Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

461 results about "Low-pressure area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A low-pressure area, low, depression or cyclone is a region on the topographic map where the atmospheric pressure is lower than that of surrounding locations. Low-pressure systems form under areas of wind divergence that occur in the upper levels of the troposphere. The formation process of a low-pressure area is known as cyclogenesis. Within the field of meteorology, atmospheric divergence aloft occurs in two areas. The first area is on the east side of upper troughs, which form half of a Rossby wave within the Westerlies (a trough with large wavelength that extends through the troposphere). A second area of wind divergence aloft occurs ahead of embedded shortwave troughs, which are of smaller wavelength. Diverging winds aloft ahead of these troughs cause atmospheric lift within the troposphere below, which lowers surface pressures as upward motion partially counteracts the force of gravity.

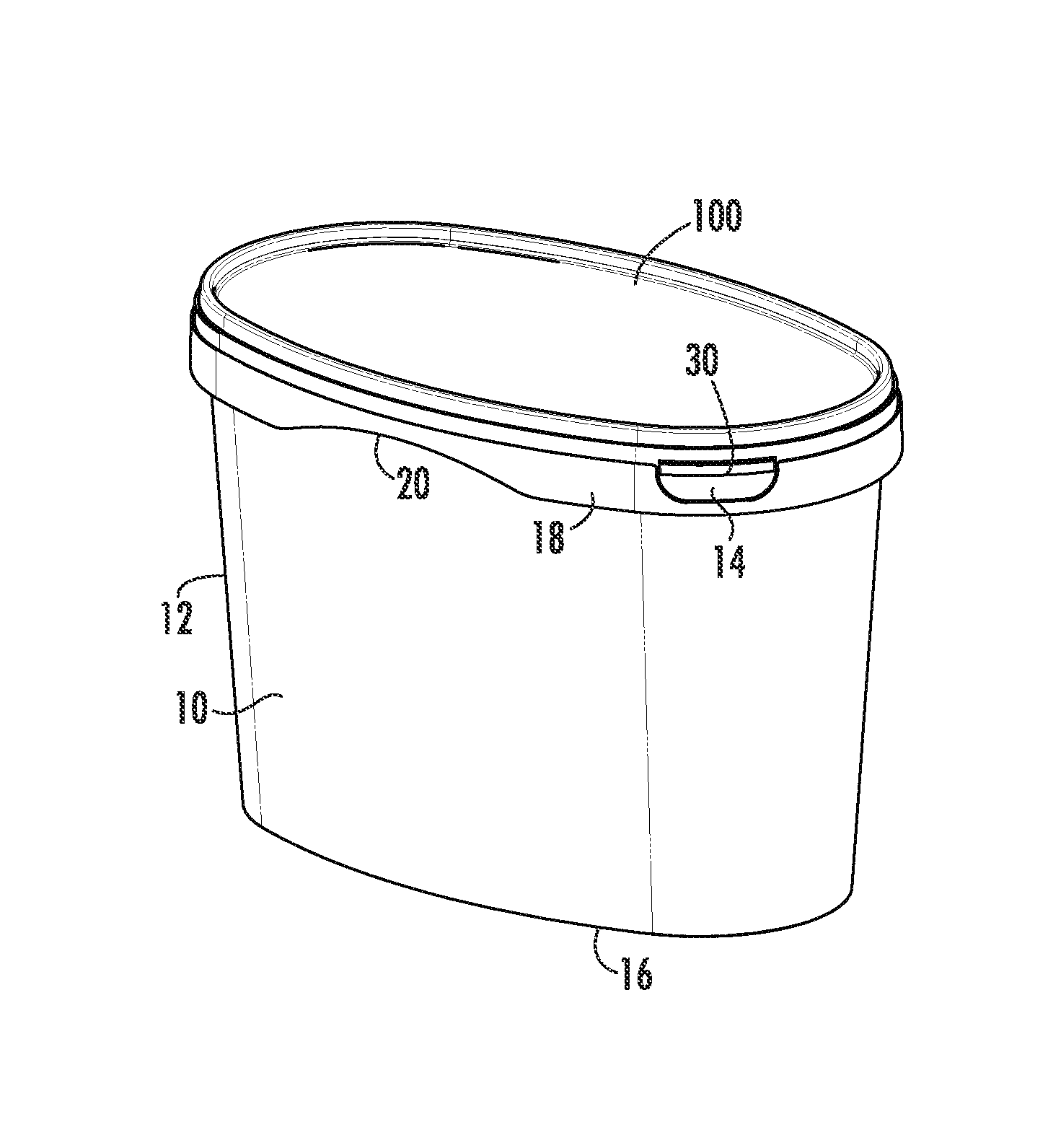

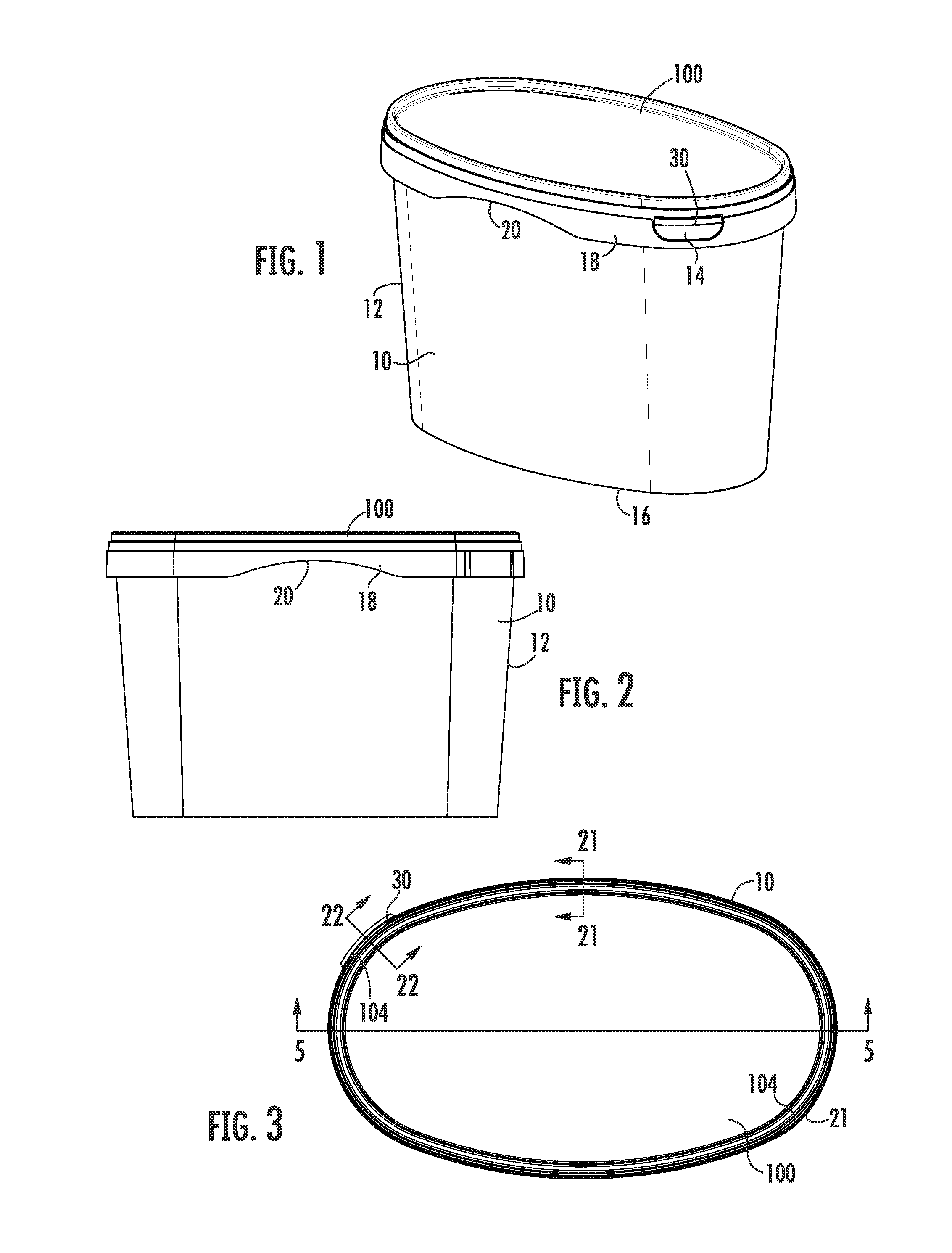

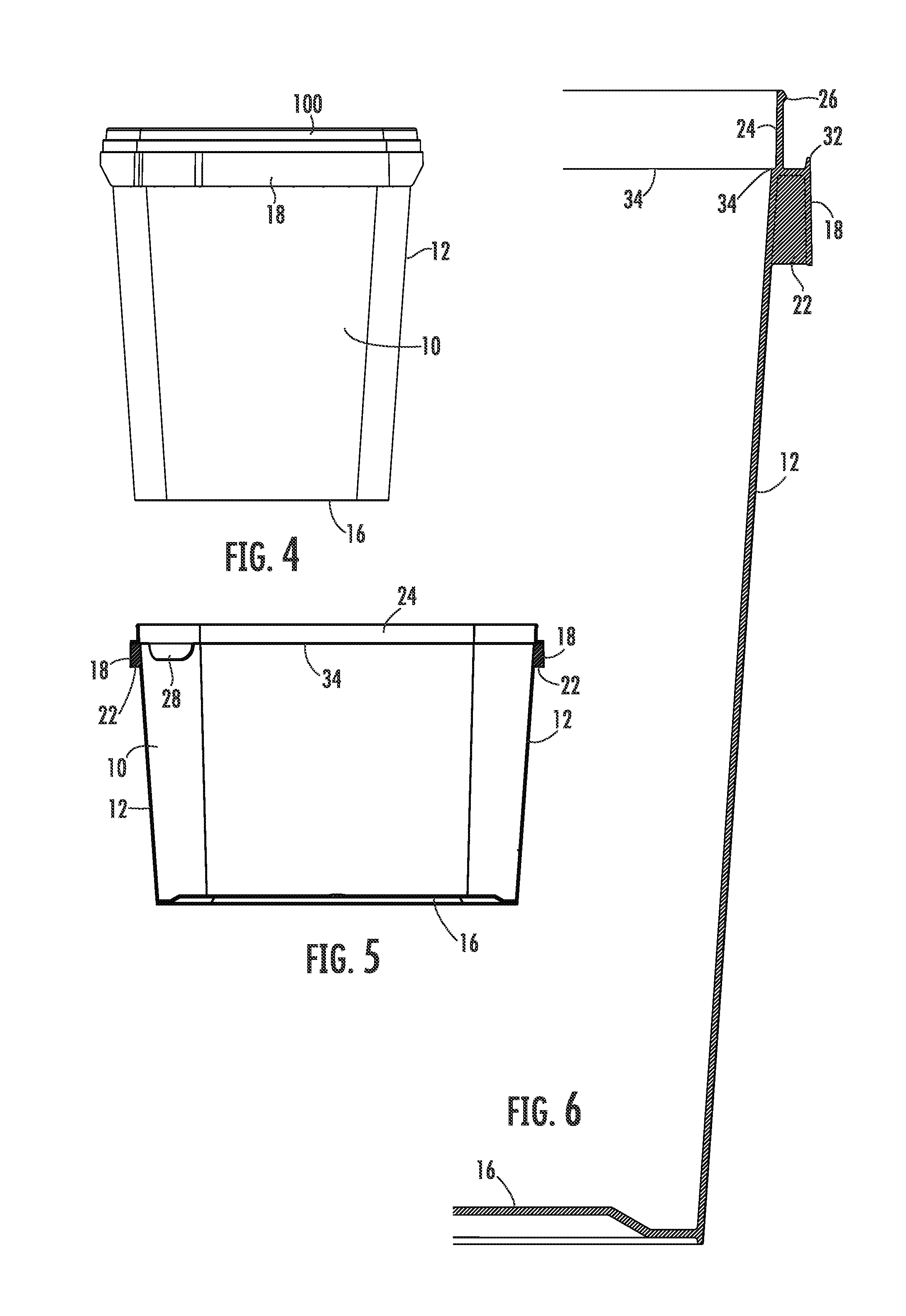

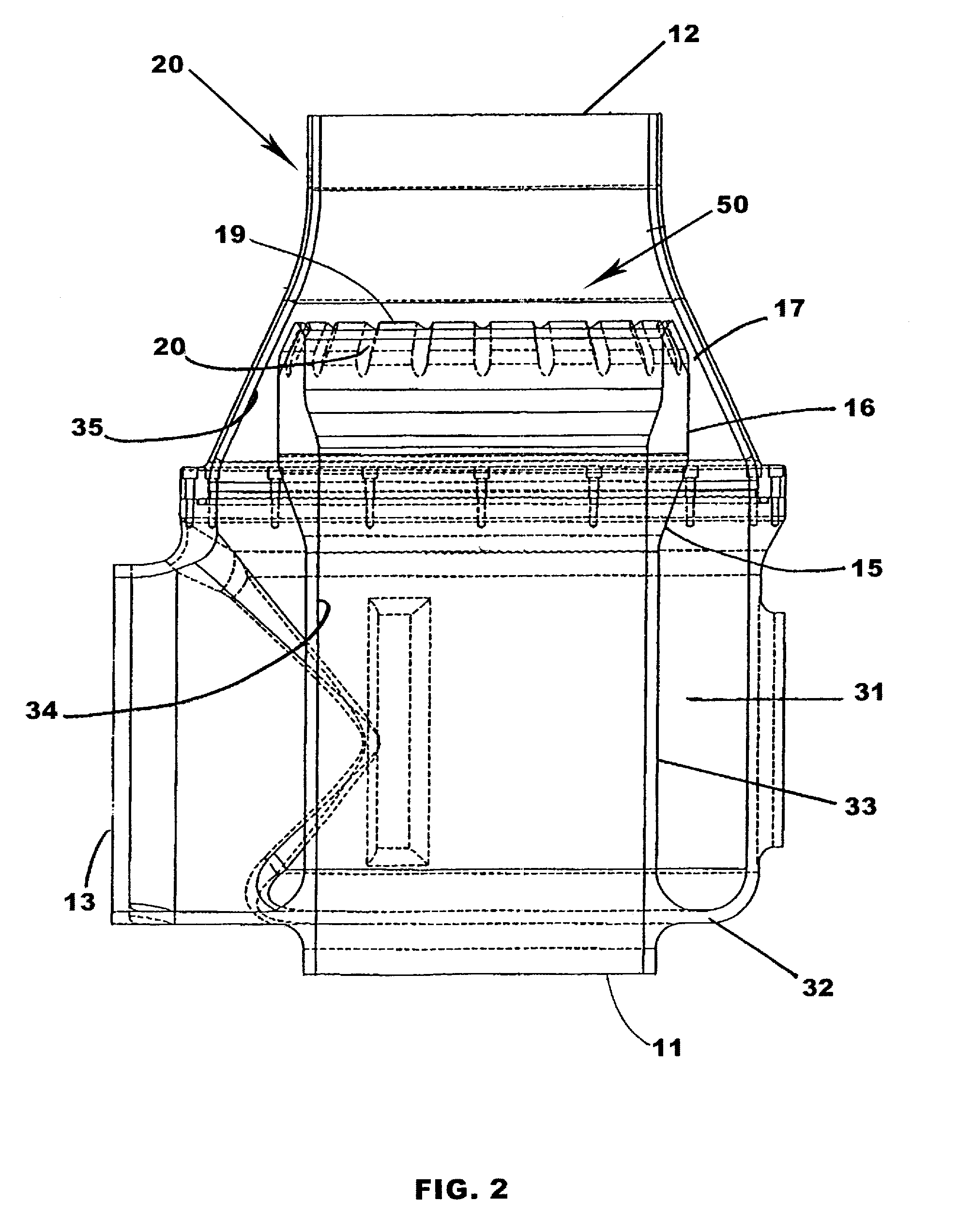

Container

Owner:WELLS ENTERPRISES

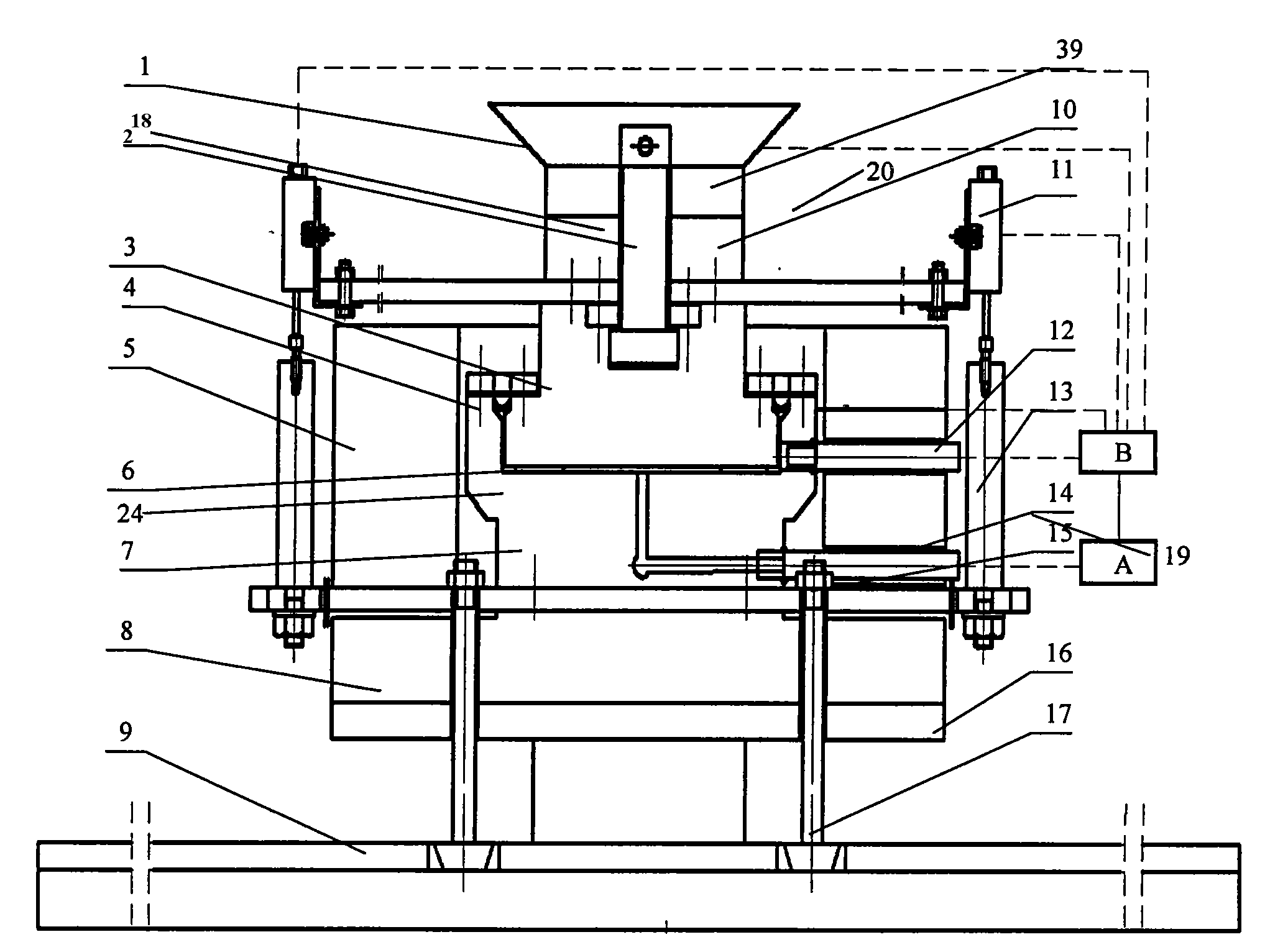

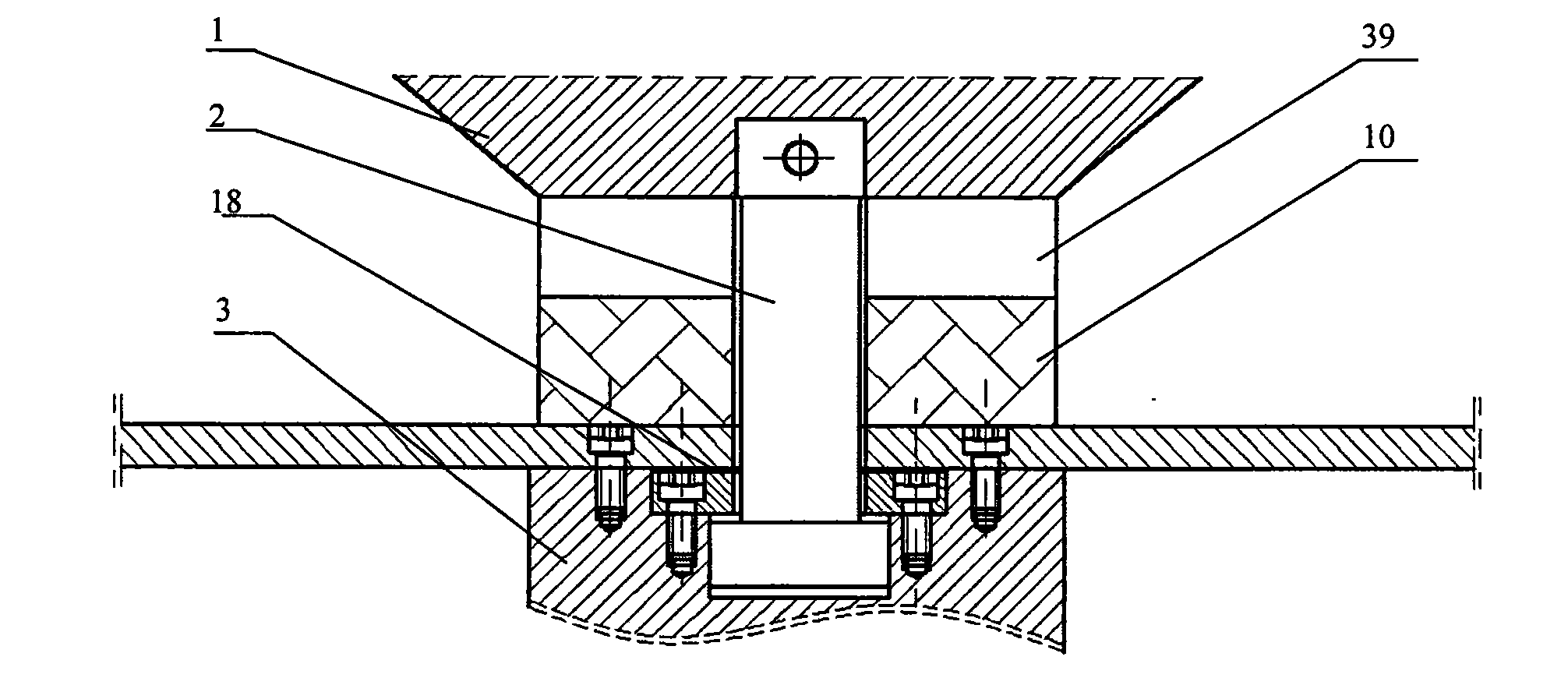

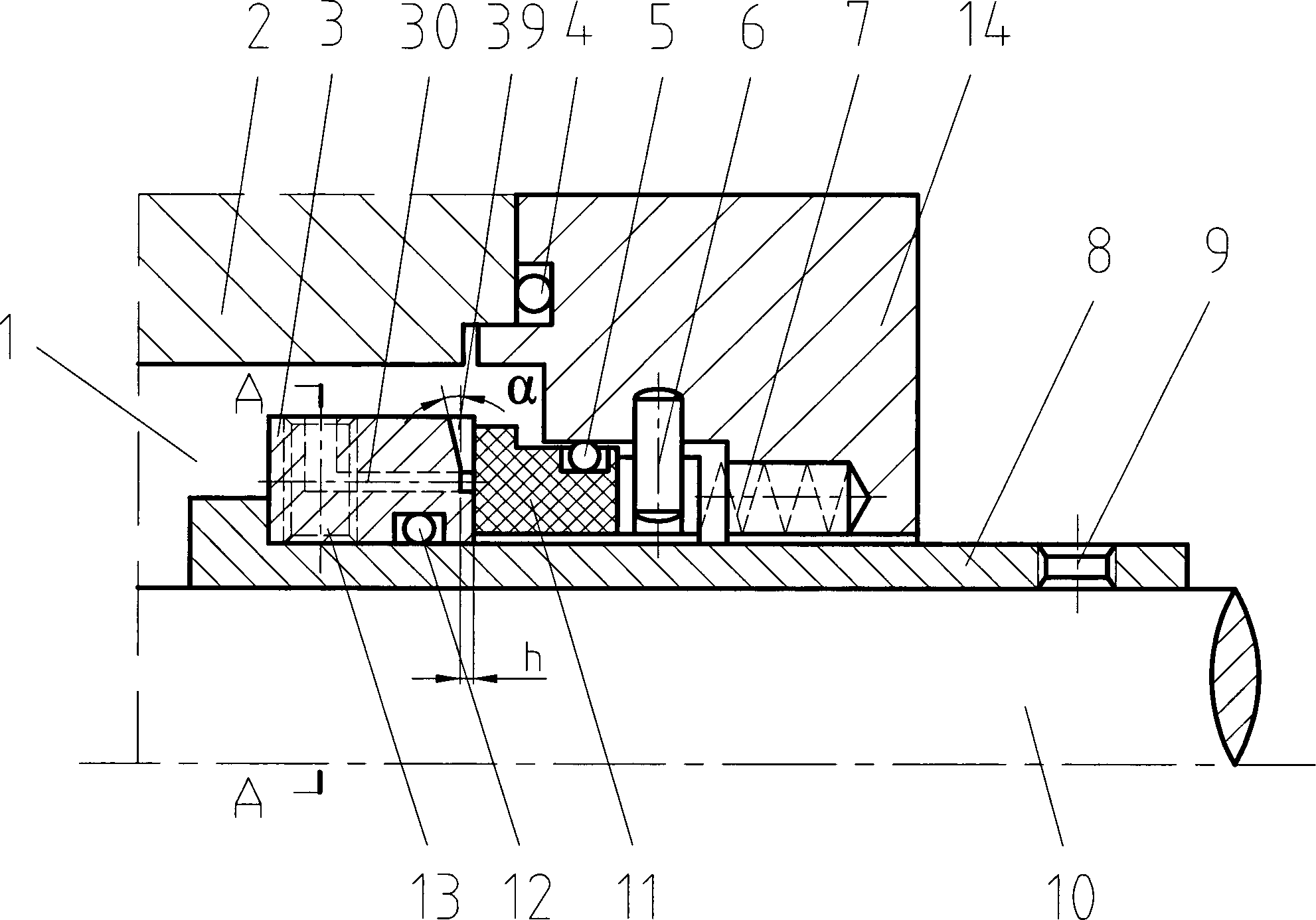

High-temperature comprehensive property evaluation experimental device of sealing spacer

InactiveCN101655437AAchieve high temperature compression reboundAchieve resilienceMeasurement of fluid loss/gain rateInvestigating material ductilityData acquisitionSmall footprint

The invention relates to a high-temperature comprehensive property evaluation experimental device of a sealing spacer, comprising a spacer loading system, a flange lifting separation system, a spacerdeformation measuring system, a heating and temperature control measuring system, a cooling heat insulation system, a medium setting system, a medium sealing and leakage rate measuring system and a data acquisition system. The invention has the advantages of high parameter, convenient experiment, compact structure of a whole experimental machine, small occupying area, and the like, takes a low-pressure area as a leakage measuring cavity, enhances the measuring precision of the pressure of the leakage measuring cavity and also effectively avoids the problem of pipeline leakage caused by takinga high-pressure area as a leakage cavity so that the measurement of the sealing property of the spacer is more accurate; and in addition, the flange lifting separation system can solve the problem ofthe difficult bonding and separation of the high-temperature experimental spacer and a flange.

