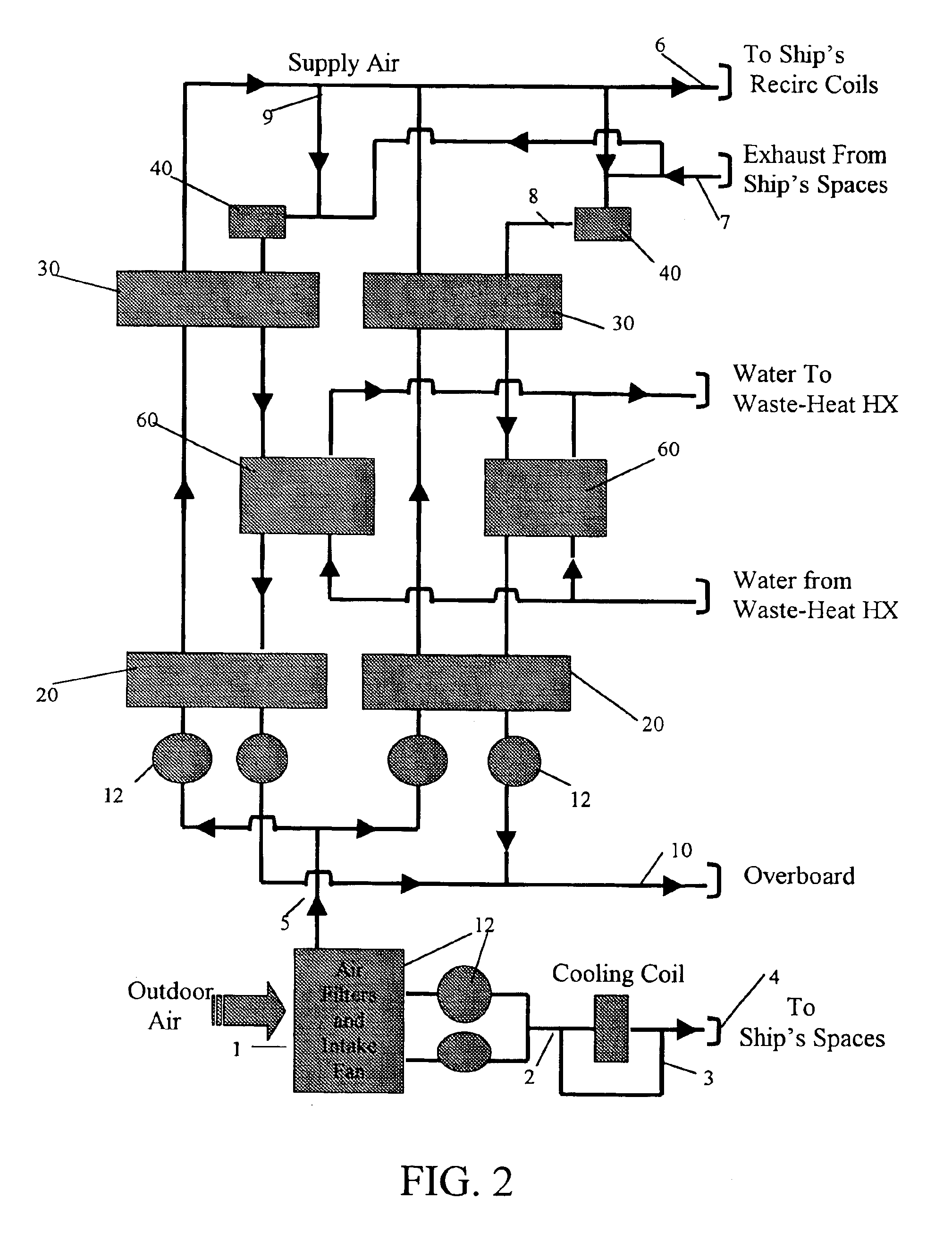

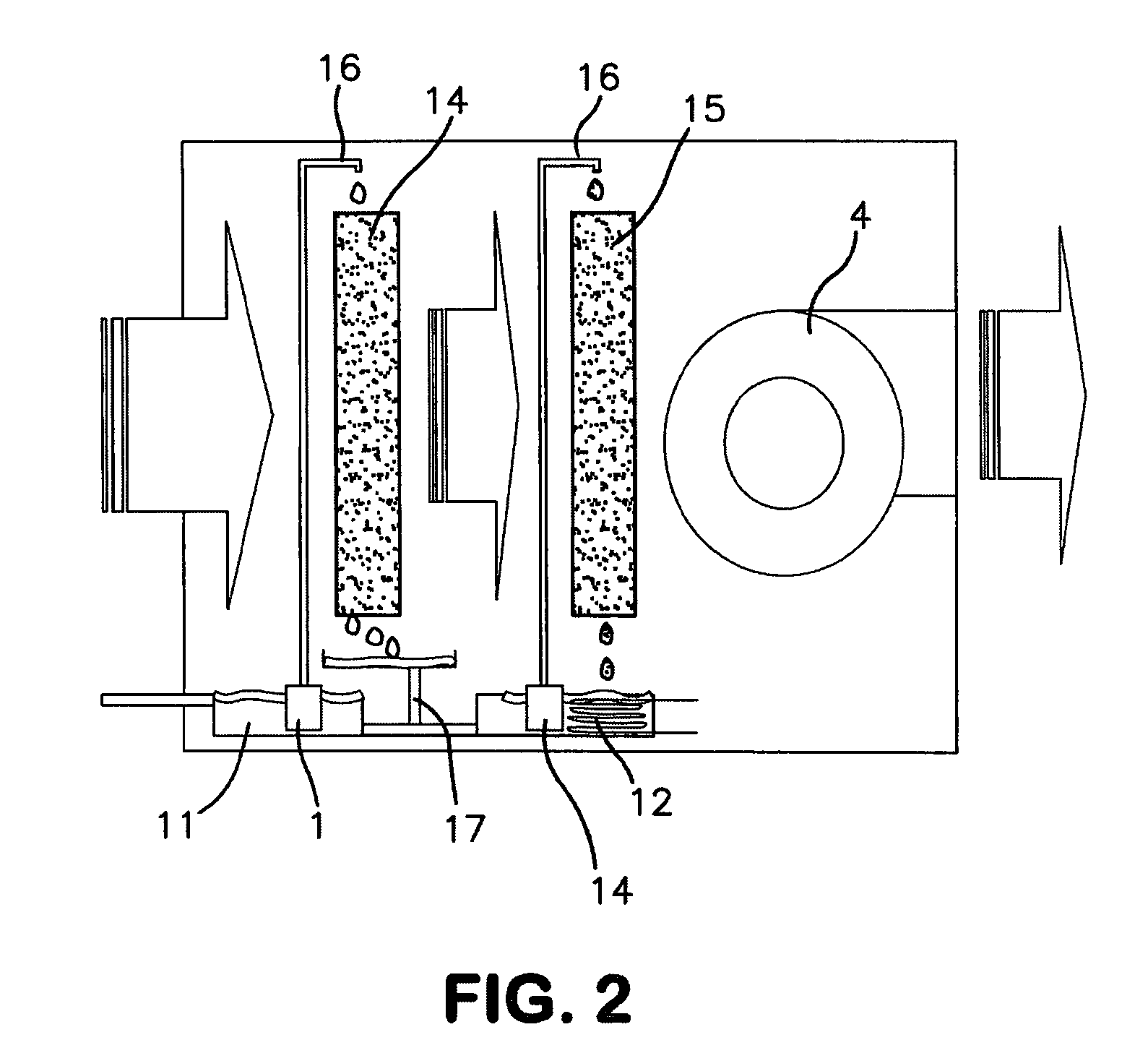

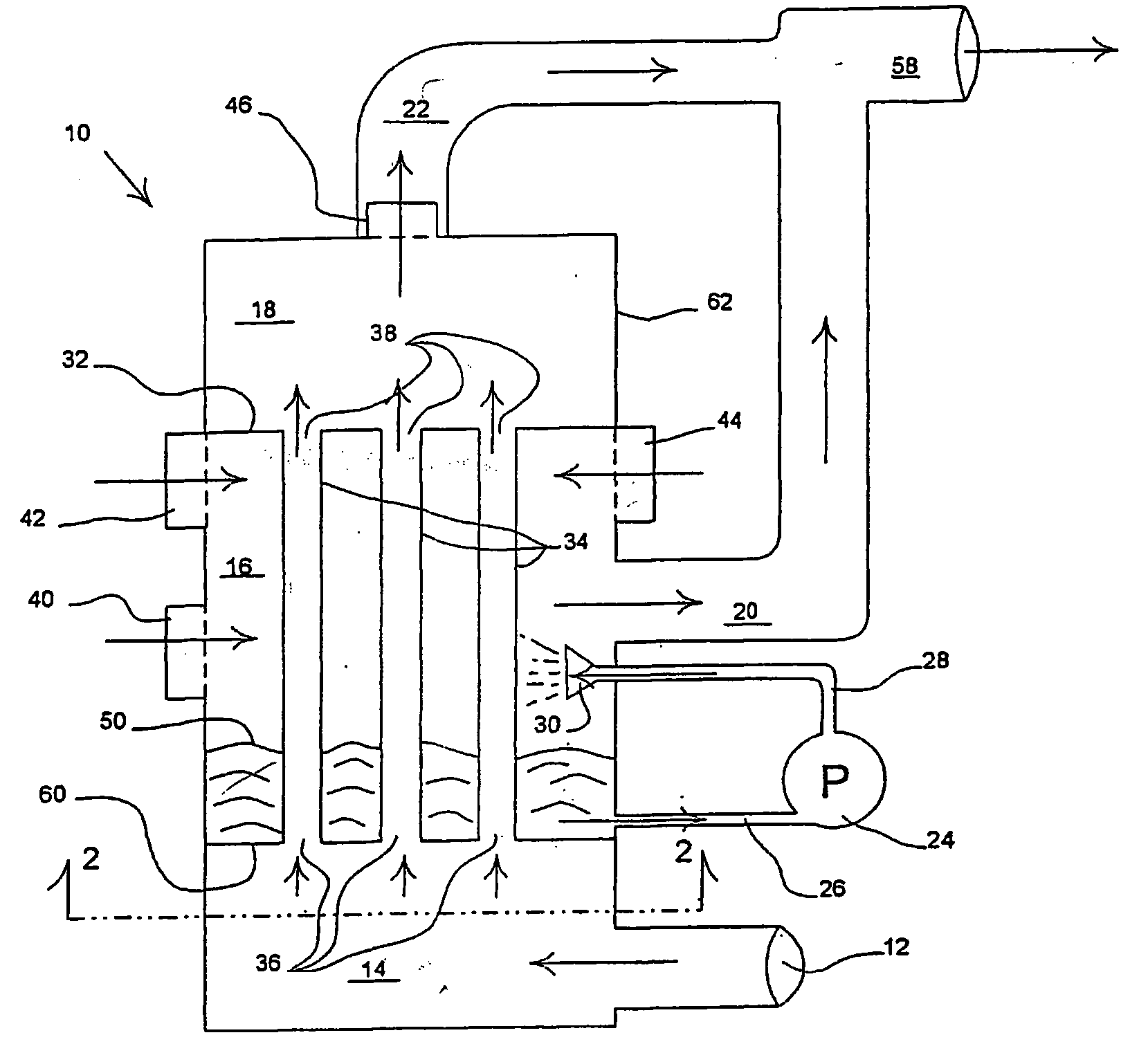

Dynamic desiccation cooling system for ships

InactiveUS6854279B1Air treatment detailsLighting and heating apparatusAir preheaterEvaporative cooler

The present invention describes methods and apparatus for controlling the humidity of air supplied to cooling coils on a gas turbine powered ship through a dynamic desiccation system. The system passes supply air through a desiccant wheel, which dries and concomitantly heats the supply air. This supply air stream is then passed through a rotatable thermal wheel, wherein heat is transferred from the dry supply air to an exhaust-air mixture, thereby conditioning the supply air for delivery and circulation to a plurality of cooling-coil units in a plurality of compartments. The exhaust air from the compartments is first mixed with some of the treated supply air to lower the absolute humidity to a value needed for effective regeneration of the desiccant wheel. An evaporative cooler then conditions the exhaust-air mixture for effective cooling of the supply air in the thermal rotor, which also serves as an air preheater for desiccant regeneration. The exhaust-air mixture is then heated to the desiccant regeneration temperature by passing the preheated exhaust air through a heat exchanger supplied with gas-turbine waste heat. After this heated exhaust-air mixture regenerates the desiccant wheel by fully drying out the desiccant on the wheel, it is expelled from the fan room.

Owner:CHIEF OF NAVAL RES OFFICE OF COUNSEL DEPT OF COUNSEL

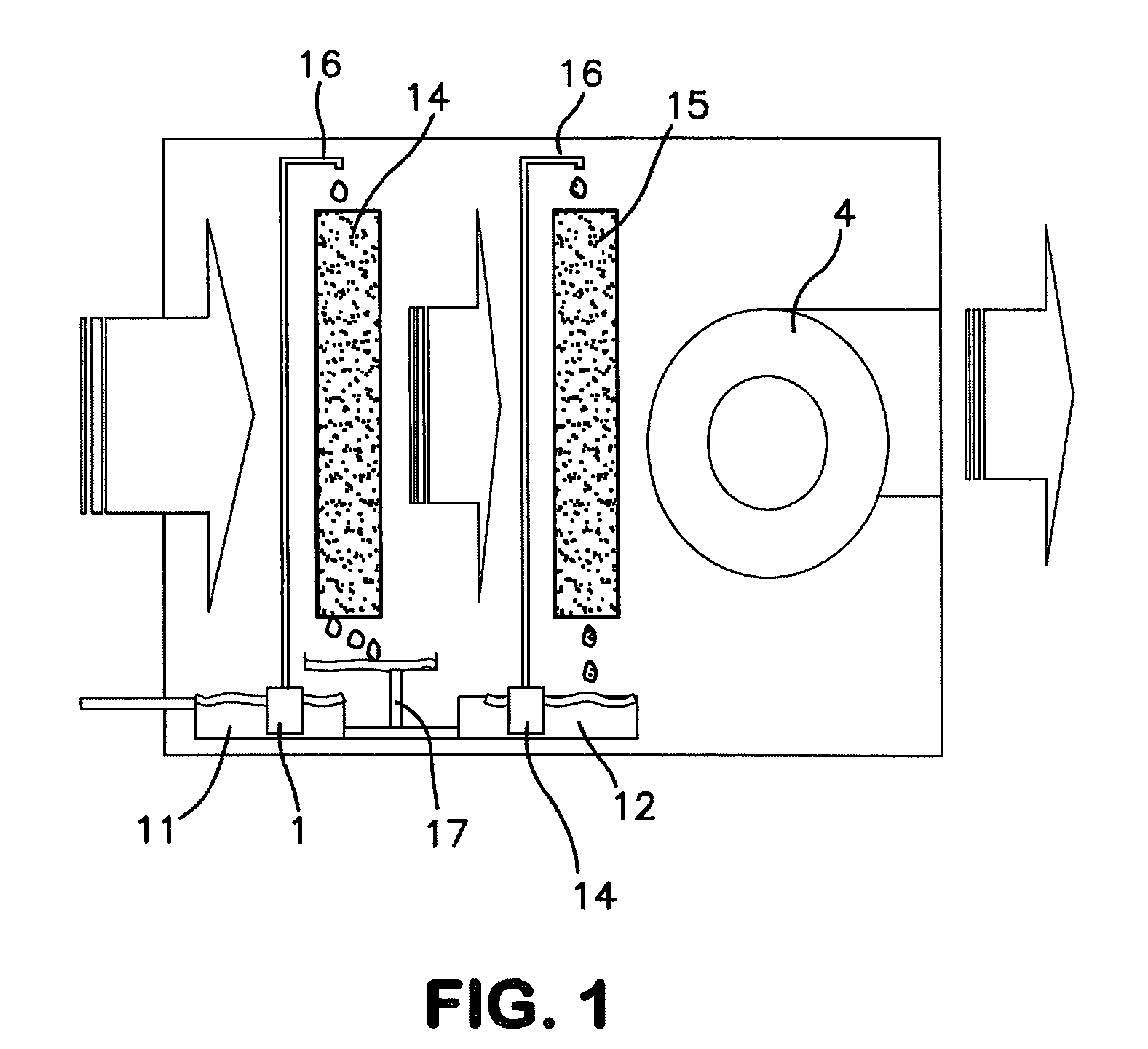

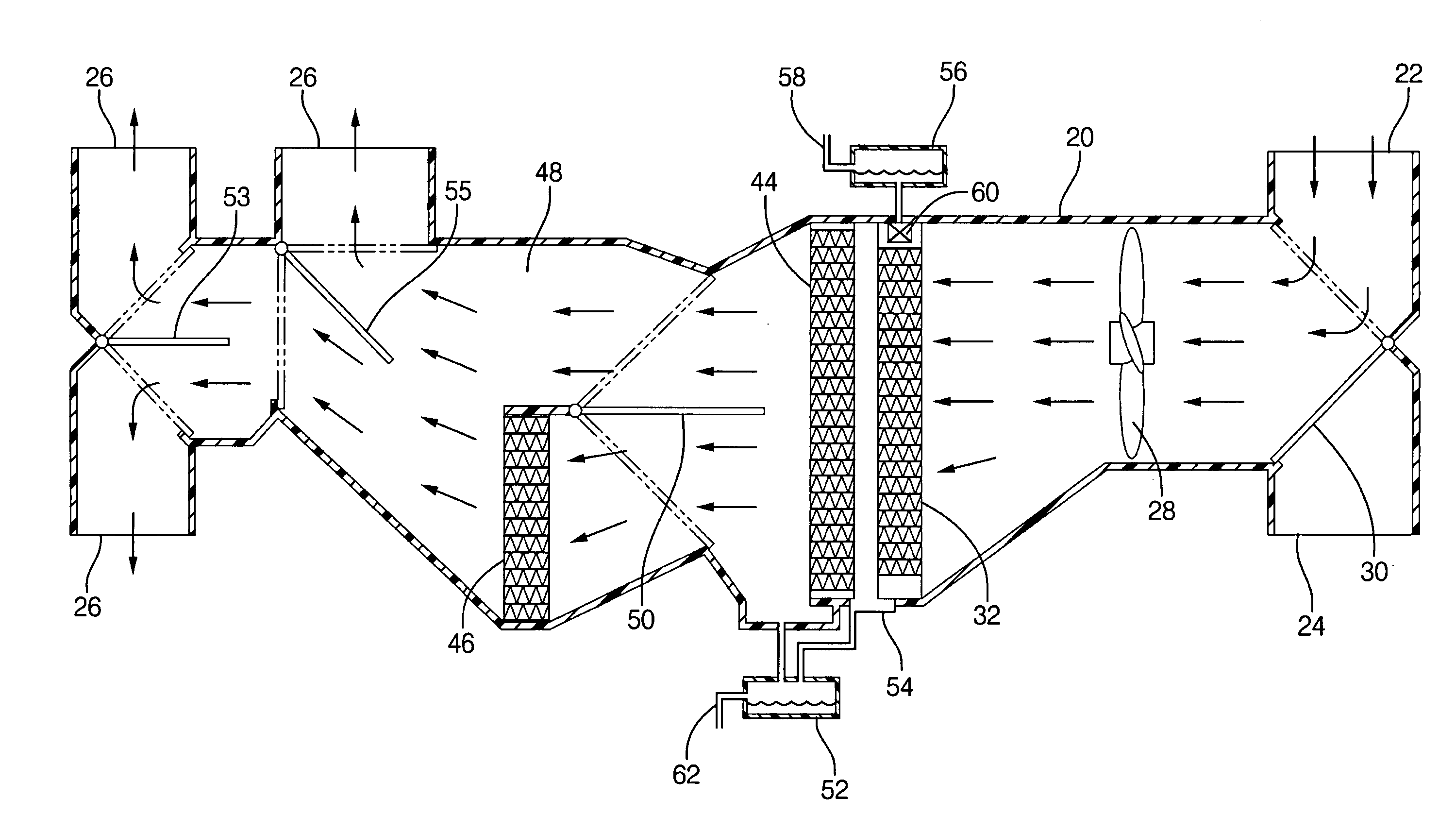

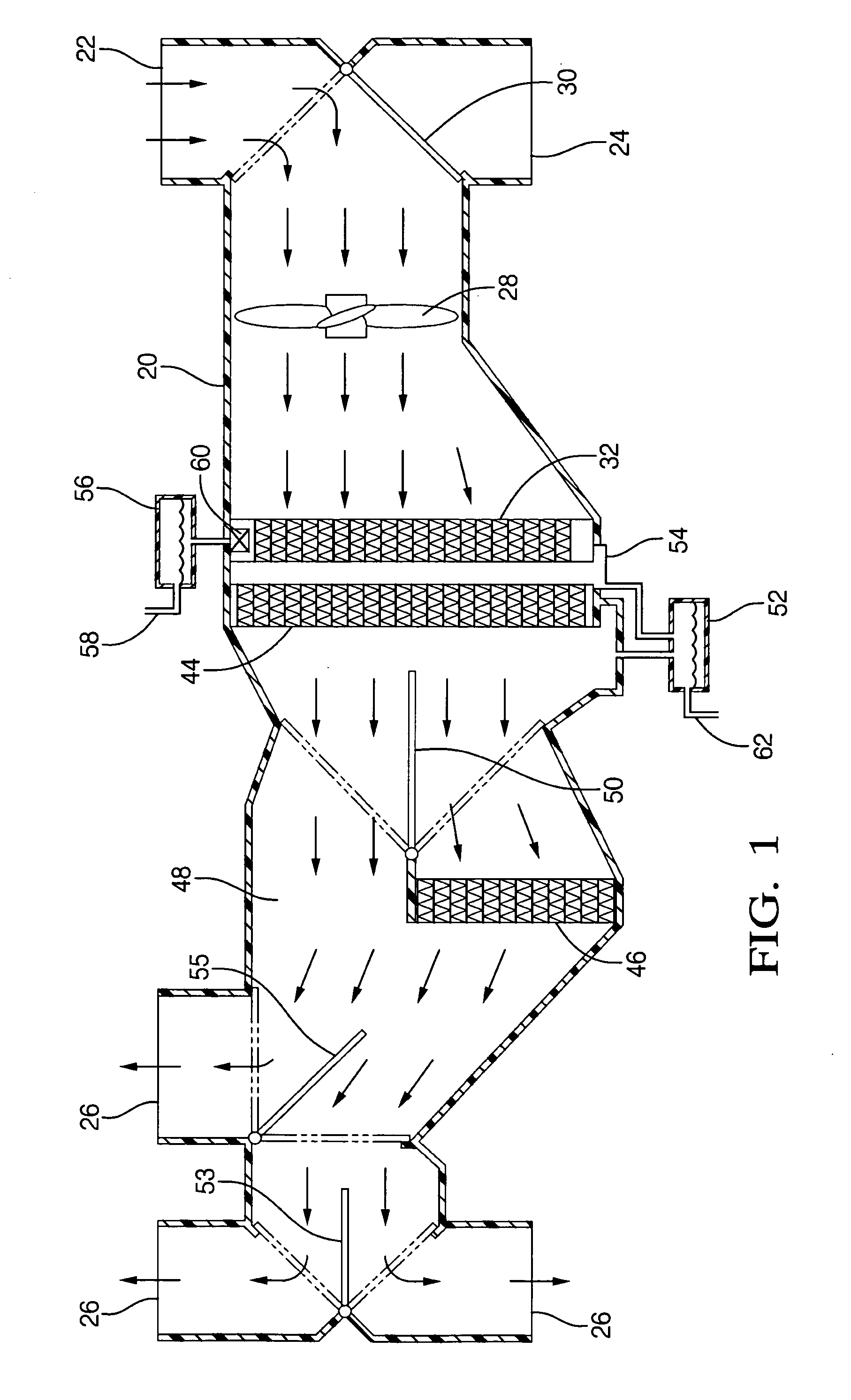

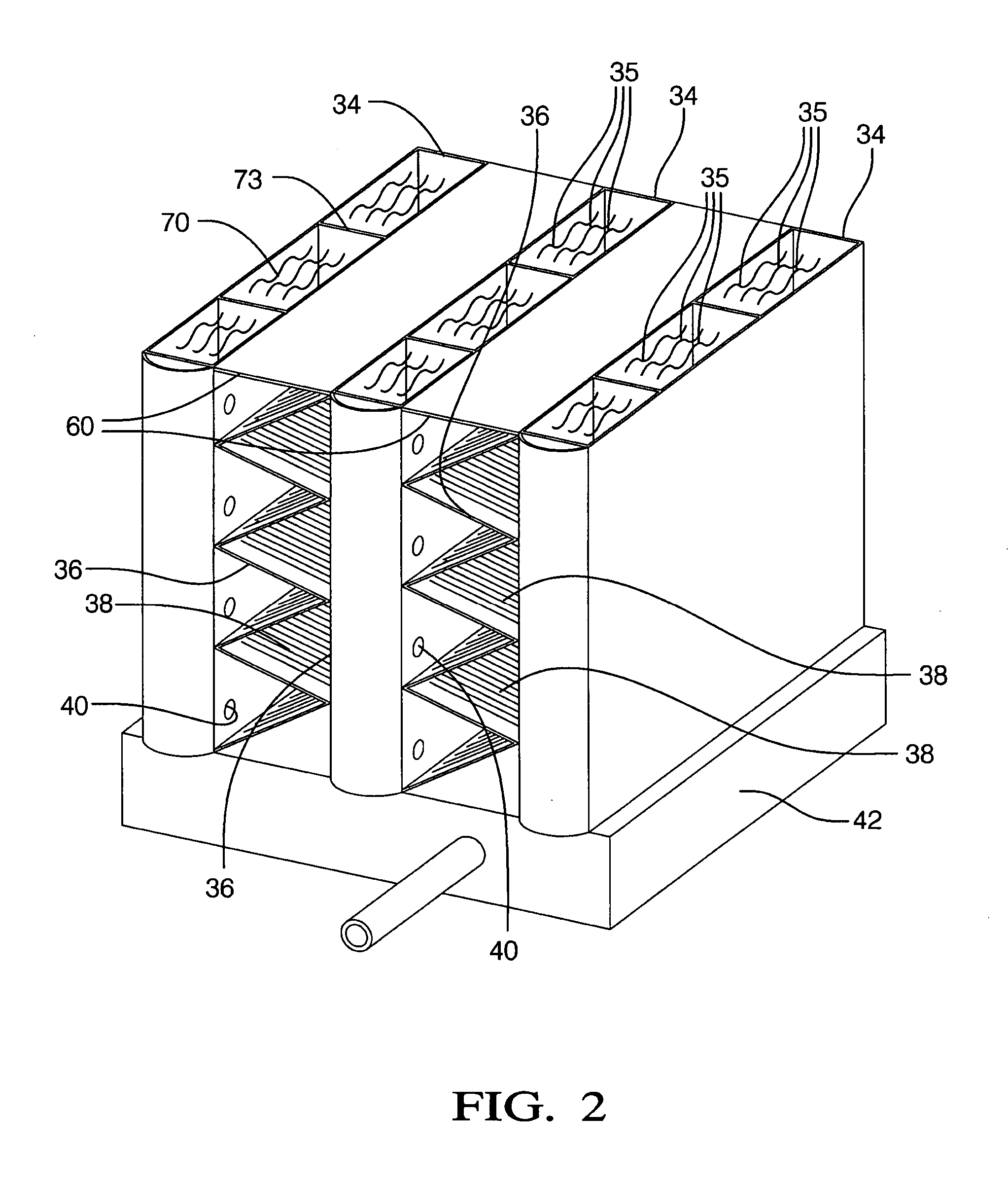

Evaporative Air Cooler With Multi Stages Cooling And Or Heating With Or Without Cooling Coil

InactiveUS20100281896A1Free-cooling systemsStationary conduit assembliesEvaporative coolerCooling coil

An outdoor air cooler with two stages includes a first stage for cooling and humidification with constant wet bulb temperature. The air cooler has a first stage pump circulating water over the first stage evaporative cooling media operating at conditions having a constant adiabatic wet bulb temperature line. The first stage tank is supplied with water from external source. The second stage includes a second set of evaporative cooling media using water from the first stage media, which is equal to or lower than outdoor air wet bulb temperature. The temperature of air leaving the second stage evaporative media follows the adiabatic wet bulb temperature line toward the second stage tank water temperature thereby cooling humidifying the treated air to stable wet and dry bulb temperatures.

Owner:AL WATBAN ALAA ABDULKAREEM

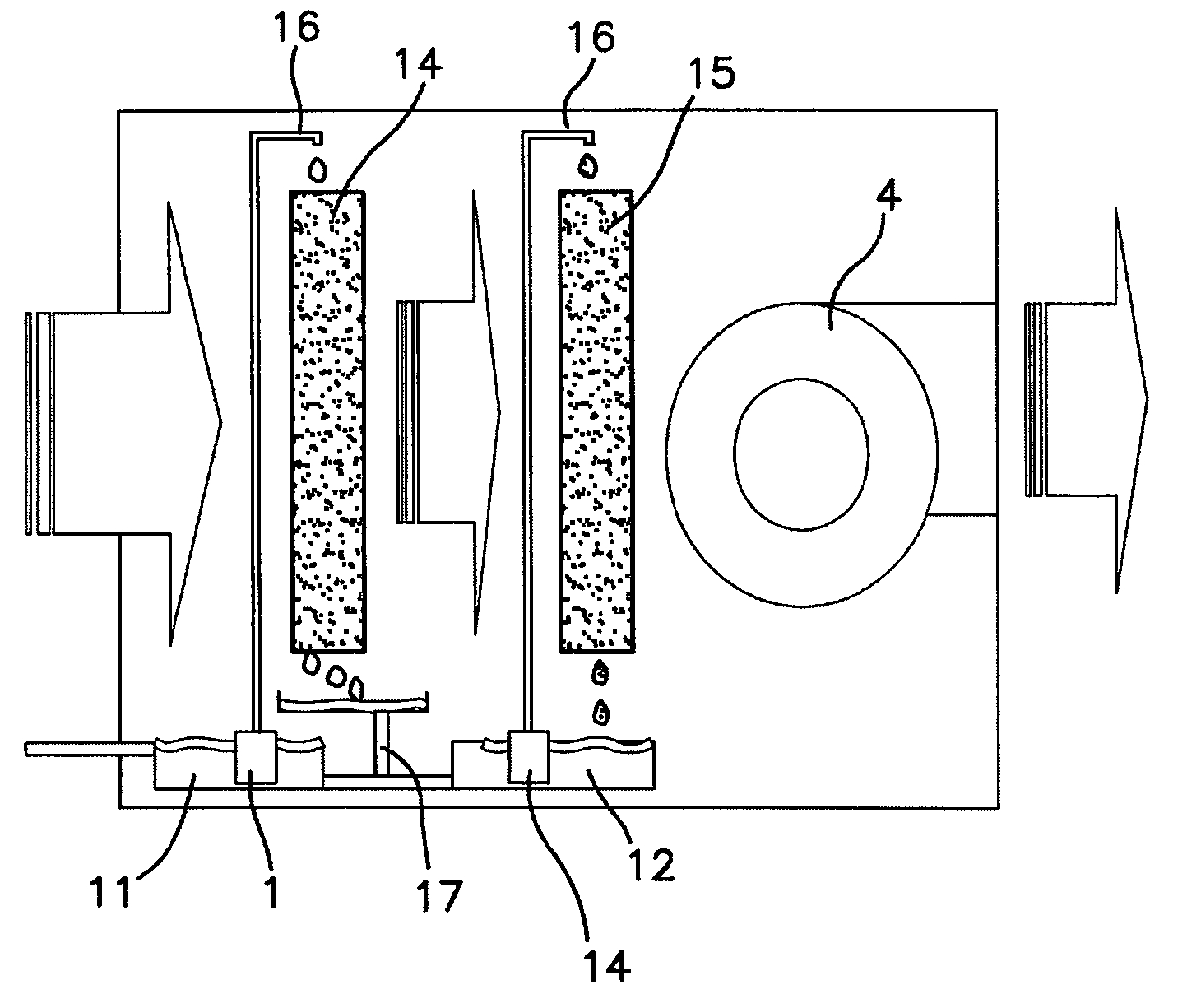

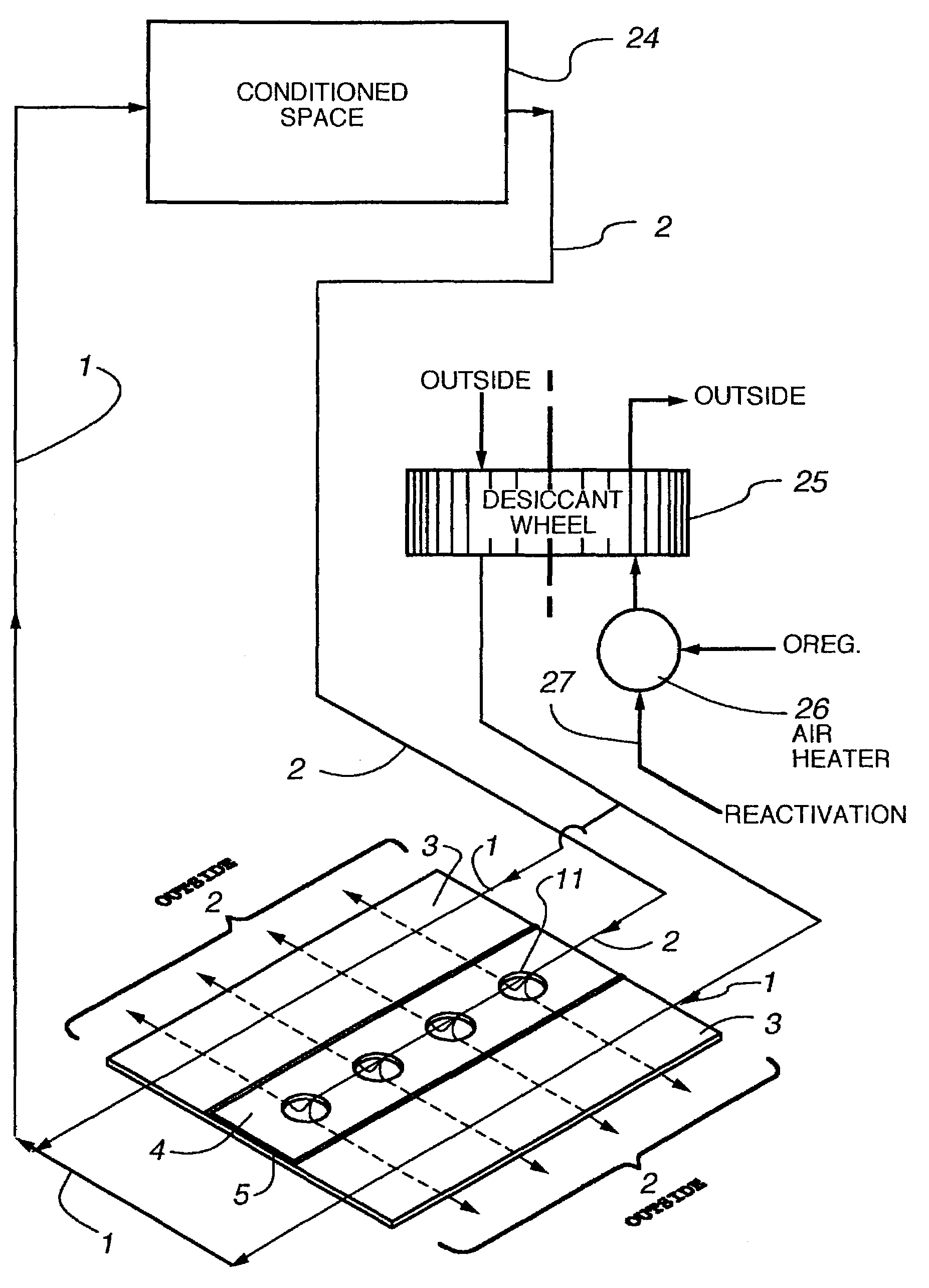

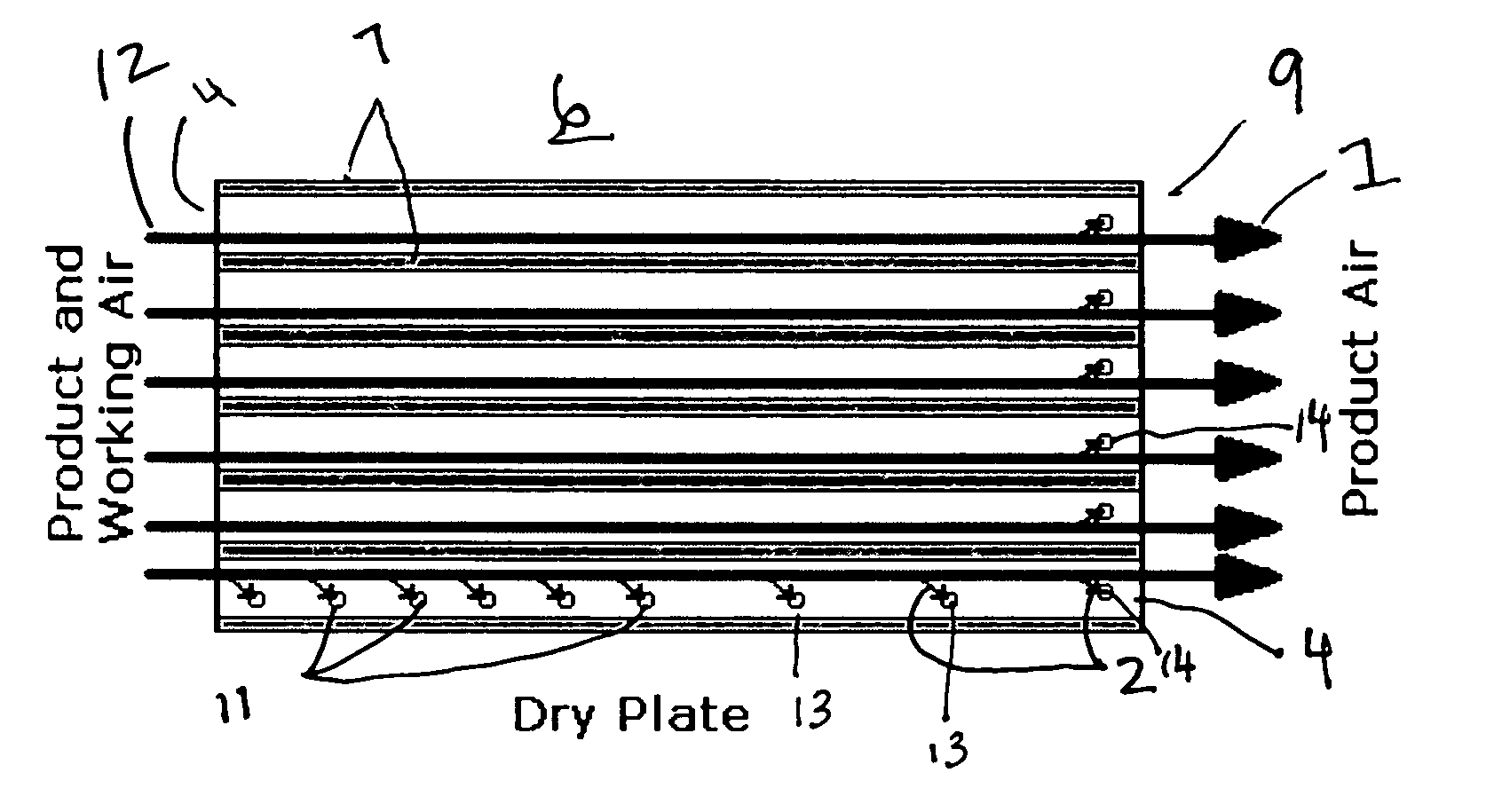

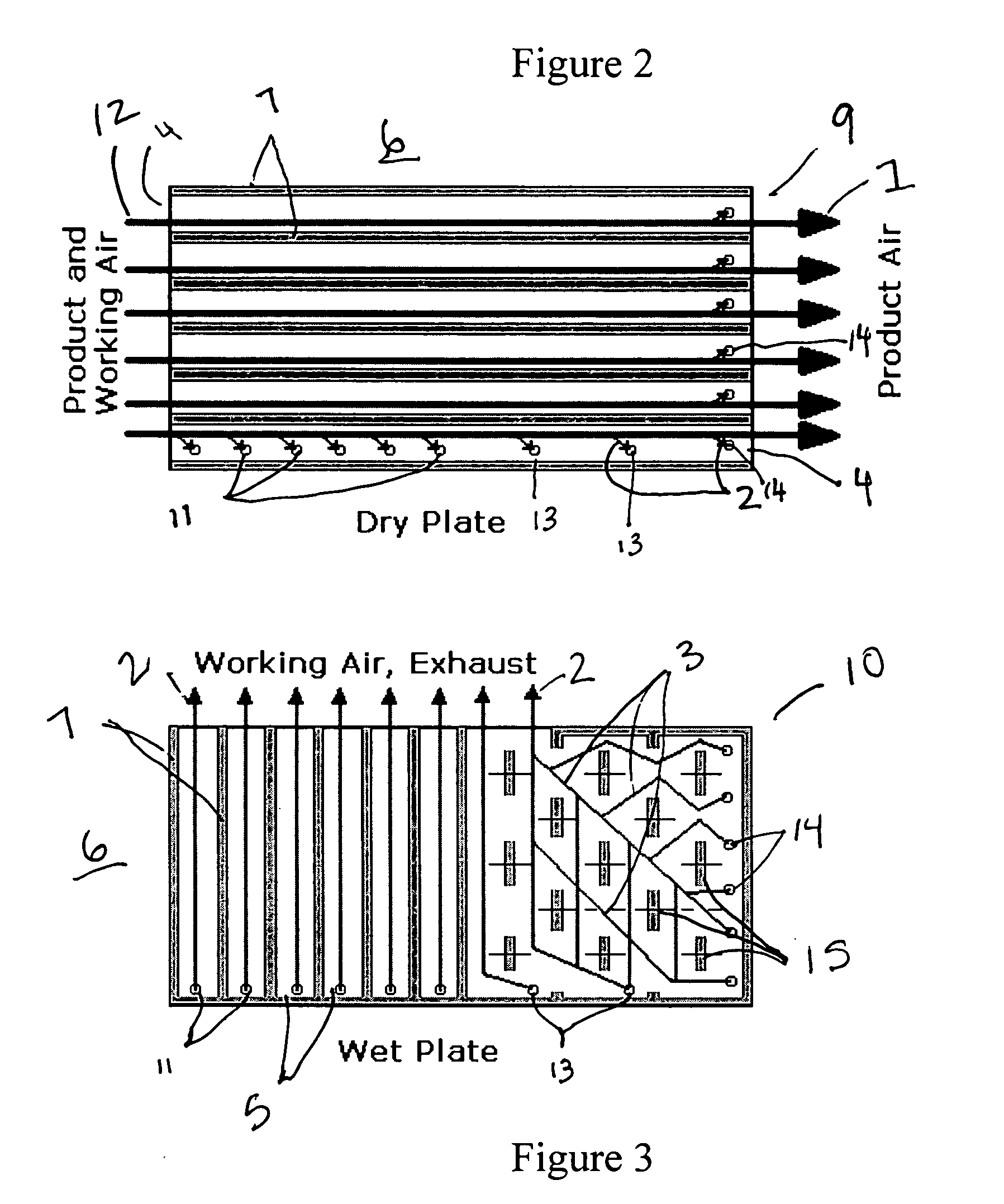

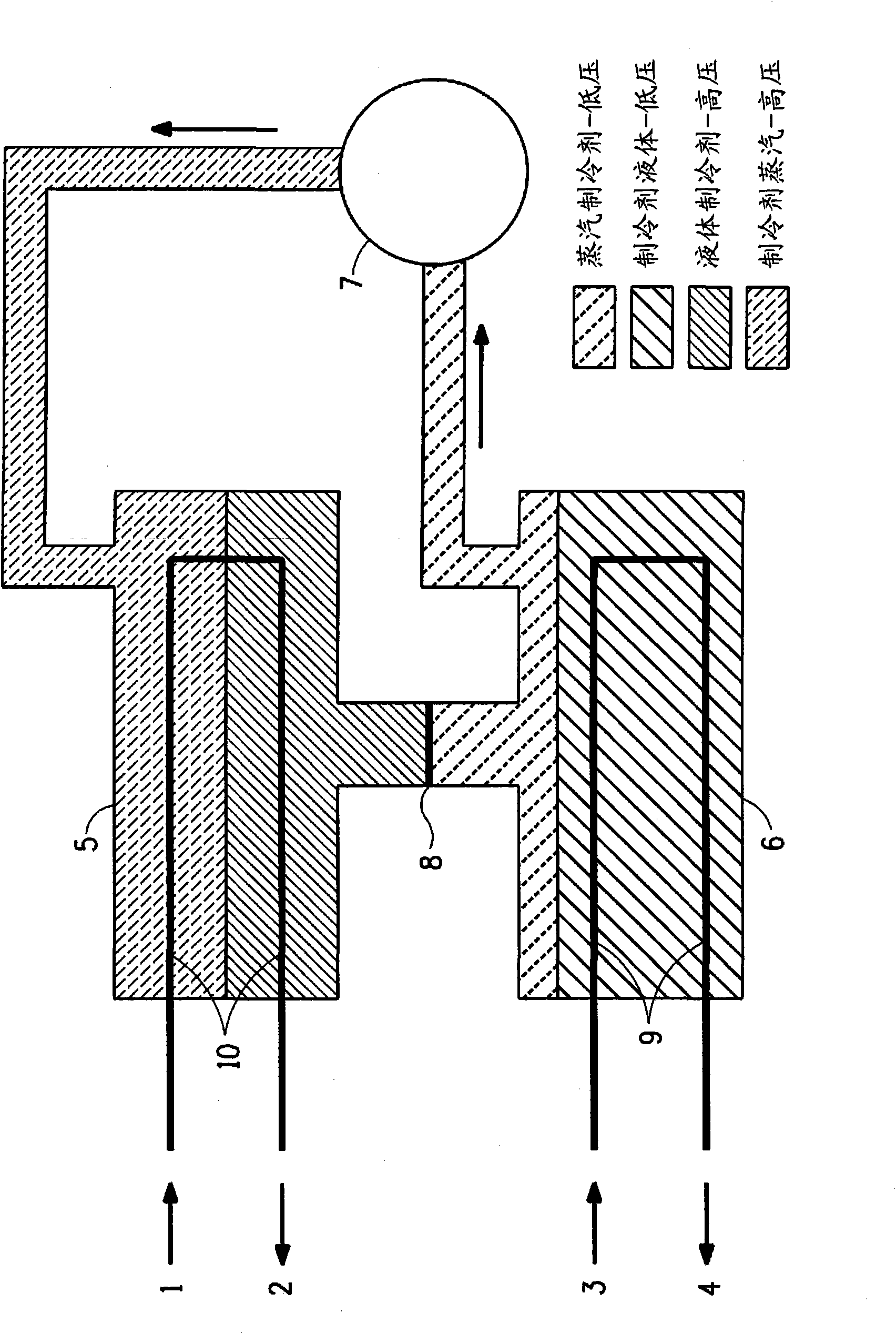

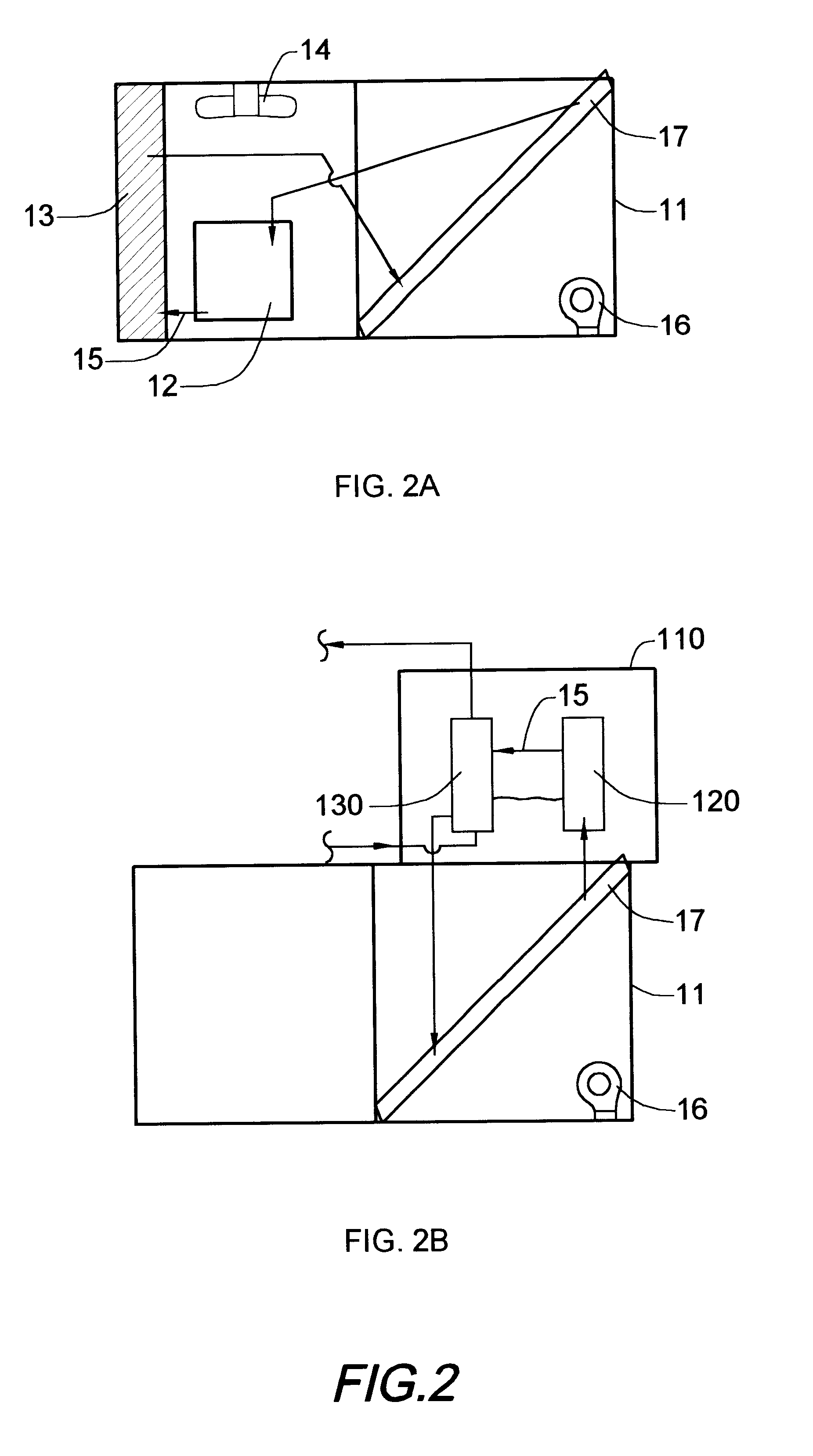

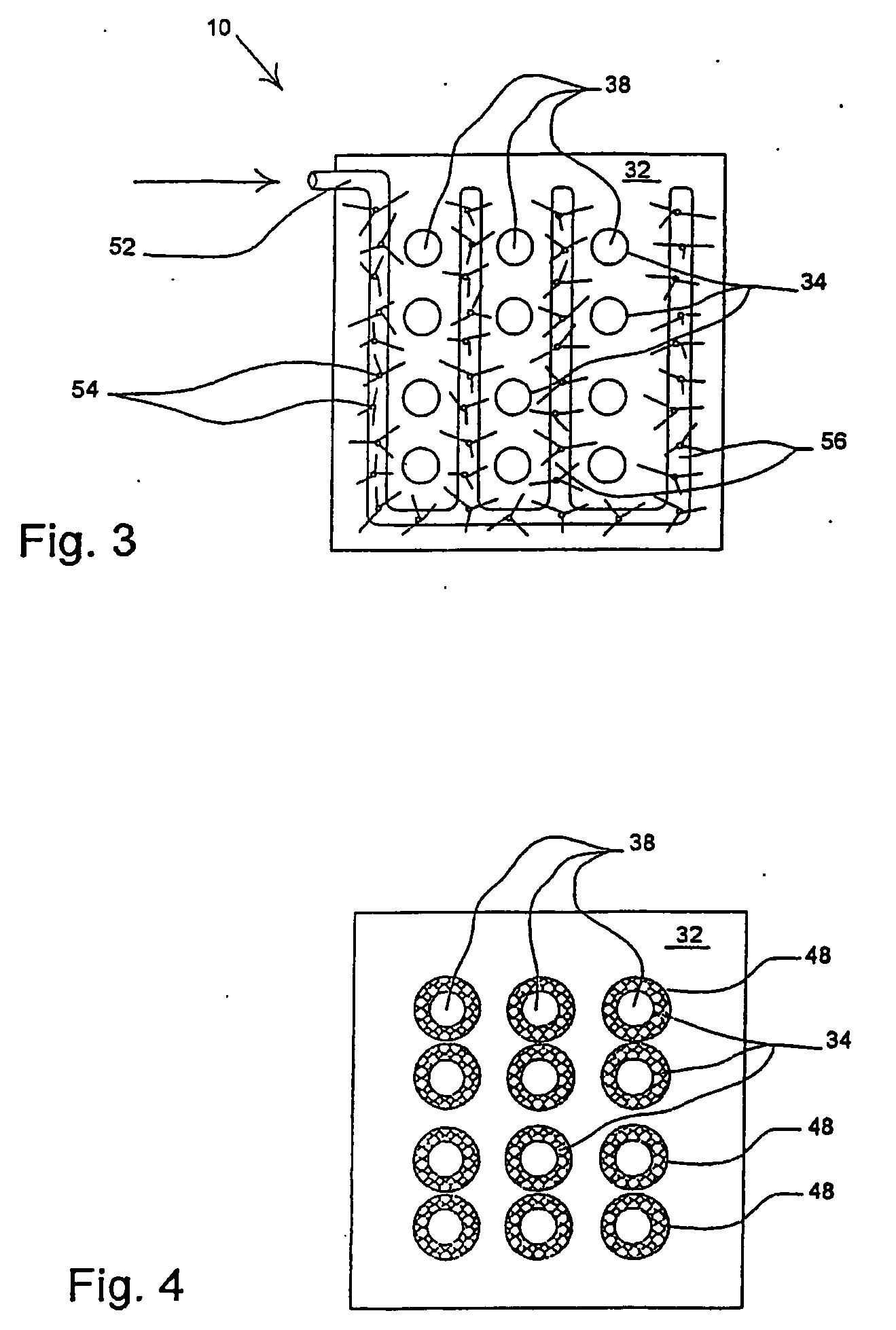

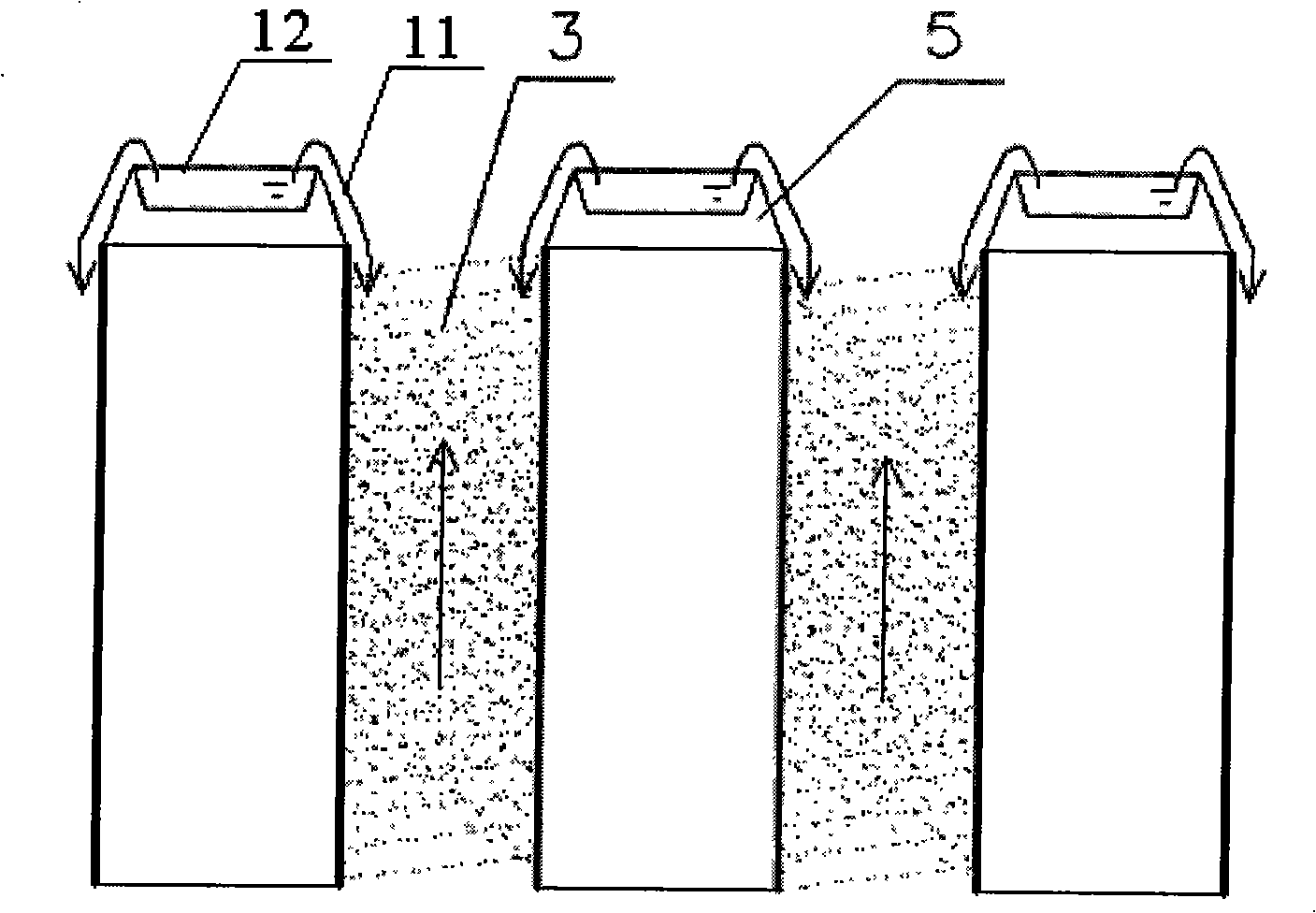

Method and plate apparatus for dew point evaporative cooler

InactiveUS7197887B2Small pressure dropReduce temperature differenceAir treatment detailsFree-cooling systemsEvaporative coolerFiber

An improved method and apparatus for indirect evaporative cooling of a fluid stream to substantially its dew point temperature. Plate heat exchanger has perforations 11 and channels 3, 4 and 5 for gas or a low temperature for liquids on a dry side and wet side. Fluid streams 1 flow across the dry side 9, transferring heat to the plate. Gas stream 2 flows across the dry side and through perforations to channels 5 on wet side 10, which it then cools by evaporative cooling as well as conductive and radiative transfer of heat from plate. A wicking material provides wetting of wet side. In other embodiments, a desiccant wheel may be used to dehumidify the gas, air streams may be recirculated, feeder wicks 13 and a pump may be used to bring water from a water reservoir, and fans may be used to either force or induce a draft. The wicking material may be cellulose, organic fibers, organic based fibers, polyester, polypropylene, carbon-based fibers, silicon based fibers, fiberglass, or combinations of them. The device may be operated in winter months to scavenge heat from exhaust gases of a space and thus pre-heat fresh air, while simultaneously humidifying the fresh air.

Owner:F F SEELEY NOMINEES

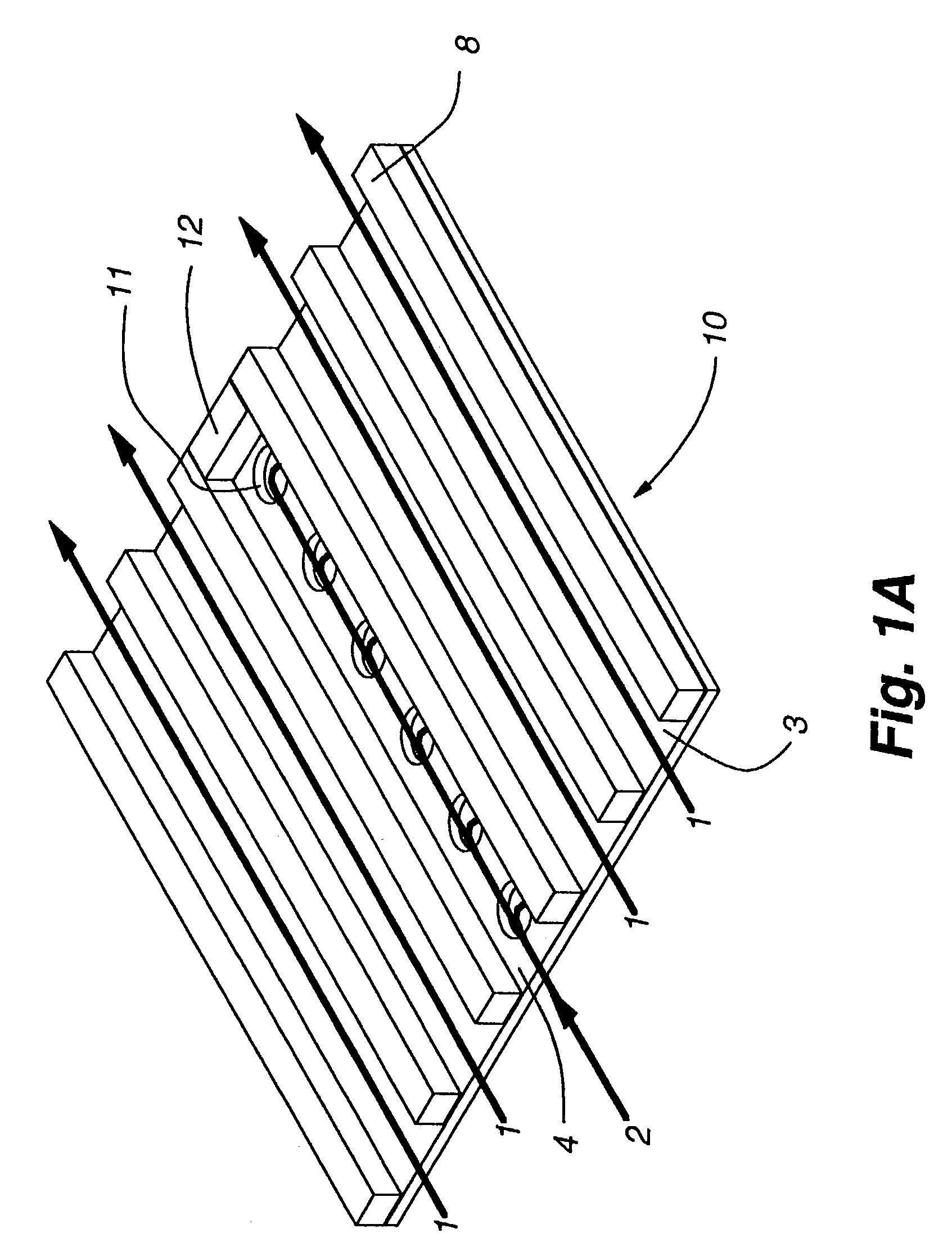

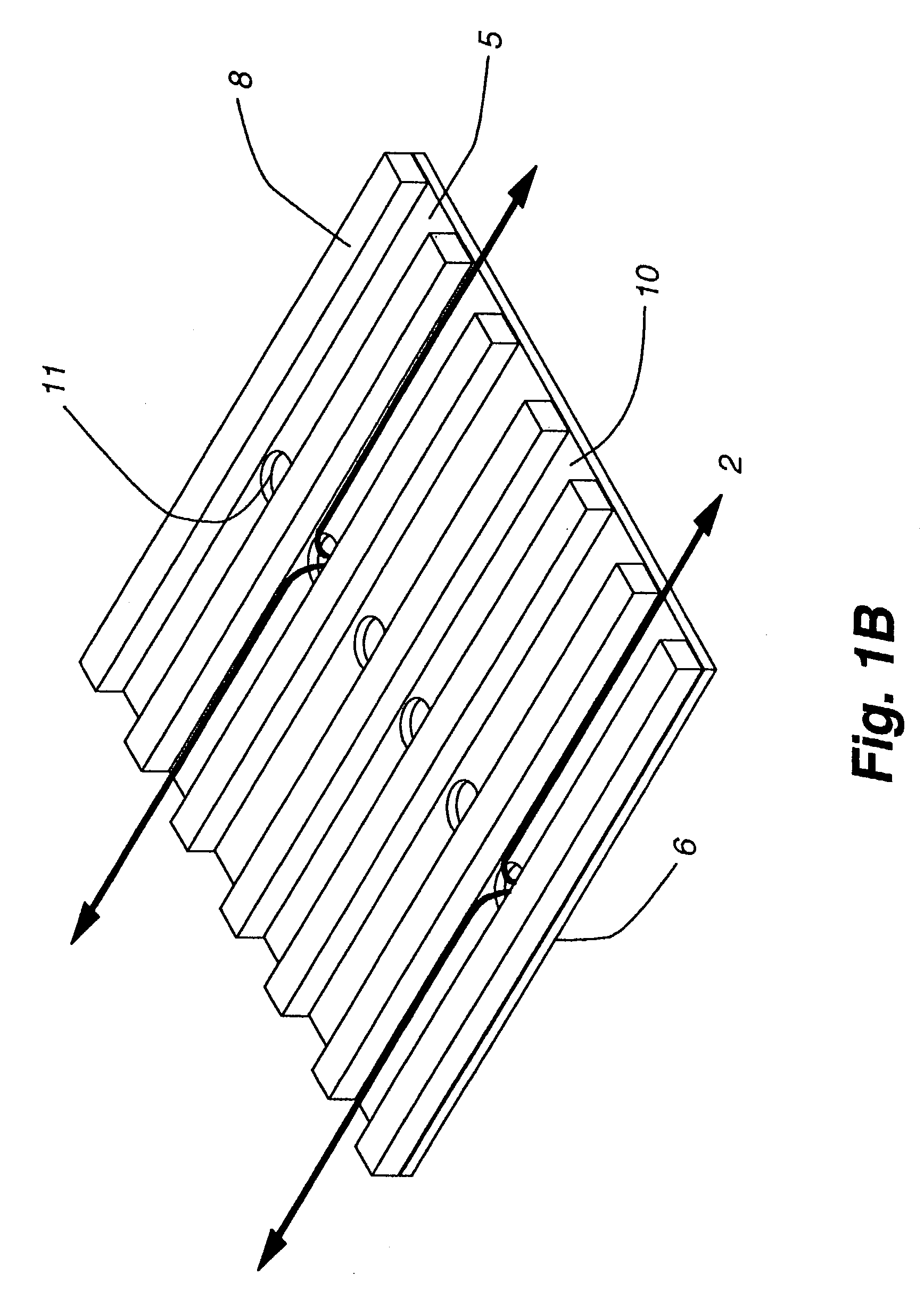

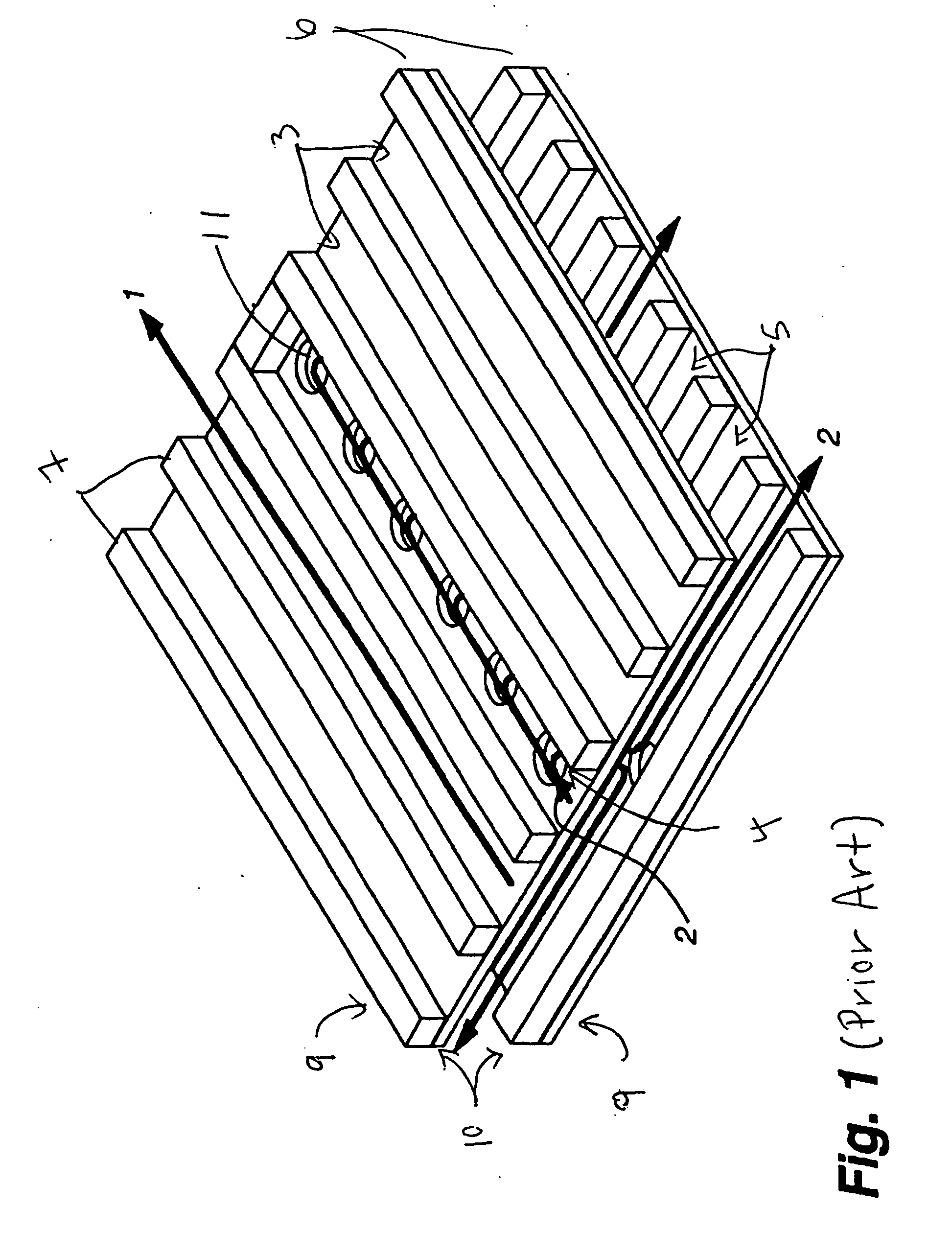

Indirect evaporative cooling of a gas using common product and working gas in a partial counterflow configuration

InactiveUS20050210907A1Increase heat loadLess working airFree-cooling systemsStationary conduit assembliesEvaporative coolerEngineering

An indirect evaporative cooler includes a number of heat transfer plates. Each plate has a wet side and a dry side, and the dry sides of adjacent plates face each other. The plate dry sides have low permeability to an evaporative liquid. Input air flows over the dry sides from an input end to an output end. Part of the input air becomes product air and exits at the output end. The rest of the input air passes through perforations in the plates to the other side of the plates to become working air. The other side of each plate is a wet side, which is wet by an evaporative liquid. Working gas flows over the wet side, evaporating the evaporative liquid and cooling the evaporative liquid, the plate, and finally the product gas by heat transfer. The perforations are formed both toward the input end of the plate and toward the output end of the plate. Part of the wet side of the plate, toward the output end of the plate, has a plurality of barriers placed to cause the working gas at that end of the plate to flow in a direction generally counter to the input air.