Owner:NANJING UNIV OF TECH

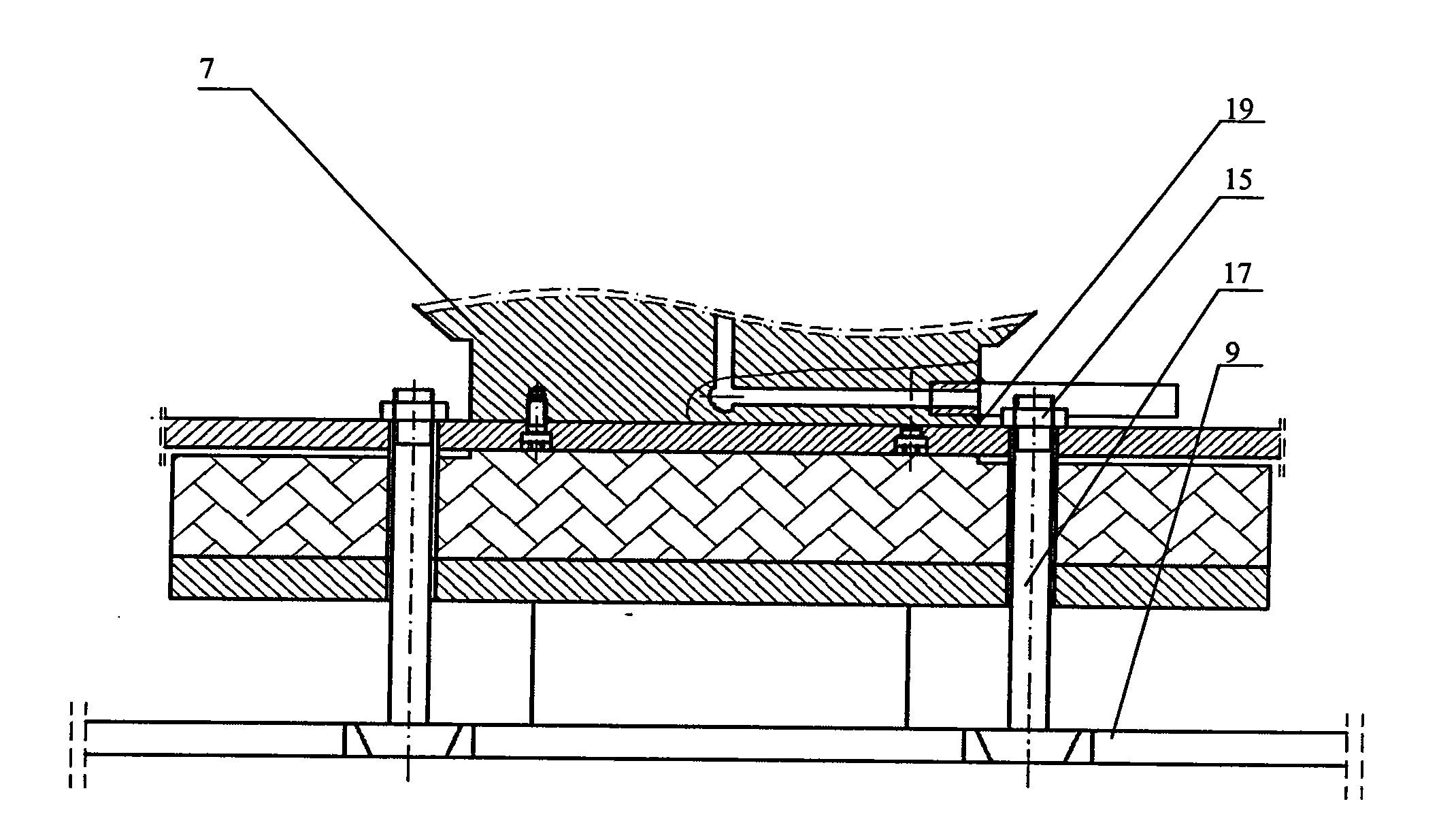

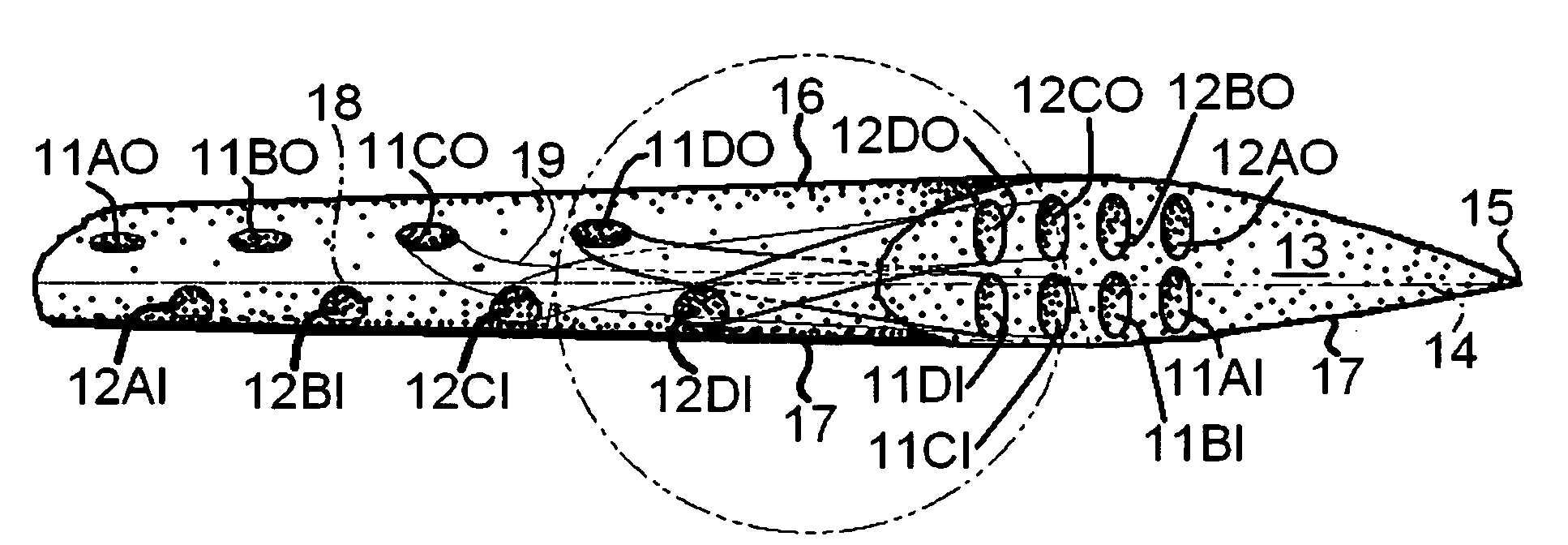

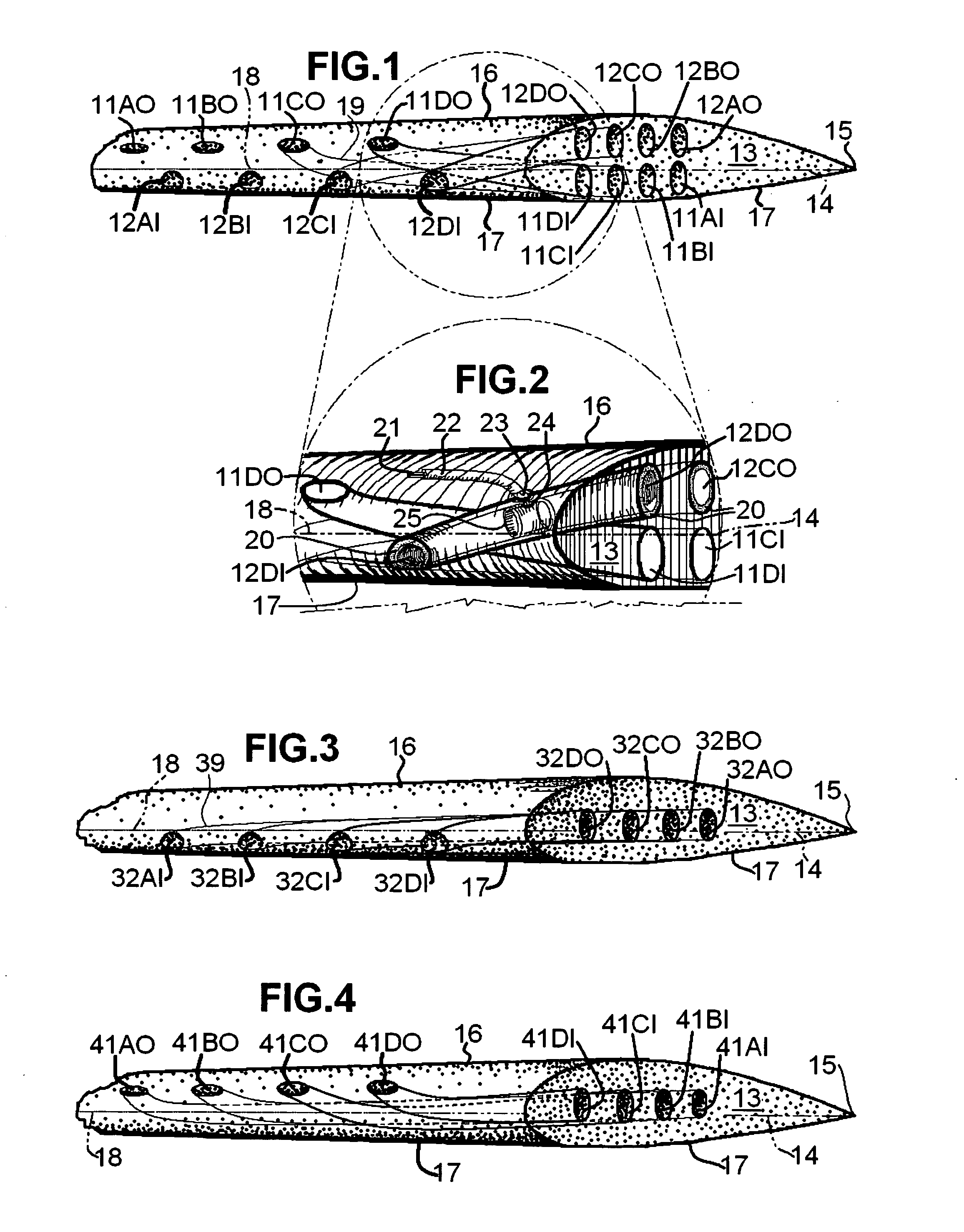

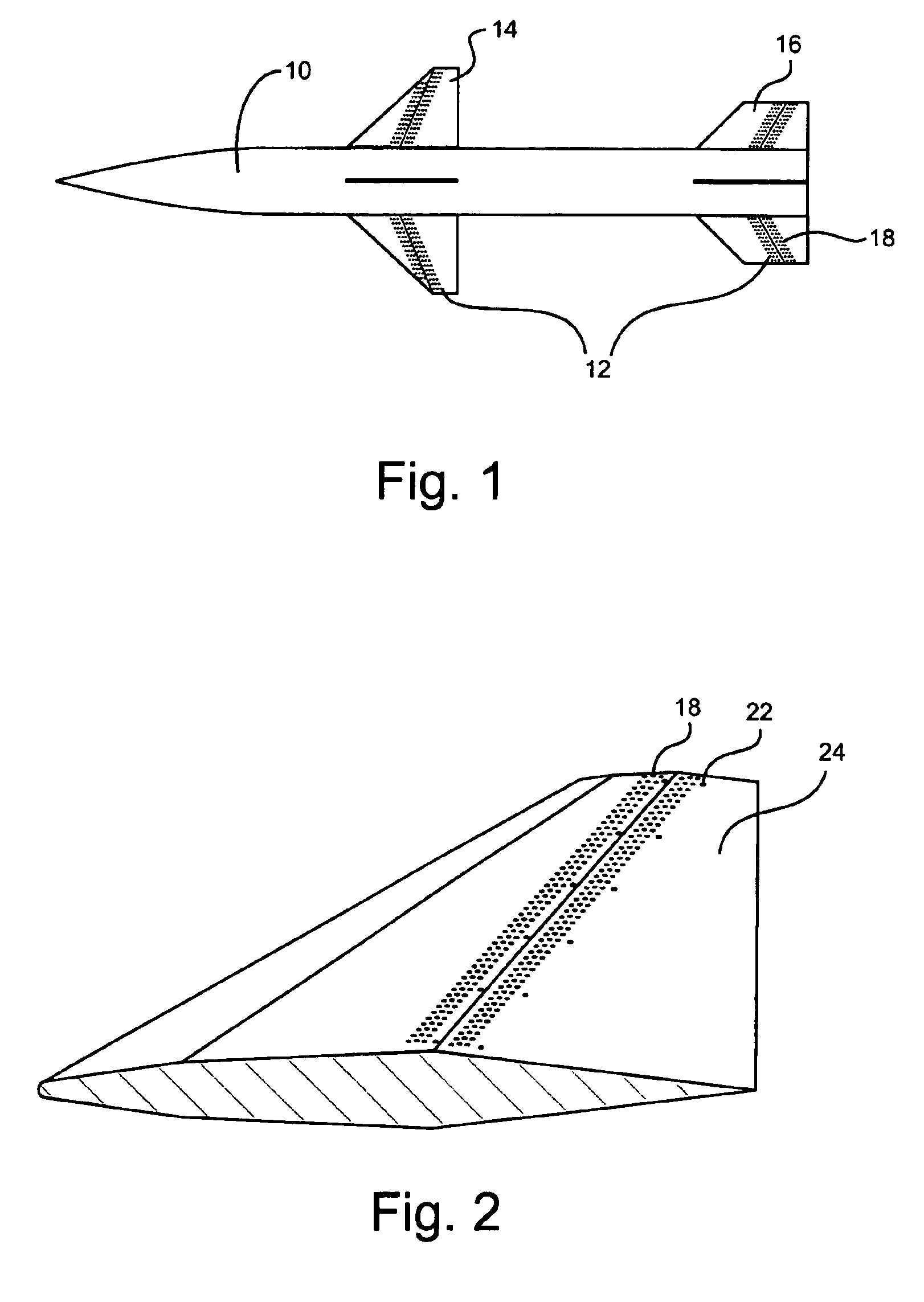

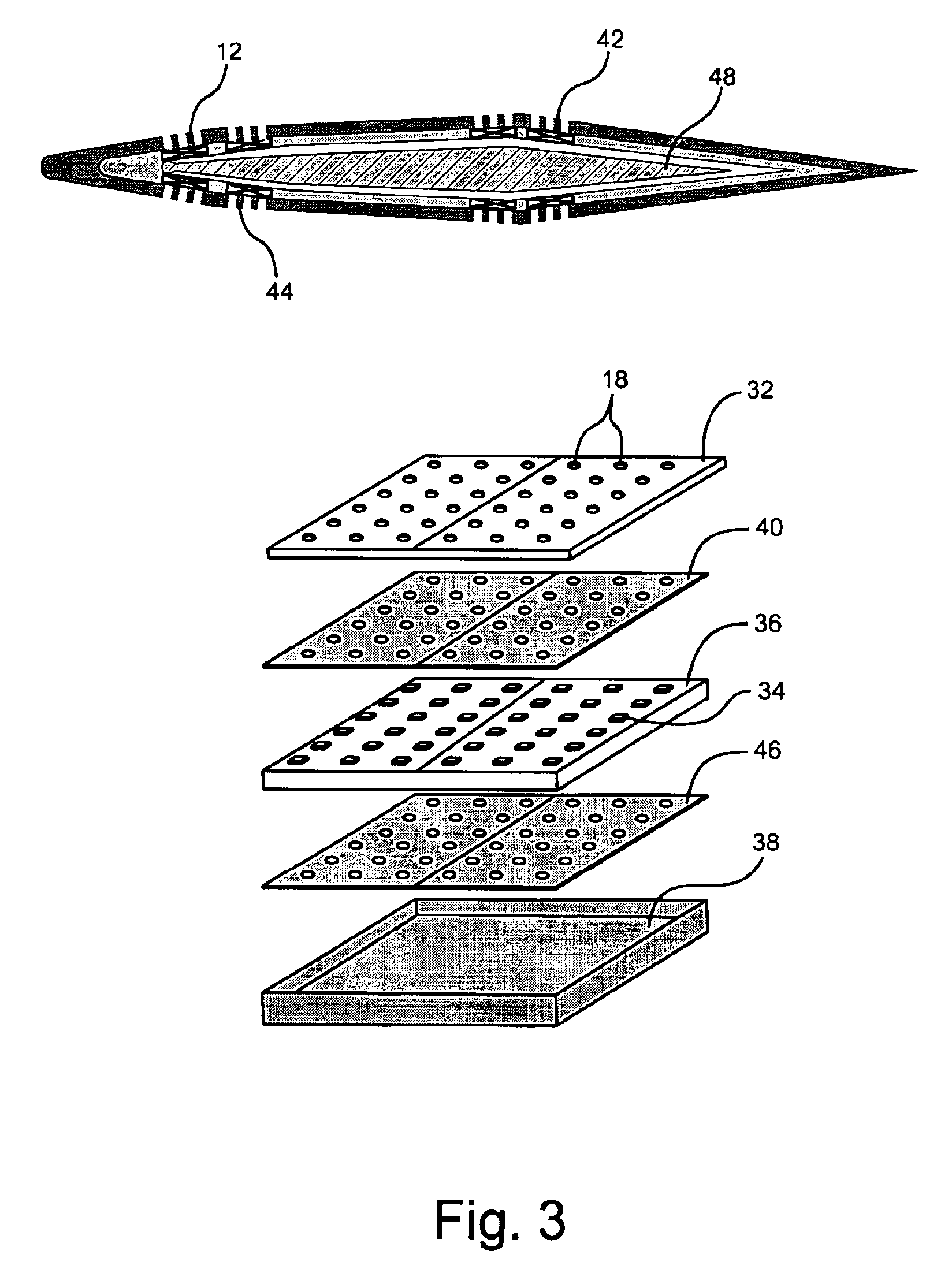

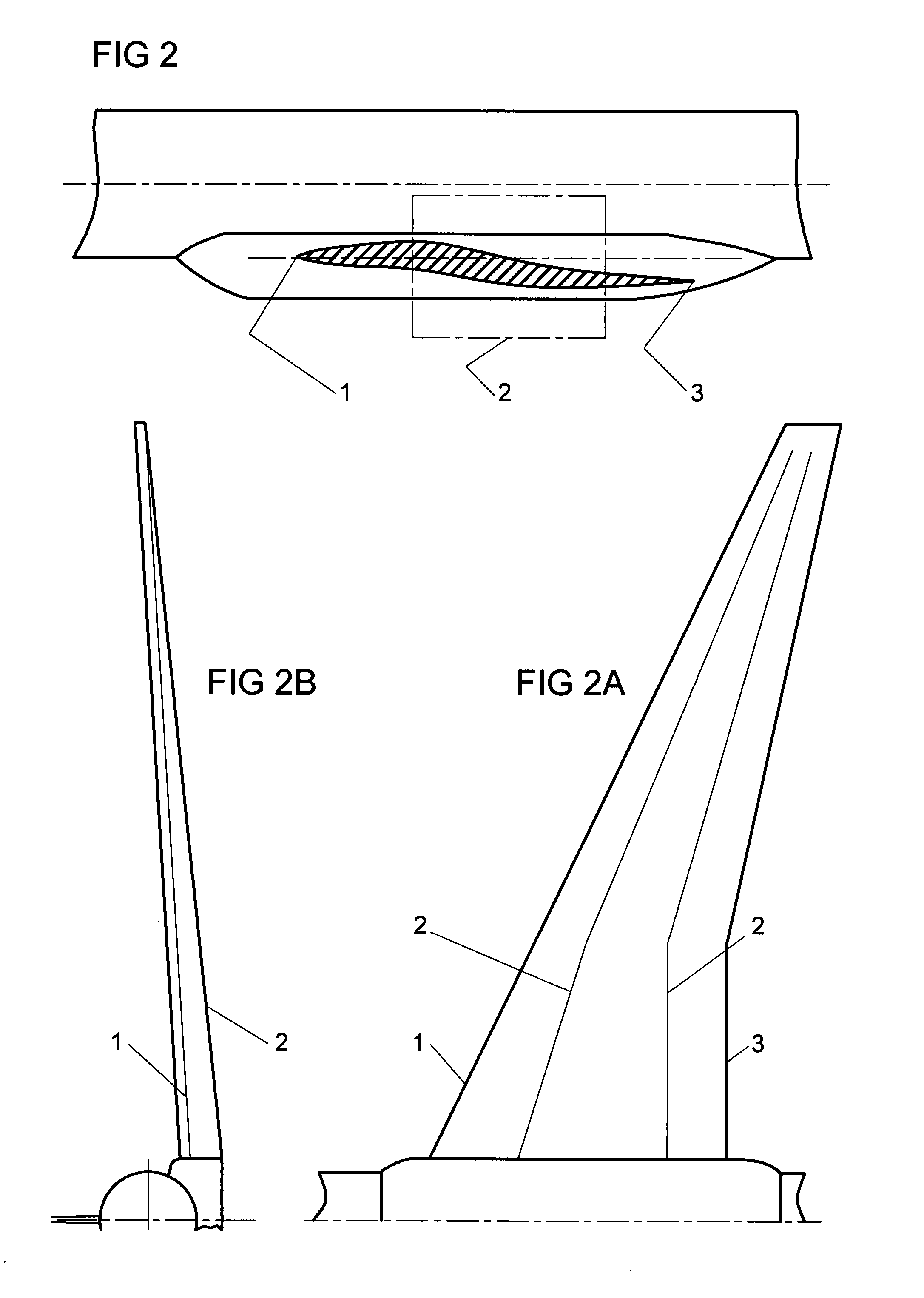

Surface flow diverting and static charging ducted pores on wing or blade tip to reduce wake and BVI noise

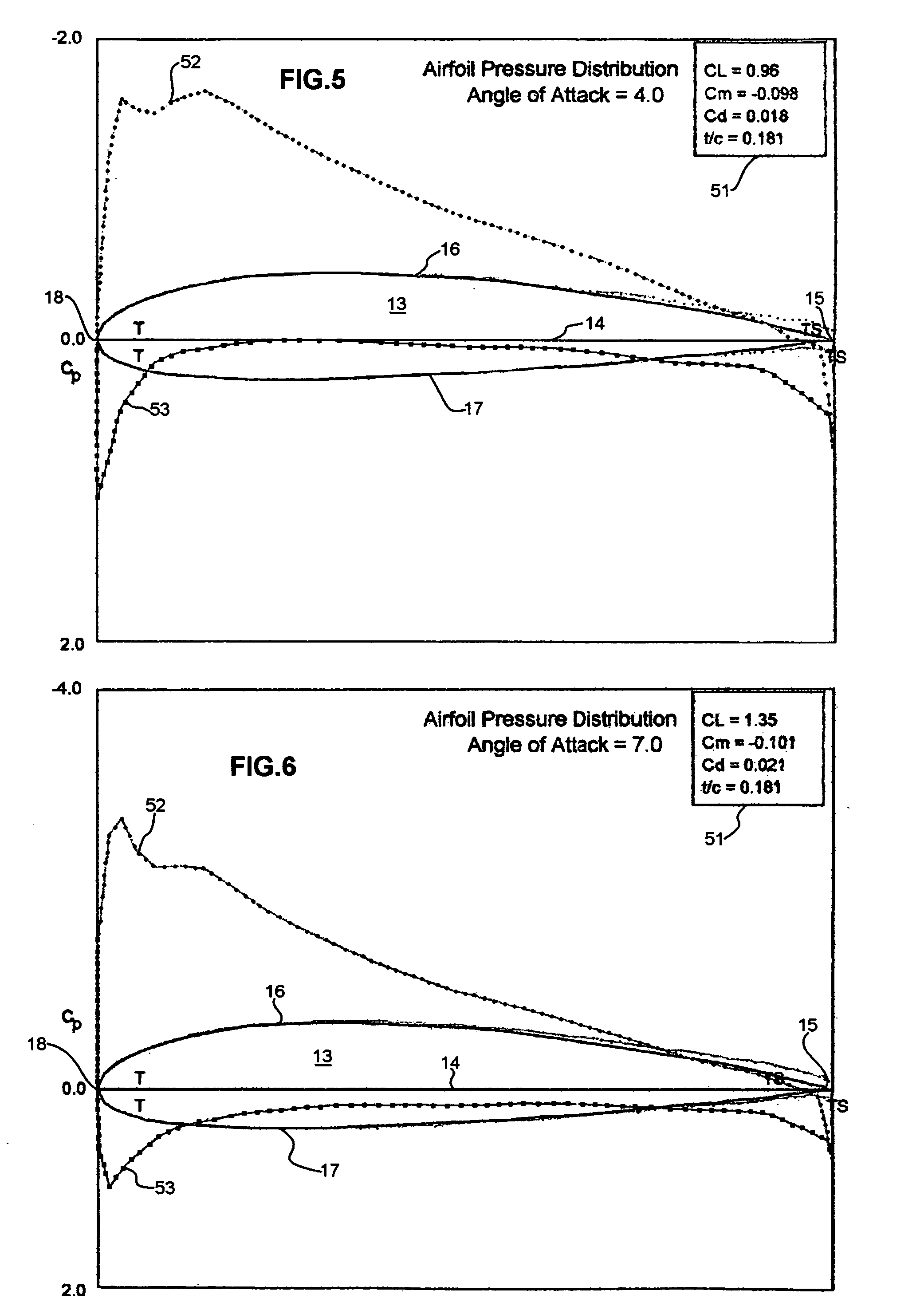

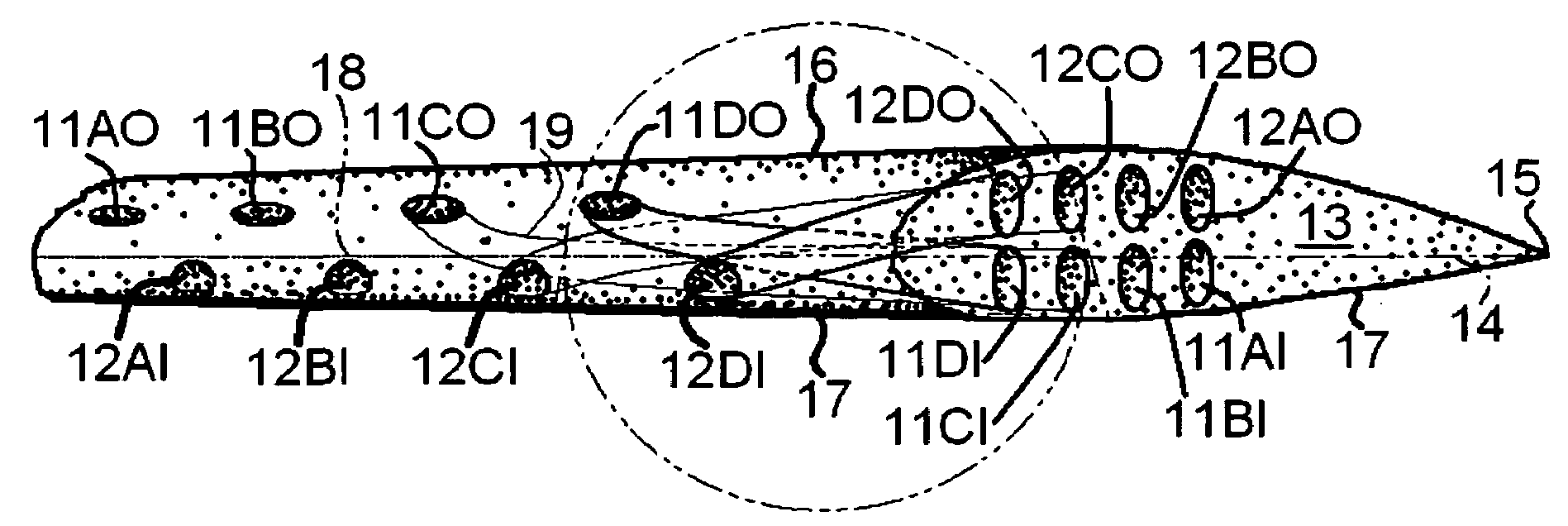

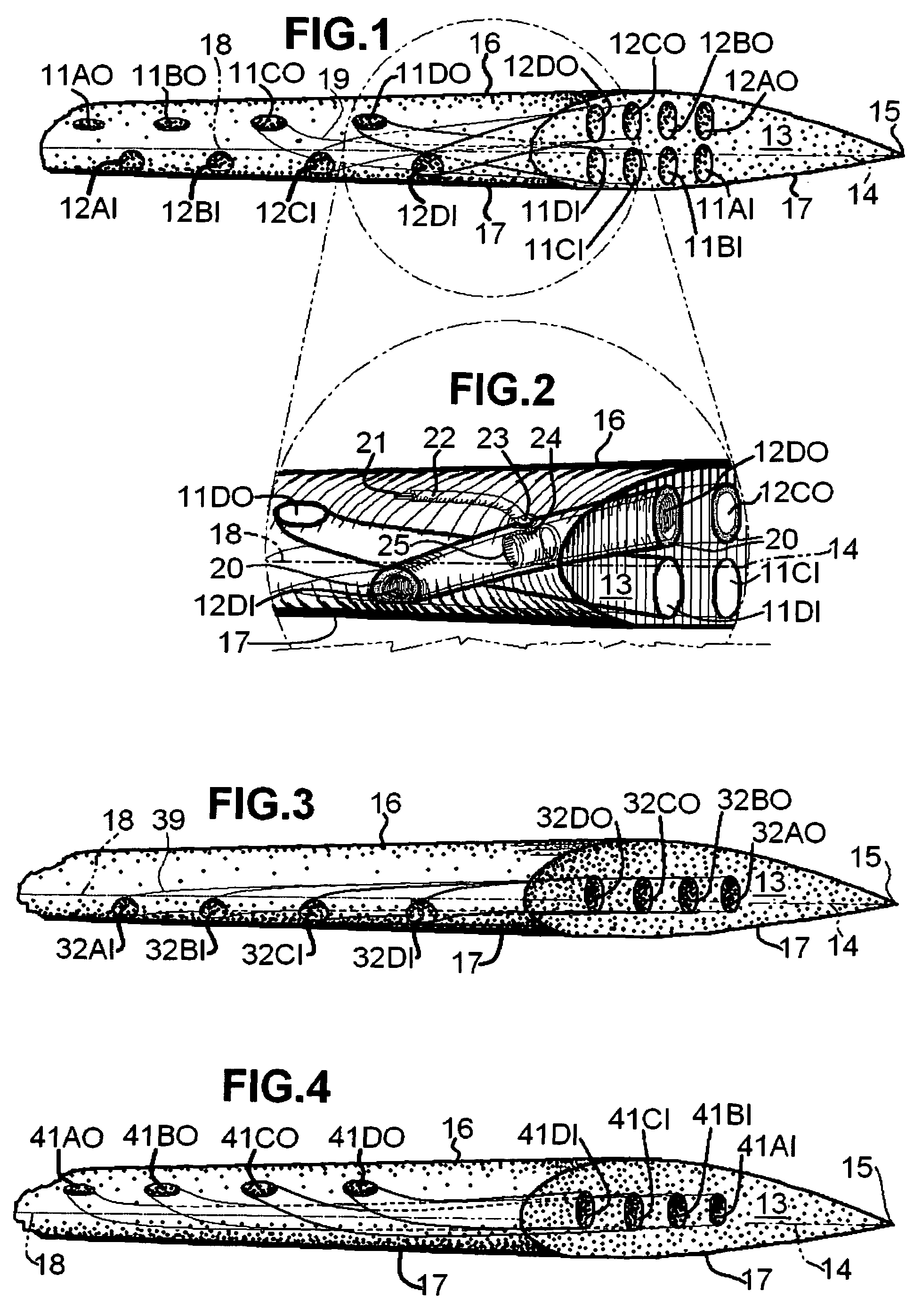

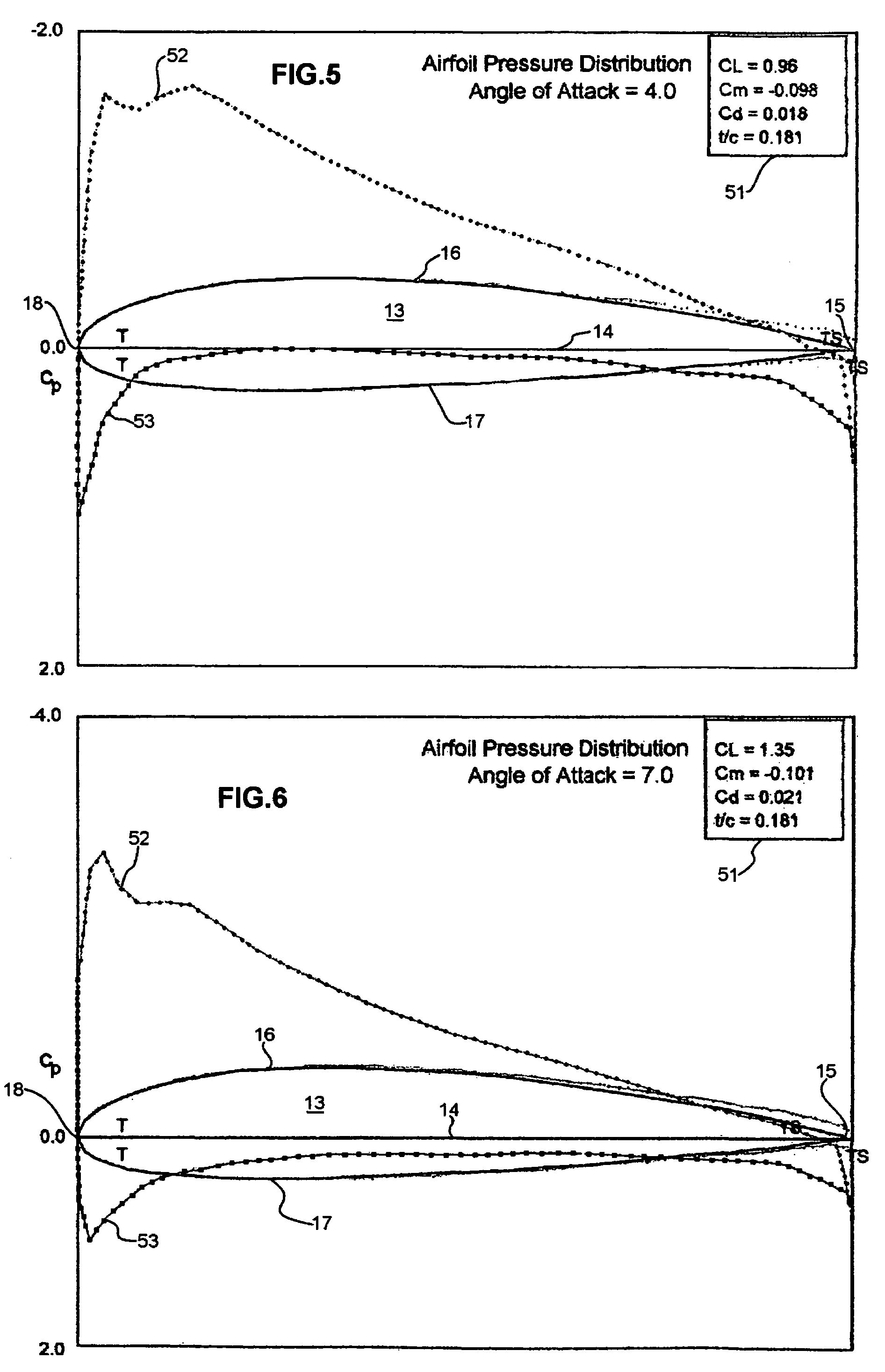

InactiveUS20070252047A1Promoting interlayer movementInfluencers by generating vorticesWing shapesElectricityLeading edge

Air pressure distribution for airfoil lower and upper surfaces is utilized to divert airflow using ducts formed in space-curve shapes placed inside the airfoil volume, through span-wise located inlets from high pressure areas on the airfoil lower surface near the leading edge and through chord-wise spaced inlets on the side face of the airfoil wing tip correspondingly to the side face of the airfoil wing tip through chord-wise spaced outlets on the side face of the airfoil wing tip and to span-wise located outlets to the low pressure areas on the airfoil upper surface. Triboelectric materials on the wing surfaces are employed to static charge the air in drag. Inside the ducts, the employment of either triboelectric linings and materials, or HV-supplied electrodes, or both, help to static charge the diverted air flow to and from the airfoil wing tip side face to diffuse wing tip vortex core early.

Owner:PAL ANADISH KUMAR

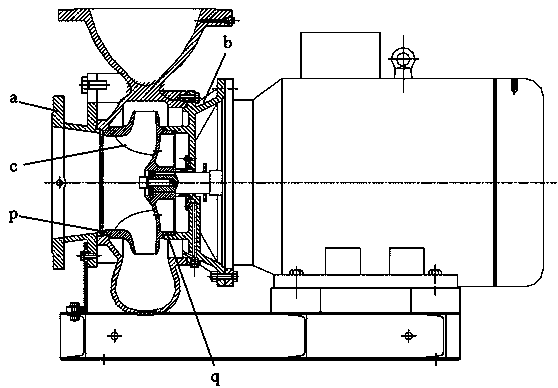

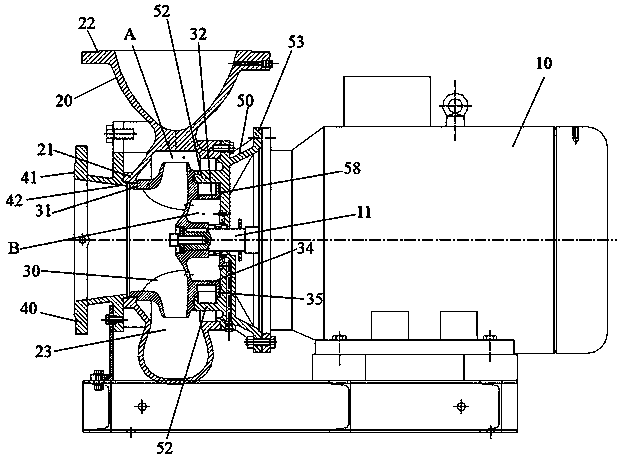

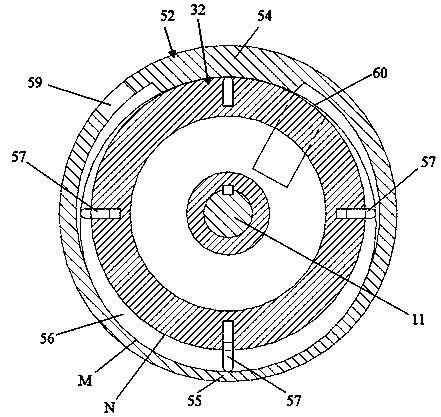

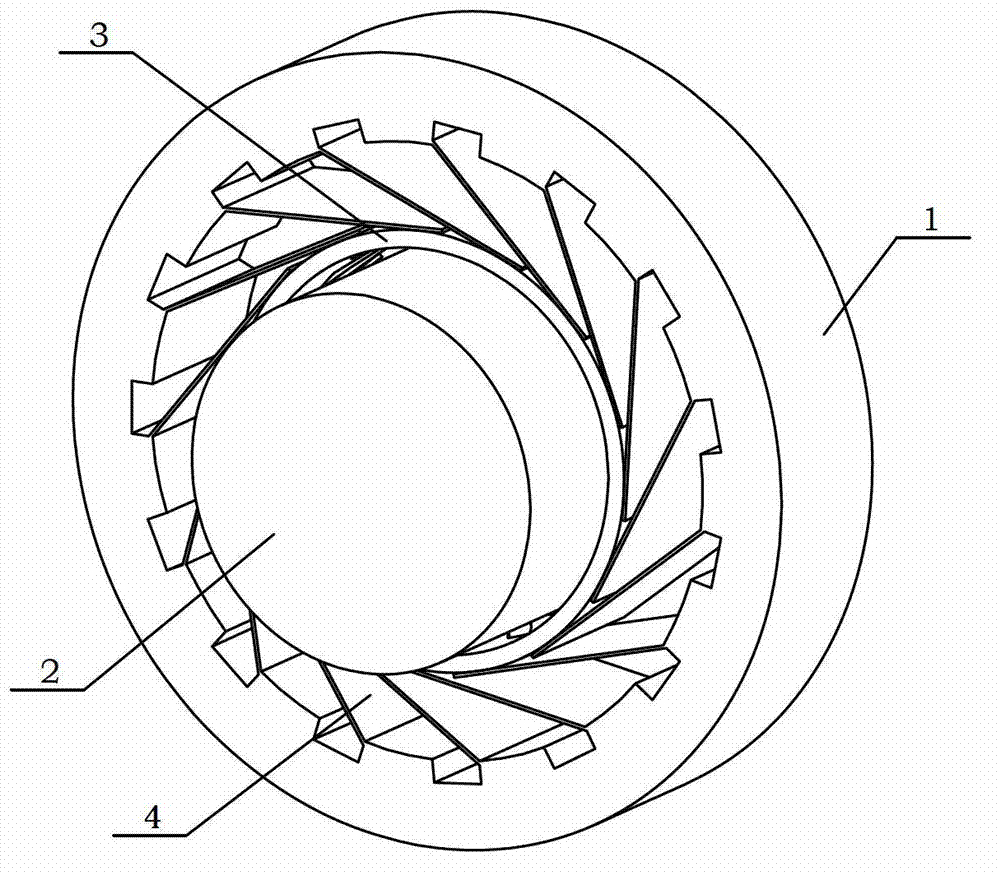

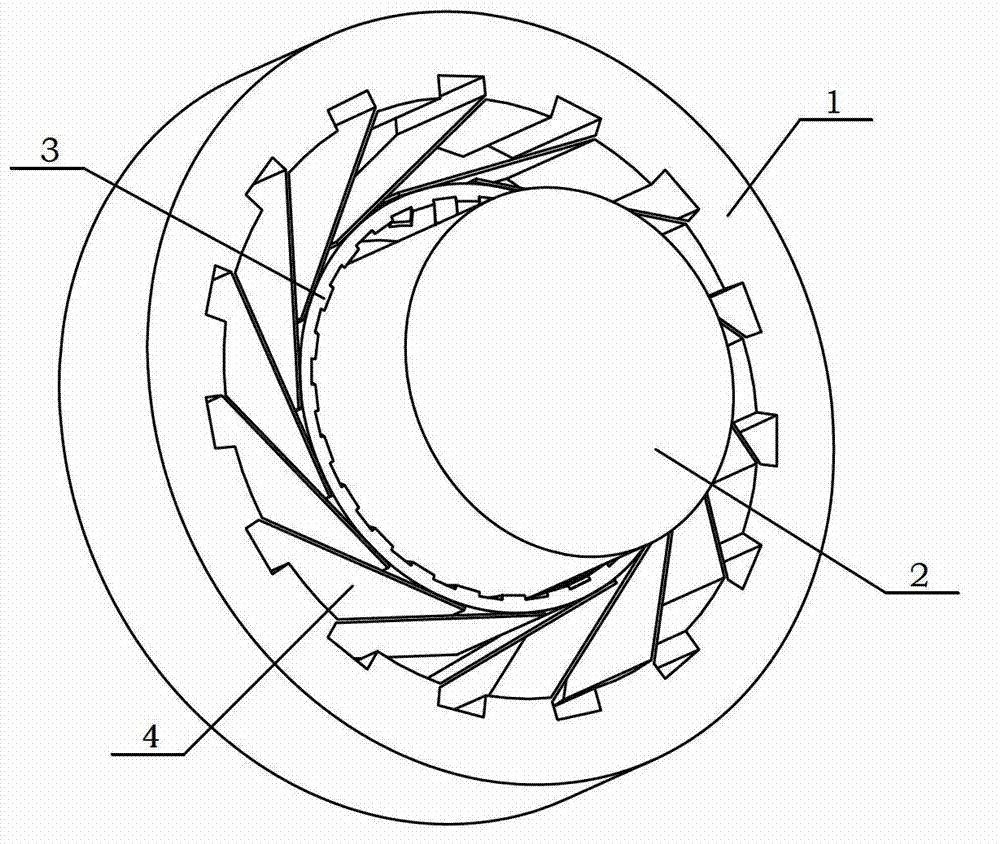

Centrifugal pump with impeller rotation boosting structure

The invention provides a centrifugal pump with an impeller rotation boosting structure, the centrifugal pump comprises a motor, a pump body, an impeller, and a front end cover and a rear end cover at the front and rear sides of the impeller, the impeller is provided with a rear seal ring, the rear end cover is provided with a seal baffle ring which extends toward the impeller and covers at the periphery of the rear seal ring, a seal cavity is formed between the seal baffle ring of the rear end cover and the rear seal ring of the impeller, and the rear seal ring is provided with a plurality of slip sheets capable of slipping into the seal cavity. Compared with the prior art, through adopting the improved design of the end cover and the impeller of the centrifugal pump and utilizing the improved structures (such as the seal cavity and the slip sheets) between the seal baffle ring and the rear seal ring, pressure difference between a high pressure area and a low pressure area at two ends of the seal cavity is converted into power for pushing the impeller to rotate during the rotation of the impeller, so that the torque output of the motor is reduced.

Owner:上海瑞晨环保科技股份有限公司

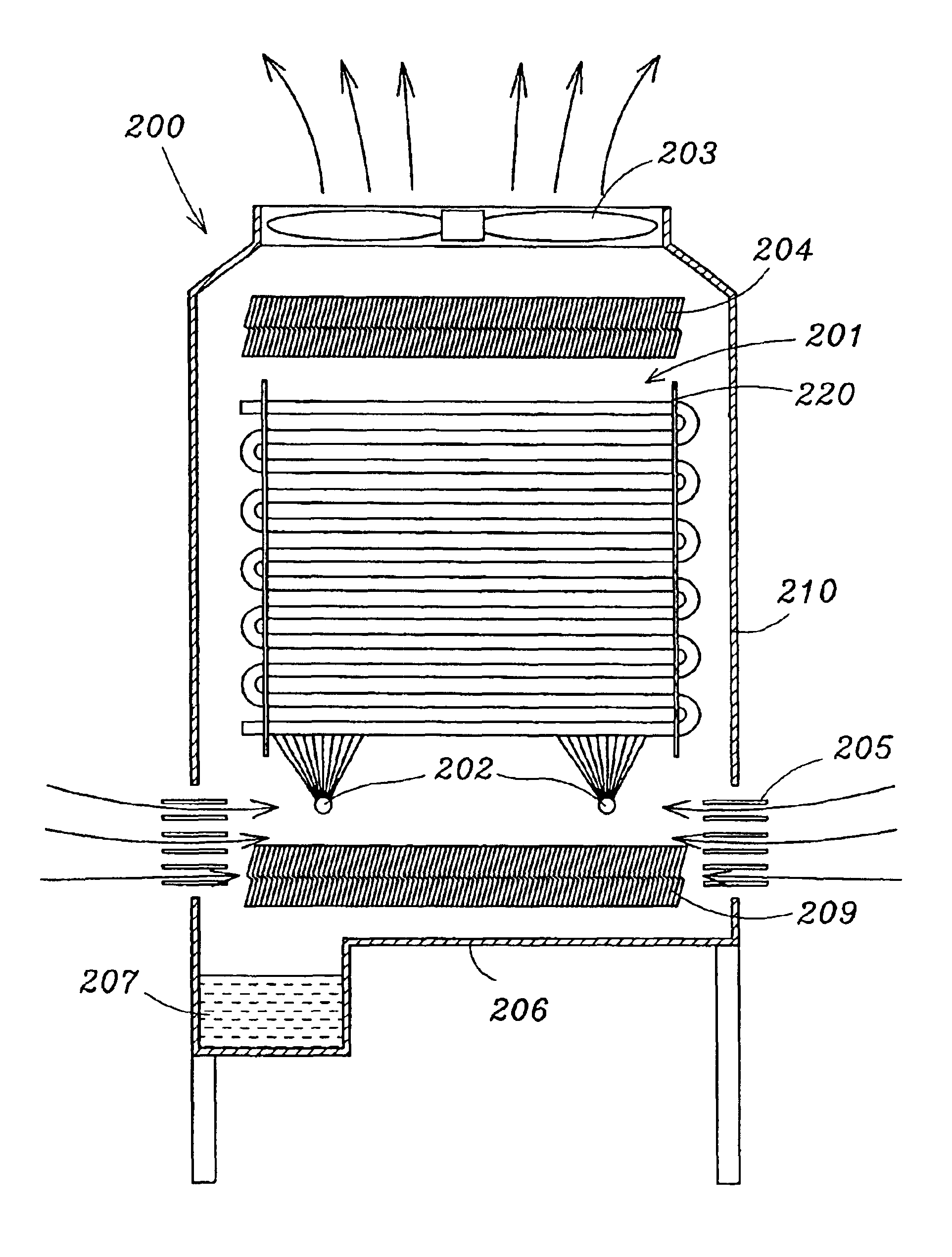

Evaporative condenser without cooling fins

InactiveUS6766655B1Solve the low heat dissipation efficiencyLong lastingEvaporators/condensersSteam/vapor condensersEvaporative coolerEvaporation

An evaporative type medium condenser without the using of conventional cooling fins comprises: characteristically a plurality of streamline cross sectional bare metal tubes disposed in parallel for medium coils to instead the conventional round sectional tubes thereof; a recycling water supply system having a plurality of water spray nozzles for spraying fine water particles onto the surface of coil tubes formed a water film continuously held thereon; a fan system to provide a wind flow blowing over the streamline tubes in a direction from a large head front portion of the streamline cross section to a gradual reduced rear portion thereof and to provide a low pressure area thereat so as to speedy the evaporation of the water film on the surface of the coils tubes for improving a high cooling efficiency to reach a high E.E.R. therefore.