Owner:IDALEX TECH INC

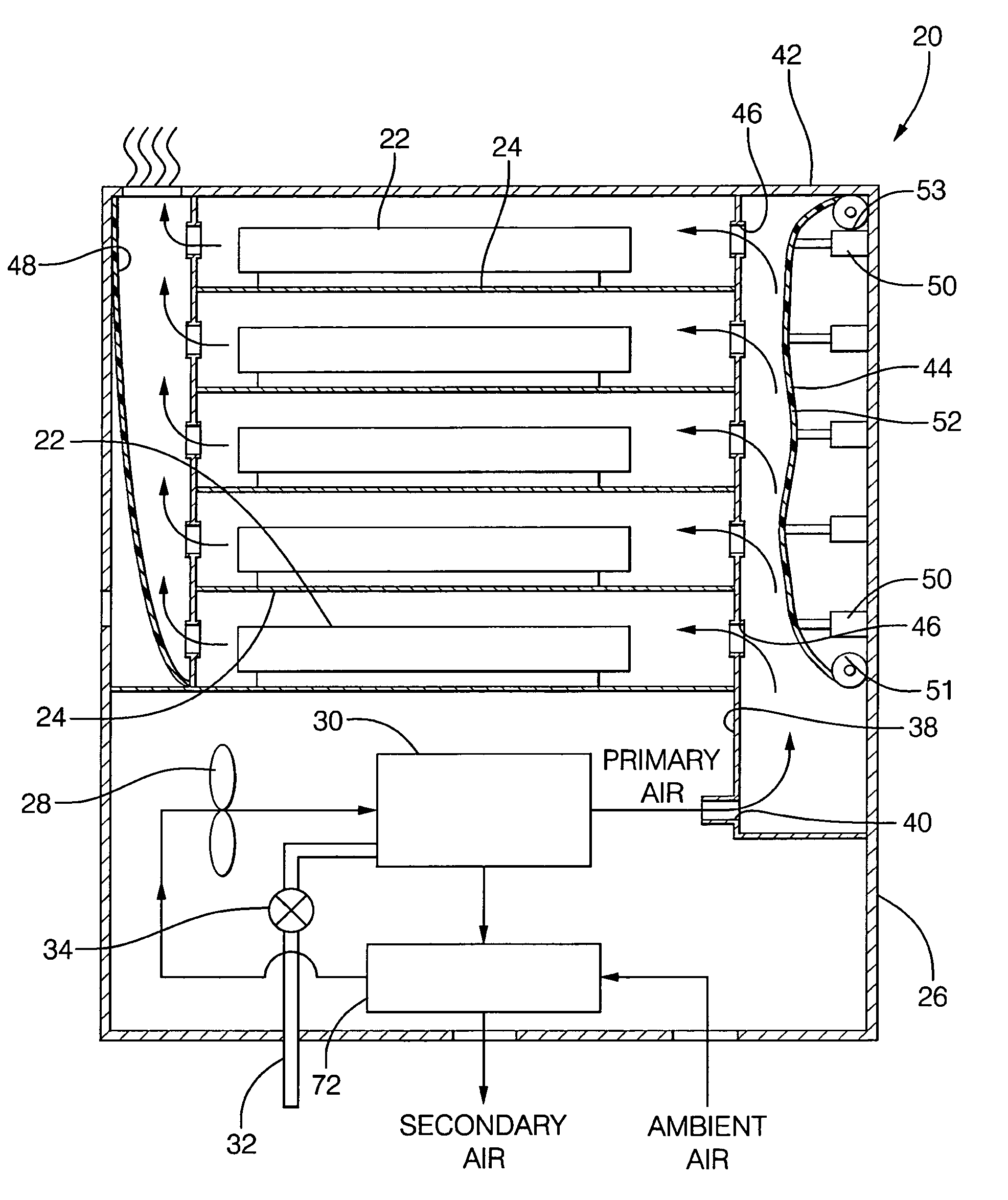

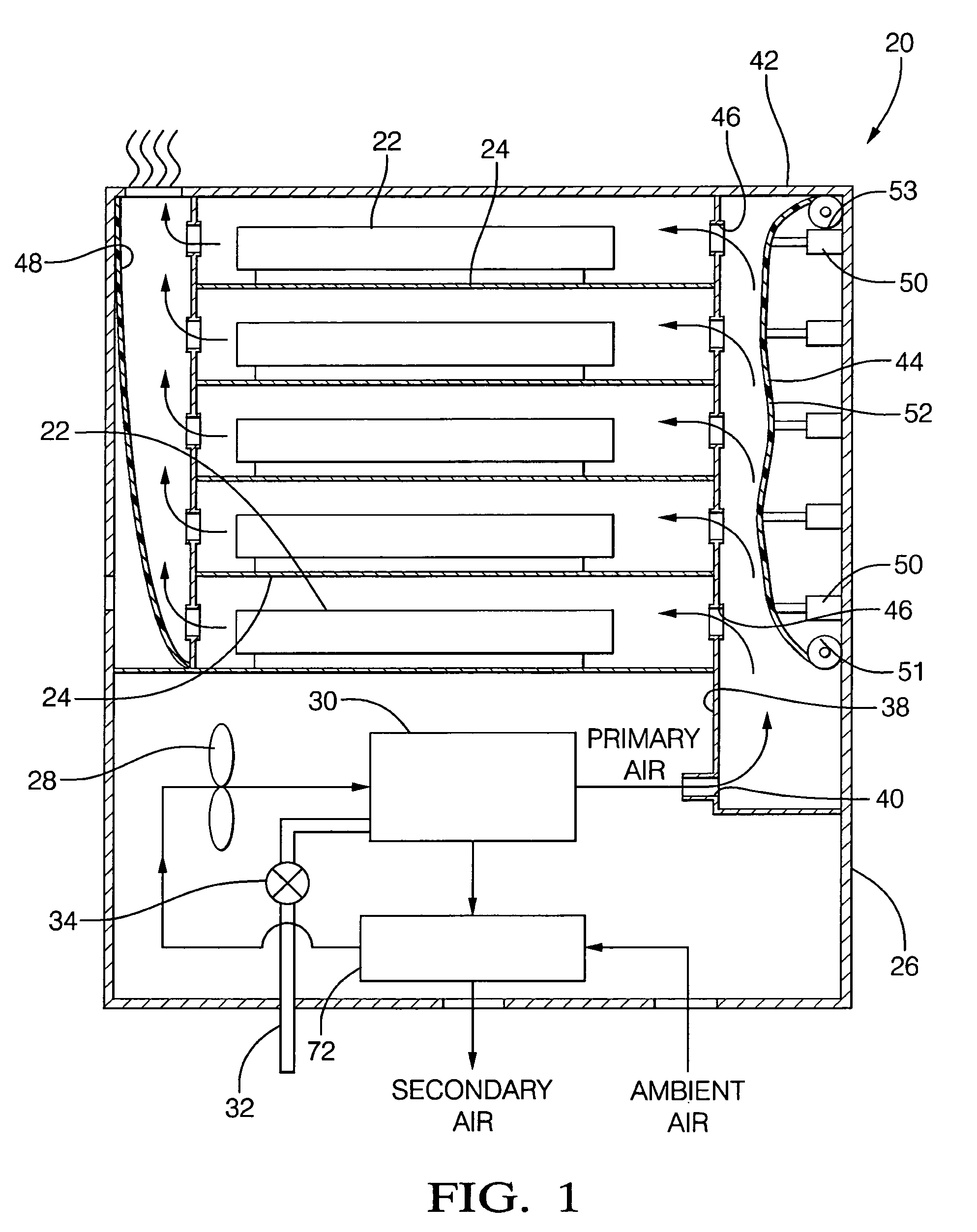

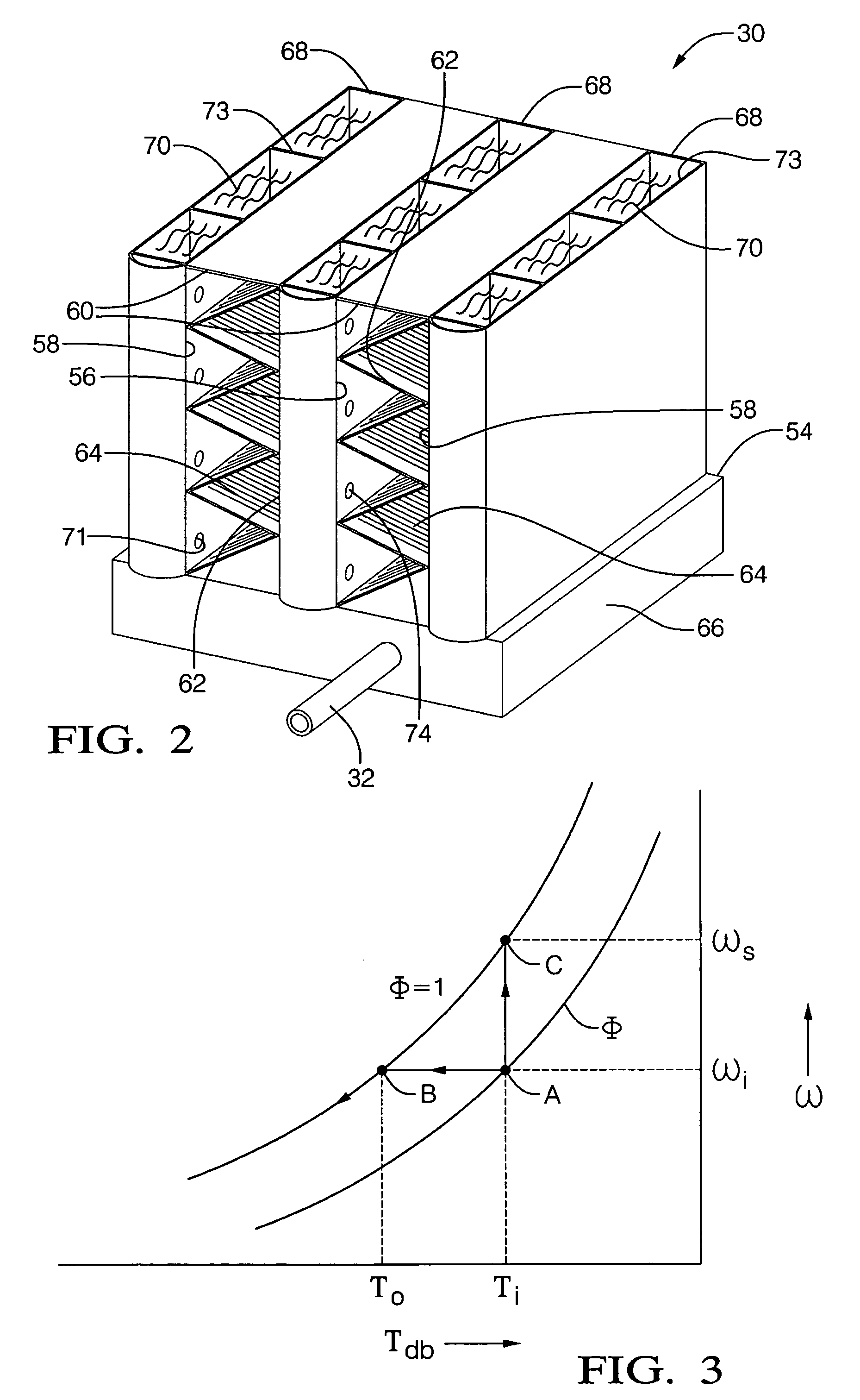

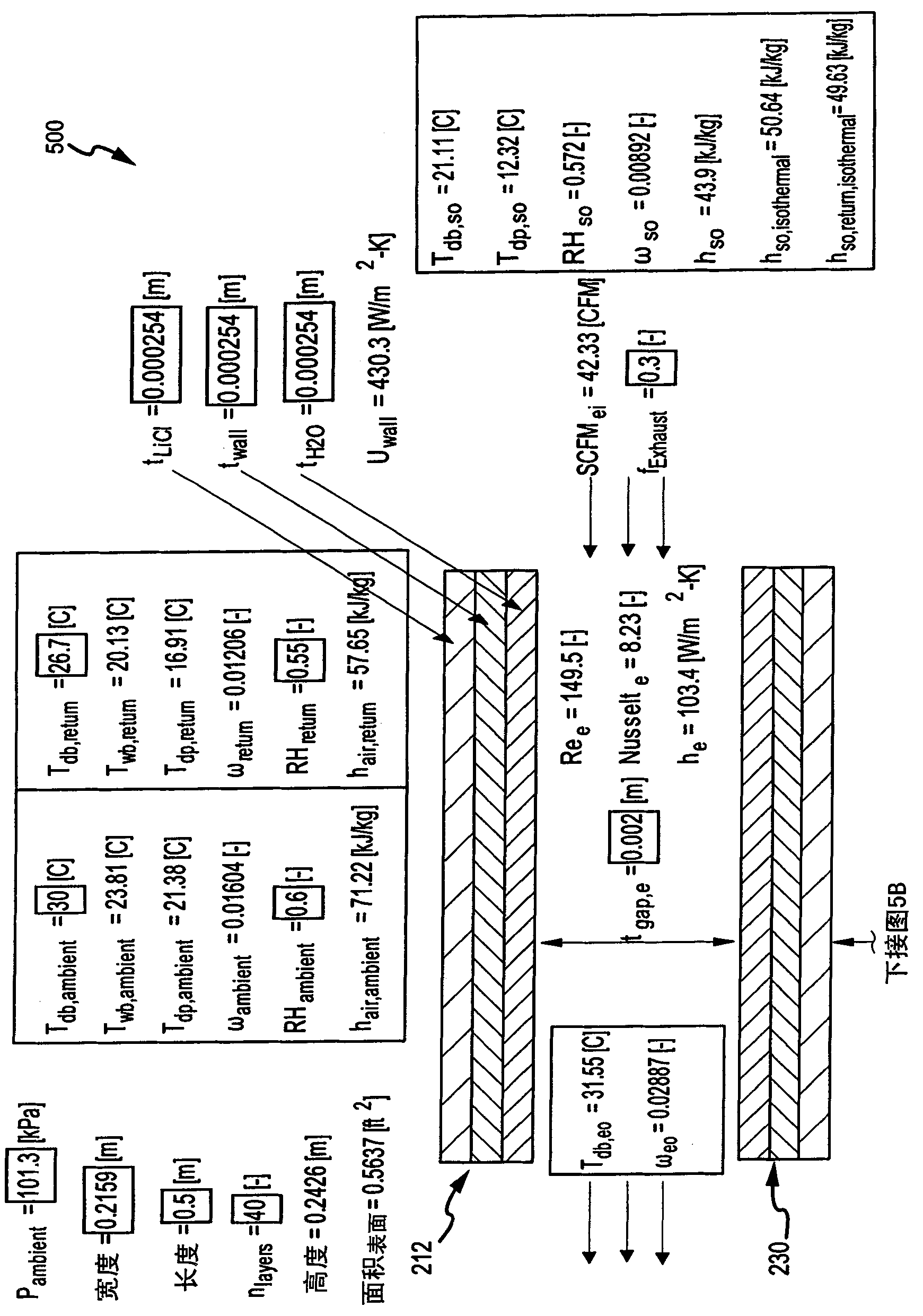

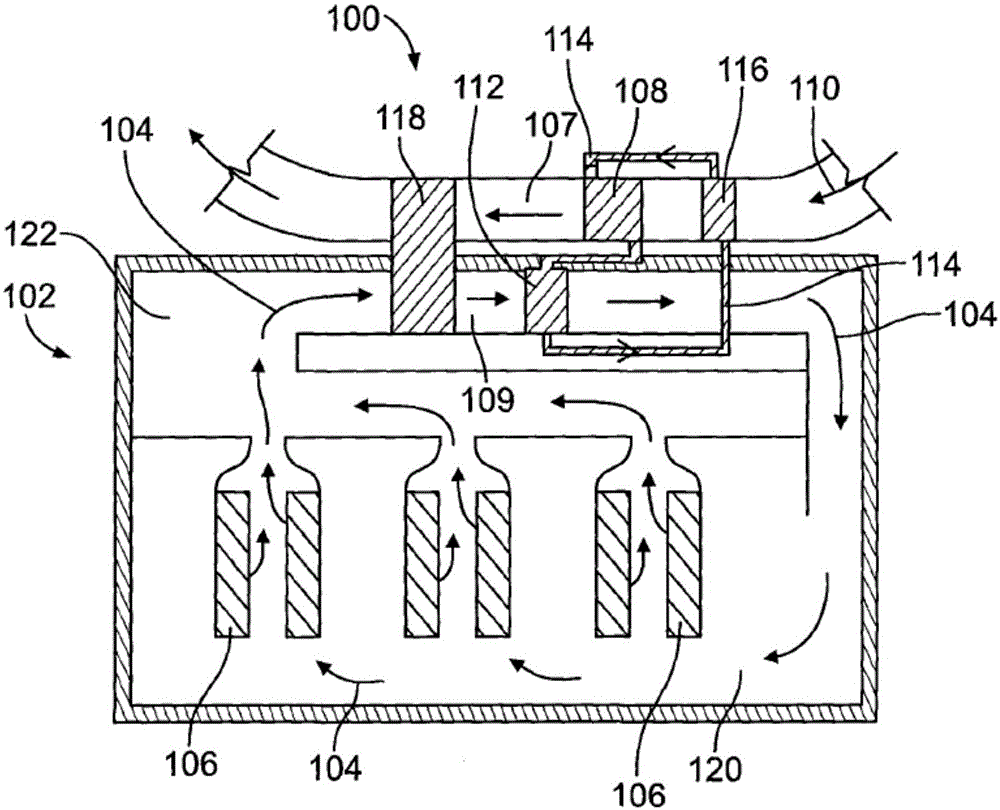

Evaporative cooling system for a data-communications cabinet

InactiveUS7438124B2More efficientEfficient systemDomestic cooling apparatusKitchen cabinetsCold airEvaporative cooler

An electronics cabinet for storing a plurality of electronic devices therein is provided and includes a fan and an evaporative cooler. The fan draws a flow of air into the cabinet, circulates the flow of air through the evaporative cooler, and then across the electronic devices for removing heat produced by the electronic devices. The evaporative cooler removes heat from the flow of air by absorbing heat from the flow of air and then dissipating the heat by evaporating a liquid into a secondary airflow, which is directed out of the cabinet. The cabinet includes a cold air plenum having an actuator for adjusting a cross-sectional area of the cold air plenum to control the airflow through each of the supports.

Owner:DELPHI TECH INC

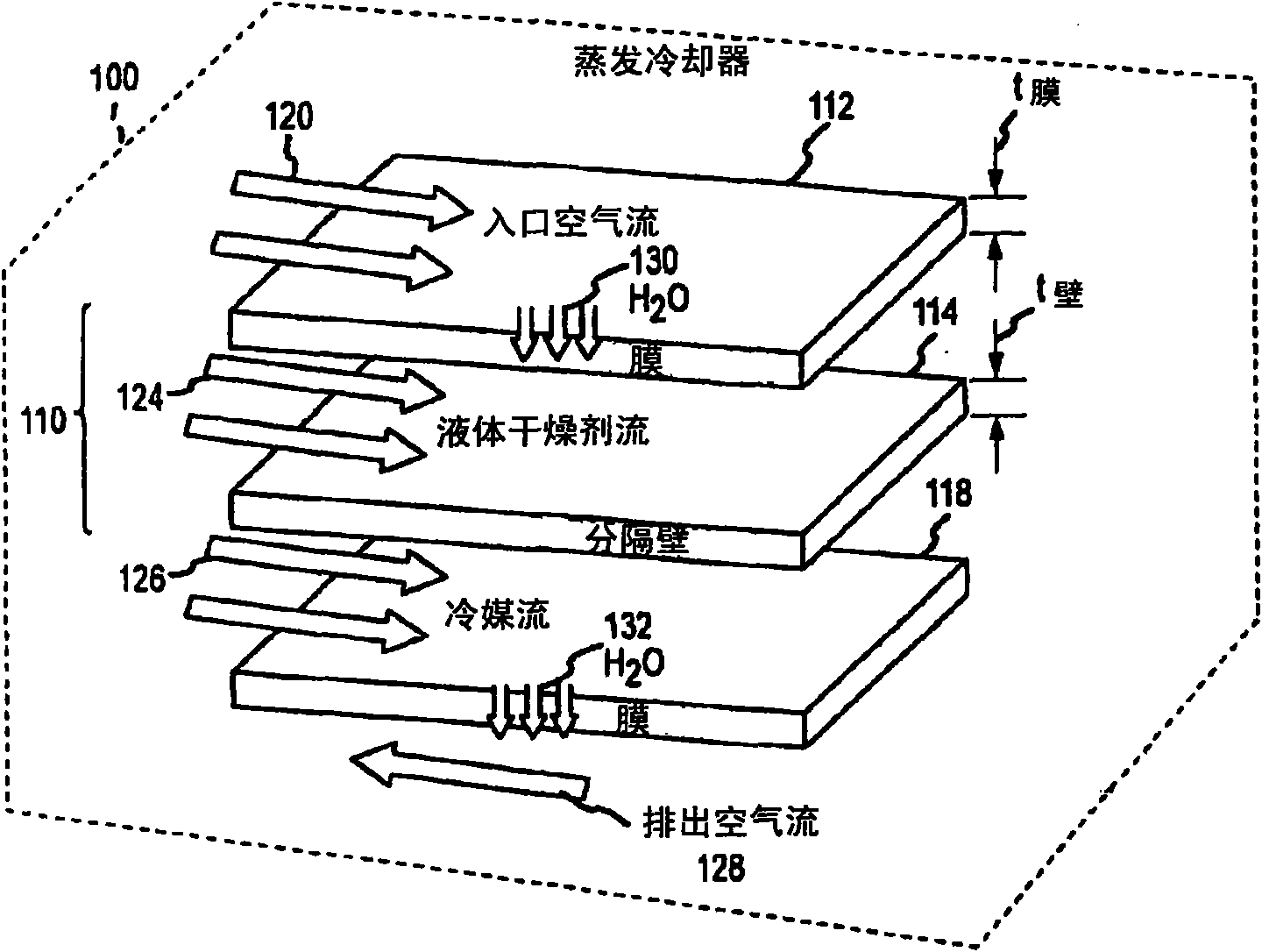

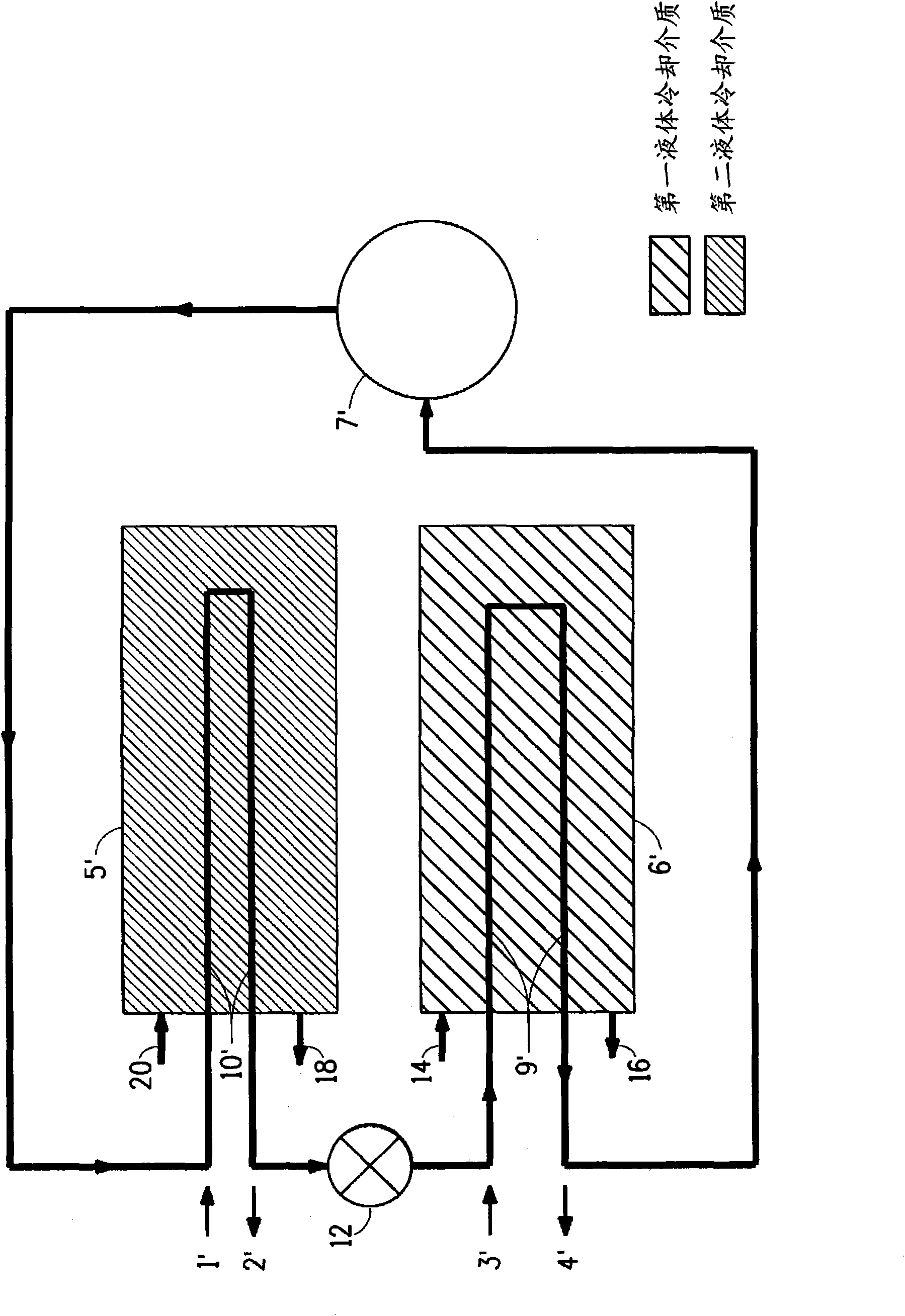

Indirect evaporative cooler using membrane-contained, liquid desiccant for dehumidification

ActiveCN102165268AFree-cooling systemsSpace heating and ventilation detailsEvaporative coolerWater vapor

An indirect evaporative cooler for cooling inlet supply air from a first temperature to a second, lower temperature using a stream of liquid coolant and a stream of exhaust or purge air. The cooler includes a first flow channel for inlet supply air and a second flow channel adjacent the first for exhaust air. The first and second flow channels are defined in part by sheets of a membrane permeable to water vapor such that mass is transferred as a vapor through the membrane from the inlet supply air to a contained liquid desiccant for dehumidification and also to the exhaust air as heat is transferred from the inlet supply air to the liquid coolant. A separation wall divides the liquid desiccant and the coolant but allows heat to be transferred from the supply air to the coolant which releases water vapor to the counter or cross flowing exhaust air.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