Owner:WU HO HSIN

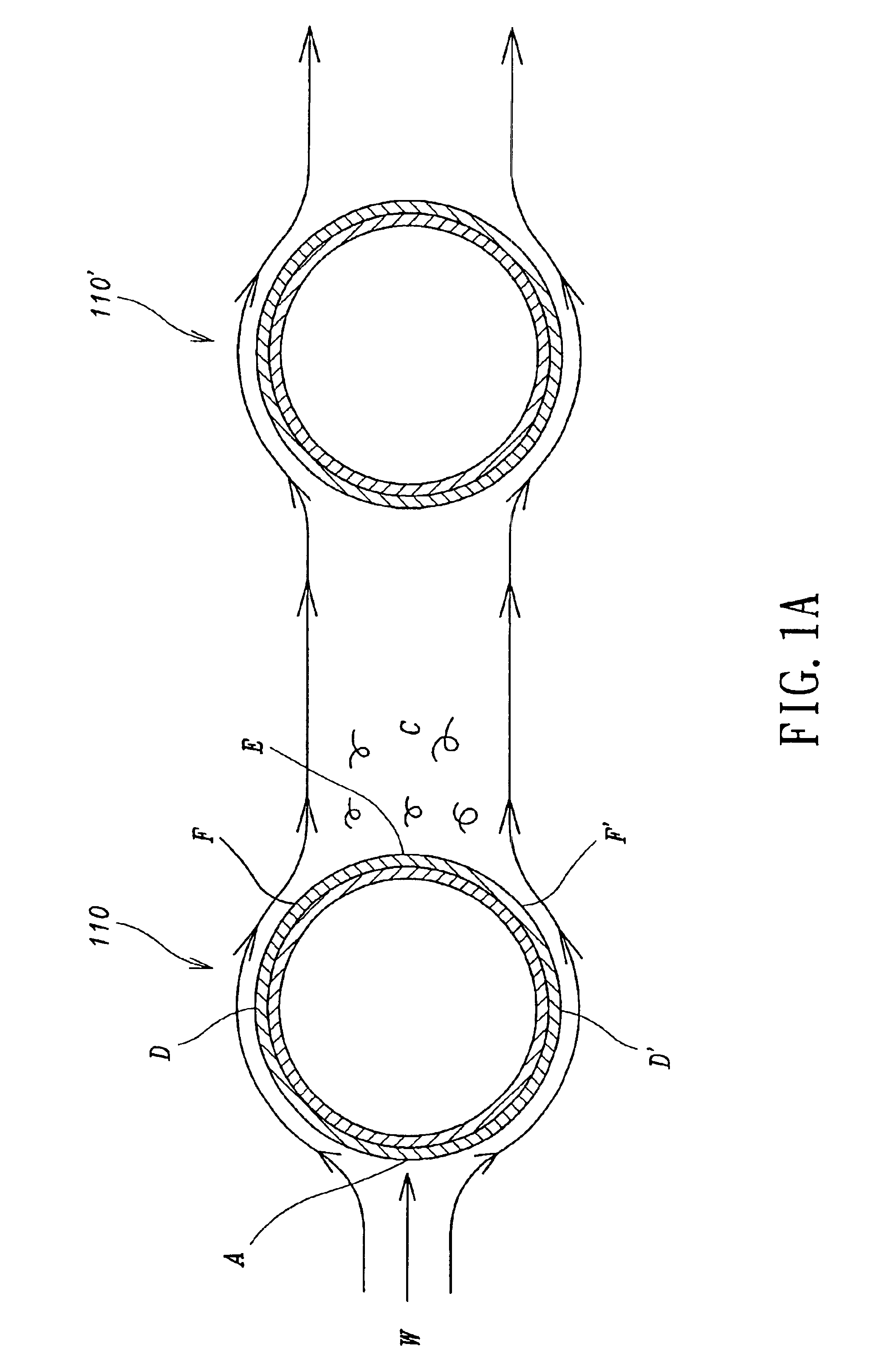

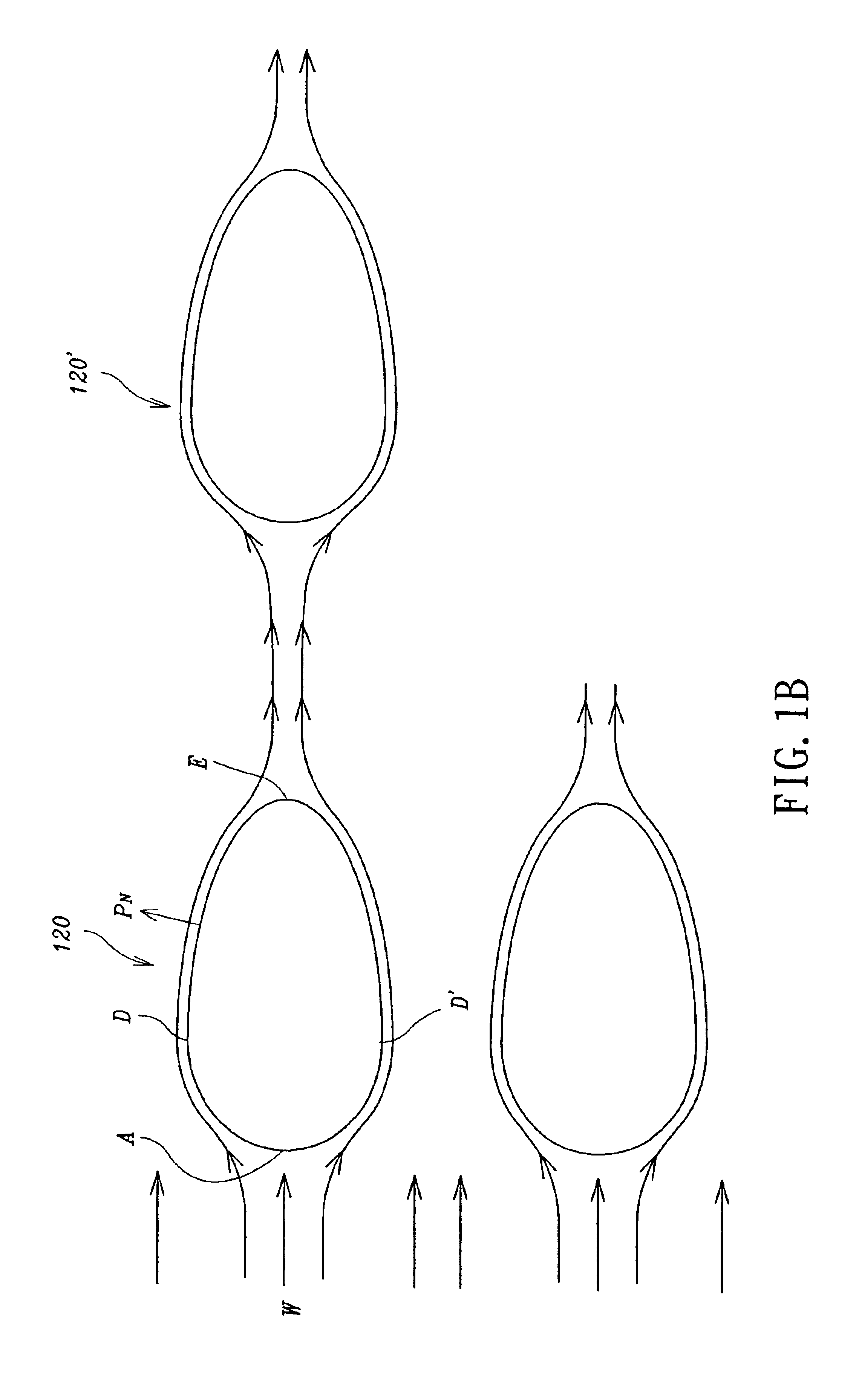

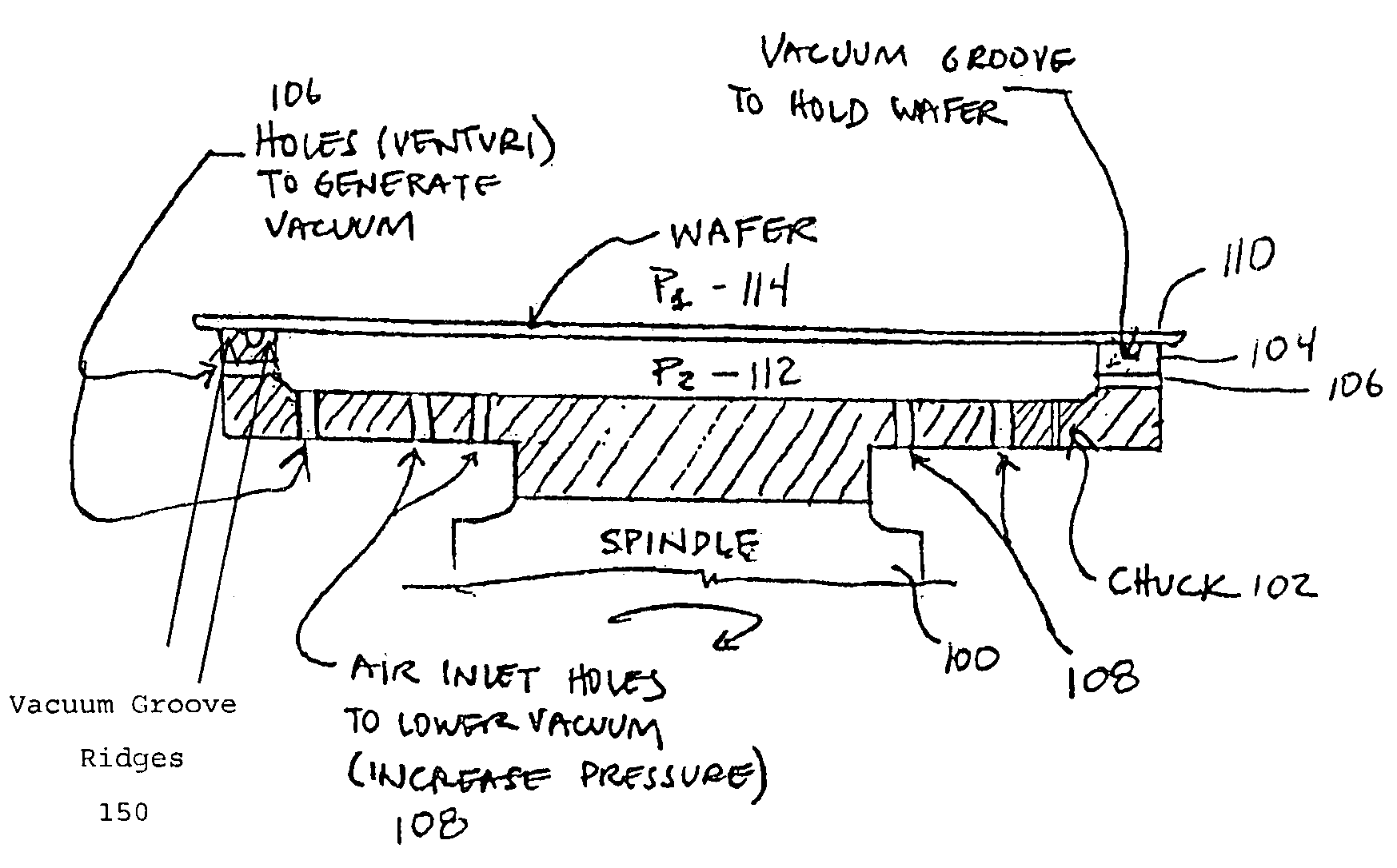

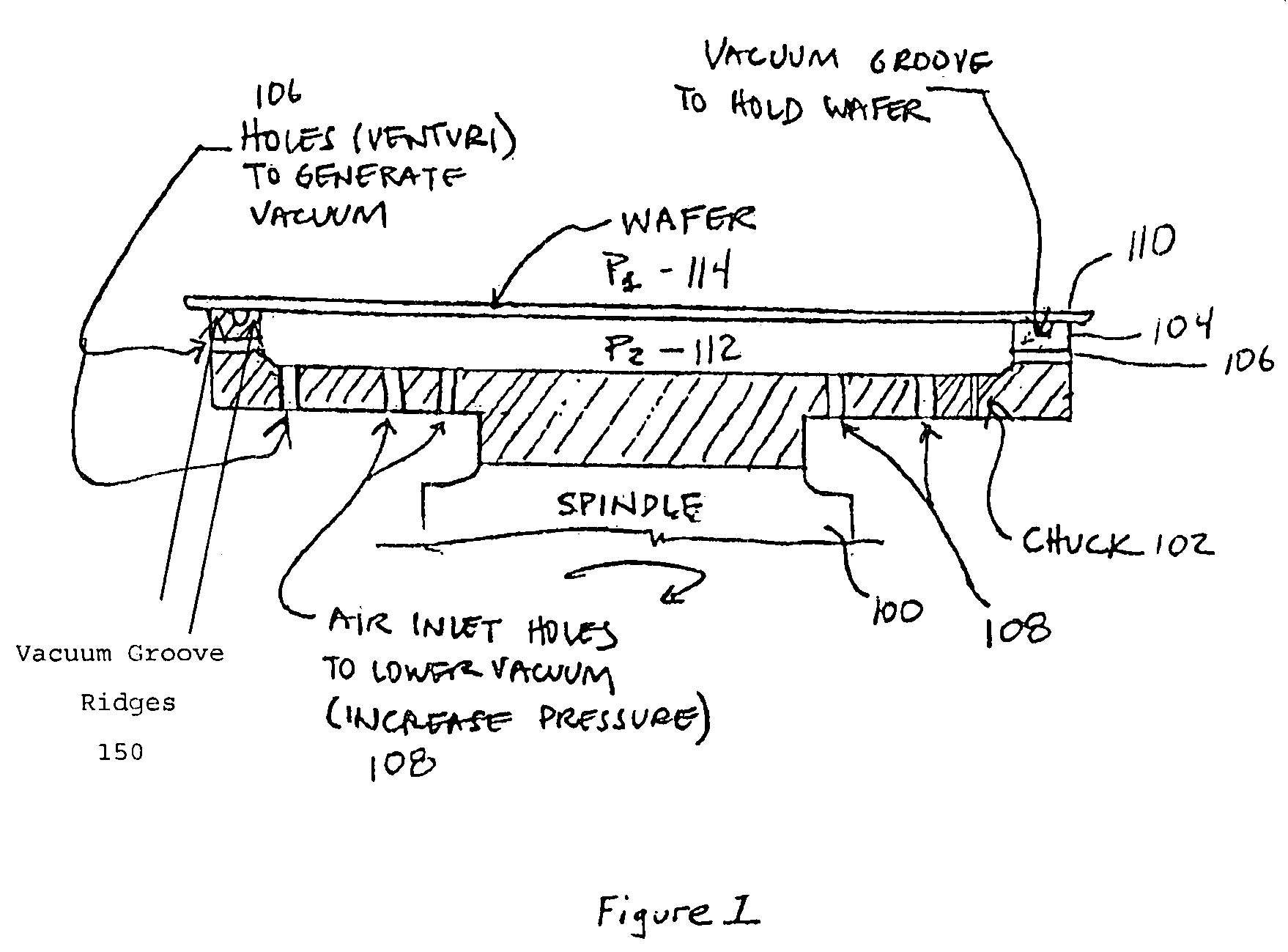

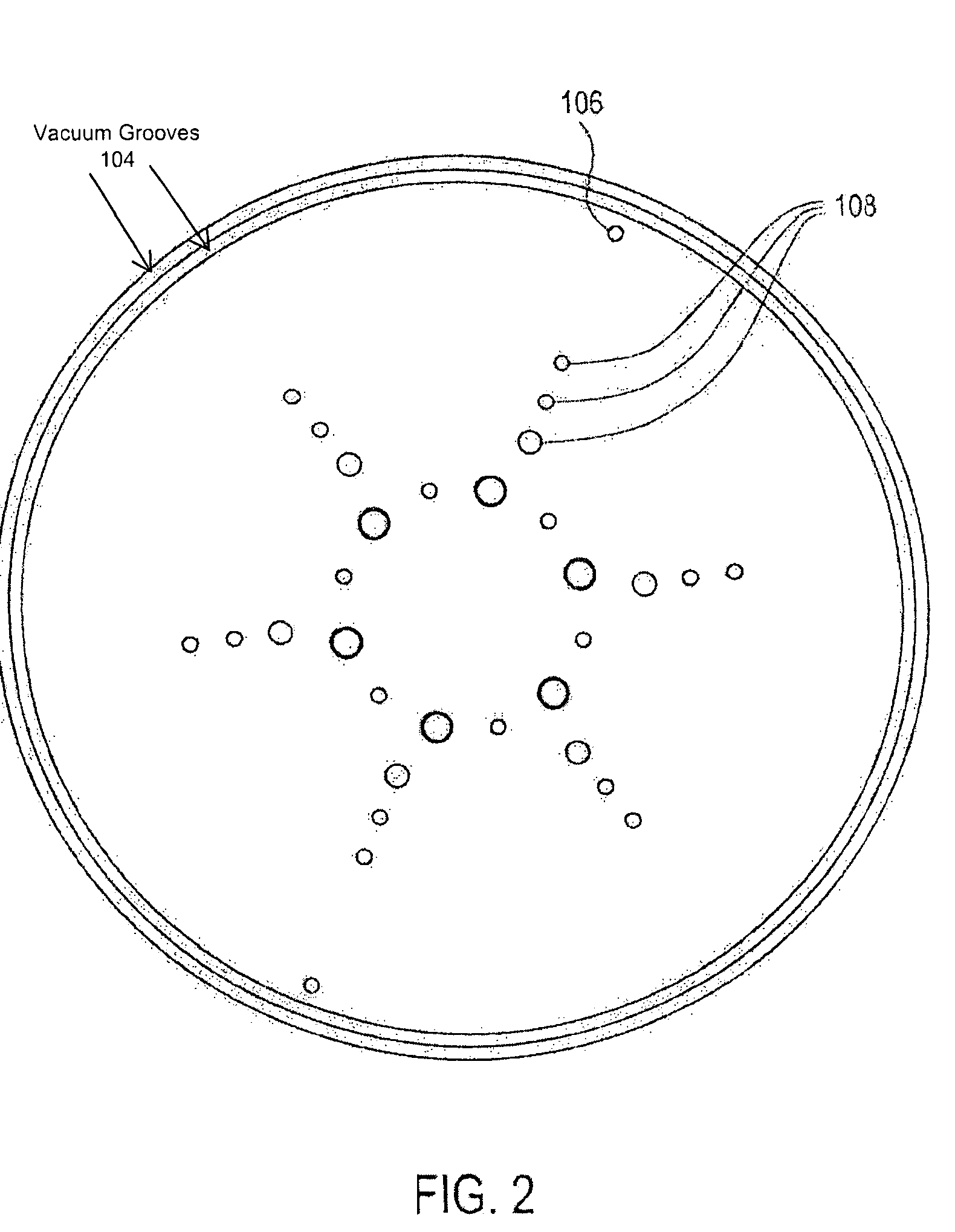

System and method for optimizing wafer flatness at high rotational speeds

ActiveUS7396022B1Reduce air pressureReduce bowingSleeve/socket jointsLiquid surface applicatorsMeasurement deviceLow-pressure area

The present invention is a chuck having a vacuum groove that is capable of holding a wafer as the chuck rotates on a spindle. As the chuck rotates the air pressure above the center of the wafer is reduced. In order to reduce the bowing of the wafer that can result from this low pressure area above the wafer, the present invention introduces venturi holes in the chuck which reduces the air pressure in the area below the wafer. In order to prevent the air pressure in the area below the wafer from decreasing too far, the present invention uses air inlet holes to balance the affect of the venturi holes in order to substantially balance the air pressure above and below the wafer which results in significantly less bowing of the wafer when compared to conventional systems. The present invention accomplishes this without requiring sensors or other active measuring devices to help reduce the bowing of the wafer.

Owner:KLA TENCOR TECH CORP

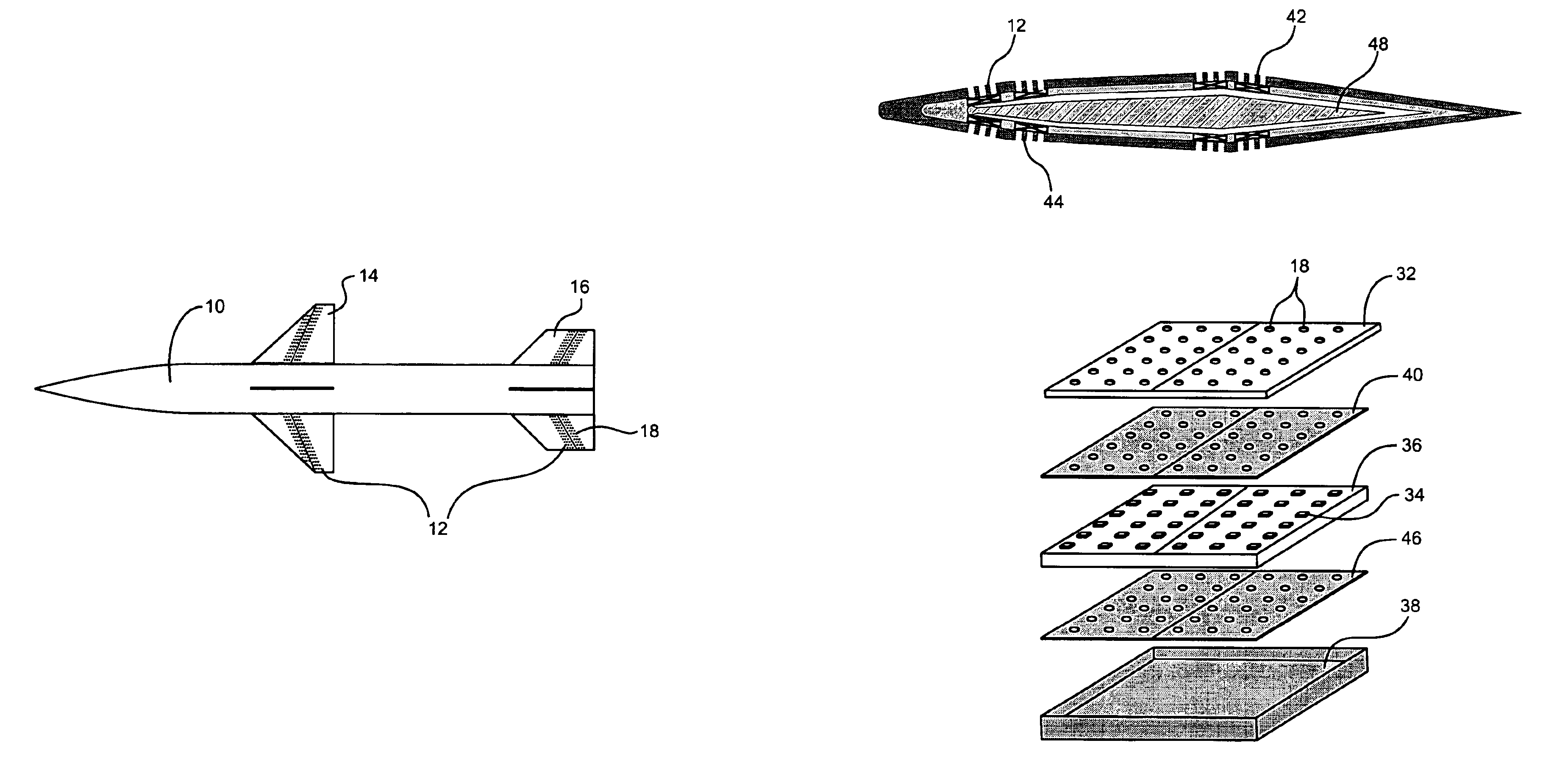

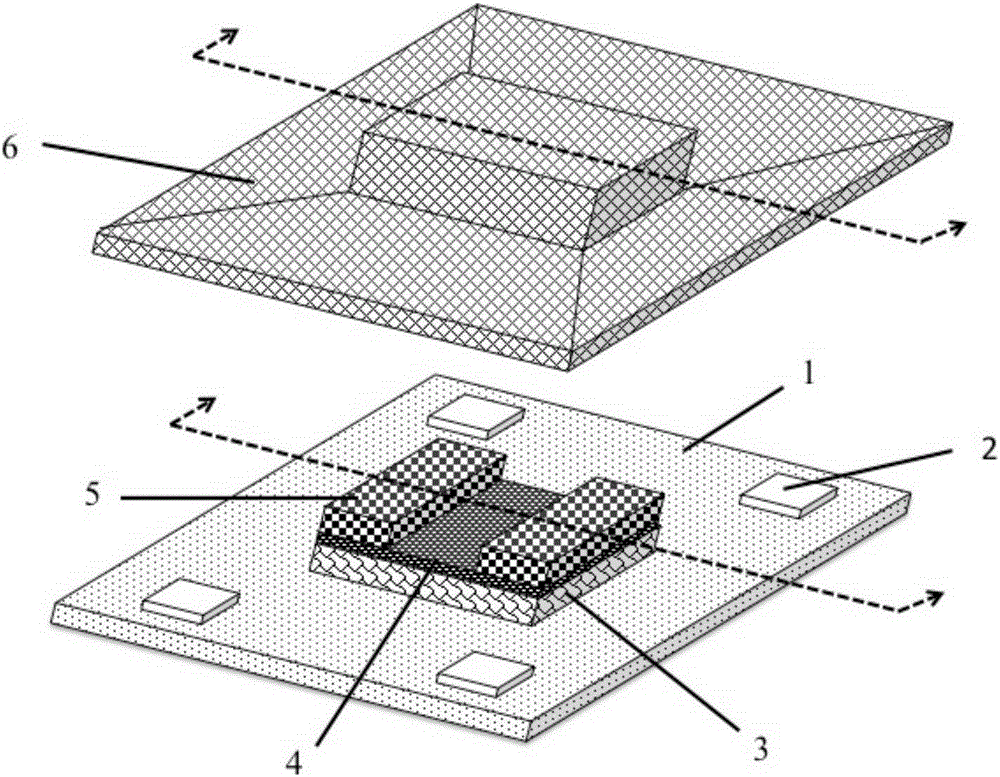

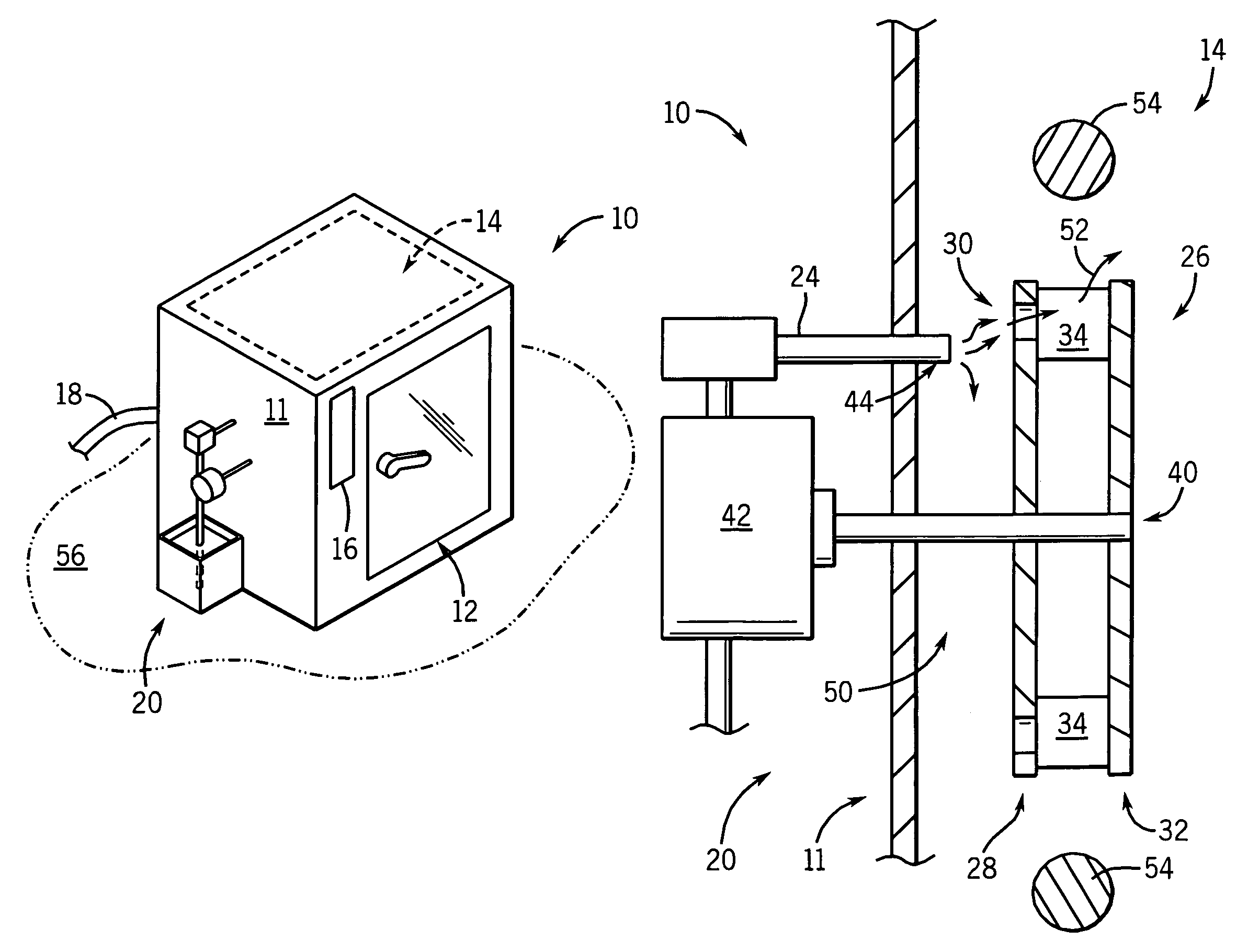

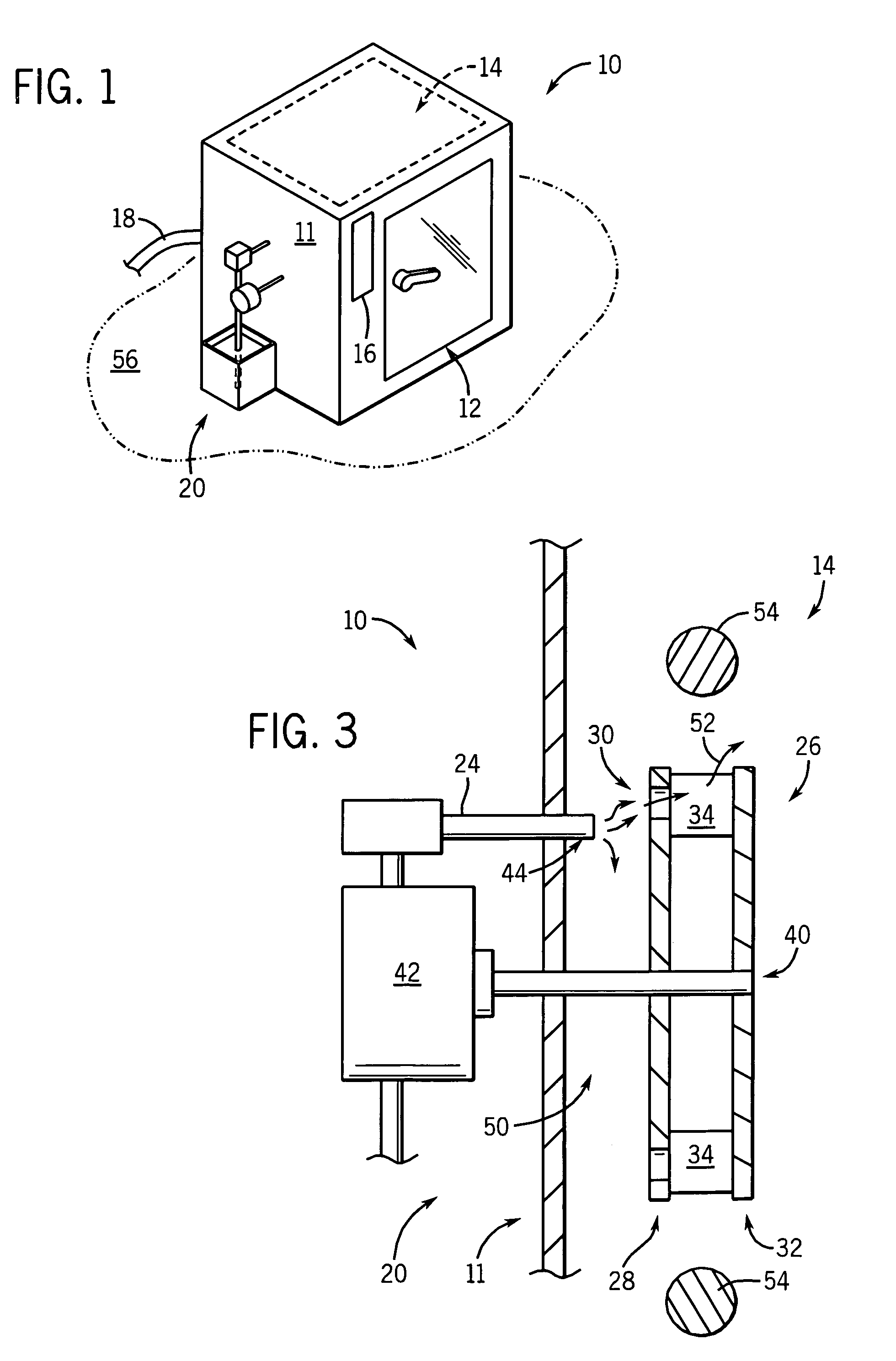

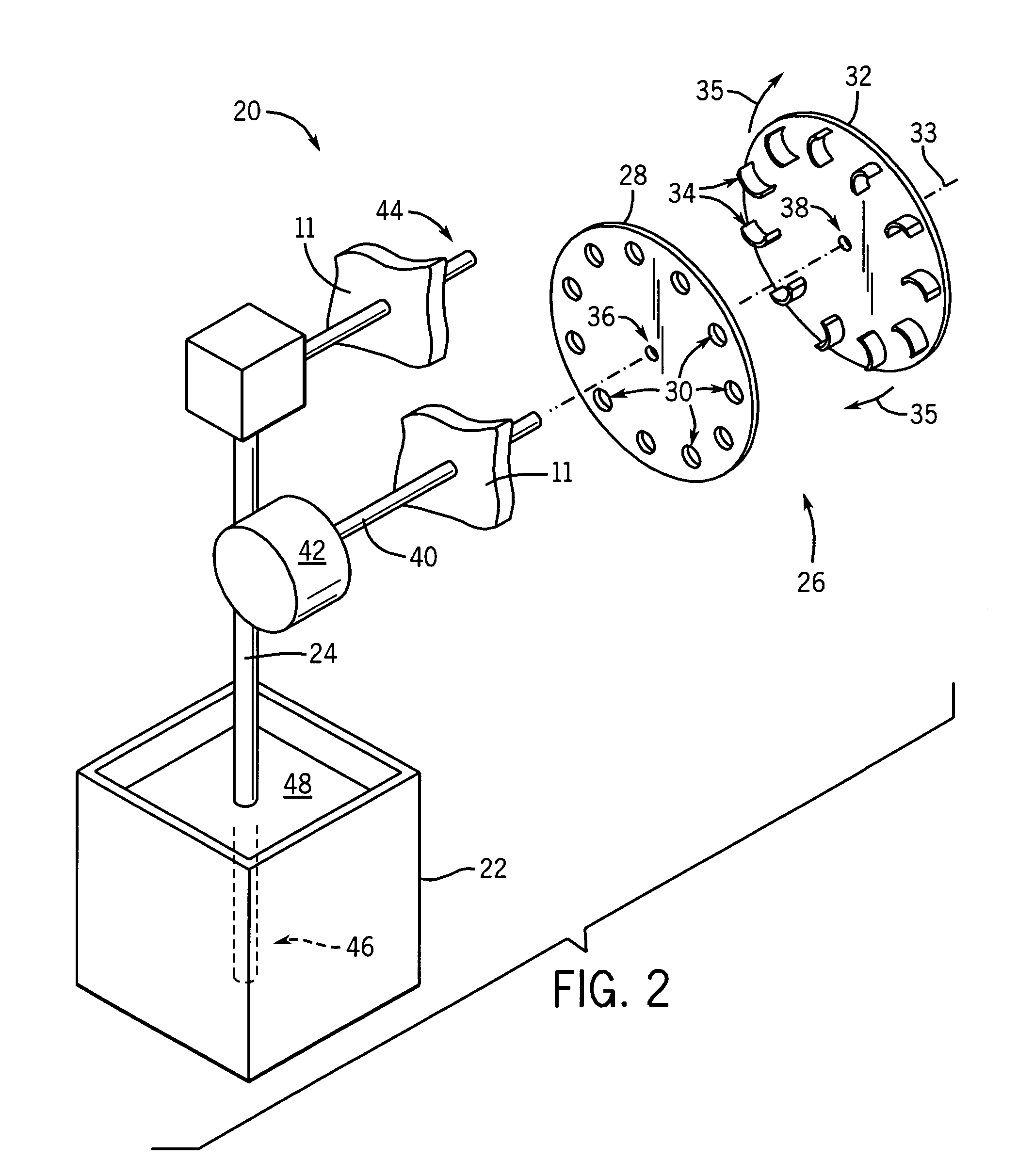

Reconfigurable porous technology for fluid flow control and method of controlling flow

The present invention relates to a reconfigurable porous technology for fluid flow control system and more particularly to reconfigurable porosity fluid flow control system for vehicles such as aircraft, missiles, ground and water vehicles to improve the performance of such vehicles. The present invention further relates to a method of operating the reconfigurable fluid flow control system.In one embodiment, the present invention includes a reconfigurable porosity system for fluid flow control on the surface of an aircraft, missile, water-craft or ground vehicle comprising a porous outer skin comprising individual pores; individually addressable valves corresponding and connected to the individual pores for opening and closing the pores; and a pneumatic system for connecting the pores wherein fluid from a high pressure area of the porous outer skin can be directed to a low pressure area of the porous outer skin by opening and closing the individually addressable valves. In another embodiment, the present invention includes a method of fluid flow control using reconfigurable porosity.

Owner:ORBITAL RES

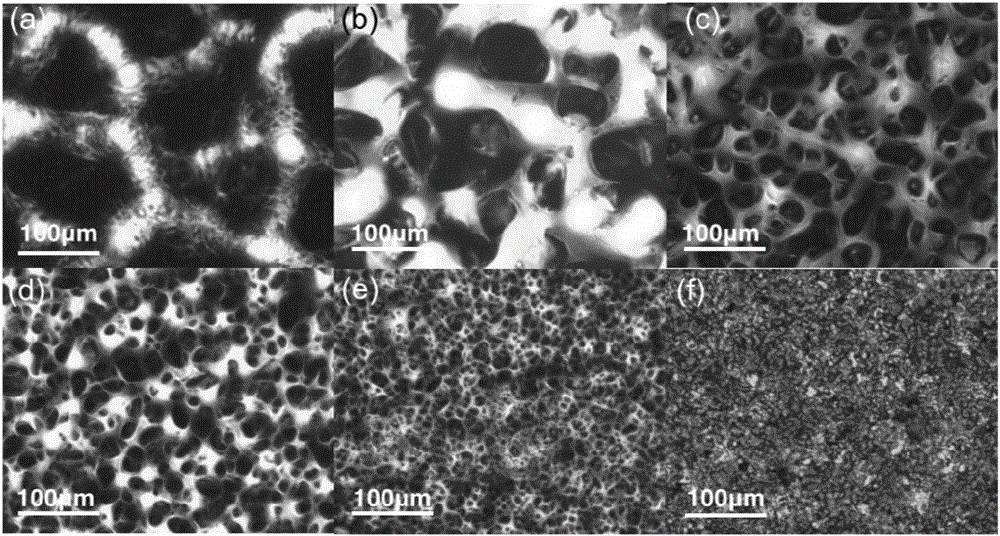

Electronic skin with irregular surface microspikes and preparation method of electronic skin

ActiveCN105203244AHigh sensitivityRelieve pressureApparatus for force/torque/work measurementChemical solutionHigh-pressure area

The invention discloses electronic skin with irregular surface microspikes. The electronic skin comprises a substrate, a support layer, a pressure-sensitive sensing layer, an electrode layers and a flexible protective layer in sequence from bottom to top, wherein the edge of the flexible protective layer is bonded with the substrate through a double-side viscous layer, so as to package the support layer, the pressure-sensitive sensing layer and the electrode layer; the microspikes are formed on the surfaces of both the support layer and the pressure-sensitive sensing layer. The electronic skin is obtained by treating a material with non-uniform surface microscopic height as a mold plate according to a chemical solution method. The electronic skin has the characteristics of double sensitivity; the sensitivity in a low-pressure area reaches up to 909 kPa<-1>; the sensitivity in a high-pressure area reaches up to 46 kPa<-1>; the total sensitivity in the pressure sensitive area can reach up to 20 kPa or higher. The electronic skin and a preparation method thereof have the advantages of being novel and simple, obvious in effect, excellent in performance and low in cost, thereby having huge potential and superiority in the field of robots.