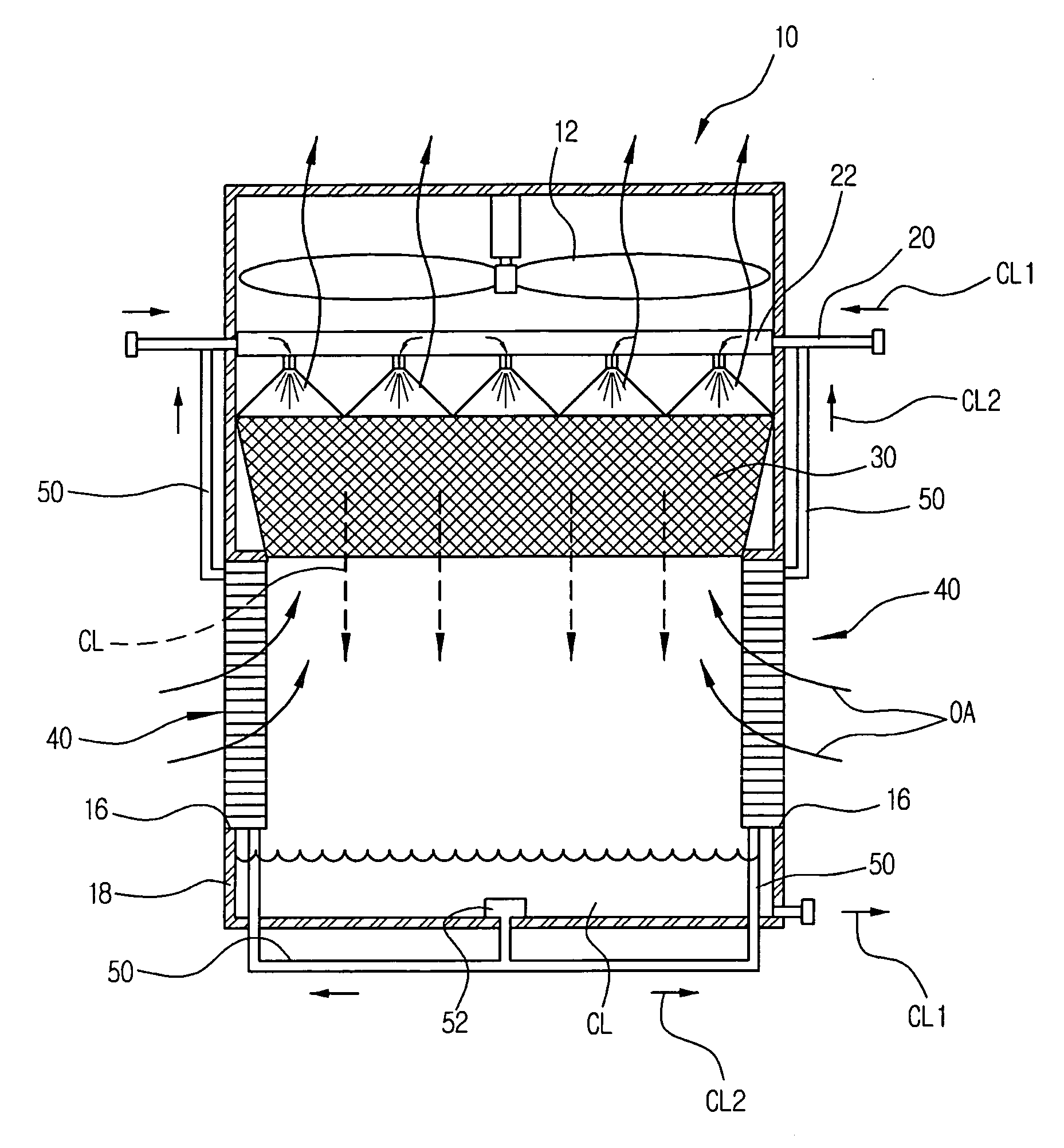

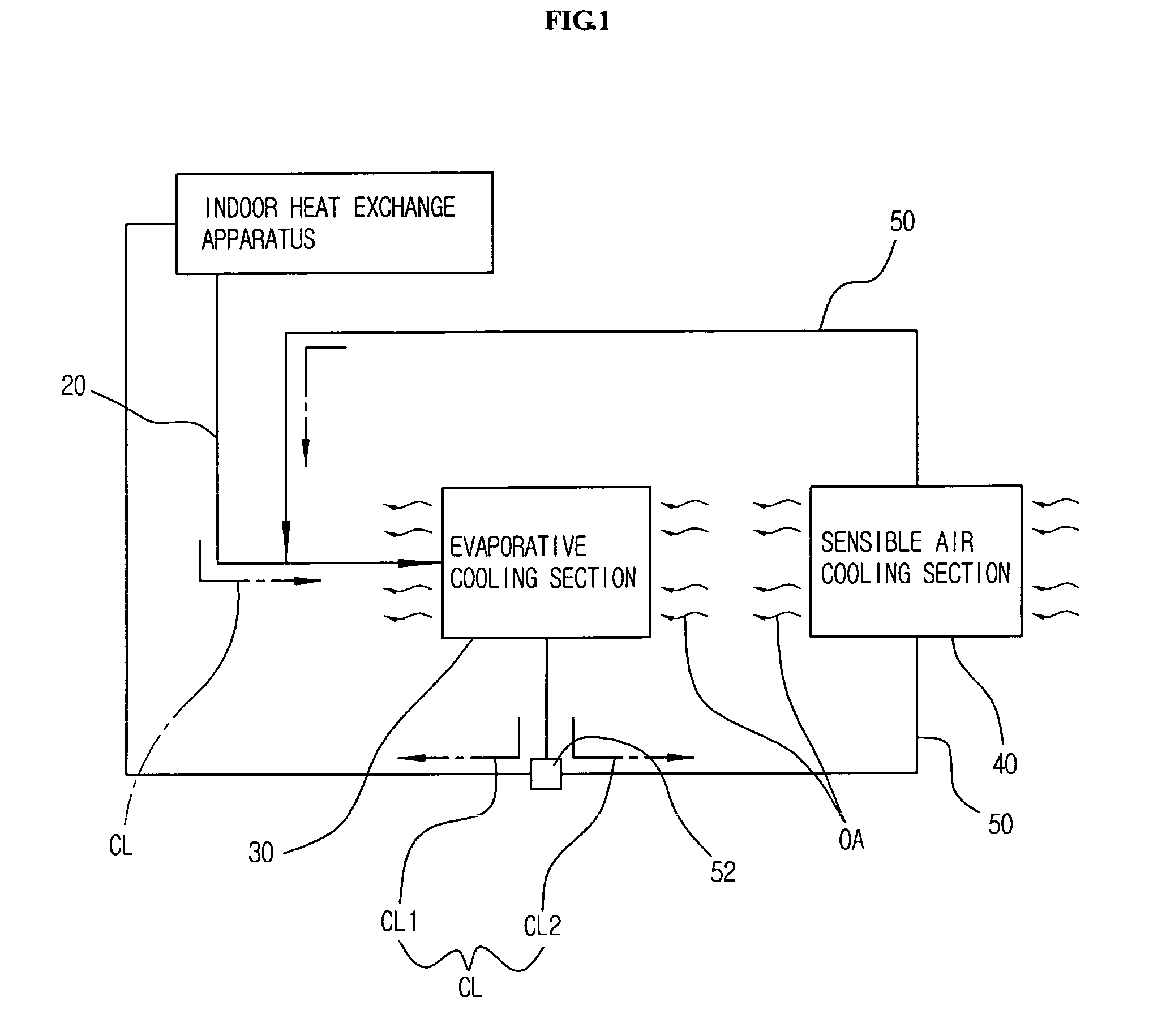

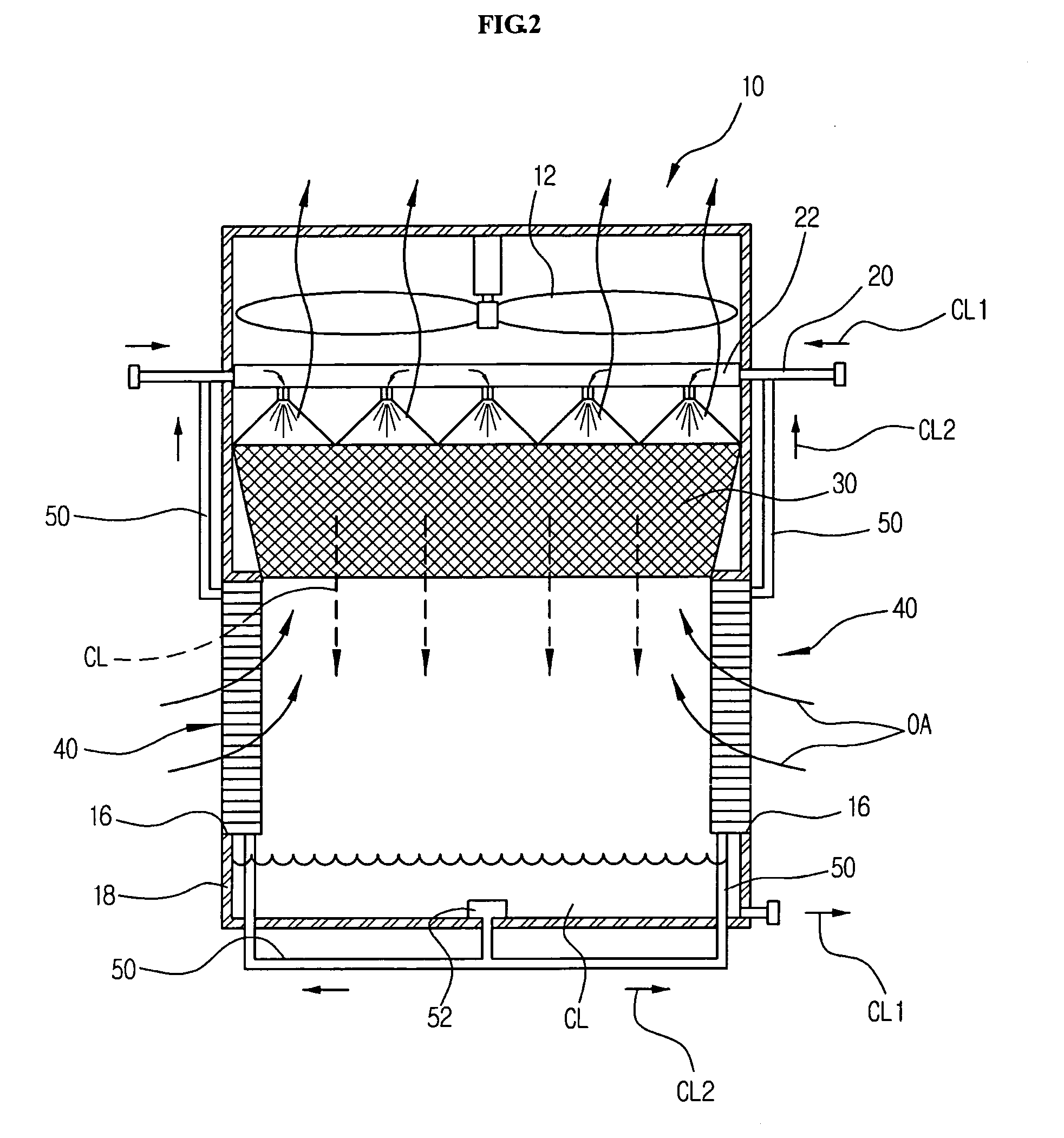

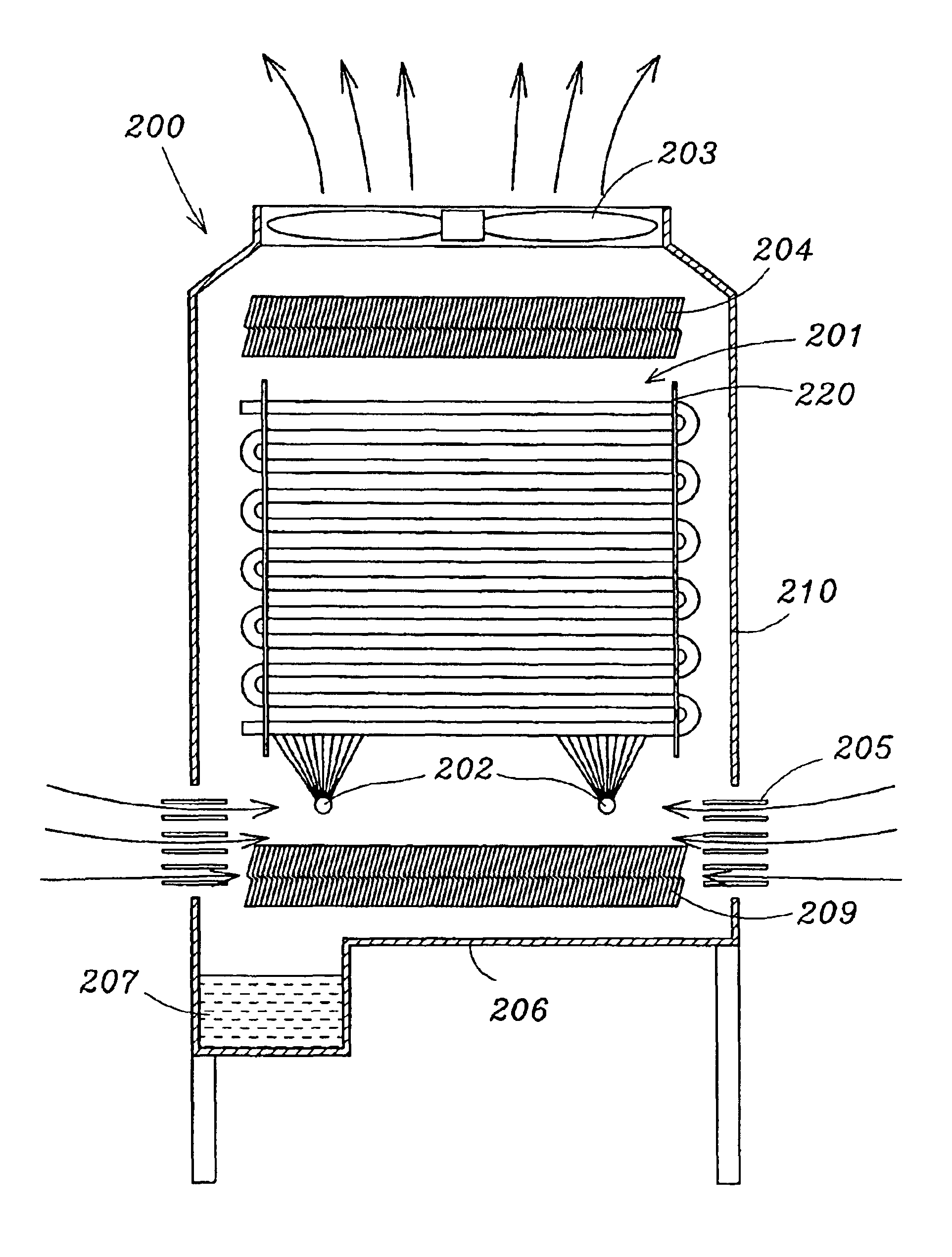

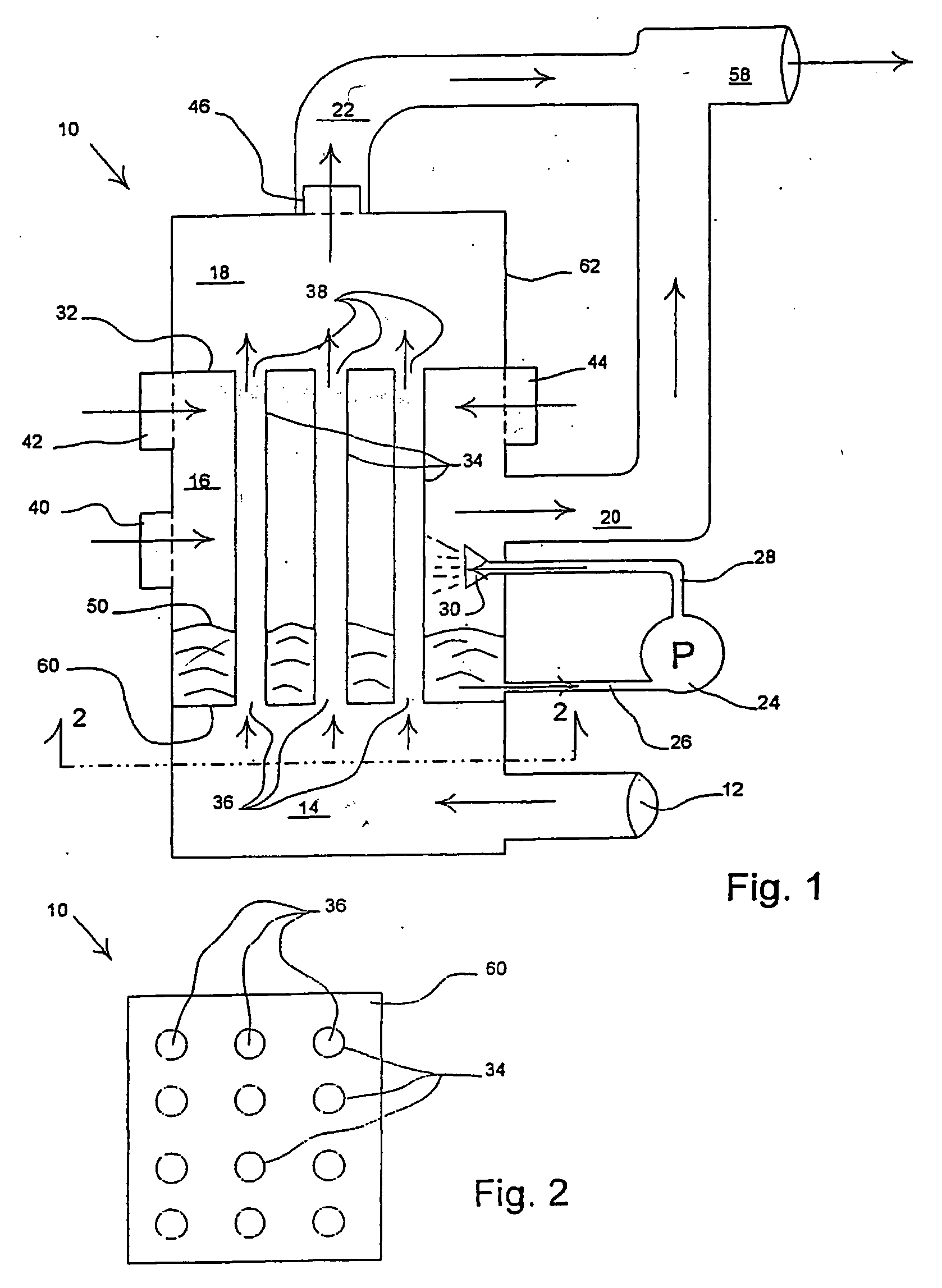

Method and apparatus for evaporative cooling of a cooling fluid

InactiveUS20050279115A1Maximize Cooling EfficiencyReduce the temperatureFree-cooling systemsEfficient regulation technologiesEvaporative coolerCooling tower

A method and an apparatus of evaporative cooling for reducing the volume of an evaporative cooler by considerably lowering the temperature of a cooling fluid are disclosed. A first cooling fluid, which comprises most part of the cooling fluid evaporatively cooled by an outside air while passing through an evaporative cooling section after circulating in an apparatus to be cooled, re-circulates in the apparatus to be cooled. A second cooling fluid, which is separated from the cooling fluid after being cooled in the evaporative cooling section, passes through a sensible air-cooling section placed at an outside air inlet. Thereby, the inflow outside air is sensibly cooled. The second cooling fluid, which passes through the sensible cooling section, re-circulates in the evaporative cooling section. Also, the outside air that is sensibly cooled by the second cooling fluid evaporatively cools the cooling fluid, which passes through the evaporative cooling section, again. This process is repeated. Accordingly, the cooling efficiency in the apparatus to be cooled becomes maximized. The second cooling fluid indirectly contacts with the outside air, so the outside air is sensibly cooled without increasing its humidity. Thus, the wet-bulb temperature of the air inhaled into the evaporative cooling section is reduced and the cooling fluid can be cooled to even a lower temperature. Also, the above structure can provide a cooling fluid of even a lower temperature, so the volume of a cooling tower or outdoor unit, etc. can be reduced considerably.

Owner:WHIZEN GLOBAL

Natural cold source cooling water chiller

InactiveCN101988722AReduce noiseSolution to short lifeLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerCooling tower

The invention relates to a natural cold source cooling water chiller which comprises an outdoor unit and an indoor unit, wherein the outdoor unit mainly consists of a refrigeration system composed of a totally-enclosed scroll compressor, an evaporator, an evaporative condenser and a natural cold source collection device, and a water channel circulating system with a three-way valve so as to realize the mechanical refrigeration of the evaporative condenser and the evaporative cooling and the air cooling of the natural cold source collection device. The water chiller is characterized in that the evaporative condenser and the high-efficiency natural cold source collection device are arranged simultaneously above a cooling circulating water pool, and an axial-flow fan is installed on upper space. When the outdoor wet-bulb temperature is higher than 6 DEG C to 8 DEG C, the evaporative condenser is mainly used to realize refrigeration, when the outdoor wet-bulb temperature is lower than 6 DEG C to 8 DEG C and higher than 0 DEG C and 2 DEG C, the natural cold source collection device which is in the form of cooling tower spraying is mainly used to realize the evaporative cooling, and when the outdoor wet-bulb temperature is lower than 0 DEG Cto 2 DEG C, the natural cold source collection device which is in the form of air cooling is mainly used to realize cooling.

Owner:郭海新 +1

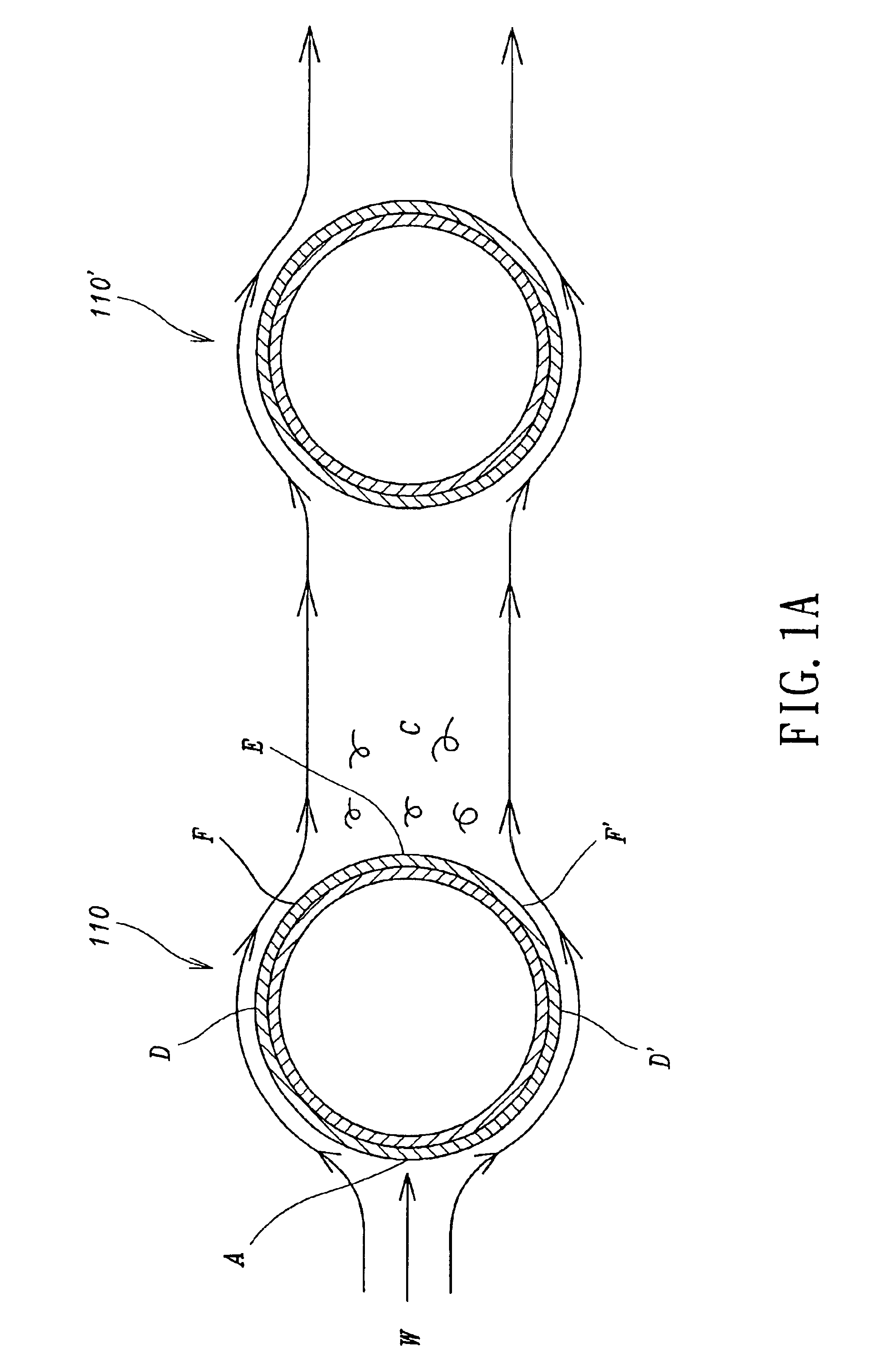

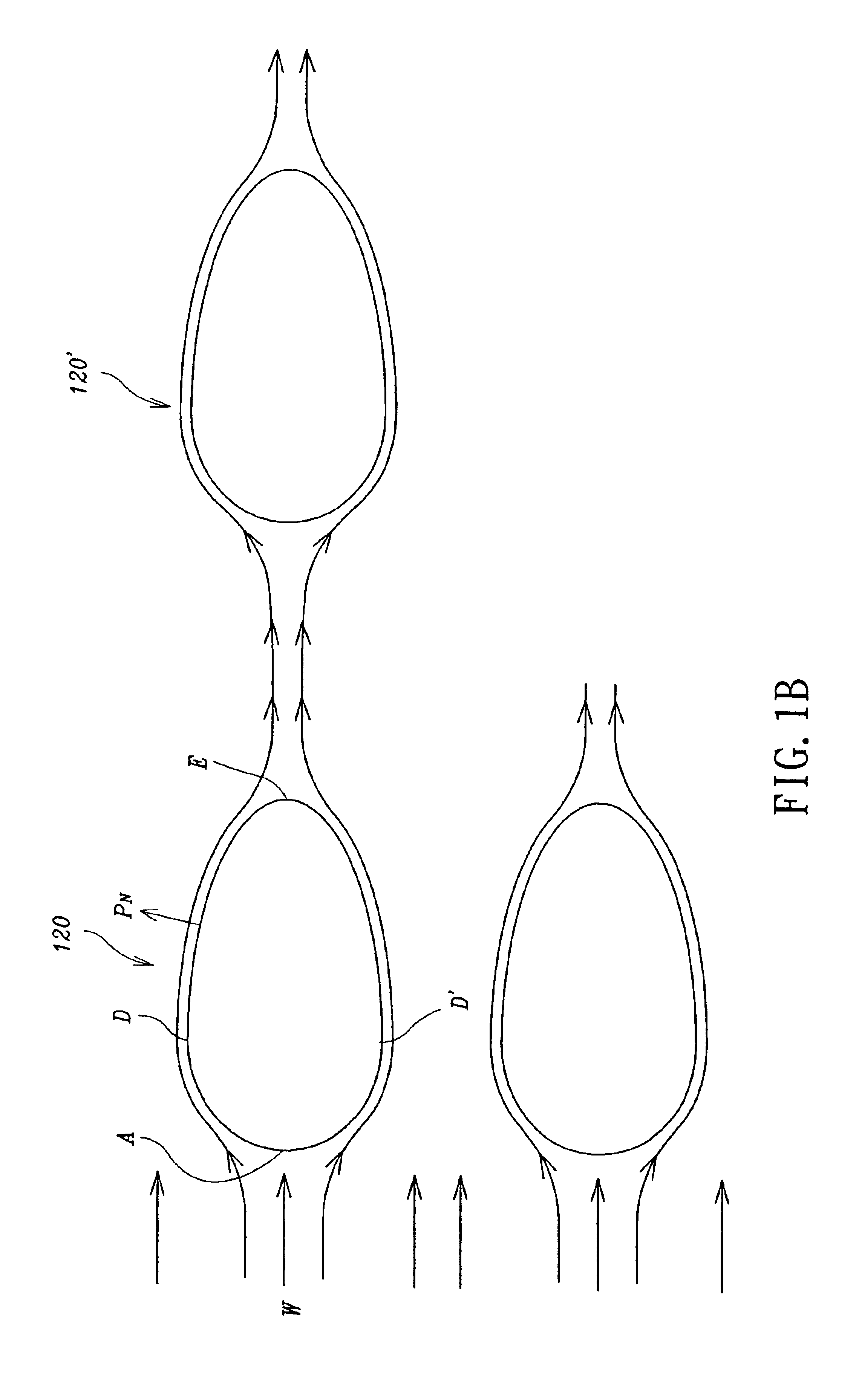

Evaporative condenser without cooling fins

InactiveUS6766655B1Solve the low heat dissipation efficiencyLong lastingEvaporators/condensersSteam/vapor condensersEvaporative coolerEvaporation

An evaporative type medium condenser without the using of conventional cooling fins comprises: characteristically a plurality of streamline cross sectional bare metal tubes disposed in parallel for medium coils to instead the conventional round sectional tubes thereof; a recycling water supply system having a plurality of water spray nozzles for spraying fine water particles onto the surface of coil tubes formed a water film continuously held thereon; a fan system to provide a wind flow blowing over the streamline tubes in a direction from a large head front portion of the streamline cross section to a gradual reduced rear portion thereof and to provide a low pressure area thereat so as to speedy the evaporation of the water film on the surface of the coils tubes for improving a high cooling efficiency to reach a high E.E.R. therefore.

Owner:WU HO HSIN

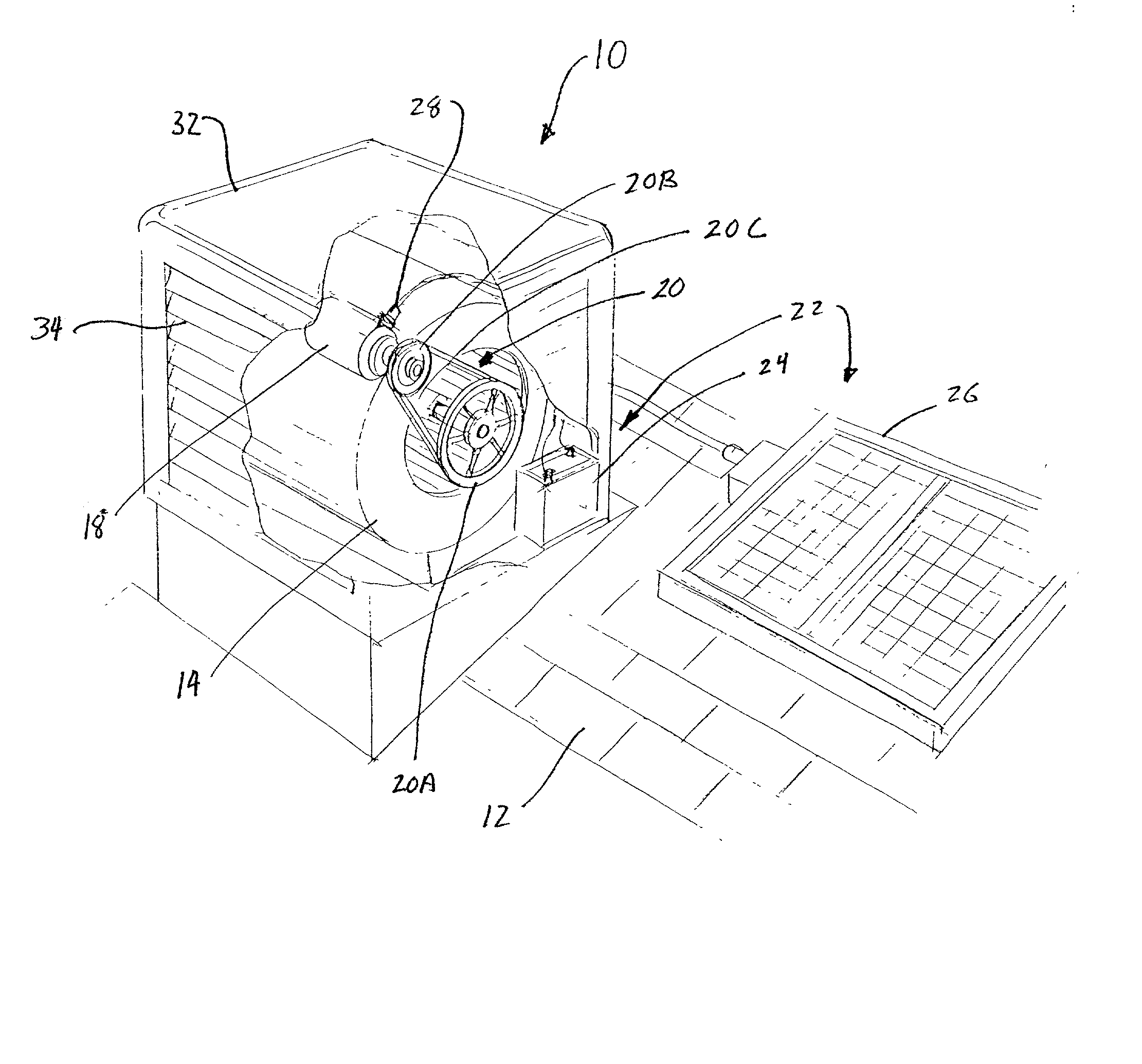

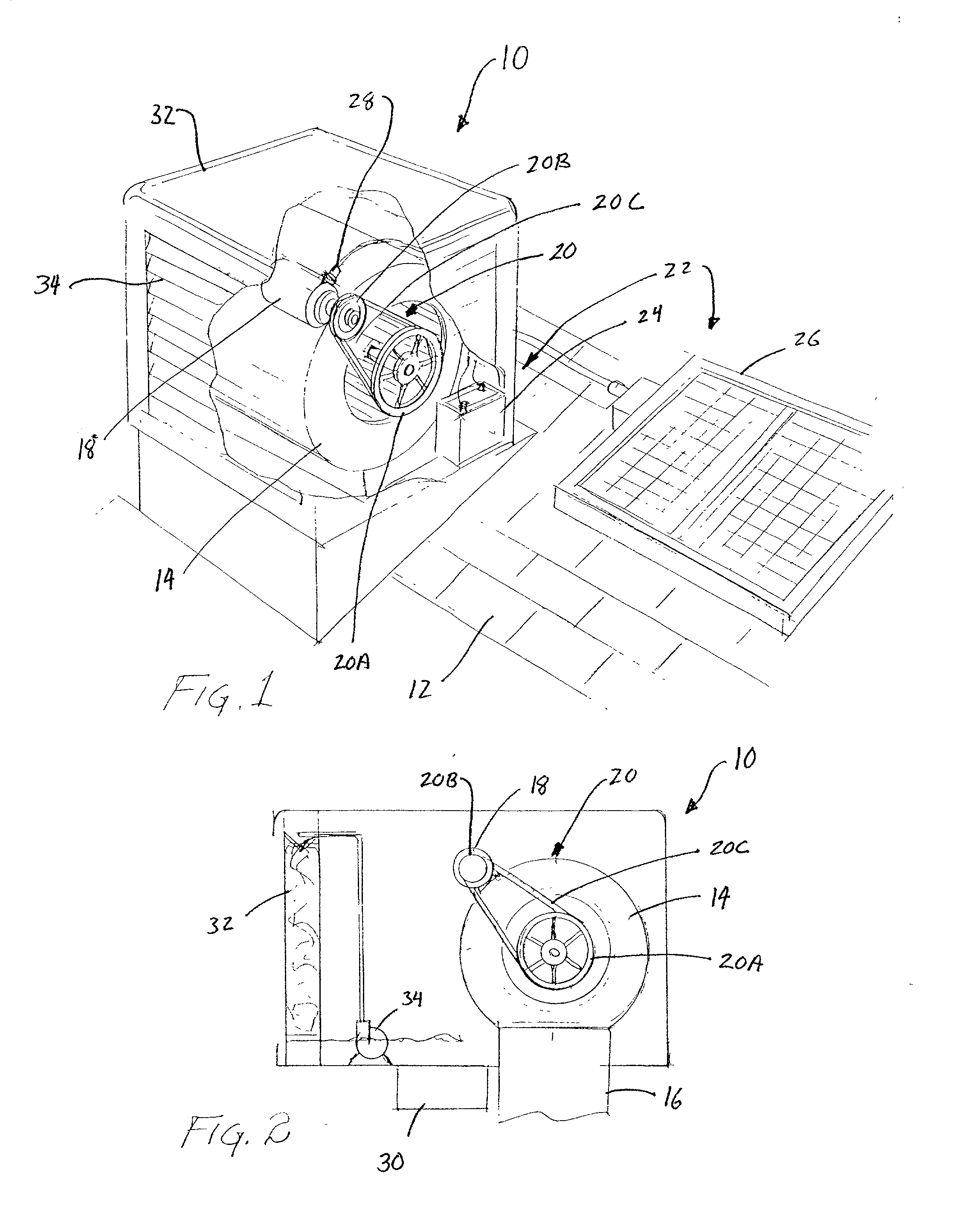

Hybrid powered evaporative cooler and method therefor

An alternative powered evaporative cooler has a squirrel cage fan. A low voltage DC motor is provided to power the squirrel cage fan. A pulley system is coupled to the squirrel cage fan and the low voltage DC motor for transferring energy from the low voltage DC motor to rotate the squirrel cage fan. A low voltage DC power source is provided to power the low voltage DC motor.

Owner:SANFORD DAVID I

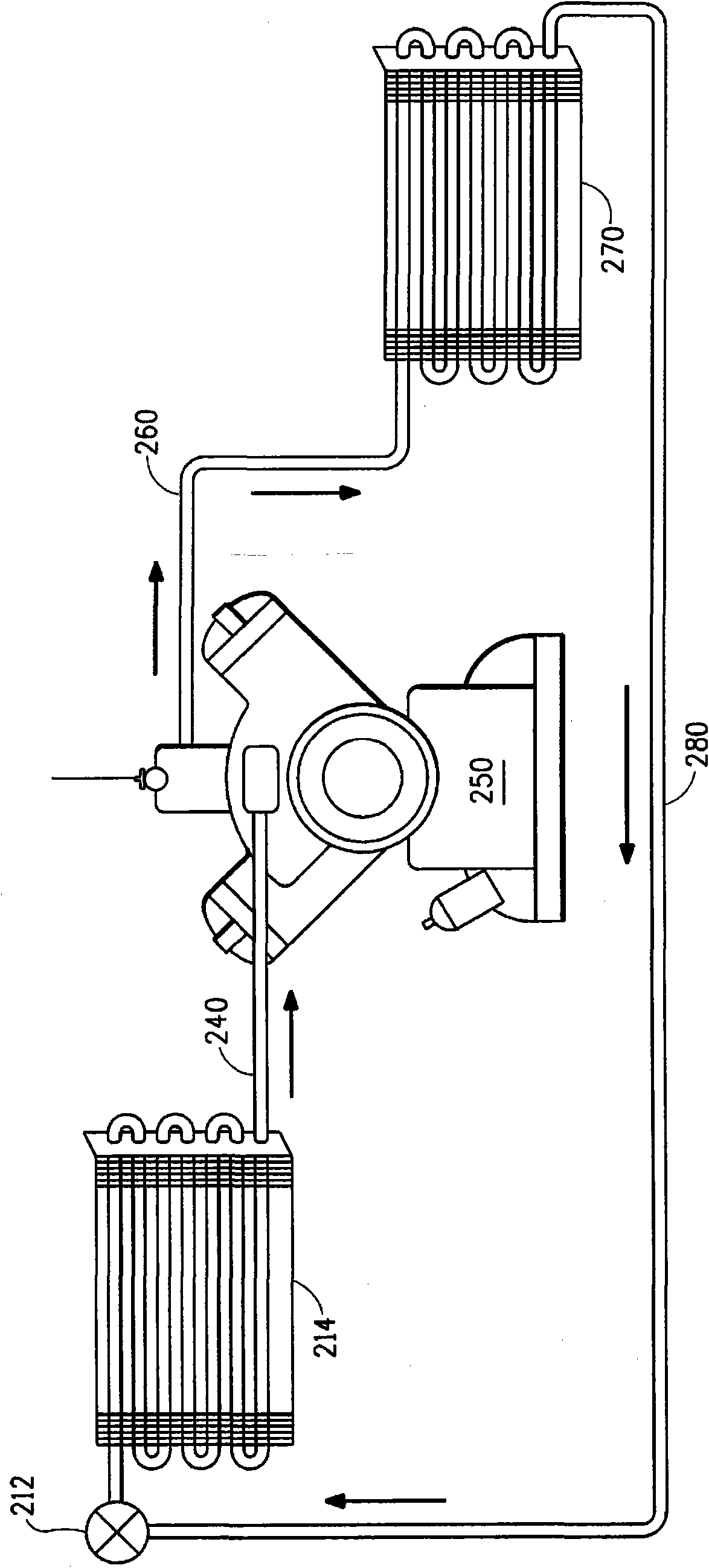

Evaporative cooler assisted automotive air conditioning system

InactiveUS20070163772A1Reduce sensible heat portionReduce the temperatureMachines/enginesStationary conduit assembliesEvaporative coolerPre conditioning

An automotive air conditioning system is disclosed comprising an evaporative cooler in series with the conventional vapor compression system. The evaporative cooler comprises an array of dry channels and a contiguous array of wet channels. The primary air stream to be conditioned by the evaporator of the conventional air conditioning system is preconditioned by the evaporative cooler by lowering its dry bulb temperature without changing its absolute humidity. An evaporator core is supported downstream of the evaporative cooler for receiving the primary air from the dry channels and thereby produces liquid condensate. The system is distinguished by conducting the liquid condensate from the evaporator core to the wicking tank for use in the wet channels of the evaporative cooler.