Owner:ZHEJIANG UNIV

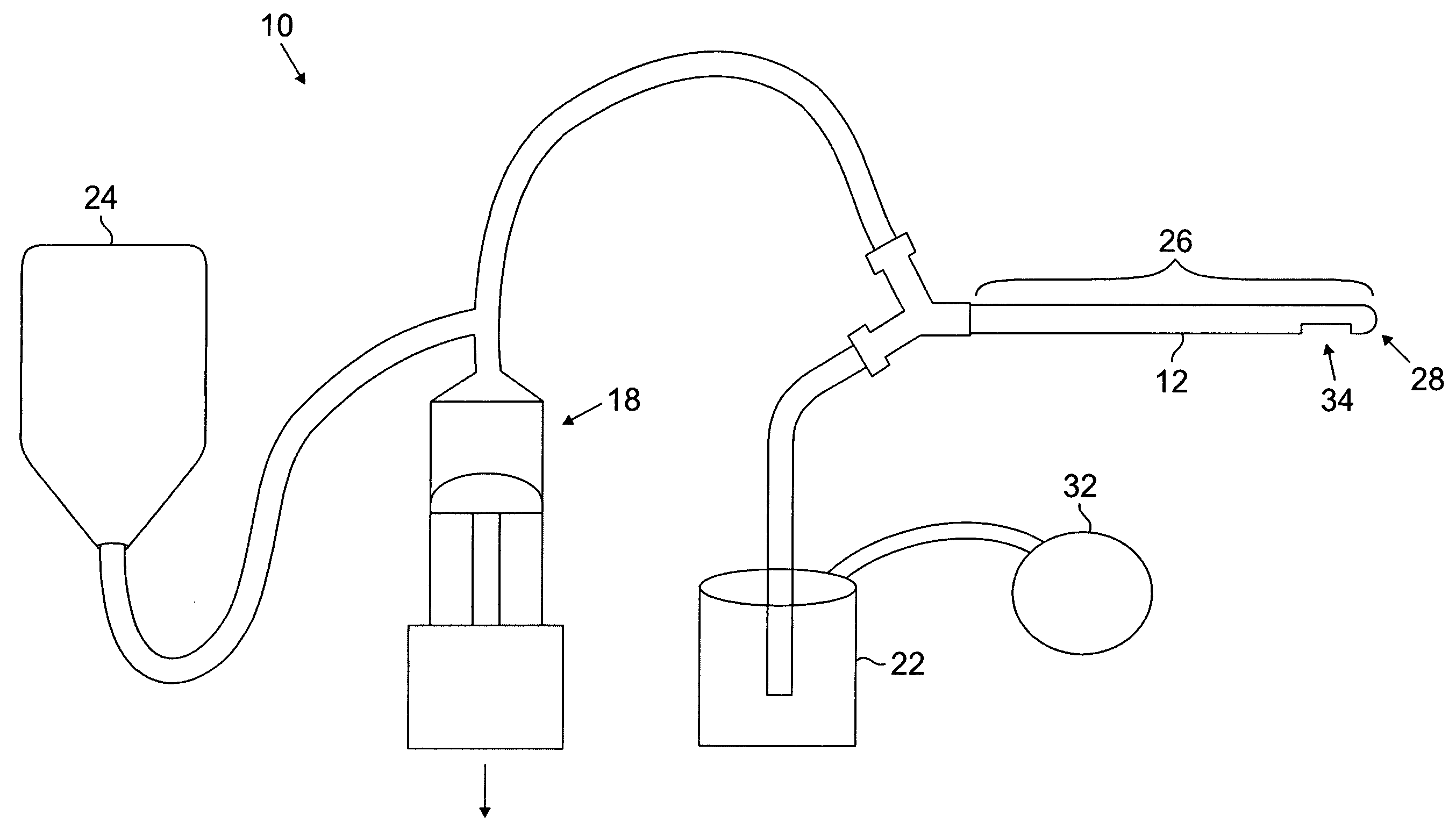

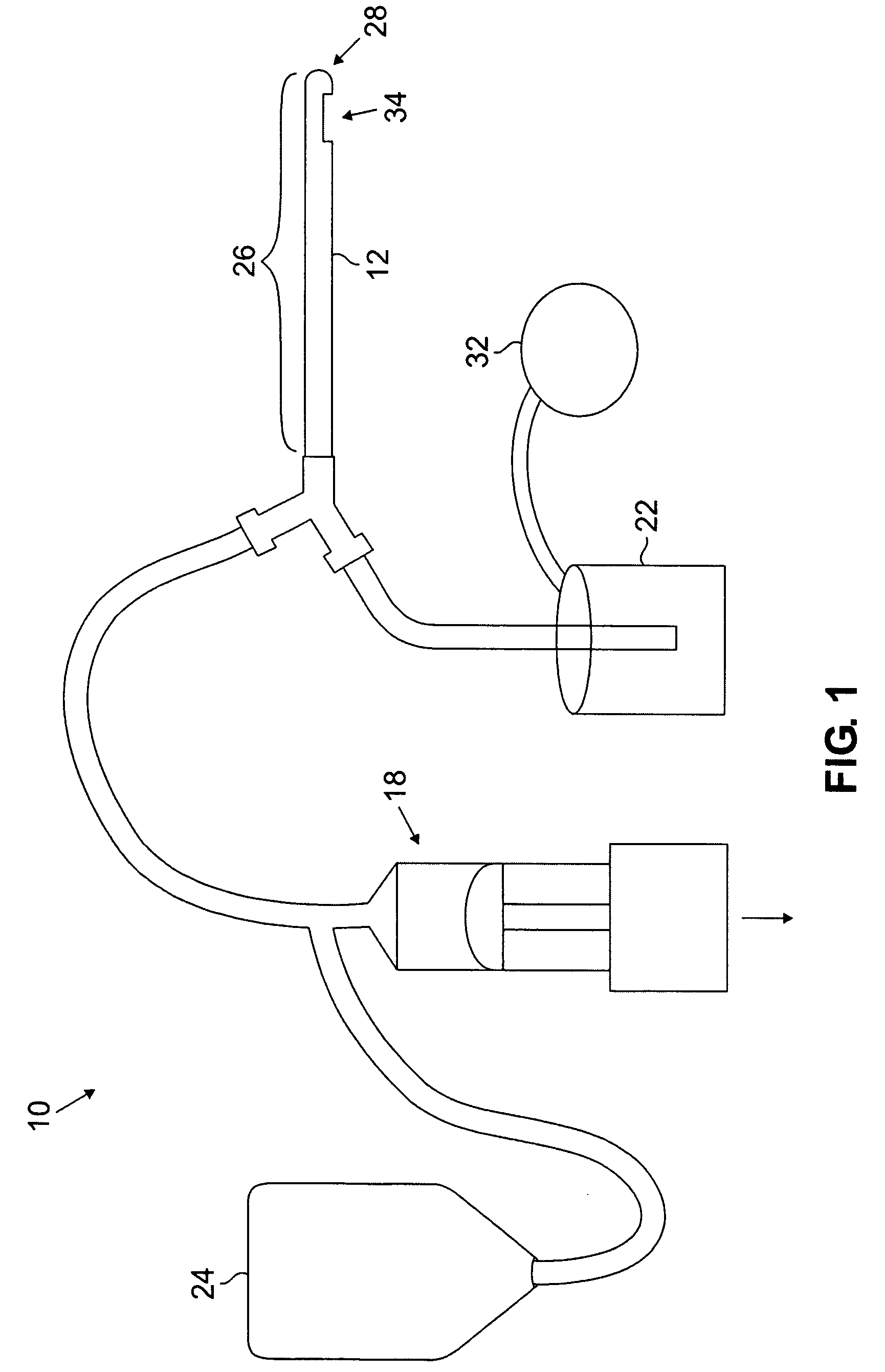

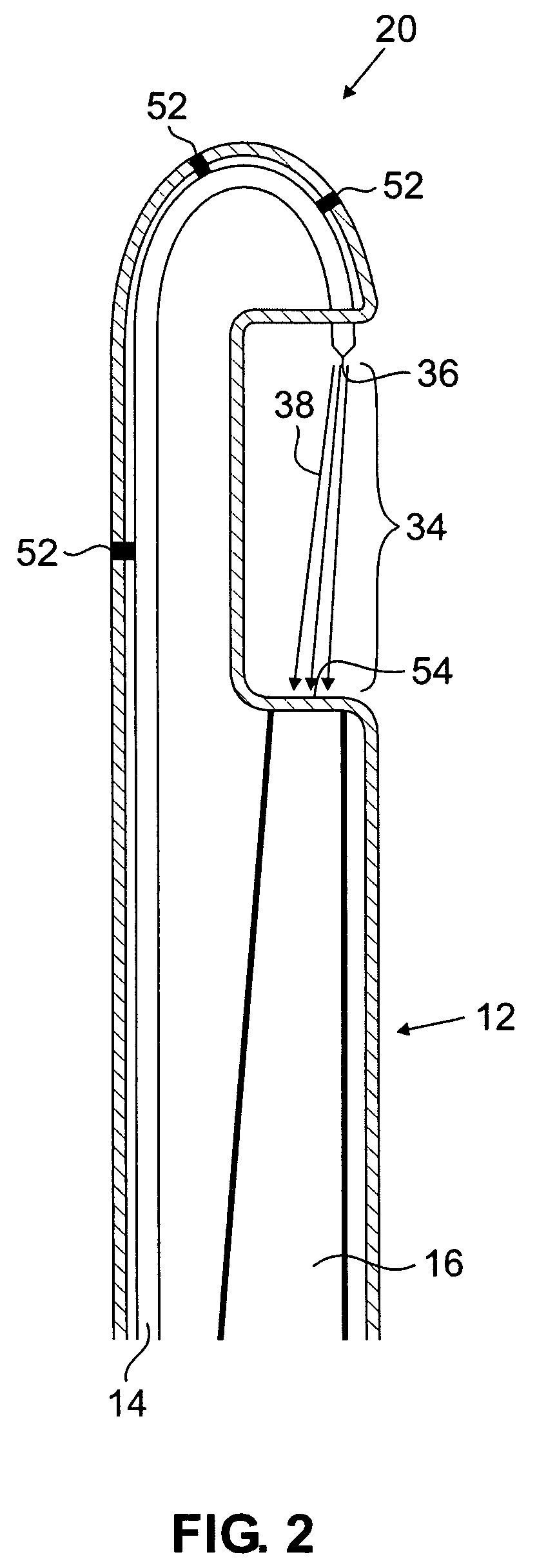

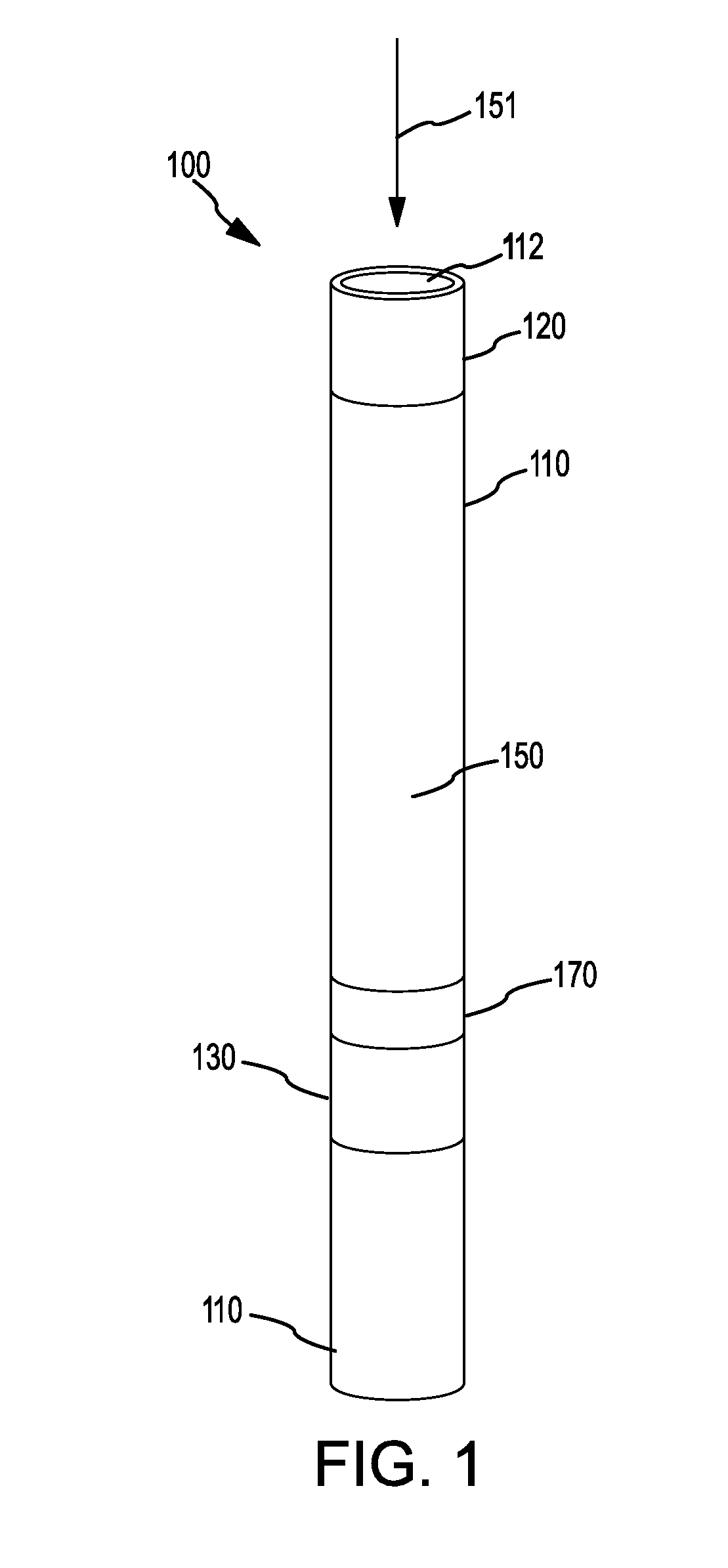

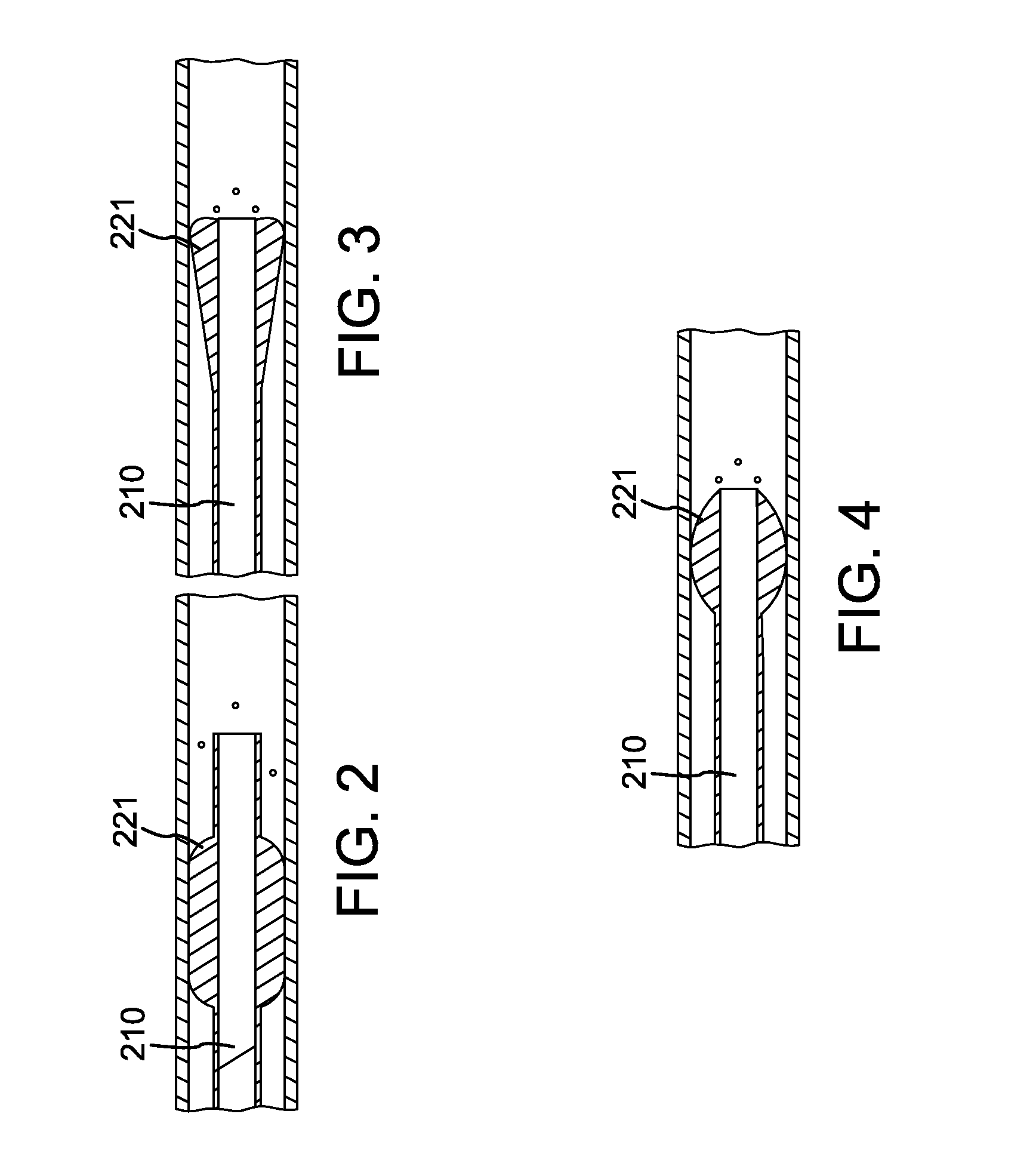

Method and device for liposuction

InactiveUS20060100606A1High precisionFacilitate microliposuctionMedical devicesIntravenous devicesLipid formationLiposuction

Systems and methods for liposuction are disclosed that use a lipid-emulsifying fluid to produce fluid jet disruption and Venturi pumping of fat tissue. The device includes a flexible or rigid probe with an inlet lumen and an outlet lumen. The inlet lumen is in fluid communication with a pump capable of producing high pressures, e.g., 250-3500 psi. The pump is in fluid communication with a volume of a liquid such as sterile saline that may or may not contain a fat emulsifier. At the end of the inlet lumen is a conical constriction or a port that accelerates the emulsification fluid to high velocities. The high velocity jet stream creates a low pressure area that draws the fat tissue into proximity with the jet stream. The jet stream directly and through turbulent vortices breaks up the fat cells. The lipid of the fat cells is subsequently emulsified by the emulsification fluid.

Owner:DOBAK JOHN D III

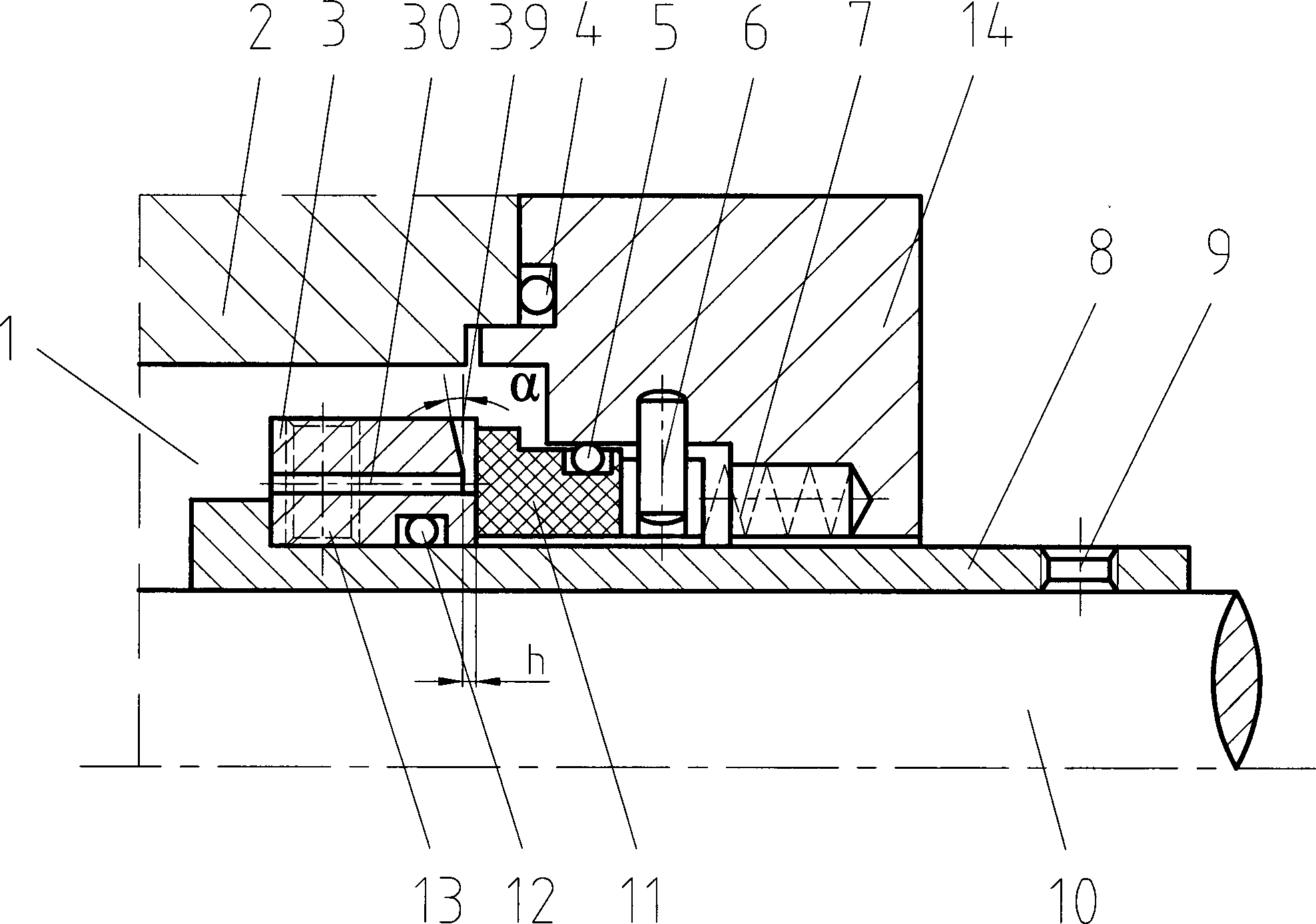

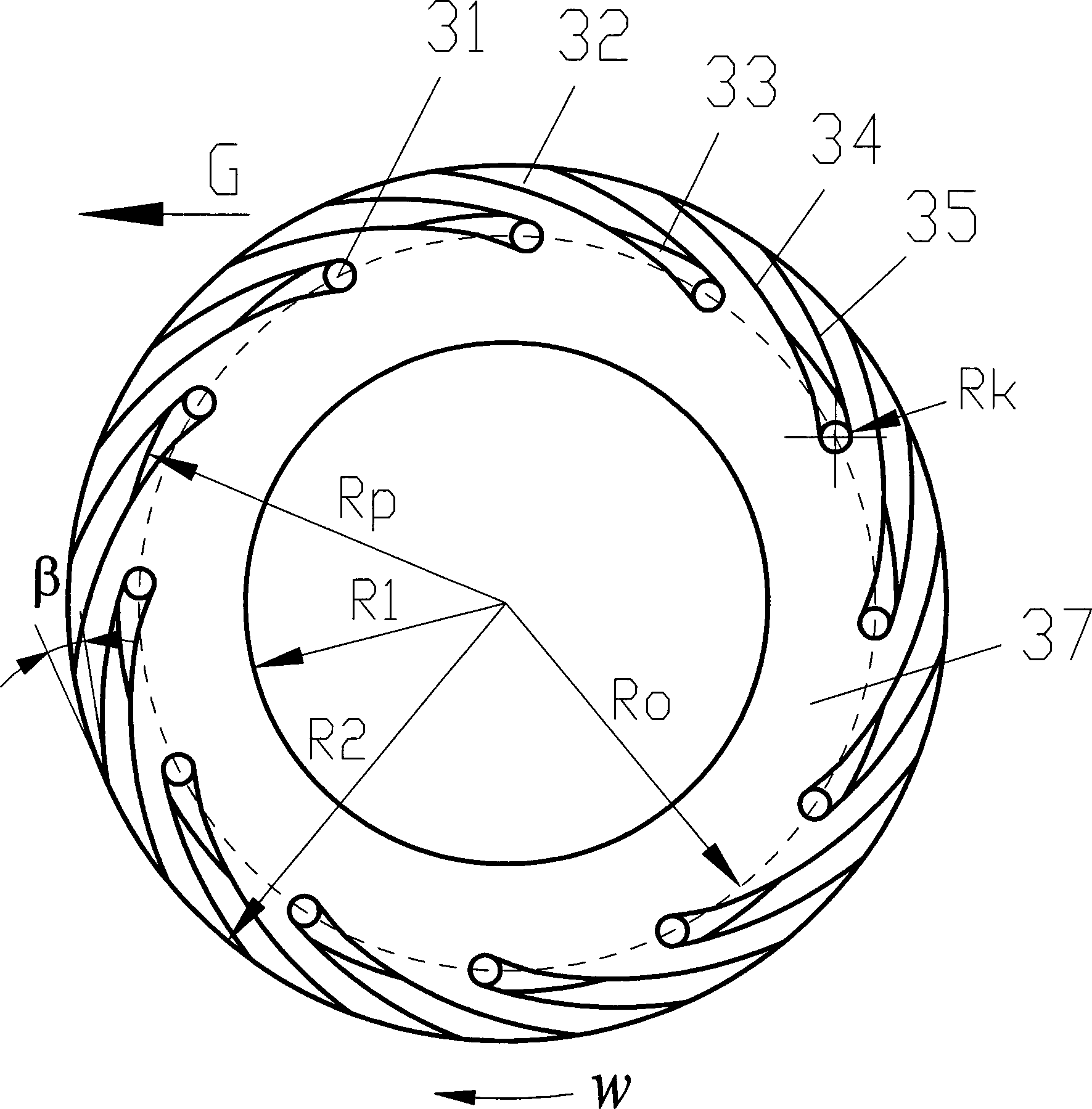

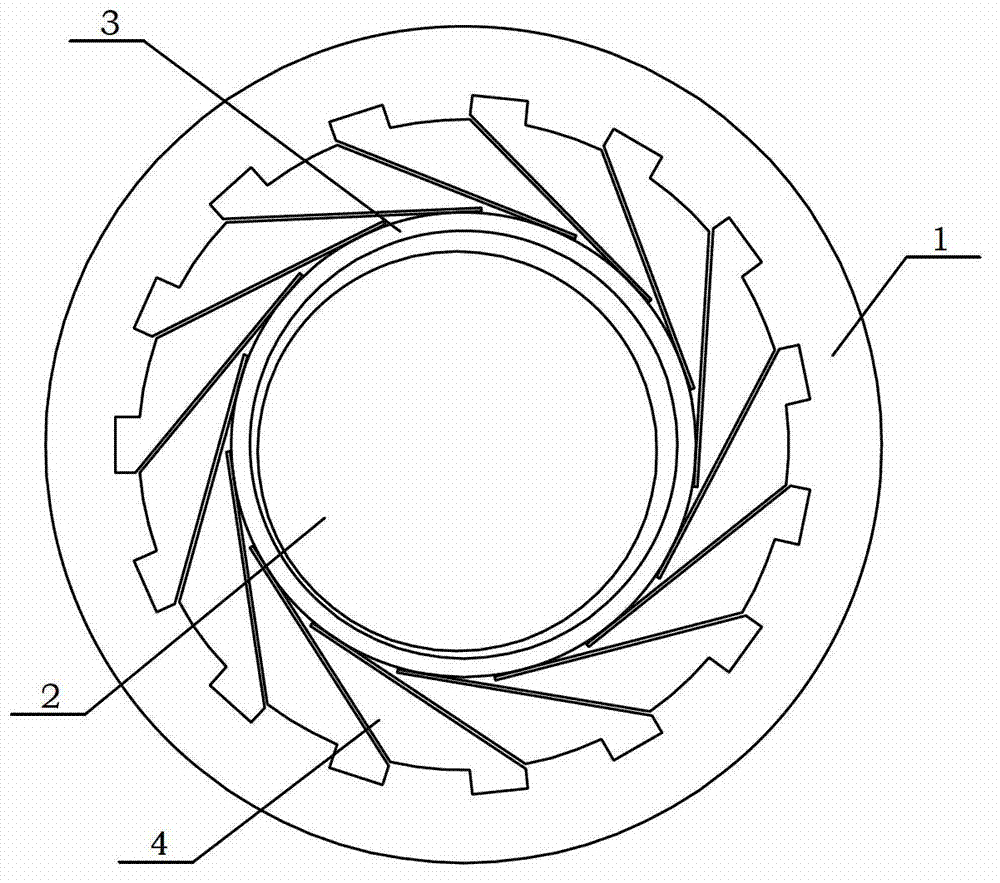

Self-pumping fluid-dynamic-pressure-type mechanical seal

The invention relates to a self-pumping fluid-dynamic-pressure-type mechanical seal. More than three groups of backwards-bent-type fluid grooves are formed in the moving ring seal end surface of the self-pumping fluid-dynamic-pressure-type mechanical seal, wherein each fluid groove is composed of a slope groove and a horizontal groove, the outlet of each fluid groove is located outside the moving ring seal end surface, and the inlet of each fluid groove is located in the middle of the moving ring seal end surface, and is communicated with a sealing cavity through an axial hole passage or an axial and radial combined hole passage on a moving ring. When the moving ring rotates, media in each fluid groove are accelerated to be high-speed fluid, the high-speed fluid flows to the outer diameter side of the moving ring and is pumped into the sealing cavity under the action of centrifugal force and forms a low-pressure area in the inlet of each backwards-bent-type fluid groove, and media in the sealing cavity flow into each backwards-bent-type fluid groove through the axial hole passage or the axial and radial combined hole passage under the action of pressure difference, wherein the axial hole passage or the axial and radial combined hole passage is arranged on the moving ring, and is communicated with the sealing cavity so as to form a new self-pumping cycle. In the process that the high-speed fluid is pumped out, the flowing speed is reduced, the pressure is increased, and certain opening force is formed as the circulating sectional area gradually increases. The self-pumping fluid-dynamic-pressure-type mechanical seal has good self-lubricating, self-washing and anti-solid-particle-interference ability and superior sealing performance.

Owner:NANJING FORESTRY UNIV

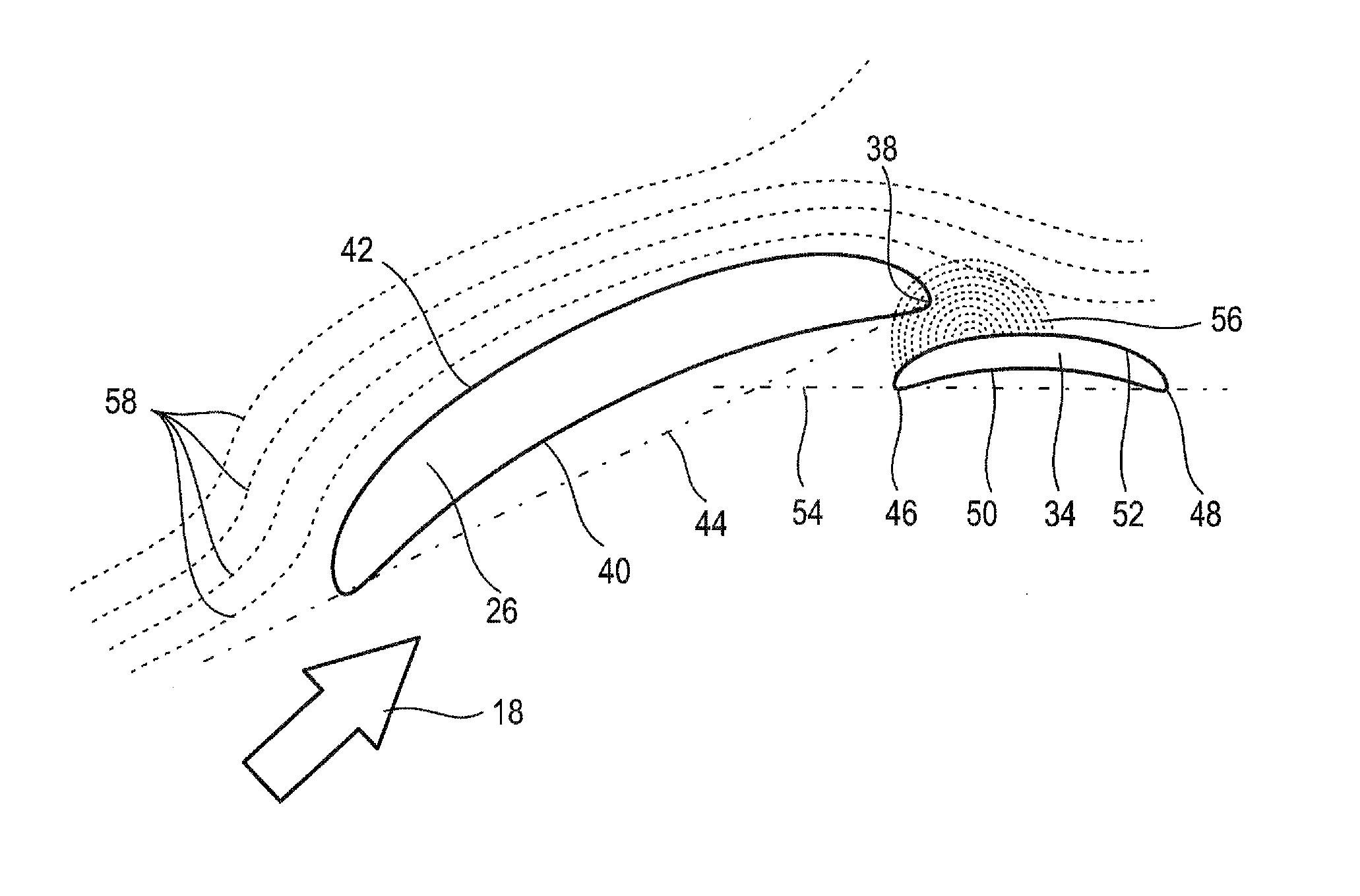

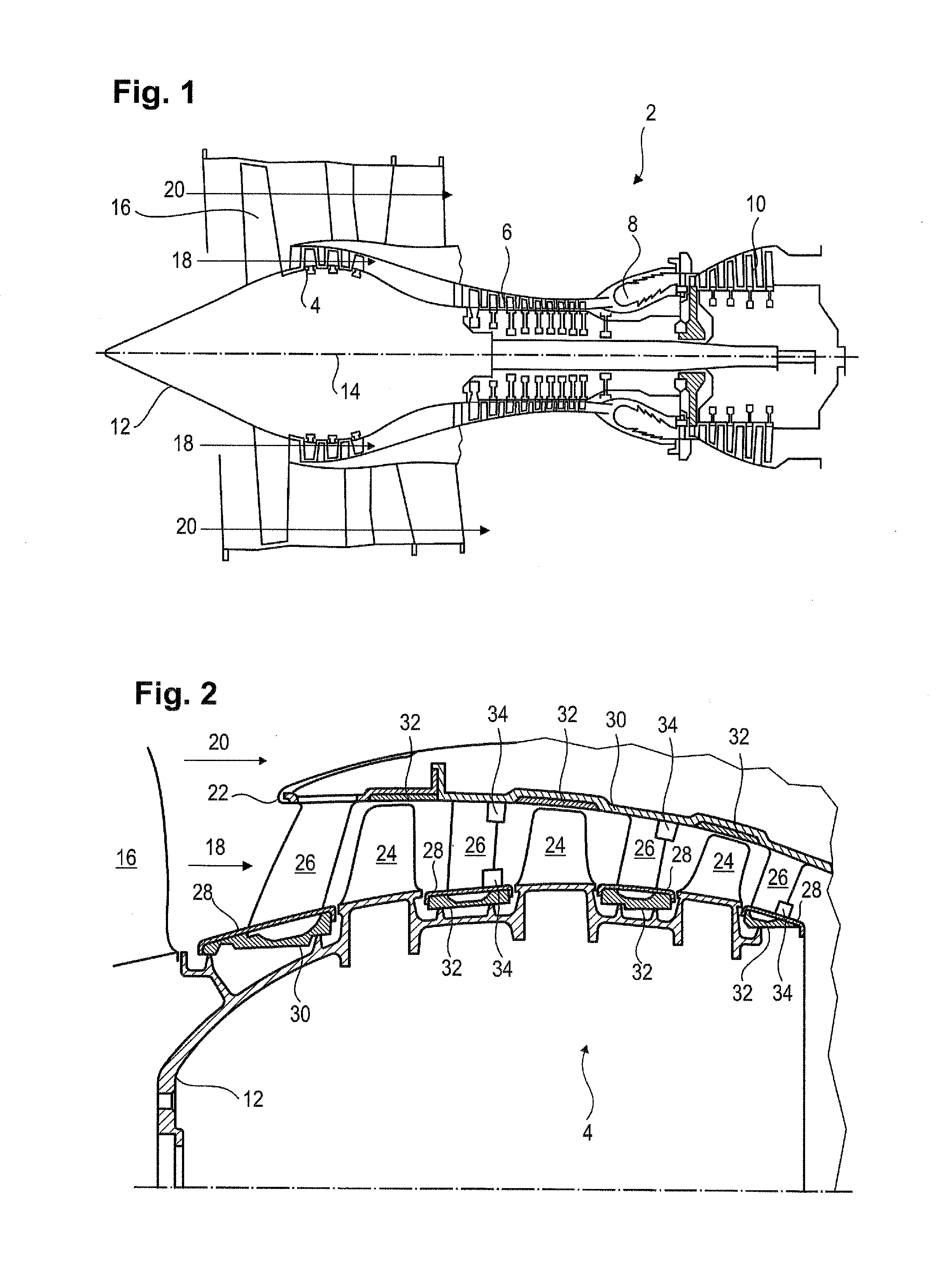

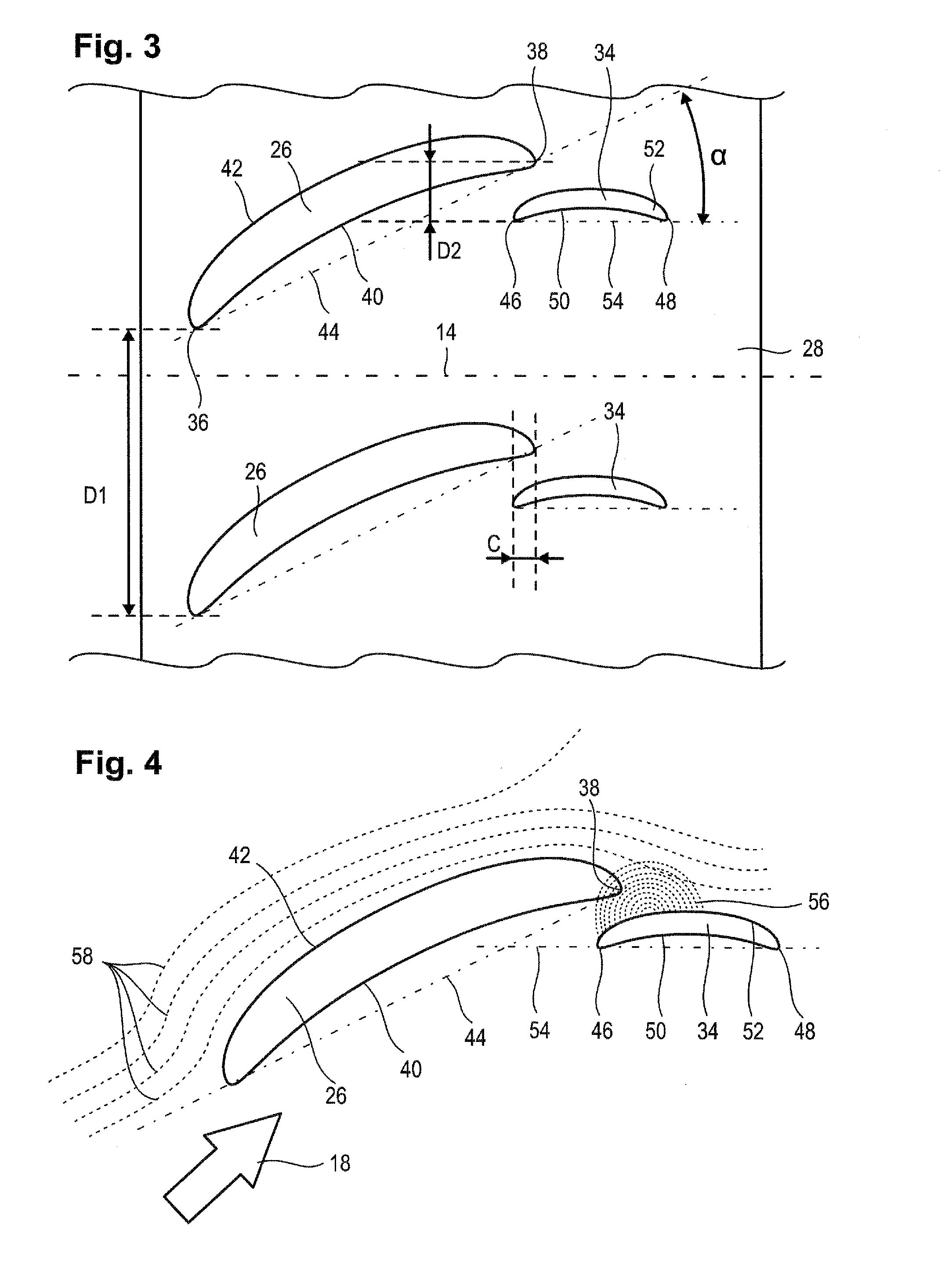

Axial Turbomachine Stator with Ailerons at the Blade Roots

ActiveUS20140328675A1Improve abilitiesStalling can be eliminatedPump componentsReaction enginesLow-pressure areaTrailing edge

The present application relates to the compressor stator of an axial turbomachine. The stator comprises an annular row of main stator blades and auxiliary blades each of which are associated with a main blade. The auxiliary blades are located at the trailing edges of the main blades and are in the vicinity of the pressure faces of the main blades. The auxiliary blades are aligned to generate a low-pressure area at the trailing edges of the main blades. Thus, a flow bypassing a main blade by its suction face is sucked in by the low-pressure area when it approaches the trailing edge of the main blade. Stalling is thus avoided and the efficiency of the machine is improved.