Owner:DELPHI TECH INC

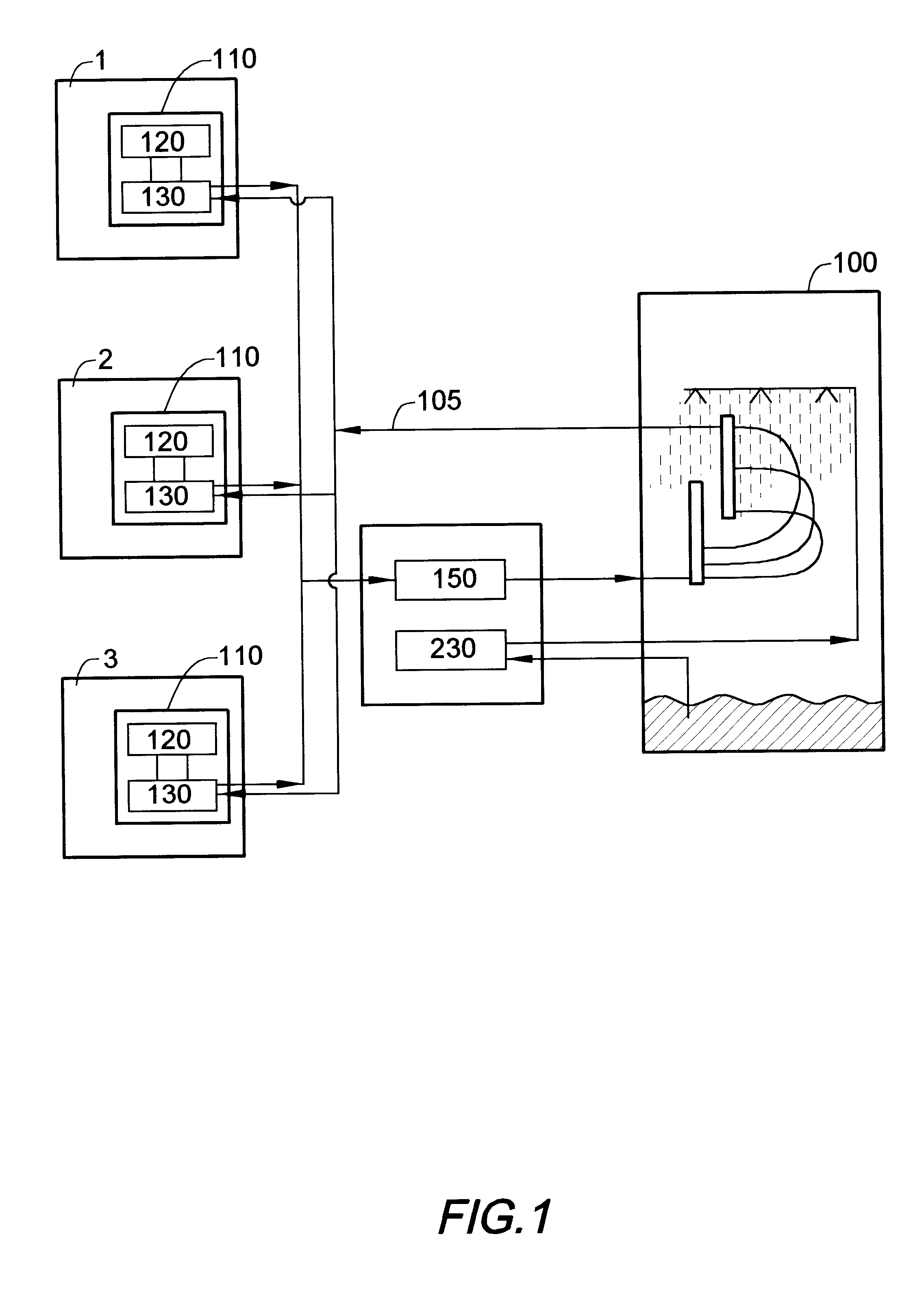

Inlet air conditioning system

InactiveUS20080298957A1Improve efficiencyPump componentsDomestic cooling apparatusEvaporative coolerMultiple forms

An embodiment of the present invention provides an air conditioning system located upstream of the inlet system for a gas turbine. The air conditioning system may comprise at least one conditioning module for adjusting the temperature of the airstream. The at least one conditioning module may have a plurality of forms including at least one of the following systems: a chiller, an evaporative cooler; a spray cooler, or combinations thereof. The specific form of the at least one conditioning module may be determined in part the configuration of the gas turbine.

Owner:GENERAL ELECTRIC CO

Non Uniform Water Distribution System for an Evaporative Cooler

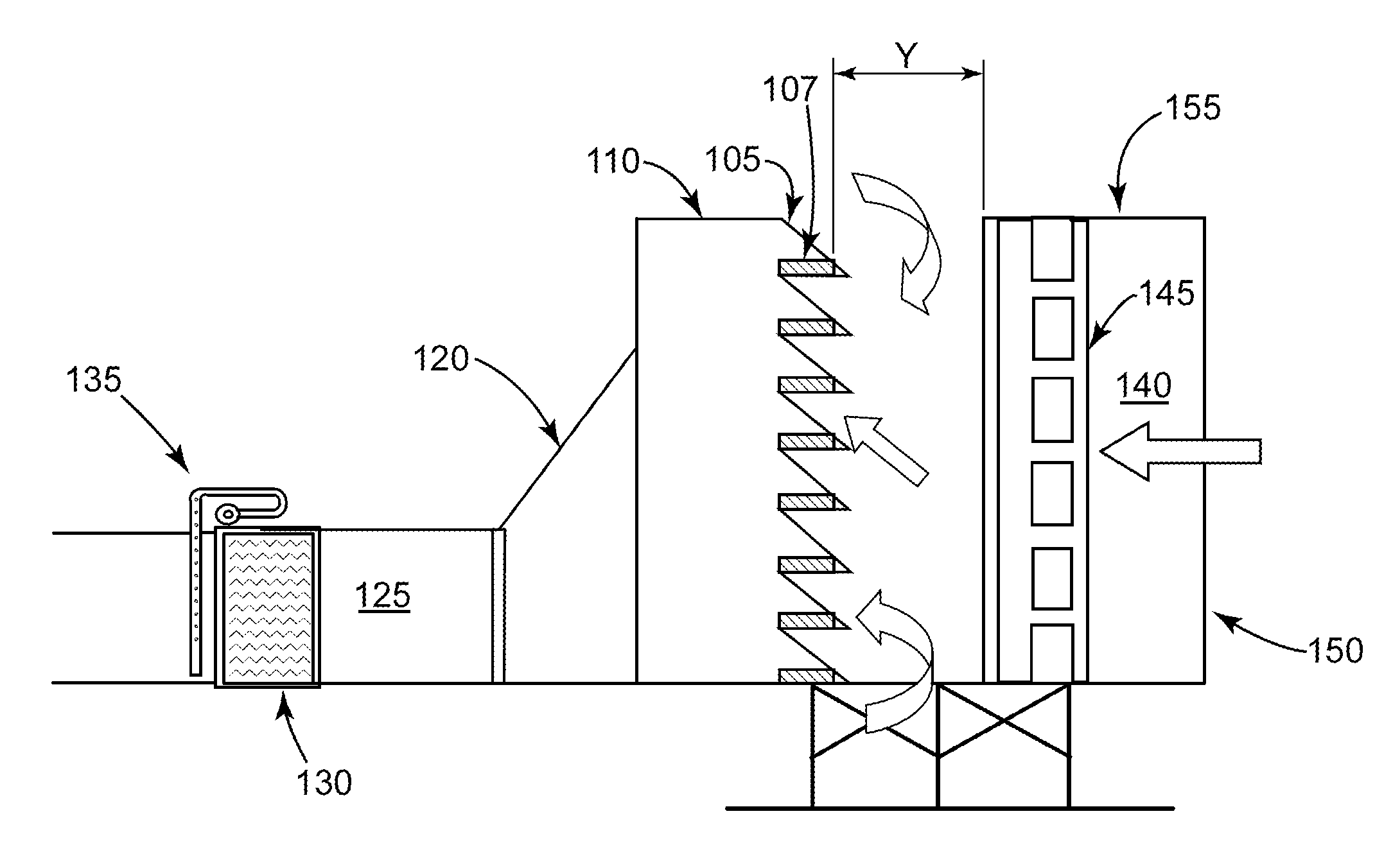

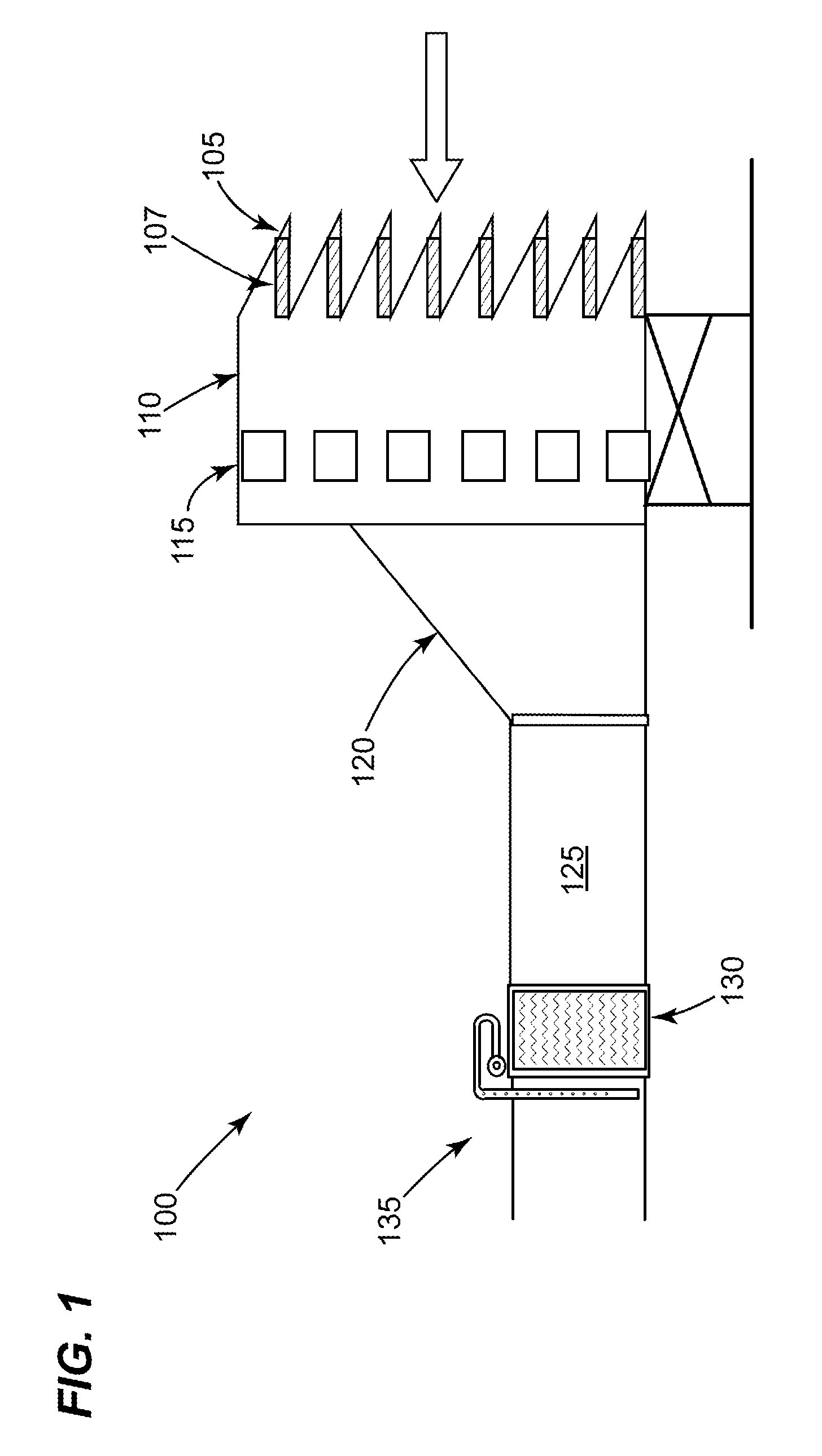

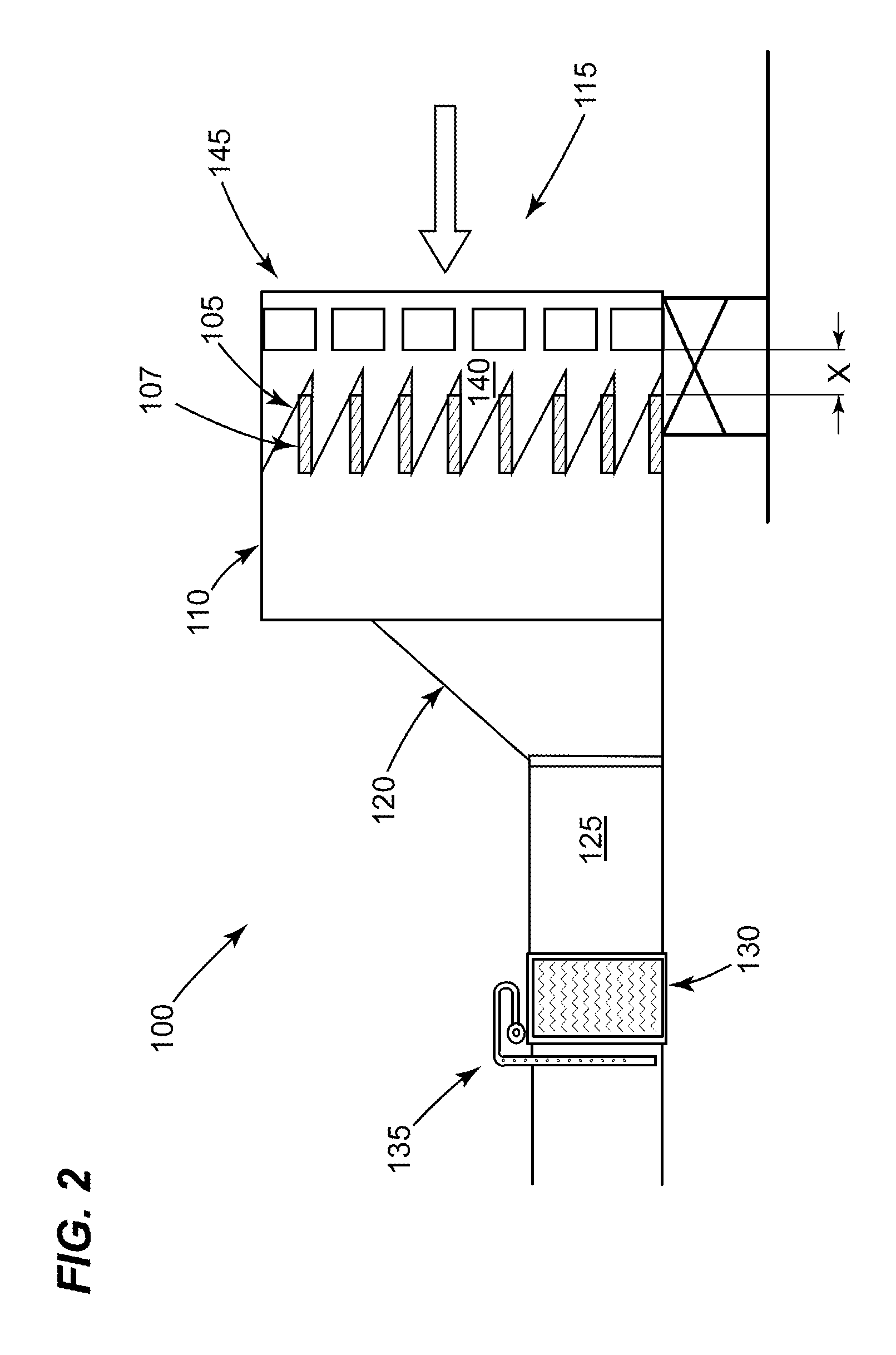

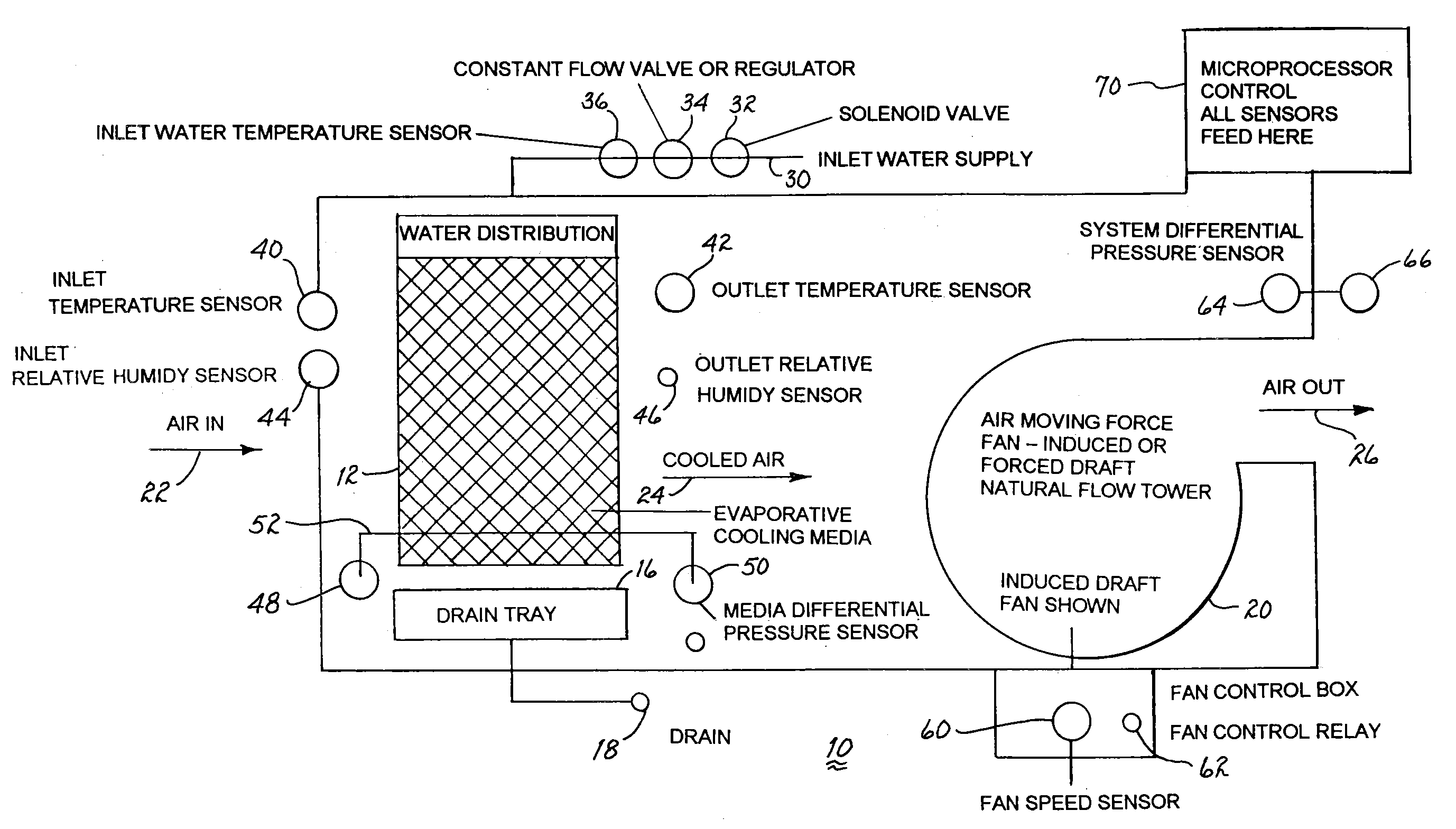

InactiveUS20080018001A1Increase concentrationHigh cooling effectiveness levelMixing methodsUsing liquid separation agentEvaporative coolerDifferential pressure

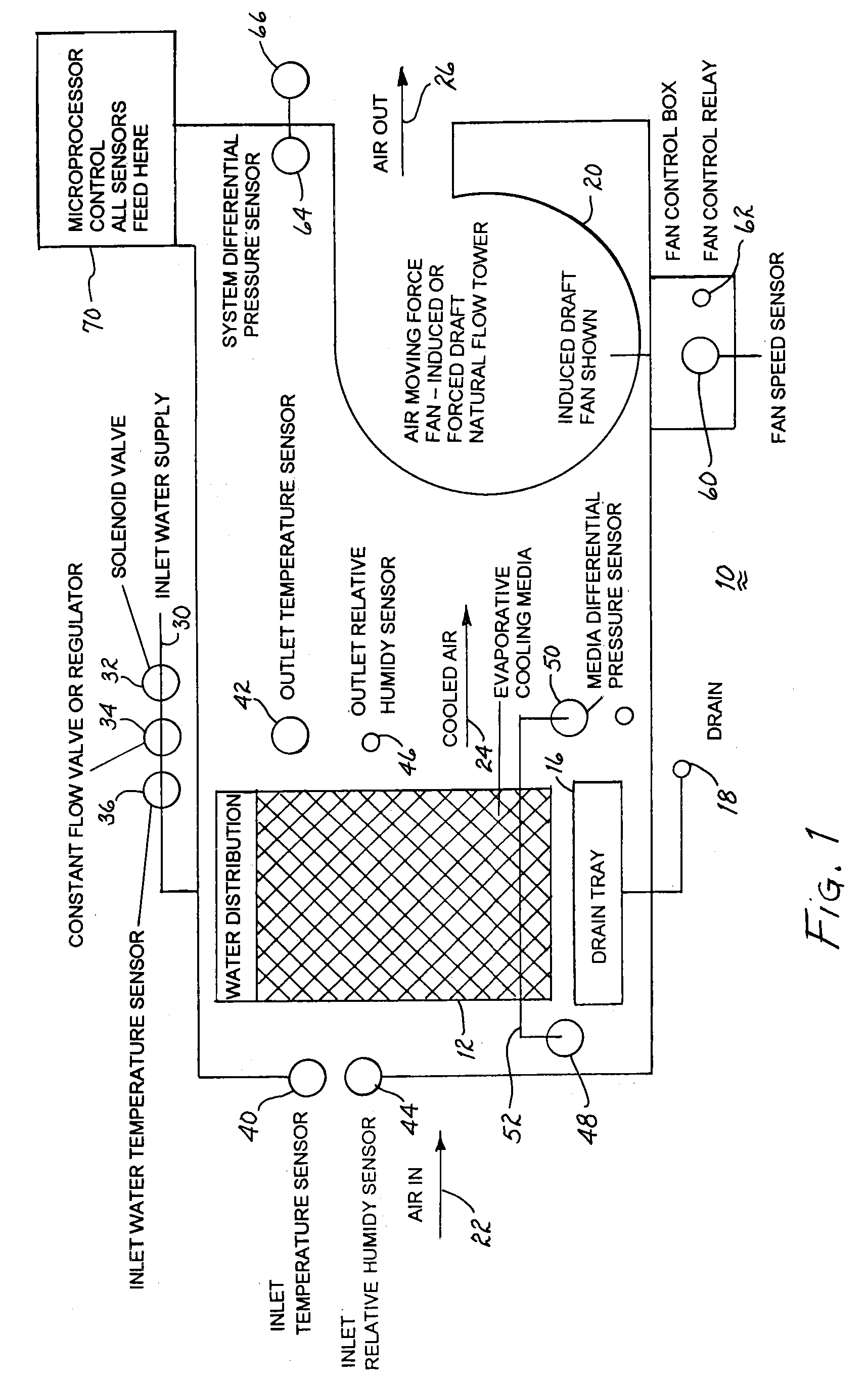

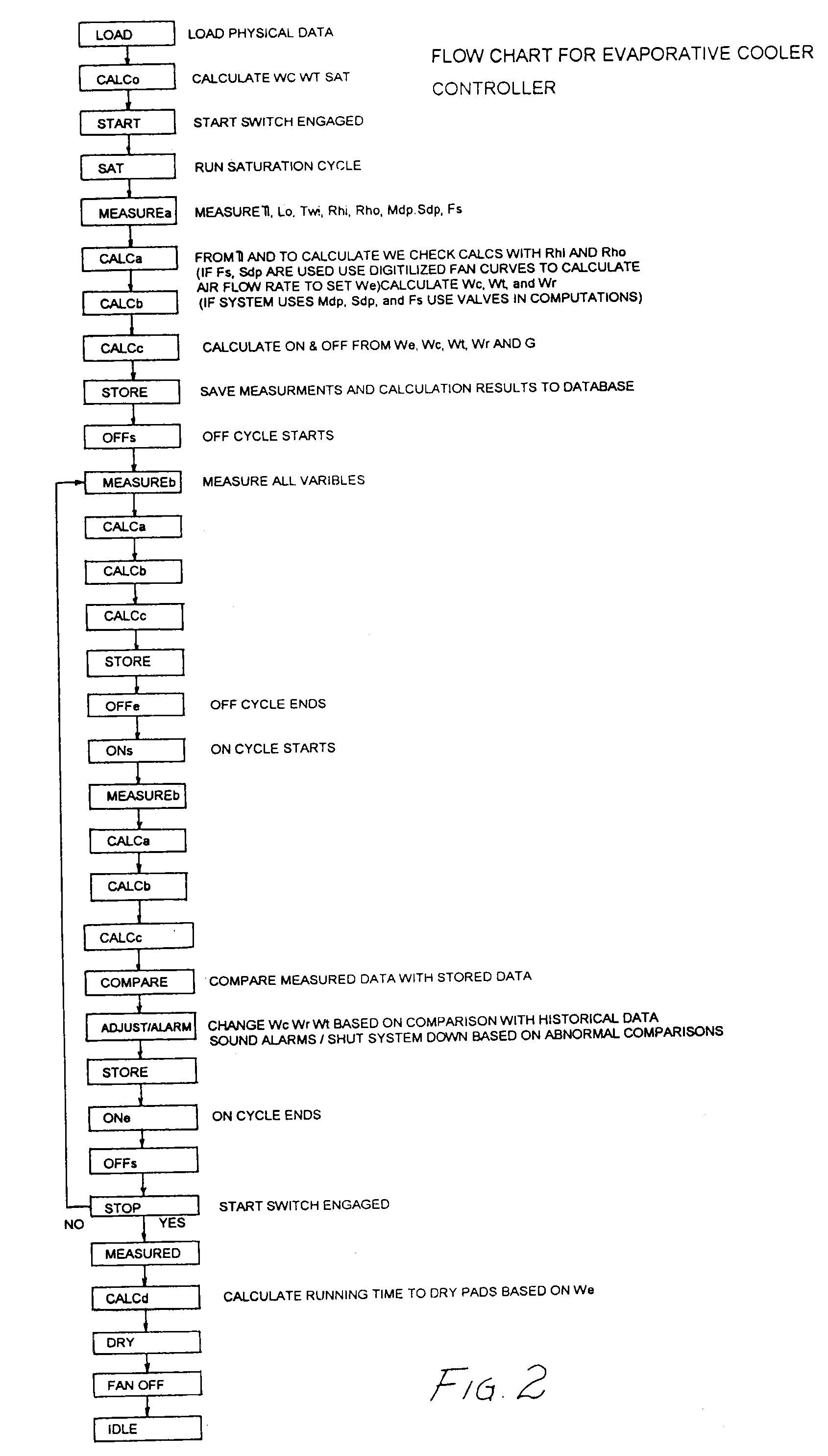

An evaporative cooler, including one or more media, distributes water from a source of water to each media through a constant flow valve. A distribution unit at each media includes a pair of spray bars for spraying water through two rows of uniformly spaced apertures disposed in each spray bar. A spray bar channel associated with each spray bar distributes the streams of water impinging thereupon from one row of apertures to the underlying media in specific locations. A distribution cap associated with each spray bar distributes streams of water impinging thereupon to the front and back edges of the underlying media. The water dripping from the media is drained. A fan or other air moving device draws air through the media to obtain cooled air resulting from evaporation of water flowing downwardly along the media. A microprocessor controller, responsive to any of one or more sensors for sensing the temperature of the air flowing into and out of the media, the relative humidity of the air flowing into and out of the media, the pressure differential between the upstream and downstream sides of the media, the temperature of the water flowing to the spray bars, the fan speed, and the pressure differential between the downstream side of the media and the downstream side of the fan, controls the flow of water and the fan speed.

Owner:AZ EVAP

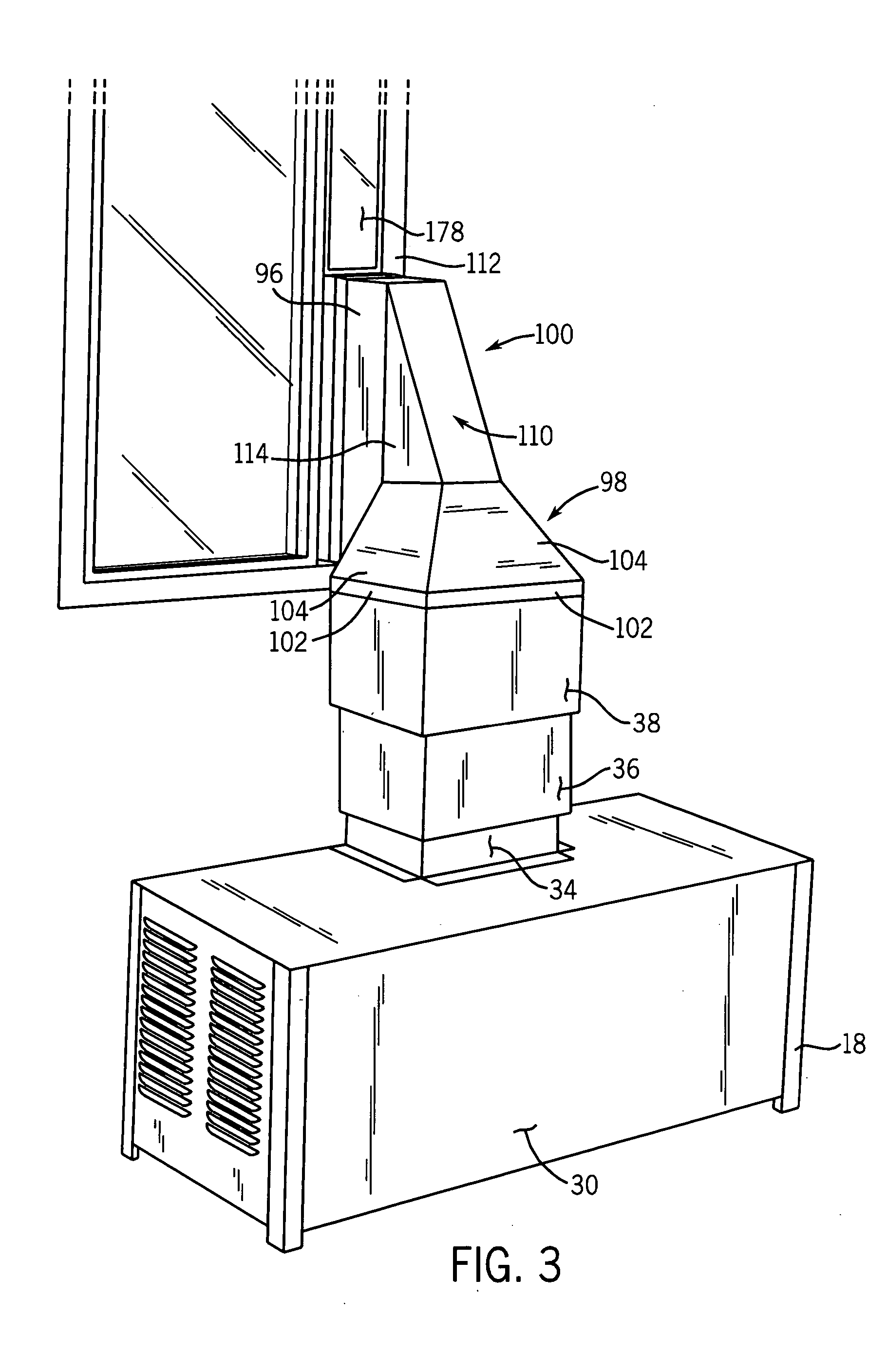

Window evaporative cooler

InactiveUS20050054282A1Lighting and heating apparatusHeating and ventilation casings/coversEvaporative coolerEngineering

A method for installing an evaporative cooler in a window located in a building includes placing an evaporative cooler housing below the bottom of the window. A duct is attached to the housing and extended upward to the window. A frame is placed between the movable portion of the window and the building. The second portion of the duct is secured to the frame and the frame is operatively secured between a movable portion of the window and the building. An evaporative cooler, adjustable duct assembly, diverter and frame assembly are also disclosed.

Owner:ADOBEAIR INC

Compositions comprising iodotrifluoromethane and uses thereof

InactiveCN101835869AReduce the temperatureHeat-exchange elementsDisinfectionEvaporative coolerIodotrifluoromethane

Disclosed are compositions comprising iodotrifluoromethane and other compounds that are useful as heat transfer fluids, including refrigerants, in a stationary air conditioning or refrigeration system, a flooded evaporator chiller or a direct expansion chiller. Also disclosed are methods for producing cooling and methods for replacing R22, R407C, R410A, R404A or R507A in such equipment.

Owner:EI DU PONT DE NEMOURS & CO

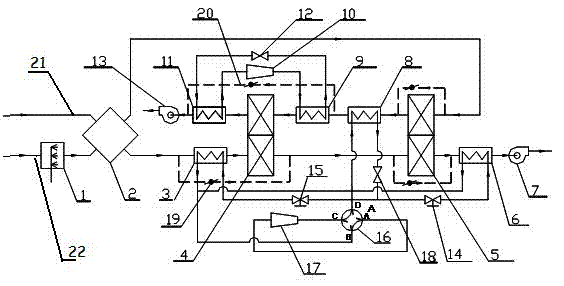

Multi-stage heat recovery compound dehumidification fresh air air handler

InactiveCN102261701ALow regeneration temperatureReduce heating energy consumptionEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerMoisture

The invention discloses a multilevel heat recovery composite dehumidifying fresh air treatment machine, which comprises an air treatment path consisting of a plate heat exchanger, a precooling dehumidifier, a drying rotary wheel, a moisture heat recovery rotary wheel, an air feed temperature regulator and an air feed fan which are connected in series in turn through an air pipe, and an air regeneration path consisting of an evaporative cooler, a plate heat exchanger, a moisture heat recovery rotary wheel, a low-temperature heat pump heat recovery device, a high-temperature heat pump condenser, a drying rotary wheel, a high-temperature heat pump evaporator and a regenerating fan which are connected in series in turn. Due to multilevel heat recovery, heating energy consumption of regenerating air and cooling energy consumption of treating air are reduced, and the aim of saving energy is fulfilled. Meanwhile, due to two-stage combined dehumidification, the dehumidifying capacity of the set can be effectively improved, and the air treatment machine is applicable to air conditioning in summer and heating in winter for various public buildings, commercial buildings and industrial buildings, and is suitable for fresh air treatment for a large central air-conditioning system and particularly suitable for fresh air treatment for an independent temperature and humidity control air-conditioning system in a warm and humid area.

Owner:HUNAN UNIV OF SCI & TECH

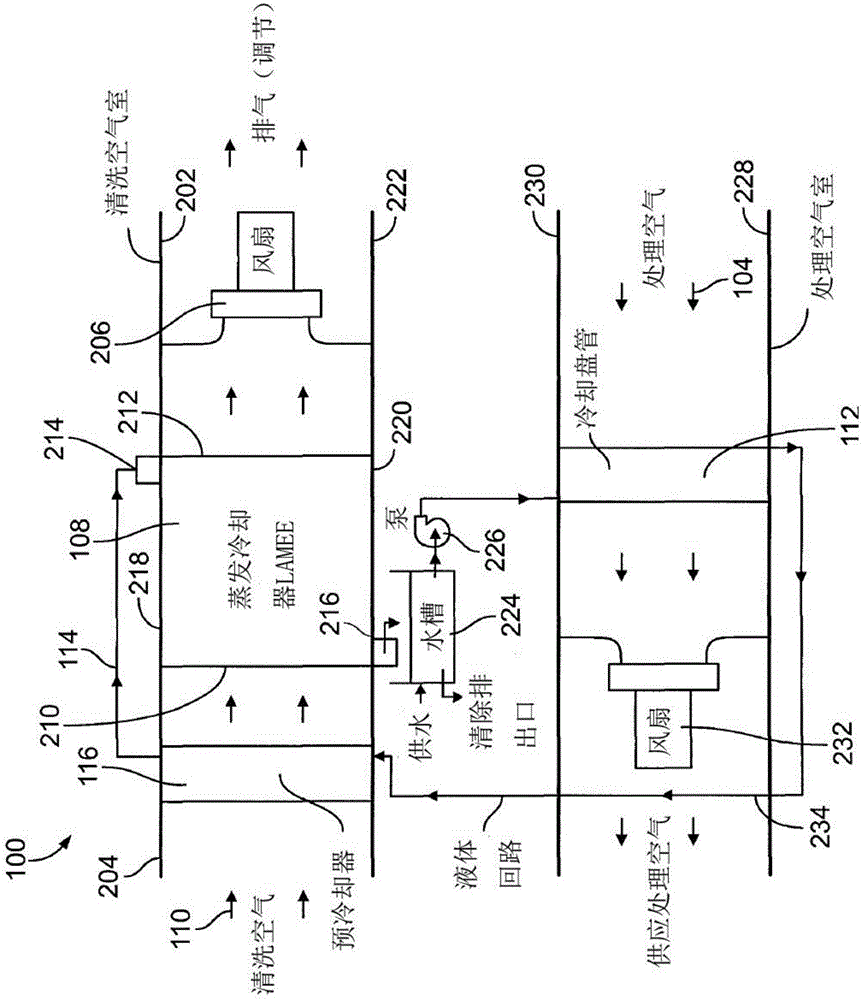

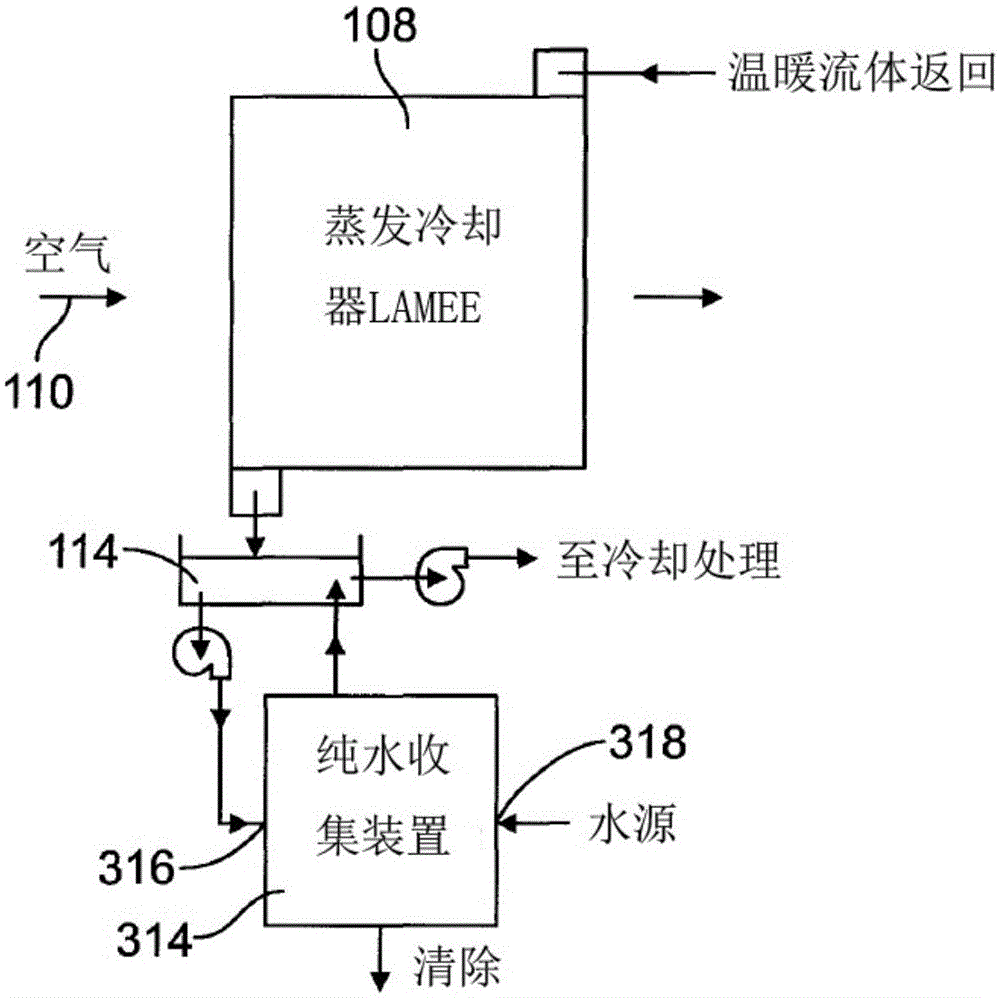

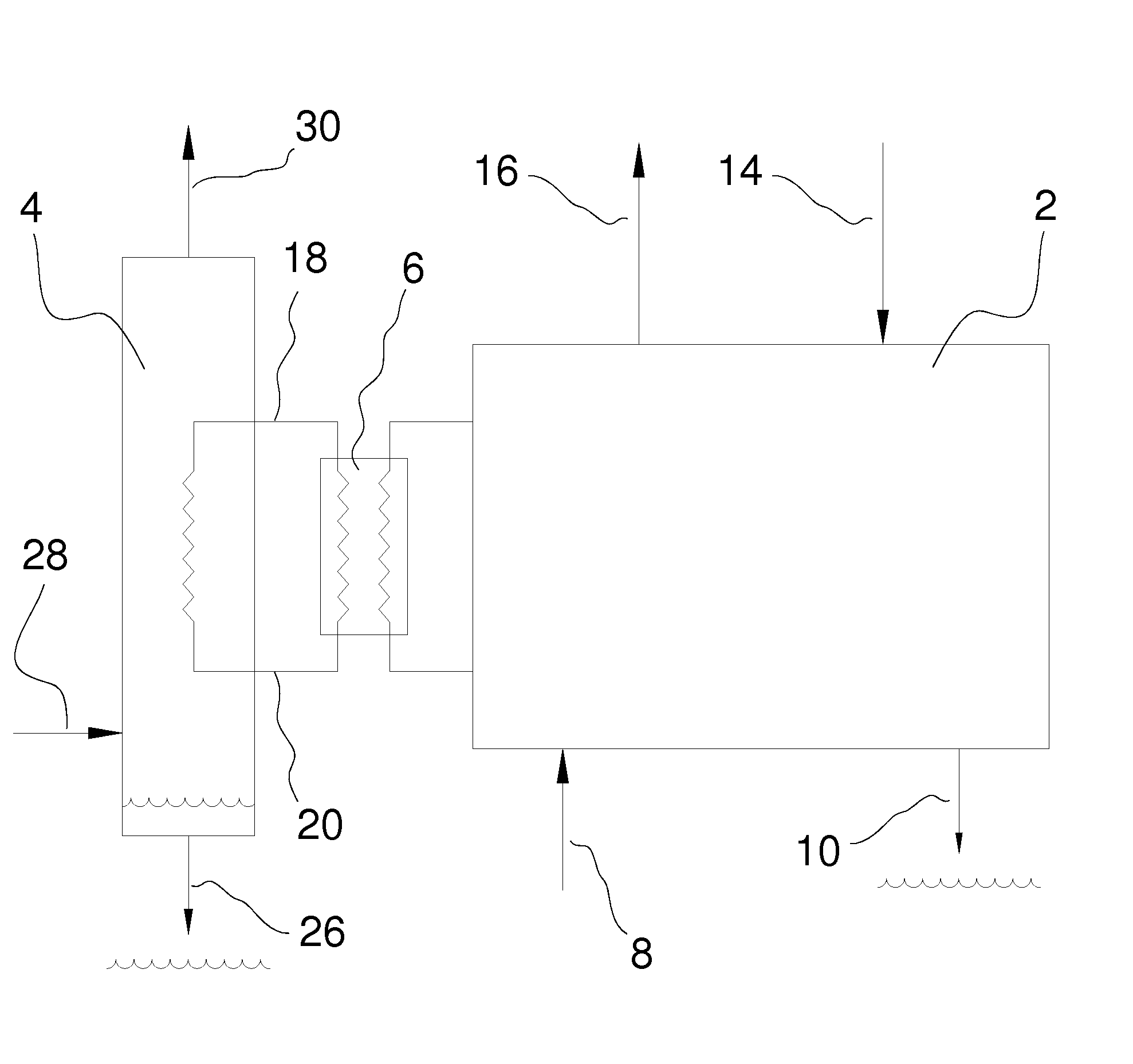

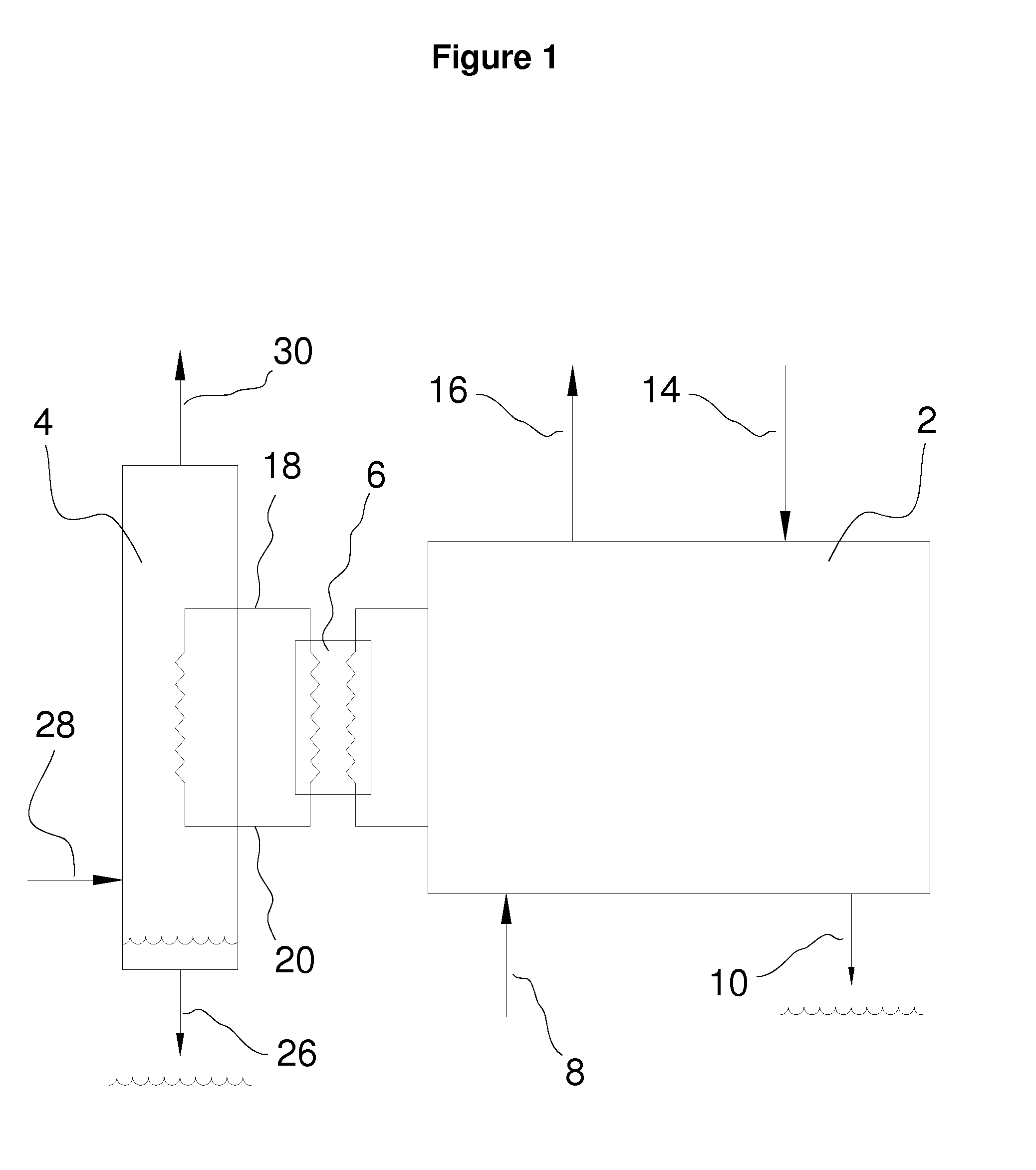

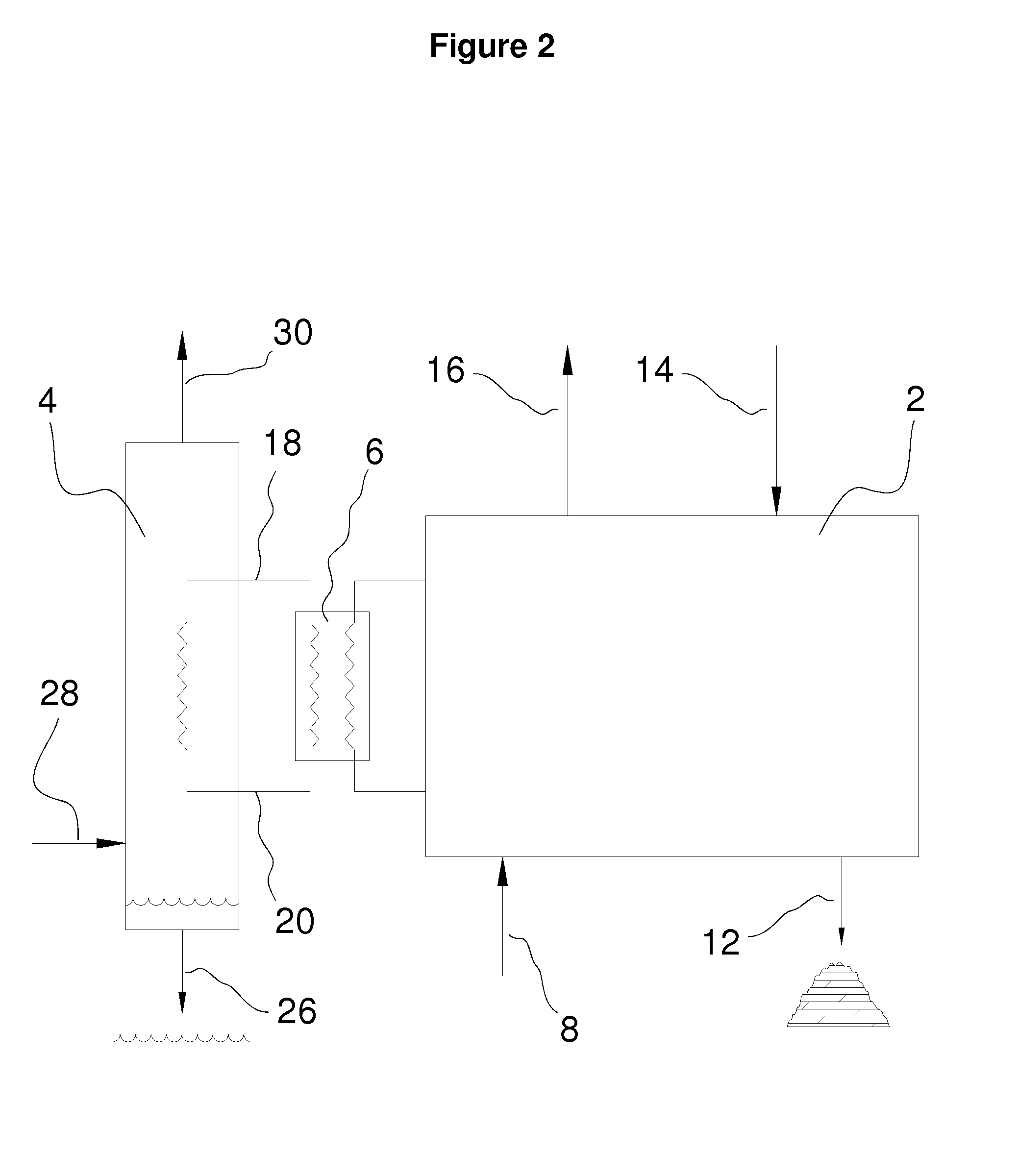

Evaporative cooling system with liquid-to-air membrane energy exchanger

ActiveCN105164484AEnergy recovery in ventilation and heatingHeat recovery systemsEvaporative coolerEngineering

An evaporative cooling system includes an evaporative cooler liquid-to-air membrane energy exchanger (LAMEE), a first liquid-to-air heat exchanger (LAHE), and a cooling fluid circuit. The evaporative cooler LAMEE is disposed within a scavenger air plenum that is configured to channel a scavenger air stream. The first LAHE is disposed within a process air plenum that is configured to channel a process air stream. The cooling fluid circuit is configured to circulate an evaporative cooling fluid between the evaporative cooler LAMEE and the first LAHE. The evaporative cooler LAMEE is configured to utilize the scavenger air stream to evaporatively cool the cooling fluid. The first LAHE is configured to receive the cooling fluid from the evaporative cooler LAMEE and to allow the cooling fluid to absorb heat from the process air stream to cool the process air stream.

Owner:NORTEK AIR SOLUTIONS CANADA INC

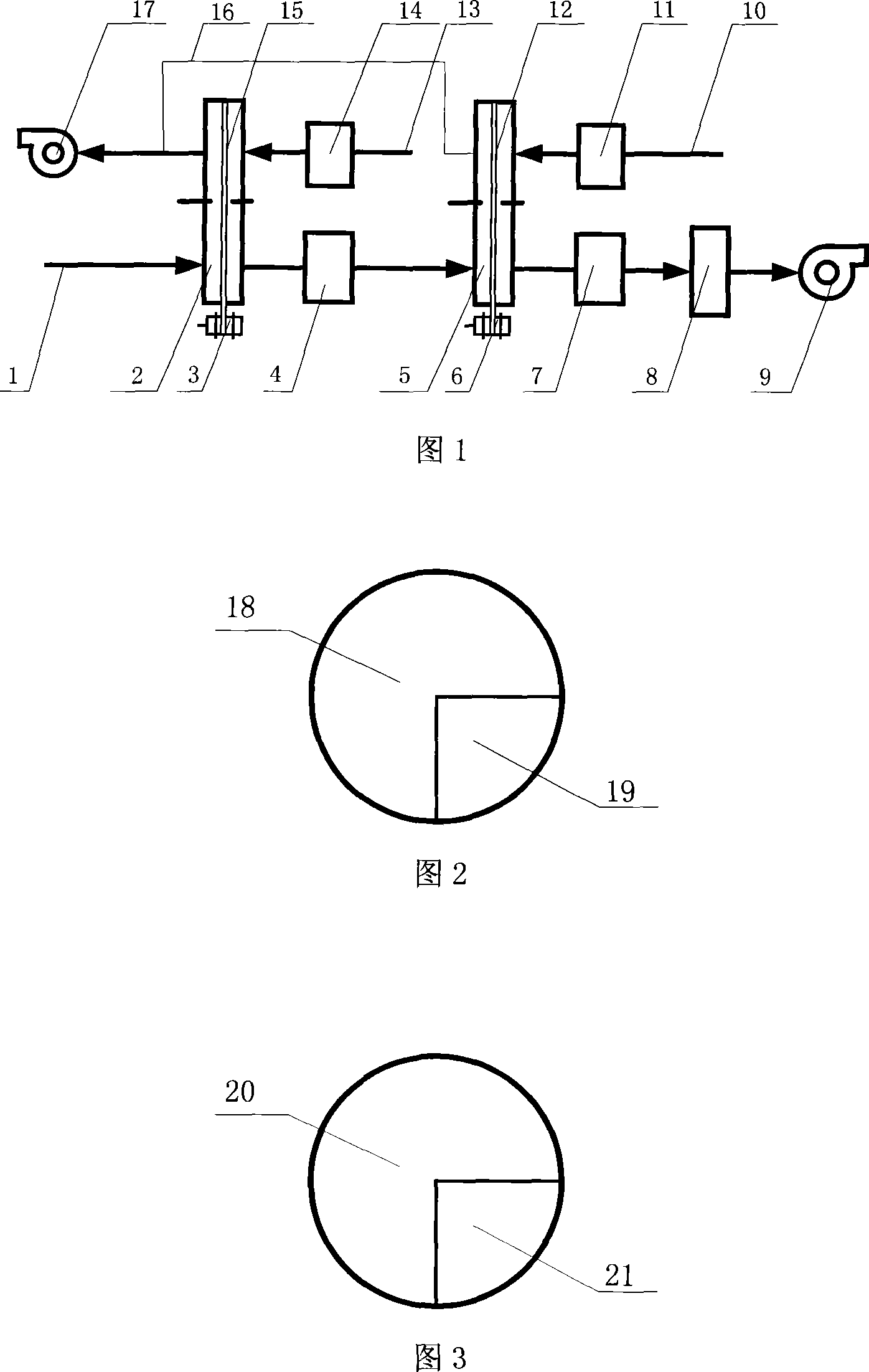

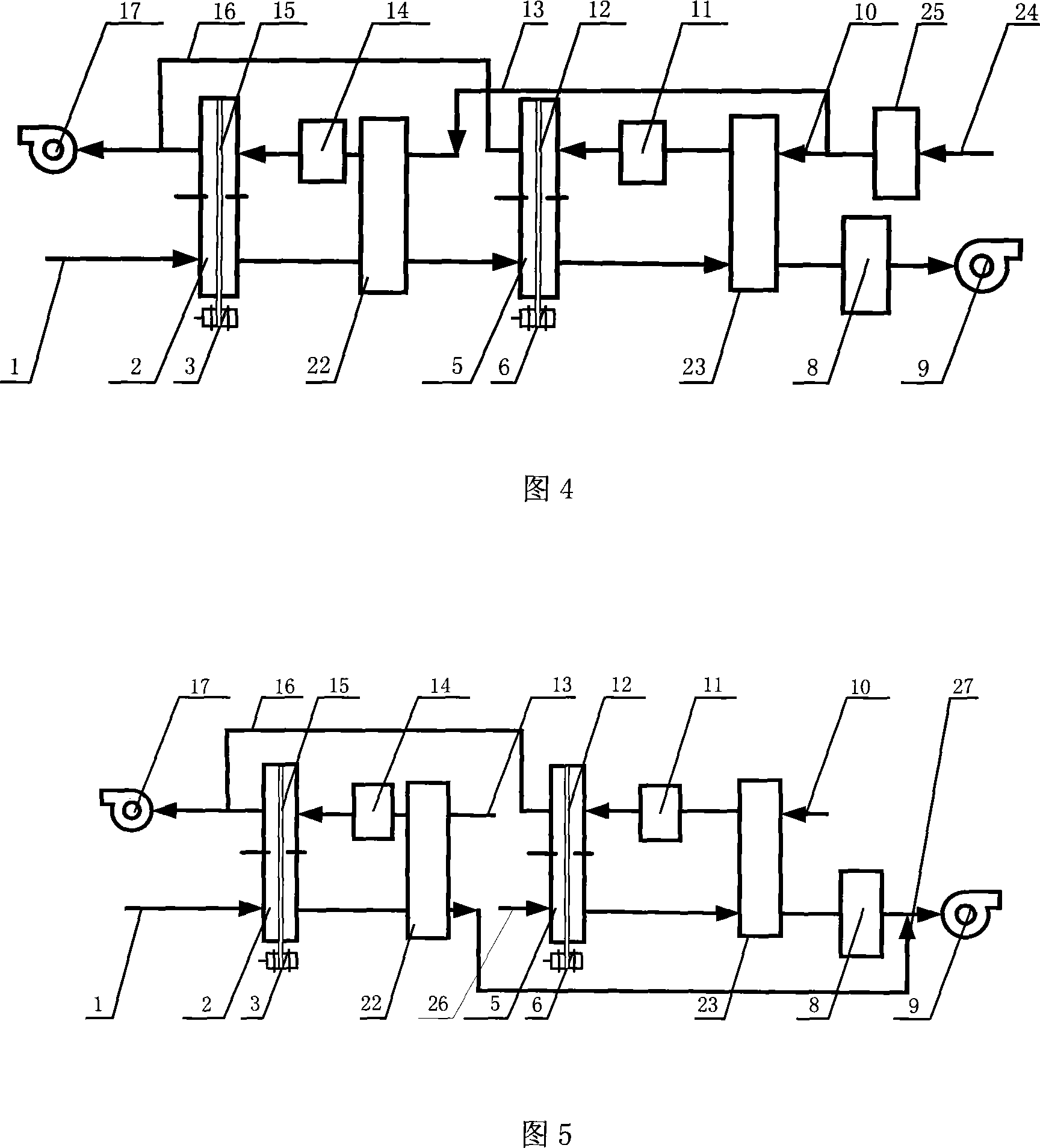

Two-stage rotating wheel dehumidification air conditioner device capable of using low-grade heat source

InactiveCN101122409AReduce the temperatureReduce moisture contentLighting and heating apparatusAir conditioning systemsElectricityEvaporative cooler

A two grade runner dehumidification air-conditioning device, which belongs to refrigeration dehumidification technical field and can make use of low grade heat source, includes two stage dehumidification runners, two stage heat exchanges, two heaters, an evaporative cooler, a treating fan, a regeneration fan, a motor and a belt or a gear. The motor is connected with the dehumidification runners through the belt or the gear and drives the dehumidification runners to rotate. Every dehumidification runner is equipped with two areas of a treating area and a regeneration area. The treating area of the first stage dehumidification runner is connected with the inlet of the first stage heat exchanger. The outlet of the first stage heat exchanger is connected with the treating area of the second stage dehumidification runner. The other side of the second stage dehumidification runner is connected with the second stage heat exchanger. The second stage heat exchange is connected with the evaporative cooler. The evaporative cooler is connected with the treating fan. The regeneration fan is respectively connected with the regeneration areas of the two stage dehumidification runners. Two heaters are respectively connected with the other sides of the regeneration areas of the two stage dehumidification runners. Enough temperature and humidity descending can be achieved by the invention without an electric refrigeration air conditioning.

Owner:SHANGHAI JIAO TONG UNIV

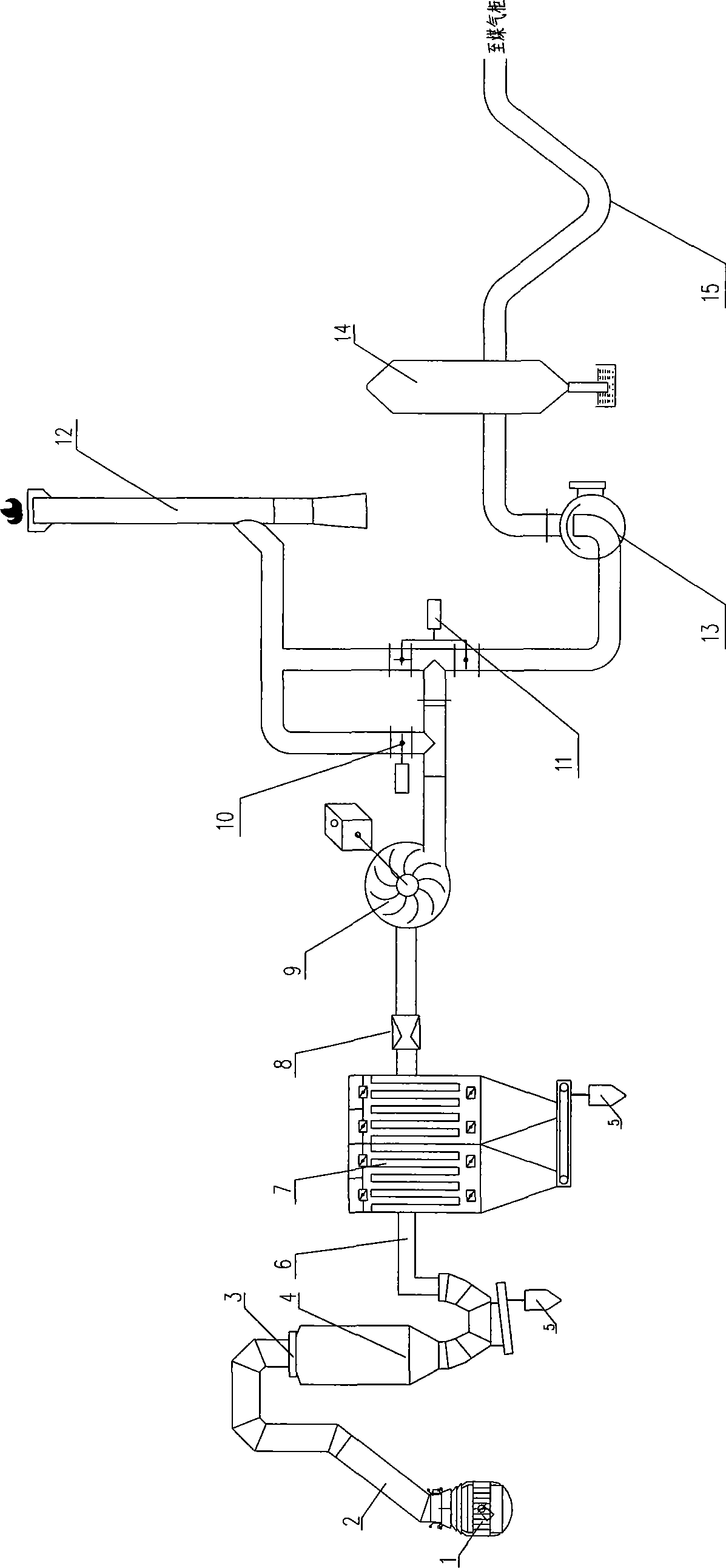

Converter gas dry method pocket type purification and recovery process and system

InactiveCN101451173AImprove purification efficiencyReduce dust concentrationAuxillary pretreatmentDispersed particle filtrationEvaporative coolerFiltration

The invention belongs to the technical field of gas purification, and discloses converter gas dry-method bag-type purification and recovery technology and a converter gas dry-method bag-type purification and recovery system. The technology comprises: a converter generates high-temperature ash-laden gas under the condition of oxygen blowing and smelting, and the temperature of the high-temperature ash-laden gas is reduced to be between 800 and 1,000 DEG C by a vapourization cooling system; the ash-laden gas enters an evaporative cooler through an expansion joint and is atomized and cooled by a two-phase injection device which is formed by vapor or nitrogen and water, and the temperature of the gas is reduced to be approximately 200 DEG C; the gas enters a bag-type duster for filtration and purification; and purified gas is subjected to switching control by a three-way switch valve according to gas recovery conditions of the system, and is recovered or discharged respectively. The invention has the advantages that the technology has high gas purification efficiency, and the system has low running resistance, energy consumption, operating cost and maintenance cost and no secondary pollution such as sewage. The technology is novel energy-saving and environment-friendly technology with wide promotion value, and can be widely applied to the converter gas purification and recovery system.

Owner:CISDI ENG CO LTD

System and method for wastewater reduction and freshwater generation

InactiveUS20080277262A1Reduction of environmental liabilityImprove reliabilityBeehive ovensAuxillariesEvaporative coolerFresh water organism

A process whereby freshwater is generated and wastewater is eliminated through the employ of waste combustion gas; wherein combustion gas is cooled below dewpoint, via the effects of a wastewater fed evaporative cooler, resulting in the combined benefits of freshwater generation from the combustion gas and evaporative reduction of the wastewater.