Owner:TECHSPACE AERO

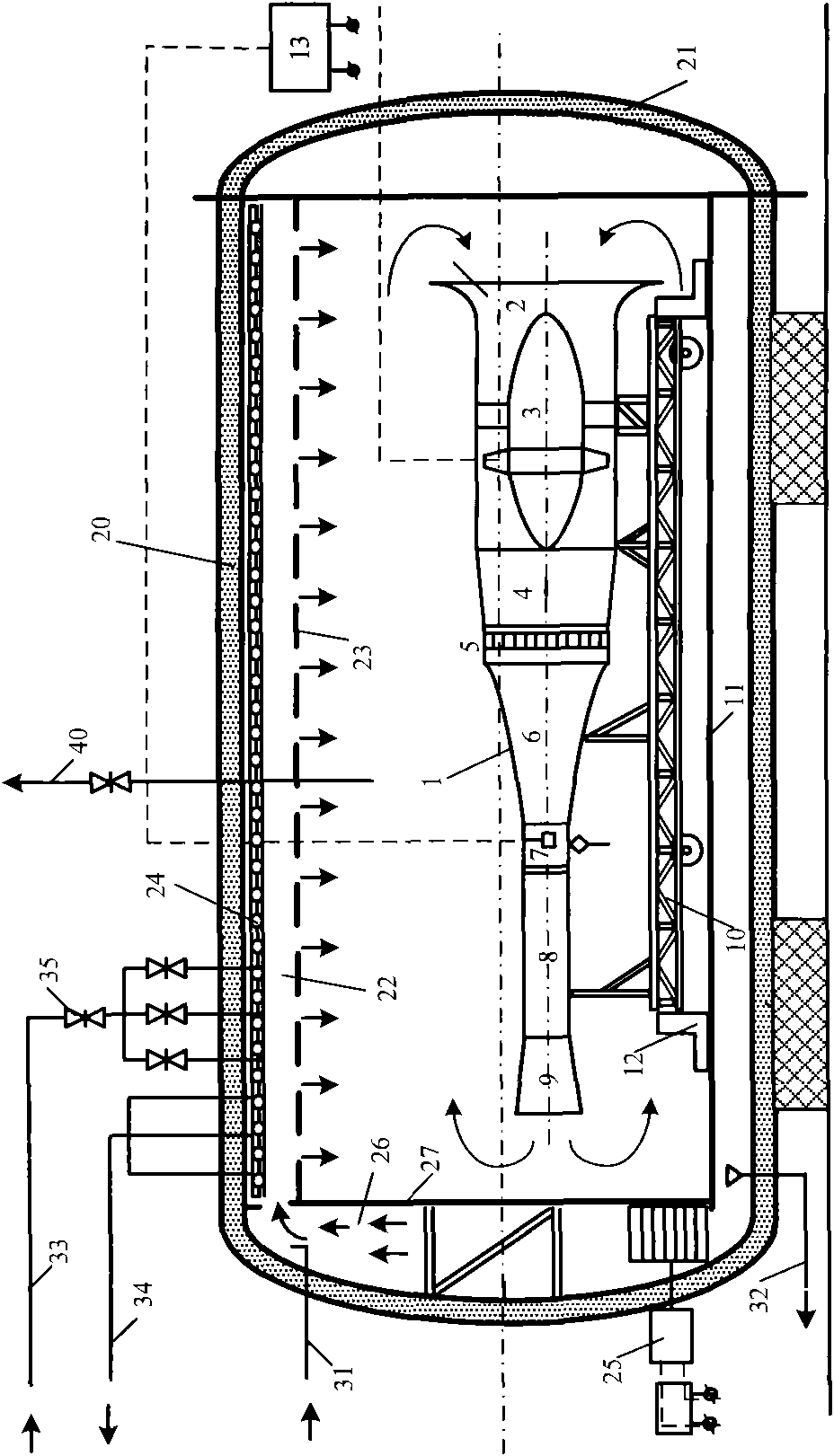

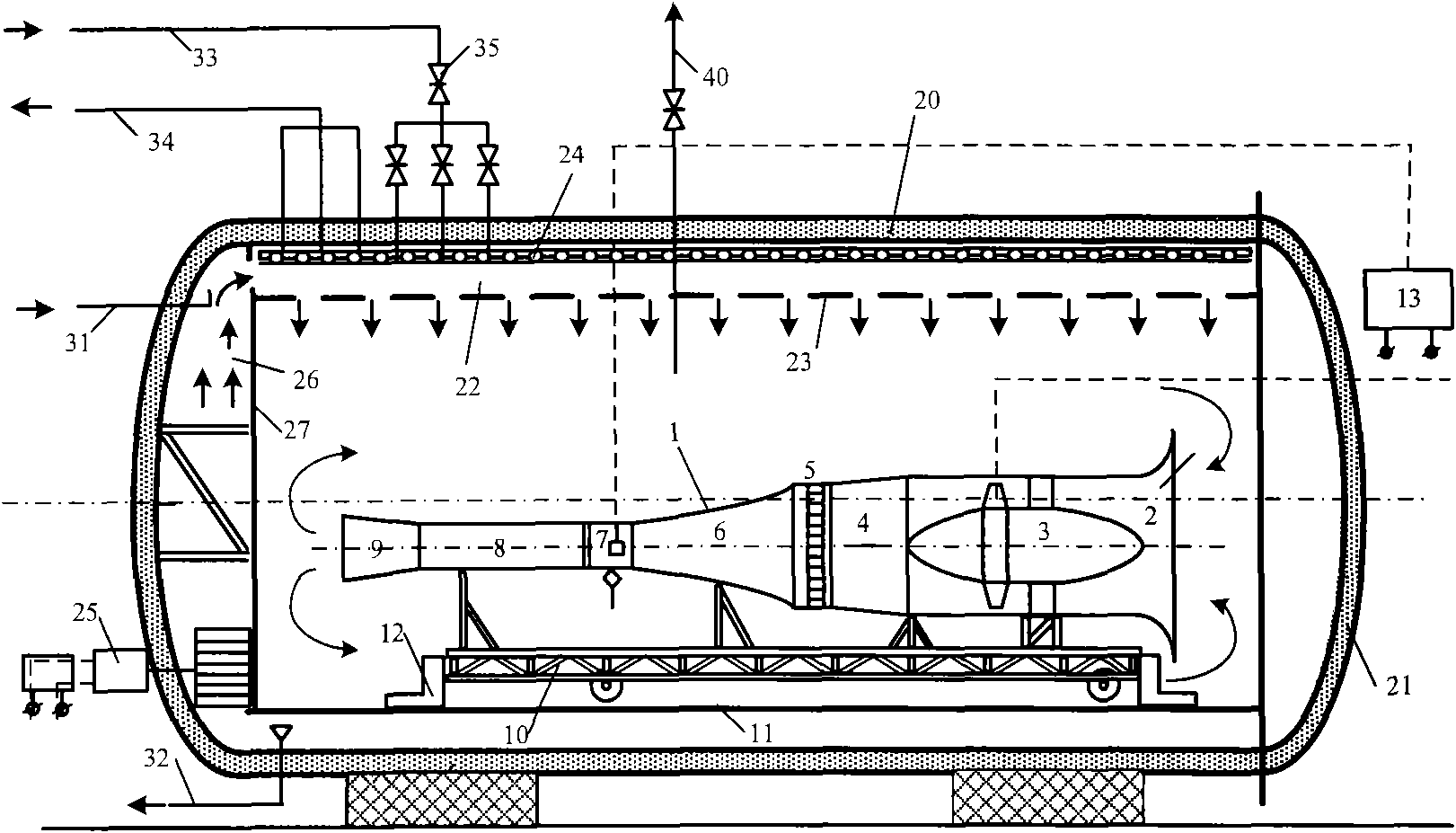

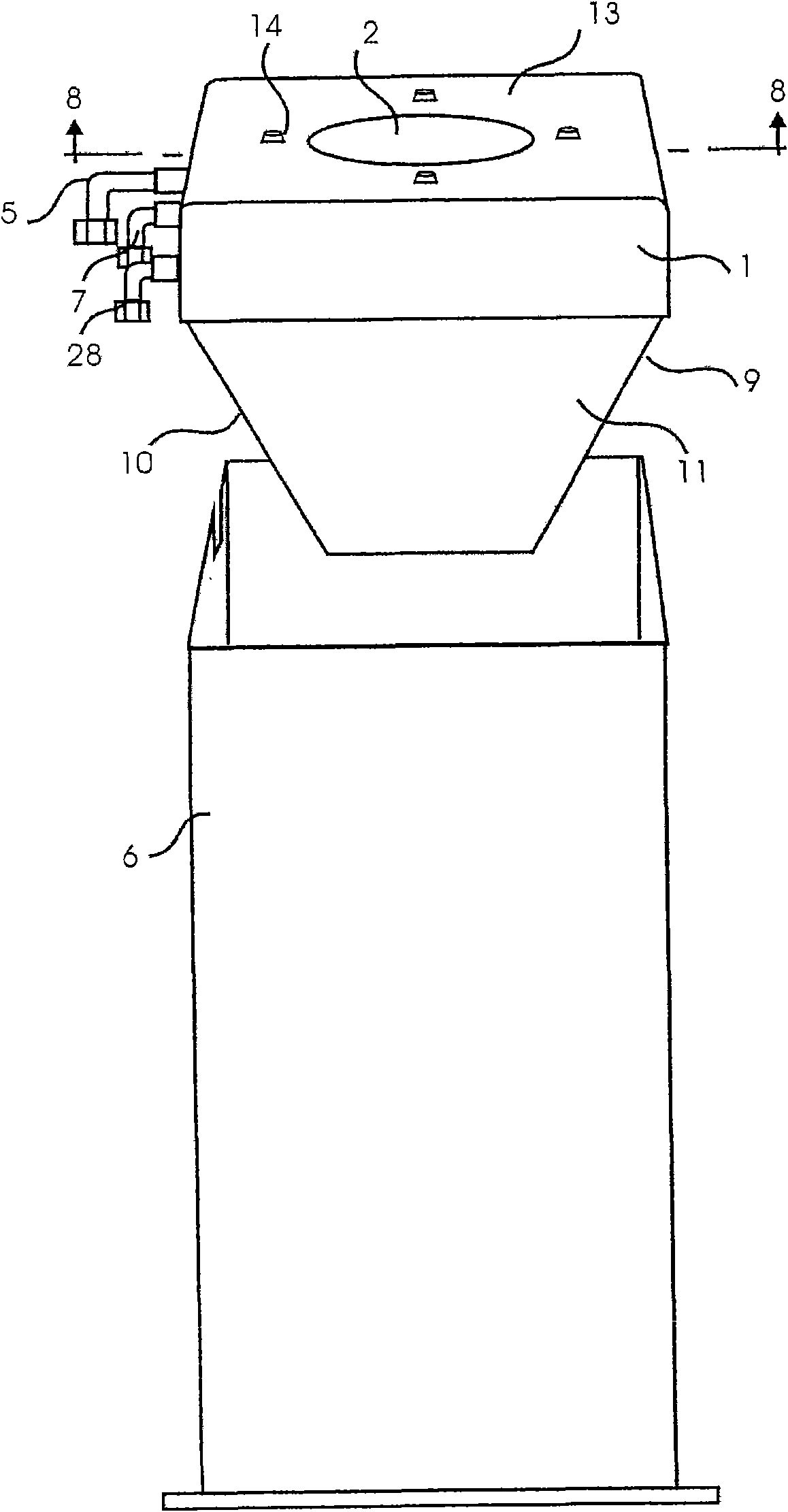

Novel low-temperature and low-pressure wind speed environment control system

InactiveCN101832619ADucting arrangementsSpace heating and ventilation safety systemsTemperature controlControl system

The invention relates to a low-temperature and low-pressure wind speed environment control system. The system is characterized in that the system comprises a sealing chamber body (20), a wind tunnel device (1), convection temperature control parts (25, 22, 31 and 32) and a radiation temperature control part (24), wherein the wind tunnel device (1) is arranged in the sealing chamber body. By matching the direct-current wind tunnel machine in the chamber with the sealing chamber body, a turbine refrigerating unit and a vacuum system, the system can realize various environments, such as normal-pressure and low-temperature icing environment, low-pressure and low-temperature icing environment and the like, can provide axial fan power for regulating the direct-current wind tunnel device, and obtain environment wind speeds to satisfy different requirements. Compared with the conventional wind tunnel, the invention can realize low-pressure and / or low-temperature and wind speed environment control with low cost, and has obvious advantages at the aspects of working power, initial investment and wind speed control. The invention has the advantages of little investment, little energy consumption, complete function, easy flow field control, and the like.

Owner:BEIHANG UNIV

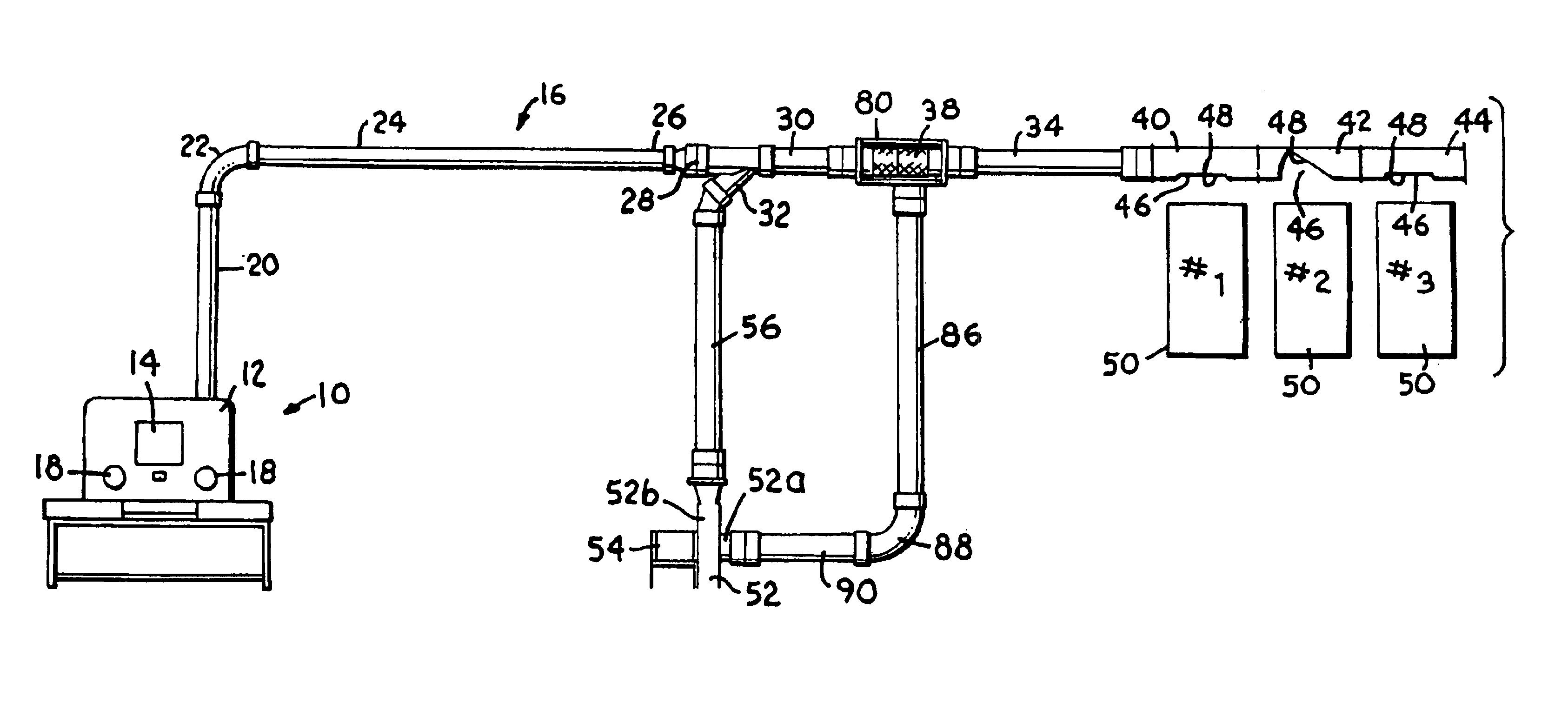

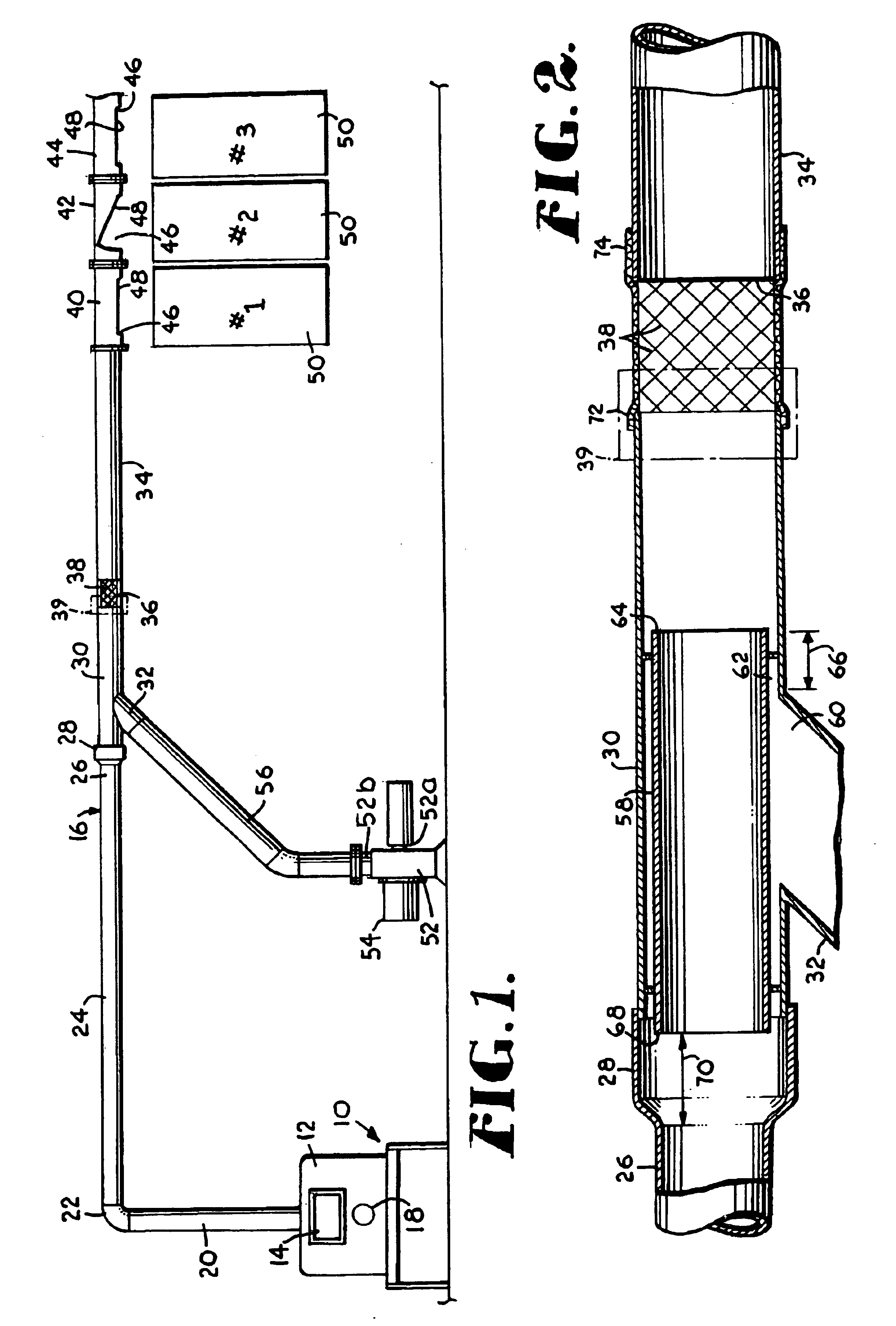

Venturi system using closed loop air return for conveying flexible fabrics

InactiveUS6942133B2Avoid disadvantagesReduces equipment cost and labor cost and space requirementLiquid/gas/vapor article treatmentBulk conveyorsAcute angleNoise level

Owner:AUTOMATION DYNAMICS

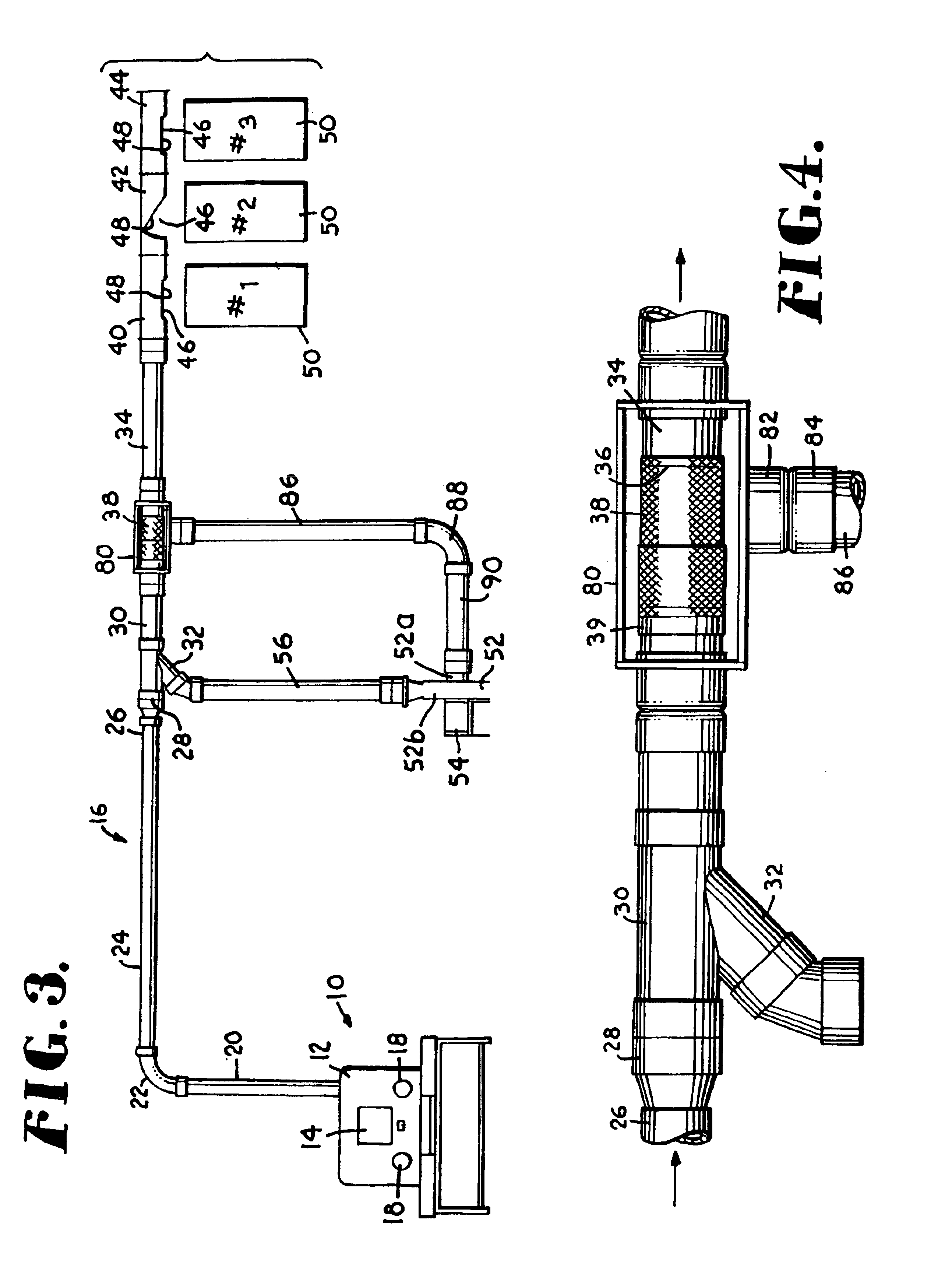

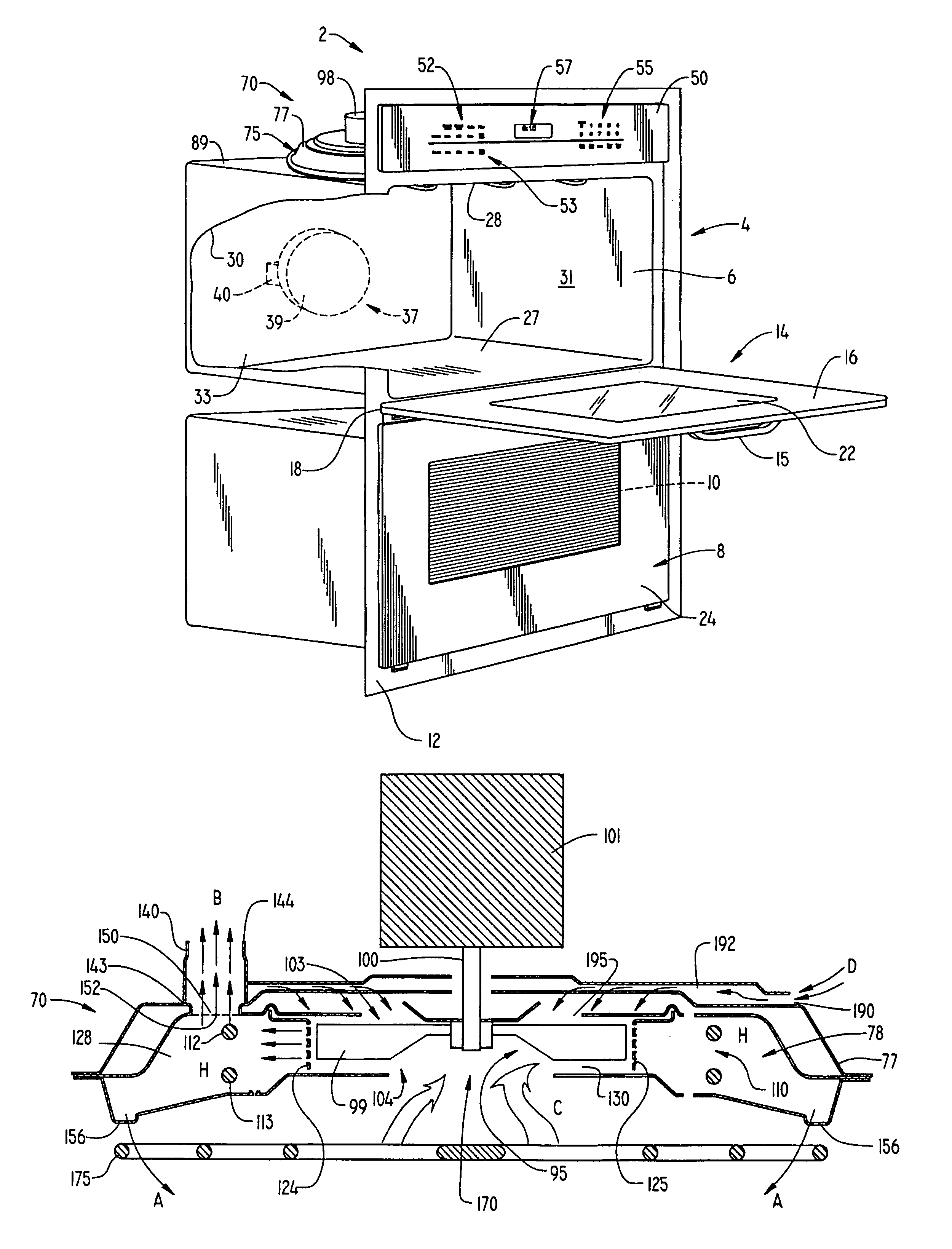

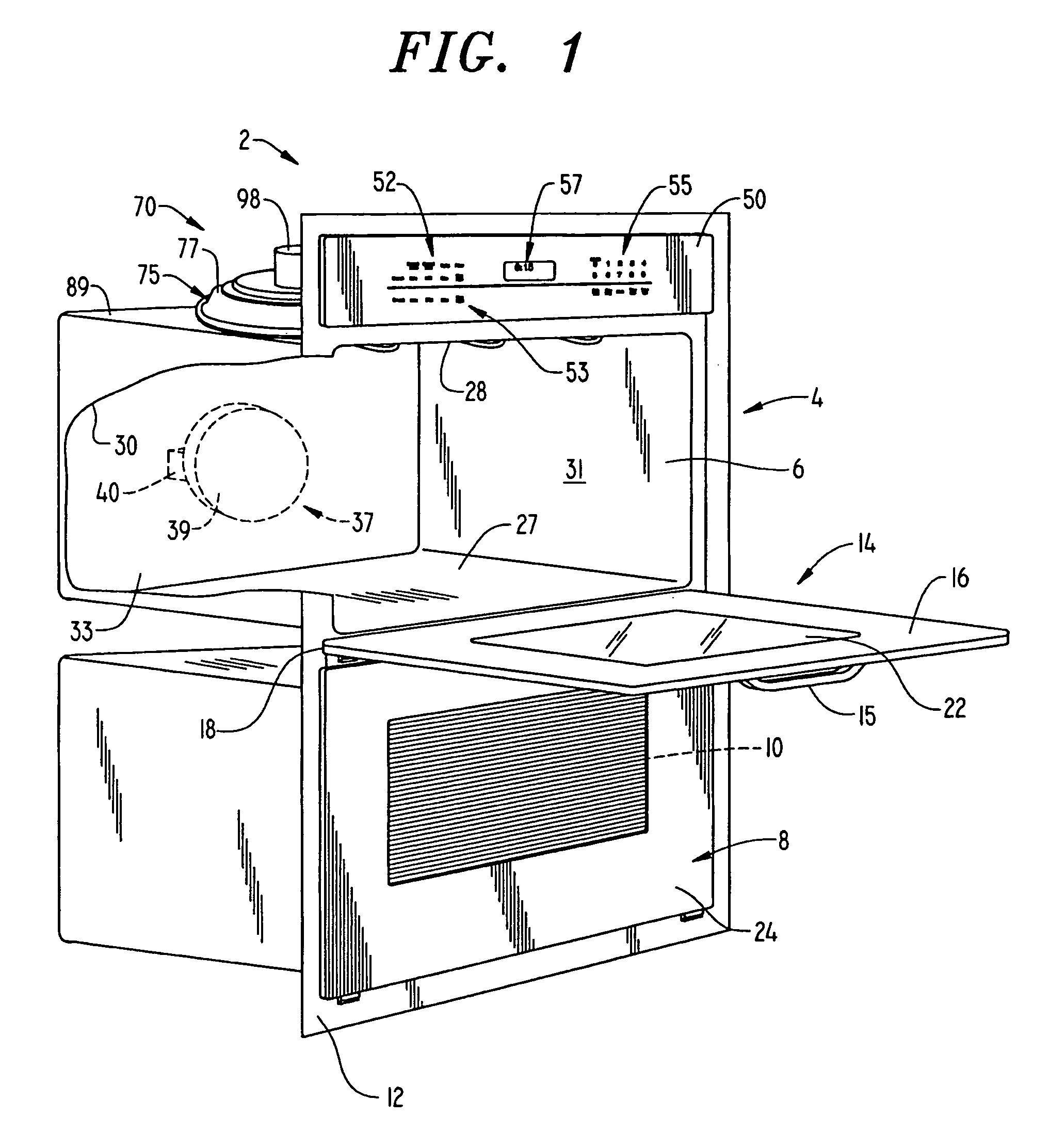

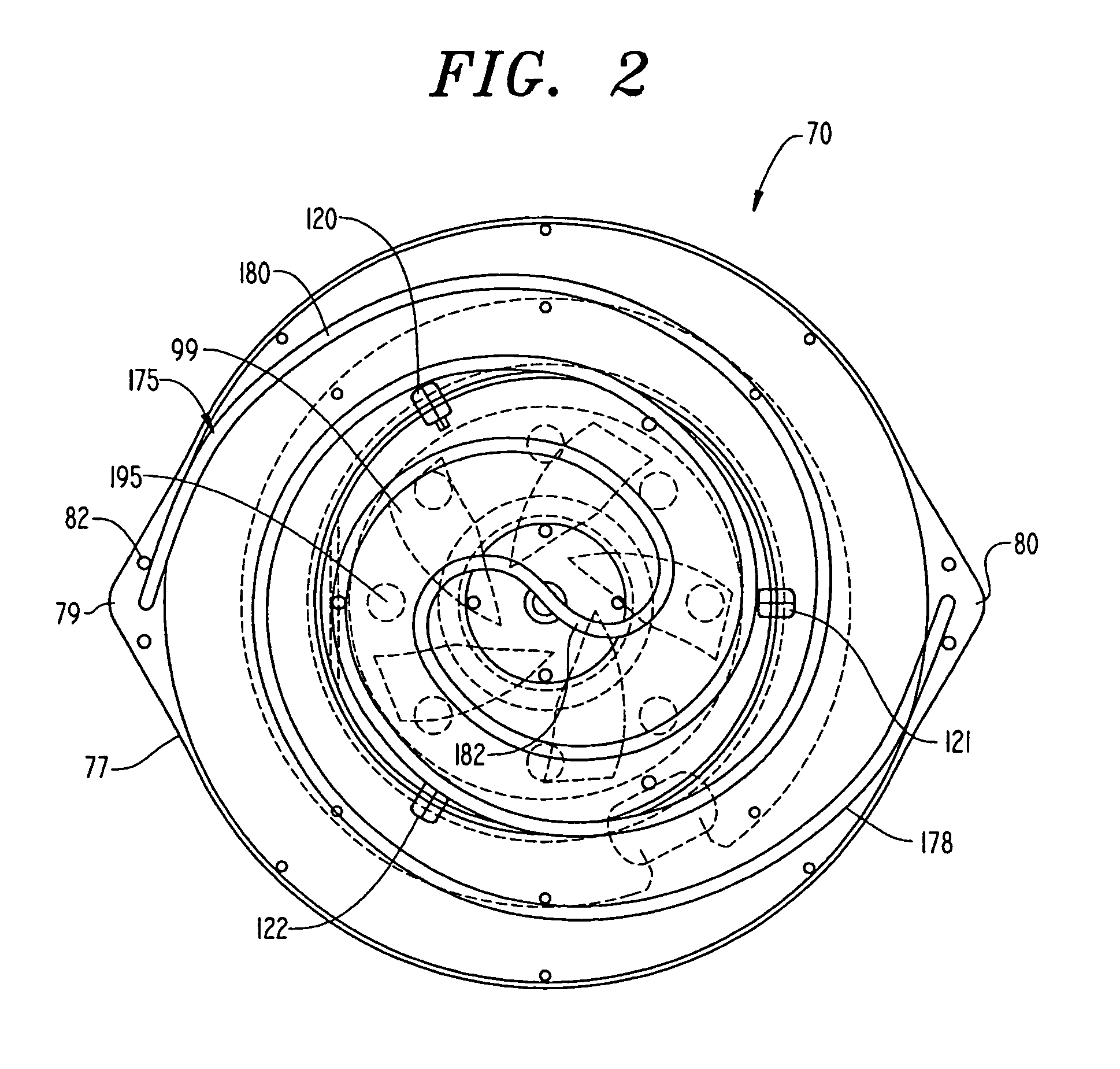

System and method for supplying water to an oven

InactiveUS7307244B2Minimizes supplyLength minimizationDomestic stoves or rangesBaking ovenLine tubingLow-pressure area

An oven includes a housing forming a cooking compartment defining an interior of the oven. A water supply line extends through the housing to position an end behind a fan within the cooking compartment. The fan is arranged within the cooking compartment near the water supply line to create a low pressure area about the end of the water supply line to draw water through the water supply line and into the fan.

Owner:ALTO SHAAM

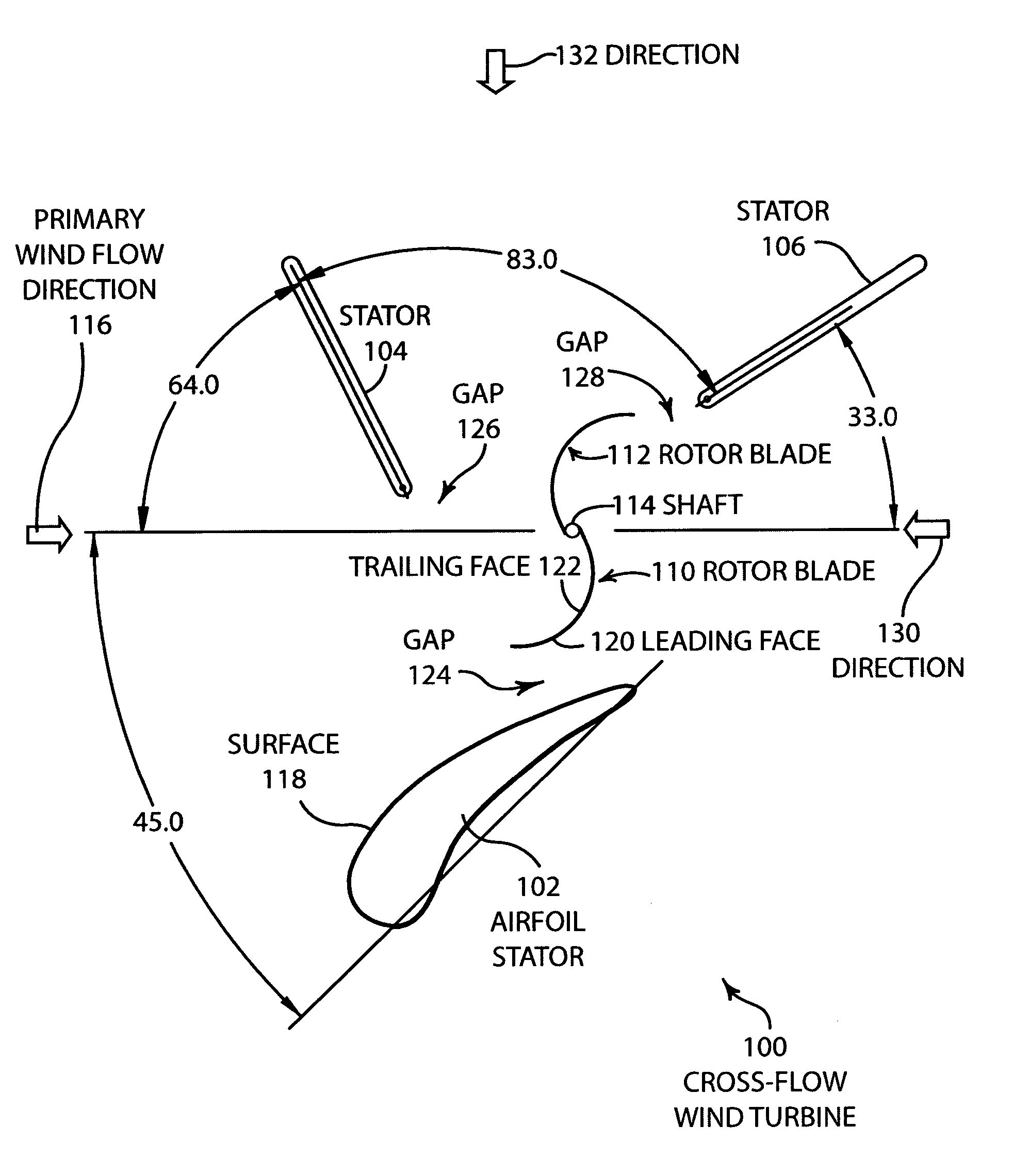

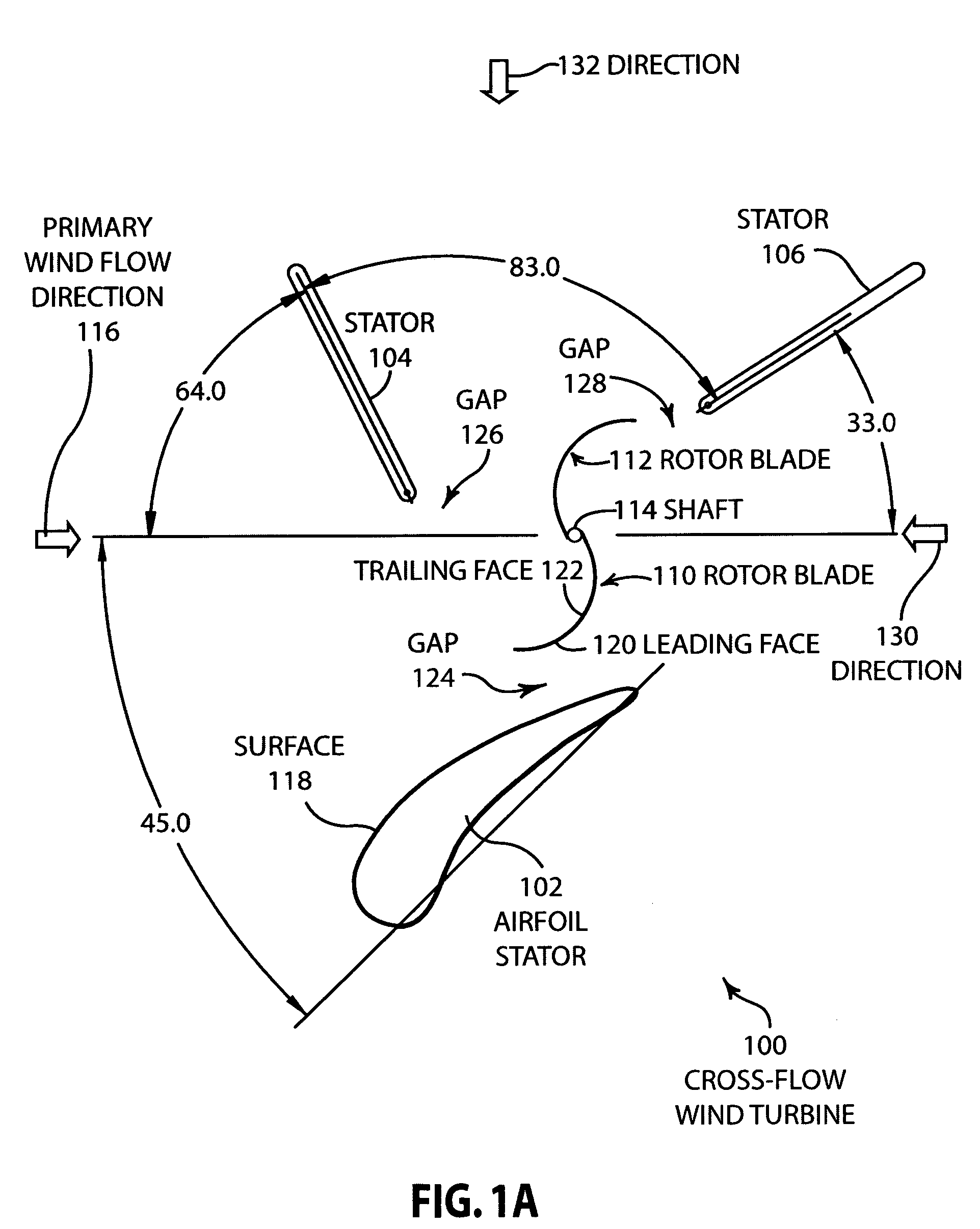

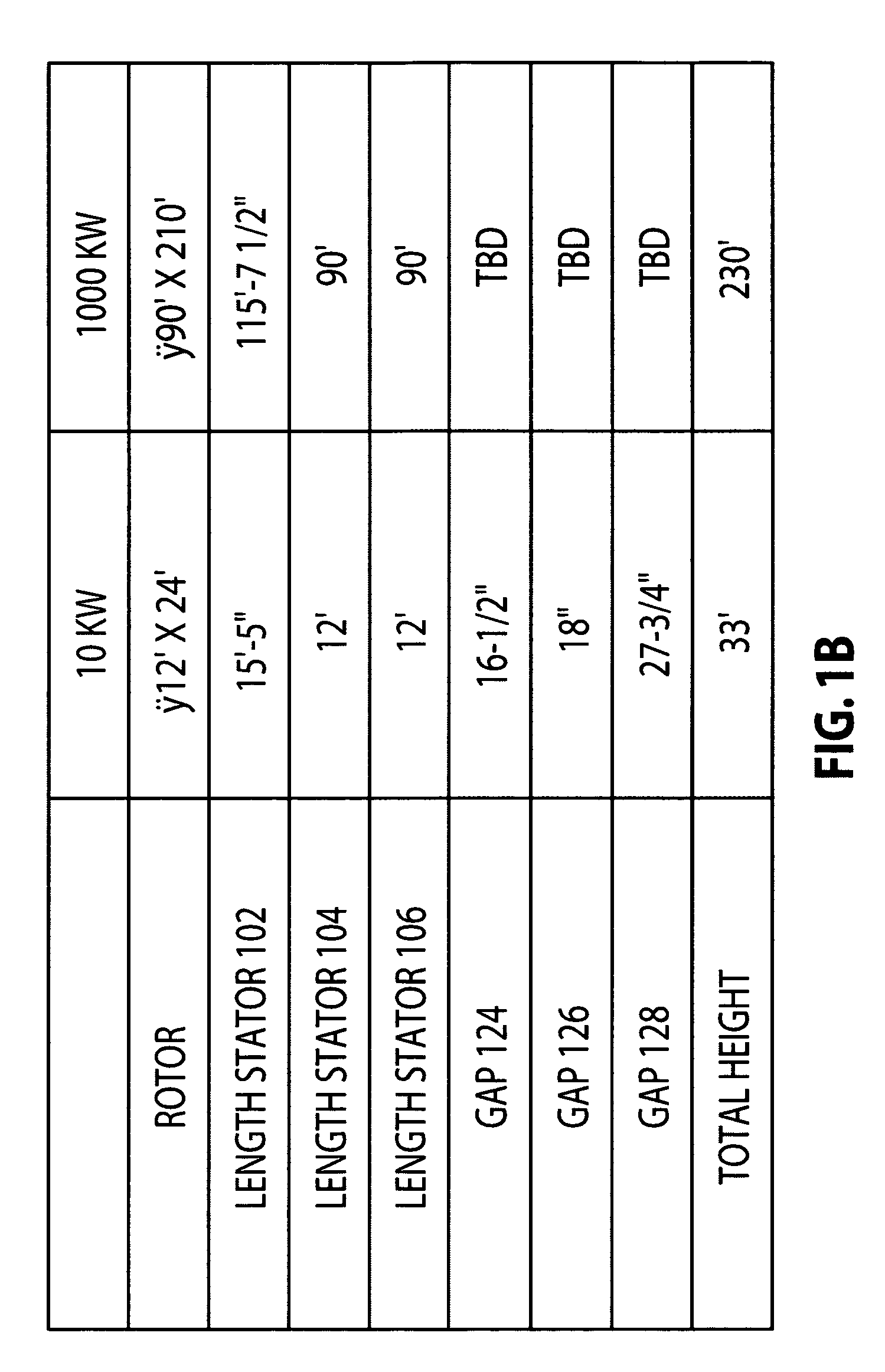

Cross-flow wind turbine

InactiveUS7189050B2Improve efficiencyEffective rotationCircumferential flow pumpsPump componentsPower cycleLow-pressure area

Disclosed are various embodiments of cross-wind turbines that are capable of providing high efficiencies over a wide range of wind velocities. An airfoil stator causes wind to accelerate along its surface and creates a low pressure area on the leading face of the rotor blade during the power stroke. A blocking stator blocks wind from impeding the movement of the rotor blades during the return cycle and directs wind onto the trailing face of the rotor blades during the power cycle. A large pressure differential is created between the leading face of the rotor blade and the trailing face of the rotor blade during the power cycle which creates a large amount of force that rotates the rotor blade about the central shaft. In some embodiments, gaps are provided between the inside edge of the rotor blade and a stationary shaft which vents wind collected by the rotor blade during certain portions of the rotation cycle. The vented wind increases the pressure on the trailing face of the rotor blades during the return cycle to further assist in the efficiency of this system.

Owner:TERRA MOYA AQUA

Pressure exhaust system for a convection cooking appliance

InactiveUS6943322B1Enough timeReduce pressureDomestic stoves or rangesCooking fumes removalHigh-pressure areaFresh air

A cooking appliance incorporates a convection heating system including a housing having an interior portion, a fan assembly, a heating element and an exhaust outlet duct. The exhaust outlet duct, within which is arranged a plurality of controlled vent openings, is positioned in a high pressure area of the convection heating system established about a periphery of the fan assembly and heating element. Oven gases are forced by the high pressure through the exhaust duct, thereby creating a corresponding reduction in pressure. The reduction in pressure establishes a low pressure area within the fan assembly which draws in fresh air in an amount equal to that exhausted through the exhaust duct.

Owner:MAYTAG

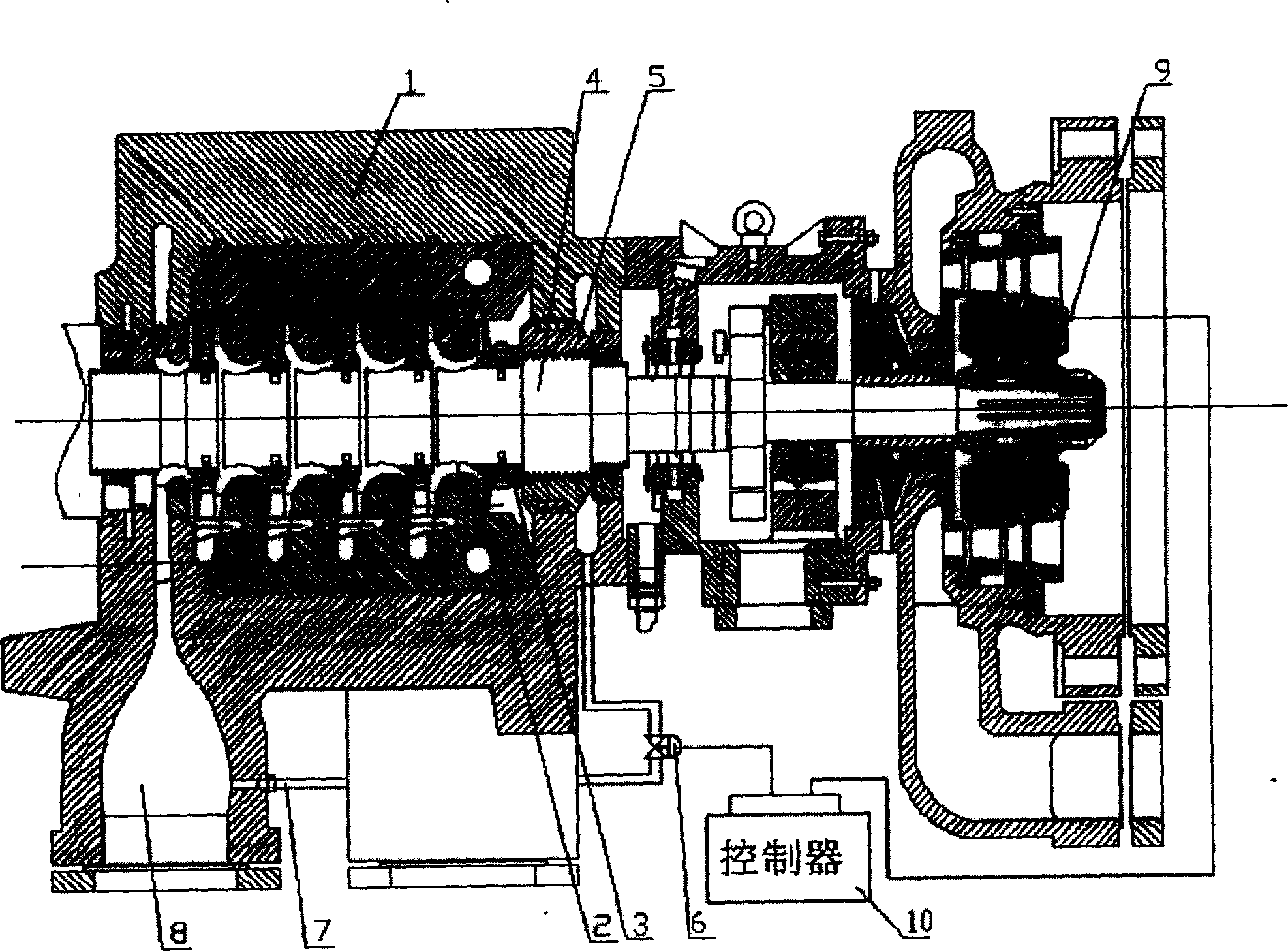

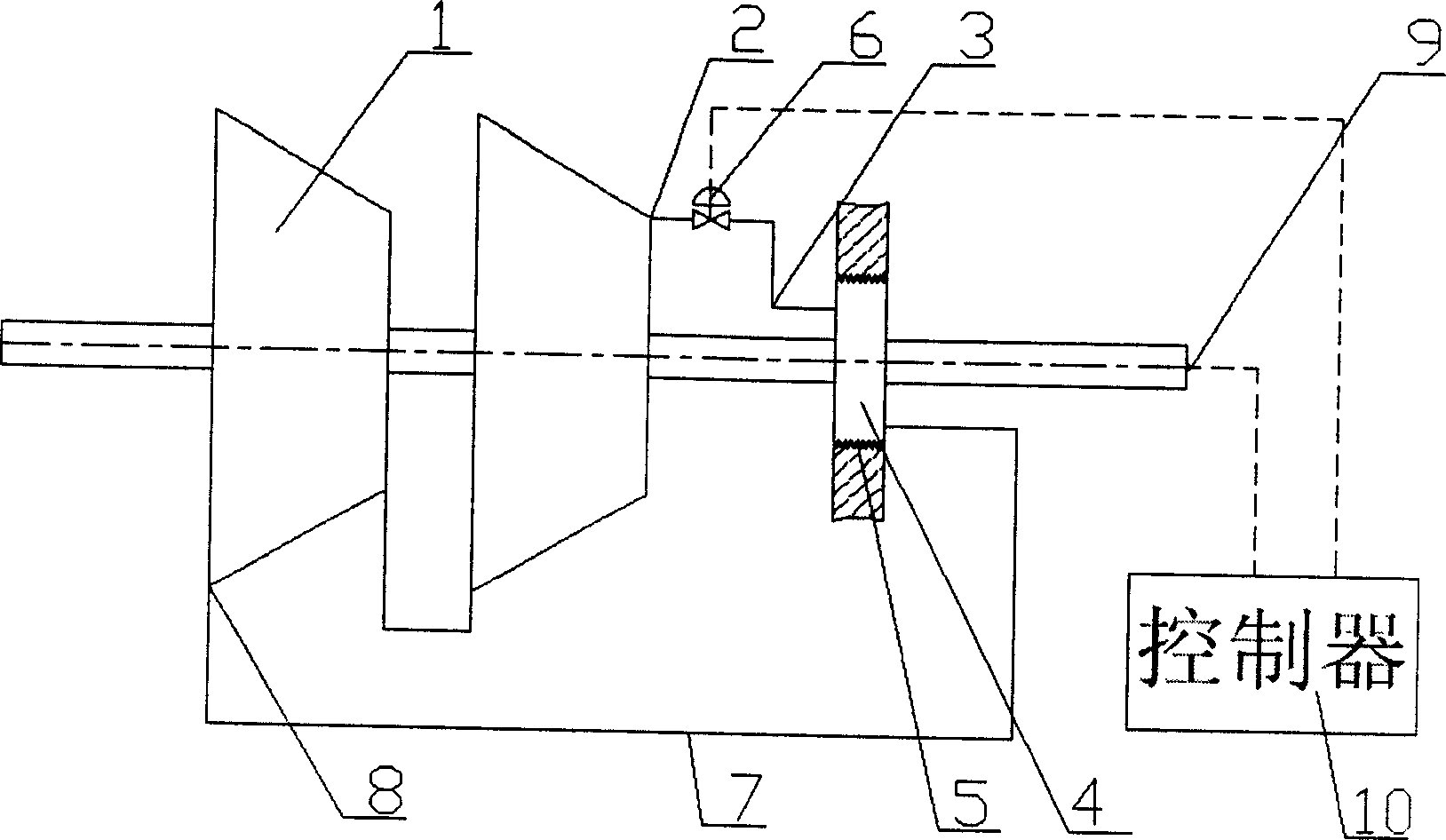

Differential thrust balance device for rotary fluid machinery

InactiveCN1749573AReal-time adjustment of differential pressureReduced residual axial forcePump controlNon-positive displacement fluid enginesHigh-pressure areaControl signal

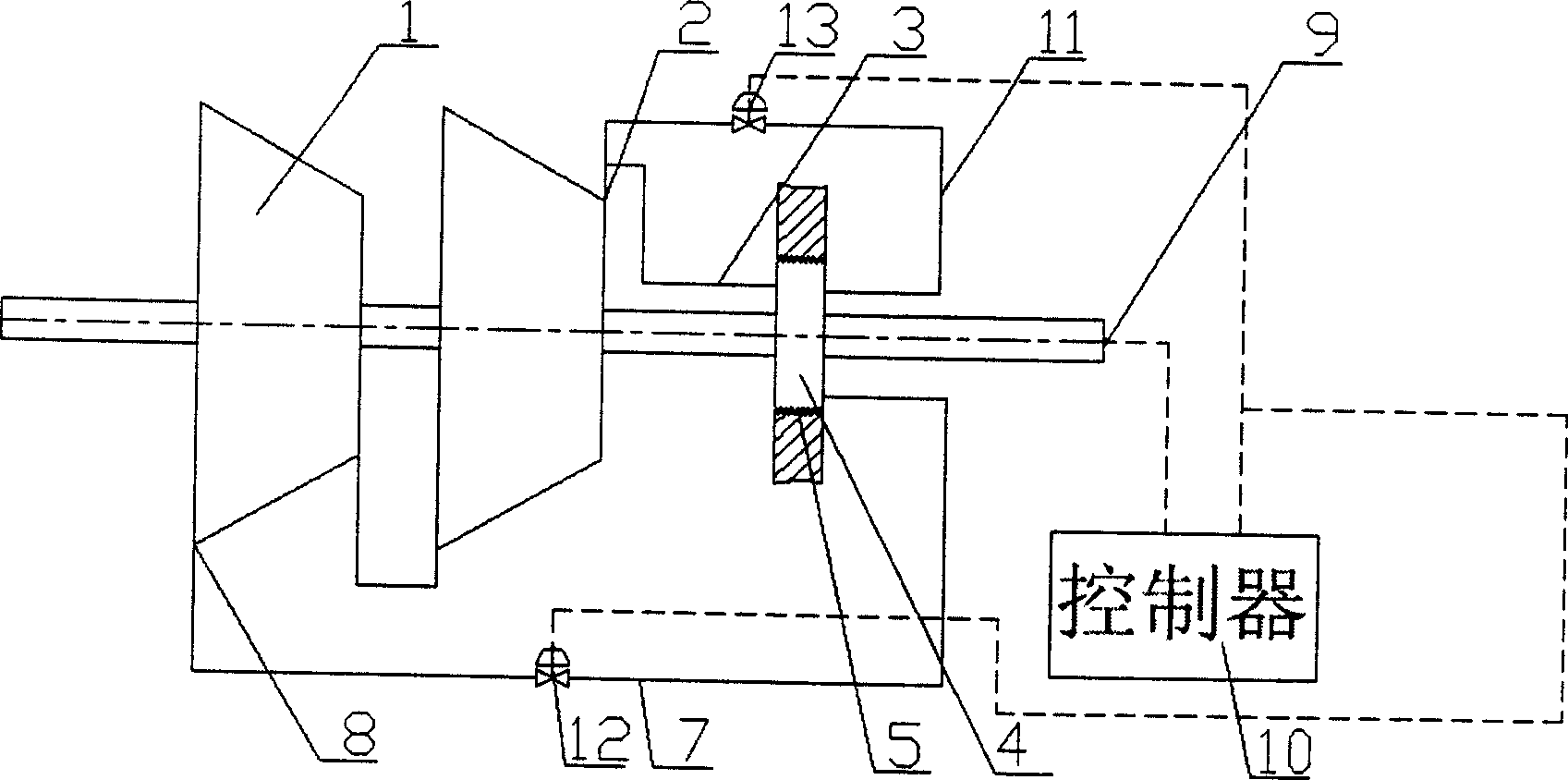

The present invention relates to differential thrust balance device, and is one kind of differential thrust balance device for rotary fluid machinery. The present invention includes thrust balance device connected to the rotating shaft of rotary fluid machinery, leakage interval for fluid medium to flow from the high pressure area to the low pressure area, thrust detecting unit, controller and flow regulator. The shaft displacement sensor, the oil film thickness sensor and the thrust detecting sensor are installed on the rotary fluid machinery. The flow regulator receives the control signal from the controller to regulate the flow rate through the fluid passage so as to regulate the pressure difference across the balance disc and thus the balance thrust. The present invention is used in the axial force balance of rotary fluid machinery to avoid the damage of the apparatus caused by axial thrust change.

Owner:BEIJING UNIV OF CHEM TECH

Surface flow diverting and static charging ducted pores on wing or blade tip to reduce wake and BVI noise

InactiveUS7637462B2Promoting interlayer movementInfluencers by generating vorticesBoundary layer controlsElectricityLeading edge

Air pressure distribution for airfoil lower and upper surfaces is utilized to divert airflow using ducts formed in space-curve shapes placed inside the airfoil volume, through span-wise located inlets from high pressure areas on the airfoil lower surface near the leading edge and through chord-wise spaced inlets on the side face of the airfoil wing tip correspondingly to the side face of the airfoil wing tip through chord-wise spaced outlets on the side face of the airfoil wing tip and to span-wise located outlets to the low pressure areas on the airfoil upper surface. Triboelectric materials on the wing surfaces are employed to static charge the air in drag. Inside the ducts, the employment of either triboelectric linings and materials, or HV-supplied electrodes, or both, help to static charge the diverted air flow to and from the airfoil wing tip side face to diffuse wing tip vortex core early.