Owner:LAYNE CHRISTENSEN COMPANY

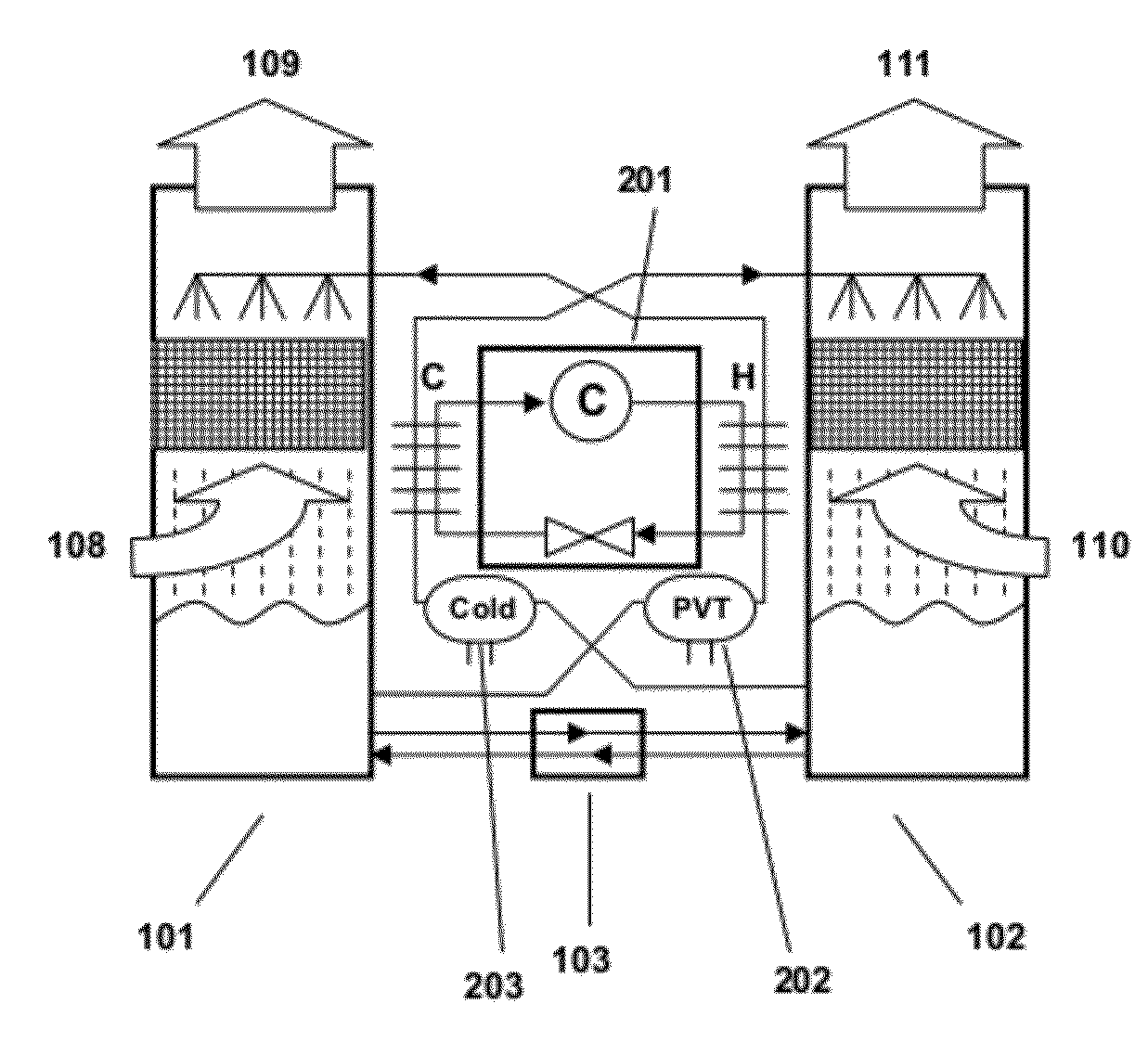

Desiccant based chilling system

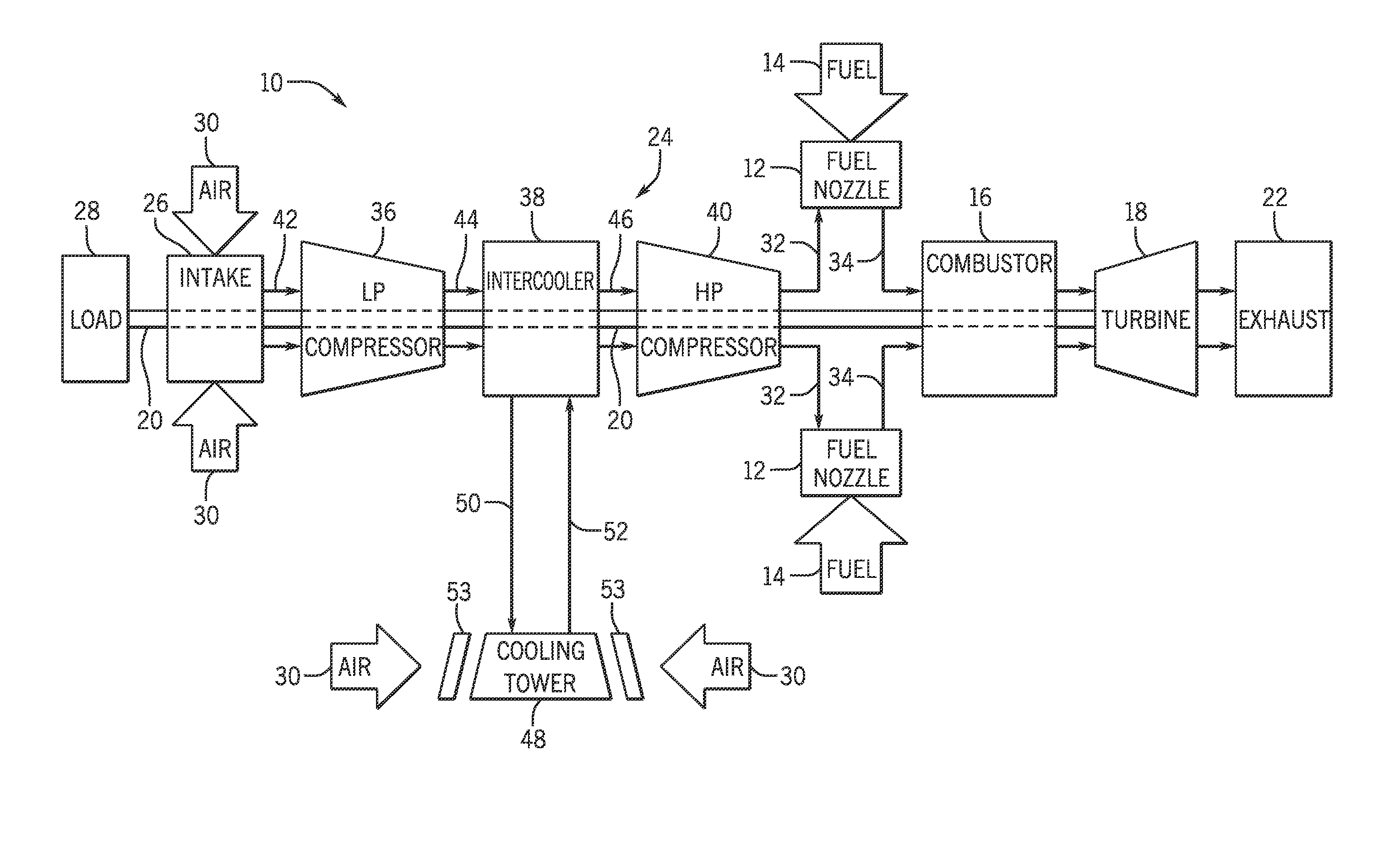

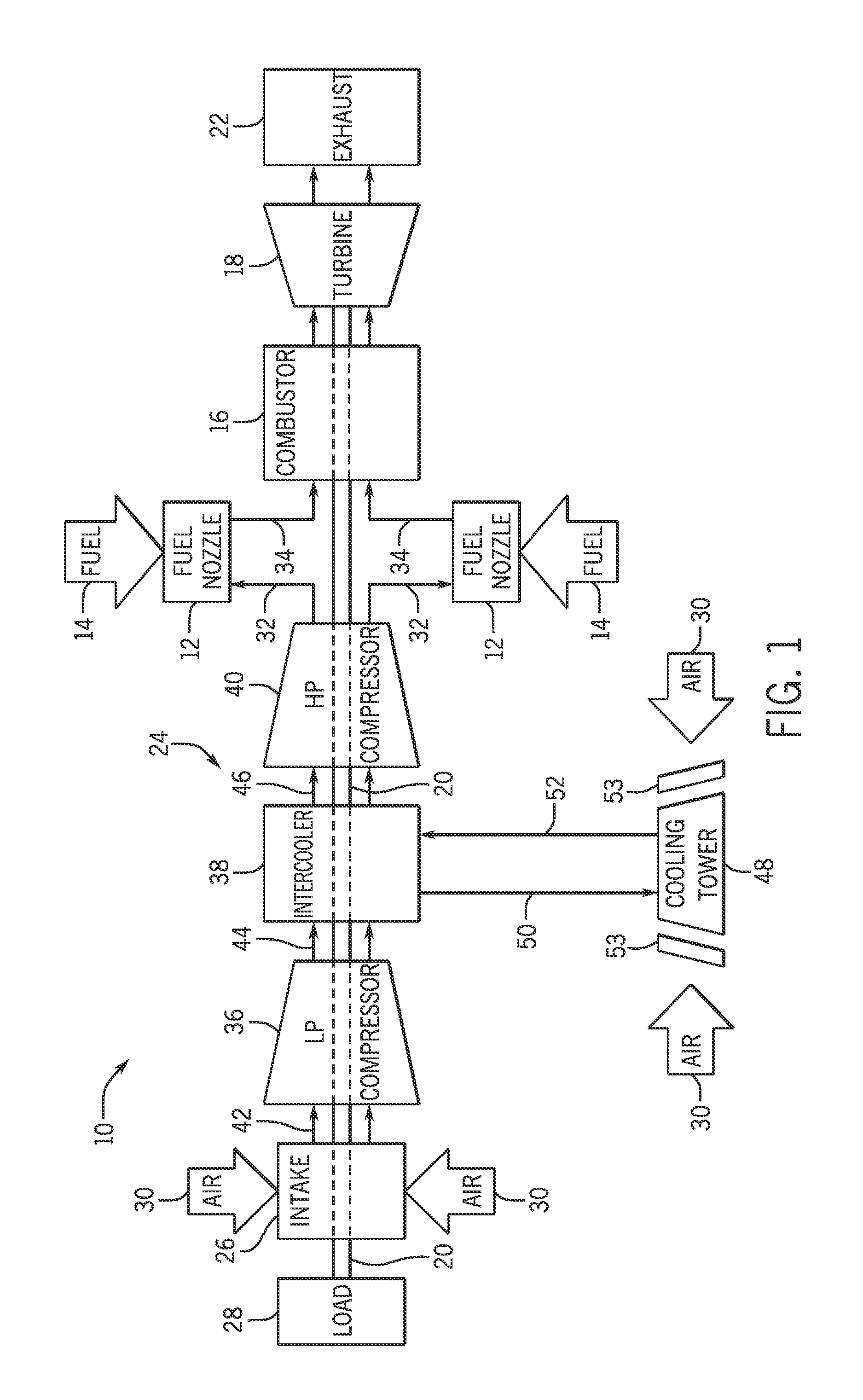

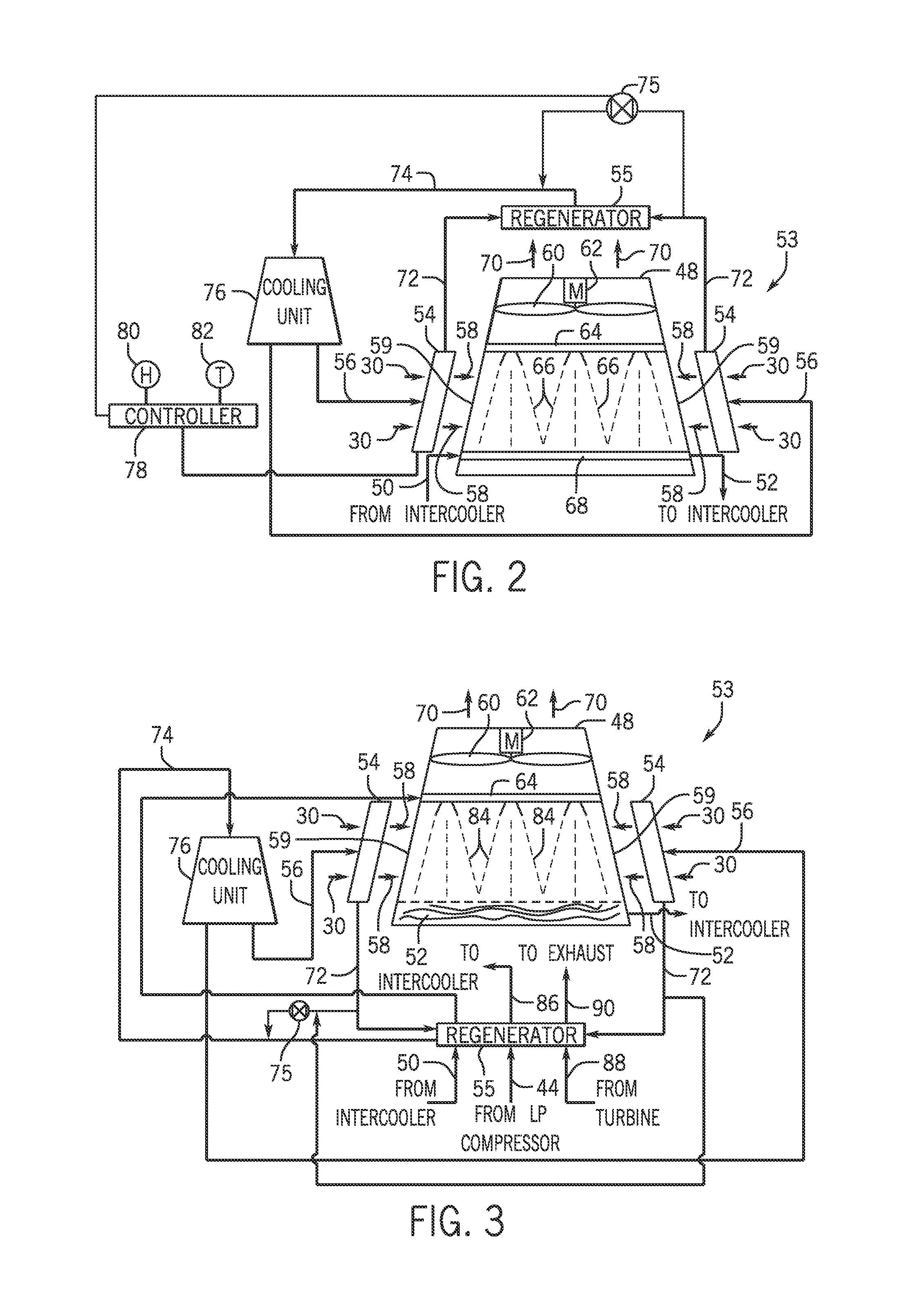

ActiveUS20140250935A1Reduce humidityReduce liquid contentDomestic cooling apparatusGas turbine plantsEvaporative coolerWorking fluid

A system includes an intercooler configured to receive an airflow from a first compressor, to transfer heat from the airflow to a working fluid, and to provide the airflow to a second compressor. The system also includes an evaporative chiller configured to receive the working fluid from the intercooler, to chill the working fluid via evaporative cooling within an ambient air environment, and to provide the working fluid to the intercooler. In addition, the system includes a desiccant system configured to reduce a humidity of ambient air within the evaporative chiller.

Owner:GENERAL ELECTRIC CO

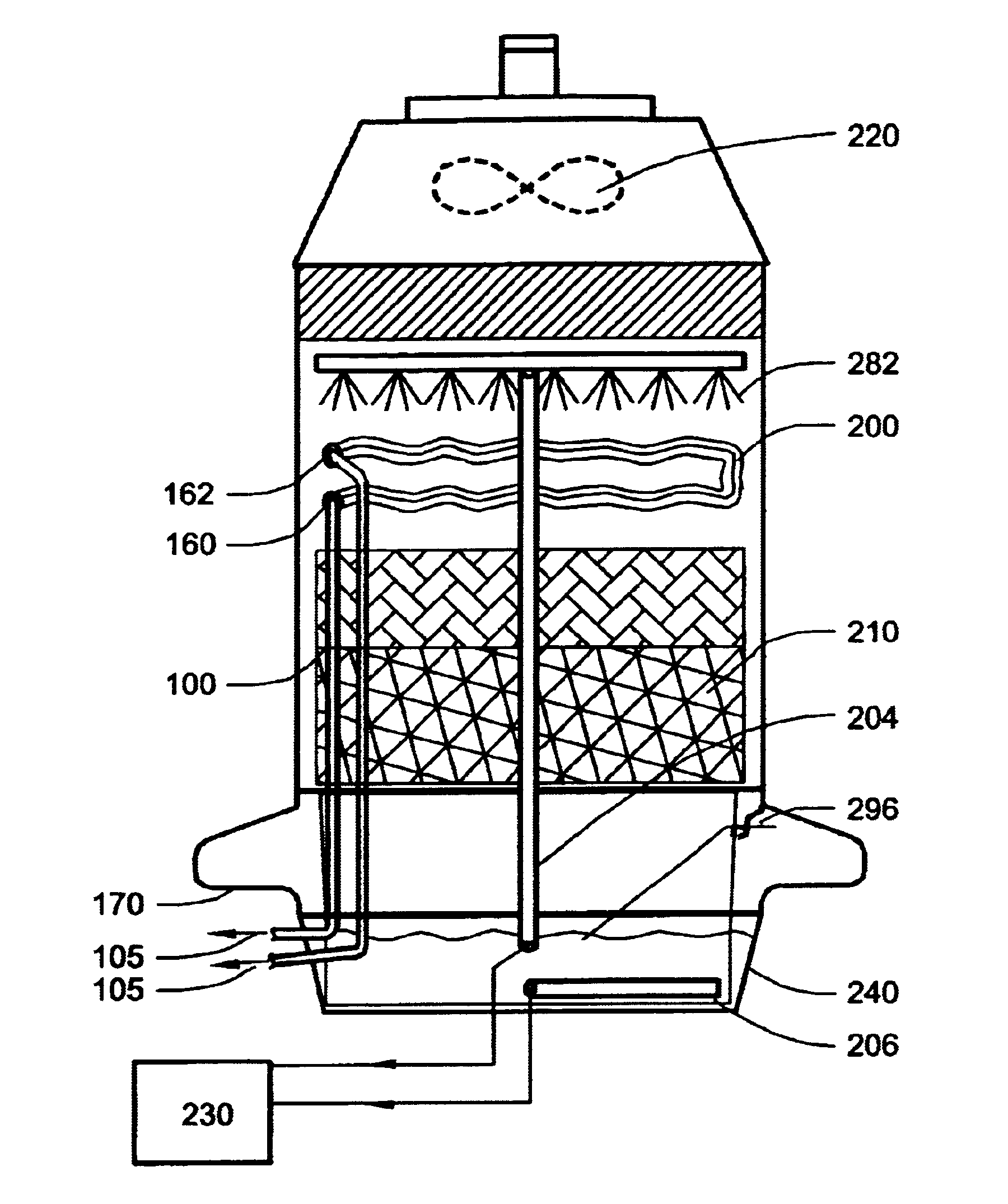

Apparatus and method for closed circuit cooling tower with corrugated metal tube elements

A closed circuit cooling tower for evaporative fluid cooler applications such as water-cooled residential and commercial air conditioning, geothermal cooling supplementation, and process cooling applications. Corrugated metal tubes are used for heat transfer to permit mechanical de-fouling, such as flexing the tubes. The cooling tower may operate at high dissolved solids, or gray water may be used in order to reduce water consumption. The cooling tower is lightweight and modular to permit retrofitting of existing rooftop air conditioning systems so that efficient evaporative cooling may be used to lower energy costs.

Owner:WORD MAC

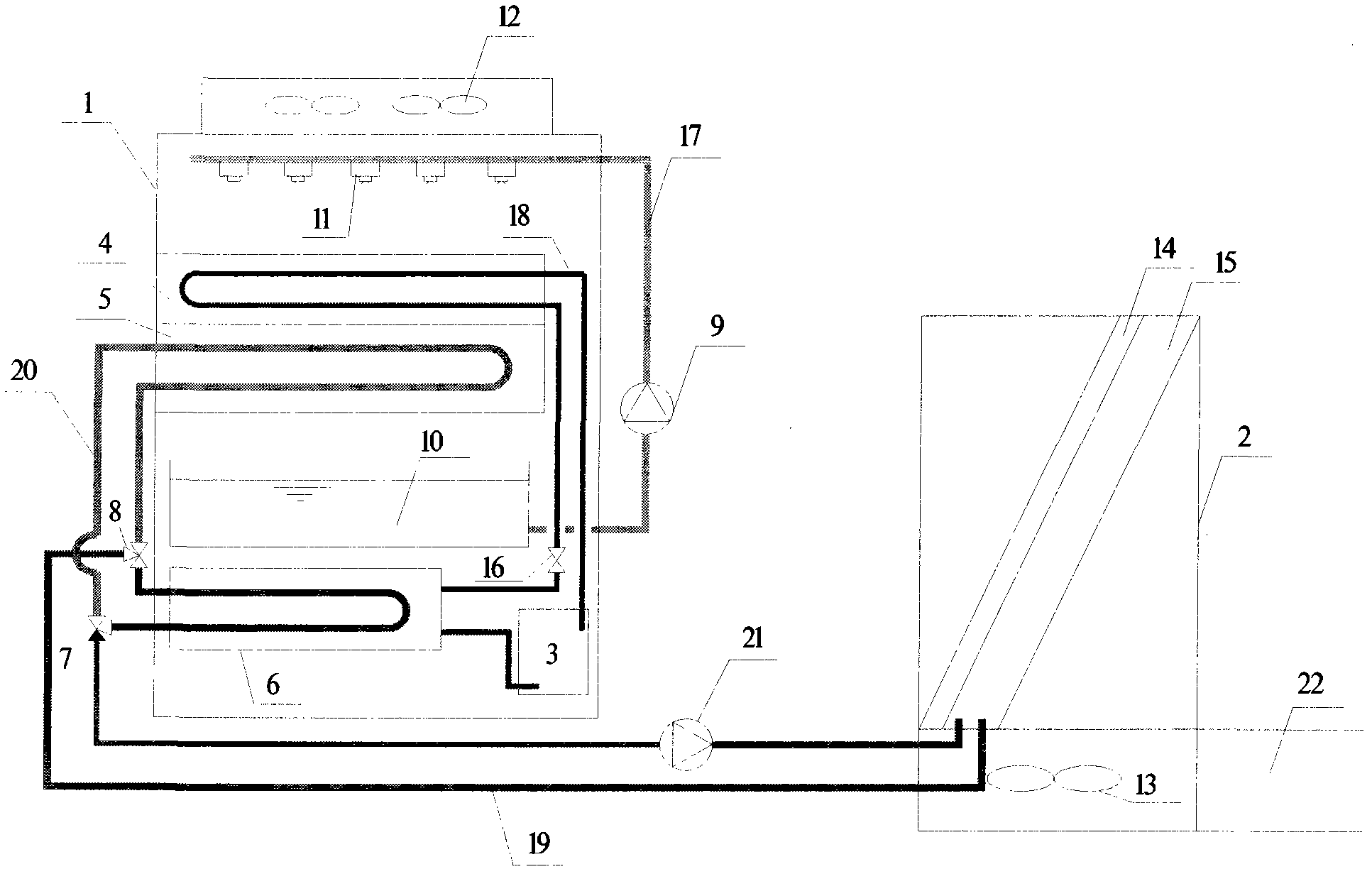

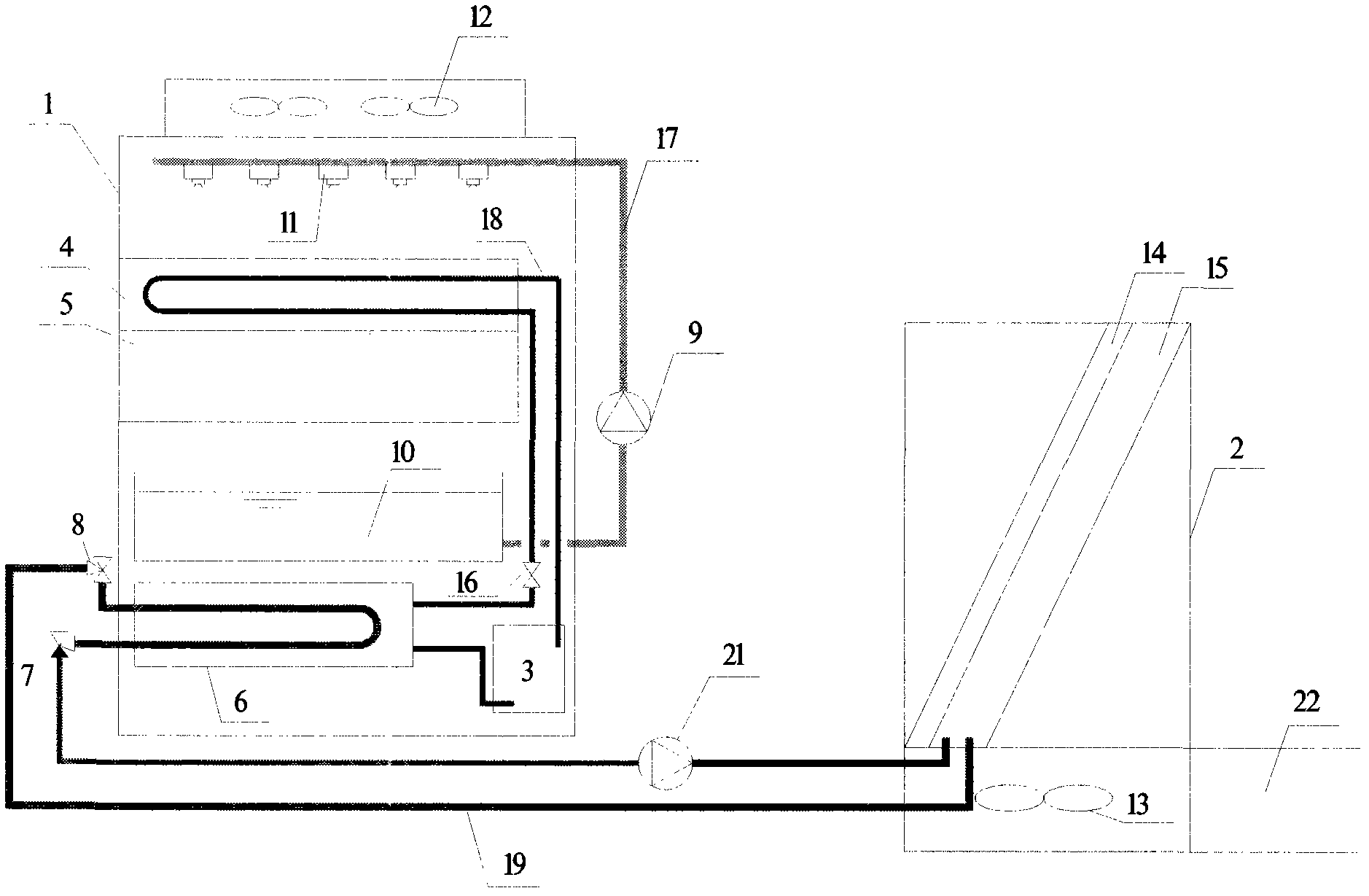

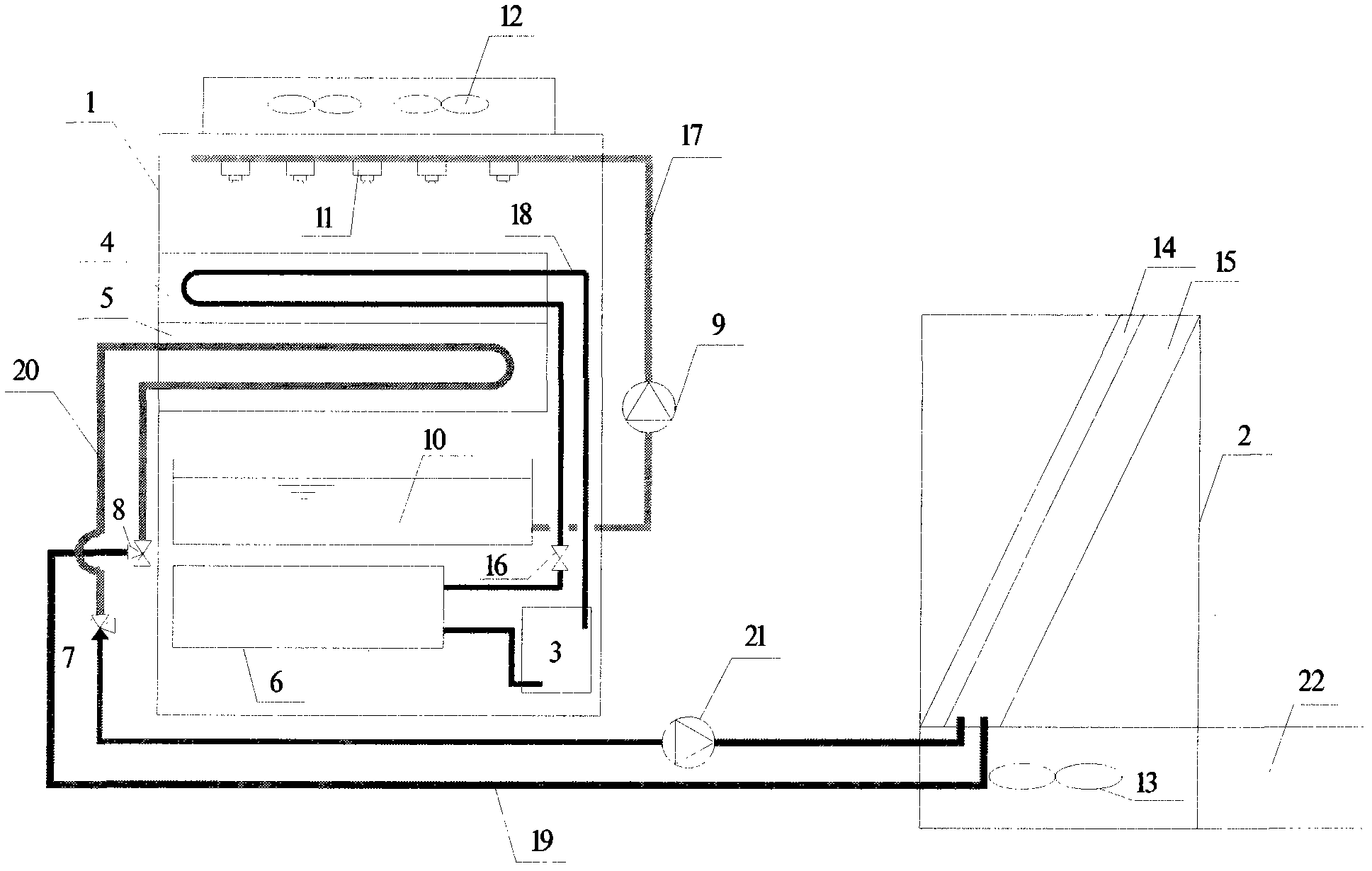

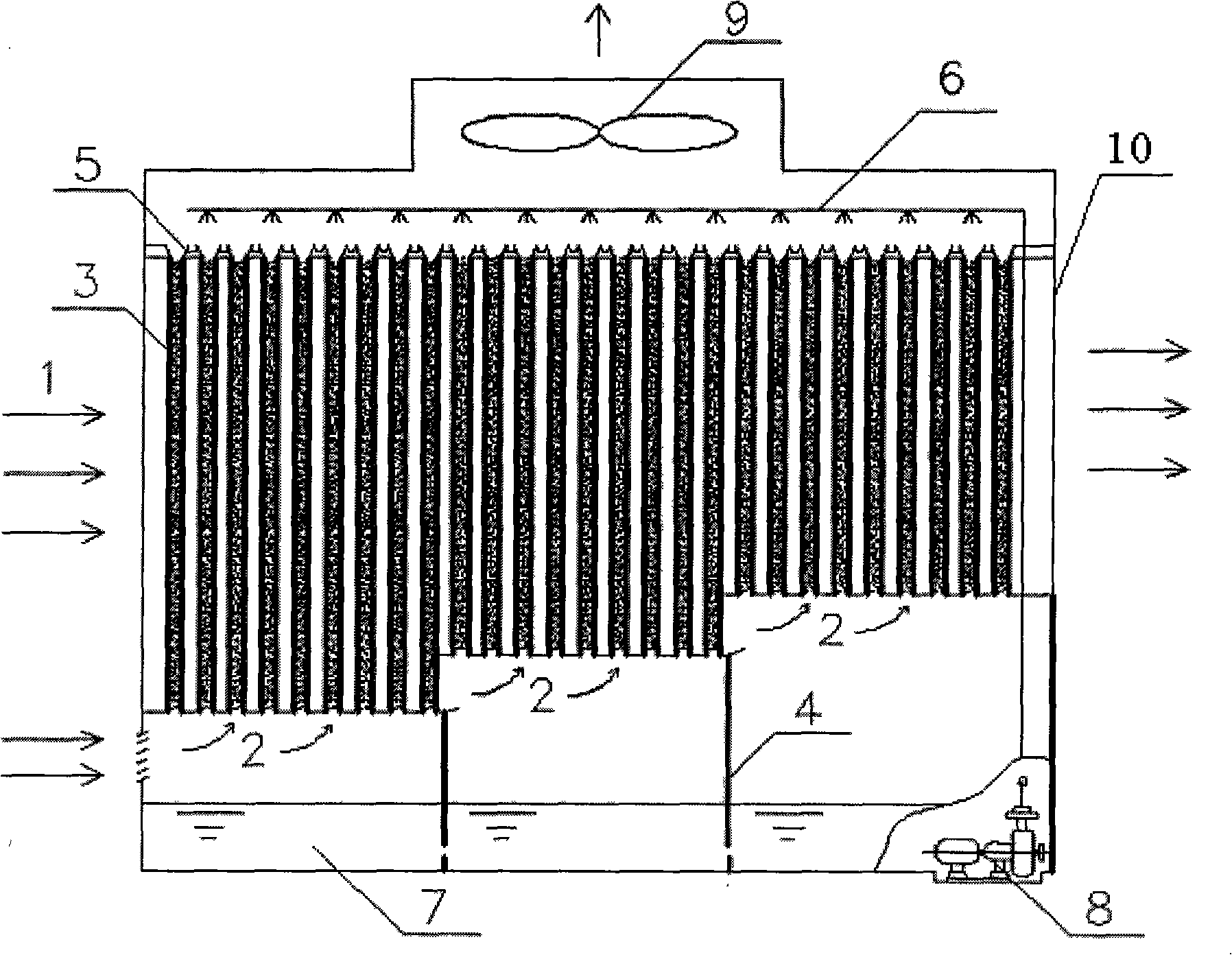

Closed evaporation cooling high-temperature cold water unit

InactiveCN101634476AImprove pre-cooling efficiencyAvoid cloggingLighting and heating apparatusAir conditioning systemsEvaporative coolerCooling coil

The invention discloses a closed evaporation cooling high-temperature cold water unit which comprises an evaporation cooling coil pipe, a filter I, a water distributing device I, a water blocking plate I and a fan, wherein the filter I, the water distributing device I, the water blocking plate I and the fan are sequentially arranged at the upper part; a group of pipe type indirect evaporative coolers are arranged outside both sides of the bottom of the evaporation cooling coil pipe; the upper part of each pipe type indirect evaporative cooler is sequentially provided with a filler II, a water distributing device II and a water blocking plate II; the lower part of each pipe type indirect evaporative cooler is provided with an opening type water tank II; the lower part of the evaporation cooling coil pipe is provided with an opening type water tank I, and the opening type water tank II and the opening type water tank I are separated by a barrier; the opening type water tank II is communicated with the water distributing device II by a pipeline; and the opening type water tank I is communicated with the water distributing device I by a pipeline. The unit can meet the requirement of the water temperature at a dry type or dry working condition sensible heat tail end, prevent a phenomenon of dew formation at the sensible heat tail end and conform to the requirement of the water temperature of an evaporation cooling semi-centralized type air-conditioning system in the northwest district.