Owner:PAL ANADISH KUMAR

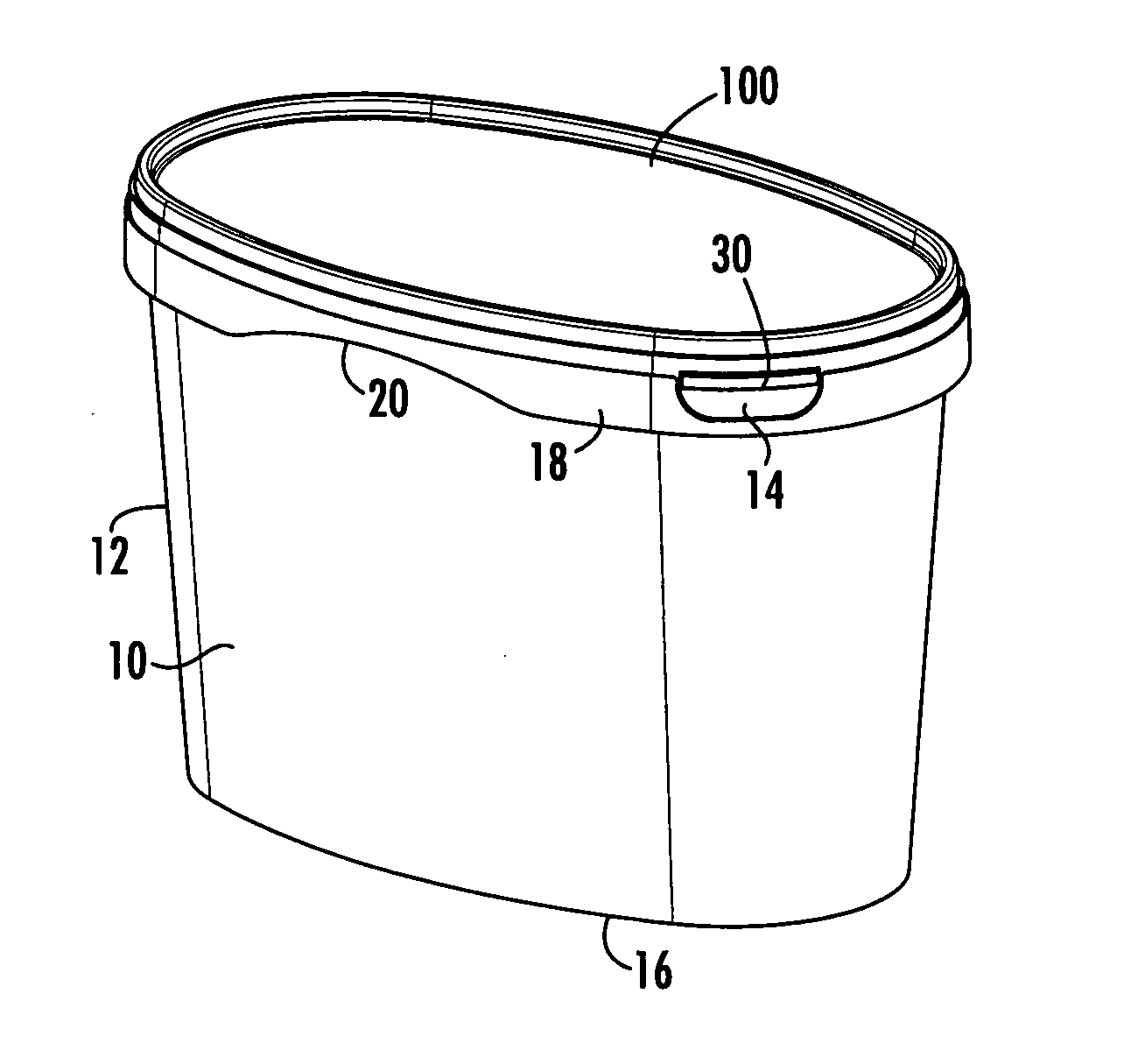

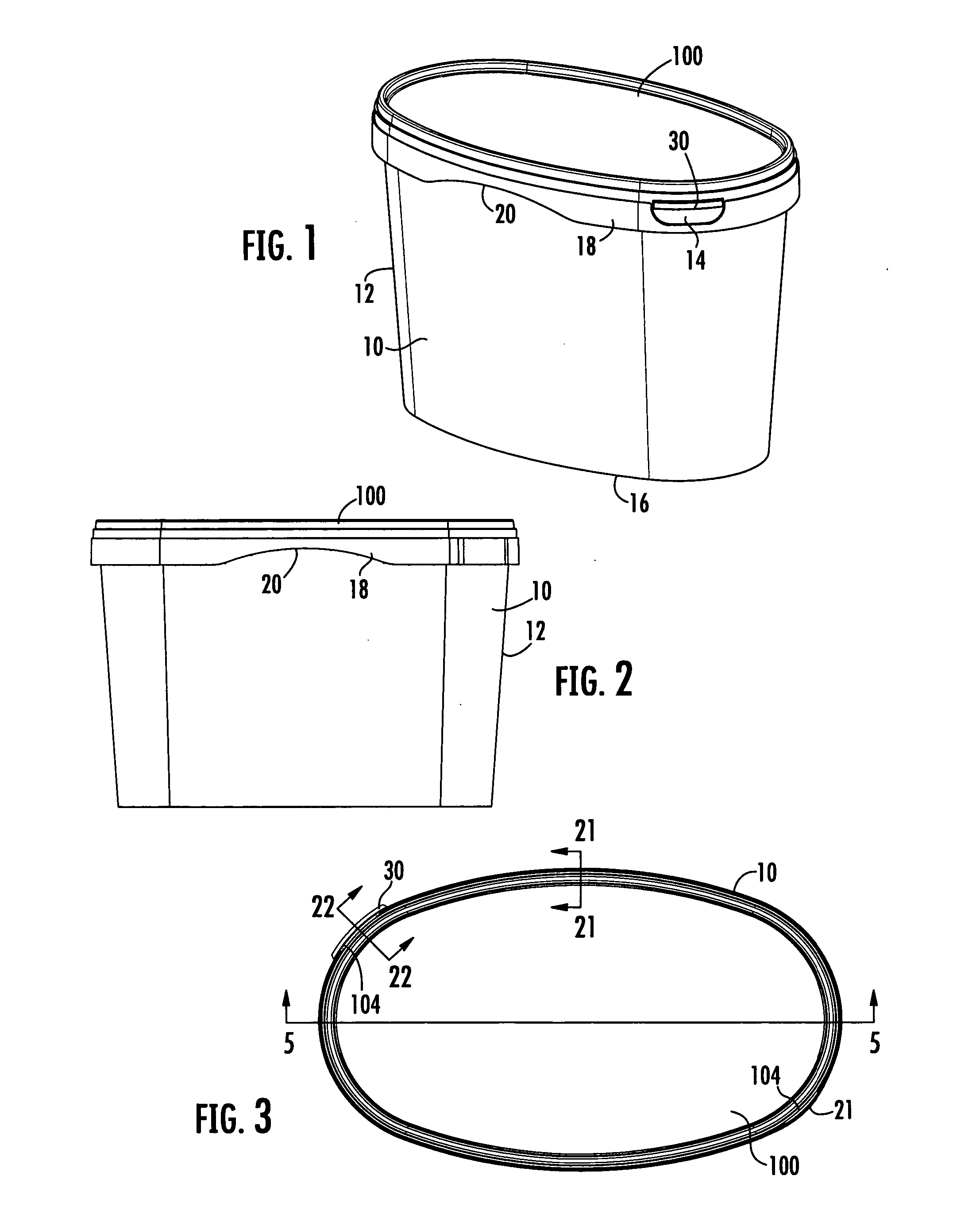

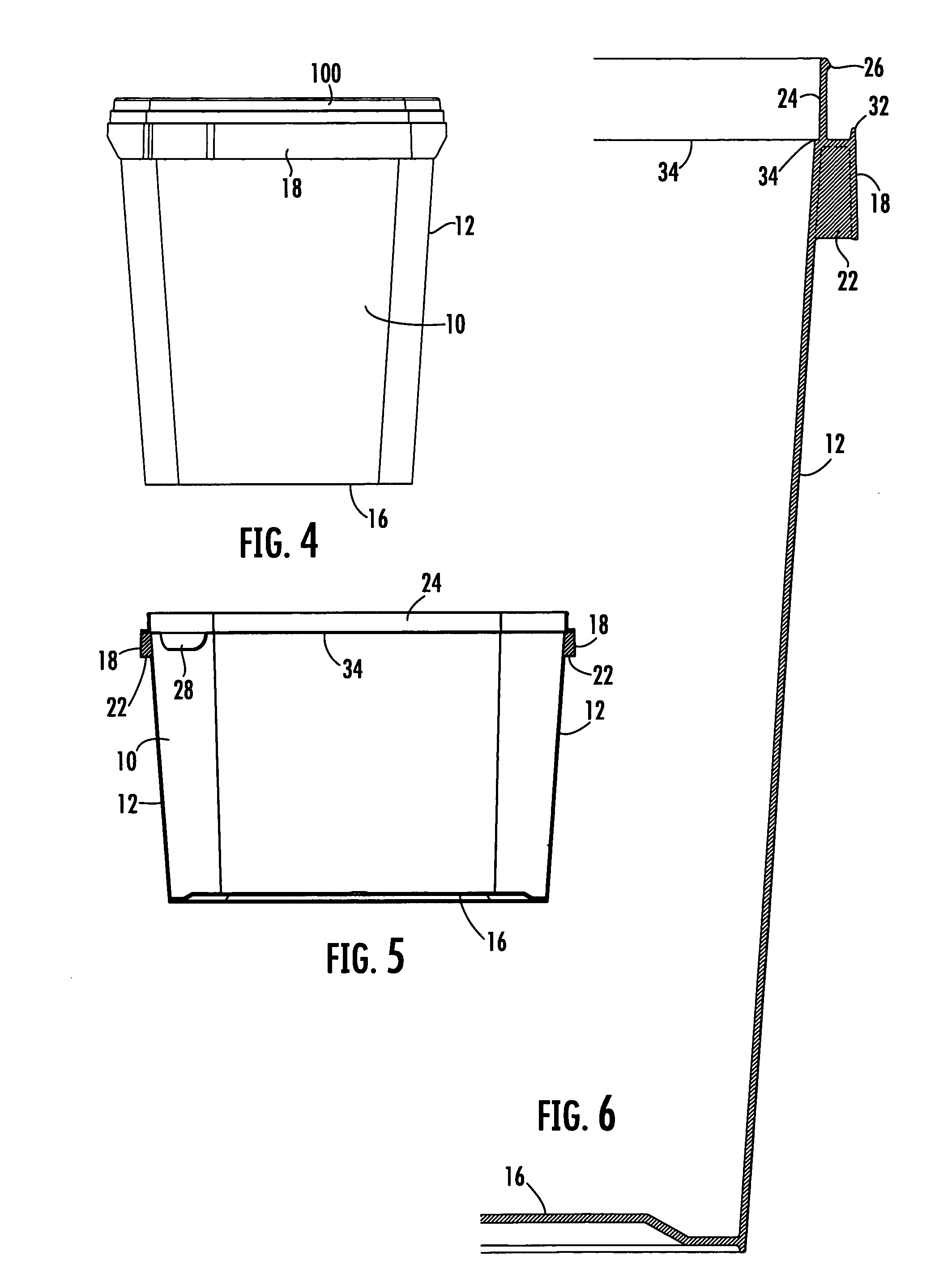

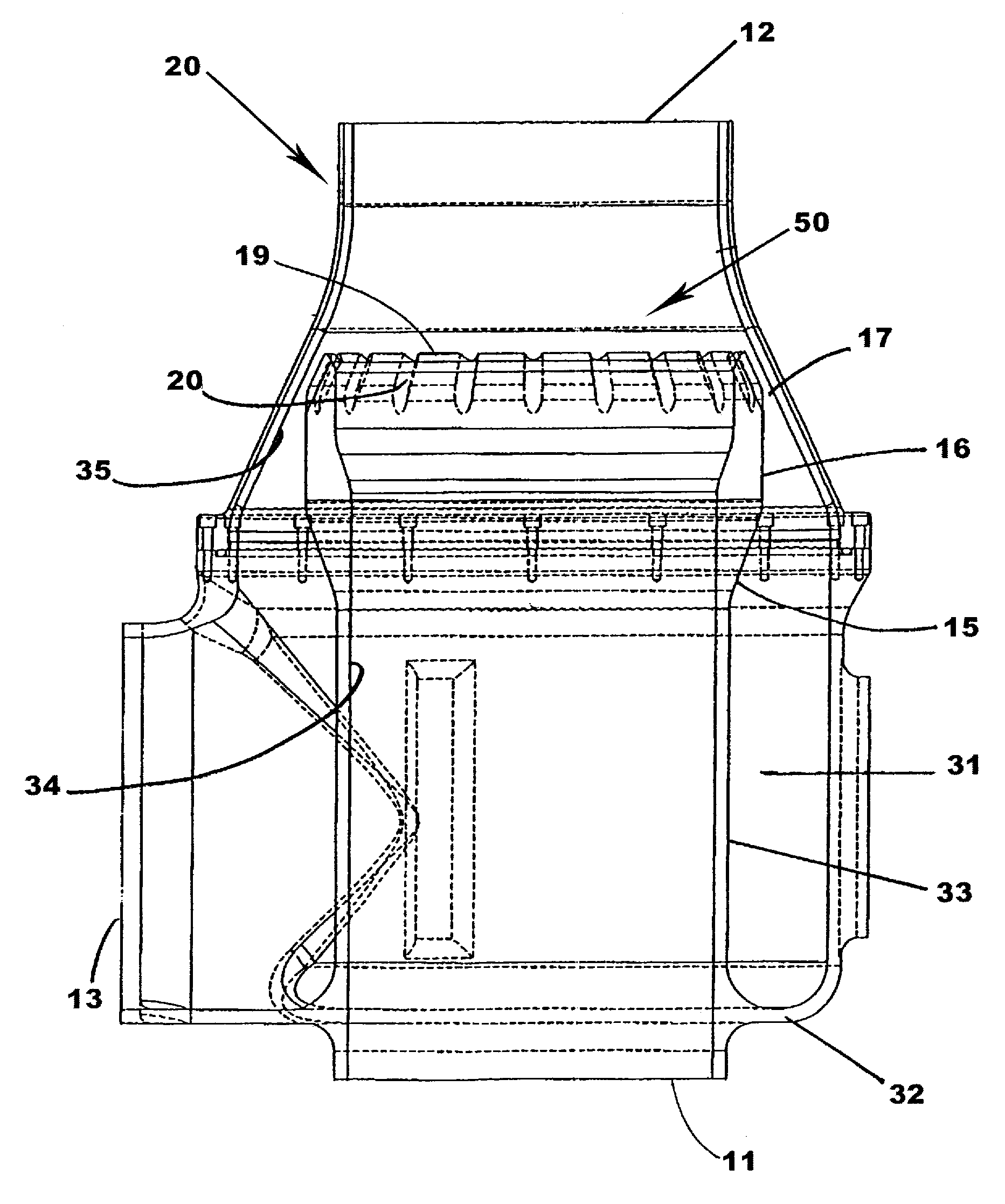

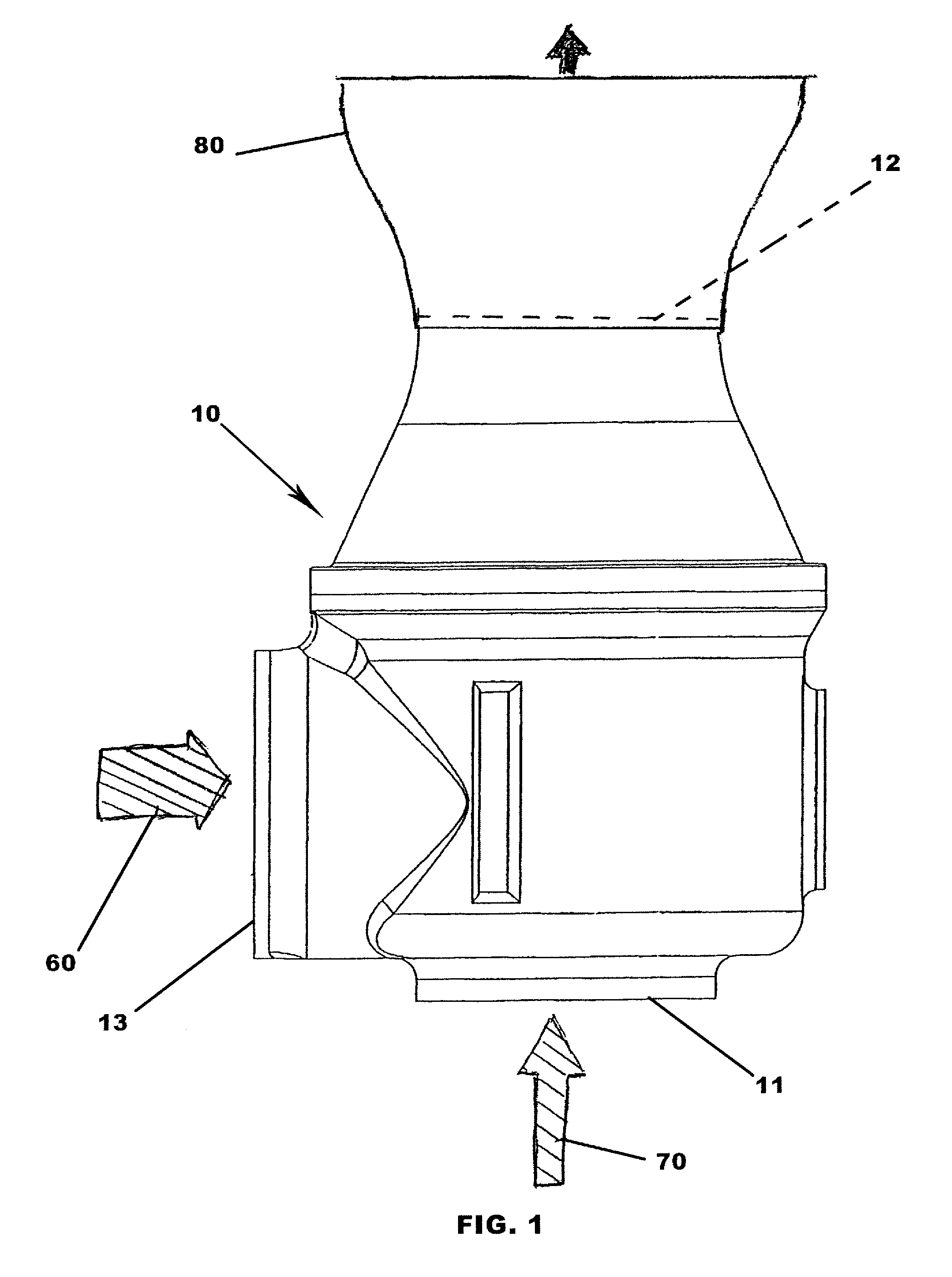

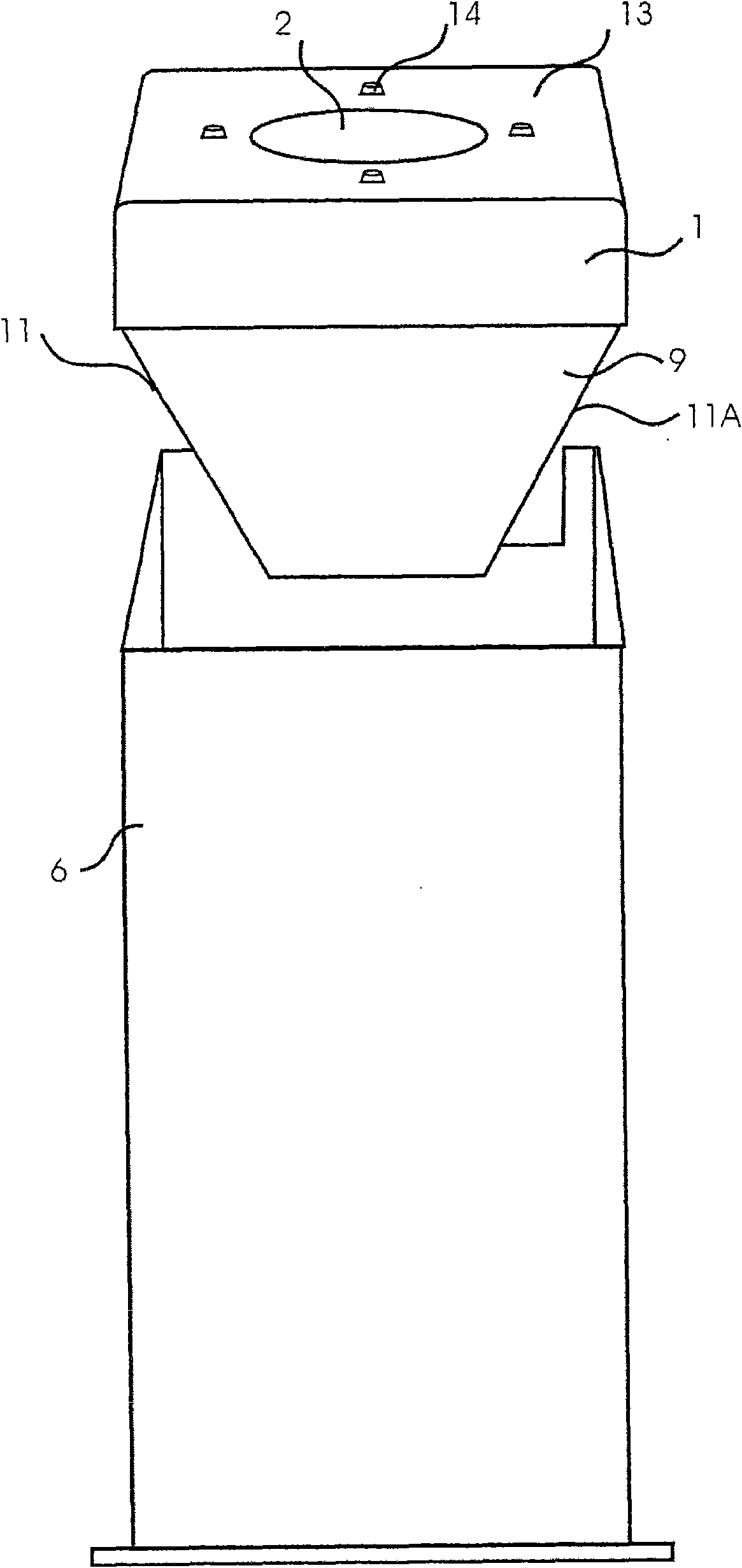

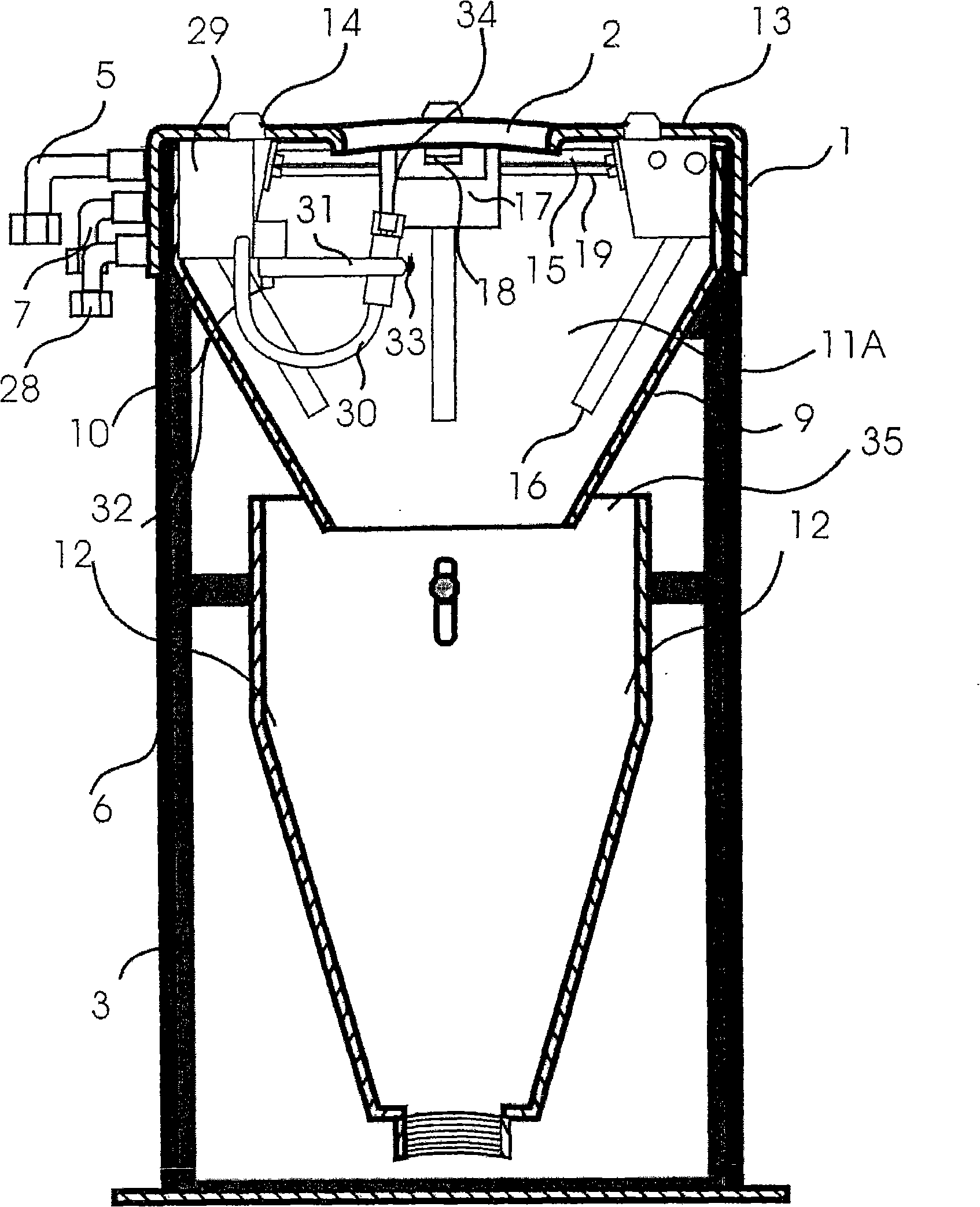

Self-venting food container

Owner:WELLS ENTERPRISES

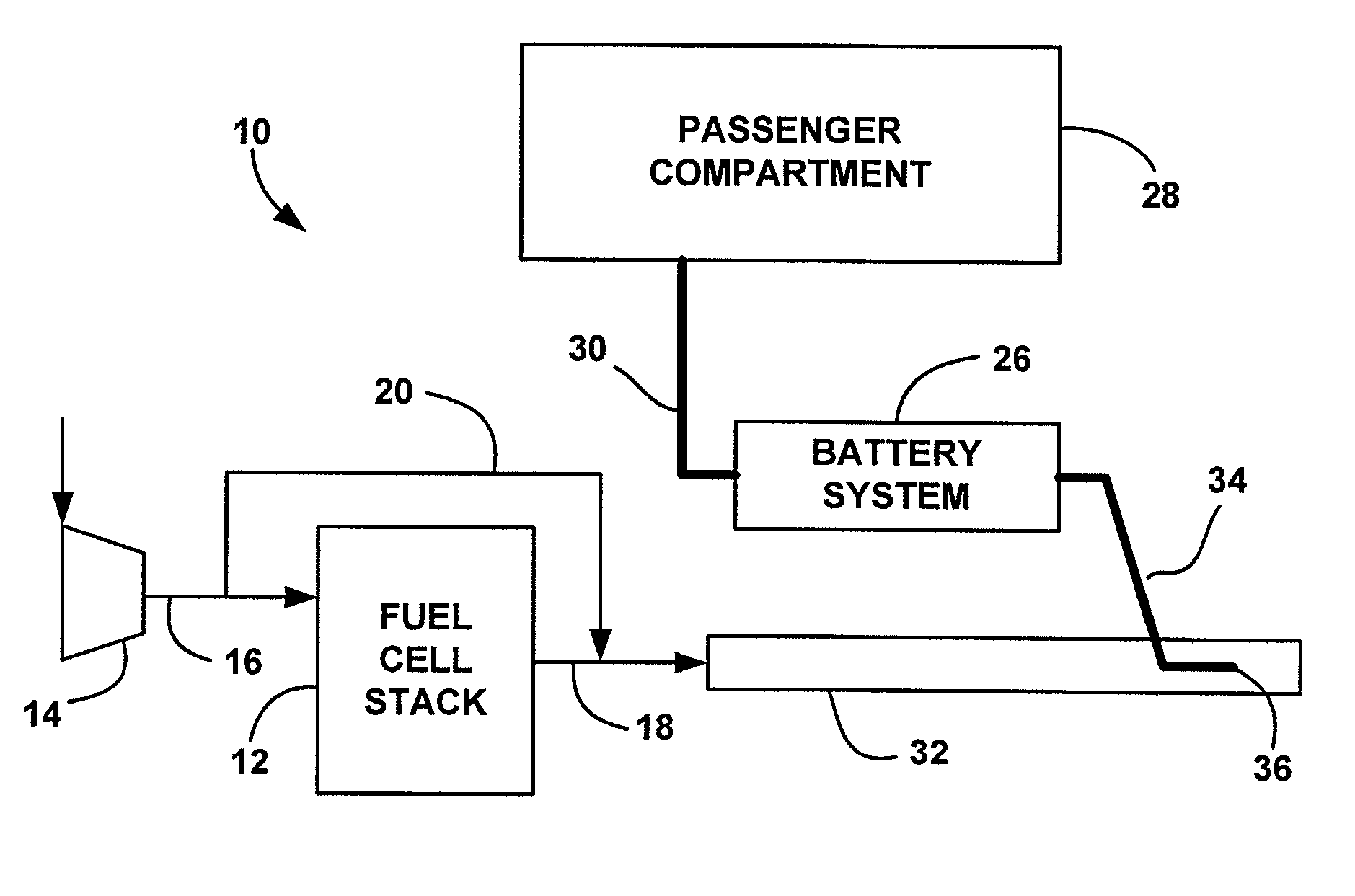

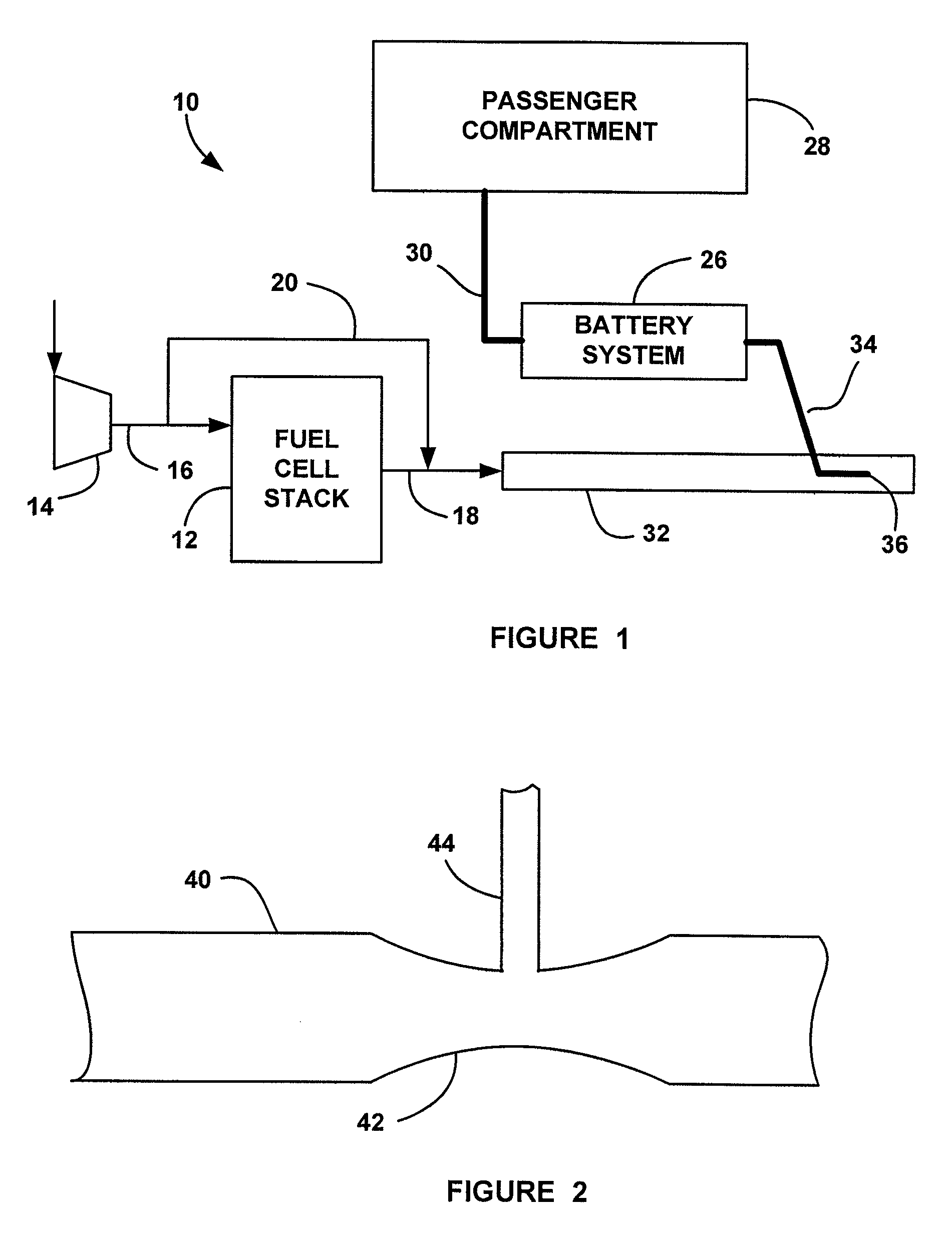

HV battery cooling with exhaust flow of fuel cell systems

A fuel cell system for a hybrid vehicle that includes a high voltage battery, where the system uses a cathode exhaust gas airflow from a fuel cell stack to draw air through a battery compartment in which the battery is mounted to provide battery cooling. An air intake line is in fluid communication with the passenger compartment of the vehicle and the battery compartment. An ejector line is in fluid communication with the battery compartment and the cathode exhaust gas pipe. The flow of the cathode exhaust gas around the injector pipe creates a low pressure area, which draws air through the battery compartment from the passenger compartment. In one embodiment, a compressor that provides the cathode inlet air to the fuel cell stack is used at low stack output loads, such as during vehicle idle, to direct air through the cathode exhaust gas pipe, and cool the battery system under low load conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

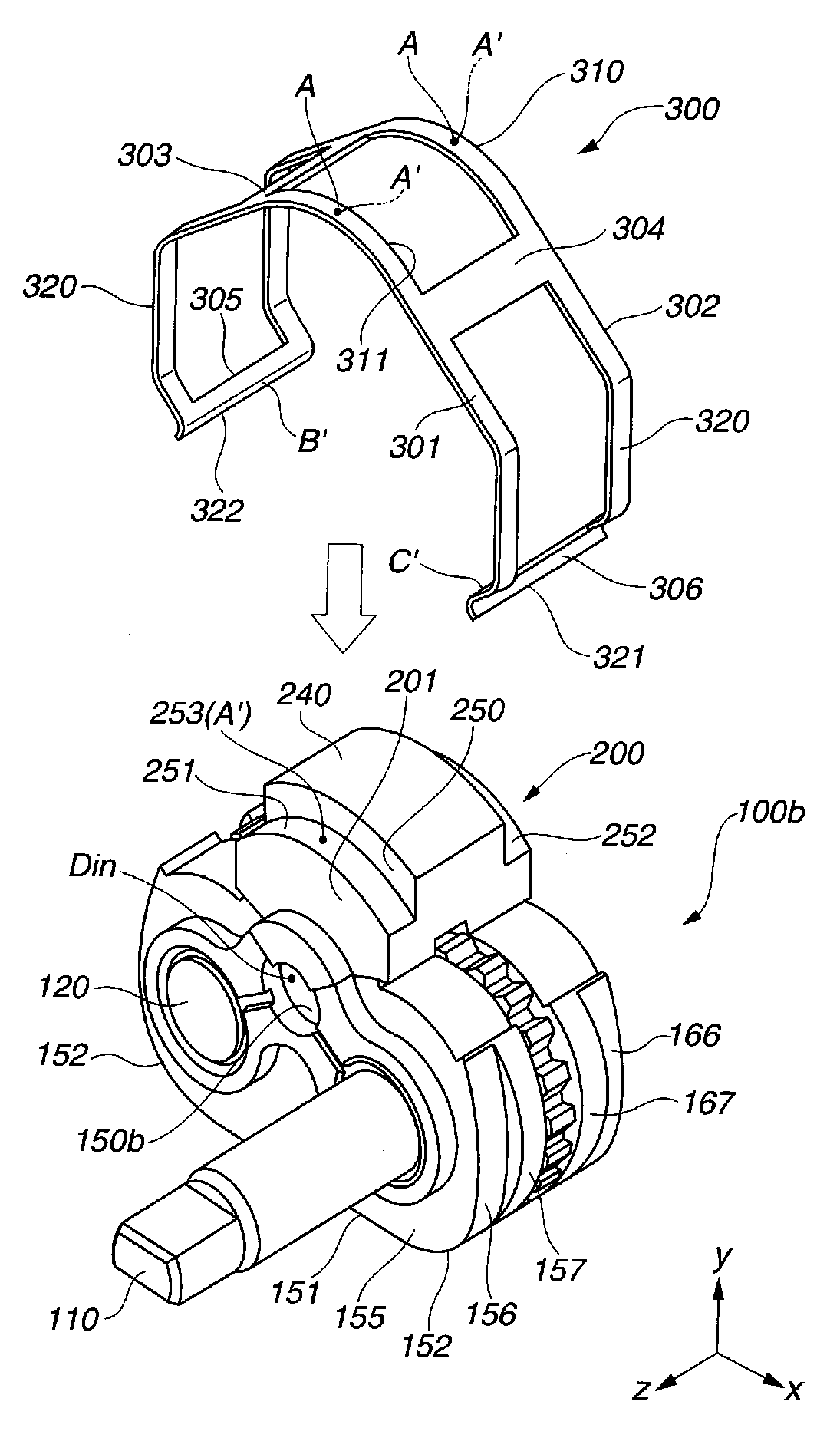

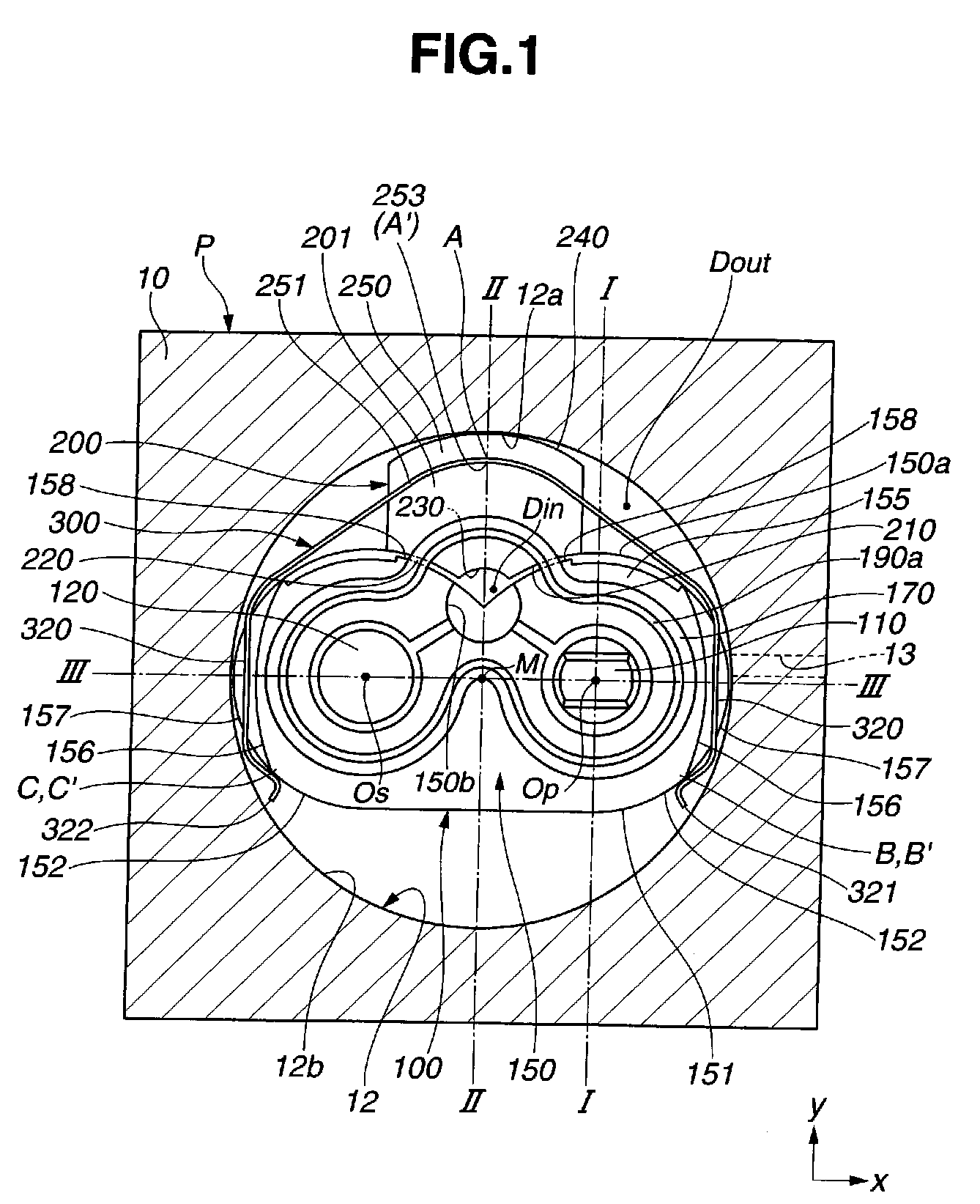

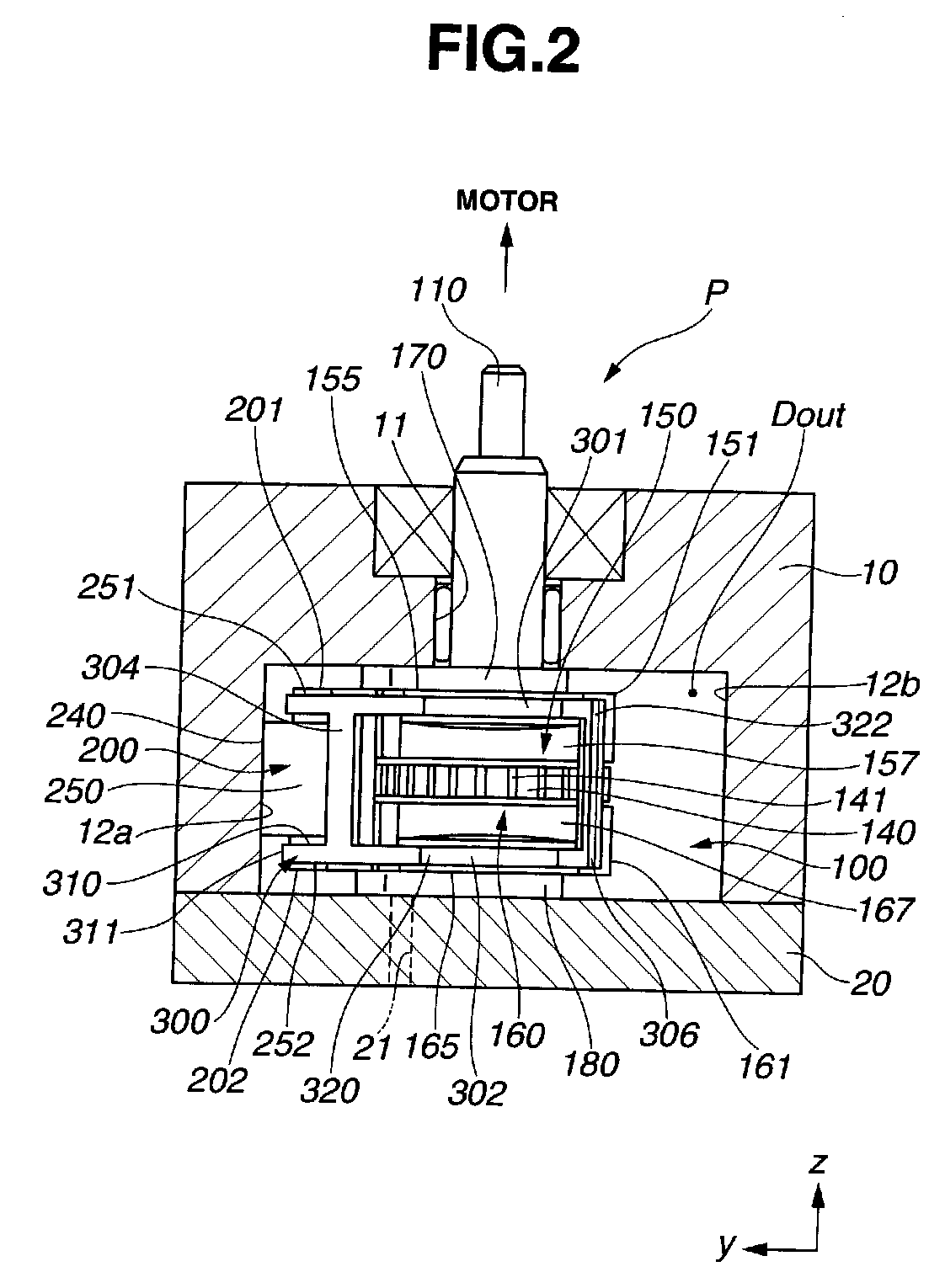

Seal apparatus of gear pump

InactiveUS20090232690A1FrictionReduce gapEngine sealsOscillating piston enginesGear pumpHigh-pressure area

A seal apparatus includes at least one pair of gears; a side plate arranged adjacent to the pair of gears; and a housing sandwiching the side plate. At least one of the side plate and the housing includes a shoulder portion. The seal apparatus further includes a seal member arranged between the housing and the side plate and arranged at the shoulder portion. The seal member separates a low pressure area from a high pressure area in a radial direction of the gear. The shoulder portion is located in the low pressure area. At least a part of the seal member faces the high pressure area. The seal apparatus further includes a backup member reinforcing the seal member and facing a tip portion of the shoulder portion; and a containing portion formed between a root portion of the shoulder portion and the seal member to be capable of containing a part of the seal member at least when the seal member is elastically deformed.

Owner:HITACHI LTD

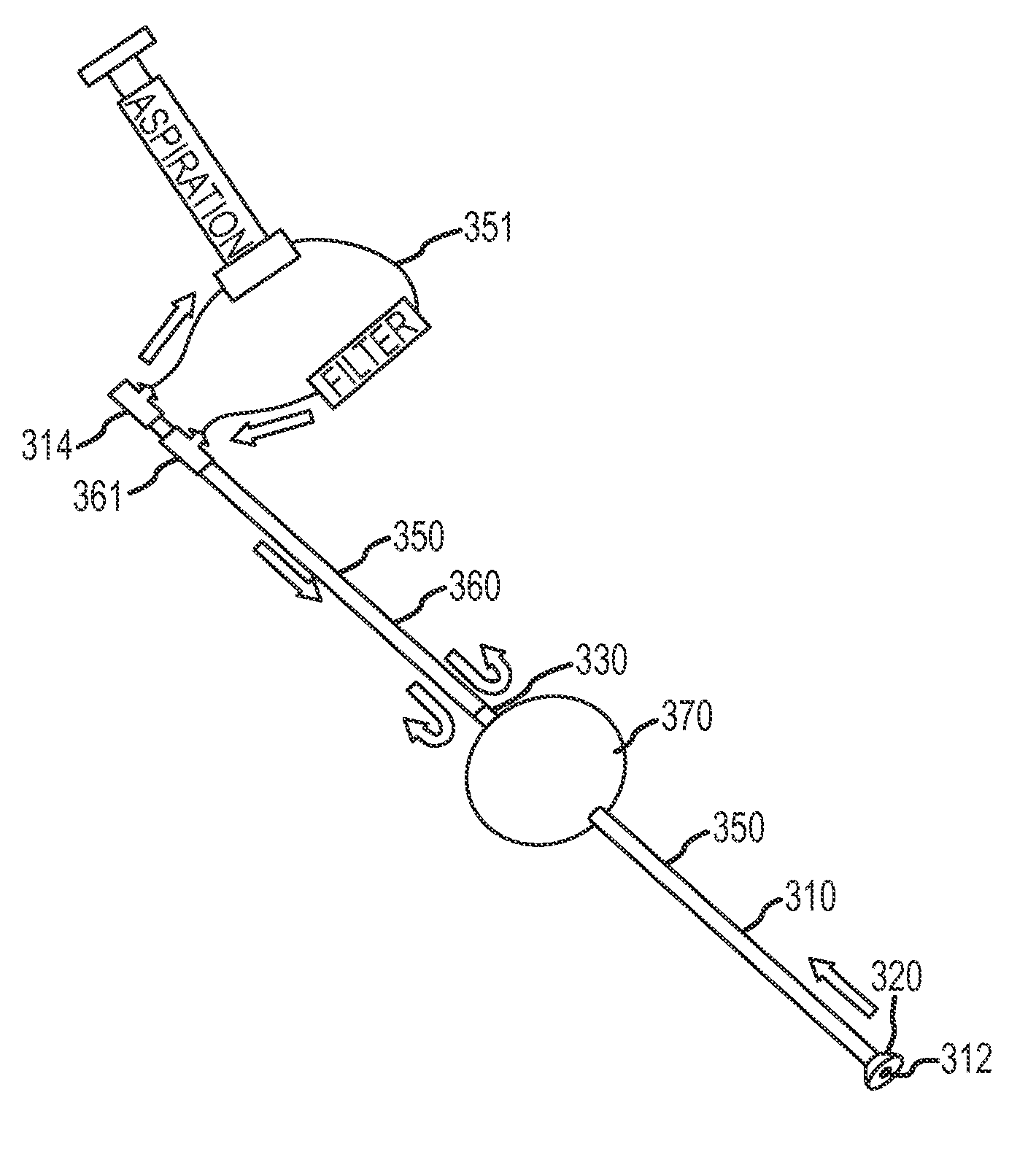

Single access flow-reversal catheter devices and methods

Embodiments herein include devices and methods directed toward creating reverse flow within a vessel and thereby providing protection against embolic debris. Embodiments comprise a catheter and a plurality of occluders that are expandable and adjustable within a lumen to create low-pressure areas that reroute blood flow and embolic debris therein.