Owner:XI'AN POLYTECHNIC UNIVERSITY

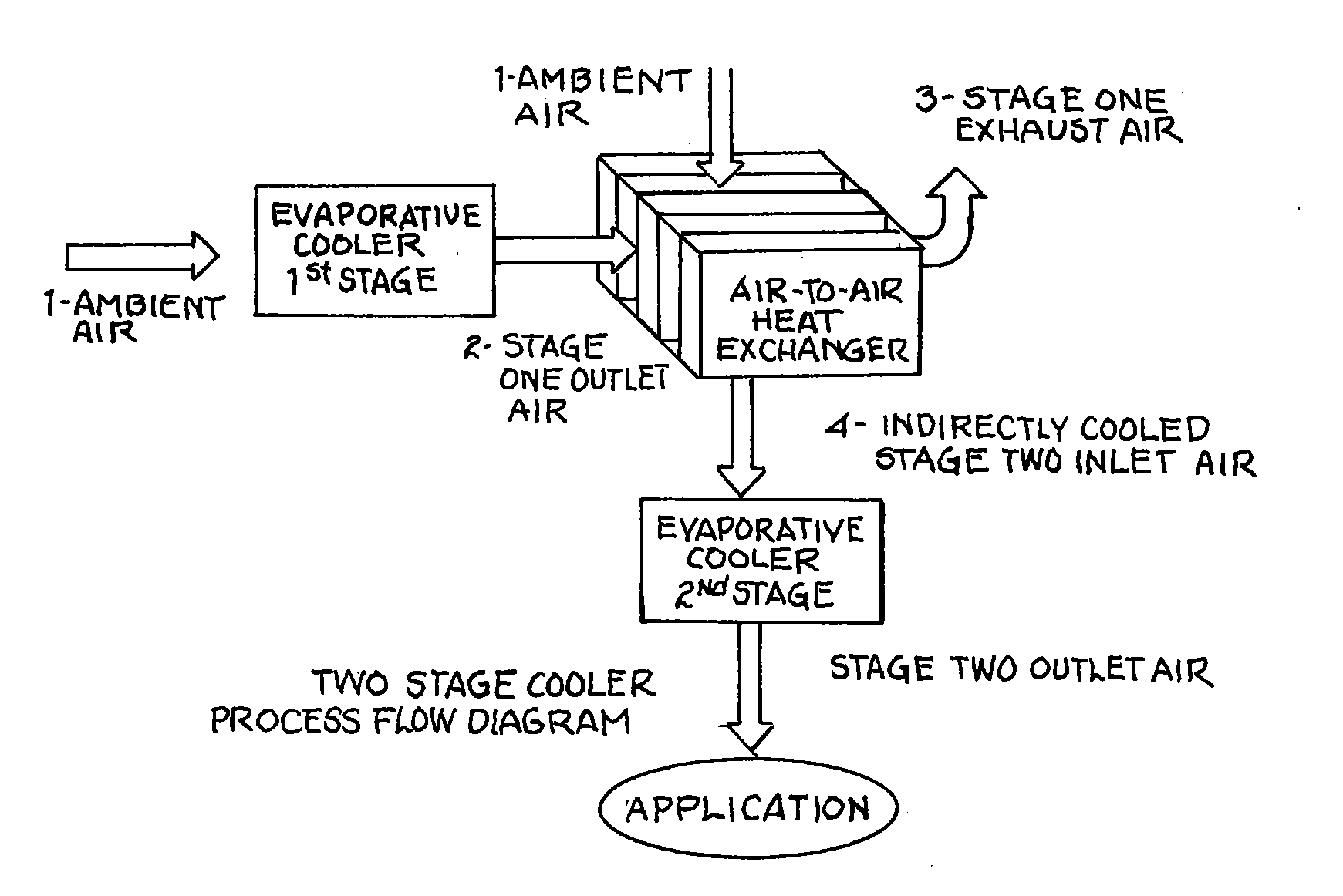

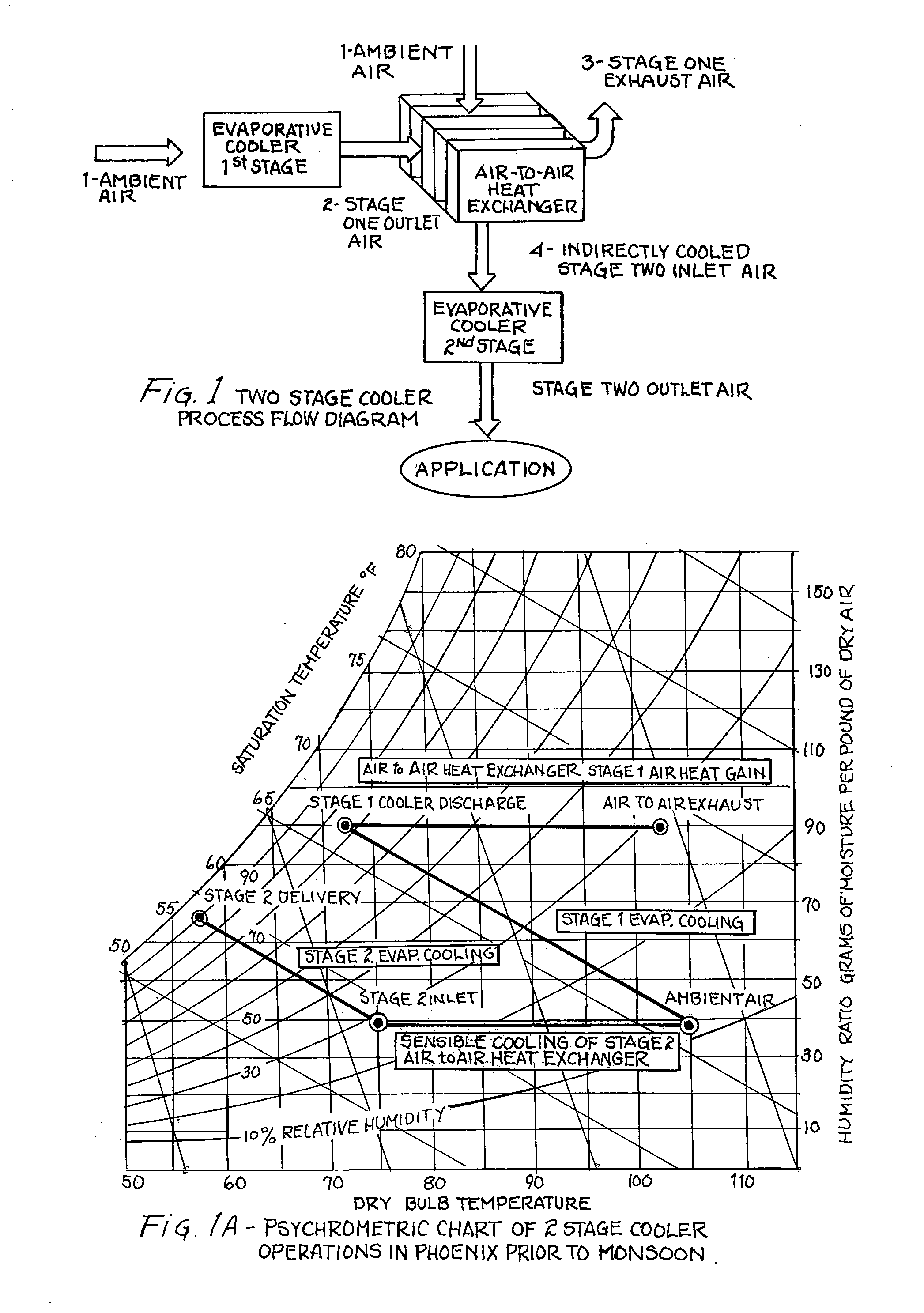

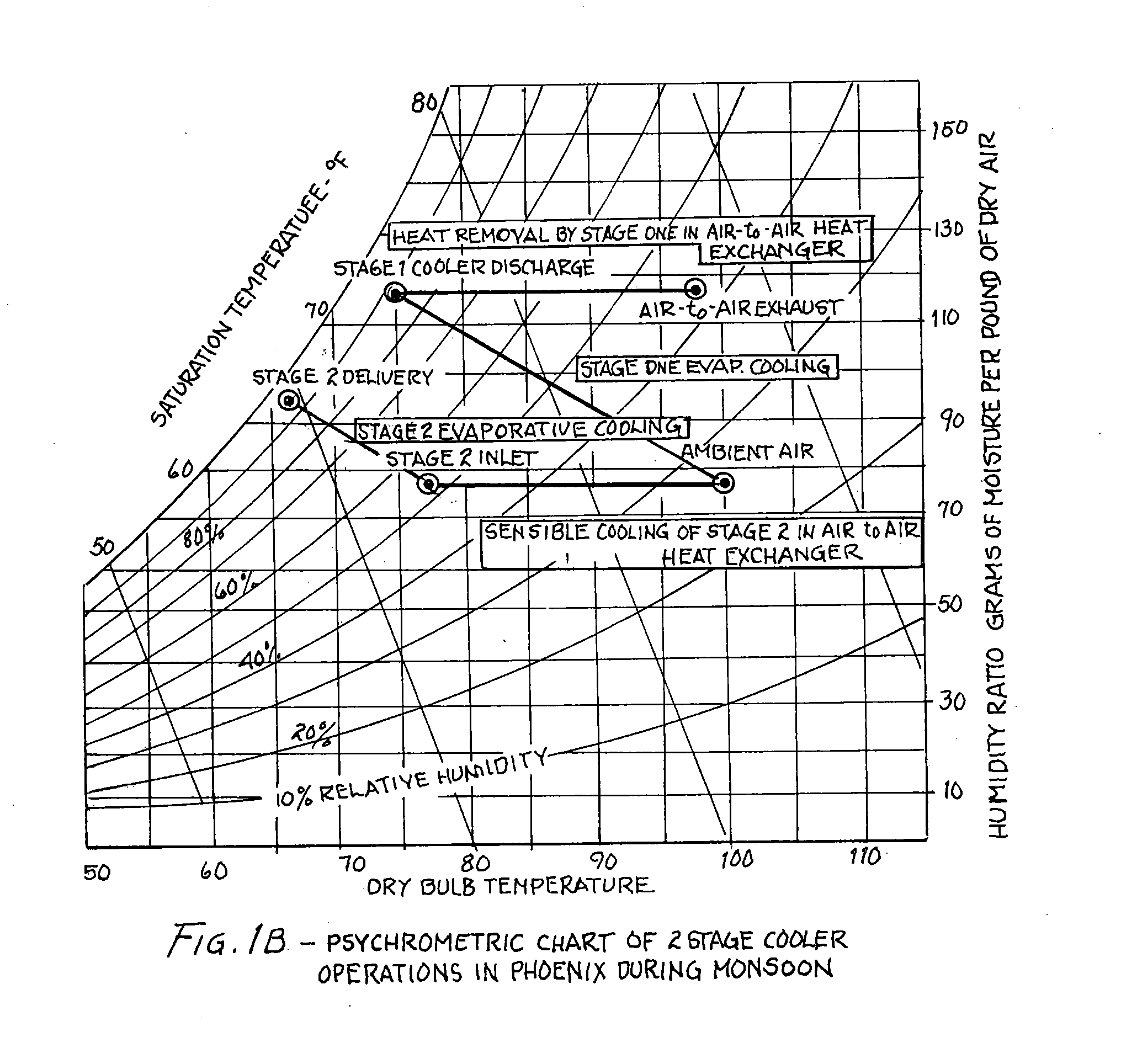

Integrated evaporative cooler and flat plate air to air heat exchanger

InactiveUS20110120693A1Reduces energy required to maintain building environmentLower energy requirementsFree-cooling systemsStationary conduit assembliesEvaporative coolerCooling tower

This invention is an integrated system comprised of a flat plate, air-to-air heat exchanger, ducting and controls, and an AZFlow™ direct evaporative cooler in configurations where the system is able to provide air that has been cooled well below the ambient wet-bulb to temperatures approaching the dew point. These include: A) a two stage cooler where one evaporative cooler performs the stage one cooling by direct evaporative cooling, of the ambient air. This air is directed to the secondary side of the air to air heat exchanger where it indirectly and sensibly cools primary air which is then cooled by a second evaporative cooler which is able to produce the desired cool air approaching the dew point; B) an energy recovery cooling system where building exhaust is collected and directed to the secondary side of the air to air heat exchanger where it indirectly and sensibly cools primary air which is then cooled by an evaporative cooler which is able to produce the desired cool air approaching the dew point; C) an indirect evaporative cooler where an evaporative cooler performs direct evaporative cooling of the ambient air. This air is directed to the secondary side of the air to air heat exchanger where it indirectly and sensibly cools primary air. This sensibly cooled primary air can be used as input to a broad number of applications including but not limited to: inlet air to cooling towers producing water chilled to temperatures approaching the dew point which itself has a broad range of uses, and building makeup air in areas other than the most humid where cooling the air below ambient conditions reduces the energy required to maintain the building environment.

Owner:AZ EVAP

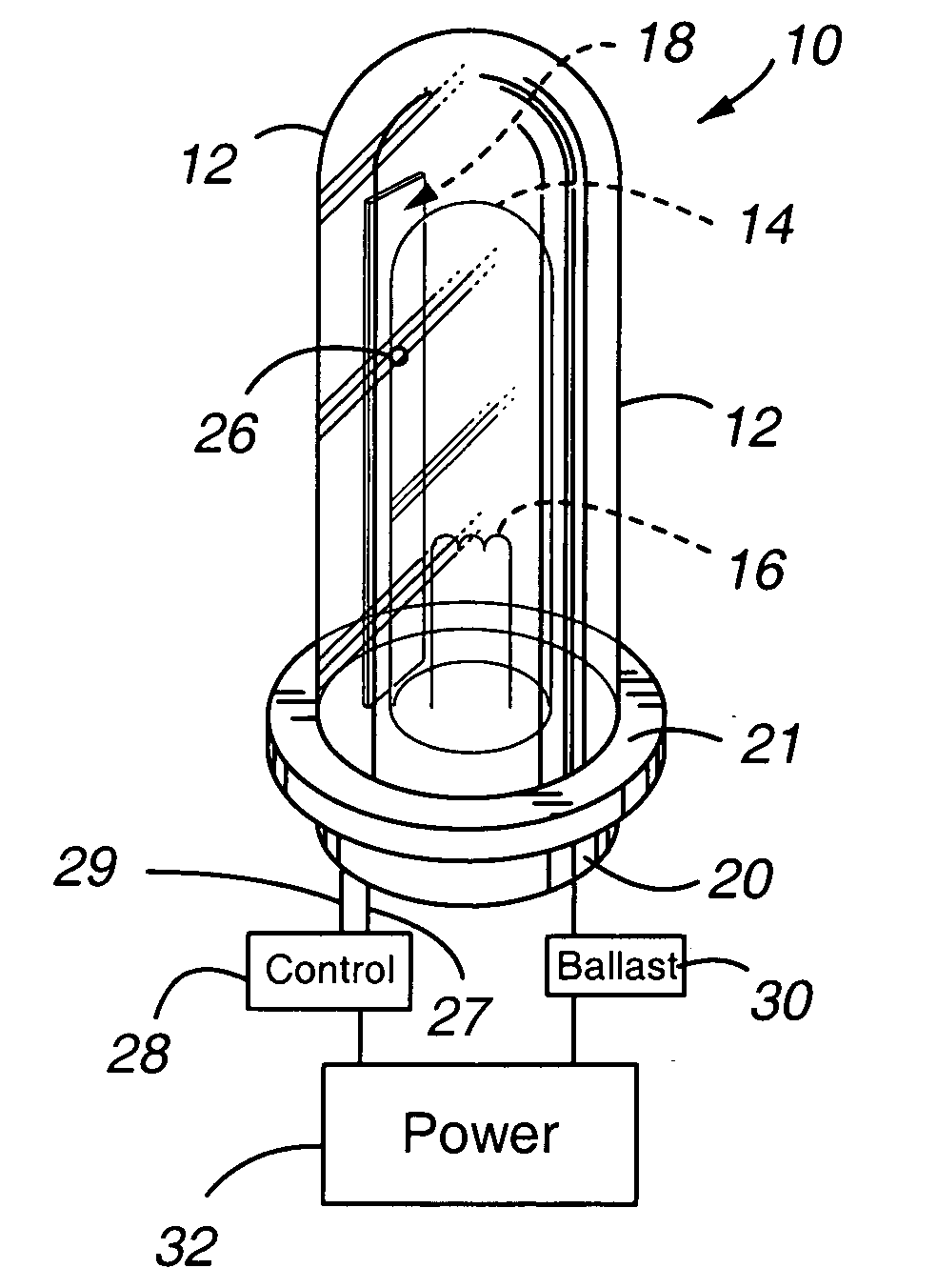

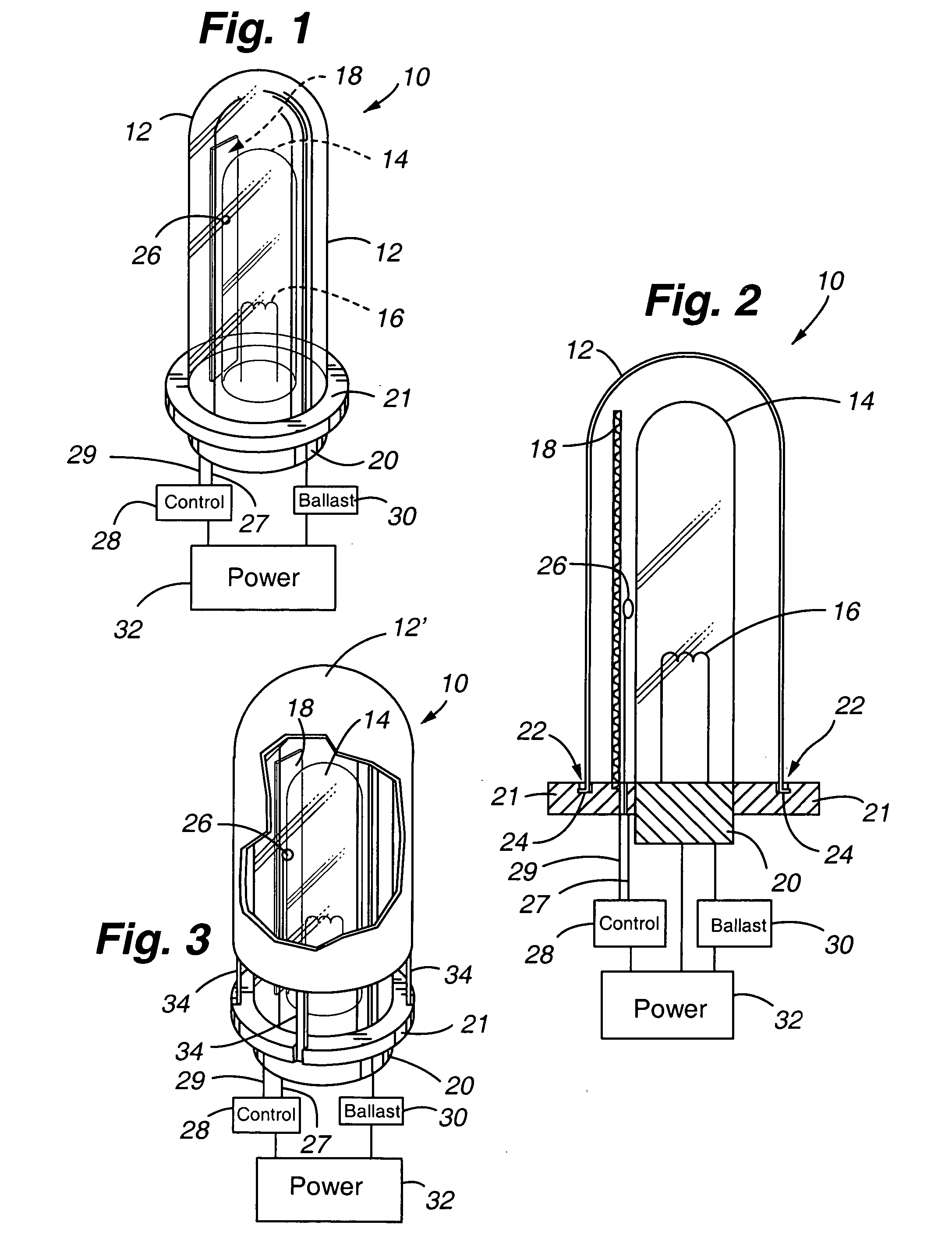

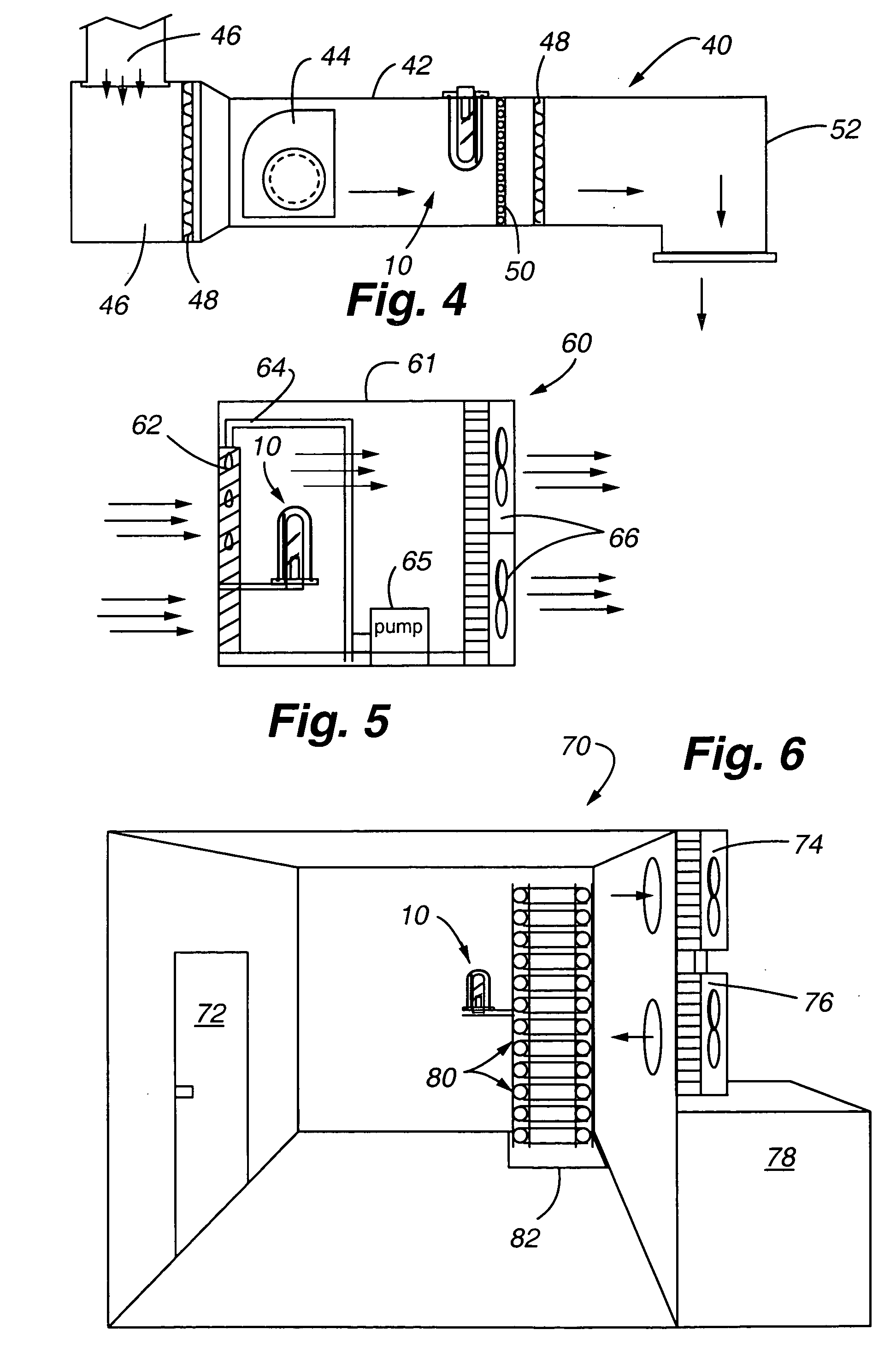

Heat controlled ultraviolet light apparatus and methods of sanitizing objects using said apparatus

InactiveUS20050178984A1Maximize efficiencyEfficient productionMechanical apparatusLighting and heating apparatusEvaporative coolerAutomatic control

Owner:BRICKLEY JAMES LAWRENCE

Cooling assembly

InactiveUS20050076665A1Easy to transportEfficient and reliable and economical and simple and effectiveFree-cooling systemsStationary conduit assembliesEvaporative coolerShell and tube heat exchanger

A process and the required apparatus for air conditioning the interior of a structure is shown which can be run entirely off a DC power source, such as a storage battery. A shell and tube heat exchanger is combined with a mechanical refrigeration system to provide a wet shell side and a dry tube side of the apparatus. In the operation of the air conditioner, a mass of distributed water is established on the wet shell side, and a flow of ambient air is passed through the wet shell side to form a resulting stream of moist air. A flow of ambient air is passed through the dry tube side and a resulting stream of dry cooled air is recovered. The streams of most and cooled air can either be combined or routed separately depending primarily upon the humidity of the surrounding environment to be cooled. The air conditioning unit is not hermetically sealed and the water consumption rate is generally less than that required for a conventional evaporative cooler.

Owner:GPM INC

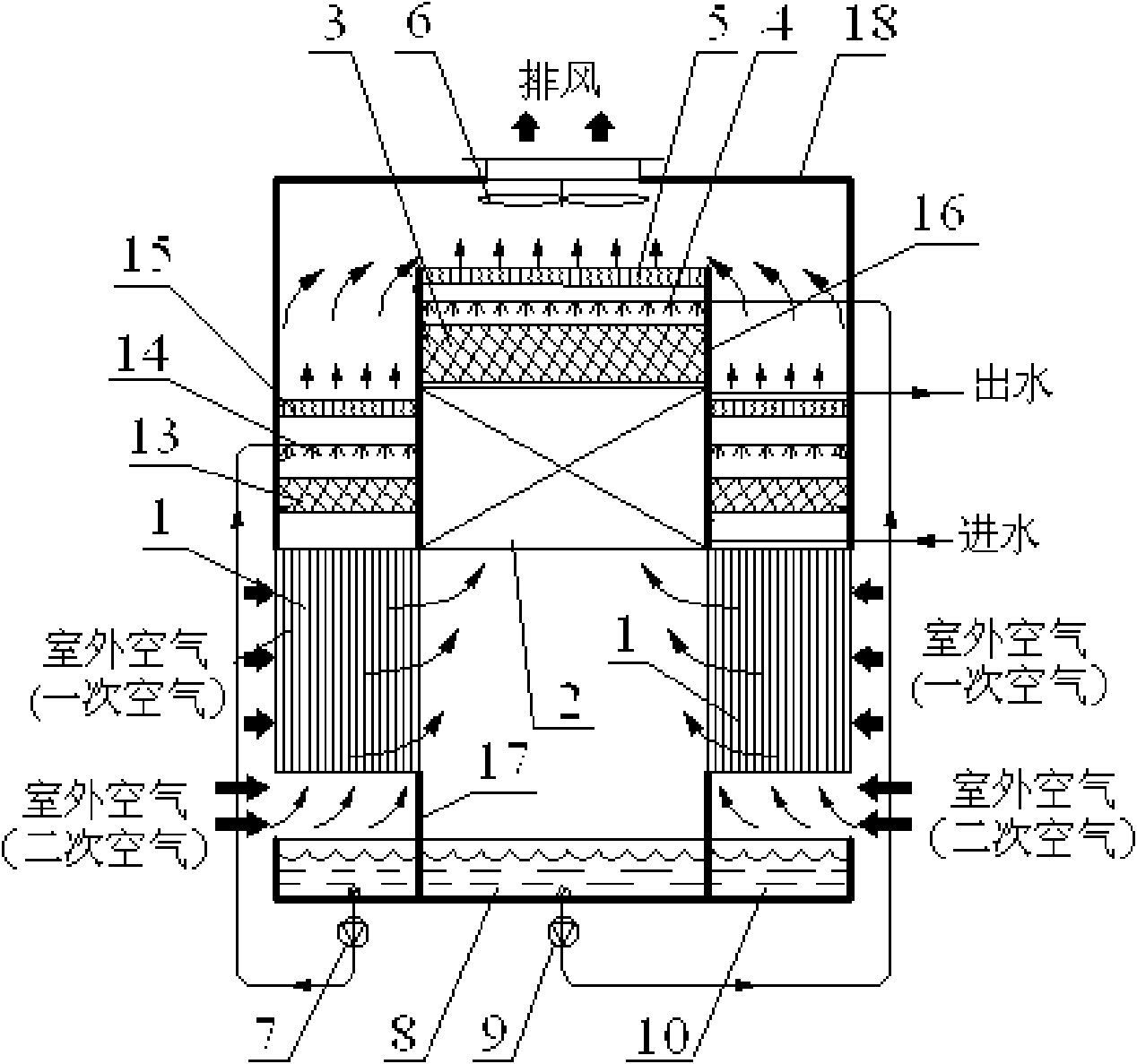

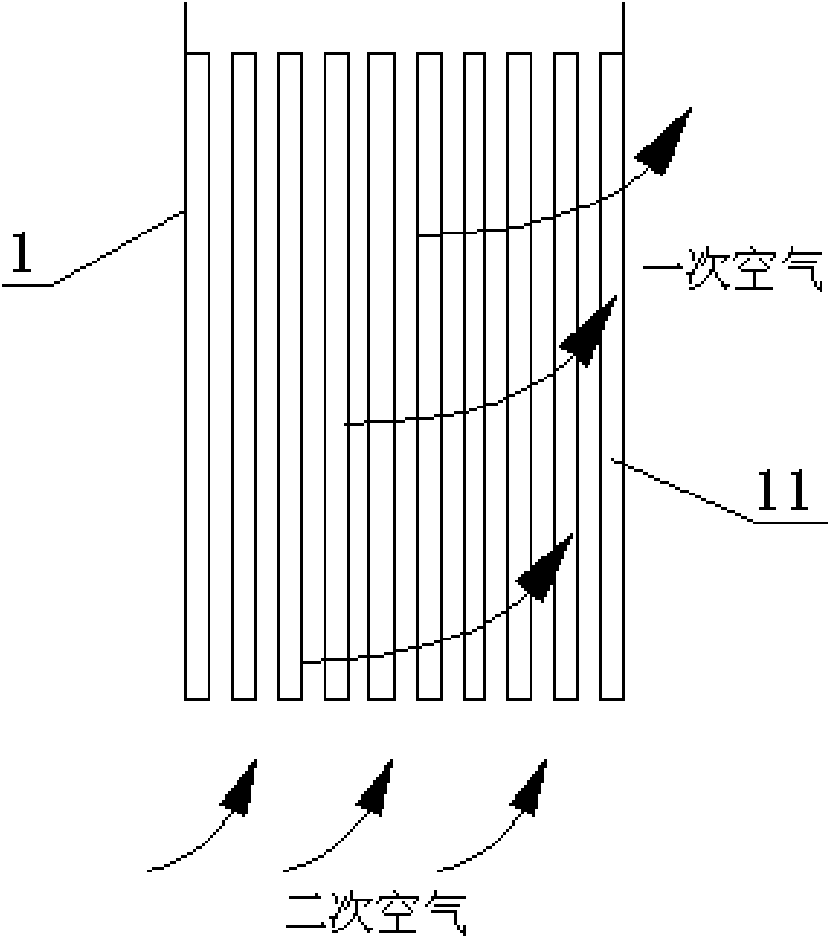

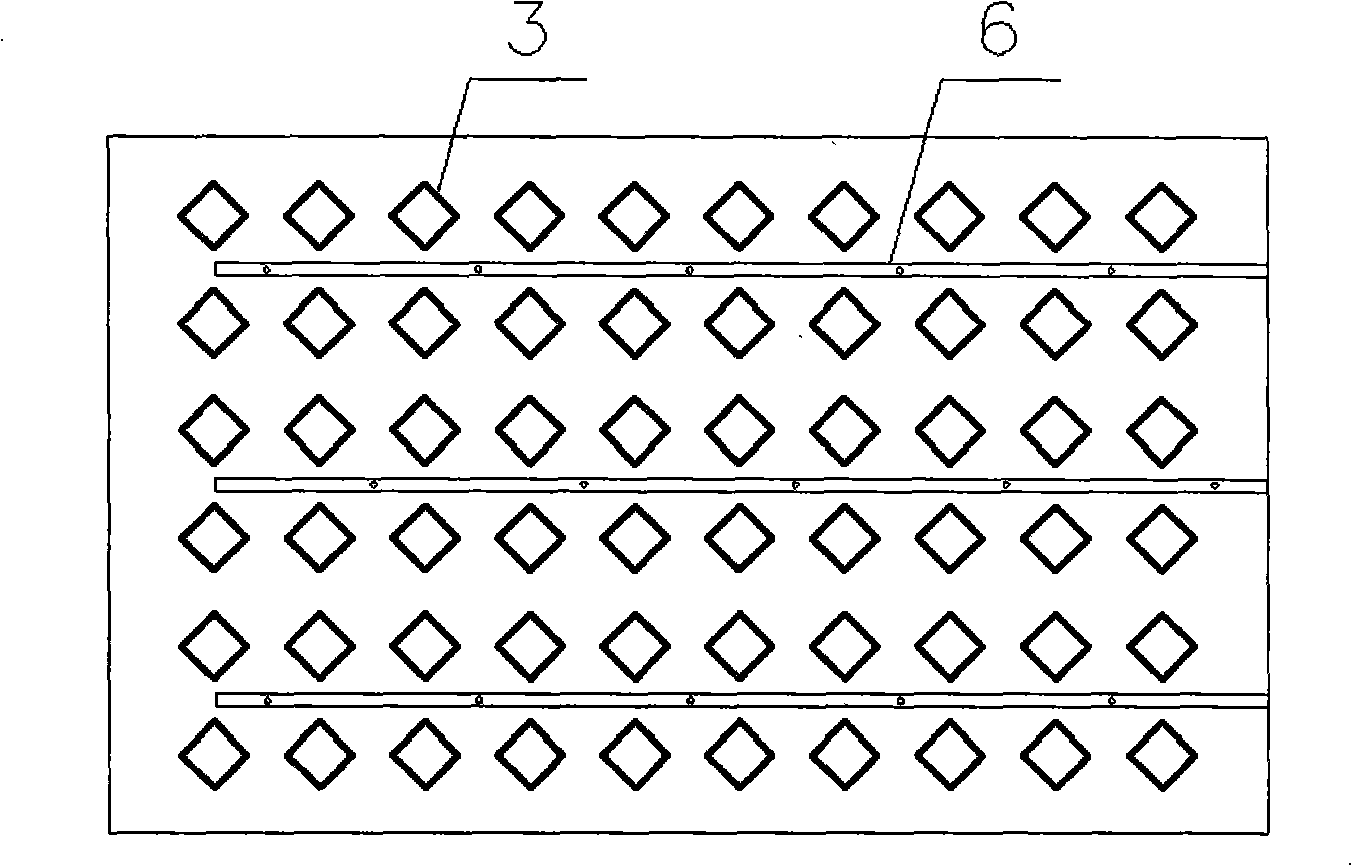

Square porous ceramic vertical tube type dew point indirect evaporative cooler

InactiveCN101329104AObvious advantage of energy savingMoisture content unchangedLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerVertical tube

The invention discloses a square porous ceramics vertical-tube dew point indirect evaporation cooler device comprising a cooler core, a water-distributing device, a fan, a water-storage and a pump which are arranged inside a cooler casing. The cooler core is formed by a plurality of heat exchanging tubes which are vertically arranged to form a multi-line multi-row matrix form which is divided into three sections; the length of the three sections of heat exchanging tube decreases progressively along a first-time air feeding direction, and clapboards are arranged between each two sections of heat exchanging tube; the water-distributing device comprises a diversion grid and a spraying tube which are arranged on the top of each heat exchanging tube. The structure of the invention leads the first-time air to horizontally pass the square ceramics bundle and leads a second-time air to flow through the bundle from bottom to top; then the first-time air sequentially passes through the three sections of the core and the temperature of the air entering the second-air channels from different section is decreased gradually, and the temperature of the final wet-bulb is also decreased gradually after a heat and moisture exchanging with water. The structure of the invention can greatly enhance the heat and moisture exchanging efficiency and the water distribution becomes more equal so as to lead the temperature of vented air to approach that of the dew point.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com