Owner:WL GORE & ASSOC INC

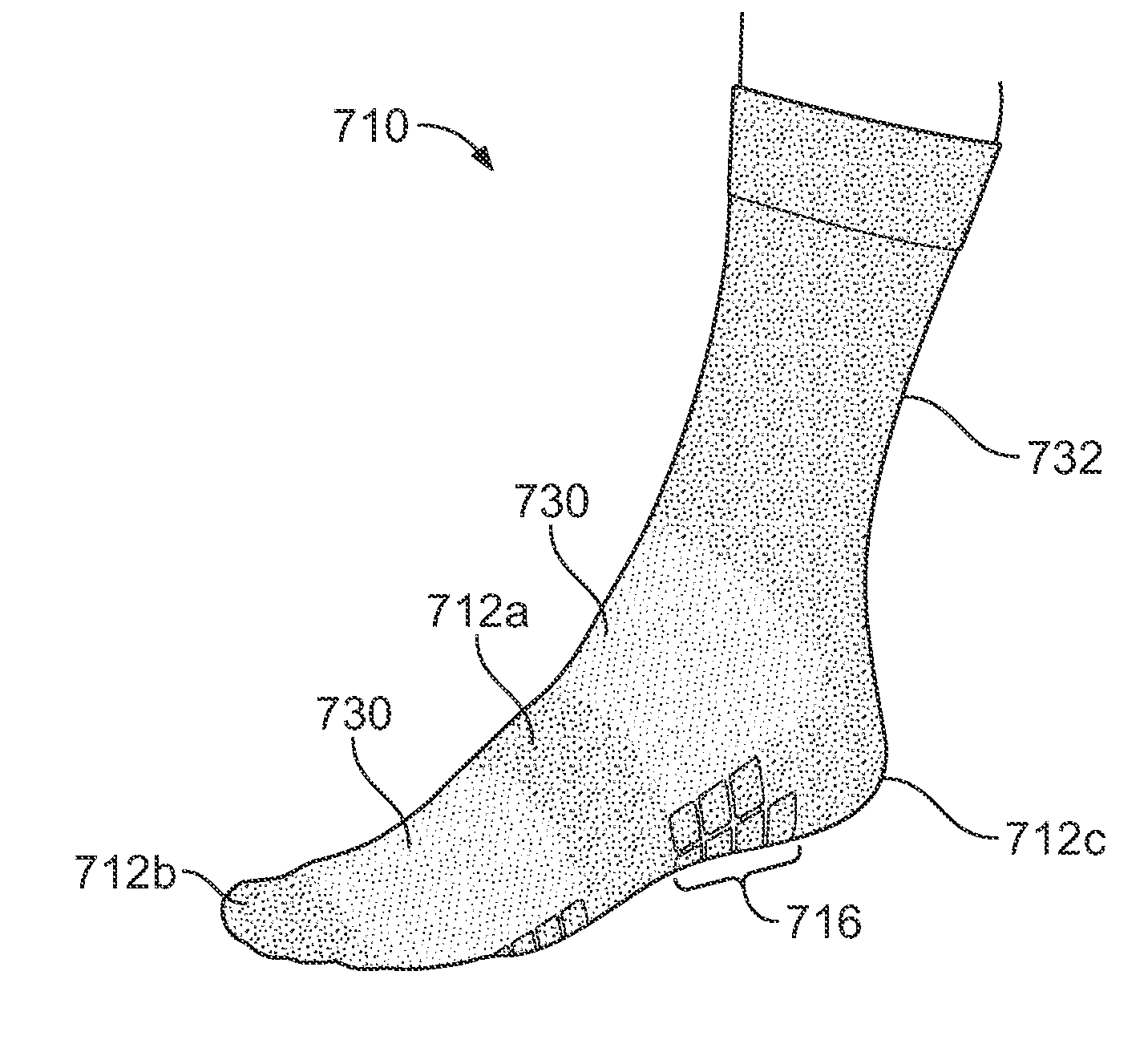

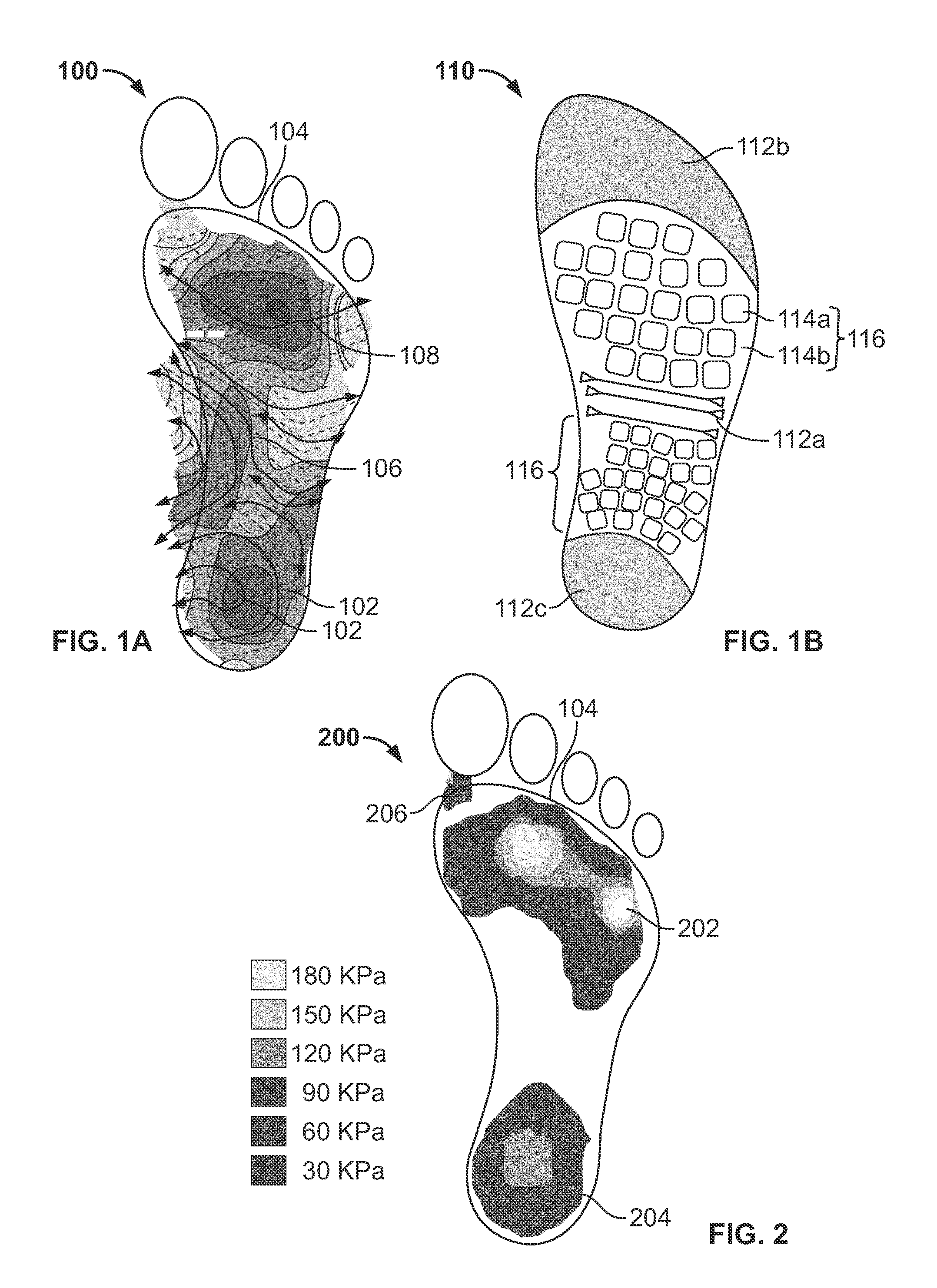

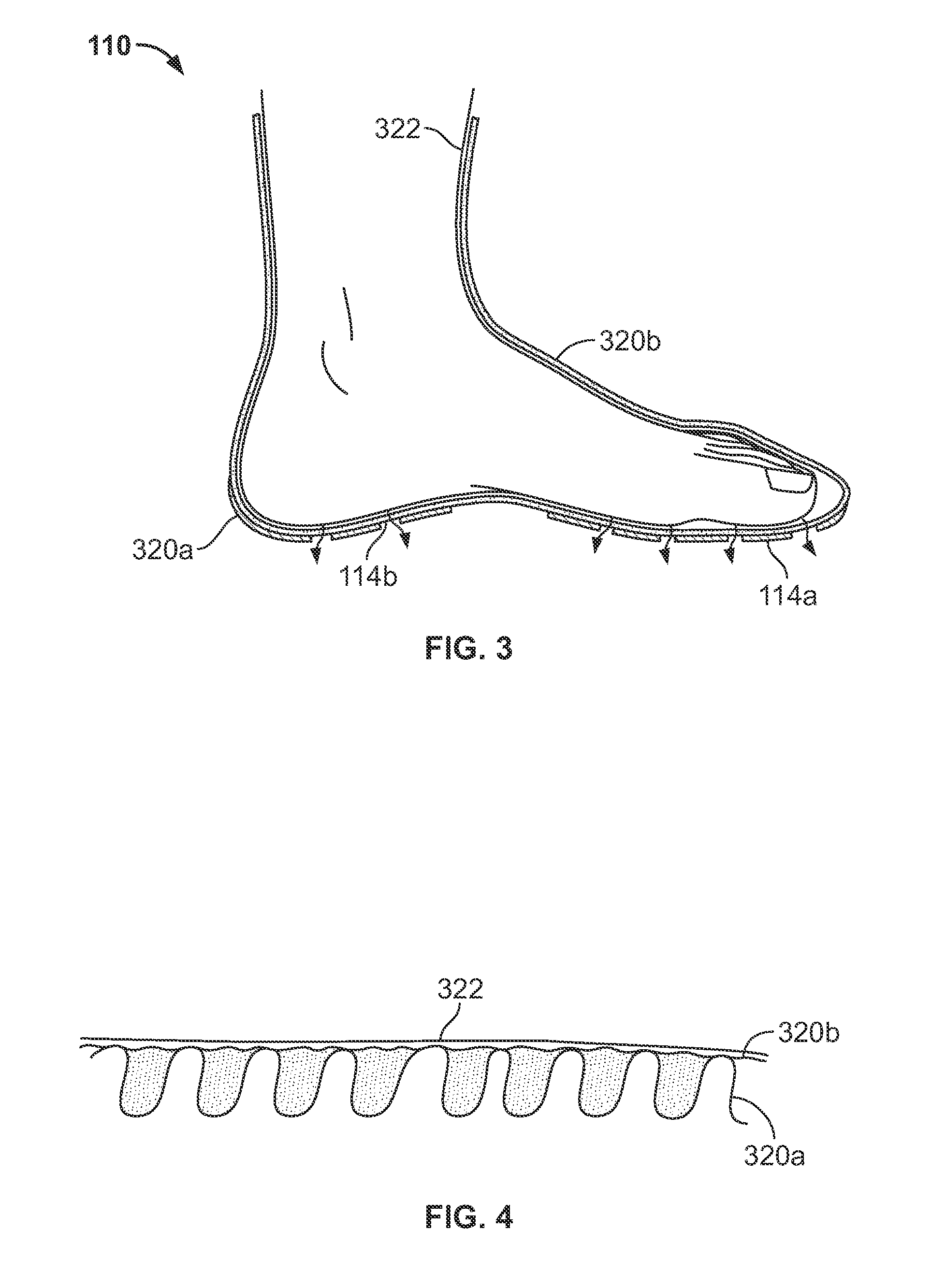

Performance dress sock

InactiveUS20140311187A1Improve wearer comfort and durabilityOrnamental textile articlesStraight-bar knitting machinesFiberHigh-pressure area

A sock having a low pressure area made of a first knit density and at least one high pressure area made of a variable knit density portion. The variable knit density has portions that are made of a second knit density greater than the first knit density. The at least one variable knit density portion is arranged transverse to an orientation of major strain. A sock may also have hydrophobic fibers located substantially across a surface of the sock adapted to be adjacent to skin when worn and hydrophilic fibers located substantially across the hydrophobic fibers and extending therefrom to form loop structures adapted for wicking moisture away from the hydrophobic fibers.

Owner:THE MIN OF SUPPLY

Fish pump

ActiveUS7462016B2Avoid damageImprove efficiencyClimate change adaptationJet pumpsPump chamberEngineering

Owner:LINDGREN PETER B

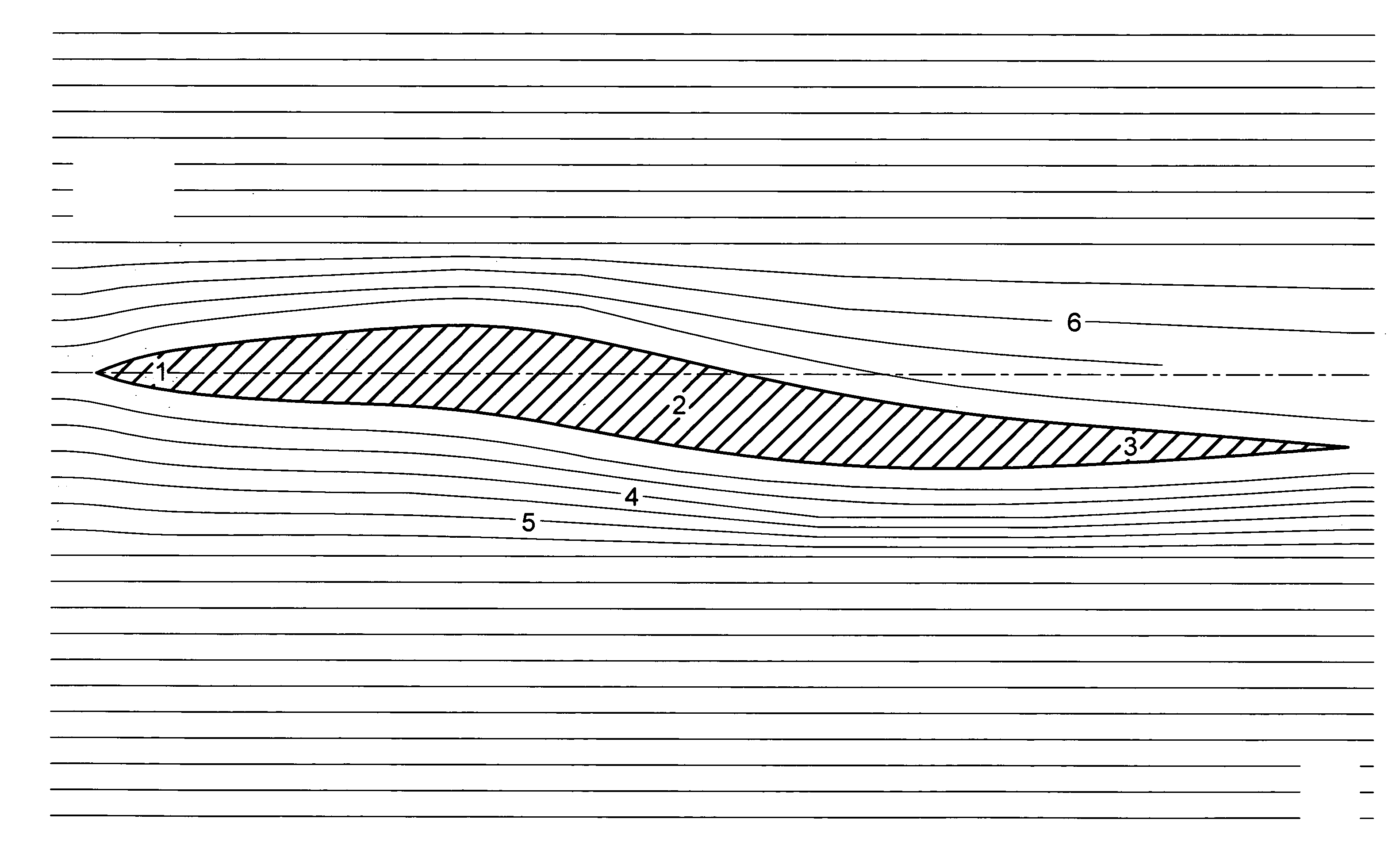

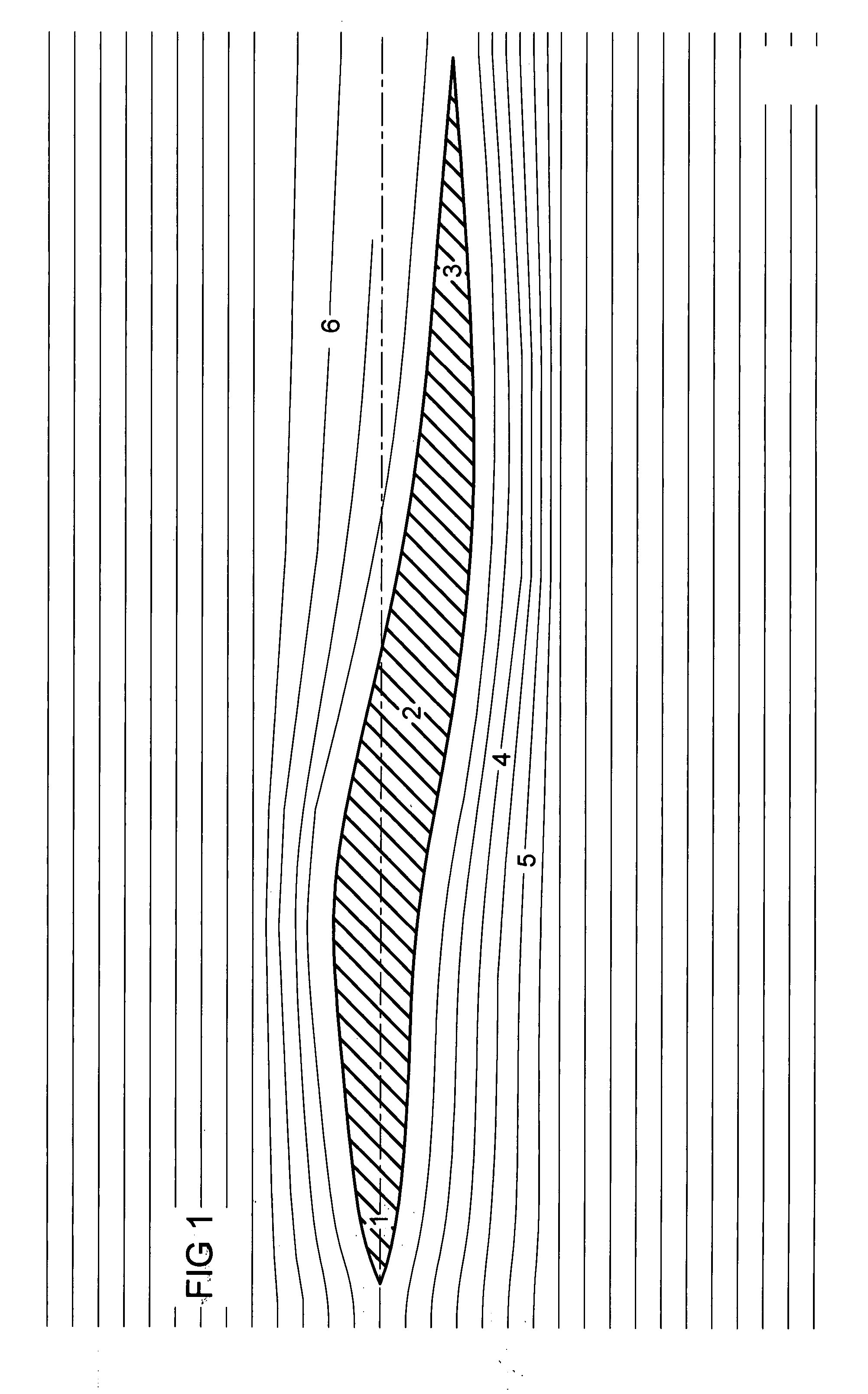

High lift and high strength aerofoil

A high lift stepped aerofoil section, incorporating a leading edge 1, trailing edge 3 and a step 2 to provide a higher vertical component in its construction; the aerofoil has greater perceived root thickness giving greater lift through compression 4 on the aerofoil under surface. The section has high pressure area 5 below the aerofoil and low pressure area 6 above the aerofoil. The aerofoil has much higher strength on all axes than conventional aerofoil sections.

Owner:HUBBARD ADRIAN ALEXANDER

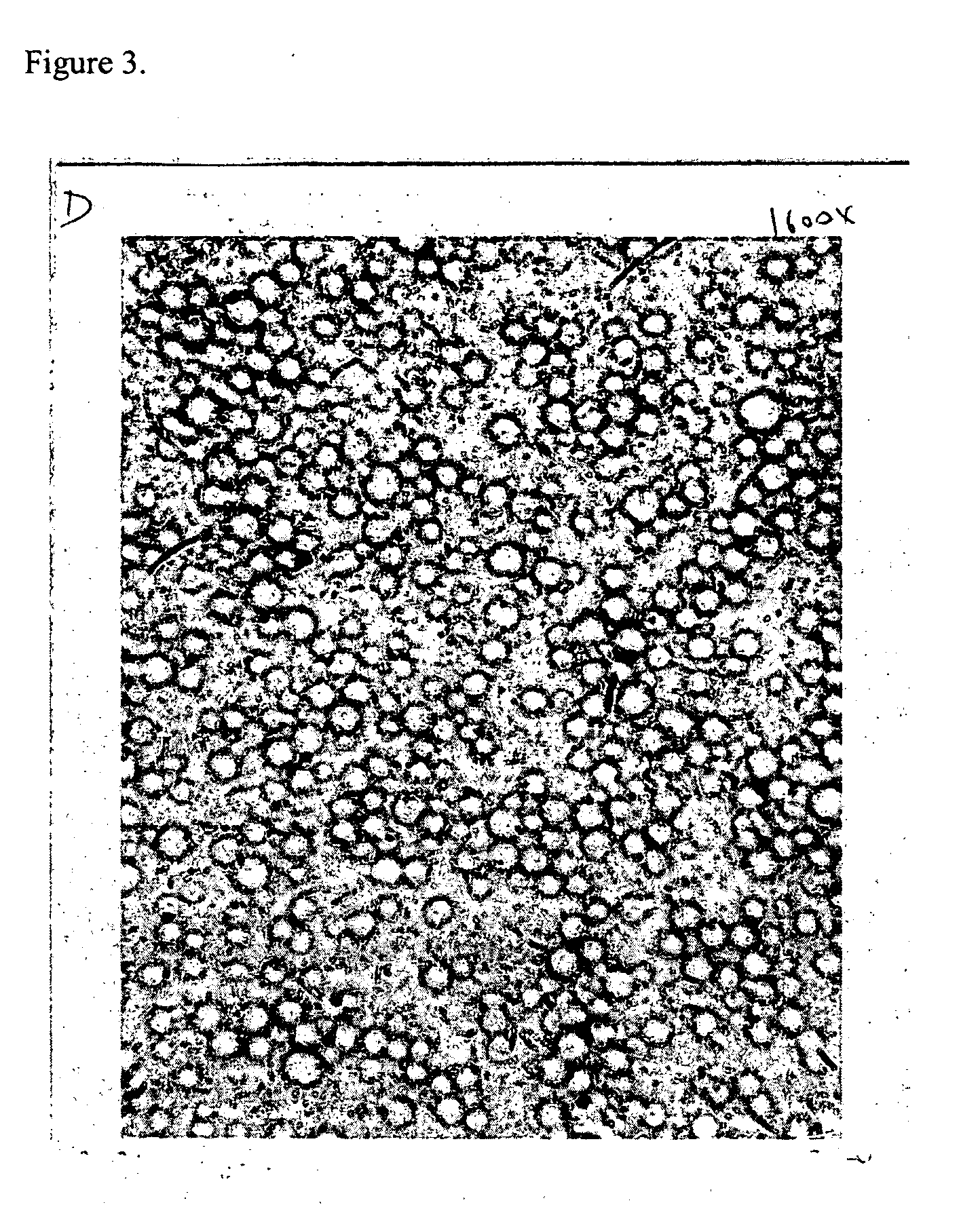

Process of producing microcapsules and product thereof

InactiveUS20050161843A1Lower resistanceGood workmanshipPhotomechanical apparatusSolid materialLiquid coreMicroparticle

This invention relates to a process for preparing microcapsules containing a hydrophobic liquid core material, the process comprising: (1) mixing an organic liquid phase which comprises the hydrophobic liquid core material with an aqueous phase comprising a stabilizer to form a premix; (2) homogenizing the premix by forcing the premix under pressure through a high pressure passage into a low pressure area to produce a microparticle dispersion, said microparticles having a mean size of greater than 1.0 micron, (3) adding an encapsulating material prior to step (4); and (4) curing the encapsulating material associated with the microparticles to form the microcapsules.

Owner:EASTMAN KODAK CO

Cleaning device for paint spraying apparatus

ActiveCN101537400APrevent escapeSpraying apparatusCleaning using liquidsLow-pressure areaEngineering

The invention relates to a device for drying a spray gun used in an automatic manufactory. The device is an effective two-stage solvent reclaiming system to lower cost in aspects of operation and environment. The device comprises a main body for accommodating a solvent spray head which is used for cleaning and inserted into the main body through non-contact seal, and an air spray head for cleaning an article once the article is cleaned. A low pressure area is generated in the main body by downwards guiding the air spray head so as to keep the air carried with a solvent in the main body. The air carried with the solvent is guided to a solvent separator positioned under the main body to reclaim the solvent.

Owner:菲利普·约瑟夫 +1

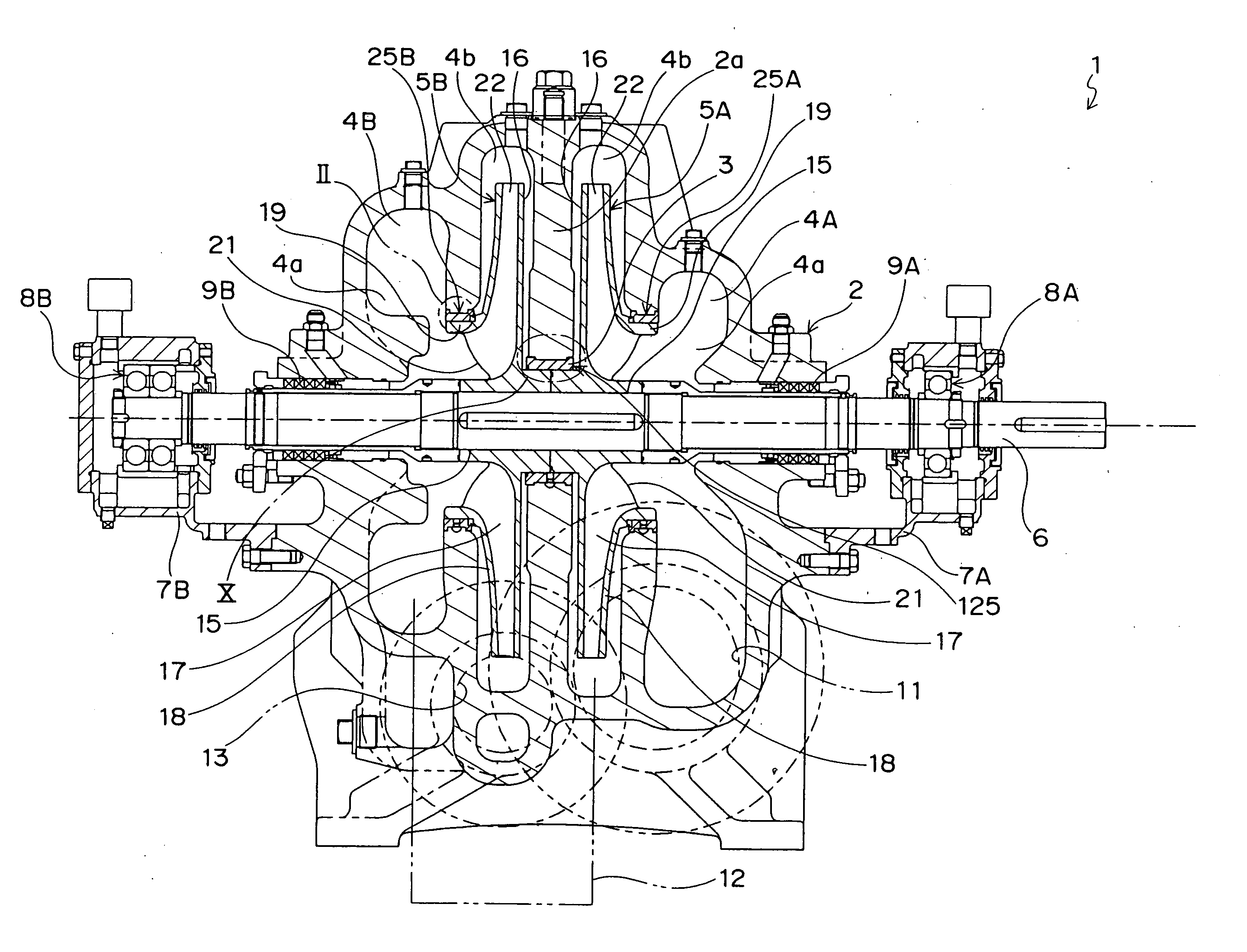

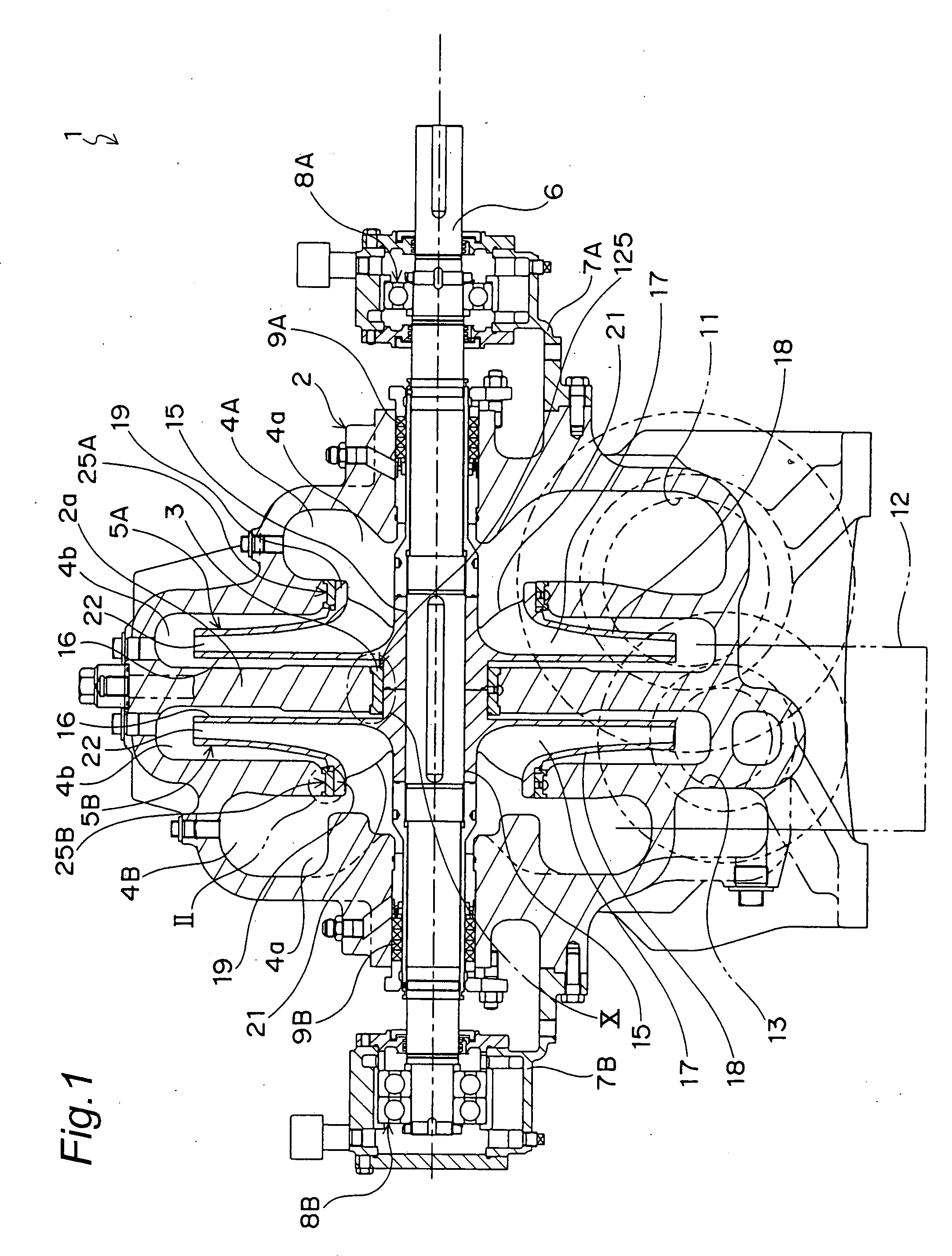

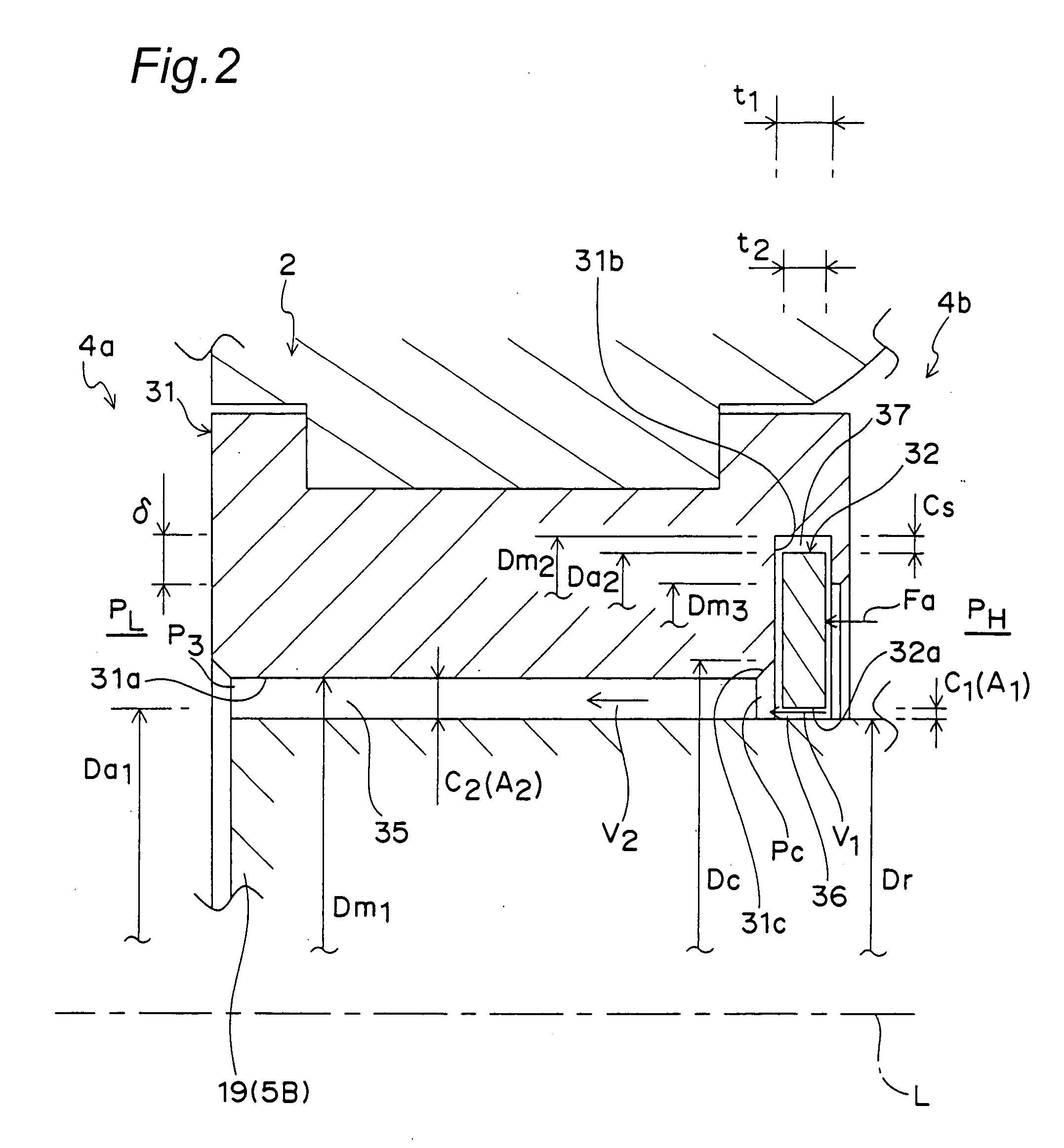

Seal device for a fluid machine

InactiveUS20070280823A1Quantity minimizationReduce vibrationPump componentsBlade accessoriesHigh-pressure areaEngineering

A seal device 25B has a wear-ring 31 fixed to a casing 2 of a centrifugal pump and a floating ring 32. An annular gap 36 between an inner peripheral surface of a through bore 32a formed in the floating ring 32 and an outer peripheral surface of a mouth ring portion 19 of an impeller 5B is smaller than an annular gap 35 between an inner peripheral surface of a through bore 31a formed in the wear-ring 31 and the outer peripheral surface of the mouth ring portion 19. Fluid leakage from a high pressure area to a low pressure area in the casing 2 through the gaps is prevented.

Owner:TORISHIMA PUMP MFG CO LTD

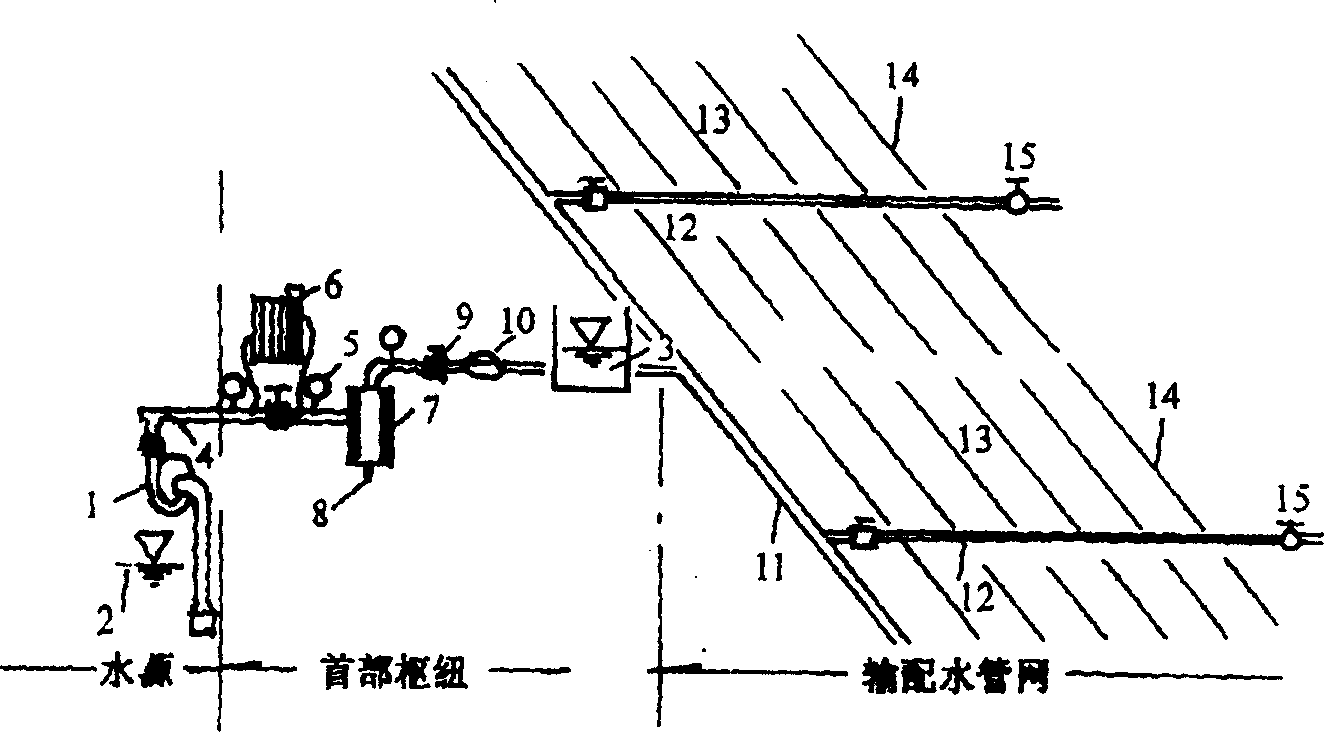

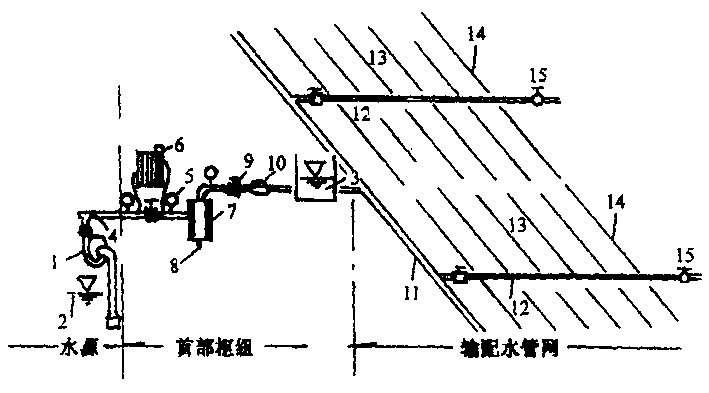

Novel low-pressure drip irrigation system

InactiveCN1481671AReduce consumptionWatering devicesCultivating equipmentsWater sourceDrip irrigation

The low pressure irrigation system of the present invention is similar to conventional one in that it consists of pressurized water source, initial key part and water conveying and distributing network. It features the landform adaptability matching the field height difference, designed dripper pressure not higher than 0.04 MPa, pressure grade of branch pipe and hair canal not higher than 0.06 MPa, constant pressure unit in the inlet of the branch pipe to make the downstream lower pressure area and make the branch pipe and the hair canal obtain stable water head. Compared with conventional dripping irradiation system, the present invention has 72.7 % lowered plastic consumption, 87.5 % lowered branch pipe inlet water head and over 30 % lowered system running power consumption.

Owner:YANGLING ENG TECH RES CENT STATE WATER SAVING IRRIGATION +1

Gas cylinder surface sealing device with cantilever support and spiral chute

InactiveCN102758918AAchieving deformation adaptabilityAvoid or reduce contact wearEngine sealsHigh-pressure areaGas cylinder

The invention discloses a gas cylinder surface sealing device with a cantilever support and a spiral chute. The device comprises a sealing retainer, a rotor journal, a floating sealing ring and a cantilever supporting plate, wherein a dynamic pressure cylindrical sealing area is formed between the cylindrical sealing interface of the floating sealing ring and the cylindrical surface of the rotor journal, a high-pressure area and a low-pressure area are respectively arranged on two sides of the floating sealing ring, and the rotor journal and the floating sealing ring rotate relatively; and the floating sealing ring is supported by a plurality of cantilever sheets which are distributed circumferentially, and the cantilever sheets are fixed by the sealing retainer. The cylindrical surface gas film sealing device realizes non-contact and small-leakage sealing while adapting to the deformation in position sealing work process through the flexibility of the support and a dynamic pressure gas film, and is adaptive to the installation space requirement on non-shaft end position sealing through the cylindrical surface structure.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com